An accurate mandrel reaming method for cylindrical forgings

A cylindrical and forging technology, which is applied in the field of precise mandrel reaming of cylindrical forgings, can solve problems such as inability to accurately form cylindrical forgings, improve product quality, improve product accuracy and production efficiency, and reduce hair loss. net ratio effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Typical embodiments embodying the features and advantages of the present invention will be described in detail in the following description with reference to the accompanying drawings. It should be understood that the present invention can have various changes in different embodiments without departing from the protection scope of the present invention, and the descriptions and illustrations therein are essentially for illustration rather than for limit the invention.

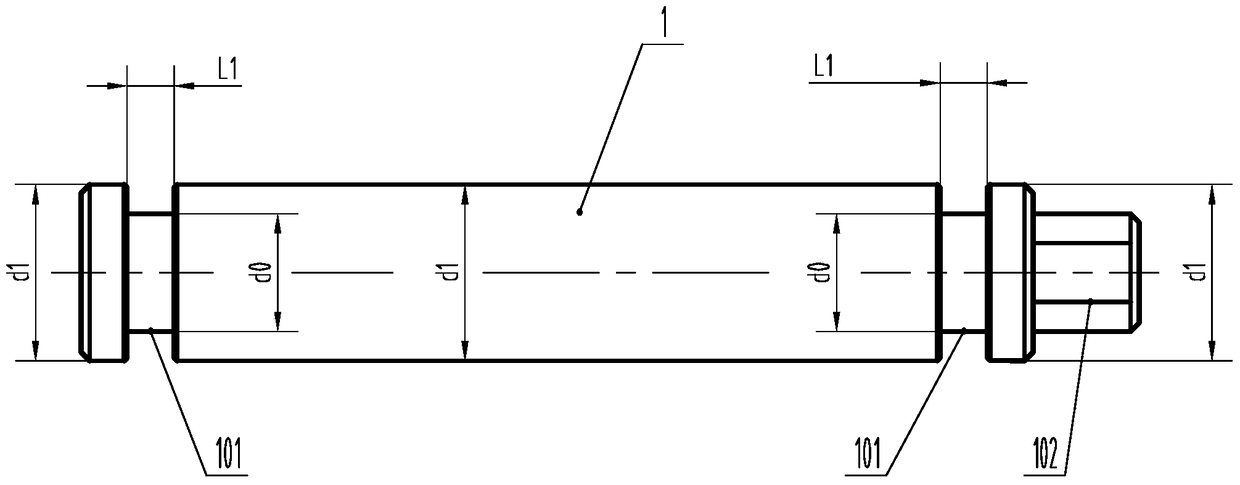

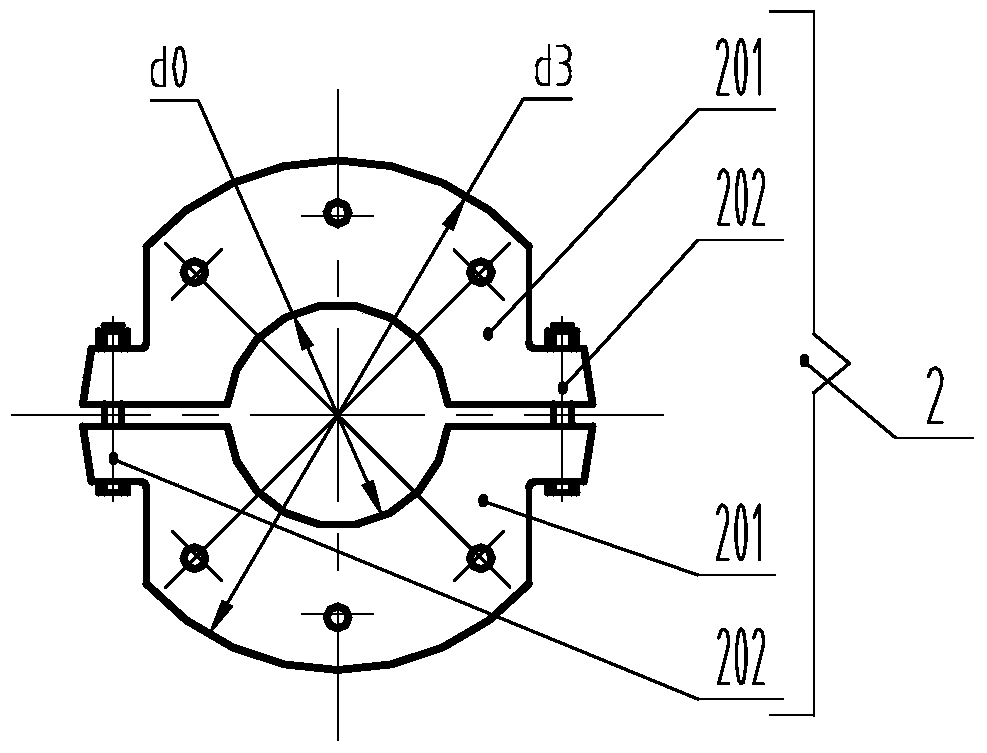

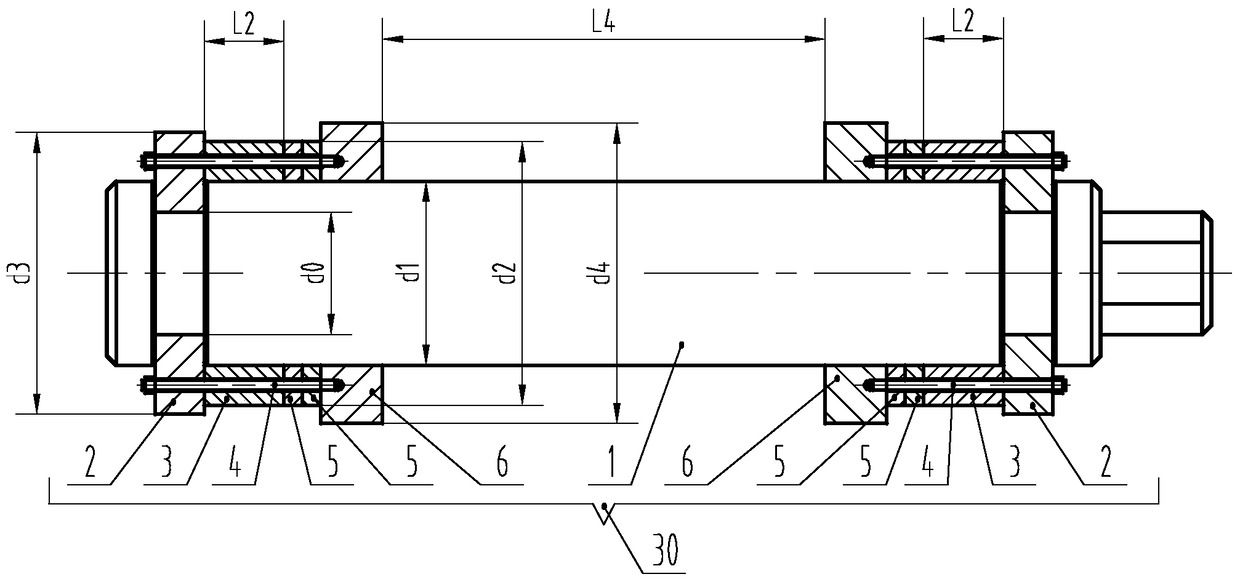

[0022] Such as Figure 1 to Figure 7 As shown, a method for accurately mandrel reaming of cylindrical forgings, the specific steps are:

[0023] ① Determine the outer diameter d4 of the reaming ring 6 according to the diameter d1 of the mandrel and the final wall thickness T of the cylindrical forging 60, and the outer diameter d4 of the reaming ring is equal to the diameter d1 of the mandrel plus 2 times the final wall of the cylindrical forging Thick T, processing and making reaming ring 6;

[0024]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com