Patents

Literature

602results about "Manufacturing material handling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

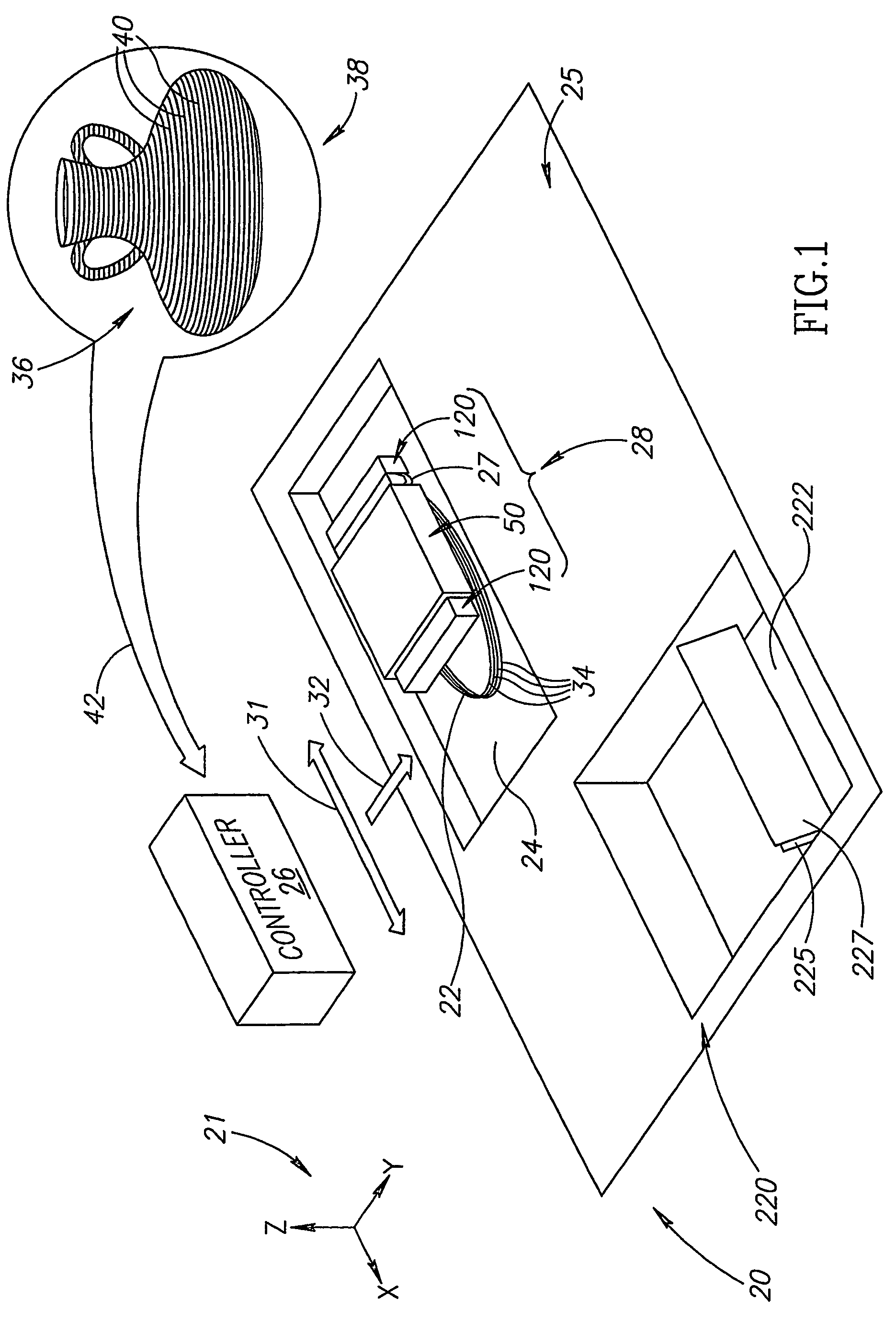

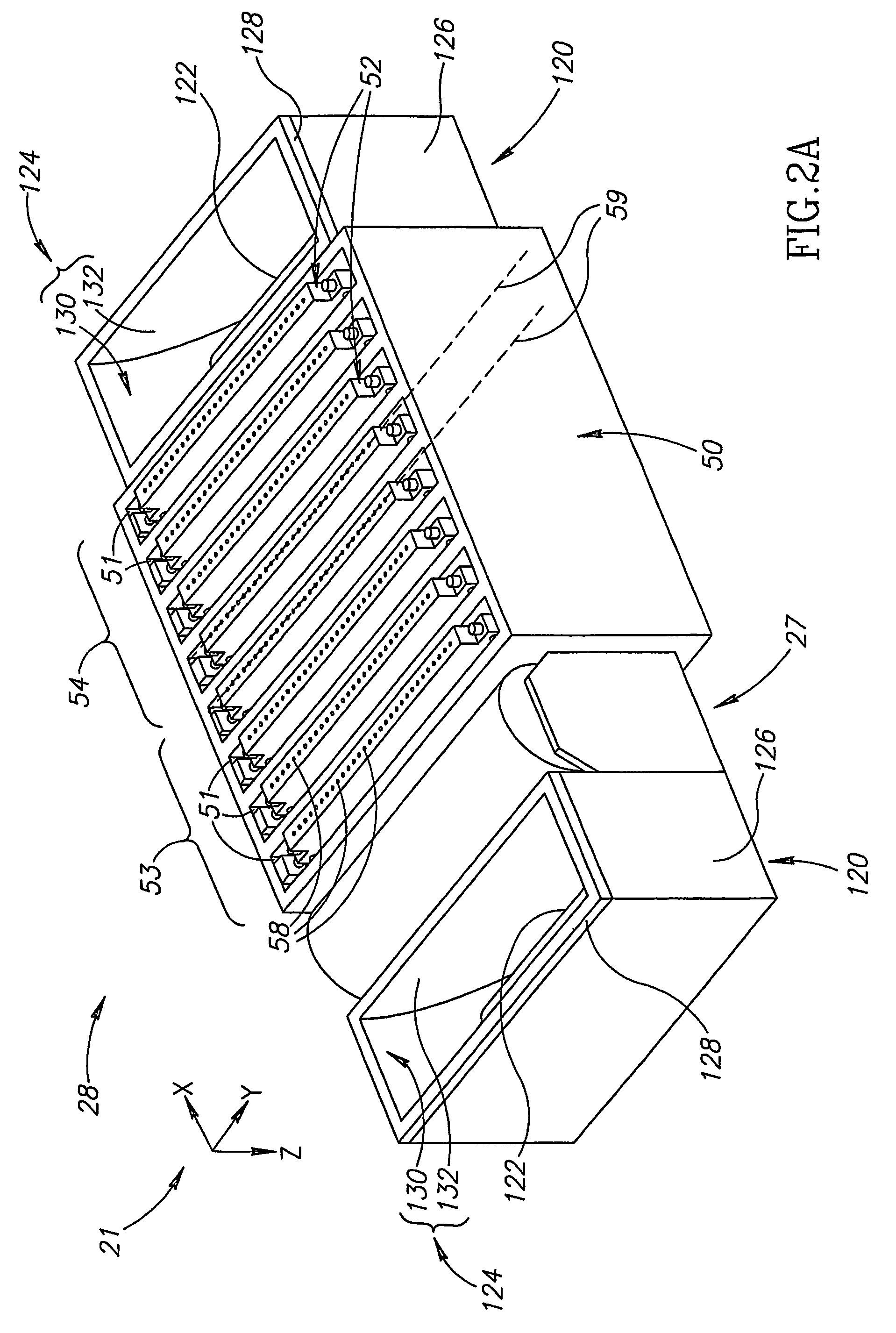

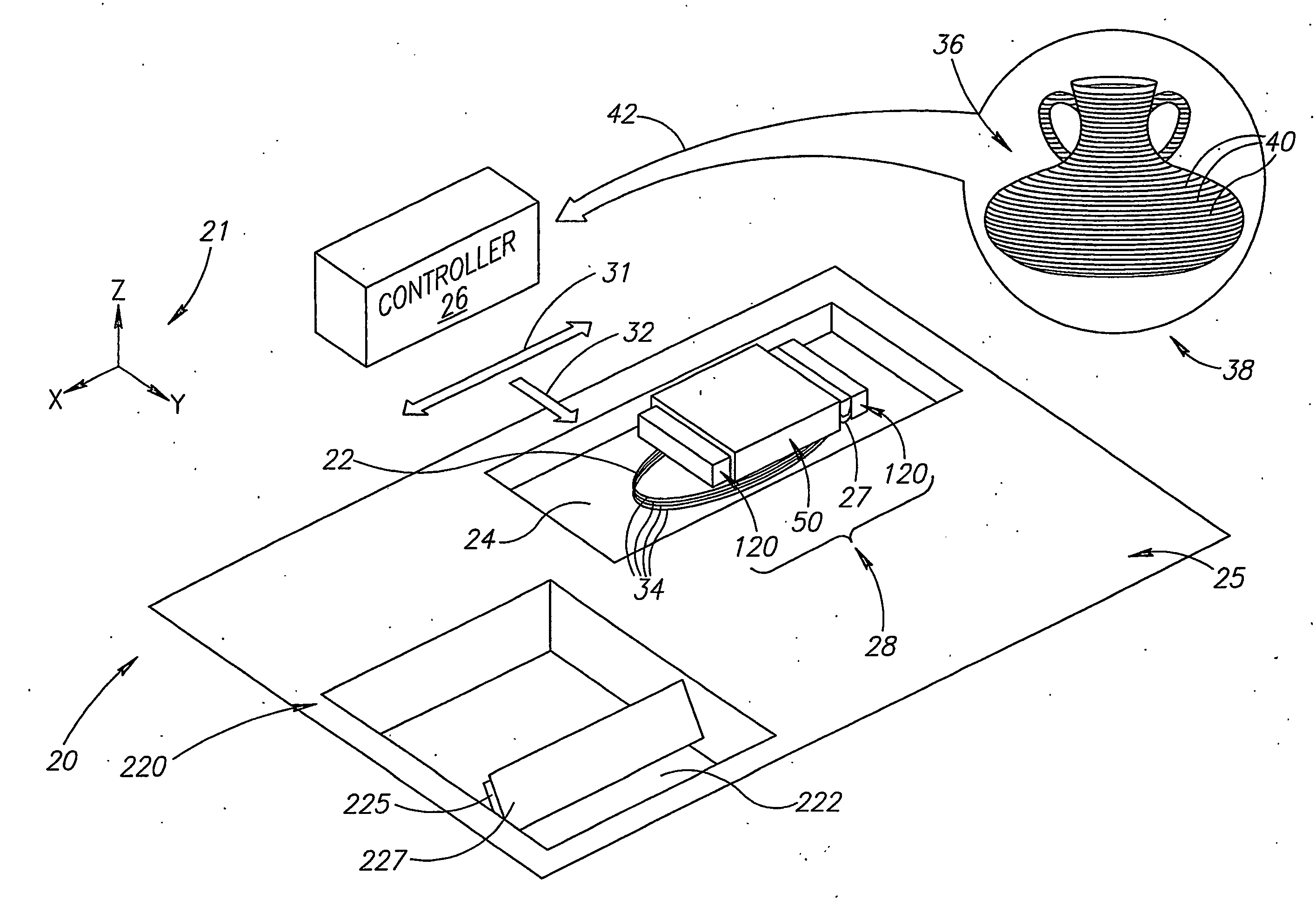

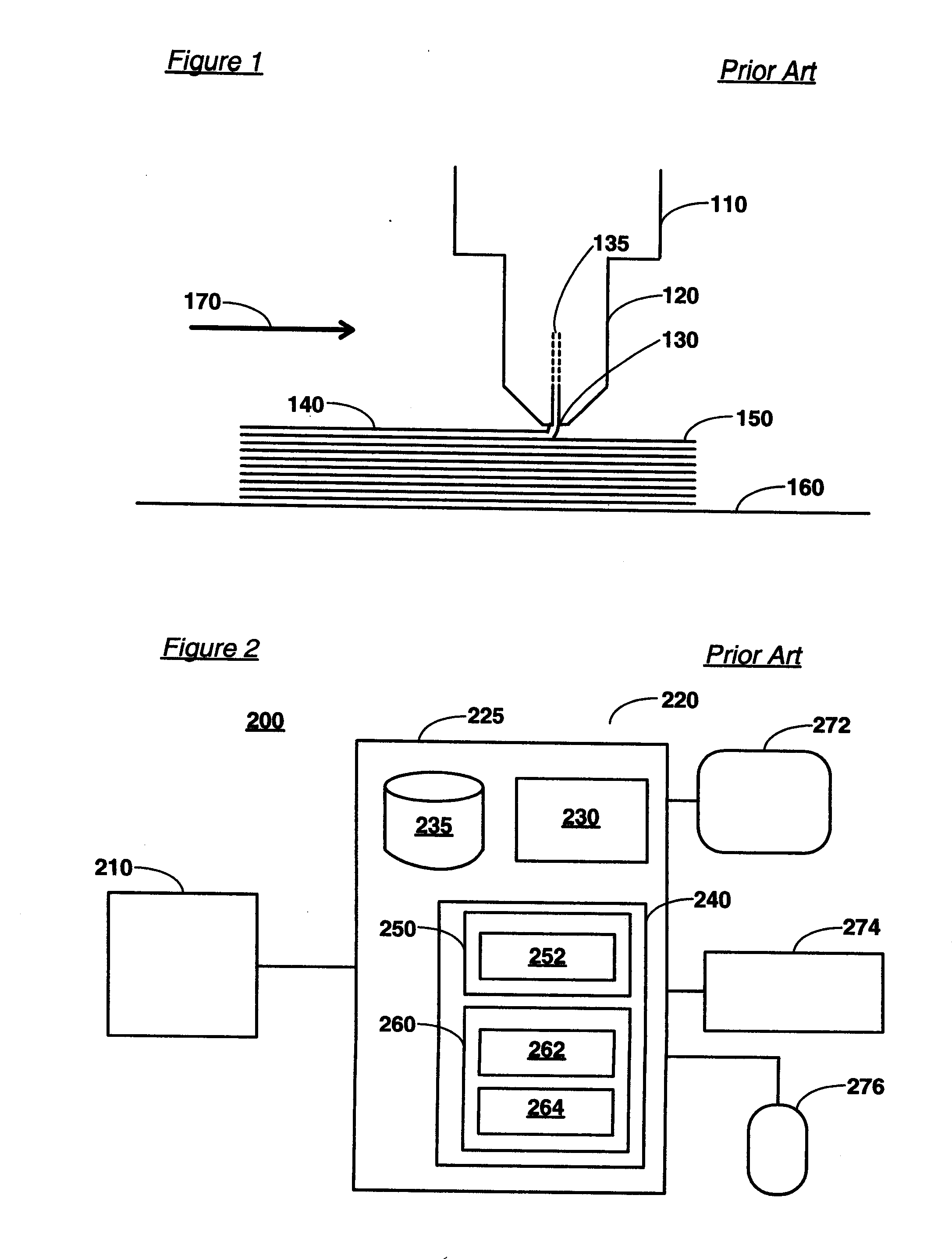

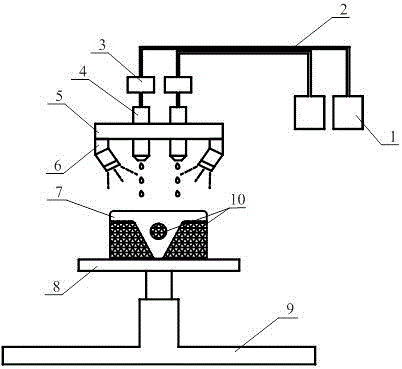

Rapid prototyping apparatus

ActiveUS7500846B2Improve operating characteristicsRapid productionConfectionerySweetmeatsThin layerEngineering

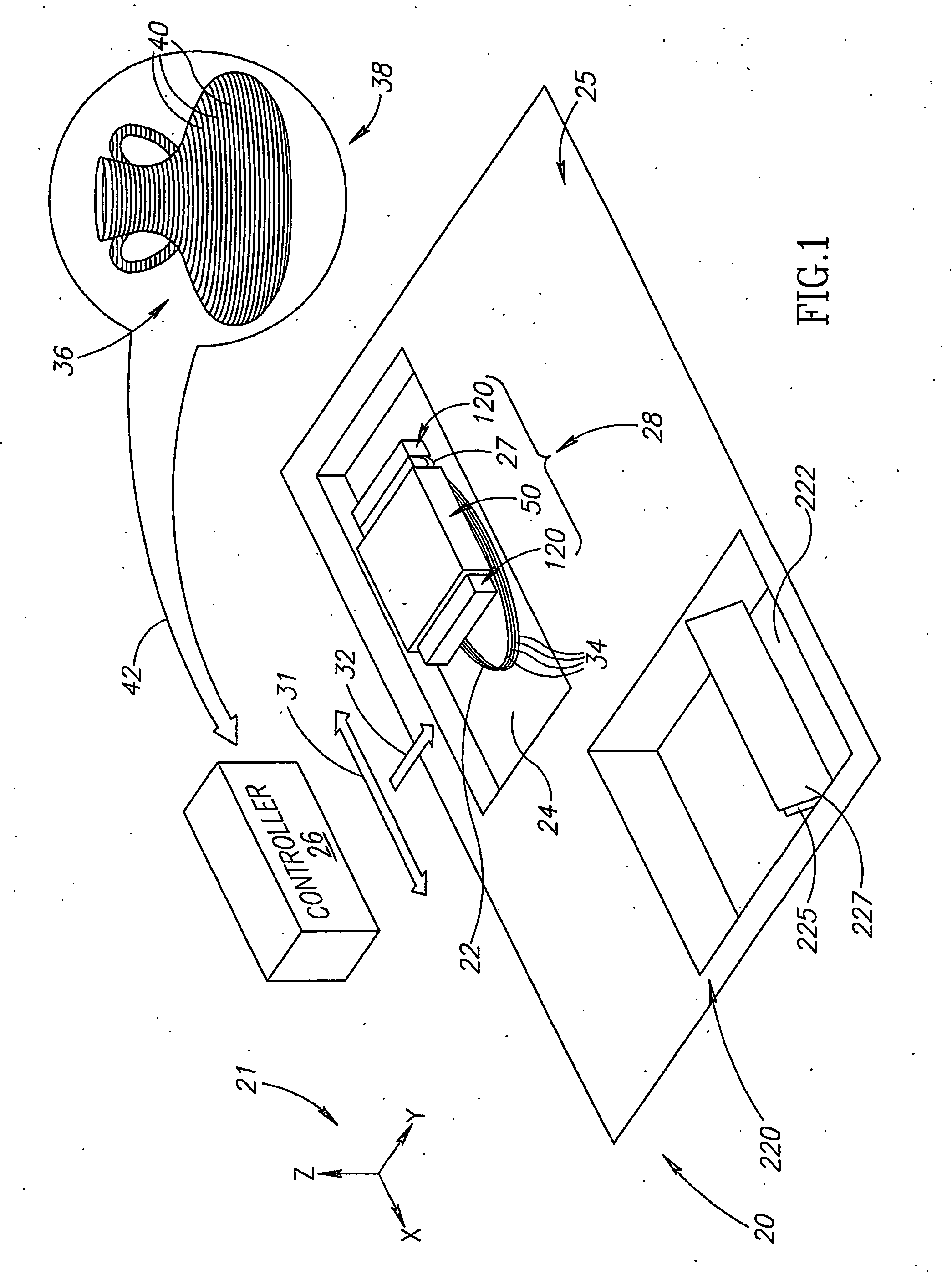

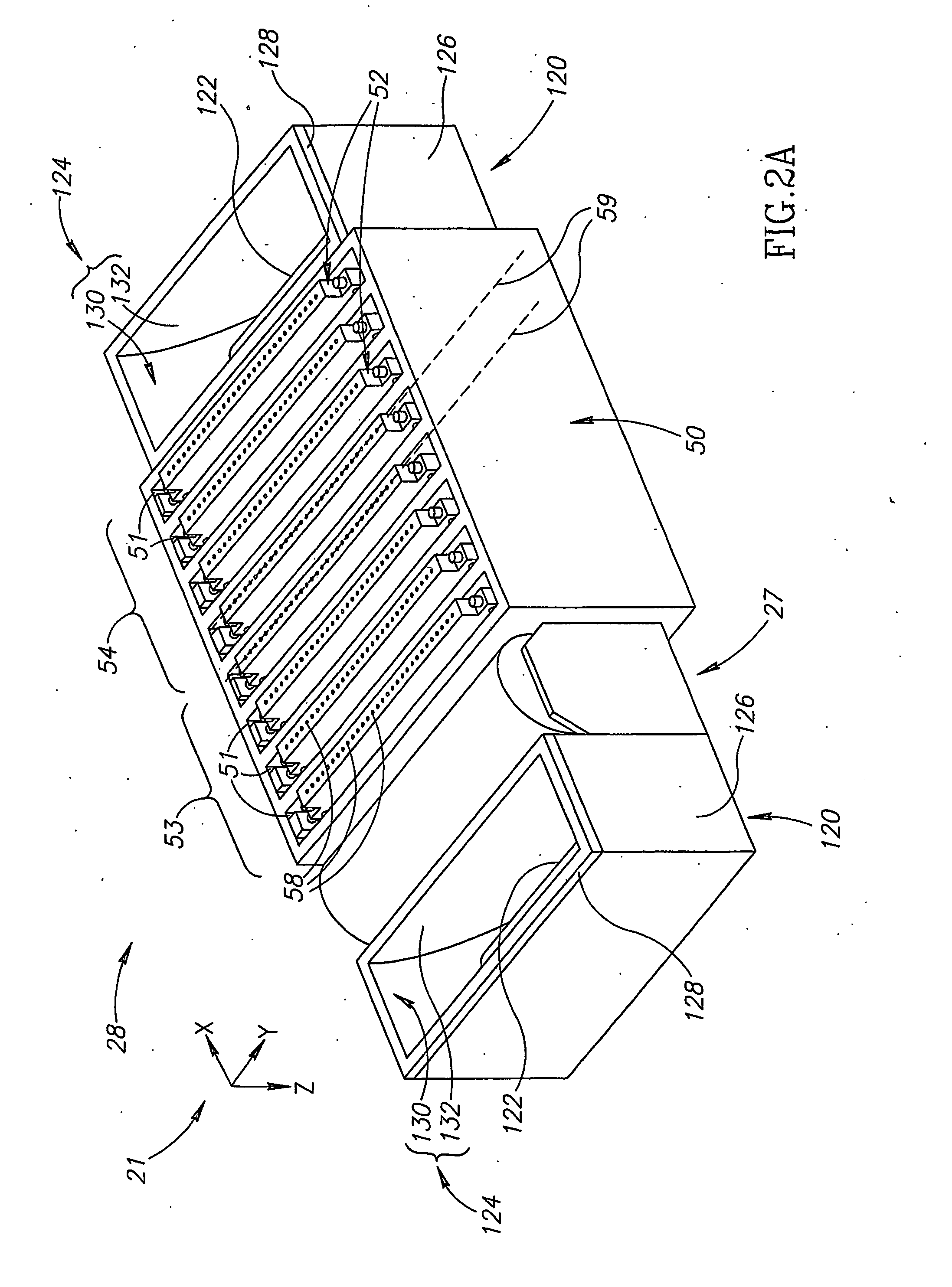

Apparatus for producing an object by sequentially forming thin layers of a construction material one on top of the other responsive to data defining the object, the apparatus comprising: a plurality of printing heads each having a surface formed with a plurality of output orifices and controllable to dispense the construction material through each orifice independently of the other orifices; a shuttle to which the printing heads are mounted; a support surface; and a controller adapted to control the shuttle to move back and forth over the support surface and as the shuttle moves to control the printing heads to dispense the construction material through each of their respective orifices responsive to the data to form a first layer on the support surface and thereafter, sequentially the other layers; wherein each printing head is dismountable from the shuttle and replaceable independently of the other printing heads.

Owner:OBJET GEOMETRIES

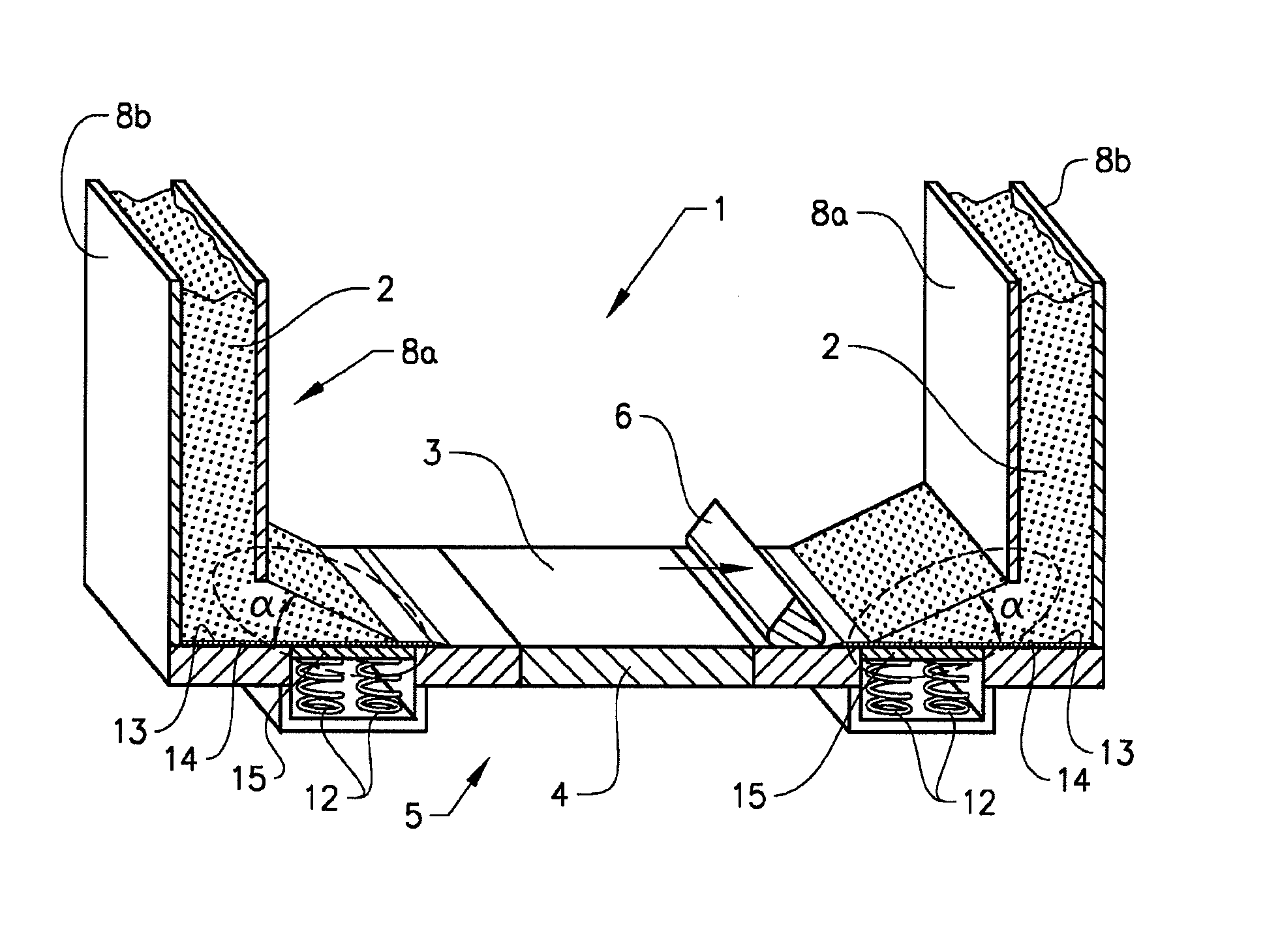

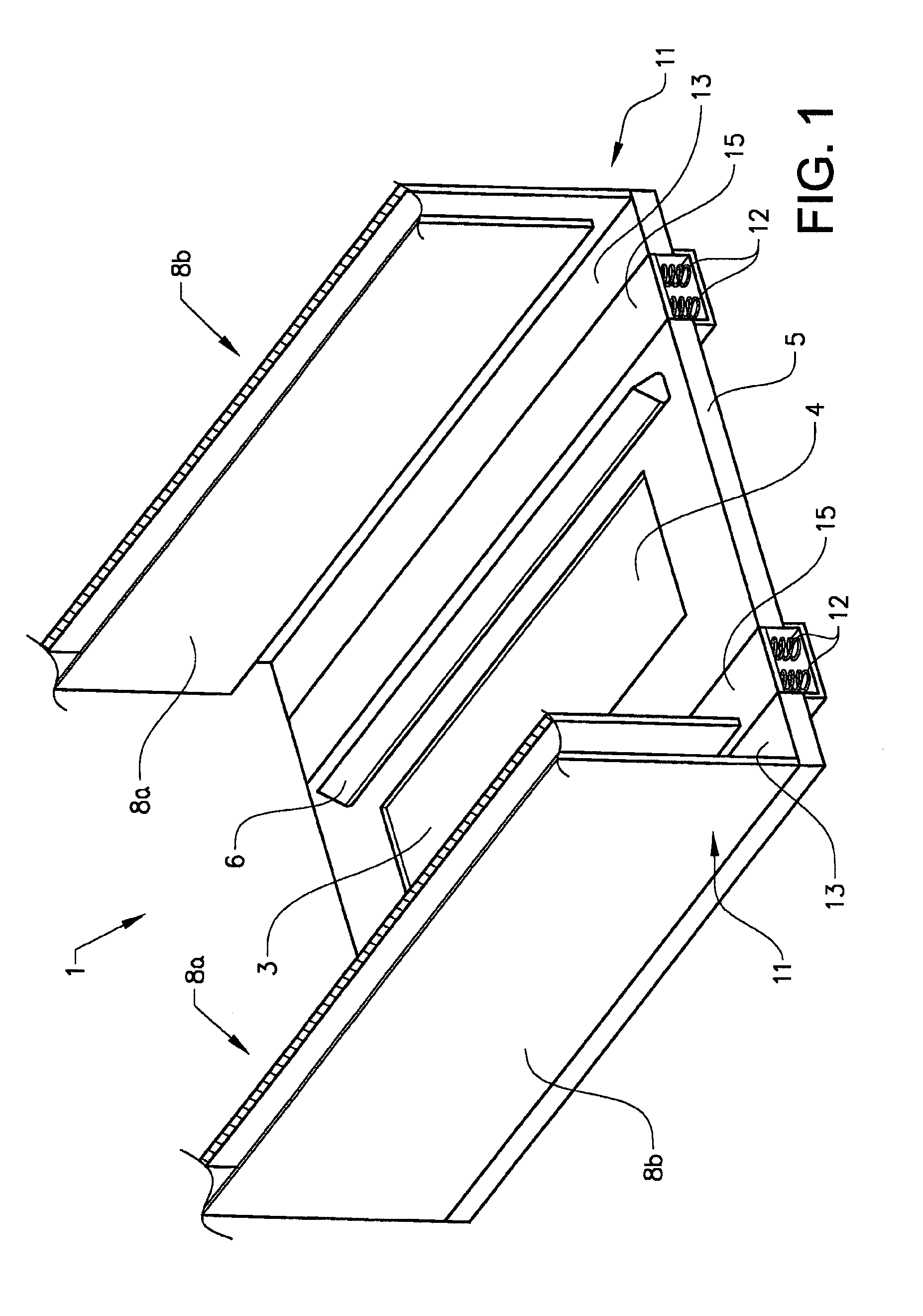

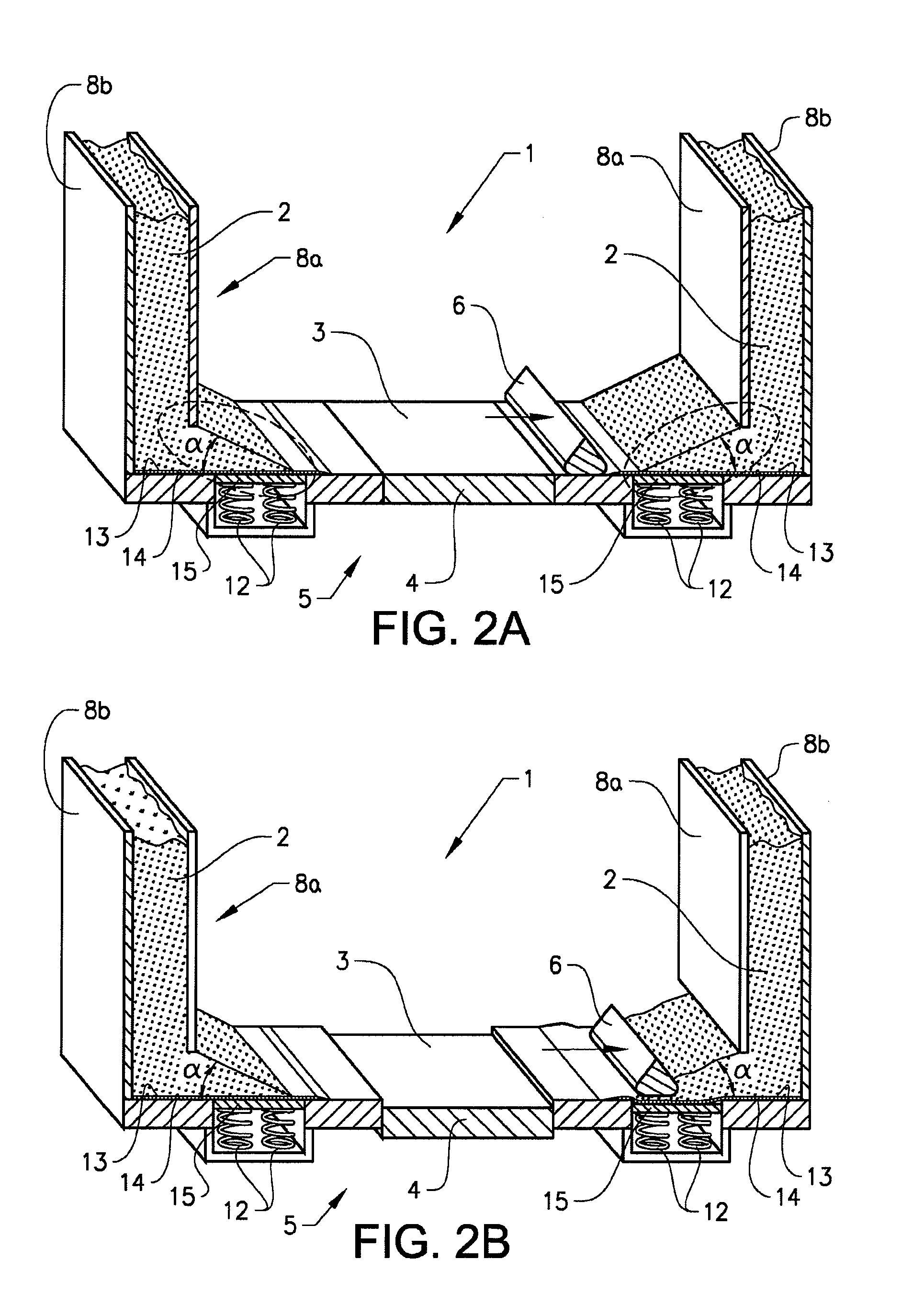

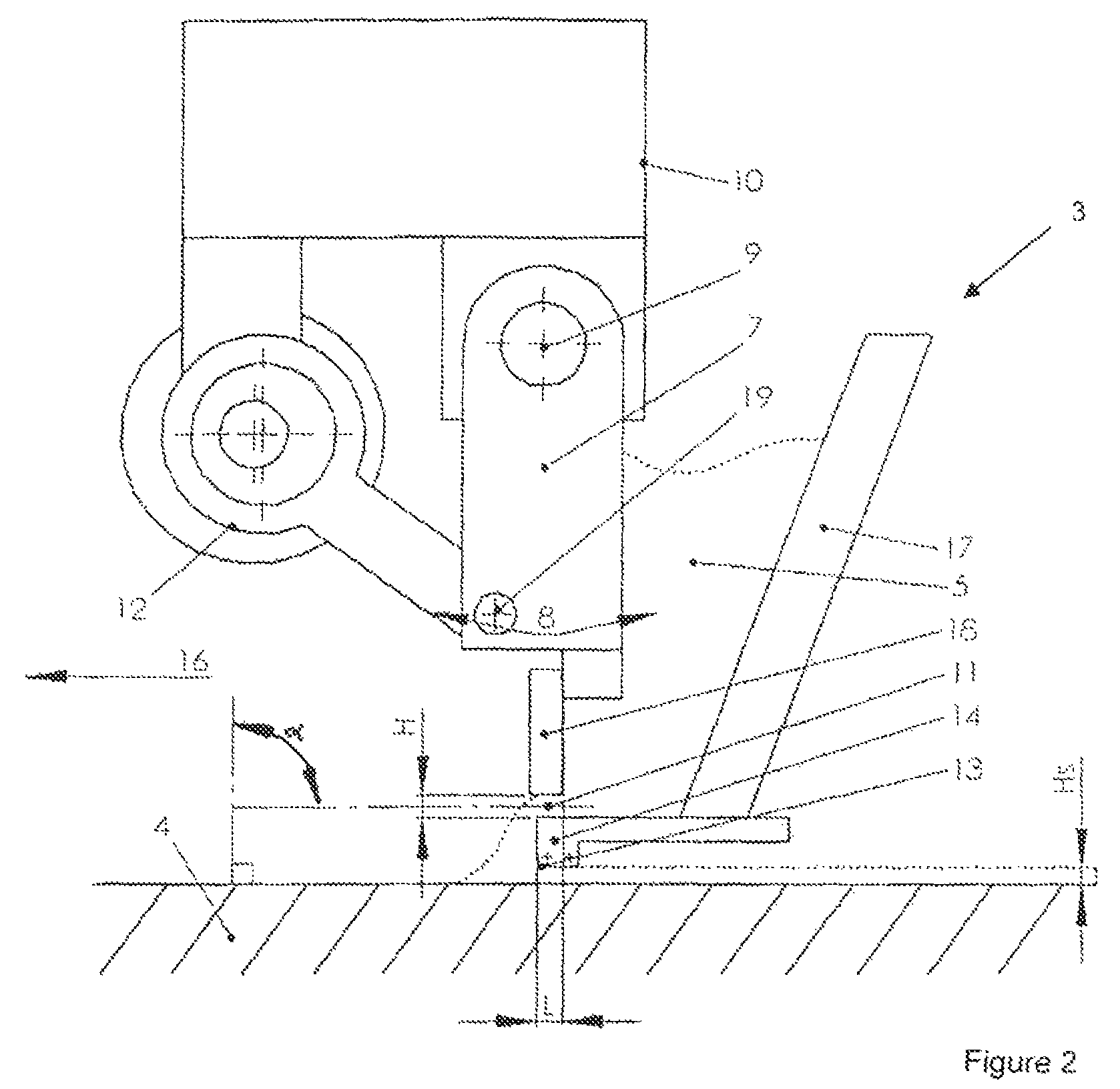

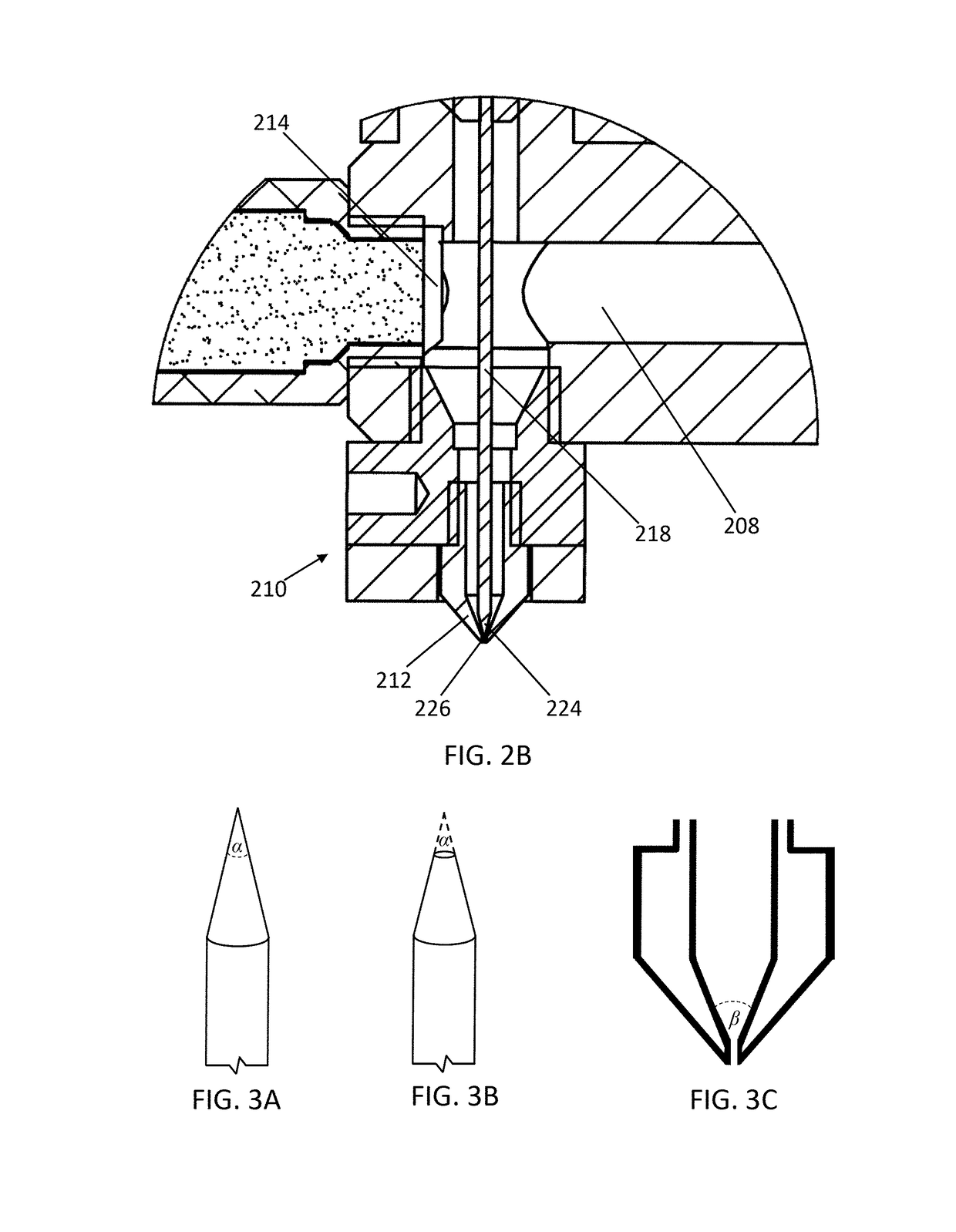

Apparatus for producing a three-dimensional object

ActiveUS8308466B2Control of sizeEasy to controlConfectionerySweetmeatsElectromagnetic radiationElectron

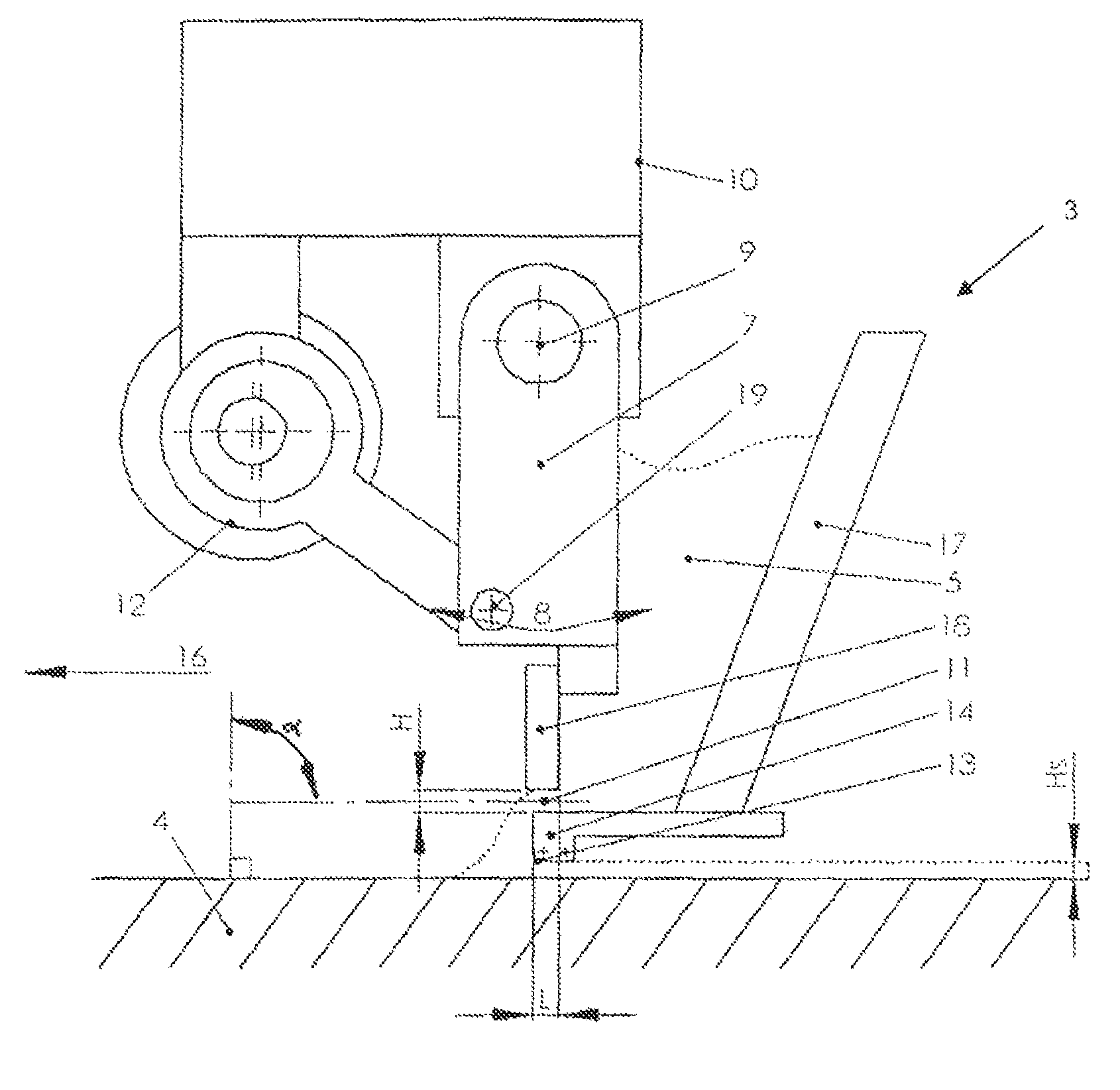

The invention concerns an apparatus (1) for producing a three-dimensional object layer by layer using a powdery material which can be solidified by irradiating it with an energy beam, such as electromagnetic radiation or an electron beam, said apparatus (1) comprising: a working area (3) onto which layers of powdery material are to be placed; a powder storage unit (11) comprising a base surface (13) for supporting a supply of powder (2); and a powder distribution member (6); wherein the base surface (13) extends along a side of the working area (3), wherein the distribution member (6) extends in a direction along the base surface (13) and said side of the working area (3) and is arranged to be moveable in a plane above, and substantially parallel to, the base surface (13) and the working area (3), and wherein the distribution member (6) is arranged to be moveable into a supply of powder (2) placed onto the base surface (13) such as to bring about a transfer of a portion of powder from a side of the distribution member (6) facing away from the working area (3) to an opposite side of the distribution member (6) facing the working area (3), said distribution member (6) further being arranged to be moveable towards and across the working area (3) so as to distribute the portion of powder onto the working area (3). The invention is characterized in that at least a part (15) of the base surface (13) is arranged to be resilient in a vertical direction.

Owner:ARCAM AB

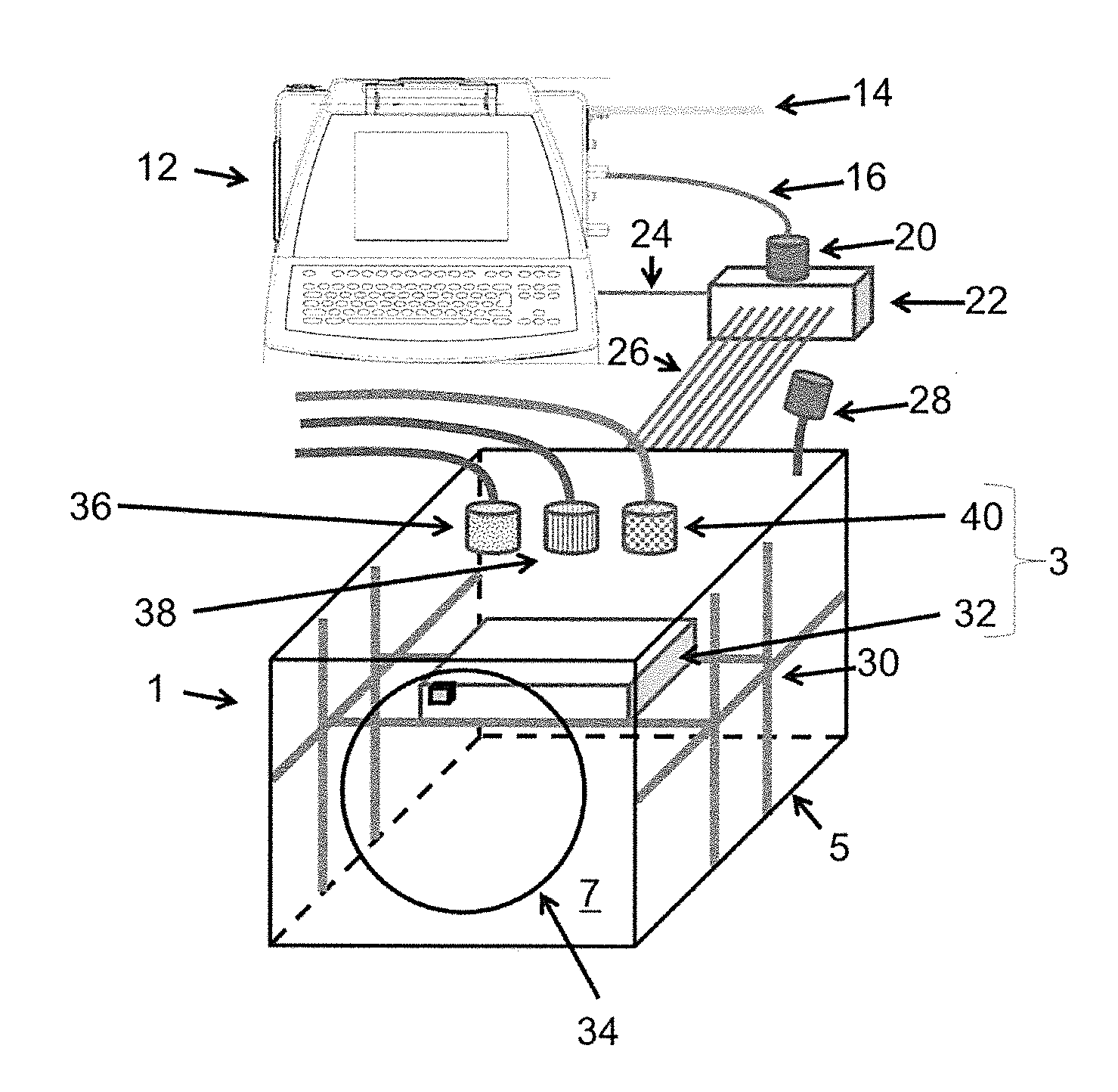

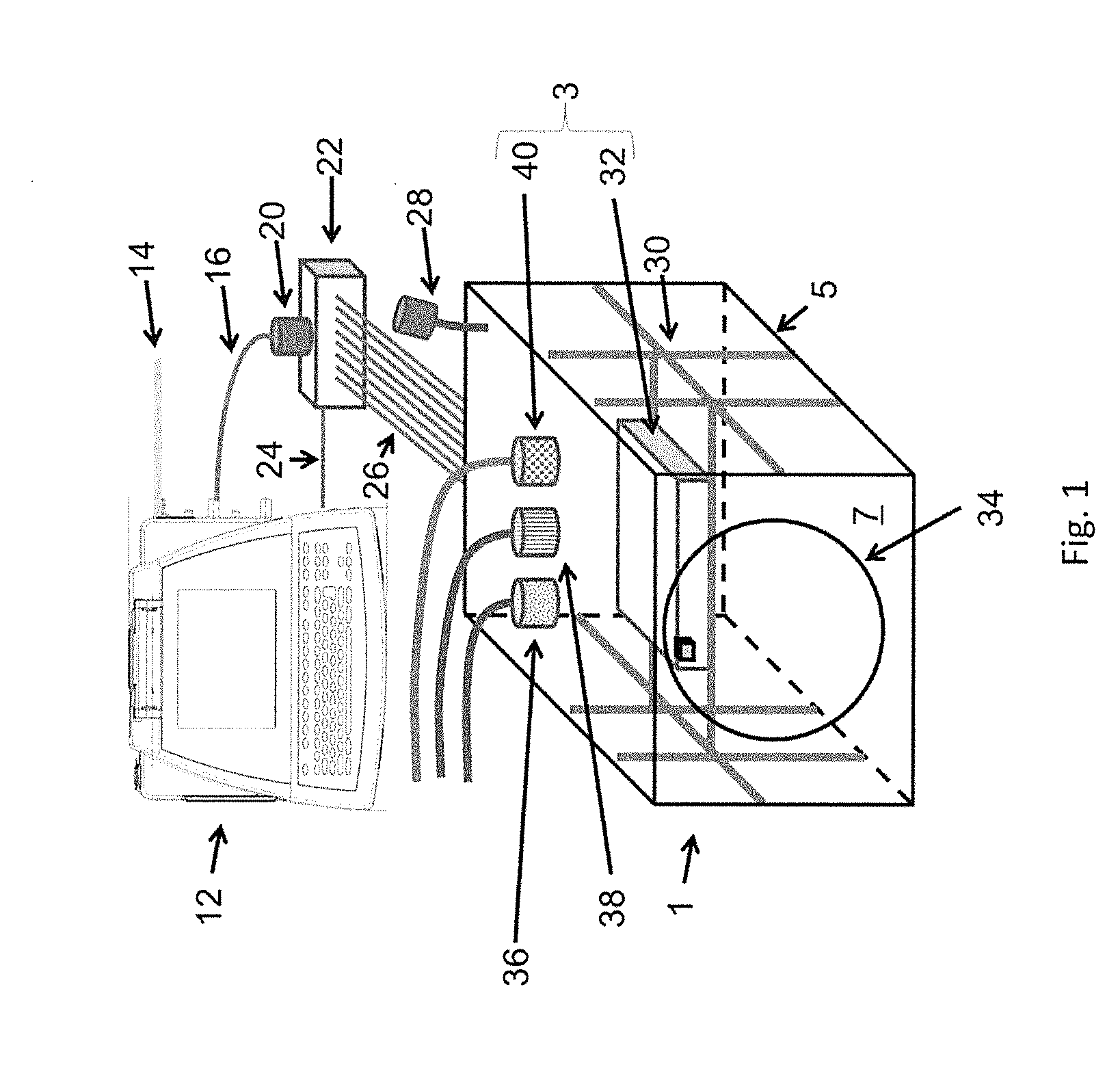

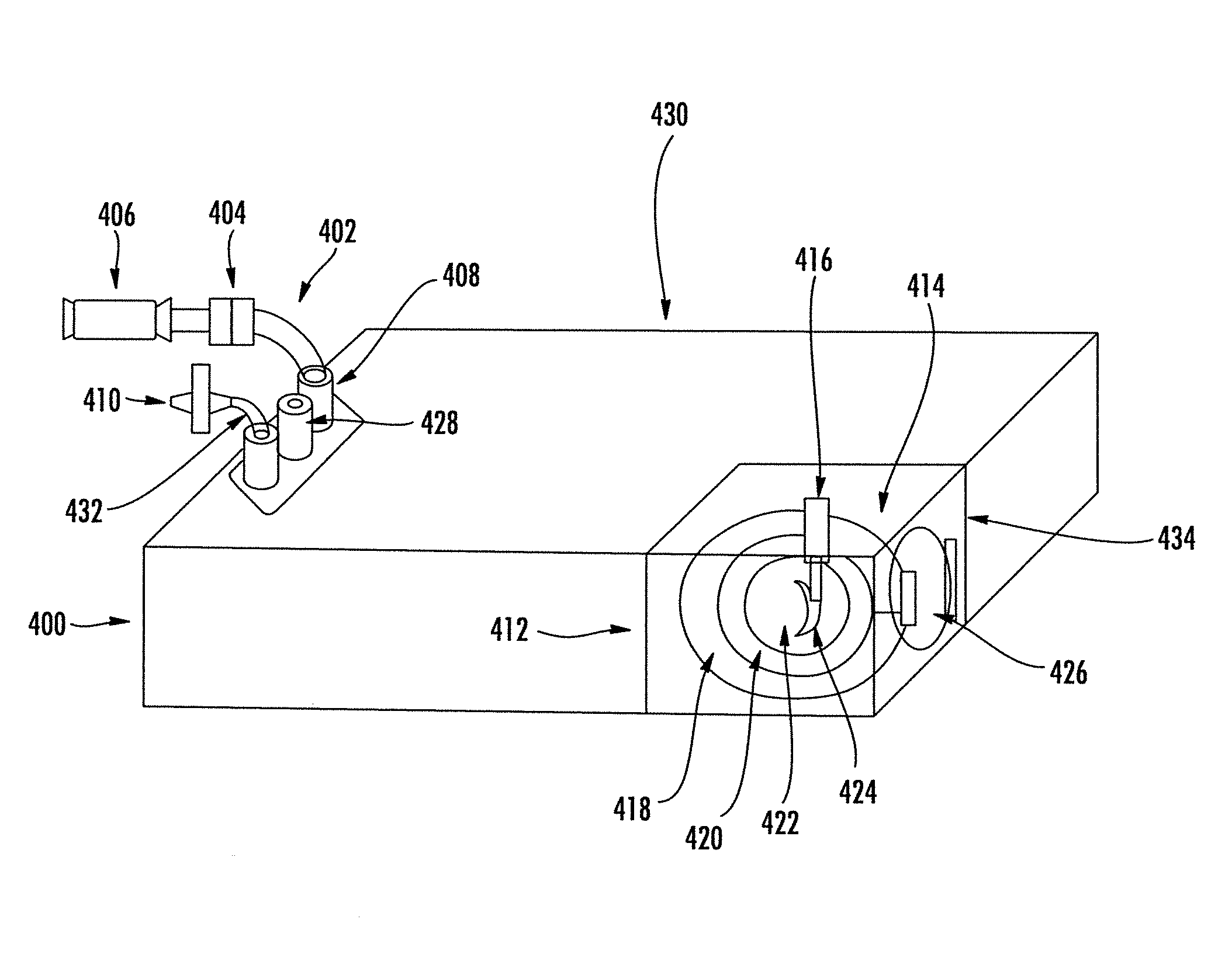

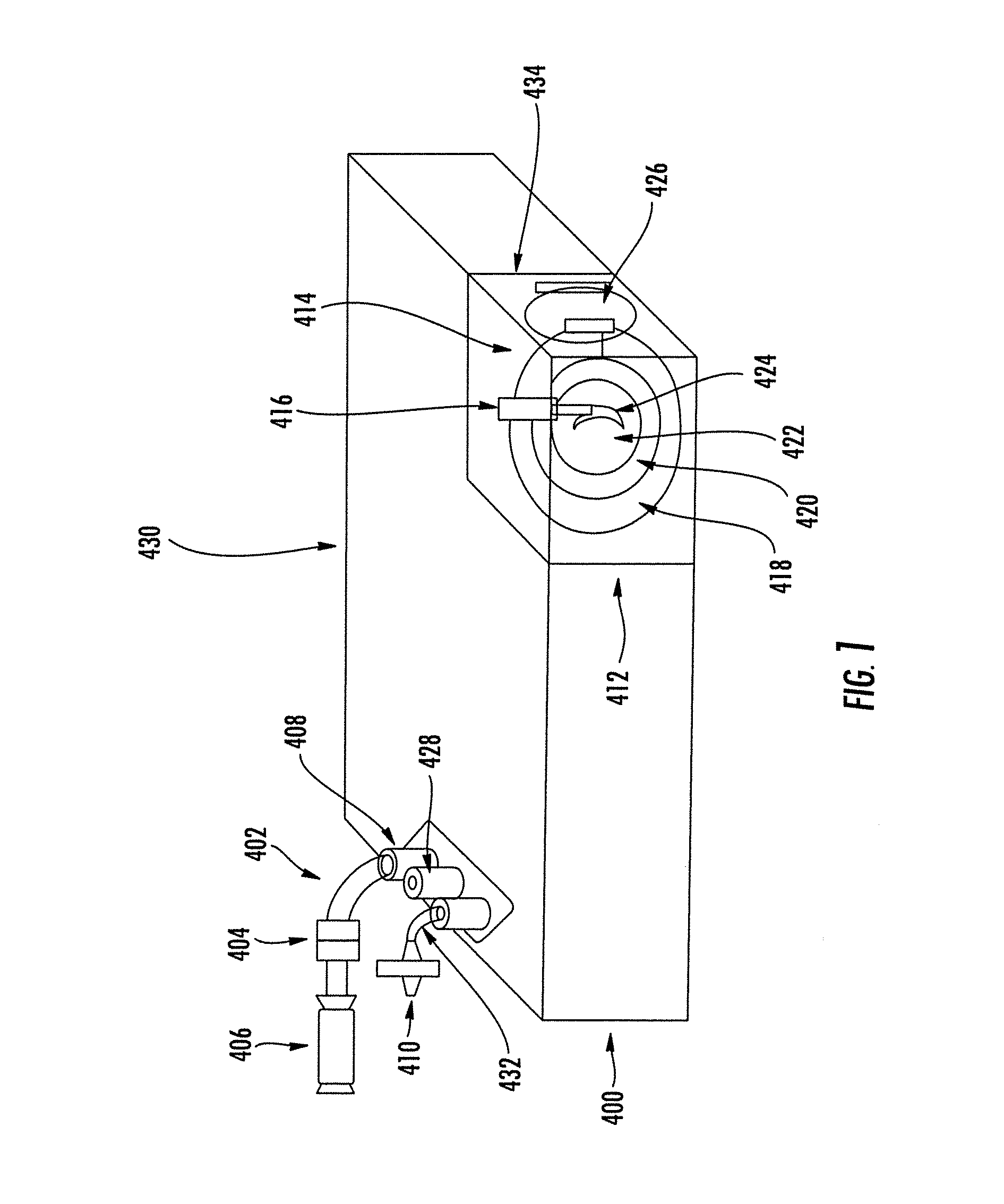

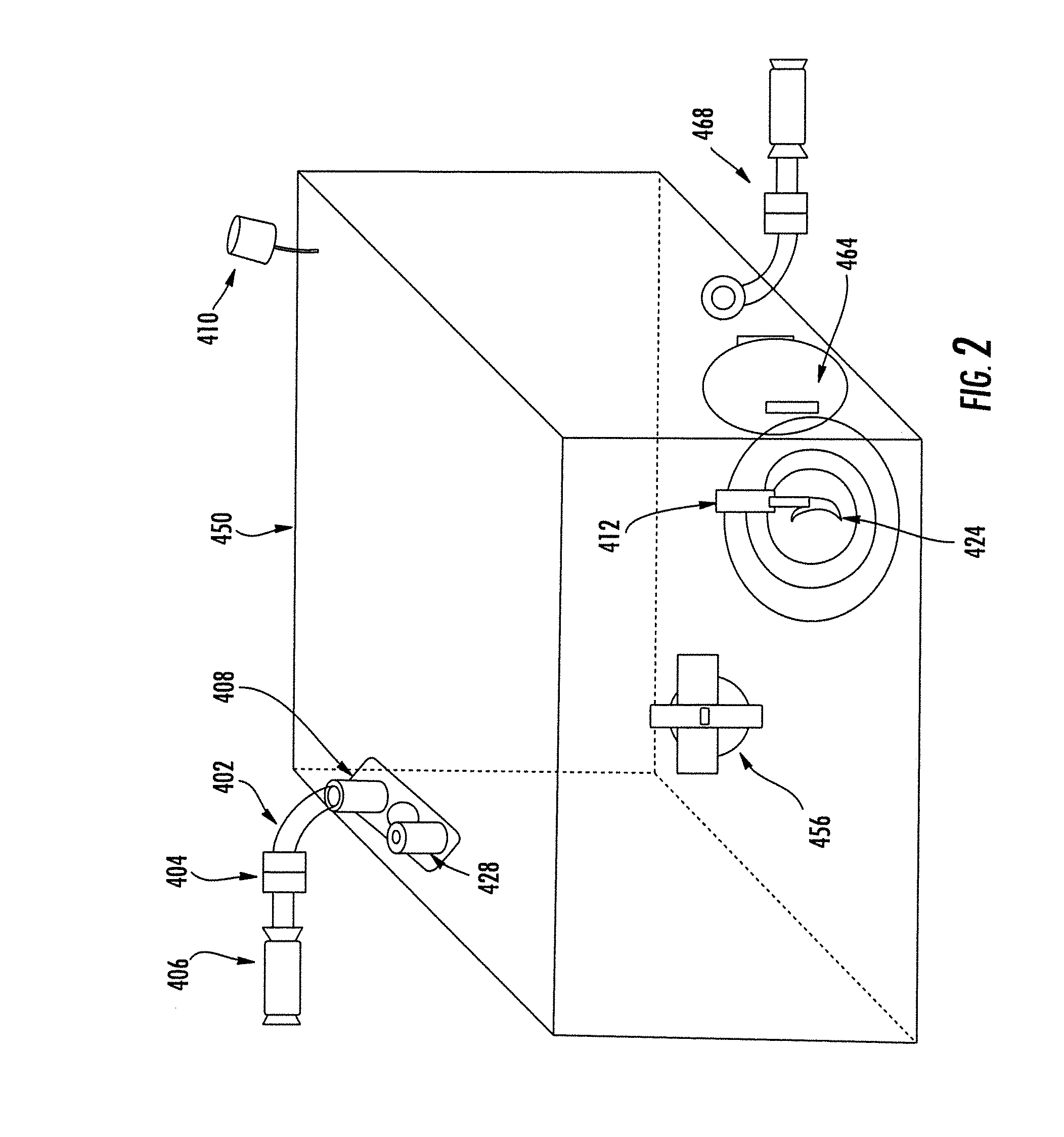

Manufacturing within a single-use container

ActiveUS20160068793A1Function increaseProgramme-controlled manipulatorBioreactor/fermenter combinationsNumerical controlThree degrees of freedom

A manufacturing assembly has at least a sterilizable chamber containing at least one of a three-dimensional printing device (additive manufacturing), a Computer Numerical Controlled (CNC) finishing head (subtractive manufacturing), a vacuum-forming unit, an injection-molding unit, a laser-cutting unit, a ultrasonic-welding unit, a robotic arman analysis device, a sampling device or a combination thereof. A plurality of individual sterilizable chambers may be aseptically connected into a network of sterilizable chambers that provides additional functionality for the manufacturing assembly. A sterilizable printer assembly may include at least one printing head, a printing platform, and a driving mechanism adapted to perform a movement of the at least one printing head relative to the printing platform along three degrees of freedom; a printer housing enclosing the printer assembly in a sterile manner, at least one aseptic connector fluidly connected to a corresponding one of the at least one printing head.

Owner:SARTORIUS STEDIM BIOTECH GMBH

Polymeric Material for Three-Dimensional Printing

A polymeric material that is capable of being employed as a build material and / or support material in a three-dimensional printer system is provided. The polymeric material is formed from a thermoplastic composition containing a continuous phase that includes a matrix polymer. A microinclusion additive and nanoinclusion additive are dispersed within the continuous phase in the form of discrete domains.

Owner:KIMBERLY-CLARK WORLDWIDE INC

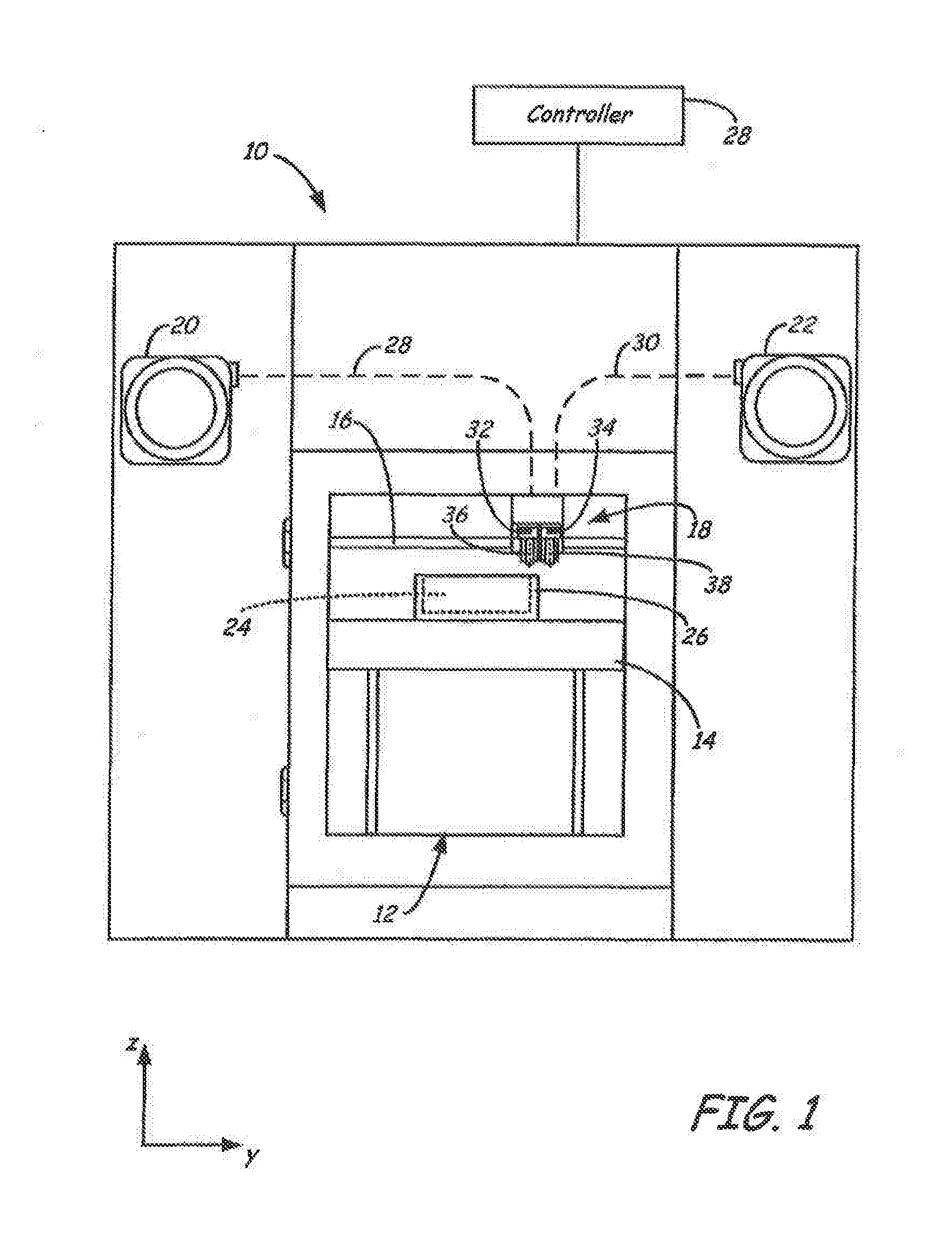

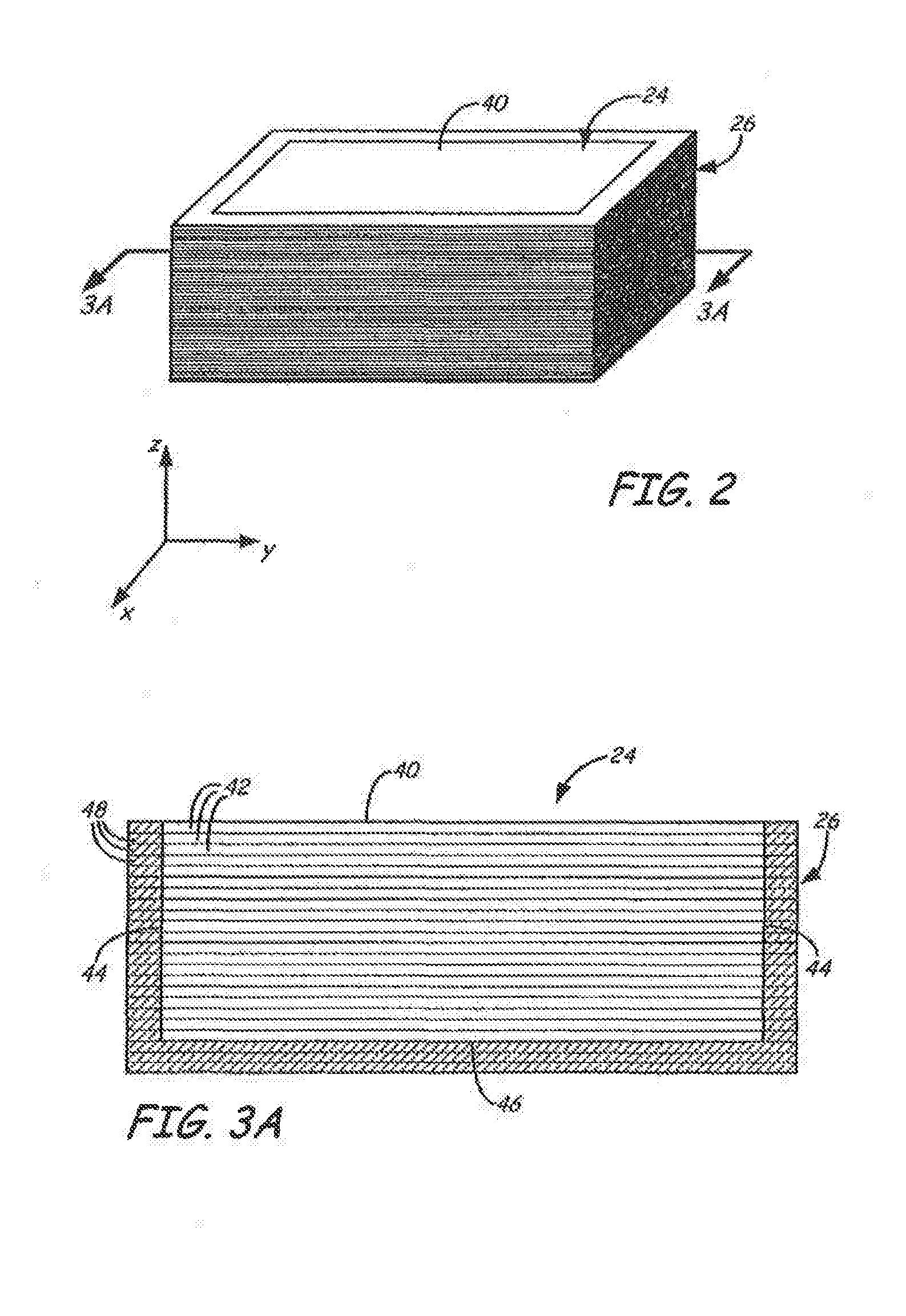

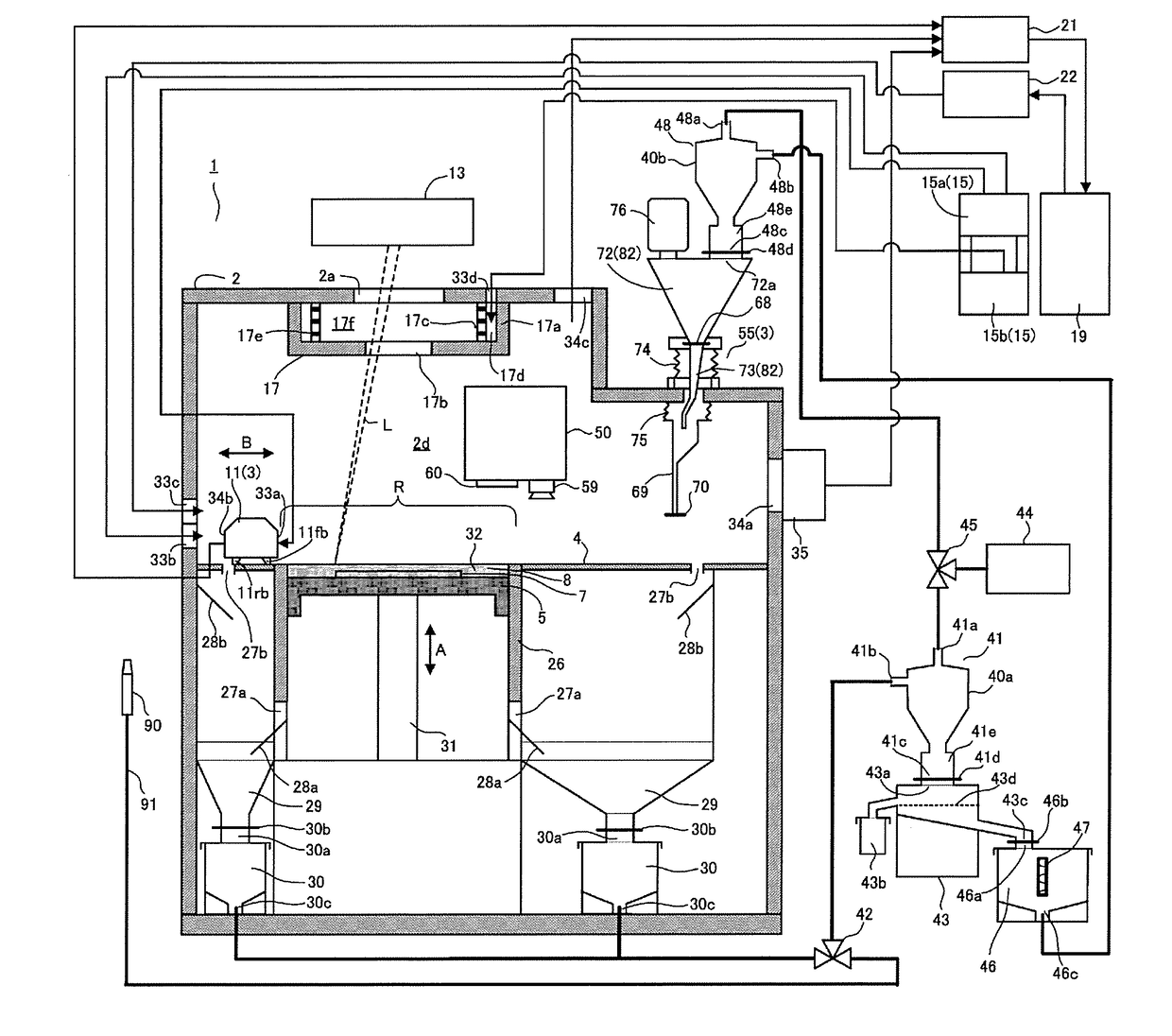

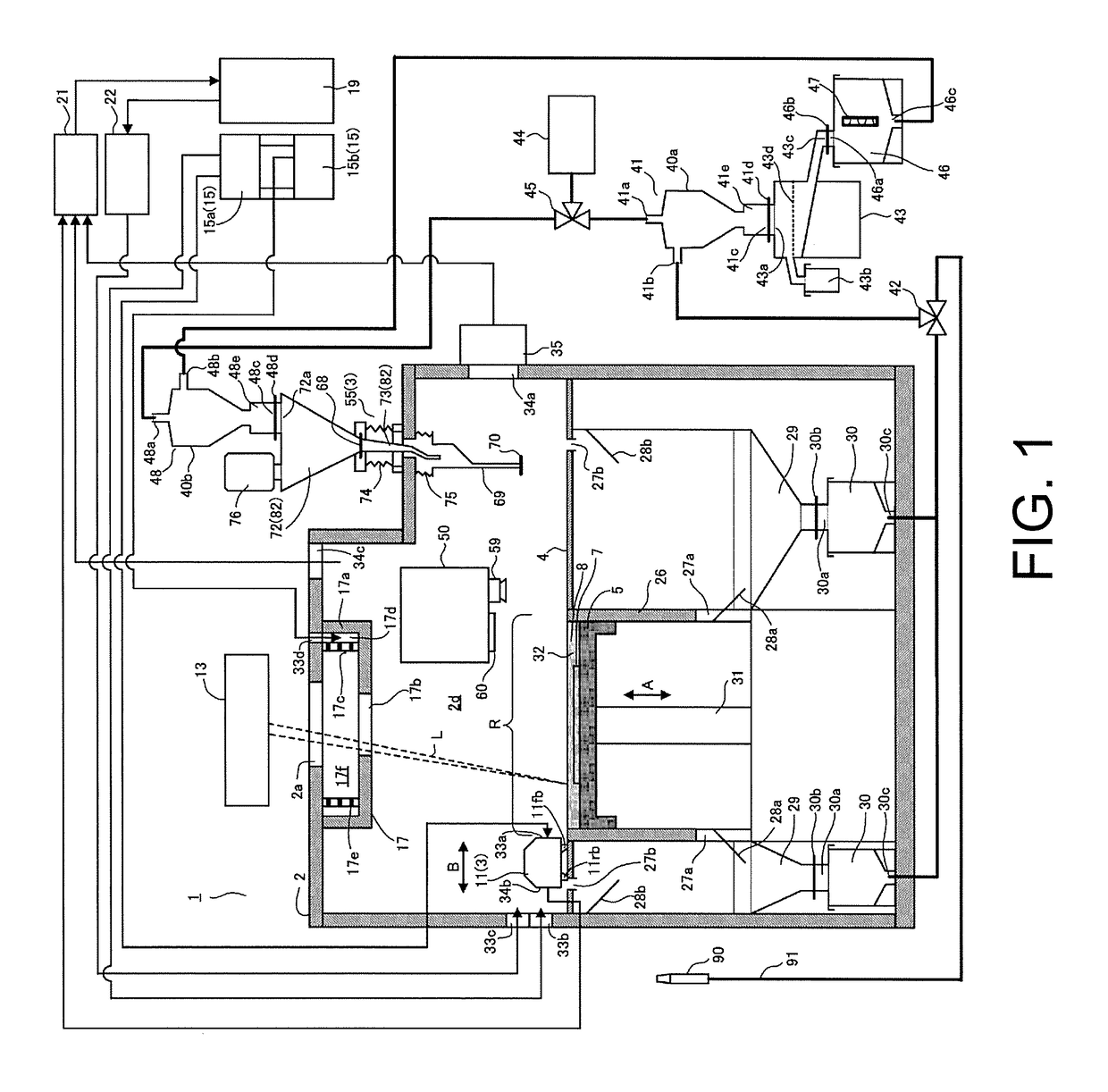

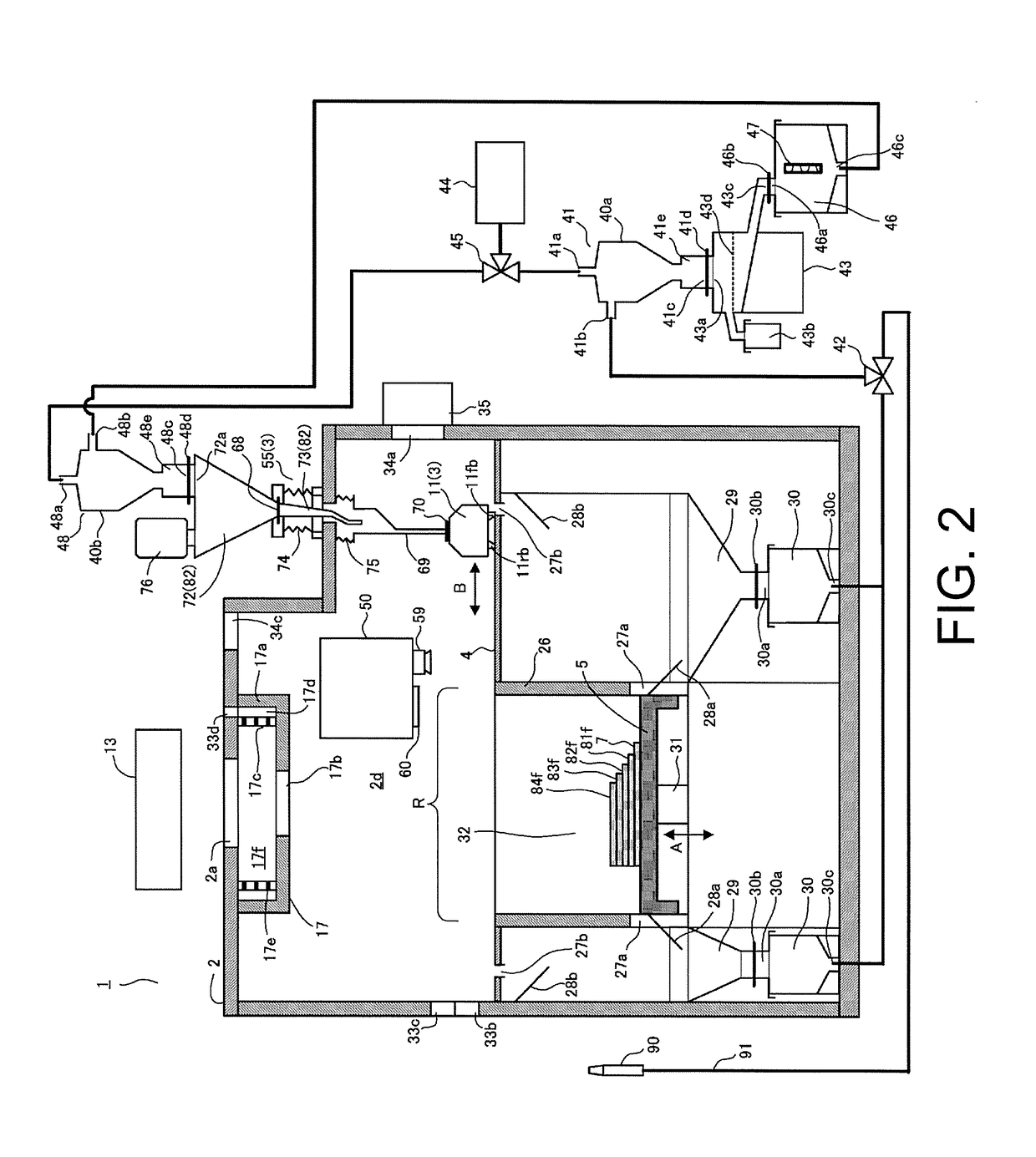

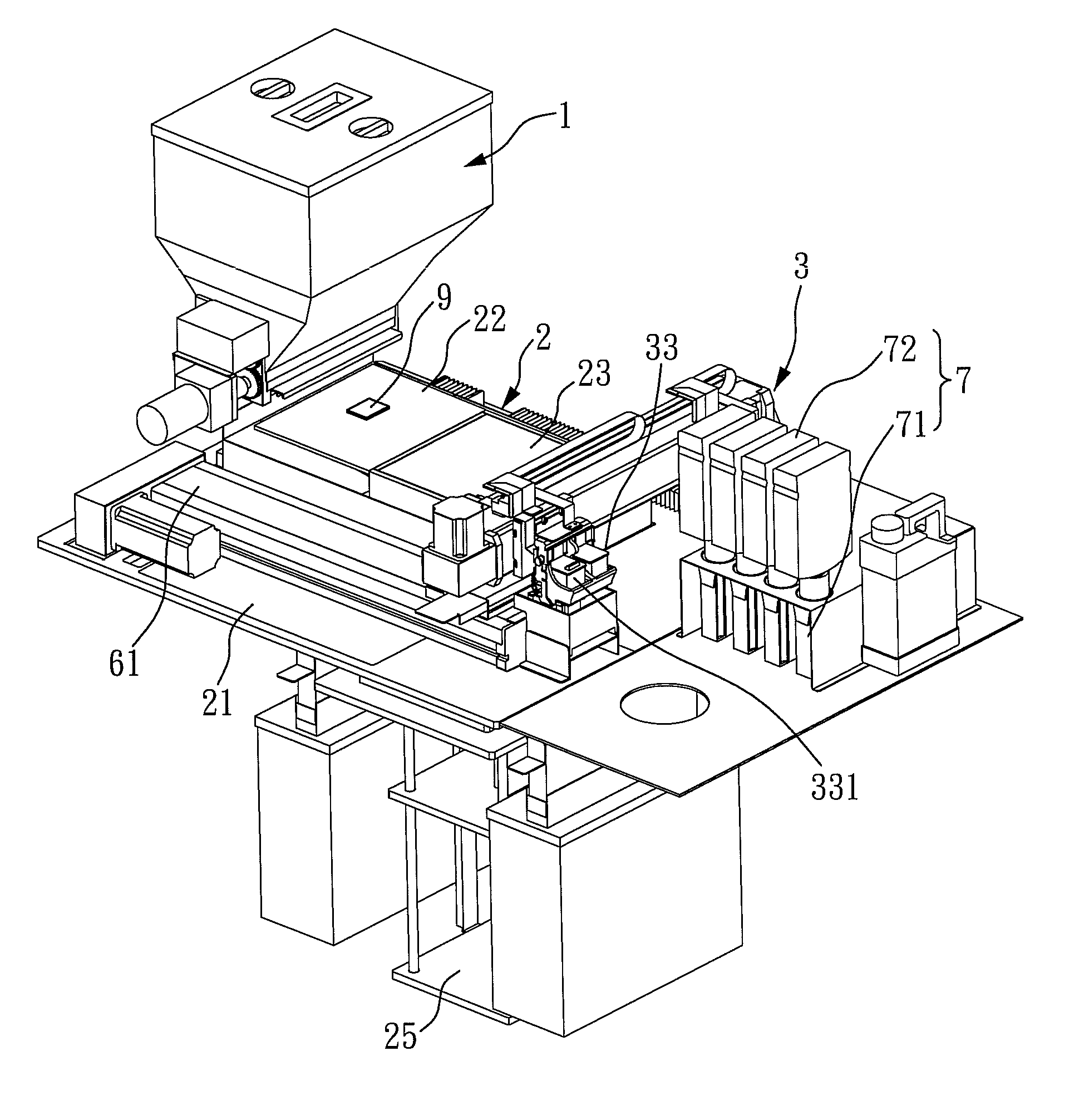

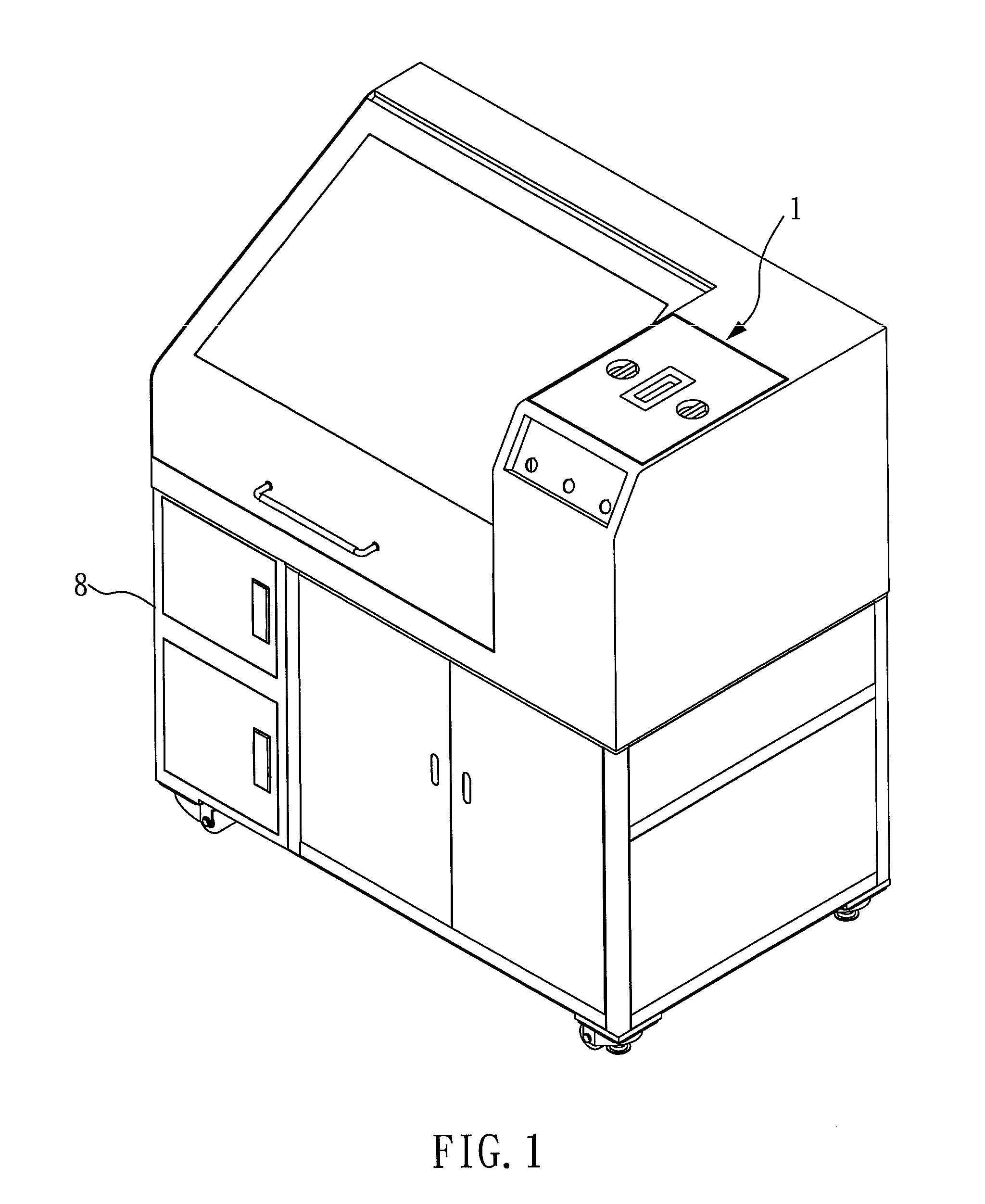

Three-dimensional printer

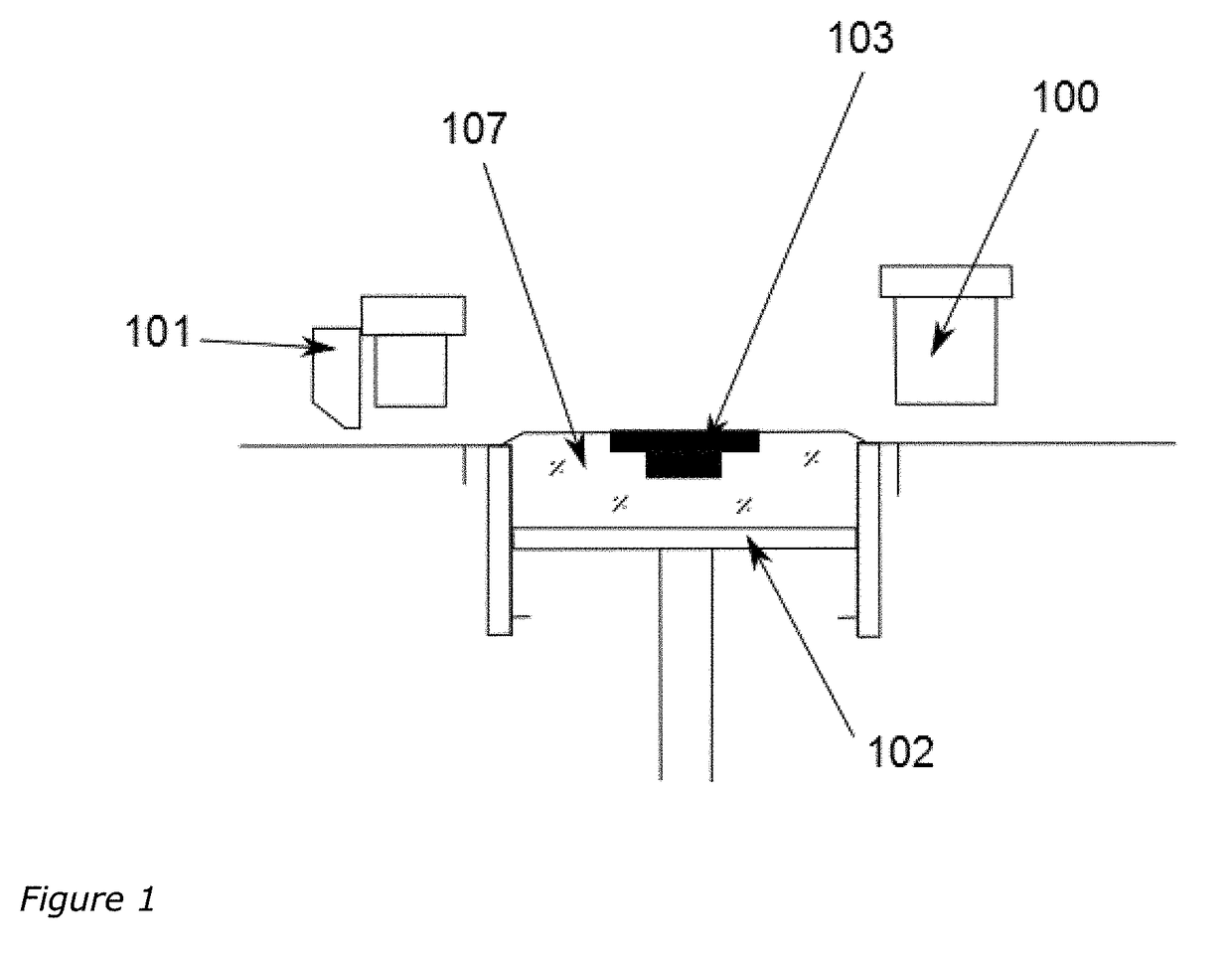

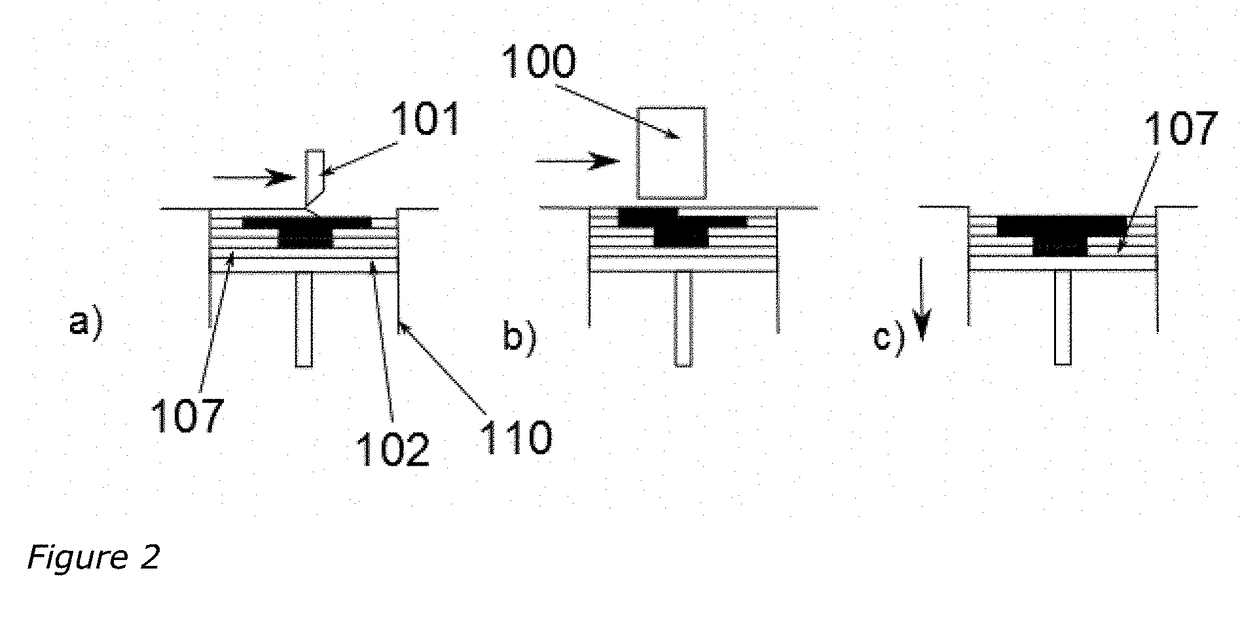

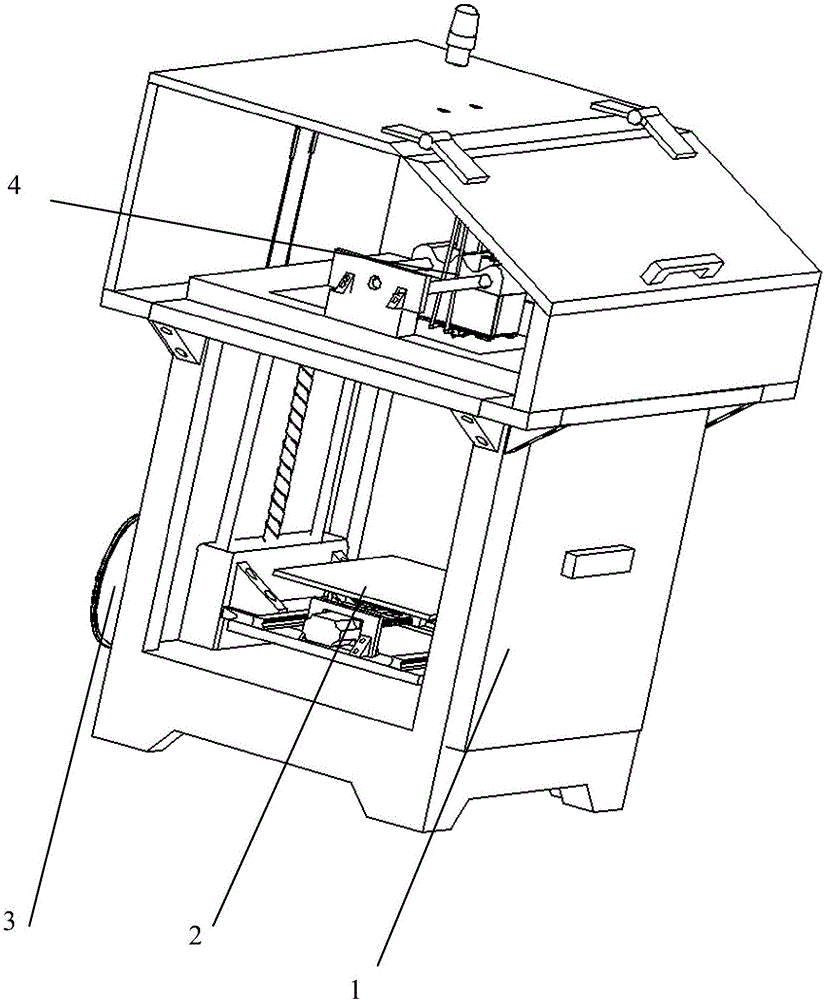

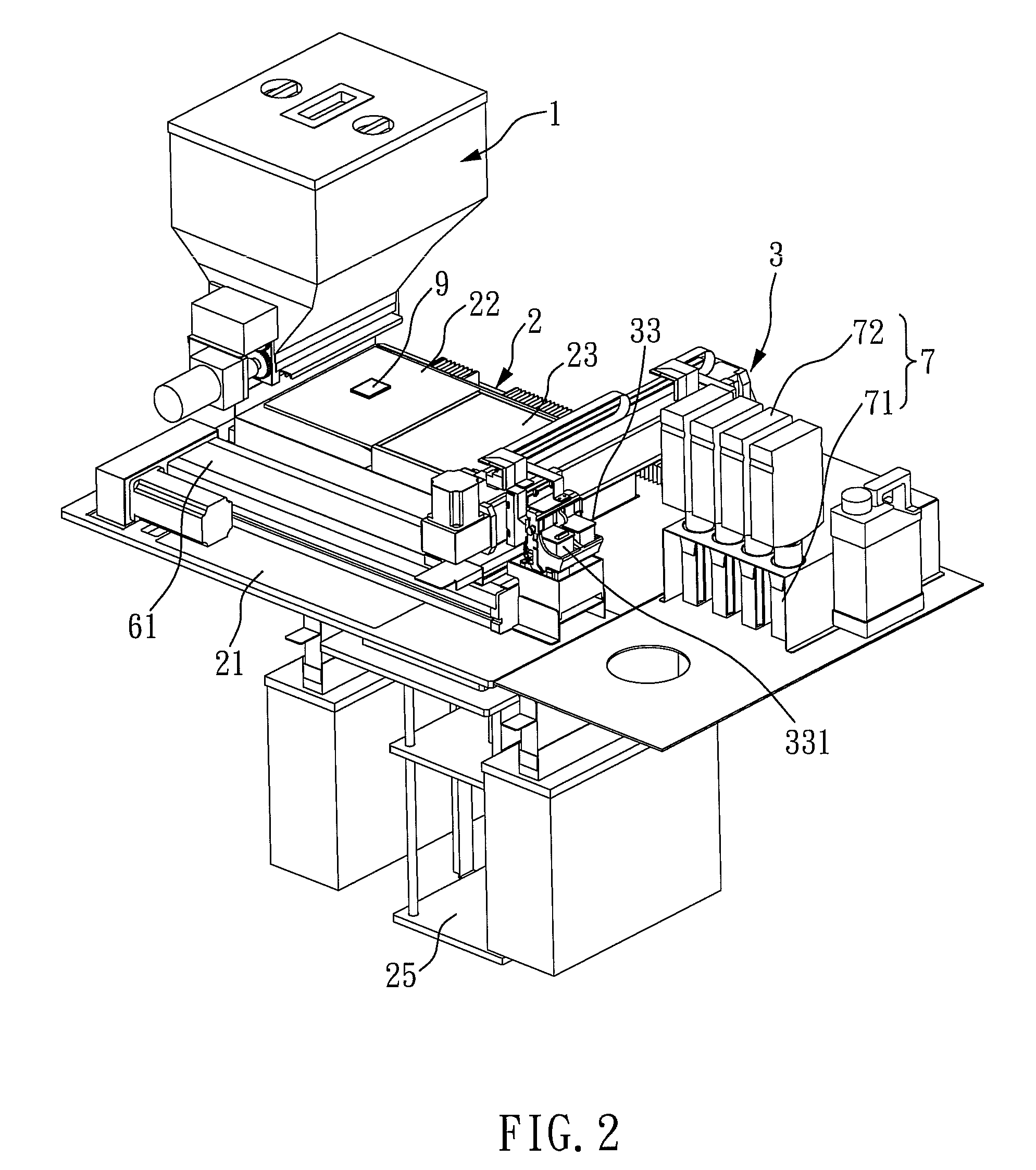

ActiveUS20170348771A1Form evenlyLong automationManufacturing enclosuresManufacturing material handlingMaterial supplyRetaining wall

A three-dimensional printer (1) includes a material supply device (3) that supplies material powder to a table which is movable vertically, a powder retaining wall (26) that surrounds the table and retains the material powder, a material-recovery bucket (30) that accommodates excess material powder and impurities discharged from the powder retaining wall, an impurity removing device (43) that removes the impurities from the material powder, and a material drying device (47) that dries the material powder. The material powder from which the impurities have been removed and which has been dried is returned and recycled to the material supply device.

Owner:SODICK CO LTD

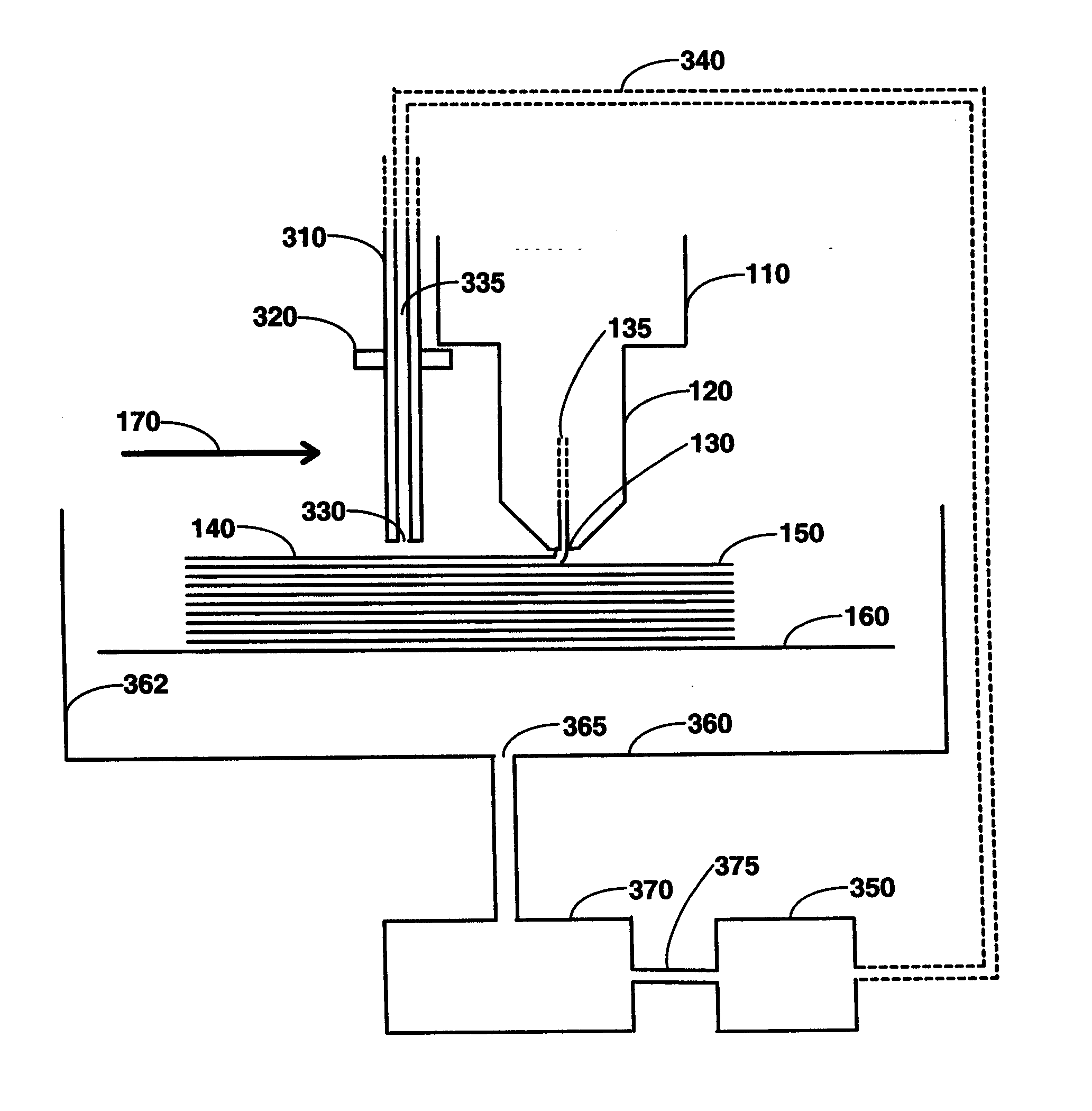

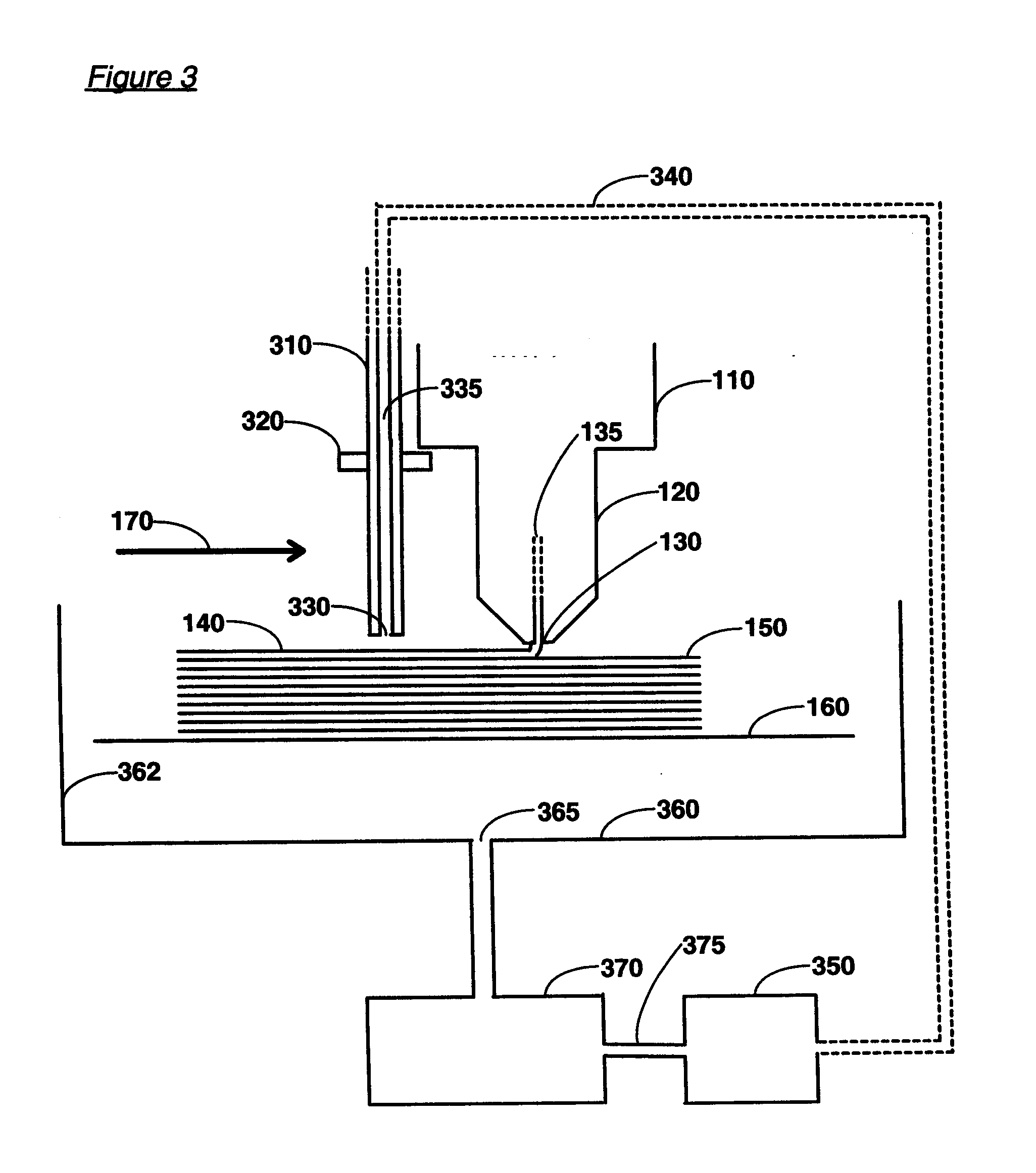

Rapid prototyping apparatus

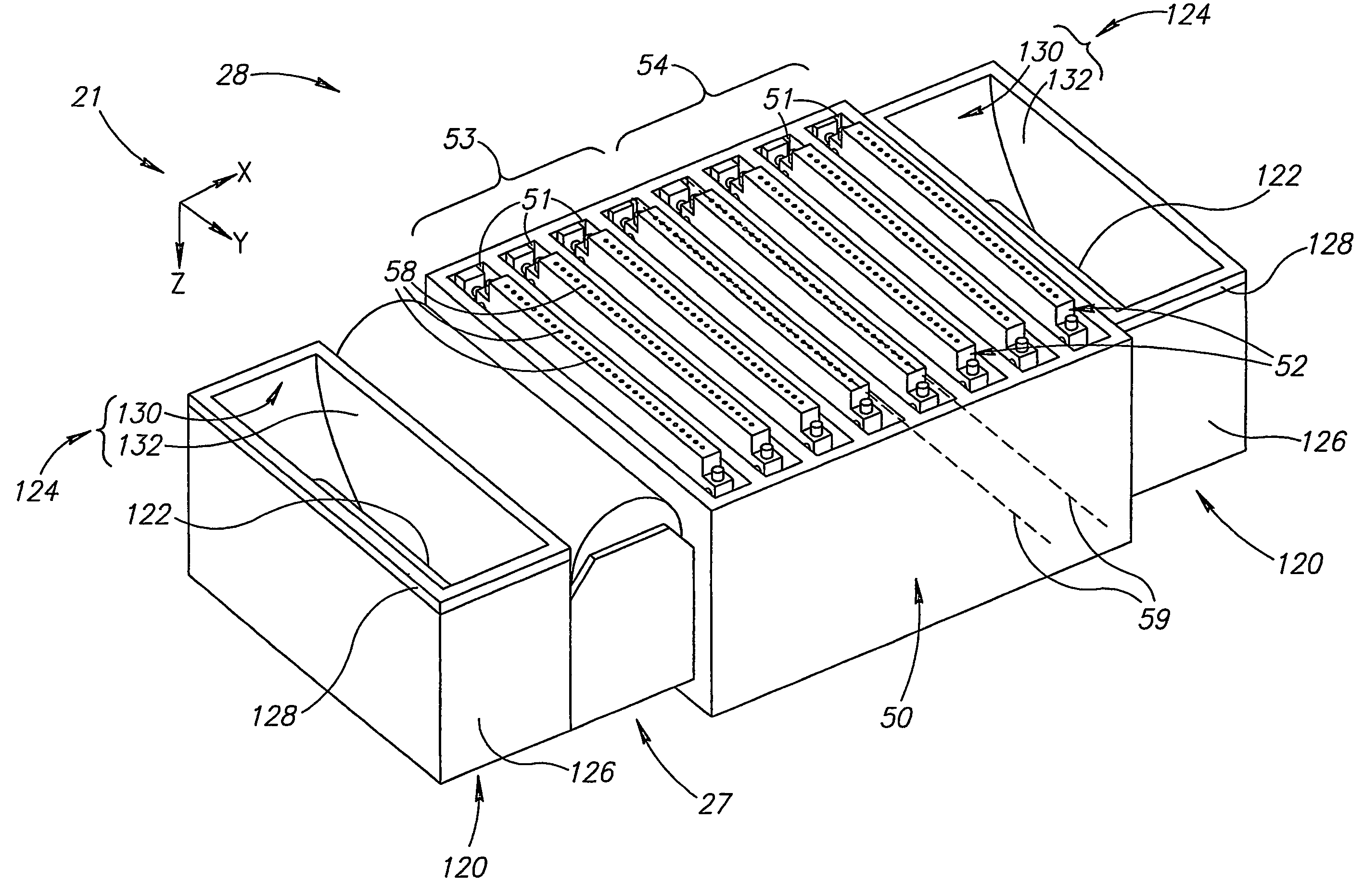

ActiveUS20070179656A1Improve structural strengthImprove operating characteristicsConfectionerySweetmeatsThin layerRapid prototyping

Apparatus for producing an object by sequentially forming thin layers of a construction material one on top of the other responsive to data defining the object, the apparatus comprising: a plurality of printing heads each having a surface formed with a plurality of output orifices and controllable to dispense the construction material through each orifice independently of the other orifices; a shuttle to which the printing heads are mounted; a support surface; and a controller adapted to control the shuttle to move back and forth over the support surface and as the shuttle moves to control the printing heads to dispense the construction material through each of their respective orifices responsive to the data to form a first layer on the support surface and thereafter, sequentially the other layers; wherein each printing head is dismountable from the shuttle and replaceable independently of the other printing heads.

Owner:OBJET GEOMETRIES

Method and device for applying fluids

ActiveUS8096262B2Avoid emissionsLiquid surface applicatorsAdditive manufacturing apparatusMechanical engineeringAngle of repose

This document describes a process and a device for applying fluids, specifically particle material, on an area to be coated, which is viewed in forward moving direction of the coater, that fluid is applied on the area to be coated and then a leveling element is run over the applied fluid, whereby the fluid is led from a metering system provided with an opening, which oscillates when applying the fluid. The opening shall be designed in such a way that when the metering system is at a standstill this is closed by forming an angle of repose of the fluid.

Owner:VOXELJET AG

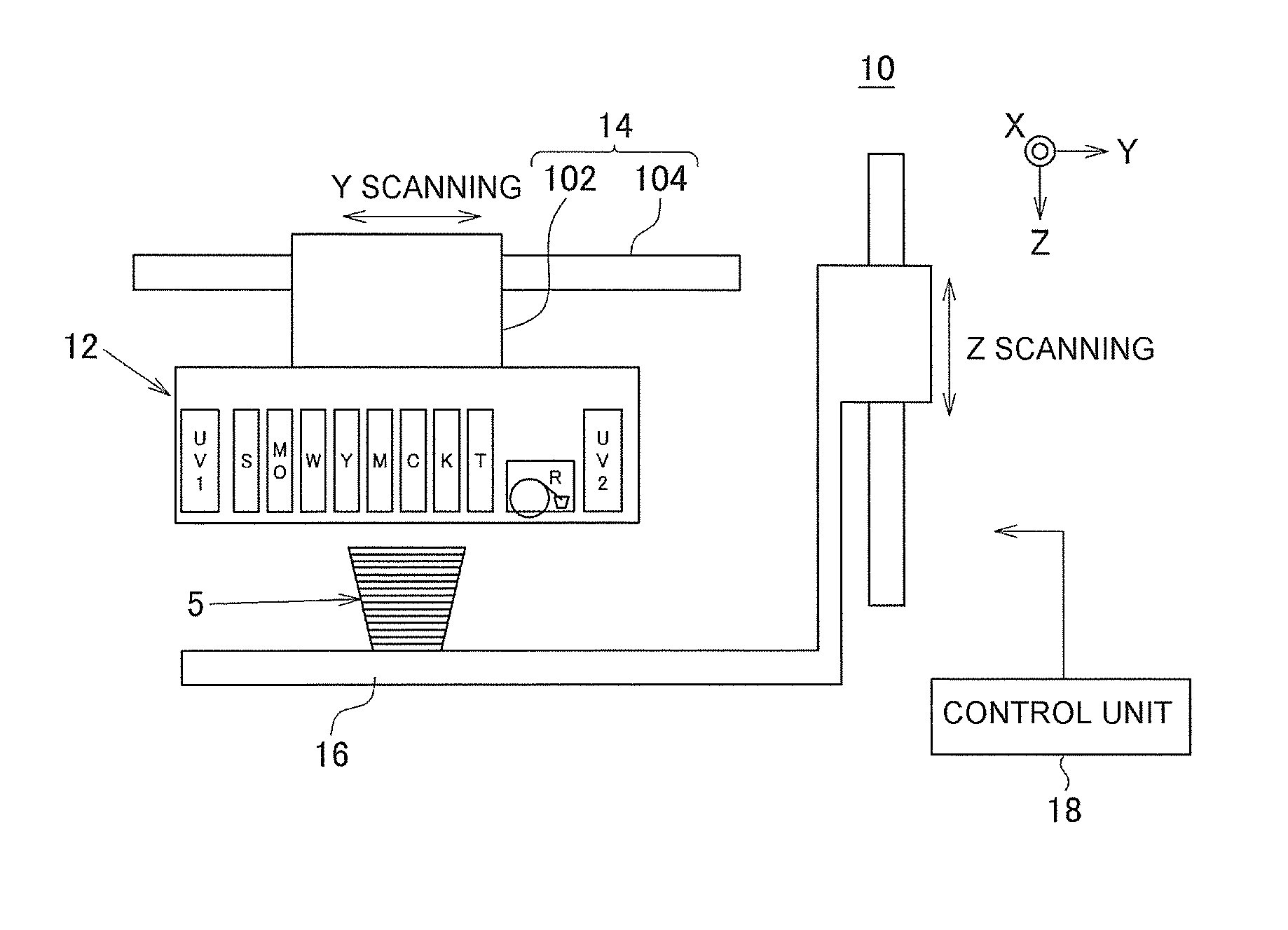

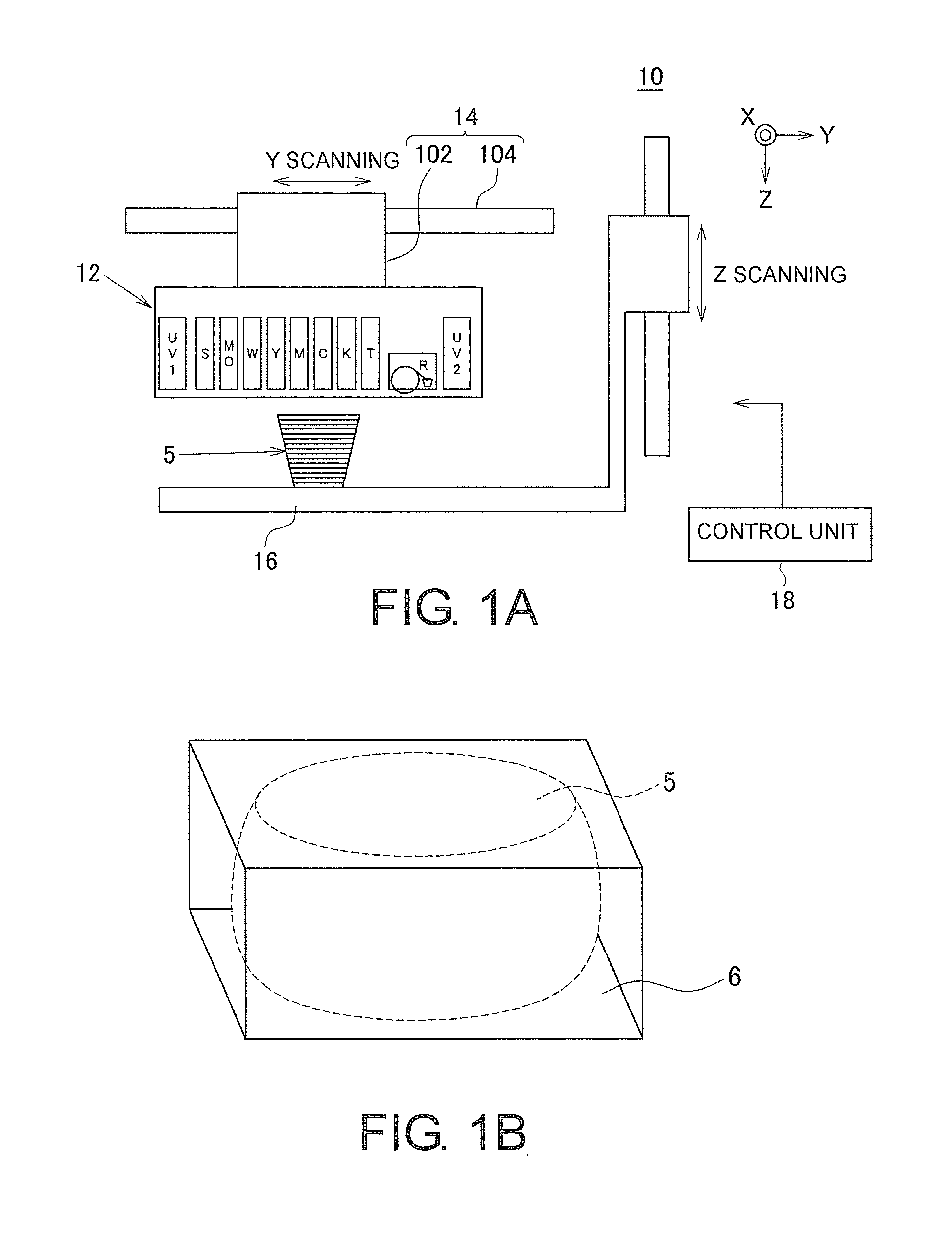

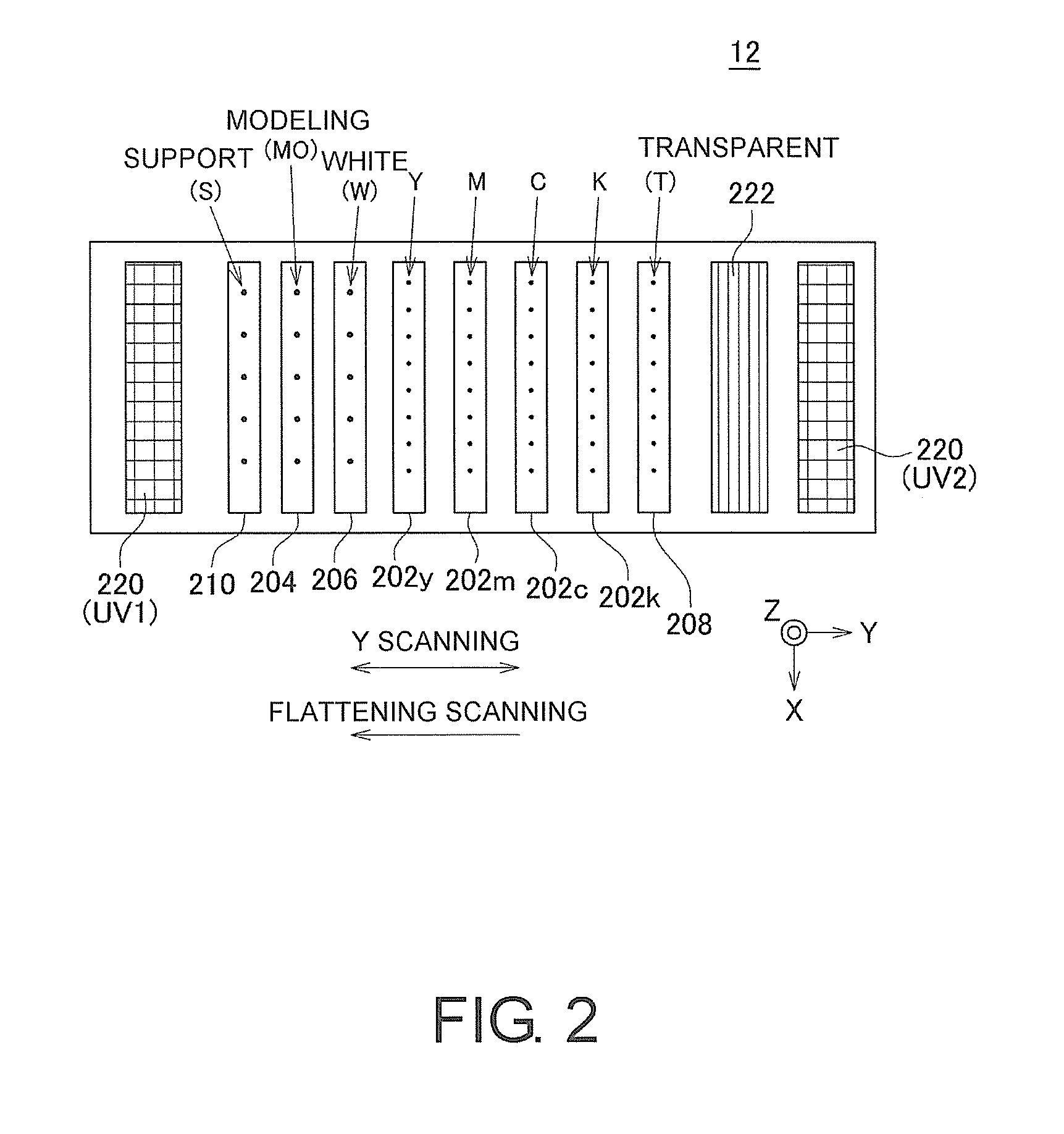

Apparatus for modeling three-dimensional object and method for modeling three-dimensional object

InactiveUS20160001505A1Increase modeling speedMouldsConfectioneryUltraviolet lightsMechanical engineering

An apparatus for modeling a three-dimensional object configured to model a three-dimensional object by a lamination modeling method includes a plurality of heads for colored inks including a curable resin and configured to discharge ink droplets of colored inks having different colors from each other by an inkjet method, an ultraviolet light source, which is a curing unit, and a control unit. When coloring a surface of the three-dimensional object, the control unit enables the plurality of heads for colored inks to discharge the ink droplets, based on an image, to an outer periphery area of the three-dimensional object, which is an area of which a color can be visibly recognized from an outside of the three-dimensional object. When not coloring the surface of the three-dimensional object, the control unit enables at least one of the heads for colored inks to discharge the ink droplets to an inner area.

Owner:MIMAKI ENG

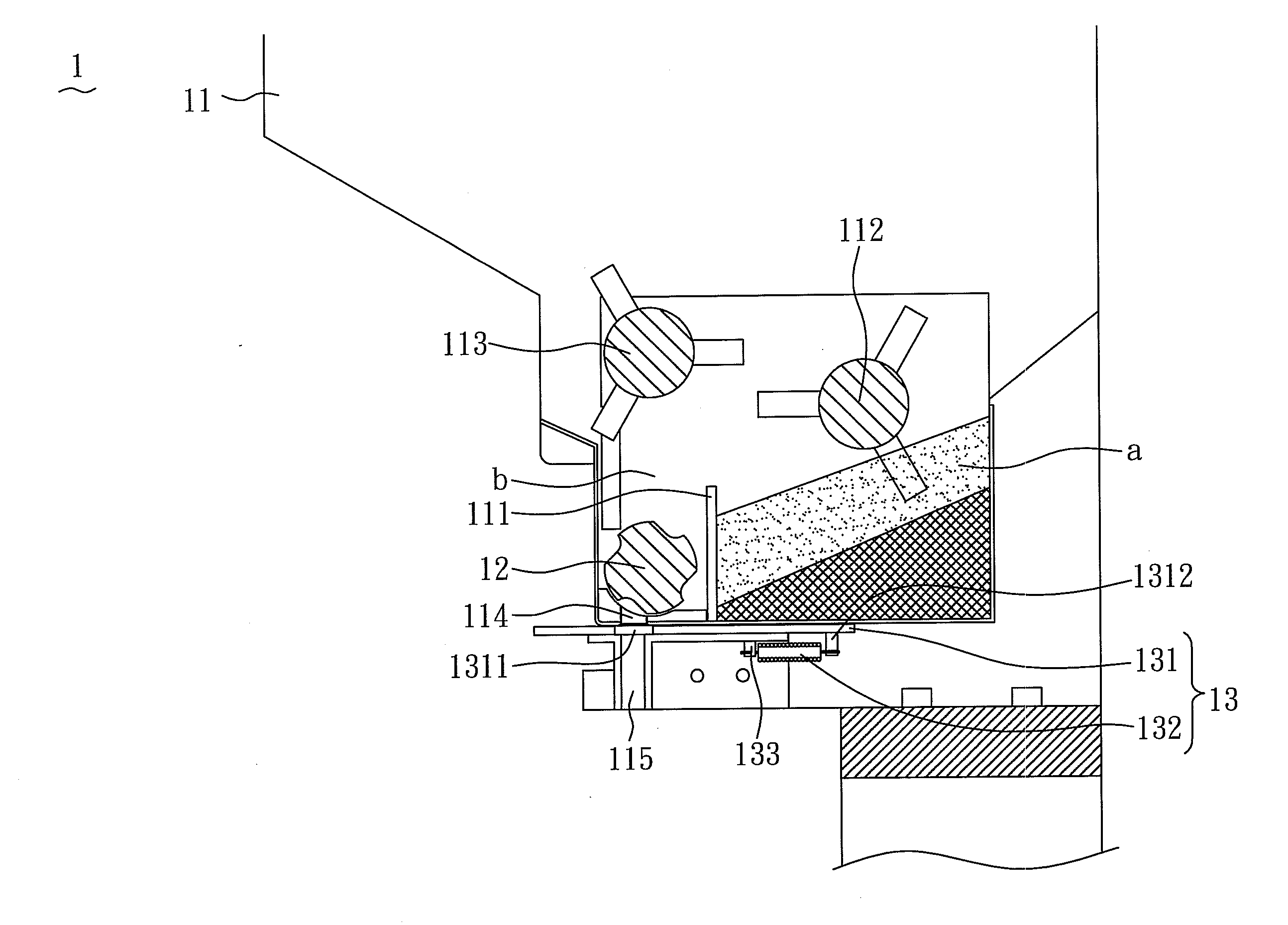

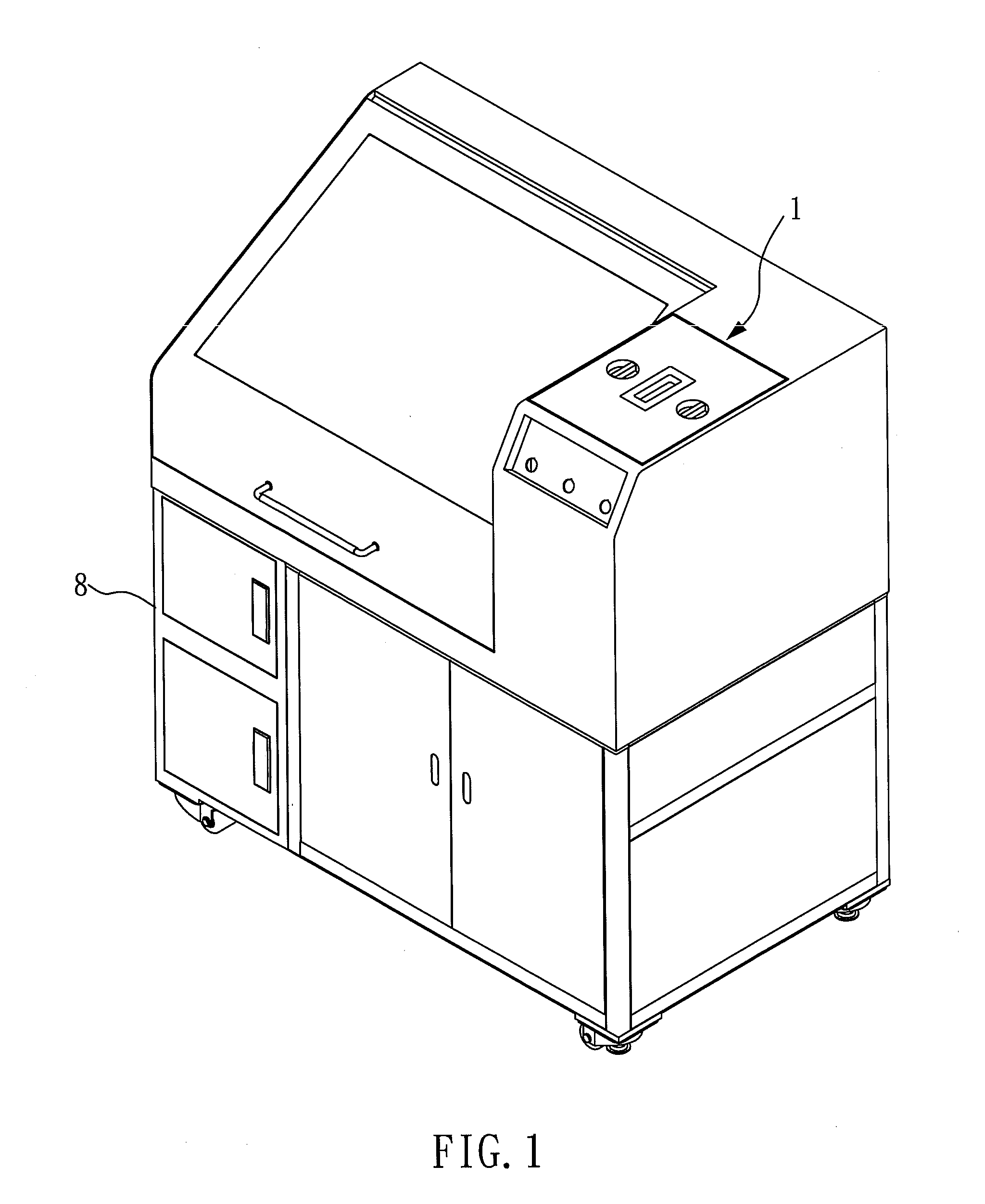

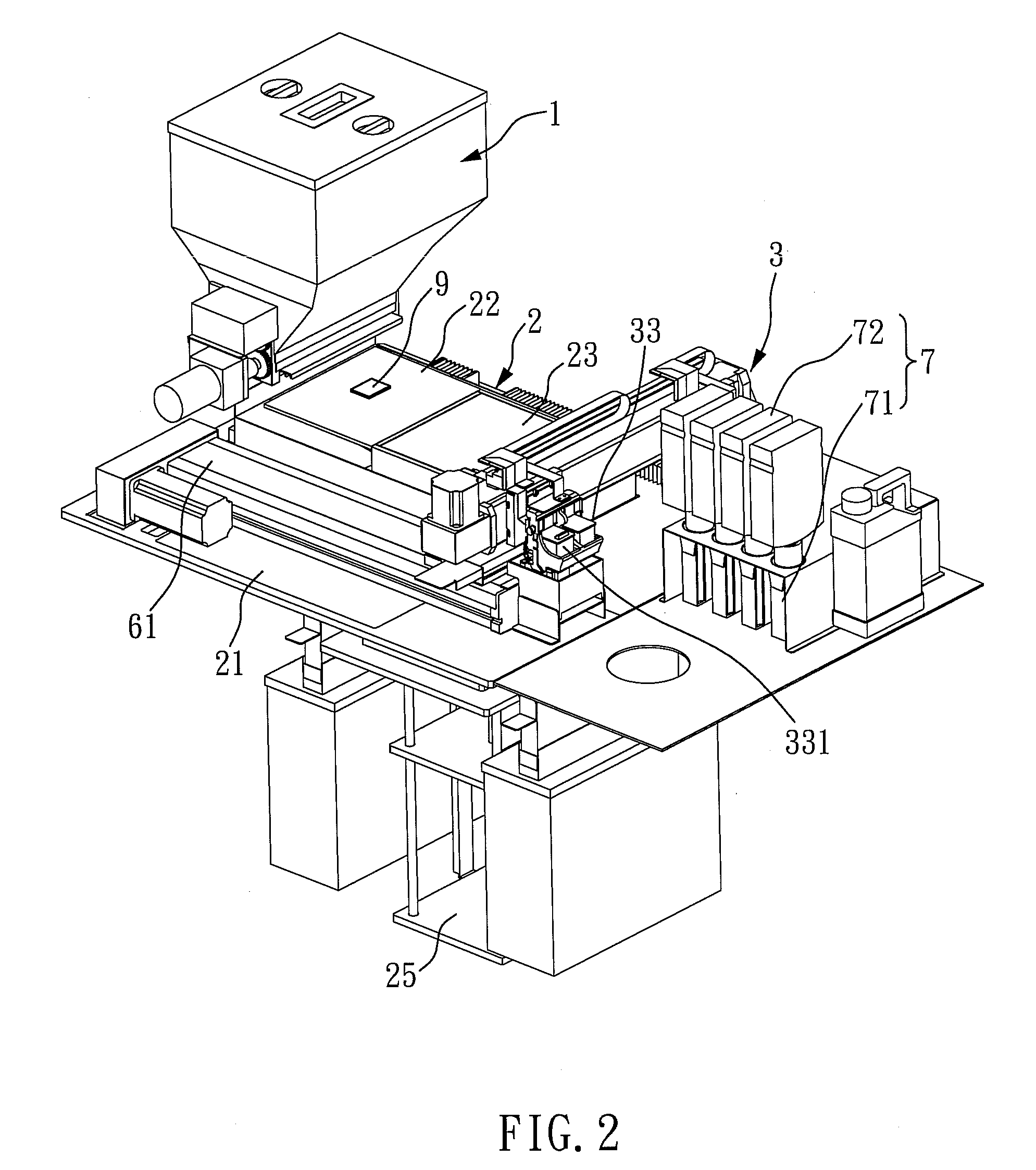

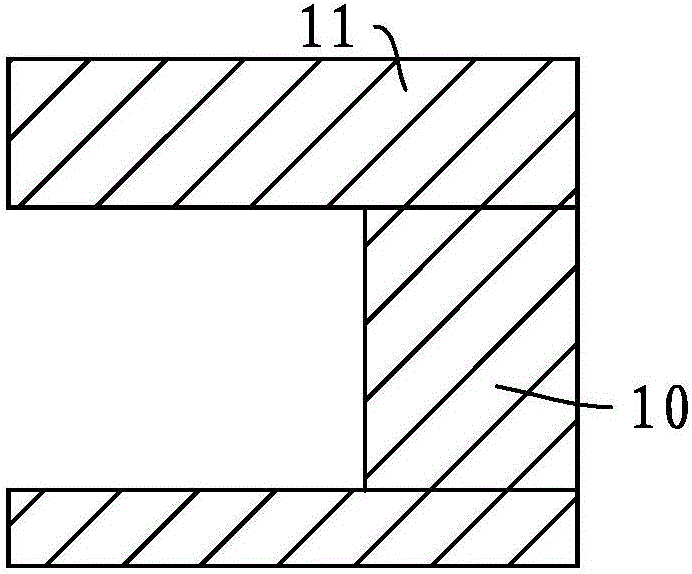

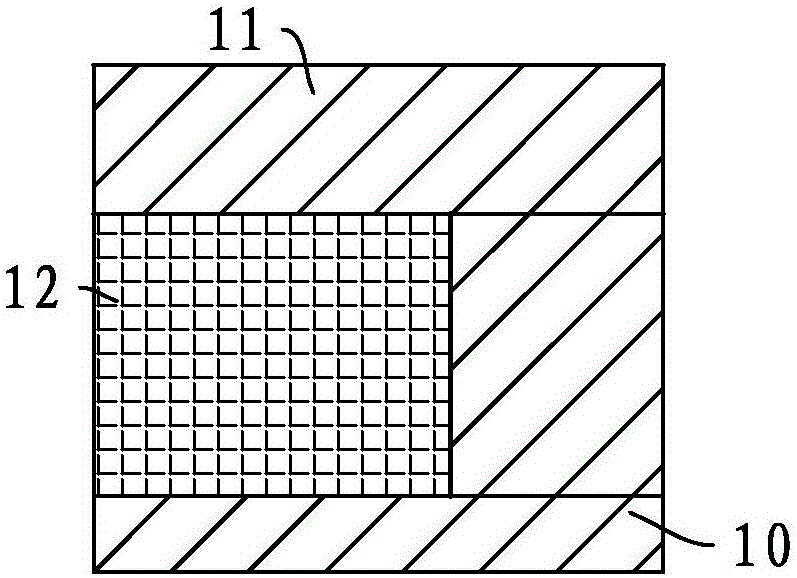

Three-dimensional object-forming apparatus

ActiveUS20110300248A1Avoid wastingLow production costManufacturing enclosuresConfectioneryEngineeringHeating system

A three-dimensional object-forming apparatus is disclosed, which includes an in-batches powder-rationing tank system, a construction tank system, a printing powder-applying system, a rapid drying heating system, a printing maintenance device, a dust-proof device, a successive liquid-supplying device, a powder auto-filtrating and recycling device, and a print quality detection device.

Owner:MICROJET TECH

Machine and process for powder-based additive manufacturing

ActiveCN104010750AImprove uniformityManufacturing enclosuresPretreated surfacesProcess engineeringMechanical engineering

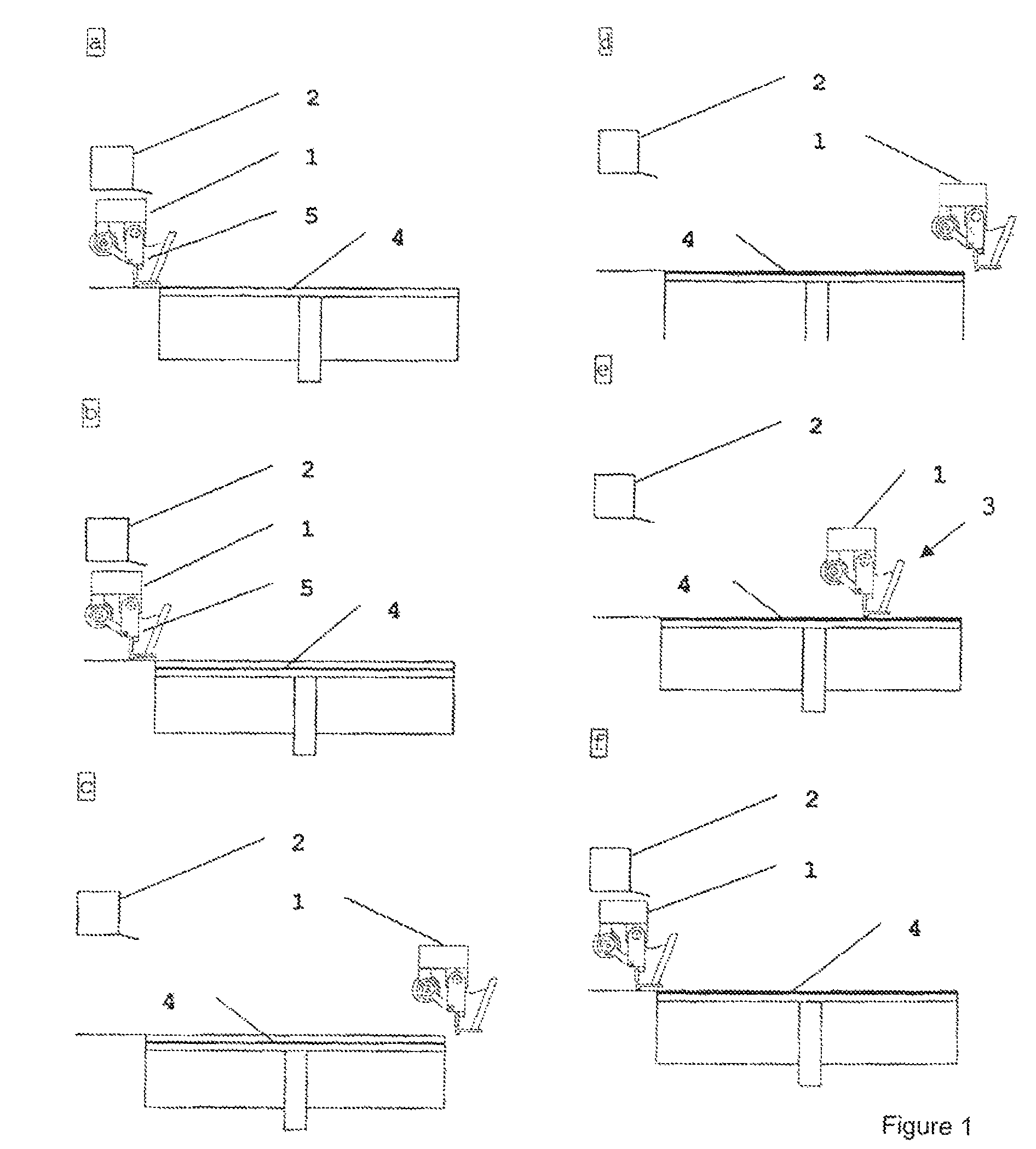

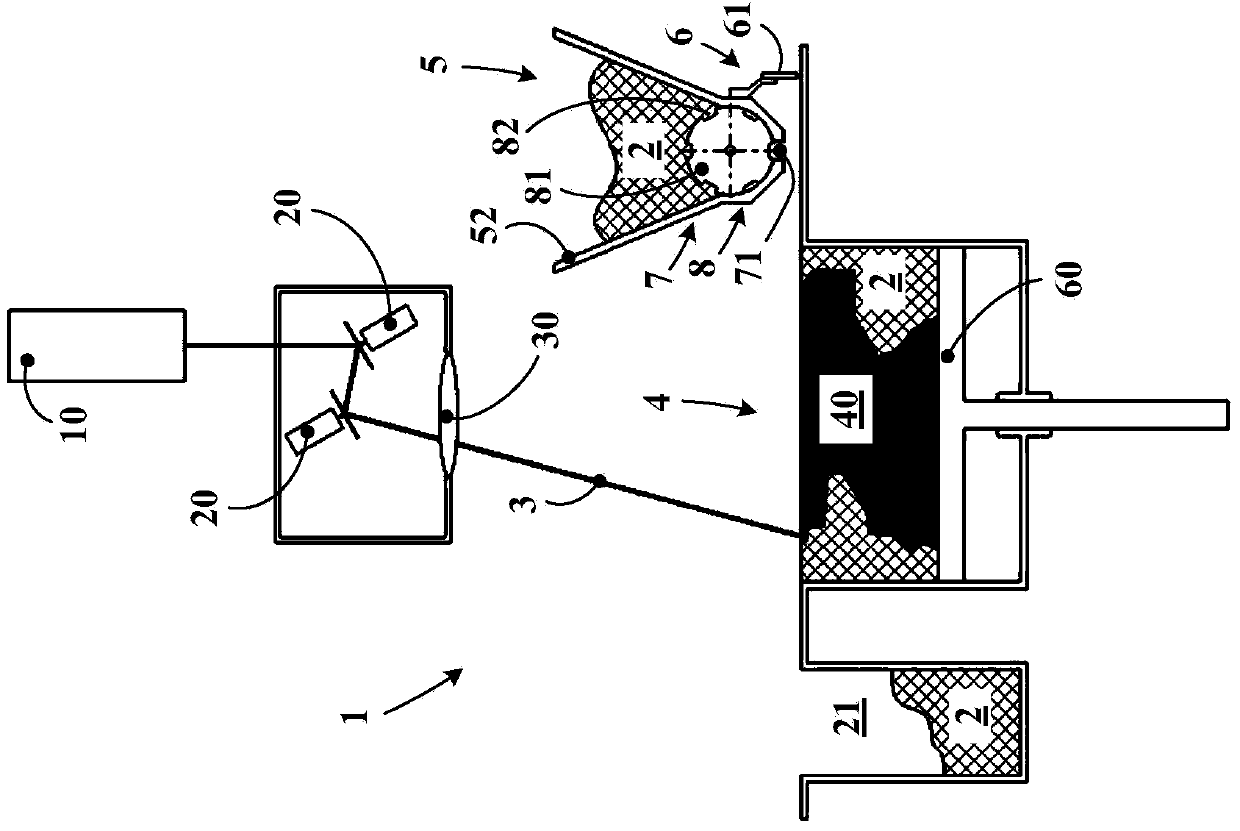

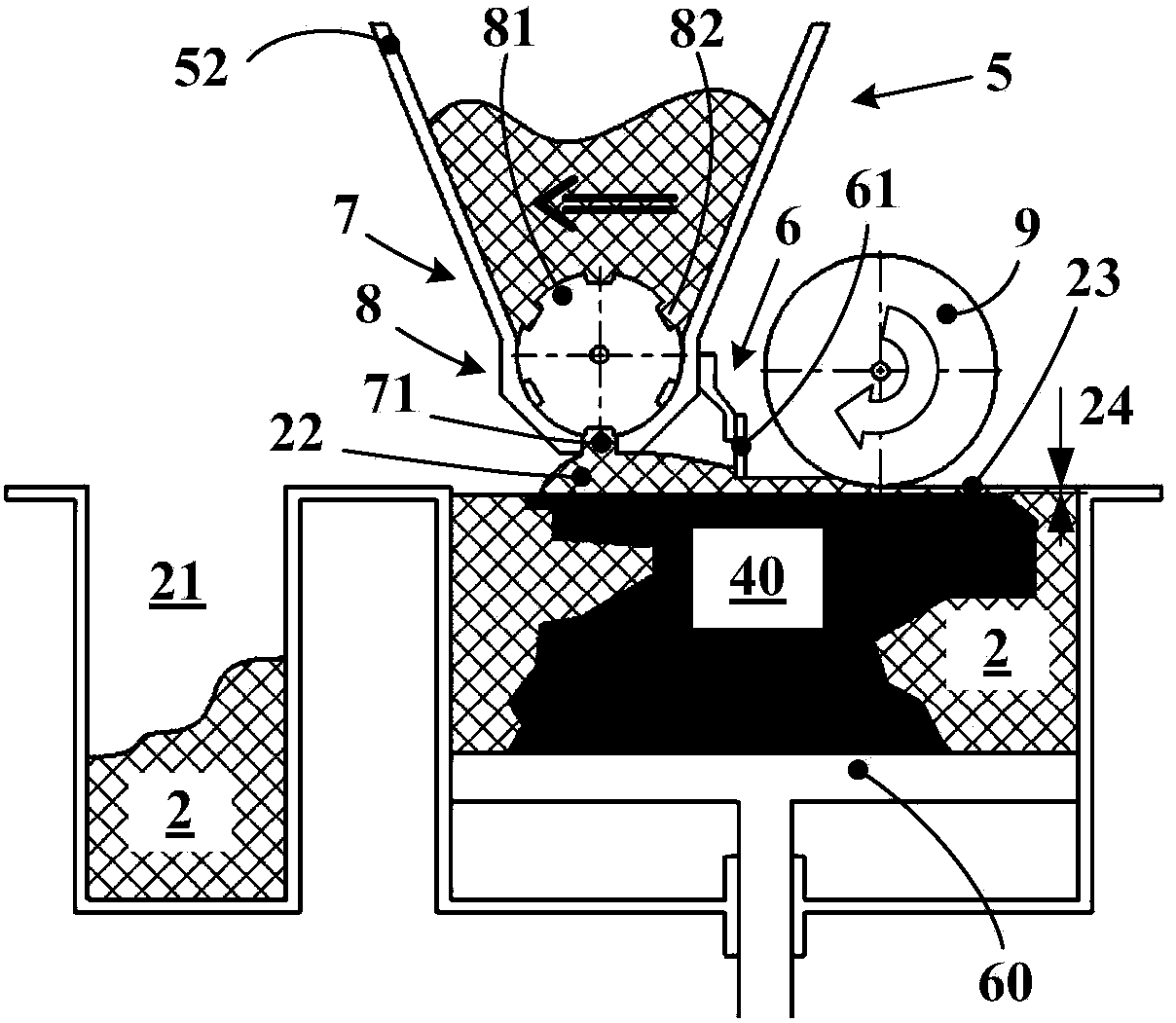

The invention in particular relates to a machine (1) for additive manufacturing that frits or melts powder (2) using an energy beam (3) acting on a powder layer (23) in a working zone (4), said machine comprising a device for producing a layer of said powder, said device comprising: means (5) of storing the powder; means (6) for distributing the powder, which means is able to travel over the working zone in order to distribute the powder in a layer (23) having a final thickness (24) tailored to the additive manufacturing; feeding means (7) able to transfer the powder from the storage means (5) to the distributing means (6); and dosing means (8) able to control the amount of powder transferred from the storage means (5) to the distributing means (6), said machine being characterised in that: the storing means (5) are located above the working zone (4); the feeding means (7) are gravitational feeding means; and the feeding means (7) and the dosing means (8) are able to move with the distributing means (6).

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

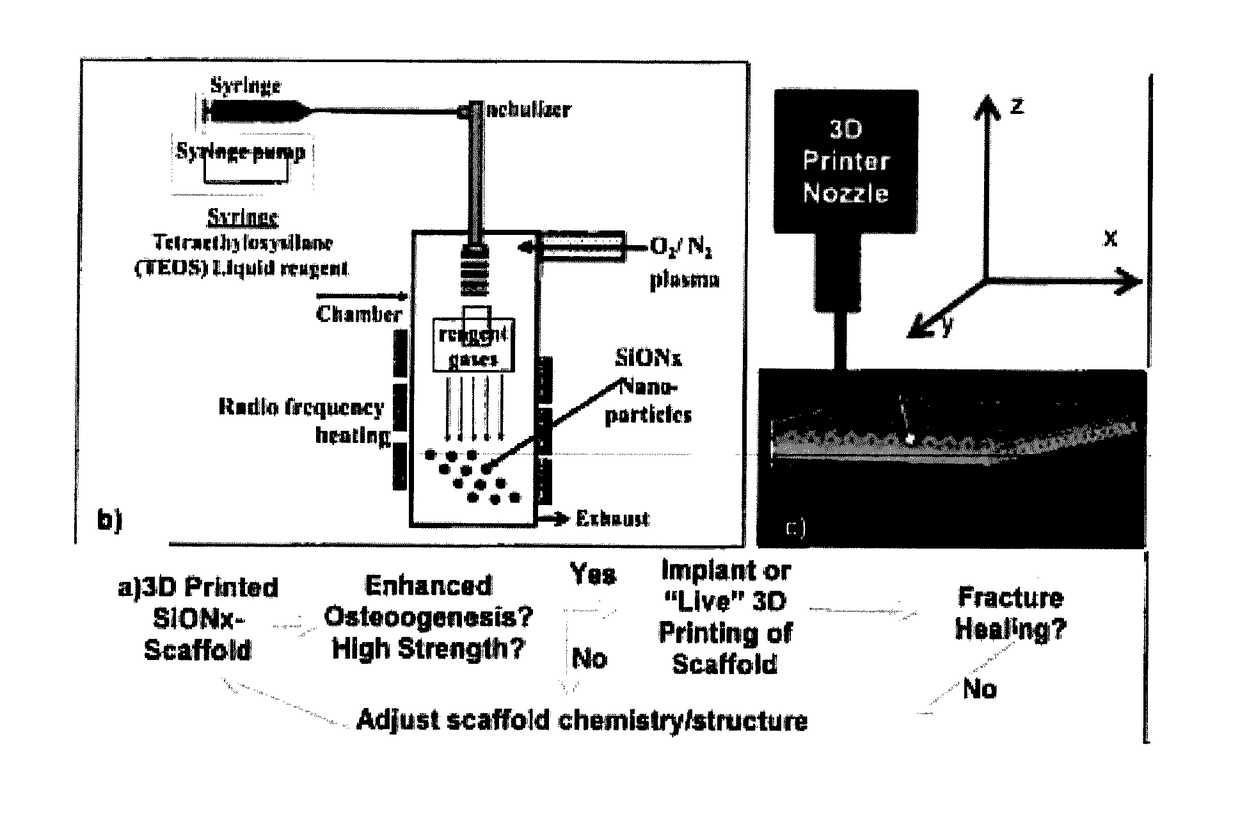

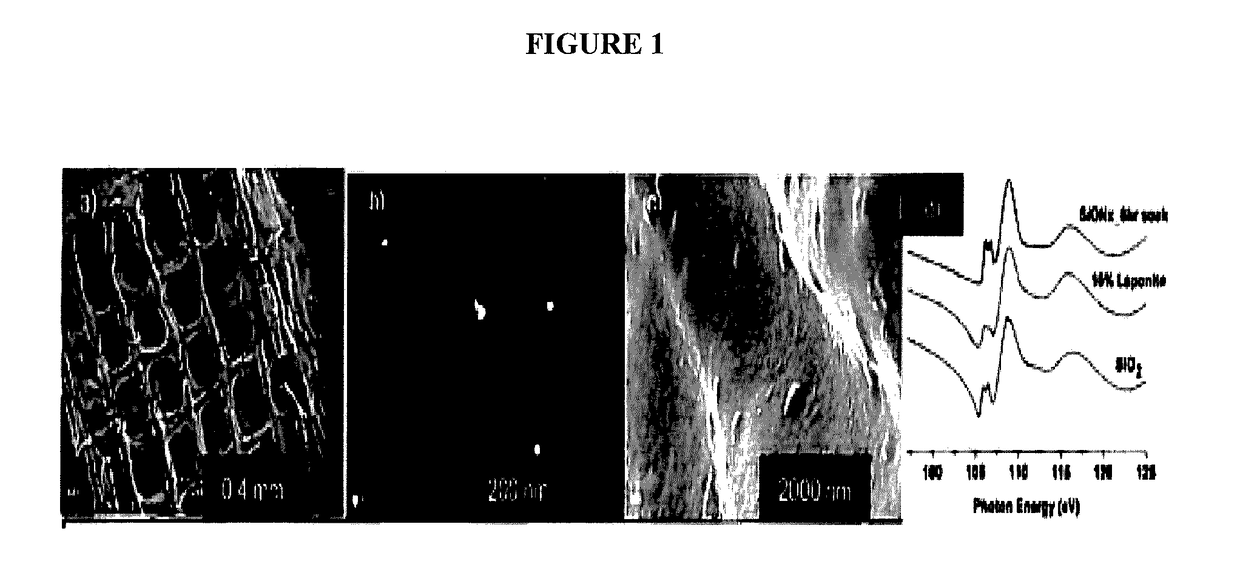

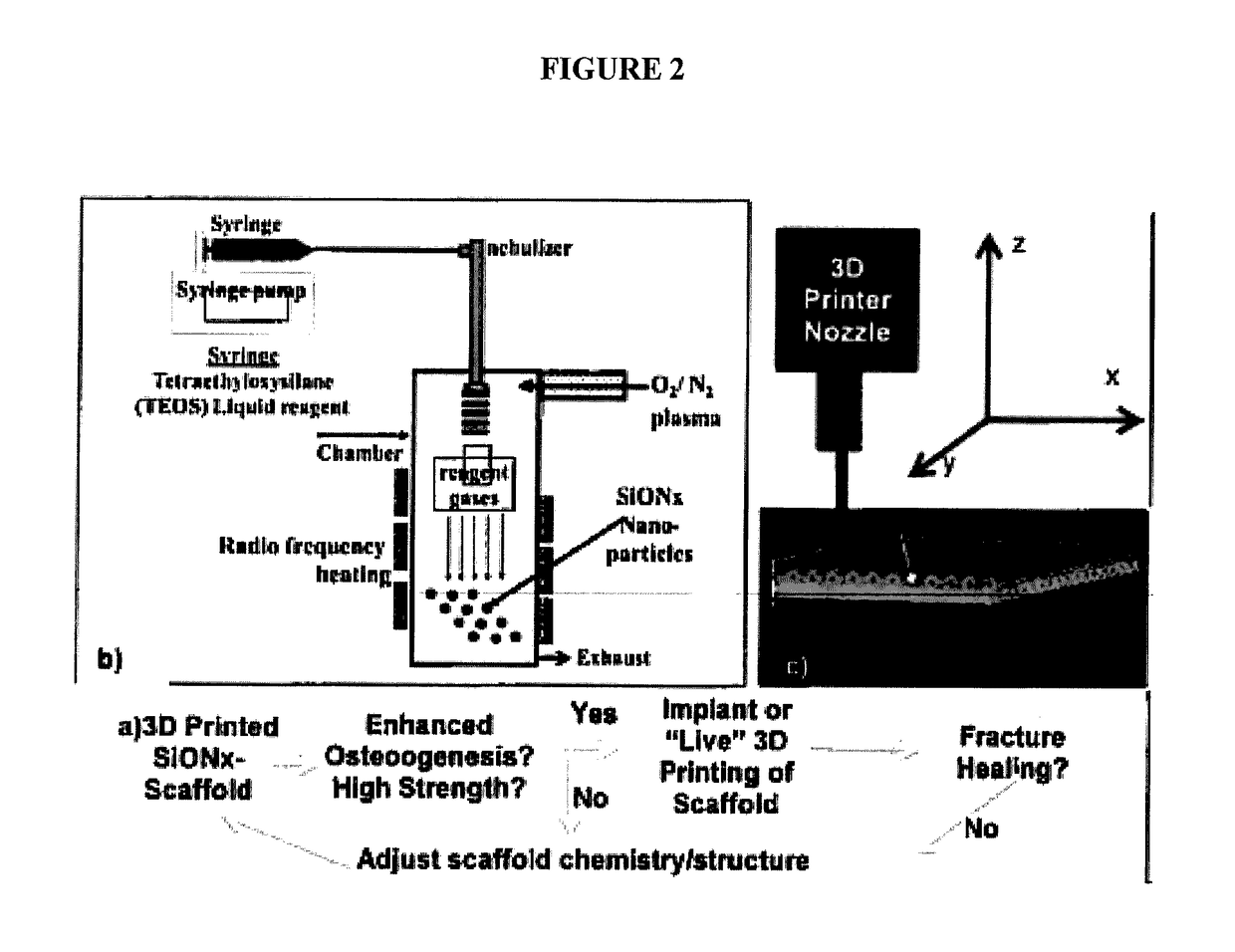

In vivo live 3D printing of regenerative bone healing scaffolds for rapid fracture healing

ActiveUS20170143831A1Promote degradationPowder deliveryOrganic active ingredientsCross-linkPoint of care

Bio-Inks and methods of using compositions comprising the bio-Inks are disclosed. 3-D tissue repair and regeneration through precise and specific formation of biodegradable tissue scaffolds in a tissue site using the bio-inks are also provided. Specific methylacrylated gelatin hydrogels (MAC) and methacrylated chitosan (MACh) preparations formulated with sucrose, a silicate-containing component (such as laponite), and / or a cross-linking agent (such as a photo-initiator or chemical initiator), as well as powdered preparations of these, are also disclosed. Kits containing these preparations are provided for point-of-care tissue repair in vivo. Superior, more complete (up to 99.85% tissue regeneration within 4 weeks applied in situ), and rapid in situ tissue repair and bone formation are also demonstrated.

Owner:TEXAS A&M UNIVERSITY +1

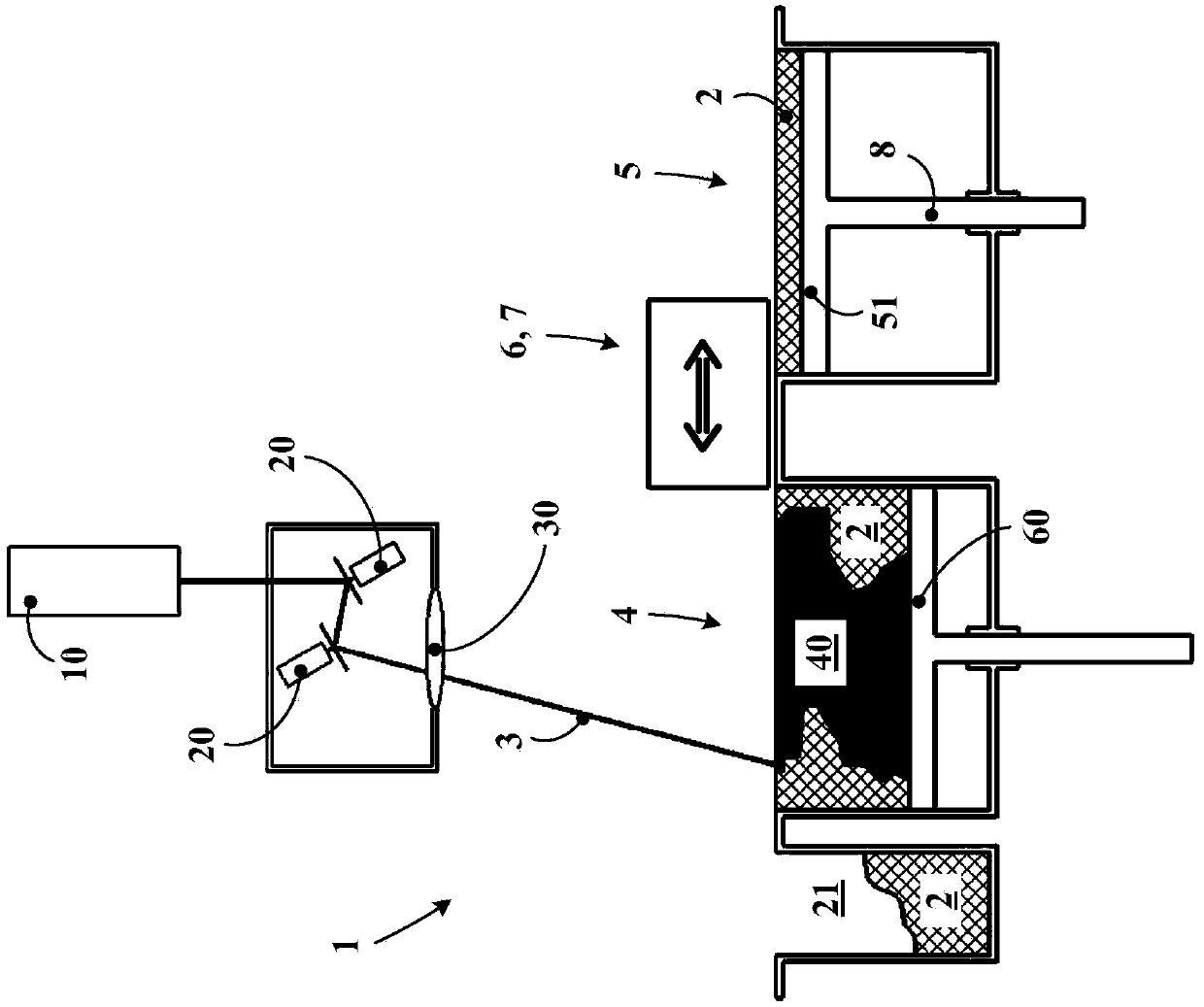

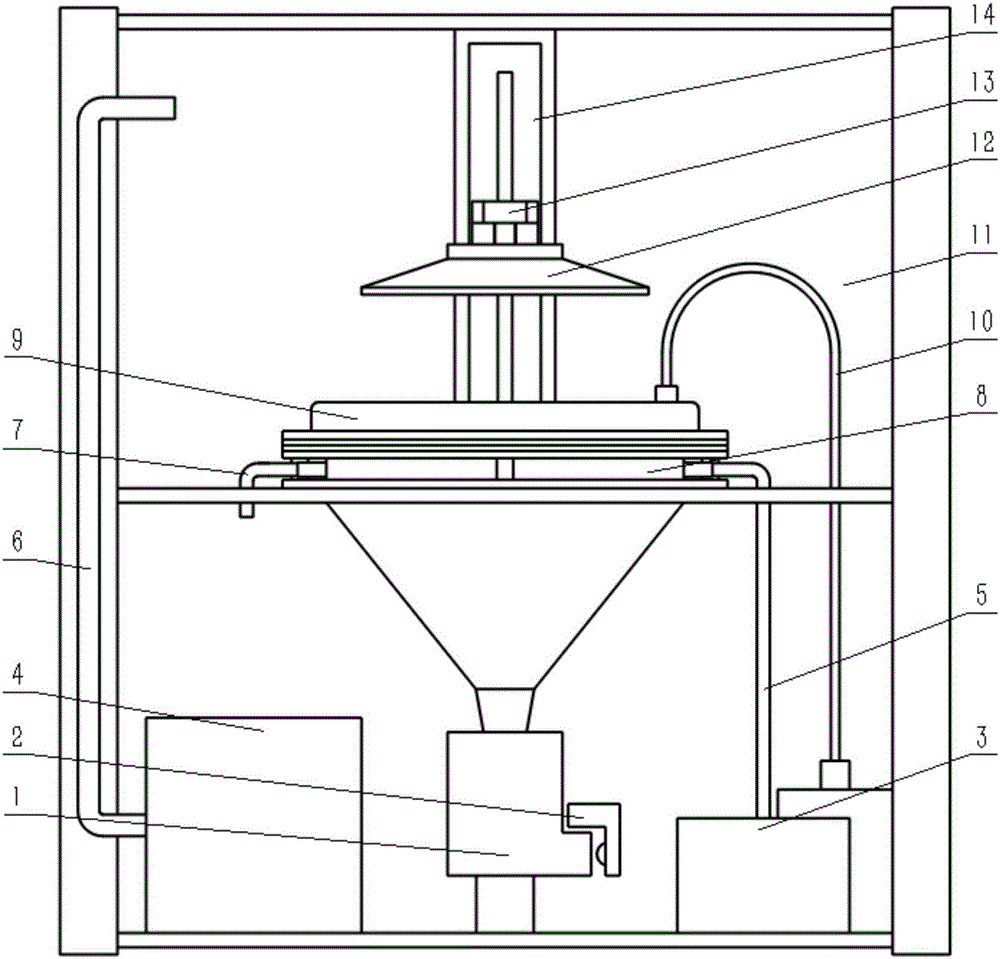

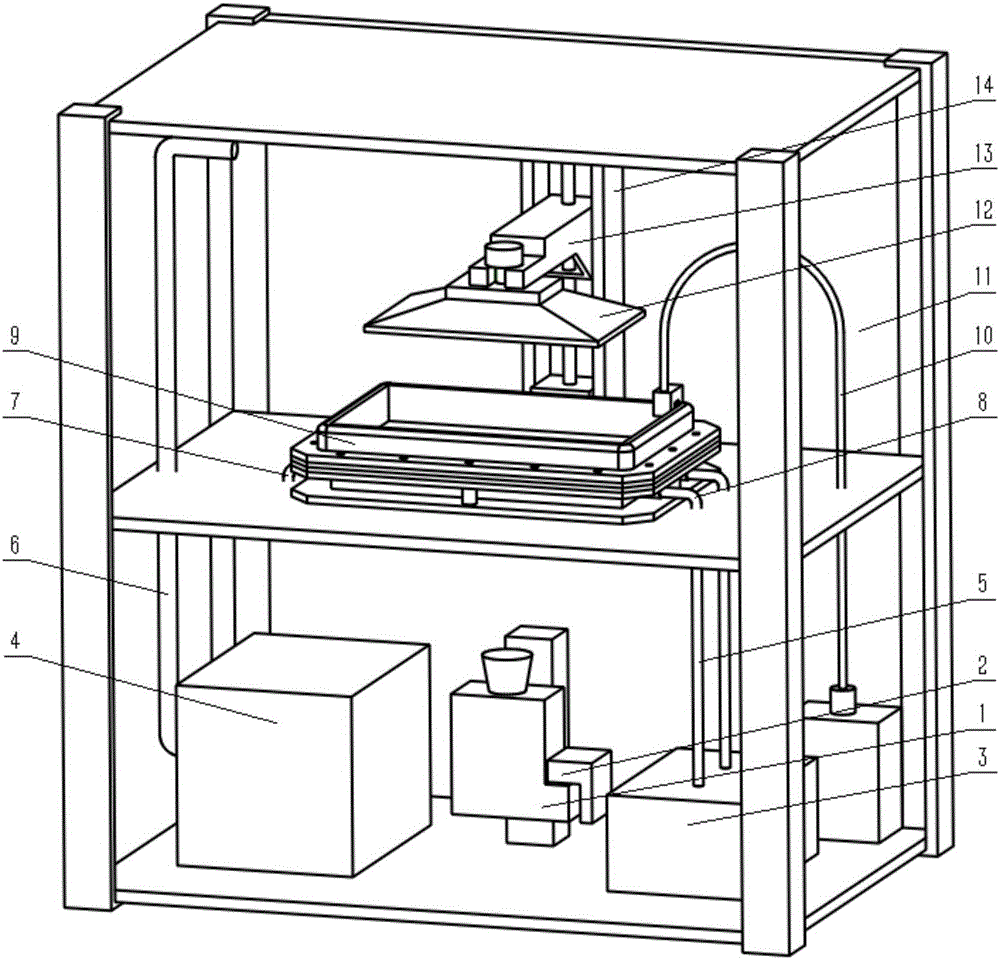

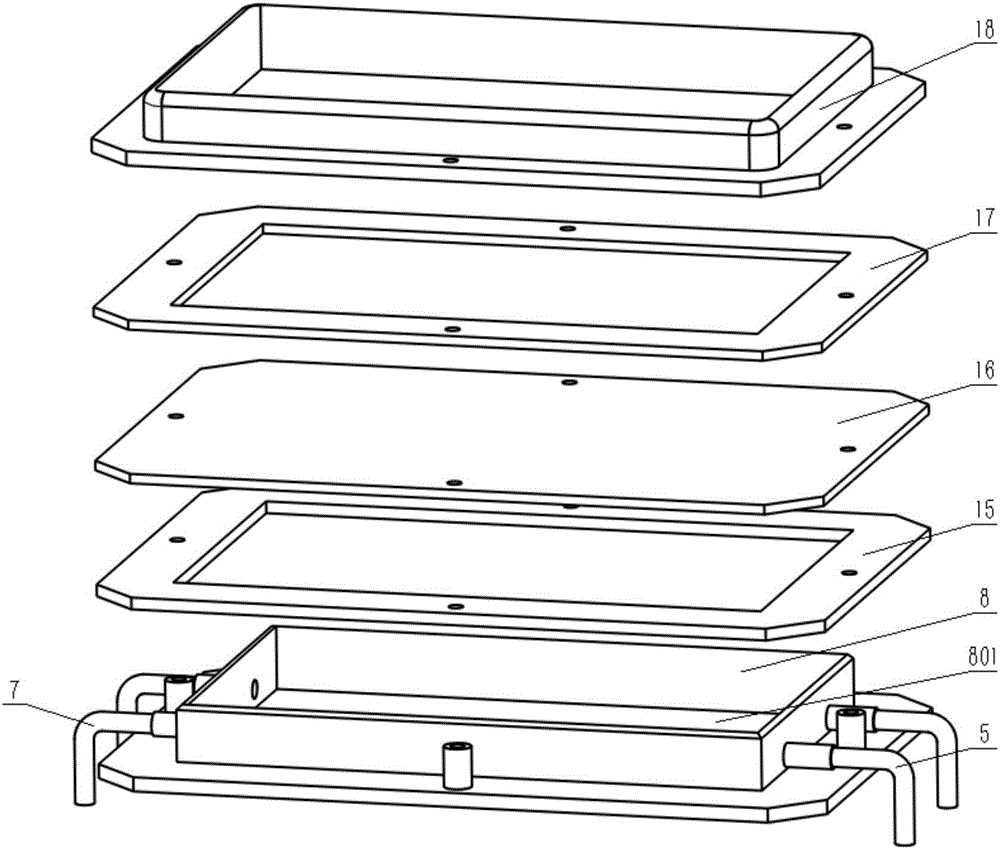

High-speed continuous photocuring type 3D printing device and working method thereof

ActiveCN106426915ALow costEfficient continuous printingManufacturing irradiation arrangementsManufacturing material handlingLiquid surfacesOxygen rich

The invention discloses a high-speed continuous photocuring type 3D printing device and a working method thereof. The 3D printing device comprises a machine case body which is divided into an upper cavity and a lower cavity by a middle partition board, wherein an image forming module is arranged in the lower cavity, a window box and an oxygen supply cooling module are arranged in the upper cavity and are combined to be fixedly mounted on the middle partition board, the oxygen supply cooling module is arranged right below the window box, and the image forming module I is arranged right below the window box; a printing platform is arranged right above the window box and is mounted on a Z-direction worktable; and the window box is connected with a raw material feeding unit. The 3D printing device is integrated with the advantages of a compound oxygen-rich film, oxygen supply cooling and liquid surface auxiliary pressurization of the window box, so that the low-cost and efficient continuous printing of large-sized products with arbitrary shapes is realized, the range of applicable materials is wide, the printed products are high in precision and quality and good in uniformity, and the process is stable and reliable. An industrial-grade solution is provided for the high-speed continuous photocuring type 3D printing.

Owner:SHENZHEN ELEGOO TECH CO LTD

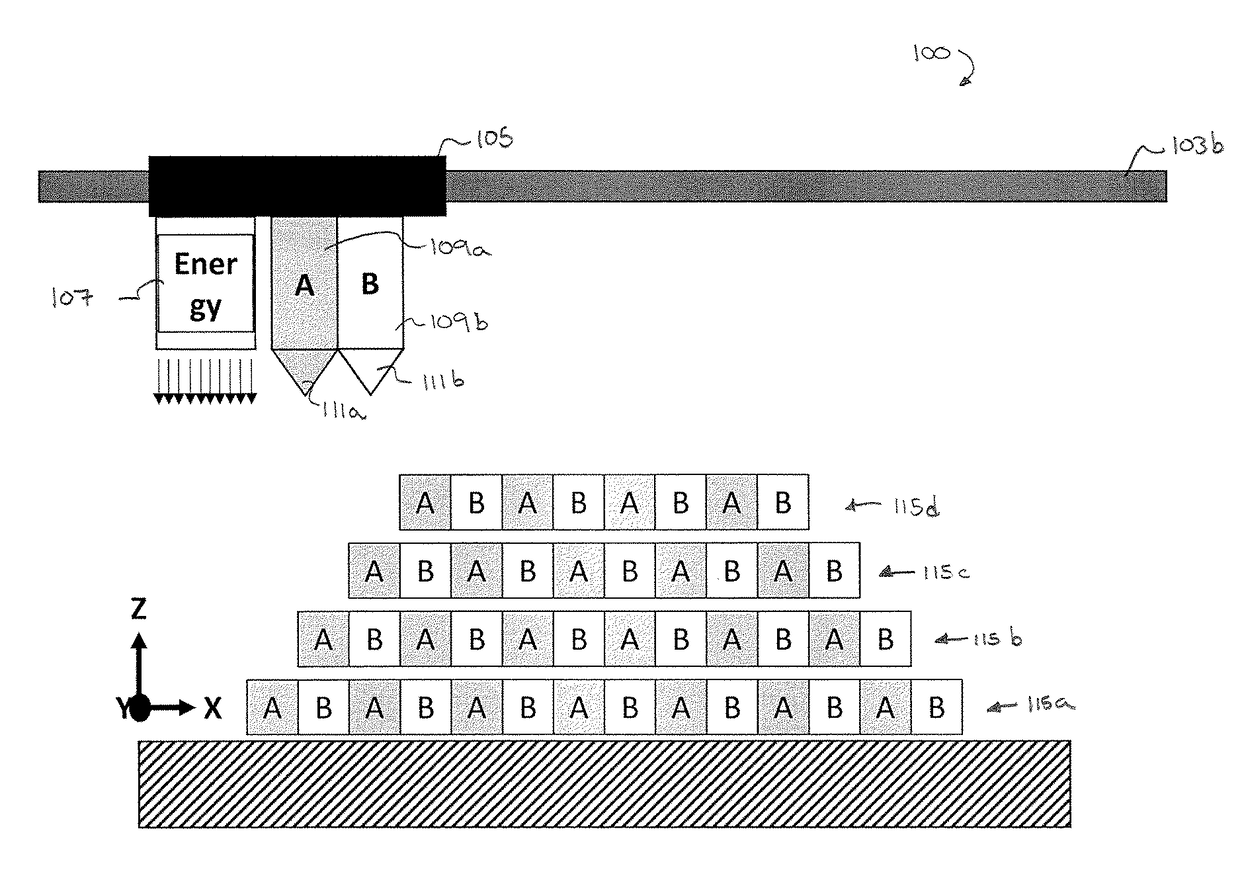

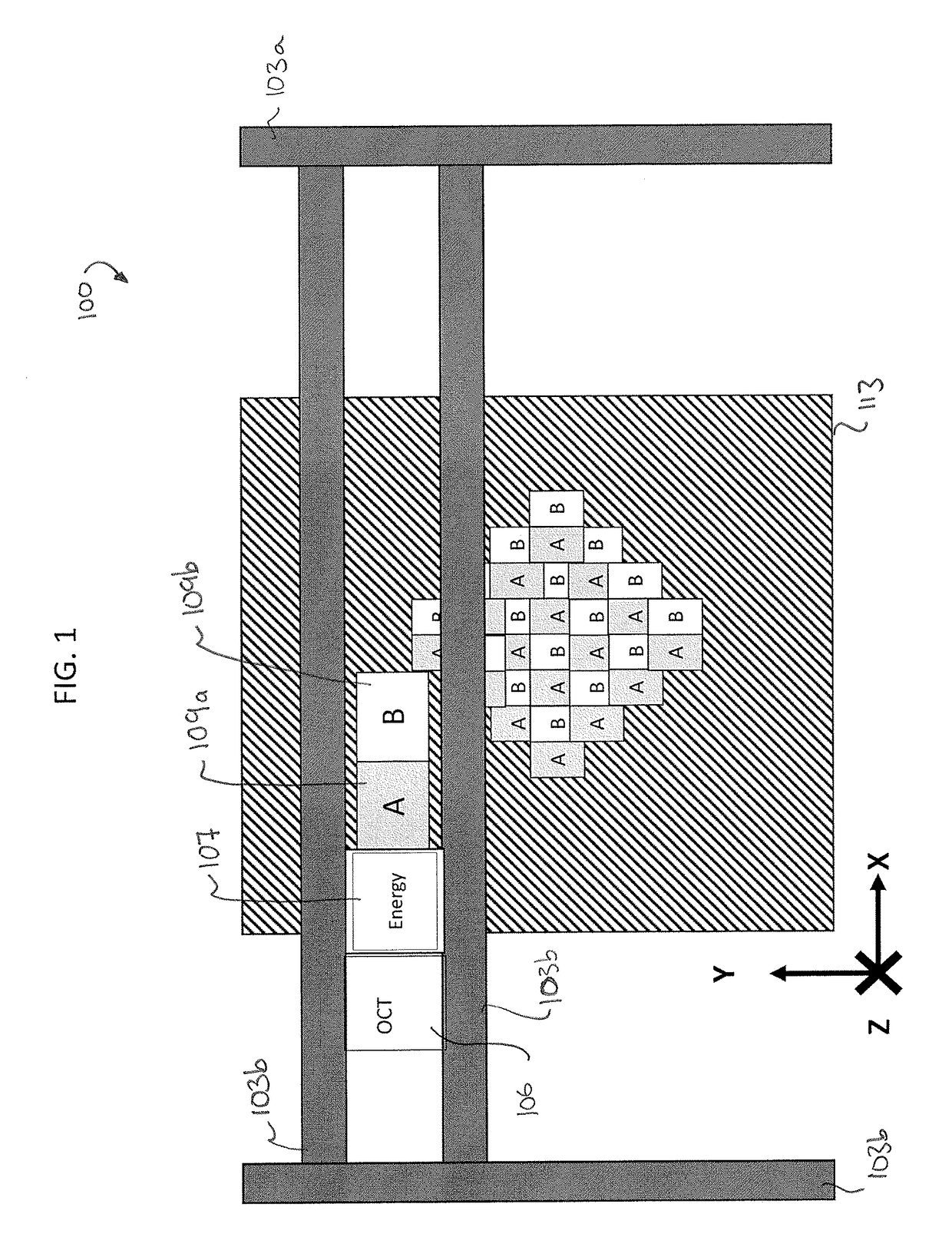

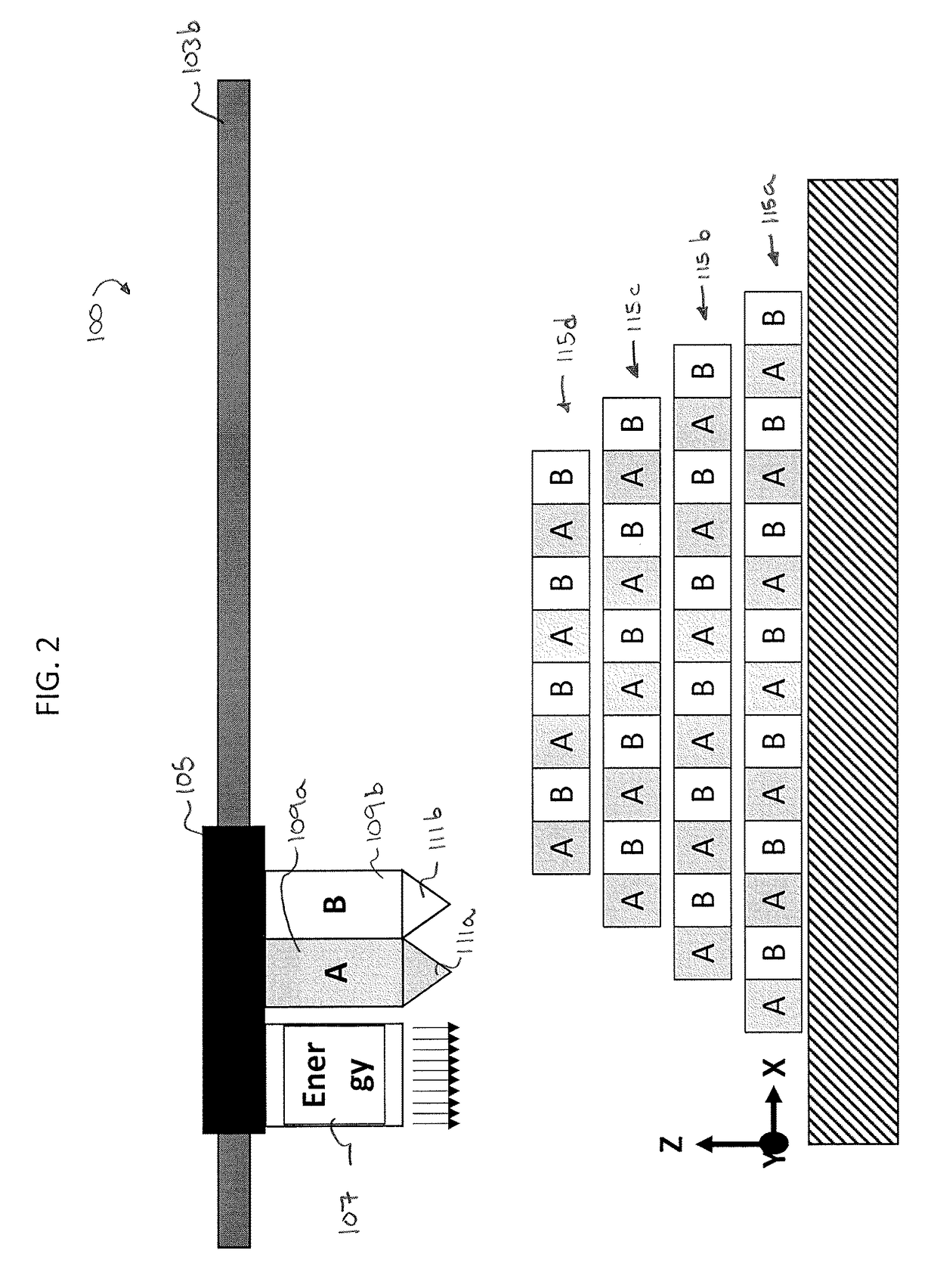

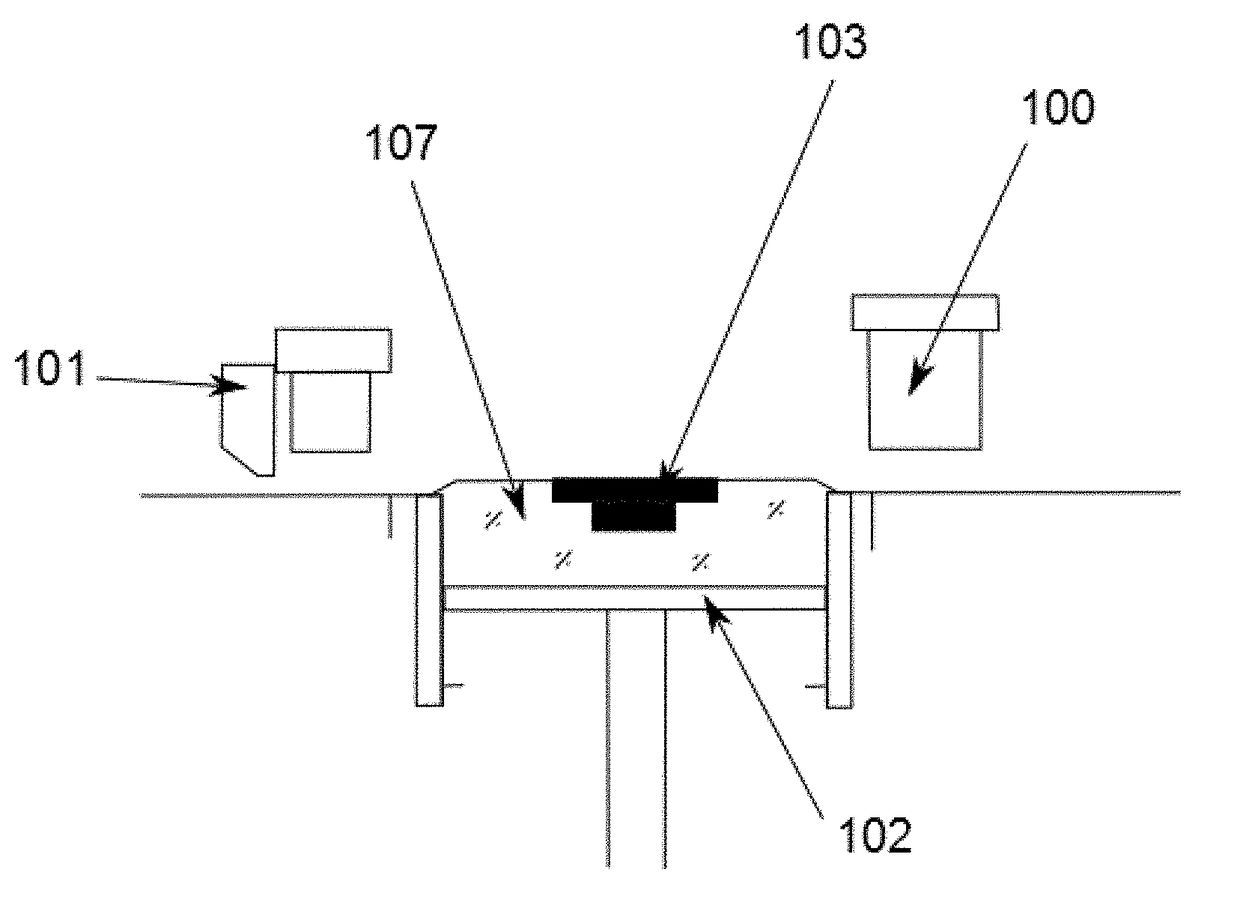

Systems, devices, and methods for inkjet-based three-dimensional printing

ActiveUS20180056582A1Maximizing numberManufacturing material handling3D object support structuresEngineeringReactive material

Devices and methods are described that provide printing of three-dimensional objects using reactive materials such as materials that result in a polyurethane formulation. Three-dimensional printing in accordance with the present disclosure can be performed using an inkjet printer or other systems that deposit or dispense material. A formulation made up of two or more reactive materials and, optionally, one or more UV-curable materials is also provided. The materials can be jetted based on a desired configuration to achieve a maximum reaction between materials, and can be based on desired jetting or molar ratios. By heating or applying energy on the jetted materials, their reaction and related solidifying can be accelerated. Corrective printing is also provided for, and can be used at desired intervals to eliminate printing errors relative to the object as modeled. Systems and methods used in conjunction with all of the same are provided.

Owner:MASSACHUSETTS INST OF TECH

Method for producing three-dimensional molded parts and regulating the moisture content in build material

A method for producing three-dimensional molded parts by means of layering, the moisture content of the build material mixture being able to be regulated.

Owner:VOXELJET AG

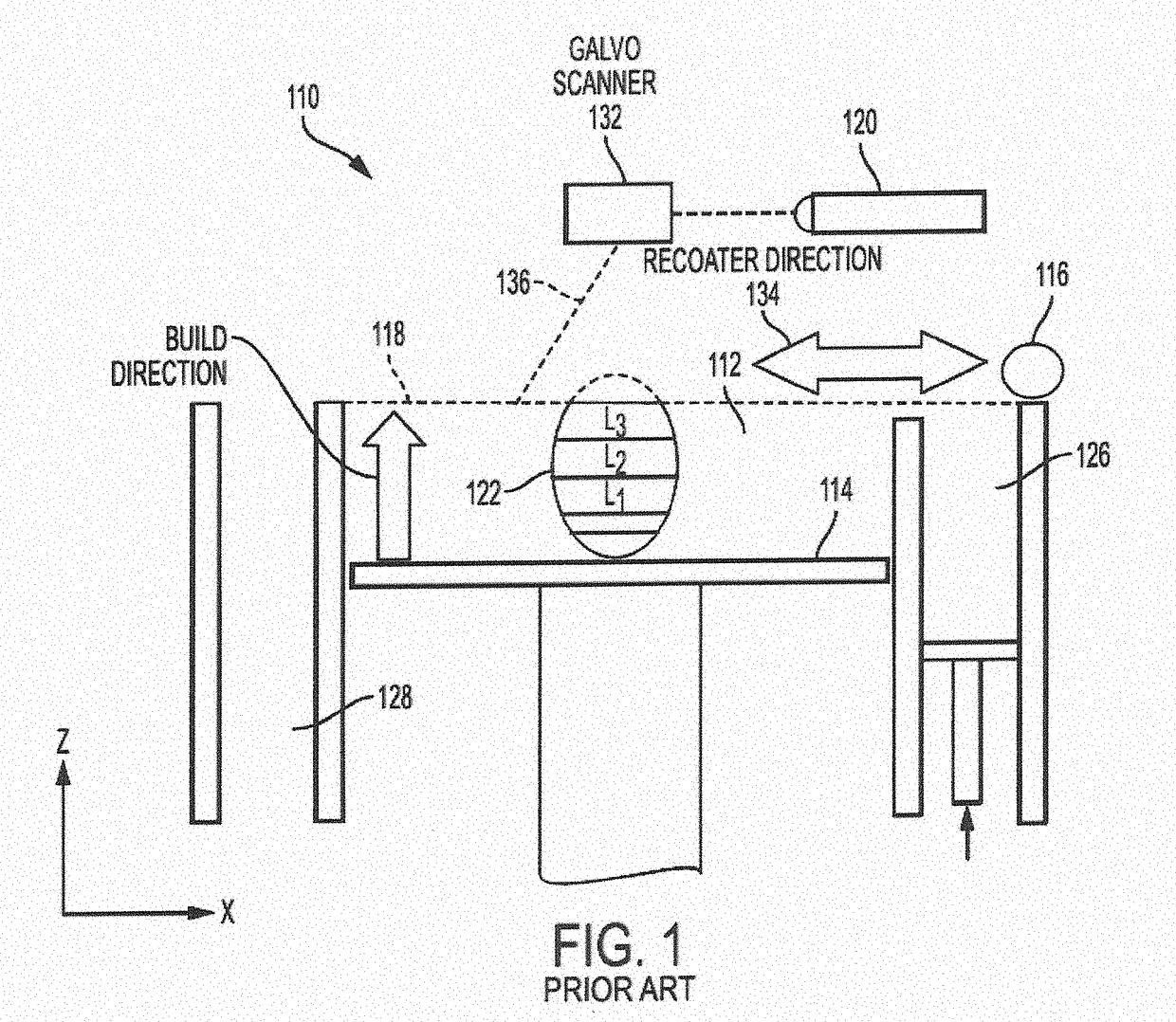

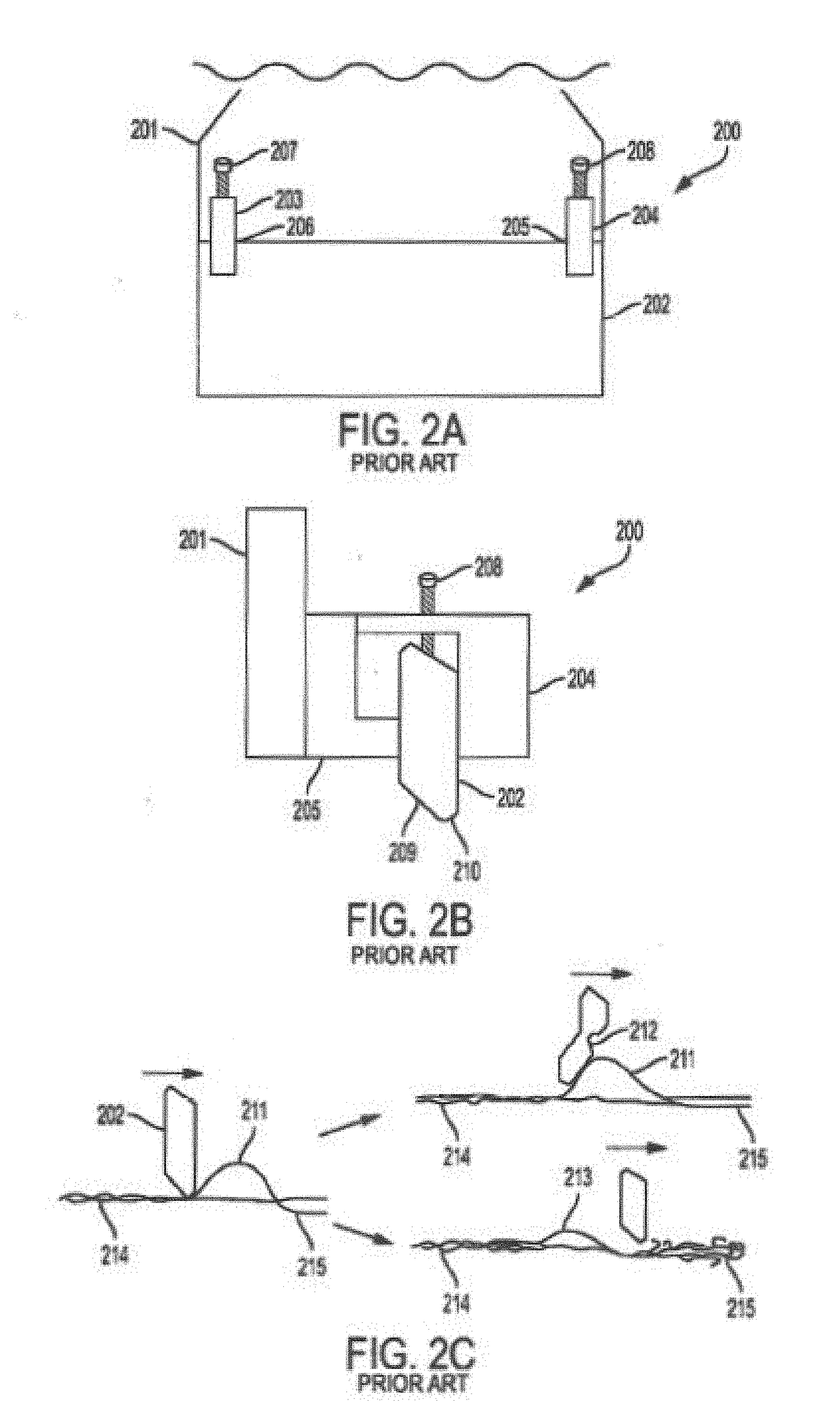

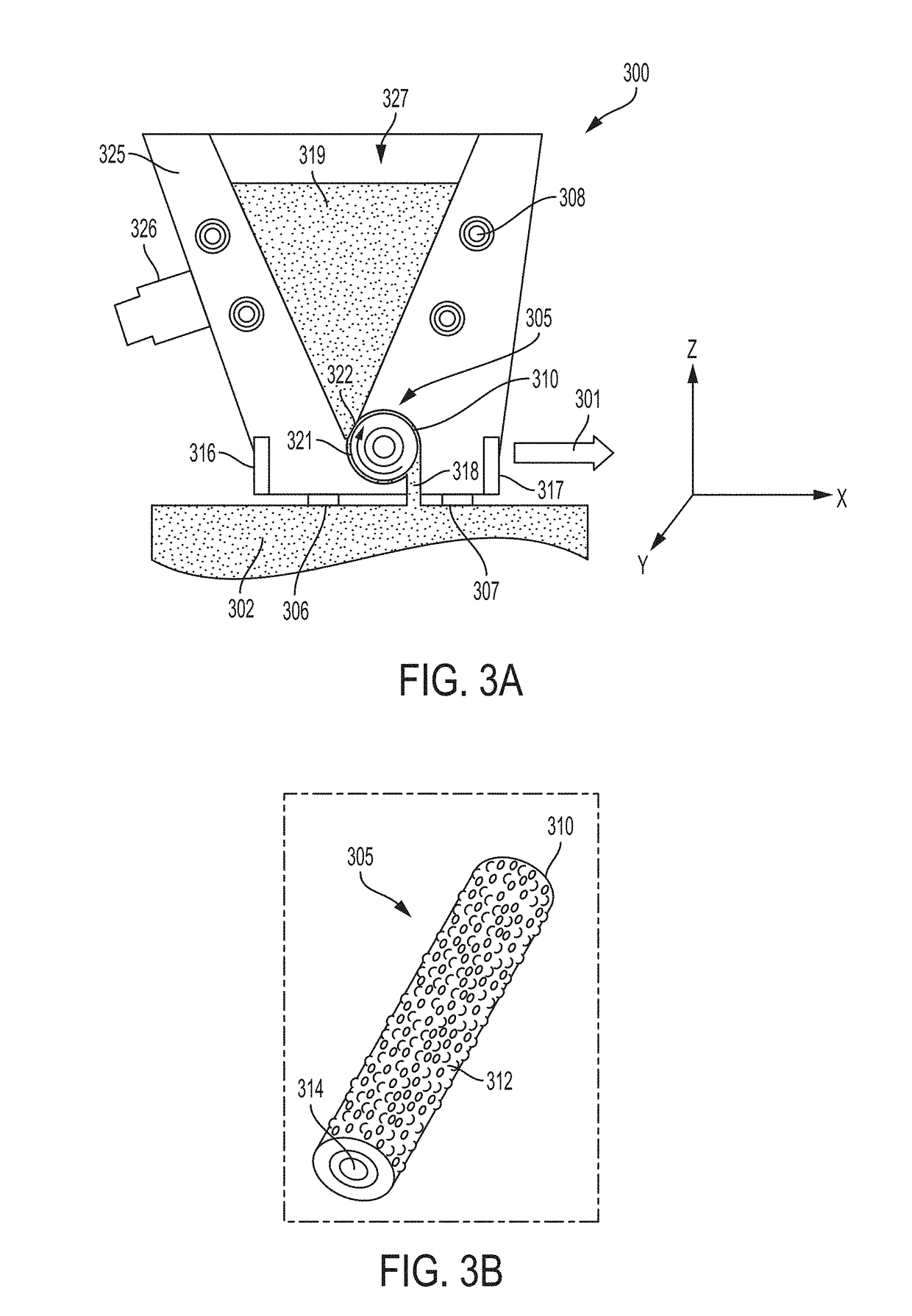

Powder bed re-coater apparatus and methods of use thereof

InactiveUS20190060998A1Liquid surface applicatorsIncreasing energy efficiencyMetallurgyDistribution system

The present disclosure relates to systems, methods, and apparatuses for supplying powder to a powder bed during an additive manufacturing process. A recoater apparatus includes a powder reservoir and a powder distribution system for conveying powder from the powder reservoir to the powder bed. The recoater apparatus further includes at least two sweep strips, wherein at least one exit of the powder distribution system is located between the two sweep strips so as to shield the exit of the powder distribution system.

Owner:GENERAL ELECTRIC CO

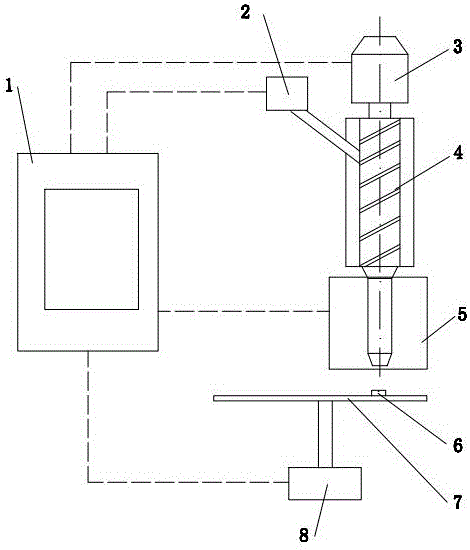

Three-dimensional printing device with injector head capable of being vibrated

ActiveCN106363903APromote meltingEnhanced mass transferManufacturing material handlingAdditive manufacturing with liquidsControl systemUltrasonic vibration

The invention relates to a three-dimensional printing device with an injector head capable of being vibrated. The device comprises a control system, a screw type extrusion system (or wire feeder), the injector head, a workbench and a workbench moving system. The injector head is connected to the lower end of the screw type extrusion system (or wire feeder) and made communicated with a discharge outlet of the screw type extrusion system (or wire feeder). The screw type extrusion system (or wire feeder) conveys materials to the injector head. The screw type extrusion system (or wire feeder) and the injector head are connected into a whole and can do X-axis and Y-axis direction horizontal movement above the workbench. The workbench moving system drives the workbench to do up-down vertical movement. The control system controls movement of the whole system, and therefore three-dimensional printing is completed. The three-dimensional printing device is characterized in that an ultrasonic vibration device is installed in the injector head. The three-dimensional printing device has the advantages that the structure is simple, molded products are large in density, tensile and impact strength is improved, and product quality is good.

Owner:SHUNDE POLYTECHNIC

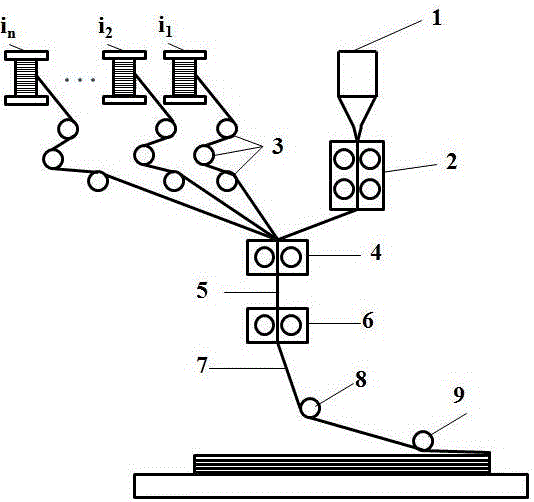

Three-dimensional printing forming method of long fiber thermoplastic composite material component

InactiveCN106515041AFully infiltratedEnhanced interface bindingAdditive manufacturing apparatusManufacturing material handlingYarnThermoplastic composites

The invention discloses a three-dimensional printing forming method of a long fiber thermoplastic composite material component, and belongs to the field of composite material forming technologies. A reinforced yarn is expanded as a thinner yarn strip, and is fully infiltrated with a drawn resin strip to form a single-layer prepreg yarn; the single-layer prepreg yarn is extruded by a shaping device to form a prepreg tow with appointed shape and size; and the prepreg tow is guided by a guide device to bond with a previous layer of composite material to form a composite material laminating structure after heating fusion by a compaction device. Through unfolding of continuous fibers and drawing of a basal body material, the method effectively improves the infiltration effect of the yarn and the resin so as to improve the interface bonding strength of the fiber and the basal body; the prepreg tow can be printed by any angle; and meanwhile, after the prepreg tow is compacted by the compaction device, the fiber volume fraction is prominently increased, so that the added material manufacturing of a high-performance composite material component with complex structure can be realized.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH

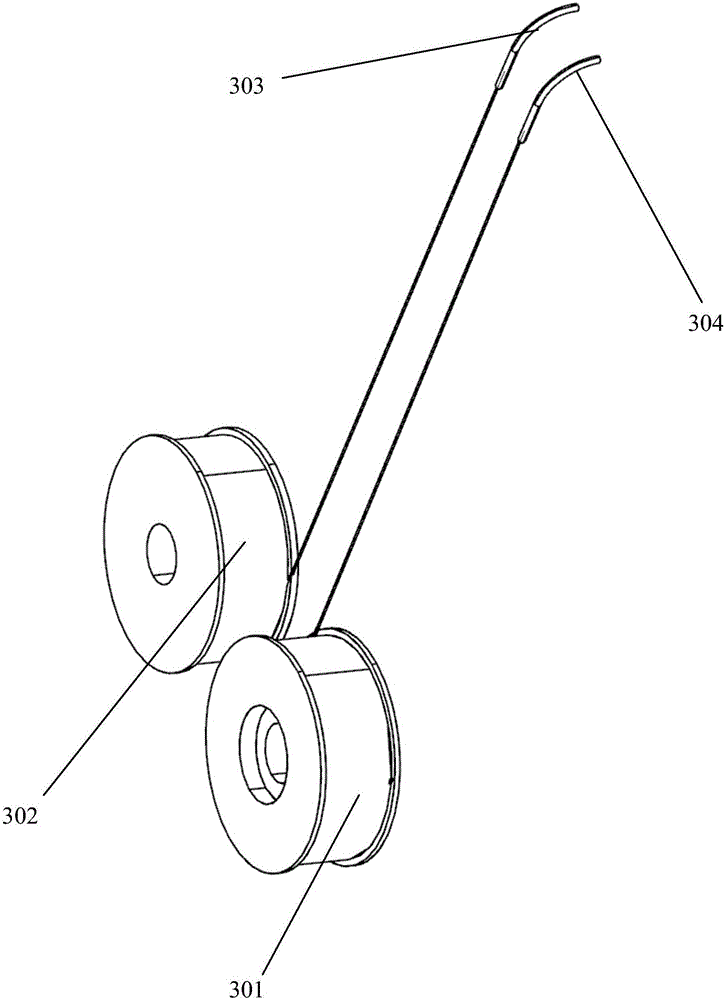

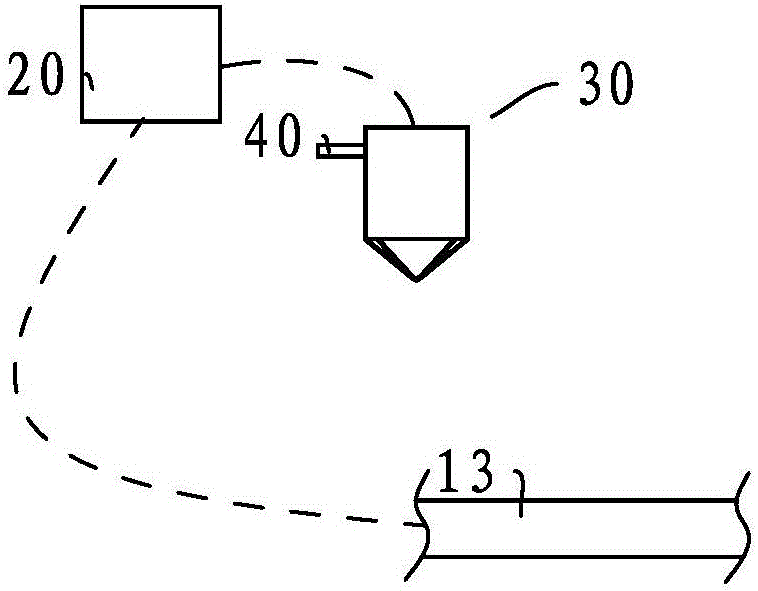

Powder recycling system

InactiveUS20160200053A1Avoid pollutionFacilitate removing excess powderConfectionerySweetmeatsMetallurgyRapid prototyping

A powder recycling system for a three-dimensional rapid prototyping apparatus is provided. The powder recycling system includes a sealed main body, a negative pressure generator, an air pressure generator, a lighting unit and a heater. When an excess powder removing process is performed to remove excess powder from a three-dimensional object, the excess powder is sieved by a screen mesh and collected by a powder collector. Consequently, the excess powder is recycled.

Owner:MICROJET TECH

3D printing

ActiveUS20150165675A1Precise deliveryAuxillary shaping apparatusManufacturing material handlingSpray nozzle3d printer

A surface portion modification apparatus is provided which is co-operable with a 3D printer. It includes a head nozzle follower assembly. The follower assembly is co-operable with a 3D printer head nozzle assembly and is operable for modifying at least a portion of a surface of the material of a 3D object printed by the head nozzle assembly of the 3D printer. It may be used to smooth the surface of an object printed by the 3D printer.

Owner:IBM CORP

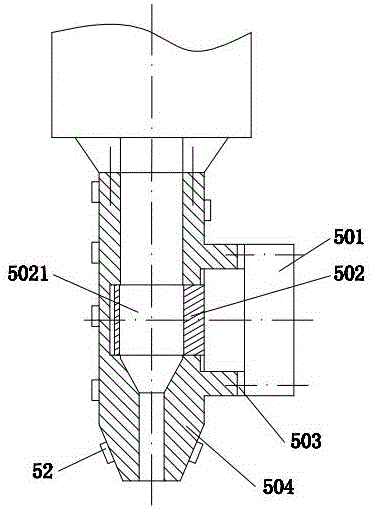

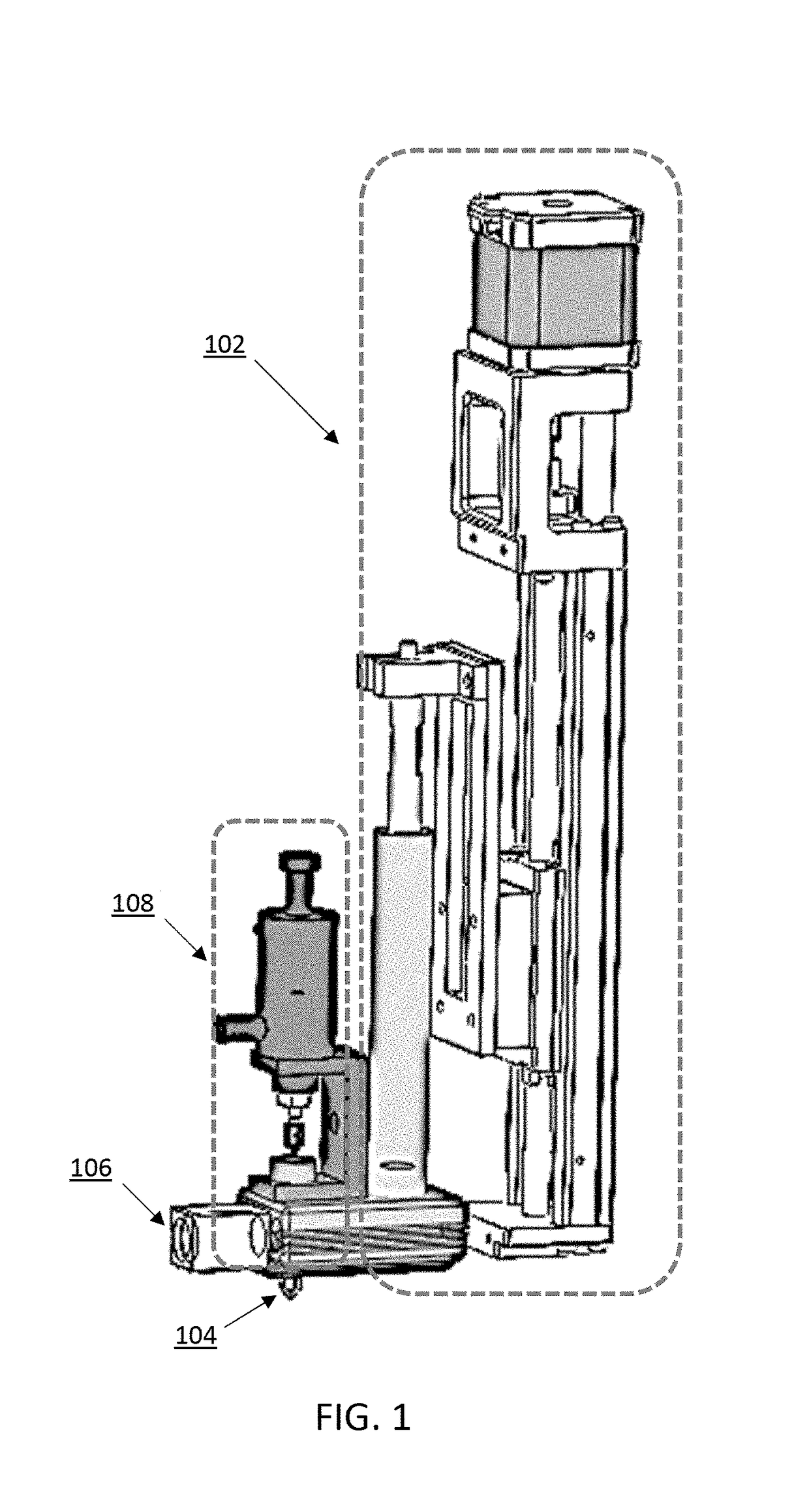

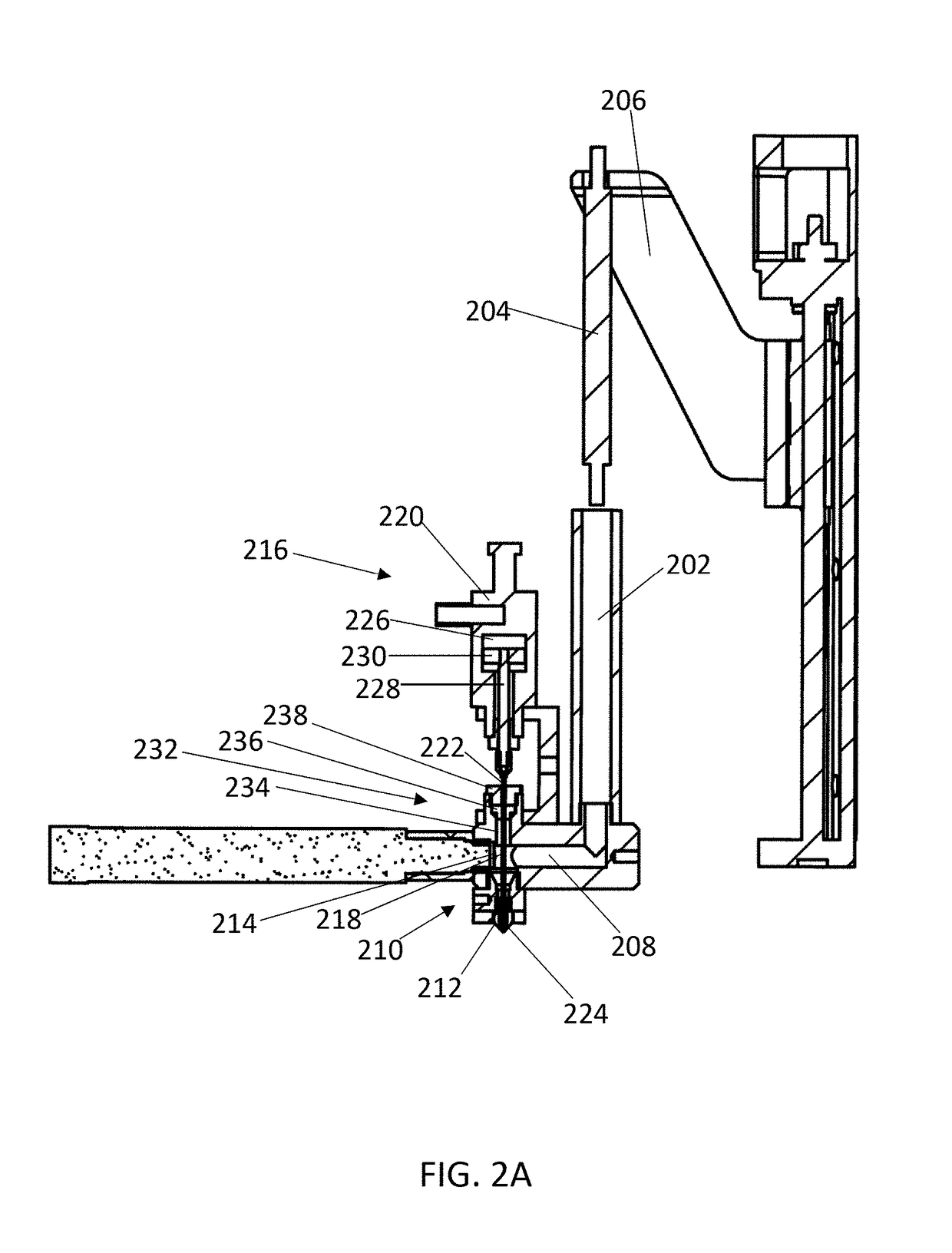

Precision pharmaceutical 3D printing device

ActiveUS10201503B1Manufacturing heating elementsManufacturing material handlingControl switchMaterial supply

Provided herein are devices and systems for depositing a material or manufacturing a product, such as a pharmaceutical dosage form, by additive manufacturing. Further provided are methods of using the devices and systems, as well as methods of manufacturing a product, such as a pharmaceutical dosage form, by additive manufacturing. In certain embodiments, the device includes a material supply system configured to melt an pressurized a material, a pressure sensor configured to detect a pressure of the material within the device, and a control switch comprising a sealing needle operable in an open position and closed position. The sealing needle extends through a feed channel containing the material and includes a taper end, wherein the tapered end of the sealing needle engages a tapered inner surface of a nozzle to inhibit flow of the material through the nozzle when the sealing needle is in the closed position.

Owner:TRIASTEK INC

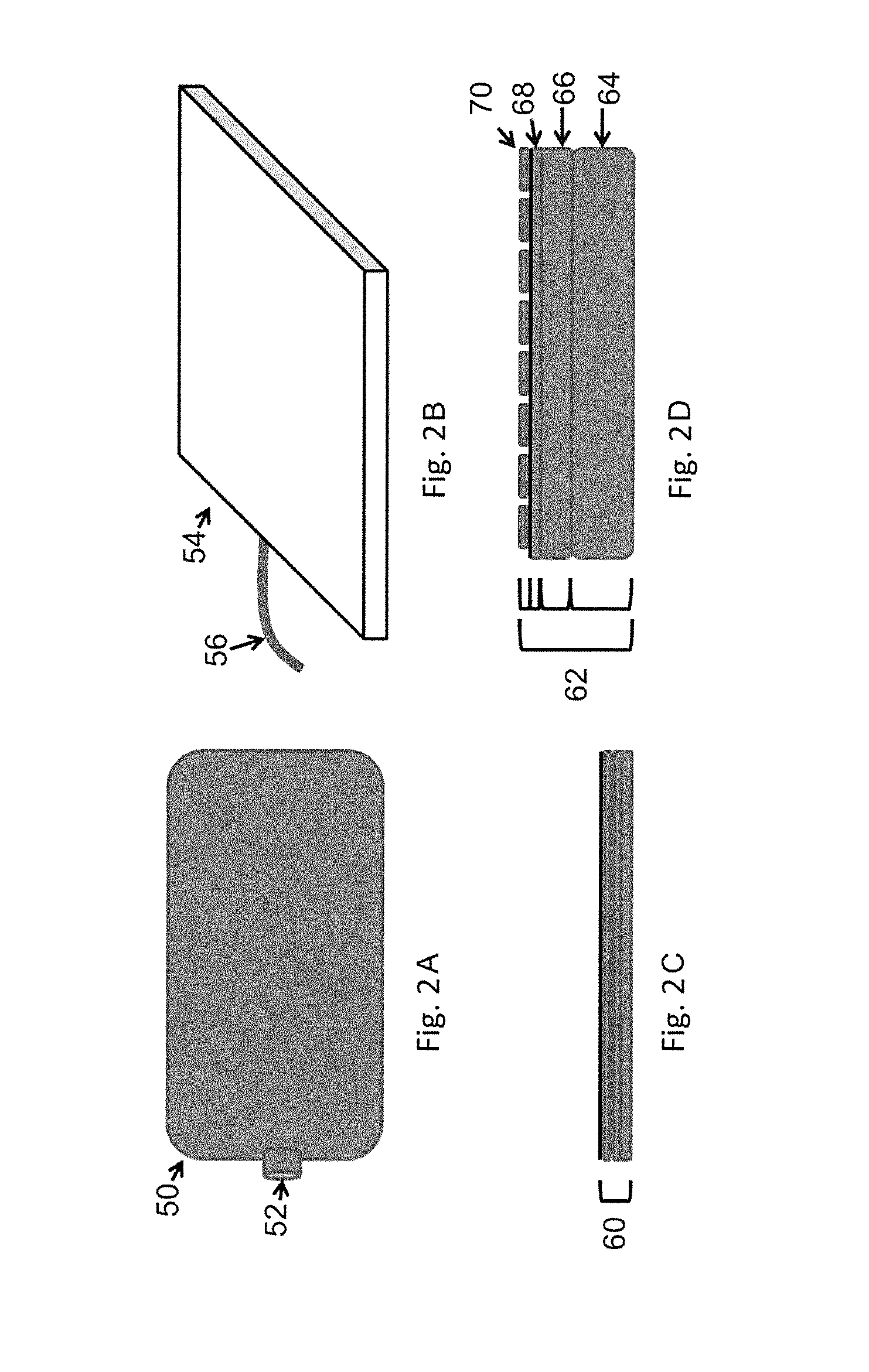

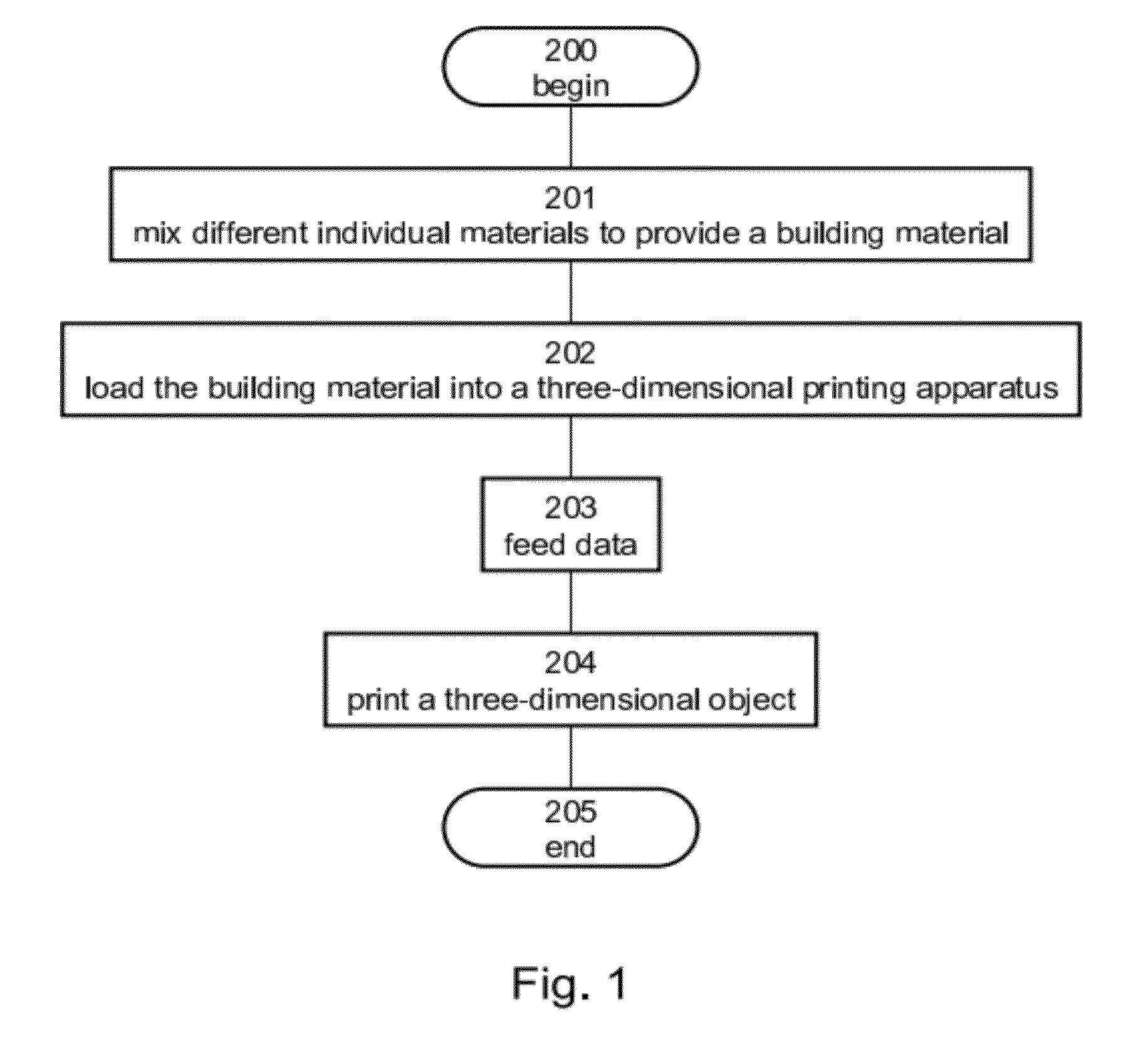

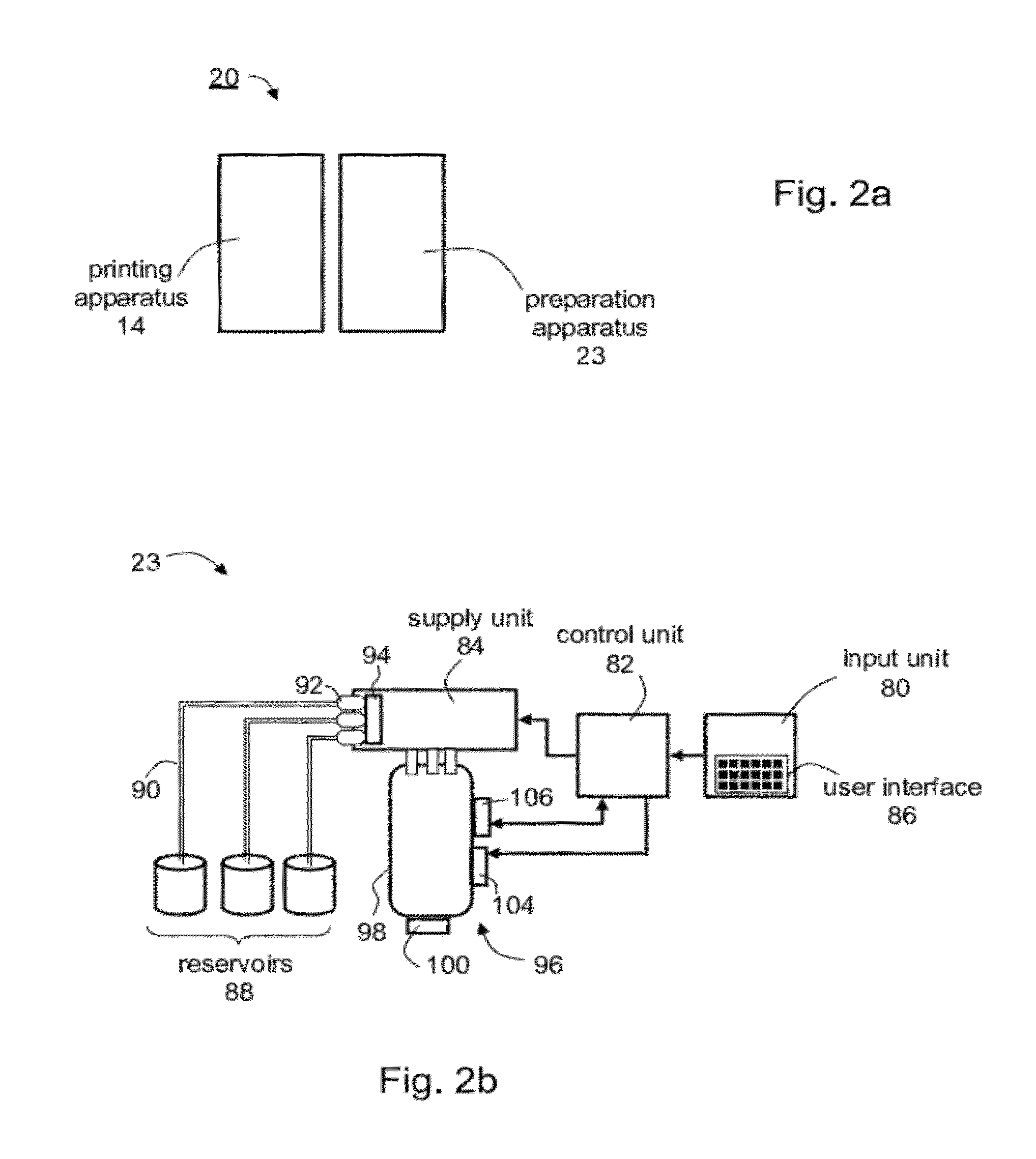

Preparation of building material for solid freeform fabrication

ActiveUS20120276233A1Additive manufacturing apparatusAuxillary shaping apparatusMulti materialMaterials science

A method suitable for solid freeform fabrication is disclosed. The method comprises mixing respective amounts of a plurality of materials such as to provide a building material characterized by at least one attribute, and using the building material for fabricating a three-dimensional object.

Owner:STRATASYS LTD

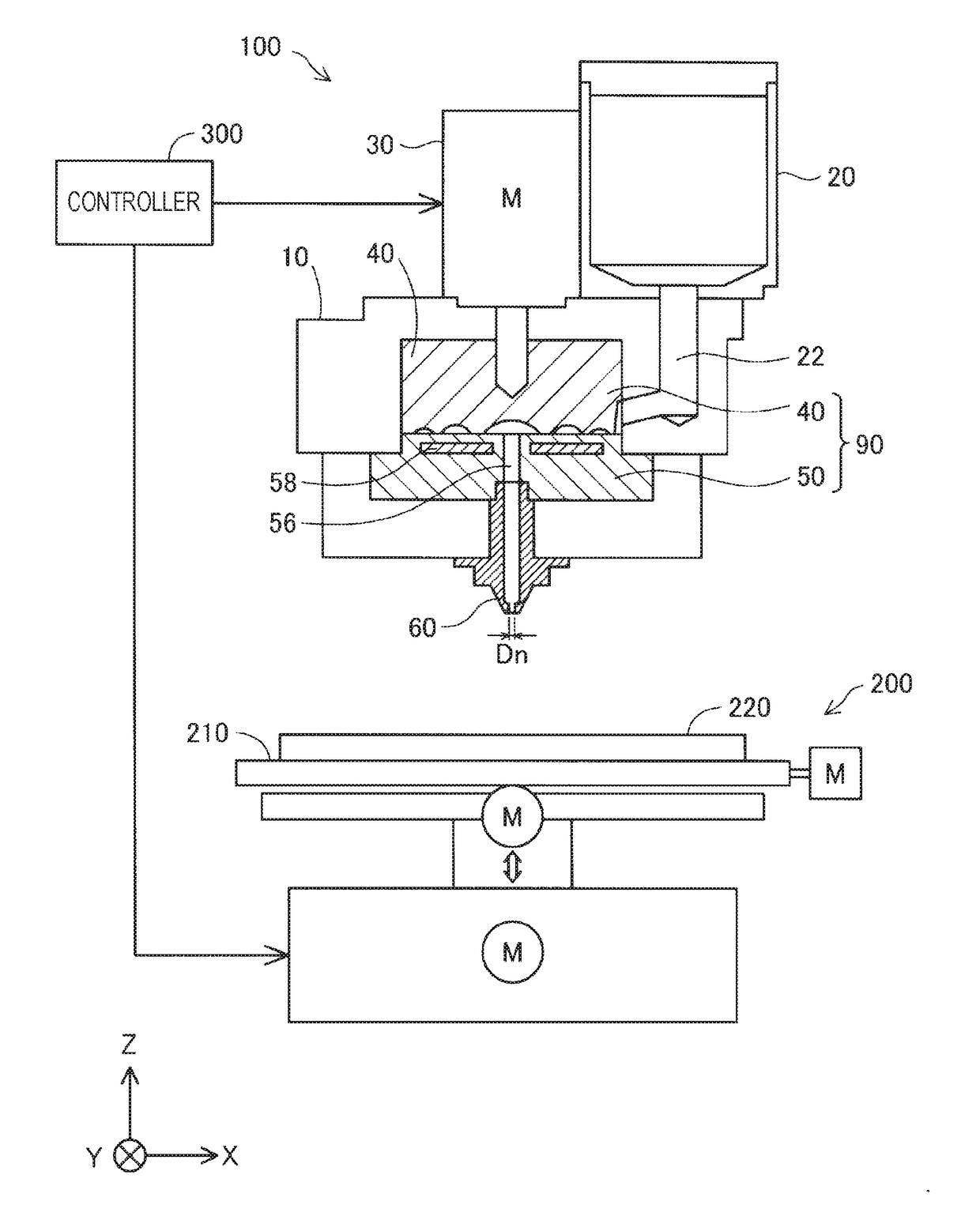

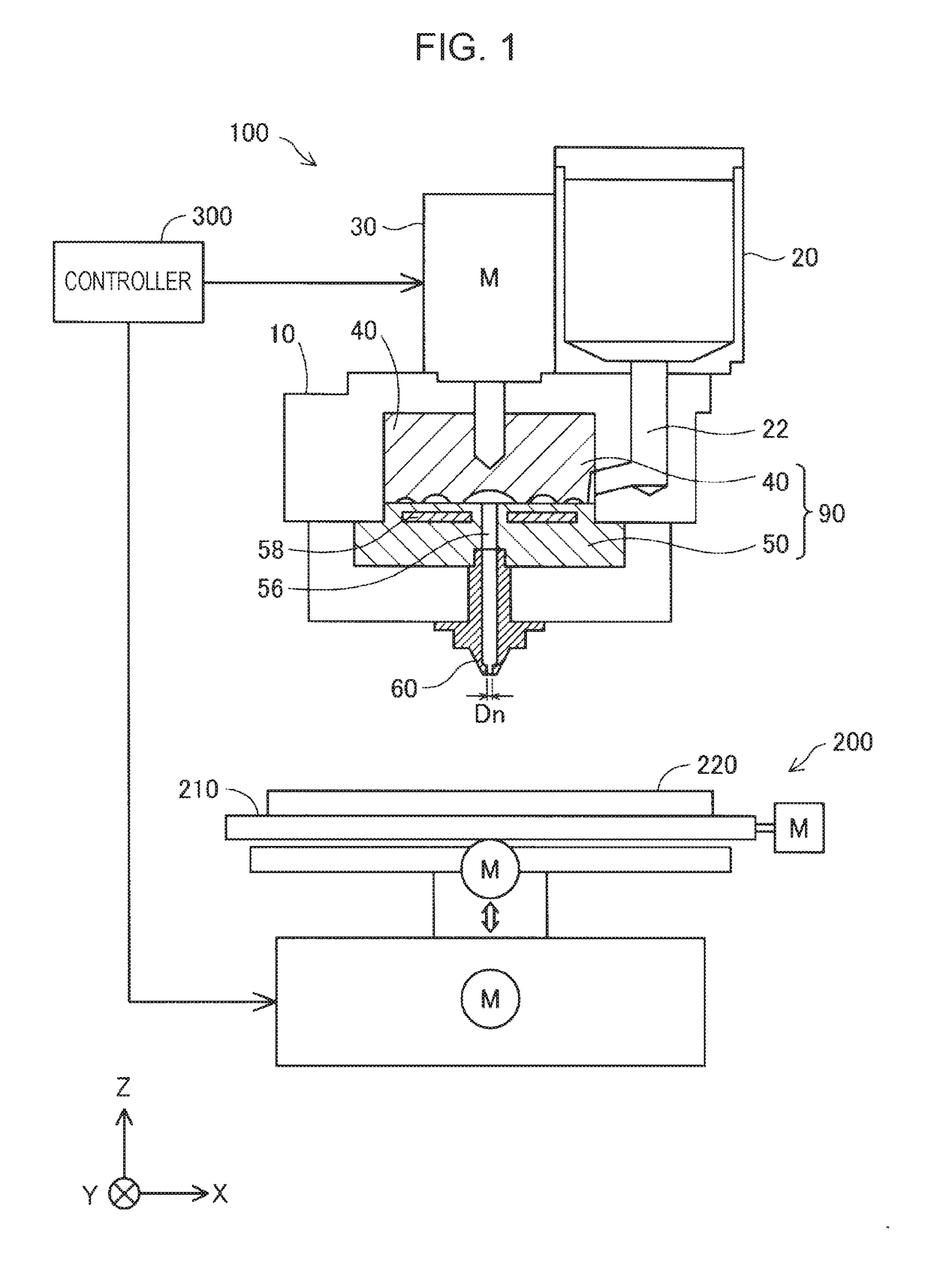

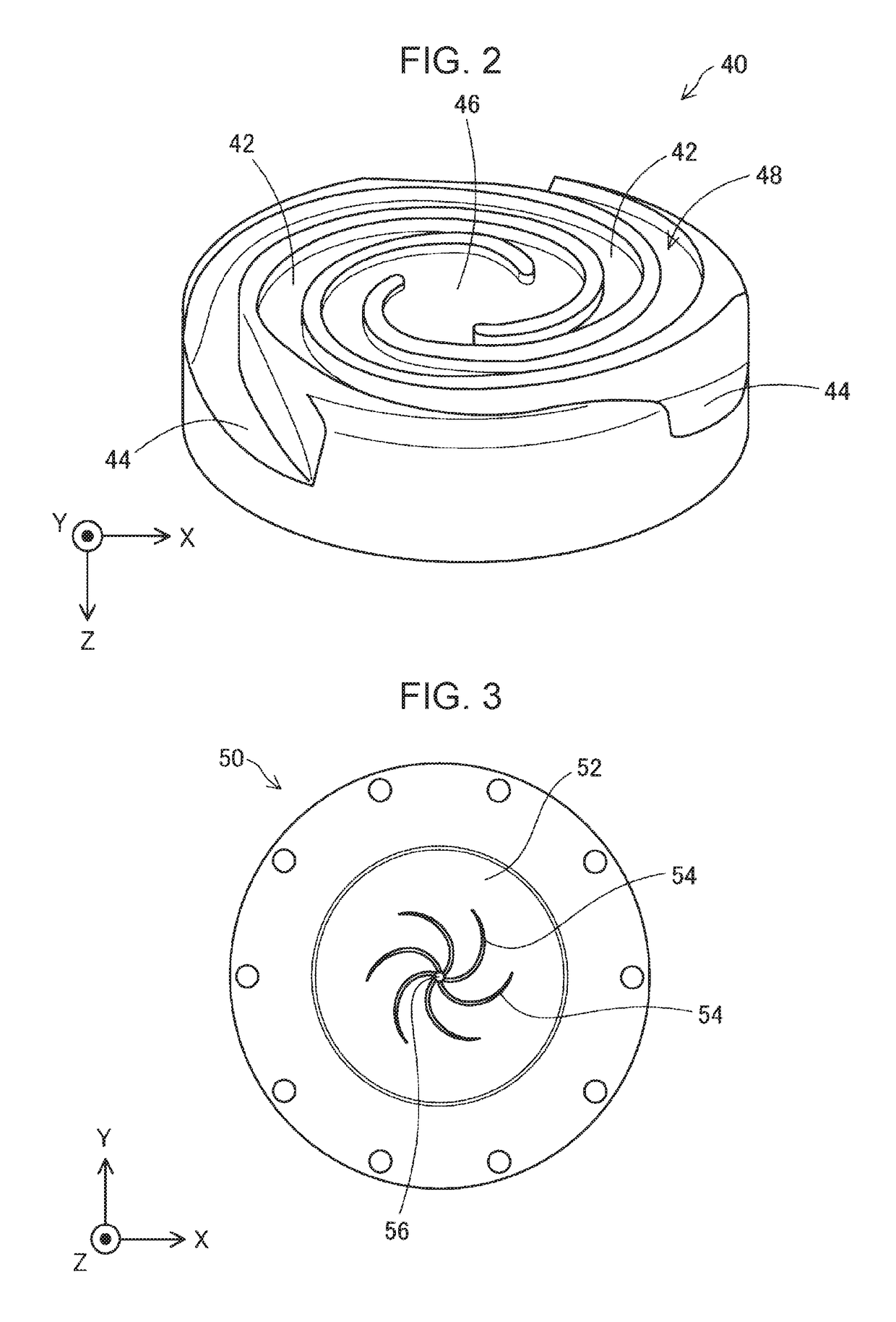

Three-dimensional modeling apparatus and three-dimensional modeling method

ActiveUS20180311894A1Reduce the overall heightSmall sizeManufacturing driving meansManufacturing heating elementsDrive motorDimensional modeling

A three-dimensional modeling apparatus includes a drive motor, a plasticizing section having a flat screw configured to be rotated by the drive motor, the plasticizing section being configured to plasticize and convert the material into a molten material by the rotation of the flat screw, and a nozzle configured to inject the molten material.

Owner:SEIKO EPSON CORP

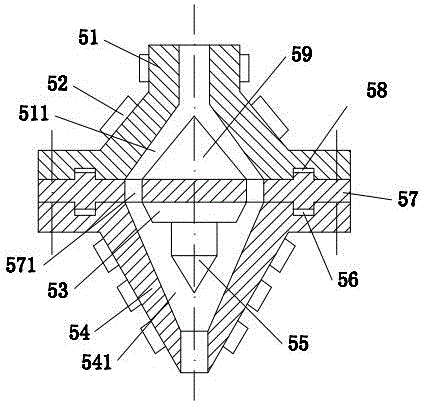

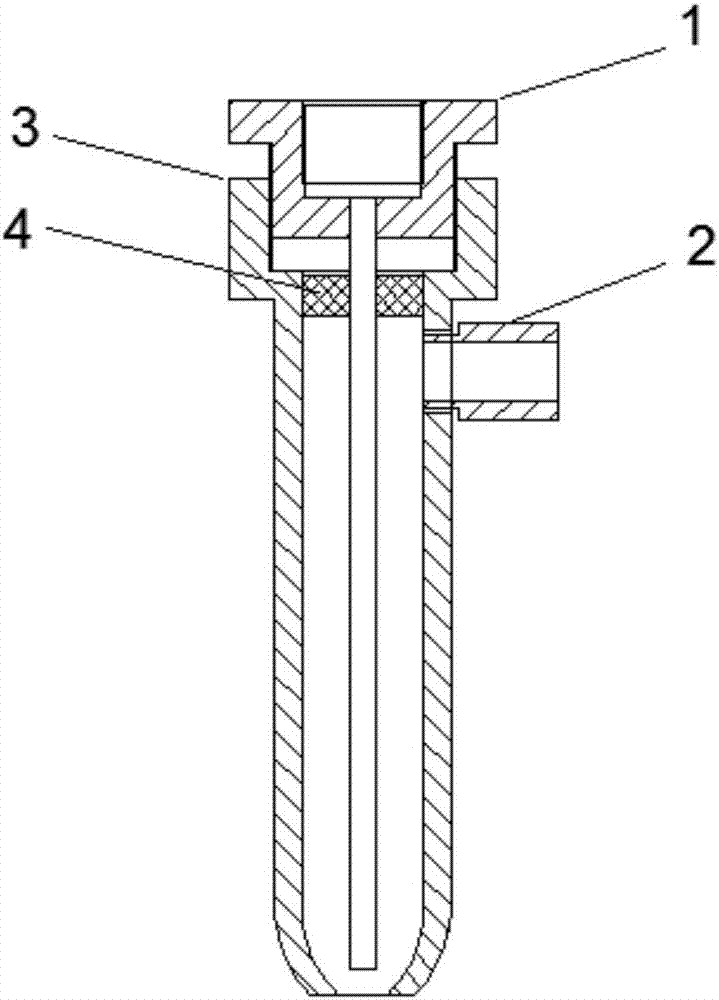

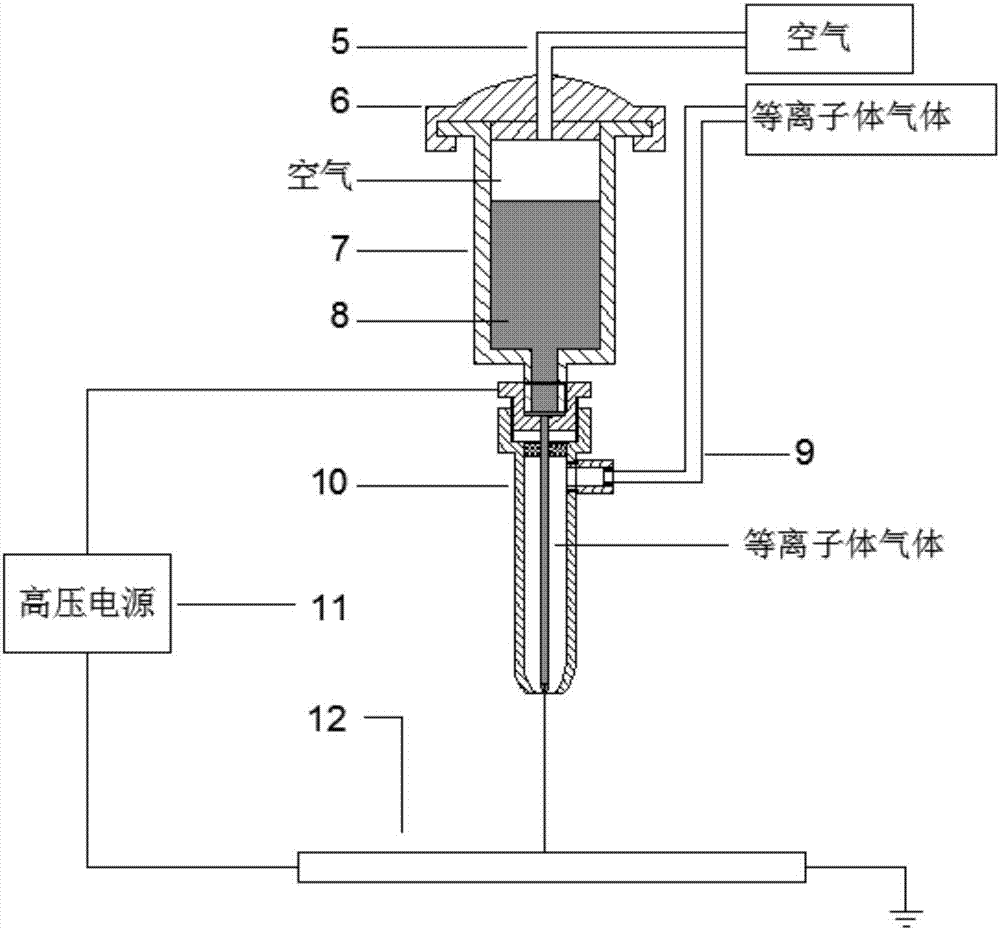

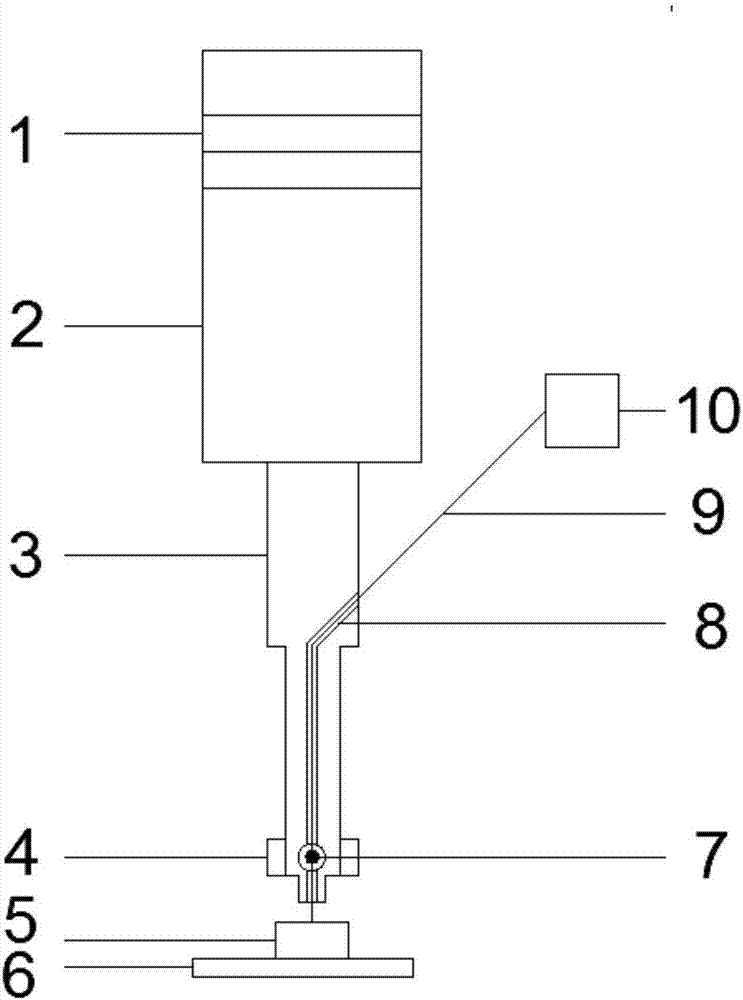

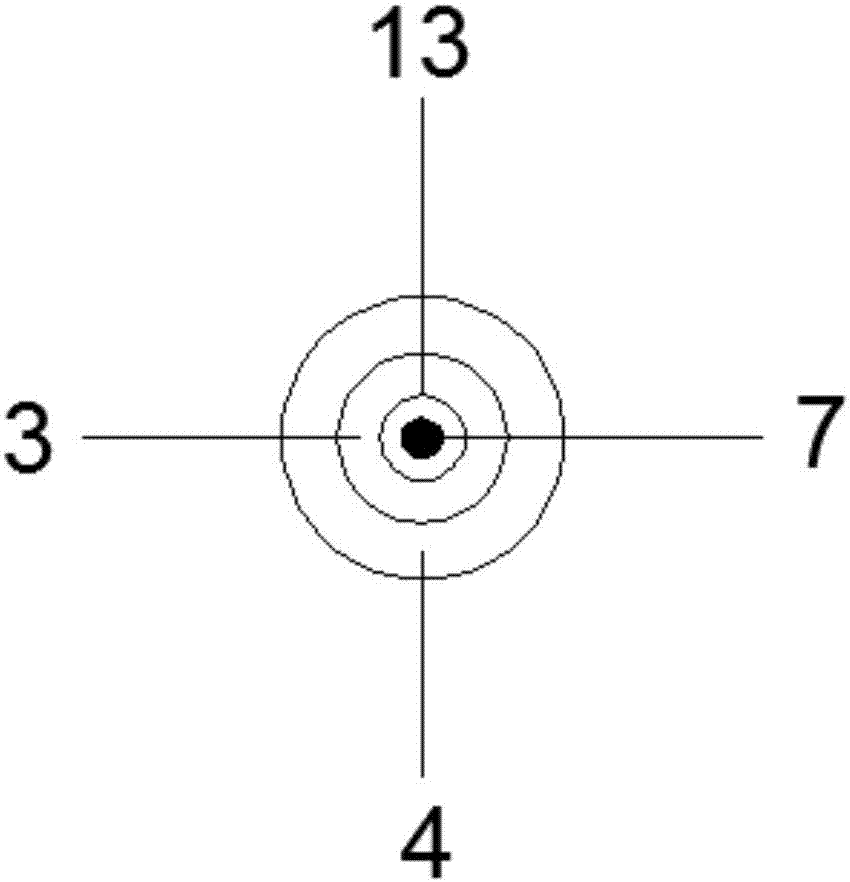

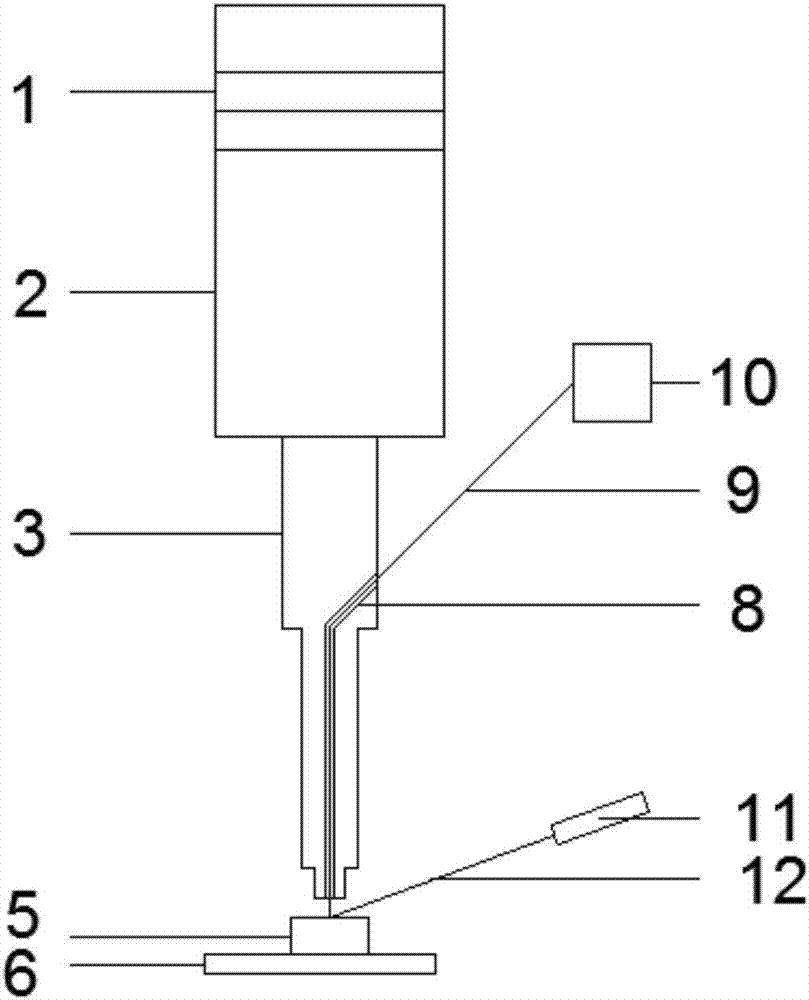

Integrated spray printing device used for additive and subtractive manufacturing

ActiveCN107199693ARealize electrojet printing processAchieve surface modificationManufacturing material handlingAdditive manufacturing processesPlasma jetProduct gas

The invention discloses a spray printing device integrating a plasma jet technology. The device comprises a spraying head, a high pressure power source, a collecting base plate and a liquid inlet barrel. According to the spray printing device, the high pressure power source is used for generating spray printing process electric field requirements and serving as a plasma jet excitation source, gas discharge is used for generating plasma jets, unified application of electric fluid spray printing machining (additive machining) and plasma etching machining (subtractive machining) is achieved on one device, and real-time surface modification of plasmas on electric spray printing materials in the machining process, sintering curing of electric spray printing deposition materials and additive and subtractive synchronization machining are included for achieving quick molding of complex patterns and multi-layer structures. By means of the spray printing device, application in a combination manner or an array manner can be achieved, and the spray printing device can be used for preparing large-area multi-layer complex structures. Through application of the spray printing device, the machining efficiency and the material performance are improved, and wide application prospects in the fields of MEMS machining and manufacturing and electric fluid jet printing are achieved.

Owner:HUAZHONG UNIV OF SCI & TECH

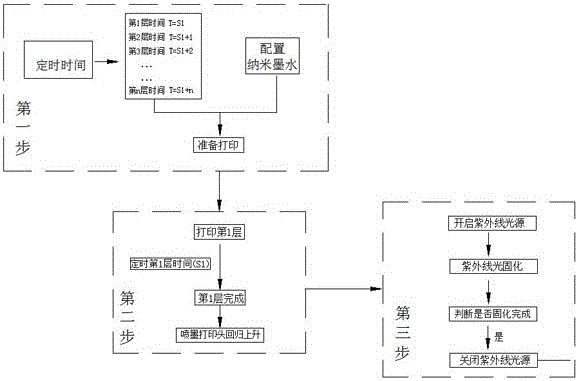

Composite material 3d printing method realized by photocuring-jetting nano ink and printer

InactiveCN106634208AHigh precisionLarge forming sizeAdditive manufacturing apparatusInksGraphicsNarrow range

The invention discloses a composite material 3d printing method realized by photocuring-jetting nano ink, and the method comprises the following steps: preparing the nano ink; by means of micro-droplet jetting, jetting the nano-ink by an ink-jet print head; dividing three-dimension modeling into a plurality of two-dimension graphs, and calculating the print time for each graph; according to the print time for each graph, turning on an ultraviolet light source in a fixed time, monitoring the temperature of curing regions in real time by a temperature sensor, monitoring the curing moulding status of nano-particle ink in printing regions, and turning off the ultraviolet light source after curing is finished; and performing printing layer by layer, and performing curing layer by layer, so as to finish product printing. The method is suitable for printing ceramics, glass, nylon or plastic products; by using the ultraviolet light for curing moulding, the technical problems in an existing 3D printing technology on narrow range of material choice, poor moulding precision, small moulding size, slow moulding speed and the like are solved. The invention also discloses a micro-droplet-jetting 3d printer which is suitable for 3D printing in the above method.

Owner:安徽泰尔控股集团有限公司

3D print head

InactiveCN107199338AGrain refinementHigh bonding strengthAdditive manufacturing apparatusManufacturing material handling3d printMolten state

The invention discloses a 3D print head. The 3D print head is characterized by comprising an ultrasonic transducer, an ultrasonic amplitude transformer and an ultrasonic welding rod. The ultrasonic transducer is connected with the ultrasonic amplitude transformer, the ultrasonic welding rod is connected with the ultrasonic amplitude transformer, the ultrasonic welding rod is provided with a through hole which is used for conveying a printing material, the through hole extends to the end portion of the ultrasonic welding rod, and a fusing device which is used for heating the printing material into a molten state is also arranged. According to the 3D print head, the ultrasonic transducer and the ultrasonic amplitude transformer generate and amplify ultrasonic vibration, the bottom of the ultrasonic welding rod makes direct contact with the molten material, the ultrasonic vibration is transmitted into the molten material, when the metal printing material is printed in a vacuum or protective atmosphere, the molten metal makes contact with a printed workpiece, an upper metal layer is connected with a lower metal layer, under the ultrasonic vibration environment, structure grains are refined, pores, cracks, incomplete fusion and other defects are reduced, the structure performance is improved, the combination strength between the layers is improved, and the printing quality is further improved.

Owner:WUHAN UNIV OF TECH

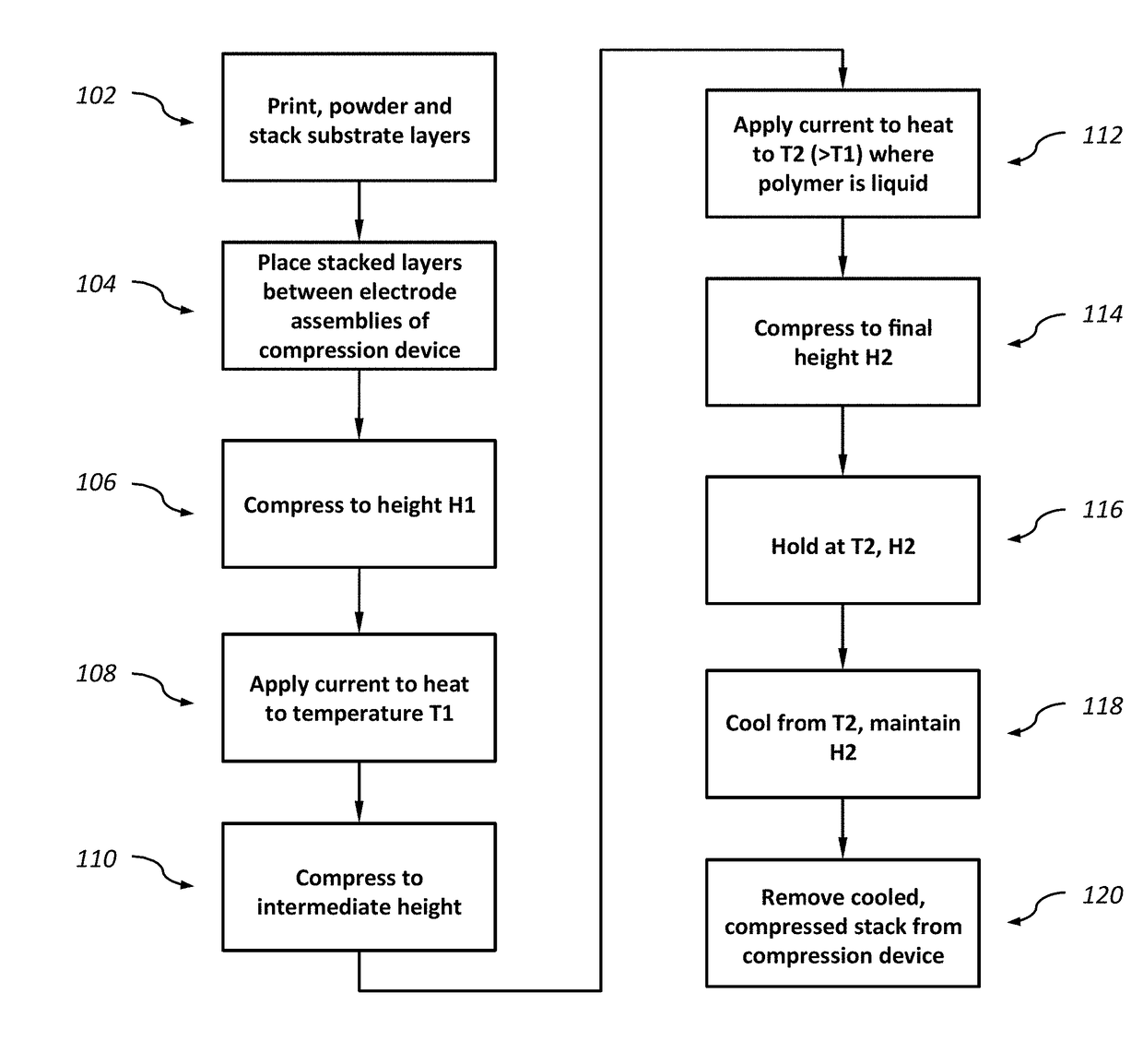

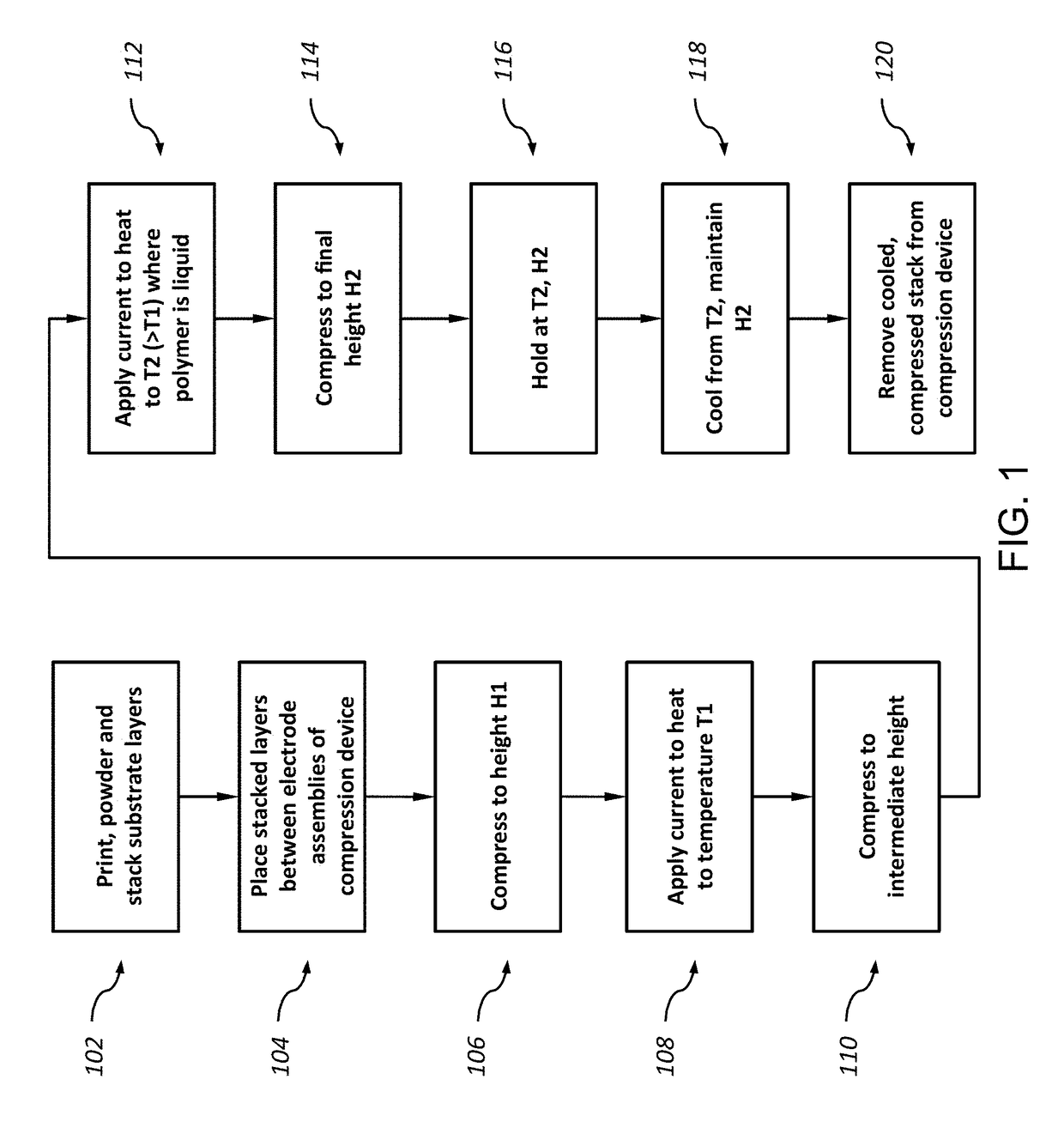

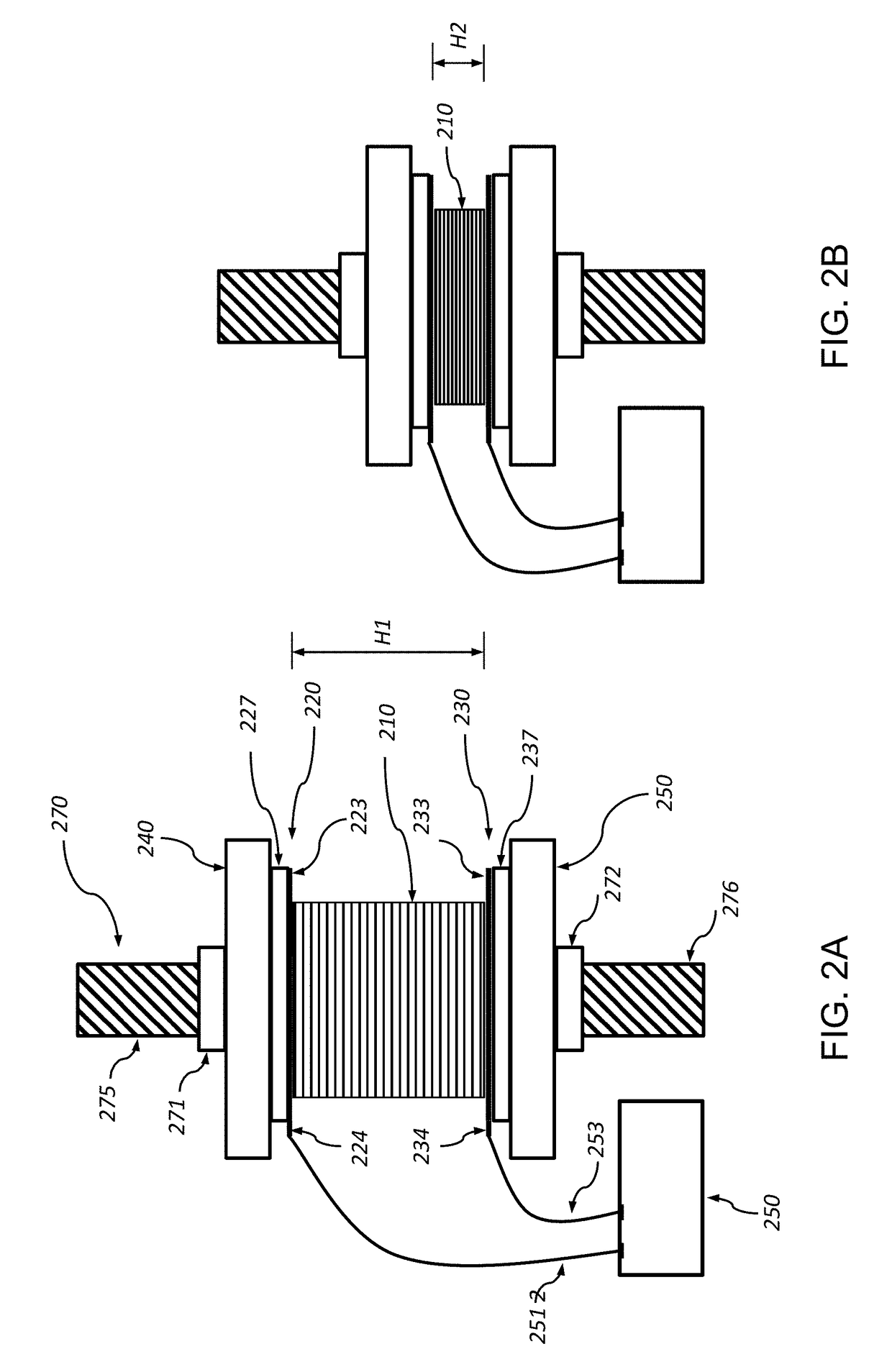

Resistive Heating-Compression Method and Apparatus for Composite-Based Additive Manufacturing

ActiveUS20180072001A1Manufacturing heating elementsIncreasing energy efficiencyFinal heightPower flow

A method and apparatus for resistive heating usable in composite-based additive manufacturing is disclosed. The method includes providing a prepared stack of substrate sheets, placing the stack between electrode assemblies of a compression device, applying a current to thereby heat the stack to a final temperature to liquefy applied powder, compressing the stack to a final height, cooling the stack, and removing the cooled, compressed stack from the compression device. The apparatus comprises at least two plates, a power supply for providing current, a first electrode assembly and a second electrode assembly.

Owner:IMPOSSIBLE OBJECTS INC

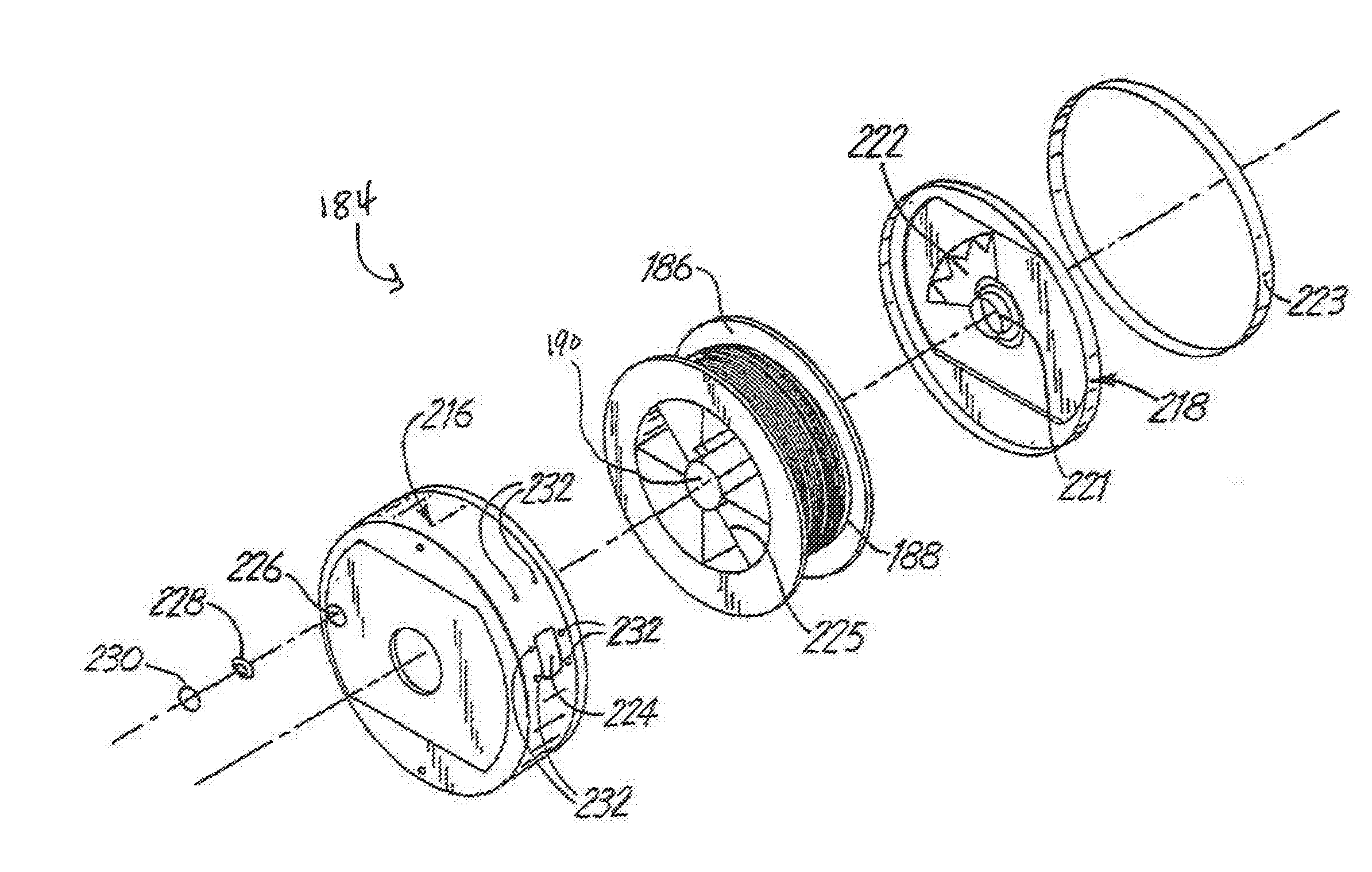

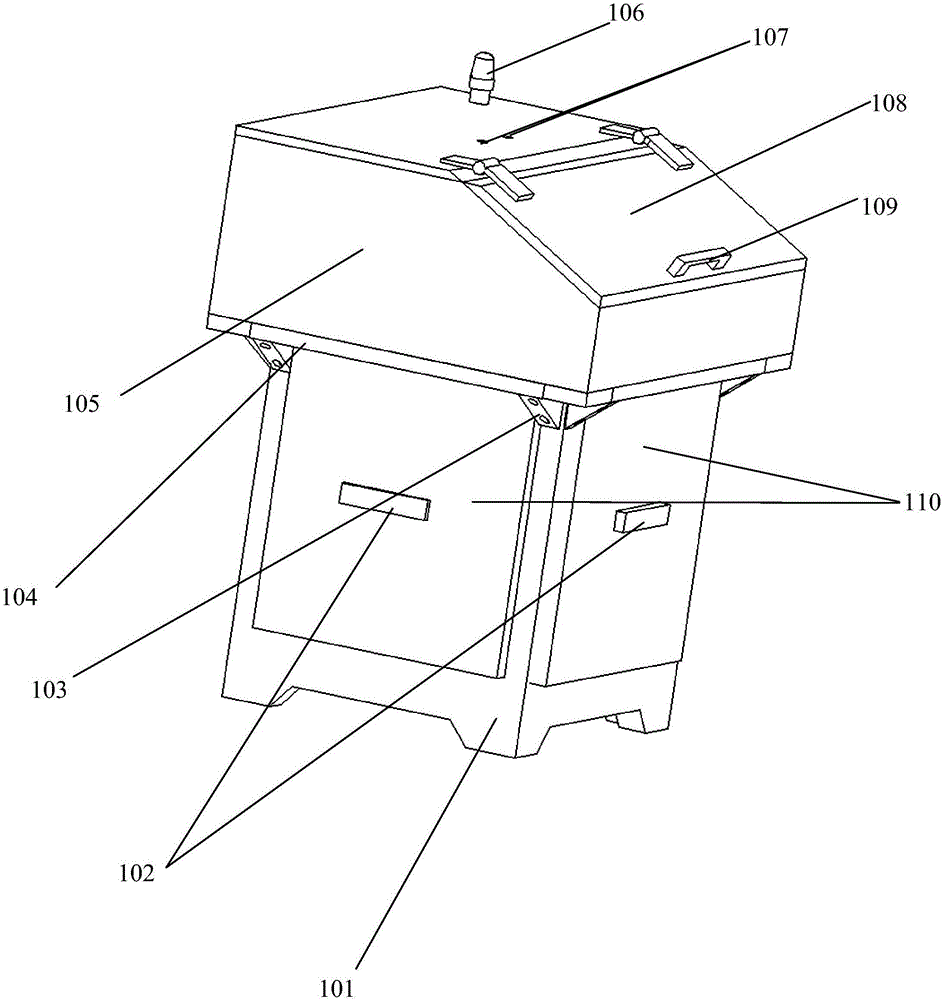

Sealed multi-material special engineering plastic additive manufacturing method and apparatus

ActiveCN106553337AImprove support strengthIncreased resistance to deformationManufacturing heating elementsManufacturing material handlingSelective laser sinteringManufacturing technology

The invention relates to sealed multi-material special engineering plastic additive manufacturing method and apparatus and belongs to the technical field of additive manufacturing of special engineering plastic. A three-axis movement platform assembly is installed inside a thermal insulation chamber assembly. A special engineering plastic filament delivery roll assembly is installed in a back surface plate of the thermal insulation chamber assembly. A spray nozzle assembly is disposed on the top of interior of the thermal insulation chamber assembly. The method and the apparatus achieve low temperature difference and low deformation in 3D printing of special engineering plastic, so that parts in complex structures, which have high crystalline degree, high mechanical strength and low surface roughness, can be formed from a high-melt-point special engineering plastic. Defects of large deformation, poor mechanical strength of a moulded part, and low size precision in a conventional high-temperature special engineering material printing process are overcome, and a defect of warping deformation during a powder moulding process in a selective laser sintering 3D printing technology is avoid. The method and the apparatus solve the problems such as high surface roughness in artificial bone 3D printing in the medical field, and have excellent medical and industrial application prospect.

Owner:JILIN UNIV

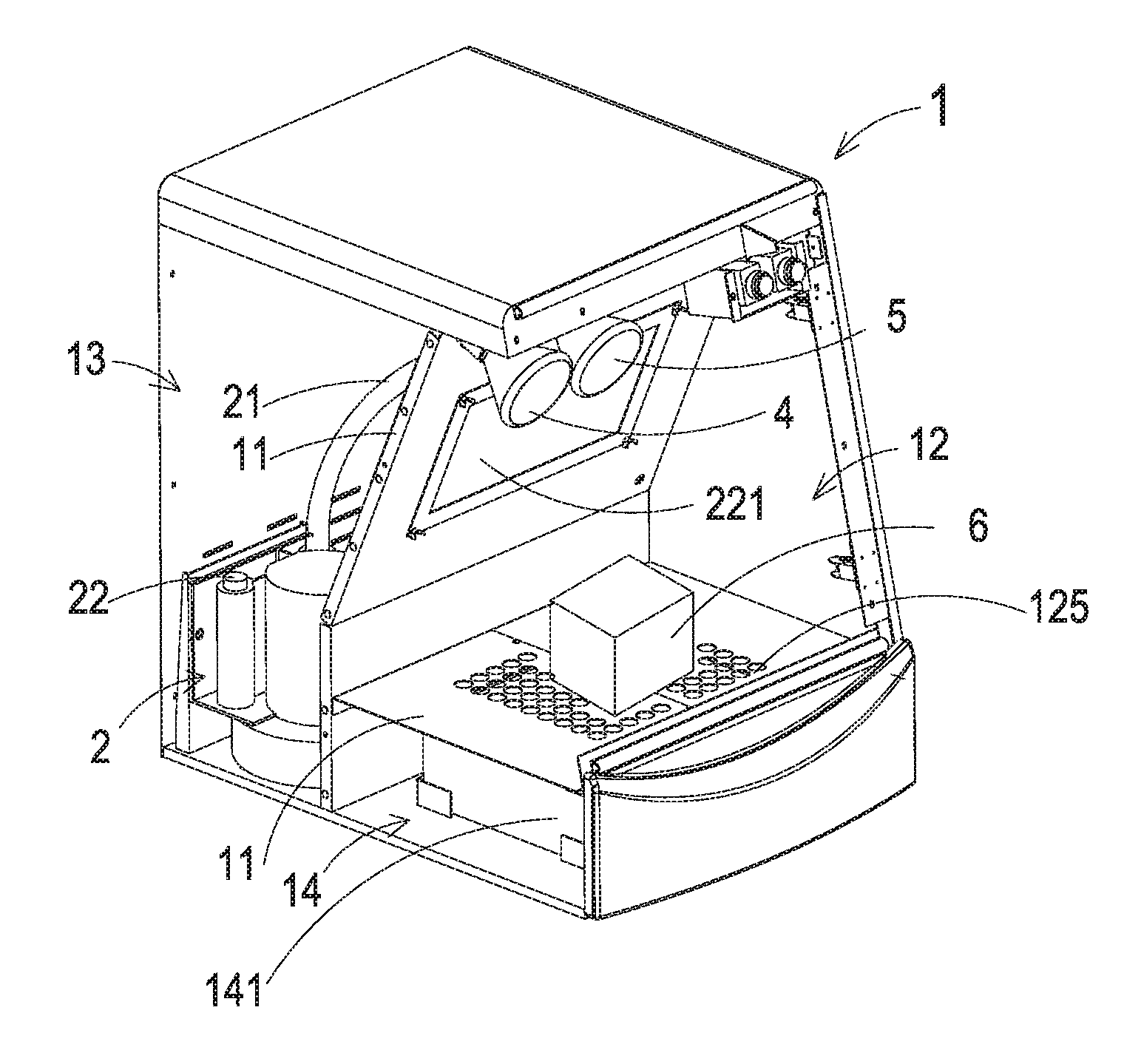

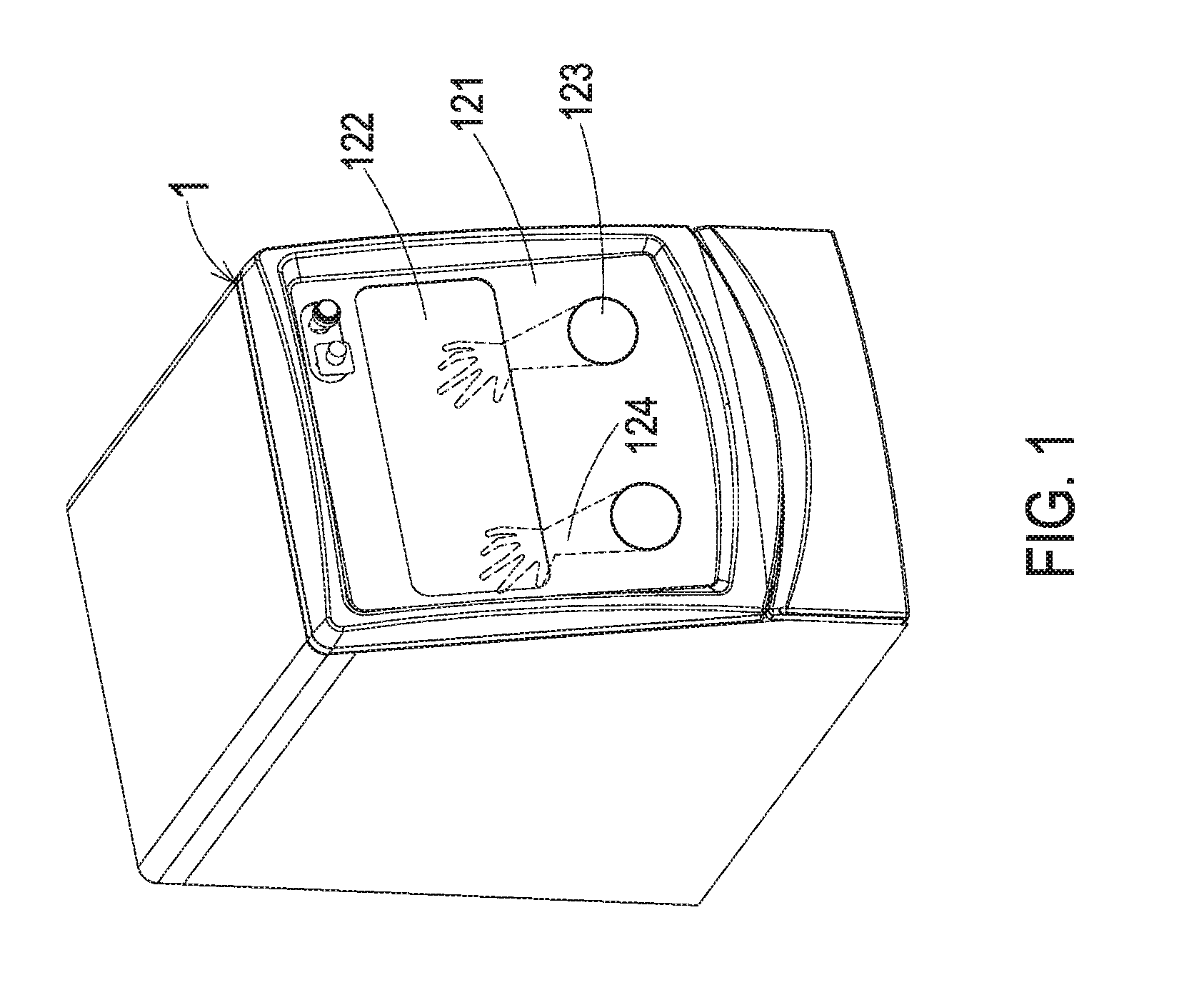

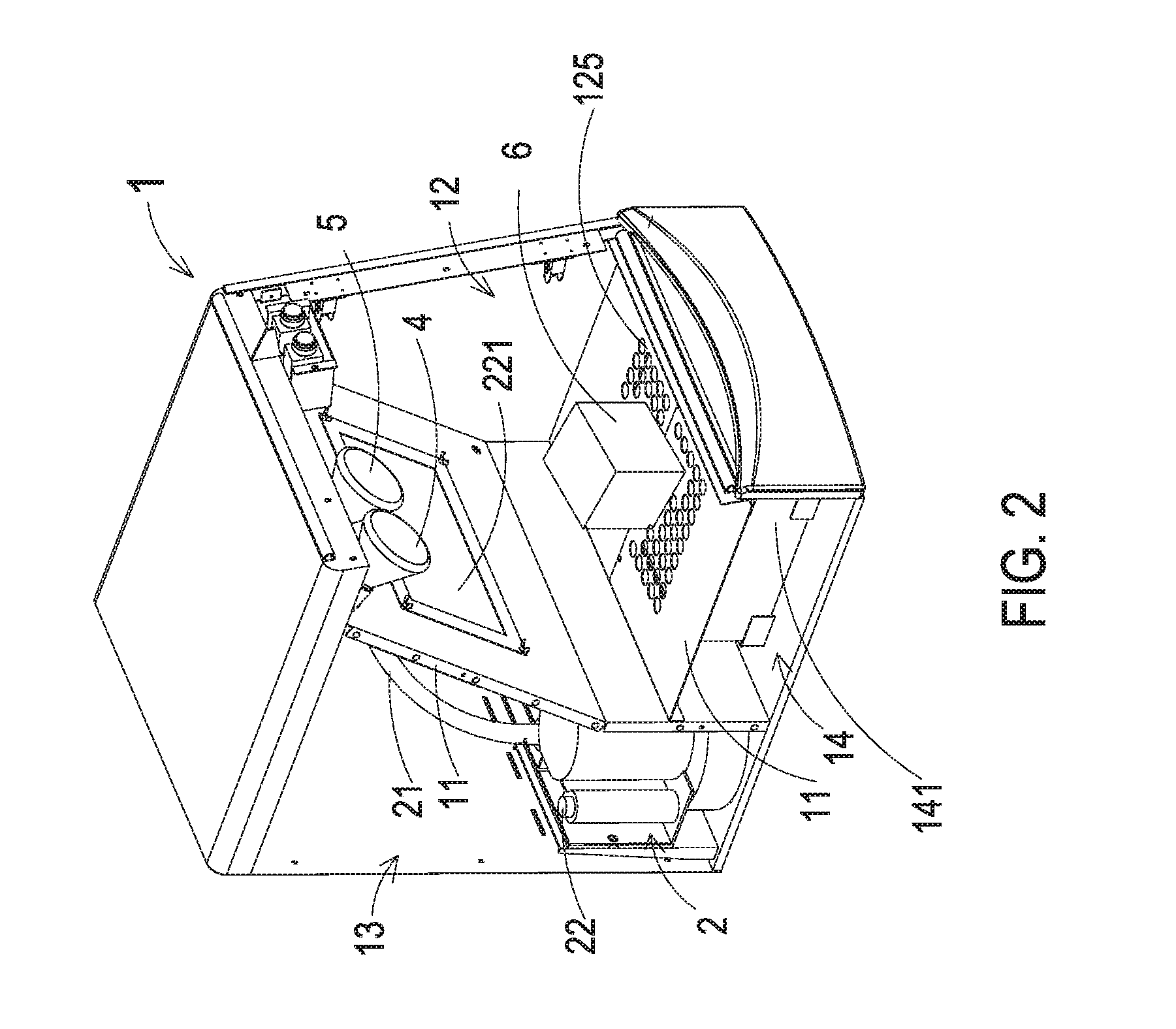

Three-dimensional object-forming apparatus

ActiveUS8523554B2Avoid wastingAdditional drawbackManufacturing enclosuresConfectioneryEngineeringHeating system

A three-dimensional object-forming apparatus is disclosed, which includes an in-batches powder-rationing tank system, a construction tank system, a printing powder-applying system, a rapid drying heating system, a printing maintenance device, a dust-proof device, a successive liquid-supplying device, a powder auto-filtrating and recycling device, and a print quality detection device.

Owner:MICROJET TECH

Three-dimensional printer having support material forming function and forming method

ActiveCN106626369ALow densityReduce weightManufacturing platforms/substratesManufacturing material handlingElectricityFoaming agent

The invention relates to a three-dimensional printer having a support material forming function. The three-dimensional printer comprises a printing head component, a printing platform and a controller, the printing head component can independently move relative to the printing platform in the three-dimensional directions; the controller is electrically connected with the printing head component and the printing platform; the printing head component comprises a fusion chamber, after being fused in the fusion chamber, a print material is deposited layer by layer on the printing platform according to the preset procedures; a first power unit is loaded with a foaming agent, and the first power unit supplies the foaming agent to the fusion chamber, so that the foaming agent is mixed and fused with the print material. When a support part is printed, the foaming agent is added into the fusion chamber, the volume of the print material expands after the foaming agent and the print material are mixed and fused, the expanded fused material is deposited layer by layer on the printing platform to form the support part, the density of the support part is correspondingly reduced, and the weight of a used support material is correspondingly reduced, so that the purpose of lowering the cost is achieved.

Owner:天津艾睿信佳科技发展有限公司

Container for accommodating at least one of at least one biologically active fluid and at least one preparatory fluid, and a method therefor

ActiveUS20160297152A1Avoid enteringImprove adhesionManufacturing driving meansManufacturing enclosuresRelative displacement3 dimensional printing

A sterilizable container for accommodating at least one of at least one biologically active fluid and at least one preparatory fluid has an area within the container configured to accommodate at least one sterilizable three-dimensional printer assembly. The sterilizable three-dimensional printer assembly includes at least one printing platform; at least one printer head for dispensing structural material onto the at least one printing platform to form thereon a three-dimensional structure; and a moving mechanism for providing a relative displacement between the at least one printer head and the at least one printing platform. The area is configured so that the fluid can reach the printer assembly.

Owner:SARTORIUS STEDIM BIOTECH GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com