Patents

Literature

928results about How to "Prevent sintering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite oxide, composite oxide carrier and catalyst

InactiveUS6306794B1Improve heat resistanceImprove homogeneityInternal combustion piston enginesDispersed particle separationHeat resistanceCerium

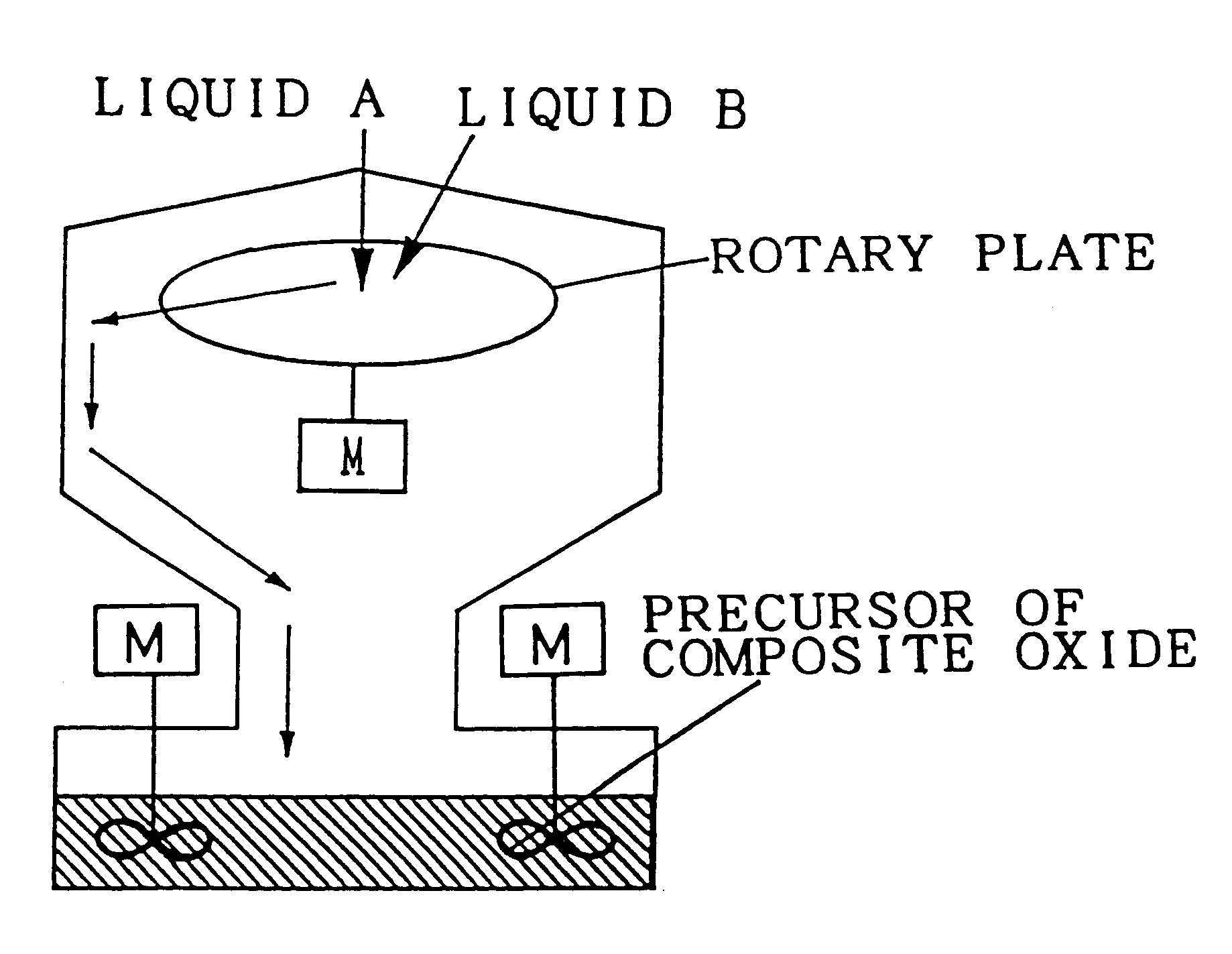

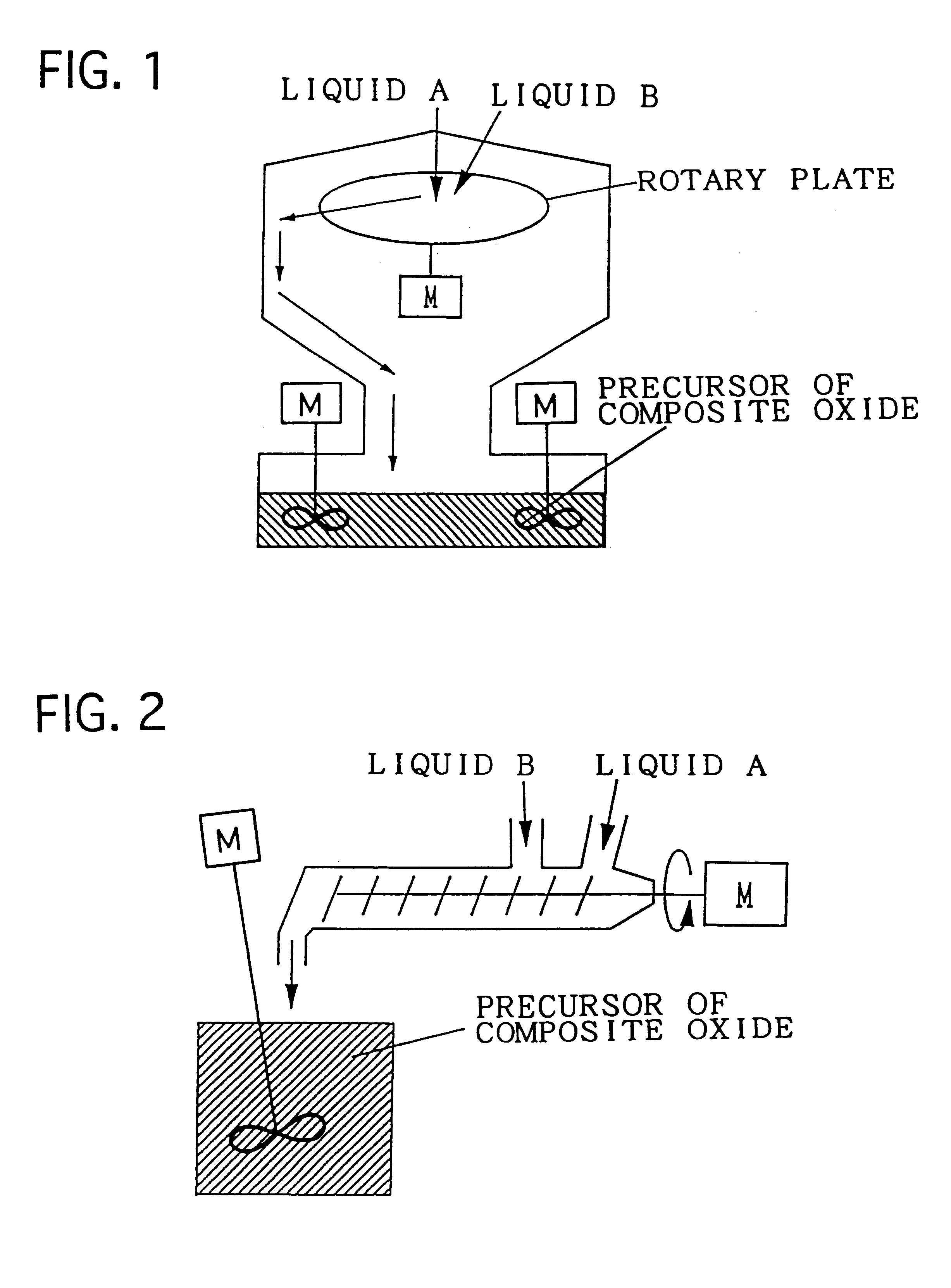

The composite oxide and the composite oxide carrier are manufactured by the precursor forming step and firing step. The composite oxide catalyst is obtained by preparing a composite of catalytic components simultaneously with the formation of the precursor of composite oxide in the step of forming the precursor of composite oxide. The composite oxide and the composite oxide carrier are composed of a composite oxide in which at least one of cerium and zirconium, and aluminium disperse with extremely high homogeneity. With this structure, the heat resistance of the carrier is improved and consequently, enlargement of particles of the composite oxide defining the carrier, and sintering of adjacent particles of the composite oxide can be restrained, whereby the catalyst using the composite oxide carrier in accordance with the present invention is excellent in heat resistance.

Owner:TOYOTA CENT RES & DEV LAB INC

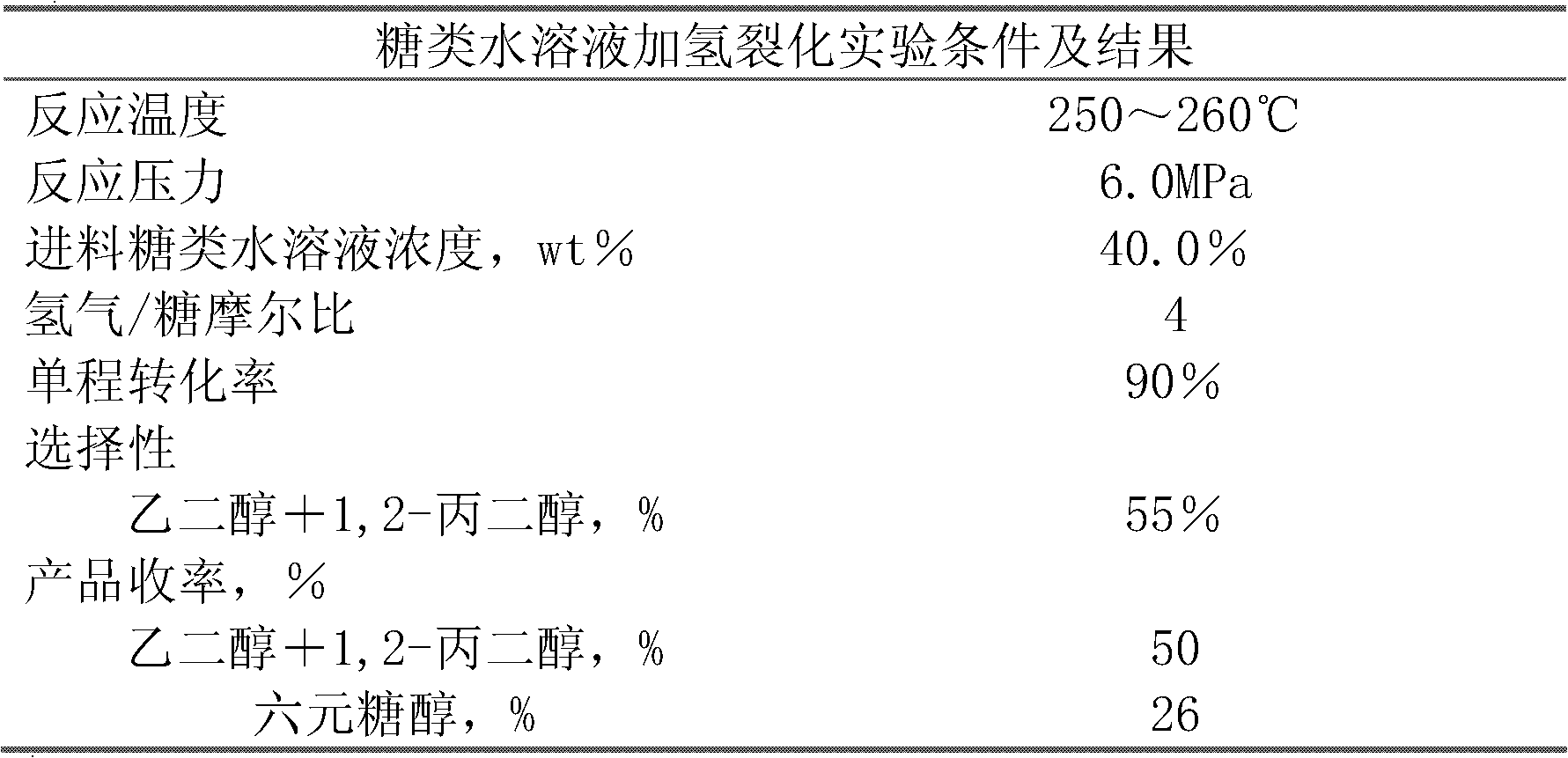

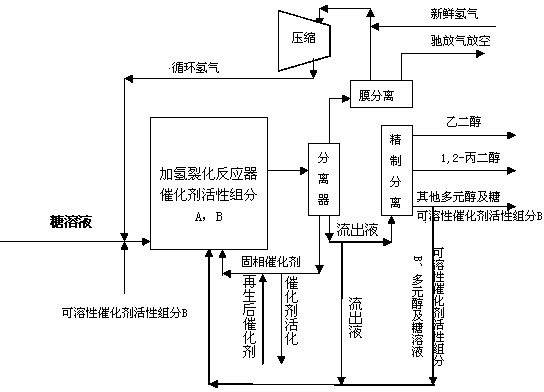

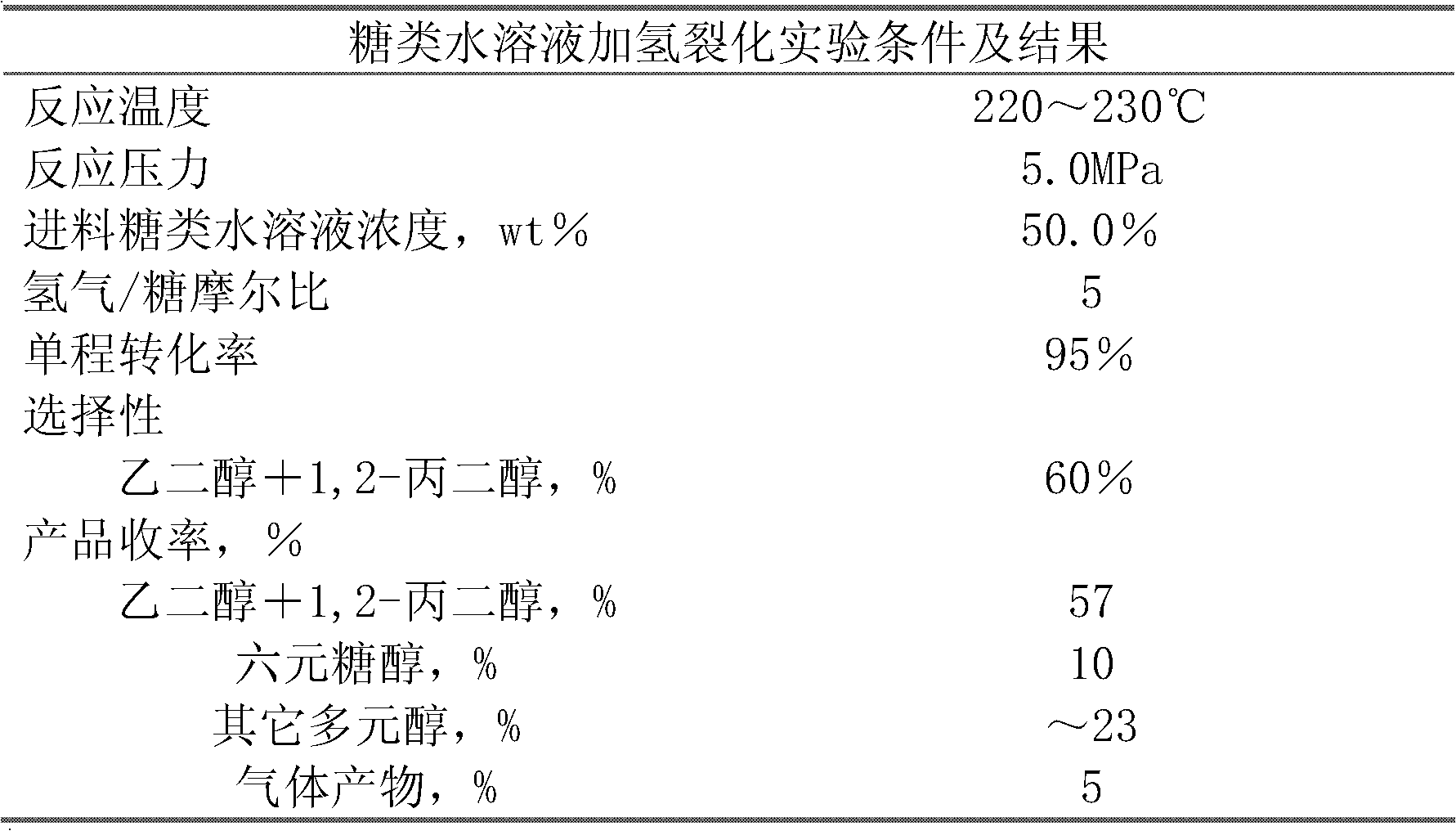

Method for producing ethylene glycol and 1,2-propylene glycol through continuous hydrocrackin of sugars

ActiveCN102643165ARealize continuous inputReduce consumptionOrganic compound preparationPreparation by OH group eliminationGas phaseOligosaccharide

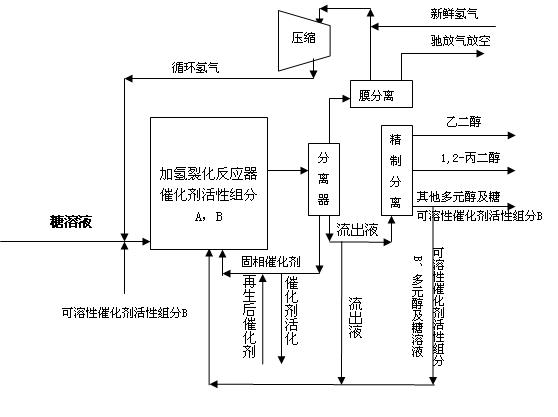

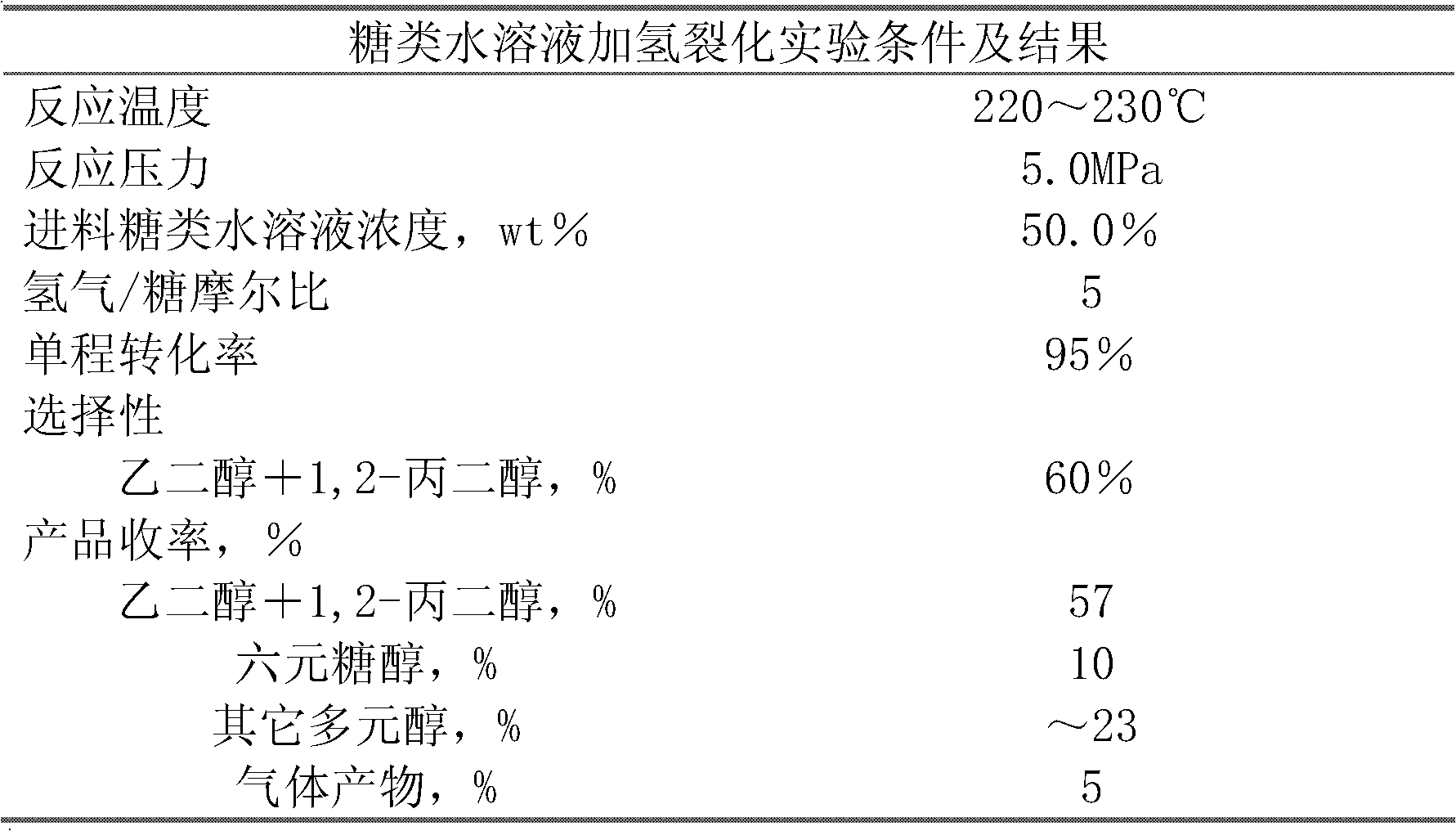

The invention relates to a continuous reaction process flow for producing ethylene glycol and 1, 2-propylene glycol through continuous hydrocrackin of sugars and provides a method for producing the ethylene glycol and the 1,2-propylene glycol through continuous hydrocrackin of sugars. In the process flow, sugars (comprising one or more than two of sugar, glucose, fructose, xylose, soluble xylo-oligosaccharide and starch) are hydrocracked in the presence of a catalyst in a reactor and the hydrocracked product enters a separating system. Hydrogen gas in a gas phase is recycled by separating and recovering; a liquid phase product partially reflows to the reactor and other liquid phase products are refined and separated to form the ethylene glycol, the propylene glycol and other polyhydric alcohols; and concentrated soluble catalyst components in the refined and separated residual component liquid phase are partially returned to the reactor.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

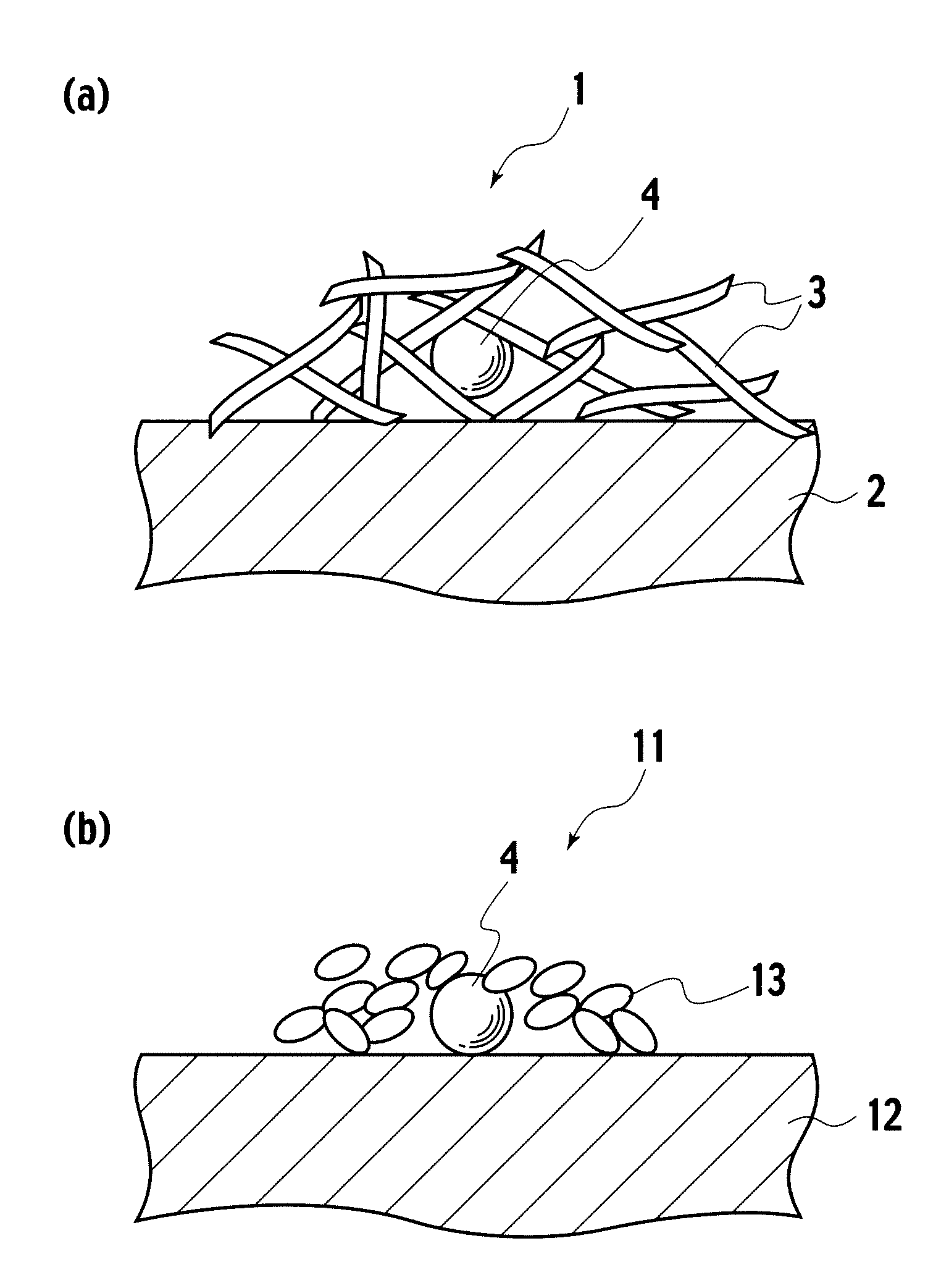

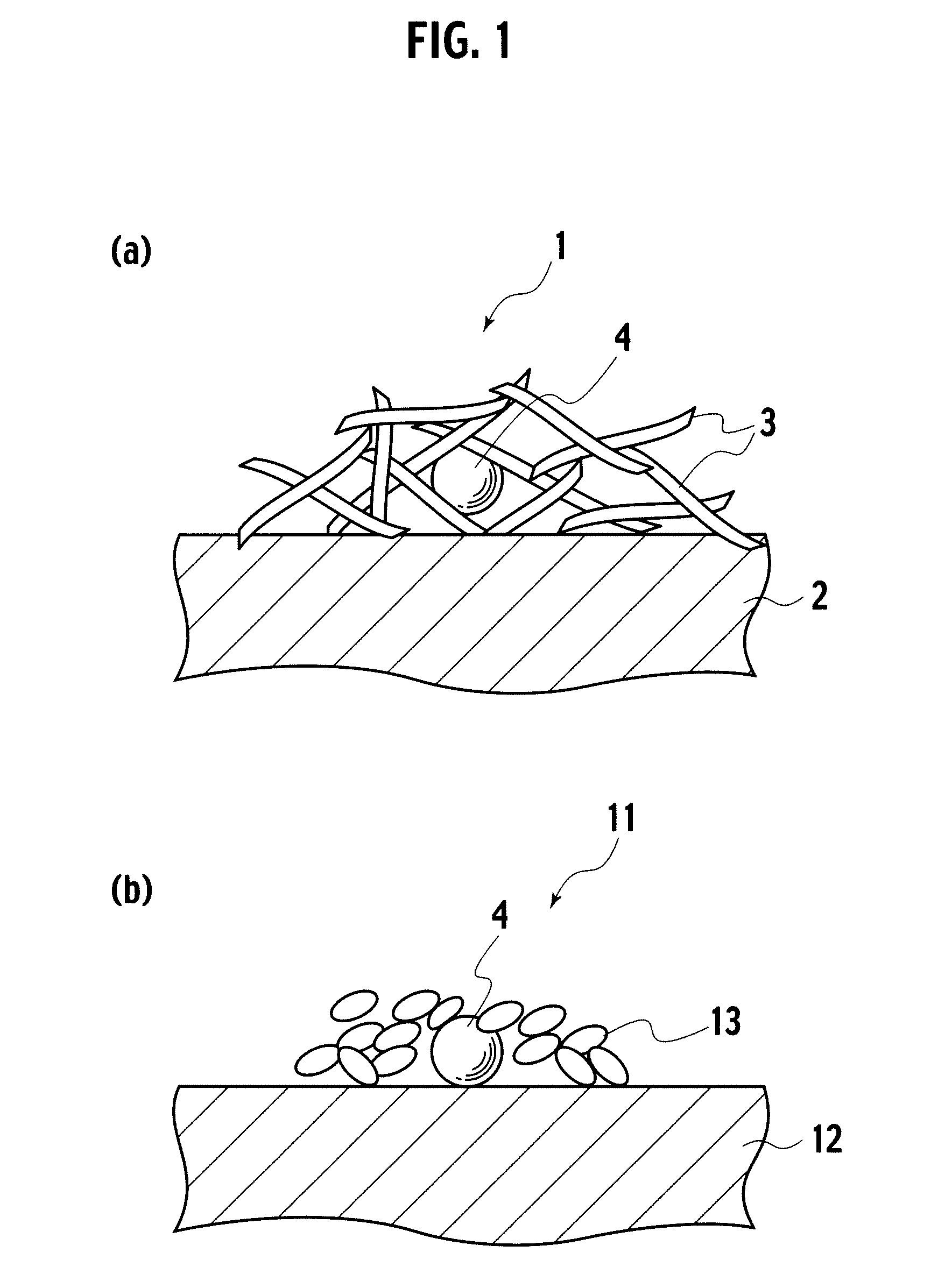

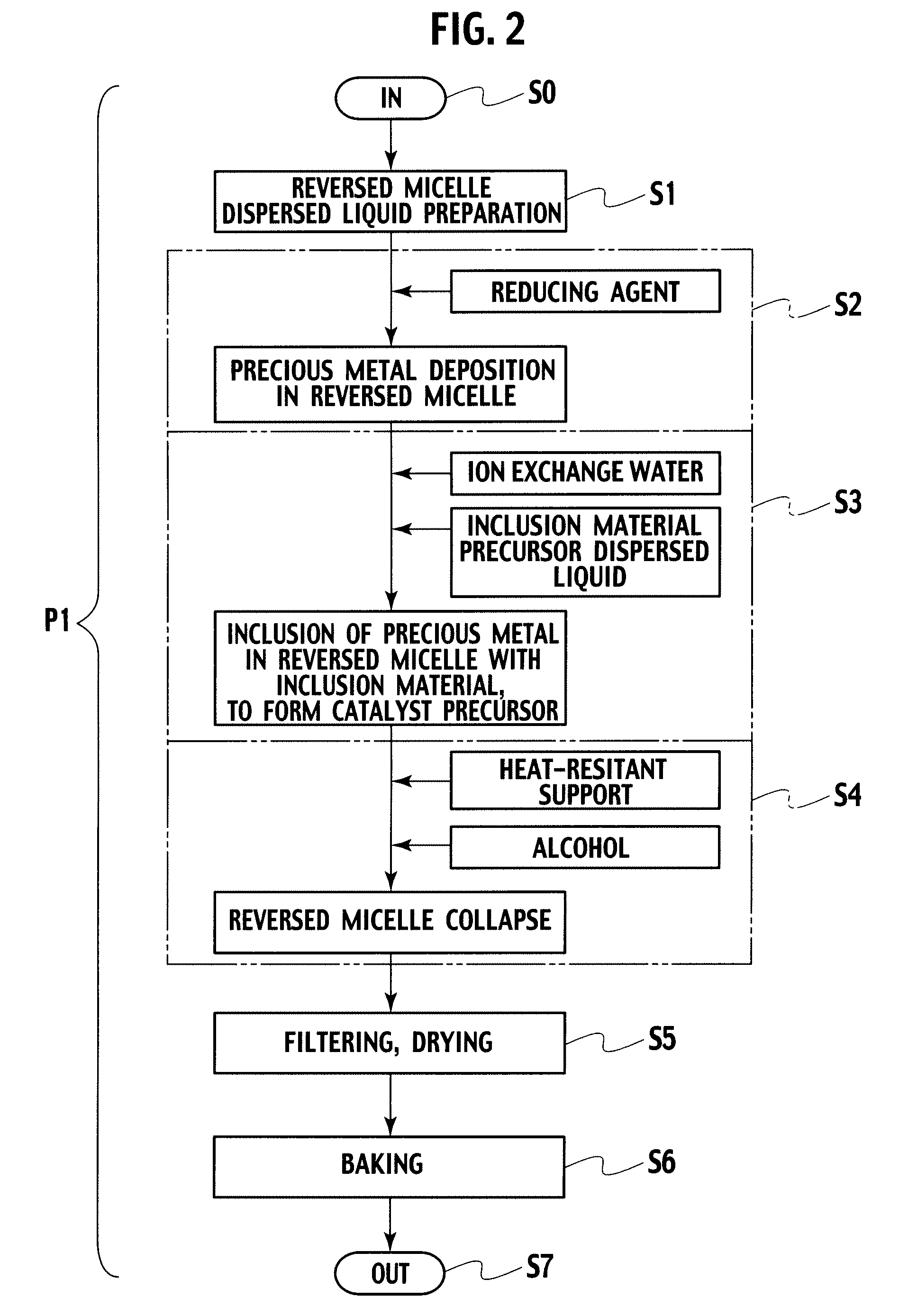

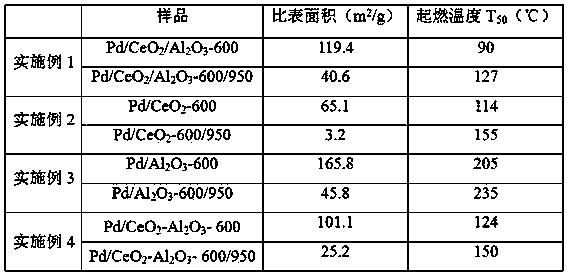

Catalyst, exhaust gas purifying catalyst, and method of producing the catalyst

InactiveUS8080494B2Reduce the probability of exposurePrevent sinteringInternal combustion piston enginesOther chemical processesExhaust gasHeat resistant

A catalyst 1 has a heat-resistant support 2 selected from among Al2O3, SiO2, ZrO2, and TiO2, and a first metal 4 supported on an outer surface of the support 2, and included by an inclusion material 3 containing a component of the support 2.

Owner:NISSAN MOTOR CO LTD

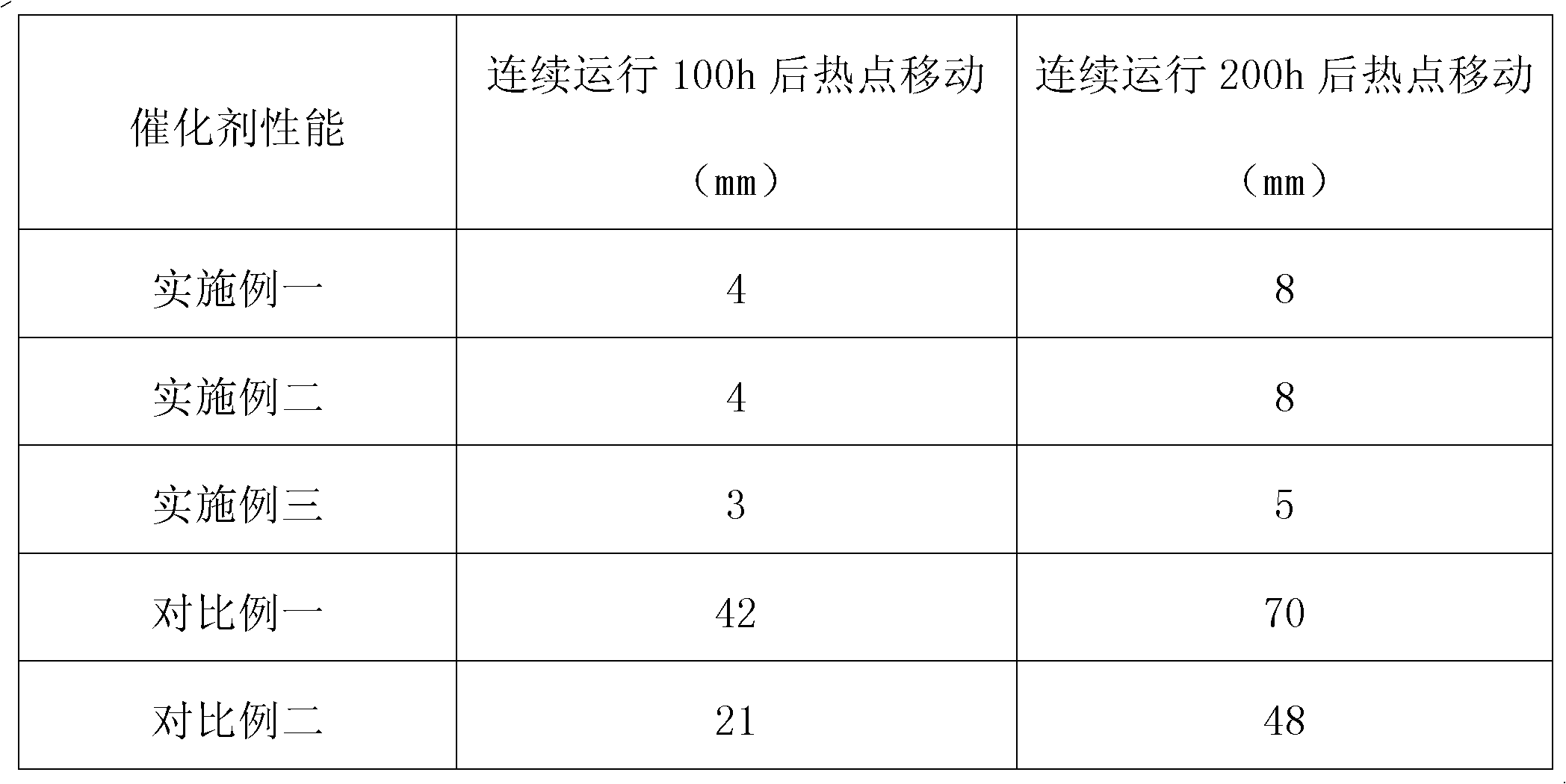

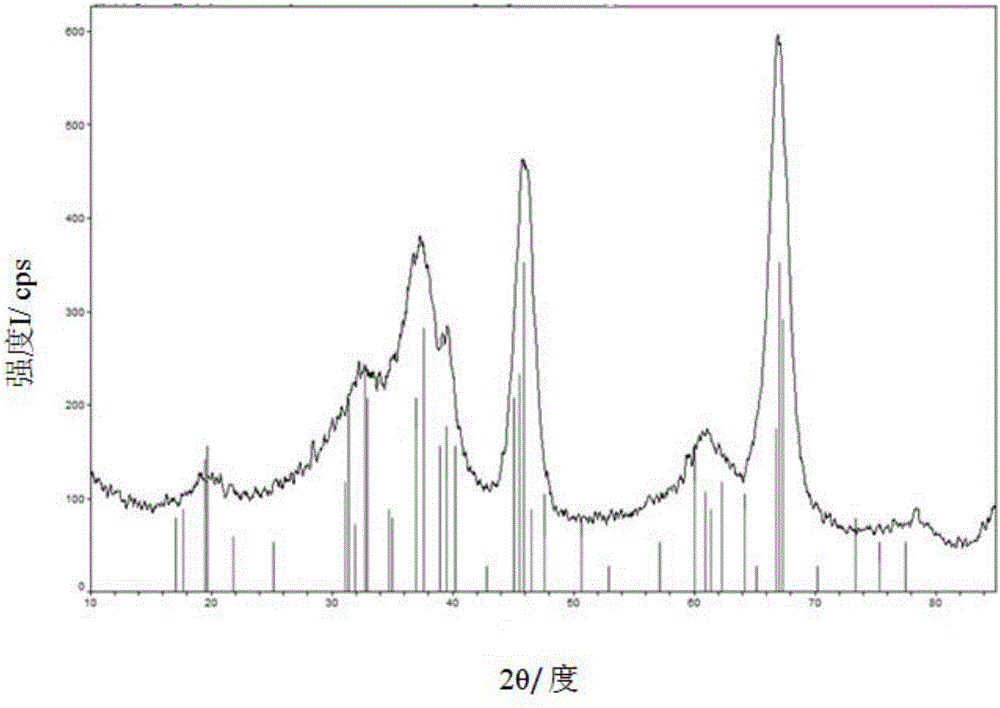

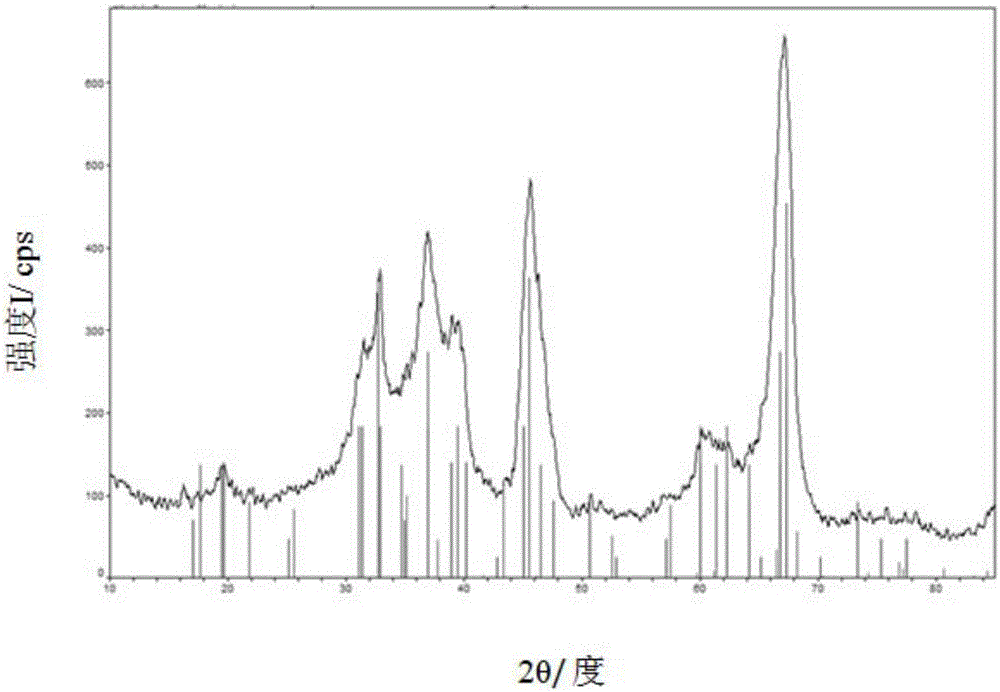

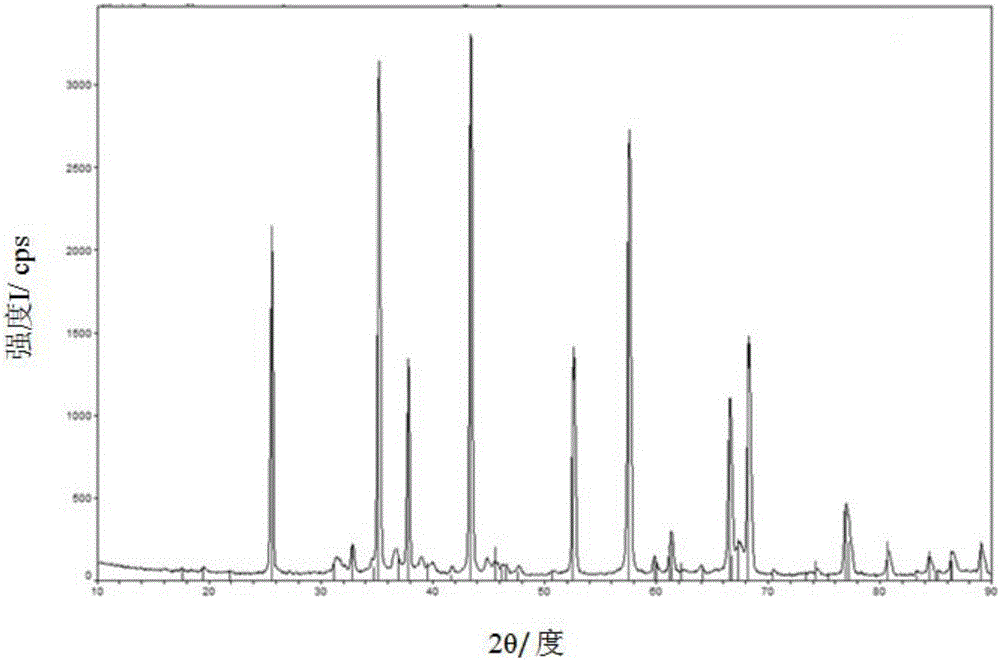

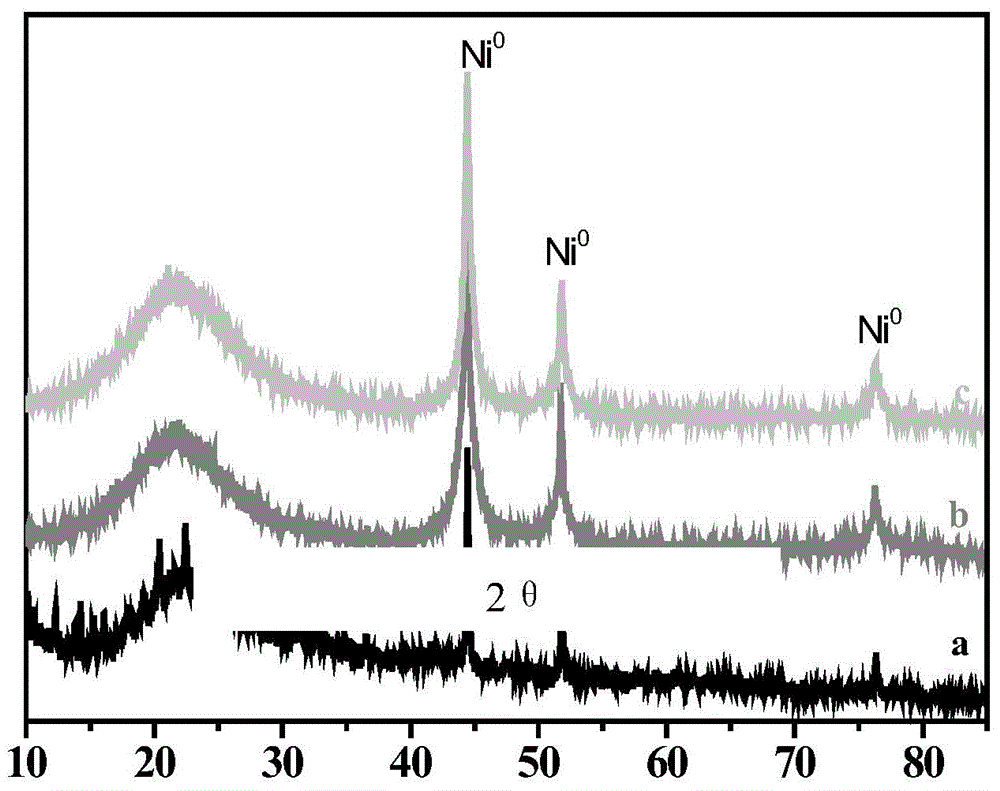

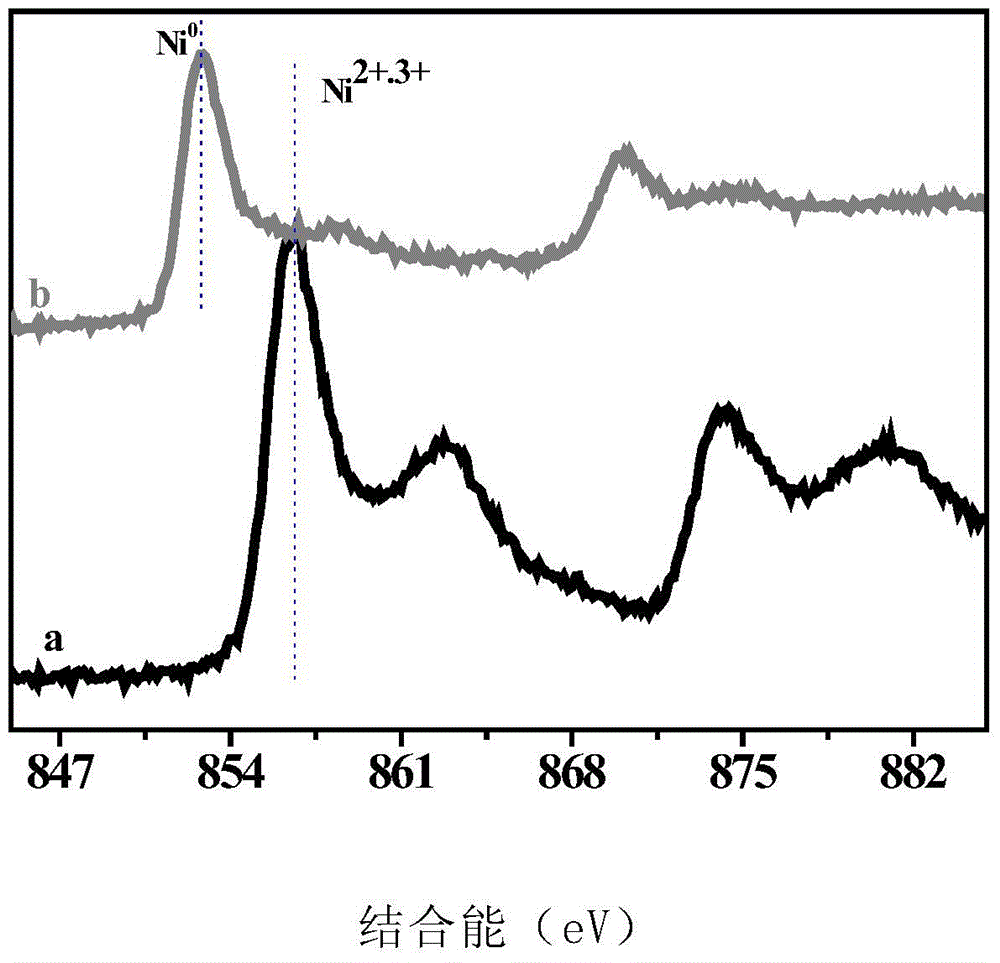

Catalyst for complete methanation of synthesis gas from coal and preparation method thereof

ActiveCN102139218AImprove stabilityHigh mechanical strengthHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsMagnesium AluminateChemistry

The invention discloses a catalyst for the complete methanation of synthesis gas from coal and a preparation method thereof. The catalyst is prepared by using NiO as an active component, one or two of rare earth metal oxides La2O3, CeO2 and Sm2O3 as a first assistant, one of alkali oxides CaO, BaO and SrO as a second assistant, and magnesium aluminate spinel formed by mixing Al2O3 with MgO as a carrier, and the obtained catalyst contains the ingredients in percent by mass as below: 20% to 70% of NiO, 15% to 50% of Al2O3, 6% to 30% of MgO, 5% to 20% of the rare earth metal oxide-type first assistant, 1% to 8% of the alkali oxide-type second assistant and 1% to 3% of graphite; the catalyst provided by the invention has the advantages of high catalytic activity, high mechanical strength, good thermal stability, strong carbon deposition resistance, strong resistance to toxicants in feed gas, excellent low temperature activity and low cost.

Owner:HUANENG CLEAN ENERGY RES INST

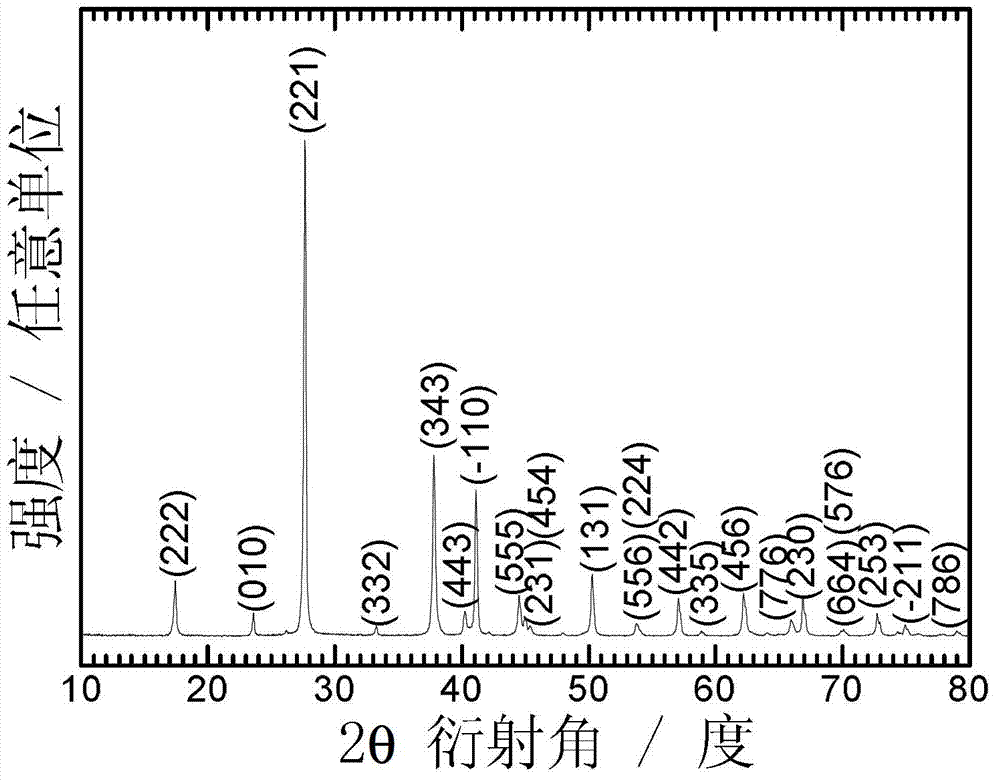

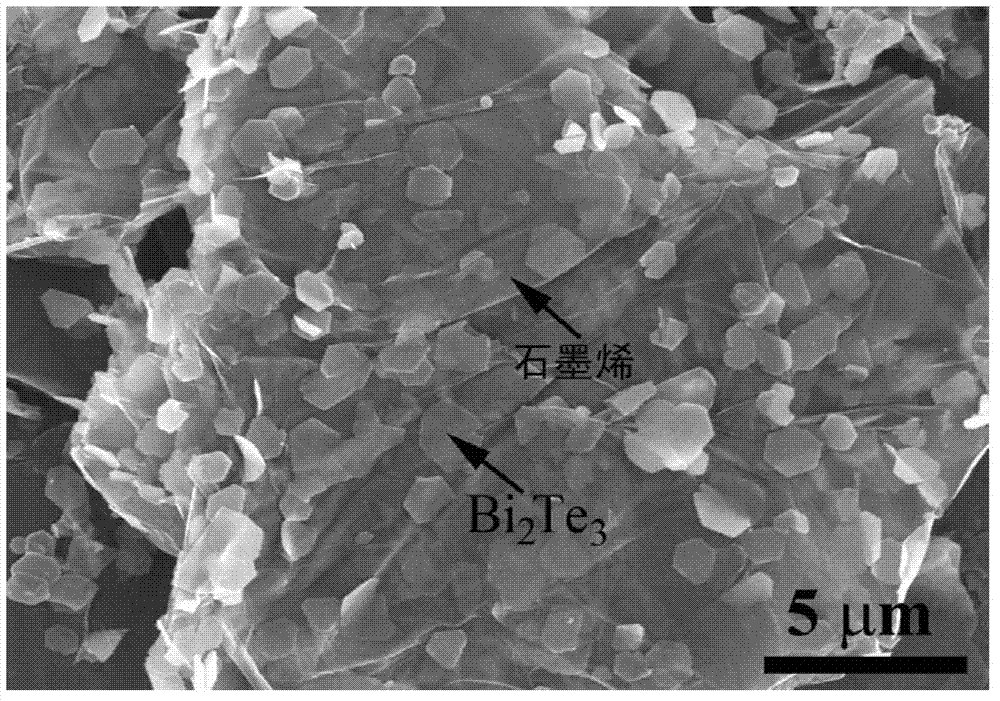

Bi2Te3 thin-piece/graphene composite material, preparation method and applications thereof

InactiveCN102760827AImprove thermoelectric performanceAvoid reunionGrapheneThermoelectric device junction materialsSolventCvd graphene

The invention discloses a Bi2Te3 thin-piece / graphene composite material. The Bi2Te3 thin-piece / graphene composite material consists of a micron-sized Bi2Te3 thin sheet and graphene. Due to the actions of dispersion, bearing and isolation of the graphene, the sintering of the micron-sized Bi2Te3 thin sheet in the heat-treatment process can be effectively prevented for maintaining effective scattering of the crystal boundary to phonons, and the great significance for improving the thermoelectric properties of the Bi2Te3 material is embodied. The composite material can be used as a thermoelectric material. The invention also discloses a preparation method of the composite material by a one-step hydrothermal method or a one-step solvothermal method, and has the advantages of simple process, low cost, short period and low energy consumption and the like.

Owner:ZHEJIANG UNIV

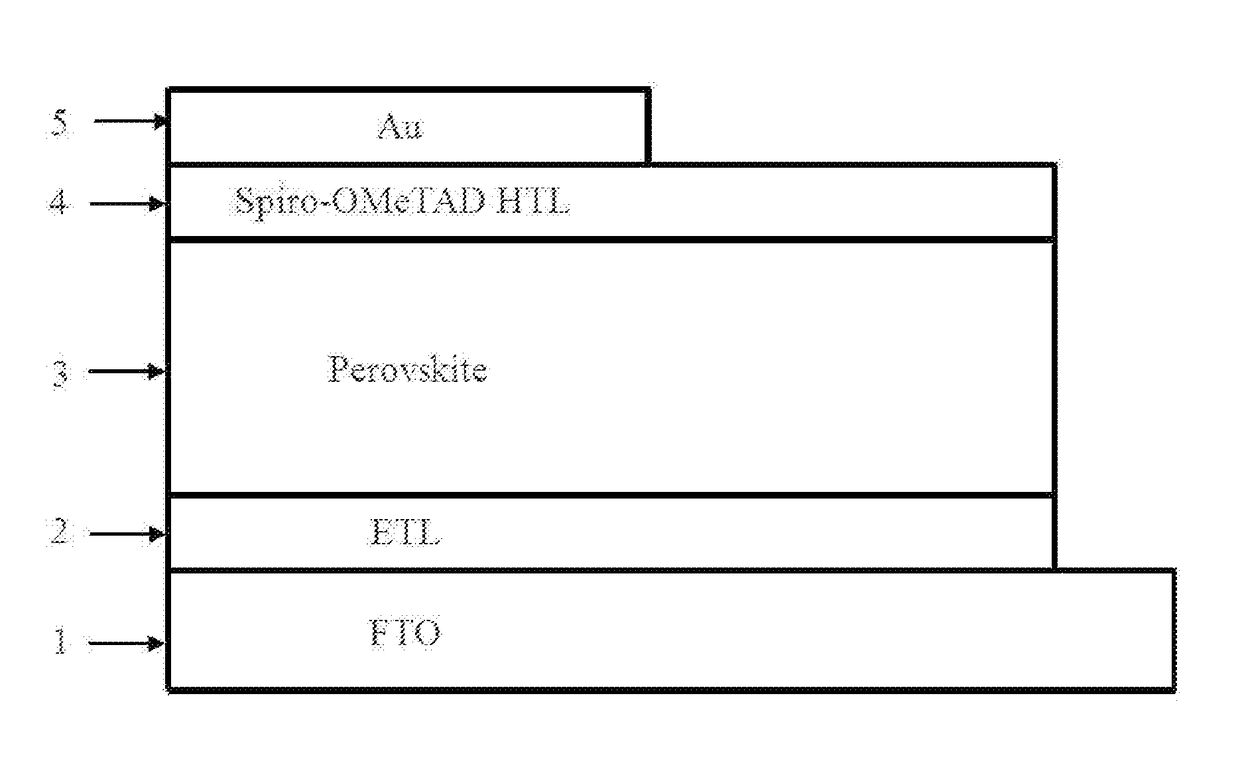

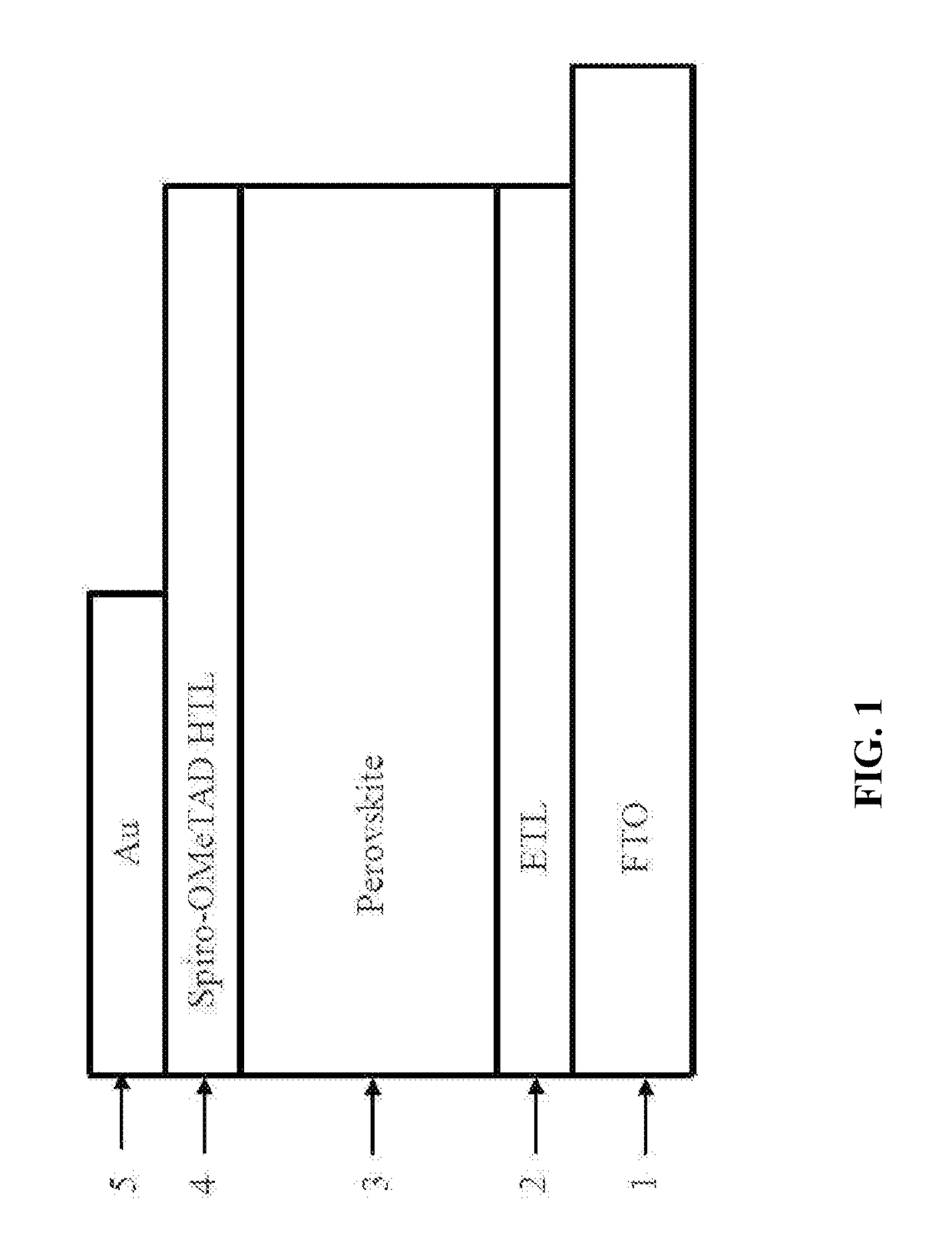

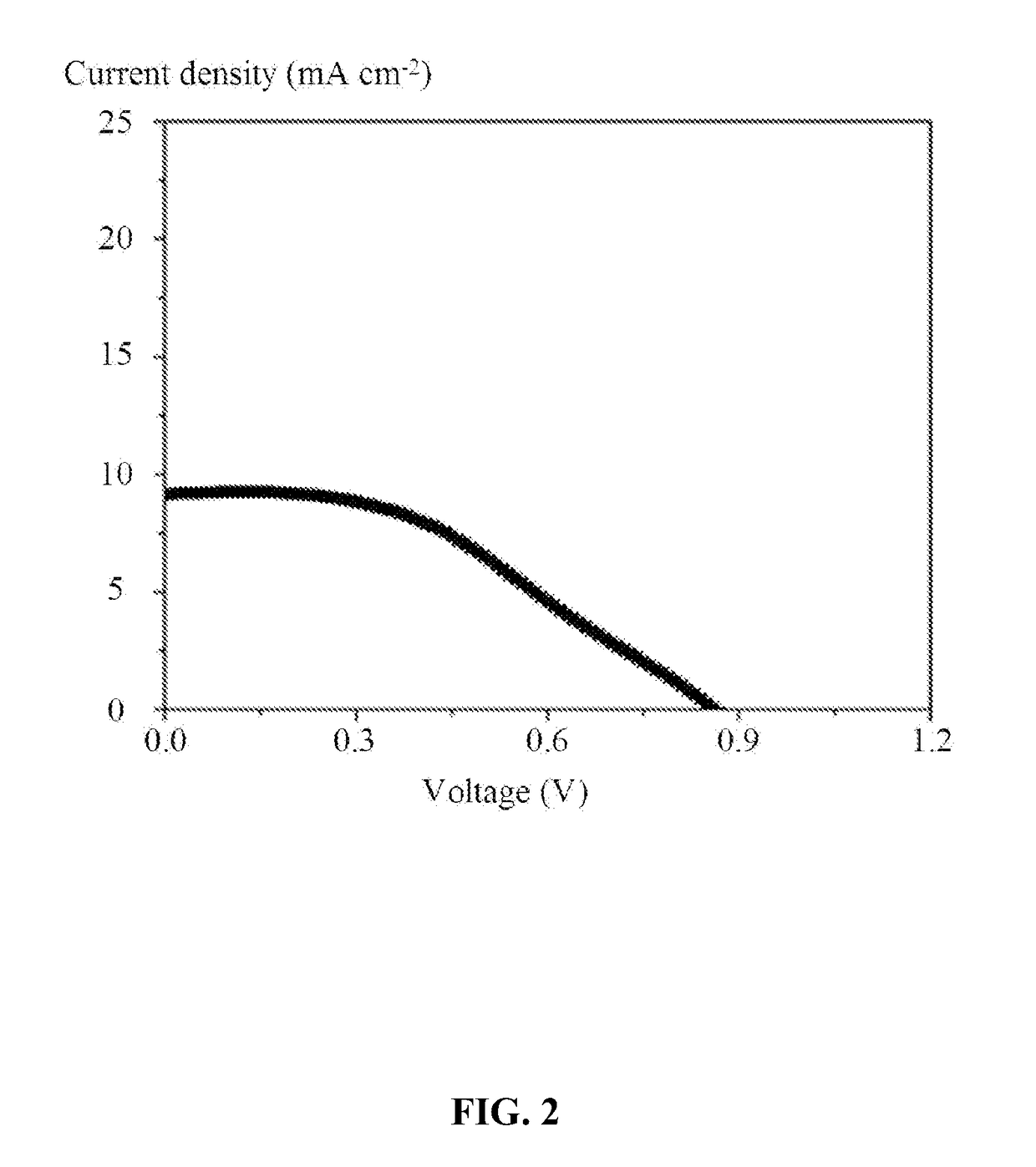

Perovskite thin-film photovoltaic cell and preparation method thereof

InactiveUS20170162809A1Low-cost and stableSimple and efficientFinal product manufactureSolid-state devicesTin dioxideTransport layer

A perovskite thin-film photovoltaic cell, including: a transparent conductive substrate, an electron transport layer, a perovskite absorption layer, a hole transport layer, and a metal electrode in that order. The electron transport layer is a tin dioxide thin-film. The invention also provides a method for preparing the perovskite thin-film photovoltaic cell. The method includes: (1) cleaning the transparent conductive substrate and then drying the transparent conductive substrate using nitrogen gas; (2) coating a SnO2 electron transport layer on the transparent conductive substrate; (3) coating a CH3NH3PbI3-xClx or CH3NH3PbI3 absorber on the electron transport layer; and (4) spin-coating a solution including hole transport material on the perovskite absorber layer and then evaporating the metal electrode.

Owner:WUHAN UNIV

Preparation method and application of titanium dioxide loaded ruthenium catalyst

InactiveCN102513102AEnhanced interactionIncrease dispersionHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsChemistryCarbon dioxide

The invention discloses a preparation method of a low-load-capacity and high-activity load type ruthenium catalyst using titanium dioxide as a carrier. According to the invention, the titanium dioxide is used as the carrier, an ageing solution is illuminated by using ultraviolet rays in a precipitation and deposition ageing process, thus interaction of a ruthenium precursor and the titanium dioxide is enhanced, the dispersion degree of the precursor is improved, and further the high-dispersion titanium dioxide loaded ruthenium catalyst is obtained. The preparation method has the advantages of simple equipment and process, high yield, and convenience for industrialized production; and the prepared ruthenium catalyst has the advantages of small ruthenium granularity and good reproducibility. The ruthenium catalyst is applied to a process for synthesizing methane by carbon dioxide through hydrogenation, and has high reactant transformation rate, high selectivity and good stability.

Owner:BEIJING UNIV OF CHEM TECH

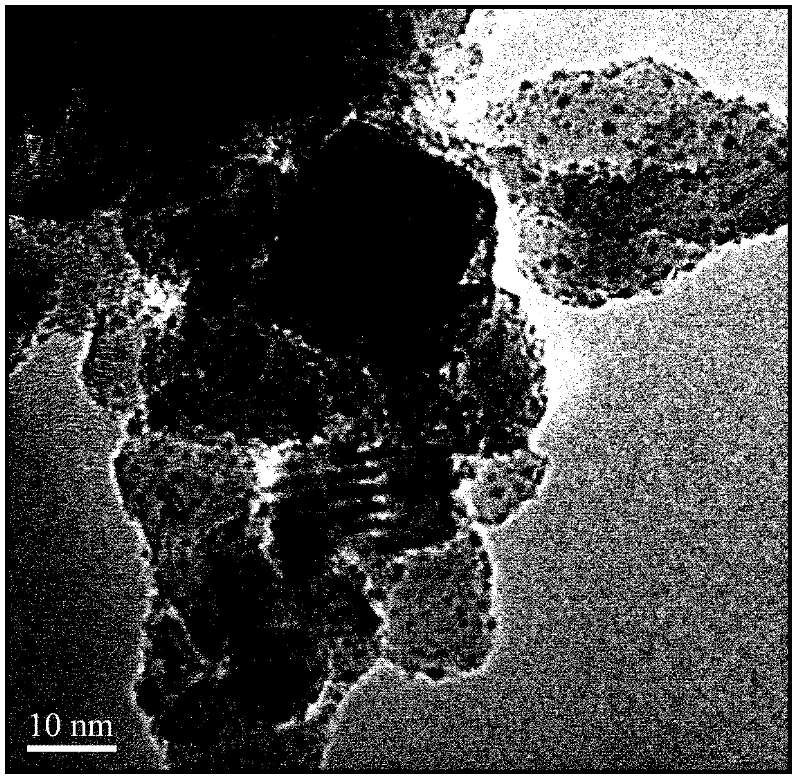

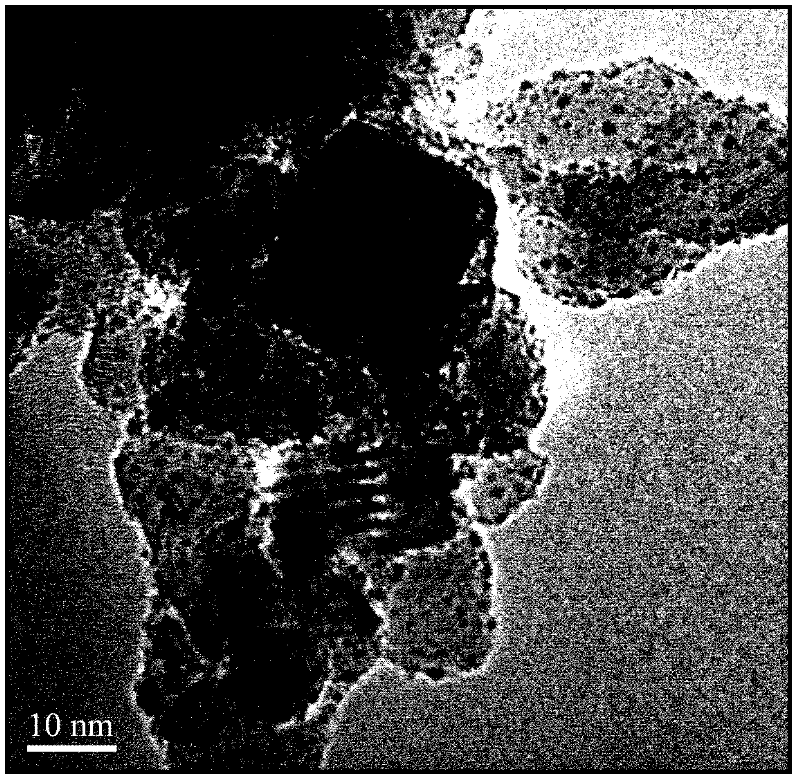

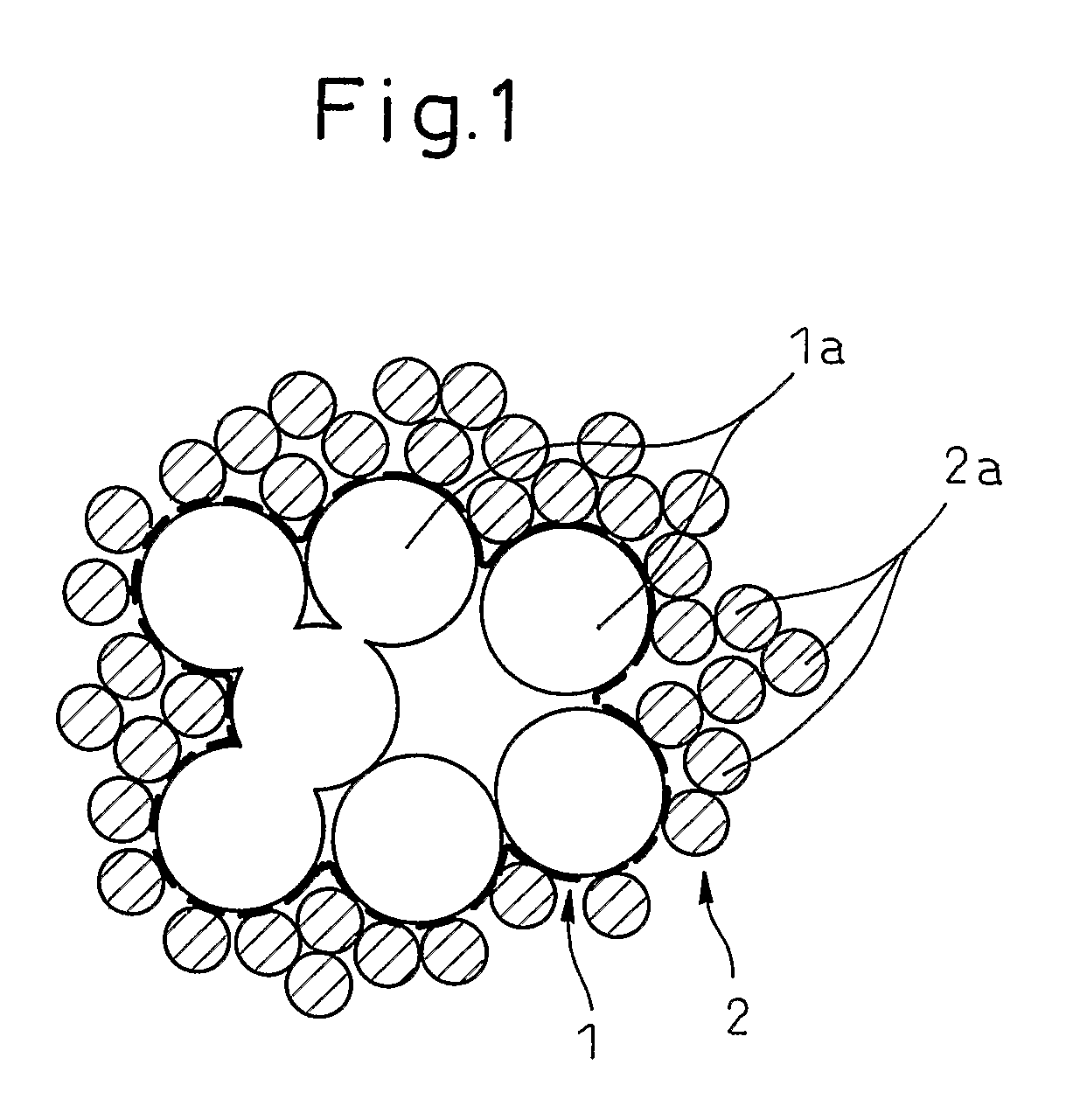

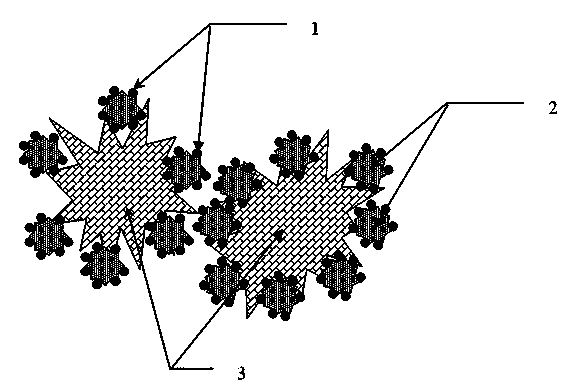

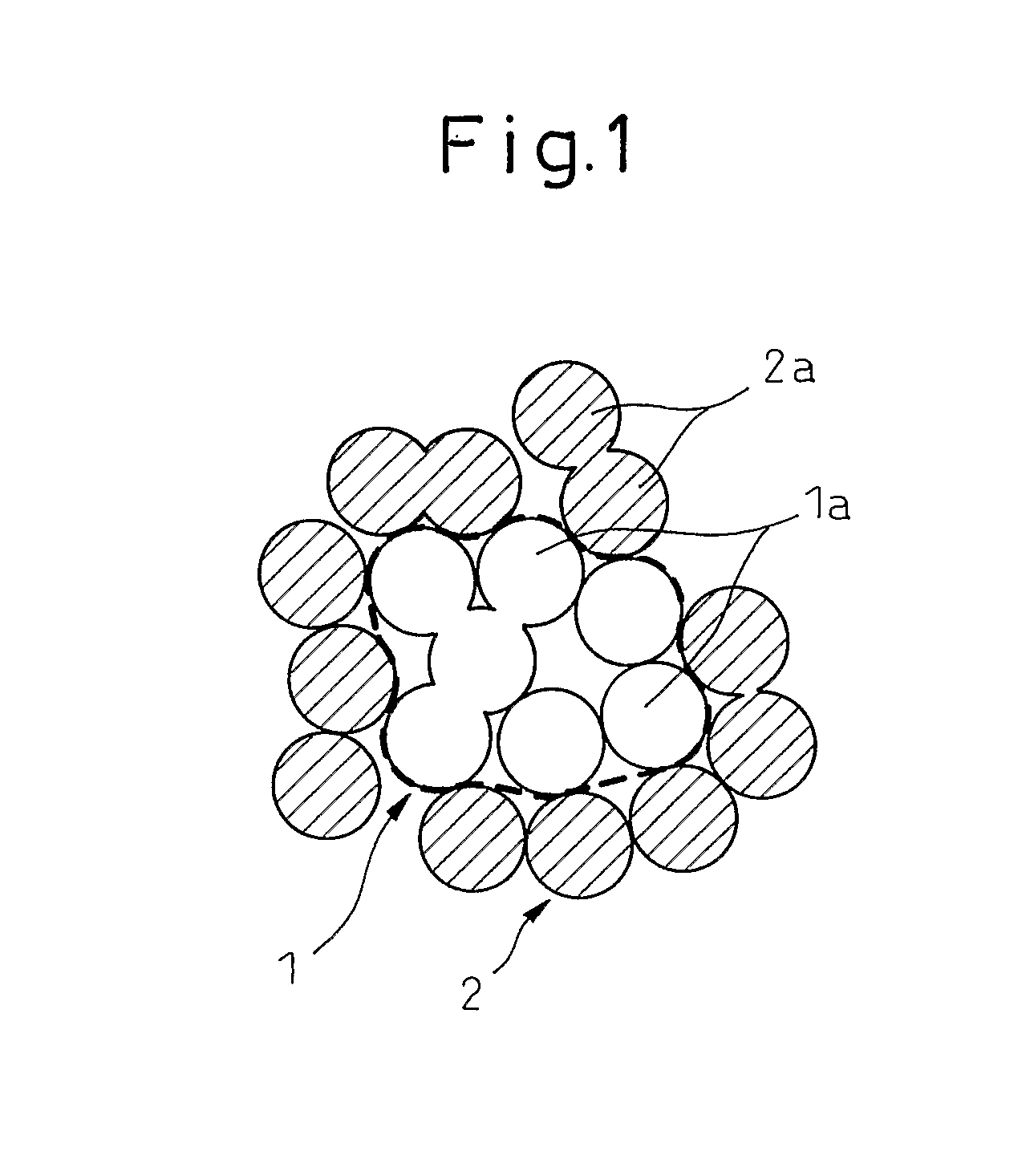

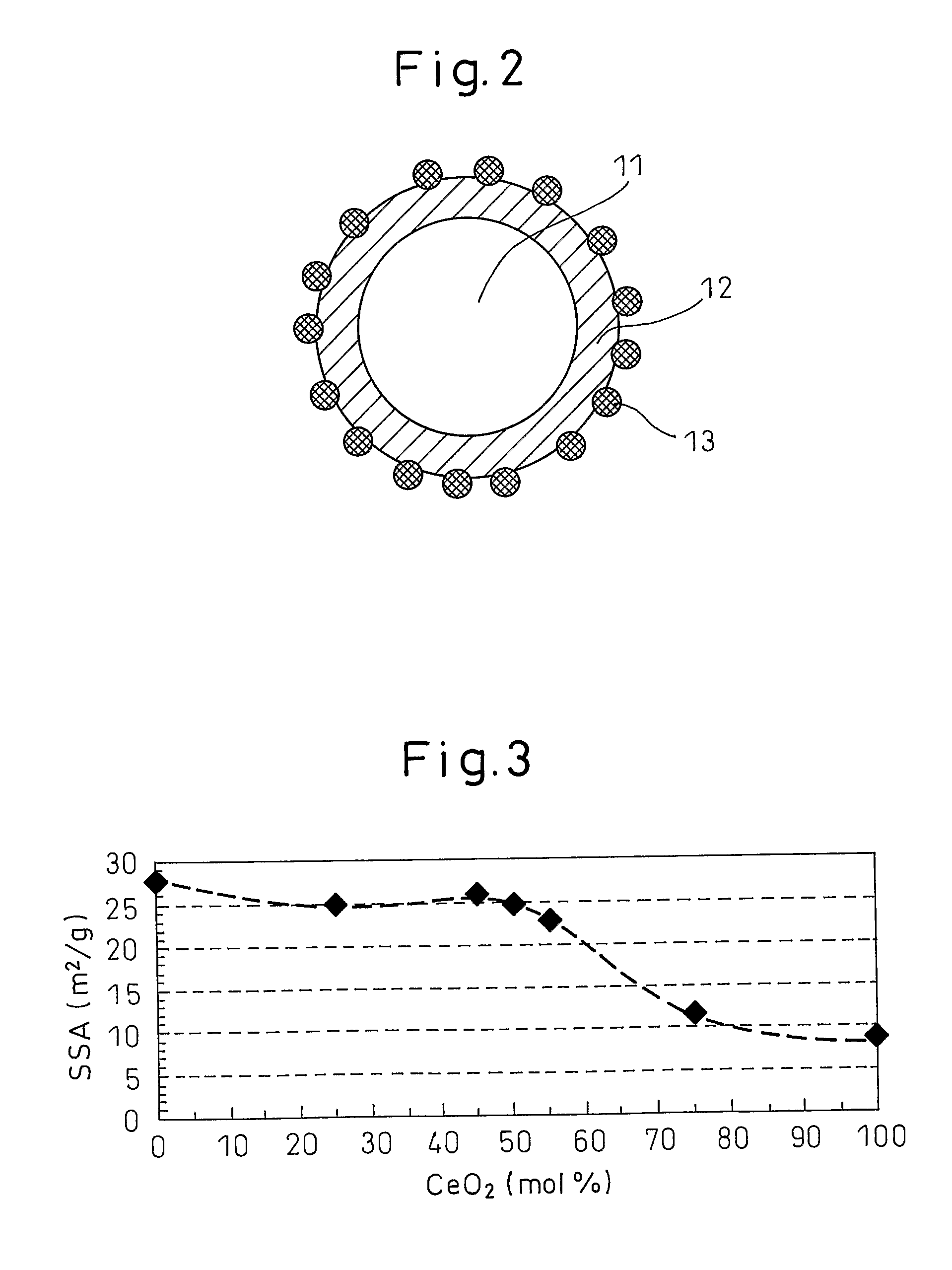

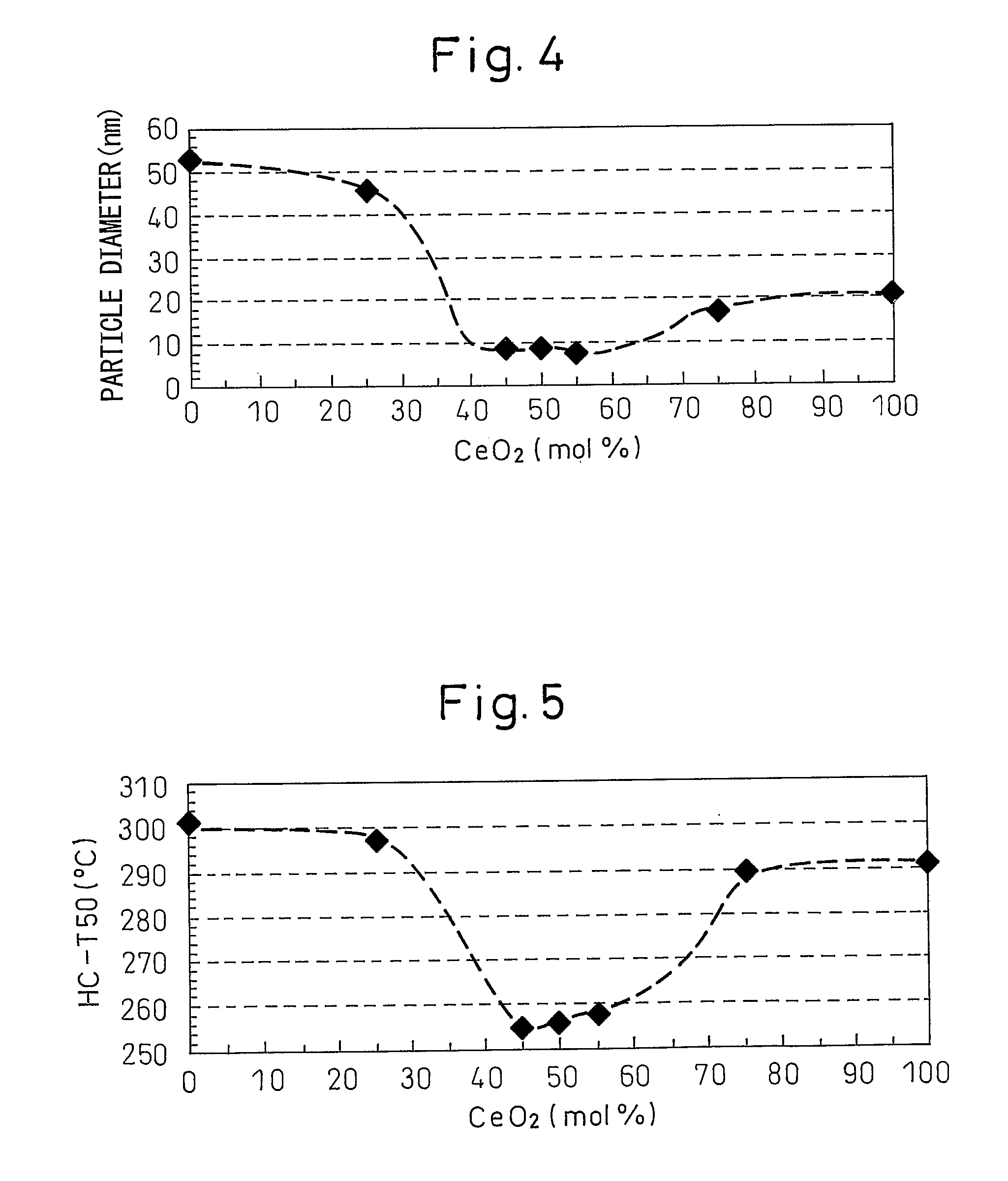

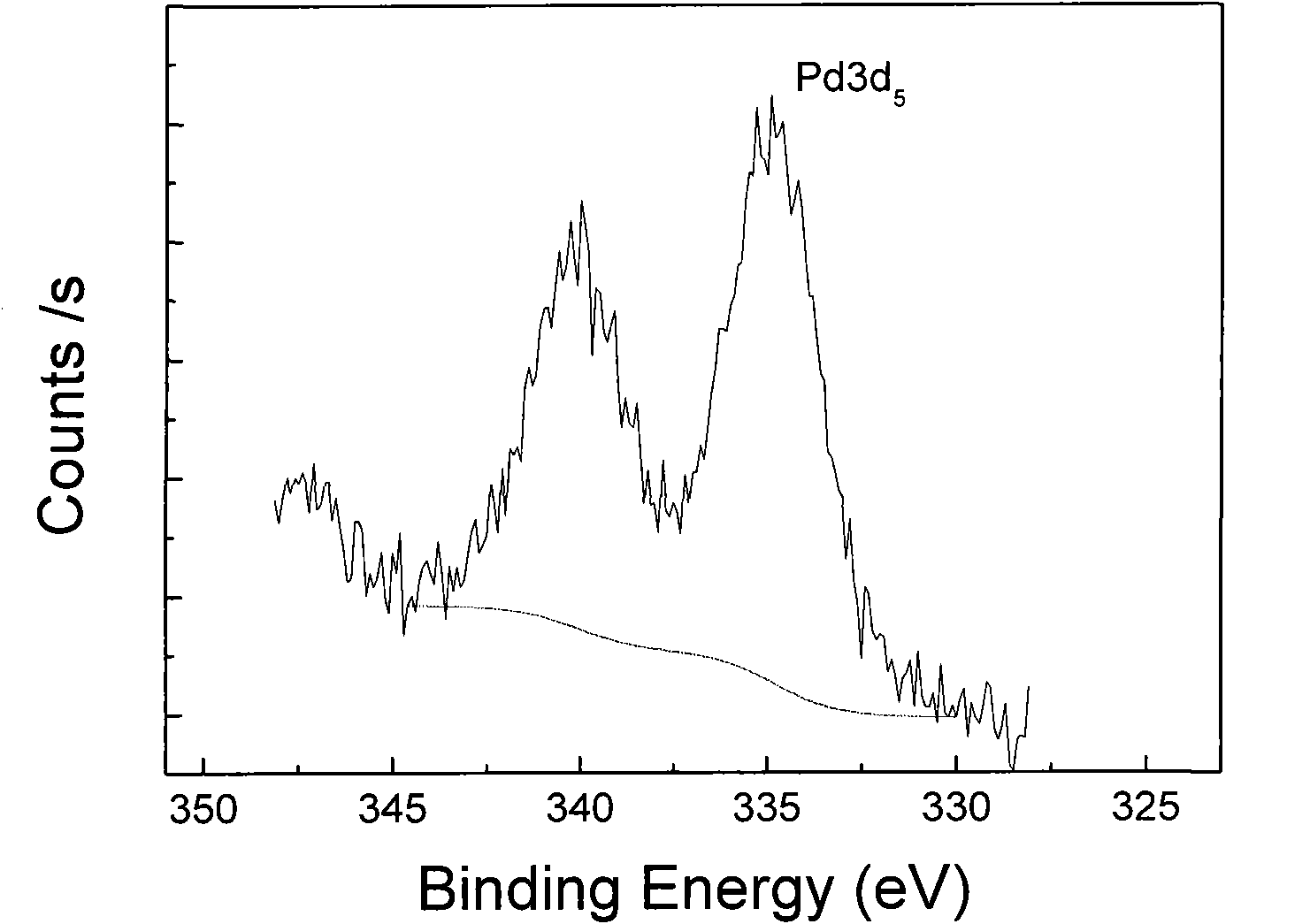

Zirconia core particles coated with ceria particles, production process thereof and exhaust gas purifying catalyst

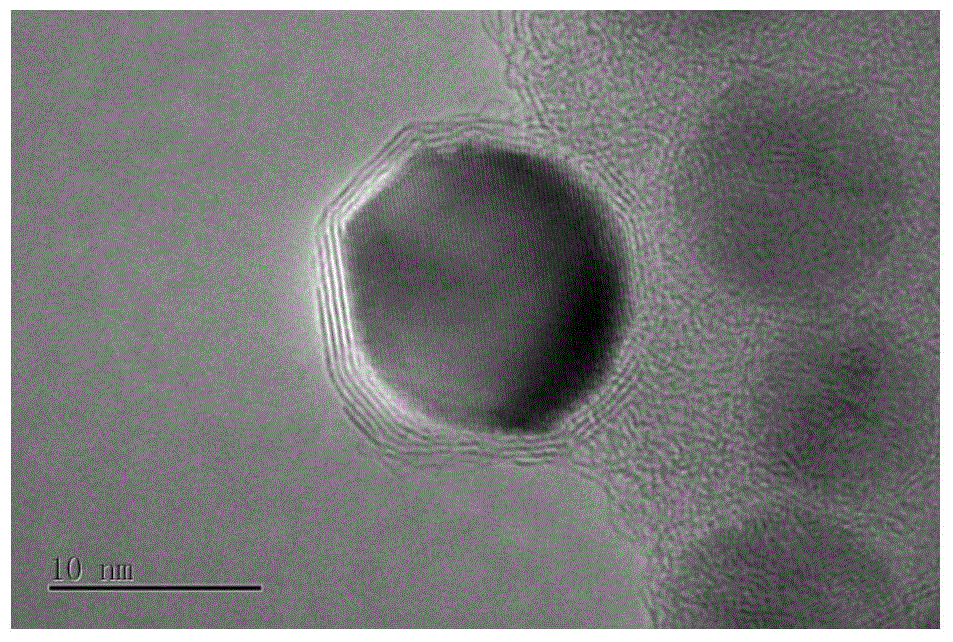

InactiveUS20070197373A1Excellent catalytic performanceEnhanced interactionInternal combustion piston enginesMolecular sieve catalystsExhaust gasChemistry

The present invention provides a metal oxide particle for a catalyst support comprising multiple species of metal oxides and capable of satisfactorily exerting the properties of the respective metal oxides, and also provide a production process therefor and an exhaust gas purifying catalyst obtained from this metal oxide particle. A metal oxide particle of the present invention comprises a core part 1 relatively rich in a first metal oxide and a surface layer 2 relatively rich in a second metal oxide, the core part and the surface layer each comprising a plurality of primary particles (1a, 2a), and the primary particle diameter of the second metal oxide being smaller than the primary particle diameter of the first metal oxide.

Owner:TOYOTA JIDOSHA KK

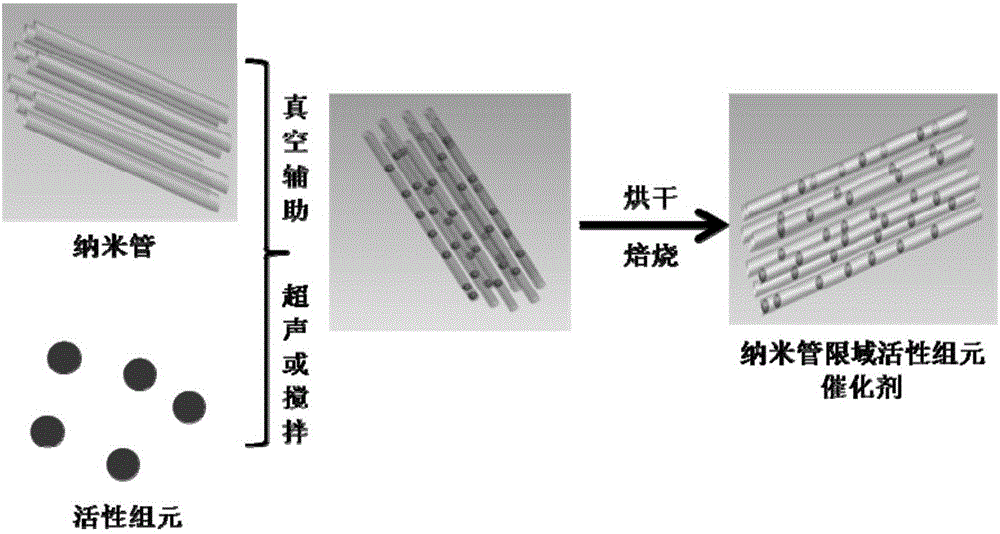

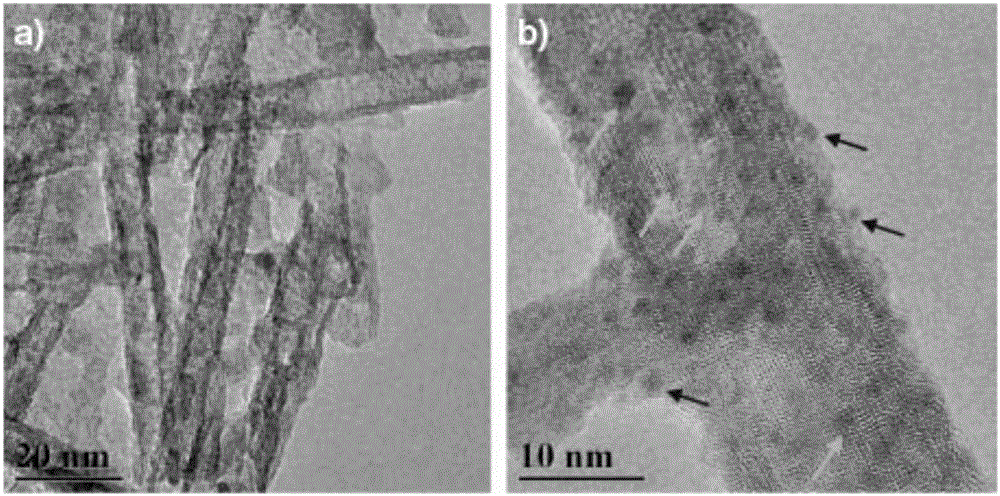

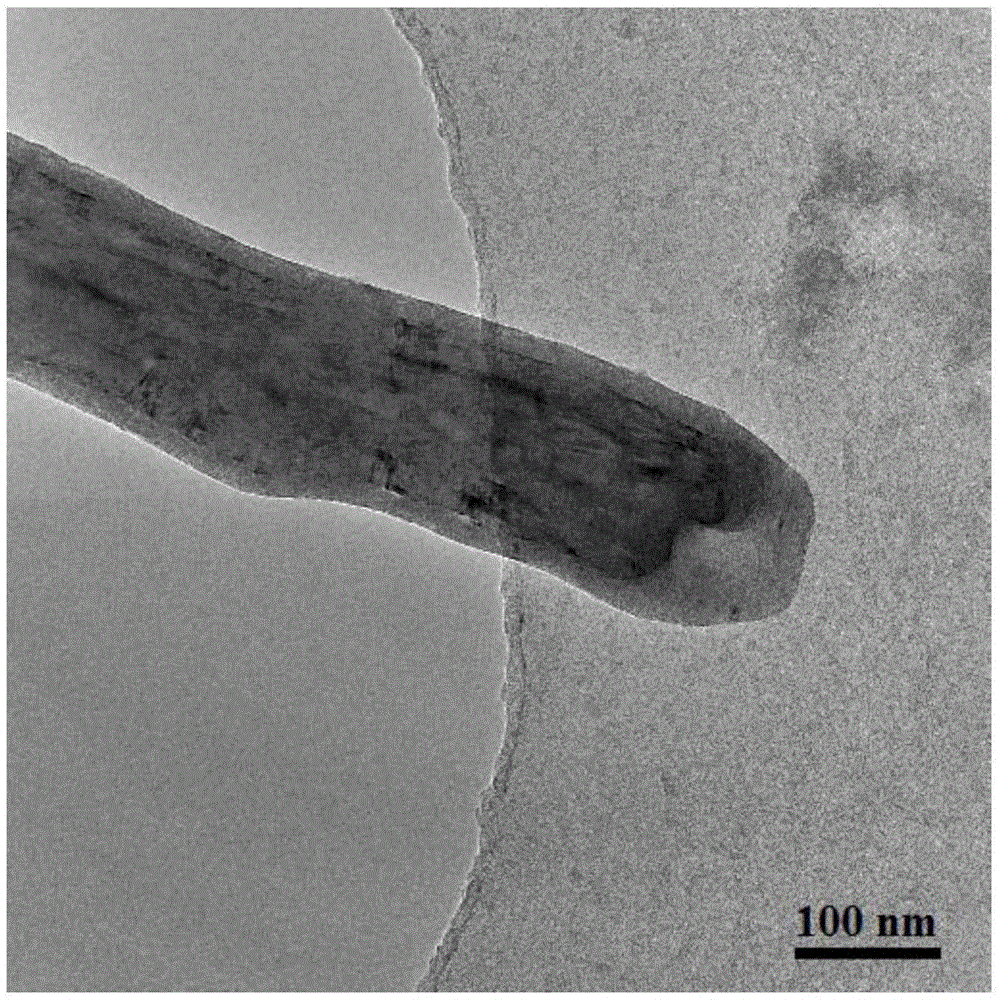

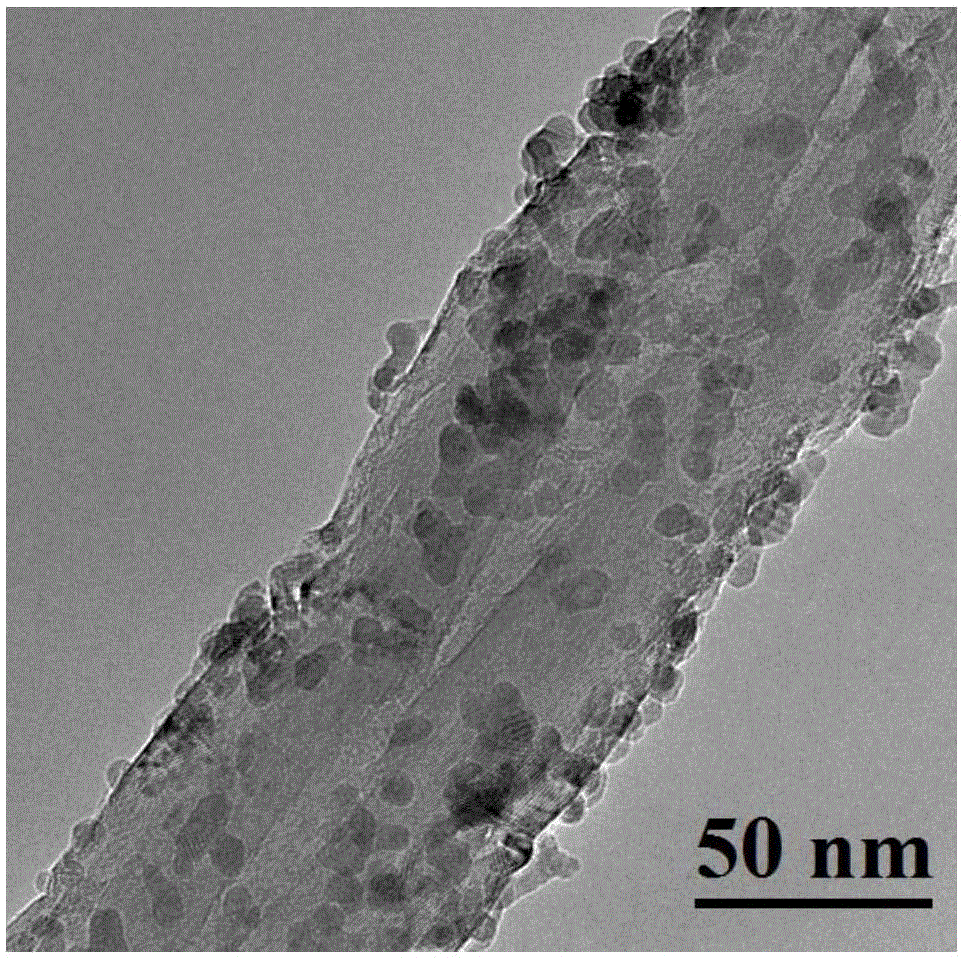

Method for low-temperature oxidative degradation of organic gas

InactiveCN106076113AImprove stabilityAvoid reunionGas treatmentHeterogenous catalyst chemical elementsReaction temperatureCatalytic oxidation

The invention discloses a method for low-temperature oxidative degradation of organic gas. The method comprises the steps that a nanotube limited-range active component catalyst is used as a catalyst, a reaction is carried out under the conditions that the temperature is 45-220 DEG C and the airspeed is 100-100000h<-1> for 0.5-1500h for a catalytic oxidation degradation reaction of organic gas, and the organic gas is oxidized into degradation reaction and water. According to the method, by means of the nanotube open-framework structure and micronanospace, the active component of the catalyst for treating organic gas is planted into the nanotube open-framework structure to prepare the nanotube limited-range active component catalyst with high activity and stability, the limited-range catalyst is used for oxidative degradation of organic gas and can rapidly oxidize the organic gas at a low temperature into carbon dioxide and water, the organic gas removal rate reaches up to 95% or more, the catalyst is high in activity and long in service life, and the problems that reaction temperature is high, catalyst activity and stability are low and the catalyst active component service life is short in the prior art are solved.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Method for producing ethylene glycol and 1,2-propylene glycol through continuous hydrocrackin of sugars

ActiveCN102643165BRealize continuous inputReduce consumptionOrganic compound preparationPreparation by OH group eliminationSucroseGas phase

The invention relates to a continuous reaction process for producing ethylene glycol and 1,2-propanediol by catalytic hydrocracking sugar conversion, and provides a method for producing ethylene glycol and 1,2-propanediol by continuous hydrogenation cracking sugar conversion. During this process, sugars (including one or more of sucrose, glucose, fructose, xylose, soluble xylooligosaccharides, and starch) are hydrocracked by catalysts in the reactor and then enter the separation system. The hydrogen in the gas phase is separated and recovered for recycling; part of the liquid phase product is returned to the reactor, and the rest of the liquid phase product is refined to separate ethylene glycol, propylene glycol, and other polyols; it exists in the remaining heavy components after refining and separation. Concentrate in the liquid phase The soluble catalyst components are partially recycled back to the reactor.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

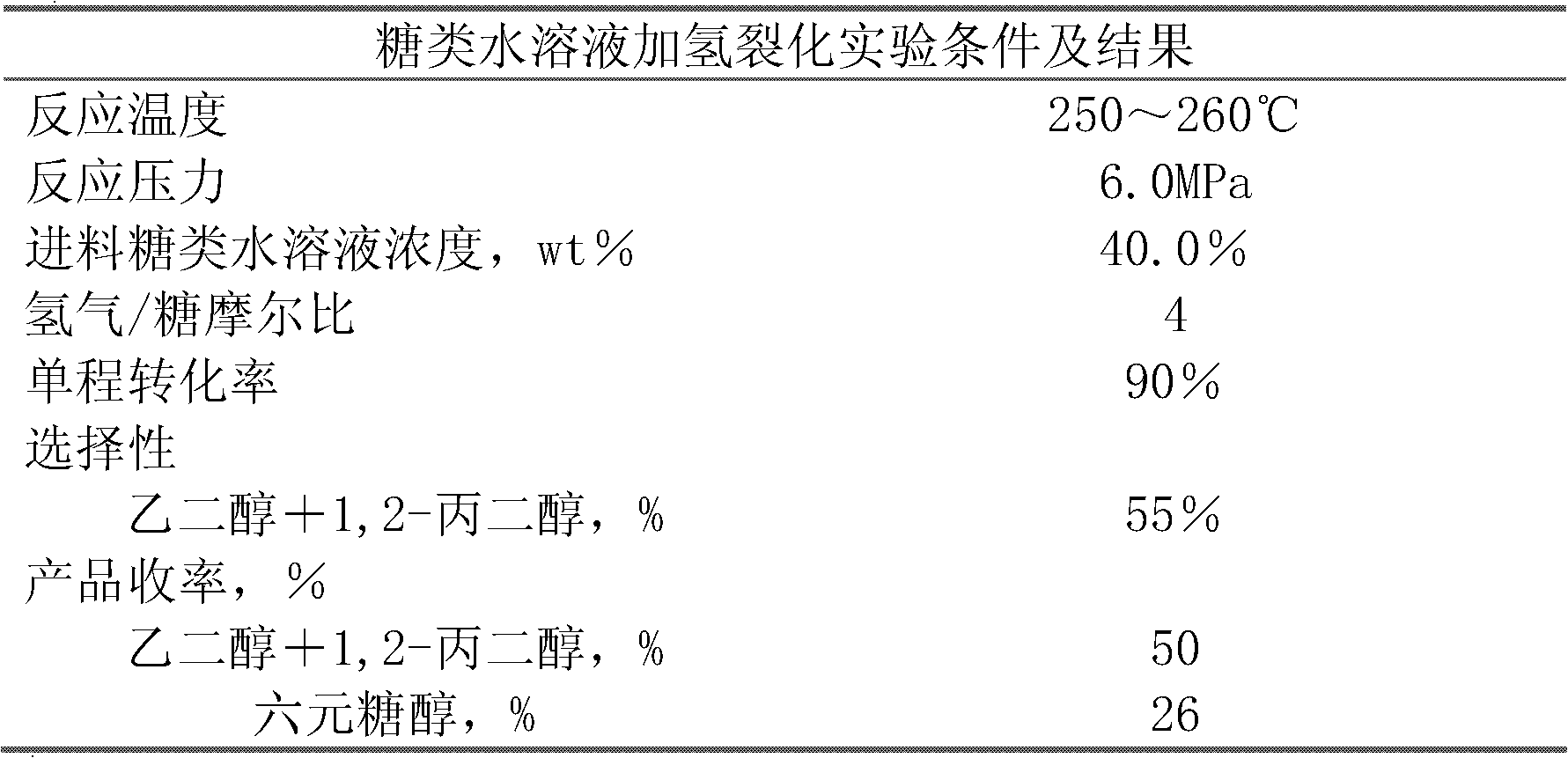

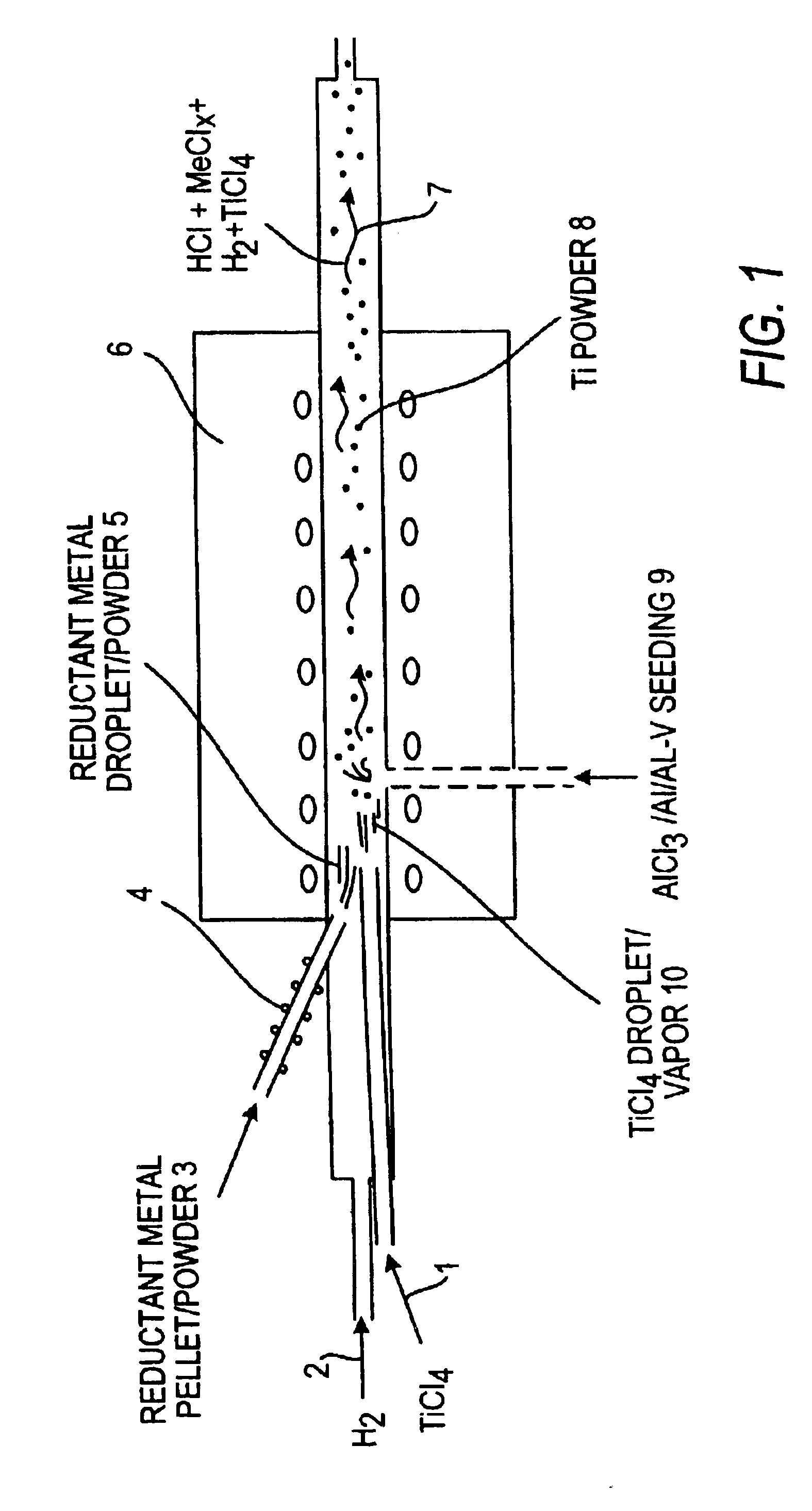

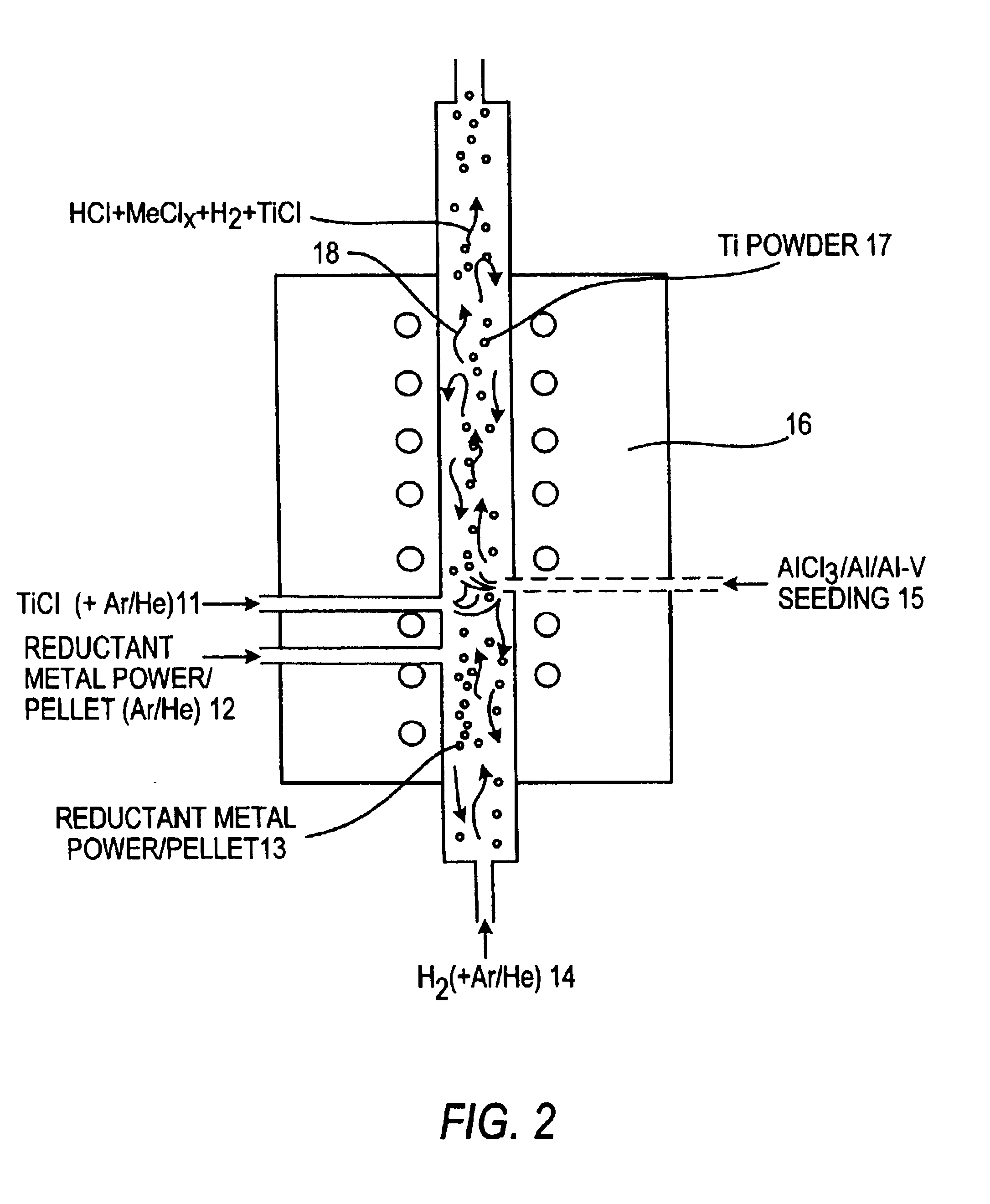

Method of making elemental materials and alloys

A method of producing an elemental material or an alloy thereof from a halide or mixtures of halides is provided. The halide or mixtures thereof are contacted with a reducing gas in the presence of reductant material, preferably in sufficient quantity to convert the halide to the elemental material or alloy and to maintain the temperature of the reactants at a temperature lower than the boiling point of the reductant material at atmospheric pressure or the sintering temperature of the produced elemental material or alloy.

Owner:TRONOX LLC

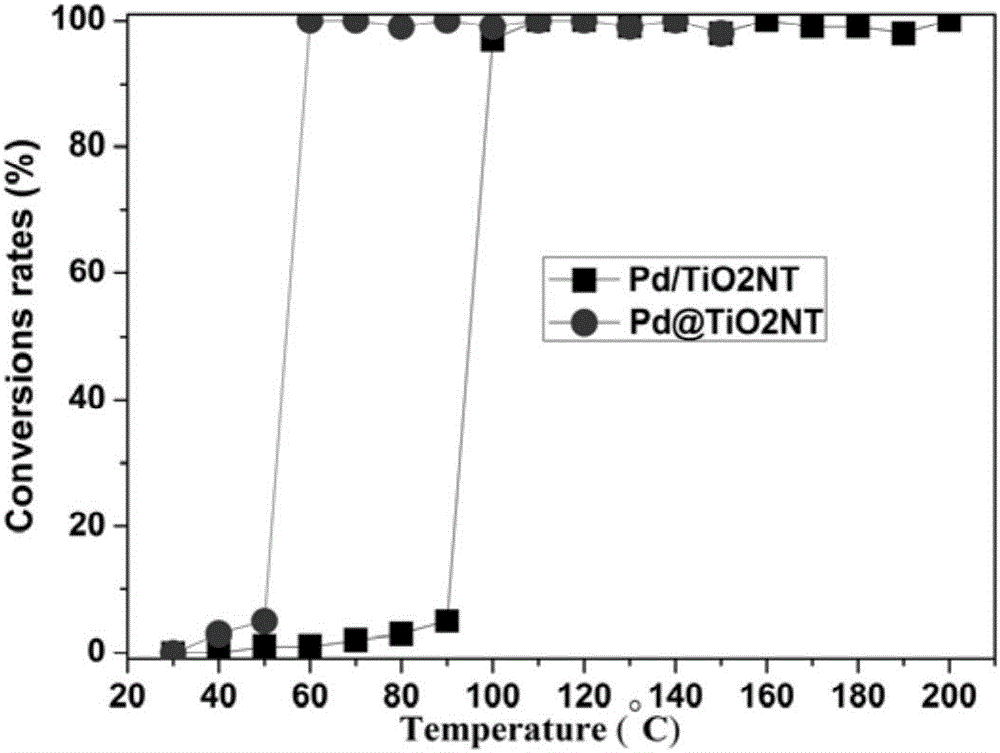

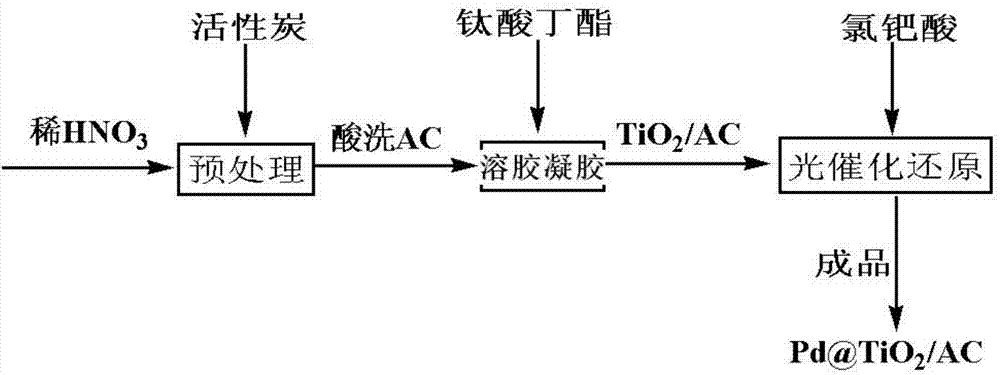

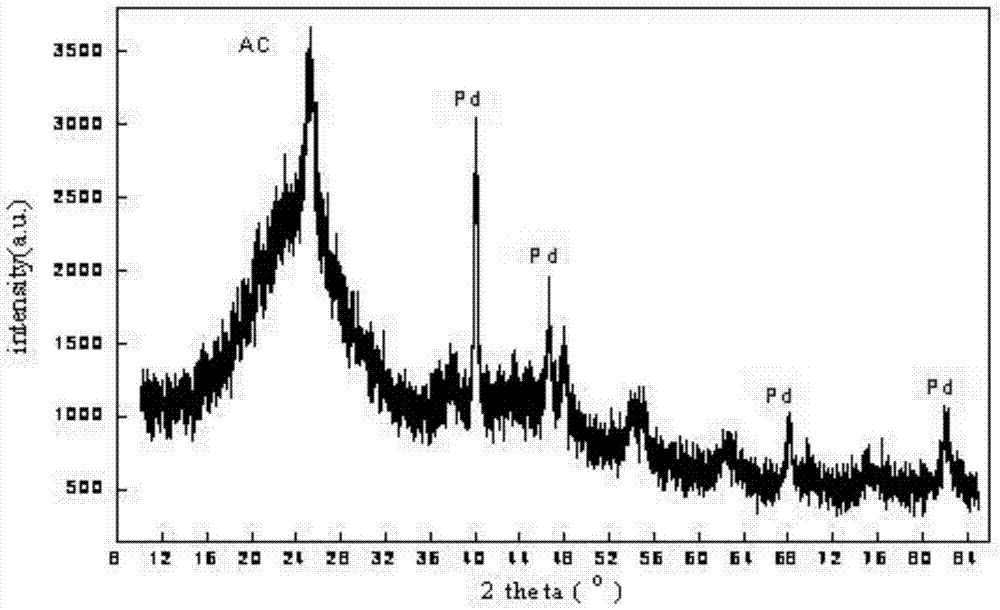

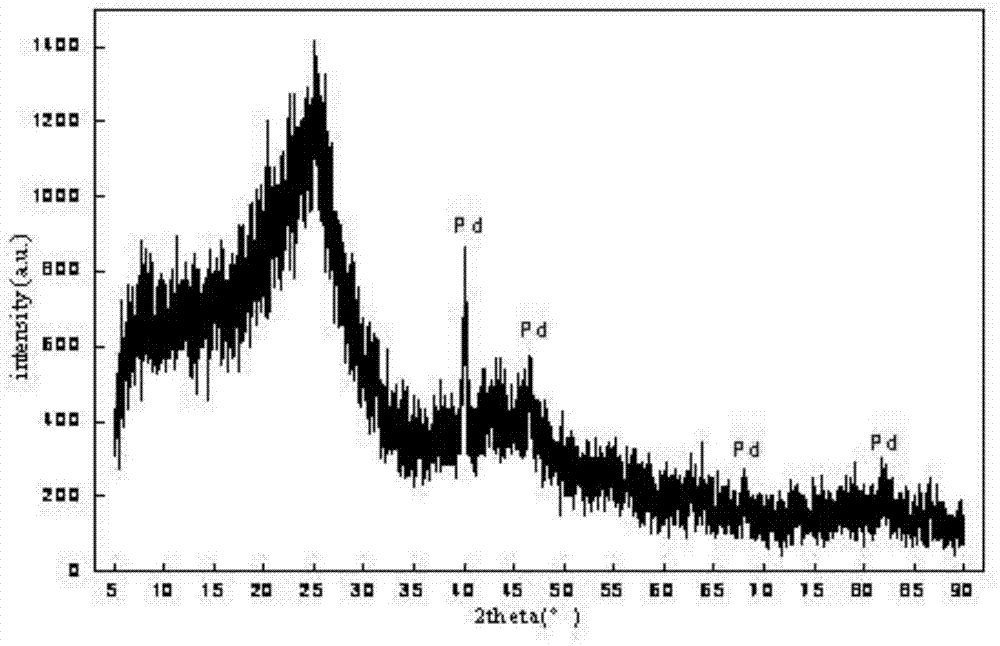

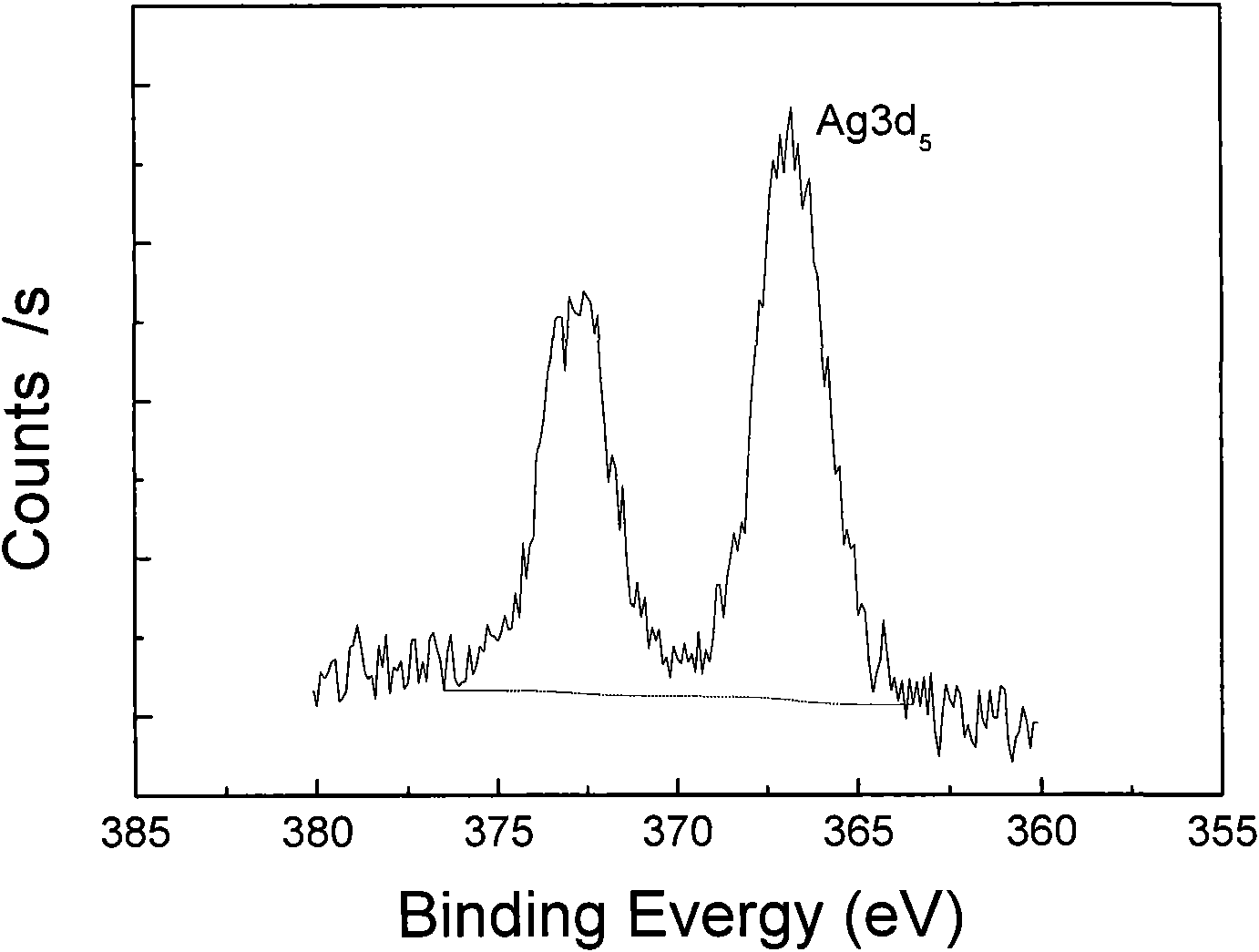

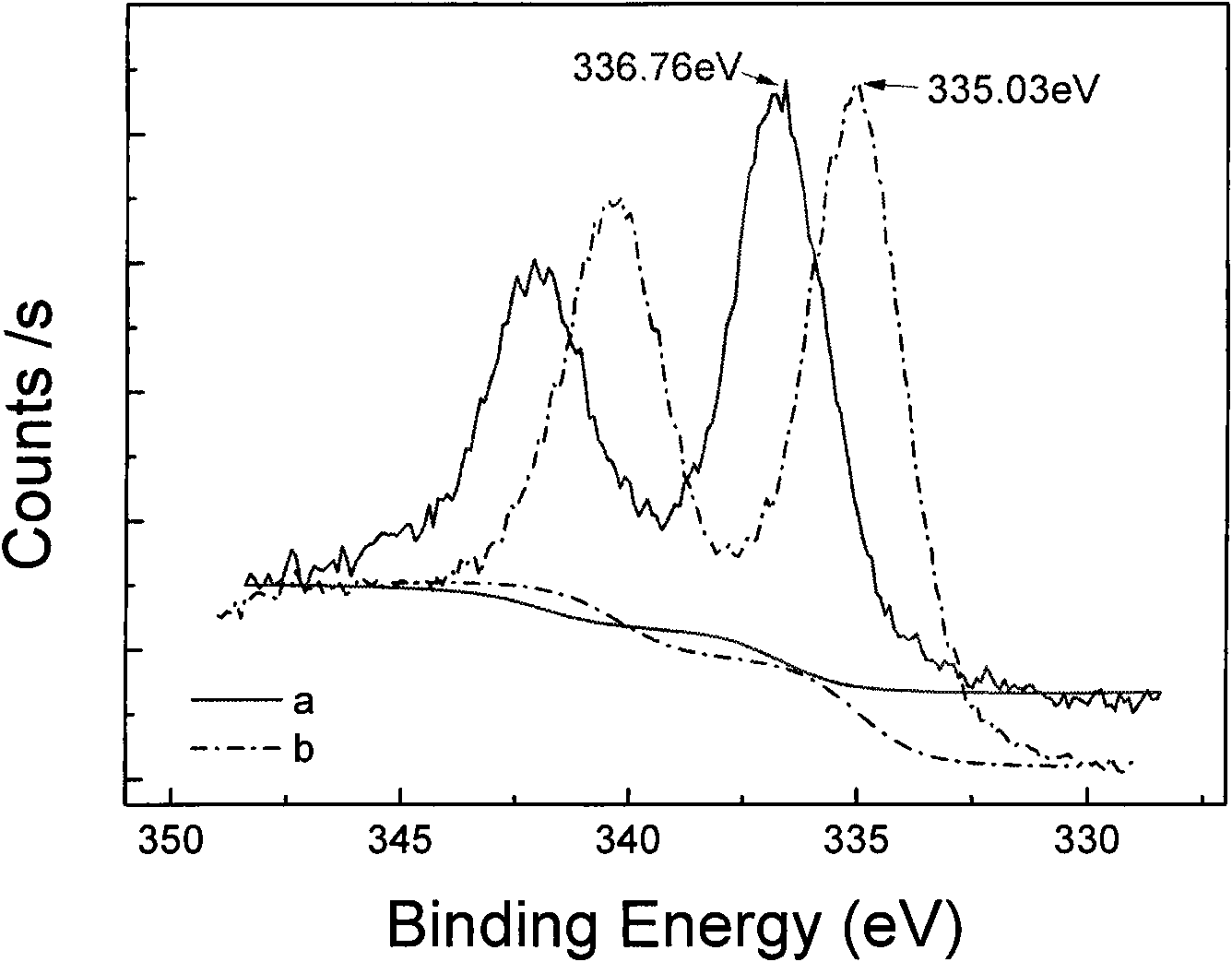

Palladium carbon catalyst as well as preparation method and application thereof

ActiveCN103691431AThe load rate is close to or even fullyFull loadOrganic compound preparationCarbonyl compound preparationActivated carbonPalladium on carbon

The invention relates to a palladium carbon catalyst which comprises the following components: (1) nanometer TiO2-modified active carbons are used as composite carriers; (2) Pd nanometer particles are used as active components, wherein the strong interaction between metals and the carriers exists in the active components and TiO2 on the composite carriers to form a Pd@TiO2 structure so as to form structural Pd@TiO2 / active carbons of the catalyst.

Owner:XIANGTAN UNIV

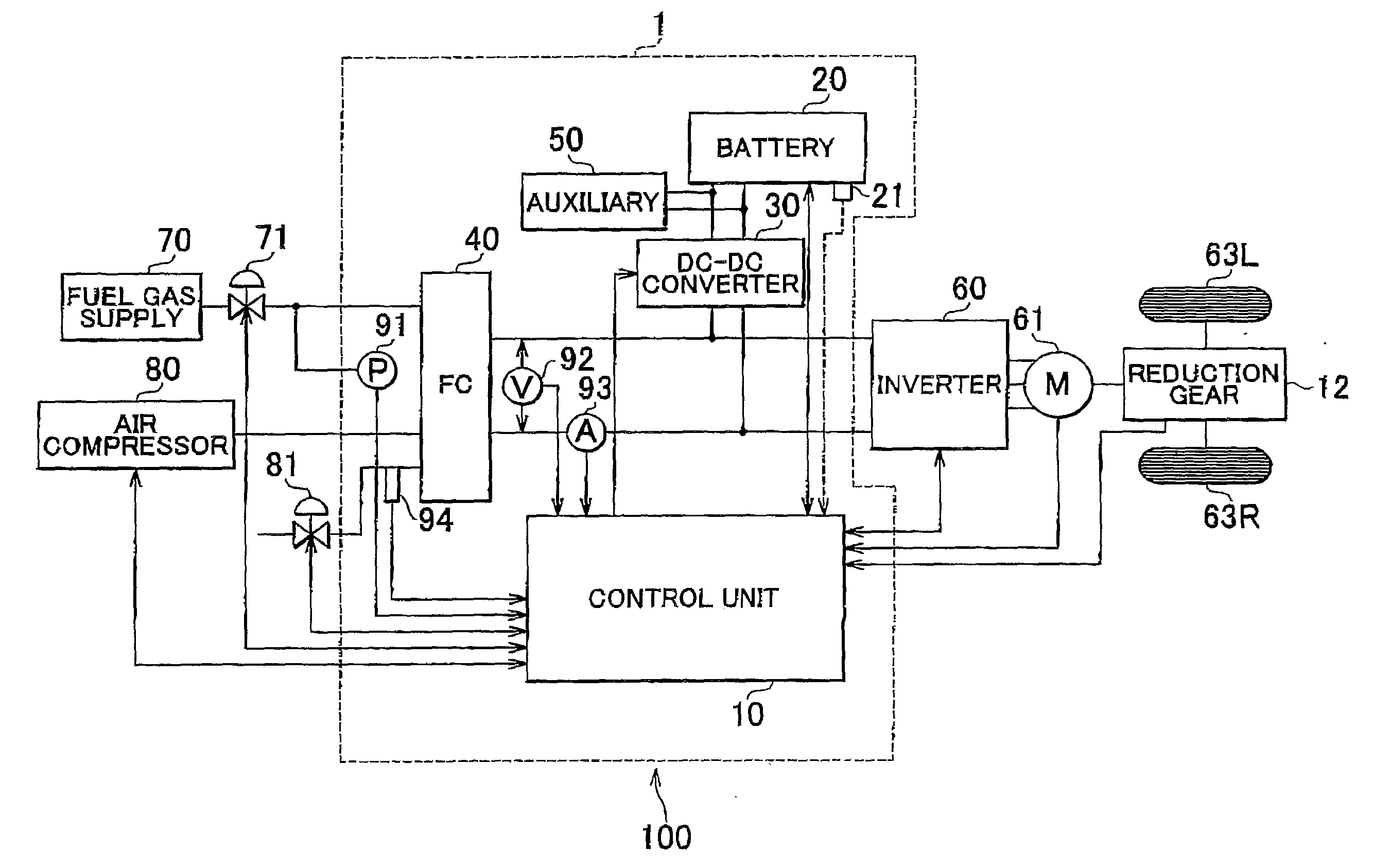

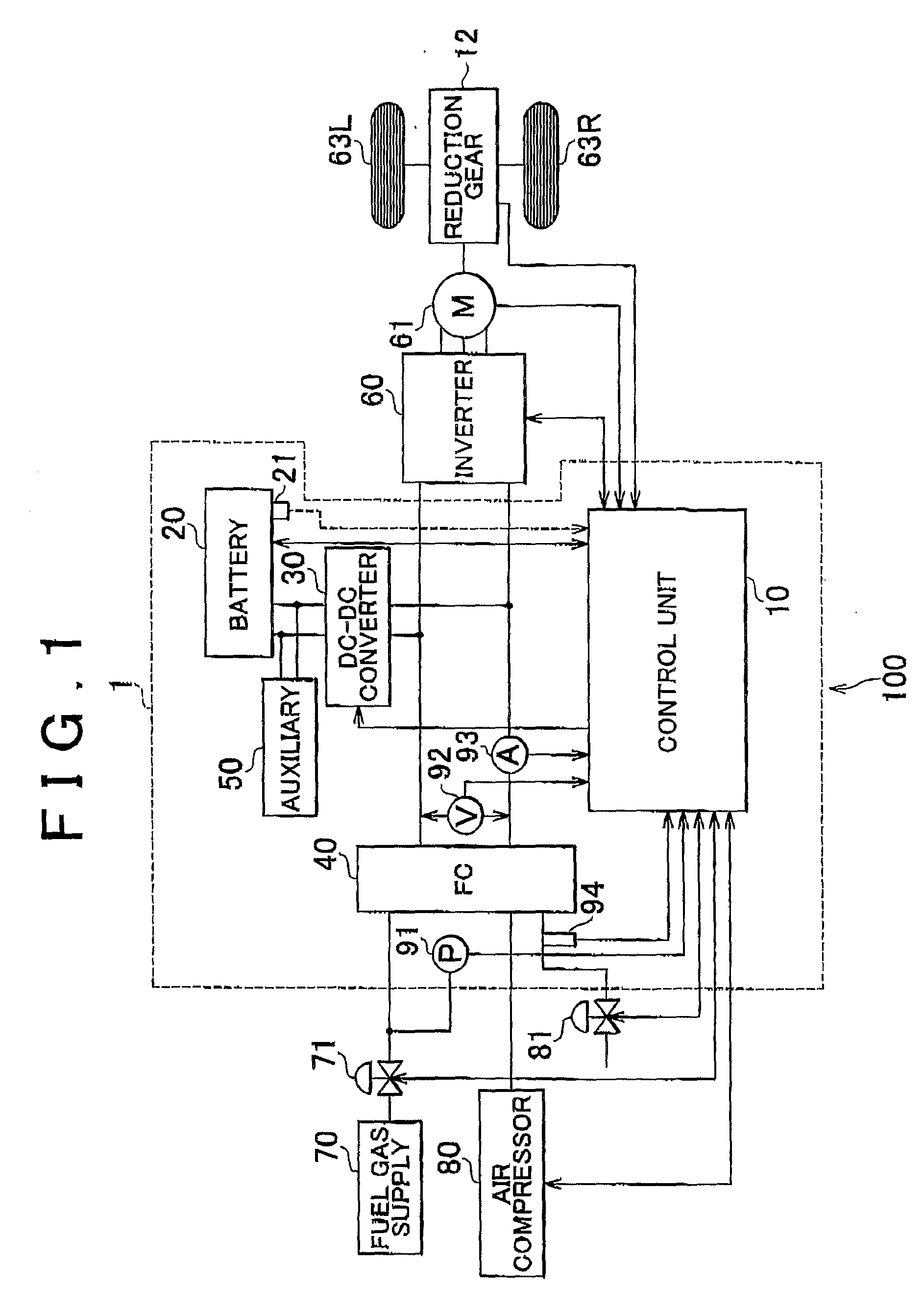

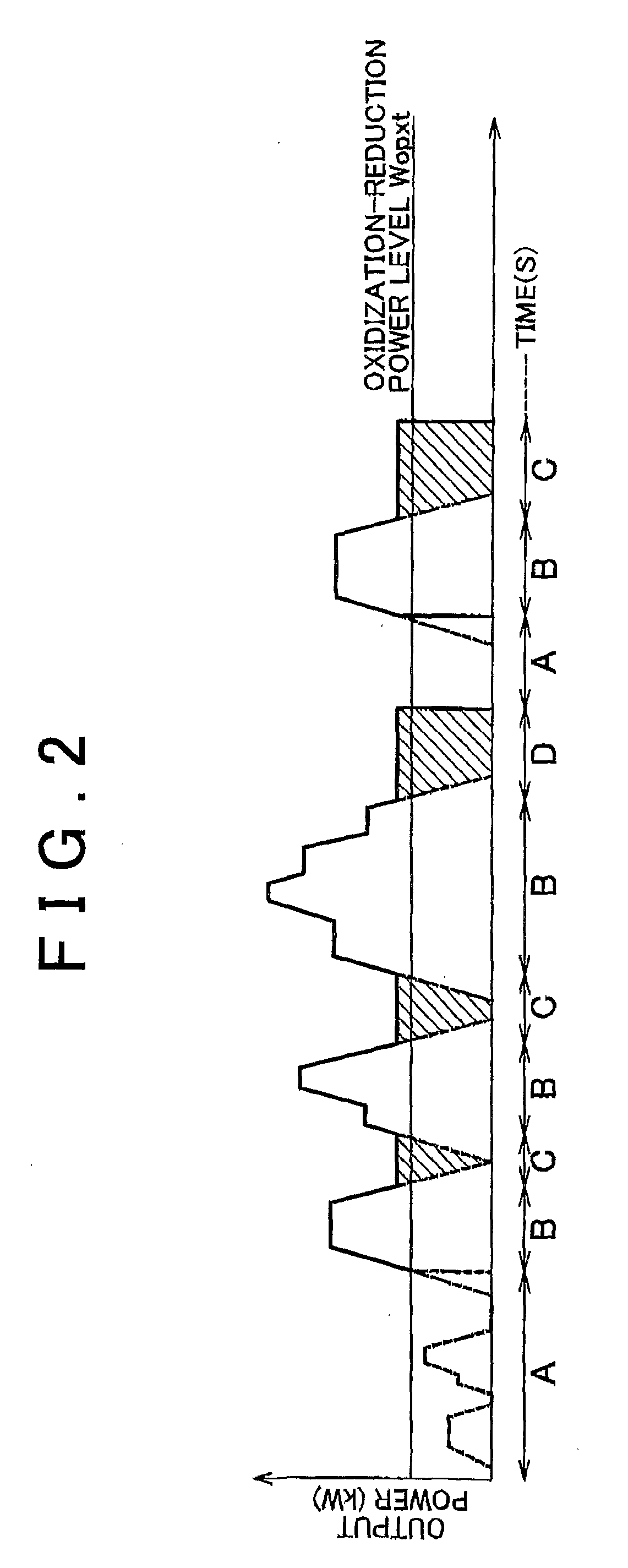

Fuel cell apparatus, vehicle including the fuel cell apparatus, and power management method for a system equipped with fuel cell unit

ActiveUS20090029197A1Lower performance requirementsPrevent sinteringFuel cell auxillariesPower to auxillary motorsFuel cellsReduction potential

Variation of the amount of power to be produced by a fuel cell unit is limited in accordance with a relationship between an output voltage of the full cell unit and an oxidization-reduction potential of catalyst of a fuel cell of the fuel cell unit. The amount of power to be used to charge or discharged from a battery is then corrected according to the limited variation of the amount of power to be produced by the fuel cell unit 40, so as to meet the required system power output.

Owner:TOYOTA JIDOSHA KK

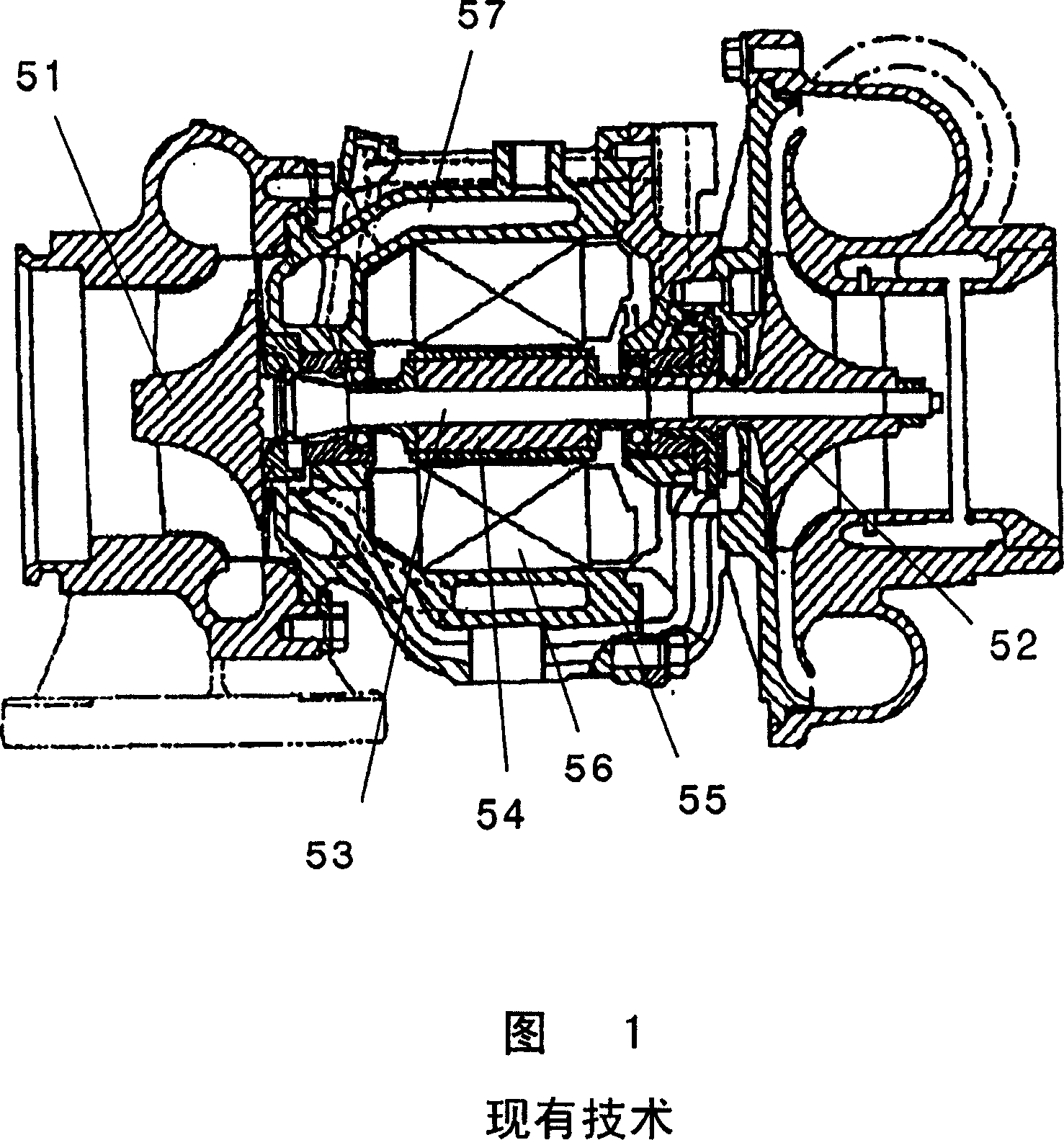

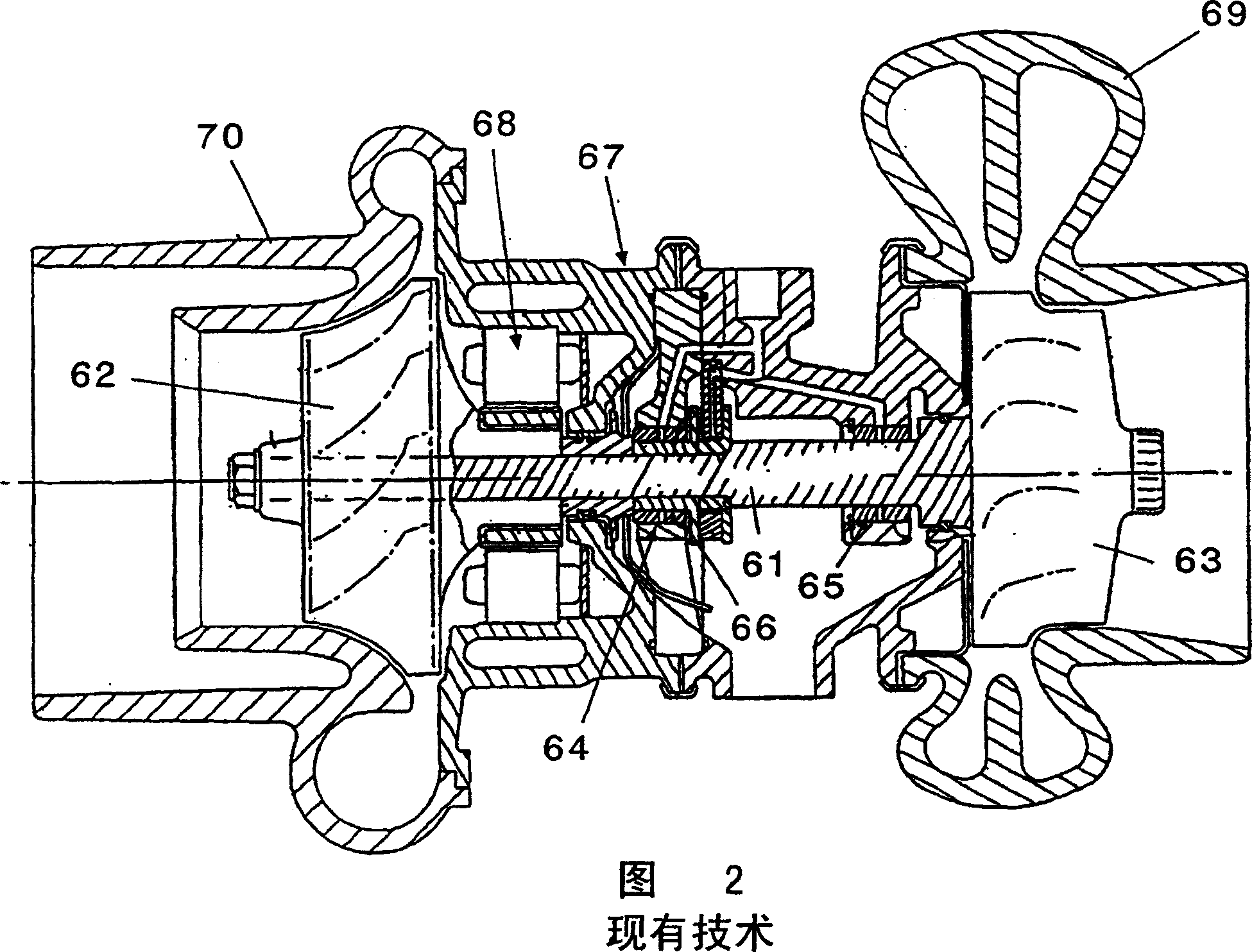

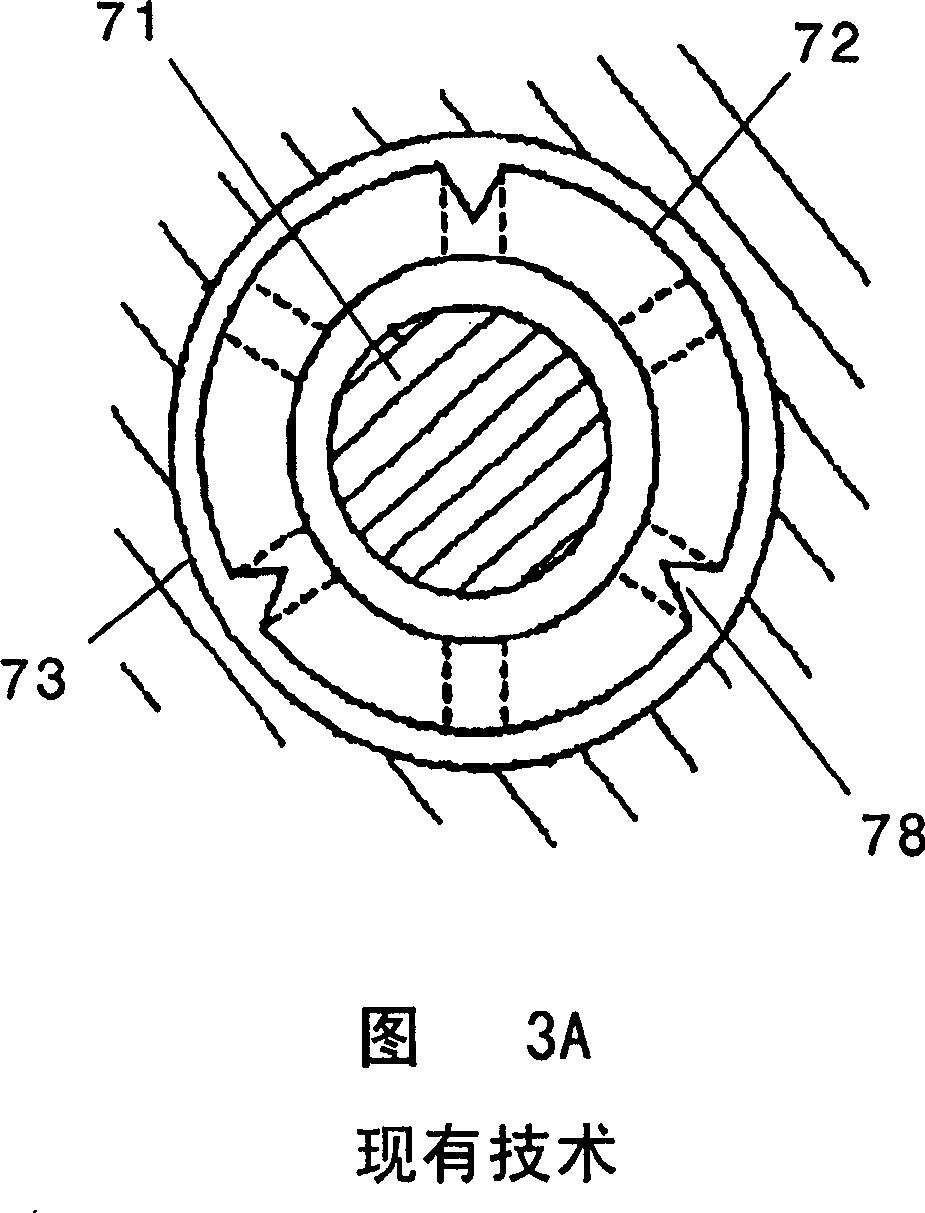

Bearing structure of motor-driven supercharger

InactiveCN1928335AReduce dynamic loadPrevent sinteringEngine manufactureBearing assemblyMotor driveEngineering

A bearing structure is provided with a turbine side bearing metal (30a) and a compressor side bearing metal (30b) in which an outer peripheral surface is fitted to a bearing hole (16a) of a bearing housing (16) with a gap, and an inner peripheral surface rotatably supports a turbine shaft (12), and a bearing locking member (32) holding the turbine side bearing metal and the compressor side bearing metal so as to be movable in a radial direction of the turbine shaft and inhibit a movement in an axial direction and a rotating direction. The inner peripheral surface and / or the outer peripheral surface of the bearing metal (30b) (or 30b) is structured as a non-complete round bearing.

Owner:IHI CORP

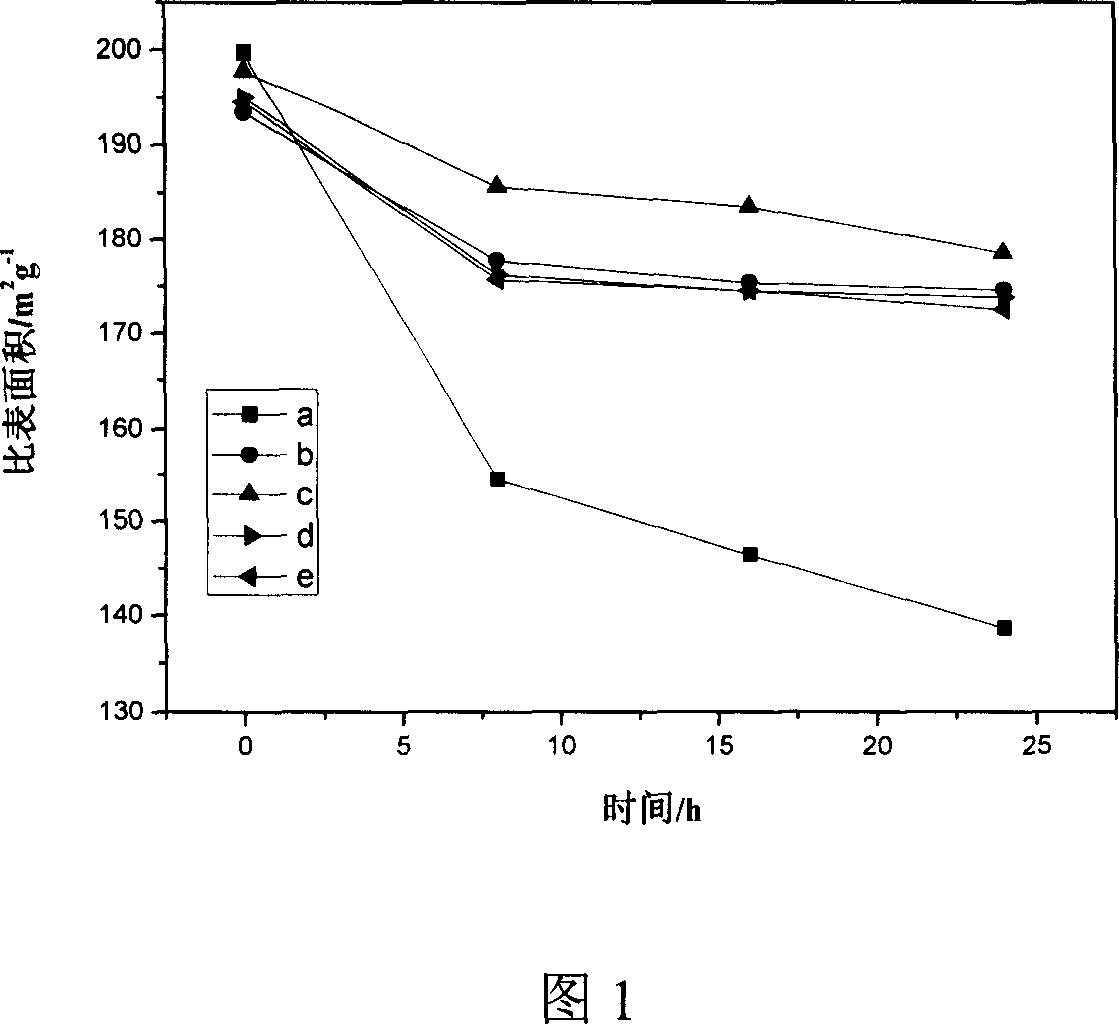

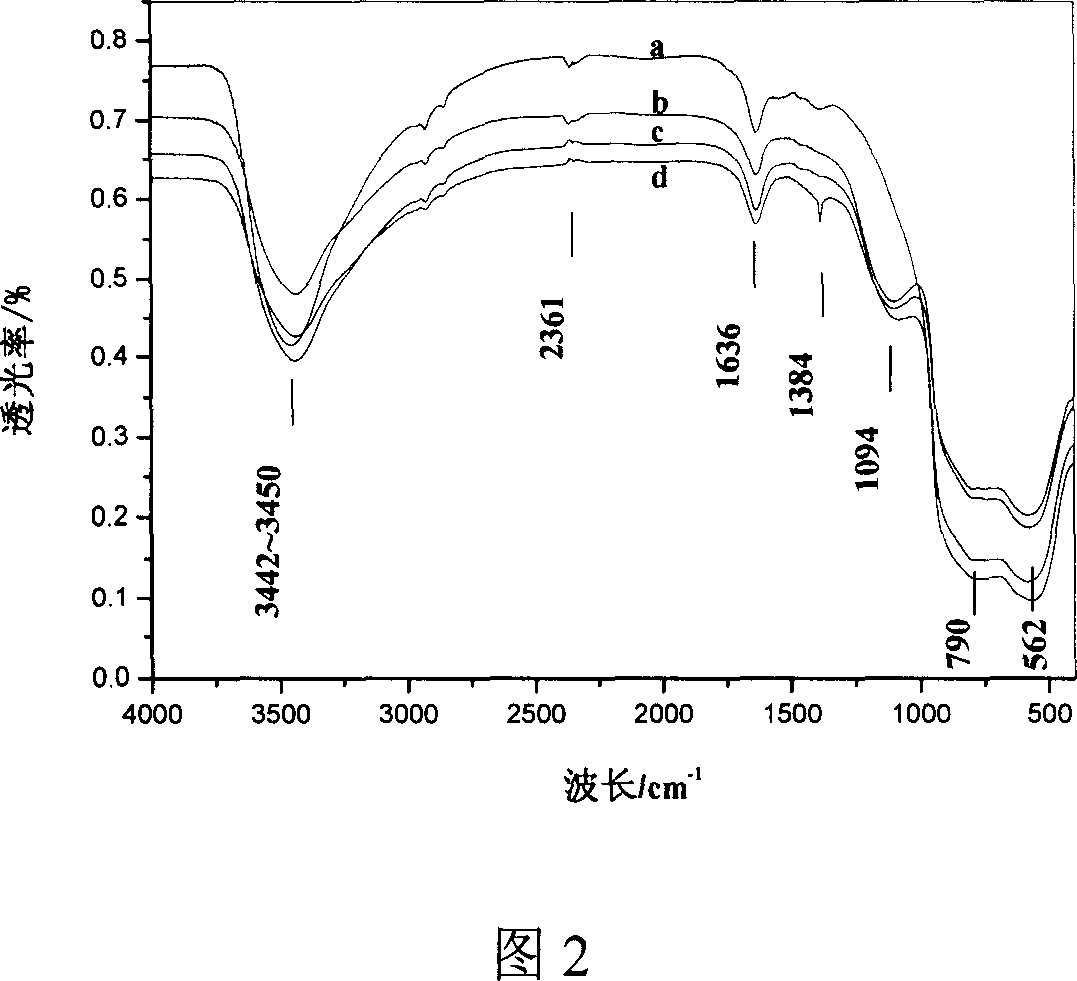

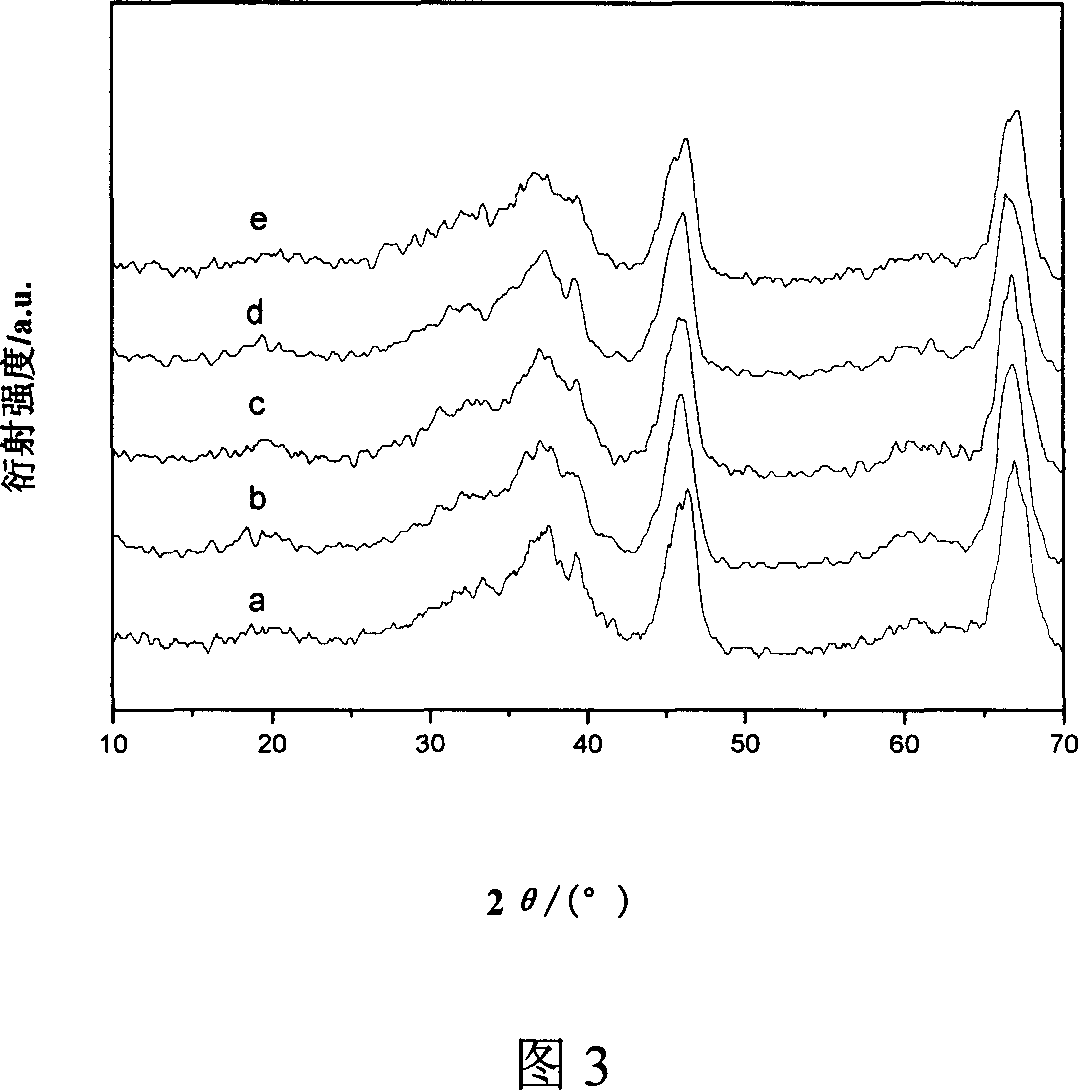

Alumina in high hydrothermal stability, and preparation method

InactiveCN1958456AHigh hydrothermal stabilityPrevent sinteringAluminium oxide/hydroxide preparationAluminium oxides/hydroxidesPhosphate ionPetrochemical

This invention provides a method for preparing spherical Al2O3 with high hydrothermal stability. Based on the mechanisms of Al2O3 sintering and phase change, the method introduces phosphate ions, which can react with OH groups on the pore walls to reduce the quantity of OH groups and change the surface acidity of Al2O3. The method can prevent the sintering and phase change of Al2O3 pore channels, thus can improve the hydrothermal stability of spherical Al2O3 carrier. The hydrothermal stability of modified spherical Al2O3 is much higher than that of unmodified spherical Al2O3. The specific surface area of modified spherical Al2O3 is 190-200 m2 / g, the pore volume is 0.85-1.25 mL / g, the particle diameters are 0.5-5 mm, the packing density is 0.3-0.55 g / cm3, and the weight content of P2O5 is 0.5-5%. The spherical Al2O3 can be used as catalyst or catalyst carrier for petrochemicals and fine chemicals.

Owner:BEIJING UNIV OF CHEM TECH

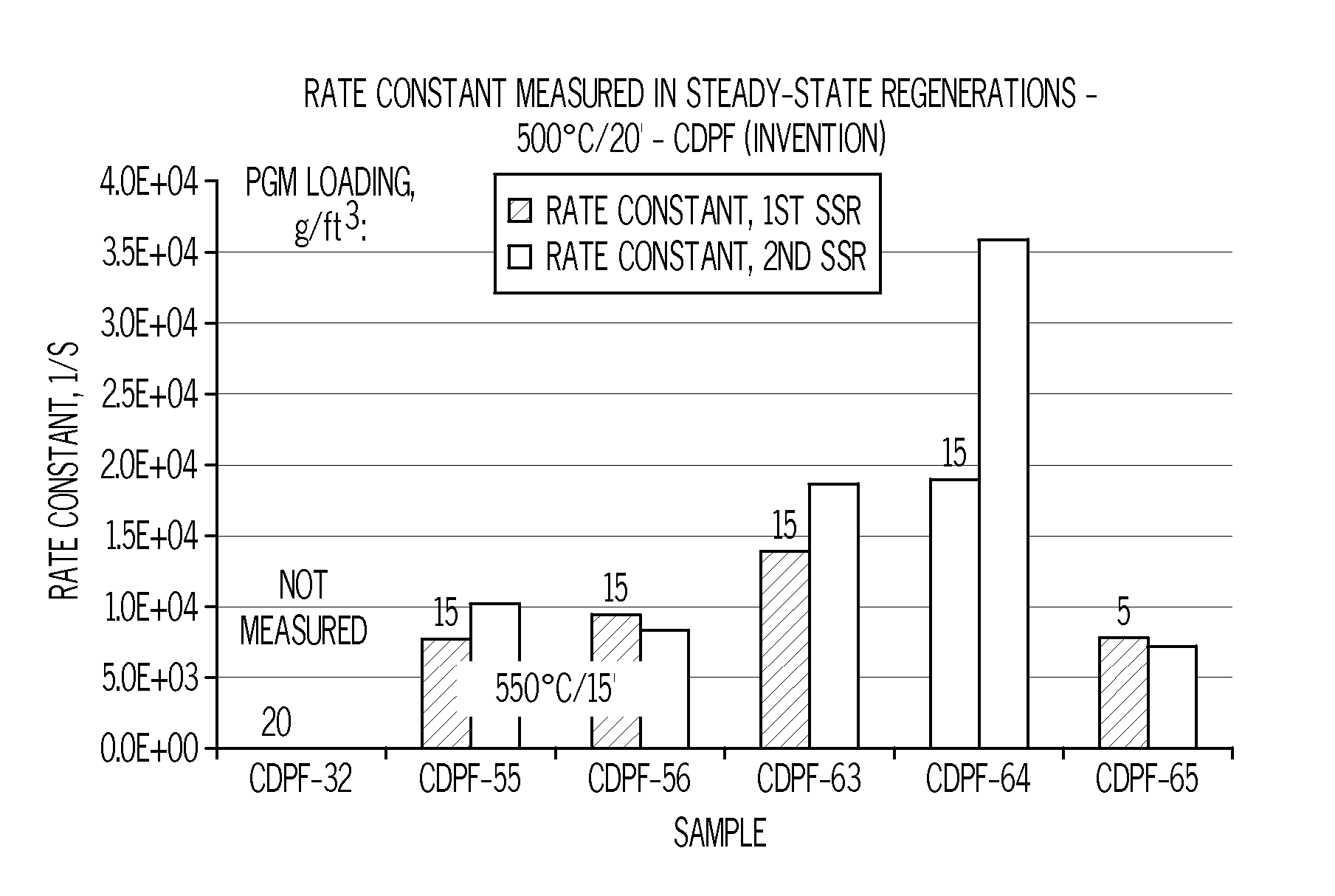

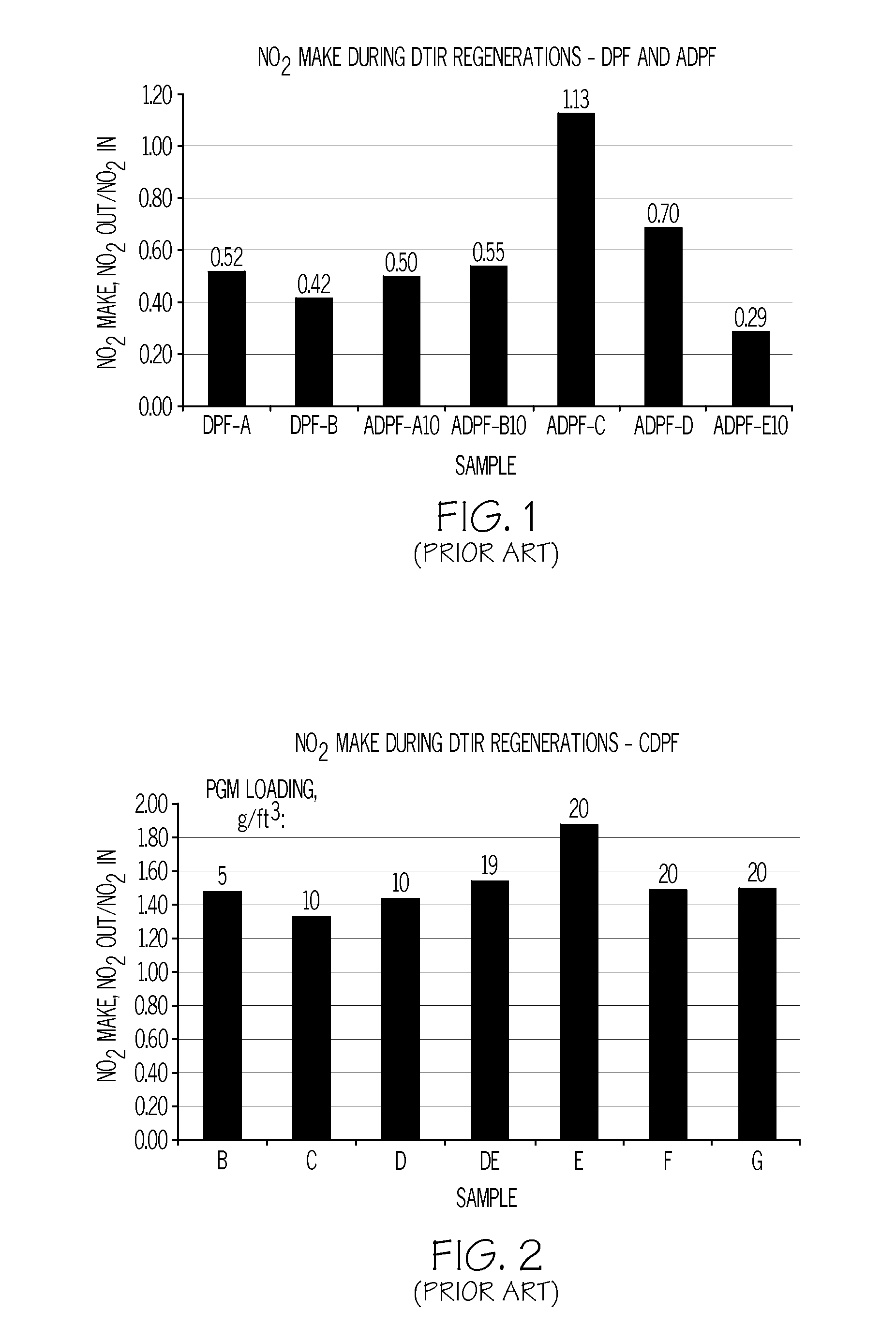

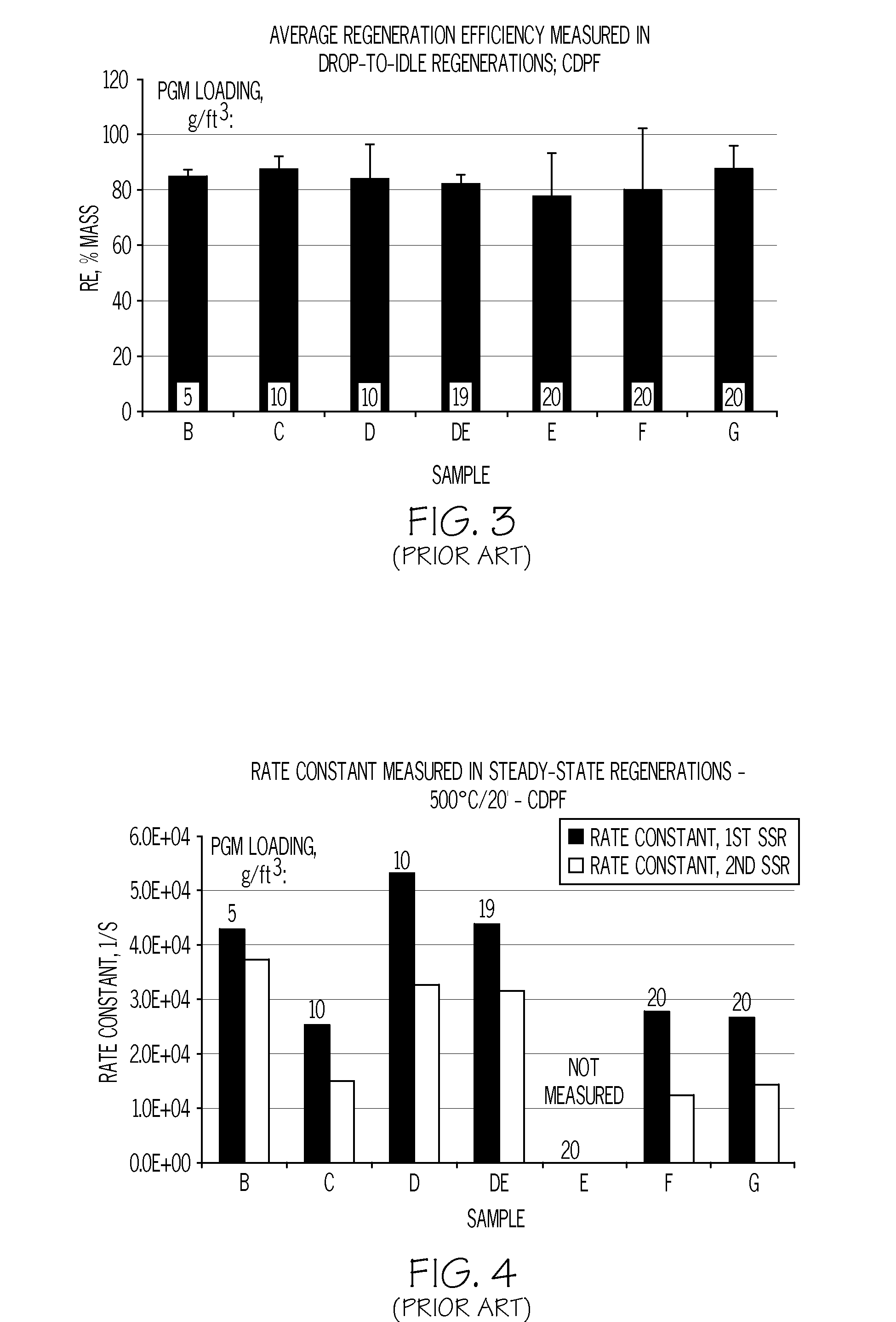

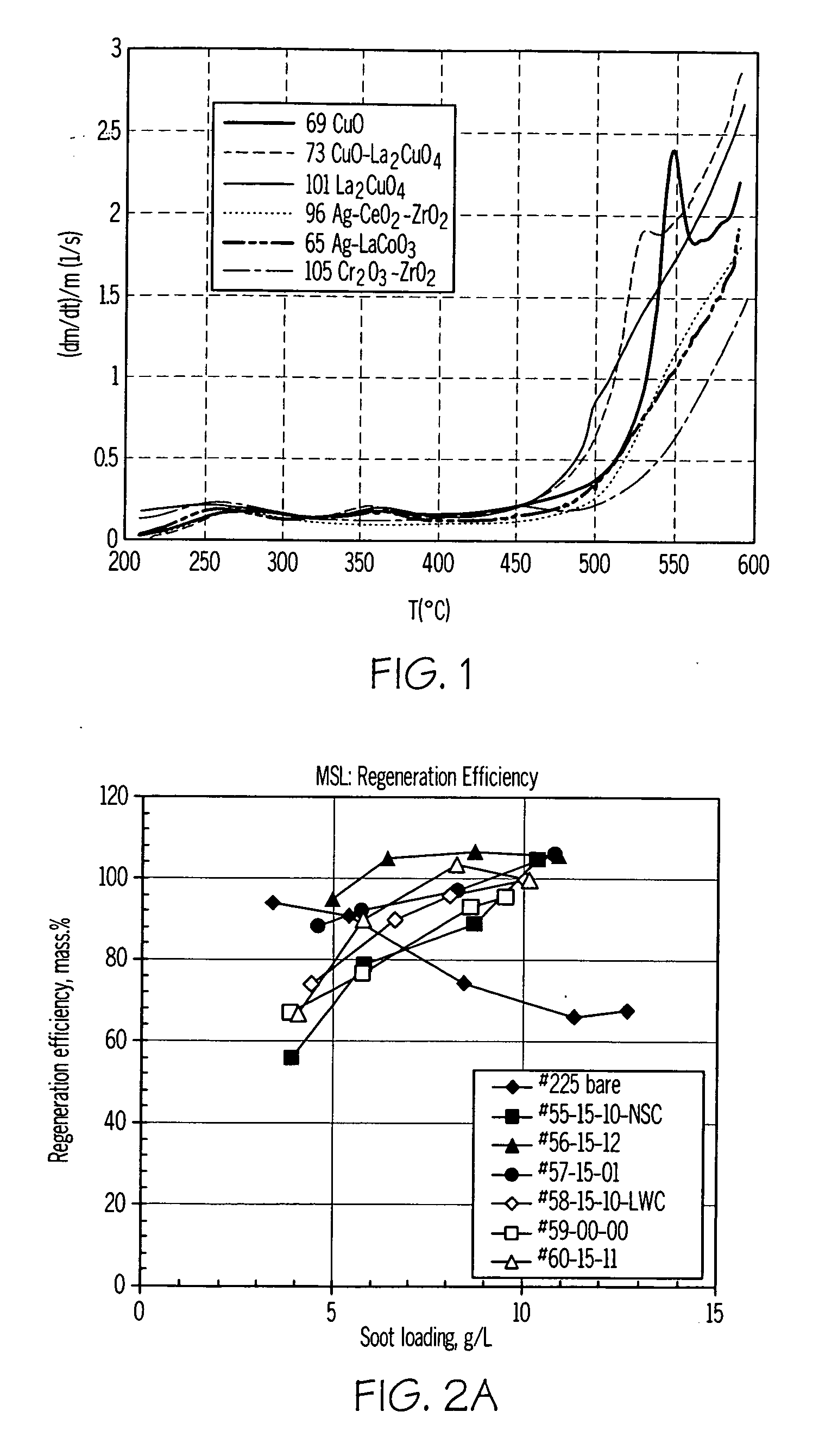

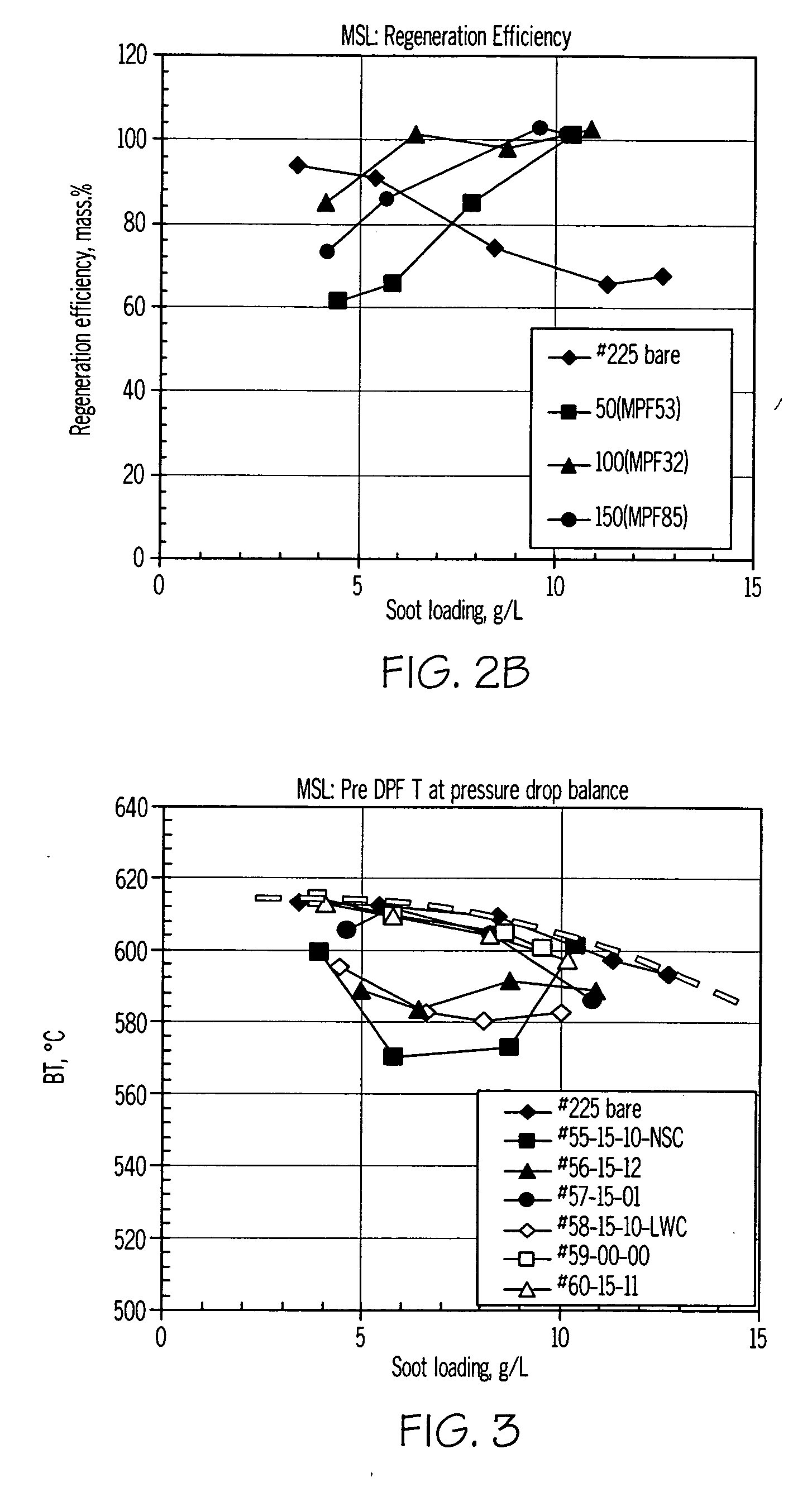

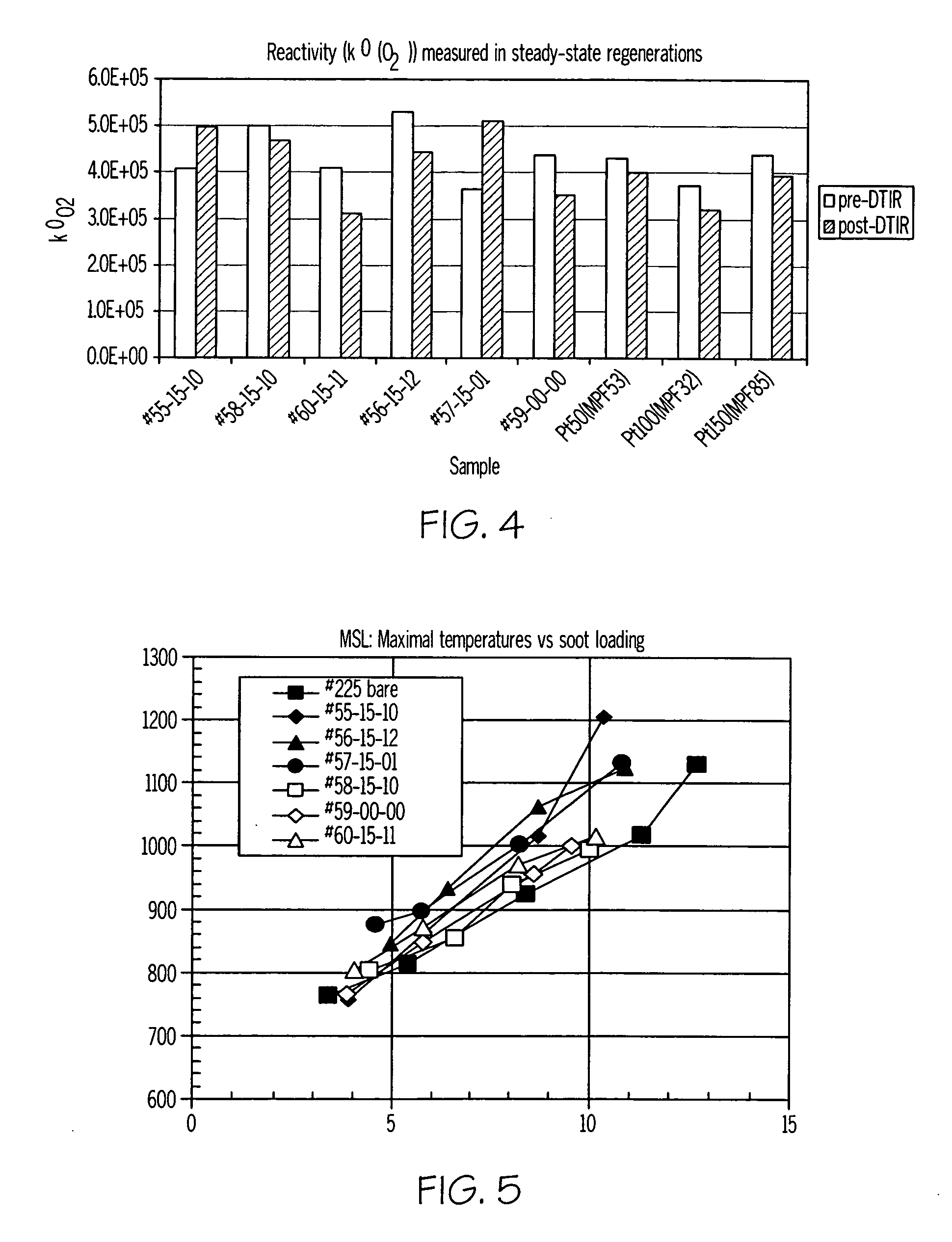

Catalyst composition for diesel particulate filter

InactiveUS20070245724A1Efficiently oxidizedLow productionOrganic chemistryNitrogen compoundsGlycerolCatalytic metal

A catalyst composition is provided for use on a diesel particulate filter which facilitates the oxidation of soot from diesel engine exhaust and which generates low NO2 emissions during regeneration of the filter. The catalyst composition includes a catalytic metal comprising a platinum group metal selected from Pt, Pd, Pt—Pd, or combinations thereof, an active metal oxide component containing Cu and La; and an oxide component selected from oxides of Co, Fe, or combinations thereof. The catalyst composition includes a support selected from alumina, silica, zirconia, or combinations thereof. The catalyst composition may be provided on a diesel particulate filter by impregnating the filter with an alumina, silica or zirconia sol solution modified with glycerol and / or saccharose, impregnating the filter with a stabilizing solution, and impregnating the filter with a solution containing the catalyst metal precursor(s), the active metal oxide precursor(s) and the Co or Fe oxide(s). The resulting catalyst coated diesel particulate filter provides effective soot oxidation, exhibits good thermal stability, has a high BET surface area, exhibits minimal backpressure, and produces low NO2 emissions during filter regeneration.

Owner:FORD GLOBAL TECH LLC

Agglomeration method for iron containing dust slime of iron and steel plants

The invention discloses an agglomeration method for iron containing dust slime of iron and steel plants; according to the method, the iron containing dust slime is shunted independently, is briquetted, is mixed with other iron ore powder, flux and coke powder, and then is sintered on the basis of the traditional technology. The agglomeration method comprises the following detailed steps of: 1), firstly, mixing the iron containing dust slime with composite binder, mixing uniformly, briquetting, so as to obtain dust slime briquette; 2), mixing the dust slime briquette with other iron ore powder, flux and coke powder, pelletizing, so as to obtain sintered mixture material; and 3), distributing the sintered mixture material by adopting the existing sintering method, igniting, sintering, cooling, granulating, finally the finished product of sintered ore is obtained. Compared with the traditional method of directly returning, sintering and mixing the dust slime, by adopting the agglomeration method, the ratio of the iron containing dust slime in the mixture material is greatly improved, and in addition, the sintered product quality index is improved. By adopting the agglomeration method, the problem on large-scale use of the iron containing dust slime of iron and steel plants is effectively solved, and the agglomeration method is beneficial for industrial production.

Owner:CENT SOUTH UNIV

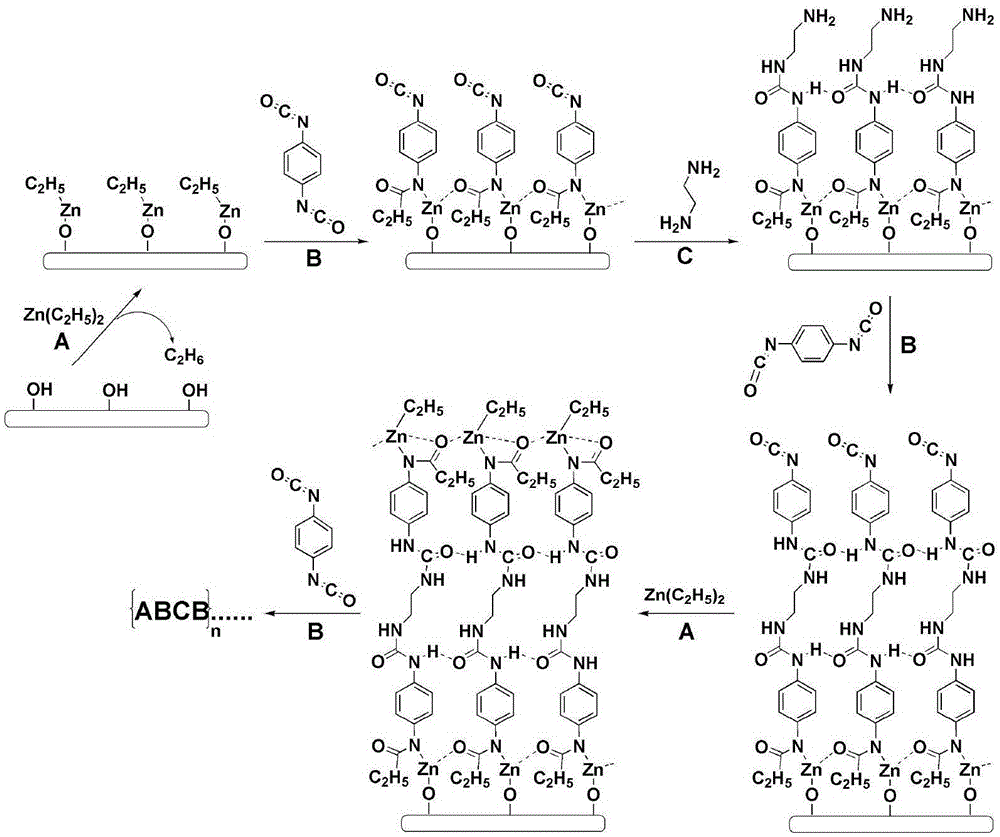

Preparation method for Cu-based hydrogenation catalyst

InactiveCN105148923AImprove hydrogenation performanceEnhanced interactionOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsReducing atmosphereGlass sheet

A preparation method for a Cu-based hydrogenation catalyst comprises the following steps: dissolving soluble copper salt into water, then adding a carrier into the solution, and uniformly loading a copper precursor on the surface of the carrier to obtain a precursor sample; mixing the precursor sample and ethanol to form a suspending liquid, coating the suspending liquid on the surface of a glass sheet, impulsing polyisocyanate into an MLD reaction cavity, then impulsing an M precursor to be subjected to monomolecular layer reaction on the sample surface in sequence to obtain a hybrid membrane coated copper precursor compound; conducting heat treatment on the compound in air to obtain a nanometer CuO-MOx compound, and then conducting reduction in the reducing atmosphere to obtain the Cu-MOx interface catalyst. The preparation method has the advantage that the Cu-MOx interface structure can be regulated and controlled.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Perovskite type methane combustion catalyst as well as preparation method and application thereof

ActiveCN106732647AExtended service lifeIncrease loadHeterogenous catalyst chemical elementsIncinerator apparatusRare-earth elementAlkaline earth metal

The invention provides a perovskite type methane combustion catalyst as well as a preparation method and application thereof. The catalyst comprises an active component and a carrier, wherein the active component has a general formula: Al-xA'xB1-yB'yO3; in the formula, A is a rare earth metal element; A' is an alkaline earth metal element; B and B' represent transition metal elements; x is more than or equal to 0 but less than or equal to 0.9; y is more than or equal to 0 but less than or equal to 0.9; the carrier consists of spherical aluminum oxide of at least two crystal phases in delta-Al2O3, theta-Al2O3 or alpha-Al2O3, The aluminum oxide carrier has larger specific surface area, so that the loading capacity of the active component on the carrier can be improved; meanwhile, the uniform dispersion of the active component is facilitated, so that the sintered agglomeration of the active component is prevented, and the service life of the catalyst is prolonged; in addition, the catalyst provided by the invention is good in activity, and the selectivity of the reaction of methane and oxygen for CO2 is high; the perovskite type methane combustion catalyst has the advantages of being low in initiation temperature, high in combustion efficiency, good in mass transfer and heat transfer performance, and the like.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

Catalyst for converting aromatic hydrocarbon from alcohol ether, and preparation method and application method thereof

ActiveCN103406140AReduce churnStable structureMolecular sieve catalystsCatalyst activation/preparationMolecular sieveDispersity

The invention relates to a catalyst for converting aromatic hydrocarbon from alcohol ether, and a preparation method and application method thereof. The catalyst is composed of molecular sieve, metal component, structural reinforcer and stability assistant. The preparation method comprises the following steps: preparing the molecular sieve, metal component, structural reinforcer and stability assistant into composite granules, treating with steam, impregnating the metal component and stability assistant, and repeating the steam treatment and impregnation many times to load the required metal component and stability assistant component in batches. The application method comprises the following step: reacting raw materials alcohol and ether at 350-550 DEG C under the pressure of 0-3 MPa, wherein the weight hourly space velocity of the reaction raw materials is 0.1-20 h<-1>. The catalyst provided by the invention can effectively reduce metal component loss in a high-temperature hydrothermal environment, and avoids metal sintering due to excessive loading of metal component at one time since the metal component dispersity is good.

Owner:HUADIAN COAL IND GRP +1

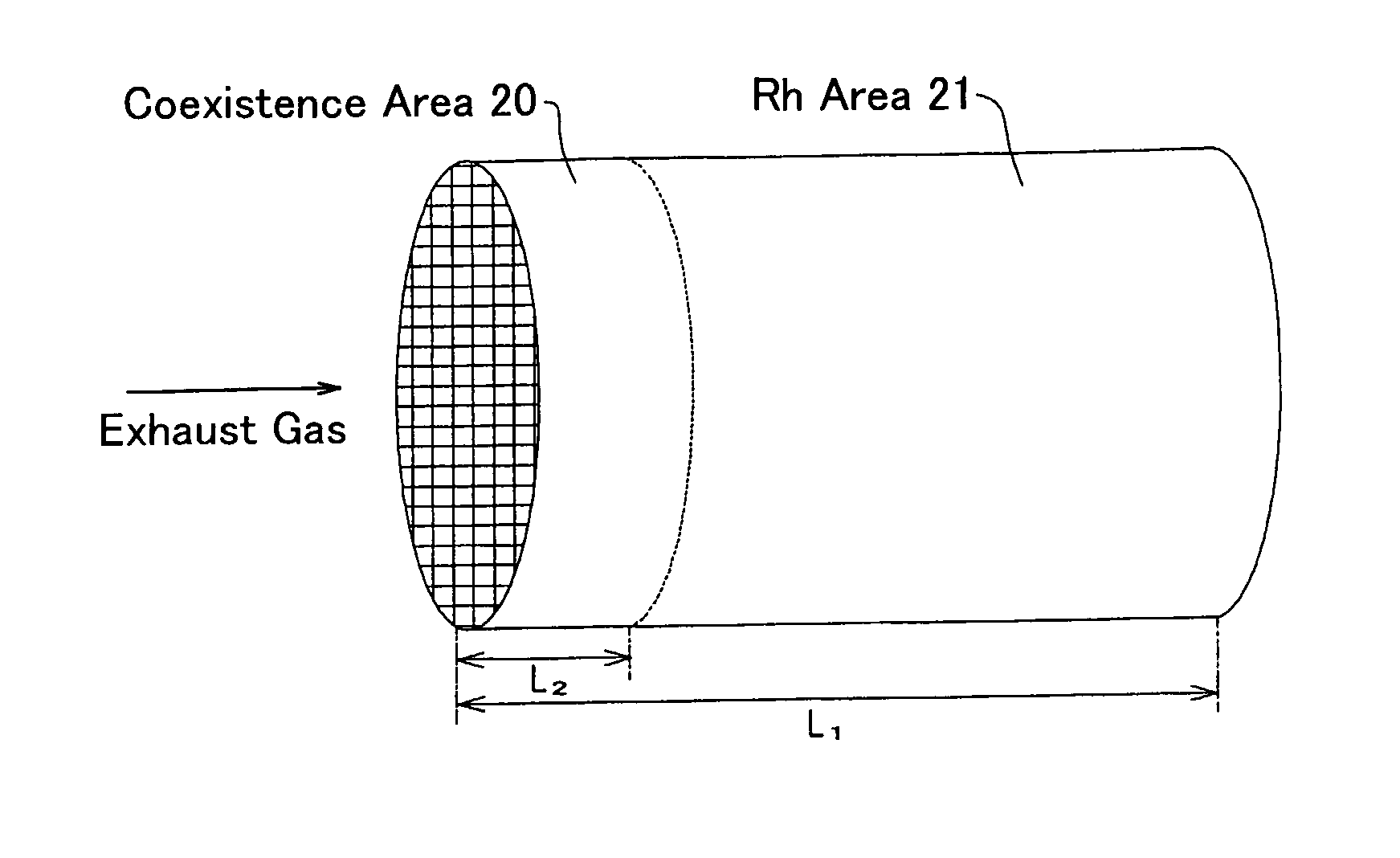

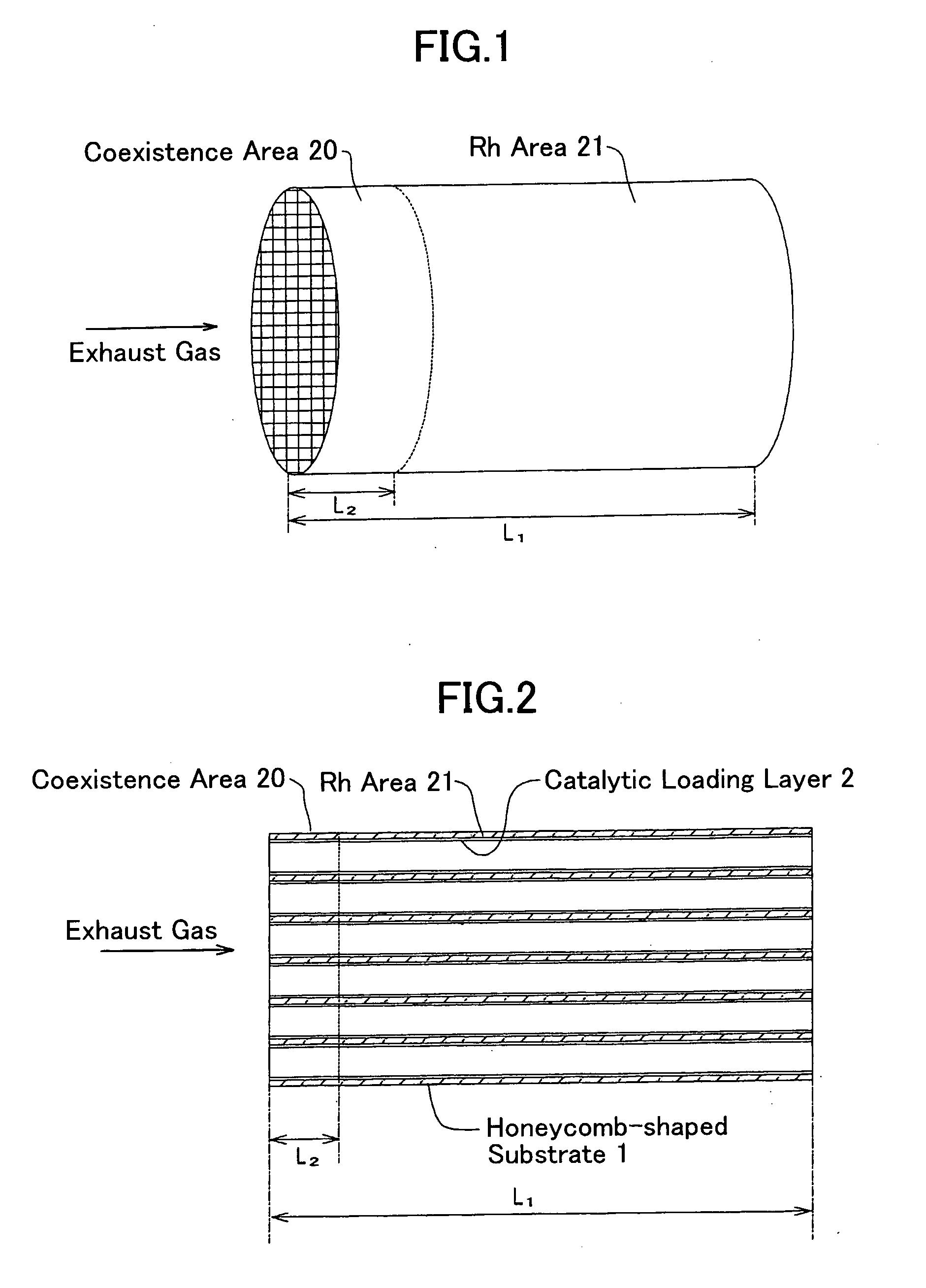

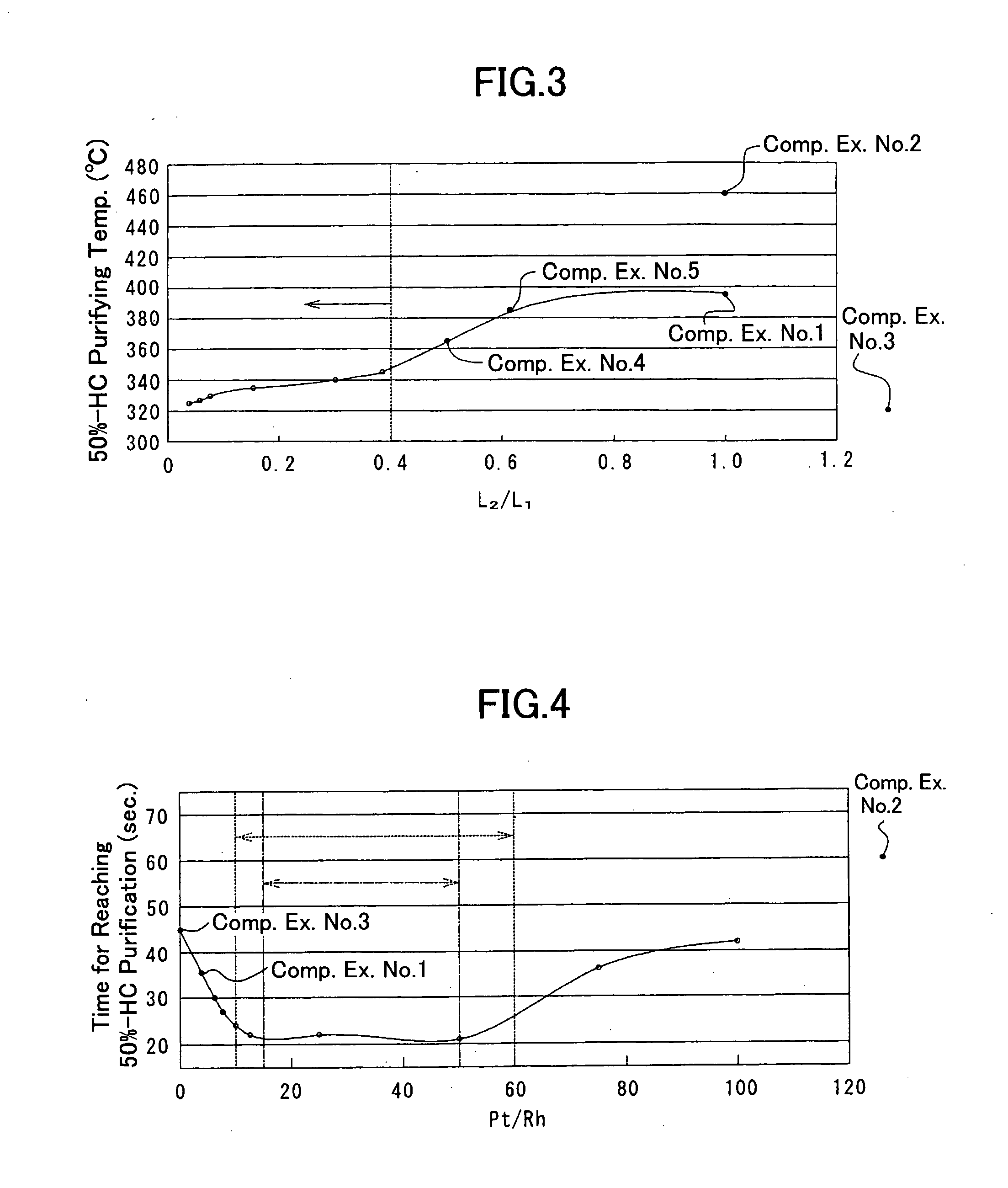

Catalyst for Purifying Exhaust Gases

InactiveUS20080081761A1Efficient use ofMaximally inhibiting deteriorationInternal combustion piston enginesDispersed particle separationPlatinumExhaust fumes

A catalyst for purifying exhaust gases includes a support substrate, and a catalytic loading layer. The support substrate demarcates an exhaust-gas flow passage, an exhaust-gas inlet end and an exhaust-gas outlet end, and has an overall length between the exhaust-gas inlet end and the exhaust-gas outlet end. The catalytic loading layer is formed on a surface of the exhaust-gas flow passage, and is composed of a porous oxide support and a noble metal. The catalytic loading layer includes a coexistence area, and a rhodium area. The coexistence area occupies the overall length of the support substrate by a factor of 4 / 10 or less from the exhaust-gas inlet end, and is composed of rhodium and platinum loaded thereon. The rhodium area is formed toward the exhaust-gas outlet end from the coexistence area, and is composed of rhodium loaded uniformly thereon in a flow direction of the exhaust gases.

Owner:TOYOTA JIDOSHA KK

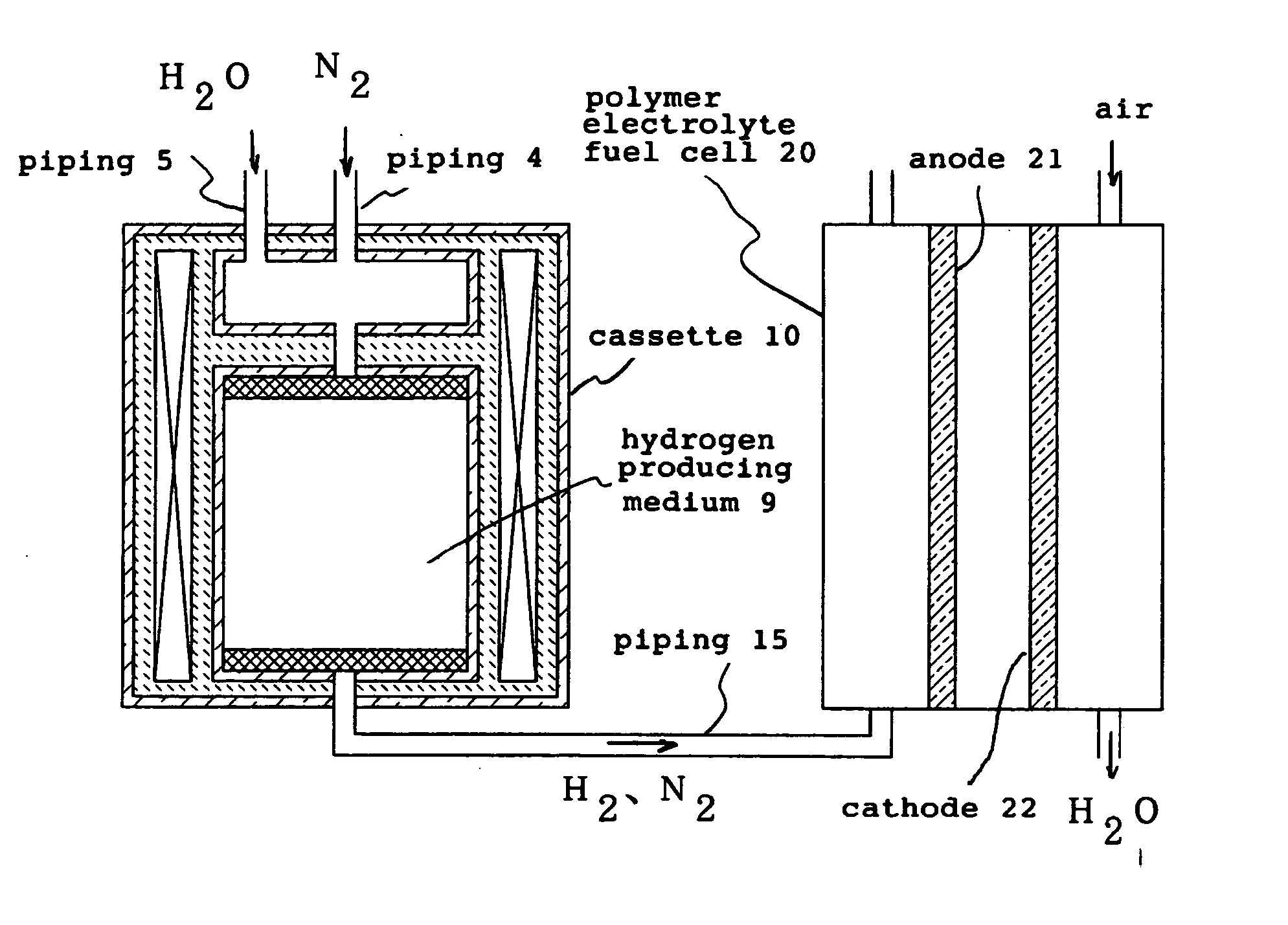

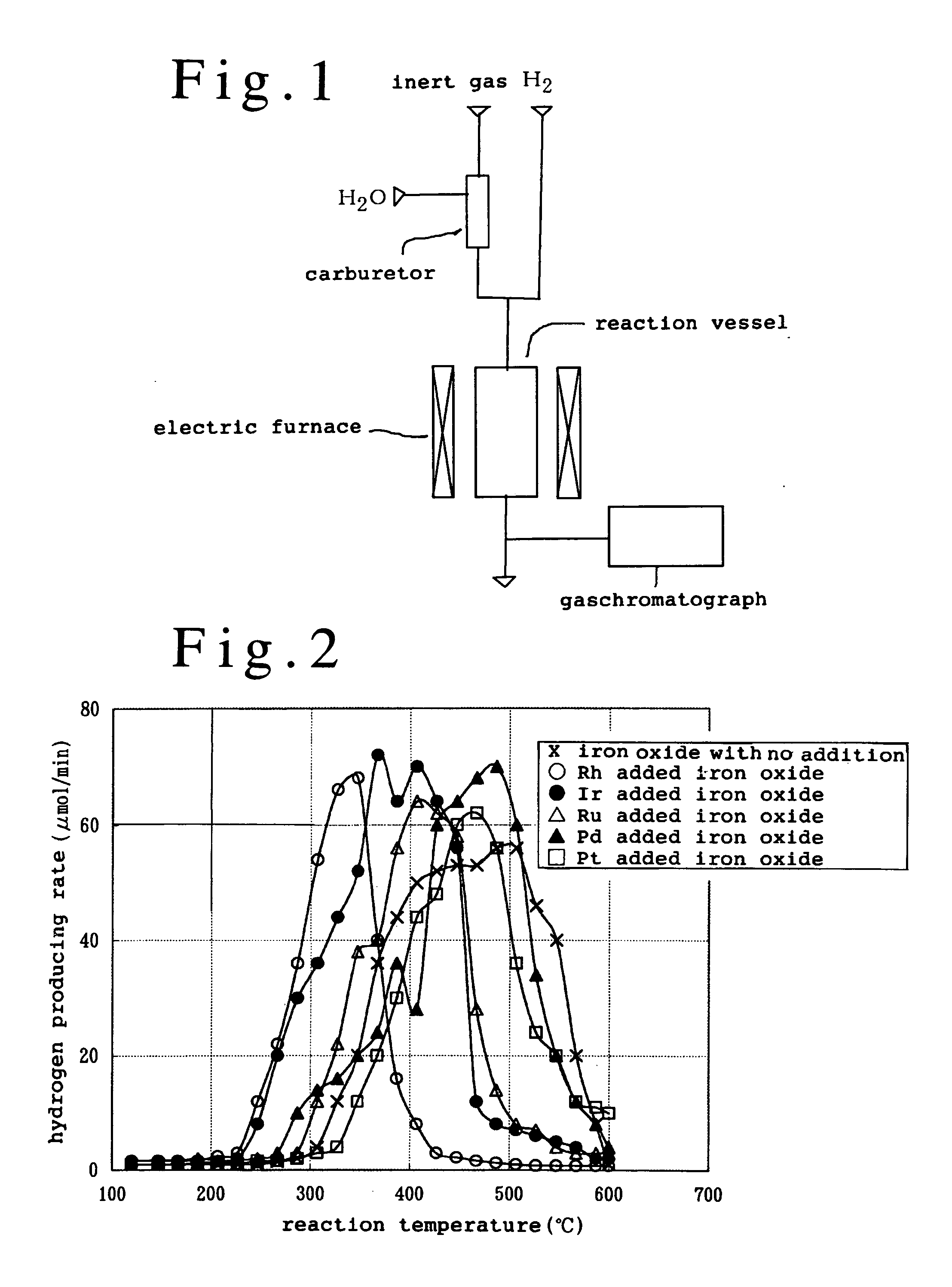

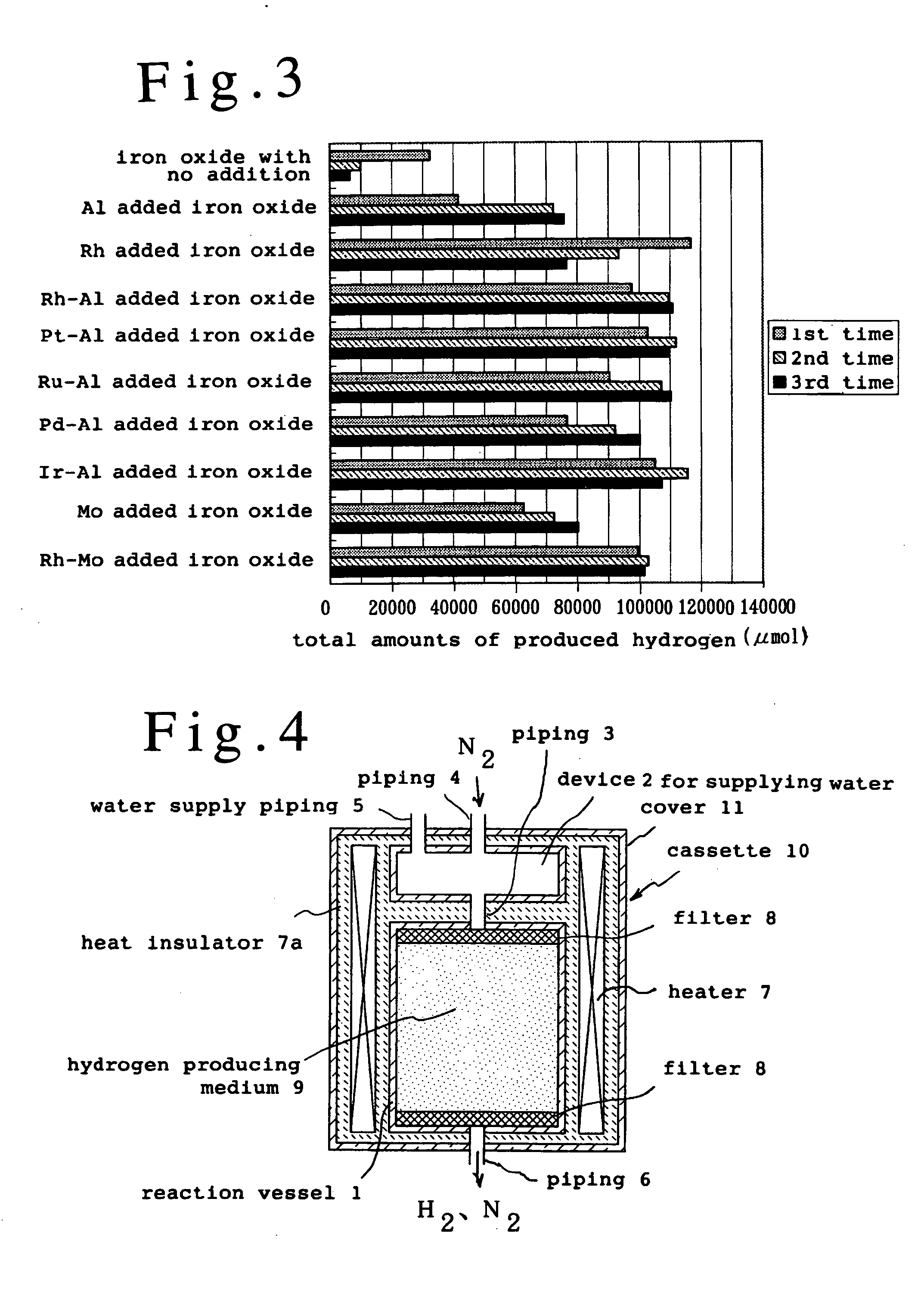

Method for producing hydrogen and apparatus for supplying hydrogen

InactiveUS20050255037A1Prevent sinteringFacilitated diffusion rateHydrogen productionGas generation devicesHydrogenGeneration rate

A method for producing hydrogen by contacting water, steam or gas containing steam with iron or iron oxide, wherein the iron or iron oxide is added with at least one metal of Rh, Ir, Ru, Pd, Pt and Os and at least one metal of Ti, Zr, V, Nb, Cr, Mo, Al, Ga, Mg, Sc, Ni and Cu. The method provides a medium for producing hydrogen which is capable of producing hydrogen at relatively low temperature and at a great generation rate, is free from the decrease of activity, and is resistance to repeated oxidation and reduction, which leads to the decomposition of water and production of hydrogen with good efficiency.

Owner:OTSUKA KK +1

Catalyst for tail gas purification and preparation method thereof

InactiveCN103464152AGood dispersionImprove thermal stabilityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsPtru catalystCerium(IV) oxide

The invention provides a catalyst for tail gas purification and a preparation method of the catalyst for tail gas purification. The catalyst for tail gas purification comprises an alumina supporter, cerium dioxide borne on alumina and a precious metal active component borne on the surface of the cerium dioxide. The alumina supporter and the cerium dioxide are prepared according to the sediment hydrothermal method. The precious metal active component is borne according to the hydrothermal in-situ reduction sediment method. According to the catalyst for tail gas purification, the interaction between the cerium dioxide and a precious metal species is strong, the cerium dioxide supporter can generate more oxygen vacancies, oxygen molecules are activated and converted into a reactive oxygen species, and therefore the activity of catalytic oxidation is improved. Interspersion and mutual contact are conducted between the alumina and the cerium dioxide, the mutual insulation function is achieved, sintering with the single cerium oxide serving as a supporter can be avoided, and the thermal stability of the alumina at a high temperature is remarkably improved.

Owner:FUZHOU UNIV

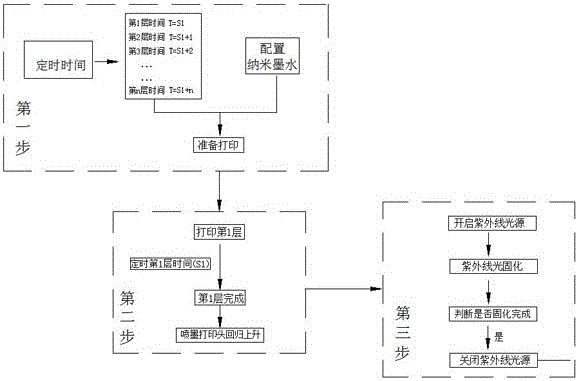

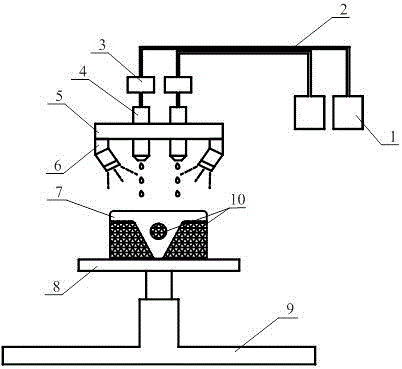

Composite material 3d printing method realized by photocuring-jetting nano ink and printer

InactiveCN106634208AHigh precisionLarge forming sizeAdditive manufacturing apparatusInksGraphicsNarrow range

The invention discloses a composite material 3d printing method realized by photocuring-jetting nano ink, and the method comprises the following steps: preparing the nano ink; by means of micro-droplet jetting, jetting the nano-ink by an ink-jet print head; dividing three-dimension modeling into a plurality of two-dimension graphs, and calculating the print time for each graph; according to the print time for each graph, turning on an ultraviolet light source in a fixed time, monitoring the temperature of curing regions in real time by a temperature sensor, monitoring the curing moulding status of nano-particle ink in printing regions, and turning off the ultraviolet light source after curing is finished; and performing printing layer by layer, and performing curing layer by layer, so as to finish product printing. The method is suitable for printing ceramics, glass, nylon or plastic products; by using the ultraviolet light for curing moulding, the technical problems in an existing 3D printing technology on narrow range of material choice, poor moulding precision, small moulding size, slow moulding speed and the like are solved. The invention also discloses a micro-droplet-jetting 3d printer which is suitable for 3D printing in the above method.

Owner:安徽泰尔控股集团有限公司

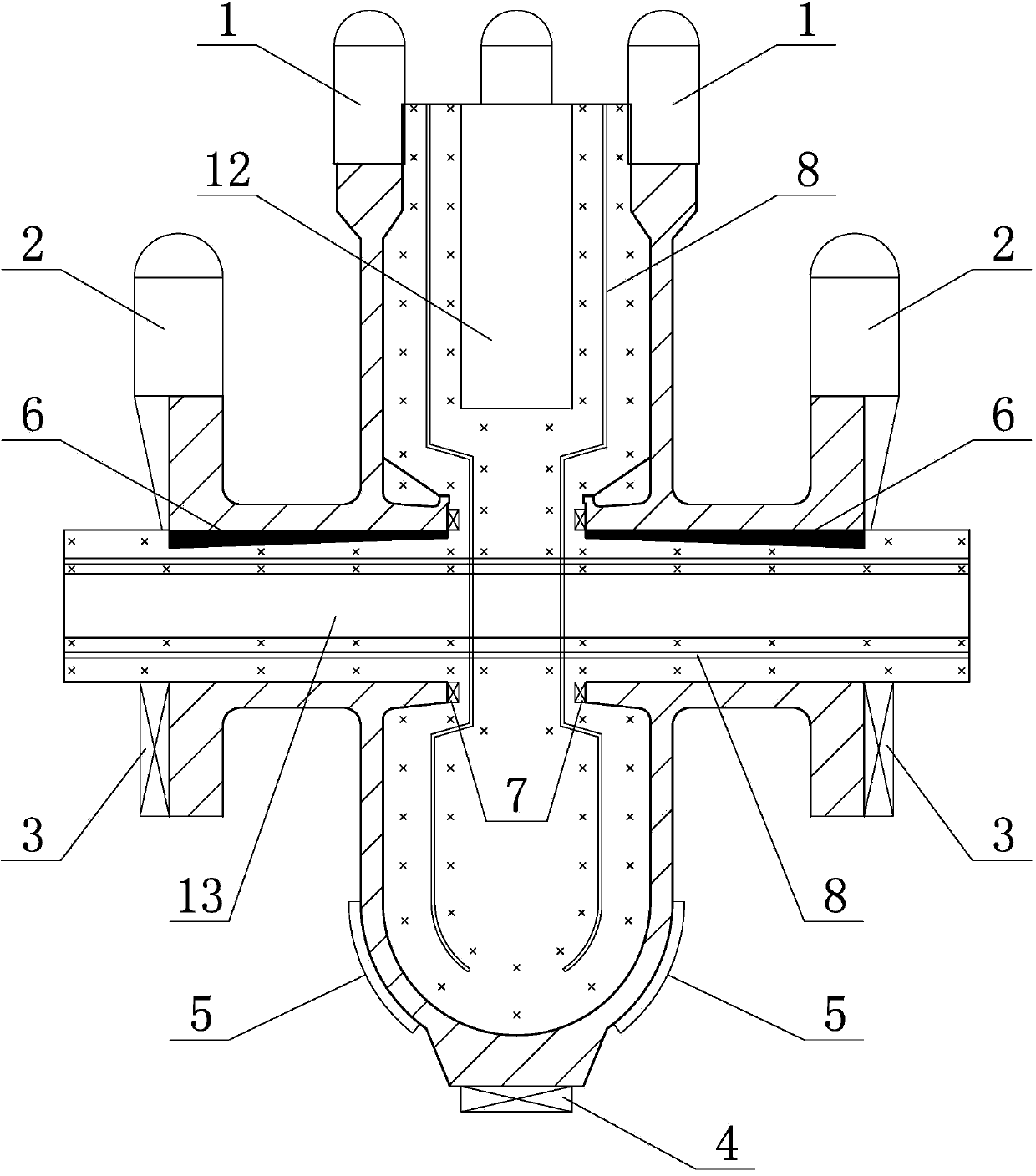

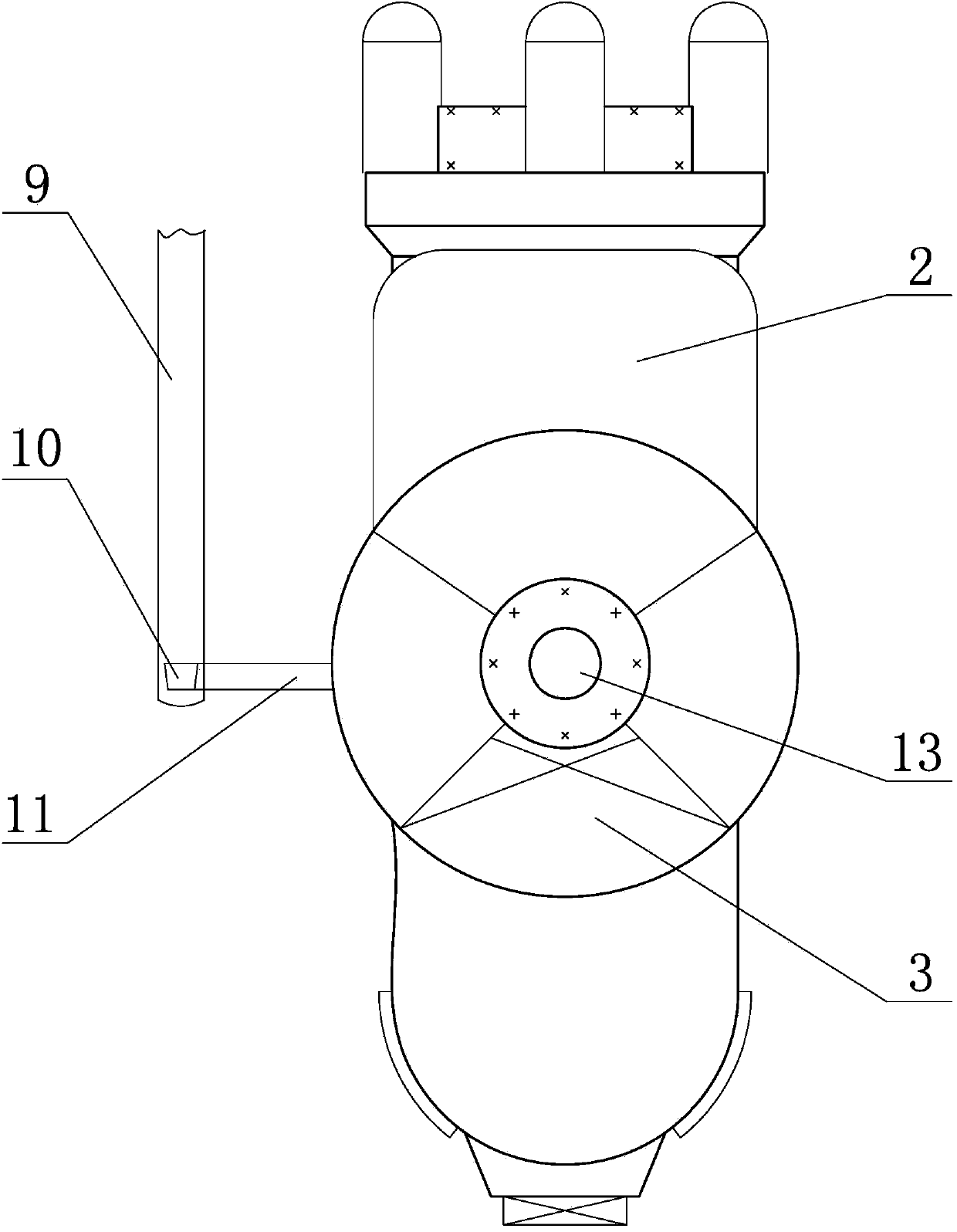

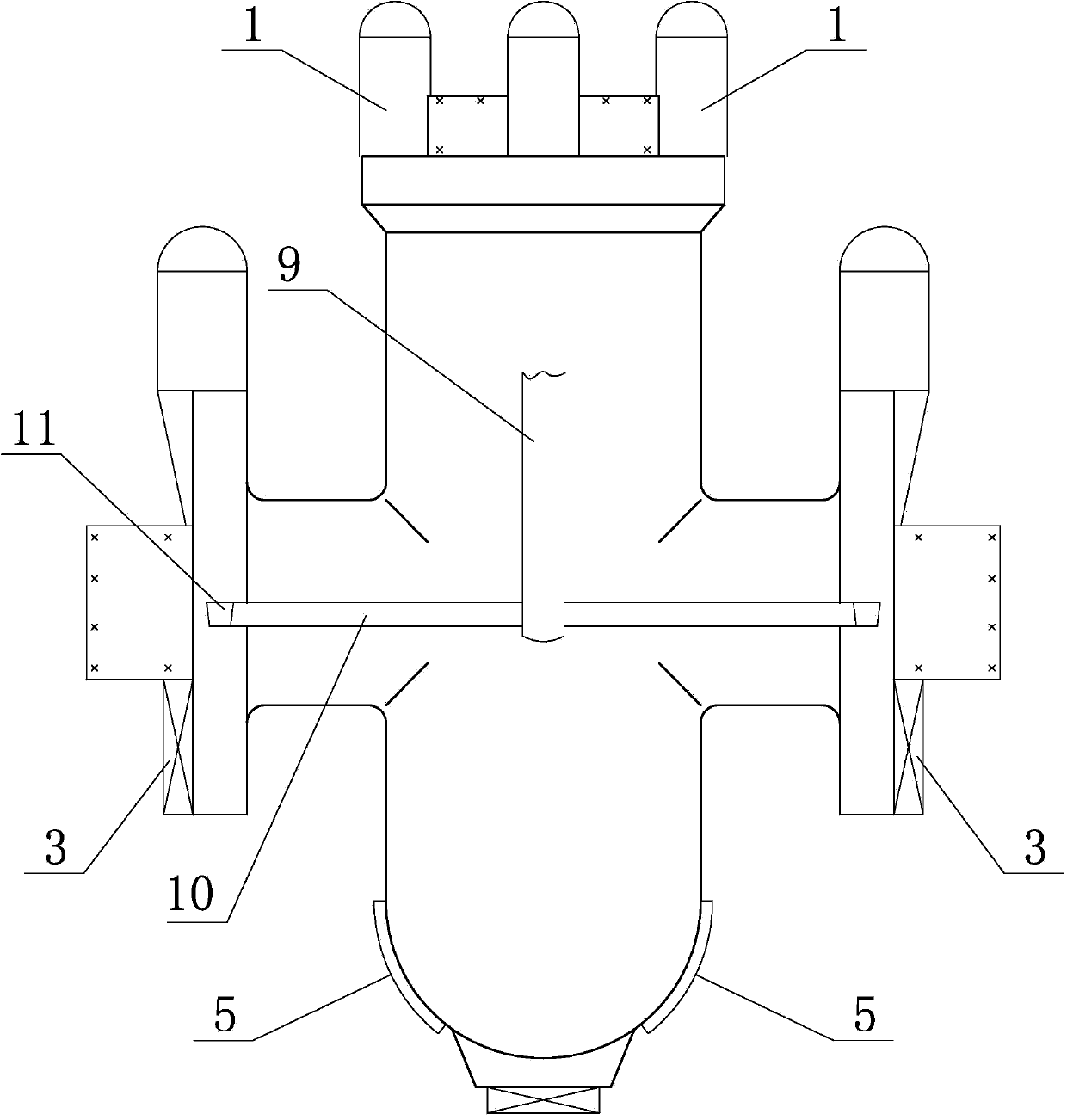

Method for casting valve body of flat gate valve

ActiveCN103433434AReduced horizontal projected areaGravity feeding is easy to implementFoundry mouldsFoundry coresMiddle lineImpurity

The invention discloses a method for casting a valve body of a flat gate valve, and belongs to the technical field of valve body casting processes. The method is technically characterized in that a valve body cavity is vertically formed between a sand mold and a sand core; a plurality of valve body heat preserving risers are uniformly arranged at the open end of the valve body through the sand mold; a flange heat preserving riser is arranged at the upper end of a flange plate on each of two sides; a first external chill is arranged at the lower end of each flange plate; a plurality of second external chills are uniformly arranged at the periphery of a valve belly below the middle line of a flange; a third external chill is arranged on the outer bottom surface of the blind end of a main body of the valve body; process supplementary ion is arranged in an inner hole of the flange plate on each of the two sides; a fourth external chill is arranged on each of two end surfaces of a valve seat table in an inner cavity of the valve body. Therefore, the probability of occurrence of casting impurities and pore defects is reduced by using a vertical pouring method, gravity feeding is easy to implement so as to be matched with the chilling action of each external chill, and castings can be fed in sequence, so that the internal quality of the castings is well improved.

Owner:SHANDONG MOLONG PETROLEUM MACHINERY

Metal@BN core-shell structure nanometer catalyst for synthesis gas methanation reaction, and preparation method thereof

ActiveCN106179438APrevent sintering and lossAvoid Catalyst DeactivationHydrocarbon from carbon oxidesPhysical/chemical process catalystsNano catalystSyngas

The invention discloses a metal@BN core-shell structure nanometer catalyst for a synthesis gas methanation reaction, and a preparation method thereof. According to the present invention, the composition of the catalyst is 5-30wt.%Mx@(BN)y / SiO2, wherein metal M nanoparticles are loaded on a SiO2 support, the loading mass percentage is 5-30%, an ultrathin boron nitride (BN) layer is covered on the surface, the catalyst has a core-shell structure, and a molar ratio y / x of the BN to the metal nanoparticles is 0.1-10; with the application of the catalyst in the methane preparation reaction through the hydrogenation of the catalytic synthesis gas, the sintering and the loss of the metal nanoparticles can be prevented, and the catalyst deactivation caused by the carbon deposition on the catalyst active site surface can be prevented with the core-shell structure; and the catalyst has high low-temperature activity and high high-temperature stability.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Autothermal catalytic marsh gas reforming process of preparing synthetic gas

InactiveCN1468800ASelf-heating reactionHigh activityHydrogenWaste based fuelSyngasCatalytic reforming

The present invention relates to the efficient clean utilization of marsh gas and is especially one new kind of catalyst for reforming methane-CO2 to produce synthetic gas. The present invention is one green process to utilize marsh gas with methane and CO2 as main components to produce synthetic gas via reformation. The present invention is significant for sustained supply of power source and environment protection.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Process for producing metal oxide particle and exhaust gas purifying catalyst

InactiveUS20070197379A1Improve heat resistancePreventing sintering of platinumInternal combustion piston enginesOther chemical processesExhaust gasPopulation

The present invention provides an exhaust gas purifying catalyst and a process for producing a metal oxide particle comprising multiple species of metal oxides and capable of satisfactorily exerting the properties of respective metal oxides. A process of the present invention comprises providing a sol containing at least a population of first colloid particles and a population of second colloid particles differing in the isoelectric point with each other; adjusting the pH of the sol to be closer to the isoelectric point of the population of first colloid particles than to the isoelectric point of the population of second colloid particles, thereby aggregating the population of first colloid particles; adjusting the pH of the sol, thereby aggregating the population of second colloid particles onto the population of first colloid particles aggregated; and drying and firing the obtained aggregate.

Owner:TOYOTA JIDOSHA KK

Acetylene selective hydrogenation catalyst and preparation method and application thereof

ActiveCN101862653AUniform particle sizeHigh activityHydrocarbon by hydrogenationCatalyst activation/preparationHydrogenation reactionRoom temperature

The invention discloses an acetylene selective hydrogenation catalyst and a preparation method and application thereof. The catalyst comprises a carrier and active metal components supported on the carrier, wherein the main active metal component palladium is elemental palladium under the conditions of room temperature and air and is prepared by reducing a palladium precursor supported on the carrier through ionizing radiation. The catalyst can be directly used in hydrogenation reaction without reduction in advance by hydrogen; the active ingredients have uniform particle size; and the catalyst has higher activity and selectivity compared with catalysts prepared by the conventional methods.

Owner:CHINA PETROLEUM & CHEM CORP +1

Soot oxidation catalyst and method of making

InactiveUS20070219088A1Efficiently oxidizedPrevent materialCombination devicesNitrogen compoundsDiesel particulate filterGlycerol

A catalyst composition for facilitating the oxidation of soot from diesel engine exhaust is provided. The catalyst composition includes a catalytic metal selected from Pt, Pd, Pt—Pd, Ag, or combinations thereof, an active metal oxide component containing Cu and La, and a support selected from alumina, silica, zirconia, or combinations thereof. The platinum group metal loading of the composition is less than about 20 g / ft3. The catalyst composition may be provided on a diesel particulate filter by impregnating the filter with an alumina, silica or zirconia sol solution modified with glycerol and / or saccharose, impregnating the filter with a stabilizing solution, and impregnating the filter with a solution containing the active metal oxide precursor(s) and the catalytic metal precursor(s). The resulting catalyst coated diesel particulate filter provides effective soot oxidation, exhibits good thermal stability, has a high BET surface area, and exhibits minimal backpressure.

Owner:FORD GLOBAL TECH LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com