Preparation method of VW93M super-high-strength large block body nano magnesium alloy

A technology of nano-magnesium and magnesium alloys, which is applied in the field of bulk nano-material preparation and can solve problems such as lack of methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] a. The mass percentage composition of the magnesium alloy is: Mg-8.0Gd-3.0Y-0.4Zr-0.05Ag-0.03Er, the magnesium alloy ingot is prepared by a semi-continuous casting method, and homogenized heat treatment is performed;

[0019] b. Extruding and deforming the homogenized alloy billet;

[0020] c. The extruded bar is subjected to rotary forging deformation at 125°C, and the deformation amount of each pass is controlled to be 15%, 15%, 10%, and the total deformation amount is 35%, and the feeding speed is controlled to be 2mm / min. In the feeding direction, the average grain size of the obtained nano-magnesium alloy is 30nm, and the finished product size is 3.5mm in diameter and 1500mm in length;

[0021] d. The swaged bar is subjected to aging heat treatment.

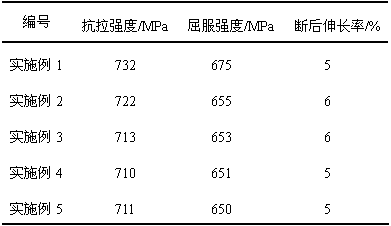

[0022] According to GB / T228-2002, the mechanical properties of the obtained nano-magnesium alloy were tested, and the results are shown in Table 1.

Embodiment 2

[0024] a. The mass percentage composition of the magnesium alloy is: Mg-8.0Gd-3.0Y-0.4Zr-0.05Ag-0.03Er, the magnesium alloy ingot is prepared by a semi-continuous casting method, and homogenized heat treatment is performed;

[0025] b. Extruding and deforming the homogenized alloy billet;

[0026] c. The extruded bar is subjected to swaging deformation at 150°C, the deformation of each pass is controlled at 10%, 15%, 10%, 10%, the total deformation is 38%, and the feeding speed is controlled at 2mm / min. After the deformation, the feeding direction is changed, and the average grain size of the obtained nano-magnesium alloy is 50nm, and the finished product size is 5mm in diameter and 2000mm in length;

[0027] d. The swaged bar is subjected to aging heat treatment.

[0028] According to GB / T228-2002, the mechanical properties of the obtained nano-magnesium alloy were tested, and the results are shown in Table 1.

Embodiment 3

[0030] a. The mass percentage composition of the magnesium alloy is: Mg-8.0Gd-3.0Y-0.4Zr-0.05Ag-0.03Er, the magnesium alloy ingot is prepared by a semi-continuous casting method, and homogenized heat treatment is performed;

[0031] b. Extruding and deforming the homogenized alloy billet;

[0032] c. The extruded bar is subjected to rotary forging deformation at 200°C, and the deformation amount of each pass is controlled to be 15%, 15%, 15%, and the total deformation amount is 39%, and the feeding speed is controlled to be 3mm / min. In the feeding direction, the average grain size of the obtained nano-magnesium alloy is 70nm, and the finished product size is 3mm in diameter and 1000mm in length;

[0033] d. The swaged bar is subjected to aging heat treatment.

[0034] According to GB / T228-2002, the mechanical properties of the obtained nano-magnesium alloy were tested, and the results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com