Method for eliminating surface cracks of ultra-wide ferrite stainless steel middle-thick plate

A surface crack and ferrite technology, which is applied in the field of ferritic stainless steel plate rolling, can solve the problems of not considering the proportion of equiaxed grains in the continuous casting slab, not considering the influence of stainless steel surface grinding and spraying, etc., and achieves the benefit of coordinated deformation , shorten the forming interval, and solve the effect of possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The following examples are used to specifically illustrate the contents of the present invention, and these examples are only general descriptions of the contents of the present invention, and do not limit the contents of the present invention.

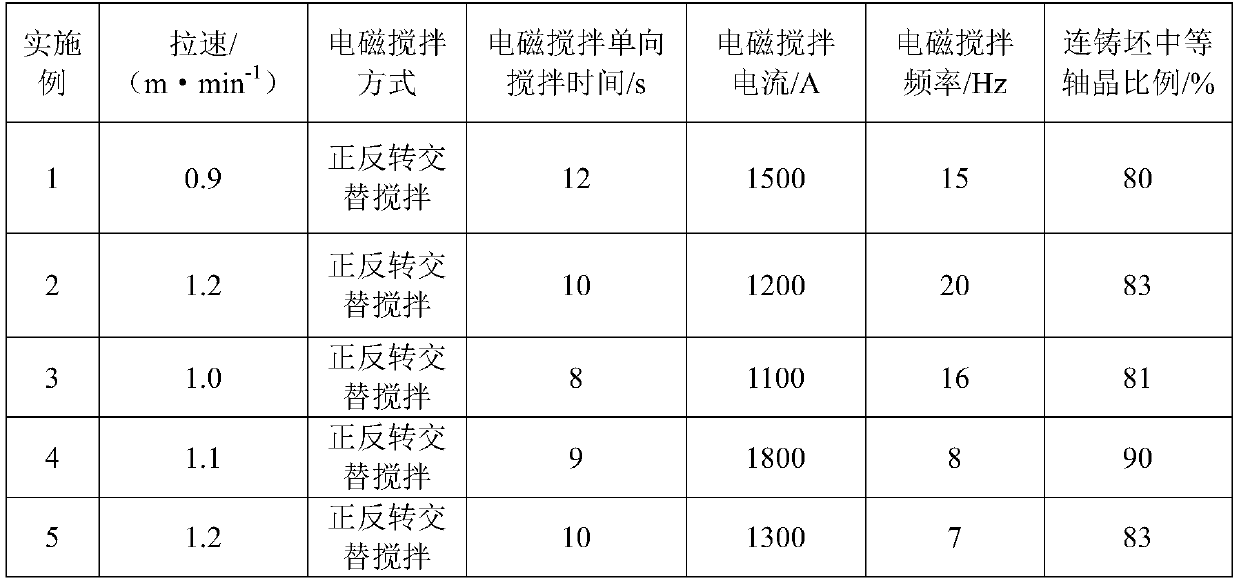

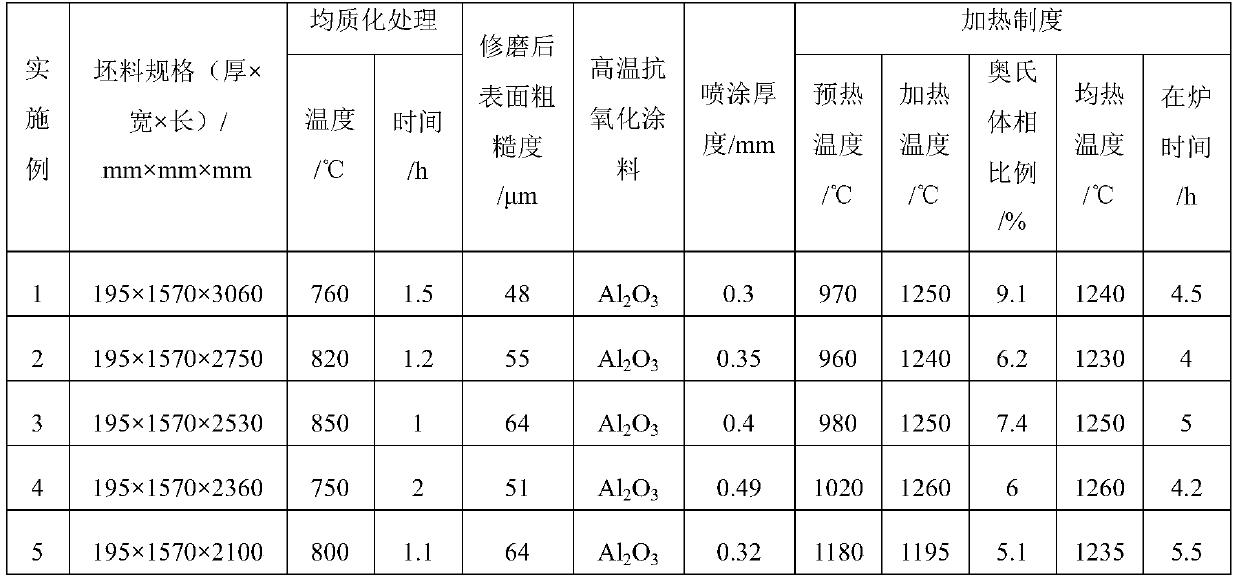

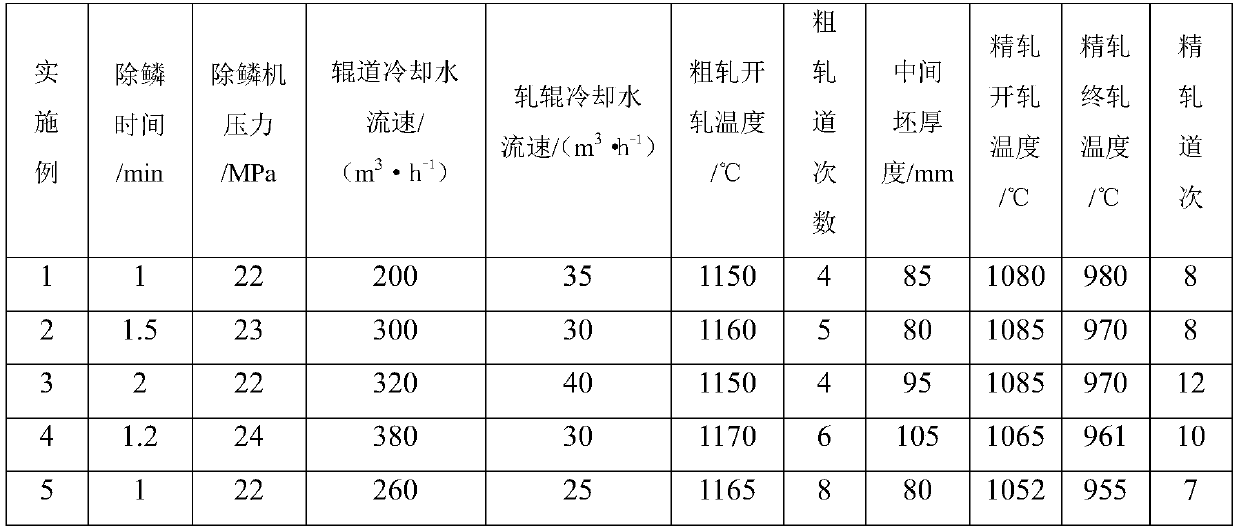

[0038] Wherein Table 1 is the chemical composition of embodiment steel, and Table 2 is the smelting process system of embodiment steel, and Table 3 is the processing method of embodiment steel slab; Table 4 is the rolling method of embodiment steel; Table 5 is embodiment The reduction rate of each pass of the steel; Table 6 is the annealing process and structure of the steel of the embodiment; Table 7 is the performance of the stainless steel of the embodiment.

[0039] The chemical composition (wt, %) of the embodiment of the present invention of table 1

[0040] Example C Si mn Cr Ti Nb Ni Cu N Ca 1 0.042 0.35 0.26 16.6 0.06 0.10 0.41 0.15 0.056 0.0011 2 0.069 0.42 0.31 16.8 0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com