Patents

Literature

98results about How to "Significantly improved" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

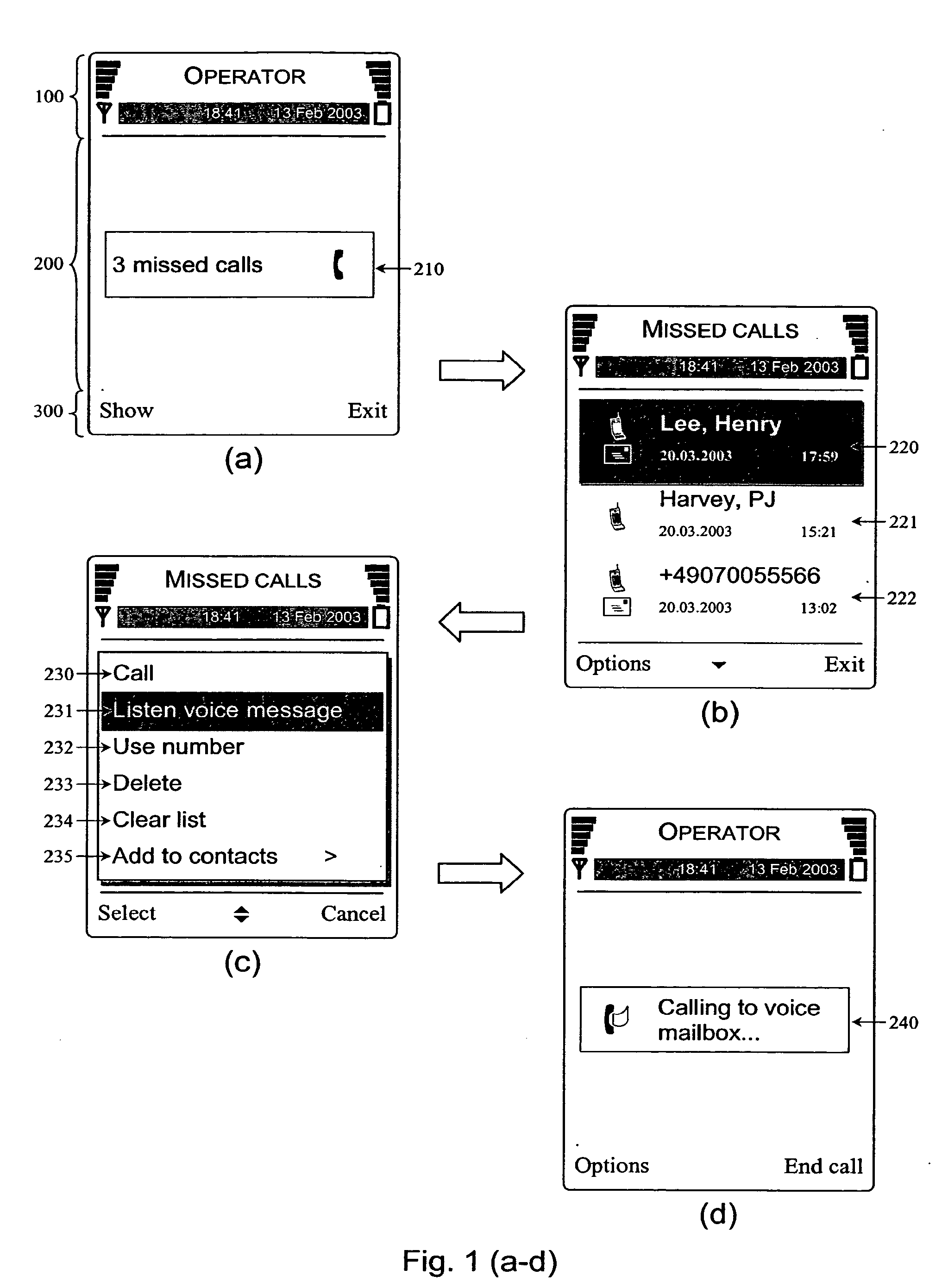

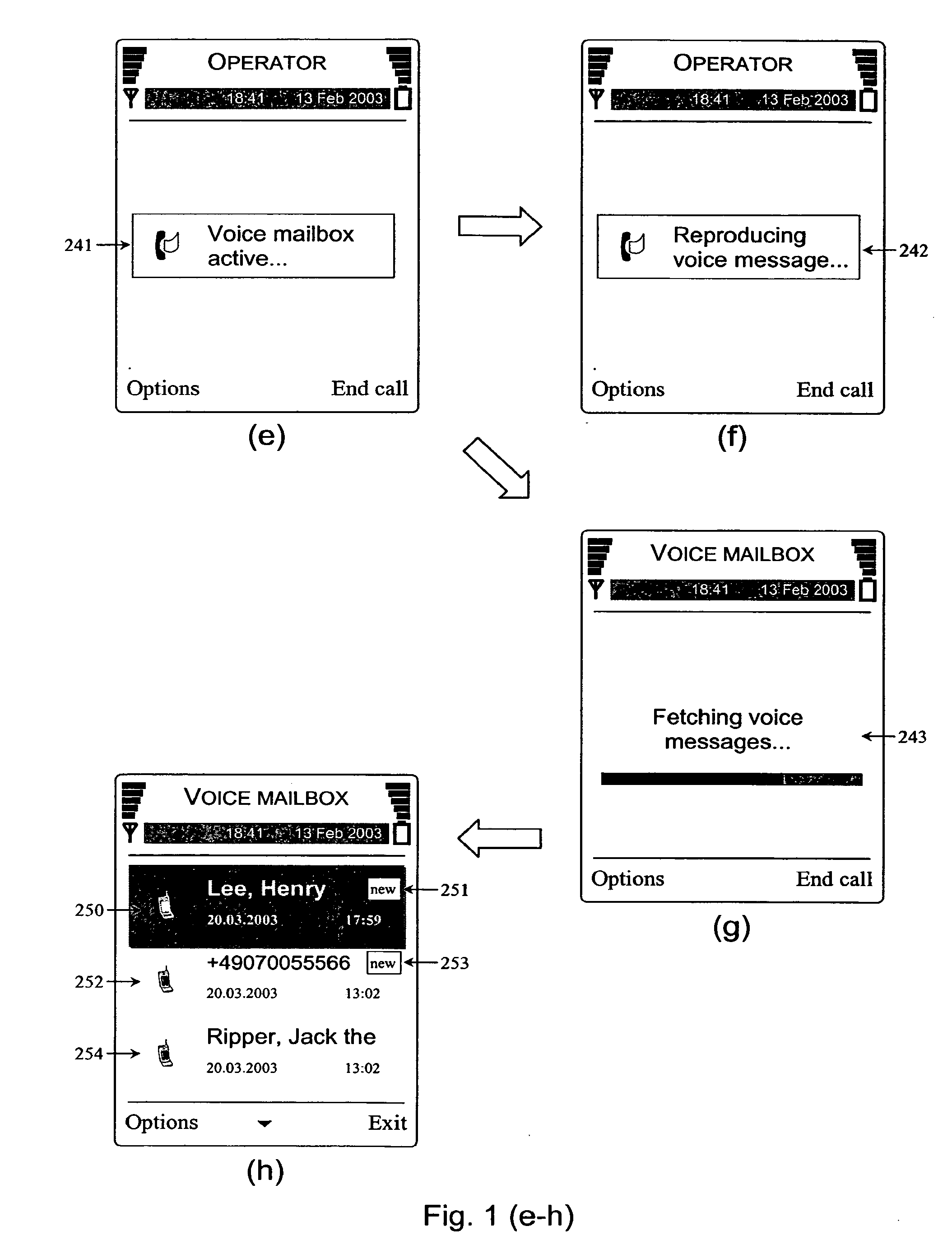

Method and device for handling missed calls in a mobile communications environment

ActiveUS7783283B2Improve usabilityImproves intelligibility and usabilitySpecial service for subscribersCalling susbscriber number recording/indicationIP Multimedia Subsystem

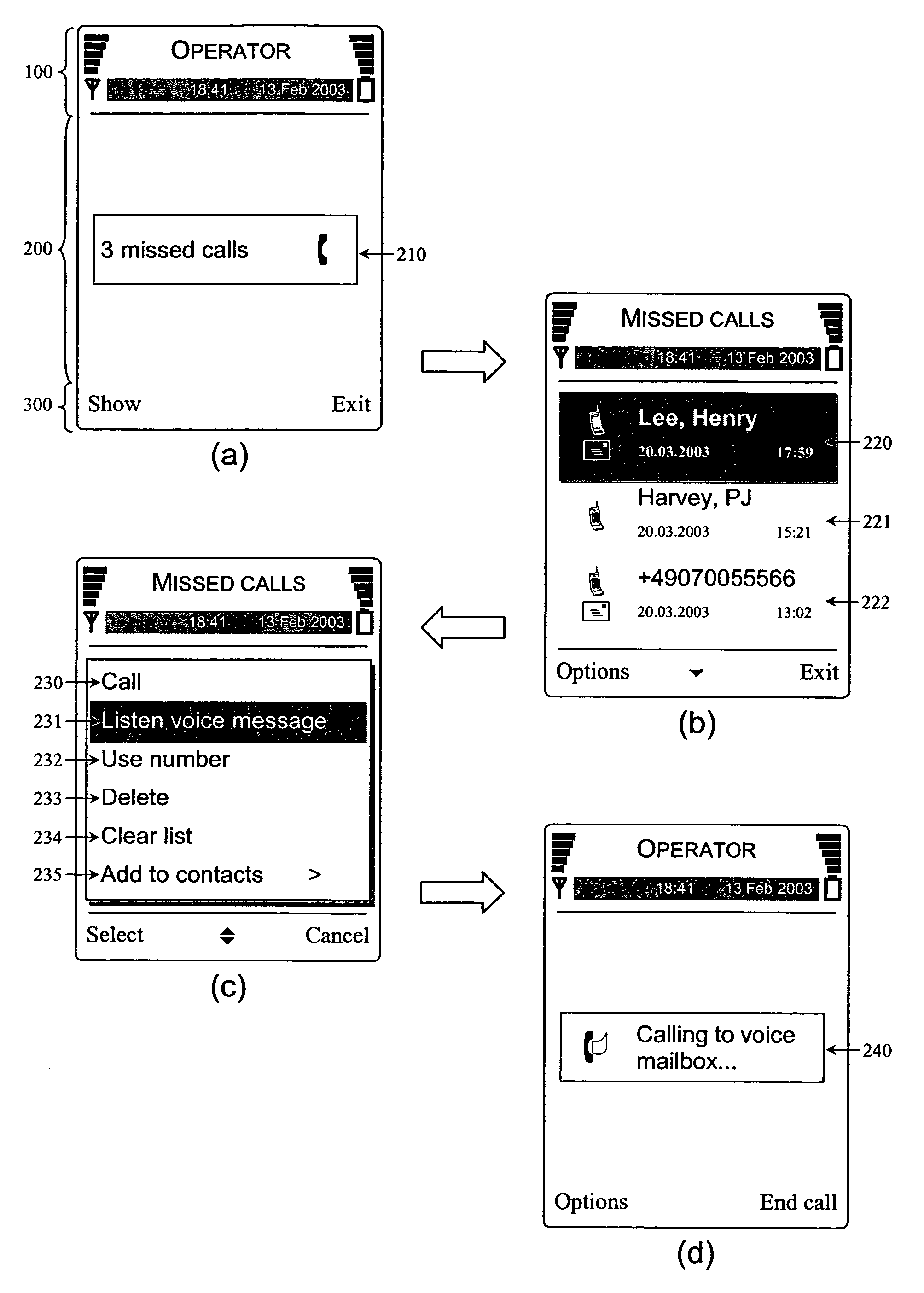

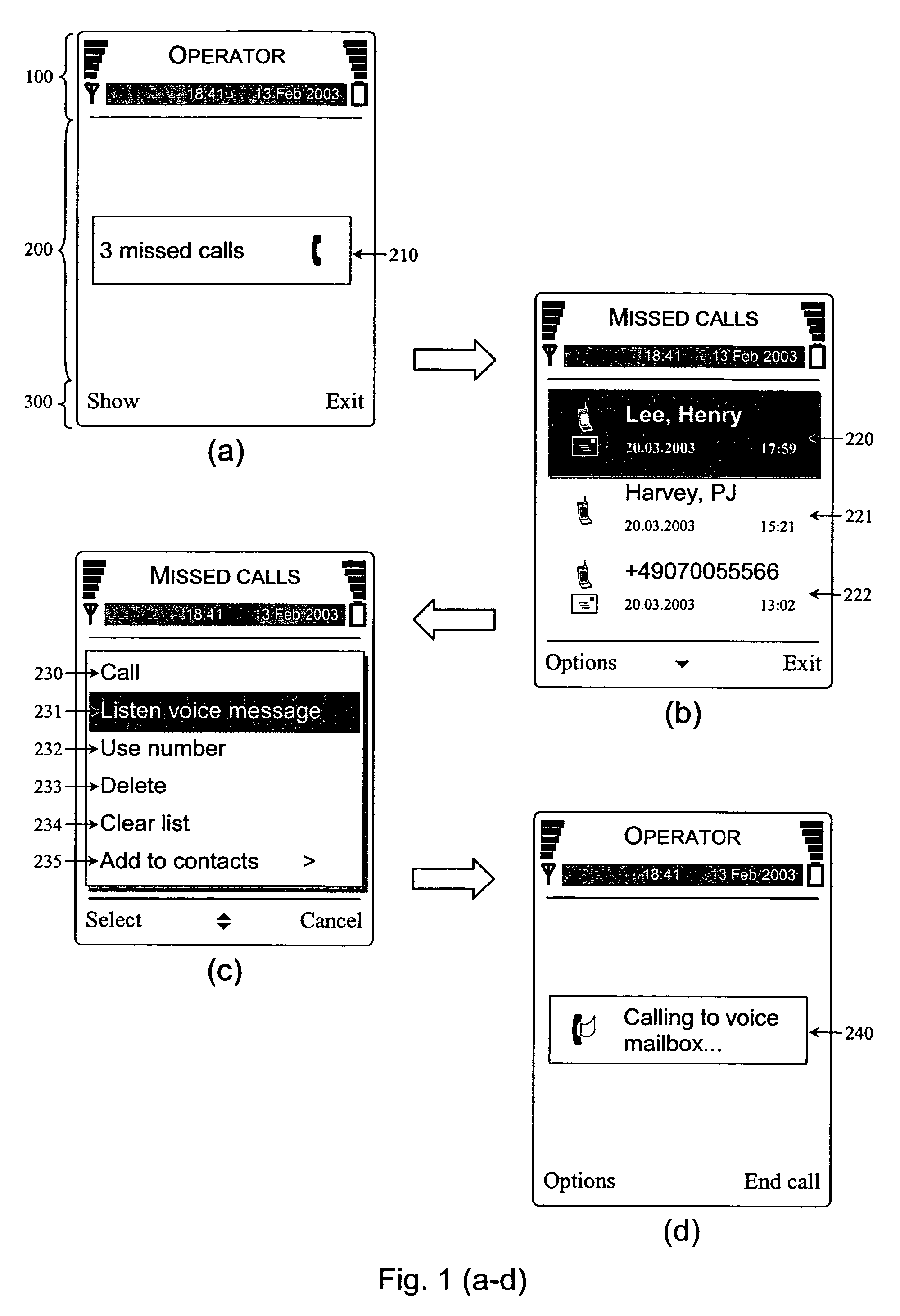

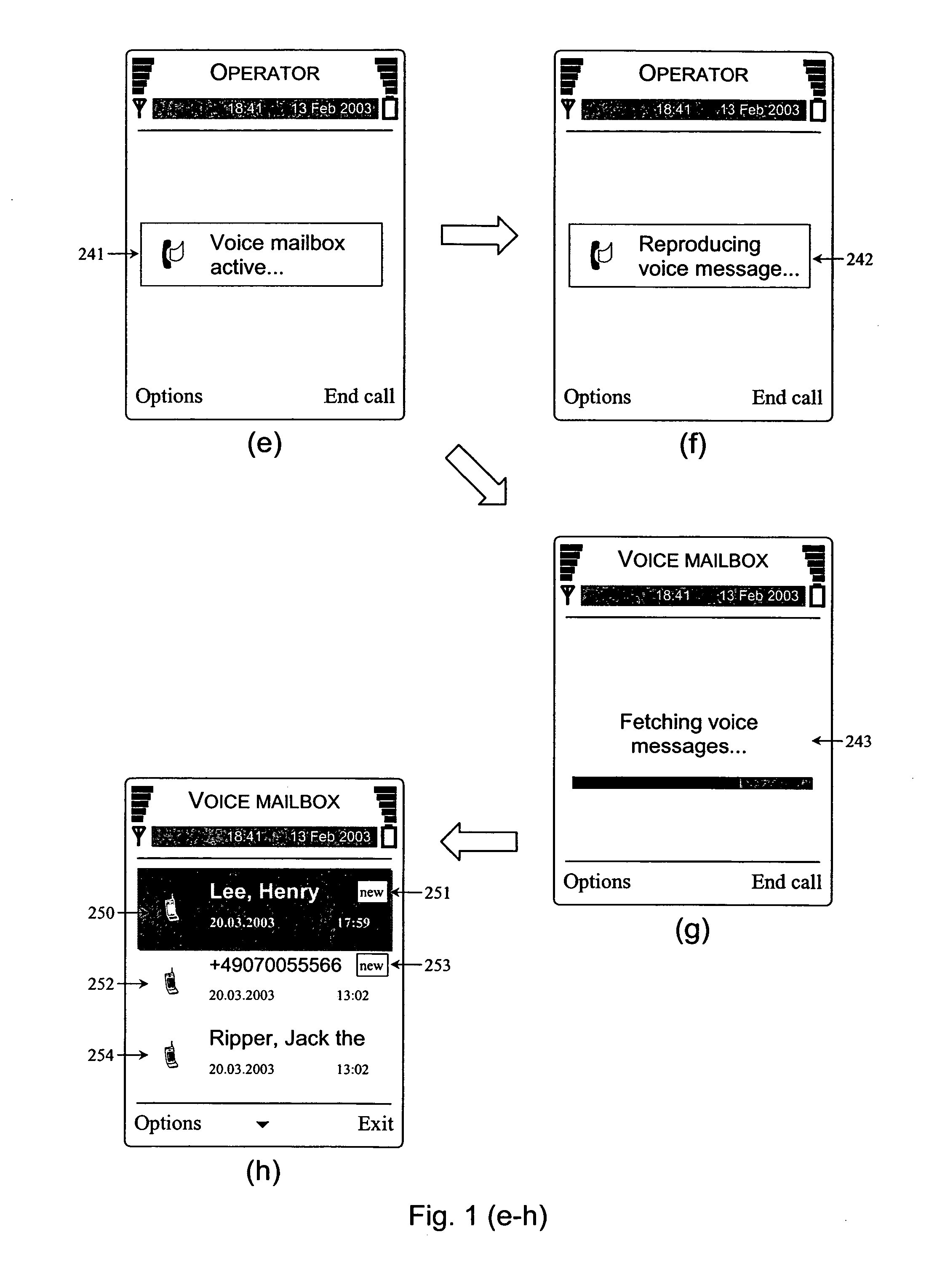

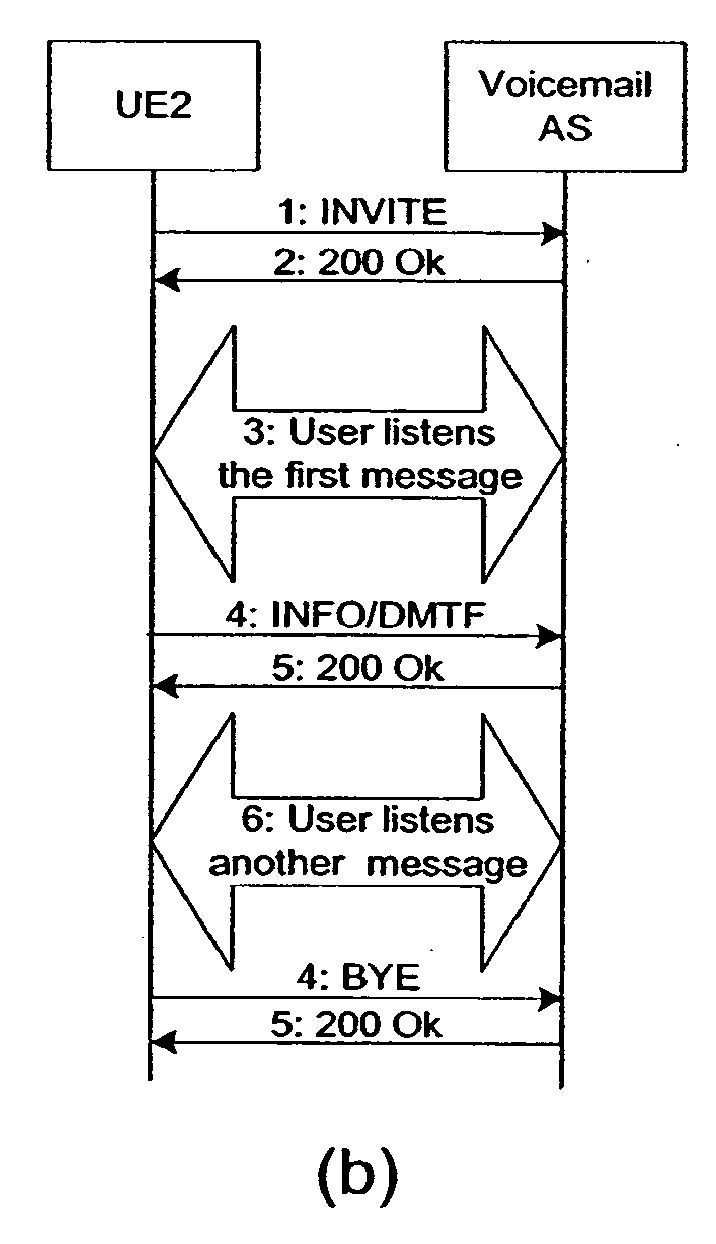

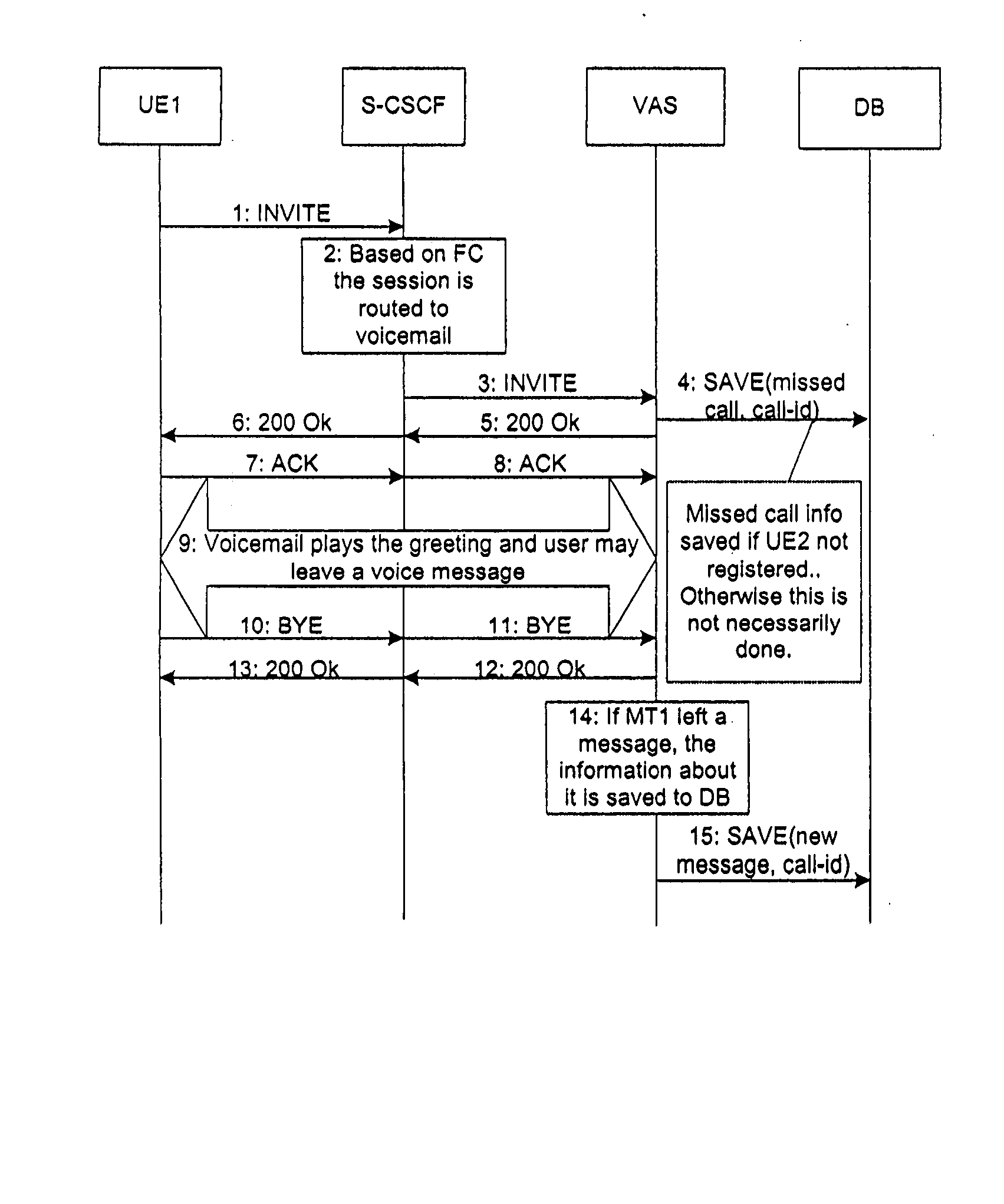

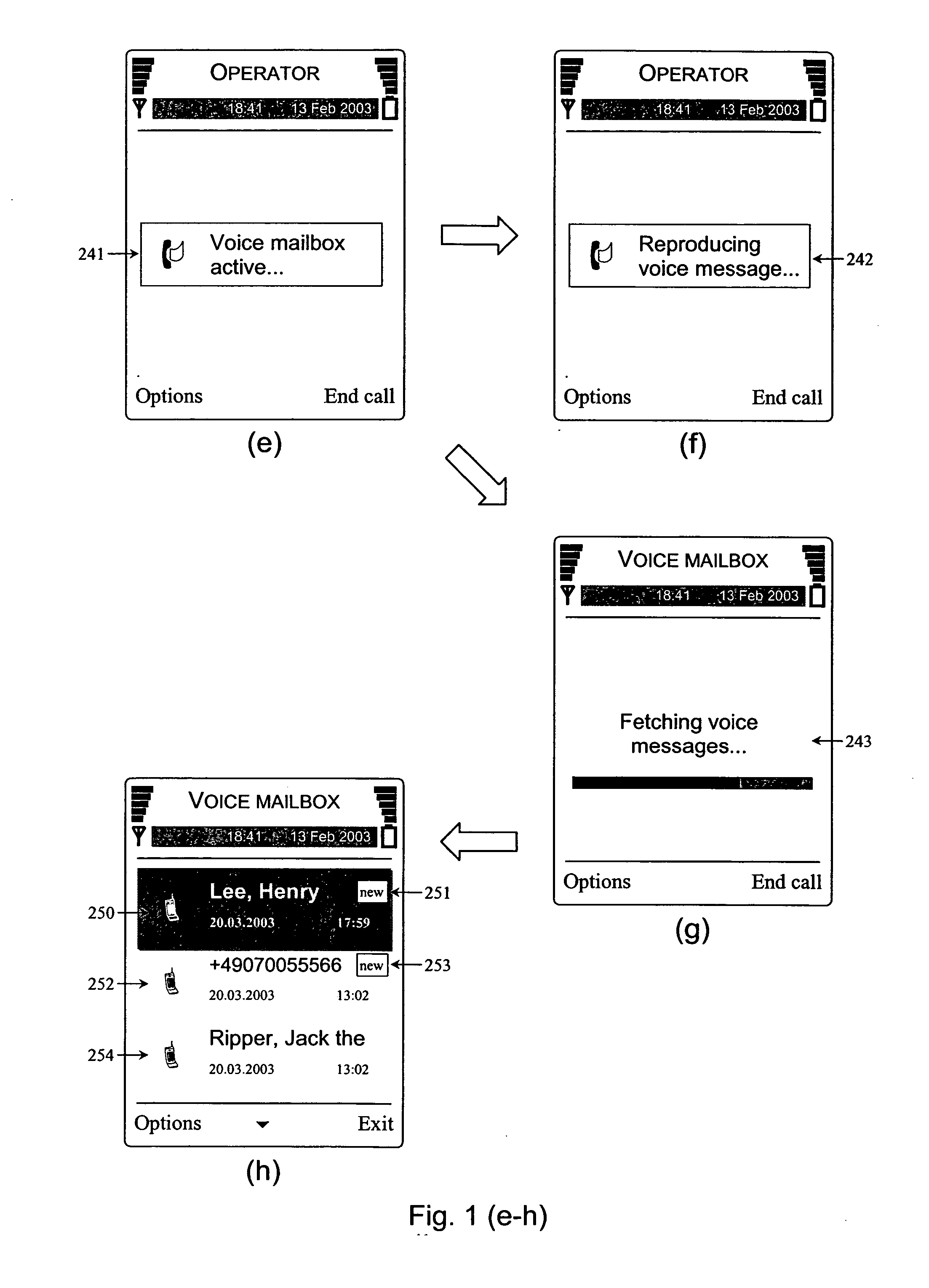

A mobile terminal comprises a registering functionality which is adapted to register terminal-based information about one or more missed call events which are not accepted by a user. Network-based information about one or more missed call events or voice messages registered by a PLMN to which the mobile terminal is subscribed is received. The network-based information is combined with the terminal-based information such that the mobile terminal is able to present the combined information to a user. Moreover, a method is provided for registering information about missed call events in a PLMN comprising at least an IP Multimedia Subsystem (IMS) which is responsible for packet data services. An incoming call received by the IMS from a calling terminal originally destined to a called mobile terminal is redirected in accordance with Filter Criteria (FC) to the IMS and information about a missed call event in accordance with the incoming call is registered by the IMS.

Owner:NOKIA TECH OY

Method and device for handling missed calls in a mobile communications environment

InactiveUS20100279662A1Improve usabilityImproves intelligibility and usabilitySpecial service for subscribersCalling susbscriber number recording/indicationIP Multimedia Subsystem

A mobile terminal comprises a registering functionality which is adapted to register terminal-based information about one or more missed call events which are not accepted by a user. Network-based information about one or more missed call events or voice messages registered by a PLMN to which the mobile terminal is subscribed is received. The network-based information is combined with the terminal-based information such that the mobile terminal is able to present the combined information to a user. Moreover, a method is provided for registering information about missed call events in a PLMN comprising at least an IP Multimedia Subsystem (IMS) which is responsible for packet data services. An incoming call received by the IMS from a calling terminal originally destined to a called mobile terminal is redirected in accordance with Filter Criteria (FC) to the IMS and information about a missed call event in accordance with the incoming call is registered by the IMS.

Owner:NOKIA CORP

Method and device for handling missed calls in a mobile communications environment

ActiveUS20050059384A1Improve usabilityImproves intelligibility and usabilitySpecial service for subscribersCalling susbscriber number recording/indicationSpeech soundIP Multimedia Subsystem

A mobile terminal comprises a registering functionality which is adapted to register terminal-based information about one or more missed call events which are not accepted by a user. Network-based information about one or more missed call events or voice messages registered by a PLMN to which the mobile terminal is subscribed is received. The network-based information is combined with the terminal-based information such that the mobile terminal is able to present the combined information to a user. Moreover, a method is provided for registering information about missed call events in a PLMN comprising at least an IP Multimedia Subsystem (IMS) which is responsible for packet data services. An incoming call received by the IMS from a calling terminal originally destined to a called mobile terminal is redirected in accordance with Filter Criteria (FC) to the IMS and information about a missed call event in accordance with the incoming call is registered by the IMS.

Owner:NOKIA TECHNOLOGLES OY

Heat-resistant ceramic edible vessel capable of being burnt over open flame and production method thereof

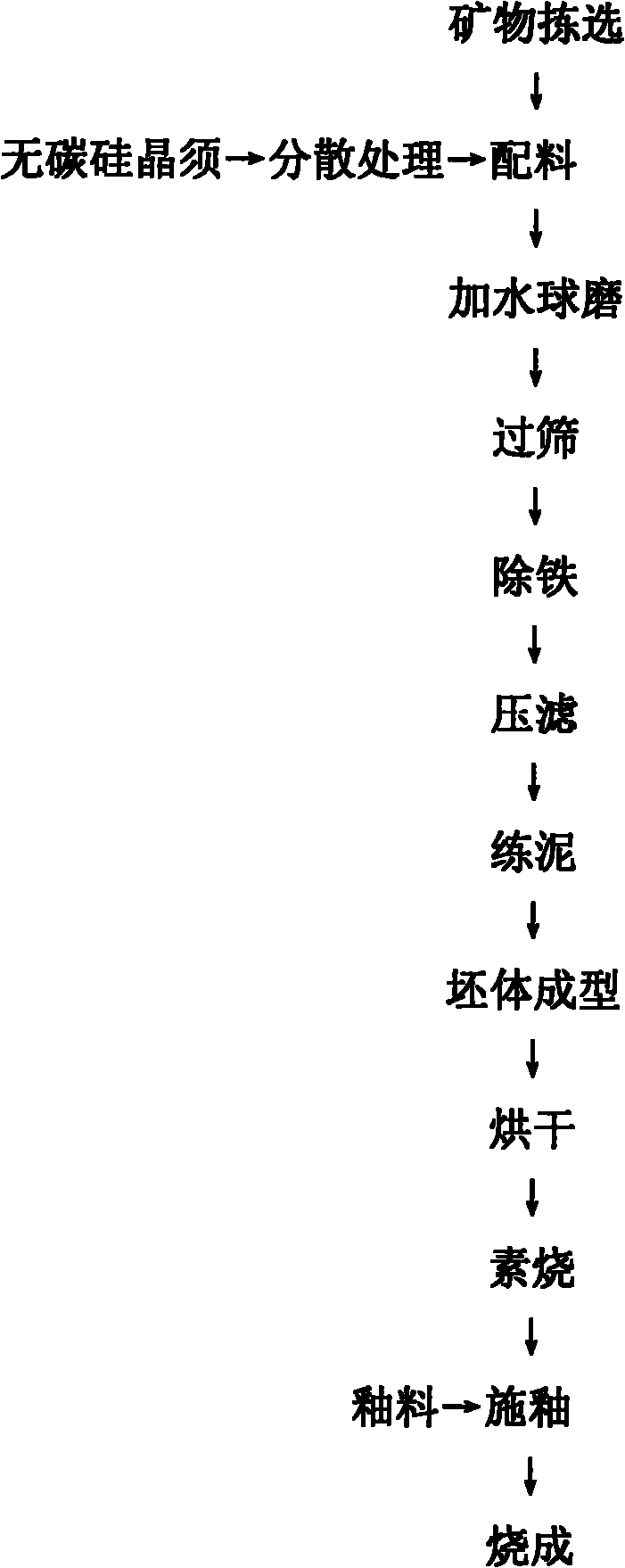

ActiveCN102320813AStrong coefficient of thermal expansionSmall coefficient of thermal expansionClaywaresBall millLow speed

The invention discloses a heat-resistant ceramic edible vessel capable of being burnt over open flame and a production method thereof. A blank body of the heat-resistant ceramic edible vessel comprises kaoline, spodumene, lithium pottery stone, carbon-free silicon whiskers, bentonite, cured steatite and clay. The production method comprises the following steps that: the carbon-free silicon whiskers are dispersed by a mechanical low-speed ball-milling method, water is used as the ball milling media, the rotating speed adopted in the ball milling process is 250r / min, the weight ratio of materials to balls to water is 1 / 2 / 1.2, the ball milling time is 3 to 4 hours, the materials are dried into dry materials after ball milling completion, and the preparation method also comprises the following steps of material proportioning, ball milling through adding water, sieving, deironing, filter pressing, pugging, forming, drying, biscuiting, glazing and sintering. The product has extremely high heat resistance and mechanical strength, and the heat stability reaches the goal that, the vessel cannot be popped through once heat exchange in water with the temperature being 800 DEG C to 20 DEG C.

Owner:GUANGDONG SHUNXIANG PORCELAIN

Method for preparing carbon nano-tube/poly L-cysteine composite modified glassy carbon electrode

InactiveCN1825105AHigh catalyticExtended service lifeMaterial electrochemical variablesDimethyl formamideBlood serum

The invention relates to a manufacture method for carbon nm tube / poly L-cysteine compound modification glass carbon electrode. The process includes the following steps: purifying the multi-wall carbon nm tube, separating into N, N-dimethyl formamide solution, dropping the solution onto the surface of glass carbon electrode, drying under infrared light, locating the electrode into dilute hydrochloric acid containing L-cysteine to take electric polymerizing; taking out the electrode compounding L-cysteine to wash and gain carbon nm tube / poly L-cysteine compound modification glass carbon electrode. The method is simple, and low cost. The product has high reliability and good repeatability. It has long useful life and could be used in electrochemistry rapidly testing for uric acid and ascorbic acid in blood serum.'

Owner:YANGZHOU UNIV

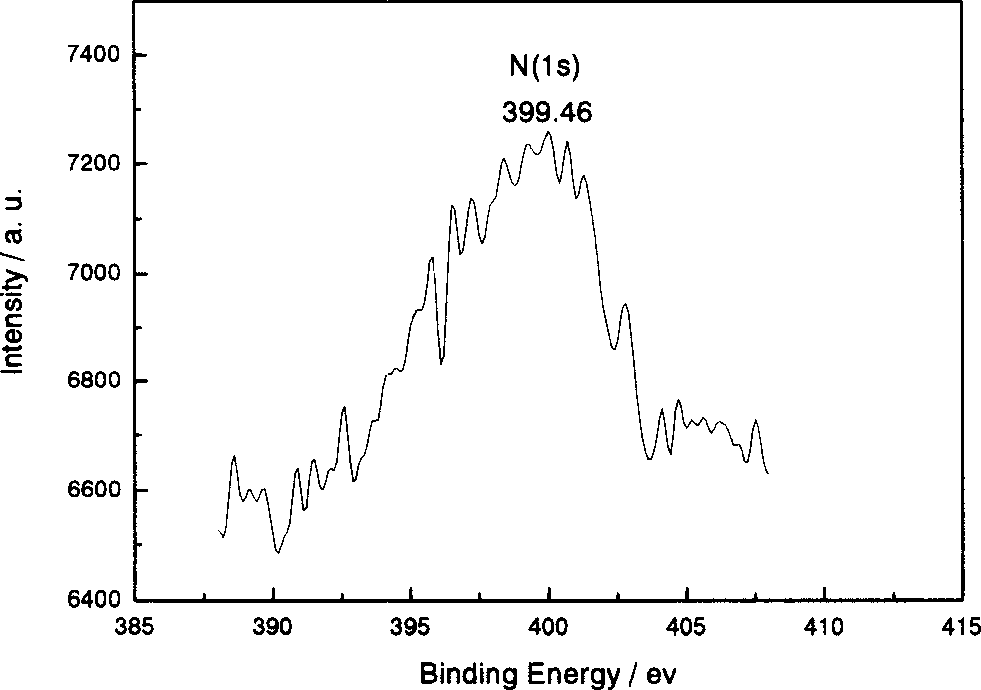

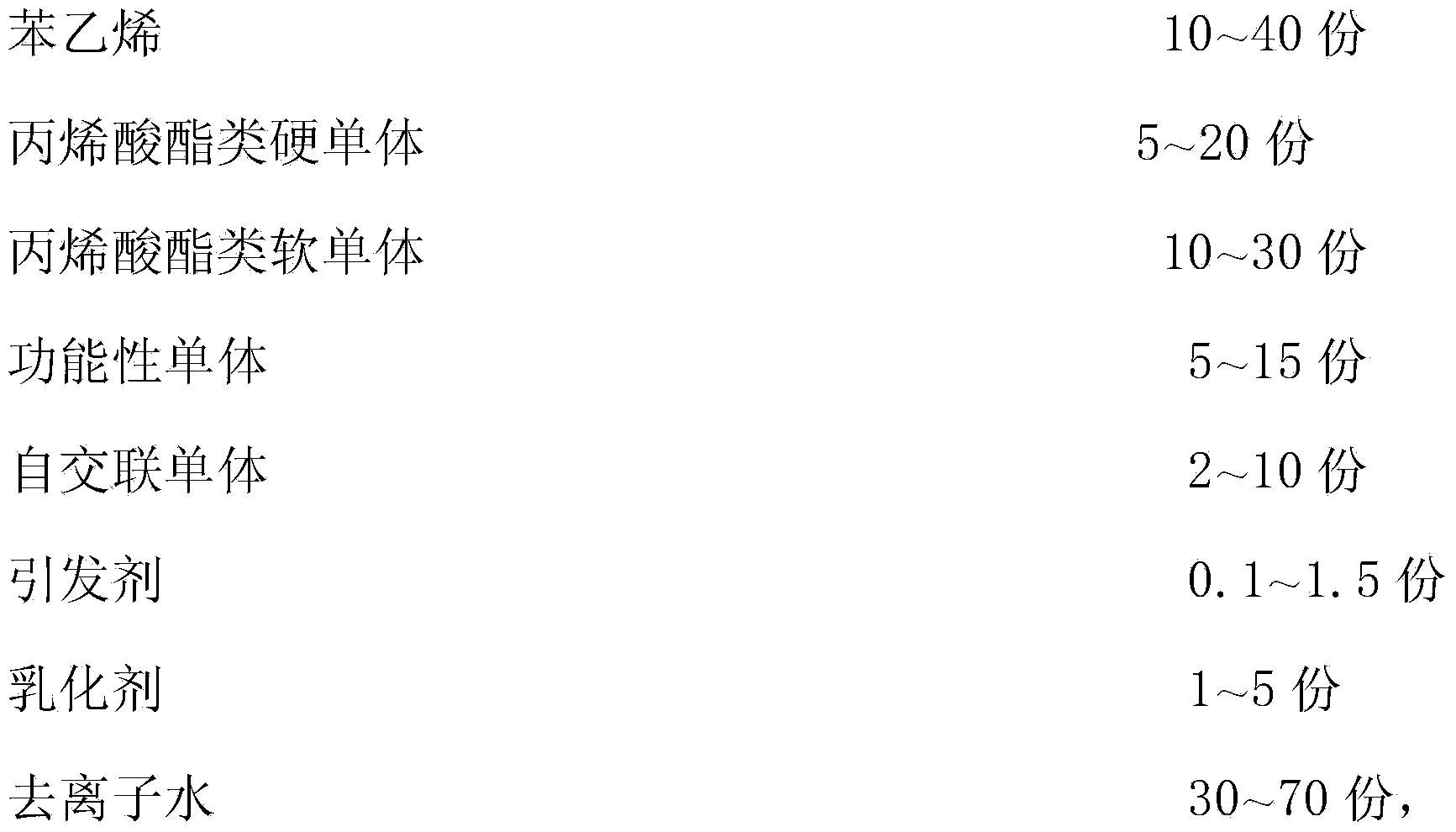

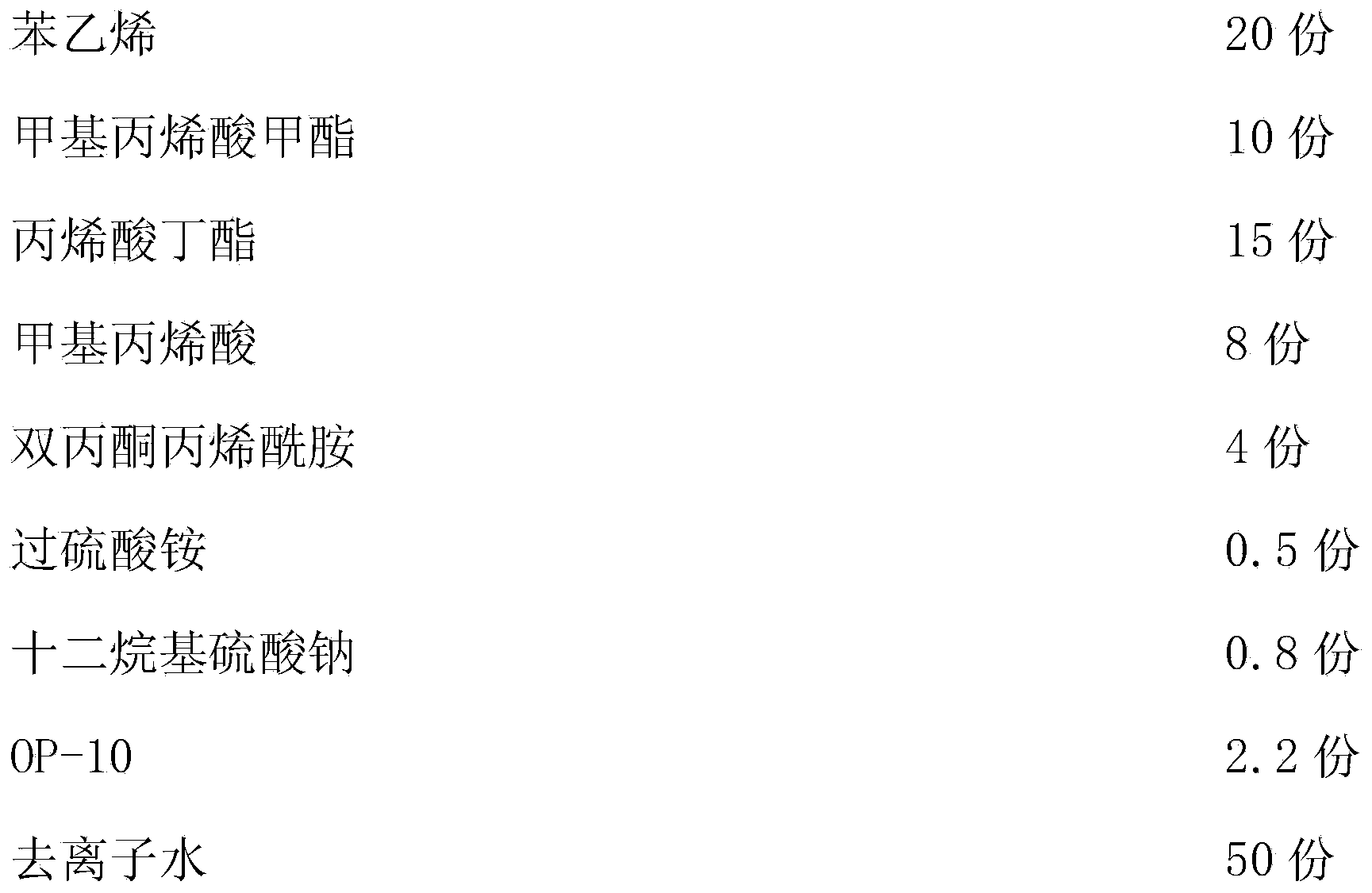

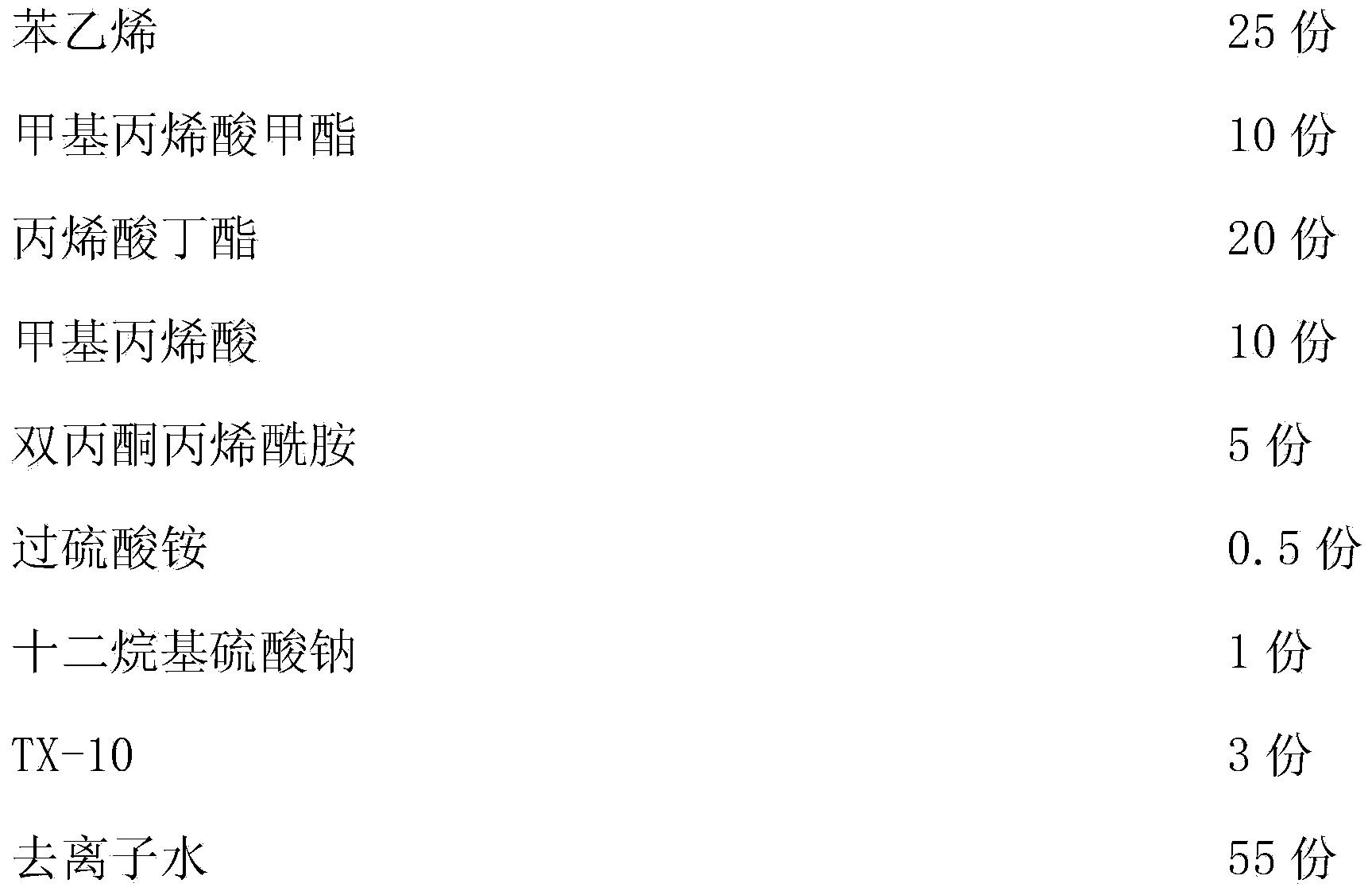

Self-crosslinking styrene-acrylic emulsion for non-woven fabrics and preparation method of self-crosslinking styrene-acrylic emulsion

The invention discloses a self-crosslinking styrene-acrylic emulsion for non-woven fabrics and a preparation method of the self-crosslinking styrene-acrylic emulsion. The styrene-acrylic emulsion for the non-woven fabrics is prepared by using styrene and acrylate monomers as main monomers, and selecting a proper self-crosslinking monomer and a functional monomer to perform a self-continuous pre-emulsification seed emulsion polymerization process. According to the preparation method disclosed by the invention, the styrene-acrylic emulsion with excellent enhancement and fixation effects on non-woven materials is prepared by controlling the process conditions of emulsion polymerization, the types and proportions of the monomers, an emulsifier, an initiator, the self-crosslinking monomer and the functional monomer; moreover, the emulsion does not have volatilization of organic solvents in use, and is green and environment-friendly without VOC (volatile organic compound), so that the self-crosslinking styrene-acrylic emulsion has good commercial application prospects.

Owner:ZHONGSHAN POLYTECHNIC

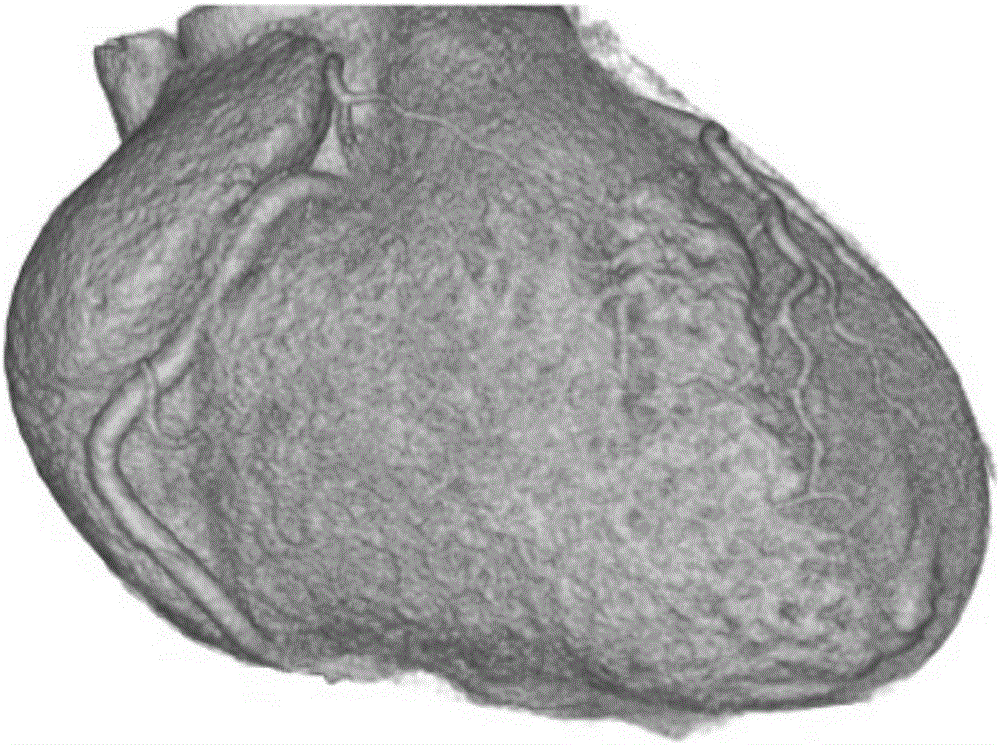

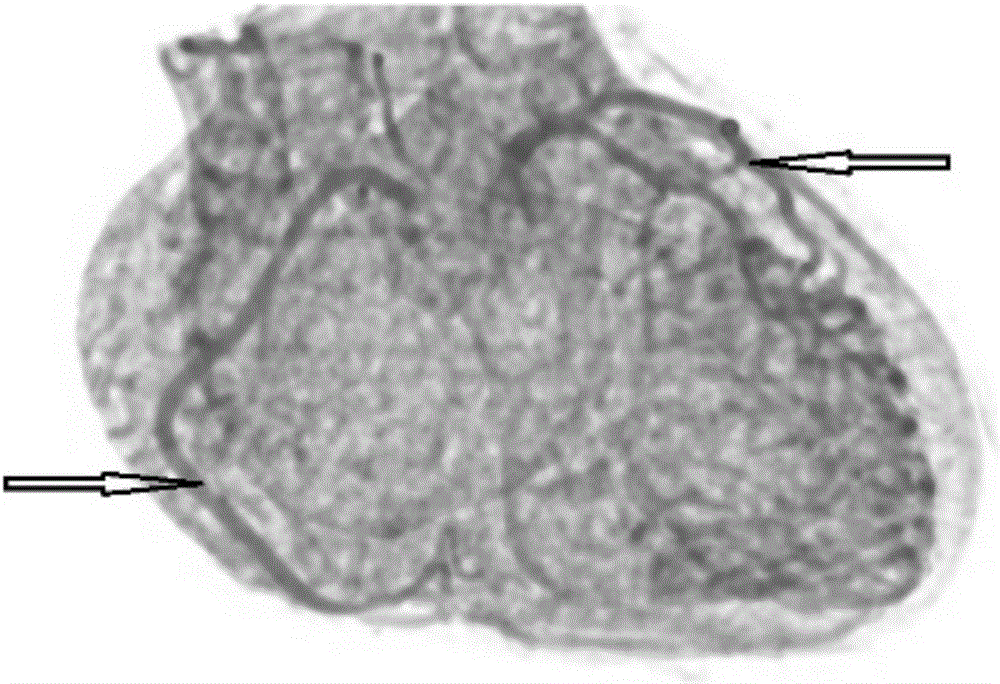

Full-automatic coronary artery segmentation method

The invention relates to a full-automatic coronary artery segmentation method. The method comprises the steps of: segmenting out a heart region; carrying out vessel enhancement processing; automatically detecting seed voxels; and segmenting a coronary artery. Firstly, the heart region comprising the coronary artery is segmented out, a segmented image nearly does not include any noisy point, and both segmentation accuracy and efficiency are superior to a result obtained by methods such as an EM algorithm and the like; by carrying out vessel enhancement processing on the heart region segmented out, a coronary image is obviously enhanced; by carrying out automatic detection of the seed voxels on the image subjected to vessel enhancement processing, a seed voxel set is detected out, the problem that a conventional region segmentation method needs manual intervention is solved, and robustness is improved; and finally, by consistency judgment, the coronary artery is segmented out. Relative to a method for carrying out region segmentation only by using a gray value as the standard, the full-automatic coronary artery segmentation method disclosed by the invention dynamically changes a consistent interval in consistency judgment, and not only avoids manual intervention, but also improves accuracy of segmenting the coronary artery.

Owner:BEIJING NORMAL UNIVERSITY

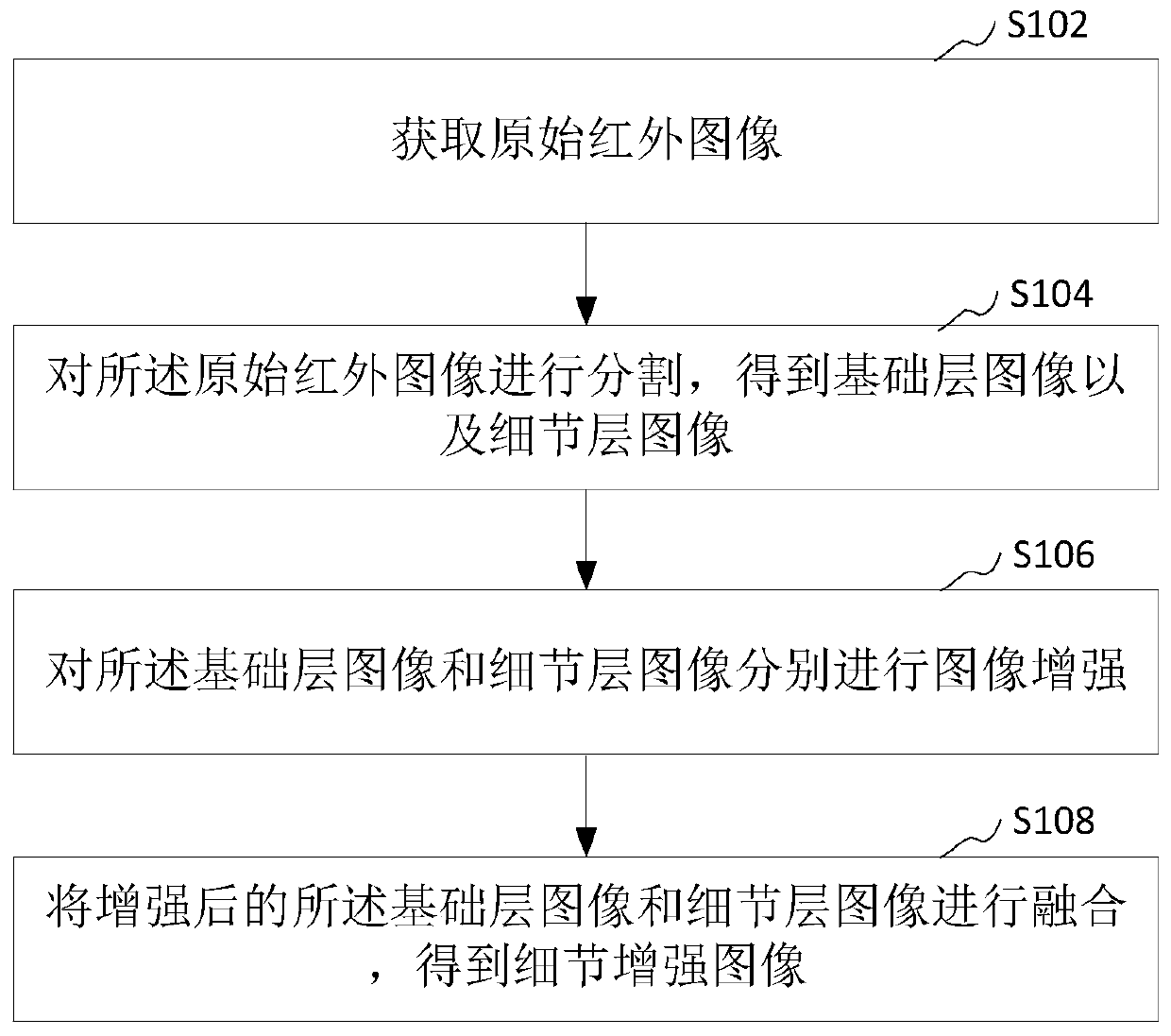

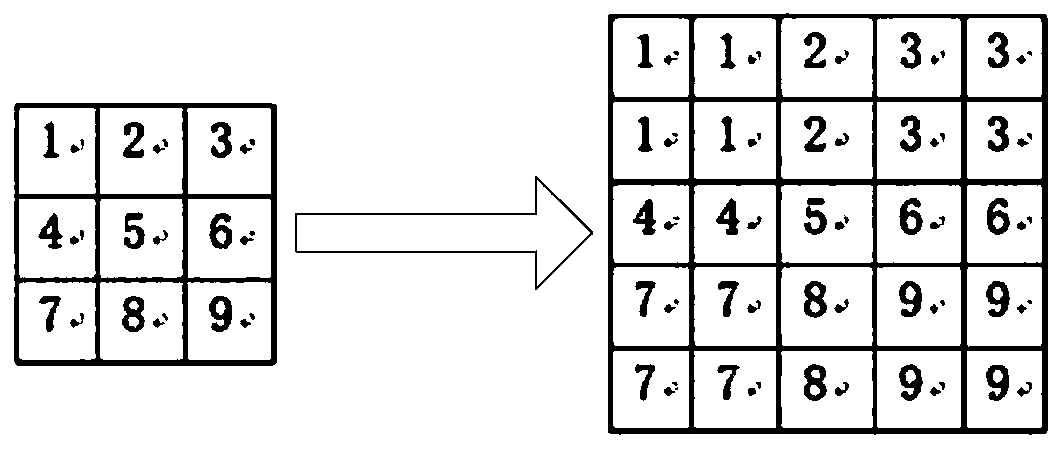

Infrared image enhancement method and device, computer equipment and storage medium

The invention relates to an infrared image enhancement method and device, computer equipment and a storage medium. The method comprises the steps of obtaining an original infrared image; Segmenting the original infrared image to obtain a basic layer image and a detail layer image; Respectively carrying out image enhancement on the basic layer image and the detail layer image; And fusing the enhanced base layer image and the detail layer image to obtain a detail enhanced image. According to the infrared image enhancement method, the details of the infrared image are obviously enhanced, the detail information of the infrared image is prevented from being lost, and the infrared image enhancement method can adapt to infrared images of most scenes.

Owner:ZHEJIANG NUMBER CHAIN TECH CO LTD

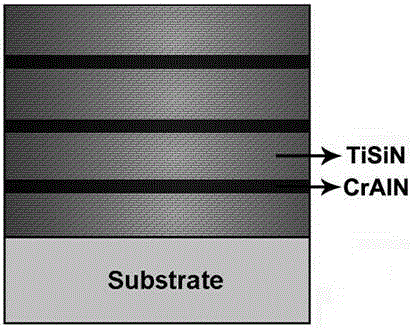

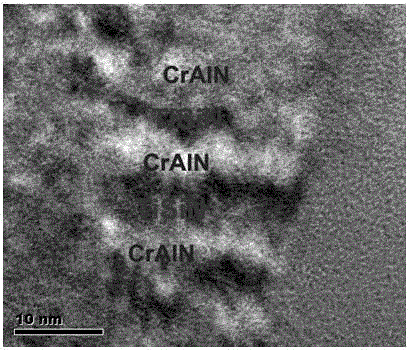

Nano-structure coating with ultra-high hardness and manufacturing method thereof

ActiveCN105296949AGood high temperature oxidation resistanceSignificantly enhancedVacuum evaporation coatingSputtering coatingSputteringNano structuring

The invention provides a nano-structure coating with the ultra-high hardness. The coating is composed of at least one TiSiN layer and at least one CrAlN layer. The TiSiN layers and the CrAlN layers are alternately deposited on a substrate. The invention further provides a manufacturing method of the nano-structure coating with the ultra-high hardness. The method includes the steps that the substrate which is polished is conveyed into an ultrasonic washing machine so as to be ultrasonically washed in anhydrous alcohol and acetone; then ion washing is performed; and after ion washing is performed, the substrate is placed in a multi-target magnetron sputtering instrument and stays in front of a TiSi composite target and a CrAl target alternately, and the nano-structure coating with the TiSiN layers and the CrAlN layers alternately superposed is obtained through sputtering. The nano-structure coating has the ultrahigh hardness and the excellent mechanical performance and high-temperature and oxidation resistance and can be used as a protective coating of a high-speed cutter and service anti-abrasion workpieces under other high-temperature conditions.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Acid electrode with good process performance

InactiveCN101954554AImprove all-position welding adaptabilityImprove restriking performanceWelding/cutting media/materialsSoldering mediaSlagRare earth

The invention discloses an acid electrode with good process performance, and belongs to the technical field of welding materials. The electrode consists of a core wire and a coating. The coating is characterized by comprising the following components in percentage by weight: 25 to 35 percent of titanium pigment and rutile, 15 to 20 percent of selected ilmenite, 5 to 10 percent of marble and dolomite, 5 to 10 percent of white mud, 3 to 8 percent of mica, 8 to 15 percent of potash feldspar, 4 to 7 percent of quartz sand, 8 to 13 percent of manganese-silicon, 2 to 4.5 percent of chalk, 1 to 1.5 percent of sodium carbonate, 3 to 5 percent of organic matters and 0.5 to 2 percent of rare earth magnesium powder, atomized iron powder and aluminum powder, wherein the grain size of each component is 40 to 200 meshes. Potassium sodium water glass is used as a bonding agent; the modulus is 2.4 to 2.7; and the Baume concentration is 36 to 39. After uniformly mixing the components of the coating of the electrode, adding the water glass and stirring uniformly to obtain a mixture, a carbon steel covered electrode is manufactured by extruding the mixture on a core wire H08A; or a low-alloy steel electrode is manufactured by extruding the mixture on a low-alloy steel core wire. The electrode of the invention has the characteristics of high arc reignition, slag detachability and all-position welding adaptability, and low cost of electrode raw material.

Owner:SHANDONG JIANZHU UNIV

Antibiotic strengthened polyvinyl chloride tube and production method thereof

The invention discloses an antibiotic strengthened polyvinyl chloride tube and a production method thereof. The antibiotic strengthened polyvinyl chloride tube comprises, by mass, 45-80% of polyvinyl chloride, 8-12% of nanometer carbon fiber, 5-10% of dioctyl phthalate, 5-10% of attapulgite, 6-9% of butadiene-acrylonitrile rubber, 3-6% of a methacrylate-acrylate copolymer, 1-3% of an antibiotic agent, 0.5-2% of a light stabilizer UV-326, 0.5-1.5% of a calcium and zinc composite stabilizer, 0.5-1% of calcium stearate and 0.1-0.5% of an antioxidant 1010. The antibiotic strengthened polyvinyl chloride tube has the advantages of excellent strengthening, antibiosis, ageing resistance and heat stability, has an antibiosis rate reaching above 98%, and also has good antibiosis and strengthening synergistic effect by adopting attapulgite as a functional filler.

Owner:殷培花

Ham sausage color adding, protecting technique

InactiveCN101455328AImprove antioxidant capacityStrong chelating abilityMeat/fish preservation by heatingFood preparationCochineal redPhytic acid

The invention discloses a hyperchromic and color fixing process of a high-temperature ham and proposes the using toner and color fixative recipe. The color fixative is comosed of carnosine, TP, citric acid, phytic acid, rosemary, L-cysteine; the toner is composed of Monascus red, cochineal red, and annatto. The disclosed hyperchromic and color fixing process of ham includes: still salting for 36 hours in a cold storage with temperature of 0-4 DEG C, and then adding the toner and color fixative for emulsifying, clystering in a stuffer with the vacuum degree of 100Pa. The used sterilizing cooking temperature and time is constant temperature at 90 DEG C for 10 minutes, constant temperature at 110 DEG C temperature 7 minutes, constant temperature at 121 DEG C for 4 minutes, and then quickly cooling to 30 DEG C within 30 minutes. The technology has obvious effect, convenient use, good thermal stability, a wide range of applications and the like features.

Owner:NANJING YURUN FOOD

Galanthamine hydrobromide compound as well as preparation method and medicine compositions thereof

ActiveCN104177368AHigh chemical purityImprove stabilityNervous disorderOrganic chemistryPharmaceutical drugCombinatorial chemistry

The invention discloses a galanthamine hydrobromide compound as well as a preparation method and medicine compositions thereof. The galanthamine hydrobromide compound disclosed by the invention has the advantages of high chemical purity and good stability, wherein the maximum content of single impurity is below 0.1%; and the stability to light and heat is particularly good. The medicine compositions of the galanthamine hydrobromide compound, prepared by adopting special auxiliary materials, have the following more obvious advantages of being good in stability, easy to implement and remarkable in economic benefit, meeting the clinical needs, reducing the production cost and realizing the industrialization.

Owner:天津梅花生物医药科技有限公司

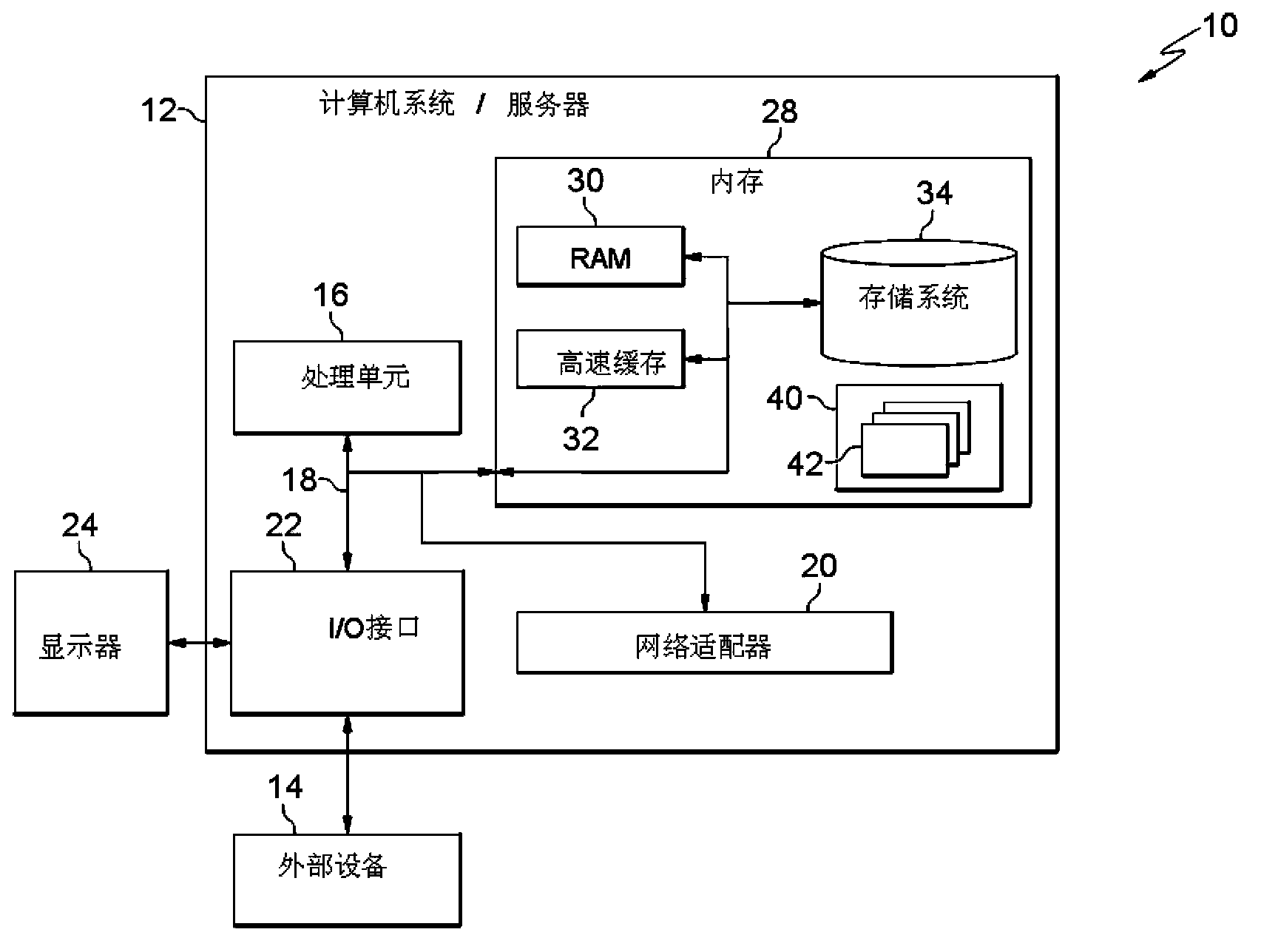

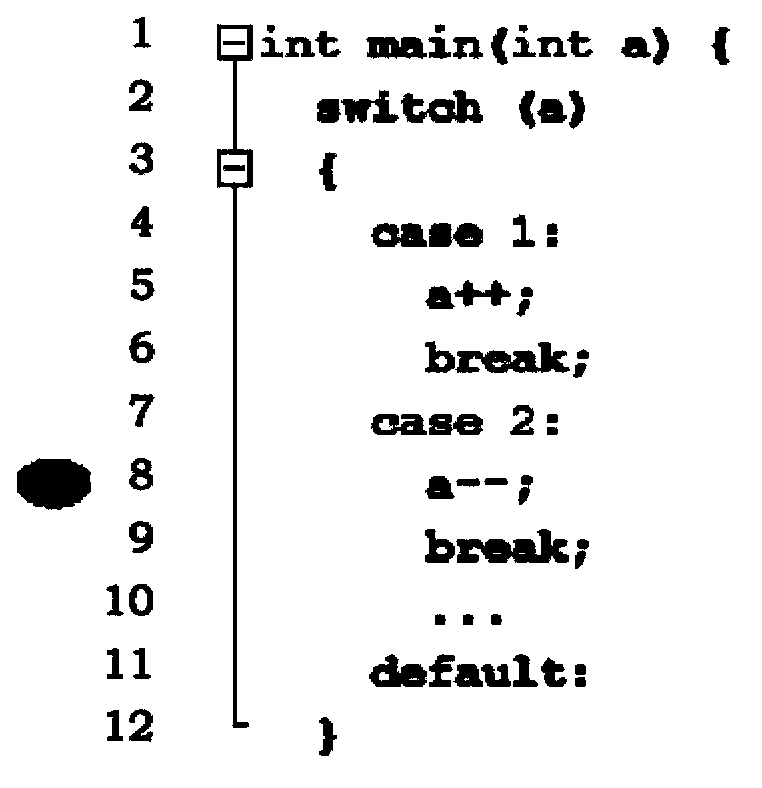

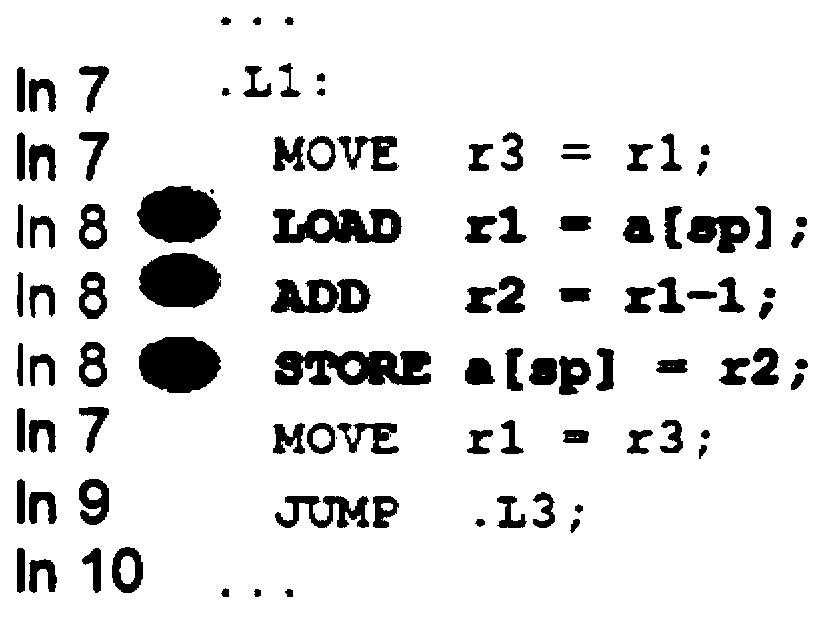

Code dynamic switching method and system for debugging process

ActiveCN104063258AImprove execution speedOptimize for debuggabilityError detection/correctionSoftware engineeringParallel computingSource code

The invention relates to a code dynamic switching method and a system for a debugging process. The method comprises the steps as follows: firstly, the binary code of a first version and a second version is created for each compilation unit in a source code program to be debugged, wherein the first version is an optimized version, while the second version is a non-optimized easily-debugging version; secondly, the binary code of the first version of each compilation unit is loaded into a memory; thirdly, the debugging operation of a user is monitored; fourthly, for responding to the determination that one of the compilation unit in the source code program is to be debugged, the binary code of the second version of the compilation unit is dynamically reloaded to the storage address with the same binary code as that of the first version of the compilation unit in the memory; fifthly, for responding to the determination that the debugging of one of the compilation unit in the source code program is cancelled, the binary code of the first version of the compilation unit is dynamically reloaded to the storage address with the same binary code as that of the second version of the compilation unit in the memory.

Owner:IBM CORP

Haematococcus health-care egg and production feed thereof

InactiveCN108669337AImprove immunityBalanced and rich in nutrientsFood processingAnimal feeding stuffYolkAnimal science

The invention discloses a feed for production of a haematococcus health-care egg, a premix or an additive containing haematococcus pluvialis powder and krill meal is added into a basic feed in a certain proportion, the accumulation of natural astaxanthin and omega-3 unsaturated fatty acids in the egg yolk of the produced egg is high, the egg yolk coloring rate of the produced egg is 20% to 50% higher than that of ordinary eggs, the produced egg is free of antibiotic residue, cholesterol content is reduced by 30% to 40%, unfavorable factors that endanger human health are reduced, the produced egg is bright in color, the egg white the produced egg is more viscous, the egg yolk the produced egg is more tough, the taste of the produced egg is more fragrant, the nutrition is more fully retained, and the produced egg is more beneficial to human health.

Owner:山东鸣惠生物科技股份有限公司

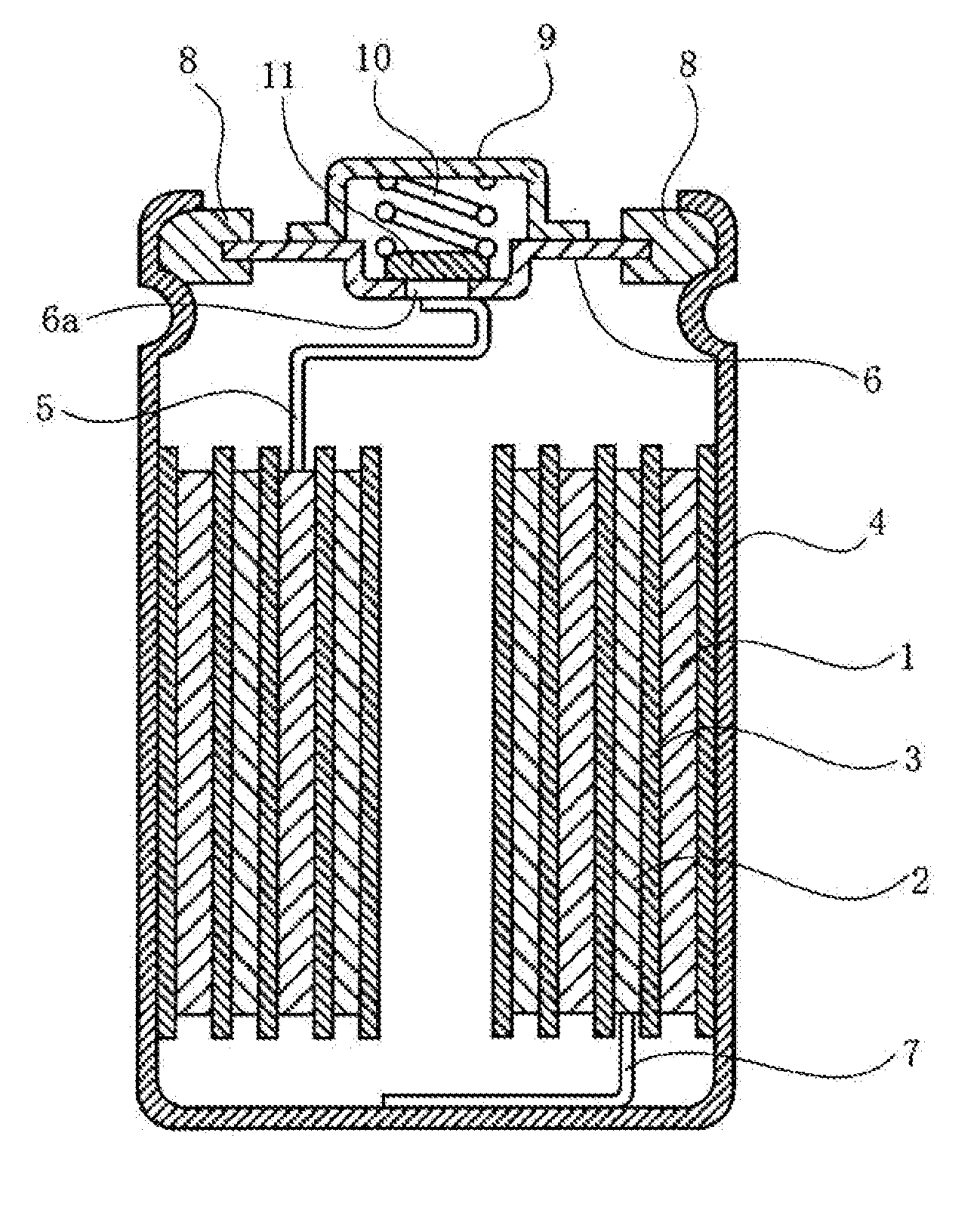

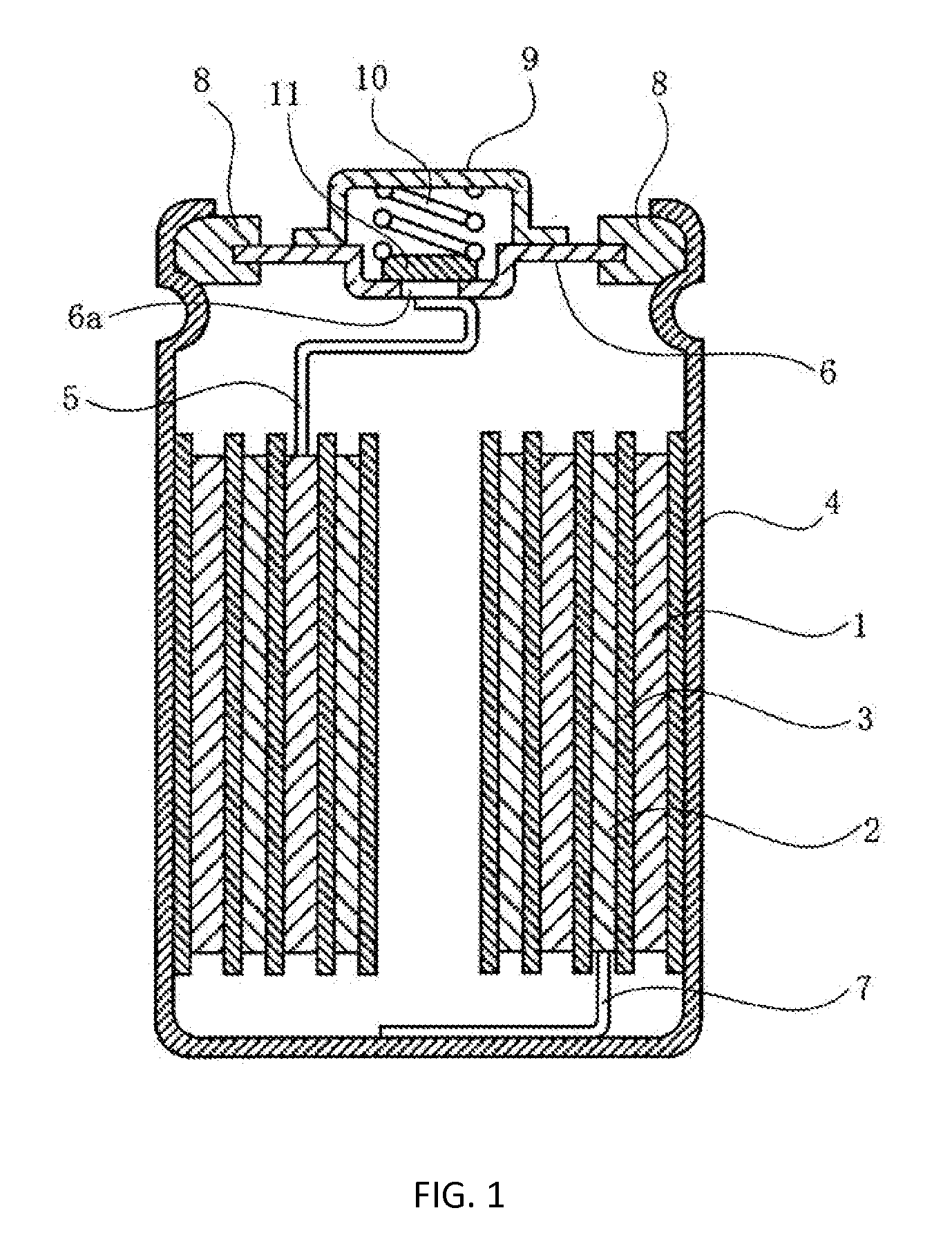

Negative electrode for alkaline storage battery and alkaline storage battery

InactiveUS20110052983A1Low costSignificantly improvedActive material electrodesSecondary cellsRare-earth elementElectrolyte

An alkaline storage battery having a positive electrode (1), a negative electrode (2), and an alkaline electrolyte solution, and the negative electrode having fluorinated oil being present on the surface thereof. The negative electrode includes a hydrogen-absorbing alloy represented by the general formula Ln1-xMgxNiy-a-bAlaMb, where Ln is at least one element selected from Zr, Ti, and a rare-earth element including Y; M is at least one element selected from the group consisting of V, Nb, Ta, Cr, Mo, Mn, Fe, Co, Ga, Zn, Sn, In, Cu, Si, P, and B; 0.05≦x≦0.30; 0.05≦a≦0.30; 0≦b≦0.50; and 2.8≦y≦3.9.

Owner:SANYO ELECTRIC CO LTD

Preparation method of organosilicon fire retardant

The invention provides a preparation method of an organosilicon fire retardant. The method comprises the steps of adding dimethyl siloxane, amino silane and a composite catalyst to a reaction kettle, reacting at an optimum temperature, purifying a product through distillation and removing an unreacted monomer to obtain a product.

Owner:普信氟硅新材料(衢州)有限公司

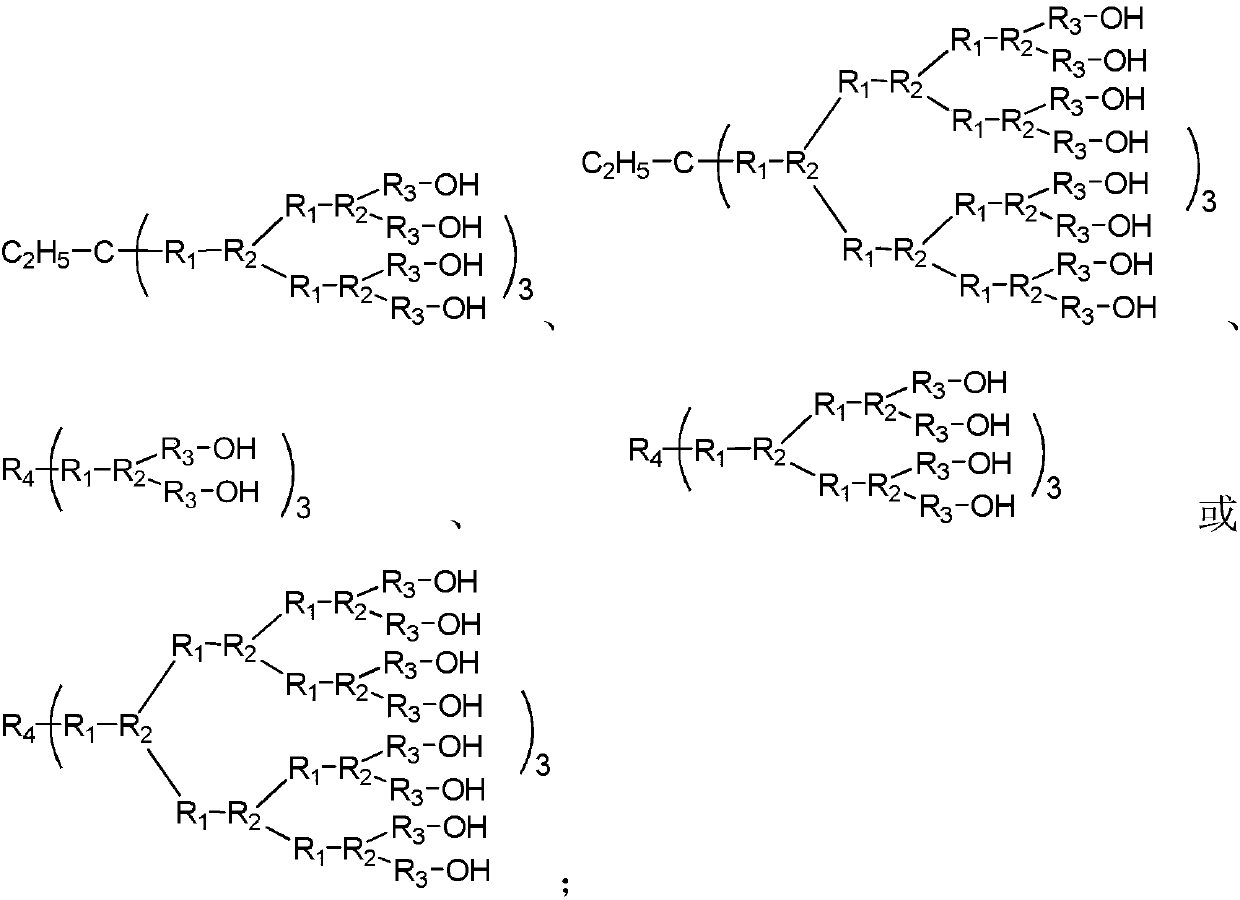

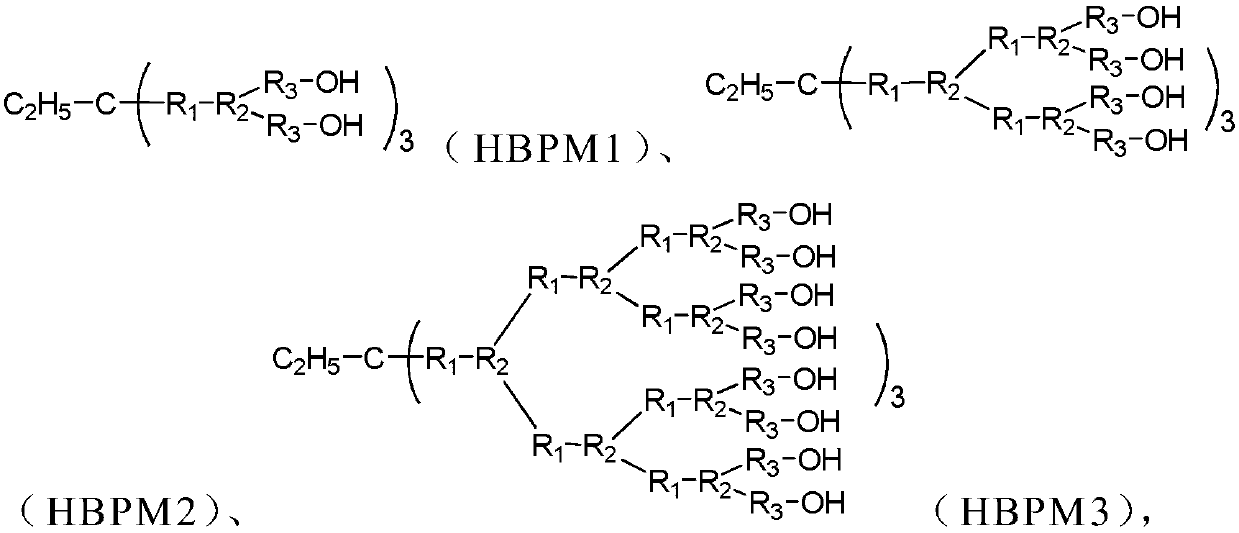

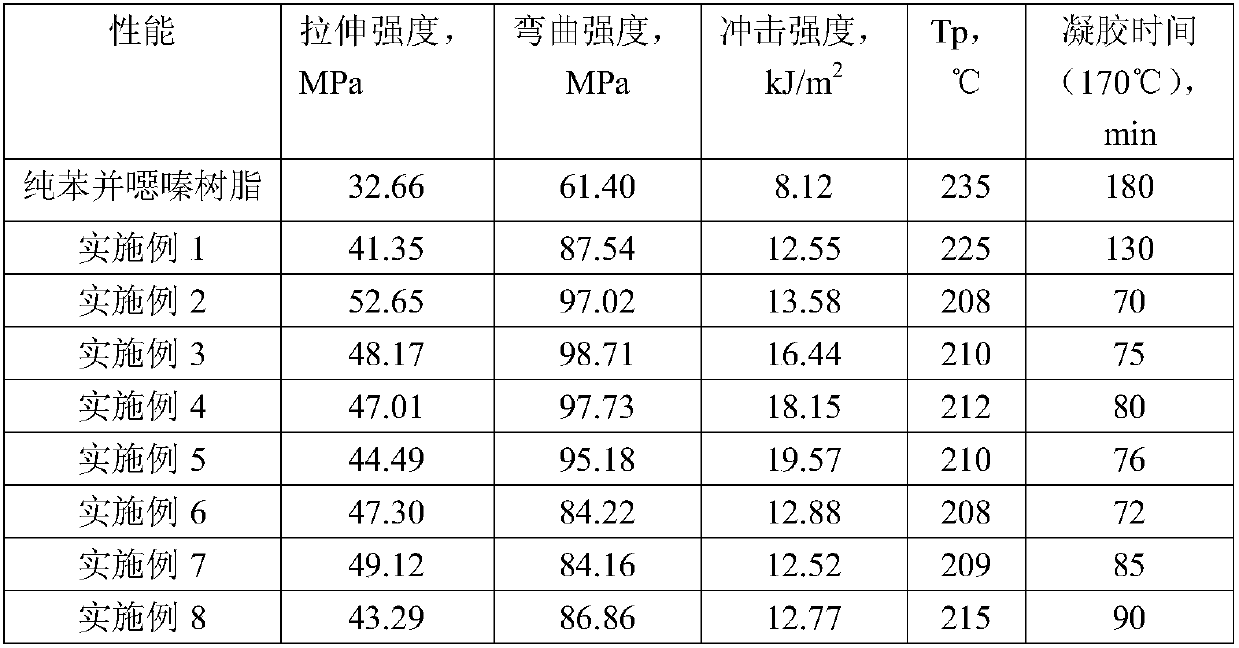

Hyperbranched ionic liquid as well as preparation method and application

InactiveCN108047440AThe synthesis process is simpleRaw materials are easy to getIonHyperbranched polymers

The invention discloses hyperbranched ionic liquid. The hyperbranched ionic liquid is obtained by carrying out thiol-olefin click reaction on a mercapto-terminated hyperbranched polymer and allyl ionic liquid, wherein the mercapto-terminated hyperbranched polymer is obtained by taking a hydroxy-terminated hyperbranched polymer and mercaptopropanoic acid or mercaptoacetic acid to react. The invention further discloses a preparation method and application of the hyperbranched ionic liquid. According to the hyperbranched ionic liquid disclosed by the invention, the hyperbranched ionic liquid is prepared through conventional reaction; a synthesis technology is simple and raw materials are easy to obtain, so that the hyperbranched ionic liquid is suitable for industrial production. Compared with a traditional modifier with a linear structure, the prepared hyperbranched ionic liquid has a good enhancing and toughening effect on benzoxazine resin; an active end group can be used for improvingthe reaction activity and compatibility of the benzoxazine resin, so that the curing temperature is reduced; the hyperbranched ionic liquid is hopefully used for electronic and electrical, aeronauticand astronautic fields and the like.

Owner:SOUTH CENTRAL UNIVERSITY FOR NATIONALITIES

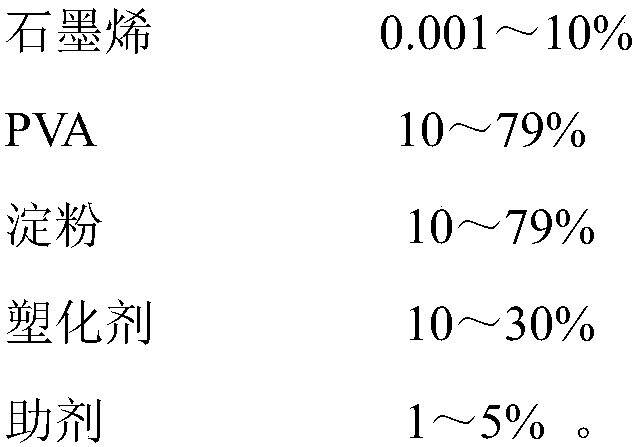

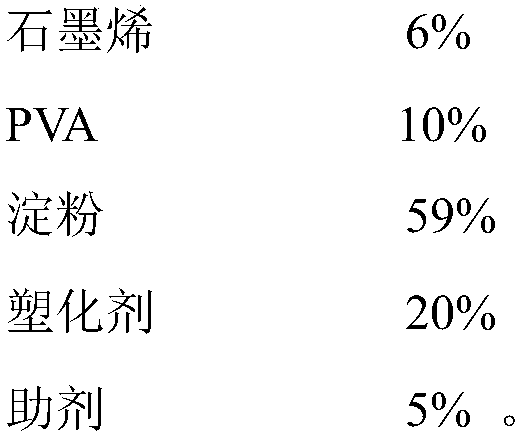

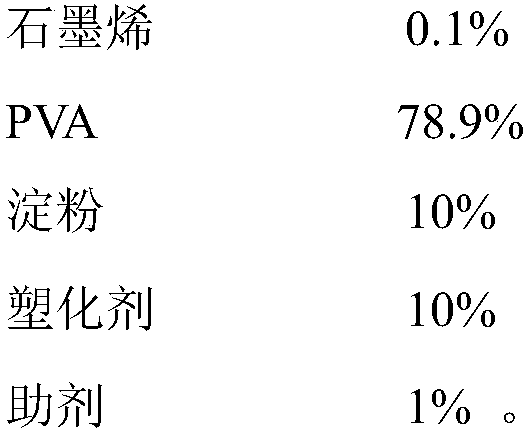

Preparation method of graphene-modified PVA composite material

The invention relates to a preparation method of a graphene-modified PVA composite material, and belongs to the technical field of polyvinyl alcohol modification. The preparation method of the graphene-modified PVA composite material provided by the invention comprises the following steps: using graphene as a modifier; pre-plasticizing with starch, PVA, a plasticizer and additives; then performingmelt intercalation plasticizing extrusion to obtain the graphene-modified PVA composite material, wherein the temperature for melt intercalation plasticizing extrusion is 145-220 DEG C. According tothe preparation method of the graphene-modified PVA composite material provided by the invention, a distance between a melting point and a decomposing point of the PVA is broadened, dry melt plasticizing extrusion is realized, a problem that the PVA cannot be processed due to yellowing and carbonization decomposition is solved, and industrial production is facilitated.

Owner:朱春英

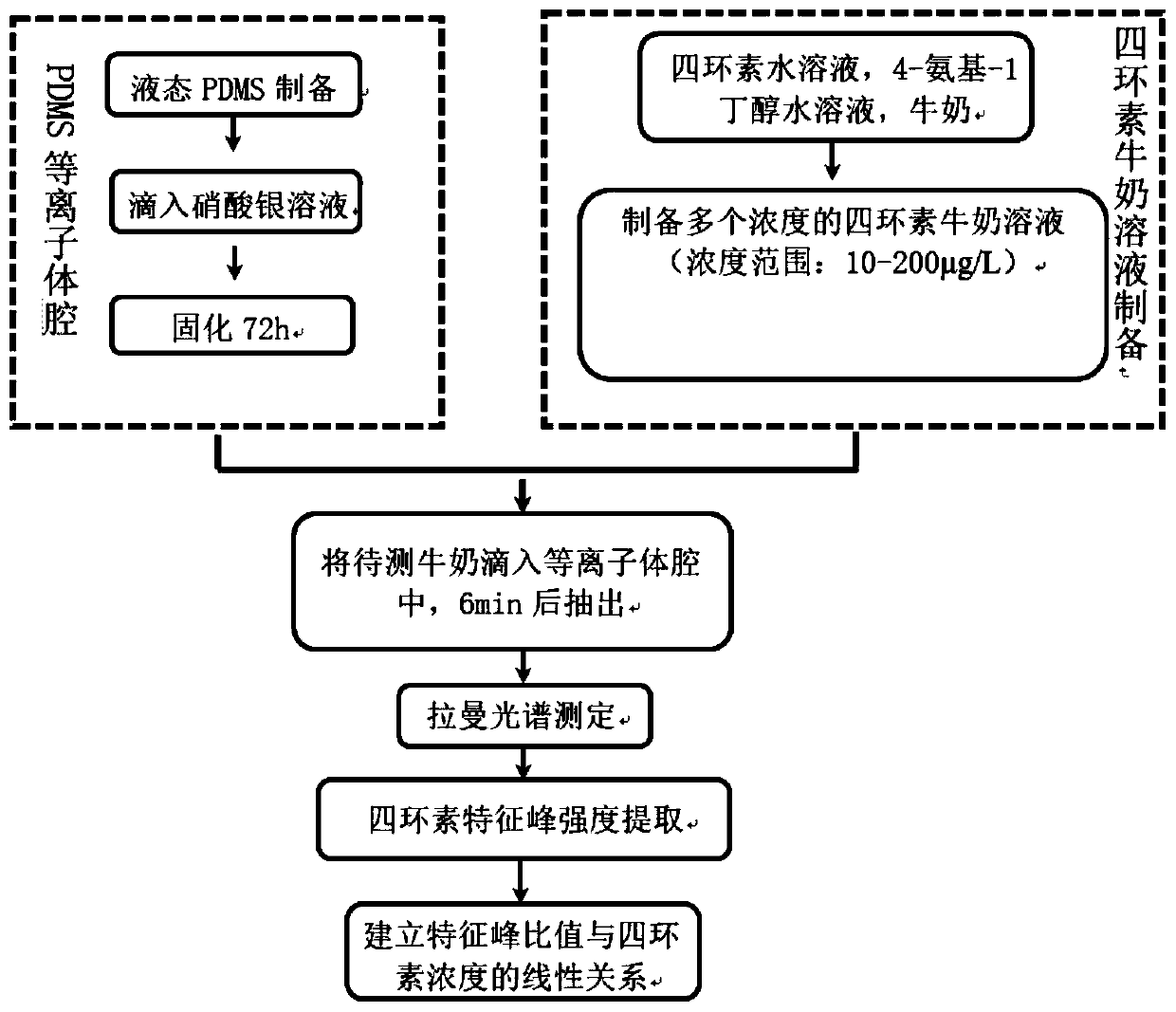

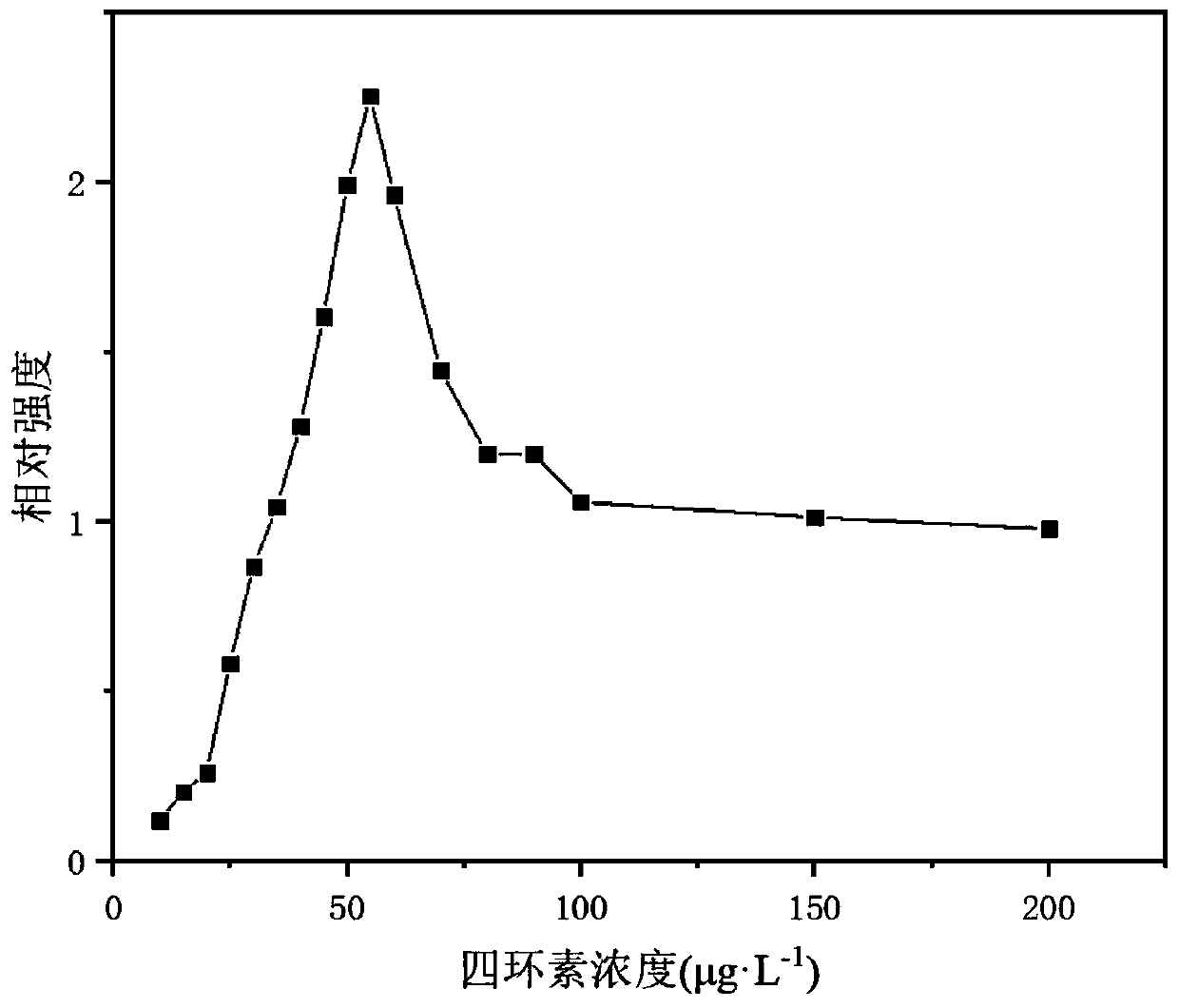

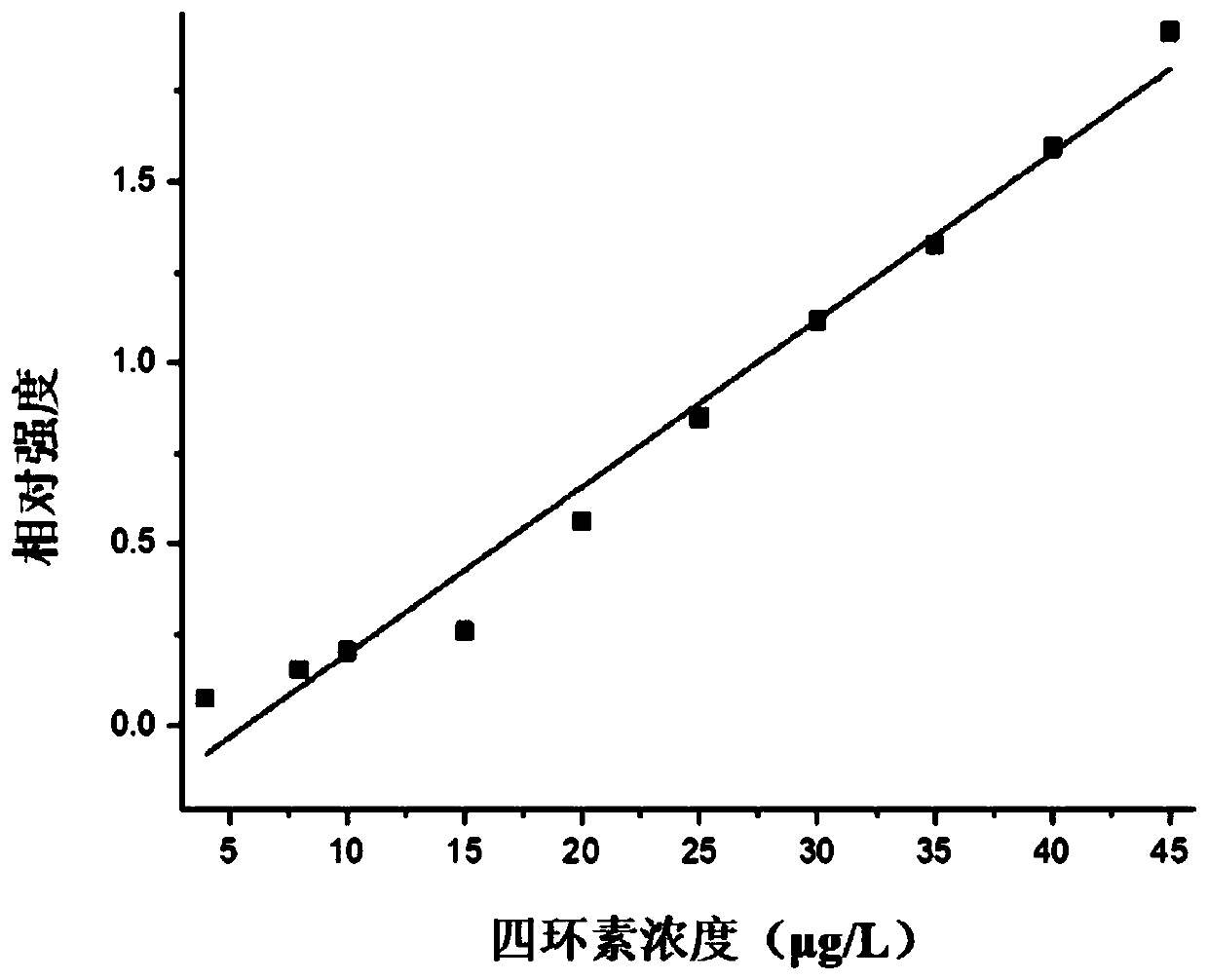

Method for detecting tetracycline in milk based on surface enhanced Raman technology

The invention discloses a method for detecting tetracycline in milk based on a surface enhanced Raman technology, and belongs to the technical field of Raman spectra. According to the invention, the nano-silver substrate with a PDMS cavity structure is used as a Raman enhanced substrate, and 4-amino-1-butanol and the SERS substrate are combined for use, so that the SERS enhancement is superior tothat of single use of a PDMS cavity or nano-silver particles. By adding 4-amino-1-butanol, SERS enhancement is better than that of single use of a PDMS cavity or nano-silver particles, and the tetracycline detection limit can reach 0.2 [mu] g / L. The PDMS plasma cavity can be used as an SERS substrate to detect tetracycline in milk, a milk sample does not need to be pretreated, the detection time is within ten minutes, the detection limit is as low as 0.2 [mu] g / L, and the method has important significance in monitoring abuse and residue of tetracycline antibiotics.

Owner:JIANGNAN UNIV

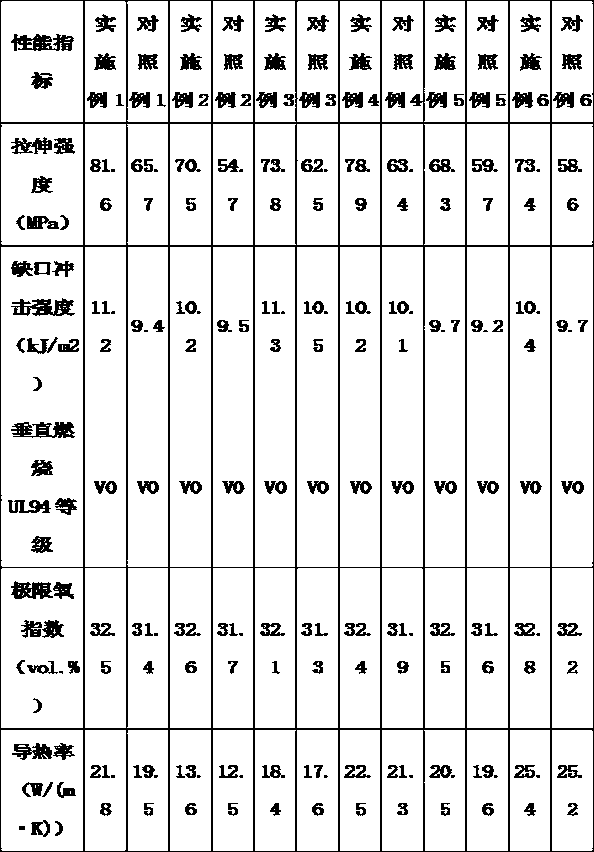

Antistatic toughened, enhanced and stiffened polybutylece terephthalate (PBT) composite material

The invention discloses an antistatic toughened, enhanced and stiffened polybutylece terephthalate (PBT) composite material, comprising the following components by mass percent: 50-70% of PBT, 5-15% of thermoplastic polyurethane (TPU), 5-15% of micron calcium carbonate, 3-5% of antistatic agent, 8-15% of aggregate-type fire retardant, 3-8% of flame retardant, 0.1-0.5% of surface treating agent, 0.1-1% of antioxidant and 0.2-1.5% of lubricating agent. The antistatic toughened, enhanced and stiffened PBT composite material has the beneficial effects that compared with the prior art, the prepared PBT composite material has the advantages that good tensile strength is kept when the gap impact toughness, the rigidity and the heat resistance can be greatly improved, the PBT composite material has significant toughening, enhancing and stiffening effects, is high in flame retardant efficiency, good in antistatic property, excellent in electric property, low in cost, simple in preparation method, convenient to operate, and easy to achieve industrialization, and can be widely applied to the fields such as electronic electricity, automobile industries, mechanical accessories, architectural structures and the like.

Owner:QINGDAO XINZHAN PLASTIC

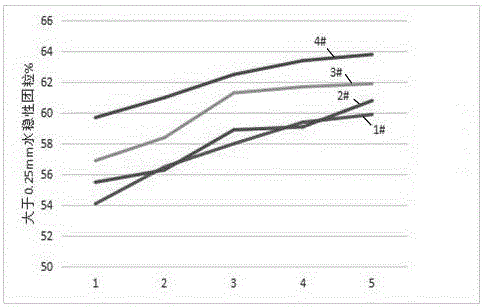

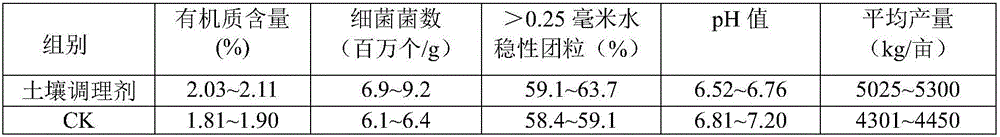

Soil conditioner for improving and remediating soil and application thereof

InactiveCN106365892ASignificantly improvedSignificant repair effectCalcareous fertilisersBio-organic fraction processingAlkalinityBacillus amyloliquefaciens

The invention provides a soil conditioner for improving and remediating soil and application thereof. The soil conditioner is prepared from decomposed organic material, phosphogypsum and bacillus amyloliquefaciens, wherein the mass ratio of the decomposed organic material in the soil conditioner is not lower than 65.0%, the mass ratio of phosphogypsum is 25%-30%, and the content of bacillus amyloliquefaciens is not lower than 2*10<8> CFU / g. The soil conditioner has an obvious soil conditioning and remediating function and can effectively promote formation of soil granular structures, improve the soil buffer capacity and the water and nutrient retention capacity, enrich beneficial microbial florae in soil, improve soil bioactivity, improve soil acidity and alkalinity and significantly condition and remediate greenhouse soil.

Owner:QINGDAO GENYUAN BIOLOGICAL TECH GRP

Nano calcium carbonate /wood composite material production method

InactiveCN104858963AImprove wear resistanceImprove bending strengthBiocideWood treatment detailsSurface-active agentsFatty alcohol

The invention discloses a nano calcium carbonate / wood composite material production method including the five steps of pretreatment of wood, preparation of a wood modifying agent, preparation of a wood modifying liquid, dipping treatment, and post drying treatment, and the wood modifying agent includes nano calcium carbonate, a surface active agent, water, sodium octoborate, diammonium phosphate, boric acid, ammonium molybdate, carbendazim, dodecyl dimethyl benzyl ammonium chloride, imidacloprid, and sodium dodecyl sulfate, and the surface active agent is one of fatty alcohol polyoxyethylene ether, polyoxyethylene amide, and sodium dodecyl benzene sulfonate. The beneficial effect is that the nano calcium carbonate / wood composite material production method has simple process, high efficiency, environmental friendliness and low cost and other advantages, and by use of the nano calcium carbonate for modification, the nano calcium carbonate / wood composite material has good enhancement, weighting, anti-erosion, stability improvement and the like.

Owner:王玉燕

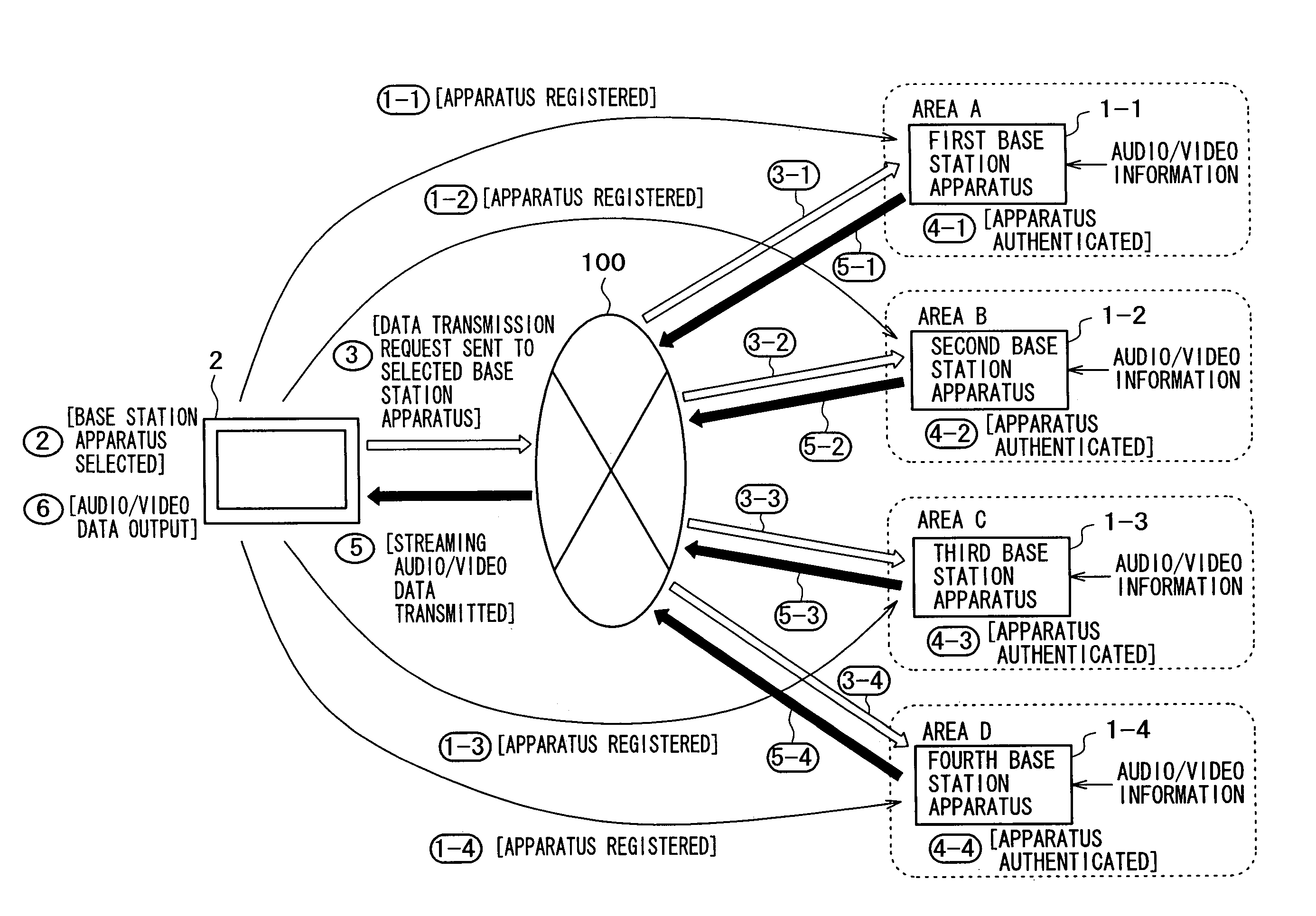

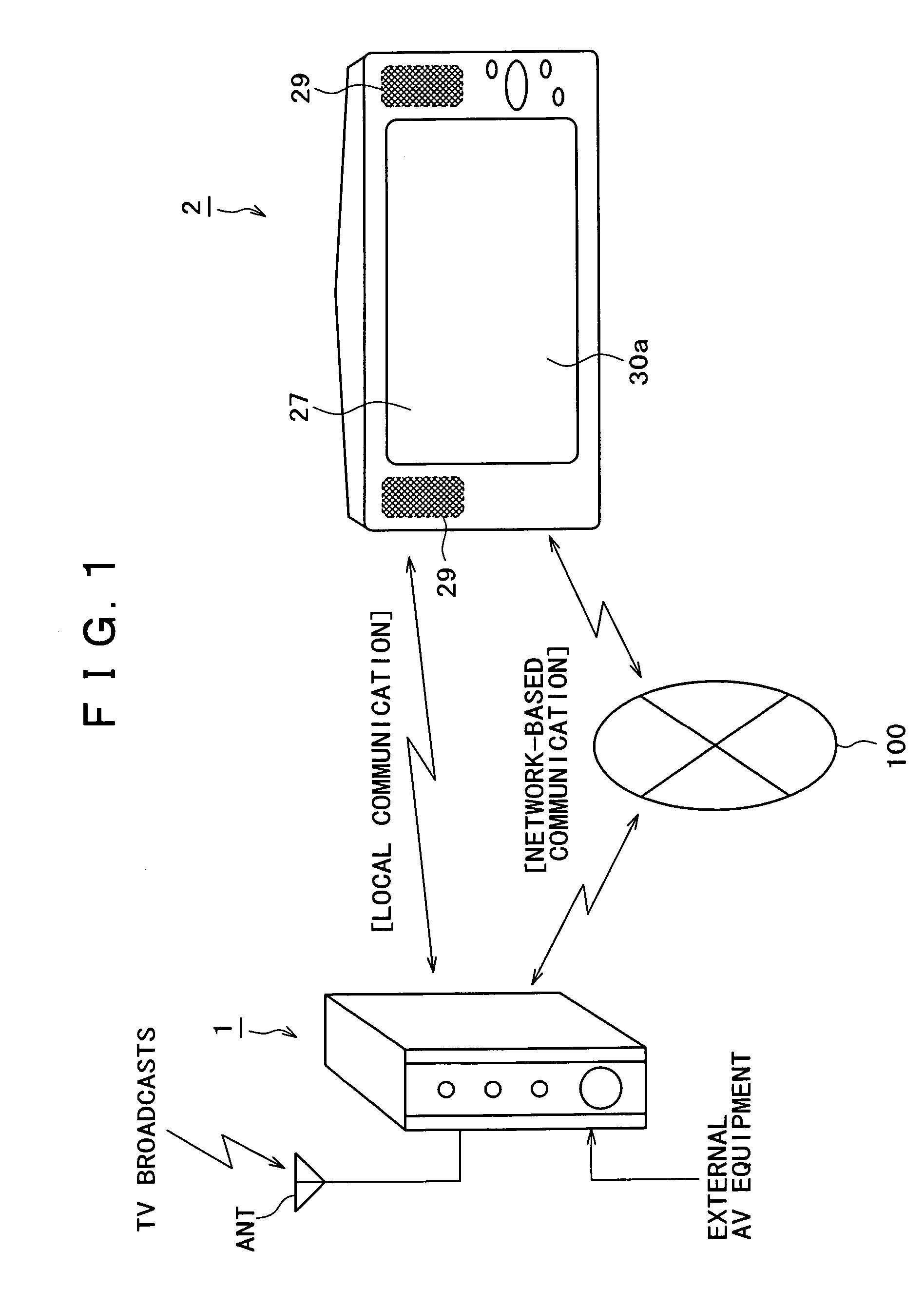

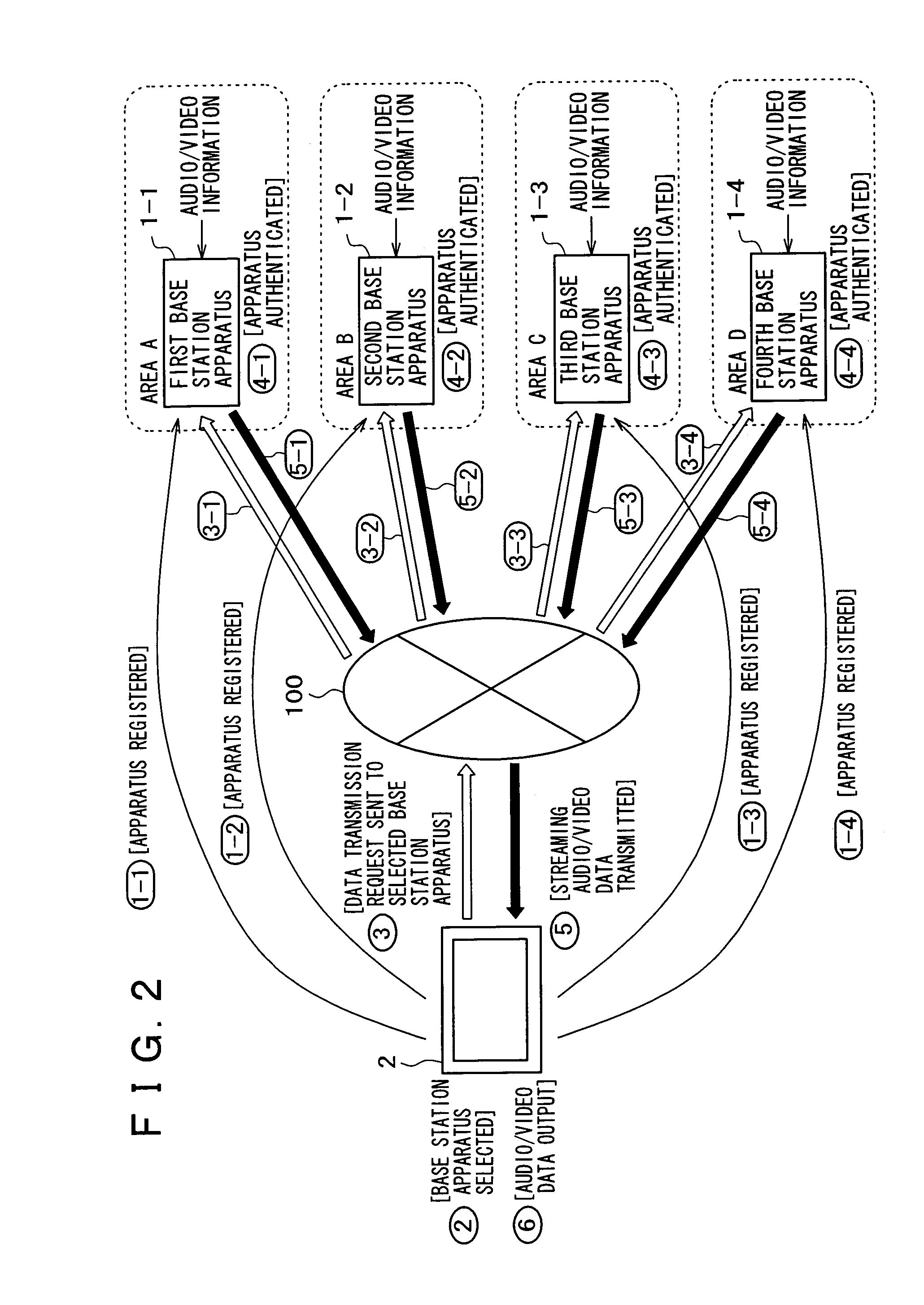

Information transmitting/receiving system, information transmitting apparatus, information receiving apparatus, and information transmitting/receiving method

ActiveUS7360000B2Significantly improvedAvoid small quantitiesSpecial service provision for substationTelevision system detailsComputer scienceBase station

An information transmitting / receiving system is disclosed which includes a base station apparatus and a monitor apparatus, the system being arranged to let the base station apparatus offer more content information to the monitor apparatus than before. On receiving a content transmission request, the base station apparatus performs an authenticating process using monitor apparatus registration information in order to send content information only to the registered monitor apparatus authorized to receive the content information. The monitor apparatus may register with a plurality of units of the base station apparatus. When the monitor apparatus selects any one of the multiple units of the base station apparatus to request transmission of content information therefrom, the selected base station unit transmits the requested content information to the requesting monitor apparatus.

Owner:SATURN LICENSING LLC

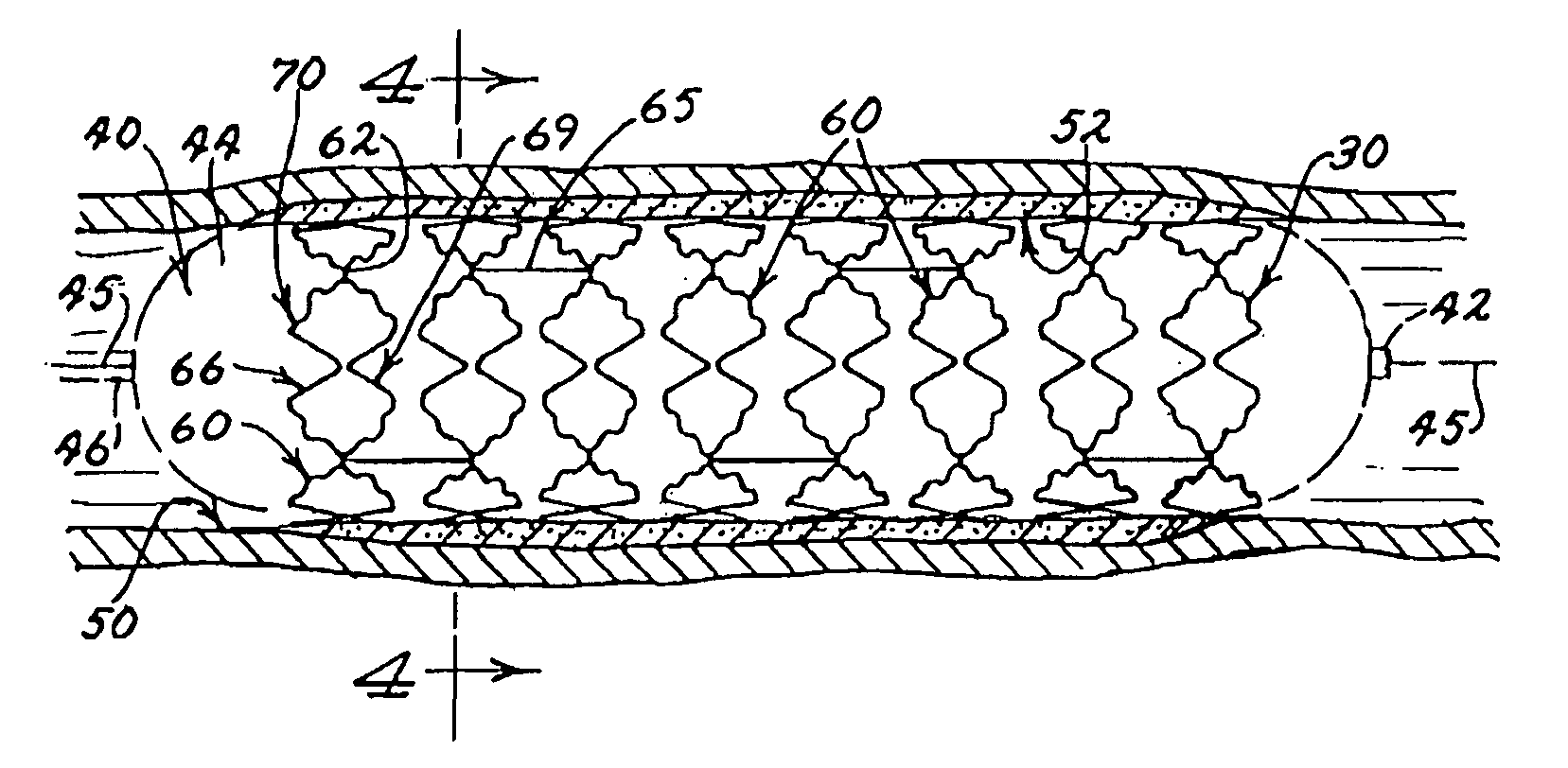

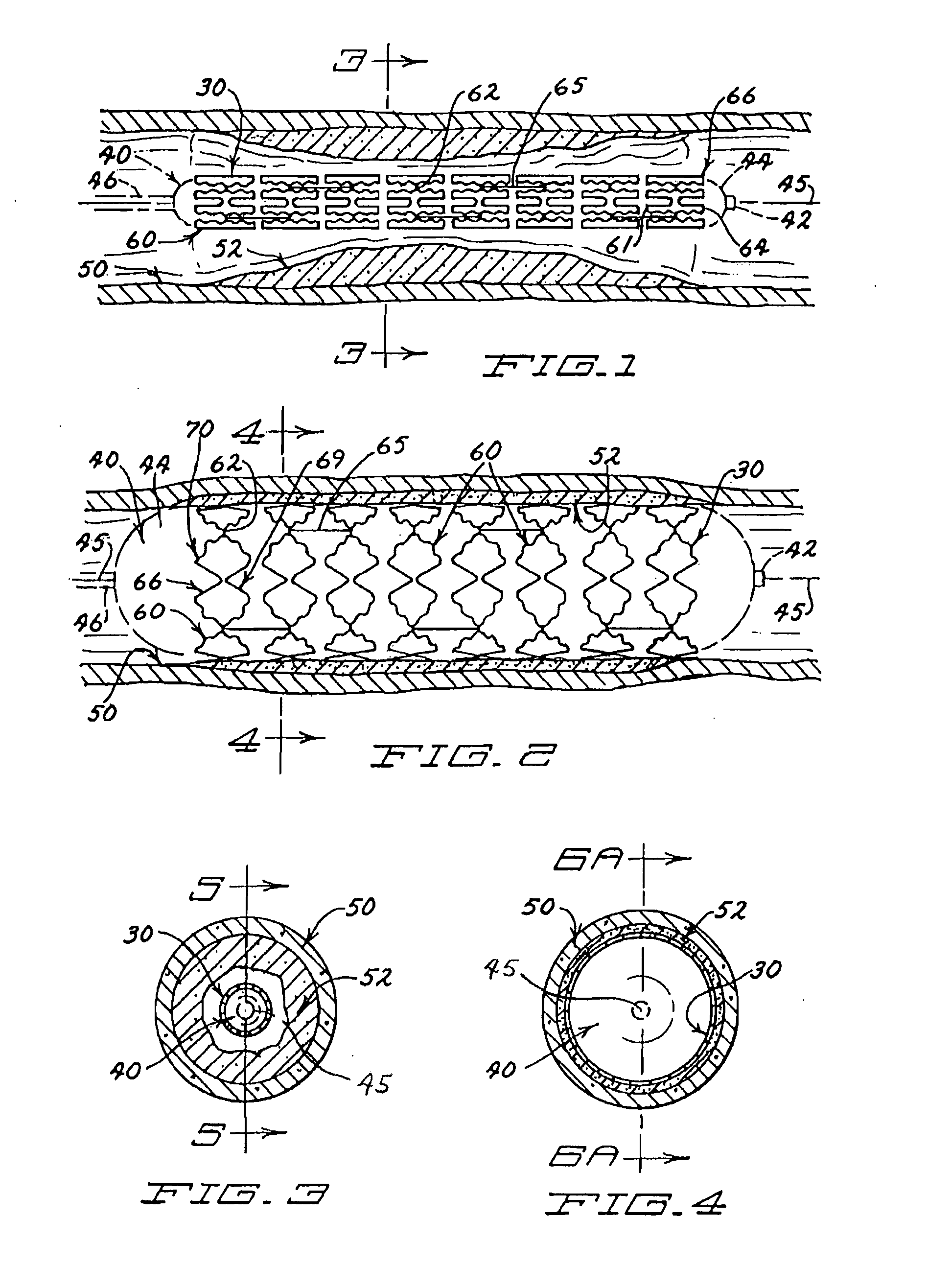

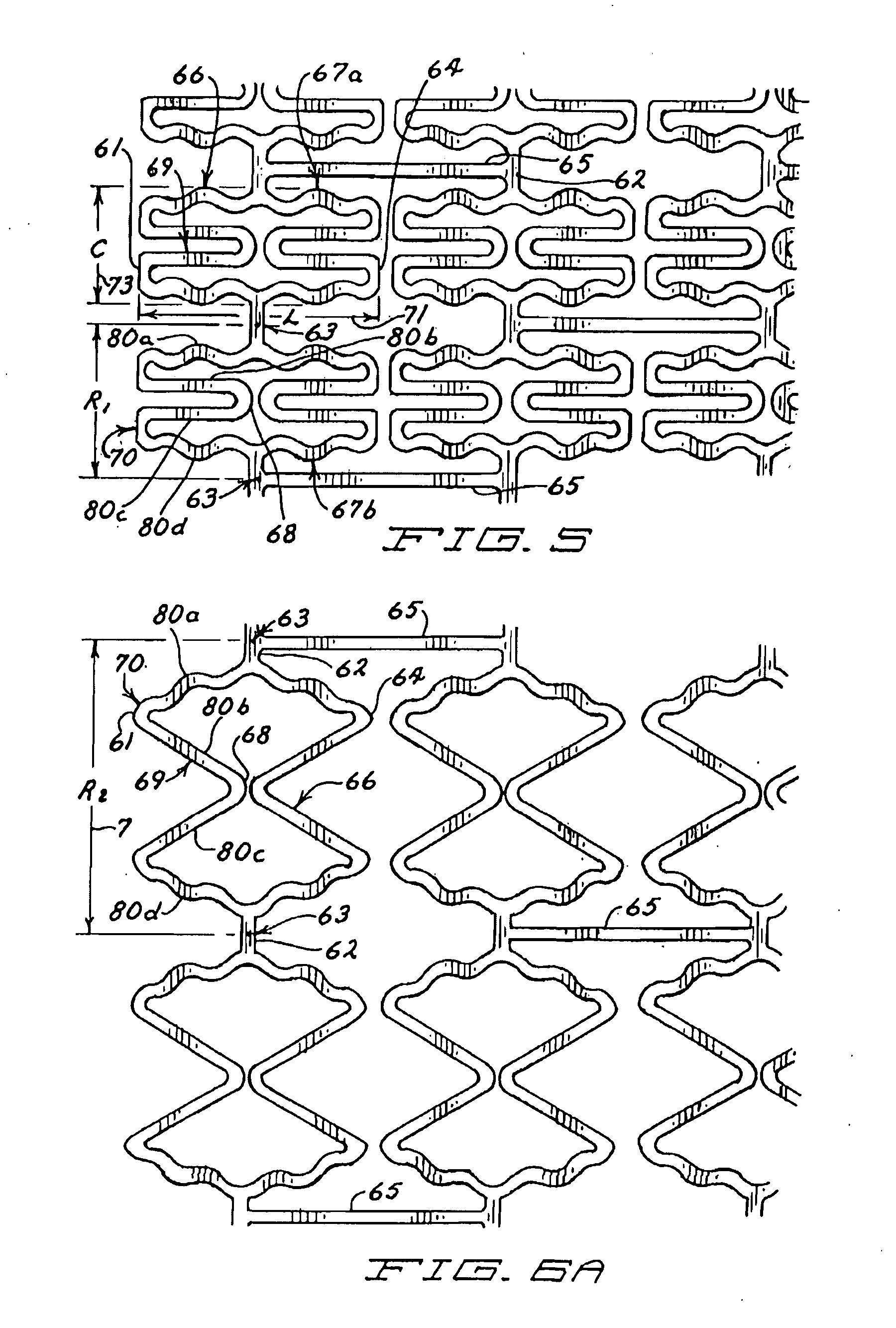

Expandable stent having a plurality of interconnected expansion modules

InactiveUS20080071354A1Small surface areaEasily and efficiently producedStentsBlood vesselsInterconnectionBiomedical engineering

Expandable stents are disclosed. The stents have a plurality of rings or modules interconnected in series, with selectable links between the rings to provide for articulation. The preferred stent includes a plurality of modules, each of the modules being radially interconnected to form a ring configured to be expandably interconnected and being interconnected to each other in series by respective interconnection bridges. Each ring including a continuous strand of a material, the continuous strand of material being interconnected end to end so as to generally encompass a radial space within the ring. The strand of material being configured to include a repeating series of interconnected repeating W-shaped strand configurations having a repeating dip, rise, dip, rise, loop, dip, rise, dip, rise, loop patterned configuration. Methods of producing the devices are also disclosed, including various etching methods.

Owner:DAS GLADWIN

Fiber laser integrated collimation optical device

The invention provides a fiber laser integrated collimation optical device. According to the scheme, the fiber laser integrated collimation optical device comprises a fiber laser, a collimator tail optical fiber and a collimation optical device. Laser emitted by the fiber laser enters the collimation optical device through collimator tail optical fiber coupling and then outputs collimated laser. According to the scheme, the fiber laser integrated collimation optical device has effects of both an optical end cap and a laser collimator, the number of optical elements is reduced, the size of the optical collimator is reduced, and the interference to the fiber laser caused by laser scattering return light is reduced.

Owner:INST OF APPLIED ELECTRONICS CHINA ACAD OF ENG PHYSICS

Efficient enhanced flame-retardant heat-conducting shading multifunctional master batch for nylon direct injection molding and preparation method thereof

ActiveCN109503969AGood modification effectSolve the technical problem of mismatching processing temperatureGlass fiberIonomer

The invention belongs to the technical field of plastic modification and processing and especially relates to an efficient enhanced flame-retardant heat-conducting shading multifunctional master batchdirectly used for nylon direct injection molding and a preparation method thereof. The multifunctional master batch is composed of a master batch A and a master batch B, wherein the master batch A comprises the following components by weight percent: 50.0-60.0wt.% of glass fiber, 25.0-35.0wt.% of high-flow nylon resin, 5.0-10.0wt.% of maleic anhydride grafted ionomer, 3.0-8.0wt.% of star-shaped nylon 6 resin and 0.1-0.3wt.% of antioxidant. Compared with the traditional plastic functional master batch, the multifunctional master batch prepared according to the invention has the advantages thatmodified efficiency loss caused by mutual shearing abrasion of glass fiber and fire retardant as well as inorganic functional modified additive grains during the processing process can be avoided; the problem of mismatching processing temperatures of the two modified systems can be solved; compared with modified efficiency of a traditional enhanced bromine flame-retardant system, modified efficiency of the two modified systems is obviously promoted; the master batch has the characteristics of easiness in dispersing and processing and can be used for injection molding after direct simple mixing with nylon 6 resin at ratio.

Owner:江苏万纳普新材料科技有限公司

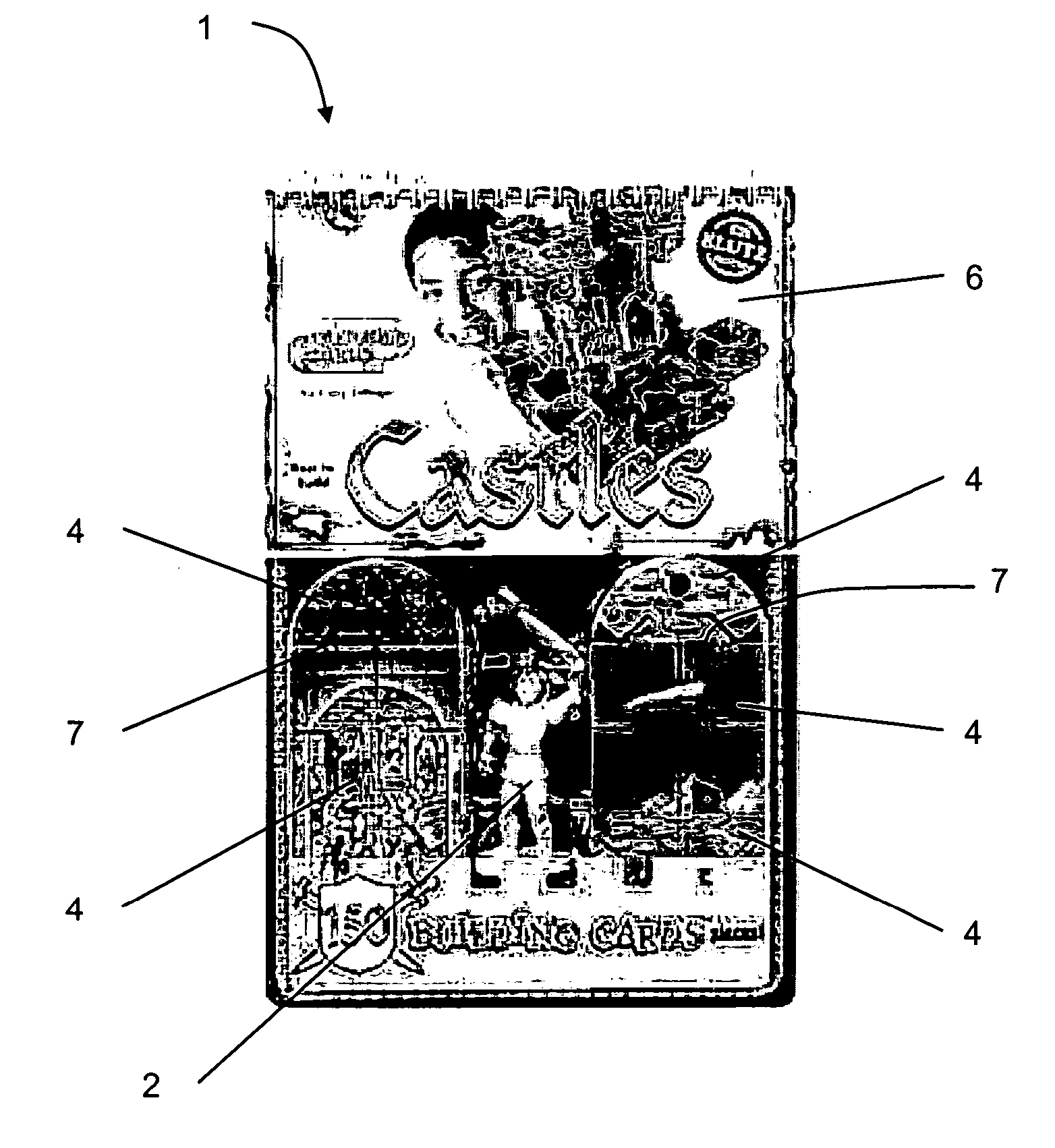

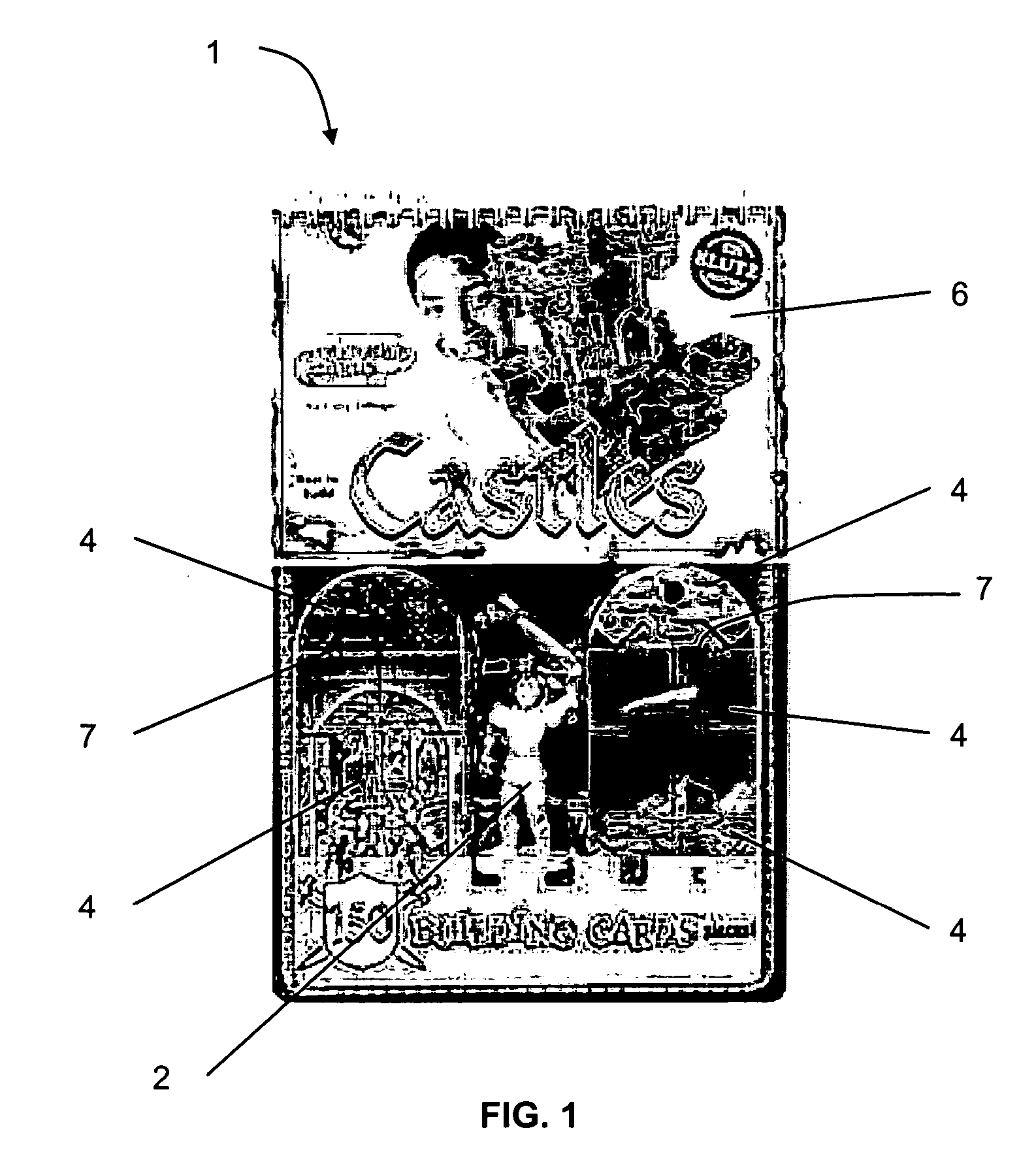

Building card kit

Owner:SCHOLASTIC

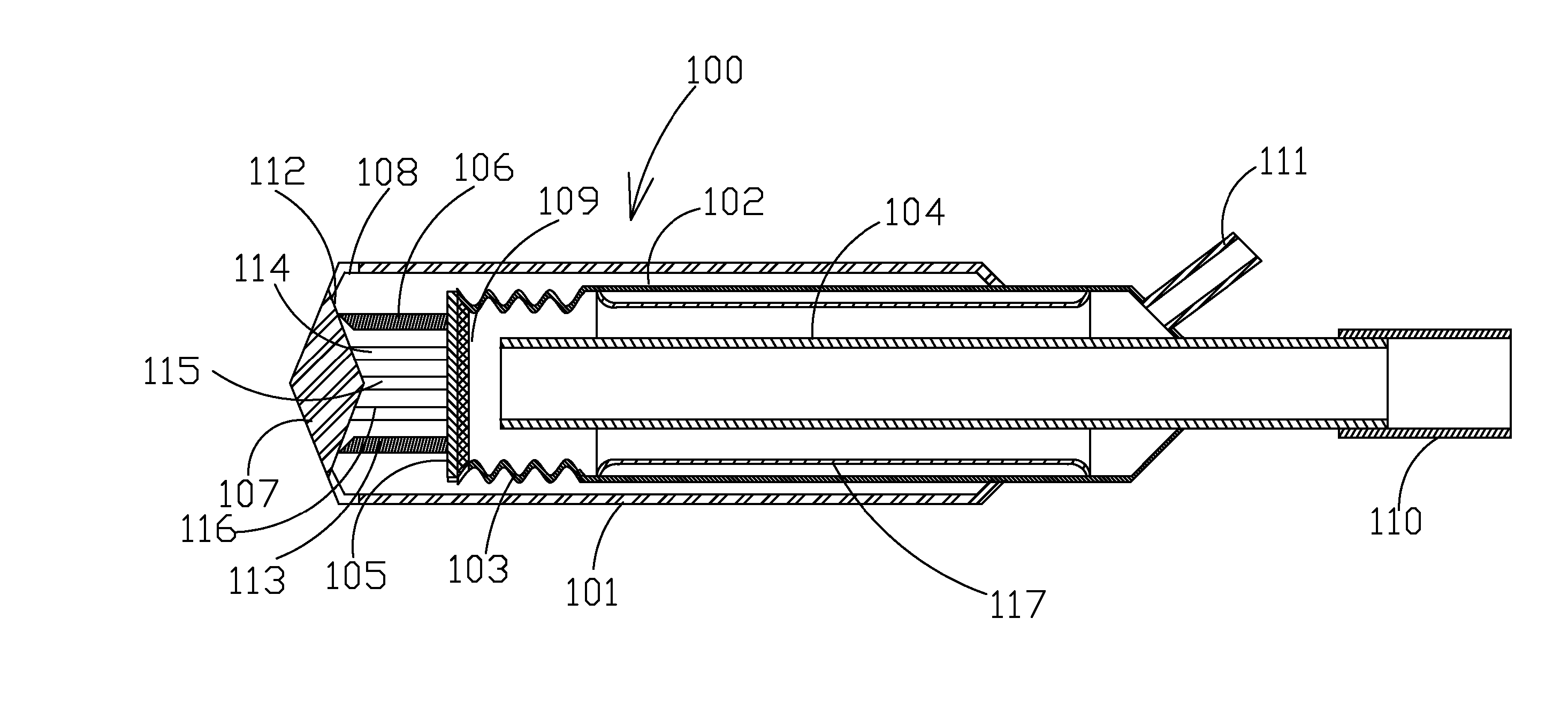

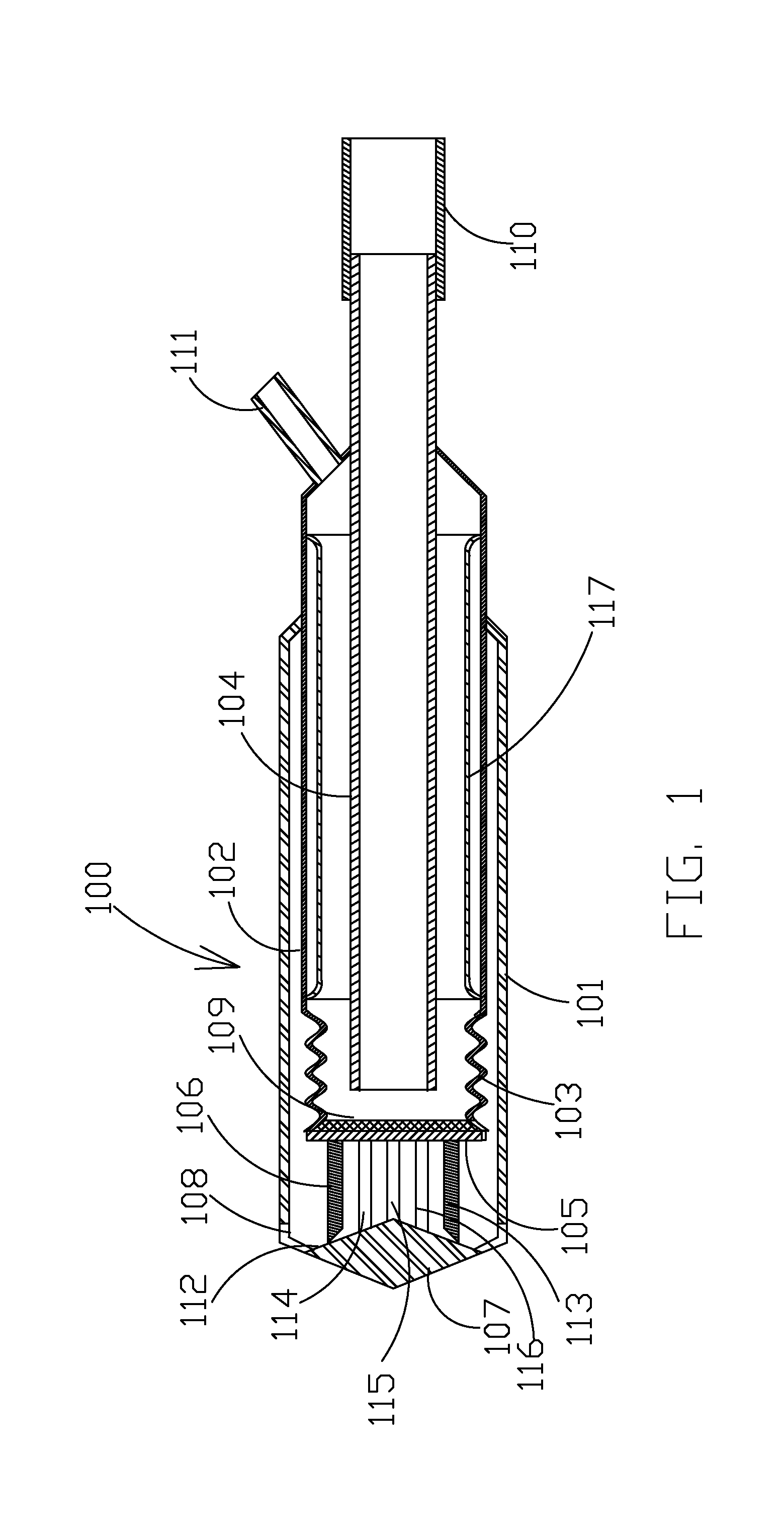

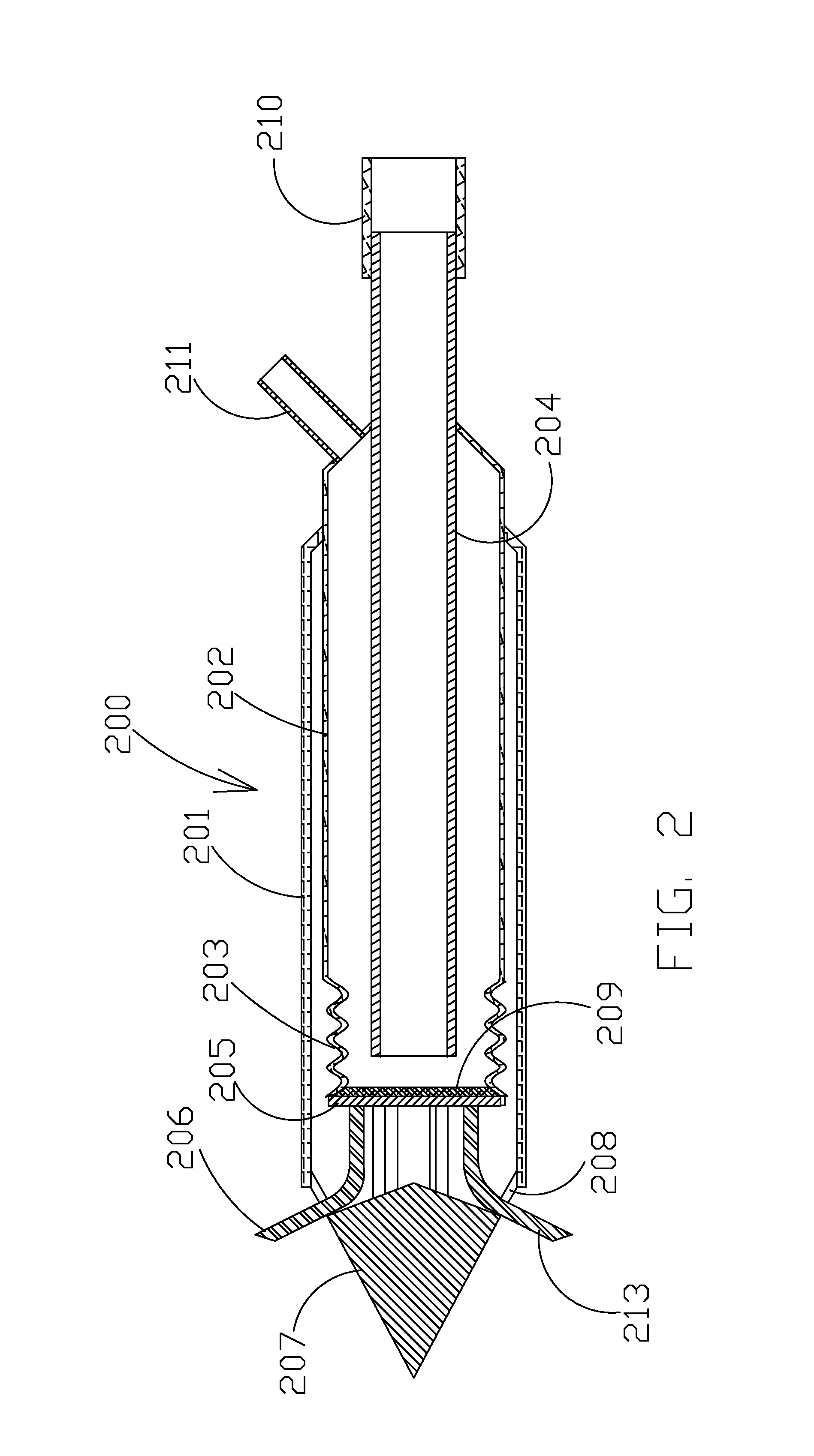

Cryogenic Probe for Treating Enlarged Volume of Tissue

ActiveUS20080033416A1Increase the effective diameterSignificantly improvedSurgical instruments for coolingDistal portionBiomedical engineering

A cryoprobe for surgical and other treatments. The cryoprobe comprises an expandable section that performs displacement of a distal cryotip forwards when there is elevation of the operation pressure in the interior of the cryoprobe. Needle-wise metal elements are installed on the external side of the cryotip. These needle-wise elements are deflecting outwards by a deflecting member fastened on the distal edge of an external shaft of the cryoprobe. This allows a significant enlargement of the frozen volume of the treated tissue with the same operation temperature and the outer diameter of the cryoprobe. In another embodiment, the needle elements are formed in a displaceable metal sheath and a distal section of a cryotip and / or special protrusions on this distal section act as the deflecting member.

Owner:ICECURE MEDICAL

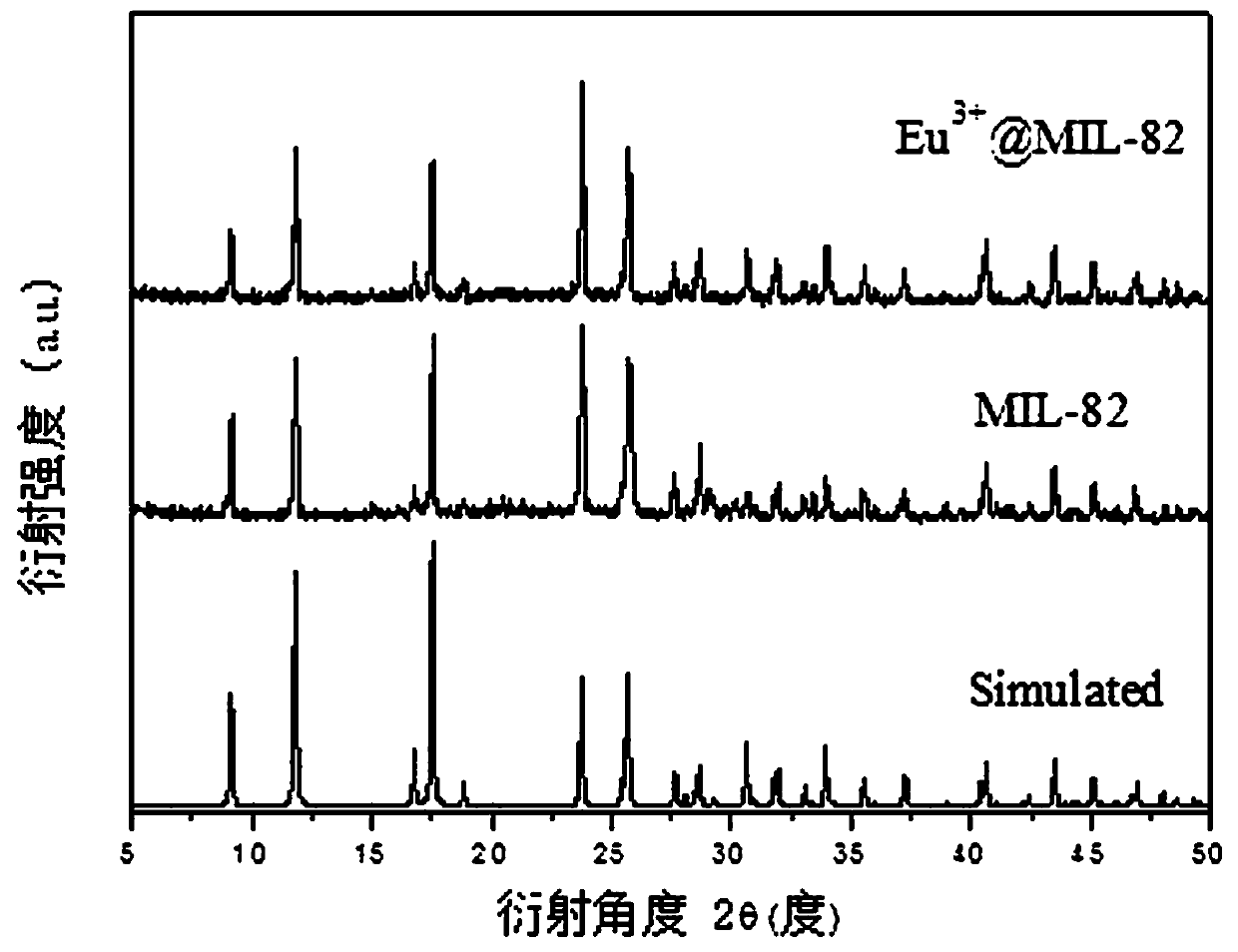

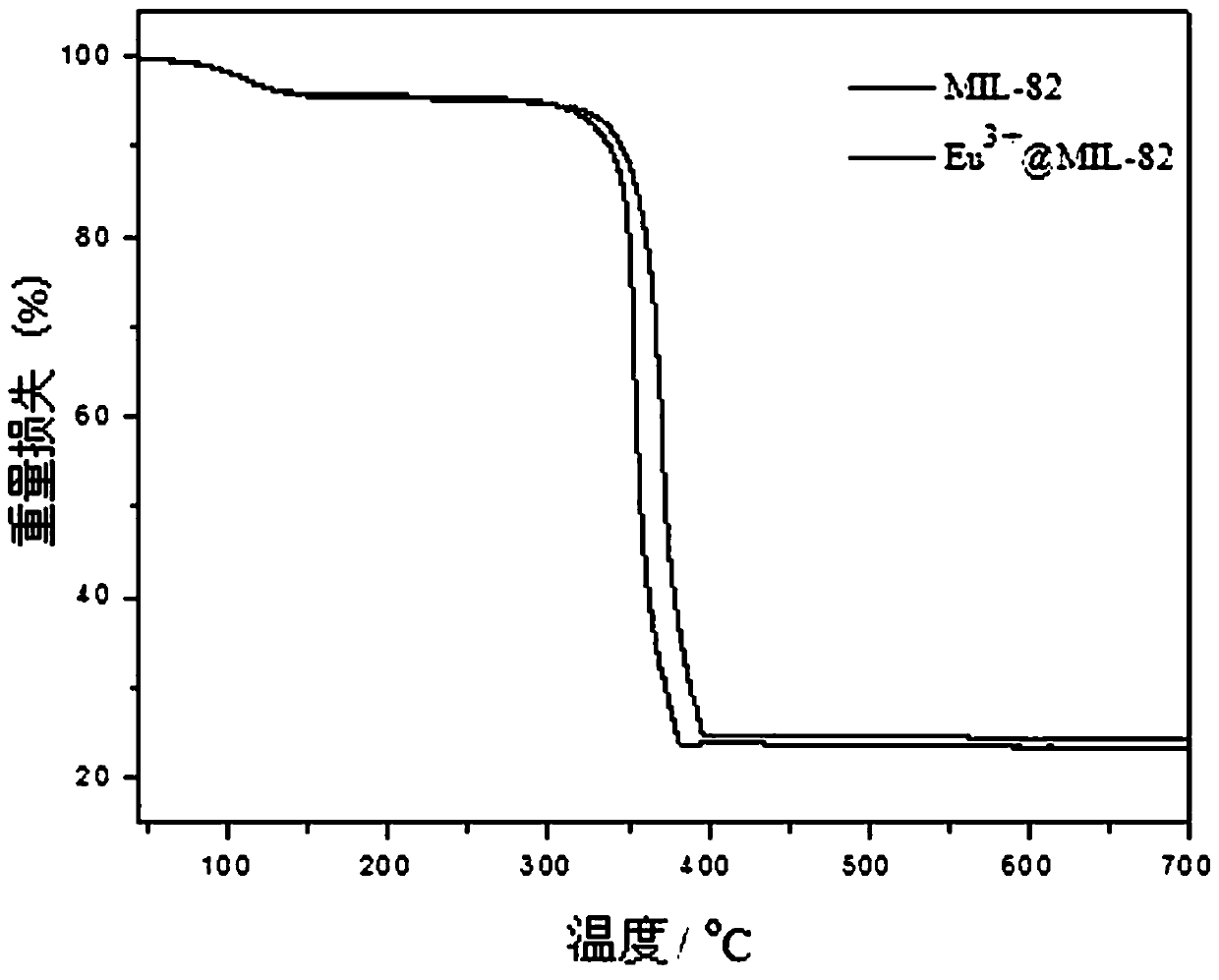

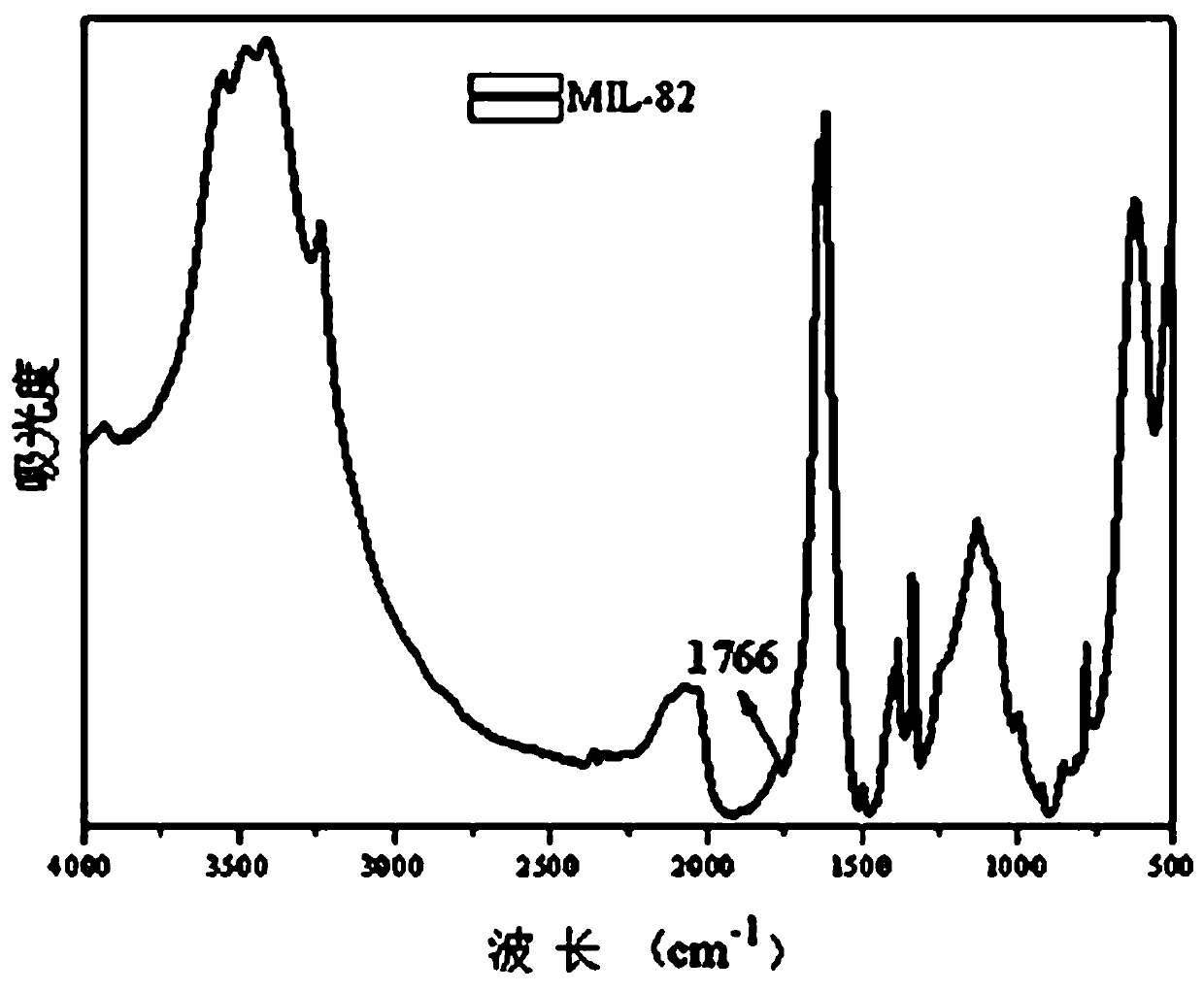

Preparation method and application of Eu<3+>-MOF material

InactiveCN110938215AHigh selectivityHigh sensitivityFluorescence/phosphorescenceLuminescent compositionsFluorescenceWater chlorination

The invention relates to a preparation method and application of an Eu<3+>-MOF material. The preparation method comprises the following steps: preparing an iron-based MOF material from ferrous chloride and pyromellitic acid and then preparing the Eu<3+>-MOF material from the prepared iron-based MOF material and europium nitrate. The prepared Eu<3+>-MOF material shows strong characteristic emissionlight of Eu<3+> and has good water stability and thermal stability. Ag<+> has good concentration dependence on the enhancement efficiency of Eu<3+>-MOF fluorescence. The detection range of Ag<+> is 0-150 [mu]M, the detection limit is 0.09 [mu]M, and the response speed of the material to Ag<+> is very fast (3 min).

Owner:YANTAI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com