A heat exchanger for waste heat utilization of flue gas

A flue gas waste heat and heat exchanger technology, which is applied in the direction of indirect heat exchangers, heat exchanger types, heat exchanger shells, etc., can solve the disadvantages of strengthening flue gas heat transfer, increasing the cost of boiler system equipment, and not compact structure, etc. problems, to achieve the effect of compact structure, high heat utilization efficiency, and prolonged contact time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

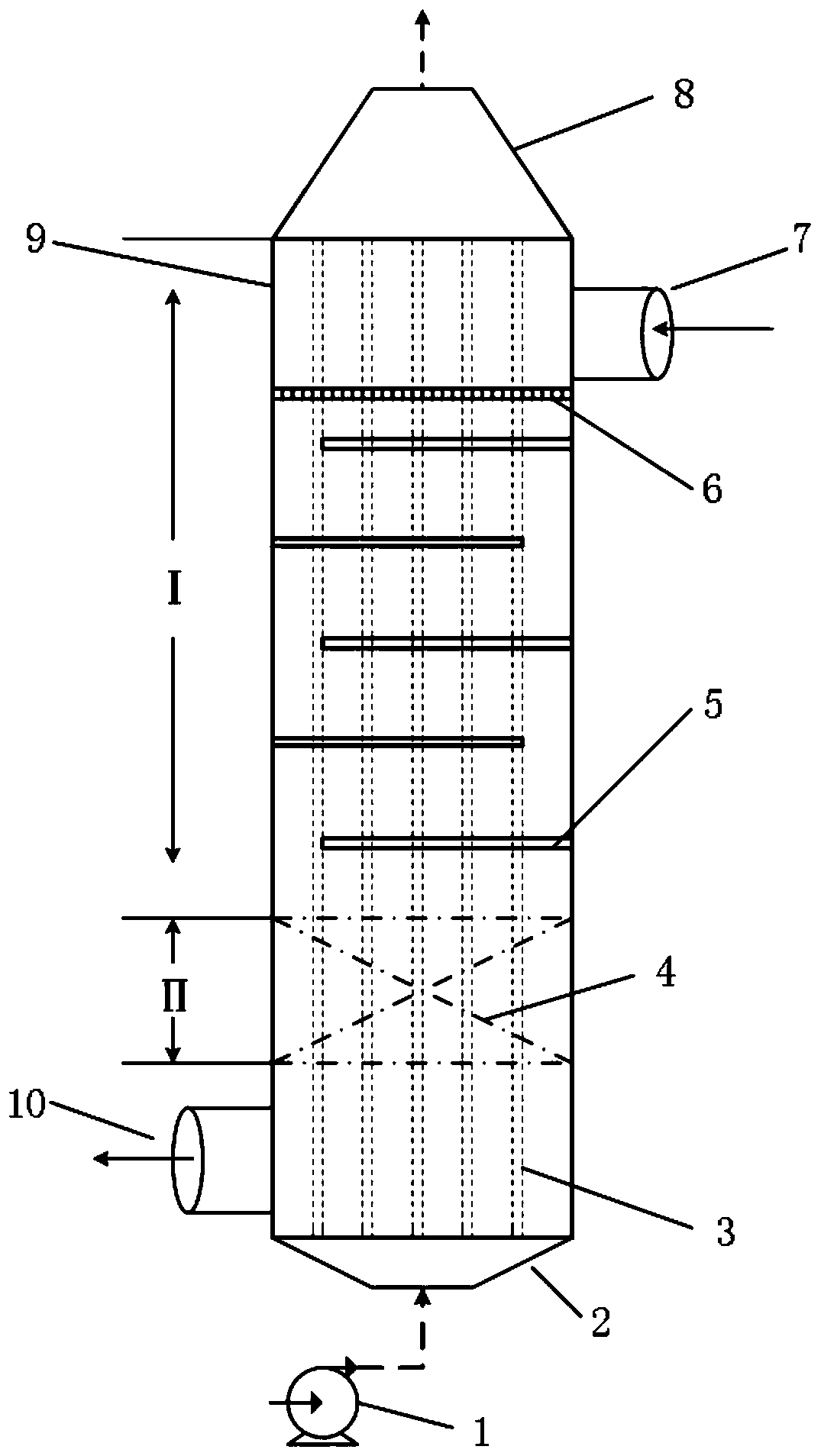

[0030] Such as figure 1 As shown, this embodiment provides a heat exchanger for waste heat utilization of flue gas, including a first flue 9, a second flue 4, a heat exchange tube 3, a baffle plate 5 and a filter plate 6;

[0031] Specifically, the first flue is set as follows: the first flue 9 is placed vertically, the first flue inlet 7 is arranged at the upper part of one side, and the first flue outlet 10 is arranged at the lower part of the other side; the first flue 9 can It is a regular long column shape such as a cuboid or cylinder.

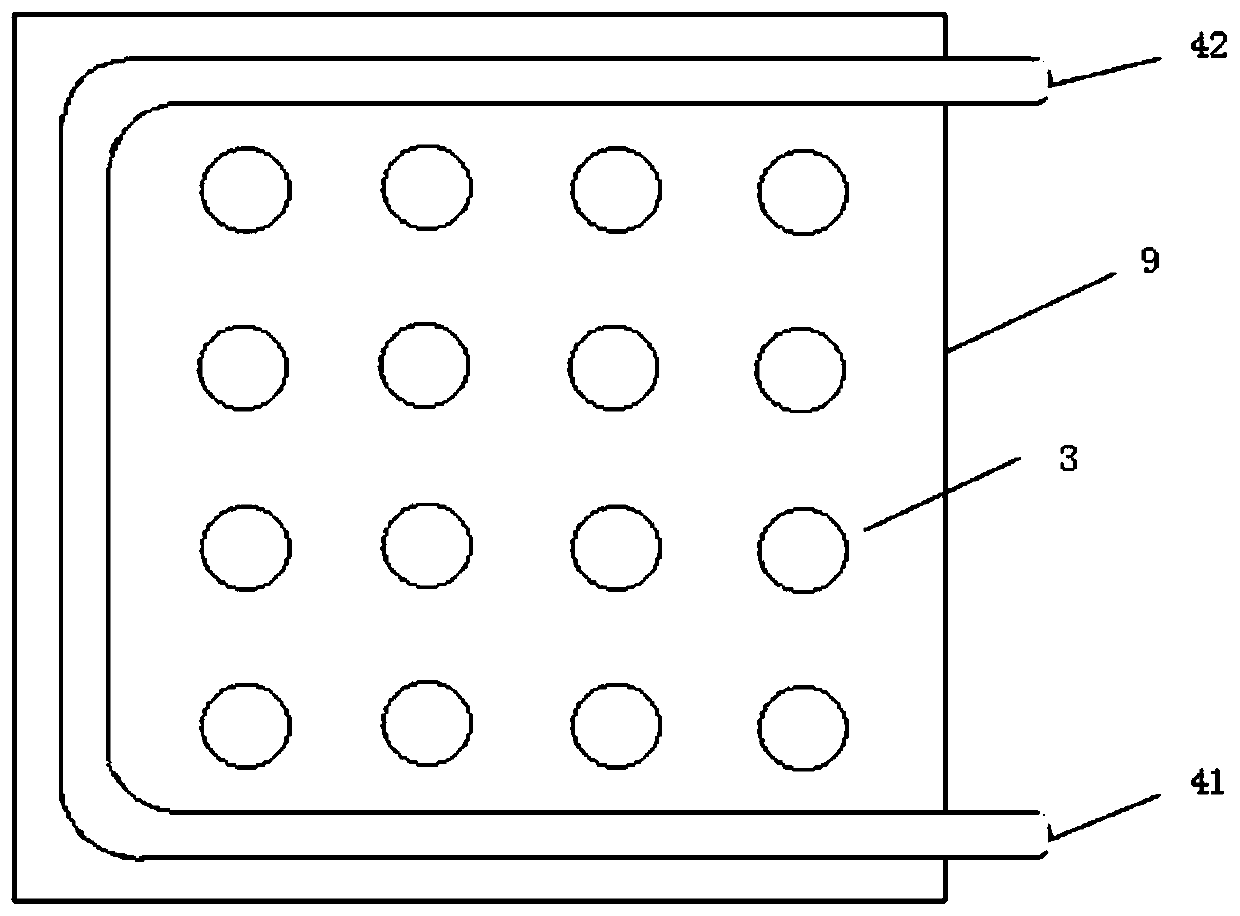

[0032] Both the baffle plate 5 and the filter plate 6 are fixedly connected in the first flue 9, and the baffle plate 5 is downstream of the filter plate 6; the second flue 4 penetrates the first flue 9, the second flue 4 is arranged downstream of the baffle 5; the heat exchange tube 3 penetrates the first flue 9, the baffle 5 and the filter plate 6, and the flue gas enters the first flue 9 , first pass through the filter plate 6 to fil...

Embodiment 2

[0042] Such as figure 1 As shown, this embodiment provides a heat exchanger for utilization of flue gas waste heat.

[0043] On the basis of Embodiment 1, the connection method of the baffle plate 5 and the filter plate 6 is improved.

[0044] Specifically, another setting method of the baffle 5 is: the baffle 5 is detachably installed on the inner wall of the first flue.

[0045]Specifically, another arrangement of the filter plate 6 is: the filter plate 6 is detachably arranged near the entrance of the first flue. Filter the solid particles with large particle size in the flue gas.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com