Catalysts grading method for coker dry gas hydrogenation for preparation of ethylene cracking feed

A technology for coking dry gas and ethylene cracking, which is applied in the processing of gas mixtures, petroleum industry, and hydrocarbon oil treatment. It can solve problems such as complex processes, and achieve the effects of reducing the impact of activity, improving activity, and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The coking dry gas is contacted with the hydrogenation catalyst for hydrogenation reaction. In the three hydrogenation reaction zones of the hydrogenation reactor: the first hydrogenation reaction zone is filled with hydrofinishing catalyst I with a loading capacity of 10ml, and the second hydrogenation reaction zone is The reaction zone is filled with hydrofinishing catalyst II, with a loading volume of 30ml, and the third hydrogenation reaction zone is filled with hydrofinishing catalyst III, with a loading volume of 60ml.

Embodiment 2

[0026] The coking dry gas is contacted with the hydrogenation catalyst for hydrogenation reaction. In the three hydrogenation reaction zones of the hydrogenation reactor: the first hydrogenation reaction zone is filled with hydrofinishing catalyst I with a loading capacity of 10ml, and the second hydrogenation reaction zone is The reaction zone is filled with hydrofinishing catalyst II, with a loading capacity of 20ml, and the third hydrogenation reaction zone is filled with hydrofinishing catalyst III, with a loading capacity of 70ml.

Embodiment 3

[0028] The coking dry gas is contacted with the hydrogenation catalyst for hydrogenation reaction. In the three hydrogenation reaction zones of the hydrogenation reactor: the first hydrogenation reaction zone is filled with hydrofinishing catalyst I with a loading capacity of 10ml, and the second hydrogenation reaction zone is The reaction zone is filled with hydrofinishing catalyst II, with a loading capacity of 40ml, and the third hydrogenation reaction zone is filled with hydrofinishing catalyst III, with a loading capacity of 50ml.

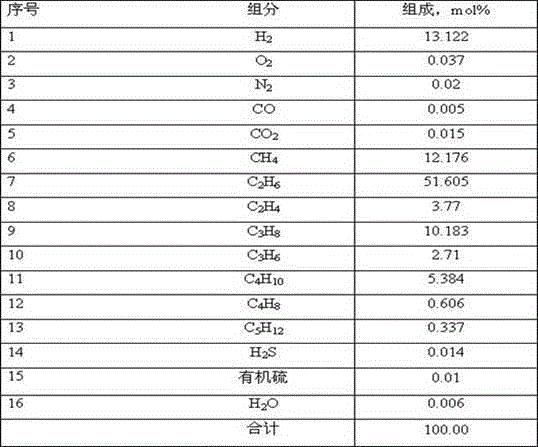

[0029]Two kinds of dry gas raw materials are used in the embodiment of the present invention, namely dry gas raw material 1 and dry gas raw material 2, and their compositions are listed in Table 1 and Table 2 respectively. Pack the internal diameter 12mm by the catalyst grading method among the embodiment 1 ~ 3, in the stainless steel reactor of long 650mm, at hydrogen partial pressure 2.5MPa, space velocity 600h -1 Under certain operating con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com