Patents

Literature

57results about How to "Low coefficient of thermal expansion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thermosetting resin composition for integrated circuit as well as prepreg and laminated board both fabricated by using composition

ActiveCN103265791AImprove heat resistanceHigh Tg characteristicSynthetic resin layered productsHigh densityPrepolymer

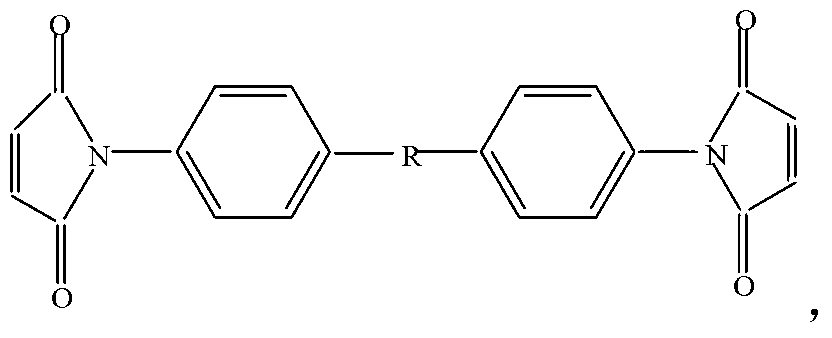

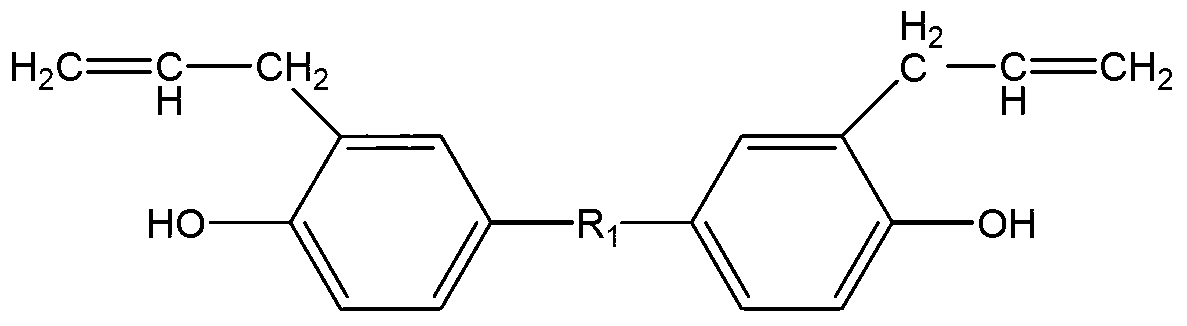

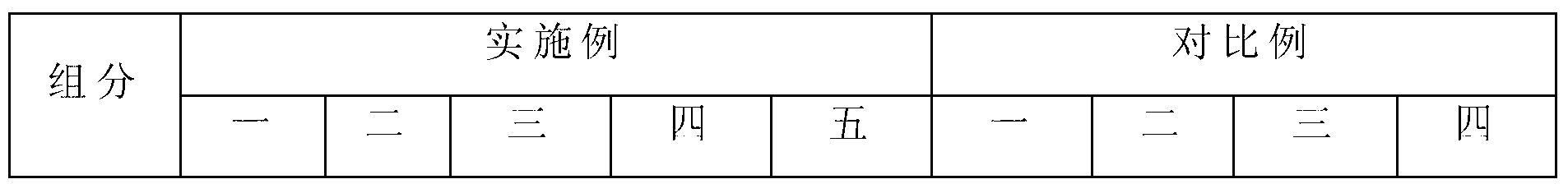

The invention discloses a thermosetting resin composition for an integrated circuit. The thermosetting resin composition comprises (a) 10-60 parts of an allyl modified bismaleimide resin prepolymer, (b) 10-40 parts of an anhydride compound, (c) 10-50 parts of benzoxazine resin, (d) 5-50 parts of epoxy resin, (e) 5-50 parts of a fire retardant, (f) 0-5 parts of a curing accelerator and (g) 0-35 parts of inorganic stuffing, wherein the number-average molecular weight of the allyl modified bismaleimide resin prepolymer is 1500-8000 g / mol. The resin composition provided by the invention keeps high heat resistance and high Tg characteristic of the allyl modified bismaleimide resin prepolymer, and achieves UL94V-0 level in halogen-free flame retardant aspect on the basis of low phosphorus content, and simultaneously, has low dielectric constant of the anhydride; and therefore, the resin composition is capable of meeting the requirements of the production process of high-performance printed circuit boards such as a high-density interconnected integrated circuit package.

Owner:SHENGYI TECH SUZHOU

Reinforced Silicone Resin Film and Nanofiber-Filled Silicone Composition

InactiveUS20100209687A1Low coefficient of thermal expansionResistant to crackMaterial nanotechnologySynthetic resin layered productsSilicone resinNanometre

Owner:ZHU BIZHONG

Ceramsite prepared by using smelting wastes, and preparation method thereof

ActiveCN103922698AHarmlessAchieve reductionCeramic materials productionClaywaresSocial benefitsSludge

The invention relates to the technical field of harmlessness treatment of smelting wastes, and especially relates to a ceramsite prepared by using smelting wastes, and a preparation method thereof. The ceramsite comprises 10-90% of smelting waste powder, 5-40% of municipal sludge, 4-20% of fly ash, 0-20% of gangue and 0.1-10% of a curing agent. The preparation method of the ceramsite comprises the following steps: 1, crushing the smelting wastes by using a crusher to prepare the smelting waste powder; 2, weighing the smelting waste powder, the municipal sludge, the fly ash, gangue and the curing agent, mixing, and uniformly stirring to prepare ceramsite powder; 3, conveying the ceramsite powder to a ball forming granulation machine, and carrying out granulation molding to prepare ceramsite balls; 4, drying the ceramsite balls; and 5, calcining he dried ceramsite balls to prepare the finished ceramsite. The ceramsite prepared in the invention has the advantages of light weight, environmental protection and wide uses; and the preparation method recycles the smelting wastes, and has good economic and social benefits.

Owner:DONGGUAN YICHENG ENVIRONMENTAL TECH

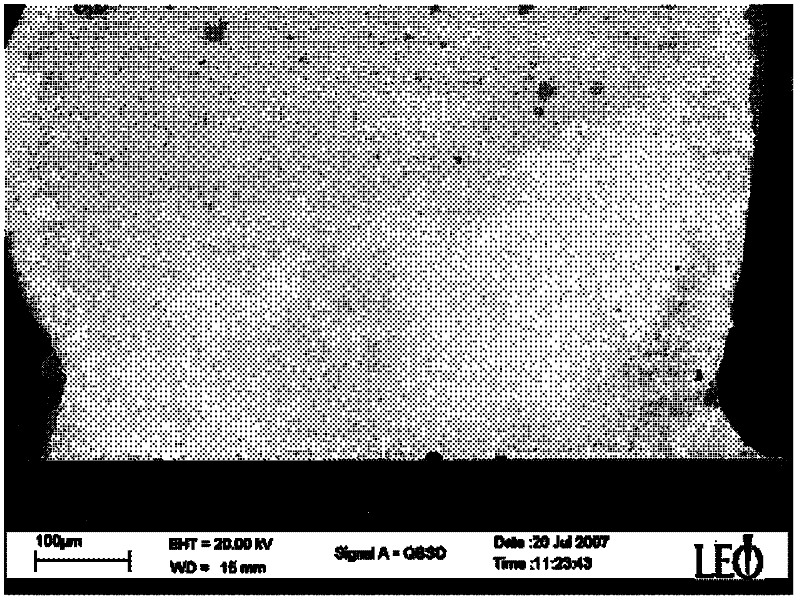

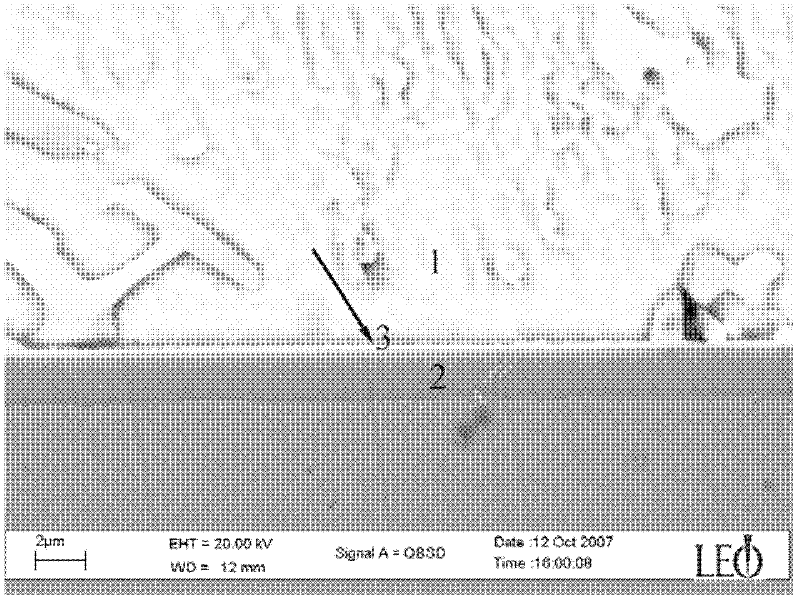

Metal-graphite composite material having high thermal conductivity and production method therefor

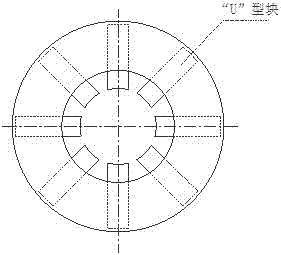

InactiveUS20100207055A1Improve thermal conductivityReliable bonding stateSemiconductor/solid-state device detailsConductive materialAlloyCopper

The present invention provides a metal-graphite composite material favorable to two-dimensional diffusion of heat and having a high thermal conductivity in two axial directions, and a production method therefor. The metal-graphite composite material of the present invention includes: 20 to 80% by volume of a scaly graphite powder; and a matrix selected from the group consisting of copper, aluminium and alloys thereof, wherein the scaly graphite powder in which a normal vector to a scaly surface thereof is tilted at 20° or higher with respect to a normal vector to a readily heat-conducting surface of the metal-graphite composite material is 15% or less relative to a whole amount of the scaly graphite powder, and the metal-graphite composite material has a relative density of 95% or higher.

Owner:SHIMANE PREFECTURAL GOVERNMENT MATSUE

Insulating composition for substrate, and prepreg and substrate using the same

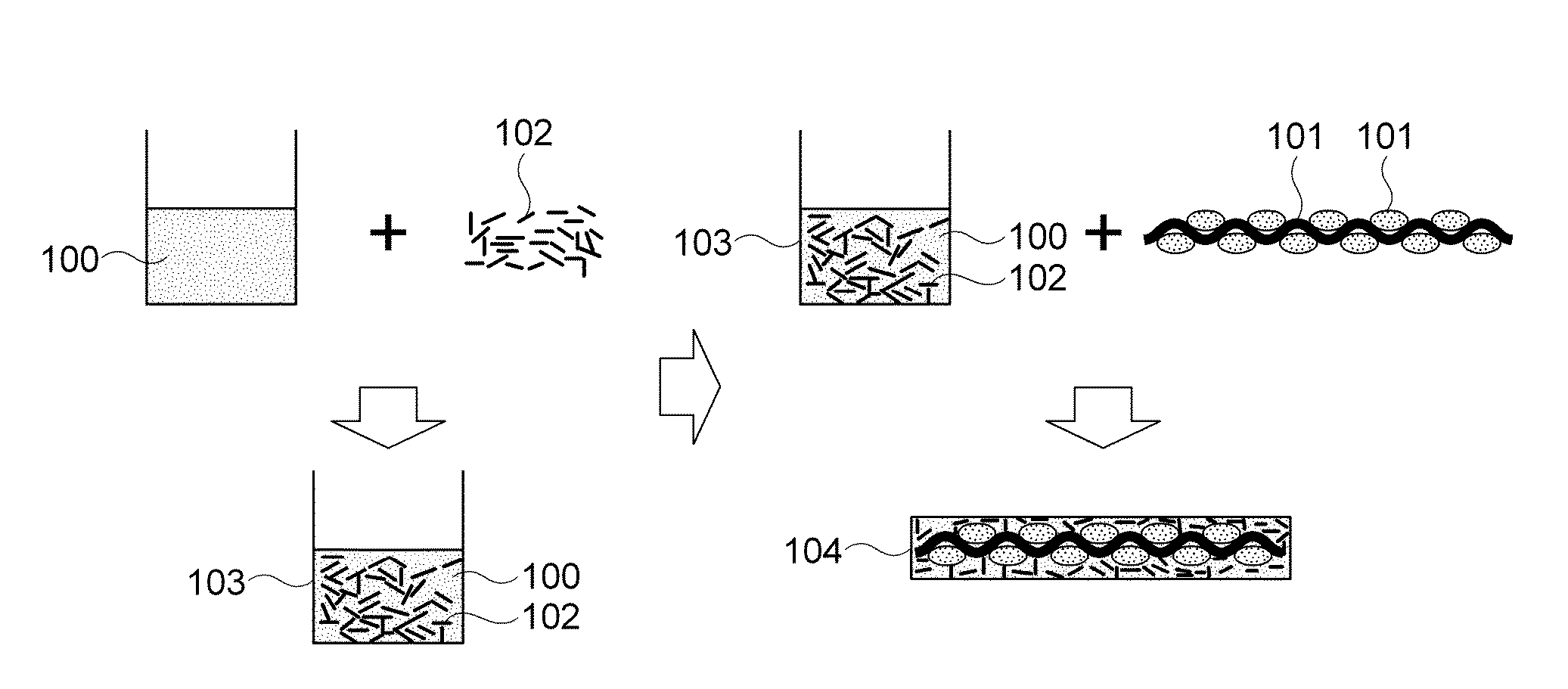

InactiveUS20130281575A1Low coefficient of thermal expansionExcellent strength and rigidityOrganic chemistryPlastic/resin/waxes insulatorsMetal alkoxideLiquid crystal

The present invention relates to an insulating composition for a substrate including a soluble liquid crystal thermosetting oligomer, a metal alkoxide, a graphene oxide, and a short fiber, and an insulating material and a substrate using the same. The insulating composition in accordance with the present invention can effectively reduce the coefficient of thermal expansion by the addition of the metal alkoxide and the graphene oxide. Therefore, it is possible to provide a substrate material with greatly increased strength and rigidity by the addition of the short fiber as well as to manufacture a substrate with improved thermal stability by using the insulating composition in accordance with the present invention as an insulating material of the substrate to minimize dimensional deformation due to heat.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

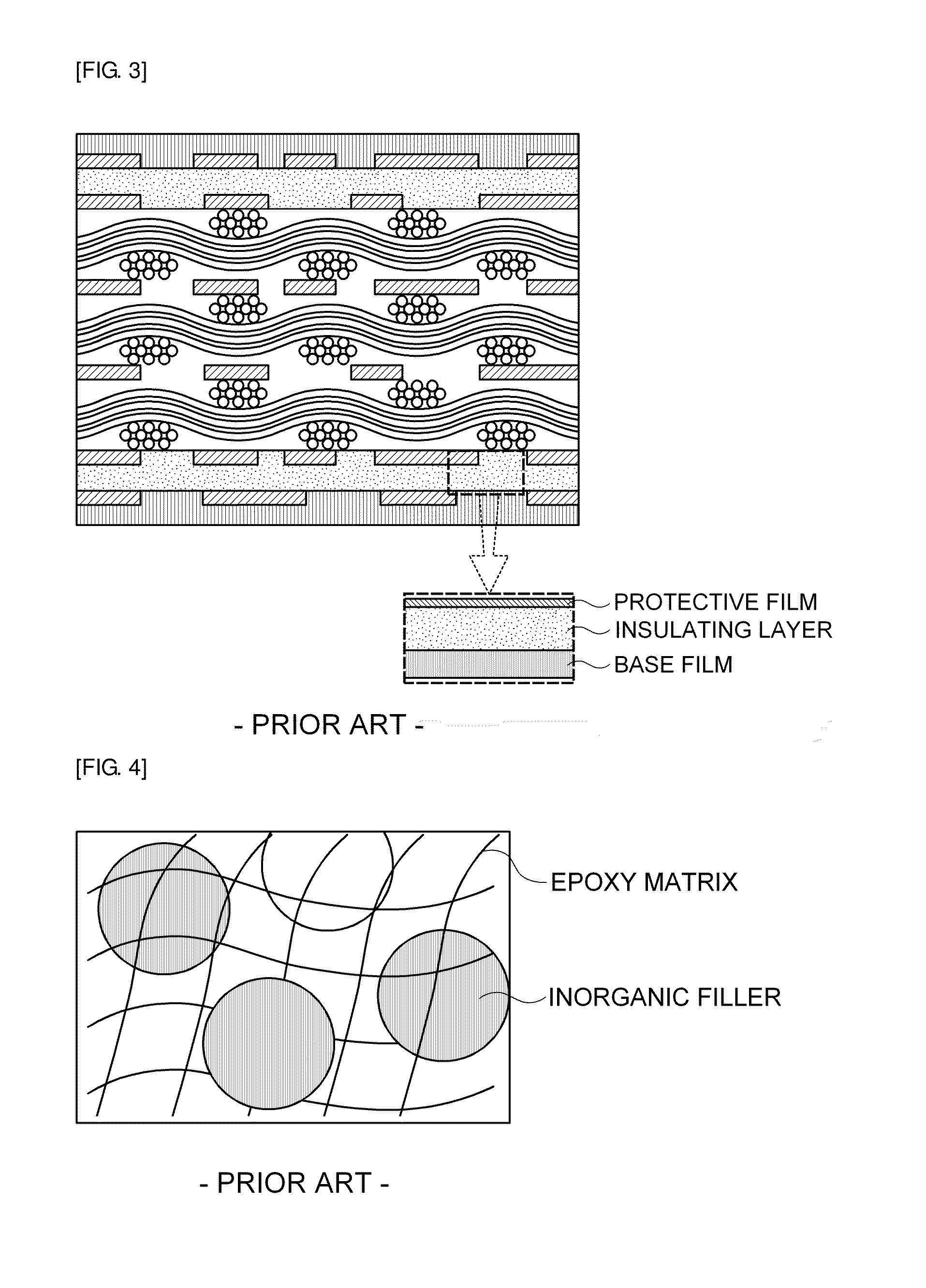

Resin composition, resin sheet, prepreg, laminate, multilayer printed wiring board, and semiconductor device

InactiveUS20110205721A1Low coefficient of thermal expansionHigh glass transition temperatureSynthetic resin layered productsLaminationPolymer scienceDevice material

Disclosed is a resin composition having a low thermal expansion coefficient and a high glass transition temperature used for the insulating layer of a multilayer printed wiring board, capable of forming an insulating layer having fine roughened shapes and imparting sufficient plating peel strength. Also disclosed are a resin sheet, a prepreg, a laminate, a multilayer printed wiring board and a semiconductor device, all of which comprising the resin composition. The resin composition is a resin composition comprising (A) an epoxy resin, (B) a cyanate ester resin, (C) an aromatic polyamide resin containing at least one hydroxyl group and (D) an inorganic filler, as essential components.

Owner:SUMITOMO BAKELITE CO LTD

Glass plate to be tempered

InactiveUS20140242391A1Low coefficient of thermal expansionImprove scratch resistanceGlass/slag layered productsGlass tempering apparatusThermal expansionHigh surface

To provide a glass plate to be tempered, which has a low thermal expansion coefficient at relatively low temperature, and which can have a sufficiently high surface compression stress by a conventional heat tempering process, even when it is thin. A glass plate to be tempered, which contains B2O3 in a range of from 12.5 to 35 mol % in its composition, the difference [X−Y] between the total content X of compounds selected from MgO, CaO, BaO, Na2O and K2O in the composition and the content Y of B2O3 in the composition being within a range of from −5 to 10 mol %, and which is to be tempered by heating and quenching.

Owner:ASAHI GLASS CO LTD

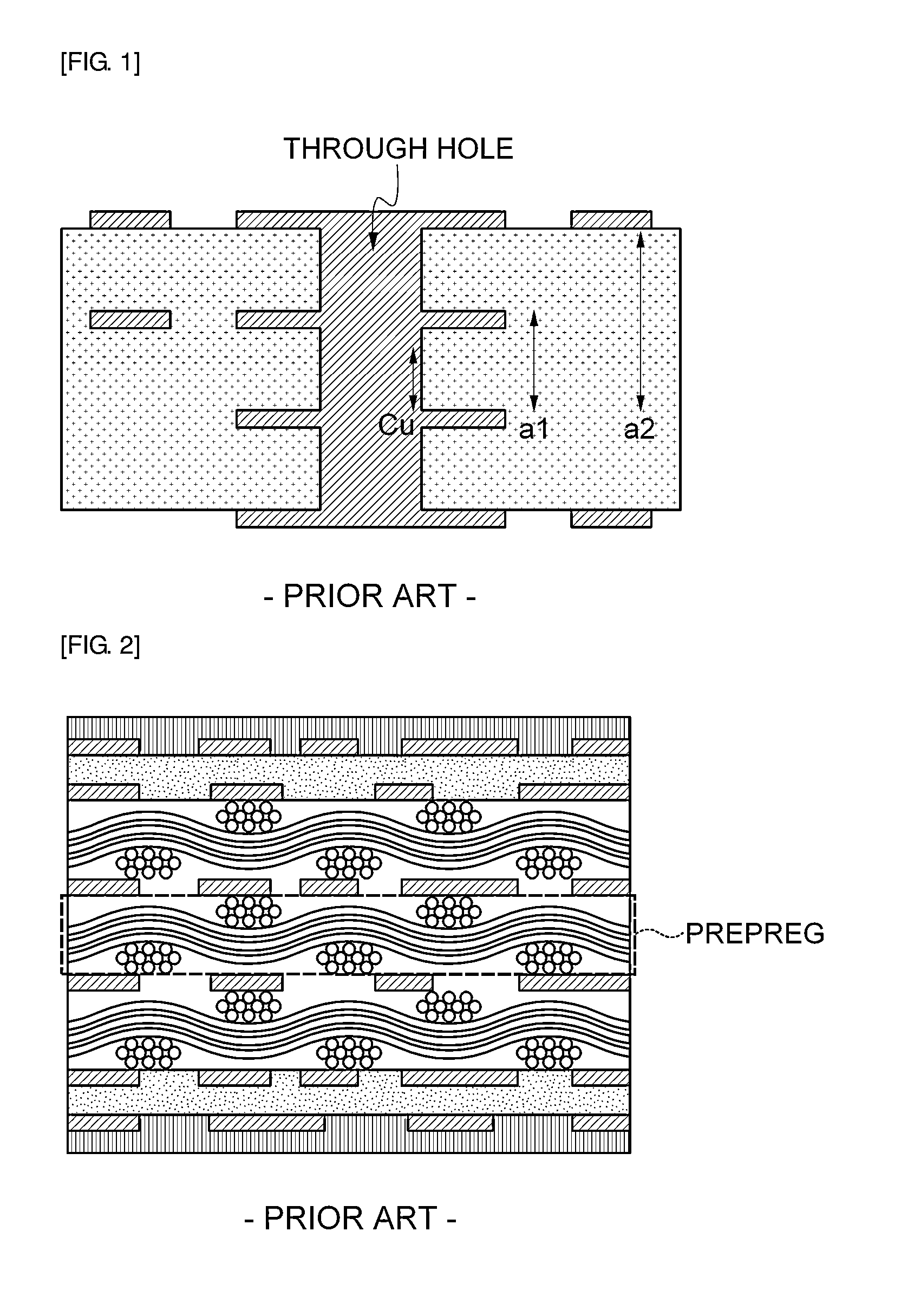

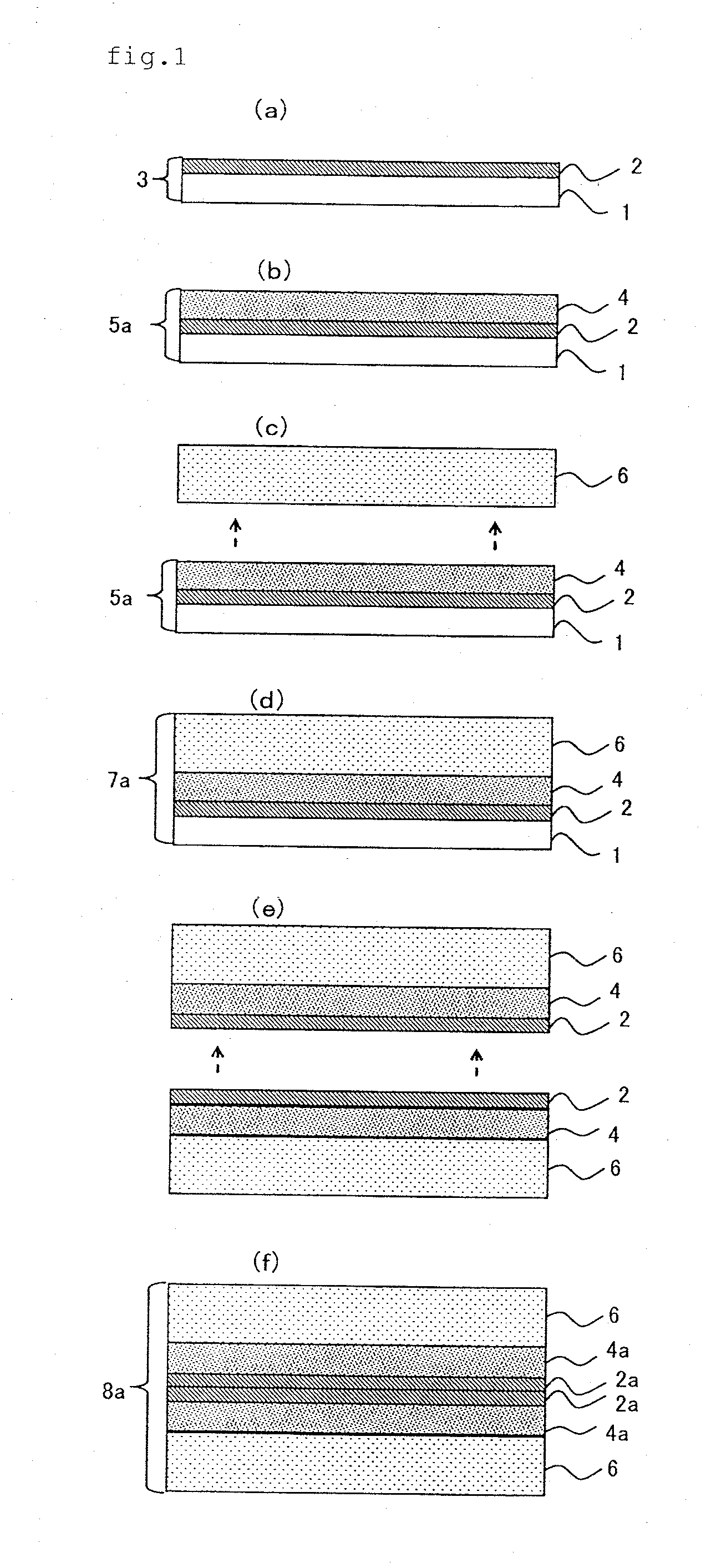

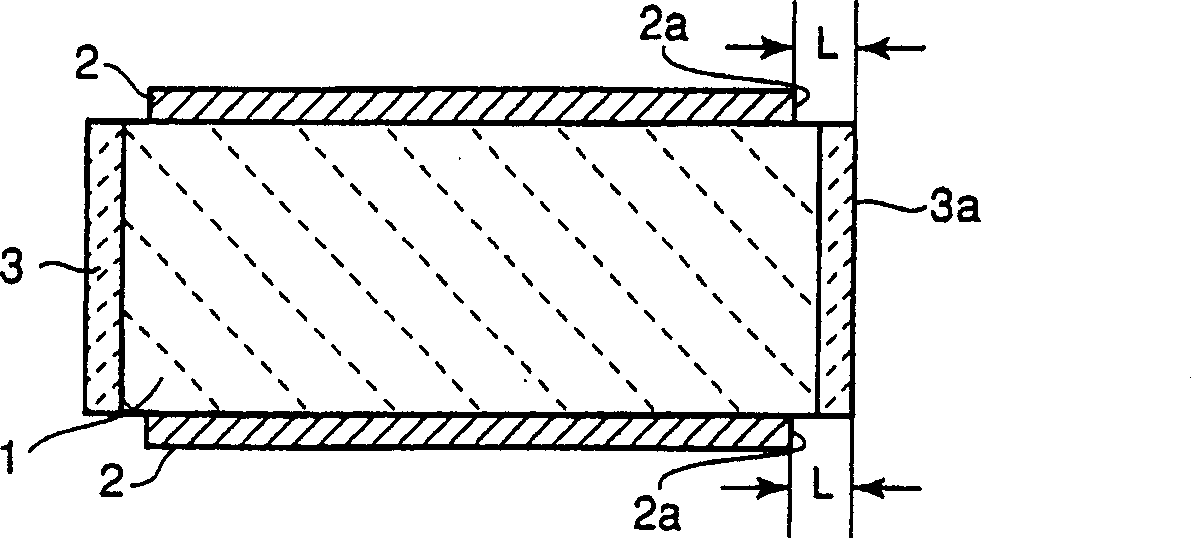

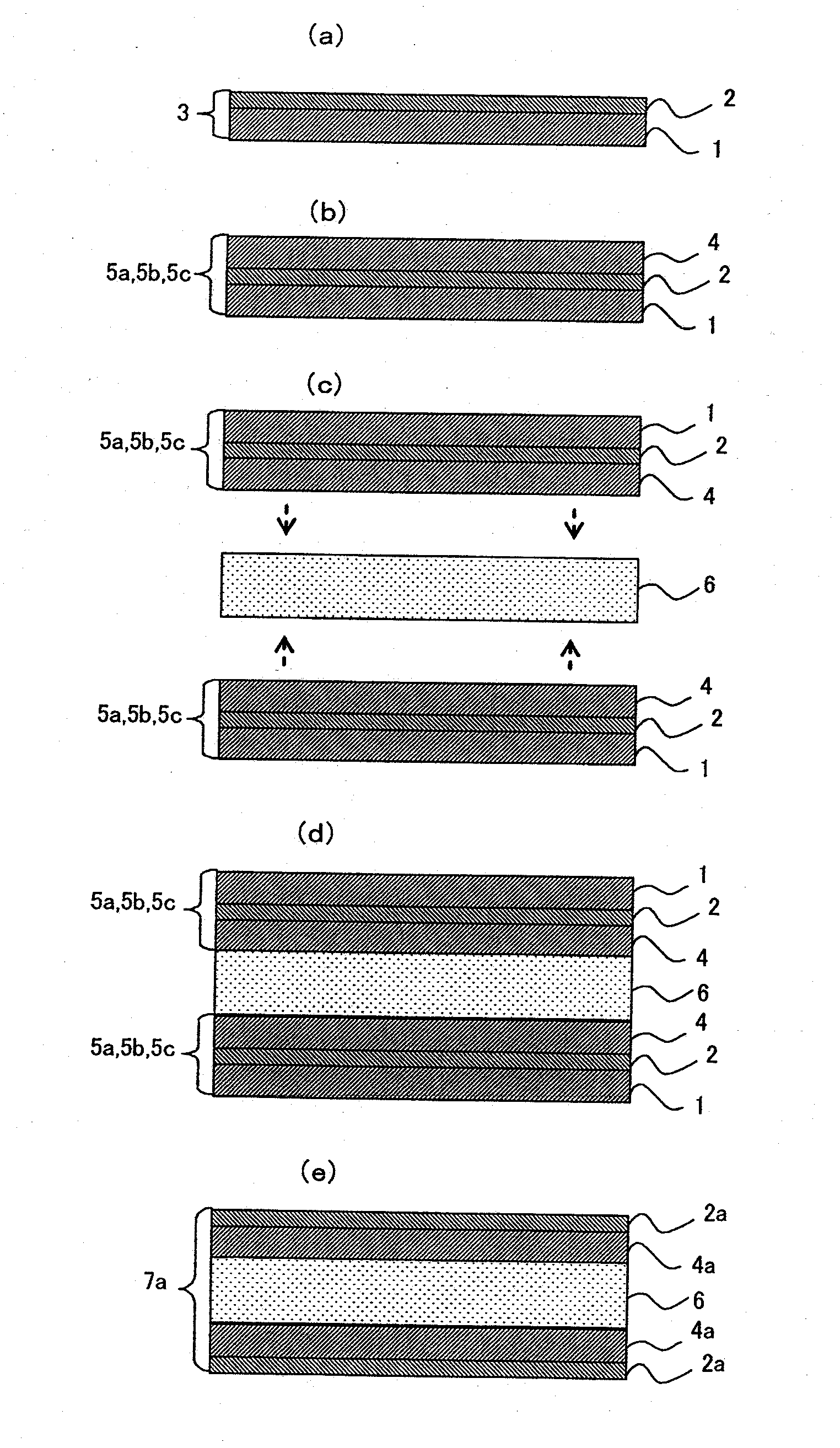

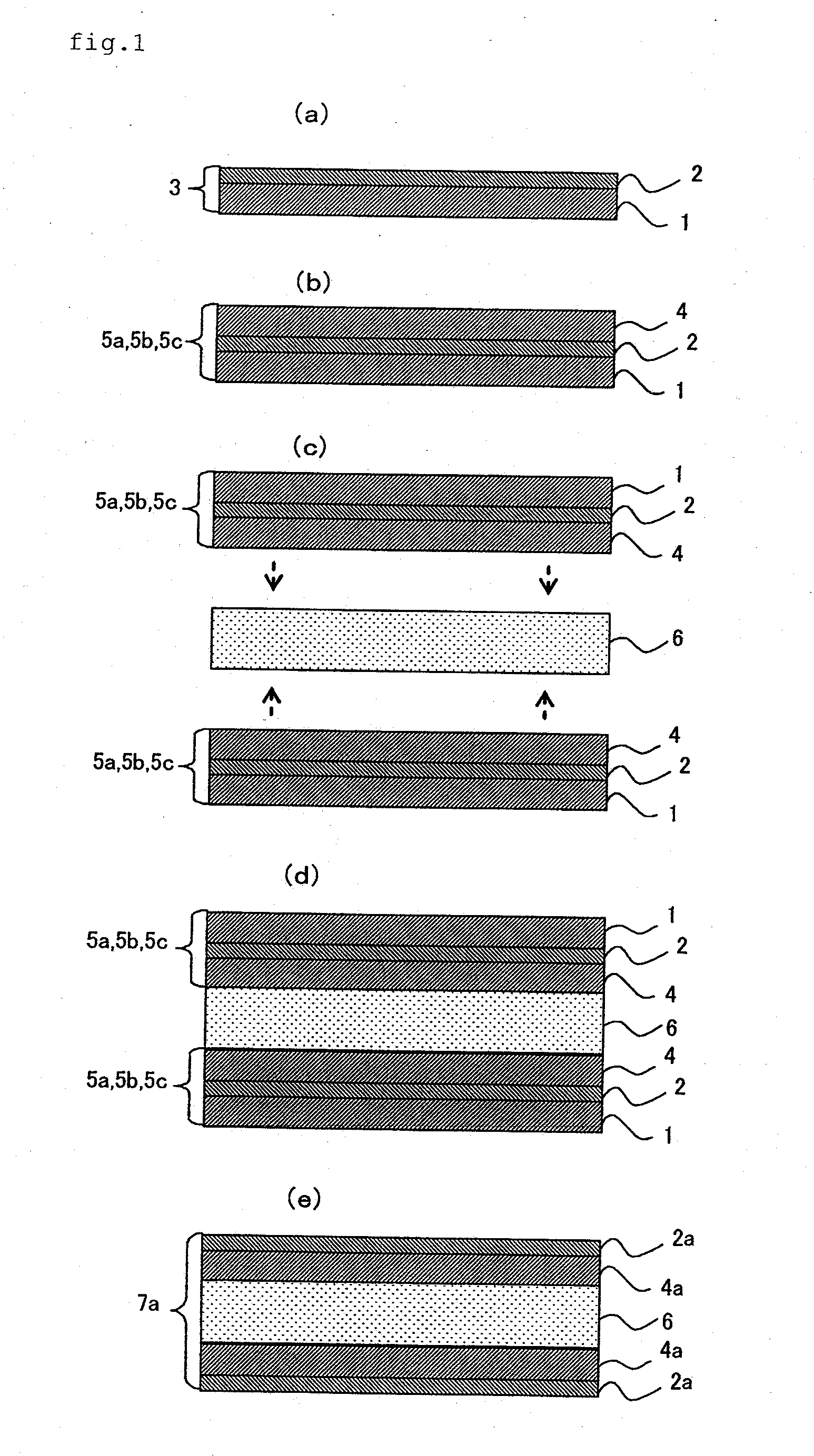

Laminate body, laminate plate, multilayer laminate plate, printed wiring board, and method for manufacture of laminate plate

InactiveUS20130112459A1Low coefficient of thermal expansionHigh elastic modulusFilm/foil adhesivesSynthetic resin layered productsInorganic fillerComposite material

A laminate body containing at least two glass substrate layers and at least one inner resin composition layer existing between the adjacent two glass substrate layers, wherein the inner resin composition layer comprises an inner resin composition that contains a thermosetting resin and an inorganic filler. A laminate plate containing at least two glass substrate layers and at least one inner cured resin layer existing between the adjacent two glass substrate layers, wherein the inner cured resin layer comprises a cured product of an inner resin composition that contains a thermosetting resin and an inorganic filler. A printed wiring board having the laminate plate and a wiring provided on the surface of the laminate plate. A method for producing the laminate plate, which comprises a cured resin layer forming step of forming a cured resin layer on the surface of a glass substrate.

Owner:HITACHI CHEM CO LTD

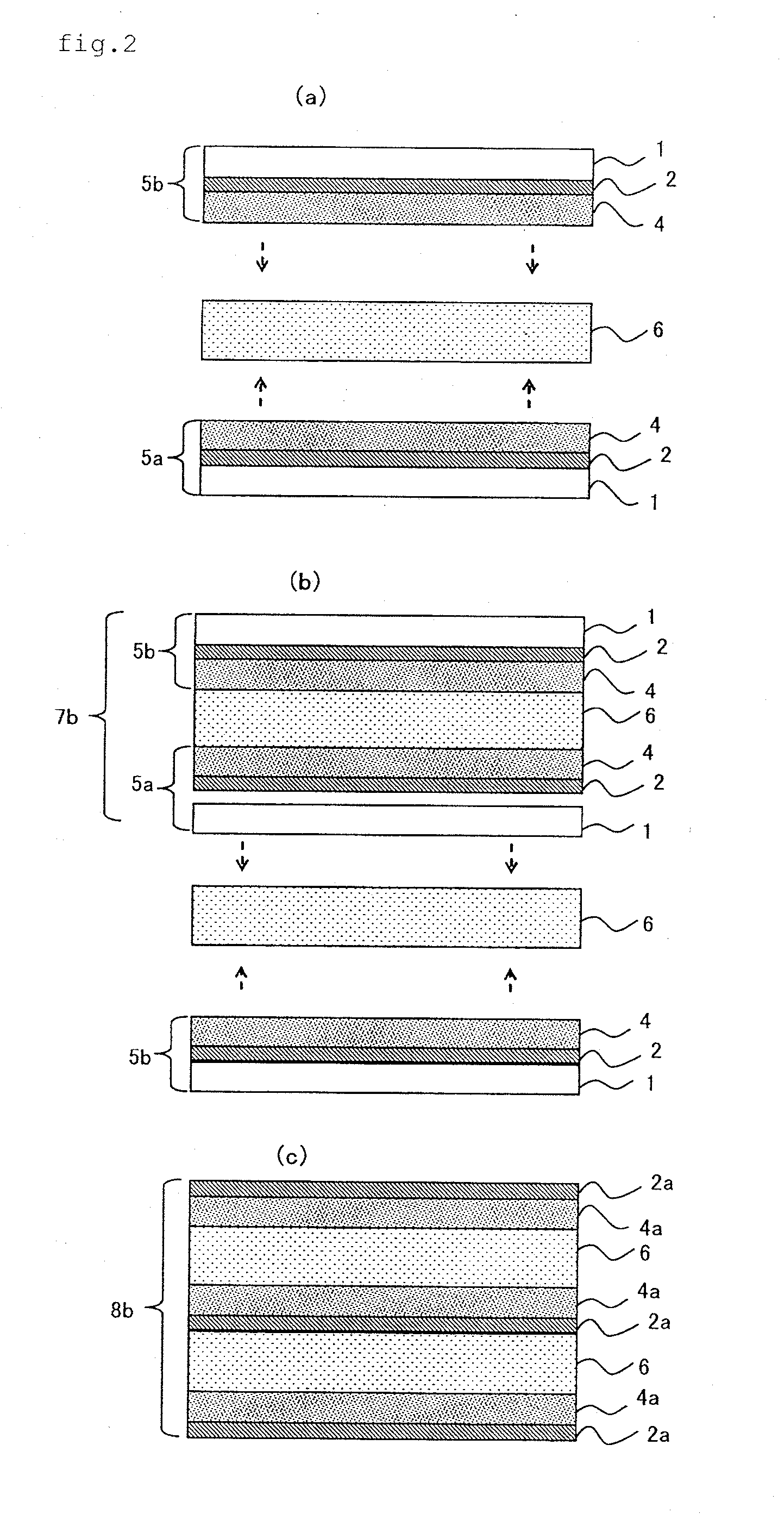

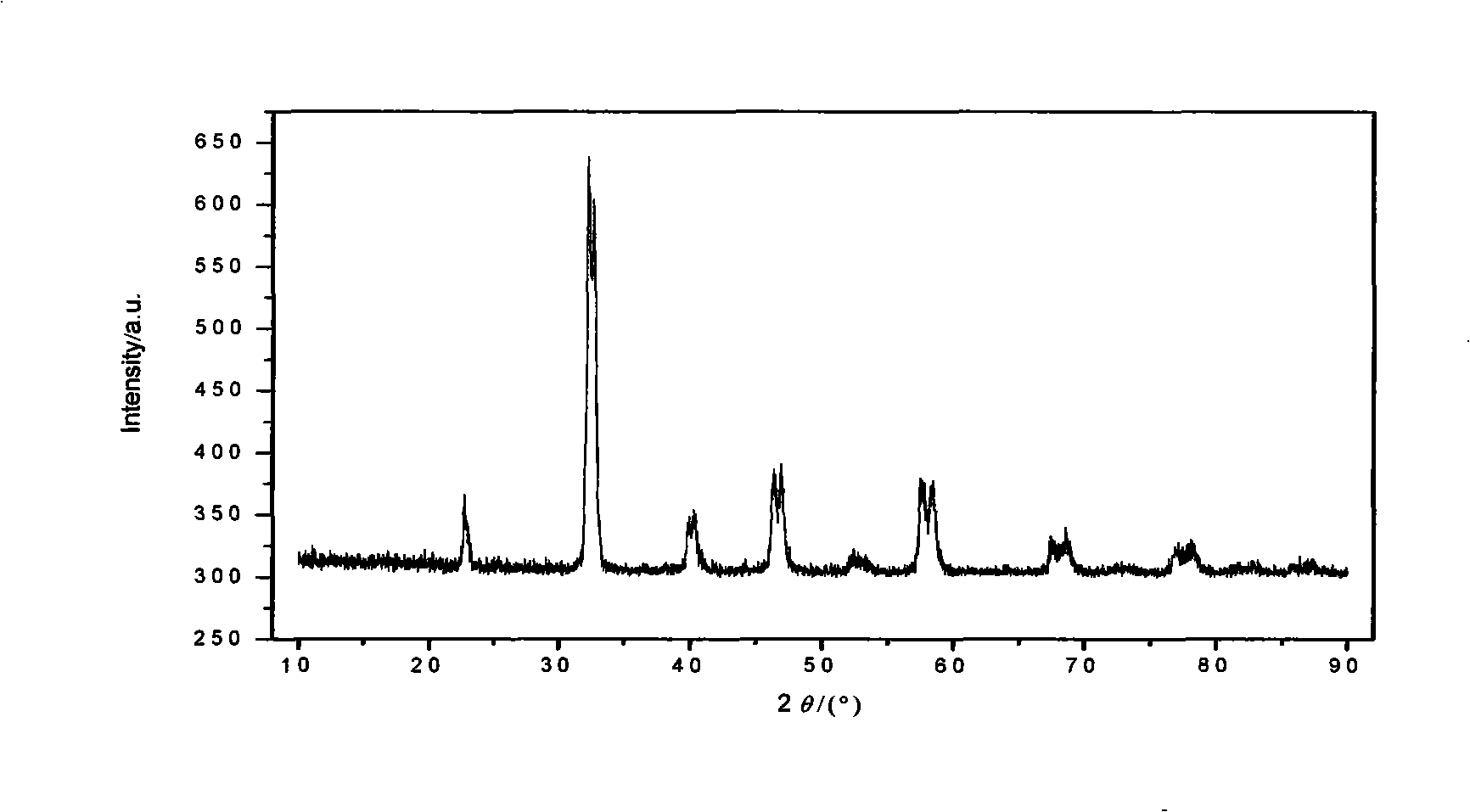

Preparation method of coal based needle coke

The invention discloses a preparation method of coal based needle coke, which comprises the following steps of: 1) adding a raw material and a diluent into a stirring kettle, stirring and separating out the solvent insoluble matter; 2) heating the mixed liquid in a 1# tubular heating furnace, and feeding the mixed liquid into a pressing hot filtration kettle; 3) filtering, filling an inert gas, pressing and performing hot filtration; 4) performing centrifugal filtration of the filtrate, and feeding the obtained purified raw material into a purified raw material tank; 5) heating the purified raw material in the 1# tubular heating furnace and performing reaction tower circular condensation polymerization, fractionating the escape component to obtain gas, light oil and heavy oil, and recycling the light oil; 6) heating the condensation polymerization concentrate in a 2# tubular heating furnace, coking by a coke tower to obtain coke, and feeding the coke oil gas into a reaction tower; and 7) feeding the prepared green coke into a calcinator, heating and calcining to obtain the product needle coke. The content of quinoline insoluble (QI) in the prepared refined purified asphalt is less than 0.15%, the yield is improved by 10-20%, the coefficient of thermal expansion of the needle coke is low, the pipeline blockage can be avoided, and the material reaction is uniform.

Owner:SHAANXI COAL & CHEM TECH INST

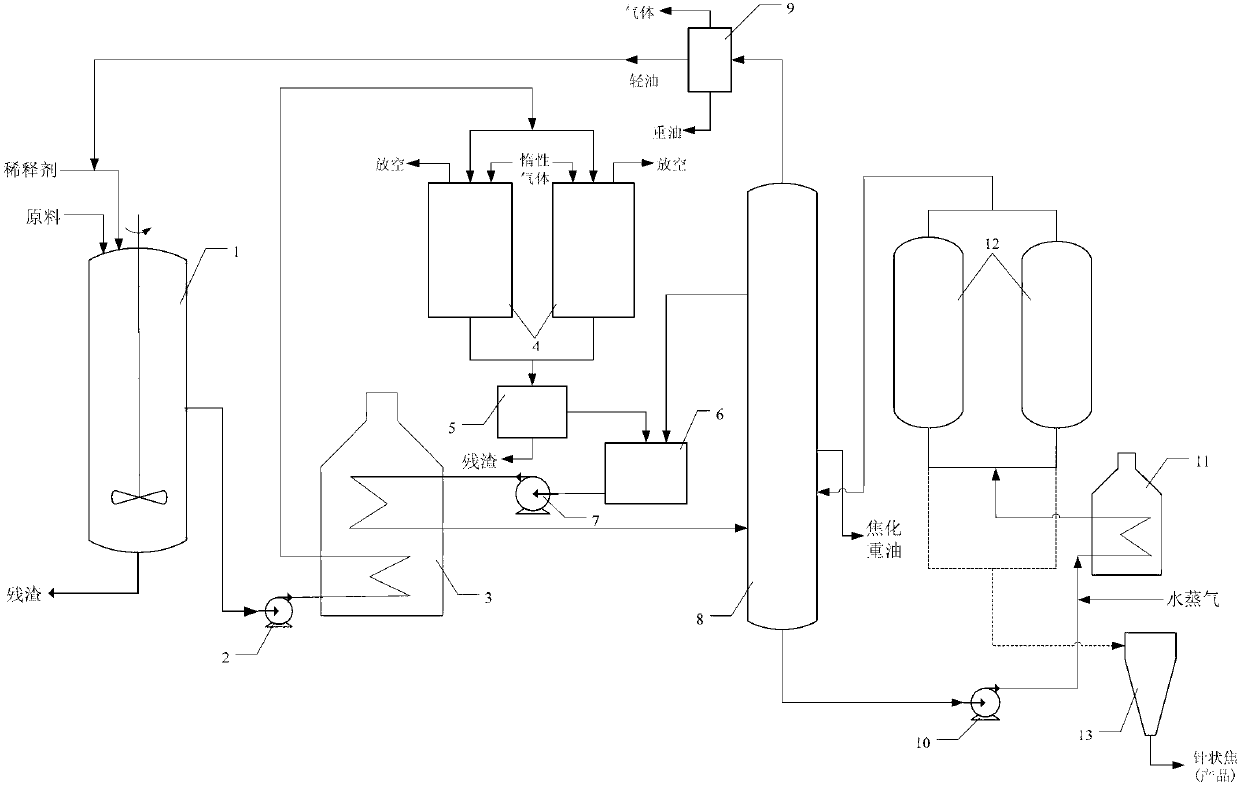

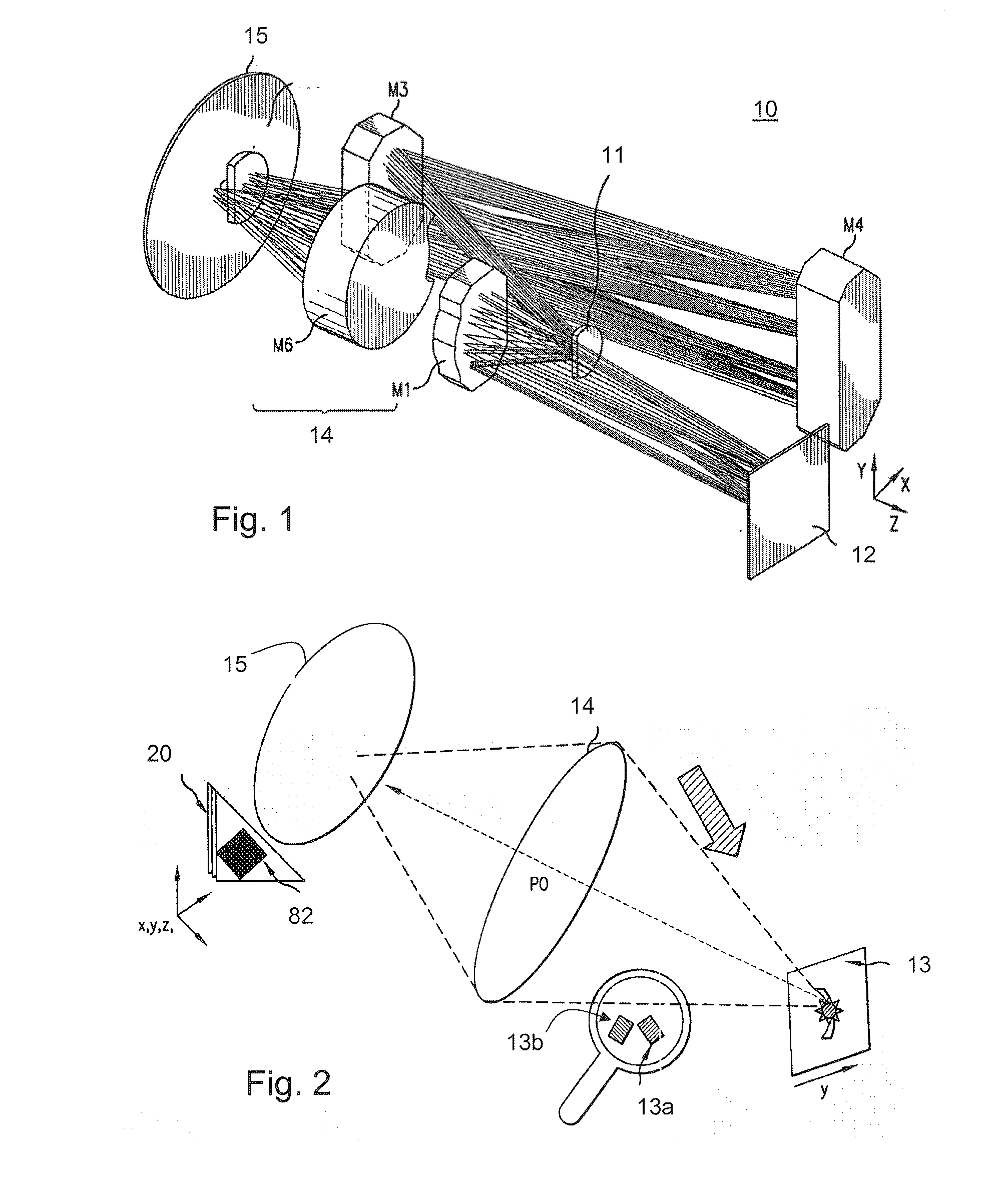

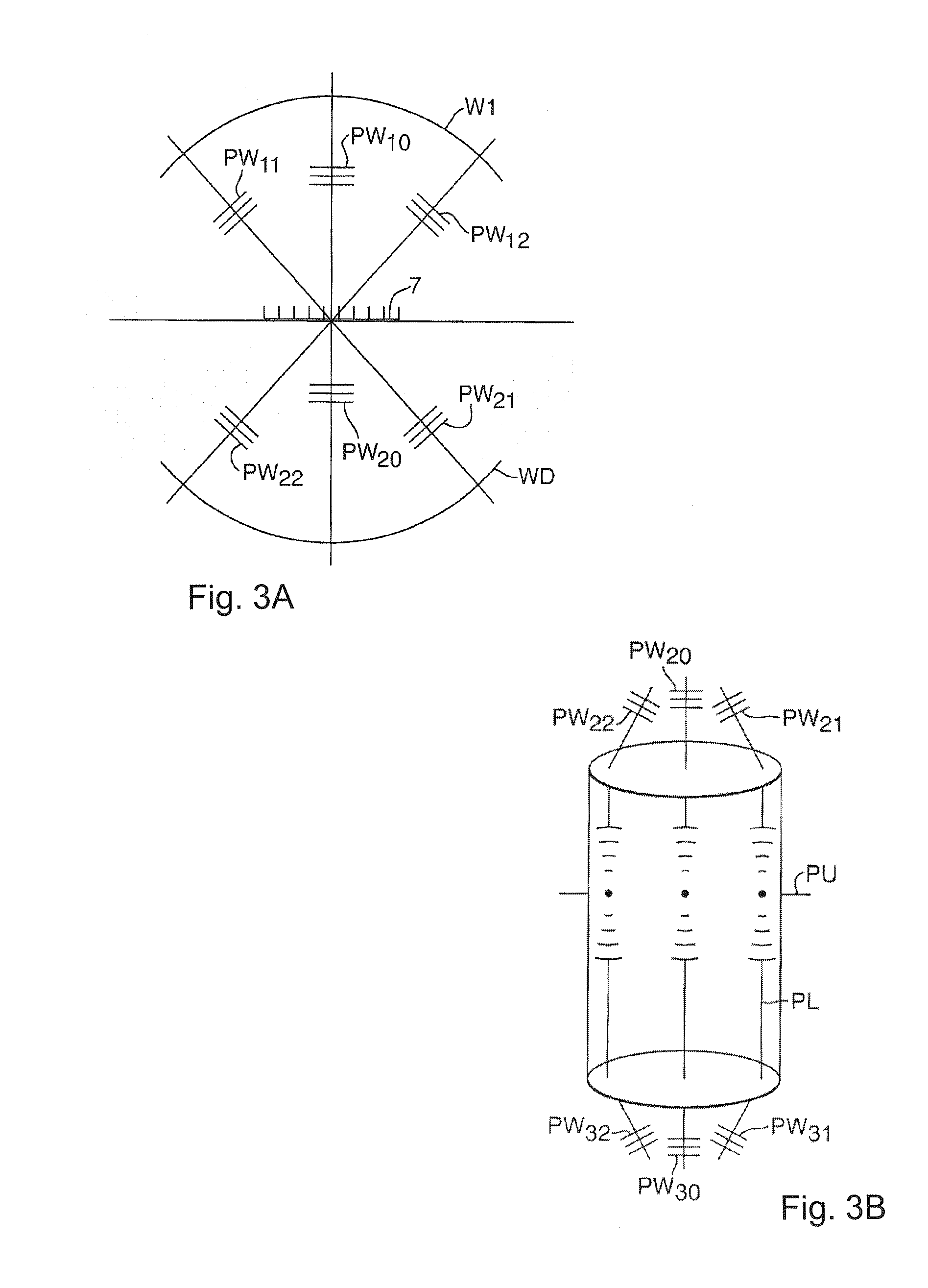

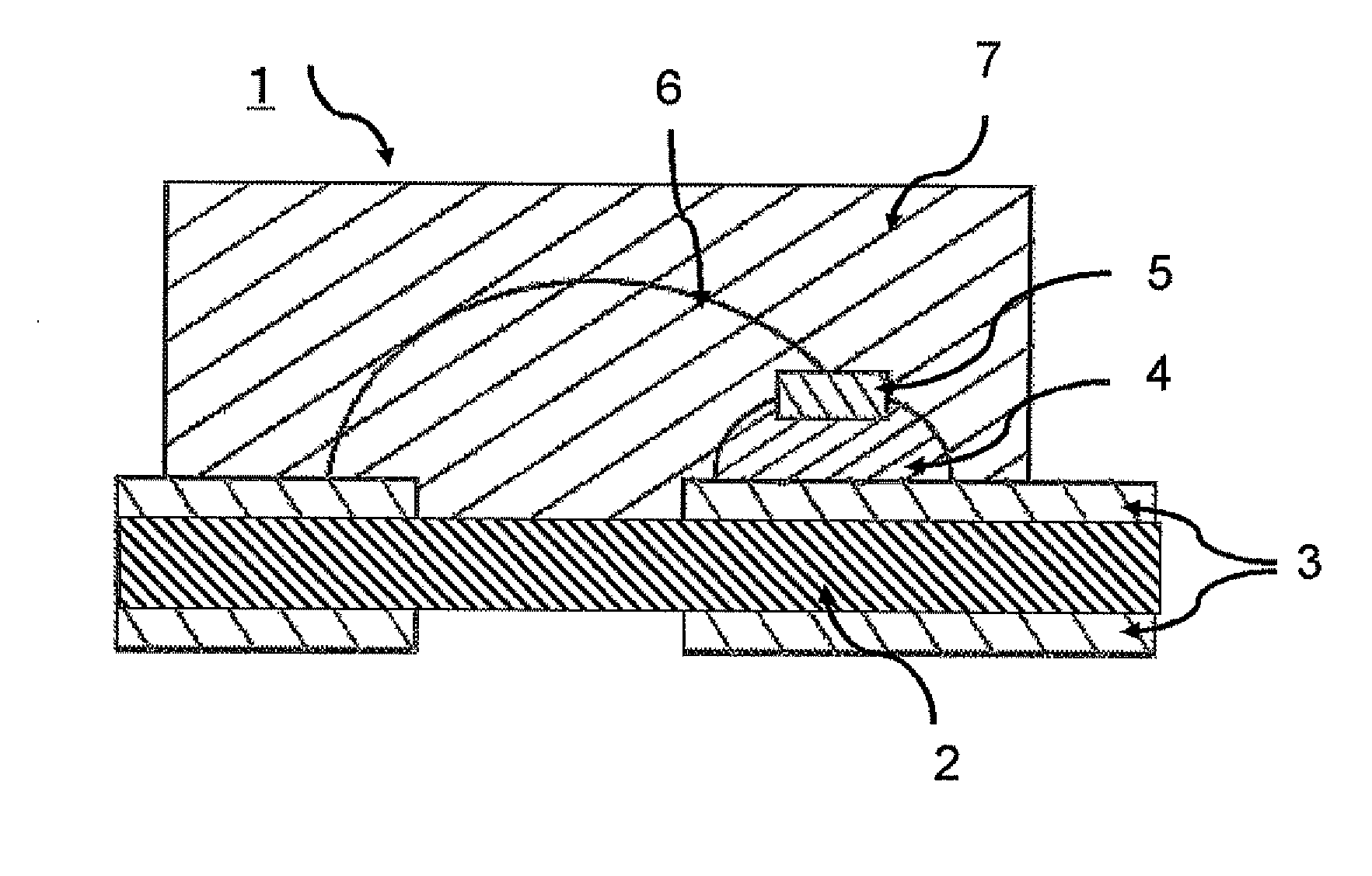

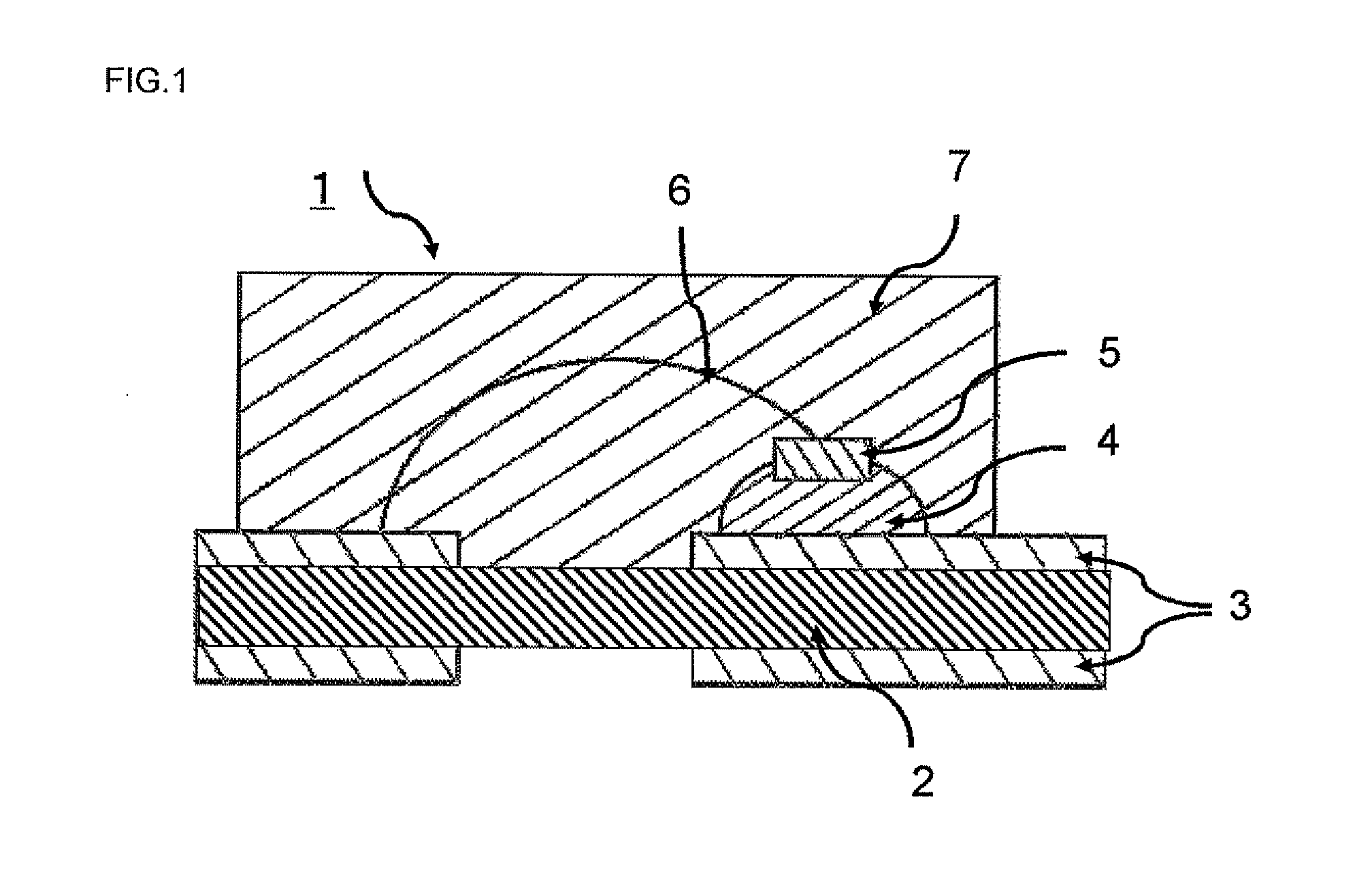

Cooling Device, Cooling Arrangement and Lithographic Apparatus Comprising a Cooling Arrangement

ActiveUS20100259734A1Easy to assembleImprove heat transfer performanceSemiconductor/solid-state device detailsSolid-state devicesEngineeringThermal contact

A cooling arrangement is described and includes a heat sink having a first thermal contact surface, an object having a second thermal contact surface and a resilient wall. The first thermal contact surface and the second thermal contact surface face each other and define a gap. The resilient wall is part of an enclosure that surrounds a space at least comprising the gap, and the cooling arrangement includes a facility to maintain a pressure difference between the space and an environment of the cooling arrangement. Additionally, a lithographic apparatus comprising such a cooling arrangement is described.

Owner:ASML NETHERLANDS BV

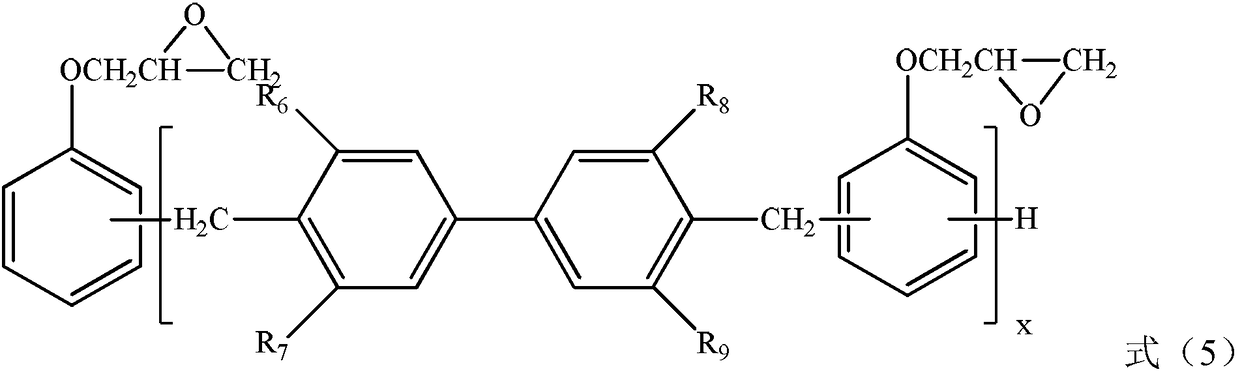

Resin composition for optical film and optical film using the same

ActiveUS20140036363A1Improve heat resistanceHigh transparencyPolarising elementsChemistryImage display

Provided are a resin composition for an optical film including an alkyl(meth)acrylate unit, a benzyl(meth)acrylate unit, a (meth)acrylic acid unit, and a unit expressed by Chemical Formula I, an optical film, a polarizing plate, and an image display device using the resin composition.

Owner:LG CHEM LTD

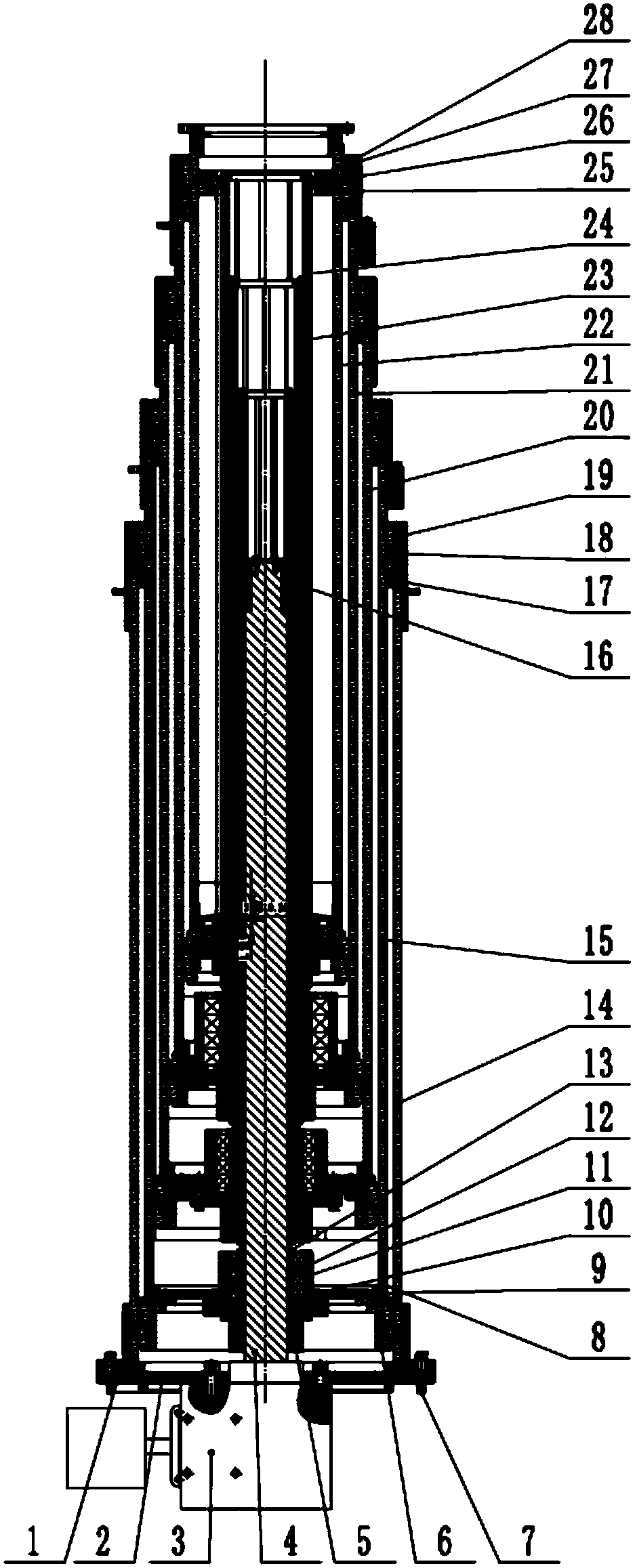

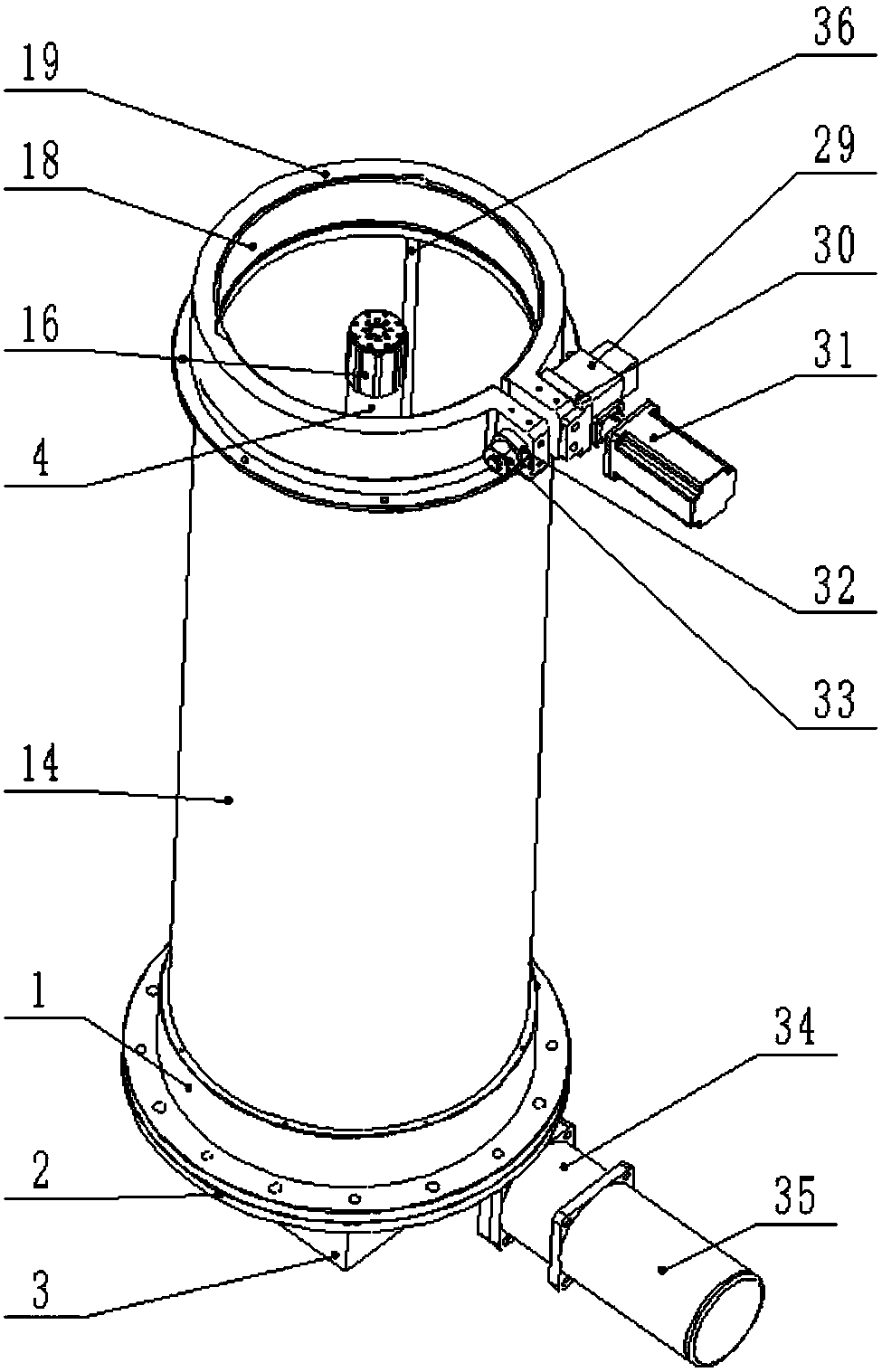

Multistage synchronous lifting device based on carbon fiber barrels

ActiveCN108408645ARealize automatic lifting operationImprove stabilityLifting framesFiberCarbon fibers

The invention provides a multistage synchronous lifting device based on carbon fiber barrels. Lifting power is provided by multiple stages of sleeve type stepped lead screws, torque is transferred among the lead screws through internal and external splines adopted for the lead screws, a main body supporting barrel is made from carbon fiber materials, a guide rail structure is embedded into the main body supporting barrel in the circumferential direction, lifting rather than rotation of carbon fibers is achieved through a guide assembly through the cooperation of the guide rail structure and aguide assembly installed on the previous stage of carbon fiber barrel, and therefore torque transferred to lead screw nuts when the lead screws ascend and descend is eliminated. A motor is adopted todrive a worm wheel and a worm to achieve holding and looseness of a holding ring of a locking mechanism, and sensing value changes of a pressure sensor are adopted as feedback signals to automaticallycontrol holding and looseness of the holding ring. The bottom of each stage of lifting barrel is provided with a guide assembly to be matched with the inner wall of the next carbon fiber barrel, a guide ring is installed inside a holding ring installed on the next carbon fiber barrel to be matched with the outer wall of the corresponding lifting barrel, and two-stage guide for lifting of the corresponding carbon fiber barrel is achieved. In the whole device, the motor is adopted to drive a worm gear reducer for driving, and the whole device has the advantages of being good in stability, low in heat expansion coefficient, automatic in lifting, free of disassembly and assembly and convenient to transport.

Owner:BEIJING CHANGCHENG INST OF METROLOGY & MEASUREMENT AVIATION IND CORP OF CHINA

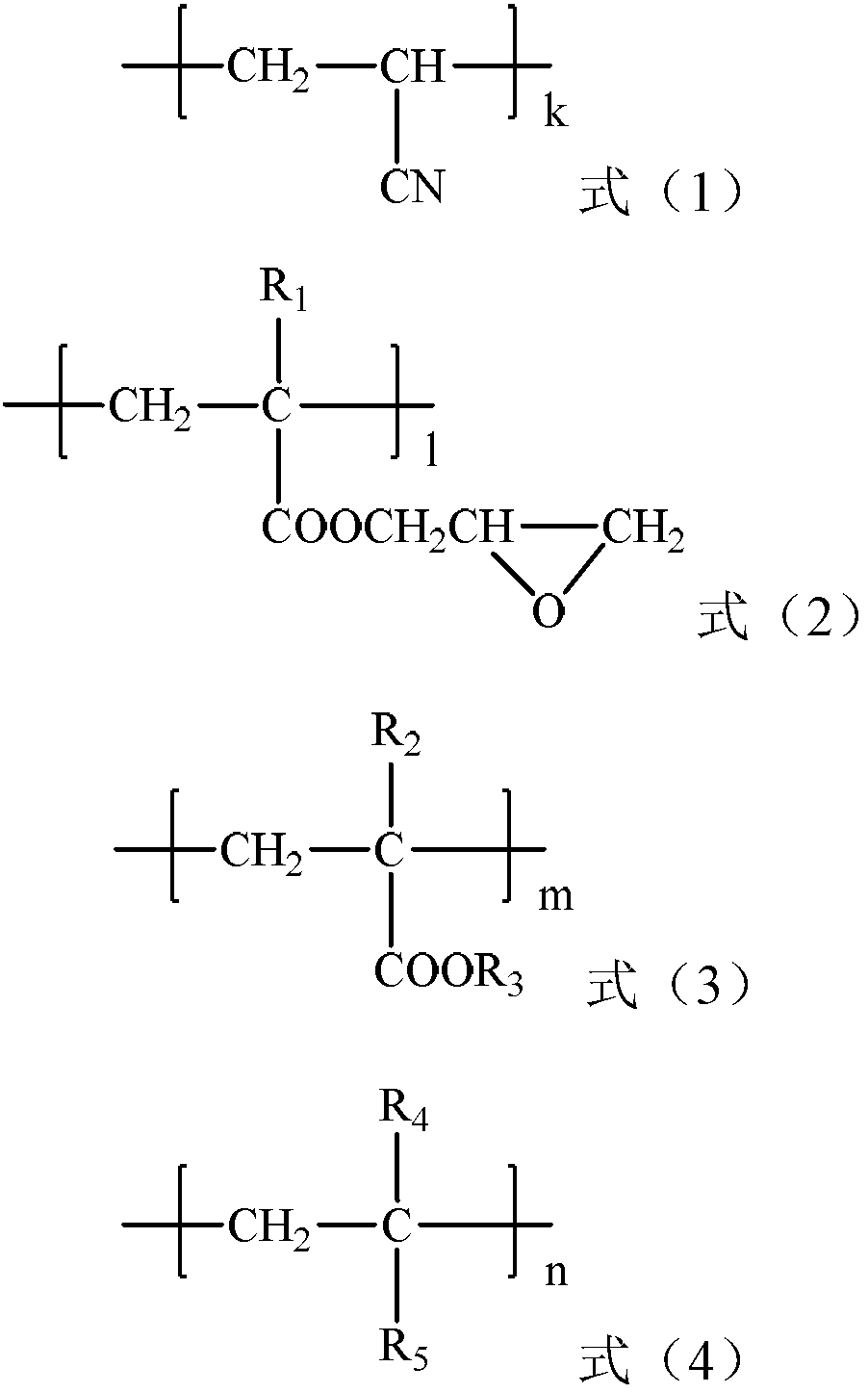

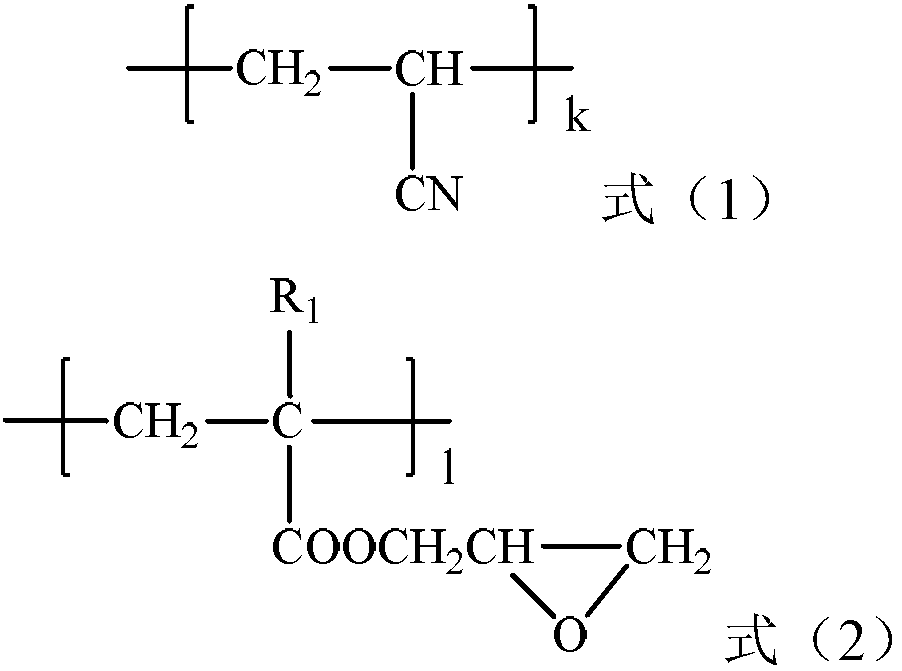

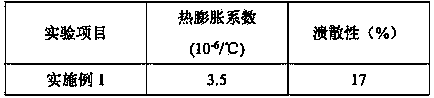

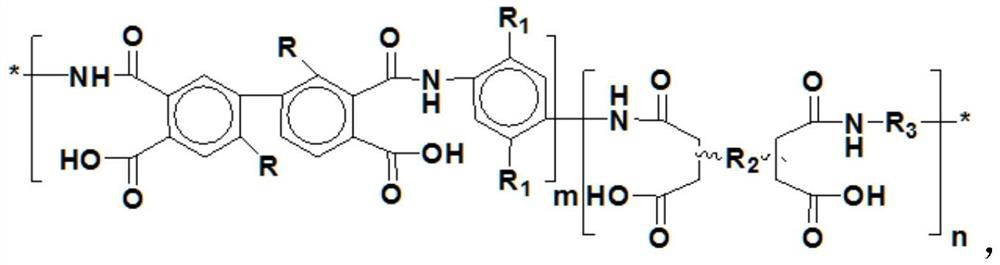

Resin composition, prepreg, laminated board and metal foil-coated laminated board

ActiveCN108239372AImprove heat resistanceExcellent heat and humidity resistanceSynthetic resin layered productsGlass/slag layered productsMetal foilFilling materials

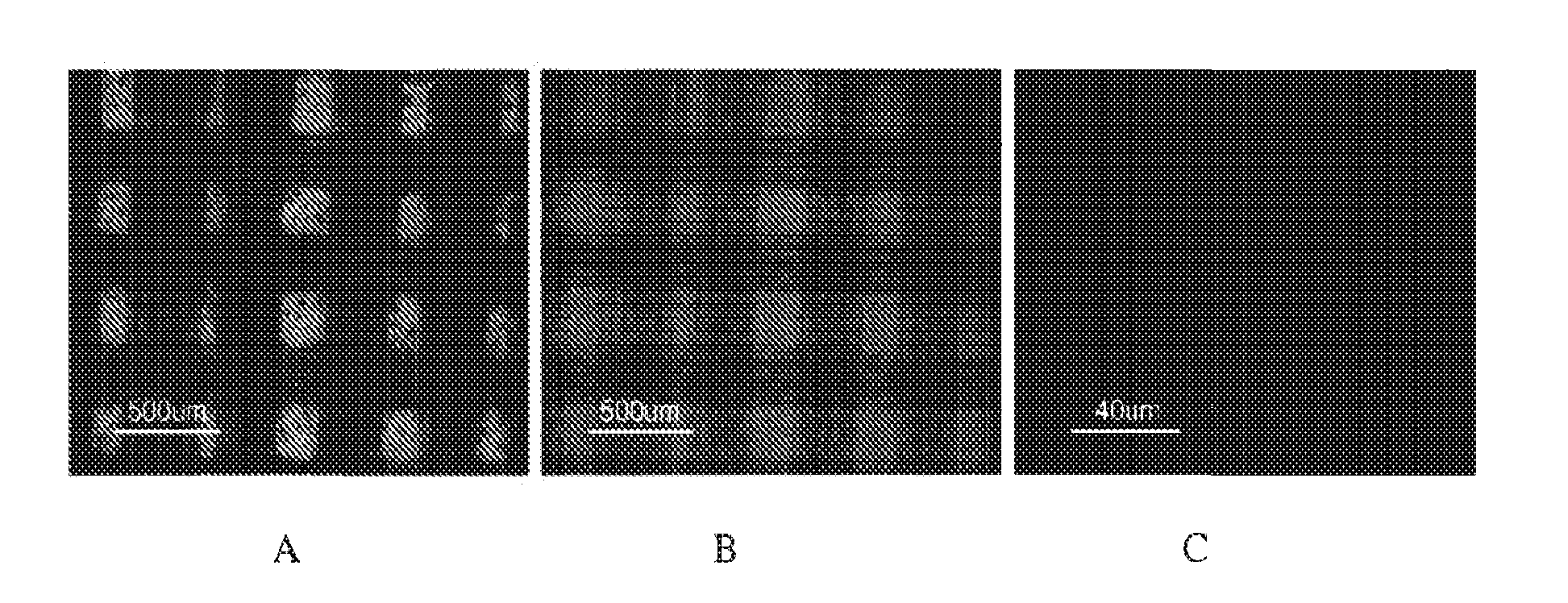

The invention provides resin compositions. Prepreg, a laminated board and a metal foil-coated laminated board which are obtained by using the resin compositions have good heat resistance, heat and humidity resistance, low coefficient of thermal expansion and low modulus. The resin compositions contain epoxy resin (A), cyanate resin (B) and bismaleimide resin (C), have structures represented by a formula (1), a formula (2), a formula (3) and a formula (4), and contain high-molecular-weight resin (D) with a weight-average molecular weight of 100,000-200,000 and inorganic filler (E).

Owner:GUANGDONG SHENGYI SCI TECH

Preparation method of copper-based composite material for cylinder sleeve

InactiveCN106367695ALow coefficient of thermal expansionFast heat conductionTransportation and packagingVacuum evaporation coatingFiberCarbon fibers

The invention discloses a preparation method of a copper-based composite material for a cylinder sleeve. The preparation method sequentially comprises the following steps that 1, raw materials are weighed, specifically, the raw materials include, by weight, 15 parts of copper-plated carbon nano tubes, 15 parts of copper-plated grapheme, 30 parts of copper-plated carbon fibers, 2.5 parts of nickel powder, 10 parts of Fe powder and 210 parts of copper powder, then 5 parts of lubricating agents are added to the raw materials, ball-milling mixing is carried out for eight hours, and then a mixture is obtained; 2, the mixture prepared in the step 1 is pressed at the pressure of 750 Mpa, and a blank is obtained; 3, the blank prepared in the step 2 is subjected to secondary sintering, and an alloy block is obtained after sintering; and 4, the alloy block treated in the step 3 is subjected to thermal treatment, and then the copper-based composite material for the cylinder sleeve is obtained. The method adopts a specific formula and process, and the obtained cylinder sleeve has the advantages of low coefficient of thermal expansion, good heat conduction property, high high-temperature strength and good wear resistance.

Owner:NINGBO XINMU NEW MATERIALS

Non-linear voltage resistance

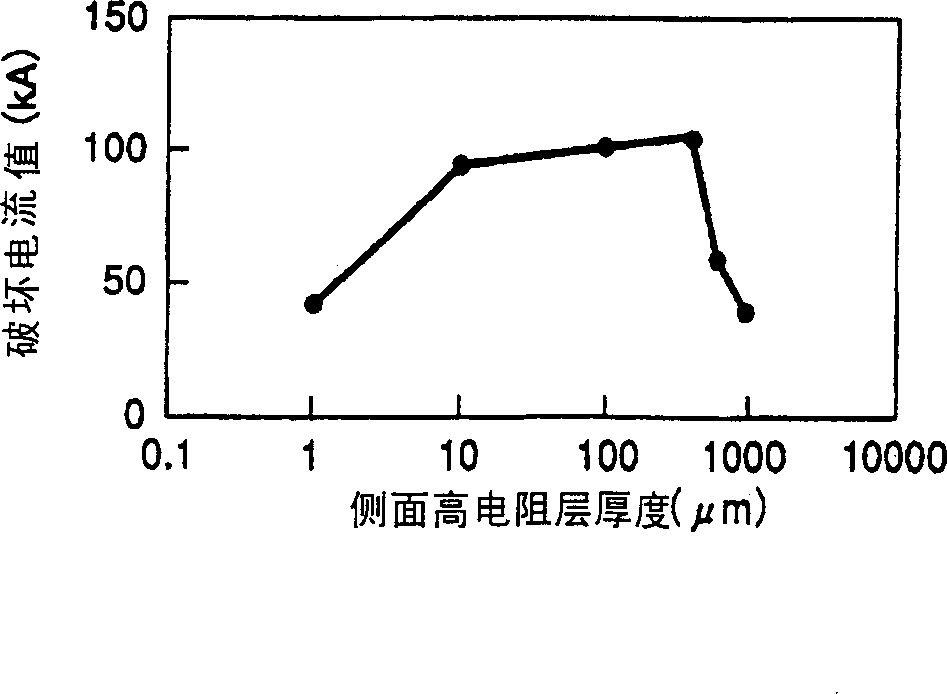

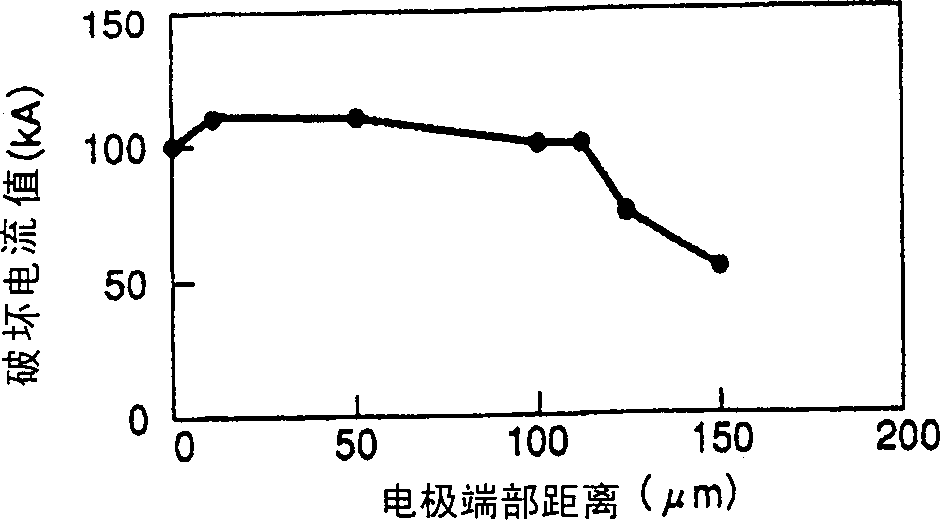

InactiveCN1340830AImprove energy absorptionImprove featuresVaristor coresOvervoltage protection resistorsNonlinear resistorHigh resistance

A voltage nonlinear resistor has a voltage nonlinear resistive body including zinc oxide, and a side face high-resistance layer provided on the side face of the resistive body. and the side high-resistance layer is made mainly of Bi(bismuth) and contains Zn(zinc), B(boron), Si(silicon), Al(aluminum), and Ba(barium) which lie within the ranges of ZnO=1.0-25 wt.%, B2O3=1.0-10 wt.%, SiO2=0.1-5 wt.%, Al2O3=0.05-3 wt.%, and BaO=0.05-3 wt.% in terms of oxides.

Owner:KK TOSHIBA

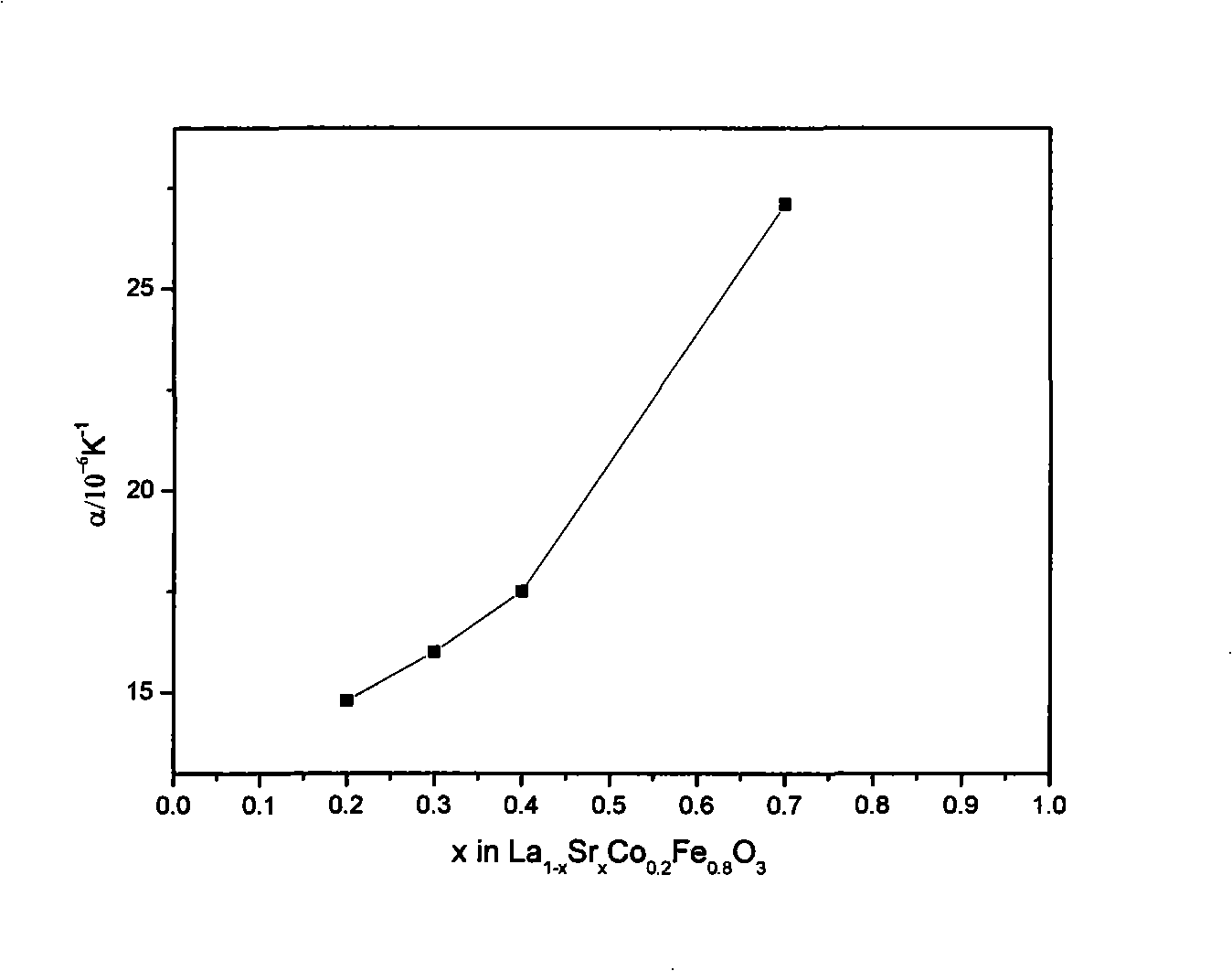

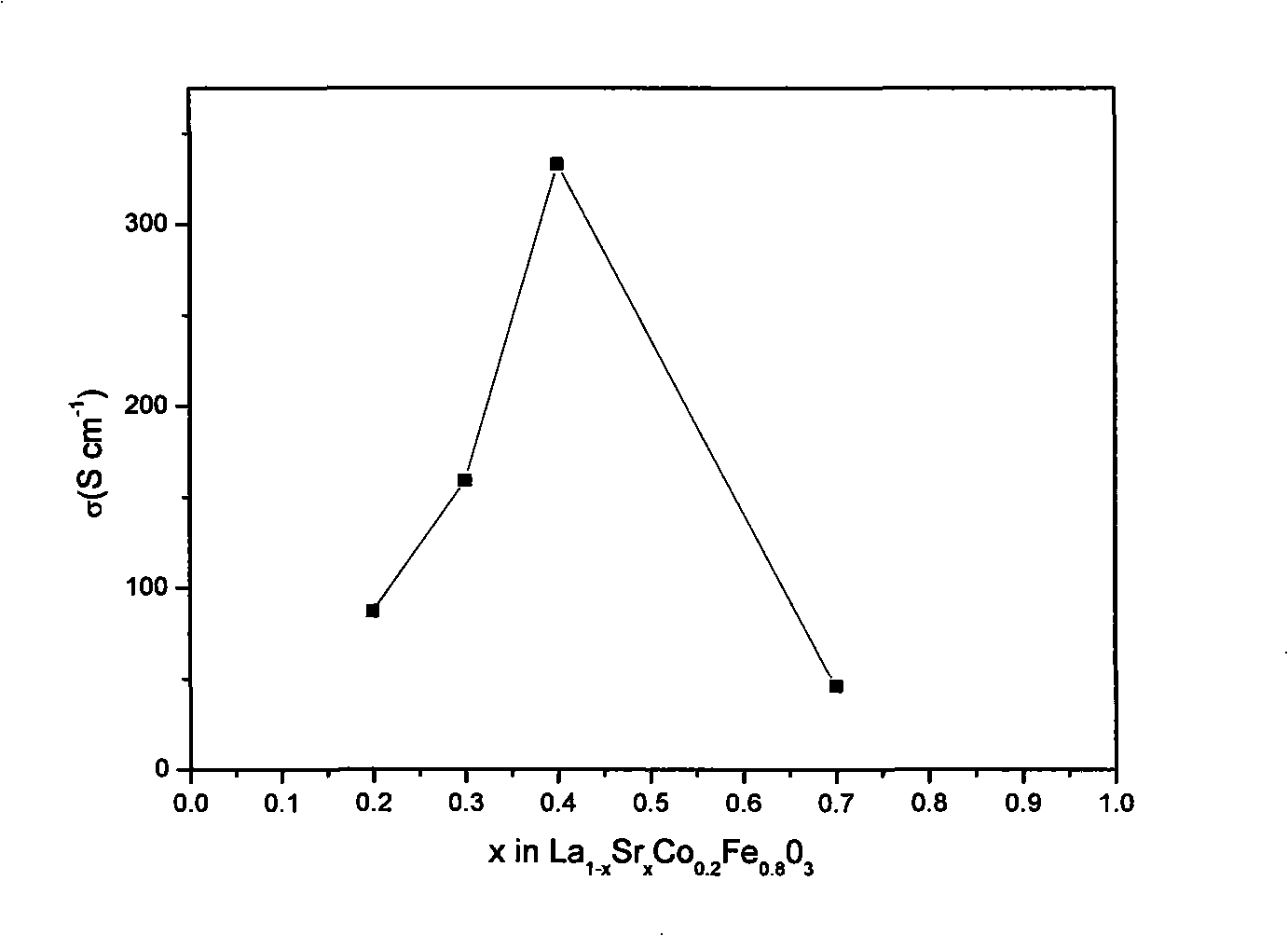

Process for synthesizing biphase nanometer fuel battery cathode material

InactiveCN101257120AImprove performanceHigh non-stoichiometric oxygenCell electrodesRare earth metal compoundsEthylenediamineReaction temperature

The invention relates to a synthetic method for a duplex nanometer fuel cell cathode material which has characteristics in including steps as follows: (1) confecting soluble salt solution according with required confecting rate for synthetic cathode material; (2) confecting complexing agent solution using edta, citric acid as main raw material; (3) mixing the solution obtained by the steps (1) and (2), adding suitable ethylene glycol, heating and beating in constant temperature, then obtaining sol; (4) drying obtained sol in drying box, and obtaining gel; (5) processing obtained gel, and changing particle specific surface size, then synthesis the duplex nanometer cell cathode material under given temperature. The method has advantages in that: synthetic method is simple, reaction temperature is lower than solid phase method, nanometer particle is mechanical mixed simply different from duplex, and has better uniformity on microcosmic interface, and is favorable for improving cathode material property.

Owner:郭道传

High-volume diamond reinforced metal-based composite material and preparation method and application thereof

ActiveCN111471978AImprove wettabilityMaintain high thermal conductivityChemical vapor deposition coatingMetal matrix compositeThermal conductivity

The invention discloses a high-volume diamond reinforced metal-based composite material and a preparation method and application thereof. The high-volume diamond reinforced metal-based composite material comprises a gradient boron-doped diamond reinforced metal-based composite material and a diamond layer strengthening phase, wherein the diamond layer strengthening phase coats the surface of the gradient boron-doped diamond reinforced metal-based composite material; the gradient boron-doped diamond reinforced metal-based composite material comprises a gradient boron-doped diamond reinforcementbody and a metal matrix; and the gradient boron-doped diamond reinforcement body comprises an undoped diamond reinforcement body and a gradient boron-doped diamond modified layer arranged on the surface of the diamond reinforcement body. According to the material, the preparation method and application thereof, the thermal conductivity is greatly improved by increasing the volume of diamond in the composite material, and meanwhile, due to the fact that a pure diamond layer is uniform in hardness, the pure diamond layer is easier to machine, and is more conveniently applied to various fields.

Owner:CENT SOUTH UNIV

Ceramsite sand used for casting and preparation method thereof

InactiveCN108405792ALow coefficient of thermal expansionLow collapse performanceFoundry mouldsFoundry coresFiberExpanded clay aggregate

The invention discloses ceramsite sand used for casting and a preparation method thereof and belongs to the field of polymer materials. The ceramsite sand used for casting comprises the following rawmaterials, aluminium oxide, silicon dioxide, boric oxide, polytetrafluoroethylene, calcium lignosulphonate and zirconium oxide fiber. The ceramsite sand used for casting is prepared by the steps of crushing, mixing, sintering and the like. According to the ceramsite sand, polytetrafluoroethylene, calcium lignosulphonate and zirconium oxide fiber are taken as a reinforcing system, so that the thermal expansivity and collapsibility of the ceramsite sand used for casting are reduced.

Owner:CHANGSHA QIUDIANBING INFORMATION TECH CO LTD

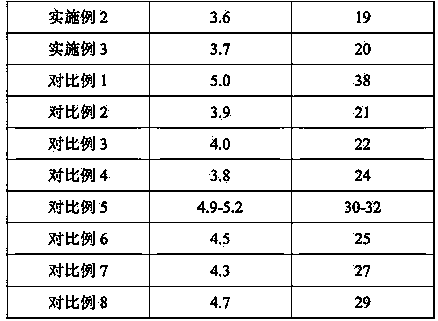

Heat-dissipating plate for high-power element

InactiveUS20180328677A1Low coefficient of thermal expansionImprove thermal conductivitySemiconductor/solid-state device detailsModifications by conduction heat transferThermal expansionThermal conductivity

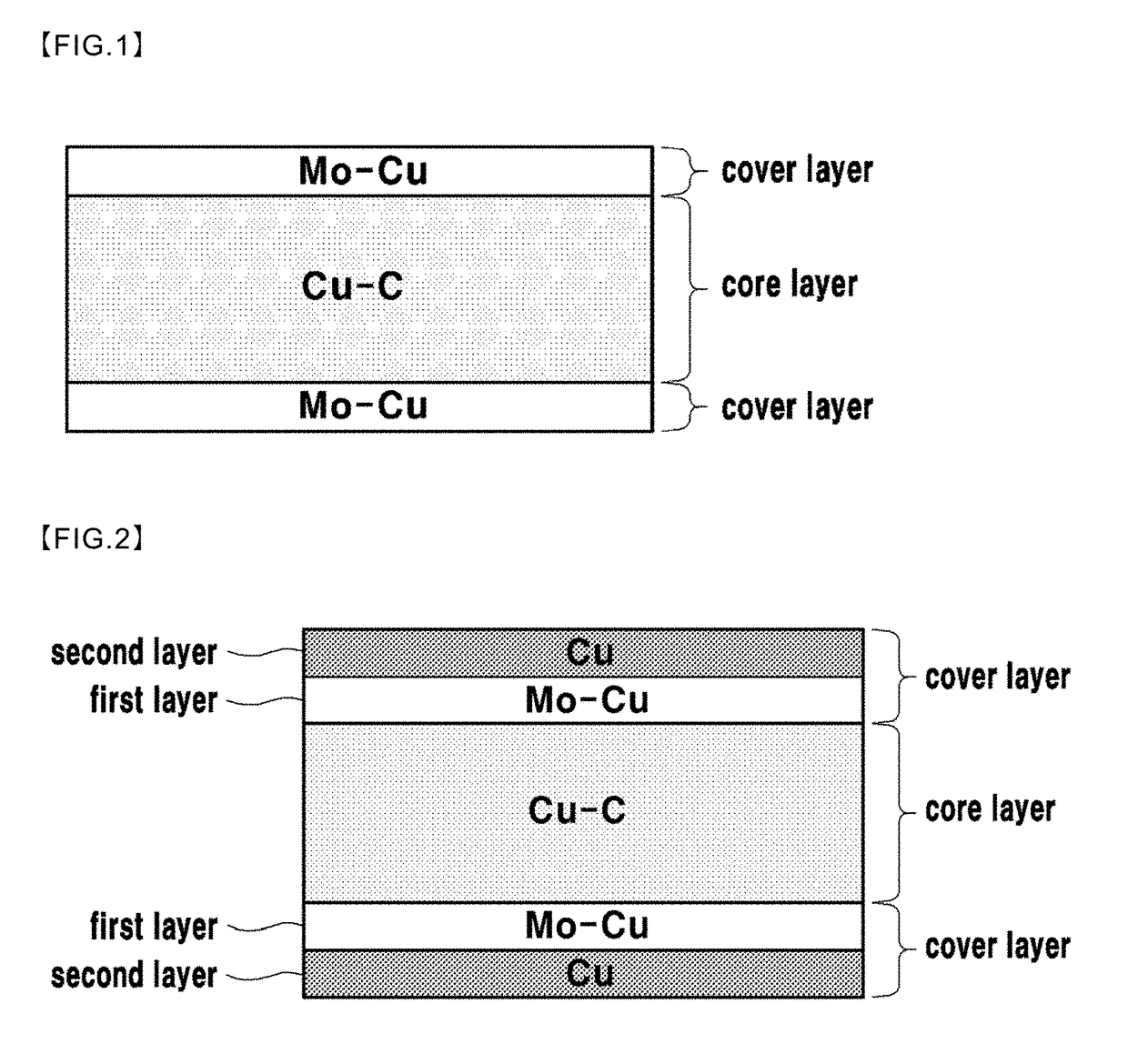

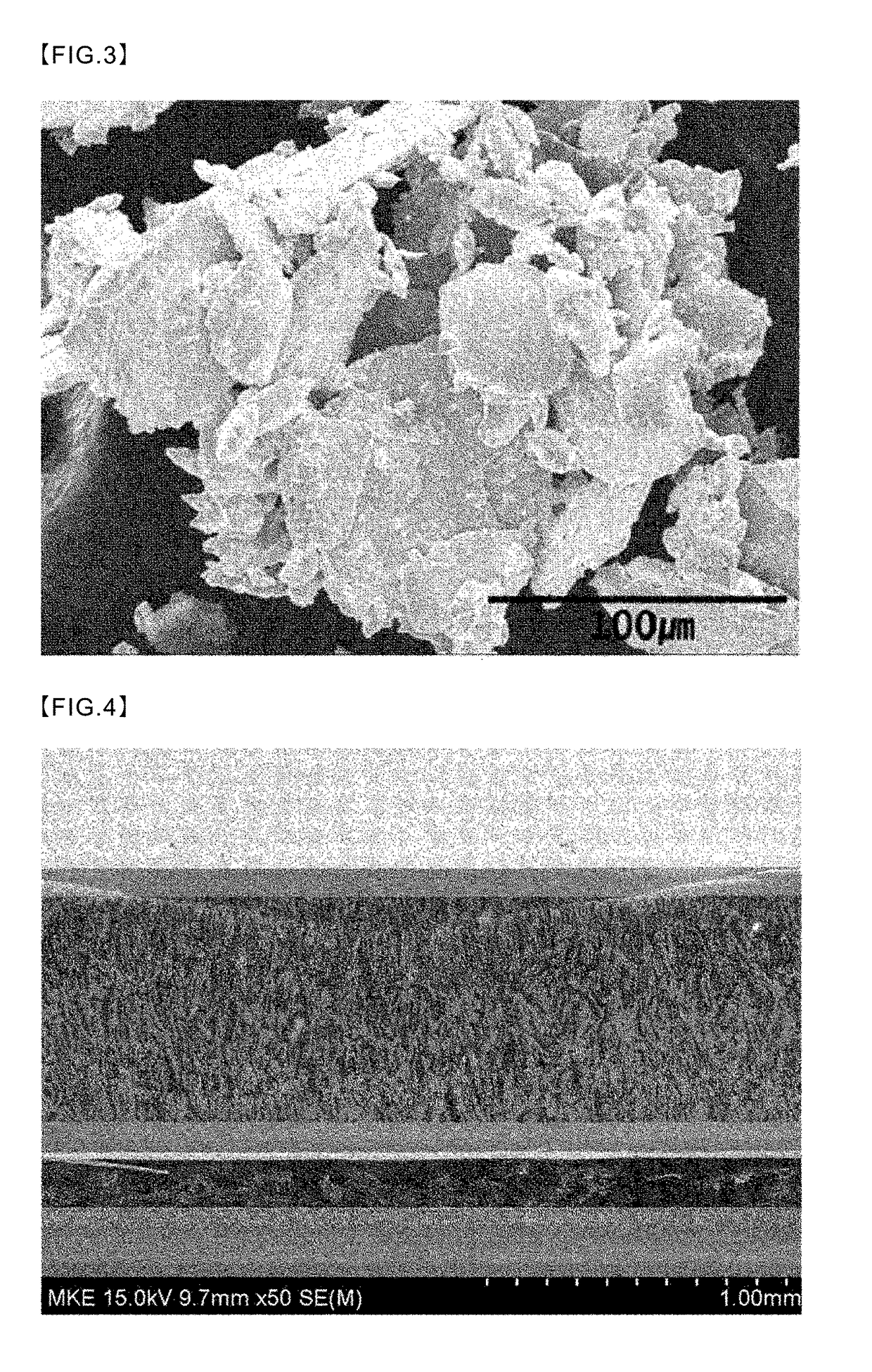

A heat-dissipating plate comprises a core layer; and two cover layers formed by being laminated on the top and bottom face of the core layer, wherein, the core layer is composed of a composite material in which a carbon phase is composited in a Cu matrix, the cover layer is composed of a Mo—Cu alloy, and the thermal conductivity in the thickness direction of the heat-dissipating plate is at least 300 W / mK, and the thermal expansion coefficient of the heat-dissipating plate in a direction perpendicular to the thickness direction is at most 9×10-6 / K.

Owner:THE GOODSYST

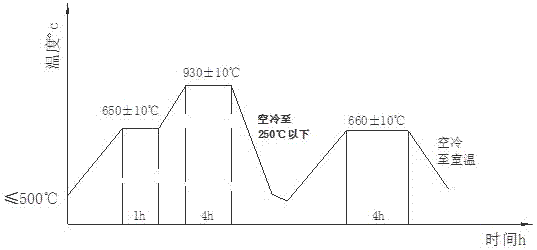

High-speed bullet train brake disc body and casting method and heat treatment method thereof

InactiveCN107354384AImprove mechanical propertiesImprove thermal conductivityBraking discsFoundry mouldsUltimate tensile strengthHeat treated

The invention discloses a high-speed bullet train brake disc body and a casting method and heat treatment method thereof. The brake disc body is obtained through casting and heat treatment, an upper disc surface and a lower disc surface of the disc body are parallel to each other, and the upper disc surface and the lower disc surface of the disc body are connected through a plurality of U-shaped blocks which are uniformly distributed. According to the physical design of the disc body, a good balance degree of the disc body during high-speed rotation is guaranteed, and the amplitude during high-speed braking of the brake disc is greatly reduced; according to the design of the casting technique of the disc body, the quality of the disc body is greatly improved, and a high safety coefficient and a long service life of the disc body in long-time continuous braking are guaranteed; and according to the design of the heat treatment technology, the strength and the impact to be borne by the disc body during high-speed braking under the extremely-cold environment are reduced, and the thermal warping deformation generated in the continuous braking process is also reduced.

Owner:JIANGSU JINSHI CASTING & FORGING

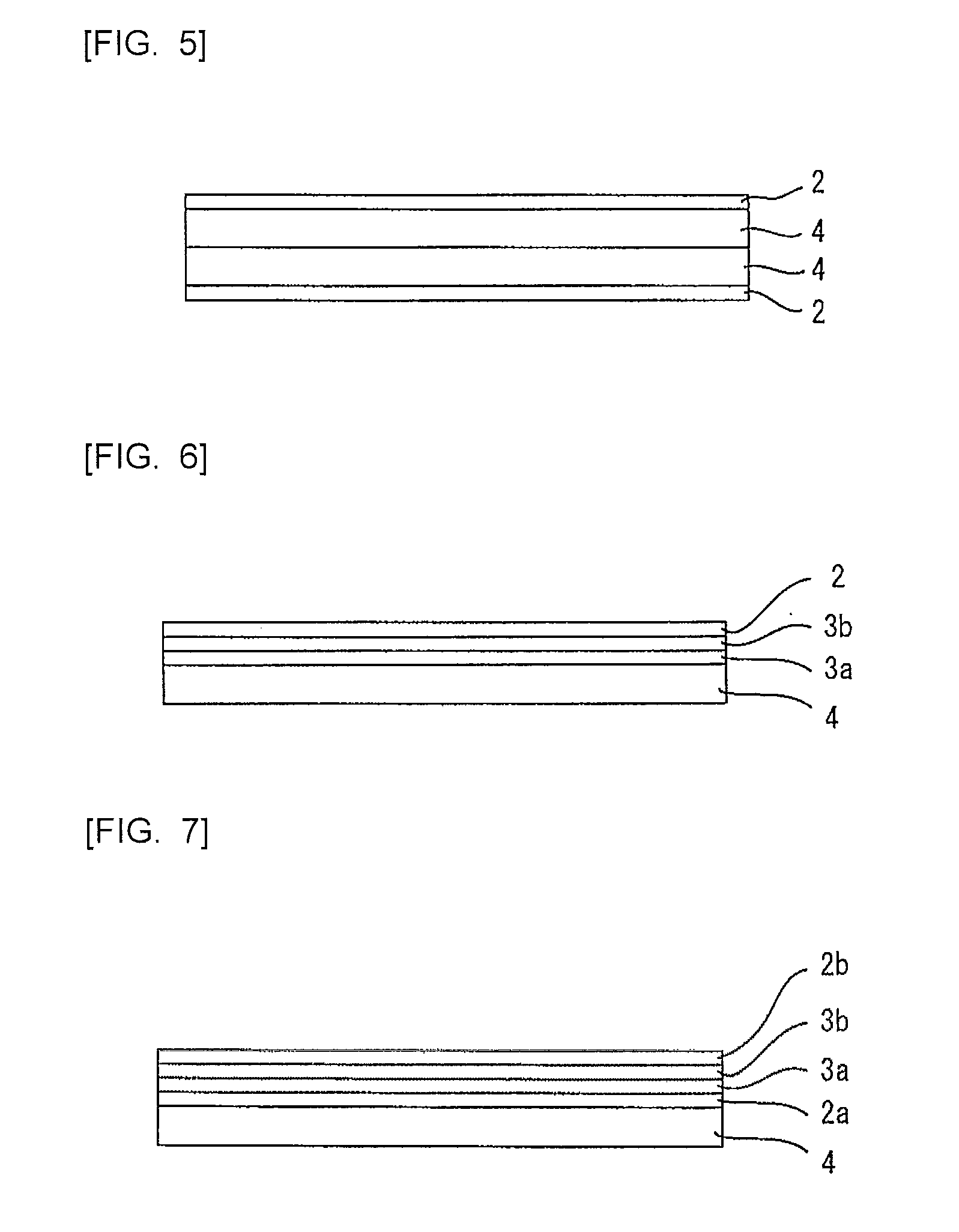

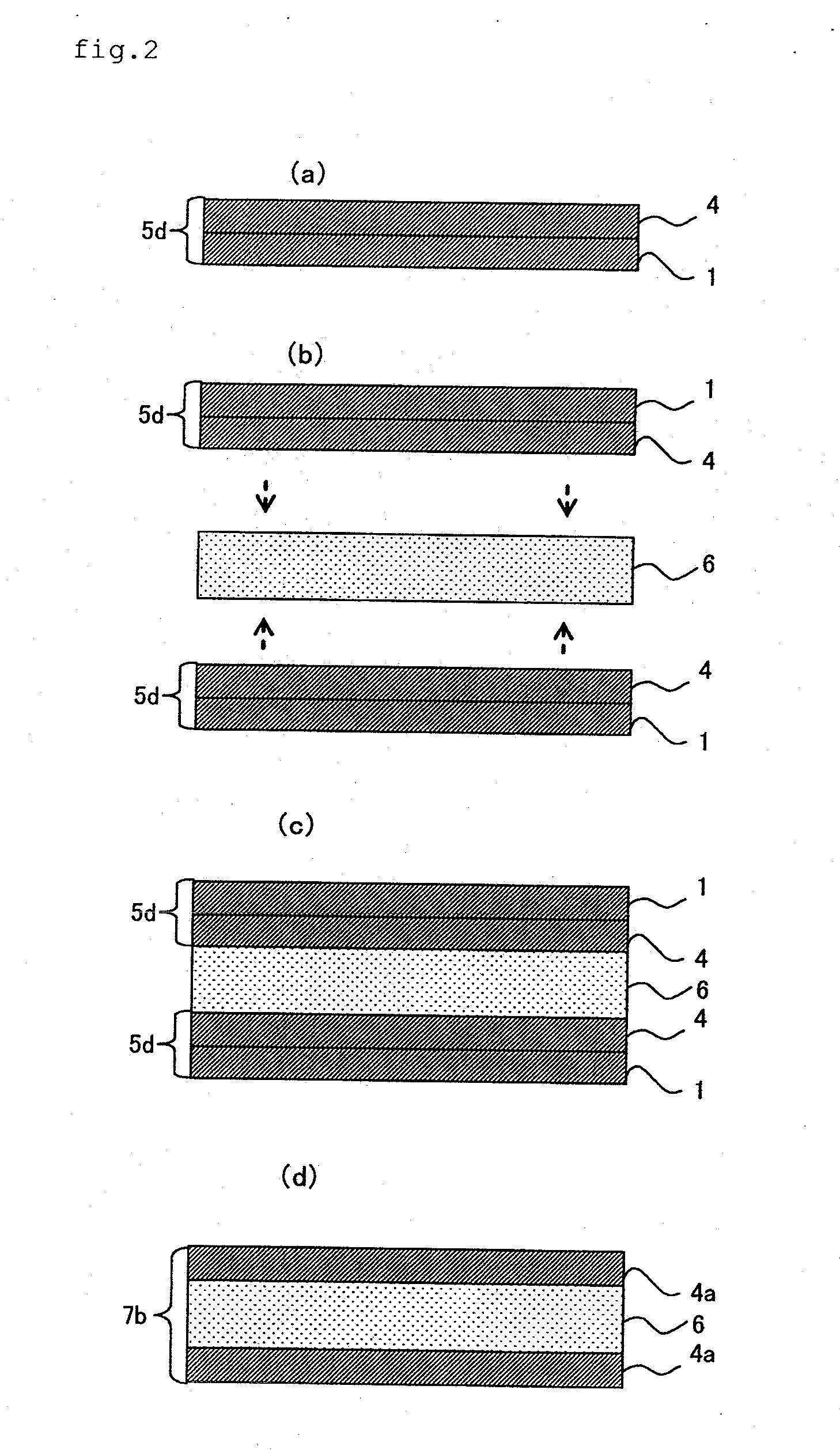

Silicone resin composition, silicone laminated substrate using the same, method for producing the same, and LED device

ActiveUS20140120793A1Maintain good propertiesHigh glass transition temperatureFibre treatmentSolid-state devicesThermal dilatationPolymer science

The invention provides a silicone resin composition for producing a silicone laminated substrate by being impregnated in a glass cloth and cured therein, comprising: (A) an organopolysiloxane with a 3-dimensional network structure composed of an R1SiO1.5 unit and an R2SiO1.5 unit and a T unit represented by an RSiO1.5 unit; (B) an organohydrogenpolysiloxane composed of an R1SiO1.5 unit, an R12SiO unit and an R1aHbSiO(4-a-b) / 2 unit; (C) a platinum group metal catalyst; and (D) a filler. There can be a silicone resin composition having a high glass transition temperature, a silicone laminated substrate excellent in properties such as heat resistance and weatherability having low thermal expansion coefficient and suppressed warp and deformation, a method for producing the same and an LED device.

Owner:SHIN ETSU CHEM IND CO LTD

Method for preparing refractory powder for casting coatings by using serpentine tailings and granite waste

InactiveCN107129314AImprove fire resistanceHigh strengthFoundry mouldsFoundry coresGranolithicFree cooling

The invention discloses a method for preparing refractory powder for casting coatings by using serpentine tailings and granite waste. The method comprises the following steps: (1) evenly mixing the serpentine tailings with the granite waste, crushing the obtained mixture, calcining, cooling to room temperature, and then carrying out ball-milling to obtain a ball abrasive A; evenly mixing silica powder with industrial aluminum oxide, and carrying out ball-milling to obtain a ball abrasive B; (3) evenly mixing the ball abrasive A with the ball abrasive B, then adding water, Suzhou clay and sodium hexametaphosphate into the obtained mixture, carrying out ball-milling, filtering, and drying to obtain a ball abrasive C; (4) carrying out pressing molding on the ball abrasive C by using a semidry method so as to prepare wafers; (5) sintering the wafers at high temperature, naturally cooling to the room temperature, crushing, smashing, and screening to obtain the refractory powder. The refractory powder prepared by method not only has higher refractoriness and strength as well as a lower thermal expansion coefficient and heat conductivity coefficient, but also has excellent thermal shock resistance and chemical corrosion resistance, thus being widely applied to the casting coatings.

Owner:SILVER ANHUI FOUNDRY

Gradient-boron-doped diamond strengthened metal matrix composite and preparation method and application thereof

ActiveCN111778506AImprove thermal conductivitySmall coefficient of thermal expansionSemiconductor/solid-state device detailsVacuum evaporation coatingLinear configurationMetal matrix composite

The invention discloses a gradient-boron-doped diamond strengthened metal matrix composite and a preparation method and application thereof. The composite includes gradient-boron-doped diamond strengthened bodies, and metal matrices, and the gradient-boron-doped diamond strengthened bodies include diamond strengthened bodies, and gradient-boron-doped diamond modified layers arranged on the surfaces of the diamond strengthened bodies. The configuration of the diamond strengthened bodies include one or more of a zero-dimensional particle configuration, a one-dimensional linear configuration, a two-dimensional piece-shaped configuration, and a three-dimensional continuous network skeleton configuration. The coupling of the gradient-boron-doped diamond strengthened bodies with different dimensions can greatly improve the mass of diamonds on the composite, and improve the heat conductivity. In addition, according to the added gradient-boron-doped diamond strengthened bodies, the gradient-boron-doped diamond modified layers account for less, so that the heat conductivity of the diamonds can not be affected, and the humidity between the diamonds and metal can be greatly improved.

Owner:CENT SOUTH UNIV

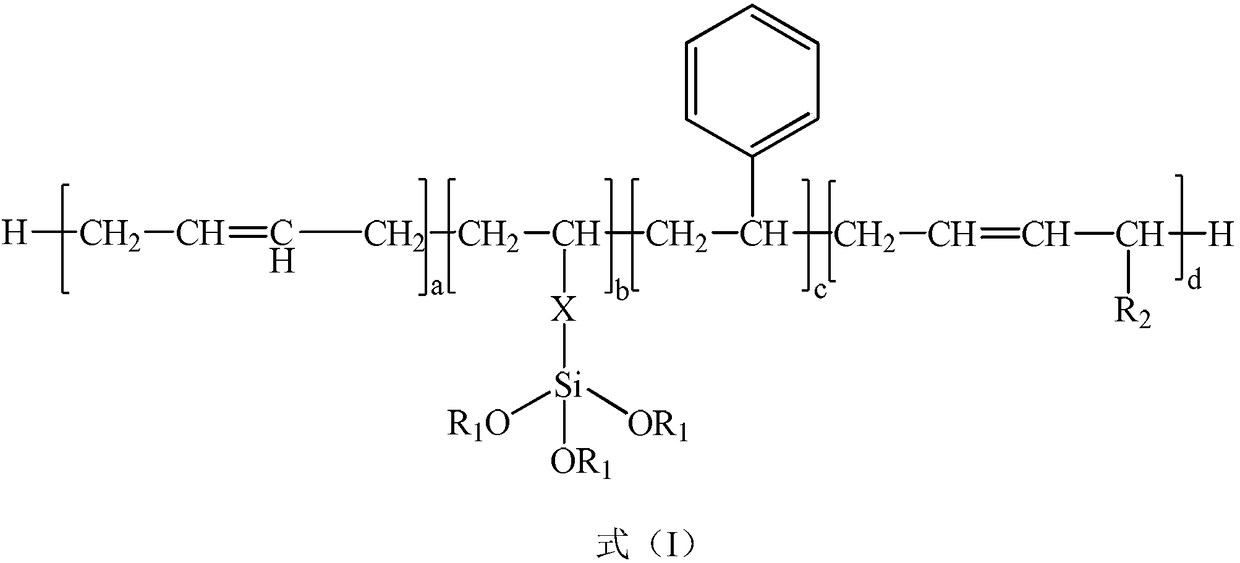

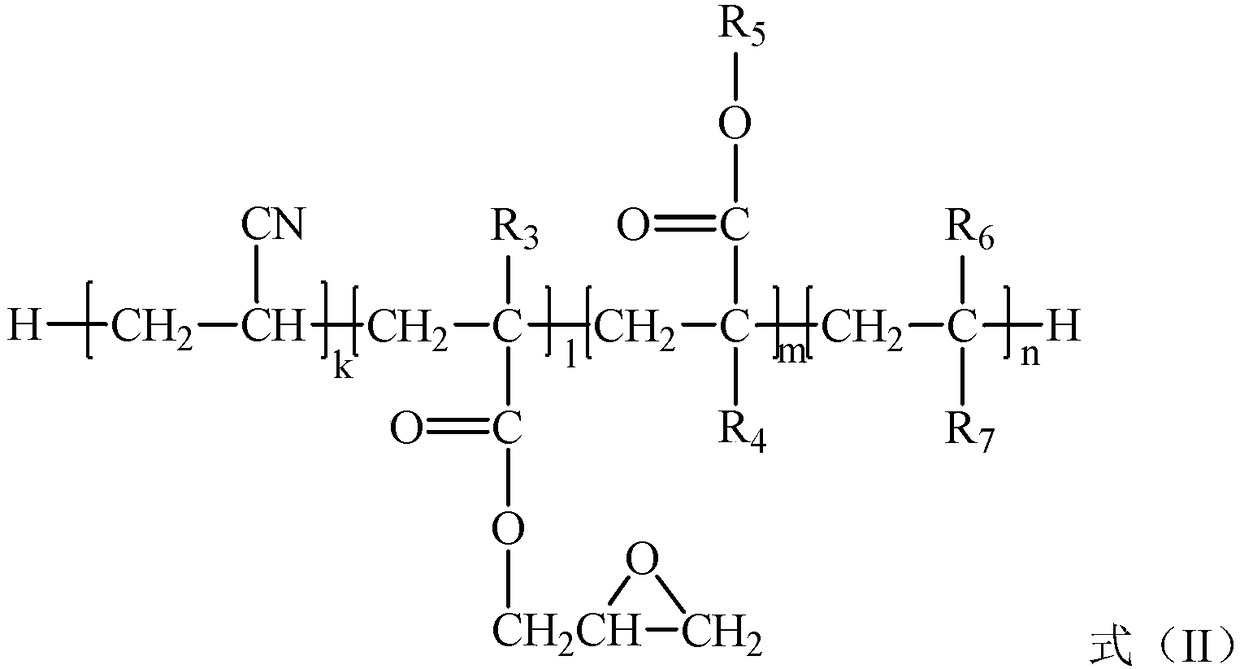

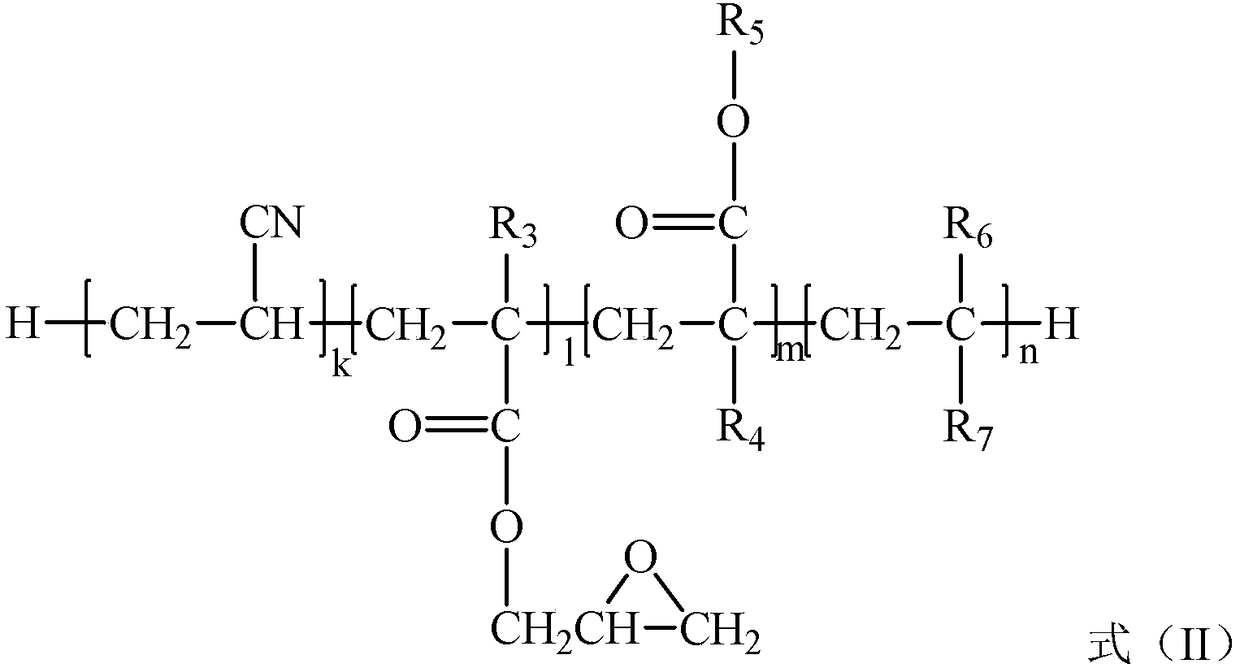

Resin composition, prepreg, laminated board and laminated board covered with metal foil

ActiveCN108559209AReduce rigiditySmall coefficient of thermal expansionElectrical equipmentCoatingsMetal foilHeat resistance

The invention relates to an epoxy modified acrylate resin composition, prepreg, a laminated board and a laminated board covered with metal foil. The prepreg, the laminated board and the laminated board covered with the metal foil are prepared by using the epoxy modified acrylate resin composition. The resin composition comprises epoxy modified acrylate resin (A), inorganic filler (C) which is subjected to surface treatment through a silane coupling agent (B) which is of a structure shown in the formula (I), epoxy resin (D), cyanate ester resin (E) and bismaleimide resin (F). The inorganic filler (C) is modified by adopting the silane coupling agent (B) of the structure shown in the formula (I), the dispersity of the inorganic filler (C) in the epoxy modified acrylate resin (A) is improved,the interlamination binding force of the prepared laminated board and the binding force of the laminated board and the metal foil are high, and the prepreg, the laminated board and the laminated board covered with the metal foil have good heat resistance, dampness-heat resistance and low thermal expansion coefficient and modulus and are suitable for high-end encapsulation. The formula (I) is shown in the description.

Owner:GUANGDONG SHENGYI SCI TECH

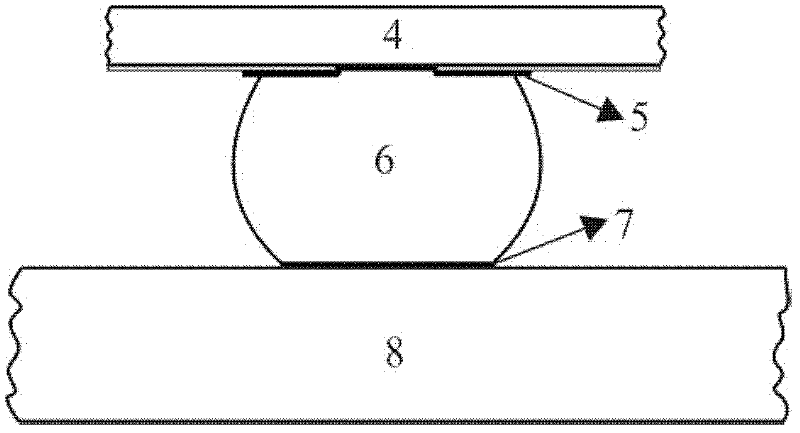

Solder bump/metallization layer connecting structure body in microelectronic package and application of solder bump/metallization layer connecting structure body

ActiveCN102420203AImprove wettabilityImprove antioxidant capacitySemiconductor/solid-state device detailsSolid-state devicesSolderabilityTin-silver-copper

The invention relates to a micro-interconnection technology in the field of microelectronic package, in particular to a solder bump / metallization (transitional) layer connecting structure body with favorable solderability in the microelectronic package and application of the solder bump / metallization (transitional) layer connecting structure body. The solder bump / metallization (transitional) layer connecting structure body and the application of the solder bump / metallization (transitional) layer connecting structure body are applied to the technical field of manufacturing of bonding pads of substrates and printed circuit boards in general microelectronic connection as well as metallization transitional layers below solder bumps in the flip-chip bonding interconnection. The connecting structure body is formed by connecting the solder bumps with the metallization layer; the metallization layer is an alloy layer formed by co-depositing 59-69 percent by weight of a ferrum element, 31-41 percent by weight of a nickel element and the balance of a cobalt element; and the solder is a tin-silver or tin-silver-copper series lead-free solder alloy with a relatively-high melting point. According to the method, a ferrum-nickel-cobalt alloy layer is plated on a copper (or nickel) layer by adopting an electroplating method. Relative to a ferrum-nickel coating, a small amount of cobalt is added so as to allow the proportion of the contents of the ferrum and the nickel to be maintained at a lower expansion coefficient in a wider range and maintained constant in a wider temperature range.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

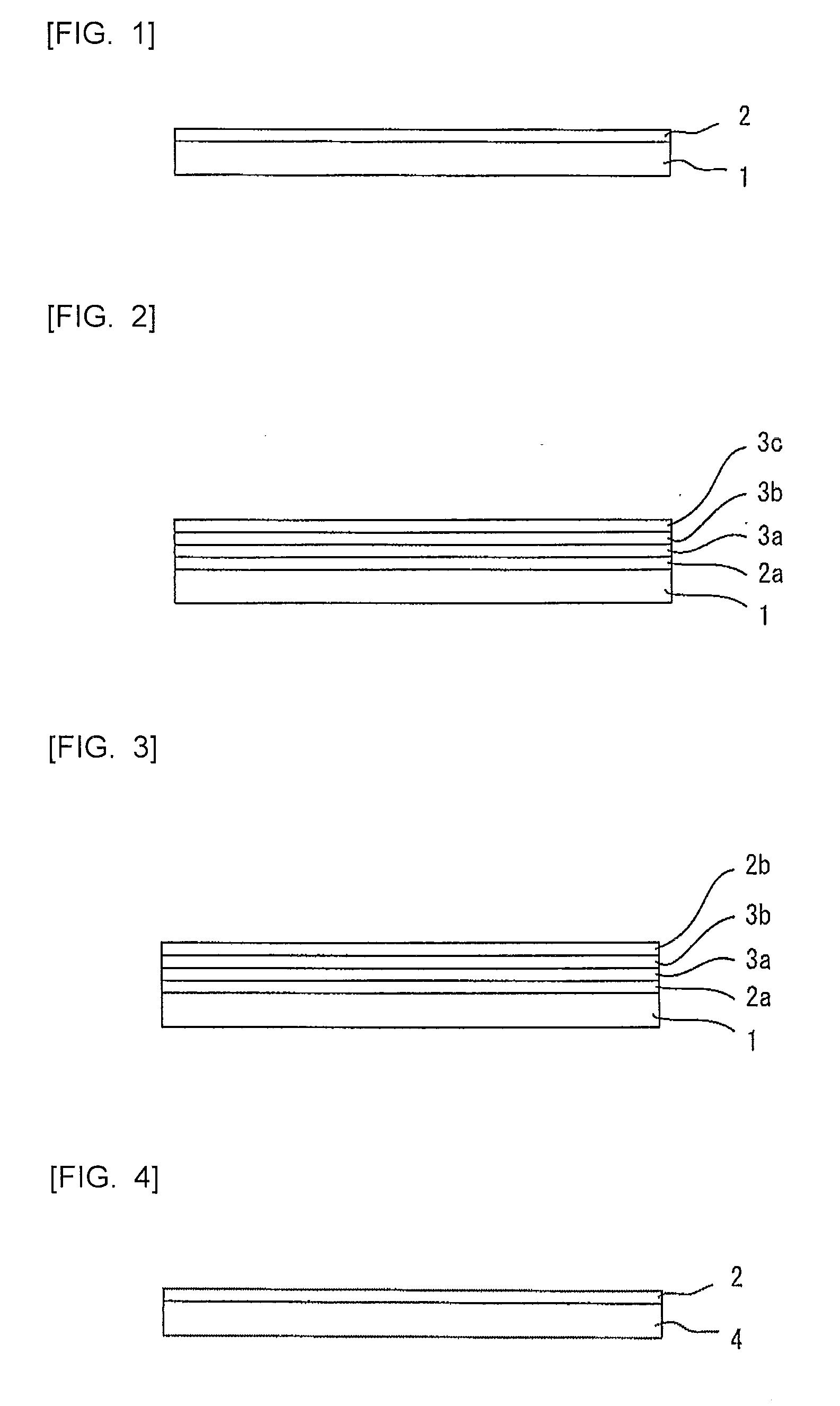

Laminate body, laminate plate, multilayer laminate plate, printed wiring board, and method for manufacture of laminate plate

ActiveUS20130112460A1Low coefficient of thermal expansionHigh elastic modulusFilm/foil adhesivesSynthetic resin layered productsInorganic fillerVolume Percentage

A laminate body containing at least one resin composition layer and at least one glass substrate layer, wherein the resin composition layer comprises a resin composition containing a thermosetting resin and an inorganic filler and the glass substrate layer accounts for from 10 to 95% by volume of the entire laminate body. A laminate plate containing at least one cured resin layer and at least one glass substrate layer, wherein the cured resin layer comprises a cured product of a resin composition that contains a thermosetting resin and an inorganic filler and the glass substrate layer accounts for from 10 to 95% by volume of the entire laminate plate. A printed wiring board having the laminate plate and a wiring provided on the surface of the laminate plate. A method for producing the laminate plate comprising a cured resin layer forming step of forming a cured resin layer on the surface of a glass substrate.

Owner:RESONAC CORP

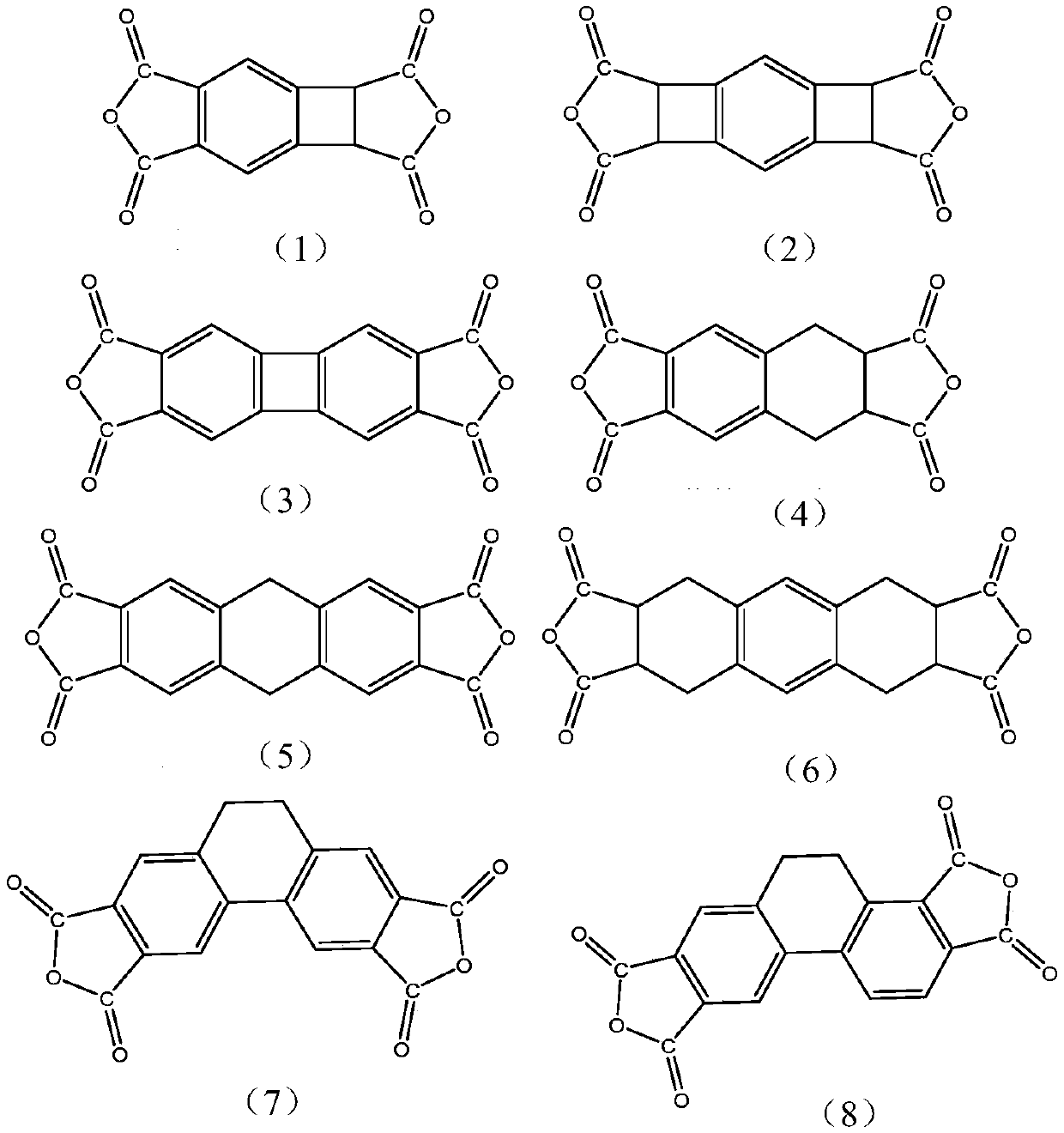

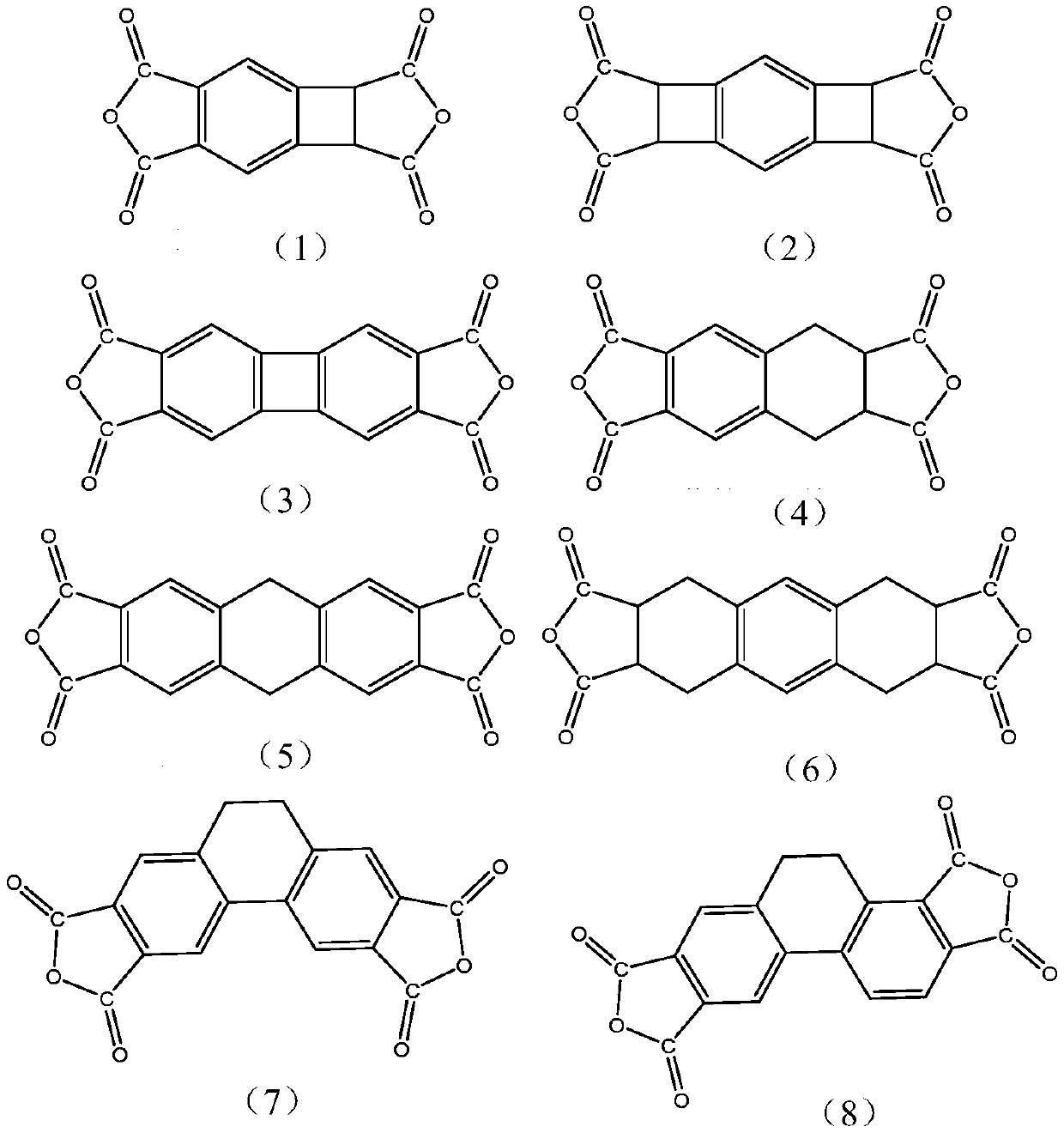

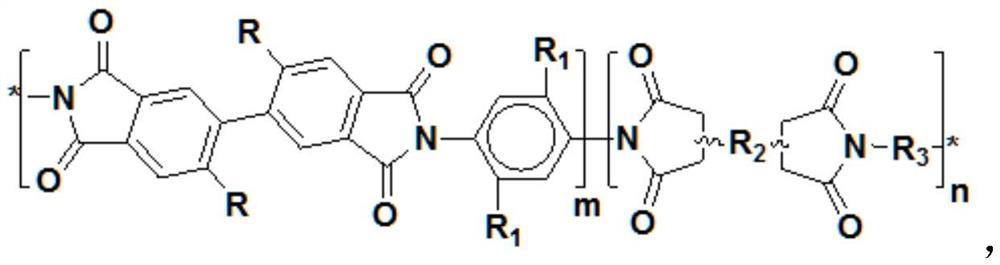

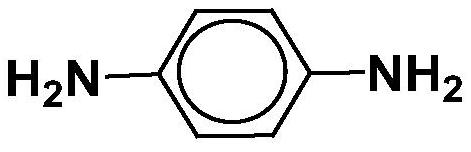

Benzodiacyclic dianhydride and low-dielectric-constant polyimide precursor film

The invention discloses a benzodiacyclic dianhydride and low-dielectric-constant polyimide precursor film. The preparation method comprises the following steps: completely dissolving diamine into an aprotic polar solvent; adding benzodiacyclic dianhydride and performing reaction at the temperature of -10 to 35 DEG C for 0.5 to 5 hours under the protection of nitrogen or inert gas to obtain a polyimide precursor solution; coating a base material with the polyimide precursor solution, and performing imidization and stress relief to prepare the low-dielectric-constant polyimide precursor film. The polyimide precursor film prepared by the method has low dielectric constant, low dielectric loss and low water-absorbing rate, and still has low dielectric constant and low dielectric loss after absorbing water; furthermore, the polyimide precursor film has excellent heat stability and mechanical property and can meet the requirement on dielectric materials by 5G communication and high-frequencyhigh-speed electronic industry.

Owner:ZHEJIANG FORST NEW MATERIAL RES INST CO LTD

Lead-free glass composites with a low thermal expansion coefficient

ActiveUS20090011917A1Low coefficient of thermal expansionUse of materialGlass compositesPowder mixture

The glass composite has a linear thermal expansion coefficient α(20-300) of 1.8×10−6K−1 to 2.4×10−6K−1, a glass transformation temperature Tg of less than 650° C., and a composition, in weight percent based on oxide content, of: 5-9, B2O3; 1-3, Na2O; 15-22, Al2O3; 61-68, SiO2; 0.2-0.5, K2O; and 5.5-8.5, MgO. It can be made by sintering a mixture of 40 to 60 wt. % of a borosilicate glass powder and 60 to 40 wt. % of a cordierite powder. The powder mixture can be used to make a glass solder for joining parts, to make a sintered body with thermal shock resistance, or for glazing or soldering PZT ceramics.

Owner:SCHOTT AG

Modified polyamide acid resin slurry and preparation method thereof, and adhesive-free copper-clad plate

PendingCN111961202AModerate viscosityMeet coating requirementsSynthetic resin layered productsElectrical equipmentPolymer sciencePolyamide

The invention discloses a modified polyamic acid resin slurry, which has the characteristics of proper viscosity, good leveling coating performance, strong adhesion and the like, and is wide in raw material source range, low in cost and suitable for large-scale production. According to the invention, the adhesive-free copper-clad plate prepared from the modified polyamic acid resin slurry and a copper foil has excellent dielectric properties, low hygroscopicity and dimensional stability, can meet the specification requirements of a high-frequency flexible printed circuit board on a copper-cladplate, and improves the quality of the circuit board; and more importantly, an adhesive-free copper-clad plate prepared from the modified polyamide acid resin slurry and a copper foil has a great cost advantage. The invention also discloses a preparation method of the modified polyamide acid resin slurry.

Owner:ZHONGSHAN POLYTECHNIC

Process for producing petroleum coke

ActiveUS20100181228A1High strengthLow coefficient of thermal expansionThermal non-catalytic crackingTreatment with plural serial cracking stages onlyHydrodesulfurizationBoiling point

A process is provided for producing petroleum coke that is high in strength and sufficiently small in thermal expansion coefficient and sufficiently suppressed from puffing. The process includes coking a feedstock containing a first heavy oil having a sulfur content of 1.0 percent by mass or less, a nitrogen content of 0.5 percent by mass or less, and an aromatic index of 0.1 or greater, produced by hydrodesulfurizing a heavy oil with a sulfur content of 1 percent by mass or more under conditions (1) where the total pressure is 10 MPa or greater and less than 16 MPa and the hydrogen partial pressure is 5 MPa or greater and 16 MPa or less or conditions (2) where the total pressure is 20 MPa or greater and 25 MPa or less and the hydrogen partial pressure is greater than 20 MPa and 25 MPa or less, and a second heavy oil with an aromatic index of 0.3 or greater and an initial boiling point of 150° C. or higher.

Owner:JX NIPPON OIL & ENERGY CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com