Patents

Literature

52results about How to "Lower furnace temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

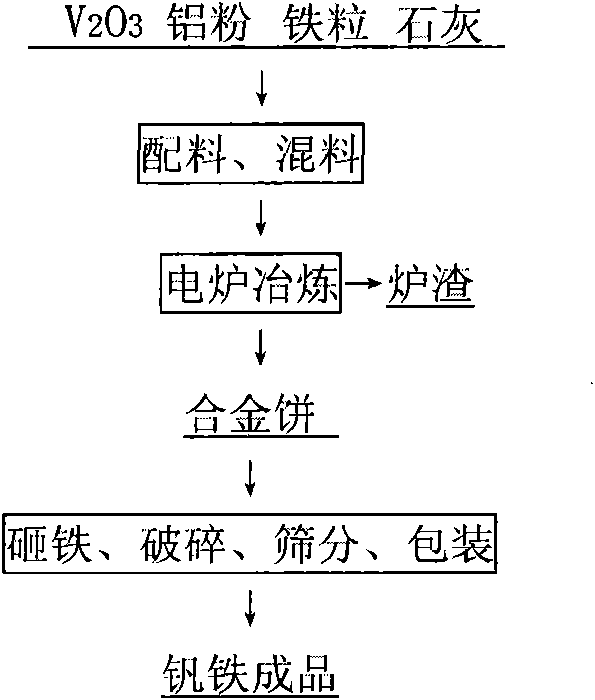

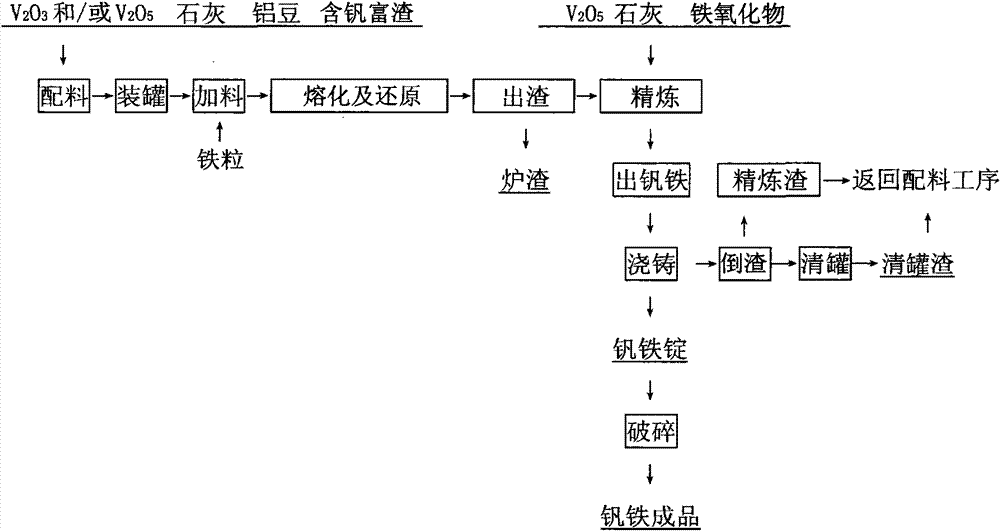

Method for smelting ferrovanadium

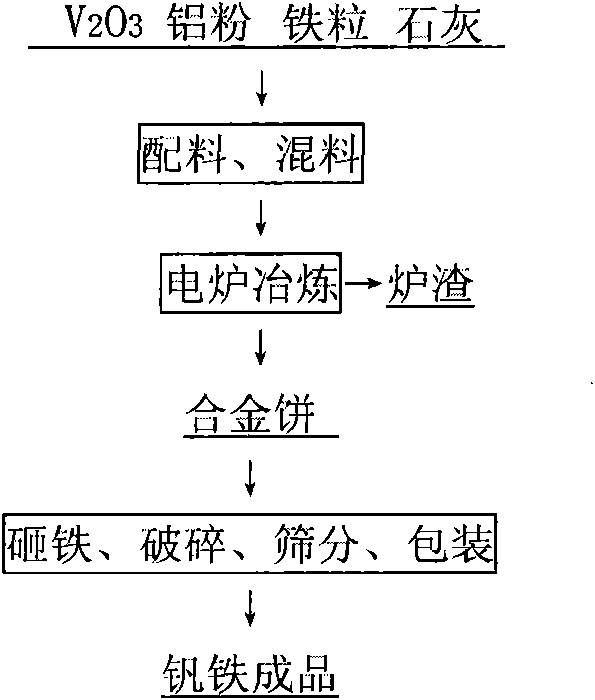

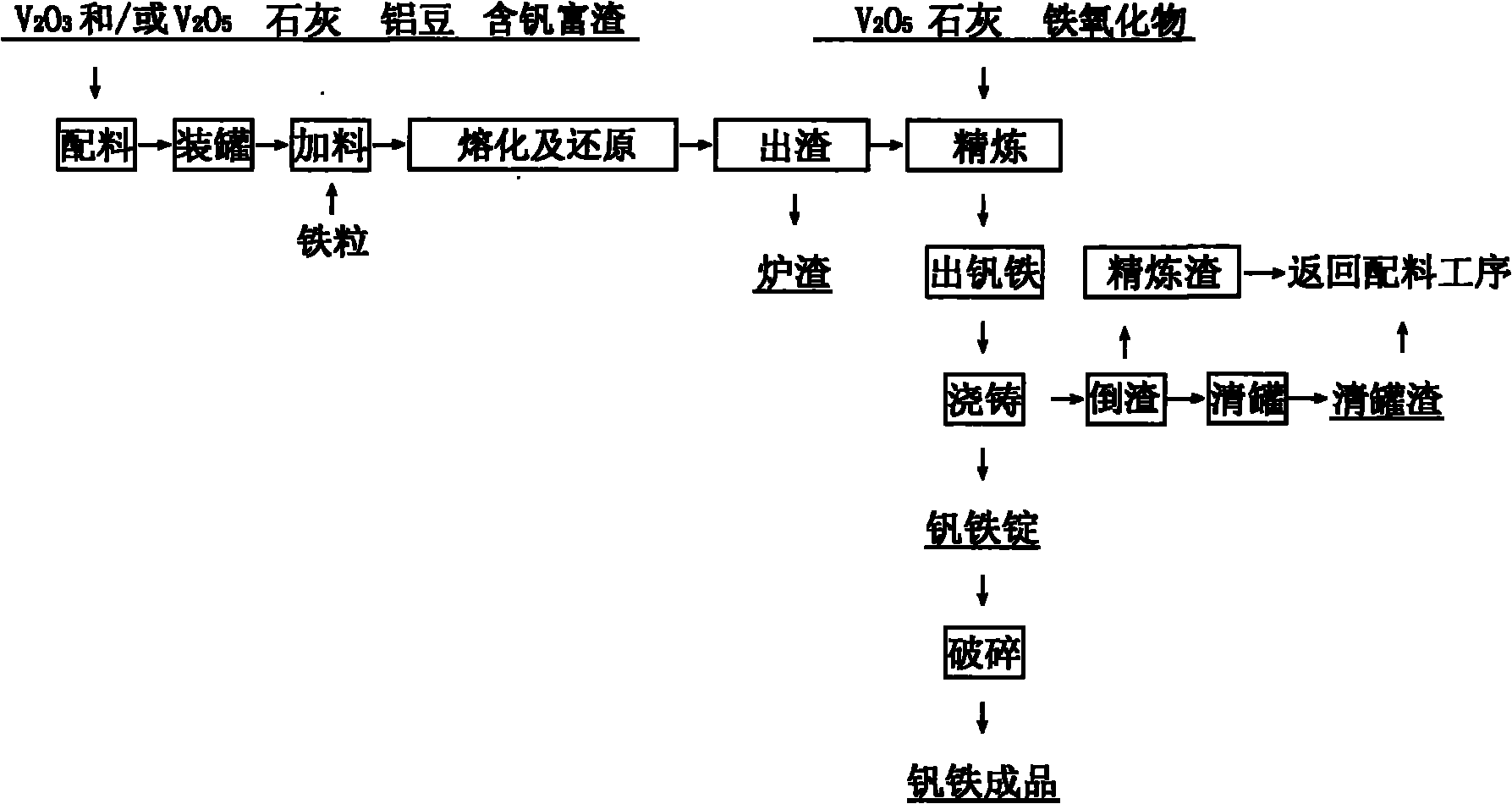

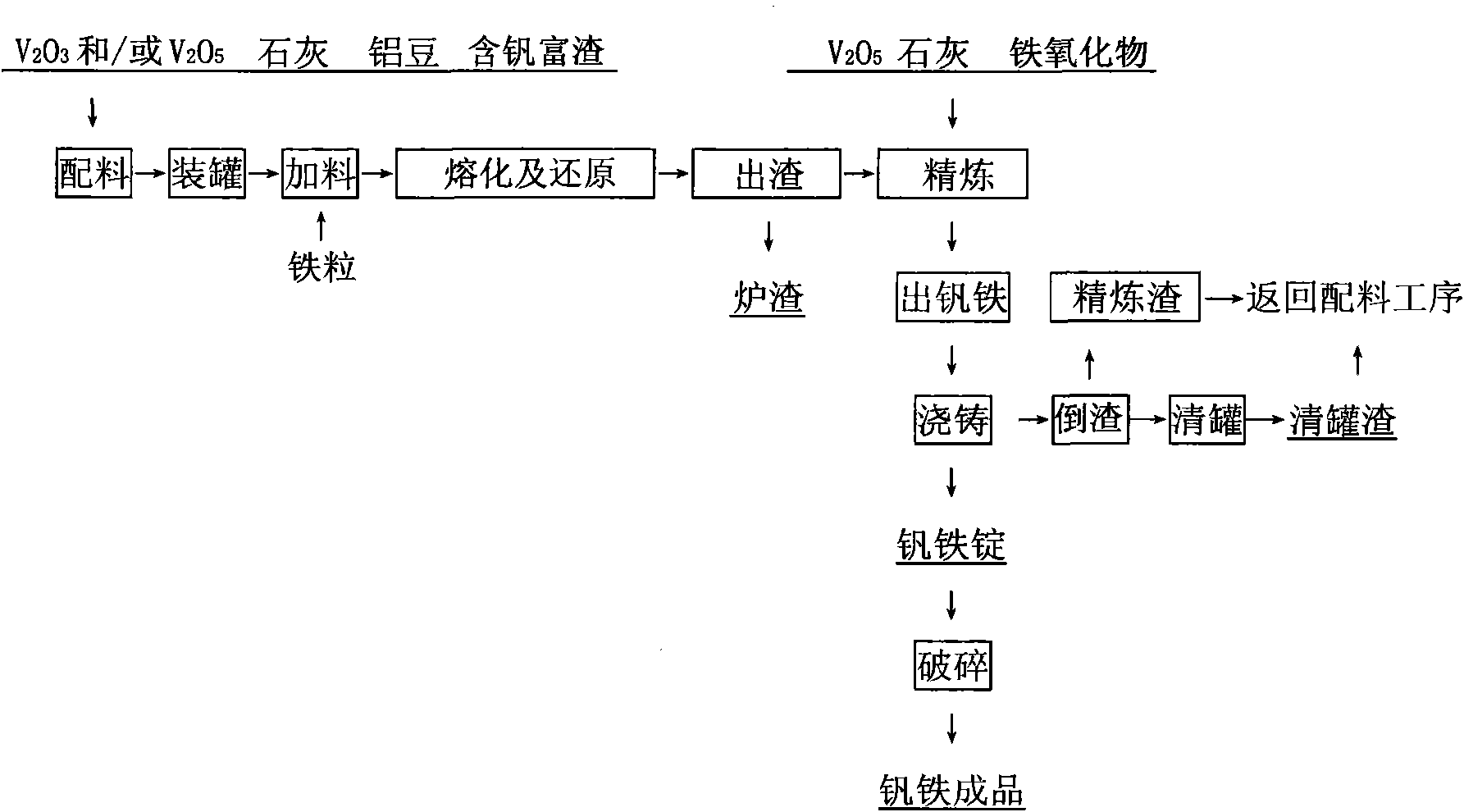

InactiveCN102115821AHigh recovery rateReduce energy consumptionProcess efficiency improvementSlagAlloy

The invention provides a method for smelting ferrovanadium, which comprises the following steps of: preparing a mixture from 10 to 35 weight percent of lime, 15 to 35 weight percent of aluminum and the balance of V2O3 and / or V2O5; adding the mixture into an electric furnace and adding a predetermined amount of iron according to the requirement simultaneously; electrifying to melt materials in theelectric furnace so as to reduce the V2O3 and / or the V2O5 by using the aluminum, and discharging 80 to 95 weight percent of slag when the content of all vanadium in the slag is less than 0.2 weight percent; adding refined materials consisting of 15 to 35 weight percent of lime, 0 to 30 weight percent of iron oxide and the balance of V2O5 into the electric furnace according to the proportion of 10to 80kg per ton of ferrovanadium, refining, and discharging alloy liquid and refined slag when the content of the aluminum and vanadium in the ferrovanadium alloy liquid meets the requirement of a ferrovanadium alloy product to be produced on the content of the aluminum and the vanadium; and casting to obtain the ferrovanadium alloy product. By the method, 97 to 99 percent of vanadium recovery rate can be achieved, and energy consumption can be reduced.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +3

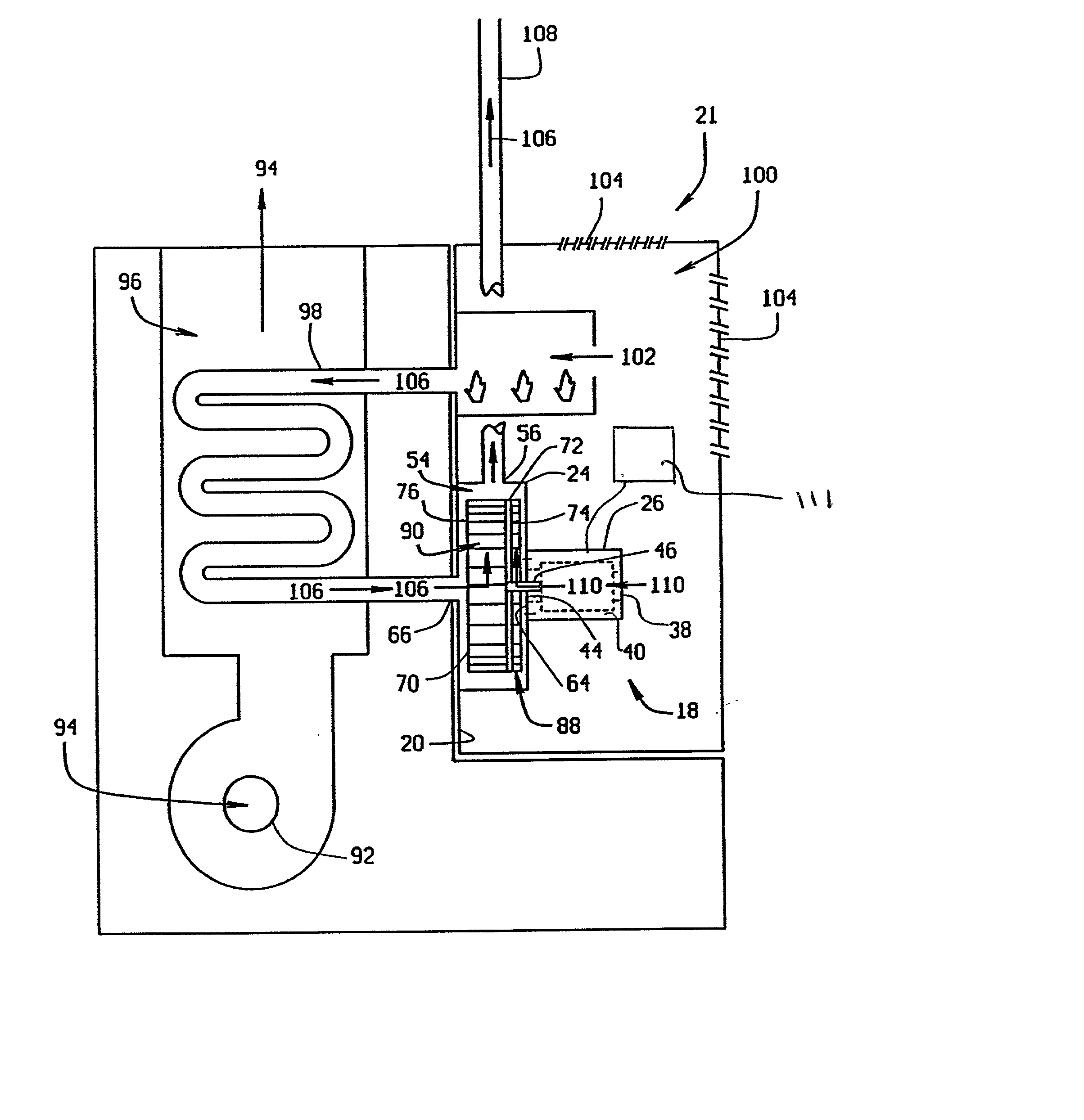

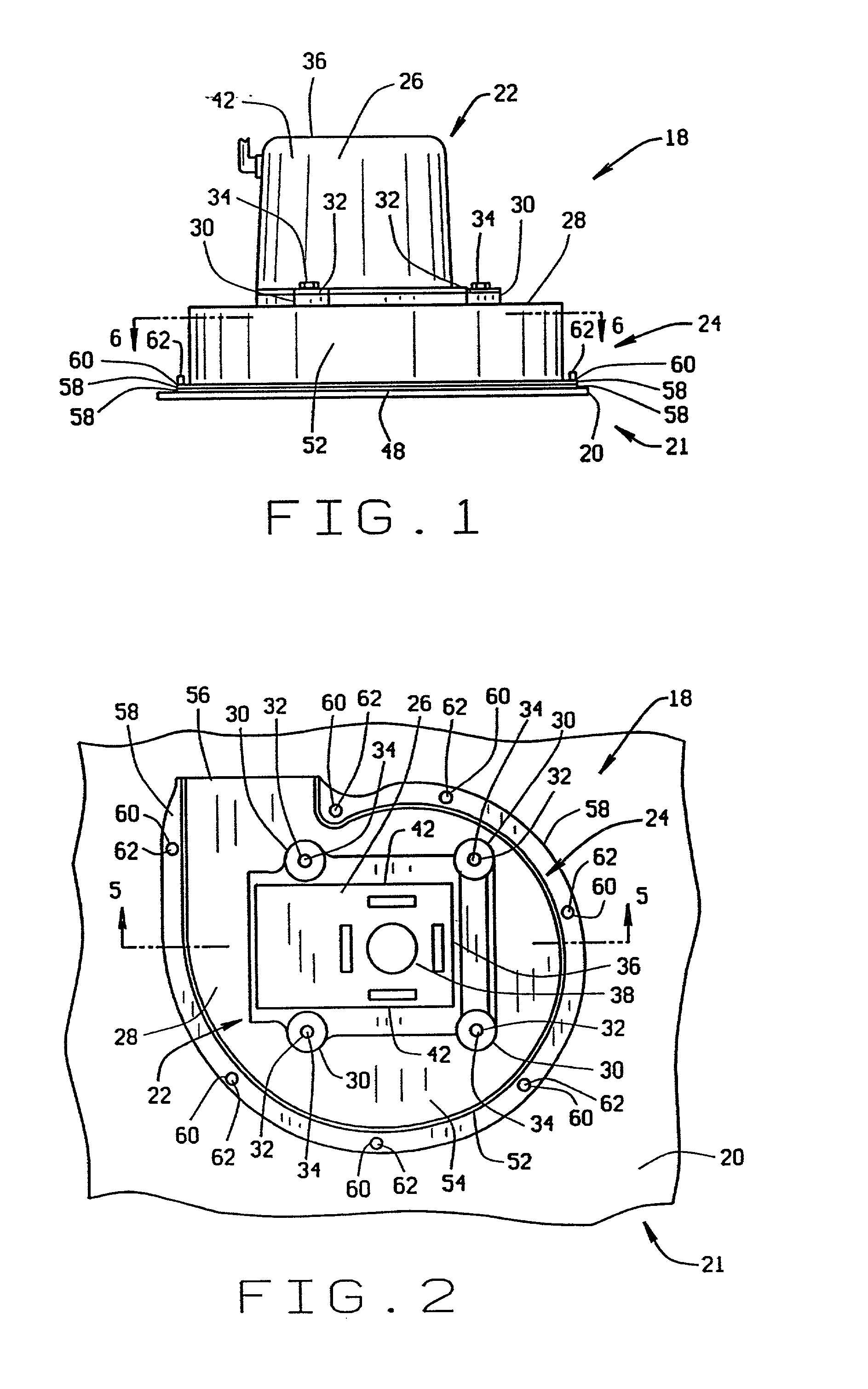

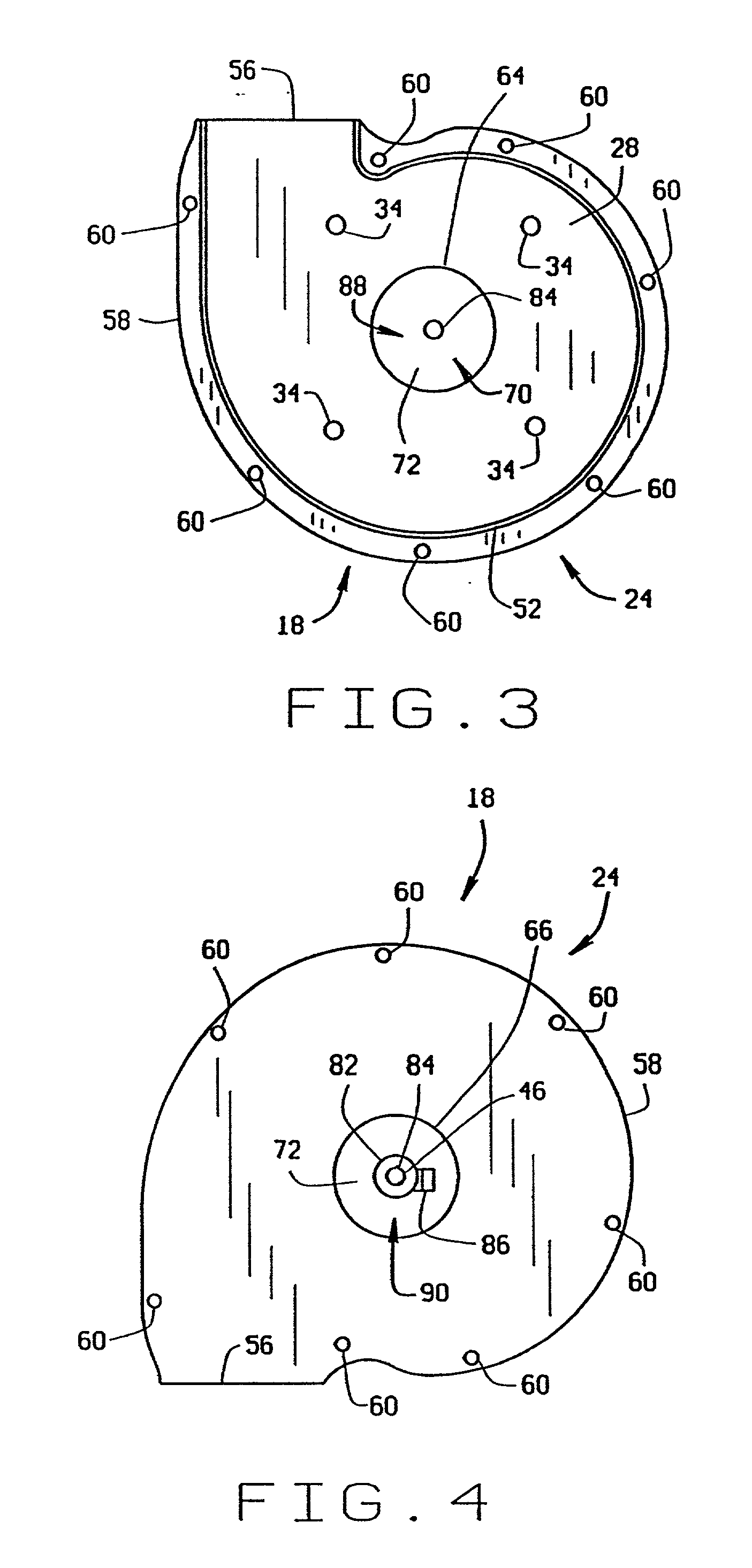

Apparatus for and method of operating a furnace blower to evaporate condensate within an exhaust flue

InactiveUS20020014233A1Reduce noiseCooler vestibulePump componentsAir heatersMotor speedExhaust valve

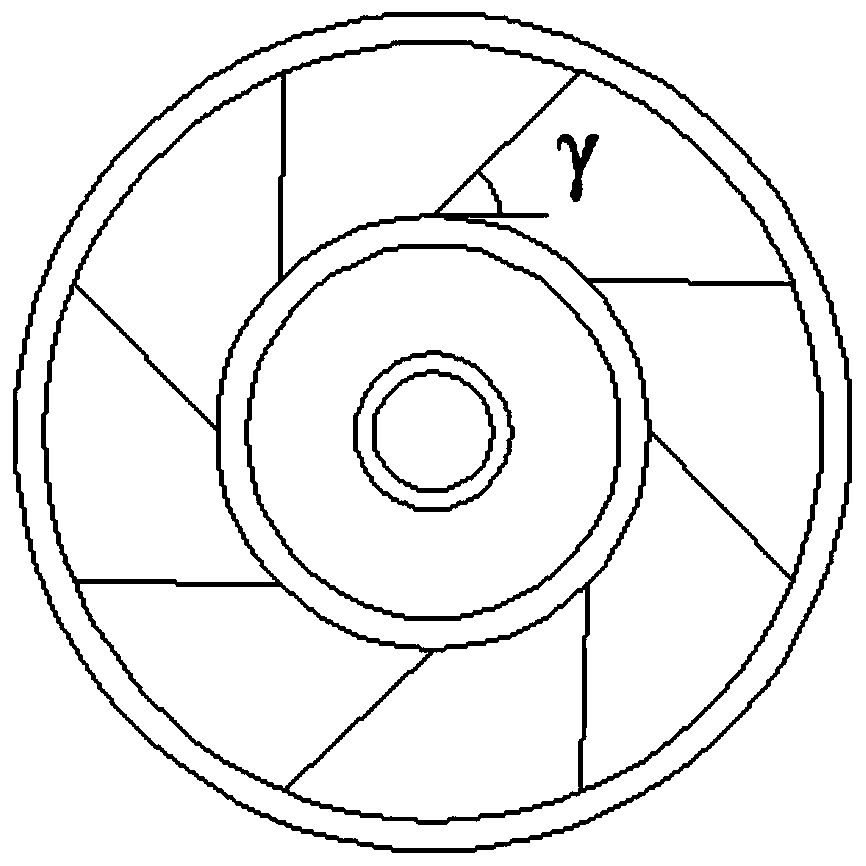

A blower for a furnace is provided where the blower has an impeller that is configured to create a primary air flow of combustion air into the blower housing and a secondary air flow of cooling air through the blower motor. The primary air flow of combustion air into the furnace generates hot exhaust gases for a heat exchanger in the furnace. The secondary air flow cools the blower motor. The secondary air flow is mixed with the hot exhaust gases in the blower housing and cools the exhaust gases before being discharged from the blower housing. A control operates the blower for a time period after each combustion cycle to introduce ambient air into the exhaust flue and chimney to ensure the evaporation of any condensate forming from the products of combustion contained in the exhaust. The blower may be a variable or multi-speed motor so that a different motor speed may be used for combustion than for the run time after combustion.

Owner:JAKEL

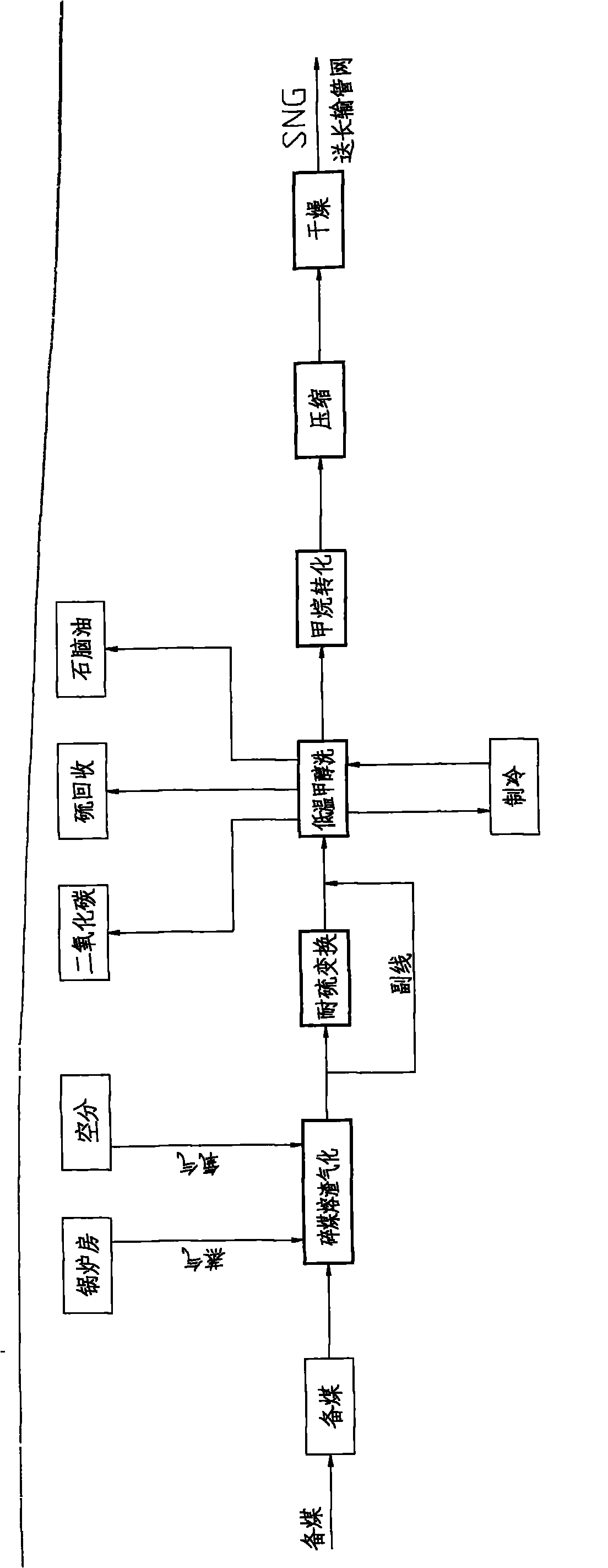

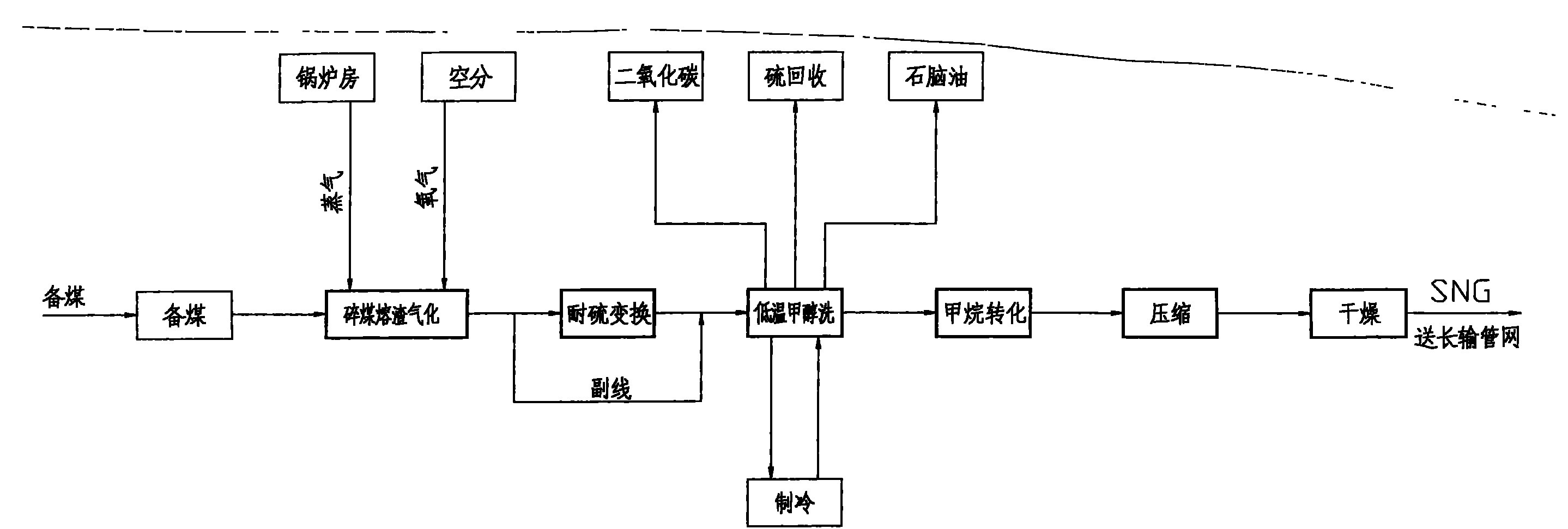

Technique for producing coal natural gas by utilizing crushed coal slag through gasification

ActiveCN101768488AMature and reliable technologyStable operation and maintenanceGaseous fuelsCombustible gas catalytic treatmentNaphthaSulfur

A technique for producing coal natural gas by utilizing crushed coal slag through gasification includes that part of crude coal gas containing CH4 produced by crushed coal slag through gasification receives sulfur tolerant shift, the other part of crude coal gas is conveyed in a sub-line and converges with the gas after sulfur tolerant shift to be cooled, the cooled gas is purified to remove CO2,H2S, naphtha and H2O and other impurities to obtain synthesis gas meeting the methane synthesis H / C ratio, the synthesis gas performs methane synthesis under the effect of methane conversion catalyst, and the methane-synthesis natural gas (SNG) is transmitted in long-distance pipeline network after compression and drying. The invention has the advantages of high gasification rate, high gasification intensity, low consumption and low water content of coal gas.

Owner:SEDIN ENG

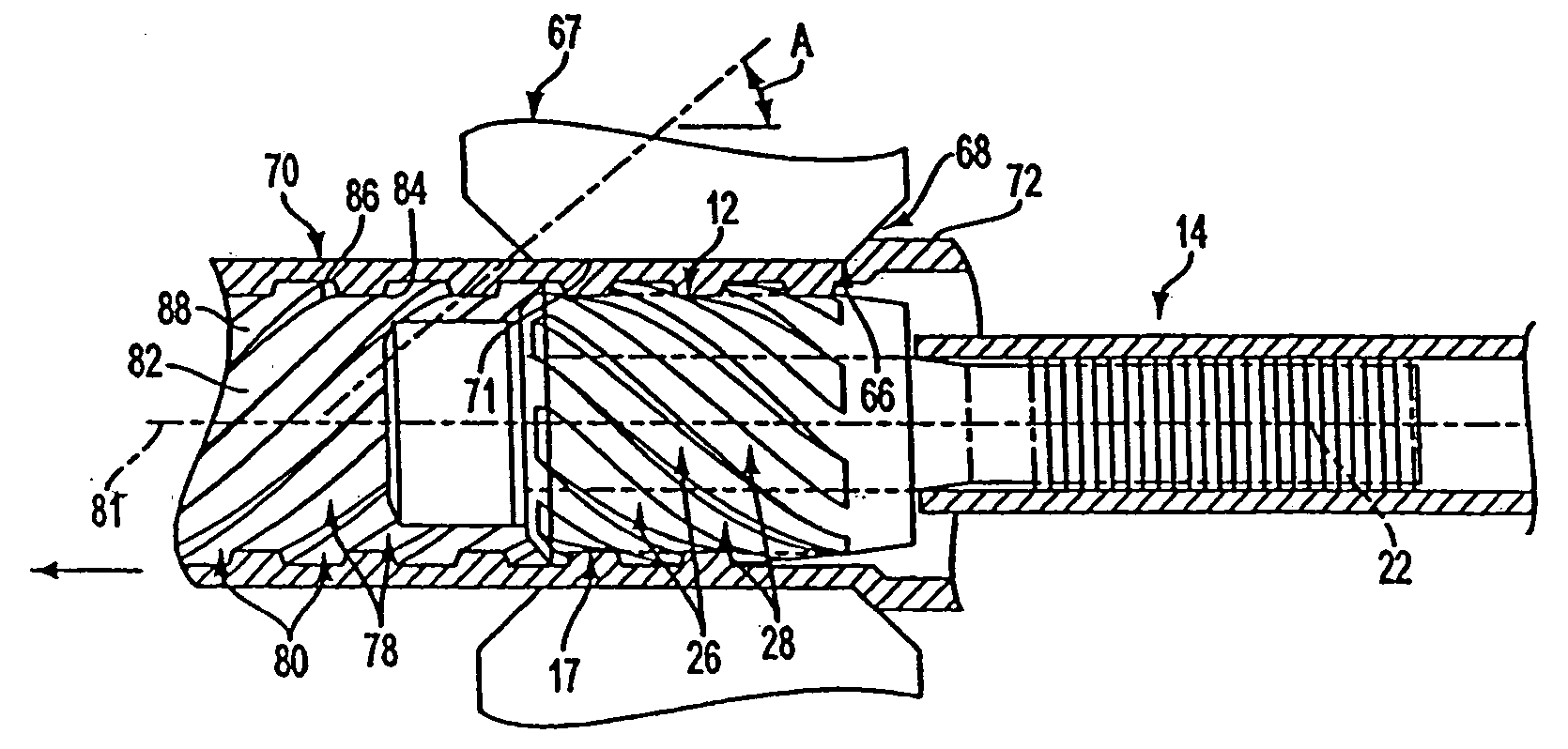

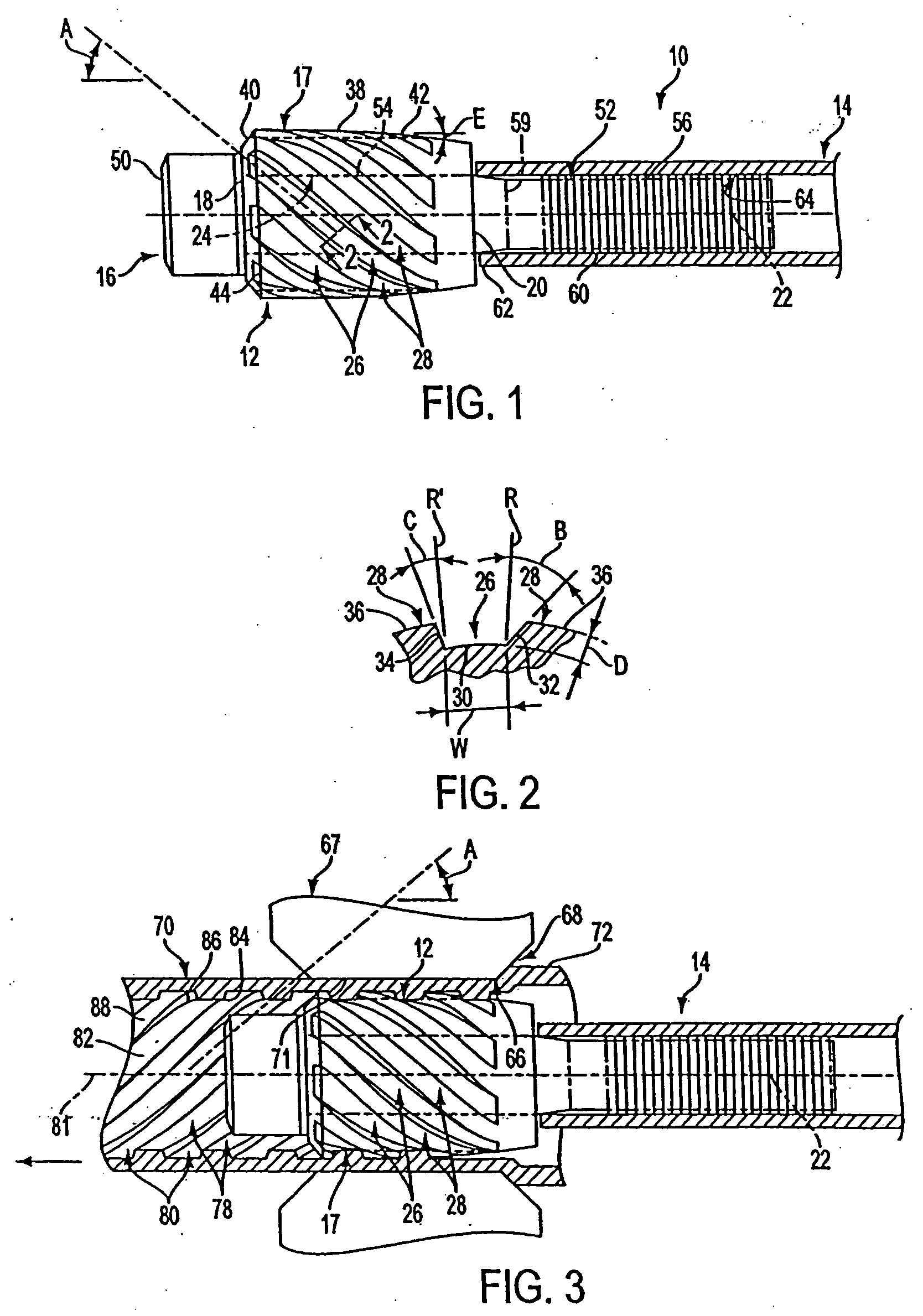

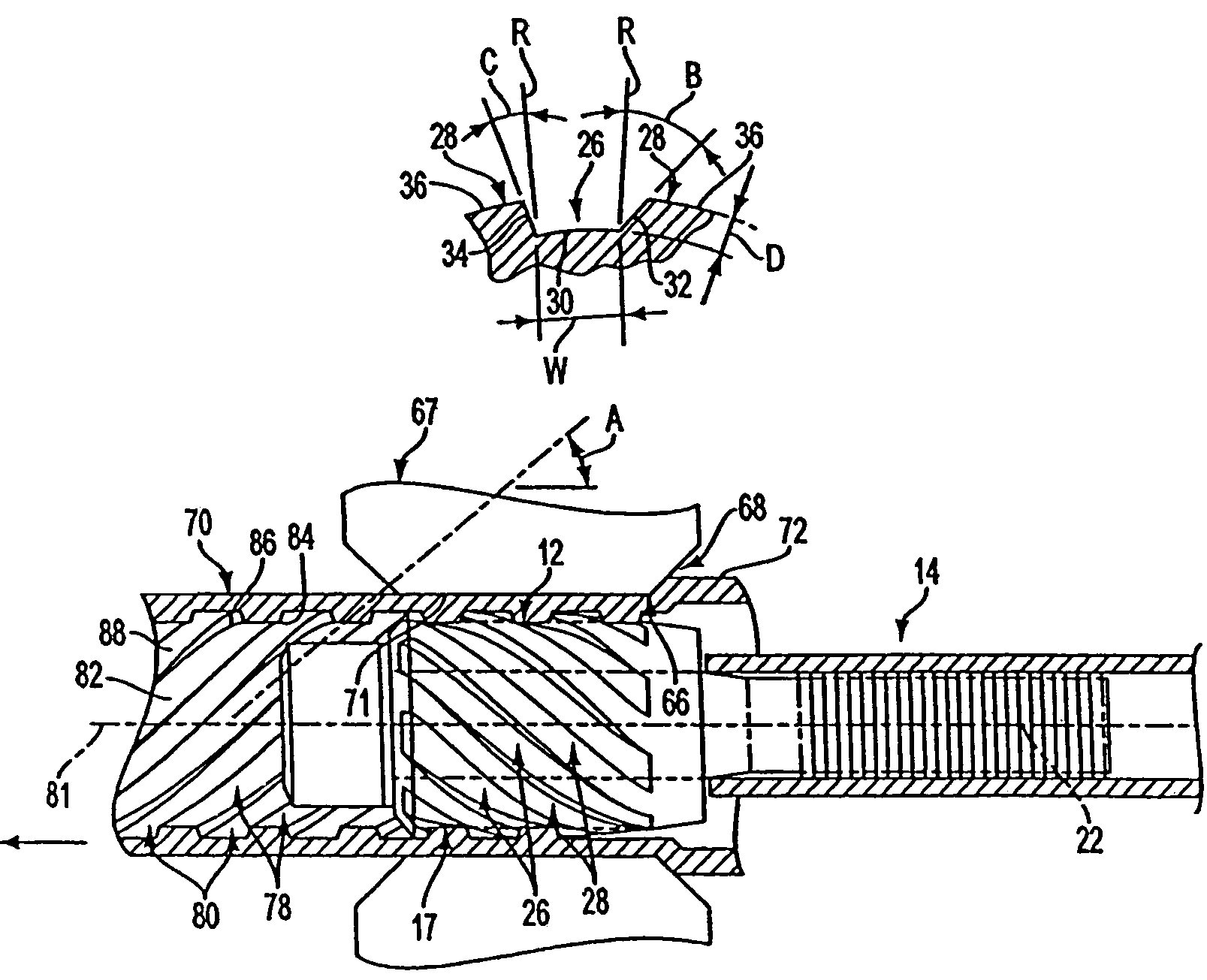

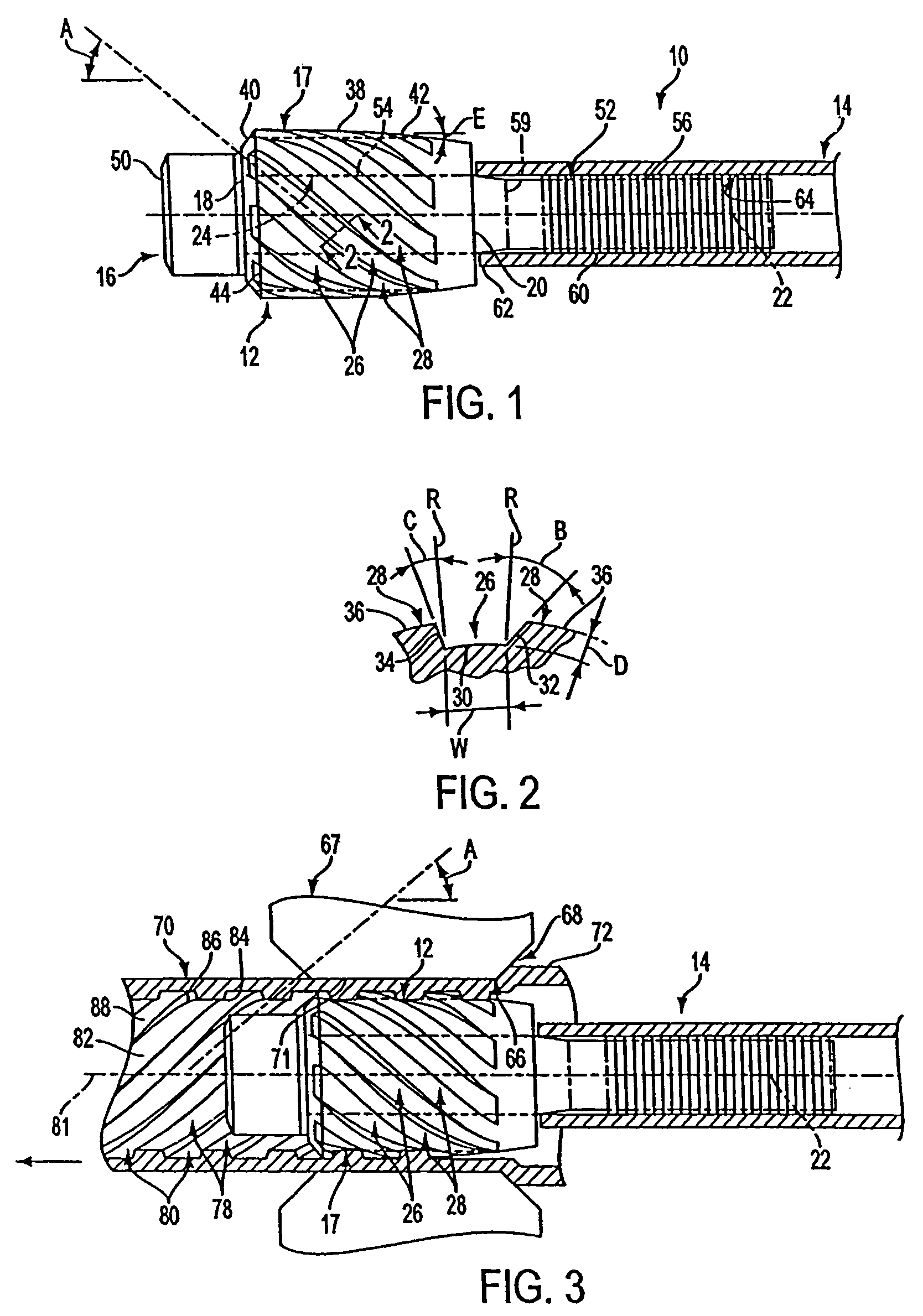

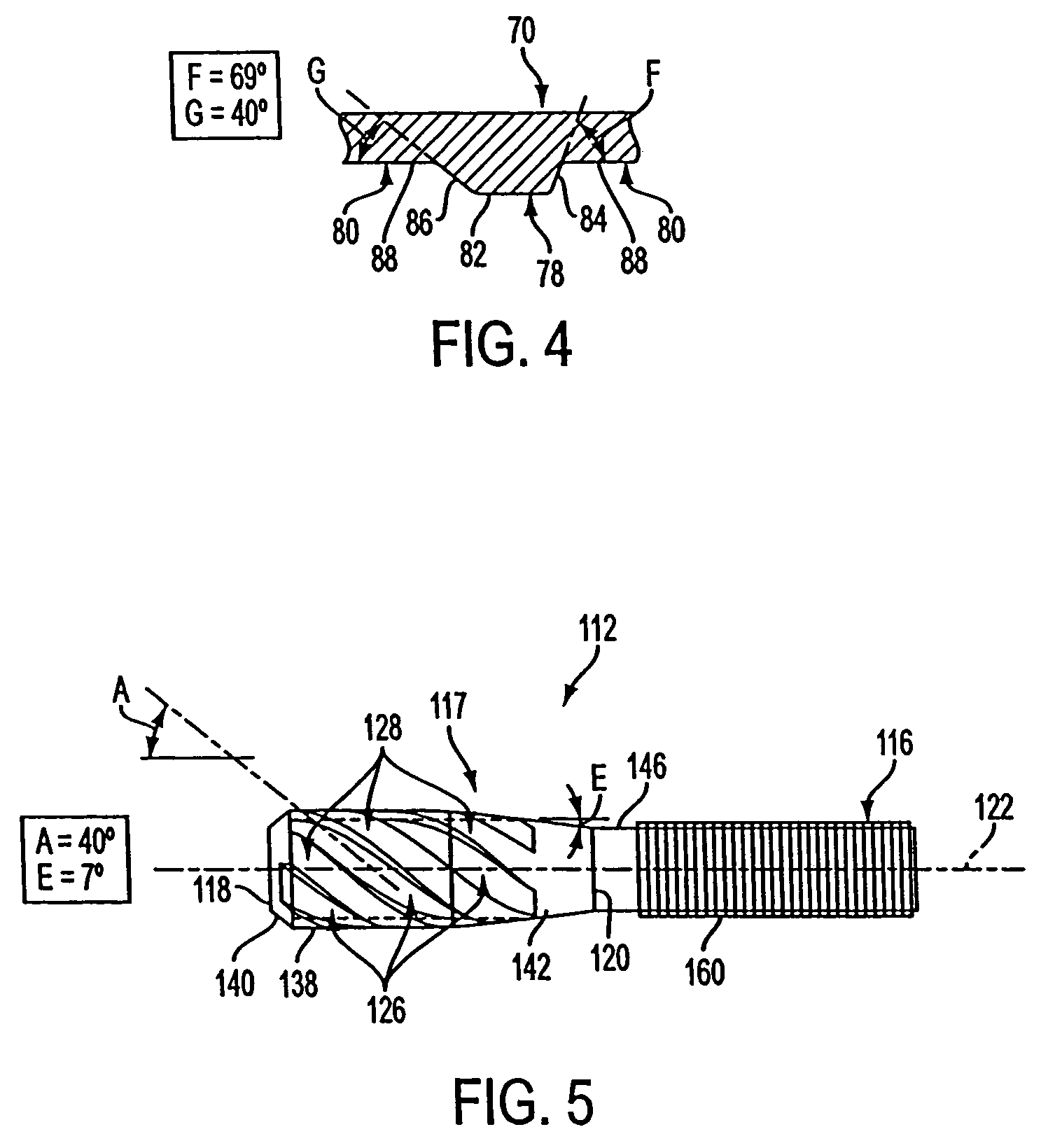

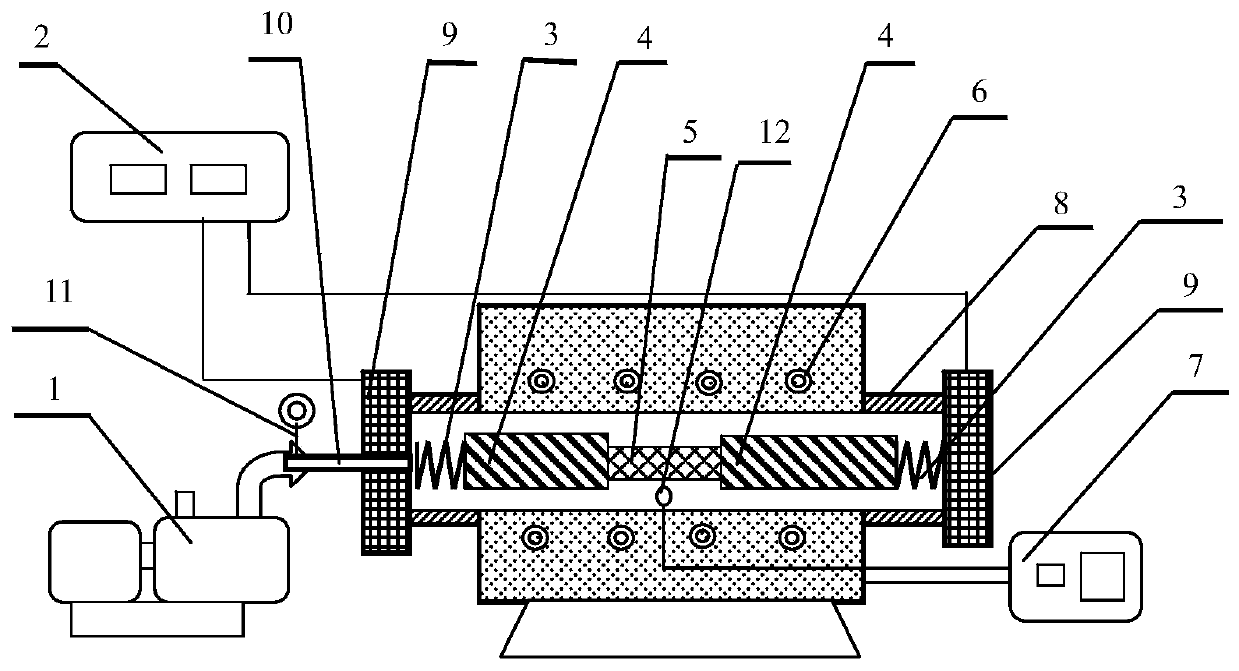

Apparatus and method for forming internally ribbed or rifled tubes

ActiveUS20050229667A1Improve productivityImprove tool lifeDrawing mandrelsMetal rolling stand detailsEngineeringHelix

A plug tool for forming internally helically ribbed tube comprises a plug body for being rotatably disposed in a die orifice of a drawing die. The plug body has a central longitudinal axis, a plurality of external grooves equally spaced about the axis and a plurality of external lands in alternating arrangement with the grooves. The grooves extend along the plug body at a helix angle to the axis. Each groove has a normal cross-section defined by a root surface and opposing flank surfaces extending angularly outwardly from the root surface to adjacent land surfaces. The flank surfaces extend angularly outwardly from the root surface in opposite directions at different angles from one another. A method for forming internally helically ribbed tube involves drawing a length of tubing over the plug body rotatably disposed in a die orifice of a drawing die and constricting the tubing in the drawing die to force the tubing into the grooves of the plug body to form a plurality of internal helical ribs in the tubing in correspondence to the grooves.

Owner:DOOSAN BABCOCK ENERGY AMERICA

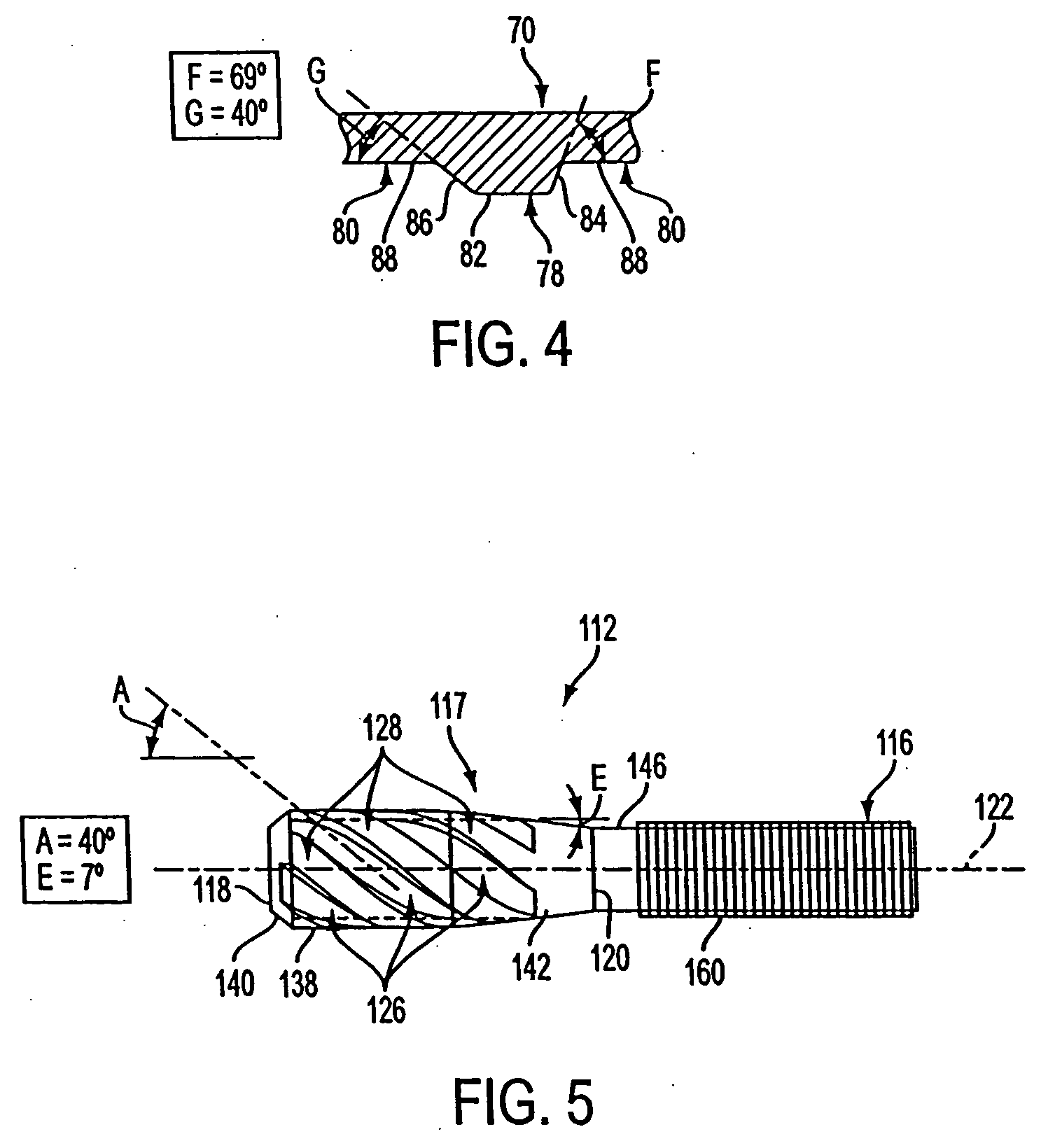

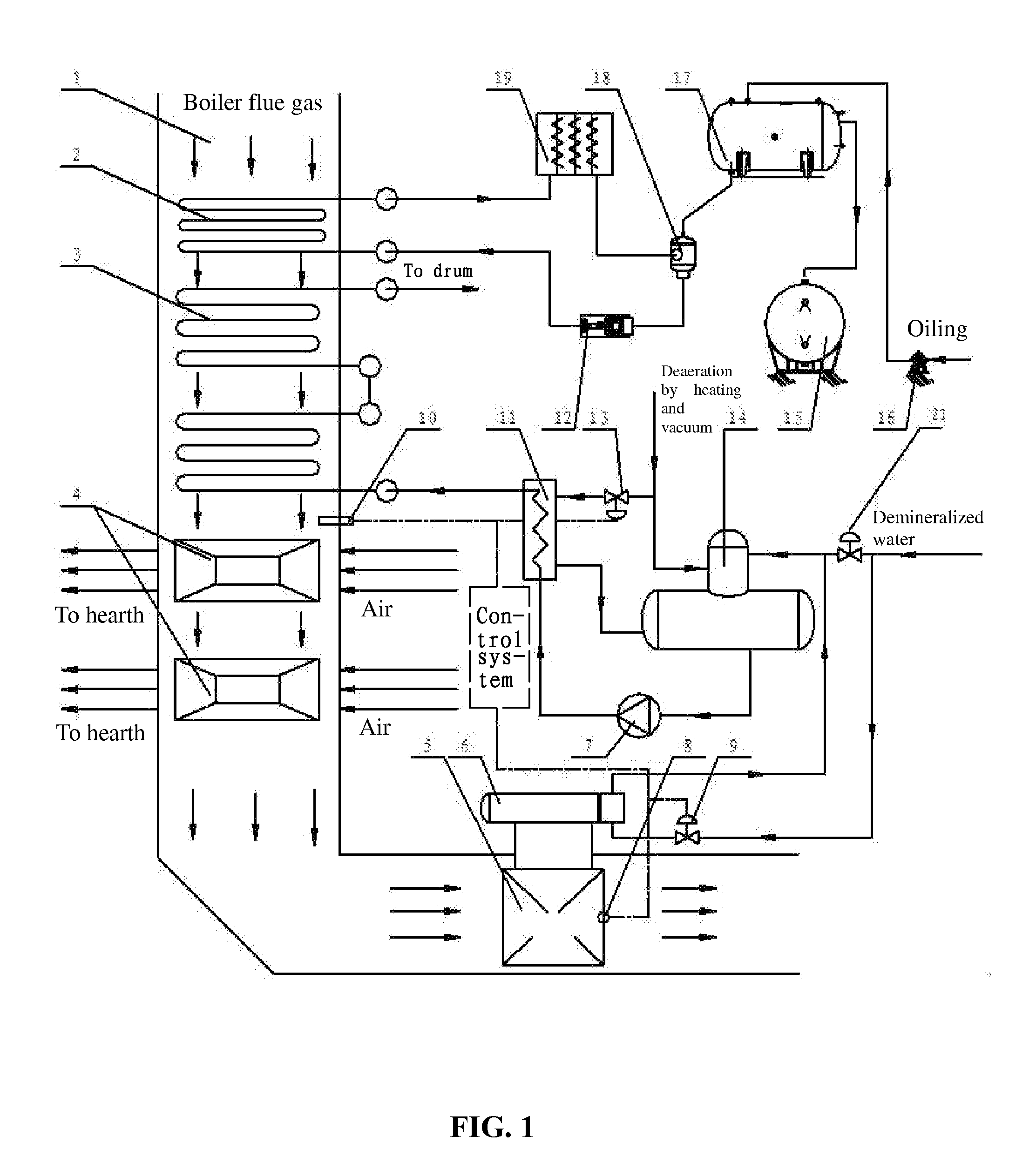

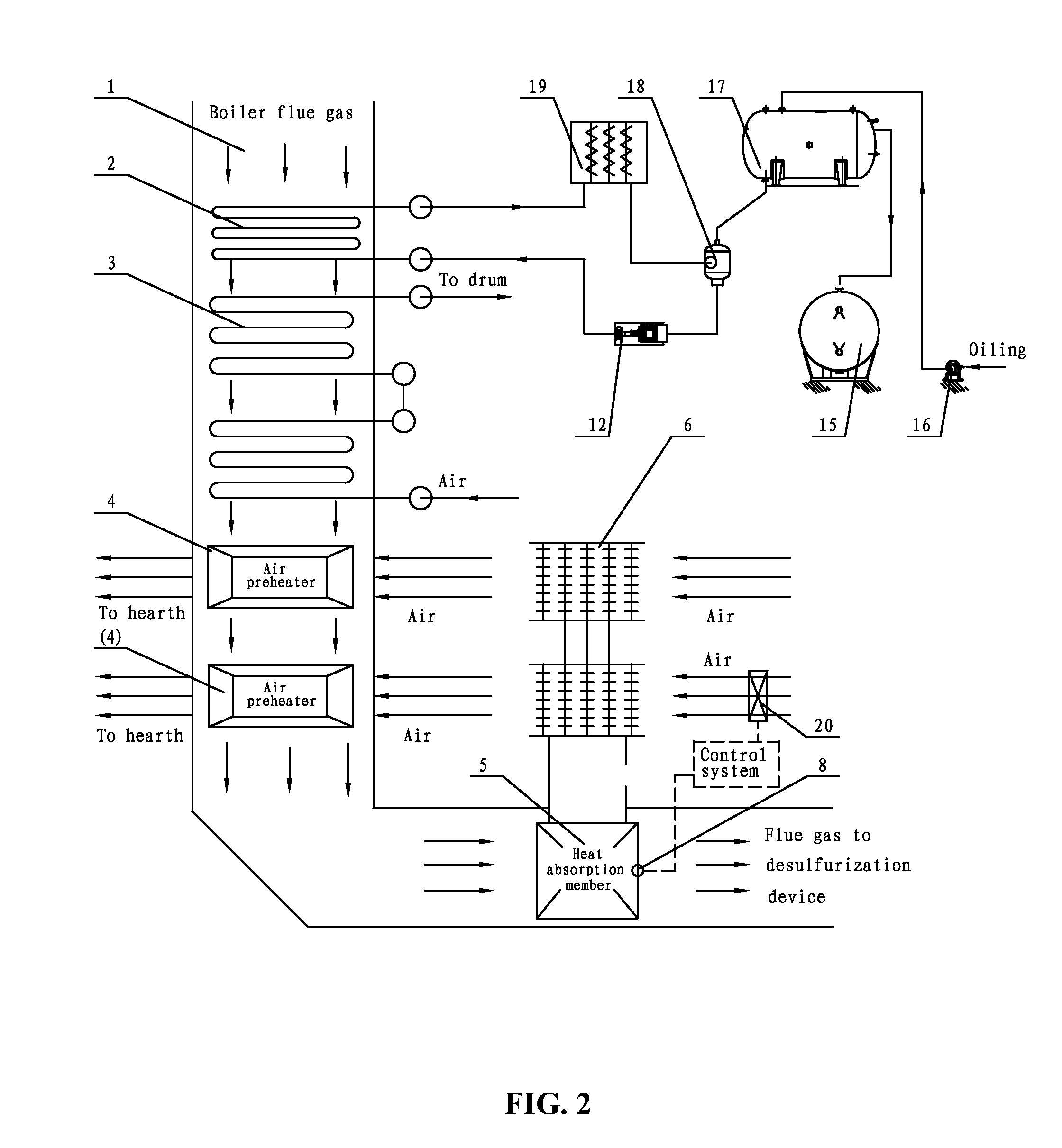

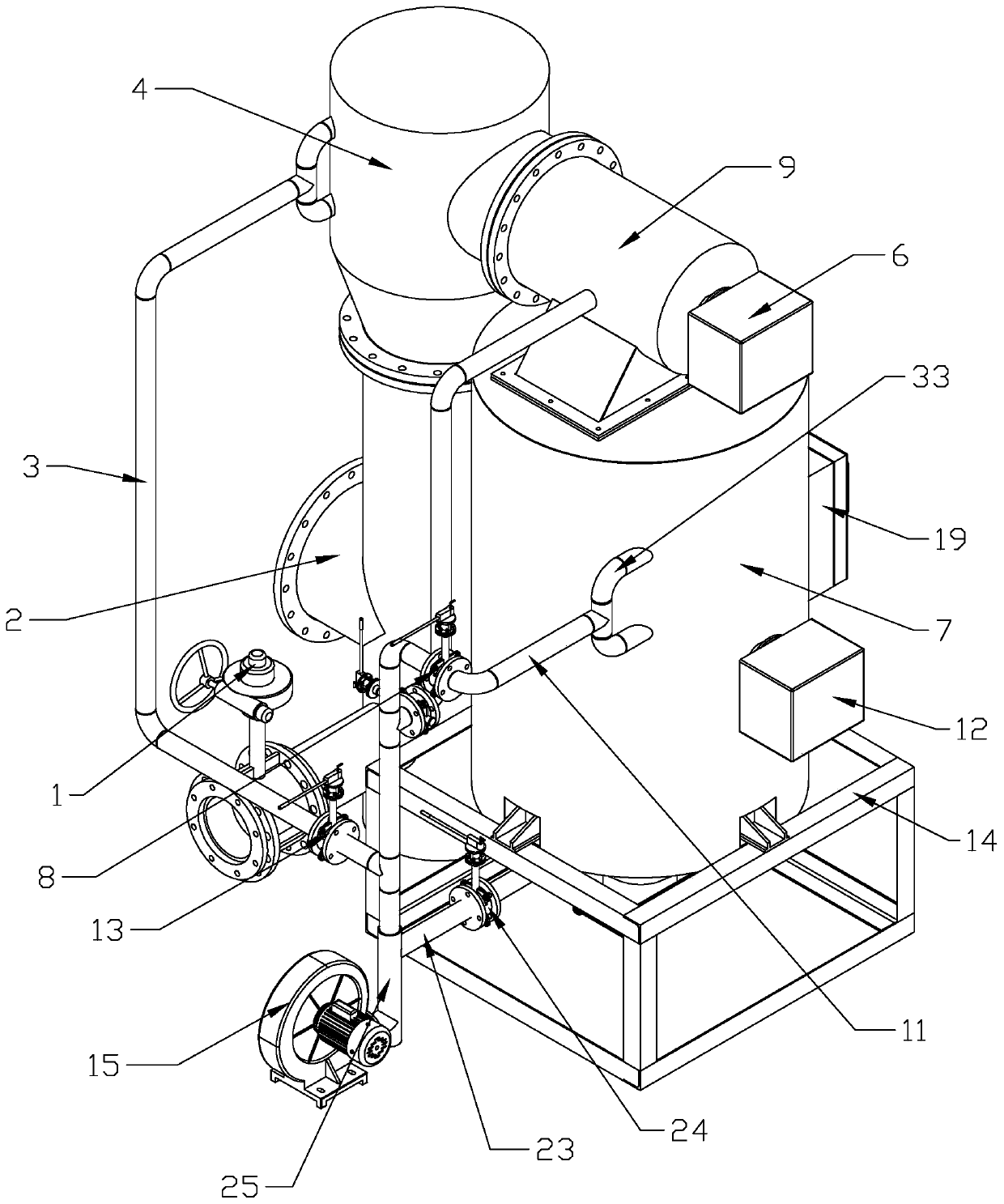

Heating system for heating heat-transfer oil usingboiler flue gas

InactiveUS20140007823A1Efficient outputLower furnace temperatureIndirect heat exchangersMachines/enginesAir preheaterFlue gas

A heating system for heating heat-transfer oil using exhaust heat of boiler flue gas. The system includes: a flue, an economizer, an air preheater, and a heat-transfer oil heater. The economizer and the air preheater are disposed in the flue along the flow direction of the flue gas. The heat-transfer oil heater is disposed inside the flue in front of the economizer and is connected to a heat consumption device via a first circulating pipe. The circulating pipe is equipped with a circulating pump.

Owner:SHANGHAI FUBO ENVIRONMENTAL PROTECTION EQUIP

Solar cell crystal silicon wafer phosphorus diffusion method

InactiveCN107331731ASimple methodReduce gas usageFinal product manufactureSemiconductor/solid-state device manufacturingChemistryNitrogen gas

The invention discloses a solar cell crystal silicon wafer phosphorus diffusion method. The method comprises the following steps: 1) a to-be-processed crystal silicon wafer is placed in a diffusion furnace, temperature is raised, and nitrogen carrying a phosphorus source, dry oxygen and large nitrogen are introduced, constant-source diffusion is carried out; 2) introduction of the nitrogen carrying the phosphorus source is stopped, temperature is raised, the dry oxygen and the large nitrogen are introduced to perform propelling; 3) the nitrogen carrying the phosphorus source and the dry oxygen are introduced, and low-temperature diffusion is carried out; 4) the introduction of the nitrogen carrying the phosphorus source is stopped, and constant-temperature propelling is carried out; 5) temperature is raised, the nitrogen carrying the phosphorus source and the dry oxygen are introduced, and constant-source diffusion is carried out; 6) the introduction of the nitrogen carrying the phosphorus source is stopped, and oxygen-existing limited-source diffusion is performed; 7) temperature is lowered, the nitrogen carrying the phosphorus source, the dry oxygen and the large nitrogen are introduced, and cooling diffusion is carried out; and 8) temperature is lowered, and the crystal silicon wafer is taken out from a boat. The phosphorus diffusion method is simple and is easy to do, and the phosphorus diffusion method is widely used; and photoelectric conversion efficiency of the silicon wafer can be effectively improved through adoption of the method, electric performance of a solar cell is improved, and the phosphorus diffusion method is suitable for promotion and application.

Owner:HEFEI DAZHUO ELECTRIC POWER CO LTD

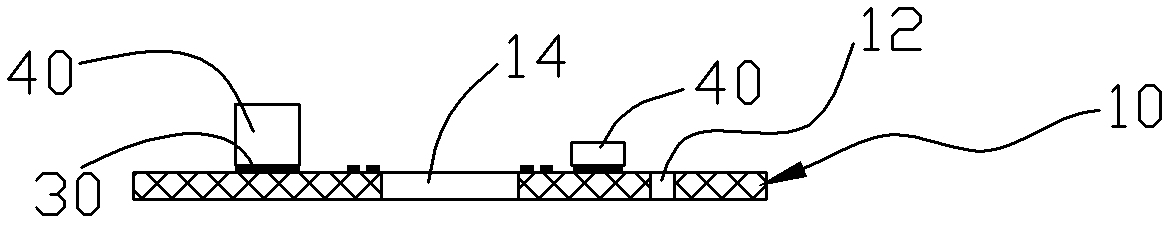

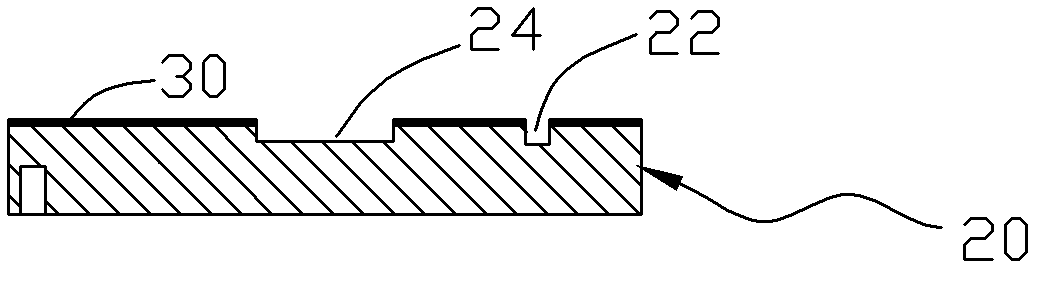

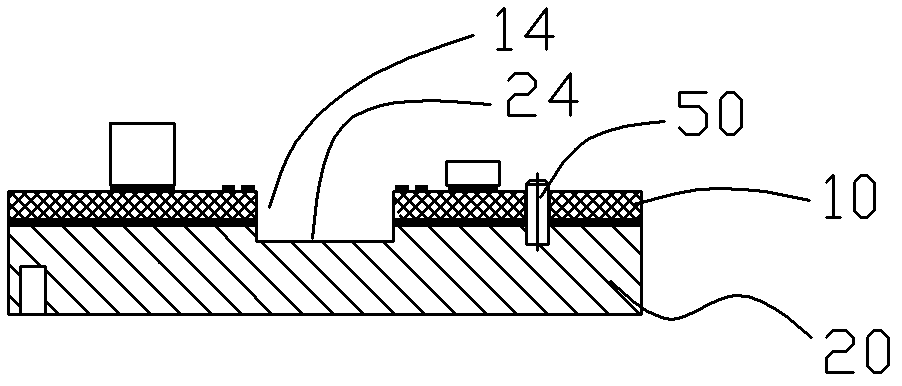

Method for assembling printed circuit board

ActiveCN102665374AReduce lossLower furnace temperaturePrinted circuit assemblingAudio power amplifierEngineering

A method for assembling a printed circuit board comprises the steps of providing a printing mother board and a metal substrate, wherein a window is arranged on the printing mother board, components are attached to the printing mother board through a surface mount technology (SMT), and an installation pit which corresponds to the window is arranged on the metal substrate; brushing a uniform layer of normal-temperature soldering tin on an upper surface of the metal substrate, aligning the printing mother board to the metal substrate, enabling the printing mother board and the metal substrate to compress each other tightly, and aligning the window to the installation pit; providing a power amplifier which penetrates through the window and is placed in the installation pit, laying the normal-temperature soldering tin on the contact portion between the power amplifier and the printing mother board and on the contact portion between the power amplifier and the installation pit, and then compressing the power amplifier, the printing mother board and the metal substrate tightly; maintaining the tight compression states between the printing mother board and the metal substrate, between the power amplifier and the printing mother board and between the power amplifier and the metal substrate, and then compressing oppositely to form an assembly to be heated, so that the normal-temperature soldering tin is melted; and cooling down the assembly, so that the printed circuit board is formed.

Owner:COMBA TELECOM SYST CHINA LTD

Method for smelting ferrovanadium

InactiveCN102115821BHigh recovery rateReduce energy consumptionProcess efficiency improvementSlagAlloy

The invention provides a method for smelting ferrovanadium, which comprises the following steps of: preparing a mixture from 10 to 35 weight percent of lime, 15 to 35 weight percent of aluminum and the balance of V2O3 and / or V2O5; adding the mixture into an electric furnace and adding a predetermined amount of iron according to the requirement simultaneously; electrifying to melt materials in theelectric furnace so as to reduce the V2O3 and / or the V2O5 by using the aluminum, and discharging 80 to 95 weight percent of slag when the content of all vanadium in the slag is less than 0.2 weight percent; adding refined materials consisting of 15 to 35 weight percent of lime, 0 to 30 weight percent of iron oxide and the balance of V2O5 into the electric furnace according to the proportion of 10to 80kg per ton of ferrovanadium, refining, and discharging alloy liquid and refined slag when the content of the aluminum and vanadium in the ferrovanadium alloy liquid meets the requirement of a ferrovanadium alloy product to be produced on the content of the aluminum and the vanadium; and casting to obtain the ferrovanadium alloy product. By the method, 97 to 99 percent of vanadium recovery rate can be achieved, and energy consumption can be reduced.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +3

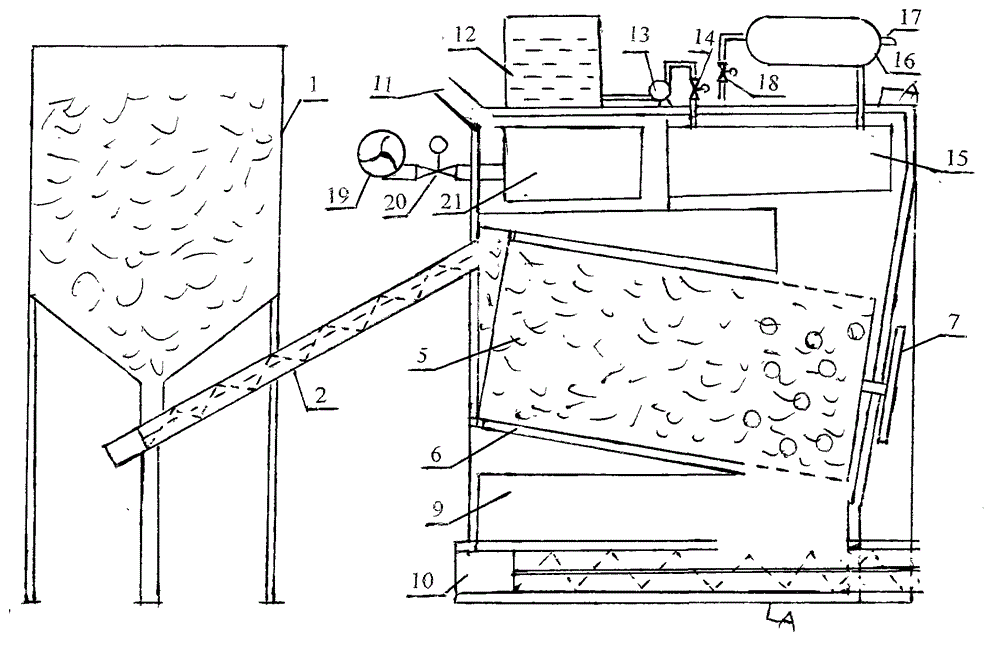

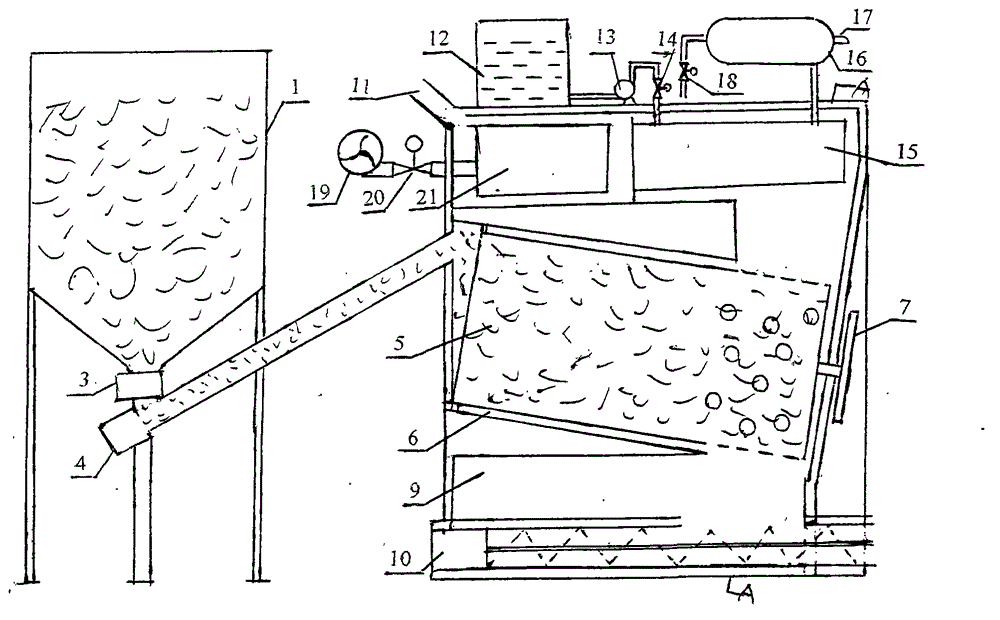

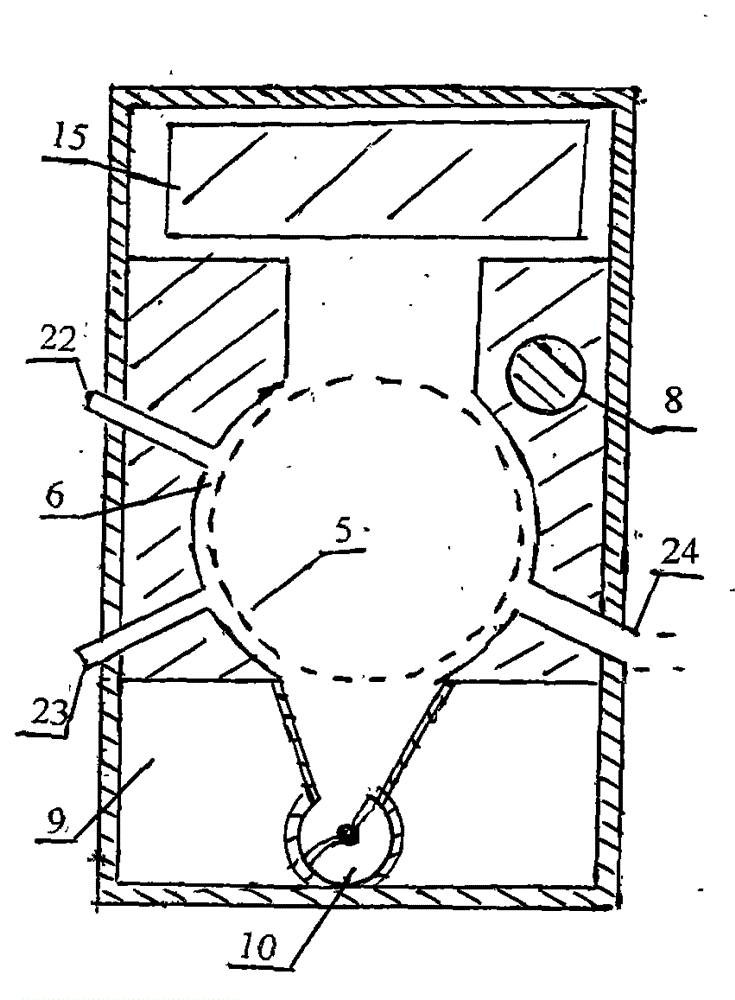

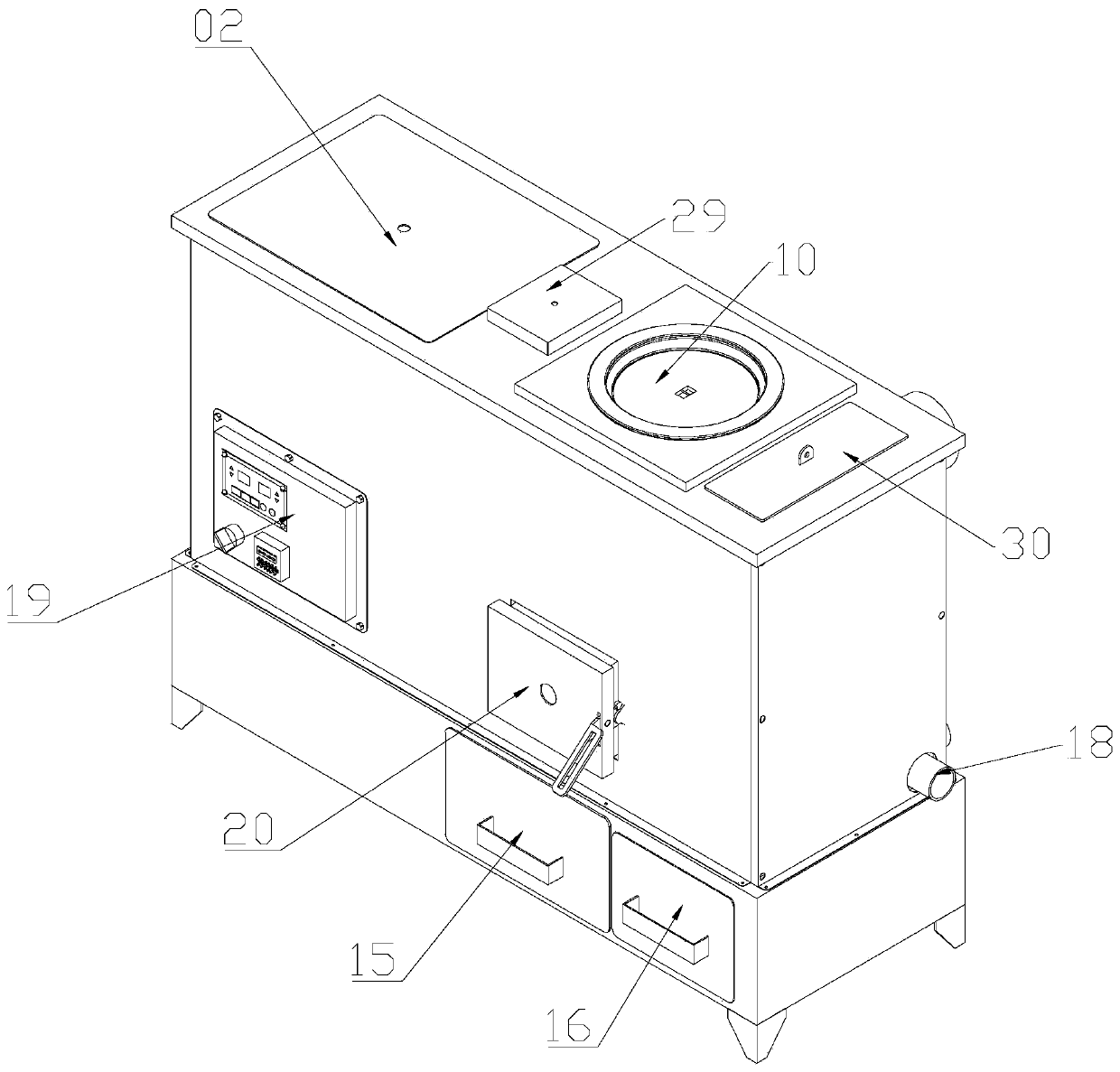

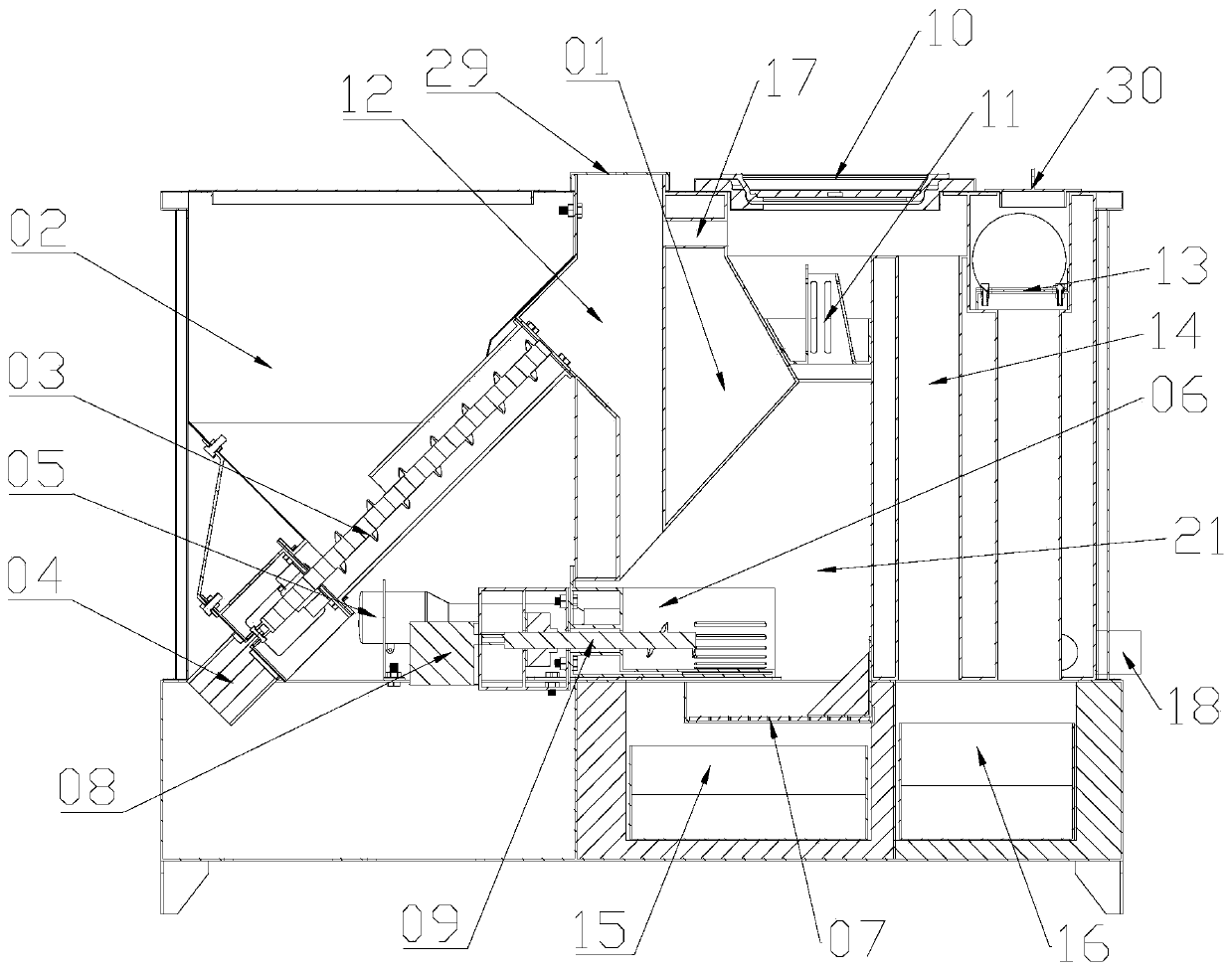

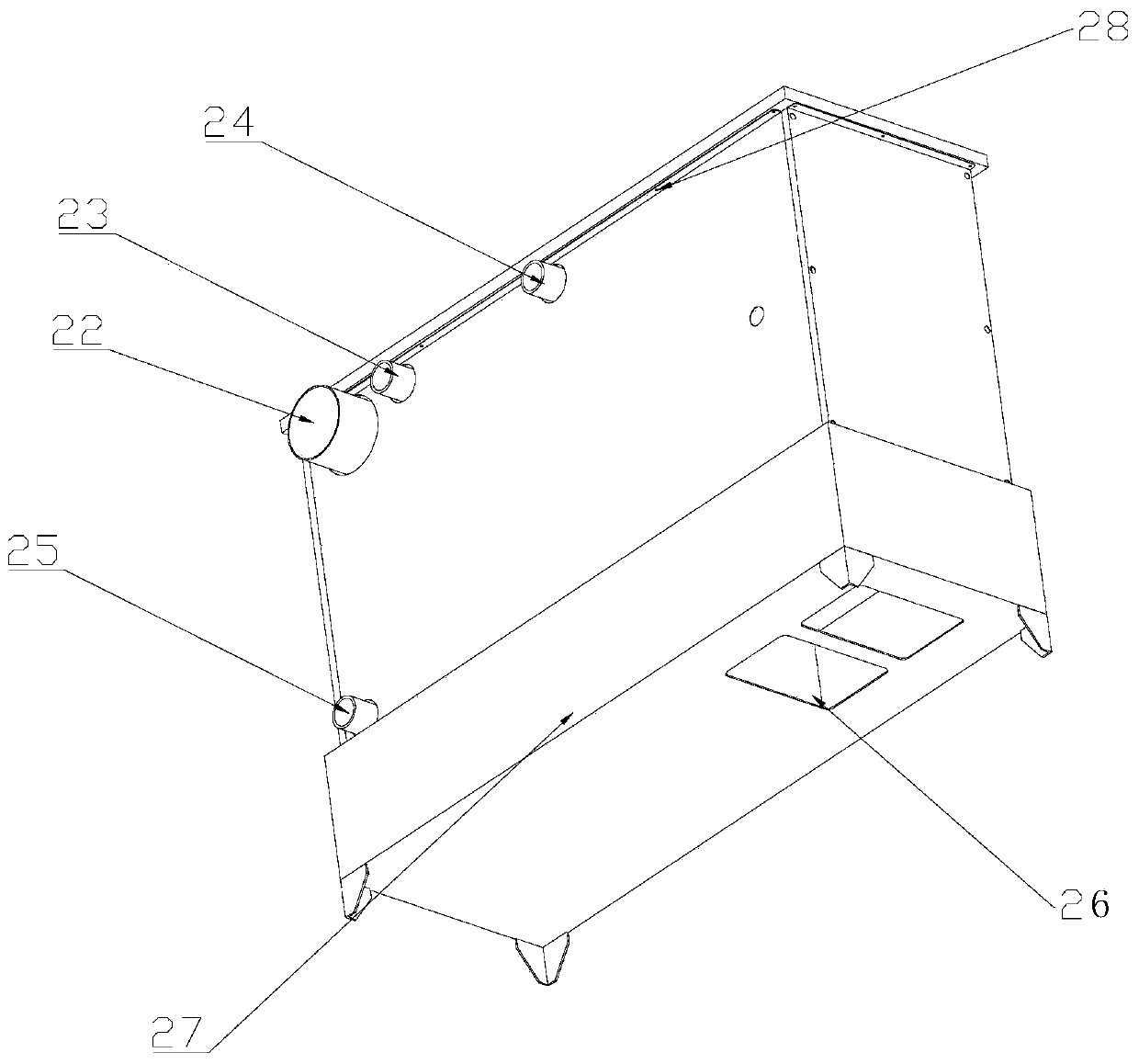

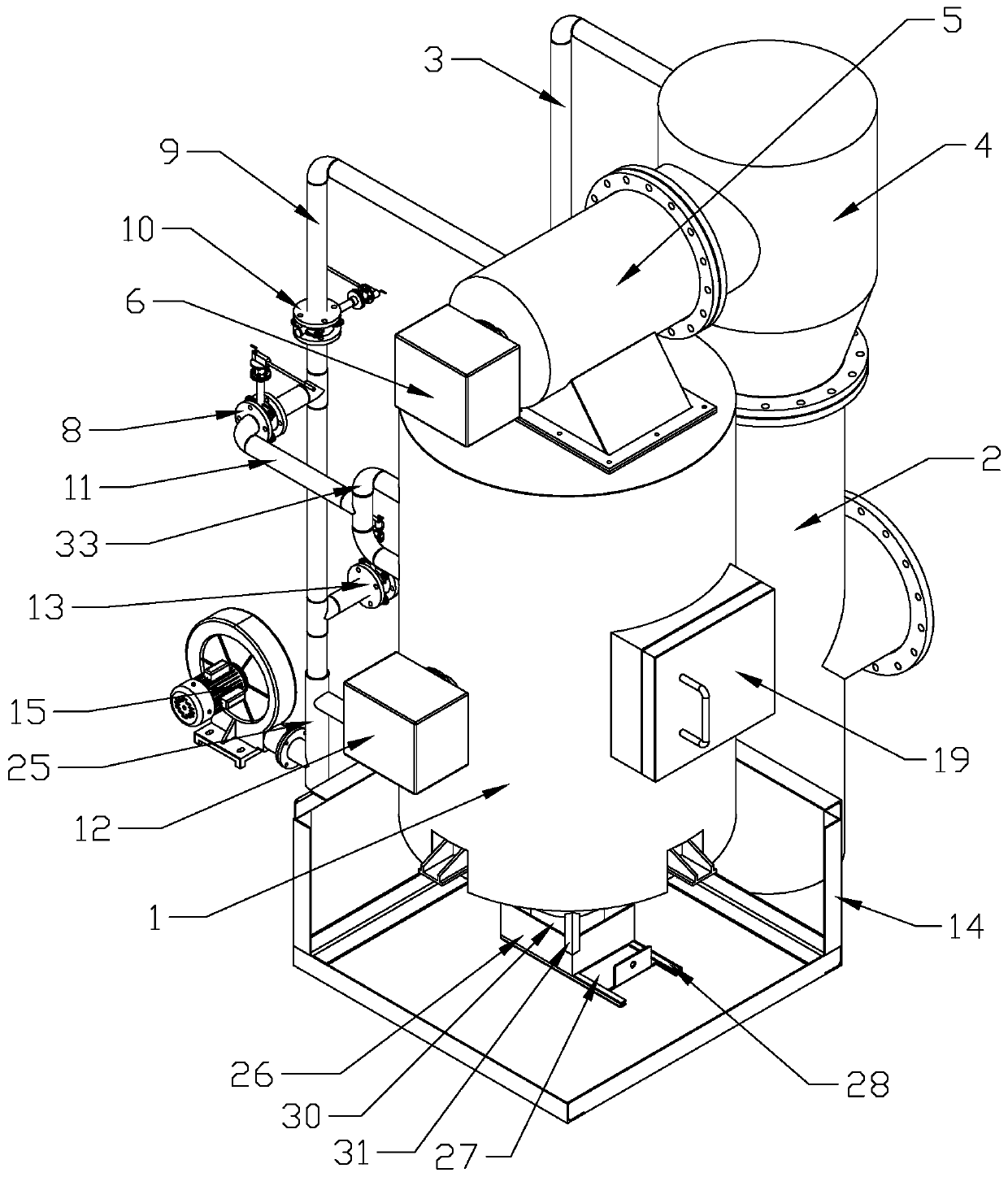

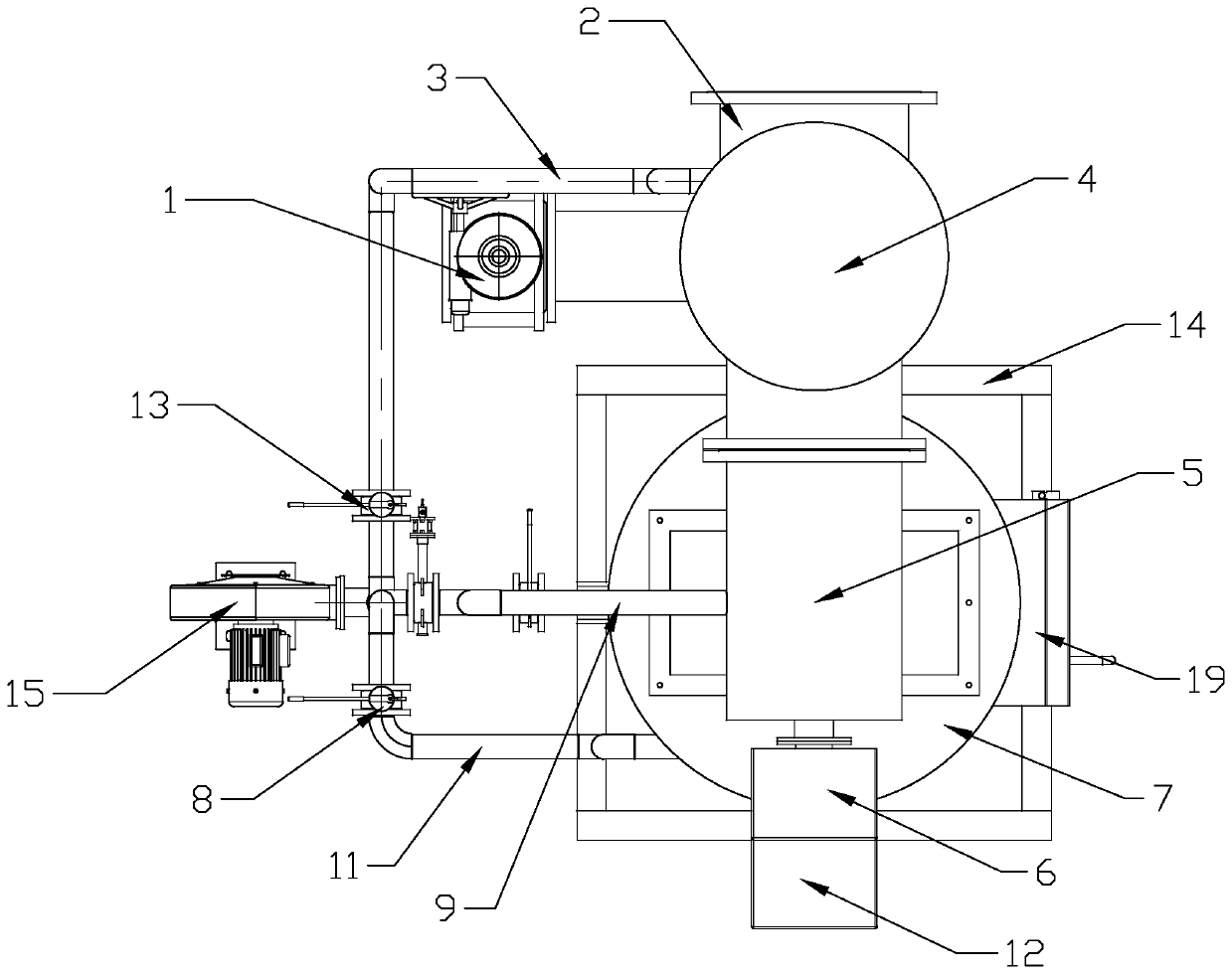

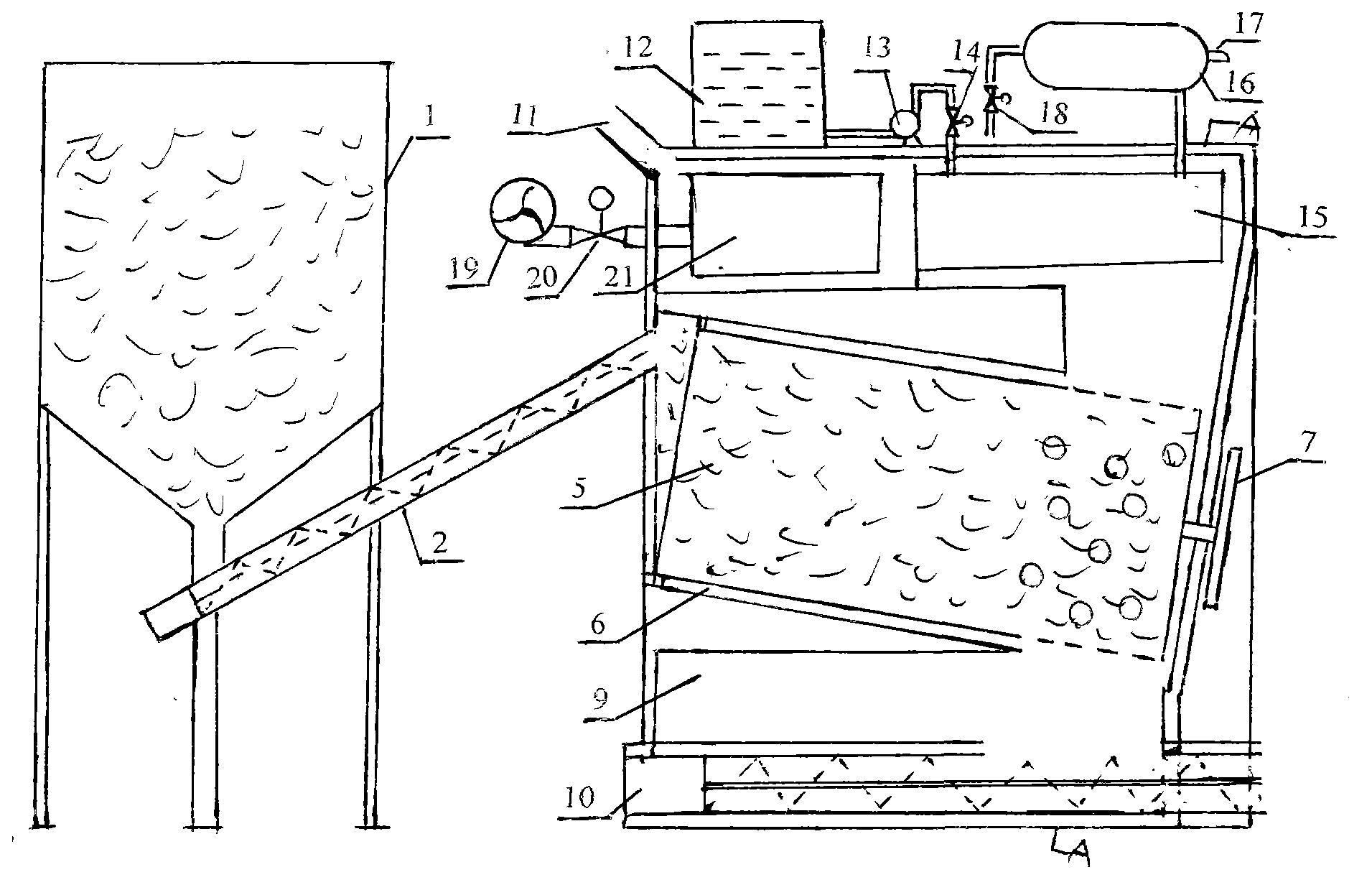

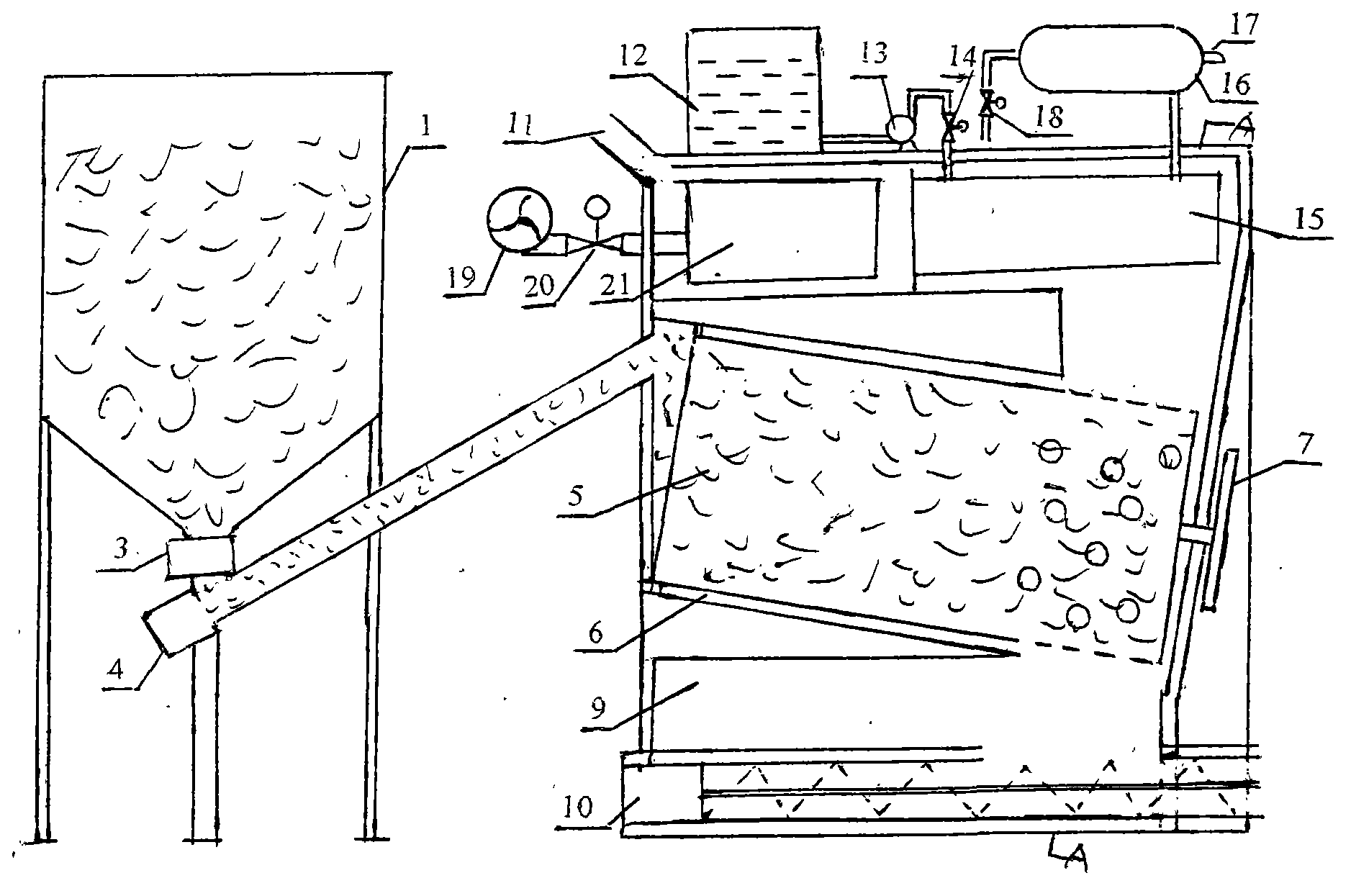

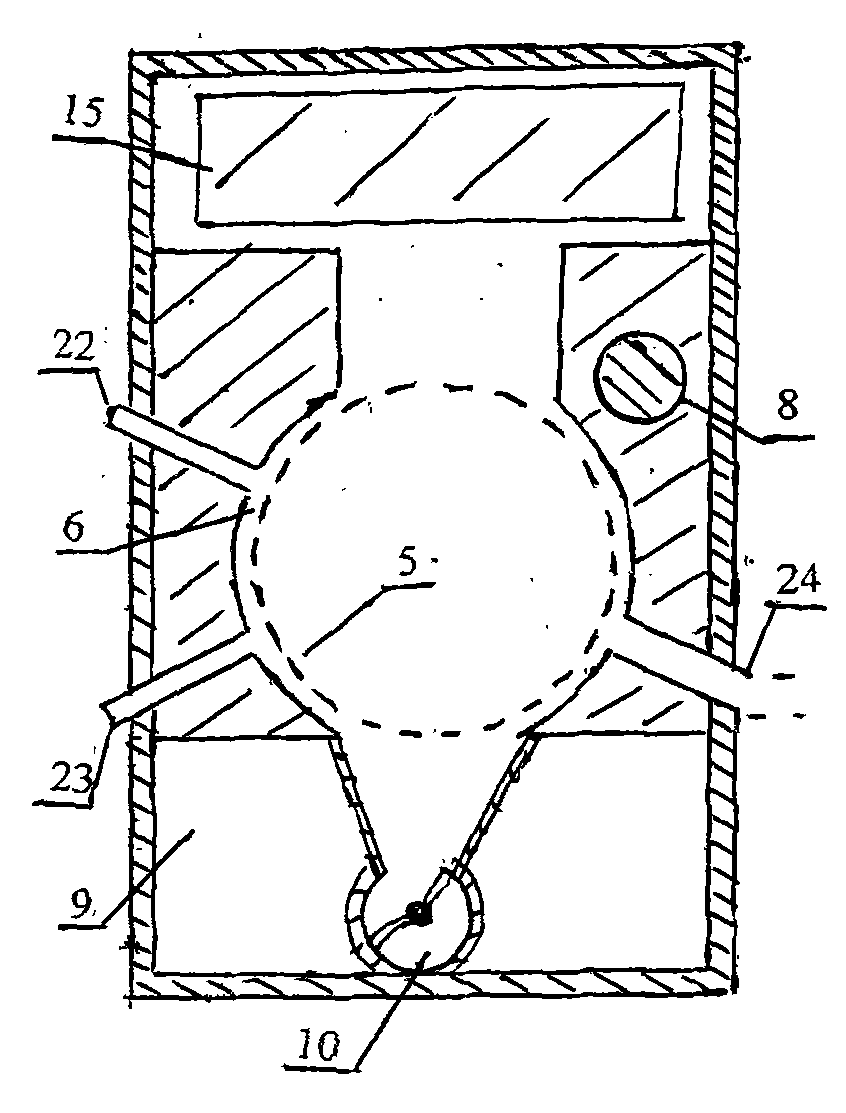

Straw gasification furnace capable of continuously producing gas

The invention discloses a straw gasification furnace capable of continuously producing gas. Straws which are cut up are fed into a material storage tank, the straws placed in the material storage tank are conveyed into a rolling tube type furnace rake by a spiral feeding machine, after the rolling tube type furnace rake is fully filled with the straws, a driving motor rotates to drive the rolling tube type furnace rake to rotate, and a plastic bottle is extruded so that diesel oil can be uniformly sprayed onto the straws in the rolling tube type furnace rake. The straws sprayed with the diesel oil are ignited by the flame of a pistol type long pipe gas ignition gun, wind blown out from a blast blower supports the smouldering of the straws in the rolling tube type furnace rake, the straws can generate a large amount of carbon monoxide during the smouldering, fireproof ceramic balls or metal balls in the rolling tube type furnace rake stir the straws so that the uniform smouldering of the straws can be realized, coal tar generated by the smouldering is heated and decomposed into low-molecule combustible gas when passing through two layers of double-layer honeycomb-shaped metal nets of the back section of the red burnt rolling tube type furnace rake, hot smoke gas heats the wind blown out from a boiler and the blast blower, the generated vapor and hot wind enter an air outlet pipe, and humid and hot air supports the smouldering of the straws, the combustible gas content in the smoke gas can be increased, and the smoke gas is cooled.

Owner:张英华

Apparatus and method for forming internally ribbed or rifled tubes

ActiveUS7021106B2Improve productivityImprove tool lifeDrawing mandrelsMetal rolling stand detailsRoot surfaceHelix angle

Owner:DOOSAN BABCOCK ENERGY AMERICA

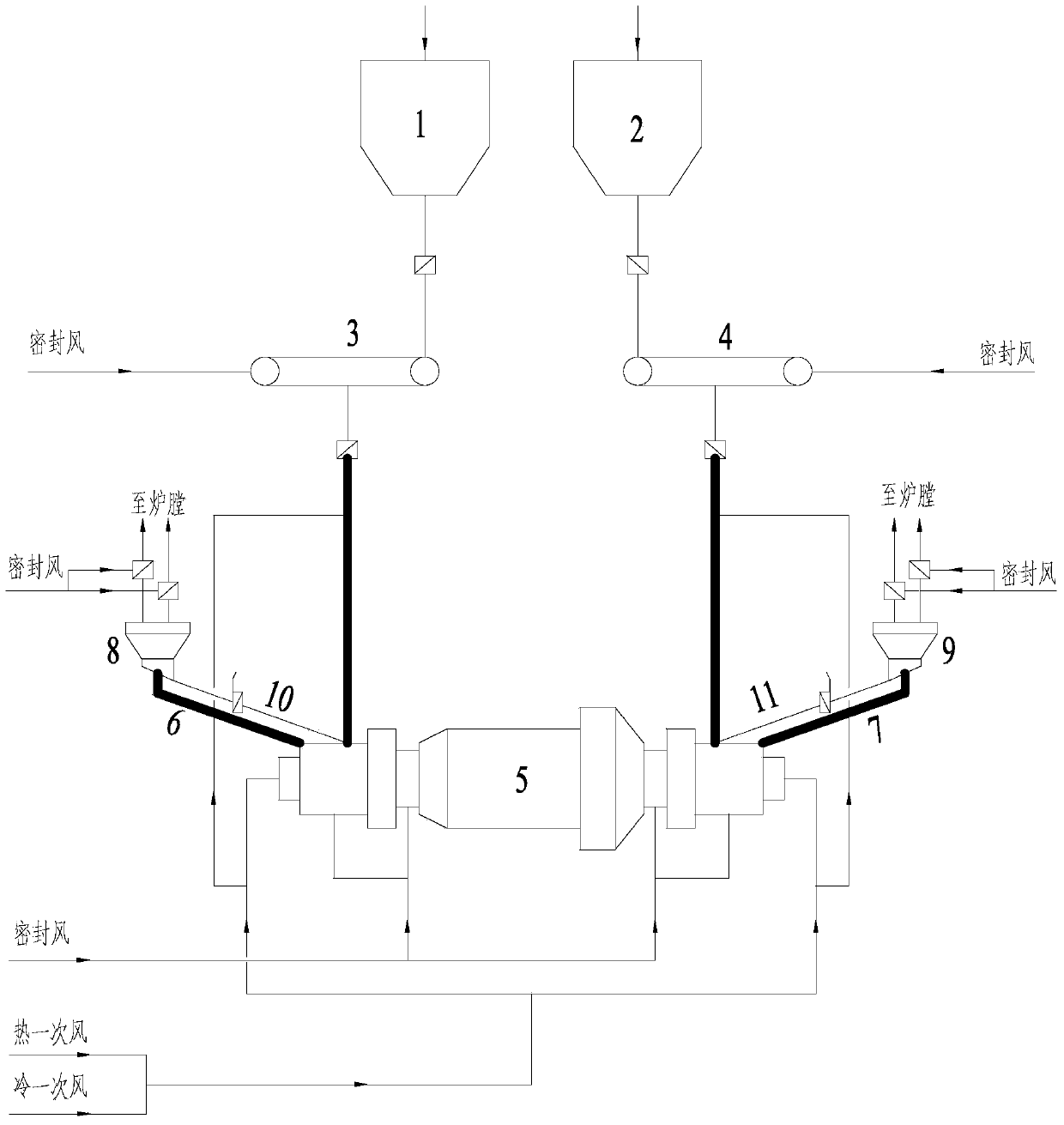

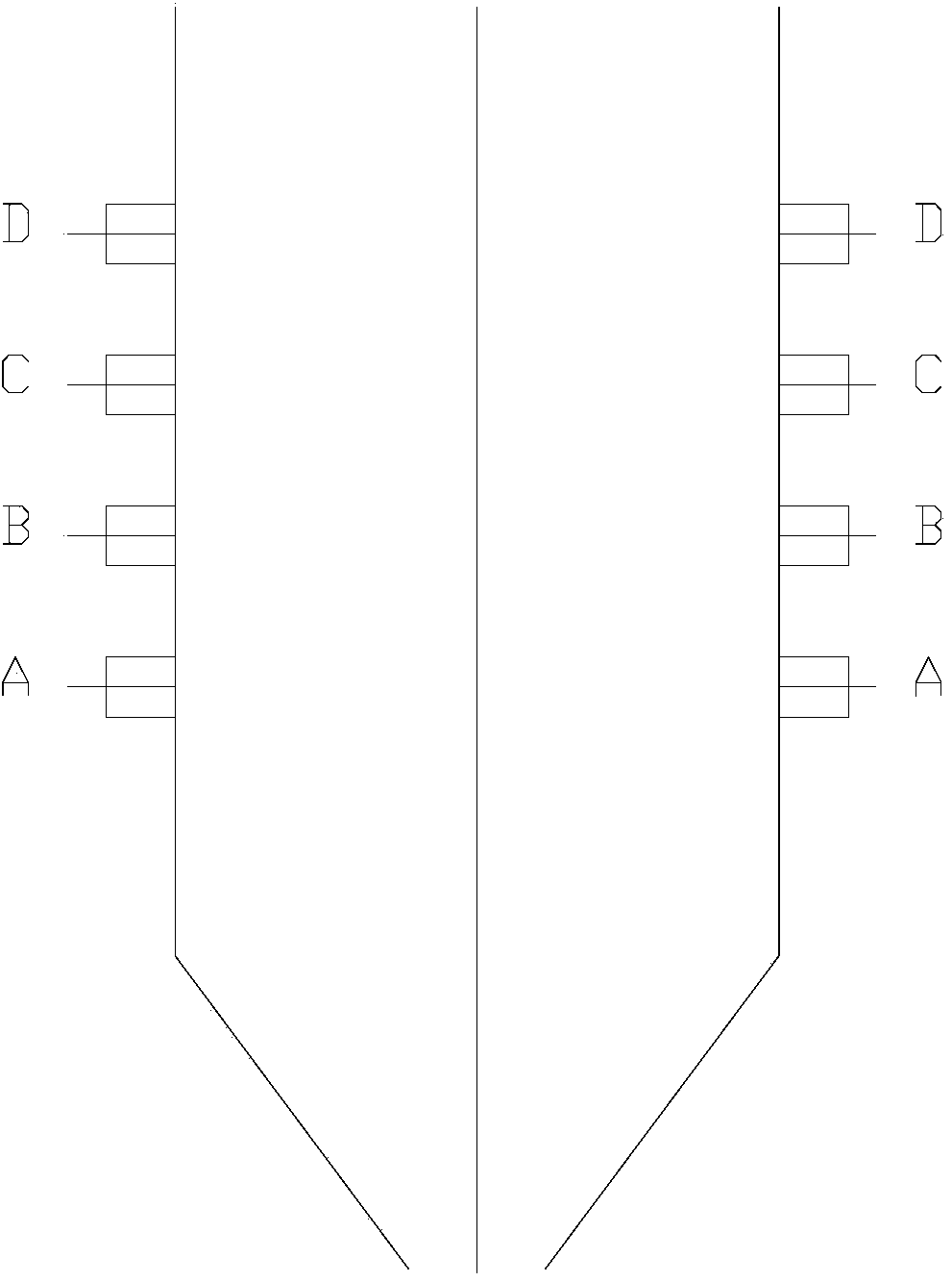

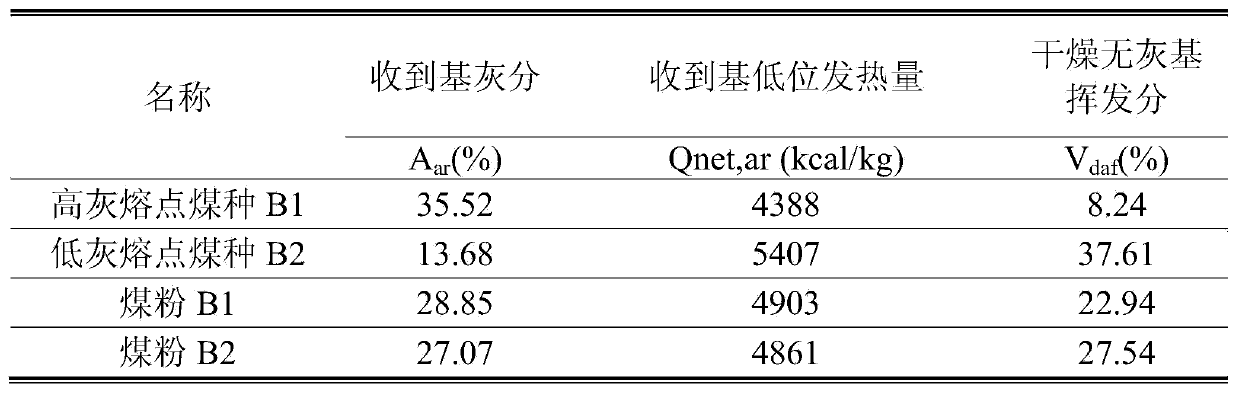

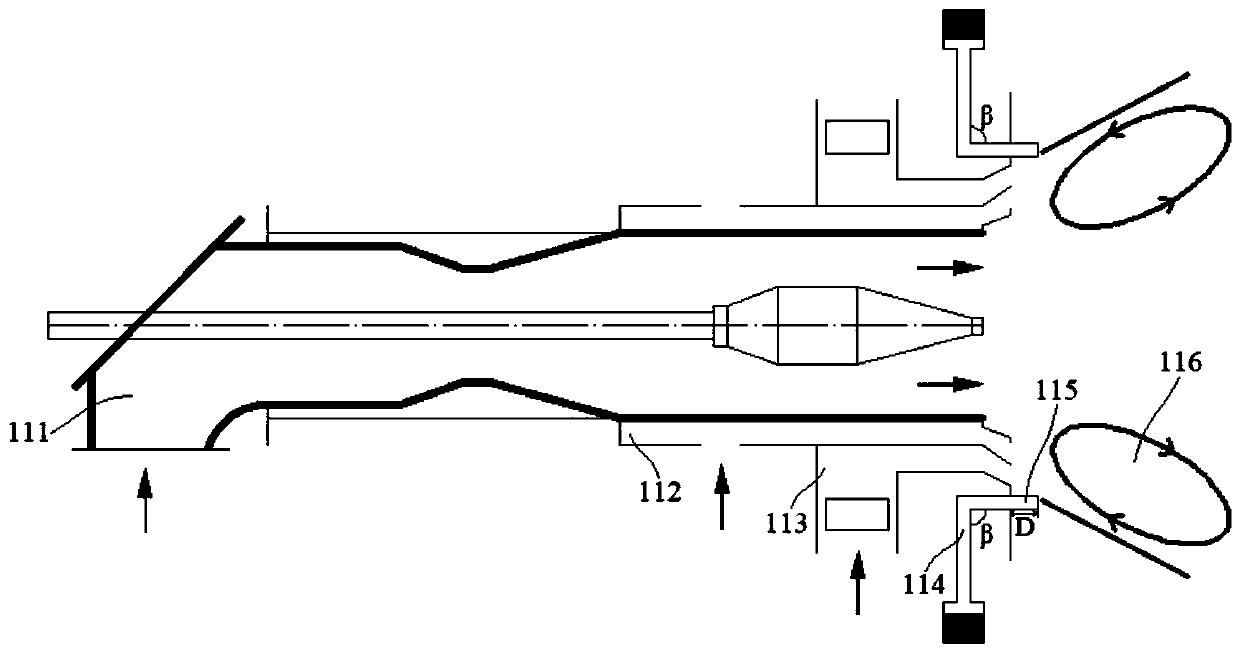

System and method of blending combustion of coal type with low ash melting point in coal-fired utility boiler

ActiveCN104180384AEnsure safetyLower furnace temperatureLump/pulverulent fuel preparationPulverizerProcess engineering

The invention discloses a system and method of blending combustion of a coal type with a low ash melting point in a coal-fired utility boiler and belongs to the technical field of coal-fired utility boiler operation. The coal-fired utility boiler is equipped with a positive-pressure, direct-firing, double-in and double-out steel ball coal pulverizer; the method of blending combustion of coal type with the low ash melting point in the coal-fired utility boiler comprises the following steps: the coal type with the low ash melting point and a coal type with a high ash melting point are sent into the steel ball coal pulverizer from one end of the positive-pressure, direct-firing, double-in and double-out steel ball coal pulverizer respectively; after thorough mixing and grinding, powder is uniformly output from two ends of the steel ball coal pulverizer; after the blending, compared with the melting point of the coal type with a low ash melting point, the melting point of the blended ash is increased to a relatively large extent; under various boiler loading, through adjusting the belt rotational speeds of coal feeders that correspond to the coal type with the low ash melting point and the coal type with the high ash melting point, the mixing proportion control is realized on the coal type with the low ash melting point. The system and method of blending combustion of coal type with the low ash melting point in the coal-fired utility boiler can improve the combustion and utilization proportion of the coal type with the low ash melting point to the utmost extent, on the basis of effectively relieving the boiler from coking and ensuring the safe operation of the boiler; the cost of fuel is reduced; the economical efficiency in the operation of the coal-fired utility boiler machine set is improved.

Owner:HUANENG POWER INTERNATIONAL +3

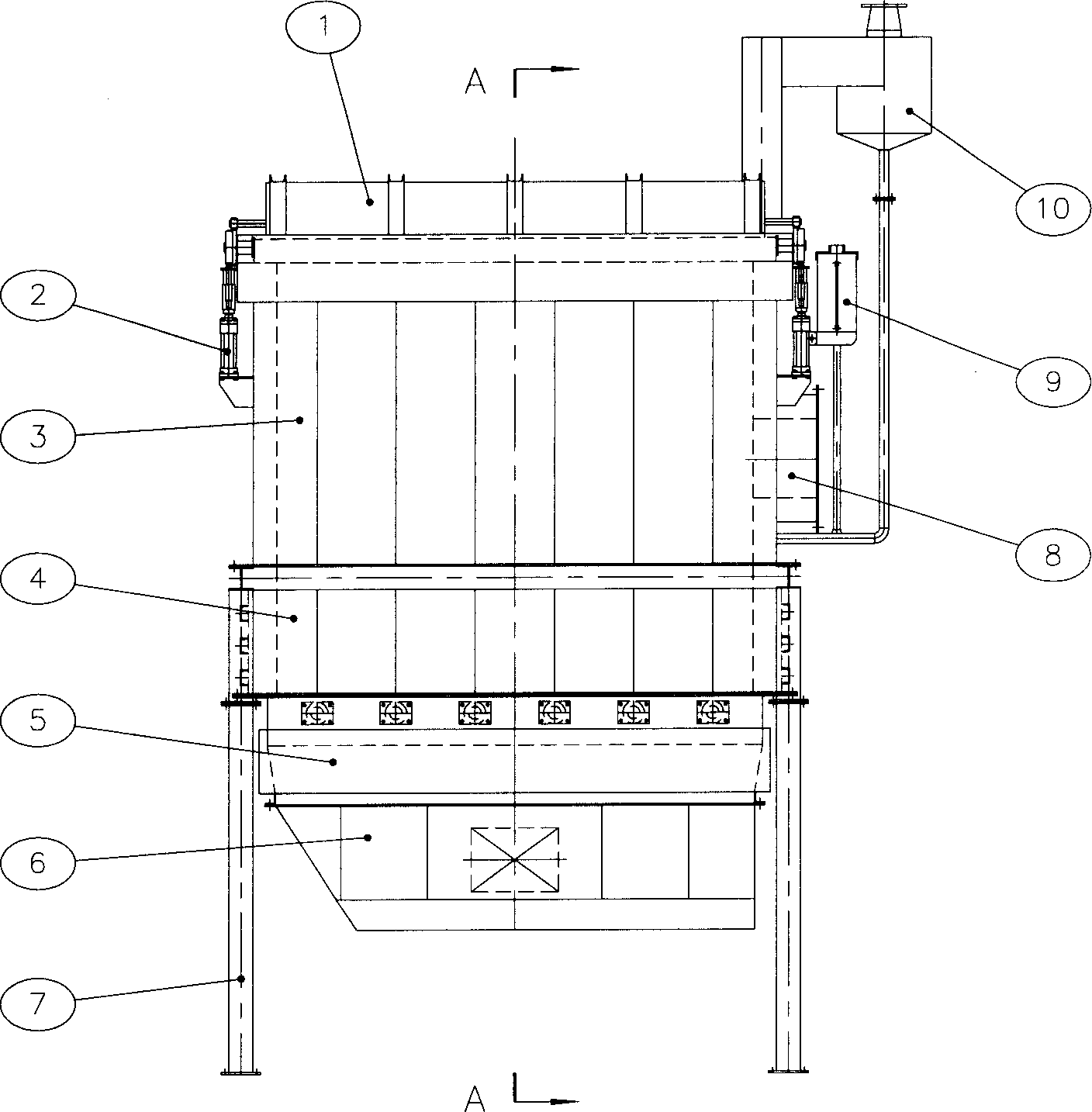

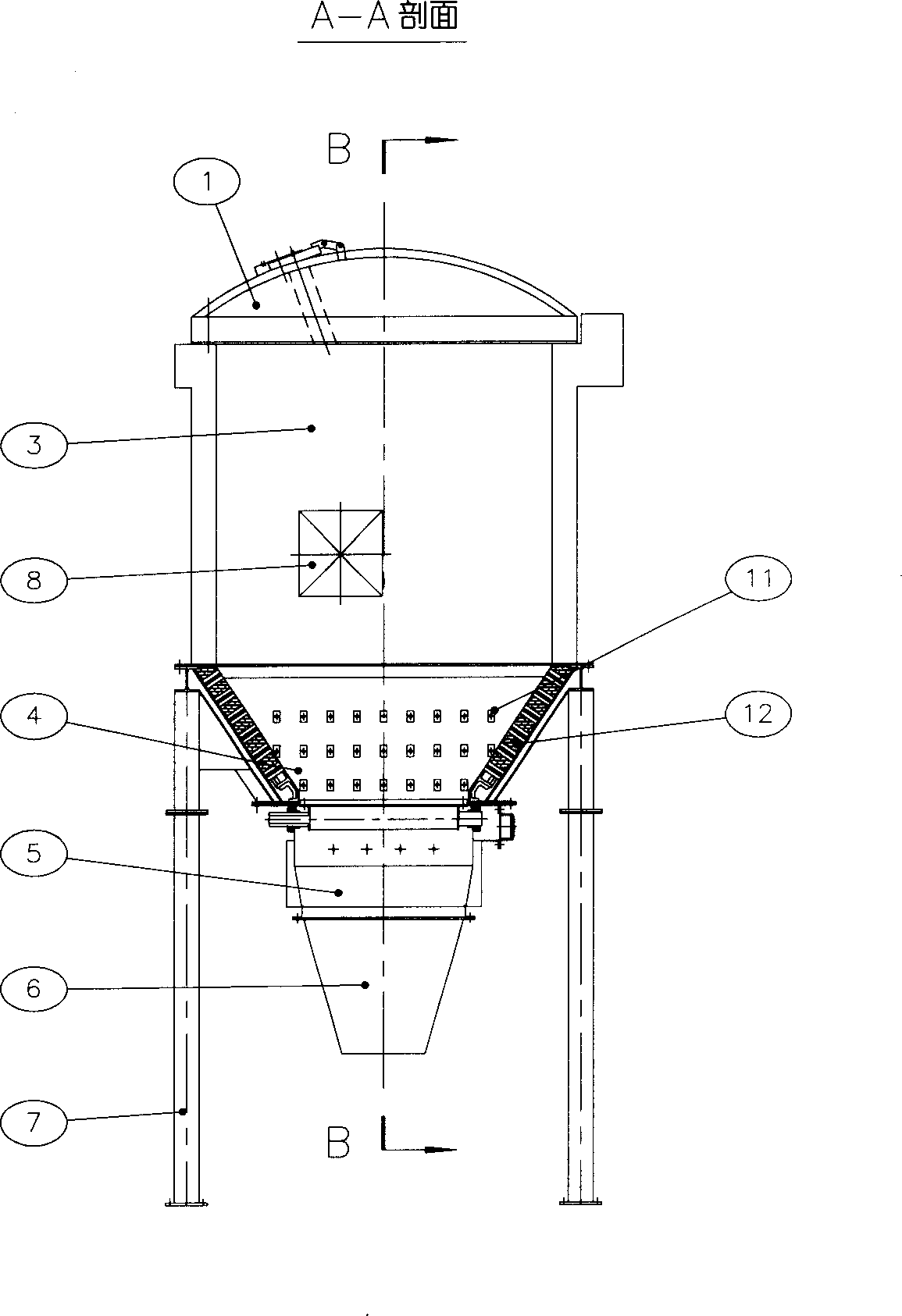

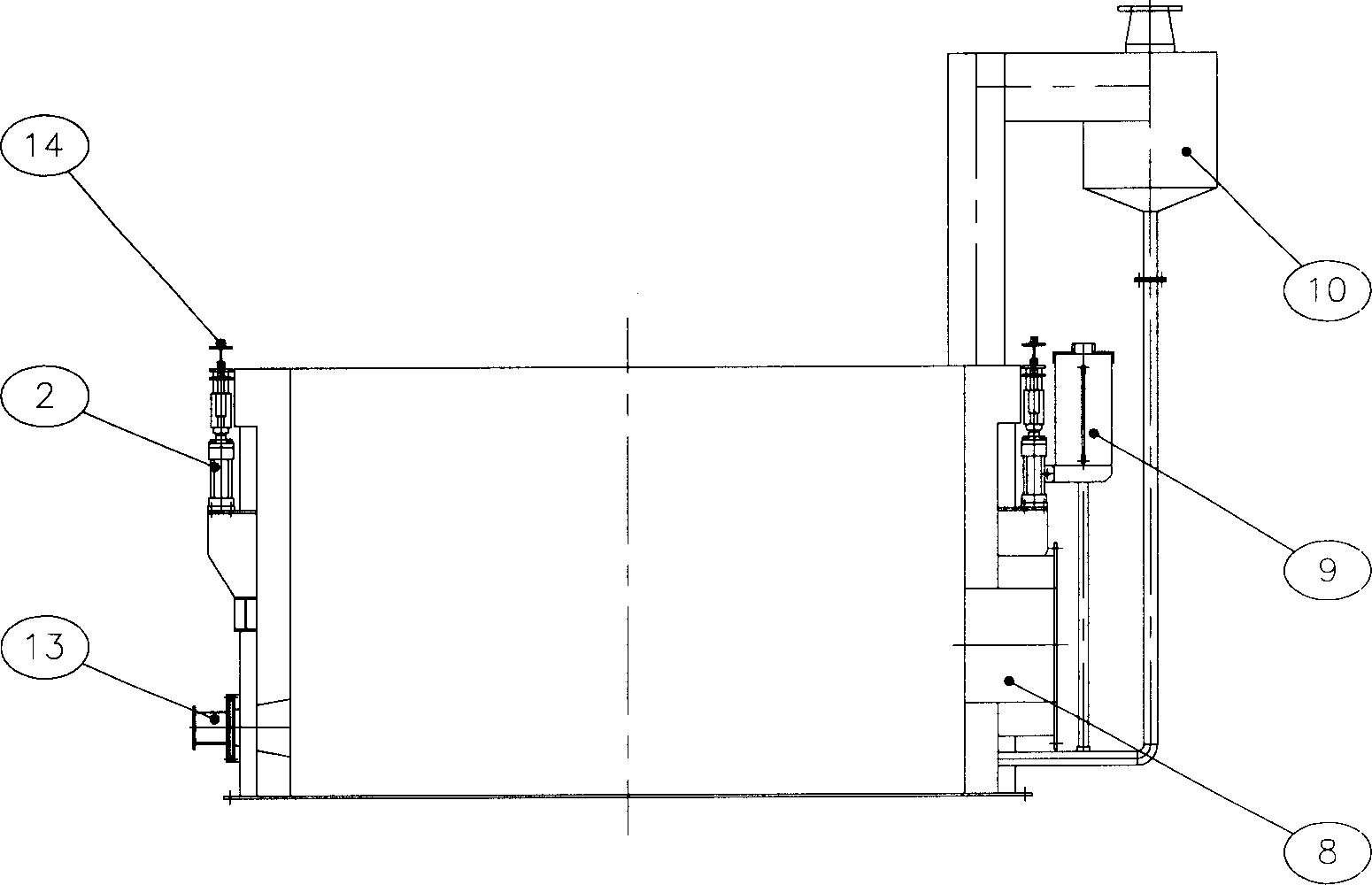

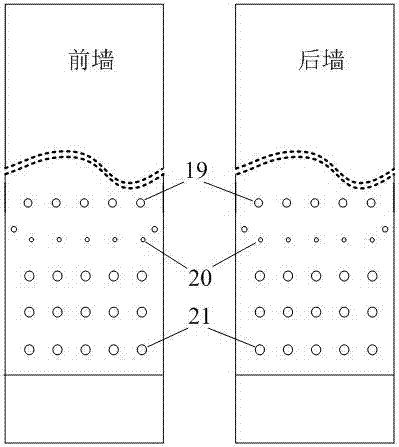

Primary combustion chamber of refuse incinerator

InactiveCN1731017AAvoid excessive heatLower furnace temperatureIncinerator apparatusExpansion tankCombustion chamber

The present invention relates to one kind of primary combustor for garbage incinerator to pyrolyze dangerous waste through incomplete combustion to produce inflammable gas. The primary combustor consists of top cover, furnace body, hearth, grate unit and slag bin. The movable top cover covers the upper surface of the furnace body, cooling water is fed into the sandwich layer of the top cover and the furnace body to form water cooling wall structure with water level controlled with an expansion water tank and certain steam space reserved. The surfaces of the hearth and the grate have high pressure air nozzles arranged, and the grate in the bottom of the hearth is maintained immobile during burning and turned by 90 deg during draining slag. The grate unit has water spraying holes in the lower part.

Owner:北京新宇未来环境工程有限公司

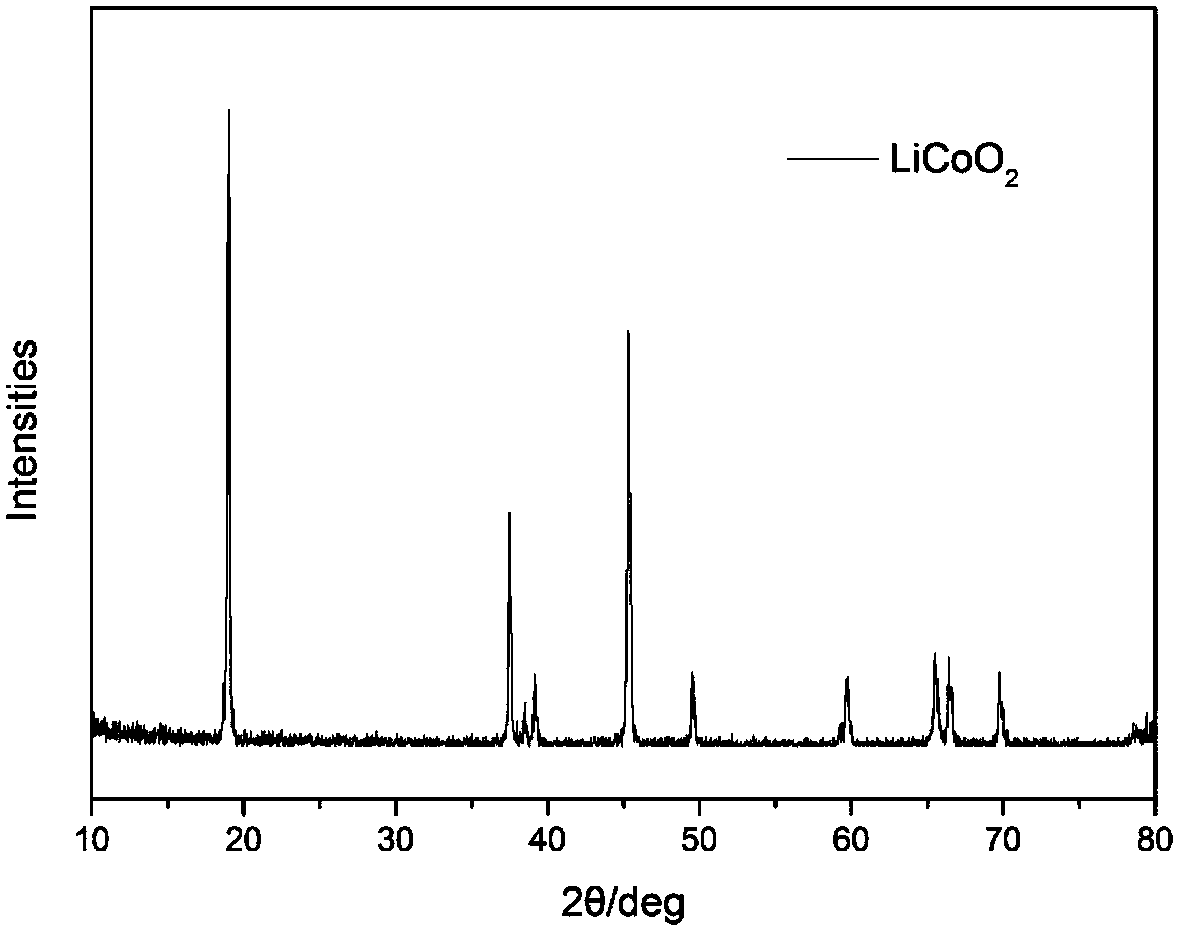

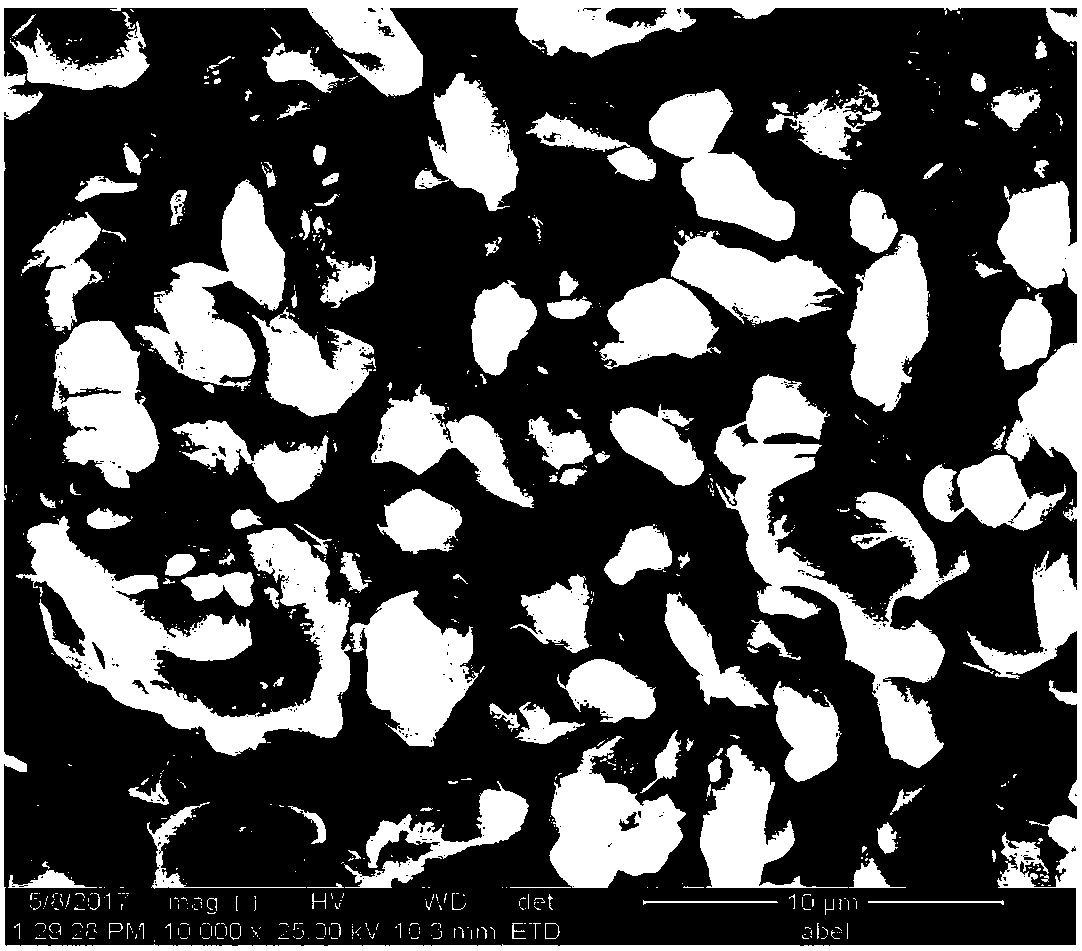

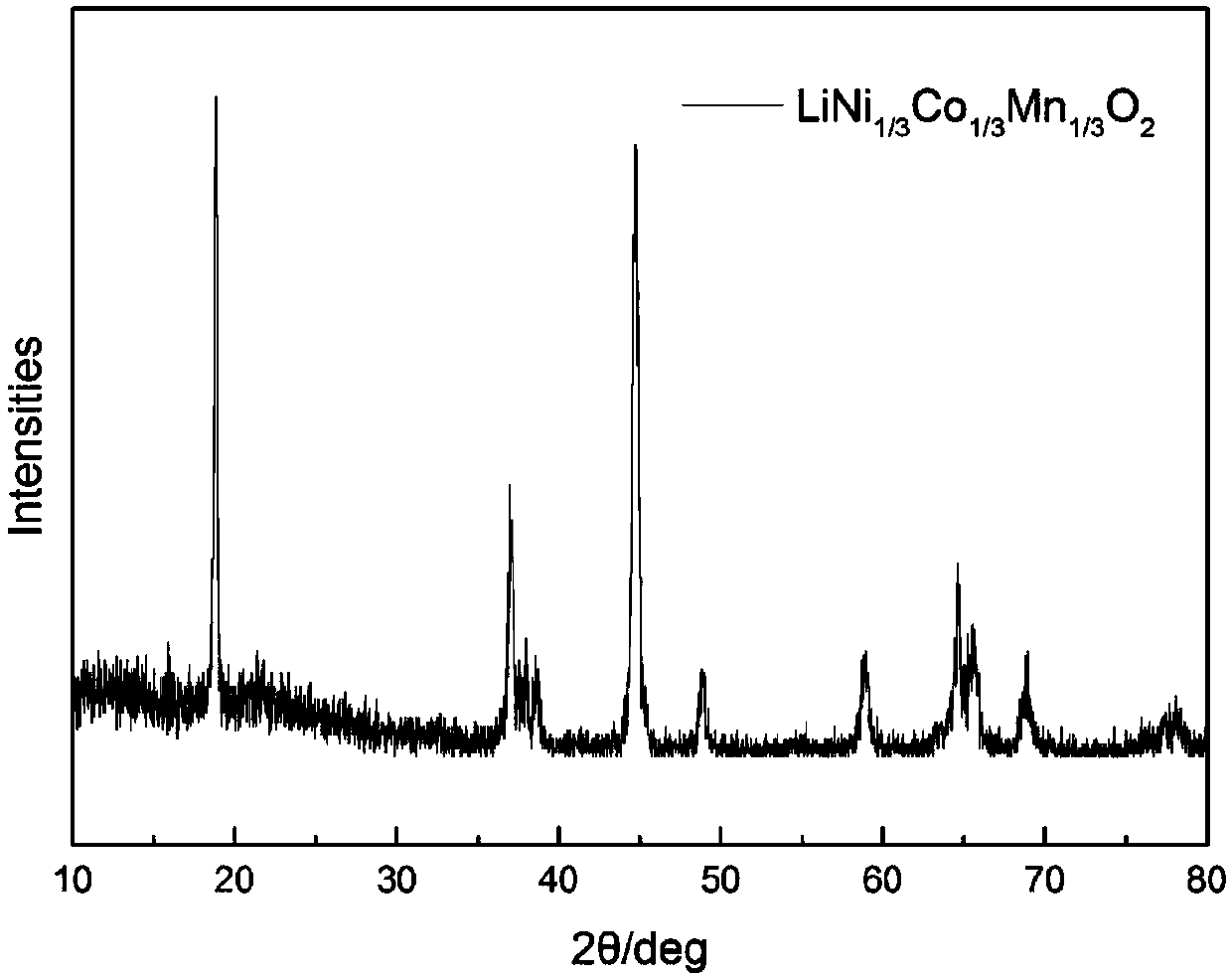

Preparation method for cathode material of lithium ion battery

InactiveCN107611414ALower furnace temperatureReduce energy consumptionCell electrodesFurnace temperatureSodium-ion battery

The invention relates to a preparation method for a cathode material by supplementing with current. The current is supplemented in the sintering process, so that the cathode material of a lithium ionbattery is acquired under the temperature lower than the conventional sintering temperature. The method can be widely applied to the preparation for the cathode materials of various lithium ion batteries. The furnace temperature (200-1000 DEG C) and energy consumption required by the cathode material prepared according to the invention are low.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Guangdong amorphophallus albus and blueberry stuffed mooncakes

InactiveCN105379813AGood ductilityNot easy to crackBaking processesBakery productsProduct processingEdible oil

The invention relates to the field of bakery product processing, in particular to Guangdong amorphophallus albus and blueberry stuffed mooncakes. The Guangdong amorphophallus albus and blueberry stuffed mooncakes comprise skin and filling. The filling is prepared from 100 parts of smashed amorphophallus albus, 10-30 parts of blueberry jam, 10-20 parts of modified starch, 10-30 parts of maltose and 10-20 parts of edible oil. The filling is prepared in the steps of smashed amorphophallus albus making, blueberry jam making, filling making, refrigeration and the like. Amorphophallus albus and blueberry are used as main materials to make the Guangdong amorphophallus albus and blueberry stuffed mooncakes with novel taste and color, the filling looks bright and tastes special, the mooncakes can strengthen the spleen and stomach and protect eyesight and also have other health-care functions, and the style of traditional Guangdong mooncakes is reserved.

Owner:项小飞

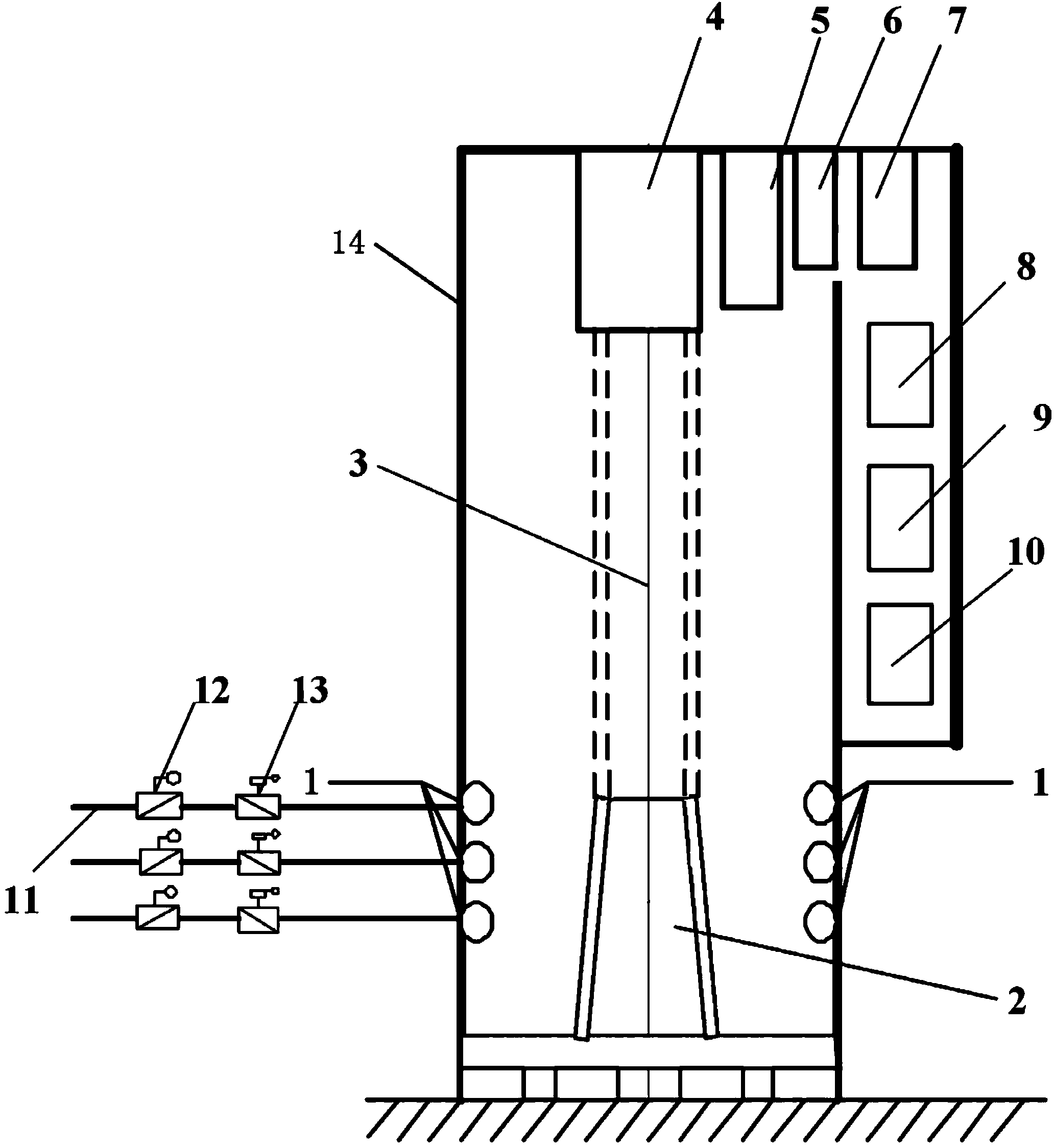

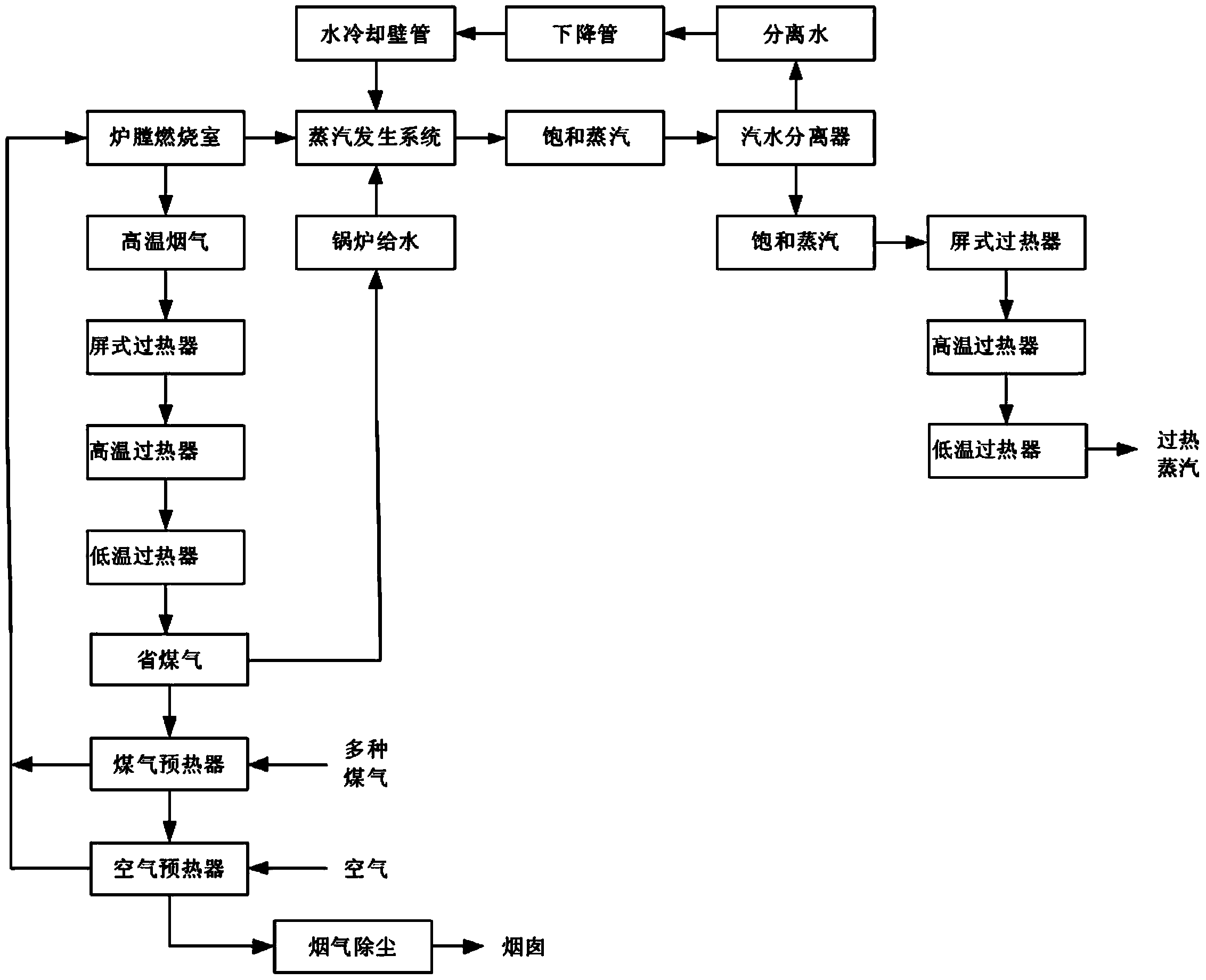

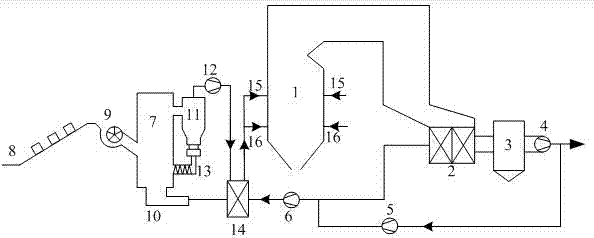

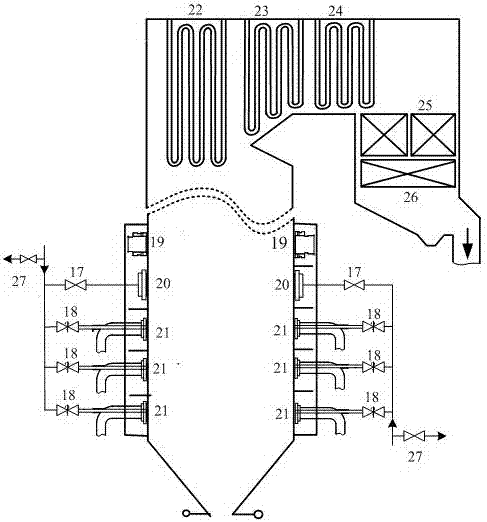

Multi-gas mixed combustion boiler and combustion method

InactiveCN104033877AShort stayEnergy savingCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelSuperheaterFlue gas

The invention discloses a multi-gas mixed combustion boiler and a combustion method, and belongs to boilers and combustion methods. The multi-gas mixed combustion boiler structurally comprises a hearth, a hearth water cooling wall, a steam generating system, a platen superheater, a high-temperature superheater, a low-temperature superheater, a coal economizer, an air preheater and a gas preheater. A gas combustion stabilizer is arranged on the lower portion of the hearth, three layers of gas combustors are arranged on the outer side of the gas combustion stabilizer, and the outer sides of the three layers of gas combustors are respectively connected with three gas pipelines. The combustion method includes enabling various gases and air to proportionally flow into the hearth to be combusted; transmitting heat to the steam generating system; enabling saturated steam to flow through the superheaters and then heating the saturated steam to obtain superheated steam; enabling flue gas to flow through the superheaters; then preheating water by the aid of the coal economizer, and heating the flue gas by the air preheater and the coal preheater; finally exhausting the flue gas into the atmosphere. The flue gas is generated after fuel is combusted. The water is about to be fed to the boiler. The multi-gas mixed combustion boiler and the combustion method have the advantages that coke-oven gas, blast-furnace gas and converter gas can be combusted by the aid of the multi-gas mixed combustion boiler and the combustion method; a large quantity of energy can be saved, severe environmental pollution due to gas emission can be prevented, the production cost can be reduced, and the like.

Owner:JIGANG GRP

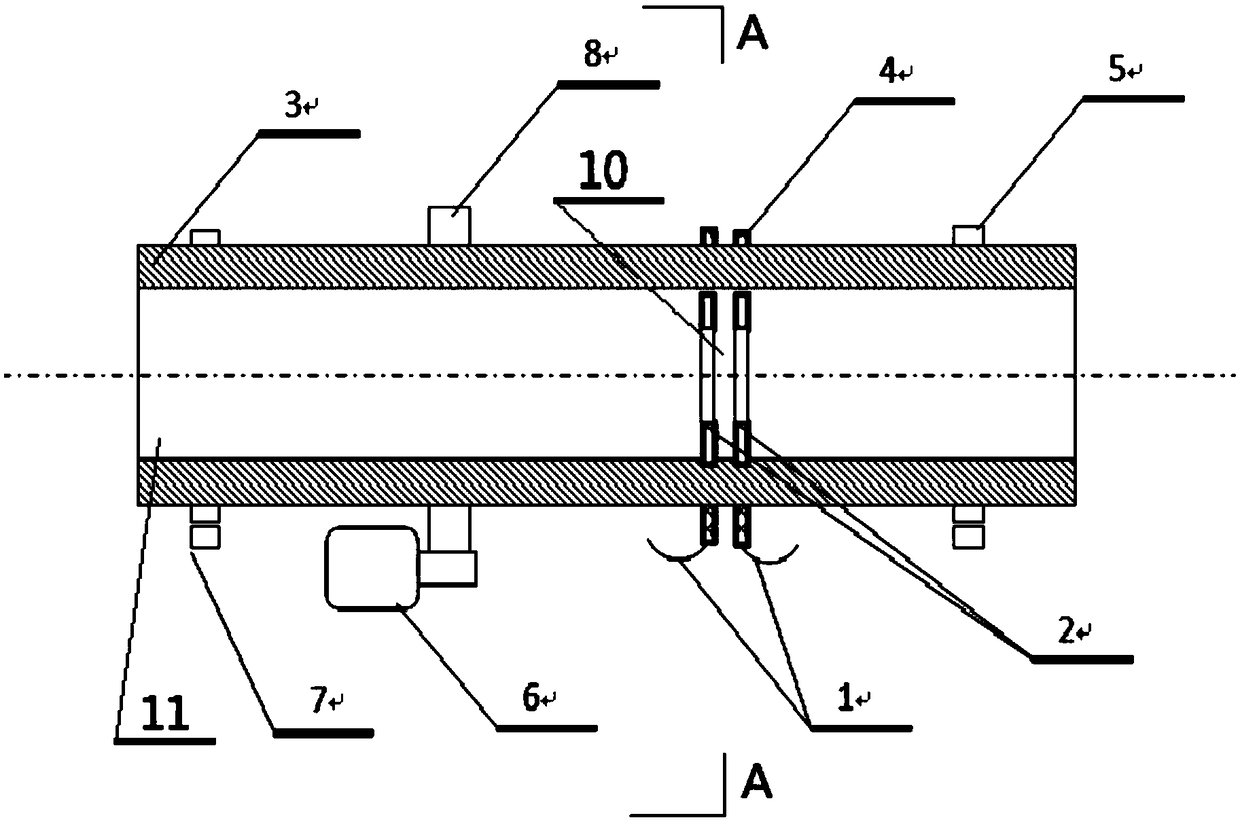

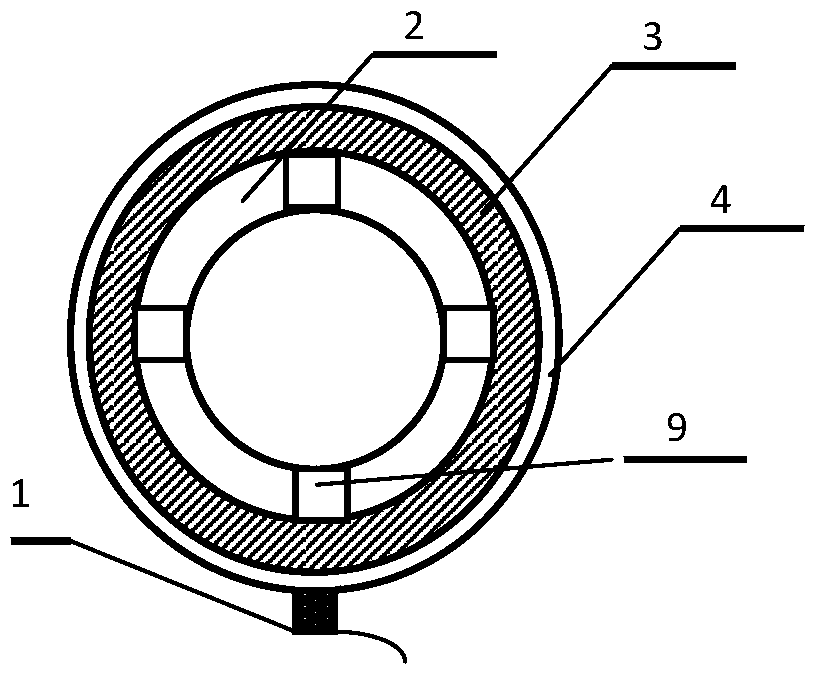

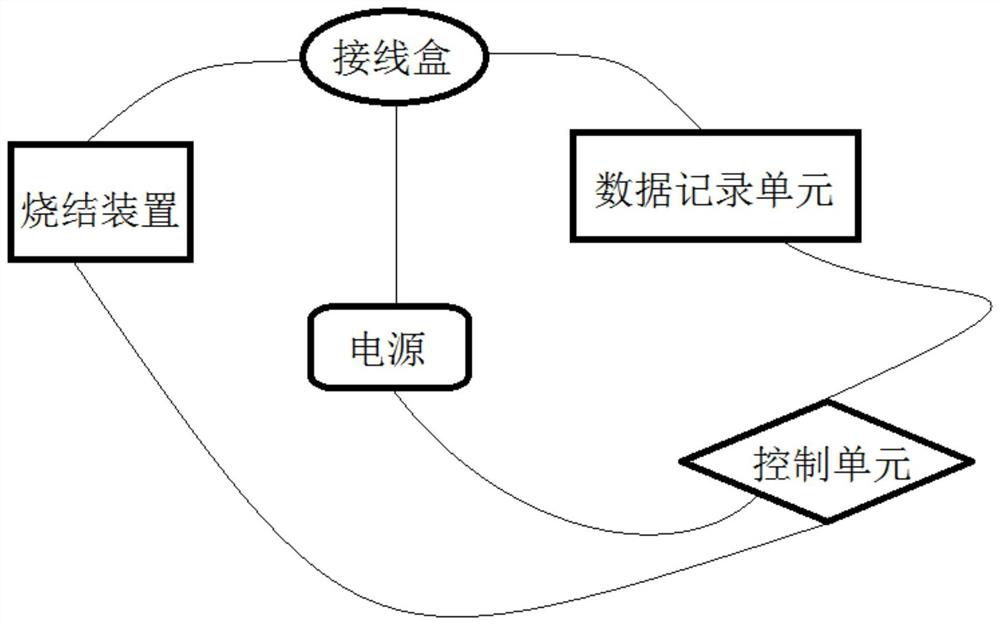

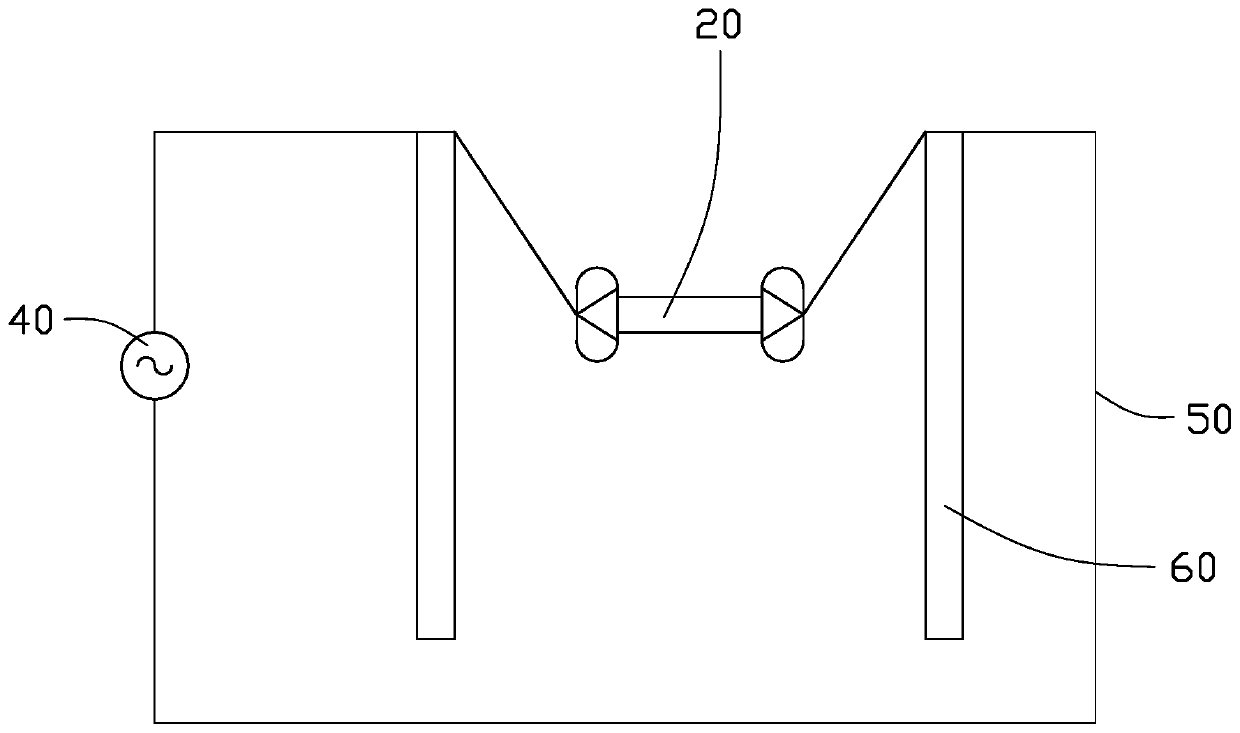

Cement clinker preparation method and device

ActiveCN109336432AQuality improvementShorten the formation timeRotary drum furnacesElectric heating for furnacesFurnace temperatureElectrolysis

The invention discloses a cement clinker preparation method and device. The method comprises the step of applying a voltage to a blank to sinter the blank to obtain cement clinker at 900-1200 DEG C, wherein the blank is obtained by pre-sintering crude cement powder at 900-1200 DEG C. The device comprises a rotary kiln, wherein a feeding hole and a discharge hole are formed in the rotary kiln; a first electrode coil and a second electrode coil are sequentially arranged inside the rotary kiln in a direction from the feeding hole to the discharge hole; notches are formed in the first electrode coil; notches are formed in the second electrode coil; the area between the first electrode coil and the second electrode coil is an electric heating area. The method is simple in process, the sinteringspeed is a hundred times or above of a conventional sintering speed, the furnace temperature can be reduced by 200 DEG C or greater, and the cement clinker is good in quality.

Owner:CHANGAN UNIV

Gadolinium zirconate-based nuclear waste solidified body and preparation method thereof

InactiveCN112358295ALower furnace temperatureImprove production efficiencyRadioactive decontaminationCompression moldingFurnace temperature

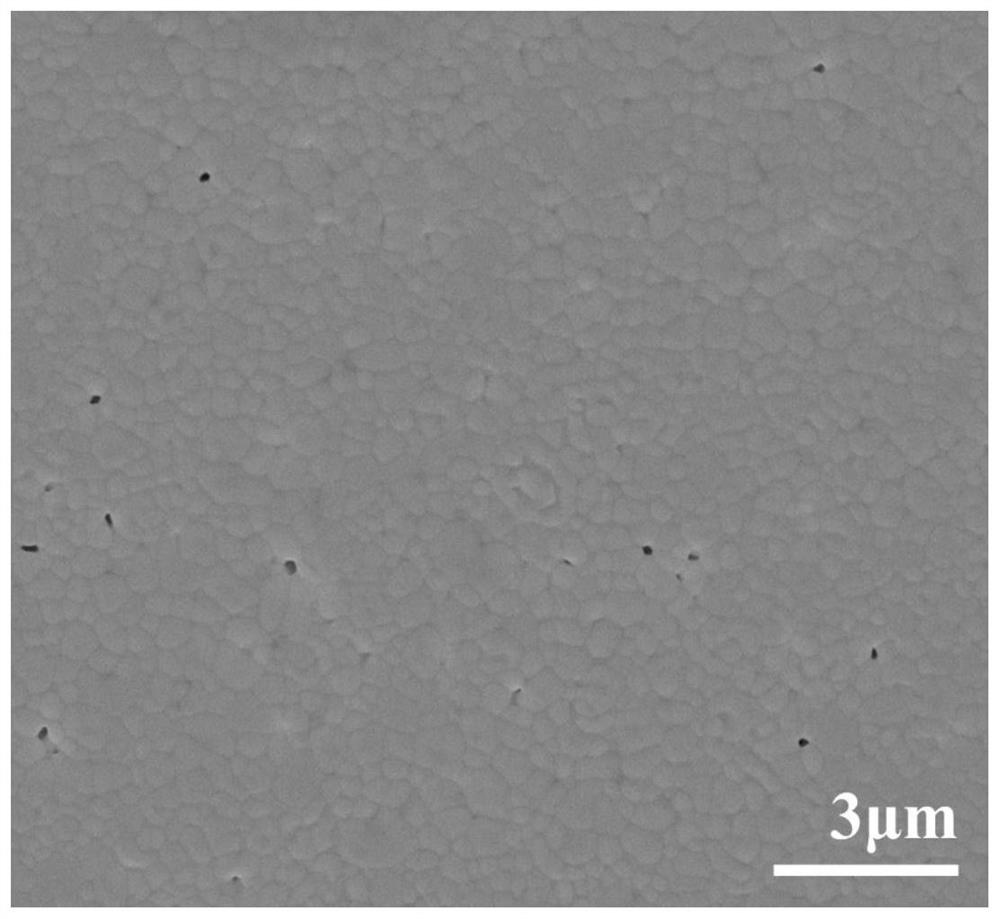

The invention provides a preparation method of a gadolinium zirconate-based nuclear waste solidified body, and belongs to the technical field of nuclear waste treatment. The preparation method comprises the following steps: mixing: putting a matrix raw material and radioactive nuclear waste into a ball-milling tank, adding zirconium dioxide ball-milling beads and a dispersing agent, and carrying out ball-milling and mixing; drying: heating and stirring the obtained uniformly mixed slurry, and then drying; compression molding: carrying out compression molding on the dried mixed powder, demolding to obtain a biscuit of the rolled zircon pyrochlore, and carrying out isostatic cool pressing on the biscuit; and flash burning: sintering thebiscuit subjected to compression molding, electrifying from room temperature during sintering temperature rise, applying constant electric fields to two ends of the biscuit, and performing flash burning at the moment when the sintering temperature rises tothe flash burning temperature so as to quickly densify thebiscuit. According to the method, an electric field assisted sintering technology, namely flash sintering, is used, so that the furnace temperature during sintering of a solidified body can be remarkably reduced, the sintering time is shortened from 72 hours to 1-10 minutes, the preparation efficiency can be effectively improved, and an ideal material with a compact microstructure and excellent performance can be obtained.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

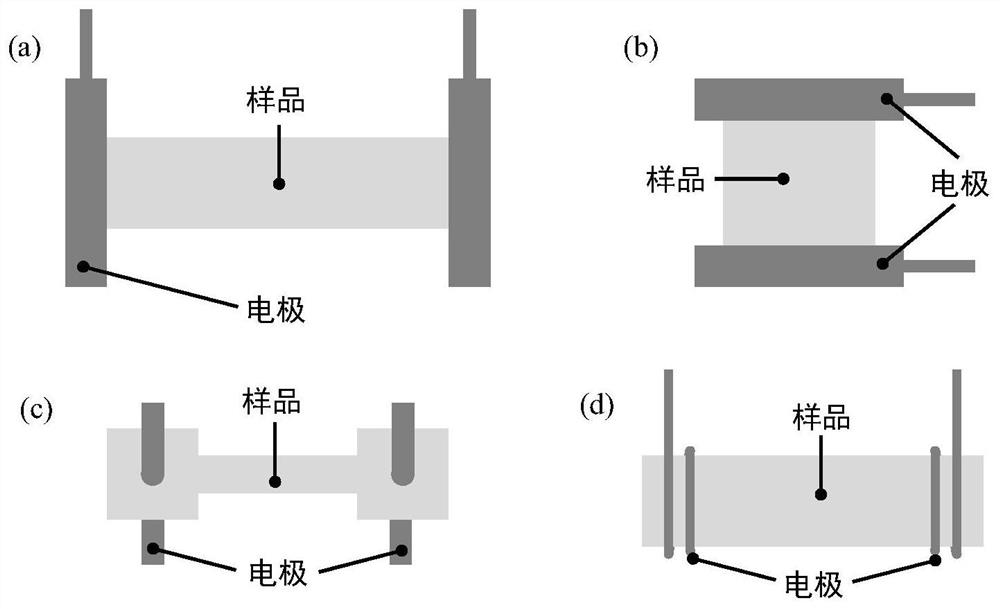

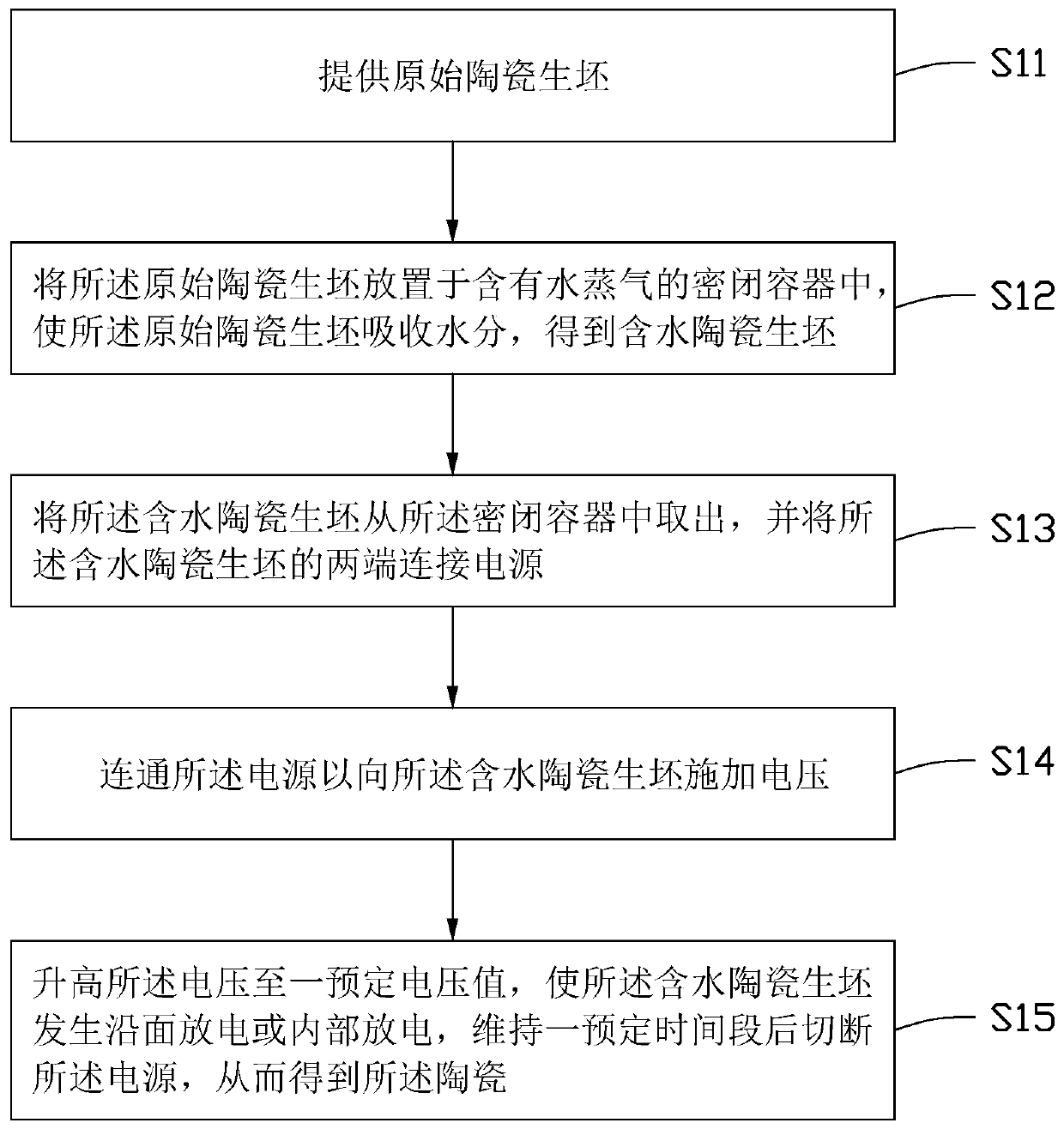

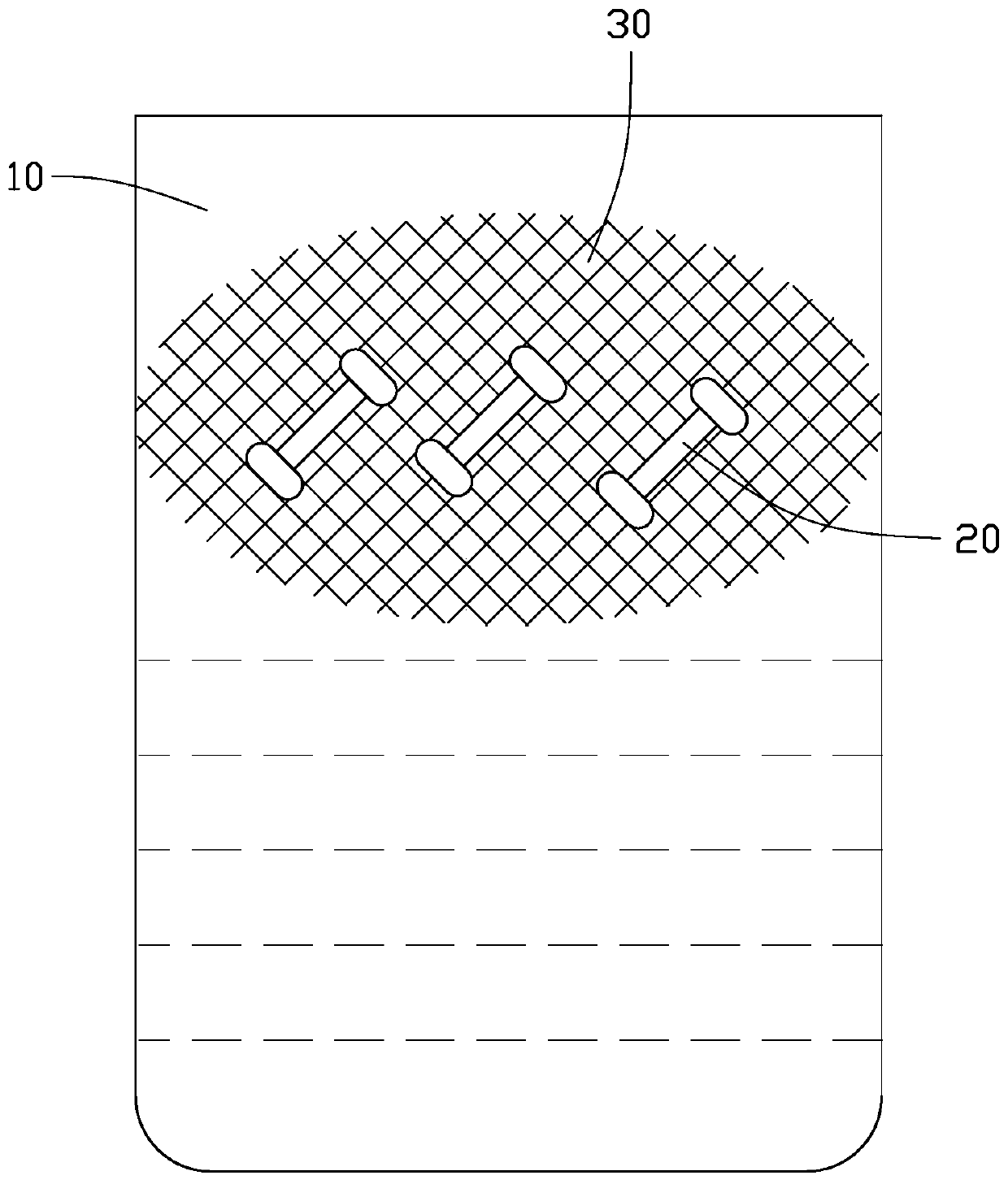

Room temperature ceramic sintering method and ceramic

The invention provides a room temperature ceramic sintering method. The room temperature ceramic sintering method comprises the following steps: providing an original ceramic green body; placing the original ceramic green body in a closed container containing water vapor to enable the original ceramic green body to absorb water to obtain a water containing ceramic green body; taking the water containing ceramic green body out of the closed container, connecting two ends of the water containing ceramic green body with a power supply; turning on the power supply to apply a voltage on the water containing ceramic green body; increasing the voltage to a preset voltage value to enable the water containing ceramic green body to generate creeping discharge or internal discharge, and cutting off the power supply after creeping discharge or internal discharge lasts for a preset period of time to obtain the ceramic. The room temperature ceramic sintering method can be used for sintering ceramicat a room temperature. The invention also provides a ceramic sintered by the room temperature ceramic sintering method.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

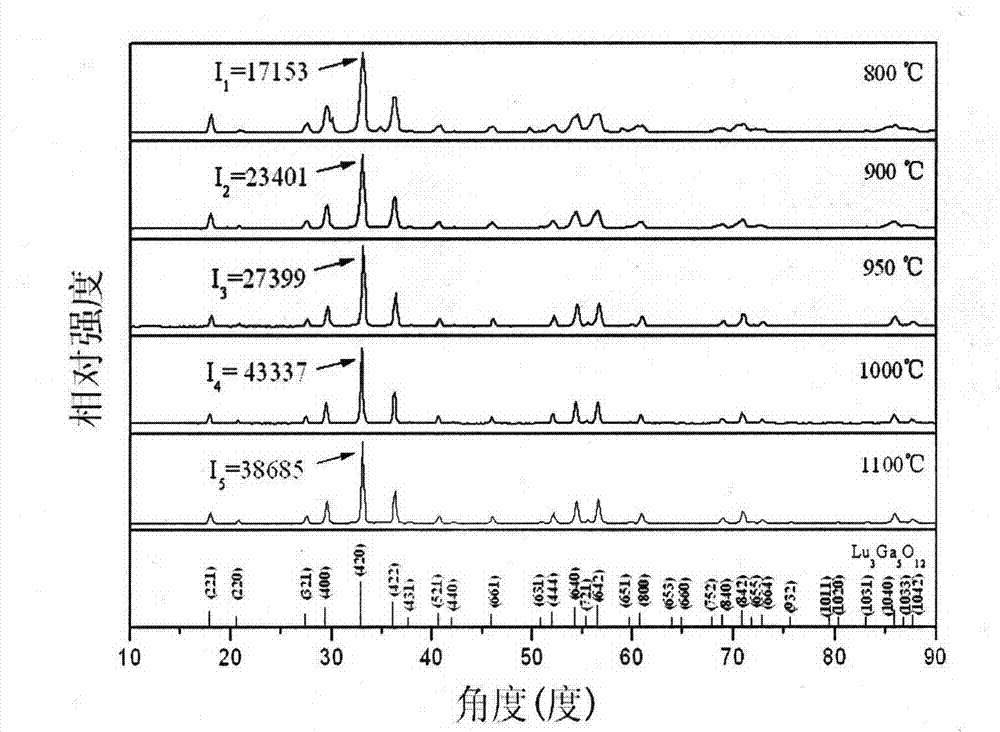

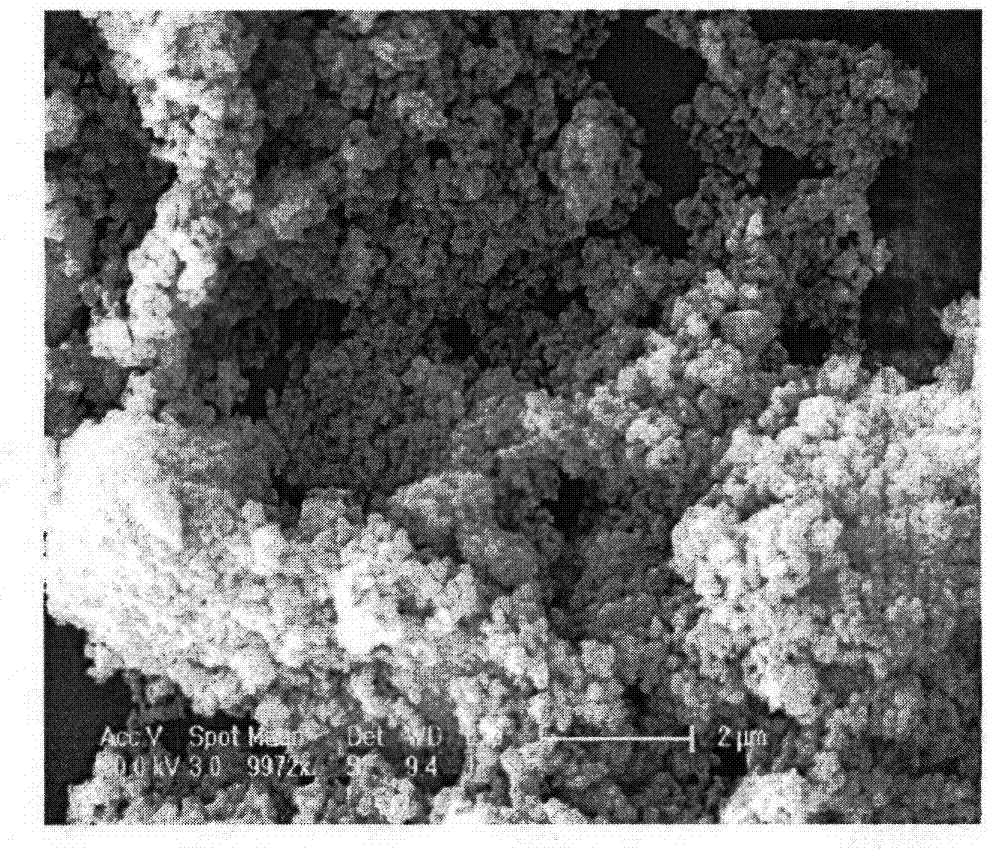

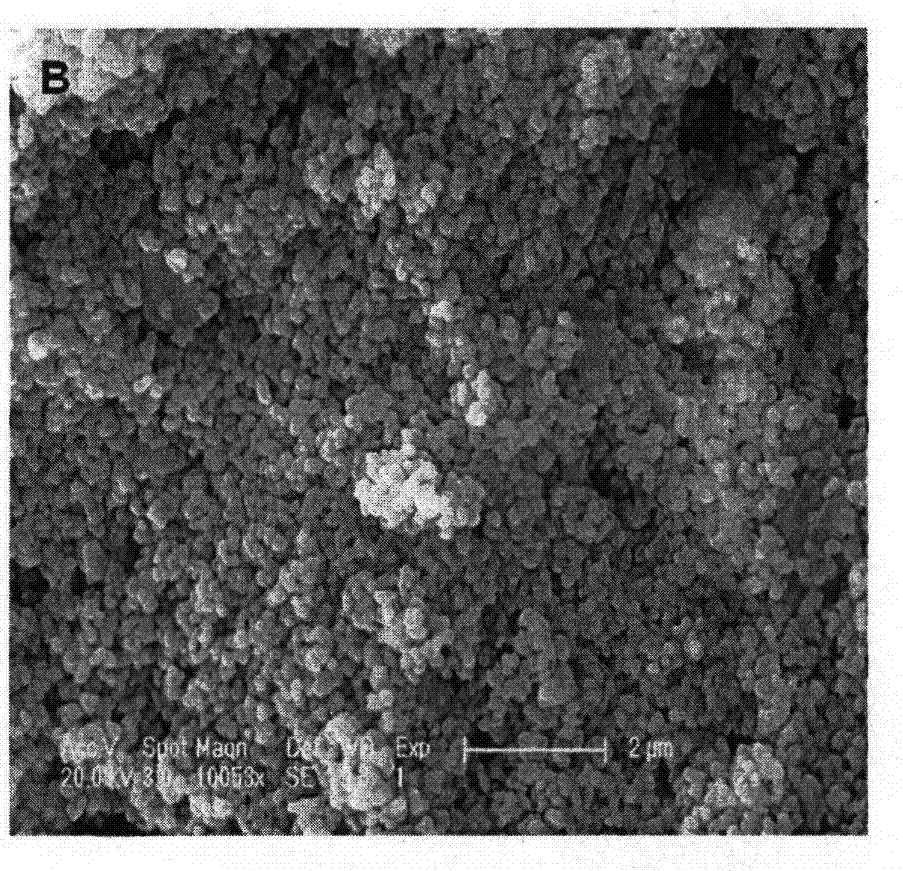

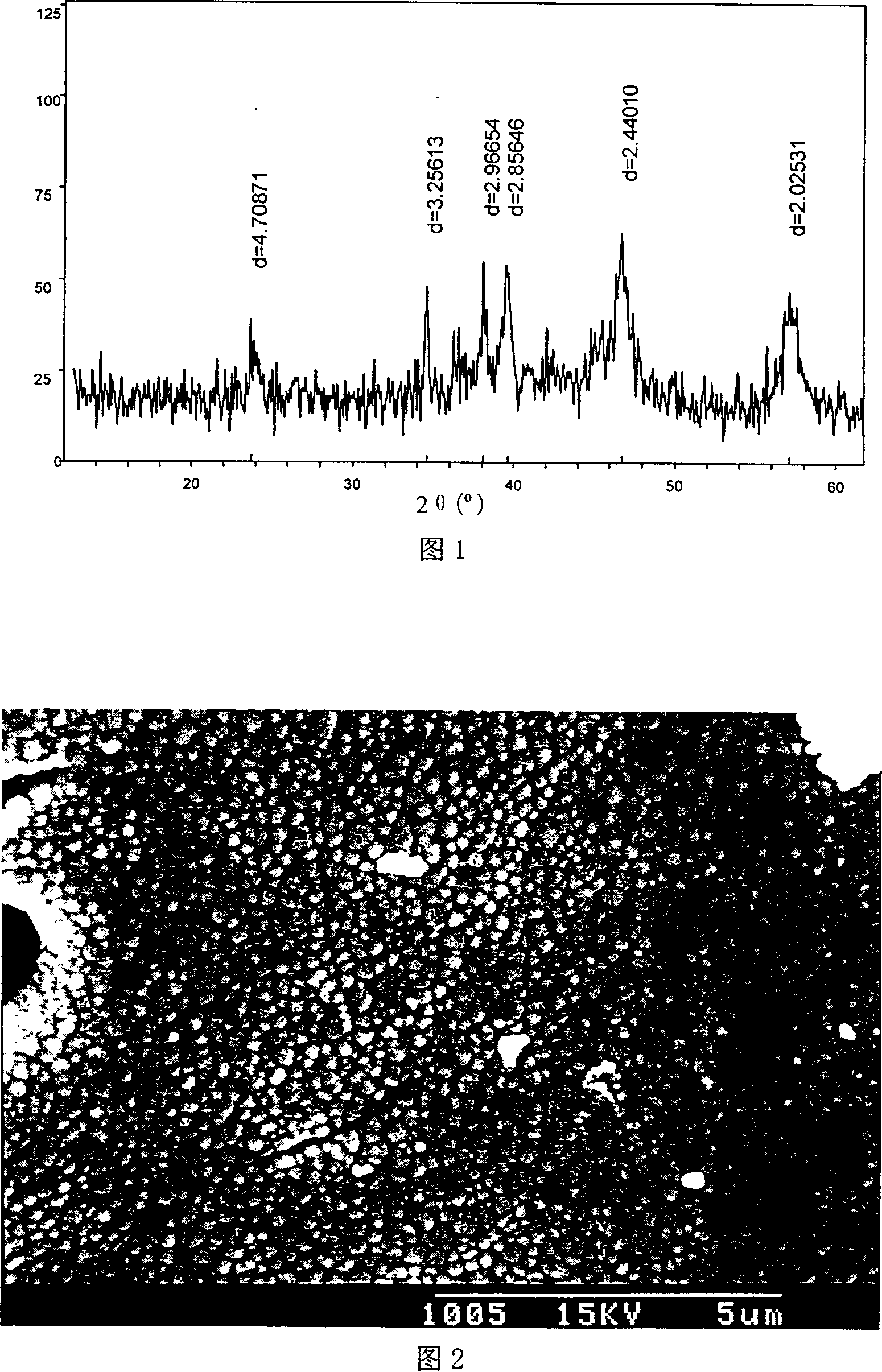

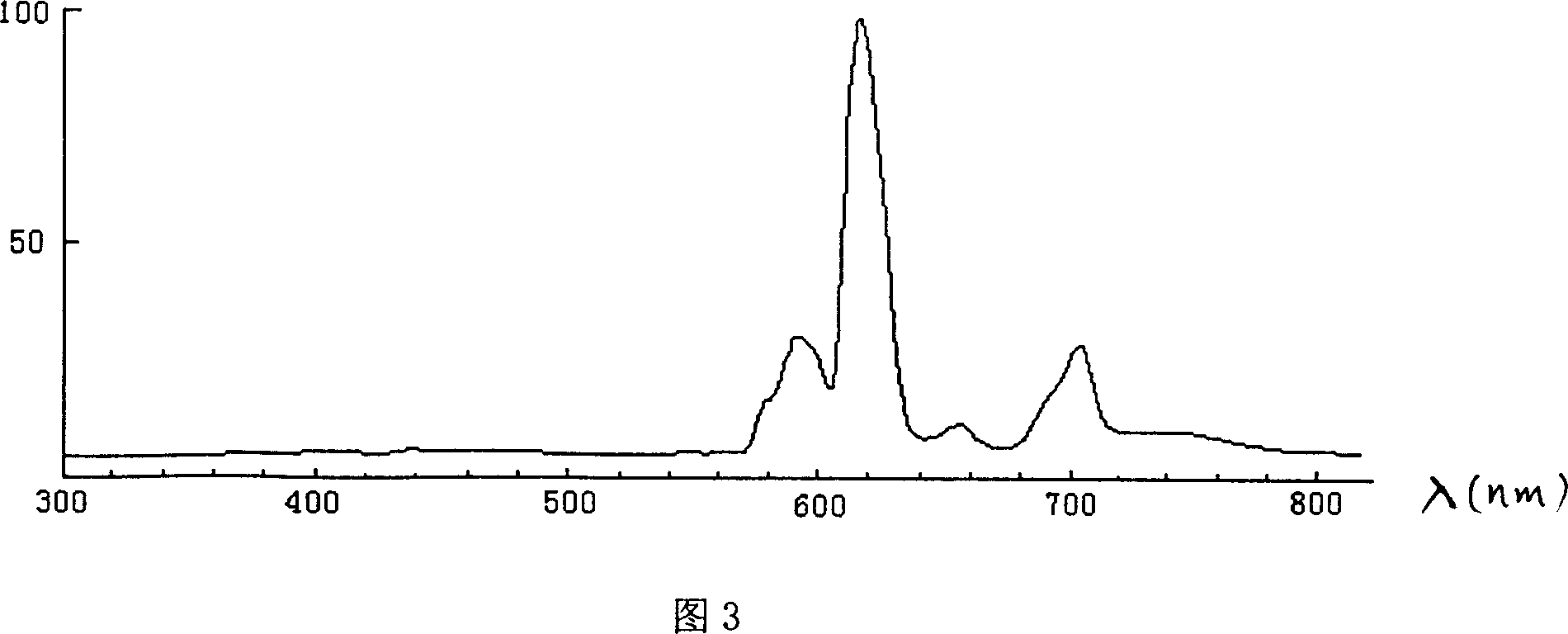

Preparation method of thulium and europium single/co-doped lutetium gallium garnet phosphor

InactiveCN103031128ANarrow emission peakWell mixedChemical industryLuminescent compositionsFurnace temperatureLutetium

The invention provides a preparation method of a thulium and europium single / co-doped lutetium gallium garnet phosphor. The chemical formula of the phosphor is Lu (3-x-y) Ga5O12: xEu<3+>, yTm <3+>, wherein x=0-0.04, y=0-0.02, and x and y cannot be zero simultaneously. A low temperature combustion method is adopted to realize uniform mixing on an ion level, the obtained product is foamy and loose, is not agglomerated and is easy in ball milling, and the color purity of the product is high. The furnace temperature of the method is greatly reduced, the production process is simple and convenient, and the method is an efficient energy-saving synthetic method. The obtained phosphor has narrow emission peak, and a half-height peak width is only 4-5nm, furthermore, under a 241nm light excitation, the phosphor can emit light with different colors, emits orange light when Eu<3 +> is singly doped, emit blue light when Tm<3+> is singly doped, emits white light when Eu<3 + >and Tm<3 +> are in a co-doped state, and white light emission is finally realized by compounding with an ultraviolet LED chip.

Owner:CHANGCHUN UNIV OF SCI & TECH

Method for repairing converter through abandoned magnesia carbon bricks

InactiveCN110042197AShort sintering timeQuick RepairManufacturing convertersProcess efficiency improvementSlagScrap

The invention discloses a method for repairing a converter through abandoned magnesia carbon bricks. The method comprises the following steps that 1-2 t abandoned magnesia carbon bricks are put into asteel scrap bucket; after tapping, slag is poured into a tapping opening on the rear portion of the converter, a defined amount of slag is left, and a converter body is moved to the position slightlylowered than the steel scrap bucket; the abandoned magnesia carbon bricks in the steel scrap bucket are poured into the converter body, and during brick pouring, the converter body ascends so that the abandoned magnesia carbon bricks in the converter can be flattened; the converter is moved to the position needing to be repaired, residual slag is poured out, little slag is left in the converter to the greatest extent as long as the surface layers of the abandoned magnesia carbon bricks can be covered; after still standing, the abandoned magnesia carbon bricks can deposit in the repaired position through gravity, the abandoned magnesia carbon bricks chemically react with the slag in the sintering process, high-melting-point mineral substances are generated on the surface of a converter lining, steel scrap is added, thus, the slag quickly condenses, and converter repairing is completed. According to the method, converter repairing is finished through the abandoned magnesia carbon bricksduring casting within the rich rhythm time, the sintering time is substantially shortened, quick converter repairing can be achieved, the large-area maintaining time is long, and the converter production efficiency is effectively improved.

Owner:YANGCHUN NEW STEEL CO LTD

Biomass hot water cooking and heating stove with double-layer micro-dynamic fire grates

InactiveCN110822483APrevent flashbackImprove burnout rateLighting and heating apparatusStove/ranges for heating waterCombustion systemEnvironmental engineering

The invention discloses a biomass hot water cooking and heating stove with double-layer micro-dynamic fire grates. The biomass hot water cooking and heating stove comprises a stove body, a controllersystem, a feeding and fire-returning prevention system, a slag removal and fire grate combustion system, an air distribution system, a heat exchange application system and a cleaning and purifying system; the slag removal and fire grate combustion system comprises a hearth arranged in the stove body, the movable fire grate arranged at the bottom of the hearth, an igniter for igniting fuel accumulated on the movable fire grate, the fixed fire grate, a slag removal auger, a slag removal motor and an ash box; the biomass fuel falls into the front section of the primary movable fire grate and slowly moves under the slight rotation of the slag removal auger to prevent coking and slagging as well as to complete preheating, volatilizing and partial burning of fixed carbon in the process; and theunburned fixed carbon is finally combusted on the secondary fixed grate. The zoned and sectionalized micro-dynamic combustion structure not only has high burn-out rate, but also effectively avoids thecommon coking and slagging problems of the biomass stove.

Owner:联合优发生物质能源徐州有限公司

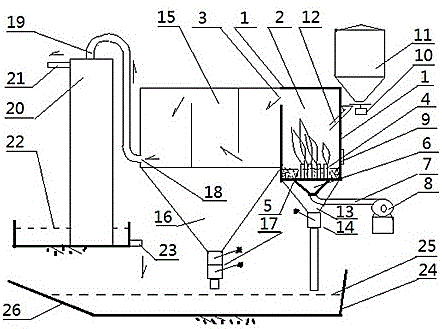

Rice husk boiling hot blast stove

Disclosed is a rice husk boiling hot blast stove. The rice husk boiling hot blast stove comprises a boiling hot blast stove body, a combustion chamber, an air outlet, a hood, an air blowing box, an air blower, an overhauling observation door, a disc feeder, a rice husk stock bin, a discharging pipe, an ash discharging hopper, an ash discharging valve, a hot air exchange chamber, a duplex ash discharging valve, an air exhaust opening, a water bath dust removal tower, an air exhaust pipe, a pool, a dust mud discharge opening and a wet ash pool. The boiling ho blast stove is characterized in that the combustion chamber is arranged in the boiling hot blast stove body, the air outlet is provided with the hot air exchange chamber, the hood is arranged on the lower portion, the air blowing box is connected with an air blowing pipe and the air blower, the disc feeder is arranged on an outlet of the rice husk stock bin, and is connected with the discharging pipe, the ash discharging hopper is arranged below the stove body, and is connected with the ash discharging valve, a hot air exchanger is mounted in the hot air exchange chamber, the ash discharging hopper and the duplex ash discharging valve are arranged below the hot air exchange chamber, the air exhaust opening in the rear portion is connected with an air inlet pipe of the water bath dust removal tower, and the air exhaust pipe is connected with an induced draft fan; wet ash is loaded in a forklift to be transported outwards, the boiling stove is simple in design and easy to operate, wastes are utilized as fuel, cost is saved, and the rice husk boiling hot blast stove is a very ideal energy-saving hot blast stove.

Owner:HUNAN DONGTINGCHUN RICE IND

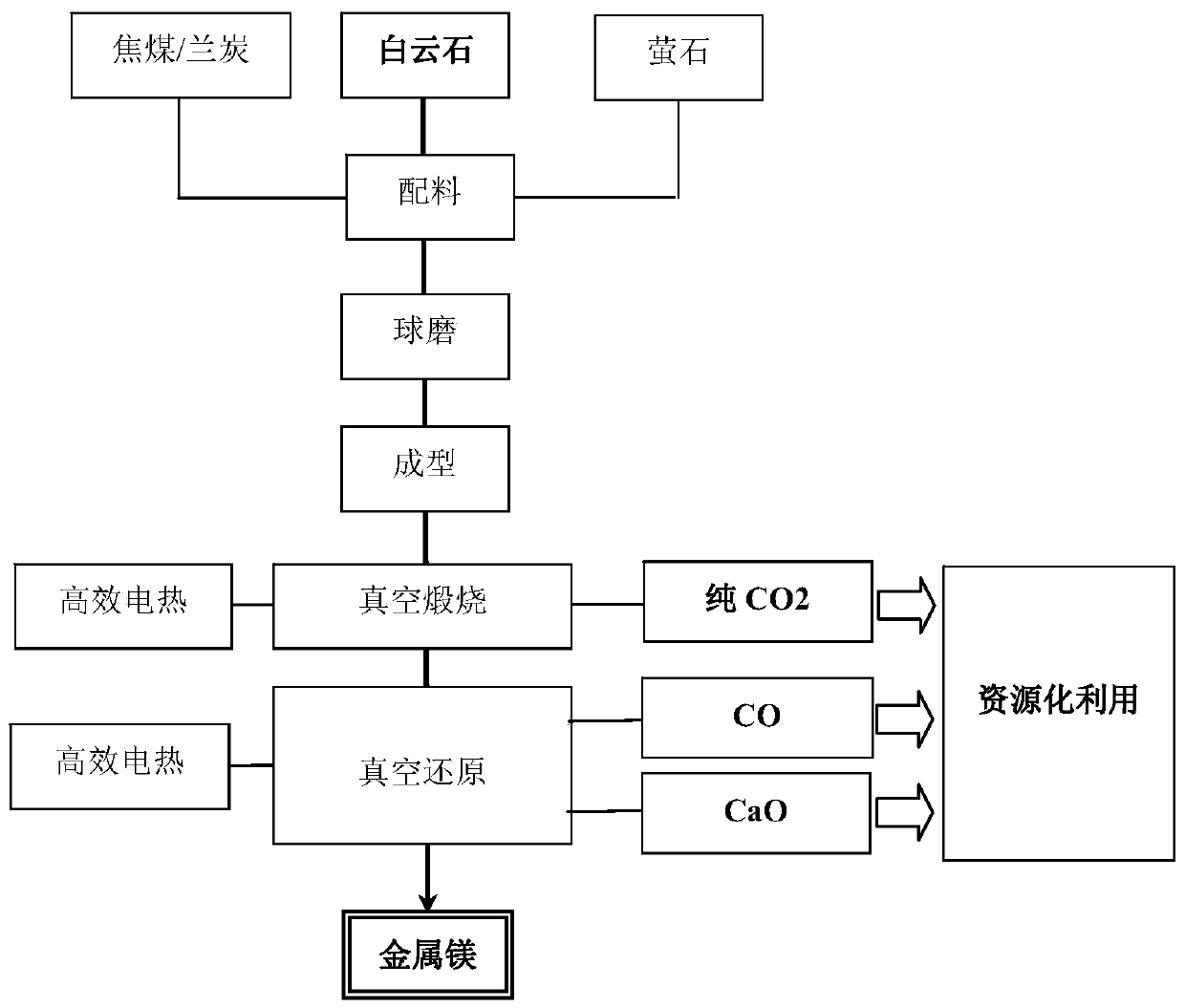

Metal magnesium carbon thermal reduction process and device

The invention discloses a metal magnesium carbon thermal reduction process and device. The process comprises the following steps that a magnesium-containing raw material, a carbon-containing reducingagent and a catalyst are used as raw materials, the raw materials are subjected to uniform mixing and forming, under certain temperature and vacuum degree conditions, current is directly conducted atthe two ends of a formed sample, and the current is controlled to carry out power-on reduction reaction, and the cooling is carried out to obtain the metal magnesium after the reaction is finished. The device comprises a reactor, a positive electrode, a negative electrode, a position buffer and a sealing cover, wherein the reactor is used for performing a metal magnesium reduction reaction, the positive electrode and the negative electrode are used for directly applying current to the reaction raw material formed parts, the position buffer is used for regulating the positive and negative electrodes, and the sealing cover is used for sealing the reactor. The process and device overcome the series of problems such as high reduction temperature, long reduction time, reversible reaction and the like of an existing carbon thermal method metal magnesium, the temperature of the reduction device can be greatly reduced, the metal magnesium can be initially reduced at room temperature, the reduction speed of the metal magnesium is greatly improved, and the process is green and environmentally friendly.

Owner:CHANGAN UNIV

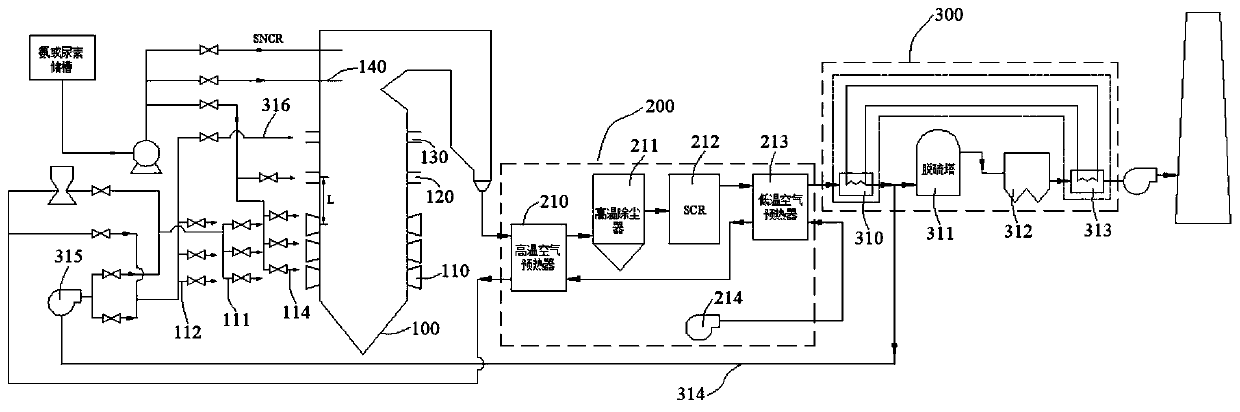

Deep denitration process for supercritical carbon dioxide coal-fired boiler

ActiveCN111450682ALower furnace temperatureReduce thermal NOx generationGas treatmentLighting and heating apparatusProcess engineeringFlue gas

The invention discloses a deep denitration process for a supercritical carbon dioxide coal-fired boiler, belonging to the technical field of NOx emission reduction. The deep denitration process comprises the following steps: three-stage ammonia injection denitration, wherein an ammonia injection combustor is used for injecting a fuel and an amino reducing agent into a main combustion area of a combustor in a boiler to form an annular high-temperature low-oxygen reduction area with a temperature of 850-1400 DEG C, and a reduction reaction is carried out in the annular high-temperature low-oxygen reduction area to achieve first-stage denitration, and a second-stage ammonia injection device and a third-stage ammonia injection device are used for respectively injecting an amino reducing agentto a main combustion area at the upper part of the high-temperature low-oxygen reduction area and a burnout area behind burnout air to realize second-stage denitration and third-stage denitration; anddedusting, desulfurization and denitrification, wherein SCR denitrification is conducted on the flue gas in a dedusting and denitrification unit, and then the flue gas is cooled to 70-90 DEG C and then sent into the boiler for circular denitrification treatment. The defect that the denitration degree is insufficient due to the fact that the temperature of the supercritical carbon dioxide coal-fired boiler is high in the prior art is overcome, deep staged denitration in the boiler is achieved through the three-stage ammonia injection denitration process, the temperature in the boiler is effectively reduced through low-temperature flue gas recirculation combustion, generation of thermal NOx is reduced, and deep denitration of the supercritical carbon dioxide coal-fired boiler is achieved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Aluminate red luminescent material and preparation process thereof

InactiveCN100999664AAchieve synthesisLower furnace temperatureLuminescent compositionsRare-earth elementLuminescent material

The present invention provides one kind of red light emitting aluminate material and its preparation process. The red light emitting aluminate material has chemical formula of MgxCa1-xAl2O4:Ry, where, x as content of Mg is 0.7-0.9, R is at least one of RE elements Eu, Dy, Nd, Ce and Ho, and y as content of RE element is 0.01-0.04. It is prepared through mixing the materials, assistant and water; heating the mixture in a high temperature furnace to react; cooling and grading. It has high light emitting performance and may be used widely in electronics, information treatment, energy source and other fields.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

Domestic garbage smokeless oil-free vertical pyrolysis gasification furnace

PendingCN110260328AAchieve reductionHarmlessIncinerator apparatusIndirect carbon-dioxide mitigationCombustionEngineering

The invention discloses a domestic garbage smokeless oil-free vertical pyrolysis gasification furnace which comprises a furnace body and air pipelines. The air pipelines comprise a second combustion air pipeline and a first combustion air pipeline which are arranged up and down and communicate with the furnace body. The first combustion air pipeline extends into the bottom of the furnace body and communicates with the bottom of the furnace body through an air distributor, and the second combustion air pipeline communicates with the upper half part of the furnace body; and the air blown by an air blower is separately sent to the first combustion air pipeline and the second combustion air pipeline. The domestic garbage smokeless oil-free vertical pyrolysis gasification furnace is simple in structure and reasonable in design; and toxic and harmful gas is completely eliminated, and the heat of garbage is truly utilized for realizing reduction and harmlessness of the garbage.

Owner:诸城市宏利圣得环境科技有限公司

Coal-fired boiler combustion operation method and combustion operation system

PendingCN107120639APrevent dust and slaggingAvoid corrosionCombustion using gaseous and pulverulent fuelGaseous fuel feeder/distributionLower gradeProcess engineering

The invention discloses a coal-fired boiler combustion operation method and a combustion operation system. According to the combustion operation method, biomass gasified gas is injected into a hearth to assist fire coal burning. Not only can the problems of the dust deposition, scorification and corrosion be avoided, but the emission concentration of SO2 and NOx can be reduced remarkably, the carbon content of flue dust is reduced, and the high grade use of low grade biomass energy is realized.

Owner:GUODIAN NANJING ELECTRIC POWER TEST RES CO LTD

Cantonese-style water chestnut paste stuffing mooncake

InactiveCN105594810AImprove ductilityNot easy to crackDough treatmentBakery productsFlavorWater Chestnuts

The invention relates to the field of bakery product processing, in particular to cantonese-style water chestnut paste stuffing mooncake which comprises skin and stuffing. The stuffing comprises 100 parts of water chestnut paste, 10-30 parts of sucrose powder and 10-20 parts of edible oil. A method for manufacturing the stuffing comprises the steps of water chestnut powder manufacture, water chestnut paste manufacture and cold storage and the like. Fresh water water chestnuts which are extensive in source are utilized to manufacture the water chestnut paste stuffing mooncake having peculiar flavor of the water chestnuts, the stuffing is unique in taste and rich in nutrition, and the style of conventional Cantonese-style mooncake is retained.

Owner:项小飞

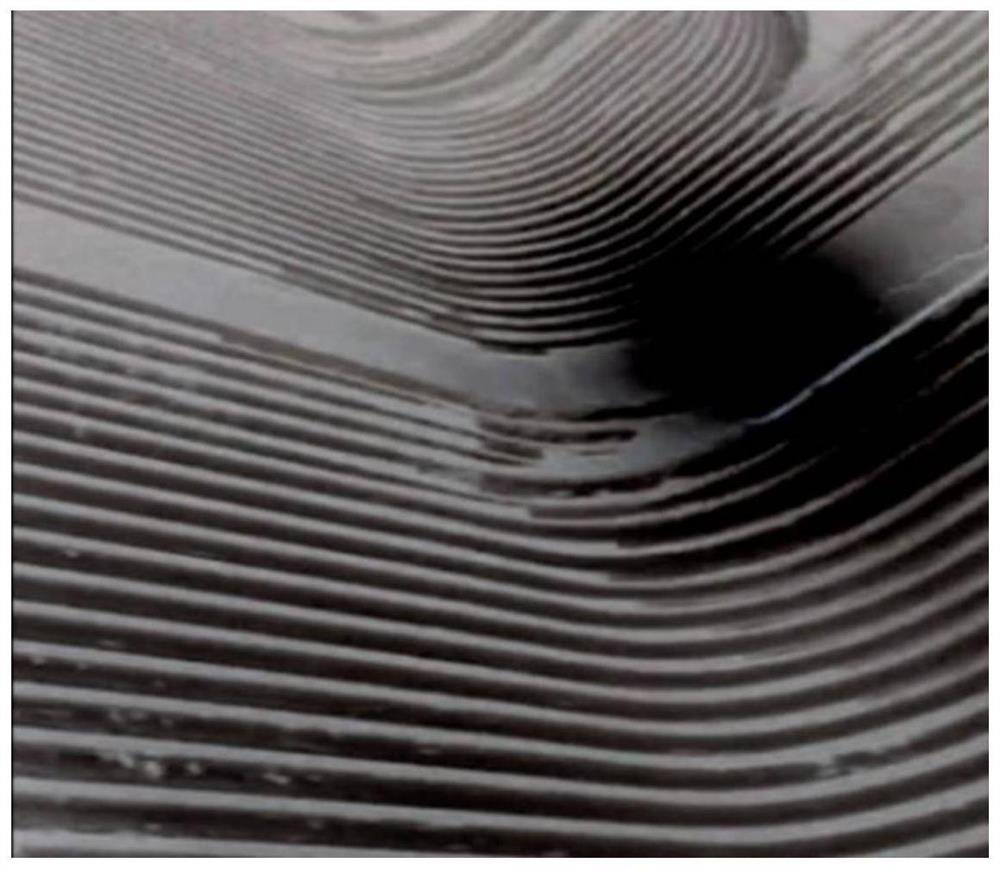

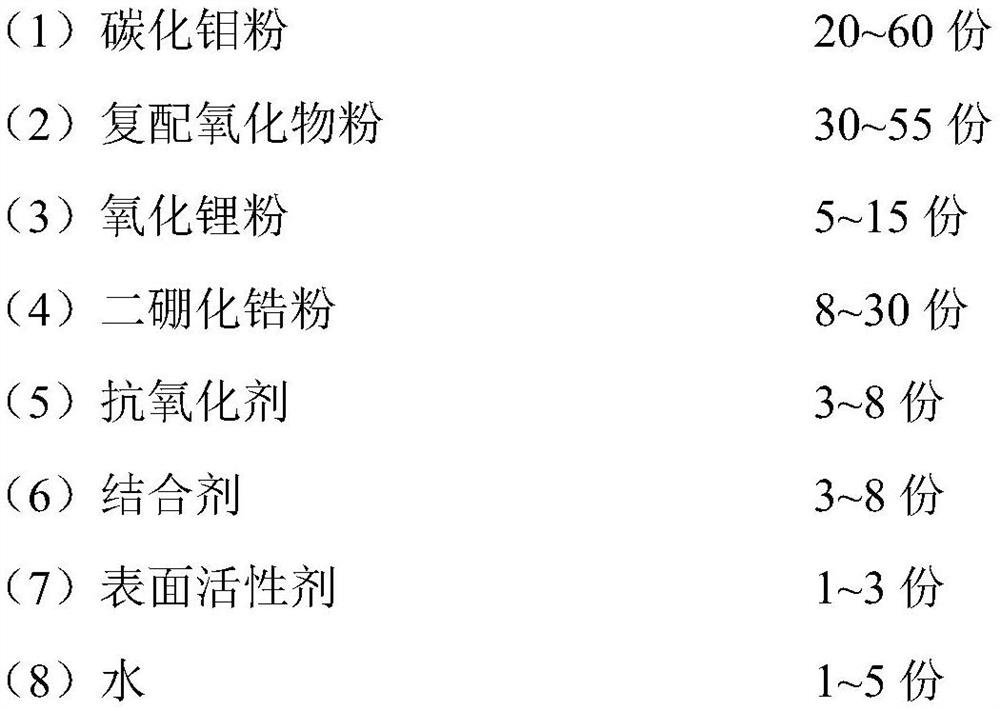

Anti-coking coating and preparation process thereof

ActiveCN114196238AAnti-cokingImprove acid and alkali corrosion resistanceLiquid surface applicatorsCoatingsLithium oxideBoride

Molybdenum carbide, lithium oxide and zirconium boride are used as main raw materials, and a compound oxide, an antioxidant, a binding agent and the like are used as auxiliary materials. A coating formed after the coating is constructed has the advantages of high wear resistance, coking resistance, acid and alkali corrosion resistance and the like in a high-temperature service environment, does not crack or fall off under the condition of cold and hot alternation, has excellent high-temperature and chemical stability, and is suitable for coking resistance of coal-fired boilers, kilns and the like in electric power, metallurgy, petrifaction and other industrial and mining enterprises.

Owner:宜兴瑞泰耐火材料工程有限公司 +2

Straw gasification furnace capable of continuously producing gas

The invention discloses a straw gasification furnace capable of continuously producing gas. Straws which are cut up are fed into a material storage tank, the straws placed in the material storage tank are conveyed into a rolling tube type furnace rake by a spiral feeding machine, after the rolling tube type furnace rake is fully filled with the straws, a driving motor rotates to drive the rolling tube type furnace rake to rotate, and a plastic bottle is extruded so that diesel oil can be uniformly sprayed onto the straws in the rolling tube type furnace rake. The straws sprayed with the diesel oil are ignited by the flame of a pistol type long pipe gas ignition gun, wind blown out from a blast blower supports the smouldering of the straws in the rolling tube type furnace rake, the straws can generate a large amount of carbon monoxide during the smouldering, fireproof ceramic balls or metal balls in the rolling tube type furnace rake stir the straws so that the uniform smouldering of the straws can be realized, coal tar generated by the smouldering is heated and decomposed into low-molecule combustible gas when passing through two layers of double-layer honeycomb-shaped metal nets of the back section of the red burnt rolling tube type furnace rake, hot smoke gas heats the wind blown out from a boiler and the blast blower, the generated vapor and hot wind enter an air outlet pipe, and humid and hot air supports the smouldering of the straws, the combustible gas content in the smoke gas can be increased, and the smoke gas is cooled.

Owner:张英华

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com