A preparation method of vanadium-doped titanium carbon sulfide battery negative electrode material and its obtained material and application

A technology of vanadium-doped titanium carbon sulfide, battery negative electrode, applied in battery electrodes, negative electrodes, secondary batteries, etc., can solve the problems of difficult lithium ion intercalation, limited lithium storage capacity, etc., and achieve good conductivity, high specific capacity, Simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

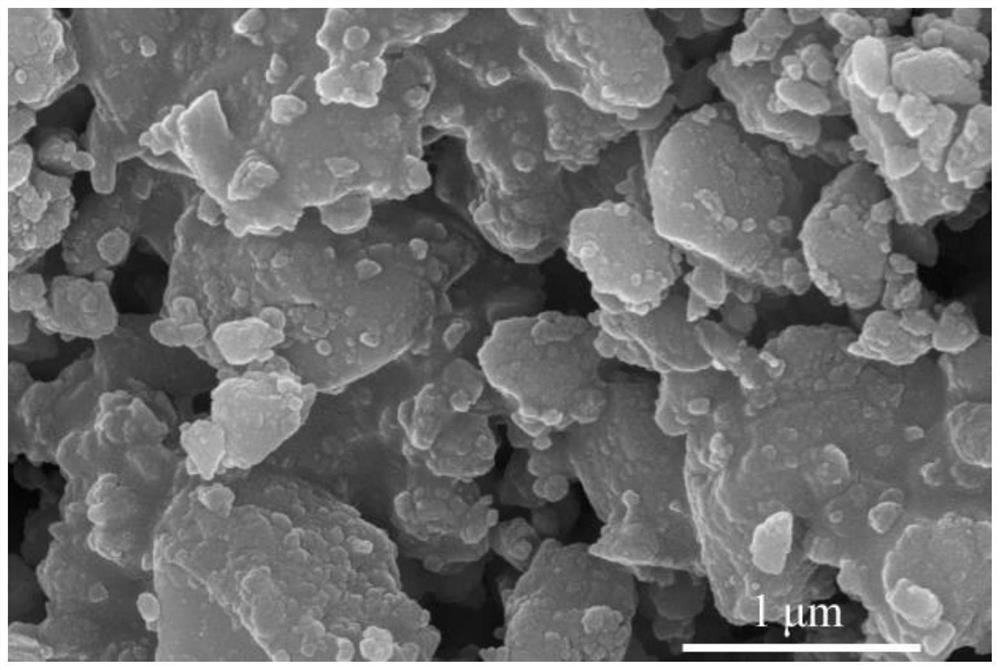

Image

Examples

Embodiment 1

[0023] Weigh 64.91g of Ti powder with a particle size of 400 mesh, 22.89g of S powder with a particle size of 400 mesh, 8.57g of C powder with a particle size of 400 mesh, and 3.64g of V powder with a particle size of 400 mesh. Mix evenly and place in a vacuum ball milling tank and pass in argon gas, use cemented carbide balls as grinding balls, and ball mill at a speed of 400r / min for 3 hours according to the ball-to-material ratio of 10:1 to obtain an activated powder. Place the activated powder in a graphite crucible and place a tungsten wire coil on the surface, place the graphite crucible in a self-propagating high-temperature synthesis device to evacuate and fill it with argon, and energize the tungsten wire coil to ignite the activated powder by ball milling for self-propagation. Propagation reaction, block product. Put the bulk product in a ball mill jar, use cemented carbide balls as grinding balls, and ball mill at a speed of 400r / min for 3 hours according to the bal...

Embodiment 2

[0025] Weigh 61.36g of Ti powder with a particle size of 400 mesh, 22.84g of S powder with a particle size of 400 mesh, 8.55g of C powder with a particle size of 400 mesh, and 7.26g of V powder with a particle size of 400 mesh. Mix evenly and place in a vacuum ball milling tank and pass in argon gas, use cemented carbide balls as grinding balls, and ball mill at a speed of 400r / min for 3 hours according to the ball-to-material ratio of 10:1 to obtain an activated powder. Place the activated powder in a graphite crucible and place a tungsten wire coil on the surface, place the graphite crucible in a self-propagating high-temperature synthesis device to evacuate and fill it with argon, and energize the tungsten wire coil to ignite the activated powder by ball milling for self-propagation. Propagation reaction, block product. Put the bulk product in a ball mill jar, use cemented carbide balls as grinding balls, and ball mill at a speed of 400r / min for 3 hours according to the bal...

Embodiment 3

[0027] Weigh 50.80g of Ti powder with a particle size of 400 mesh, 22.69g of S powder with a particle size of 400 mesh, 8.50g of C powder with a particle size of 400 mesh, and 18.02g of V powder with a particle size of 400 mesh. Mix evenly and place in a vacuum ball milling tank and pass in argon gas, use cemented carbide balls as grinding balls, and ball mill at a speed of 400r / min for 3 hours according to the ball-to-material ratio of 10:1 to obtain an activated powder. Place the activated powder in a graphite crucible and place a tungsten wire coil on the surface, place the graphite crucible in a self-propagating high-temperature synthesis device to evacuate and fill it with argon, and energize the tungsten wire coil to ignite the activated powder by ball milling for self-propagation. Propagation reaction, block product. Put the bulk product in a ball mill jar, use cemented carbide balls as grinding balls, and ball mill at a speed of 400r / min for 3 hours according to the ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com