Patents

Literature

351 results about "Stannous sulfate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Stannous Sulfate, Technical S1550 | 7488-55-3 Stannous Sulfate, Technical is also known as Tin(II) sulfate. It is often a source of tin(II) ions uncontaminated by tin(IV) species. It absorbs moisture from the air and is able to dissolve in it which forms a solution.

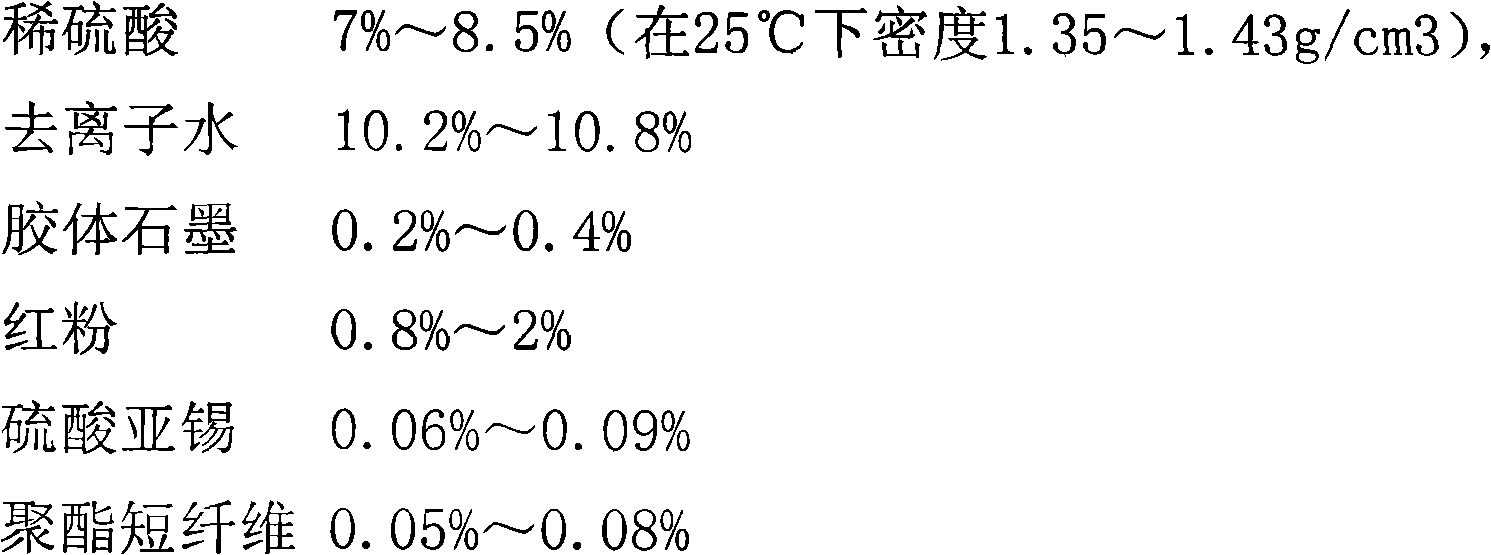

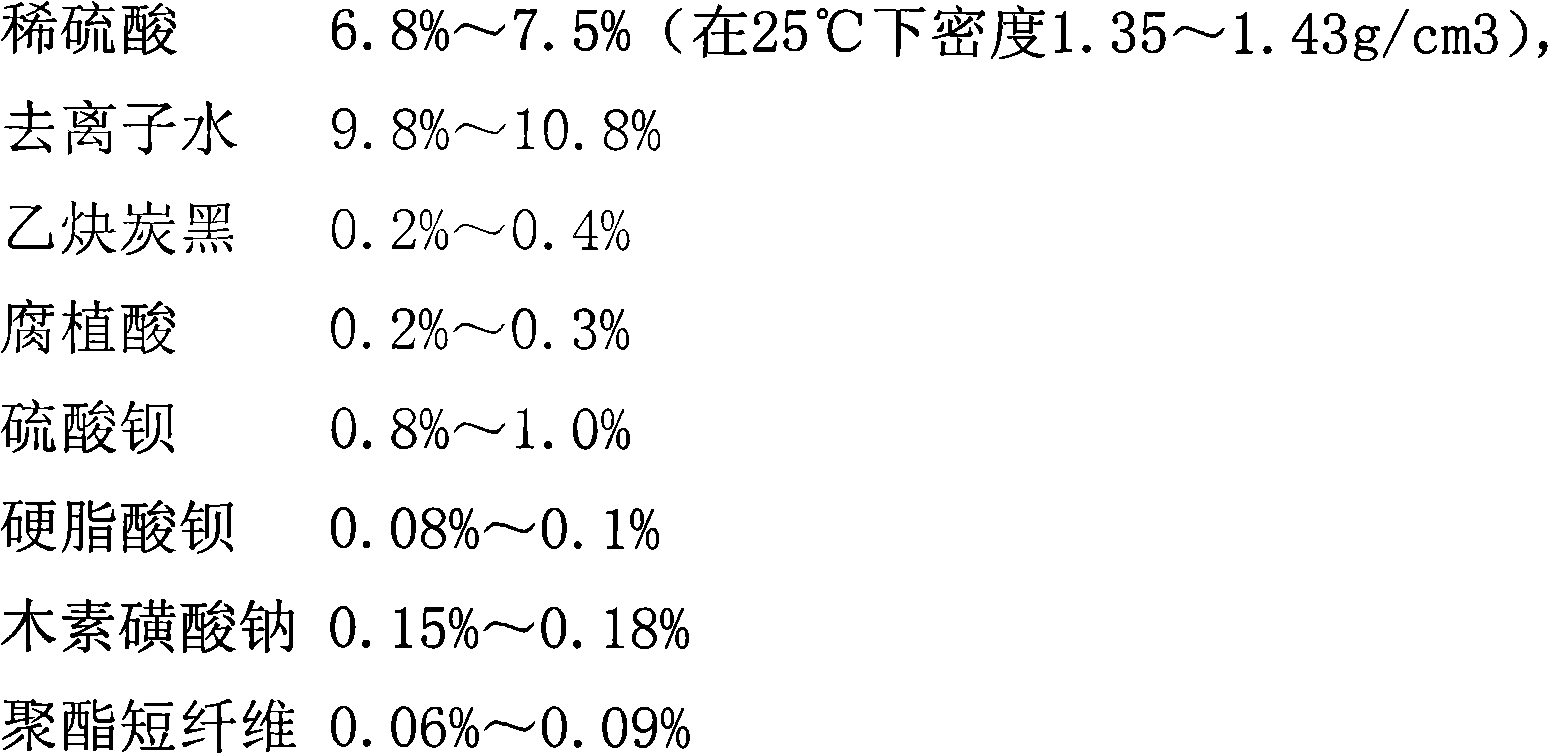

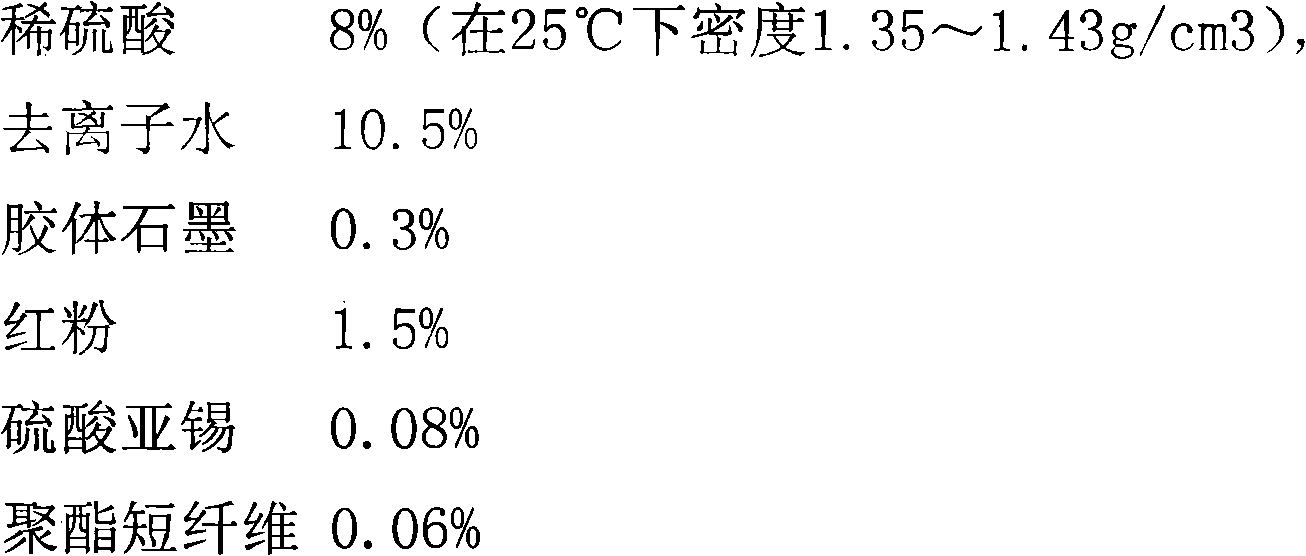

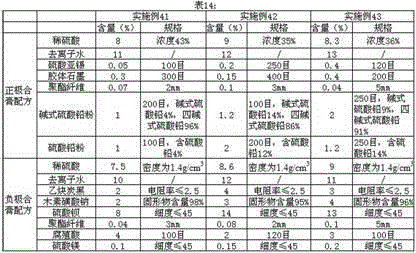

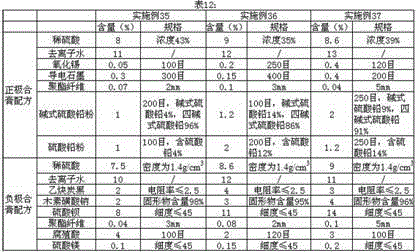

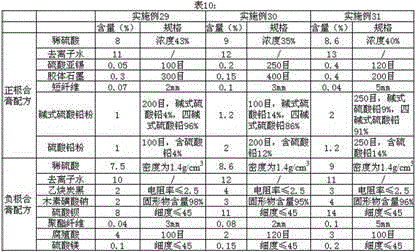

Formula and preparation method of high energy storage lead-acid battery lead paste

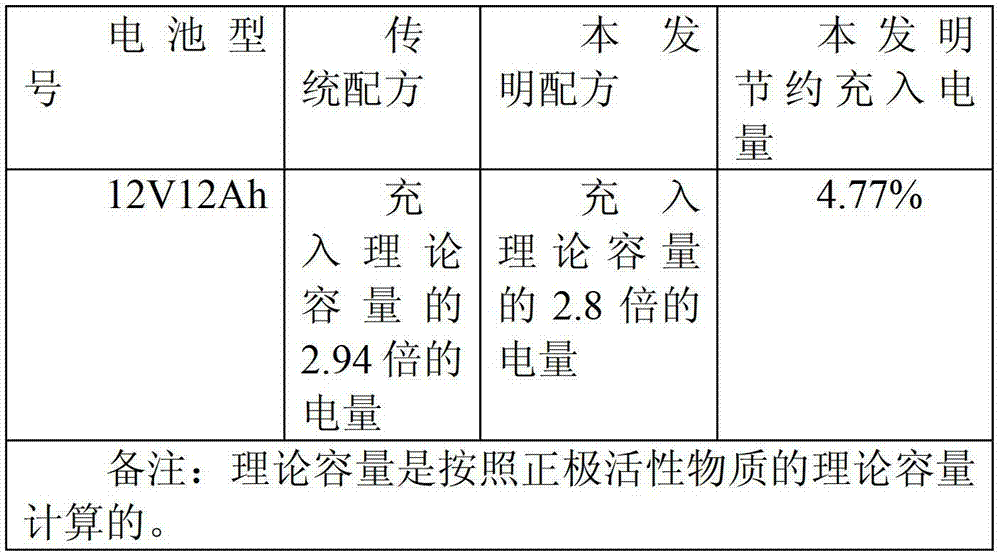

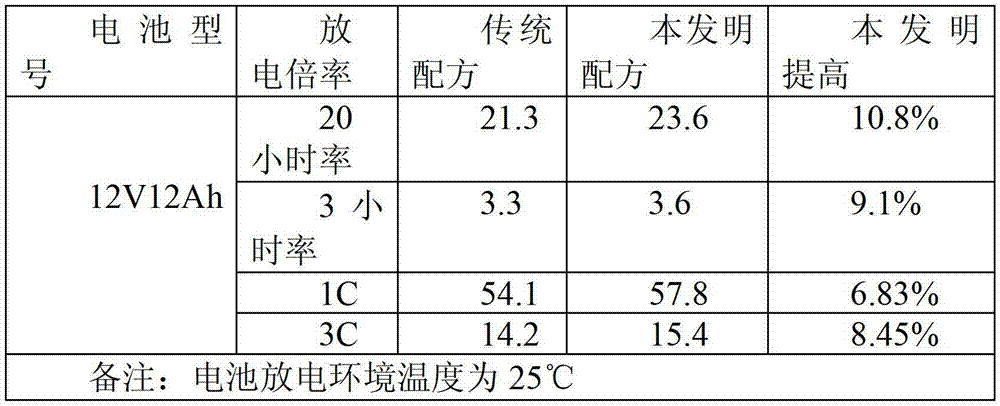

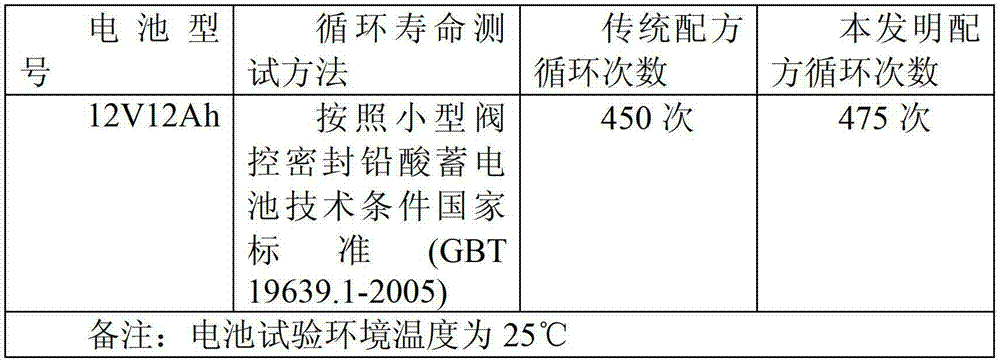

ActiveCN102354751AImprove charging efficiencyHigh initial capacityLead-acid accumulator electrodesFiberPolyester

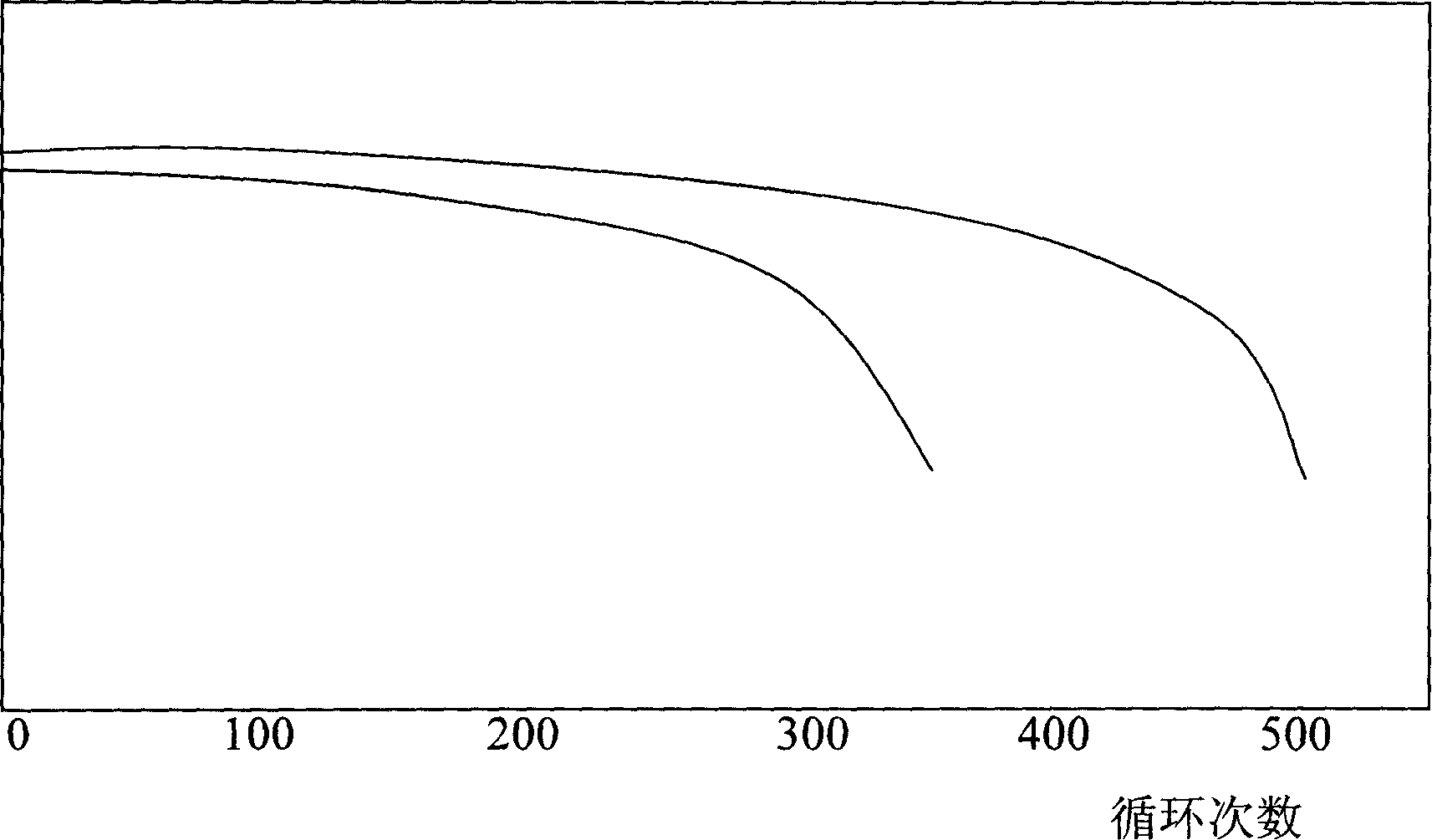

The invention provides a formula and preparation method of a high energy storage lead-acid battery lead paste and relates to the technical field of lead-acid batteries. The formula of a positive plate lead paste comprises the following raw materials: 7-8.5% of dilute sulphuric acid, 10.2-10.8% of deionized water, 0.2-0.4% of colloidal graphite, 0.8-2% of red powder, 0.06-0.09% of stannous sulfate, 0.05-0.08% of polyester staple fiber and the balance of lead powder; the formula of a negative plate lead paste comprises the following raw materials: 6.8-7.5% of dilute sulphuric acid, 9.8-10.8% of deionized water, 0.2-0.4% of acetylene black, 0.2-0.3% of humic acid, 0.8-1.0% of barium sulfate, 0.08-0.1% of barium stearate, 0.15-0.18% of sodium lignosulphonate, 0.06-0.09% of polyester staple fiber and the balance of lead powder. The battery prepared by the lead paste has the advantages of high initial capacity and long cycle life; and the overdischarge resistance and charge acceptance of the battery are higher than the standard requirements.

Owner:TIANNENG BATTERY GROUP +4

Colloidal electrolyte of lead acid accumulator

Owner:CHAOWEI POWER CO LTD

Lead paste of deep adhesive type specially-cured lead carbon battery

ActiveCN106129357AControl stratification problemHigh strengthLead-acid accumulatorsCell electrodesCapacitanceFiber

The invention relates to lead paste of a deep adhesive type specially-cured lead carbon battery. Positive electrode lead paste comprises the following constituents: 600-1,200kg of lead powder, 5-80kg of red lead, 10-60kg of 4BS seed crystal, 0.6-3.6kg of aquadag, 0.3-3.6kg of stannous sulfate, 0-3.0kg of antimonous oxide, 0.6-3.6kg of potassium phosphate, 0.5-1.8kg of fumed silica, 0.8-1.8kg of short fiber and 48-130kg of 1.40g / ml dilute sulphuric acid, and negative electrode lead paste comprises the following constituents: 600-1,000kg of lead powder, 3-12kg of barium sulfate, 1-8kg of humic acid, 0.5-2.5kg of lignin, 0.3-1.8kg of fumed silica, 0.05-1.5kg of sodium carboxymethyl cellulose (CMC), 0.5-2.5kg of PTFE emulsion, 8-10kg of graphite, 1-16kg of acetylene black / carbon black, 2-18kg of active carbon / capacitance carbon / carbon, 0.05-1.8kg of bismuth oxide / bismuth carbon sulfide bismuth, 0.01-1.2kg of graphene, 0.02-2.0kg of carbon nanofiber tube, 0.8-1.8kg of short fiber and 76-80kg of 1.40g / ml dilute sulphuric acid.

Owner:ANHUI HONGDA ELECTRICAL SOURCE

Lead paste formula of energy storing accumulator and preparation method thereof

InactiveCN101887971AMeet charging requirementsSolution to short lifeLead-acid accumulator electrodesFiberPolyester

The invention discloses a lead paste formula of energy storing accumulators. An anode lead paste formula comprises the following raw materials of 6.5wt% to 8wt% of dilute sulphuric acid, 10wt% to 11wt% of deionized water, 15wt% to 30wt% of red lead, 0.1wt% to 0.3wt% of aquadag, 0.08wt% to 0.25wt% of stannous sulfate, 0.06wt% to 0.10wt% of polyester staple fiber and the balance of lead powder; and a cathode lead paste formula comprises the following raw materials of 7.5wt% to 8.5wt% of dilute sulphuric acid, 9wt% to 10wt% of deionized water, 0.5wt% to 0.8wt% of barium sulfate, 0.15wt% to 0.25wt% of acetylene carbon black, 0.30wt% to 0.40wt% of humic acid, 0.06wt% to 0.10wt% of polyester staple fiber and the balance of lead powder. After being made into accumulators, the lead paste prepared by the formula and the preparation method thereof has high initial capacity and cycle life, has high overdischarge resistant performance and charging accepting capability far higher than standard requirements, and can fully meet requirements for performance of the energy storing accumulators.

Owner:张天任

Gel electrolyte capable of prolonging service life of lead-acid battery

InactiveCN104091968APrevent gelAvoid reunionLead-acid accumulatorsElectrolyte immobilisation/gelificationElectrochemical responseElectrolytic agent

The invention discloses gel electrolyte capable of prolonging the service life of a lead-acid battery. The gel electrolyte contains the following raw materials in percentage by weight: 0.1 to 0.5 percent of polyethylene glycol, 0.1 to 1 percent of stannous sulfate, 0.5 to 1.5 percent of sodium sulfate, 0.5 to 1 percent of phosphoric acid, 0.05 to 2 percent of an organic silicon polymer, 0.5 to 8 percent of fumed silica, 35 to 45 percent of sulfuric acid and the balance being de-ionized water. According to the gel electrolyte, the polyethylene glycol is used as a colloid stabilizer and can prevent colloids from being gelled or agglomerated before being filled into the battery and enhance the stability of the colloids to form a stable three-dimensional mesh structure; the stannous sulfate can be oxidized into stannic tin to improve the electrical conductivity of an active substance and the recharging capability of the battery which is discharged; the sodium sulfate can provide a certain quantity of sulfate radicals for electrochemical reaction in the electrolyte to reduce the degree of supersaturation of lead sulfate crystals; silicon-oxygen bonds and hydrogen bonds in the organic silicon polymer can effectively reduce the softening speed of the active substance, inhibit the passivation of the active substance on the surface layer and prolong the service life of the battery.

Owner:ZHEJIANG TIANNENG BATTERY JIANGSU NEW ENERGY

Lead plaster for low temperature resistant lead storage battery for electric scooter and preparation method of lead plaster

ActiveCN103779557AInhibition of \"shrinkage\"Inhibit \"passivation\"Cell electrodesFiberElectrical battery

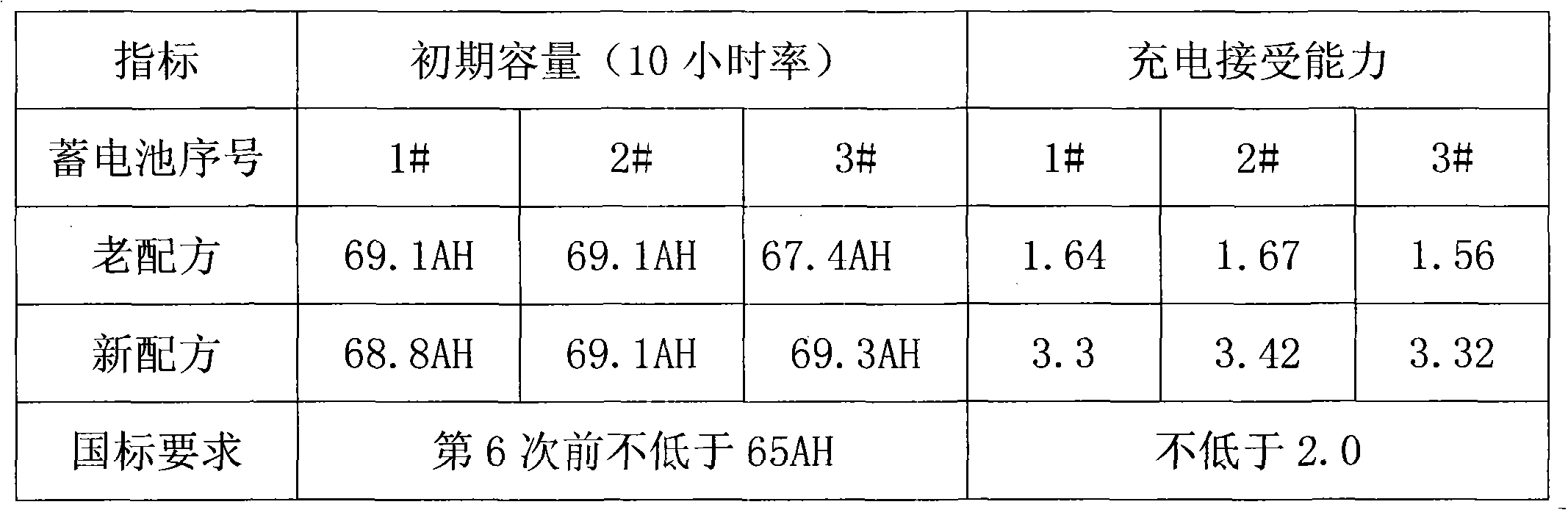

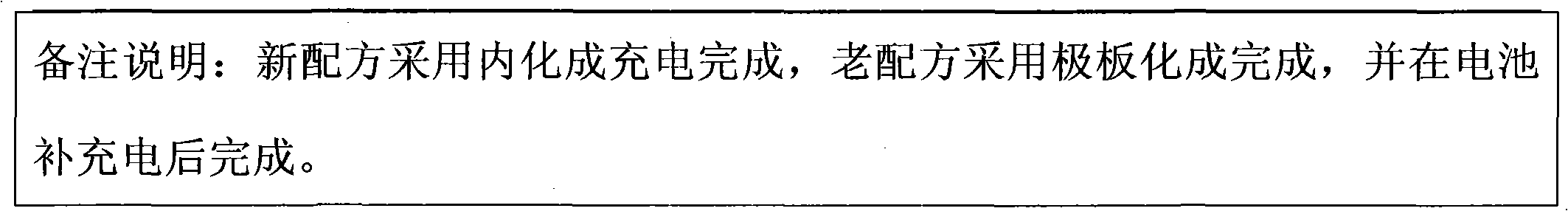

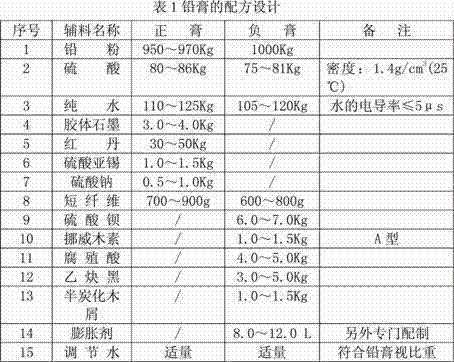

The invention relates to a lead plaster for a low temperature resistant lead storage battery for an electric scooter and a preparation method of the lead plaster. The lead plaster comprises an anode lead plaster and a cathode lead plaster, wherein the anode lead plaster comprises the following components in parts by weight: 950-970 parts of lead powder, 80-86 parts of 1.3-1.4g / cm<3> sulfuric acid, 110-125 parts of pure water, 3.0-4.0 parts of colloidal graphite, 30-50 parts of red lead, 1.0-1.5 parts of tin sulfate, 0.5-1.0 part of sodium sulfate and 0.7-0.9 part of short fiber; the cathode lead plaster comprises the following components in parts by weight: 1000 parts of lead powder, 75-81 parts of 1.3-1.4g / cm<3> sulfuric acid, 105-120 parts of pure water, 0.6-0.8 part of short fiber, 6.0-7.0 parts of barium sulfate, 1.0-1.5 parts of Norway lignin, 4.0-5.0 parts of humic acid, 3.0-5.0 parts of acetylene black and 1.0-1.5 parts of semi-carbonized saw dust. According to the lead plaster and the preparation method thereof, the acceptance performance when the battery is charged at low temperature is improved and the discharge capacity is increased; the lead plaster disclosed by the invention is applicable to low-temperature environment and is especially suitable for northeast and northwest regions in China.

Owner:河北超威电源有限公司

Colloidal electrolyte formula for lead-acid storage battery

ActiveCN101908649AStrong water retentionEliminate passivationFinal product manufactureLead-acid accumulators constructionPolyethylene glycolPhosphoric acid

The invention discloses a colloidal electrolyte formula for a lead-acid storage battery, comprising the following components in percentage by weight: 0.8-10 percent of fumed silica, 0.4-0.8 percent of polyethylene glycol, 0.03-0.6 percent of bismuth trioxide, 0.05-0.3 percent of antimonous oxide, 0.05-0.5 percent of stannous sulfate, 0.3-1 percent of phosphoric acid, 0.5-2 percent of anhydrous sodium sulfate, 25-40 percent of sulfuric acid and 50-60 percent of water. The invention has the advantages that: after using a colloidal electrolyte of the invention, with regard to the lead-calcium alloy storage battery, the phenomenon that a common colloidal electrolyte cannot adapt to a lead-calcium alloy storage battery can be effectively improved, the early-stage capacity attenuation effect of the lead-calcium alloy battery can be improved, the deep electrical discharge cycle life, the low-temperature heavy-current charging and discharging performances and the rechargeable performance after being discharged of the lead-calcium battery can be further enhanced, the use safety of the battery can be improved and the overall use cost of the battery can be reduced.

Owner:CHAOWEI POWER CO LTD

Polycarboxylic acid series water reducing agent using allyl polyglycol as raw material and synthesizing method thereof

The invention belongs to the technical field of building materials, in particular to a polycarboxylates water reducing agent taking allyl polyethylene glycol as raw material and a synthetic method thereof. The polycarboxylates water reducing agent is made from raw materials of allyl polyethylene glycol, maleic anhydride, methacrylate, ammonium persulfate, stannous sulfate, sodium hydroxide and water which are compounded in appropriate weight proportion and protected by nitrogen, through heating reaction. Compared with the prior art, the invention is characterized in that two-step synthesis is not necessary, and the cost of raw materials is very low, the product of the process is of stable performance and good market prospect.

Owner:TONGJI UNIV

Positive lead paste of lead-acid storage battery pole plate for deep circulation

InactiveCN105140511APromote growthNot easy to fall offLead-acid accumulatorsCell electrodesFiberGas phase

The invention discloses a positive lead paste of a lead-acid storage battery pole plate for deep circulation. The positive lead paste comprises the following components based on a proportion by weight: 750-1,000 of lead powder, 0.5-2 of antimonous oxide, 0.5-2 of bismuth trioxide, 0.5-2 of stannous sulfate, 0-2 of magnesium sulfate, 0-2 of aluminum sulfate, 0.5-2 of zinc oxide, 0.5-3 of colloidal graphite, 0.5-2 of fiber, 50-250 of red lead, 80-98 of dilute sulphuric acid, 1-5 of carboxy methylated cellulose (CMC), 0.5-5 of silicon dioxide and 100-110 of pure water, wherein the dosages of the magnesium sulfate and the aluminum sulfate in the raw materials are not 0 simultaneously, and the length of the fiber is 4 to 10 millimeters. In the positive lead paste of the lead-acid storage battery pole plate for deep circulation, disclosed by the invention, the antimonous oxide and the bismuth trioxide which can be used for preventing a hydrated polymer chain from being decomposed, reducing a crystallization trend and preventing softening and shedding are added, the gas-phase silicon dioxide and the CMC which can be used for improving the adhesion strength of an active substance and the magnesium sulfate, the aluminum sulfate and the zinc oxide which can be used for facilitating the generation of a hydrated active substance chain and improving an interface of a grid and the active substance are added, the optimal effect of the positive lead paste is achieved by adjusting the proportion of the additives, thus, the capacity fading of a front stage is avoided, and the service lifetime for deep circulation of a battery is prolonged.

Owner:武汉非凡储能电源系统有限公司

Positive lead paste of lead-acid storage battery

The invention discloses a positive lead paste of a lead-acid storage battery. The positive lead paste is composed of the following raw materials by mass percent: 6.8-10% of 1.4 g / cm<3> sulfuric acid, 9-11% of de-ionized water, 5-16% of red lead, 0.05-0.06% of short fiber, 0.10-015% of carbon fibers, 0.1-0.3% of silicon dioxide, 0.1-0.4% of anisotropic graphite, 0.05-0.28% of stannous sulfate and the balance of lead powder. The positive lead paste of the lead-acid storage battery is characterized in that various positive active materials such as anisotropic graphite, stannous sulfate, silicon dioxide and red lead are added on the basis of a certain content of water and acids in the positive lead paste material so that the porosity of the positive plate is improved and the early-stage capacity and the vimetric specific energy of the lead-acid storage battery are enhanced; and as a result, the formation efficiency of batteries is improved.

Owner:CHAOWEI POWER CO LTD

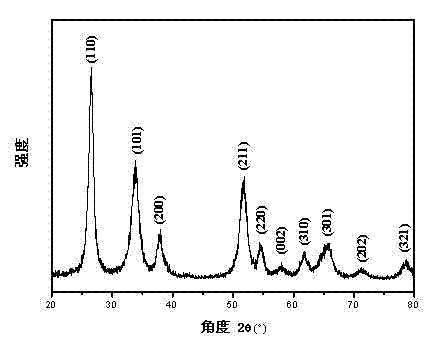

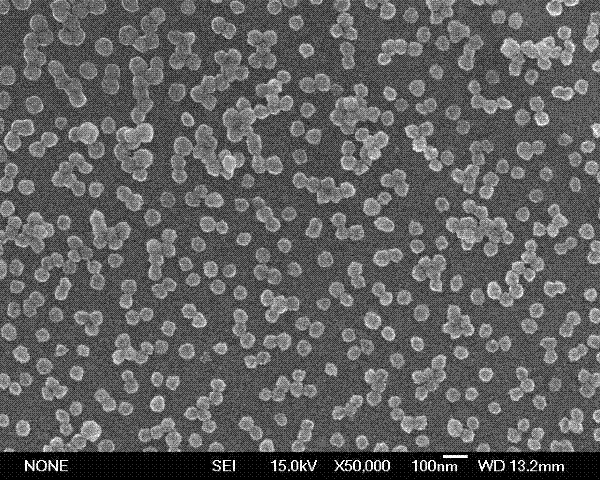

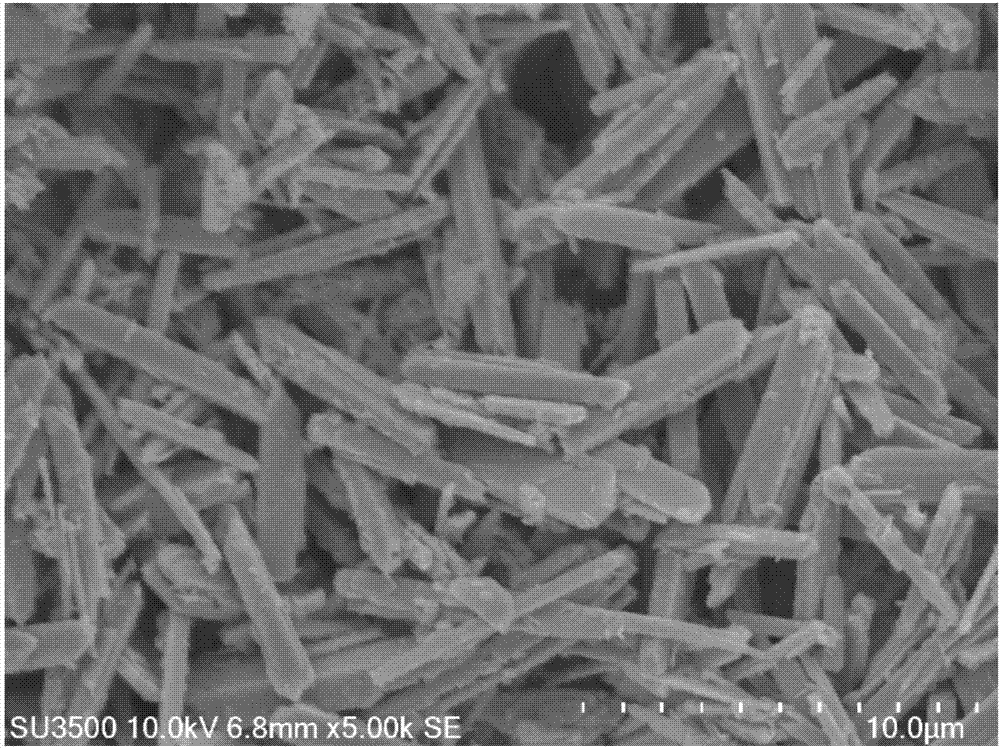

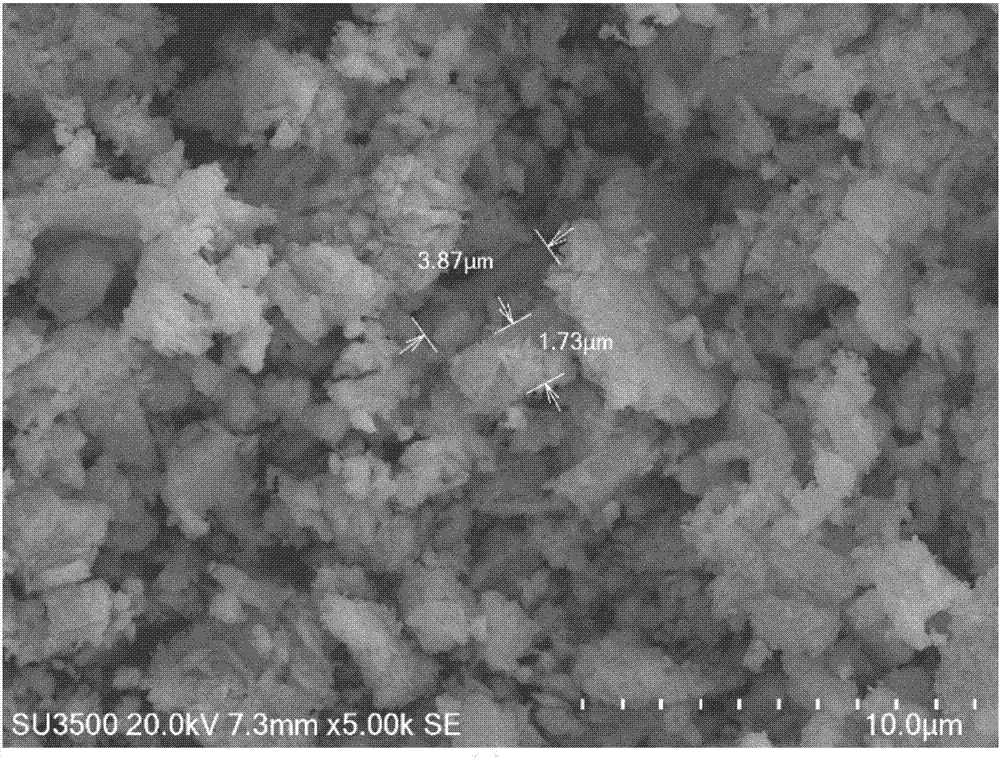

Synthetic method of tin dioxide nanomaterials

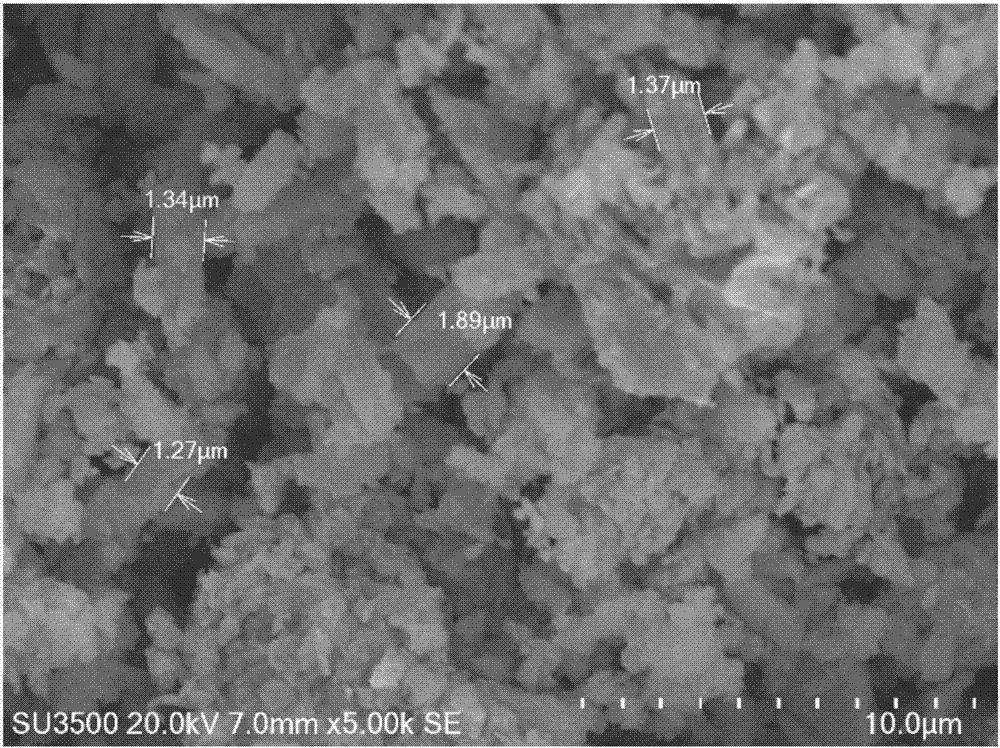

InactiveCN102267718ASmall particle sizeGood monodispersityNanotechnologyTin oxidesTin dioxideHydration reaction

The invention relates to a preparation method of tin dioxide nanometer material. The specific steps of the method are as follows: using stannous sulfate (SnSO4) and trisodium citrate dihydrate (Na3C6H5O7 2H2O) as raw materials, the amount of the two is used as a measurement basis according to a certain molar ratio, that is, SnSO4:Na3C6H5O7 2H2O=2 :5~4, weigh it and add it to a certain amount of mixed solution of absolute ethanol and deionized water with a volume ratio of (1:9~9), stir it quickly for 1~2 hours and then put it into the autoclave React at 120-200°C for 2-48 hours, wash with deionized water and ethanol several times after cooling, and obtain tin dioxide nanomaterials after drying. The invention has simple process, good repeatability and can be produced in batches. The particle size of the obtained tin dioxide nanosphere is about 50nm, and the monodispersity is good.

Owner:SHANGHAI UNIV

Polycarboxylic acid series water reducing agent using allyl polyglycol as raw material and synthesizing method thereof

Owner:TONGJI UNIV

Lead acid storage battery electrolyte additive and preparation method thereof

ActiveCN103050738ALower internal resistanceReduce heatLead-acid accumulatorsEthylenediamineInternal resistance

The invention discloses a lead acid storage battery electrolyte additive and a preparation method thereof. Concentrated sulphuric acid is added into a certain quantity of purified water obtained through ion exchange to prepare dilute sulfuric acid, EDTA (Ethylene Diamine Tetraacetic Acid), aluminum sulfate, sodium sulfate, cadmium sulfate, stannous sulfate, magnesium sulfate, cobaltous sulfate, copper sulfate and potassium sulfate are added into 1L dilute sulfuric acid, which is taken out and heated, step by step according to the formula quantity, and the mixture is fully stirred and cooled to the room temperature to obtain the lead acid storage battery electrolyte additive. According to the invention, the cycle life of a traditional storage battery is remarkably improved, lead dendritic crystals in the battery are effectively prevented from short circuit, the internal resistance of the battery in the later period of cycle life is reduced, the charge acceptance capability is improved, water loss during charging is reduced, heat generated during battery charging is decreased and the battery is protected against thermorunaway. The lead acid storage battery electrolyte additive is suitable for various lead acid storage batteries, such as lead acid storage batteries for starting up automobiles and motorcycles, deep-cycle batteries and AGM (Absorptive Glass Mat) valve-regulated sealed lead acid storage batteries for power vehicles, flat-plate / tubular flooded storage batteries and flat-plate / tubular colloid storage batteries and the like.

Owner:易德维能源科技(深圳)有限公司

Preparation method of nanoscale stannic oxide hollow sphere

InactiveCN102583266ANo pollution in the processRaw materials are cheap and easy to getNanotechnologyElemental selenium/telluriumGas detectorPotassium hypochlorite

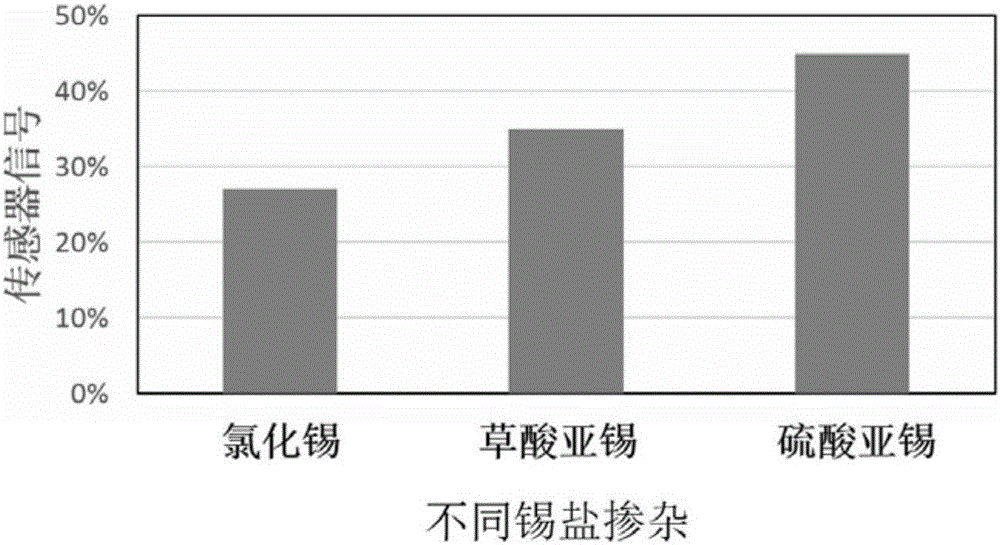

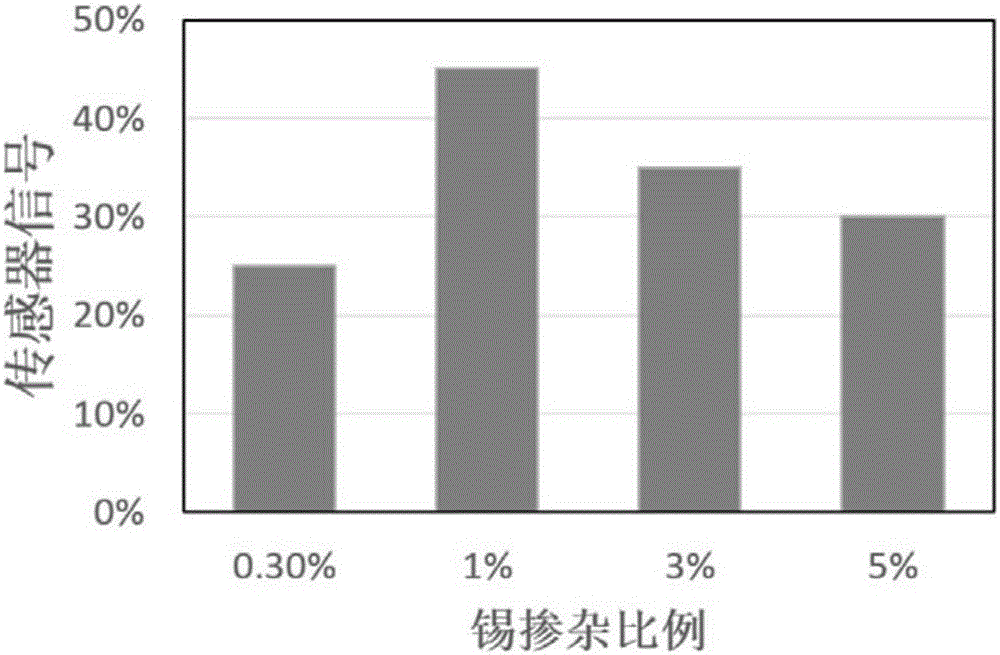

The invention belongs to the field of nano materials and relates to a preparation method of a nanoscale stannic oxide hollow sphere. The method is characterized in that stannous salts and oxidants serve as reaction materials and a hydro-thermal method is used for preparation under the acidic condition at the PH value between 1.0 and 4.0; the stannous salts consist of at least one of stannous sulfate, stannous chloride and stannous oxalate; the oxidants consist of at least one of hydrogen peroxide, chloric acid, hypochlorous acid, potassium chlorate, sodium chlorate, potassium hypochlorite and sodium hypochlorite; and PH value of solutions is adjusted by one of sulphuric acid, hydrochloric acid, oxalic acid and sodium hydroxide. The preparation method does not use any sacrificial templates and organic solvents and is environmentally friendly, simple in process, mild in reaction condition, low in energy consumption, easy to control, high in product purity, and suitable for large-scale industrial production. The nanoscale stannic oxide hollow sphere can be applicable to gas sensors, lithium ion batteries, catalysts and photoelectronic devices.

Owner:SHANDONG UNIV

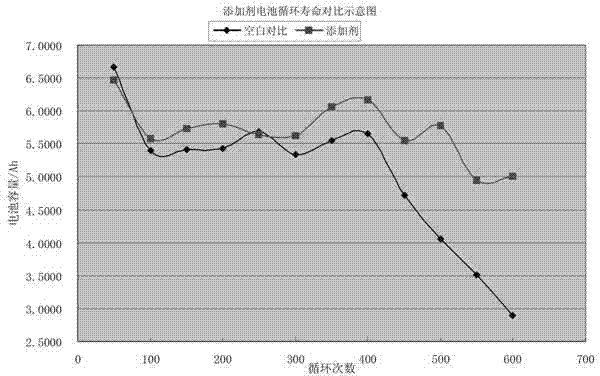

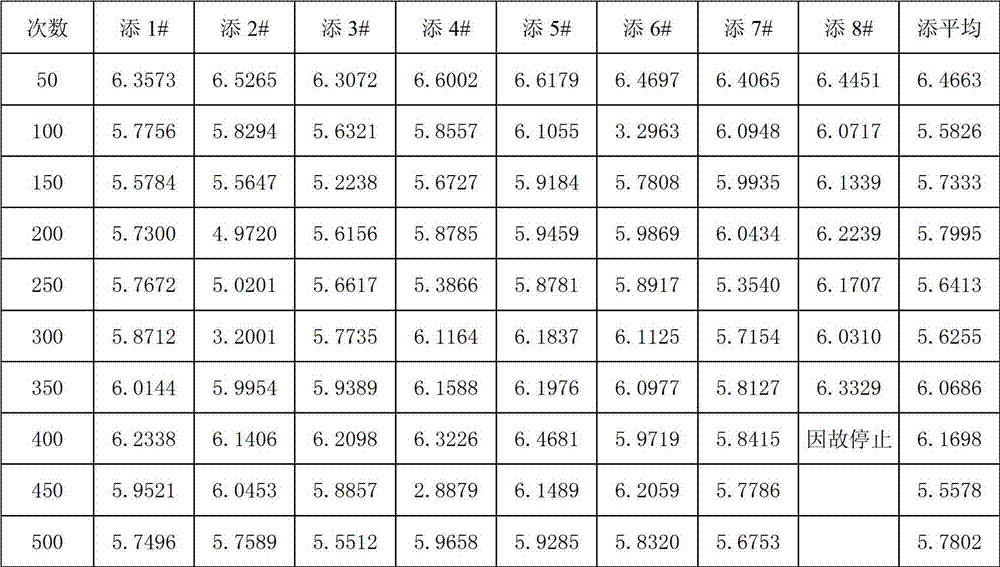

Electrolyte additive of lead-acid storage battery and preparation method for electrolyte additive

InactiveCN106654392AImprove conductivityAvoid decompositionLead-acid accumulatorsElectrochemistrySilicon dioxide

The invention relates to an electrolyte of a lead-acid storage battery, particularly to an electrolyte additive of the lead-acid storage battery; the electrolyte additive of the lead-acid storage battery can improve electrochemical performance, prolong the cycle life and improve capacity of the battery. The additive is prepared from graphene oxide, silicon dioxide, sulfate, stannous sulfate and EDTA-Na. By virtue of the electrolyte additive, the electrochemical performance and the capacity of the battery can be effectively improved and the cycle life of the lead-acid storage battery can be prolonged.

Owner:TIANNENG GRP HENAN ENERGY TECH

Deep cycle battery lead paste preparation method with characteristic of easy 4BS generation

ActiveCN107331862AAvoid conversionEffective control of contentLead-acid accumulator electrodesPower batteryDry mixing

The invention discloses a deep cycle battery lead paste preparation method with a characteristic of easy 4BS generation, and belongs to the technical field of lead storage battery production. The preparation method comprises: (1) carrying out dry mixing on lead powder and additives excluding diantimony trioxide and stannous sulfate, adding water, carrying out wet mixing, adding sulfuric acid accounting for more than 80% of the total acid amount, carrying out a stirring reaction, and controlling the reaction temperature at 65-85 DEG C to obtain a first acid mixing lead paste; and (2) adding diantimony trioxide and stannous sulfate to the remaining sulfuric acid to obtain a sulfuric acid mixed solution, mixing the sulfuric acid mixed solution into the first acid mixing lead paste, carrying out a stirring reaction, and cooling to achieve a temperature of less than 45 DEG C to obtain the deep cycle battery lead paste. According to the present invention, the acid adding is performed twice in the method, and the 4BS-inhibiting components such as diantimony trioxide and stannous sulfate are added at the late stage, such that the power battery lead paste formula is not affected, and a certain amount of the 4BS can be effectively obtained.

Owner:TIANNENG BATTERY GROUP

Mixed lead paste capable of improving binding force of positive grid of lead-acid storage battery and lead paste and preparation method of mixed lead paste

InactiveCN107887591AEffective solution to bindingSolve the bonding problemLead-acid accumulatorsCell electrodesFiberBinding force

The invention discloses mixed lead paste capable of improving the binding force of a positive grid of a lead-acid storage battery and lead paste and a preparation method of the mixed lead paste. The method comprises the following steps of adding lead powder which is 80-90% of total mass to a paste mixing machine, adding the following raw materials by percentages: 8-10% of sulfuric acid, 0.1-0.3% of stannous sulfate, 0.08-0.10% of conductive fiber, 0.3-0.5% of colloidal graphite, 0.05-0.15% of sodium borate and 1.0-1.2% of antimonic oxide, carrying out dry mixing for 8-10min, adding deionized water, carrying out wet mixing for 2min, adding residual paste and carrying out wet mixing for 8-10min; and dropwise adding the sulfuric acid which is 8-10% of total mass and stirring for 10-12min to obtain the lead paste of which the apparent density is 4.4+ / -0.02g / cm<3>. According to the mixed lead paste, the interface problem between an existing battery grid and an active material of the lead paste can be effectively solved, the bonding force between the positive grid and the lead paste is improved, the strength of a polar plate is improved and the cycle life of the battery is prolonged.

Owner:HENAN CHAOWEI POWER SUPPLY

Grid alloy and diachylon formula of battery plate of electrombile

InactiveCN102839296AEasy to useAvoid pollutionLead-acid accumulator electrodesElectrical batteryElectric-vehicle battery

The invention relates to a grid alloy and a diachylon formula of a battery plate of an electrombile. The grid alloy of the positive electrode comprises the following components by weight: 1.3-1.5% of tin, 0.07-0.09% of calcium, and 0.01-0.03% of aluminum; the grid alloy of the negative electrode comprises the following components by weights: 0.6-0.8% of tin, 0.09-0.11% of calcium and 0.01-0.03% of aluminum; the diachylon formula comprises the following components by weight: 1000kg of lead powder served as the main material, and additive auxiliary materials including 0.2-0.3% of active carbon, 0.1-0.12% of short fiber, 0.1-0.12% of stannous mono-sulphate, and 0.2-0.22% of antimonous oxide; and the materials for mixing are as follows 11.0%-11.5% of pure water, 10.5-11.0% of sulfuric acid with 1.40g / ml under 25 DEG C based on the concentration. The pollution of the cadmium to the environment is removed; the stannous mono-sulphate and the antimonous oxide are added to the diachylon formula; and a high-temperature high-humidity solidifying technology is adopted, so that the strength of the polar plate is ensured, and the circulating capacity of a battery can be improved.

Owner:SHAOGUAN QUJIANG GREATBASE POWER TECH

Method for preparing stannous pyrophosphate

InactiveCN101234757AReduce turbidityImprove plating qualityPhosphorus compoundsTurbidityRoom temperature

The invention discloses a method for preparing stannous pyrophosphate. The technique of the method is as follow: stannous chloride and stannous sulfate with a short time retention period (0 to 72 hours) reacts with stoichiometric alkali metal pyrophosphate solution (thickness of 1 to 30 percent) in room temperature; the reaction precipitate is washed by water until Cl<-> is less than 1 percent; white powder products are obtained after filtering, drying and crashing. The complex compound solution which is formed by the products and alkali metal pyrophosphate is colourless and transparent, and has a turbidity degree merely of 0 to 5.

Owner:易鹤翔

Container formation process for valve-regulated lead storage battery

InactiveCN104300179AImprove match rateImprove cycle lifeFinal product manufactureLead-acid accumulators constructionProcess engineeringBattery cell

The invention discloses a container formation process for a valve-regulated lead storage battery. The container formation process comprises the steps of battery acidifying, forming and matching. Dilute sulfuric acid with adensity of 1.24-1.26g / cu.cm. at 25 DEG.C is quantitatively added in the battery, wherein the concentrated sulfuric acid content is 31%-33%, the anhydrous sodium sulfate content is 0.8%-1.5%, the stannous sulfate content is 0.1%-0.15%, and the rest is pure water. Each unit cell of each valve-regulated lead storage battery semi-finished product is quantitatively acidified twice; the active substances in the battery are fast and sufficiently transformed through an advanced formation process; compared with the traditional container formation process, the formation time is shortened by 40% and more, the charging amount is reduced by 20% and more, the battery matching rate is improved by 5% and more, and the cycle life of the battery is improved by 20% and more. The container formation process disclosed by the invention further has an advantage that the acid extraction process in the tradition production process is cancelled, so that the uniformity of the battery is improved, the labor consumption is reduced, and the production cost is lowered.

Owner:TIANNENG GRP HENAN ENERGY TECH

High-power and long-lifetime power lead-acid storage battery and preparation method thereof

InactiveCN106058175AHigh specific powerReduce dehydrationFinal product manufactureCell electrodesFiberActivated carbon

The invention relates to the technical field of storage batteries, and discloses a high-power and long-lifetime power lead-acid storage battery. Positive lead paste comprises the following components in parts by weight: 900-1,000 parts of lead oxide powder, 0-100 parts of red lead, 5-30 parts of tetrabasic lead sulphate, 10-100 parts of conductive graphite, 0.4-1 part of a short fiber, 60-100 parts of sulfuric acid solutions and 100-150 parts of water; negative lead paste comprises the following components in parts by weight: 950-1050 parts of lead oxide powder, 1-8 parts of activated carbon, 8-15 parts of barium sulfate, 0.4-1 part of a short fiber, 1-5 parts of sulfonated aromatic polymers, 60-100 parts of sulfuric acid solutions and 100-150 parts of water; and an electrolyte comprises the following components in parts by weight: 950-1050 parts of sulfuric acid solutions, 1-5 parts of sulfate, 2-8 parts of stannous sulfate, 15-80 parts of silica sol and 4-15 parts of sodium carboxymethylcellulose. According to the lead-acid storage battery, the service lifetime of the battery can be effectively prolonged; and the power of the battery can be effectively improved.

Owner:CHAOWEI POWER CO LTD

Positive plate of lead storage battery and preparation method thereof

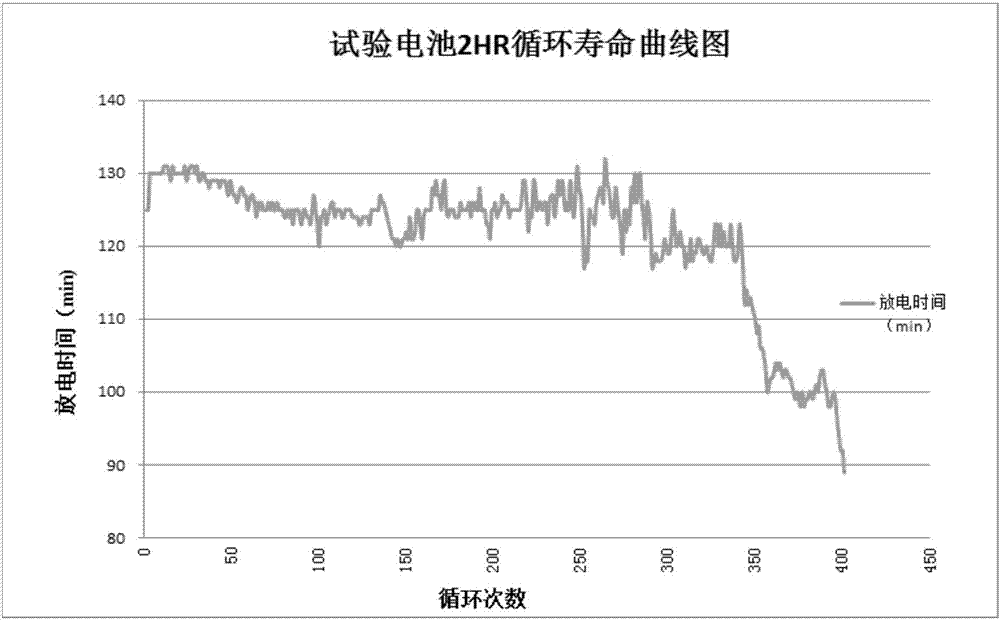

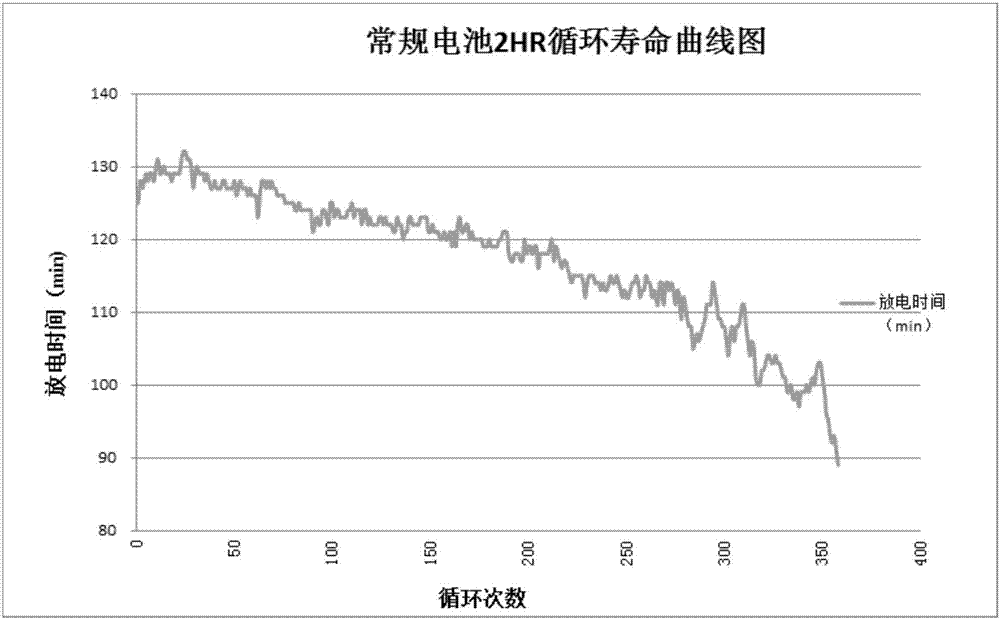

ActiveCN106910872AHigh initial capacityExtend your lifeElectrode manufacturing processesLead-acid accumulatorsSize increaseReaction temperature

The invention discloses a positive plate of a lead storage battery and a preparation method thereof, and belongs to the technical field of lead storage batteries. A lead paste raw material of the positive plate comprises lead powder, an additive, water and sulfuric acid; the additive comprises diantimony trioxide and stannous sulfate; the preparation of lead paste is completed in two parts: in the first part, the additive contains the diantimony trioxide and the stannous sulfate, the reaction temperature is controlled not to be greater than 50 DEG C, and first lead paste containing 3BS is prepared; in the second part, the two additives are not contained, the reaction temperature is controlled to be 80-85 DEG C, and second lead paste containing 4BS is prepared; the first lead paste and the second lead paste are physically mixed, so that an effective amount of 3BS and 4BS is simultaneously contained in the positive lead paste; meanwhile, the battery performance in terms of initial capacity and battery life is improved. The positive plate disclosed by the invention has the benefits that a medium temperature lead paste mixing and curing process is adopted, the conversion of the 4BS and the further particle size increase are avoided, the particle size and the content of the 4BS in the lead paste are effectively controlled, and the battery consistency is ensured.

Owner:TIANNENG BATTERY GROUP

Colloid electrolyte capable of improving service life of lead-acid cell

InactiveCN104218261APrevent gelAvoid reunionLead-acid accumulatorsElectrolyte immobilisation/gelificationElectrochemical responseElectrolytic agent

The invention discloses a colloid electrolyte can improve the service life of a lead-acid cell, and the colloid electrolyte comprises the following raw materials by weight: 0.1-0.5% of polyethylene glycol, 0.1-1% of stannous sulfate, 0.5-1.5% of sodium sulfate, 0.5-1% of phosphoric acid, 0.05-2% of organosilicon polymer, 0.5-8% of fumed silica, 35-45% of sulfuric acid, and balanced of deionized water. The polyethylene glycol as a colloid stabilizer can prevent the occurrence of colloid coacervation or agglomeration before colloid is poured into the cell, colloidal stability is enhanced, and a stable three-dimensional network structure is formed; the stannous sulfate can be oxidized to tetravalent tin, the active material electrical conductivity and recharge ability after the cell is discharged can be improved, the sodium sulfate in the electrolyte can provides a certain amount of sulfate radicals for the electrochemical reaction, the degree of supersaturation of lead sulfate crystals can be reduced, formation of a lead sulfate layer with poor electrical conductivity can be prevented; the phosphoric acid can refine the grain diameter of the lead sulfate crystals; and silicon oxygen bonds and hydrogen bonds in the organosilicon polymer can effectively reduce the active material softening speed, inhibit the surface active material passivation, and improve the service life of the cell.

Owner:ZHEJIANG TIANNENG BATTERY JIANGSU NEW ENERGY

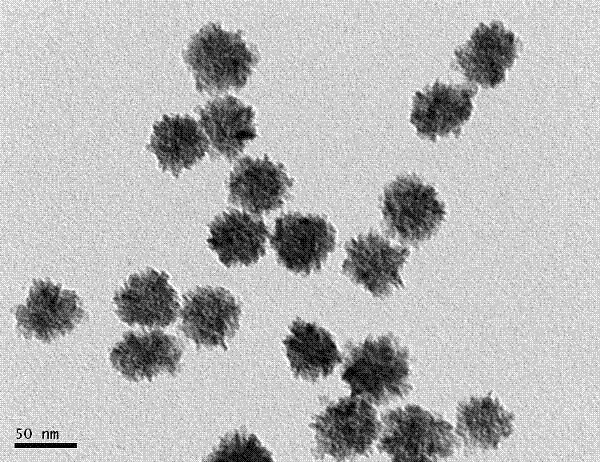

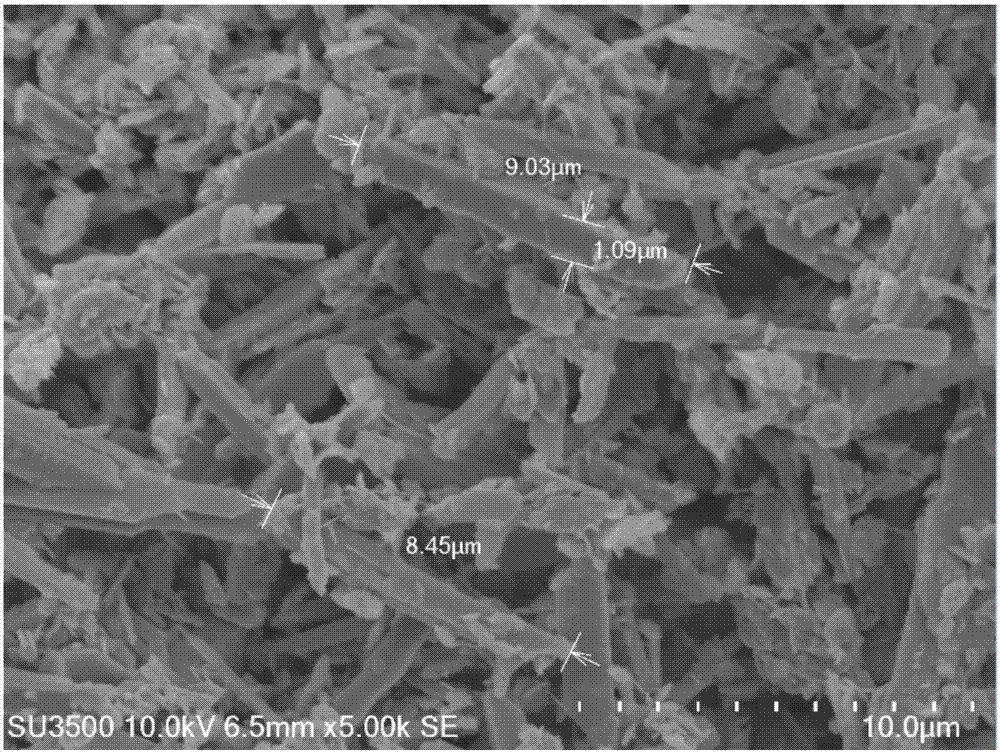

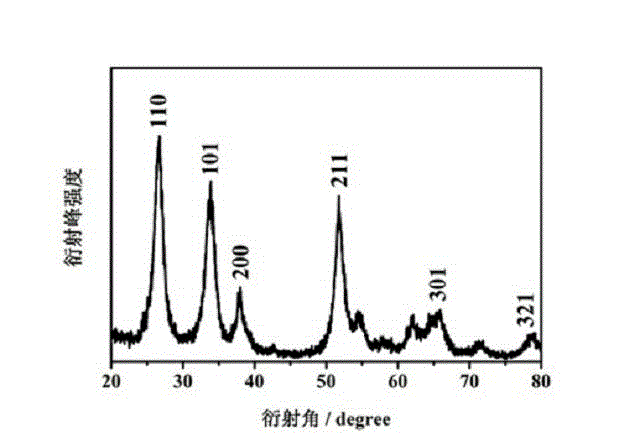

Hydrothermal synthesis method of tin dioxide nano material

InactiveCN103332726ALarge specific surface areaUniform shapeMaterial nanotechnologyTin oxidesTin dioxideGas detector

The invention relates to a hydrothermal synthesis method of a tin dioxide nano material, belonging to the technical field of inorganic chemistry and material synthesis. The hydrothermal synthesis method is characterized by comprising the following step of: with stannous sulfate (SnSO4) as a tin source and water as a solvent, preparing the tin dioxide nano material with flower-like characteristic and uniform morphology through a simple hydrothermal process under the auxiliary crystallization action of small molecular alkali tetrapropylammonium hydroxide (TPAOH), wherein the tin source of the raw materials can be stannous chloride (SnCl2), sodium stannate (Na2SnO3) or the like and the SnO2 nano material with uniform morphology can be obtained by using the tin source. The method has the advantages of simpleness in operation, controllable conditions, easiness in obtainment of the raw materials, no addition of organic solvents in the reaction process, large specific surface area of the prepared material, uniform morphology, good crystallinity and the like and has wider application prospects in the fields such as lithium batteries, gas sensors, photocatalysis, solar cells and the like.

Owner:SHANGHAI UNIV

Composite paste for inner formation of lead-acid storage battery

ActiveCN105280916AImprove low temperature performanceImprove charge reception capabilityCell electrodesFiberPolyester

The invention provides a composite paste for an inner formation of a lead-acid storage battery. Positive composite paste lead powder comprises the following chemical components of a positive composite paste in percentage by mass: 8%-9% of 35%-43% dilute sulphuric acid, 11%-13% of deionized water, 0.05%-0.4% of tin oxide or stannous mono-sulphate, 0.15%-0.4% of colloidal graphite or conductive graphite, 0.04%-0.1% of a short fiber or polyester fiber, 1%-2% of basic lead sulphate powder and 1%-2% of lead sulfate powder; and negative composite paste lead powder comprises the following chemical components of a negative composite paste in percentage by mass: 7.5%-9% of 35%-43% dilute sulphuric acid, 10%-12% of deionized water, 2%-4% of acetylene carbon black, 2%-4% of sodium lignosulphonate, 8%-14% of barium sulfate, 0.04%-0.1% of the short fiber or polyester fiber, 2%-4% of humic acid and 0.1%-0.2% of magnesium sulfate. By the technical scheme, the initial capacity of the lead-acid storage battery can be significantly improved; and the lifetime of the battery can be prolonged.

Owner:济源市万洋绿色能源有限公司

Tin plating electrolyte

The invention discloses tin plating electrolyte. The tin plating electrolyte comprises the following components 60 to 90g / L of tin methane sulfonate, 10 to 30g / L of tin sulfate, 110 to 140mg / L of p-cresolsulphonic acid, 60 to 120mg / L of sulfosalicylic acid, 30 to 50g / L of phosphinic acid, 45 to 70mg / L of 2,2-PySSPy, 15 to 25mg / L of 8-hydroxyquinoline, 20 to 30mg / L of catechins, 10 to 15g / L of 2,2-dihydroxy diethyl sulfide, 5 to 10mg / L of hexadecylpyridinium bromide, 8 to 12 g / L of dodecyl-phenol polyoxyethylene ether, 5 to 10g / L of ethylene glycol, 4 to 8g / L of benzalacetophenone, 5 to 10g / L of sodium hexametaphosphate, 4 to 8g / L of sodium dodecyl sulfate, and the balance of deionized water. According to the tin plating electrolyte, Sn2<+> can be effectively restrained to convert into Sn4 <+> in an electrolytic process by improving an electrolyte formula, and the stability of plating solution is improved; and meanwhile, the throwing power of the electrolyte is increased, and the luminance, the corrosion resistance and the welding performance of tin coatings are improved.

Owner:郎溪县金科金属有限公司

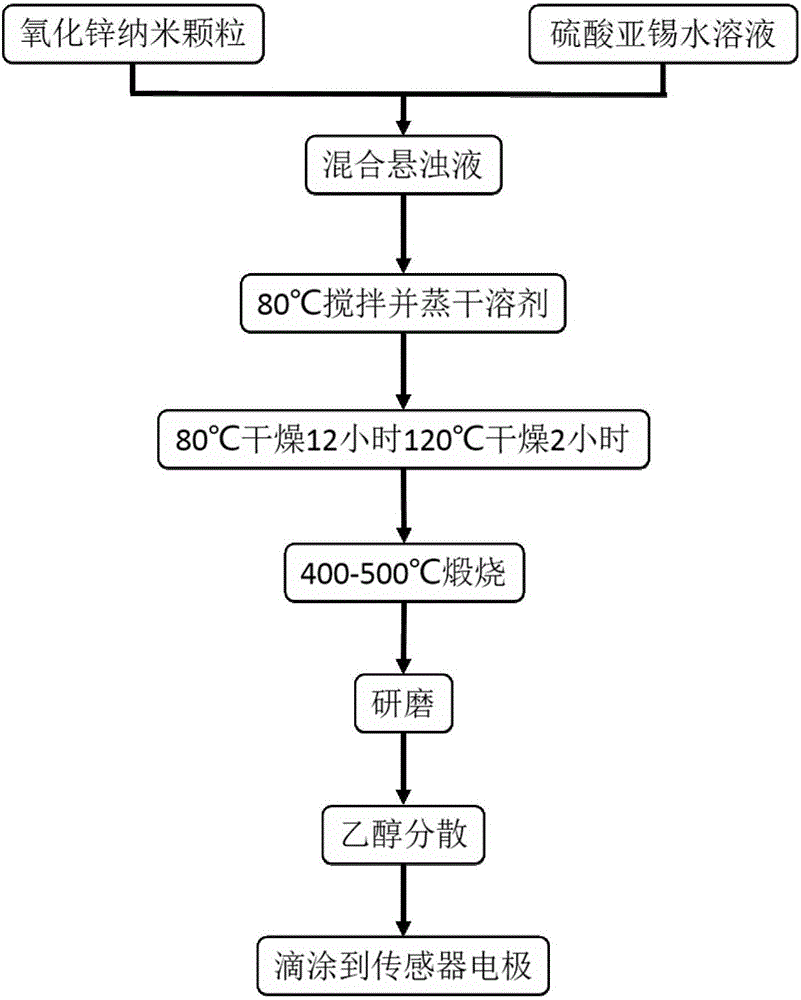

Tin-doped photocatalysis formaldehyde sensing material, preparation method thereof and formaldehyde sensor

The invention relates to a tin-doped photocatalysis formaldehyde sensing material, a preparation method thereof and a formaldehyde sensor. The tin-doped photocatalysis formaldehyde sensing material comprises zinc oxide nanoparticles and a tin additive. When the material is prepared, the zinc oxide nanoparticles synthesized in advance are evenly scattered in a tin salt solution, and a solution A is obtained; the solution A is stirred to dry the solvent through evaporation, and a precipitate B is obtained; then high-temperature calcination is carried out on the precipitate B to obtain a product C namely, the photocatalysis formaldehyde sensing material. Preferably, the tin salt is stannous mono-sulphate. The tin-doped photocatalysis formaldehyde sensing material is low in cost, high in sensitivity and high in selectivity. The lower limit of detection of formaldehyde is lowered to 0.1 ppm. The selectivity of the material for ethyl alcohol is improved.

Owner:PEKING UNIV +1

Lead-acid storage battery electrolyte solution and preparation method thereof

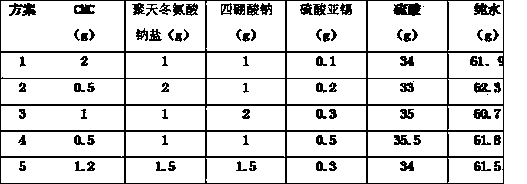

InactiveCN103715463AReduce dehydrationExtend your lifeLead-acid accumulators constructionAcid electrolytesSodium polyaspartateCarboxymethyl cellulose

The invention relates to an electrolyte solution, and especially relates to a lead-acid storage battery electrolyte solution and a preparation method thereof. The lead-acid storage battery electrolyte solution is characterized by being prepared from 0.5-2 g of sodium carboxymethyl cellulose, 1-2 g of sodium polyaspartate, 1-2 g of sodium tetraborate, 0.1-0.5 g of stannous sulfate, 32-36 g of sulfuric acid and 58-65 g of pure water. The invention aims to provide the lead-acid storage battery electrolyte solution and the preparation method thereof, and solves the problem of short service life of a storage battery.

Owner:HENAN CHAOWEI POWER SUPPLY

Low-temperature chemical tinning solution and tinning method

InactiveCN101760730AEasy to storeFor long-term storageLiquid/solution decomposition chemical coatingTinningThiourea

The invention provides low-temperature chemical tinning solution and a tinning method; the tinning solution is divided into A solution and B solution, the A solution comprises stannous sulfate, stannous chloride or stannic chloride, concentrated sulfuric acid, polyethylene glycol, triethanolamine and the like; B solution comprises thiocarbamide and concentrated sulfuric acid; the tinning method is as follows: copper or copper alloy is soaked in the A solution for 30-180s, and then is soaked in the B solution for 60-300s, so as to carry out tinning and obtain silvery white bright tinning layer, the solution working temperature is 10-35 DEG C; in the invention, the tinning is stable, tinning speed is rapid, the cost is low, the solution is energy saving and environment-protection and has practical value.

Owner:TAIYUAN NORMAL UNIV

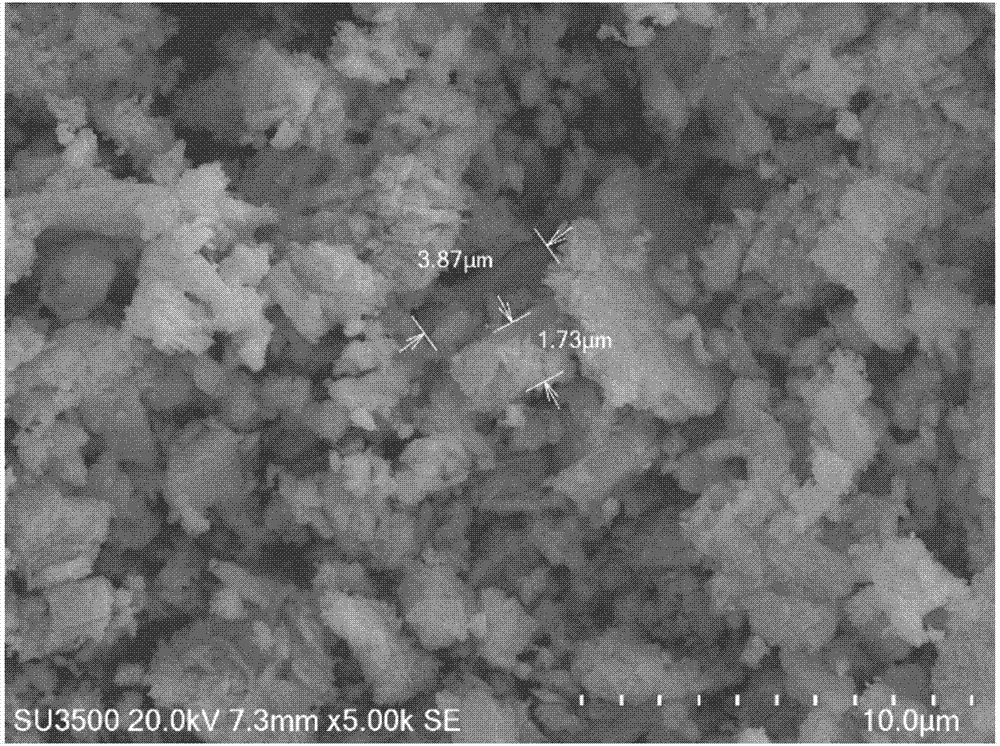

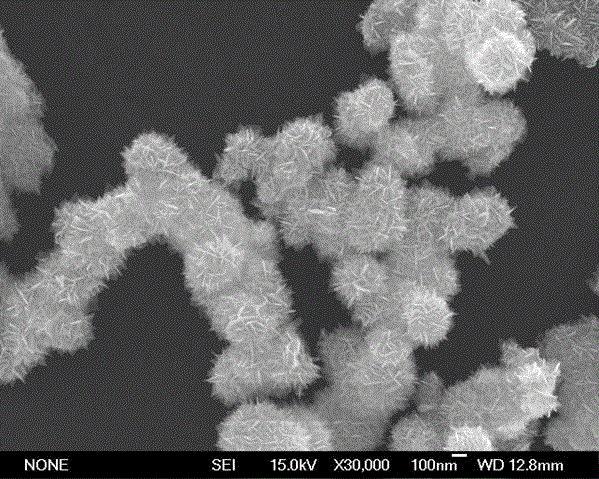

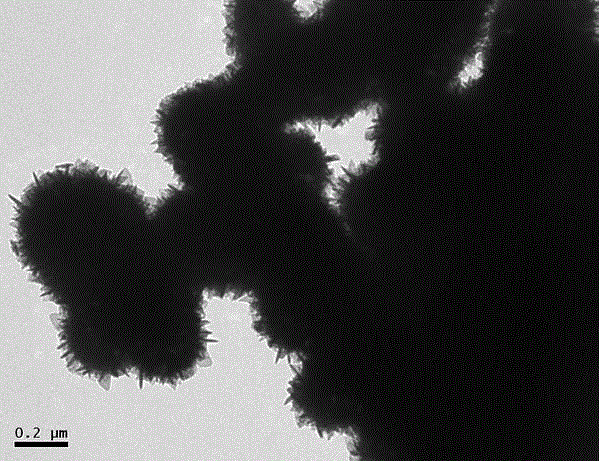

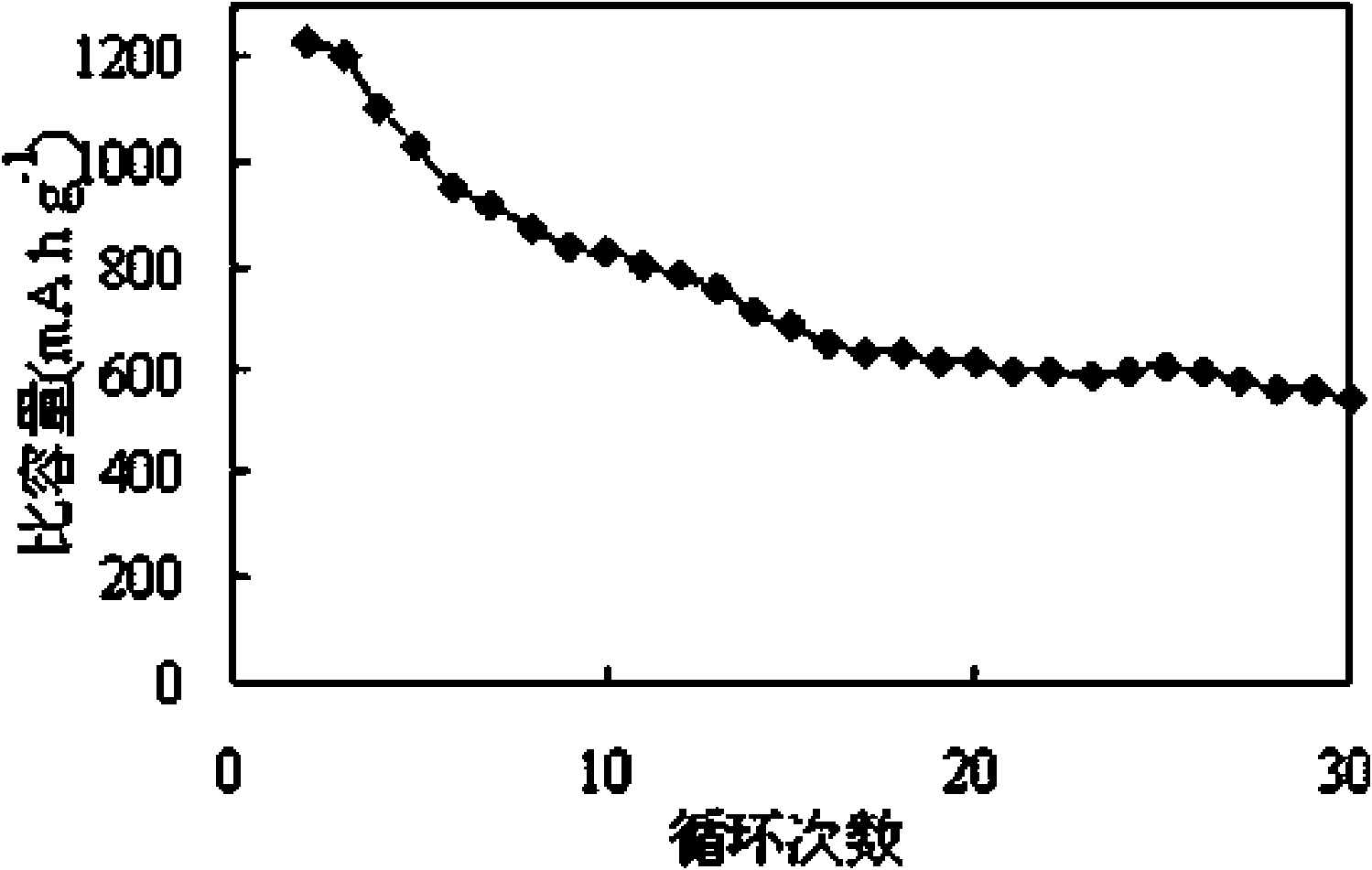

Method for preparing tin dioxide nano hollow sphere comprising nano rods and application in lithium battery

InactiveCN101638247ASimple and fast operationLow costNanostructure manufactureElectrode manufacturing processesTin dioxideLithium-ion battery

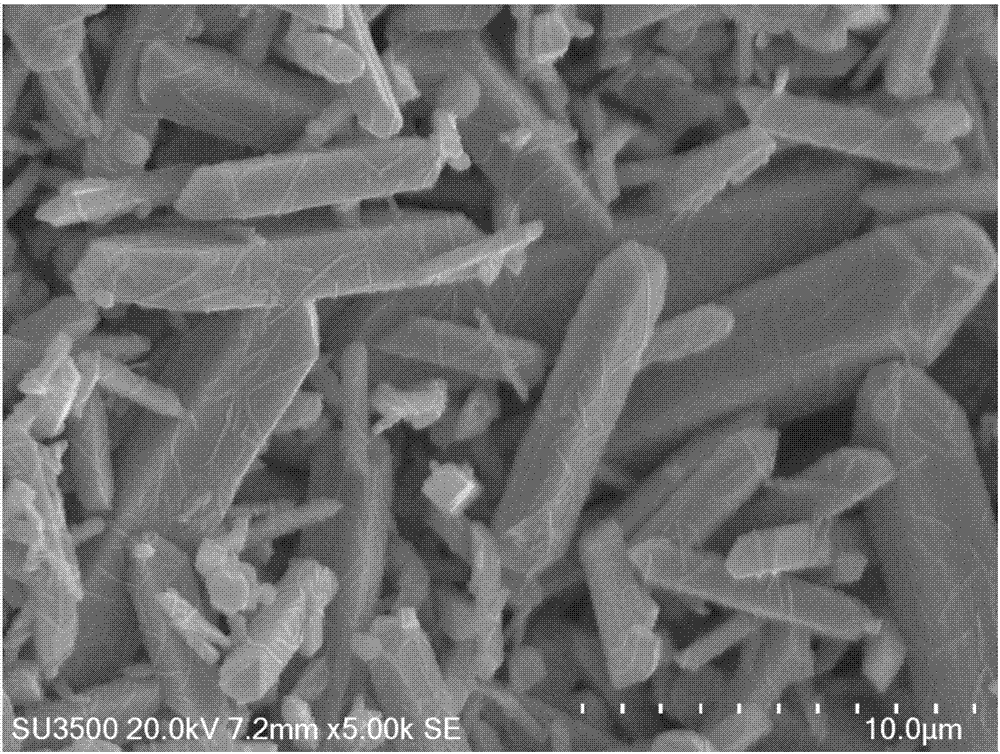

The invention provides a method for preparing a tin dioxide nano hollow sphere comprising nano rods and application in a lithium battery. The method for preparing the nano hollow sphere comprises thefollowing concrete steps: adding stannous sulfate into 50 ml of ionized water; then filling stannous sulfate aqueous solution into a stainless steel reaction vessel with a polytetrafluoroethylene substrate to carry out hydrothermal reaction at 200 DEG C for one day; washing and filtering the obtained product for three times by deionized water, drying at 70 DEG C for four hours and obtaining the high-purity nano hollow sphere which comprises the nano rods and is used for the lithium ion battery and a gas sensor or a solar energy electrical nano hollow sphere comprising the nano rods. The methodhas simple and convenient operation, low cost, high purity, favorable performance and no pollution.

Owner:FUZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com