Patents

Literature

600results about How to "Good activity and stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

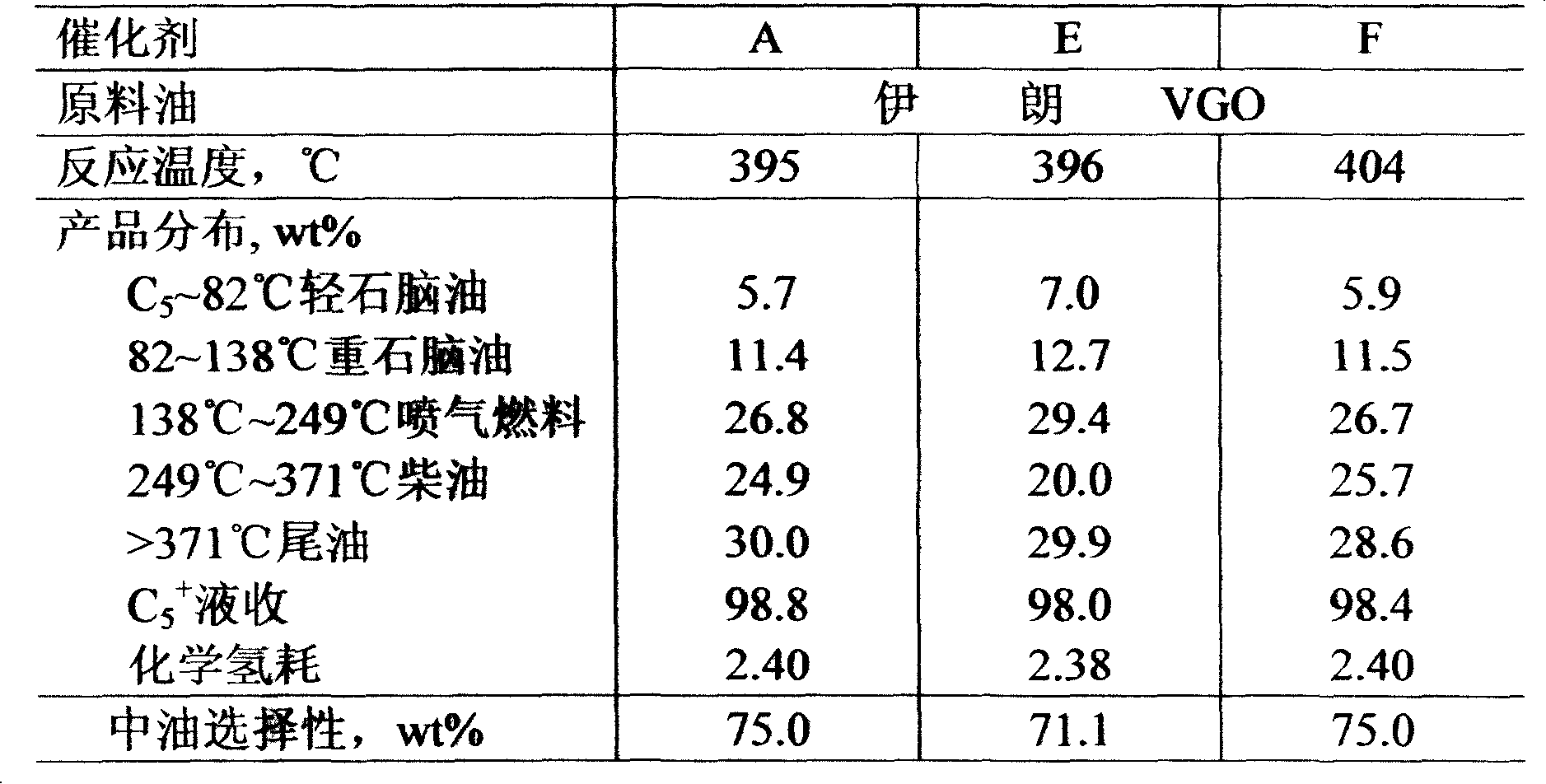

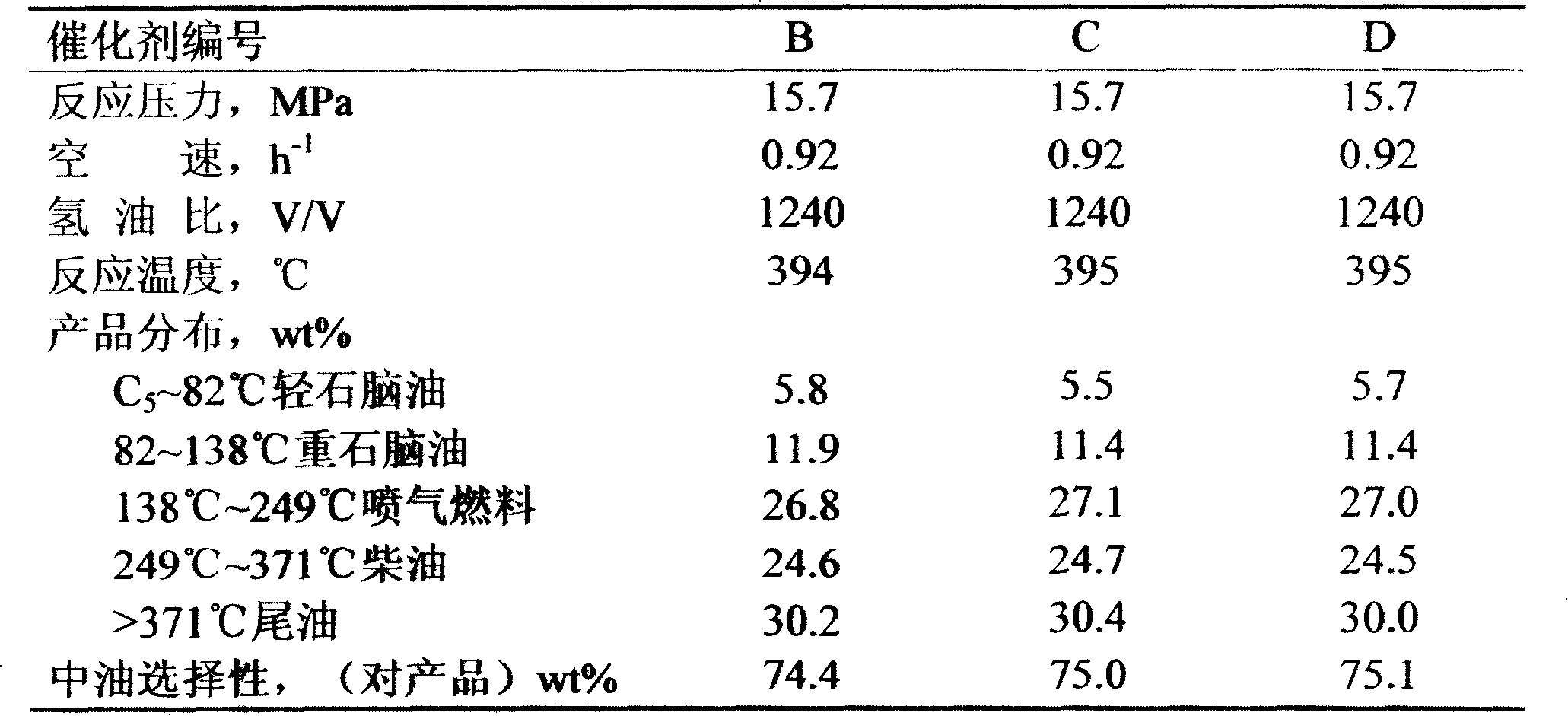

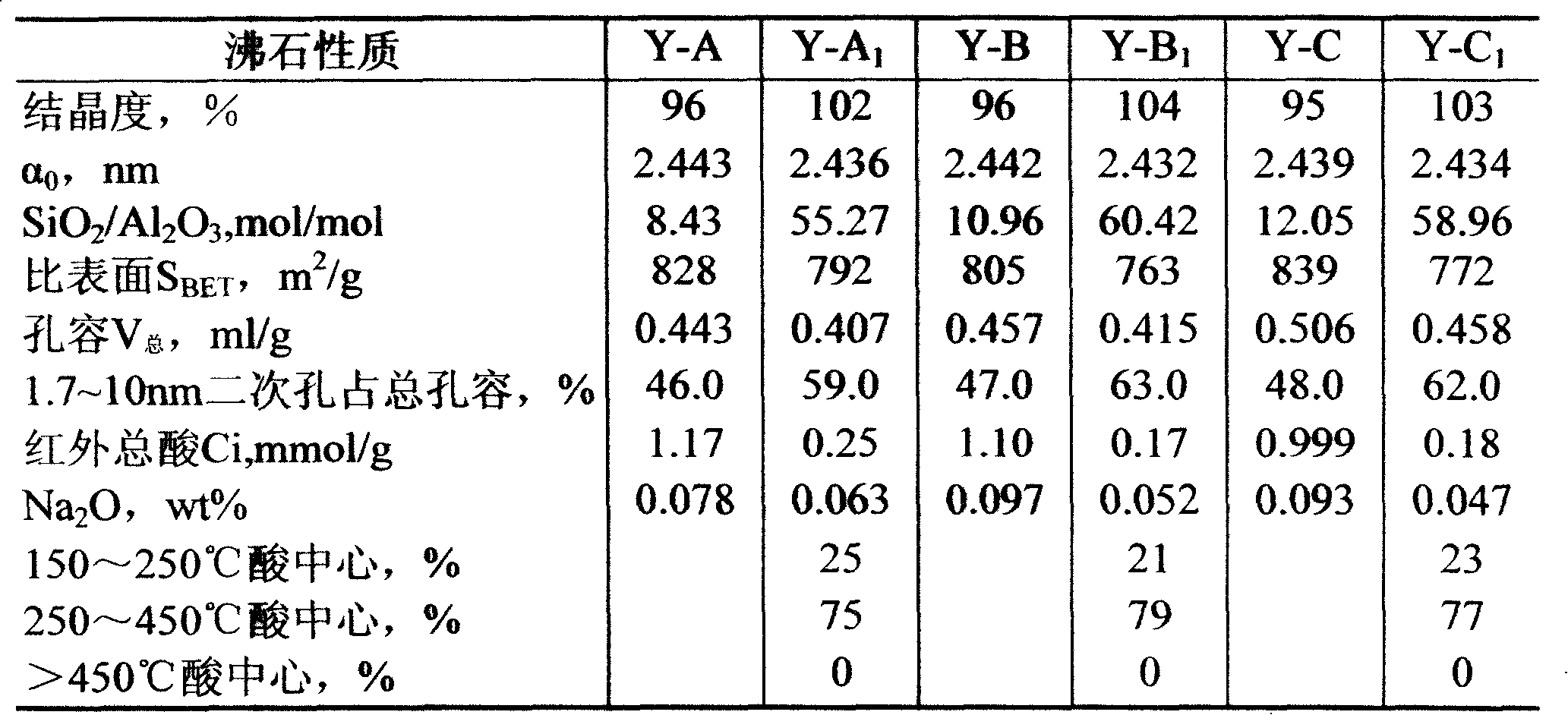

High active high medium oil selective hydrocracking catalyst and preparation thereof

ActiveCN101239324AHigh crystallinityLow cell parametersMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveSingle stage

The present invention provides a hydrocracking catalyst having high activity, high medium oil selectivity, catalyst constitute uses amorphous silica-alumina as a carrier, Y type molecular sieve processed by special modification is an acidity component, the molecular sieve has a high crystallinity and a lower cell parameter, a plenty quadric hole, larger surface, in addition, has a small acid center, even distribution, no strong acid center, 70-80% is moderate intensity acid center, 20-30% is weak acid center, and the molecular sieve also has a strong anti-nitrogen ability and better damaging ability, the hydrocracking catalyst using the molecular sieve has a better hydrocracking activity, and a higher medium oil selectivity, and a strong anti-nitrogen ability at the same time. The invention uses heavy hydrocarbon single stage or single stage serial hydrocracking process generate midbarrel oil product, and has better activity and medium oil selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Silicon/graphene laminar composite material for lithium ion battery cathode and preparation method thereof

ActiveCN102064322ALarge active surface areaImprove cycle performanceCell electrodesSurface-active agentsElectrochemistry

The invention relates to a preparation method of a silicon / graphene laminar composite material for lithium ion battery cathode. The composite material adopts a laminar sandwich structure, silicon nano-particles are dispersed on each lamina of the grapheme, the laminas of the grapheme are separated from one another by the silicon nano-particles and the edges of the laminas are in lapped joint so as to constitute a laminar conductive network structure. The preparation method thereof comprises the steps of: formulating anhydrous silicon tetrachloride, surface active agent, sodium naphthalene and graphite oxide to tetrahydrofuran solution, adding the tetrahydrofuran solution into a reactor for reaction in vacuum at the temperature ranging from 380 to 400 DEG C, filtering the reactant to result in the product, and then washing, drying and heating the product to obtain the silicon / grapheme composite material. The preparation method of the invention has the advantages of simple preparation process and great easiness for industrial production; and the silicon / graphene laminar composite material prepared according to the method includes excellent conductivity, power performance, electrochemical activity and cycle stability, and is particularly suitable for manufacturing lithium ion battery cathode.

Owner:深圳清研紫光科技有限公司

A hydrogenation method for producing diesel oil in low sulphur

ActiveCN101092573AHigh activityLow operating pressureRefining to eliminate hetero atomsLiquid productHydrogen

This invention discloses a hydrogenation method for producing low-sulfur diesel oil. The method comprises: mixing base oil with hydrogen, introducing into a hydrogenation reactor to orderly contact hydrogenation protecting agent, hydrorefining catalyst I, hydrorefining catalyst II and freely selected hydrorefining catalyst III for reactions, cooling the effluent, and separating to obtain hydrogen-rich gas and liquid product. With the synergism of the catalysts, the whole catalyst activity is improved. By the method, high-sulfur, high-nitrogen and high-metal content diesel oil fraction can be treated under mild conditions, and low-sulfur diesel oil that can meet Europe III standard and Europe IV standard can be obtained. The method has such advantages as simple process, low operation pressure, low apparatus investment and low operation cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic cracking catalyst and preparing method thereof

InactiveCN1552801AHigh activityGood activity and stabilityCatalytic crackingRare earthComposite substrate

A catalytic cracking catalyst and its production are disclosed. The catalyst consists of clay 20 - 80m%, silica sol 5 - 30m%, pseudodiaspore 0 - 30%, faujusite with cell parameters of (2.432 - 2.472nm) 5 - 40%, and balanced of ZSM-5 zeolite, beta zeolite and their mixture, oxide selected from Sb, rare earths, Ti, Mg, Zn, P, Sr or their mixture. It uses silica sol as substrate or silica sol and pseudodiaspore as composite substrate to increase macromolecular cracking ability and to improve wearproof performance. It can be produced by non-continuous process or multi-stream continuous process with easy mass production.

Owner:中国石油化工集团公司长岭炼油化工有限责任公司

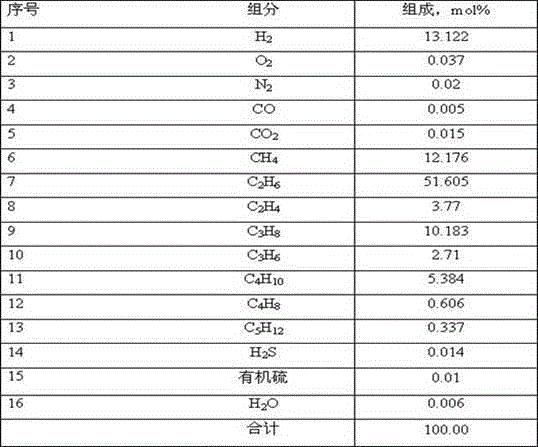

Catalysts grading method for coker dry gas hydrogenation for preparation of ethylene cracking feed

ActiveCN105273756AHigh activityLow costGaseous mixture working upHydrogenation reactionReaction temperature

The invention discloses a catalysts grading method for coker dry gas hydrogenation for preparation of ethylene cracking feed. According to the method, coker dry gas is contacted with a hydrogenation catalyst to carry out a hydrogenation reaction, and olefin in coker dry gas is saturated to further obtain an ethylene cracking feedstock, wherein three hydrogenation reaction zones are successively arranged in a hydrogenation reactor. By reasonable grading of catalysts in different systems, advantages of the respective catalysts during different hydrogenation processes are fully performed. By synergism among the catalysts and by cooperation of reaction temperature gradients of the three hydrogenation reaction zones, activity of the monolithic catalyst is raised.

Owner:CHINA PETROLEUM & CHEM CORP +1

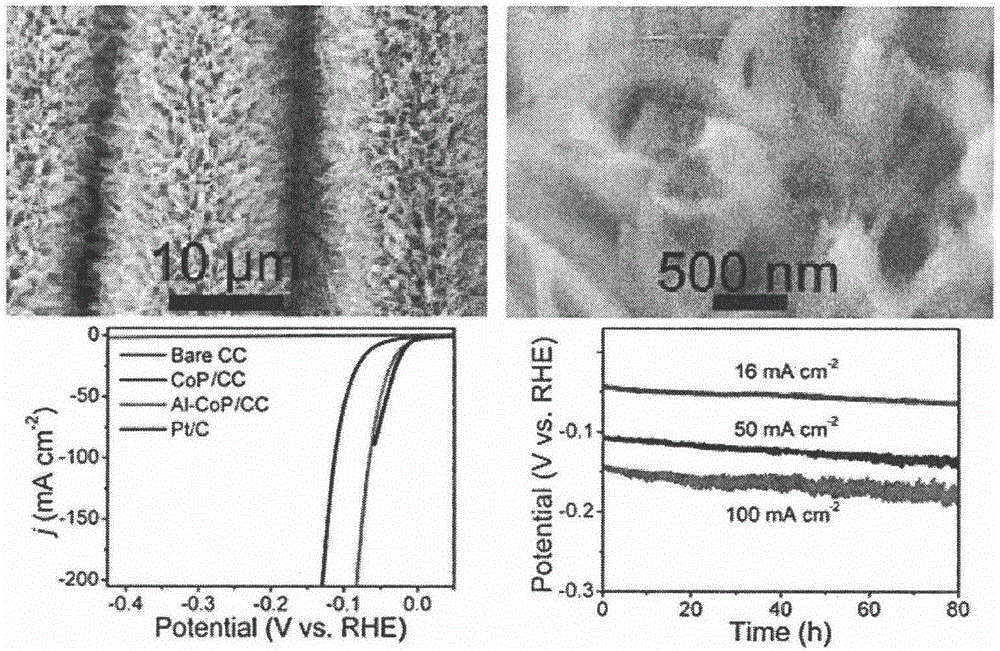

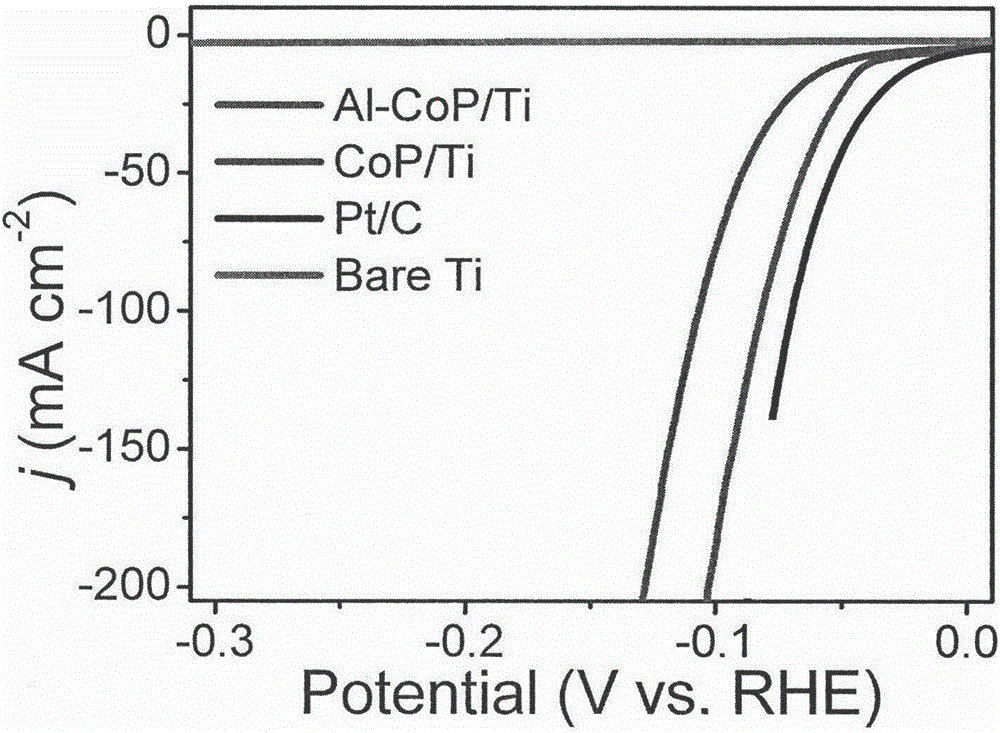

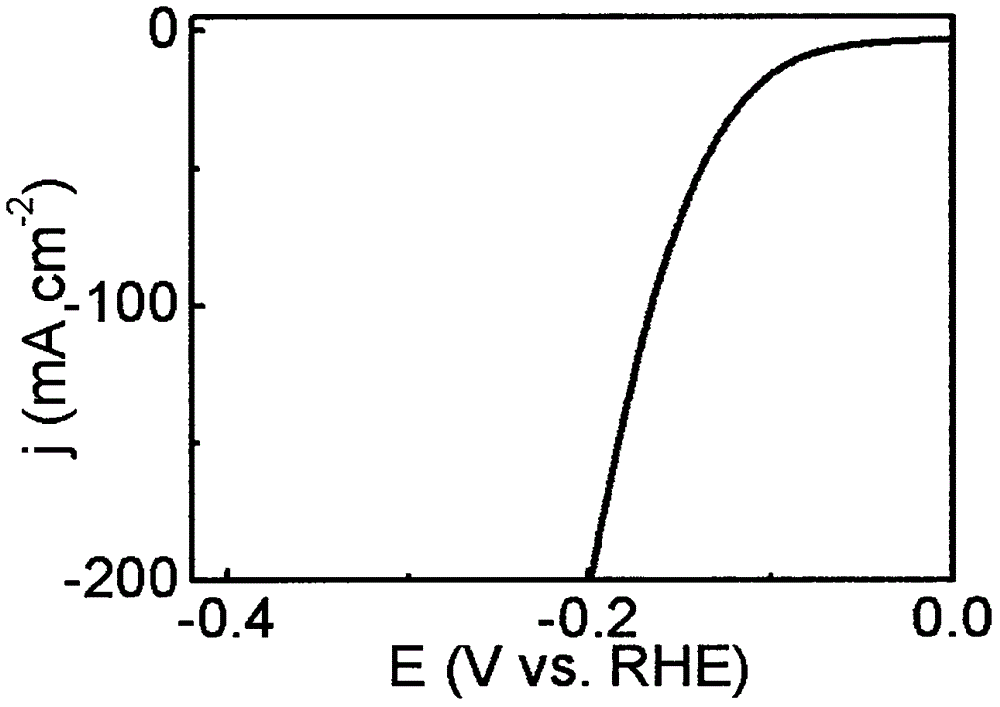

Water electrolytic hydrogen production catalytic electrode of self-supporting metal-doped cobalt phosphide nano structure

InactiveCN105839131AEfficient water electrolysis hydrogen productionGood activity and stabilityElectrodesNano structuringFuel cells

The invention discloses a preparation method for a self-supporting metal-doped cobalt phosphide nano structure and an application of the self-supporting metal-doped cobalt phosphide nano structure as a catalytic electrode in water electrolytic hydrogen production, and belongs to the technical field of hydrogen energy and fuel cells. According to the invention, a metal element is firstly used as a doping agent for introducing cobalt phosphide, in-situ growth, on the surface of a collector, of the cobalt phosphide is realized, the catalytic activity and the structural stability are improved, the problem that a powder catalyst needs a polymer binder for being effectively fixed on the surface of the electrode is solved, and therefore, the self-supporting metal-doped cobalt phosphide nano structure is suitable for large-scale industrial hydrogen production application.

Owner:成都玖奇新材料科技有限公司

Catalyst for liquid phase alkylation of ethylene to prepare ethylbenzene

InactiveCN1506340AHigh hydrothermal stabilityImproved water resistance and regenerationMolecular sieve catalystsHydrocarbonsOrganic acidMolecular sieve

The present invention relates to one kind of catalyst for liquid phase alkylation of ethylene to prepare ethylbenzene and aims at raising the stability and regeneration performance of catalyst. The present invention adops beta-zeolite molecular sieve with SiO2 / Al2O3 molar ratio of 10-50 as catalyst, and the catalyst is processed first with high temperature steam and then with organic acid before use, and this raises the stability and regeneration performance of catalyst. The present invention may be used in the industrial production of liquid phase alkylation to prepare ethylbenzene.

Owner:CHINA PETROLEUM & CHEM CORP +1

A recapitalization generating oil hydrogenation catalysts and its preparing method

ActiveCN101157031ANo need to regenerateReduce lossesHydrocarbon oils refiningMetal/metal-oxides/metal-hydroxide catalystsOrganic acidActive component

The invention discloses reformate hydrogenation catalyst and the production method thereof. The invention is characterized in that the catalyst consists of a main active component, auxiliary agent, and carriers, the structural formula is Pd-Ma (Mb) / carriers; the main active component is a double noble metal component Pd, and the content is 0.01 to 0.5 wt percent; Ma is one of Au, Ag, Pt, Rh, and Ir, and the content is 0.01 to 0.5 wt percent; Mb is one of Sn, Pb, Sb, and Bi, and the content is 0.2 to 1.0 wt percent; the rest are carriers; inorganic acid or organic acid is taken as competitive adsorption auxiliary agent to achieve that the active component presents the distribution of an eggshell-shaped shallow layer, the active metal and the auxiliary agent are loaded by a distribution impregnation method or a co-impregnation method, and then the hydrogenation catalyst is produced through drying and roasting.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Hydrogenation purification method for siliceous distillate

ActiveCN101343565AIncrease capacityFast inactivationTreatment with hydrotreatment processesPurification methodsHydrogen

The invention relates to a silicon-containing distillate oil hydrofining method, which adopts the method that the silicon-containing distillate oil raw material and hydrogen pass through at least two hydrofining catalyst beds under the hydrofining condition, the silicon-containing distillate oil raw material first passes through a hydrogenising catalyst bed with the silicon catching function, and then passes through a conventional hydrofining catalyst bed; wherein the hydrogenising catalyst with the silicon catching function has a greater pore volume and a specific surface area and a relatively lower metal content. Compared with the prior art, the method has the advantages that the process is simple, the good hydrodesulfurization and hydrodedenitrification performance is kept on the premise of enhancing the silicon-containing ability, and the running period of the device is effectively prolonged. The method can be applied to various silicon-containing distillate oil hydrofining processes.

Owner:CHINA PETROLEUM & CHEM CORP +1

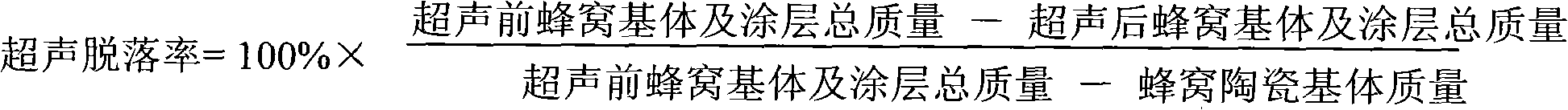

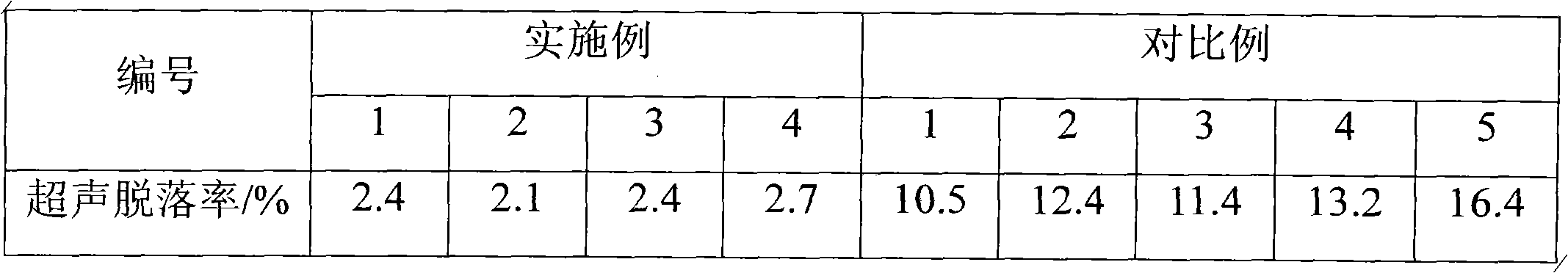

Preparation method of catalytic combustion catalyst

ActiveCN102049312ASimple preparation processEasy to operateDispersed particle separationCatalyst activation/preparationOperational performanceAirflow

The invention discloses a preparation method of a catalytic combustion catalyst. The method comprises the following steps: firstly, performing hydrothermal pretreatment on a honeycomb ceramic matrix; secondly, soaking the honeycomb ceramic matrix with alumina sol; and finally, loading additives and precious metal active components. The catalyst coating obtained by the method of the invention has high bonding degree with the matrix, is difficult to crack and peel off and has less dosage of additives. Thus, the catalyst has good operational performance and activity stability and can maintain higher activity under the scouring of high space velocity airflow and thermal shock, so that the long-term stable operation of the catalyst can be ensured.

Owner:CHINA PETROLEUM & CHEM CORP +1

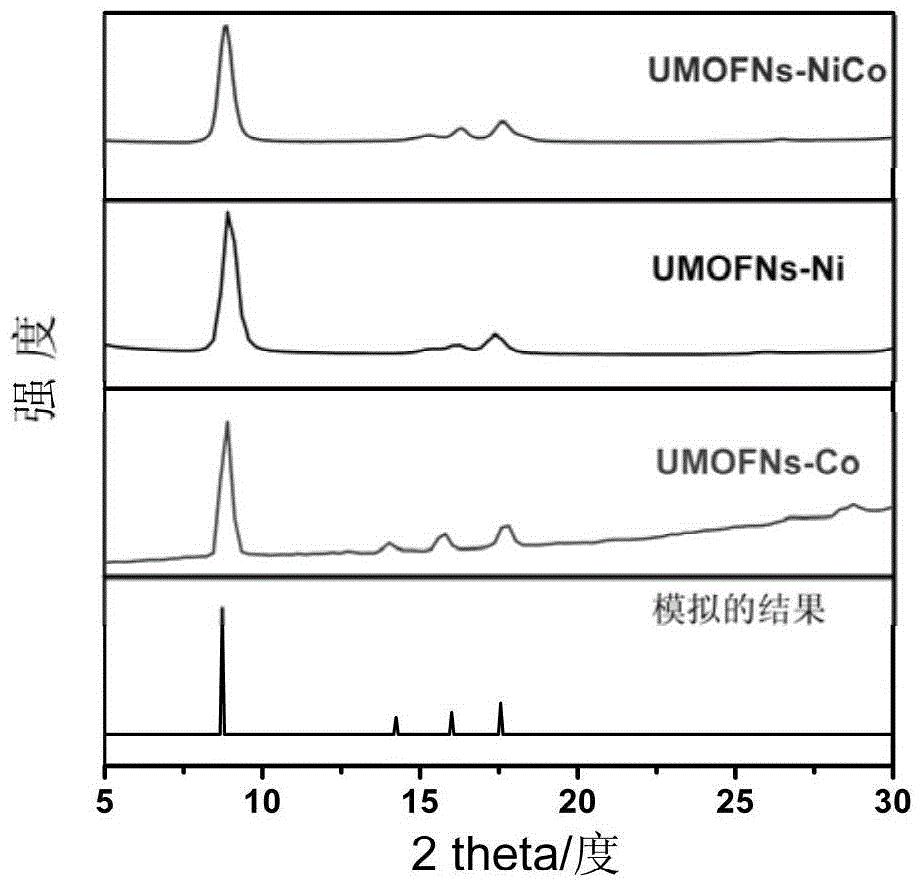

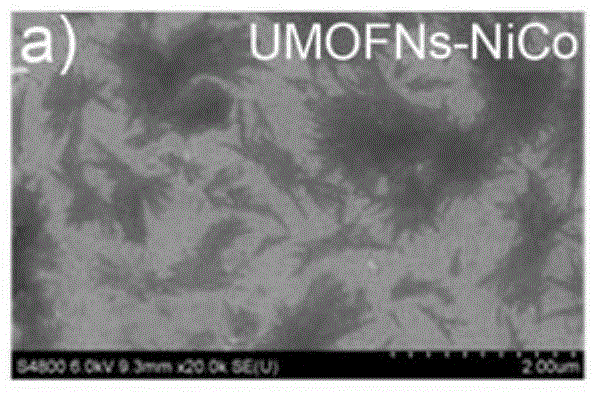

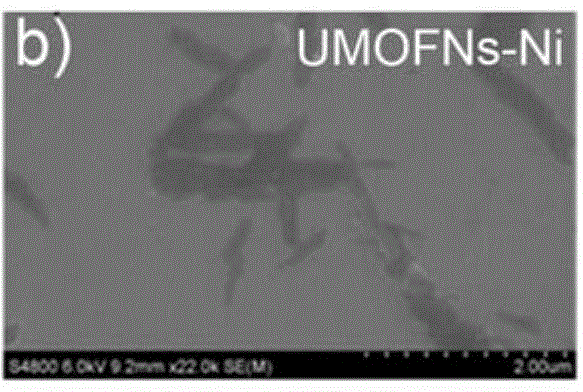

Metal-organic framework nanosheet as well as preparation method and application thereof

ActiveCN105732728ALarge specific surface areaGood chemical stabilityOrganic-compounds/hydrides/coordination-complexes catalystsNickel organic compoundsElectrolysisProduction effect

The invention discloses a metal-organic framework nanosheet as well as a preparation method thereof and application thereof in oxygen evolution reaction of electrolysis water. According to the preparation method, the energy consumption is low, the reaction is rapid, reaction conditions are mild, the thickness of the obtained metal-organic framework nanosheet is 3nm-5nm, the specific surface area can reach 450m<2>.g<1>, and the alkali resistance and the chemical stability are good. The metal-organic framework nanosheet can be prepared into an electrolysis water oxygen production electrode, and a particular ultra-thin sheet structure can be in well contact with the surface of the electrode, so that influences on mass transfer, diffusion and material resistance in the electrochemical oxygen production process are overcome, the initial oxidation potential can reach 1.42V, and the overpotential at 10mA / cm<2> can reach 250mV. By virtue of a 24-hour test, the oxygen production effect is still maintained above 99.6%, the activity, stability and price of the metal-organic framework nanosheet are superior to those of traditional noble metal RuO2, and extremely high actual application value is achieved.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

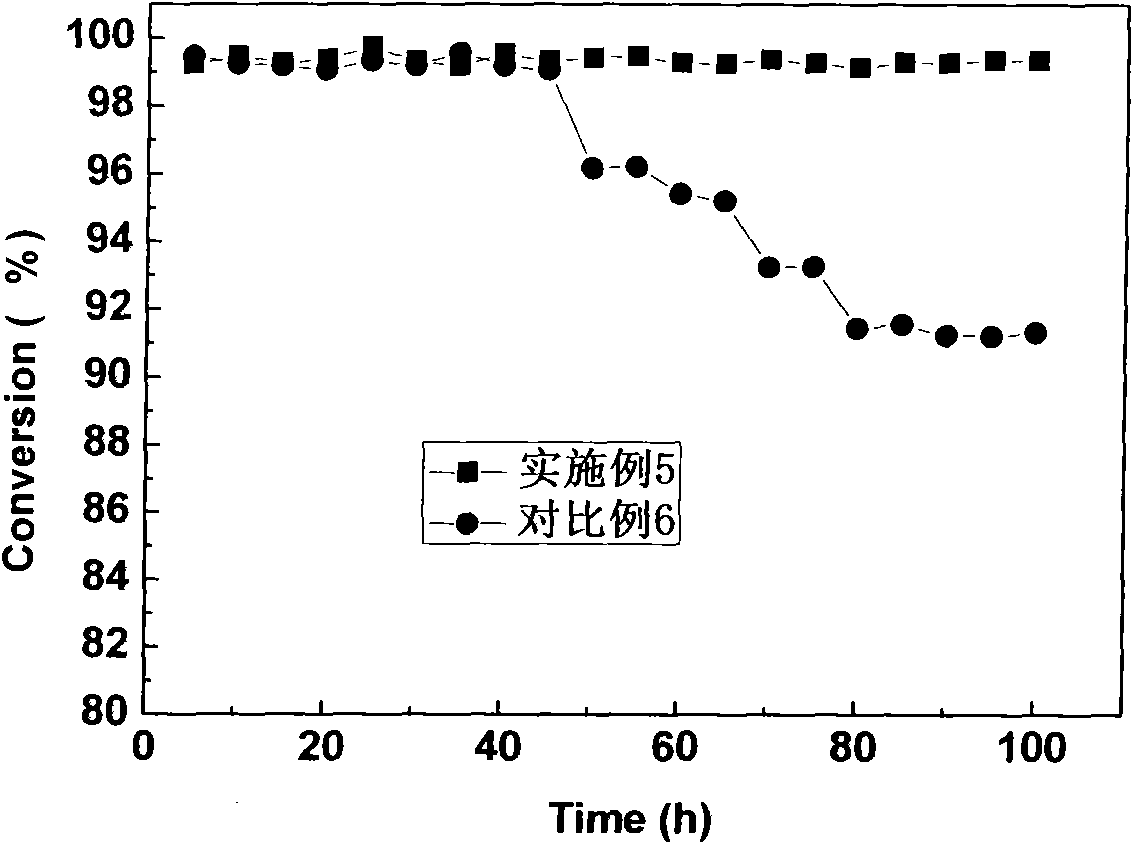

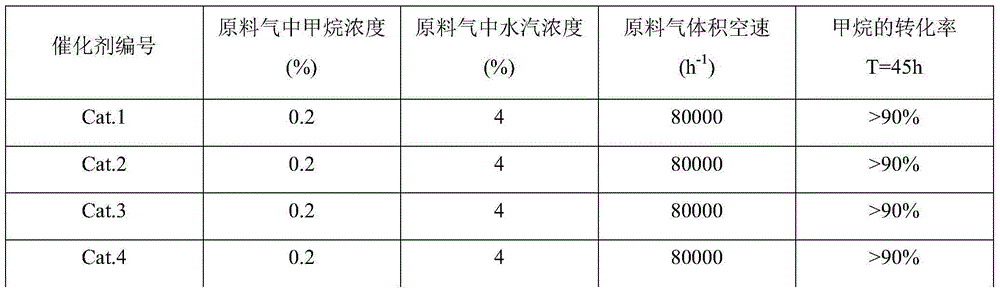

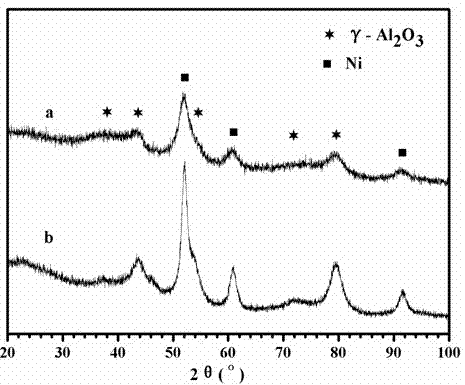

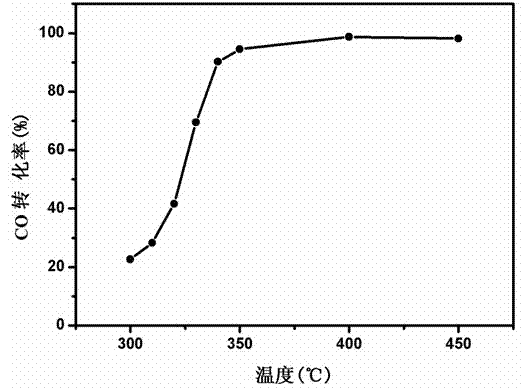

Method for preparing complete methanation catalyst for hydrothermal chemical process

ActiveCN102029161AGood activity and stabilityGood hydrothermal stabilityHydrocarbon from carbon oxidesCatalyst activation/preparationChemical synthesisPtru catalyst

The invention provides a method for preparing a complete methanation catalyst for a hydrothermal chemical process. The catalyst comprises the following components: 10 to 75 percent of active nickel ingredient, 10 to 90 percent of high-temperature resistant carrier and 0.1 to 15 percent of rare-earth auxiliary agent, wherein the content is counted on the basis of metal oxide, and the percentage is weight percentage of the total weight of the active ingredient, the carrier and the auxiliary agent. The preparation method comprises the following steps of: (a) forming a catalyst precursor by using the hydrothermal chemical synthesis process; and (b) preparing the obtained catalyst precursor into the complete methanation catalyst by filtering, washing, drying, roasting, forming, re-roasting and reducing. The method is convenient for crystallization and precipitation of catalyst materials, and has simple process and good repeatability. The method provides guarantee for meeting the current increasing clean energy requirement, and has irreplaceable important effect on the enhancement of energy / resource safety at the same time.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

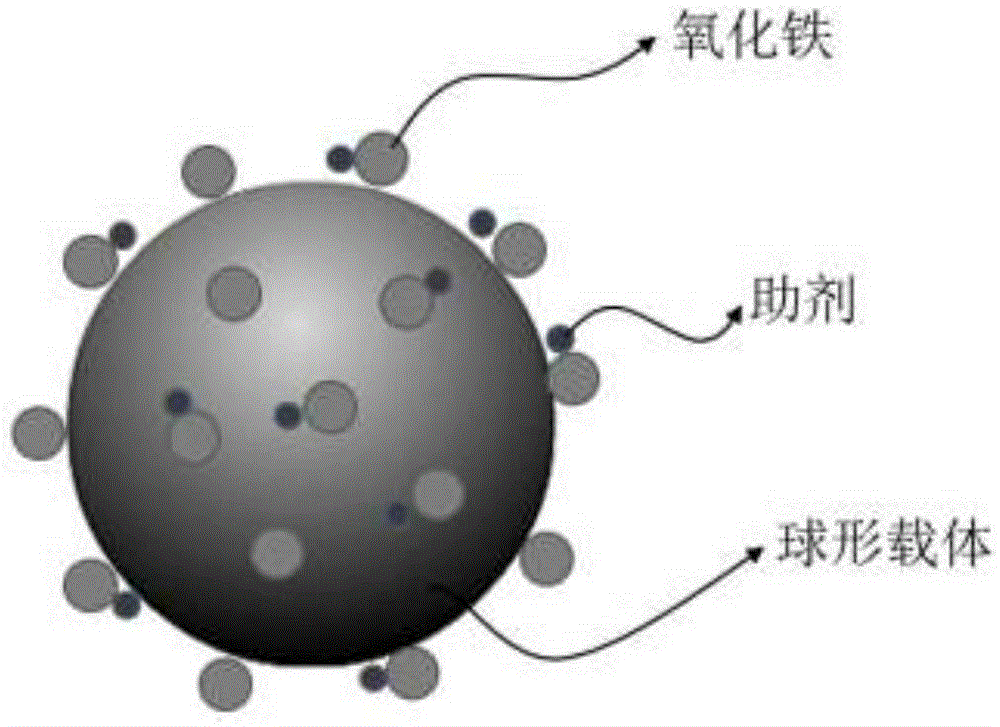

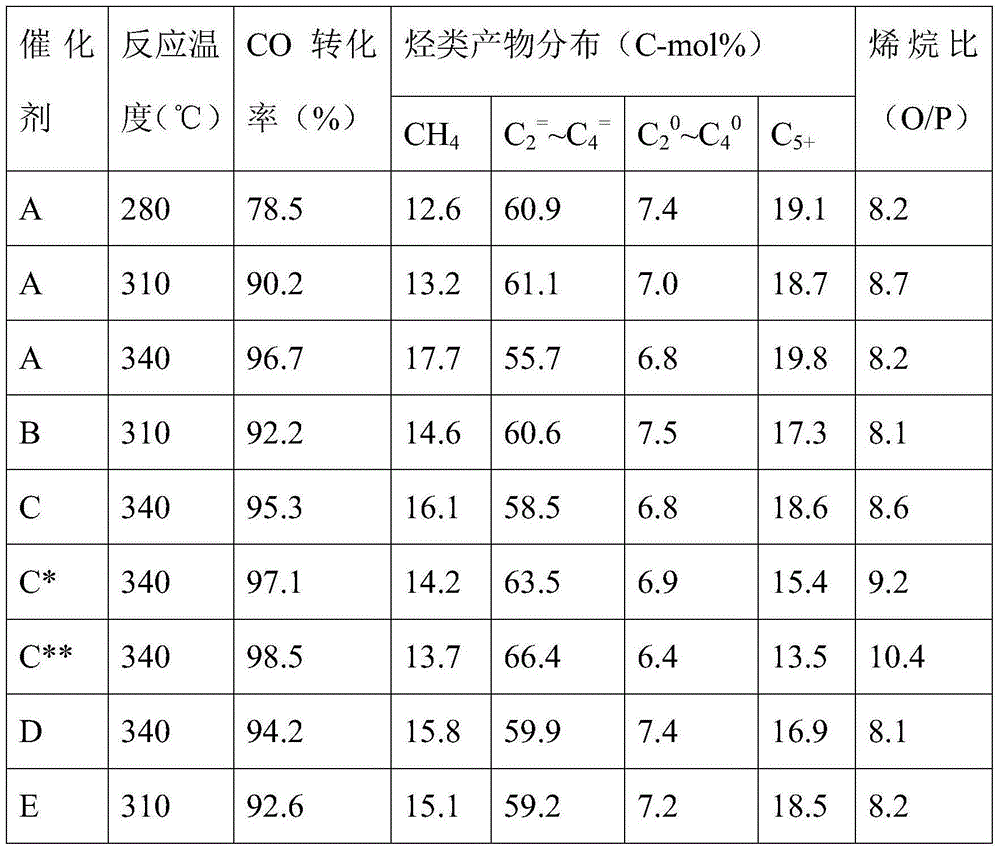

Catalyst facilitating direct preparation of light olefins from syngas as well as preparation and application of catalyst

ActiveCN105195189AEasy to prepareEasy to operateHydrocarbon from carbon oxidesLiquid hydrocarbon mixture productionAlkaneSyngas

The invention discloses a preparation method of a catalyst facilitating highly selective synthesis of light olefins from syngas. A compound adopting a spherical or ellipsoidal structure is taken as a carrier to be loaded with iron oxide and added with auxiliaries and is used for Fischer-Tropsch reaction for the syngas. The catalyst has very high catalytic activity on one hand and can effectively reduce alkane generated through secondary reaction hydrogenation of light olefins, and the selectivity of light olefins is improved. The preparation method of the catalyst is simple, and the catalyst has very good application prospects.

Owner:JIANGNAN UNIV

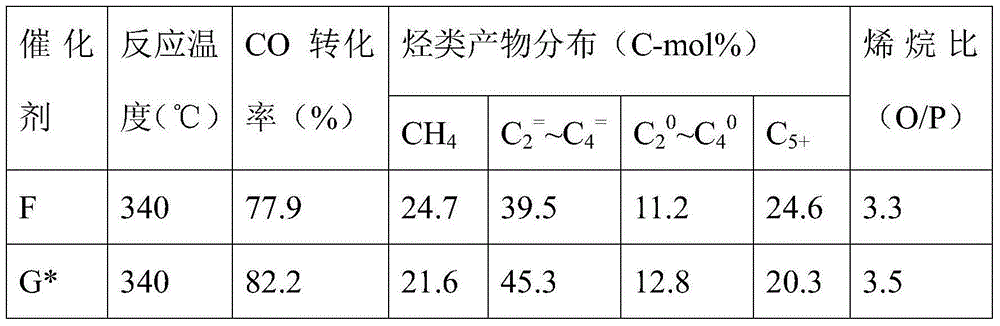

Non-noble metal oxide combustion catalyst, and preparation method and use thereof

InactiveCN105381800AEasy to synthesizeLow costDispersed particle separationCatalyst activation/preparationChemical synthesisCobalt(II,III) oxide

The present invention relates to a non-noble metal oxide combustion catalyst and a preparation method and use thereof, and belongs to the technical field of energy utilization and environment protection. The catalyst is iron oxide, cobaltosic oxide, nickel oxide, cupric oxide, vanadium oxide, chrome oxide, manganese dioxide or cerium dioxide prepared according to the following steps: (1) using hydrothermal chemical synthesis to form a precursor of a catalyst; and (b) washing, filtering, shaping, drying and calcinating the obtained precursor of the catalyst, and finally forming a combustion catalyst or coating the precursor of the catalyst on a carrier to form a combustion catalyst. The catalyst prepared by the method can be used in catalytic combustion of methane and other VOC gas, and has the advantages that the synthesis process is simple, the cost is low, the catalytic activity and hydrothermal stability is high, and the light-off temperature and complete combustion temperature of methane are low.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

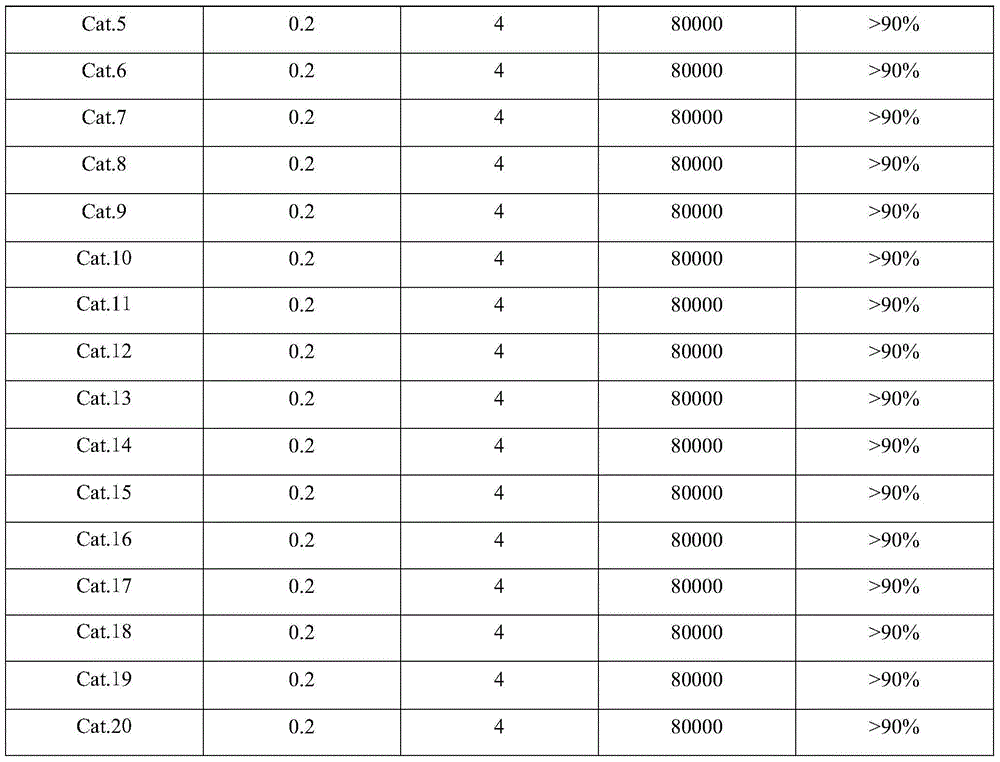

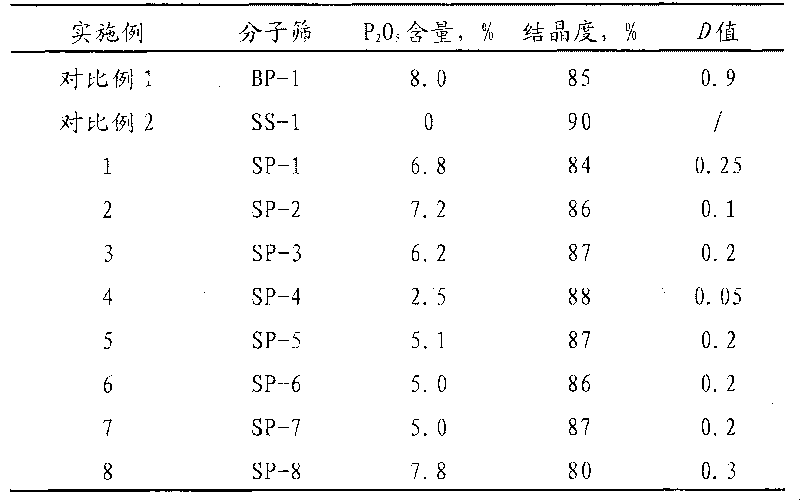

Silicon and phosphorus modified ZSM-5 molecular sieve and preparation method thereof

ActiveCN101759199AHigh crystallinityGood choicePentasil aluminosilicate zeoliteCrystallinityComputational chemistry

The invention provides a silicon and phosphorus modified ZSM-5 molecular sieve and a preparation method thereof; the relative crystallinity of the molecular sieve is at least 75%; the distribution D of the phosphorus is larger than or equal to 0 and less than or equal to 0.5, wherein the D is equal to P(S) / P(C); the P(S) shows the phosphorus content at one fifth of the distance of crystal grains of the molecular sieve characterized with a TEM-EDX method from the edge to the center; and the P(C) show the phosphorus content at the center of the crystal grains of the molecular sieve. Compared with the prior art, the phosphorus contained in the silicon and phosphorus modified ZSM-5 molecular sieve provided by the invention is unevenly distributed on the surface layer and central layer of the molecular sieve. When the molecular sieve is used as a catalyst and applied to toluene alkylation with methanol for preparing p-xylene, the molecular not only shows excellent selectivity on the p-xylene and simultaneously has better activity and stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

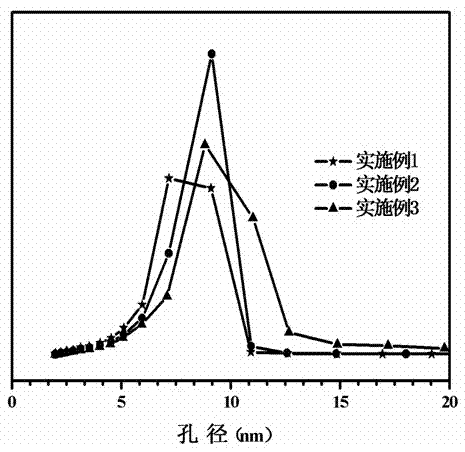

Carbon monoxide methanating catalyst and preparation method thereof

InactiveCN103480375ARaw materials are readily availableLow priceHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsHigh concentrationFiltration

The invention discloses a carbon monoxide methanating catalyst with high hydrothermal stability and a preparation method thereof, and belongs to the technical field of preparation of catalysts. The carbon monoxide methanating catalyst is prepared mainly by a co-precipitation method according to the following steps: taking alumina (Al2O3) as a carrier and metal nickel as an active component, adding Zr and transition metals as additives, uniformly mixing salt solutions, precipitating, aging, performing suction filtration, washing, drying and calcining the mixture. The preparation method is simple; raw materials are easily available; the cost is low; and the prepared catalyst has the characteristics of high specific surface area, large pore volume and concentrated pore size distribution, is applicable to hydrogenation reactions, in particular to methanation reaction of high-concentration carbon monoxide, and has the advantages of wide using temperature range, high catalytic activity, high hydrothermal stability and the like.

Owner:FUZHOU UNIV

Preparation method of dimethyl sulfoxide

ActiveCN103787932AImprove conversion rateImprove effective utilizationOrganic chemistryOrganic compound preparationMolecular sieveTitanium

The invention provides a preparation method of dimethyl sulfoxide, the method is as follows: in oxidation reaction conditions, dimethyl sulfide is contacted with at least one oxidant, and the catalyst contains at least one titanium silicon molecular sieve. According to the preparation method of the dimethyl sulfoxide, the dimethyl sulfide conversion rate is high, the effective utilization rate of the oxidant is high, the dimethyl sulfoxide selectivity is good, the usage amount of the dimethyl sulfide and the oxidant can be effectively reduced, and the production cost of the dimethyl sulfoxide can be reduced. According to the method of the invention, the activity stability of the catalyst is good, even by long-time continuous operation and multiple-times of cycle use of the catalyst, a high dimethyl sulfide conversion rate, a high effective utilization rate of the oxidant and high dimethyl sulfoxide selectivity also can be achieved. In addition, the method of the invention is mild in reaction condition, easy to control, and suitable for mass production.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of kaolin type fluid catalytic cracking catalyst

InactiveCN1429882AHigh zeolite contentStrong resistance to heavy metalsCatalytic crackingHigh resistanceMicrosphere

A catalyst for catalytic cracking process is prepared from kaolinite, solid crystal seed, assistant, organic disperser and / or adhesive through spray drying, shaping microspheres, high-temp calcining,crystallizing reaction on sodium silicate and sodium hydroxide to obtain crystallized microspheres (content of NaY zeolite is 20-70%, ratio of zeolite silica-alumina is 4.0-6.0), calcining, and exchanging with NH4 and Re3 three times. Its advantages are high resistance to heavy metal, high activity and stability, and low cost.

Owner:QILU PETRO CHEM - SINOPEC

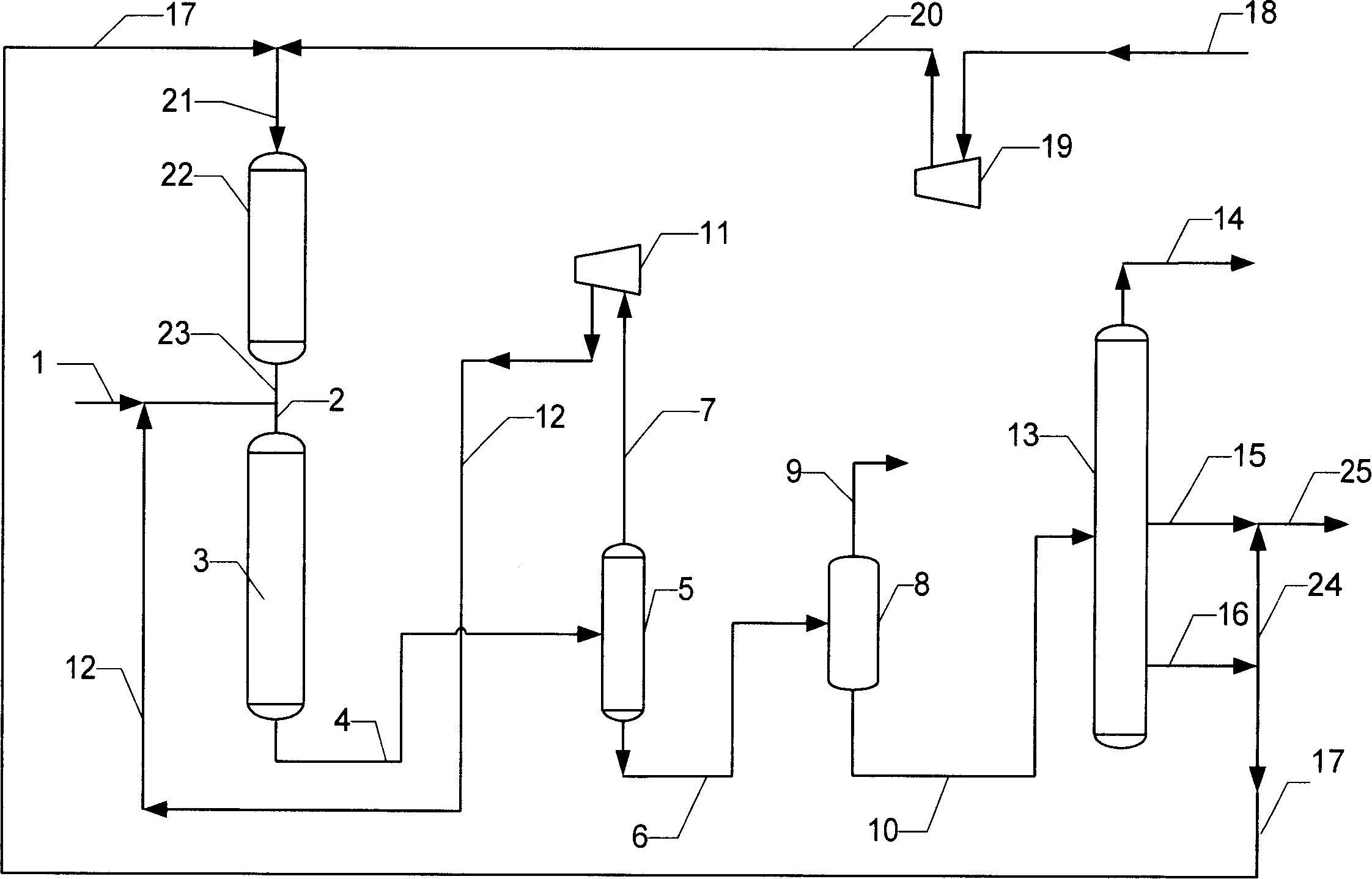

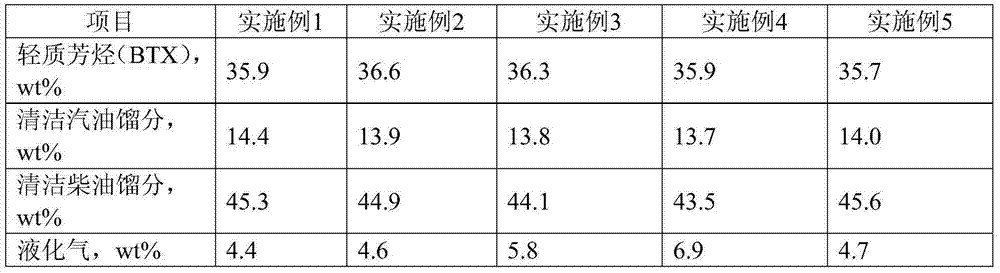

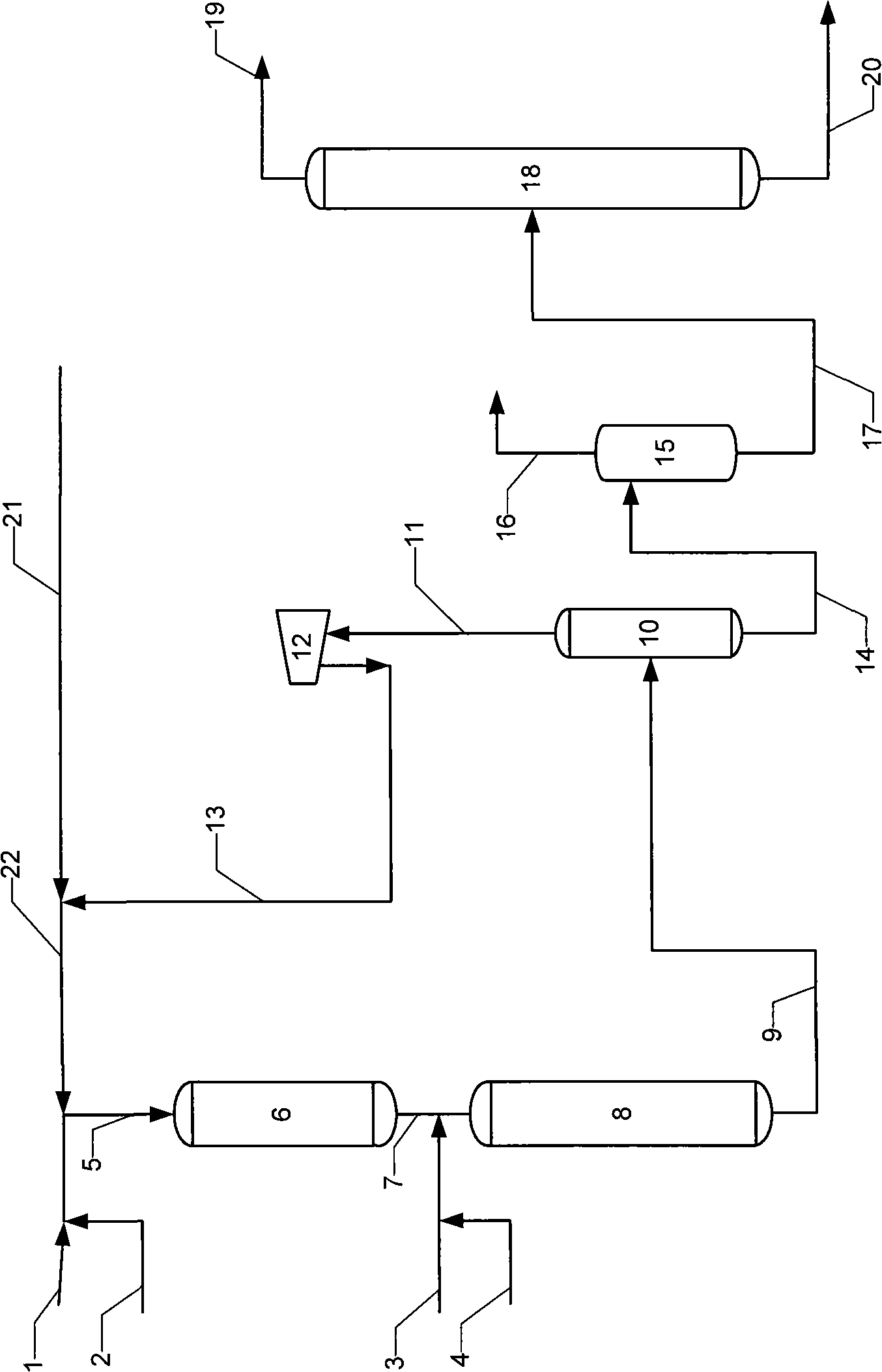

Hydrogenation method for producing clean diesel oil

The present invention relates to a hydrogenation method for producing clean diesel oil, after the raw material oil is mixed with circulating hydrogen, the mixture enters into a second hydrogenating reactor area, under the action of hydrogenation refining catalyst, the reaction is performed, after the reaction effusion is cooled, separated and fractionated, naphtha distillate, light diesel oil distillate and heavy diesel oil distillate are got, after a part or whole heavy diesel oil distillate is mixed with new hydrogen, the mixture enters into a first hydrogenating reactor area, and contacts with the hydrogenating reforming catalyst to perform reaction, the reactant enters into the second hydrogenating reactor area directly without separation, the left heavy diesel oil distillate and the light diesel oil distillate are mixed to get the diesel oil product. The adoption method of the present invention can treat high sulpher, high nitrogen and high drying point diesel oil distillate, under the relaxer operation condition, 2 type and 3 type of standard clean diesel oil which meet the requirement of the World Fuel Oil Code can be got. The present invention has simple flow and low operation pressure, the investment for equipments and the operation cost are all comparatively lower.

Owner:CHINA PETROLEUM & CHEM CORP +1

Zeolite-Containing Hydrocarbon-Converting Catalyst, the Preparation Process Thereof, and a Process for Converting Hydrocarbon Oils with the Catalyst

ActiveUS20070293714A1High activityImprove stabilityCatalytic crackingMolecular sieve catalystsAlkaline earth metalRare earth

A catalyst for converting hydrocarbons includes, based on the weight of the catalyst, 1-60% by weight of a zeolite, 0.1-10% by weight of an assistant catalytic component, 5-98% by weight of a thermotolerant inorganic oxide, and 0-70% by weight of a clay in terms of the oxide. The zeolite is a MFI-structured zeolite-containing phosphor and transition metal(s) or a mixture of the zeolite and a macroporous zeolite, which comprises, based on the weight of the mixture, 75-100% by weight of said MFI-structured zeolite containing phosphor and transition metal(s) and 0-25% by weight of the macroporous zeolite. In terms of the mass of the oxide, the MFI-structured zeolite containing phosphor and transition metal(s) has the following anhydrous chemical formula: (0-0.3)Na2O.(0.3-5.5)Al2O3.(1.0-10)P2O5.(0.7-15)M1xOy.(0.01-5)M2mOn(0-10)RE2O3.(70-97)SiO2 I or (0-0.3)Na2O.(0.3-5)Al2O3.(1.0-10)P2O5.(0.7-15)MpOq.(0-10)RE2O3.(70-98)SiO2 II The assistant catalytic component is one or more selected from the group consisting of the alkali earth metals, Group IVB metals, non-noble metals of Group VIII, and rare earth metals of the Periodic Table of the Elements. This catalyst has a higher ability to convert petroleum hydrocarbons and higher yields for propylene, ethylene, and light aromatics.

Owner:CHINA PETROCHEMICAL CORP +1

Preparation method of high activity fluid catalytic eracking catalyst

InactiveCN1429883AHigh zeolite contentStrong resistance to heavy metalsCatalytic crackingCatalyst activation/preparationHigh resistanceAdhesive

A high-activity catalyst for catalytic cracking process is prepared from kaolinite, solid seed, assistant, organic disperser and adhesive through spray drying, shaping, microspheres, high-temp calcining, crystallizing reaction on sodium silicate and sodium hydroxide to obtain crystallized microspheres content of zeolit is 20-70%, ratio of zeolit silica-alumina is 4.0-6.0), calcining, and exchanging with NH4 and Re3 three times. Its advantages are high resistance to heavy metal, high activity and stability, and low cost.

Owner:CHINA PETROLEUM & CHEM CORP

Nano hydrogenation catalysts composition and method of producing the same

ActiveCN101172235ALarge particle sizeHigh surface areaMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsSolubilityInorganic oxide

The invention discloses nano-composite hydrogenation catalyst composition and a preparation method thereof. The catalyst composition includes active metal oxide and the composition of porous melt-resistant inorganic oxide. By utilizing the property that the precursors of the melt-resistant inorganic oxide, promoter oxide and the active metal oxide can form super-solubility nanometre micelle under the existence of surfactant with the VB value less than 1 and hydrocarbon composition, the invention facilitates the precursors and the hydroxide formed by precipitant to be in situ synthesized inside a micelle, so as to avoid the augment of the particle diameter of the oxide, and to facilitate the particle diameter to be in a single dispersed state. The catalyst of the invention has high specific surface area, large pore volume, large pore diameter, wide application range and good activity stability. The method of the invention has the advantages that the nano particle diameter is easy to be controlled, the distribution range of the particle diameter is narrow and the proportion of the carrier and the active component can be adjusted. The amount of the surfactant and the hydrocarbon component used for the method of the invention is less, and the cost is low.

Owner:CHINA PETROLEUM & CHEM CORP +1

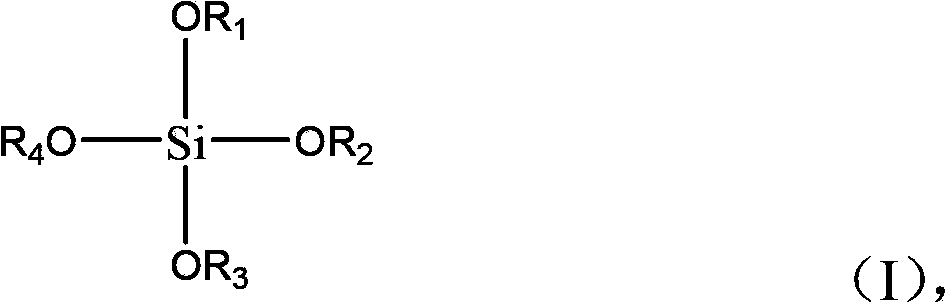

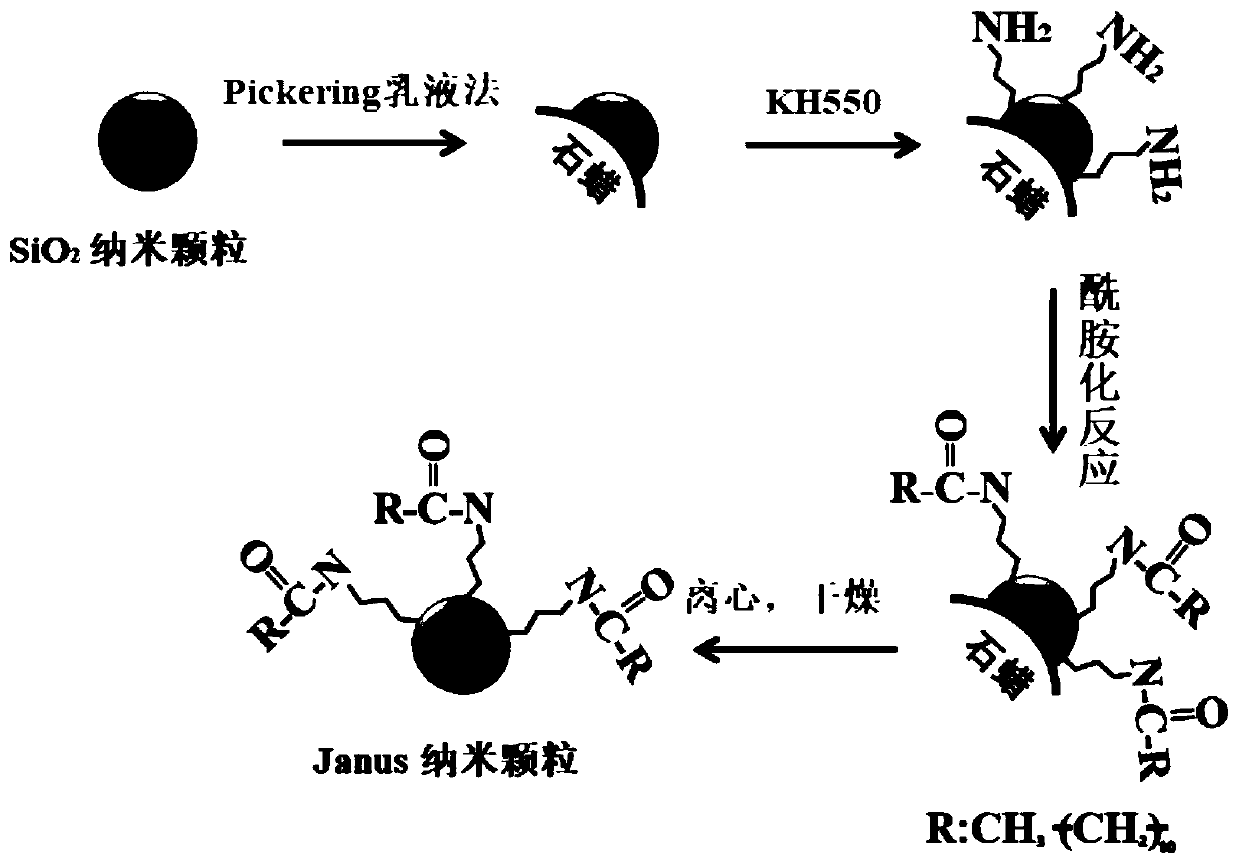

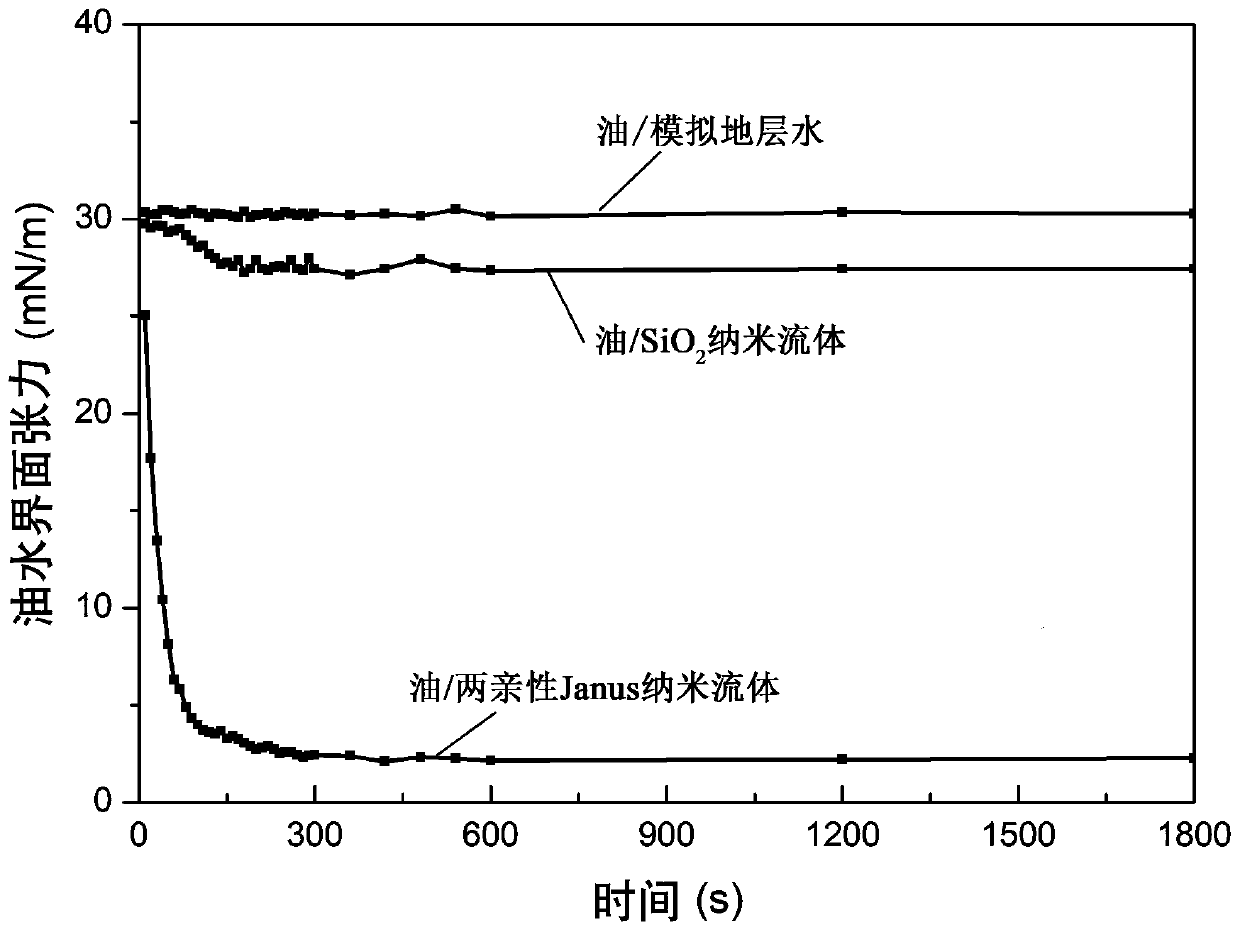

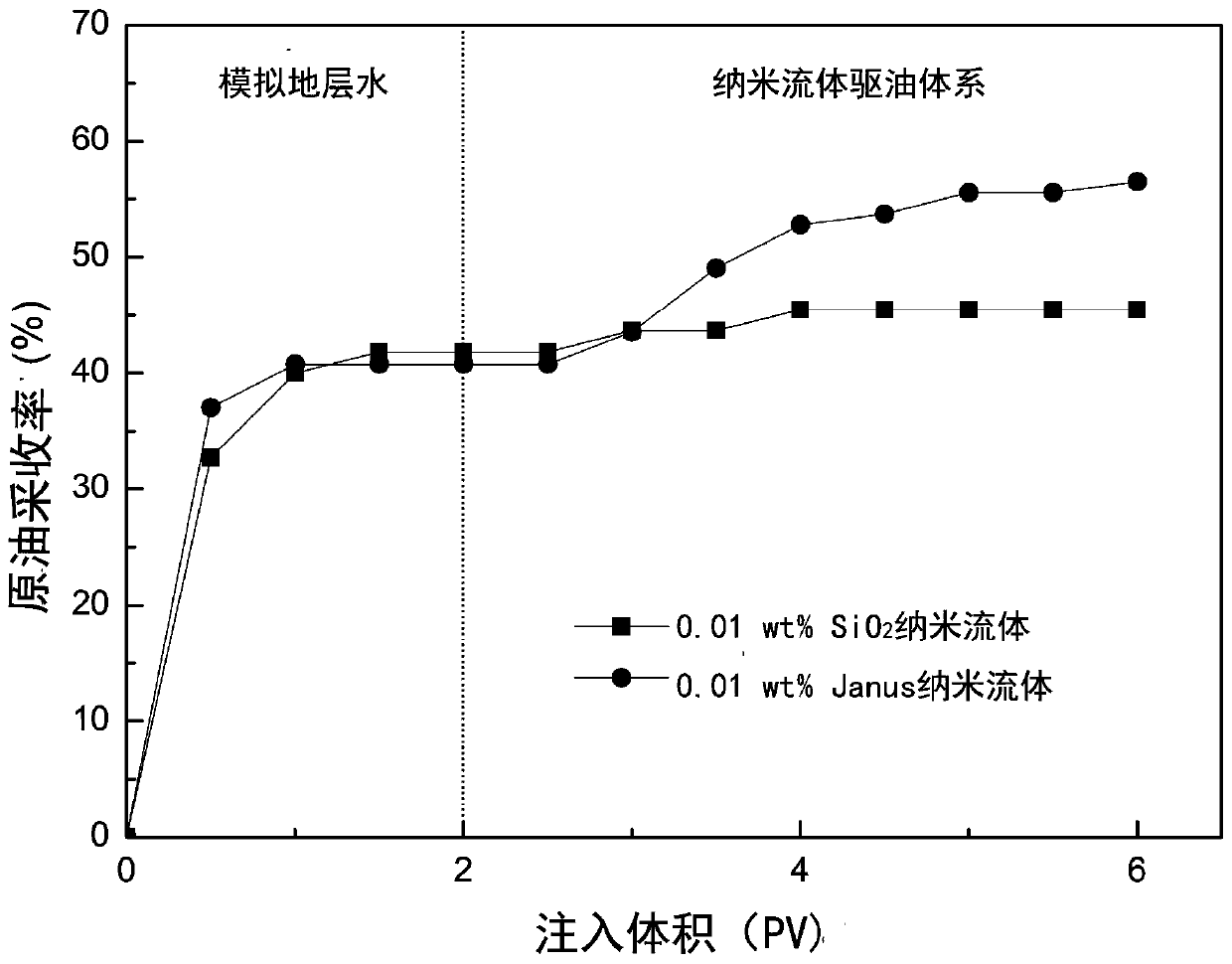

Amphiphilic Janus nano particle and preparation method and application thereof

InactiveCN111303853AThe synthesis steps are simpleGood interfacial propertiesDrilling compositionParaffin waxPtru catalyst

The invention provides an amphiphilic Janus nano particle and a preparation method and application thereof. The preparation method comprises the following steps: dispersing silicon dioxide nanoparticles in water to obtain a dispersion liquid, mixing the dispersion liquid and liquid paraffin, heating and stirring in a water bath to form a Pickering emulsion, cooling to obtain small wax balls, adding a silane coupling agent into the small wax balls for modification to obtain modified small wax balls, mixing the modified small wax balls, an amidation catalyst and C12-C18 saturated fatty acid, andcarrying out an amidation reaction process to obtain organic hydrophobic chain grafted oil-water amphiphilic nanoparticles, and removing paraffin in the organic hydrophobic chain grafted oil-water amphiphilic nanoparticles to obtain the amphiphilic Janus nano particles. When the surfactant is used as an oil-displacing agent, oil-water interfacial tension can be effectively reduced at low concentration, rock wettability is changed, oil-displacing efficiency of nanofluid is remarkably improved, economic cost is reduced, and the surfactant has a wide application prospect.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

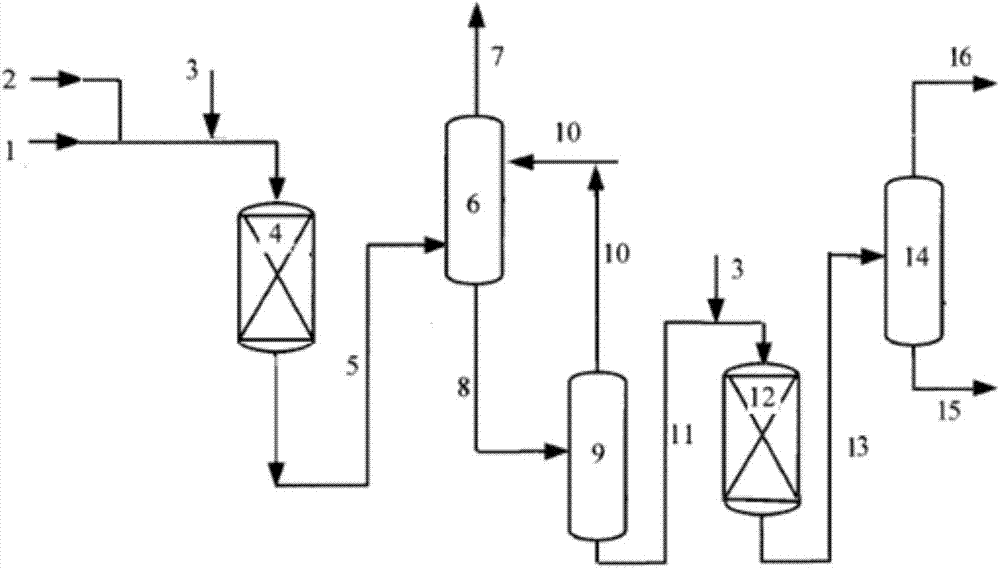

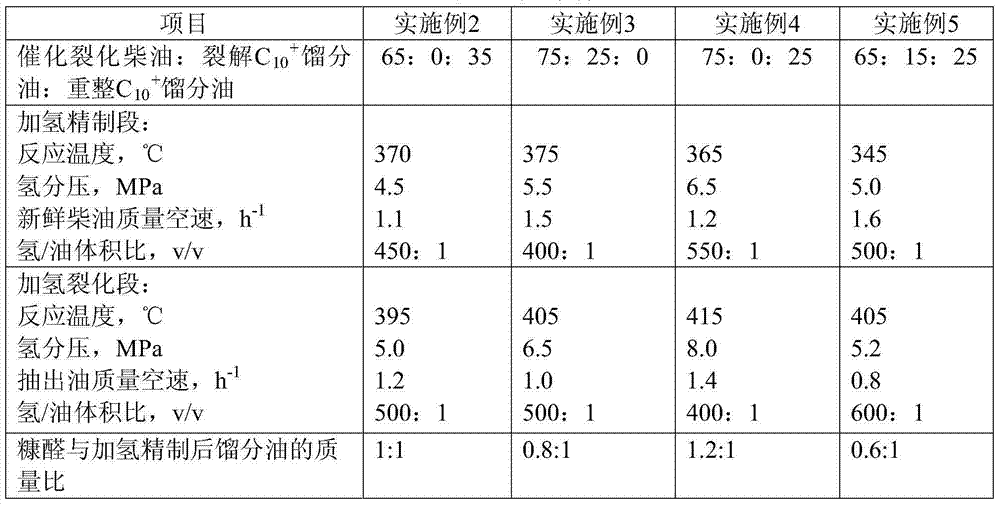

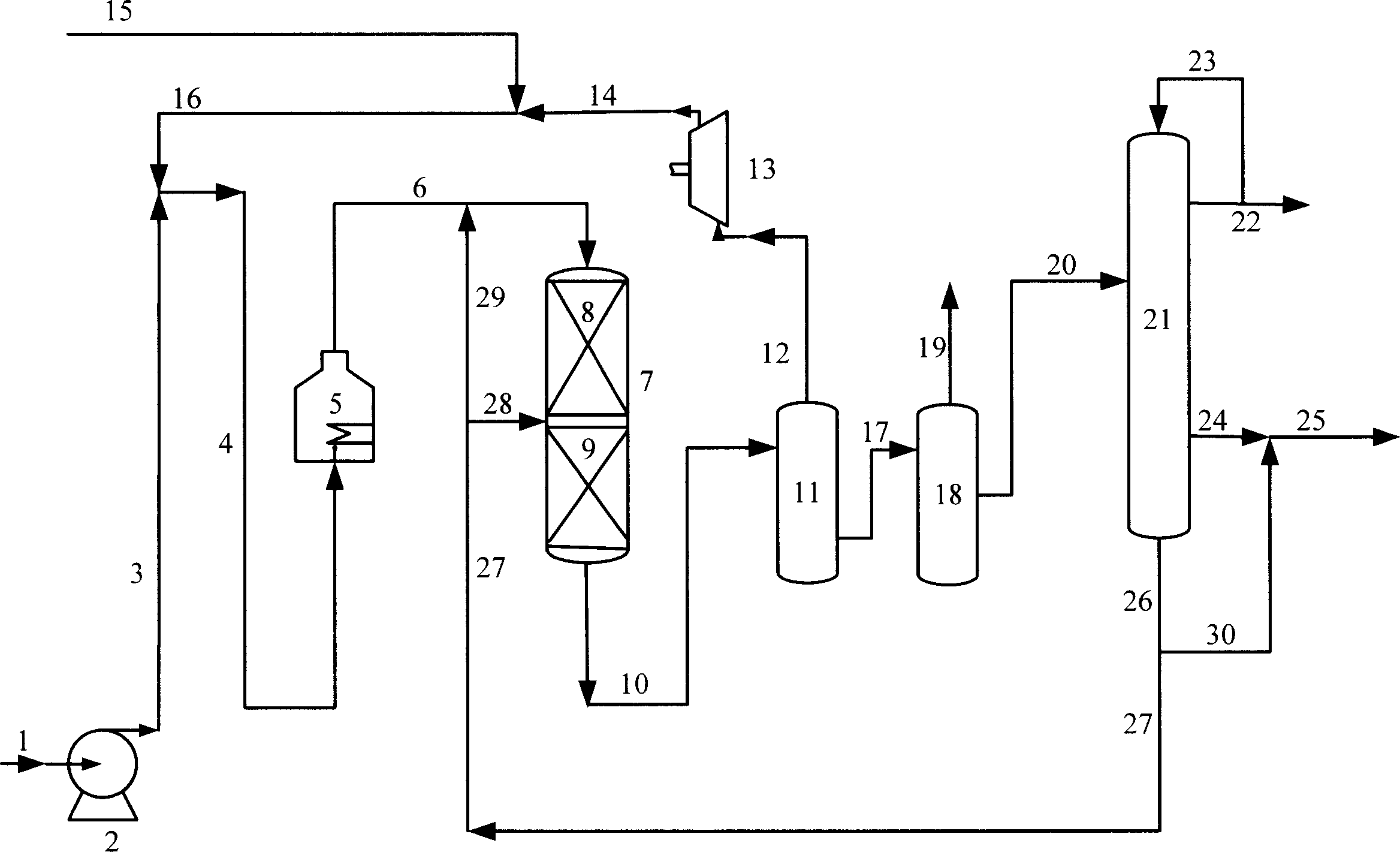

Method for mixed production of light-weight aromatic hydrocarbon by use of catalytic cracking diesel and C10<+> distillate oil

ActiveCN103897731AThe content of sulfur and nitrogen impurities is reducedAchieve enrichmentHydrocarbon by hydrogenationHydrocarbonsAlkaneGasoline

The invention relates to a method for mixed production of light-weight aromatic hydrocarbon by use of catalytic cracking diesel and C10<+> distillate oil. The method comprises the following steps: firstly mixing the catalytic cracking diesel and the C10<+> distillate oil with hydrogen, performing a hydrofining reaction to remove sulfur and nitrogen, saturate olefin and appropriately saturate aromatic hydrocarbon; then, extracting a hydrofining product by using an extraction solvent to obtain extract oil containing rich aromatic hydrocarbon and raffinate oil containing rich alkane; using the raffinate oil as a clean diesel oil concoction component, and performing rectification separation on the extract oil to obtain aromatic hydrocarbon extract oil; performing a hydrocracking reaction on the aromatic hydrocarbon extract oil, performing cutting separation on a hydrocracking product, using a distillate oil product greater than 195 DEG C as the clean diesel oil concoction component, feeding the distillate oil product smaller than 195 DEG C as an aromatic hydrocarbon raw material into an aromatic hydrocarbon treatment device to obtain a light-weight aromatic hydrocarbon product and a clean gasoline concoction component. By adopting the method provided by the invention, the yield of the light-weight aromatic hydrocarbon is increased, and meanwhile high-quality clean fuel oil is obtained and the high additional value utilization of the C10<+> distillate oil is achieved.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Method for producing diesel oil with low sulphur and low arene

ActiveCN101092575ASimple processLow operating pressureTreatment with hydrotreatment processesHydrogenGasoline

This invention discloses a method for producing low-sulfur low-arene diesel oil. The method comprises: mixing base oil and hydrogen, introducing into a hydrogenation reactor, reacting in the first hydrogenation region by contacting hydrorefining catalyst I, directly introducing the reaction product into the second hydrogenation region without separation, reacting by contacting hydrorefining catalyst II, cooling and separating the reaction product to obtain hydrogen-rich gas and liquid substance, circulating the hydrogen-rich gas for repeated use, introducing the liquid substance into a fractionating system, fractionating to obtain crude gasoline fraction, light diesel oil fraction and heavy diesel oil fraction, introducing part or all of the heavy diesel oil fraction bake to the hydrogenation reactor. By the method, high-sulfur, high-nitrogen and high-metal content diesel oil fraction can be treated under mild conditions, and clean diesel oil (with low sulfur content and low arene content) can be obtained. The method has such advantages as simple process, low operation pressure, low apparatus investment and low operation cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

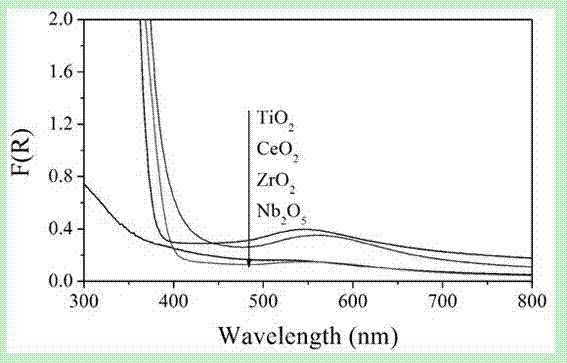

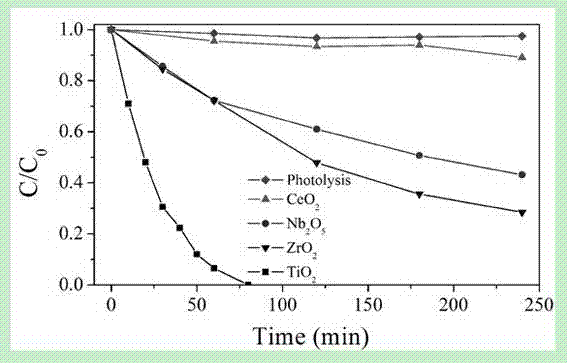

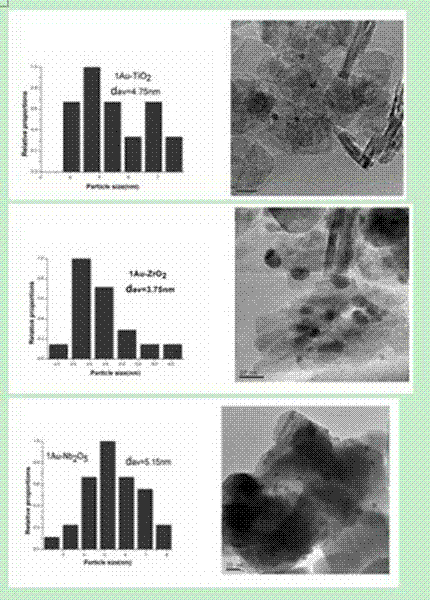

Preparation method of visible light catalyst with surface plasmon effect and application thereof

InactiveCN102350346AEfficient depositionControllable sizeCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsActive componentNanoparticle

The invention relates to a preparation method of a visible light catalyst with a surface plasmon effect and application thereof. The active component of the visible light catalyst is a precious metal Au, and the carrier is one of TiO2, CeO2, Nb2O5, SiO2, Ta2O5, Al2O3 and ZrO2, wherein, Au accounts for 0.2-5% in mass content, and the particle size of Au particle is 2-20nm. Preparation of the catalyst consists of two steps: the first step is to prepare a carrier; the second step is to prepare an Au / TiO2 (CeO2, SiO2, Al2O3, Nb2O5, Ta2O5, ZrO2) visible light catalyst with a plasmon effect througha sol precipitation method. Au nanoparticles prepared by the method of the invention have good dispersibility, easily controllable size, high active component utilization rate, as well as the effect of high efficiency photocatalytic degradation of organic pollutants by visible light.

Owner:FUZHOU UNIV

Process for producing ultralow sulfur diesel fuels

ActiveCN101311252AReduce sulfur contentReduce PAH contentTreatment with hydrotreatment processesPolycyclic aromatic hydrocarbonNaphtha

The invention relates to a production method for ultra-low sulfur diesel oil; wherein, after mixed with hydrogen, straight-run atmosphere 3rd side cut distillate and (or) diesel oil heavy distillate enter(s) a first hydrogenation reaction zone and reacts under the action of hydro-upgrading catalyst and hydrofining catalyst; after mixed with the reaction effluent of the first hydrogenation reaction zone, straight-run atmosphere 2nd side cut distillate and (or) diesel oil light distillate enter(s) a second hydrogenation reaction zone and reacts under the action of the hydrofining catalyst; the reaction effluent of the second hydrogenation reaction zone is cooled, separated and distilled to obtain naphtha fraction and diesel products. The method provided by the invention can treat the diesel distillate with high sulfur, high nitrogen and high final boiling point, and under mild operating conditions, obtain clear diesel products with low content of sulfur and polycyclic aromatic hydrocarbons as well as high cetane number; meanwhile, the product quality can reach the indexes of the IV European emission standard.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic cracking co-catalyst for high yield diesel oil and its preparing method

ActiveCN1900226AStrong resistance to heavy metalsGood activity and stabilityCatalytic crackingMicrosphereRare earth

The present invention is catalytically cracking co-catalyst for raising diesel oil yield and its preparation process. The co-catalyst is prepared with sprayed microballoon containing kaolin, pseudo boehmite and water galss, and through high temperature roasting over 900 deg.c, extraction with sodium hydroxide or other strong alkali to form pore channels, and final supporting phosphorus and RE oxide. The co-catalyst contains phosphorus in 1-3.5 wt%, RE oxide in 1-5 wt%, no zeolite component and sodium oxide less than 0.6 wt%. Adding certain amount of the co-catalyst into FCC catalyzing apparatus can raise diesel oil yield, improve product distribution and raise the utilization rate of available catalyst.

Owner:PETROCHINA CO LTD

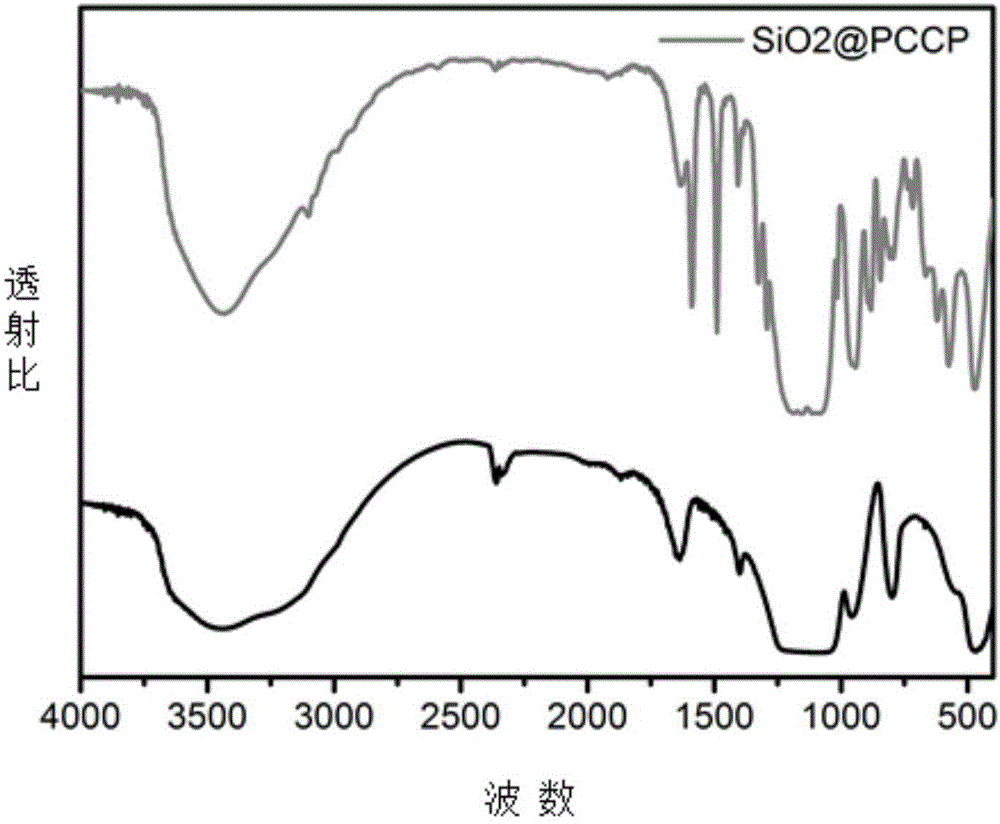

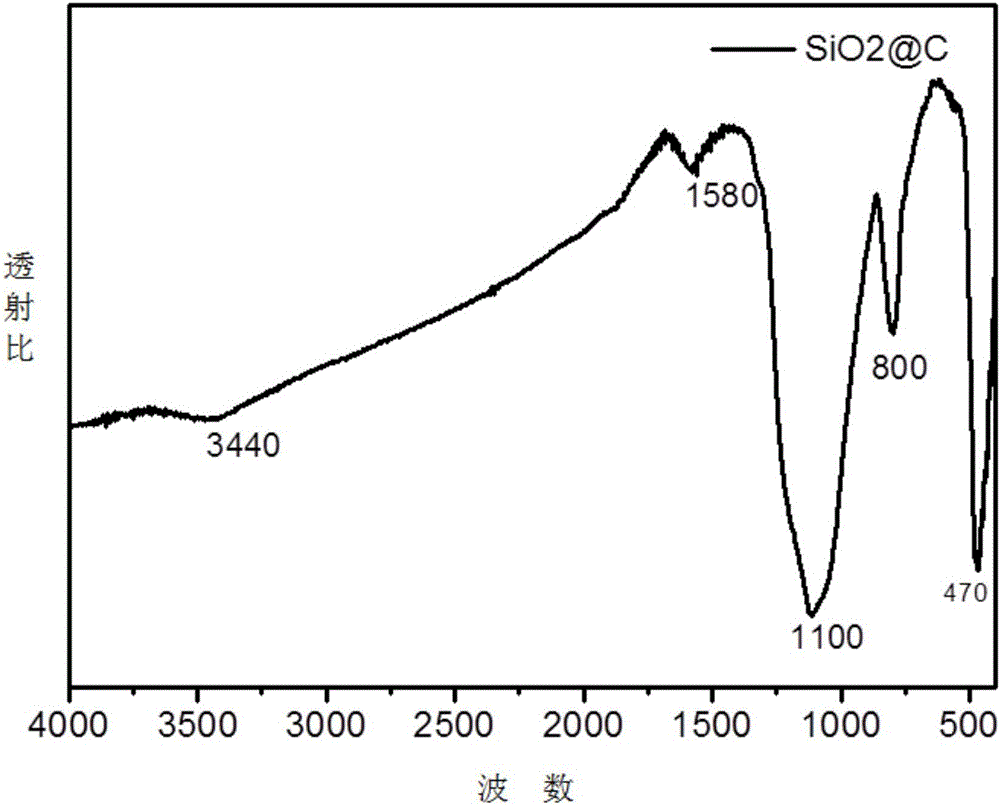

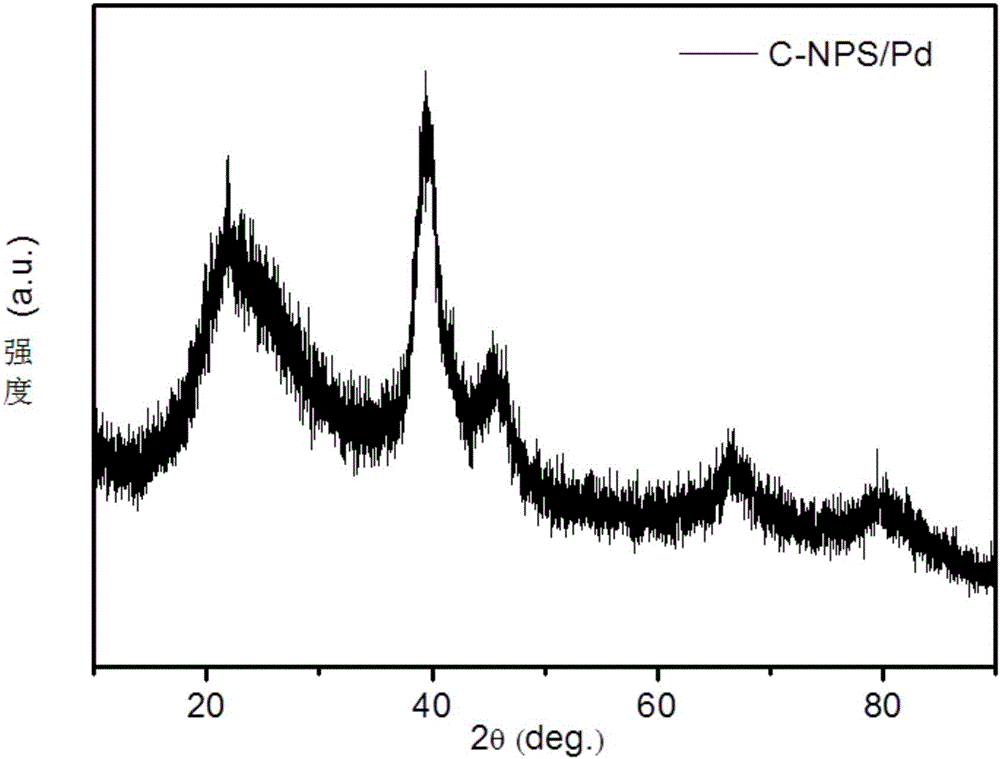

Heteroatom doped hollow carbon sphere material loaded precious metal nano particle and preparation thereof

ActiveCN106006549ASimple manufacturing processSuitable for large-scale productionMaterial nanotechnologyCell electrodesEtchingPolyphosphazene

The invention relates to a heteroatom doped hollow carbon sphere material loaded precious metal nano particle and preparation thereof. The preparation comprises the following steps that firstly, heteroatom doped hollow carbon spheres are prepared, wherein 1-1, silicon dioxide serves as a template, comonomer phosphonitrilic chloride trimer and 4,4-dyhydroxyl bi-phenol are added, a polymerization reaction is carried out, and polyphosphazene wrapping silicon dioxide is generated; 1-2, the polyphosphazene wrapping silicon dioxide is calcined, and heteroatom doped carbon spheres with silicon dioxide as cores are obtained; 1-3, ultrasonic etching continues to be carried out, and after washing and drying, the heteroatom doped hollow carbon spheres are obtained; secondly, the prepared heteroatom doped hollow carbon spheres are dispersed into water, a precious metal precursor and a complexing agent are added, pH is adjusted to be 8-14, a reducing agent is added, stirring is carried out for a reaction, and after drying, the target product is obtained. Compared with the prior art, the catalyst has good electrocatalytic activity and electrochemical stability, and the preparation process is simple.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

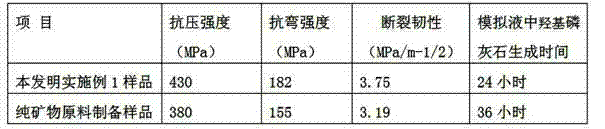

Biological microcrystalline glass prepared by utilizing phosphate tailings and preparation method thereof

The invention relates to biological microcrystalline glass prepared by utilizing phosphate tailings and a preparation method thereof. The biological microcrystalline glass comprises the following raw materials in parts by weight: 30 to 35 parts of the phosphate tailings, 15 to 25 parts of quartz sand, 10 to 16 parts of aluminium hydroxide, 20 to 28 parts of calcium hydrophosphate, 9 to 13 parts of calcium fluoride, 0 to 5 parts of magnesium oxide, 0 to 5 parts of zinc oxide and 0.5 part of sodium borate, wherein the utilization rate of the tailings reaches more than 30%. Compared with a product produced by utilizing conventional chemical raw materials, the biological microcrystalline glass has better physical and chemical properties and realizes reduction in the raw material cost by more than 30%. Based on the SiO2-Al2O3-P2O5-CaO-CaF2 system, the magnesium and the zinc are utilized to replace the partial calcium, so that a new magnesium-series wagnerite phase and a zinc-series zinc pointed crystal phase are generated, and therefore, the brittleness of the biological microcrystalline glass is improved while the mechanical strength is improved. In addition, the biocompatibility, the bioactivity and the chemical stability of the biological microcrystalline glass are improved.

Owner:CHINESE ACAD OF GEOLOGICAL SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com