A kind of method for synthesizing metal sulfide by carbothermal reaction

A metal sulfide, carbothermal reaction technology, applied in the preparation of sulfide/polysulfide, aluminum sulfur compounds, chemical instruments and methods, etc., can solve harsh experimental conditions, difficult to achieve large-scale realization, titanium tetrachloride Difficulties and other problems, to achieve the effect of short process flow and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) According to titanium dioxide (with TiO 2 Calculated) / activated carbon (calculated by C / ) sublimated sulfur (calculated by S) weigh about 30g of the mixture according to the material ratio of 1:2:2.2, take ethanol as a dispersant, mix by ball milling and dry it for later use.

[0034] (2) Take 1-5g of the mixed powder and press it into a cylindrical test piece with a mold with a diameter of 20cm under a pressure of 20Mpa, and then put the pressed test piece into a corundum tube and vacuum seal. The sealed reactor was placed in a vertical muffle furnace, the temperature was raised to 1000° C. for 20 hours, and cooled with the furnace to obtain titanium sulfide.

Embodiment 2

[0036] (1) Titanium dioxide (with TiO 2 Calculate) / activated carbon (calculated by C / ) sublimation sulfur (calculated by S) weigh 13.39g of titanium dioxide, 4.02g of activated carbon, 12.59g of sublimated sulfur according to the mass ratio of 1:2.1:2.35, take ethanol as a dispersant, pass After mixing by ball milling, dry for use.

[0037] (2) Take 1-5g of the mixed powder and press it into a cylindrical test piece with a mold with a diameter of 20cm under a pressure of 20Mpa, and then put the pressed test piece into a corundum tube and vacuum seal. The sealed reactor was placed in a vertical muffle furnace, and the temperature was raised to 1200° C. for 10 hours, followed by cooling in the furnace to obtain titanium sulfide.

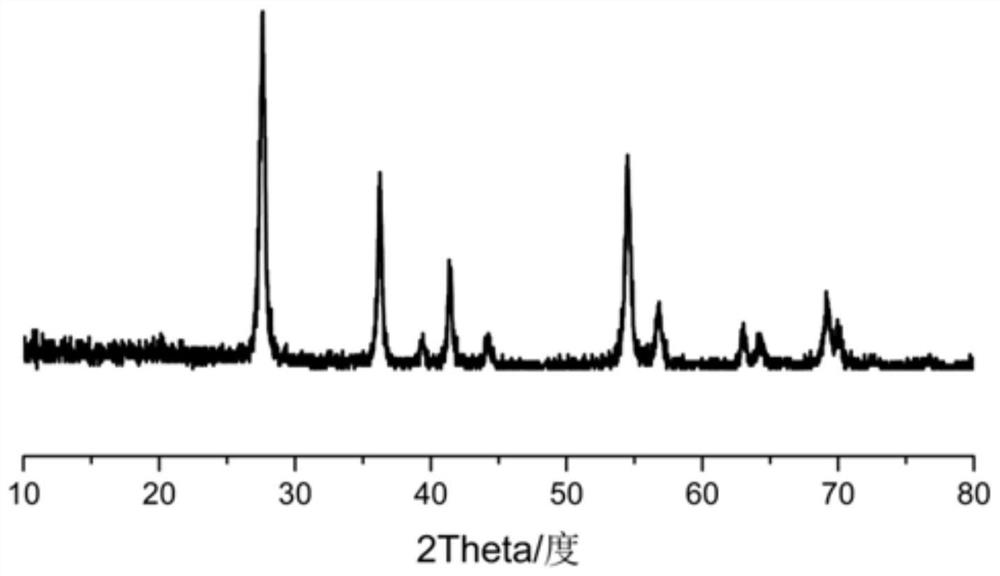

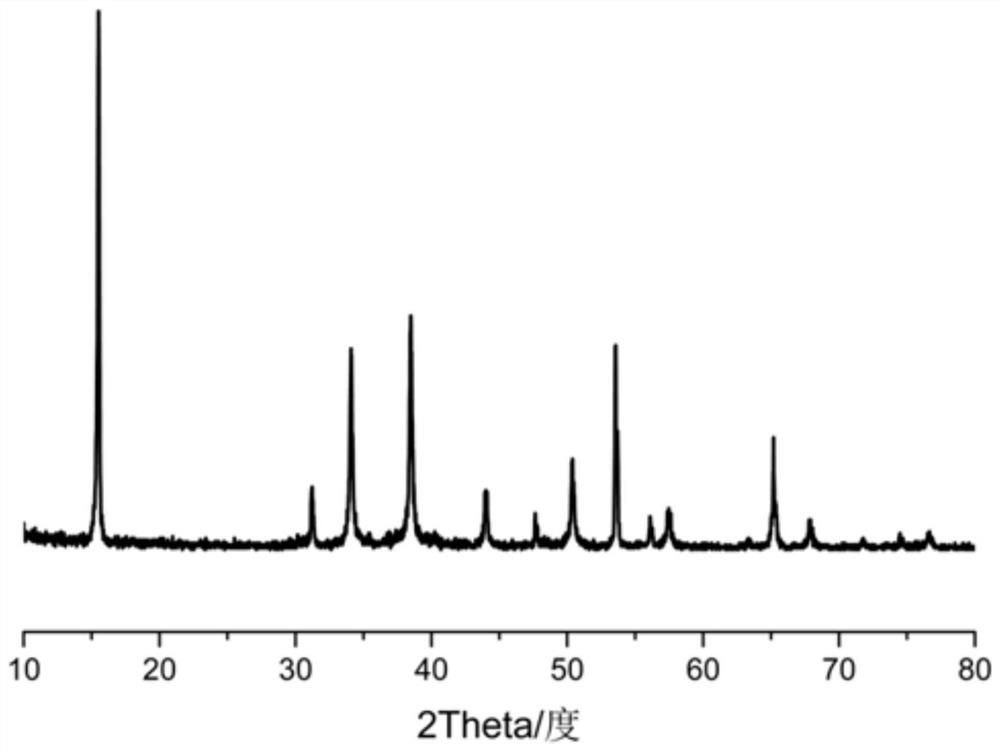

[0038] The titanium dioxide and the product obtained in step (2) are respectively subjected to XRD detection, and the obtained diffraction pattern is as follows: figure 1 and 2 It is shown that the product obtained by the reaction is titanium sulfid...

Embodiment 3

[0040] (1) Al2O3 (with Al 2 O 3 Calculate) / activated carbon (calculated by C / ) sublimation sulfur (calculated by S) weigh 12.34g of aluminum oxide, 4.5g of activated carbon, 13.16g of sublimated sulfur according to the mass ratio of substances 1:3.1:3.4, take ethanol as The dispersant is mixed by ball milling and dried for later use.

[0041] (2) Take 1-5g of the mixed powder and press it into a cylindrical test piece with a mold with a diameter of 20cm under a pressure of 20Mpa, and then put the pressed test piece into a corundum tube and vacuum seal. The sealed reactor was placed in a vertical muffle furnace, and the temperature was raised to 1650° C. for 10 hours, followed by cooling in the furnace to obtain aluminum sulfide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com