Aquadag recycling bin

A technology of graphite milk and recovery box, applied in the direction of removing smoke and dust, chemical instruments and methods, cleaning methods and utensils, etc., can solve the problems of power consumption of exhaust fans, drawing into outdoor air or sewers, pollution, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

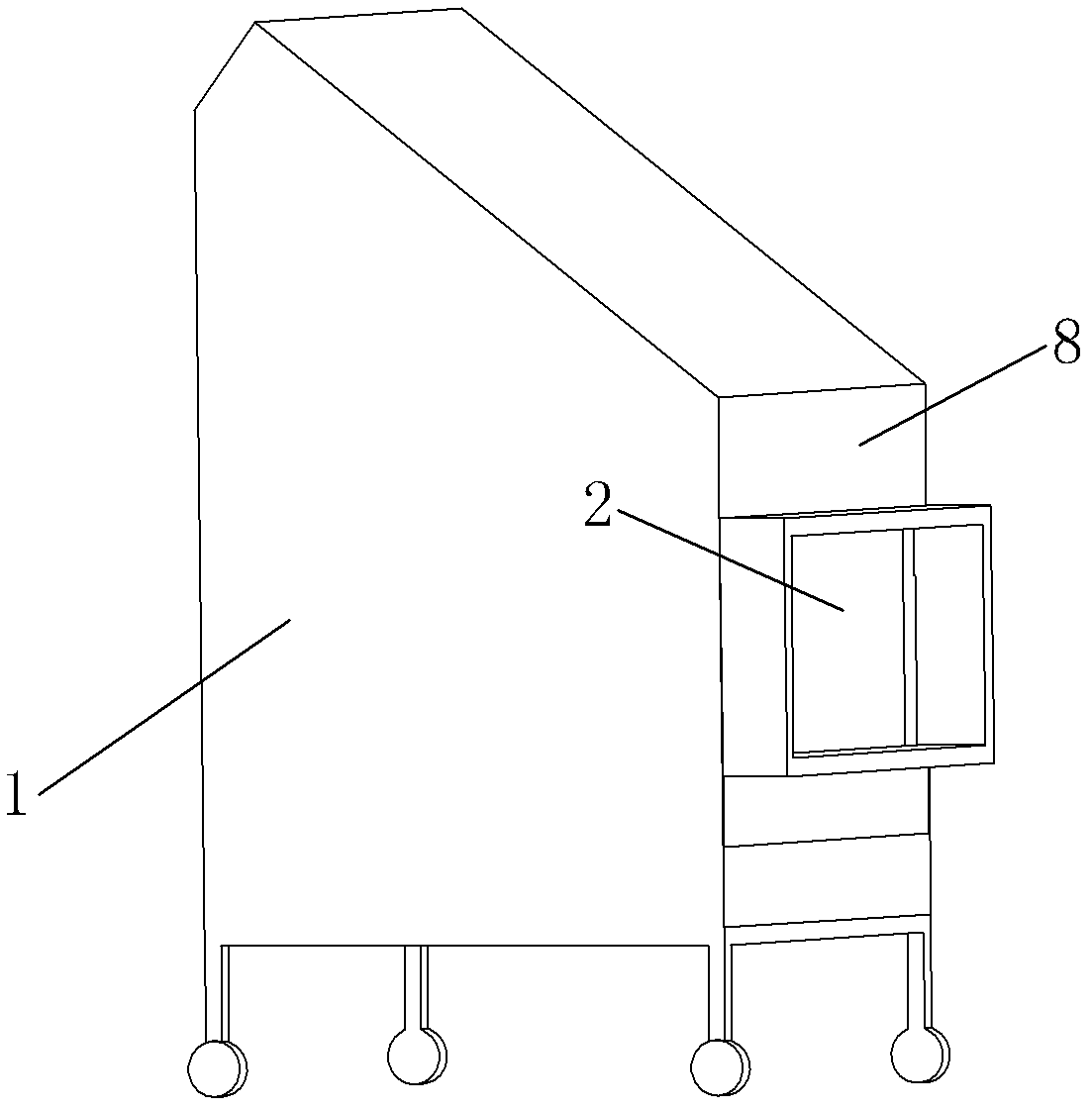

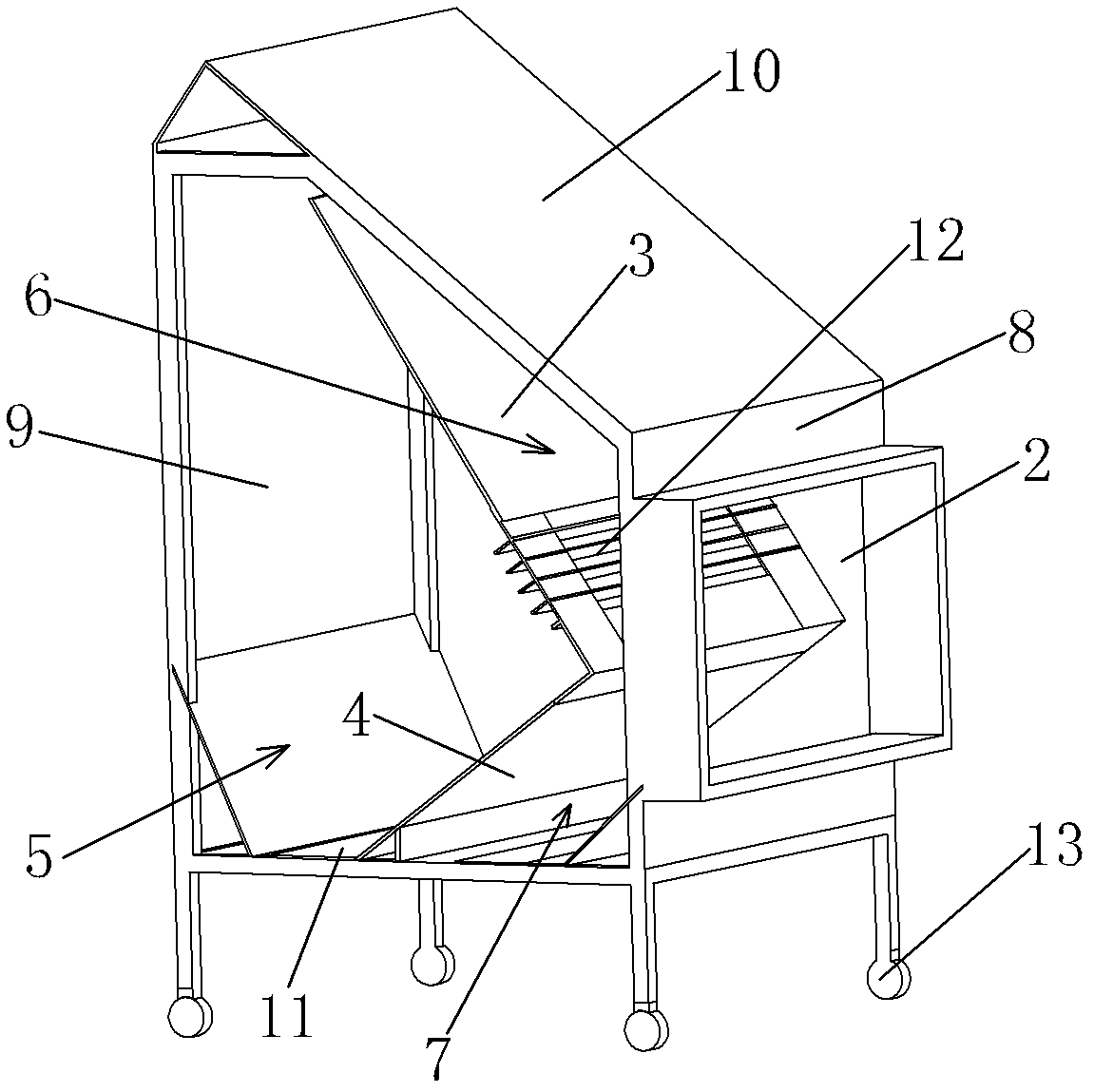

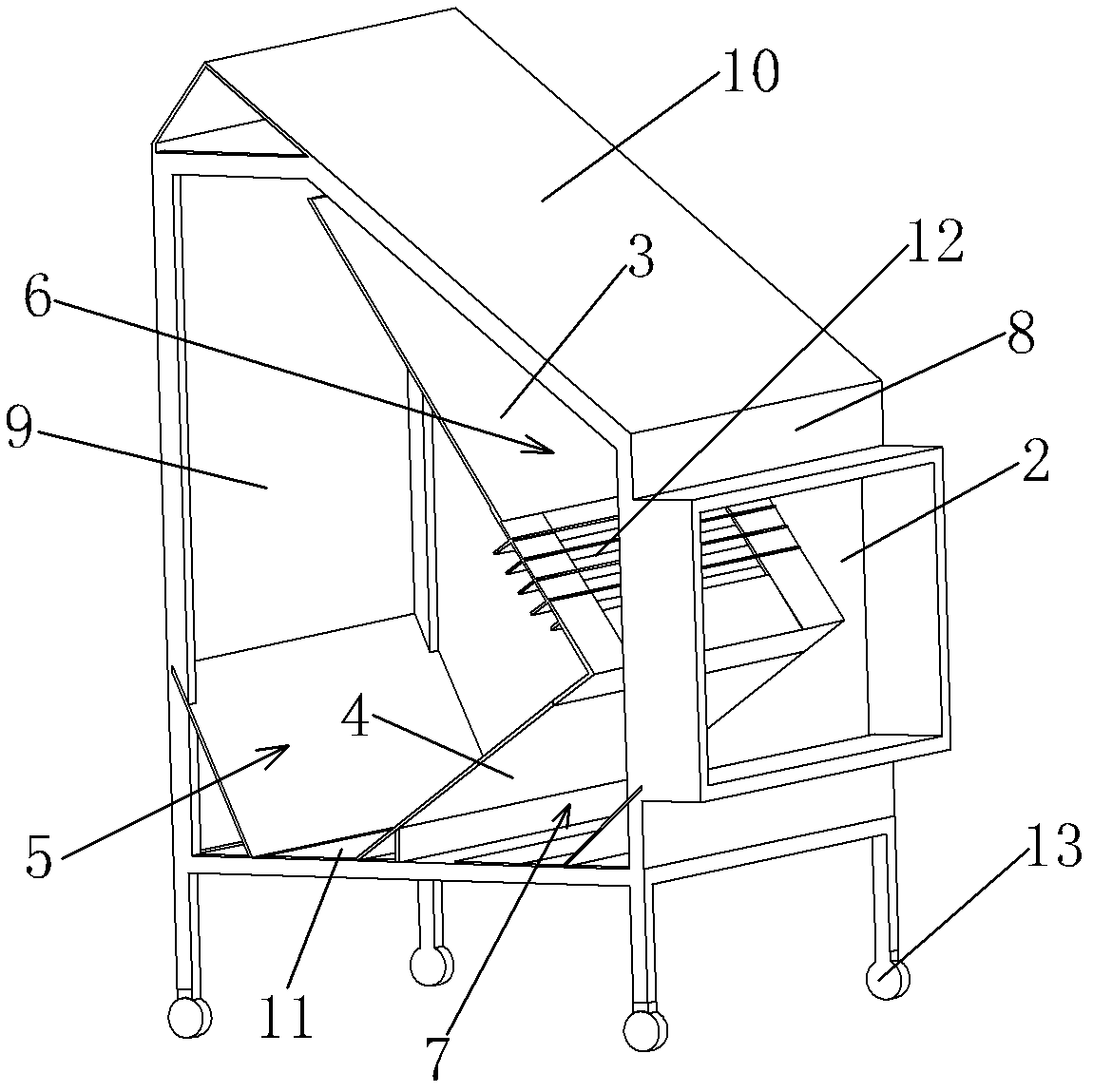

[0014] Embodiment: a kind of graphite milk recovery box, as figure 1 , figure 2 Shown, comprise box body 1, have air inlet 2 on box body right side wall 8, be provided with first dividing plate 3, second dividing plate 4 in box body 1, described first dividing plate 3, The second dividing plate 4 is all inclined with respect to the horizontal plane, and the second dividing plate 4 is positioned at the below of the first dividing plate 3, and the lower end of the first dividing plate 3 links to each other with the upper end of the second dividing plate 4, and the first dividing plate 3 is connected with the second dividing plate. The connection of the two partitions 4 is close to the air inlet 2 and keeps a certain distance from the air inlet 2, and the connection between the first partition 3 and the second partition 4 is flush with the middle of the air inlet 2, and the first partition Plate 3, the second separator 4 separate the box body 1 into a water-based graphite milk ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com