Composite material 3d printing method realized by photocuring-jetting nano ink and printer

A nano-ink and composite material technology, applied in the field of 3D printing, can solve the problems of low operation and maintenance costs, poor precision and surface quality of parts, and low strength of parts, so as to achieve high material utilization rate, guaranteed characteristics, and reduced production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0046] The ceramics are prepared as nano-ceramic powder with a diameter of 100±5nm, and the prepared nano-ceramic powder is mixed with a photosensitive resin and an ink regulator to form a nano-ceramic ink. Among them, nano-ink is prepared by mixing 10% of photosensitive resin, 88% of ceramic powder, and 2% of ink conditioner.

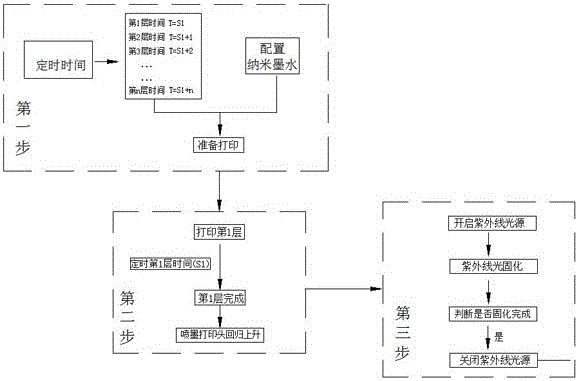

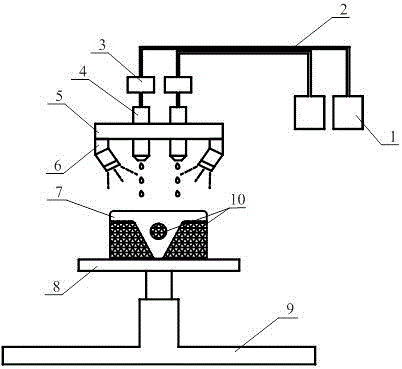

[0047] According to the 3D modeling requirements of the ceramic device to be printed, the 3D model is layered and cut into several layers of 2D graphics, the printing path is planned according to the shape of each layer, the amount of material required for each layer is calculated, and a single inkjet printing is set The speed at which the nano-ink is ejected from the head is 500m / s, the number of inkjet printing heads is 4, and the temperature of the forming cavity is 30°C. Calculate the printing time of each layer and the sum of the return and rise time T of the inkjet printing head, and the power of the selected ultraviolet light source It is 1.2W. ...

specific Embodiment 2

[0051] The glass is prepared as glass powder with a diameter of 300±30nm, and the prepared nano-ceramic powder is mixed with a photosensitive resin and an ink regulator to form a nano-ceramic ink. Among them, nano-ink is prepared by mixing 25% of photosensitive resin, 72% of glass powder, and 3% of ink regulator.

[0052] According to the 3D modeling requirements of the glass device to be printed, the 3D model is layered and cut into several layers of 2D graphics, the printing path is planned according to the shape of each layer, the amount of material required for each layer is calculated, and a single inkjet printing is set The speed at which the nano-ink is ejected from the head is 20m / s, the number of inkjet printing heads is 6, the temperature of the forming cavity is 60°C, the printing time T of each layer is calculated, and the power of the selected ultraviolet light source is 3W.

[0053] The inkjet starts, the inkjet print head sprays nano-ink, stops printing after ti...

specific Embodiment 3

[0055] The glass is prepared as a plastic powder with a diameter ranging from 10 to 80 nm, and the prepared nano-ceramic powder is mixed with a photosensitive resin and an ink regulator to form a nano-plastic ink. Among them, nano-ink is prepared by mixing 15% of photosensitive resin, 80% of plastic powder, and 5% of ink regulator.

[0056] According to the 3D modeling requirements of the plastic device to be printed, the 3D model is layered and cut into several layers of 2D graphics, the printing path is planned according to the shape of each layer, the amount of material required for each layer is calculated, and a single inkjet printing is set The speed at which the nano-ink is ejected from the head is 5m / s, the number of the inkjet printing head is 1, the temperature of the forming cavity is 30°C, the printing time T of each layer is calculated, and the power of the selected ultraviolet light source is 0.5W.

[0057] The inkjet starts, the inkjet print head sprays nano-ink...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com