Method for mixed production of light-weight aromatic hydrocarbon by use of catalytic cracking diesel and C10<+> distillate oil

A technology for catalytic cracking of diesel oil and light aromatics, which is applied in the fields of chemical instruments and methods, hydrogenation of hydrocarbons, hydrocarbons, etc., can solve the problems of small-scale equipment and unobvious economic benefits, and achieve good activity stability and adaptability of raw materials Good performance and reduce the difficulty of hydrofining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

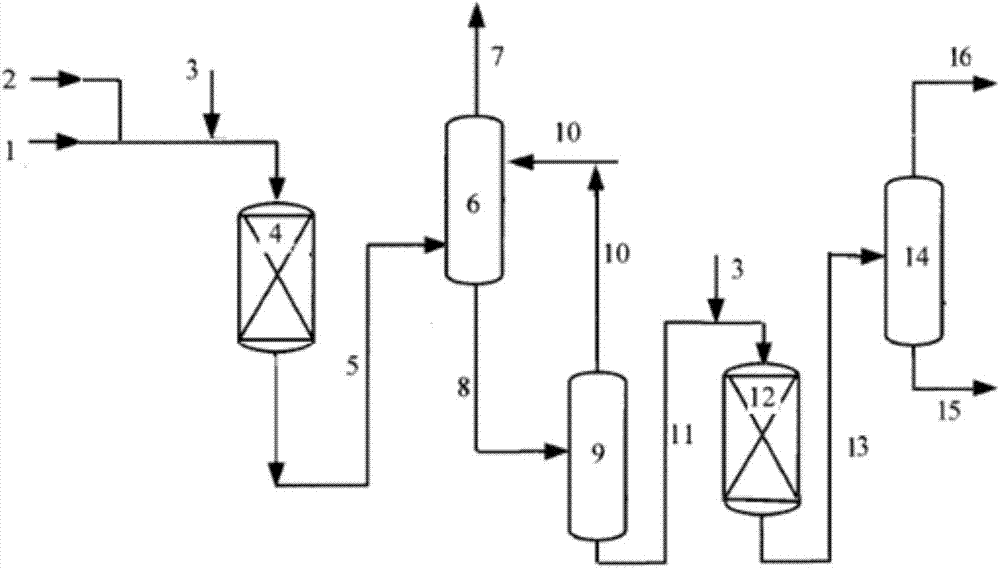

Method used

Image

Examples

Embodiment 1

[0058] Process the catalytic cracking diesel oil rich in aromatics, C by the inventive method 10 + Distillate oil, producing light aromatics and clean fuel oil products.

[0059] Catalytically cracked diesel oil, cracked C 10 + Distillate oil mixed feedstock (mass ratio 65:35) is feedstock oil, which is mixed with hydrogen and then sent to a fixed-bed high-pressure hydrogenation unit, with a loading capacity of 200mL of hydrofining catalyst. The reaction temperature is 360°C, the hydrogen partial pressure is 5.5MPa, and the mass space velocity of the raw material oil in the hydrofining section is 1.2h -1 , The hydrogen / oil volume ratio is 500:1.

[0060] Take the mass ratio of furfural and hydrorefined distillate oil as 1:1 for solvent extraction, take 500g of hydrorefined product and 500g of furfural into the separatory funnel, fully oscillate to mix evenly, and let it stand for stratification. Take the raffinate of the upper layer, its mass is 125g, add 125g of water th...

Embodiment 2~5

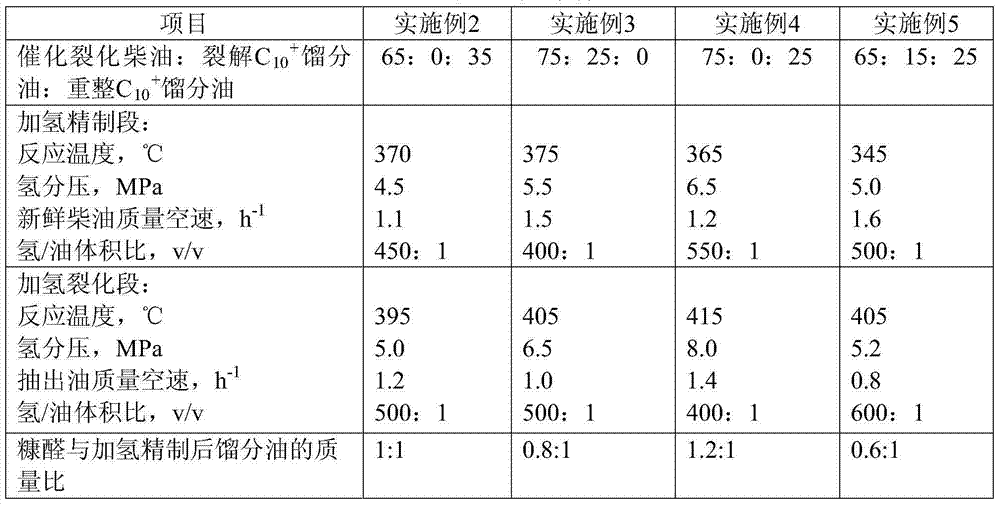

[0066] Press the method step of embodiment 1 successively to catalytic cracking diesel oil, C 10 + Distillate oil is processed, the difference is the ratio of raw materials, the selection of reaction conditions and the amount of extraction solvent, the selected test conditions are shown in Table 4.

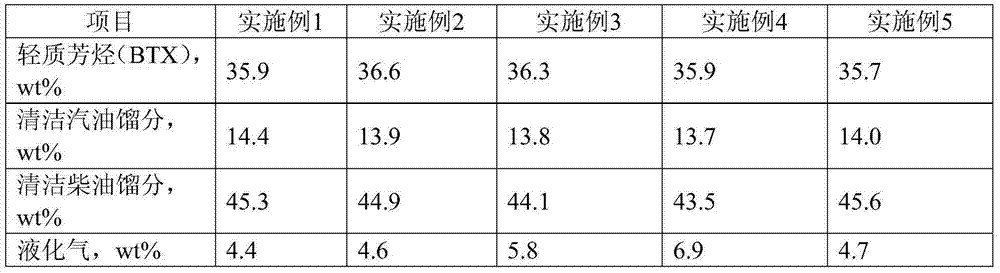

[0067] FCC diesel and C 10 + Distillate mixed feedstock calculation, the properties of different distillate products are shown in Table 5 and Table 6, and the yields of different distillate products are shown in Table 7.

[0068] Table 4 Test conditions

[0069]

[0070] Table 5 Properties of clean diesel distillates

[0071] project Example 1 Example 2 Example 3 Example 4 Example 5 Density(20℃),g / cm 3 0.835 0.836 0.838 0.836 0.832 Sulfur content, μg / g 8 7 4 8 7 Nitrogen content, μg / g 7 6 5 7 8 Aromatics, wt% 19.8 22.5 18.3 18.5 20.4 PAHs, wt% 1.5 2.2 1.4 1.2 2.3 cetane number 46 45 47 47 46 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com