Patents

Literature

30 results about "Titanium sulfide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Titanium(II) sulfide (TiS) is an inorganic chemical compound of titanium and sulfur. A meteorite, "Yamato 691", contains tiny flecks of this compound, making it a new mineral called Wassonite.

Electrode active material for lead-acid storage battery

InactiveCN106876666AHigh specific powerIncrease specific energyLead-acid accumulatorsCell electrodesTitanium nitrideAtomic cluster

The invention discloses an electrode active material for a lead-acid storage battery. The electrode active material comprises lead powder and a non-metallic titanium compound; the lead powder comprises one or more kinds of metal lead powder, ball-milling lead powder, Barton lead powder, Pb<2>O powder, PbO powder, Pb<2>O<3> powder, Pb<3>O<4> powder and PbO<2> powder; and the non-metallic titanium compound comprises one or more kinds of titanium sulfide, titanium nitride, titanium boride, titanium carbide, titanium hydride, titanium hydroxide, titanium silicide, a symbiotic blend of the abovementioned compounds on an atomic micro level or atomic cluster level, and doped compounds formed by doping the abovementioned compounds with one or more kinds of F, Sb, Sn, Ca, Bi, Co, Ca, Al, Mg, N, P, O and C. By virtue of the electrode active material for the lead-acid storage battery with an improved formula, the specific power, specific energy, charging-discharging efficiency, cycle life, low-temperature performance and the like of the lead-acid storage battery can be obviously improved.

Owner:杨春晓

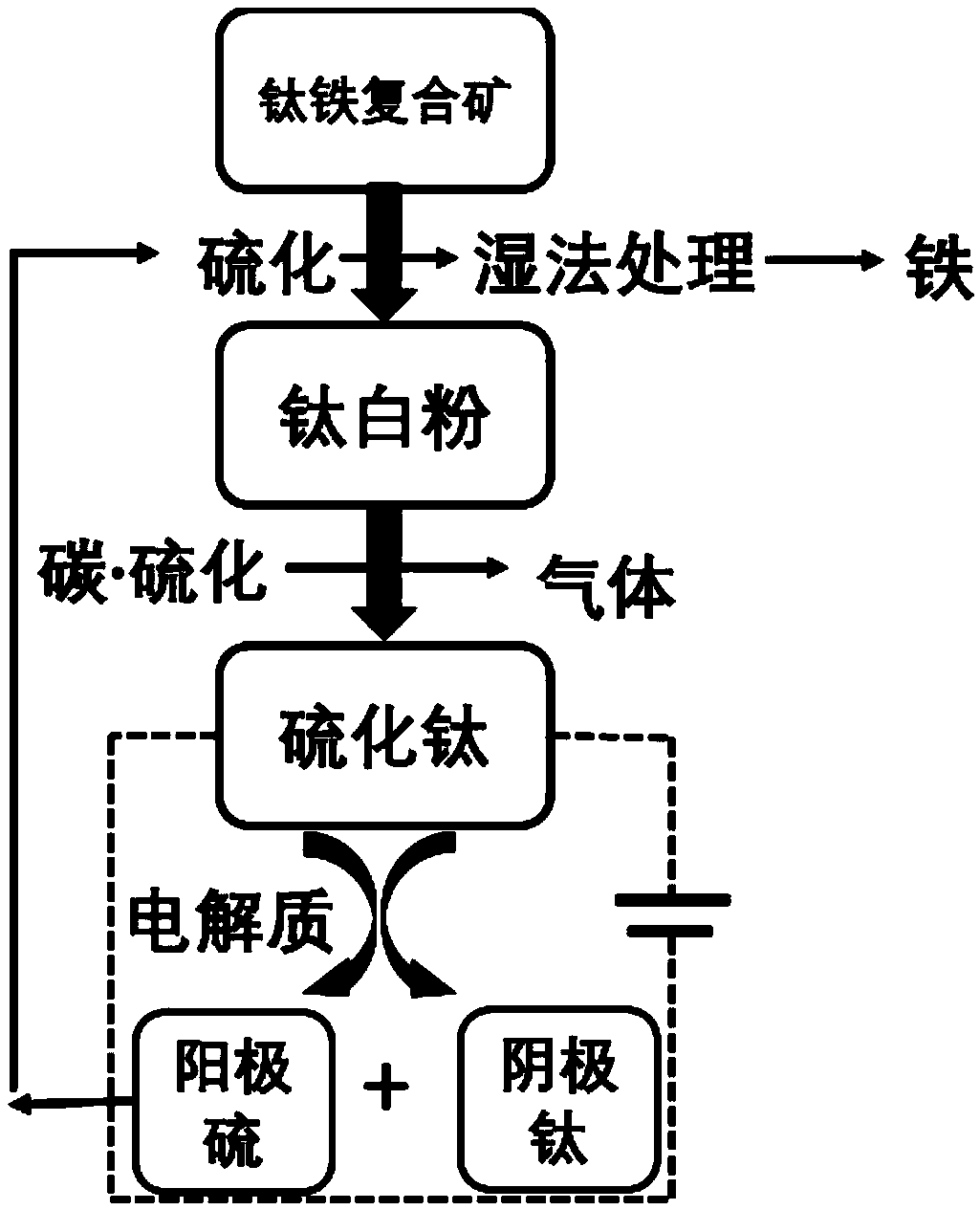

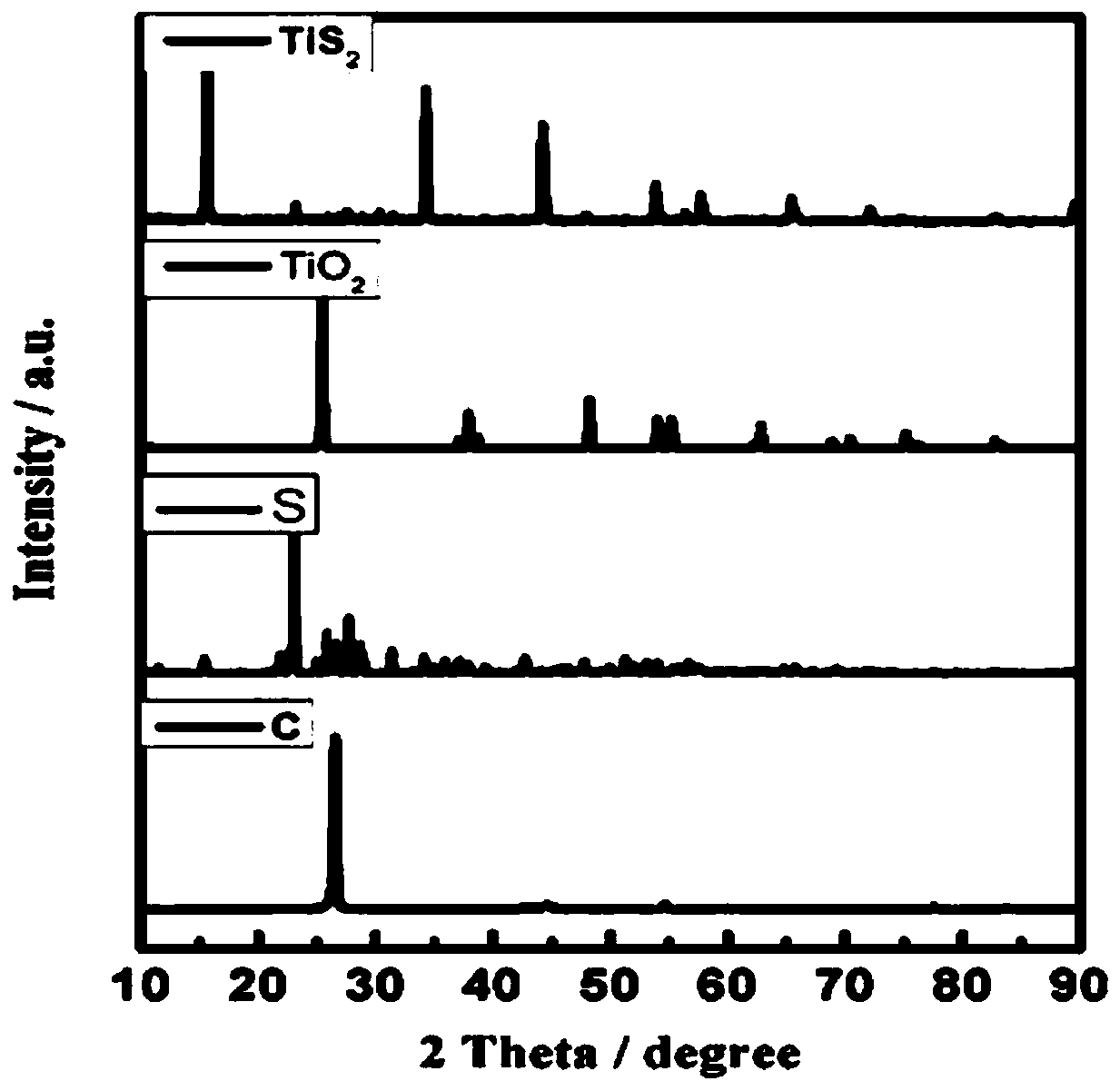

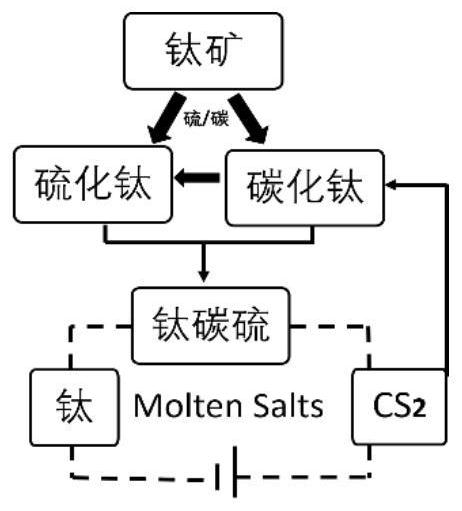

Method for preparing metallic titanium through vulcanization and electrolysis of titanium and iron composite ore and carbon

ActiveCN109280941AImprove electrolysis efficiencyLess intermediatesSolid state diffusion coatingProcess efficiency improvementElectrolysisAlkaline earth metal

The invention provides a method for preparing metallic titanium through vulcanization and electrolysis of titanium and iron composite ore and carbon, and relates to the technical field of extraction of non-ferrous metals. A titanium sulfide anode is adopted for electrolysis, the method has the advantages of high electrolysis efficiency, few intermediate products and capability of directly obtaining the high-purity metallic titanium, continuous production can be realized, production of anode mud can be avoided, and energy minerals can be recycled efficiently. The method comprises the followingsteps that S1, a titanium-containing materiel, a titanium-containing reducing agent and a sulfur-containing reducing agent in the molar ratio ranging from 1:2.0:2.0 to 1:2.5:3.0 are evenly mixed, a mixture is prepared and is subjected to complete vulcanization, and a titanium sulfide product is prepared; S2, a solid solution is prepared from the titanium sulfide product; S3, the metallic titaniumis extracted from molten halide salt of alkali metal or alkaline-earth metal with the electrolysis method, the solid solution is used as the anode during electrolysis, and the metallic titanium is obtained at the cathode. The technical scheme is applicable to the process for preparing the metallic titanium through electrolysis.

Owner:UNIV OF SCI & TECH BEIJING

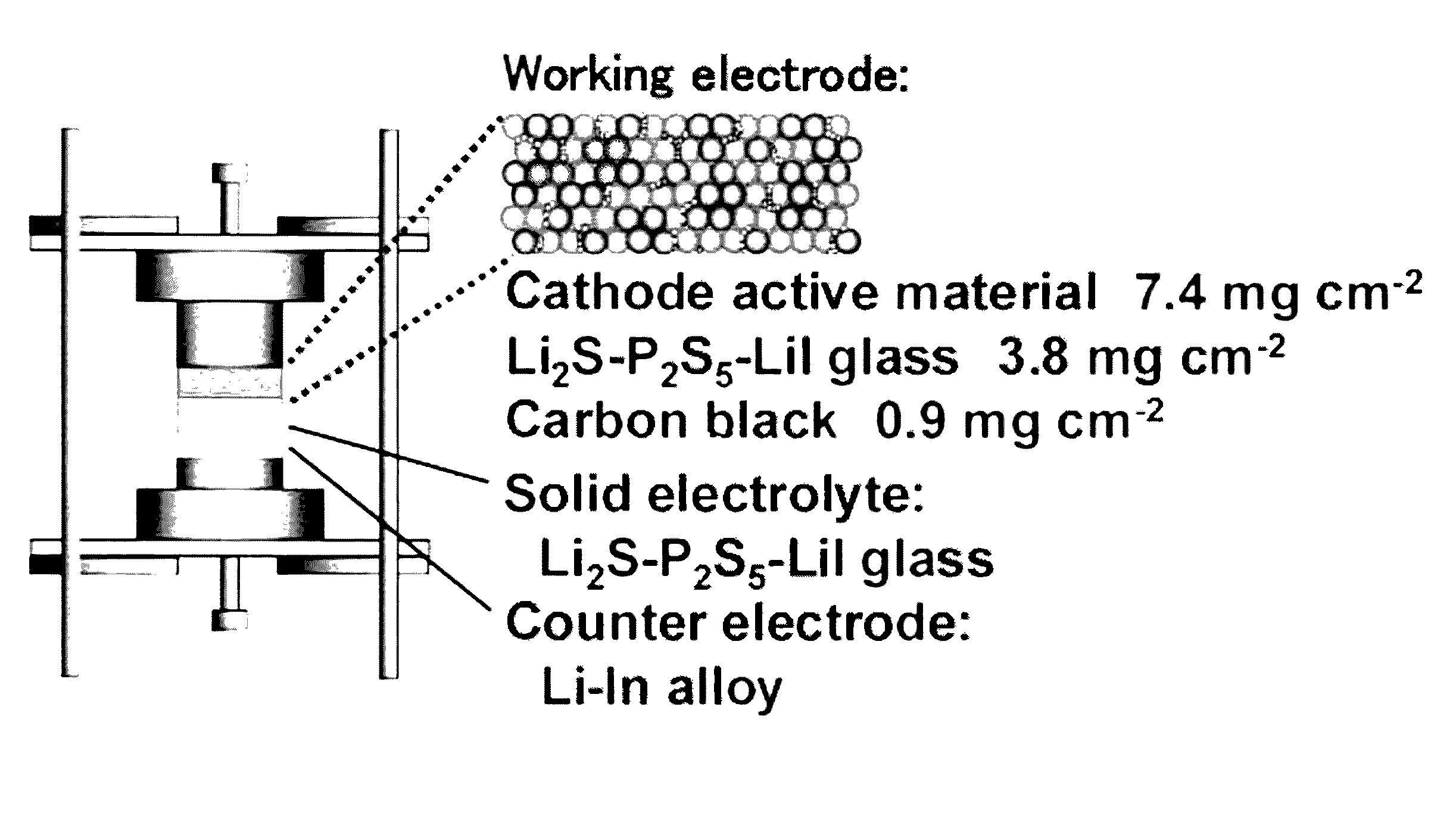

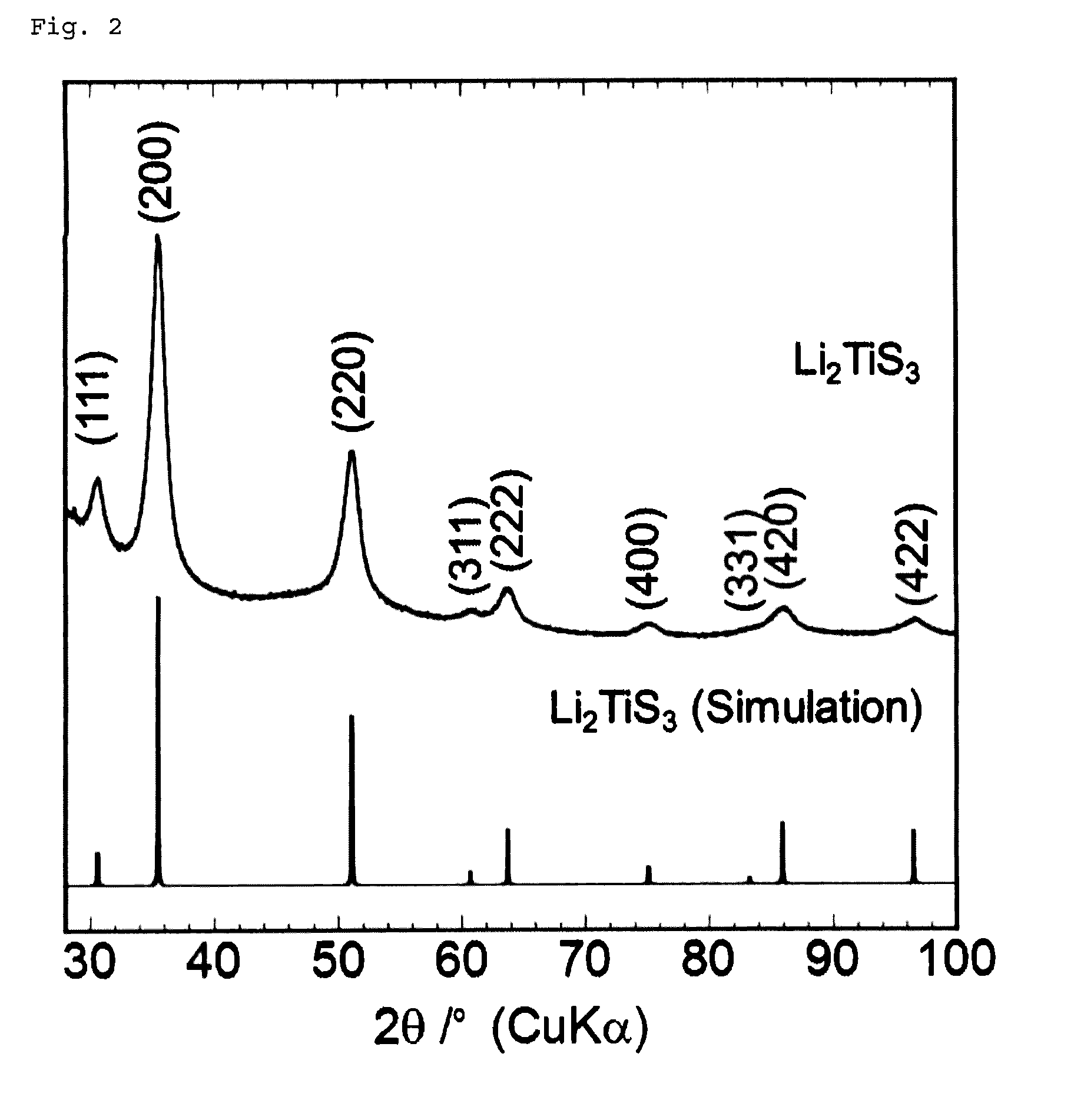

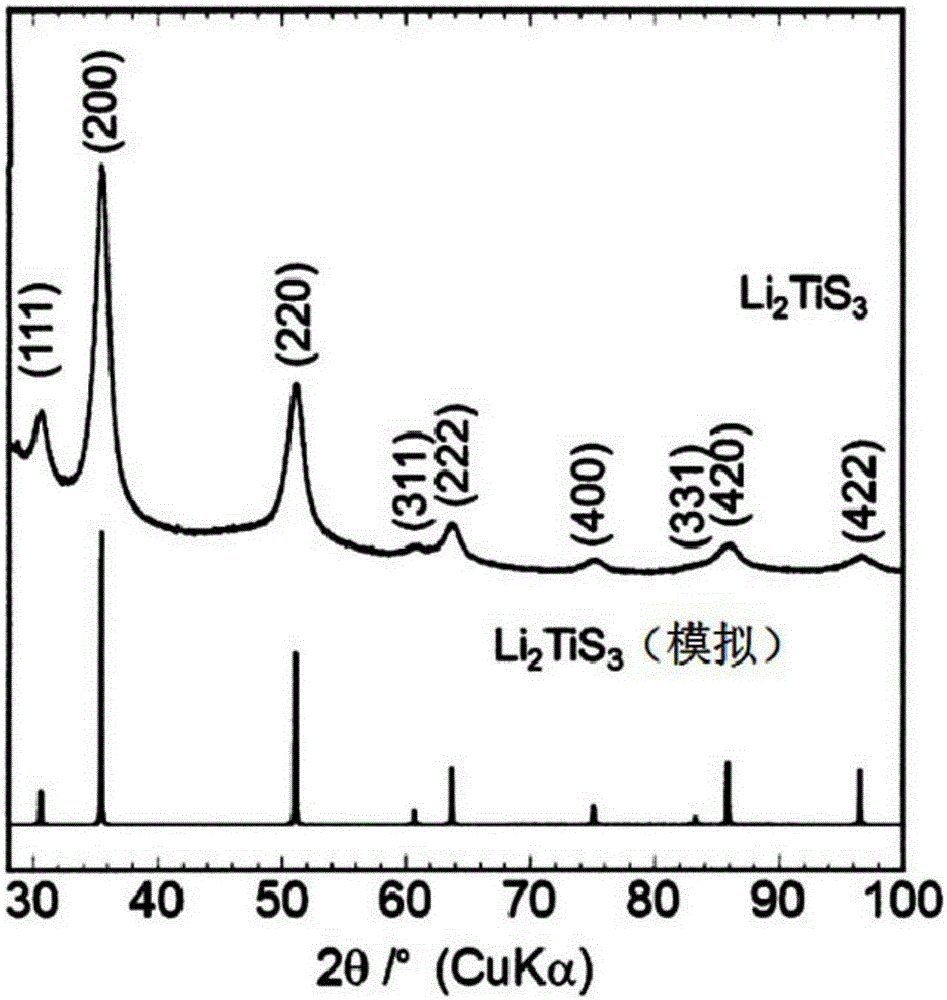

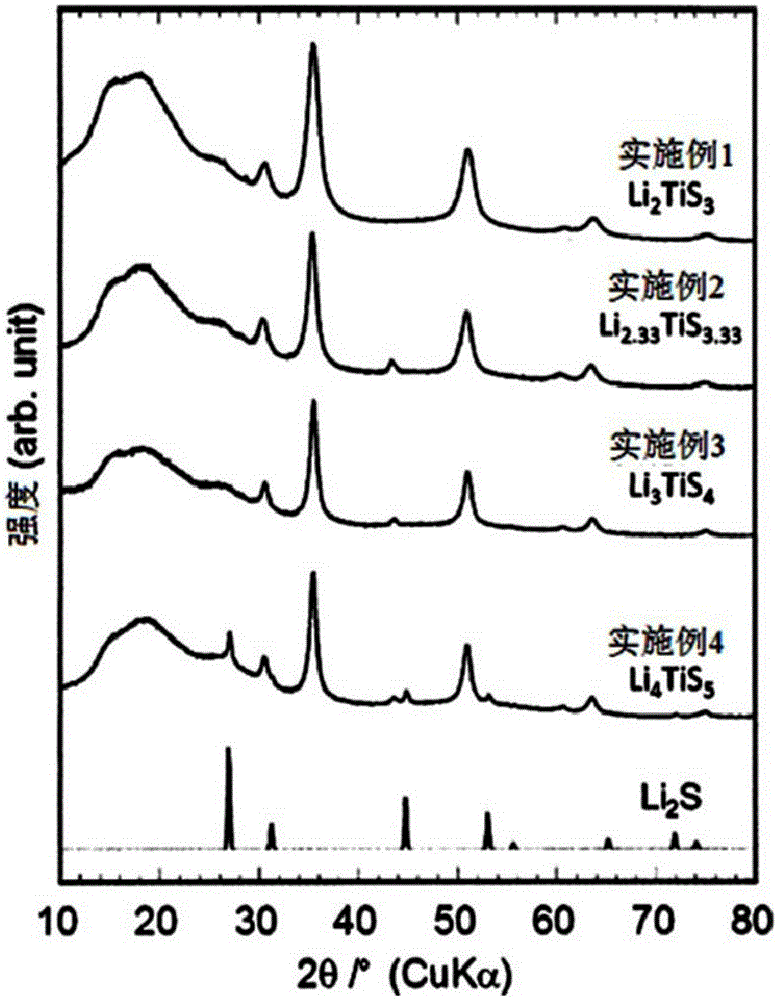

Lithium titanium sulfide, lithium niobium sulfide, and lithium titanium niobium sulfide

ActiveUS20160285097A1High charge and discharge capacityStable structurePositive electrodesTitanium compoundsNiobiumSulfur

The present invention provides a novel lithium titanium sulfide, lithium niobium sulfide, or lithium titanium niobium sulfide that contains a sulfide containing lithium, titanium and / or niobium, and sulfur as constituent elements, and that has excellent charge-discharge performance (especially excellent charge-discharge capacity and charge-discharge potential) useful as a cathode active material or the like for lithium batteries, such as metal lithium secondary batteries or lithium-ion secondary batteries. Particularly preferred are, for example, (1) lithium titanium sulfide containing lithium, titanium, and sulfur as constituent elements and having a cubic rock salt crystal structure, (2) lithium niobium sulfide containing lithium, niobium, and sulfur as constituent elements and having a diffraction peak at a specific position in an X-ray diffractogram, and (3) lithium titanium niobium sulfide containing lithium, titanium, niobium, and sulfur as constituent elements and having a diffraction peak at a specific position in an X-ray diffractogram.

Owner:NAT INST OF ADVANCED IND SCI & TECH

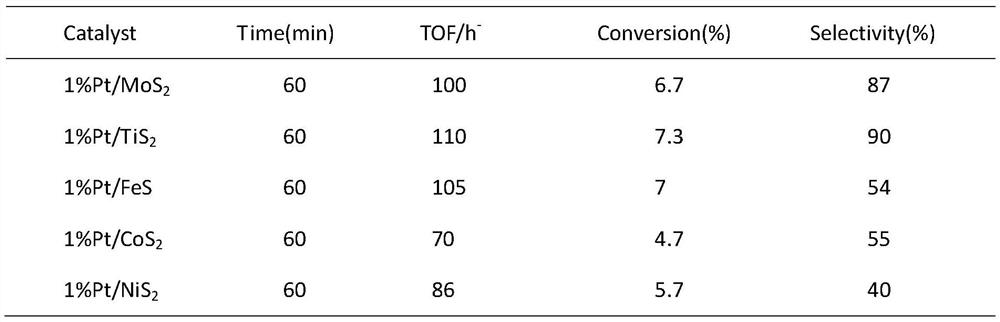

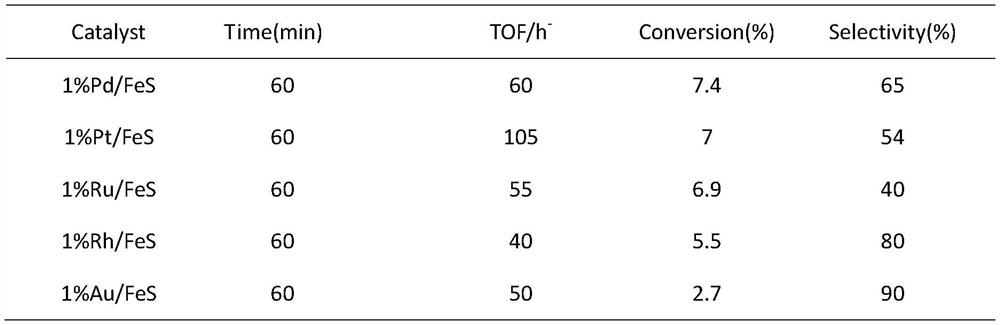

Hydrogenation catalyst modified by using solid-phase modifier and application of hydrogenation catalyst

ActiveCN110639613AAvoid Toxic ResiduesGood for repeated applicationHydrocarbon by hydrogenationOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystPalladium catalyst

The invention discloses a hydrogenation catalyst modified by using a solid-phase modifier and an application of the hydrogenation catalyst. The hydrogenation catalyst is a mixture of a supported palladium catalyst and the solid-phase modifier, or a metal palladium material supported by using the solid-phase modifier as a carrier; when the hydrogenation catalyst is the mixture of the supported palladium catalyst and the solid-phase modifier, the mass ratio of the solid-phase modifier to the supported palladium catalyst is (0.1-500):1; and when the hydrogenation catalyst is the metal palladium material supported by using the solid-phase modifier as the carrier, the loading amount of metal palladium is 0.1-20 wt%, wherein the solid-phase modifier is polyphenylene sulfide or a metal sulfide, and the metal sulfide is at least one selected from the group consisting of silver sulfide, barium sulfide, cadmium sulfide, cerium sulfide, ferrous sulfide, ferrous disulfide, lithium sulfide, sodiumsulfide, nickel sulfide, manganese sulfide, molybdenum sulfide, selenium sulfide, tungsten sulfide, zinc sulfide, copper sulfide and titanium sulfide. The hydrogenation catalyst provided by the invention has high catalytic activity in selective hydrogenation of alkynes, and can effectively improve the catalytic selectivity of a target olefin product.

Owner:ZHEJIANG SUPERIOR TECH CORP LTD

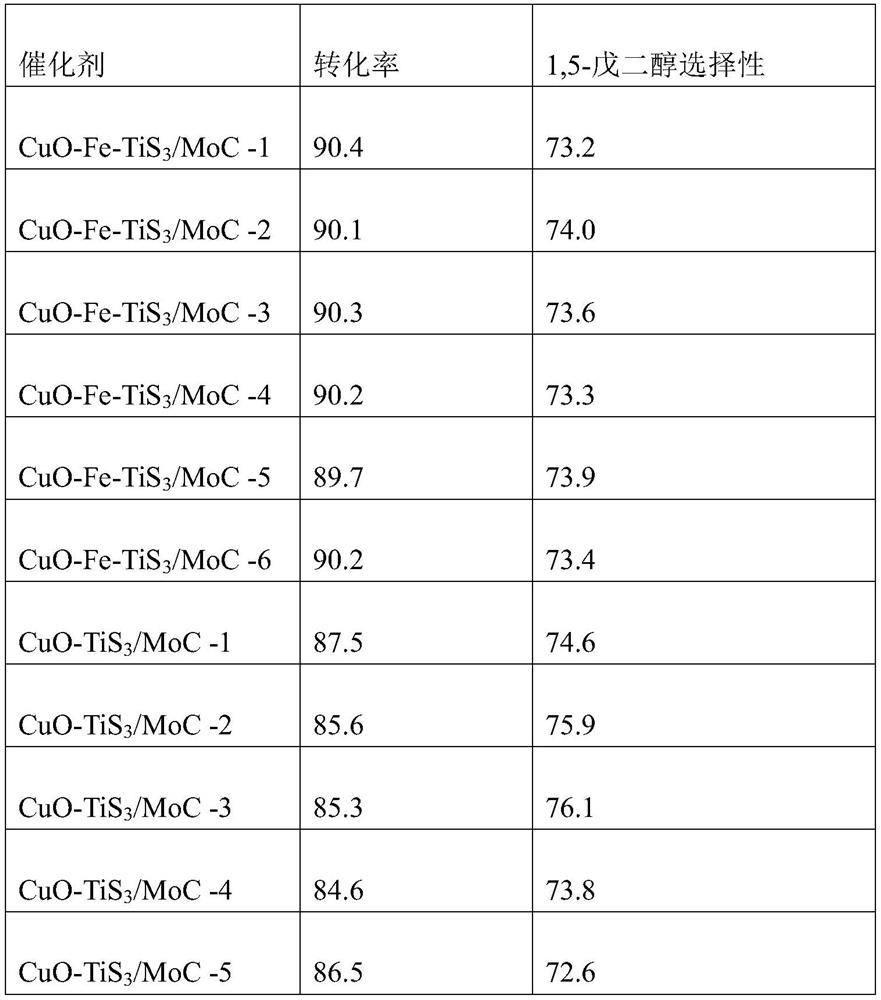

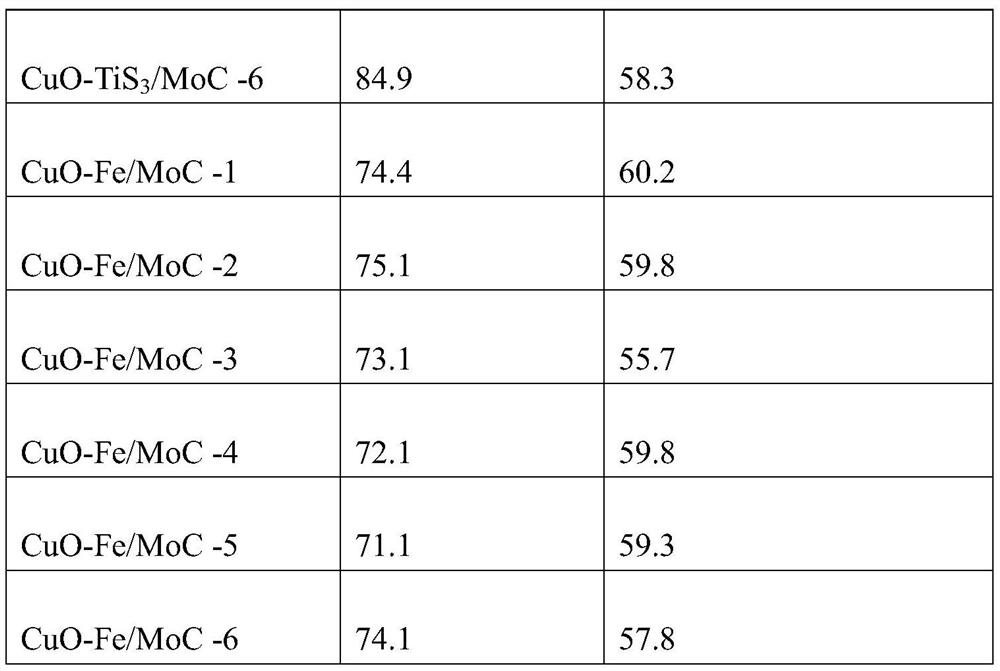

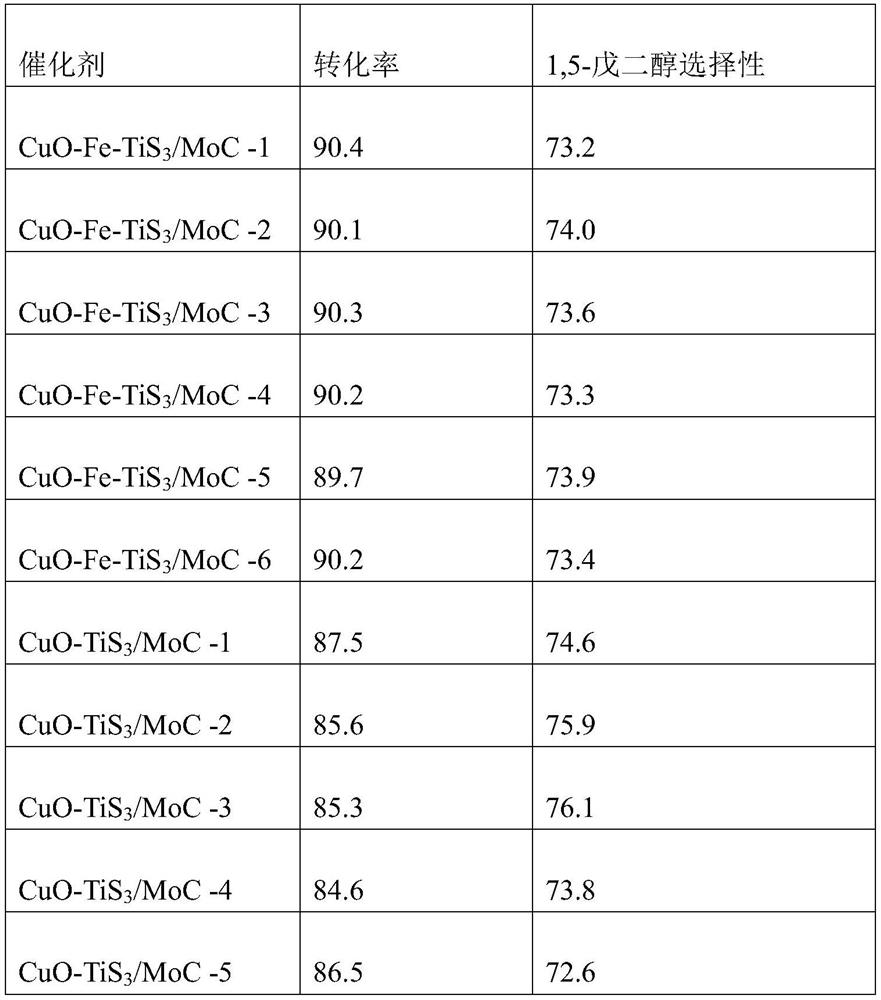

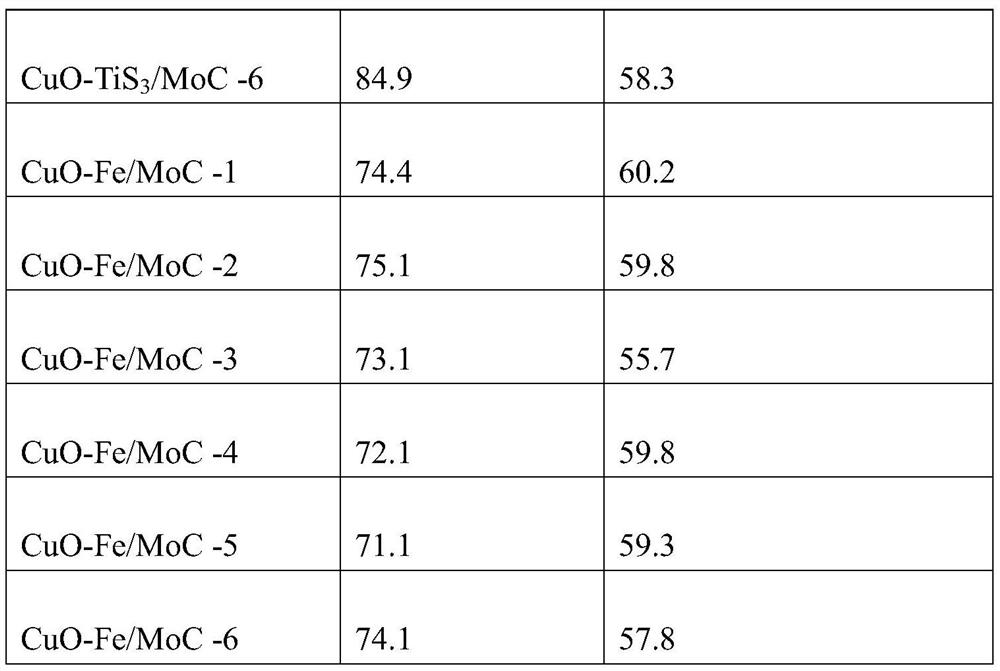

Hydrogenation catalyst and preparation method thereof, and application of hydrogenation catalyst in catalyzing tetrahydrofurfuryl alcohol hydrogenation to prepare 1,5-pentanediol

ActiveCN111715264ALow costEnhanced electron transfer capabilityPhysical/chemical process catalystsPreparation by oxygen reductionPtru catalystTitanium sulfide

The invention discloses application of a molybdenum carbide-dispersed copper oxide-titanium trisulfide catalyst to catalytic hydrogenation of tetrahydrofurfuryl alcohol to prepare 1,5-pentanediol. According to the method, copper oxide is used as an active component, one or more modification metals selected from iron, cobalt, nickel, zinc, chromium and vanadium are used for modifying the active component, titanium trisulfide is used as a cocatalyst, a composite component is loaded on a molybdenum carbide carrier, and the formed catalyst is applied to catalytic conversion of tetrahydrofurfuryl alcohol to prepare 1,5-pentanediol. According to the method, the catalyst is prepared from non-noble metal, so cost is low, and stability is good.

Owner:WANHUA CHEM GRP CO LTD

Process for the production of 2-hydroxy-4-methythiobutyric acid ammonium salt

InactiveUS7485748B2High nutritional valueOrganic compound preparationPreparation from nitrilesSingle processTitanium sulfide

A process for preparing 2-hydroxy-4-methylthiobutyric acid ammonium salt involves reacting 3-methylthiopropionaldehyde with hydrogen cyanide to form 2-hydroxy-4-methylthiobutyronitrile, and subsequently hydrolyzing the 2-hydroxy-4-methylthiobutyronitrile by catalytic hydrolysis to form the ammonium salt of the 2-hydroxy-4-methylthiobutyric acid in a single process step. One catalyst may be used in the hydrolysis for the whole reaction. The catalyst is preferably a solid containing a titanium compound such as, e.g., titanium nitride, titanium sulfide or titanium dioxide. The 2-hydroxy-4-methylthiobutyric acid ammonium salt produced by this process is nutritional and can be used as an additive in feedstuffs.

Owner:EVONIK DEGUSSA GMBH

Method for rapidly displaying titaniferous inclusions in field condition based on corrosion principle

InactiveCN102680304AShow accurate and validAvoid confusing field of viewPreparing sample for investigationMaterial analysis by optical meansField conditionsMembrane technology

The invention belongs to the technical field of a method for rapidly displaying titaniferous inclusions in the field condition based on a corrosion principle, in particular relates to the technical field of metallographic sample preparation of the field metallographic displaying method of titanium nitride and titanium sulfide inclusions in steels, and the like. The method includes the steps of preparing metallographic samples and grinding the samples with 2000 # abrasive paper; corroding surfaces of the ground samples with special chemical reagent, wherein effects of polishing and appearance displaying of titaniferous inclusions can be achieved simultaneously; and performing observation with a field metallographic microscope or sampling analysis by using the membrane coating technology. According to the method, shapes of the titanium nitride and titanium sulfide inclusions can be highlighted, thus, matrix should be prevented from presenting metallographic structures to confuse the field of view, further, field metallographic sample preparation difficulties can be simplified, and sample preparation efficiency can be improved. Besides, titaniferous inclusions in steels can be displayed accurately and efficiently, and the method has the advantages that sample preparation is convenient, displaying effect is good, generality is high and the like.

Owner:NORTHEAST POWER SCI RES INSTITUTION +2

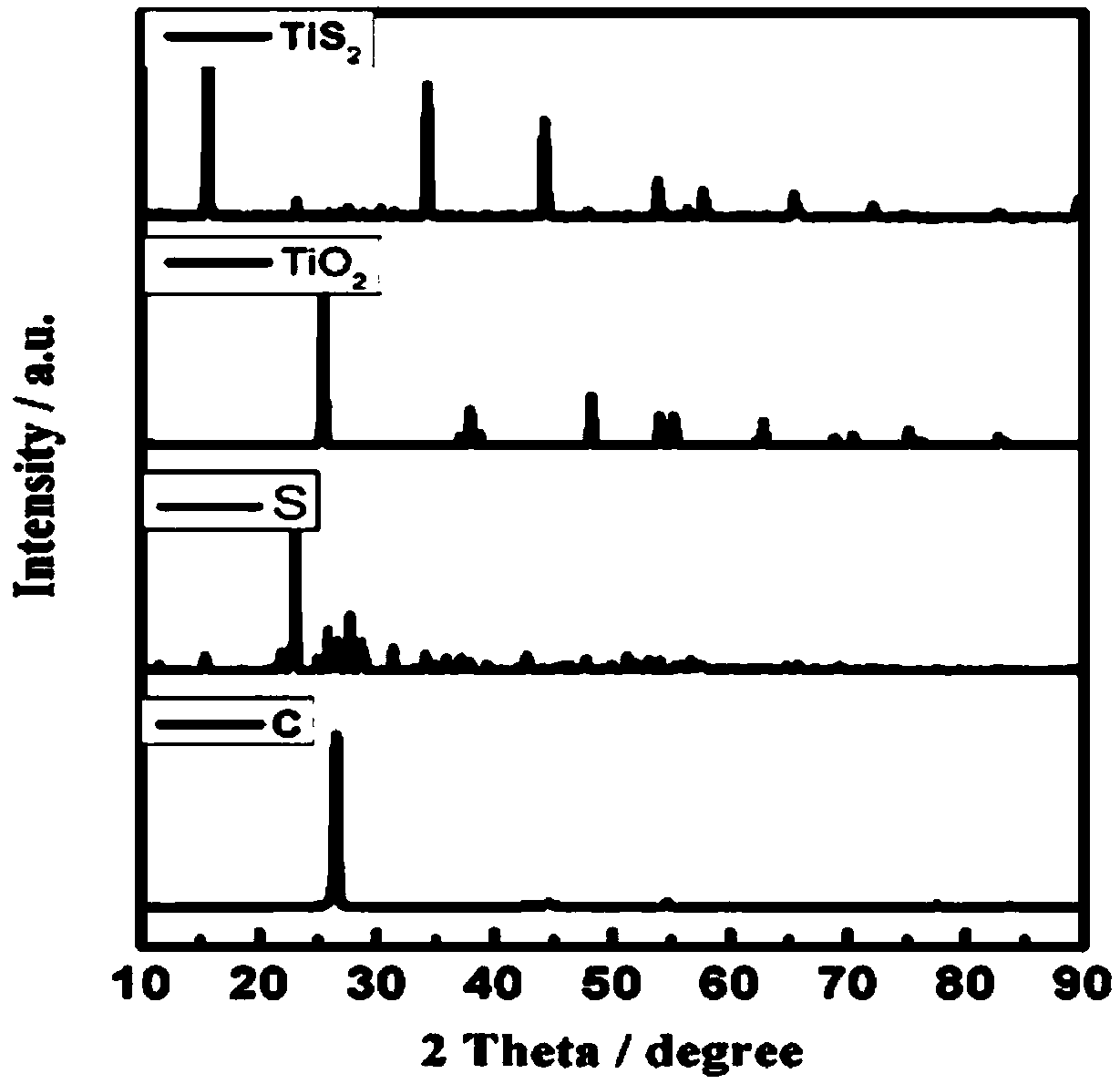

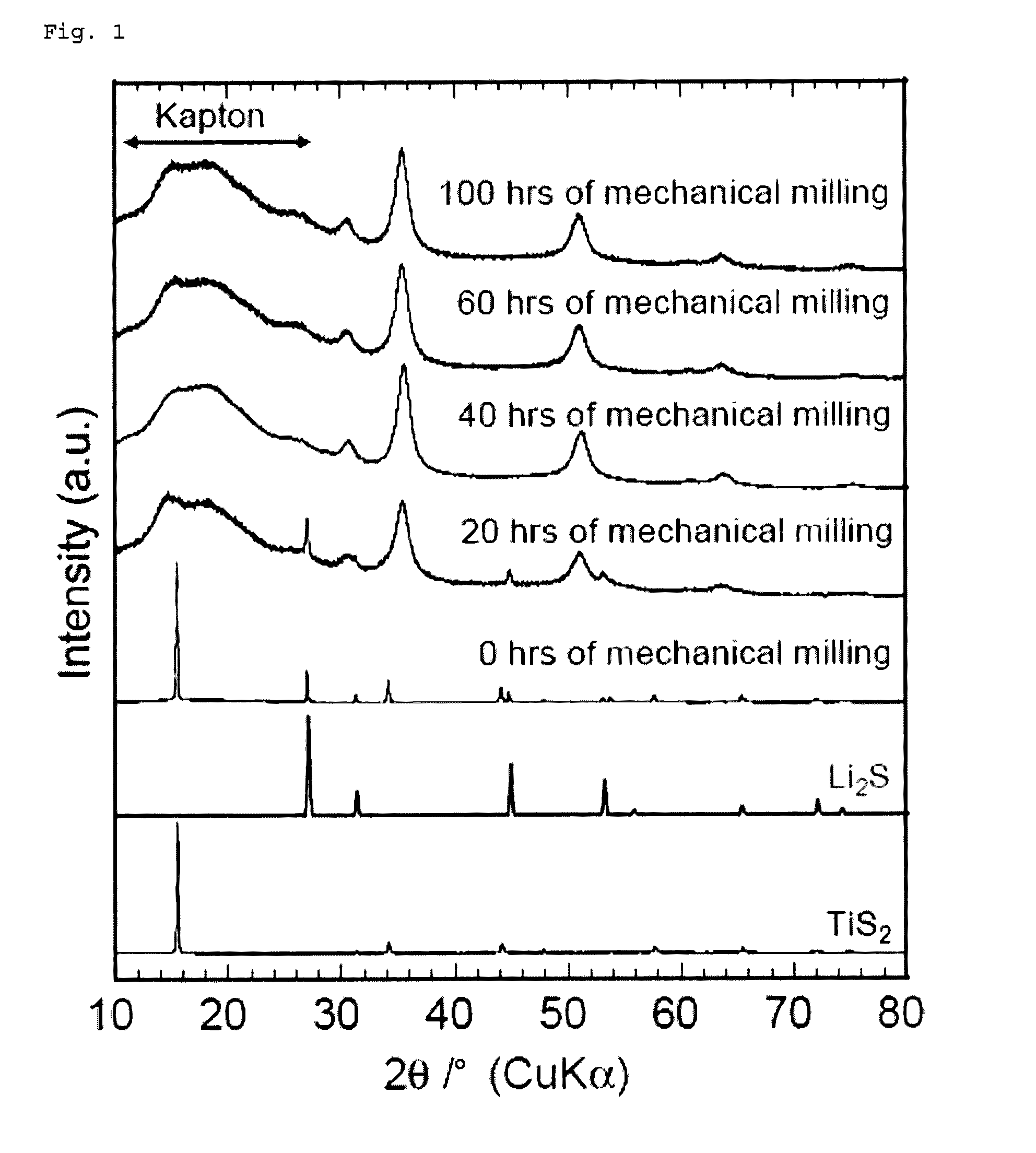

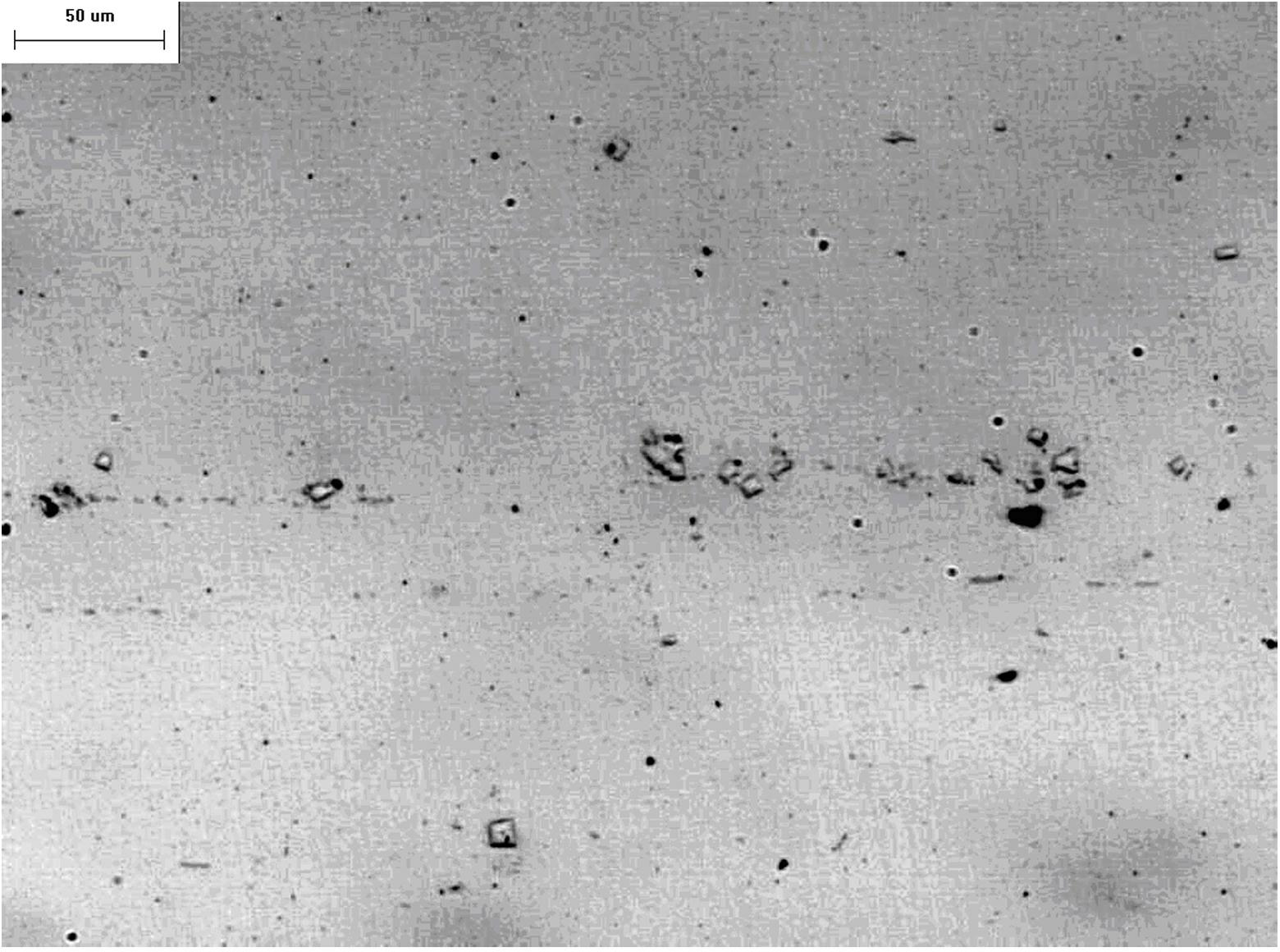

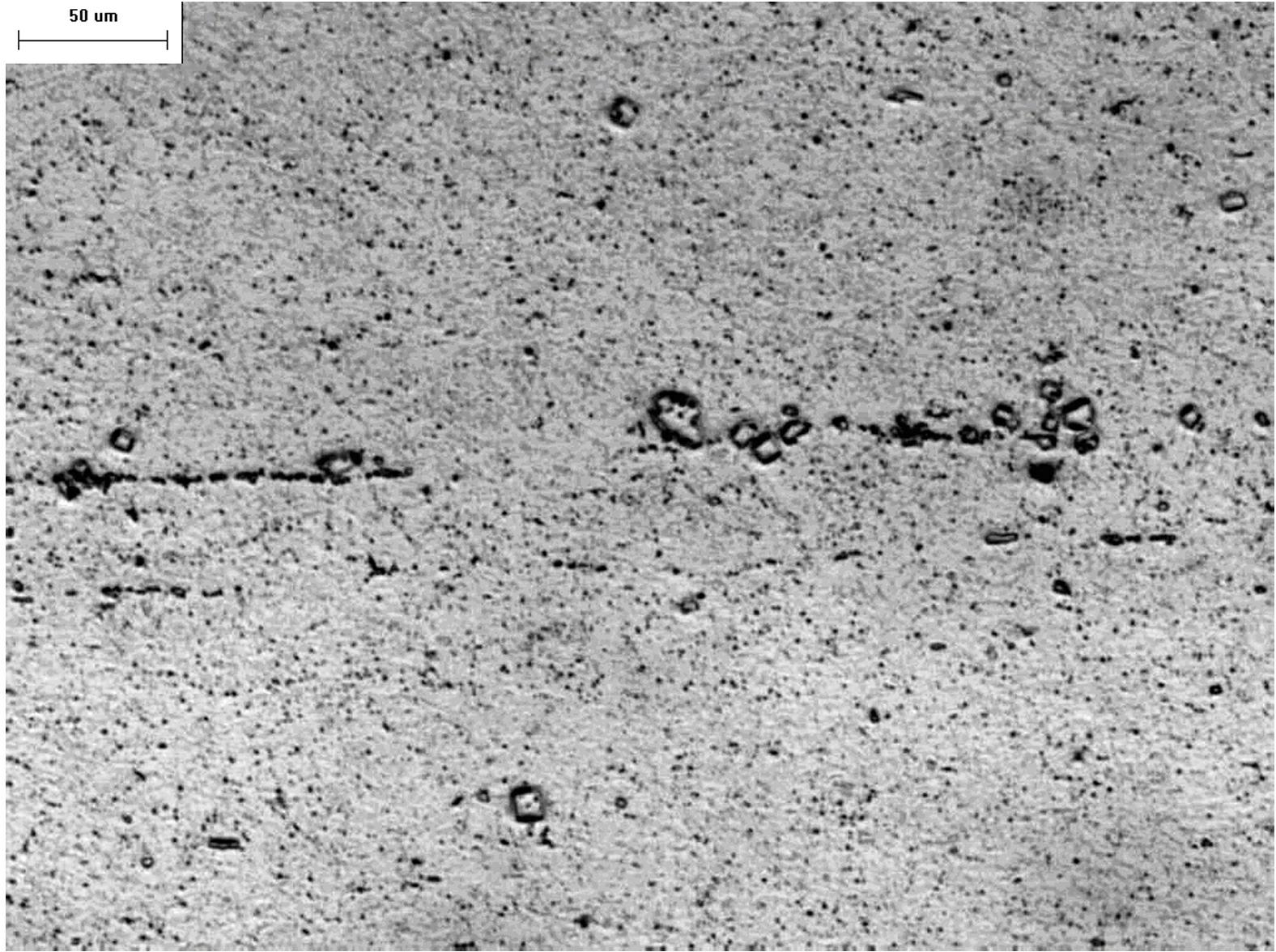

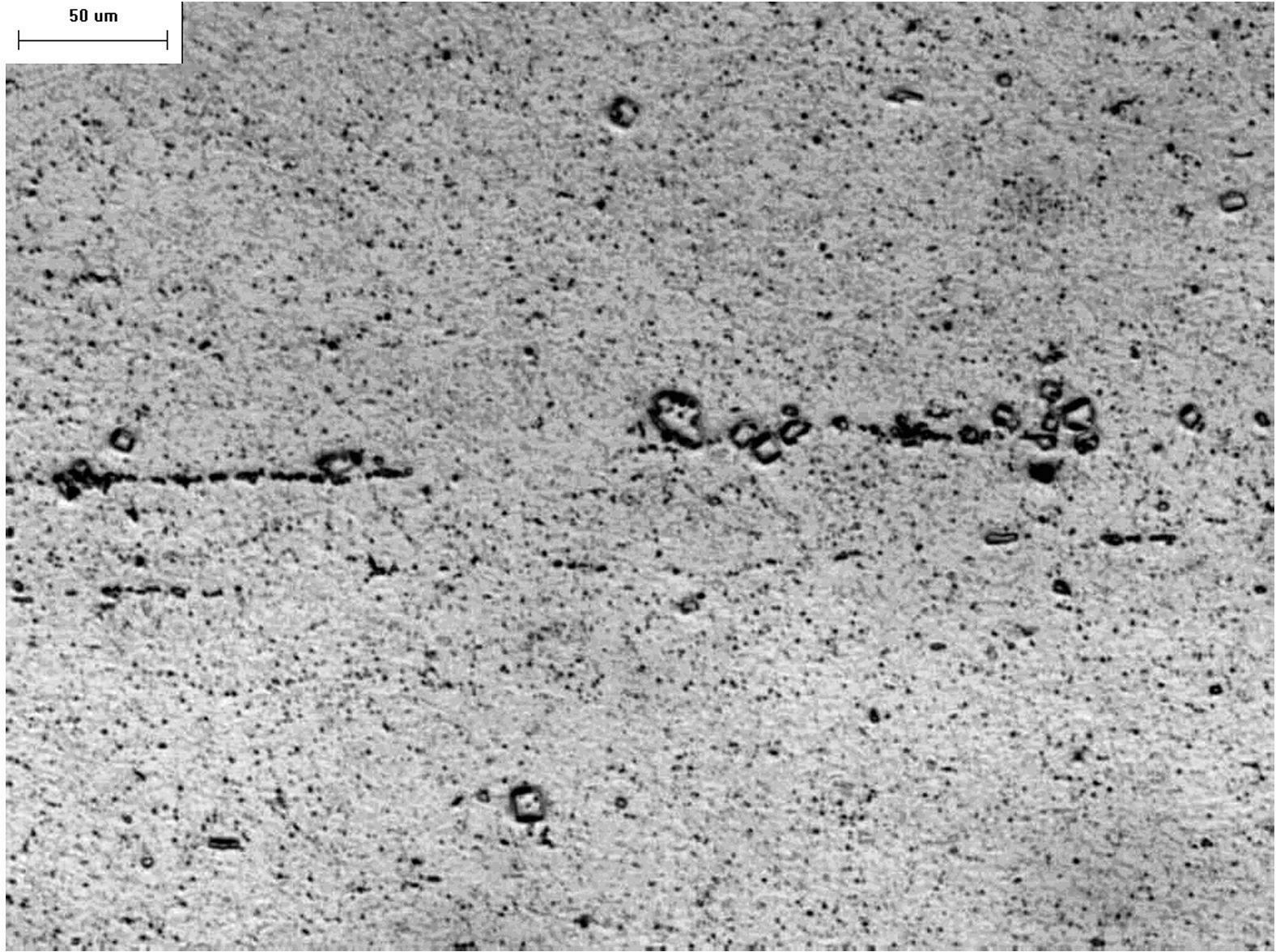

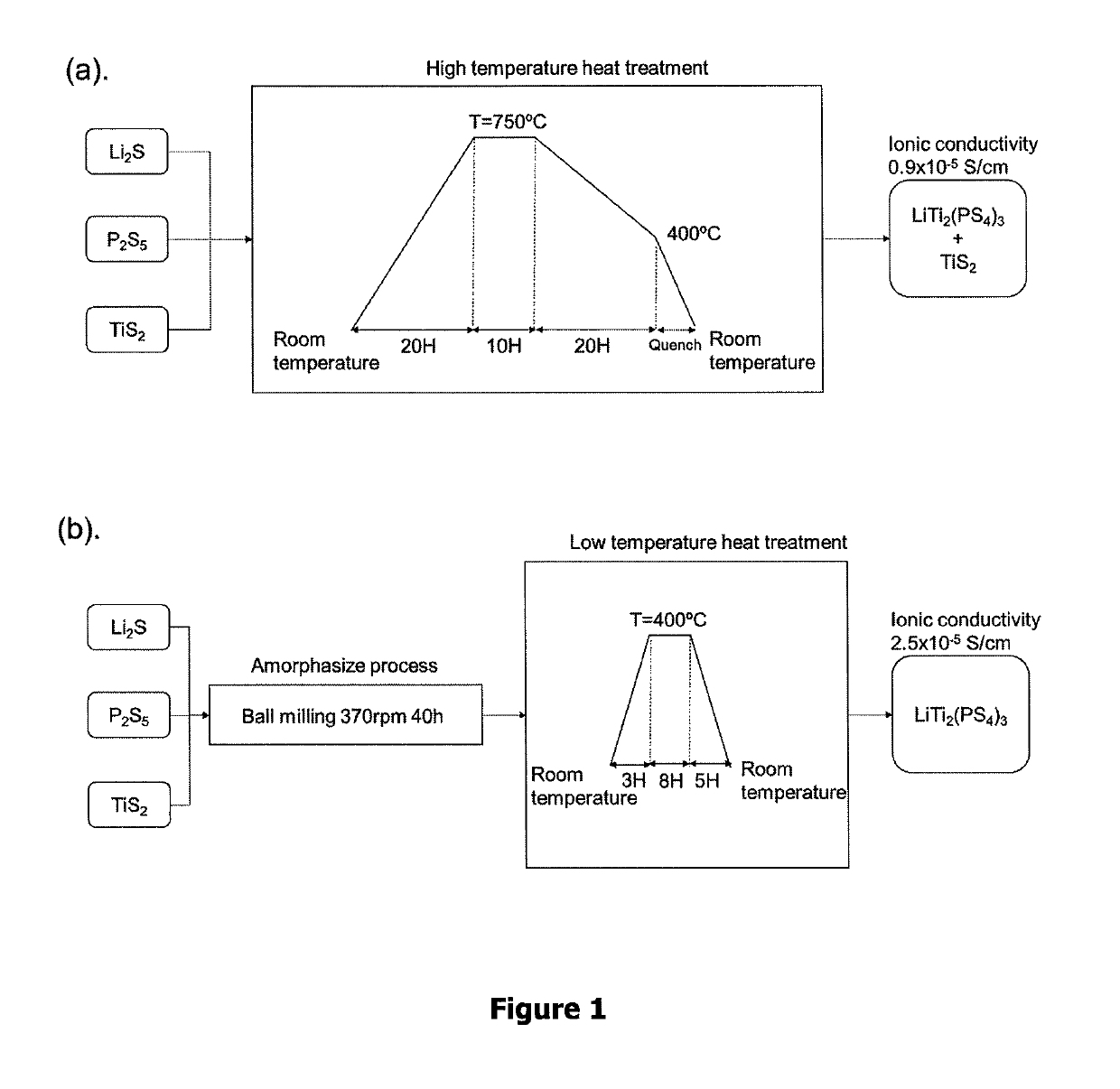

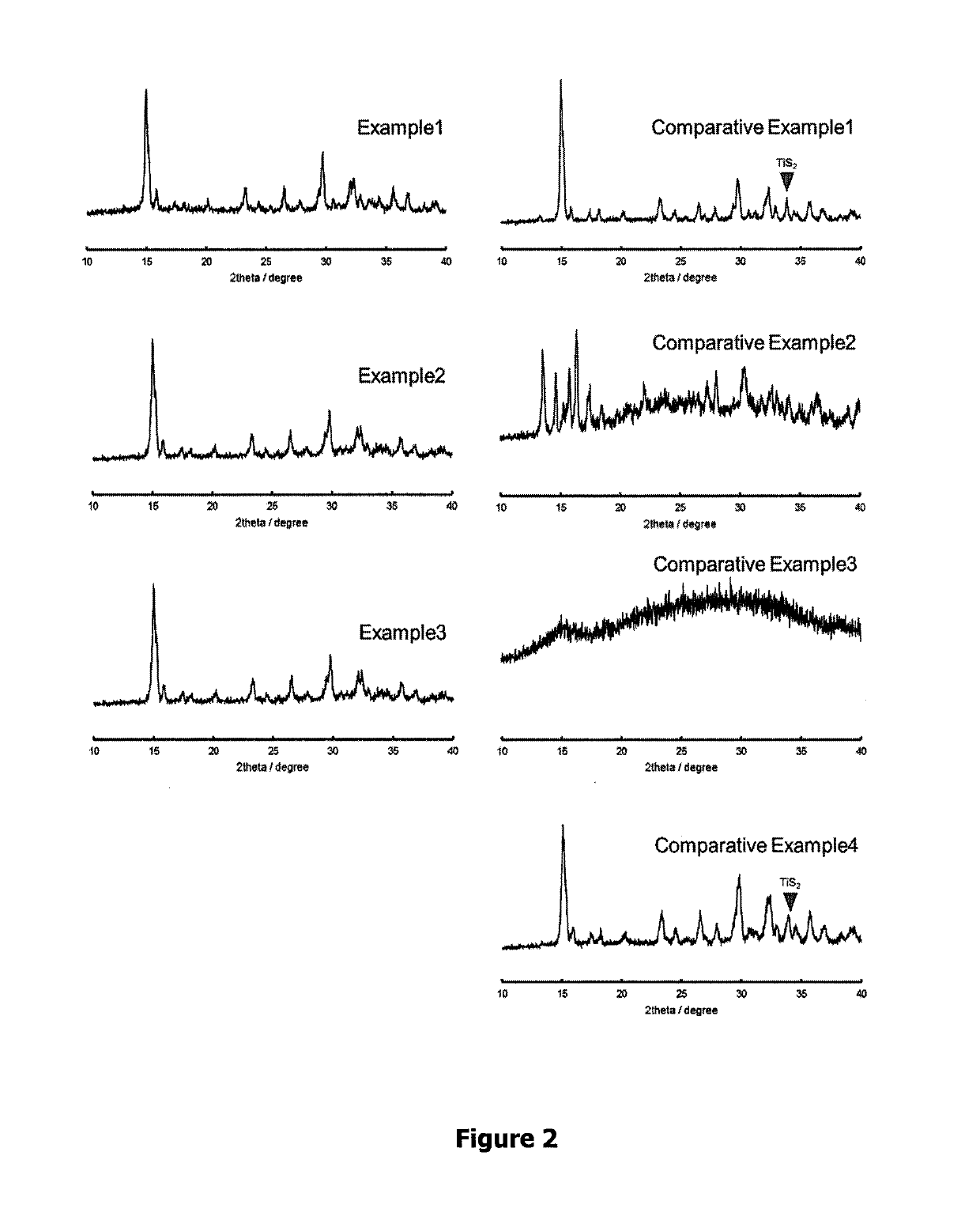

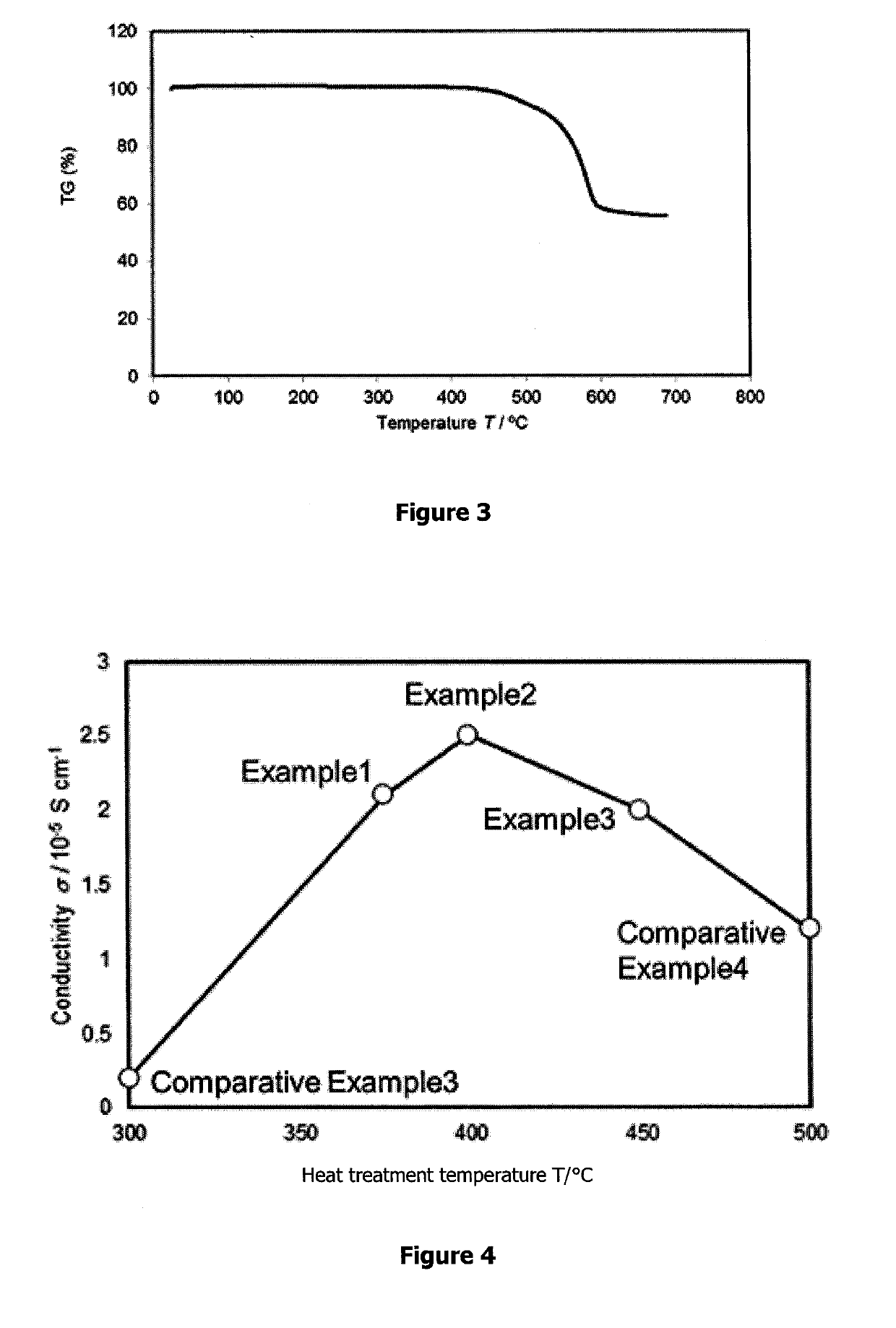

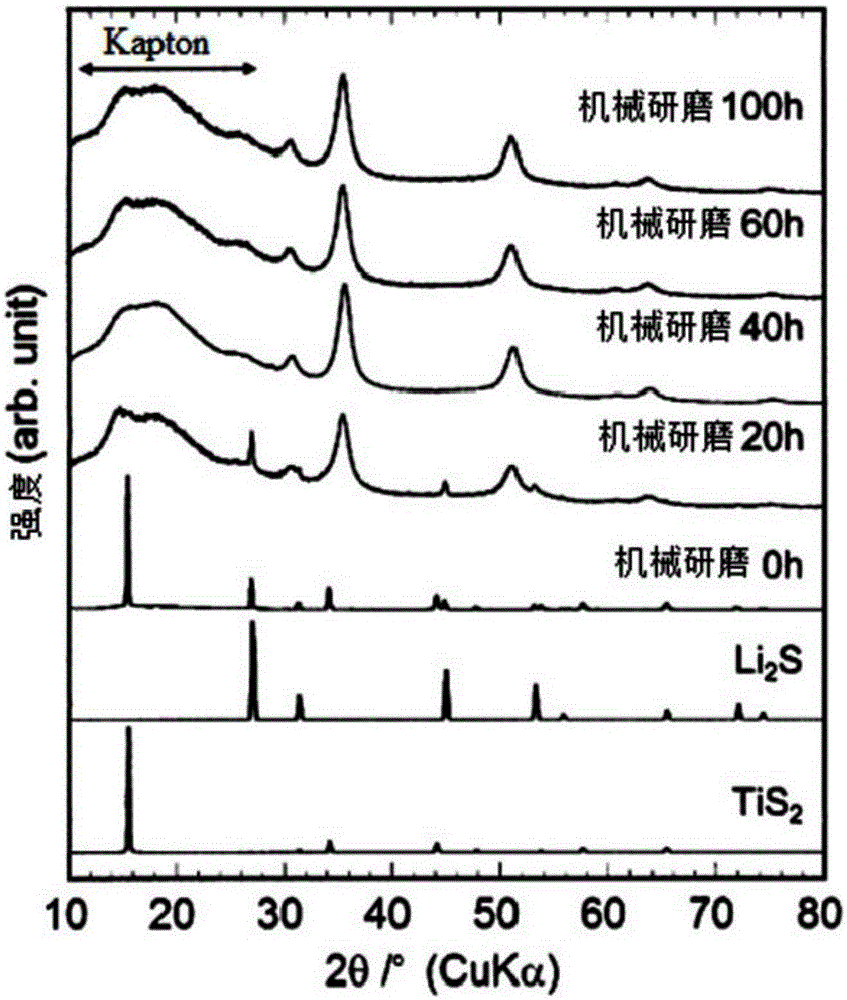

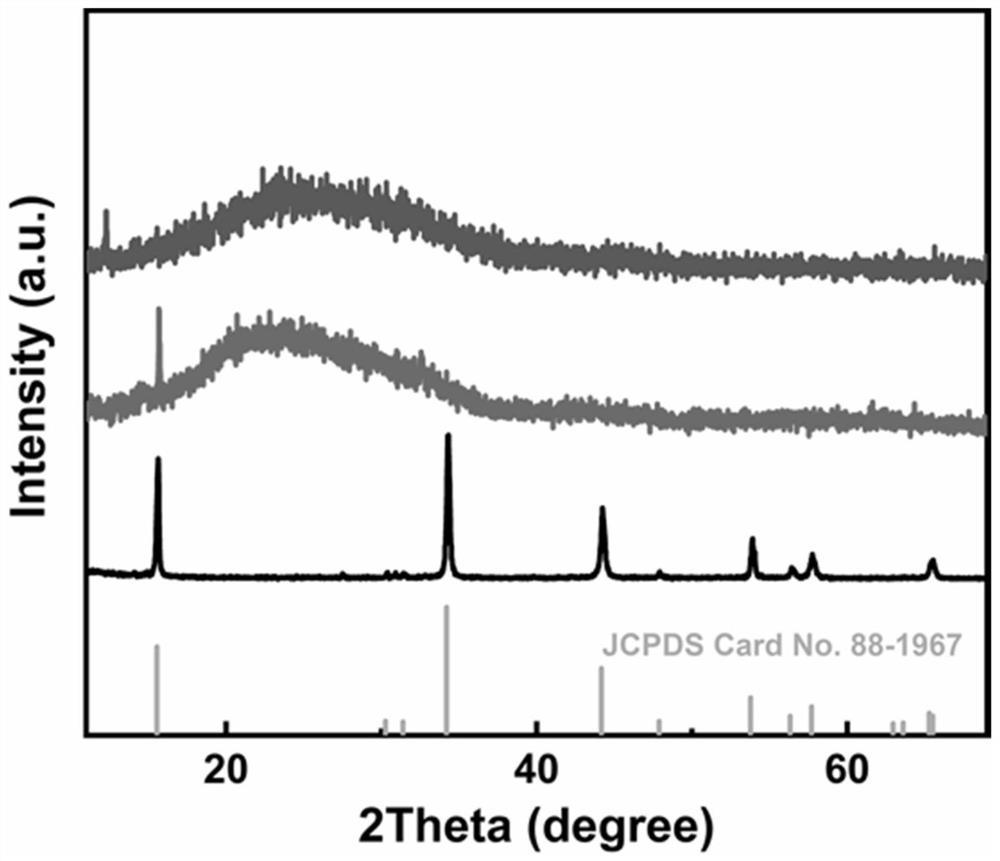

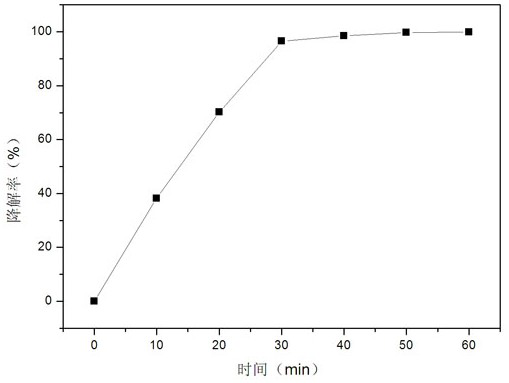

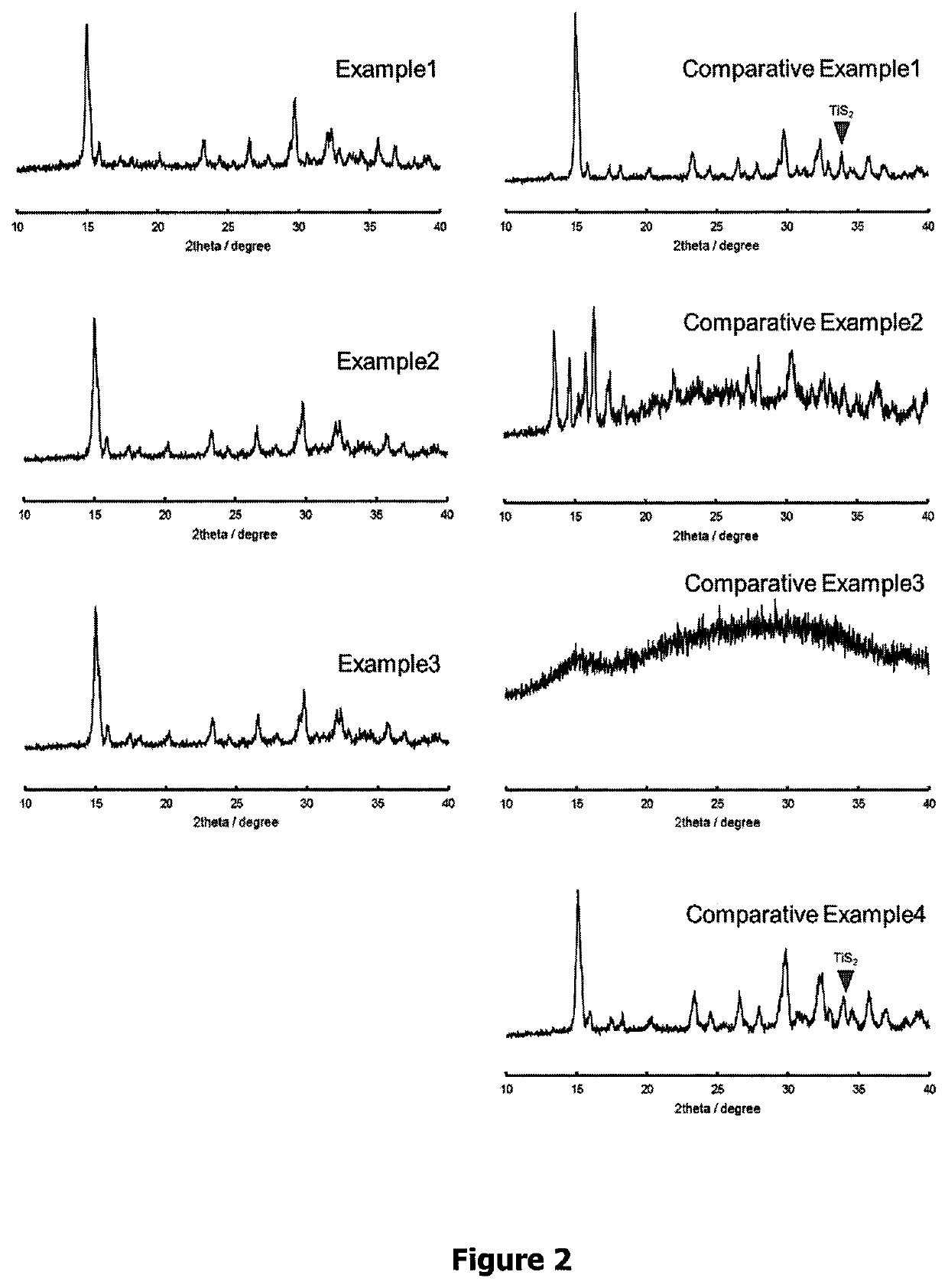

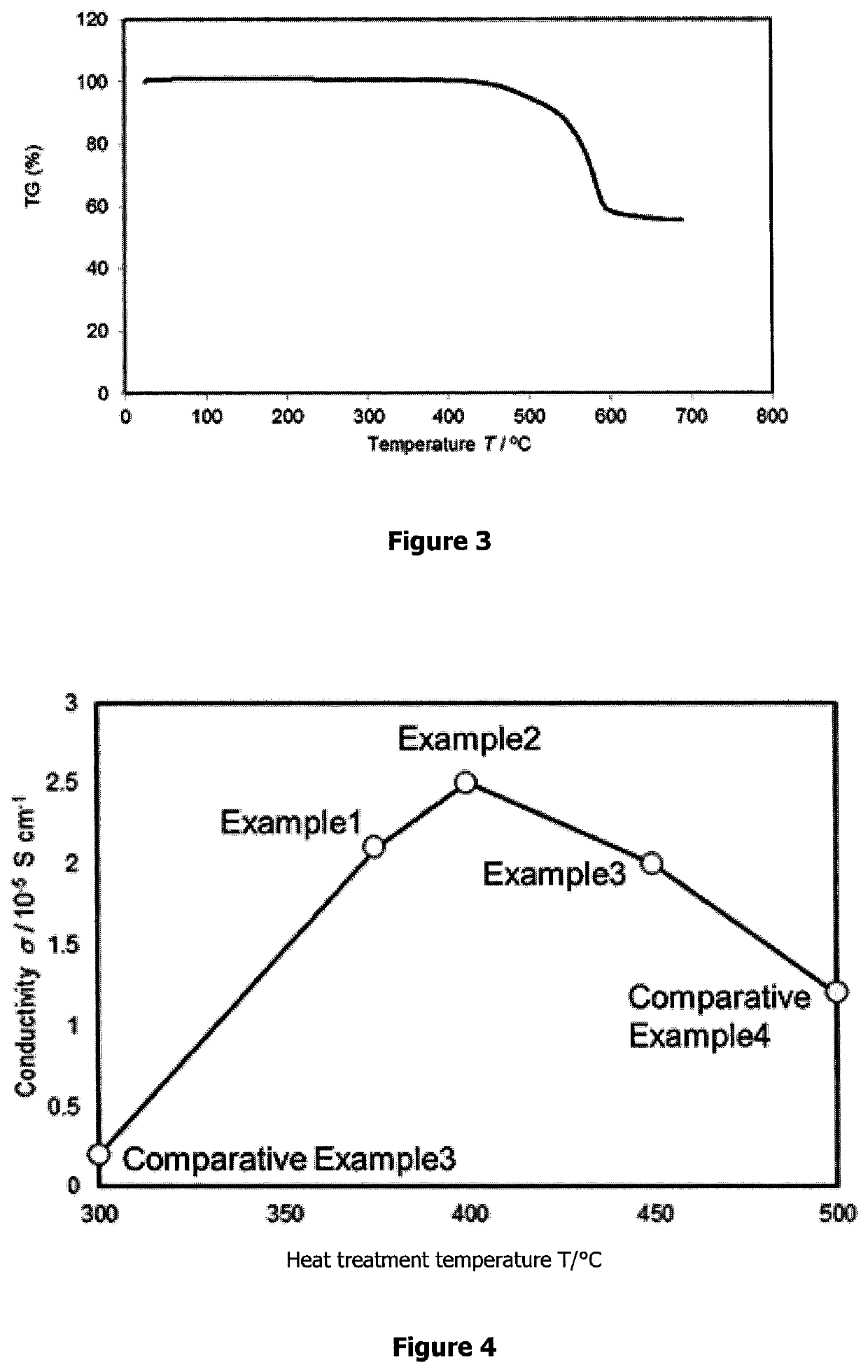

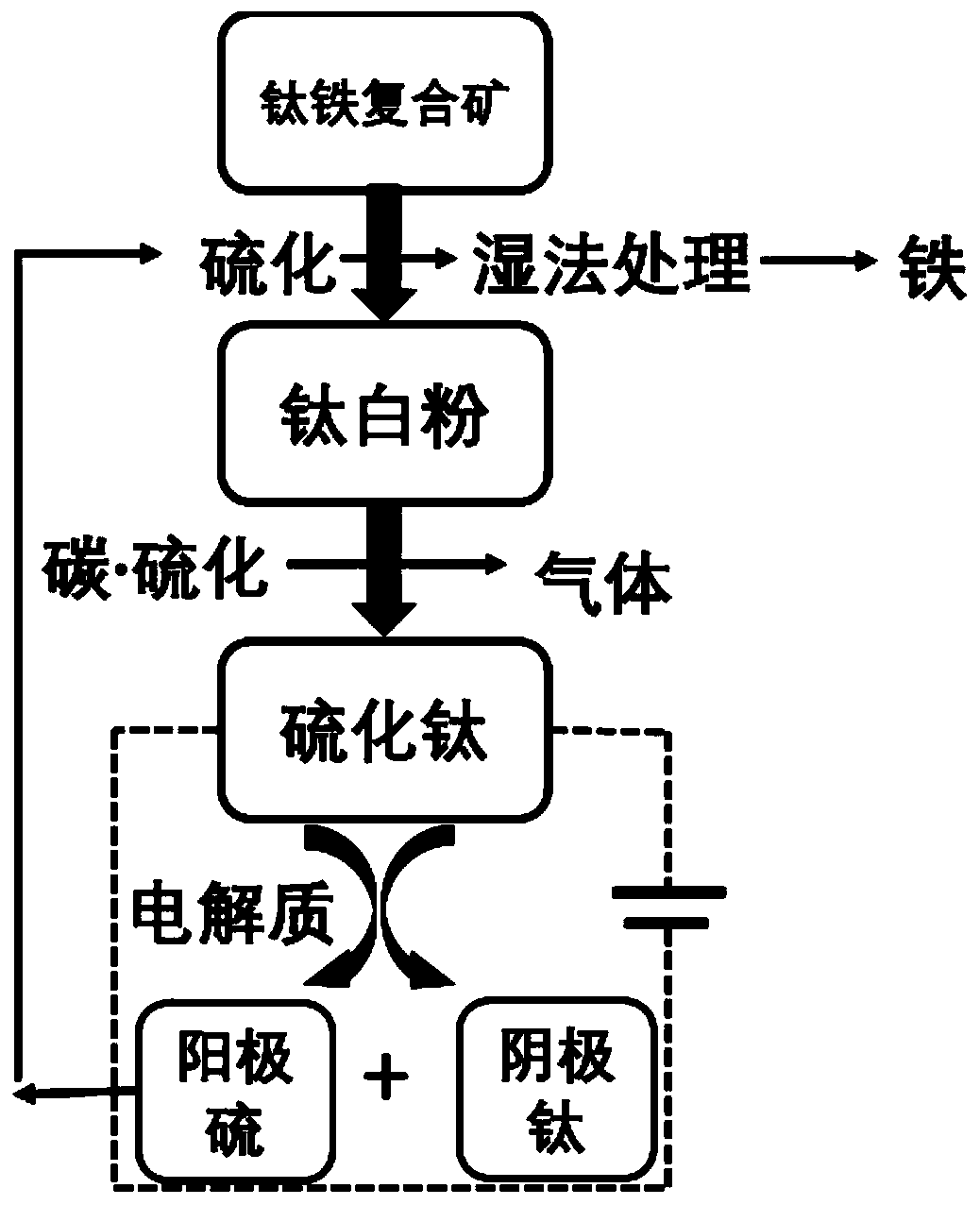

METHOD OF SYNTHESIS OF LiTi2(PS4)3

ActiveUS20190177163A1Solid electrolytesPhosphorus sulfur/selenium/tellurium compoundsSynthesis methodsMechanical milling

A method of synthesis of lithium titanium thiophosphate LiTi2(PS4)3 including the steps of: (a) providing a mixture of lithium sulfide Li2S, phosphorus sulfide P2S5 and titanium sulfide TiS2; (b) subjecting the mixture prepared in step (a) to a preliminary reaction step through mechanical milling or melt-quenching to produce an intermediate amorphous sulfide mixture; (c) subjecting the mixture prepared in step (b) to a heat treatment step at a maximum plateau temperature of at least 350° C. and less than 500° C.

Owner:TOYOTA JIDOSHA KK

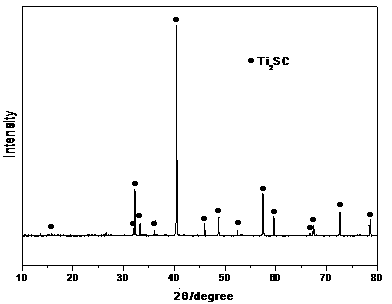

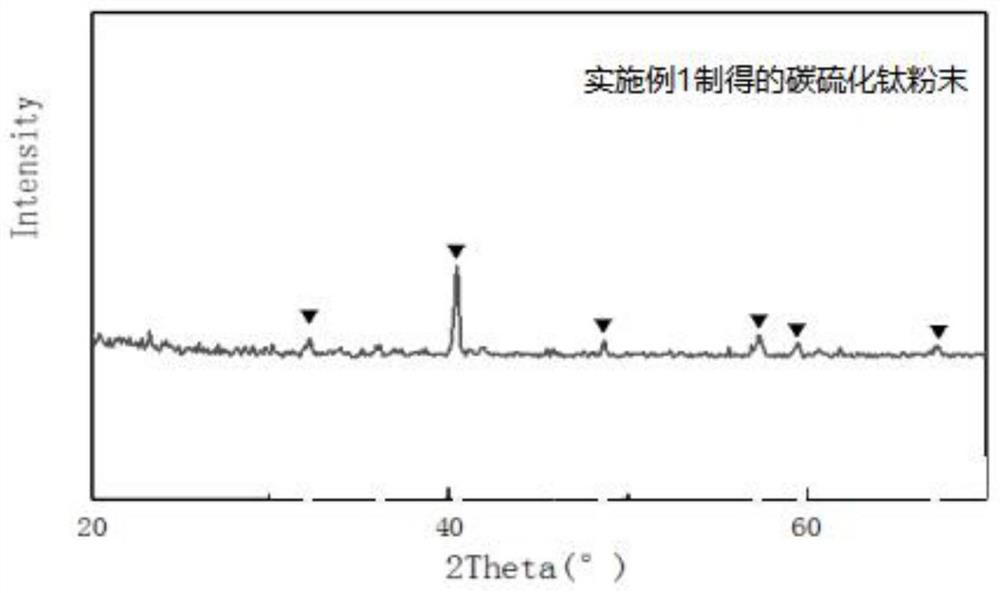

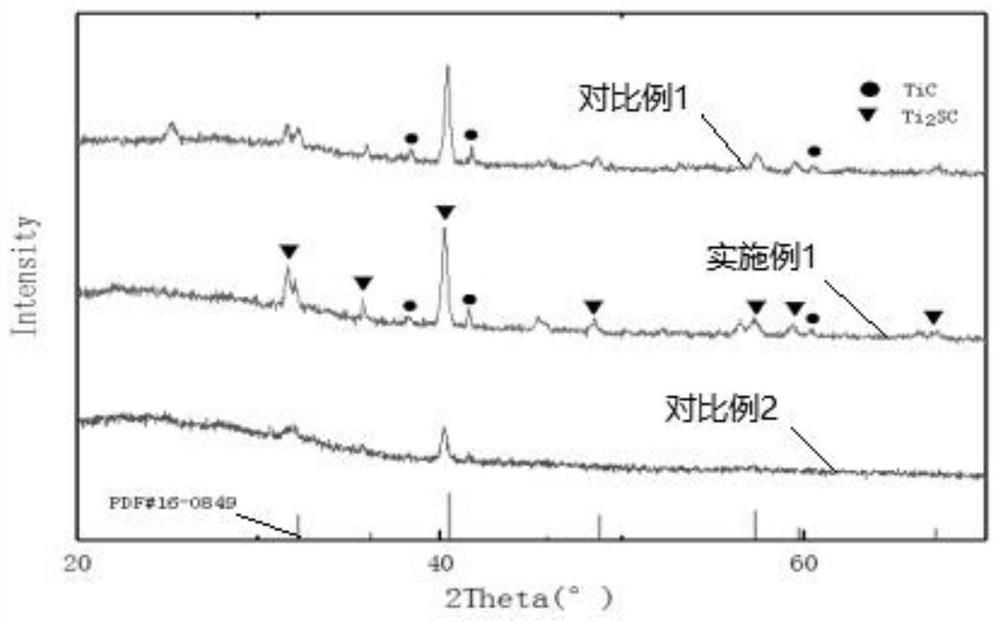

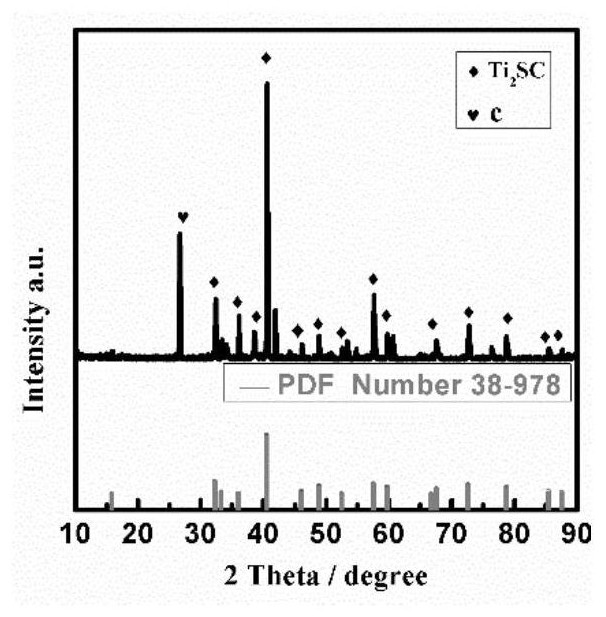

Novel method for synthesizing Ti2SC ceramic by microwave heating

The invention relates to a preparation method of Ti2SC ceramic by microwave synthesis, which is characterized by comprising the following steps: taking titanium powder, titanium disulfide powder and graphite powder in a mole ratio of (2.5-3):3:(1.0-1.2), evenly mixing, pelleting, and carrying out microwave heating on the pellet material under the protection of inert gas which can not generate chemical reaction on the raw material and reactant, thereby synthesizing the high-purity Ti2SC ceramic. The method can be used for quickly preparing the Ti2SC ceramic powder, greatly reduces the reaction temperature and reaction time, enhances the efficiency by tens of times as compared with the traditional Ti2SC ceramic preparation method, and obtains the favorable single-phase sample.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

Lithium titanium sulfide, lithium niobium sulfide, and lithium titanium niobium sulfide

ActiveCN105189358ARealize chargingRealize charging and dischargingPositive electrodesTitanium compoundsNiobiumNickel–lithium battery

Provided is a novel lithium titanium sulfide, lithium niobium sulfide, or lithium titanium niobium sulfide endowed with the excellent charge / discharge performance (especially the excellent charge / discharge capacity and charge / discharge potential) useful for a positive electrode active material or the like for a lithium battery such as a metal lithium secondary battery or a lithium ion secondary battery by a sulfide containing lithium, titanium and / or niobium, and sulfur as constituent elements. Particularly preferred are (1) lithium titanium sulfide containing lithium, titanium, and sulfur as constituent elements and having a cubic rock-salt crystal structure, (2) lithium niobium sulfide containing lithium, niobium, and sulfur as constituent elements and having a diffraction peak at a specific position in an x-ray diffractogram, (3) lithium titanium niobium sulfide containing lithium, titanium, niobium, and sulfur as constituent elements and having a diffraction peak at a specific position in an x-ray diffractogram, or the like.

Owner:NAT INST OF ADVANCED IND SCI & TECH

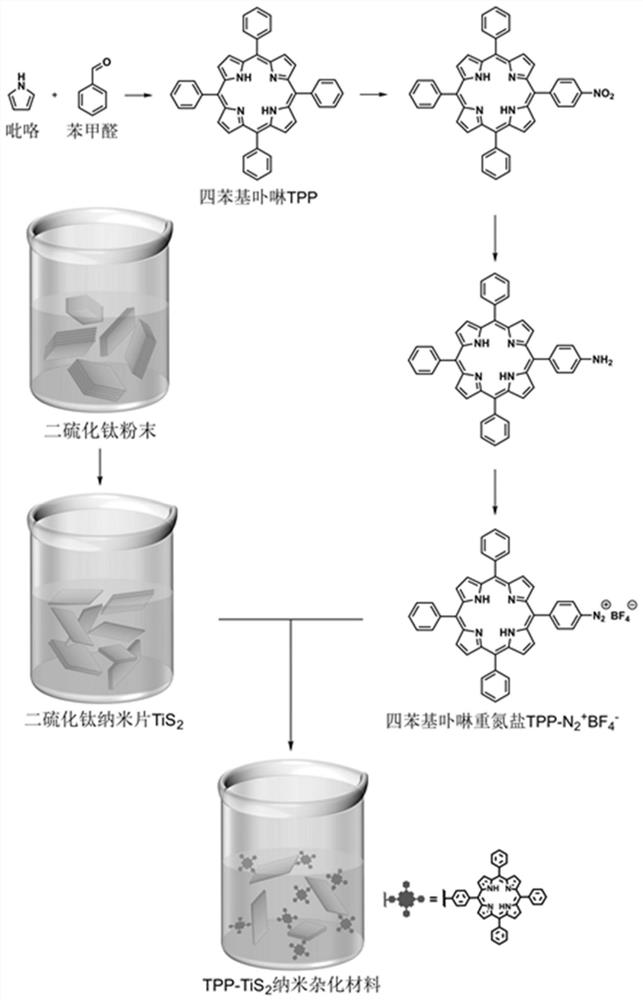

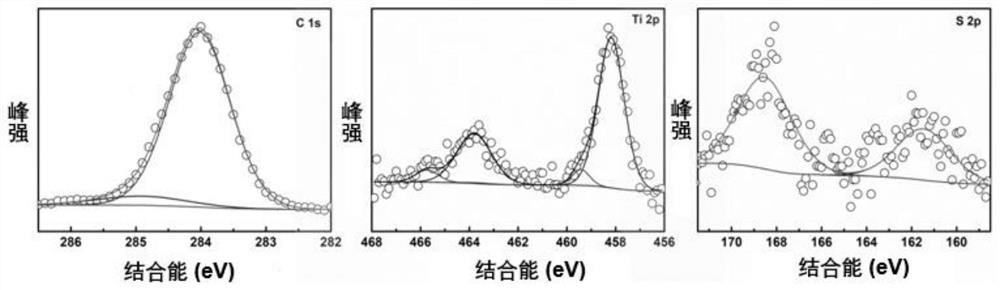

Tetraphenylporphyrin covalently functionalized titanium disulfide nonlinear nano hybrid material and preparation thereof

ActiveCN113735866AExtend modifiabilityRich preparation methodOrganic chemistry methodsPhotovoltaic energy generationTitanium disulfideNano hybrid

The invention relates to a tetraphenylporphyrin covalent functionalized titanium disulfide nonlinear nano hybrid material and preparation thereof, the hybrid material is obtained by a free radical addition reaction of tetraphenylporphyrin diazonium salt TPP-N2 + BF4-and sulfur atoms on the surface layer of a titanium disulfide nanosheet, and the hybrid material is a first example about the covalent functionalization of the titanium disulfide nanosheet at present. Compared with a hybrid material obtained by simply and physically mixing the two types of optical functional materials, the hybrid material obtained by bonding carbon-sulfur covalent bonds shows a remarkably enhanced saturated absorption phenomenon in a visible light range. According to the invention, chemical modification methods of titanium disulfide are enriched, and the obtained material has a wide application prospect in the photoelectric fields of nonlinear optical devices and the like.

Owner:TONGJI UNIV

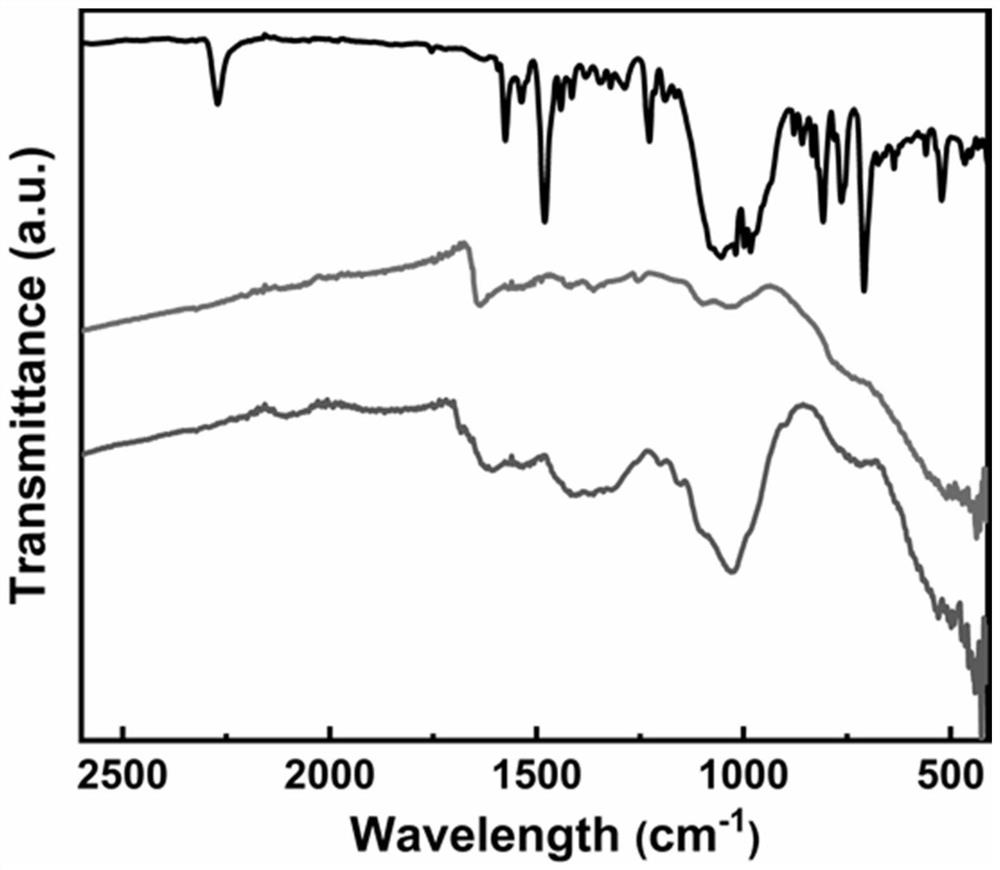

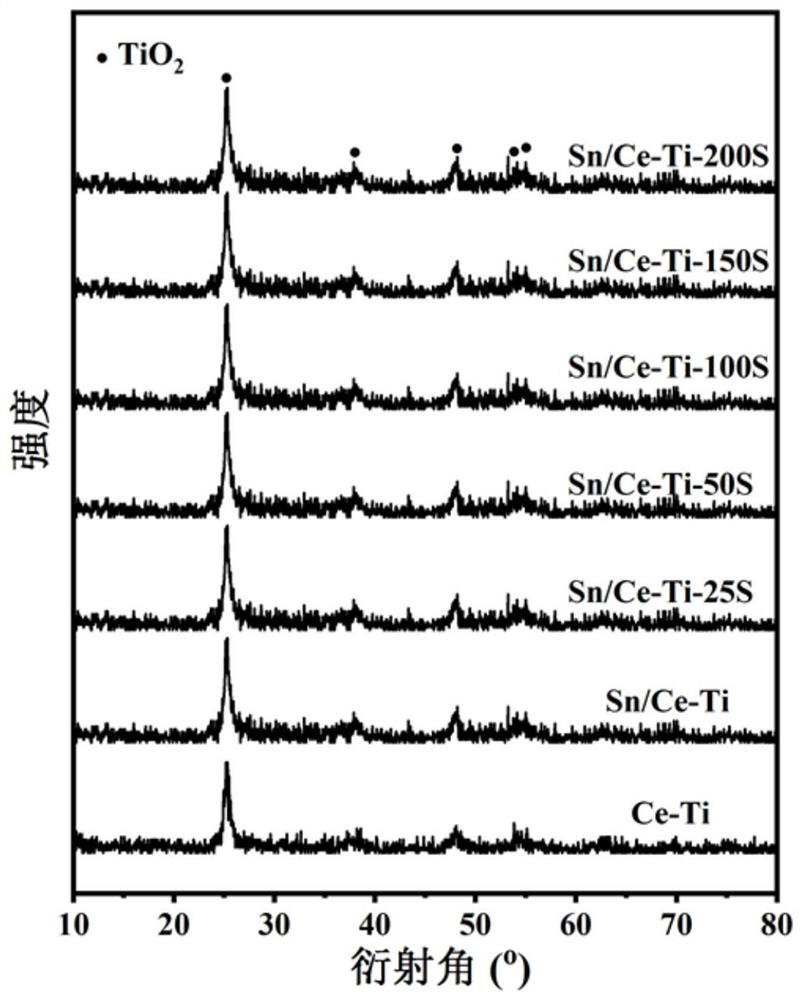

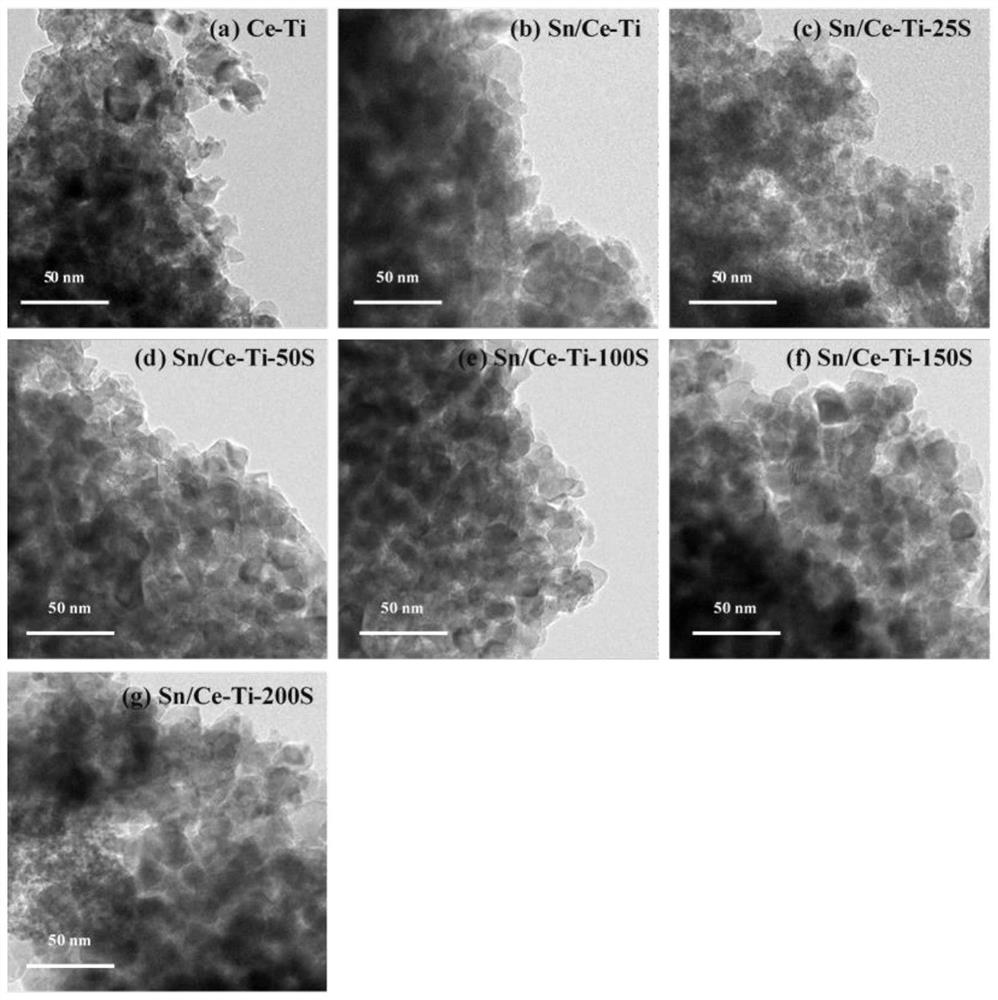

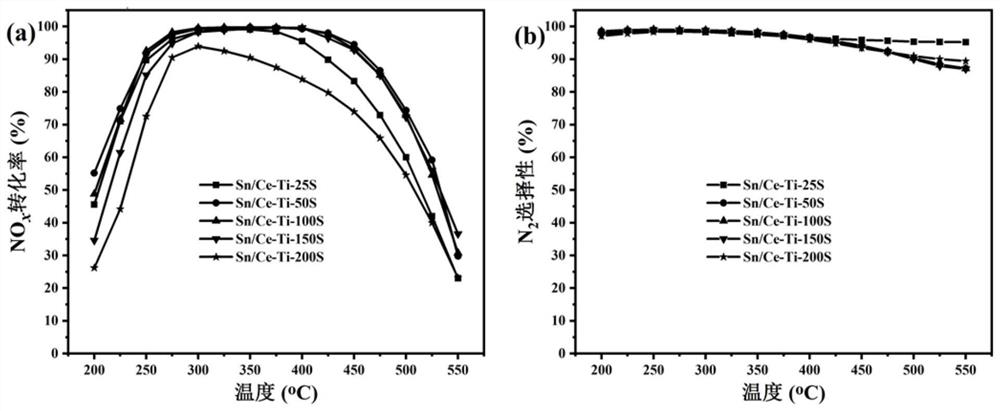

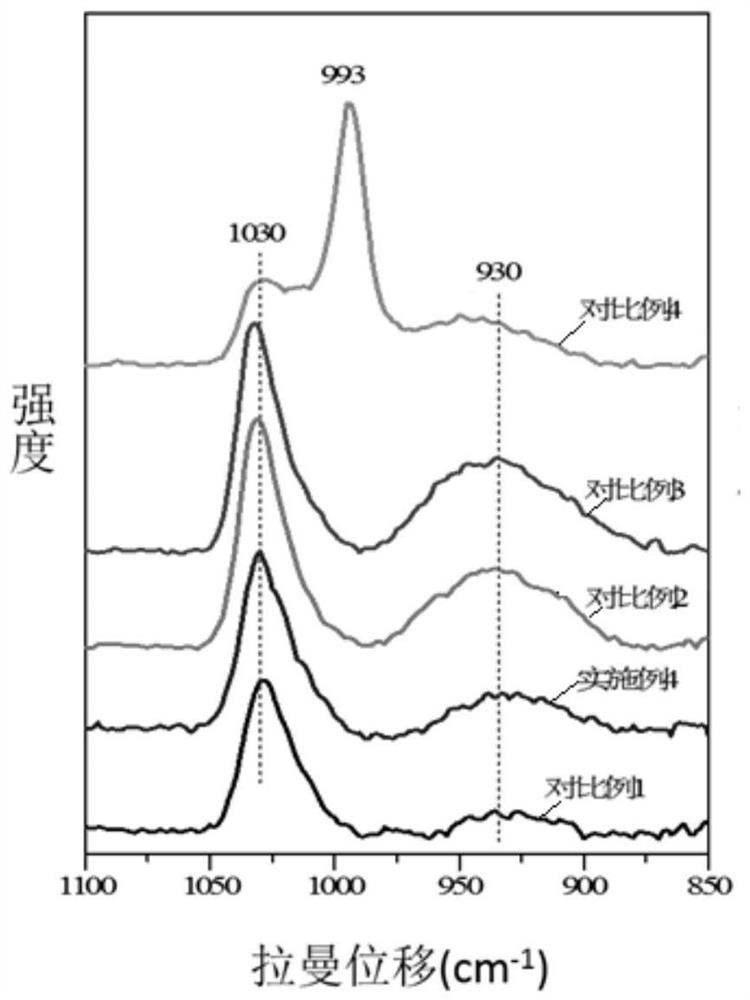

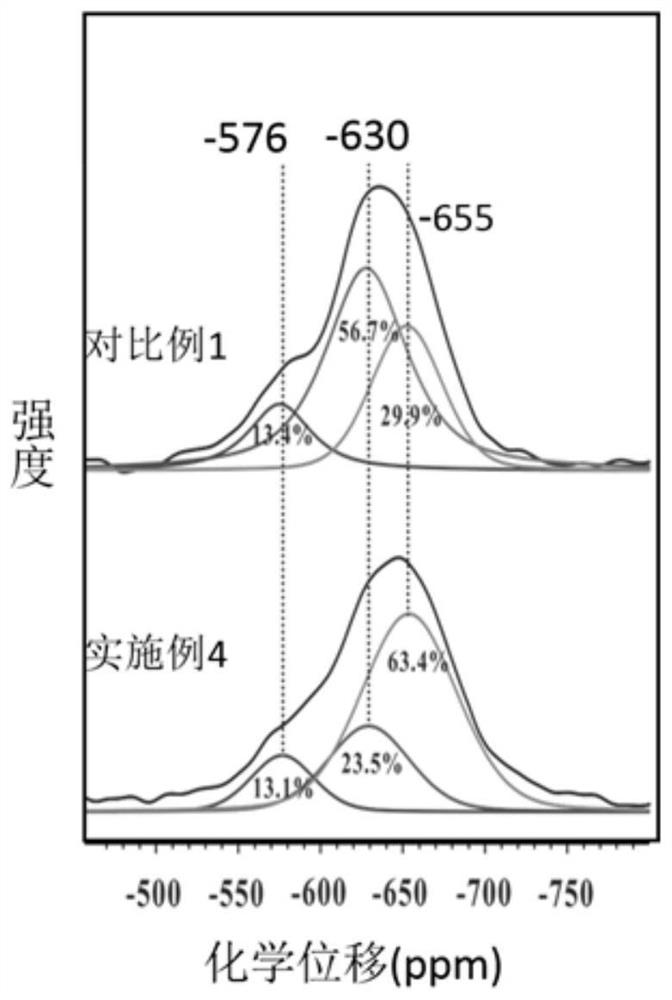

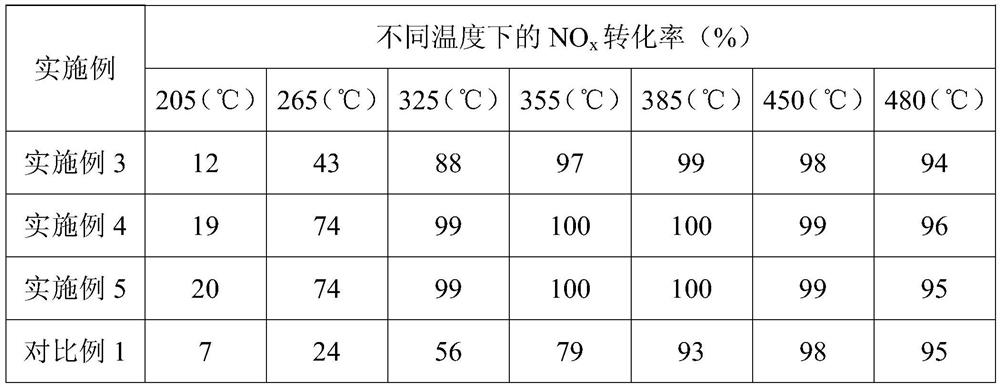

Gas-phase cerium titanium sulfide supported tin oxide catalyst and preparation method and application thereof

PendingCN113522316ALarge specific surface areaImprove thermal stabilityGas treatmentPhysical/chemical process catalystsPtru catalystFlue gas

The invention belongs to the field of flue gas denitration catalysts, and particularly relates to a gas-phase cerium titanium sulfide supported tin oxide catalyst and a preparation method and application thereof. The invention discloses a preparation method of a gas-phase cerium-titanium sulfide supported tin oxide catalyst. The preparation method comprises the following steps: (1) preparing a cerium-titanium solid solution carrier; (2) preparing a cerium-titanium supported tin oxide catalyst; and (3) preparing the gas-phase cerium titanium sulfide supported tin oxide catalyst. The prepared catalyst is large in specific surface area and good in thermal stability, and shows excellent catalytic performance, water resistance and sulfur resistance in NH3-SCR catalysis.

Owner:UNIV OF JINAN

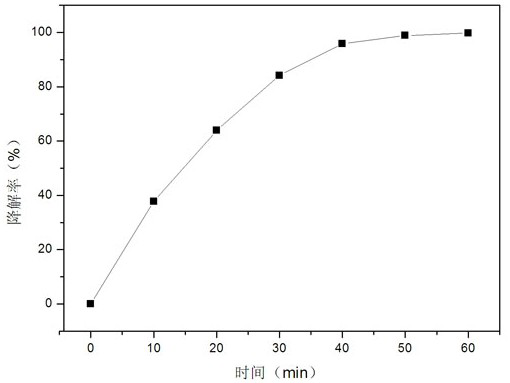

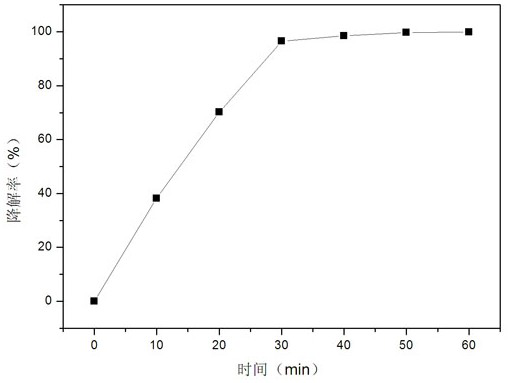

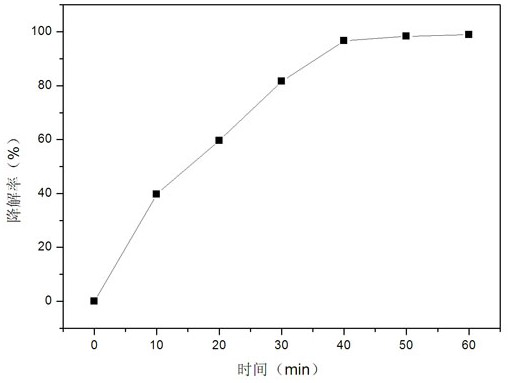

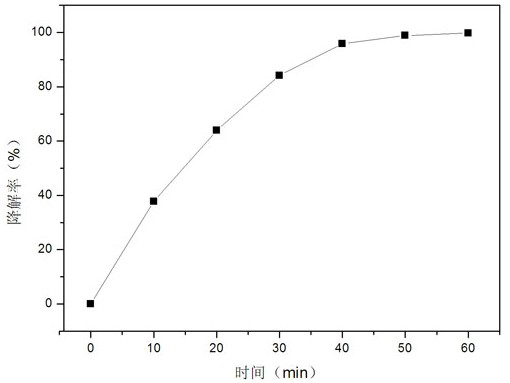

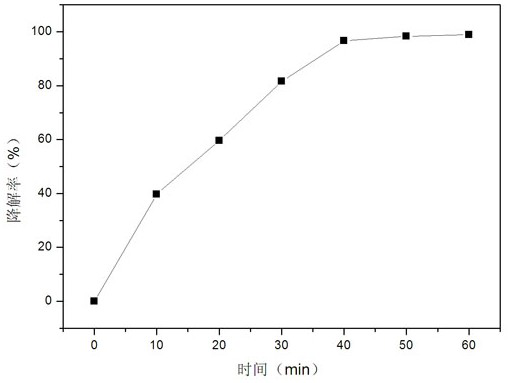

Preparation method, product and application of oxygen-deficient titanium disulfide and carbon nano-disc photocatalytic material

ActiveCN112604698ALarge specific surface areaImprove photocatalytic performancePhysical/chemical process catalystsWater/sewage treatment by irradiationTitanium disulfideAlkane

The invention provides a preparation method of an oxygen-deficient titanium disulfide and carbon nano-disc photocatalytic material, and the method comprises the following steps: adding organic titanium salt into oleylamine, stirring, introducing inert gas, and performing heating to sufficiently mix the solution; injecting mercaptan into the solution, performing stirring and heating, keeping the temperature for 20-30 minutes, and performing natural cooling to room temperature; dropwise adding the obtained solution into liquid alkane, and separating and drying precipitates to obtain a titanium disulfide@C nano disc; placing the pure titanium disulfide@C nanodisk in a hydrogen atmosphere, and performing calcining to obtain the oxygen-deficient titanium disulfide@C nanodisk. According to the preparation method of the oxygen-deficient titanium disulfide and carbon nano-disc photocatalytic material, the titanium disulfide and carbon nano-disc photocatalytic material has a large specific surface area, and the oxygen-deficient defects play an important role in improving the photocatalytic performance of the material. The photocatalytic performance of the material is favorably improved. Under the condition of ultraviolet light catalysis, after 60 min, the degradation rate of tetracycline reaches 99.8%. The preparation process is relatively simple and easy to operate.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

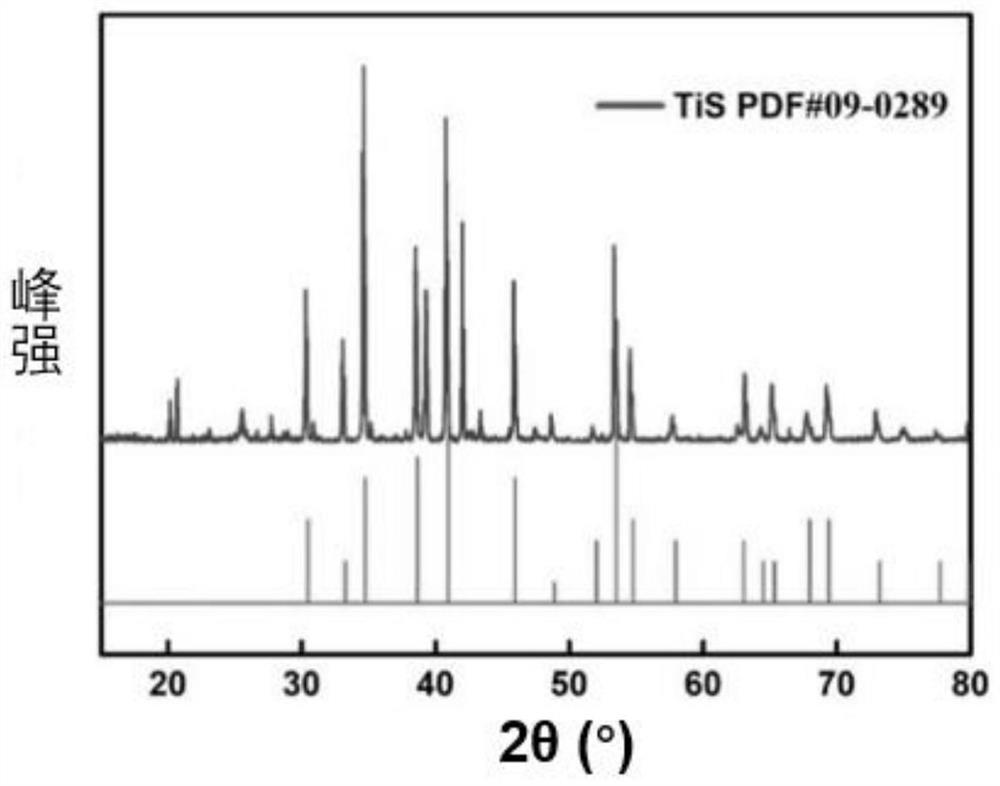

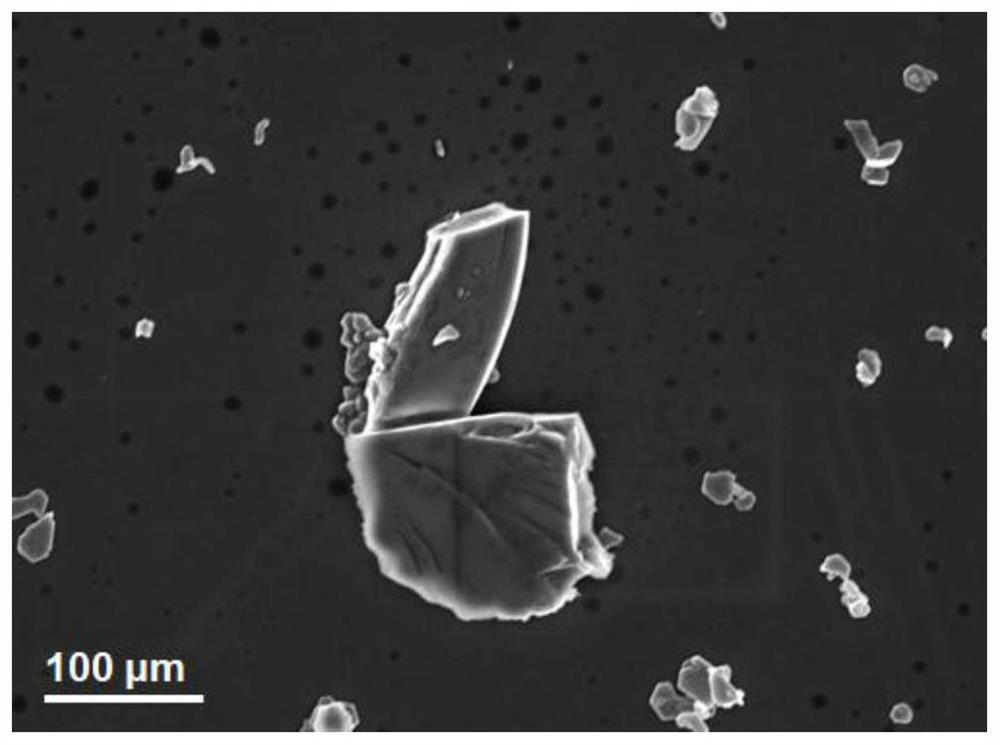

Titanium monosulfide particles and composite material thereof, preparation, application and coating material thereof

PendingCN114477272AIrregular dispersionImprove the lubrication effectTitanium sulfidesMolten spray coatingTitanium monosulfideTitanium sulfide

The invention belongs to the technical field of solid lubricating materials, and particularly relates to titanium monosulfide particles, a composite material of the titanium monosulfide particles, preparation and application of the titanium monosulfide particles and a coating material. The titanium monosulfide particles are of a layered structure formed by stacking two-dimensional nanosheets. The invention discloses a novel TiS particle, and experimental results prove that the titanium monosulfide used as a high-temperature-resistant coating has the following unexpected excellent properties: the friction coefficient is in a decreasing trend along with the increase of the temperature (which is obviously different from the trend of the traditional material, the increase of the temperature and the decrease of the friction coefficient); and the lowest friction coefficient of 0.08 is realized at the temperature of 1000 DEG C. The invention further discloses the ZrO2 (at) TiS composite material. Compared with pure titanium monosulfide, the lubricating property of the ZrO2-coated TiS composite material coating is relatively reduced, but the reduction of the preparation cost provides guarantee for the effects of the ZrO2-coated TiS nano composite material in different fields.

Owner:CHONGQING UNIV

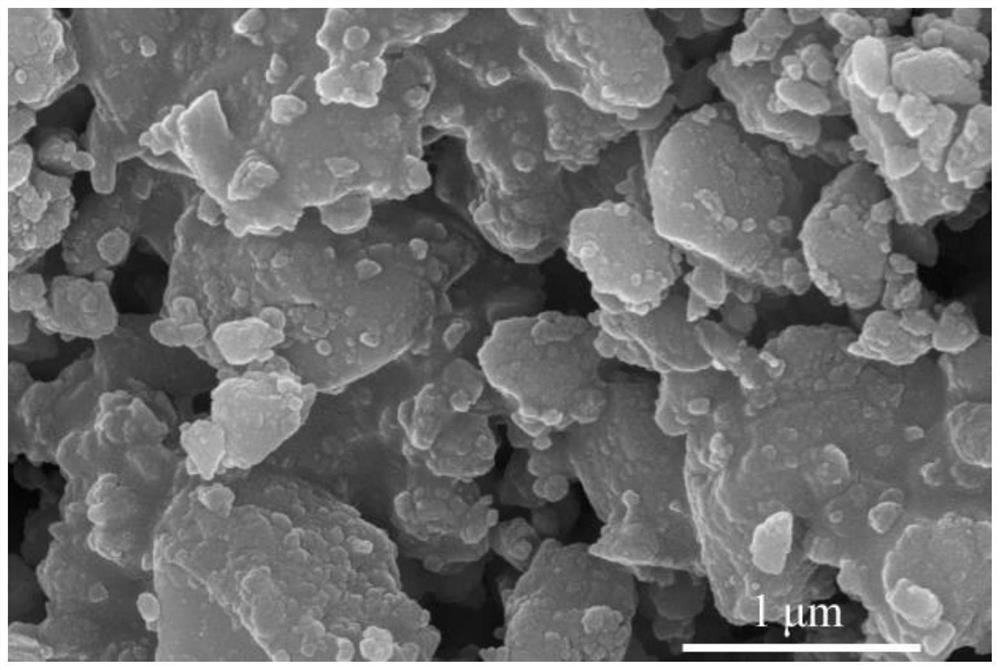

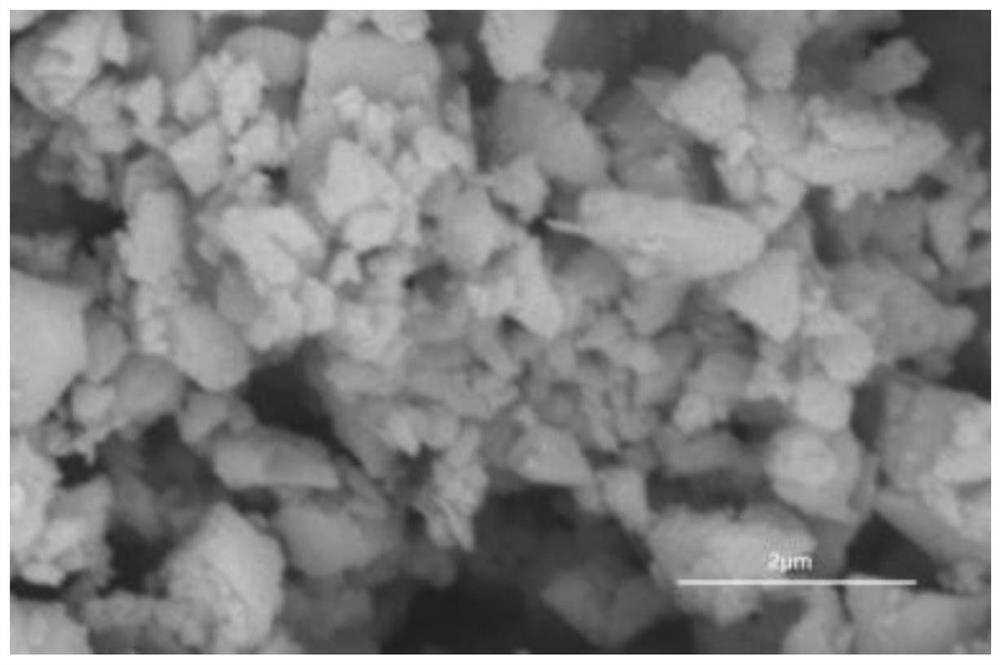

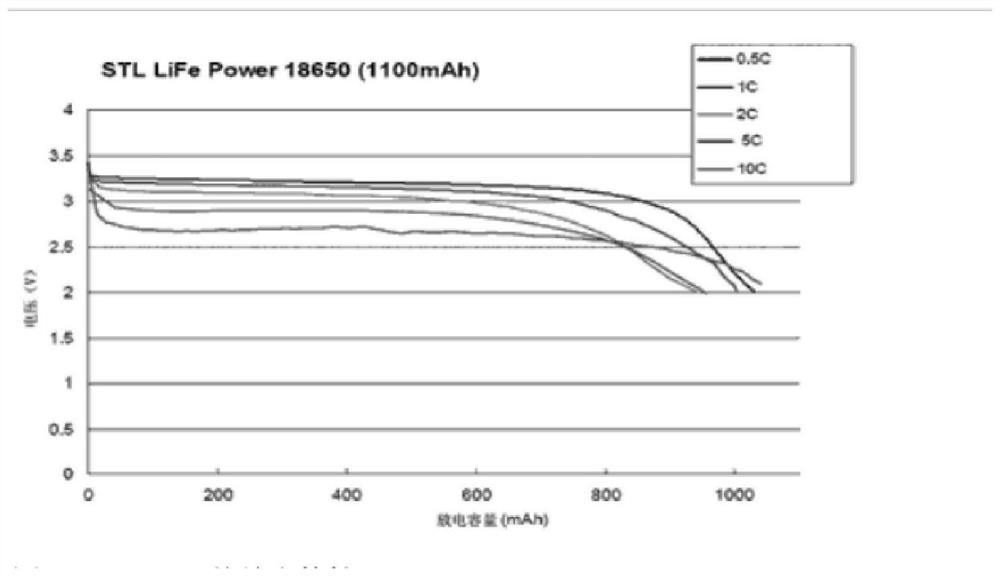

A preparation method of vanadium-doped titanium carbon sulfide battery negative electrode material and its obtained material and application

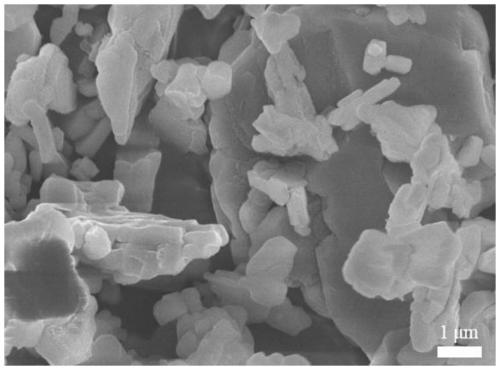

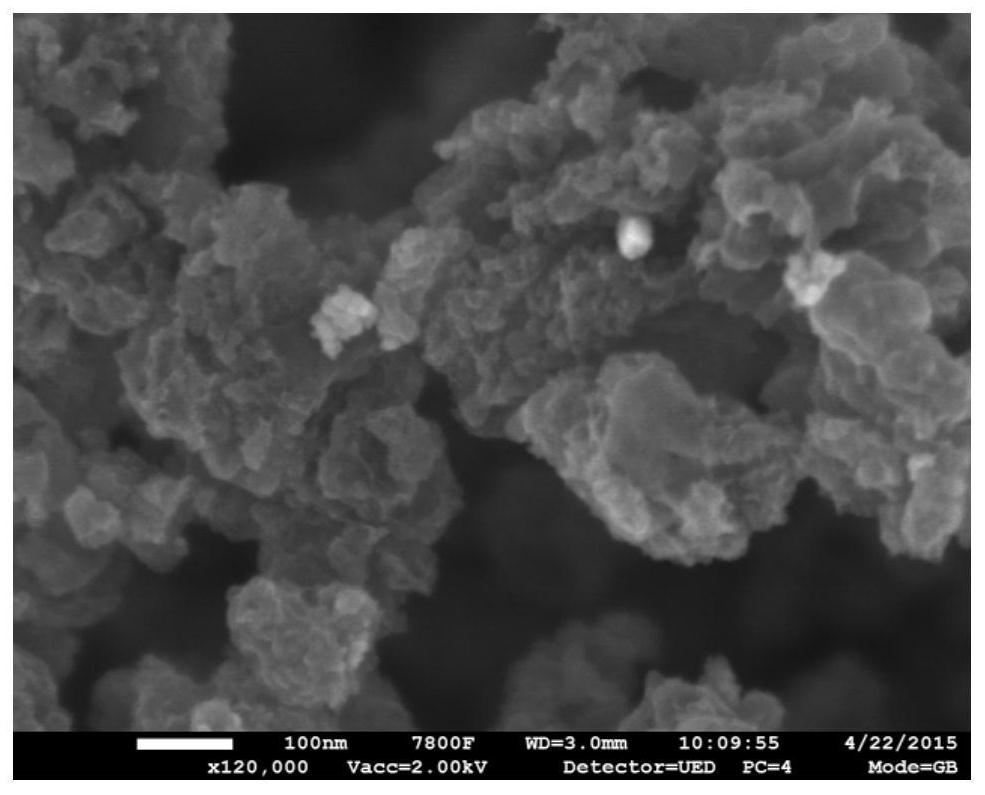

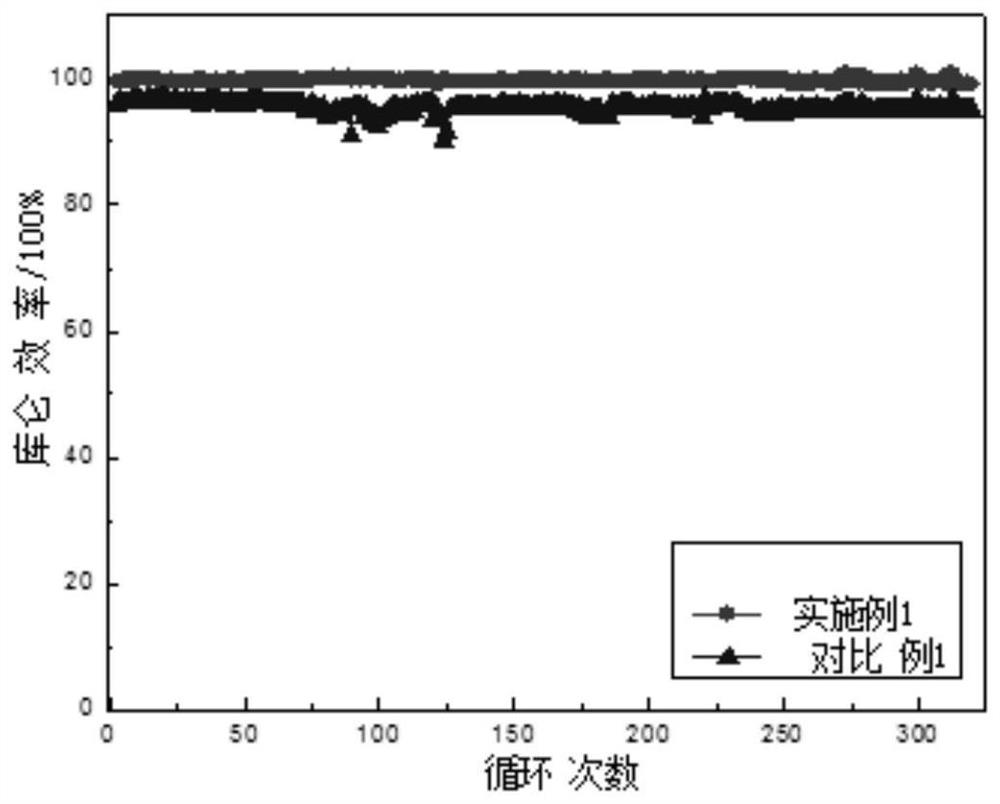

ActiveCN108075135BHigh specific capacityImprove conductivitySecondary cellsNegative electrodesElectrical batteryTitanium sulfide

The invention discloses a preparation method of a vanadium-doped carbon sulfide titanium battery negative electrode material. The preparation method of the vanadium-doped carbon sulfide titanium battery negative electrode material comprises the following steps: (1) weighing vanadium powder, titanium powder, sulfur powder and carbon powder, and ball-milling to obtain initial raw materials; (2) performing high-temperature self-propagating reaction on the initial raw materials to prepare a solid block-shaped sample; (3) performing ball-milling treatment on the solid block-shaped sample to obtaina powdered small-granule sample; and (4) performing ultrasonic treatment, centrifugation and drying on the powdered small-granule sample to obtain the vanadium-doped carbon sulfide titanium battery negative electrode material. The invention also discloses the vanadium-doped carbon sulfide titanium battery negative electrode material prepared by the preparation method as well as application of thevanadium-doped carbon sulfide titanium battery negative electrode material to preparation of a lithium ion battery. Compared with the prior art, the preparation process is simple, rapid and pollution-free, and the vanadium-doped carbon sulfide titanium battery negative electrode material prepared by the method has high specific capacity, has high conductivity, electrochemical activity and cyclingstability and is particularly suitable for manufacturing the lithium ion battery negative electrode.

Owner:YANCHENG INST OF TECH

A kind of preparation method of two-dimensional nanometer titanium disulfide and thin film electrode thereof

ActiveCN108573813BImprove stabilityExtended service lifeLight-sensitive devicesPhotovoltaic energy generationTitanium disulfideThiourea

The invention relates to preparation methods of 2D nanometer titanium disulfide and a 2D nanometer titanium disulfide film electrode, and belongs to the technical field of electrochemistry. The preparation method of 2D nanometer titanium disulfide comprises the following steps that a sulfur source, a solvent and titanium tetrachloride are added to an autoclave, and make reaction for 0.5-12 hours at the temperature of 180-300 DEG C; the sulfur source and the titanium tetrachloride is in the mol ratio of 1: (0.09-2), the amount of the solvent is 40-70% of the volume of the autoclave, the sulfursource includes thiourea or dimethylthiourea, and the solvent includes toluene or xylene. The 2D nanometer titanium disulfide film electrode and the 2D nanometer titanium disulfide flexible adhesive tape based electrode are obtained in a coating method, and the 2D nanometer titanium disulfide film electrode is also prepared in an in-situ growth method, and the electrodes are high in stability andphotoelectric performance and long in service life, and can used to replace a platinum electrode.

Owner:HENAN UNIVERSITY

A kind of hydrogenation catalyst modified by solid phase modifier and its application

ActiveCN110639613BAvoid Toxic ResiduesGood for repeated applicationOrganic-compounds/hydrides/coordination-complexes catalystsPreparation by hydrogenationPtru catalystPalladium catalyst

Owner:ZHEJIANG SUPERIOR TECH CORP LTD

A kind of hydrogenation catalyst and preparation method thereof and application in catalyzing tetrahydrofurfuryl alcohol hydrogenation to produce 1,5-pentanediol

ActiveCN111715264BLow costImprove anti-sintering performancePhysical/chemical process catalystsPreparation by oxygen reductionPtru catalystTitanium sulfide

Owner:WANHUA CHEM GRP CO LTD

Preparation method, product and application of an oxygen-deficient titanium disulfide@carbon nanodisk photocatalytic material

ActiveCN112604698BLarge specific surface areaImprove photocatalytic performancePhysical/chemical process catalystsWater/sewage treatment by irradiationTitanium disulfideAlkane

The invention provides a preparation method of an oxygen-deficient titanium disulfide@carbon nanodisk photocatalytic material. The organic titanium salt is added to oleylamine and stirred, an inert gas is introduced, and the solution is heated to be fully mixed; and mercaptan is injected into the above solution, Stir and heat, keep at this temperature for 20-30 min, and naturally cool to room temperature; drop the obtained solution into liquid alkane, and separate and dry the precipitate to obtain titanium disulfide@C nanodiscs; pure titanium disulfide@C nanodiscs The disks were placed in a hydrogen atmosphere and calcined to obtain oxygen-deficient titanium disulfide@C nanodisks. The invention provides a preparation method of an oxygen-deficient titanium disulfide@carbon nano-disk photocatalytic material. The titanium disulfide@carbon nano-disk photocatalytic material has a larger specific surface area, and the oxygen-deficient defect plays an important role in improving the photocatalytic performance of the material. plays a very important role. It is beneficial to improve the photocatalytic performance of the material. Under UV photocatalytic conditions, the degradation of tetracycline reached 99.8% after 60 min. The preparation process is relatively simple and easy to operate.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

Method of synthesis of LiTi2(PS4)3

ActiveUS11161740B2Solid electrolytesPhosphorus sulfur/selenium/tellurium compoundsMechanical millingPhysical chemistry

A method of synthesis of lithium titanium thiophosphate LiTi2(PS4)3 including the steps of: (a) providing a mixture of lithium sulfide Li2S, phosphorus sulfide P2S5 and titanium sulfide TiS2; (b) subjecting the mixture prepared in step (a) to a preliminary reaction step through mechanical milling or melt-quenching to produce an intermediate amorphous sulfide mixture; (c) subjecting the mixture prepared in step (b) to a heat treatment step at a maximum plateau temperature of at least 350° C. and less than 500° C.

Owner:TOYOTA JIDOSHA KK

A kind of ilmenite composite ore carbon vulcanization-electrolytic method for preparing titanium metal

ActiveCN109280941BImprove electrolysis efficiencyLess intermediatesSolid state diffusion coatingProcess efficiency improvementElectrolysisTitanium metal

The invention provides a method for preparing titanium metal by ilmenite composite ore carbon sulfide-electrolysis, which relates to the technical field of non-ferrous metal extraction. It adopts titanium sulfide anode for electrolysis, and has the advantages of high electrolysis efficiency, less intermediate products, and high-purity titanium directly. Advantages, it can also be produced continuously without producing anode slime, and realizes efficient recycling of energy minerals; the method steps include S1, mixing titanium-containing materials, carbon-containing reducing agents, and sulfur-containing reducing agents in a molar ratio of 1:2.0:2.0 ~1:2.5:3.0 ratio is uniformly mixed to make a mixture, and the mixture is completely vulcanized to prepare a titanium sulfide product; S2, prepare the titanium sulfide product into a solid solution; S3, in a molten salt electrolyte system Metal titanium is extracted by electrolysis, the anode is the solid solution during electrolysis, the anode recovers sulfur gas, and the cathode obtains metal titanium. The technical scheme provided by the invention is suitable for the processes of sulfidation of titanium-containing ores and electrochemical extraction of metallic titanium.

Owner:UNIV OF SCI & TECH BEIJING

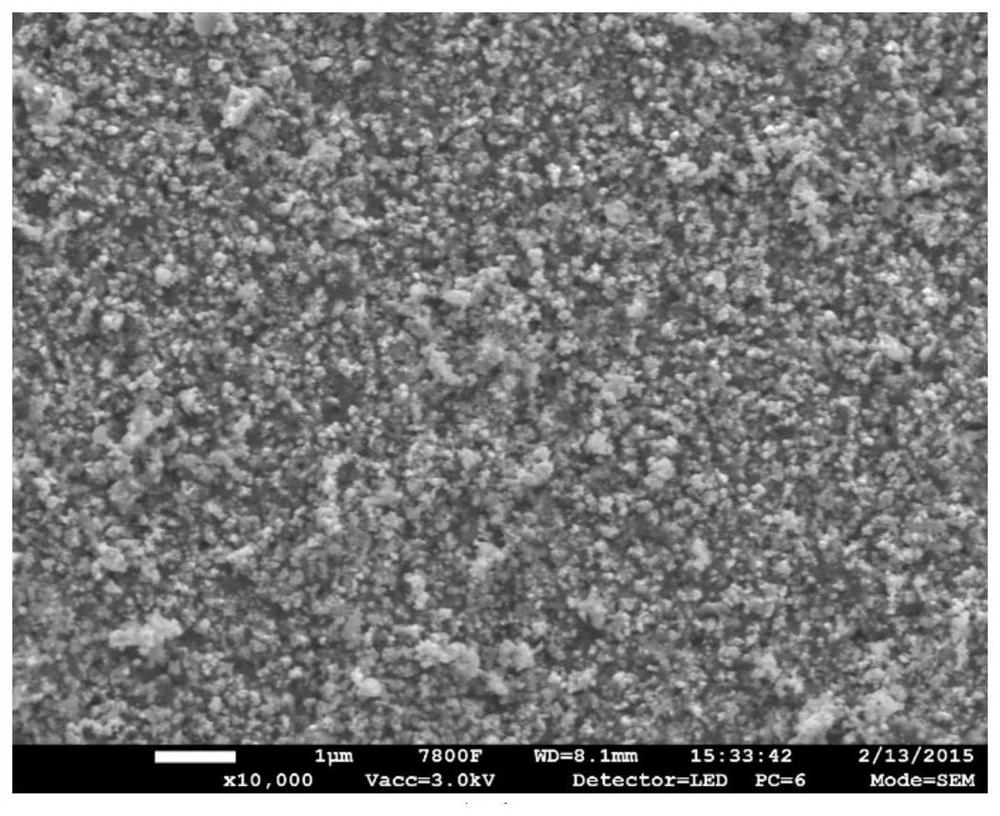

Preparation method of surface-modified titanium sulfide battery negative electrode material

ActiveCN112010308AHigh specific capacityAdjust surface oxygen contentOxy/sulfo carbidesSecondary cellsElectrical batteryModified carbon

The invention provides a preparation method of a surface-modified carbon sulfide titanium battery negative electrode material. The preparation method comprises mixing titanium powder, sulfur powder and graphite powder according to a mole ratio of (1.4-2.2): (0.8-1.2): (0.8-1.2), adding the mixed powder into a self-propagating synthesis reaction kettle, carrying out a high temperature self-propagating reaction process, carrying out ball milling treatment on the obtained blocky sample to obtain a powdery small-particle sample, adding the powdery small-particle sample into absolute ethyl alcohol,carrying out solvent ultrasonic treatment, centrifuging, drying to obtain titanium sulfide powder, mixing the titanium sulfide powder and sodium borohydride in a weight ratio of 1: 4 in an argon atmosphere, heating, and cooling to room temperature to obtain the titanium sulfide / sodium borohydride composite material. The method disclosed by the invention is simple to operate, low in energy consumption, low in cost and environment-friendly, and the prepared surface-modified titanium sulfide negative electrode material is high in specific capacity, has good conductivity, electrochemical activity, cycling stability and rate capability, and is suitable for a negative electrode of a lithium ion battery.

Owner:YANCHENG INST OF TECH

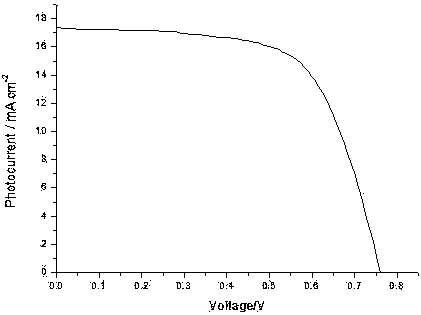

A kind of perovskite solar cell with black phosphorus as hole transport layer and preparation method

ActiveCN106129256BGood chemical stabilityLow costFinal product manufactureSolid-state devicesTitanium disulfideHole transport layer

The invention provides a perovskite solar cell with black phosphorus as the hole transport layer. On the black phosphorus hole transport layer are a perovskite structure light-absorbing layer, an electron transport layer and a transparent conductive electrode in sequence, and the positive electrode is prepared on black phosphorus. the backside of the hole transport layer. The black phosphorus hole transport layer has more excellent chemical stability and lower cost than organic matter as the hole transport layer, and improves the output power and photoelectric conversion efficiency of the solar cell, and further doping in the black phosphorus hole transport layer Titanium disulfide, titanium disulfide molecules can be easily nested in the defect position of the black phosphorus crystal, thereby reducing the crystal defect of the black phosphorus hole transport layer and further improving the photoelectric conversion efficiency.

Owner:ANHUI HUASUN ENERGY CO LTD

Application of a Supported Single-Atom Noble Metal Catalyst in the Esterification of Unsaturated Hydrocarbon Carboxymethyl

ActiveCN112830877BHigh activityHigh selectivityPhysical/chemical process catalystsPreparation by carbon monoxide or formate reactionPtru catalystChromium(III) sulfide

The invention discloses the application of a supported single-atom noble metal catalyst in the esterification reaction of unsaturated hydrocarbon carboxymethyl. The active component is any one or more of Ru, Rh, Ir, Pt, Pd, Ag, Au. The load of metal is 0.05%-1.5%, the carrier is any one of chromium sulfide, manganese sulfide, iron sulfide, cobalt sulfide, nickel sulfide, copper sulfide, zinc sulfide, molybdenum sulfide, tungsten sulfide, titanium sulfide, the catalyst Preparation: After mixing the carrier and the active metal, calcining at a certain temperature. The catalyst is used for methyl esterification of unsaturated hydrocarbon carboxymethyl to prepare methyl ester compound, and has good activity and selectivity. Compared with the system in which homogeneous nickel carbonyl or palladium-phosphine complexes are used as catalysts and highly corrosive sulfuric acid or sulfonic acid is added as auxiliary agents, the heterogeneous reaction process provided by the invention is environmentally friendly, simple to operate, and recyclable Take advantage of other advantages.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

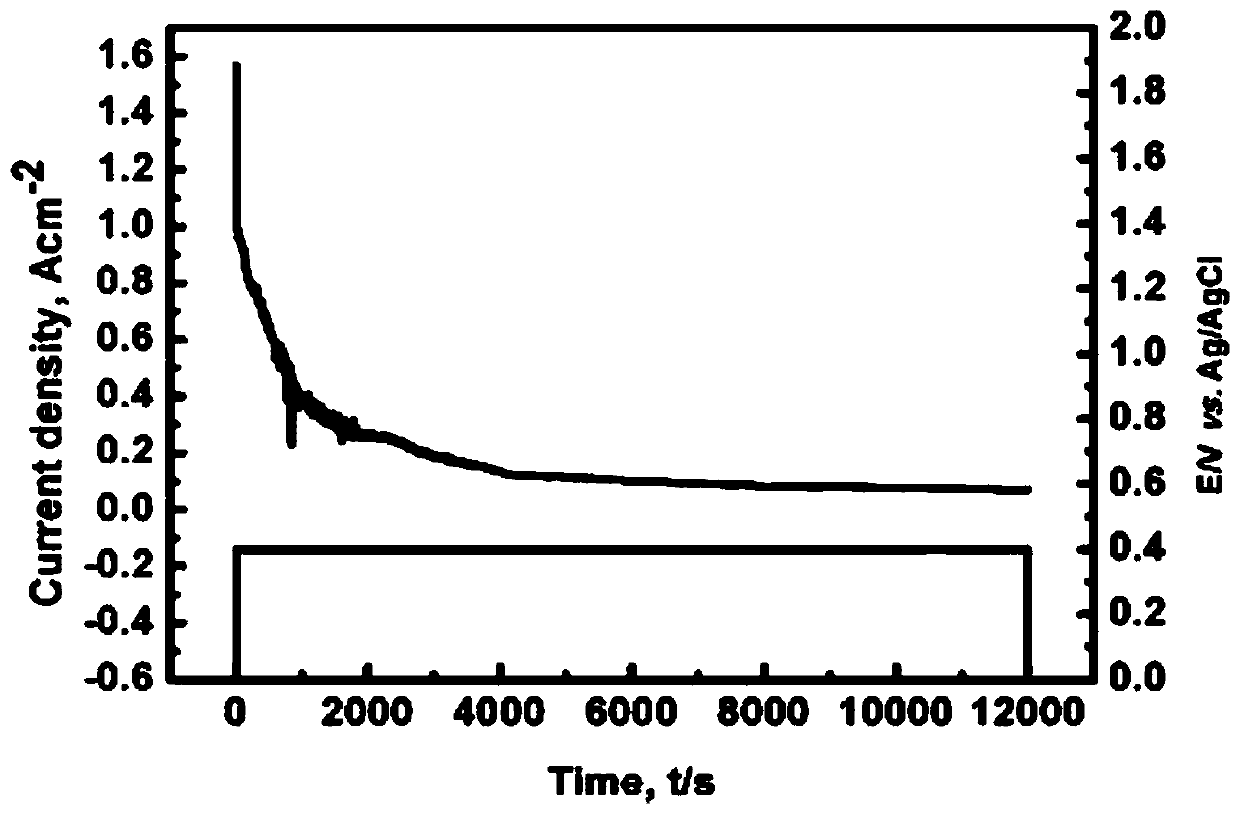

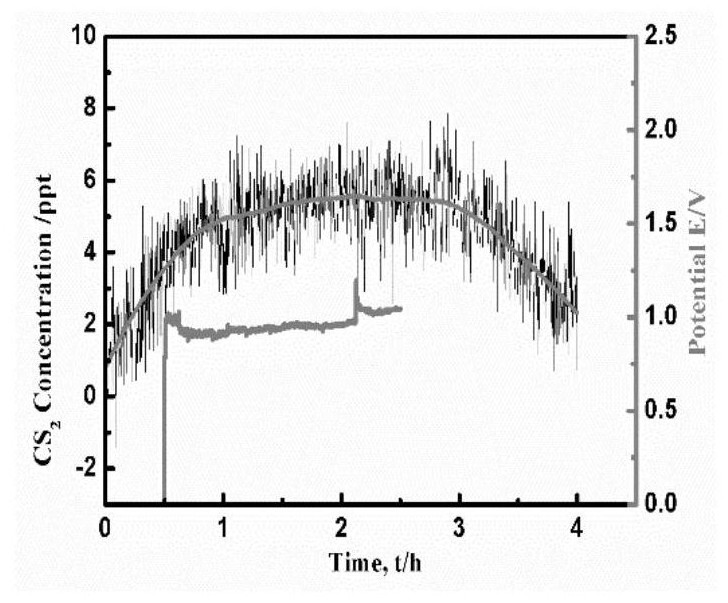

A kind of electrolysis-titanium carbon sulfur anode-method for preparing metal titanium

The invention discloses a method for preparing metallic titanium through titanium / carbon / sulfur soluble anode electrolysis, and relates to the technical fields of nonferrous metallurgical mineral treatment and titanium extraction metallurgy adopting molten salt electrochemistry. According to the method, a titanium-carbon-sulfur anode material with high electrical conductivity is successfully prepared by taking titanium-containing mineral raw materials, carbon (C) and sulfur (S) as raw materials, and via sintering and other technologies. The metallic titanium is successfully prepared in a molten salt electrolyte system through the titanium-carbon-sulfur anode. The titanium / carbon / sulfur soluble anode is adopted, the metallic titanium is deposited at a cathode in a molten salt electrolysis process, the anode generates CS2 gas, and the gas is effectively applied to treatment for minerals to prepare a titanium sulfide raw material; and the method is simple in process, low in energy consumption, continuous in production, and capable of realizing efficient and cyclic utilization for energy resources.

Owner:UNIV OF SCI & TECH BEIJING

Battery composite positive electrode and electrochemical battery composed thereof

ActiveCN109830653BEasy to manageEasy to controlPhosphatesCell electrodesTitanium disulfideElectrical battery

Owner:BEIJING LIKAIYUAN TECH

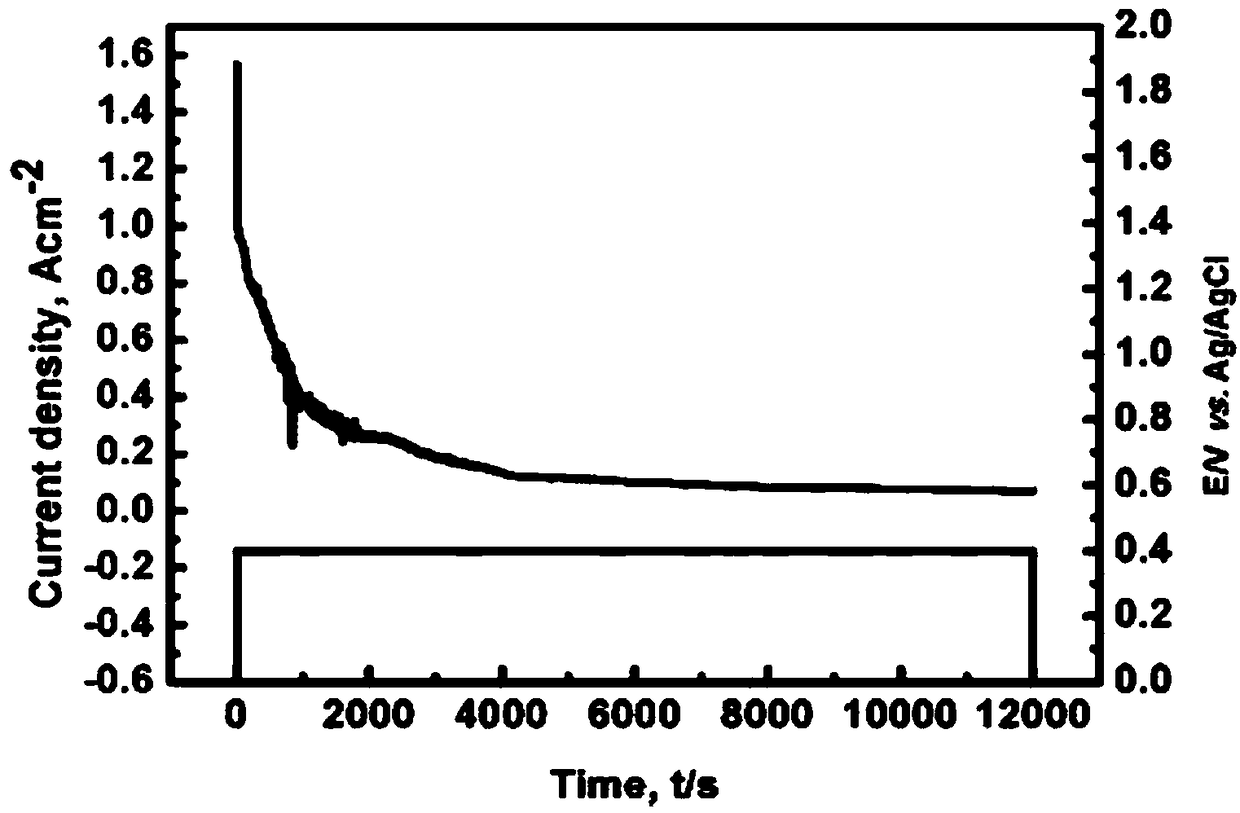

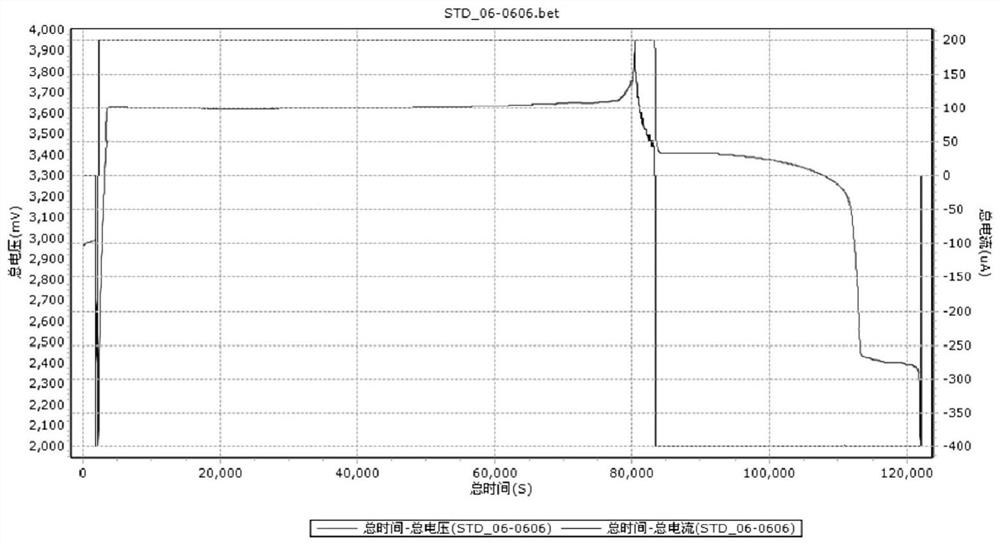

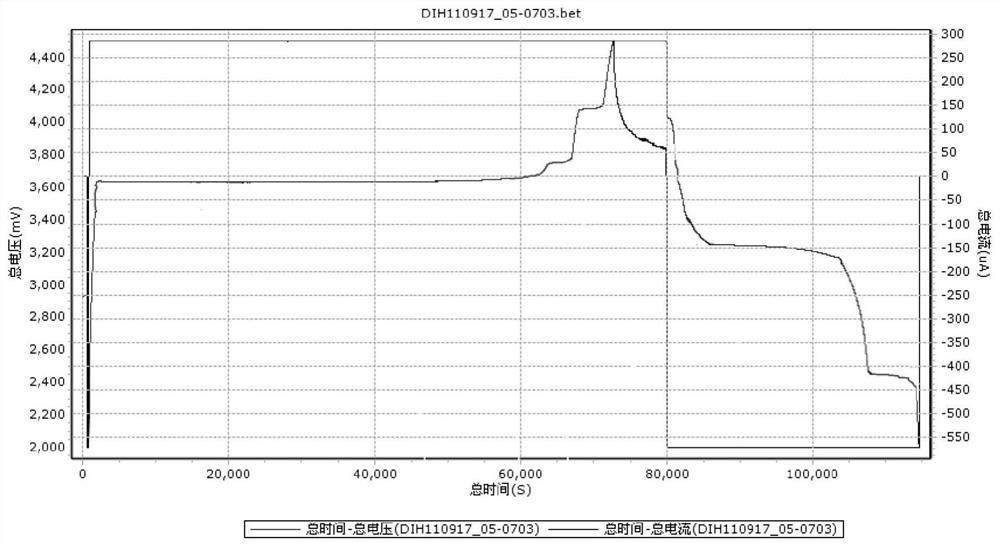

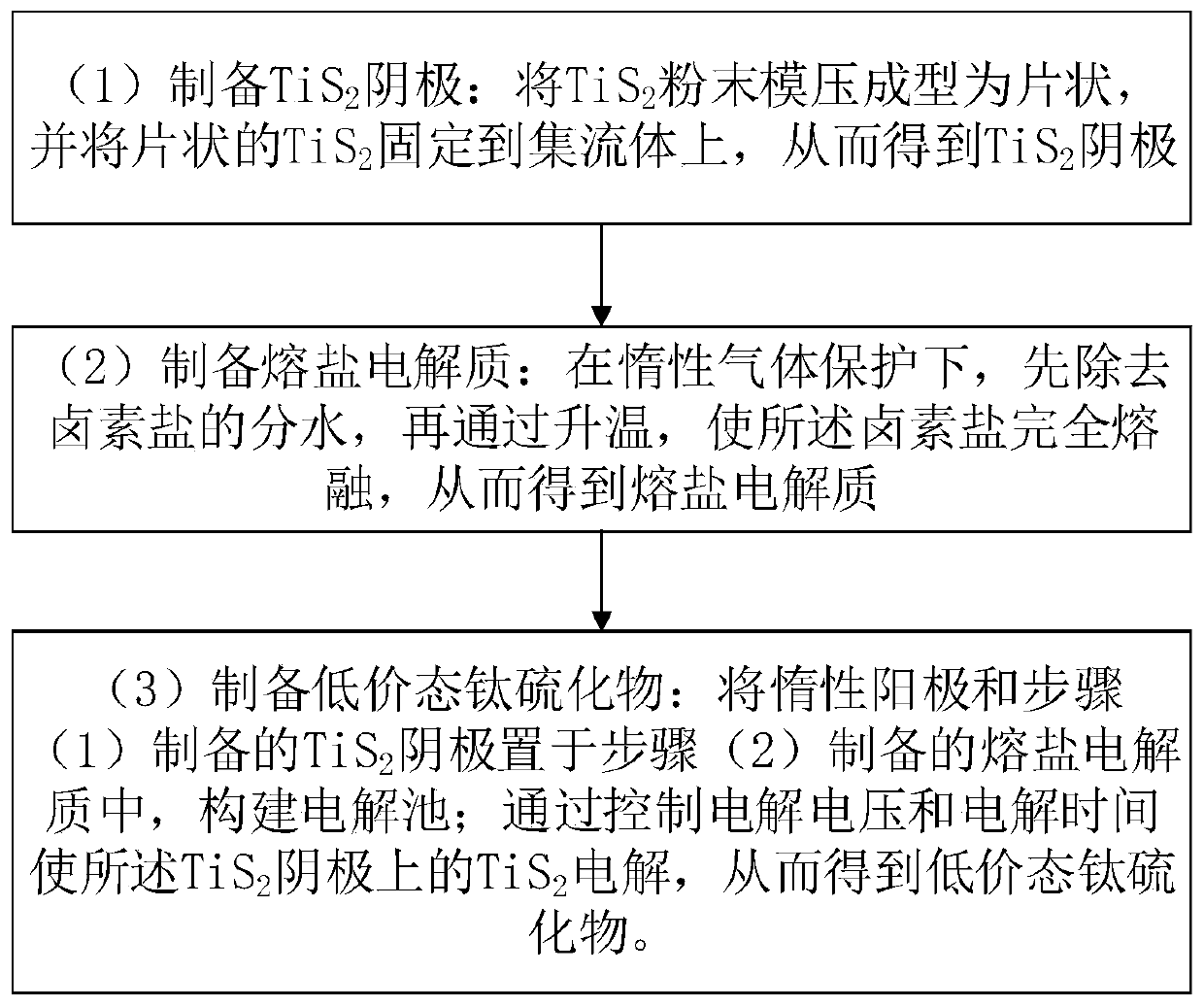

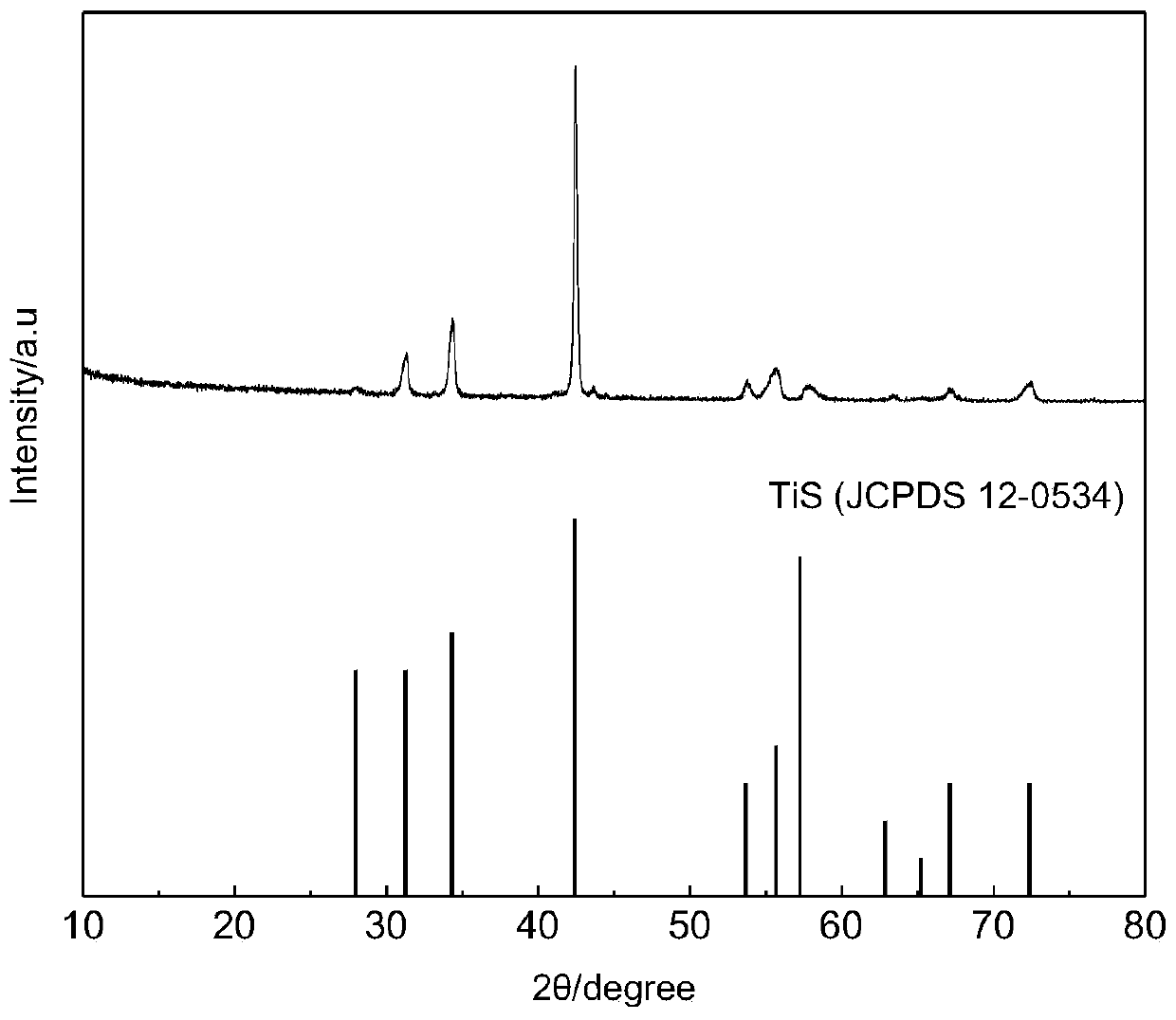

Low-valence titanium sulfide as well as preparation method and application thereof

ActiveCN111321421AImprove conductivityHigh controllability of ingredientsTitanium sulfidesElectrolysis componentsSulfide compoundElectronic conductivity

The invention discloses a low-valence titanium sulfide, a preparation method and an application thereof. The method comprises the steps that 1, a TiS2 cathode is prepared, specifically, TiS2 powder issubjected to compression molding to be in a sheet shape, the sheet-shaped TiS2 is fixed to a current collector, and therefore the TiS2 cathode is obtained; (2) a fused salt electrolyte is prepared: under the protection of inert gas, firstly water of haloid is removed, and then heating is carried out to completely melt the haloid so as to obtain the fused salt electrolyte; (3) low-valence titaniumsulfide is prepared: an inert anode and the TiS2 cathode prepared in the step (1) are put into the molten salt electrolyte prepared in the step (2), and an electrolytic tank is constructed; and the TiS2 on the TiS2 cathode is electrolyzed by controlling the electrolysis voltage and the electrolysis time, so that the low-valence titanium sulfide is obtained. According to the method, TiS2 is used as a raw material for preparing the TiS2 cathode, haloid is used for preparing the fused salt electrolyte, and the low-valence titanium sulfide with high conductivity is obtained by controlling the electrolysis voltage and the electrolysis time.

Owner:HUAZHONG UNIV OF SCI & TECH

A kind of positive electrode material for zinc-bromine flow battery and its preparation and application

ActiveCN109786761BReduce osmotic pollutionReduce concentrationCell electrodesRegenerative fuel cellsTitanium disulfideElectrochemical response

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Filtering barrel material for precision filter

InactiveCN109126291AImprove mechanical propertiesIncrease usage intensityFiltration separationManganeseTitanium sulfide

The invention relates to a filtering barrel material for a precision filter. The filtering barrel material is prepared from, by weight, 48-55 parts of aluminum-magnesium alloy, 24-30 parts of manganese, 16-22 parts of silicon carbide, 15-20 parts of titanium sulfide, 5-8 parts of phosphorus and 1-2 parts of color hardener. The filtering barrel material is easy to process, excellent in product mechanical performance, high in strength and long in service life.

Owner:宜兴市韦德同机械科技有限公司

A kind of vanadium-titanium sulfide catalyst and its preparation method and application

ActiveCN109174125BGood activity at low temperatureImprove purification efficiencyPhysical/chemical process catalystsDispersed particle separationPtru catalystPhysical chemistry

The invention provides a vanadium-titanium sulfide catalyst as well as its preparation method and application. Vanadium titanium sulfide catalyst of the present invention, the carrier of described catalyst is the TiO of sulfide 2 , the active component is V loaded on the carrier 2 o 5 , with the sulfurized TiO 2 The mass of the carrier is 100% in terms of the V 2 o 5 The mass of the active component is 1-3%. Vanadium titanium sulfide catalyst of the present invention is in 200000h ‑1 The space velocity and the temperature range of 300-450°C have a NOx purification efficiency higher than 90%, and the operating temperature window is wide. The preparation method of the vanadium-titanium sulfide catalyst of the present invention is simple, and the low-temperature activity is improved by controlling the polymerization state of vanadium on the catalyst surface, and the prepared vanadium-titanium sulfide catalyst can be used for NH 3 ‑SCR process catalytic purification of NO x .

Owner:INST OF URBAN ENVIRONMENT CHINESE ACAD OF SCI +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com