Preparation method of coal based needle coke

A technology of needle coke and coal series, applied in coking ovens, coking carbonaceous materials, petroleum industry, etc., can solve the problems of easy formation of mosaic structure, easy slagging, small coke output, etc., to avoid pipeline blockage, reaction uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

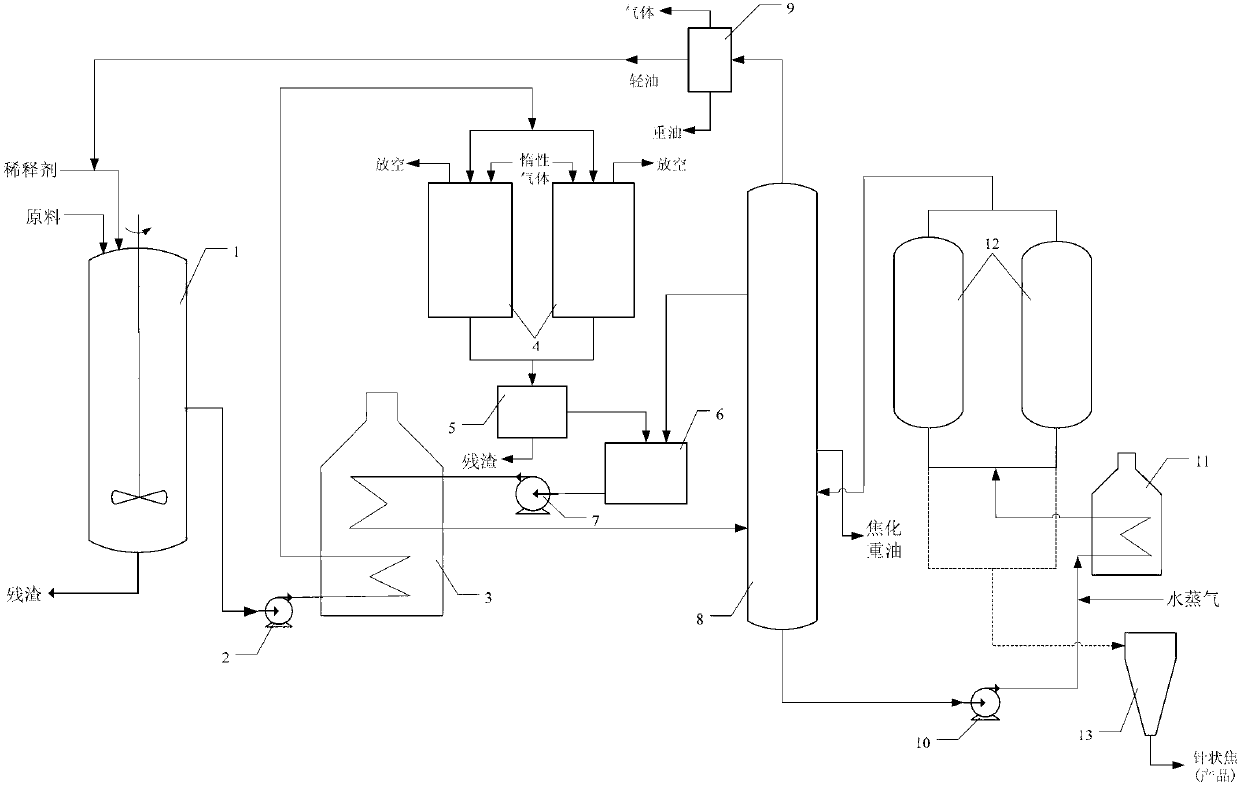

[0036] The preparation method of coal series needle coke of the present invention adopts such as figure 1 The device shown in Fig. 1 shows that the preparation device of coal-based needle coke includes a stirred tank 1 and a 1# heating furnace 3 connected to the stirred tank 1 through a raw material pump 2 and a pipeline, and the 1# heating furnace 3 is respectively connected to the stirred tank 1 through a pipeline. Connected with pressurized hot filter kettle 4, purified raw material tank 6 and reaction tower 8, 1# heating furnace 3 and purified raw material tank 6 are connected through polycondensation feed pump 7 and pipeline; pressurized hot filtered kettle 4 is two identical The bottom of the two kettle bodies is connected to the centrifuge 5, and the centrifuge 5 is connected to the purified raw material tank 6; the top of the reaction tower 8 is connected to the fractionation tank 9, and the fractionation tank 9 is connected to the feed port of the stirring tank 1 to fo...

Embodiment 1

[0052] Add coal tar and diluent washing oil into the stirring tank 1 according to the mass ratio of 1:1, and after being fully mixed, it is pumped out by the raw material pump 2 and sent to the 1# tubular heating furnace 3 for heating. Autoclaved filter kettle 4, the filter material layer is made of diatomite and stainless steel filter screen, the particle size of diatomite particles is 70 mesh, the mesh number of stainless steel filter screen is 300 mesh, and the thickness of the filter layer is 5 cm. 2 , pressurized to 0.2MPa, the filtrate after hot filtration enters the three-legged centrifuge 5, the filter cloth mesh of the centrifuge is 800 mesh, and is centrifugally filtered at a speed of 1000 rpm, and the purified raw material obtained is sent by the pump 7 Enter the 1# tubular heating furnace 3, after heating, enter the reaction tower 8 for polycondensation, the circulation ratio of the polycondensation concentrate extraction and the recycled material is 1:5, the operat...

Embodiment 2

[0054] Add coal tar and diluent washing oil into the stirring tank 1 according to the mass ratio of 1:10, and after being fully mixed, it is pumped out by the raw material pump 2 and sent to the 1# tubular heating furnace 3 for heating. Autoclaved filter kettle 4, the filter material layer is composed of expanded perlite and stainless steel filter screen, the particle size of expanded perlite particles is 400 mesh, the mesh number of stainless steel filter screen is 700 mesh, and the thickness of the filter layer is 10 cm. 2 , pressurized to 2MPa, the filtrate after hot filtration enters into the three-legged centrifuge 5, the filter cloth mesh number of the centrifuge is 1300 mesh, and is centrifugally filtered at a speed of 2000 rpm, and the purified raw material obtained is sent into by the pump 7 To 1# tubular heating furnace 3, after heating, enter the reaction tower 8 for polycondensation, the cycle ratio of polycondensation concentrate extraction and recycled material is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com