Preparation technology of nanometer tin-silver-copper soldering powder

A preparation process, nano-tin technology, applied in manufacturing tools, welding equipment, welding media, etc., can solve problems such as unfavorable energy saving and emission reduction, high welding temperature, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Take a beaker 1 wrapped with tinfoil, weigh 3.4360g (0.016mol) of stannous sulfate, 0.0376g (0.156mmol) of copper nitrate trihydrate, add 20mL of deionized water, add a magnet and stir to dissolve; take another beaker wrapped with tinfoil In beaker 2, weigh 0.1105g (0.650mmol) of silver nitrate, add 20mL of deionized water; add the magnet and stir to dissolve, pour the silver nitrate solution into beaker 1, rinse beaker 2 with 10mL of deionized water, wash the Pour the water into beaker 1, stir for 10 minutes, and prepare the precursor solution.

[0026] Weigh 4.840 g (0.127 mol) of reducing agent sodium borohydride, the molar ratio of sodium borohydride to metal elements is 7:1, add 100 mL of absolute ethanol to prepare sodium borohydride reducing agent solution.

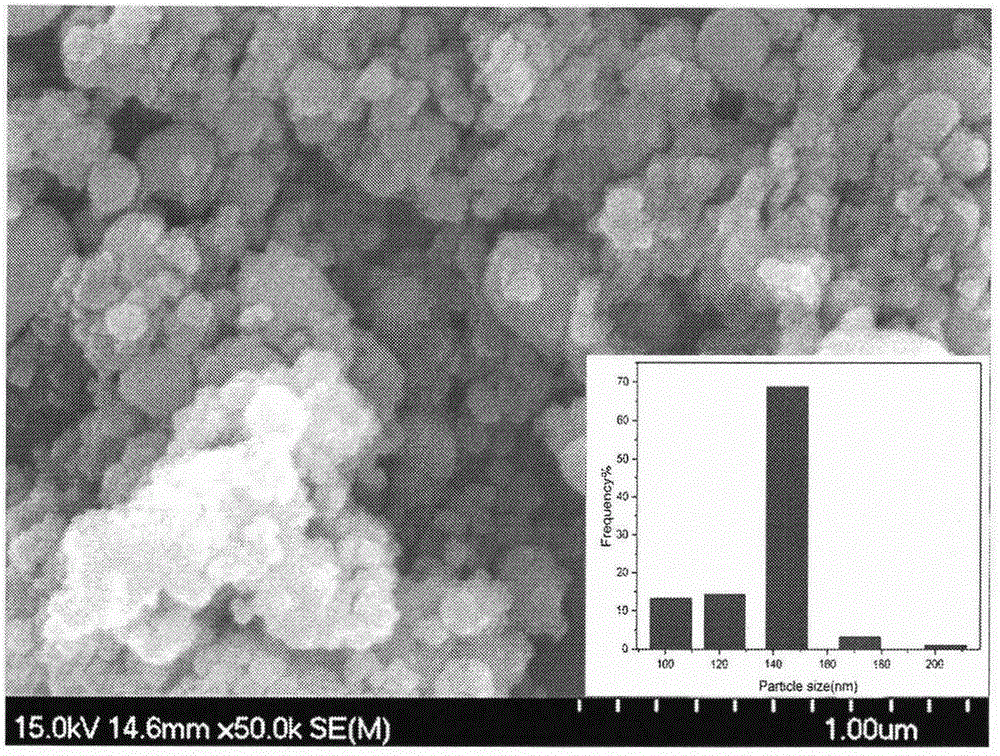

[0027] In an ice-water bath at 0°C, quickly pour the reducing agent solution into the precursor solution, and vigorously stir the reaction for 1 hour to obtain a solution containing metal particles; carry ou...

Embodiment 2

[0031] The same method as in Example 1 configures the precursor solution and the reducing agent solution, then adds 1.7g of the surfactant 1,10-phenanthroline in the reducing agent solution, and the mass ratio of the metal precursor to the surfactant is 2:1. Other preparation processes are the same as in Example 1.

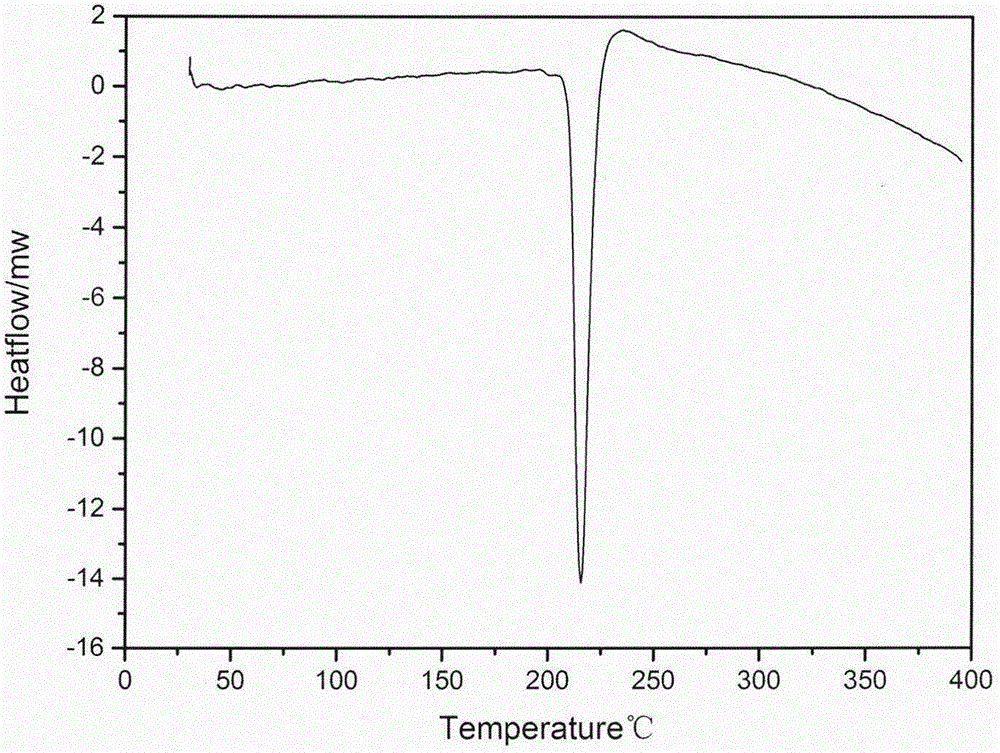

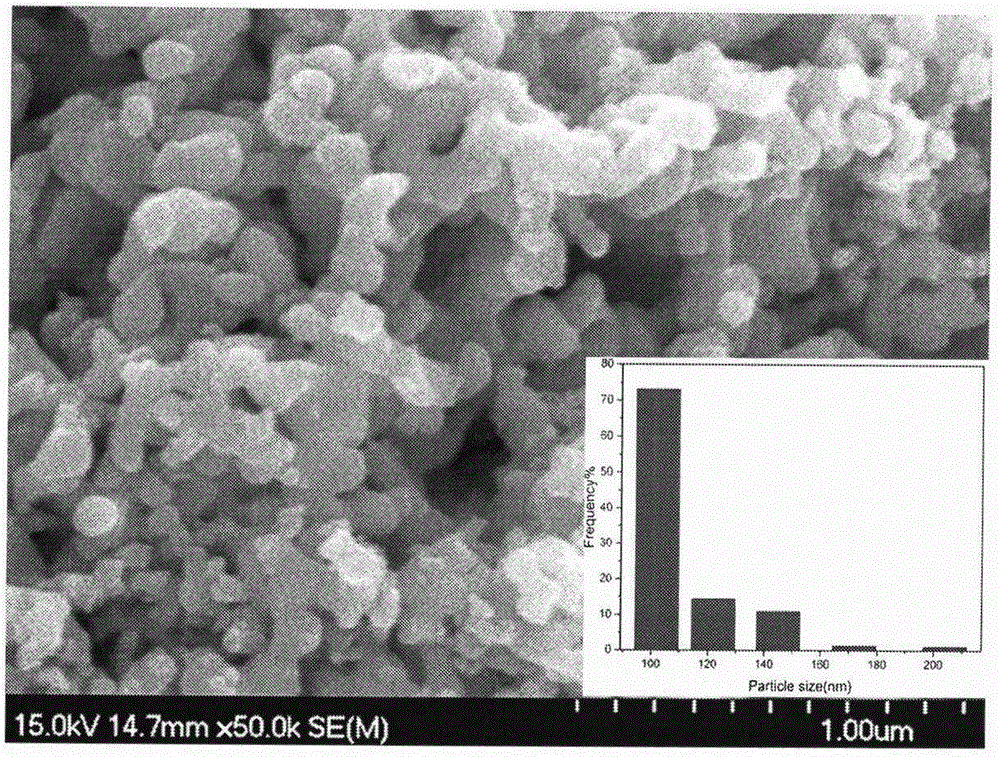

[0032] image 3 It is the scanning electron microscope picture and the particle size distribution map of the solder powder in Example 2. The particle size of the nanopowder is in the range of 50-150nm, and the surface of the metal particle is coated with a surfactant, so the boundaries of the particles are blurred, and more than 70% of the particles The diameter distribution is around 100nm. Figure 4 It is the thermal analysis diagram of the solder powder in Example 2. The melting point of the sample has dropped from 215.4°C in Example 1 to 211.6°C. It is confirmed that the addition of surfactant reduces the agglomeration between particles, the particle size de...

Embodiment 3

[0034] The same method as in Example 1 configures the precursor solution and the reducing agent solution, then adds 3.5g of the surfactant o-phenanthroline in the reducing agent solution, the quality of the metal precursor and the mass ratio of the surfactant are 1: 1. Other preparation processes are the same as in Example 1.

[0035] Figure 5 It is the thermal analysis chart of the solder powder of embodiment 3. The melting point of the sample is 209.5°C, demonstrating that the increase in surface activity lowers the melting point.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com