Oblique pole type crystallizer electromagnetic stirring device

An electromagnetic stirrer and crystallizer technology, applied in the field of steel continuous casting equipment, can solve the problems of hindering the floating of inclusions, affecting the quality of continuous casting slabs, and unsatisfactory stirring, so as to prolong the residence time and facilitate full removal. The effect of improving cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

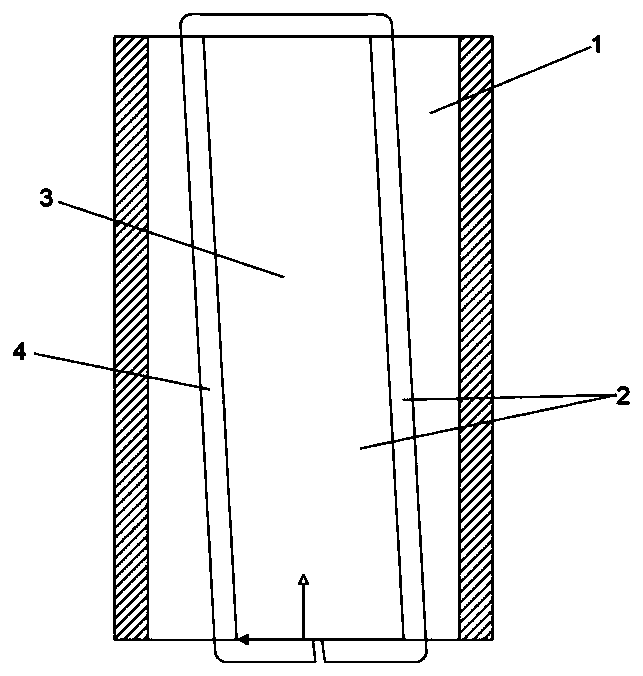

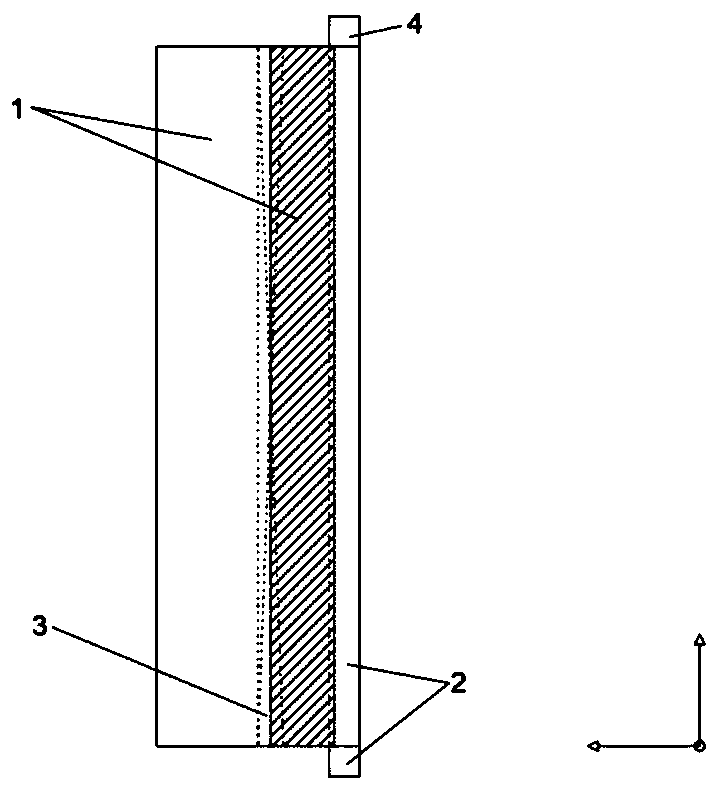

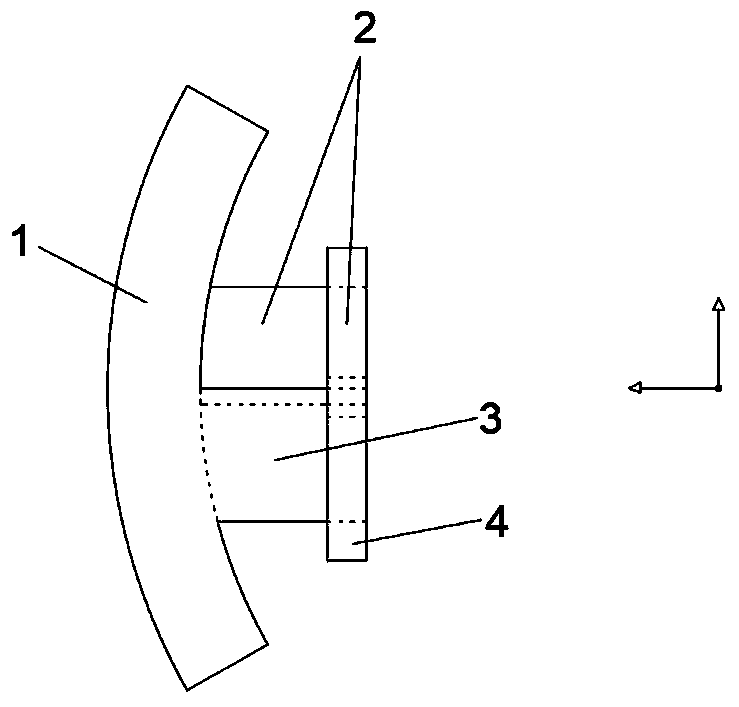

[0045] At present, the mold electromagnetic stirrer commonly used in the industry produces a rotating magnetic field. The essence of electromagnetic stirring is to use the electromagnetic field to intensify the movement of the molten steel in the liquid cavity of the casting slab, thereby strengthening the steel. The process of liquid convection, heat transfer and mass transfer produces thermodynamic and kinetic conditions that inhibit the development of columnar crystals, promote uniform composition, floating and fine inclusions, and uniform distribution, thereby controlling the solidification structure of the slab and improving the quality of the slab.

[0046] However, the electromagnetic force generated by the rotating magnetic field of the conventional mold electromagnetic stirrer still cannot stir the billet corners well. In this application, an oblique pole electromagnetic stirrer is used to stir the molten steel in the mold with a larger magnetic field. To the stirring eff...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com