Ultrasonic monitoring device, system and method for ash deposition and slagging of coal gasifier water-cooled wall

A monitoring device and monitoring system technology, applied in the direction of measuring devices, using ultrasonic/sonic/infrasonic waves, instruments, etc., can solve the problems of reduced heat transfer performance, reduced efficiency of coal gasifier, and affecting work safety, etc., to achieve low cost and avoid The phenomenon of dust accumulation and slagging, and the effect of ensuring safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

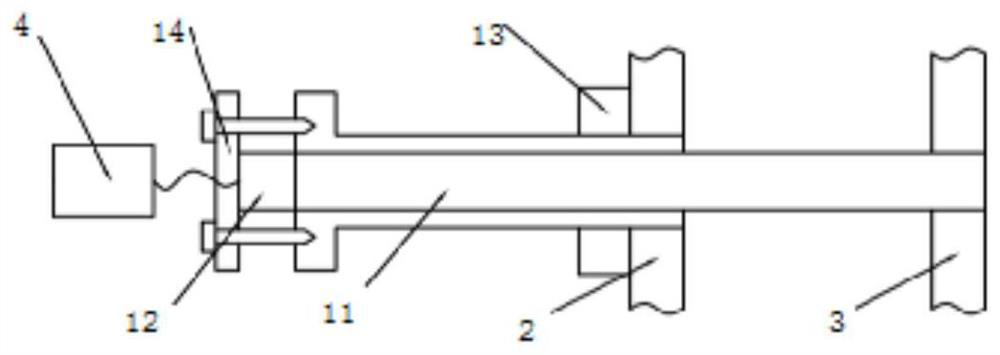

[0030] See attached figure 1 An ultrasonic monitoring device for ash accumulation and slagging on the water wall of a coal gasification furnace is installed in the coal gasification furnace. The monitoring device 1 includes: a waveguide 11 and an ultrasonic sensor 12 .

[0031] One end of the waveguide 11 passes through the outer wall 2 of the coal gasifier, and is attached to the inner wall of the water-cooled wall 3 of the coal gasifier; the waveguide 11 is fixed to the outer wall 2 by the first fixing device 13; the first fixing device 13 Ensure that one end surface of the waveguide 11 is flush with the inner wall surface of the water-cooled wall 3 to prevent the waveguide 11 from moving. In this example, the waveguide 11 is made of stainless steel. Stainless steel has a high temperature resistance of 800°C, can be used in high temperature environments, and has the characteristics of strong corrosion resistance, high toughness, and low sound attenuation. The shape of the ...

Embodiment 2

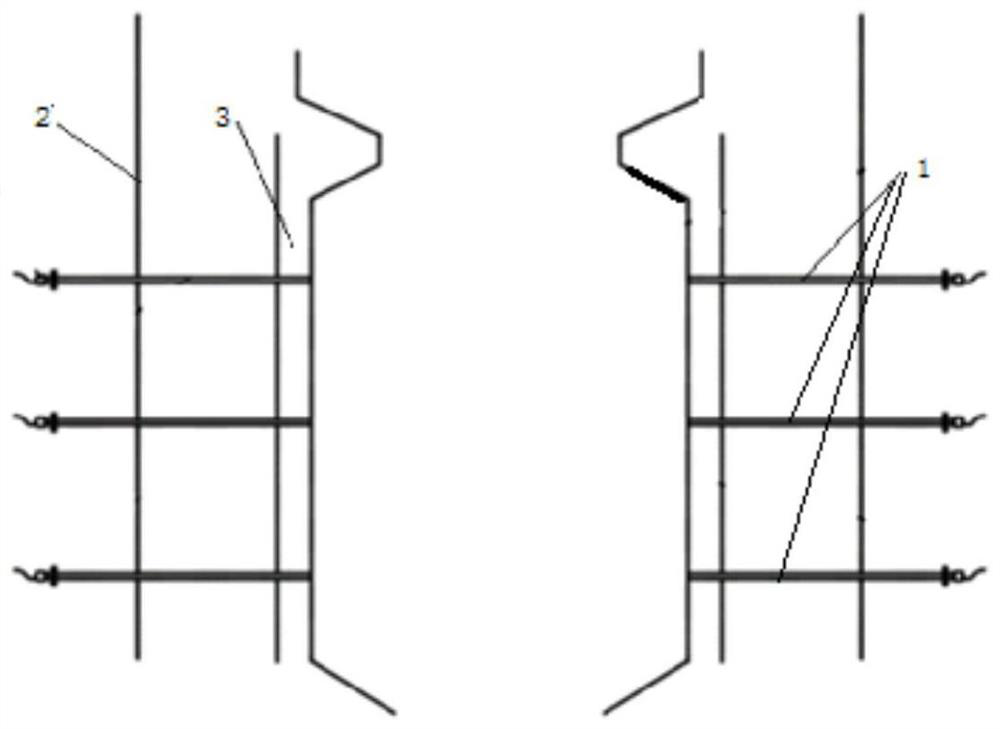

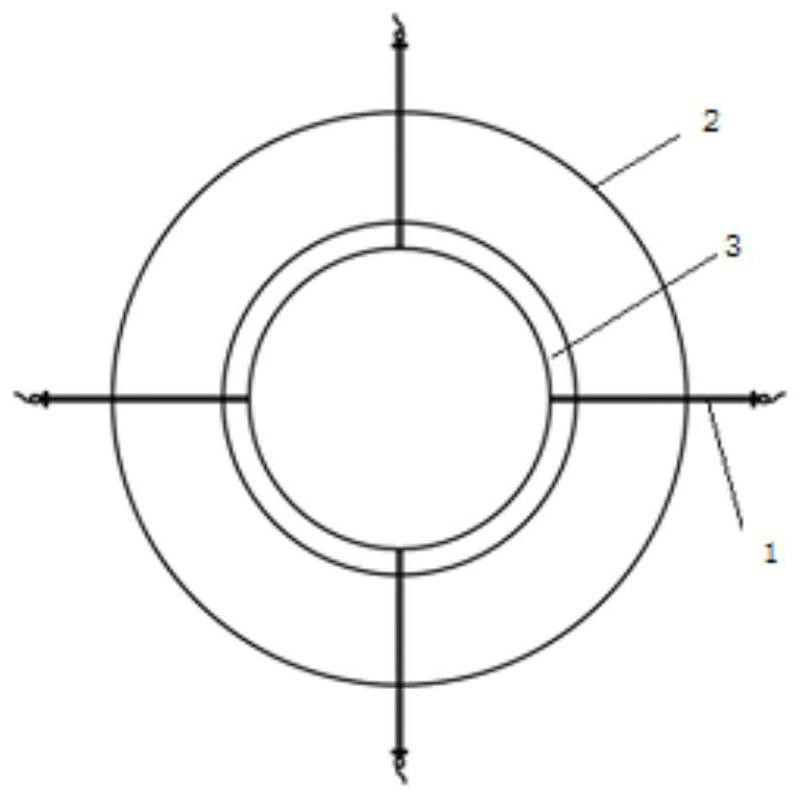

[0038] See attached figure 2 , 3 4. Ultrasonic monitoring system for ash accumulation and slagging on the water wall of coal gasifier, which uses the monitoring device 1 described in Embodiment 1. The monitoring device 1 is divided into 3 layers at equal intervals on the water wall 3, and each layer is surrounded by Four monitoring devices 1 are arranged in the direction; all monitoring devices 1 are connected with the computer 4 to form a monitoring system.

[0039] The ash accumulation and slagging of the water wall 3 vary with different heights, and the same height may also be different due to various factors. The 12 monitoring devices 1 are all connected to the computer 4 through data lines, and can realize online monitoring of the ash thickness of the entire coal gasifier.

Embodiment 3

[0041] Ultrasonic monitoring method for ash accumulation and slagging on the water wall of a coal gasifier, which uses the monitoring system described in Example 2. Since the monitoring system is arranged in three layers from top to bottom in the entire coal gasifier, each layer has 11 waveguides. The temperature is different, so to get the thickness value, the sound velocity at different temperatures must be obtained first. Establish the relationship between the temperature and the waveguide 11 and the sound velocity of the ash through experiments, and obtain the sound velocity under the temperature environment where the monitoring device 1 of each layer is located; use the formula to obtain the thickness of the ash:

[0042]

[0043] Wherein: d is the thickness of ash; t is the time when the ultrasonic sensor 12 receives the reflection signal from the bottom of the ash; h is the length of the waveguide 11; c 1 is the speed of sound in the waveguide 11; c 2 is the speed of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com