Perovskite type methane combustion catalyst as well as preparation method and application thereof

A methane combustion and perovskite-type technology, which is applied in the fields of environmental protection and chemical engineering, can solve problems such as inapplicability, and achieve the effects of prolonging service life, good mass and heat transfer performance, and increasing load capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The preparation method of the perovskite type methane combustion catalyst provided by the present embodiment comprises the following steps:

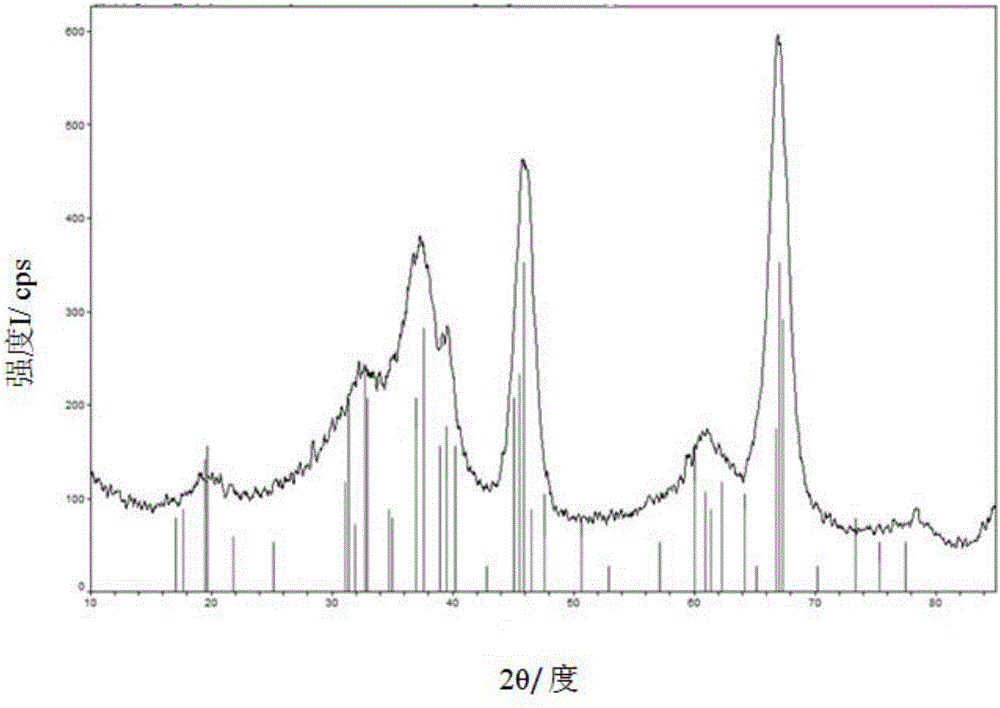

[0036] (1) Weigh 1kg ball nuts and put them into a pan granulator, spray a small amount of 5wt% aluminum sol to wet the ball nut surface, then add pseudoboehmite powder and alumina sol alternately, until the particles grow up to After 4-6mm, take it out and sieve the balls with a particle size of 4-6mm. In this step, add 102.9kg of pseudoboehmite powder and 22kg of aluminum sol; dry the above-mentioned alumina pellets at 120°C for 2 hours, Roasted for 4 hours to obtain δ-Al 2 o 3 and θ-Al 2 o 3 Alumina spherical support of mixed crystal phase (such as figure 1 Shown), the water absorption rate of the carrier is 50%.

[0037] (2) Add 38.0gLa 2 o 3 Put it into a 500mL beaker, add 66.7mL of nitric acid with a mass concentration of 65-68%. At this time, it will emit heat and gas. After the dissolution is completed, a colorless ...

Embodiment 2

[0040] The preparation method of the perovskite type methane combustion catalyst provided by the present embodiment comprises the following steps:

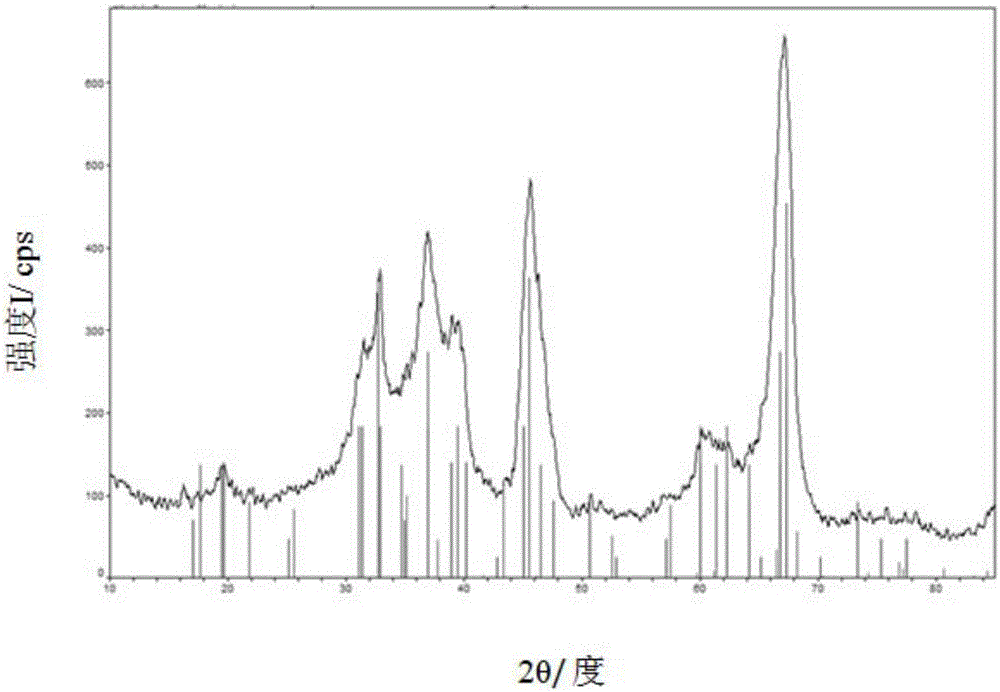

[0041] (1) Weigh 2.1kg ball nuts and put them into a pan granulator, spray a small amount of 7wt% aluminum sol to wet the ball ball surface, then add pseudoboehmite powder and alumina sol alternately, and wait for the particles to grow After reaching 4-6mm, take it out and sieve the balls with a particle size of 4-6mm. In this step, 102.1kg of pseudoboehmite powder and 12kg of aluminum sol are added; the above-mentioned alumina pellets are dried at 80°C for 12 hours, ℃ for 3 hours to obtain an alumina spherical carrier with a water absorption rate of 40%.

[0042] (2) 54.3gLa 2 o 3 Put it into a 500mL beaker, add 95.2mL of nitric acid with a mass concentration of 65-68%. At this time, it will emit heat violently and emit gas. After the dissolution is completed, a colorless and transparent solution is obtained. Then add 133.3mL o...

Embodiment 3

[0045] The preparation method of the perovskite type methane combustion catalyst provided by the present embodiment comprises the following steps:

[0046] (1) Weigh 5.3kg ball nuts and put them into a pan granulator, spray a small amount of 9wt% aluminum sol to wet the ball nut surface, then add pseudo-boehmite powder and alumina sol alternately, and wait for the particles to grow After reaching 4-6mm, take it out and sieve the balls with a particle size of 4-6mm. In this step, add 99kg of pseudo-boehmite powder and 8.8kg of aluminum sol; dry the above-mentioned alumina pellets at 100°C for 8 hours, ℃ for 3 hours to obtain an alumina spherical carrier with a water absorption rate of 45%.

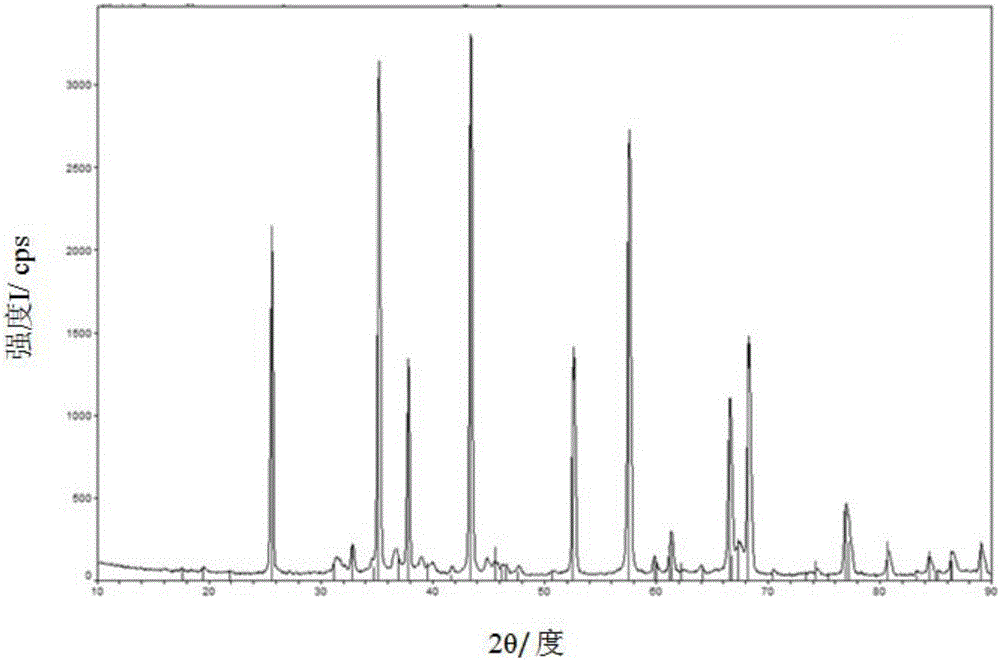

[0047] (2) Add 5.4gLa 2 o 3 Put it into a 500mL beaker, add 9.5mL of nitric acid with a mass concentration of 65% to 68%. At this time, it will exotherm violently and emit gas. After the dissolution is completed, a colorless and transparent solution is obtained. Weigh 130.2gCe(NO 3 ) 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com