Patents

Literature

31 results about "Final height" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

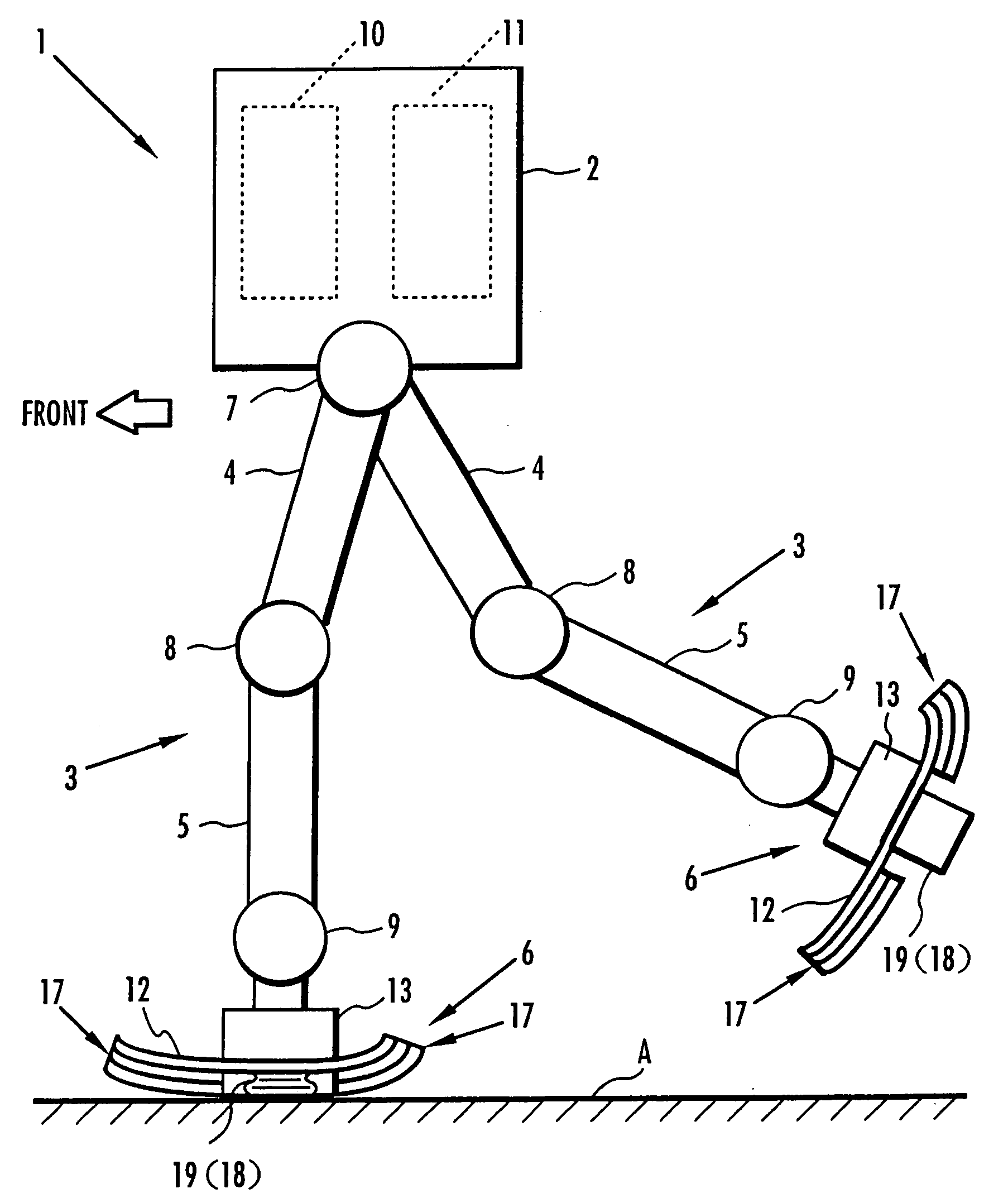

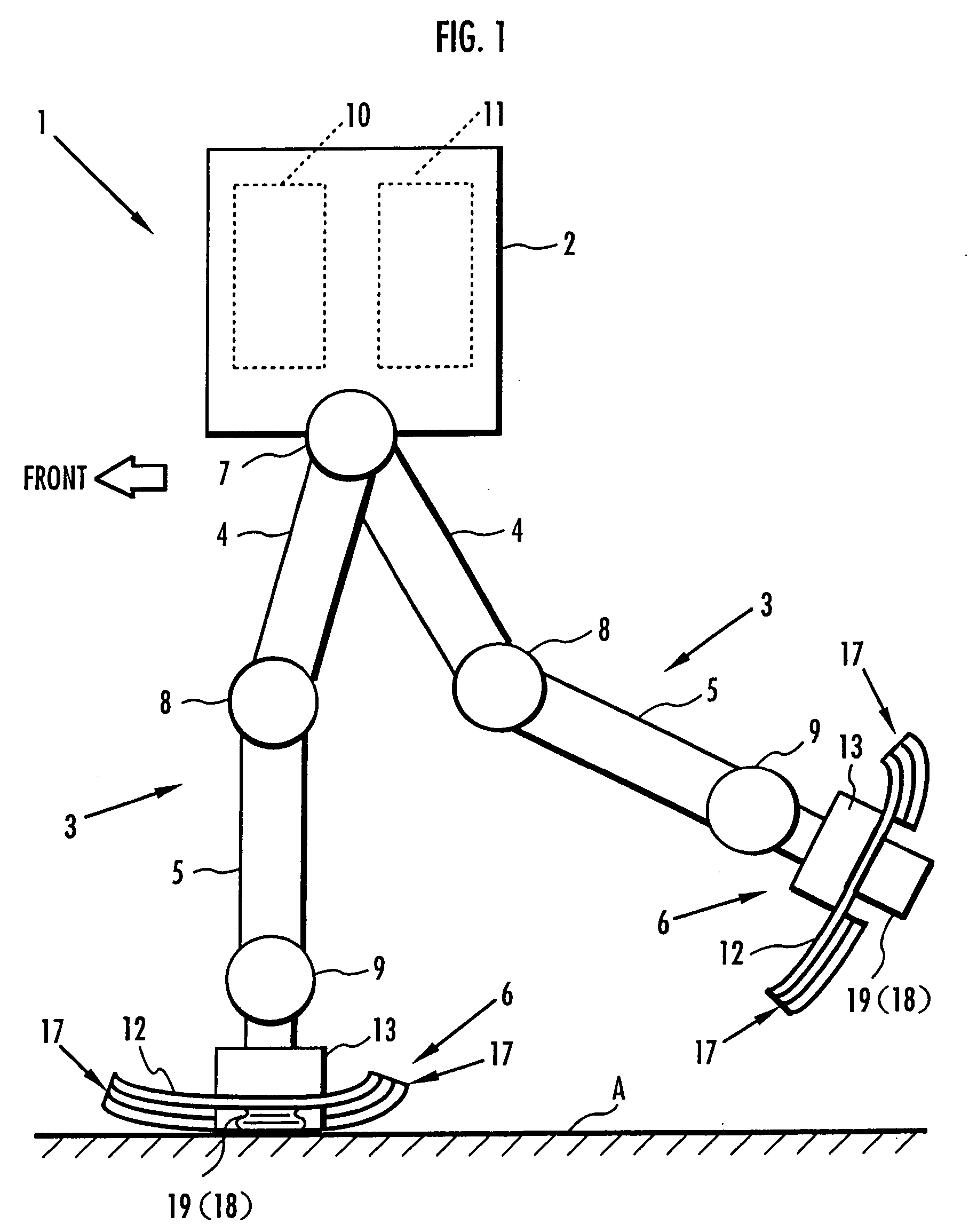

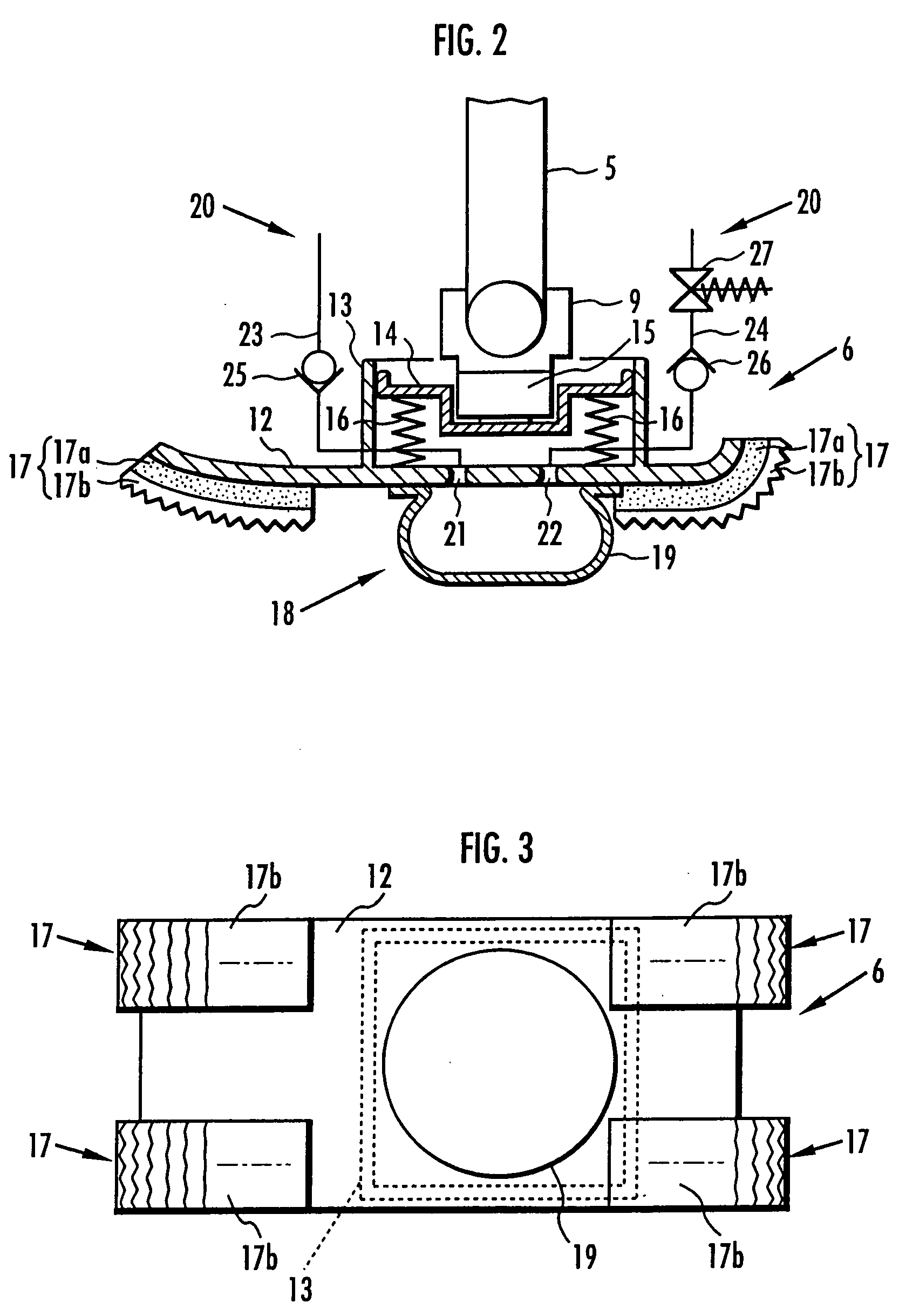

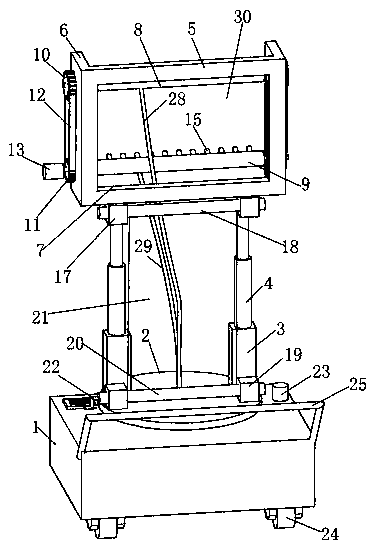

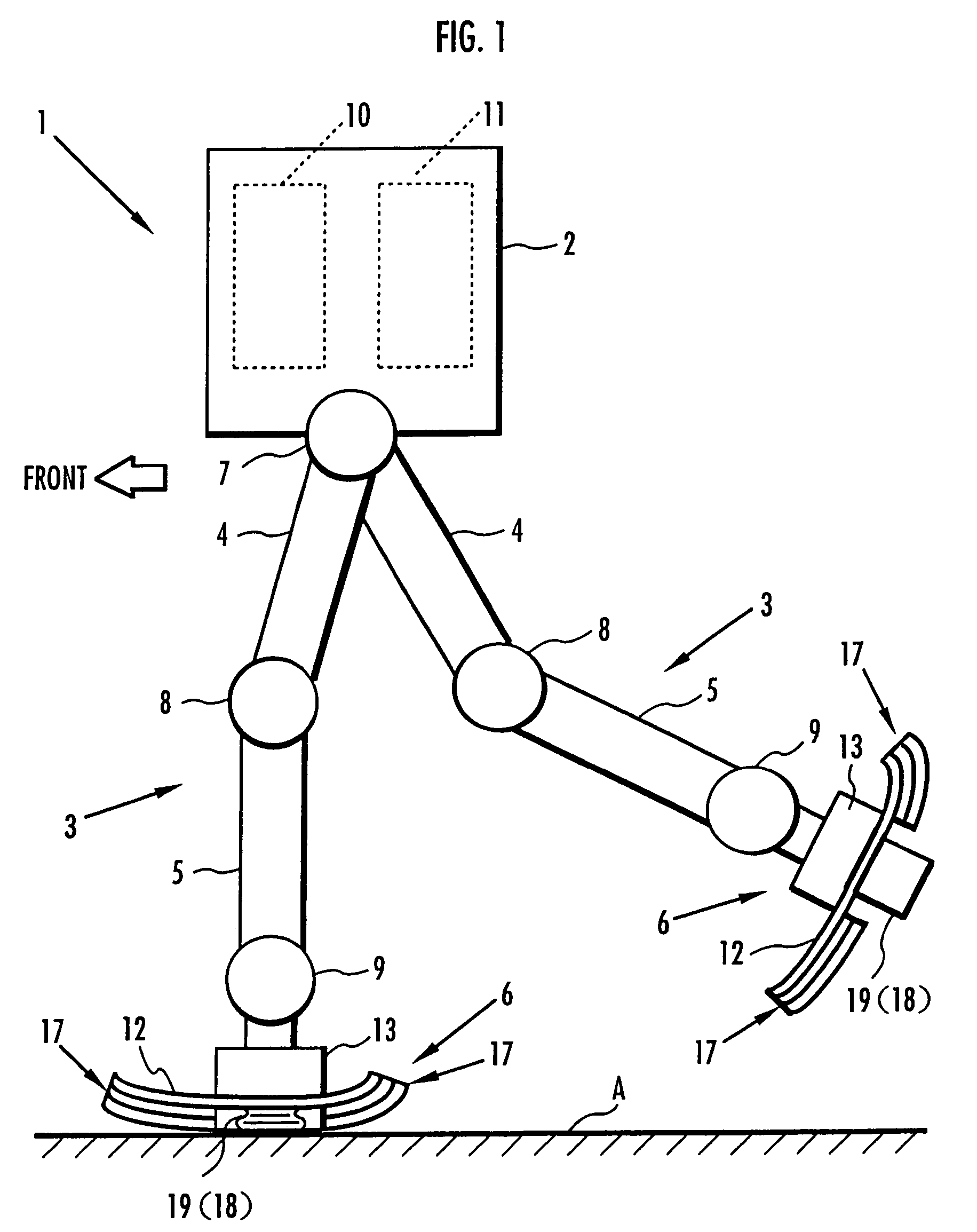

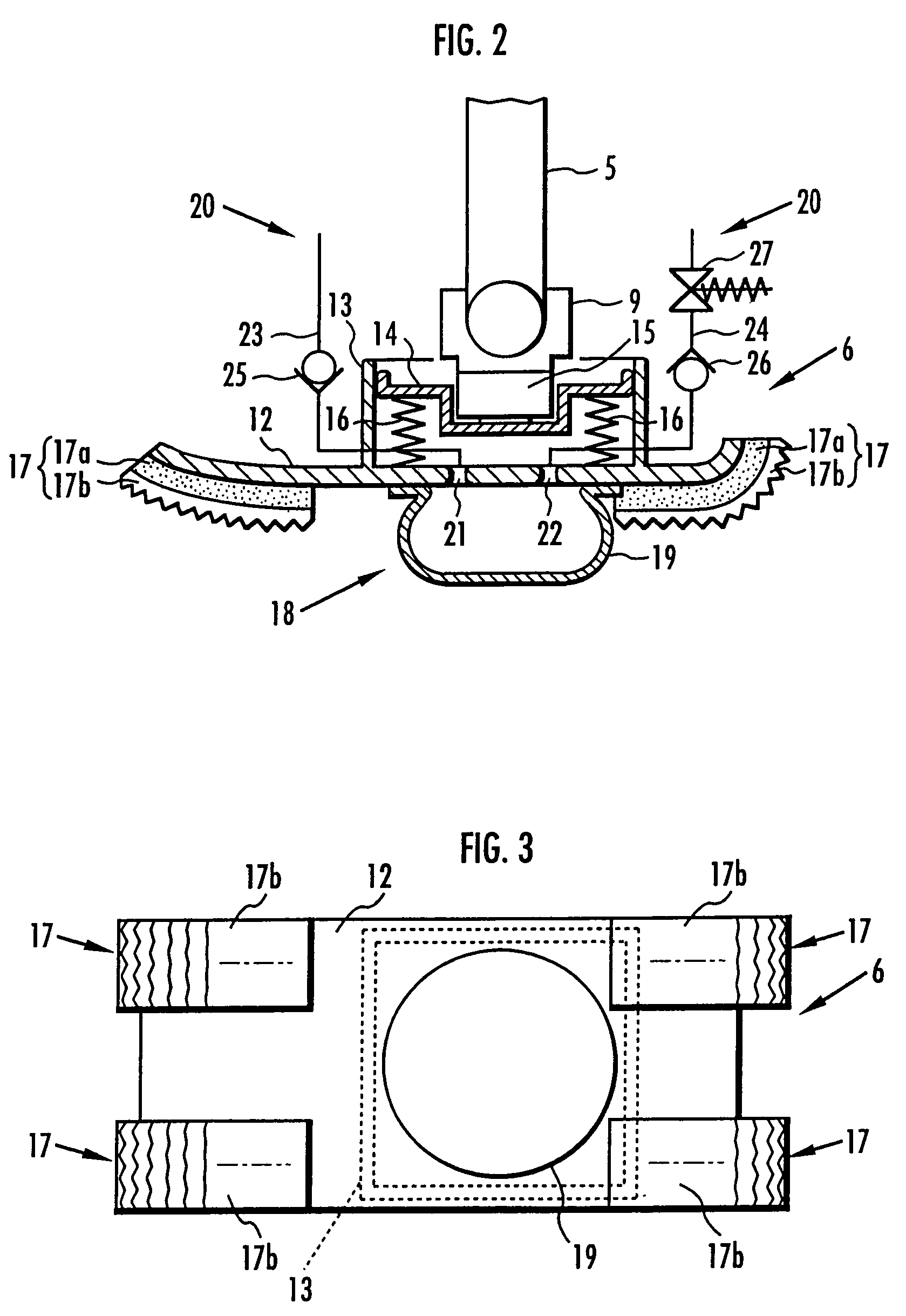

Device for absorbing floor-landing shock for legged mobile robot

InactiveUS20050120820A1Increase shock loadIncrease contactGas based dampersProgramme control in sequence/logic controllersFinal heightSolenoid valve

A landing shock absorbing device 18 disposed in a foot mechanism 6 of a leg of a robot, wherein an inflatable bag-like member 19 (variable capacity element) is provided at a bottom face side of the foot mechanism 6. The bag-like member 19 is constructed of an elastic material such as rubber. The air in atmosphere may flow into and out of the bag-like member 19 by inflow / outflow means 20 equipped with a solenoid valve 27, and the like. In a lifting state of the foot mechanism 6, inflow of the air into the bag-like member 19 is controlled, thereby controlling the final height of the bag-like member 19 in an inflated state to the height in response to a gait type of the robot. While properly reducing an impact load during a landing motion of the leg of a legged mobile robot depending on the gait type of the robot, stability of a posture of the robot may easily be secured, resulting in allowing a configuration to be lighter in weight.

Owner:HONDA MOTOR CO LTD

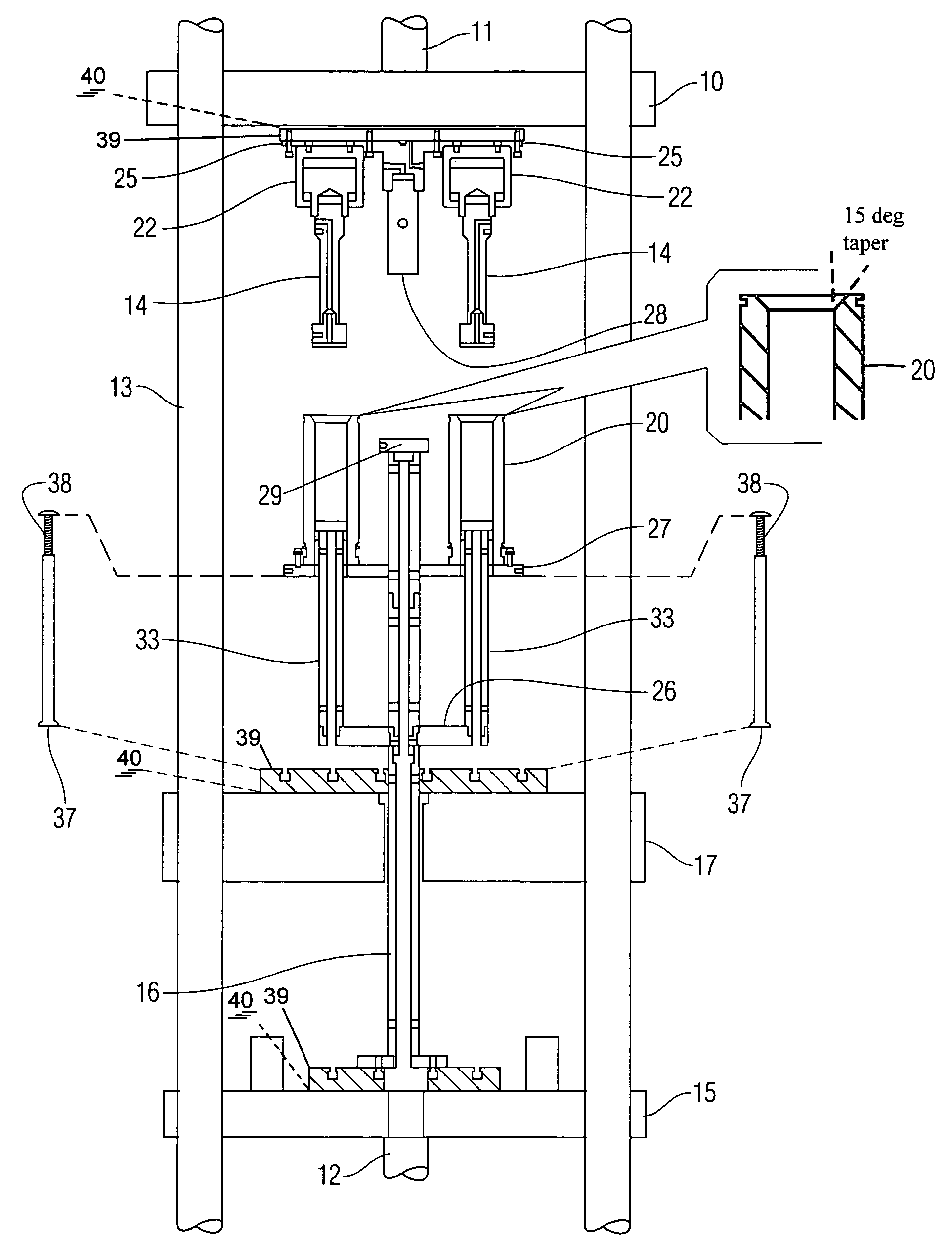

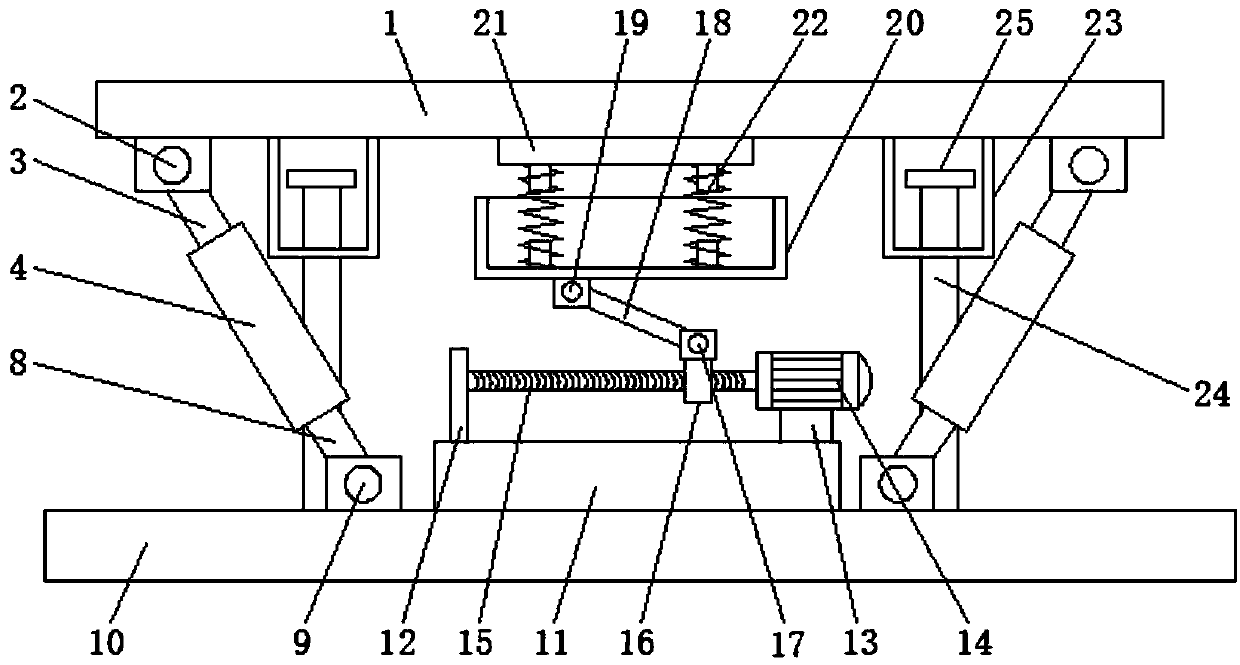

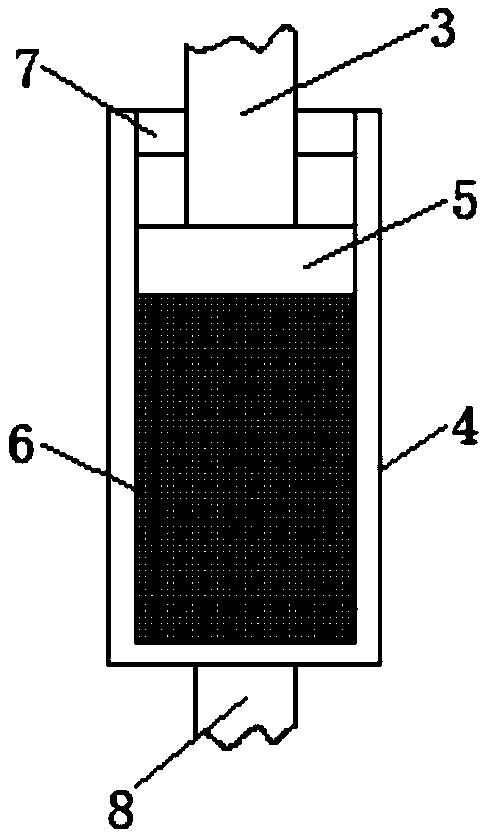

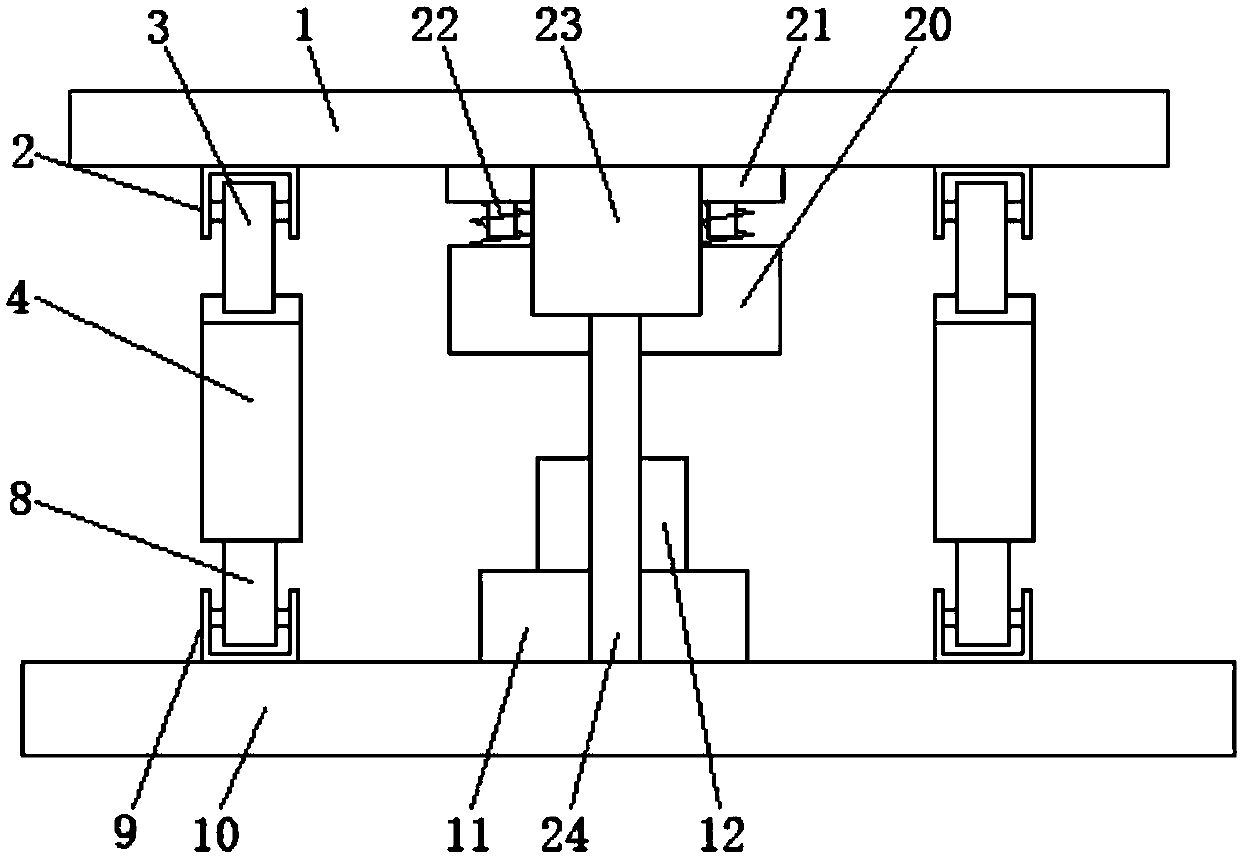

Multiple position press

InactiveUS7150617B1The degree of freedom becomes largerConfectionerySweetmeatsFinal heightHydraulic cylinder

A modular press assembly for performing multiple position pressing with a single press. The modular press assembly includes a floating mount attached to the upper platen of the press, a hydraulic cylinder, and a press ram coupled to the cylinder which automatically guides itself precisely into axial alignment with a die situated on a lower platen and containing material to be pressed. A plurality of such press assemblies are mounted on the upper platen and are connected through respective flow control valves to an independent hydraulic control system to allow adjustment of the travel of the multiple press rams. This configuration facilitates multiple position pressing and equally divides the total press force from the single hydraulic press, distributing it among each of the multiple positions independent of the final height of each pressed body.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

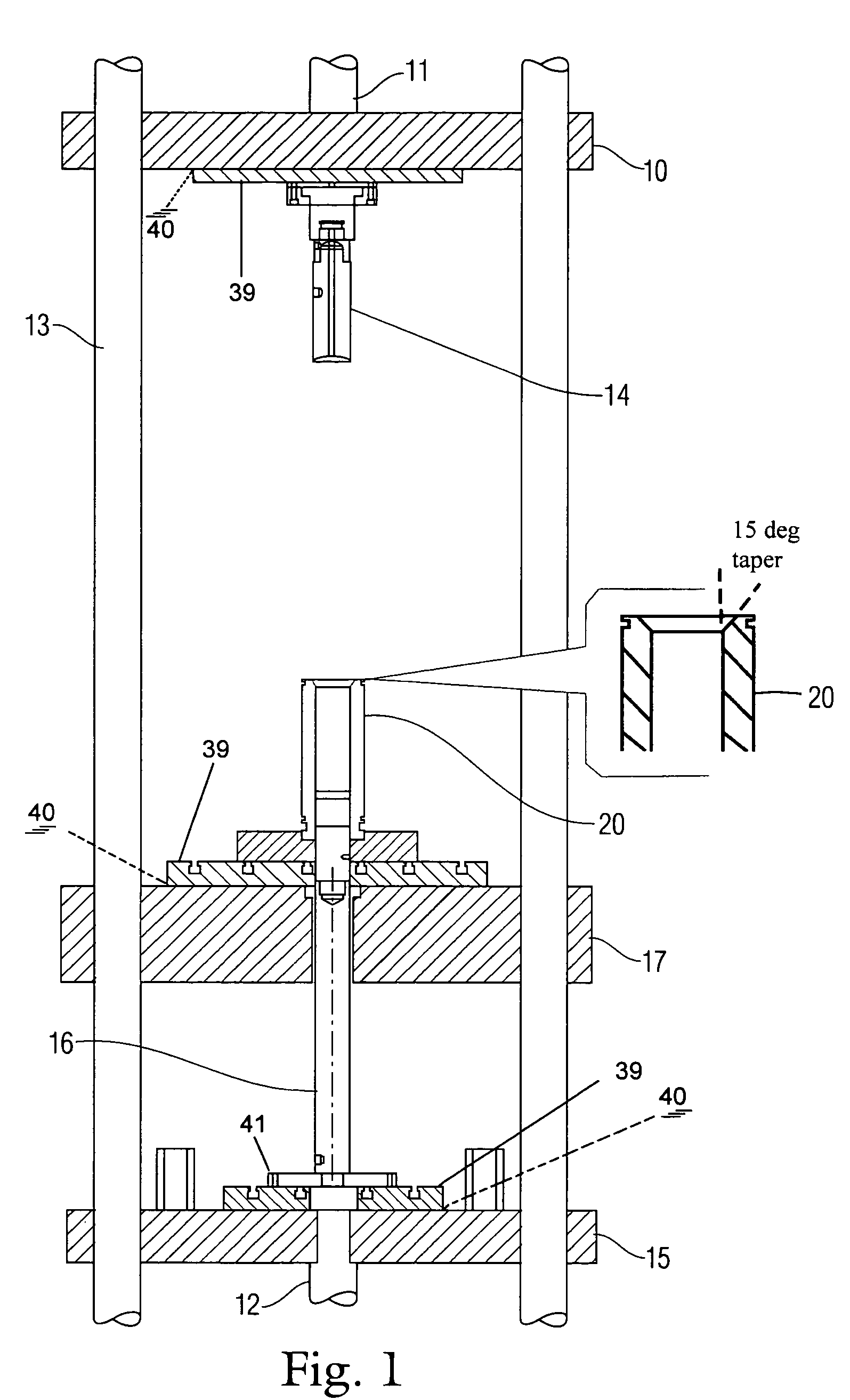

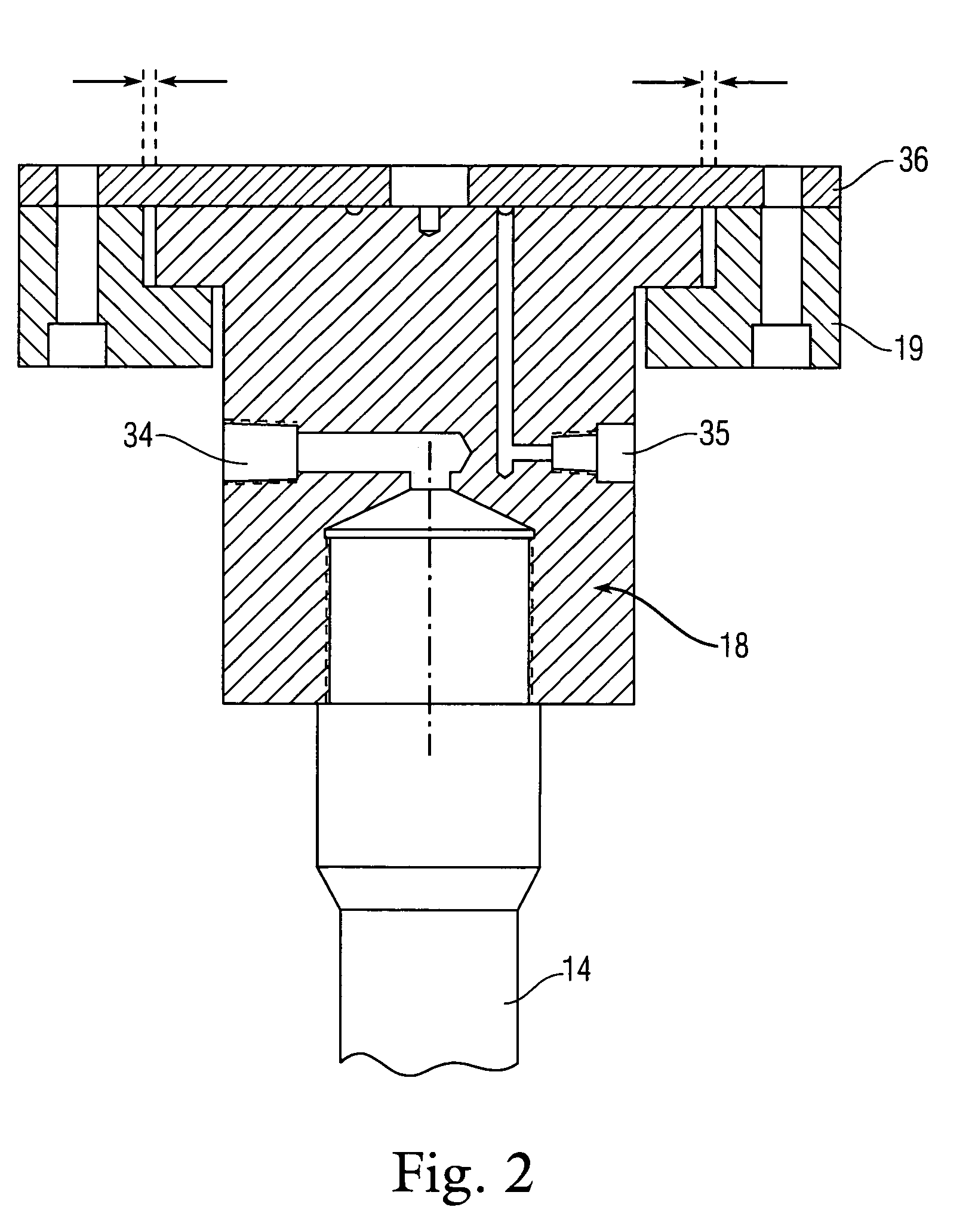

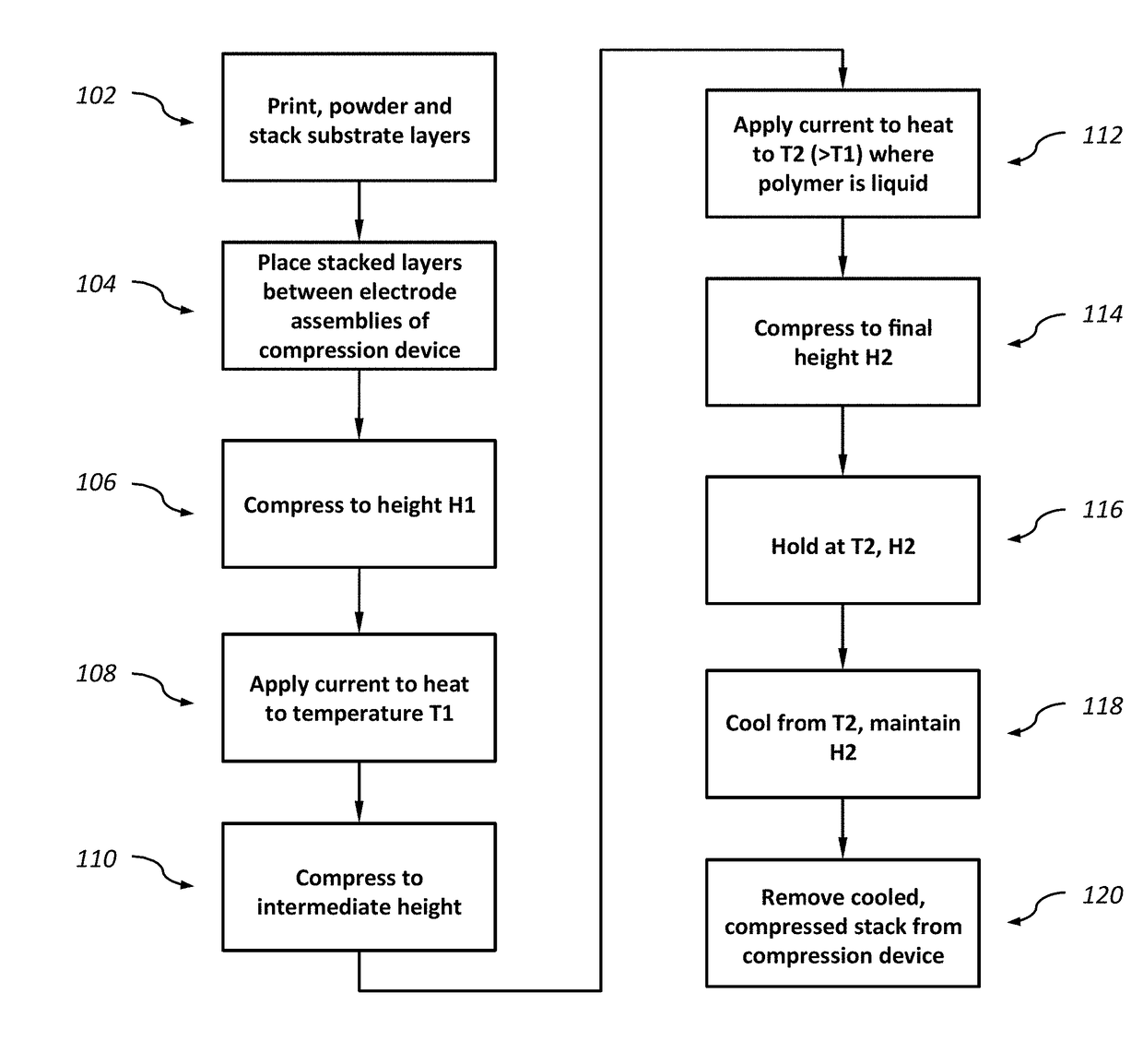

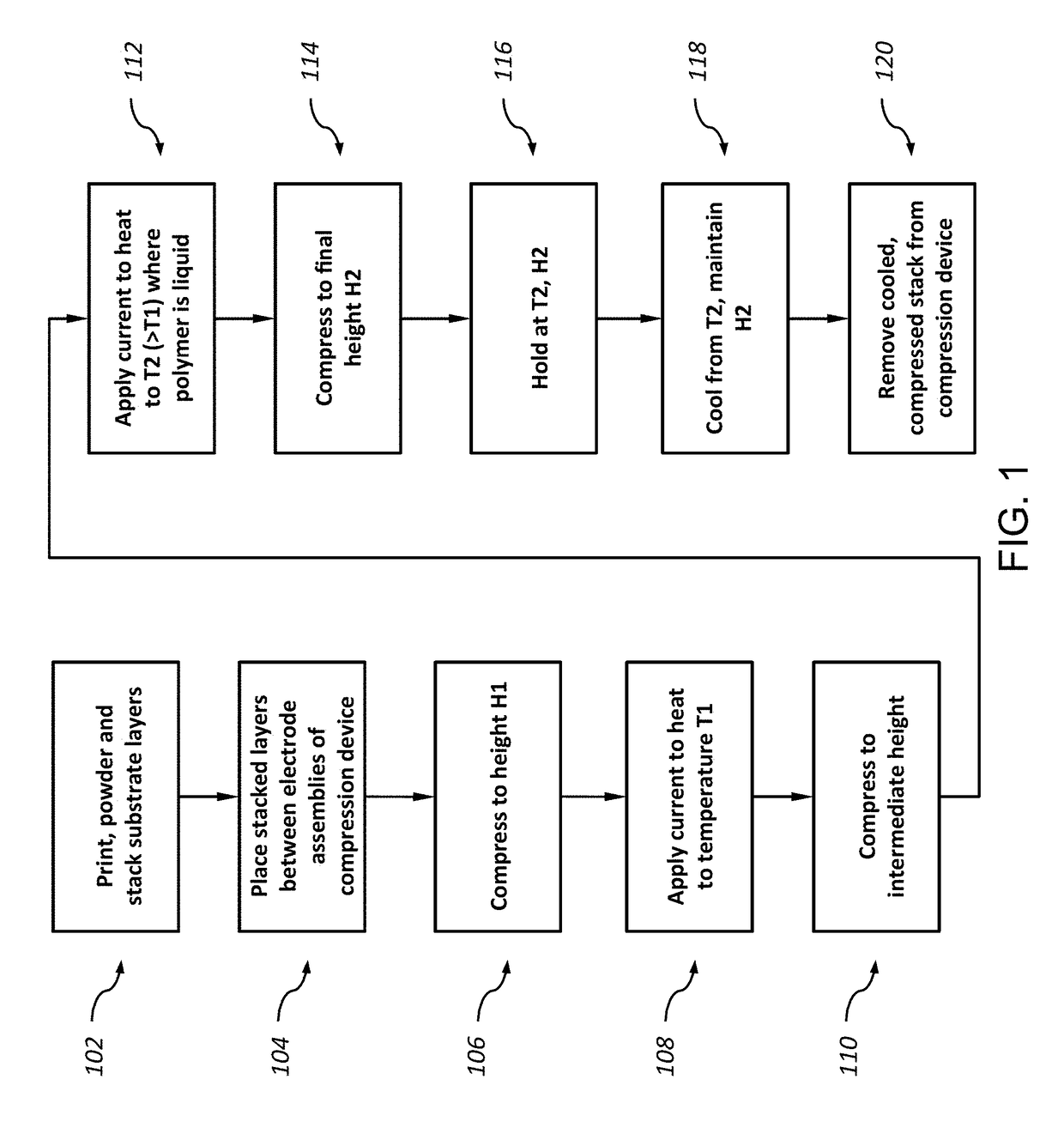

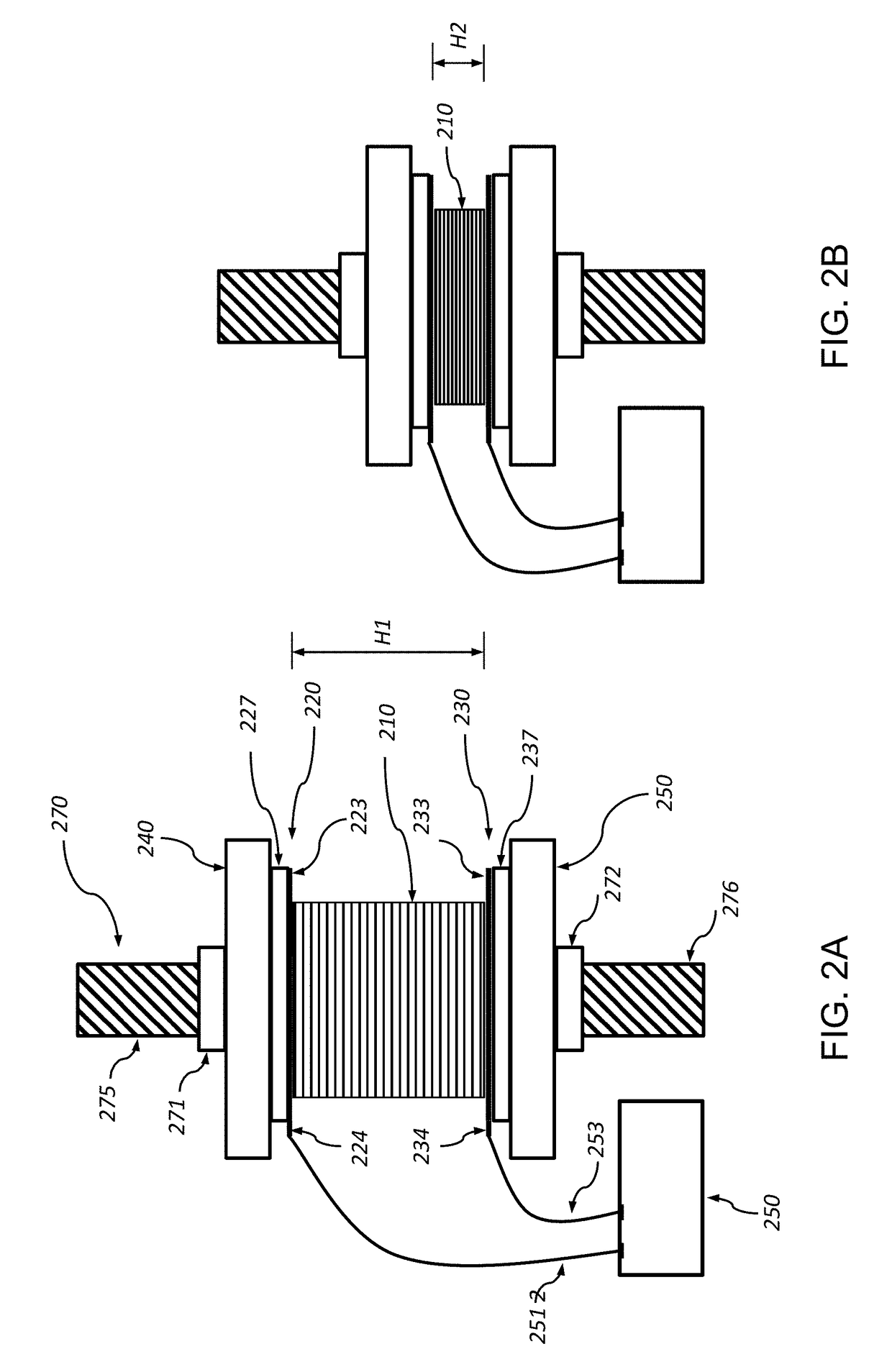

Resistive Heating-Compression Method and Apparatus for Composite-Based Additive Manufacturing

ActiveUS20180072001A1Manufacturing heating elementsIncreasing energy efficiencyFinal heightPower flow

A method and apparatus for resistive heating usable in composite-based additive manufacturing is disclosed. The method includes providing a prepared stack of substrate sheets, placing the stack between electrode assemblies of a compression device, applying a current to thereby heat the stack to a final temperature to liquefy applied powder, compressing the stack to a final height, cooling the stack, and removing the cooled, compressed stack from the compression device. The apparatus comprises at least two plates, a power supply for providing current, a first electrode assembly and a second electrode assembly.

Owner:IMPOSSIBLE OBJECTS INC

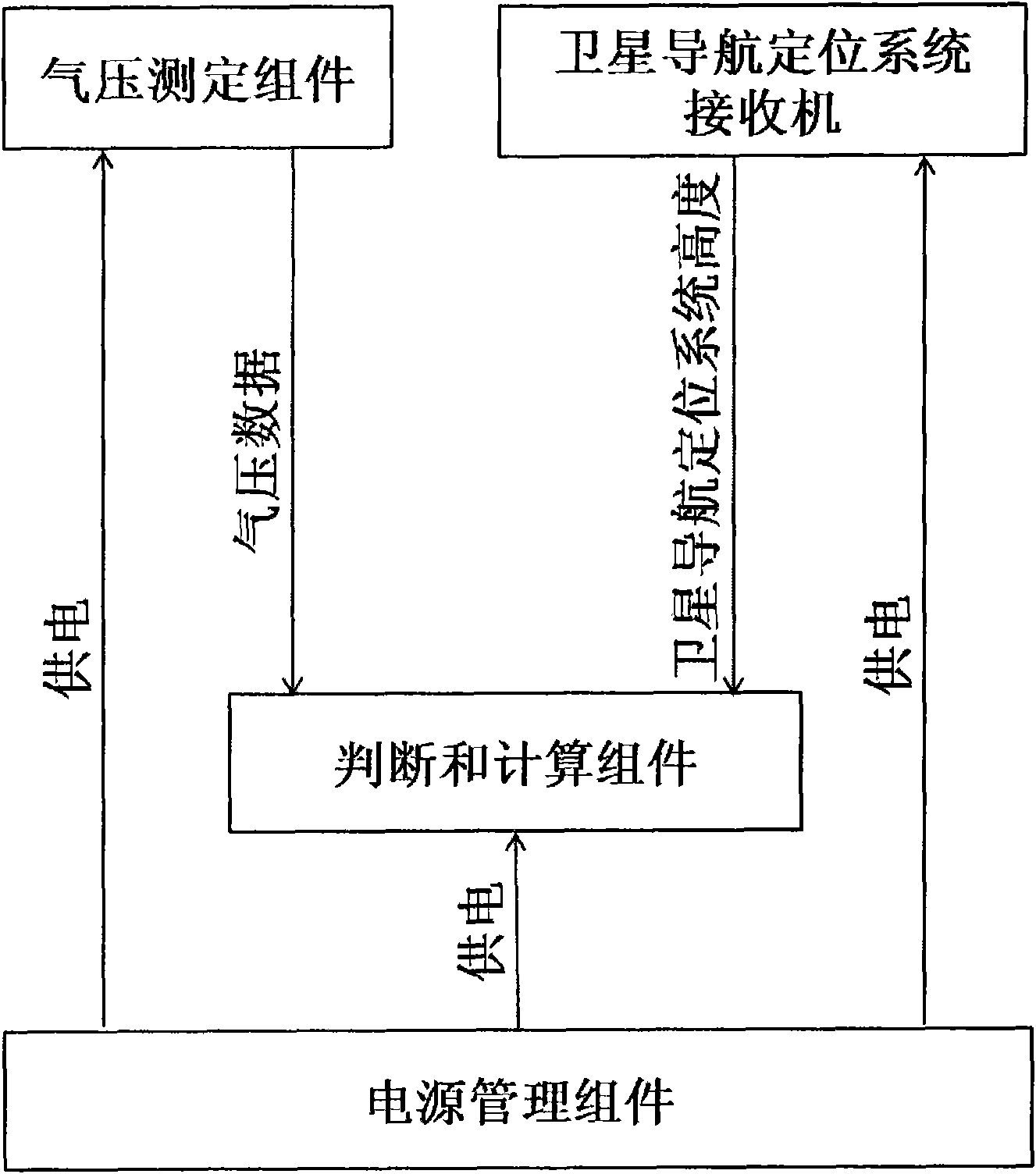

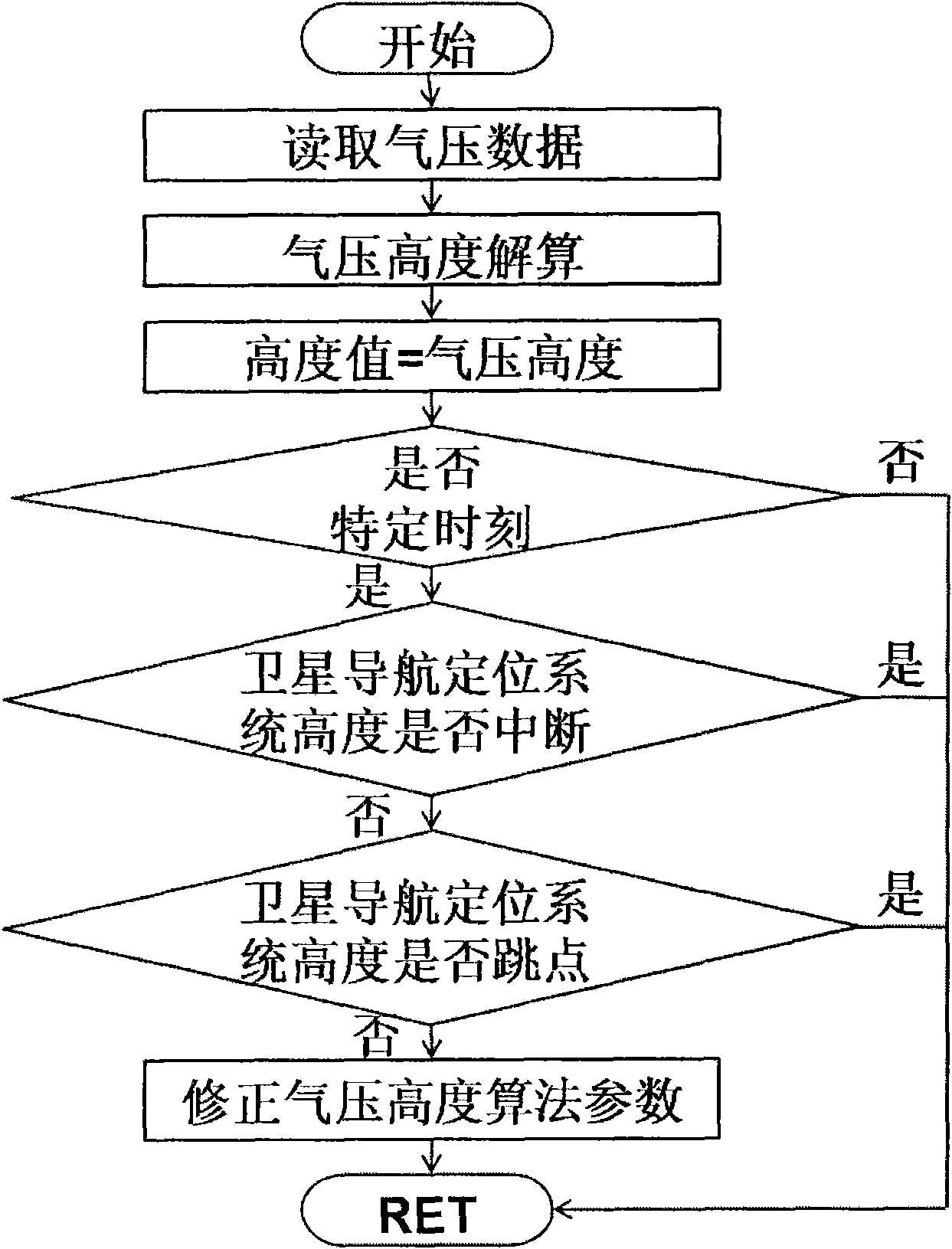

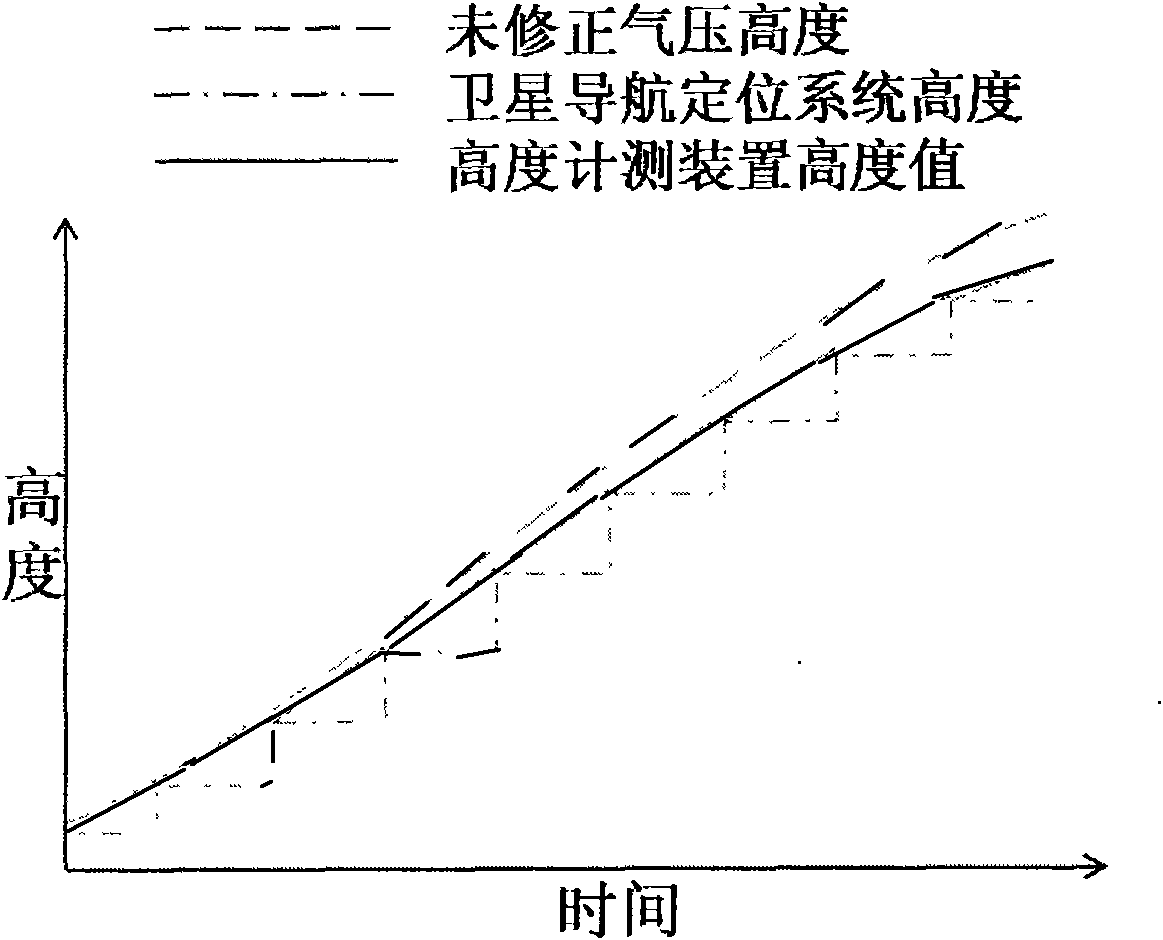

Height measuring device

InactiveCN101666643AHigh altitude value update rateWork reliablyBeacon systems using radio wavesHeight/levelling measurementFinal heightAtmospheric pressure

The invention relates to a height measuring device based on the atmospheric pressure measurement and the data processing of a satellite navigation and positioning system, belonging to the field of height measuring equipment. An atmospheric pressure measuring component and a receiver of the satellite navigation and positioning system are respectively connected with a judgment component and a computing component; the atmospheric pressure measuring component computes atmospheric pressure height according to the atmospheric pressure; the receiver of the satellite navigation and positioning systemcomputes the height of the satellite navigation and positioning system and judges whether the satellite navigation and positioning system discontinues or skips points; when the satellite navigation and positioning system does not discontinue or skip points, the atmospheric pressure height can be corrected by the height of the satellite navigation and positioning system; and when the height of thesatellite navigation and positioning system is not updated or discontinues or skips points, the final height value is equal to the value of the atmospheric pressure height so that a correct and reliable height value with high update rate can be obtained.

Owner:TSINGHUA UNIV

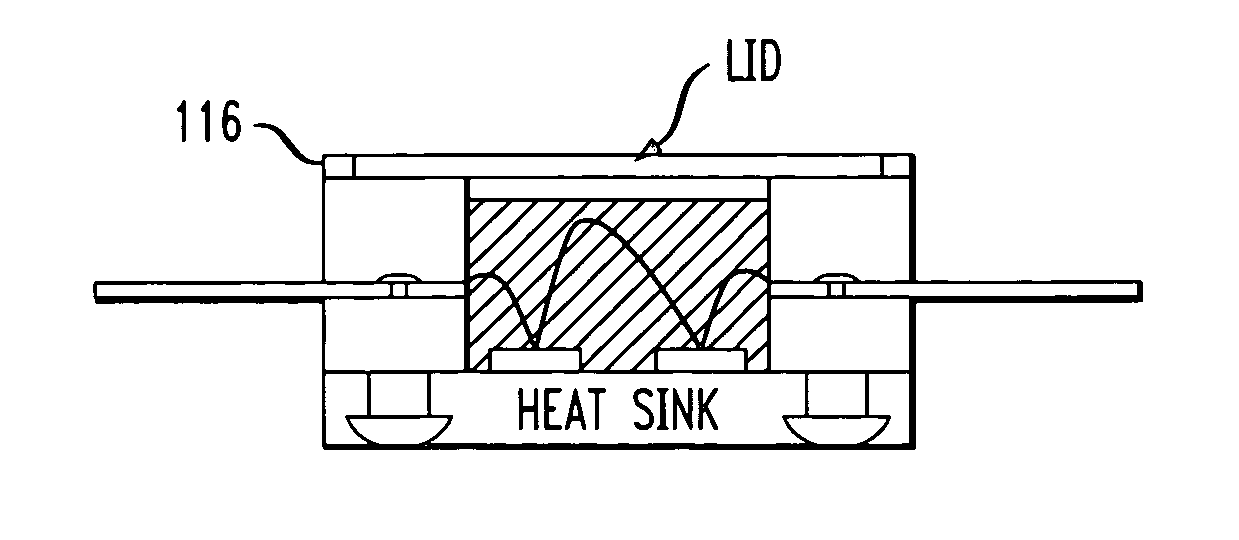

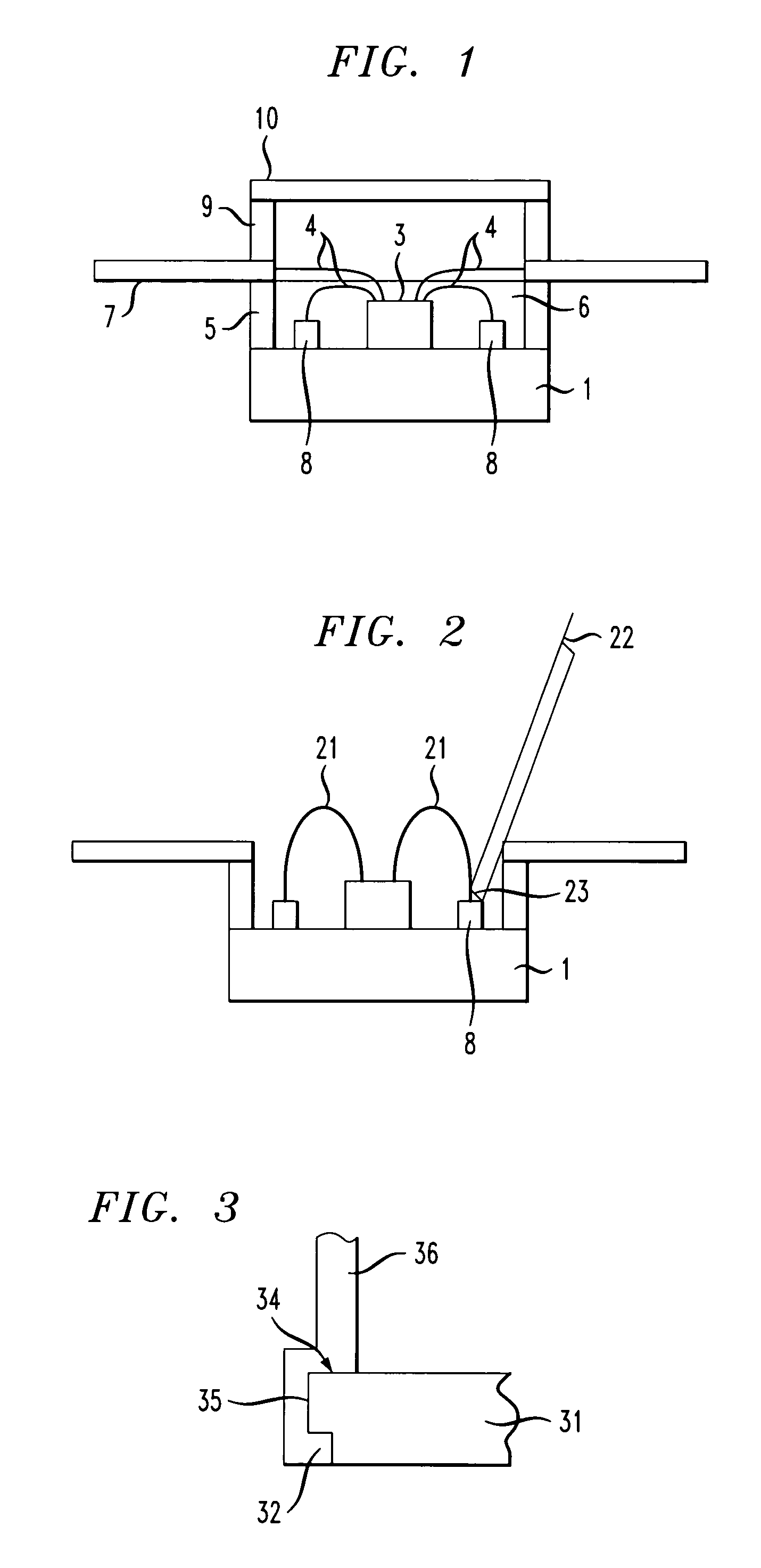

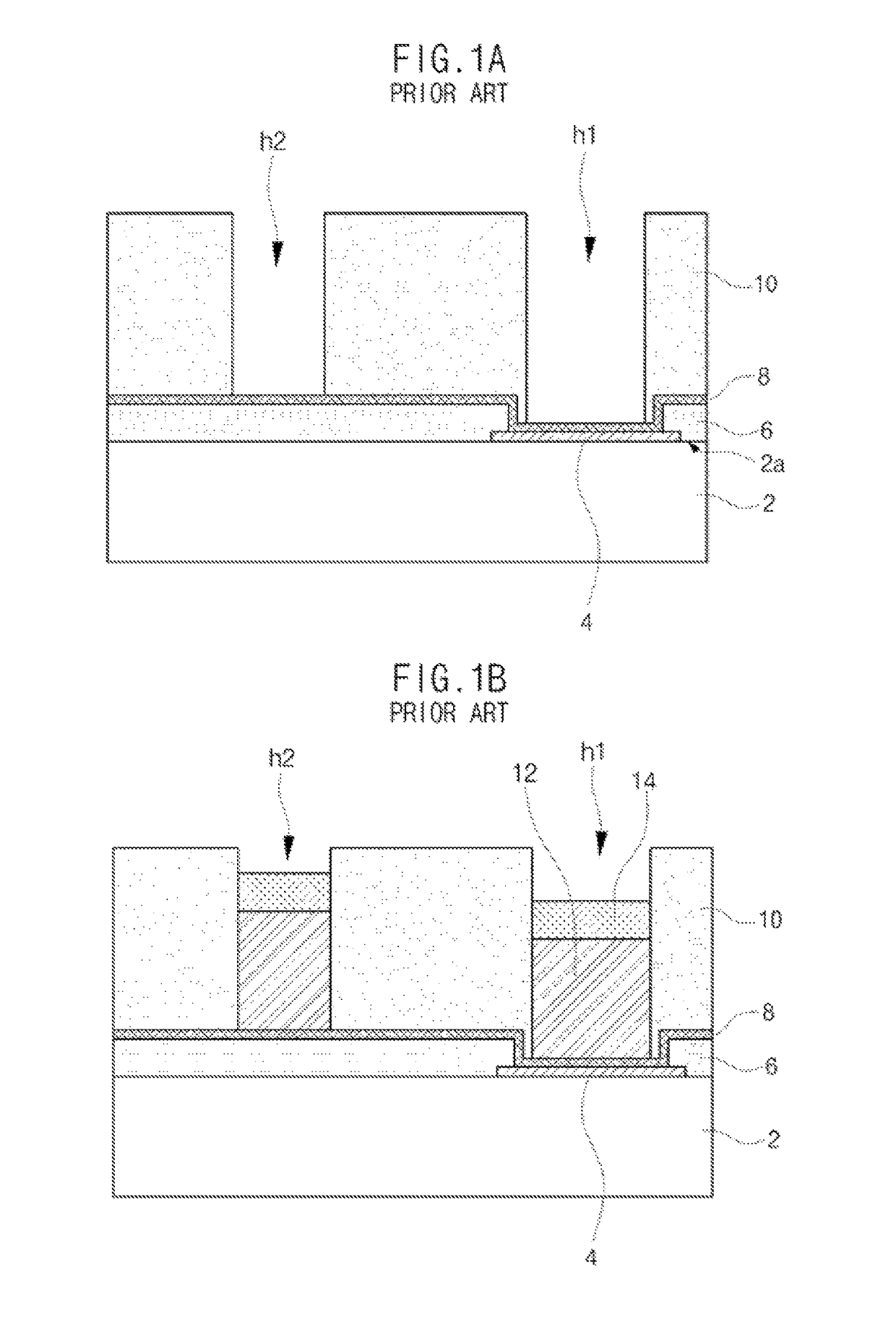

Device packages

ActiveUS20060172465A1Undesirable interactionInhibiting undesirable interactionSemiconductor/solid-state device detailsSolid-state devicesFinal heightAudio power amplifier

Devices such as amplifiers are built on a heat sink having a perimeter wall surrounding active electronic devices. Surprisingly formation of wire bonds to such devices tends to be degraded if they have an aspect ratio greater than 2:1. This problem is overcome by forming wire bonds before such walls have a height of 30 mils and after bond formation extending the walls to their final height.

Owner:BELL SEMICON LLC

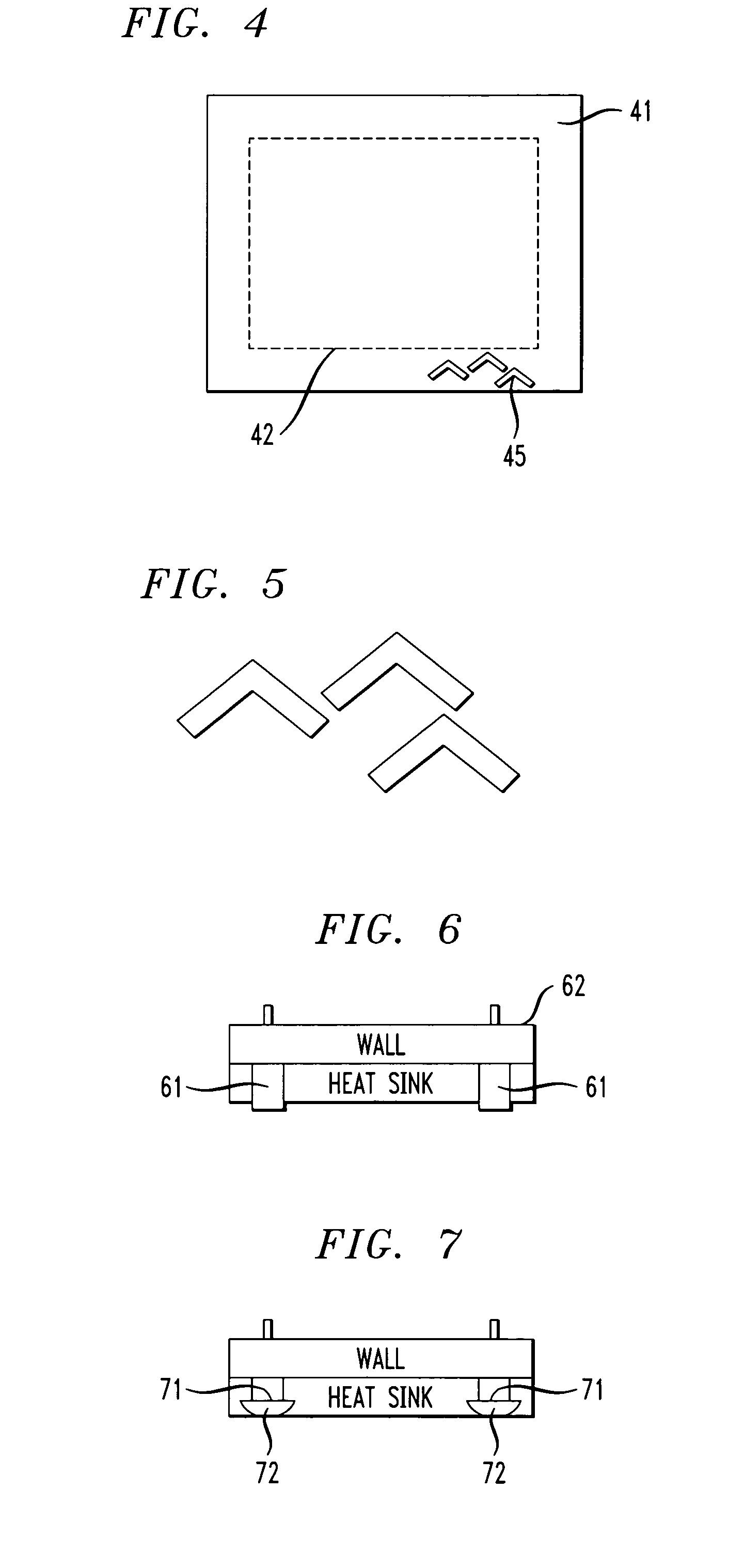

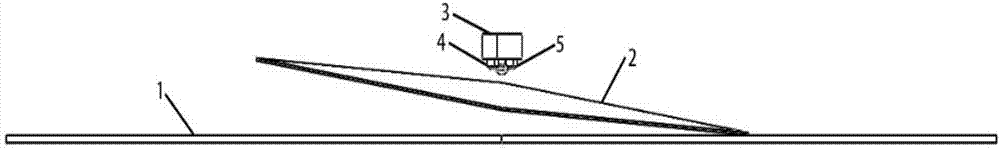

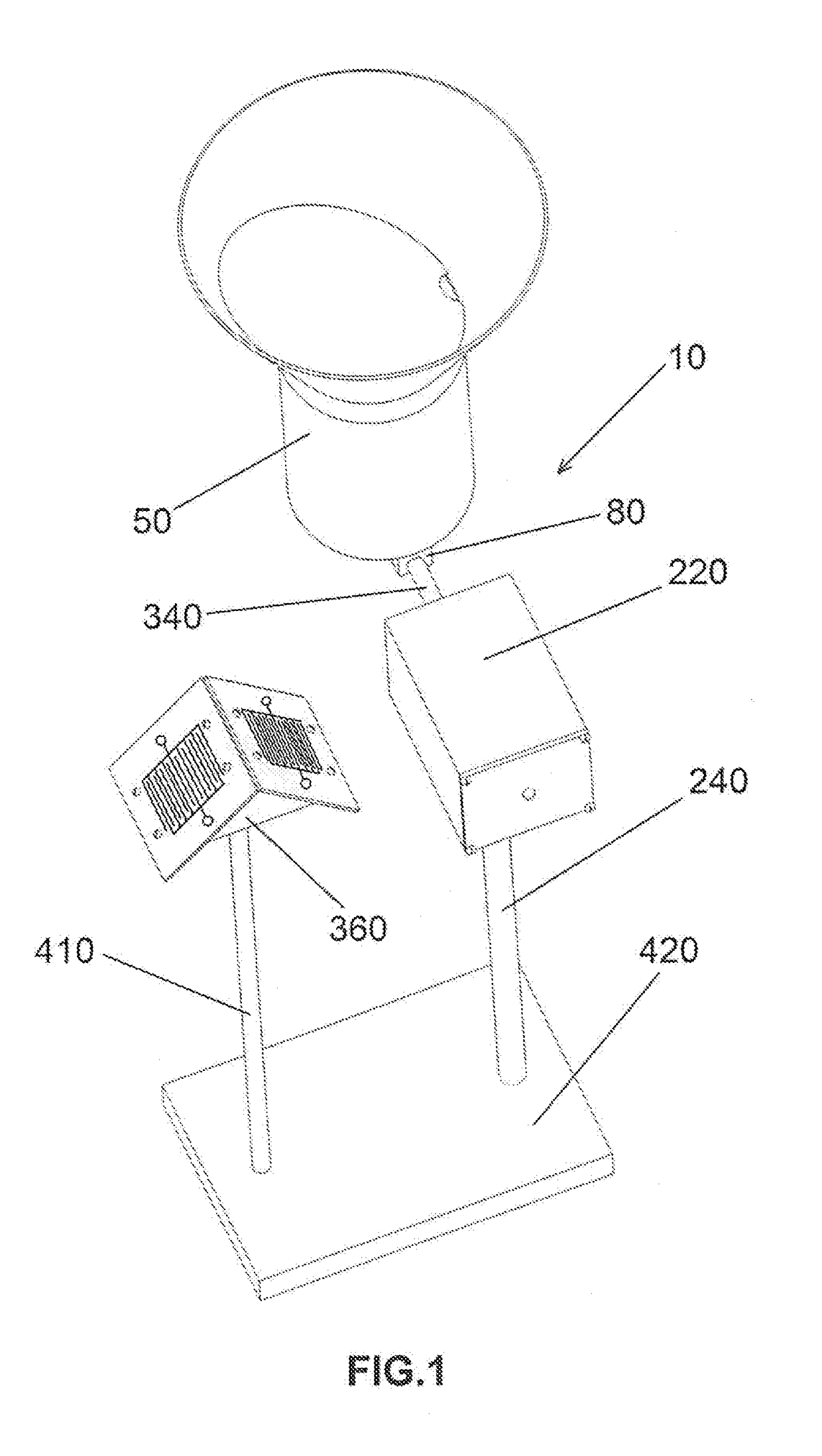

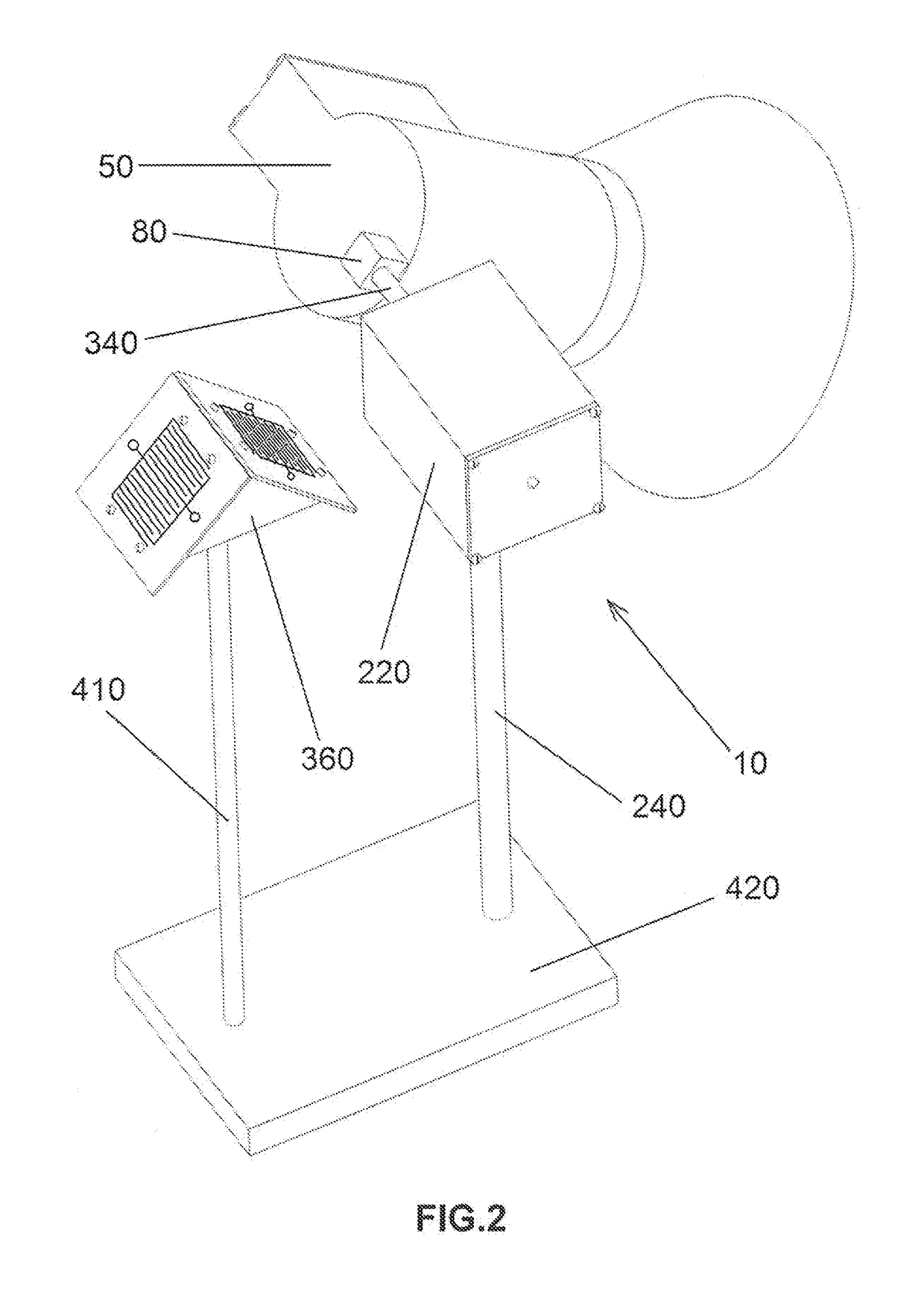

Ramp compensation device and method for FDM type 3D printer platform during inclination

ActiveCN107379530AResolve skewManufacturing platforms/substratesIncreasing energy efficiencyFinal heightComputer printing

The invention relates to a ramp compensation device for a FDM type 3D printer platform during inclination. The ramp compensation device comprises a horizontal supporting table, a hot bed arranged on the horizontal supporting table and a printing head located above the hot bed. A first distance measuring sensor and a second distance measuring sensor for measuring the height difference of the hot bed in a printing region are arranged on the printing head; the first distance measuring sensor and a second distance measuring sensor are arranged in central symmetry related to the printing head; and the mean value of measured values of the two distance measuring sensors is taken as the final height difference. The invention also discloses a ramp compensation method for the FDM type 3D printer platform during inclination. By performing printing compensation on corresponding height difference by analytical calculation to further establish a horizontal substrate, the problem that the quality of printout is affected as height error exists in a common 3D printer manual adjusting platform and a model deflects as the printing height is only compensated in only one direction by automatic leveling is solved.

Owner:SOUTH CHINA UNIV OF TECH

Automatic rainfall measurement system

InactiveUS20180341042A1Affect accuracyImprove accuracyRainfall/precipitation gaugesInvestigating moving fluids/granular solidsFinal heightElectrical conductor

An automatic rainfall measurement system with a set of control circuitry measures the height of rainwater or any other conductive liquid by means of a plurality of conductors attached to the wall of the container of the system's rain gauge. A rain detector detects falling raindrops and sends an electrical signal to the control circuitry of the rain gauge. Consequently, an electromechanical system rotates the container of the rain gauge from its initial downward facing position to its final vertical position so that the rain gauge starts collecting raindrops and measuring rainfall. After that it stops raining, and the final height of the rainwater is measured, the electromechanical system rotates the container of the rain gauge back to its initial downward facing position so that the rainwater inside the container is drained away by the gravitational force.

Owner:SOLTANI FARIBORZ

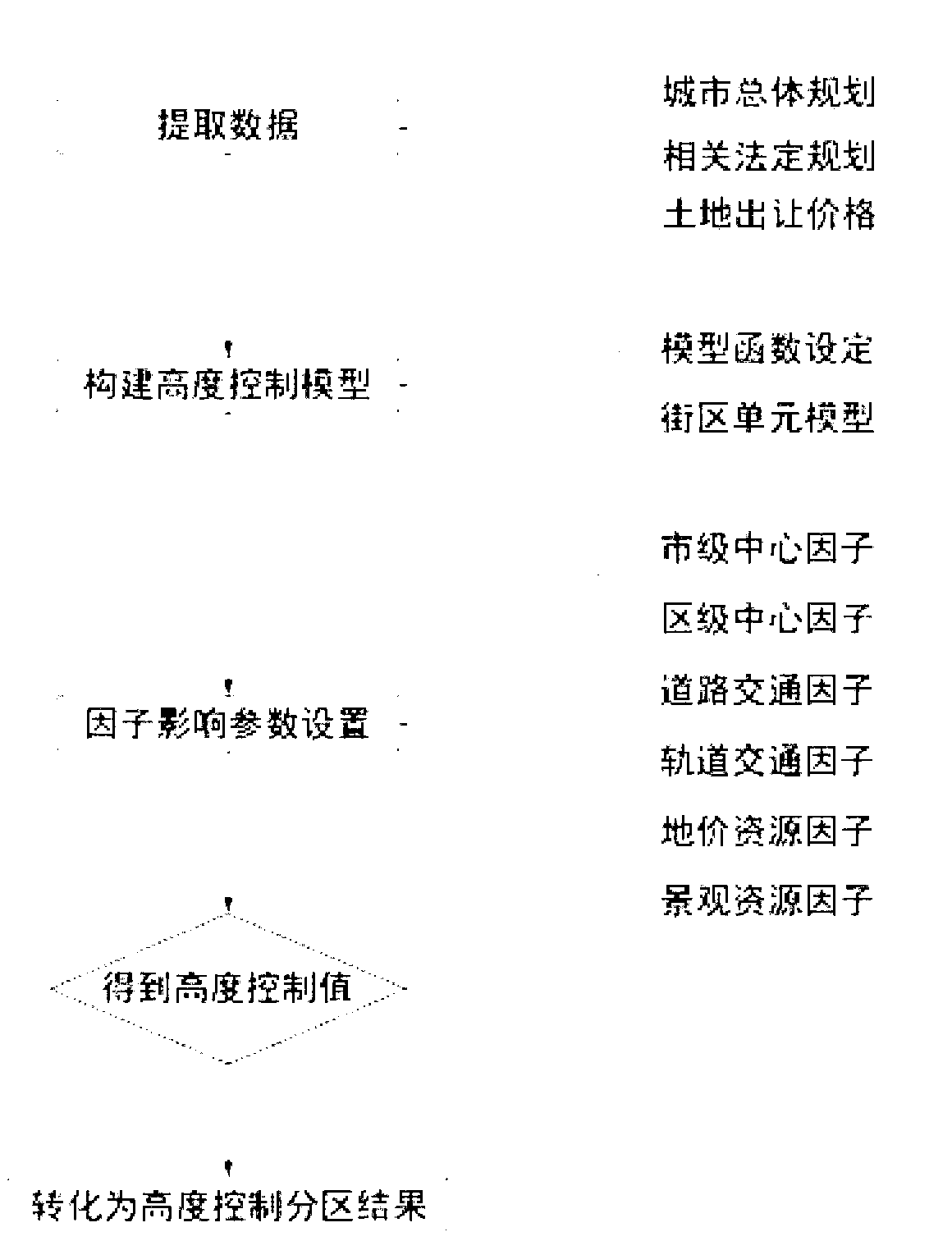

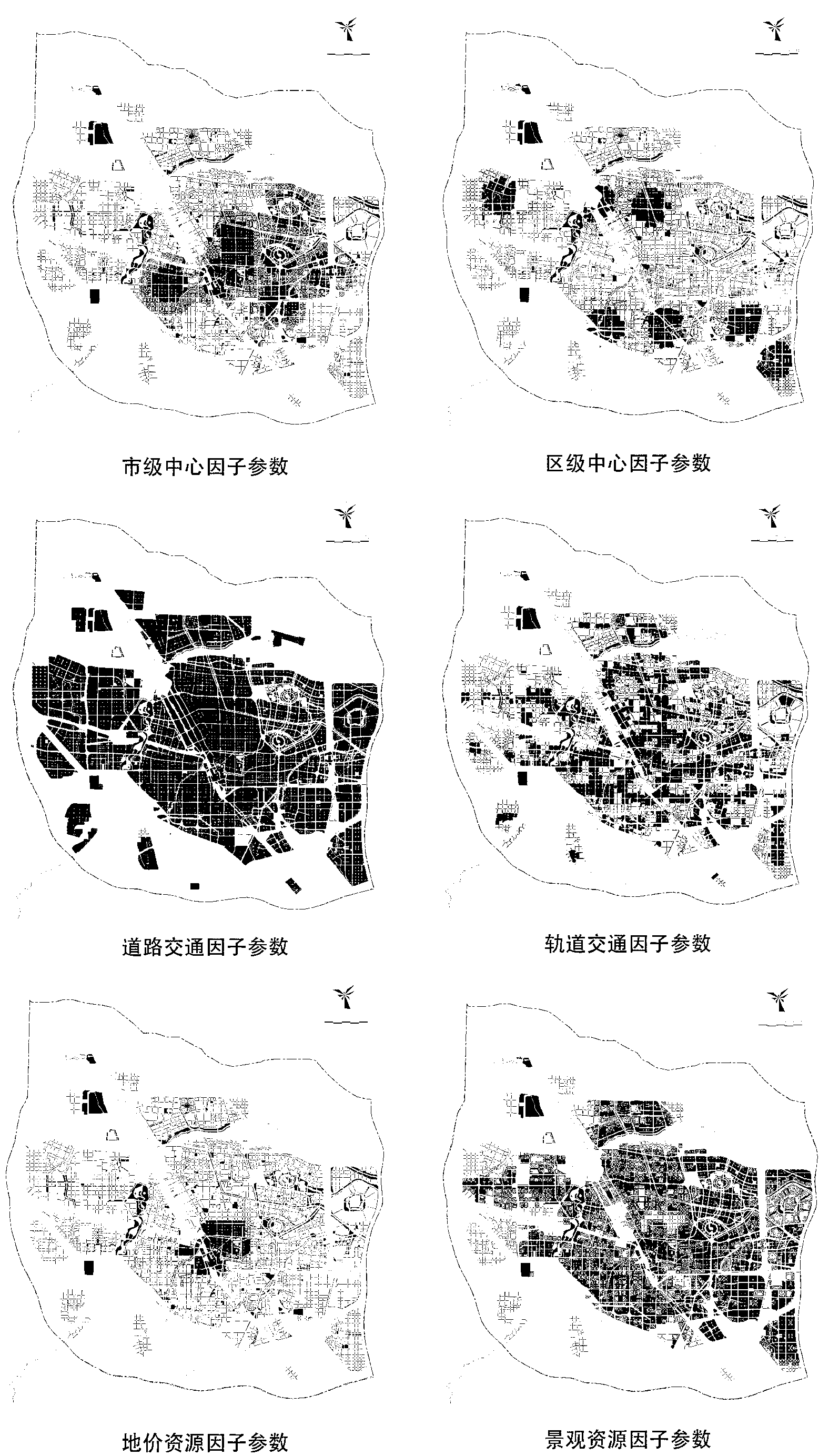

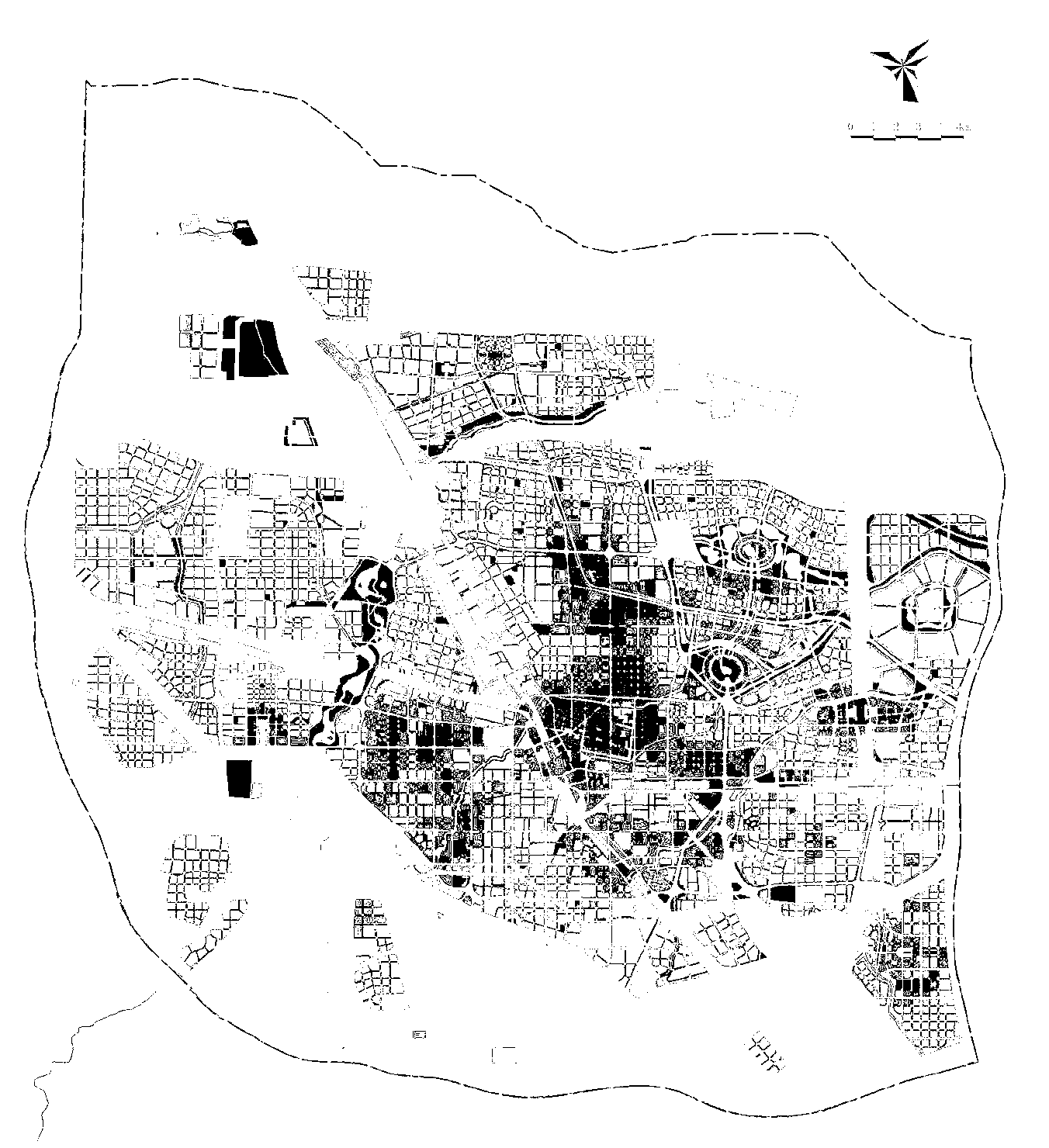

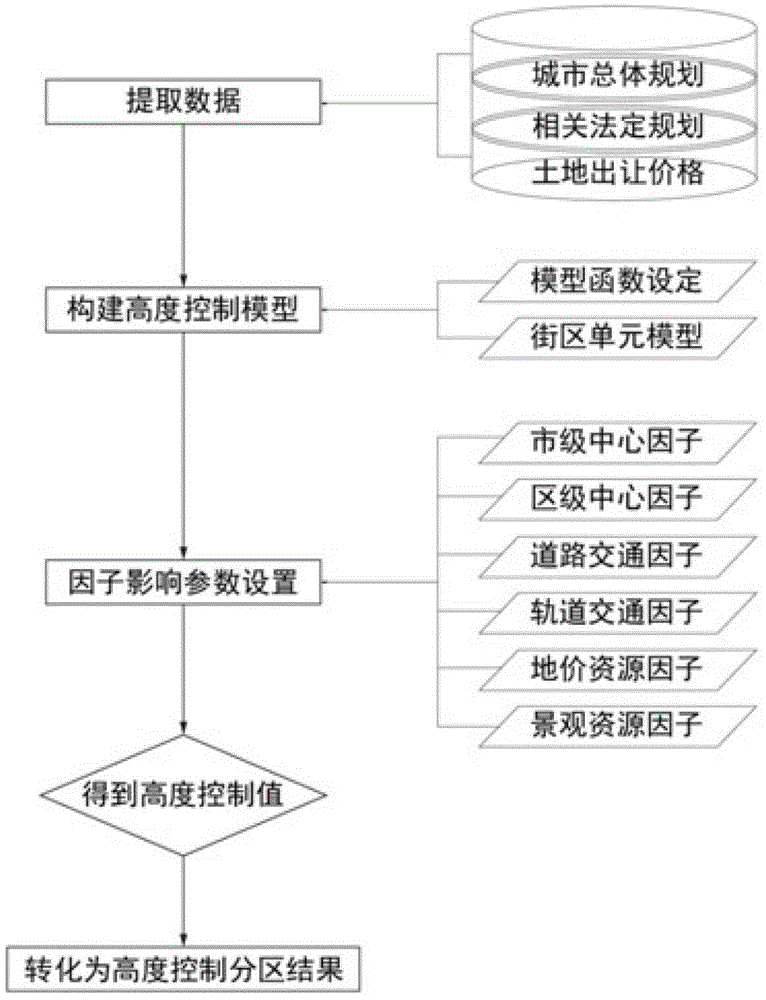

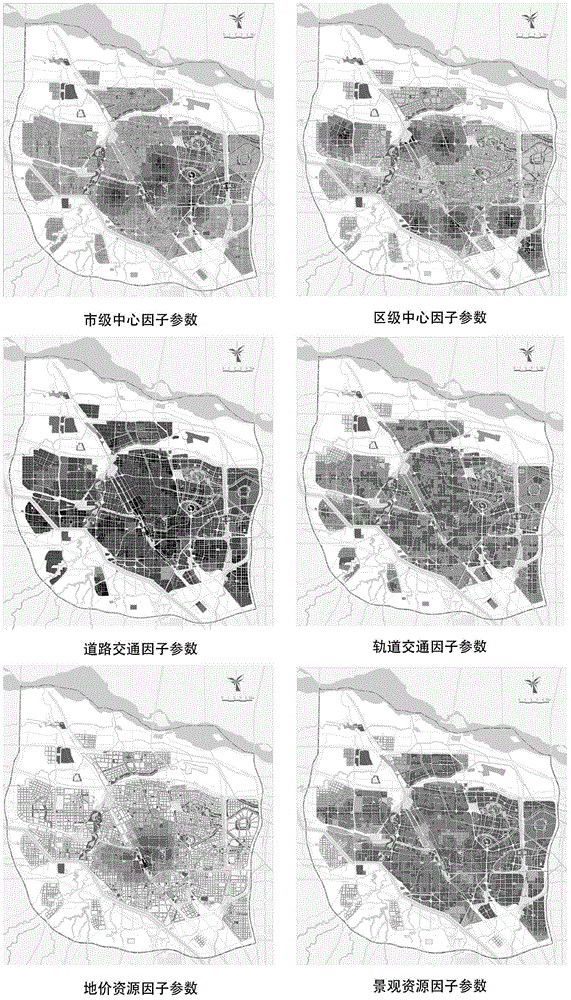

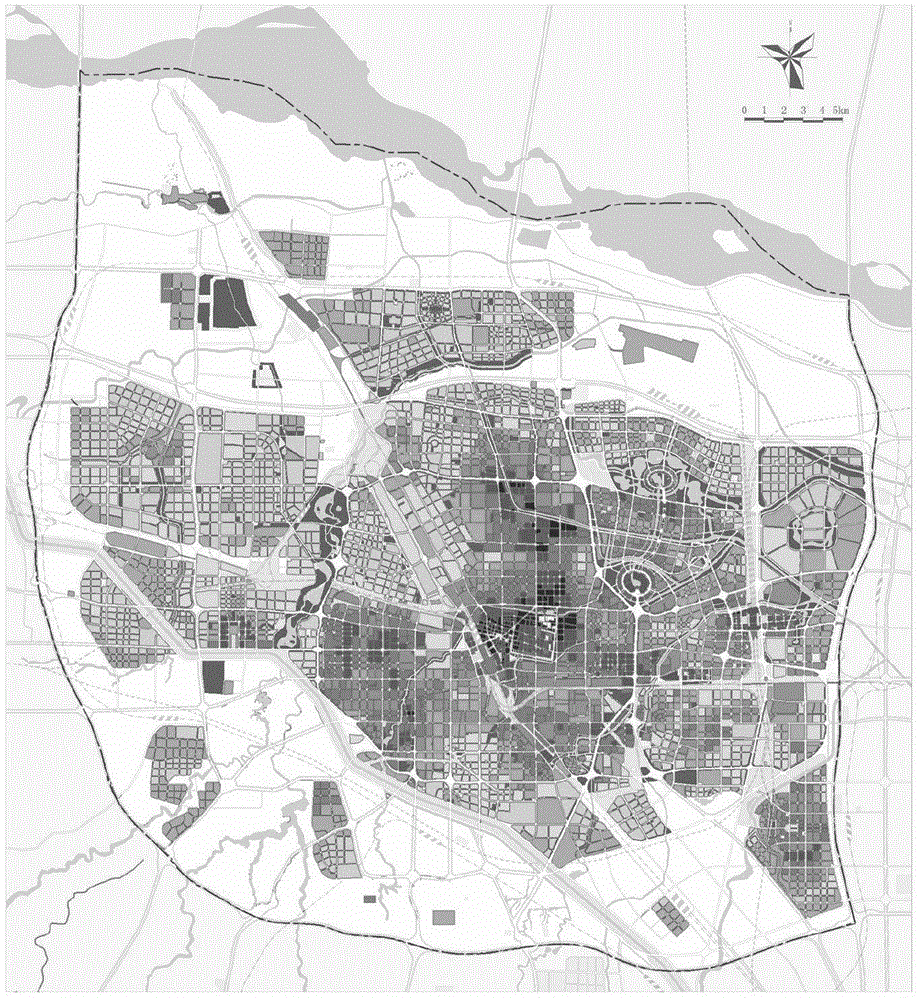

Overall city height control partition method based on comprehensive divisor evaluation

The invention discloses an overall city height control partition method based on comprehensive divisor evaluation. According to the overall city height control partition method based on comprehensive divisor evaluation, required data materials are extracted from relevant legal planning results such as overall city planning first and are imported to a digital technology platform and converted to impact factor control parameters according to a height control mathematic model built after researches, height control values of all street units are obtained, standardized correction is further conducted on the height control values according to a Saaty method, and the final height control partition result is obtained after conversion is conducted on the height control values. The overall city height control partition method based on comprehensive divisor evaluation is based on objective and rational analysis and comprehensive and overall evaluation modes, the data materials are easy to obtain, and therefore the city heights can be effectively controlled in a macro-level mode.

Owner:SOUTHEAST UNIV

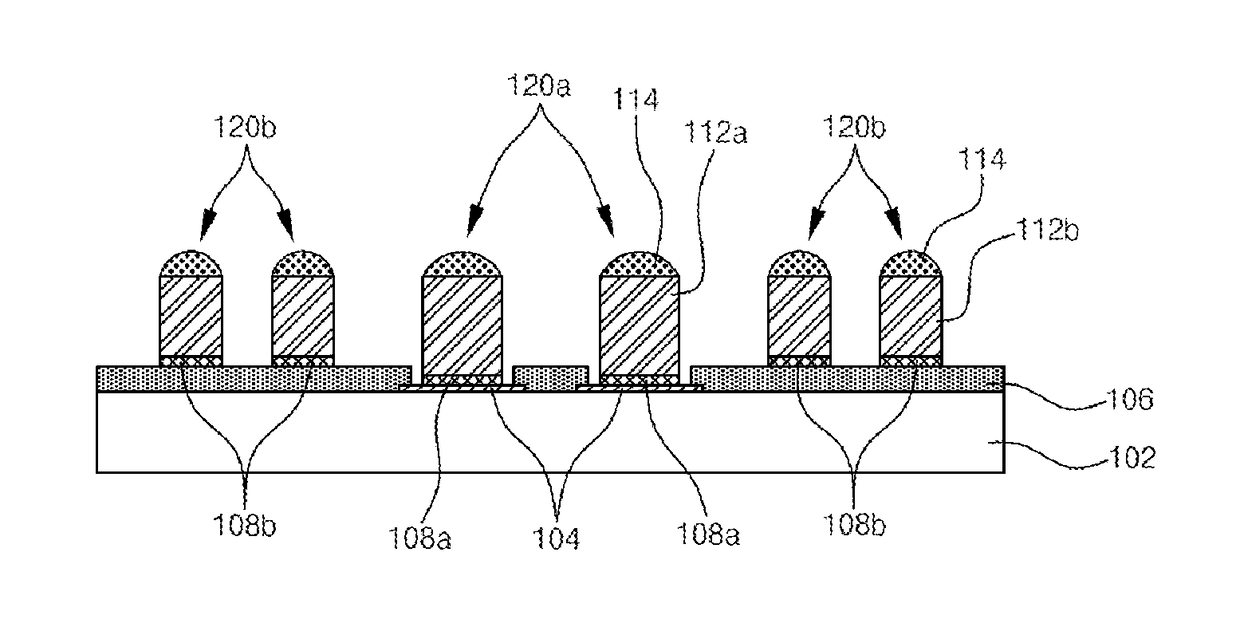

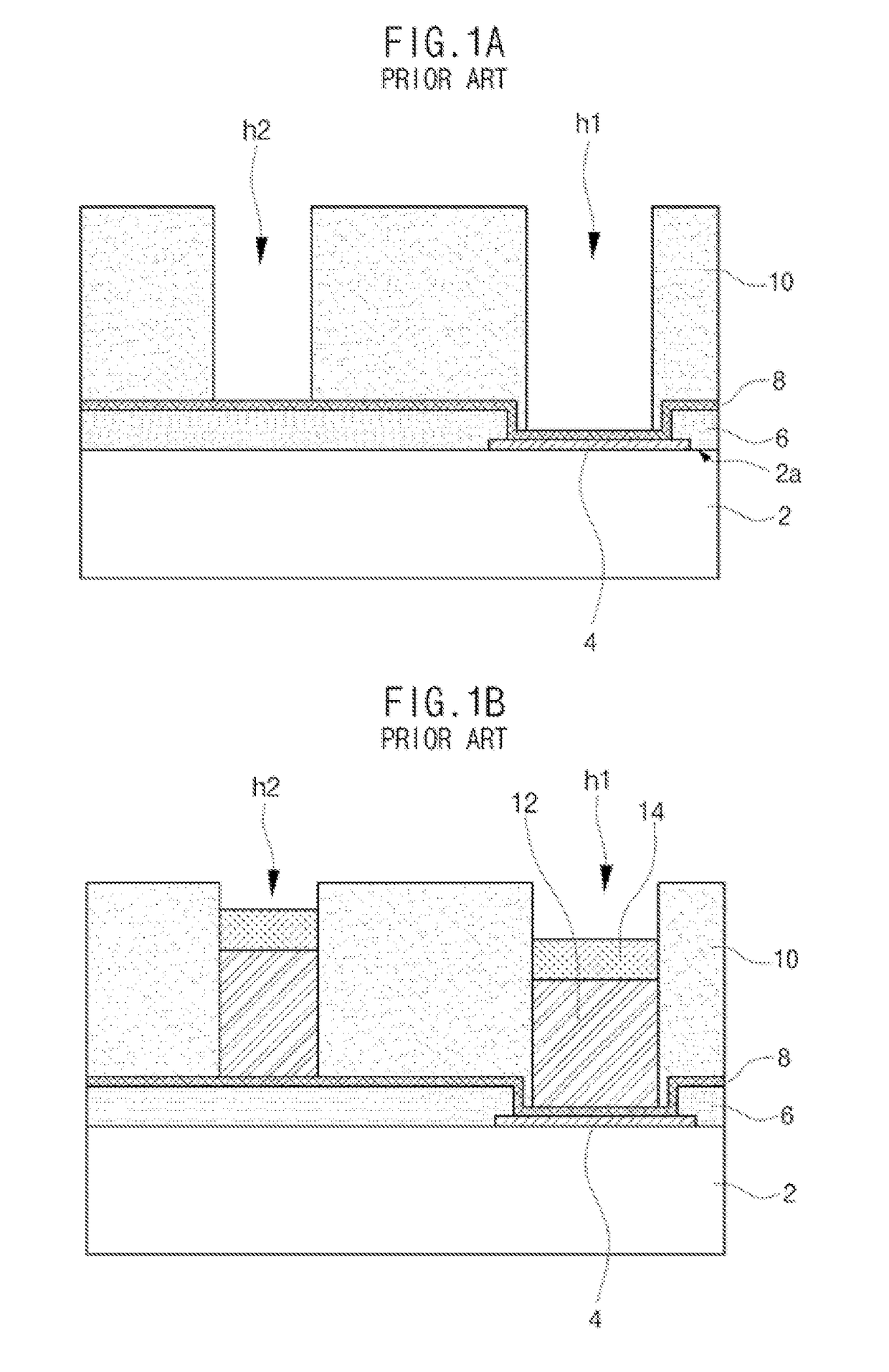

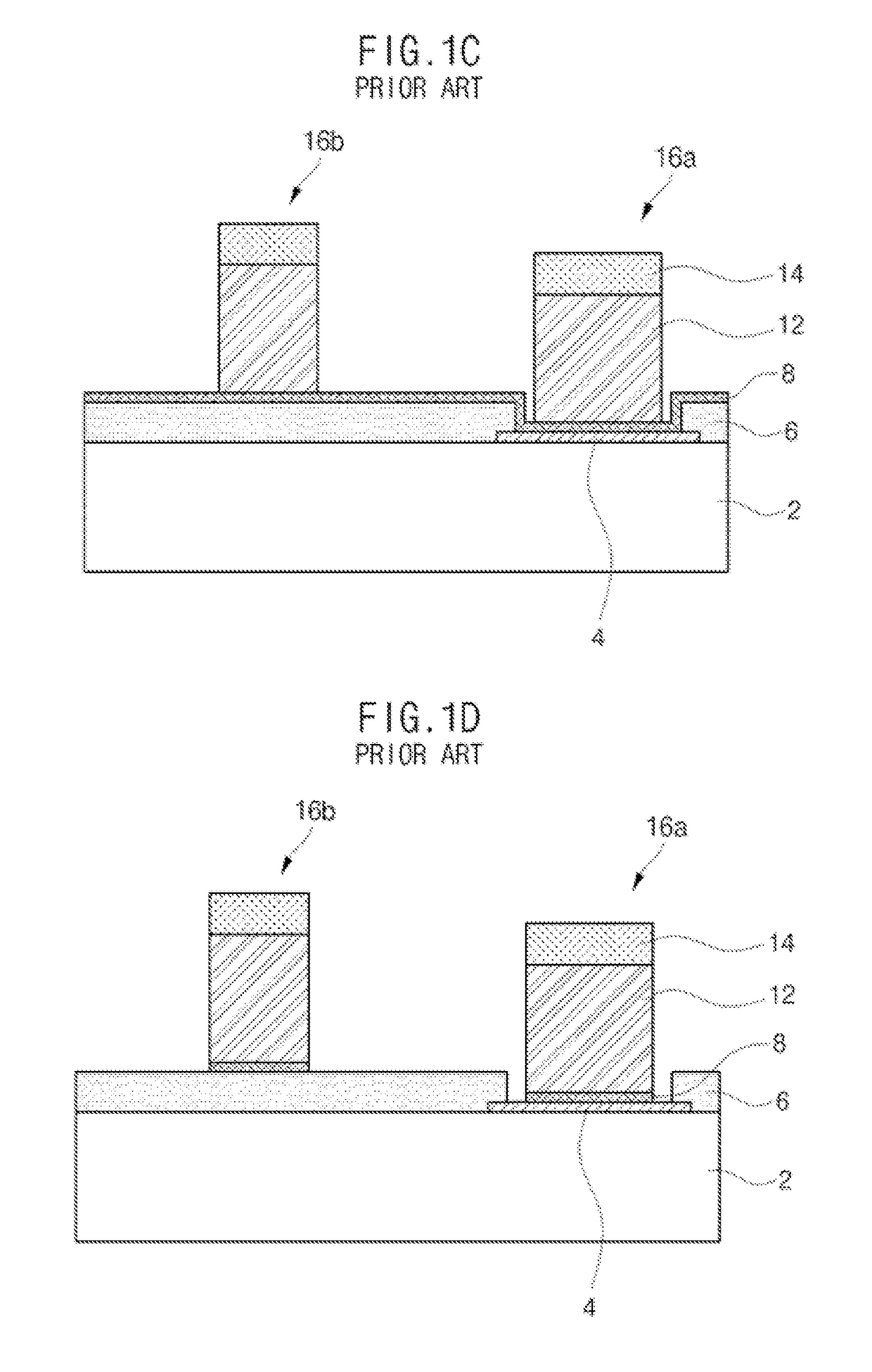

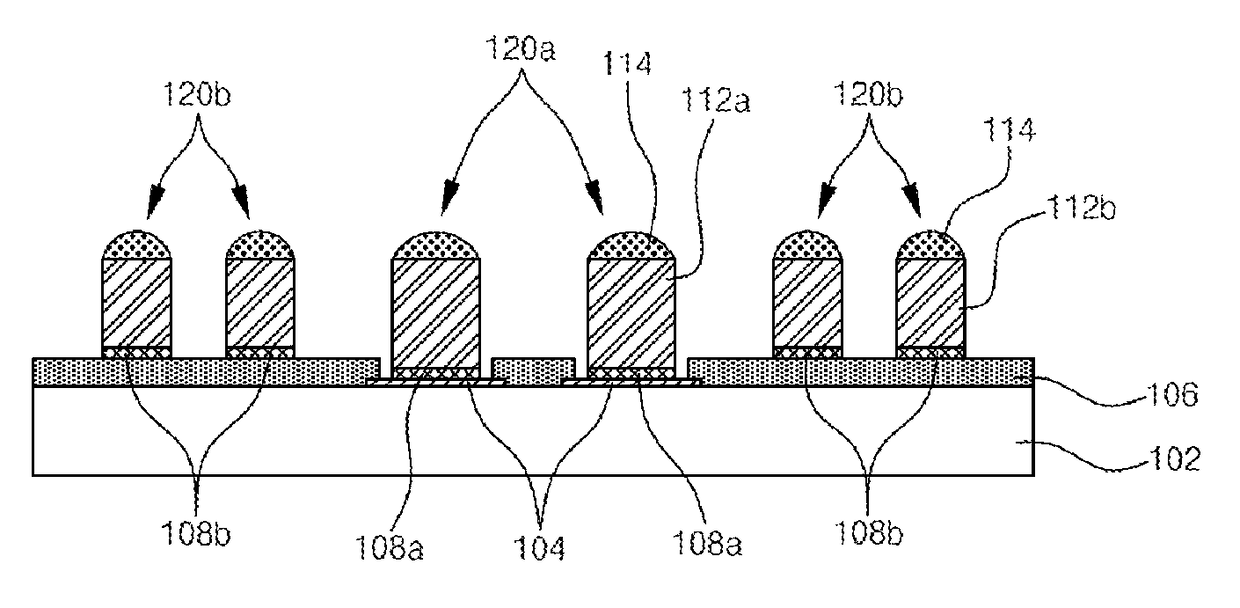

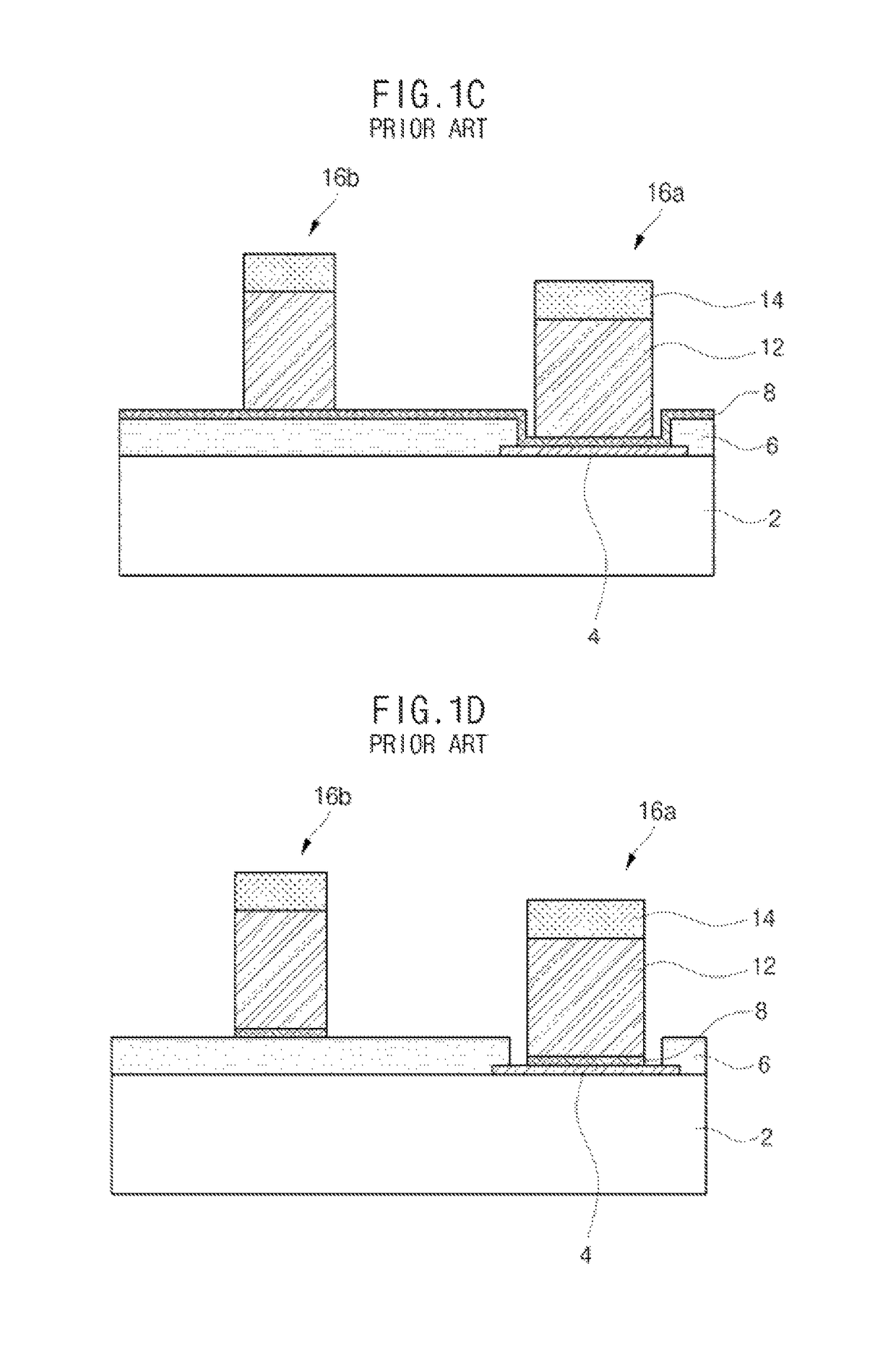

Method for forming bump of semiconductor package

ActiveUS20180174990A1Semiconductor/solid-state device detailsSolid-state devicesFinal heightSemiconductor package

The present invention provides a method for forming bumps of a semiconductor package to suppress a final height difference between main bumps and support bumps that is caused by a height difference between areas of an underlying layer when viewed on a cross-section. The method may include forming first seed layer patterns and second seed layer patterns which are disposed in the areas and are separated from each other, over the underlying layer having the height difference. The method may include forming the main bumps and the support bumps of which final heights are the same when viewed on the cross-section in the areas, by performing electroplating through using, as electrodes, the first seed layer patterns and the second seed layer patterns which are disposed in the areas and are separated from each other, under different conditions in the areas.

Owner:SMART MODULAR TECH LX S A R L

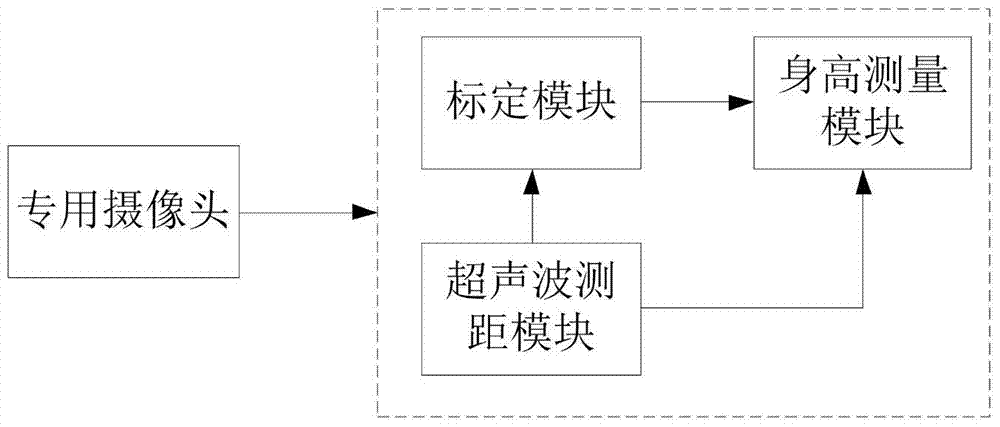

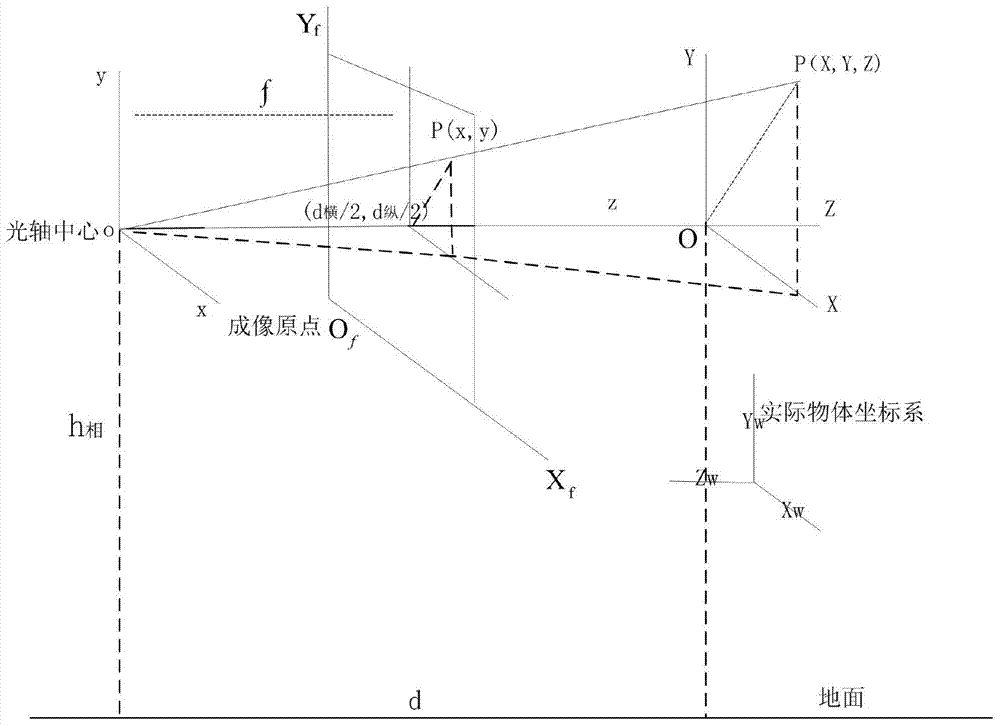

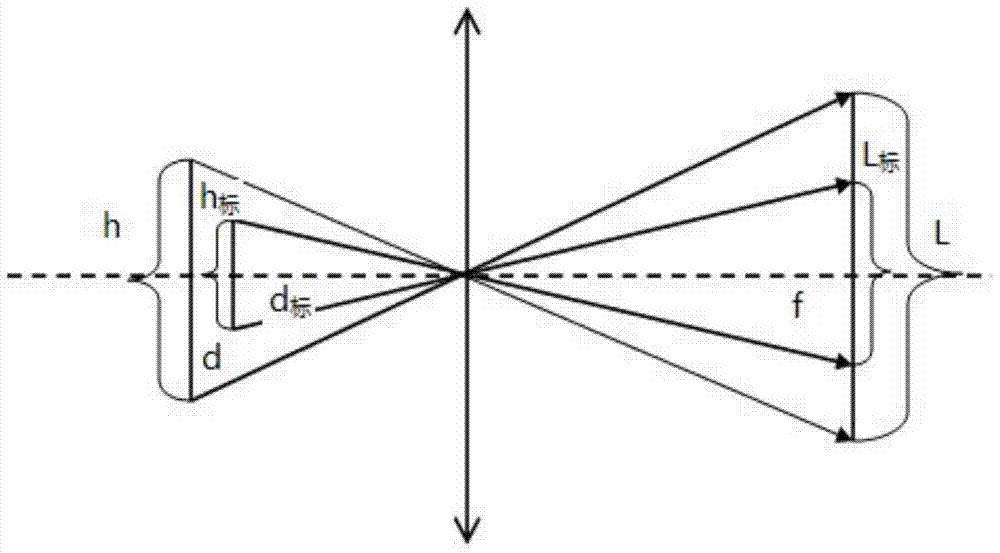

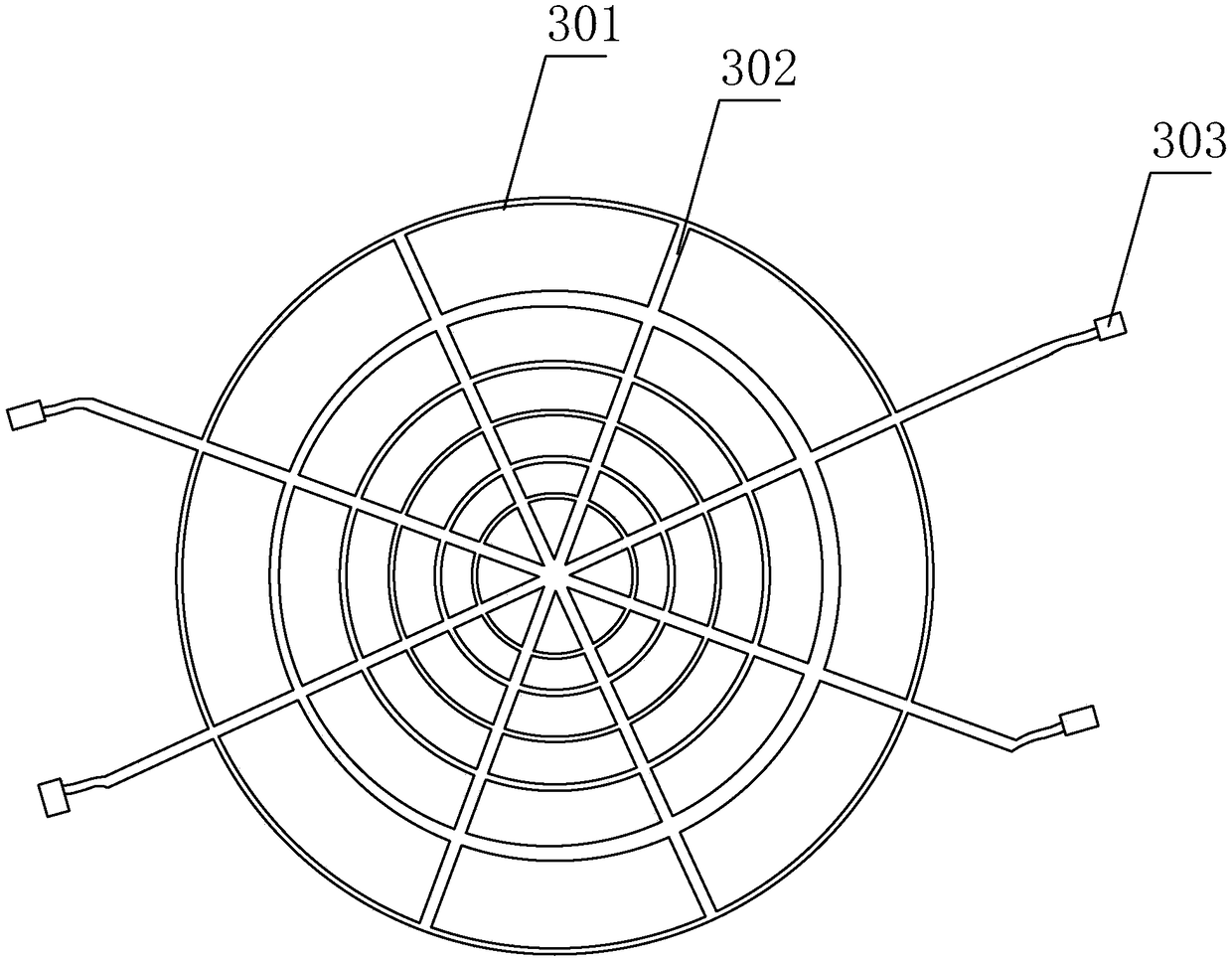

Non-contact height automatic measuring system and non-contact height automatic measuring method

InactiveCN104720814ASimple structureAccurate height measurement dataDiagnostic recording/measuringSensorsFinal heightData information

The invention discloses a non-contact height automatic measuring system. The non-contact height automatic measuring system comprises a camera, a calibration flat plate, a calibration module, an ultrasonic distance measuring module and a height measuring module, wherein the camera is used for acquiring calibration parameter images from the calibration flat plate and shooting an image of a person whose height is about to be measured; the calibration module is used for calibrating parameters through the calibration flat plate and the camera; the ultrasonic distance measuring module is controlled by the height measuring module and is used for judging the distance from the person whose height is about to the measured to a measuring system; and the height measuring module is used for analyzing and calculating data information acquired by the modules so as to obtain final height data. The non-contact height automatic measuring system is simple in structure and is operated full-automatically; and when the position of the person is changed relative to the camera, accurate height measurement data can still be acquired.

Owner:天津市天大百睿精密仪器技术有限公司

Method for forming bump of semiconductor package

ActiveUS10032738B2Semiconductor/solid-state device detailsSolid-state devicesFinal heightSemiconductor package

The present invention provides a method for forming bumps of a semiconductor package to suppress a final height difference between main bumps and support bumps that is caused by a height difference between areas of an underlying layer when viewed on a cross-section. The method may include forming first seed layer patterns and second seed layer patterns which are disposed in the areas and are separated from each other, over the underlying layer having the height difference. The method may include forming the main bumps and the support bumps of which final heights are the same when viewed on the cross-section in the areas, by performing electroplating through using, as electrodes, the first seed layer patterns and the second seed layer patterns which are disposed in the areas and are separated from each other, under different conditions in the areas.

Owner:SMART MODULAR TECH LX S A R L

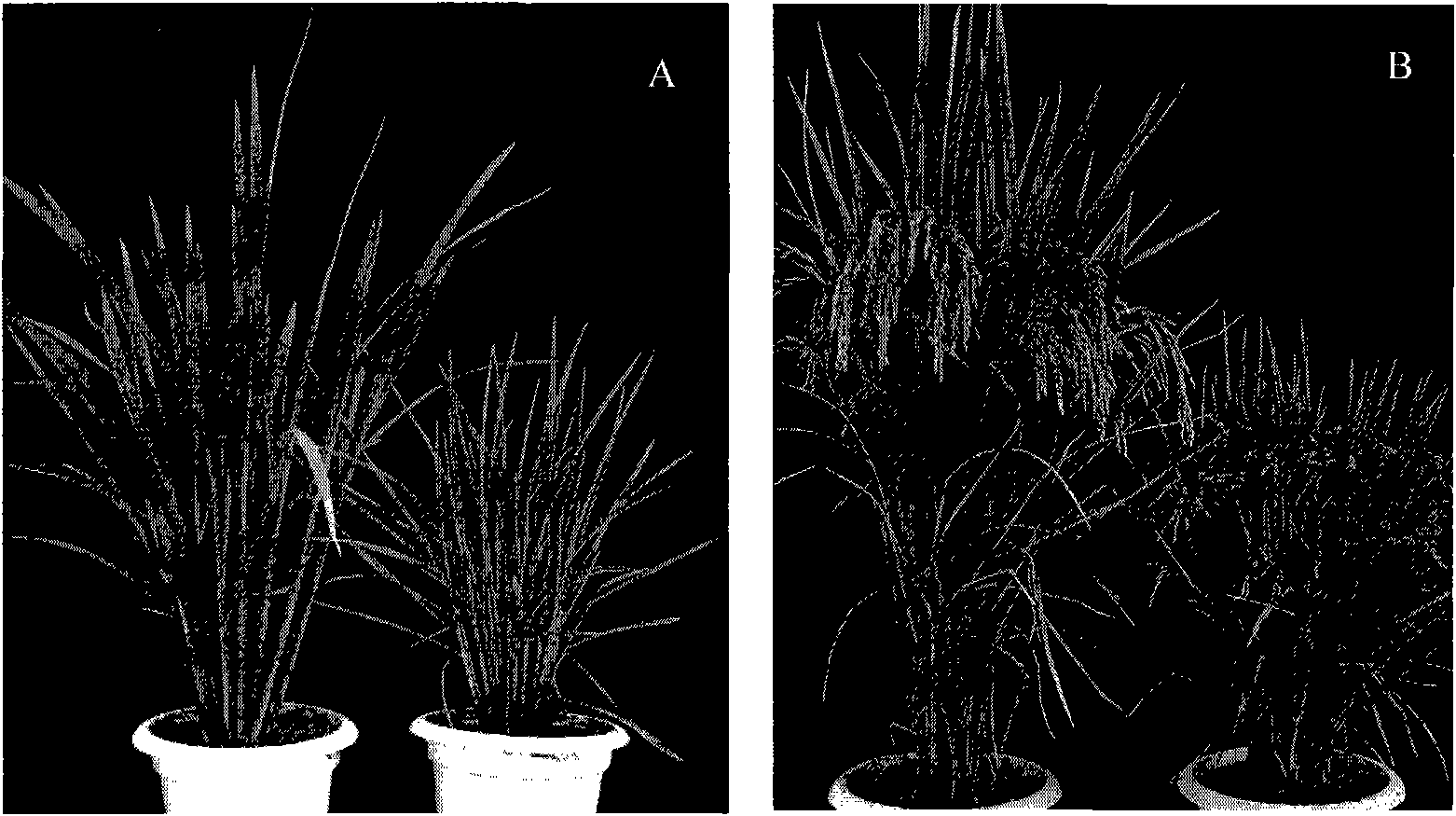

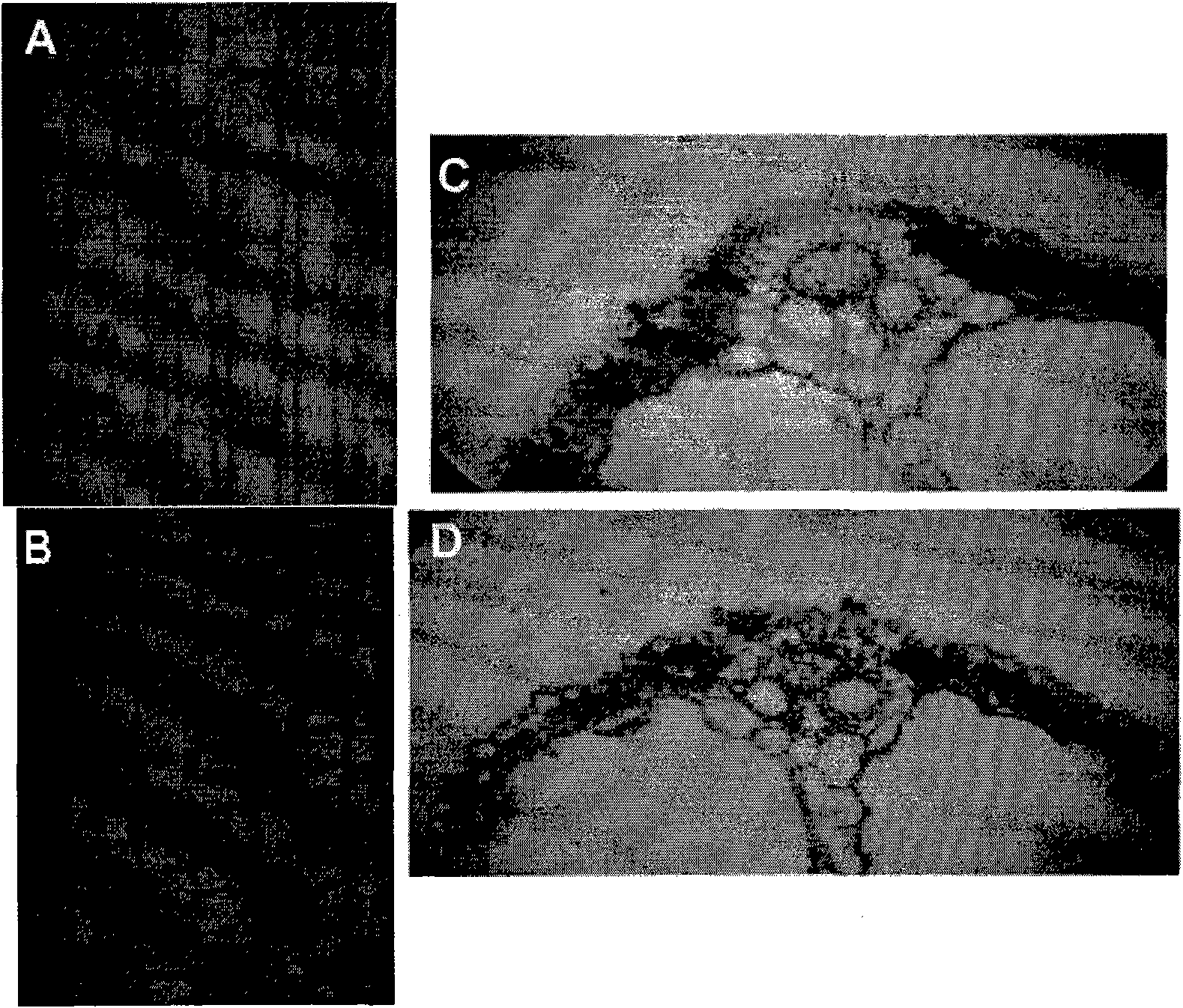

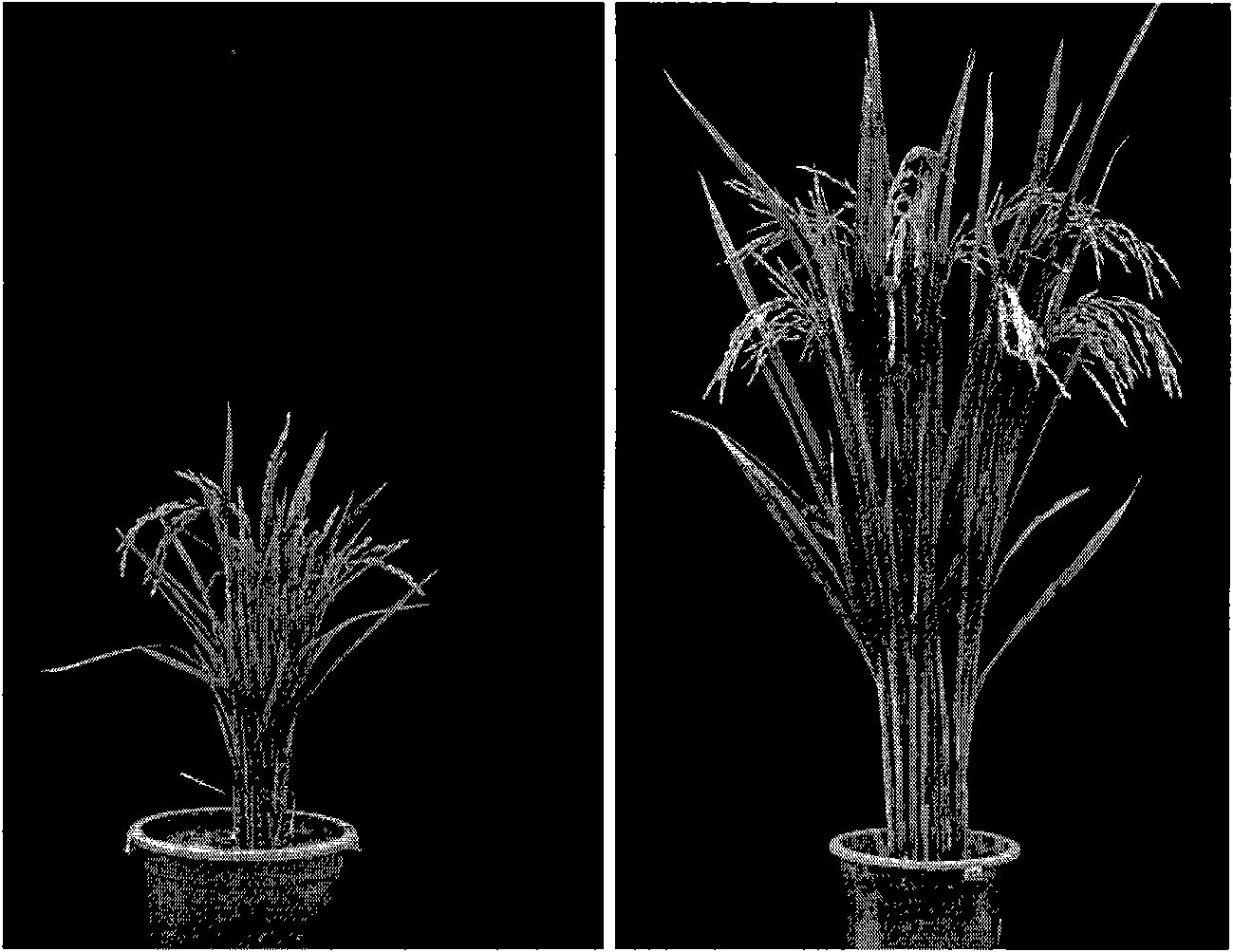

Rice final height-related protein, coding gene thereof and application thereof

ActiveCN101619094AExcellent agronomic traitsHas a high leaf width traitFungiBacteriaFinal heightAgricultural science

The invention discloses a rice final height-related protein, a coding gene thereof and application thereof. The protein is an a) protein or b) protein, wherein the a) protein is formed by an amino acid sequence expressed as the No.2 sequence in a sequence list; and the b) protein is formed by substituting and / or reducing and / or adding one or more amino acids to the amino acid sequence expressed as the No.2 sequence in sequence list, related to the final height of rice and derived from the a) protein. The coding gene of the protein particularly is a 1) gene, 2) gene or 3) gene: the 1) gene is a DNA molecule having a amino acid sequence expressed as the No.1 sequence in the sequence list; under strict conditions, the 2) gene can be crossed with the DNA sequence defined by the No.1 sequence in the sequence list and code the DNA molecule of the rice final height-related protein; and the 3) gene has over 90 percent homology with the 1) gene, and can code the DNA molecule of the rice final height-related protein. The rice final height-related protein and the coding gene thereof have important application values in molecular breeding work.

Owner:INST OF GENETICS & DEVELOPMENTAL BIOLOGY CHINESE ACAD OF SCI

Multi-user cooperation type floor positioning method and system

ActiveCN105938189AEliminate cumulative errorsGuarantee the safety of lifePosition fixationNavigation by speed/acceleration measurementsFinal heightInformation processing

The invention, which relates to the wireless information processing technology, discloses a multi-user cooperation type floor positioning method and system. The method comprises: (S1), a target positioning unit and a cooperation unit receive respective wireless signals, collect signal information, and send information including information collected by an inertial sensor to a server side; (S2), a floor positioning model is constructed and model data information is obtained; and (S3), a system parameter of a floor positioning algorithm is calculated and a final height value of the target positioning unit is obtained. The method and system have the following beneficial effects: on the basis of severe environments like a fire environment and multiple positioning workers, connection between the destination positioning staff and the auxiliary positioning staff is established and the accumulated error of the destination positioning staff is eliminated, so that the effective floor positioning function is realized and the life safety of the positioning staff can be guaranteed substantially.

Owner:SHENZHEN UNIV

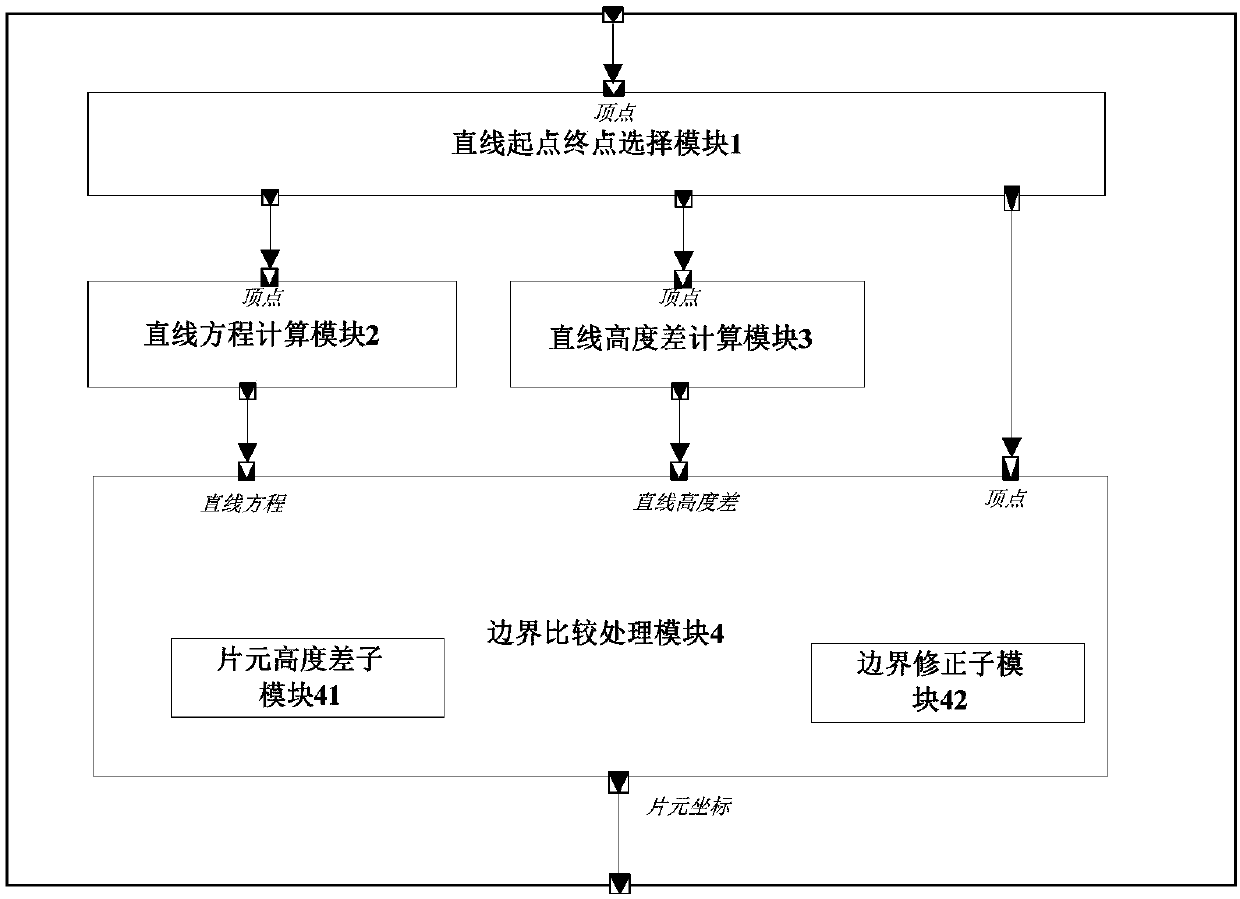

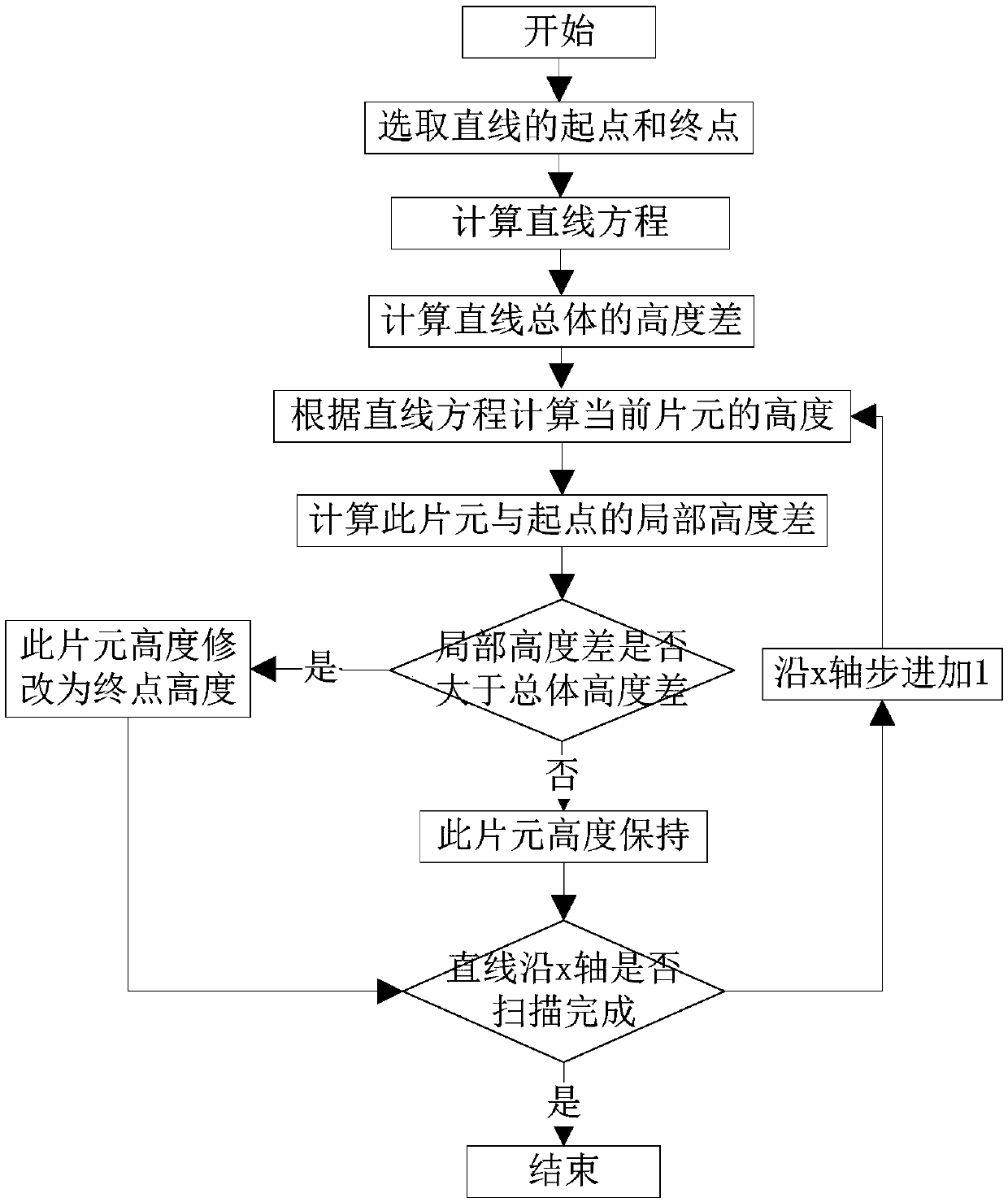

TLM microstructure for a GPU hardware line rasterization boundary algorithm

ActiveCN109657328ASolve inaccurateEnergy efficient computingSpecial data processing applicationsFinal heightHeight difference

The invention relates to the technical field of computer hardware modeling, and provides a GPU hardware line rasterization boundary algorithm-oriented TLM microstructure, which is characterized in that a straight line starting point and ending point selection module (1) sends a selected starting point and ending point to a straight line equation calculation module (2) and a straight line height difference calculation module (3); The linear equation calculation module (2) carries out linear equation calculation and sends a linear equation to the boundary comparison processing module (4); The straight line height difference calculation module (3) calculates the maximum height difference of a straight line and sends the straight line height difference to the boundary comparison processing module (4); And the boundary comparison processing module (4) receives the linear equation and the linear height difference to perform boundary comparison processing, when the local height difference isgreater than the linear maximum height difference, the height of the sheet element is assigned as the final height, otherwise, the height is kept. And scanning the complete straight line, and calculating the coordinate of each chip element on the straight line.

Owner:XIAN AVIATION COMPUTING TECH RES INST OF AVIATION IND CORP OF CHINA

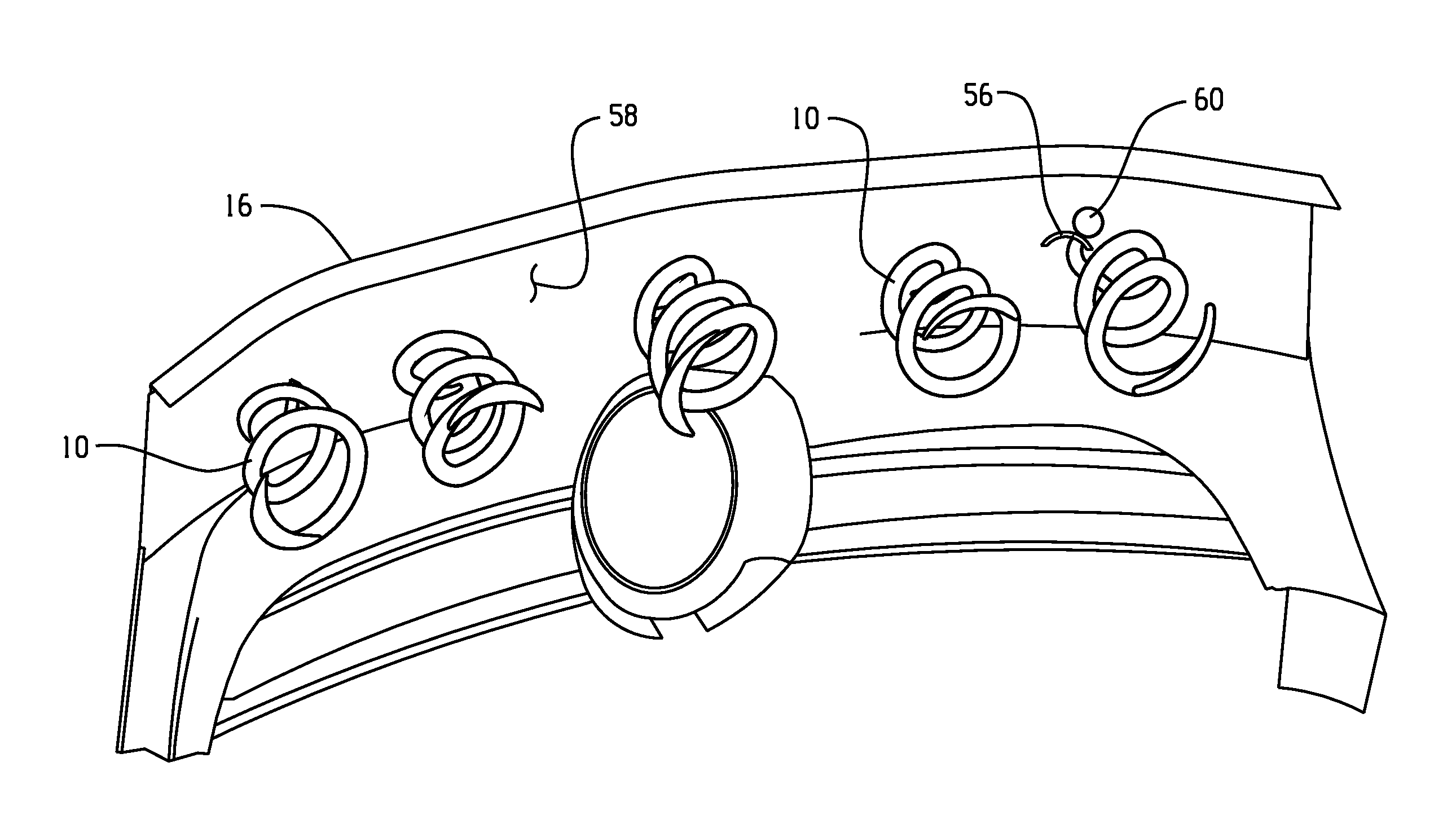

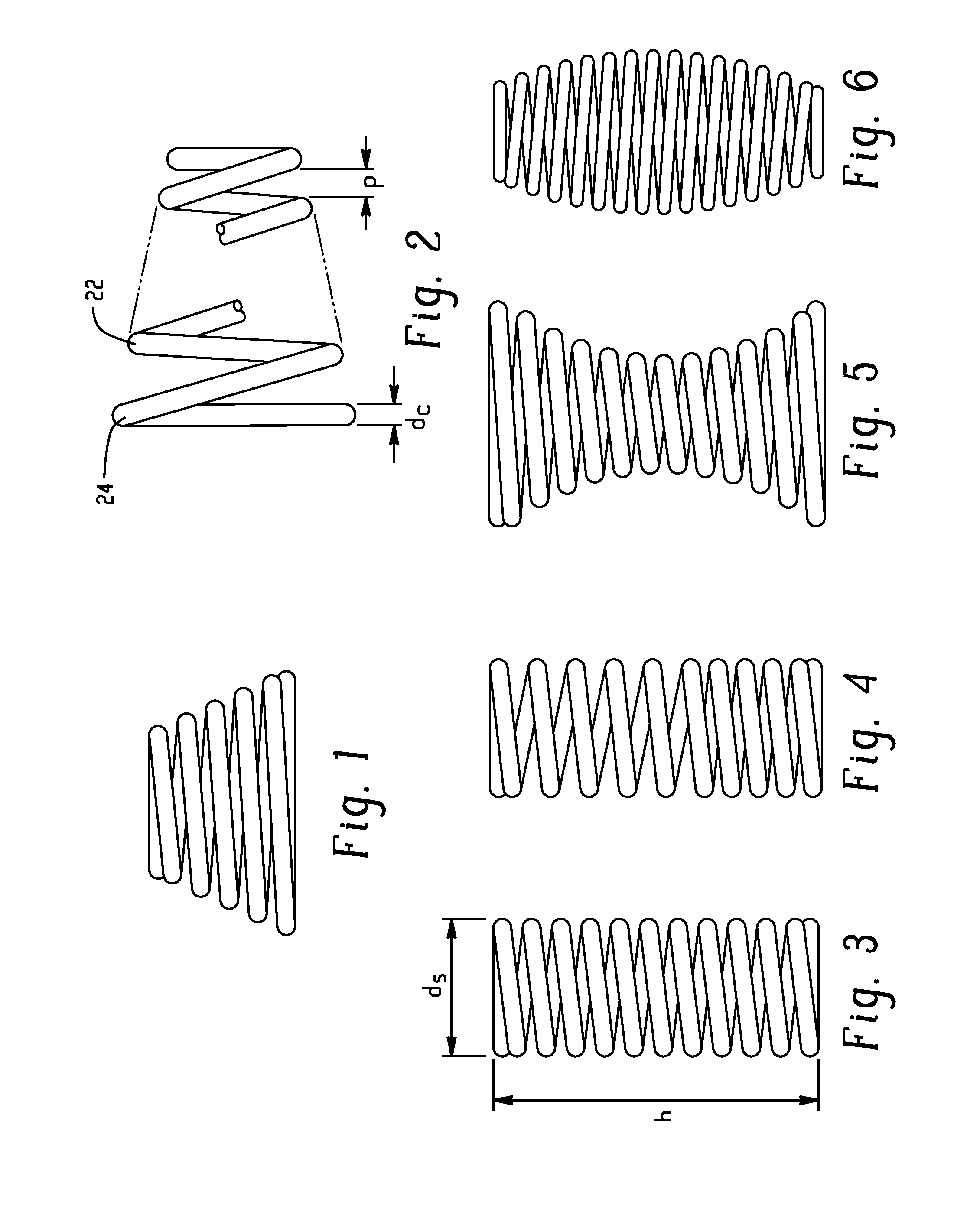

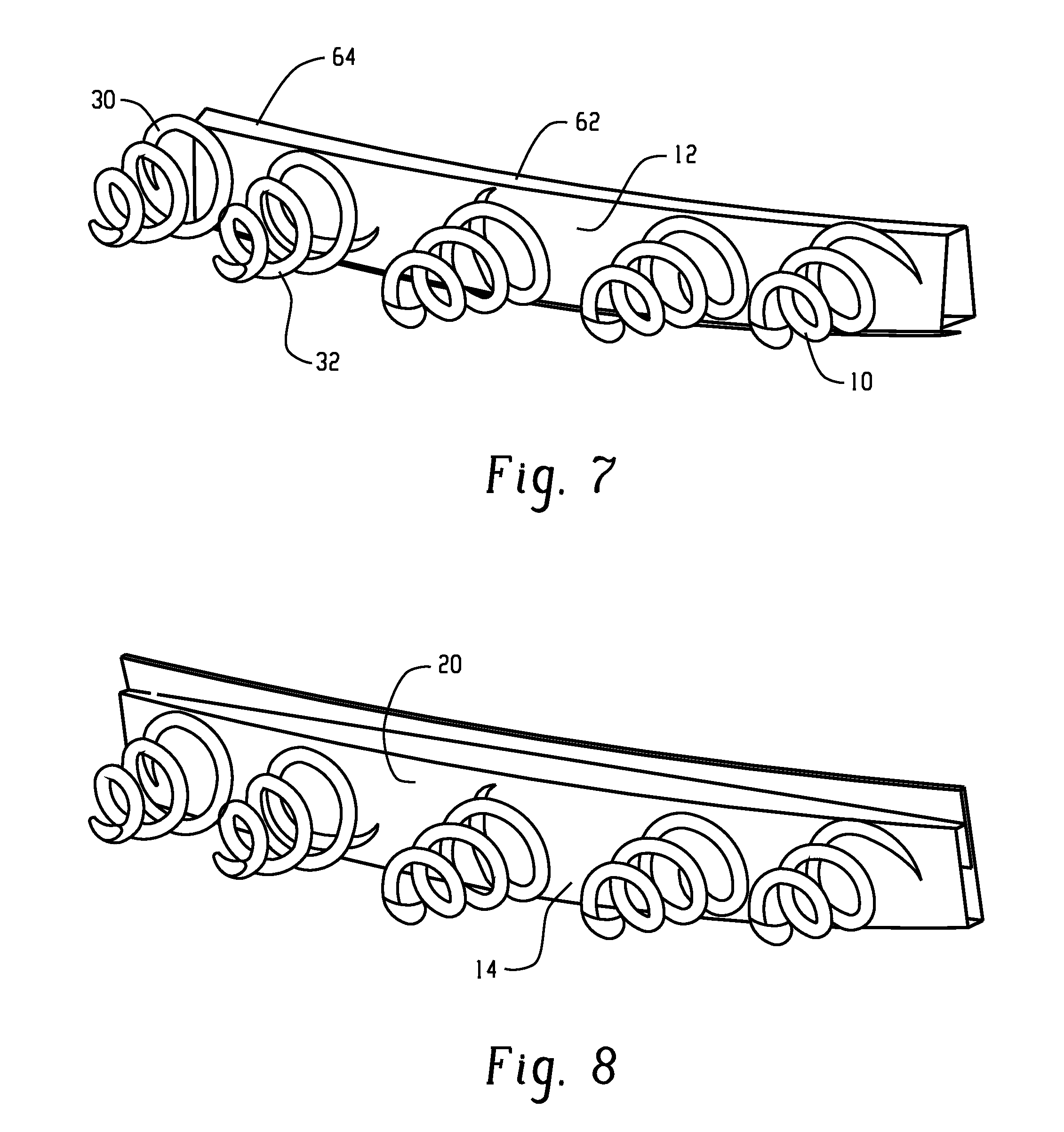

Plastically deformable coil energy absorber systems

Owner:SABIC GLOBAL TECH BV

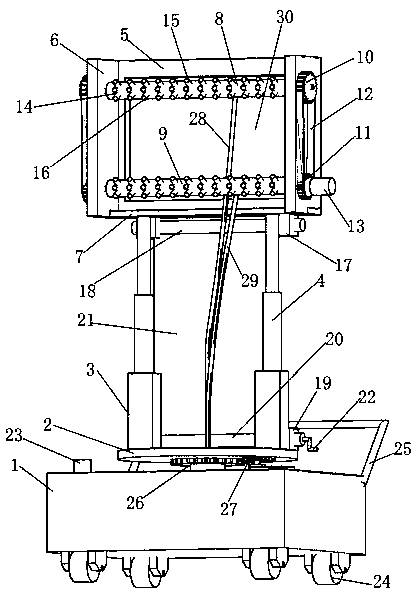

Fruit tree pesticide-spraying device

ActiveCN109452244AImprove securityGuaranteed observationInsect catchers and killersFinal heightFruit tree

The invention relates to the technical field of agricultural pesticide-spraying devices, in particular to a fruit tree pesticide-spraying device. The fruit tree pesticide-spraying device comprises a cart body, a turntable arranged at the top of the cart body, two supporting blocks fixed to the upper surface of the turntable in a bilateral symmetry way, two extensible devices respectively arrangedat the tops of the two supporting blocks, angle-adjustable pesticide-spraying mechanisms fixed to the tops of the two extensible devices and safety isolation mechanisms arranged between the angle-adjustable pesticide-spraying mechanisms and the turntable. By designing the angle-adjustable pesticide-spraying mechanisms for the fruit tree pesticide-spraying device, pesticide-spraying nozzles can spray pesticides in the upper, middle and lower directions, and the spraying nozzles on an upper-end feeding pipe and a lower-end feeding pipe can flexibly achieve angle adjustment. The final heights ofthe angle-adjustable pesticide-spraying mechanisms are adjusted through the extensible devices, so that the pesticide-spraying device flexibly adjusts the pesticide-spraying height according to the height of each fruit tree, and an operator can flexibly turn the angle-adjustable pesticide-spraying mechanisms to any angle.

Owner:山东长兴农业发展有限公司

Device for absorbing floor-landing shock for legged mobile robot

InactiveUS7378811B2Reduce momentumReduce shock loadProgramme-controlled manipulatorGas based dampersFinal heightSolenoid valve

A landing shock absorbing device 18 disposed in a foot mechanism 6 of a leg of a robot, wherein an inflatable bag-like member 19 (variable capacity element) is provided at a bottom face side of the foot mechanism 6. The bag-like member 19 is constructed of an elastic material such as rubber. The air in atmosphere may flow into and out of the bag-like member 19 by inflow / outflow means 20 equipped with a solenoid valve 27, and the like. In a lifting state of the foot mechanism 6, inflow of the air into the bag-like member 19 is controlled, thereby controlling the final height of the bag-like member 19 in an inflated state to the height in response to a gait type of the robot. While properly reducing an impact load during a landing motion of the leg of a legged mobile robot depending on the gait type of the robot, stability of a posture of the robot may easily be secured, resulting in allowing a configuration to be lighter in weight.

Owner:HONDA MOTOR CO LTD

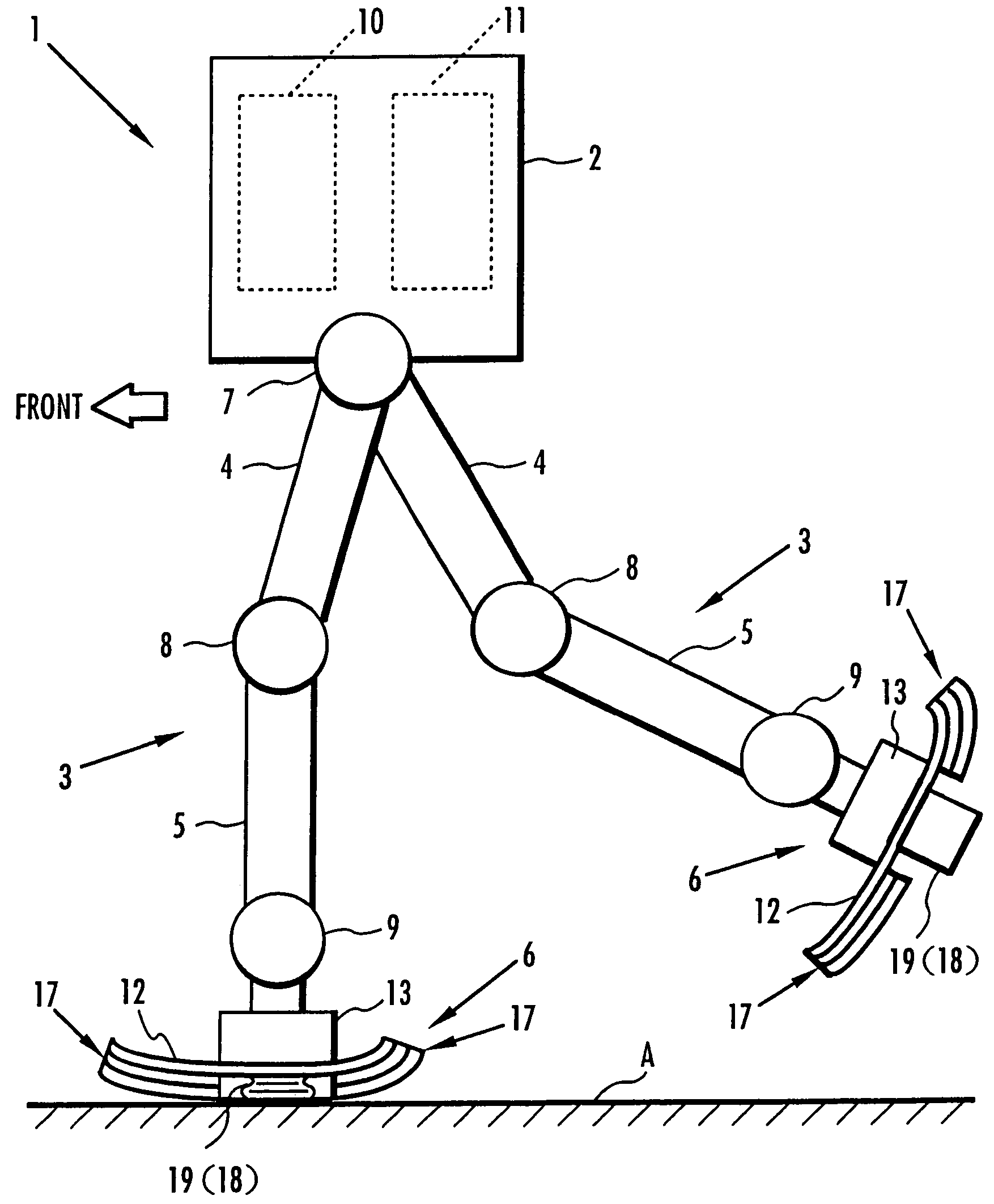

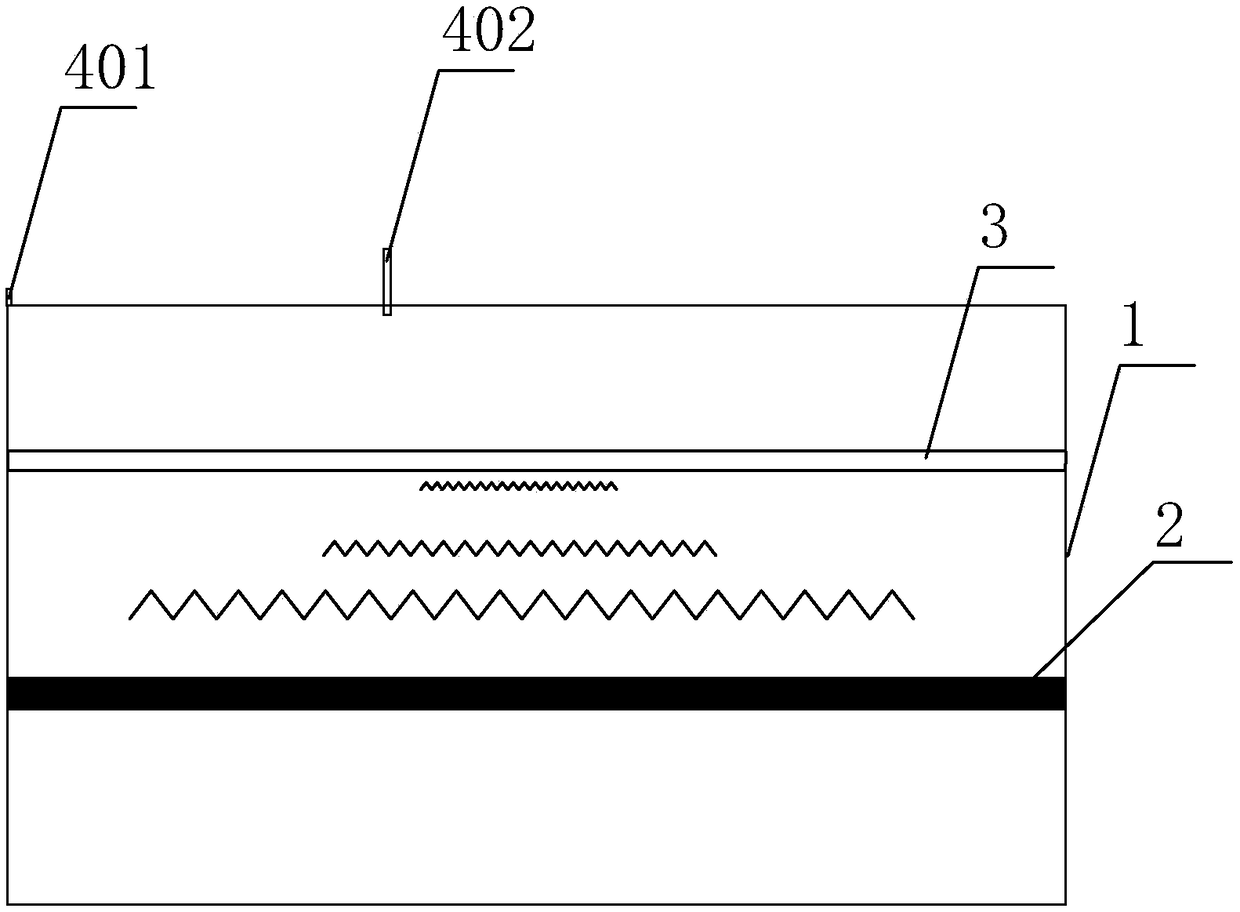

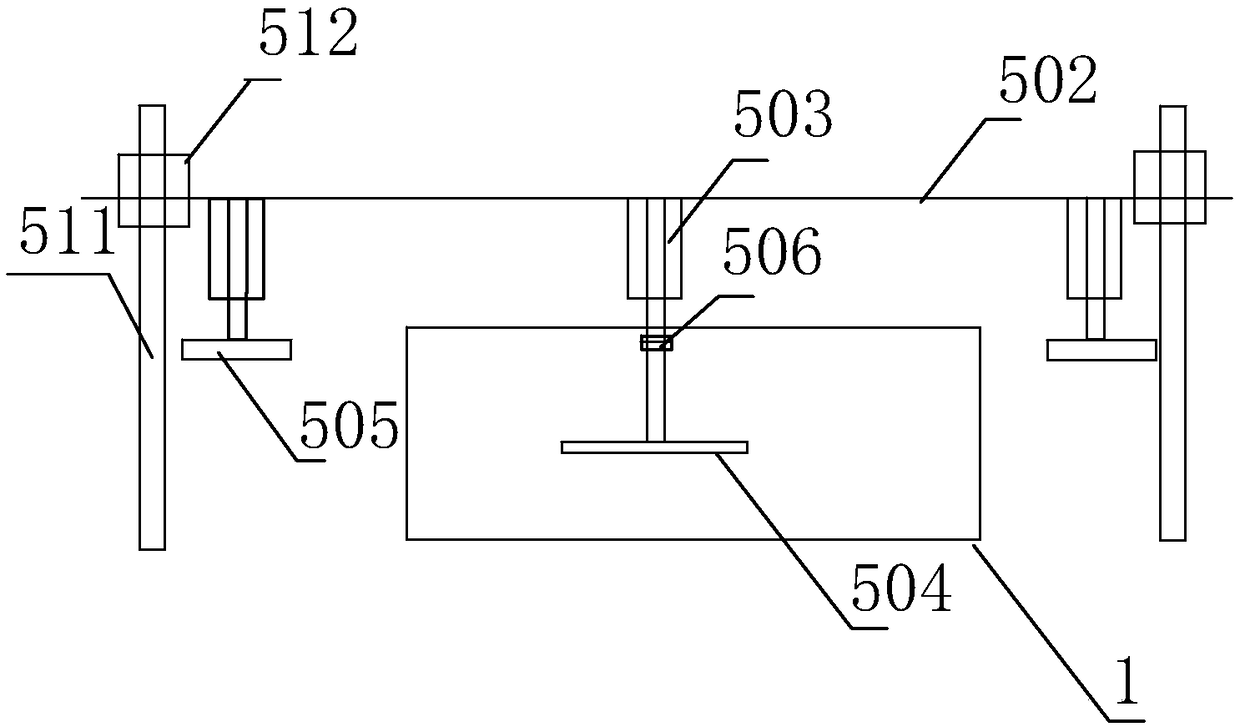

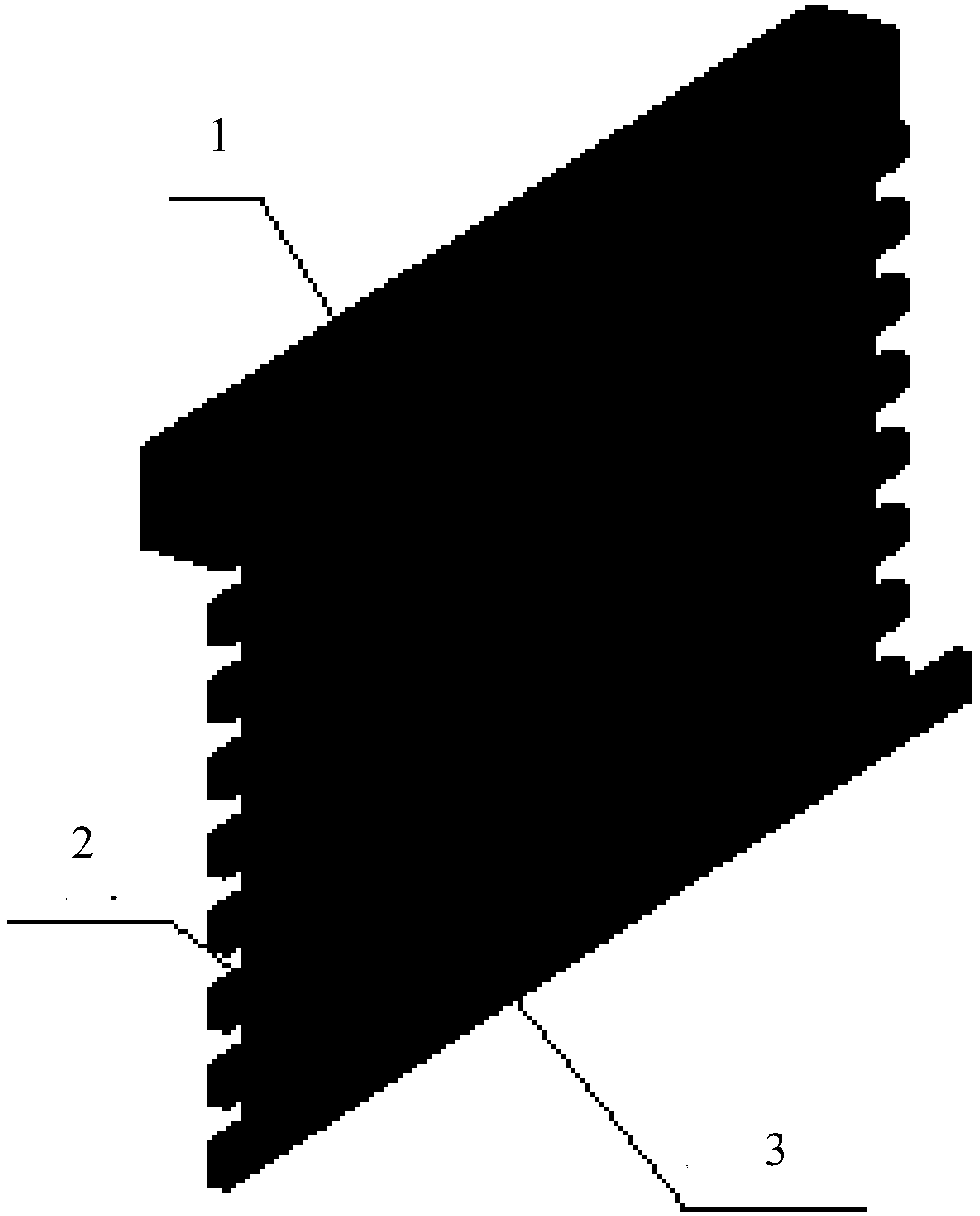

Device capable of simulating surface subsidence of mining area in coal mine teaching

InactiveCN108615448AReduce intensityIncrease compactionEducational modelsFinal heightTest efficiency

The invention discloses a device capable of simulating the surface subsidence of a mining area in coal mine teaching, and the device comprises a simulation frame (1), a coal layer (2) and a pluralityof other rock stratums, wherein the coal layer (2) and the plurality of other rock stratums are disposed in the simulation frame (1). A water-bearing layer (3) is disposed above the coal layer (2), and a water-bearing layer simulation system is disposed in the water-bearing layer (3). The simulation frame (1) is provided with an overlying rock subsidence monitoring system, and the overlying rock subsidence monitoring system comprises a straight rule (402) and a horizontal laser instrument (401) disposed on the simulation frame (1). The horizontal laser instrument (401) is disposed at the leftside of the simulation frame (1), and the height is equal to the final height of the top where an aggregate material is laid. The device provided by the invention has the functions of measuring a subsidence angle and simulating the permeability coefficient of the water-bearing layer (3). Meanwhile, the device is simple in structure, is compact in function, is low in test cost, is high in test efficiency, and is high in precision.

Owner:蒋嫚

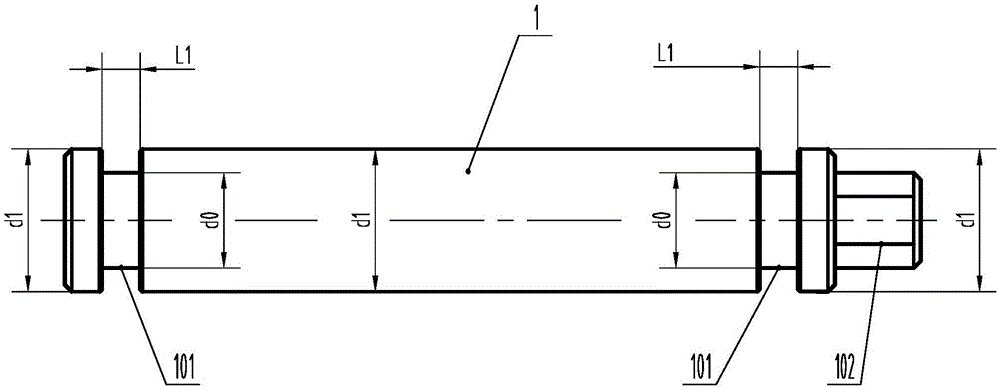

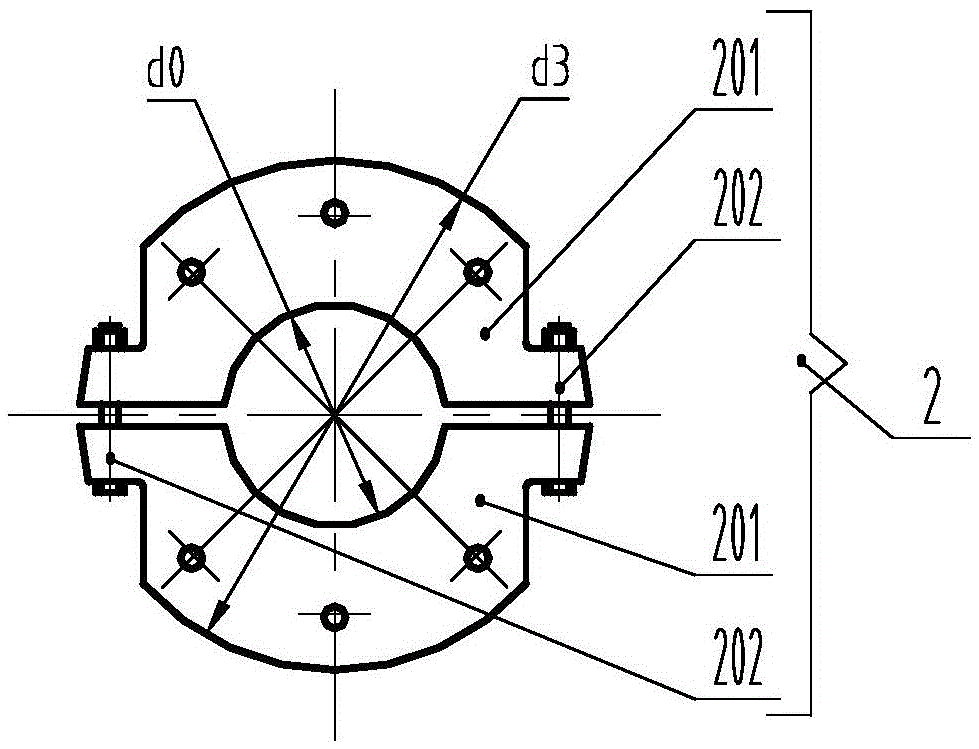

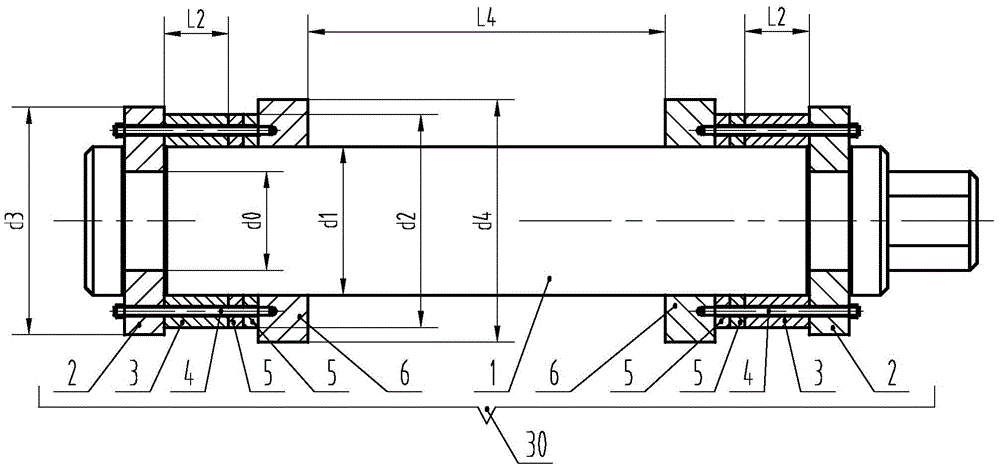

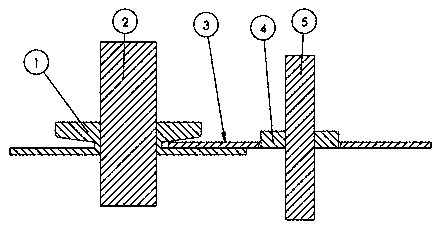

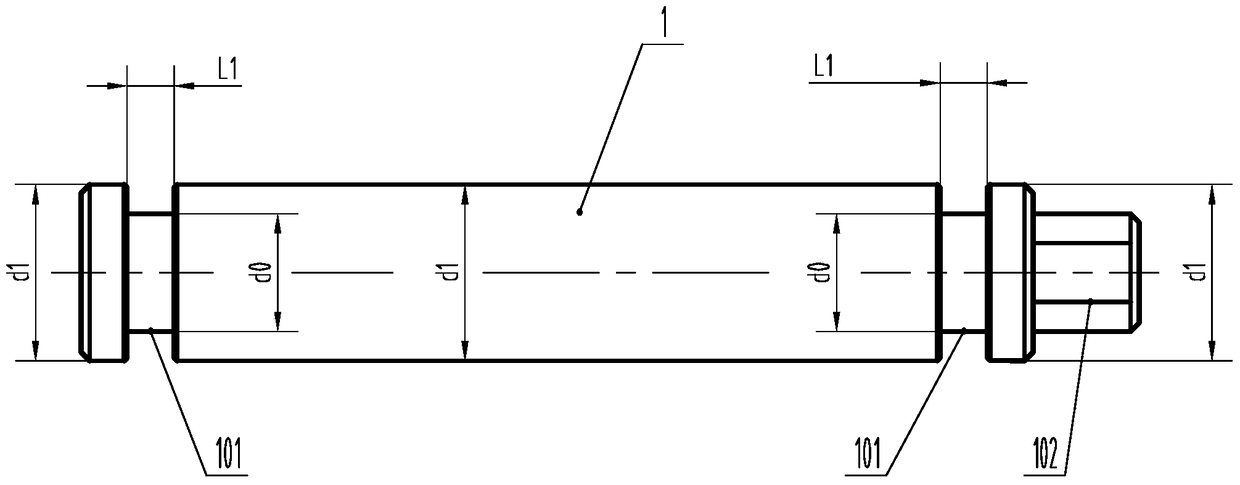

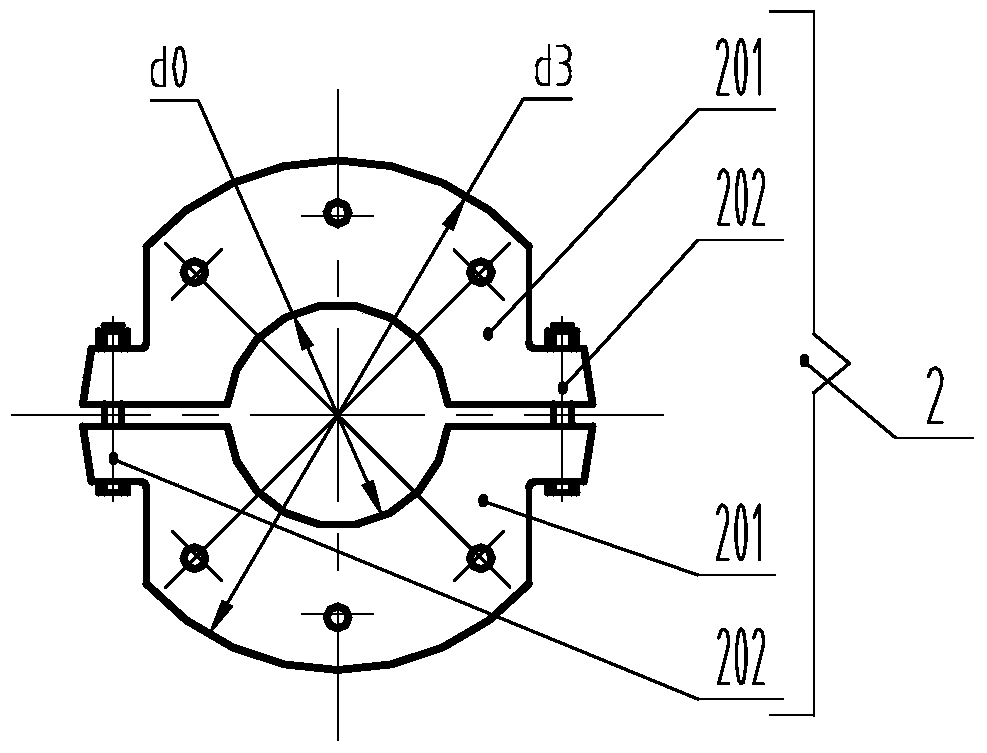

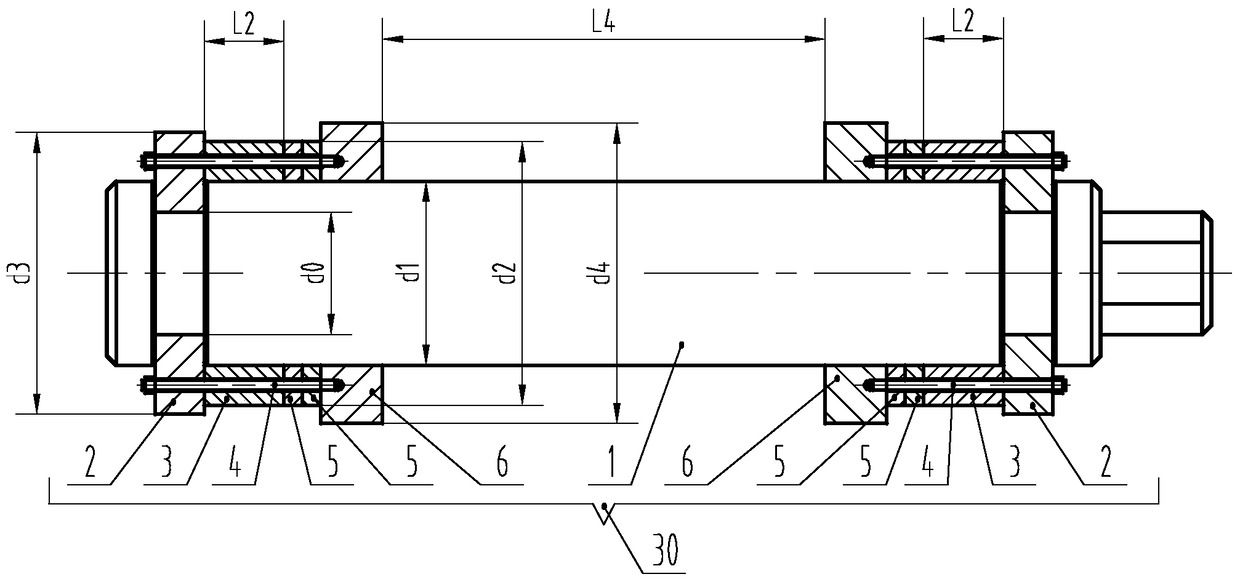

Cylindrical forge piece precise mandrel broaching method

ActiveCN105598331AReduce gross to net ratioIncreased hydrostatic stressForging/hammering/pressing machinesFinal heightMetallic materials

The invention discloses a cylindrical forge piece precise mandrel broaching method and belongs to the field of hot working of metal materials. The technical problem that a cylindrical forge piece cannot be accurately formed in the prior art is solved. The method comprises the steps that broaching rings are machined and manufactured on the basis that the outer diameter of each broaching ring is equal to the sum of the mandrel diameter and two times of the final wall thickness of the cylindrical forge piece; a combined mandrel composed of a mandrel, two semi-ring assemblies, two bushing rings, two broaching ring fastening double-screw bolt sets, N adjusting backing rings and two broaching rings are assembled, and the number of the adjusting backing rings is increased or decreased to enable the distance between the two broaching rings is equal to the final height of the cylindrical forge piece; the combined mandrel is inserted into an initial blank of the cylindrical forge piece and achieves centering, and the combined mandrel is placed on a mandrel supporter; a pressing machine with an upper anvil is pressed down, and mandrel broaching is started; the upper anvil is pressed down to the outer side faces of the broaching rings, and broaching is finished. The cylindrical forge piece precise mandrel broaching method is used for cylindrical forge piece broaching, and has the advantages that deformation is uniform and accurate, the force piece core portion is good in tightness, production efficiency is high, and the cost is low.

Owner:山西成业锻造股份有限公司

Platen for decorating plate machining

InactiveCN107717910AHeight adjustableImprove practicalitySpecial ornamental structuresWork benchesFinal heightBuffer tank

The invention provides a platen for processing a decorative plate, which relates to the field of mechanical processing. The platen for processing decorative boards includes a fixing plate, and the four corners of the bottom of the fixing plate are provided with first connecting seats, and the first connecting seats are movably connected with the top ends of the pressure rods, and the bottom ends of the pressure rods pass through the reducing rods. The shock absorber extends to the inside of the shock absorber and is fixedly connected to the top of the pressure block, the inside of the shock absorber and the bottom of the pressure block are provided with hydraulic oil, and the bottom of the shock absorber is fixedly connected to the top of the connecting rod , the bottom end of the connecting rod is flexibly connected with the second connecting seat. The platen used for processing the decorative board drives the screw to rotate through the motor, so that the movable block slides along the surface of the screw, and then drives the movable rod to move the buffer box, so that the fixed plate slides along the surface of the guide rod, so that it is convenient for fixing The height of the board can be adjusted, which is finally suitable for people of all heights to operate for a long time, effectively improving the practicality.

Owner:广东澳林板业有限公司

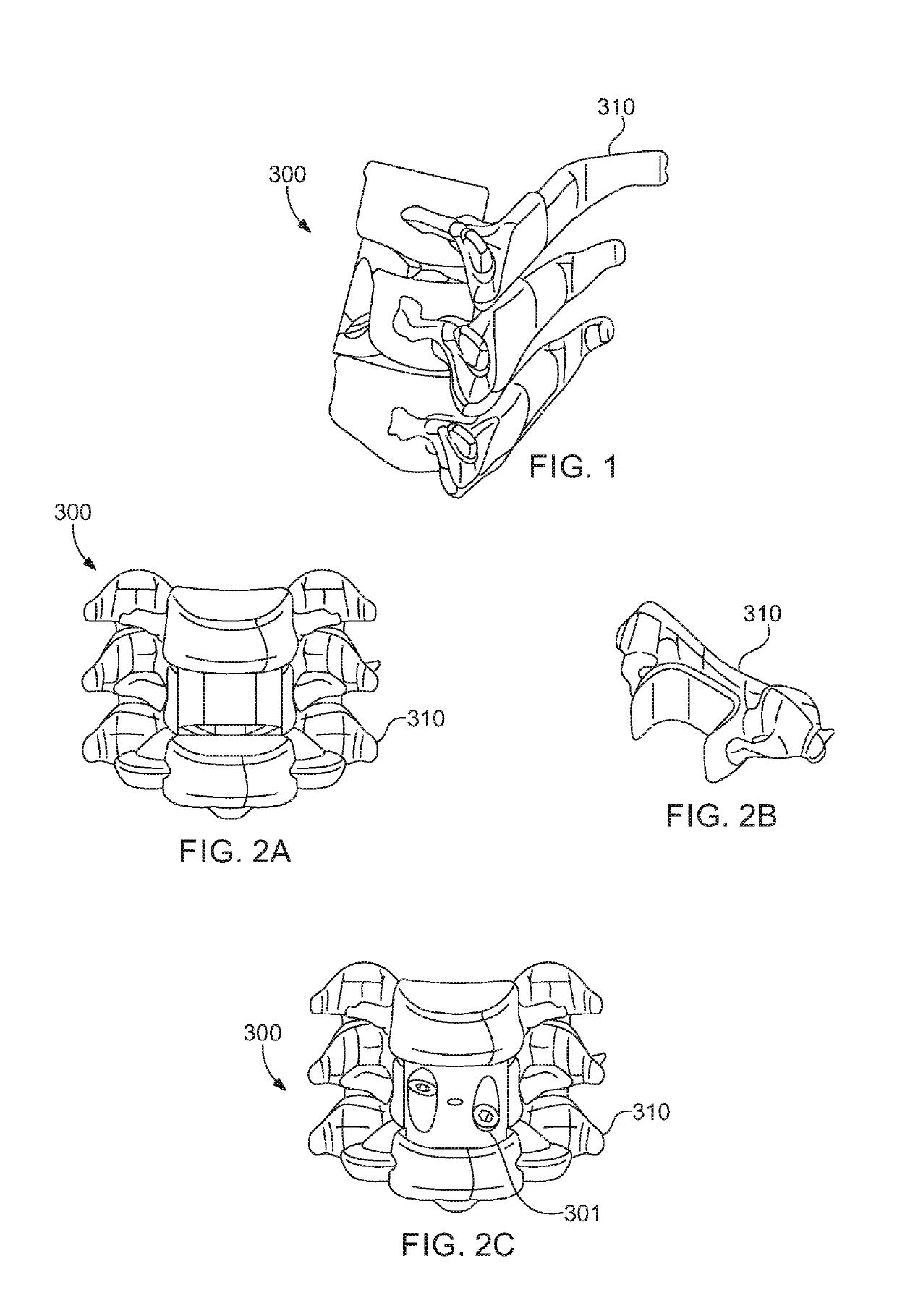

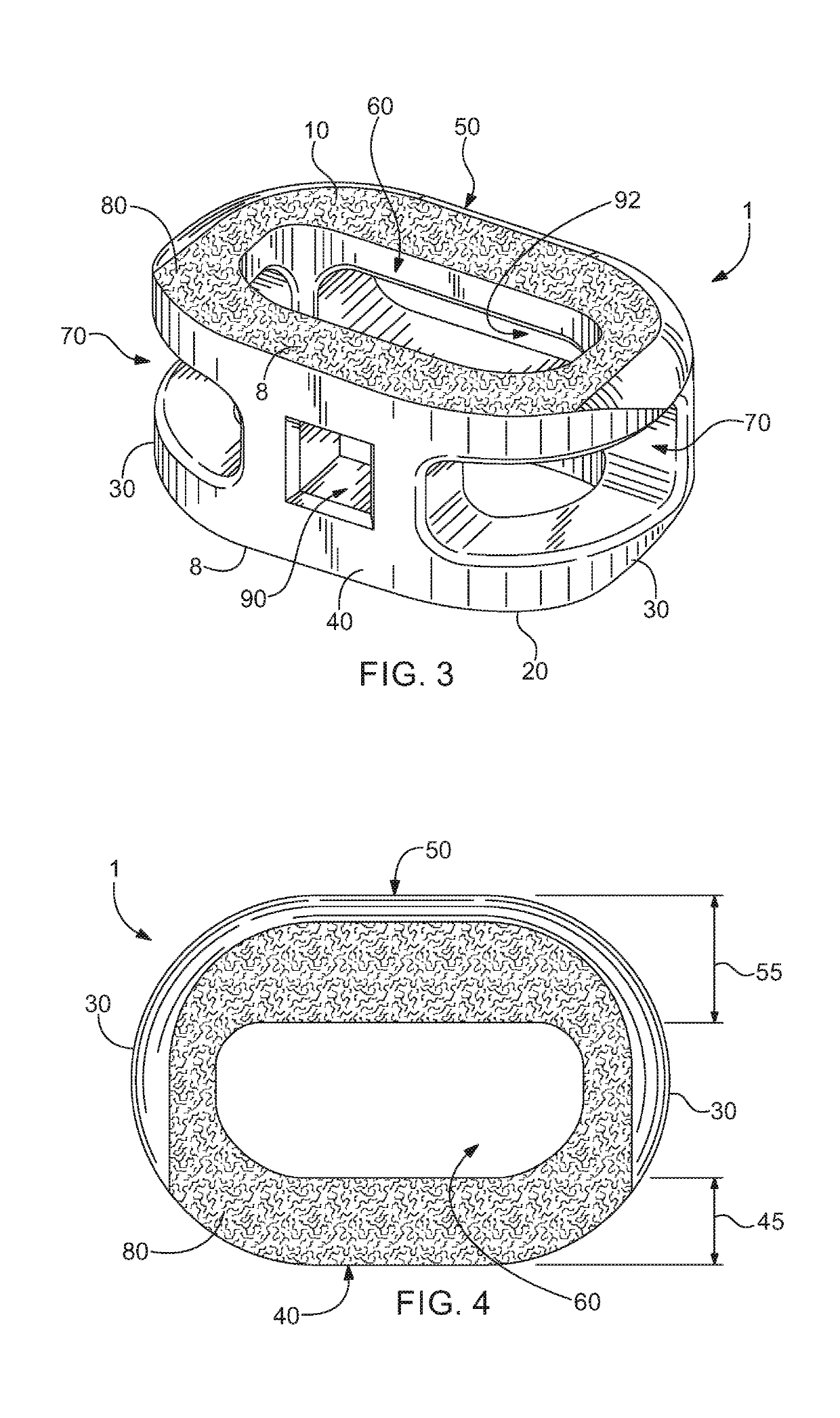

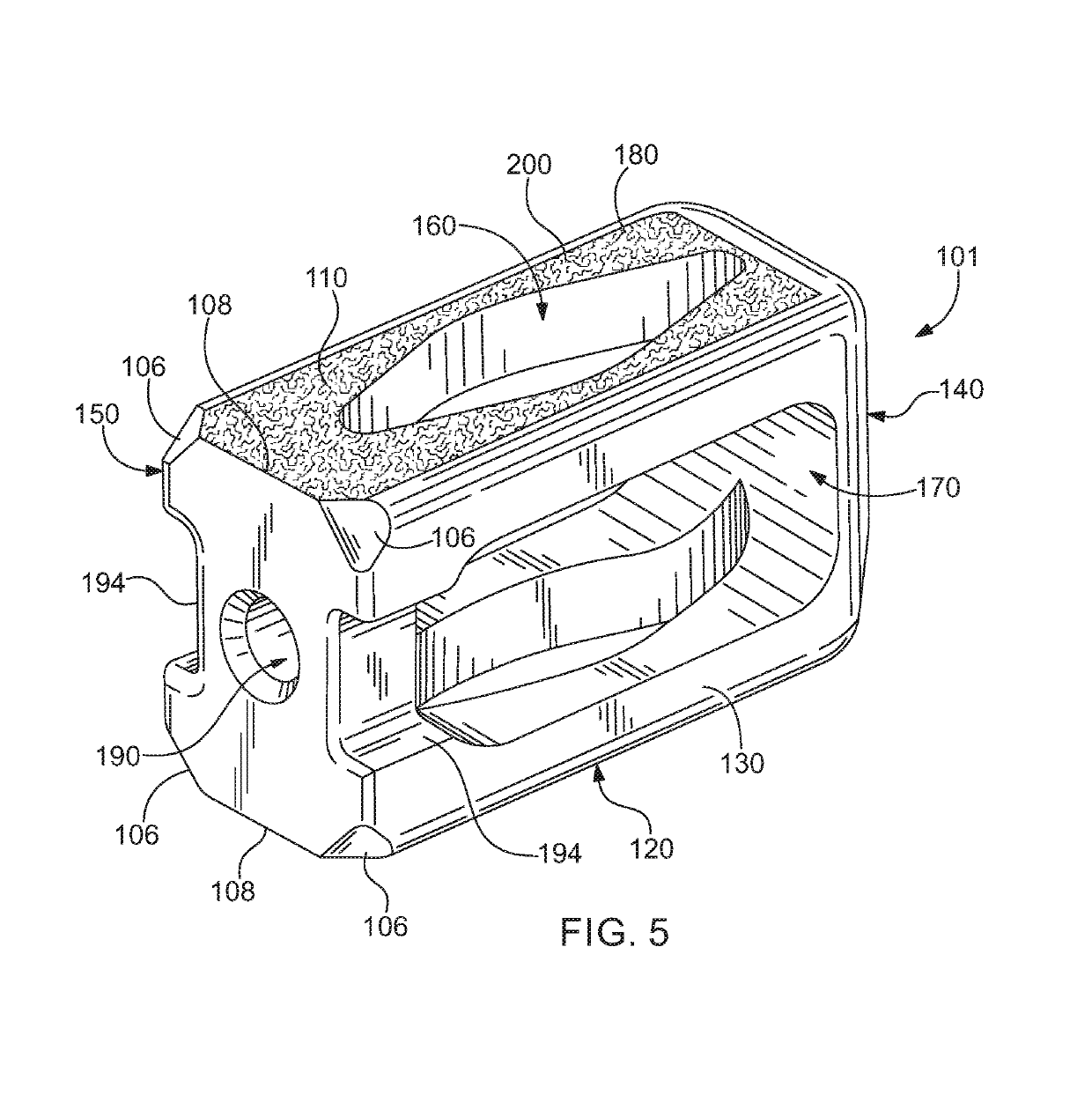

Modular adjustable corpectomy cage

A system for use during surgical procedures. The system includes an implant and a tool. The implant combines a modular adjustable cage and a shim that locks the cage into position, after the cage has been adjusted to its final position and at its final height, in situ. The tool combines an expander and an inserter. A related method of using the system is also provided.

Owner:TITAN SPINE

A GPU line rasterization boundary calculation optimization method

ActiveCN109685875AOptimizing Rasterization AlgorithmsResolve issues with altitude threshold exceededFilling planer surface with attributes3D-image renderingFinal heightIntersection of a polyhedron with a line

The invention relates to the technical field of computer hardware modeling, and provides a GPU (Graphics Processing Unit) line rasterization boundary calculation optimization method, which comprises the following steps of: 1, selecting a starting point and an end point of a straight line, and selecting the starting point and the end point of the straight line; 2, calculating the height of each chip element, and calculating the height of each chip element according to a linear equation when a straight line is scanned; Step 3, calculating the height difference between each chip element and the starting point, keeping the height of the straight line starting point, and calculating the height difference between the current chip element and the starting point according to the height value obtained in the previous step; And 4, boundary comparison: comparing the height difference calculated in the step 3 with the overall height difference of the straight line: when the height difference is greater than the overall height difference of the straight line, modifying the height of the sheet element to be the final height, otherwise, keeping the height of the sheet element. The method solves the problem that the height threshold value substituted by error accumulation exceeds, especially the problem that the intersection points of adjacent lines are not uniform during continuous line drawing, and optimizes the GPU line rasterization algorithm.

Owner:XIAN AVIATION COMPUTING TECH RES INST OF AVIATION IND CORP OF CHINA

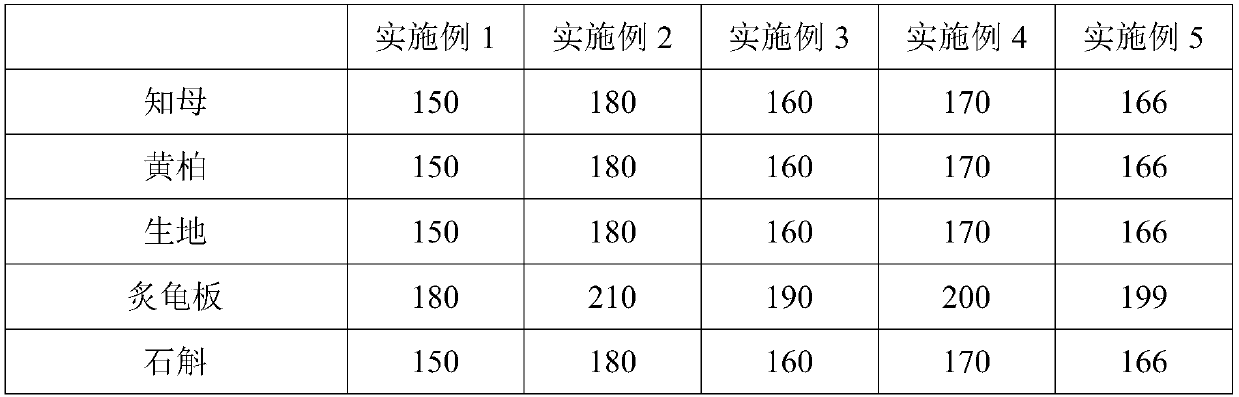

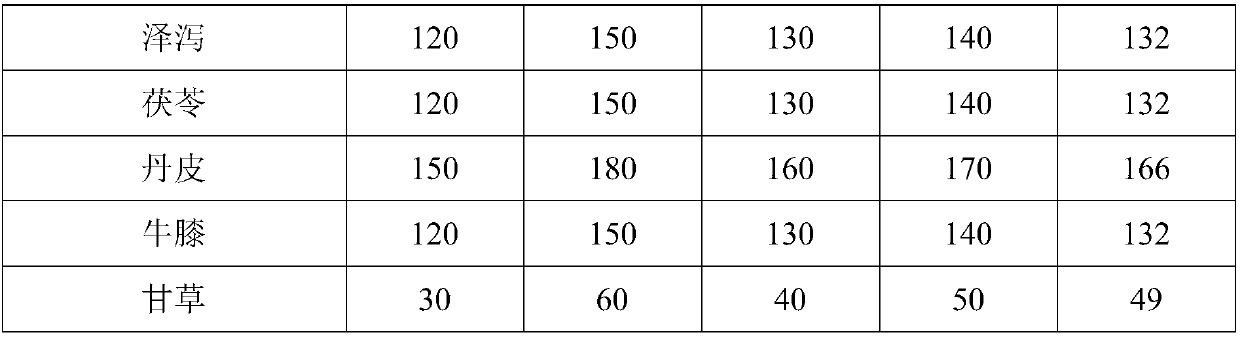

Medicine for treating ICPP and preparation method of medicine

InactiveCN107823447ADefinite curative effectNo obvious side effectsNervous disorderUnknown materialsFinal heightSide effect

The invention discloses a medicine for treating ICPP and a preparation method thereof. The medicine comprises the following components: anemarrhena, cortex phellodendri, habitat, broiled tortoise shell, dendrobium, alisma, poria cocos, paeonol, achyranthes bidentata and licorice. The drug can effectively improve children's final height, delay menstrual cramps, help improve children's psychological toughness and resilience, and have positive effects on children's long-term psychological behavior and intelligence. The medicine has the advantages of remarkable effect, no toxic side effect and no adverse reaction when treating ICPP.

Owner:GUANGZHOU HOSPITAL OF TRADITIONAL CHINESE MEDICINE

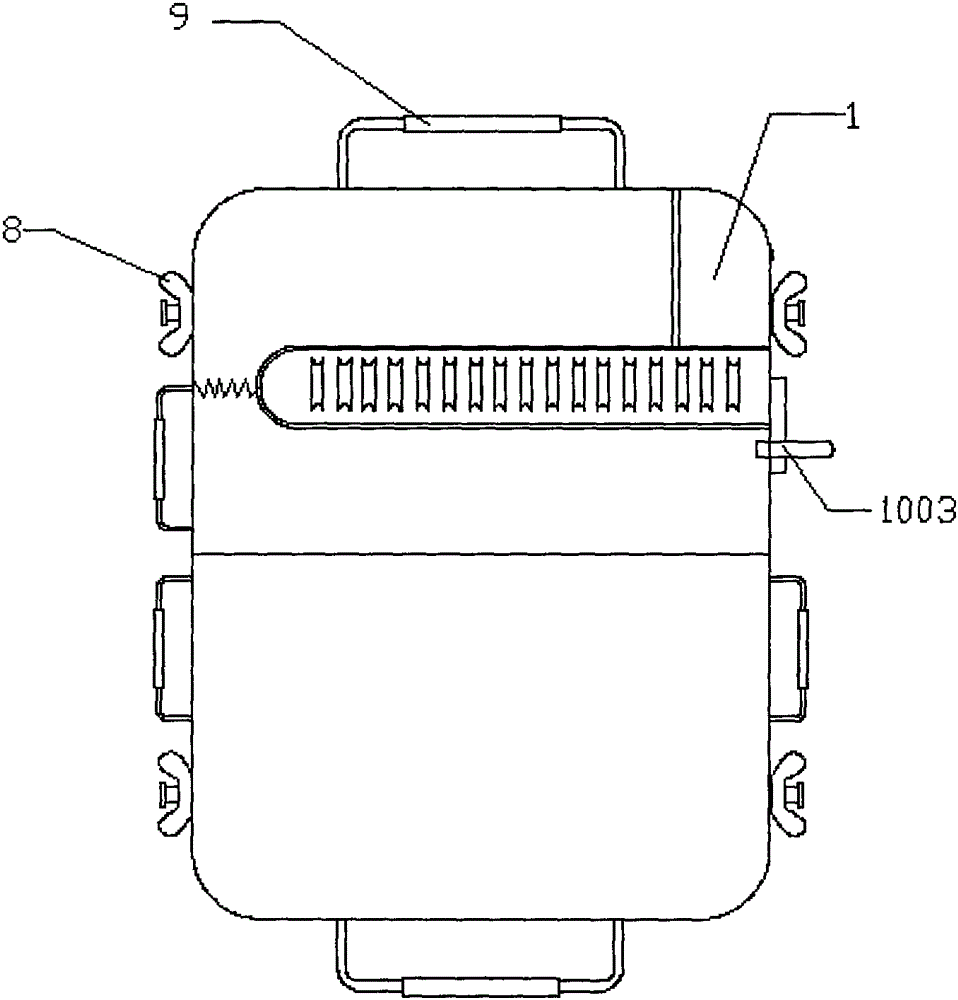

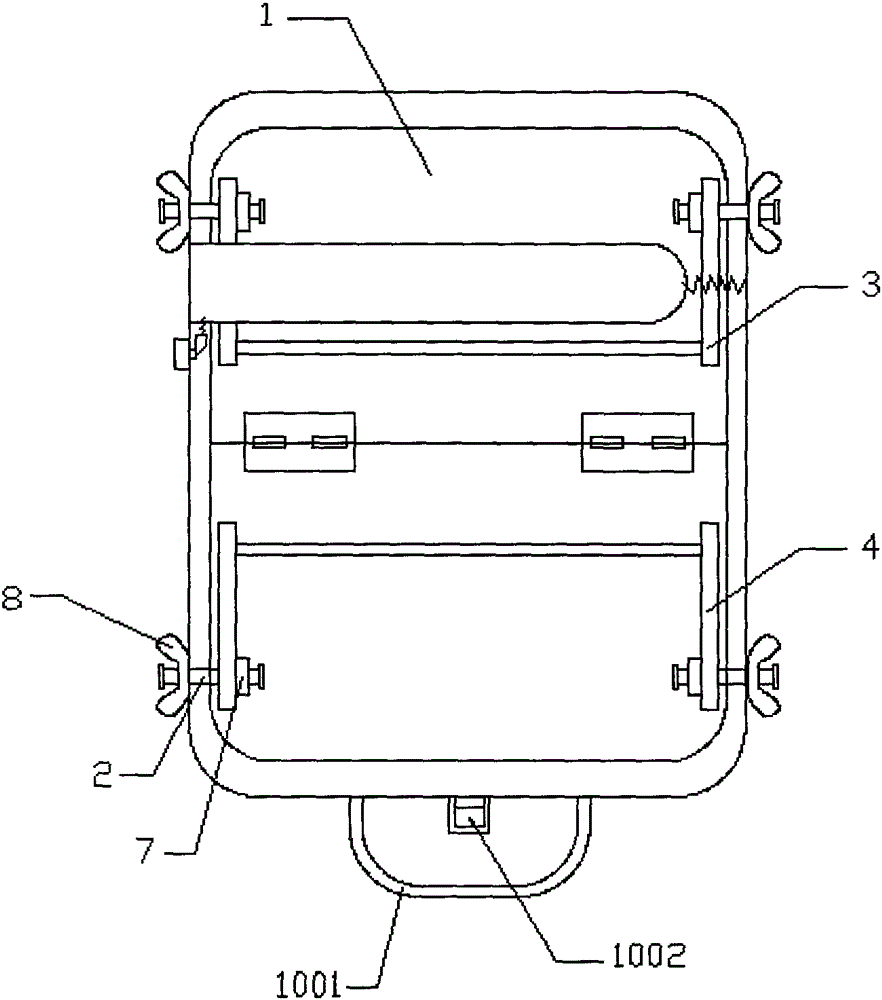

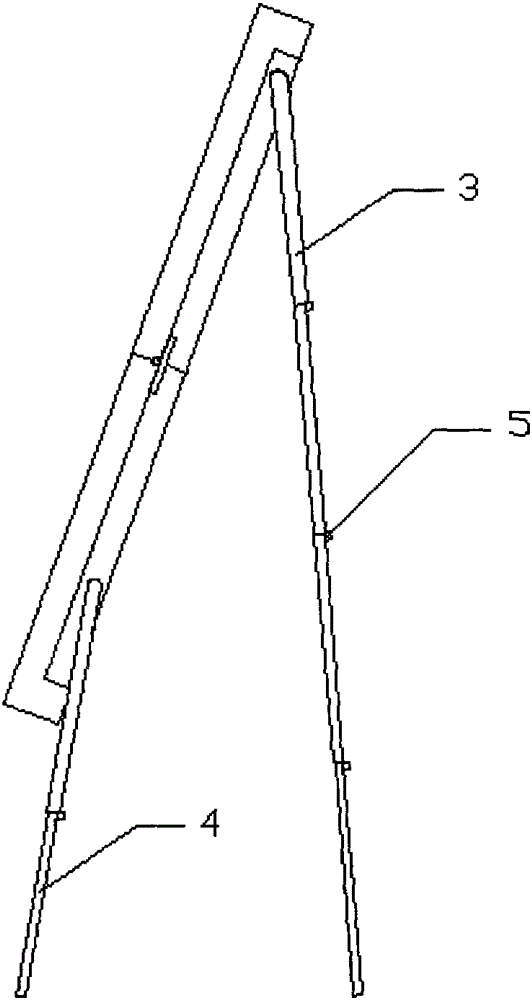

Multi-component painting easel device

The invention discloses a multi-component painting easel device. The multi-component painting easel device comprises a drawing board, double-screw bolts, an upper-end telescopic support, a lower-end telescopic support, spring fasteners, springs, fixing nuts, fixing clamp rings and paper clamp fasteners. According to the multi-component painting easel device, the folded drawing board is completely unfolded through a hinge by opening a locking fastener, the telescopic supports on the back surface of the drawing board are opened to reach the height appropriate for users and then locked in length through support clamp fasteners, the final height of the telescopic supports is fixed under the effect of the double-screw bolts, the fixing nuts and the fixing clamp rings, and finally paper is fixed to the drawing board through the paper clamp fasteners on the drawing board. The multi-component painting easel device is simple in structure, multifunctional, small in size, light in weight and convenient to take along by users.

Owner:张朝阳

BIM-based secondary structure wall arrangement method and system

InactiveCN108108539AReduced manual workloadAvoid the disadvantages of manual masonry layoutGeometric CADDesign optimisation/simulationFinal heightEngineering

The invention provides a BIM-based secondary structure wall arrangement method and system. The method comprises the following steps of: arranging complete brickworks at the position of a wall body under a girder of a BIM model from top to bottom according to heights of mortar joints between to-be-arranged brickworks, wherein the brickworks are arranged from top to bottom so that brickwork cuttingat the upper part of a secondary structure is avoided; after the brickworks are arranged into a variable height range of the guide wall, stopping the arrangement of the brickworks; and taking a difference height between a total height and an arrangement height of the brickworks as a final height of the guide wall so that raw materials of the brickworks are not cut, wherein the brickworks are completely arranged to form the wall body, so that the defects of manual brickwork arrangement are avoided, the brickwork arrangement efficiency of secondary structures is greatly improved, the manual workload of users is reduced, and the effects such as beauty and sound insulation of the secondary structures are enhanced.

Owner:SHANGHAI CONSTR NO 5 GRP CO LTD

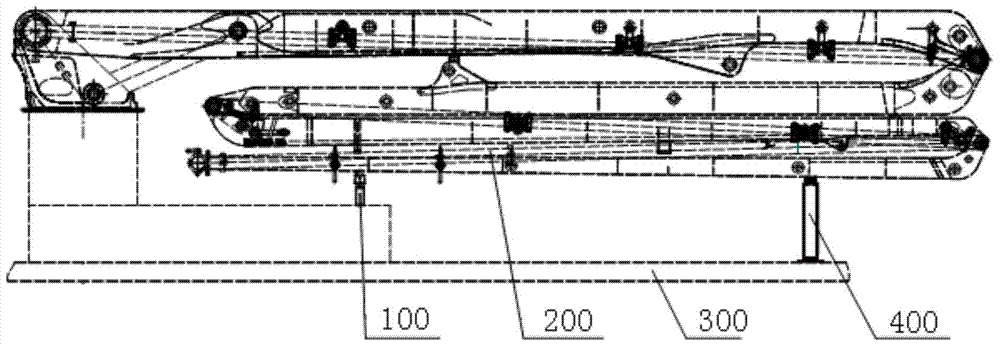

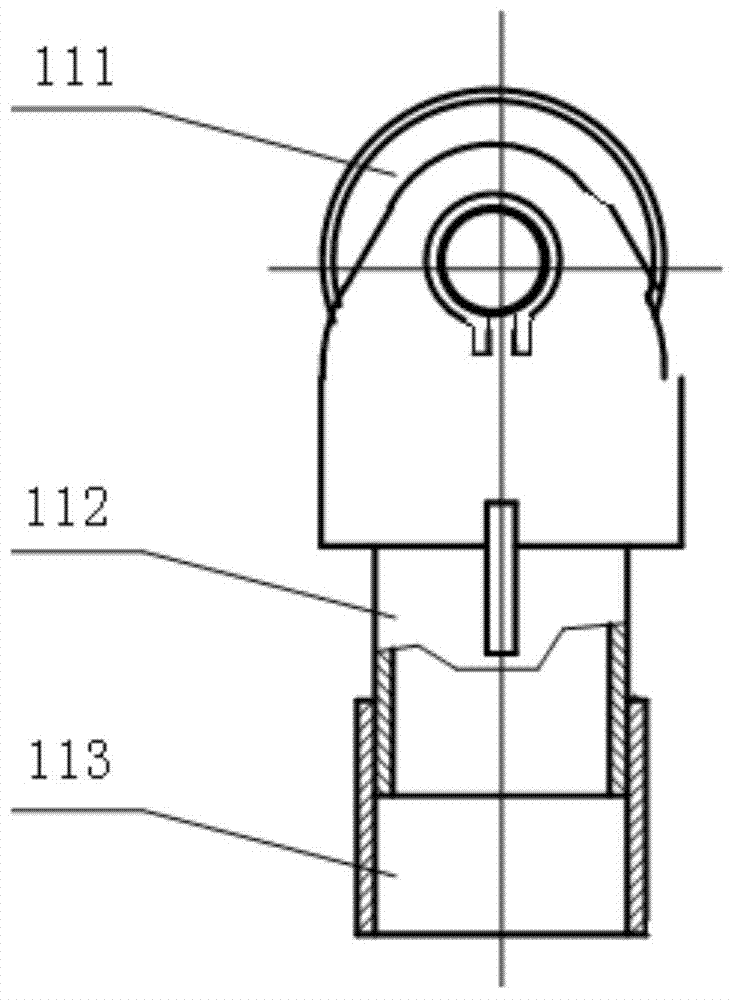

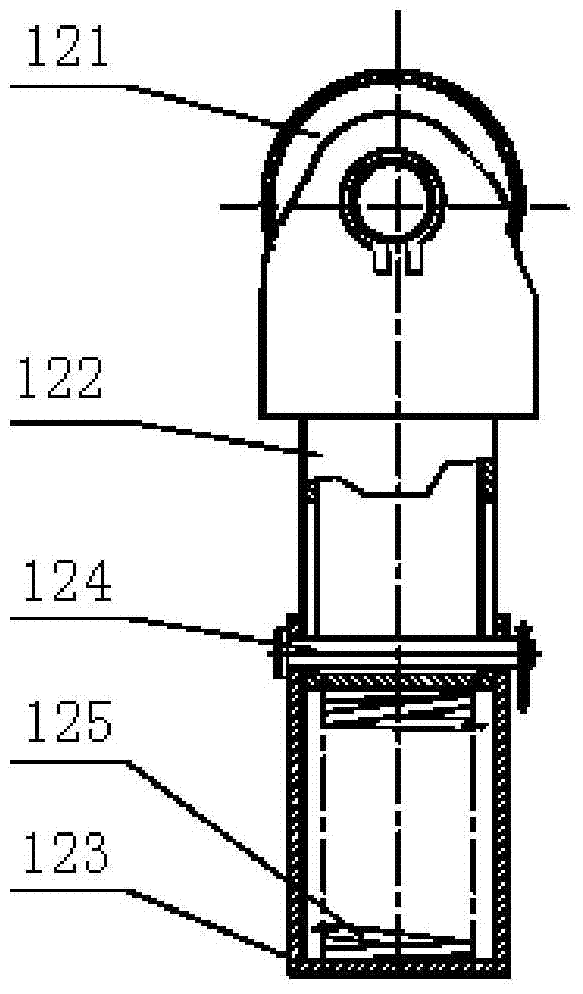

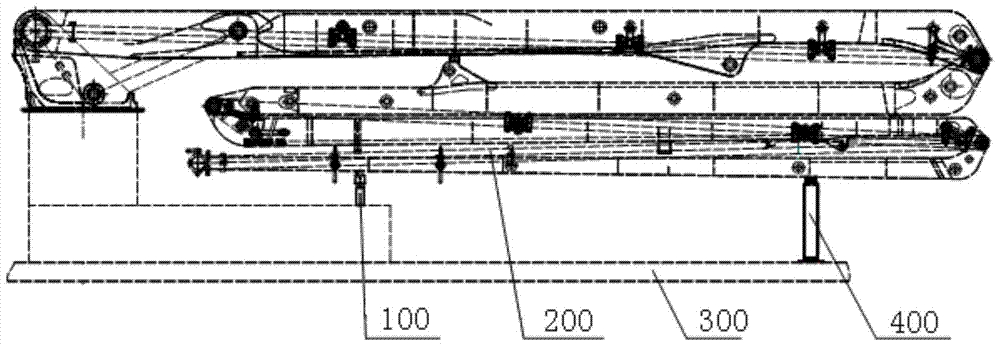

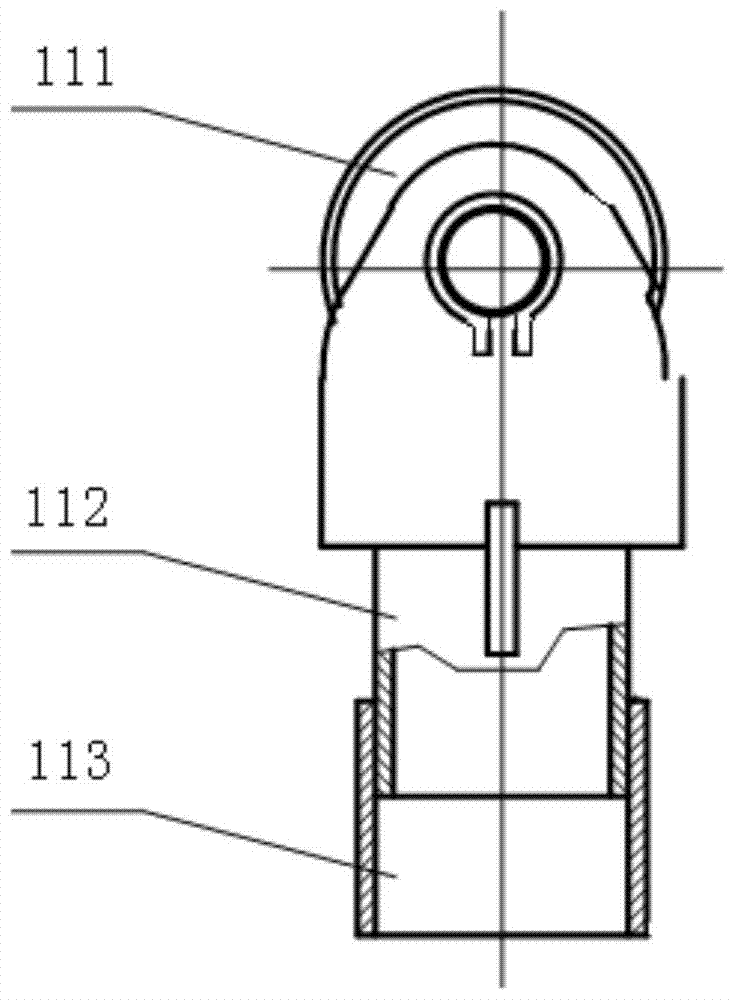

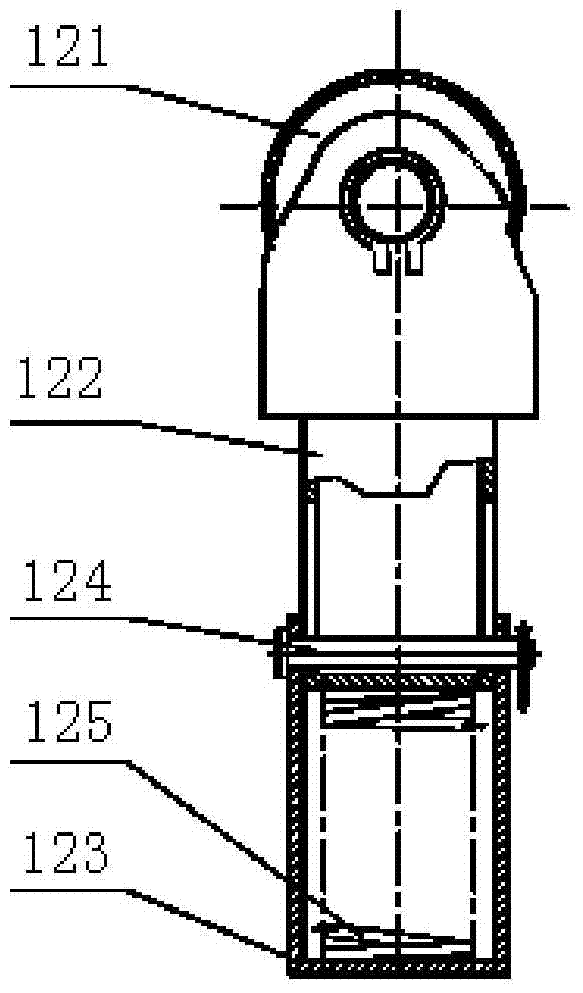

Arm rest auxiliary supporting device and pump car with device

The invention discloses an arm rest auxiliary supporting device and a pump car with the arm rest auxiliary supporting device. The arm rest auxiliary supporting device comprises an upper connecting frame, a rolling wheel, a bottom frame and a spring, wherein the rolling wheel is arranged on the upper connecting frame and is used for providing auxiliary supporting for an arm rest; the upper connecting frame is sleeved with the bottom frame, and the upper connecting frame can vertically slide relative to the bottom frame; and the spring is arranged between the upper connecting frame and the bottom frame and is used for providing elastic supporting force for the upper connecting frame. The arm rest auxiliary supporting device can adjust height by itself, and is in elastic contact with an arm rest assembly, and therefore the arm rest assembly can be effectively supported; the consistency of the arm rest auxiliary supporting device is good, and the phenomenon that a support is too high, and consequently, an arm rest deforms, or the support is too short, and consequently, a gap exists between the support and the arm rest is avoided. The final height of the arm rest auxiliary supporting device is adjusted without fit welding of an assembly field, and the production efficiency is high.

Owner:河北雷萨重型工程机械有限责任公司

An arm support structure and a pump truck having the same

The invention discloses a boom supporting structure and a pump truck having the same. The boom support structure includes a boom main support and a boom auxiliary support device. The boom auxiliary support device includes: an upper connecting frame; rollers, which are arranged on the upper connecting frame, to provide auxiliary support for the boom; a bottom frame, which is sleeved with the upper connecting frame, and the upper The connecting frame can slide up and down relative to the bottom frame; and a spring, which is arranged between the upper connecting frame and the bottom frame, is used to provide elastic support for the upper connecting frame. The boom auxiliary support device of the present invention can adjust the height by itself, and is in elastic contact with the boom assembly, so as to realize effective support for the boom assembly, the consistency of the product is good, and avoid the deformation of the boom caused by the bracket being too high Or the bracket is too short to cause a gap between the bracket and the boom. In addition, there is no need to adjust the final height of the auxiliary support device of the arm frame by welding on the assembly site, and the production efficiency is high.

Owner:河北雷萨重型工程机械有限责任公司

Rolling forming method for disc-type section forging

The invention relates to a rolling forming method for a disc-type section forging, which comprises the following steps: heating an alloy ingot to a temperature of 1150-1180 DEG C; improving the cast structure of the alloy ingot through upsetting and stretching; conducting punching, reaming and rounding processes to manufacture an annular plate blank with a thickness of 1 / 2 of a final height; feeding the annular plate blank into a furnace and heating the annular plate blank to the temperature of 1150-1180 DEG C, taking out the annular plate blank and placing the annular plate blank on a ring mill; carrying out a process that a main roller bushing is sleeved with the main roller, and a core roller bushing is sleeved with the core roller; switching on the ring mill, the ring mill starts to rotate under the driving of the main roller and the core roller, pressing the tapered rollers a and b on two end surfaces of a prefabricated blank respectively, starting to roll, and switching off the ring mill after the size is in place to obtain the ring-milled special-shaped ring piece. By the adoption of the rolling forming method for the disc-type section forging, a utilization rate of the material is greatly improved; and after heat treatment, only small-margin mechanical processing is required, without cutting off metal fibers, so that the service life and the comprehensive performance ofa product are improved, and the manufacturing period is short.

Owner:GUIZHOU AEROSPACE XINLI CASTINGSAND FORGINGS

An accurate mandrel reaming method for cylindrical forgings

ActiveCN105598331BReduce gross to net ratioIncreased hydrostatic stressForging/hammering/pressing machinesFinal heightMetallic materials

The invention discloses a cylindrical forge piece precise mandrel broaching method and belongs to the field of hot working of metal materials. The technical problem that a cylindrical forge piece cannot be accurately formed in the prior art is solved. The method comprises the steps that broaching rings are machined and manufactured on the basis that the outer diameter of each broaching ring is equal to the sum of the mandrel diameter and two times of the final wall thickness of the cylindrical forge piece; a combined mandrel composed of a mandrel, two semi-ring assemblies, two bushing rings, two broaching ring fastening double-screw bolt sets, N adjusting backing rings and two broaching rings are assembled, and the number of the adjusting backing rings is increased or decreased to enable the distance between the two broaching rings is equal to the final height of the cylindrical forge piece; the combined mandrel is inserted into an initial blank of the cylindrical forge piece and achieves centering, and the combined mandrel is placed on a mandrel supporter; a pressing machine with an upper anvil is pressed down, and mandrel broaching is started; the upper anvil is pressed down to the outer side faces of the broaching rings, and broaching is finished. The cylindrical forge piece precise mandrel broaching method is used for cylindrical forge piece broaching, and has the advantages that deformation is uniform and accurate, the force piece core portion is good in tightness, production efficiency is high, and the cost is low.

Owner:山西成业锻造股份有限公司

Zoning method of urban overall height control based on factor comprehensive evaluation

The invention discloses an overall city height control partition method based on comprehensive divisor evaluation. According to the overall city height control partition method based on comprehensive divisor evaluation, required data materials are extracted from relevant legal planning results such as overall city planning first and are imported to a digital technology platform and converted to impact factor control parameters according to a height control mathematic model built after researches, height control values of all street units are obtained, standardized correction is further conducted on the height control values according to a Saaty method, and the final height control partition result is obtained after conversion is conducted on the height control values. The overall city height control partition method based on comprehensive divisor evaluation is based on objective and rational analysis and comprehensive and overall evaluation modes, the data materials are easy to obtain, and therefore the city heights can be effectively controlled in a macro-level mode.

Owner:SOUTHEAST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com