Patents

Literature

1280results about How to "Fully removed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

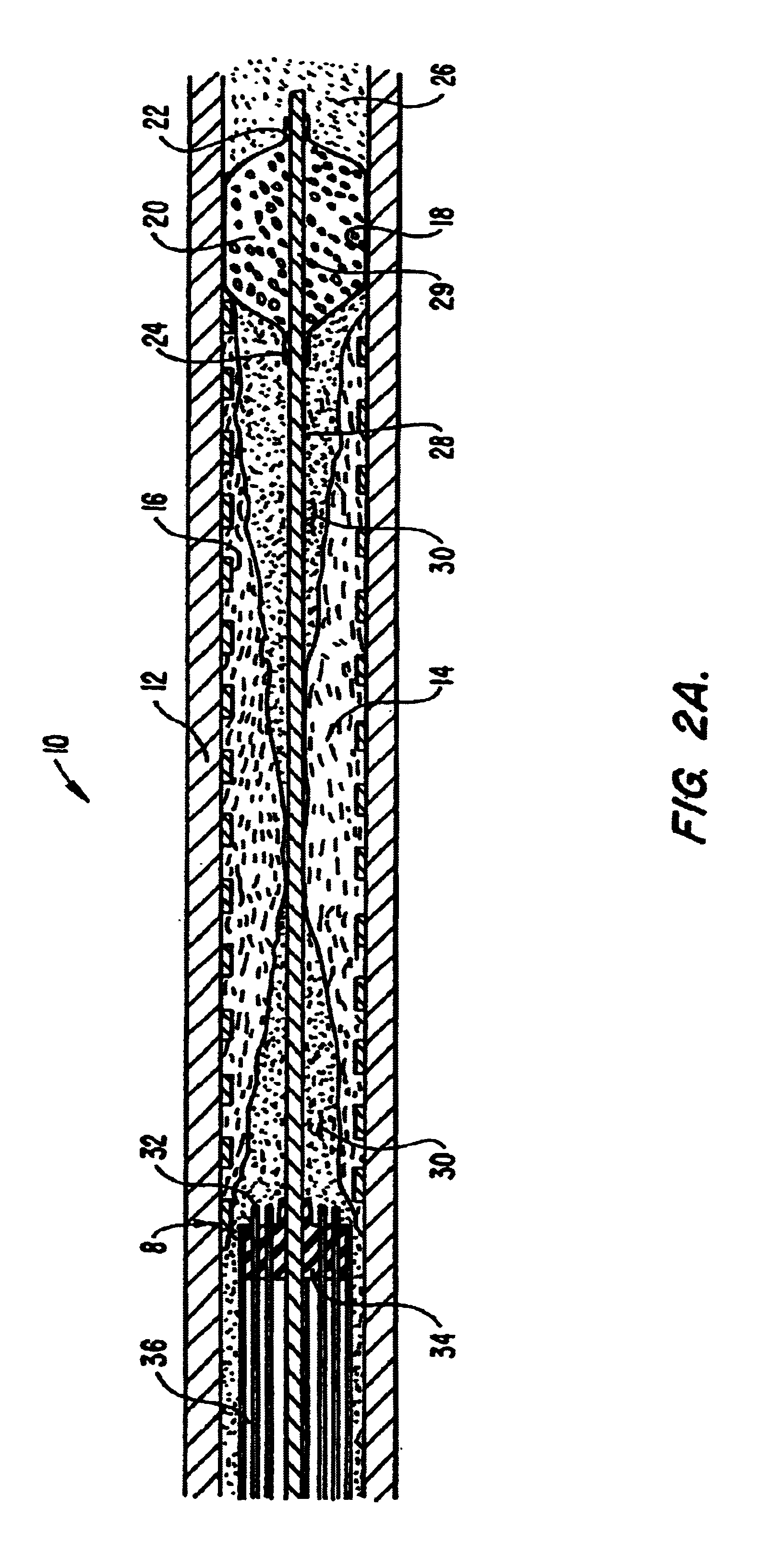

Electrosurgical systems and methods for recanalization of occluded body lumens

InactiveUS6855143B2Speed up the flowEliminate potentialSurgical instruments for heatingTherapeutic coolingCoronary arteriesDistal portion

The present invention comprises electrosurgical apparatus and methods for maintaining patency in body passages subject to occlusion by invasive tissue growth. The apparatus includes an electrode support disposed at a shaft distal end having at least one active electrode arranged thereon, and at least one return electrode proximal to the at least one active electrode. In one embodiment, a plurality of active electrodes each comprising a curved wire loop portion are sealed within a distal portion of the electrode support. The apparatus and methods of the present invention may be used to open and maintain patency in virtually any hollow body passage which may be subject to occlusion by invasive cellular growth or invasive solid tumor growth. Suitable hollow body passages include ducts, orifices, lumens, and the like, with exemplary body passages including the coronary arteries. The present invention is particularly useful for reducing or eliminating the effects of restenosis in coronary arteries by selectively removing tissue in-growth in or around stents anchored therein.

Owner:ARTHROCARE

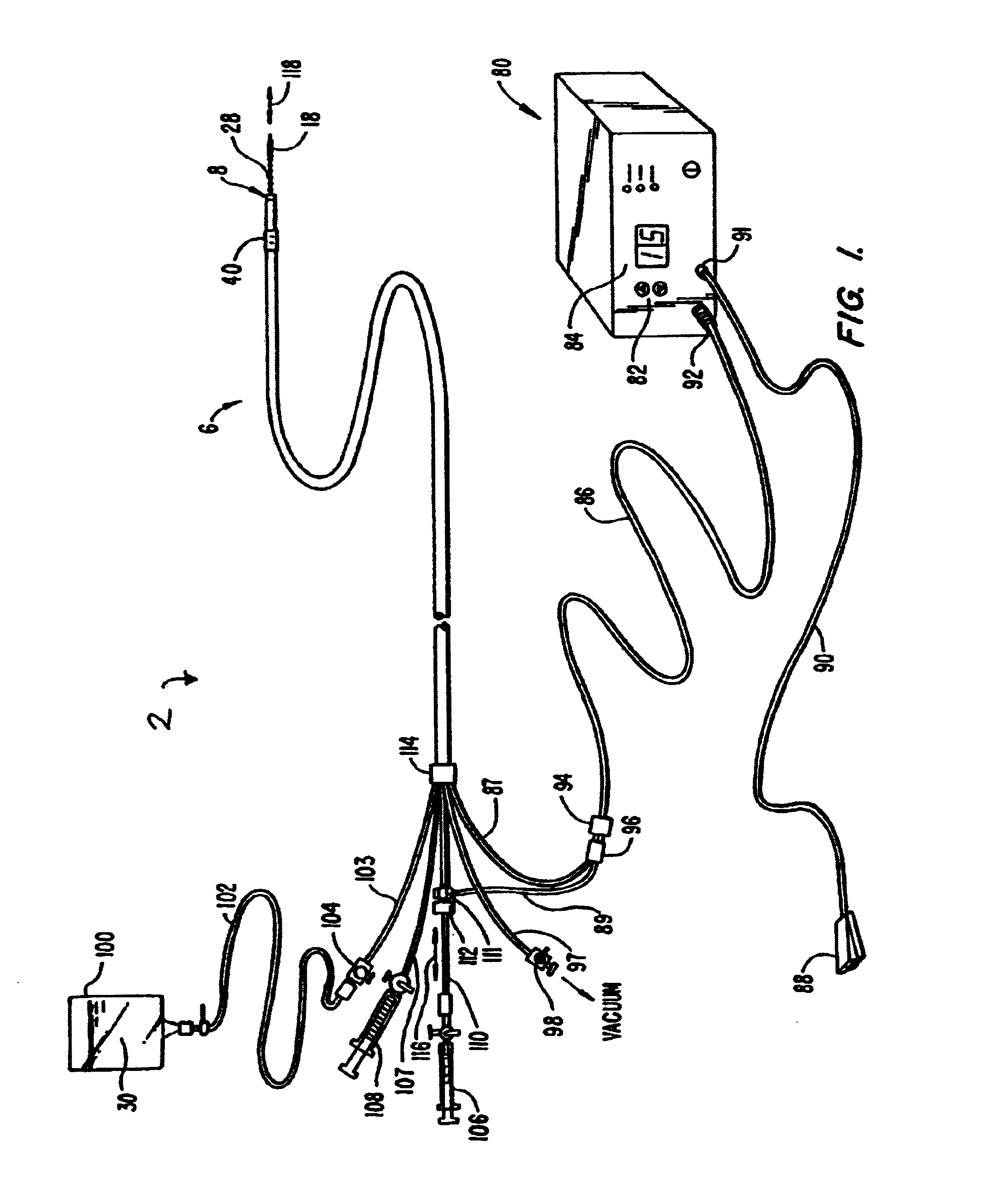

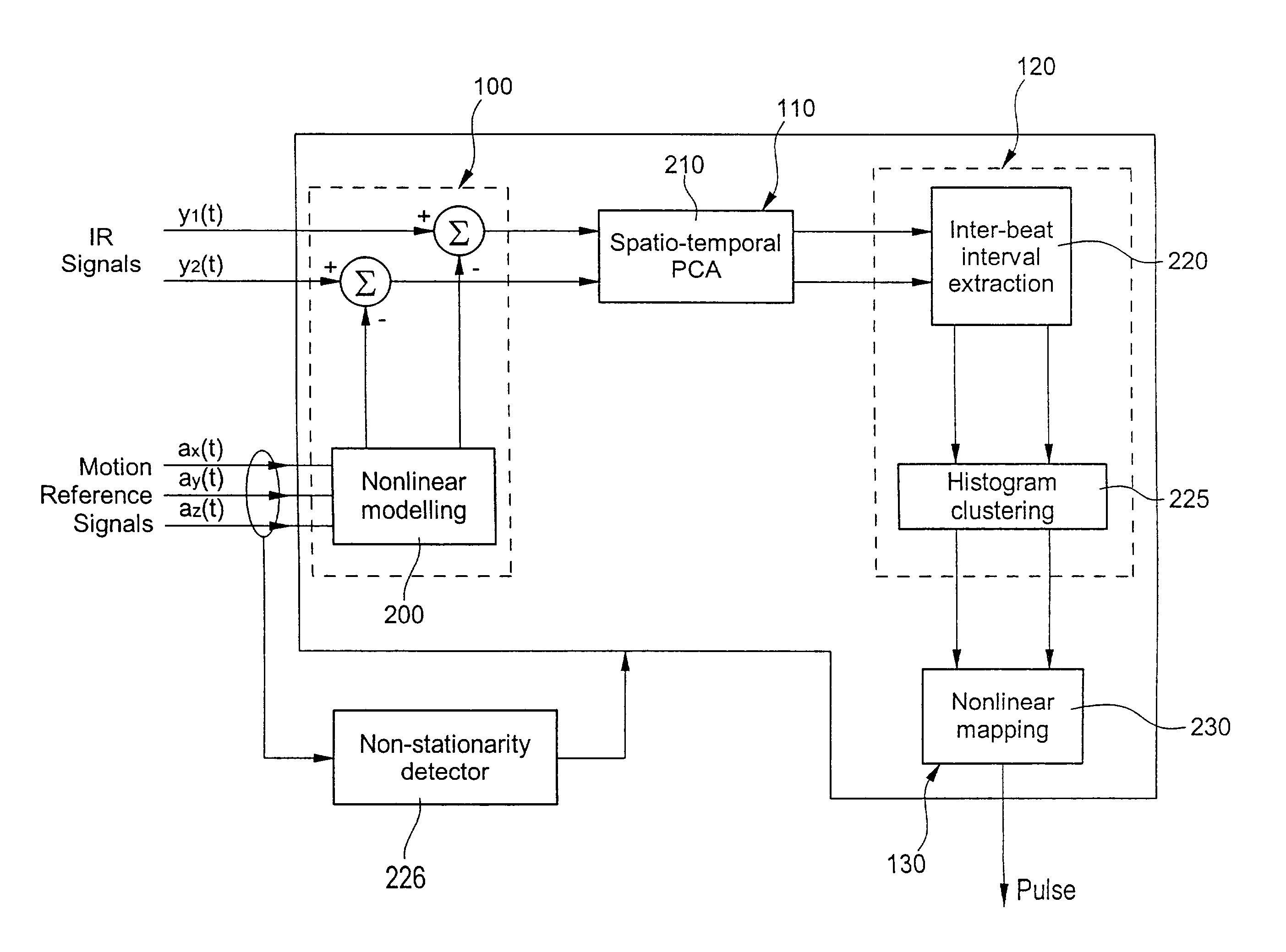

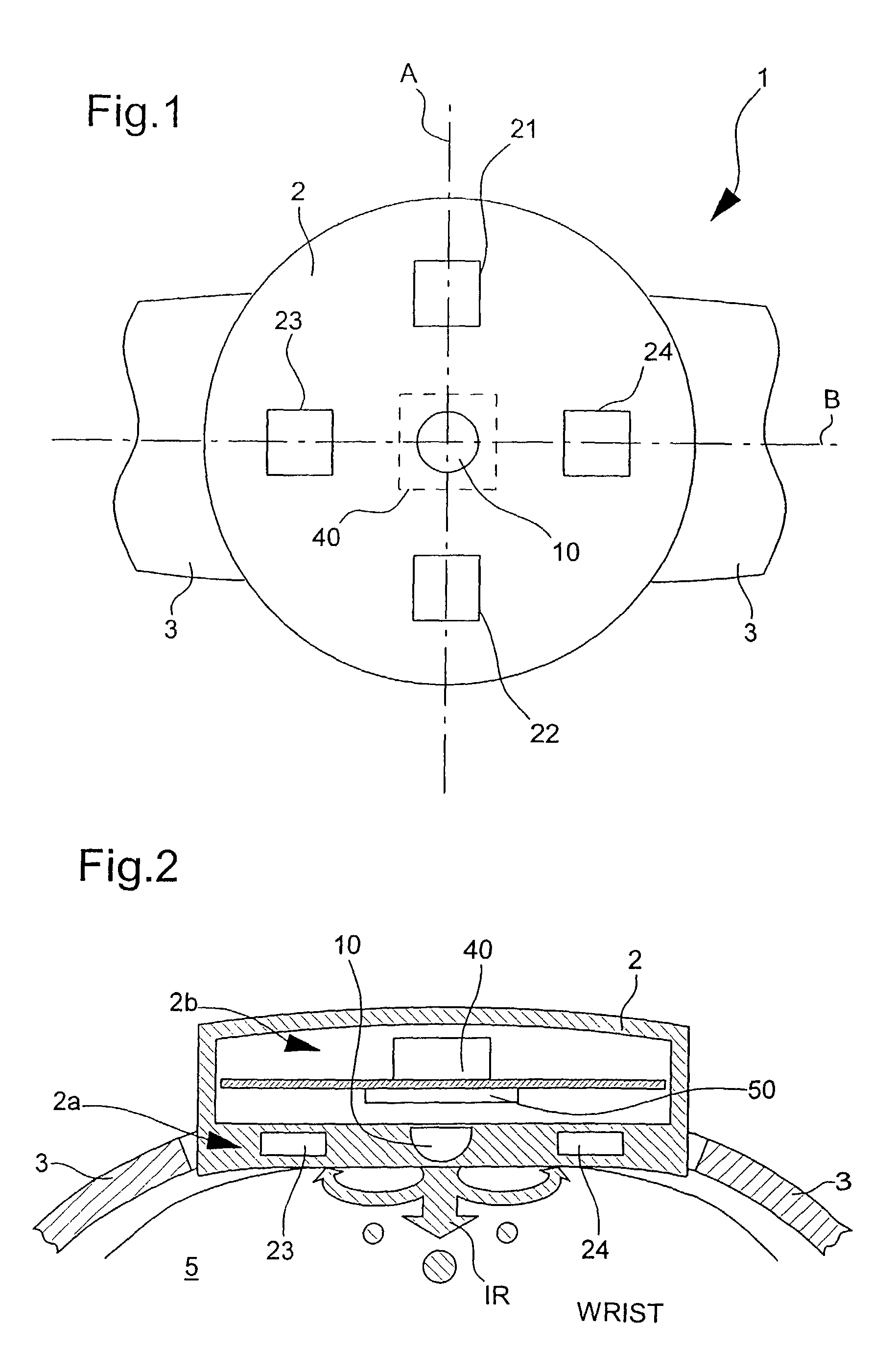

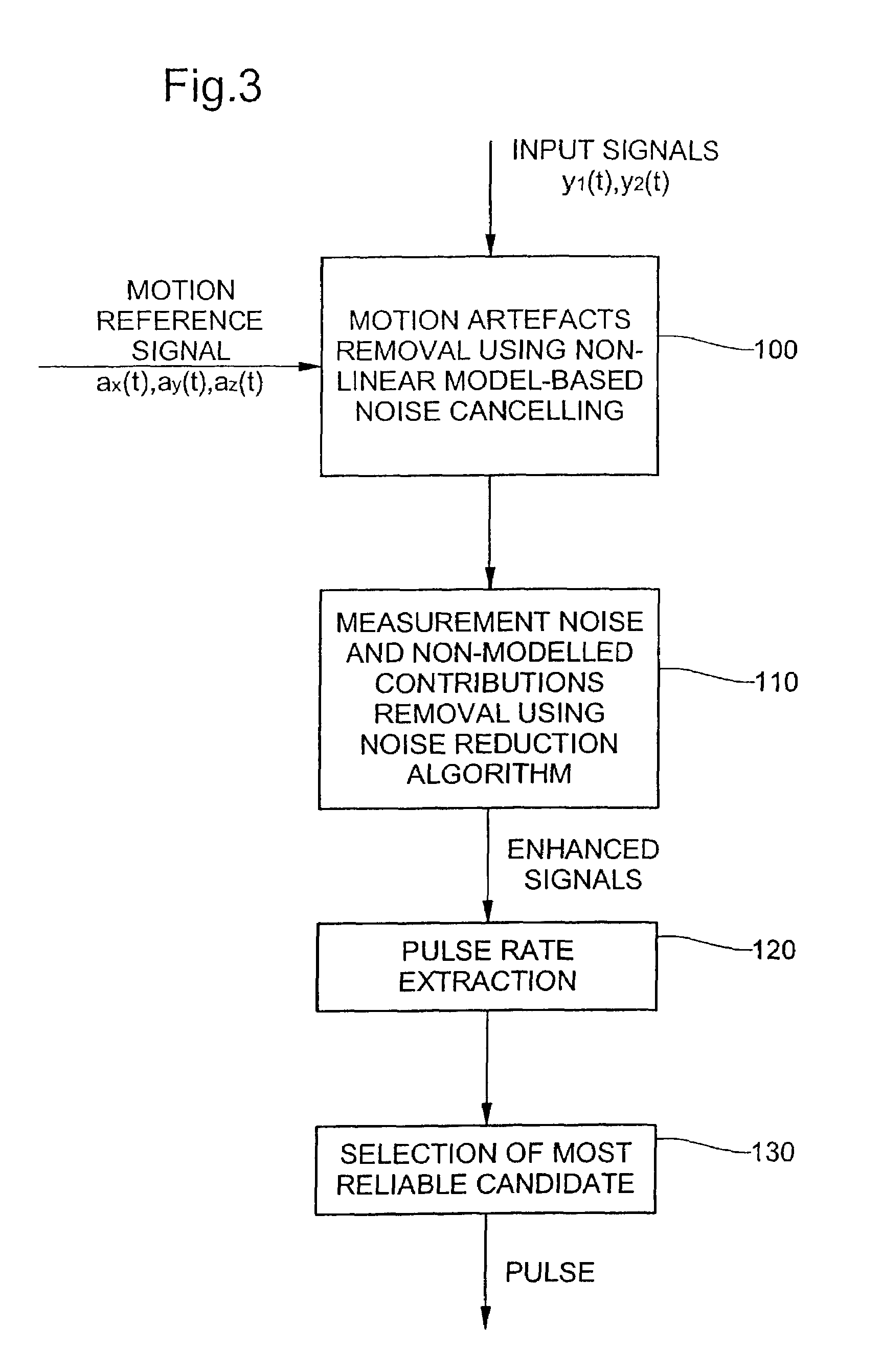

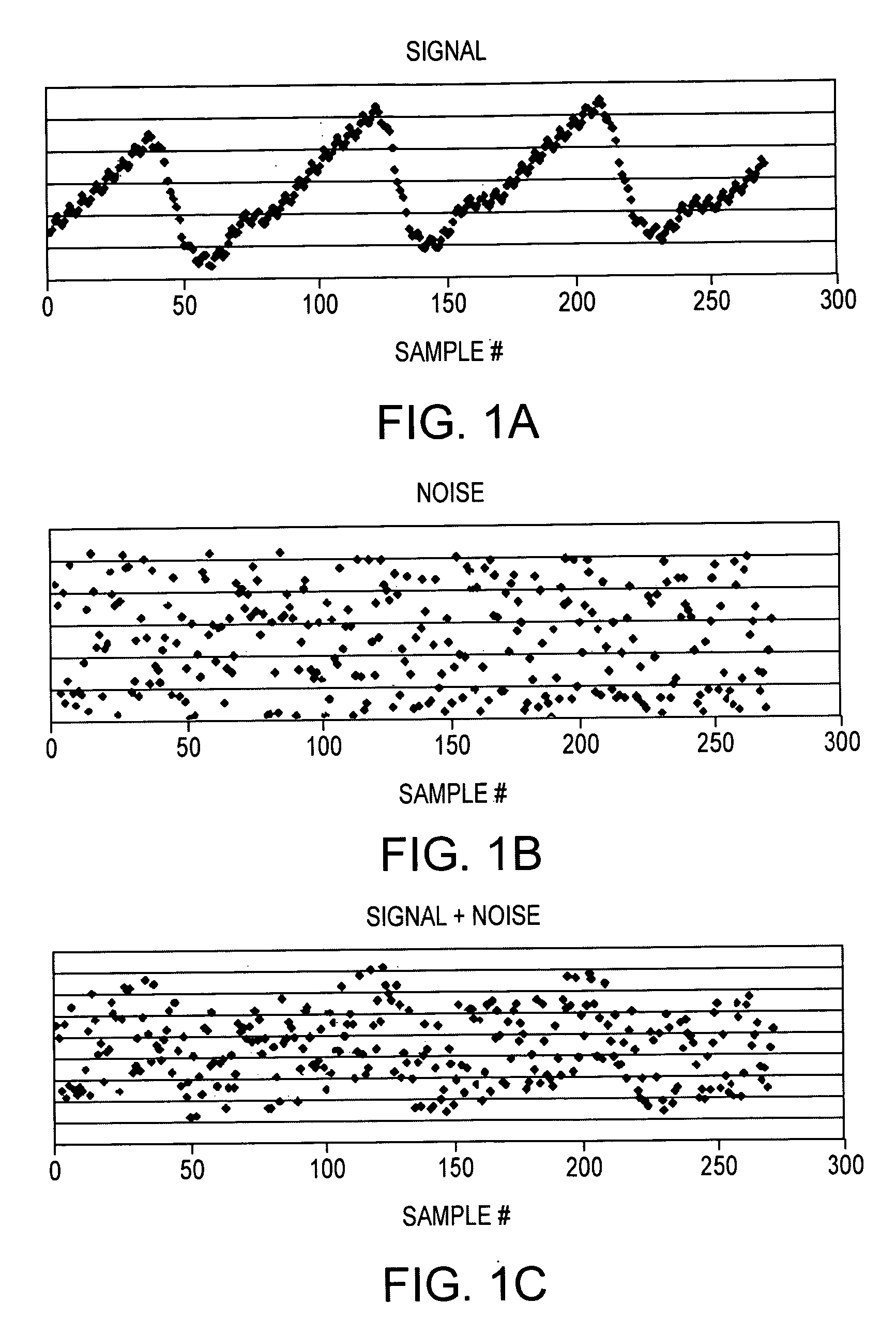

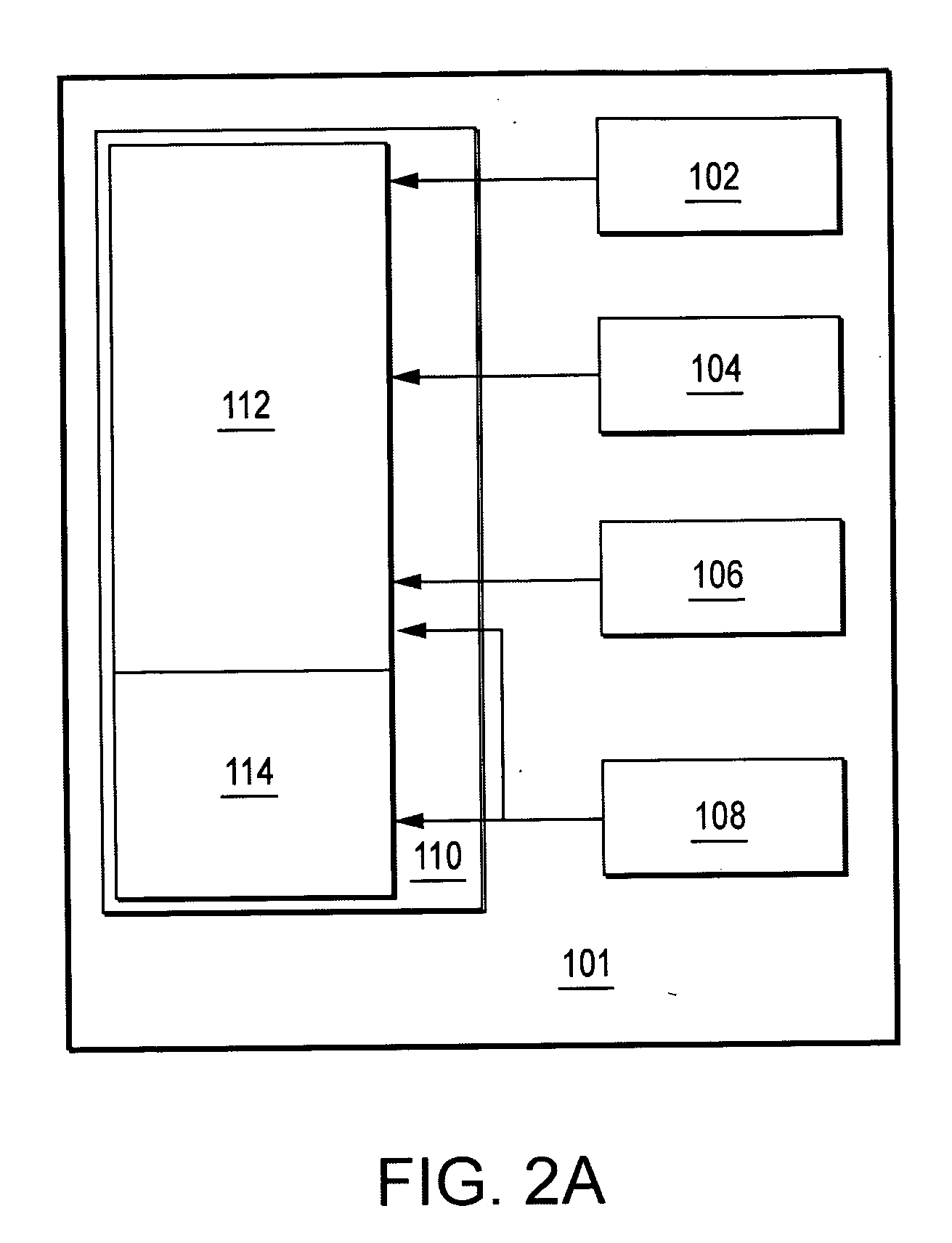

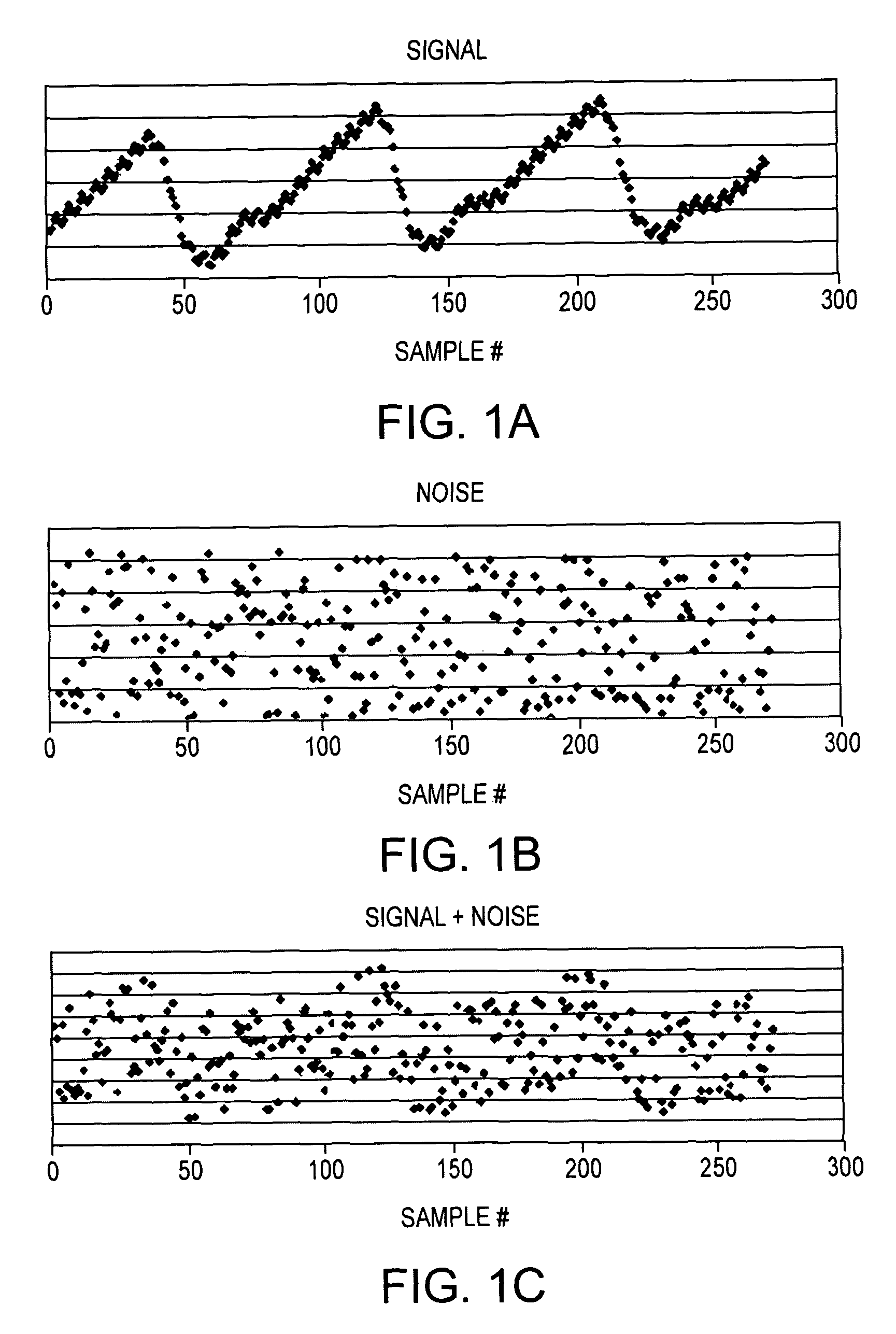

Method and device for pulse rate detection

InactiveUS7018338B2Accurately monitoring and detecting heart rateFully removedCatheterSensorsHuman bodyNoise reduction algorithm

Portable pulse rate detecting device for contact with human body tissue, including a light-emitting source for emitting radiant energy directed at through human body tissue; at least first and second light detectors for detecting intensity of radiant energy after propagation through human body tissue and for providing first and second input signals as a function of such propagation, a detecting device for providing a motion reference signal, and processing means for removing motion-related contributions from the first and second input signals and subtracting a calculated model based on the motion reference signal from each of the first and second input signals, wherein the processing means is also for removing measurement noise and residual non-modeled contributions from the first and second enhanced signals using a noise reduction algorithm.

Owner:MENDEL BIOTECHNOLOGY INC +1

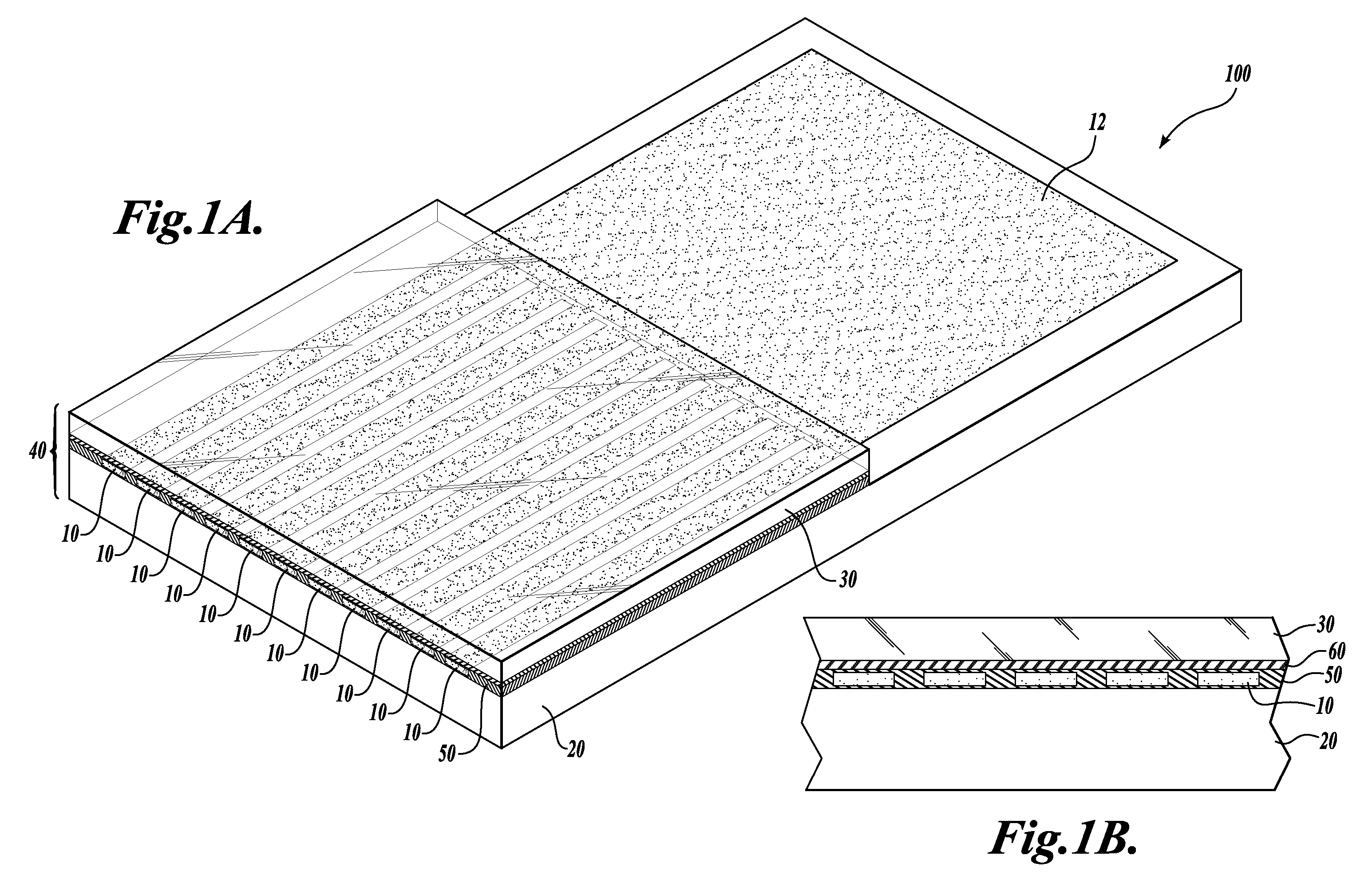

Skin grafting devices and methods

The present invention provides skin grafting and devices that comprise a systematic approach to the process of skin grafting, i.e., harvesting, post-excision processing and application of donor skin and pre and post-graft treatment of the recipient site.

Owner:KCI LICENSING INC

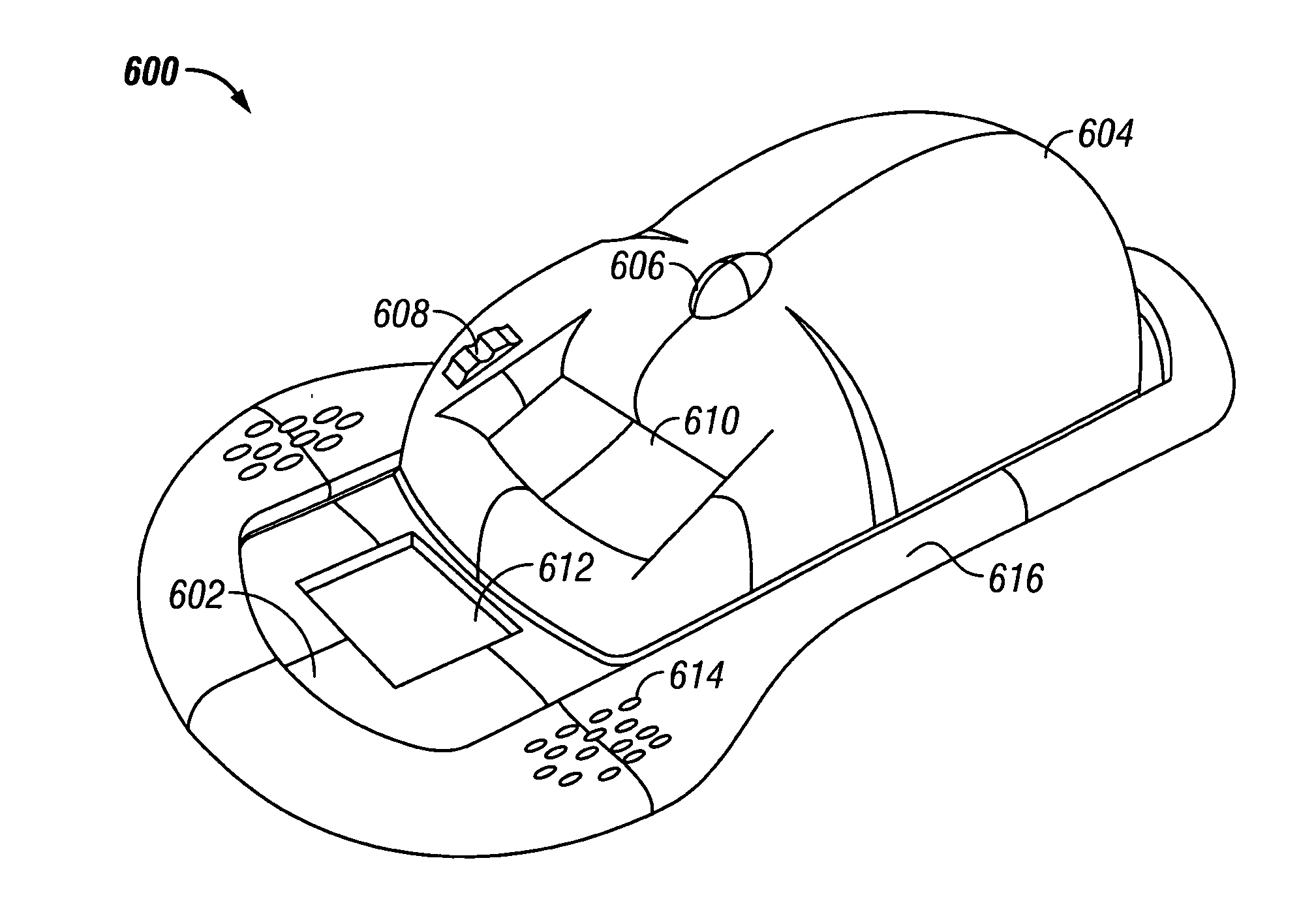

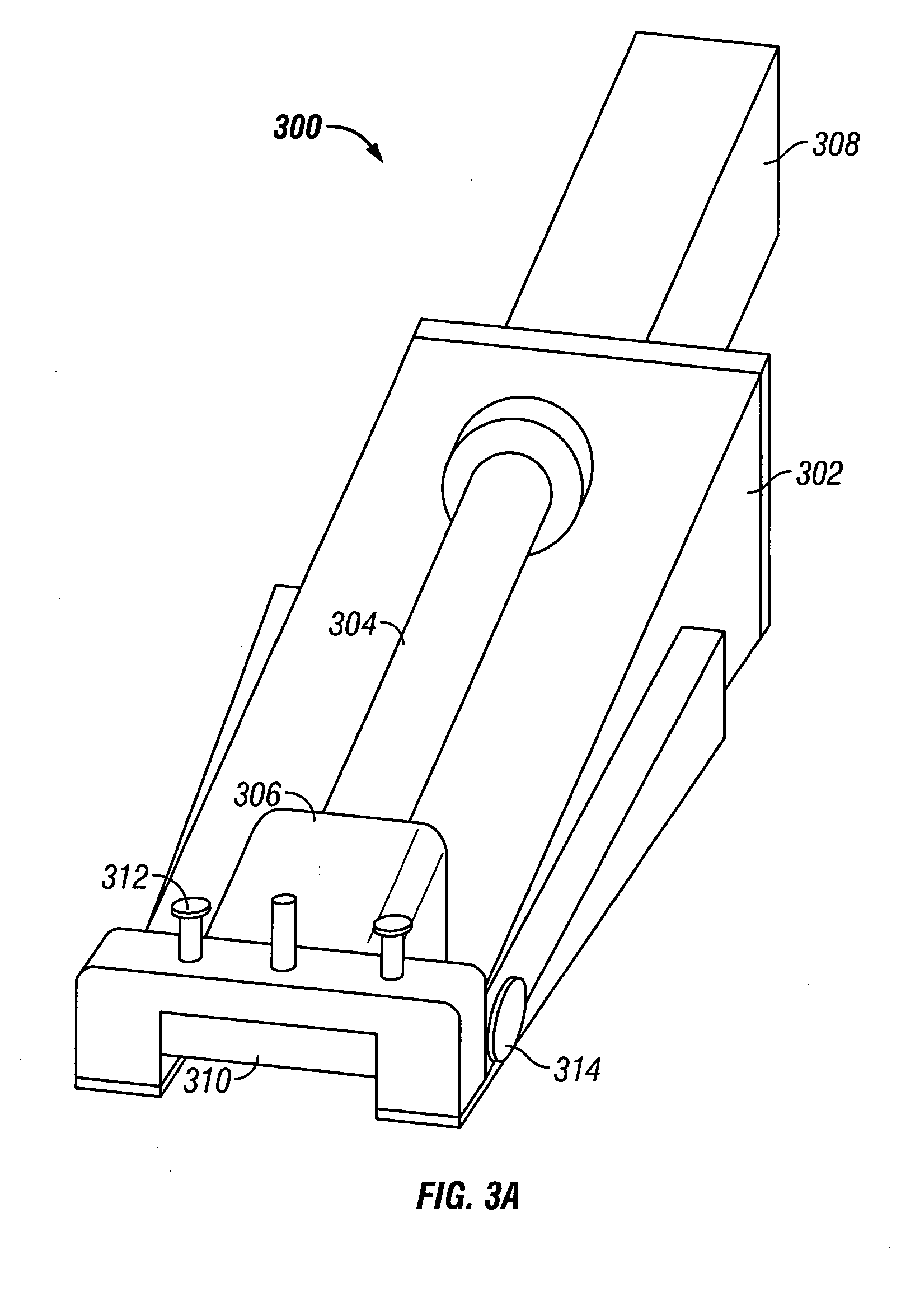

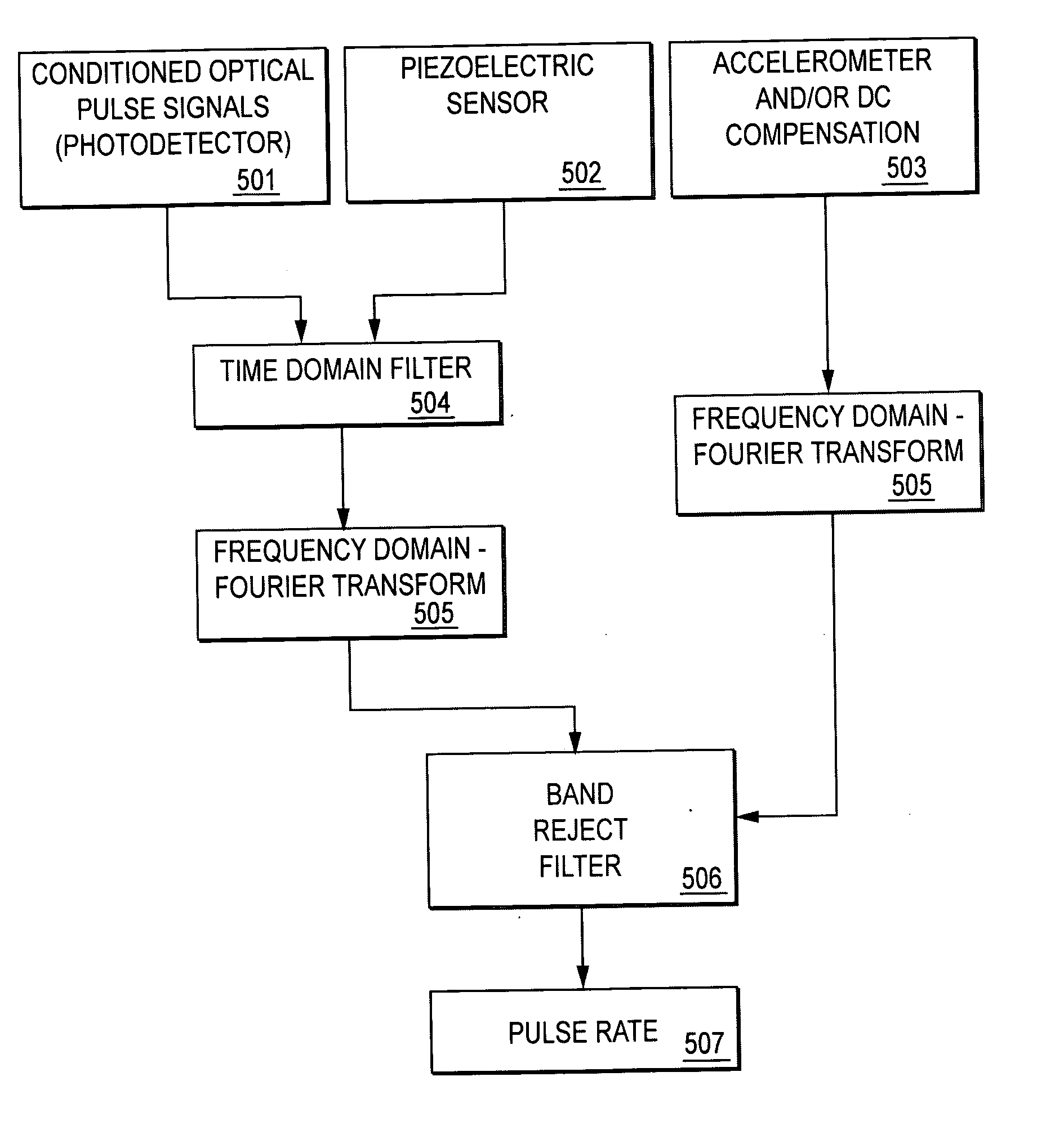

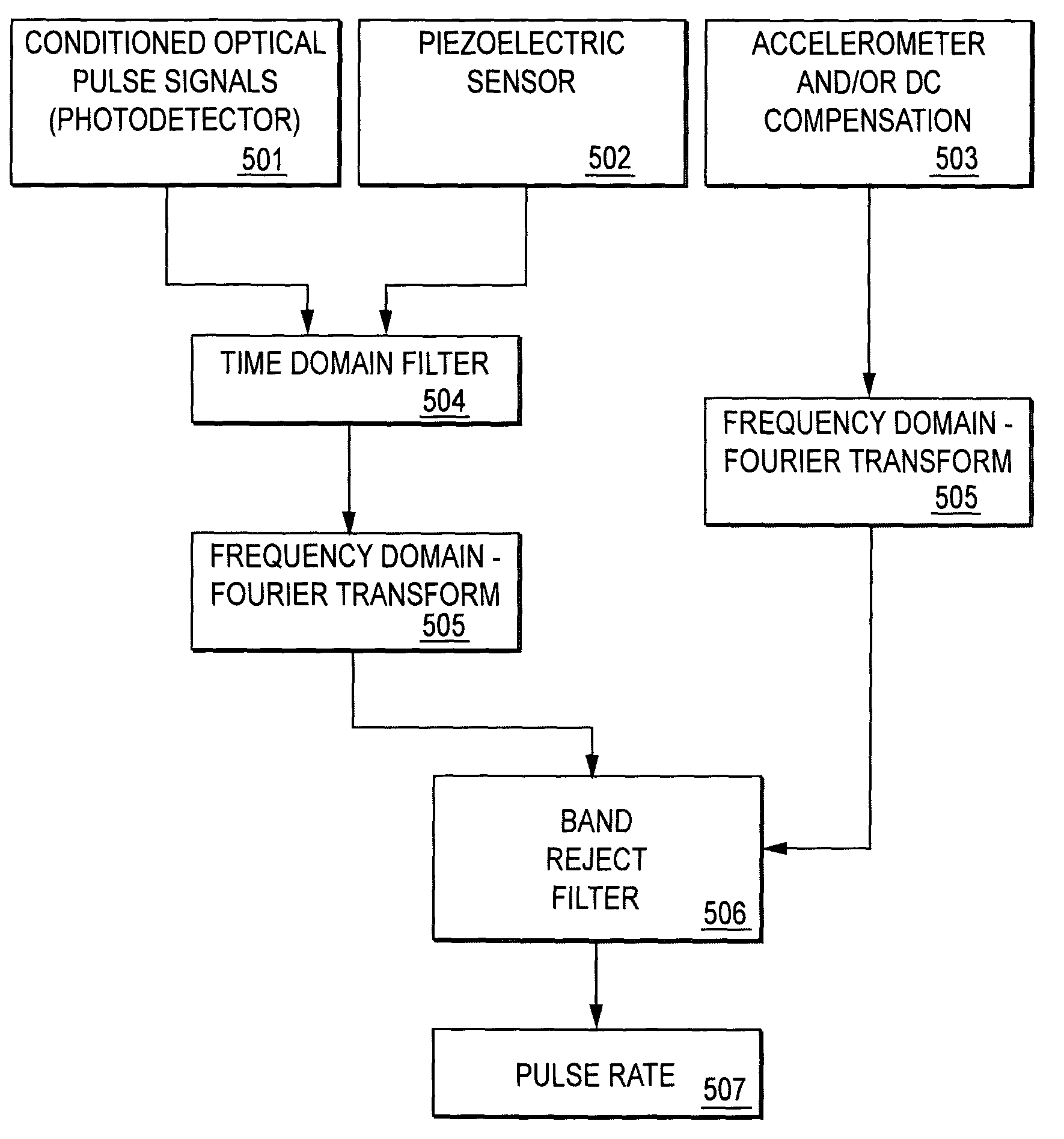

Motion cancellation of optical input signals for physiological pulse measurement

InactiveUS20060084879A1Accurate monitoringAccurately detecting pulse rateCatheterDiagnostic recording/measuringAccelerometerControl signal

A pulse rate sensor that includes an accelerometer for measuring periodic motion and a piezo sensor for detecting erratic motion is capable of more accurately determining pulse rate by accounting for these types of motion. The pulse rate sensor in accordance with the present invention diminishes pulse rate signal degradation due to erratic motion through a combination of algorithms that control signal boosting, waveform refinement and signal noise suppression.

Owner:INTEL CORP

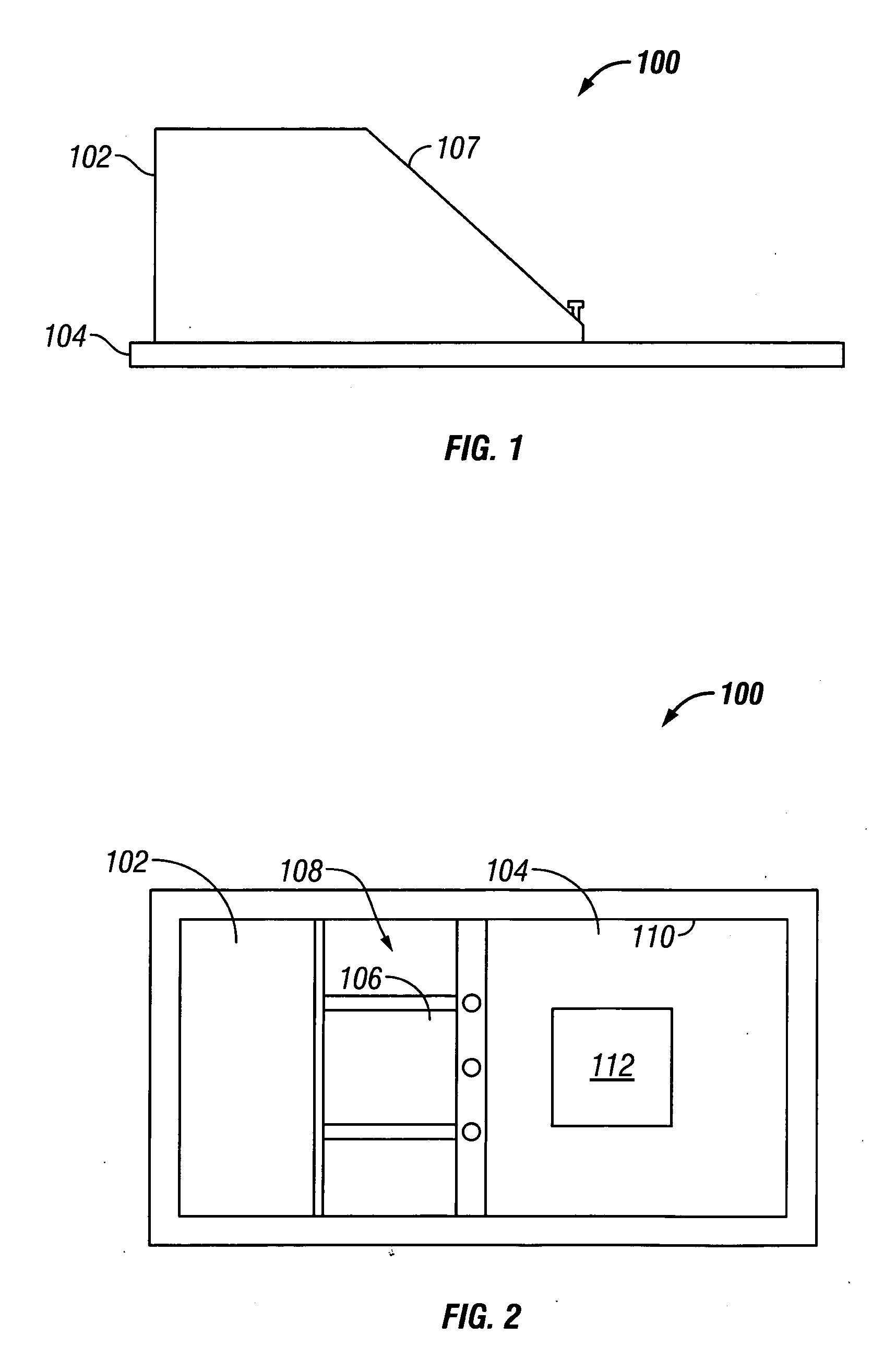

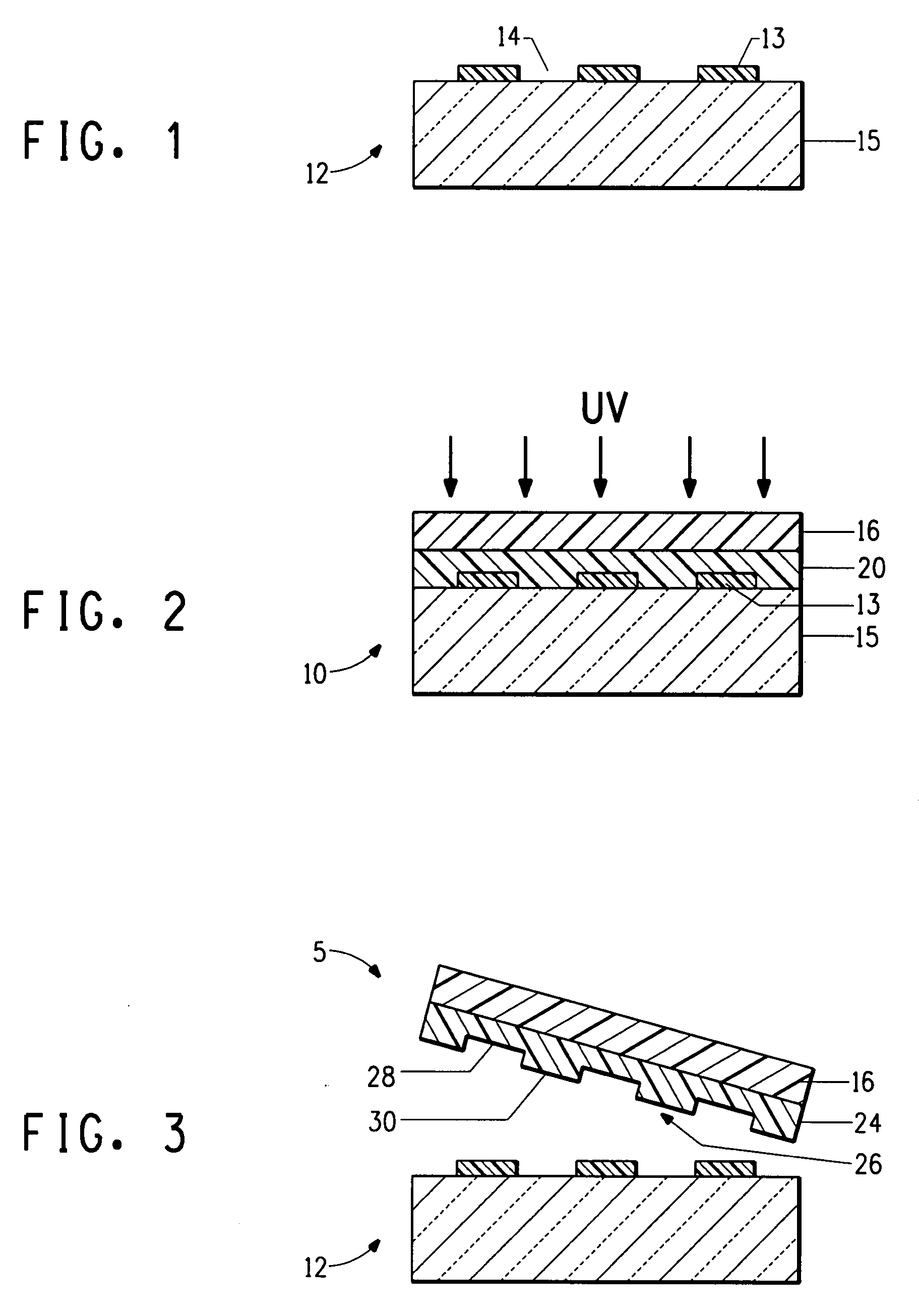

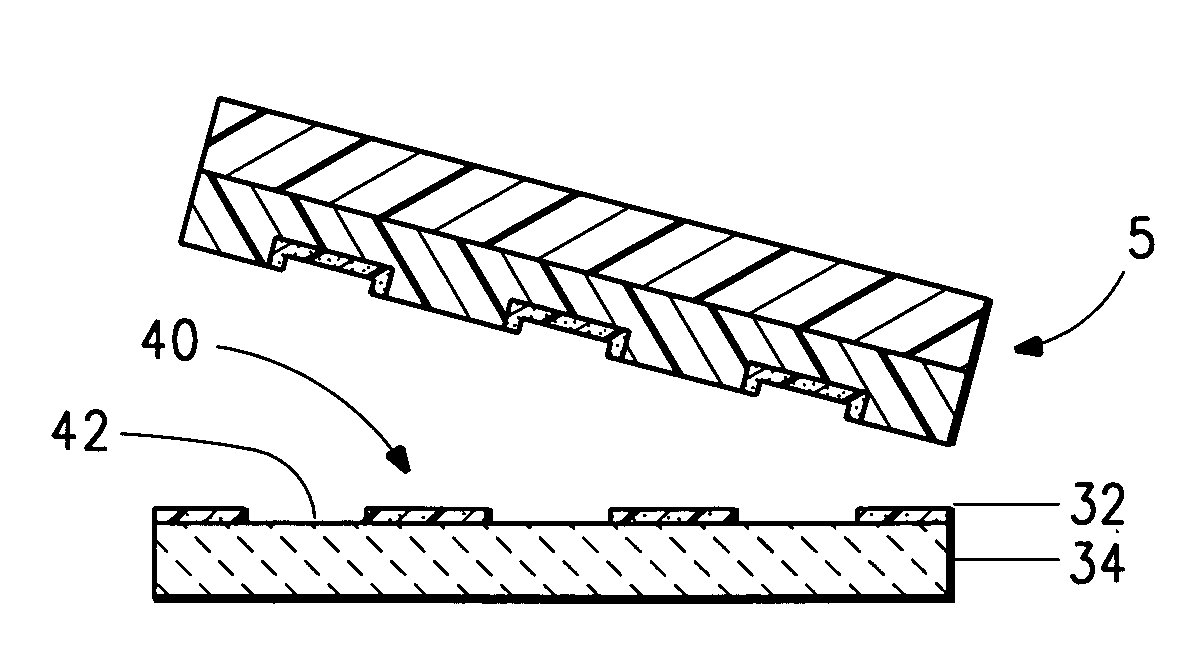

Method to form a pattern of functional material on a substrate by treating a surface of a stamp

InactiveUS20080233280A1Fully removedNanostructure manufactureLayered productsCompound (substance)Electron

The invention provides a method to form a pattern of functional material on a substrate. The method uses an elastomeric stamp having a relief structure with a raised surface and having a modulus of elasticity of at least 10 MegaPascal. At least the raised surface of the stamp is treated by exposing the stamp to heat, radiation, electrons, a stream of charged gas, chemical fluids, chemical vapors, and combinations thereof, to enhance wettability of the surface. A composition of the functional material and a liquid is applied to the relief structure and the liquid is removed to form a film on the raised surface. The elastomeric stamp transfers the functional material from the raised surface to the substrate to form a pattern of the functional material on the substrate. The method is suitable for the fabrication of microcircuitry for electronic devices and components.

Owner:EI DU PONT DE NEMOURS & CO

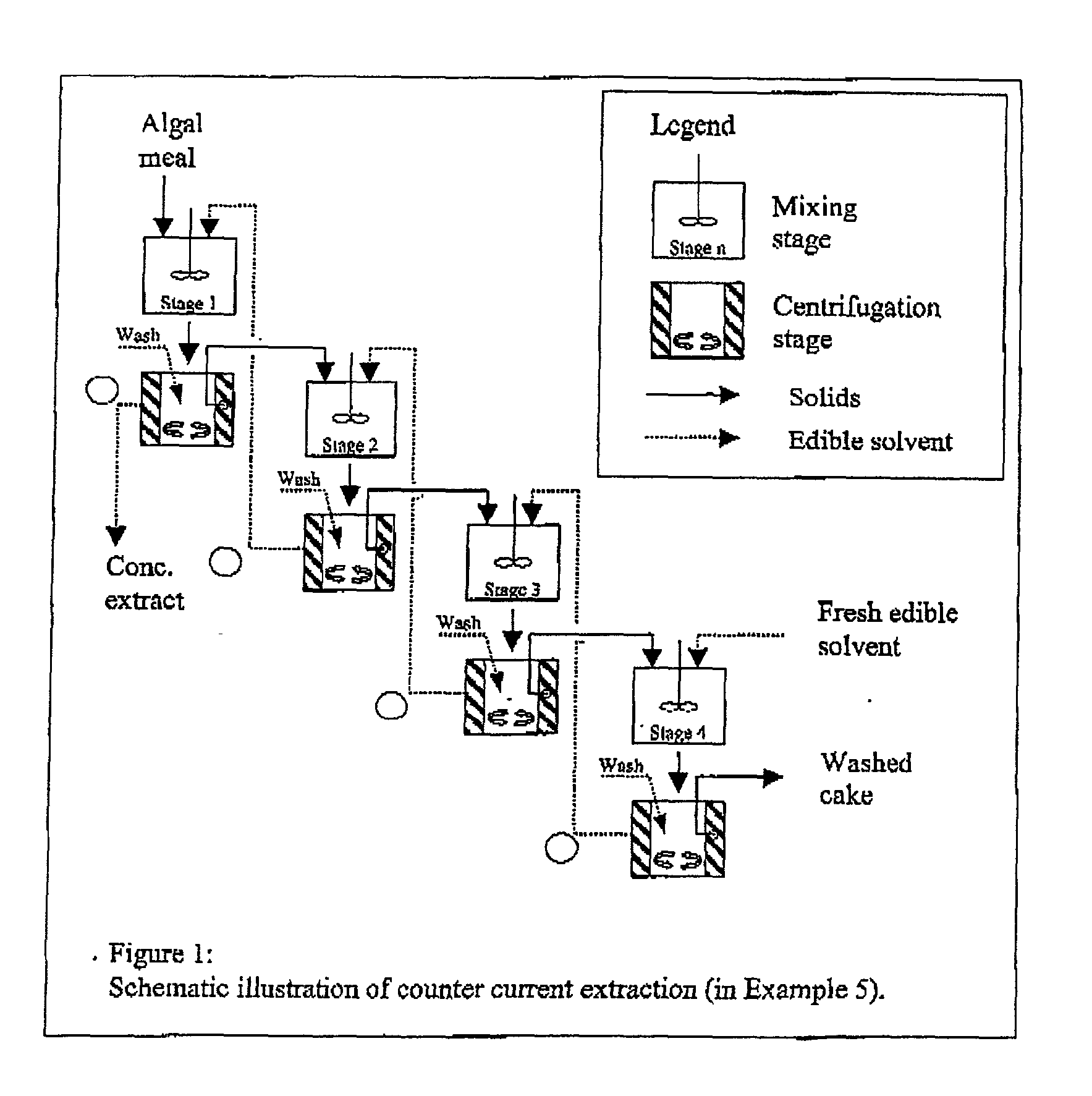

Edible solvent extraction of carotenoids from microorganisms

InactiveUS20030054070A1Efficient extractionEnriching carotenoid contentLiquid hydrocarbon mixture productionHydrocarbonsParticulatesAnimal food

A process for extracting carotenoids from a carotenoid-containing starting material produced by microorganisms is described. Said starting material is admixed with edible solvent to effectuate the transfer of carotenoids. Separation of the carotenoid-enriched edible solvent is improved by the formation of a "cake", composed of said carotenoid-containing particulate solids, and, as required, a certain quantity of suitable filtration aid to modify the cake's consistency. Mechanical aids accelerate the separation of the carotenoid-enriched edible solvent. Said mixture may be hydrated to aid the removal of solids and gums from the carotenoid containing edible solvent. The carotenoid-enriched edible solvent is filtered though said cake to reduce the particulate load including any undesirable microbial load. A counter-current process increases the carotenoid concentration of the extract. The carotenoid-enriched edible solvent can be used as an ingredient in human and animal foodstuffs and dietary supplements for the possible prevention and treatment of illnesses and diseases.

Owner:AQUSRCH

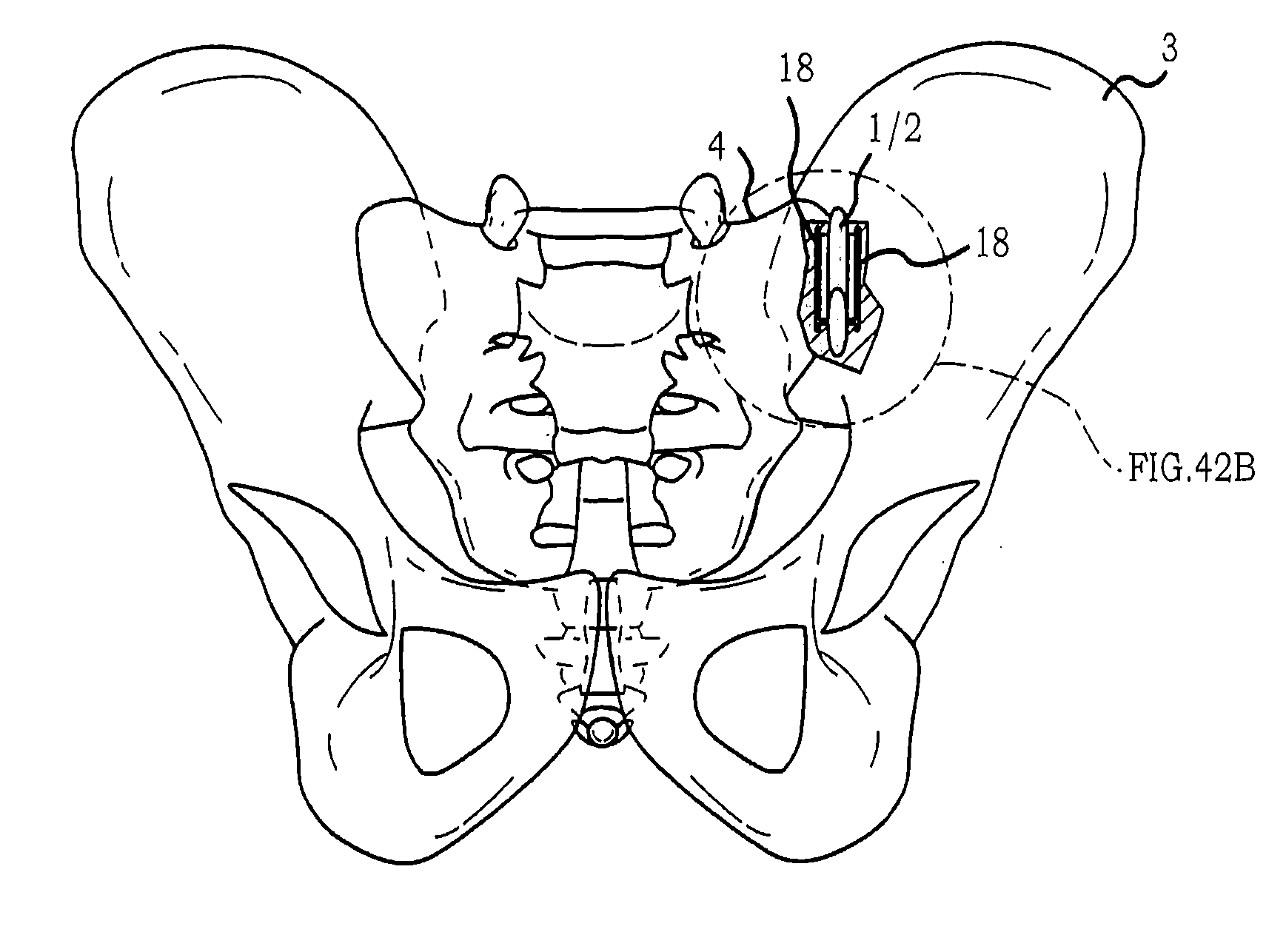

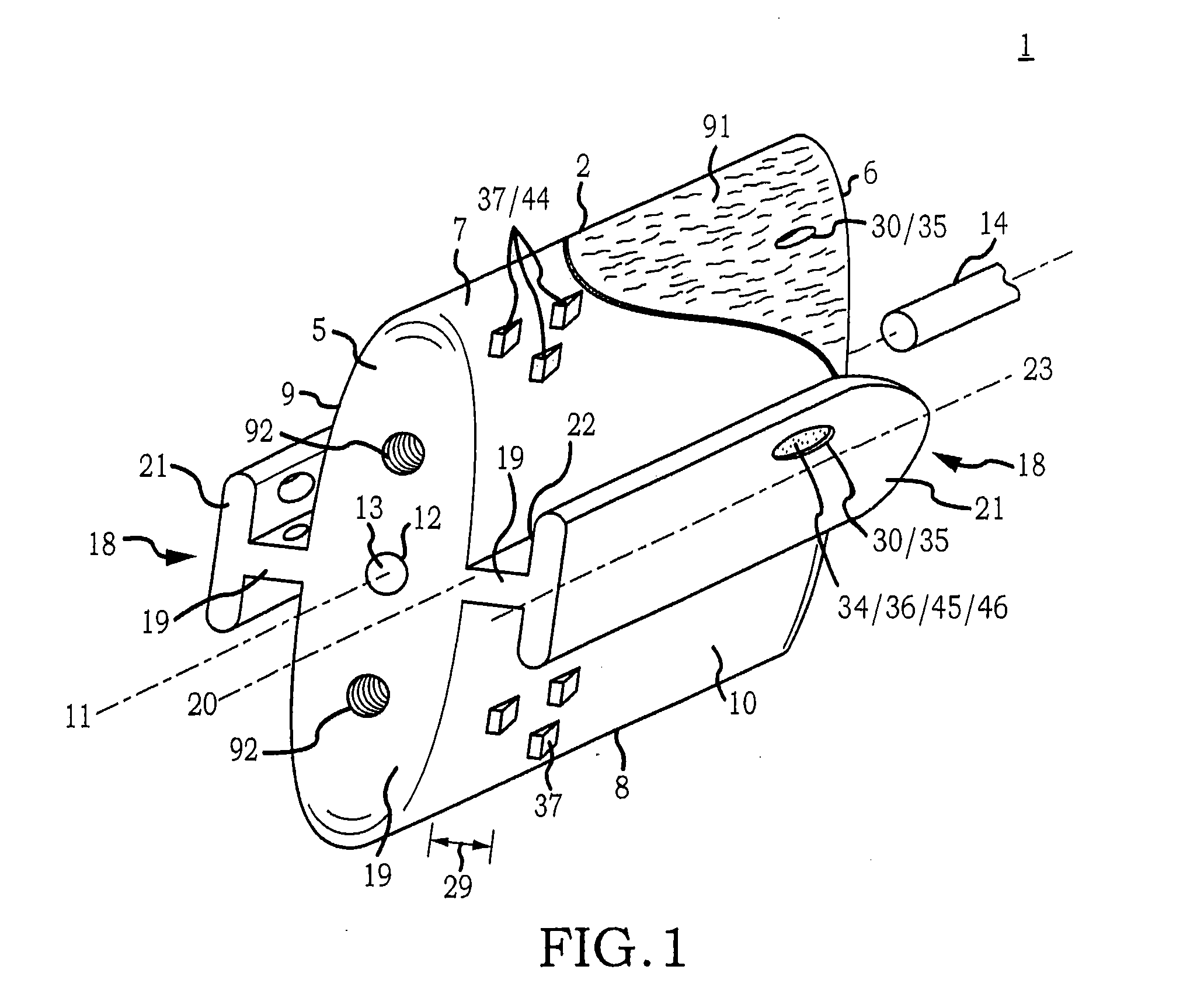

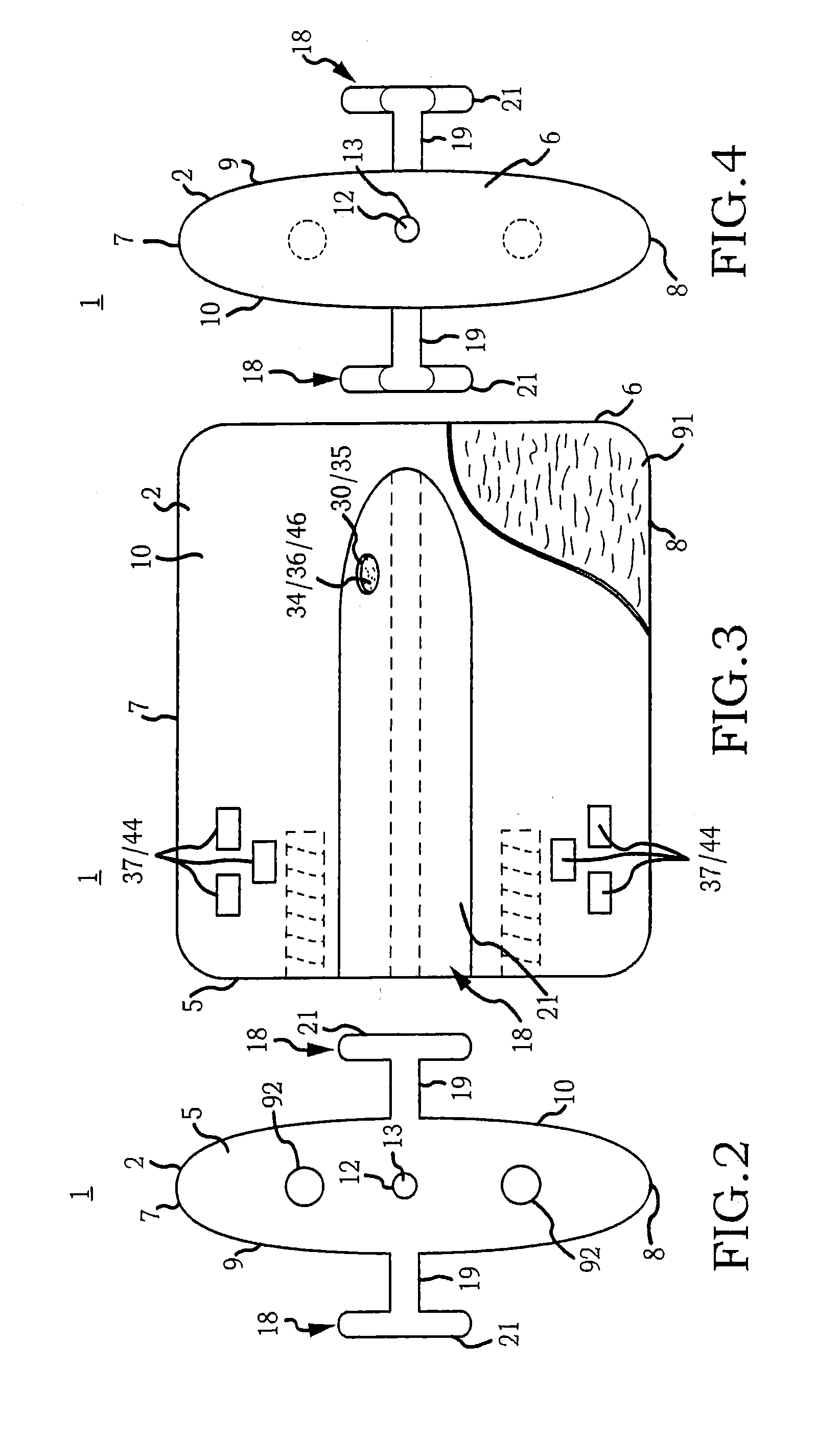

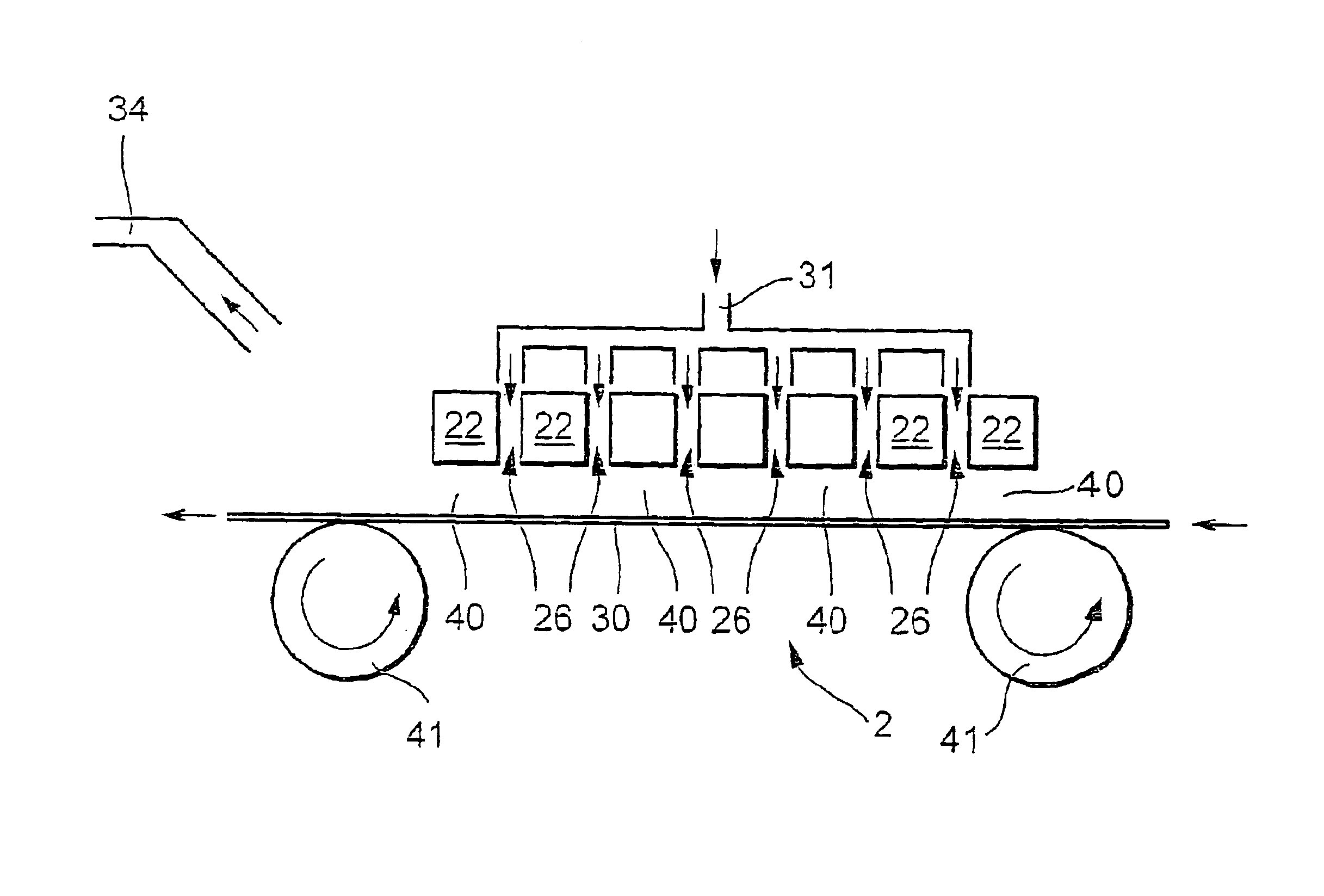

Sacroiliac joint implant system

ActiveUS20140142700A1Improve stabilityFully removedAdditive manufacturing apparatusInternal osteosythesisArticular surfacesArticular surface

Accordingly, a broad object of the invention can be to provide an inventive implant to facilitate stabilization while allowing an amount of motion of a sacroiliac joint. Embodiments of the sacroiliac joint implant can provide an elongate body, which can further include at least one fixation member, or a pair of fixation members which extend a distance outward from the longitudinal axis of the implant body adapted for non-transverse placement between the articular surfaces of the sacroiliac joint, and as to certain embodiments can further provide a third fixation member and additionally a fourth fixation member each adapted to extend a distance outward from the elongate body into the bone of the sacrum or the ilium.

Owner:JCBD

Device and method for charge removal from dielectric surfaces

InactiveUS6934142B2Optimized charge removalEasy to operateElectric discharge tubesEmergency protective arrangements for automatic disconnectionElectricityDielectric surface

A device and a method for at least partial removal of electric charges from dielectric surfaces, in particular surfaces of plastic films, paper webs or plastic fibers are described. First, a plasma is generated through microstructure discharges with a plasma device in at least one plasma region. In addition, the dielectric surface is introduced into the plasma region with a feed mechanism and is temporarily exposed to electrically charged particles generated by the plasma there.

Owner:ROBERT BOSCH GMBH

Method of making silane compositions

ActiveUS7498015B1Good ink stabilityDeposition process is enhancedHydride purification/stabilisationSilicon compoundsSilanesCharge carrier mobility

A method of making hydrogenated Group IVA compounds having reduced metal-based impurities, compositions and inks including such Group IVA compounds, and methods for forming a semiconductor thin film. Thin semiconducting films prepared according to the present invention generally exhibit improved conductivity, film morphology and / or carrier mobility relative to an otherwise identical structure made by an identical process, but without the washing step. In addition, the properties of the present thin film are generally more predictable than those of films produced from similarly prepared (cyclo)silanes that have not been washed according to the present invention. The present invention advantageously provides semiconducting thin film structures having qualities suitable for use in electronics applications, such as display devices or RF ID tags, while enabling high-throughput manufacturing processes that form such thin films in seconds or minutes, rather than hours or days as with conventional photolithographic processes.

Owner:ENSURGE MICROPOWER ASA

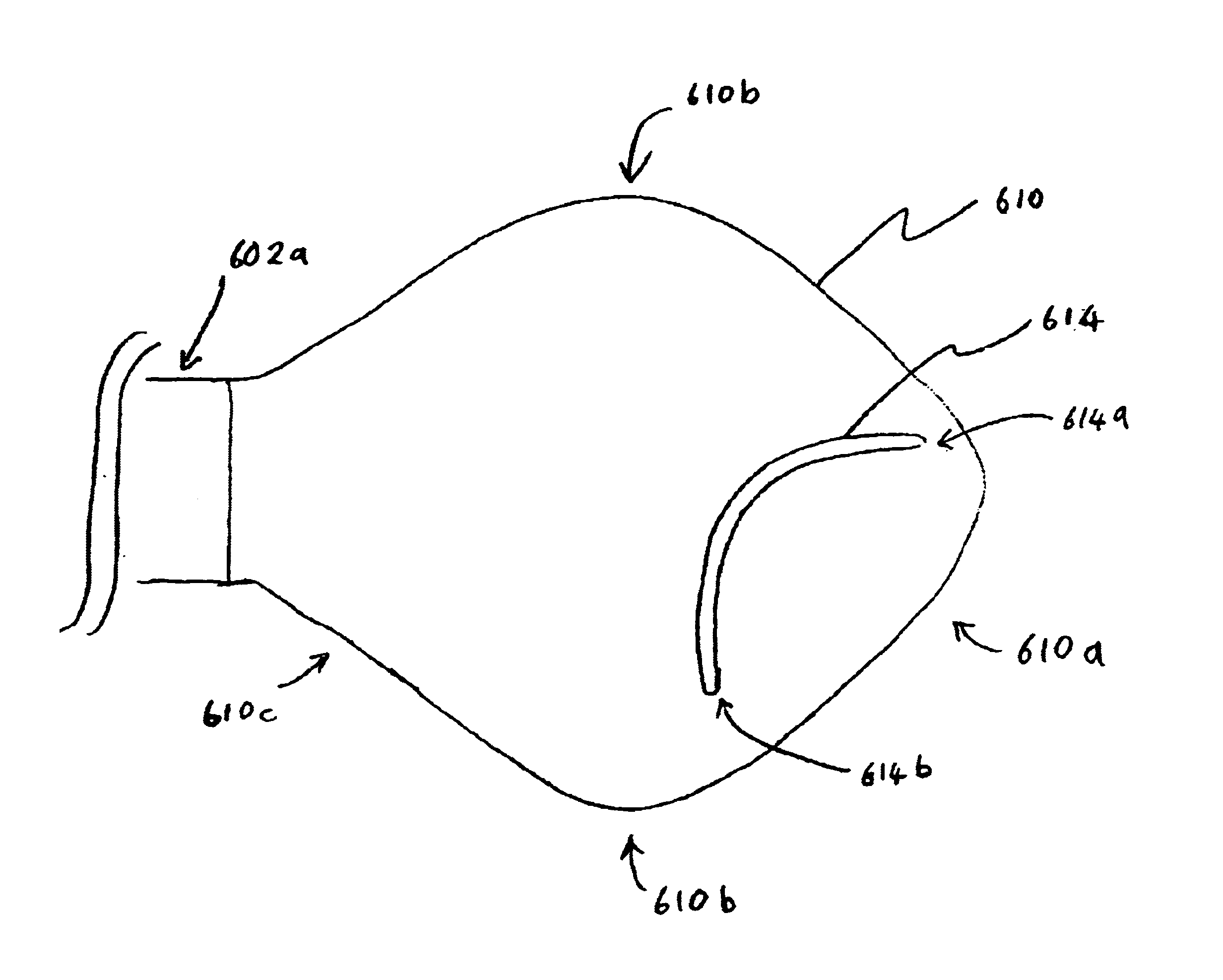

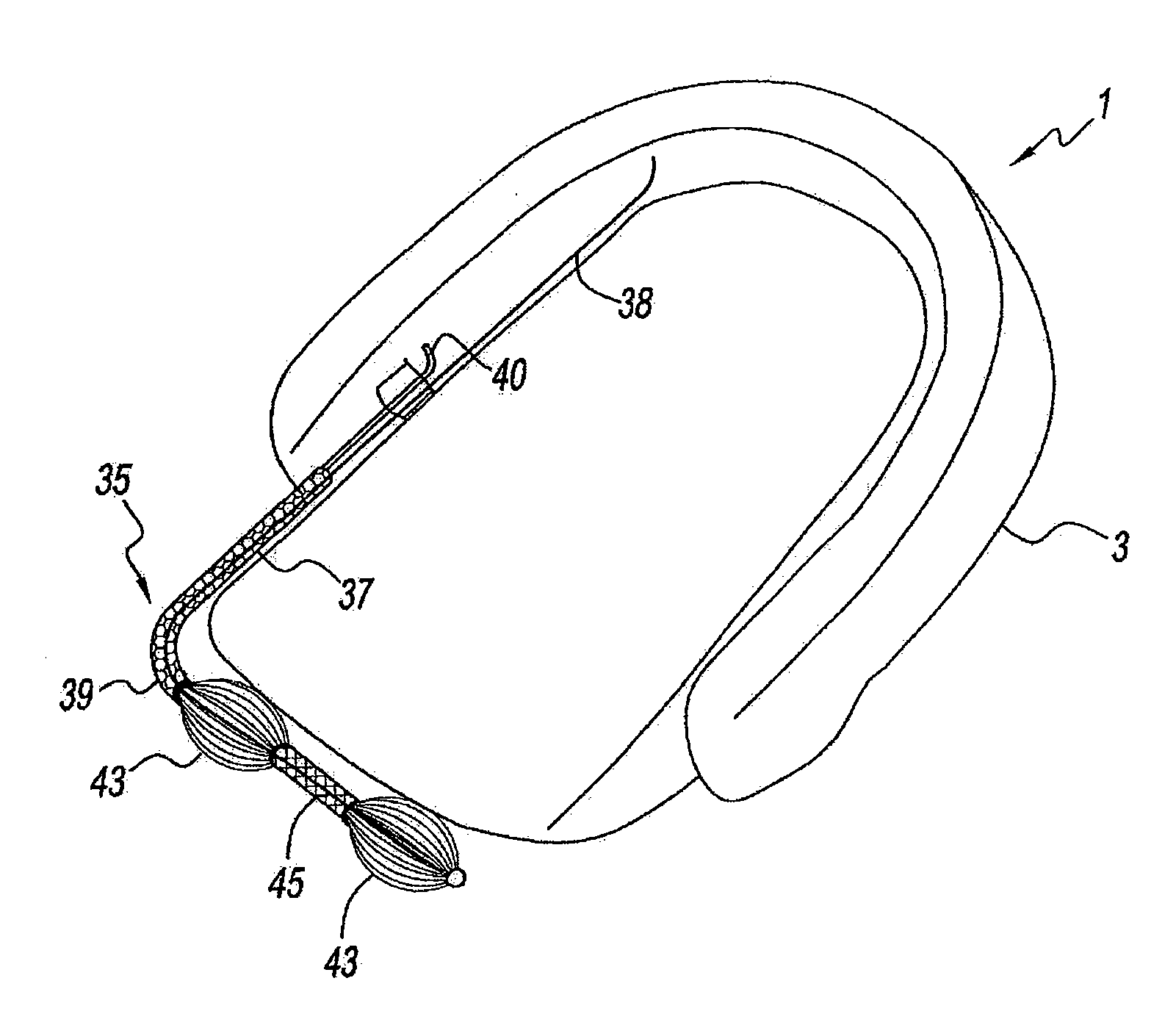

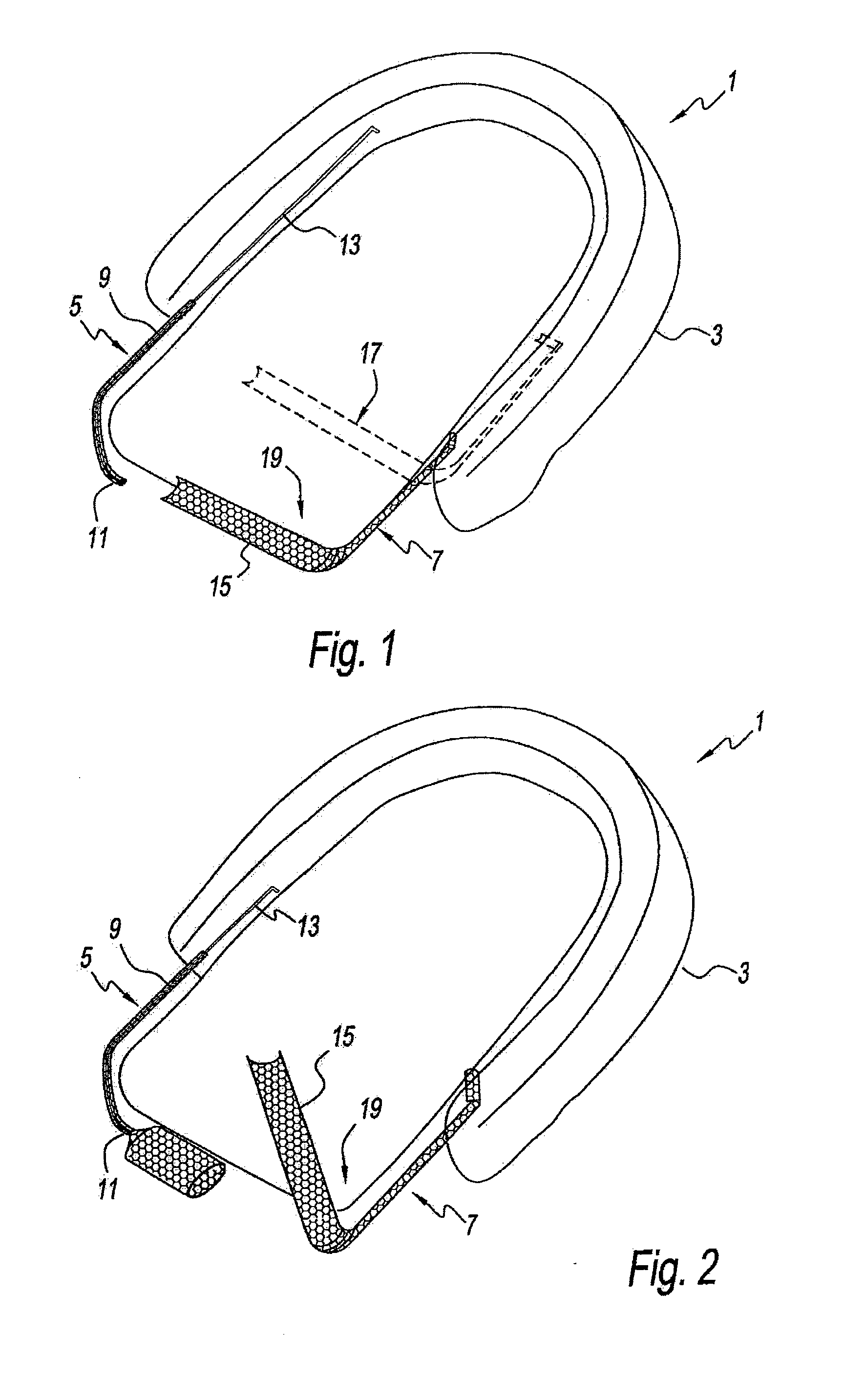

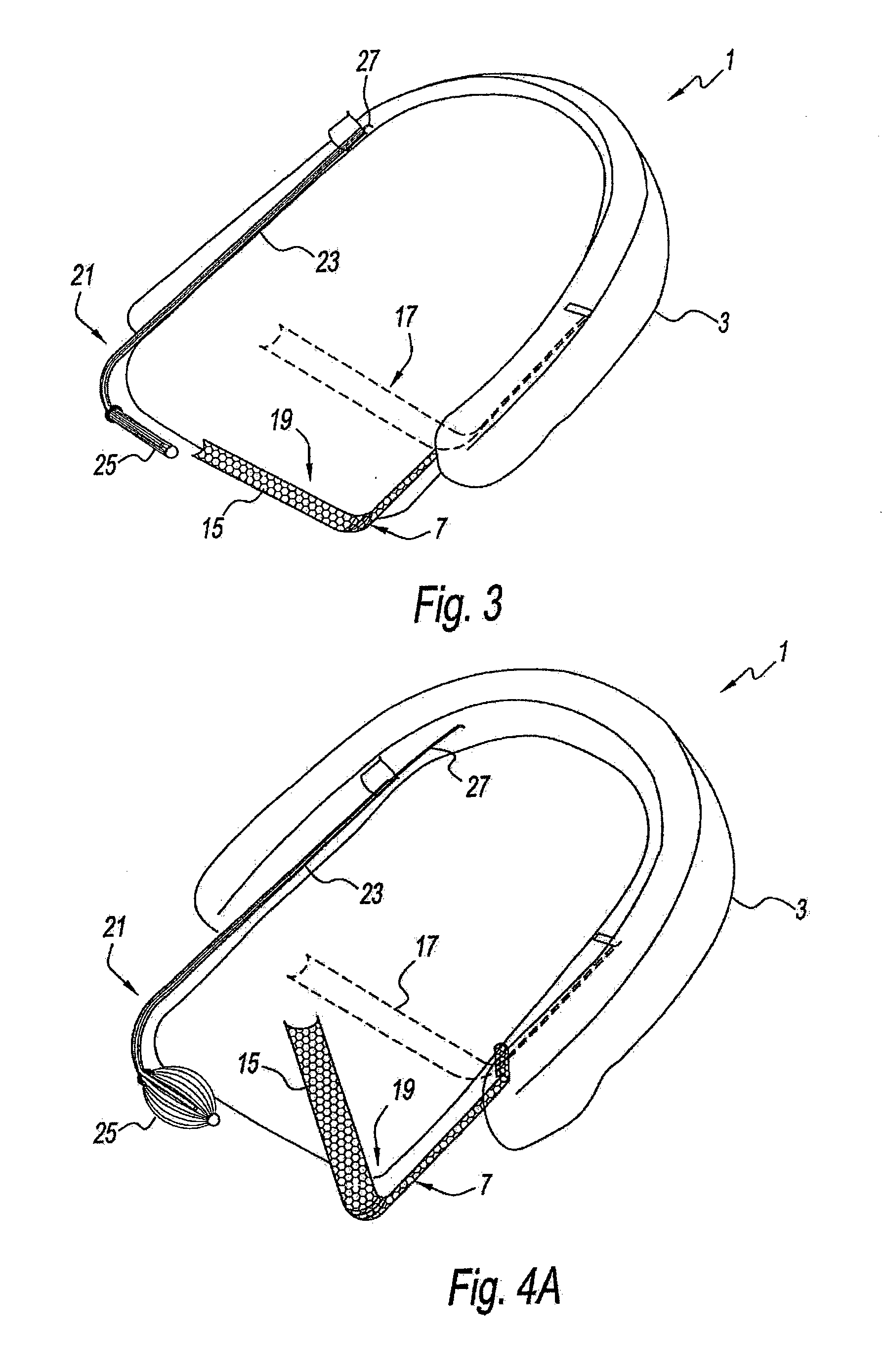

Devices, systems and methods for the treatment of sleep apnea

ActiveUS20110226264A1Minimizing the gag reflexFully removedTracheal tubesBronchoscopesTreatment sleepNasopharyngeal airway

A medical appliance for the treatment of one or more sleep disorders such as obstructive sleep apnea in a patient, the appliance comprising: a biasing member for inserting behind and exerting a force upon the patient's soft palate or tongue, wherein the biasing member is inserted in a reduced or minimized form and then expanded or firms once in place to exert the force. The appliance may be nasally inserted or be placed through the mouth. In a particular configuration, both the soft palate and tongue are biased to prevent obstruction of the flow of air in the nasopharyngeal airway.

Owner:LUMEN DEVICES

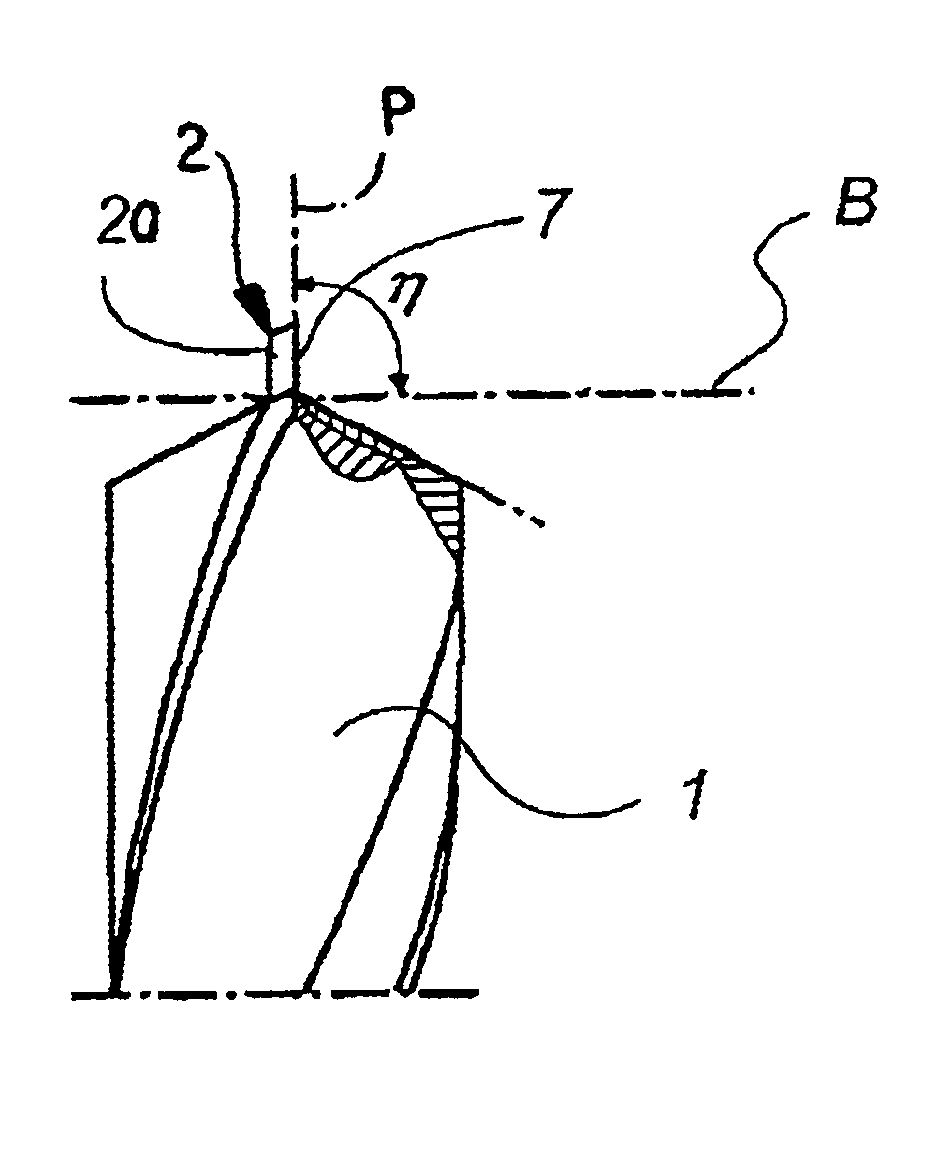

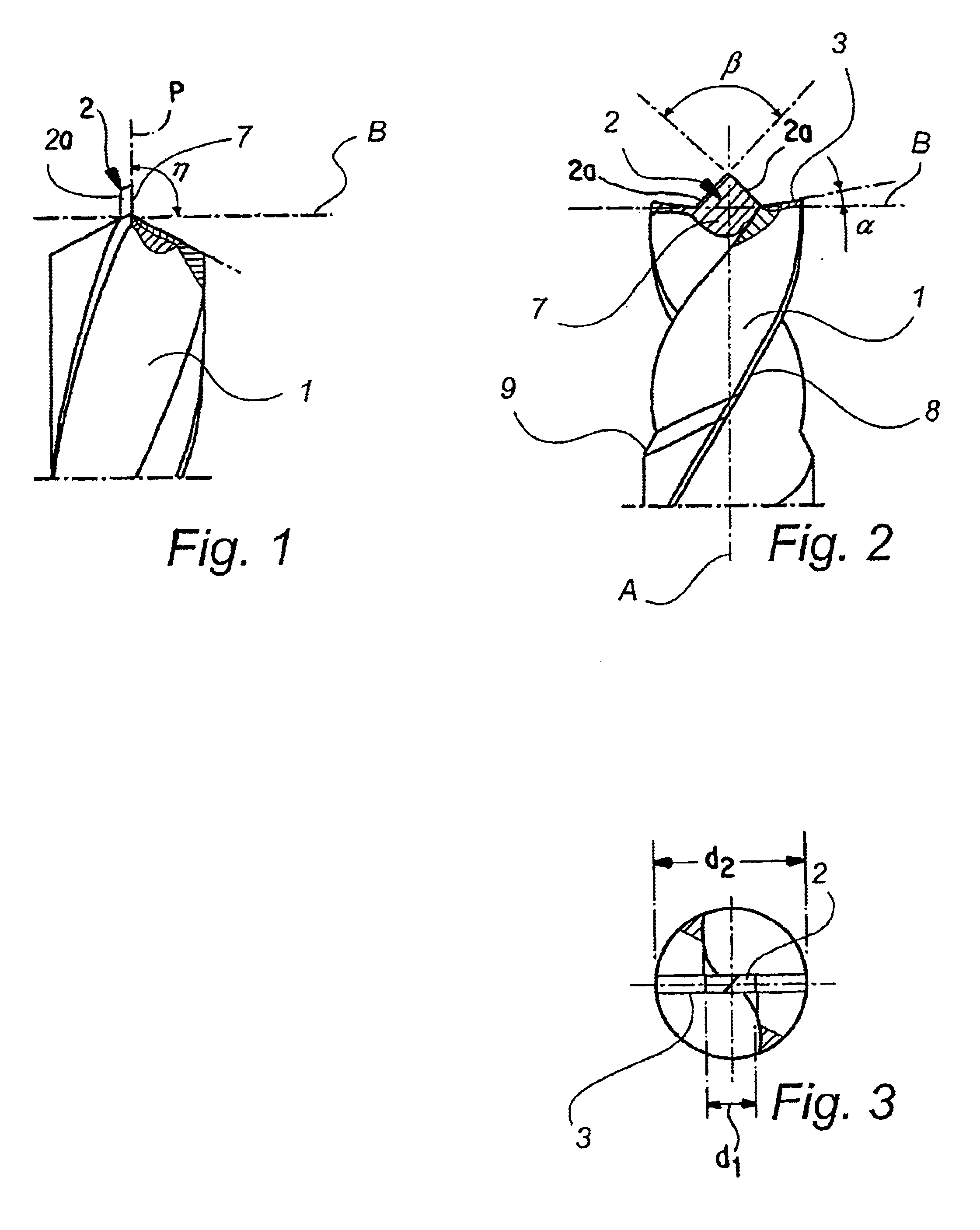

Drill bit with pilot point

InactiveUS6857832B2Fully removedAvoid coatingWood turning toolsTransportation and packagingEngineeringDrill

A drill bit for the working of metal has a center pilot tip that transforms into straight cutting edges extending towards the outer periphery of the bit. Each cutting edge forms a cutting angle of 1-20° with a reference plane oriented perpendicular to of the drill axis. Each a cutting edge is inclined in a radially inward and axially rearward direction toward the drill axis. The center tip forms a pilot point angle of 90±2° and a has base that takes up 23-45 percent of the total diameter of the cutting section of the drill bit. The tip has a tip angle of 90±10°.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

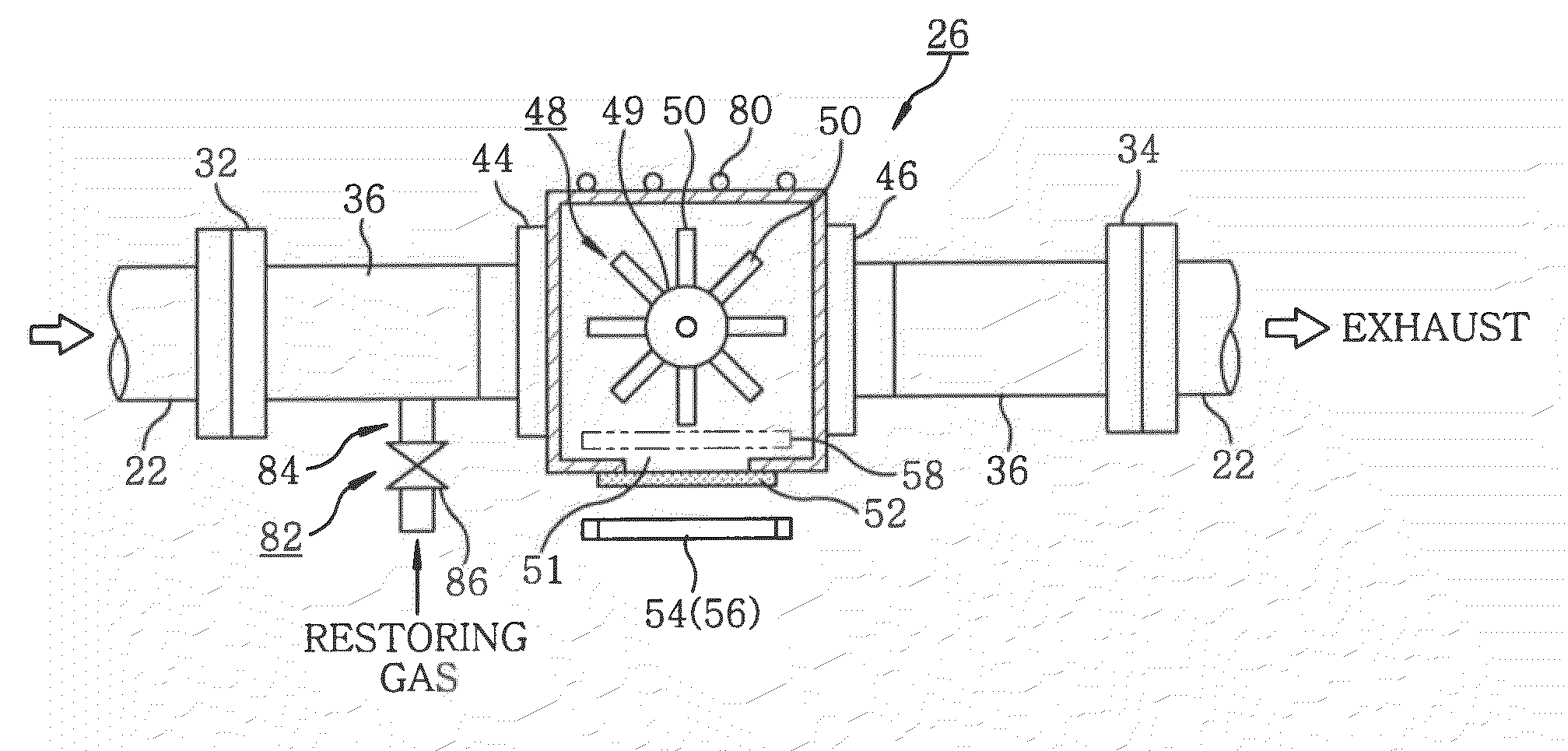

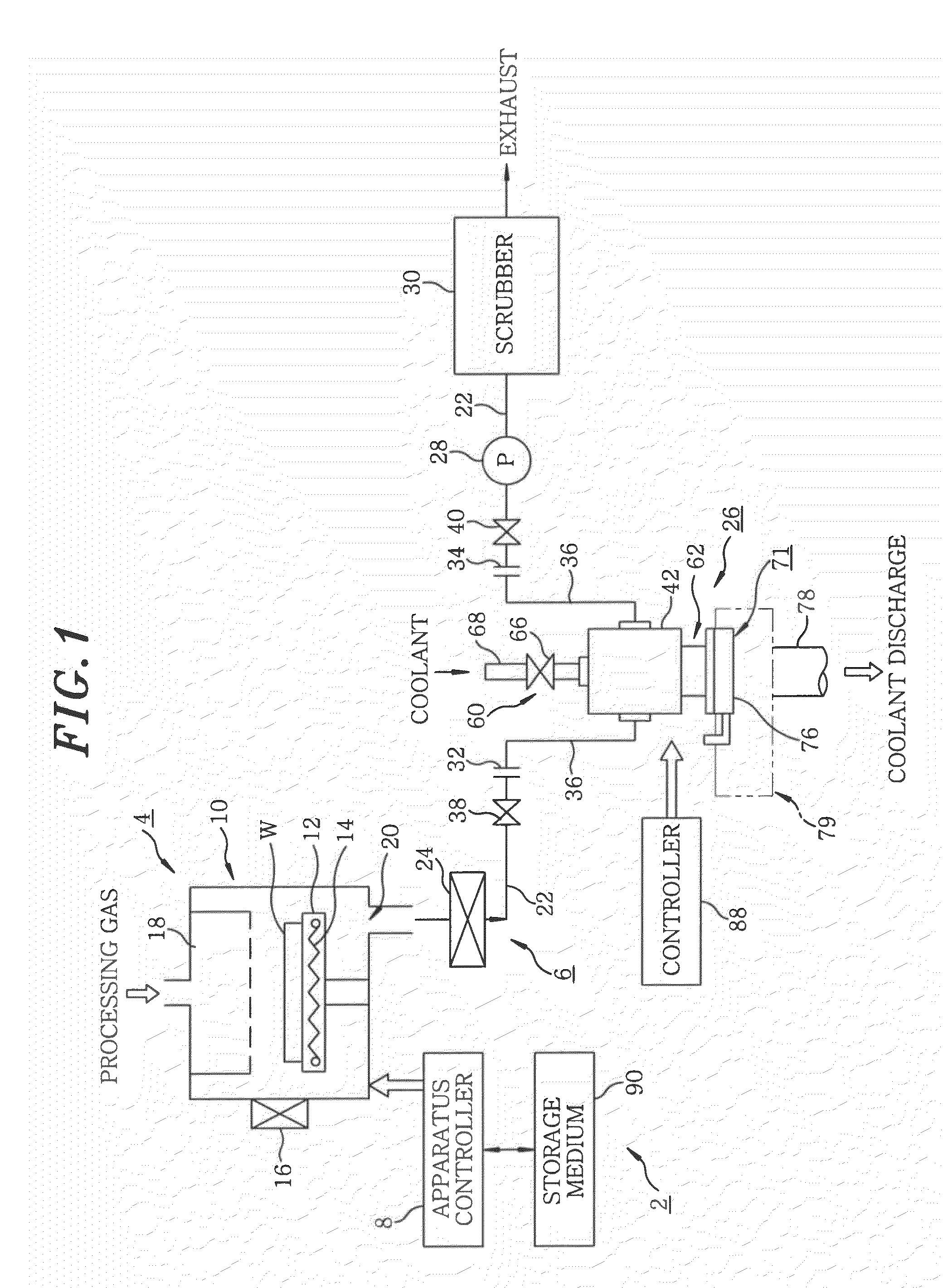

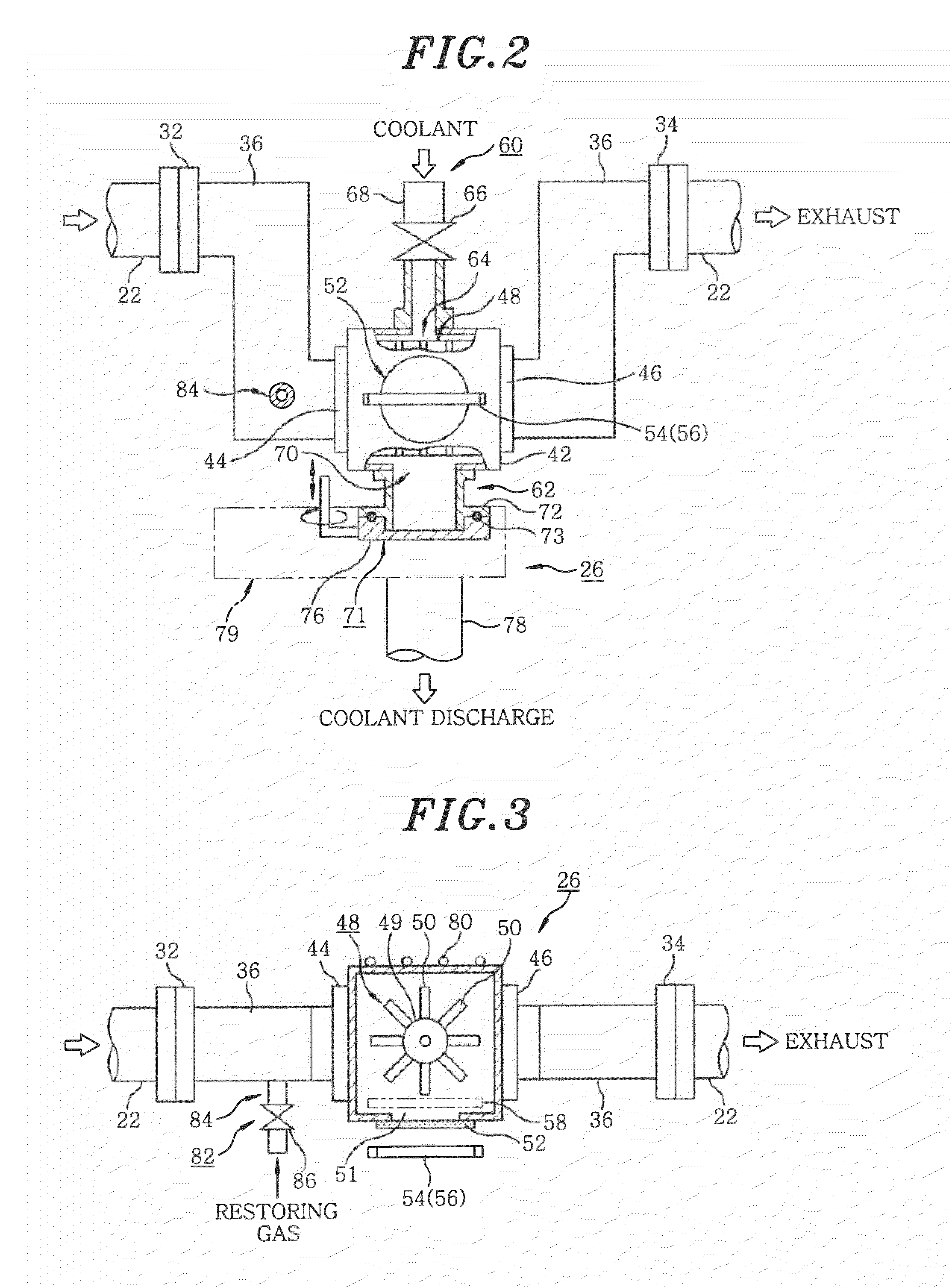

Trap apparatus, exhaust system and processing system using same

InactiveUS20100012292A1Fully removedPrevent leakageCombination devicesSolidificationEnvironmental engineeringHandling system

Provided is a trap apparatus, disposed in an exhaust passage 22 for discharging an exhaust gas from a processing chamber 10 for processing a wafer W, thereby to trap exhaust from the exhaust gas, so that the exhaust trapped by a trap element can be efficiently removed to regenerate the trap element. The trap apparatus includes a housing 42 disposed in the exhaust passage, a trap element 48 disposed in the housing for trapping the exhaust, a trap heating unit 54 for heating the trap element, a coolant introducing unit 60 for introducing a coolant into the housing, a coolant discharging unit 62 for discharging the coolant from the housing, and a controller 88 which performs a control to introduce the coolant from the coolant introducing unit into the housing, while the trap element being heated by the trap heating unit, to remove the exhaust trapped by the trap element.

Owner:TOKYO ELECTRON LTD

Motion cancellation of optical input signals for physiological pulse measurement

InactiveUS7993276B2Accurately monitoring and detecting pulse rateFully removedCatheterDiagnostic recording/measuringAccelerometerControl signal

A pulse rate sensor that includes an accelerometer for measuring periodic motion and a piezo sensor for detecting erratic motion is capable of more accurately determining pulse rate by accounting for these types of motion. The pulse rate sensor in accordance with the present invention diminishes pulse rate signal degradation due to erratic motion through a combination of algorithms that control signal boosting, waveform refinement and signal noise suppression.

Owner:INTEL CORP

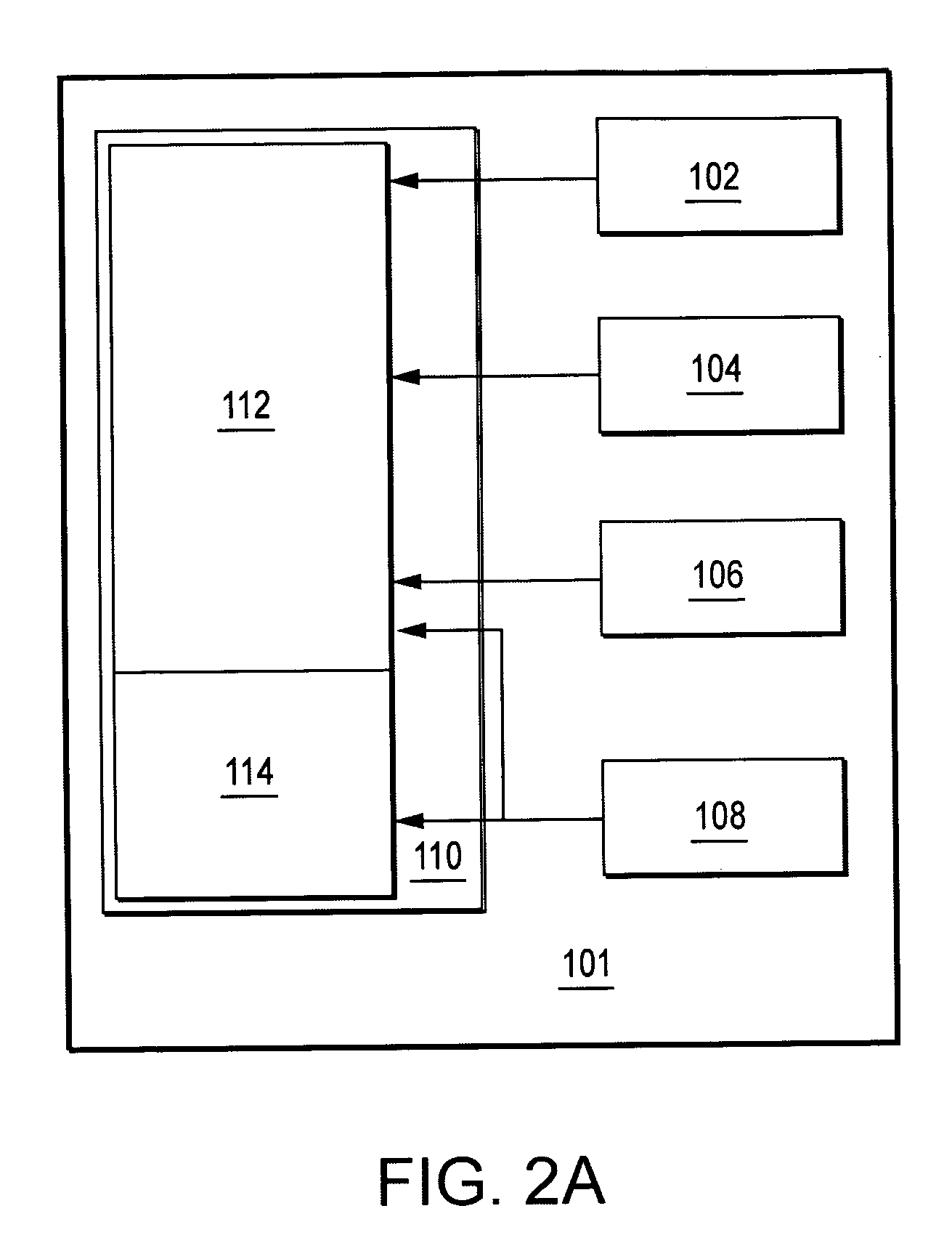

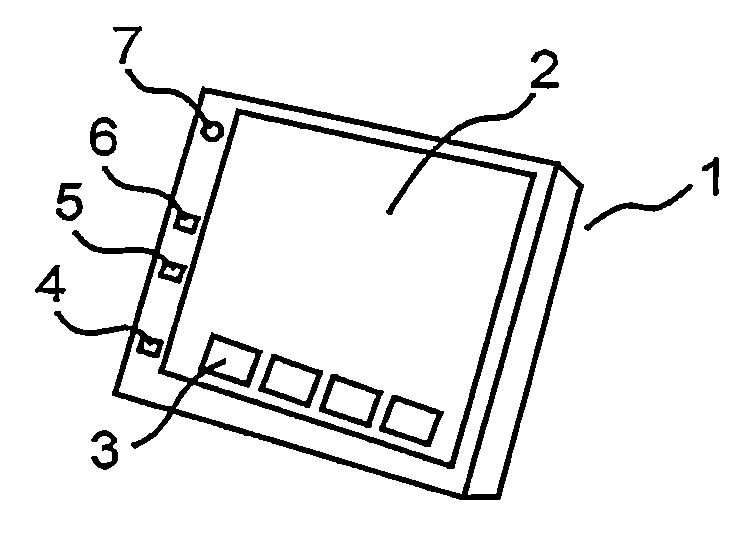

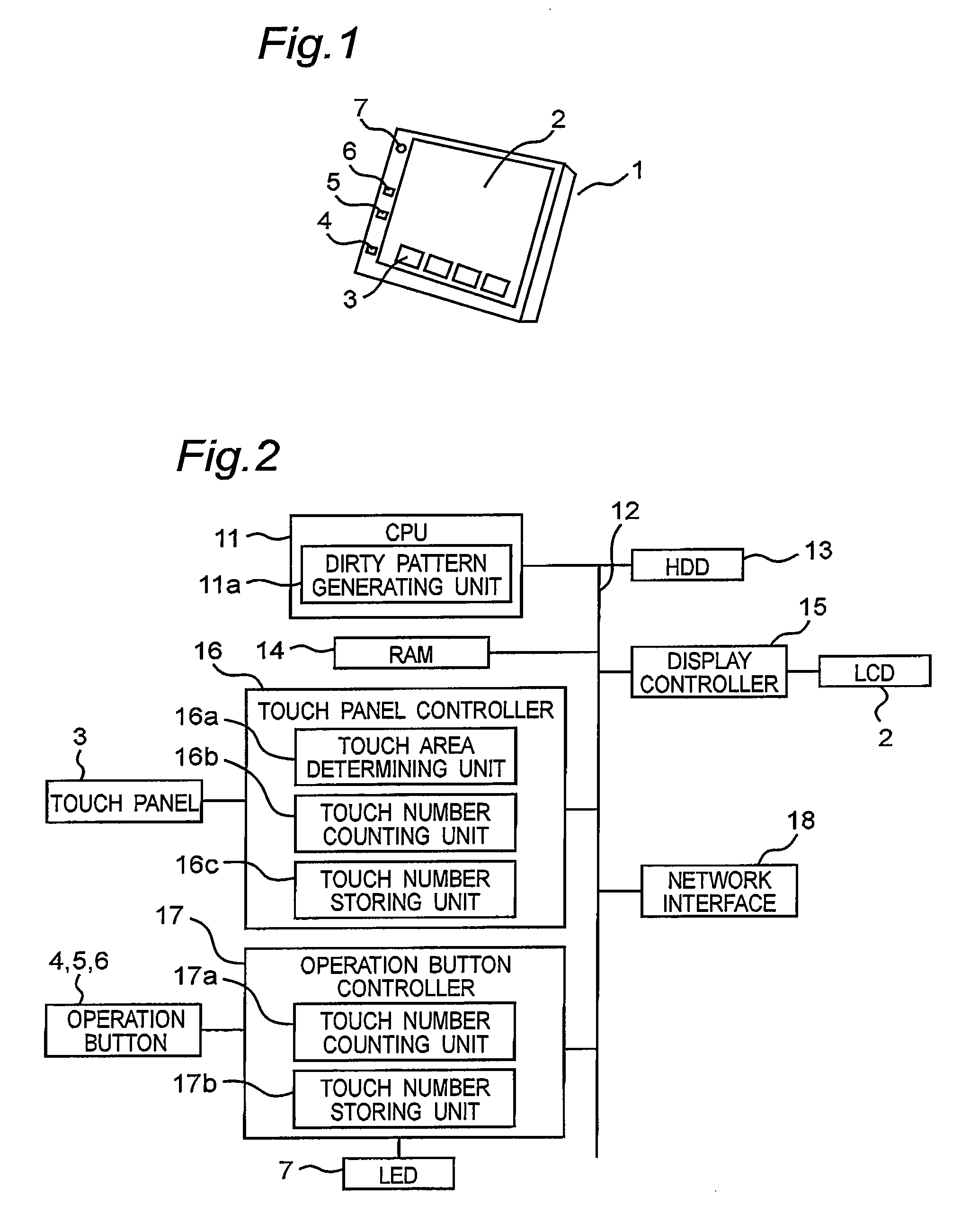

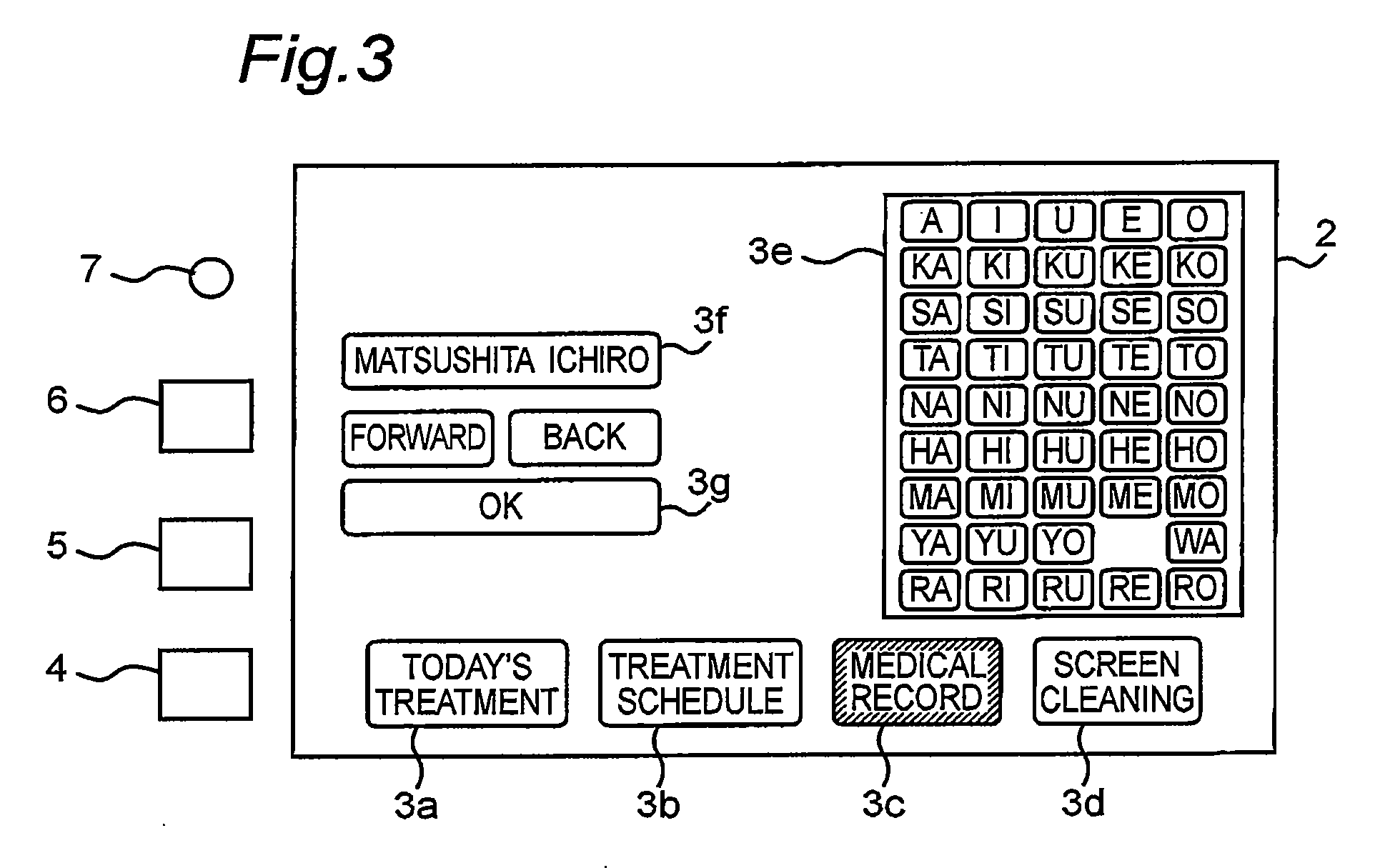

Information terminal device

ActiveUS20100033444A1Avoid cleaning modeRemove stainsInput/output processes for data processingCounting NumberNormal mode

An information terminal device has a touch panel and a display unit which are integrally configured, and an operation button provided around the display unit, and the information terminal device includes: a touch number counting unit operable to count number of times of touching the operation button; a touch number storing unit operable to store the number of times counted by the touch number counting unit; and a control unit operable to control the information terminal device by switching an operation mode between a normal mode for working the information terminal device according to operations of the touch panel and the operation button and a cleaning mode for cleaning the touch panel, wherein in the cleaning mode, the control unit prohibits an application from being executed according to operations of the touch panel and the operation button, and terminates the cleaning mode when the number of times of touching the operation button counted by the touch number counting unit reaches a predetermined number.

Owner:PANASONIC CORP

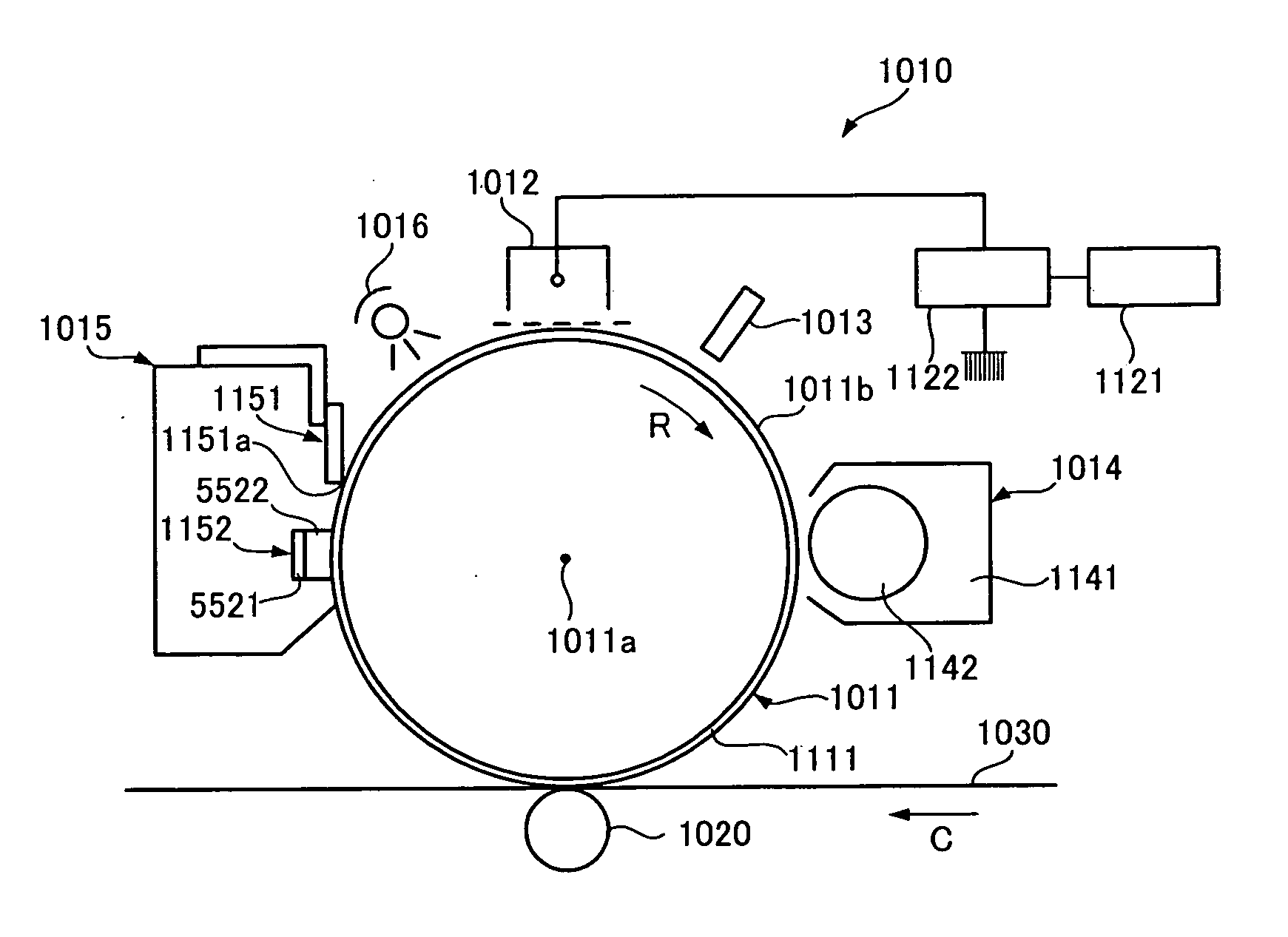

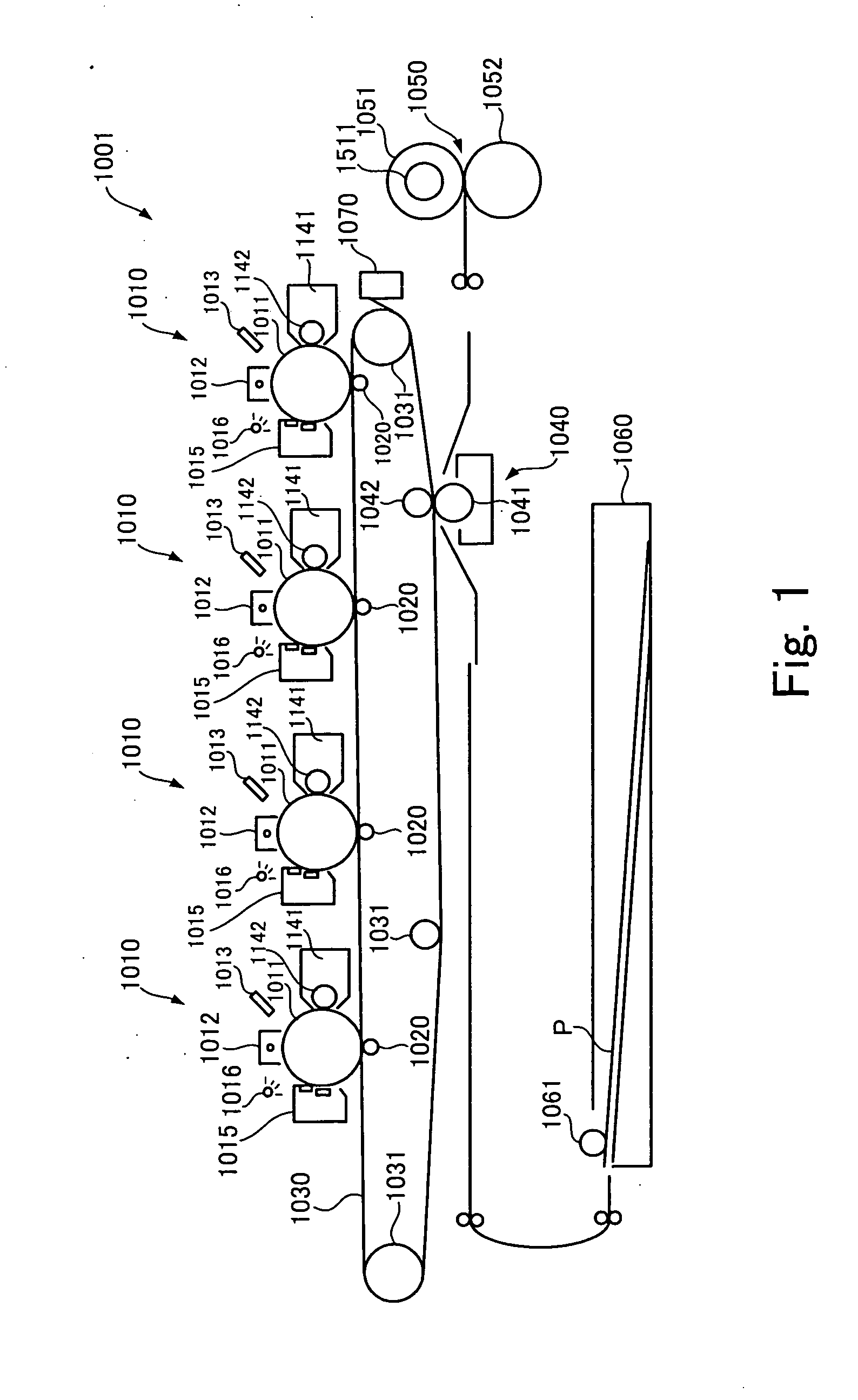

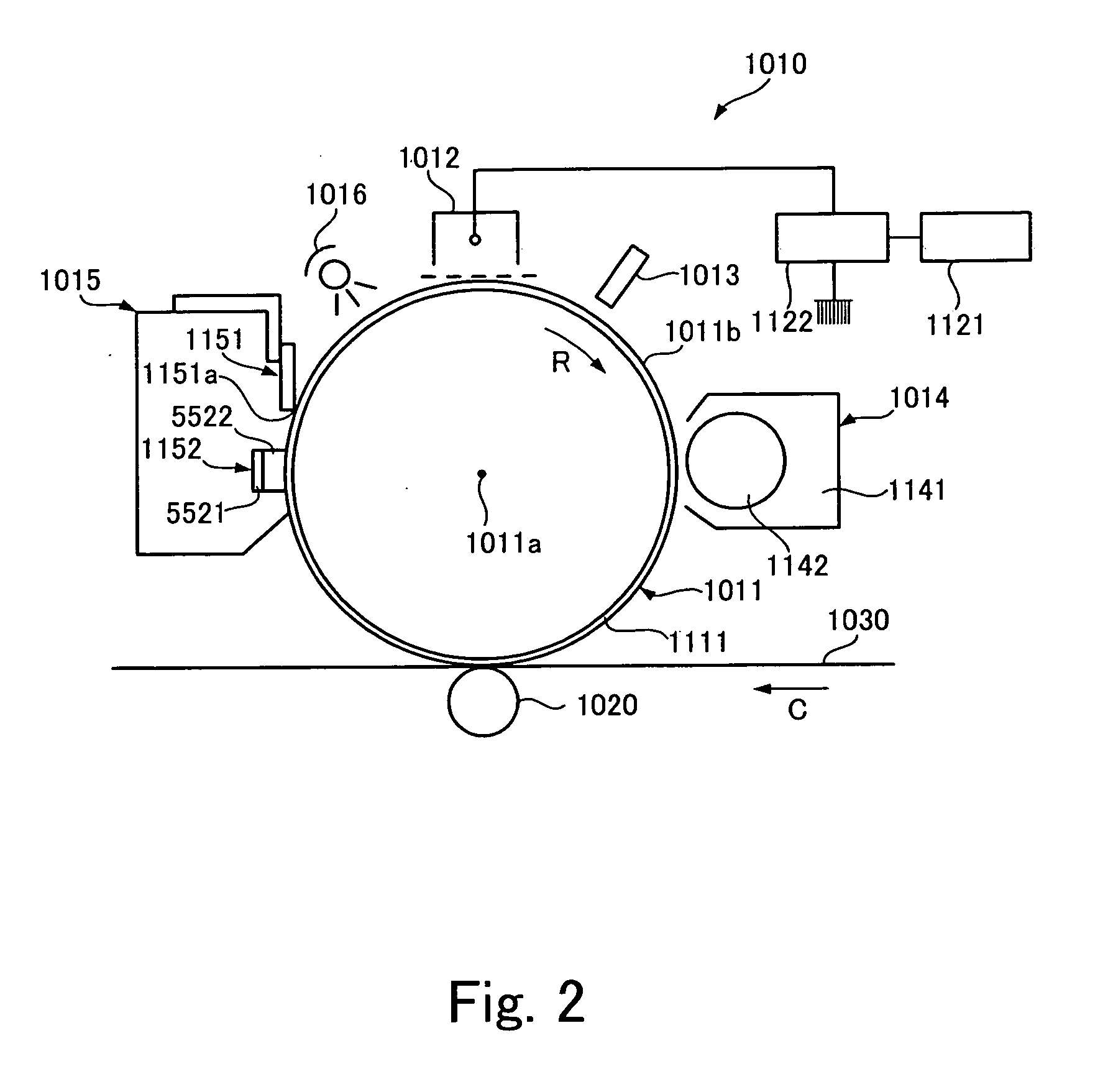

Cleaning unit and image forming apparatus

This invention relates to a cleaning unit comprising: a cleaning blade that keeps a front end of rubber material in contact with the surface with a pressure so as to scrape residual toner left on the surface of the photoreceptor and a fiber body having multiple fibers in contact with the surface of the photoreceptor in the upstream in the cyclic moving direction of the surface of the photoreceptor with respect to the cleaning blade, wherein the cleaning blade satisfies conditions A≧−2.5×B+102 and 6.3≦B≦19.6, where A designates a contact angle (°) with pure water under 23° C., 55% RH and B designates 100% modulus (MPa) at 23° C.

Owner:FUJIFILM BUSINESS INNOVATION CORP

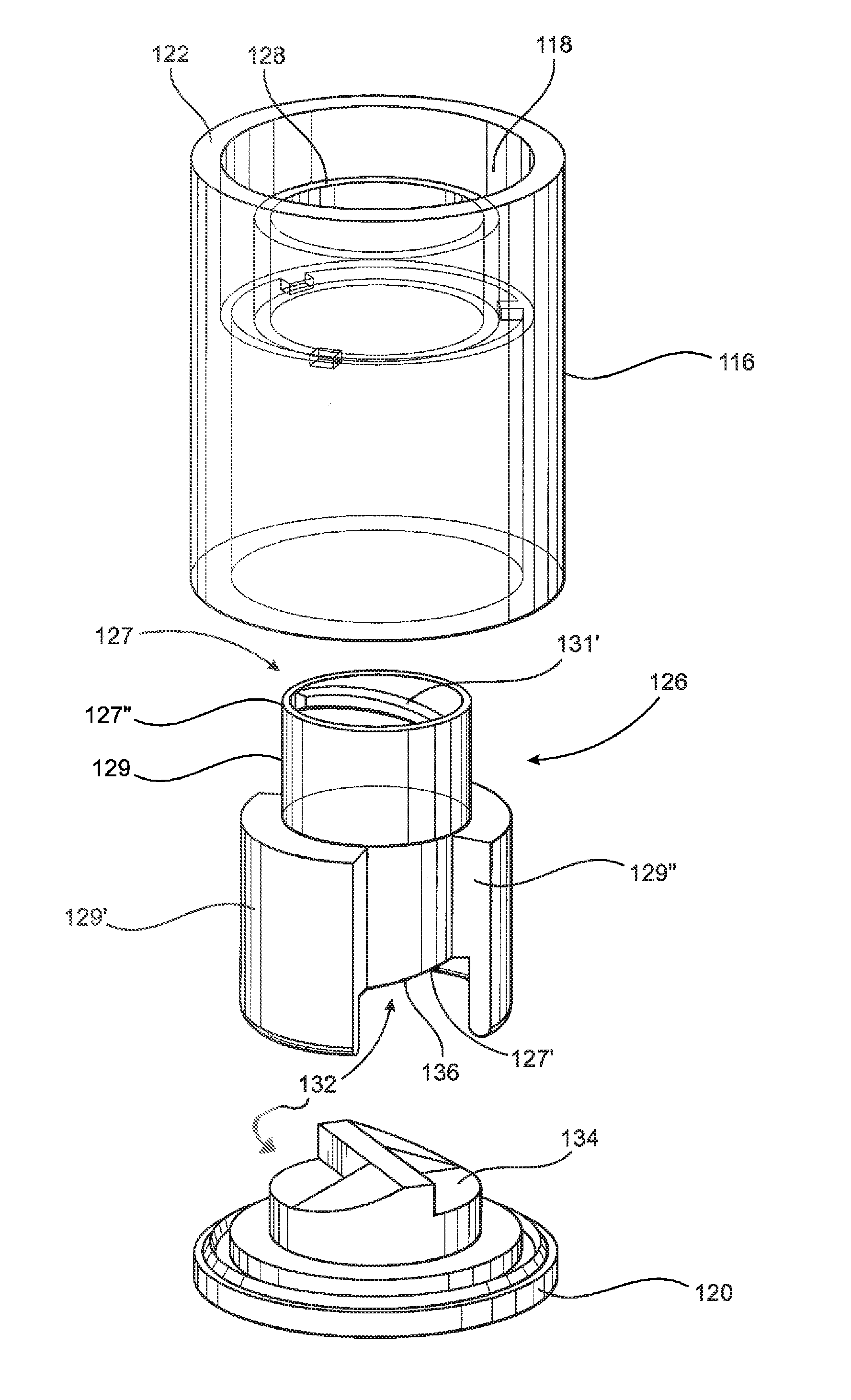

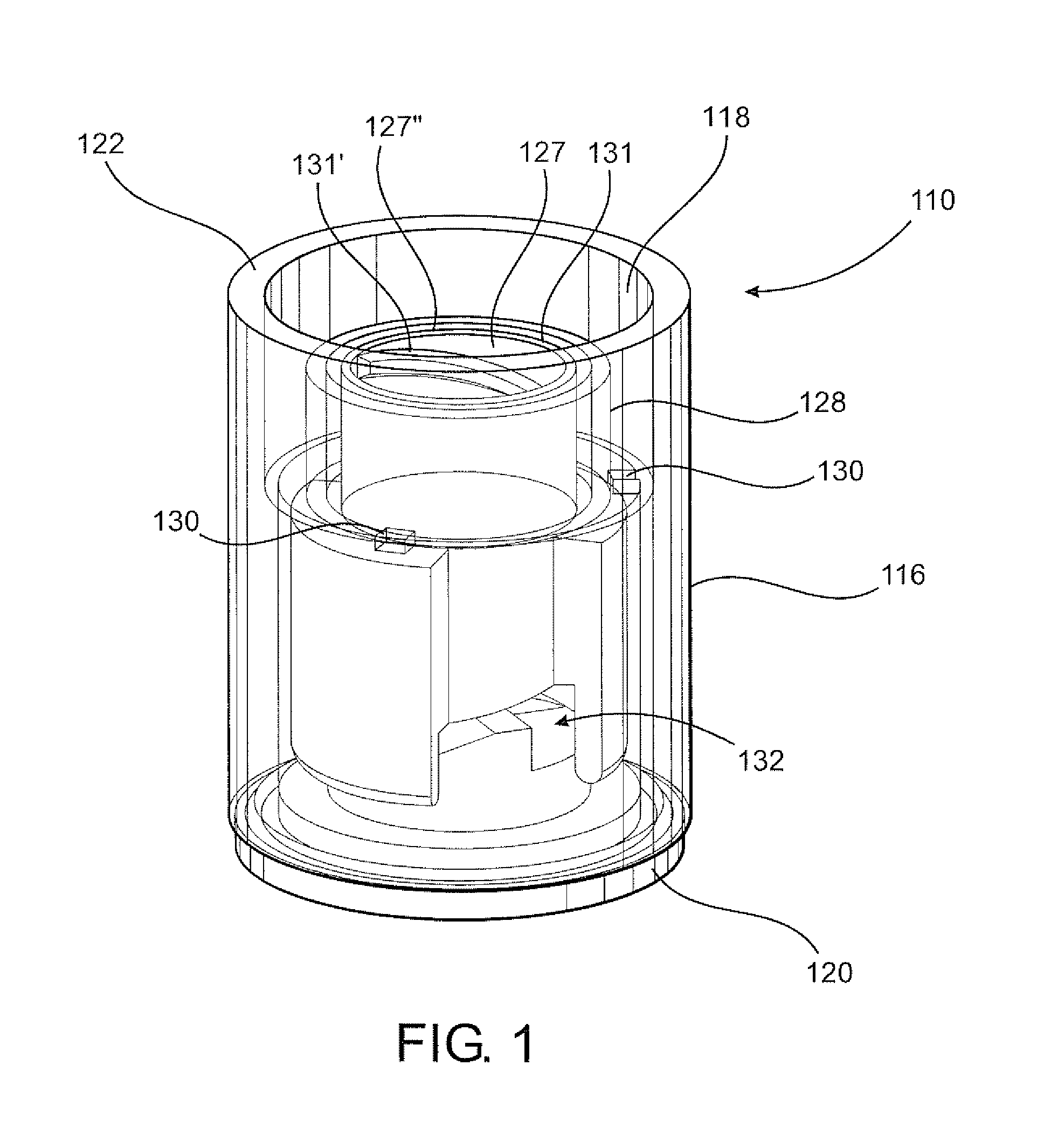

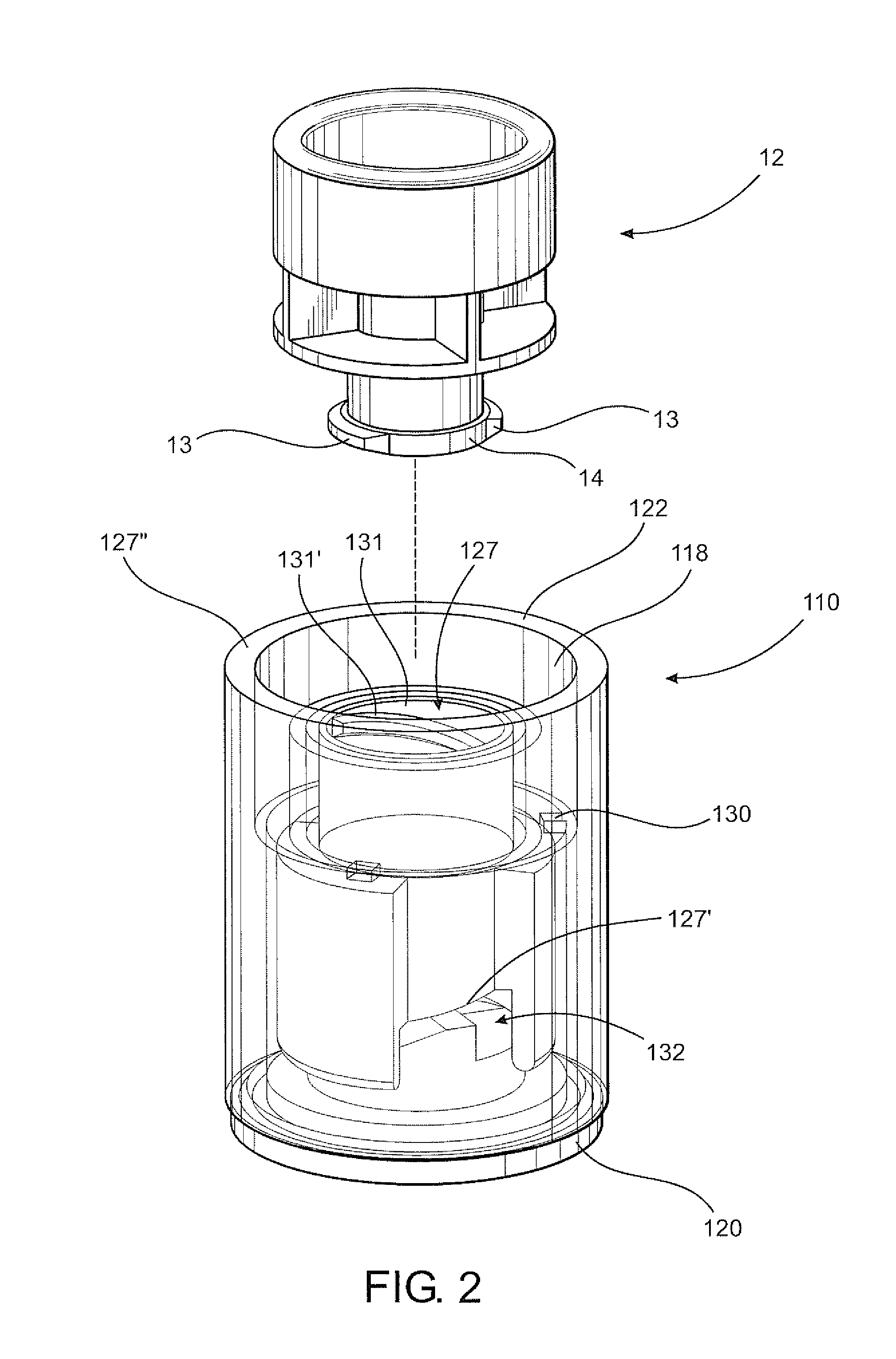

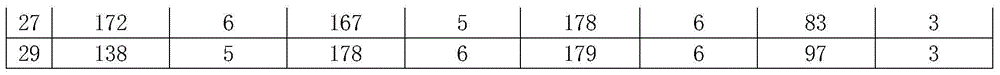

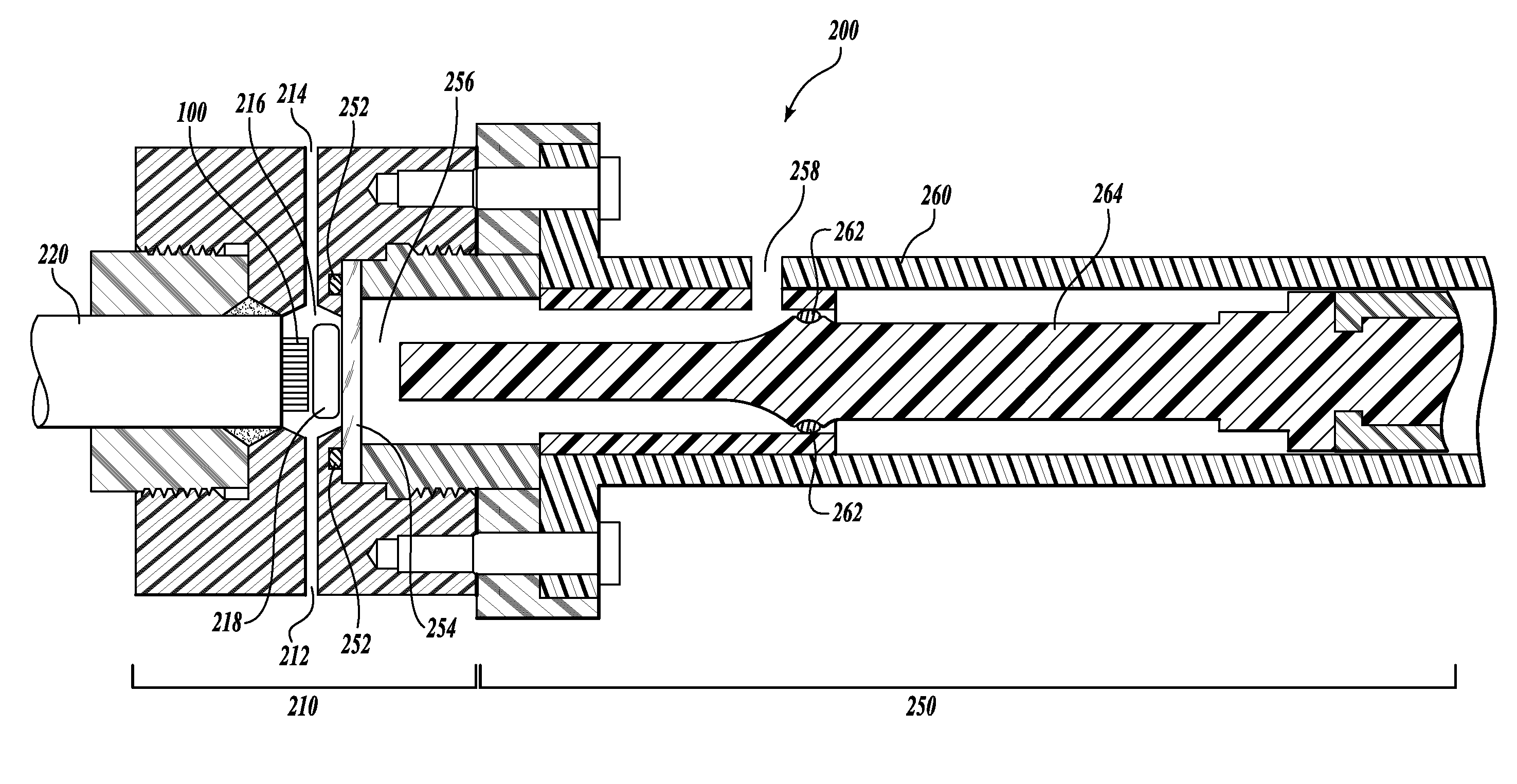

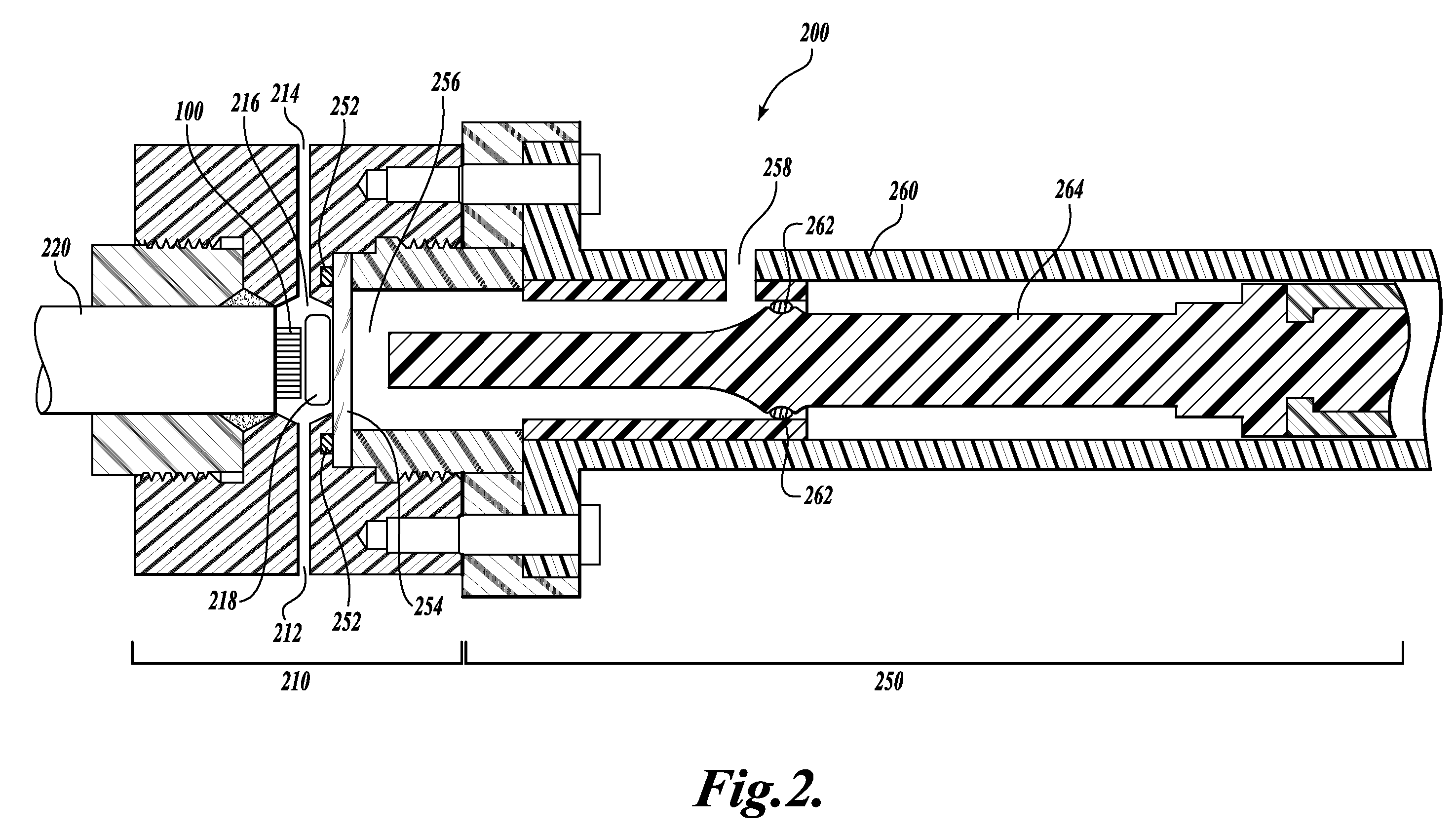

Tamper indicating closure assembly

ActiveUS8864707B1Optimize allocationEasy to addIntravenous devicesTube connectorsAxial forceEngineering

A closure assembly structured for use with a female luer connector and operative to indicate an accomplished or attempted tampering thereof. A connector cover is movably and removably disposed within a housing and includes an interior chamber disposed and structured to receive an access port of the female connector. An indicator member is removably connected to an interior of the housing in surrounding relation to the connector cover and a drive assembly associated with both the connector cover and the housing is operable to concurrently rotate and axially advance the interior chamber into enclosing relation to the access port. Attempted removal of the housing from the female connector, such as by an applied axial force to the housing, will detach the indicated member from the housing and dispose it in a visually observable position surrounding the connector cover, thereby indicating attempted access.

Owner:MEDICAL DEVICE ENG

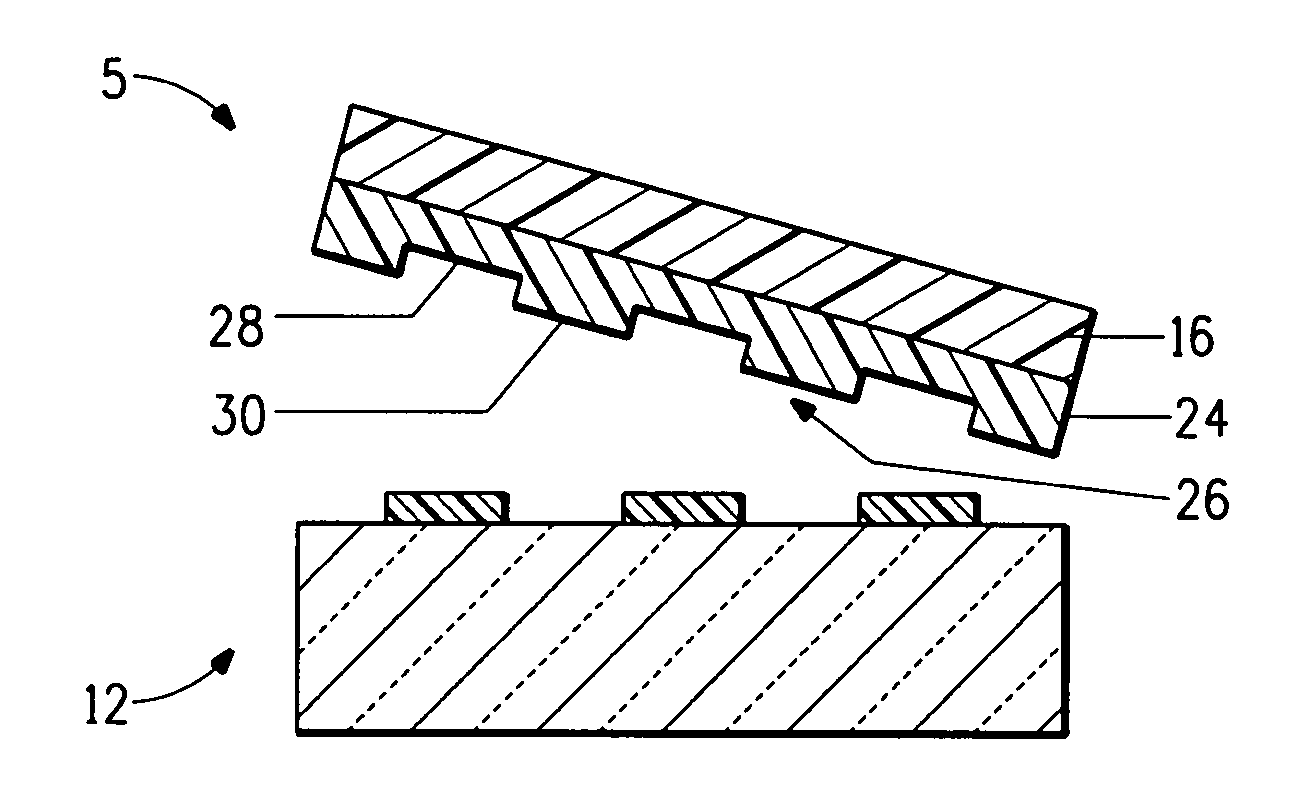

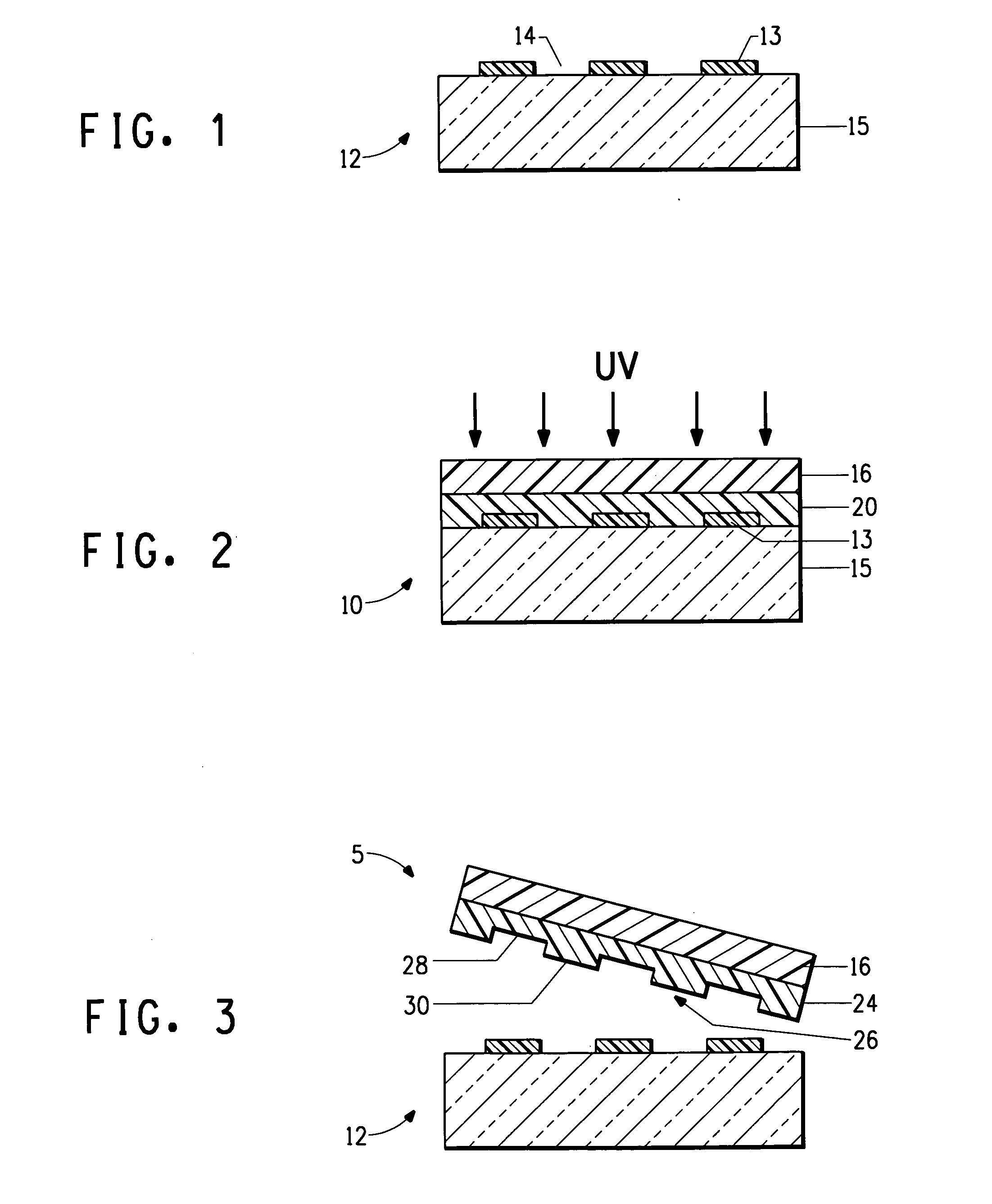

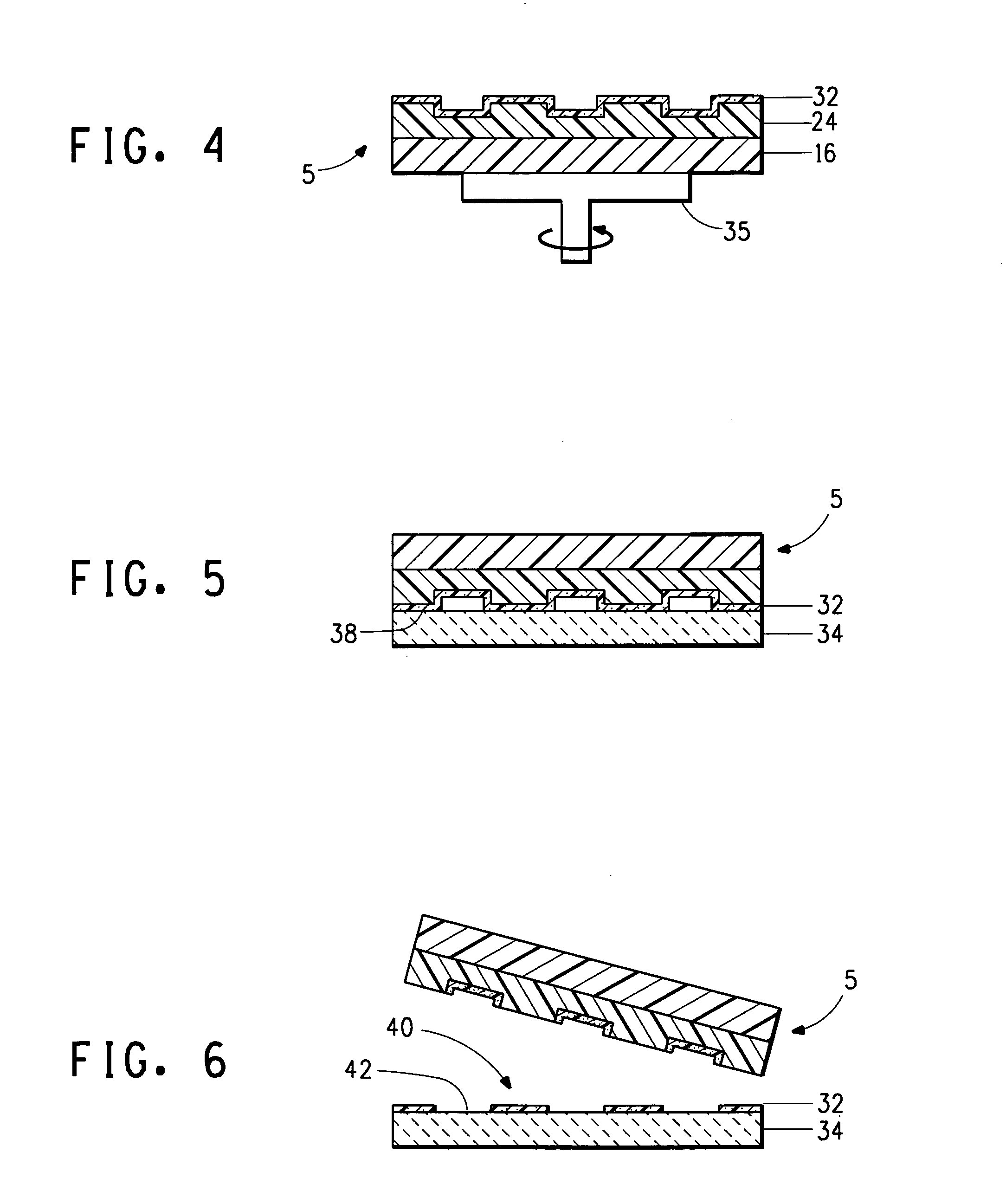

Method to form a pattern of functional material on a substrate

InactiveUS20080083484A1Fully removedDecorative surface effectsIndividual molecule manipulationElastic modulusLiquid composition

The invention provides a method to form a pattern of a functional material on a substrate. The method uses an elastomeric stamp having a relief structure with a raised surface and having a modulus of elasticity of at least 10 MegaPascal. A liquid composition of the functional material and a liquid is applied to the relief structure and the liquid is removed to form a film on the raised surface. The elastomeric stamp transfers the functional material from the raised surface to the substrate to form a pattern of the functional material on the substrate. The method is suitable for the fabrication of microcircuitry for electronic devices and components.

Owner:EI DU PONT DE NEMOURS & CO

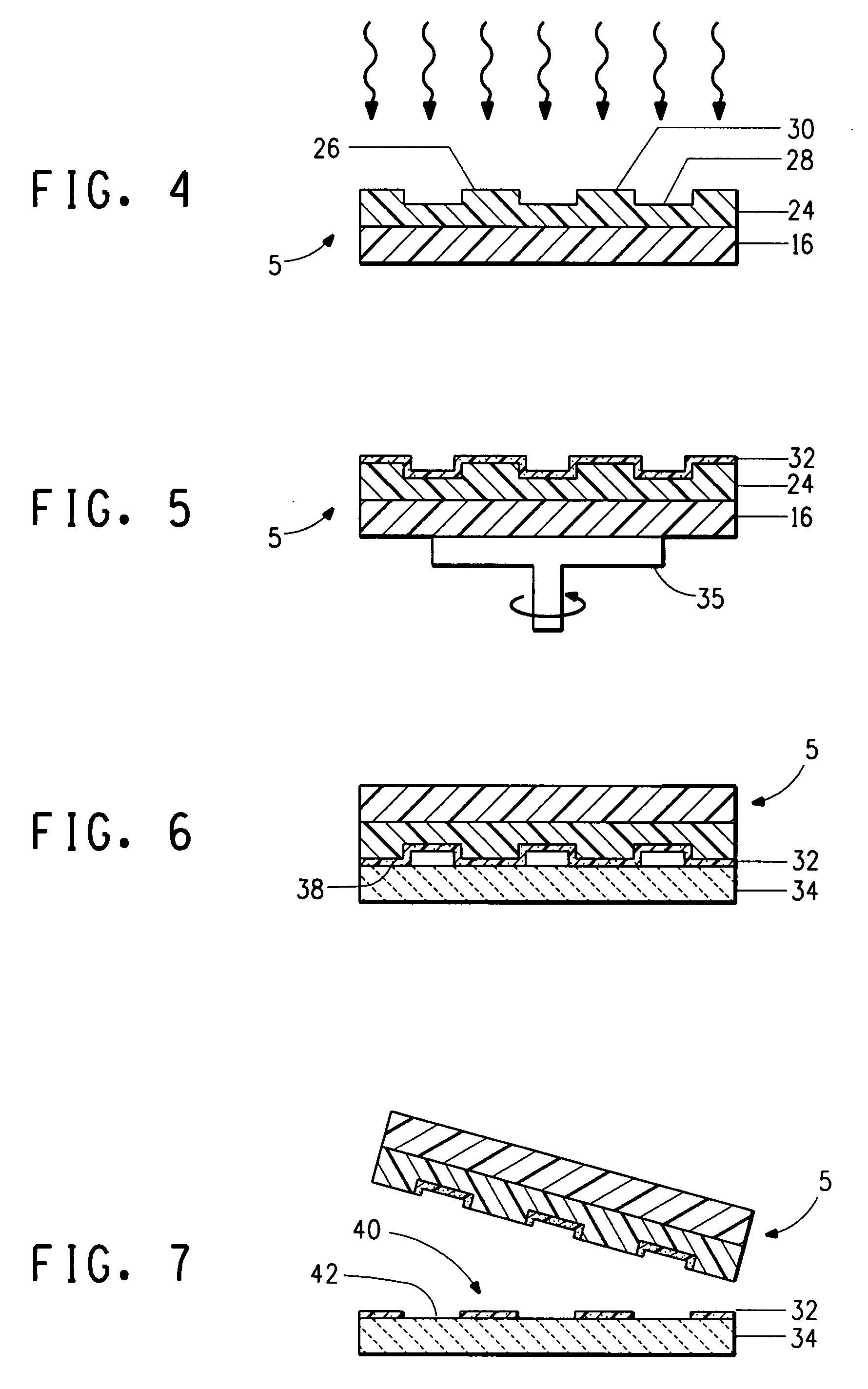

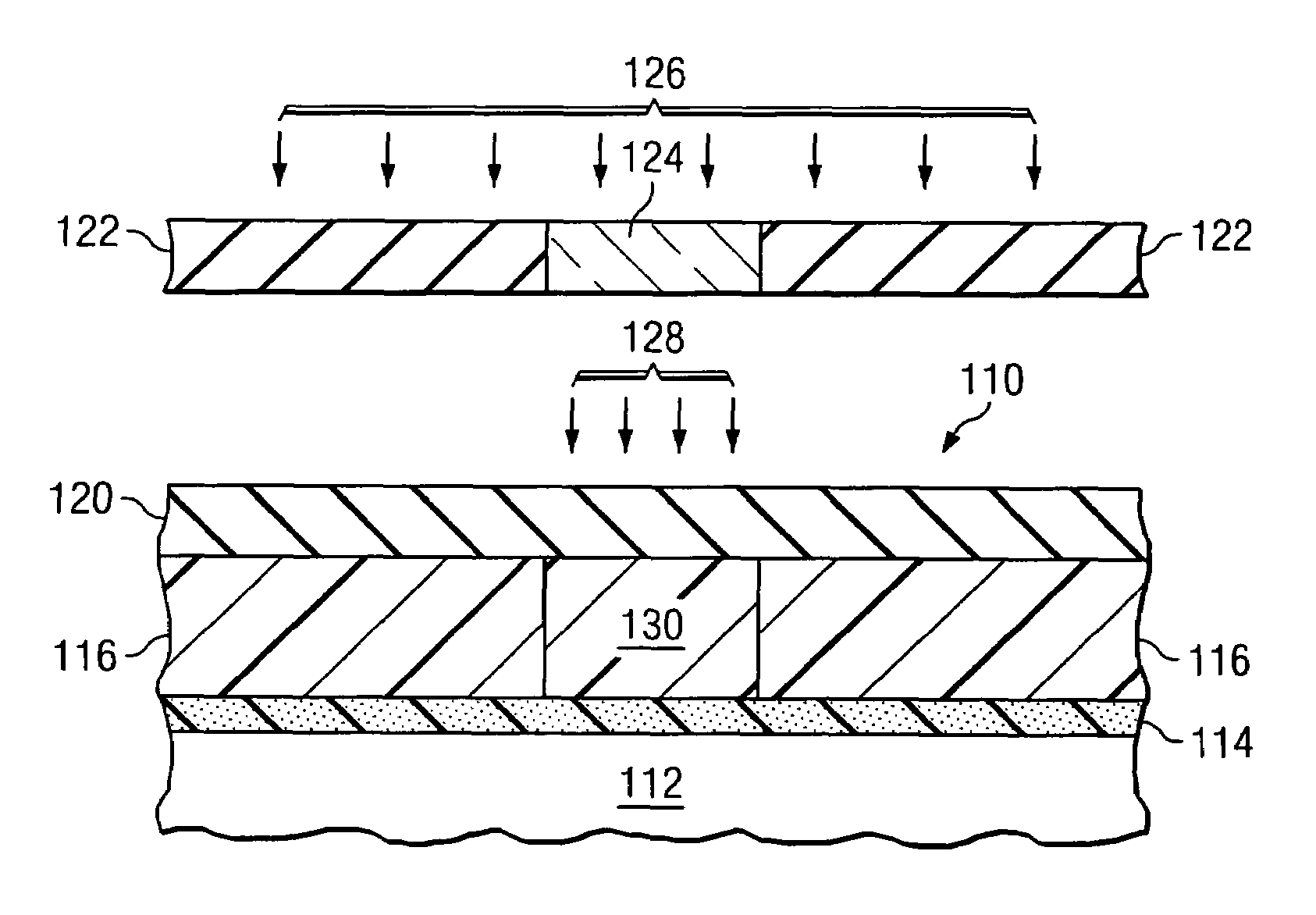

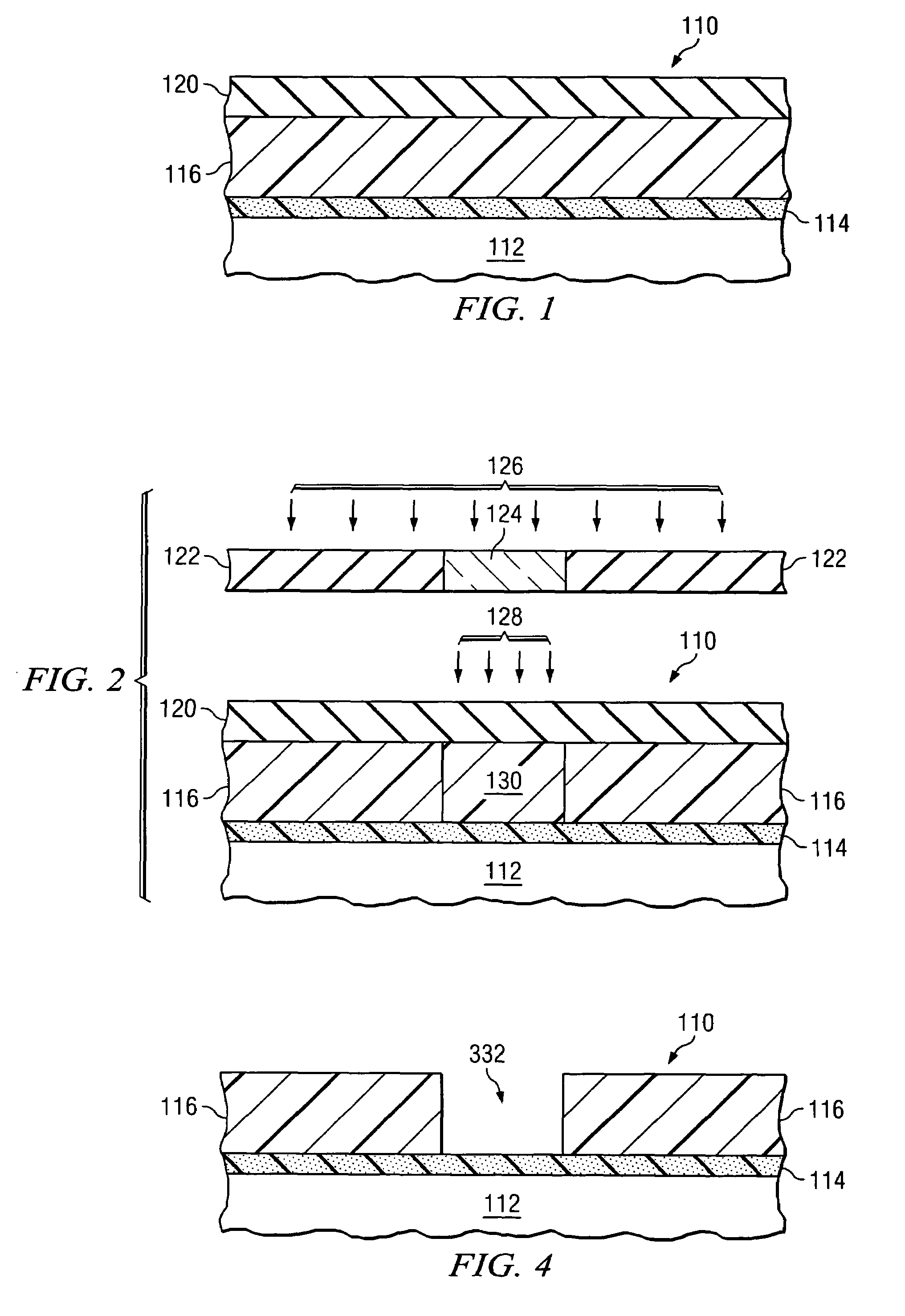

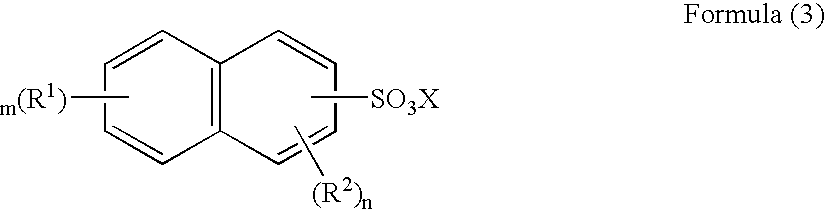

Post exposure resist bake

InactiveUS7396482B2Reduce morbidityFully removedDecorative surface effectsSemiconductor/solid-state device manufacturingResistPhotoacid

A preferred embodiment of the invention provides a method for forming an integrated circuit. The method comprises forming a resist layer on a substrate. Preferably, the photoresist layer comprises a photo acid generator (PAG). Embodiments include irradiating the resist through a mask to generate a photoacid in the resist, heating the resist at a first temperature, and then heating the resist at a second temperature. Heating at the first temperature evaporates water from the resist. Heating at the second temperature deprotects the resist.

Owner:POLARIS INNOVATIONS LTD

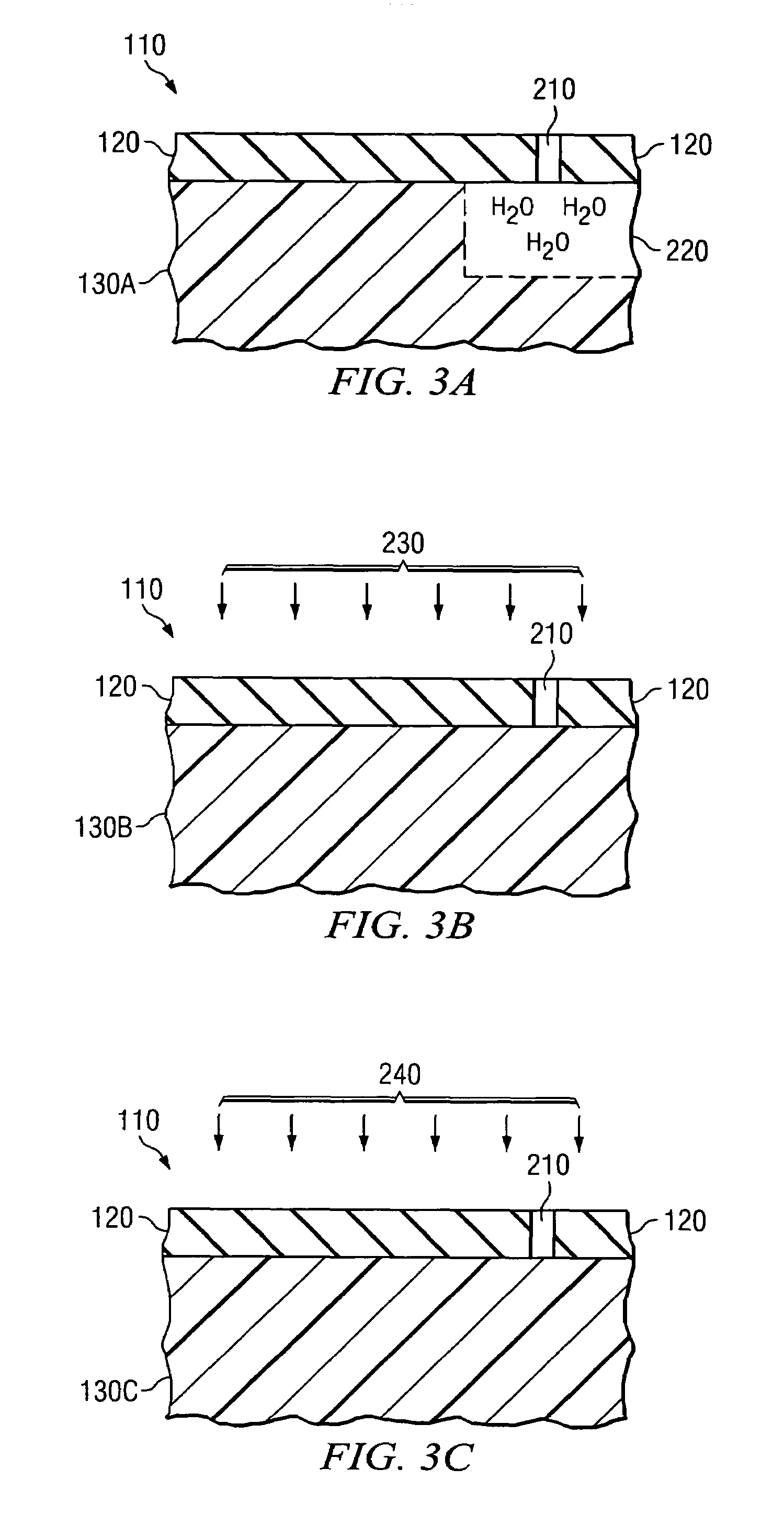

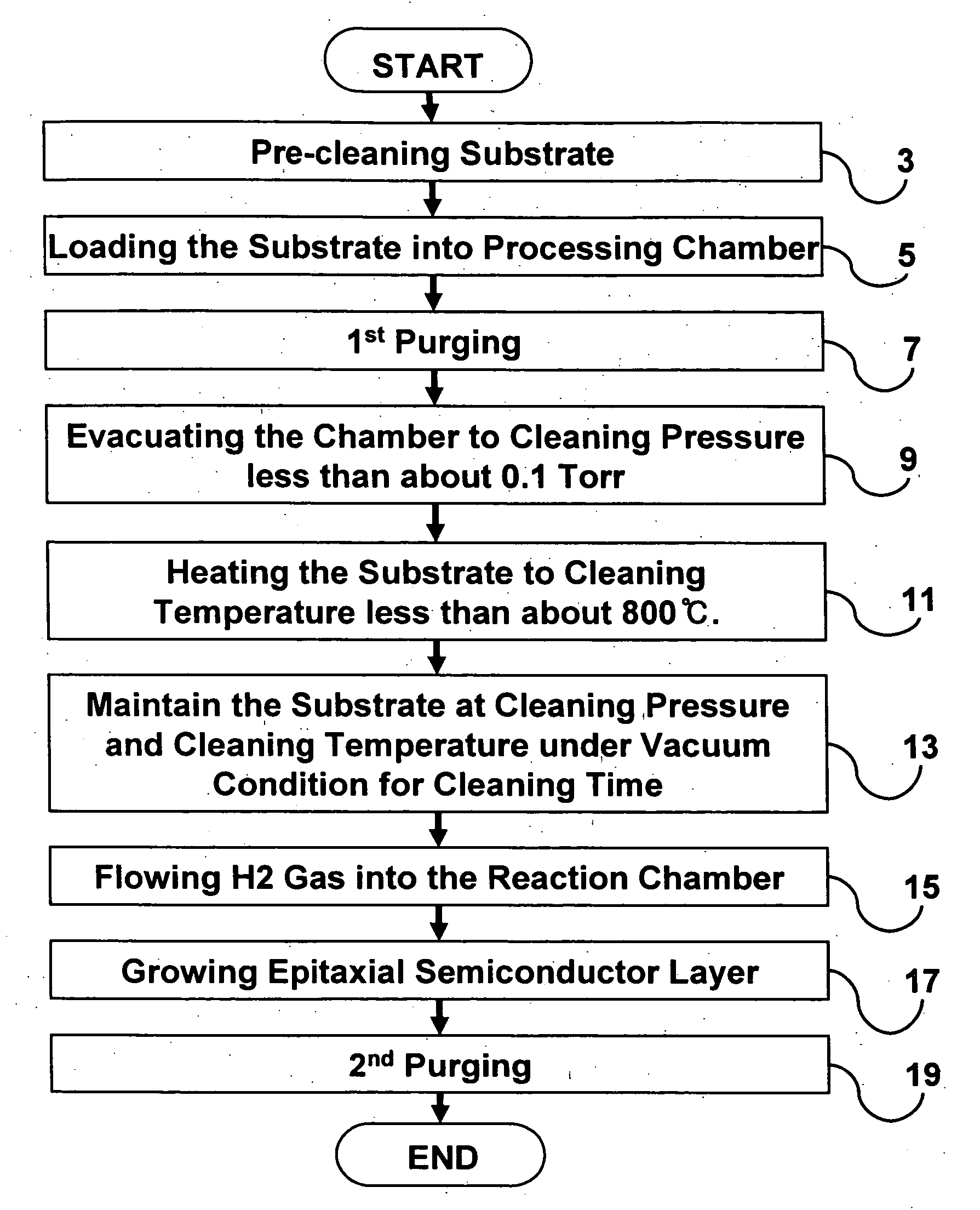

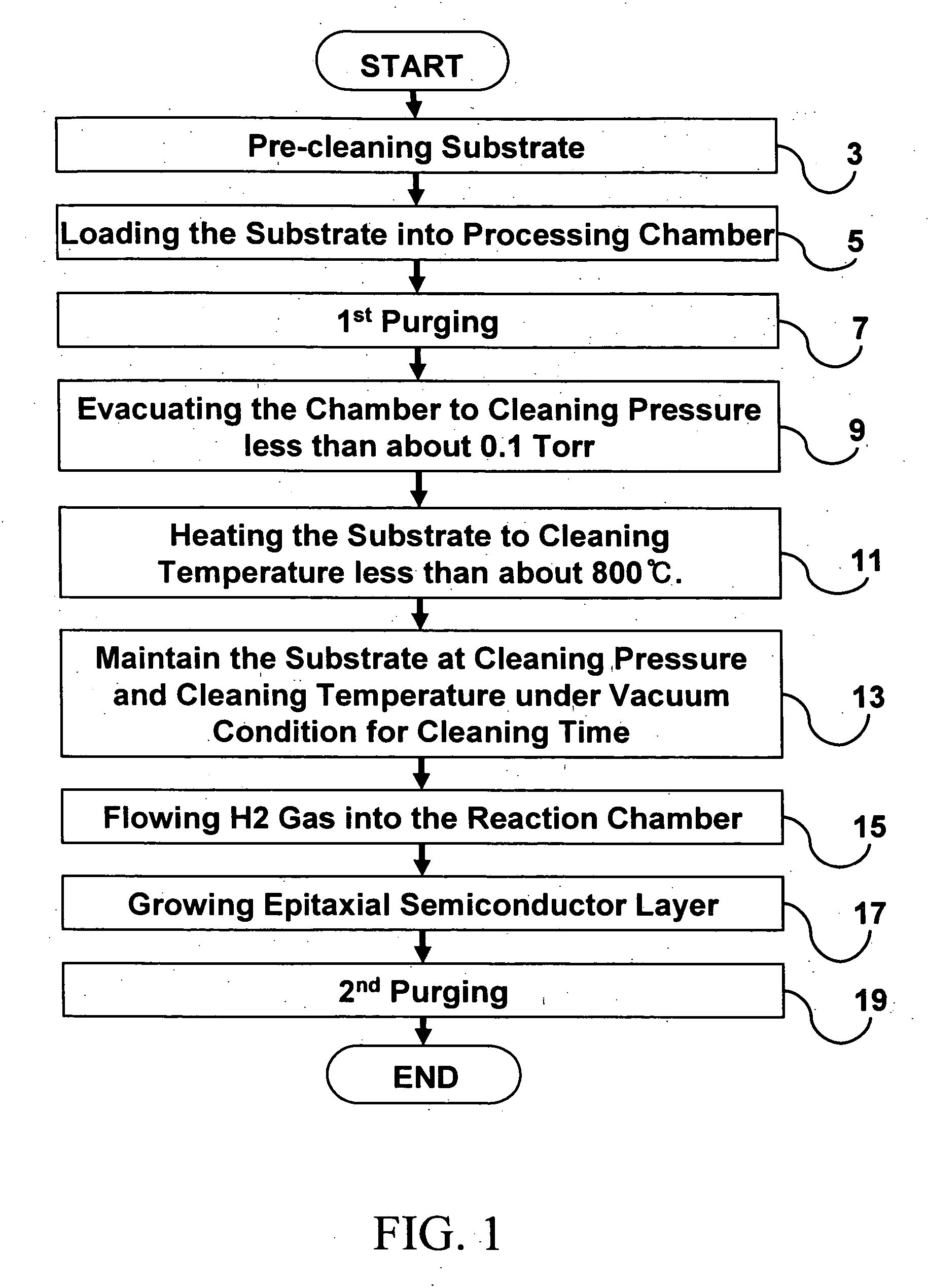

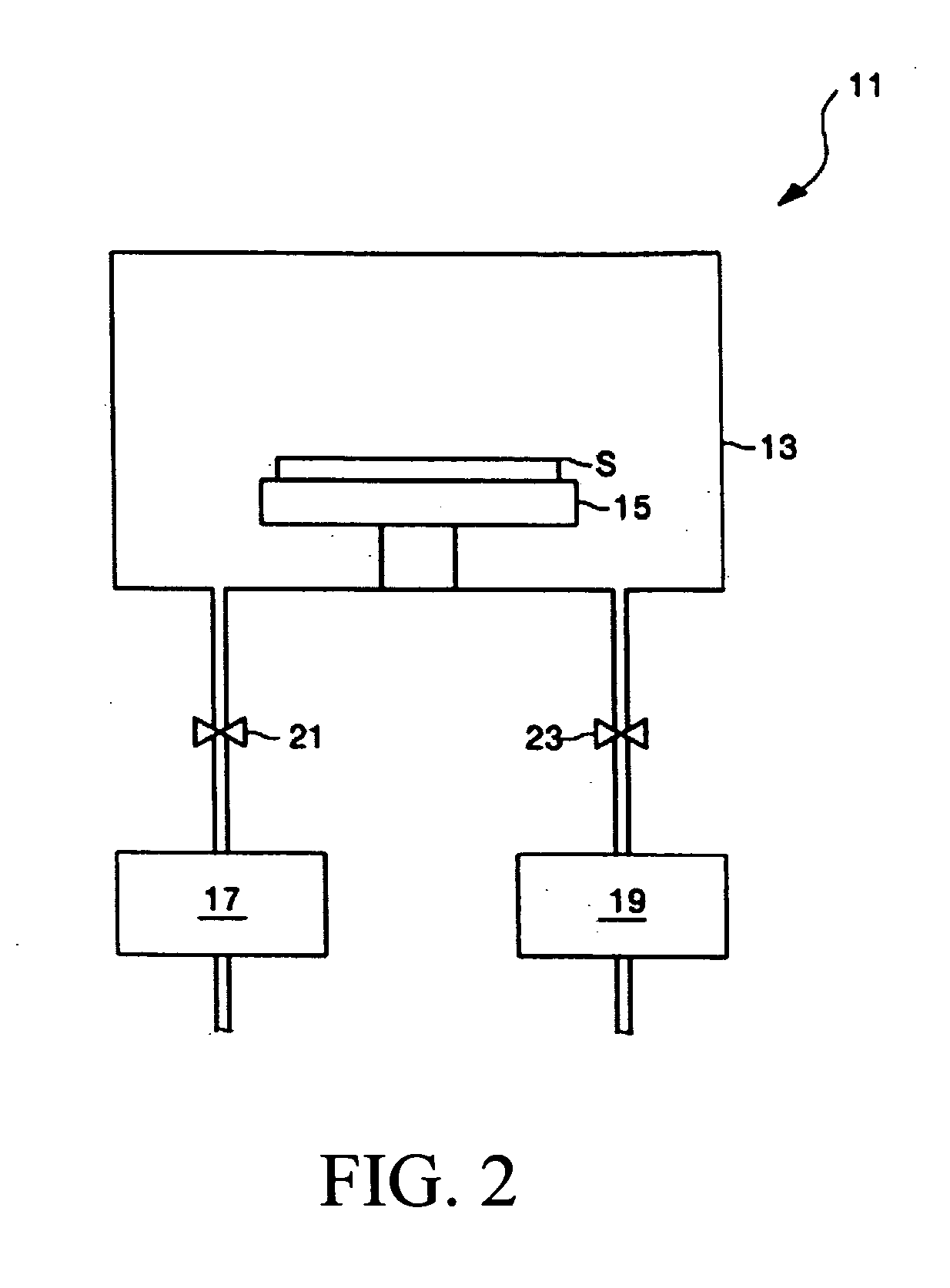

Methods for in-situ cleaning of semiconductor substrates and methods of semiconductor device fabrication employing the same

InactiveUS20060156970A1Reduce the possibilityReduce processing timePolycrystalline material growthMixing/kneading with horizontally-mounted toolsDecompositionGas composition

Provided is an in-situ precleaning method for use in conjunction with epitaxial processes that utilizes temperatures at or below those typically utilized during the subsequent epitaxial deposition under pressure and ambient conditions suitable for inducing decomposition of semiconductor oxides, such as native oxides, from exposed semiconductor surfaces. The reduced temperature and the resulting quality of the cleaned semiconductor surfaces will tend to reduce the likelihood of temperature related issues such as unwanted diffusion, autodoping, slip, and other crystalline stress problems while simultaneously reducing the overall process time. The combination of pressure, ambient gas composition and temperature maintained within the reaction chamber are sufficient to decompose semiconductor oxides present on the substrate surface. For example, the reaction chamber may be operated so that the concentration of evolved oxygen within the reaction chamber is less than about 50%, or even less than 10%, of the equilibrium vapor pressure under the cleaning conditions.

Owner:SAMSUNG ELECTRONICS CO LTD

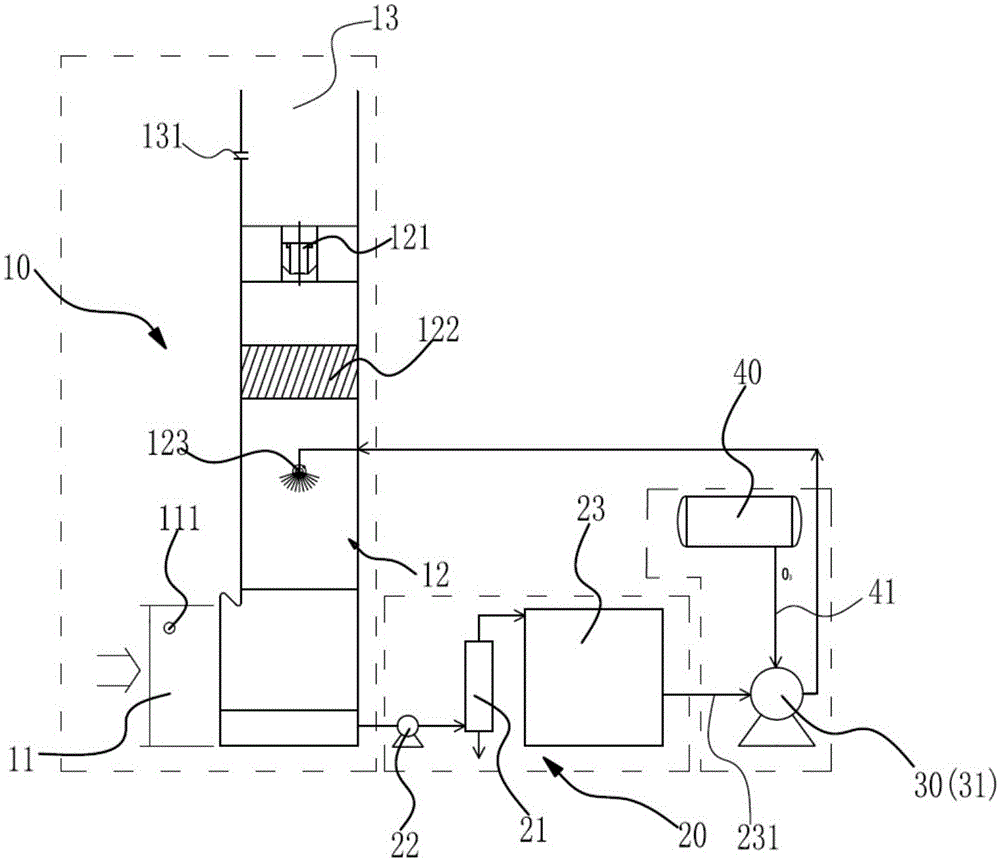

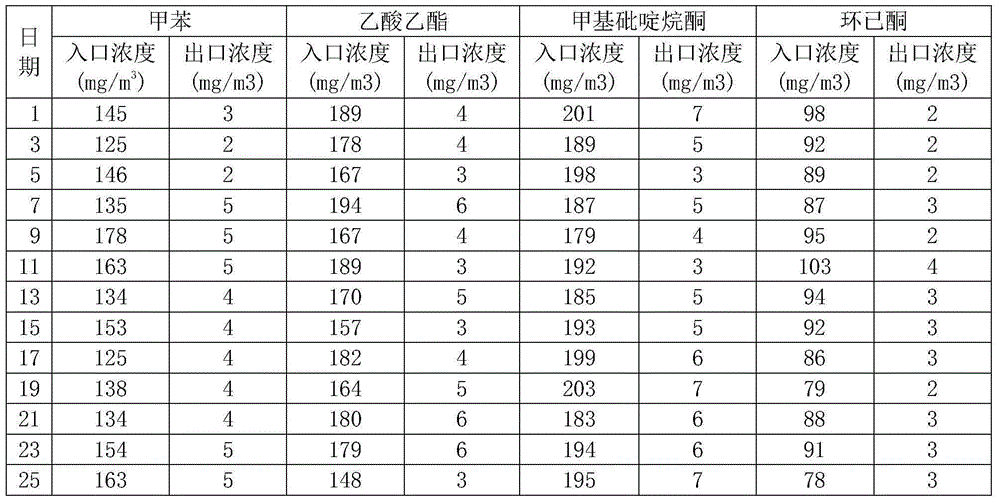

VOC (volatile organic compound) treatment system adopting ozone and micro-nano-bubbles

InactiveCN105056726AEfficient removalImprove adsorption capacityDispersed particle separationAir quality improvementMicro nanoFiltration

The invention discloses a VOC (volatile organic compound) treatment system adopting ozone and micro-nano-bubbles. The system comprises a waste gas treatment device, a spray liquid circulating filtration device, a micro-nano-bubble generation device and an ozone generation device, wherein the waste gas treatment device comprises a waste gas inlet, a waste gas purification chamber and a waste gas outlet; an axial flow fan, a gas-water separator and a micro-nano-bubble water mist spray nozzle are arranged in the waste gas purification chamber sequentially from top to bottom. The system adopts the ozone and the micro-nano-bubbles to degrade VOCs, a treatment method is safer than other treatment methods, the operation is convenient, and the treatment cost is low; the VOC removal rate can be higher than 96% by the aid of optimization selection of a spray liquid and mutual actions of the ozone generation device, the micro-nano-bubble generation device and the spray nozzle.

Owner:DONGGUAN BOSO ENVIRONMENTAL TECH CO LTD

Tamper indicating closure assembly

ActiveUS9463310B1Optimize allocationEasy to addIntravenous devicesTube connectorsAxial forceAccess port

A closure assembly structured for use with a female luer connector and operative to indicate an accomplished or attempted tampering thereof. A connector cover is movably and removably disposed within a housing and includes an interior chamber disposed and structured to receive an access port of the female connector. An indicator member is removably connected to an interior of the housing in surrounding relation to the connector cover and a drive assembly associated with both the connector cover and the housing is operable to concurrently rotate and axially advance the interior chamber into enclosing relation to the access port. Attempted removal of the housing from the female connector, such as by an applied axial force to the housing, will detach the indicated member from the housing and dispose it in a visually observable position surrounding the connector cover, thereby indicating attempted access.

Owner:MEDICAL DEVICE ENG

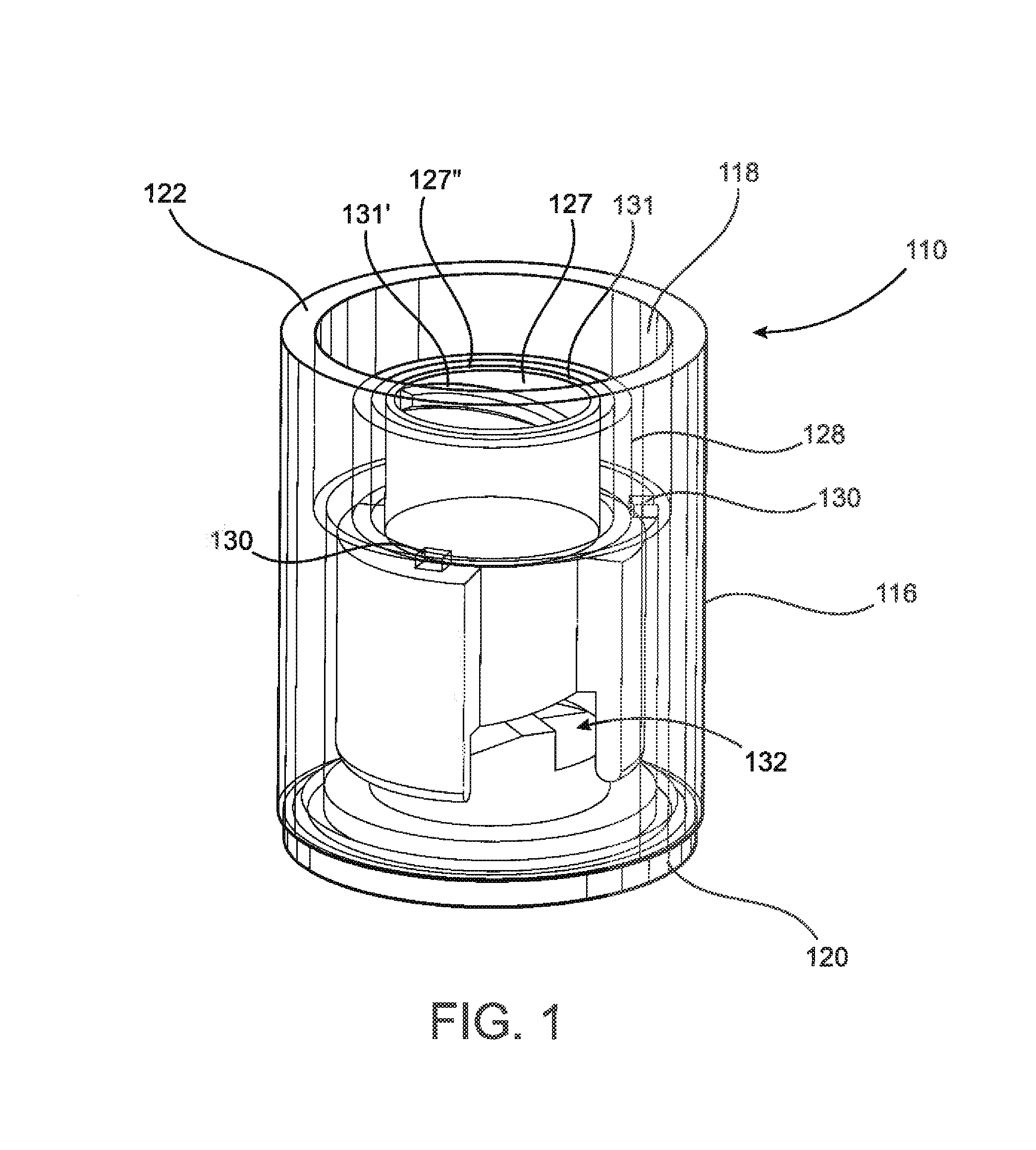

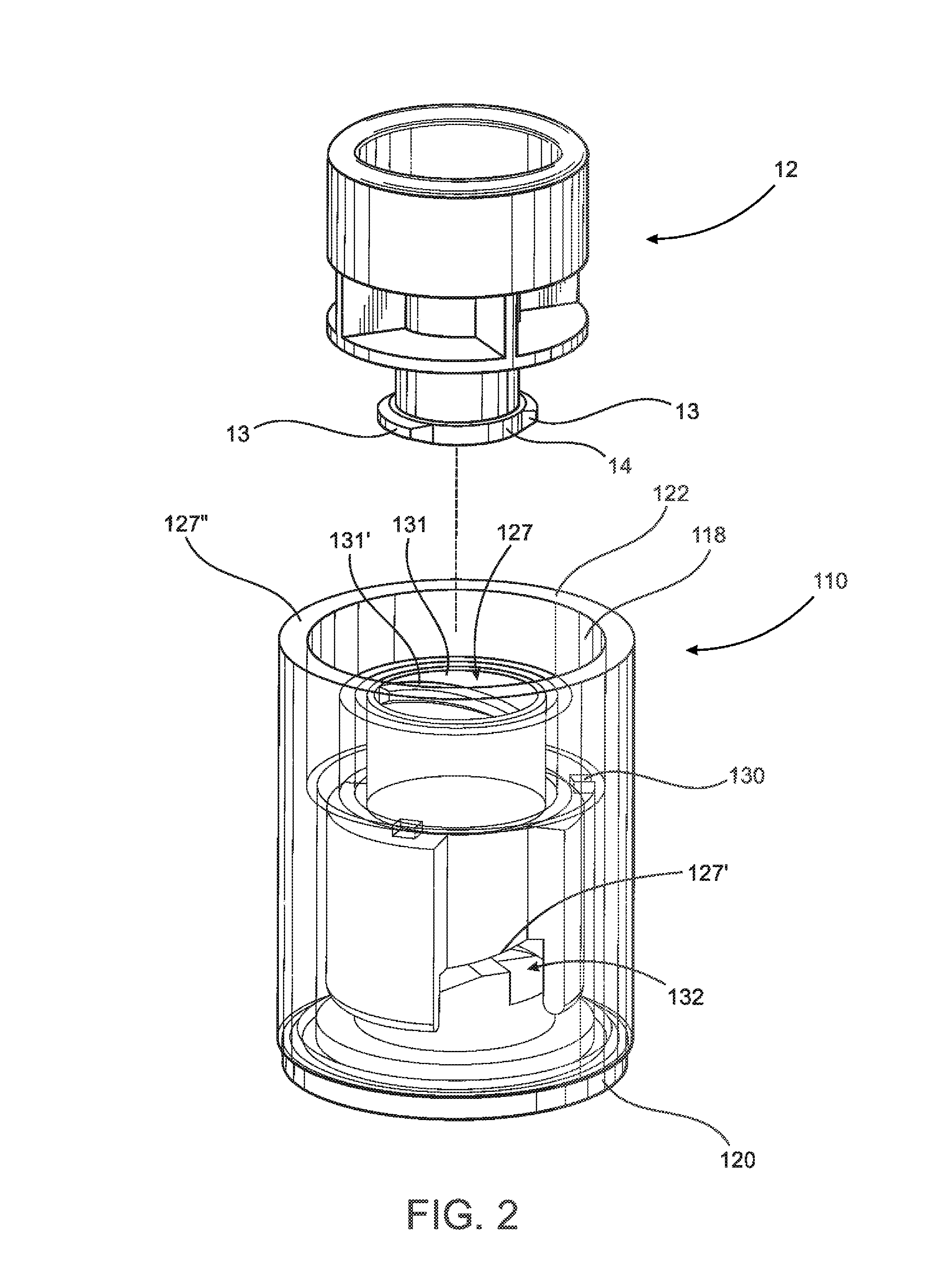

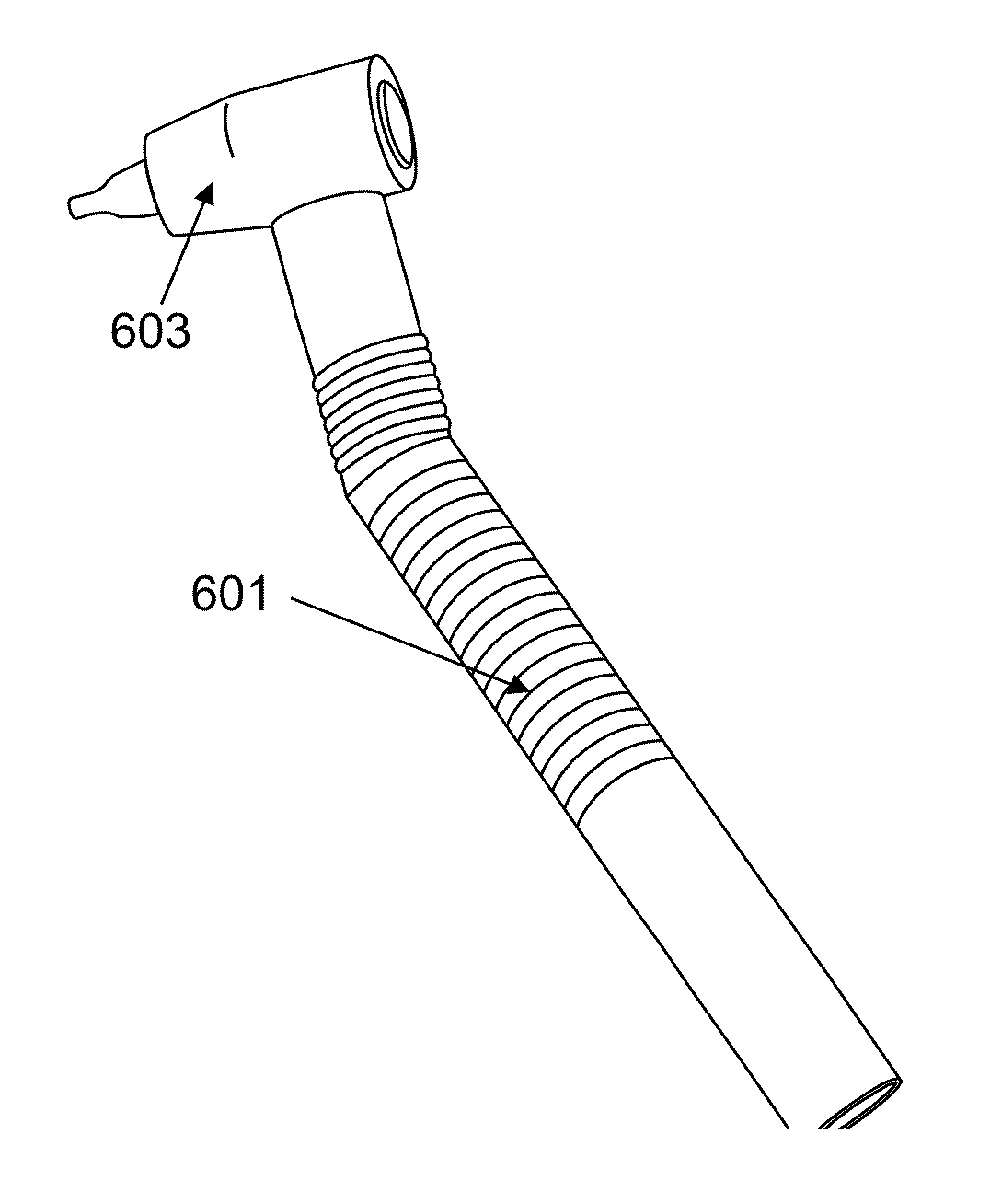

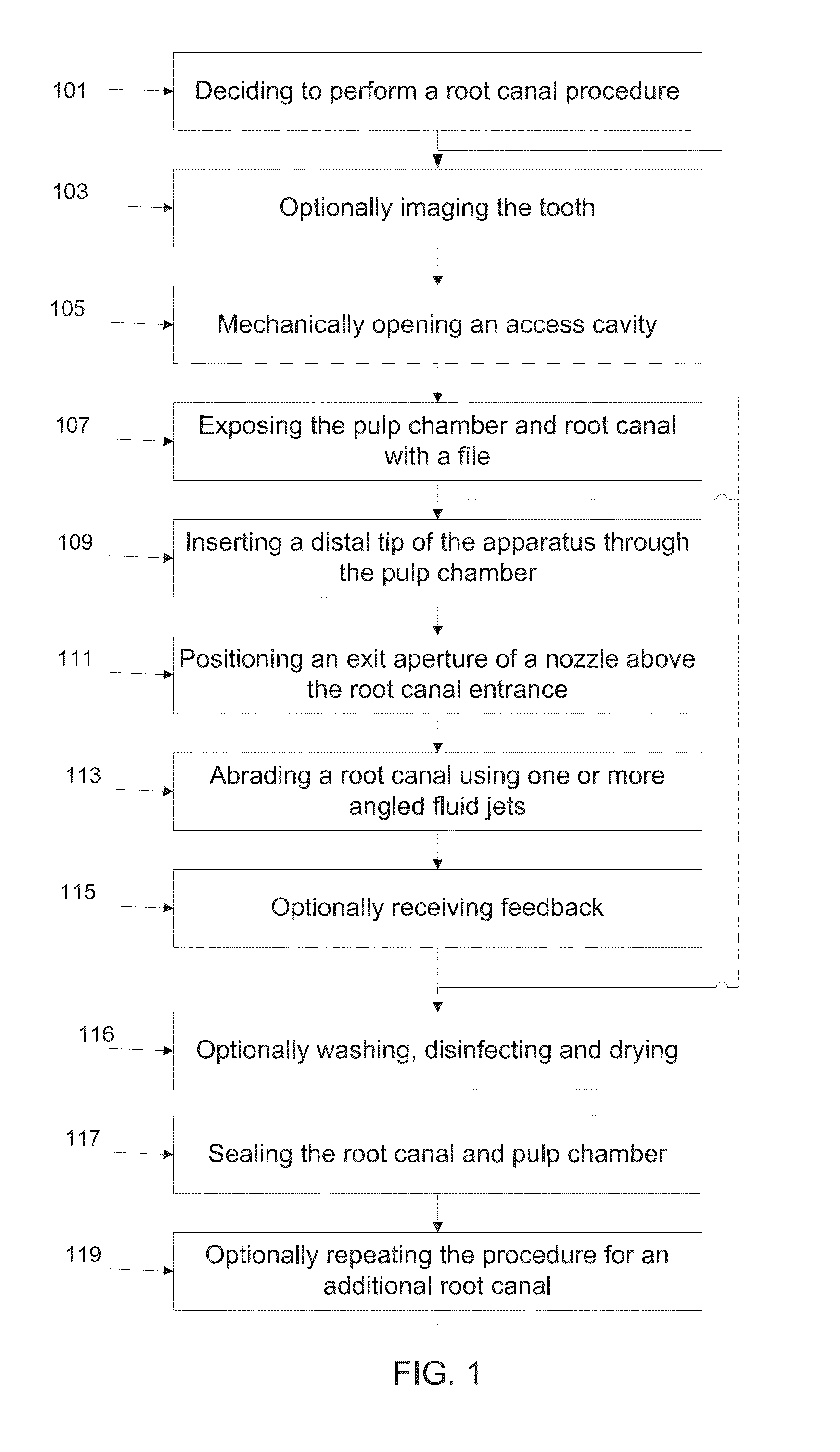

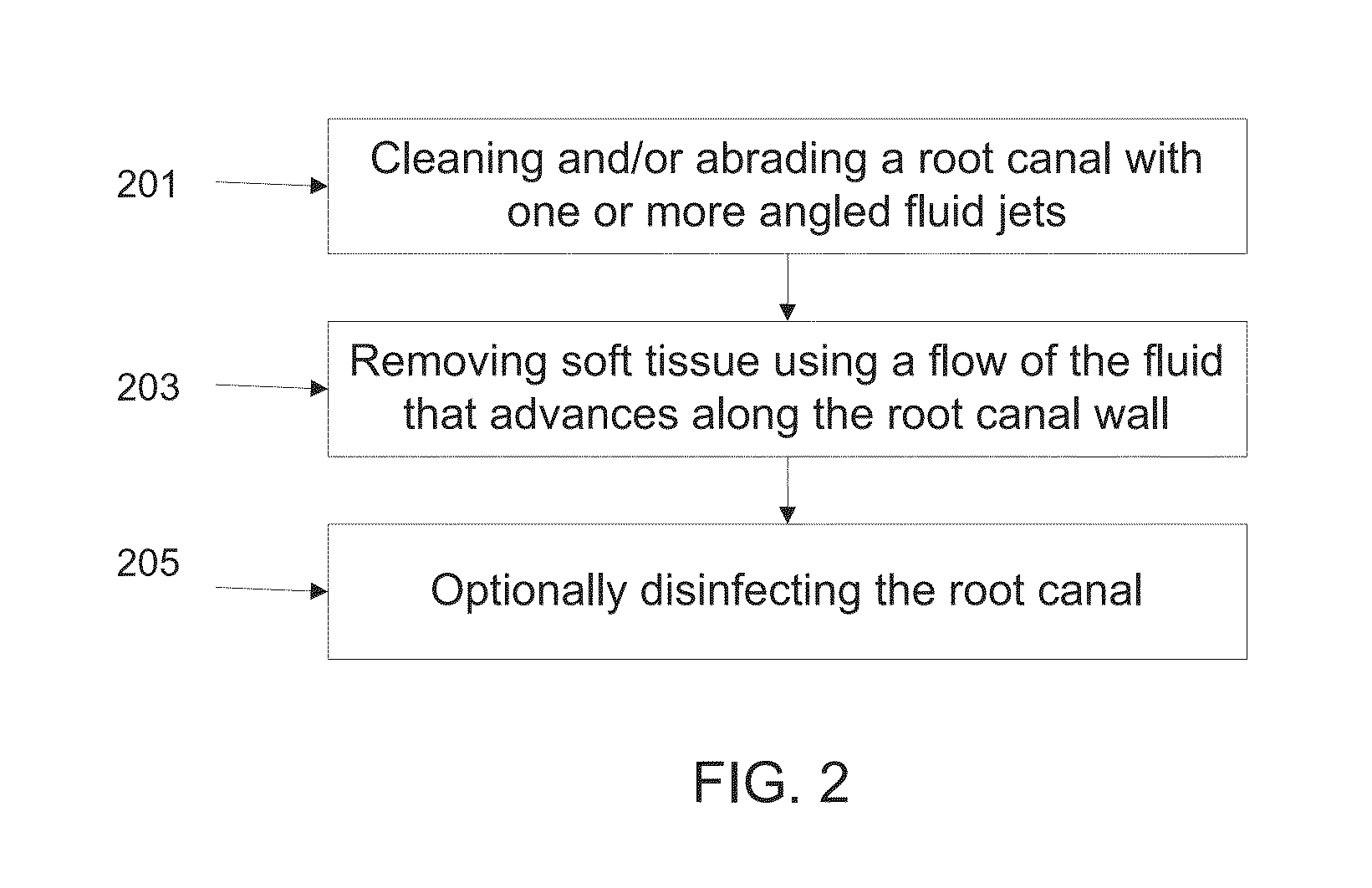

Apparatus and method for endodontic treatment

ActiveUS20150044631A1Increase rotation speedSpeed up the flowWheelchairs/patient conveyanceDental toolsEndodontic therapyDental Pulp Cavity

An apparatus for endodontic treatment, comprising: a nozzle connected to a fluid source comprising: a tip small enough to be inserted into a pulp chamber of a tooth; an inner geometry which forms a flow parameters including non-axial flow direction of nozzle fluid flowing through the inner geometry such that discharge fluid discharged from the inner geometry increase rotation of root canal fluid within a root canal sufficiently to remove tissue from the root canal.

Owner:FLUIDFILE +1

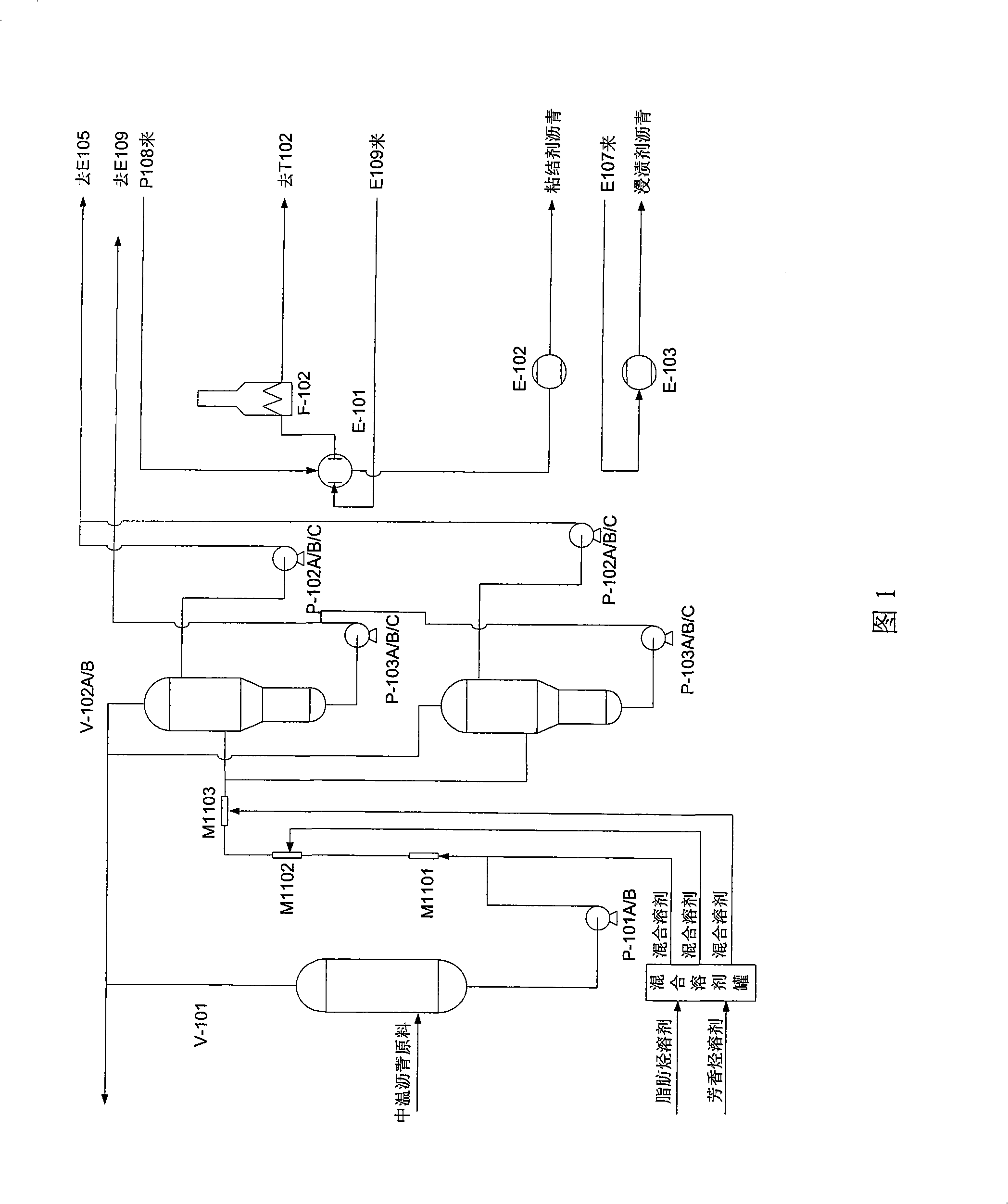

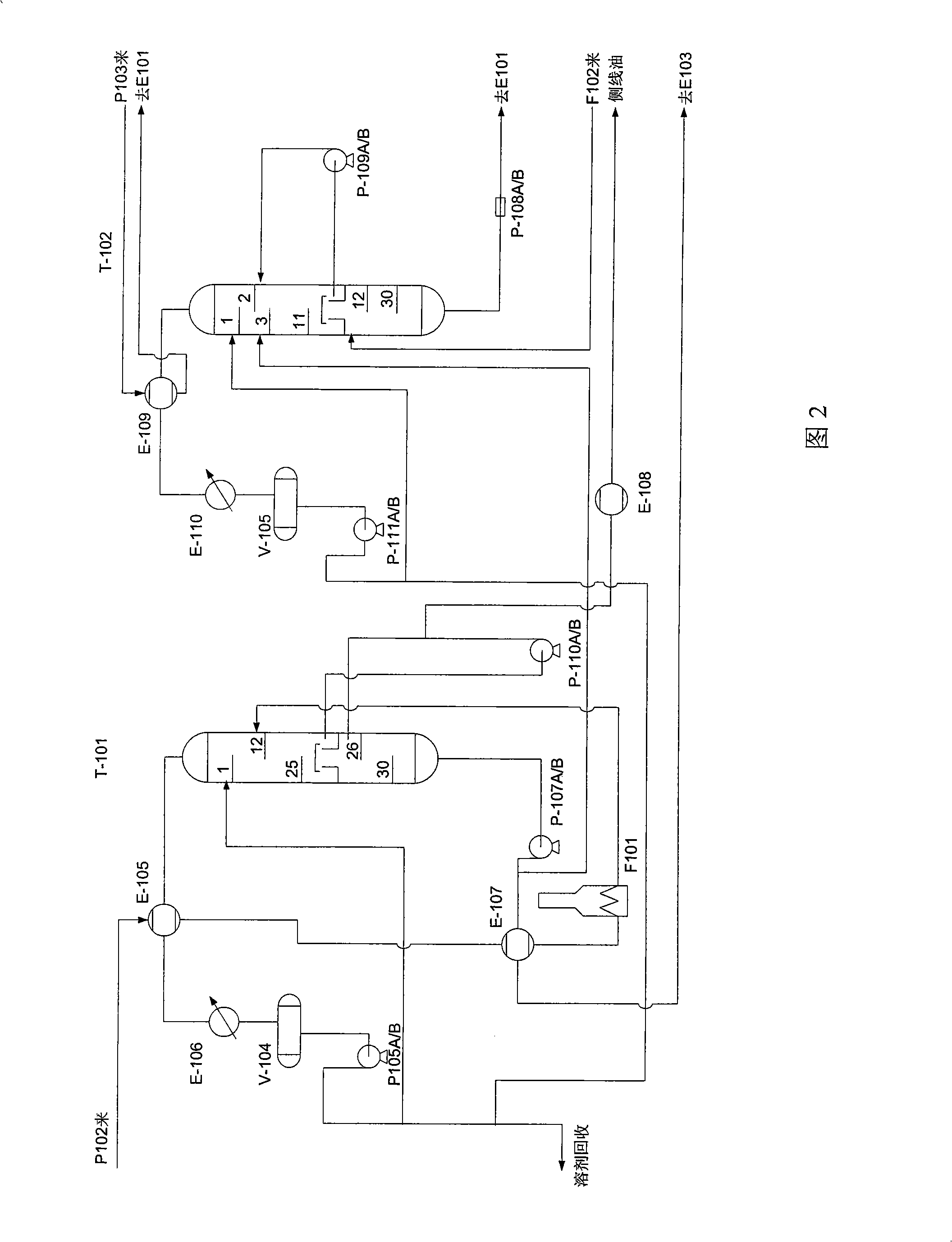

Production process of dipping agent bitumen

ActiveCN101289625AImprove extraction efficiencyReduce manufacturing costWorking-up pitch/asphalt/bitumen by selective extractionSurface treatment compositionsSolventChemistry

The invention relates to a method for manufacturing impregnant bitumen. The method comprises the following steps: aliphatic hydrocarbon solvent and aromatic hydrocarbon solvent are selected to make mixed solvent; mid-temperature coal pitch or coal tar maltha and the mixed solvent are fed in at least three stages of mixers in a certain proportion, and then are fed in an extracting tower for separation after fully mixing; light phase bitumen and heavy phase bitumen with less quinoline insoluble content are extracted for separation inside the extracting tower; and the impregnant bitumen is obtained through the steam stripping of the light phase bitumen inside a stripping tower. The method makes use of equipment with simple structure, and bitumen blockage is not easy to occur; moreover, the method can realize continuous industrial production of high-quality impregnant bitumen, and reduces cost.

Owner:山西宏特煤化工有限公司

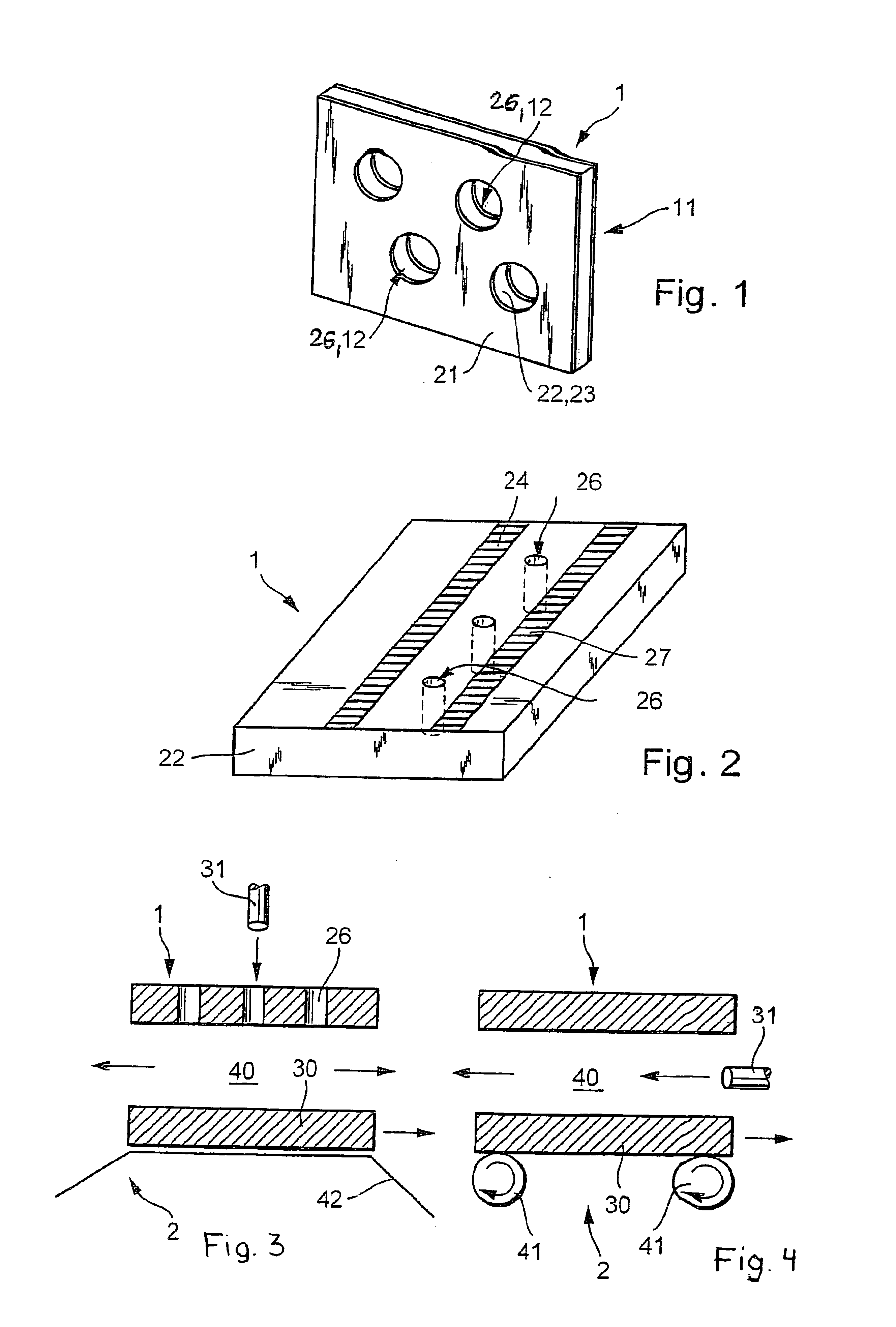

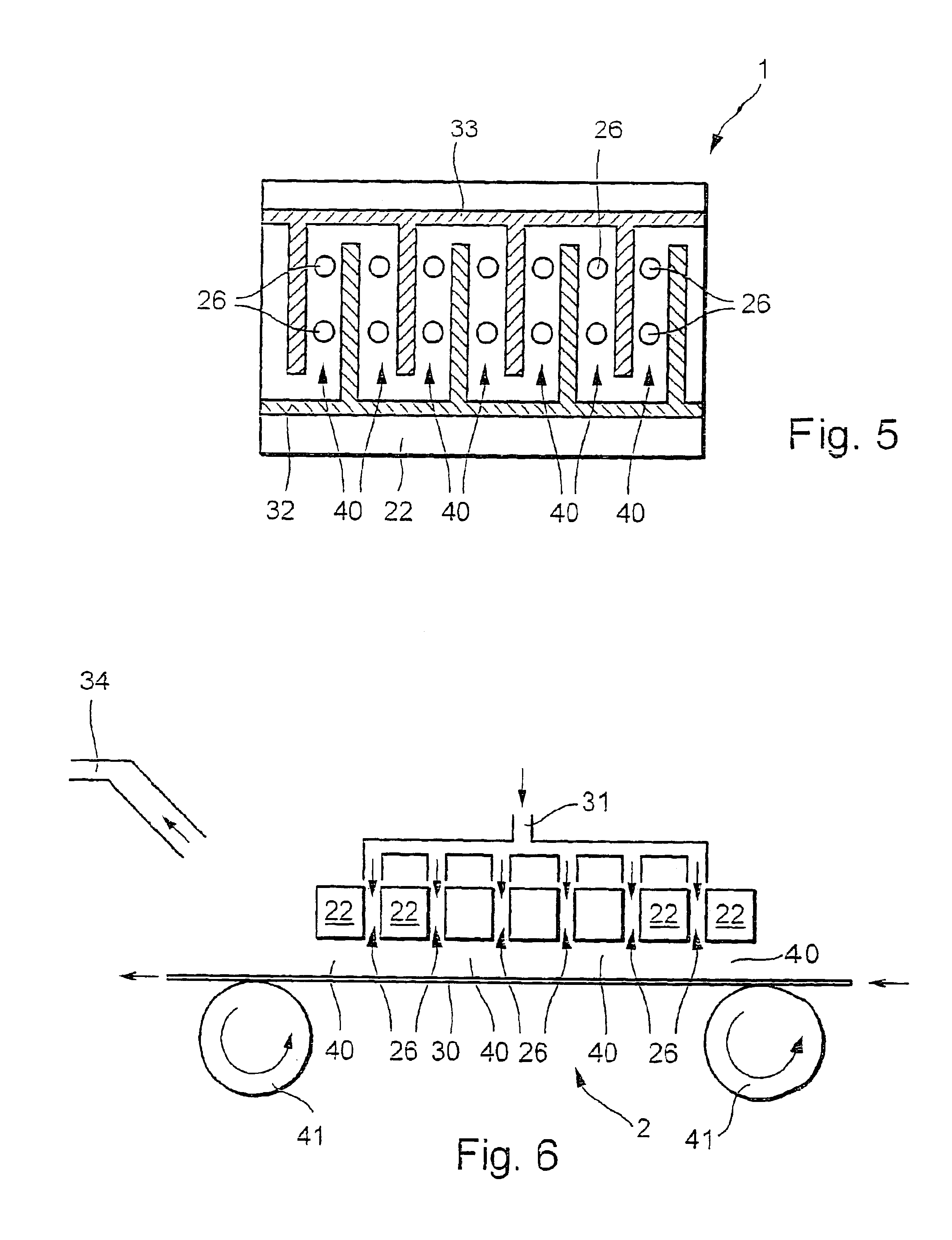

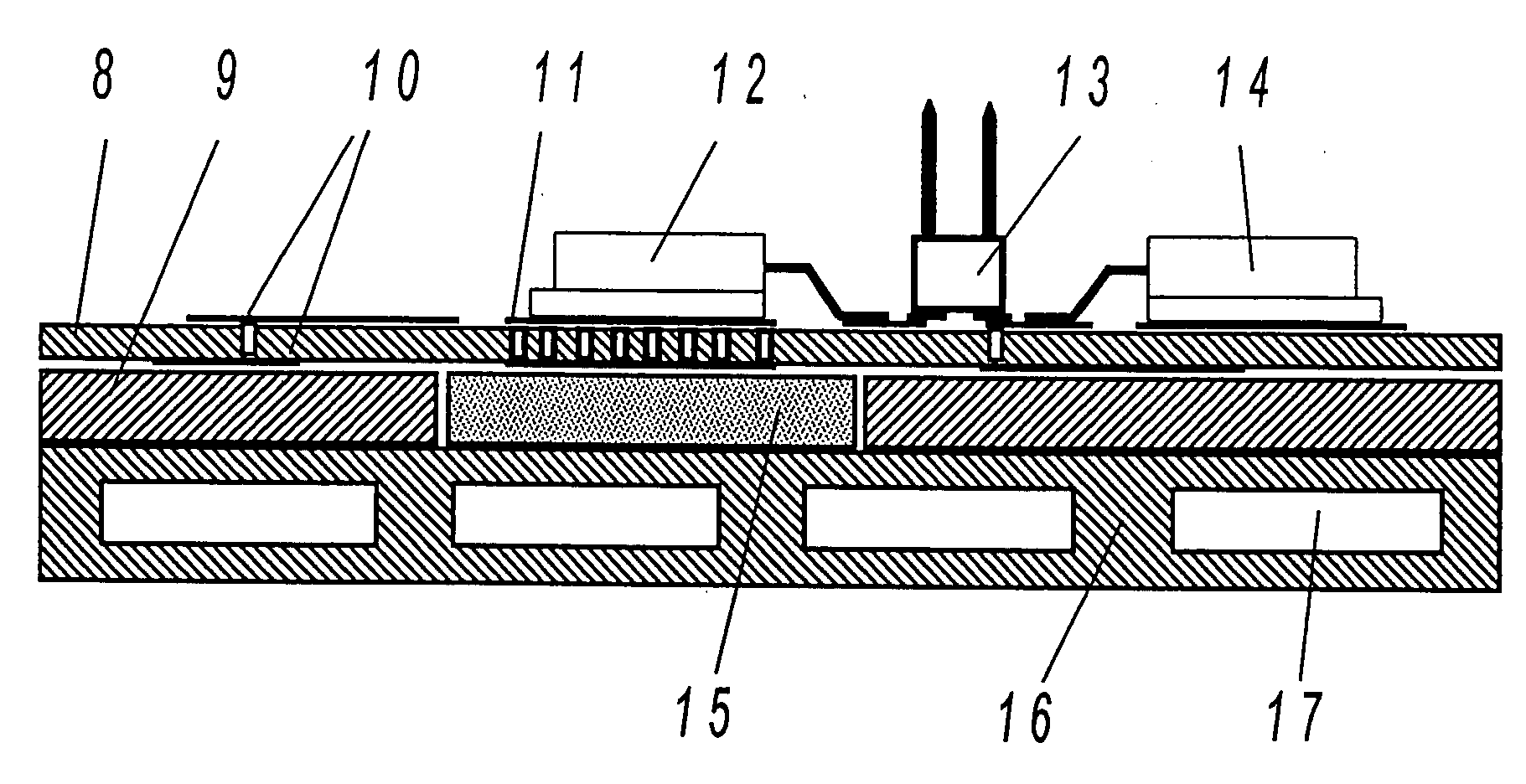

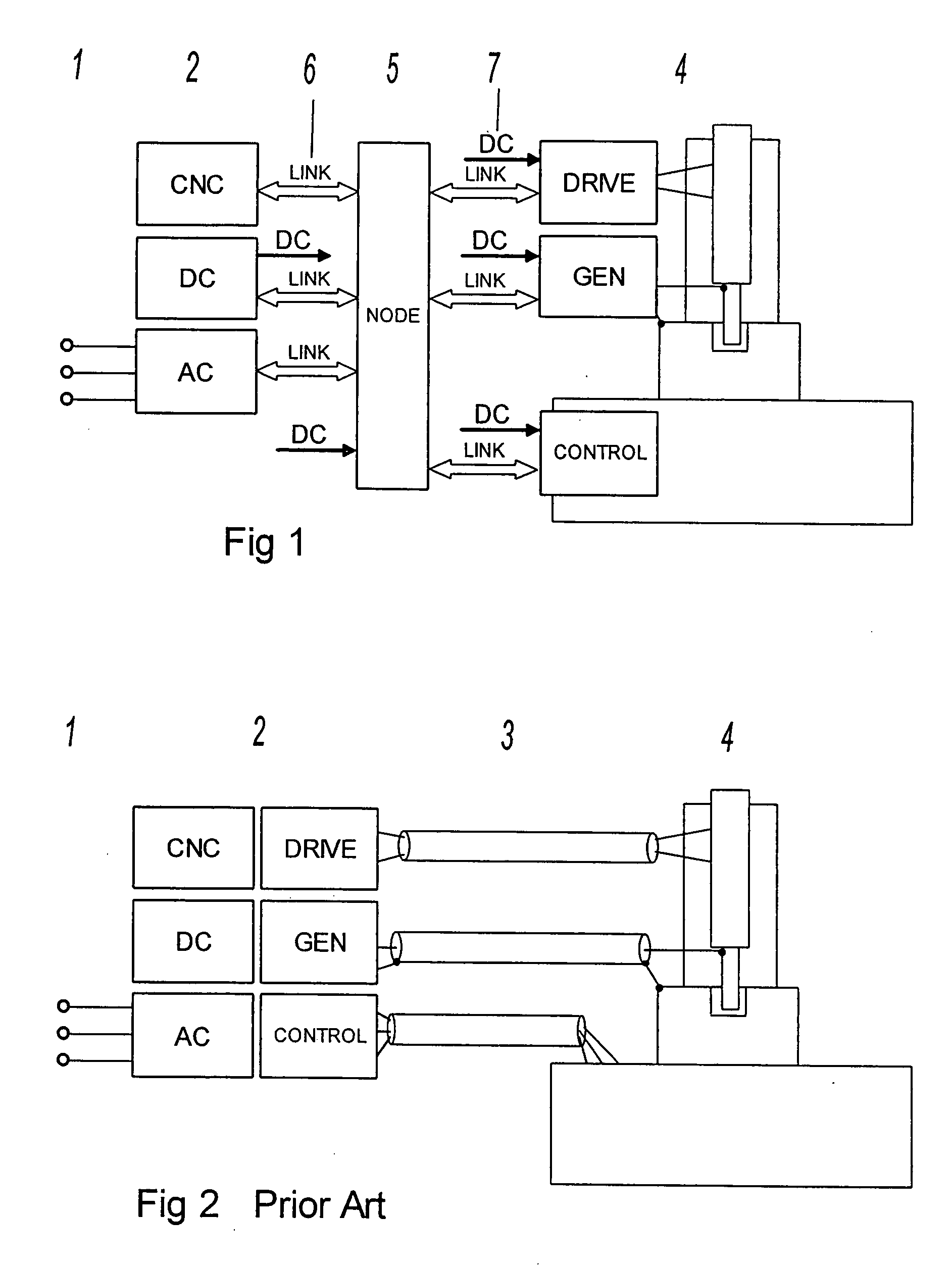

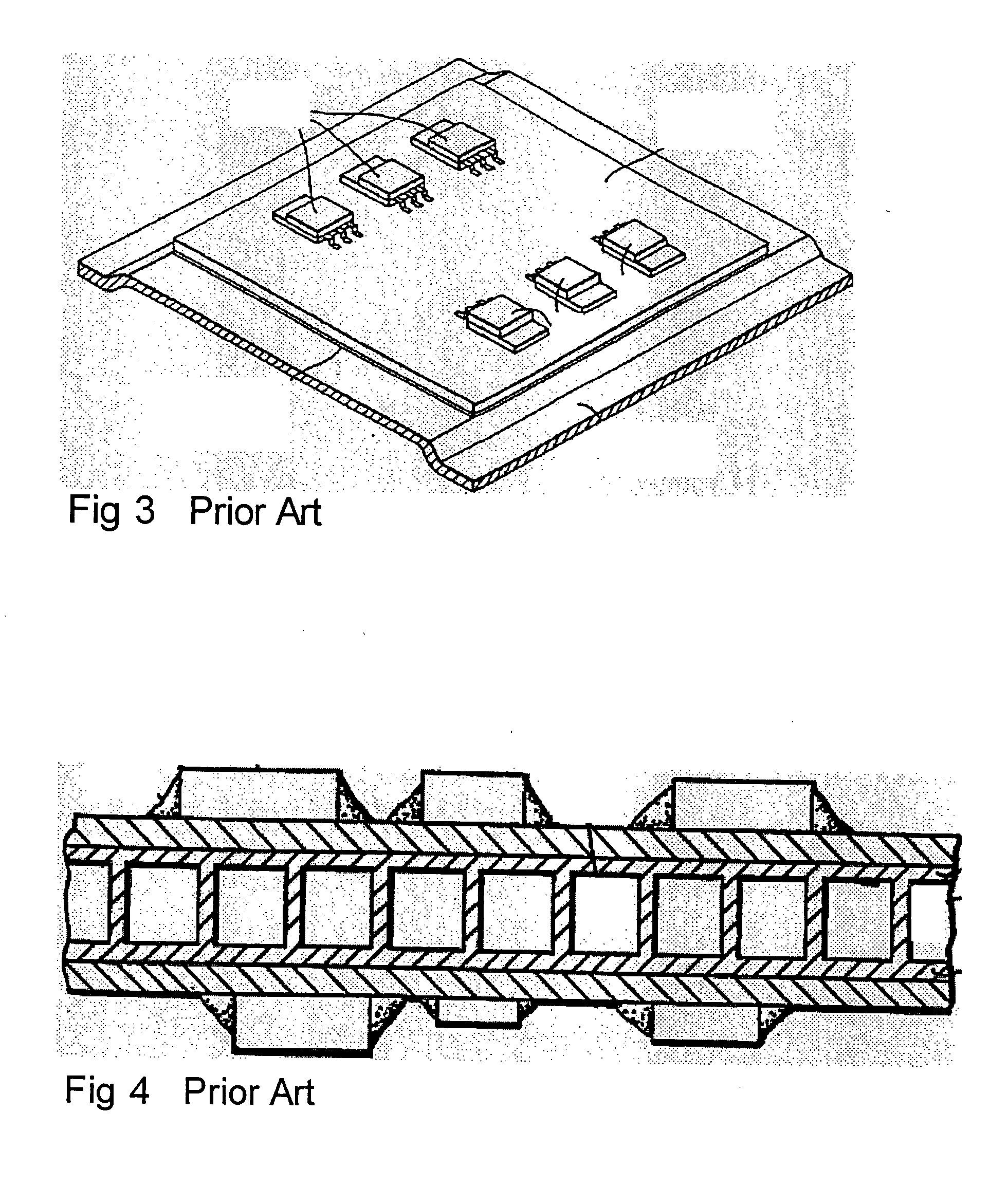

Circuit board unit and method for production thereof

InactiveUS20080160246A1Adequate heat dissipationFully removedLayered productsSemiconductor/solid-state device detailsSurface mountingHigh heat

The invention relates to a circuit board unit and a method for production thereof. The circuit board unit comprises a circuit board topmost laminate with conductive tracks on the upper side for mounting surface-mountable devices. The circuit board topmost laminate features a thickness dimensioned such that the anticipated heat dissipated by the surface-mountable devices is transported from the upper side to the underside of the circuit board laminate to good effect. The circuit board unit further comprises an electrically insulating laminate arranged under the circuit board topmost laminate, inserts made of a material with good heat conductivity and electrical insulation embedded in the electrically insulating laminate at sites below surface-mountable devices with high heat dissipation, and a cooling plate arranged below the electrically insulating laminate and the inserts.

Owner:CHARMILLES TECH SA +1

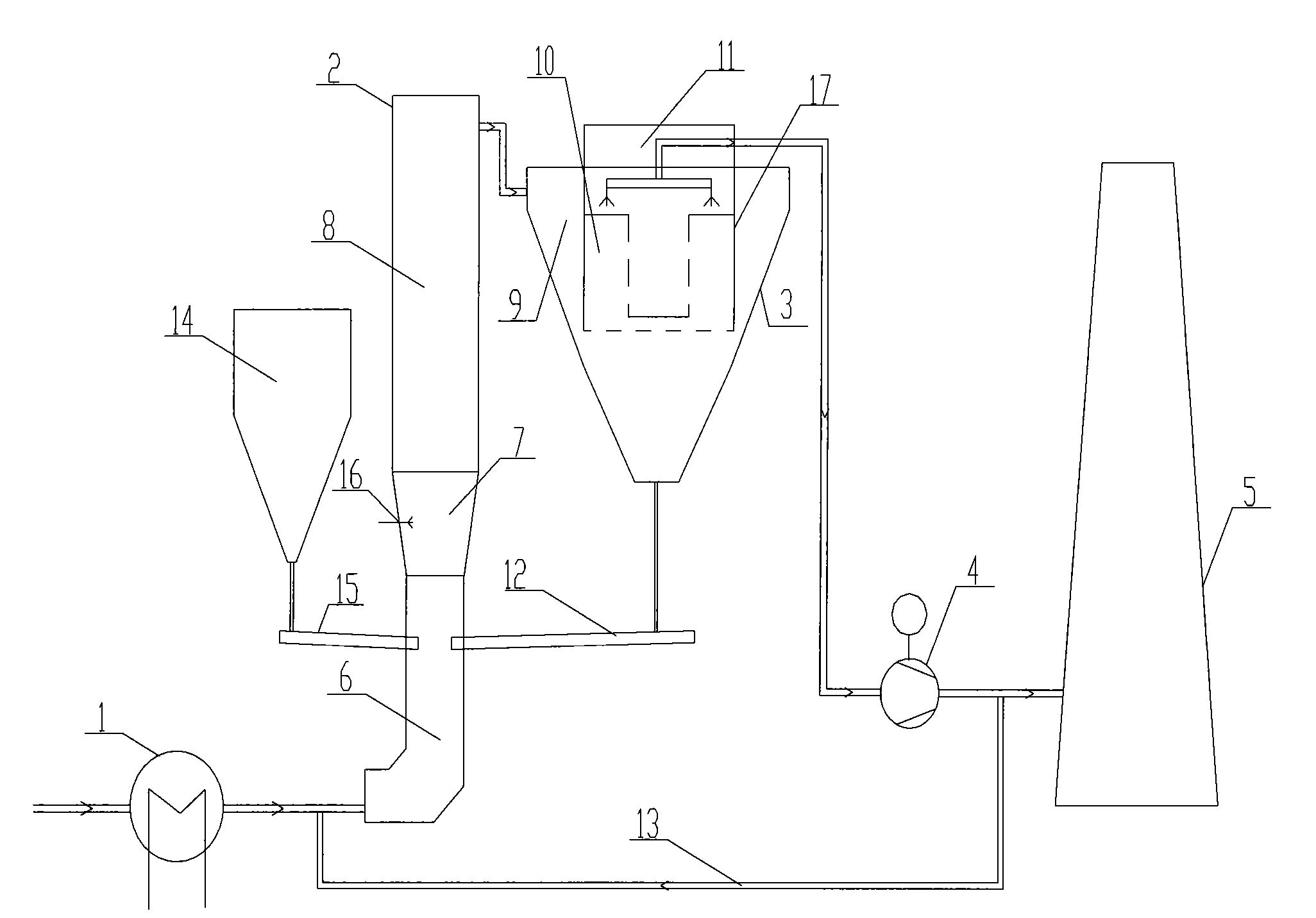

Clearing device for smoke pollutants of glass kiln and clearing method thereof

InactiveCN101628201ASolution to short lifeReduce loadCombination devicesGlass furnace apparatusSmall footprintEngineering

The invention relates to smoke treatment, in particular provides a clearing device for smoke pollutants of a glass kiln and a clearing method thereof. The clearing device is suitable for the glass kiln with high smoke temperature, smaller smoke amount, high clearing efficiency, stable system operation, simple structure and small floor area and is provided with an afterheat recovery boiler, a reaction tower, a bag dust collector, a circulating fluidization flume, a clean smoke recirculating flue, an absorbent bin and a feeding air flume which are sequentially connected. The clearing method comprises the following steps: smoke emitted by the glass kiln enters the afterheat recovery boiler; original smoke emitted by the afterheat recovery boiler enters a high-temperature reaction region of the reaction tower for premixing treatment with an absorbent, is accelerated by a Venturi accelerating region before entering a circulating fluidization reaction region and is cooled and purified before entering the bag dust collector; the purified smoke emitted from the reaction tower firstly enters the bag dust collector to remove particles and is emitted to a chimney by a draft fan in a purification chamber; and reaction dust emitted by the reaction tower is collected by the bag dust collector and is returned to the high-temperature reaction region.

Owner:FUJIAN LONGKING DSDN ENGINEERING CO LTD

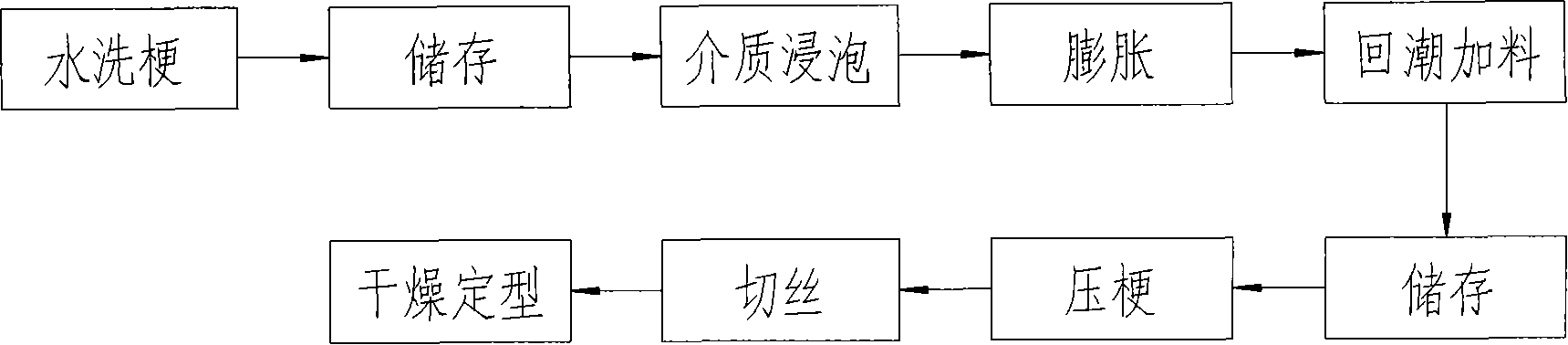

Technique of pre-expanding treating cabo

ActiveCN101108028AFully removedLarge specific surface areaTobacco preparationTobacco treatmentFilling materialsEngineering

A tobacco stalk pre-expending processing technics is provided, which is characterized in that: the technics comprises the following procedures: washing, storing, expanding in liquid and marinating with interface the tobacco stalk, expanding the stalk strips, moisture regaining and feeding, storing, pressing sticks and drying for shaping. The technics method of the invention changes the expanding of cut rolled stem into expanding the tobacco stick by using marinating with high temperature and low pressure and then expanding with high temperature and reduced preddure, thus sufficiently eliminating the bad flatus in the tobacco stick as the flatus of the wood or the corrupt straws; the tobacco stick after expanded has increased cells and remarkably enhanced ratio surface, thus the material liquid can filter into the tobacco sticks sufficiently to becoming a natural filling material and adaptation carrier for adjusting the cigarette fragrance and style; the cigarette stick after expanded is large in volume, which, after pressed, is easy being cut into silkiness (similar as the physical behavior of tobacco shred); after dried and shaped normally, the cut rolled stem can crisp naturally, thus increasing the filling capacity. The cut rolled stem processed by the technics method of the invention is basically similar with tobacco shred in color and shape and the alloying evenness of the tobacco shred is increased; besides, the tobacco shred has no bad aftertaste when smoking, but has strong filling capacity and enhanced internal quality.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

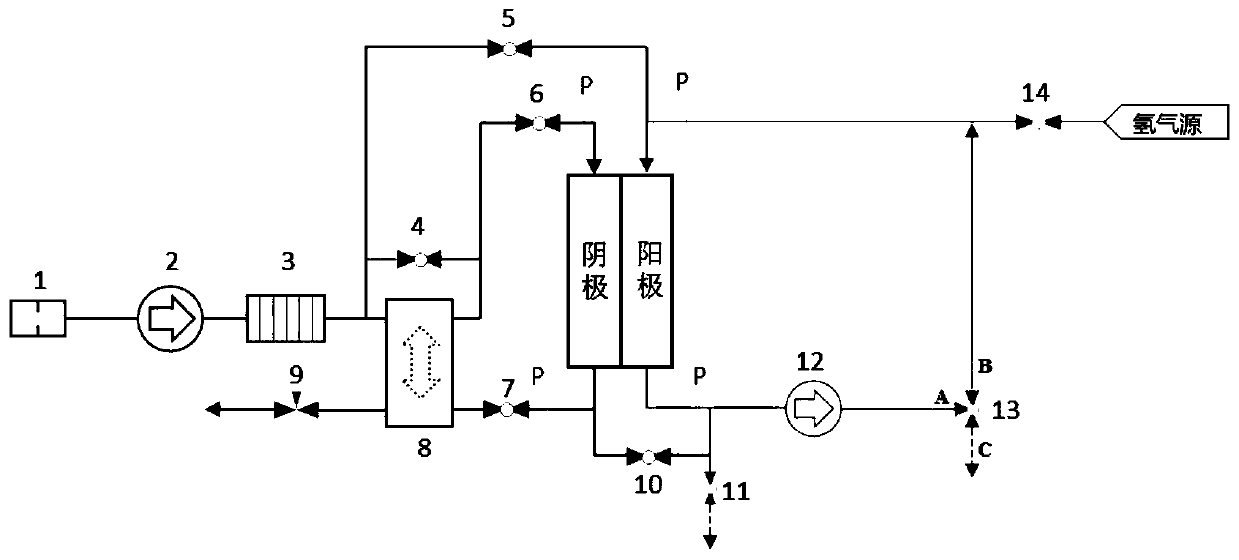

Fuel cell engine purging system and control method thereof

The invention discloses a fuel cell engine purging system and a control method thereof. The fuel cell engine purging system is mainly composed of an air filter, an air compressor, an intercooler, a humidifier bypass valve, an anode purging shut-off valve, an electric pile air inlet shut-off valve, an electric pile air outlet shut-off valve, an air humidifier, a back pressure valve, a vacuum shut-off valve, a hydrogen tail exhaust valve, a hydrogen cycle pump, a three-way steering valve and a hydrogen inlet shut-off valve. The residual water can be fully removed in a short time with low energyconsumption.

Owner:佛山市清极能源科技有限公司

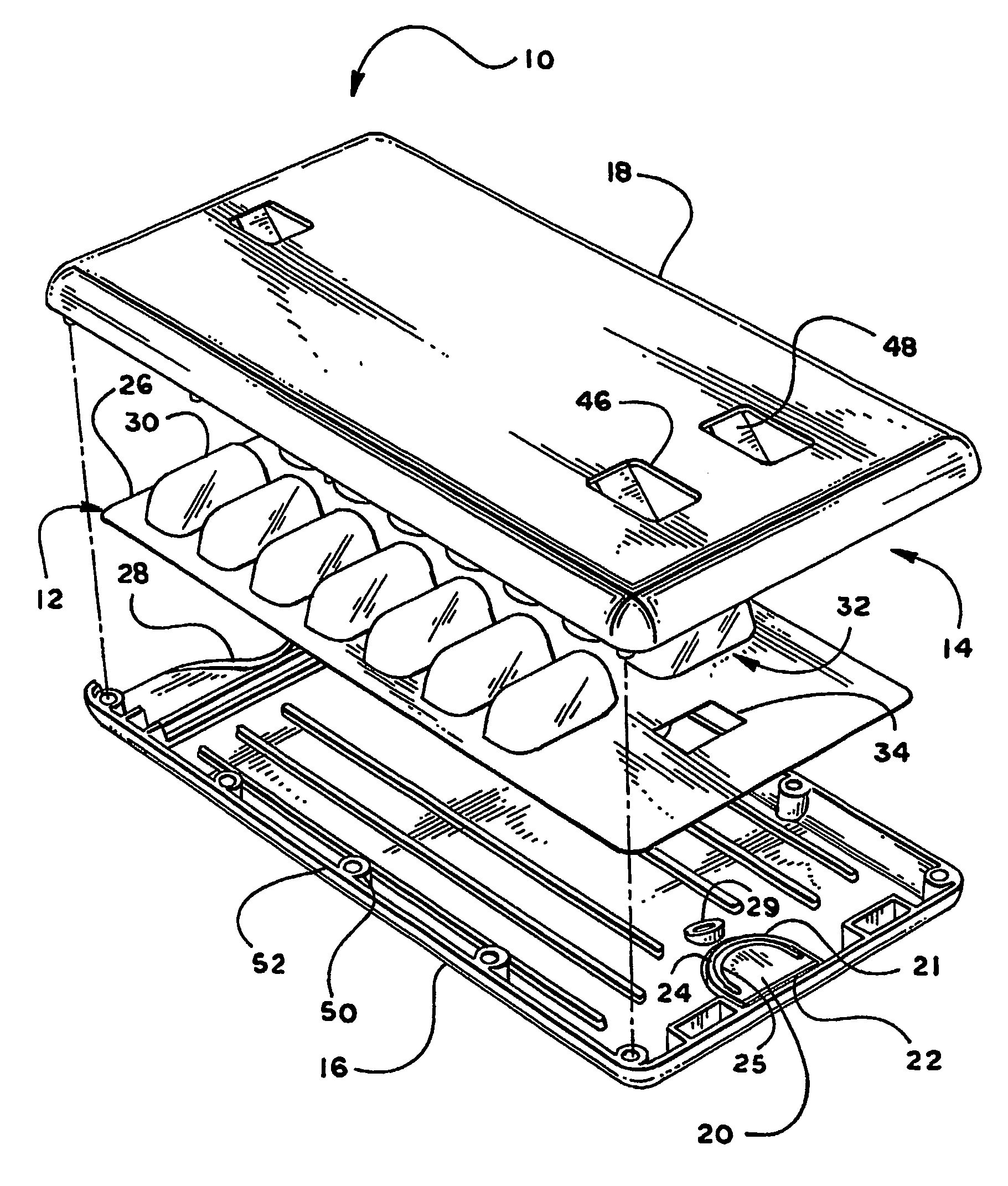

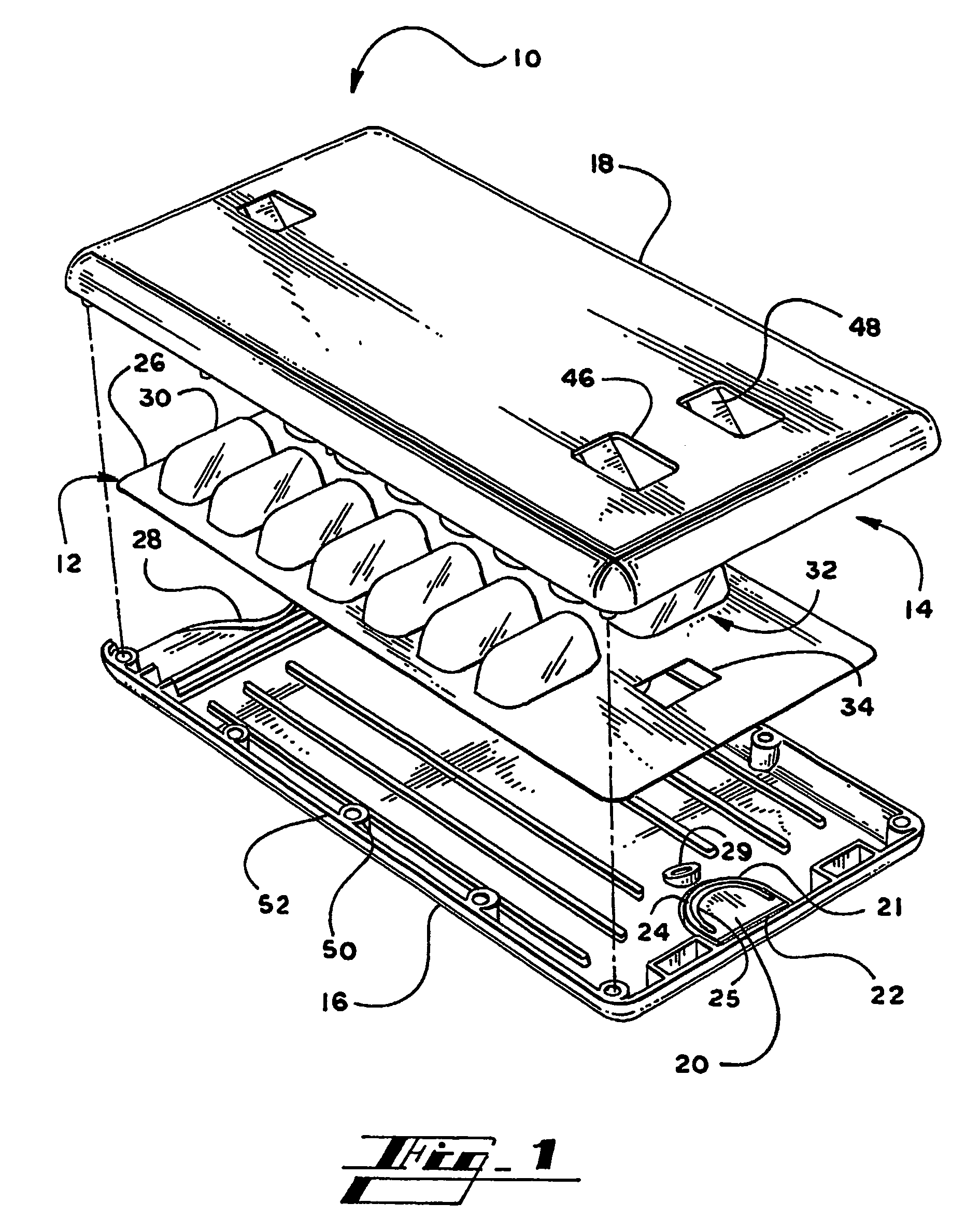

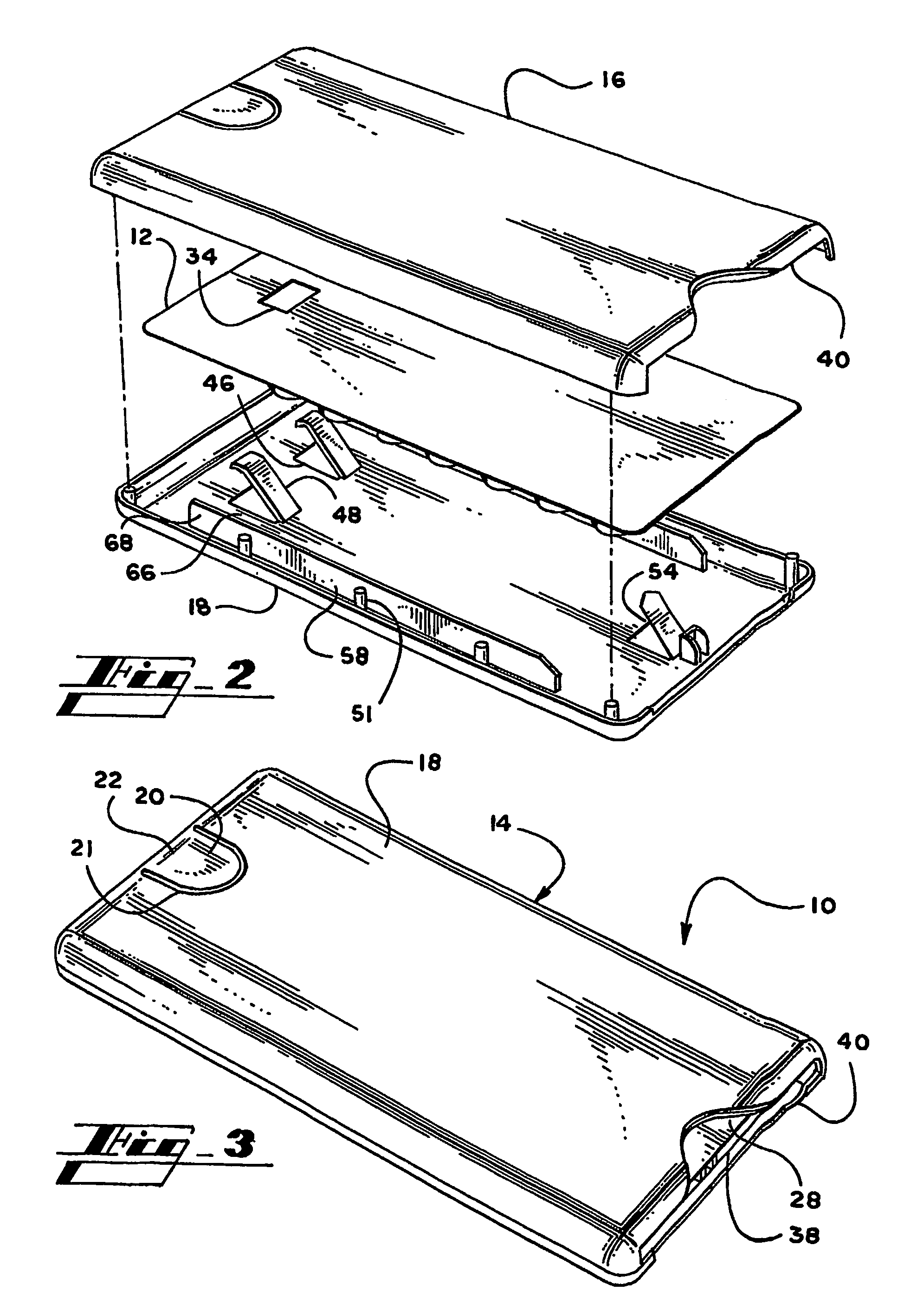

Unit dose locking container

ActiveUS7591372B2Lower assembly costsFully removedSmall article dispensingArticle unpackingDetentEngineering

A package has a sliding blister card and a locking sleeve made from a base and a top. The card is made from conventional blister dose packaging material, with blisters formed in a single layer plastic top holding medicaments on a sealing paper, board, or foil layer. The top and base form a closed case, open along one end. The blister card is slid into the sleeve until detent(s) engage aperture(s). Appurtenant(s) adjacent to the detent(s) urge the blister card to engage the detent(s) at the card's receiving aperture. Pressing on release disengages the card and detent by warping the card to move the aperture away from the detent so that the card may be slid through the open end of the sleeve. Reverse pressure easily slides the blister card back into the containment element without manipulation of parts.

Owner:WESTROCK MWV LLC

Method for cleaning a surface of a substrate

InactiveUS6896744B2Improve efficiencyFully removedDetergent mixture composition preparationSemiconductor/solid-state device manufacturingHydrofluoric acidEtching

A highly efficient method for cleaning a substrate, whereby in the cleaning of the substrate, ① in a short time, {circle around (2)} both particle contaminants and metal contaminants can be removed, and ③ a problem associated therewith, such as re-deposition of contaminants or a dimensional change due to etching, can be remarkably reduced, and which has the following characteristics.A method for cleaning a surface of a substrate, which comprises at least the following steps (1) and (2), wherein the step (2) is carried out after carrying out the step (1):Step (1): A cleaning step of cleaning the surface of the substrate with an alkaline cleaning agent containing a completing agent, andStep (2): A cleaning step employing a cleaning agent having a hydrofluoric acid content C (wt %) of from 0.03 to 3 wt %, wherein the cleaning time t (seconds) of the substrate with said cleaning agent is at most 45 seconds, and C and t satisfy the relationship of 0.25≦tC1.29≦5.

Owner:MITSUBISHI CHEM CORP

Method for ultrasonic cleaning of a working electrode in electrochemical cell useful for automated trace metals measurement

ActiveUS20080017523A1Reduced effectivenessFully removedPhysical/chemical process catalystsWeather/light/corrosion resistanceTrace metalAcoustic wave

Methods for cleaning and regenerating a working electrode in an electrochemical cell; method for measuring the concentration of a metal in a liquid sample in an electrochemical cell having a working electrode, the method including a step for cleaning and / or regenerating the electrode; and an assembly having an ultrasonic device in sonic communication with an electrochemical cell.

Owner:AMS TRACE METALS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com