Machine and process for powder-based additive manufacturing

An additive manufacturing, powder technology, applied in the field of powder-based additive manufacturing, to achieve the effect of improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In different figures, identical or similar elements bear the same reference signs. However, the description of their structure and their function will not be systematically repeated.

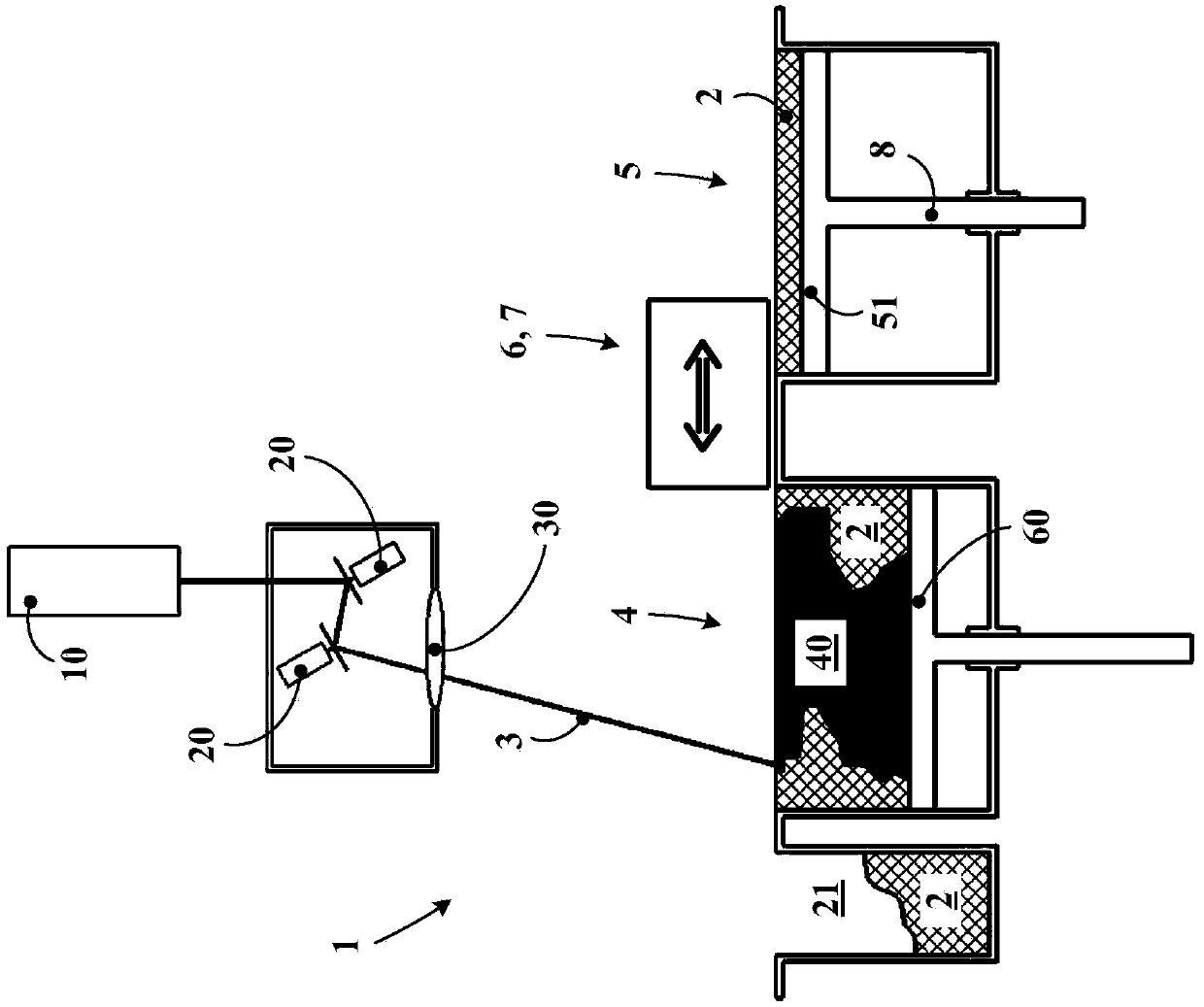

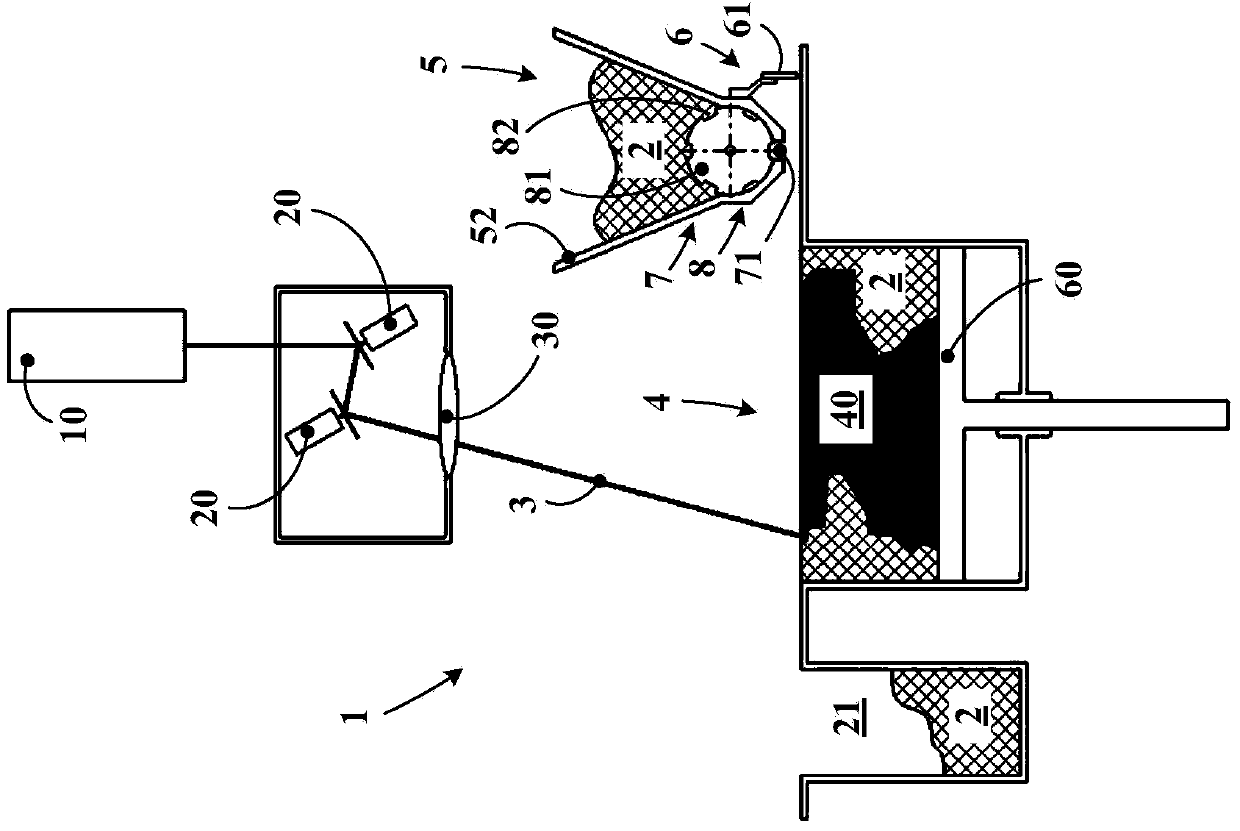

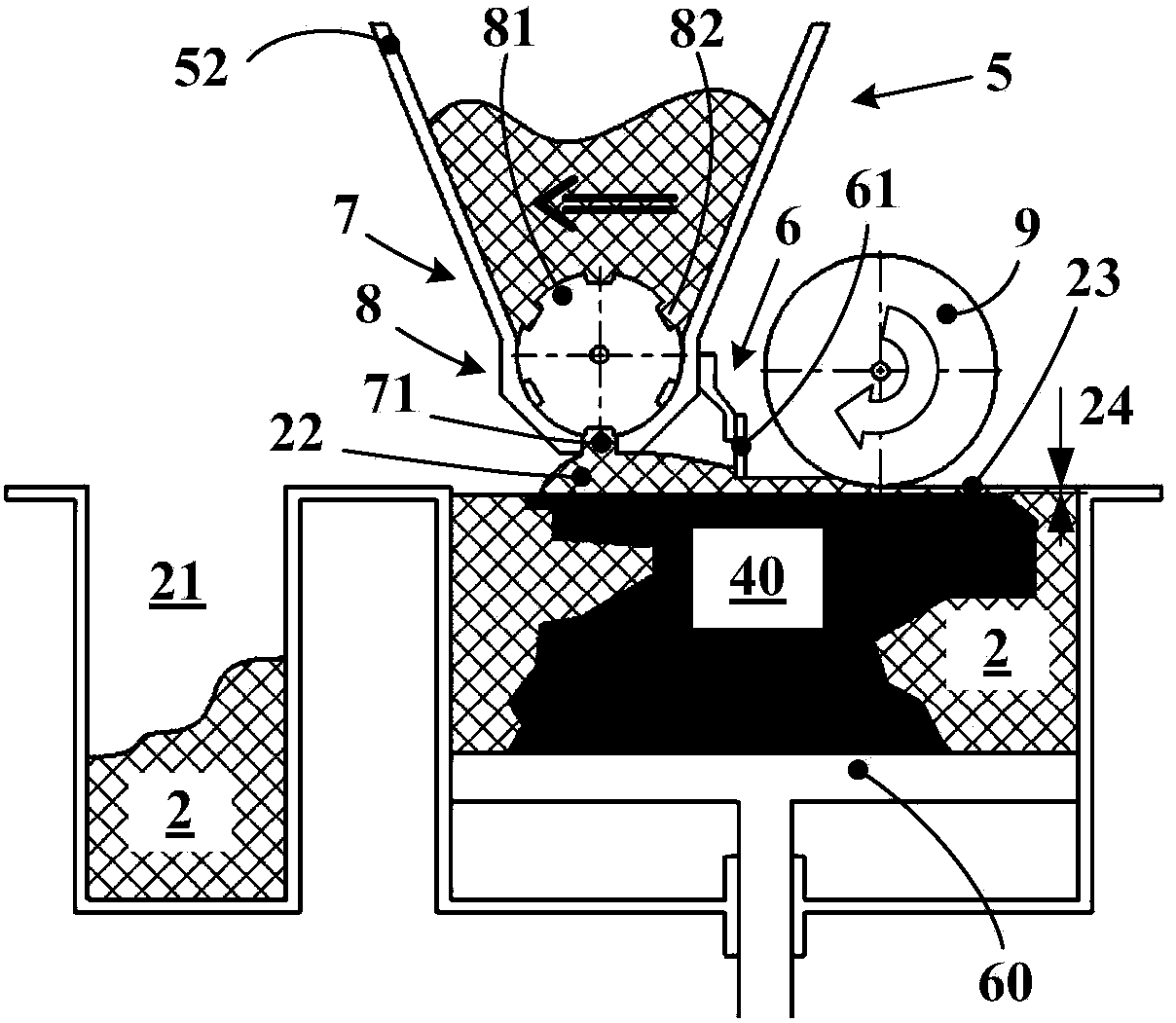

[0046] In FIG. 1 , a machine for additively manufacturing a component 40 according to the prior art is schematically shown. An energy source, in this case a laser source 10 , emits a laser beam 3 whose direction is controlled by a mirror subjected to a galvanometer 20 . The optical lens 30 allows the beam 3 to be focused at the level of the working area 4 so as to heat the upper layer of the powder 2 according to a precise pattern, thus melting the powder in a selective manner. After the powder layer has been processed by the beam, the working tray 60 is lowered by unit thickness and covered with a new powder layer, continuing in this way to form the assembly 40 layer by layer. Depending on the type of energy beam and the powder used, the thickness of the powder layer may vary from a fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com