Powder metallurgy formula of full-hydraulic steering gear stator and rotor pair and manufacturing process

A technology of powder metallurgy and steering gear, which is applied to the powder metallurgy formula of the stator and rotor pairs of the full hydraulic steering gear, the powder metallurgy manufacturing process of the stator and rotor pairs of the full hydraulic steering gear, and the powder metallurgy formula field, which can solve the problem of low material utilization and processing Low efficiency, low processing precision and other problems, to achieve the effect of high material utilization, high processing efficiency and high processing precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

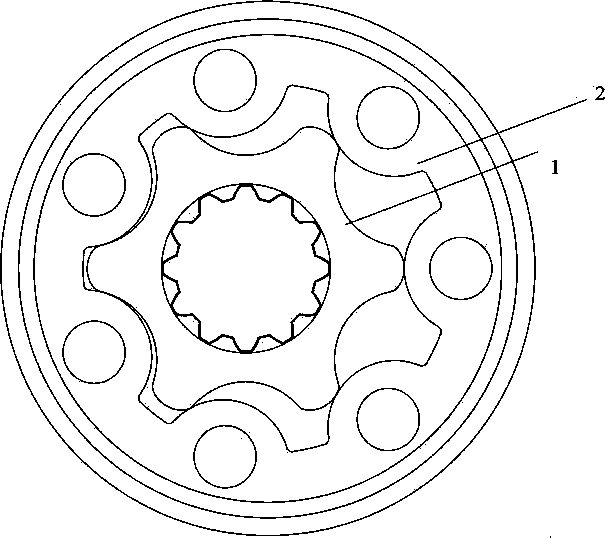

Image

Examples

Embodiment 1

[0027] (1) stir powder

[0028] According to the specific properties required by the product, various metal and non-metal elements are purposely added to make the finished product achieve the expected mechanical properties. The product requires high dimensional accuracy, good toughness, good dimensional stability, strong wear resistance, and good rust resistance. The formula we use is: 94.5% atomized iron powder, 0.6% colloidal graphite, 1% electrolytic copper, 1.7% nickel powder, 0.5% molybdenum powder, 0.4% chromium powder, 0.6% manganese sulfide, 0.7% micronized wax and 5ml spindle Oil / 100 kg.

[0029] Accurately weigh the raw materials and pour them into a special powder mixer to stir for 30-60 minutes. After pouring out and cooling for 1 hour, the next process can be carried out.

[0030] (2) Compression molding

[0031] The designed stator 2 pressing mold is installed on a 300-ton powder metallurgy mechanical press, and then the stirred raw materials are loaded into t...

Embodiment 2

[0046] (1) stir powder

[0047] According to the specific properties required by the product, various metal and non-metal elements are purposely added to make the finished product achieve the expected mechanical properties. The product requires high dimensional accuracy, good toughness, good dimensional stability, strong wear resistance, and good rust resistance. The formula we use is: 90.5% atomized iron powder, 1.2% colloidal graphite, 2.6% electrolytic copper, 2.0% nickel powder, 2.0% molybdenum powder, 0.5% chromium powder, 0.5% manganese sulfide, 0.7% micronized wax and 30ml spindle Oil / 100 kg.

[0048] Accurately weigh the raw materials and pour them into a special powder mixer to stir for 30-60 minutes. After pouring out and cooling for 1 hour, the next process can be carried out.

[0049] (2) Compression molding

[0050] The designed stator pressing mold is installed on a 300-ton powder metallurgy mechanical press, and then the stirred raw materials are loaded into ...

Embodiment 3

[0065] (1) stir powder

[0066] According to the specific properties required by the product, various metal and non-metal elements are purposely added to make the finished product achieve the expected mechanical properties. The product requires high dimensional accuracy, good toughness, good dimensional stability, strong wear resistance, and good rust resistance. The formula we use is: 92.7% atomized iron powder, 0.7% colloidal graphite, 4% electrolytic copper, 0.8% nickel powder, 1.2% molybdenum powder, 0.2% chromium powder, 0.1% manganese sulfide, 0.3% micronized wax and 20ml spindle Oil / 100 kg.

[0067] Accurately weigh the raw materials and pour them into a special powder mixer to stir for 30-60 minutes. After pouring out and cooling for 1 hour, the next process can be carried out.

[0068] (2) Compression molding

[0069] The designed stator pressing mold is installed on a 300-ton powder metallurgy mechanical press, and then the stirred raw materials are loaded into th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com