Preparation method of visible light catalyst with surface plasmon effect and application thereof

A surface plasmon and catalyst technology, applied in the field of photocatalysis, can solve the problems of low utilization rate of active components, uneven dispersion of gold particles, difficult particle size control, etc. Simple and easy preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] (1) Anatase TiO 2 The preparation steps of the carrier are as follows: add 25mL n-tetrabutyl titanate and 3mL hydrofluoric acid into the autoclave, stir evenly at room temperature, seal the autoclave, put it in an oven at 150-200°C for 12-48h, and wash it several times Centrifuge, dry and grind to get anatase TiO 2 .

[0025] (2) The preparation steps of zirconia carrier are as follows: add 25mL zirconia chloride and 3mL sodium hydroxide solution with a concentration of 1.0M into the autoclave, stir well at room temperature, put it in an oven at 150-200℃ for 12-48h , washed and centrifuged several times, dried and ground to obtain zirconia.

[0026] (3) Other carriers (rutile TiO 2 , CeO 2 , SiO 2 、 Ta 2 o 5 、Al 2 o 3 , Nb 2 o 5 ) from Alfa Aesar company, the particle size range is 40-500 nm.

[0027] (4) Add 80mL of ethylene glycol and 0.1-1g of carrier into a round-bottomed flask, ultrasonicate for 10-20min with an ultrasonic power of 100W, stir vigorously f...

Embodiment 1

[0029] Preparation of Visible Light Catalyst with Surface Plasmon Effect

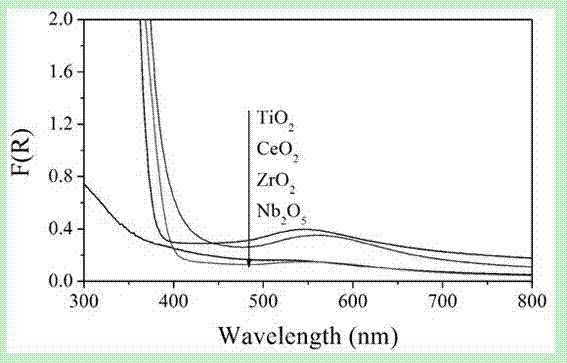

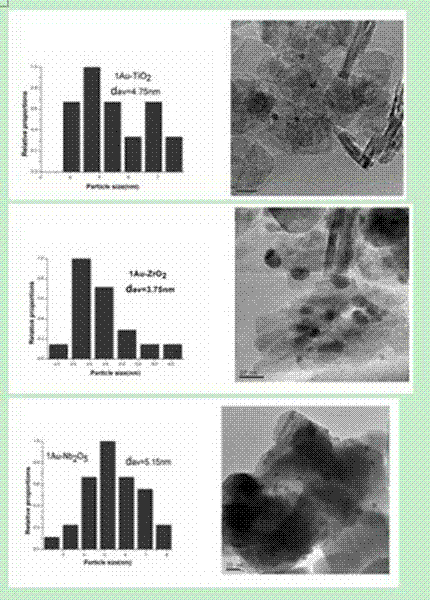

[0030] 80mL of ethylene glycol and 0.5g of TiO 2 Put it into a round-bottom flask, ultrasonically disperse, stir evenly, put it into an oil bath, heat it to 120°C, and after a period of argon gas flow, add 3mL of sodium hydrosulfide in ethylene glycol solution (3mmol / L) and 15mL of ethylene glycol solution of polyvinylpyrrolidone (0.18mol / L), then add 2mL of HAuCl 4 solution (10mg / mL), after 2h of reaction, the round bottom flask was transferred to an ice-water bath. After cooling, several times of centrifugation, washing with deionized water, and drying, the visible light catalyst is obtained. figure 1 The ultraviolet-visible diffuse reflection diagram of the visible light catalyst with surface plasmon effect synthesized by this preparation method is shown. It can be found from the figure that the prepared catalyst has a strong SPR characteristic absorption peak of Au at 550 nm.

Embodiment 2

[0032] Visible light photocatalyst degradation of rhodamine B with surface plasmon effect

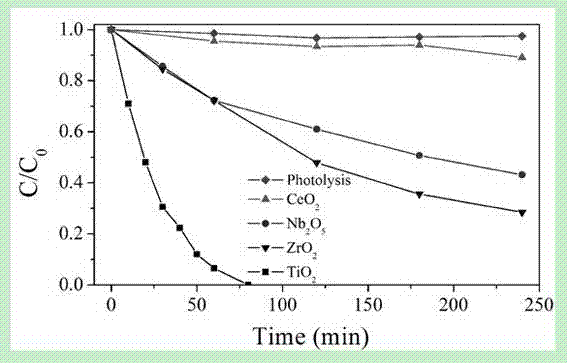

[0033] The obtained visible light photocatalyst with surface plasmon effect is used for photocatalytic degradation of Rhodamine B, and 80 mg sample is weighed and added to 80 mL RhB solution (10 -5 mol / L), and stirred for 1 h in the dark, so that the RhB solution reached the adsorption / desorption equilibrium on the surface of the catalyst, and then turned on the light source to carry out the photocatalytic reaction. The photodegradation uses a xenon lamp (greater than 420nm), and the photodegradation amount of rhodamine B is detected by a Cary-500 spectrophotometer. The photodegradation of rhodamine B under different conditions is as follows: figure 2 shown. It can be seen from the figure that rhodamine B basically does not degrade when no catalyst is added, and the catalysts of different supports all show good visible light catalytic activity, among which the activity of titanium di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com