Patents

Literature

56 results about "Aquadag" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aquadag is a trade name for a water-based colloidal graphite coating commonly used in cathode ray tubes (CRTs). It is manufactured by Acheson Industries, a subsidiary of ICI. The name is a shortened form of "Aqueous Deflocculated Acheson Graphite", but has become a generic term for conductive graphite coatings used in vacuum tubes. Other related products include Oildag, Electrodag and Molydag. Deflocculation refers to the distribution of powdered high purity graphite in an aqueous solution containing approximately 2% to 10% by weight of various Tannic/Gallotannic acid variants and separating the colloidal graphite suspension from the remaining unsuspended graphite particulates. The product names are often printed with DAG in upper case (e.g. AquaDAG). It is used as an electrically conductive coating on insulating surfaces, and as a lubricant.

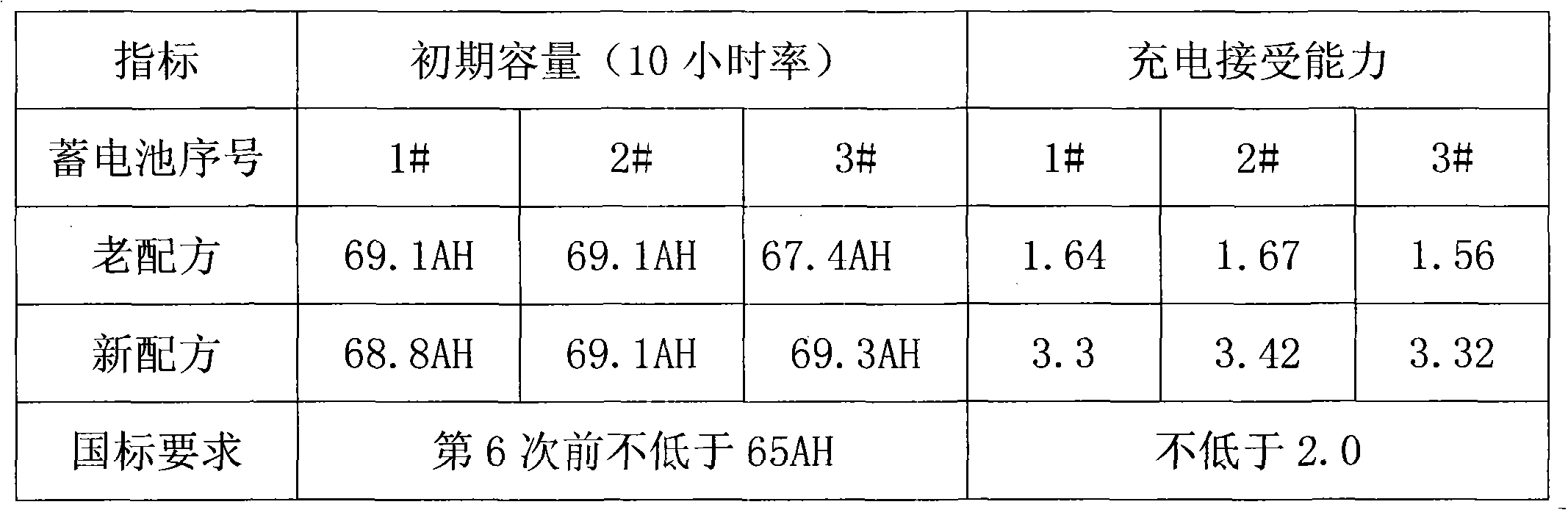

High-capacity formation lead paste and preparation method thereof

InactiveCN102931410AIncrease capacityExtended service lifeLead-acid accumulator electrodesFiberPolyester

The invention discloses a high-capacity formation lead paste. An anode lead paste comprises the raw materials of lead powder, deionized water, dilute sulphuric acid and anode auxiliary materials, and particularly comprises 100 parts by weight of lead powder, 6.6-7.4 parts by weight of dilute sulphuric acid, 10-11 parts by weight of deionized water, 3-5 parts by weight of red lead, 0.1-0.3 part by weight of aquadag, 0.08-025 part by weight of stannous mono-sulphate, 0.03-0.05 part by weight of bismuth trioxide, 0.03-0.05 part by weight of antimonous oxide and 0.06-0.1 part by weight of polyester staple fiber; and a cathode lead paste comprises the raw materials of lead powder, deionized water, dilute sulphuric acid and cathode auxiliary materials, and particularly comprises 100 parts by weight of lead powder, 6.5-8.5 parts by weight of dilute sulphuric acid, 9-10 parts by weight of deionized water, 0.5-0.8 part by weight of barium sulfate, 0.15-0.25 part by weight of acetylene carbon black, 0.30-0.40 part by weight of humic acid and 0.06-0.1 part by weight of polyester staple fiber. The invention also discloses a preparation method of the high-capacity formation lead paste.

Owner:CHAOWEI POWER CO LTD

Lead paste of deep adhesive type specially-cured lead carbon battery

ActiveCN106129357AControl stratification problemHigh strengthLead-acid accumulatorsCell electrodesCapacitanceFiber

The invention relates to lead paste of a deep adhesive type specially-cured lead carbon battery. Positive electrode lead paste comprises the following constituents: 600-1,200kg of lead powder, 5-80kg of red lead, 10-60kg of 4BS seed crystal, 0.6-3.6kg of aquadag, 0.3-3.6kg of stannous sulfate, 0-3.0kg of antimonous oxide, 0.6-3.6kg of potassium phosphate, 0.5-1.8kg of fumed silica, 0.8-1.8kg of short fiber and 48-130kg of 1.40g / ml dilute sulphuric acid, and negative electrode lead paste comprises the following constituents: 600-1,000kg of lead powder, 3-12kg of barium sulfate, 1-8kg of humic acid, 0.5-2.5kg of lignin, 0.3-1.8kg of fumed silica, 0.05-1.5kg of sodium carboxymethyl cellulose (CMC), 0.5-2.5kg of PTFE emulsion, 8-10kg of graphite, 1-16kg of acetylene black / carbon black, 2-18kg of active carbon / capacitance carbon / carbon, 0.05-1.8kg of bismuth oxide / bismuth carbon sulfide bismuth, 0.01-1.2kg of graphene, 0.02-2.0kg of carbon nanofiber tube, 0.8-1.8kg of short fiber and 76-80kg of 1.40g / ml dilute sulphuric acid.

Owner:ANHUI HONGDA ELECTRICAL SOURCE

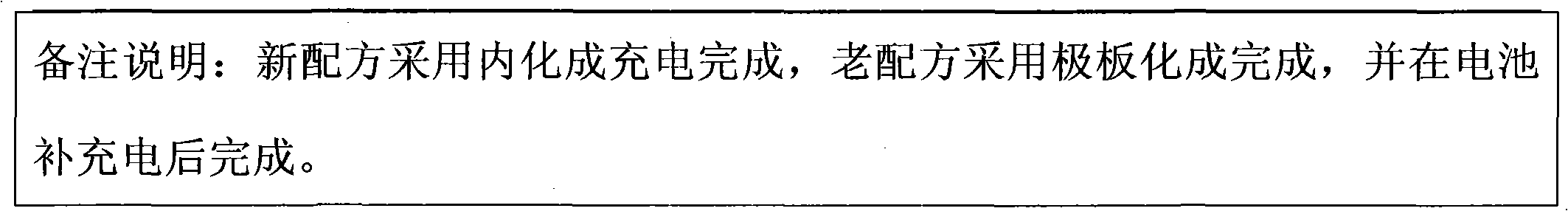

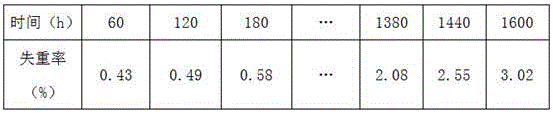

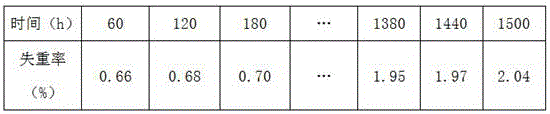

Lead paste formula of energy storing accumulator and preparation method thereof

InactiveCN101887971AMeet charging requirementsSolution to short lifeLead-acid accumulator electrodesFiberPolyester

The invention discloses a lead paste formula of energy storing accumulators. An anode lead paste formula comprises the following raw materials of 6.5wt% to 8wt% of dilute sulphuric acid, 10wt% to 11wt% of deionized water, 15wt% to 30wt% of red lead, 0.1wt% to 0.3wt% of aquadag, 0.08wt% to 0.25wt% of stannous sulfate, 0.06wt% to 0.10wt% of polyester staple fiber and the balance of lead powder; and a cathode lead paste formula comprises the following raw materials of 7.5wt% to 8.5wt% of dilute sulphuric acid, 9wt% to 10wt% of deionized water, 0.5wt% to 0.8wt% of barium sulfate, 0.15wt% to 0.25wt% of acetylene carbon black, 0.30wt% to 0.40wt% of humic acid, 0.06wt% to 0.10wt% of polyester staple fiber and the balance of lead powder. After being made into accumulators, the lead paste prepared by the formula and the preparation method thereof has high initial capacity and cycle life, has high overdischarge resistant performance and charging accepting capability far higher than standard requirements, and can fully meet requirements for performance of the energy storing accumulators.

Owner:张天任

Low-density carbon/carbon heat preservation material oxidation-resistant coating and preparation process thereof

Provided is a low-density carbon / carbon heat preservation material oxidation-resistant coating and a preparation process thereof. The oxidation-resistant coating is composed of an inner bottoming coating and an outer coating. The inner bottoming coating is prepared from, by weight, 60-100 parts of aquadag and 0-65 parts of resin and curing agent; the outer coating is prepared from, by weight, 30-60 parts of aquadag, 60-100 parts of resin and curing agent, 2-15 parts of sintering aid and 2-15 parts of adhesive. The preparation process of the low-density carbon / carbon heat preservation material oxidation-resistant coating is further included. The affinity of the low-density carbon / carbon heat preservation material oxidation-resistant coating and a matrix is high, and the potential safety hazards of cracking and stripping of a graphite powder coating are solved. The low-density carbon / carbon heat preservation material oxidation-resistant coating can be used in a high-temperature environment, and has the advantages of being free of cracking and dust overflowing.

Owner:HUNAN NANFANG BOYUN NOVEL MATERIAL

Formula of additive for improving low-temperature charge property of lead-acid storage battery

InactiveCN103904331AHigh strengthImprove conductivityLead-acid accumulatorsCell electrodesPorosityFiber

The invention relates to a storage battery plate additive, belonging to the field of low-temperature storage battery charge property improvement. To improve the low-temperature charge property of a power storage battery, a formula of a lead plaster additive for storage battery positive and negative plates is provided. When the conductivity of active substances is improved, the porosity and the strength of the active substances are also improved, so that the low-temperate charge acceptance capability of the storage battery is improved, and the circulation service life of the battery is prolonged. The formula is achieved by combining the following additives: conductive graphite fibers or conductive carbon fibers are added into the lead plaster, with the addition amount accounting for 0.05-0.08% of the weight of lead oxide so that the mechanical strength and the conductivity of lead plaster are improved; the following auxiliary materials in percentage by weight of lead powder are added: 0.2% of acetylene black, 0.03% of aquadag, 0.03-0.05% of gas phase silicon dioxide, 0.06-0.08% of red lead, and 10% of pure water; the materials are sufficiently stirred into suspension, and subsequently the suspension is added into the lead powder and is stirred.

Owner:陈荣

Positive plate of lead storage battery for electric bicycle

InactiveCN102244248AMeet the use requirementsPrevent antimony-free effectLead-acid accumulator electrodesFiberHigh rate

The invention discloses a positive plate of a lead storage battery for an electric bicycle. The anode active material comprises the following components in parts by weight: 100 parts of aluminum powder, 3-8 parts of polybase lead sulfate, 0.3-1 part of antimonous oxide, 0.3-4 parts of aquadag, 0.3-4 parts of active carbon material, 0.3-3 parts of conductive fiber framework and 3-18 parts of dilute sulphuric acid. The weight ratio of the anode active material to a positive grid is (81-87): (13-19), wherein the positive grid is a complex alloy of lead. Through the invention, the components and proportion of the active substances of the polar plate are improved and optimized so that multiple carbon materials are contained, and the positive grid is further improved; and the obtained lead storage battery has excellent low-temperature performance, good high-rate discharge performance and long cycle life, and is particularly advantageous to the market competition of electric bicycles.

Owner:JIANGSU SHUANGDENG GROUP

High-performance lead paste composition

InactiveCN104466172AActive substance strongHigh strengthLead-acid accumulator electrodesFiberGas phase

The invention discloses a high-performance lead paste composition. The high-performance lead paste composition is characterized by comprising the following components in percentage by mass: 80-82% of lead powder, 9-10% of purified water, 7-8% of sulfuric acid, 0.2-0.3% of gas phase silicon dioxide colloid mother liquid, 0.1-0.3% of antimony trioxide, 0.2-0.5% of aquadag, 0.4-1.0% of brief fiber, and 0.3-0.8% of tetrabasic lead sulfate. The high-performance lead paste composition introduces the tetrabasic lead sulfate seed crystal on the basis of the sulfate, the aquadag and the brief fiber; active substances in the lead paste can be high in intensity, and low in formation difficulty; after a battery is assembled, the battery is large in initial capacity, and long in circulating life; the initial capacity is improved by 15%; the circulating life is prolonged by 20%; the lead paste intensity is improved by 15%.

Owner:TIANNENG BATTERY GRP ANHUI

Method for manufacturing universal joint for automobile

The invention discloses a method for manufacturing a universal joint for an automobile. The method comprises the following steps of preparing and casting a rod material by weight, wherein the rod material comprises C greater than or equal to 0.27% and less than or equal to 0.34%, Si greater than or equal to 0.15% and less than or equal to 0.35%, Mn greater than or equal to 0.71% and less than or equal to 0.91%, P greater than or equal to 0.15% and less than or equal to 0.25%, S greater than or equal to 0.018% and less than or equal to 0.025%, Cr greater than or equal to 0.71% and less than or equal to 0.95%, Mo greater than or equal to 0.30% and less than or equal to 0.40%, Ni greater than or equal to 1.60% and less than or equal to 2.20%, Cu greater than or equal to 0.10% and less than or equal to 0.20%, and the balance Fe and impurities. The method adopts a cool temperature finish forge forming method, a rod material forging stock is subjected to cold forging and preliminary shaping, preheated to 200-250 DEG C, dipped into aquadag and then heated to 800-900 DEG C, and subjected to warm forging shaping. The method is convenient to manufacture, high in efficiency, easy to forge and form, good in strength of a forged universal joint, long in service life, safe and reliable and suitable for large-scale production of various models of universal joints.

Owner:CHANGLI FORGING

Mould release agent for precision forging forming and preparation method of mould release agent

The invention relates to a mould release agent for precision forging forming. The mould release agent comprises the following ingredients in percentage by weight: 8 to 12 percent of silica gel, 35 to 45 percent of aluminum hydroxide, 18 to 22 percent of talc powder, 8 to 12 percent of hibiscus leaf extraction liquid, 2.5 to 3.5 percent of dispersing agents, 2.5 to 3.5 percent of defoaming agents, 3 to 4 percent of stabilizing agents and the balance of water. The mould release agent provided by the invention is applicable to precision forging moulds made of aluminum, copper, steel and iron and the like, a preparation method is simple, the silica gel in the mould release agent has the effect of bonding all ingredients and simultaneously takes neutralization reaction with the aluminum hydroxide, the talc powder and the hibiscus leaf extraction liquid respectively have the effects of lubricating the inner surface of a mould, and have the effects of smoothening the surface of a product, and the hibiscus leaf extraction liquid has the cleaning and lubricating effects. The mould release agent provided by the invention is used on the precision forging mould, is suitable for being used for smoothening the surface of the product, and meets the precision forging requirements, meanwhile, the mould release agent does not contain aquadag, aquadag dust cannot be generated in the use process, the work environment is protected, and the influence cannot be caused on the human body respiration.

Owner:葛秀林

Preparation method for TiC high-boron low alloy high-speed steel-based steel bonded cemented alloy

The invention discloses a preparation method for TiC high-boron low alloy high-speed steel-based steel bonded cemented alloy. Titanium and graphite powder are mixed with the mole ratio of atoms of C / Ti as 0.7-1.1 to form in-situ synthetic TiC mixed powder; vanadium iron powder, chromium iron powder, FeMo powder, boron iron powder, ferrosilicon powder, ferromanganese powder, iron powder, nickel powder, copper powder, aquadag and rare earth materials are mixed according to the needed proportion of the mass ratio of the bonding phase metal chemical components; and steel balls are put into for ball grinding, absolute ethyl alcohol serving as a medium and polyvinyl acetate are added, and slurry is dried after ball milling and then compressed to be molded and sintered to be the steel bonded cemented alloy. The in-situ reaction synthesis technology and the liquid phase sintering technology are combined, and the TiC high-boron low alloy high-speed steel-based steel bonded cemented alloy is prepared. The TiC is synthesized in an in-situ mode inside the base body through reaction in the sintering process, the size of reinforced particles is fine, and the base body interfaces are bonded better and clean. The preparation process is simple and convenient to implement, and the comprehensive mechanical performance of the alloy is improved.

Owner:JIANGSU HUICHENG MACHINERY MFG

Graphite paper and barium titanate ceramic film capacitor and preparation method thereof

ActiveCN103346014AHigh dielectric constantReduce leakage currentThin/thick film capacitorFixed capacitor electrodesOxide ceramicBarium titanate

The invention provides a graphite paper and barium titanate ceramic film capacitor. The graphite paper and barium titanate ceramic film capacitor comprises one or more layers of inner electrodes, ceramic dielectric layers among the inner electrodes, insulating layers between the dielectric layers and the inner electrodes, and end electrodes at the two ends. The graphite paper and barium titanate ceramic film capacitor is characterized in that the inner electrodes are made of graphite paper materials, the dielectric layers are barium titanate ceramic film, the end electrodes are formed by coating conductive aquadag in a dried mode, the insulating layers are aluminum oxide ceramic film, and the outermost layer of the graphite paper and barium titanate ceramic film capacitor is wrapped and packaged by barium titanate ceramic. A preparation method for the graphite paper and barium titanate ceramic film capacitor comprises the steps of (1) using graphite paper as the inner electrodes, (2) carrying out film pulling forming in aluminum oxide ethanol dispersion liquid, (3) carrying out film pulling forming and lamination in barium titanate ethanol dispersion liquid after drying, (4) using barium titanate powder to carry out packaging, and (5) carrying out integral pressure forming and vacuum hot pressing sintering to form the graphite paper and barium titanate ceramic film capacitor. The graphite paper and barium titanate ceramic film capacitor prepared through the preparation method has the advantages of being excellent in performance, high in dielectric constant, low in cost, simple in production technology and controllable in structure, and facilitating commercial production.

Owner:OCEAN UNIV OF CHINA

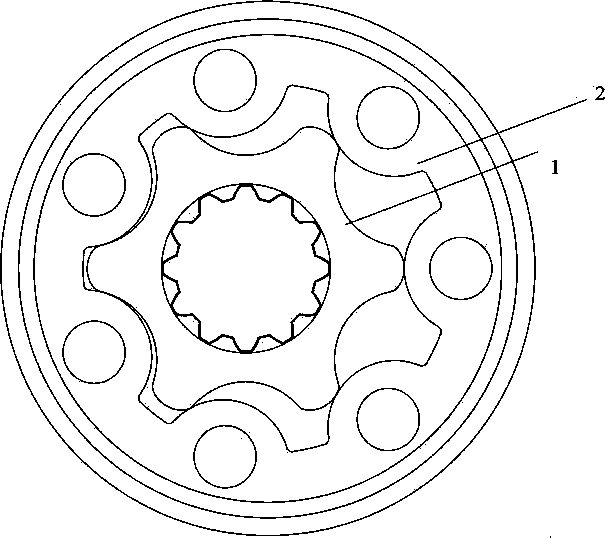

Powder metallurgy formula of full-hydraulic steering gear stator and rotor pair and manufacturing process

ActiveCN103611925AIngredient ratio scienceImprove wear resistanceTurbinesOther manufacturing equipments/toolsAquadagSpindle oil

The invention discloses a powder metallurgy formula of a full-hydraulic steering gear stator and rotor pair. The powder metallurgy formula is characterized in that the powder metallurgy formula comprises, by weight, 90.5% to 94.5% of atomized iron powder, 0.6% to 1.2% of aquadag, 1.0% to 4.0% of electrolytic copper, 0.8% to 2.0% of nickel powder, 0.5% to 2.0% of molybdenum powder, 0.2% to 0.5% of chromium powder, 0.1% to 0.6% of manganese sulfide, 0.3% to 0.7% of micronized wax and balance spindle oil, wherein every 100kg of the powder metallurgy formula contains 5mL to 30mL of spindle oil. The invention further discloses a powder metallurgy manufacturing process of the full-hydraulic steering gear stator and rotor pair. The powder metallurgy manufacturing process includes the dosing step, the powder stirring step, the pressing and forming step, the sintering and alloying step, the shaping and shape correcting step, the machining step, the steam processing step and other steps. By means of the powder metallurgy formula and the manufacturing process, the effects of being scientific in material composition proportion, good in wear resistance, not prone to abrasion, high in machining efficiency, material utilization rate and machining accuracy, good in rust protection performance and the like are achieved, and the market requirements can be completely met.

Owner:ANHUI HENGJUN POWDER METALLURGY TECH

Preparation method of high-strength-and-toughness heat-resisting VC steel bonded hard alloy

The invention relates to a preparation method of a high-strength-and-toughness heat-resisting VC steel bonded hard alloy. The preparation method is characterized in that V205 powder(vanadium) and graphite powder are prepared according to the C / V205 atomic ratio ranging from 0.4 to 0.5 to form in-situ synthesis VC mixed powder; and chromium iron powder, ferro-molybdenum powder, ferrovanadium powder, ferroboron powder, iron powder, nickel powder, copper powder, aquadag and rare earth raw materials are prepared according to the needed proportion of the bonding phase metal chemical component mass ratio, steel balls are added for ball milling, absolute ethyl alcohol is added to serve as a medium and PVA, and slurry is dried to be pressed, formed and sintered after ball milling to obtain the steel bonded hard alloy. According to the preparation method, the in-situ reaction synthetic technique and the liquid phase sintering technique are combined, and the high-strength-and-toughness heat-resisting VC steel bonded hard alloy is prepared. As VC is obtained through in-situ synthesis inside a base in reacting in the sintering process, the reinforced particle size is small, the surface is free of sharp corners, base interface bonding is better, and an interface is clean. By means of the steel bonded alloy preparing method, the comprehensive mechanical property of the alloy can be improved, the price is low, and the process is simple and convenient.

Owner:JIANGSU HUICHENG MACHINERY MFG

Ceramic fiber reinforced nano ceramic bond diamond grinding wheel and preparation method thereof

InactiveCN105983912AHigh strengthImprove toughnessAbrasion apparatusGrinding devicesFiberNanoceramic

The invention discloses a ceramic fiber reinforced nano ceramic bond diamond grinding wheel. In a preparation process of the ceramic fiber reinforced nano ceramic bond diamond grinding wheel, raw materials such as nano graphite powder and beta-eucryptite are mixed with nanoscale silicon dioxide and aluminium oxide to form a mixture, and the mixture is calcined to form a nanoscale composite nano ceramic bond. Compared with the conventional ceramic bond, the nanoscale composite nano ceramic bond has higher strength and toughness and lower sintering temperature, the high-temperature wettability is better, a thermal expansion coefficient is lower, and a control property to an abrasive is good. In addition, raw materials such as ceramic fiber and aquadag powder that are added to raw materials for grinding wheel production have obvious reinforcing, toughening, temperature resisting and lubricating effects. The ceramic fiber reinforced nano ceramic bond diamond grinding wheel has good abrasion resistance, and high heat resistance and thermal conductivity; the surface of the ceramic fiber reinforced nano ceramic bond diamond grinding wheel is lubricative; the grinding precision of a workpiece is high; the grinding speed is high; and the grinding efficiency can be improved obviously.

Owner:安徽威铭耐磨材料有限公司

Nano diatomite containing modified furan resin sand for steel casting and preparation method for nano diatomite containing modified furan resin sand

The invention discloses nano diatomite containing modified furan resin sand for a steel casting. Aquadag powder, microcrystal ceramic powder and quartz sand of different grain diameters and different ratios are selected as molding sand materials of the resin sand, and after high-temperature pouring, good gas permeability is achieved, the appearance is flat and smooth, and the style is stable. Due to the addition of nano tourmaline powder, the gas permeability of the molding sand is further increased. Compared with traditional furan resin, a prepared nano diatomite containing modified furan resin adhesive has the beneficial effects of being small in gas forming amount, few in organic matter residue, low in viscosity, high in bonding force, high in strength and the like, the utilization rate is higher, and the use amount is smaller. The prepared molding sand is good in mobility and easy to remove, and the quality of the obtained steel casting is effectively improved.

Owner:郭伟

Long-life deep cycle positive active material and preparation method thereof

The invention discloses a long-life deep cycle positive active material and a preparation method of the material. The material comprises the following components by weight: 100 parts of lead powder, 0.08 to 0.2 parts of polyester staple fiber, 0.1 to 0.5 aquadag, 0.5 to 3 parts of tetrabasic lead sulfate, 1.5 to 5 parts of red lead, 0.1 to 0.5 parts of antimony trioxide, 0.1 to 0.5 part of polyvinylidene fluoride, 0.08 to 0.2 parts of antimony trioxide, 0.08 to 0.2 parts of stannous sulfate, 10 to 15 parts of distilled water and 8 to 10 parts of dilute sulfuric acid. The material and the preparation method of the invention has the advantages that compared with the common battery, the battery further processed and prepared by the material and preparation method of the invention is high in pole plate mechanical strength, good in battery consistency, small in contact resistance of the active material grid and long in deep cycle lifetime of the battery.

Owner:江苏海宝电池科技有限公司

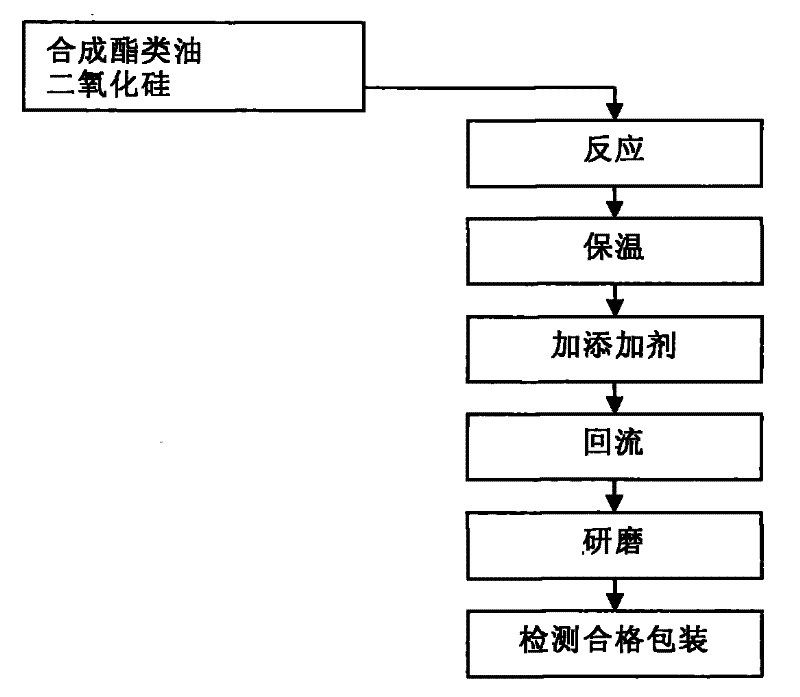

Ultra high temperature lubricating grease and production method thereof

ActiveCN101445759BPrevent sinteringImprove high temperature resistanceAdditivesChemical industryAquadag

Owner:无锡中石油润滑脂有限责任公司

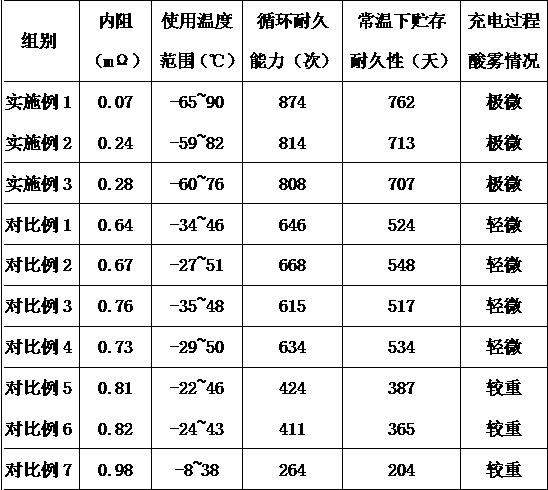

Super-energy olefin polymer lead storage battery unformed plate lead paste

ActiveCN109904448AIncrease specific energyImprove acceleration performanceLead-acid accumulatorsCell electrodesFiberCarbon fibers

The invention relates to the technical field of lead storage batteries, in particular to super-energy olefin polymer lead storage battery unformed plate lead paste. The super-energy olefin polymer lead storage battery unformed plate lead paste contains positive plate lead paste and negative plate lead paste; the positive plate lead paste contains lead powder, red lead, tetrabasic lead sulfate, bismuth trioxide, stannous sulfate, a polytetrafluoroethylene emulsion, carbon fibers, graphite olefin fibers, potassium sulfate, a graphene solution, ultrapure water and sulfuric acid; and the negativeplate lead paste contains lead powder, ultrafine barium sulfate, sodium sulfate, sodium lignosulphonate, humic acid, aquadag, a graphene solution, acetylene black, conductive carbon black N220, graphite olefin fibers, carbon fibers, ultrapure water and sulfuric acid. A lead storage battery made from the battery positive and negative plate lead paste prepared through the method is extremely small in internal resistance and wide in temperature adaptive range, produces tiny acid mist in the charging process, is extremely small in self-discharge, can be used under an extra large current, is strongin circulation durability and belongs to novel environment-friendly energy-saving batteries.

Owner:汉和新能源有限公司

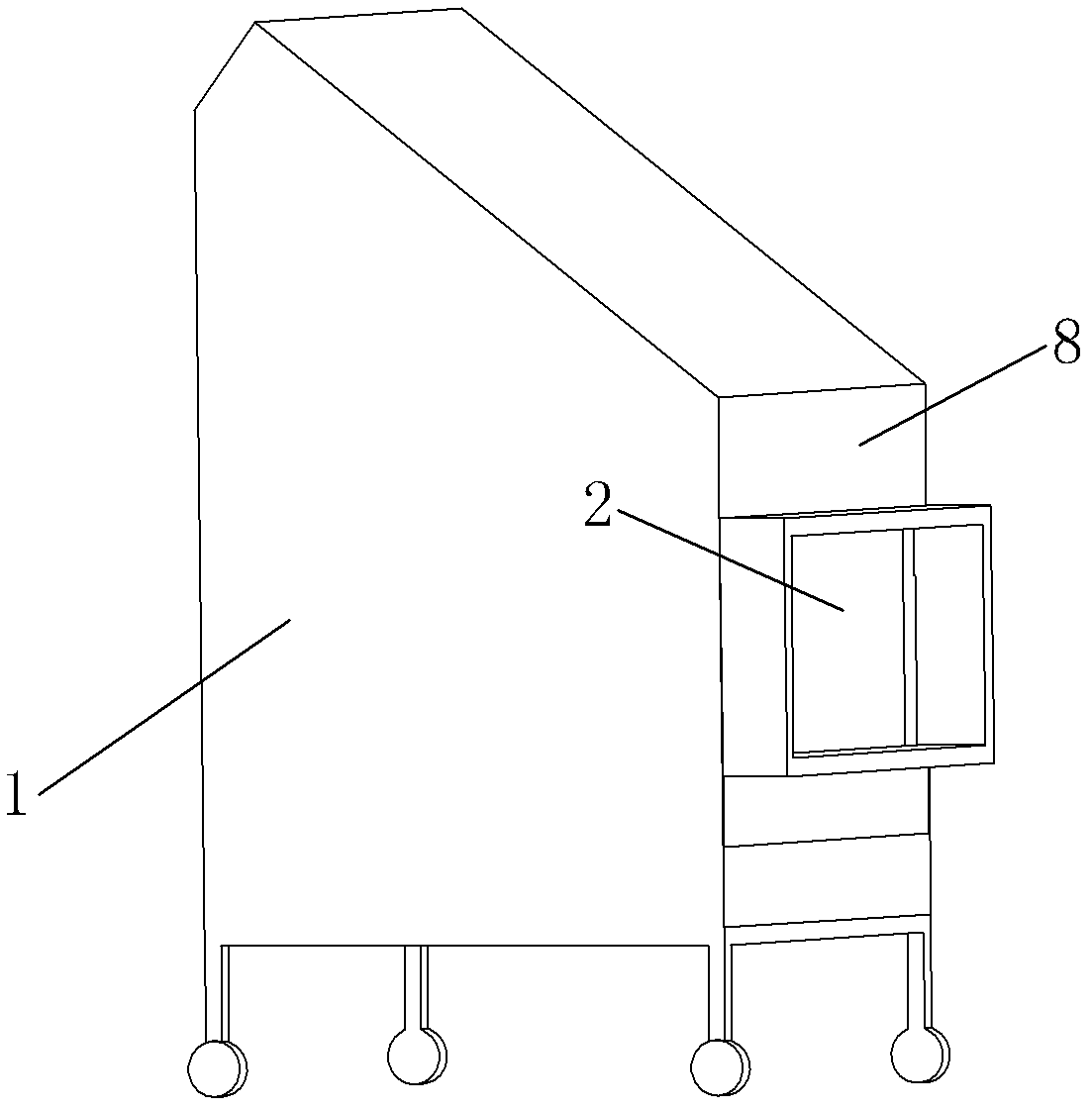

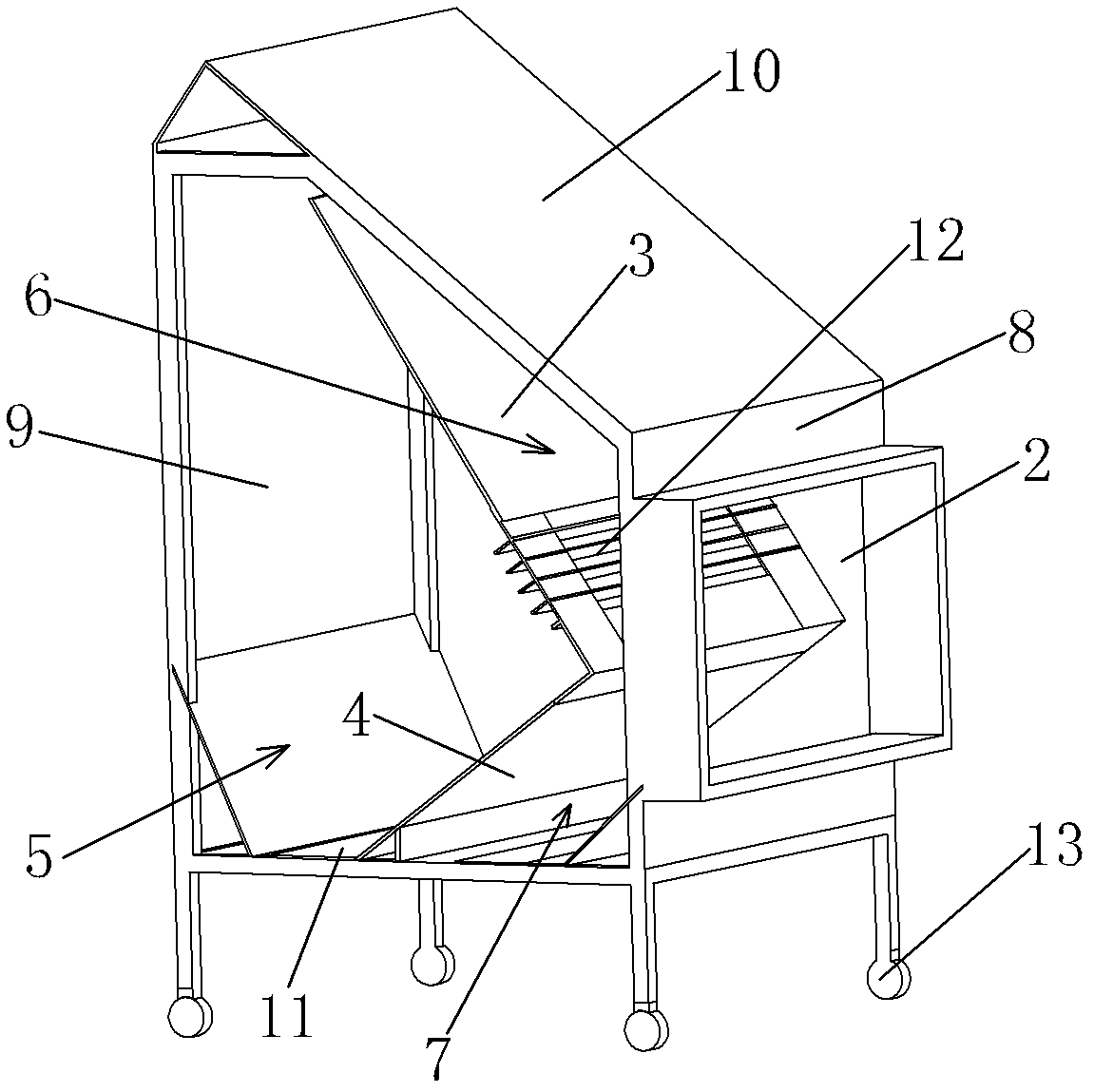

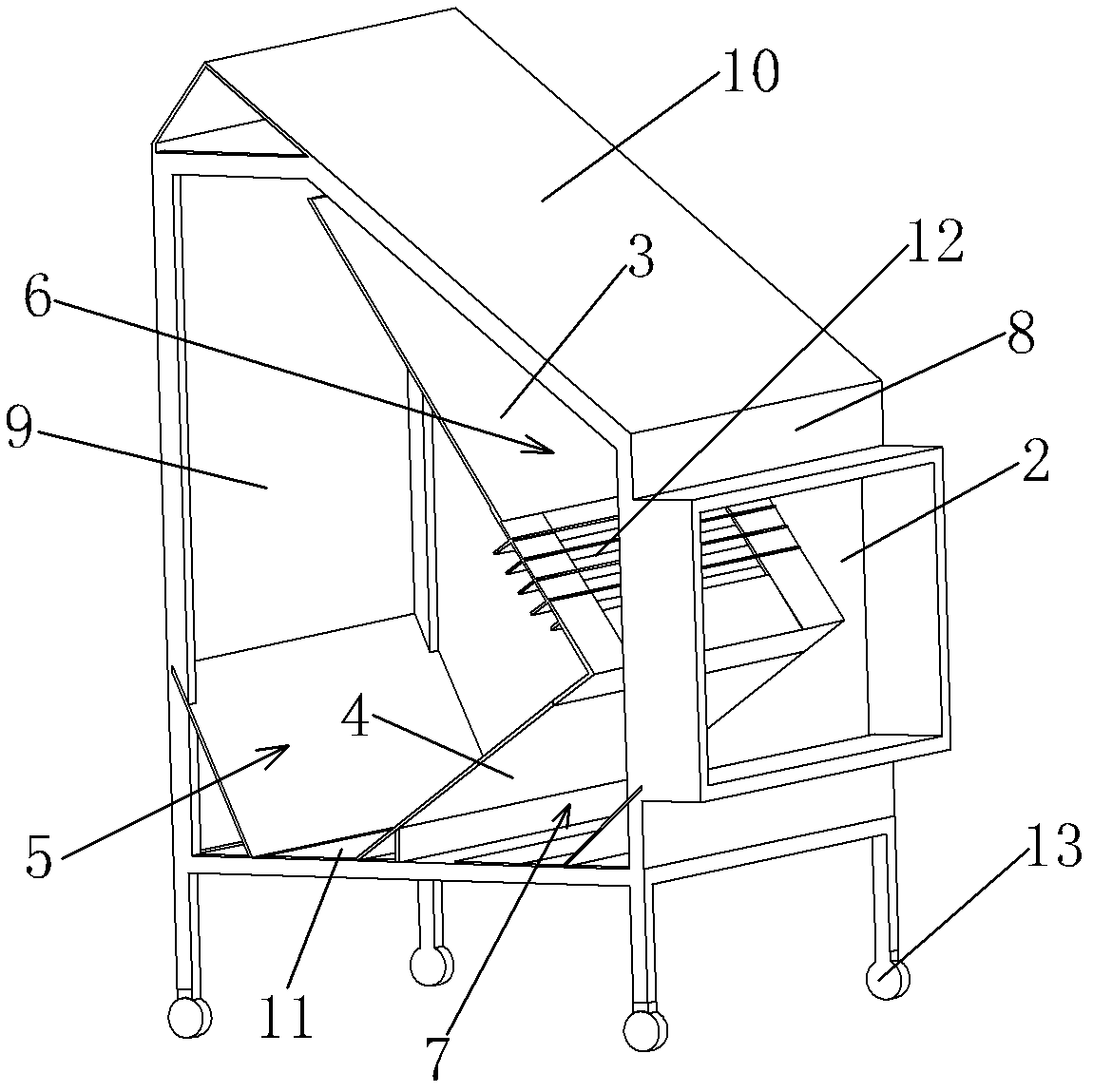

Aquadag recycling bin

The invention discloses an aquadag recycling bin, which comprises a bin body. The right side wall of the bin body is provided with a gas inlet, a water-based aquadag collecting area, an atomized aquadag negative pressure treatment area and a work piece oxide skin collecting area, which are partitioned by a first partition and a second partition, are arranged in the bin body, the first partition and the second partition are oblique relative to the horizontal plane, the second partition is positioned below the first partition, the lower end of the first partition is connected with the upper endof the second partition, and a grille communicated with the water-based aquadag collecting area is arranged on the lower portion of the first partition. The longitudinal section of atomized aquadag negative pressure treatment area is triangular, and the atomized aquadag negative pressure treatment area is provided with a large opening close to the gas inlet of the bin body and a small opening faraway from the gas inlet of the bin body so that negative pressure is formed, atomized graphitic lubricant is collected into the bin according to the negative pressure principle to be cooled to water-based graphite which falls to the water-based aquadag collecting area from the grille, while work piece oxide skins fall to the work piece oxide skin collecting area after being cooled. Collected aquadag is reusable, free from power consumption, pollution-free and economical in cost.

Owner:QINGDAO YUANDA GRAPHITE

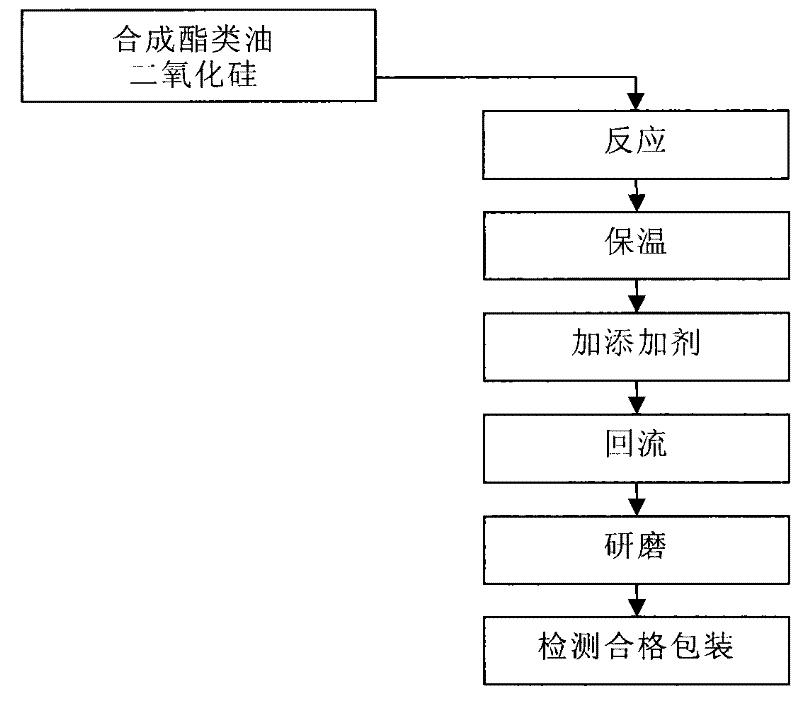

Bi-component low-temperature fast-drying aquadag and production process thereof

InactiveCN101280137AImprove conductivityNo poresInksElectrically-conductive paintsScreen printingBenzoyl peroxide

The invention relates to two-component low temperature fast dry graphite emulsion and the production process, belonging to the electronic technical field which produces the conductive rubber press-key and the novel conductive contact material used for the PCB. The composition is divided into the first component graphite emulsion and the second component graphite emulsion; the first component graphite emulsion contains microcrystalline graphite powder, styrene, ethylene-vinyl acetate copolymer emulsion and titanium dioxide powder; the second component graphite emulsion contains microcrystalline graphite powder, benzoyl peroxide, dibutyryl and ethylene-vinyl acetate copolymer emulsion. The first component and the second component graphite emulsions are used for stirring and coating with the weight ratio of 1:1; in the two-component low temperature fast dry graphite emulsion and the production process, the graphite emulsion is printed or coated on silicon rubber or PCB substrate to have the advantages of good film conductive performance, ink silk-screen printing of the silicon rubber, direct shift printing and coating of the silicon rubber, good fluidity of the emulsion, short time in drying and curing, preventing the air holes of the conductive film, avoiding the high-power ultraviolet lamp for curing and low power consumption.

Owner:CHENZHOU FAYUAN MINING IND

Thermal insulation board coating layer

InactiveCN108300008AImprove insulation effectStrong resistance to sudden change in ambient temperature differenceAnti-corrosive paintsLow-density polyethyleneAntioxidant

The invention discloses a thermal insulation board coating layer, and relates to the technical field of thermal insulation board, wherein the thermal insulation board coating layer comprises the components: hard polyurethane foam, ultra low density polyethylene, trichloroethylene, carboxymethyl chitosan, 3,4-dimethylpyrazolate, sodium aluminate, polyglycerol fatty acid ester, dicyclohexylcarbodiimide, 4-dimethylaminopyridine, p-methylbenzene sulfonic acid, terpene resin, ammonium polyphosphate, triphenyl phosphate, polyamide modified phenolic epoxy resin, aquadag, polytetrafluoroethylene, an organic bismuth antioxidant, a copper oxide powder, concentrated hydrochloric acid, silane, an antioxidant auxiliary agent, propylene asphaltic resin, an alkali solution, deionized water, and ethanol.The thermal insulation board coating is safe and non-toxic, has the advantages of good heat preservation, high temperature resistance, low temperature resistance, strong environment temperature difference sudden change resistance, and corrosion resistance, and can directly coat the surface of a thermal insulation board; through the processing treatment technology, the thermal insulation board withbetter thermal insulation effect is obtained, all layers are combined closely in use, the structure is stable, the structure design is beneficial to weight reduction and material saving, and economicinput in thermal insulation problem is reduced, and the cost performance ratio is high.

Owner:ANHUI DEQUAN NEW BUILDING MATERIALS TECH CO LTD

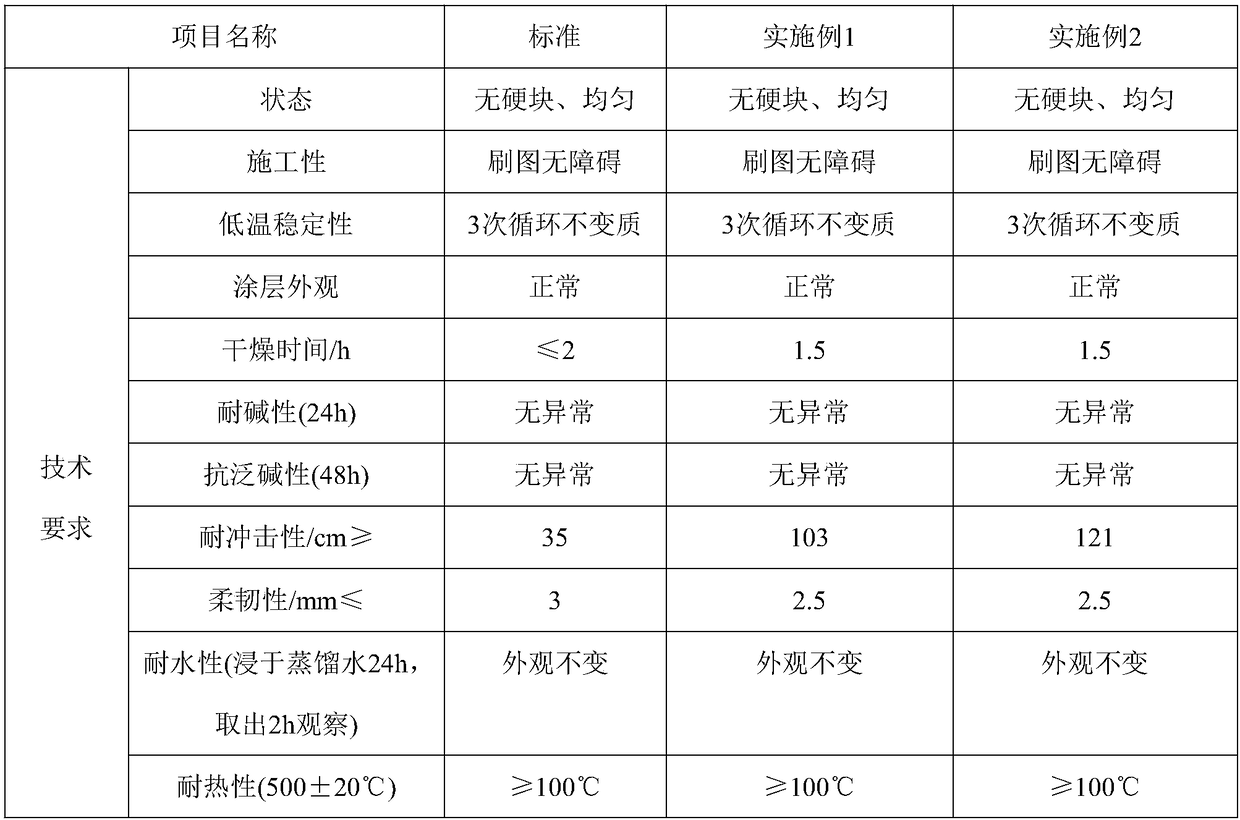

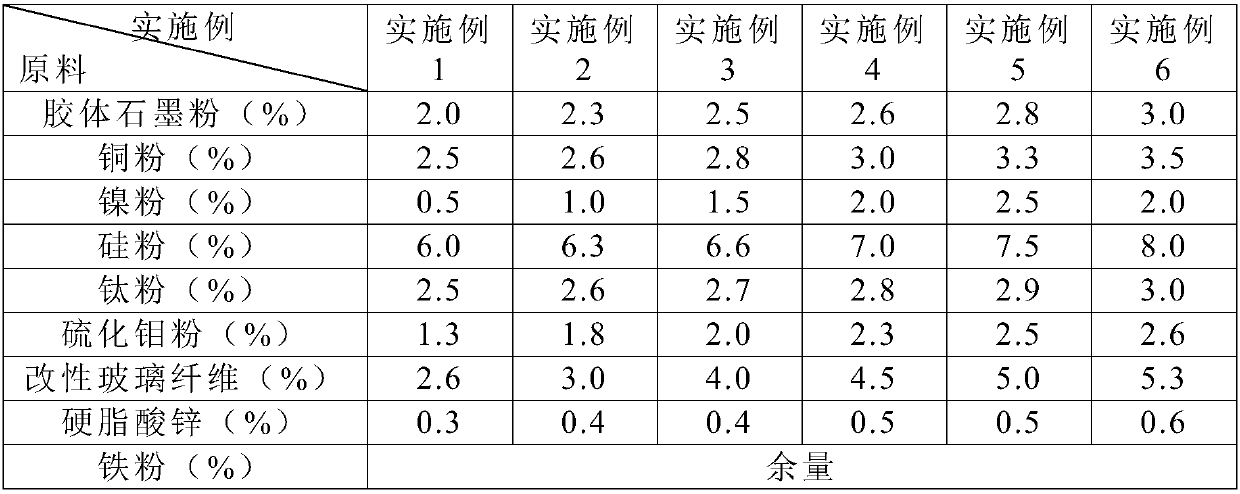

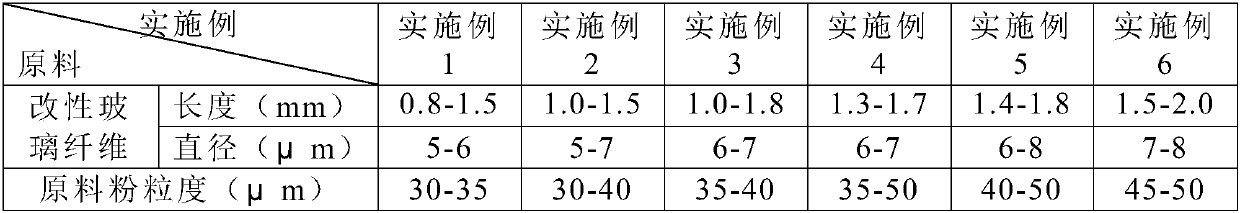

Automobile damper compression valve seat and preparation method thereof

The invention relates to an automobile damper compression valve seat and a preparation method thereof and belongs to the technical field of powder metallurgy. The automobile damper compression valve seat is formed by sintering the following raw materials in percentage by mass: 2.0-3.0% of aquadag powder, 2.5-3.5% of copper powder, 0.5-2.0% of nickle powder, 6-8% of ganister sand, 2.5-3.0% of titanium powder, 1.3-2.6% of molybdenum sulfide powder, 2.6-5.3% of modified glass fiber, 0.3-0.6% of zinc stearate and the balance of iron powder. The automobile damper compression valve seat has the advantages of being high in strength, resisting shock and small in deformation.

Owner:NINGBO RUIFENG AUTO PARTS

Novel technology for preparing expandable graphite by using liquid insert method

The invention discloses a novel technology for preparing expandable graphite by using a liquid insert method, which takes high crystalline flake graphite as a raw material, the granularity is 50 meshes, the carbon content is 99%, the technology comprises the following steps: uniformly mixing graphite and a strong oxidant ammonium nitrate in a container, adding sulfuric acid and continuously stirring, reacting for 50 minutes under temperature of 50 DEG C, performing pumping filtration and washing the obtained aquadag after deposition to neutrality, and drying under the temperature of 60 DEG C to obtain the expandable graphite. The novel technology for preparing expandable graphite by using the liquid insert method has the advantages of simple operation, mild and stable reaction, can stabilize the puffed rate of the final product, production cost is reduced, no waste liquid is discharged, and no pollution is generated.

Owner:温学敏

Roller surface treatment process

InactiveCN103628053AHigh hardnessQuality improvementMolten spray coatingSuperimposed coating processAlcoholAquadag

The invention relates to a roller surface treatment process. The roller surface treatment process is characterized by comprising the following steps of 1) cleaning the surface of the roller with a solution prepared from methyl alcohol and nitric acid according to the volume ratio; 2) dissolving aquadag with alcohol, adding water to prepare a graphite lubricating liquid, and spraying the graphite lubricating liquid onto the surface of the roller; and 3) heating up circulating water with steam so as to introduce into the roller to heat up the roller circularly, then drying the surface of the roller. According to the roller surface treatment process, the surface of the roller is cleaned by the solution prepared from methyl alcohol and nitric acid by certain volume ratio, then the surface of the roller is washed by water so as to form a light yellow ferric oxide coating, so that the hardness of the surface of the roller is improved; the lubricating agent mixed by aquadag, alcohol and water by certain proportion is sprayed on the surface of the roller, so that the lubricating effect of the surface of the roller is improved, graphite particles are prevented from blocking off a spray gun or forming on the surface of a cast-rolling plate blank; as the roller is heated by hot water circularly, the temperature difference of the inner wall and the outer wall of the roller is lowered, the stress of the roller is prevented from concentrating in the process of erecting the plate, and the service life of a cast-rolling roller shell is prolonged.

Owner:湖州市银鑫轧辊有限公司

Novel releasing agent

InactiveCN106906037AExtended service lifeImprove casting qualityLubricant compositionChemical reactionHeat resistance

The invention discloses a novel releasing agent. The novel releasing agent is prepared from the following raw materials and formulation components in parts by weight: 70 to 95 parts of aquadag, 2 to 3 parts of edible salt, 7 to 8 parts of an emulsifying agent, 1 to 5 parts of polyacrylamide, 1 to 2 parts of a defoamer, 1 to 7 parts of organic silicon resin and 20 to 30 parts of deionized water. The novel releasing agent disclosed by the invention has good heat insulation and heat control effects; the service life of a mold can be prolonged, and the casting quality can be improved; the novel releasing agent has good lubricating property, releasing property, chemical stability and high-temperature adhesiveness, is unlikely to produce a chemical reaction, is easy for coating, has extremely high heat resistance, is unlikely to age the coating, is unlikely to freeze and solidify at too low temperature, and is low in cost.

Owner:ANHUI CHENGYOU AUTO PARTS MFG

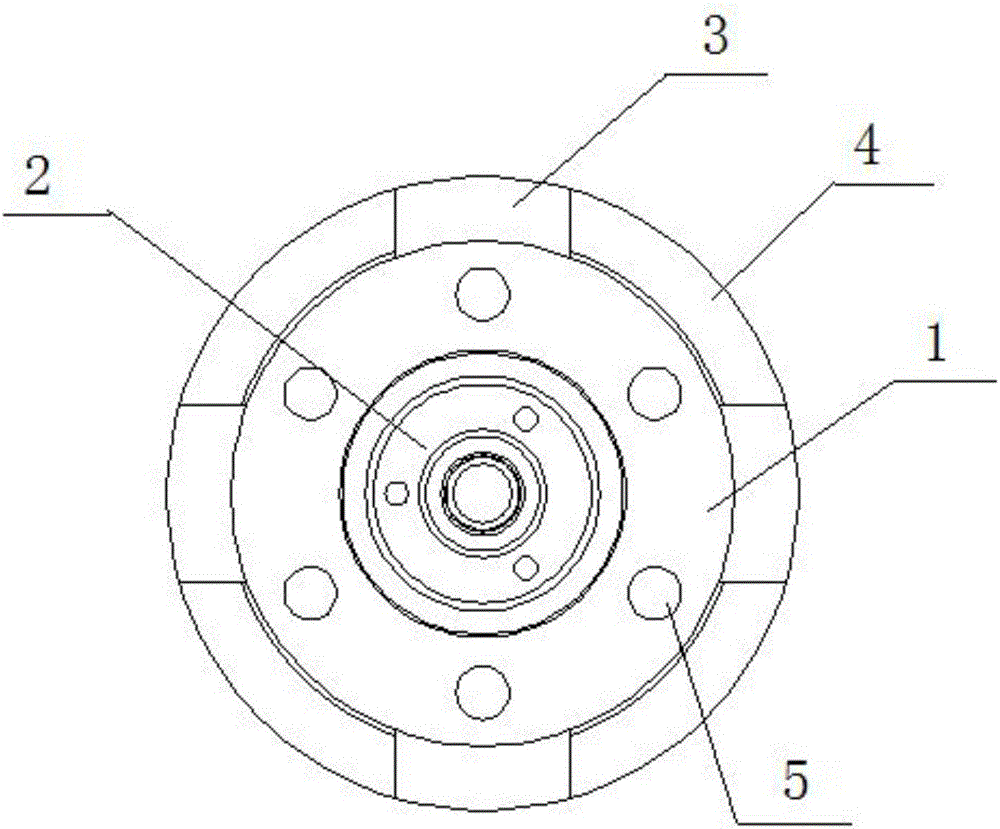

Bottom valve

ActiveCN106363179AImprove densification performanceIncrease induced internal stressTransportation and packagingMetal-working apparatusPorosityAquadag

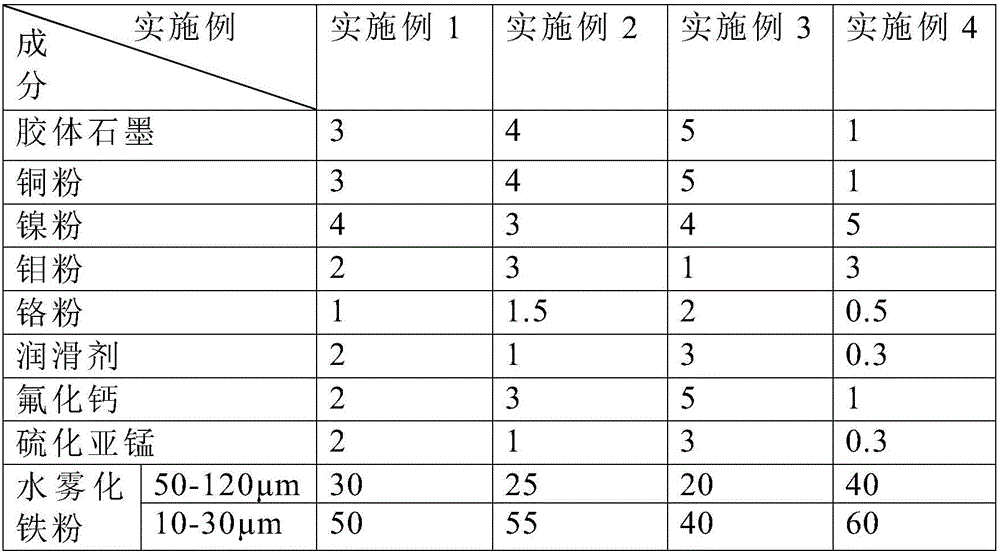

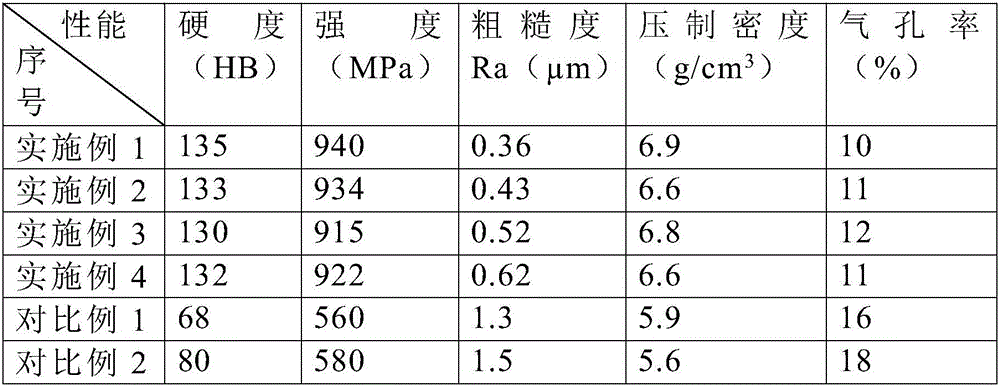

The invention relates to a bottom valve, and belongs to the technical field of powder metallurgy. The bottom valve comprises a disc-shaped main body, a shaft boss, grooves and protrusions, wherein the grooves and the protrusions are arranged on the edge of the main body evenly, the main body and the shaft boss are arranged coaxially, and the grooves and the protrusions are arranged alternately; and a plurality of through holes are further formed in the main body and located in the inner sides of the grooves and the protrusions. The bottom valve is prepared from, by weight, 1-5 parts of aquadag, 1-5 parts of copper powder, 3-5 parts of nickel powder, 1-3 parts of molybdenum powder, 0.5-2 parts of chromium powder, 0.3-3 parts of lubricating agents, 1-5 parts of calcium fluoride, 0.3-3 parts of manganous sulphide, and 60-100 parts of water-atomized iron powder, wherein the water-atomized iron powder is formed by compounding two kinds of water-atomized iron powder with different particle sizes and specifically includes 20-40 parts of water-atomized iron powder with the particle size being 50-120 [mu]m and 40-60 parts of water-atomized iron powder with the particle size being 10-30 [mu]m. The bottom valve is low in surface porosity, small in dimensional tolerance, high in density, hardness and strength, and long in service life.

Owner:宁波拓发汽车零部件有限公司

Lithium cobaltate battery anode/cathode paste production and formation charging method

InactiveCN109994738AImprove corrosion resistanceImprove ductilityElectrode carriers/collectorsLi-accumulatorsAquadagMaterials science

The invention relates to a lithium cobaltate battery anode / cathode paste production and formation charging method. The method comprises the steps of A, anode formula preparation; B, anode material mixing; and C, cathode material mixing, wherein the step B comprises the steps of (1) dehydration pretreatment of raw materials; (2) material ball-milling; and (3) operation. Through the method, conductivity is improved, and the corrosion resistance of a collector is improved; by adding tin (Sn) into anode aluminum foil, the ductility of the aluminum foil can be improved, and the processing performance of the aluminum foil is improved; since nano-aquadag and a carbon nano tube are adopted as anode conductive agents, the conductivity is improved; according to formation charging, reverse charging is performed first, it is convenient for an anode to form a conductive network, so that formation charging in a later period is performed efficiently, and the specific capacity of a battery is increased; through two times of discharge after a constant current and a constant voltage in sequence, thorough formation is guaranteed, and active substances are activated; dormant standing is performed twice between the two times of discharge, so that depolarization is guaranteed, the formation charging acceptance ability can be improved beneficially, electricity is saved, formation efficiency is improved, and meanwhile a cooling function is achieved; and a product is high in specific capacity and long in life.

Owner:程艳青

Preparation method of high-strength-and-toughness ultrahigh-manganese-steel based VC steel bonded hard alloy

The invention relates to a preparation method of a high-strength-and-toughness ultrahigh-manganese-steel based VC steel bonded hard alloy. The preparation method is characterized in that V205 powder(vanadium) and graphite powder are prepared according to the C / V205 atomic ratio ranging from 0.4 to 0.5 to form in-situ synthesis VC mixed powder; and ferro-molybdenum powder, ferrovanadium powder, chromium iron powder, ferromanganese iron powder, silicon iron powder, iron powder, nickel powder, aquadag and rare earth raw materials are prepared according to the needed proportion of the bonding phase metal chemical component mass ratio, steel balls are added for ball milling, absolute ethyl alcohol is added to serve as a medium and PVA, and slurry is dried to be pressed, formed and sintered after ball milling to obtain the steel bonded hard alloy. According to the preparation method, the in-situ reaction synthetic technique and the liquid phase sintering technique are combined, as VC is obtained through in-situ synthesis inside a base in reacting in the sintering process, the reinforced particle size is small, the surface is free of sharp corners, base interface bonding is better, and an interface is clean. By means of the steel bonded alloy preparing method, the comprehensive mechanical property of the alloy can be improved, the price is low, and the process is simple and convenient.

Owner:JIANGSU HUICHENG MACHINERY MFG

Wear-resistant impact-resistant cable material for automobiles and preparation method thereof

InactiveCN105176076AImprove wear resistanceImprove impact resistanceWear resistant2-Ethylhexanoic acid

The invention discloses a wear-resistant impact-resistant cable material for automobiles and a preparation method thereof. The cable material is prepared from the following raw materials, by weight, 56-74 parts of nylon 66, 32-44 parts of ultra-high molecular weight polyethylene, 14-22 parts of a styrene-acrylonitrile-acrylate ternary block copolymer, 18-24 parts of poly(neopentyl glycol adipate), 16-22 parts of natural emery, 10-15 parts of aquadag powder, 2-3 parts of cobalt 2-ethylhexanoate, 3-5 parts of magnesium hypophosphate, 4-7 parts of Fischer-tropsch wax, 12-16 parts of Tetraoctyl Pyromellitate, 3-4 parts of antimony tri(n-dodecanethiol), 15-20 parts of a composite flame retardant, 1-2 parts of an antioxidant 1076 and 1-2 parts of an antioxidant 5057. The prepared cable material has superior comprehensive physical properties, high mechanical strength and excellent abrasive resistance and impact resistance, is used to greatly prolong service life of a cable, and meets use requirements of automobile wires and cables.

Owner:ANHUI CHUNHUI INSTR CABLE GROUP

High-temperature anti-sticking coating, preparation method of high-temperature anti-sticking coating, high-temperature anti-sticking vessel and preparation method of high-temperature anti-sticking vessel

InactiveCN109401576ASimple componentsImprove stabilityFireproof paintsPolyether coatingsAlloyAquadag

The invention discloses high-temperature anti-sticking coating. The high-temperature anti-sticking coating is prepared from the following components: high purity water, n-butanol, PEG6000, aquadag, tween-80, yttrium oxide powder and metal oxide powder, wherein the metal oxide powder is one or more of alumina powder, zirconia powder and titanium oxide powder. The invention further provides a preparation method of the high-temperature anti-sticking coating, a high-temperature anti-sticking vessel and a preparation method of the high-temperature anti-sticking vessel, so that the problems of carburization and bonding during sintering of cemented carbide are avoided.

Owner:晋城富联鸿刃科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com