Patents

Literature

276results about How to "High sulfur content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

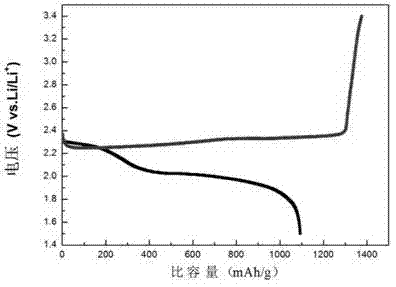

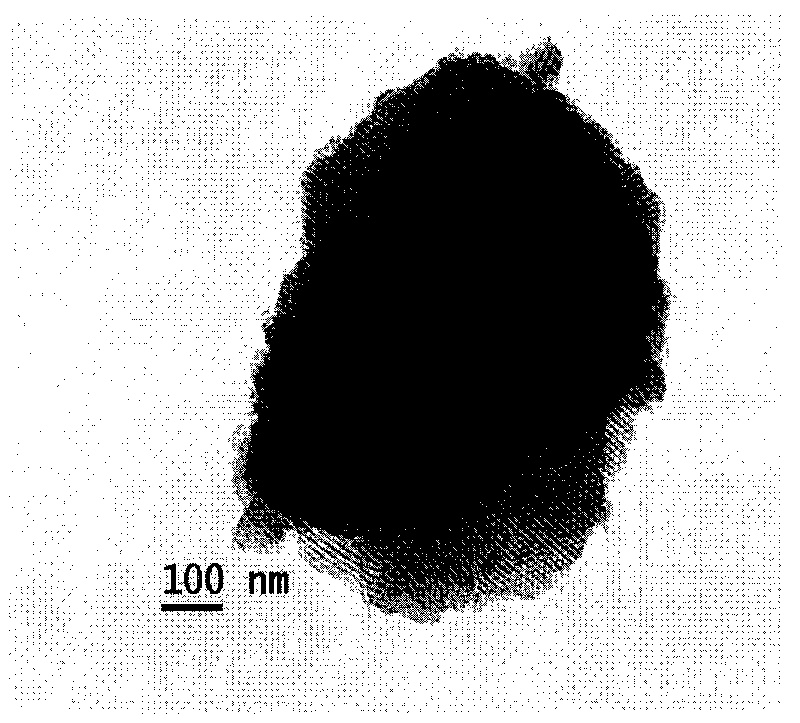

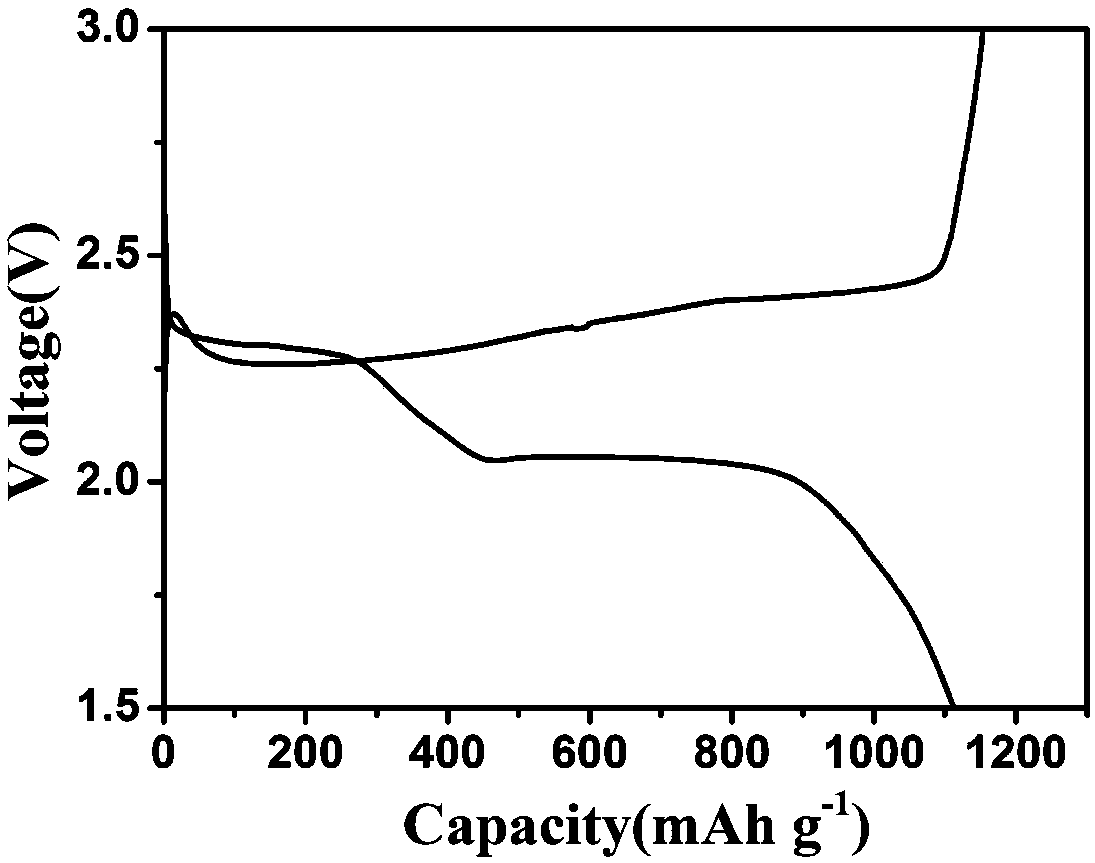

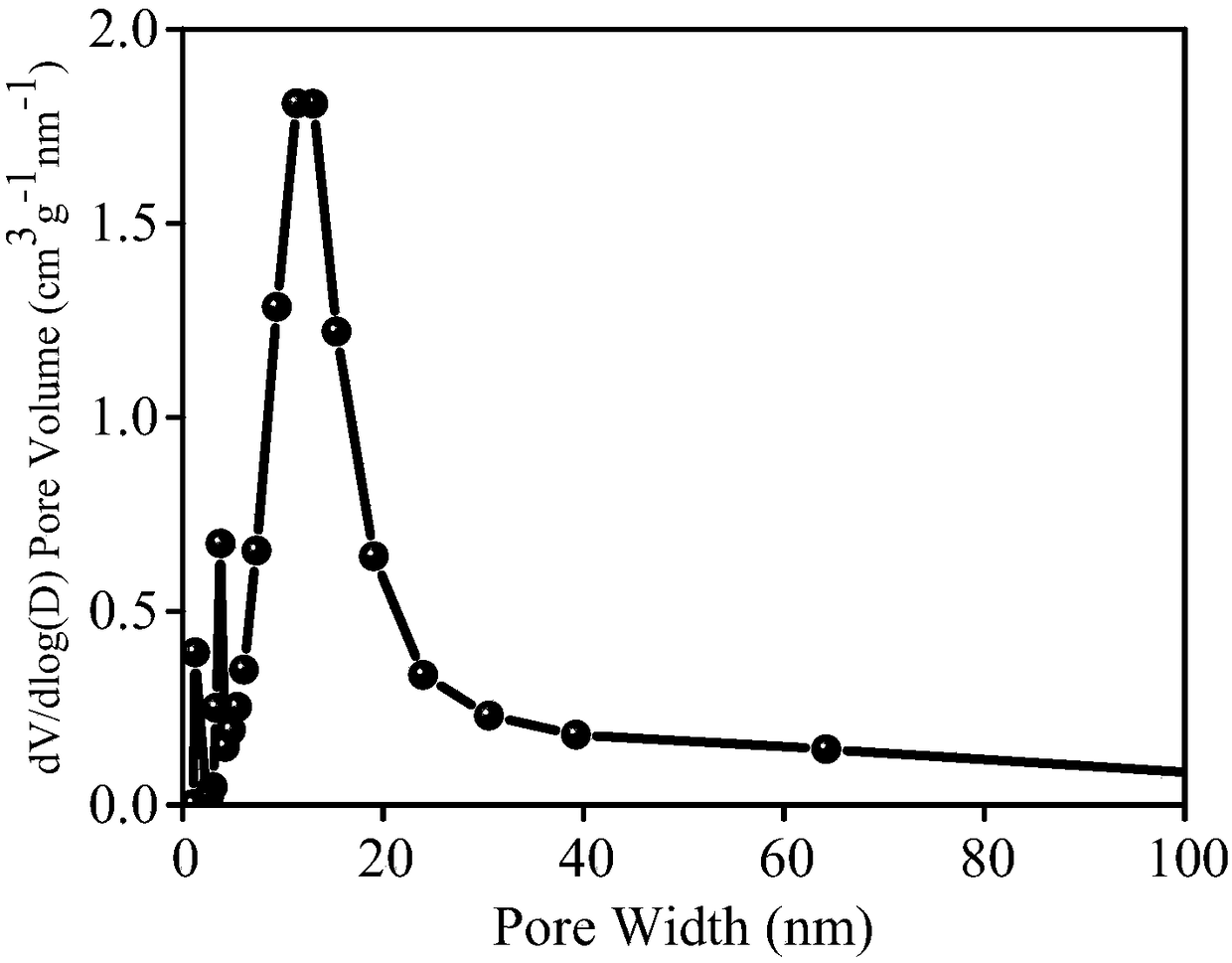

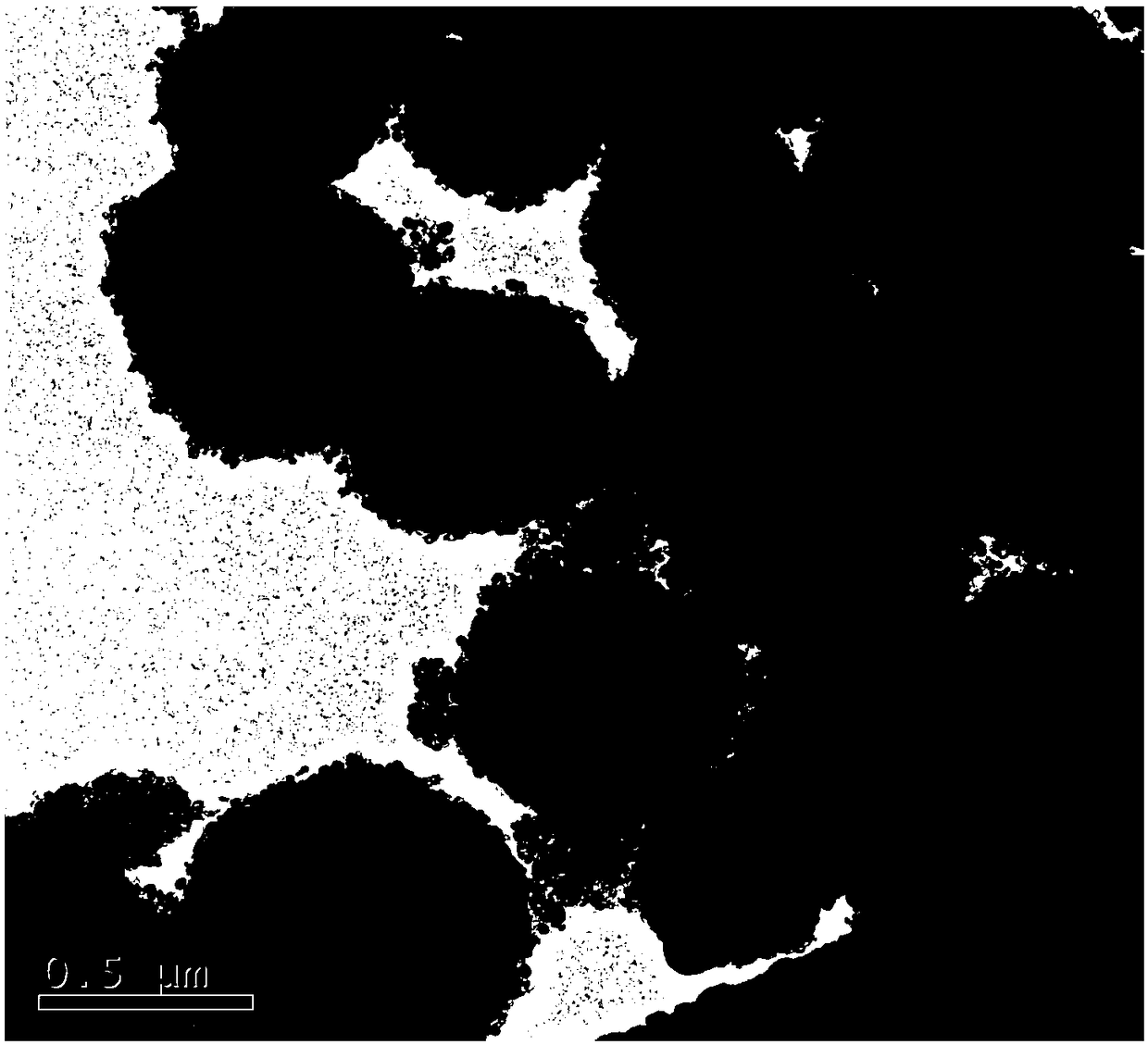

Lithium-sulfur battery cathode material and preparation method thereof

ActiveCN102780001AInhibition of dissolutionImprove cycle performanceCell electrodesMetal-organic frameworkDissolution

The invention discloses a lithium-sulfur battery cathode material and a preparation method thereof. The cathode material is formed by in-situ compositing of a mesoporous metal-organic framework and elemental sulfur. The mesoporous metal-organic frame is of a laminated pore structure consisting of a macro pore, a meso pore and a micro pore, wherein the pores are communicated with one another. The structure can adsorb more elemental sulfur and can simultaneously inhibit the dissolution of sulfur elementary substance and multi-sulfur compounds in electrolyte, so that the cycle performance of a lithium-sulfur battery is improved and high utilization rate of an active substance of the cathode material is kept. A sulfur and metal-organic framework material composite cathode material is prepared by a two-step process of low-temperature liquid phase composition and sulfur extraction, a composite material precursor with homogeneously dispersed high load sulfur content can be obtained through in-situ compositing at a low temperature with a liquid-phase preparation method, redundant sulfur on the surface of the precursor and in pore passages is extracted by an organic solvent, the aperture of the composite material can be further effectively adjusted and controlled, selective distribution of sulfur is realized, and the composite material with excellent electrochemical performance is obtained. By adopting the preparation method, the distribution of the sulfur in the composite material can be effectively improved, and the electrochemical performance of the composite material is optimized. Meanwhile, the preparation method is simple and is easy to perform industrially, and mass production is facilitated.

Owner:CENT SOUTH UNIV +1

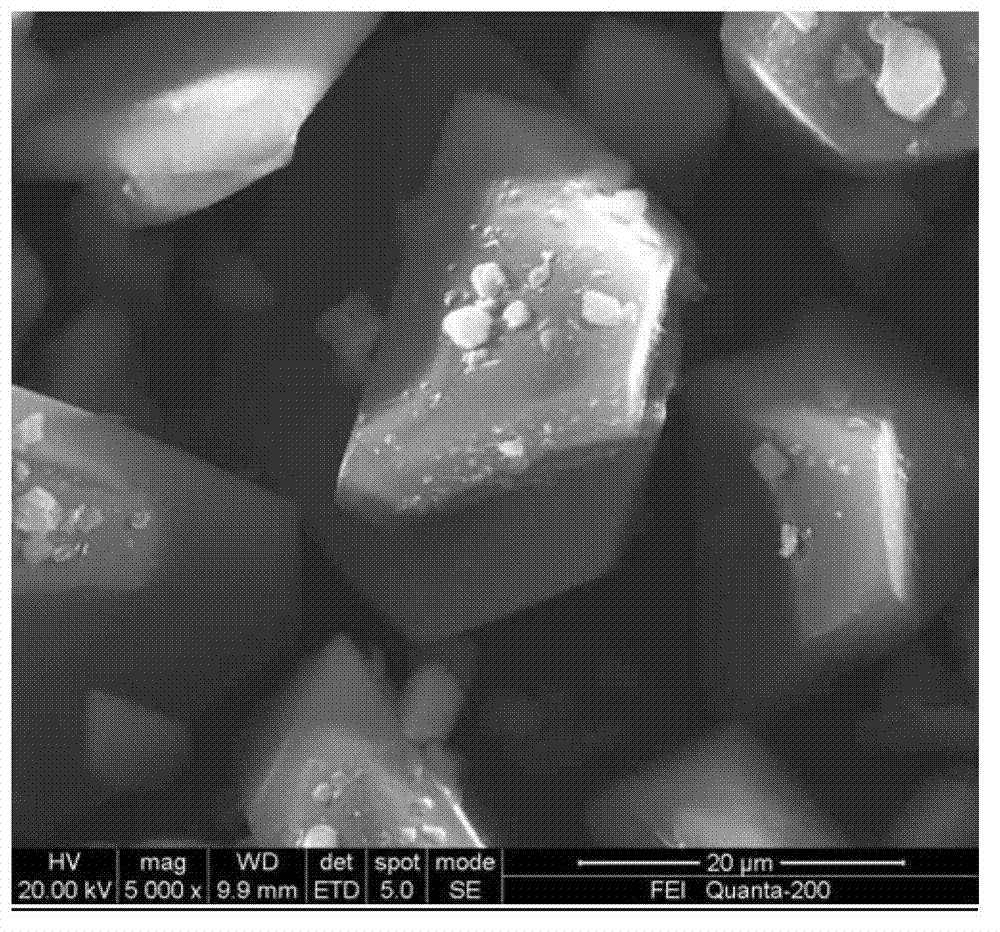

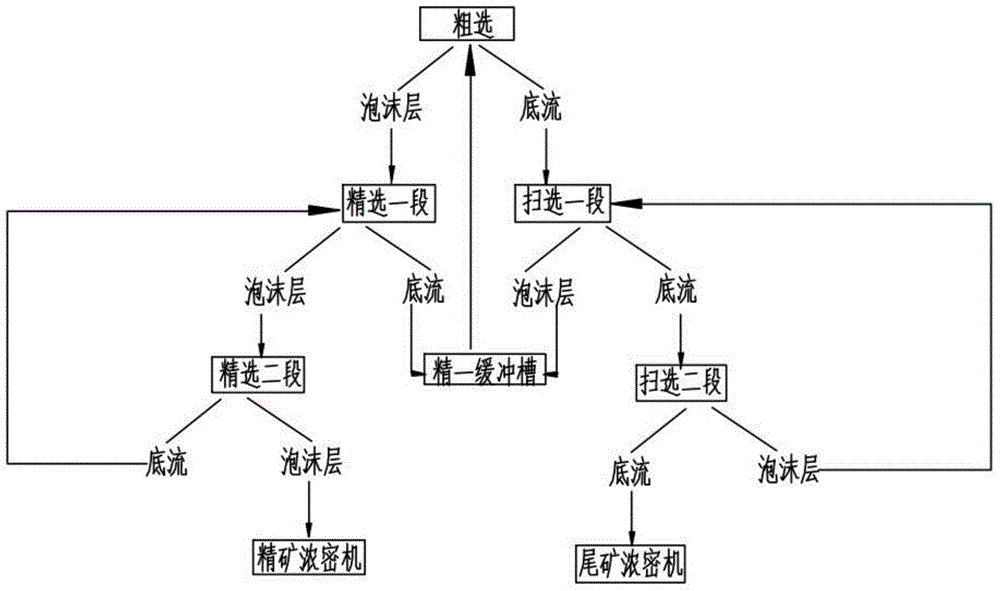

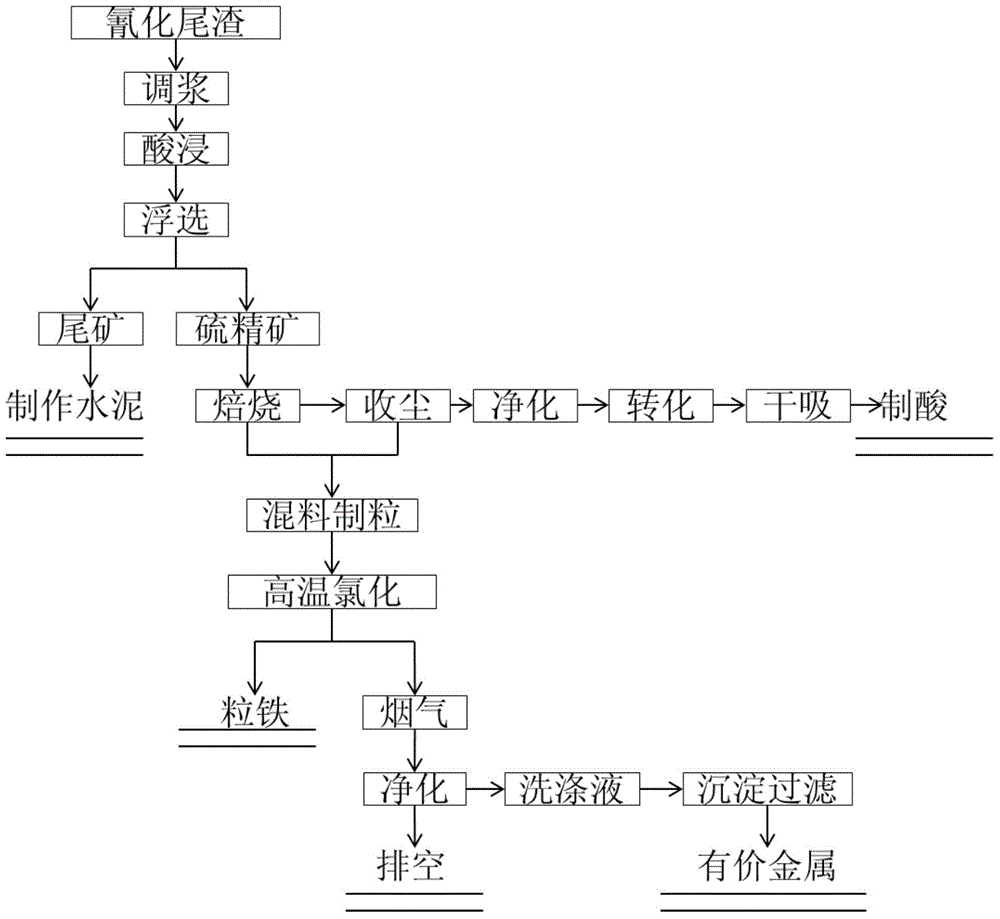

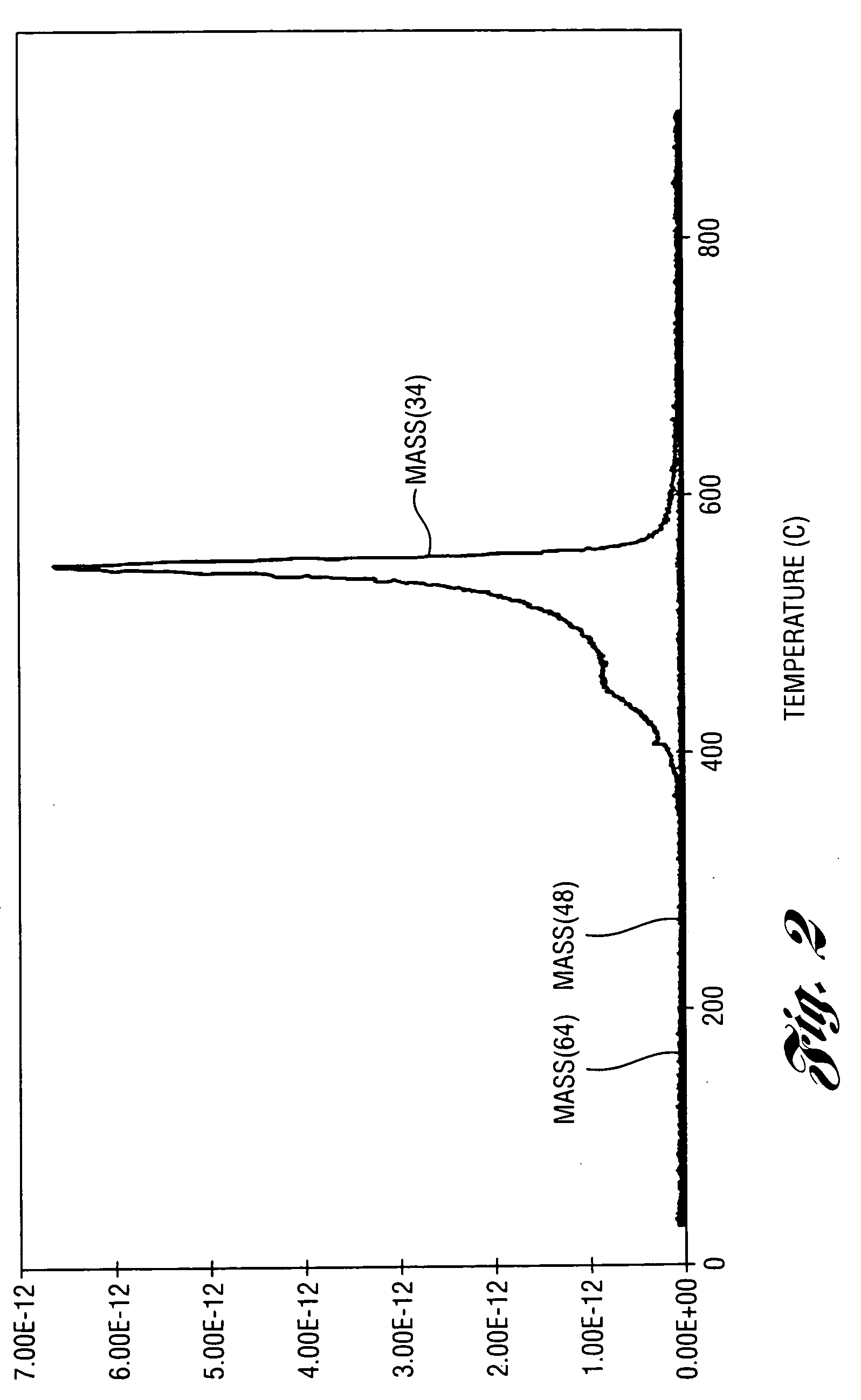

Comprehensive recycling method of cyanide tailing slag

ActiveCN103981370AEfficient separation and recoveryImprove utilization efficiencySolid waste managementSulfur compoundsCyanideSulfur

The invention belongs to the technical field of metallurgical waste slag recovery and in particular relates to a comprehensive recycling method of cyanide tailing slag. Cyanide tailings is floated to obtain sulfur concentrate and tailing, sulfur concentrate is roasted by weak oxygen to obtain sulfuric acid, and pyritic slag is subjected to chlorination roasting to enable valuable elements to be recycled. By virtue of the comprehensive recycling method disclosed by the invention, the valuable elements can be efficiently separated and recovered from cyanide tailing slag, and cyanide tailing slag is utilized to a maximum extent, the comprehensive utilization efficiency of resources is improved and the pollution of cyanide tailing slag to the environment is reduced.

Owner:ZHAOJIN MINING +1

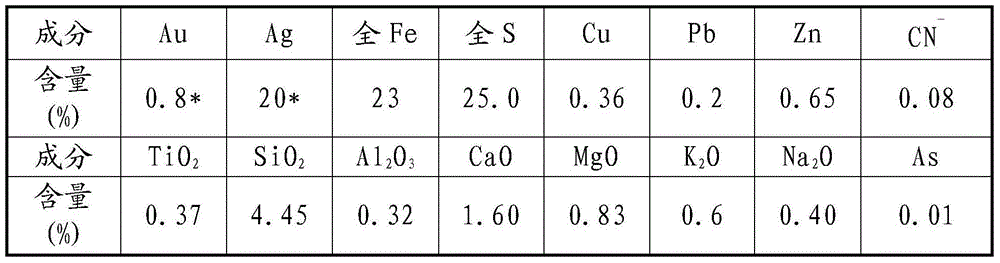

Catalyst system and method for the reduction of NOx

ActiveUS20060133976A1Improve efficiencyReduce NOxNitrous oxide captureNitrogen compoundsIndiumCobalt

A catalyst system for the reduction of NOx comprises a catalyst comprising a metal oxide catalyst support, a catalytic metal oxide comprising at least one of gallium oxide or silver oxide, and at least one promoting metal selected from the group consisting of silver, cobalt, molybdenum, tungsten, indium, bismuth and mixtures thereof. The catalyst system further comprises a gas stream comprising an organic reductant, and a compound comprising sulfur. A method for reducing NOx utilizing the said catalyst system is also provided.

Owner:GENERAL ELECTRIC CO

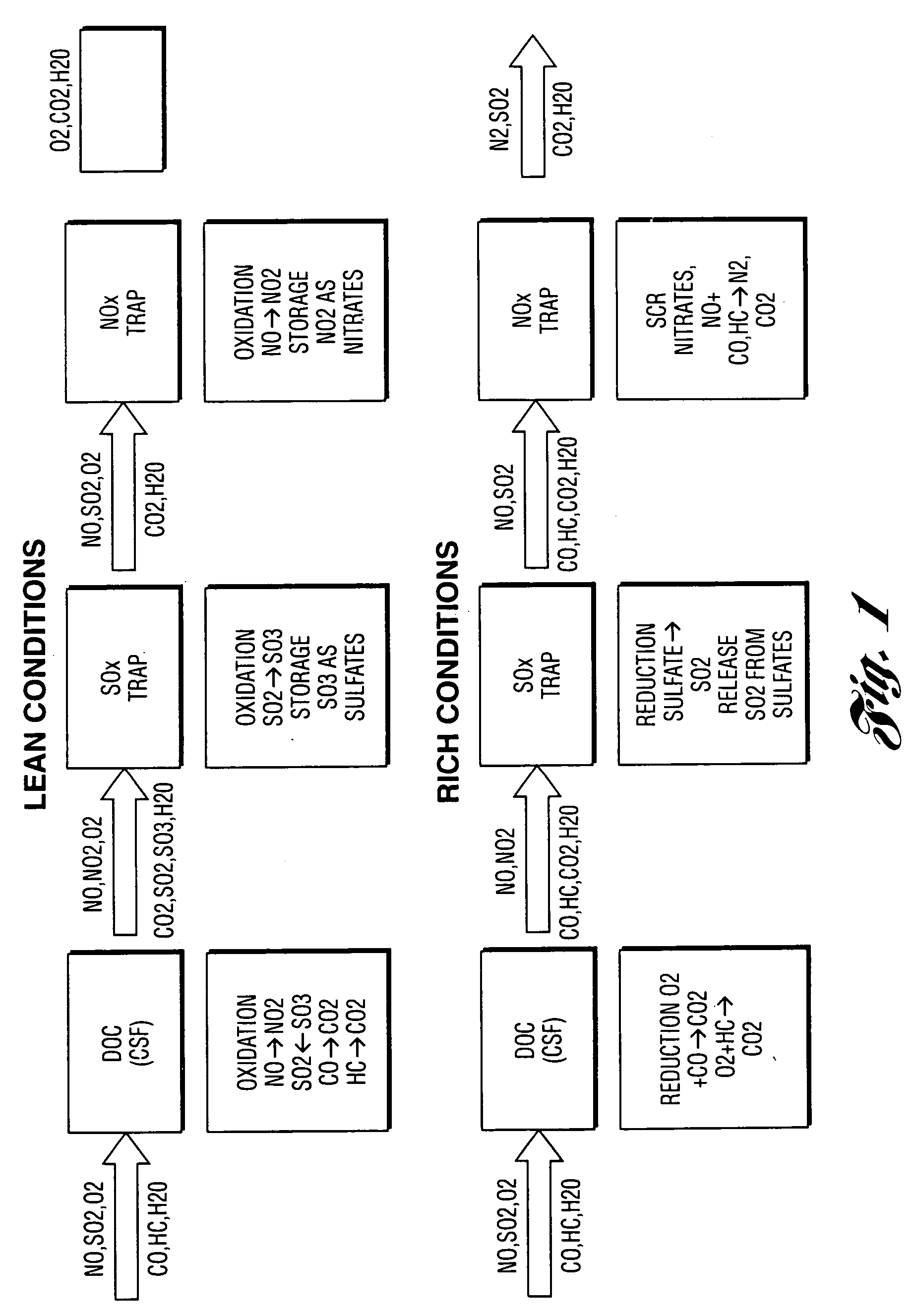

SOx trap for diesel and lean-burn gasoline automotive applications

InactiveUS20050145827A1Reduce gas emissionsAvoid problemsCombination devicesGas treatmentSulfurGasoline

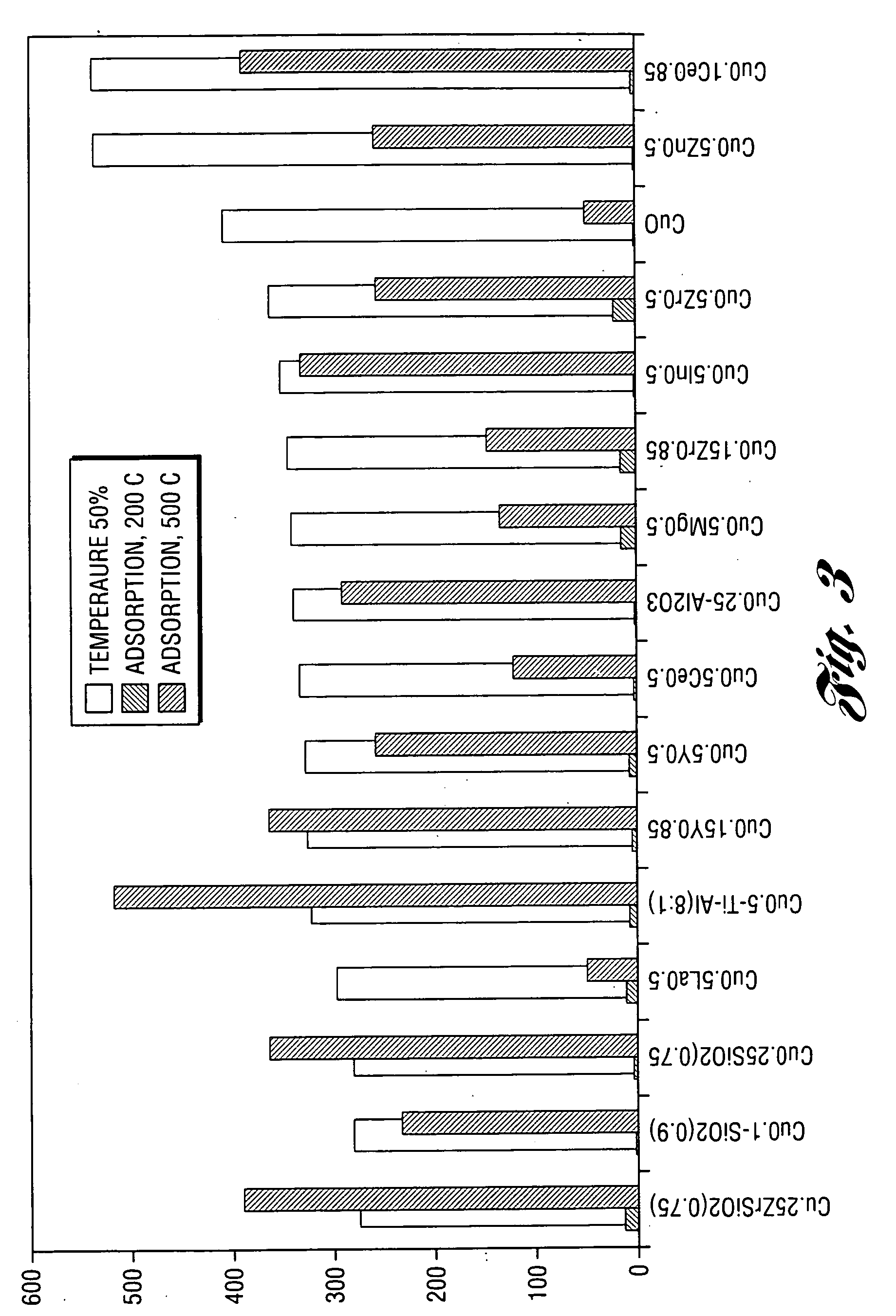

The present invention provides a regenerable catalyst composition suitable for entrapping SOx. The composition of the invention comprises a copper oxide having the formula (Cu / (A oxide) where A oxide is SiO2, Zr—SiO2, A12O3, TiO2—Al2O3, ZrO2 and In2O3 or mixtures thereof. Copper loading may vary from about 10 to 60 mol % and is preferably about 25 mol %. The catalyst composition adsorbs SOx as metal sulfate under lean conditions and desorbs accumulated SOx as SO2 under rich conditions. Such reversible SOx trap are able to operate under conventional NOx trap operating conditions to prevent sulfur poisoning of the NOx trap. Furthermore, these traps may be regenerated under rich conditions at 300-450° C. In another embodiment of the present invention, an irreversible SOx trap capable of collecting SOx under lean conditions is provided. The traps of this embodiment include praseodymia, zirconia-praseodymia and mixed manganese-yttria and mixtures thereof.

Owner:FORD GLOBAL TECH LLC

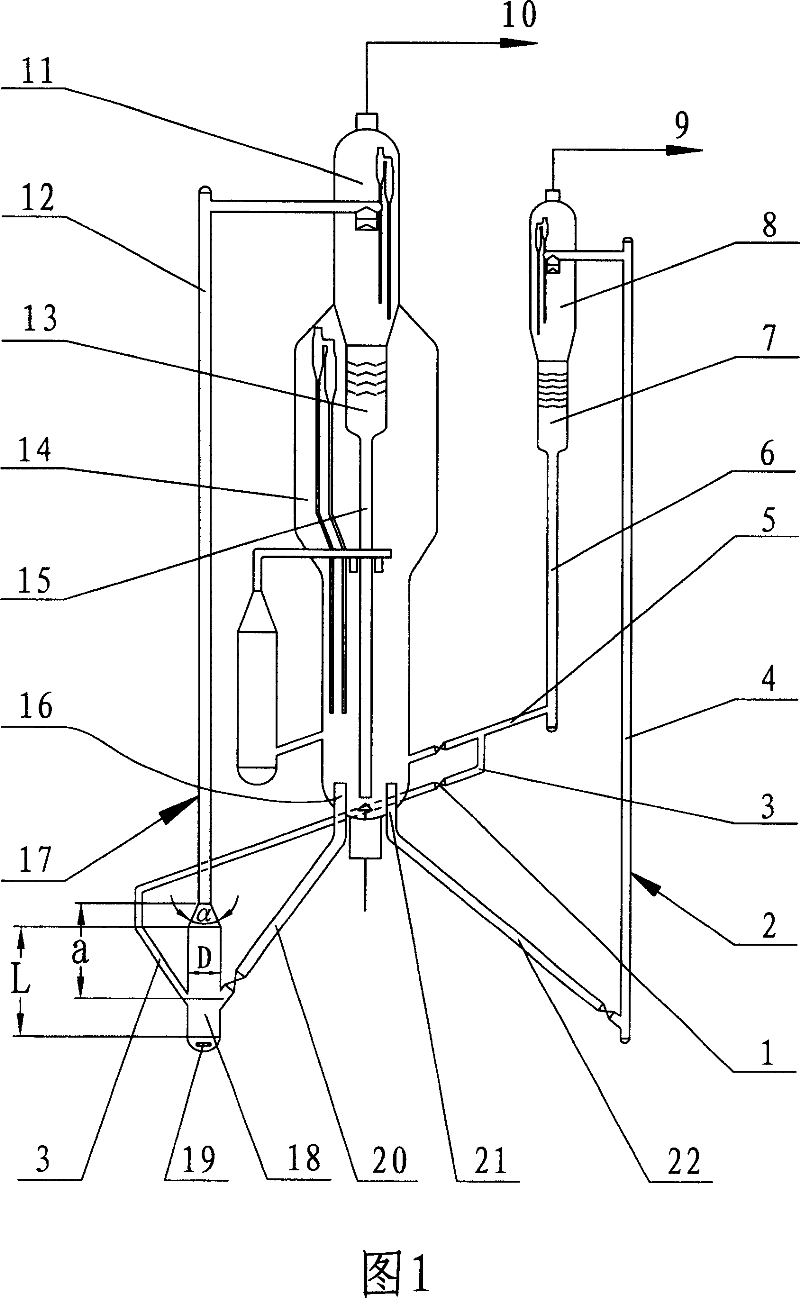

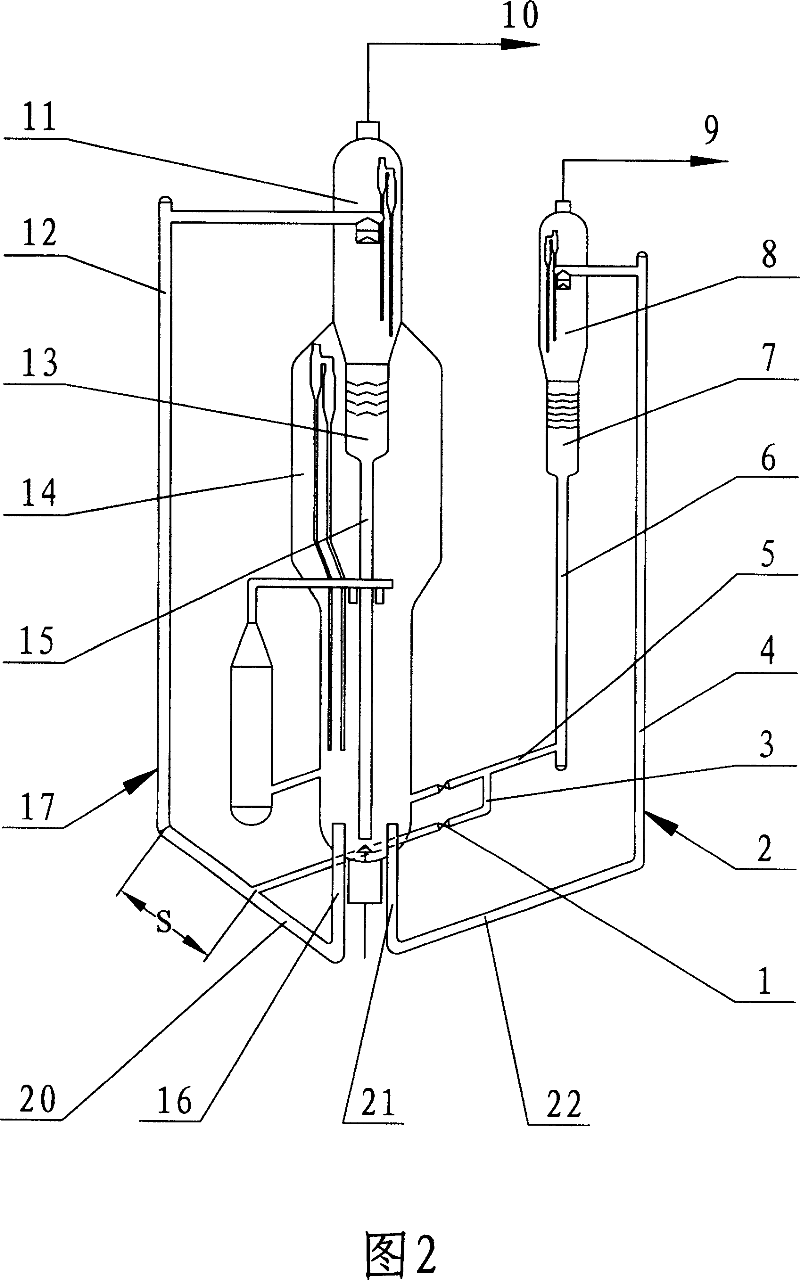

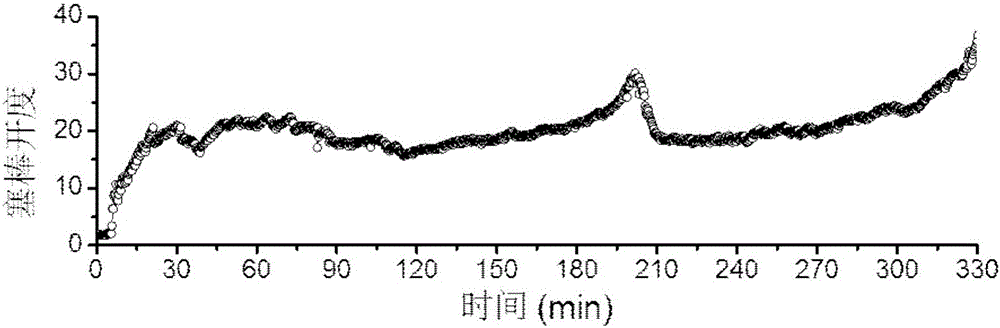

Catalytic cracking method and apparatus

ActiveCN100338185CReduce carbon contentHigh activityCatalytic crackingChemical industryControl valves

The invention discloses a kind of catalysis crack method and its device in petroleum chemical industry, to solve the problems as the whole activeness reduction of mixed catalysts and the flexibility lack of adjusting the agent-oil proportion of heavy oil riser reactor caused by the mixing wise of the spend catalyst and regenerating catalyst of the present two-riser catalysis crack device. The main characteristics of the invention method are: part of the spent catalyst from the light hydrocarbon riser reactor (4) gets into catalyst mixer through the spent catalyst duct (3) set flow control valve (1) after water vapour stripped in the stripping section (7) of the second settler, and gets into heavy oil riser reactor (12) to react after mixed by the effect of water vapour with the regenerating catalyst form regenerator (14) in catalyst mixer. The method of the invention is suitable to be used in the two-riser catalysis crack craft and the three-riser catalyst crack craft set heavy oil riser reactor; the invention has disclosed related devices.

Owner:SINOPEC LUOYANG PETROCHEM ENG CORP

Molten steel smelting technology for preventing nozzle clogging during sulfur-containing aluminium-containing steel pouring process

The invention relates to a molten steel smelting technology for preventing nozzle clogging during sulfur-containing aluminium-containing steel pouring process. The molten steel smelting technology comprises the steps of converter or electric furnace steelmaking, LF steel ladle refining, VD or RH vacuum refining, and continuous steel casting. According to the molten steel smelting technology, molten iron without desulfuration is directly supplied to a converter or an electric furnace for steelmaking, and iron sulfide powder is added into slag in the later period of LF steel ladle refining, so that the content of sulfur elements in the slag is increased, the reaction between the molten steel and the slag is inhibited during the vacuum treatment process, the loss amount of S elements in the molten steel is decreased, Al2O3 inclusions and CaS inclusions which are liable to cause nozzle clogging are reduced, the problem of nozzle clogging can be eliminated, the production is guaranteed to be smoothly carried out, and the production cost is reduced.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE +1

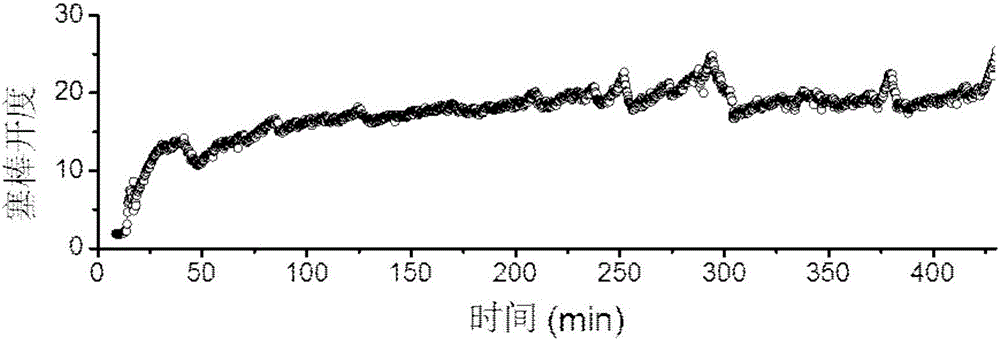

Ordered nanostructure sulphur/mesoporous carbon composite material for anode of lithium ion battery

InactiveCN101728538AIncrease capacityGood dispersionElectrode carriers/collectorsSulfurConductive materials

The invention relates to an ordered nanostructure sulphur / mesoporous carbon composite material for anode of a lithium ion battery; the composite material is formed by taking the ordered carbon-based mesoporous material as a carrier and loading nanometer sulphur in porous channels; the composite material is sulphur-mesoporous carbon composite material which has high sulphur content, good dispersibility, high capacity and good stability, thereby overcoming the disadvantages of electricity-conducting material, finding good carrier material for the lithium-sulphur batteries and opening up new application field for the mesoporous material; the method in the invention has the advantages of low preparation process and low cost.

Owner:SHANGHAI UNIV

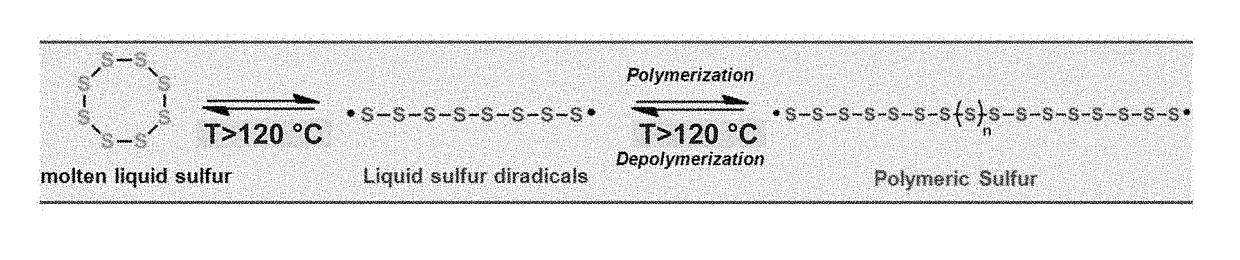

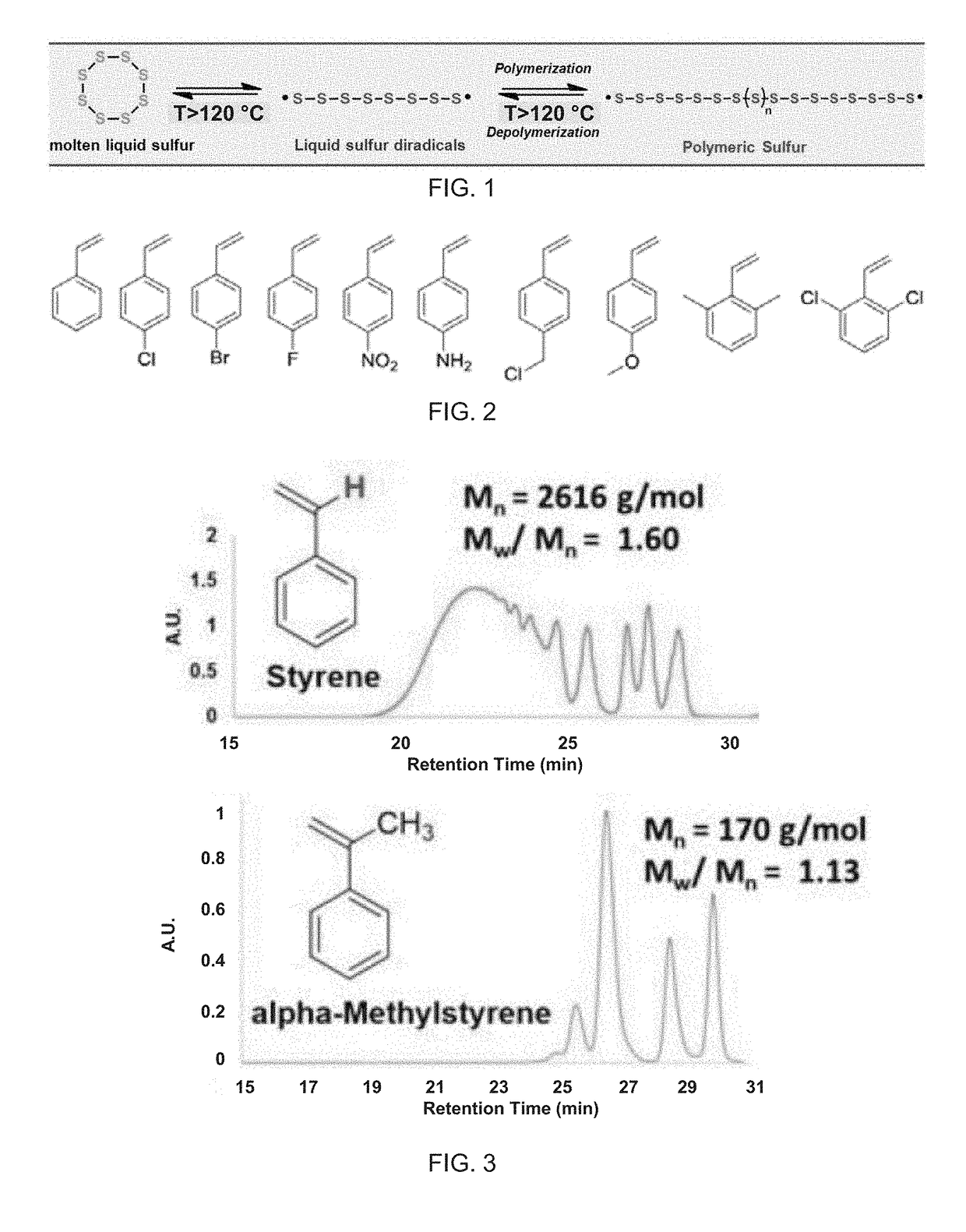

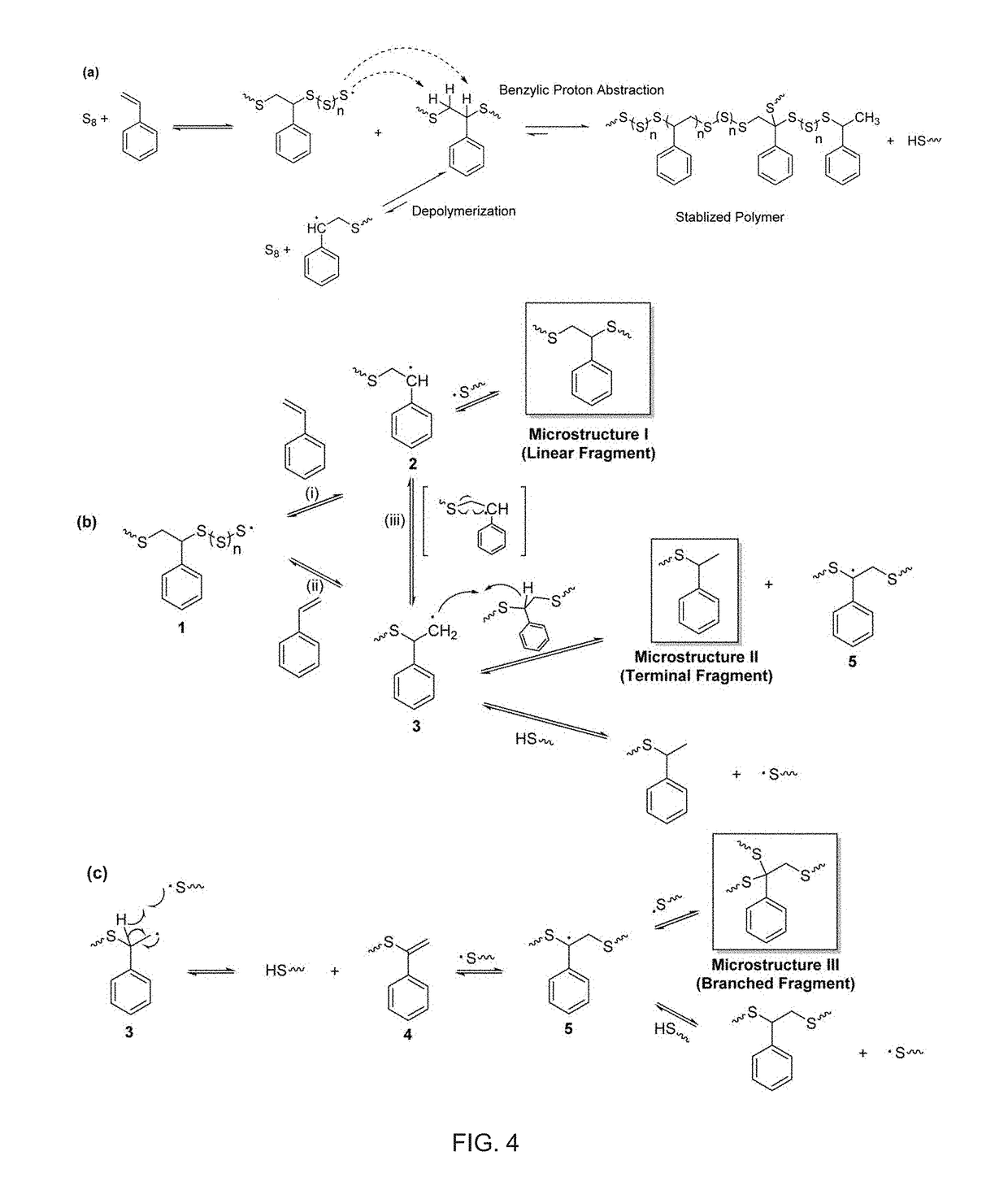

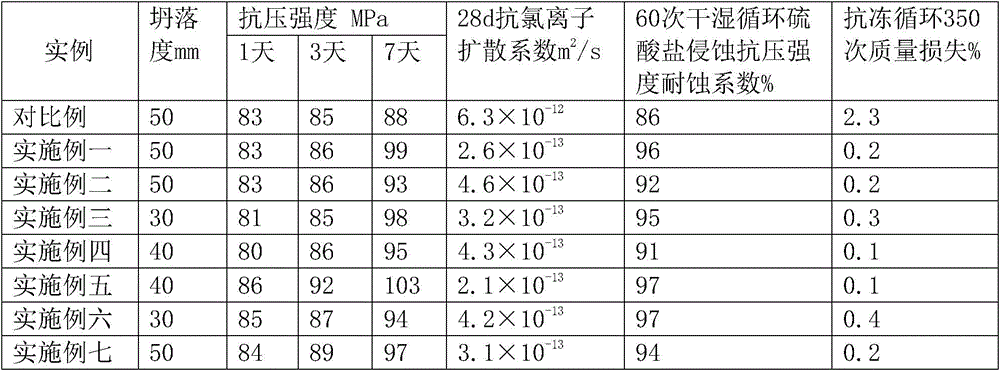

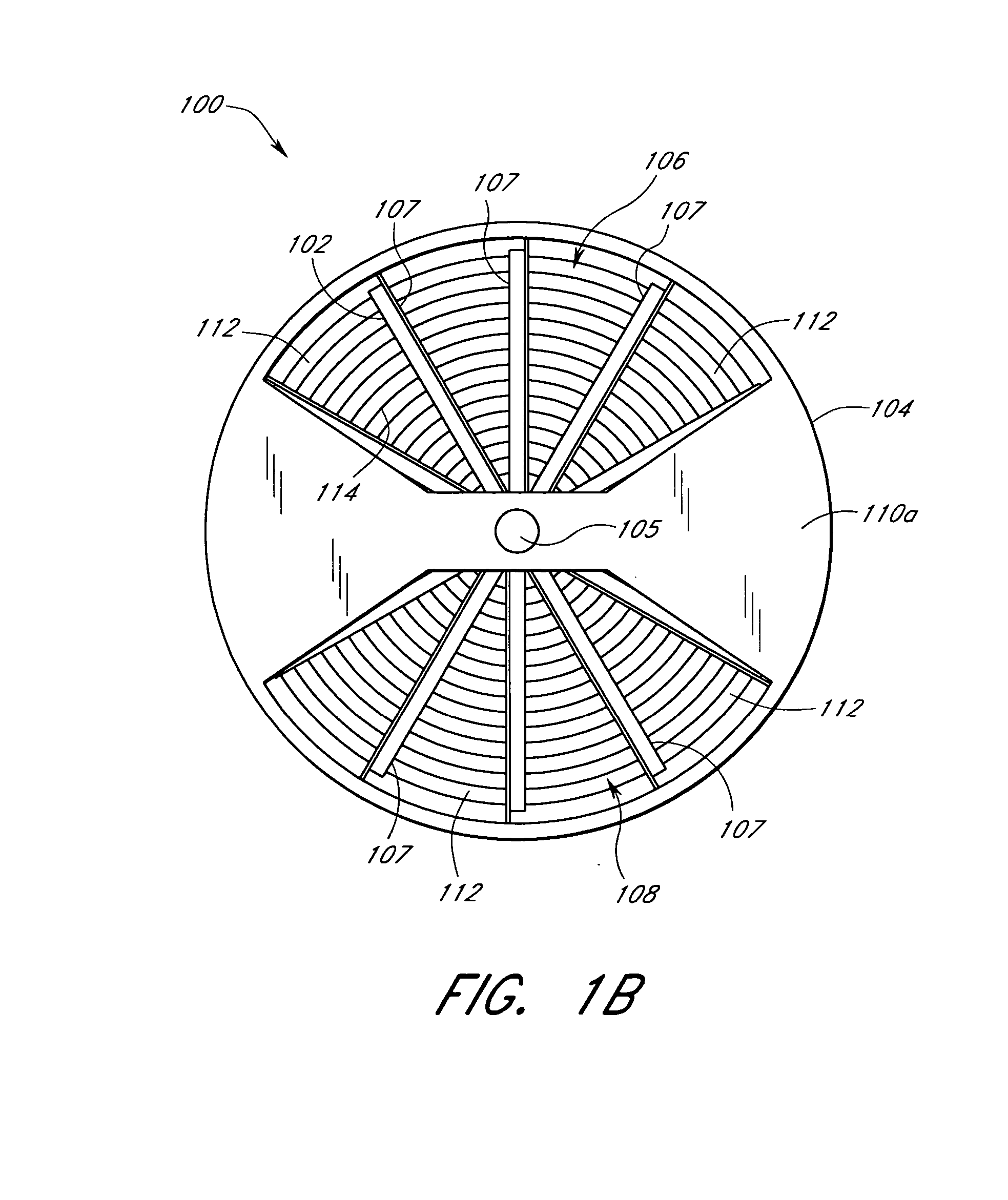

Copolymerization of elemental sulfur to synthesize high sulfur content polymeric materials

ActiveUS20180208686A1High sulfur contentFunction increaseCell electrodesLi-accumulatorsElastomerThermoplastic

Copolymerization of elemental sulfur with functional comonomers afford sulfur copolymers having a high molecular weight and high sulfur content. Nucleophilic activators initiate sulfur polymerizations at relative lower temperatures and in solutions, which enable the use of a wider range of comonomers, such as vinylics, styrenics, and non-homopolymerizing comonomers. Nucleophilic activators promote ring-opening reactions to generate linear polysulfide intermediates that copolymerize with comonomers. Dynamic sulfur-sulfur bonds enable re-processing or melt processing of the sulfur polymer. Chalcogenide-based copolymers have a refractive index of about 1.7-2.6 at a wavelength in a range of about 5000 nm-8μιτι. The sulfur copolymer can be a thermoplastic or a thermoset for use in elastomers, resins, lubricants, coatings, antioxidants, cathode materials for electrochemical cells, dental adhesives / restorations, and polymeric articles such as polymeric films and free-standing substrates. Optical substrates are constructed from the chalcogenide copolymer and are substantially transparent in the visible and infrared spectrum.

Owner:THE ARIZONA BOARD OF REGENTS ON BEHALF OF THE UNIV OF ARIZONA

Autoclaving-free prestressed high-strength tube pile concrete and tube pile manufacturing method

The invention relates to autoclaving-free prestressed high-strength tube pile concrete and a tube pile manufacturing method. The concrete is prepared from the following components in parts by mass: 300-420 parts of PI or PII 52.5 cement, 5-80 parts of mineral powder, 5-100 parts of lithium slag powder, 5-40 parts of glass microbead powder, 680-720 parts of sand, 1125-1170 parts of broken stones, 125-135 parts of water, 4-5 parts of a polyocarboxy acid water reducing agent and 2-5 parts of an exciting agent. After stirring and shaping are performed, only constant-pressure steaming is performed for 6-8 hours, the strength requirement of C80 can be met, the energy consumption is reduced, and besides, the lithium slag powder which is industrial waste is utilized for the autoclaving-free concrete tube pile, so that the problem of resource wasting and the problem of environmental pollution are solved to a certain extent.

Owner:SOUTHEAST UNIV

S-loaded activated carbon for mercury removal from flue gas and preparation method thereof

InactiveCN101474551AEfficient removalHigh sulfur contentOther chemical processesDispersed particle separationMaterials preparationActivated carbon

The invention provides a sulfur-carrying active carbon for smoke gas demercuration and a preparation method thereof. The mass percentage content of sulfur of the sulfur-carrying active carbon is 18-30%, and the sulfur is evenly distributed on the surface of the active carbon and chemically combined with the active carbon; the granularity of the sulfur-carrying active carbon is 20-40 meshes.The preparation method comprises material preparation, thermo-precipitation preparation and cooling. In the invention, cheap sulfur is used as an additive agent of the active carbon, the content of the sulfur in the active carbon can reach 18-30% through the method of thermo-precipitation, and mercury in the smoke gas can be desorbed effectively. After the technique of thermo-precipitation, the active carbon has the advantages that the content of the sulfur is high and the sulfur is evenly distributed on the surface of the active carbon. In addition, the specific surface area, pore volume and pore diameter property and the like of the active carbon remain the same; the invention also is characterized in that the technique and the method are simple, the operation is easy and the cost is low, the method can be widely applied to the demercuration of smoke gas of coal-fired power factory and the like.

Owner:CHONGQING UNIV

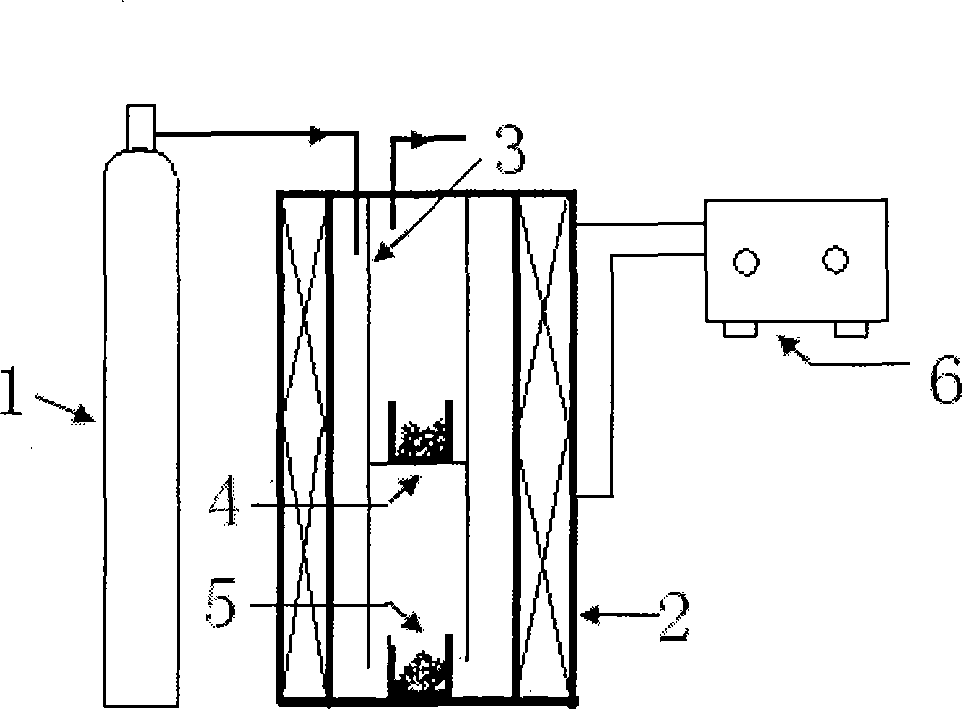

Hydrocatalyst and its preparing process

InactiveCN1356378AImprove hydrodesulfurization activityHigh activityHydrocarbon oils refiningNaphtha reformingActive componentSulfur

A hydrocatalyst for decreasing S and olefine contents in poor gasoline and increasing its octane value is prepared from the metallic active component which is two or three of MoOe, CoO and NiO and the carrier prepared from TiO2, modified ZSM-5 molecular sieve and adhesive.

Owner:LUOYANG PETROCHEMICAL ENG CORP SINOPEC

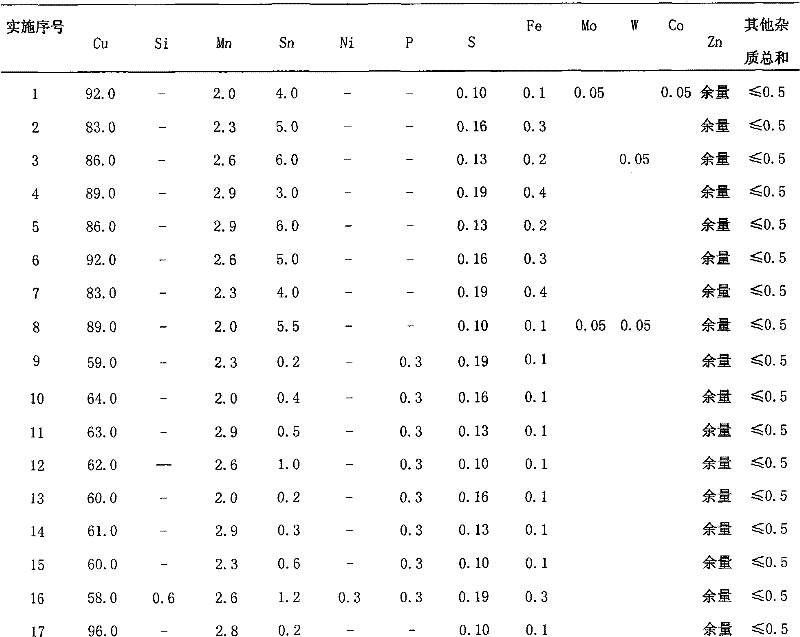

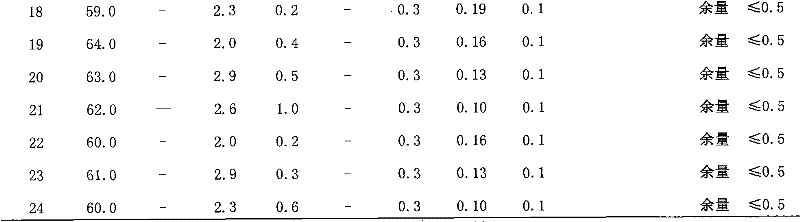

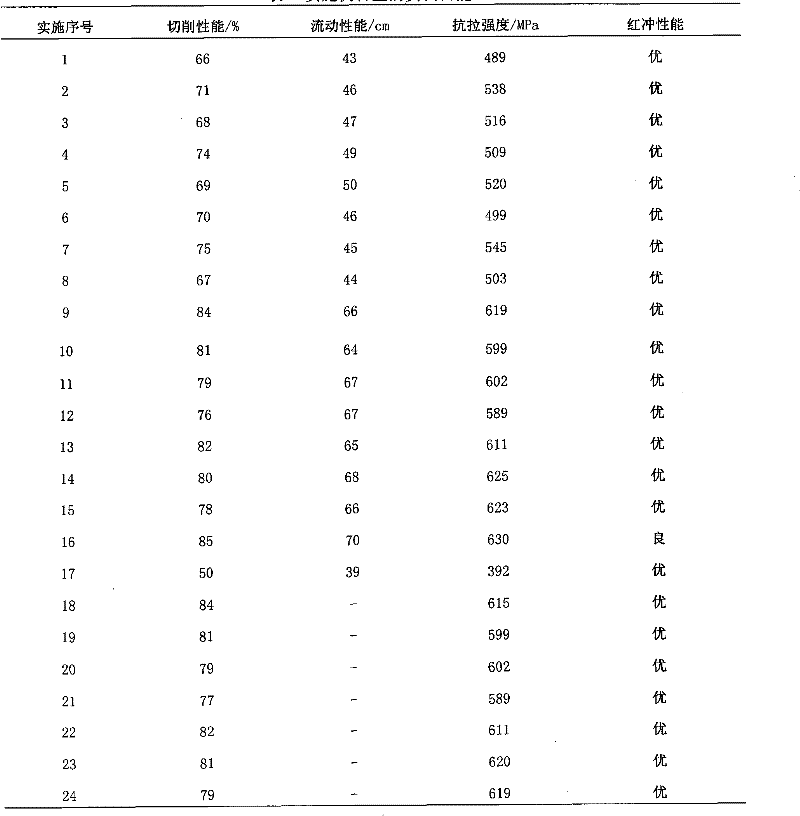

Leadless free-cutting copper alloy and preparation method

A leadless free-cutting copper alloy and a preparation method. The copper alloy comprises the following elements by mass: 58.0%-96.0% of copper, 2.0%-2.9% of manganese, 0.2%-6.0% of tin, not more than 0.3% of phosphor, not more than 0.3% of nickel, 0.10%-0.19% of sulfur, 0.1%-0.9% of the sum of 1-3 elements selected from silicon, iron, molybdenum, tungsten, and cobalt, and the balance of zinc. In the alloy, the mass ratio of manganese and sulfur is more than 10 and less than 30; the other elements are impurities, and the mass fraction of any one of the impurities is not more than 0.03%; the sum of the mass fractions of all the impurities is not more than 0.5%. The preparation method comprises the following steps: melting and alloying the base metal element of copper and the important metal element of manganese, adding other alloy elements and performing homogenization, performing refining, adding sulfide or sulfur, performing homogenization and adding zinc rapidly, immediately casting into a ingot casting or performing atomization to obtain powder. The leadless free-cutting copper alloy and the preparation method of the invention are applicable to cutting processing, hot forging processing, and polishing processing of copper alloy.

Owner:HUNAN TERRY NEW MATERIALS COMPANY

Carbon preparation material based on coke modification and sulphur-applying activated char, and production process thereof

InactiveCN101428795AHigh activation reactivityReduced corrosion resistance requirementsSulfurRoom temperature

The invention relates to carbon preparation material and sulfuric active carbon based on the modification of coke and a preparation method thereof. The invention adopts the scheme that the preparation method comprises the following steps: dipping the coke in KOG solution for 1 to 24 hours at the temperature of 20 to 100 DEG C, wherein the mass ratio of KOH and the coke is 0.05 to 0.5:1; carrying out heat treatment to the coke after being dipped for 1 to 5 hours under the condition of inert atmosphere and 300 to 700 DEG C; then cooling the coke to the room temperature; and finally preparing the carbon preparation material after the coke is washed and dried. The carbon preparation material prepared can react for 1 to 5 hours under the conditions that the mass ratio of active gas flow rate and the carbon preparation material is 5 to 30:1 L / min / kg and the temperature is 350 to 850 DEG C, so as to prepare the sulfuric active carbon. The invention has the advantages of saved alkali consumption and energy consumption, shortened activating treatment time, high yield, and reduced corrosion resistant requirements of the material; the prepared carbon preparation material has high reaction activation; and the sulfuric active carbon prepared by the carbon preparation material has larger specific surface area and high sulphur content, and exits in a straight chain sulfuric shape as the subject of S2 and S6.

Owner:WUHAN UNIV OF SCI & TECH

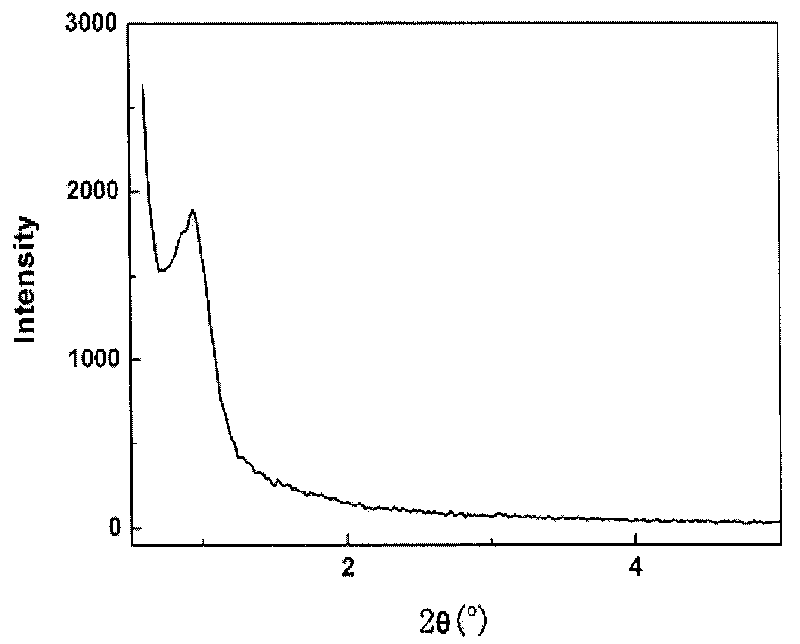

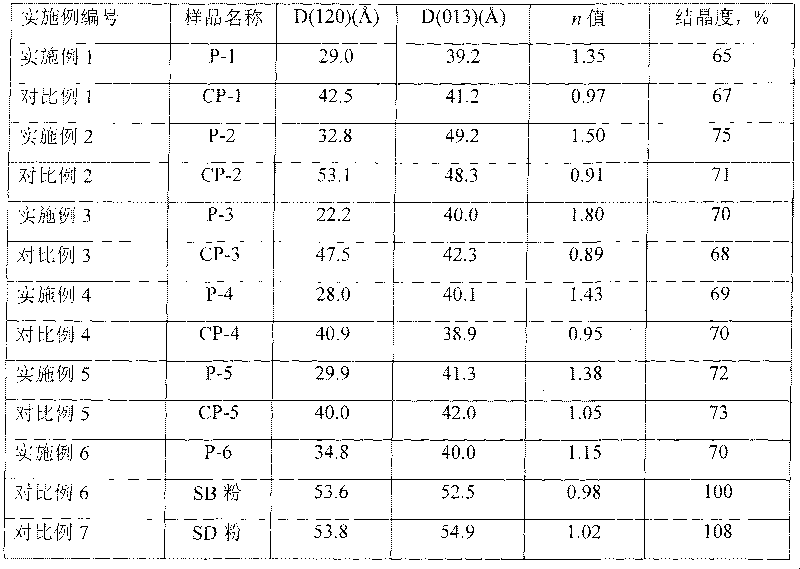

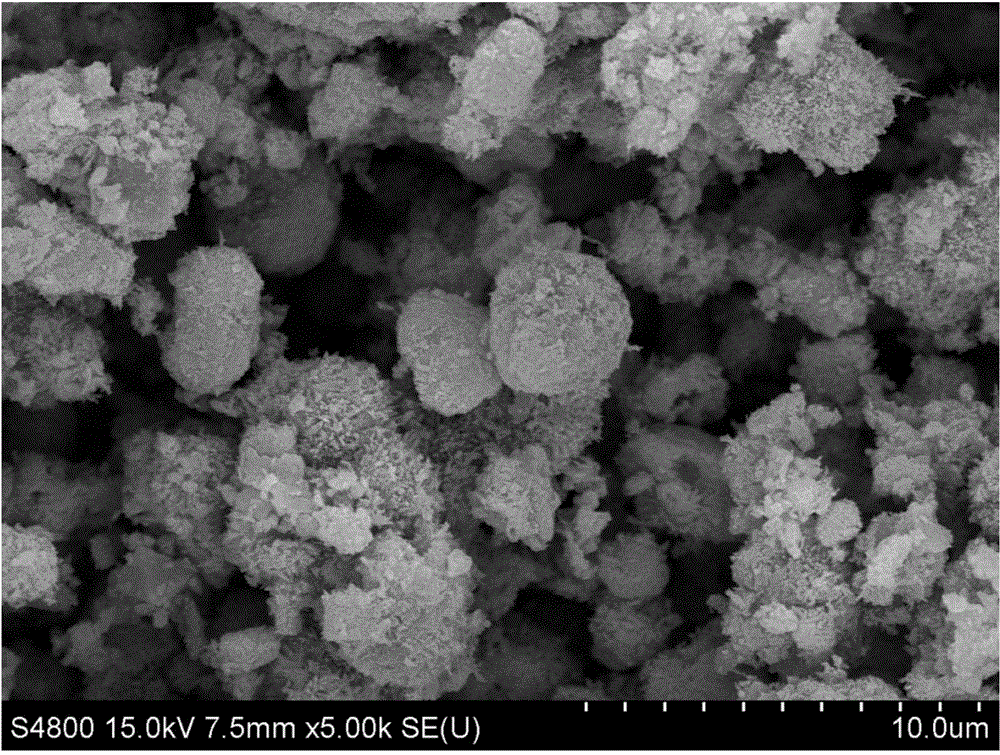

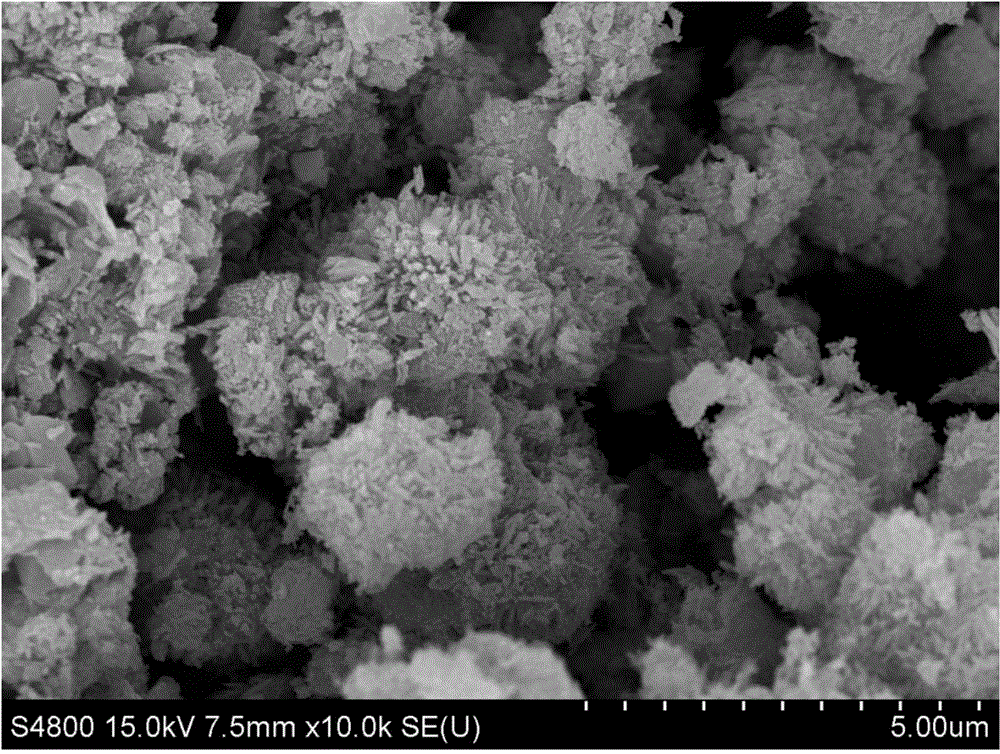

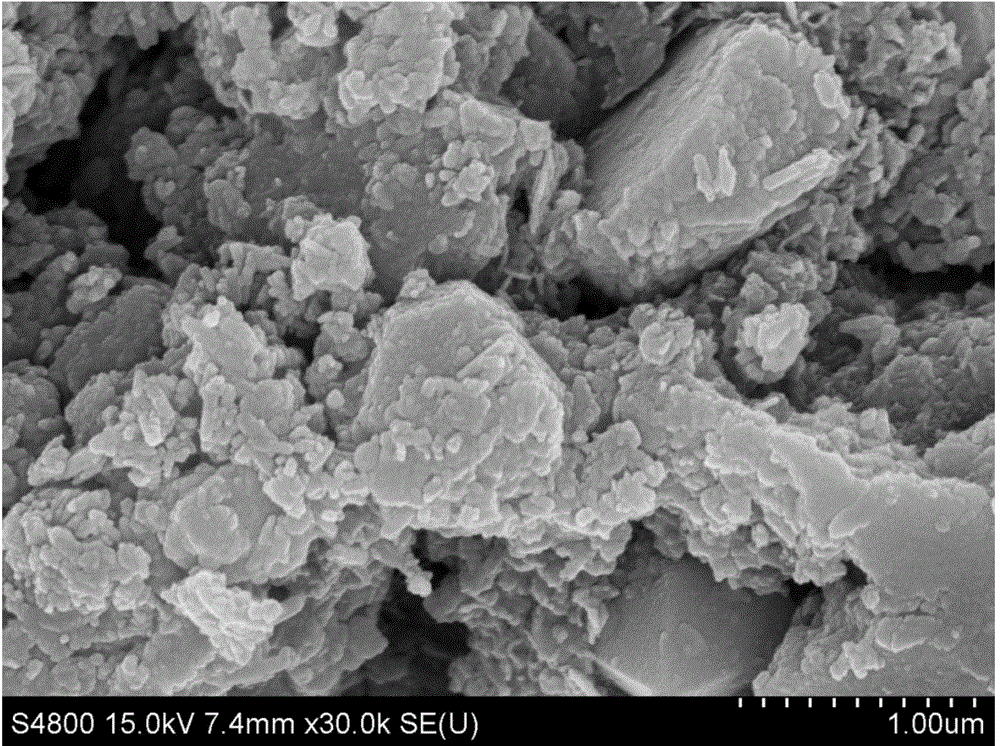

Pseudo-boehmite, preparing method and aluminium oxide prepared from pseudo-boehmite

ActiveCN101746789AExcellent hydrodesulfurization performanceHigh sulfur contentAluminium oxides/hydroxidesBoehmiteCrystallite

The present invention relates to a pseudo-boehmite, a preparing method and aluminium oxide prepared from the pseudo-boehmite. For the pseudo-boehmite, n is not smaller than 1.1 and not bigger than 2.5, n=D (031) / D (120), the D (031) represents the crystal grain size of the crystal surface represented by 031 peak in the x-ray diffraction (XRD) spectrum of pseudo-boehmite crystal grains, and the D (120) represents the crystal grain size of the crystal surface represented by 120 peak in the XRD spectrum of the pseudo-boehmite crystal grains. The 031 peak refers to the peak of which the 2thet is from 34 degrees to 43 degrees in the XRD spectrum, the 120 peak refers to the peak of which the 2thet is from 23 degrees to 33 degrees, D=klam( Bcos thet), K is a Scherrer constant, lam is the diffraction wave length of a target type material, B is the half-peak width of the diffraction peak, and 2thet is the position of the diffraction peak. Aluminium oxide obtained by roasting the pseudo-boehmite is more suitable for being used as a catalyst carrier. The catalyst has superior hydrgen desulphurization properties.

Owner:CHINA PETROLEUM & CHEM CORP +1

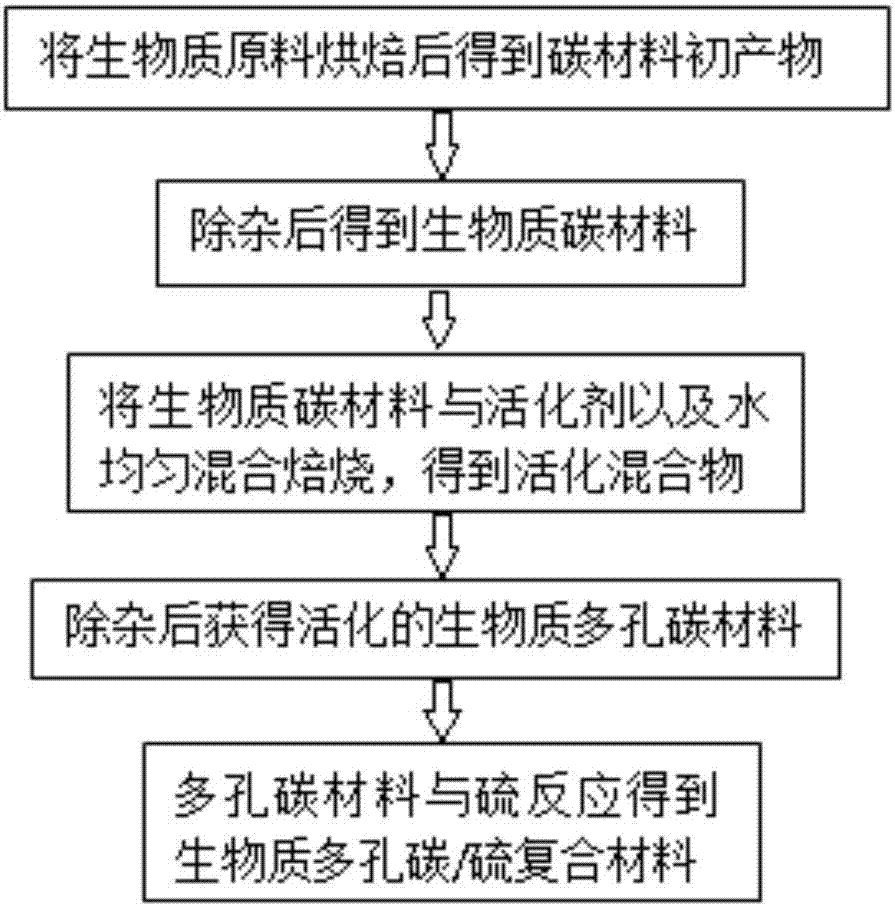

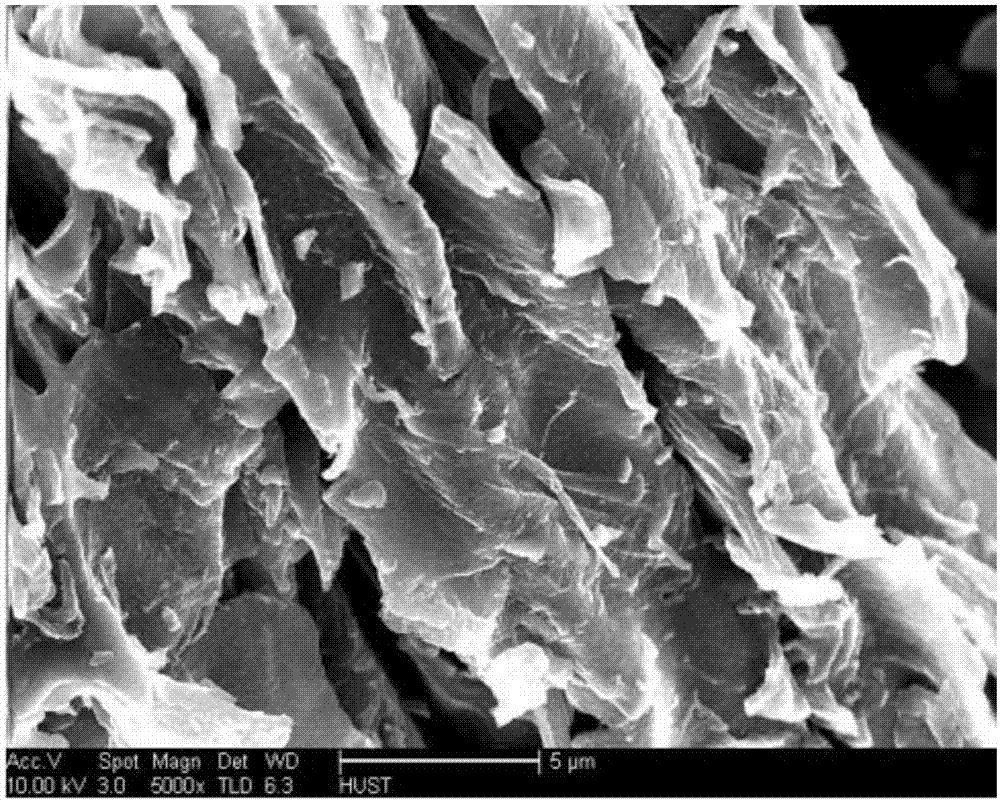

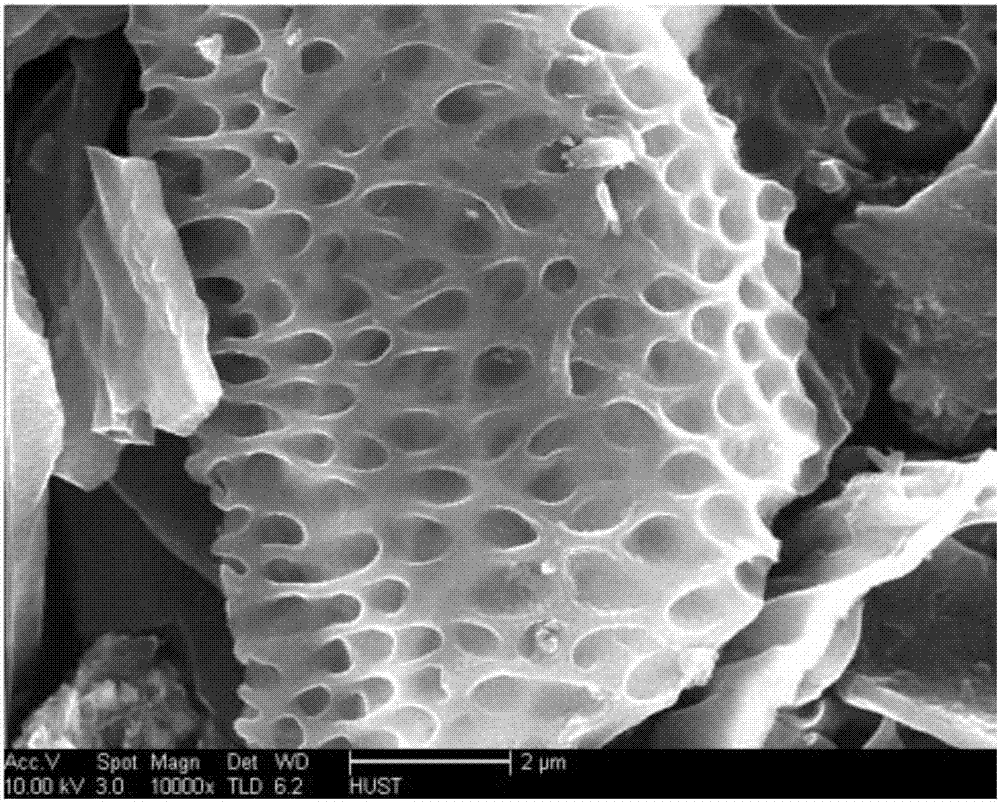

Preparation method and application of biomass-based porous carbon/sulfur composite

InactiveCN106981644AHigh value utilizationImprove cycle stabilityHybrid capacitor electrodesCell electrodesBiomass carbonPorous carbon

The invention belongs to the field of lithium-sulfur battery cathode materials and particularly relates to a preparation method of a preparation method of biomass-based porous carbon / sulfur composite, comprising the specific steps of S1, calcining biomass material to obtain a primary product of carbon material; S2, removing impurities from the primary product of carbon material to obtain biomass carbon material; S3, mixing well the biomass carbon material with an activator and water, and calcining to obtain activated mixture; S4, removing impurities from the mixture to obtain activated porous carbon material; S5, mixing the porous carbon material with sulfur for the purpose of reacting to obtain the porous carbon / sulfur composite. The invention also discloses application of the porous carbon / sulfur composite as a cathode material in batteries or supercapacitors. A battery prepared with the biomass carbon / sulfur composite prepared herein has high discharge capacity, good cycle stability and high coulombic efficiency, and has a promising application.

Owner:HUAZHONG UNIV OF SCI & TECH

Sorbent for removing mercury from flue gas and preparation method thereof

ActiveCN101497029AEfficient removalHigh sulfur contentOther chemical processesDispersed particle separationActivated carbonSorbent

The invention discloses an adsorbent for removing mercury from flue gas and a method for preparing the same. The adsorbent comprises active carbon and sulfur evenly distributed on the surface of the active carbon; the grain size of the active carbon is between 20 and 40 meshes, and the mass percentage content of the sulfur is between 1 and 17 percent; in the method, the low-priced sulfur is used as the additive of the active carbon, and the adsorbent is obtained by the thermal precipitation method, thereby effectively removing the mercury from the flue gas; the adsorbent has the characteristics of high sulfur content, even distribution of sulfur on the surface of the active carbon and the like, and in the aspects of specific surface area, pore volume, pore diameter, and the like, the active carbon also has the advantages of the common active carbon; the adsorbent can be placed in a fixed adsorption bed or fluidized adsorption bed; when the adsorbent is used to remove mercury from the mercury-containing flue gas and other gases, the adsorbent can achieve obvious effect and long time of usage; moreover, the adsorbent has the advantages of simple technological process, easy operation and low cost, and can be widely applied to the mercury removal of the flue gas in a coal-fired power plant.

Owner:CHONGQING UNIV +1

Amorphous (Lithium) Sulfide or (Lithium) Titanium Niobium Sulfide

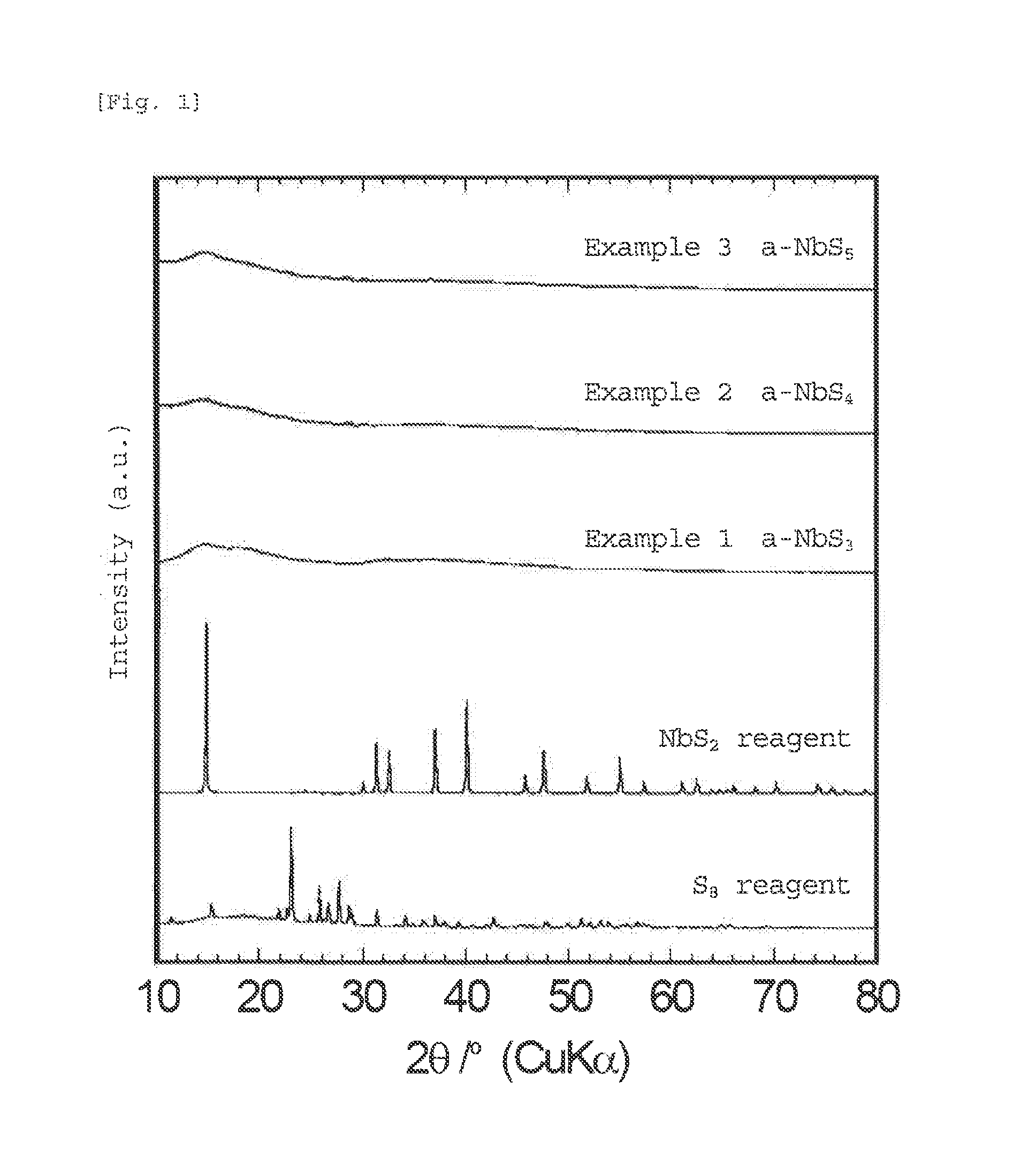

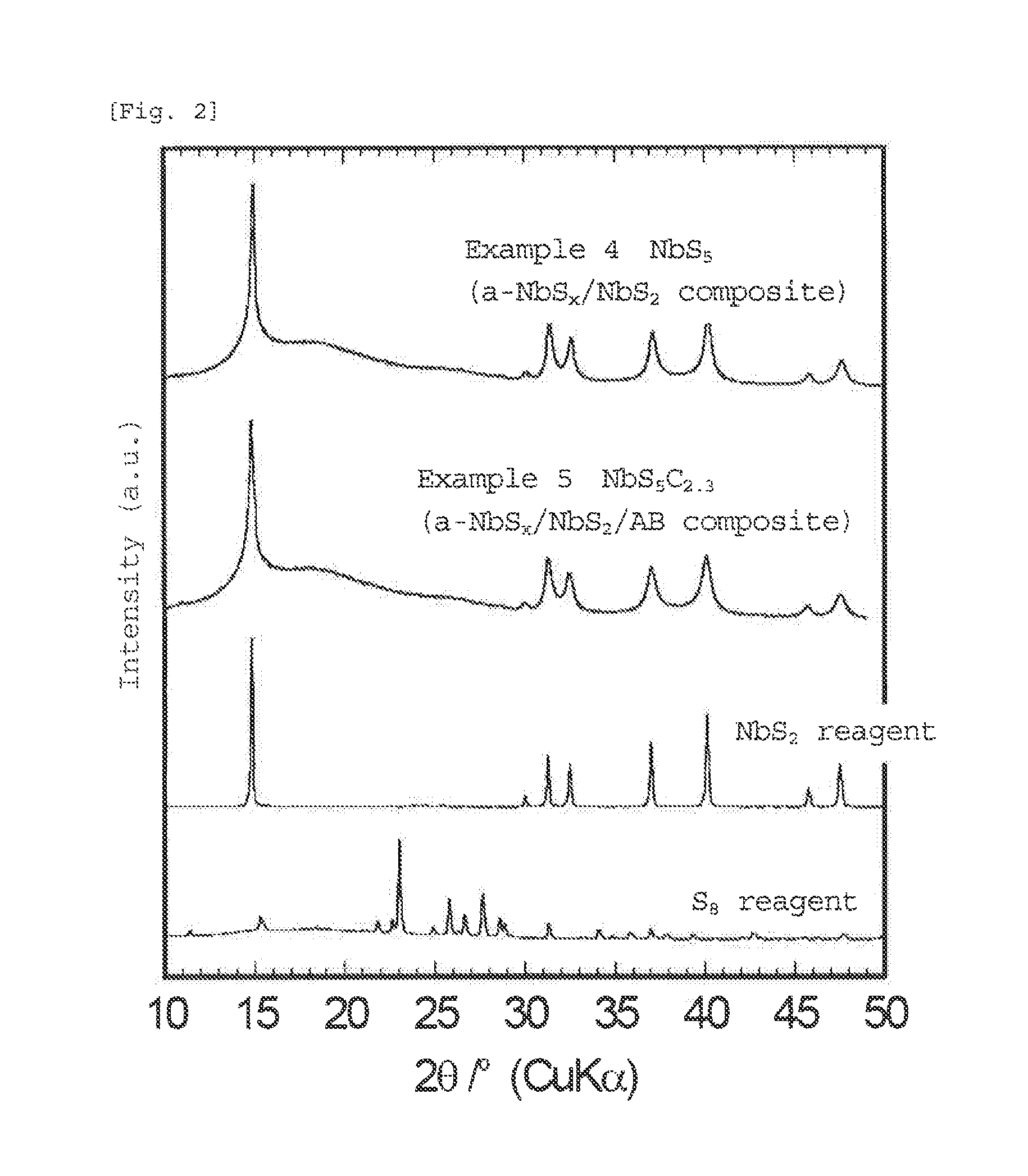

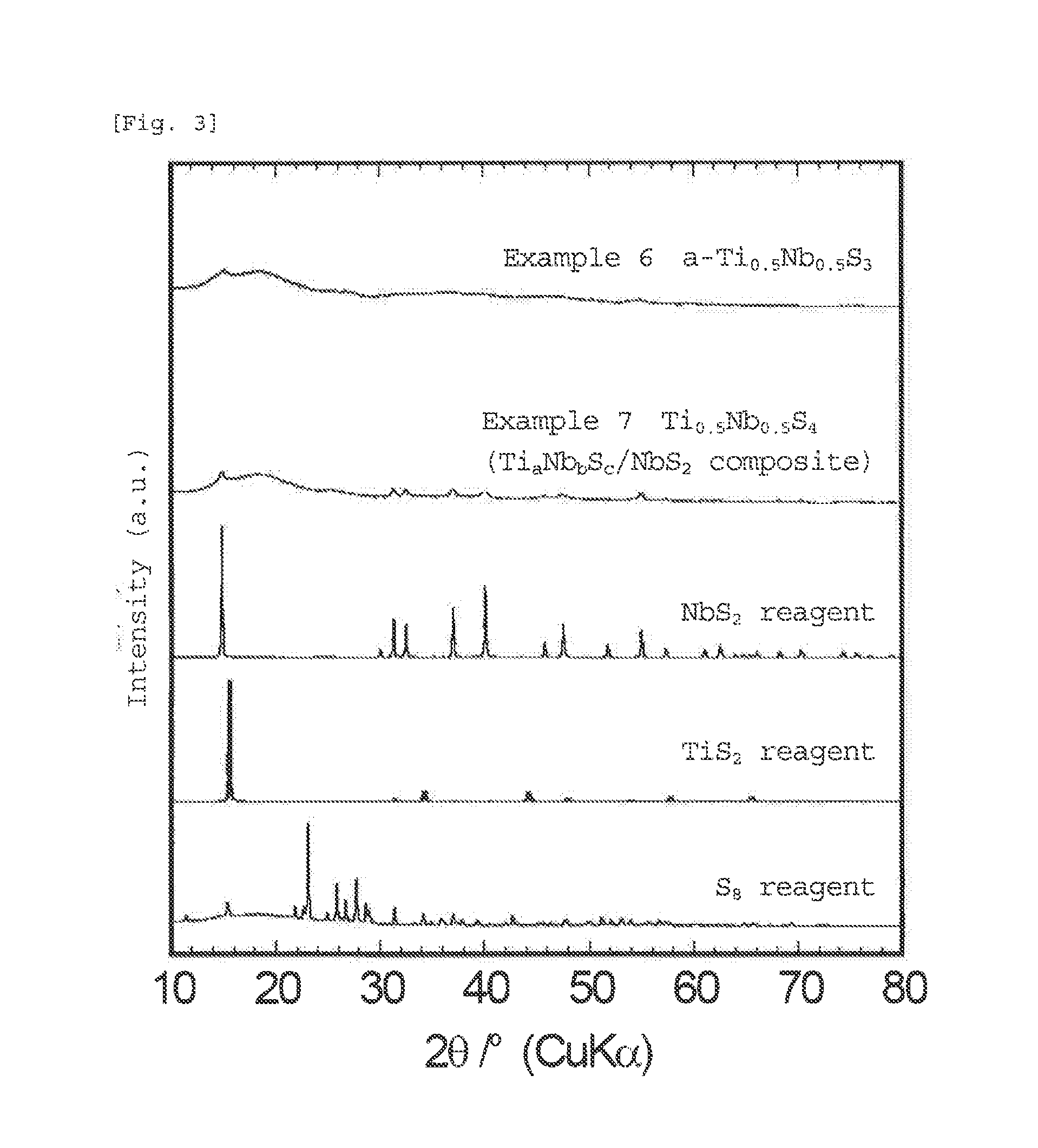

ActiveUS20160308210A1Raise the ratioHigh charge and discharge capacityTitanium sulfidesPositive electrodesNiobiumTitanium

The sulfide of the present invention comprises an amorphous (lithium) niobium sulfide having an average composition represented by formula (1): Lik1NbSn1 (wherein 0≦k1≦5; 3≦n1≦10; and when n1≧3.5, k1≦0.5), or an amorphous (lithium) titanium niobium sulfide having an average composition represented by formula (2): Lik2Ti1-m2Nbm2Sn2 (wherein 0≦k2≦5; 0<m2<1; 2≦n2≦10; and when n2≧3.5, k2≦1.5). The sulfide of the present invention is a material that is useful as a cathode active material for lithium batteries, such as lithium primary batteries, lithium secondary batteries, and lithium ion secondary batteries, and has a high charge-discharge capacity, high electrical conductivity, and excellent charge-discharge performance.

Owner:NAT INST OF ADVANCED IND SCI & TECH

Preparation method of positive electrode material of lithium sulfur battery

ActiveCN108172795ASimple preparation processImprove cycle performanceMaterial nanotechnologyCell electrodesDoped grapheneOxygen

The invention discloses a preparation method of a positive electrode material of a lithium sulfur battery. The preparation method comprises the following steps of putting graphene oxide, nanometer sulfur powder, boric acid and urea into a ball milling tank, performing ball milling and then adding into deionized water to obtain a mixture solution, performing ultrasonic wave dispersion at a normal temperature for 1-3h to obtain a mixed suspension liquid, and carrying out a spray drying process to prepare a boron nitrogen oxygen co-doped graphene / sulfur composite three-dimensional structured positive electrode material of the lithium sulfur battery. The boron nitrogen oxygen co-doped graphene / sulfur compound obtained in the invention has a simple and convenient preparation process; and through the simple spray drying process, the loosening and porous structure is manufactured, a relatively large specific surface area is obtained, and performance for bearing a large amount of elementary nanometer sulfur powder is further achieved, thereby improving the sulfur content of the positive electrode material.

Owner:INT ACAD OF OPTOELECTRONICS AT ZHAOQING SOUTH CHINA NORMAL UNIV

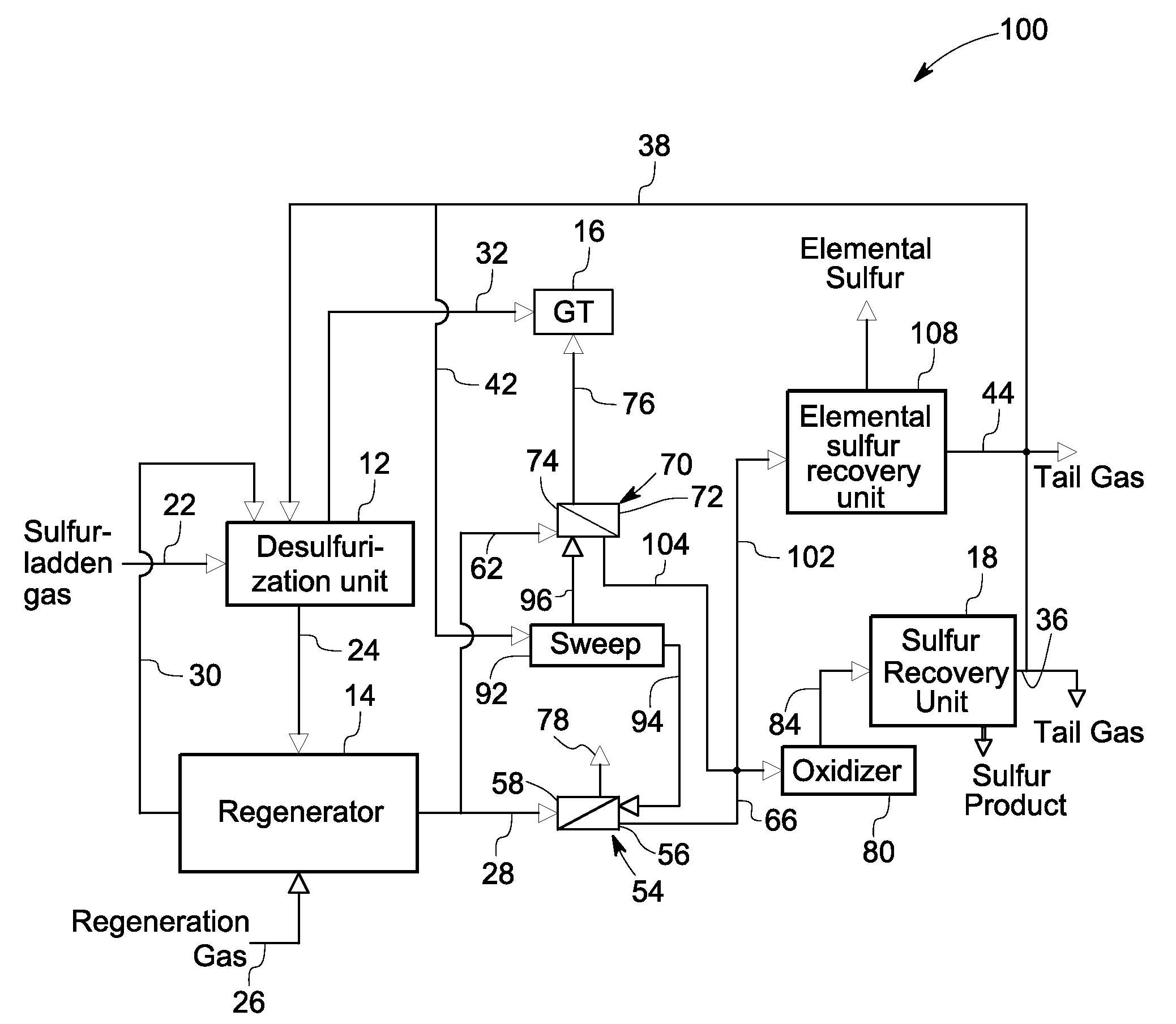

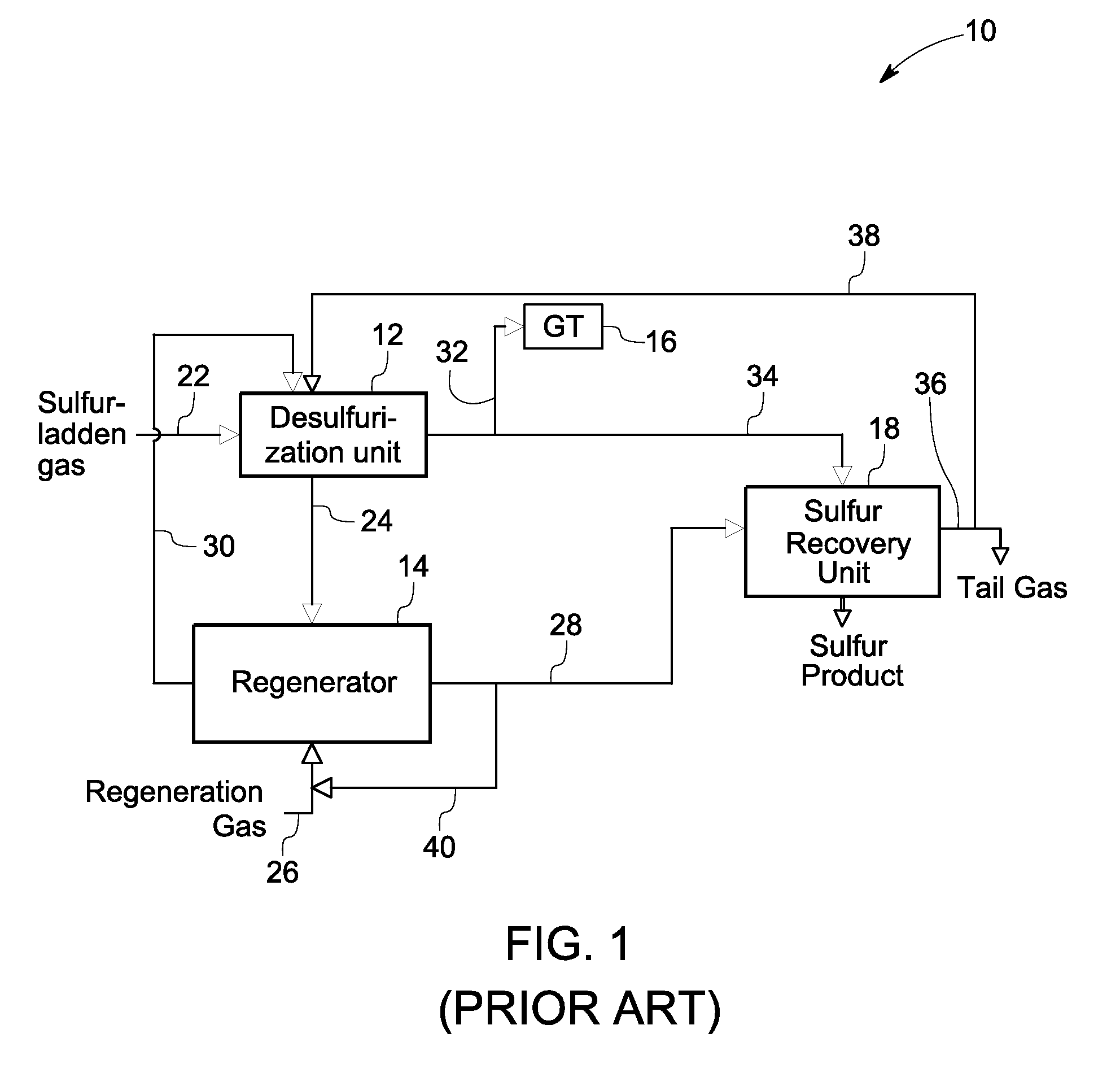

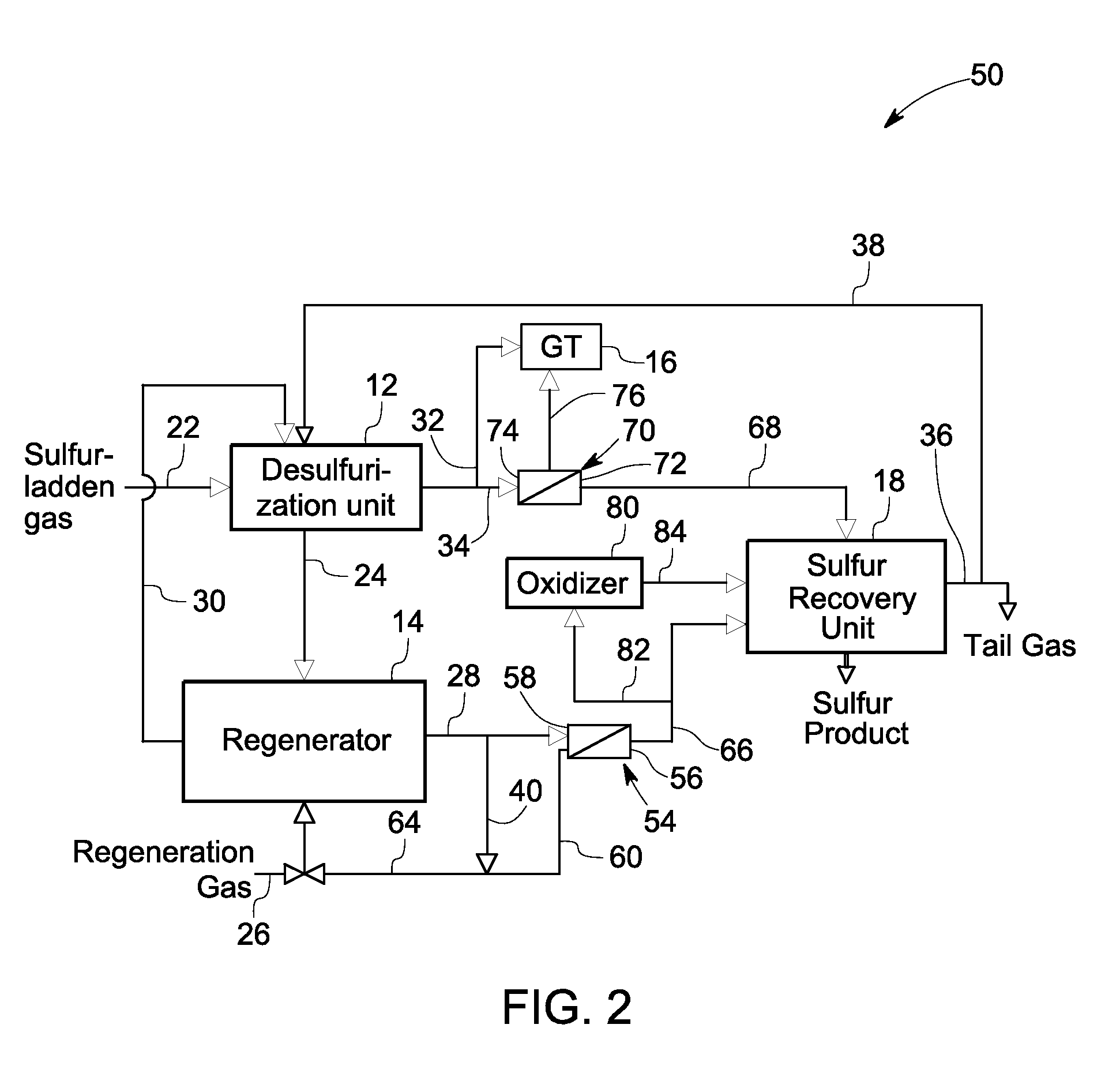

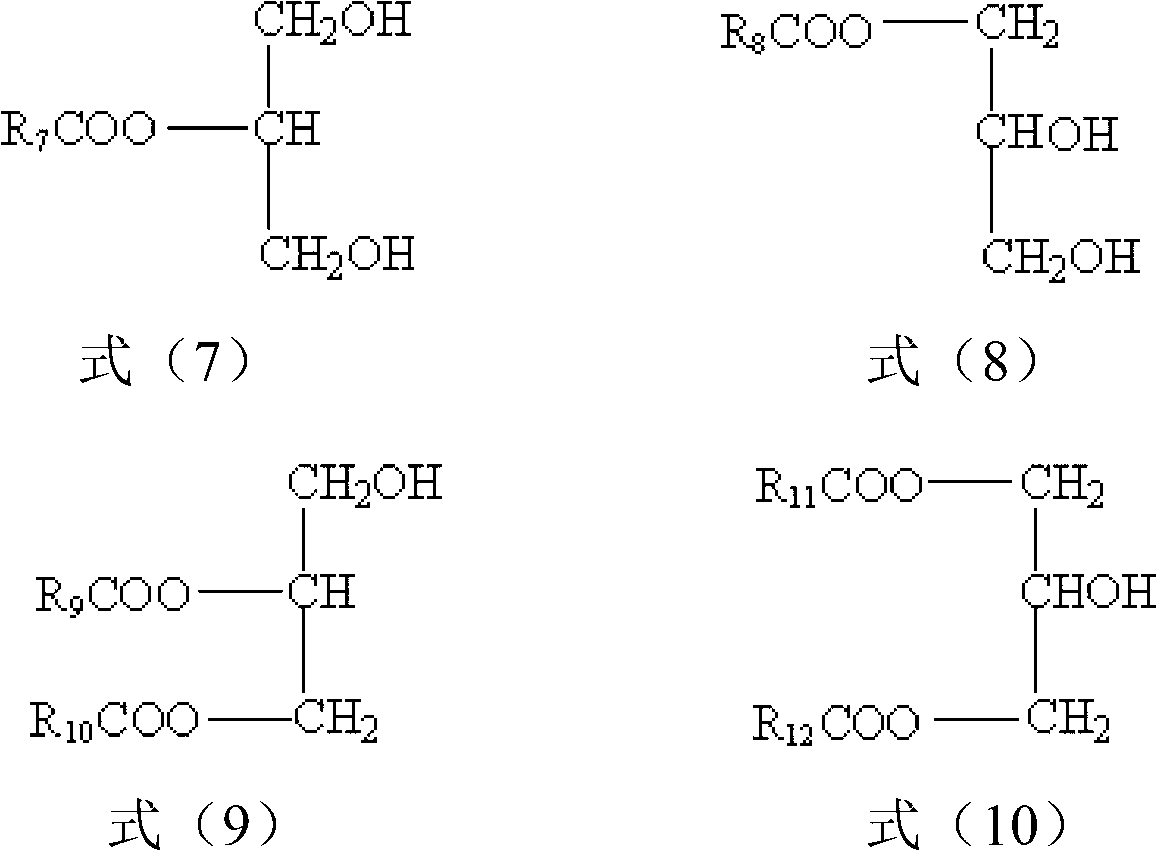

System and method for sulfur recovery

ActiveUS20110033370A1Reduce the amount requiredImprove efficiencyCombination devicesExhaust apparatusSulfur productProduct gas

Disclosed herein are various types of systems and methods for the efficient production of sulfur from a sulfur-laden gas. The system described herein includes a desulfurization unit, a regenerator receiving sulfurized mass from the desulfurization unit, a sulfur recovery unit, a sulfur track in fluid communication with the regenerator and the sulfur recovery unit, and a sulfur concentrator on a sulfur track. The sulfur stream coming out of the regenerator is concentrated using the sulfur concentrator and converted into a sulfur product at the sulfur recovery unit.

Owner:AIR PROD & CHEM INC

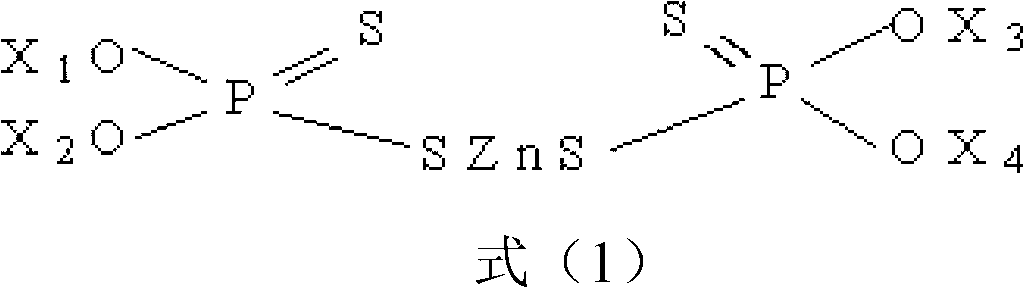

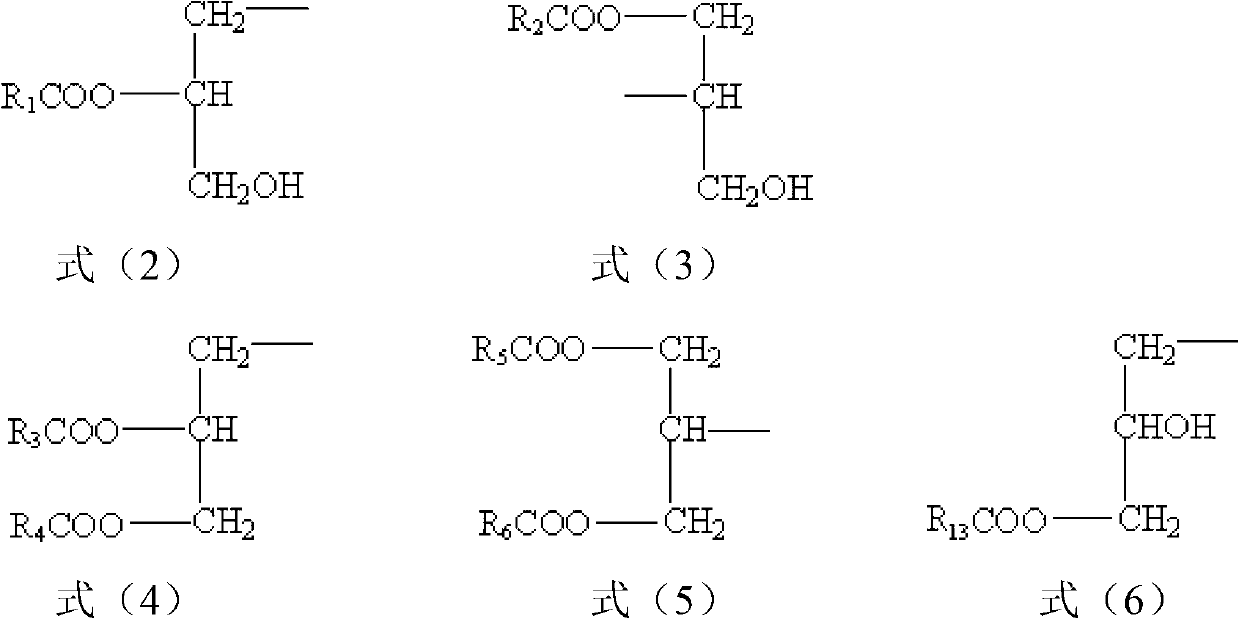

Extreme pressure antiwear agent and preparation method thereof and lubricating oil combination

Owner:CHINA PETROLEUM & CHEM CORP +1

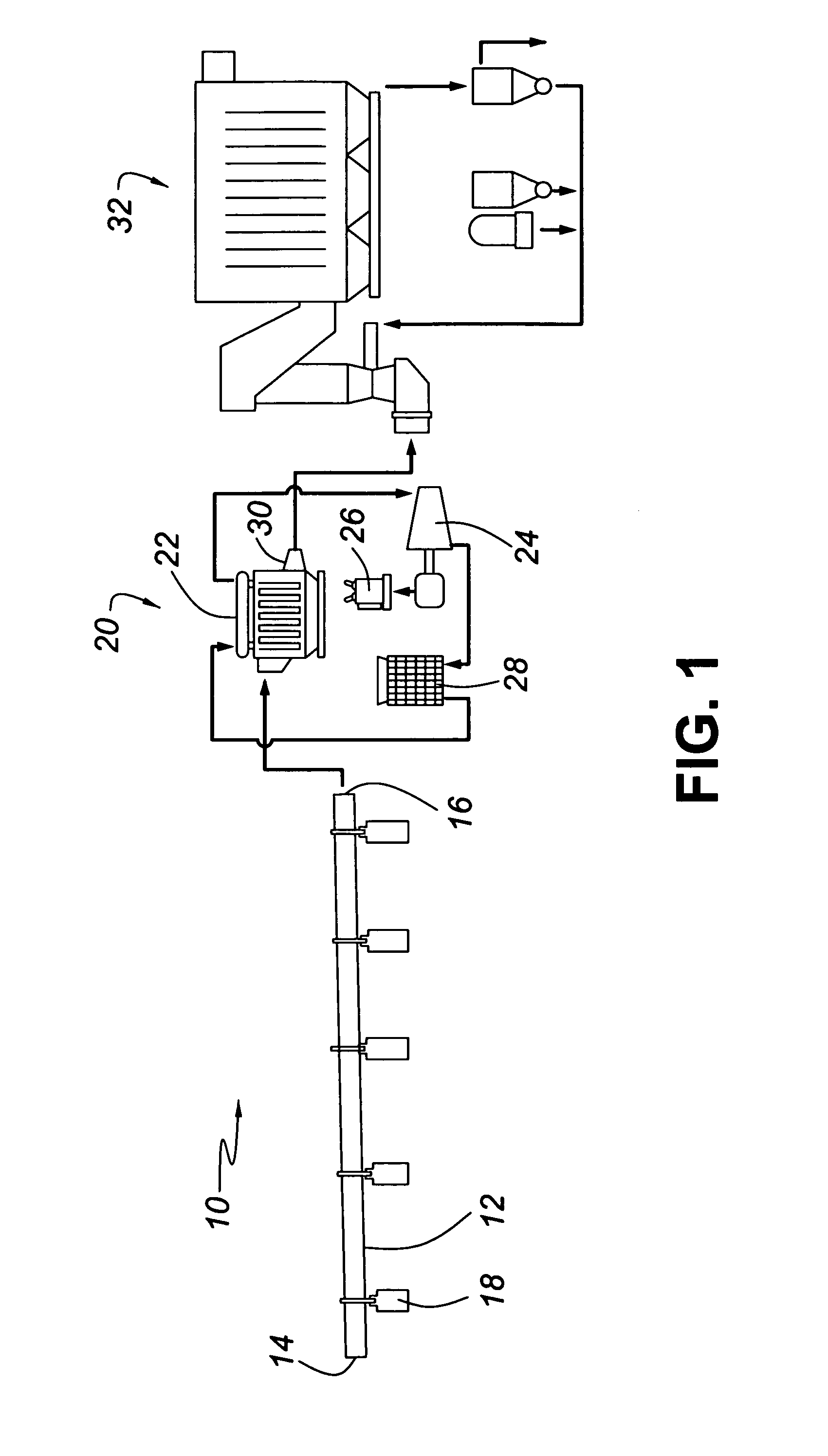

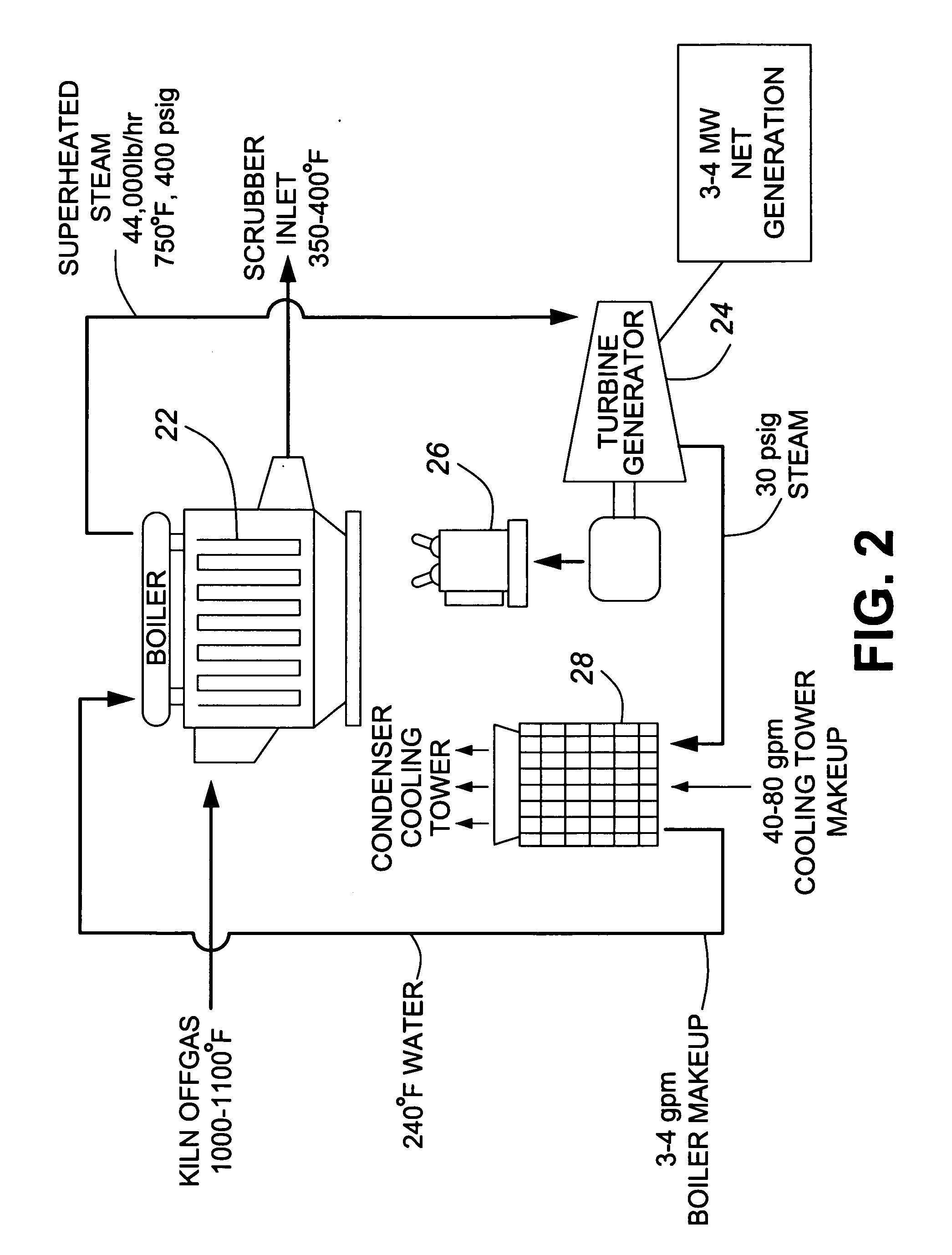

Integrated lime kiln process

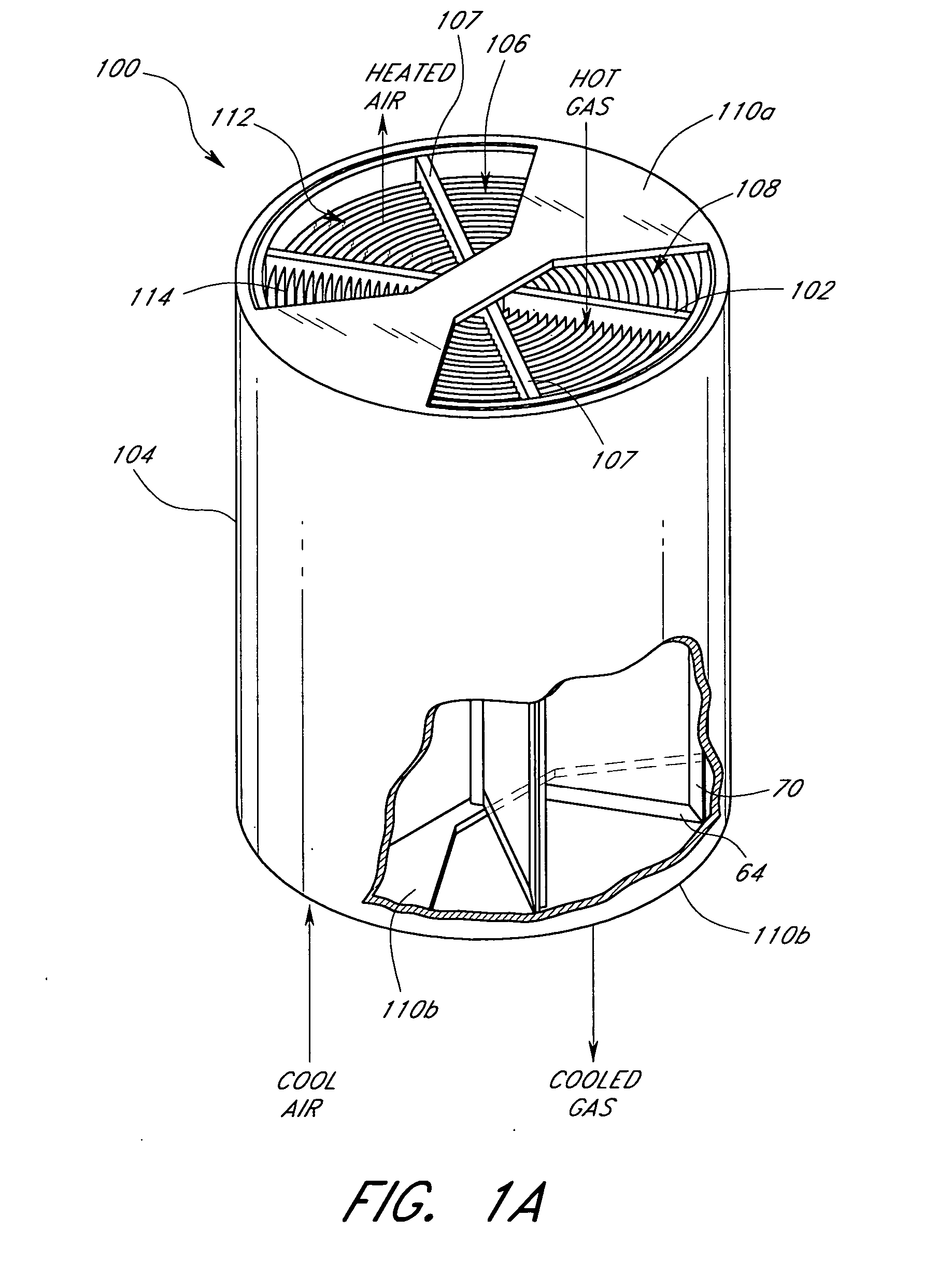

ActiveUS20080031794A1Optimizing pollutantSimple technologyUsing liquid separation agentRotary drum furnacesWaste heat recovery unitPlate heat exchanger

A process and system for recovering waste heat from a kiln used for lime or cement production. The system unifies the kiln, a waste heat recovery and power generation circuit and a dry scrubber for scrubbing the pollutants from the kiln offgas. Essentially, the system employs the boiler component of the waste heat recovery and power generation circuit as a heat exchanger to recover the waste heat from the kiln, which is used to drive the steam turbines. The heat absorption from the latter stage lowers the temperature of the kiln offgas sufficiently for optimum performance from the scrubber. The presence of lime particles in the offgas effectively protects the boiler tube surfaces from corrosion which would occur at optimum scrubber temperatures, and subsequently provides the lime required as a scrubbing medium for the dry scrubber. Further, the efficient scrubbing allows for the use of any fuel for firing the kiln inclusive of high sulphur content compounds. A process for effecting the technology is also provided.

Owner:GRAYMONT PA INC

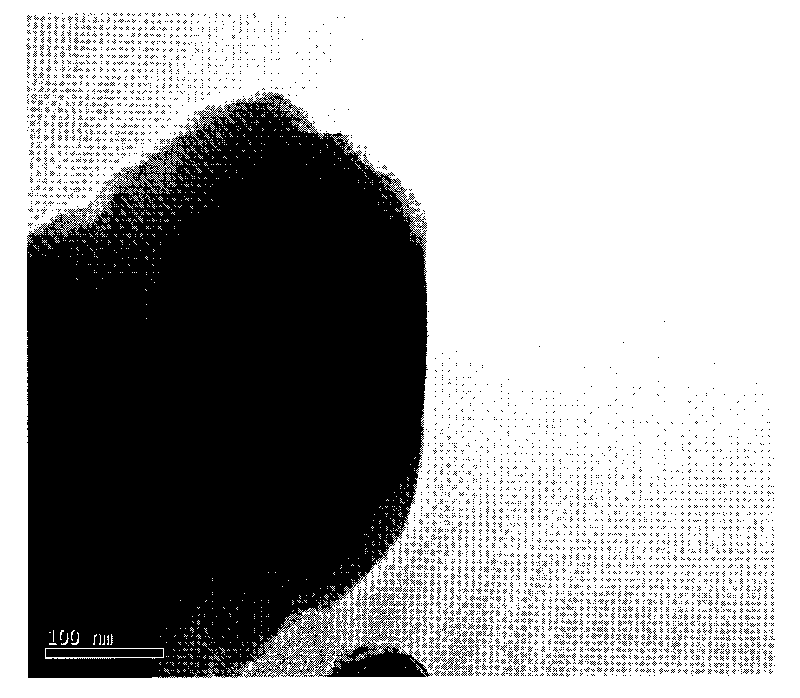

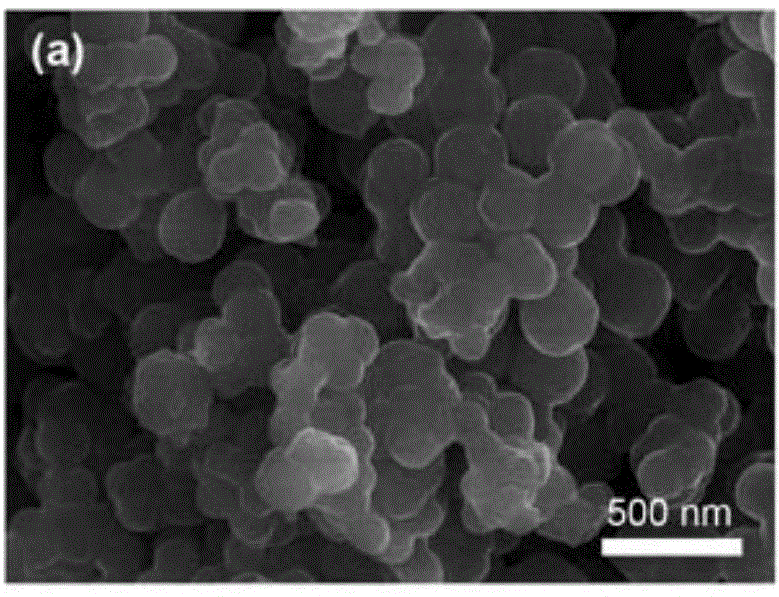

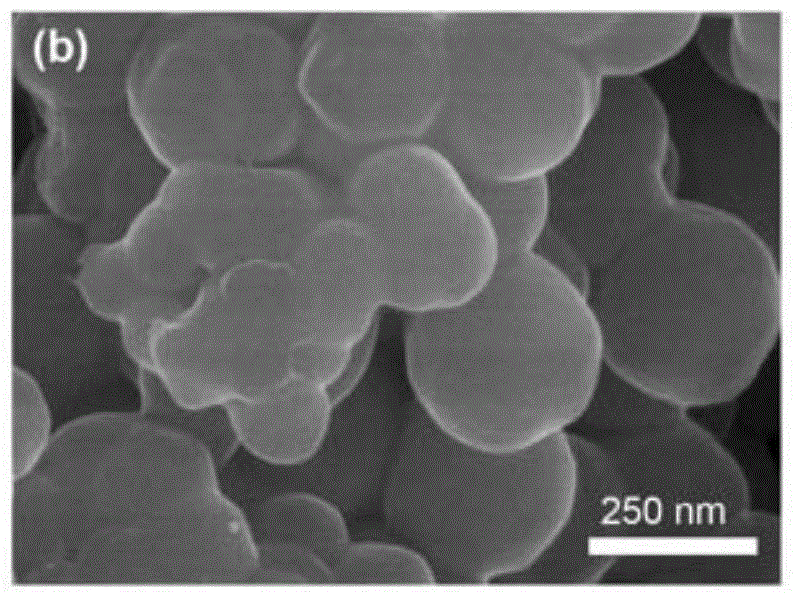

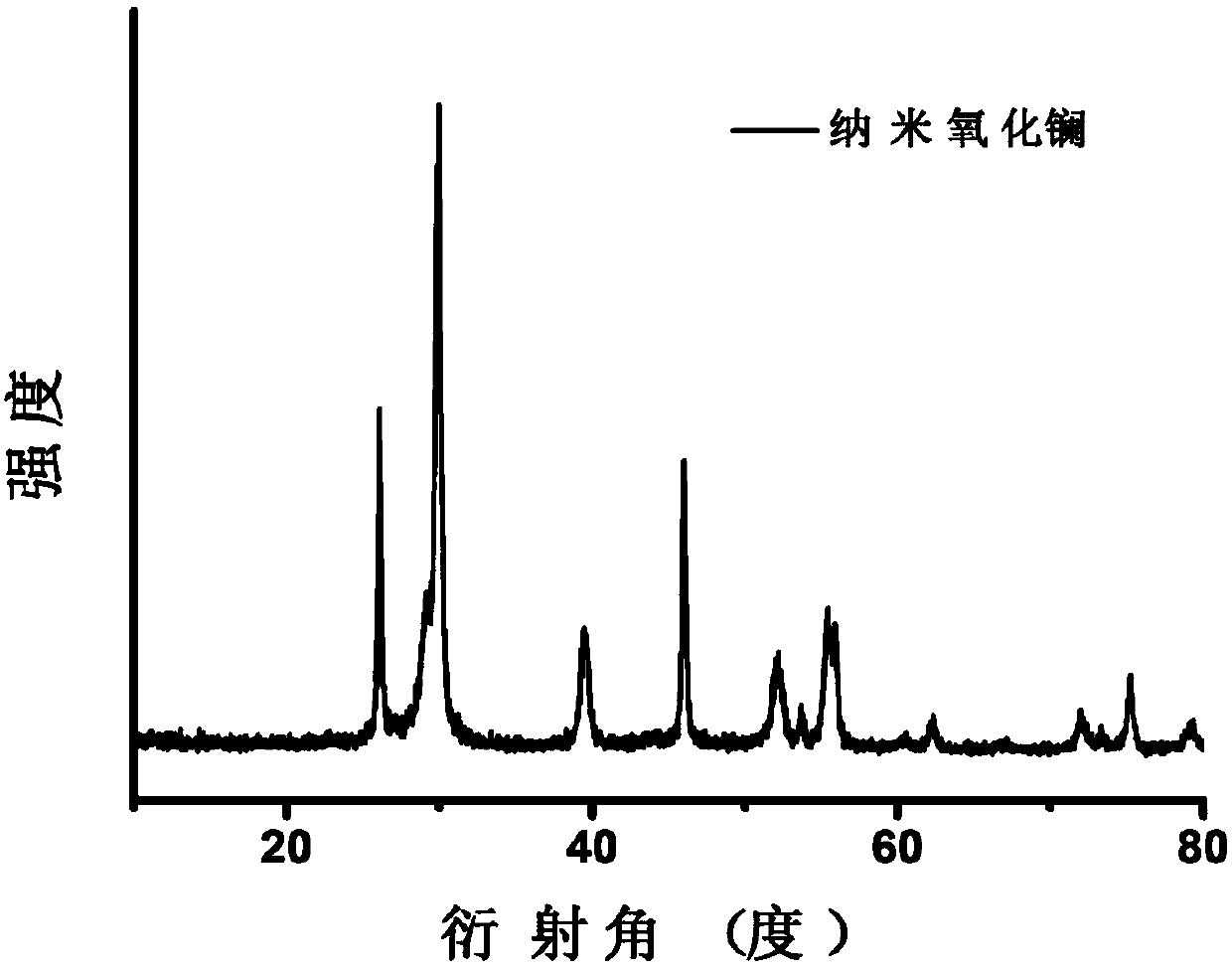

Thin-wall local graphitization porous carbon sphere material, preparation method thereof and application thereof in lithium sulfur battery

The invention discloses a thin-wall local graphitization porous carbon sphere material, a preparation method thereof and application thereof in a lithium sulfur battery. The porous carbon sphere material is a local graphitization porous carbon nanosphere with thin wall holes; the preparation method of the thin-wall local graphitization porous carbon sphere material comprises the steps that water-base resin, water-soluble inorganic salt, a surface active agent and transition metal salts are dissolved into water to obtain a spraying solution; the spraying solution is sprayed and dried to obtaina local graphitization porous carbon nanosphere precursor; the local graphitization porous carbon nanosphere precursor is subjected to pyrolysis to obtain the thin-wall local graphitization porous carbon sphere material. The preparation method is simple in technology and good in repeatability, the prepared thin-wall local graphitization porous carbon sphere material has the advantages of being good in electrical conductivity, large in aperture, high in specific surface area and the like, the thin-wall local graphitization porous carbon sphere material is applied to a lithium sulfur battery sulfur carrier, the high specific capacity, long cycling stability and high rate capability are achieved, and the wide application prospect is achieved.

Owner:CENT SOUTH UNIV

Method for treating chrome-containing wastewater by catalytic reduction of petaloid magnetic iron oxide/molybdenum sulfide composite

InactiveCN104828902ALow costHigh Photocatalytic Removal EfficiencyPhysical/chemical process catalystsWater/sewage treatment by irradiationFerrous sulfate heptahydrateIon

The invention relates to a method for treating chrome-containing wastewater by catalytic reduction of a petaloid magnetic iron oxide / molybdenum sulfide composite. The method comprises the following steps: weighing ferrous sulfate heptahydrate and sodium chlorate, dissolving in deionized water, stirring until the solution becomes light yellow, reacting in a high-pressure reaction kettle, carrying out centrifugal separation to obtain ferric oxide, drying, and pulverizing into powder; weighing the ferric oxide powder, molybdenum trisulphate dihydrate and thiocarbamide, dissolving in deionized water, stirring uniformly, transferring the mixture into a high-pressure reaction kettle, reacting, and carrying out centrifugal separation; cleaning with ethanol and deionized water; and drying to obtain the ferric oxide / molybdenum sulfide composite finished product, adding the finished product into hexavalent-chrome-containing wastewater with the initial concentration of 5-20 mg / L, stirring uniformly, irradiating with a metal halide lamp for more than 30 minutes, determining the hexavalent chrome concentration after treatment, and calculating the removal rate. The ferric oxide / molybdenum sulfide composite for treating hexavalent-chrome wastewater has the advantages of high removal rate and low treatment cost.

Owner:YANGZHOU UNIV

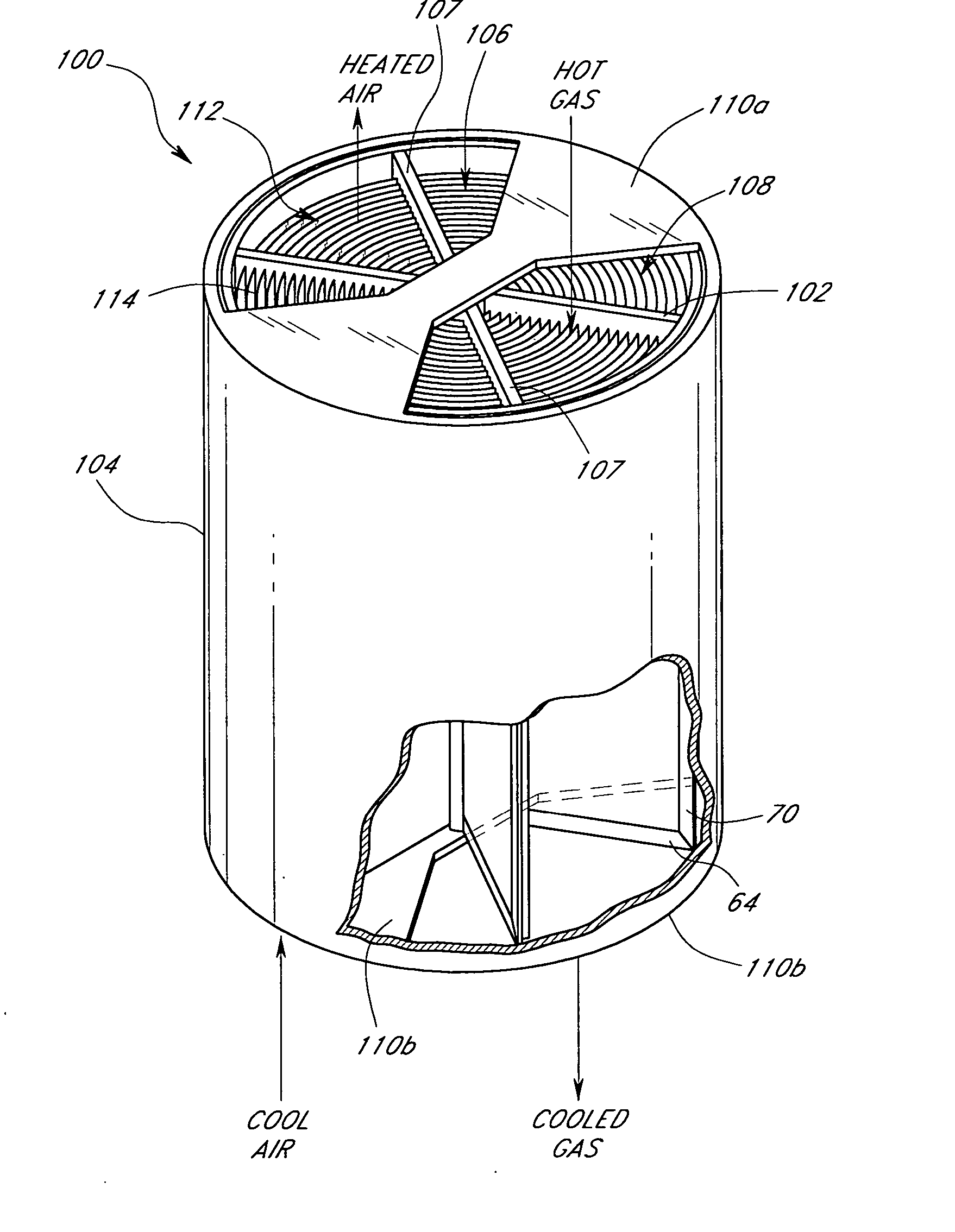

Heat exchanger having powder coated elements

InactiveUS20060254756A1High sulfur contentReduce the temperatureCombustion processCorrosion preventionFlue gasProtection layer

Powder coated heat exchange elements for a heat exchanger. Powder coating provides improved protective coating on surfaces of heat exchange elements. In many applications, the heat exchange elements are subjected to harsh operating conditions that promote corrosion. Traditional enamel coating tends to fracture when subjected to mechanical stresses thereby allowing corrosion inducing agents to penetrate and corrode the underlying surfaces. Powder coating reduces breaches in the protective layer. Powder coating may be adapted to withstand high temperatures so as to make them suitable for use in harsh operating environments. One such environment can be found in the processing of flue gas from fossil burning power generators, where the flue gas has a relatively high temperature and high sulfur content.

Owner:PARAGON TECH

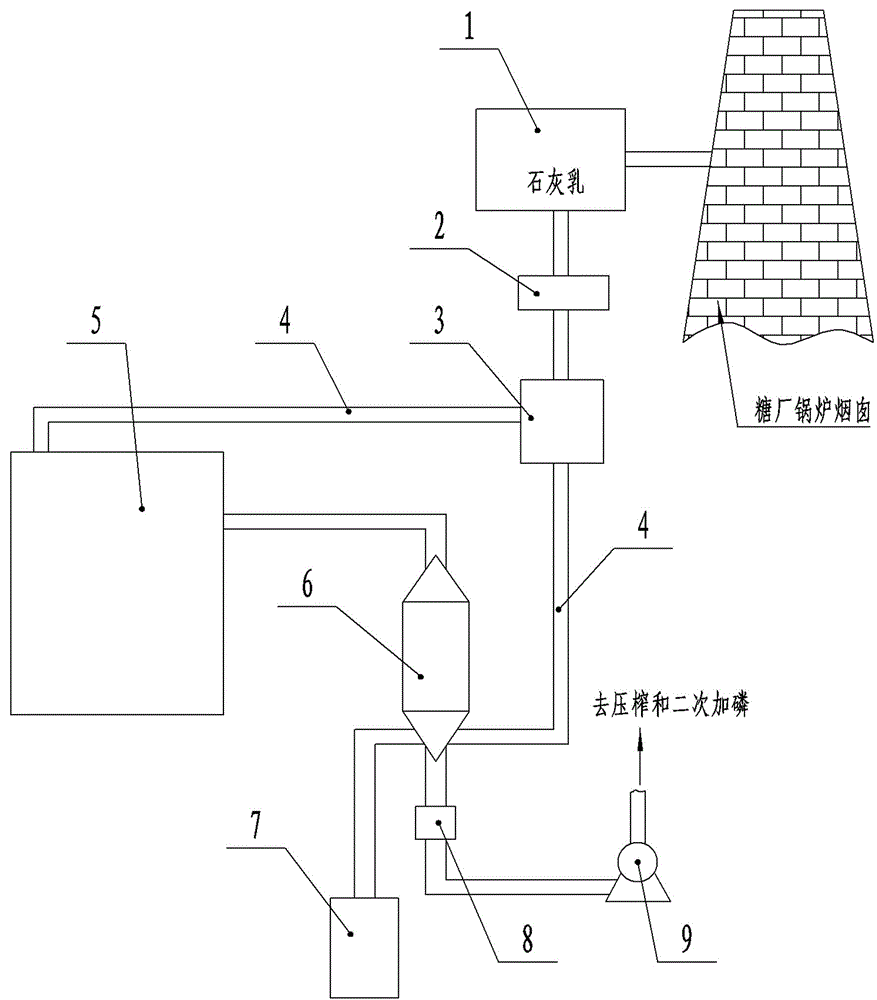

Preparation method of emulsion antioxidant product

The invention provides a preparation method of an emulsion antioxidant product and belongs to the technical field of preparation of synthetic material antioxidant products. The emulsion antioxidant product is used for acrylonitrile butadiene styrene acrylonitrile butadiene styrene (ABS) grafting powder by means of an emulsion polymerization technology. Phenolic antioxygen Wingstay-L, an active ion radical trapping agent and a methylene di-sulfo ester compound are compounded according to the proportion to form a complex antioxidant, the complex antioxidant, isotridecyl alcohol polyoxyethylene ether or nonyl phenol polyoxyethylene ether and a dilution dispersing agent are mixed and stirred through a high speed shearing machine at the heating condition of 80-120 DEG C to form a homogeneous mixed liquid, and quantitative deionized water and an anionic surface active agent are added to continue to perform high speed shearing and stirring so as to obtain the antioxidant product having a water-soluble particle emulsion state, namely the emulsion antioxidant product.

Owner:浩瀚化学有限责任公司

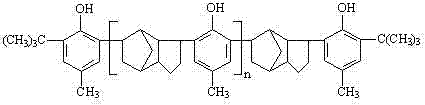

Method and equipment for recovering, activating and utilizing carbon dioxide from sugar refinery

InactiveCN104437060AIncrease profitEmission reductionPurification using alkaline earth metal compoundsDispersed particle separationCalcium bicarbonateJuice clarification

The invention discloses method and equipment for recovering, activating and utilizing carbon dioxide from a sugar refinery. The method comprises the following steps: introducing low-content carbon dioxide contained in flue gas of a boiler of the sugar refinery into a carbon dioxide adsorption tower, and reacting the carbon dioxide with lime cream inside the carbon dioxide adsorption tower to form a calcium carbonate solution; introducing a part of the calcium carbonate solution into phosphoric acid to generate calcium dihydrogen phosphate and the carbon dioxide, wherein the calcium dihydrogen phosphate is used for squeezing and secondary phosphorus addition; reacting the other part of the other part of the calcium carbonate solution with the carbon dioxide to generate calcium hydrogen carbonate, and pumping to mixed juice preliming, a floating device overflow pipe and a filtered juice quick-sinking reactor by using a calcium hydrogen carbonate pump. The method disclosed by the invention can be used for generating the calcium carbonate by reacting the low-concentration carbon dioxide contained in the flue gas of the boiler with the lime cream and preparing the calcium hydrogen carbonate and the calcium dihydrogen phosphate as clarifying agents used for the sugar refinery by utilizing the calcium carbonate and the phosphoric acid, thereby achieving the purpose of cane juice clarification by removing a part of colloid and non-sugar components in an adsorbing way, enhancing the CO2 utilization rate and reducing the discharge amount of the carbon dioxide from a chimney of the sugar refinery.

Owner:GUANGXI DAXIN COUNTY LEIPING YONGXIN SUGAR

High-sulfur fertilizer coal modification method and application thereof in coking coal blending

The invention provides a new technology of thermal solution extraction of high-sulfur fertilizer coal and application thereof in coking coal blending. In the new technology, the high-sulfur fertilizer coal is continuously treated by thermal extraction in a fixed bed reactor or thermal solution extraction in a clearance type reaction still with an organic solvent under proper conditions, after thermal state filtering and separation, a high yield high-sulfur and low-ash thermal solution product is obtained, and the product is used for coking coal blending. By such thermal solution extraction, all the ash component and inorganic sulfur of the thermal solution product are removed, in comparison with the original high-sulfur fertilizer coal, the cohesiveness of the thermal solution product is improved, the sulfur content is reduced obviously, the sulfur is completely the organic sulfur, and the organic sulfur is easy to remove in the subsequent coking process. With the thermal solution product used in the coking coal blending process, the coke quality can be improved obviously, the sulfur content of the coke is lowered, or on the premise of guaranteeing the coke quality, the non-coking coals, such as the subbituminous coal, can be properly added, so that the coal blending coking cost can be lowered, and the coking coal source is stabilized and expanded.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

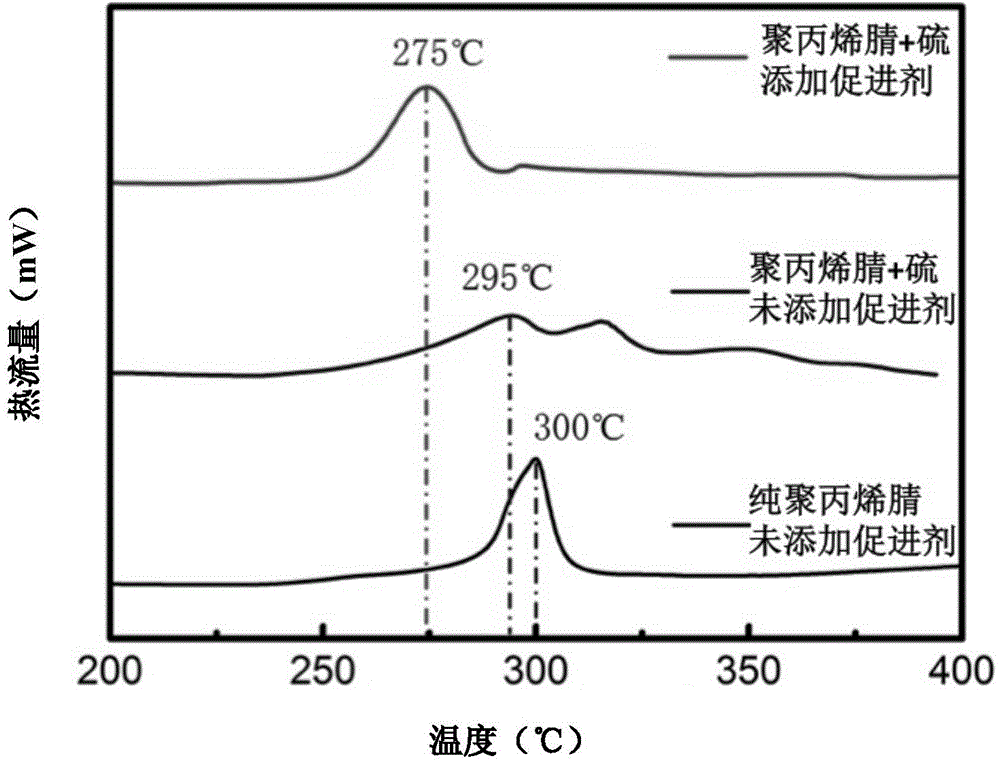

Method for increasing sulfur content of sulfur-carbon composite through vulcanization accelerator

InactiveCN105633351AHigh sulfur contentImprove discharge capacityCell electrodesCarbon compositesLithium–sulfur battery

The invention discloses a method for increasing a sulfur content of a sulfur-carbon composite through a vulcanization accelerator. The method comprises the steps of enabling a carbon source, a sulfur source and the vulcanization accelerator to be mixed and ball milled to obtain a uniform mixture; and putting the uniform mixture into a sealed container, and pumping protective gas to enable the mixture to be fully reacted at a vulcanizing temperature of 100-700 DEG C to obtain the sulfur-carbon composite. The method provided by the invention is simple and effective, and capable of greatly increasing the sulfur content of the sulfur-carbon composite; therefore, the electrochemical performance of a lithium-sulfur battery taking the sulfur-carbon composite as the positive electrode material can be improved; for example, the discharge capacity and the cycling stability of the battery can be dramatically improved while other impurities affecting the operation of the battery are not introduced either.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

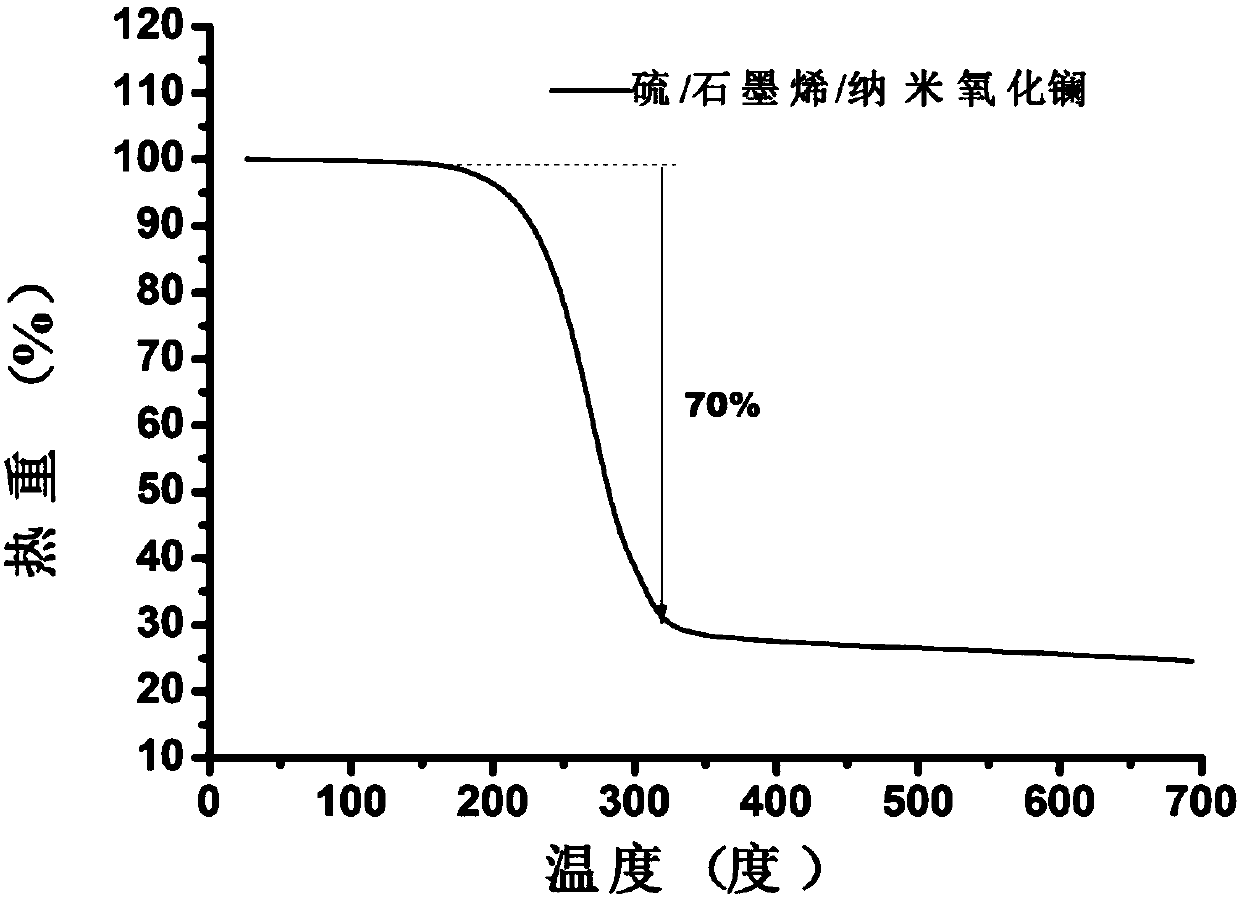

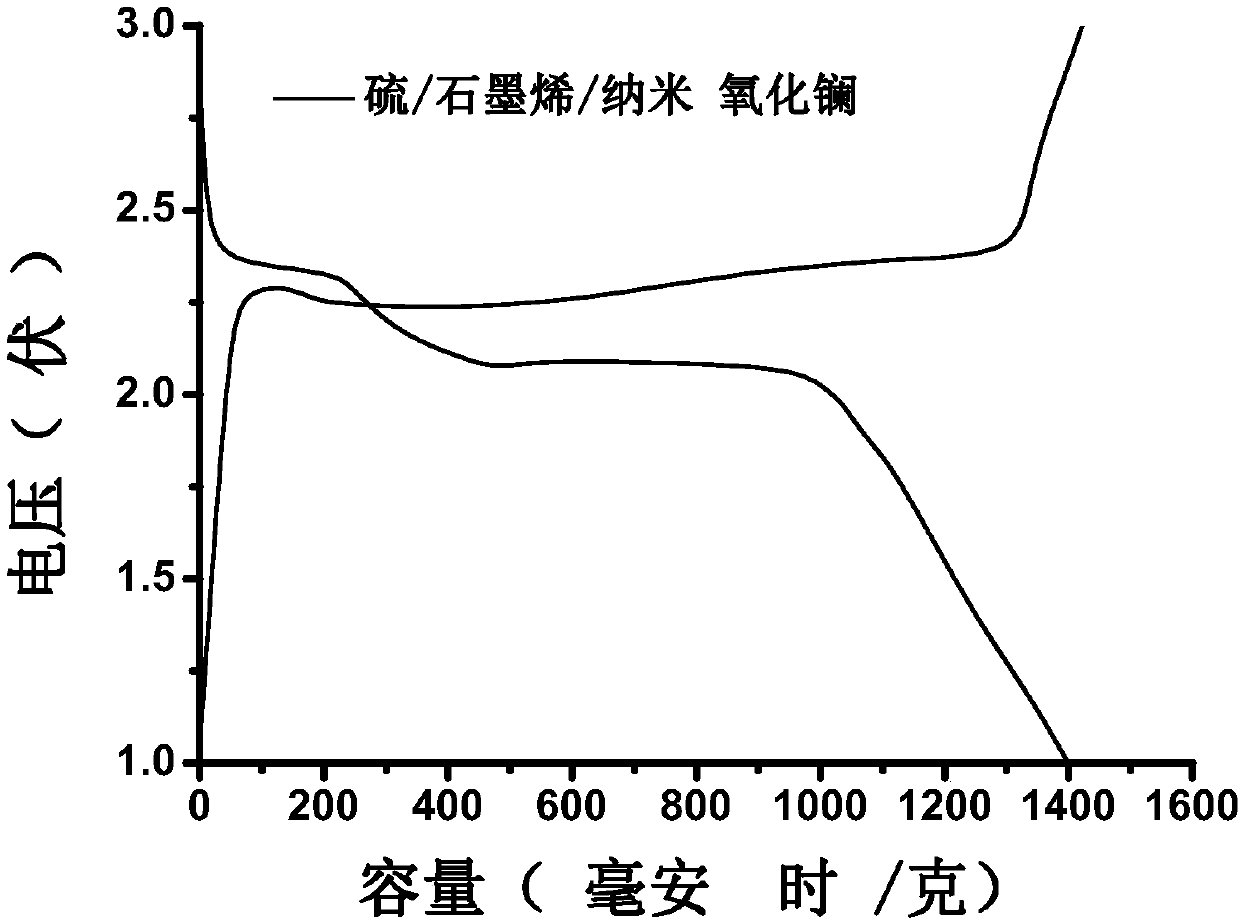

Preparation method of nano lanthanum oxide/graphene/sulfur composite material

ActiveCN107742707ASimple processReduce manufacturing costMaterial nanotechnologyCell electrodesCvd grapheneCarbon disulfide

The invention relates to a preparation method of a nano lanthanum oxide / graphene / sulfur composite material. The method comprises the following steps: adding a carbon disulfide / sulfur solution into a graphene oxide / nano lanthanum oxide mixed suspension liquid, and performing hydrothermal reaction in a stainless steel reaction kettle for 5 to 24 h; and cleaning, and vacuum freeze-drying, thus obtaining the nano lanthanum oxide / graphene / sulfur composite material. According to the preparation method, the reduction of the graphene oxide, the doping of nano metal oxide and the thermal reaction of the loaded sulfur solvent are innovatively completed in one step, so that the reaction efficiency is improved, the preparation process is simple, and the weaknesses in the prior art that the utilizationrate of the lithium-sulfur battery positive active substances is low, the rate capacity is poor, the cycle life is short, the reaction efficiency is low, and the preparation process is complex are overcome.

Owner:SYNERGY INNOVATION INST OF GDUT HEYUAN

Method for purification of coarse sulfur

InactiveCN101397127AEasy industrialization of purification processHigh yieldSulfur preparation/purificationControl systemSulfur

The invention relates to a method for purifying crude sulfur, in particular to a method for purifying the byproduct crude sulfur of coke-oven gas of coke plant by a vacuum distillation method, belonging to the technical field of coal chemical. By adopting the vacuum distillation method, the vacuum distillation is carried out in an external heating typed vacuum furnace under the conditions of 5-400Pa of system pressure, 50-100 DEG C of distillation temperature and 15-120 minutes of distillation time, thus gaining the sulfur with the purity reaching national class-A. Furthermore, according to raw material composition and the requirement of product purity, one-step distillation or two-step distillation or multi-step distillation can be selected to purify the raw material and gain the sulfur product of needed quality. The method has the advantages of simple process flow, low sulfur purification cost, small environmental pollution, good industrial prospect, and the like.

Owner:KUNMING UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com