A non-continuous point blank holder for a fine blanking die and its process parameter design method

A blankholder, non-continuous technology, applied in the field of fine blanking die non-continuous point blankholder and its process parameter design, can solve the problem that the non-continuous point blankholder has no systematic definition, etc., to improve the surface integrity The effect of high efficiency, cost reduction, and improvement of plastic deformation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

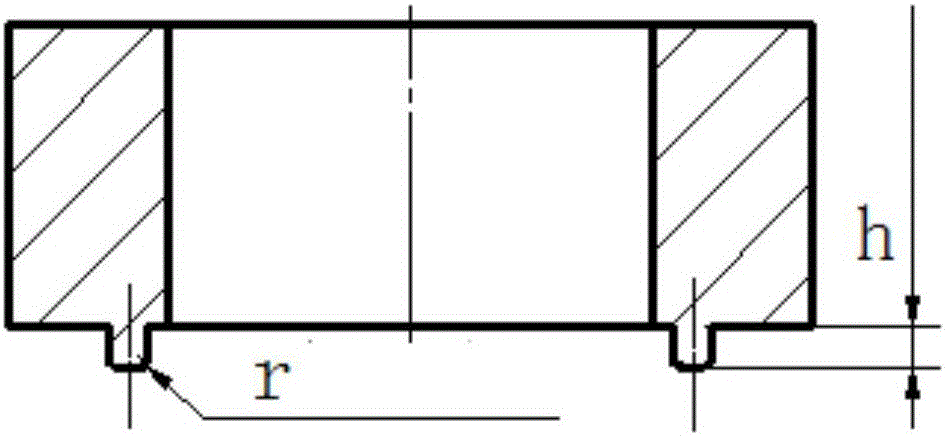

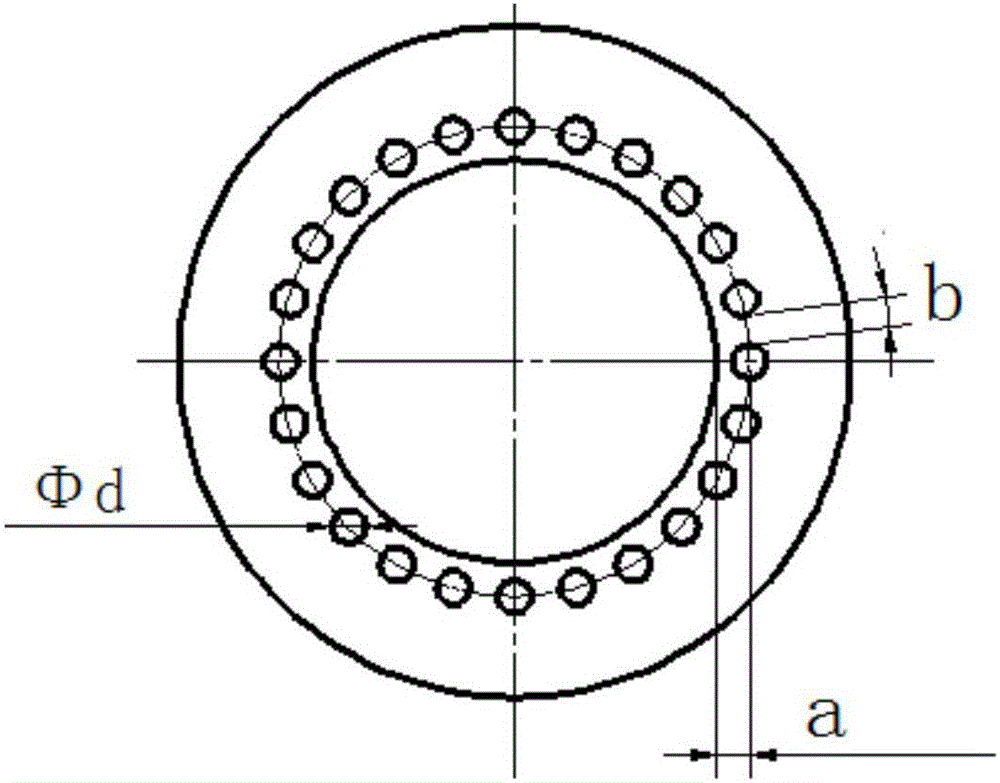

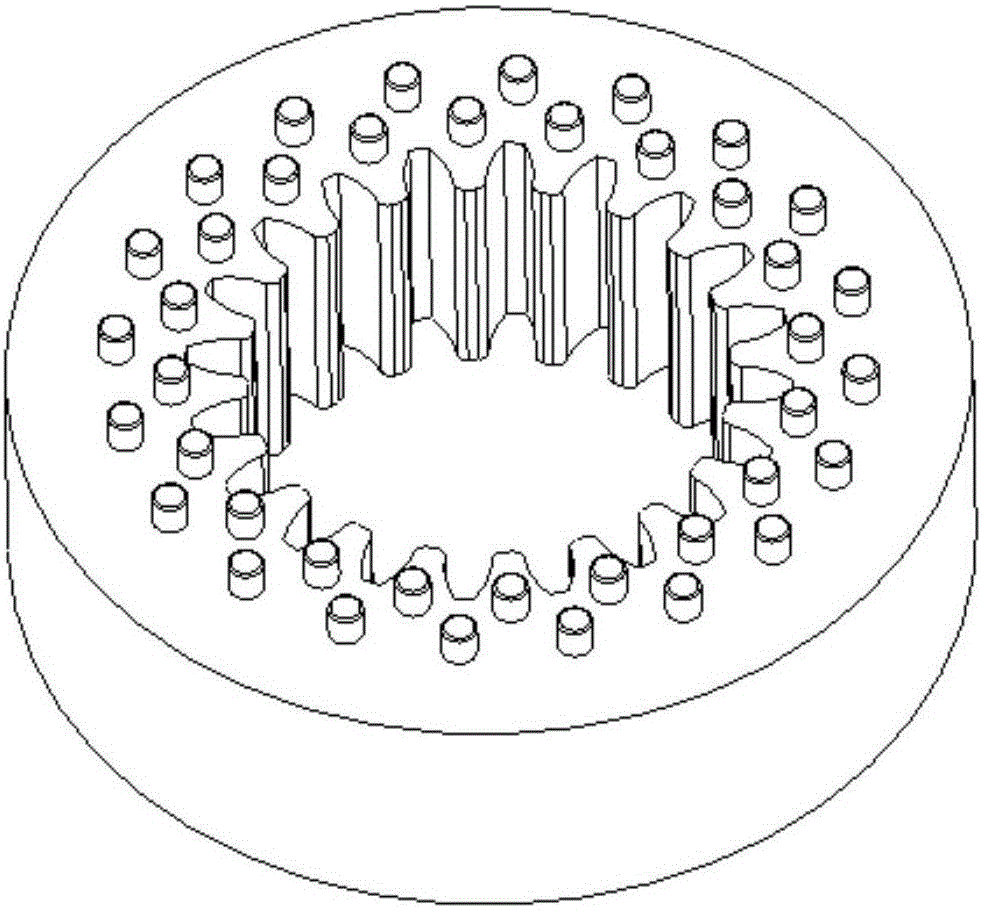

[0025] Such as Figure 1-Figure 3 As shown, a discontinuous point-type blank holder of a fine blanking die, the blank holder includes a point-type blank-holder body, and the lower surface of the point-type blank-holder body is uniform along the outline of the part to be formed by fine blanking. Lay out a set of convex points, each convex point is provided with a rounded corner, when the thickness of the part to be fine-blanked is less than 5mm, the point-type blankholder is single-sided, and the distance between the edges of adjacent convex points b The ratio of the diameter Φd of the raised point...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com