Coal-fired boiler combustion operation method and combustion operation system

The technology of a coal-fired boiler and its operating method, which is applied in the field of electric power, can solve the problems of high fuel system cost and many safety hazards, and achieve the effects of reducing emission concentration, cost, and carbon content of fly ash

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings.

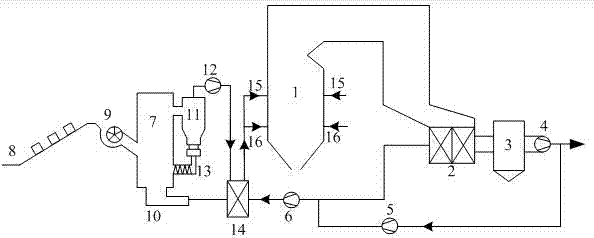

[0028] Such as figure 1 As shown, the combustion operation system of the coal-fired boiler of the present invention reforms the existing coal-fired boiler, including a biomass gasification gas generation device outside the furnace, and the bundled biomass is transported to the feeder 9 through the conveyor belt 8 , and then enter the gasifier 7, while the gasification medium enters the gasifier 7 from the gasification furnace wind chamber 10, and the biomass gasification gas produced by the gasification of biomass in the gasifier 7 enters the cyclone separator 11, and is separated Most of the biomass ash, unburned biomass ash and separated bed material particles are re-transported to the gasifier 7 through the auger 13 provided at the lower part, and the biomass gasification gas passes through the gas-gas heat exchanger 14 The temperature is lowered to about 400°C, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com