Biomass gel-based dry water powder extinguishing agent and preparation method thereof

A technology of biomass and fire extinguishing agent, which is applied in the direction of fire prevention equipment, etc., can solve the problems of insufficient water cooling performance, unsatisfactory fire extinguishing effect of large-scale fires, and structural damage of dry water fire extinguishing agent. Abundant reserves, the effect of improving fire extinguishing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A biomass gel-based dry water powder fire extinguishing agent, its raw materials and mass percentages are: 8% hydrophobic fumed silica, 0.2% calcium carbonate, 1.5% carrageenan, 0.1% silicon ether copolymer, and the balance is to ionized water.

[0035] The specific preparation method is: dissolving carrageenan in deionized water to prepare a carrageenan solution, and then adding CaCO 3, mixed at a speed of 1000 rpm for 30 minutes, and then added the silicone ether copolymer (the silicone ether copolymer can extend and spread on the surface of the liquid film, thereby making the liquid film thinner and ruptured to produce water-oil phase separation. The phases are continuously pulled and stretched until the liquid film ruptures, which leads to the destruction and disappearance of the foam, and avoids the foam from hindering the formation of the core-shell structure), stirs and dissolves evenly, immediately adds hydrophobic fumed silica, and rotates at 3000 rpm Stir for...

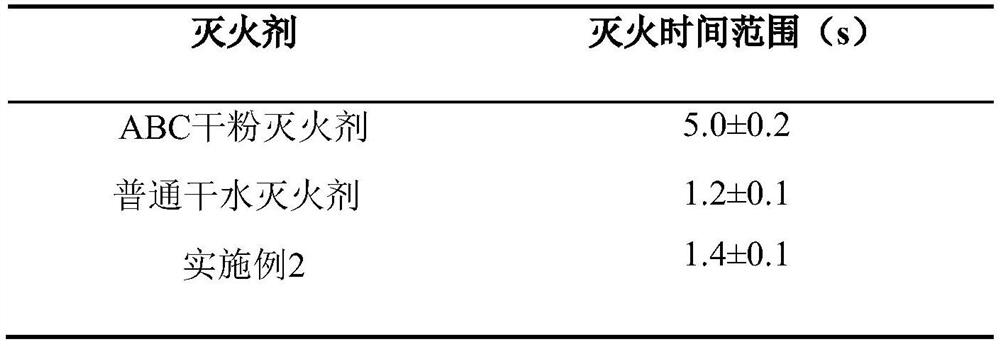

Embodiment 2

[0046] A biomass gel-based dry water powder fire extinguishing agent, its raw materials and mass percentages are: 8.3% hydrophobic fumed silica, 1.0% sodium chloride, 0.1% carrageenan, 0.5% cyclodextrin, silicon ether copolymer 0.1%, the balance is deionized water.

[0047] 0.1g carrageenan is dissolved in deionized water to prepare 10g carrageenan solution (concentration 1wt%), and 0.55g cyclodextrin is dissolved in deionized water to prepare 40g cyclodextrin solution (concentration 1.4wt%), and then the resulting Pour the carrageenan solution and the cyclodextrin solution into two dropping funnels respectively, put the beaker containing 50g NaCl solution (concentration 2.2wt%) into the ultrasonic container, adjust the temperature to 20°C, and turn on the ultrasonic switch after the temperature is constant And adjust a certain stirring speed (500r / min), control a certain dropping speed (60ml / min) and drop the carrageenan and cyclodextrin solution into the NaCl solution drop b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com