Micro plastic continuous separation and enrichment device and method

A technology for separation, enrichment and microplastics, which is applied in the direction of plastic recycling, recycling technology, etc., can solve the problems of inability to achieve continuous separation, reduce separation efficiency, and complex overall structure, and achieve efficient and convenient separation methods, simple device structure, and increased The effect of recycling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Add 0.5017g of polyethylene microplastic particles with a particle diameter of less than 5mm (average diameter of 350μm) into the air-dried soil with a volume of 10% of the separator, mix evenly, and use it as a simulated sediment sample.

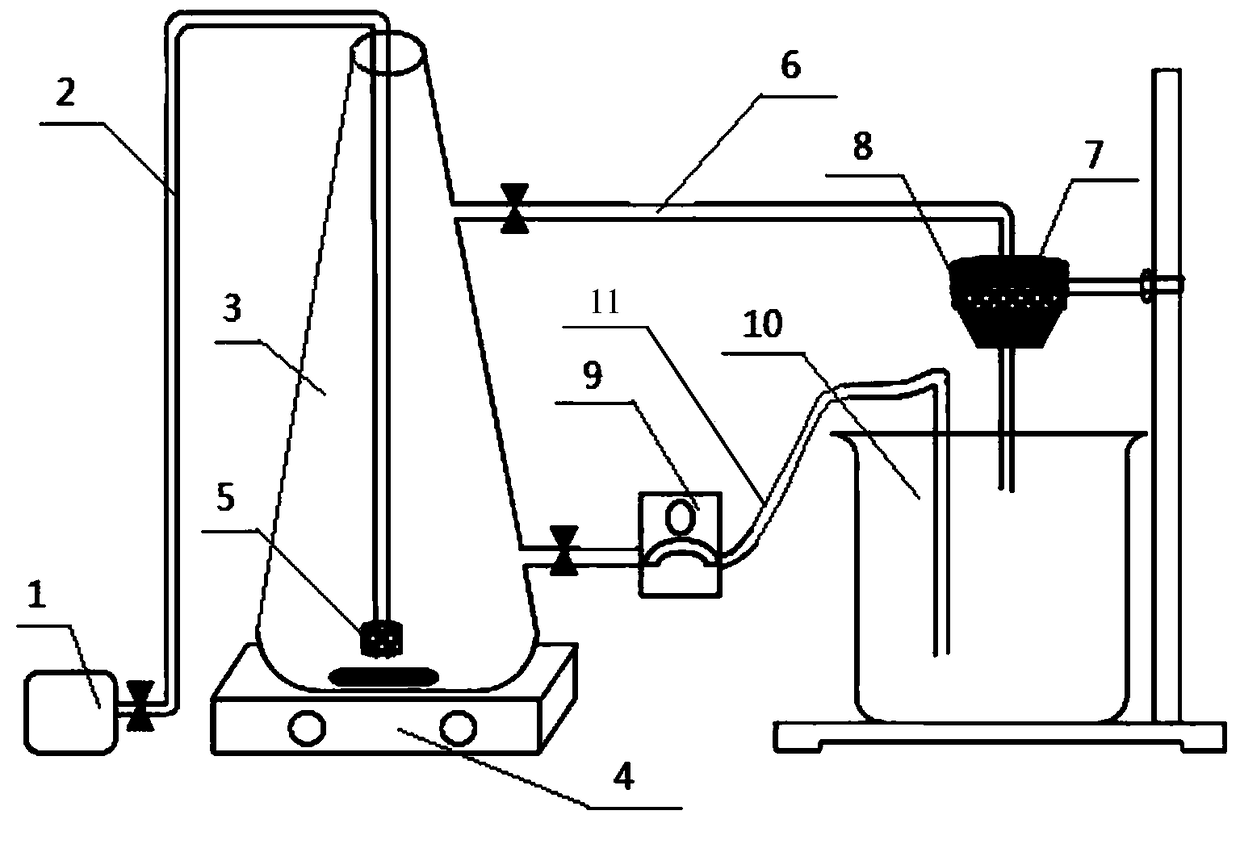

[0030] like figure 1As shown, add the simulated sediment sample to be separated in the separator 3, open the control switch of the peristaltic pump 9 and the inlet of the separator 3; add the density solution in the storage tank 10, so that the density solution passes through the peristaltic pump from the storage tank 10 9. Pump into the separator 3 with a magnetic stirring speed of 70rpm to obtain a suspension A mixed with the density solution and the sample to be separated. The distance between them is about 2.0 cm. The components of the density solution are inorganic salt solution and biodegradable surfactant. The inorganic salt solution is a saturated solution of sodium chloride, and the biodegradable surfactant is Sophora Glyco...

Embodiment 2

[0034] Add 0.5017g of polyethylene microplastic particles with a particle diameter of less than 5mm (average diameter of 350μm) into the air-dried soil with a volume of 8% of the separator, and mix evenly, as a simulated sediment sample.

[0035] Prepare the density solution, the density solution components are inorganic salt solution and biodegradable surfactant, the inorganic salt solution is a saturated solution of sodium chloride and sodium iodide, and the biodegradable surfactant is a concentration of 5mg / L alkyl Glycoside solution. The flow rate of the peristaltic pump is 300mL / min, the speed of the magnetic stirrer is 1000rpm, the gas flow rate of the air pump is 5L / min, the aperture of the screen is 250μm, the cycle time is 1h, the drying time is 6h, and the temperature is 90°C; other operating steps are the same

[0036] Example 1.

[0037] The final mass obtained was 0.4918 g, the sample recovery rate was 98.03%, and it was identified as added polyethylene microplas...

Embodiment 3

[0039] Add 0.5017g of polyethylene microplastic particles with a particle diameter of less than 5mm (average diameter of 350μm) into the air-dried soil with a volume of 6% of the separator, mix evenly, and use it as a simulated sediment sample.

[0040] Preparation density solution, density solution component is inorganic salt solution and biodegradable surfactant, and inorganic salt solution is the saturated solution of sodium iodide, and biodegradable surfactant is that concentration is respectively sophorolipid 1mg / L, cascarna A mixed solution of glycolipid 1mg / L and alkyl glycoside 1mg / L. The flow rate of the peristaltic pump is 150mL / min, the speed of the magnetic stirrer is 200rpm, the gas flow rate of the air pump is 2L / min, the aperture of the screen is 45μm, the cycle time is 3h, the drying time is 3h, and the temperature is 94°C; other operation steps are carried out in the same way example 1.

[0041] The final mass obtained was 0.4977g, the sample recovery rate wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com