Solder bump/metallization layer connecting structure body in microelectronic package and application of solder bump/metallization layer connecting structure body

A technology for connecting structural bodies and microelectronic packaging, applied in the field of micro-interconnection, can solve the problems of fatigue failure of connecting bodies, loss of function, consumption of metallization layer, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

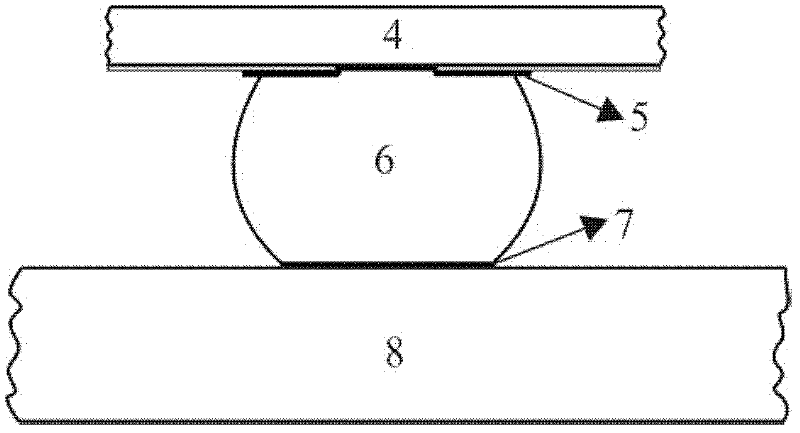

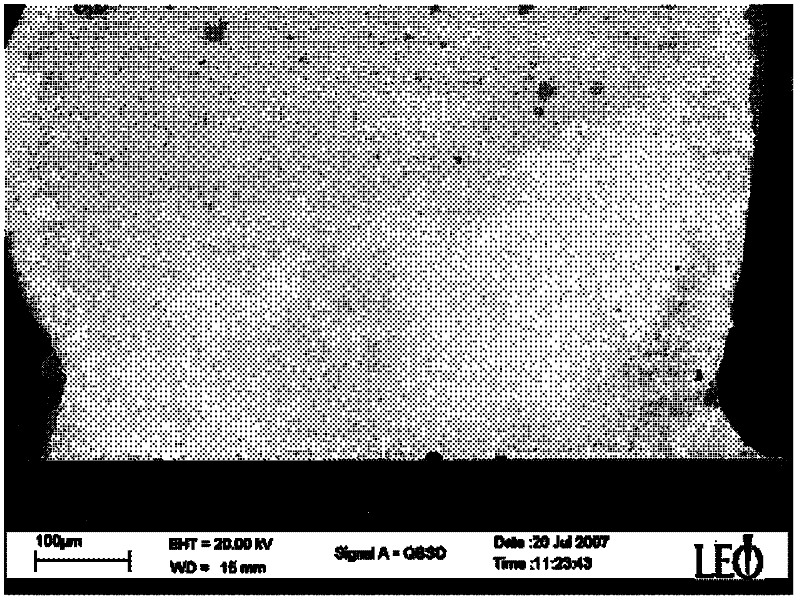

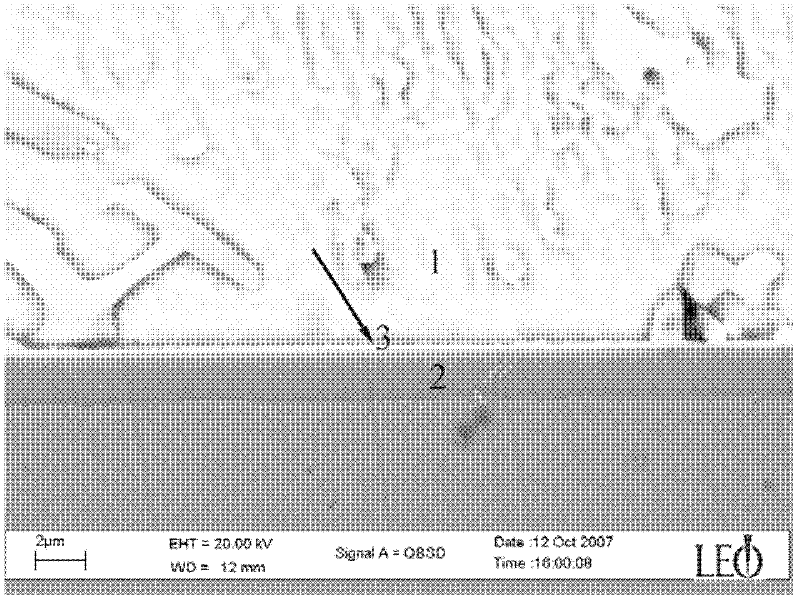

[0040] Electroplate a layer of iron-nickel-cobalt alloy on the surface of a conductive substrate such as copper or nickel, or on the surface of a non-conductive substrate covered by a conductive film. The composition and thickness of the electroplating layer can be adjusted according to actual requirements. Such as figure 1 As shown, the coating realized by the present invention can be used as the iron-nickel-cobalt metallization layer 7 of the pad on the substrate and on the printed circuit board 8, and the lower iron-nickel-cobalt of the tin-silver-copper solder bump 6 in the chip 4 flip-chip welding connection Metallization layer 5 is used. Such as figure 2 As shown, the macroscopic cross-sectional view of the iron-nickel-cobalt plating / tin-silver-copper spherical bump connector.

[0041] A thin layer of iron-nickel-cobalt layer is plated on the copper substrate by means of electroplating, and its composition is: 60% of iron, 35% of nickel and 5% of cobalt (percentage by...

Embodiment 2

[0045] The difference from Example 1 is:

[0046] The composition of the iron-nickel layer is: iron 59%, nickel 35%, cobalt 6%;

[0047] Solder composition: tin 95.8%, silver 3.5%, copper 0.7%.

Embodiment 3

[0049] The difference from Example 1 is:

[0050] The composition of the iron-nickel layer is: iron 63%, nickel 33%, cobalt 4%;

[0051] Solder composition: tin 98.5%, silver 1%, copper 0.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com