Method for producing diesel oil with low sulphur and low arene

A low-aromatic and diesel technology, applied in the field of low-aromatic diesel and low-sulfur production, can solve problems such as high operating risk, high cost, and reduced operational flexibility, and achieve low operating pressure, simple process, and low equipment investment and operating costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

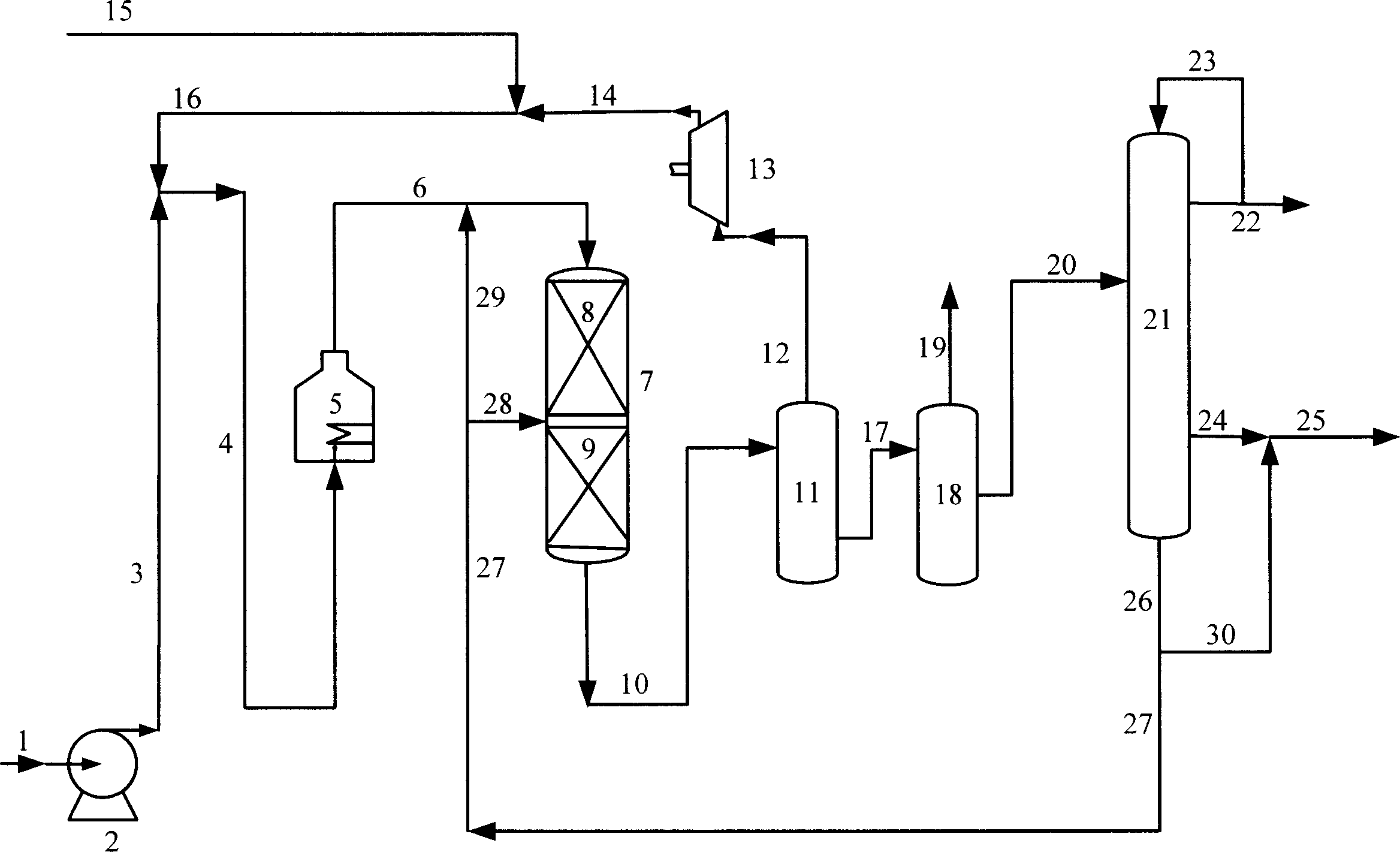

Method used

Image

Examples

preparation example Construction

[0021] The preparation method of described preferred hydrotreating catalyst I is:

[0022] The hydrated aluminum oxide and additives are mixed and molded, dried, and then calcined at 500-1000° C. for 1-6 hours under air to obtain the carrier. The carrier is immersed in the prepared aqueous solution of cobalt-containing compound and molybdenum-containing compound for 2-5 hours, dried at 100-300°C for 1-6 hours; calcined at 350-550°C for 1-6 hours to obtain catalyst products.

[0023]The cobalt compound and molybdenum compound aqueous solutions can be prepared by conventional methods. The cobalt compound and the molybdenum compound are respectively selected from one or more of their soluble compounds. Wherein the cobalt compound is preferably one or more of cobalt nitrate, cobalt chloride, and basic cobalt carbonate, and the molybdenum compound is preferably ammonium molybdate. The hydrated alumina is preferably pseudoboehmite.

[0024] The hydrorefining catalyst II is a met...

Embodiment 1

[0039] The raw material oil A is mixed with hydrogen and enters the hydrogenation reactor, passes through the first hydrogenation reaction zone and the second hydrogenation reaction zone in turn, and reacts with the hydrofinishing catalyst I and the hydrofinishing catalyst II respectively, and the reaction product After cooling and separation, the obtained hydrogen-rich gas is recycled, and the obtained liquid phase stream enters the fractionation system, and after fractionation, naphtha fraction, light diesel fraction and heavy diesel fraction are obtained, of which 40% by weight of the heavy diesel fraction is returned In the second hydrogenation reaction zone in the hydrogenation reactor, the fractionation point of the light diesel fraction and the heavy diesel fraction is 330° C., and the filling volume ratio of the hydrofinishing catalyst I and the hydrofinishing catalyst II is 5:5. The reaction conditions of this embodiment are as shown in Table 2, and the main properties...

Embodiment 2

[0041] The raw material oil A is mixed with hydrogen and enters the hydrogenation reactor, passes through the first hydrogenation reaction zone and the second hydrogenation reaction zone in turn, and reacts with the hydrofinishing catalyst I and the hydrofinishing catalyst II respectively, and the reaction product After cooling and separation, the obtained hydrogen-rich gas is recycled, and the obtained liquid phase stream enters the fractionation system, and after fractionation, naphtha fraction, light diesel fraction and heavy diesel fraction are obtained, and 80% of the heavy diesel fraction is returned to In the second hydrogenation reaction zone in the hydrogenation reactor, the fractionation point of the light diesel fraction and the heavy diesel fraction is 320° C., and the loading volume ratio of the hydrofinishing catalyst I and the hydrofinishing catalyst II is 3:7. The reaction conditions of the present embodiment are as shown in Table 2, and the main properties of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com