A kind of high conductivity mg-zn-sn-sc-xca magnesium alloy and its preparation method

A high-conductivity, magnesium alloy technology, applied in the field of light metal materials, can solve the problems of poor electrical conductivity and large gap, and achieve the effects of good room temperature mechanical properties, light weight, high tensile strength and yield strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025]The present invention also provides a method for preparing a high-conductivity Mg-Zn-Sn-Sc-xCa magnesium alloy, which sequentially includes alloy smelting, homogenization treatment and hot extrusion, and the specific steps are as follows:

[0026] Step S1, alloy smelting: first, according to the mass percentage composition of the Mg-Zn-Sn-Sc-xCa magnesium alloy, calculate the ratio of alloy elements, weigh the alloy raw material magnesium ingot, magnesium-scandium master alloy, magnesium-calcium master alloy, tin and zinc;

[0027] Next, put the graphite crucible in the vacuum induction melting furnace, then put the stainless steel crucible loaded with the alloy raw material into the graphite crucible, vacuumize the vacuum induction melting furnace to make the vacuum less than 0.1Pa, into an inert protective gas, and start heating to the alloy melting temperature to fully melt the alloy raw material to obtain an alloy melt; finally, cool and extrude the stainless steel c...

Embodiment 1- Embodiment 13

[0033] Example 1-Example 13 The composition design of the Mg-Zn-Sn-Sc-xCa magnesium alloy is shown in Table 1.

[0034] Example 1-Example 13 The process parameters of the preparation method of Mg-Zn-Sn-Sc-xCa magnesium alloy are shown in Table 2.

[0035] Table 3 shows the compositional design and preparation method of comparative example 1-comparative example 10 magnesium alloys.

[0036] Table 1 Example 1-Example 13 Composition design of Mg-Zn-Sn-Sc-xCa magnesium alloy (wt%)

[0037] .

[0038] Table 2 Example 1-Example 13 Mg-Zn-Sn-Sc-xCa magnesium alloy preparation method process parameters

[0039] .

[0040] Table 3 Composition Design and Preparation Method of Comparative Example 1-Comparative Example 10 Magnesium Alloy (wt%)

[0041] .

[0042] The Mg-Zn-Sn-Sc-xCa magnesium alloy prepared above is evaluated as follows:

[0043] Conductivity test method: use the Sigmascope SMP10 conductivity tester produced by FISCHER in Germany to measure the relative conduct...

Embodiment 14- Embodiment 19

[0056] Table 5 Example 14-Example 19 Composition design of Mg-Zn-Sn-Sc-xCa magnesium alloy (wt%)

[0057] .

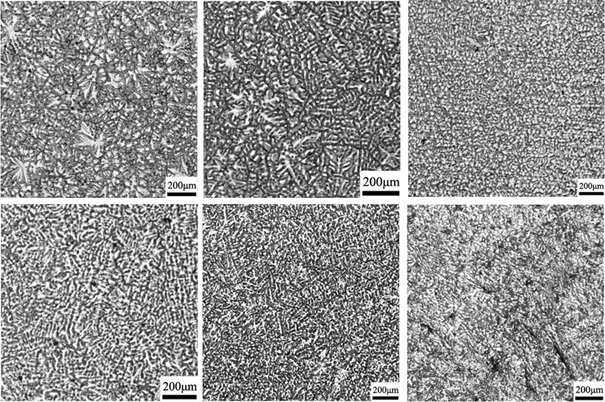

[0058] The Mg-Zn-Sn-Sc-xCa magnesium alloy designed in Example 14-Example 19 in Table 5 is prepared with reference to the preparation method of Example 1, and the metallographic appearance of the obtained as-cast Mg-Zn-Sn-Sc-xCa magnesium alloy is obvious. Microorganisms such as figure 1 shown. From figure 1 It can be seen that with the increase of Sn and Ca content in the Mg-Zn-Sn-Sc-xCa alloy, the metallographic structure of the alloy tends to be uniform, the grains become finer, and the grain refinement effect is obvious.

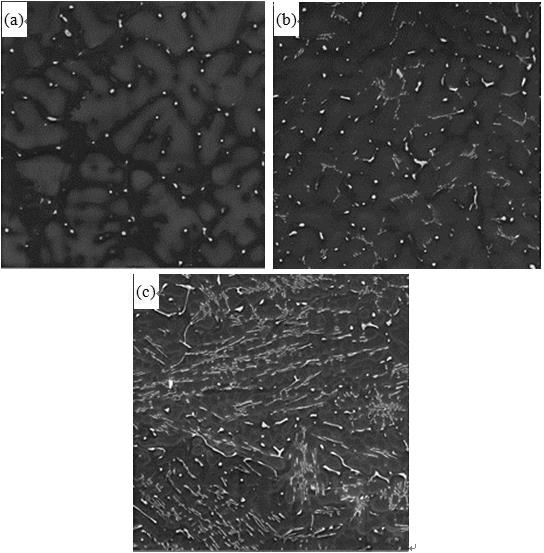

[0059] figure 2 SEM scanning electron microscope microstructure pictures of as-cast Mg-Zn-Sn-Sc-xCa magnesium alloy show that after adding Ca element, the structure is more uniform, the grains are obviously refined, and the electrical conductivity of Mg-Zn-Sn-Sc-xCa magnesium alloy The efficiency has been significantly improved; adding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com