Patents

Literature

35results about "Titanium sulfides" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

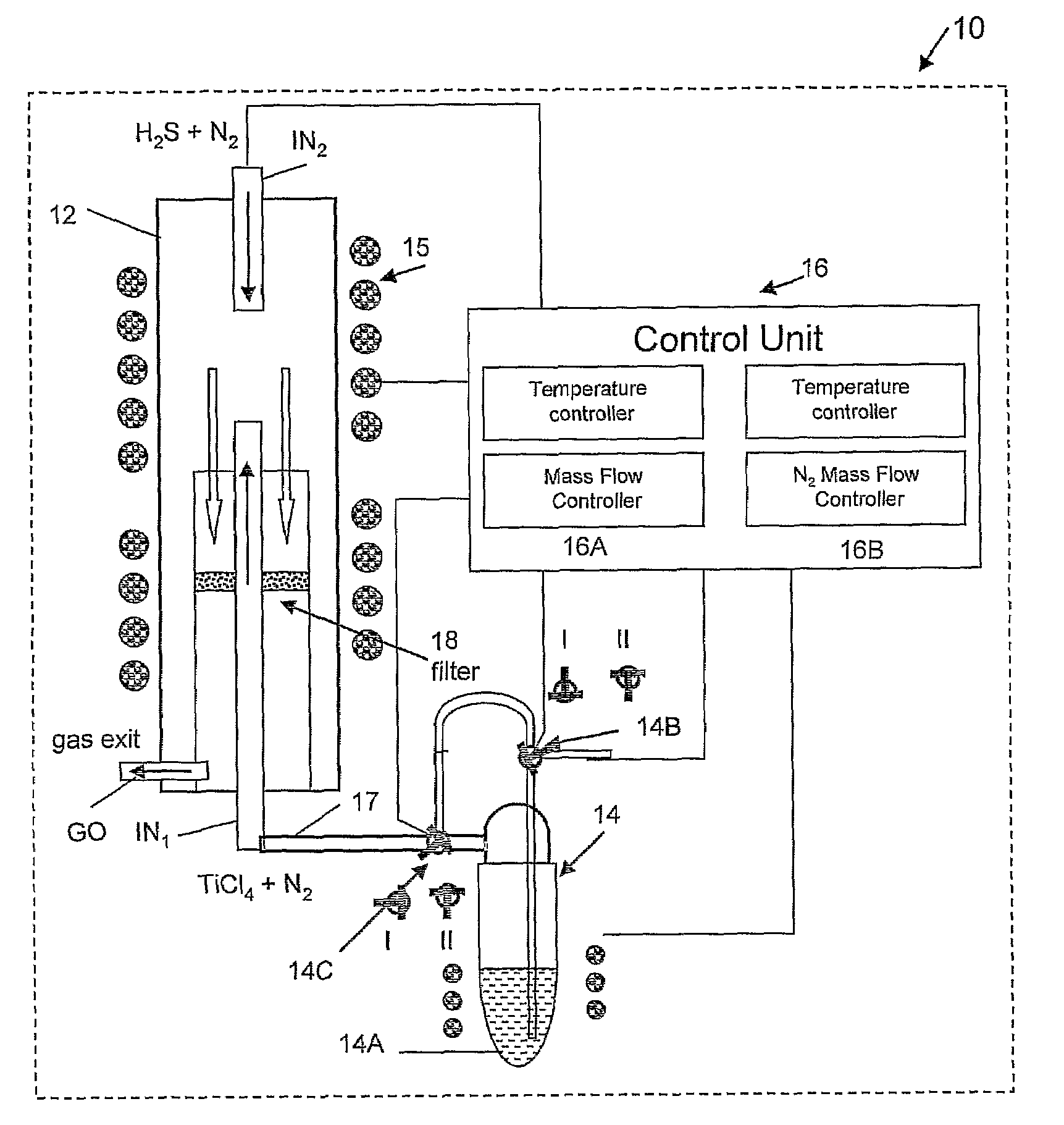

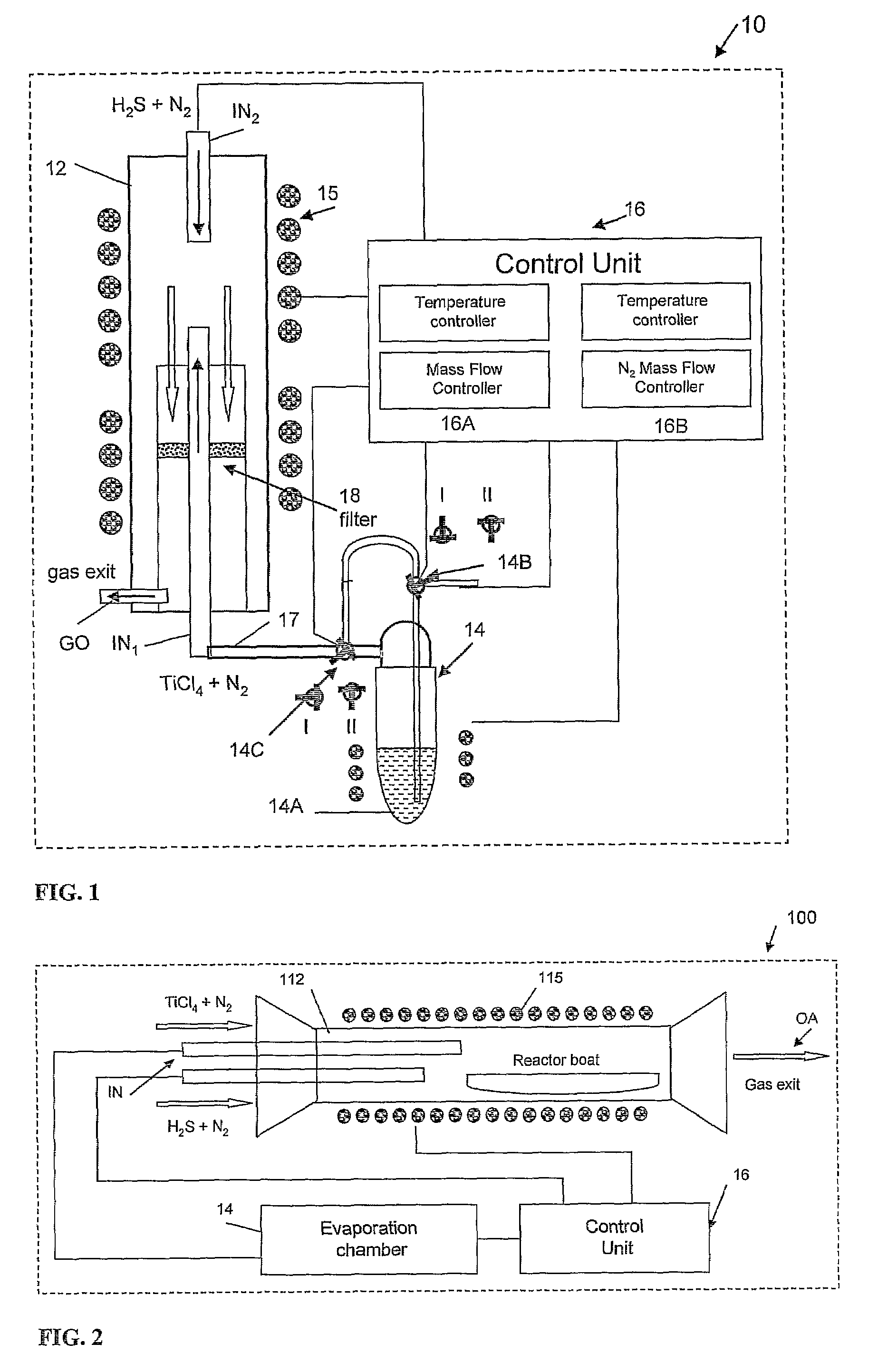

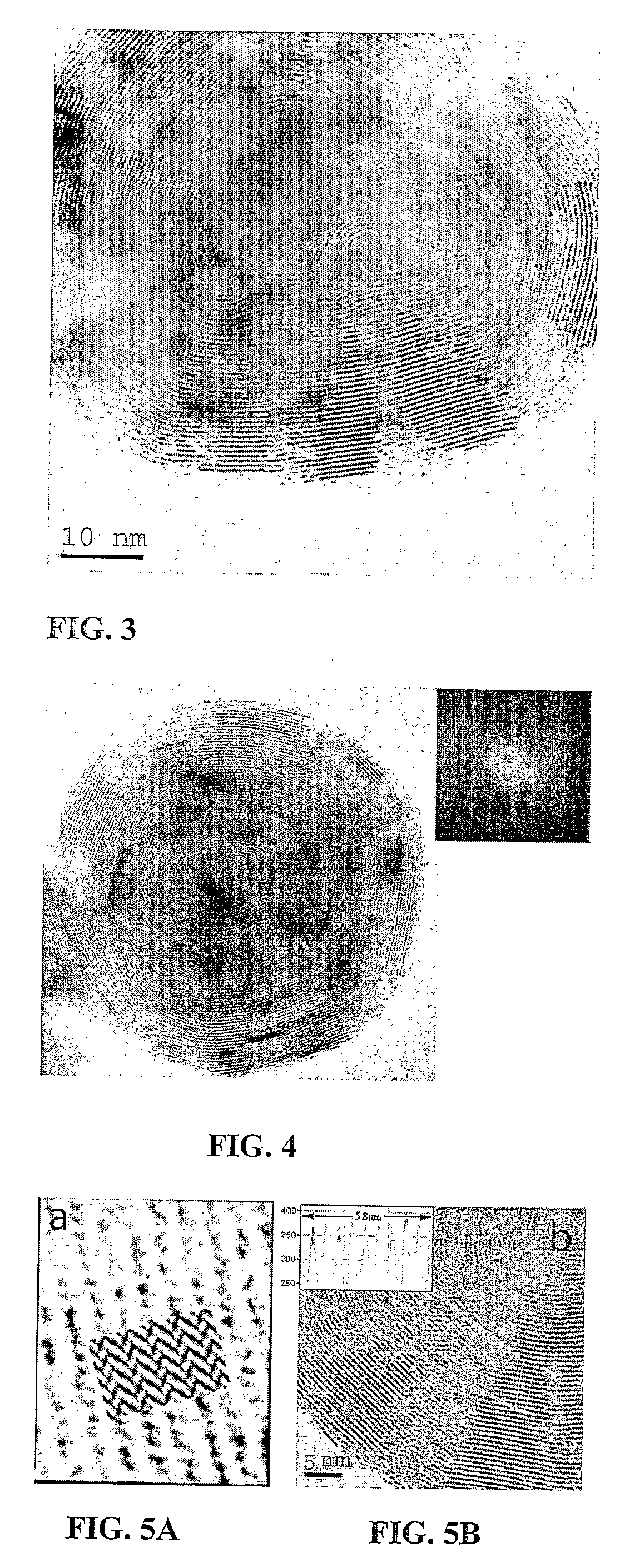

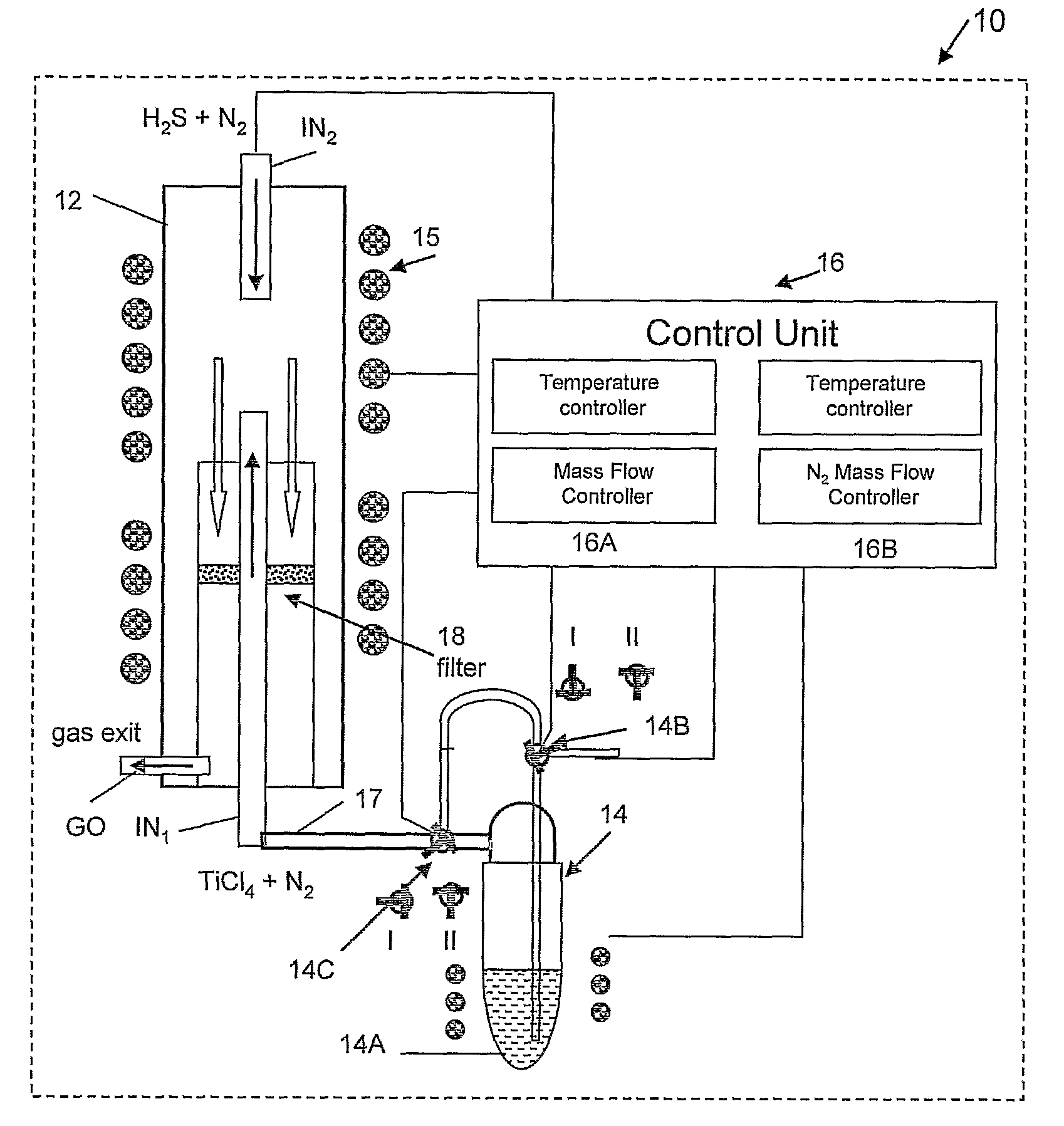

Process and apparatus for producing inorganic fullerene-like nanoparticles

ActiveUS7641886B2Easy to produceImproved propertyMaterial nanotechnologyNanostructure manufactureGas phaseMetal chalcogenides

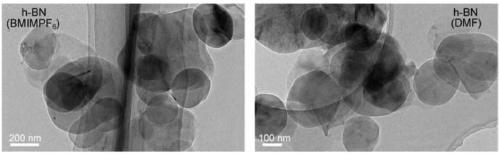

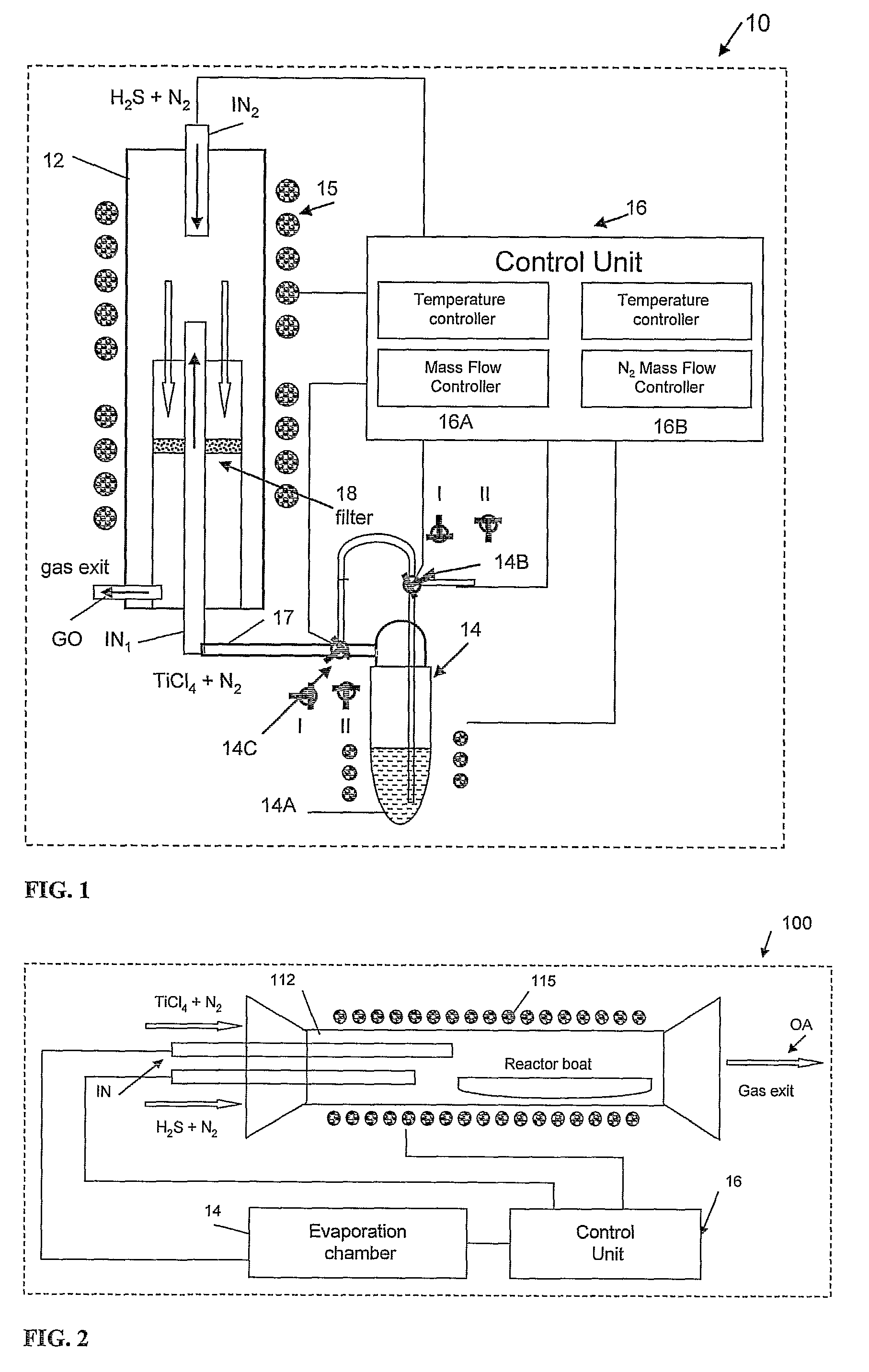

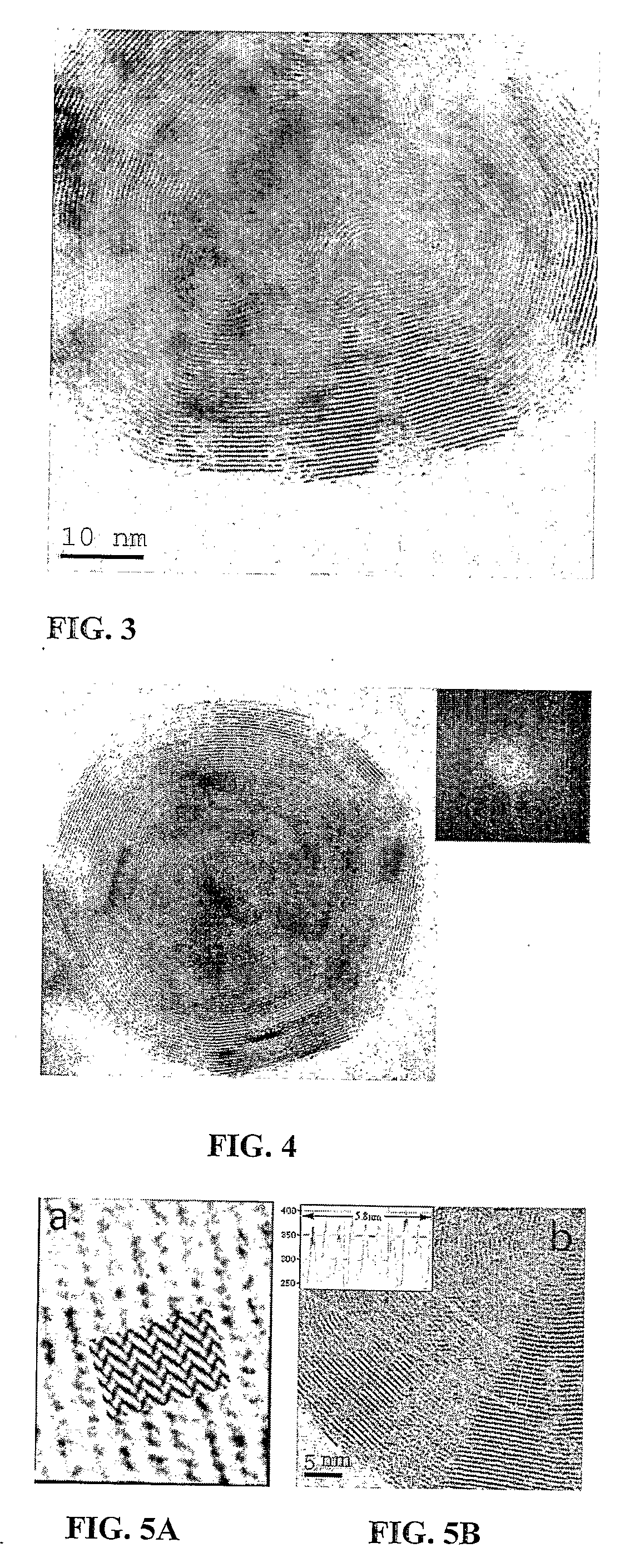

The present invention provides a process for obtaining fullerene-like metal chalcogenide nanoparticles, comprising feeding a metal precursor (INi) selected from metal halide, metal carbonyl, organo-metallic compound and metal oxyhalide vapor into a reaction chamber (12) towards a reaction zone to interact with a flow of at least one chalcogen material (IN2) in gas phase, the temperature conditions in said reaction zone being such to enable the formation of the fullerene-like metal chalcogenide nanoparticles product. The present invention further provides novel IF metal chalcogenides nanoparticles with spherical shape and optionally having a very small or no hollow core and also exhibiting excellent tribological behavior. The present invention further provides an apparatus for preparing various IF nanostructures.

Owner:A Y Y T TECHCAL APPL & DATA UPDATE +1

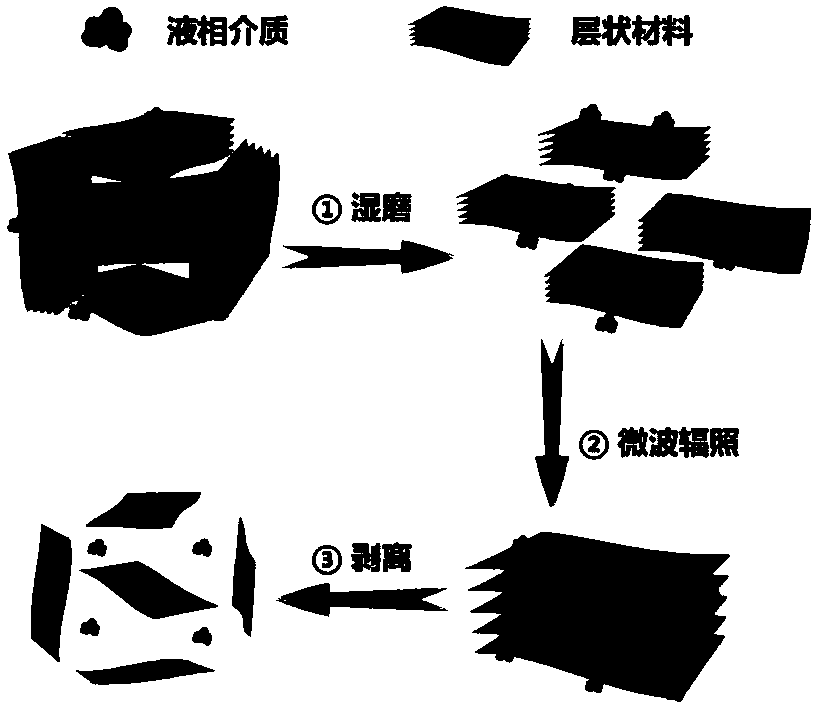

Method for preparing two-dimensional nanosheets by microwave-assisted liquid phase stripping of layered material

ActiveCN109205578AGood chemical stabilityHigh yieldMaterial nanotechnologyTantalum compoundsLiquid mediumUltrasonic dispersion

The invention discloses a method for preparing two-dimensional nanosheets by microwave-assisted liquid phase stripping of a layered material. The method comprises the following specific steps: 1) carrying out wet grinding of precursor powder of the layered material with a liquid medium in a mortar; 2) washing the wet-ground mixture with a same liquid medium and transferring into a microwave reaction tube; 3) placing the microwave reaction tube into a microwave reaction device, and carrying out microwave irradiation; 4) after microwave irradiation, washing and filtering the microwave mixture, and collecting a filter membrane; 5) carrying out ultrasonic dispersion of the obtained filter membrane in an organic solvent, and carrying out centrifugal separation, wherein a supernatant is a nanosheet dispersion liquid, and a precipitate is a separated unpeeled phase; and 6) filtering the obtained nanosheet dispersion liquid, collecting a filter membrane, and carrying out vacuum drying to obtain the nanosheet powder. The method is universal, fast and efficient in peeling various layered materials, and the prepared nanosheets are ultra-thin, large in size, small in peeling size reduction andhigh in chemical stability, and have broad application prospects in basic scientific researches, electronics, catalysis, energy, sensing and other hot fields.

Owner:SHANGHAI JIAO TONG UNIV

Two-dimensional nanosheet and preparation method and usage thereof

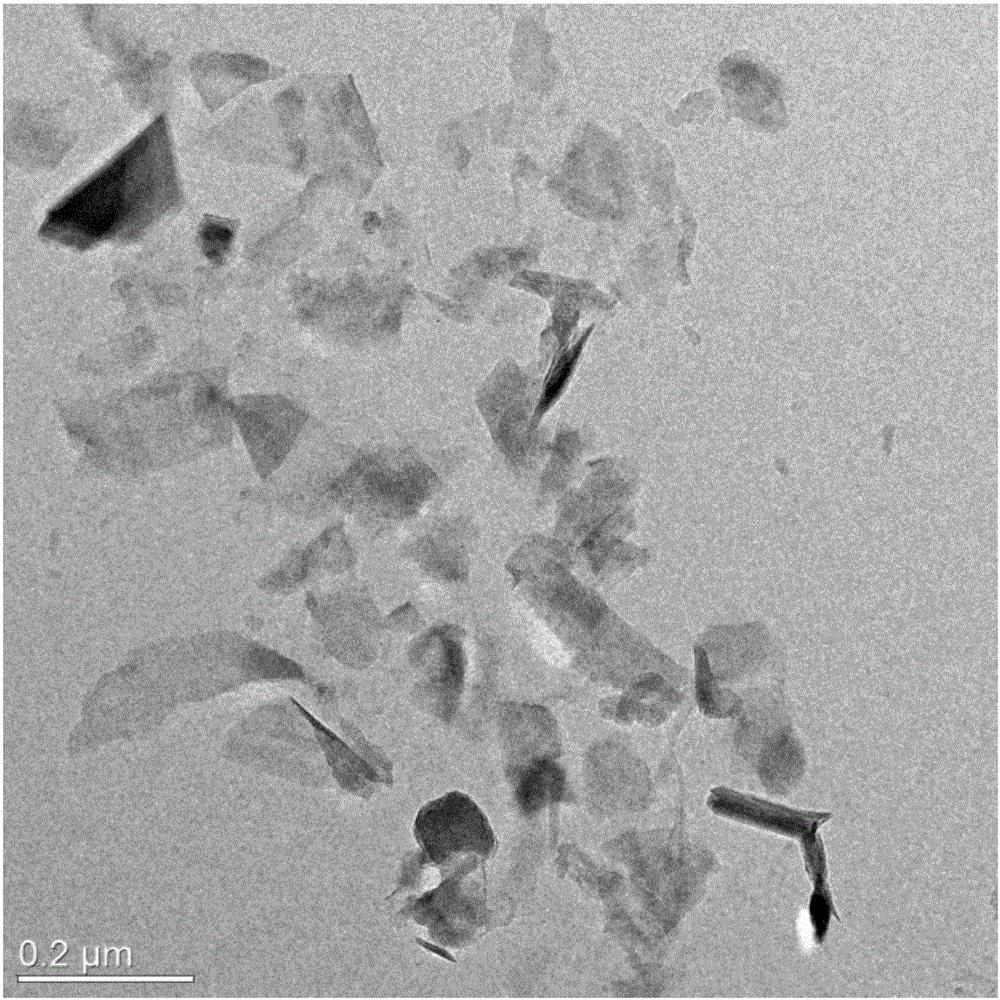

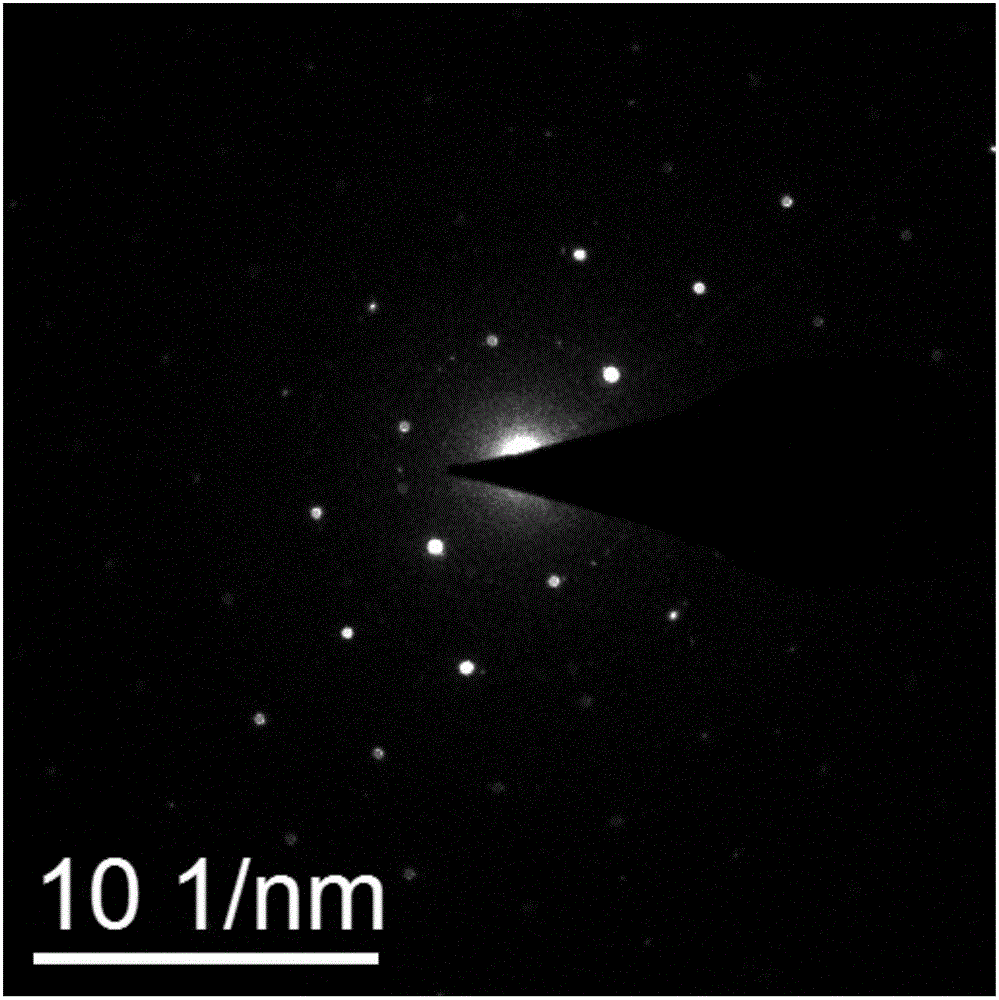

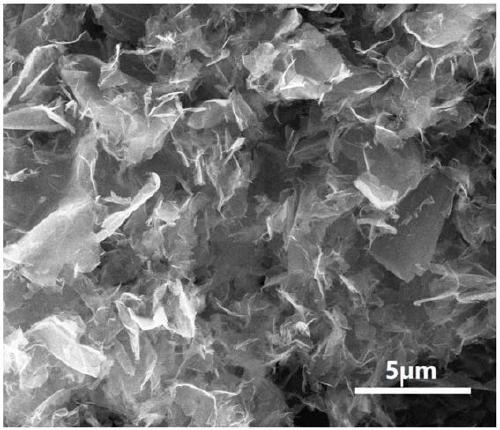

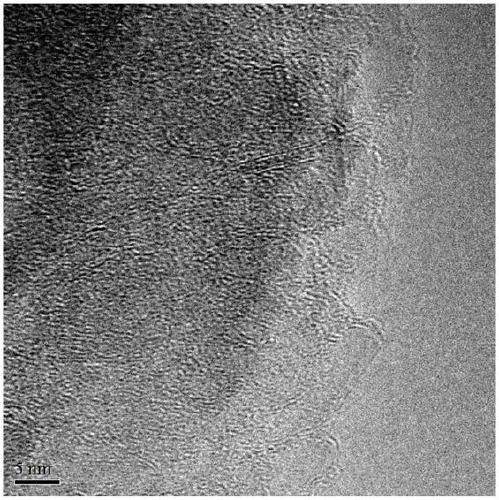

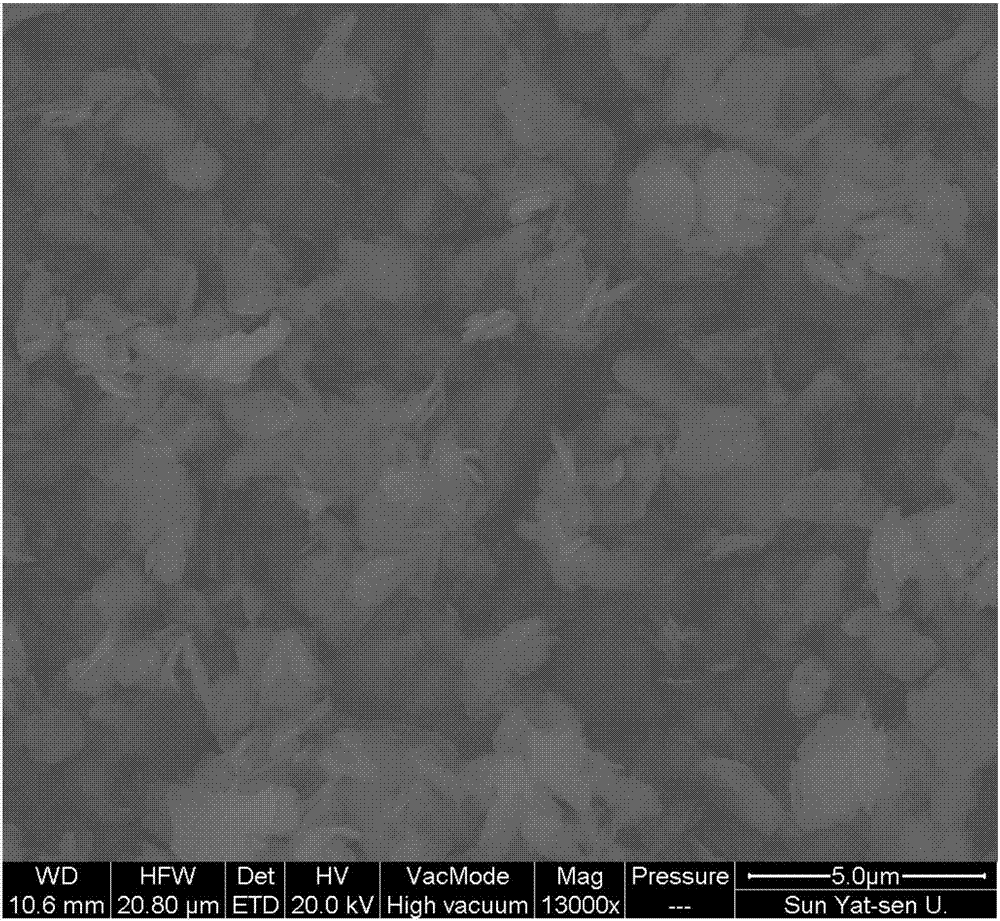

InactiveCN110371932ALower synthesis costSuitable for large-scale industrial productionMaterial nanotechnologyTitanium sulfidesTransmittanceOrganic matter

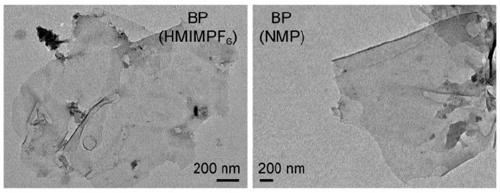

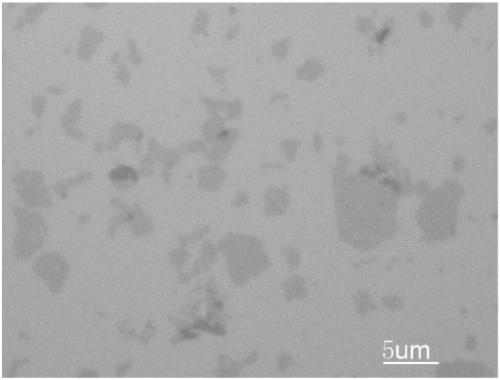

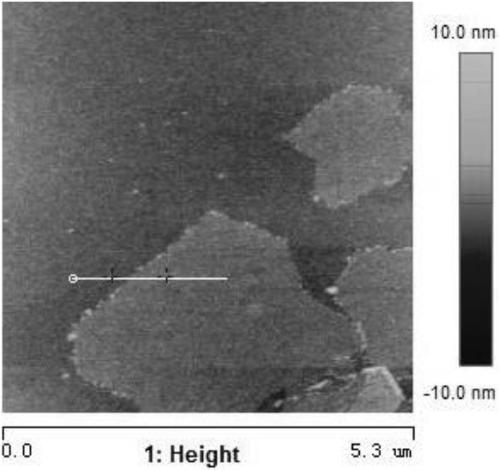

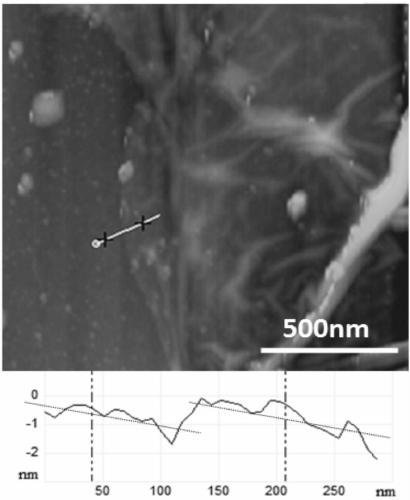

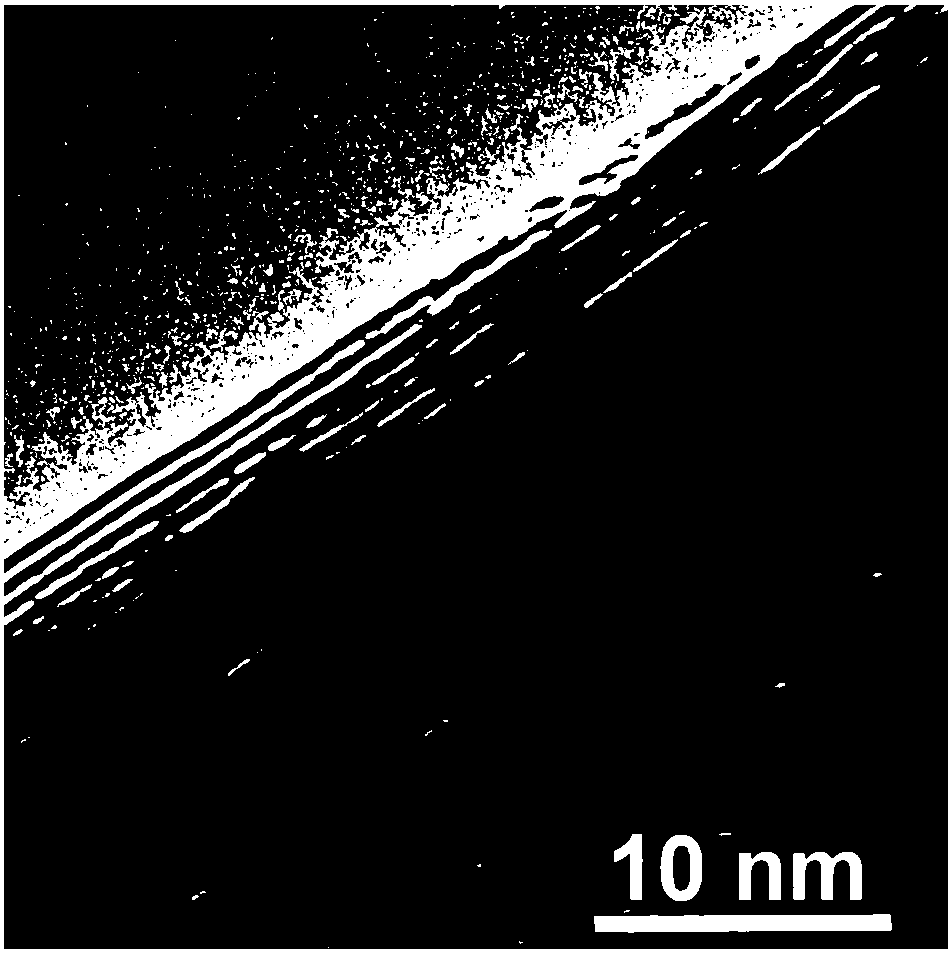

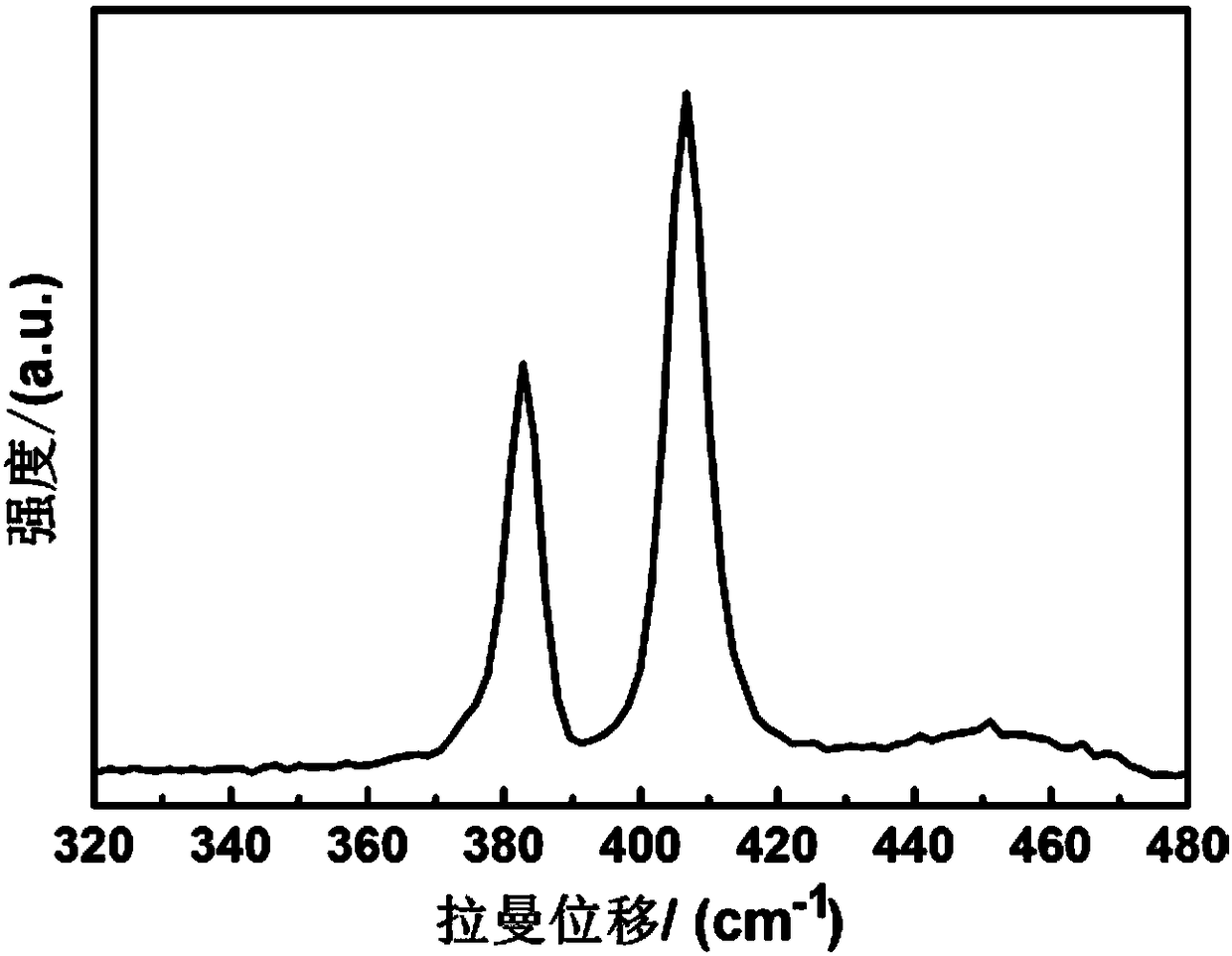

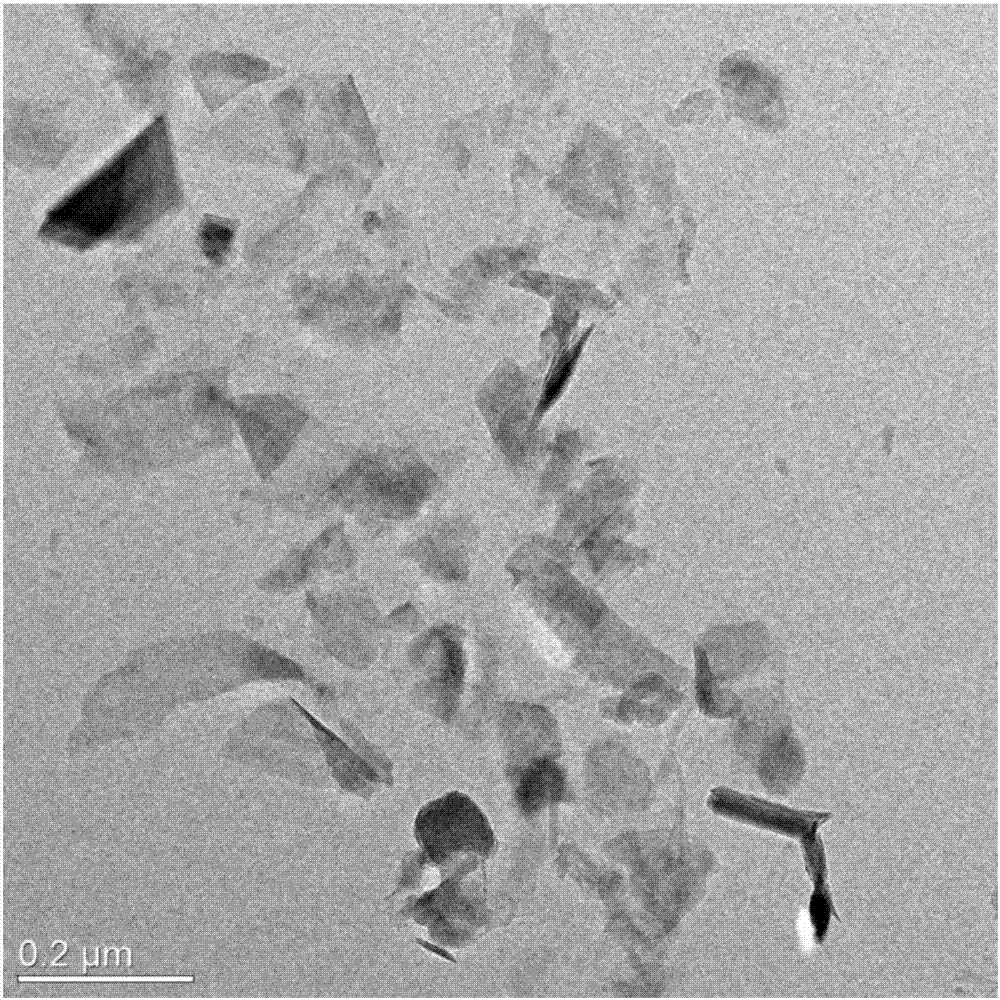

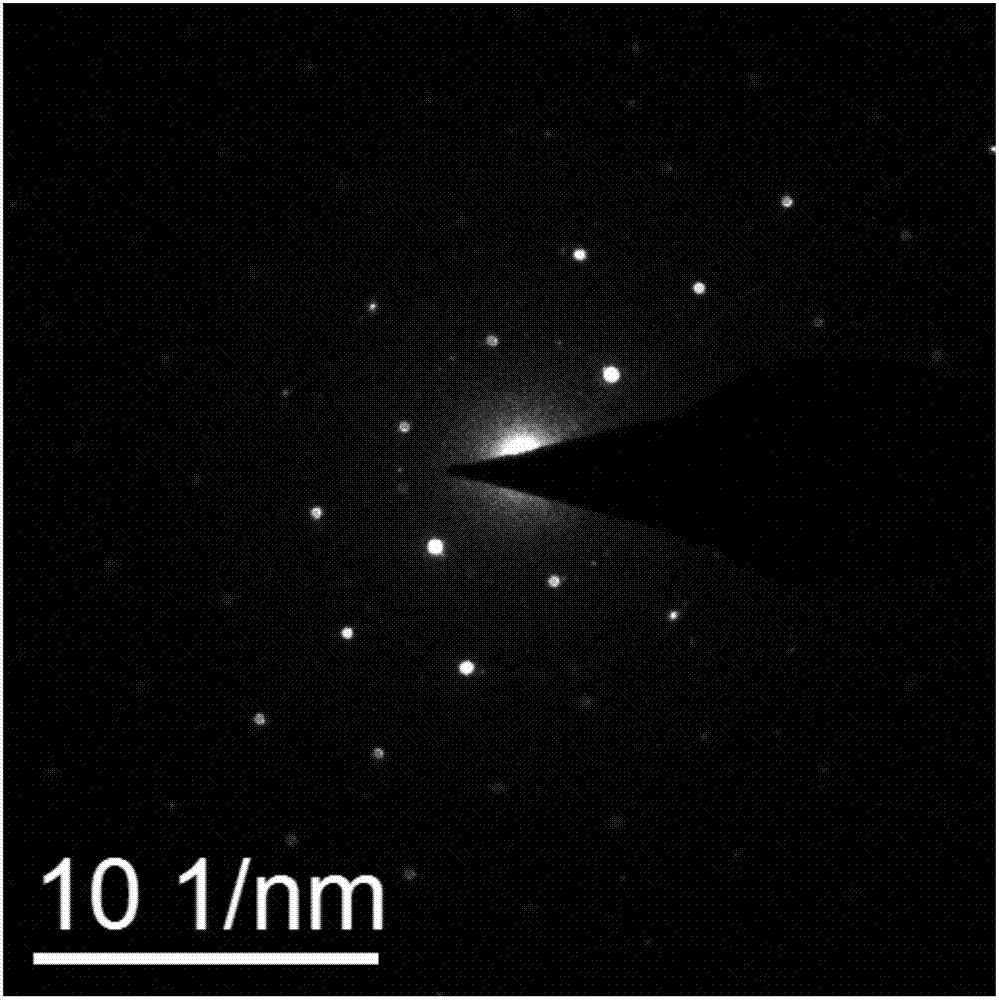

The invention provides a two-dimensional nanosheet and a preparation method and usage thereof. Through a means of solution stripping, the two-dimensional nanosheet which is large in sheet layer size,high in quality and small in defect number and mainly takes a single layer is prepared. The morphology of the two-dimensional nanosheet is represented through an optical microscope, a scanning electron microscope, a transmission electron microscope and an atomic force microscope. A Raman spectrum is utilized to represent that the two-dimensional nanosheet obtained through solution stripping and atwo-dimensional nanosheet obtained through a chemical vapor deposition method have the equally high crystalline quality. An infrared transmittance spectrum is utilized to represent successful modification of organic matter to the two-dimensional nanosheet. Research results show that the two-dimensional nanosheet synthesized through the preparation method has the advantages of being large in size,high in quality, small in defect number, easy to modify and the like.

Owner:INST OF CHEM CHINESE ACAD OF SCI +1

Method for producing dispersions of nanosheets

Owner:UCL BUSINESS PLC

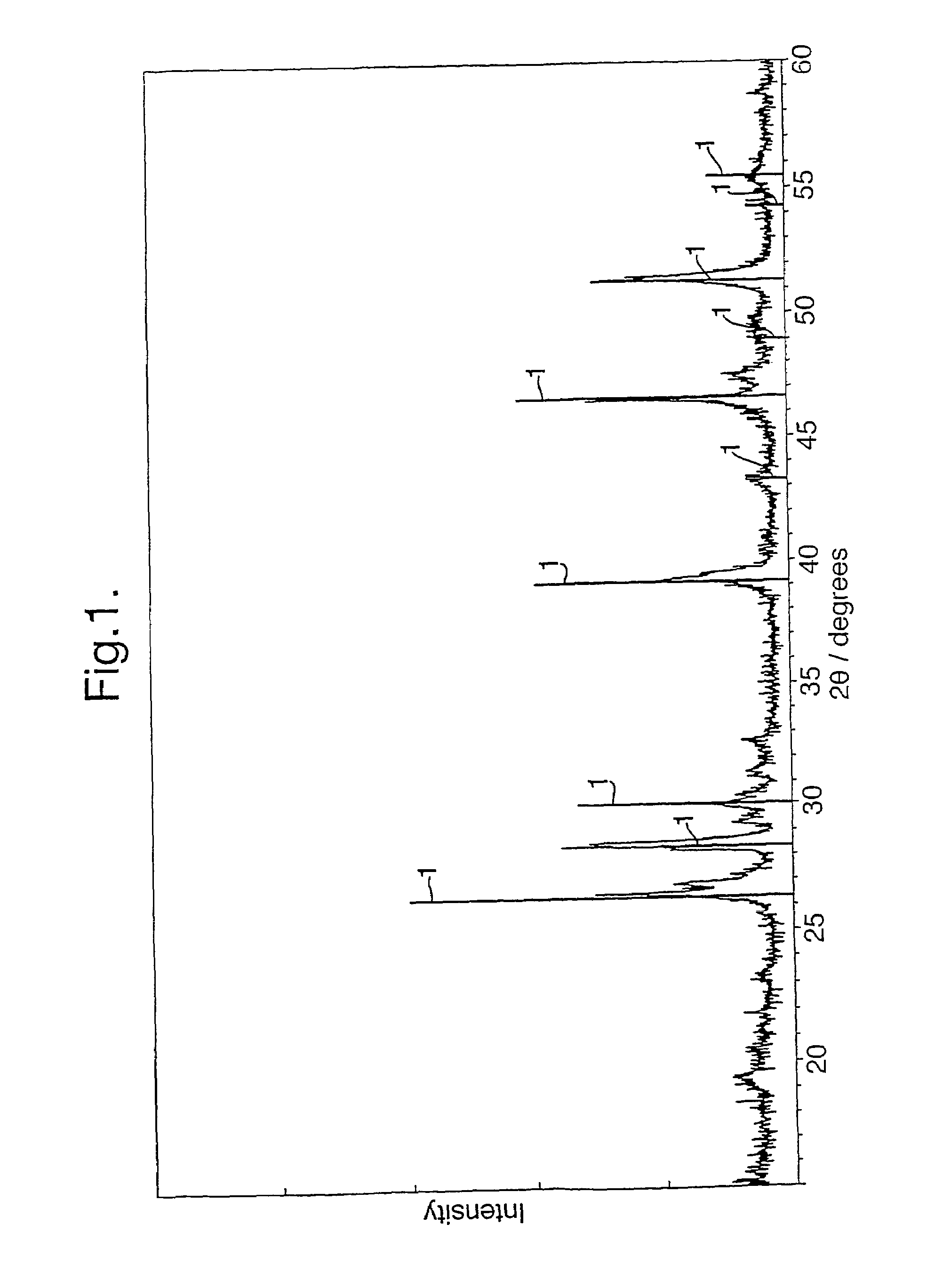

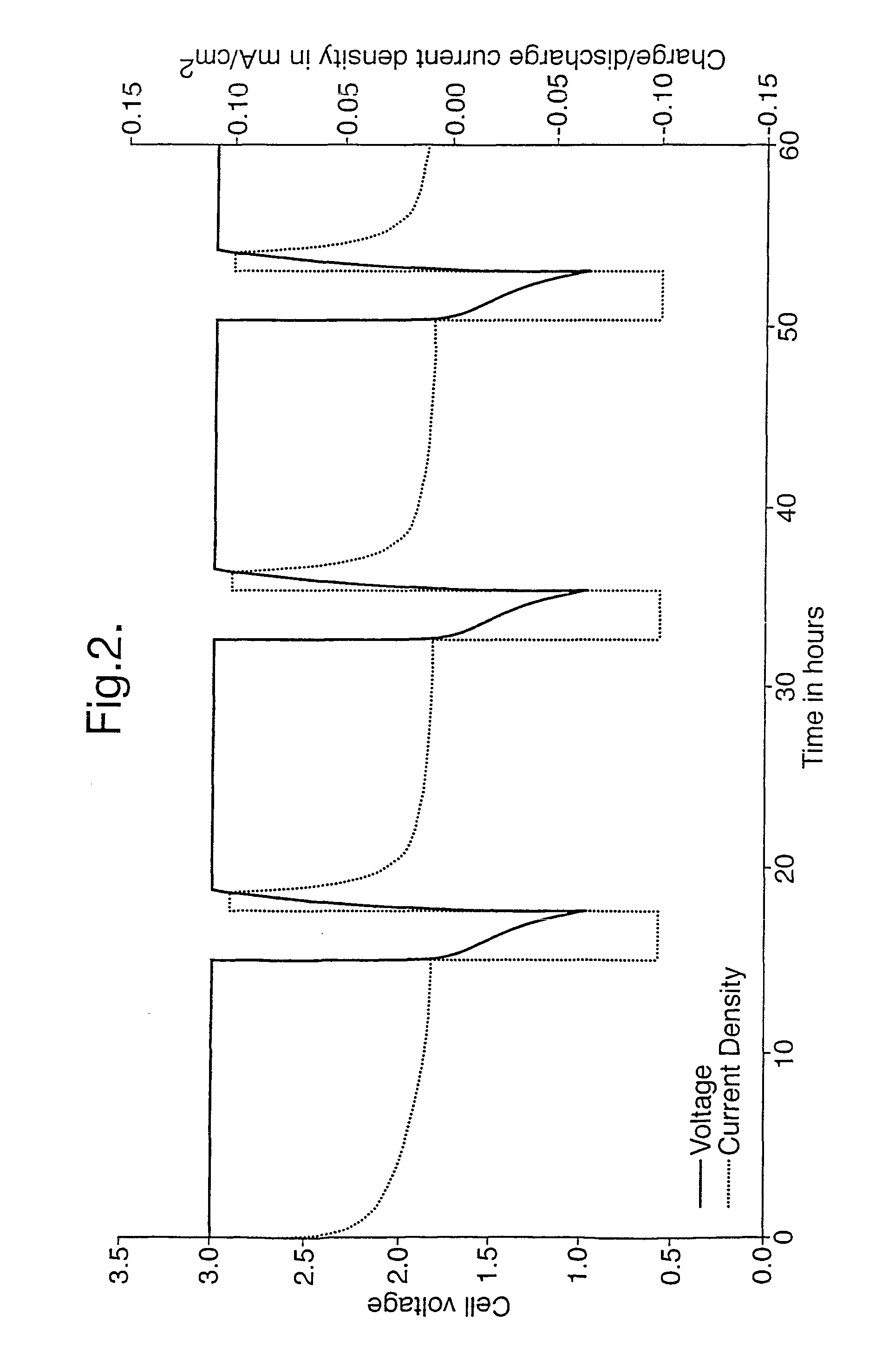

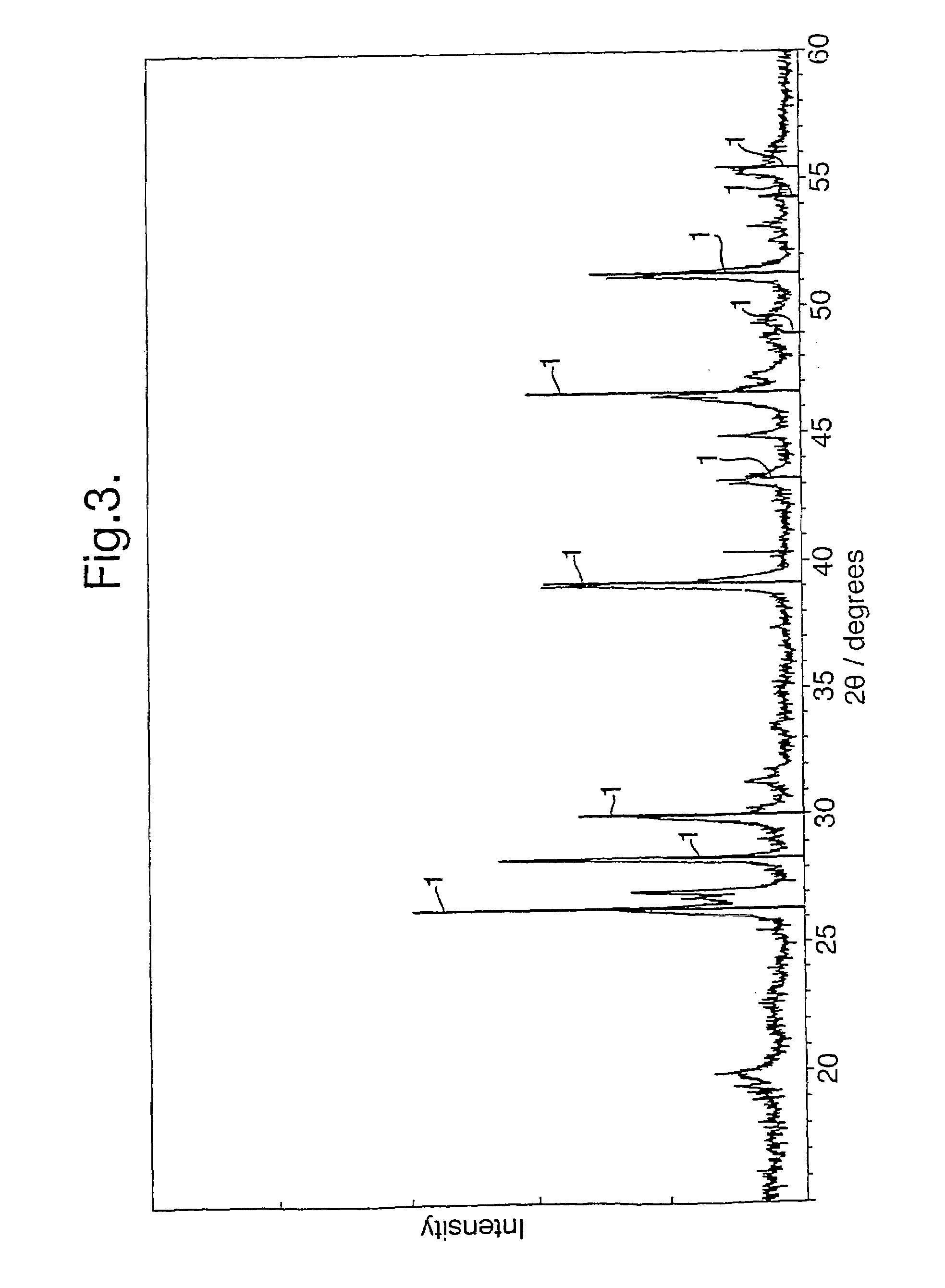

Synthesis of lithium iron sulphides and their use as cathodes

A process for the production of a lithium transition metal sulphide such as lithium iron sulphide, the process comprising reacting a transition metal sulphide with lithium sulphide in a solvent comprising a molten salt or a mixture of molten salts. Lithium transition metal sulphides obtained using this process are useful in the production of electrodes, in particular for rechargeable lithium batteries.

Owner:QINETIQ LTD

Preparing method for two-dimensional material

ActiveCN106219608AHigh yieldHigh activityTitanium sulfidesGrain treatmentsFiltrationEconomic benefits

The invention discloses a preparing method for a two-dimensional material. According to the method, the ball milling technology and the liquid-phase ultrasonic stripping technology are combined to prepare the two-dimensional material, and meanwhile, the method of combining centrifugal separation and vacuum filtration is adopted for separating the two-dimensional material and a stripping solvent. The two-dimensional material prepared with the method has the advantages of being high in purity and yield and the like, and materials used in the method can be reused. The method is free of pollution to the environment, high in production efficiency and good in economic benefit. The two-dimensional material prepared with the method can be used for the fields such as photoelectric detection, catalysis, energy storage, lubrication, gas detection and superconduction.

Owner:广东一纳科技有限公司

Method for preparing two-dimensional inorganic nanomaterial by mechanical force intercalation stripping

InactiveCN109250693AImprove stripping efficiencyShort manufacturing timeRare earth metal oxides/hydroxidesNitrogen compoundsHigh energyCrystal structure

The invention relates to the technical field of inorganic nanomaterial preparation, and in particular, relates to a method for preparing a two-dimensional inorganic flaky nanomaterial by mechanical force intercalation stripping of a three-dimensional inorganic layered crystal material. With mixed metal halide as an intercalation and stripping medium, the purified layered inorganic crystal materialand the intercalation and stripping medium are subjected to solid-phase high-energy ball milling treatment together, mixed powder after ball milling treatment is washed with water to remove the intercalation and stripping medium, the three-dimensional layered material can be highly efficiently made into the corresponding two-dimensional flaky material. The method has universality for stripping ofthe inorganic non-metallic layered crystal material, has the advantages of simple preparation process, short production cycle, and high yield of the two-dimensional material, does not affect a crystal structure of the two-dimensional material, and the intercalation and stripping medium can be reused without causing environmental pollution.

Owner:深圳烯材科技有限公司

Two-dimensional material nanometer roll as well as preparation method and application thereof

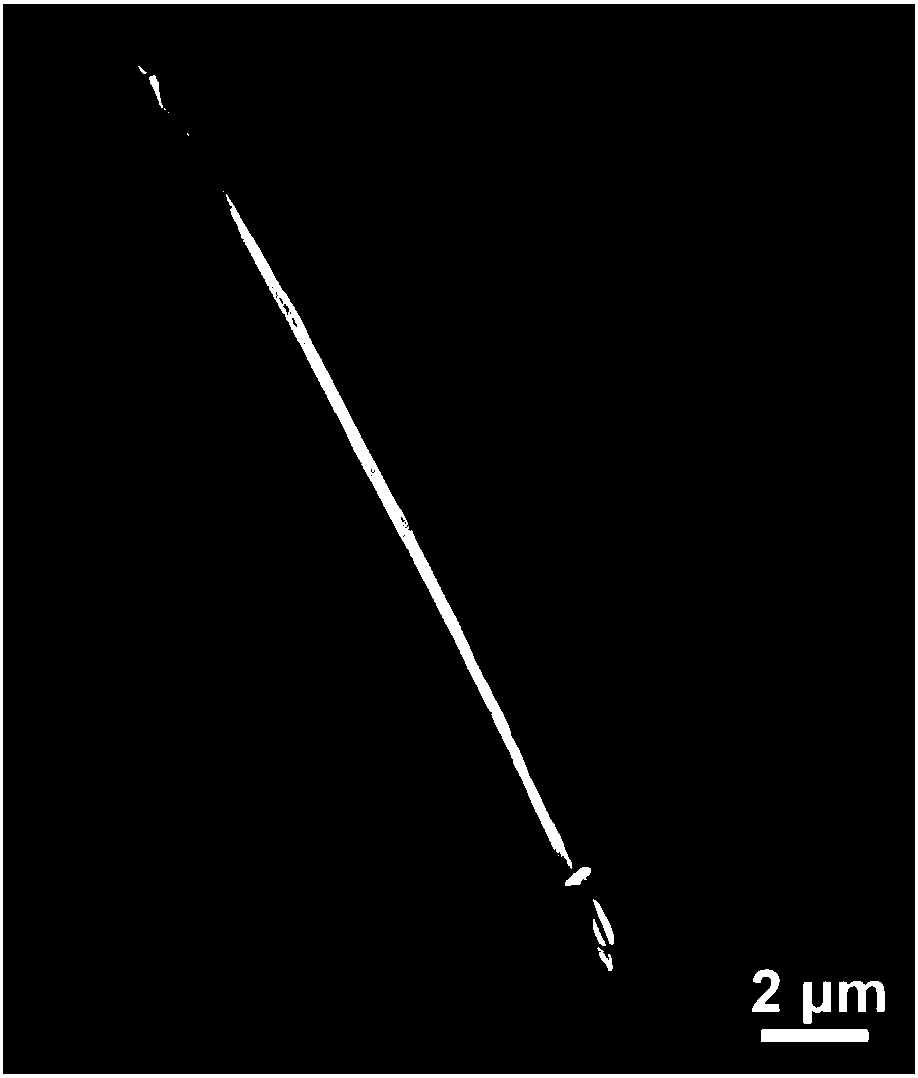

InactiveCN108217608ASimple and flexible operationLower synthesis costMaterial nanotechnologyTantalum compoundsField-effect transistorNanomaterials

The invention relates to the field of a nanometer material and preparation thereof, and discloses a two-dimensional material nanometer roll as well as a preparation method and application thereof, wherein the two-dimensional material nanometer roll is obtained by soaking and / or dripping and coating a solution onto the surface of a two-dimensional material thin film and thus automatically curling the two-dimensional material thin film, wherein the two-dimensional material nanometer roll is in a hollow rod shape; the length is 50nm to 1cm; the outer diameter is 5 to 500nm; the inner hollow layerdiameter is 2 to 100 nm; the layer space is 0.3 to 10 nm. The migration rate of a prepared field effect transistor based on the two-dimensional material nanometer roll is 8 to 4000 cm / (V.sec). By using the method, the two-dimensional material nanometer roll with high quality can be prepared at high yield. In addition, the operation of the method is simple and flexible; the synthesis cost is low;the reaction time is short.

Owner:INST OF CHEM CHINESE ACAD OF SCI

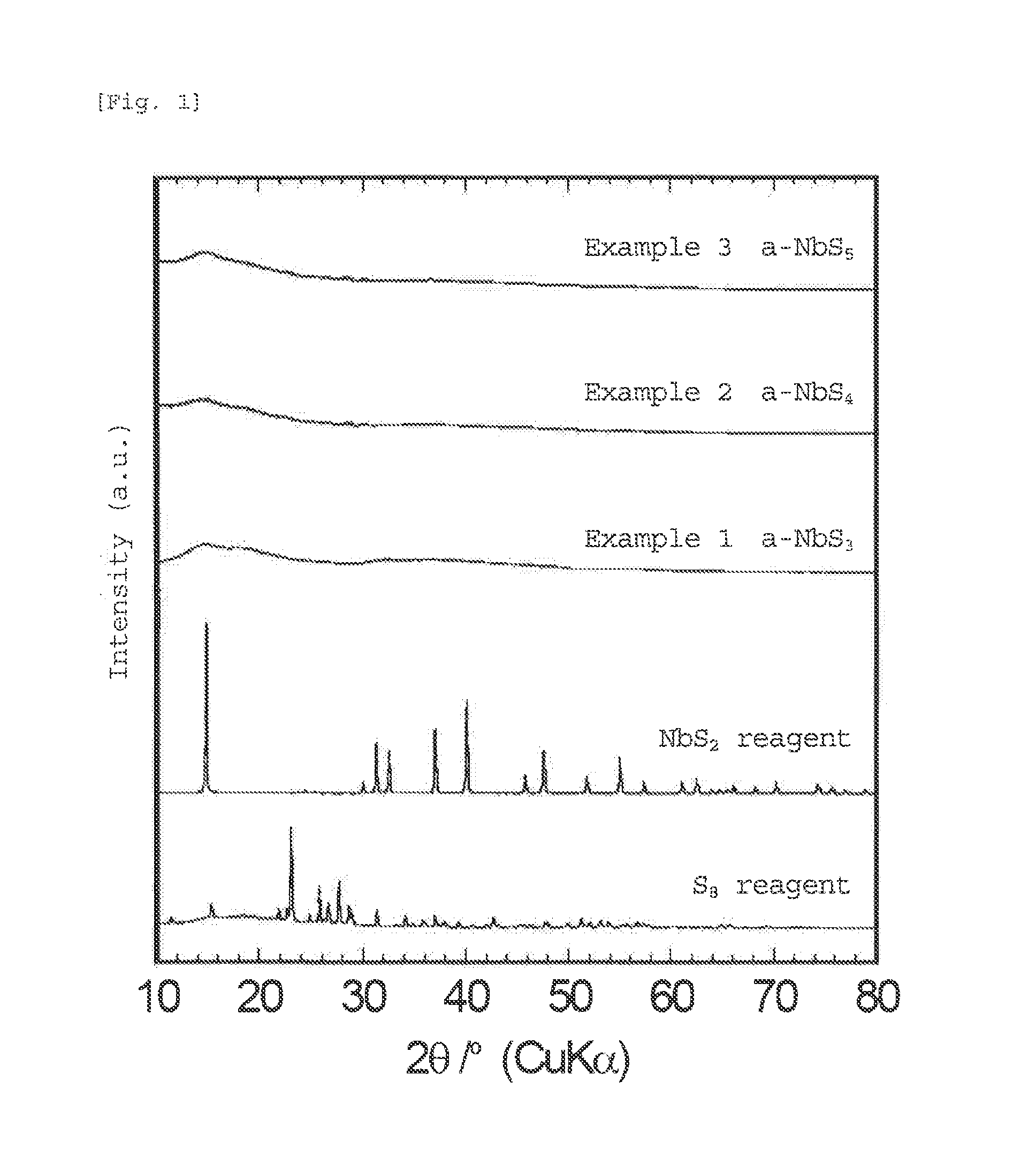

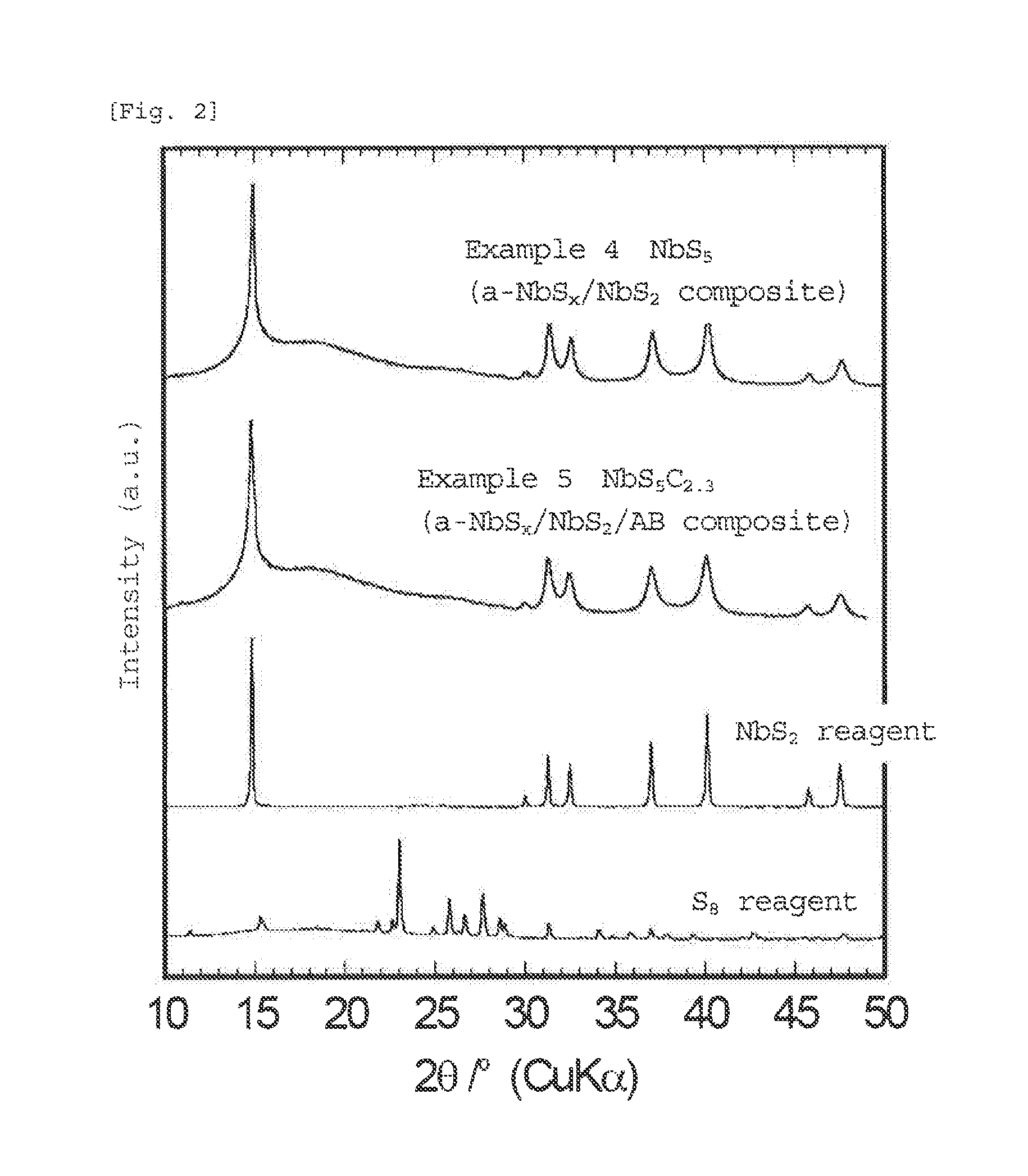

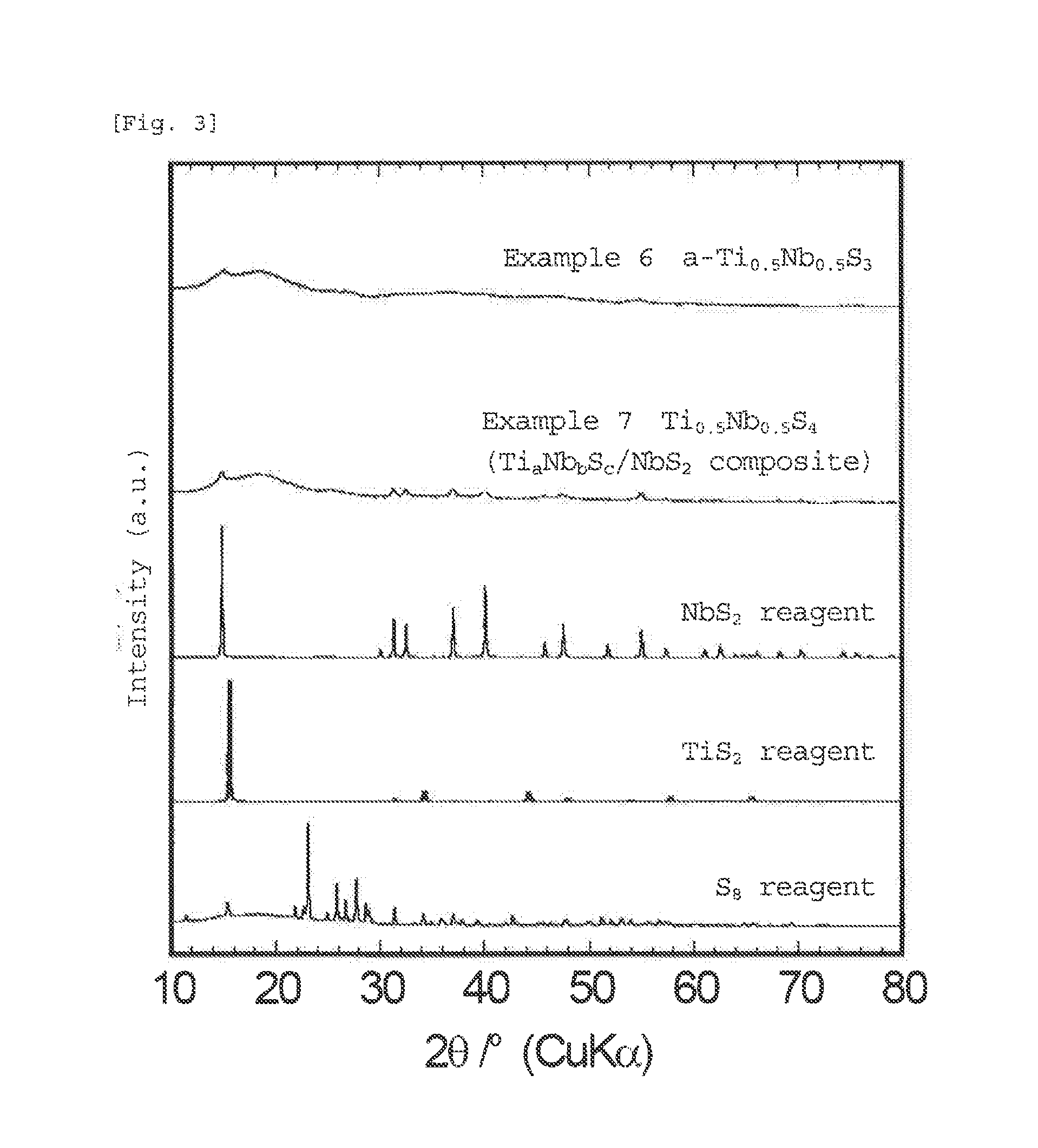

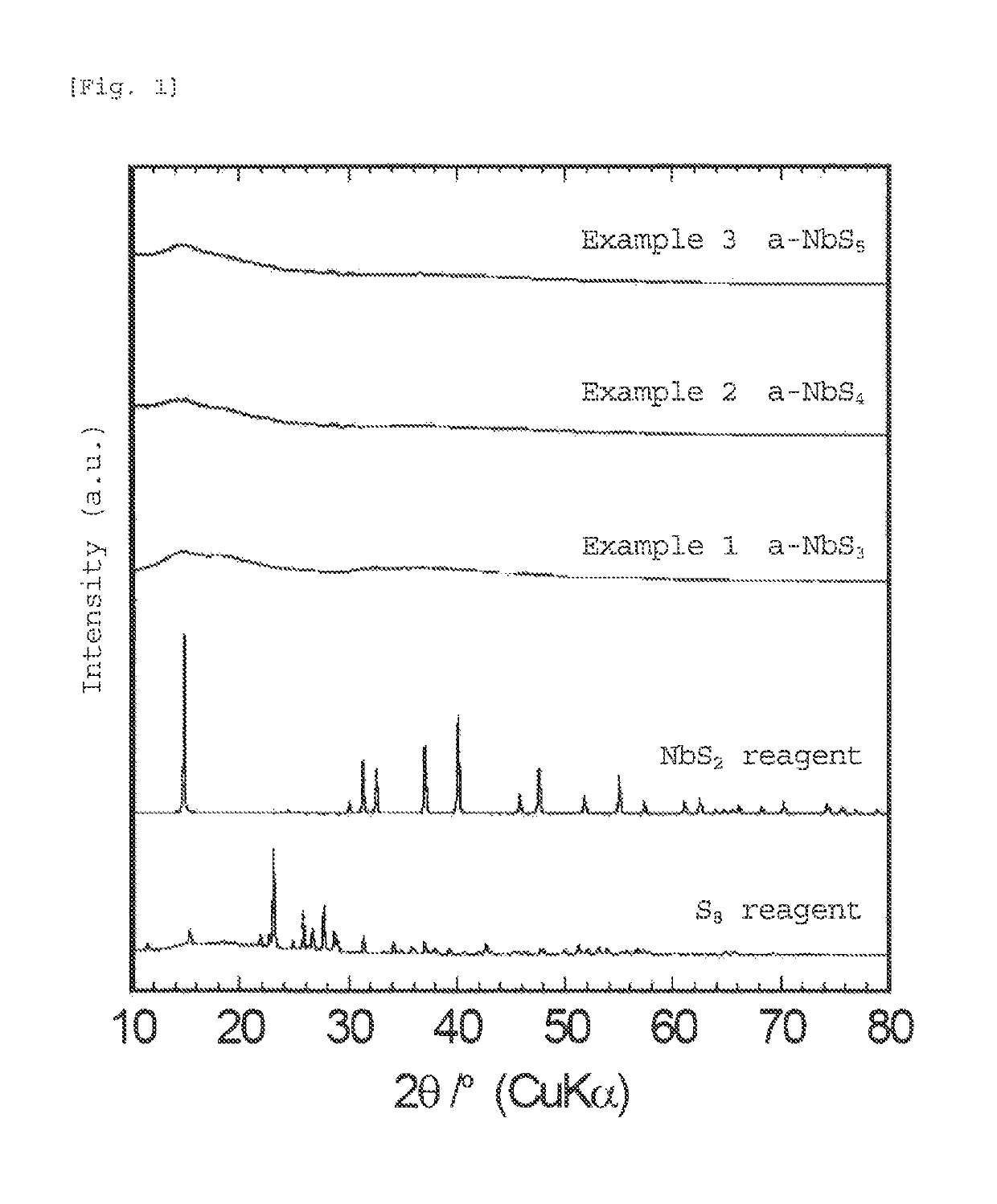

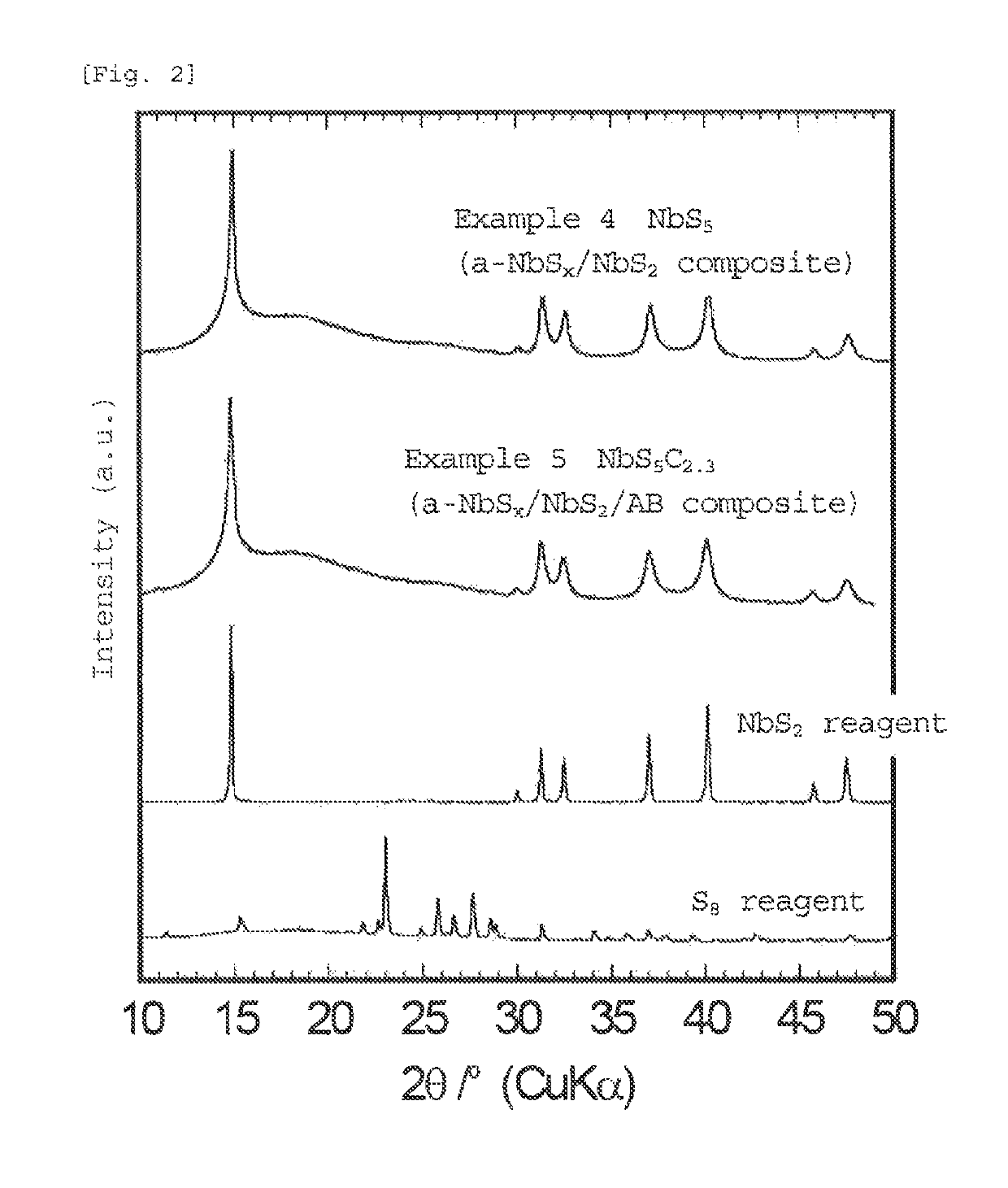

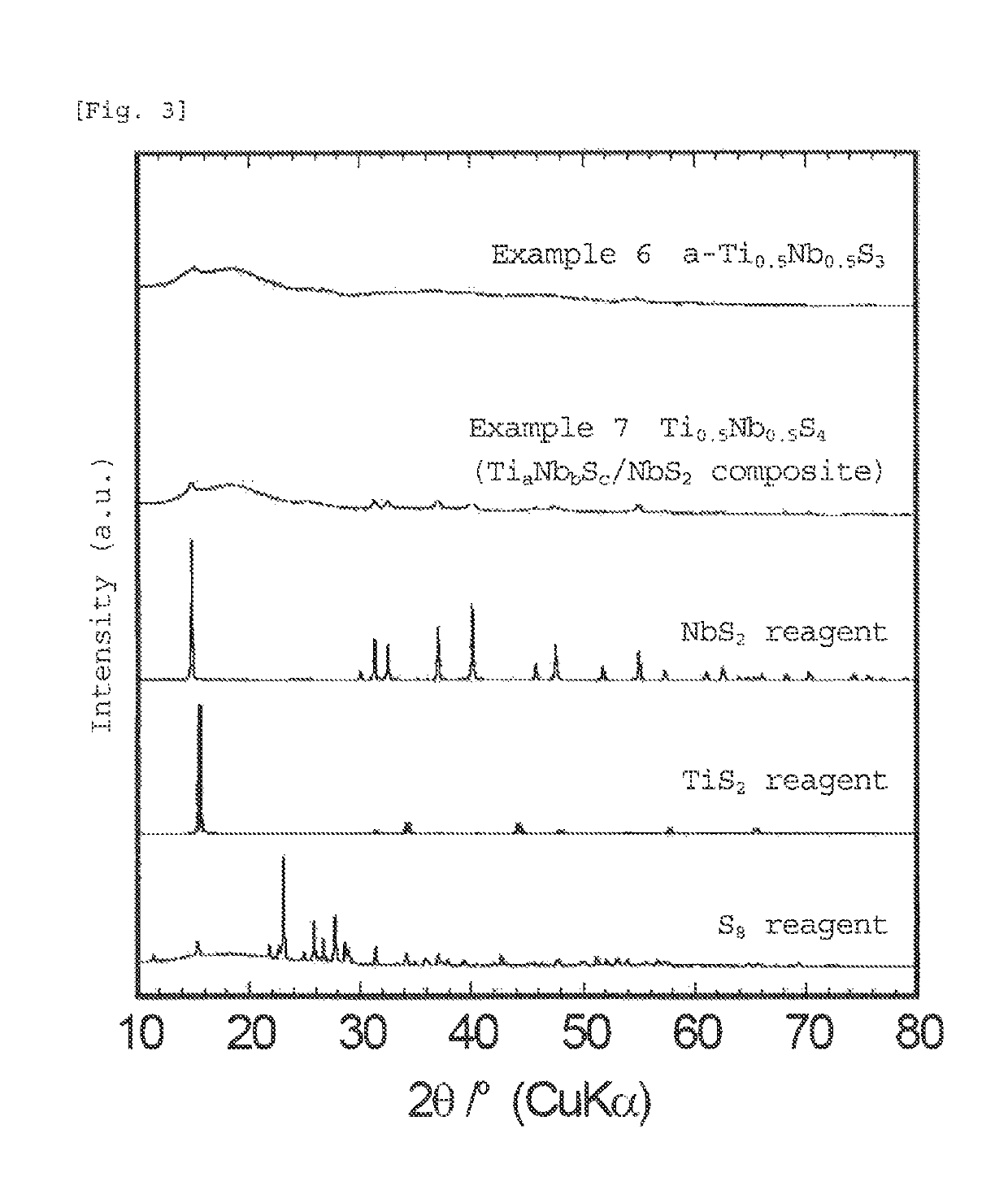

Amorphous (Lithium) Sulfide or (Lithium) Titanium Niobium Sulfide

ActiveUS20160308210A1Raise the ratioHigh charge and discharge capacityTitanium sulfidesPositive electrodesNiobiumTitanium

The sulfide of the present invention comprises an amorphous (lithium) niobium sulfide having an average composition represented by formula (1): Lik1NbSn1 (wherein 0≦k1≦5; 3≦n1≦10; and when n1≧3.5, k1≦0.5), or an amorphous (lithium) titanium niobium sulfide having an average composition represented by formula (2): Lik2Ti1-m2Nbm2Sn2 (wherein 0≦k2≦5; 0<m2<1; 2≦n2≦10; and when n2≧3.5, k2≦1.5). The sulfide of the present invention is a material that is useful as a cathode active material for lithium batteries, such as lithium primary batteries, lithium secondary batteries, and lithium ion secondary batteries, and has a high charge-discharge capacity, high electrical conductivity, and excellent charge-discharge performance.

Owner:NAT INST OF ADVANCED IND SCI & TECH

Process And Apparatus For Producing Inorganic Fullerene-Like Nanoparticles

ActiveUS20080170984A1Easy to produceImprove abilitiesMaterial nanotechnologyNanostructure manufactureGas phaseOxohalide

The present invention provides a process for obtaining fullerene-like metal chalcogenide nanospheres, comprising: (a) feeding a metal halide, metal carbonyl, organo-metallic compound or metal oxyhalide vapor into a reacting chamber towards a reacting zone to interact with a flow of at least one chalcogen material in gas phase, the temperature conditions in said reacting zone being such enabling the immediate formation of spherical nucleation seeds of the product; (b) controllably varying the flow of said metal halide, metal carbonyl, organo-metallic compound or metal oxyhalide vapor into said reacting chamber thereby controlling the amount, morphology and size of the so-produced nanospheres, to obtain substantially non-hollow fullerene-like metal calcogenide nanospheres in solid form. The present invention further provides novel IF metal chalcogenides with substantially non-hollow, spherical shape, and having excellent tribological behaviour. The present invention also provides an apparatus for preparing various IF nanostructures.

Owner:A Y Y T TECHCAL APPL & DATA UPDATE +1

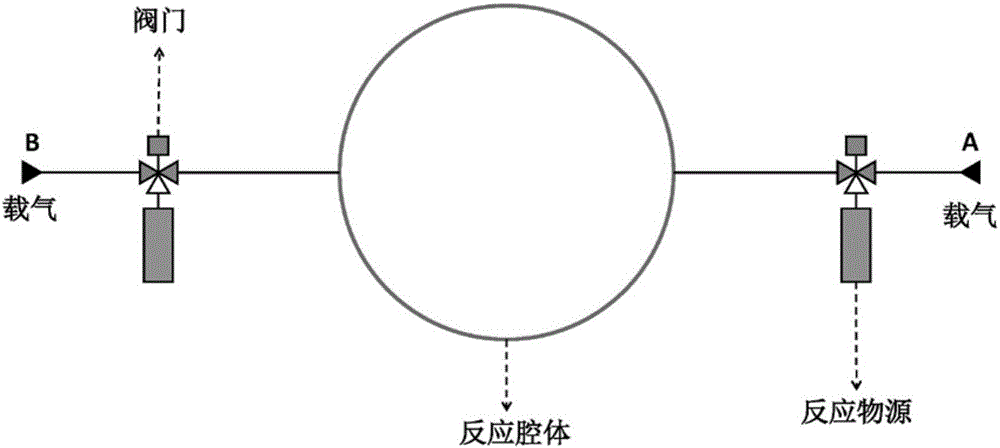

Method for growing single-layer and multi-layer transition metal sulfides through alternating injection of reactants

InactiveCN105800566ARealize large area preparationPrecise and controllable growth conditionsTitanium sulfidesSulfide/polysulfide preparationReaction temperatureMetallic sulfide

The invention discloses a method for growing single-layer and multi-layer transition metal sulfides through alternating injection of reactants. By the adoption of the method, deposition reaction of the reactants is achieved alternately, the number of layers and area of grown transition metal sulfides are controlled by controlling reaction temperature and time, and layered transition metal sulfides high in quality are obtained. The method has the advantages that growth condition is accurate and controllable, operation is easy and convenient, and large-area preparation of transition metal sulfides can be achieved. The method has broad application prospects in fields such as nano-electronical appliances, lubricating materials and photocatalysis.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

Cathode active material, and cathode and magnesium battery including the same

Owner:SAMSUNG ELECTRONICS CO LTD +1

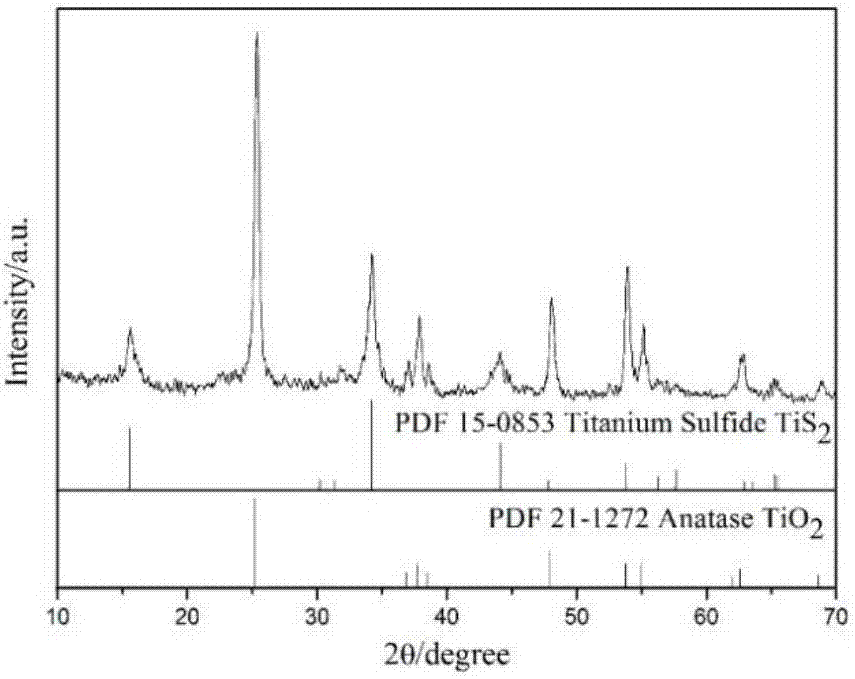

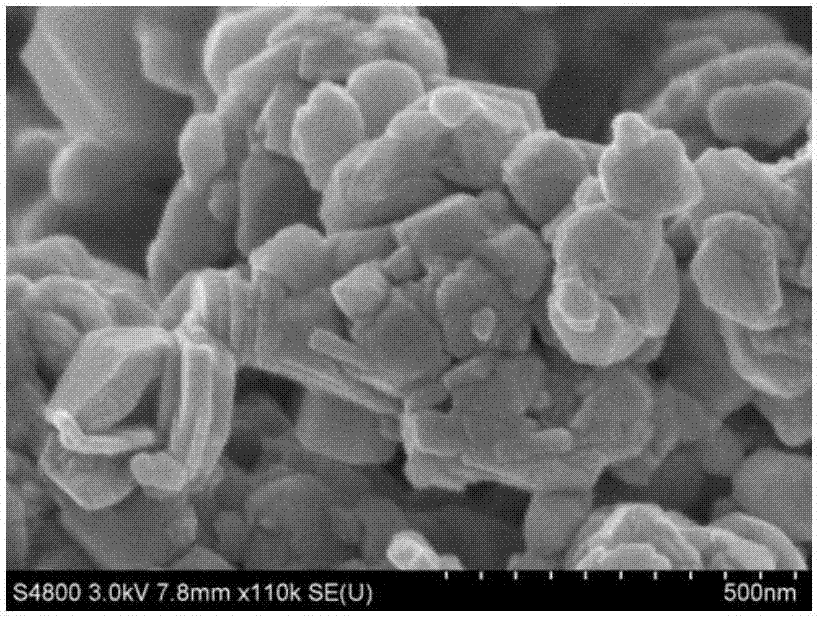

Method for synthesizing titanium dioxide/ titanium disulfide composite material by using one-step vulcanization method

InactiveCN107337233AEasy to prepareShort cycleMaterial nanotechnologyTitanium sulfidesTitanium disulfideVulcanization

The invention discloses a method for synthesizing a titanium dioxide (TiO2) / titanium disulfide (TiS2) composite material by using an one-step vulcanization method. The method for synthesizing the TiO2 / TiS2 composite material comprises the steps of adding butyl titanate dropwise into an ethanol solution to form a mixed solution A, adding ethanol into deionized water to form a mixed solution B, adding the mixed solution A dropwise to the mixed solution B, and sonicating the obtained mixture with ultrasonic waves to obtain a transparent solution C; adjusting the pH of the solution C to 6, and obtaining a solution D; adding the solution D into a inner container made of polytetrafluoroethylene, and controlling the filling ratio for a reaction; after the reaction is completed, washing, drying, and grinding so as to obtain a TiO2 precursor; placing the TiO2 precursor and thioacetamide in a porcelain boat, and covering the porcelain boat with a cover; putting the whole porcelain boat with the cover into a low-temperature tube furnace for a sintering reaction; after the temperature drops to a room temperature, taking out the sample of TiO2 precursor and thioacetamide, grinding the sample into a powder sample, and obtaining the TiO2 / TiS2 composite material. The method for synthesizing the TiO2 / TiS2 composite material has the advantages of being simple and short in period, the block size of the prepared material is ten to several hundred nanometers, and the prepared material has the advantages of being high in purity, high in crystallinity and even in morphology.

Owner:SHAANXI UNIV OF SCI & TECH

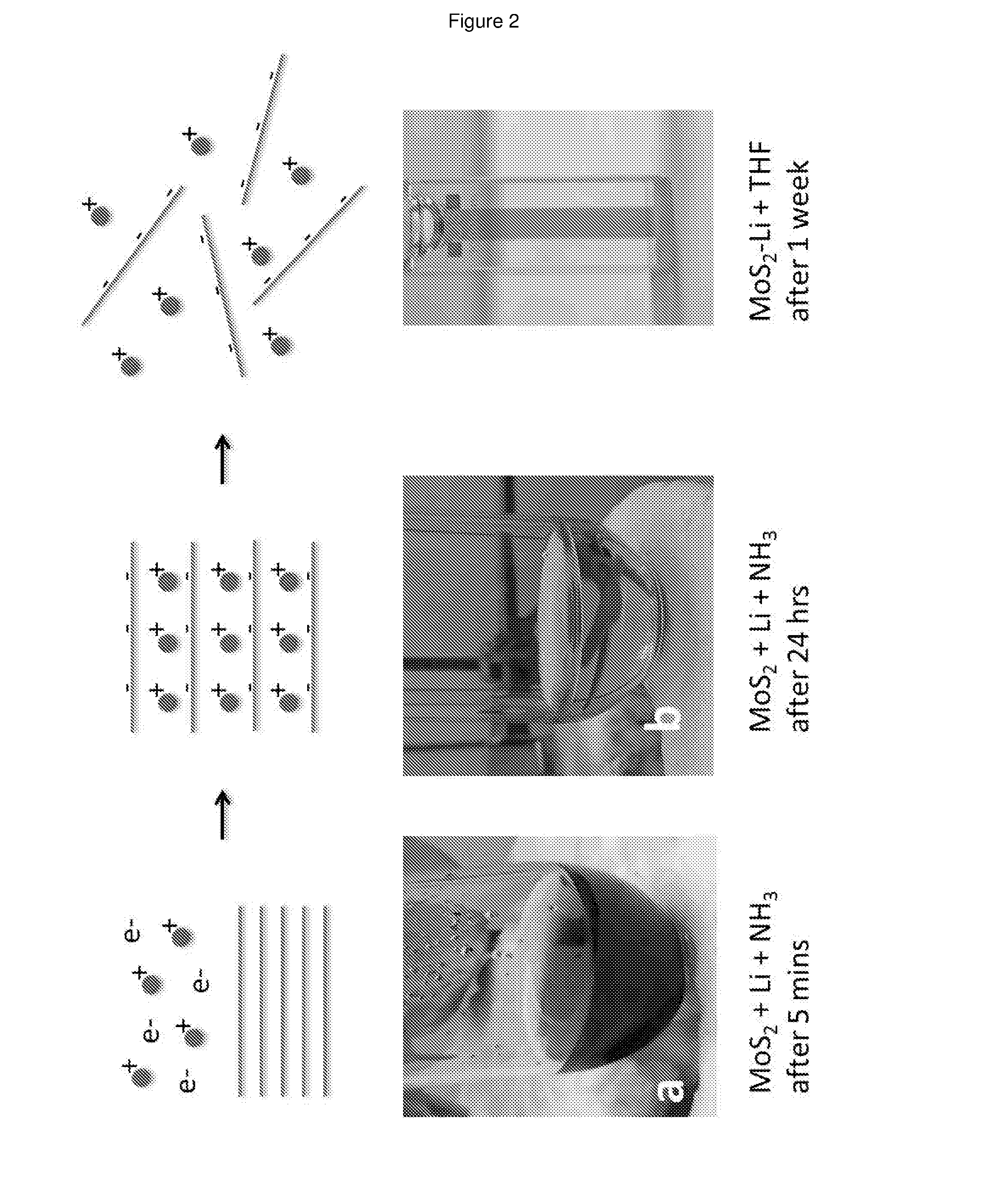

Method for producing dispersions of nanosheets

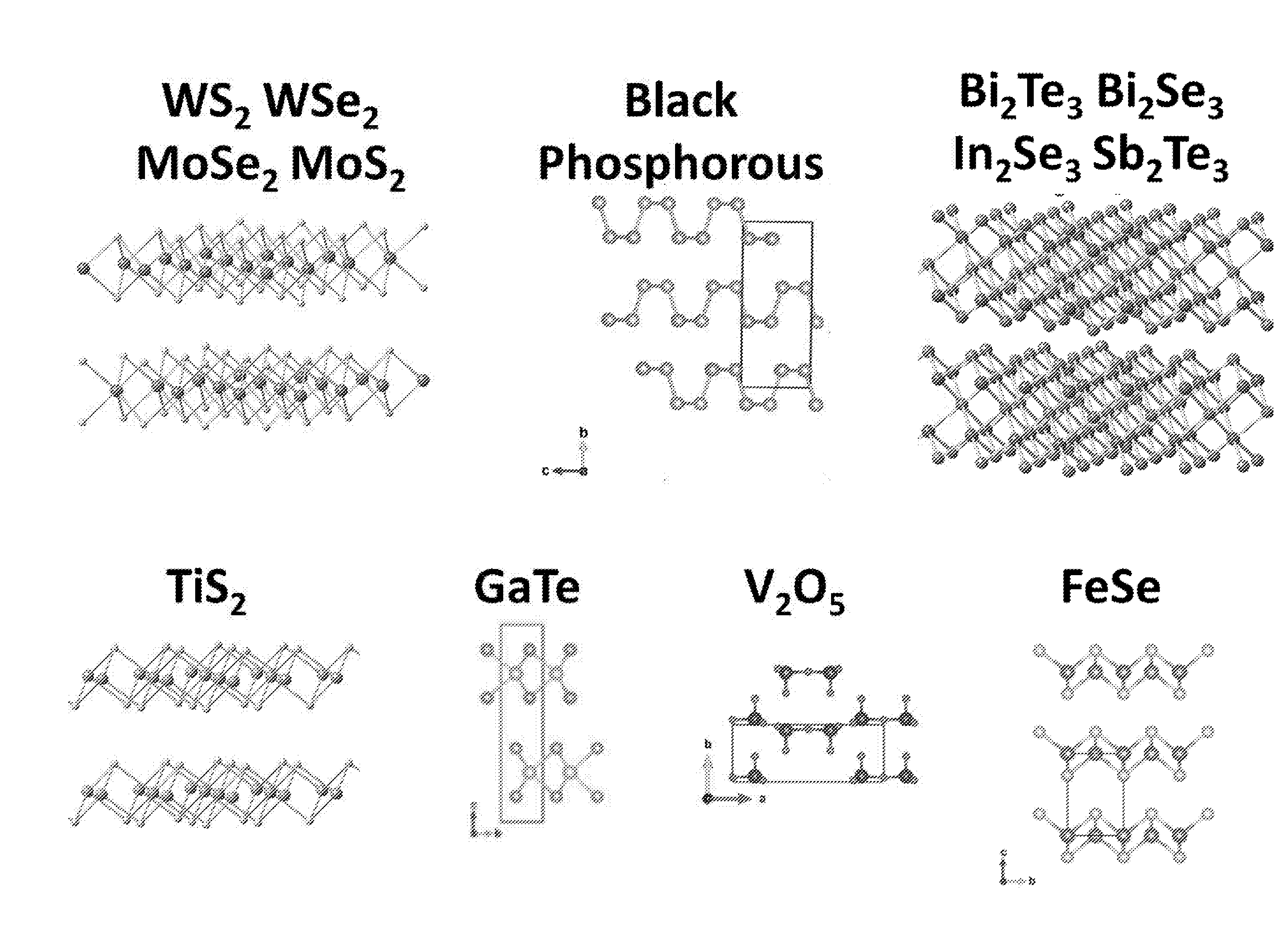

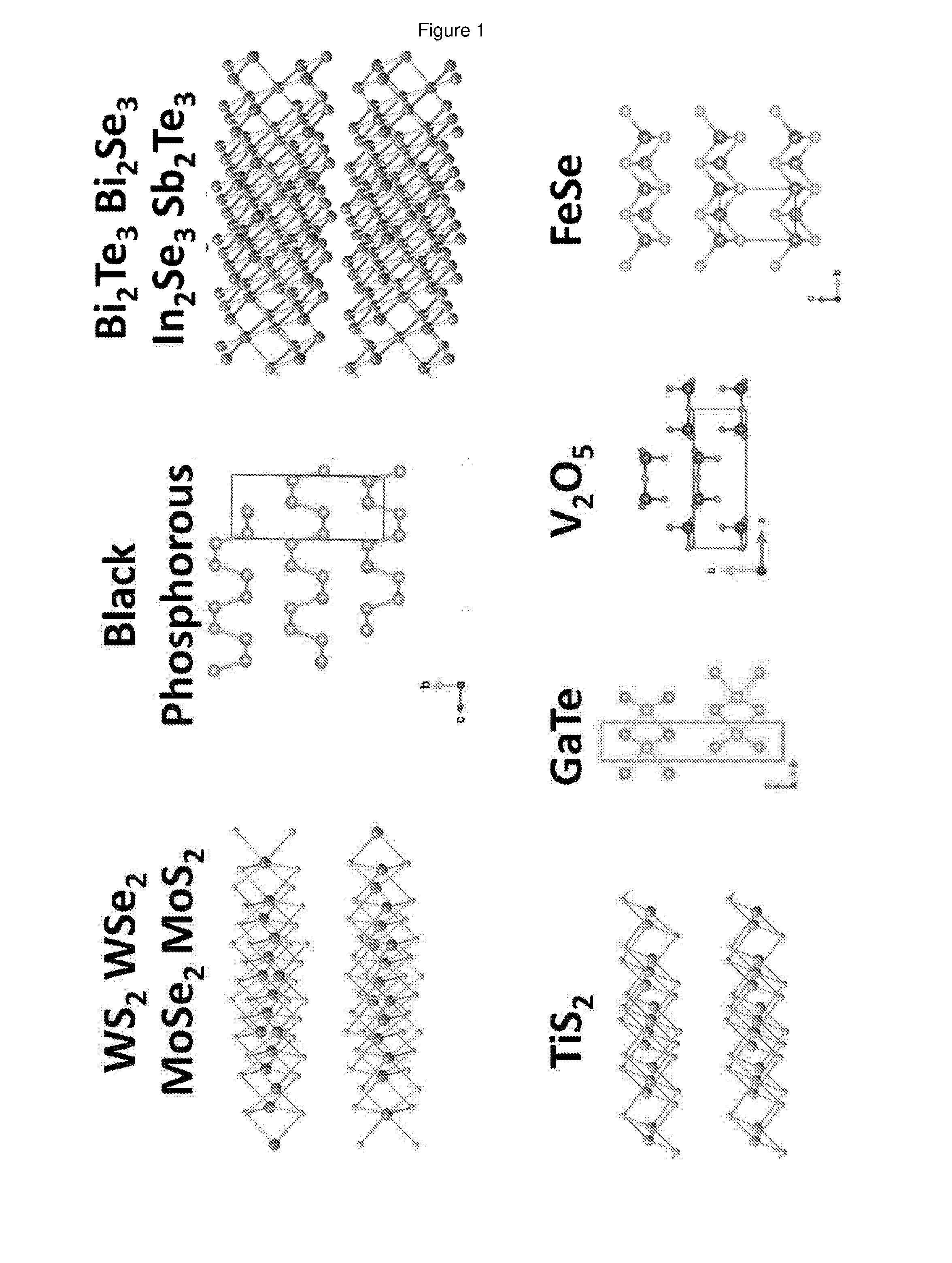

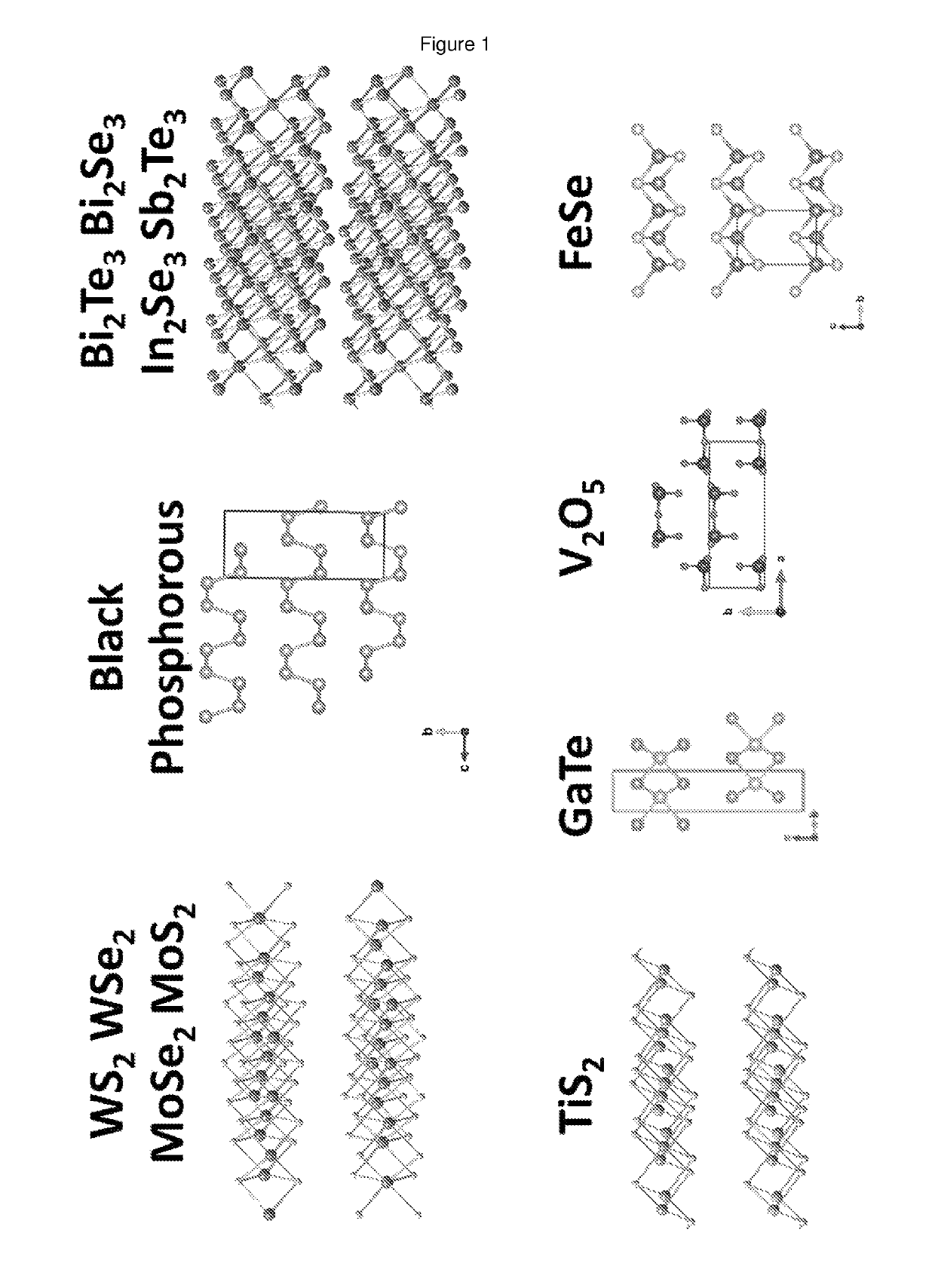

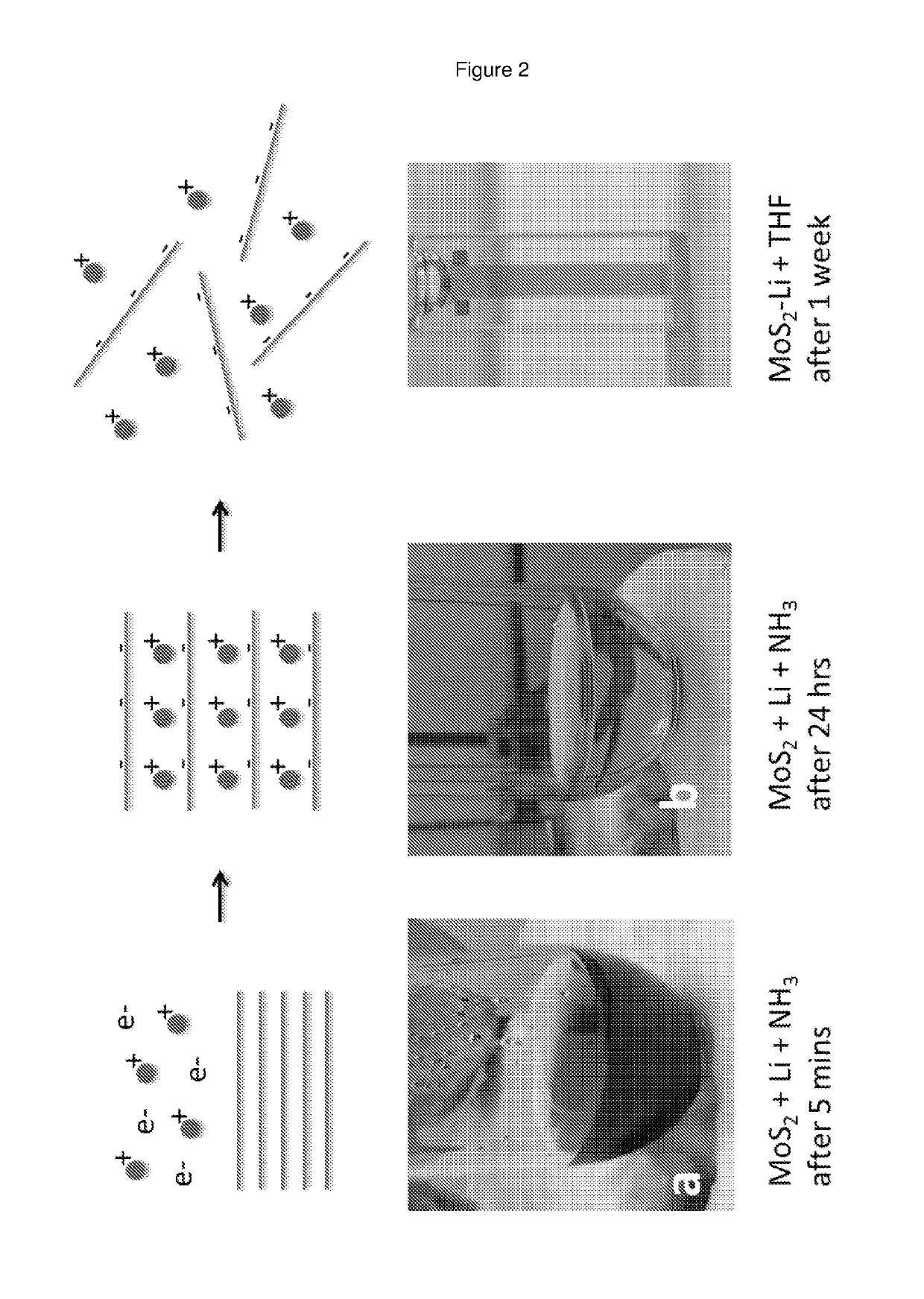

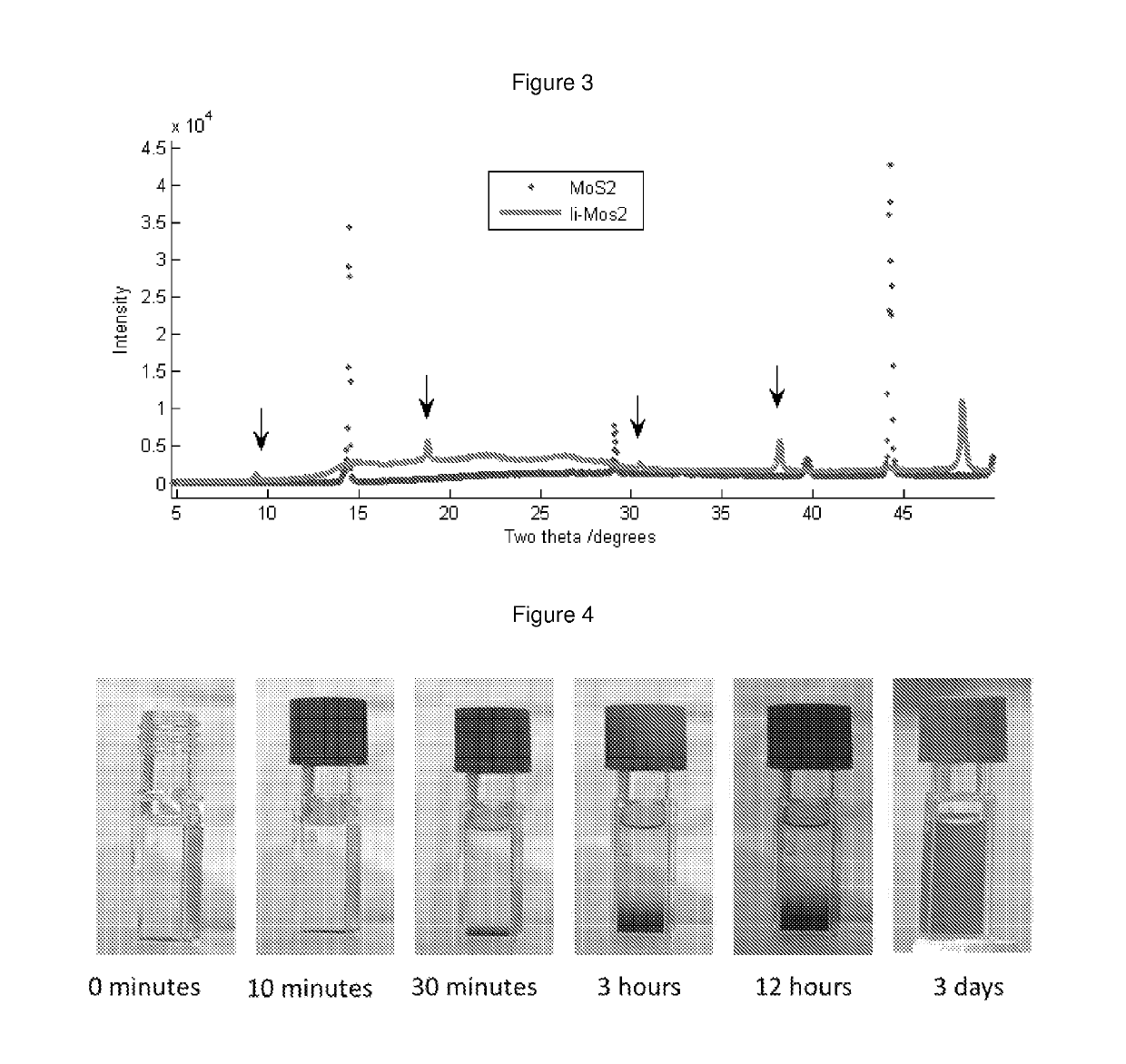

ActiveUS10309027B2Avoiding the damage caused by such an agitation processTantalum compoundsZirconium compoundsSolventOxypnictide

The present invention provides a method for producing a solution of nanosheets, comprising the step of contacting an intercalated layered material with a polar aprotic solvent to produce a solution of nanosheets, wherein the intercalated layered material is prepared from a layered material selected from the group consisting of a transition metal dichalcogenide, a transition metal monochalcogenide, a transition metal trichalcogenide, a transition metal oxide, a metal halide, an oxychalcogenide, an oxypnictide, an oxyhalide of a transition metal, a trioxide, a perovskite, a niobate, a ruthenate, a layered III-VI semiconductor, black phosphorous and a V-VI layered compound. The invention also provides a solution of nanosheets and a plated material formed from nanosheets.

Owner:UCL BUSINESS PLC

A kind of preparation method of two-dimensional material

ActiveCN106219608BHigh yieldHigh activityTitanium sulfidesCarbon compoundsFiltrationEconomic benefits

Owner:广东一纳科技有限公司

Preparation method for preparing two-dimensional layered transition metal sulfide

PendingCN111333040AEasy to getLow priceTitanium sulfidesRare earth metal sulfidesManufactured materialSulfide compound

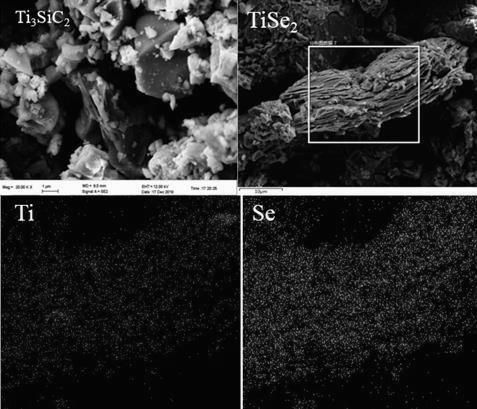

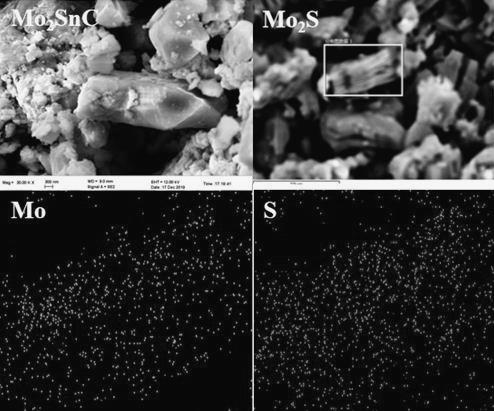

The invention discloses a preparation method for preparing two-dimensional layered transition metal sulfide. The two-dimensional layered transition metal sulfide is mainly an MAX-phase ceramic powderraw material composed of the following elements. Wherein the M element is Ti, Nb, V, Y, Nb, Mo, Ta, W, Hf, Cr and Mn; wherein the element A is Al, Si, Ge, Sn, Ga and Sb; powder of max-phase ceramic ofwhich the X element is B, C, N and Si and powder of MAB-phase ceramic are used as raw materials; in the atmosphere containing H2S, H2Se and H2Te gas, the powder is heated for more than 5 hours withinthe temperature range of 500-1400 DEG C, and organ-shaped TMDCS powder can be obtained after the obtained powder is subjected to ball milling. According to the method, a CVD method and a mechanical stripping high-cost method for preparing the TMDCS are eliminated, an organ-shaped structure which cannot be obtained through the CVD method and the mechanical stripping method can be obtained, the cost is obviously reduced, and application and popularization of a two-dimensional TMDCS material are often facilitated.

Owner:苏州凯发新材料科技有限公司

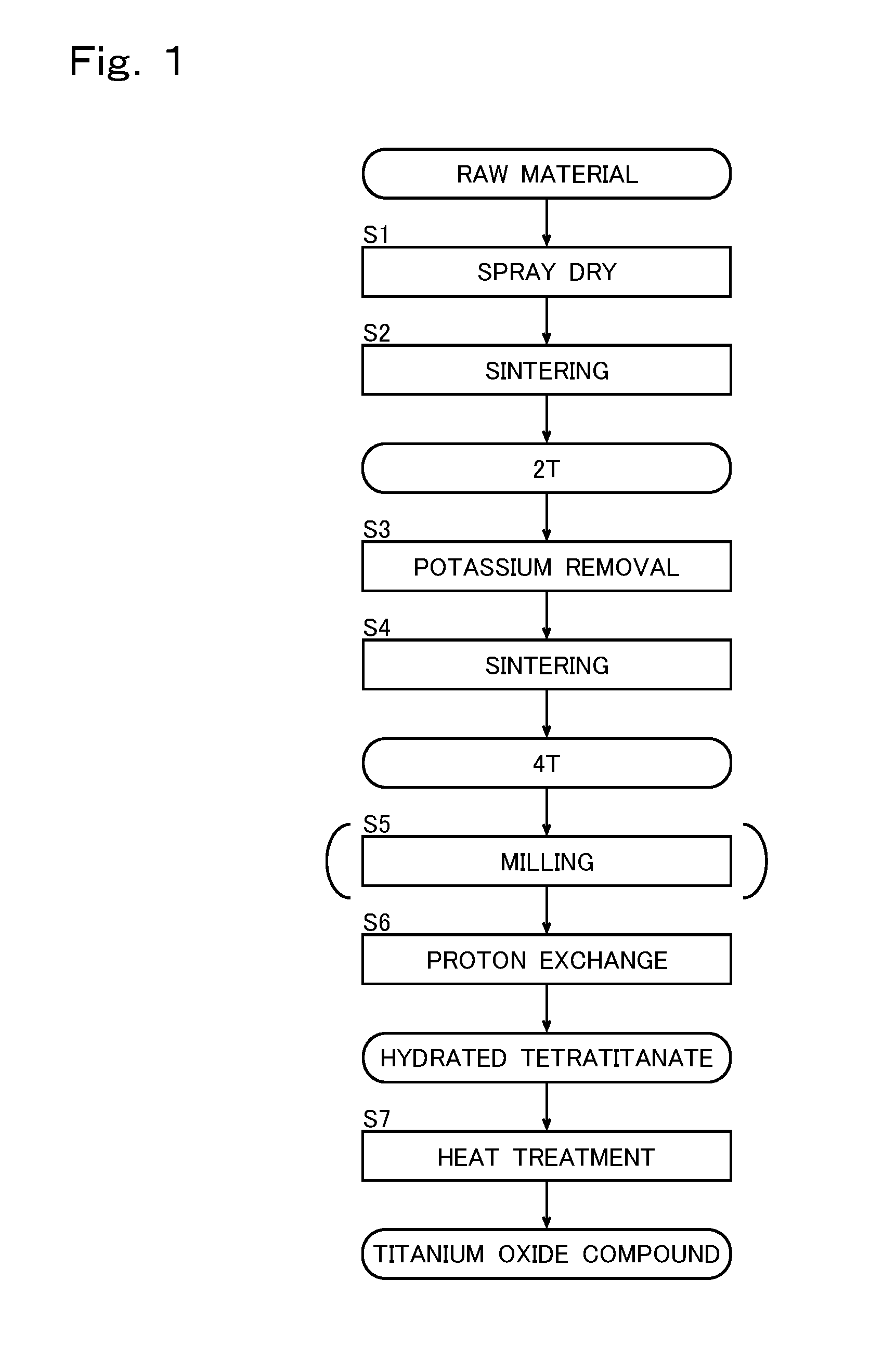

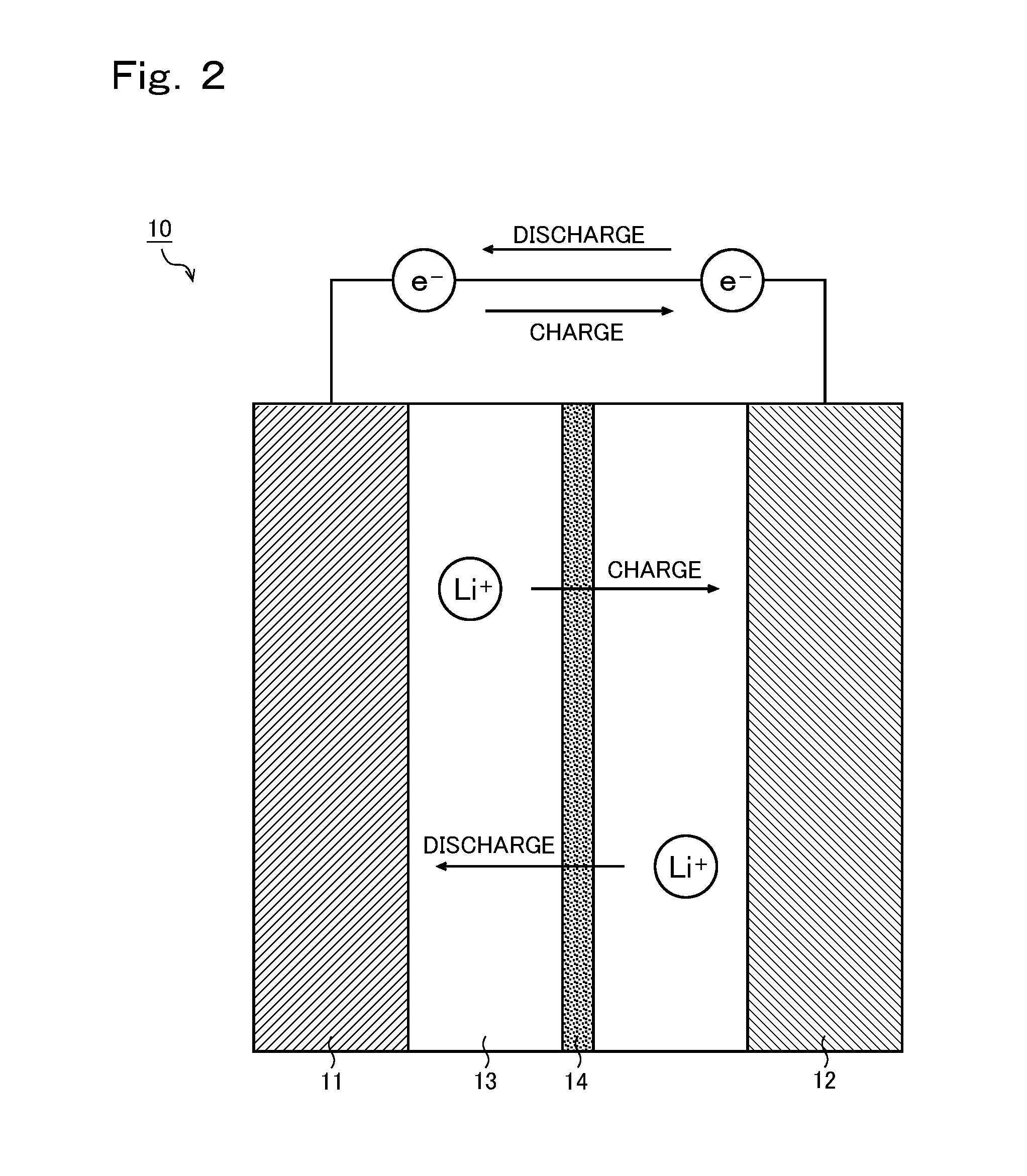

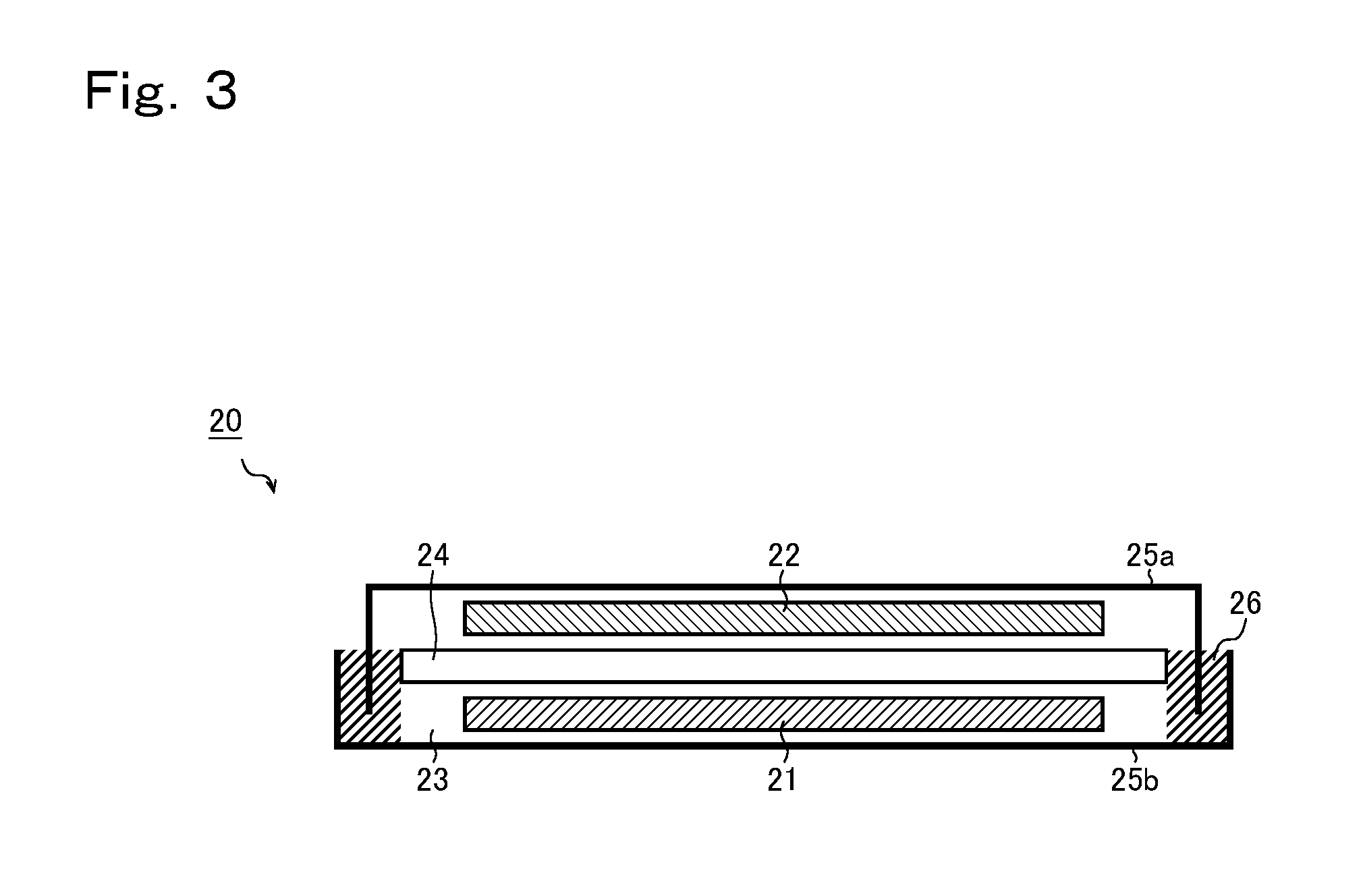

Titanium oxide compound, and electrode and lithium ion secondary battery each manufactured using same

ActiveUS20160043393A1High initial charge/discharge efficiencyDecreasing specific surface areaTitanium sulfidesAlkali titanatesLithiumTitanium

A titanium oxide compound according to the present invention comprises bronze-type titanium oxide or titanium oxide mainly composed of bronze-type titanium oxide, and contains calcium and / or silicon. The titanium oxide compound contains 0.005 to 2.5 mass % inclusive of calcium or 0.15 to 0.55 mass % inclusive of silicon, or contains 0.005 to 1.2 mass % inclusive of calcium and 0.15 to 0.2 mass % inclusive of silicon, or contains 0.005 to 0.1 mass % inclusive of calcium and 0.15 to 0.5 mass % inclusive of silicon.

Owner:KUBOTA LTD

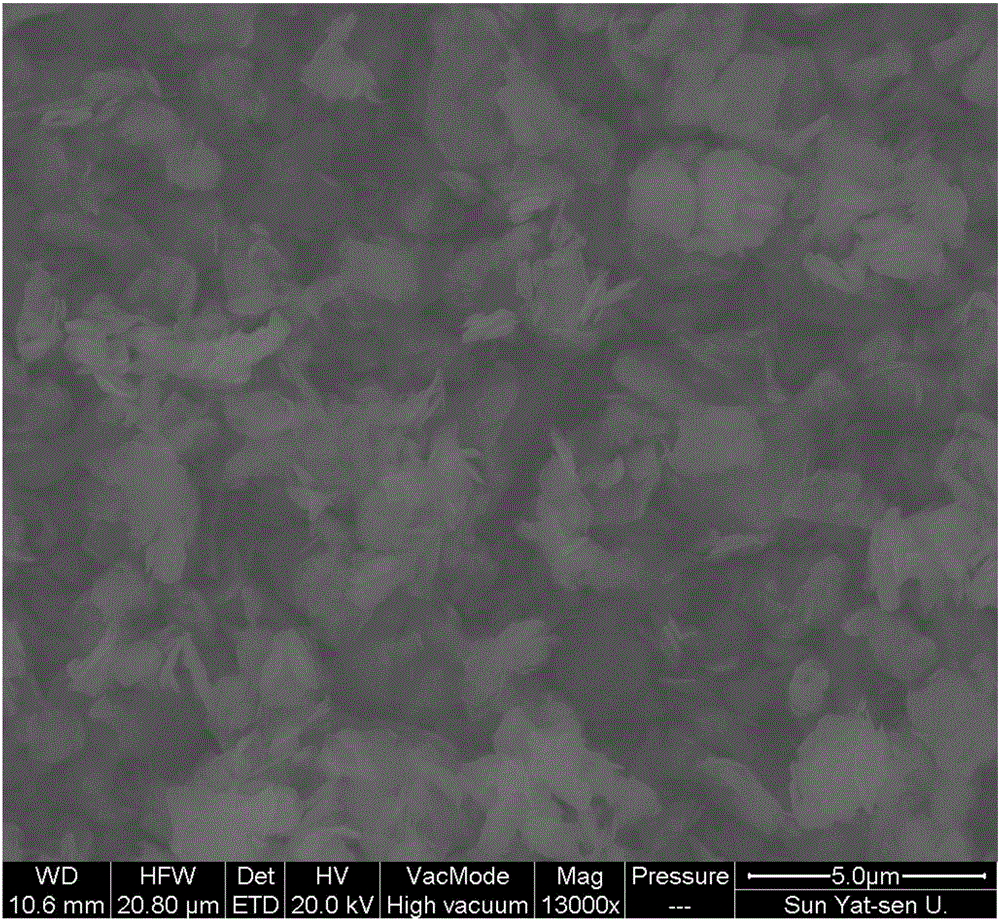

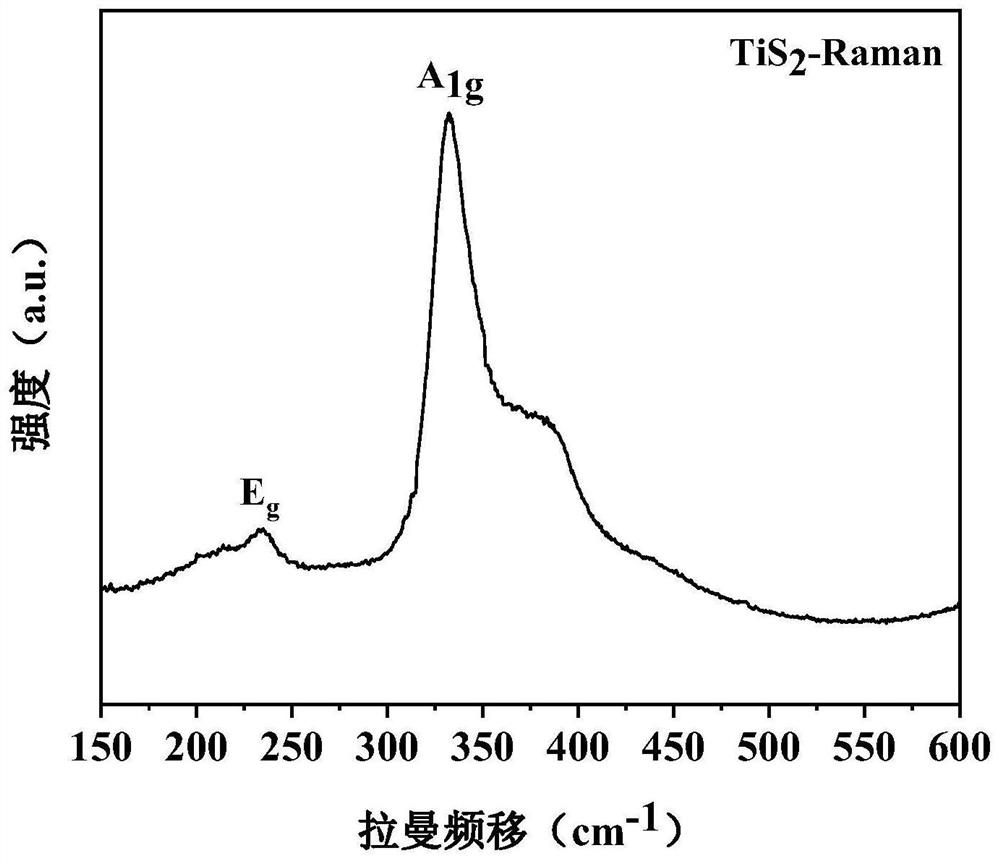

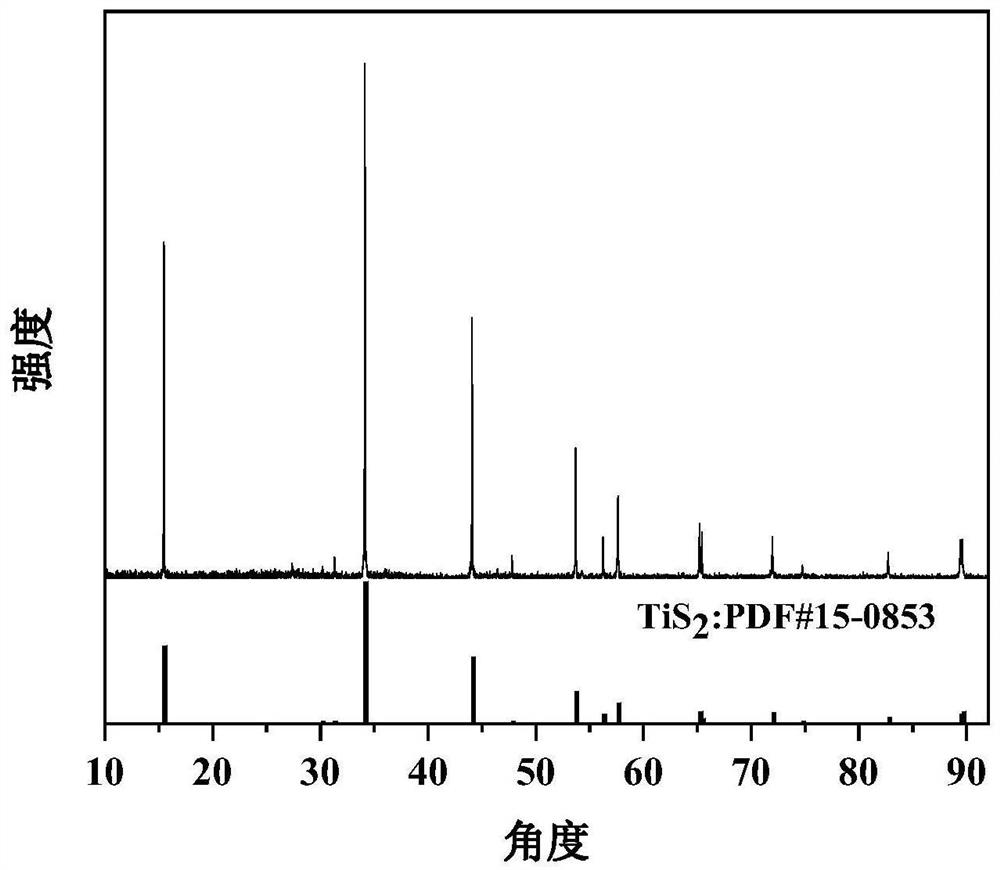

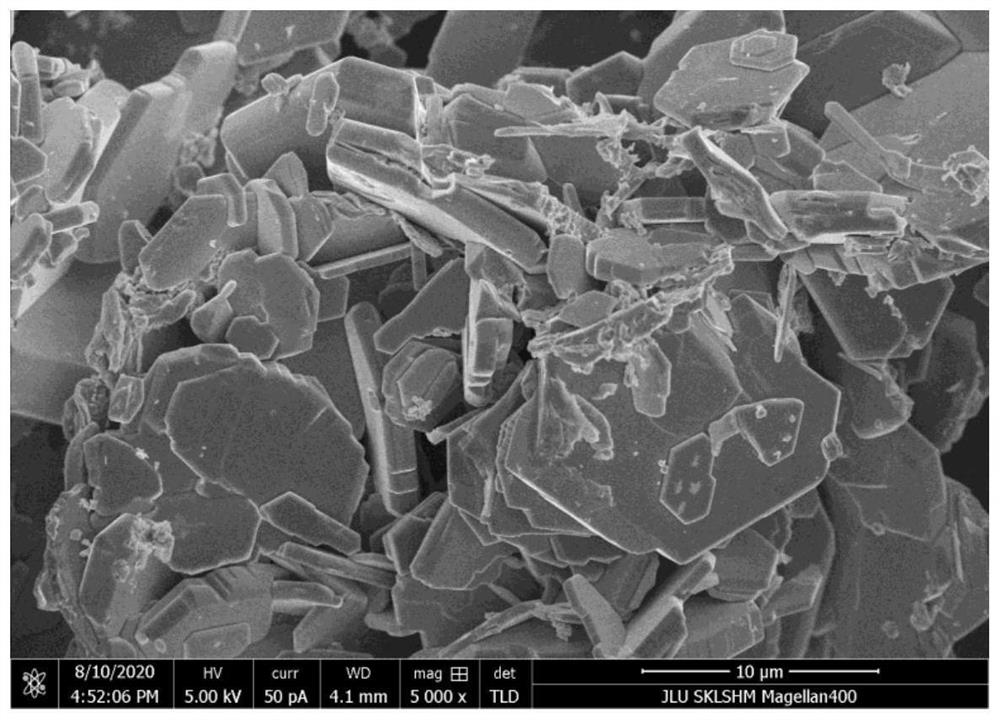

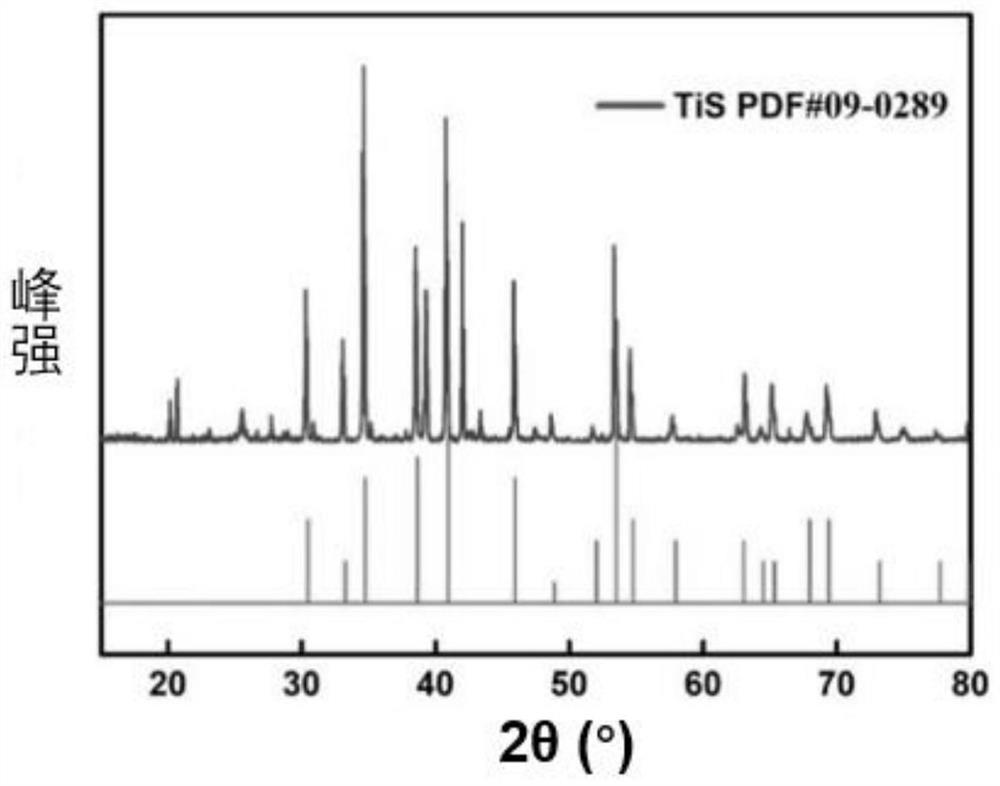

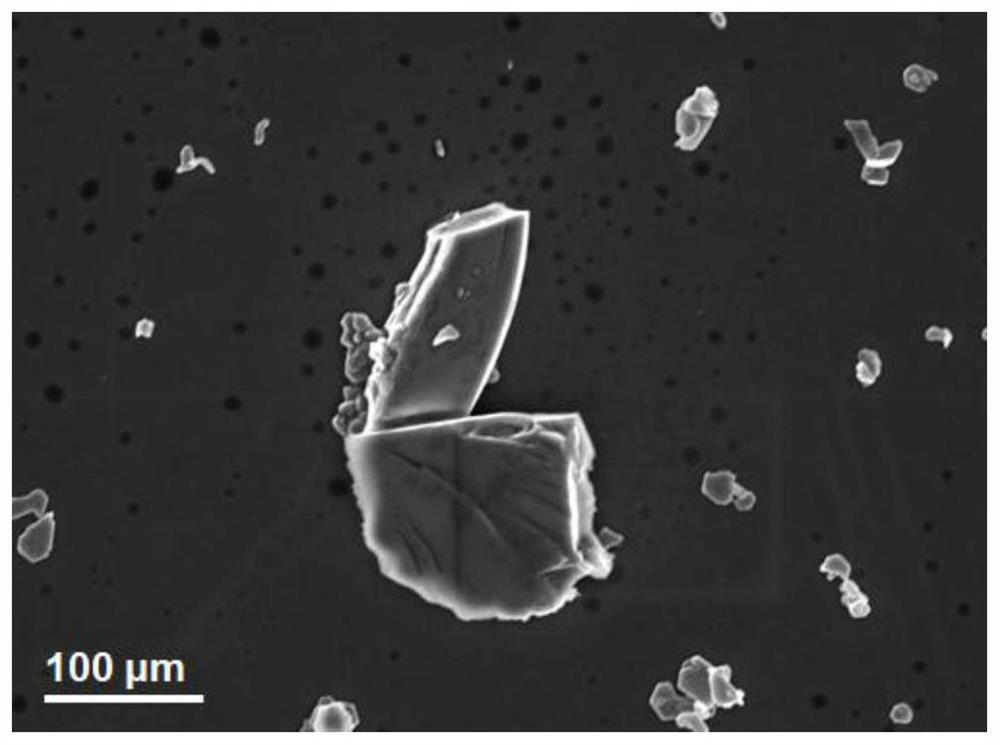

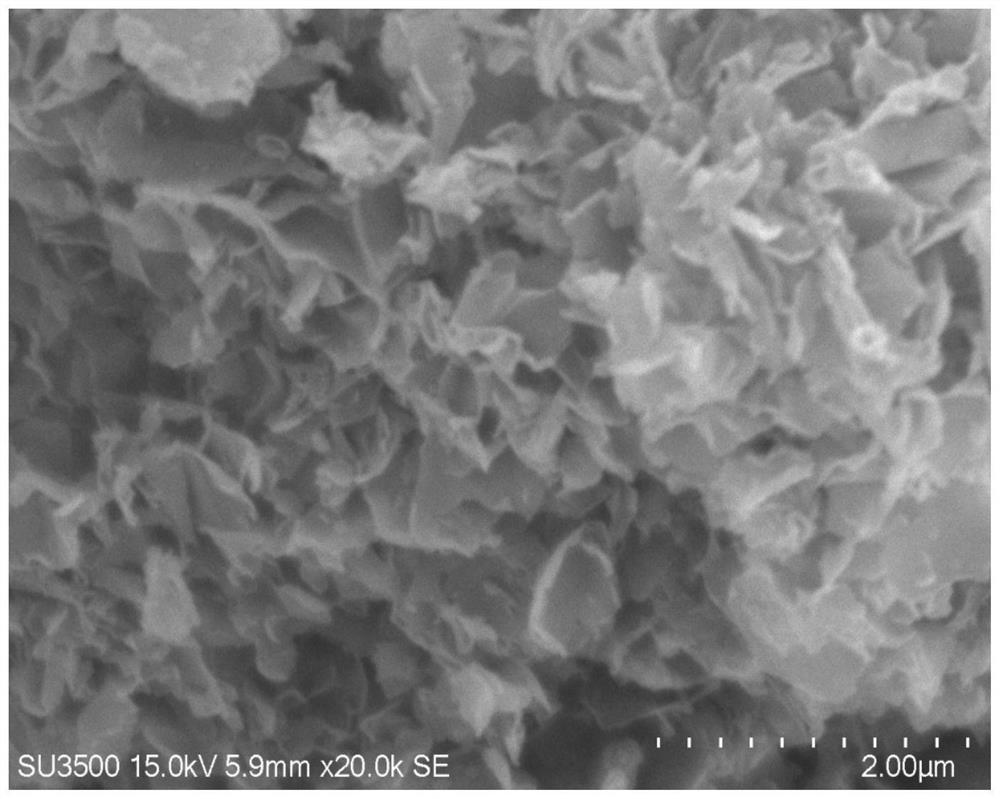

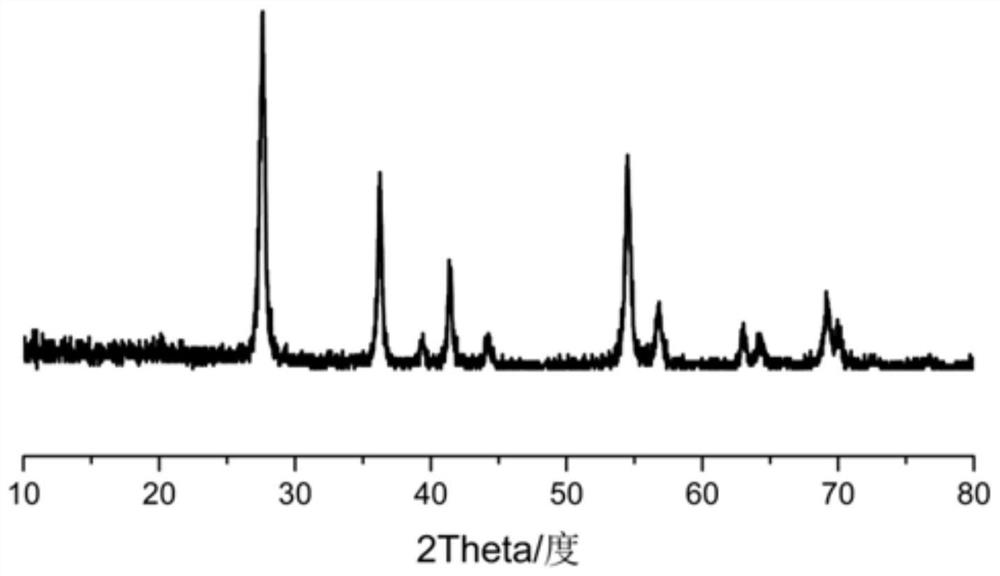

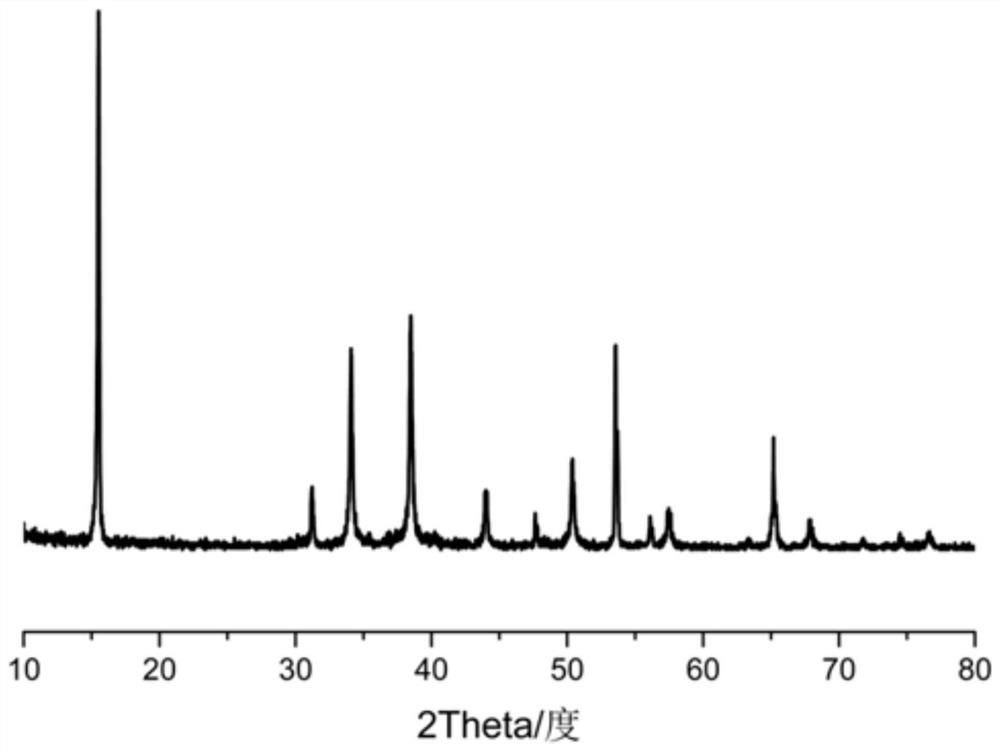

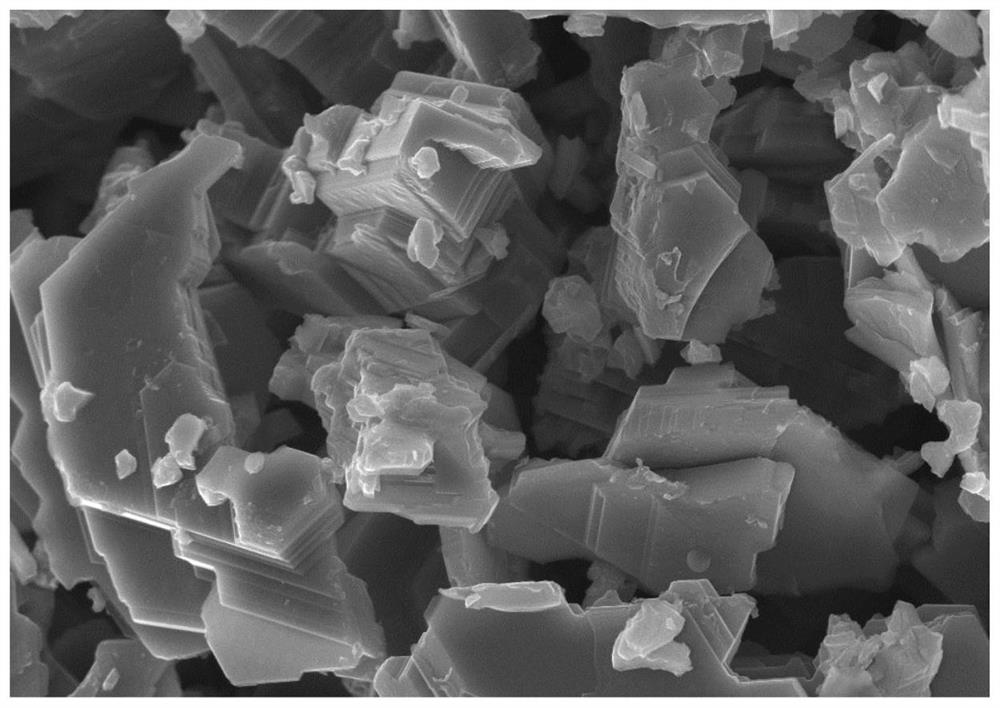

Method for preparing titanium disulfide crystal and product

InactiveCN112111788AHigh purityEvenly distributedTitanium sulfidesPolycrystalline material growthTitanium disulfideMaterials science

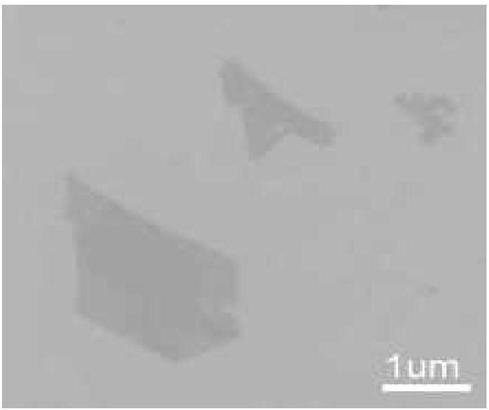

The invention discloses a method for preparing a titanium disulfide crystal and a product, and belongs to the technical field of preparation of IVB-VIA group transition metal chalcogenide. The preparation method comprises the following steps: sequentially filling a quartz tube with titanium powder and sulfur powder in a glove box, conducting standing for 1-2 hours, sealing the quartz tube, placingthe quartz tube under a baking lamp at 120 DEG C for 4-6 hours, placing the quartz tube into a tube furnace, conducting vacuumizing for three times, introducing argon, carrying out sealed reaction inthe tube furnace for 4-8 hours, and conducting cooling to room temperature to obtain titanium disulfide crystals. The titanium disulfide crystal is a 1T-TiS2 hexagonal crystal, and the space group ofthe titanium disulfide crystal is P-3m1. The crystal is of a layered structure. The length of a wafer is 10-11 [mu]m, the width of the wafer is 11-13 [mu]m, and the thickness of the wafer is 1-2 [mu]m. The method is simple and easy to operate, good in repeatability and low in cost, and the prepared TiS2 crystal has the advantages of being high in purity, complete in wafer development, uniform indistribution and the like.

Owner:JILIN UNIV

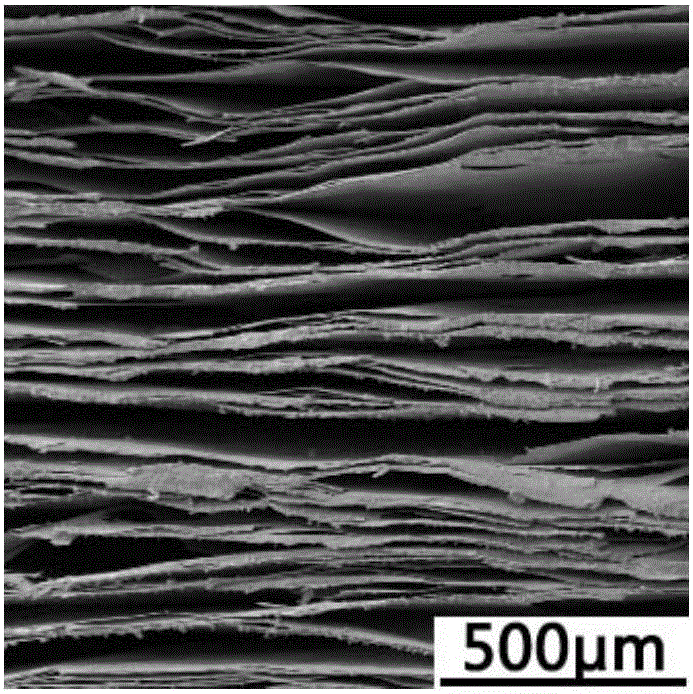

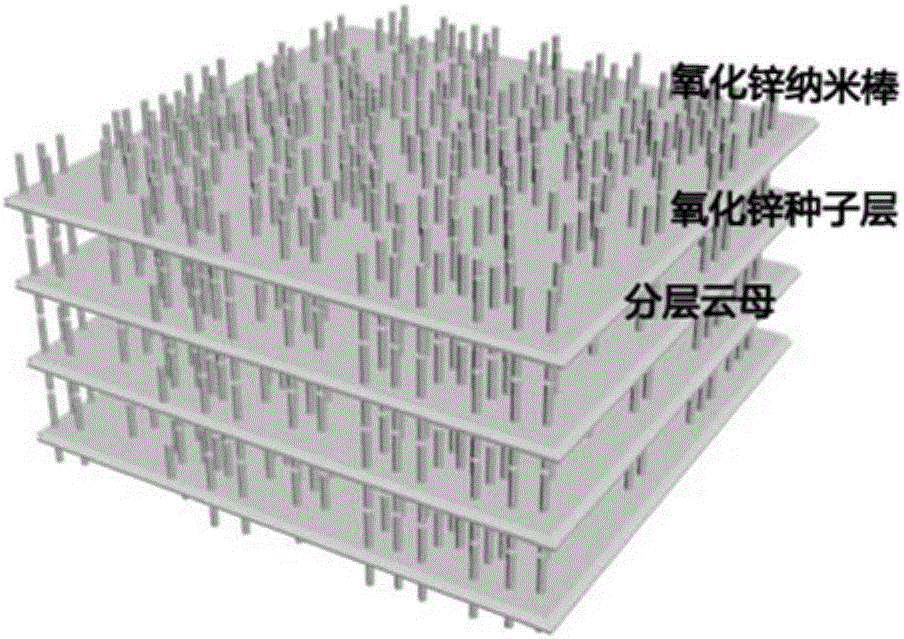

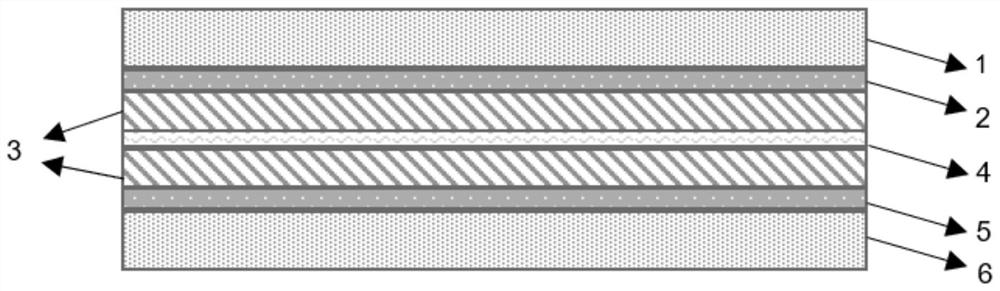

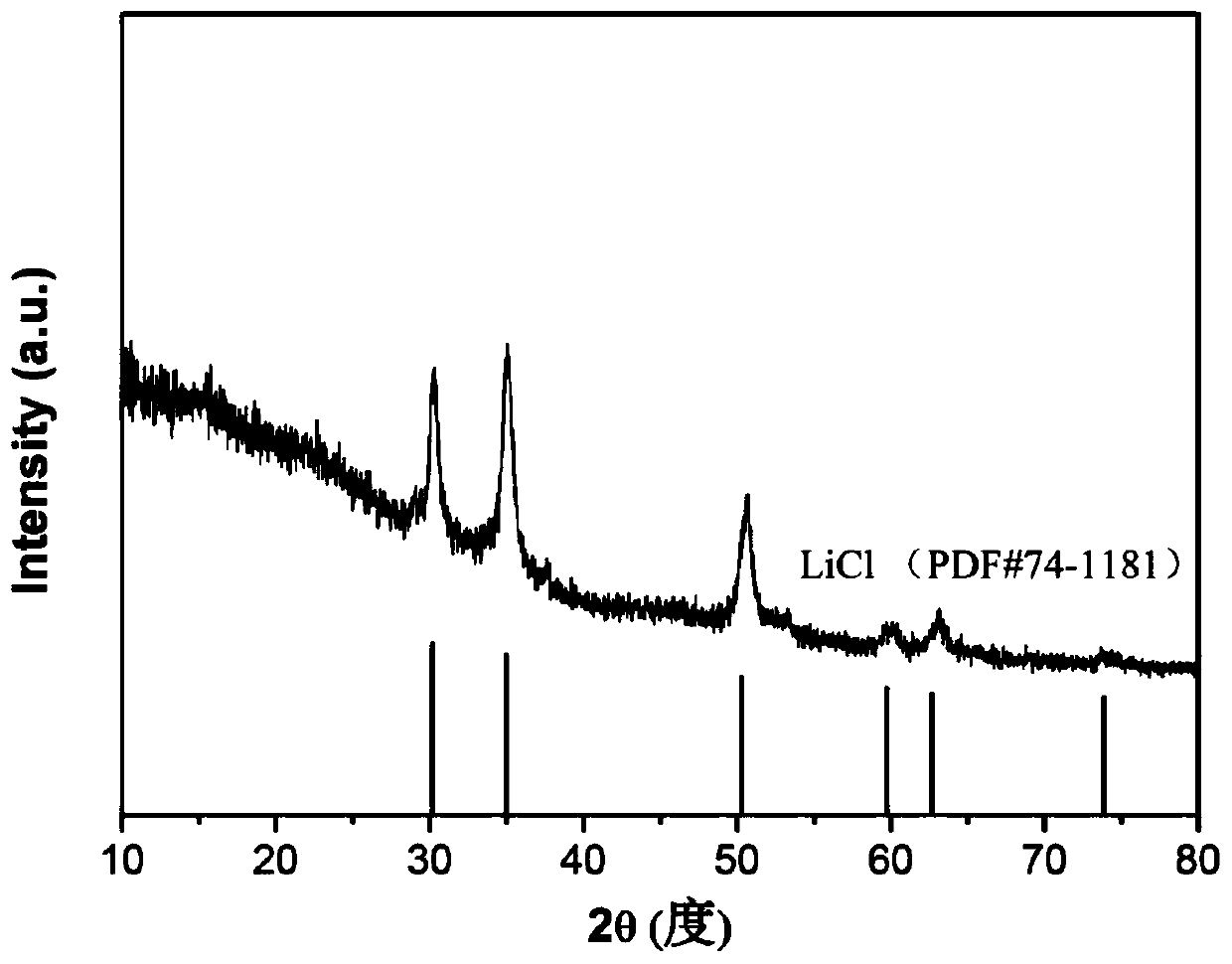

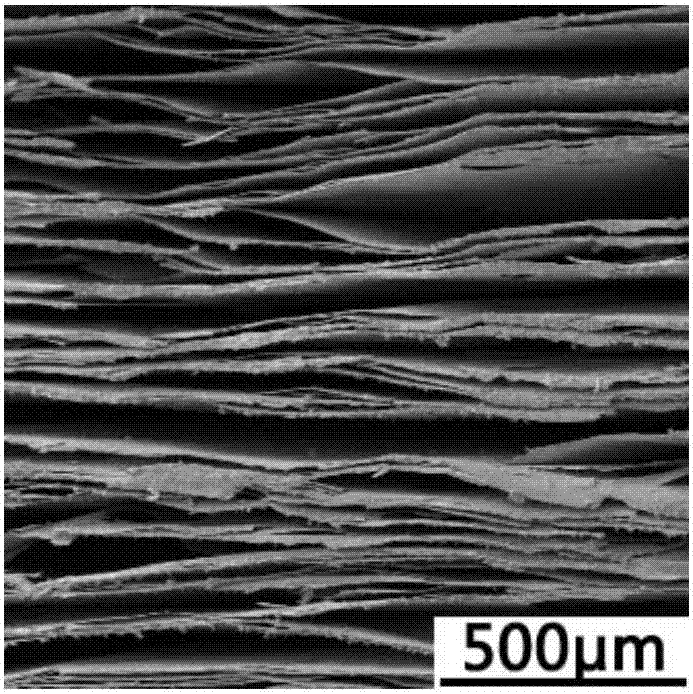

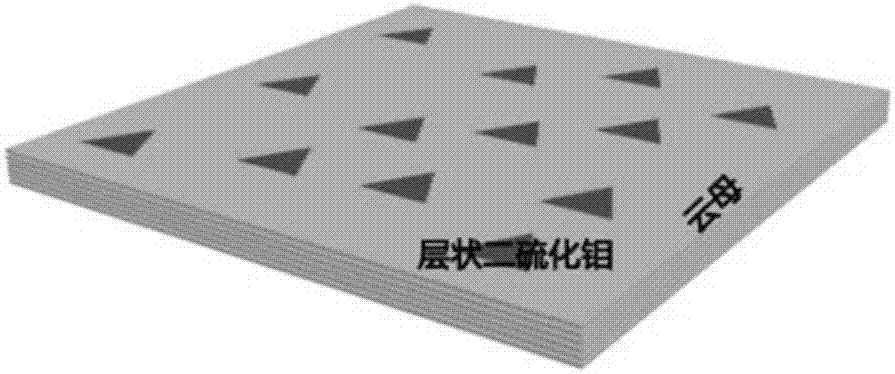

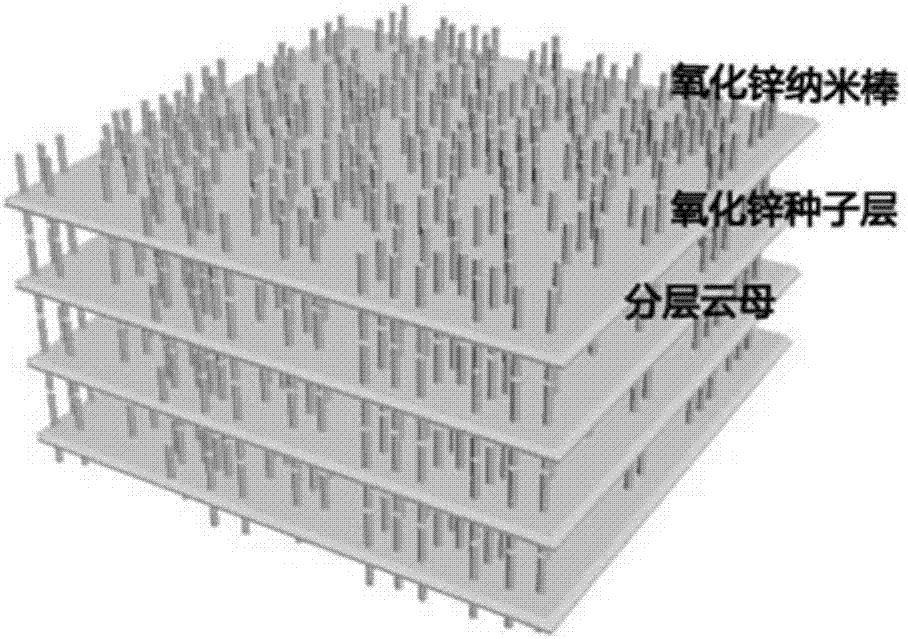

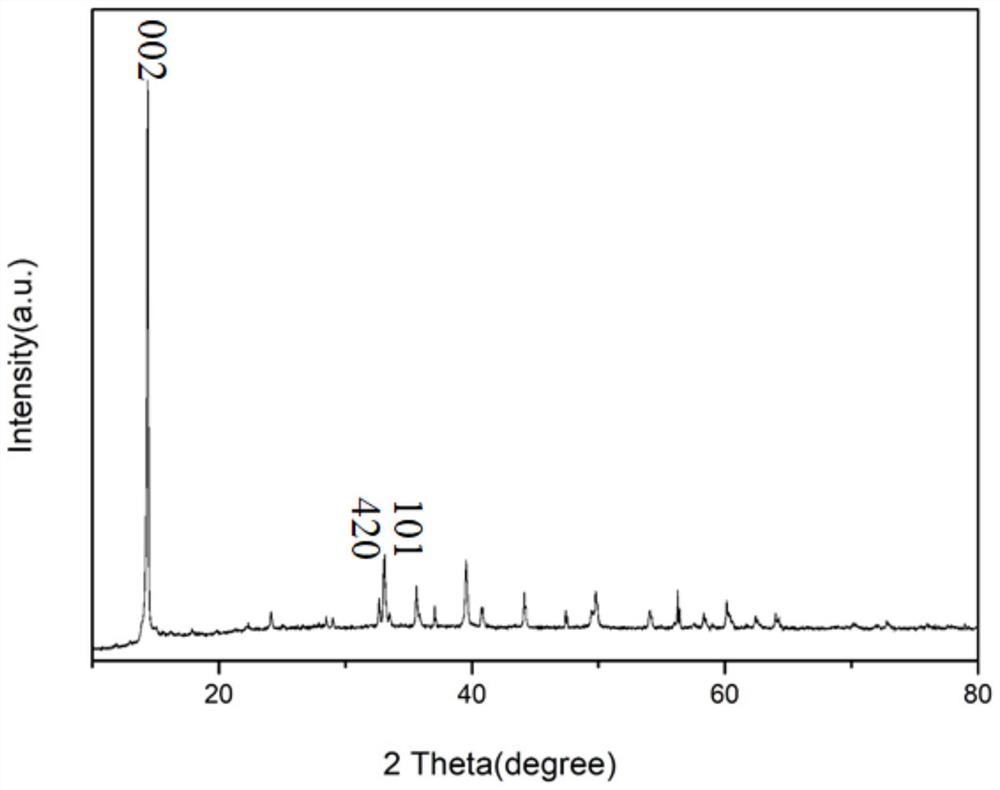

Preparation method of nano-material and mica composite multilayered structure

ActiveCN105905946ALow costImprove protectionTitanium sulfidesMaterial nanotechnologyGas phaseMetallic sulfide

The invention discloses a preparation method of a nano-material and mica composite multilayered structure. According to the method, mica is layered by controlling temperature and time; then, an oxide reactant of 2-50 nm thick is prepared in the mica layers by vapor deposition; and finally, a hydrothermal reaction or a high temperature gas-solid reaction is carried out to obtain a metal sulfide or oxide nano-material and mica composite multilayered structure. The invention has the following advantages: preparation conditions are controllable; cost is low; yield is high; operation is simple and convenient; and three-dimensional structure compounding can be realized. The invention has a wide application prospect in fields of nano-electronic devices, catalysis and the like.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

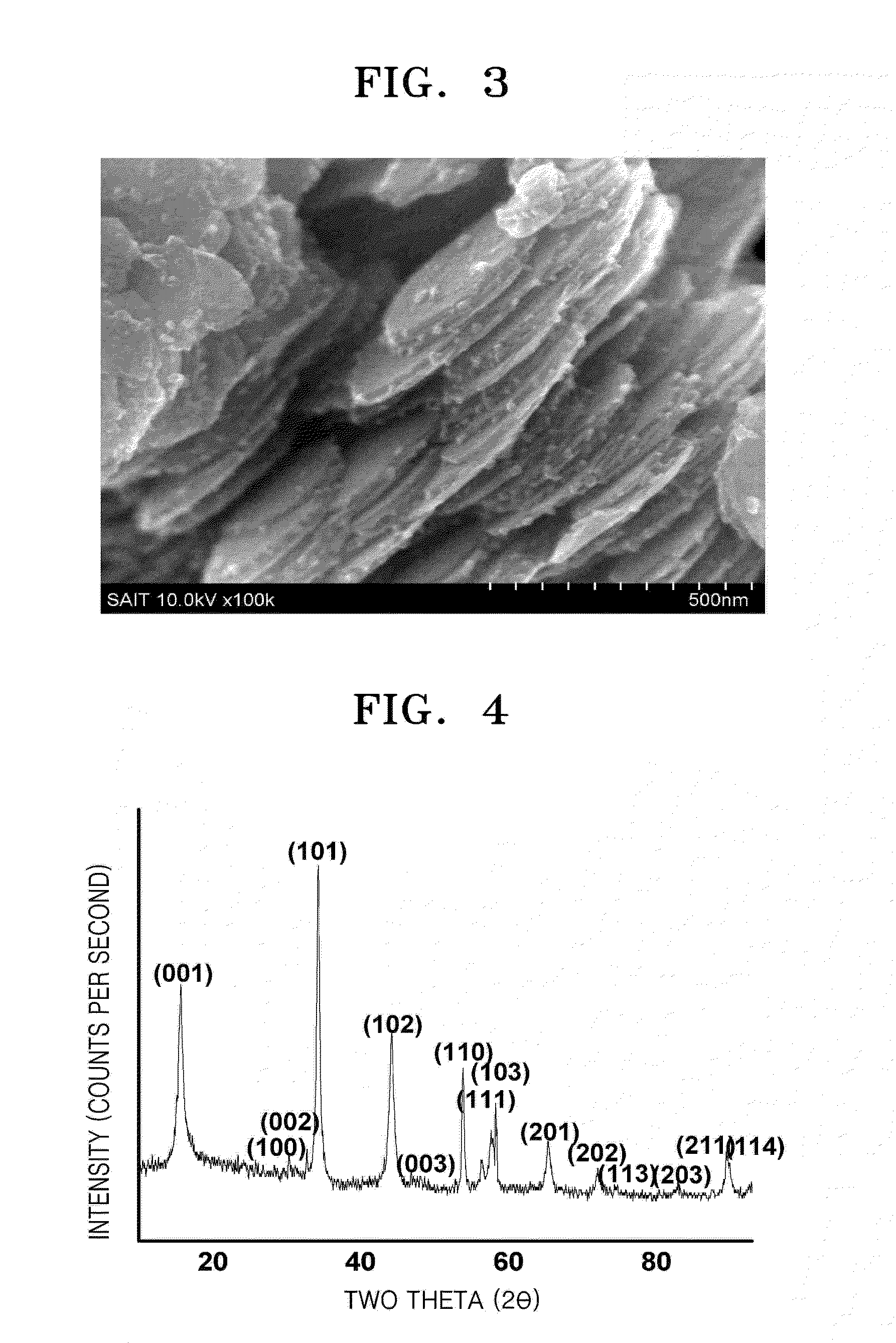

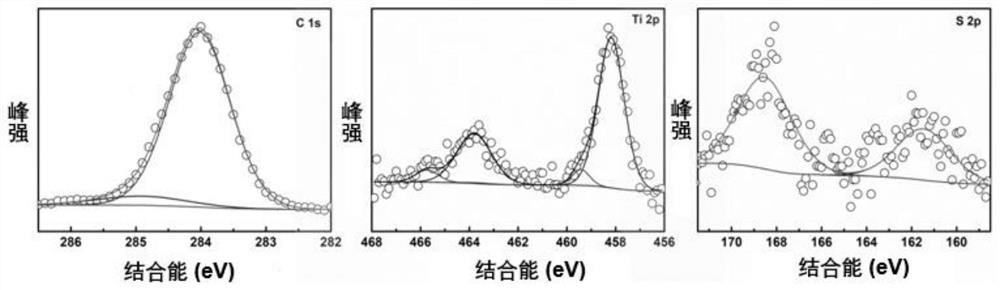

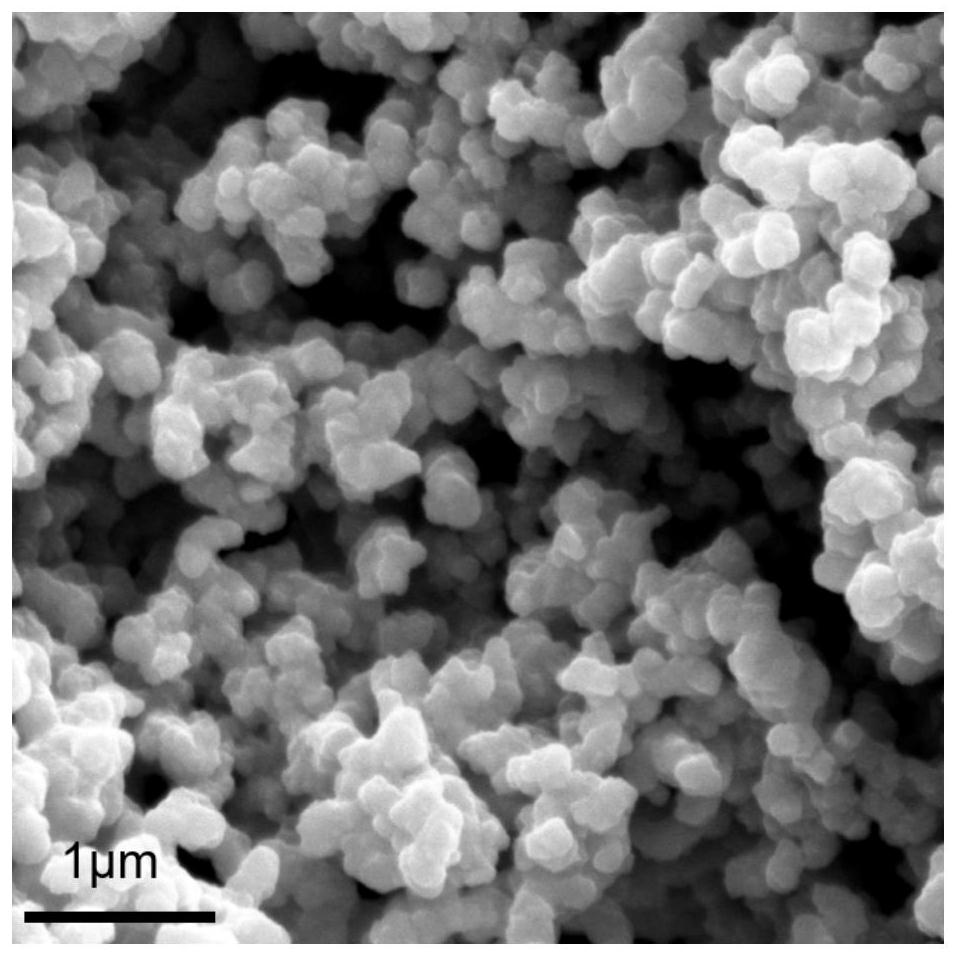

Titanium monosulfide particles and composite material thereof, preparation, application and coating material thereof

PendingCN114477272AIrregular dispersionImprove the lubrication effectTitanium sulfidesMolten spray coatingTitanium monosulfideTitanium sulfide

The invention belongs to the technical field of solid lubricating materials, and particularly relates to titanium monosulfide particles, a composite material of the titanium monosulfide particles, preparation and application of the titanium monosulfide particles and a coating material. The titanium monosulfide particles are of a layered structure formed by stacking two-dimensional nanosheets. The invention discloses a novel TiS particle, and experimental results prove that the titanium monosulfide used as a high-temperature-resistant coating has the following unexpected excellent properties: the friction coefficient is in a decreasing trend along with the increase of the temperature (which is obviously different from the trend of the traditional material, the increase of the temperature and the decrease of the friction coefficient); and the lowest friction coefficient of 0.08 is realized at the temperature of 1000 DEG C. The invention further discloses the ZrO2 (at) TiS composite material. Compared with pure titanium monosulfide, the lubricating property of the ZrO2-coated TiS composite material coating is relatively reduced, but the reduction of the preparation cost provides guarantee for the effects of the ZrO2-coated TiS nano composite material in different fields.

Owner:CHONGQING UNIV

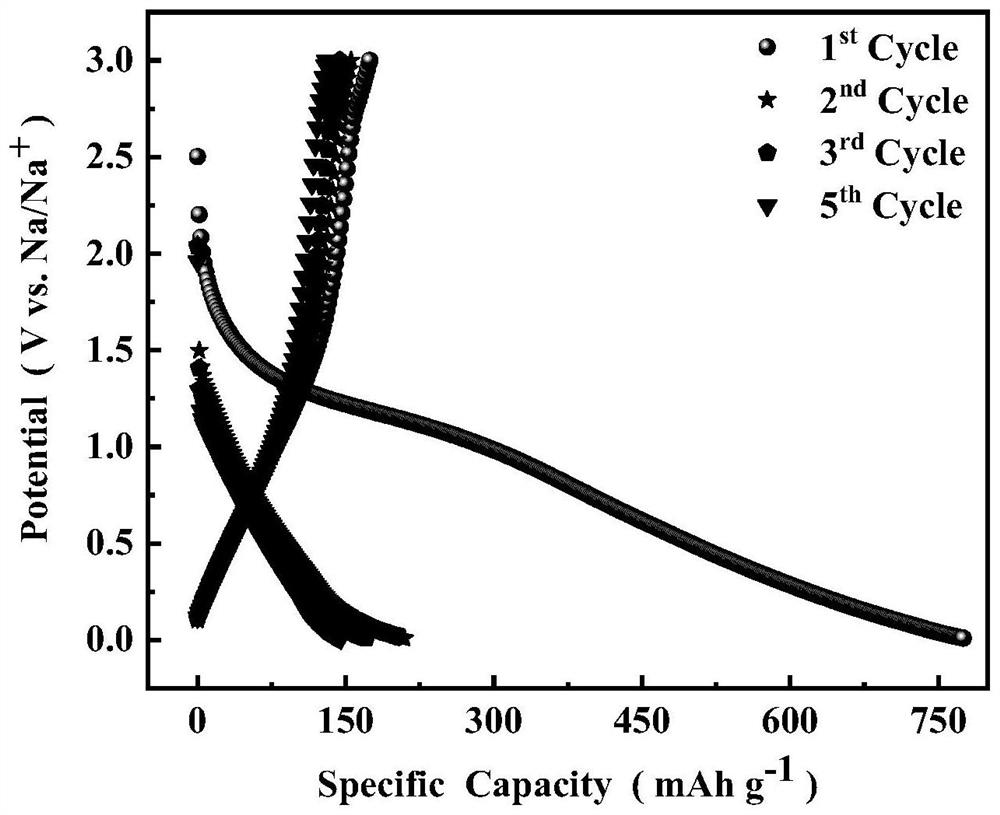

Negative electrode material, preparation method thereof and sodium ion battery

PendingCN113937281ALower diffusion barrierImprove intrinsic conductivityTitanium sulfidesCobalt sulfidesElectrical batteryCyclic stability

The invention relates to the technical field of battery materials, in particular to a negative electrode material, a preparation method thereof and a sodium ion battery. The negative electrode material comprises a transition metal sulfide, and nitrogen ions and selenium ions doped in the transition metal sulfide. The intrinsic conductivity of the transition metal sulfide can be improved through nitrogen doping, an ion transmission channel can be expanded through introduction of selenium, and through the advantages of nitrogen and selenium anions, the rate capability and cycling stability of the transition metal sulfide negative electrode material are improved while the capacity of the transition metal sulfide negative electrode material is not reduced, so that the negative electrode material has a very good application prospect.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

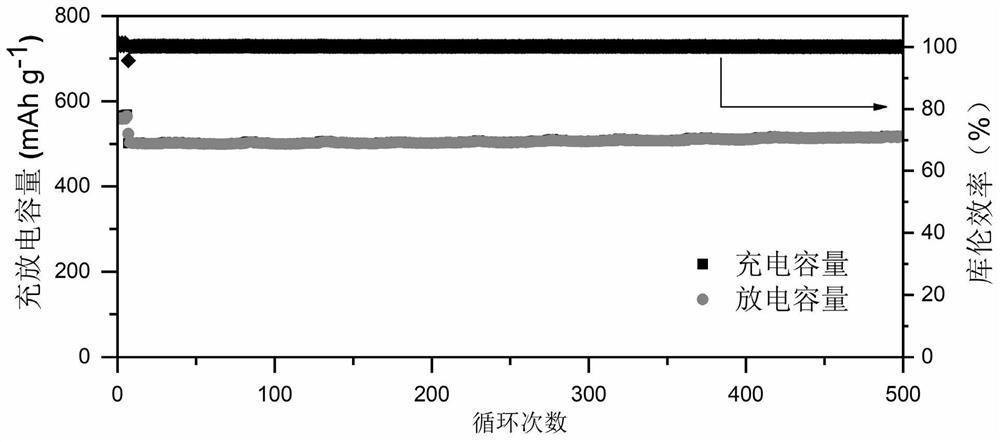

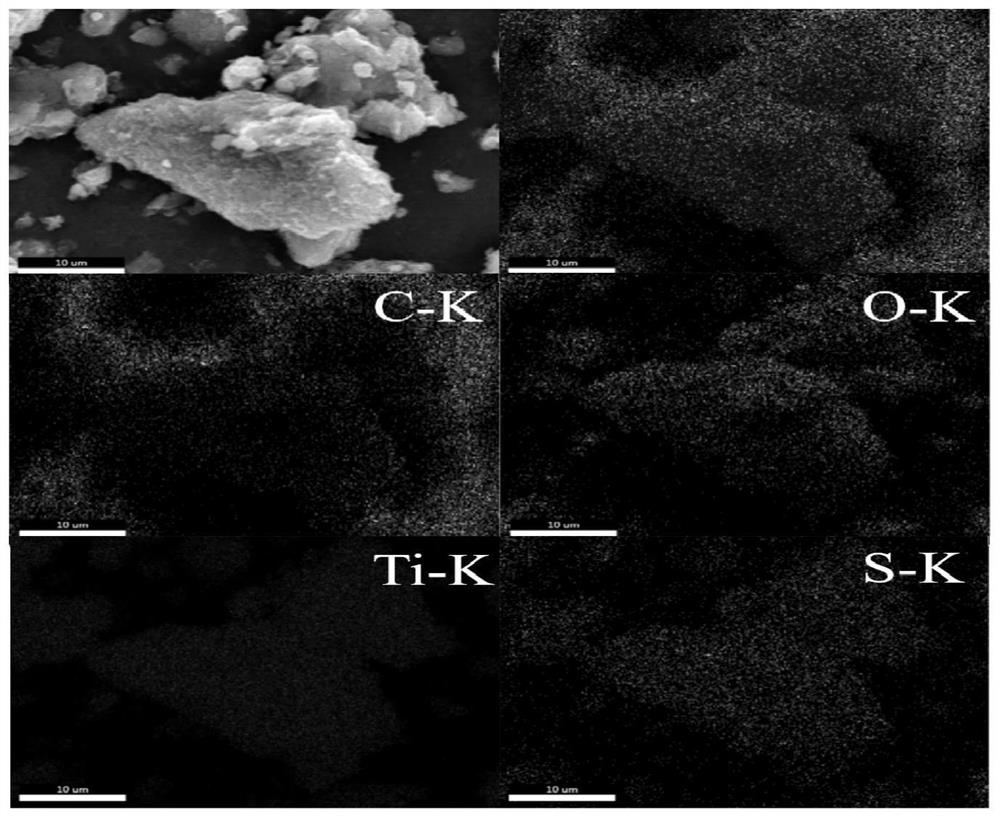

Nano-sheet TiS2/Ti3C2TX MXene/C composite material as well as preparation method and application thereof

ActiveCN114538505ASuppress stackingReduce cycle degradation issuesTitanium sulfidesMaterial nanotechnologyElectrical batteryPhysical chemistry

The invention discloses a nanosheet-shaped TiS2 / Ti3C2TX MXene / C composite material as well as a preparation method and application of the nanosheet-shaped TiS2 / Ti3C2TX MXene / C composite material. According to the preparation method disclosed by the invention, a few layers of Ti < 3 > C < 2 > TX MXene coated with dopamine hydrochloride are subjected to local vulcanization, and the nano-sheet TiS < 2 > / Ti < 3 > C < 2 > TX MXene / C composite material is prepared. According to the preparation method disclosed by the invention, MXene is taken as a starting material, local vulcanization and derivation are carried out on the MXene to prepare the TiS2 nanosheet, and the derived and grown TiS2 can inhibit stacking of the MXene to a certain extent, so that the problem of cycle performance reduction caused by structural collapse is effectively reduced, and finally, excellent electrochemical sodium storage performance is shown; and particularly, when being used as a sodium-ion battery negative electrode material, the sodium-ion battery negative electrode material has relatively high sodium storage capacity and good cycle performance and rate capability.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

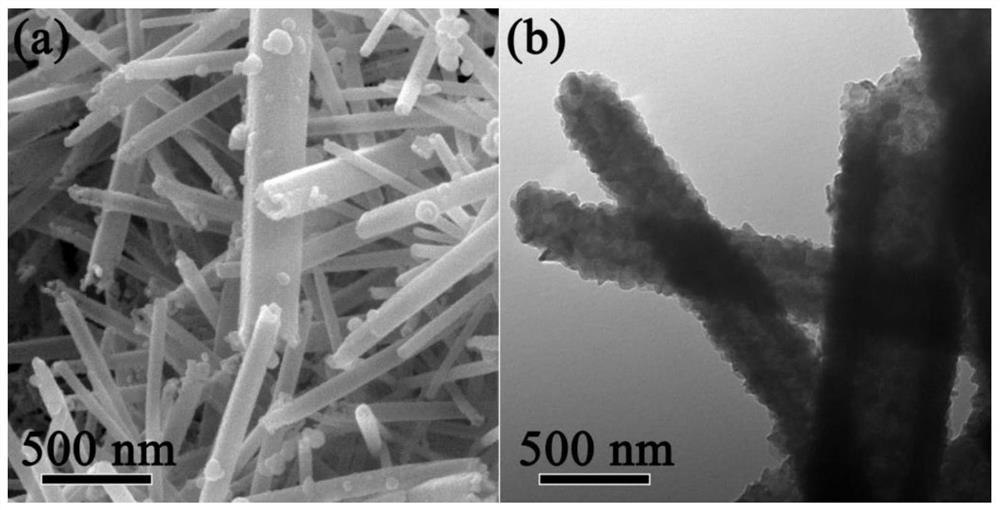

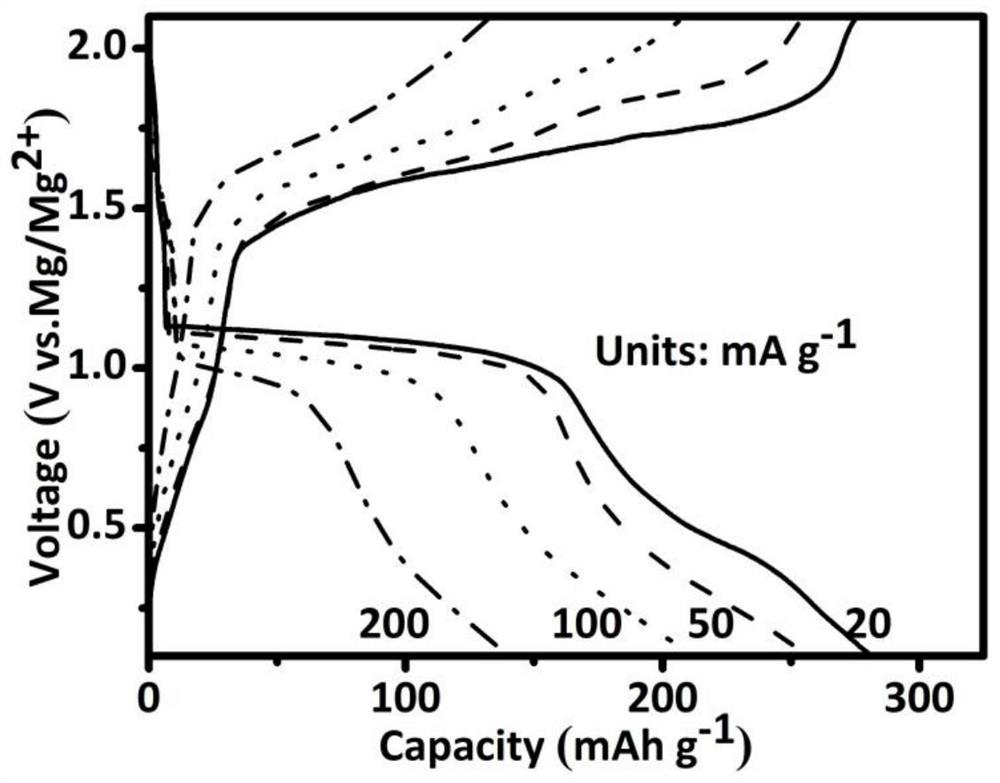

Universal preparation method of transition metal sulfide nanotube and application of transition metal sulfide nanotube as cathode material of rechargeable magnesium battery

InactiveCN111994942AWell stockedLow priceTitanium sulfidesCell electrodesMetallic sulfideGlycol synthesis

The invention relates to a universal preparation method of a transition metal sulfide nanotube and application of the transition metal sulfide nanotube as a rechargeable magnesium battery cathode material. The preparation method comprises the following steps of: uniformly mixing a solvent ethylene glycol and deionized water according to a certain volume ratio to obtain a mixed solvent; heating themixed solvent in a water bath to a certain temperature, adding a certain amount of transition metal source substance and sulfur source substance into the mixed solvent, reacting for a period of timewhile stirring, centrifugally washing the product with deionized water and ethylene glycol for multiple times after the reaction is finished, and drying to obtain the transition metal sulfide nanotube. The preparation method has the advantages that the synthesis method is simple, rapid, easy to adjust and low in cost, and the synthesized product has a stable hollow tubular structure and has high specific capacity, ideal cycling stability and excellent rapid charging and discharging performance when being used as a cathode material of a rechargeable magnesium battery.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Method for synthesizing titanium disulfide by mechanical ball milling

PendingCN110526285AImprove operational safetyRational use of resourcesTitanium sulfidesTitanium disulfideRoom temperature

The invention discloses a method for synthesizing titanium disulfide by mechanical ball milling. The titanium disulfide is prepared from the steps that titanium tetrachloride and lithium sulfide are used as raw materials, titanium disulfide powder and titanium tetrachloride are added to a sealed ball milling tank according to a certain ratio under inert gas shielding, operation is performed for aperiod time in a certain rotating speed at a room temperature, after the ball milling reaction is completed, a removed mixture is distilled, filtered, washed and dried, and the titanium disulfide is obtained. The method is simple in process and high in safety.

Owner:ZHEJIANG UNIV OF TECH

Preparation method of nanomaterial and mica composite multilayer structure

ActiveCN105905946BLow costImprove protectionTitanium sulfidesMaterial nanotechnologyGas phaseMetallic sulfide

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

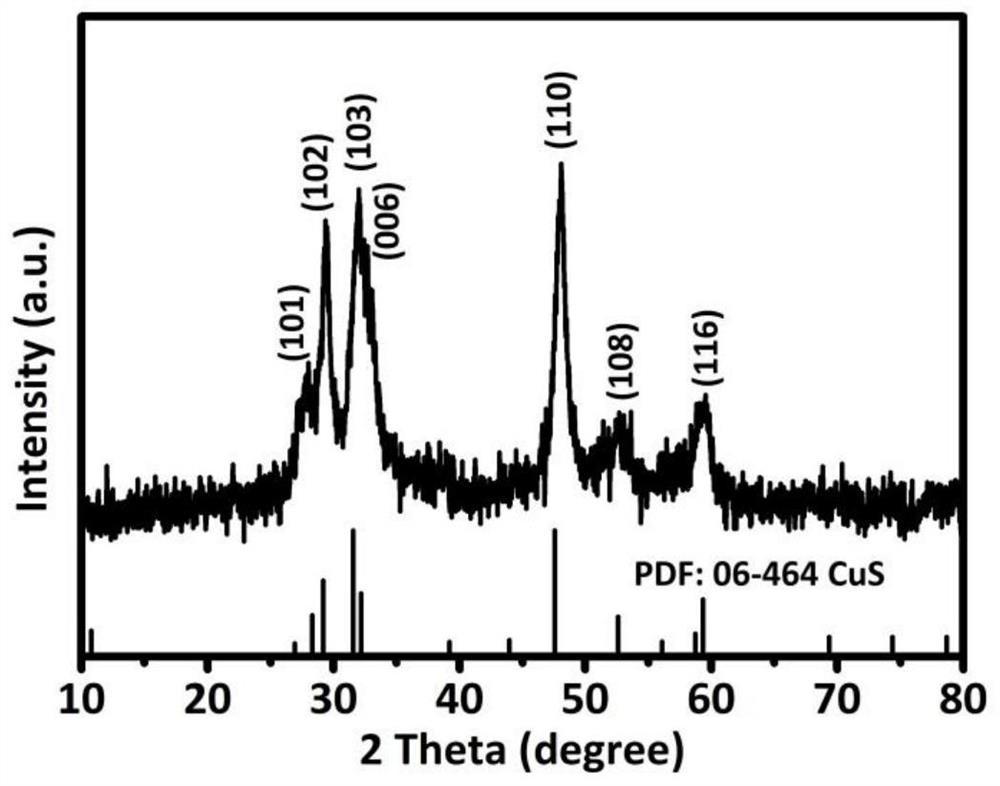

Preparation method and application of carbon or transition metal doped iron-sulfur compound composite material

PendingCN112960700AReduce spontaneous responseRaise the potentialTitanium sulfidesCarbon compoundsIron sulphurLithium-ion battery

The invention belongs to the technical field of lithium ion batteries, and particularly relates to a preparation method and application of a carbon or transition metal doped iron-sulfur compound composite material. The preparation method comprises the following steps: full mixing an organic solvent and an inorganic solvent to obtain a mixed solvent, adding an iron source, a transition metal source or a carbon source into the mixed solvent, heating to carry out organic-inorganic hybridization reaction, filtering, washing a filter cake, drying, and calcining the dried filter cake in a sulfur source environment to obtain the target product. The prepared carbon or transition metal doped iron-sulfur compound composite material is used as an active substance of a positive electrode material in an alkali metal ion battery.

Owner:TIANMU LAKE INST OF ADVANCED ENERGY STORAGE TECH CO LTD

Amorphous (lithium) niobium sulfide or (lithium) titanium niobium sulfide

ActiveUS10269465B2High charge and discharge capacityRaise the ratioTitanium sulfidesPositive electrodesNiobiumCharge discharge

The sulfide of the present invention comprises an amorphous (lithium) niobium sulfide having an average composition represented by formula (1): Lik1NbSn1 (wherein 0≤k1≤5; 3≤n1≤10; and when n1≥3.5, k1≤0.5), or an amorphous (lithium) titanium niobium sulfide having an average composition represented by formula (2): Lik2Ti1-m2Nbm2Sn2 (wherein 0≤k2≤5; 0<m2<1; 2≤n2≤10; and when n2≥3.5, k2≤1.5). The sulfide of the present invention is a material that is useful as a cathode active material for lithium batteries, such as lithium primary batteries, lithium secondary batteries, and lithium ion secondary batteries, and has a high charge-discharge capacity, high electrical conductivity, and excellent charge-discharge performance.

Owner:NAT INST OF ADVANCED IND SCI & TECH

Electron-ion mixed conductor electrolyte, preparation method thereof and all-solid-state battery

PendingCN114497712AImprove electronic conductivityAvoid generatingTitanium sulfidesPhosphorus sulfur/selenium/tellurium compoundsAll solid stateElectrical conductor

The invention discloses an electron-ion mixed conductor electrolyte, a preparation method thereof and an all-solid-state battery, and relates to the field of all-solid-state batteries, transition metal sulfide, lithium-containing sulfide and sulfide solid electrolyte are compounded to construct an electron-ion mixed conductor sulfide solid electrolyte containing lithium transition metal sulfide. The electronic conductivity of the solid electrolyte is obviously improved, the solid electrolyte is mixed with an oxide positive electrode to form an ion-electron hybrid network positive electrode, the interface resistance can be reduced, and the battery performance is improved.

Owner:ZHEJIANG FUNLITHIUM NEW ENERGY TECH CO LTD

A kind of method for synthesizing metal sulfide by carbothermal reaction

ActiveCN110002407BShort processSimple processTitanium sulfidesSulfide/polysulfide preparationSulfurPhysical chemistry

The invention discloses a method for synthesizing the sulfide of metal M by carbothermal reaction, wherein M is Ti, Zr, Hf, Cr, Mo, W, V, Nb, Ta, Fe, Co, Ni, Mn, Cu, Zn, Si, Ge, Pb, Sn, Ag, Au, Pt, Pd, Rh, Ir, Ru, Os, Re, Al, B, Ga, In, Tl, Sc, Y, U, One or more of lanthanide series and actinide series. The metal oxide is uniformly mixed with carbon and sulfur in a certain proportion, and the mixture is reacted in a high temperature vacuum environment to prepare the solid sulfide of metal M. The method starts from metal oxides, the raw materials used are cheap and easy to obtain, the production process is simple, safe and feasible, and the reaction speed is fast, which provides a new method for mass production of metal sulfides.

Owner:WUHAN UNIV

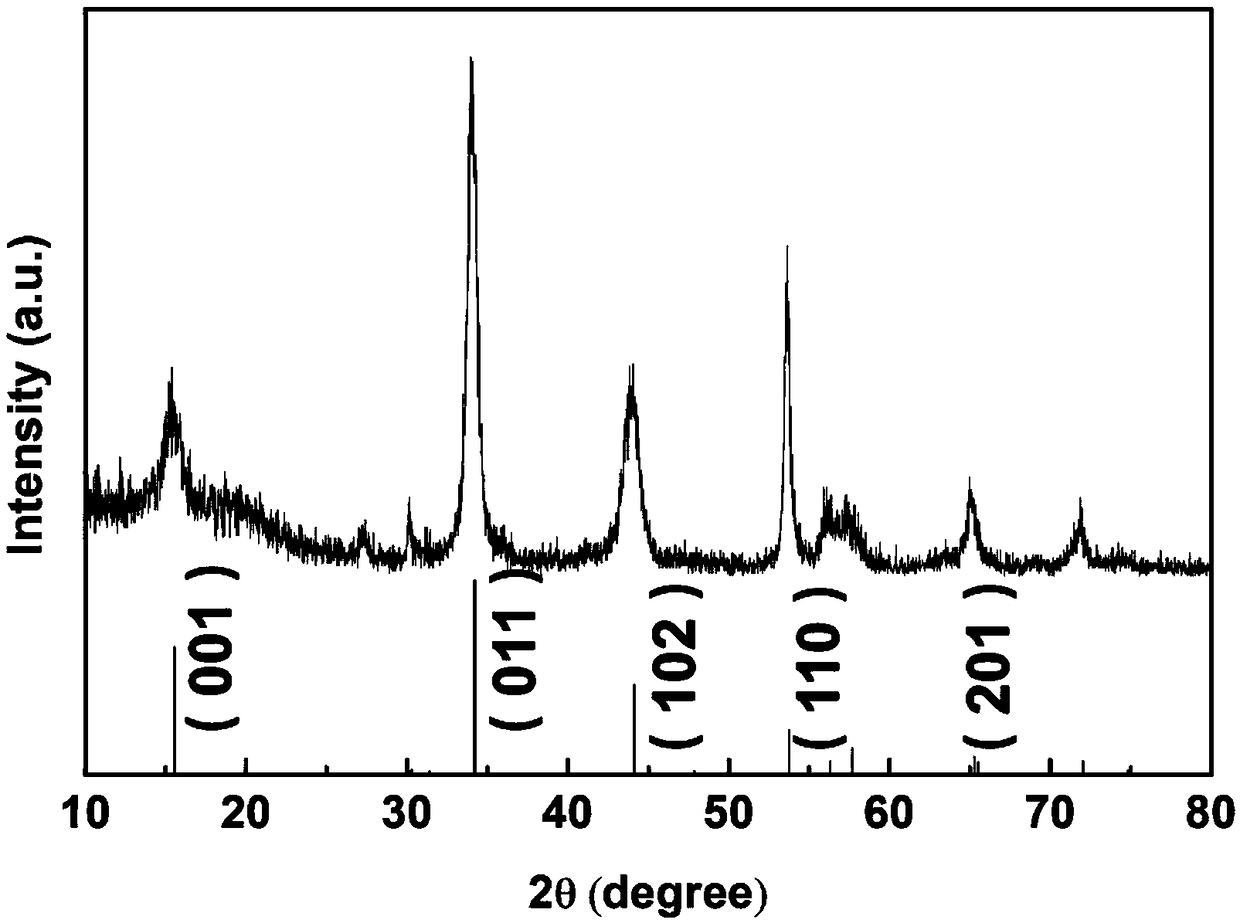

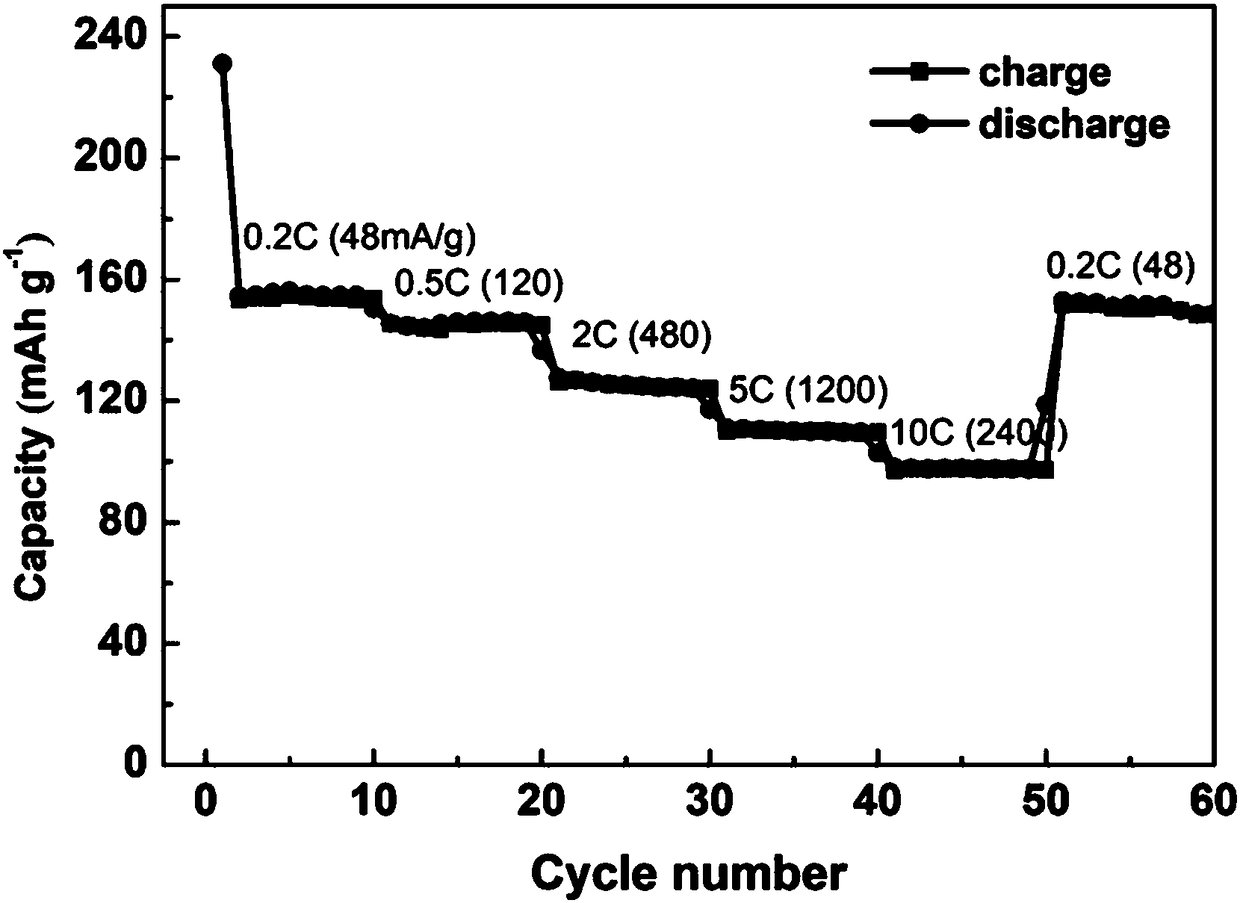

Preparation method of lithium battery cathode ultrathin nano material with high rate capability

InactiveCN108585032AGood repeatabilitySimple methodTitanium sulfidesMaterial nanotechnologyHigh rateChemical solution

The invention relates to a preparation method of a lithium battery cathode ultrathin nano material with high rate capability. The preparation method comprises the following steps: dispersing a sulfursource to a high-boiling-point solvent to obtain a precursor A of a sulfur source; under continuous stirring and protective atmosphere, adding a titanium source into the precursor A to obtain a mixedsolution B, wherein a mole ratio of a titanium source to the sulfur source is 1: (0.5 to 3); heating the mixed solution B to 250 to 320 DEG C, and preserving the heat for 30 to 180 min; at the end ofheat preservation, cooling the mixed solution to room temperature, and performing separation, cleaning and drying to obtain the lithium battery cathode ultrathin nano material with high rate capability. According to the preparation method disclosed by the invention, a transition-family metal sulfide in a two-dimensional layered material is synthesized by adopting a chemical solution method, so that a high-temperature and high-long-time-consumption solid phase process and complicated equipment are avoided; the whole process is convenient and easy to operate; only the heat preservation is performed at 250 to 320 DEG C for 30 to 180 min; the repetitiveness is high.

Owner:SHAANXI UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com