Universal preparation method of transition metal sulfide nanotube and application of transition metal sulfide nanotube as cathode material of rechargeable magnesium battery

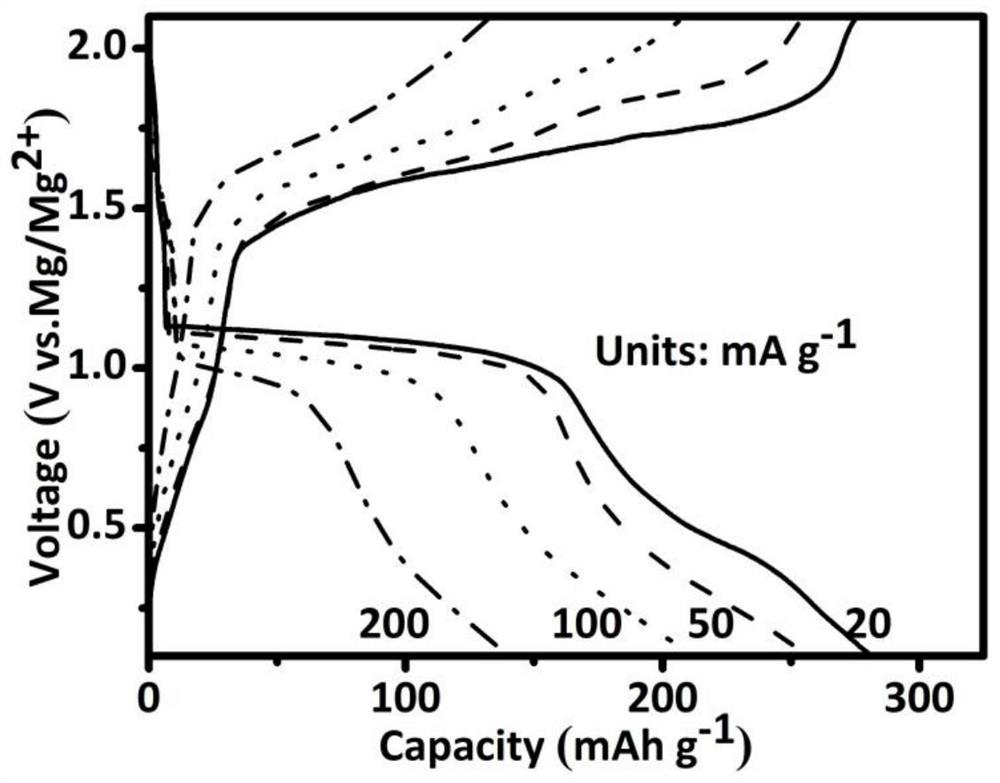

A metal sulfide and transition metal technology, applied in battery electrodes, chemical instruments and methods, copper sulfide, etc., can solve the problem of high energy consumption, achieve high specific capacity, low price, and the synthesis method is simple, fast and easy to adjust.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] A general preparation method of transition metal sulfide nanotubes and its application as a positive electrode material for rechargeable magnesium batteries, the preparation steps are as follows:

[0023] (1) Mix a certain amount of ethylene glycol and deionized water evenly;

[0024] (2) The mixed solvent in step 1 is heated to a certain temperature in a water bath under stirring;

[0025] (3) adding a metal source substance and a sulfur source substance to the mixed solvent in step 2;

[0026] (4) The mixed system in step 3 is stirred and reacted for a certain period of time to obtain reactants, and the products are washed and dried to obtain transition metal sulfide nanotubes.

specific Embodiment 1

[0028] (1) Take a clean 200mL beaker, add 30mL ethylene glycol and 10mL deionized water into the beaker, and stir to obtain a colorless and clear solution.

[0029] (2) Place the beaker in step (1) in a water bath, turn on the heating device, and heat the mixed solution to 60°C.

[0030] (3) Add 2.5 mmol of copper nitrate trihydrate and 1.3 mmol of sodium thiosulfate to the mixed solution in step (2) at the same time, and react for 25 minutes under stirring to obtain a dark green turbid solution.

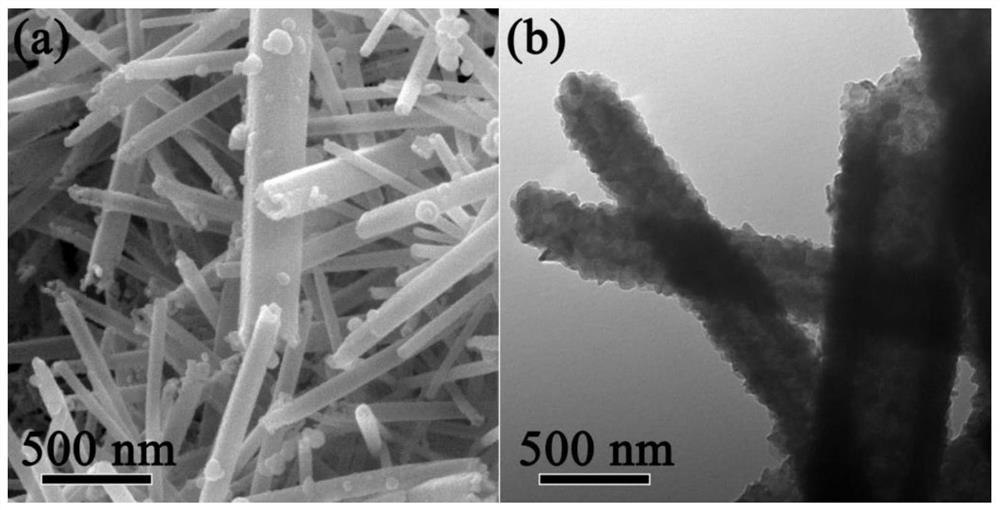

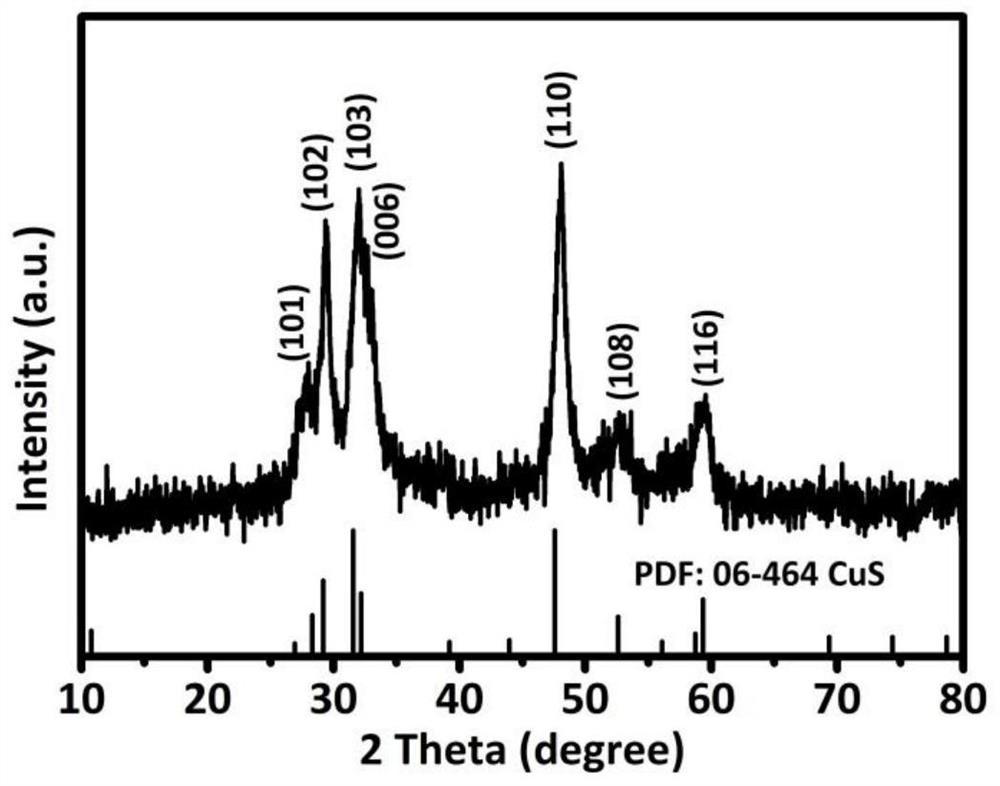

[0031] (4) The turbid solution in step (3) was centrifuged and washed several times with ethanol and deionized water, and the product obtained by centrifugation was dried at 80° C. for 12 hours to obtain CuS nanotubes.

specific Embodiment 2

[0033] (1) Take a clean 200mL beaker, add 30mL ethylene glycol and 10mL deionized water into the beaker, and stir to obtain a colorless and clear solution.

[0034] (2) Place the beaker in step (1) in a water bath, turn on the heating device, and heat the mixed solution to 60°C.

[0035] (3) 2.5 mmol of copper sulfate pentahydrate and 1.3 mmol of sodium thiosulfate were simultaneously added to the mixed solution in step (2), and stirred for 25 minutes to obtain a dark green turbid solution.

[0036] (4) The turbid solution in step (3) was centrifuged and washed several times with ethanol and deionized water, and the product obtained by centrifugation was dried at 80° C. for 12 hours to obtain CuS nanotubes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com