Patents

Literature

95 results about "Tin-silver-copper" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

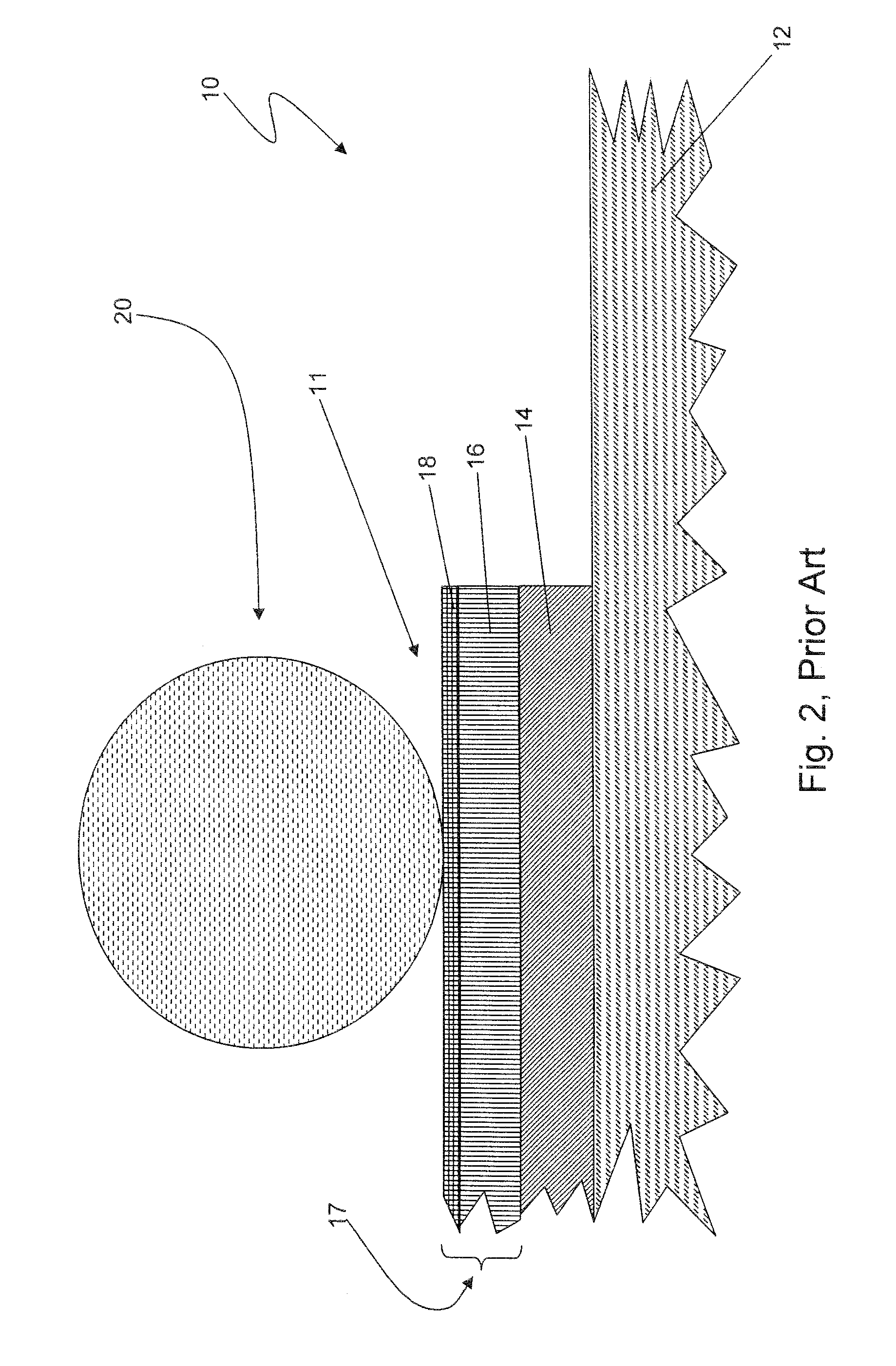

Tin-silver-copper (SnAgCu, also known as SAC), is a lead-free (Pb-free) alloy commonly used for electronic solder. The tin-silver-copper alloy has been the prevailing alloy system used to replace tin-lead because it is near eutectic, with adequate thermal fatigue properties, strength, and wettability. Lead-free solder is gaining much attention as the environmental effects of lead in industrial products is recognized, and as a result of Europe’s RoHS legislation to remove lead and other hazardous materials from electronics. Japanese electronics companies have also looked at Pb-free solder for its industrial advantages.

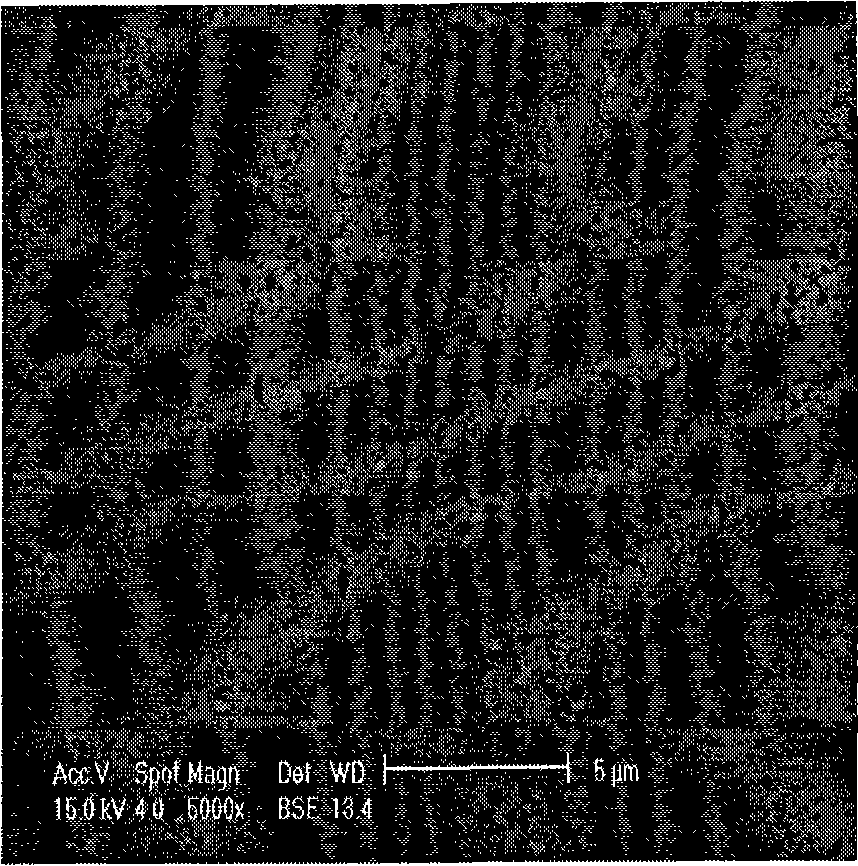

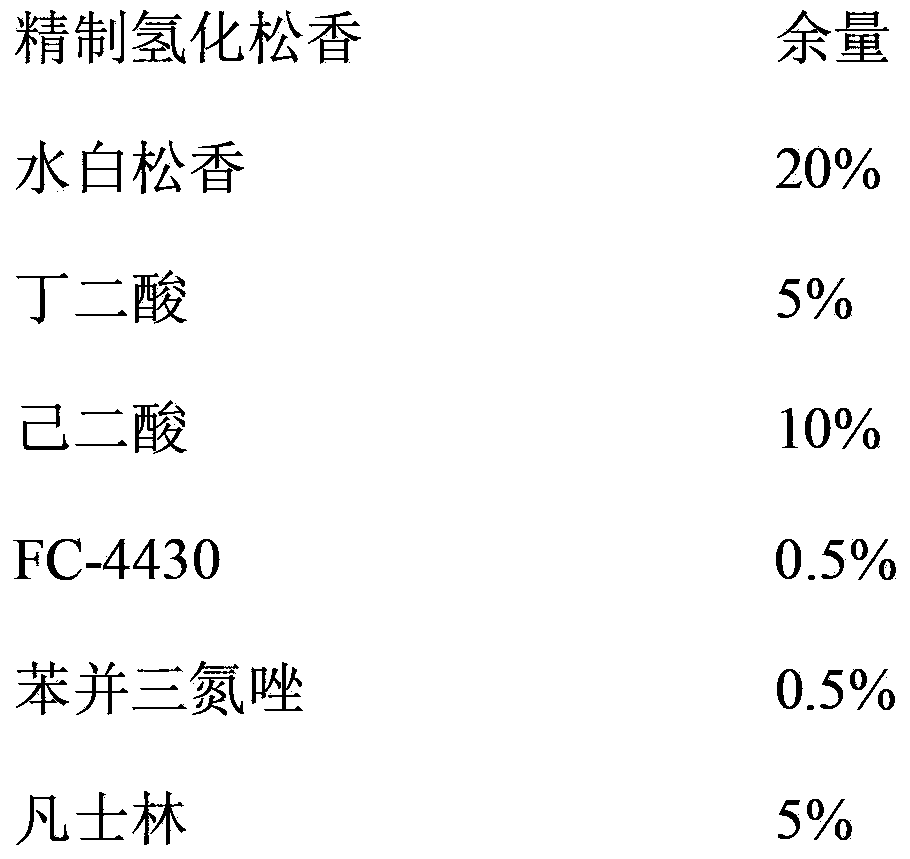

Halogen-free cleaning-free rosin flux, and preparation and application thereof

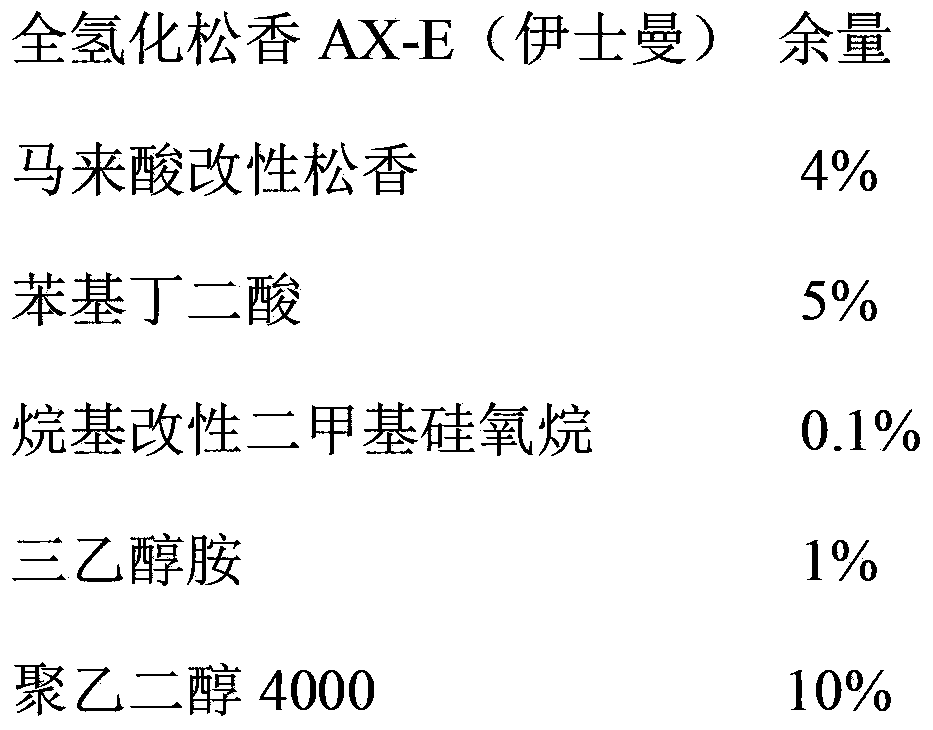

ActiveCN102513732ALess corrosiveSlow growth rateWelding/cutting media/materialsSoldering mediaSolventSolder paste

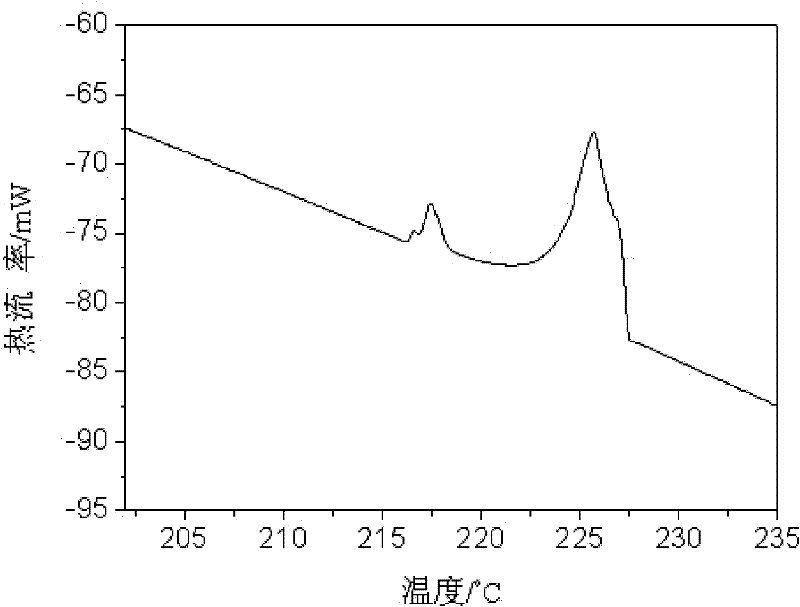

The invention discloses a halogen-free cleaning-free rosin flux, and preparation and application thereof, and particularly relates to a flux suitable for surface mount lead-free welding paste, preparation of the flux and application of the flux. The flux comprises 20-50% (mass fraction, the same below) of rosin, 5-25% of film-forming agent, 30-50% of high boiling solvent, 3-8% of activator and 2-5% of thixotropic agent, and the flux does not contain any halogen. In order to control growth of interface IMC (intermediate compound) during welding, 0.3-1% of combined inhibitor is added. The welding paste prepared with the flux and lead-free tin-silver-copper powder has the advantages of excellent printing performance, fine weldability, less post-weld residue, thin and even welding spot interface IMC and excellent mechanical property, and is capable of meeting the requirement of high-end electronic products on packaging.

Owner:CENT SOUTH UNIV

Solder alloy, solder paste, and electronic circuit board

ActiveUS9221132B2Low costEasy to oxidizePrinted circuit assemblingComponent plug-in assemblagesIndiumTin-silver-copper

A solder alloy is a tin-silver-copper solder alloy containing tin, silver, copper, nickel, antimony, bismuth, and indium, and substantially does not contain germanium, wherein relative to the total amount of the solder alloy, the silver content is more than 0.05 mass % and less than 0.2 mass %, and the antimony content is 0.01 mass % or more and less than 2.5 mass %.

Owner:HARIMA CHEM INC

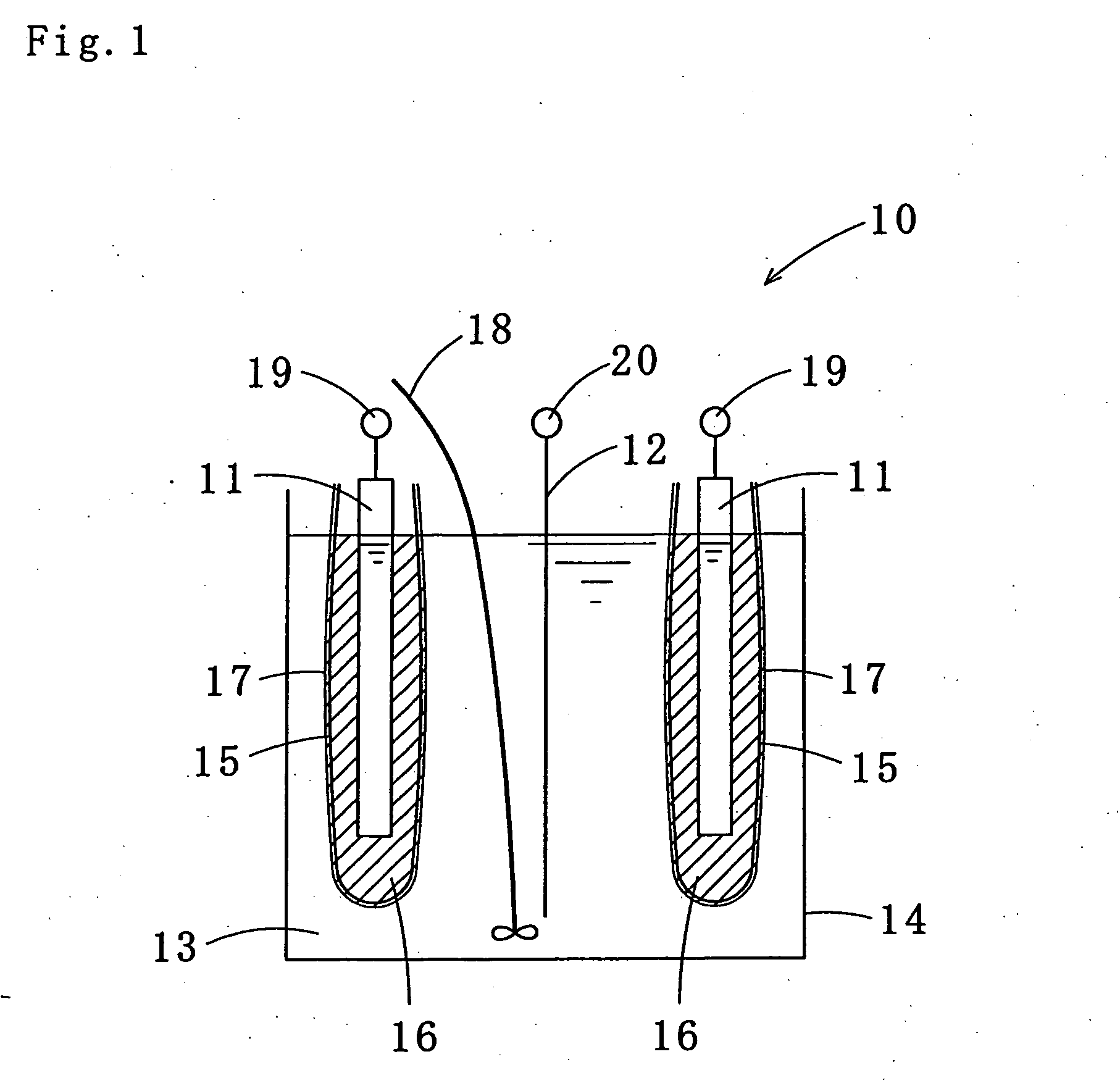

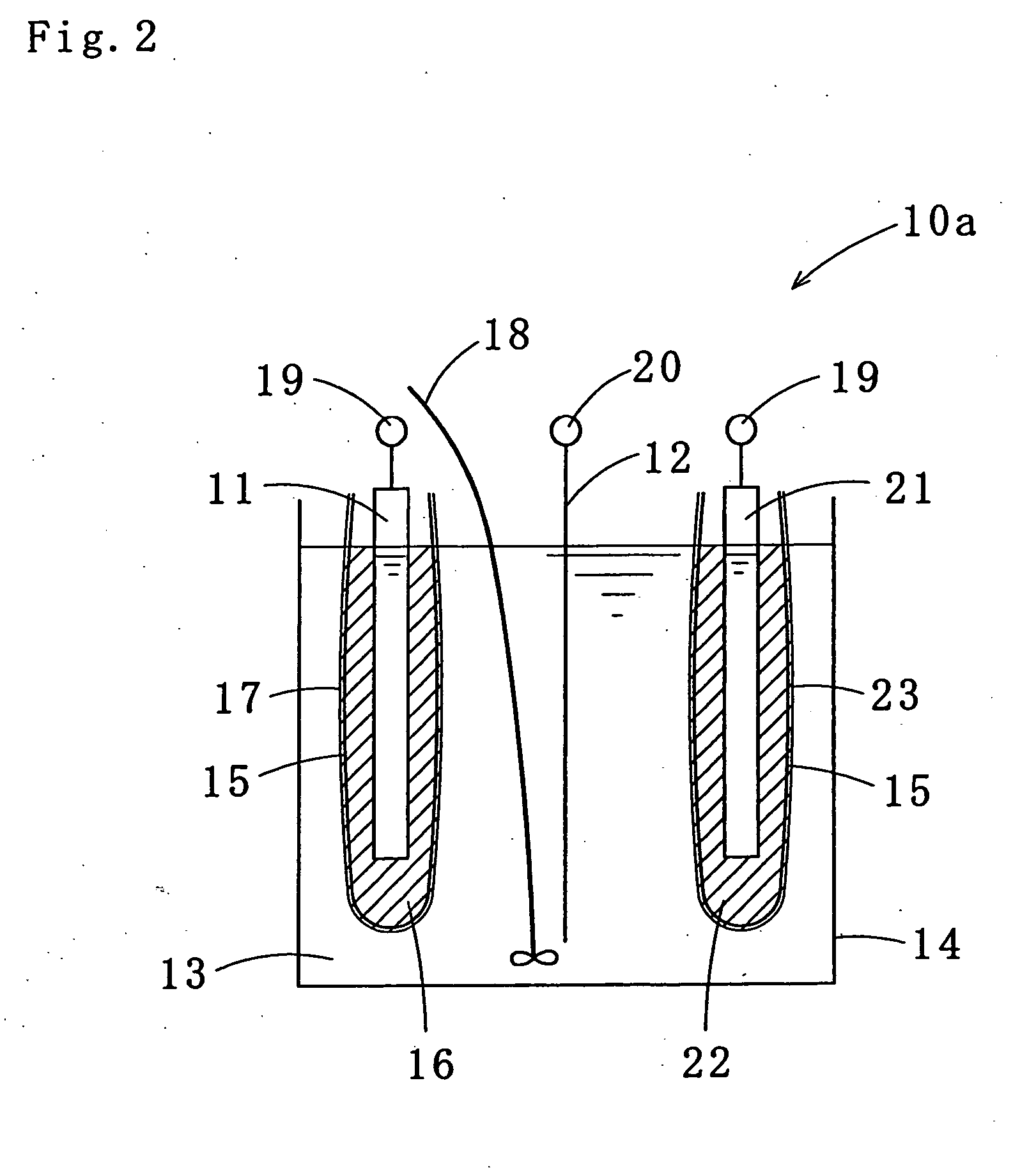

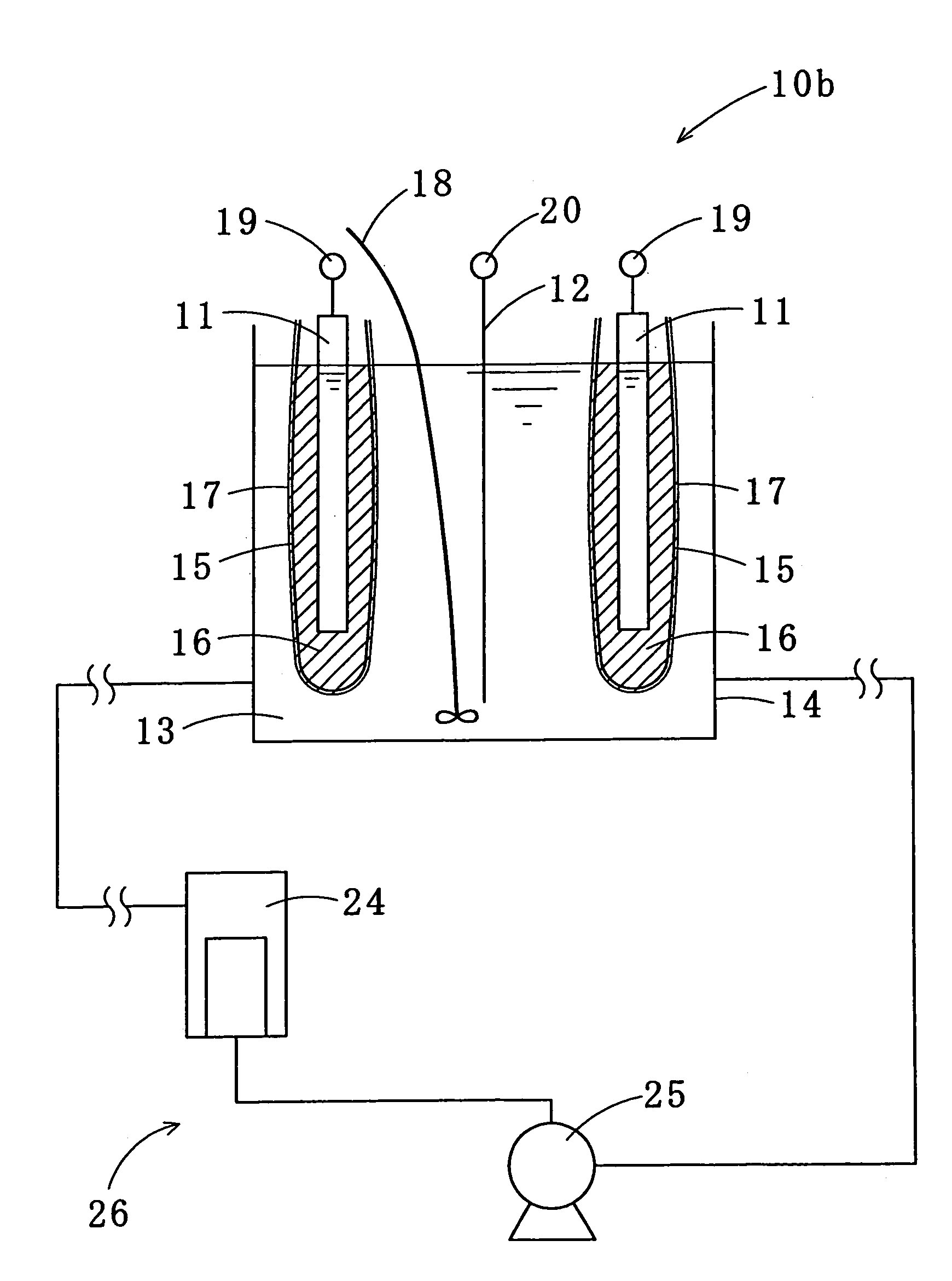

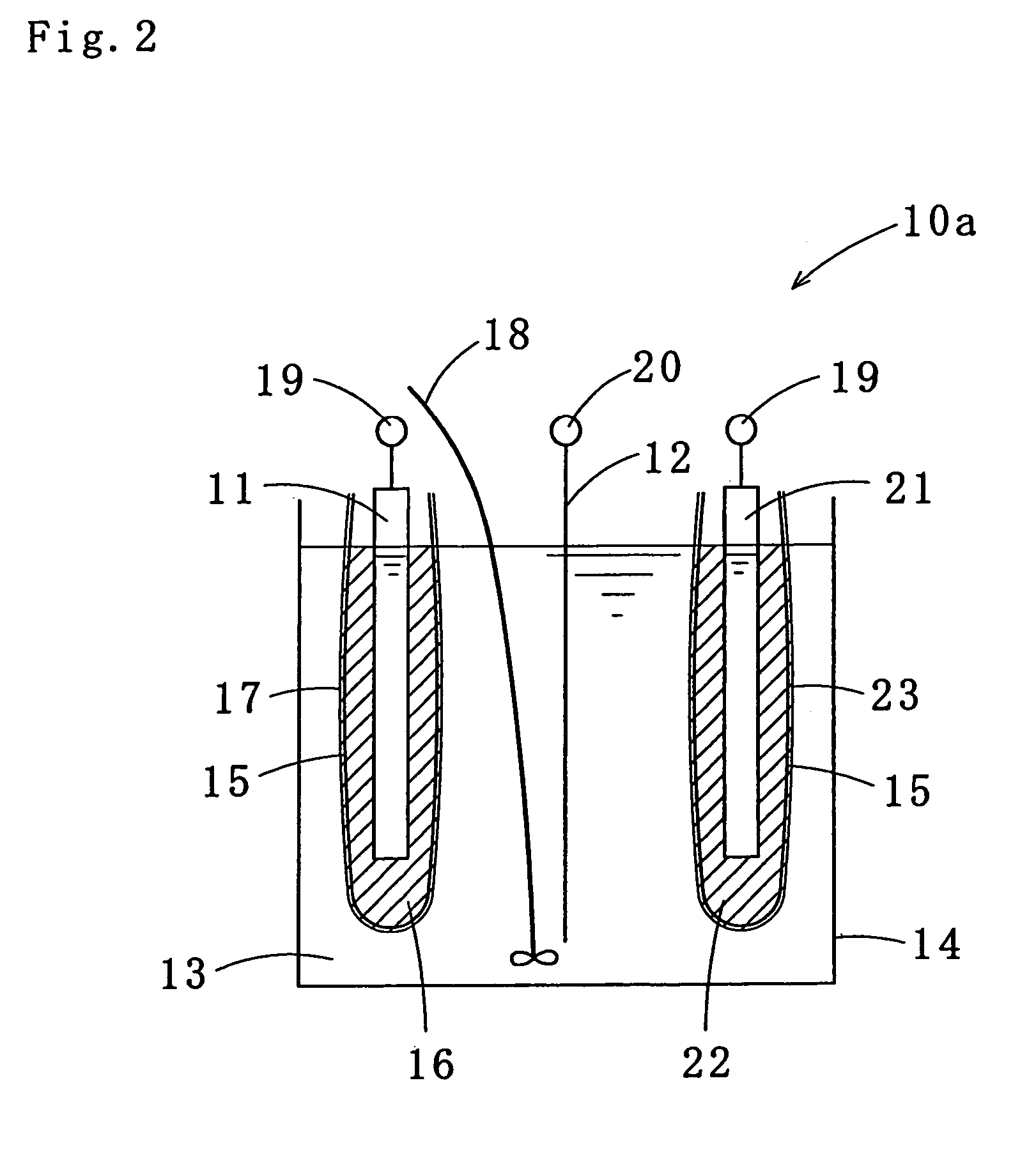

Tin-silver-copper plating solution, plating film containing the same, and method for forming the plating film

InactiveUS20050184369A1High joining strengthLow heating temperatureCellsPrinted circuit assemblingTin-silver-copperCopper

A tin-silver-copper contains plating solution which comprises water which is a primary medium, a sulfonic acid, a tin ion, a copper ion and a silver ion, wherein concentrations of the silver ion, the tin ion and the copper ion are 0.0015 to 0.1 mol / L, 0.21 to 2 mol / L and 0.002 to 0.02 mol / L, respectively; a plating film which has 2.6 to 3.4 weight percent of silver, 0.4 to 0.7 weight percent of copper and the substantially balanced amount of tin; an electrolytic plating method for use in forming the above plating film from the above plating solution; and a soldering method using the plating film.

Owner:SHINRYOI CORP

Tin-silver-copper plating solution, plating film containing the same, and method for forming the plating film

InactiveUS7273540B2Less solidGood storage stabilityCellsPrinted circuit assemblingPorous membraneTin-silver-copper

An electrolytic plating method, including: preparing a plating solution including water which is a primary medium, a sulfonic acid, and tin, copper, and silver ions, and a complexing agent, concentrations of the sulfonic acid, and tin, copper, and silver ions being 0.5 to 5 mol / L, 0.21 to 2 mol / L, 0.002 to 0.02 mol / L, and 0.01 to 0.1 mol / L, respectively, a mole ratio of the silver-ion concentration to the copper-ion concentration being in a range of 4.5 to 5.58; and separating a solution around a soluble anode containing 90 percent or more of tin from the plating solution on a cathode side by a non-ionic micro-porous membrane having a pore diameter of 0.01 to 0.05 μm and a thickness of 5 to 100 μm.

Owner:SHINRYOI CORP

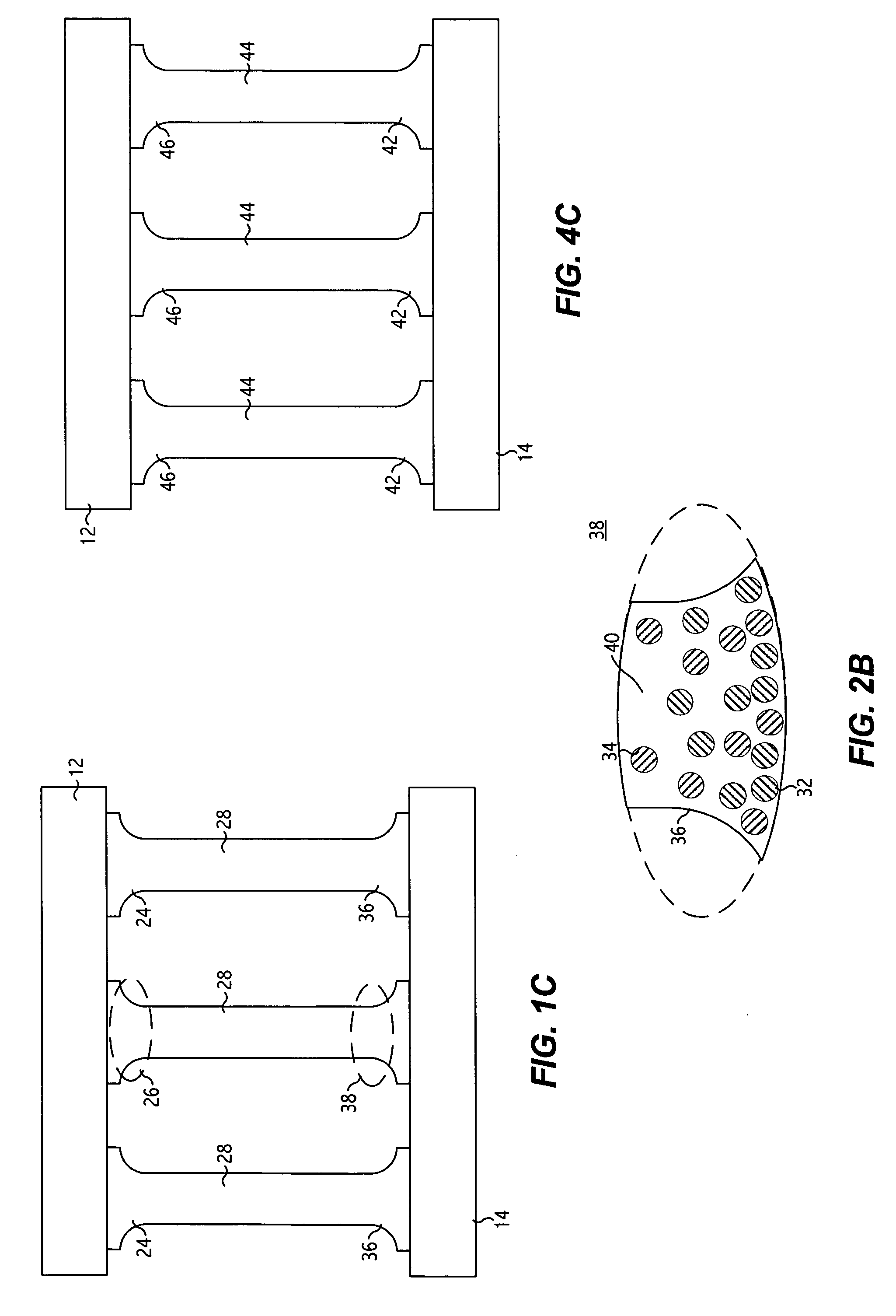

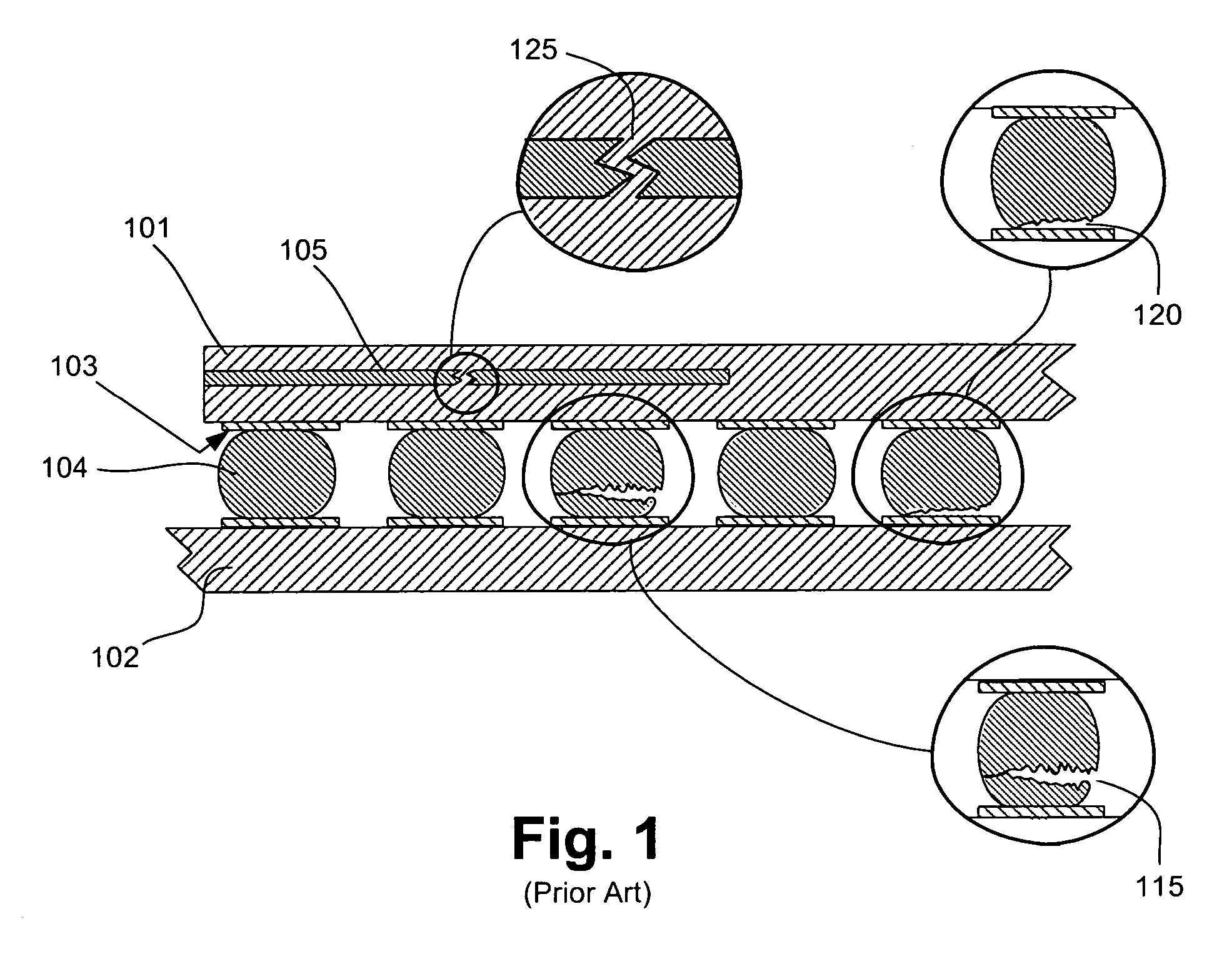

Soldering Method and Related Device for Improved Resistance to Brittle Fracture

ActiveUS20100243300A1Easy to optimizeLess-prone to brittle failureSolid-state devicesComponent plug-in assemblagesTin-silver-copperBrittle fracture

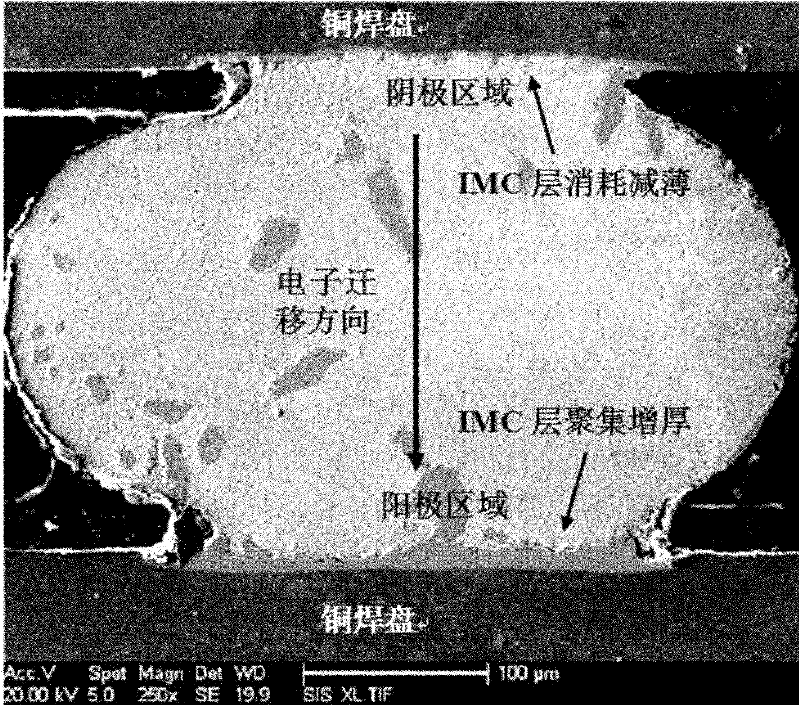

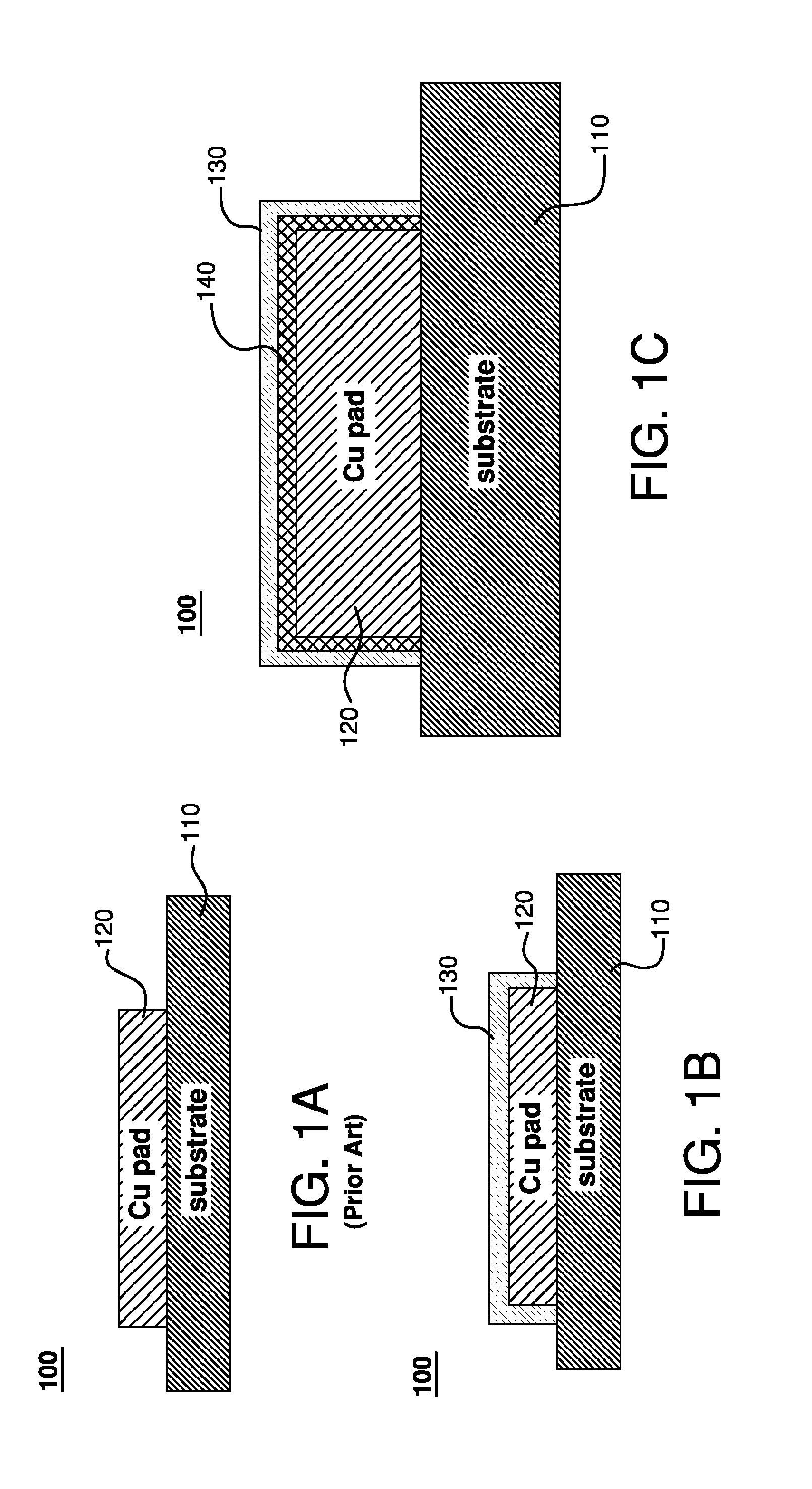

A lead-free solder joint is formed between a tin-silver-copper solder alloy (SAC), SACX, or other commonly used Pb-free solder alloys, and a metallization layer of a substrate. Interaction of the SAC with the metallization layer forms an intermetallic compound (IMC) that binds the solder mass to the metallization layer. The IMC region is substantially free of any phosphorous-containing layers or regions.

Owner:BELL SEMICON LLC

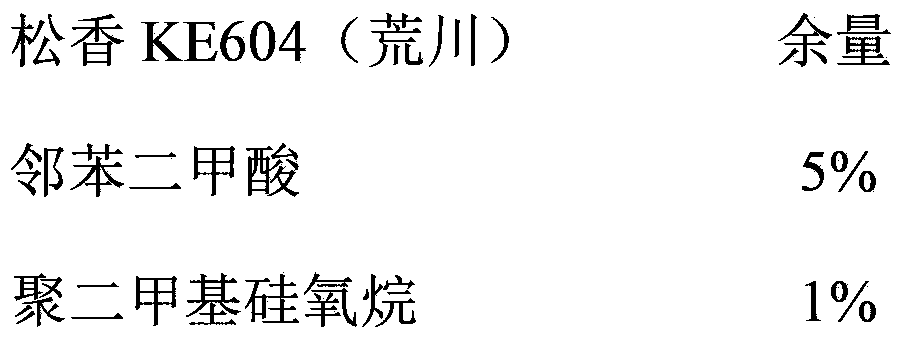

Halogen-free scaling powder used for lead-free solder paste and preparation method thereof

ActiveCN103008921AHigh surface insulation resistanceNo penetrating corrosionWelding/cutting media/materialsSoldering mediaAntioxidantActive agent

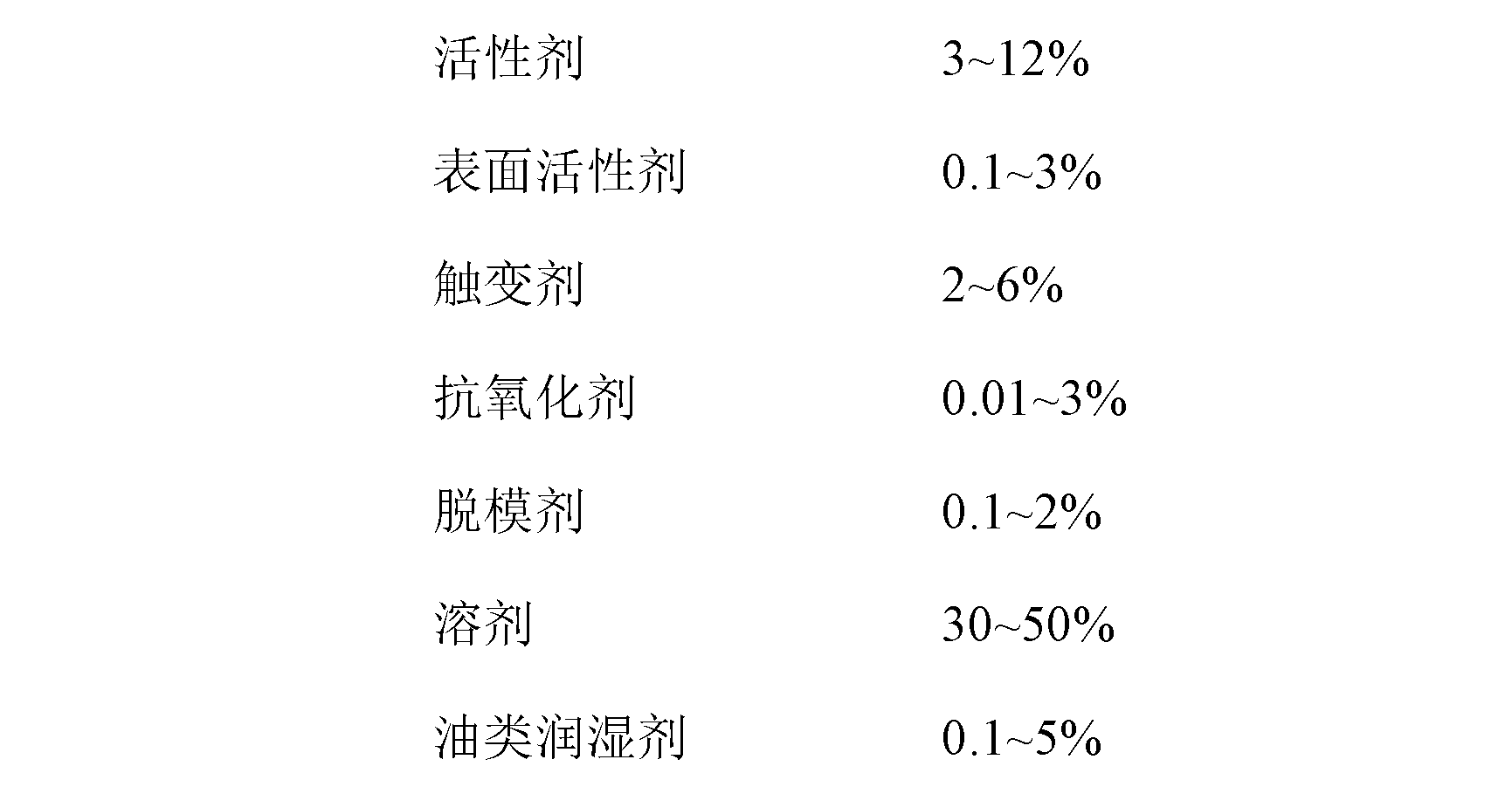

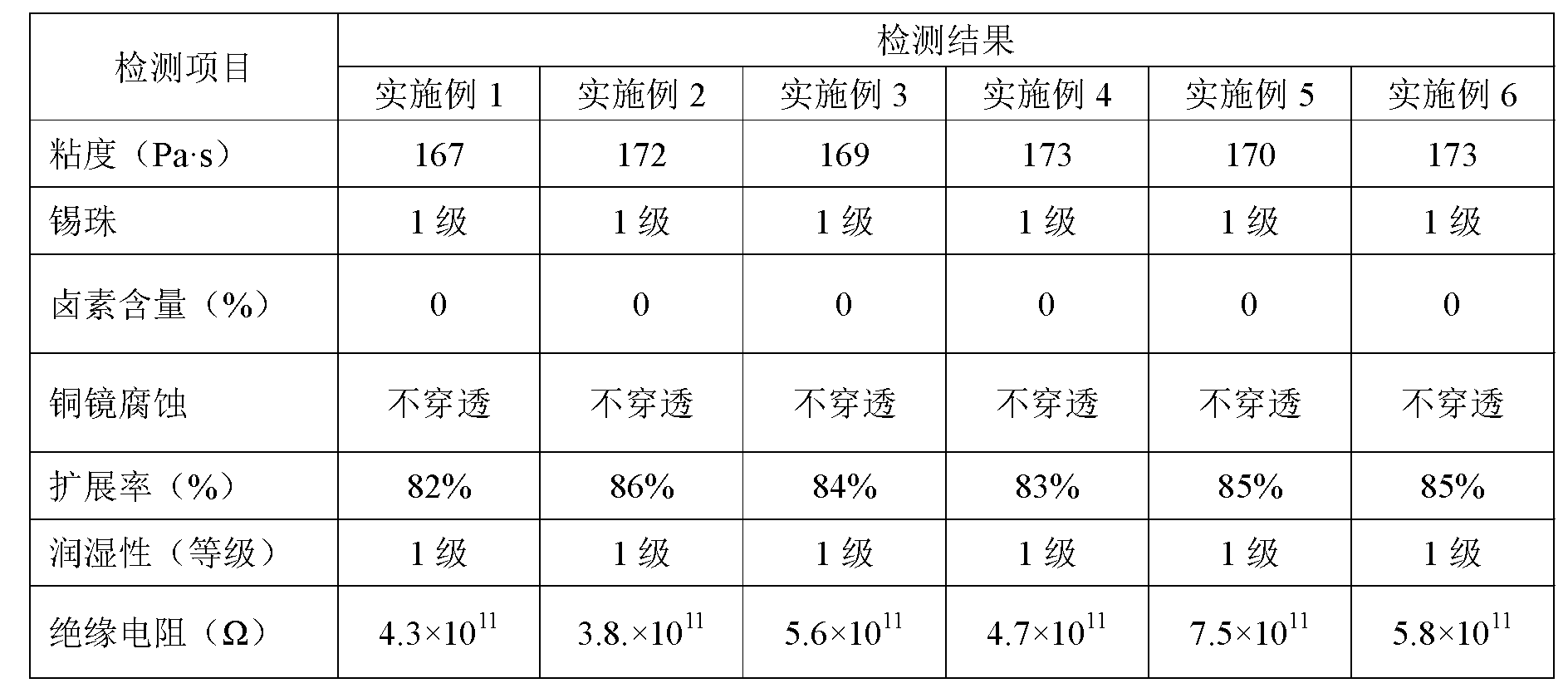

The invention relates to a halogen-free scaling powder used for a lead-free solder paste and a preparation method thereof. The halogen-free scaling powder used for the lead-free solder paste is characterized by being composed of the following components by weight percent: 25-55% of modified rosin, 3-12% of active agent, 0.1-3% of surface active agent, 2-6% of thixotropic agent, 0.01-3% of antioxidant, 0.1-2% of release agent, 30-50% of solvent and 0.1-5% of oil wetting agent, wherein the scaling powder does not contain halogen; the activity of the scaling powder can be obviously improved through adding organic carboxylic acid and hydroxy carboxylic acid as the active agent, and combining the active agent with the surface active agent; and in addition, the oil wetting agent is used, so that a layer of thin continuous oil membrane is enabled to cover the surface of a welding spot in a whole reflow soldering technological process of the solder paste, thereby playing an oxygen insulating function, and greatly improving the expansibility and the wetting property. The solder paste prepared by the scaling powder provided by the invention and a tin-silver-copper lead-free solder has the advantages of being good in printing performance, clean in demoulding, good in solderability and strong in wettability, having no penetrability corrosion in a bronze mirror after soldering, being high in soldering spot reliability and excellent in mechanical property, and capability of satisfying the high reliability requirements of high-end electronic products.

Owner:广东中实金属有限公司 +1

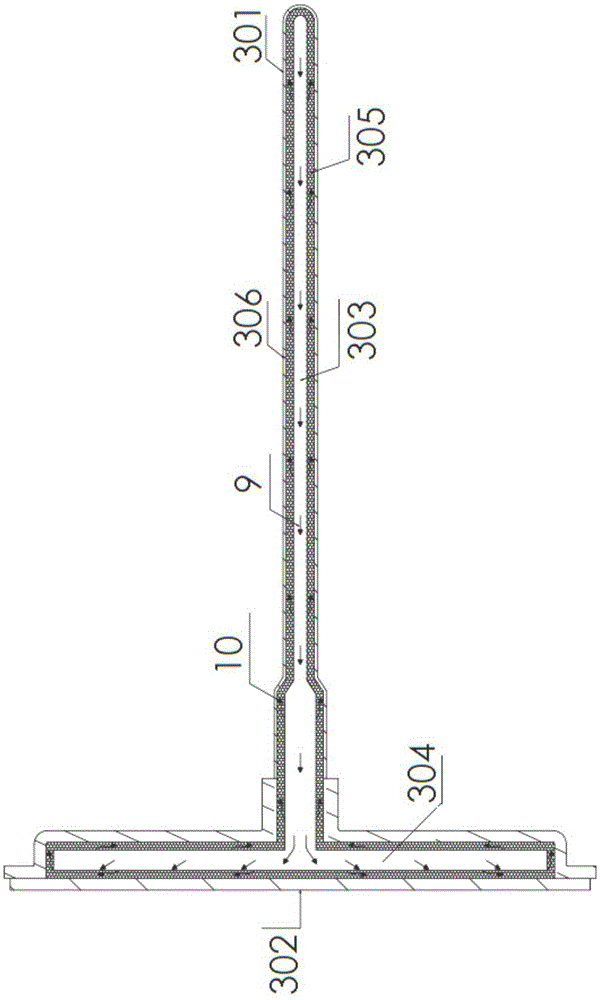

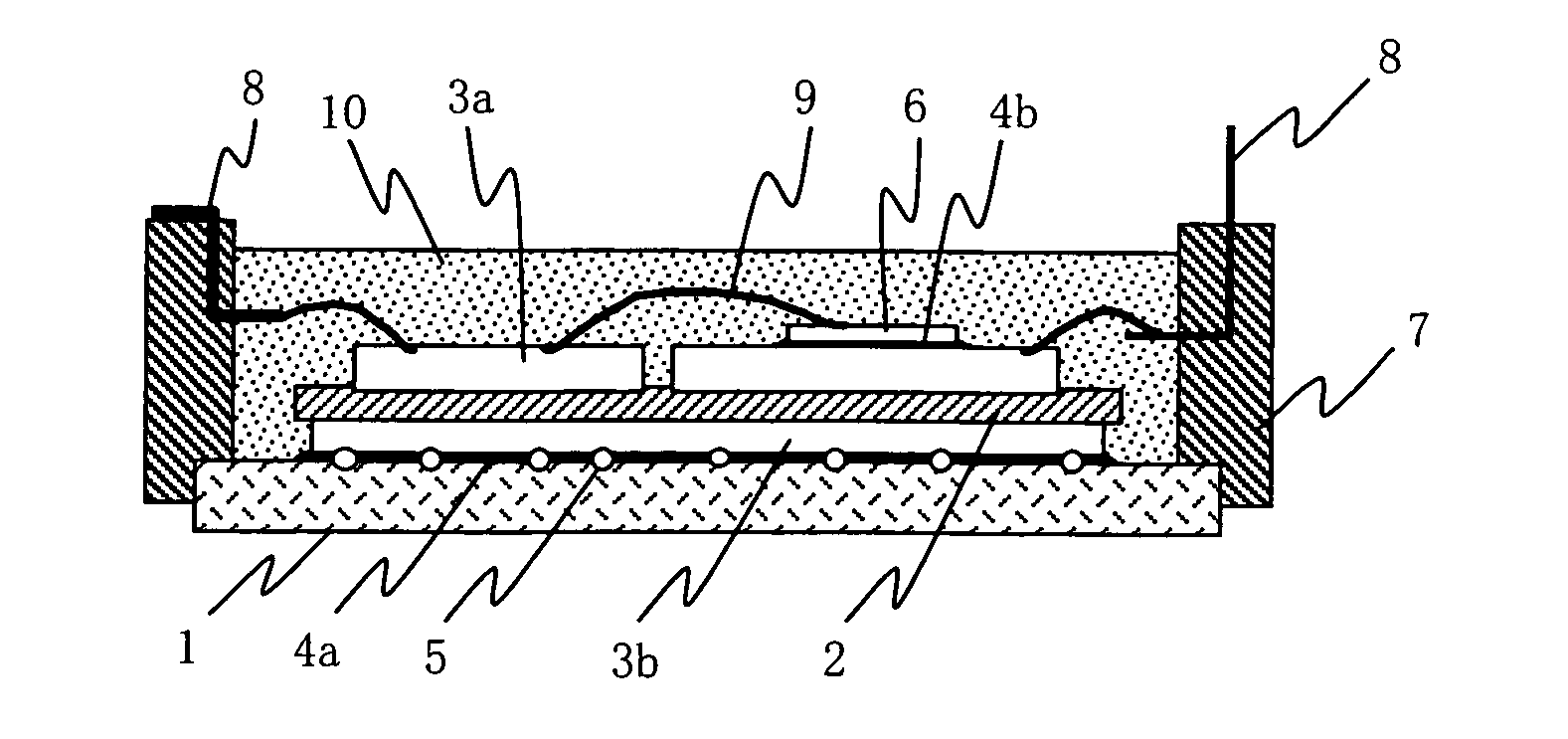

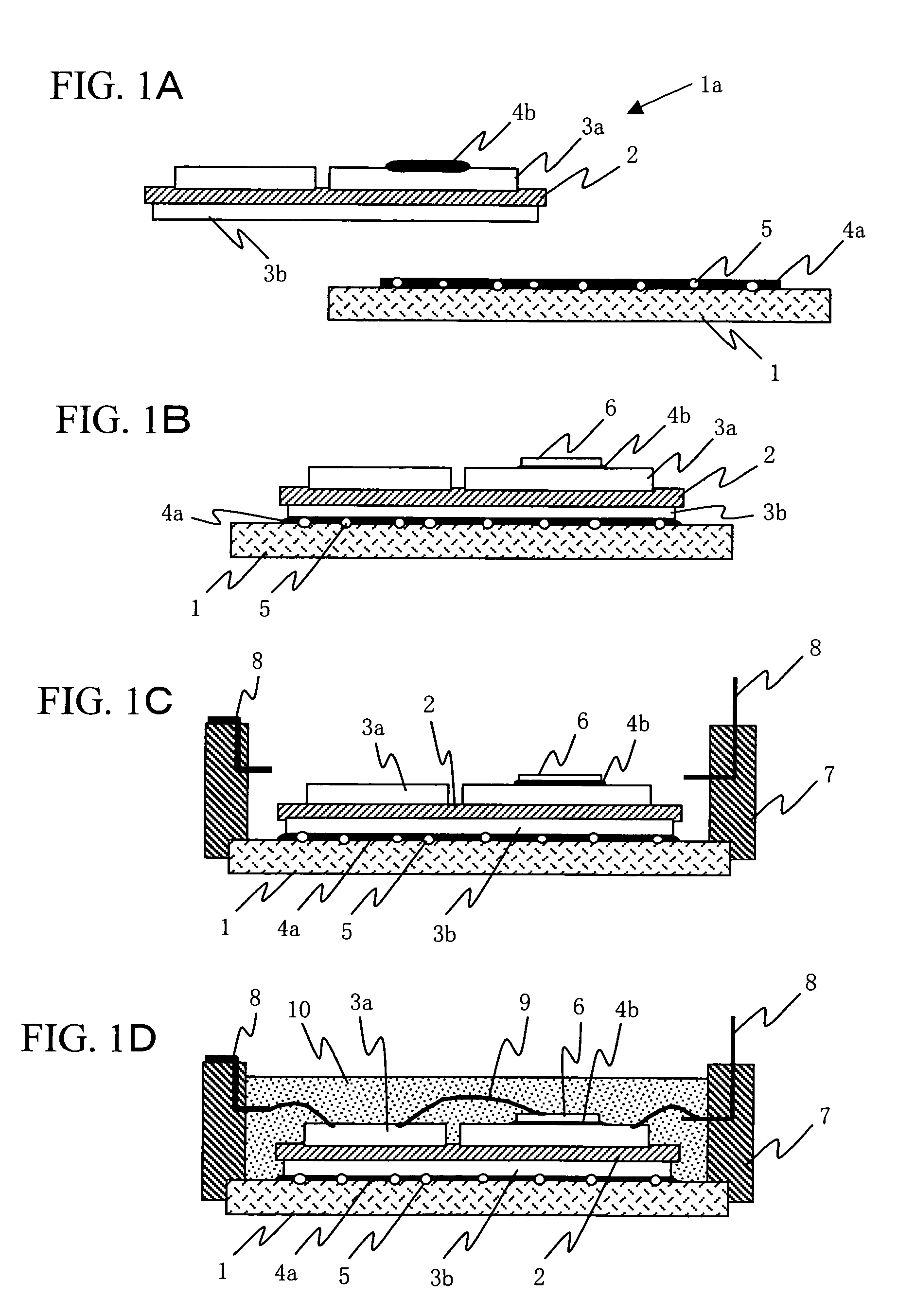

Resin encapsulated semiconductor device and the production method

ActiveUS20050221538A1Easy to moveHigh strength propertiesPrinted circuit assemblingLine/current collector detailsDevice materialSilica gel

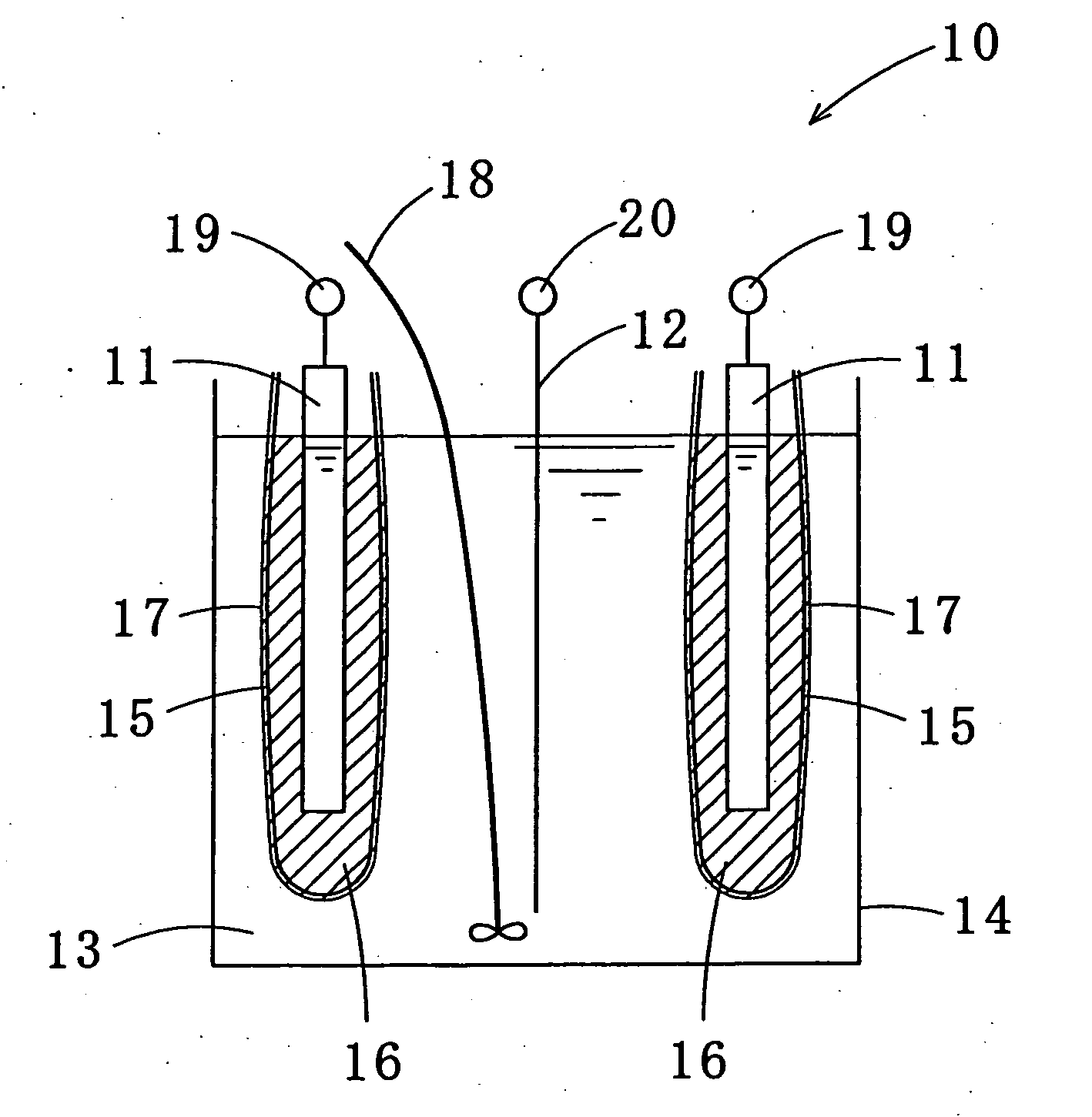

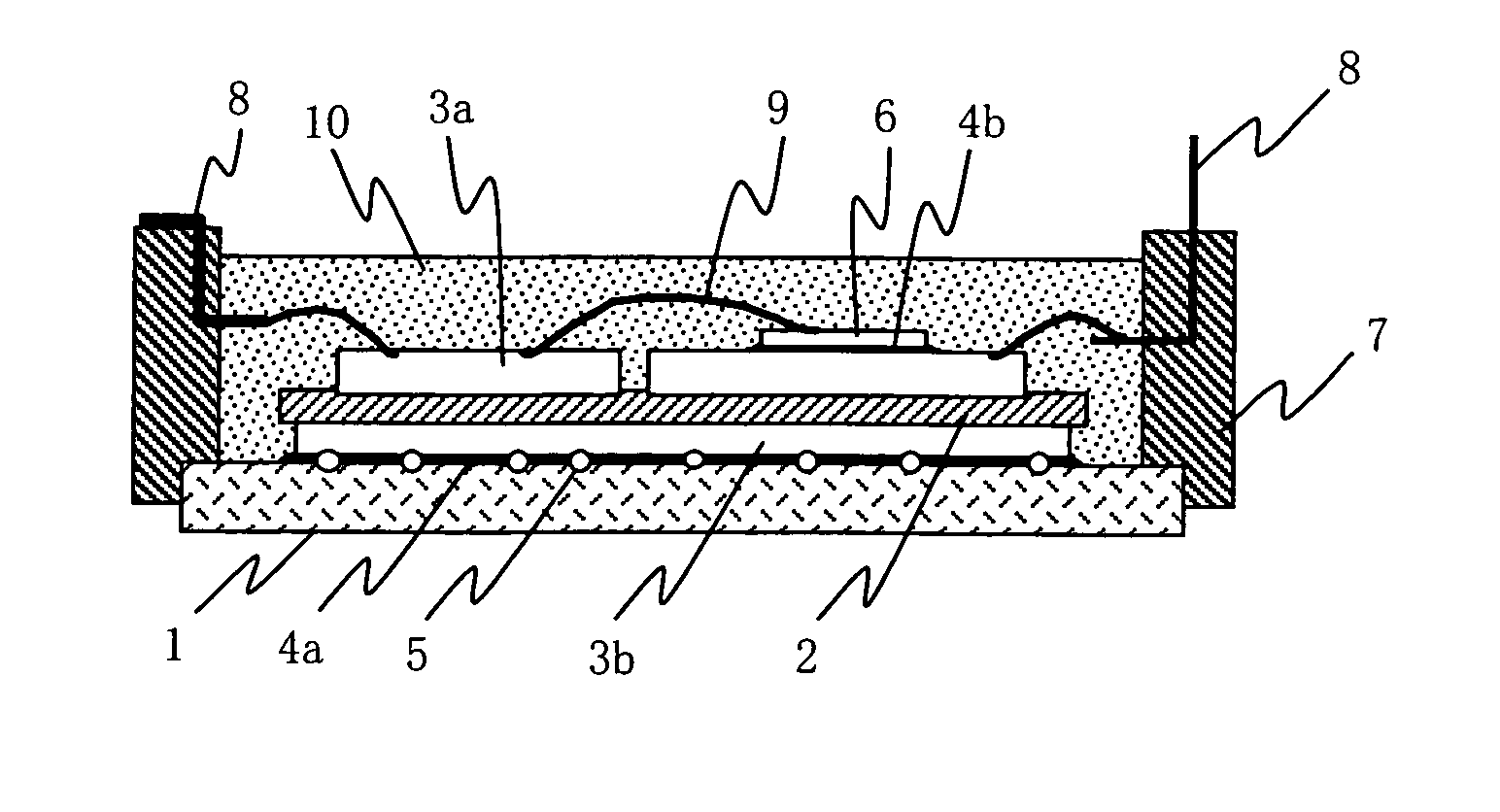

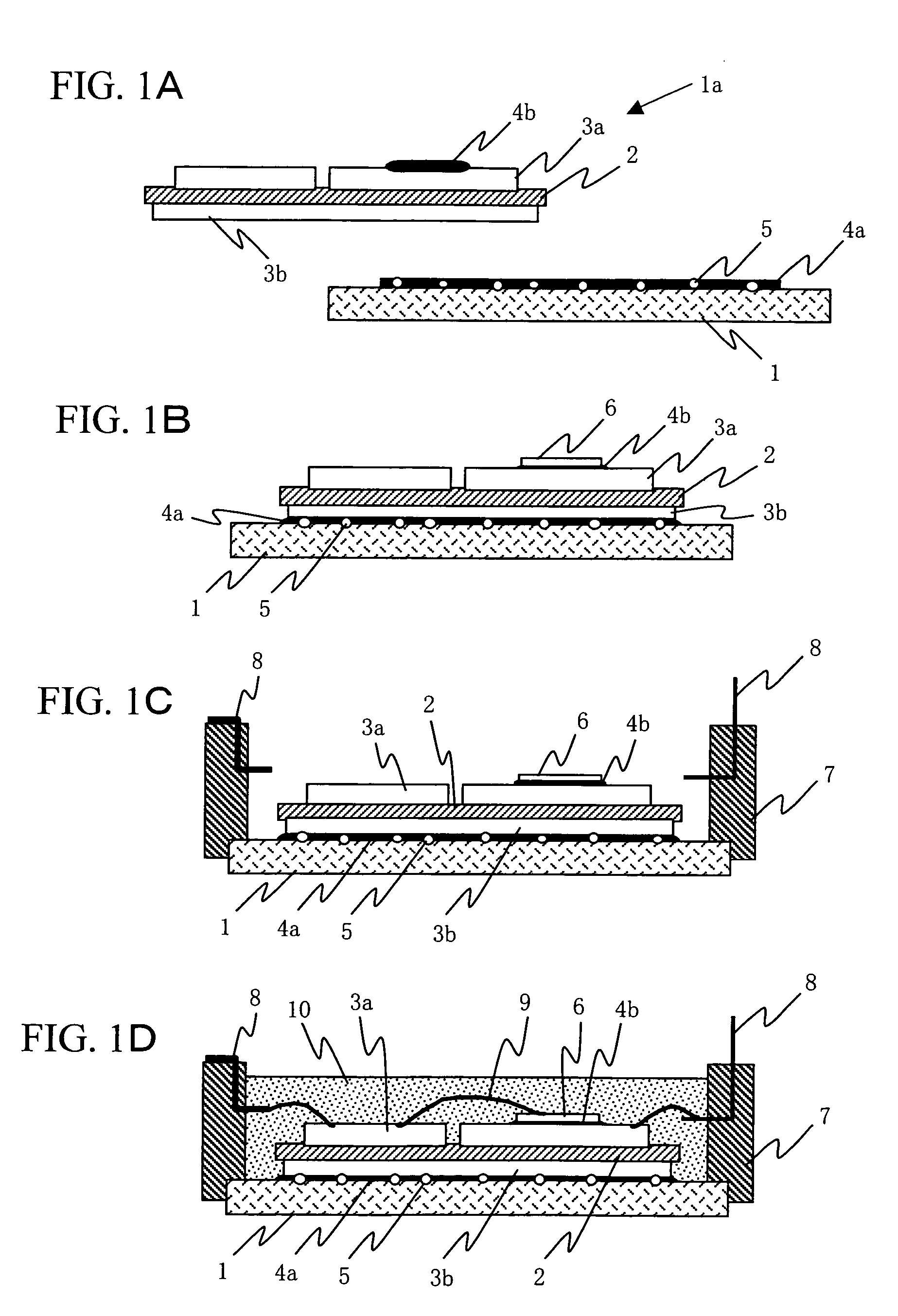

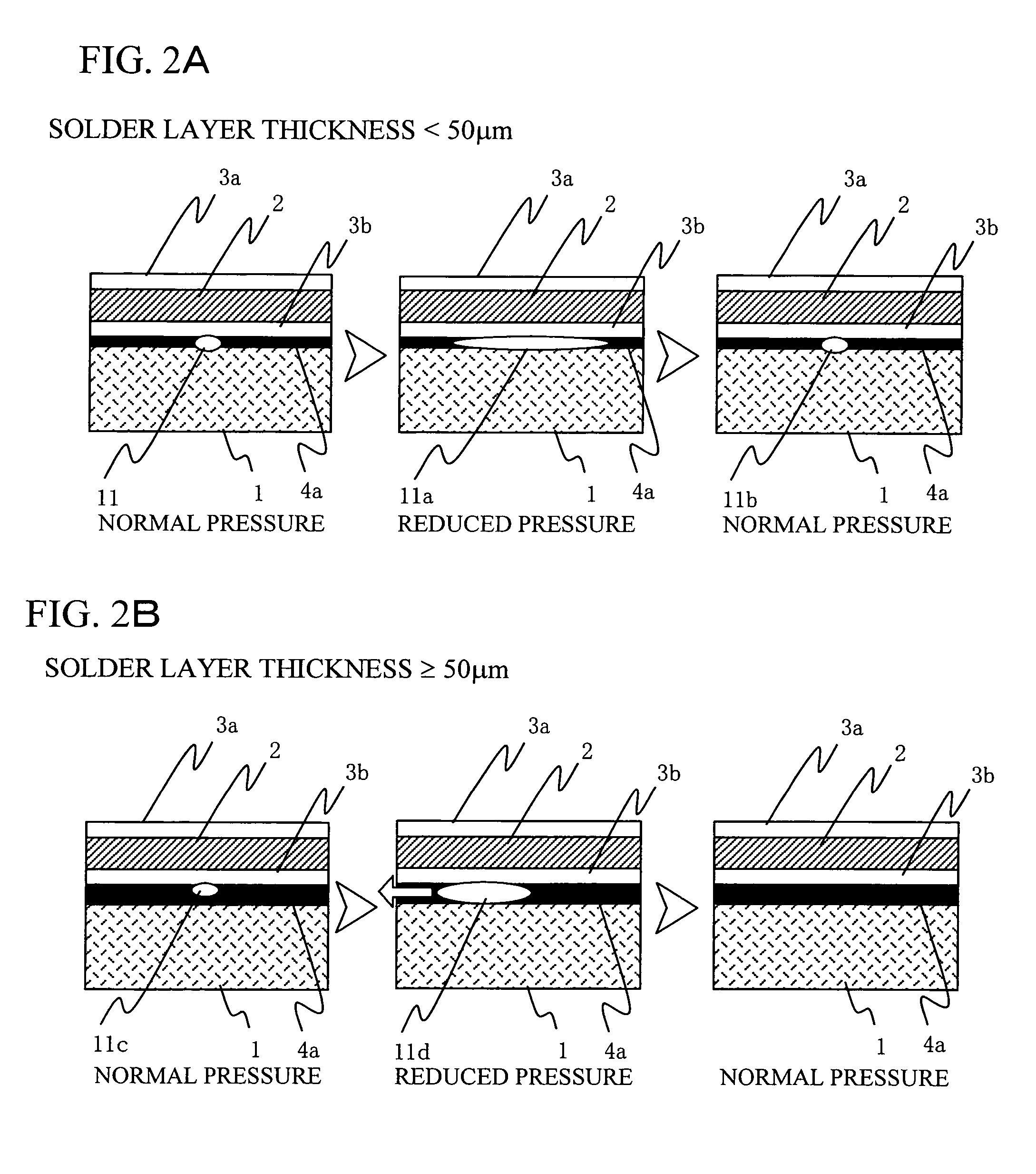

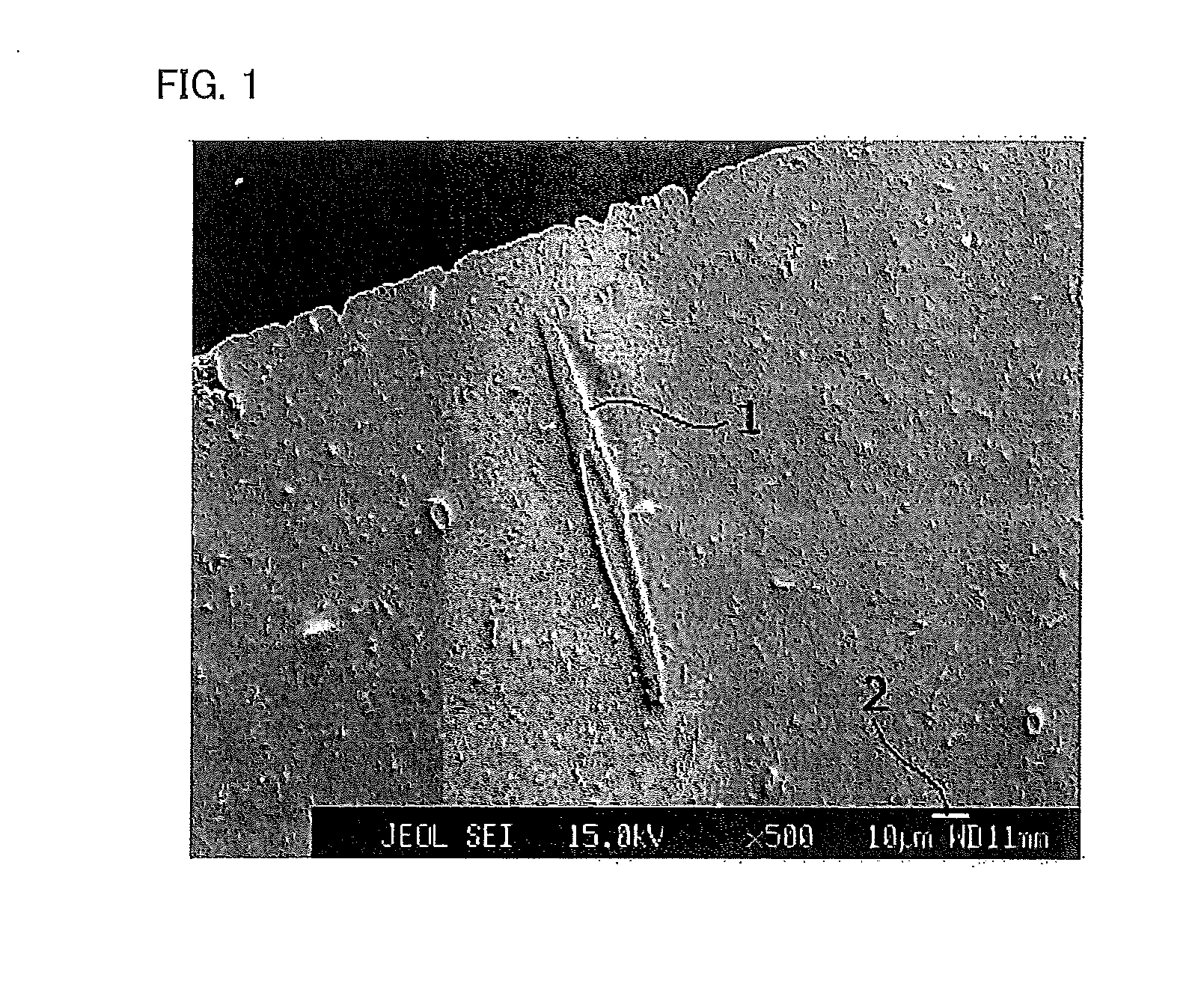

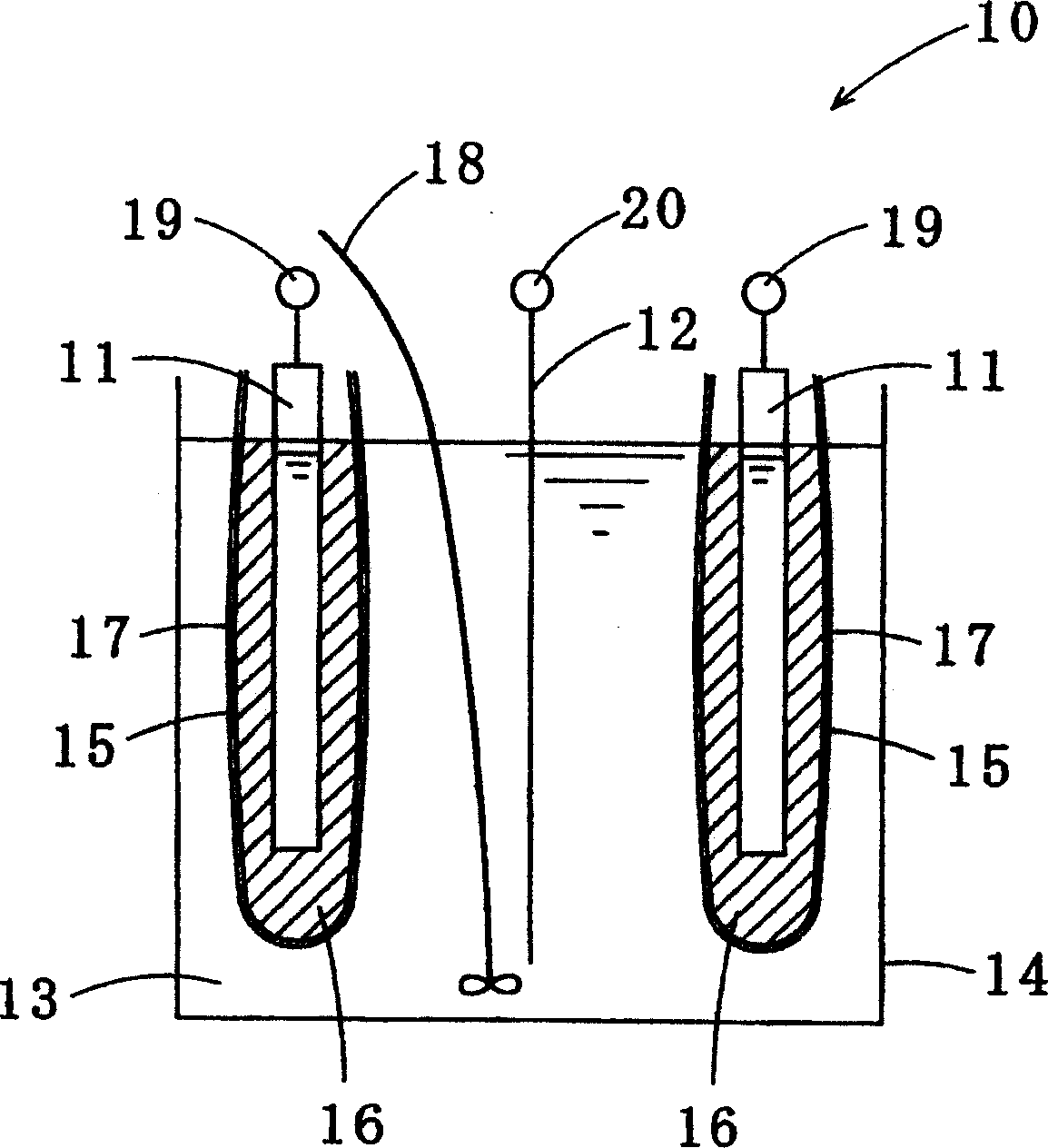

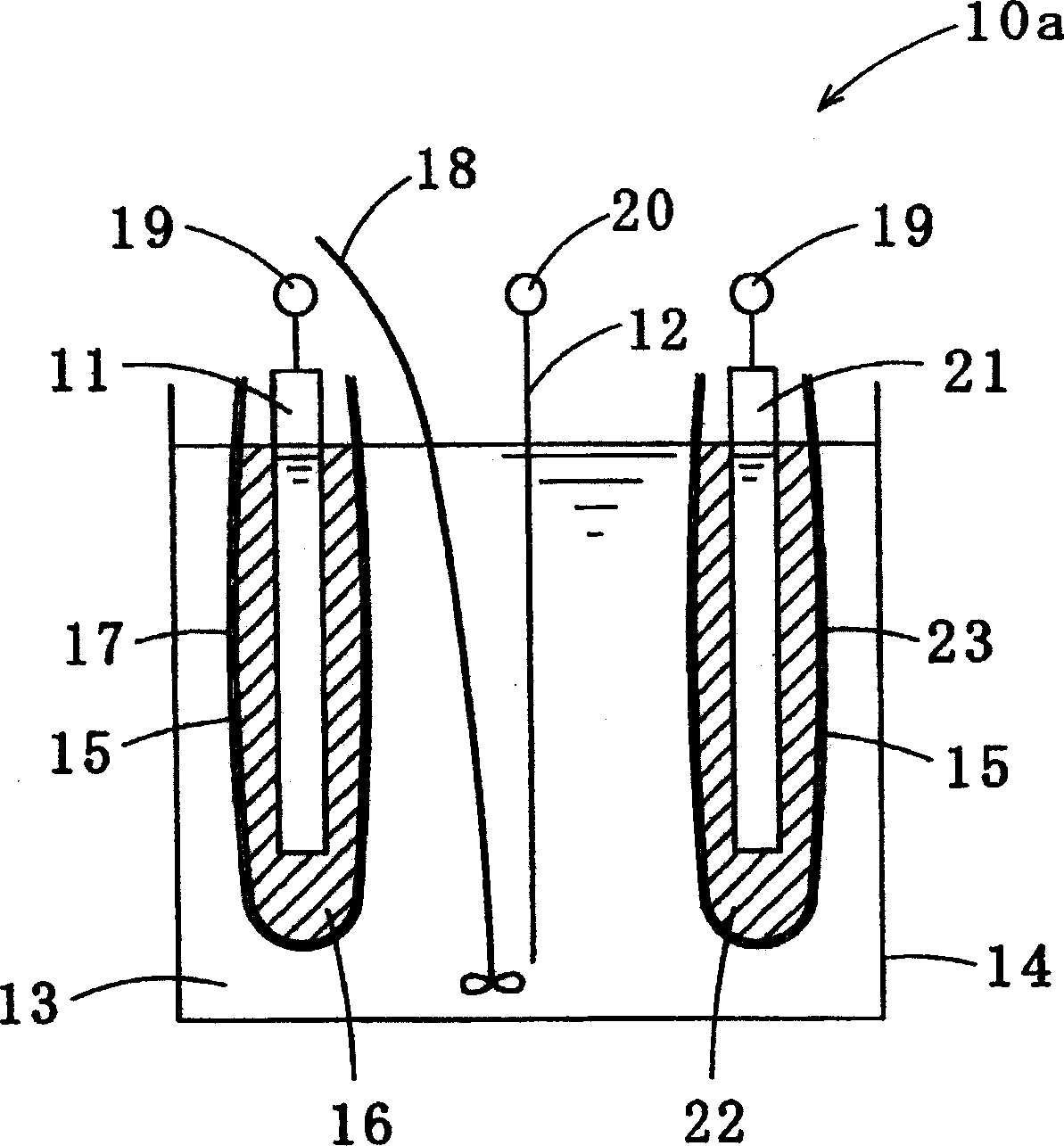

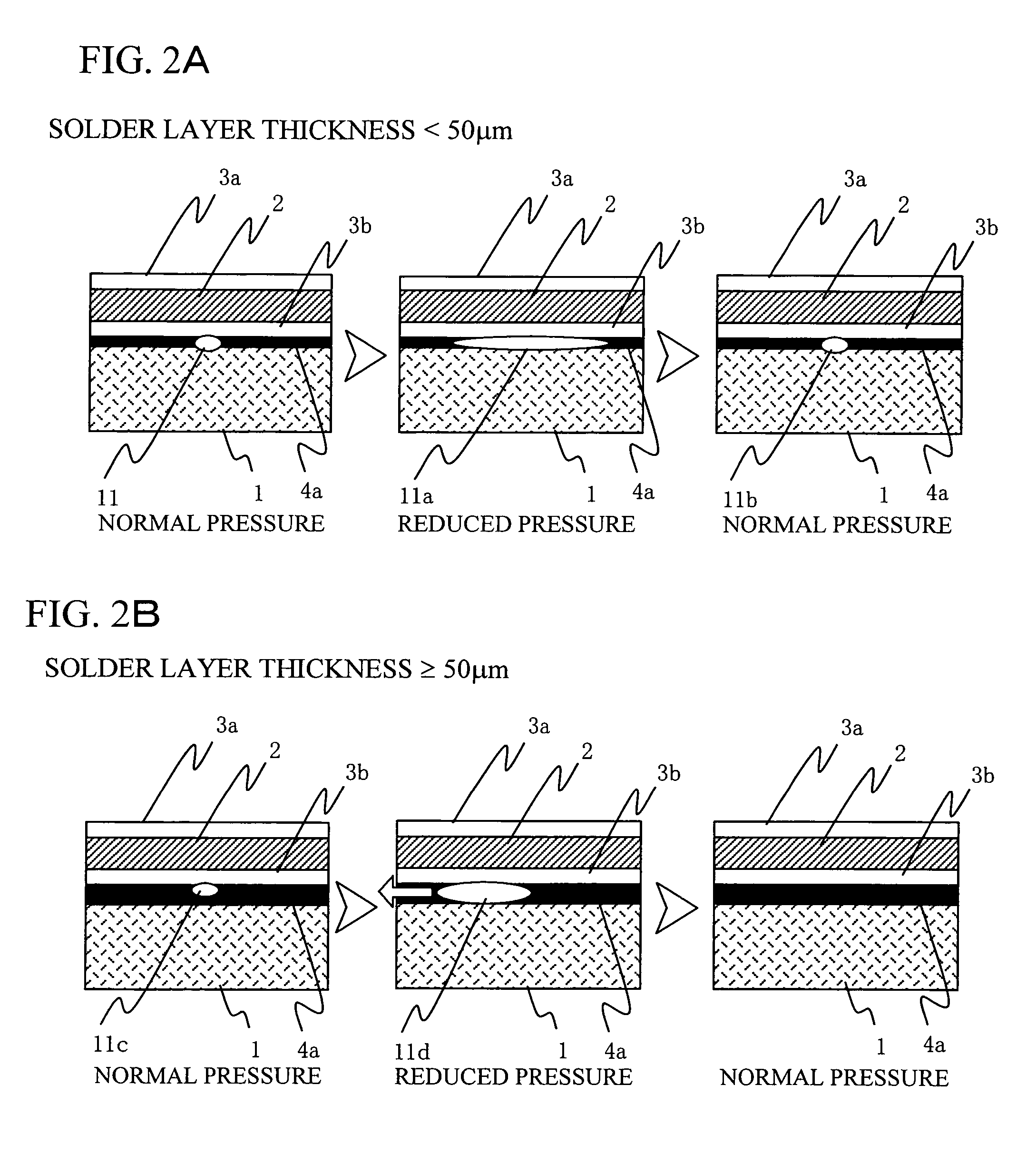

A semiconductor device having both high strength and high thermal radiation that is capable of being applied to mounting on automobiles experiencing many thermal cycles, and a manufacturing method thereof are provided. A circuit board 1a for a resin encapsulated semiconductor module device has a configuration where a silicon nitride plate 2 with a thickness of 0.635 mm has copper plates of 1.0 mm and 0.8 mm bonded to both sides thereof via active metal. A copper plate 3a is bonded to the surface side of the silicon nitride plate 2, and a prescribed circuit pattern is formed on the copper plate 3a. Tin-silver-copper cream solder layers 4a and 4b with a thickness of 200 μm are formed at a prescribed location on the circuit pattern 3a on which a semiconductor element 6 is mounted and at a prescribed location of a base plate 1 on which the circuit board 1a is disposed. Nickel particles 5 having a maximum particle size of 100 μm and an average particle size of 70 μm are dispersed in the solder 4a on the base plate 1 of good thermal conductivity. A semiconductor element (chip) 6, the circuit board 1a, and the base plate 1 are disposed on predetermined locations. Thereafter, they are set in a reflow oven (not shown in the drawings) for reflow soldering. After the inside of the reflow oven is replaced by a nitrogen atmosphere, the reflow oven is heated to 280° C. At the time when solder is melted, the inside of the oven is decompressed to 1 Pa, nitrogen is introduced, and the reflow oven is cooled to about room temperature, thereby completing the solder bonding step. After flux is washed, an outer case 7 with an insert-molded outlet terminal 8 is adhered to the base plate 1 and a predetermined connection is conducted via an aluminum bonding wire 9. Then, silicone gel 10 is injected into a package delimited via the base plate 1 and the outer case 7, and the silicone gel 10 is heat-hardened, thereby completing a resin encapsulated semiconductor device A.

Owner:HITACHI LTD +1

Solder alloy, solder paste, and electronic circuit board

ActiveUS20150305167A1Improve featuresMelting point can be suppressedPrinted circuit assemblingWelding/cutting media/materialsSolder ballTin-silver-copper

A solder alloy is a tin-silver-copper solder alloy, and contains tin, silver, copper, bismuth, nickel, and cobalt. Relative to the total amount of the solder alloy, the silver content is 2 mass % or more and 4 mass % or less, the nickel content is 0.01 mass % or more and 0.15 mass % or less, and the cobalt content is 0.001 mass % or more and 0.008 mass % or less.

Owner:HARIMA CHEM INC

Tin-silver-copper plating solution, plating film containing the same, and method for forming the plating film

A tin-silver-copper containing plating solution which comprises a medium having water as its primary component, a sulfonic acid, a tin ion, a copper ion and a silver ion, wherein concentrations of the silver ion, the tin ion and the copper ion are 0.015 to 0.1 mol / L, 0.21 to 2 mol / L and 0.002 to 0.02 mol / L, respectively; a plating film which comprises 2.6 to 3.4 wt % of silver, 0.4 to 0.7 wt % of Cu and the substantially balanced amount of tin; an electrolytic plating method for use in forming the above plating film from the above plating solution; and a soldering method using the plating film. The plating solution exhibits high stability, and the plating film has a low melting point.

Owner:SHINRYOI CORP

Lead-free tin solder paste and preparation method thereof

InactiveCN105014253AImprove adhesionImprove stabilityWelding/cutting media/materialsSoldering mediaOrganic acidActive agent

The invention discloses a lead-free tin solder paste and a preparation method thereof. The lead-free tin solder paste comprises the raw materials by mass percent: 80-90% of tin-silver-copper alloy tinpowder and 10-20% of lead-free flux, wherein the tin-silver-copper alloy tin powder comprises the componentsby mass percent: 0.3-3.0% of silver, 0.5-0.7% of copper and 96.5-99.0% of tin, and the lead-free flux comprises the componentsby mass percent: 20-35% of solvent, 30-45% of rosin, 5-10% of surface active agent, 10-20% of organic acid, 3-10% of antioxidant and 2-8% of thixotropic agent. The rosin which is a mixture of hydrogenated rosin and polymerized rosin according to a weight ratio of 1:(1-3) is adopted, so that the prepared lead-free tin solder paste is good in adhesive force and stability; by adjusting a ratio of the solvent to the rosin, the prepared lead-free tin solder paste has a wider viscosity range and good printing performance; with the compounding of various organic acid, the prepared lead-free tin solder paste is halogen-free, and the activity of the lead-free tin solder paste is improved greatly; the surface active agent is compounded with the solvent with high boiling point, low viscosity and low volatility, so that the prepared lead-free tin solder paste is long in printing time, and excellent in insulating property.

Owner:JIANGSU BOQIAN NEW MATERIALS

Stannum-silver-copper three-part alloy leadless solder paste

InactiveCN101269444AAvoid damageLower peak temperatureWelding/cutting media/materialsSoldering mediaTin-silver-copperPeak value

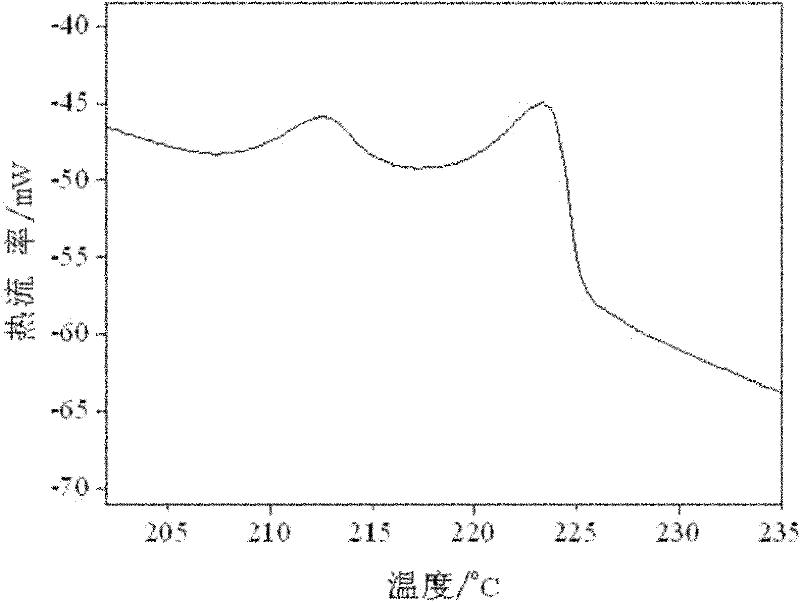

The invention relates to a tin-silver-copper ternary alloy lead-free soldering paste. Alloy welding powder is made to the soldering paste through bismuth-tin binary eutectic alloy welding powder Bi48Sn42 and Sn-Ag-Cu ternary alloy welding powder with a melting point between 200 to 230 DEG C as well as scaling powder; wherein, the bismuth-tin binary eutectic alloy welding powder takes the 80 to 90 percent of mass percent; the tin-copper binary eutectic alloy welding powder takes 9.6 to 19.5 percent of mass percent; the scaling powder takes 0.1 to 0.5 percent of mass percent. The tin-silver-copper ternary alloy lead-free soldering paste keeps the peak value temperature in reflow soldering process between 210 to 215 DEG C, greatly reducing the peak value temperature and the possibility of damaging a breadboard and an element device.

Owner:CHANGSHA TAIHUI NETWORK TECH

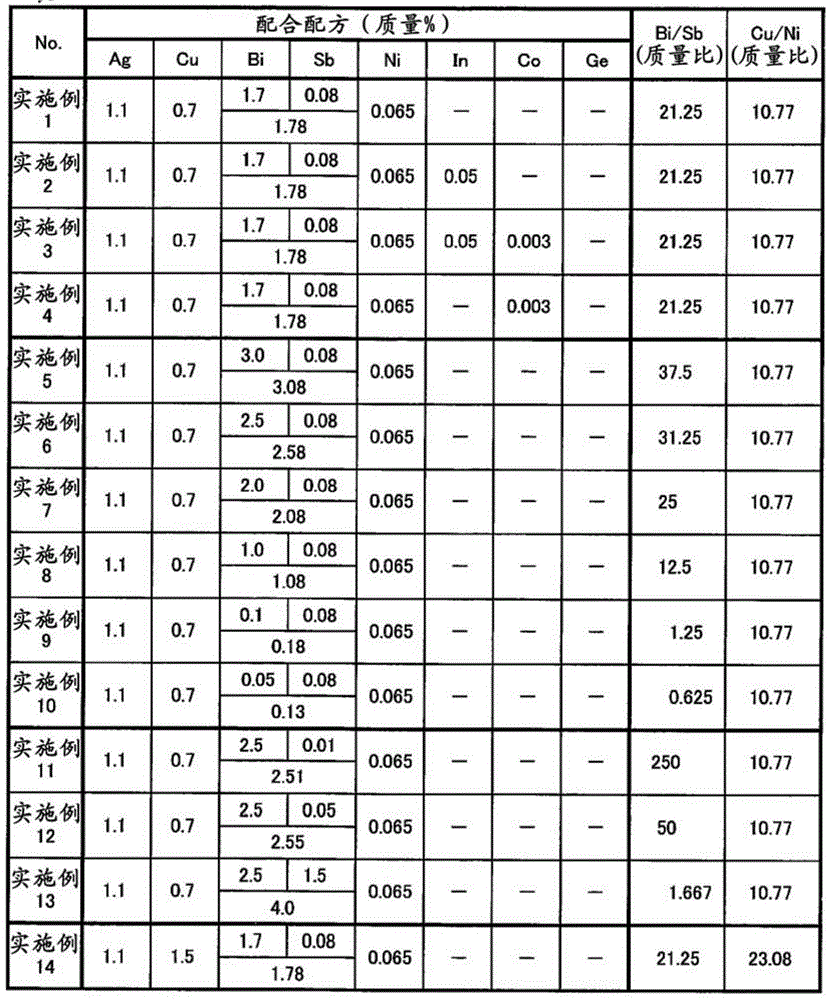

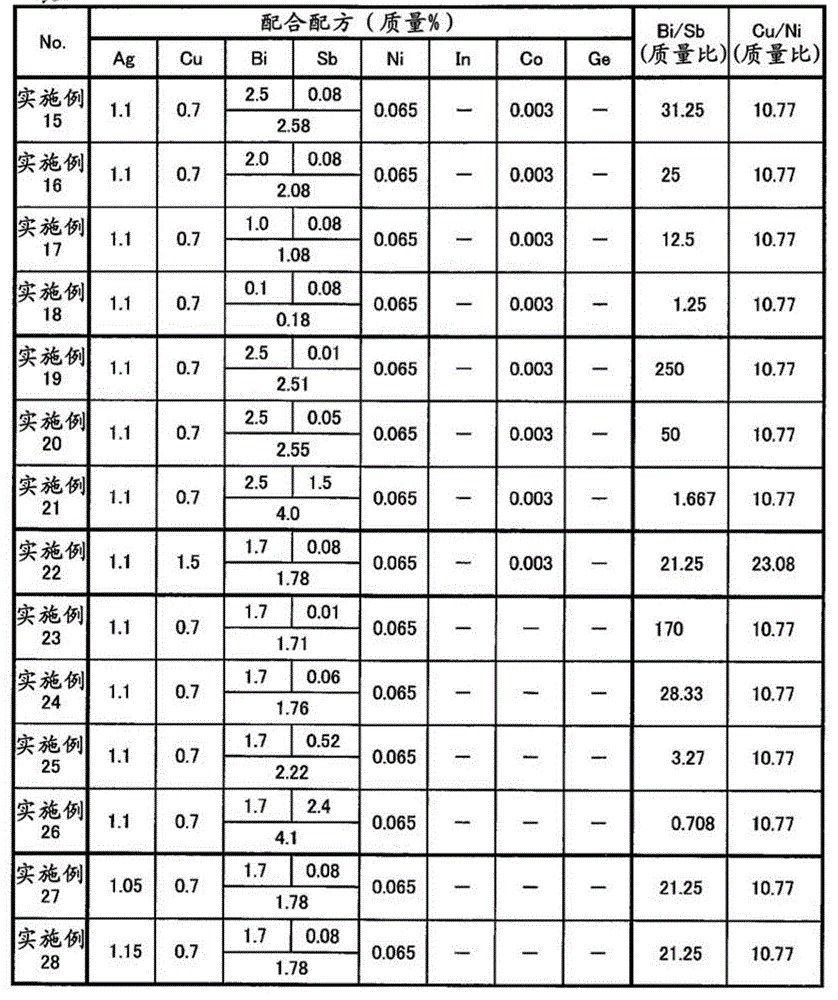

Solder alloy, solder paste, and electronic circuit board

ActiveUS20150136461A1Low costEasy to oxidizePrinted circuit detailsPrinted circuit aspectsTin-silver-copperCopper

A solder alloy of a tin-silver-copper solder alloy, containing tin, silver, antimony, bismuth, copper, and nickel, and substantially does not contain germanium, relative to the total amount of the solder alloy, the silver content is more than 1.0 mass % and less than 1.2 mass %, the antimony content is 0.01 mass % or more and 10 mass % or less, and the bismuth content is 0.01 mass % or more and 3.0 mass % or less.

Owner:HARIMA CHEM INC

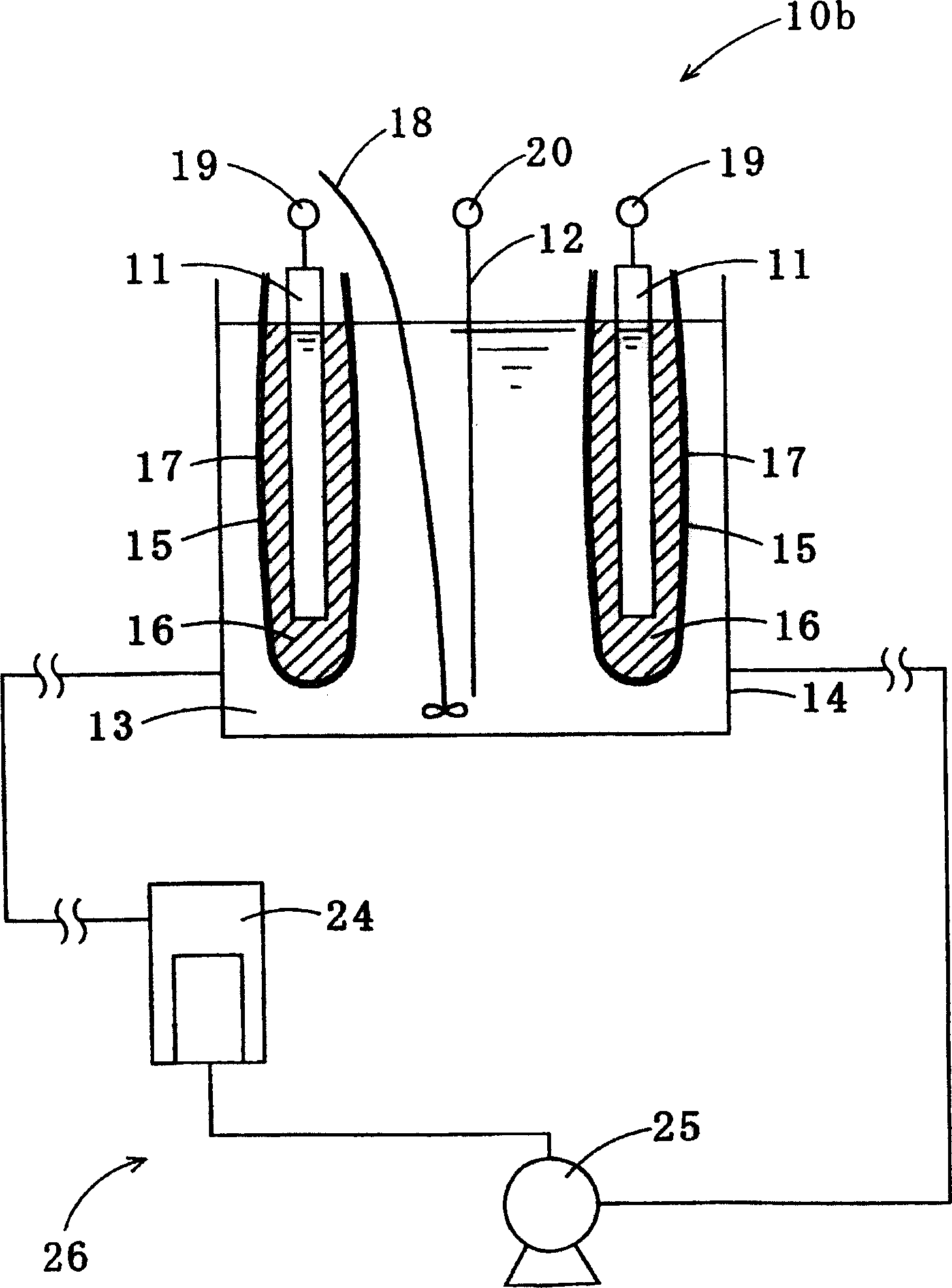

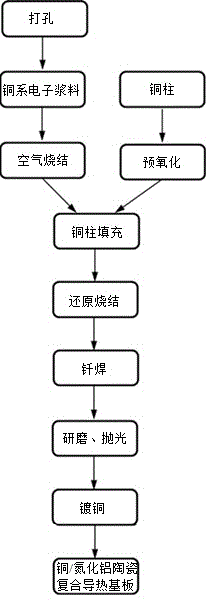

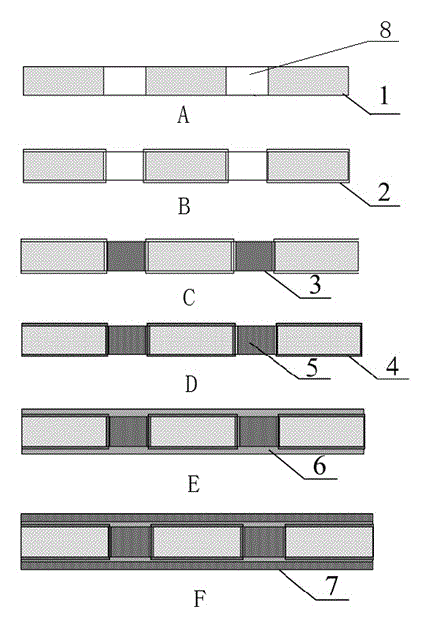

Preparation method for copper/aluminium nitride ceramic composite heat-conductive substrate

InactiveCN104064478AGuaranteed smoothGuaranteed flow capacitySemiconductor/solid-state device detailsSemiconductor/solid-state device manufacturingCopper platingCeramic composite

The invention discloses a preparation method for a copper / aluminium nitride ceramic composite heat-conductive substrate. The method comprises the following steps: 1) providing through holes in the surface of an aluminium nitride substrate; 2) coating copper electronic paste layers on the double surfaces of the aluminium nitride substrate; 3) filling the through holes with pre-oxidation copper cylinders; 4) carrying out overall sintering for 30 min; 5) carrying out brazing after the double surfaces of the aluminium nitride substrate being coated with tin silver copper solder materials; 6) carrying out surface polishing; and 7) carrying out copper plating processing directly and forming uniform copper layers, and thus, the copper / aluminium nitride ceramic composite heat-conductive substrate is obtained. The through holes in the copper / aluminium nitride ceramic composite heat-conductive substrate produced with the preparation method are communicated up and down; the combination between the metalized layers in the holes and the ceramic substrate is strong; the middle copper cylinders can realize the communication of the copper layers on the upper and lower surfaces; and the copper / aluminium nitride ceramic composite heat-conductive substrate helps the transmission of electrical signals and has the advantages of ideal heat-conductive effect, low thermal expansion coefficients and good conductivity and the like.

Owner:NANJING MING KUANG ELECTRONICS TECH

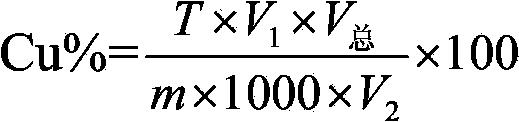

Method for measuring copper content in tin-silver-copper solder through iodometry

InactiveCN103776820AAccurate measurementReduce distractionsMaterial analysis by observing effect on chemical indicatorPreparing sample for investigationPotassium thiocyanateDissolution

Provided is a method for measuring copper content in tin-silver-copper solder through iodometry. The method comprises the following steps: a copper standard solution is prepared and the titer of the copper standard solution is measured. A sample to be measured is weighed and added into an Erlenmeyer flask. Concentrated sulfuric acid is added and the mixture is heated for dissolution. The above solution is cooled to the room temperature, perchloric acid is added, after the sample is dissolved fully, heating is carried out until white smoke is generated, concentrated hydrochloric acid is dropwise added into the above solution in batches to remove the tin element in the solution, and the solution is subjected to concentration. The Erlenmeyer flask is taken down and cooled to the room temperature, deionized water is added, the constant volume is 100mL and the above solution is shaken up. Then an ammonium hydroxide solution is added and copper ammonia complex ions are formed. Then ammonium bifluoride is added into the solution and stirred until the blue color disappears. The above solution is cooled to the room temperature by utilization of running water. The solution is placed for half a minute, then potassium iodide is added, and immediately the solution is subjected to titration by a sodium hyposulfite standard solution until a shallow yellow color appears. Then a potassium thiocyanate solution and a starch solution are added, and the solution is subjected to titration by the sodium hyposulfite standard solution until a blue color disappears. The volume of the consumed sodium hyposulfite solution is recorded, and the content of copper in the sample is calculated.

Owner:BEIJING INST OF NONFERROUS METALS & RARE EARTH

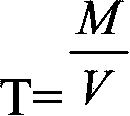

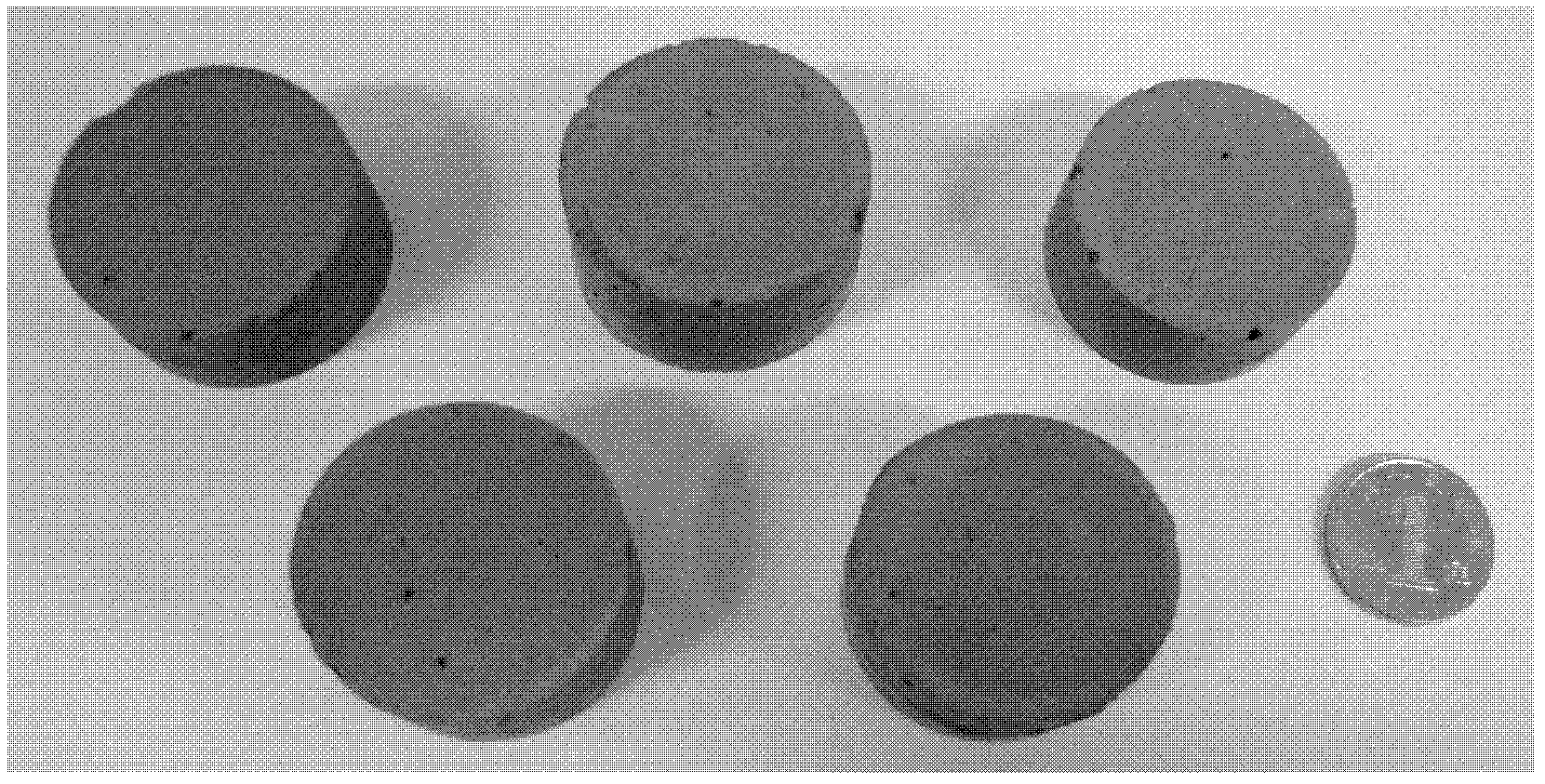

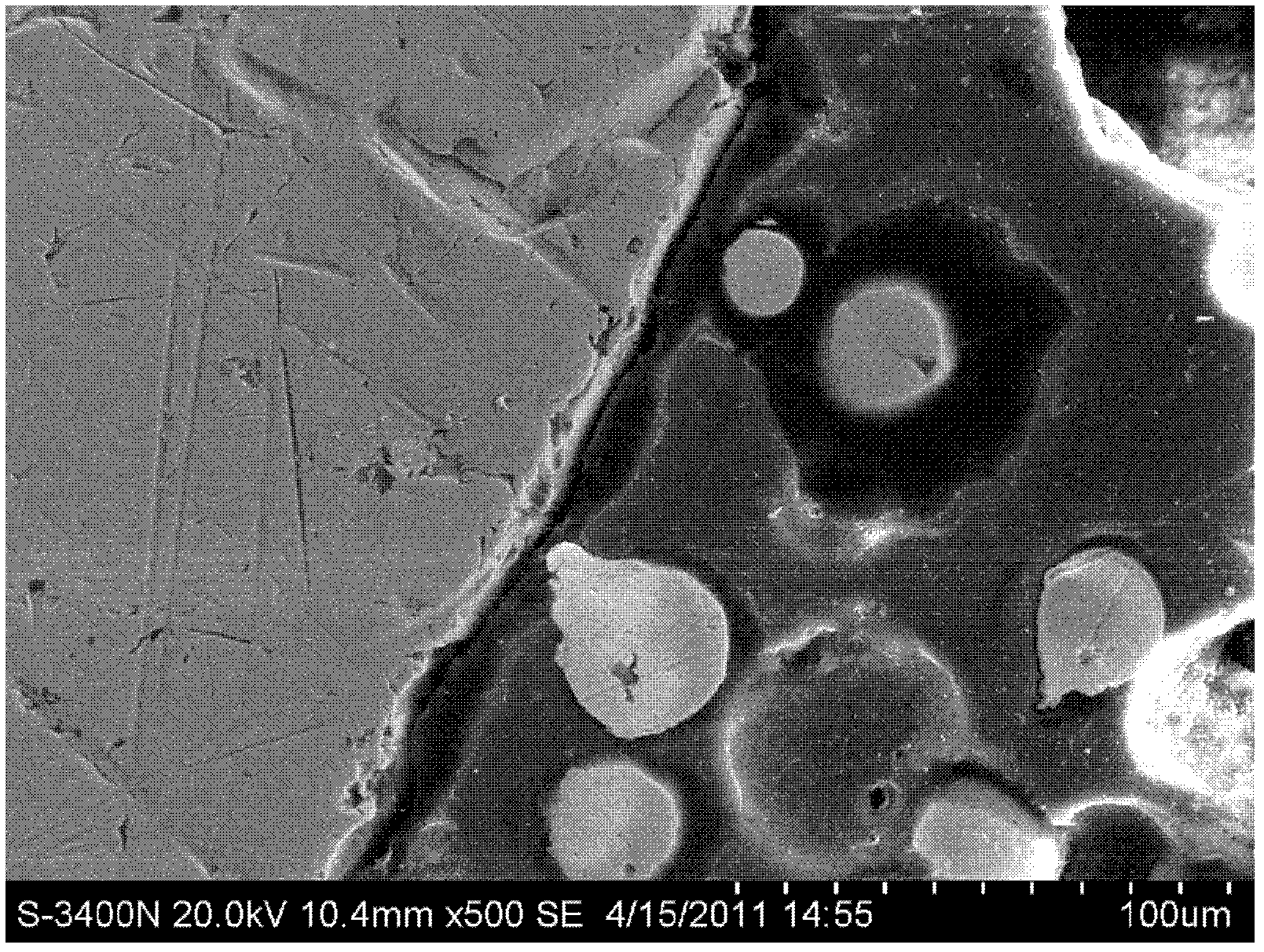

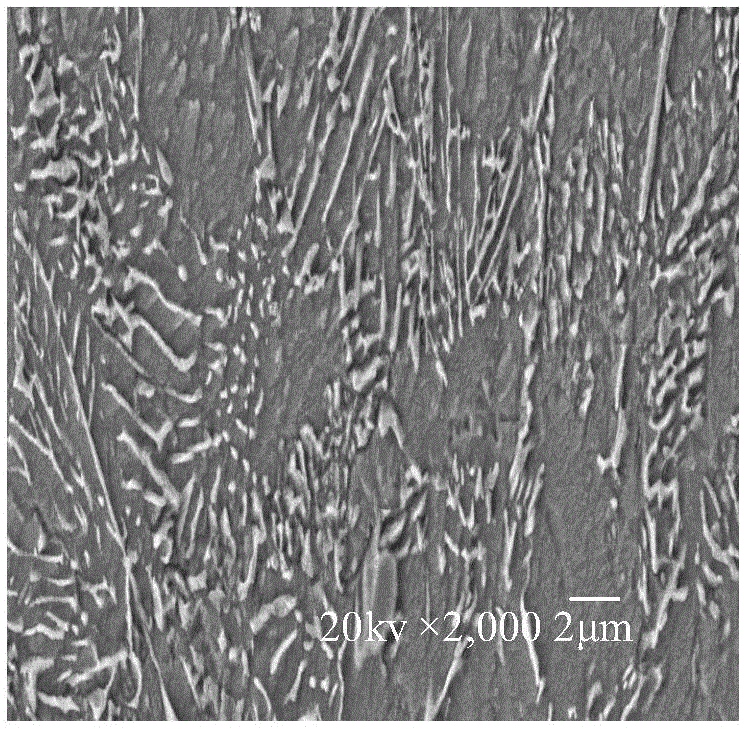

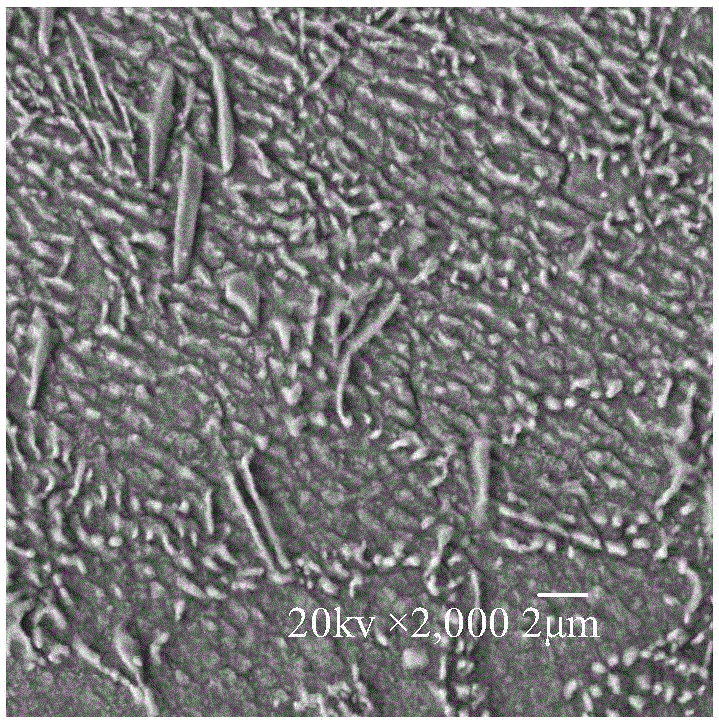

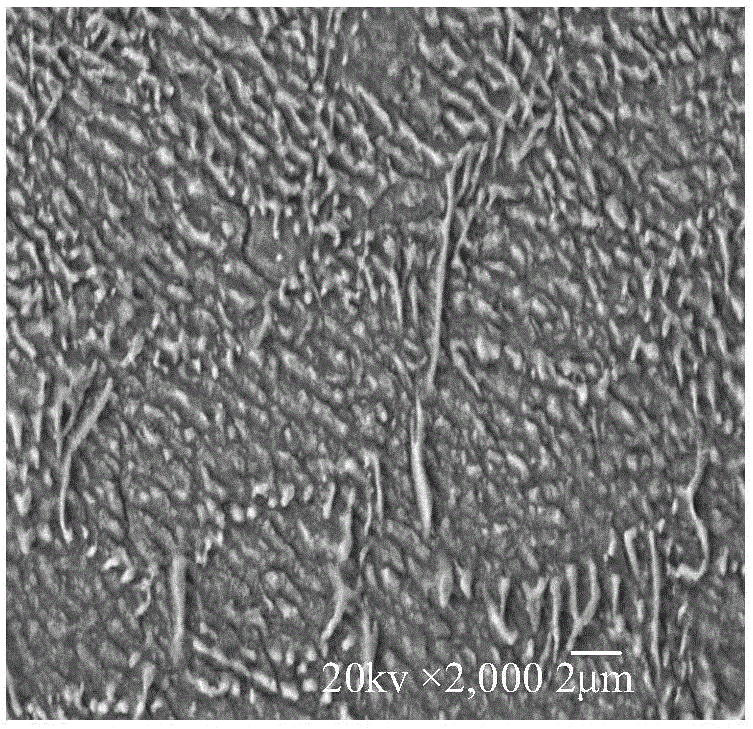

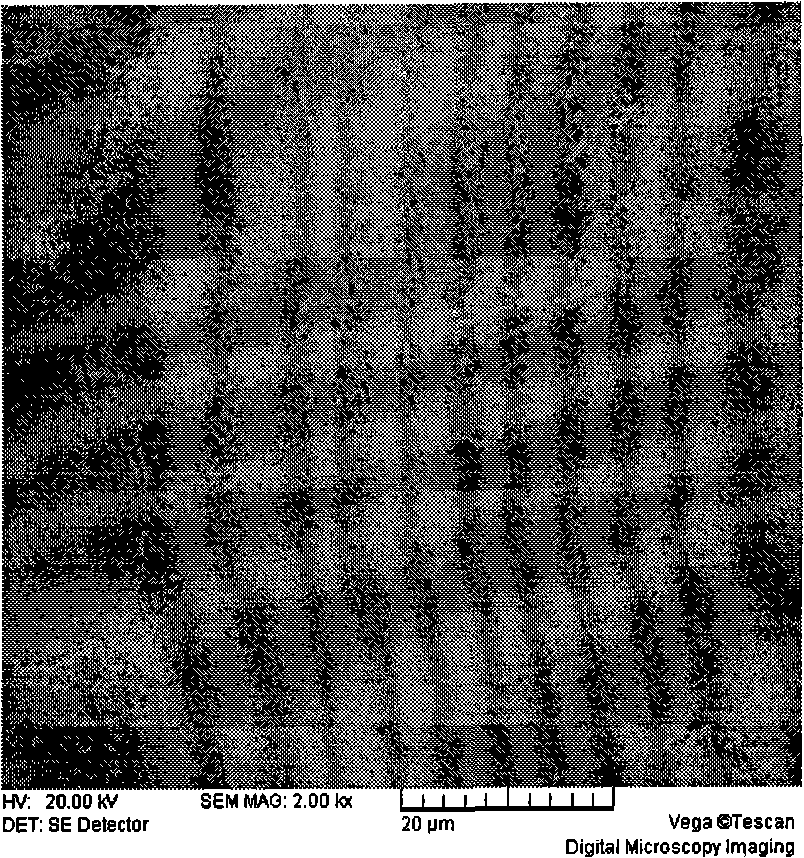

Conducting resin for scanning electronic microscope and preparation method thereof

InactiveCN102504485ASolve processing problemsAffect imagingAntifouling/underwater paintsPaints with biocidesEpoxyEthylene diamine

The invention discloses conducting resin for a scanning electronic microscope and a preparation method thereof, which belongs to the technical field of resin composite materials. The conducting resin adopts epoxy resin as a base material, ethylene diamine as a curing agent, and tin-silver-copper powder or silver-coated copper powder as conductive particles, and comprises the following components by mass percent: 32-34% of epoxy resin, 3-4% of ethylene diamine and 62-65% of tin-silver-copper powder or silver-coated copper powder. Ethylene diamine is added into epoxy resin and simultaneously uniformly stirred; the conductive particles are added and stirred at the same time till the conductive particles are completely uniformly dispersed and glue-like mixture reaches a substantially cured degree; the glue-like mixture is added into a die; and the glue-like mixture is dried and cured at room temperature, and then samples are taken out. The conducting resin can fully meet the requirements of SEM (scanning electron microscope) observation.

Owner:BEIJING UNIV OF TECH

Ceramic substrate and copper clad foil low-temperature connecting soldering paste and production process thereof

InactiveCN106312361AImprove wettabilityQuality assuranceWelding/cutting media/materialsSoldering mediaActive agentSolvent

The invention relates to the field of electronic packaging, in particular to a ceramic substrate and copper clad foil low-temperature connecting soldering paste for a powder module and a production process thereof. The soldering paste is composed of brazing filler metal powder and scaling powder; the brazing filler metal powder is tin-silver-copper-titanium powder, the mass fraction of the Sn in the tin-silver-copper-titanium powder ranges from 35%-50%, the mass fraction of the Ag in the tin-silver-copper-titanium powder ranges from 15%-35%, the mass fraction of the Cu in the tin-silver-copper-titanium powder ranges from 20%-40%, and the mass fraction of the Ti in the tin-silver-copper-titanium powder ranges from 4%-8%; and the scaling powder mainly comprises, by weight, 24%-35% of rosin, 45%-50% of a solvent, 2%-6% of a corrosion inhibitor, 8% of an active agent, 6% of a thixotropic agent and 4%-15% of a thickening agent. According to connection of a ceramic substrate and copper, the process can be simplified, the connecting temperature can be remarkably reduced, the heat stress and the interface voidage are accordingly reduced, and the connector quality is accordingly improved.

Owner:HARBIN INST OF TECH AT WEIHAI

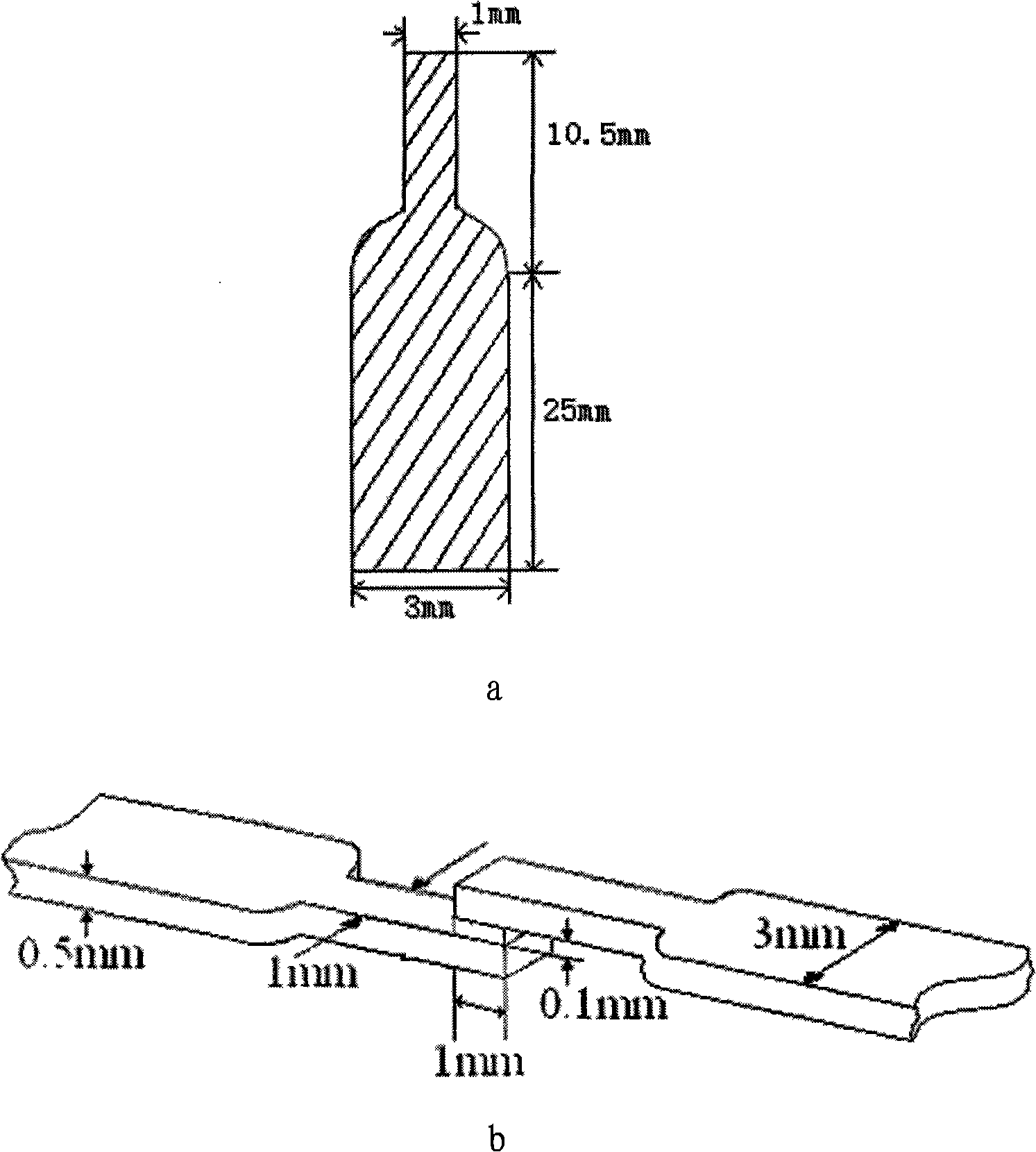

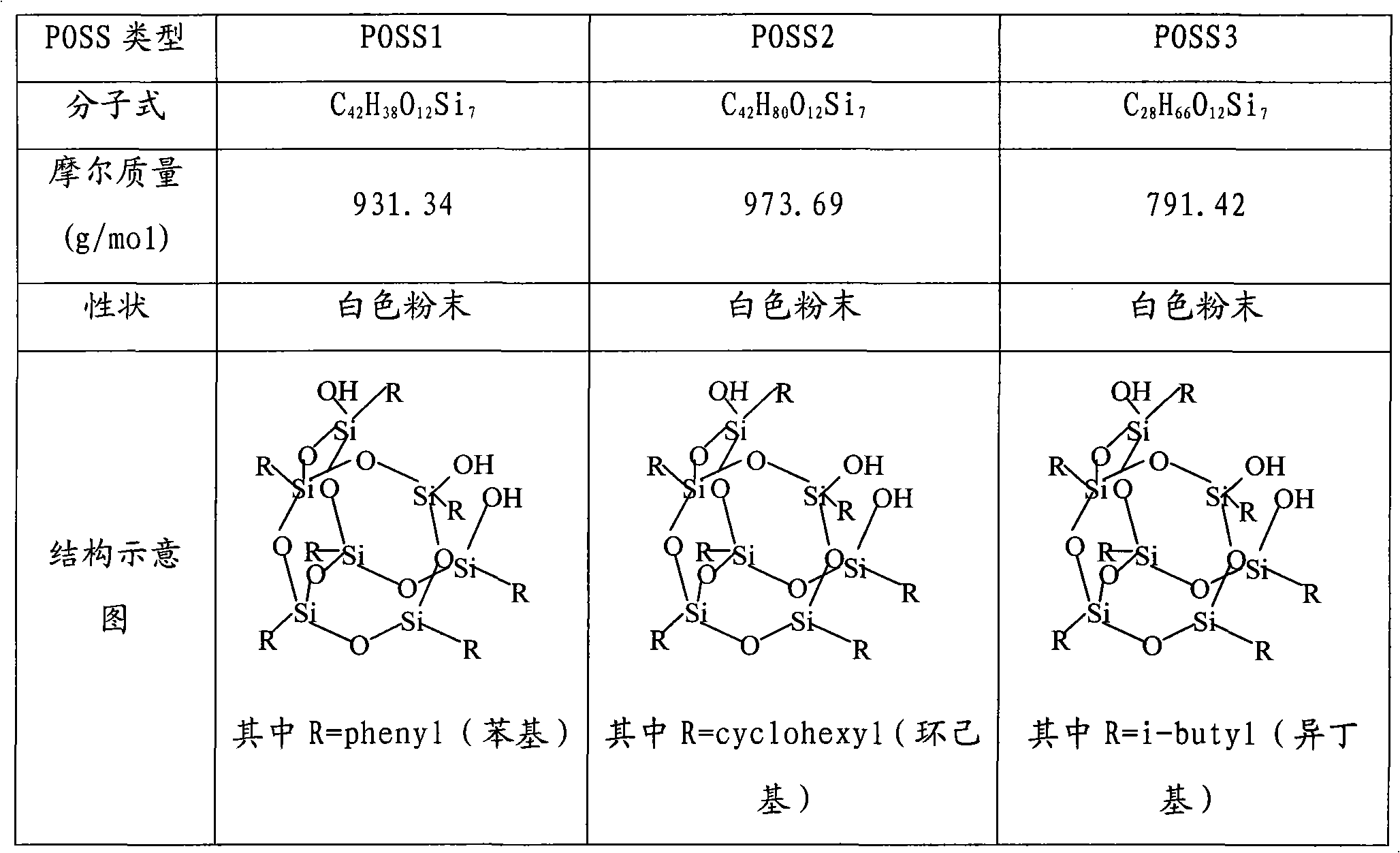

Nanostructure-enhanced tin-silver-copper-base leadless compound solder and preparation thereof

InactiveCN101279405AImprove mechanical propertiesImprove reliabilityWelding/cutting media/materialsSoldering mediaManufacturing technologyTin-silver-copper

The invention relates to a tin, silver and copper based lead-free composite solder with enhanced nanometer-structure and a preparation method thereof, which belong to the technical field of the manufacturing of metal-based lead-free composite solders. The existing spreading process for SnSn-Ag-Cu series lead-free solder is characterized by poor processing performance, short creep rupture service life and high cost. The composite solder of the invention consists of 97 wt percent to 99 wt percent of commercial Sn-3.0Ag-0.5Cu solder paste and 1 wt % to 3 wt % of enhanced particles (POSS1, POSS2 or POSS3). The solder paste consists of 85 wt percent of Sn-3.0Ag-0.5Cu solder and 15 wt % of flux. The tin, silver and copper based lead-free composite solder with enhanced nanometer-structure is prepared by stirring and mixing the solder paste and enhanced particles according to the component concentration for 15 to 30 minutes. The composite solder of the invention has the advantages of good wettability and good creep rupture resistance, high shearing strength, excellent mechanical property, long creep rupture service life of the soldered joint and simple preparation process, etc.

Owner:BEIJING UNIV OF TECH

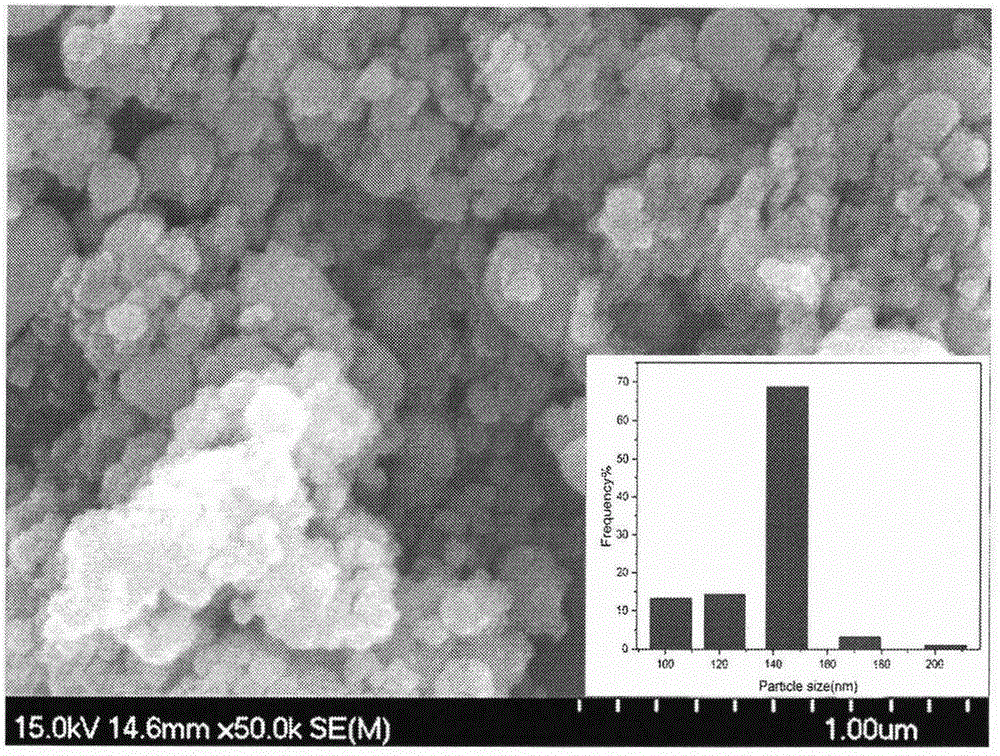

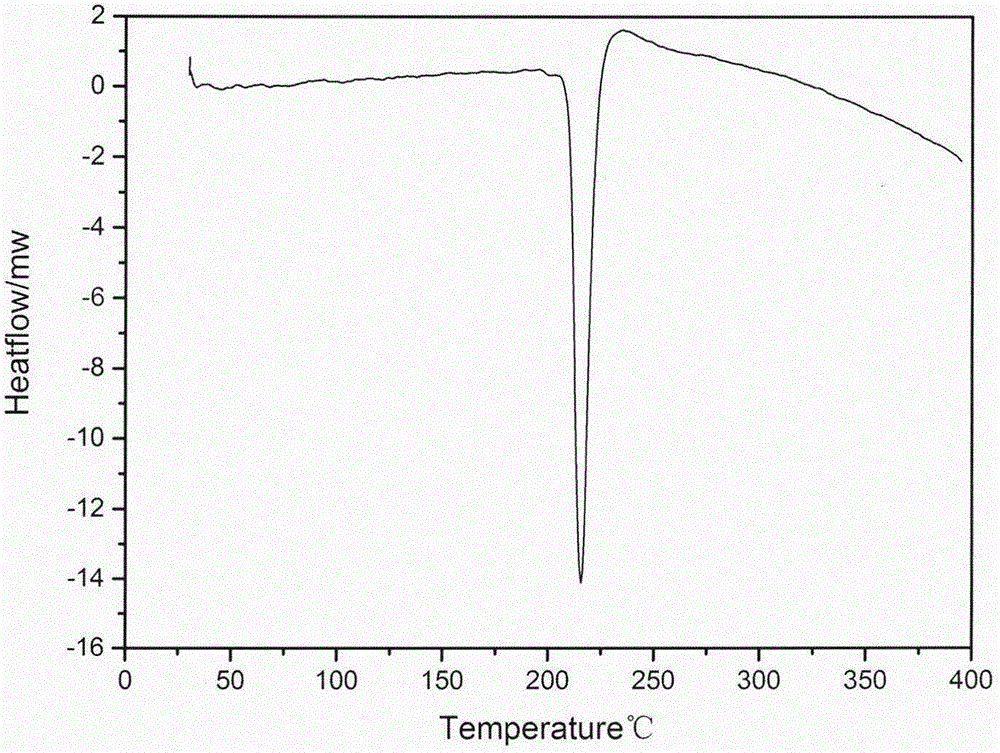

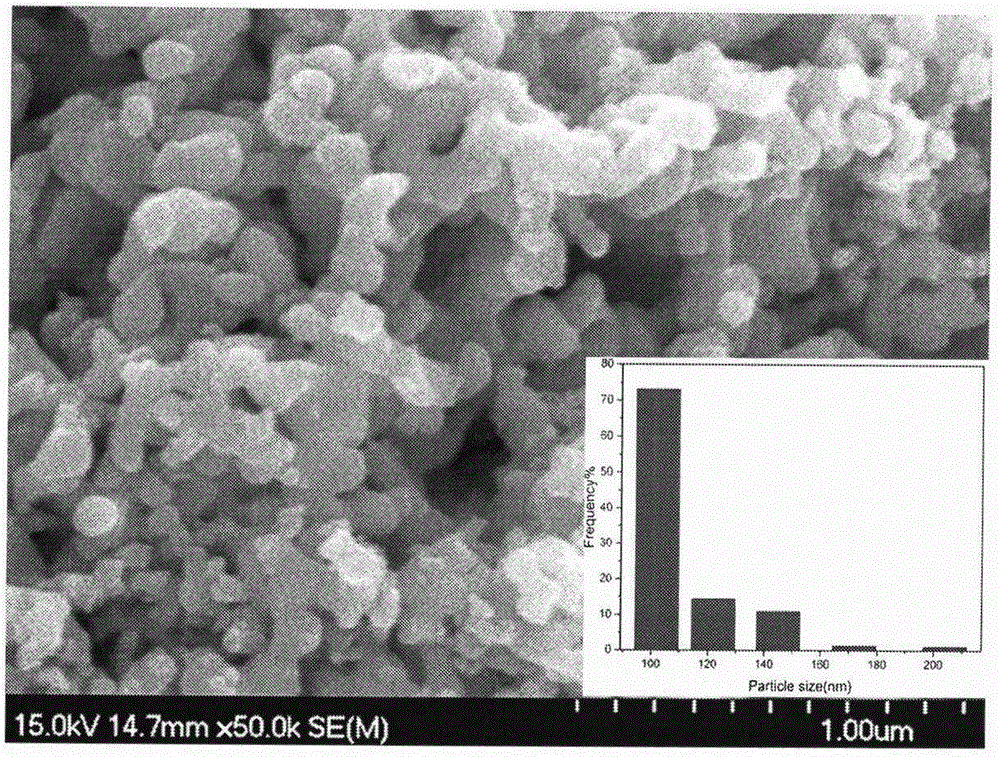

Preparation technology of nanometer tin-silver-copper soldering powder

InactiveCN106475711ASmall sizeIncreased reunionWelding/cutting media/materialsSoldering mediaMass ratioReaction temperature

The invention discloses a preparation technology of nanometer tin-silver-copper soldering powder and belongs to the technical field of packaging materials. According to the preparation technology of the nanometer tin-silver-copper soldering powder, nanometer lead-free soldering powder is prepared through a chemical reduction method, the synthesis process conditions are regulated and controlled from the aspects of screening of a precursor and a reducing agent, the type of a surface active agent, adjustment of the concentration of the surface active agent, the reaction temperature, the drying temperature and the like, the dimensions and shapes of nanometer metal particles are effectively controlled, and therefore the melting point of the nanometer metal soldering powder is lowered. When the mass ratio between the metal precursor and the surface active agent is 1:1, the reaction temperature is 0 DEG C, the drying temperature is 20 DEG C, a reducing agent solution is rapidly poured into a precursor solution, the nanometer tin-silver-copper soldering powder with the melting point lower than that of existing nanometer tin-silver-copper alloy can be obtained according to the preparation technology, and the low-temperature soldering demand of electronic packaging is met. The preparation technology of the nanometer tin-silver-copper soldering powder is simple, convenient, mild in production condition, low in energy consumption and cost and suitable for industrial production.

Owner:CHINA JILIANG UNIV

Low-cost anti-aging brazing filler material used for electronic packaging and preparation method thereof

InactiveCN102172805ALow silver contentHigh melting pointWelding/cutting media/materialsSoldering mediaSolderabilityUltimate tensile strength

The invention relates to a low-cost anti-aging brazing filler material used for electronic packaging and a preparation method thereof, relating to a soft brazing filler material and a preparation method thereof. The invention solves the technical problems that the traditional low silver content lead free brazing filler material has higher silver content, multiple elements are added, metallurgy preparation is complex, a curing crack can be easily caused and the melting point is higher. The brazing filler material comprises the following components: 0.60-0.79% of Ag, 0.50-0.90% of Cu, 0.02-0.20% of Ni, 2.10-4.00% of Bi and the balance of Sn. The preparation method comprises the step of carrying out smelting on Sn, Ag, Cu, Ni and Bi for twice, thus the brazing filler material is obtained. The melting point of the brazing filler material is 205-219 DEG C, the wettability and weldability are good, the cost is reduced by 30-43% compared with the brazing filler material SAC305, and the jointstrength and high temperature aging resistance of the brazing filler material are improved compared with SAC305 and SAC0307. The brazing filler material provided by the invention can be applied to the fields of electronic packaging, manual welding of packaging, wave soldering and reflow soldering.

Owner:HARBIN UNIV OF SCI & TECH

Brazing powder for ultrasonic assisted brazing and brazing method

ActiveCN109759741AEnable low-temperature interconnectsSave heating energyWelding/cutting media/materialsSoldering mediaBiological activationCobalt

The invention provides brazing powder for ultrasonic assisted brazing and a brazing method. The brazing powder is prepared by uniformly mixing tin copper powder or tin silver copper powder, or powderof the tin copper powder mixed with the tin silver copper powder with any one kind, or any two kinds, or any three kinds, or any four kinds, or any five kinds of nickel powder, cobalt powder, copper powder, tin powder and titanium powder of active nanoparticles with the diameters being 1-1000nm according to the mass ratio being at most 20%. According to the brazing powder for ultrasonic assisted brazing and the brazing method, the temperature is low during welding, and the active nanoparticles are adopted; by oscillation heating of an ultrasonic generator, the metallurgical reaction between solder or the nanoparticles and a base material is promoted, the full-solid phase or semisolid state low-temperature interconnection of lead-free solder is realized, and the welding temperature is morethan 30% lower than conventional liquid phase interconnection; oscillating activation and friction generated by the ultrasonic generator can cause an oxidation film on the surface of the welding basematerial to be broken to achieve the effect of film removal, thus gas pollution from a welding flux is reduced, the welding pollution is less, and the joint quality is high.

Owner:CHONGQING UNIV OF TECH

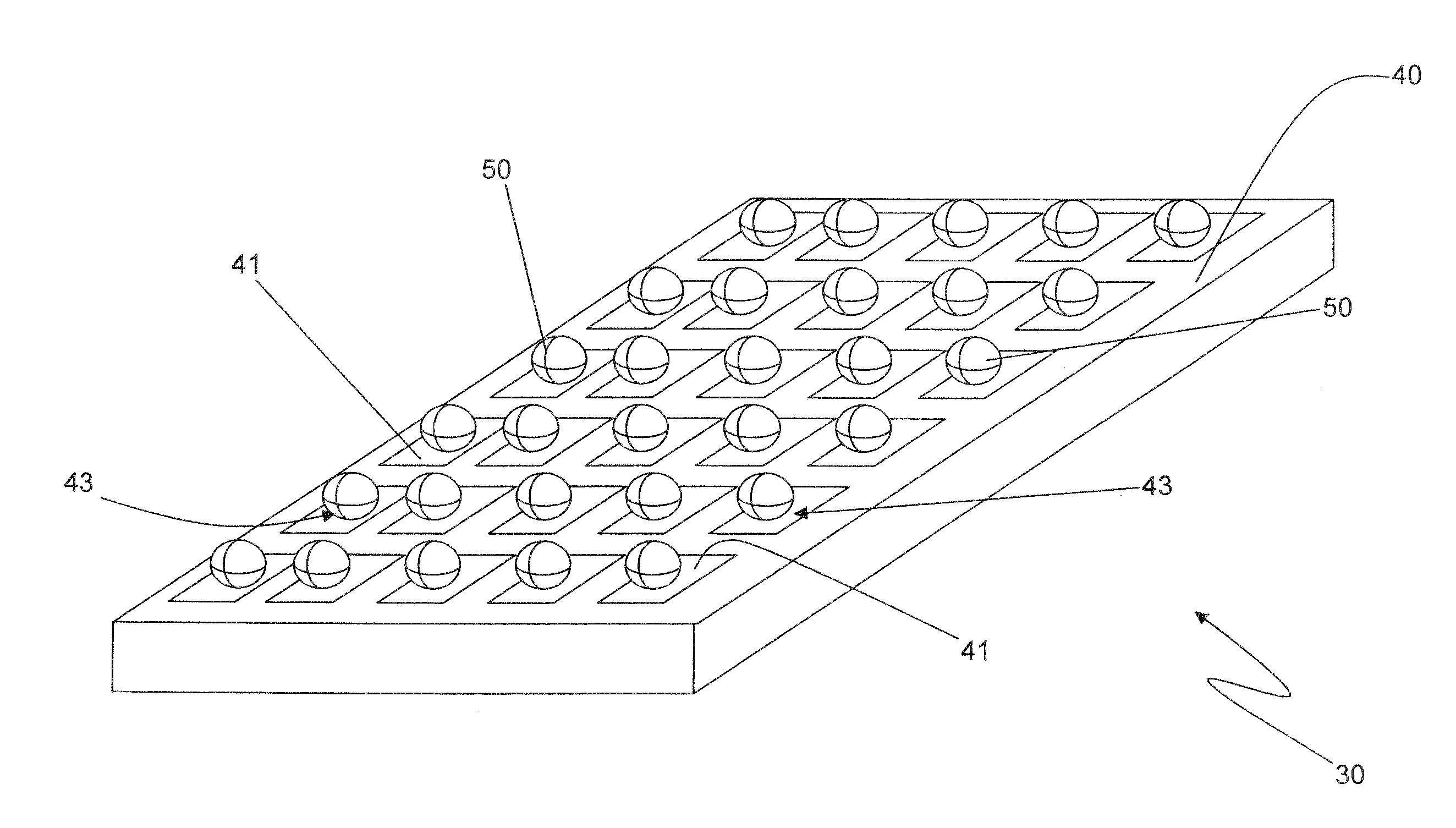

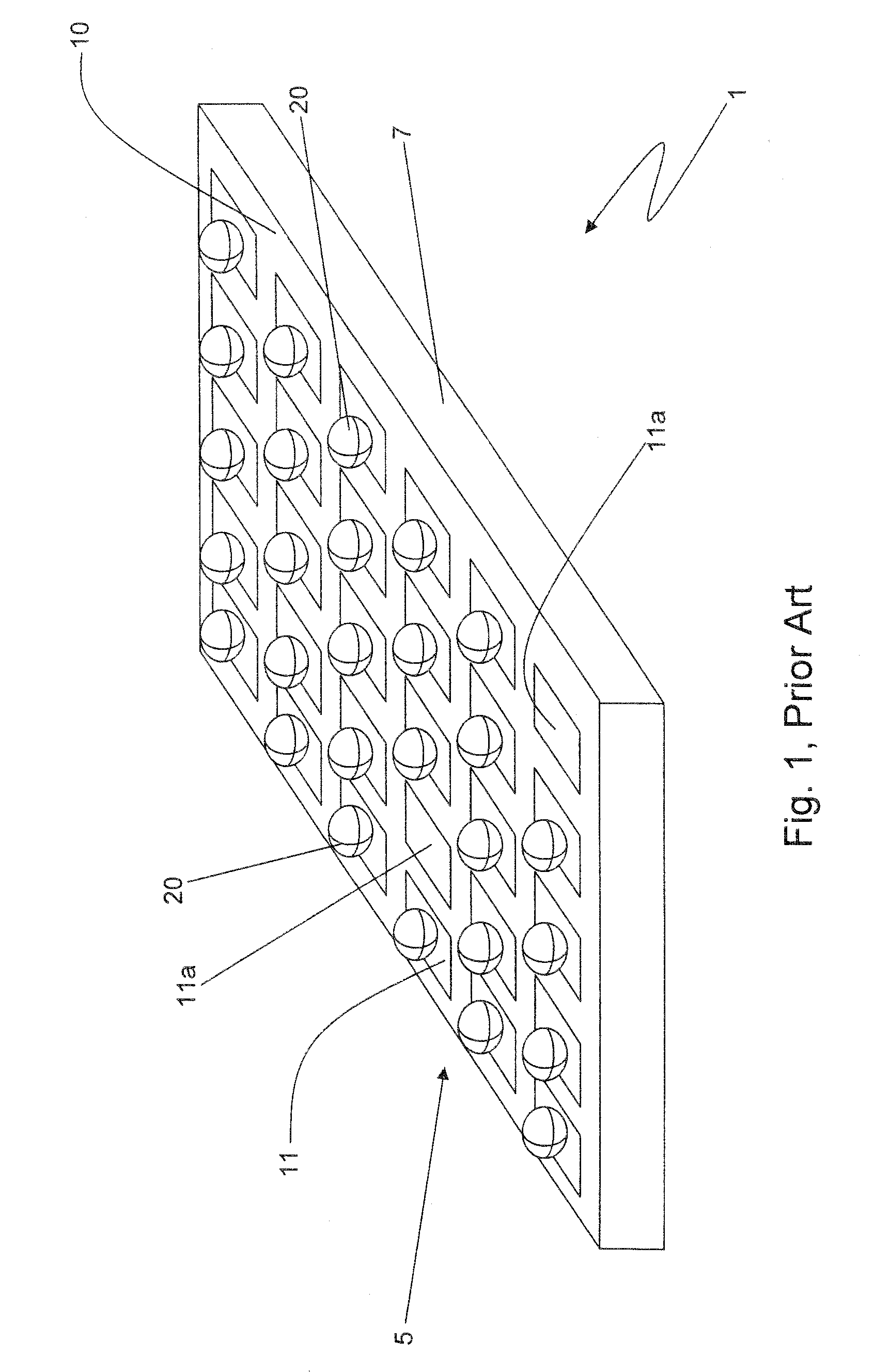

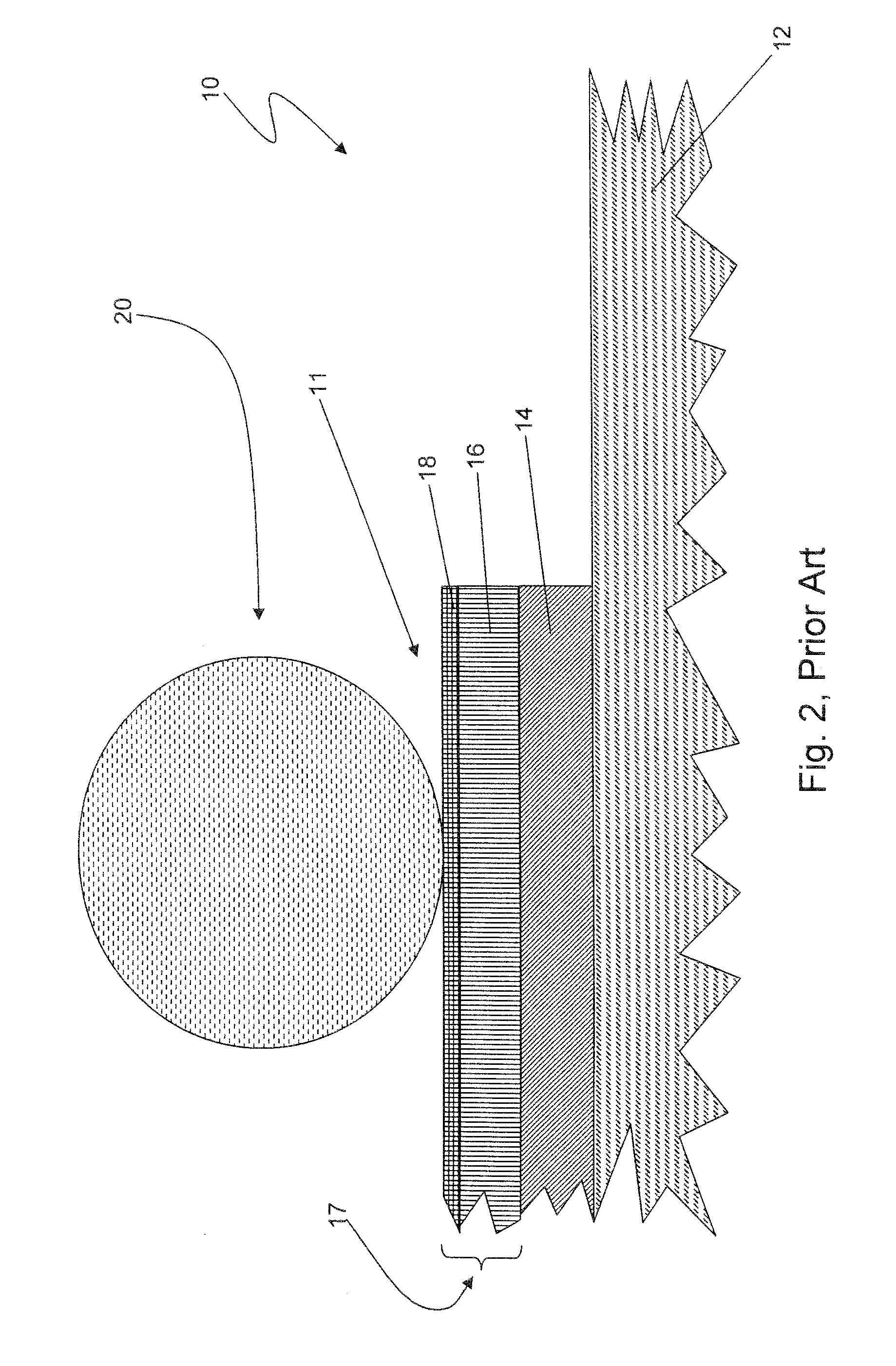

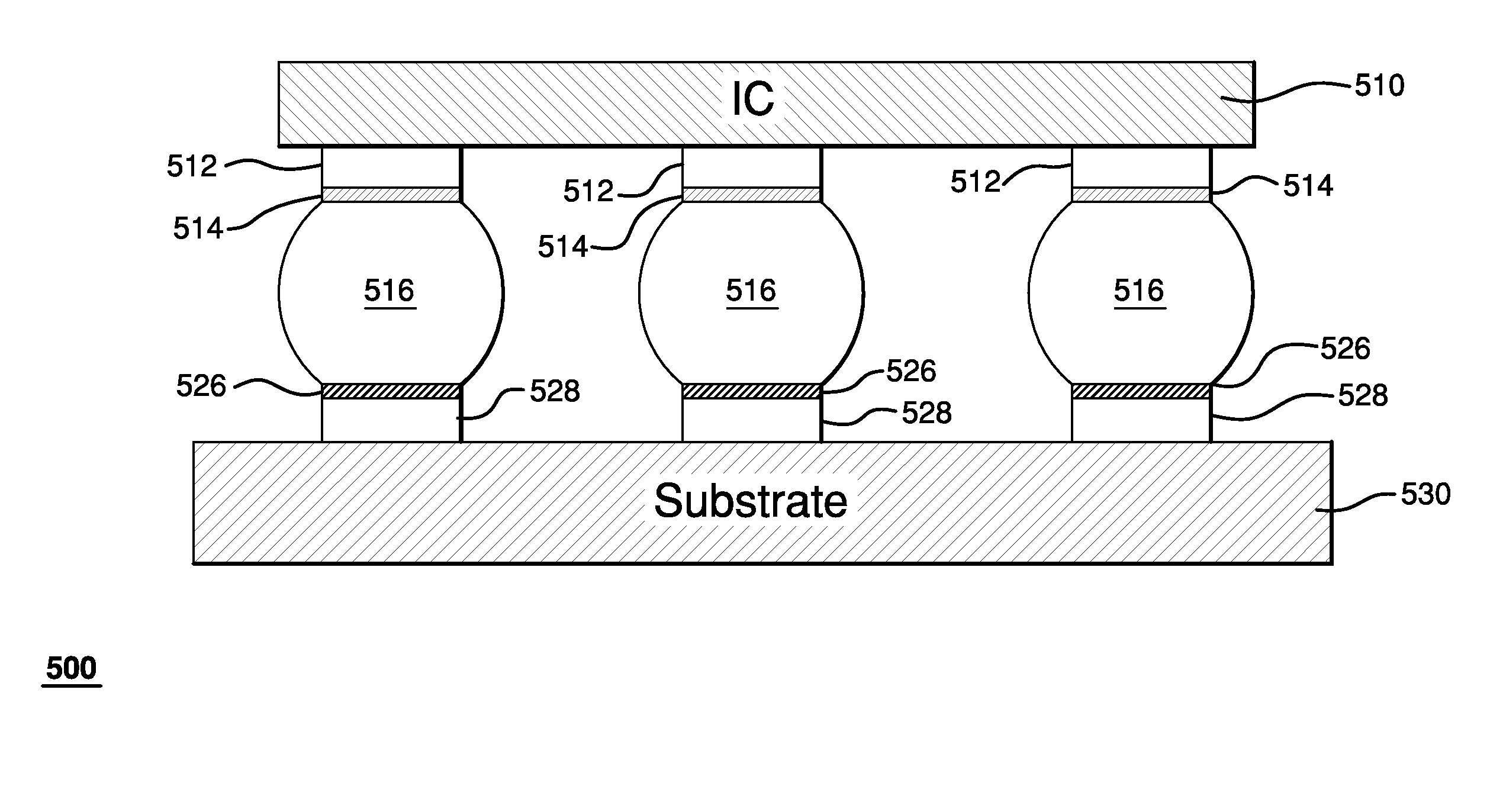

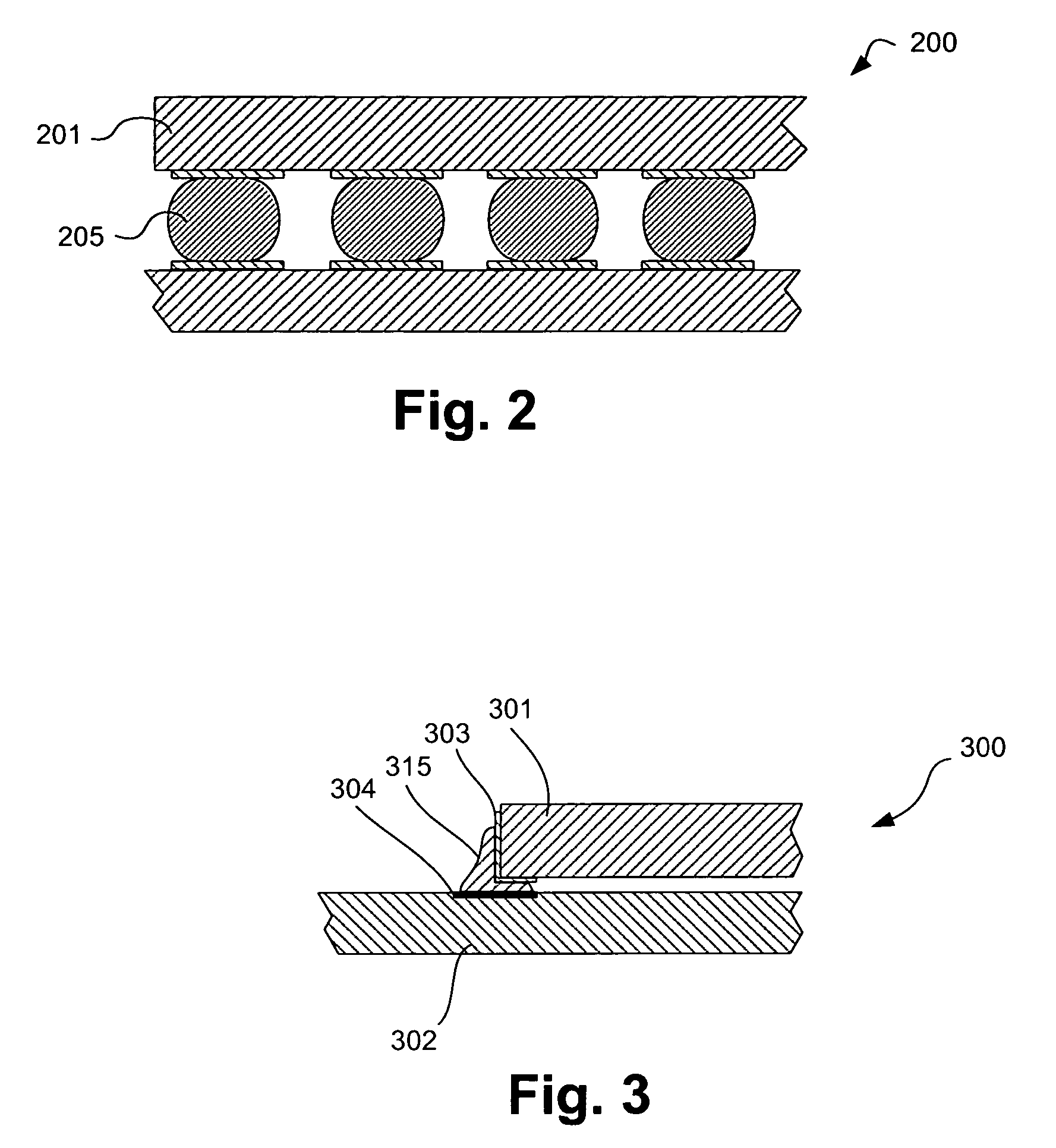

Grid array package using tin/silver columns

InactiveUS20070059548A1Good electrical contactLow thermal expansionFinal product manufacturePrinted circuit manufactureTin-silver-copperThermal expansion

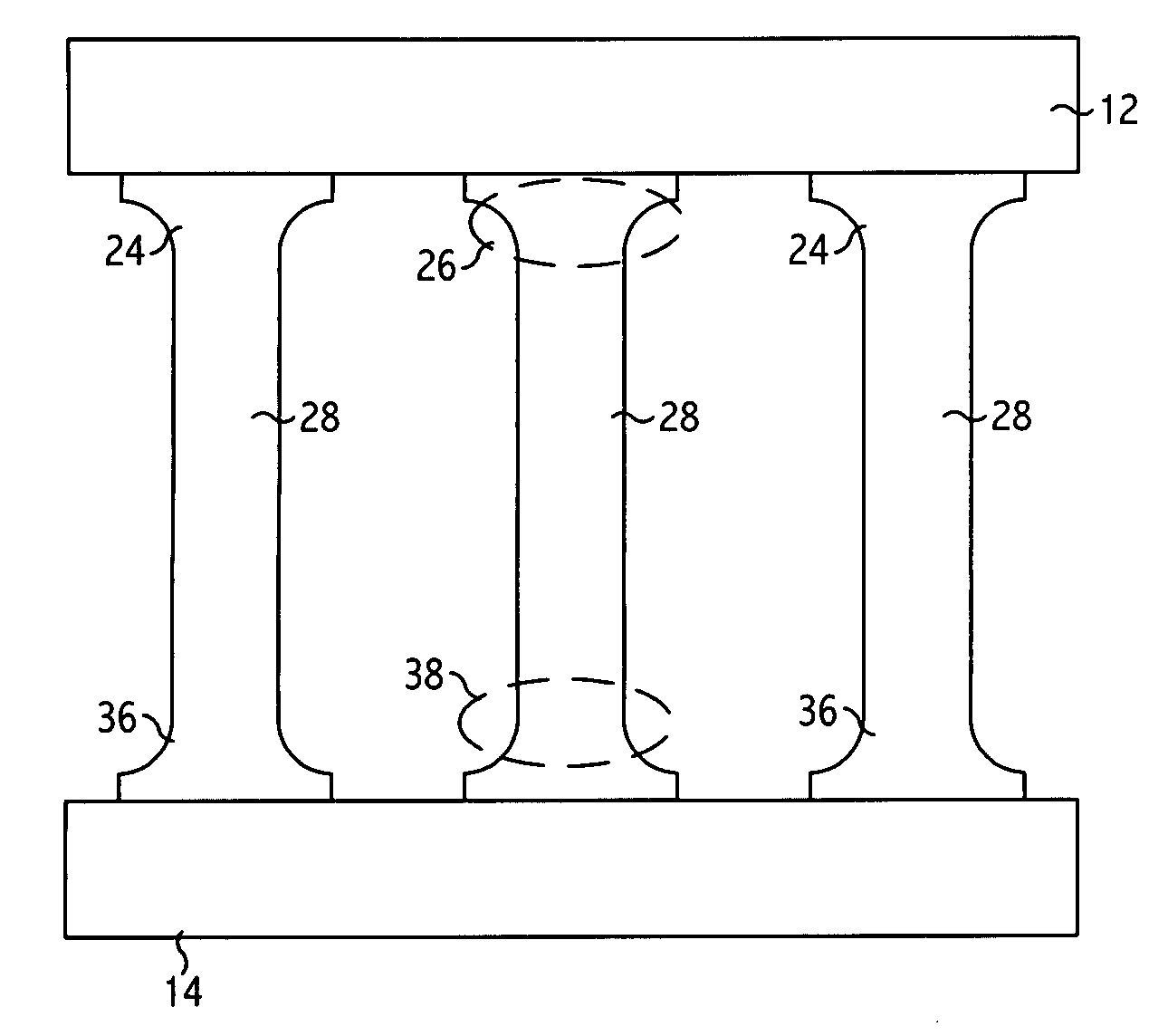

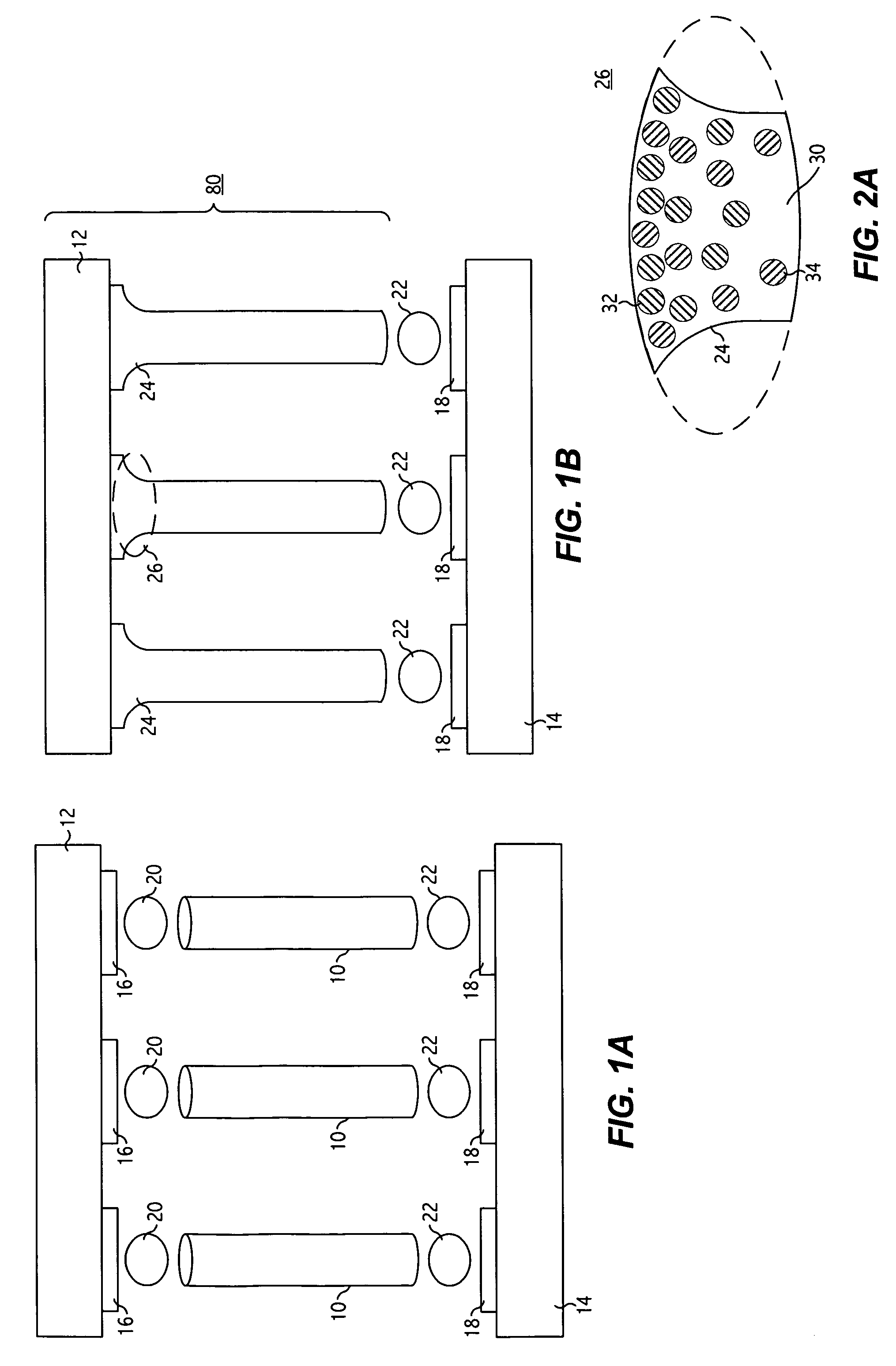

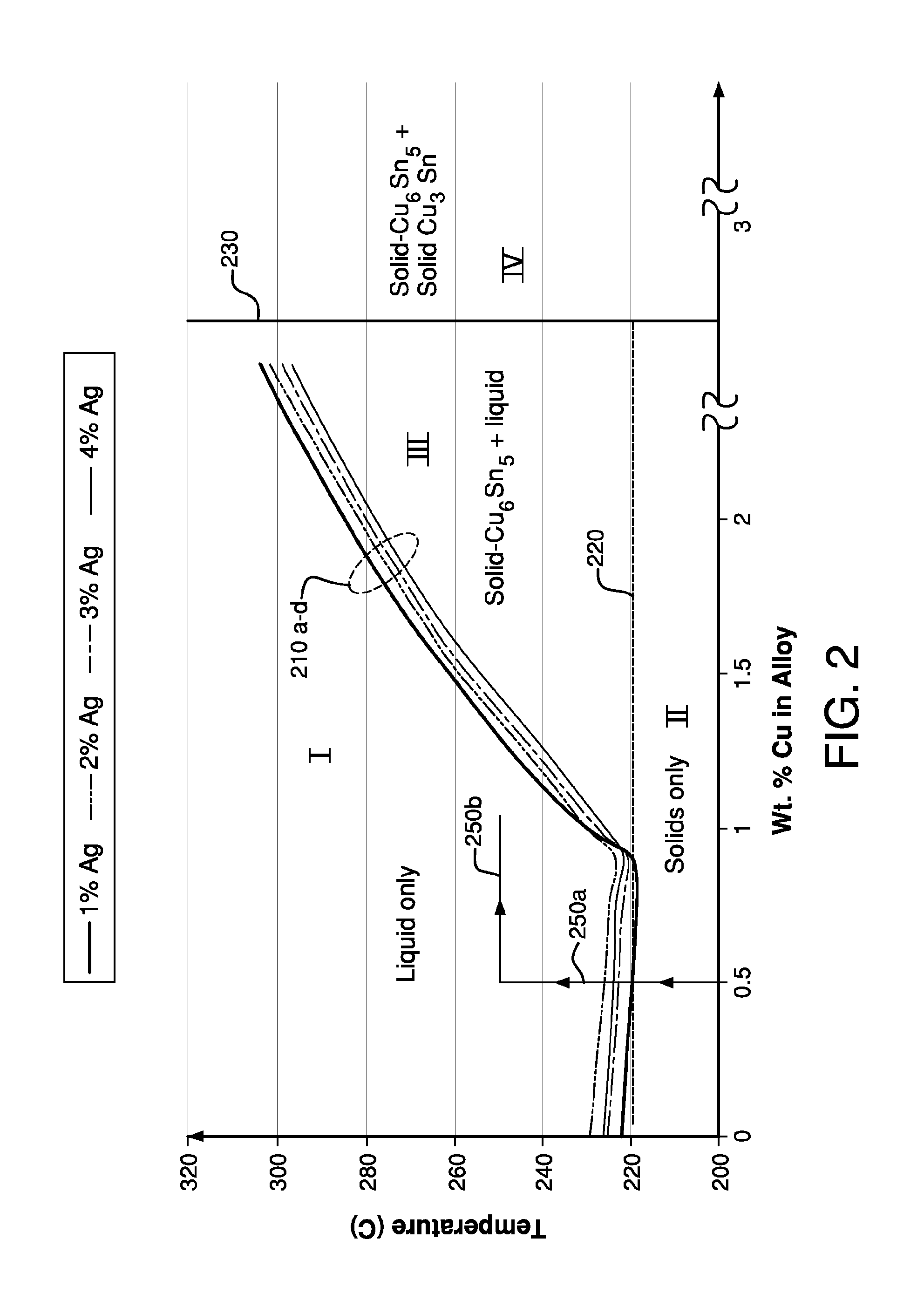

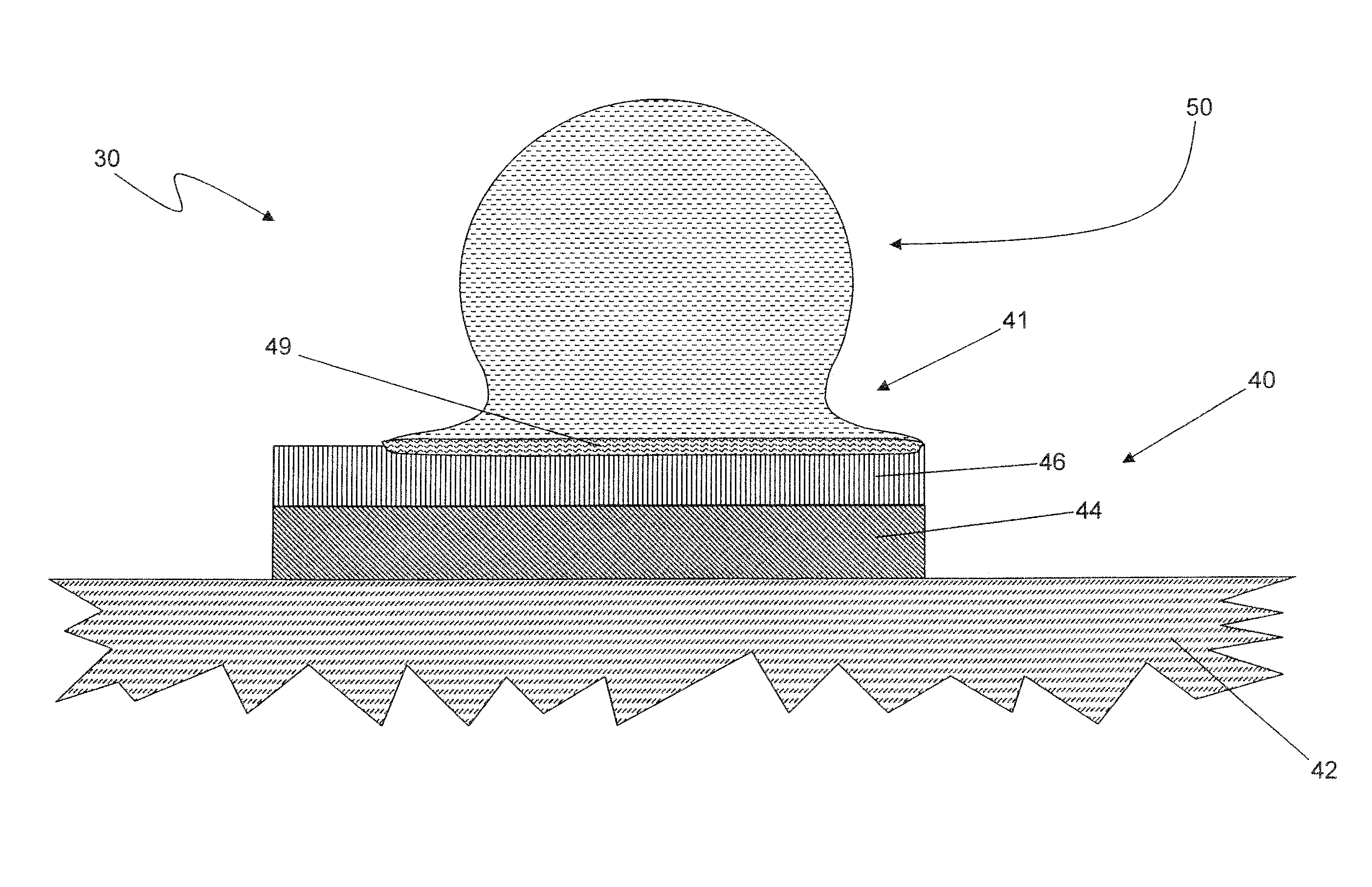

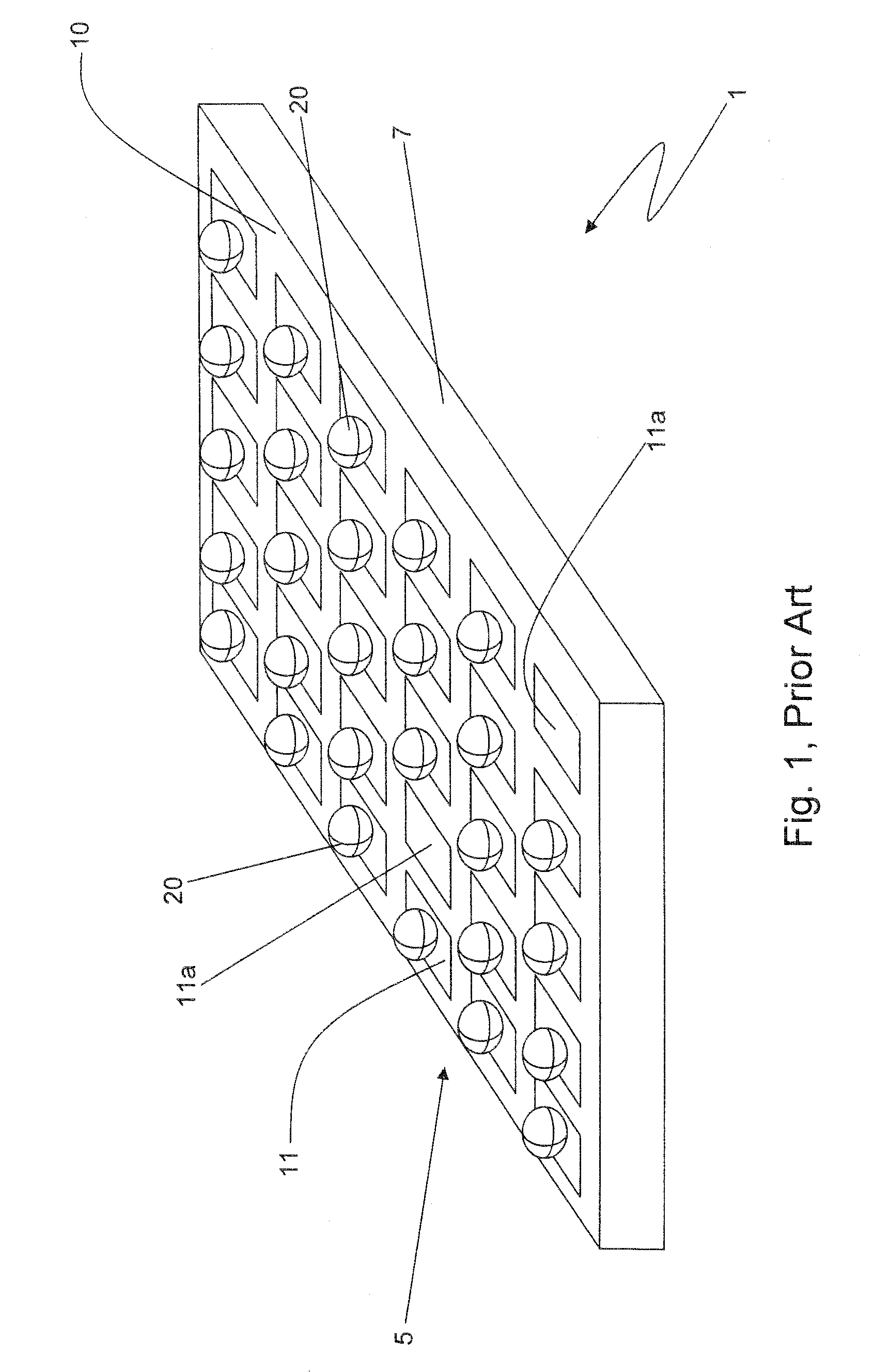

Techniques have been developed to provide, in some embodiments, an attachment structure for mechanically and electrically connecting substrates that is robust to differences in coefficients of thermal expansion. In some realizations lead-free alloy columns are joined to bonding pads on electronic packages having relatively low coefficients of thermal expansion (CTEs) using Pb-free solder from the same alloy system. In some embodiments, a thermal hierarchy in the tin-silver-copper (Sn—Ag—Cu or SAC) ternary alloy system is provided. In some embodiments an attachment system with a high-liquidus alloy column, an intermediate-liquidus solder, and a low-liquidus solder, all three of which components have compositions in the SAC alloy system, is provided.

Owner:SUN MICROSYSTEMS INC

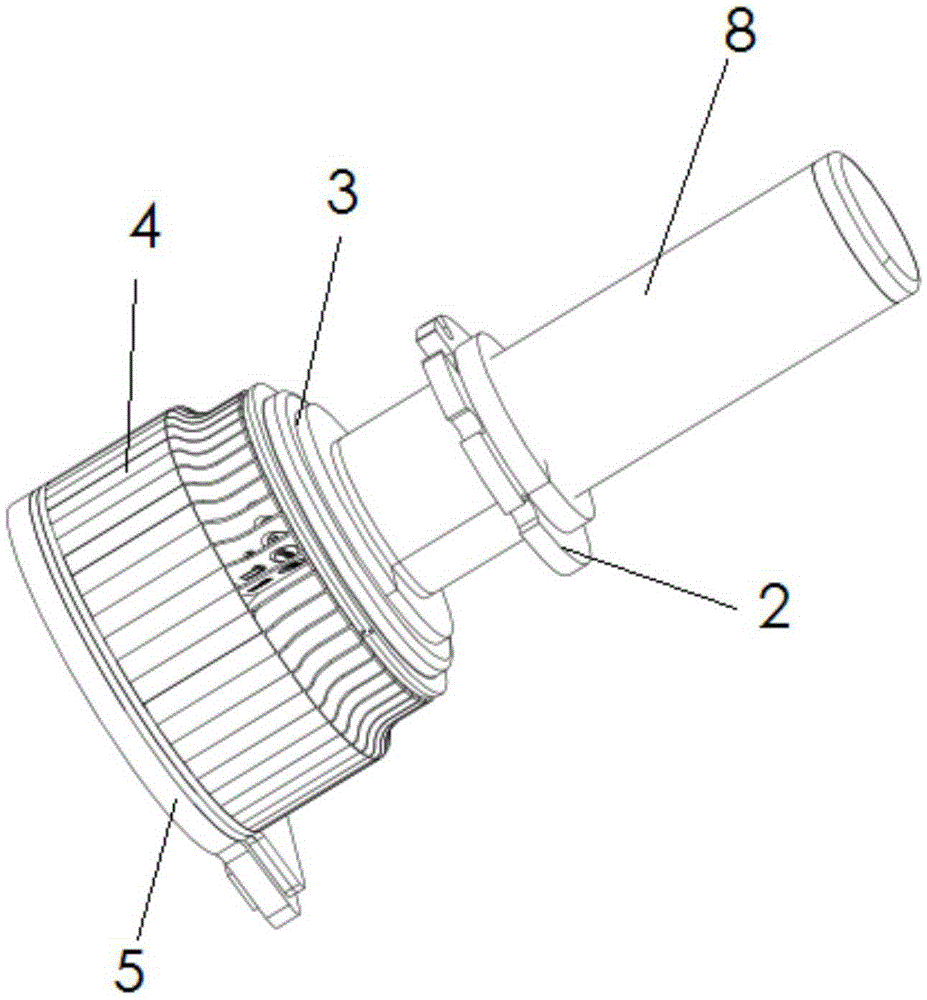

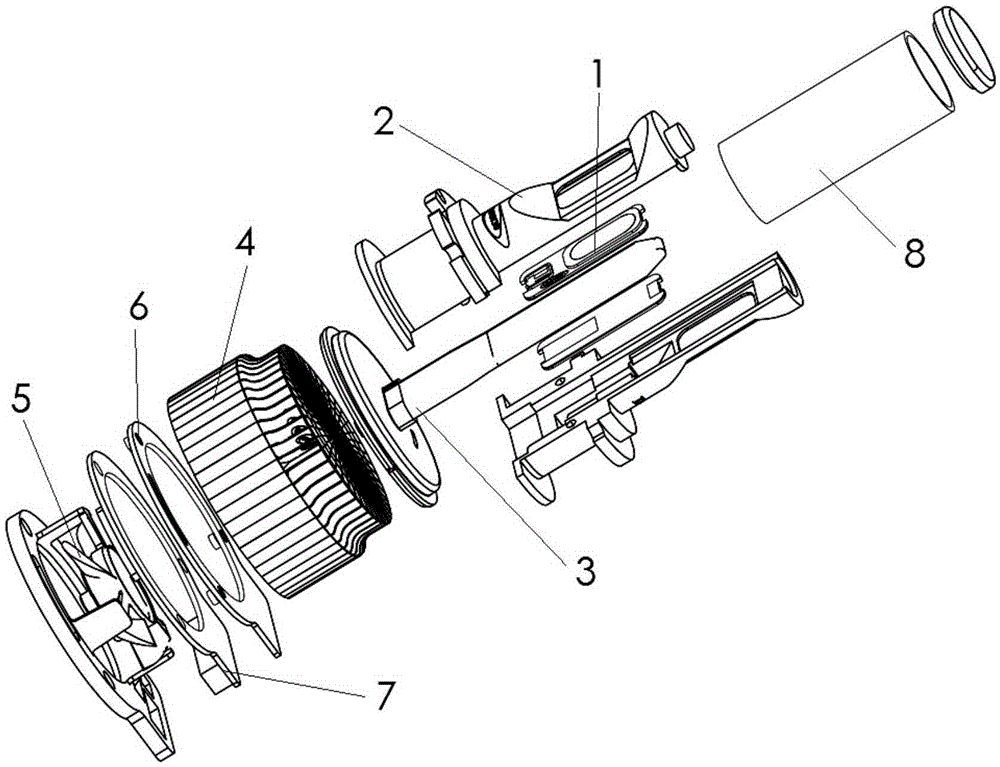

LED automobile head lamp

InactiveCN105371214AMeet the focusConvenient lightingVehicle headlampsLighting heating/cooling arrangementsTin-silver-copperEngineering

The invention relates to the technical field of automobile lamps, in particular to an LED automobile head lamp. The LED automobile head lamp comprises a stereoscopic even-temperature board, LED-COB light sources, an outer bulb metal cover, a finned heat sink and a fan. The stereoscopic board is of a T-shaped stereoscopic structure and is internally provided with a vacuum evaporation cavity and a condensation cavity, and a capillary core layer is arranged. The LED-COB light sources are pasted to the outer surfaces of the evaporation cavity, the front end of the finned heat sink is pasted to the outer surface of the condensation cavity, and the fan is arranged at the back end of the finned heat sink. The outer lamp metal cover is made of magnesium alloy materials. Besides the fan, the parts are connected in a high-temperature welded mode through tin-silver-copper environment-friendly solder paste. According to the LED automobile head lamp, the four heat sinking technical means including phase change heat sinking, metal-cooling-fin heat conduction heat sinking, air-cooling heat sinking and radiation heat sinking are integrated, and heat sinking efficiency is high; the anti-vibration effect is good, and the structure is firm; installation is convenient, focusing is accurate, an original bulb can be perfectly replaced, and the LED automobile head lamp is suitable for various vehicle types.

Owner:GUANGZHOU GONGZHU SCI HLDG CO

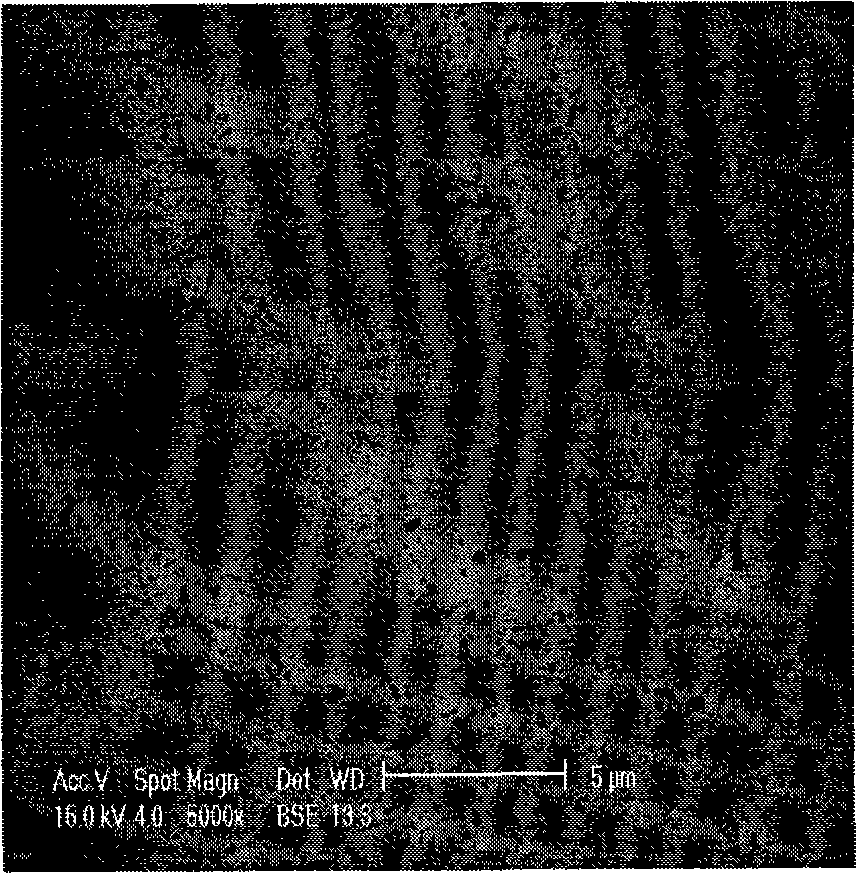

Tin-silver-copper composite solder paste enhanced by titanium dioxide nanoparticles and preparation method thereof

InactiveCN105057911AGrowth inhibitionAvoid abnormal growthWelding/cutting media/materialsSoldering mediaTin-silver-copperComposite solder

The invention belongs to the technical field of welding materials and discloses tin-silver-copper composite solder paste enhanced by titanium dioxide nanoparticles and a preparation method thereof. The composite solder paste is obtained by blending tin-silver-copper lead-free solder paste and the titanium dioxide nanoparticles. The preparation method includes the following steps that the titanium dioxide nanoparticles are added into the tin-silver-copper lead-free solder paste with the mass ratio being 96.5:3:0.5, the titanium dioxide nanoparticles are evenly distributed in the tin-silver-copper lead-free solder paste through mechanical stirring, and accordingly the tin-silver-copper composite solder paste enhanced by the titanium dioxide nanoparticles is obtained. According to the tin-silver-copper composite solder paste, by adding the titanium dioxide nanoparticles, growth of an Ag3Sn phase in the solder paste is restrained, microhardness and mechanical property of the composite solder paste are improved, and growth of intermetallic compounds of a solder joint interface can be effectively restrained, crystal grains of the intermetallic compounds of the solder joint interface are refined, soldering reliability is improved, and the application prospect is good.

Owner:SOUTH CHINA UNIV OF TECH

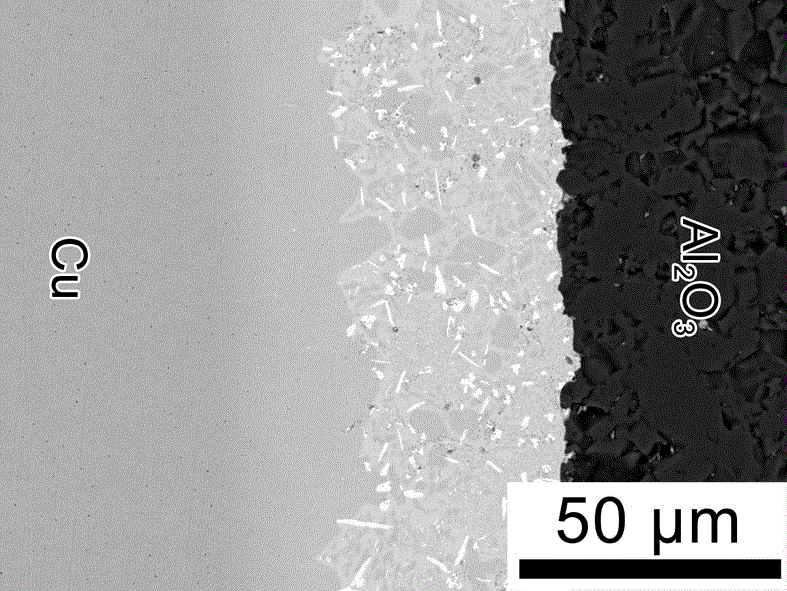

Inhibition of copper dissolution for lead-free soldering

InactiveUS20100319967A1Inhibition of dissolutionSolid-state devicesPretreated surfacesCopper platingTin-silver-copper

A device fabrication method, according to which a tin-copper-alloy layer is formed adjacent to a copper-plated pad or pin that is used to electrically connect the device to external wiring. Advantageously, the tin-copper-alloy layer inhibits copper dissolution during a solder reflow process because that layer is substantially insoluble in liquid Sn—Ag—Cu (tin-silver-copper) solder alloys under typical solder reflow conditions and therefore shields the copper plating from direct physical contact with the liquefied solder.

Owner:AGERE SYST INC

Soldering method and related device for improved resistance to brittle fracture with an intermetallic compound region coupling a solder mass to an Ni layer which has a low concentration of P, wherein the amount of P in the underlying Ni layer is controlled as a function of the expected volume of the solder mass

A lead-free solder joint is formed between a tin-silver-copper solder alloy (SAC), SACX, or other commonly used Pb-free solder alloys, and a metallization layer of a substrate. Interaction of the SAC with the metallization layer forms an intermetallic compound (IMC) that binds the solder mass to the metallization layer. The IMC region is substantially free of any phosphorous-containing layers or regions.

Owner:BELL SEMICON LLC

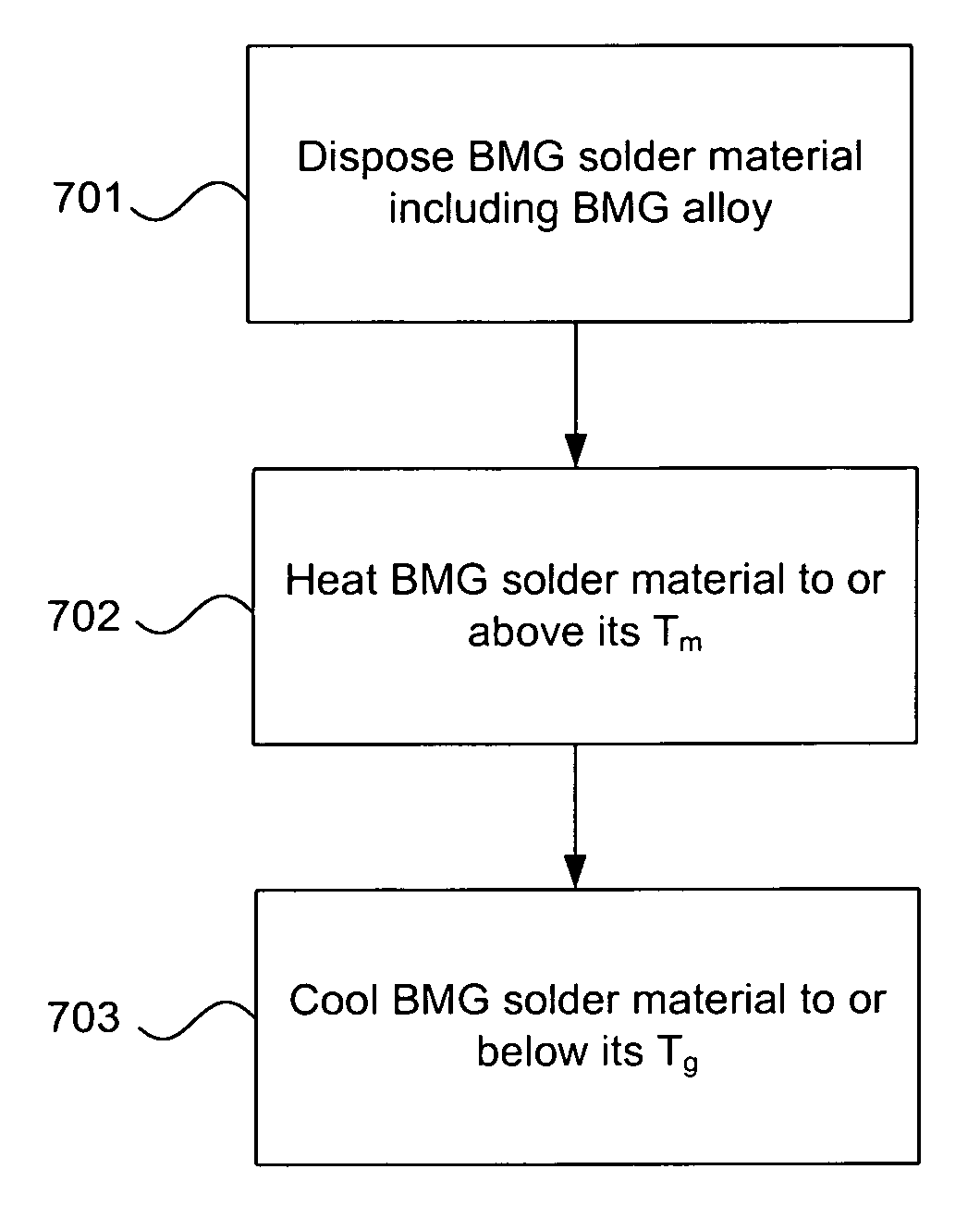

Bulk metallic glass solder material

InactiveUS7628871B2Printed circuit manufactureWelding/cutting media/materialsDielectricThermal expansion

High strength, reliable bulk metallic glass (BMG) solder materials formed from alloys possessing deep eutectics with asymmetric liquidous slopes. BMG solder materials are stronger and have a higher elastic modulus than, and therefore are less likely than crystalline solder materials to damage fragile low k interlayer dielectric (ILD) materials due to thermal stress in materials with different coefficients of thermal expansion (CTE).BMG solder materials may physically, electrically, or thermally couple a feature to another feature, or any combination thereof. For example, in an embodiment of the invention, a BMG solder material may physically and electrically couple an electronic component to a printed circuit board. In another embodiment of the invention, a BMG solder material may physically and thermally couple an integrated heat sink to a semiconductor device.Many embodiments of a BMG solder material are also lead-free, so they comply with lead-free product requirements, while providing a better solution than other lead-free solder materials such as tin-silver-copper.

Owner:INTEL CORP

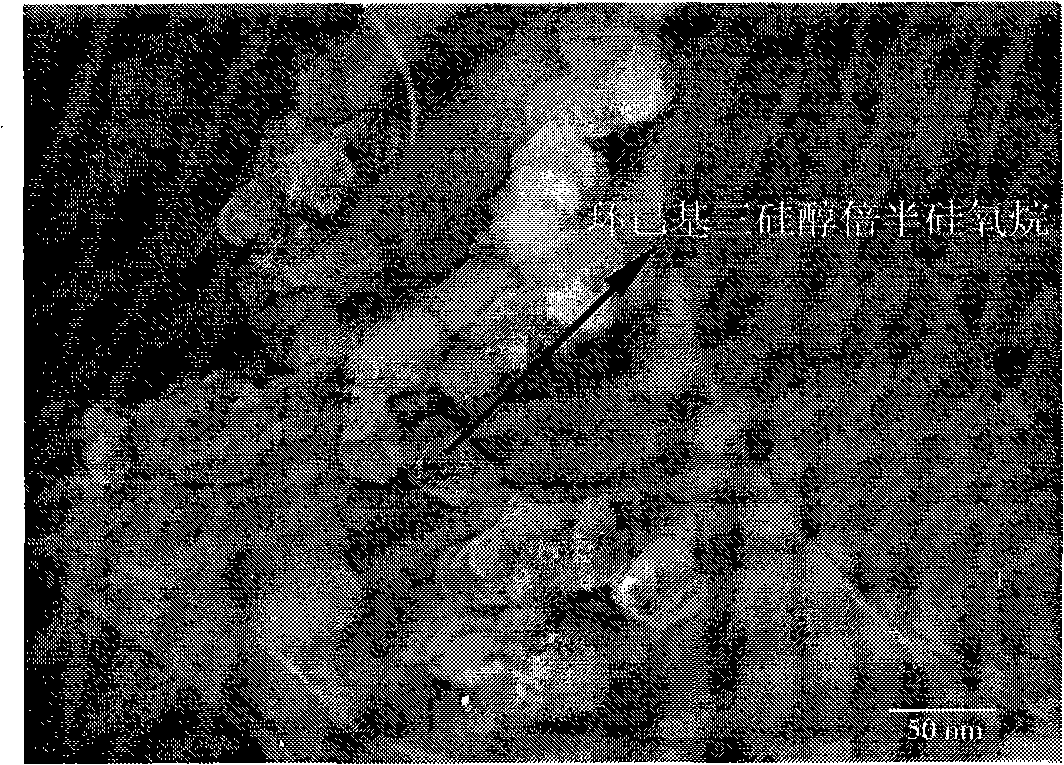

Trimethyl-silyl polysilsesquioxane particle reinforced type tin-silver-copper composite soldering paste and preparation method thereof

InactiveCN102019514ARefining tin-rich phase β-SnInhibition formationWelding/cutting media/materialsSoldering mediaTrimethylsilaneMegasonic cleaning

The invention discloses trimethyl-silyl polysilsesquioxane particle reinforced type tin-silver-copper composite soldering paste and a preparation method thereof, belonging to a composite lead-free solder technology. A composite solder comprises 1-5 percent by weight of trimethyl-silyl polysilsesquioxane particle in tin-silver-copper solders with a weight ratio of 96.5:3:0.5. The preparation method of the solder comprises the following steps of: firstly, putting the 1-5 percent by weight of trimethyl-silyl polysilsesquioxane particle and a no-clean flux into a breaker; putting the breaker in an ultrasonic wave cleaner and shaking the mixture for 1 hour in the ultrasonic wave cleaner; adding tin-silver-copper soldering paste; manually stirring for 30 minutes to prepare the composite soldering paste; putting the composite soldering paste on a ceramic substrate; putting the ceramic substrate in a refluxing furnace and refluxing the ceramic substrate at maximum temperature of 538K in the refluxing furnace to obtain a trimethyl-silyl polysilsesquioxane particle reinforced type tin-silver-copper composite solder. In the prepared composite solder, a matrix of beta-Sn phase is thinned, and the growth of an Ag3Sn phase is inhibited.

Owner:CHONGQING UNIV

Low-splash and halogen-free welding agent for tin wires and preparation method thereof

InactiveCN103394824AHigh surface insulation resistanceImprove wettabilityWelding/cutting media/materialsSoldering mediaActive agentAlloy

The invention discloses a low-splash and halogen-free welding agent for tin wires and a preparation method thereof. The welding agent is mainly used for agent cores of tin-based alloy tin wires. The welding agent is composed of, by weight, 80-90% of rosin and rosin derivatives, 5-15% of active agents, 0.1-2% of efficient surface active agents, 0.5-2% of corrosion inhibitors and 3-10% of viscosity modifiers. The prepared halogen-free welding agent for the tin wires is needless of any halogen element, is little in splash and smoke when welding is conducted, has high activity, is high in surface insulation resistance, and can be used for preparing tin-lead series tin wires, tin-copper series tin wires and tin-silver-copper series tin wires. The prepared tin wires are good in wetting performance, high in reliability after being welded, and light and full in welding point.

Owner:BEIJING COMPO ADVANCED TECH

Resin encapsulated semiconductor device and the production method

ActiveUS7372132B2High strengthImprove thermal conductivityPrinted circuit assemblingLine/current collector detailsMetal bindingAluminium

A semiconductor device having both high strength and high thermal radiation that is capable of being applied to mounting on automobiles experiencing many thermal cycles, and a manufacturing method thereof are provided. A circuit board 1a for a resin encapsulated semiconductor module device has a configuration where a silicon nitride plate 2 with a thickness of 0.635 mm has copper plates of 1.0 mm and 0.8 mm bonded to both sides thereof via active metal. A copper plate 3a is bonded to the surface side of the silicon nitride plate 2, and a prescribed circuit pattern is formed on the copper plate 3a. Tin-silver-copper cream solder layers 4a and 4b with a thickness of 200 μm are formed at a prescribed location on the circuit pattern 3a on which a semiconductor element 6 is mounted and at a prescribed location of a base plate 1 on which the circuit board 1a is disposed. Nickel particles 5 having a maximum particle size of 100 μm and an average particle size of 70 μm are dispersed in the solder 4a on the base plate 1 of good thermal conductivity. A semiconductor element (chip) 6, the circuit board 1a, and the base plate 1 are disposed on predetermined locations. Thereafter, they are set in a reflow oven (not shown in the drawings) for reflow soldering. After the inside of the reflow oven is replaced by a nitrogen atmosphere, the reflow oven is heated to 280° C. At the time when solder is melted, the inside of the oven is decompressed to 1 Pa, nitrogen is introduced, and the reflow oven is cooled to about room temperature, thereby completing the solder bonding step. After flux is washed, an outer case 7 with an insert-molded outlet terminal 8 is adhered to the base plate 1 and a predetermined connection is conducted via an aluminum bonding wire 9. Then, silicone gel 10 is injected into a package delimited via the base plate 1 and the outer case 7, and the silicone gel 10 is heat-hardened, thereby completing a resin encapsulated semiconductor device A.

Owner:HITACHI LTD +1

Solder alloy, solder paste, and electronic circuit board

InactiveCN104487203AContains a low proportionLow costPrinted circuit assemblingPrinted circuit detailsTin-silver-copperCopper

This solder alloy is a tin-silver-copper-based solder alloy, contains tin, silver, antimony, bismuth, copper, and nickel, essentially does not contain germanium, and with respect to the total quantity of solder alloy, has a silver content of 1.0-1.2 mass% exclusive, an antimony content of 0.01-10 mass% inclusive, and a bismuth content of 0.01-3.0 mass% inclusive.

Owner:HARIMA CHEM INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com