Patents

Literature

257results about How to "Avoid coating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

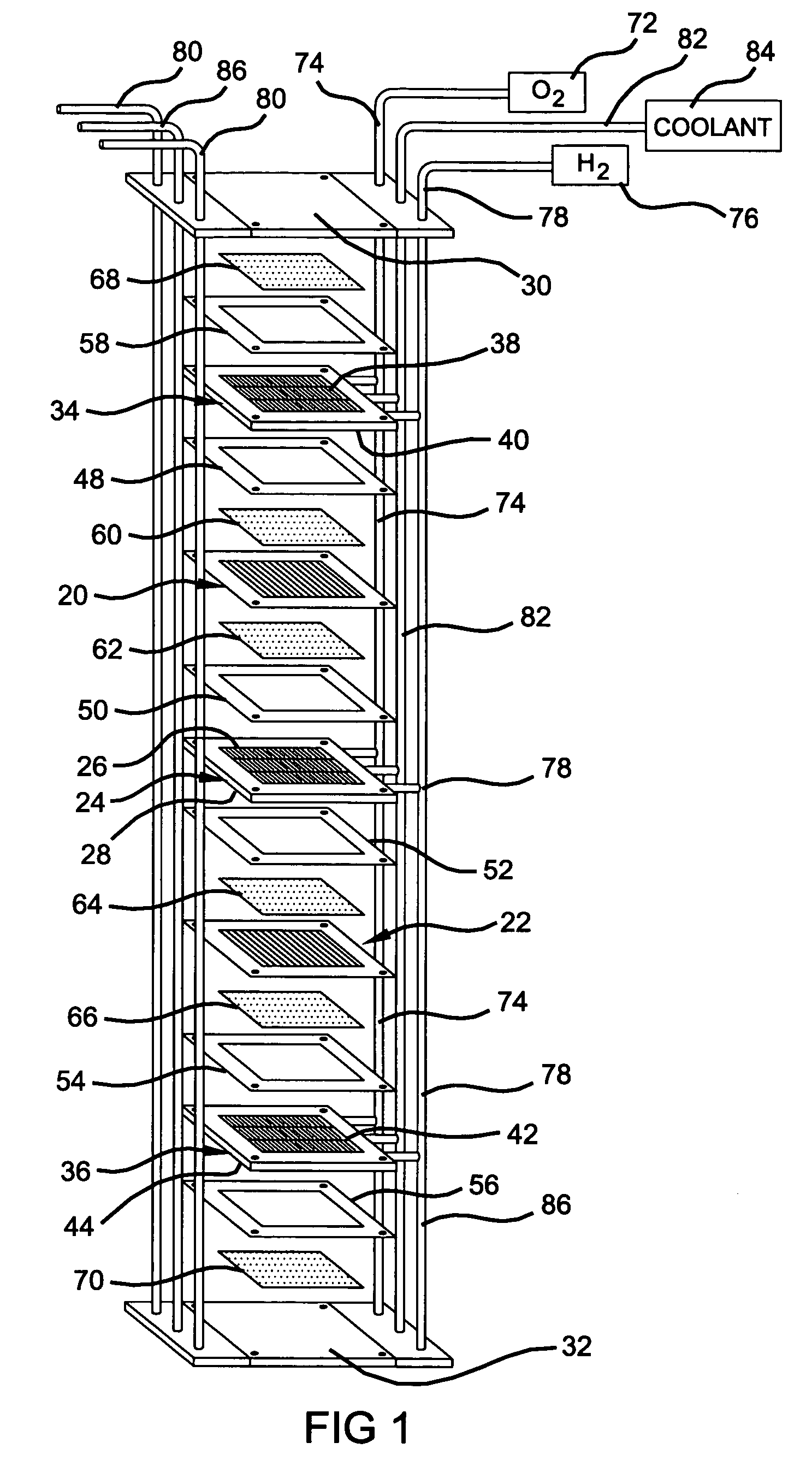

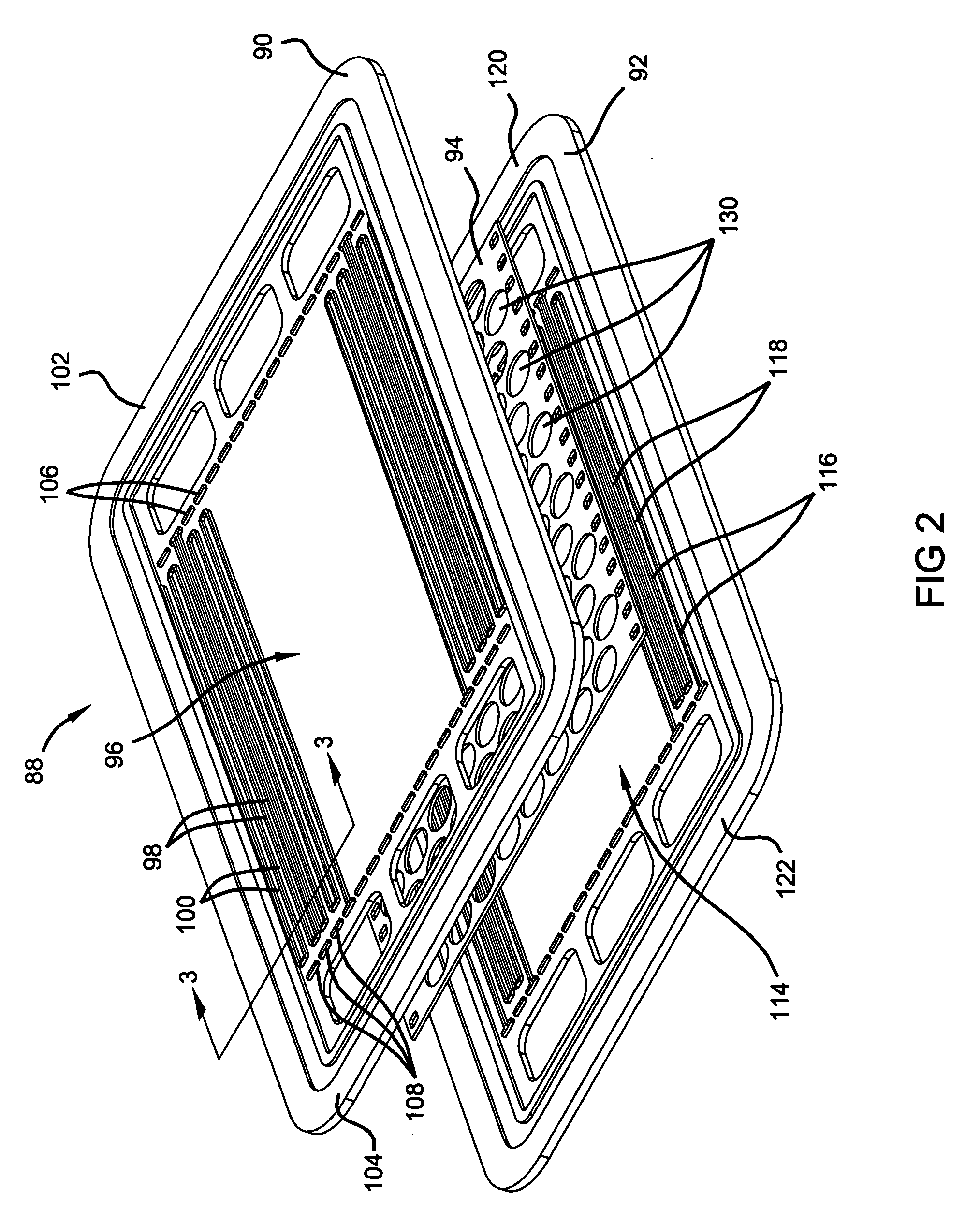

Laser welding of conductive coated metallic bipolar plates

ActiveUS20050252892A1Less corrosion resistantReduced corrosion resistanceFuel cells groupingFinal product manufactureFuel cellsEngineering

The present invention discloses a method of efficiently manufacturing fuel cells having coated bipolar plates. The present invention contemplates the laser welding together of individual plates already having a coating thereon to form the bipolar plates that are used in a fuel cell. The laser welding of the coated plates together does not result in sensitization of the plates to a magnitude sufficient to cause an undesirable level of corrosion resistance. This result is achieved regardless of the presence of the organic coating in the region of the plates being welded and regardless of the ablating of the organic coating by the laser beam.

Owner:GM GLOBAL TECH OPERATIONS LLC

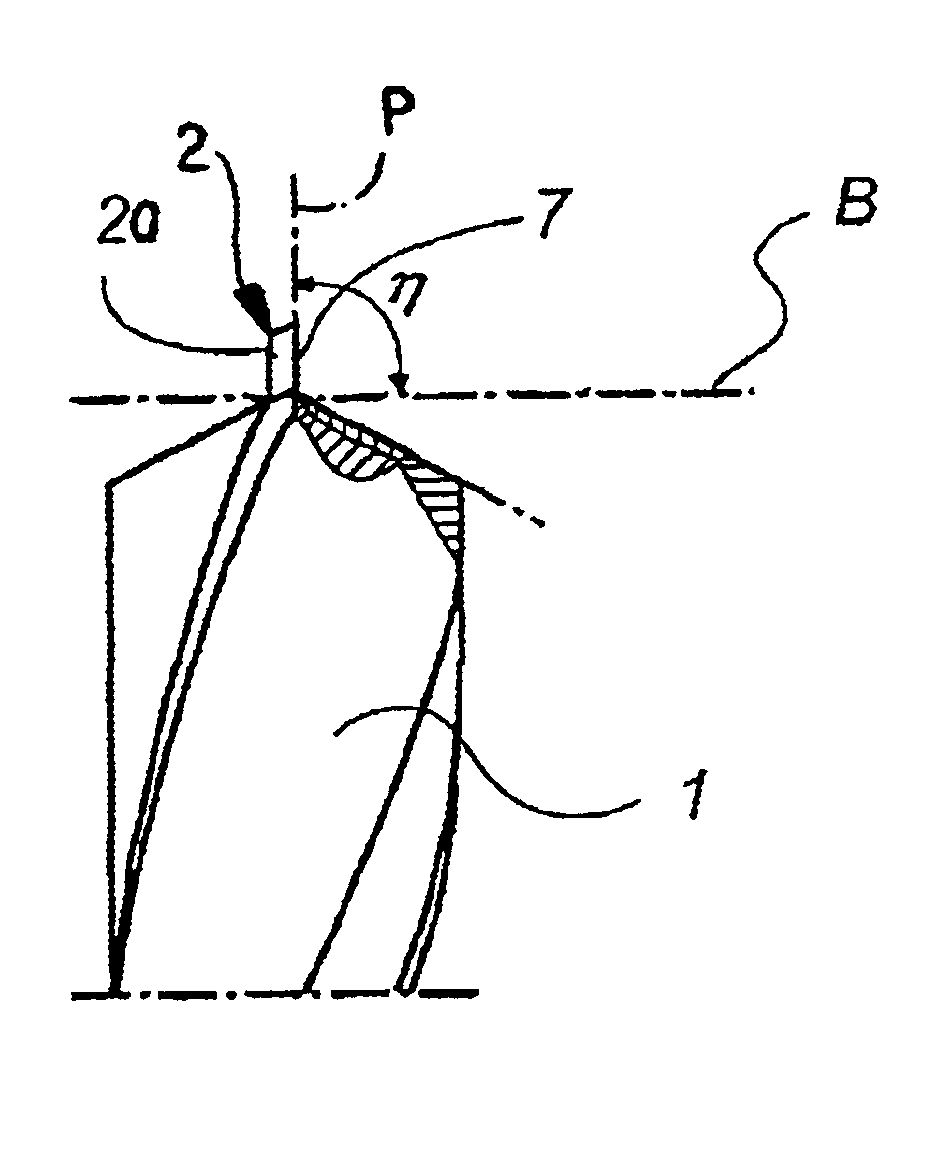

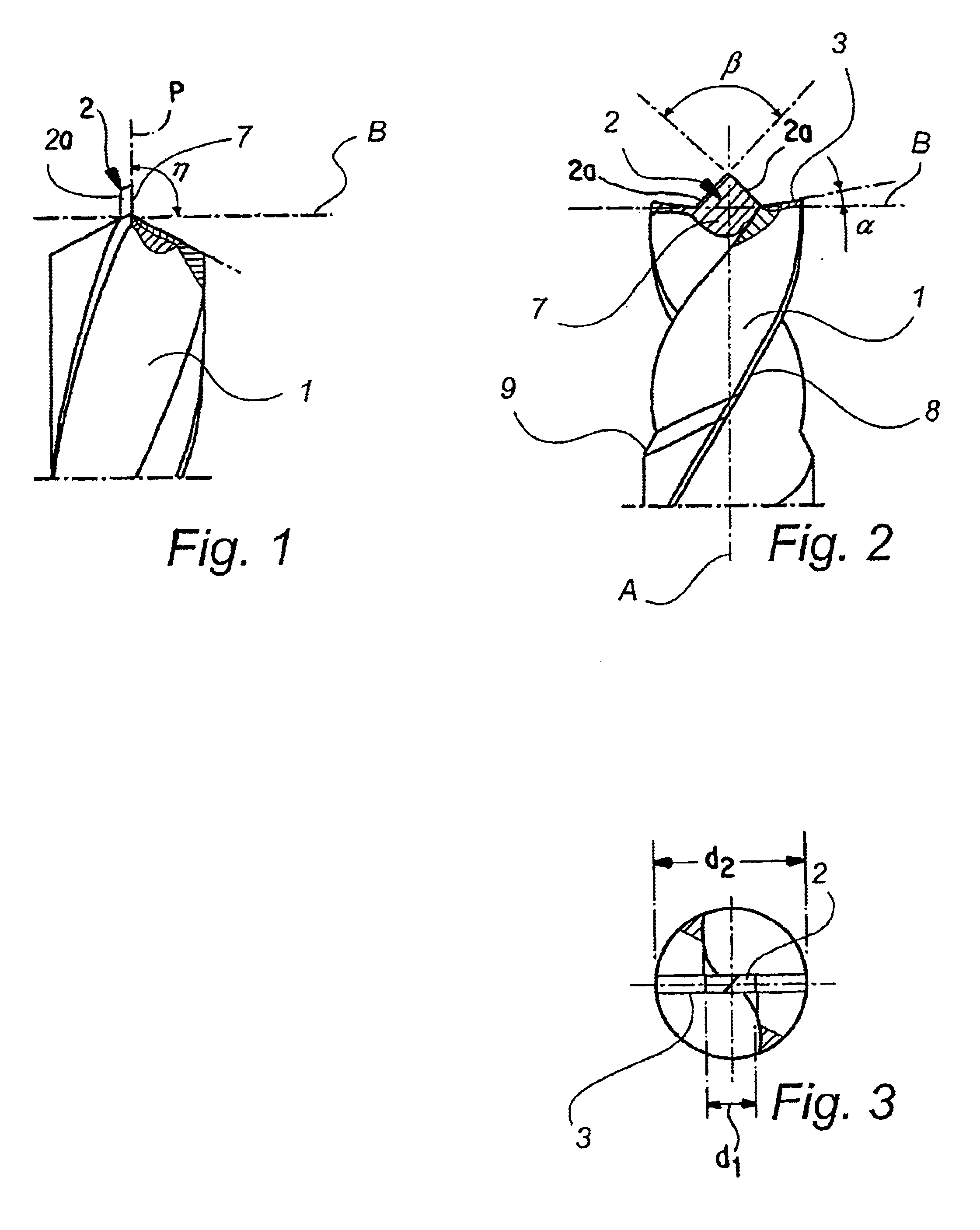

Drill bit with pilot point

InactiveUS6857832B2Fully removedAvoid coatingWood turning toolsTransportation and packagingEngineeringDrill

A drill bit for the working of metal has a center pilot tip that transforms into straight cutting edges extending towards the outer periphery of the bit. Each cutting edge forms a cutting angle of 1-20° with a reference plane oriented perpendicular to of the drill axis. Each a cutting edge is inclined in a radially inward and axially rearward direction toward the drill axis. The center tip forms a pilot point angle of 90±2° and a has base that takes up 23-45 percent of the total diameter of the cutting section of the drill bit. The tip has a tip angle of 90±10°.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

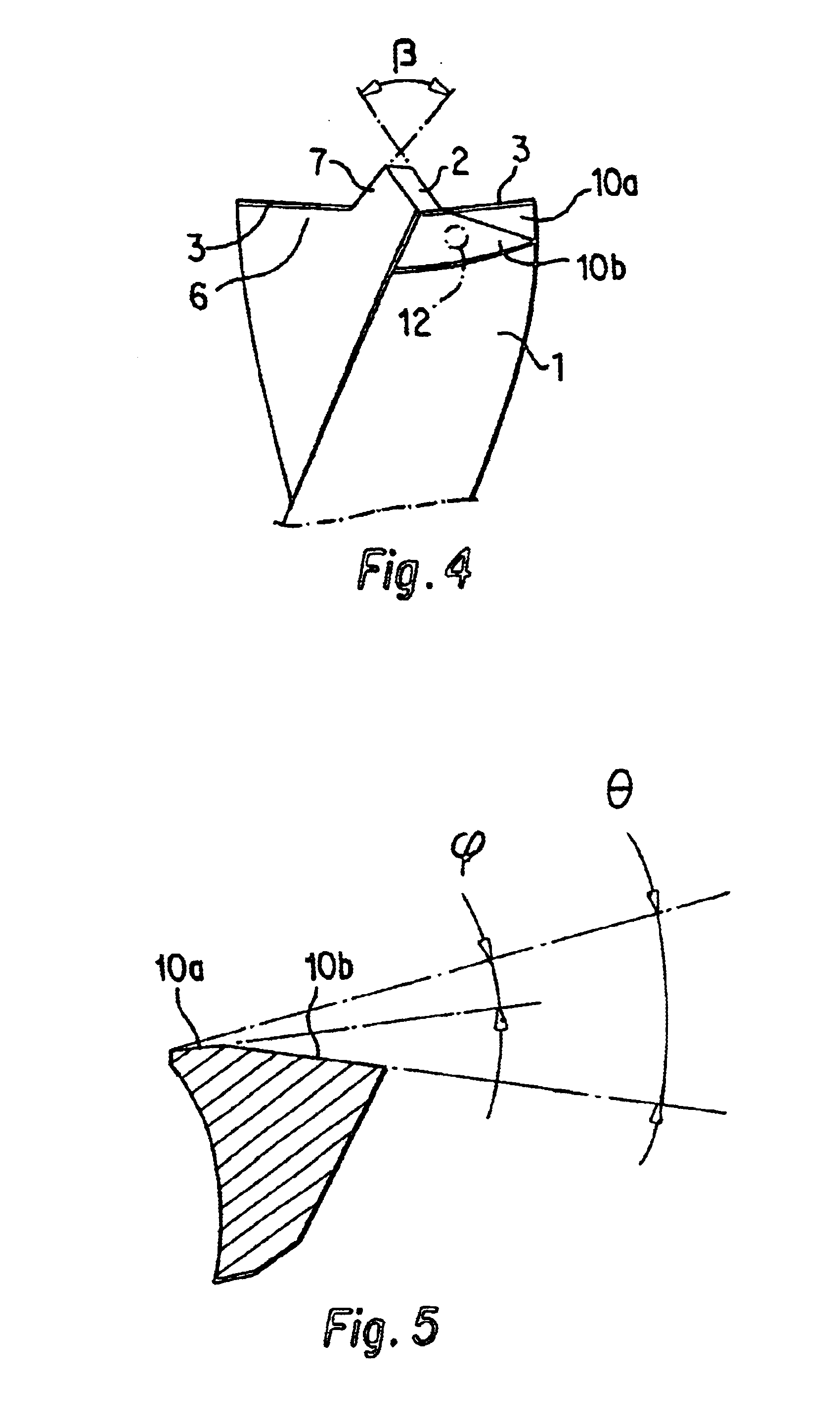

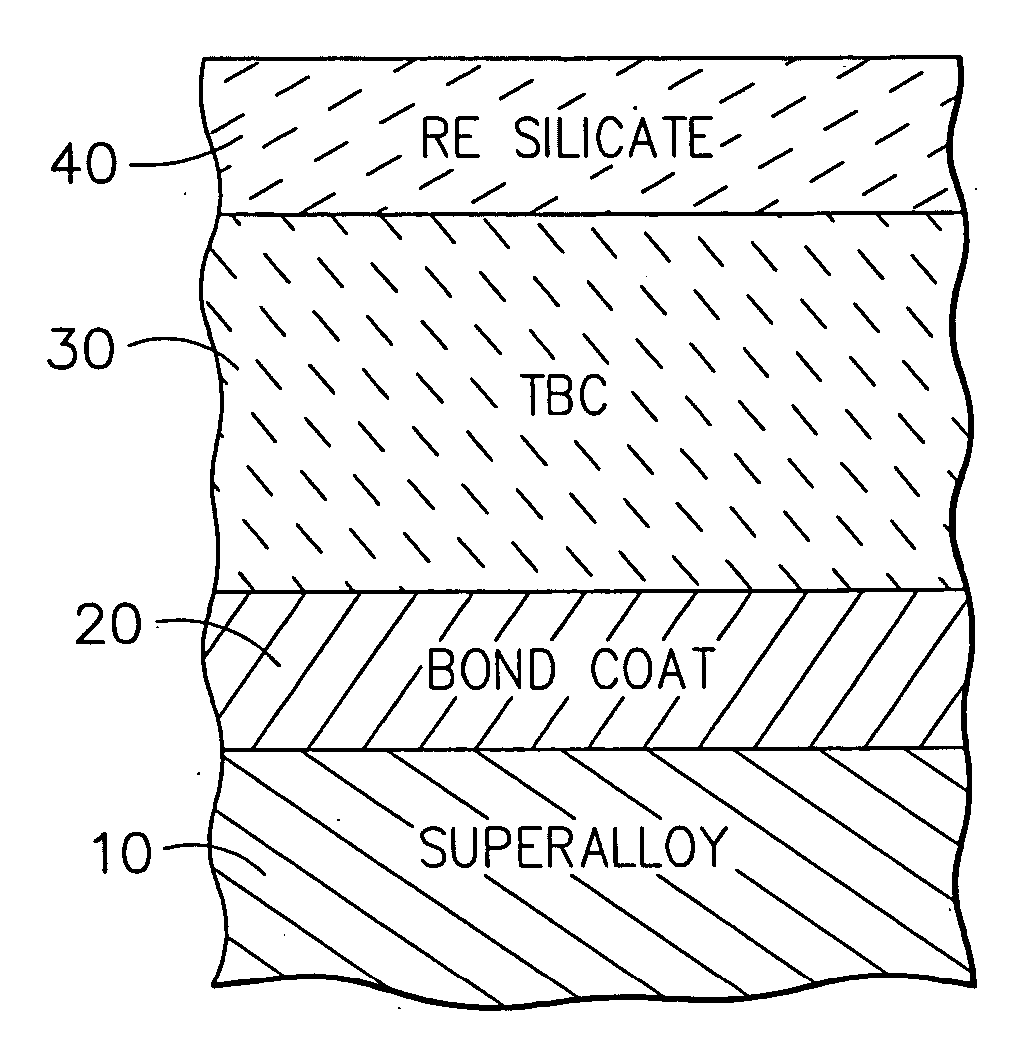

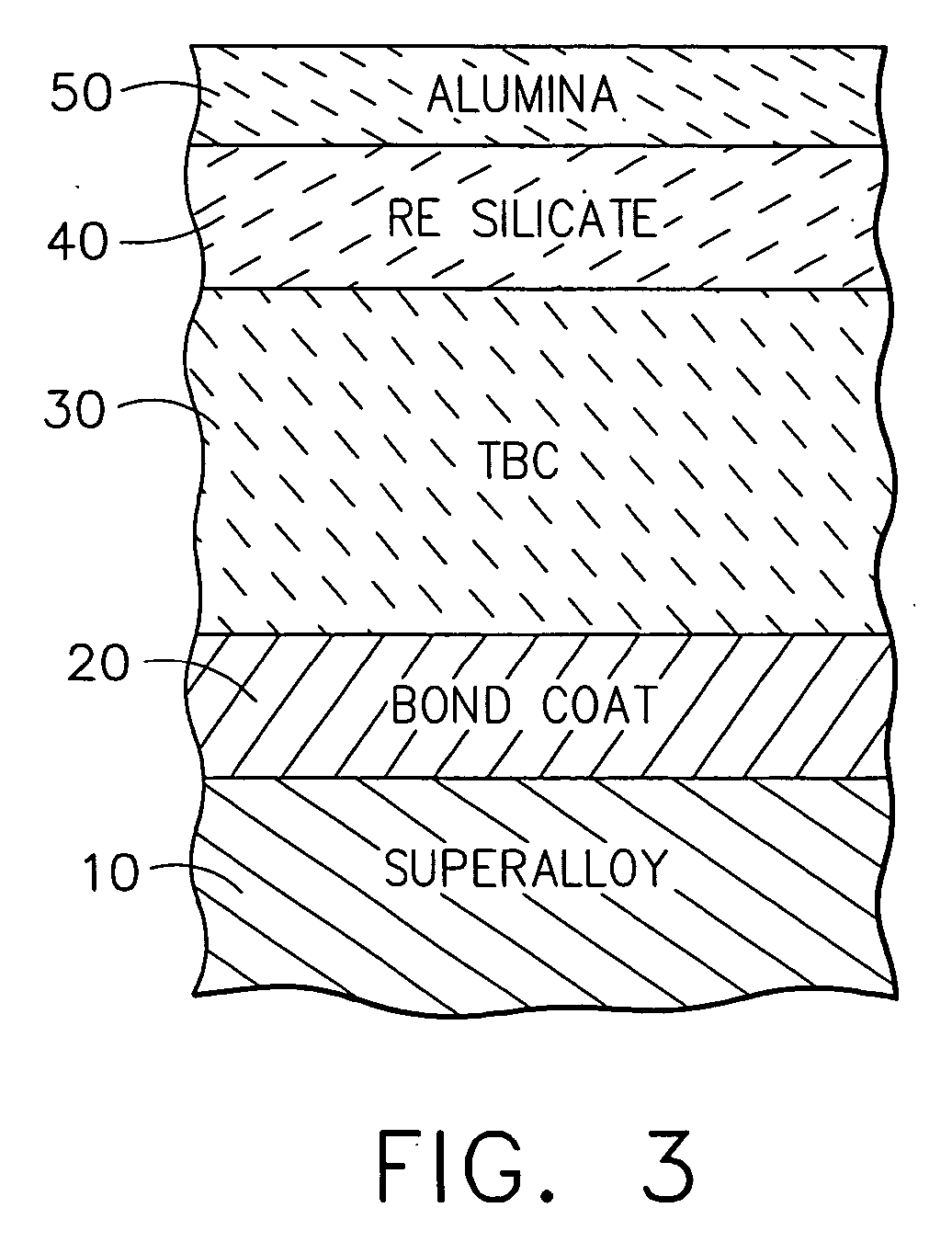

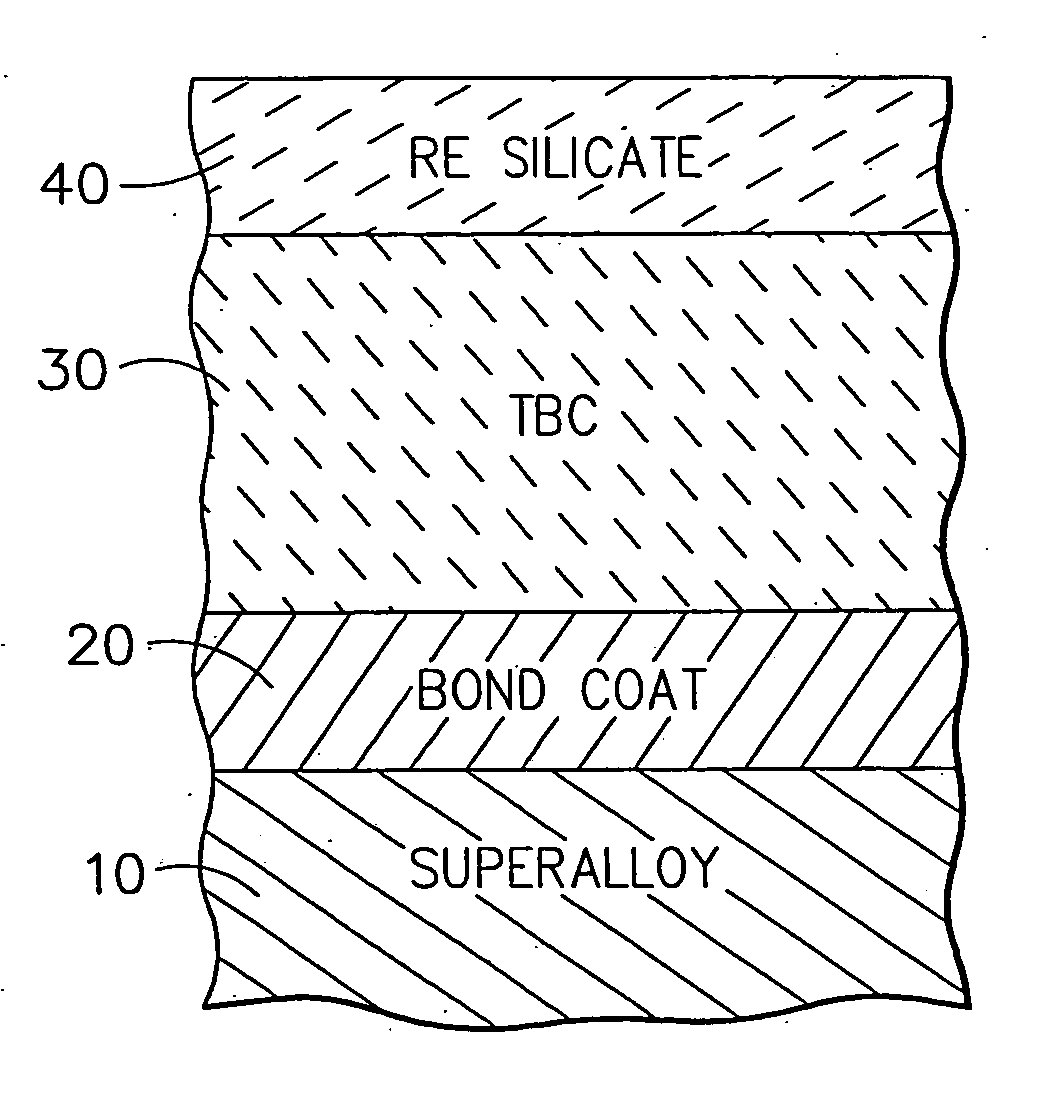

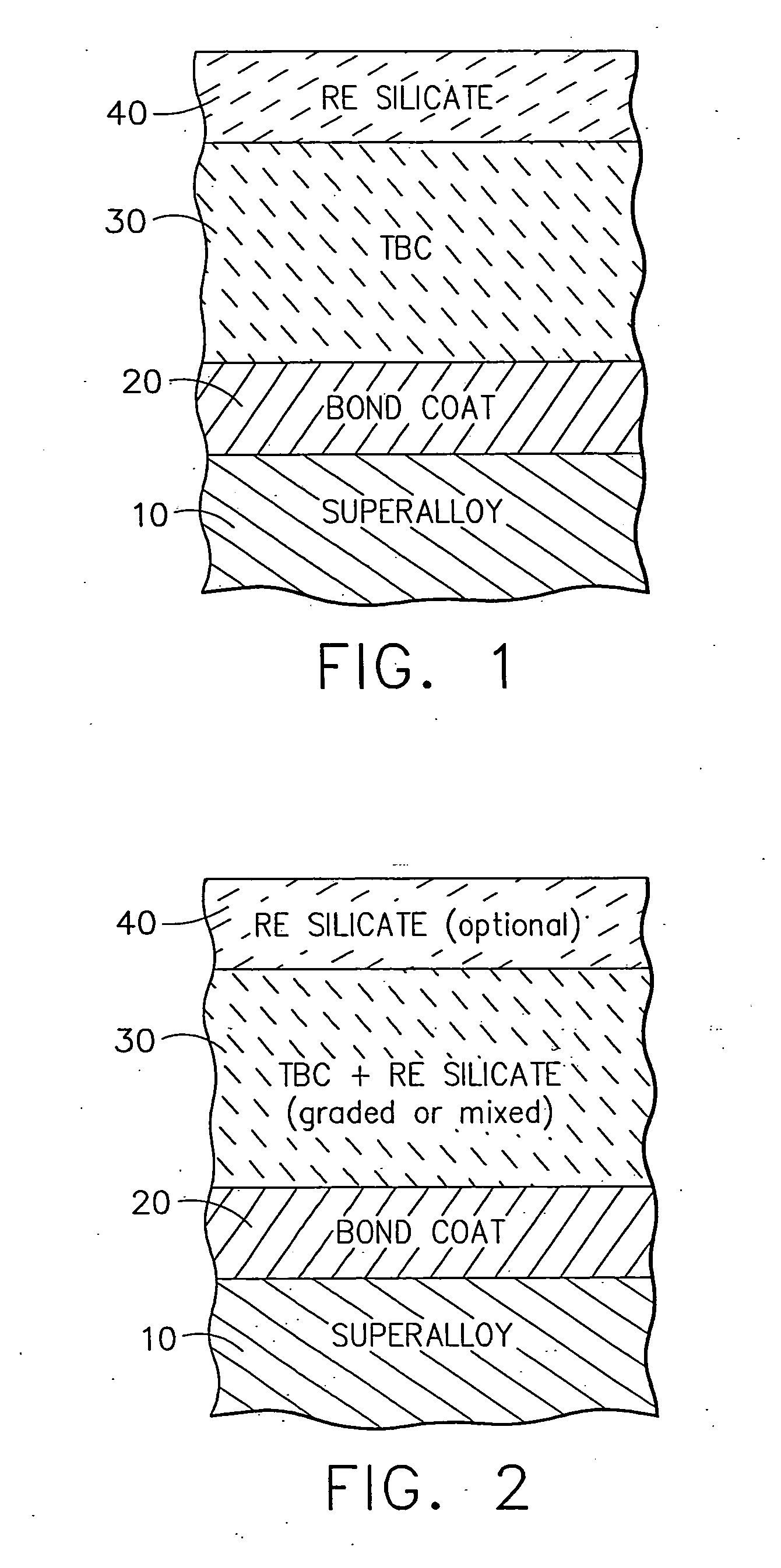

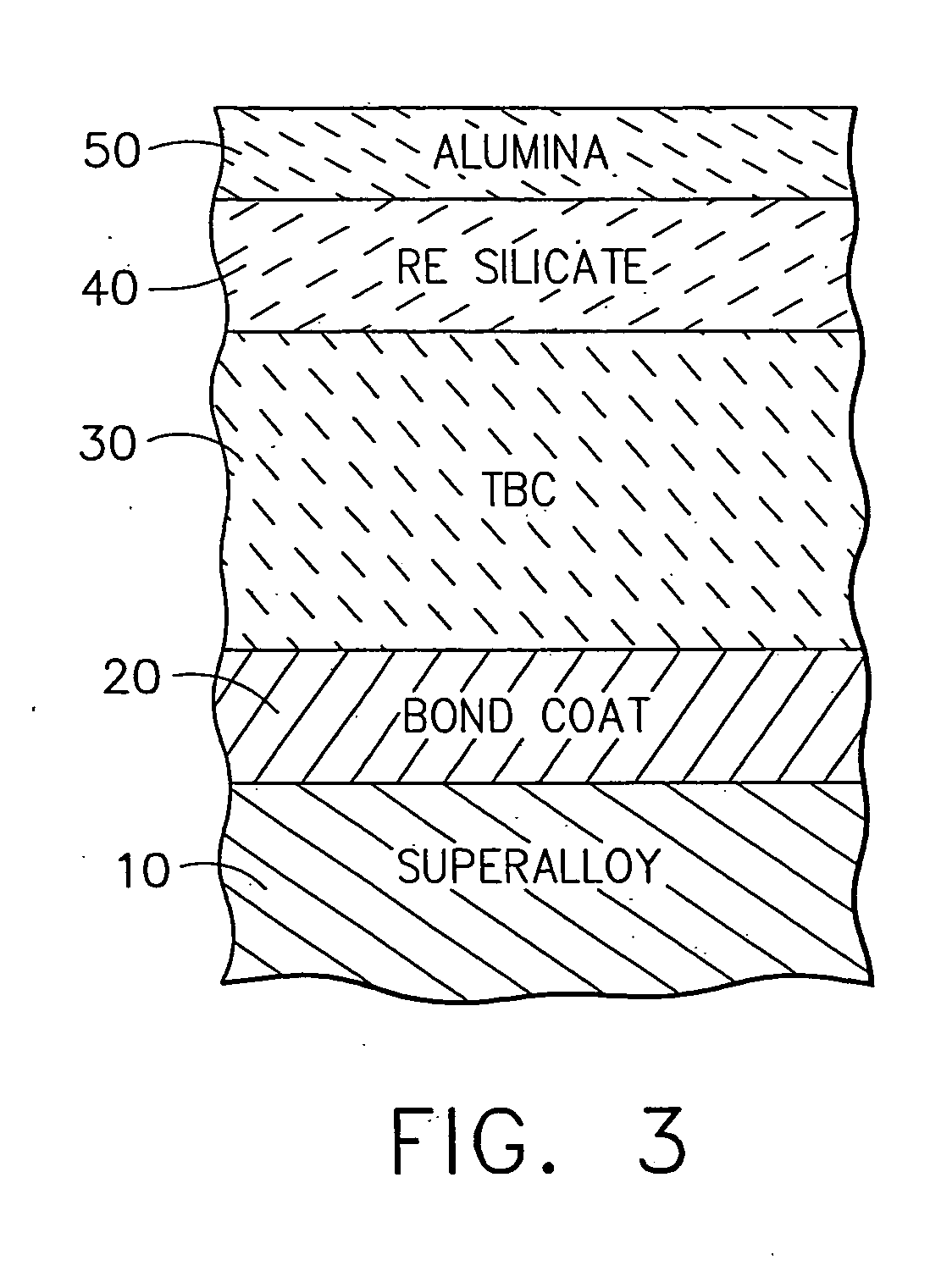

Protection of thermal barrier coating by an impermeable barrier coating

ActiveUS20060115659A1Avoid coatingPrevents infiltration of the contaminant compositionLiquid surface applicatorsMolten spray coatingRare earthThermal barrier coating

According to an embodiment of the invention, disclosed is a composite comprising a porous thermal barrier coating on a metallic part and an impermeable barrier coating adjacent to the outer surface of the thermal barrier coating. The impermeable barrier coating is dense and non-porous and comprises a rare earth silicate, the impermeable barrier coating thereby preventing infiltration of the contaminant composition into the thermal barrier coating.

Owner:GENERAL ELECTRIC CO

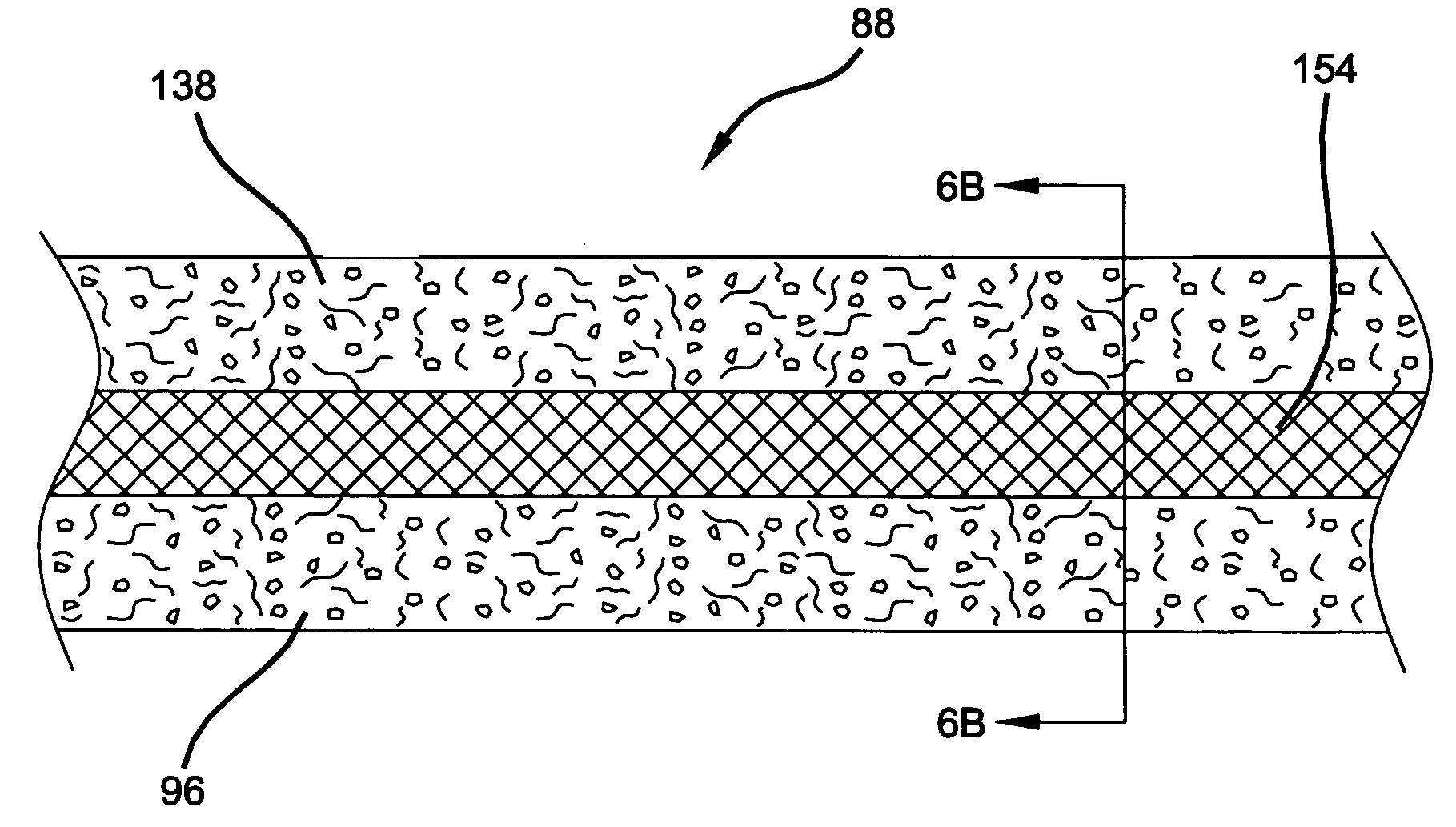

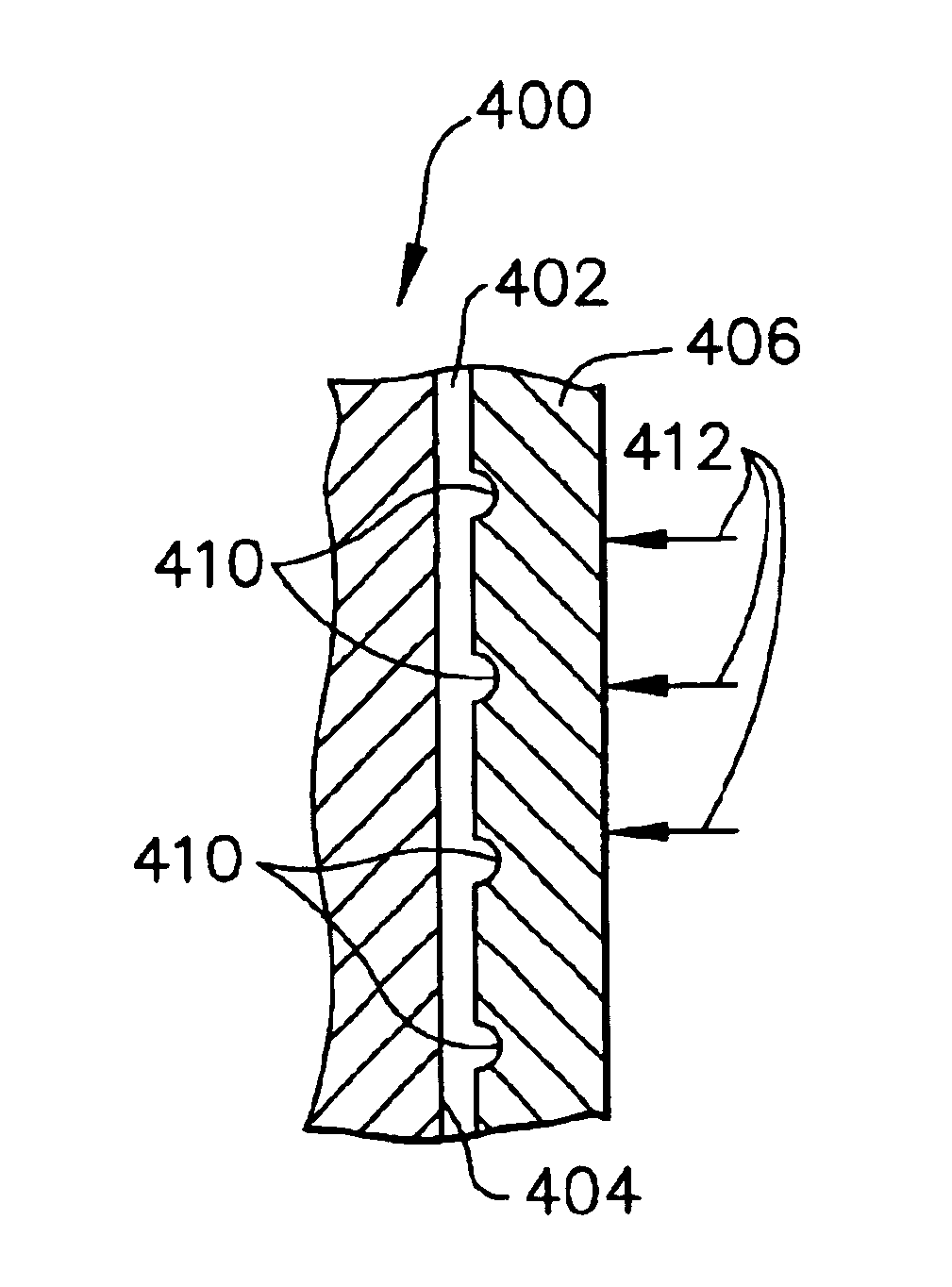

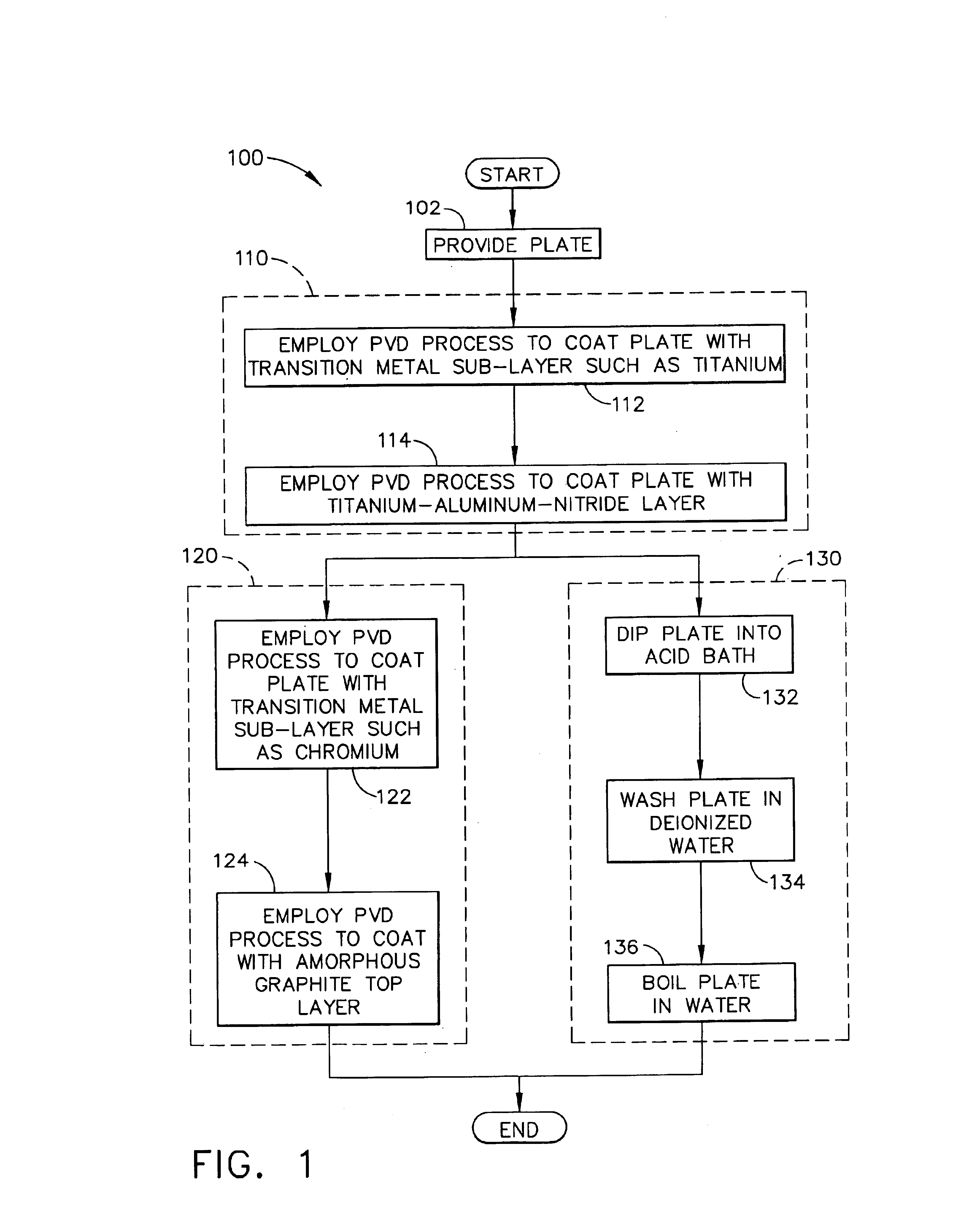

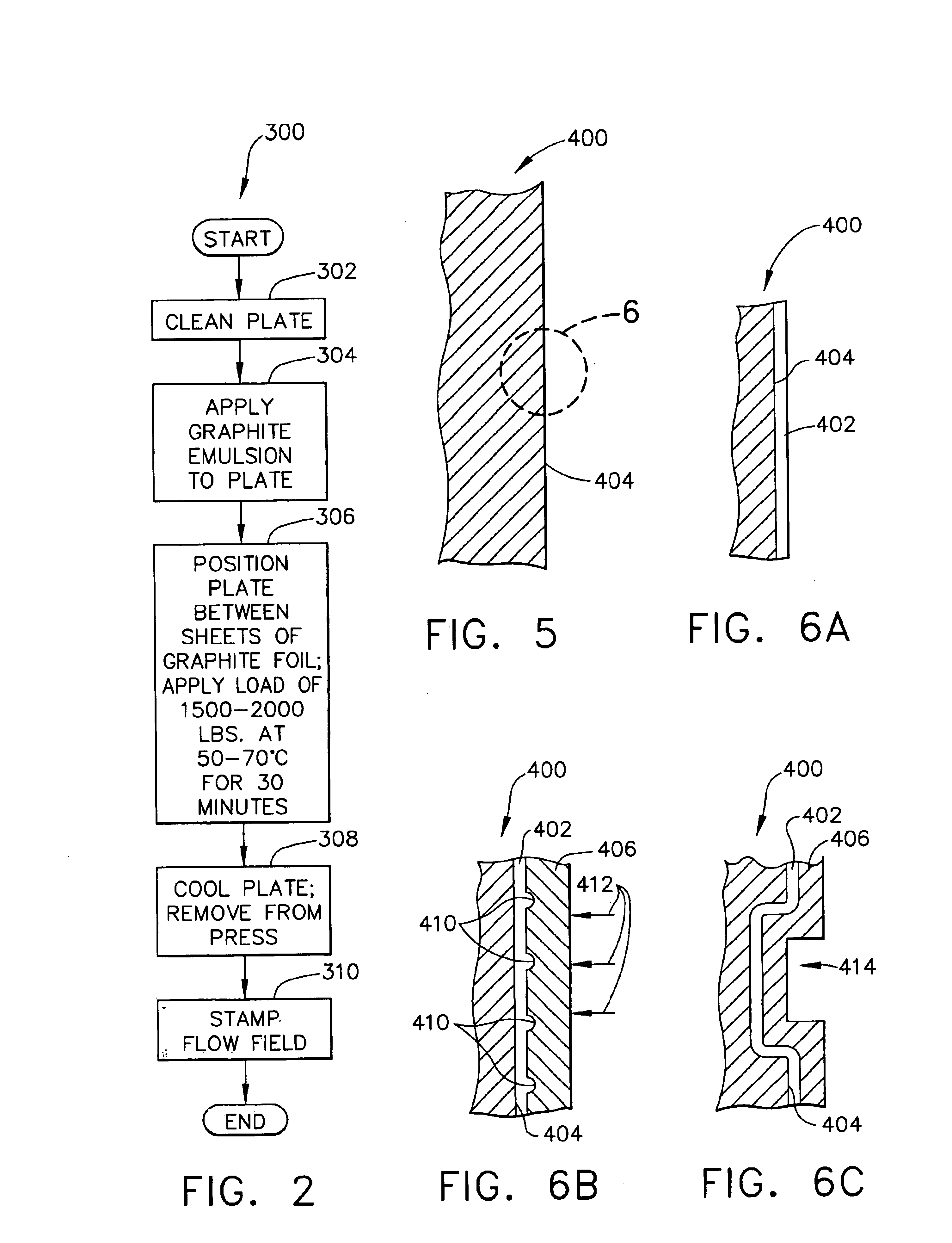

Corrosion resistant coated fuel cell plate with graphite protective barrier and method of making the same

InactiveUS6864007B1Avoid corrosionConductivity is not affectedSolid electrolytesFinal product manufacturePorosityFuel cells

A corrosion resistant coated fuel cell plate and method of making the same are embodied in a metal plate provided with a graphite emulsion coating and then a layer of graphite foil which is pressed over the coating. The graphite emulsion bonds the graphite foil to the metal plate and seals fine scale porosities in the graphite foil. Flow fields are formed by stamping the coated fuel cell plate.

Owner:ALLIEDSIGNAL INC +1

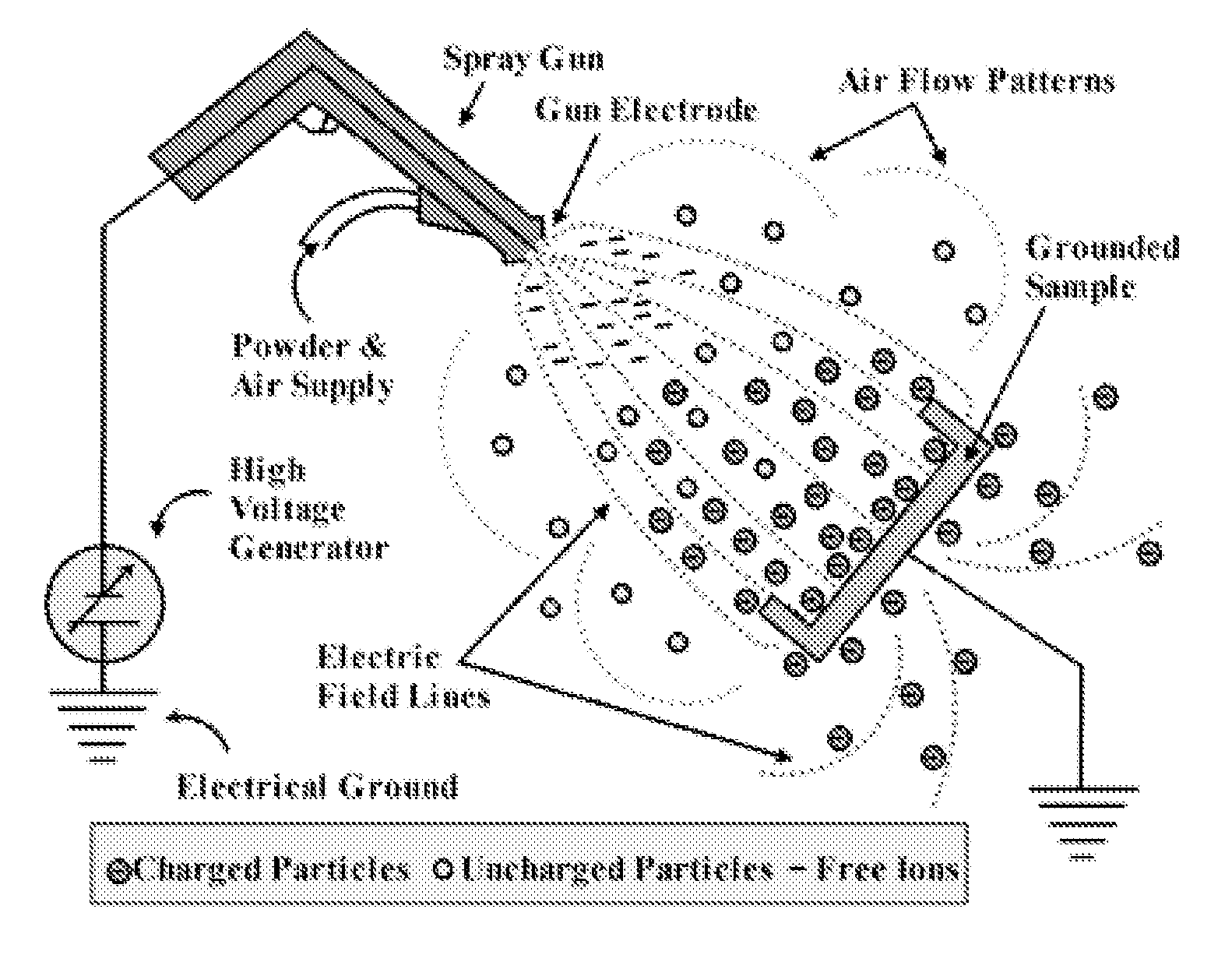

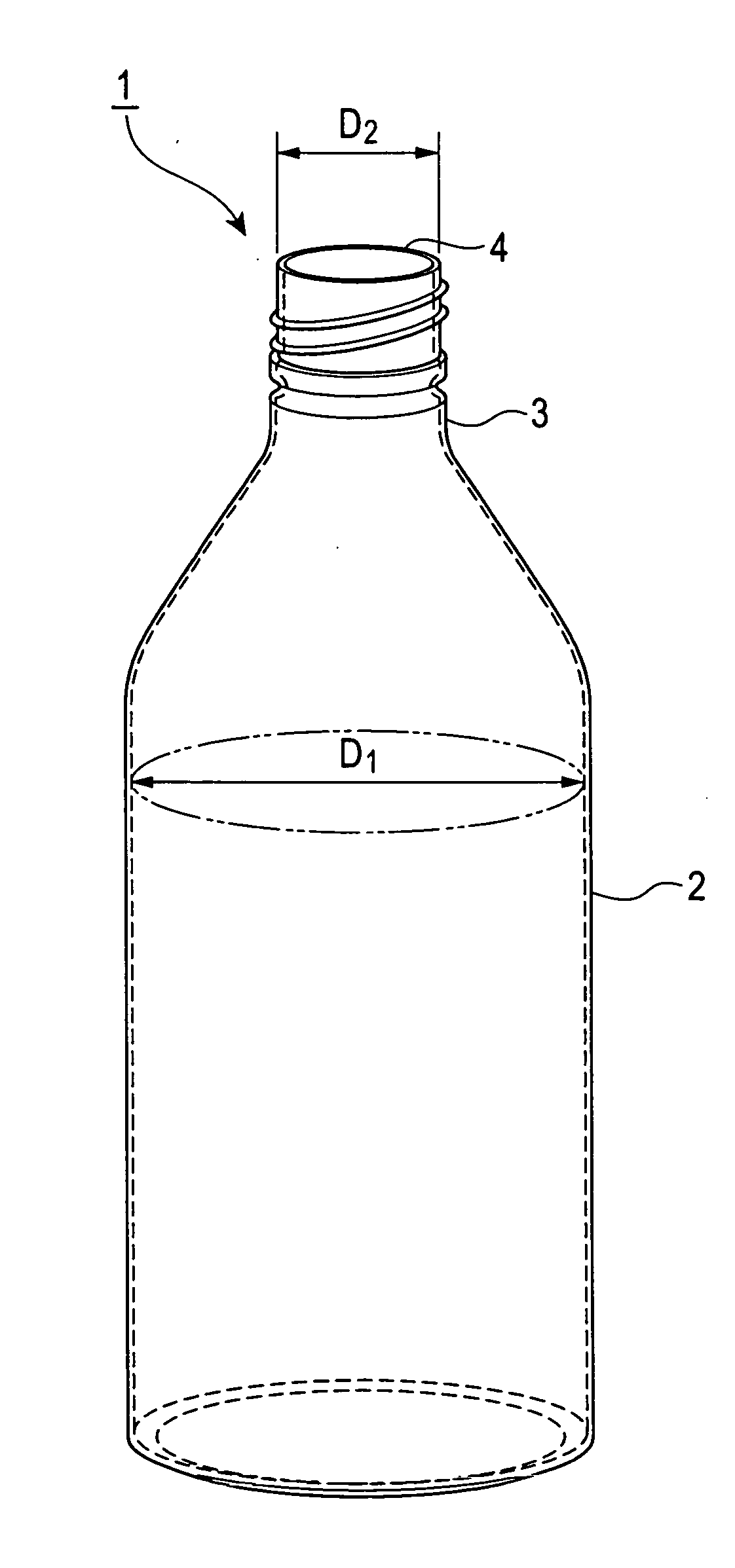

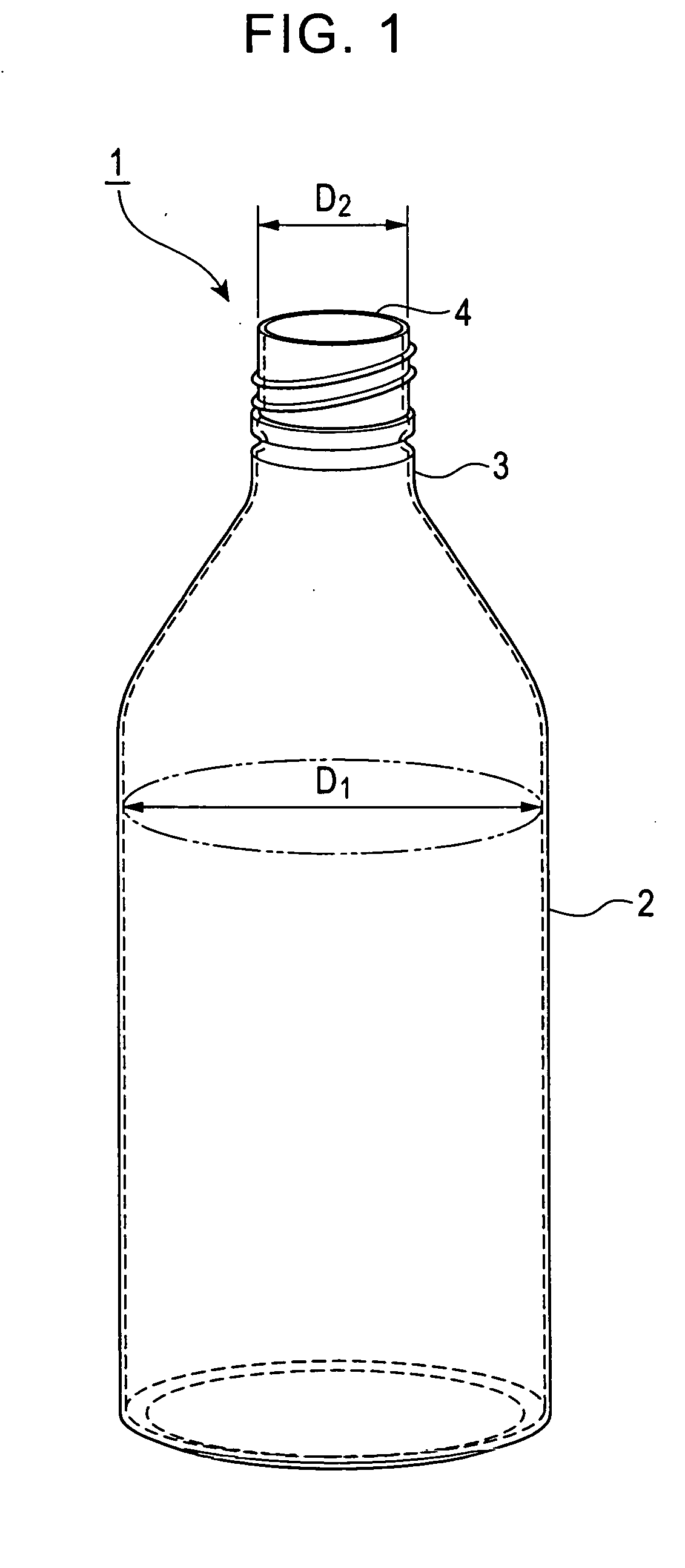

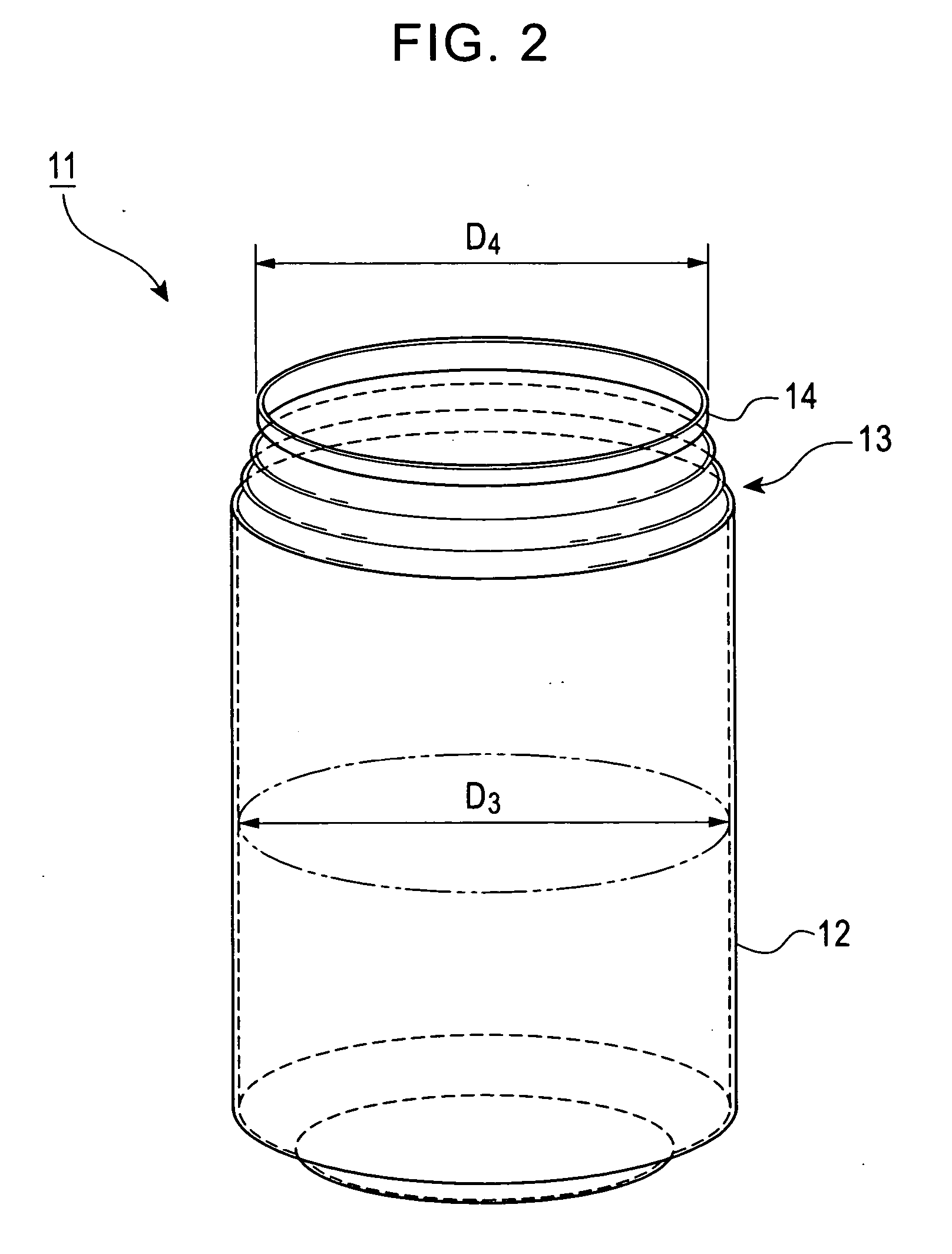

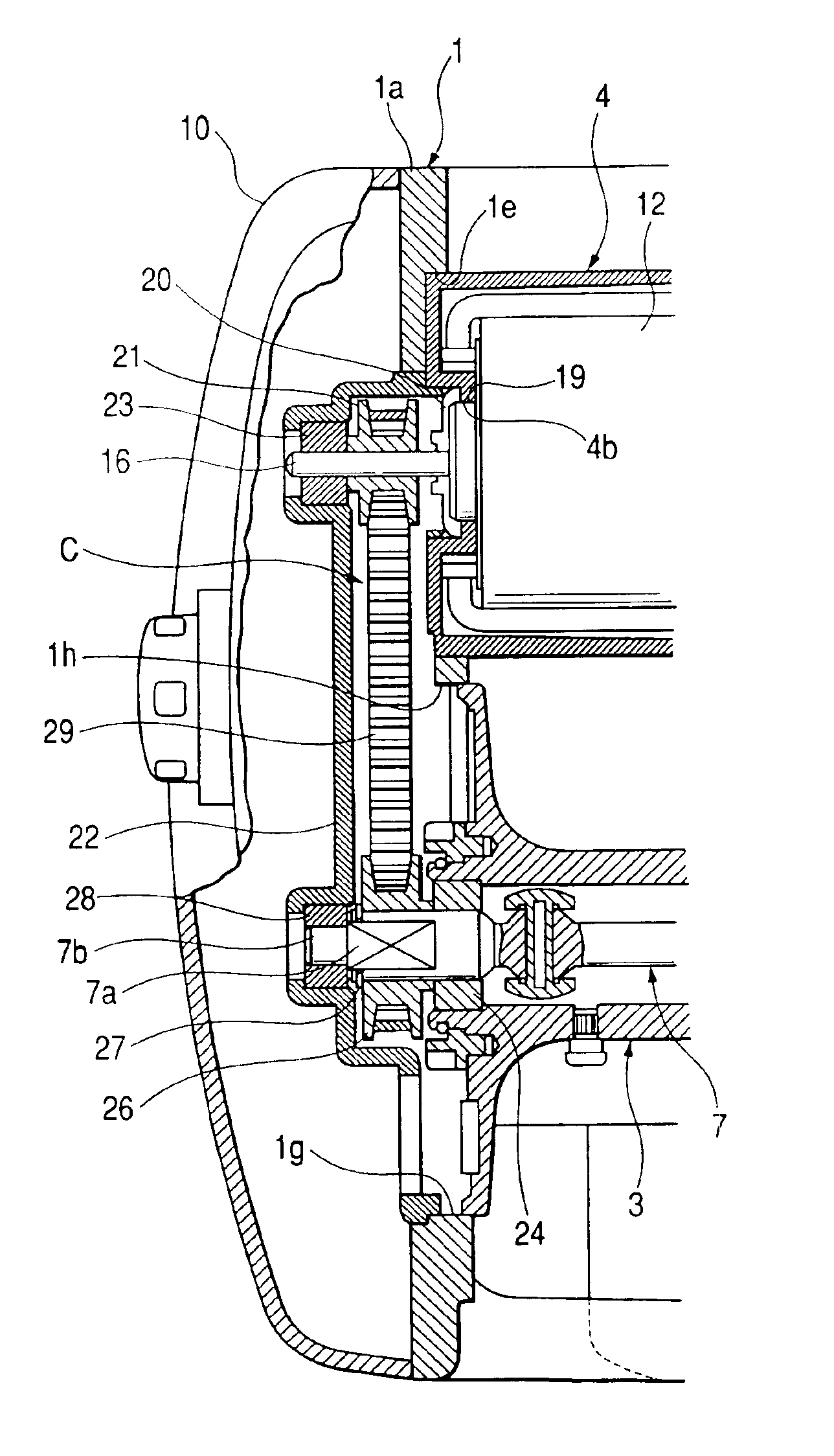

Holding device and method for coating a substrate

ActiveUS7718213B1Avoiding coating defectEffective applicationSpraying apparatusPharmaceutical containersBiomedical engineeringCoating

A holding device and method is provided for efficiently applying a coating on the exterior surface of a tubular hollow body, while preventing coating application on the interior surface and coating defects. The holding device of the present invention comprises at least two structures contacting the inner surface of the tubular hollow body and extending to a portion where the structures are connected and rotary motion is induced to rotate the tubular hollow body. The structures are arranged and shaped so that an inner hollow section is formed in which excess coating material can accumulate.

Owner:IOOS LLC

Powder coating composition, method for the curing thereof, and articles derived therefrom

InactiveUS20030134978A1Avoid coatingSynthetic resin layered productsThin material handlingAcrylic resinPolymer SMA

A powder coating composition includes an acid-functional polyester resin and a matting agent selected from styrene-maleic anhydride copolymers and acid-functional acrylic resins. The compositions provide low gloss finishes at low curing temperatures, as well as consistent gloss over a wide range of curing temperatures.

Owner:ROHM & HAAS CO

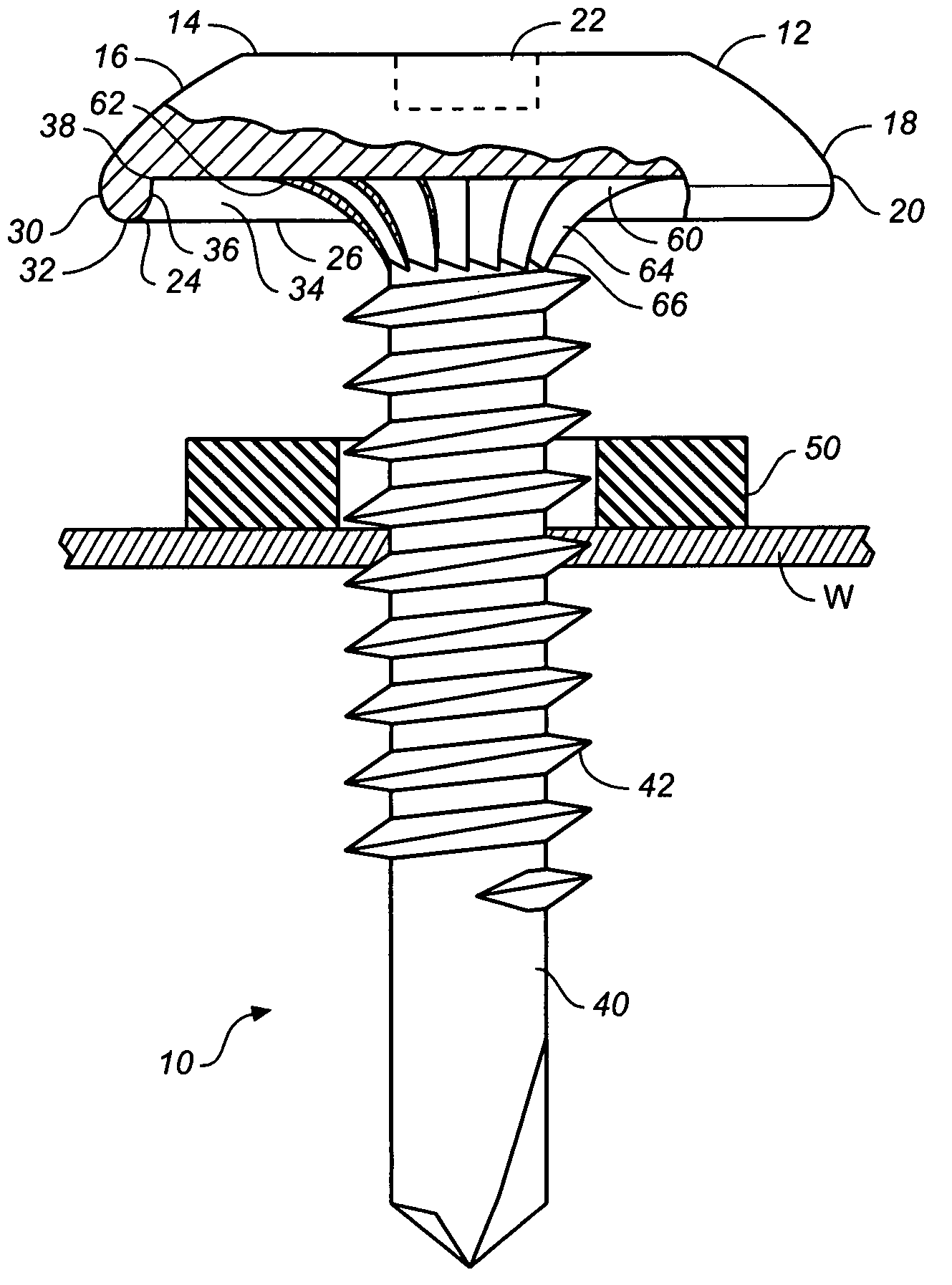

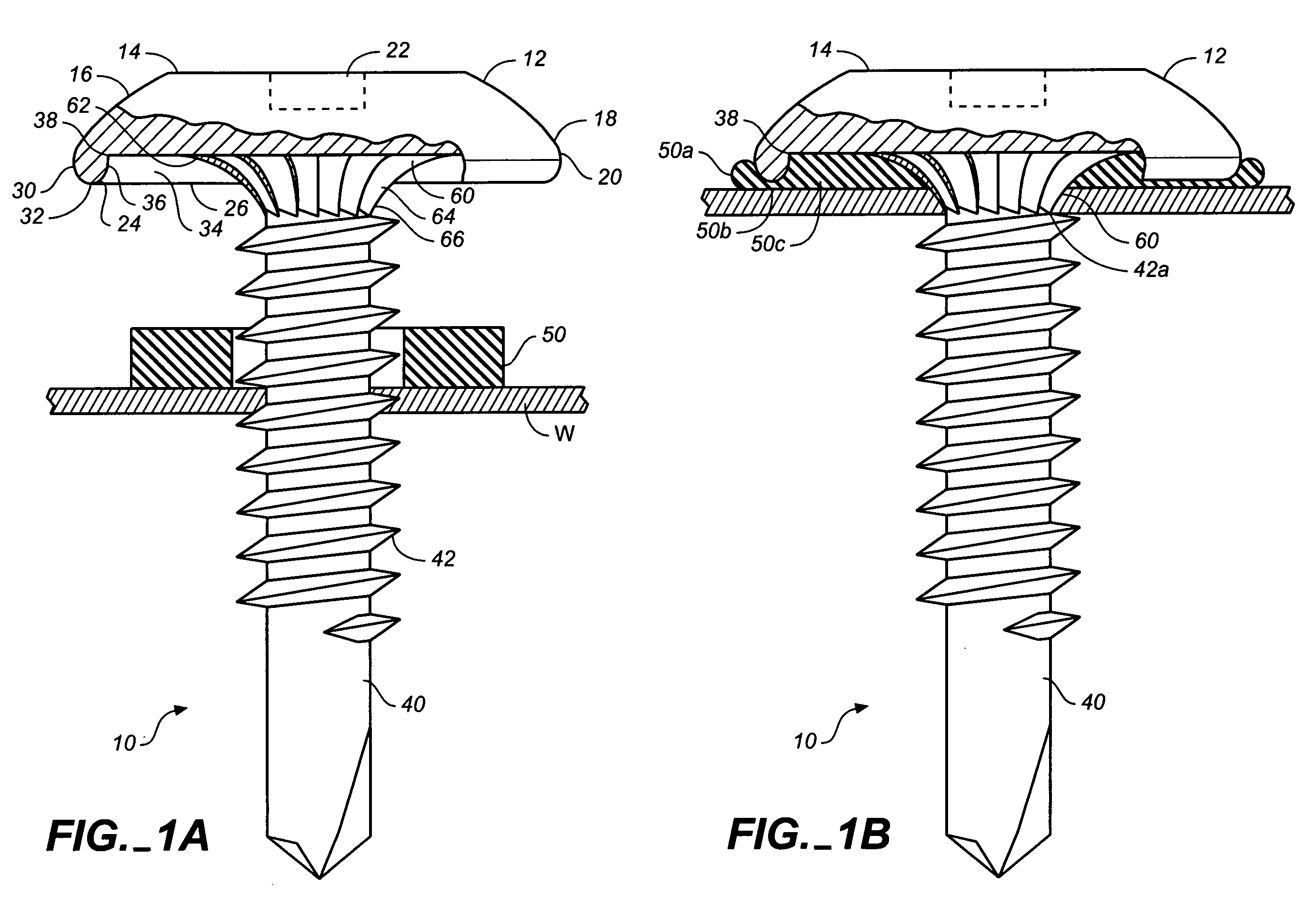

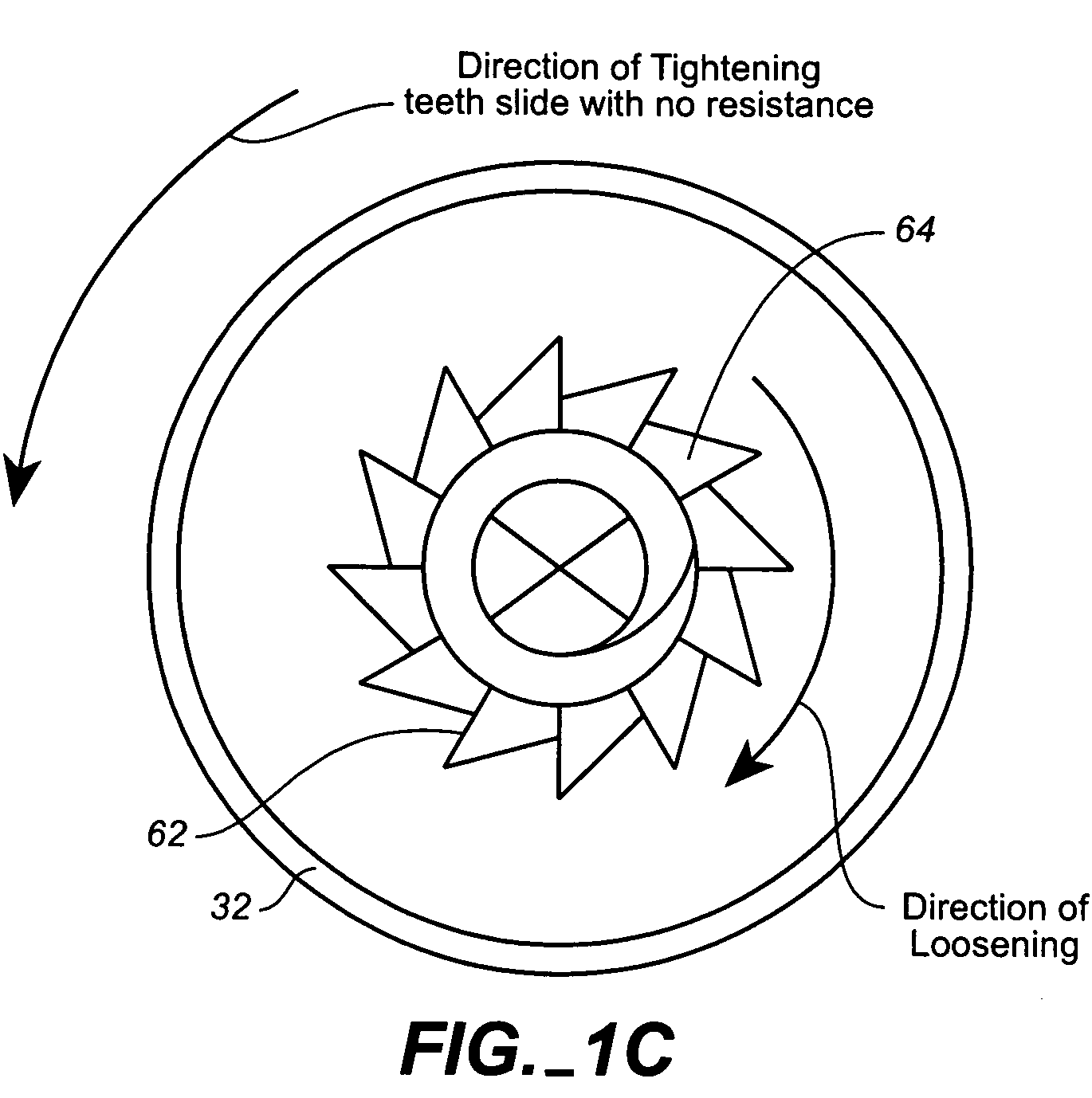

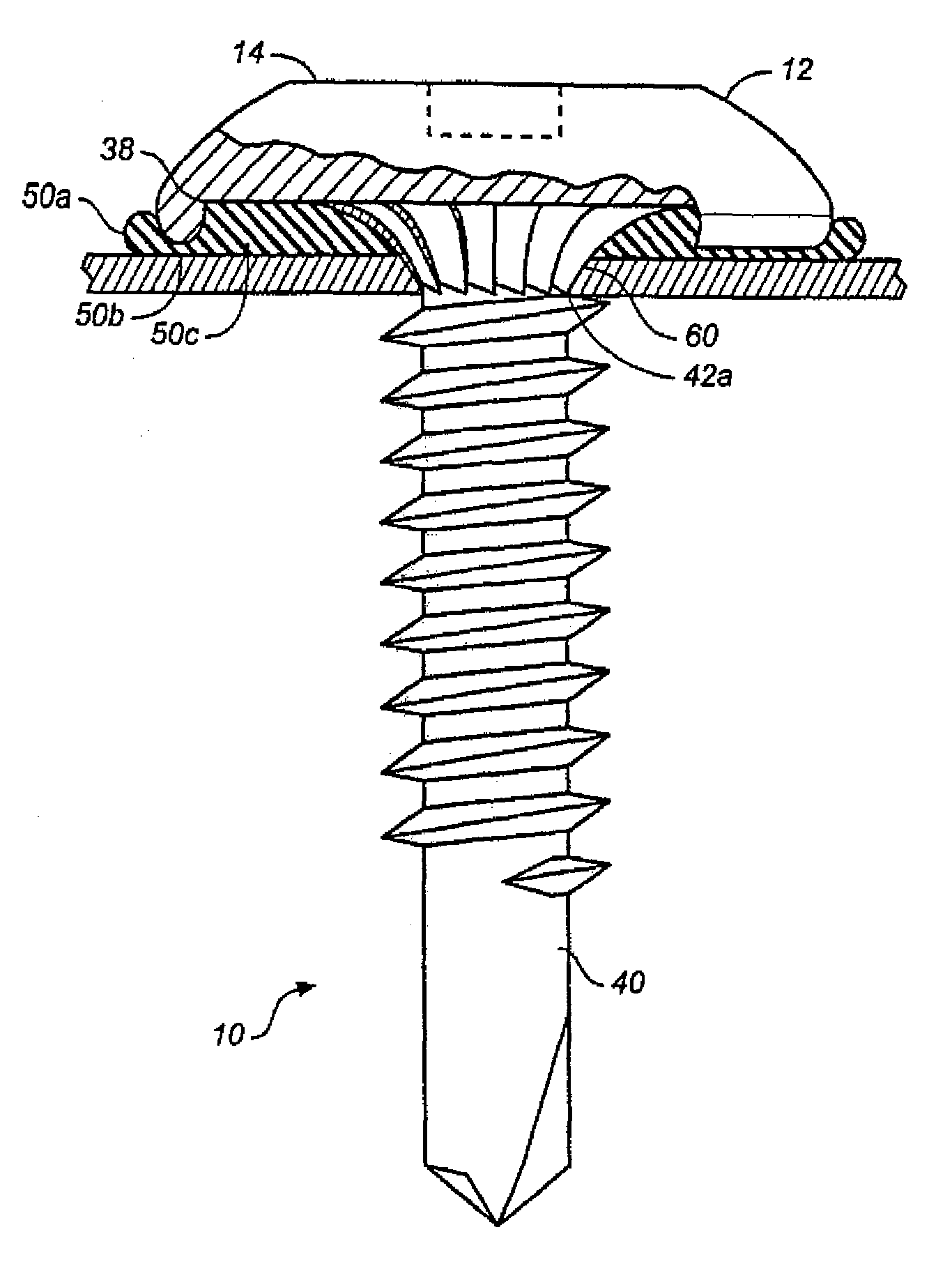

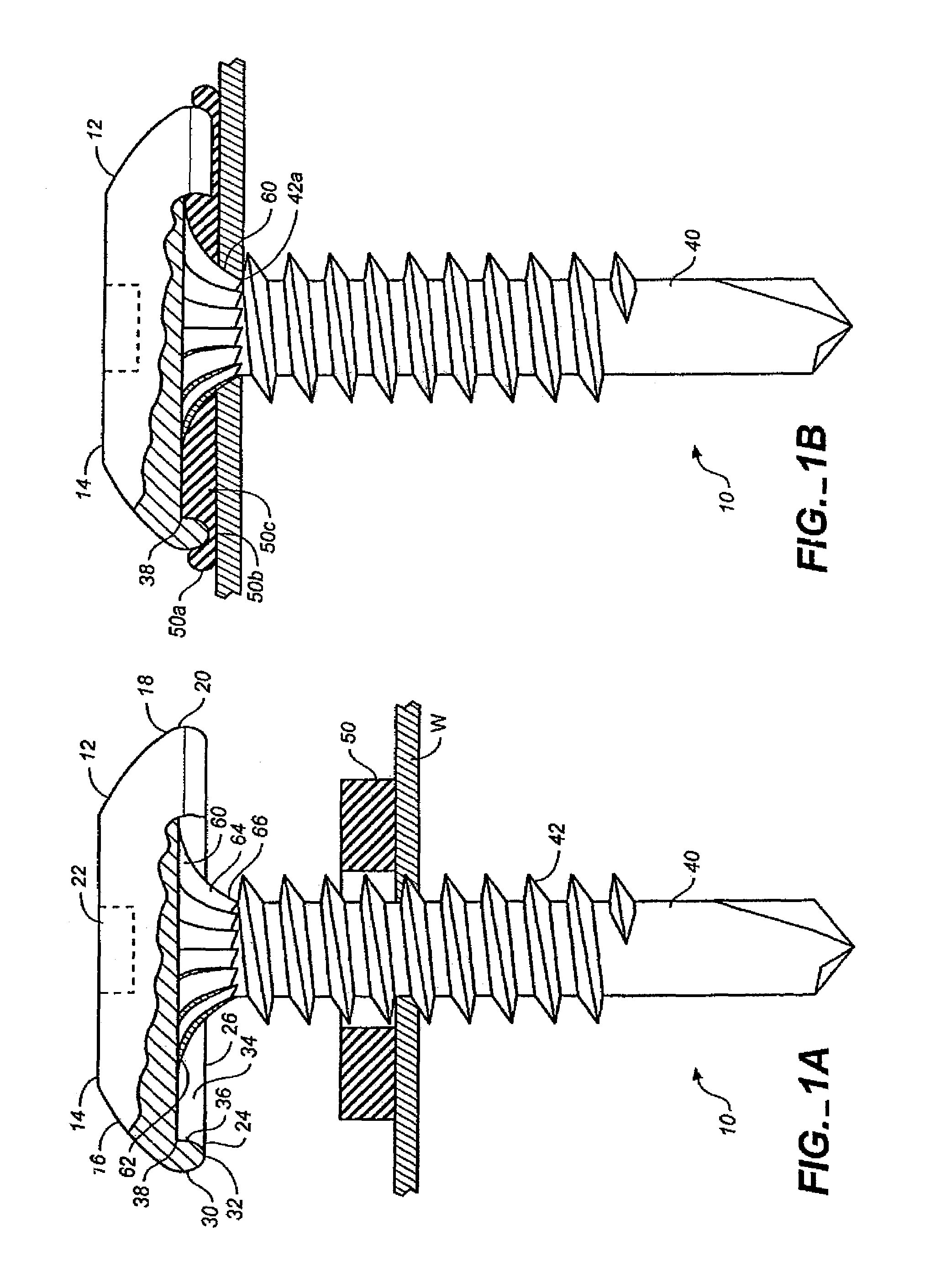

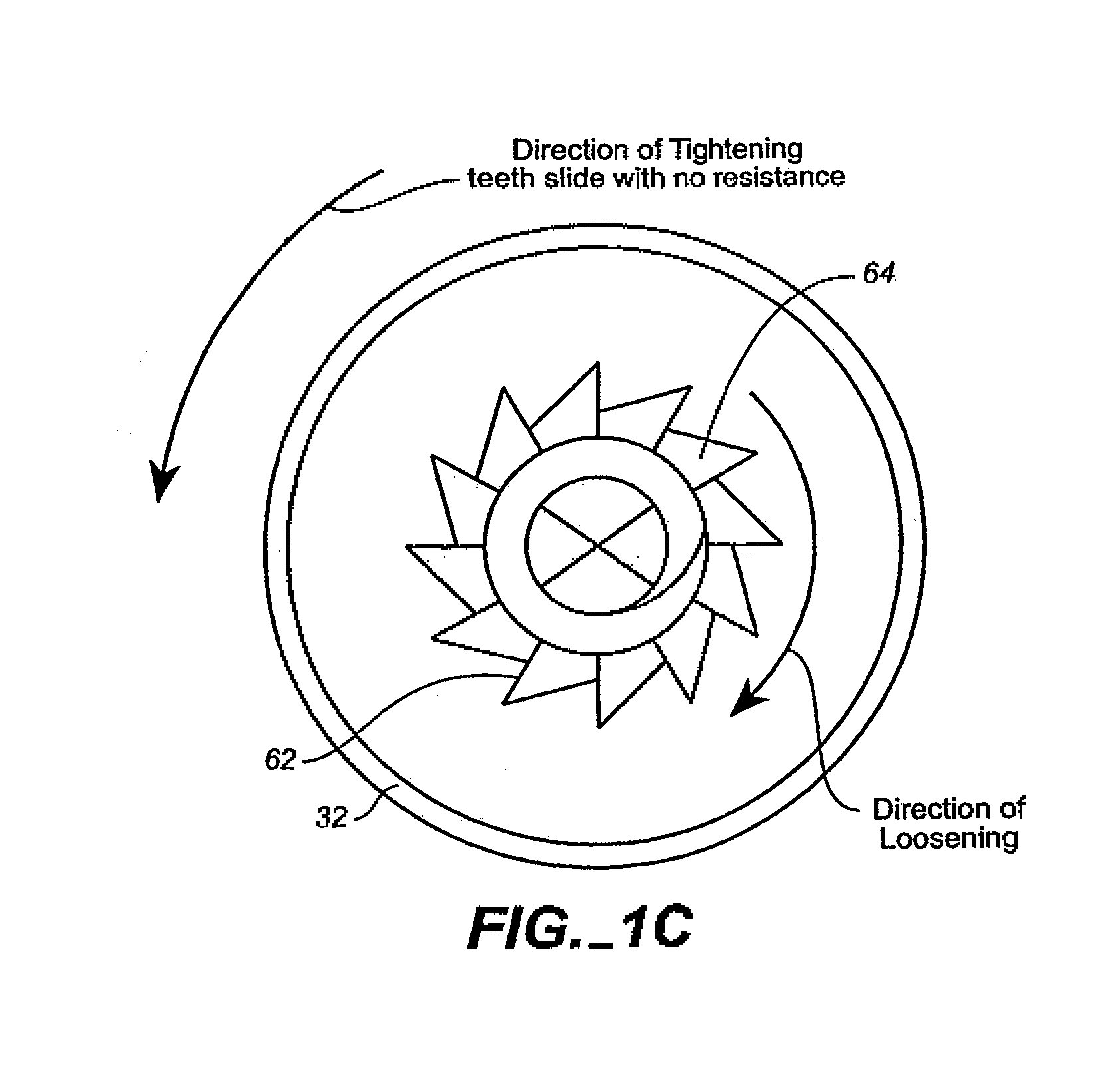

Fastener apparatus for roofing and steel building construction

A fastener apparatus includes a frusto-hemispherical head portion having a flat top surface, a curved outer surface, a base portion, and a peripheral edge, with the flat top surface bearing a tool fitting. A downwardly-depending lip portion extends from the head peripheral edge and defines an annular recess in the base, the annular recess having a flat upper surface. The lip has a curved outer edge, a curved lower edge, and an inner edge having a curved lower portion and a vertical upper portion terminating in the annular recess flat upper surface. A shank portion is connected to the base and bears screw threads and a tip. An annular gasket portion is carried on the shank, and has a first uncompressed position contained radially within the annular recess, and a second compressed position extending radially beyond the lip outer edge. As the fastener is installed in a workpiece, the gasket expands to contact the lip inner edge and extend beneath the curved lower edge to form a seal between the fastener head and the workpiece. The fastener may include locking teeth terminating in the head base, adapted to resist loosening of the fastener from the workpiece. The curved outer surface of the fastener may include asymmetric ridges adapted to mechanically engage moving snow or ice to resist loosening of the fastener from the workpiece. The fastener head preferably has a width to height ratio of between 3:1 to 5:1.

Owner:DREAM WEAVER

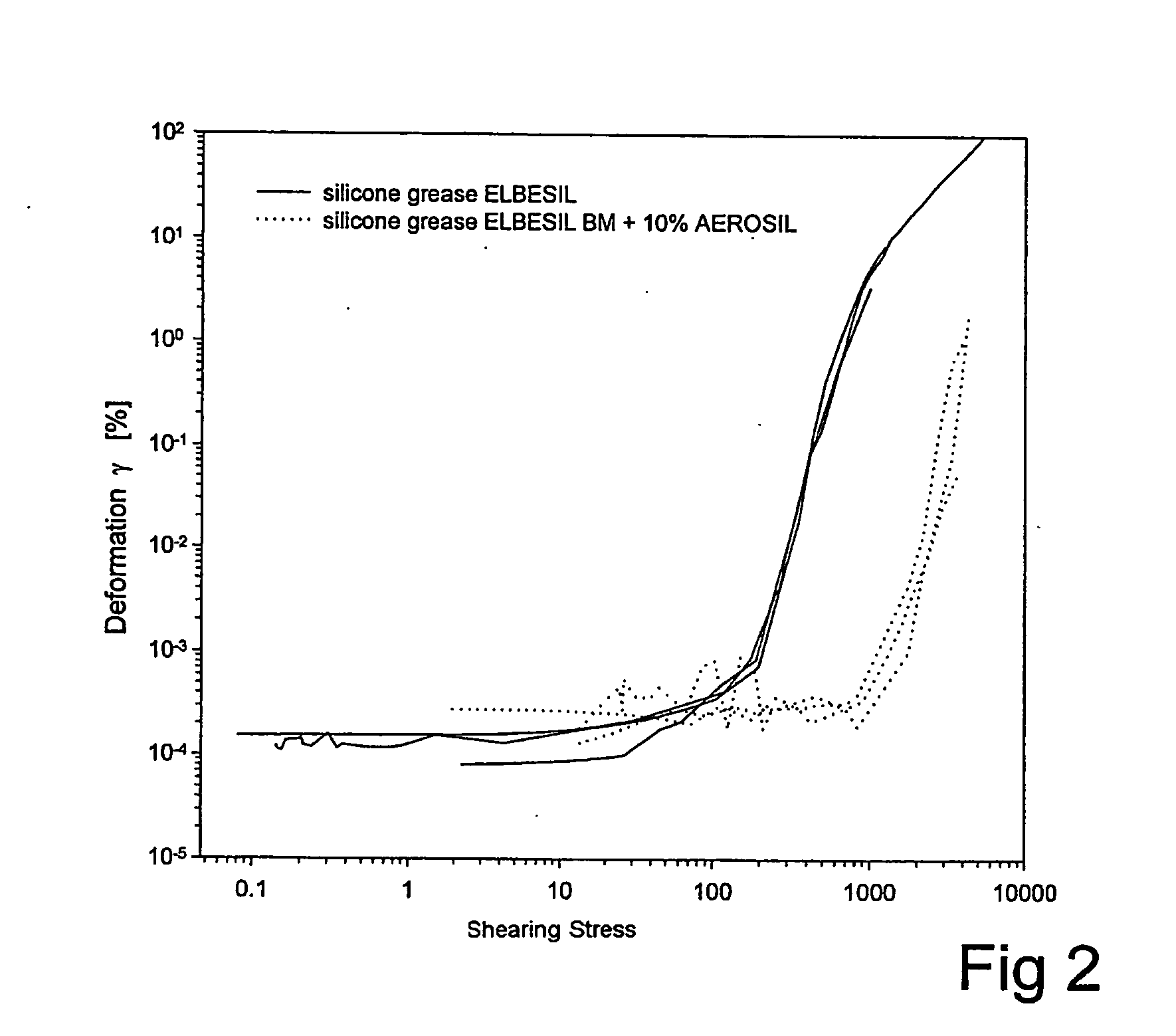

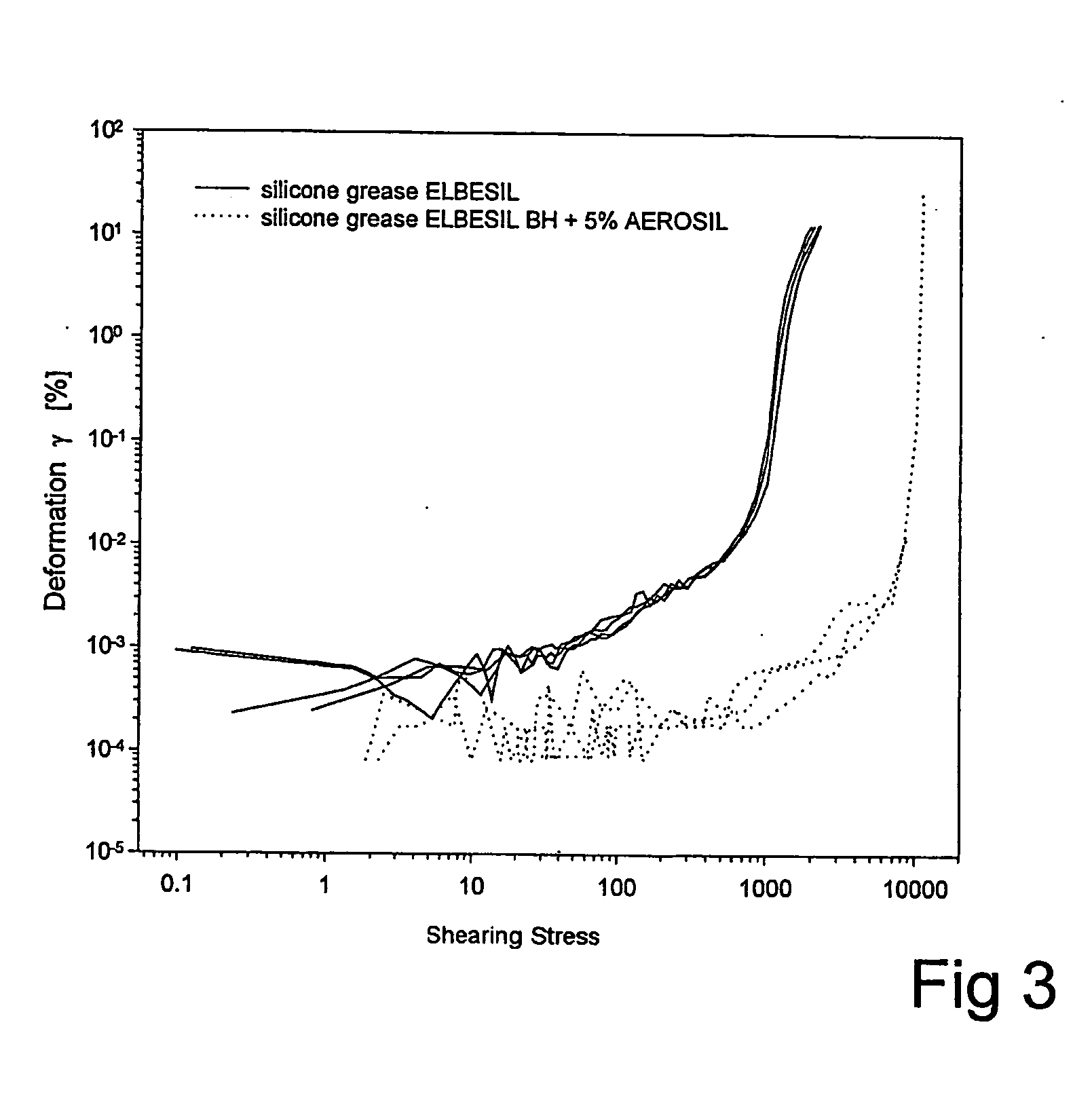

Viscoelastic coating paste for protecting against macrofouling and method for producing a coating

InactiveUS20060144286A1Improve antifouling performanceConvenient coatingFireproof paintsAntifouling/underwater paintsWall shearMacroscopic scale

A non-toxic anti-fouling coating paste having a rheologic switching behavior based on a flow point, which can be set to the hydrodynamic and biological environmental conditions of a submarine component to be protected and which is between 5 Pa and 2,000 Pa above the wall shearing stress of the unfouled component to form a substrate which prevents colonization by marine fouling organisms.

Owner:CGGVERITAS SERVICES HLDG U S +1

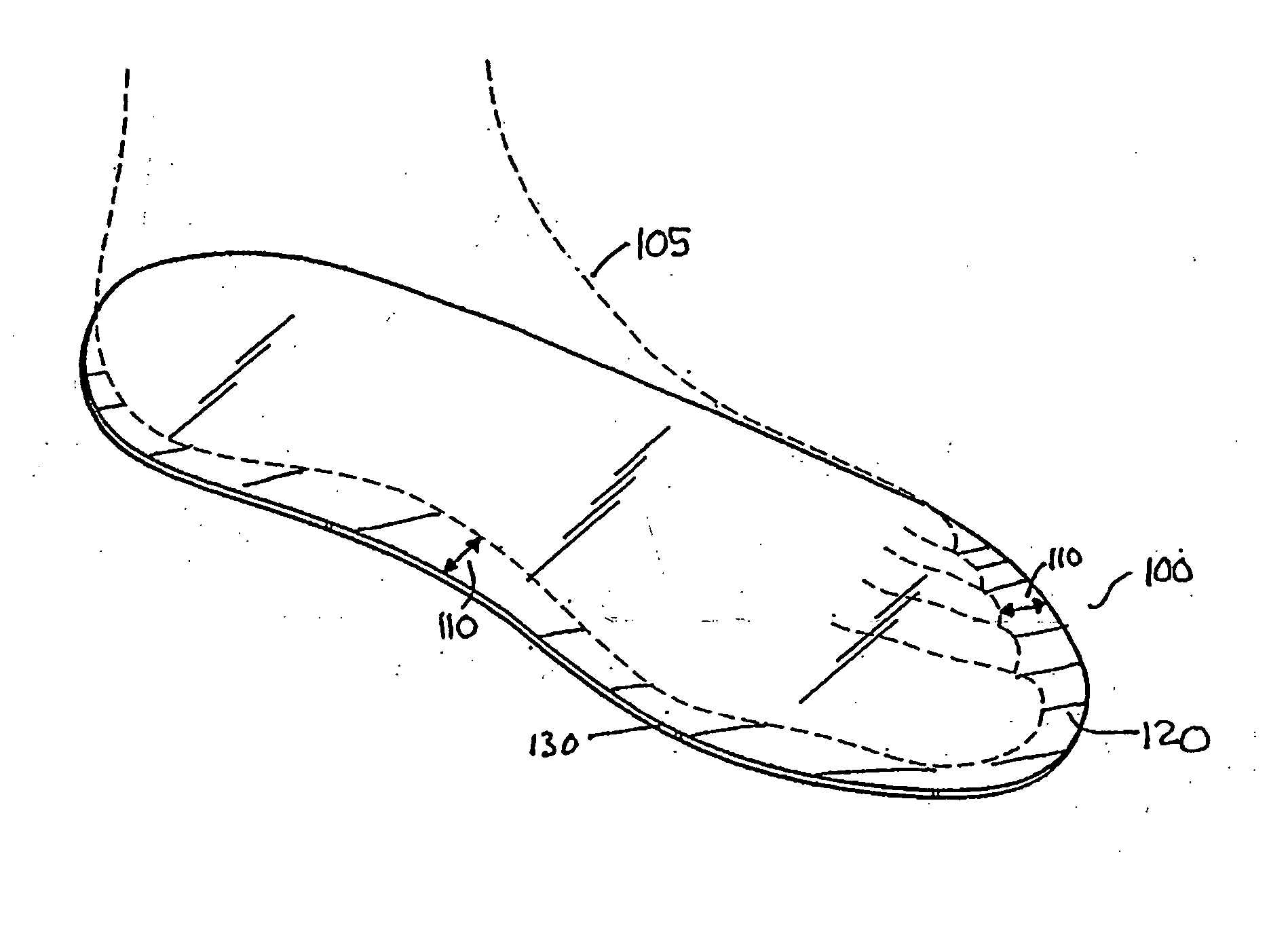

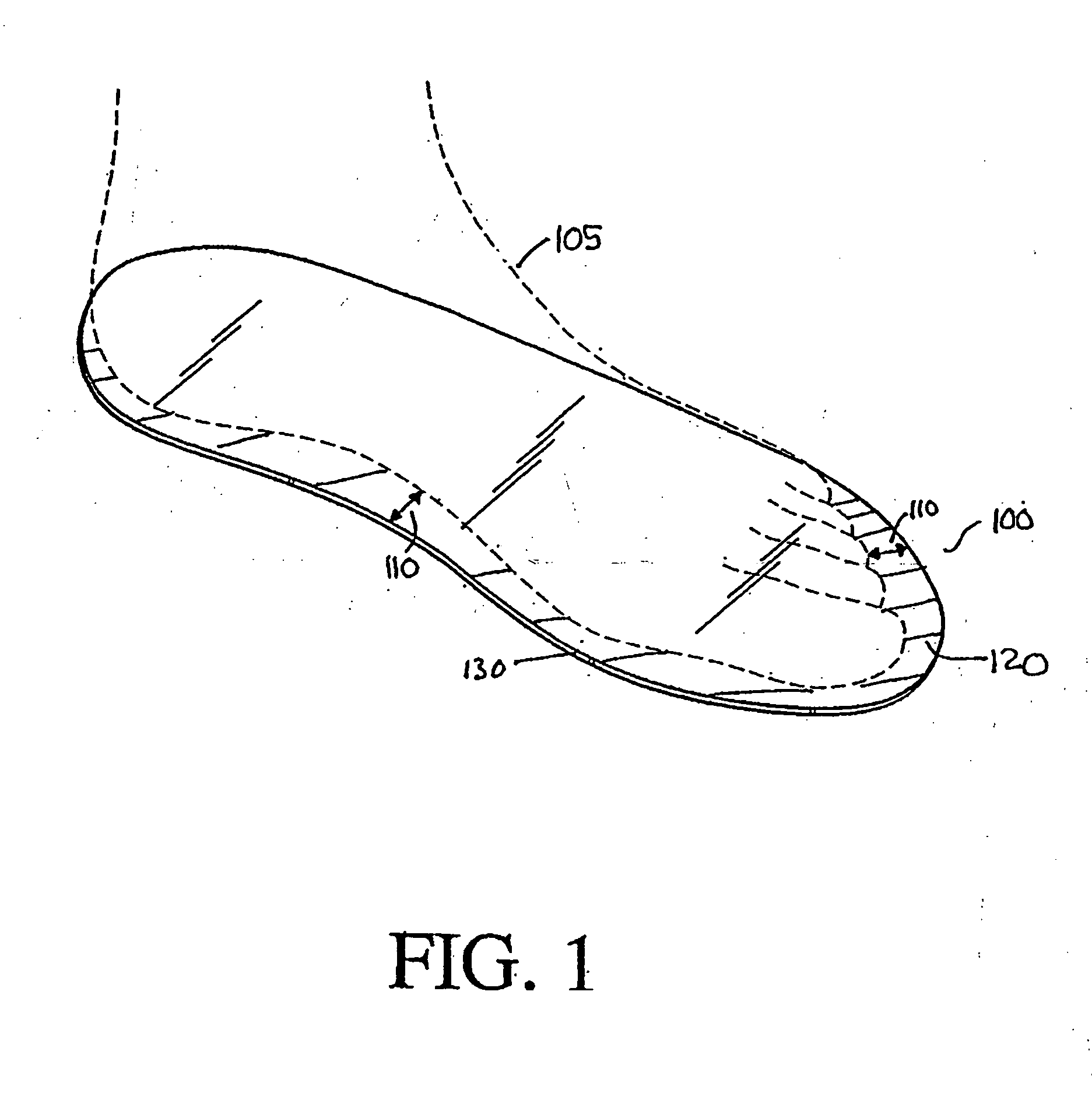

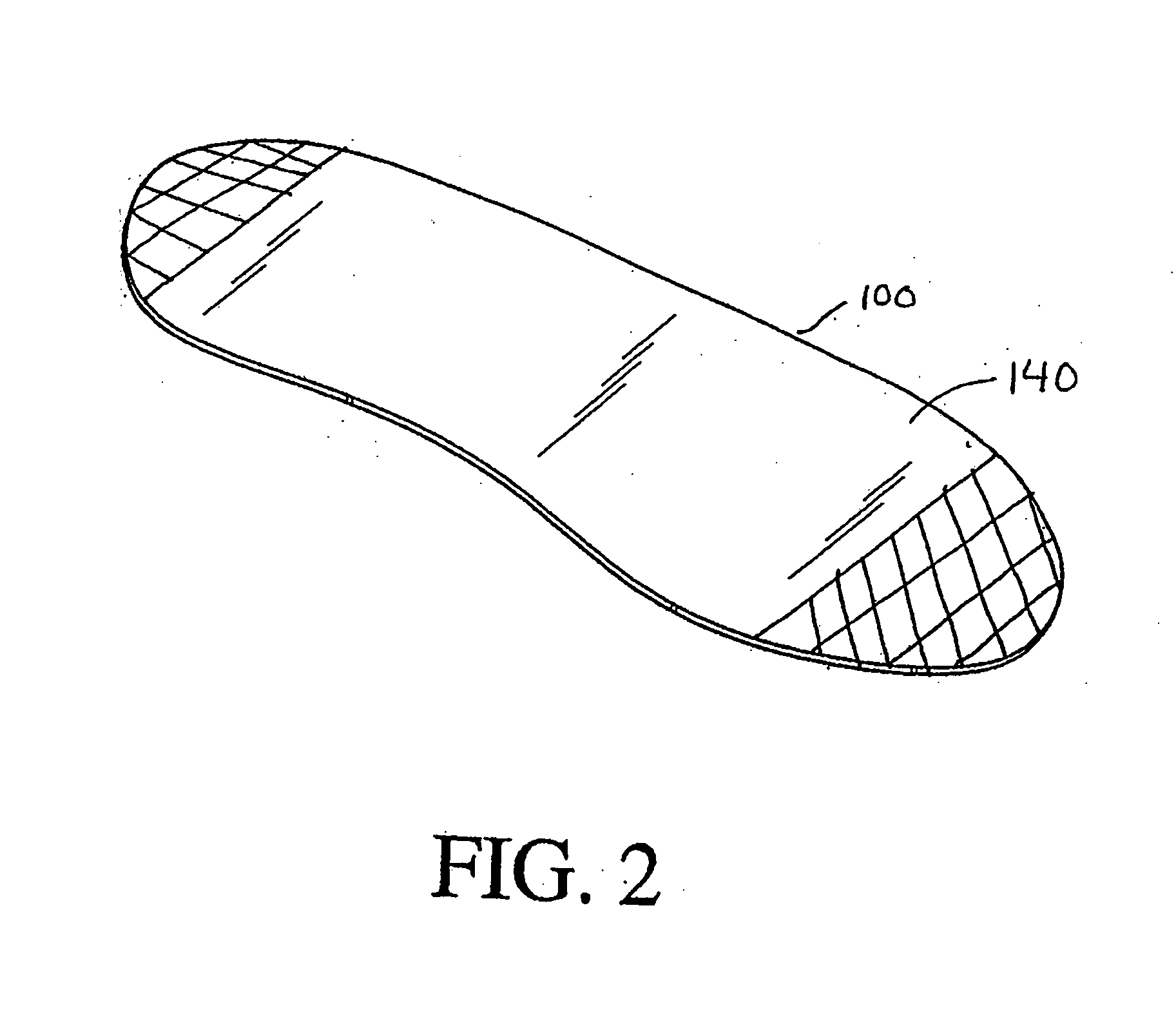

Self-adhering pedicure footwear

A cushioned foot pad configured to adhere to the bottom surface of an individual's foot without the use of straps, ties, or other securing devices the might otherwise engage with the toes and toenails of the individual during use. The cushioned foot pad may be configured to accommodate a variety of different foot shapes and sizes in a unitary design through the use of detachable pad portions. The cushioned foot pad is relatively inexpensive to manufacture and may be stored in bulk without consuming undo space.

Owner:STRONG VONDA MANLEY

Fastener apparatus for roofing and steel building construction

A fastener apparatus includes a frusto-hemispherical head portion having a flat top surface, a curved outer surface, a base portion, and a peripheral edge, with the flat top surface bearing a tool fitting. A downwardly-depending lip portion extends from the head peripheral edge and defines an annular recess in the base, the annular recess having a flat upper surface. The lip has a curved outer edge, a curved lower edge, and an inner edge having a curved lower portion and a vertical upper portion terminating in the annular recess flat upper surface. A shank portion is connected to the base and bears screw threads and a tip. An annular gasket portion is carried on the shank, and has a first uncompressed position contained radially within the annular recess, and a second compressed position extending radially beyond the lip outer edge. As the fastener is installed in a workpiece, the gasket expands to contact the lip inner edge and extend beneath the curved lower edge to form a seal between the fastener head and the workpiece. The fastener may include locking teeth terminating in the head base, adapted to resist loosening of the fastener from the workpiece. The curved outer surface of the fastener may include asymmetric ridges adapted to mechanically engage moving snow or ice to resist loosening of the fastener from the workpiece. The fastener head preferably has a width to height ratio of between 3:1 to 5:1.

Owner:DREAM WEAVER

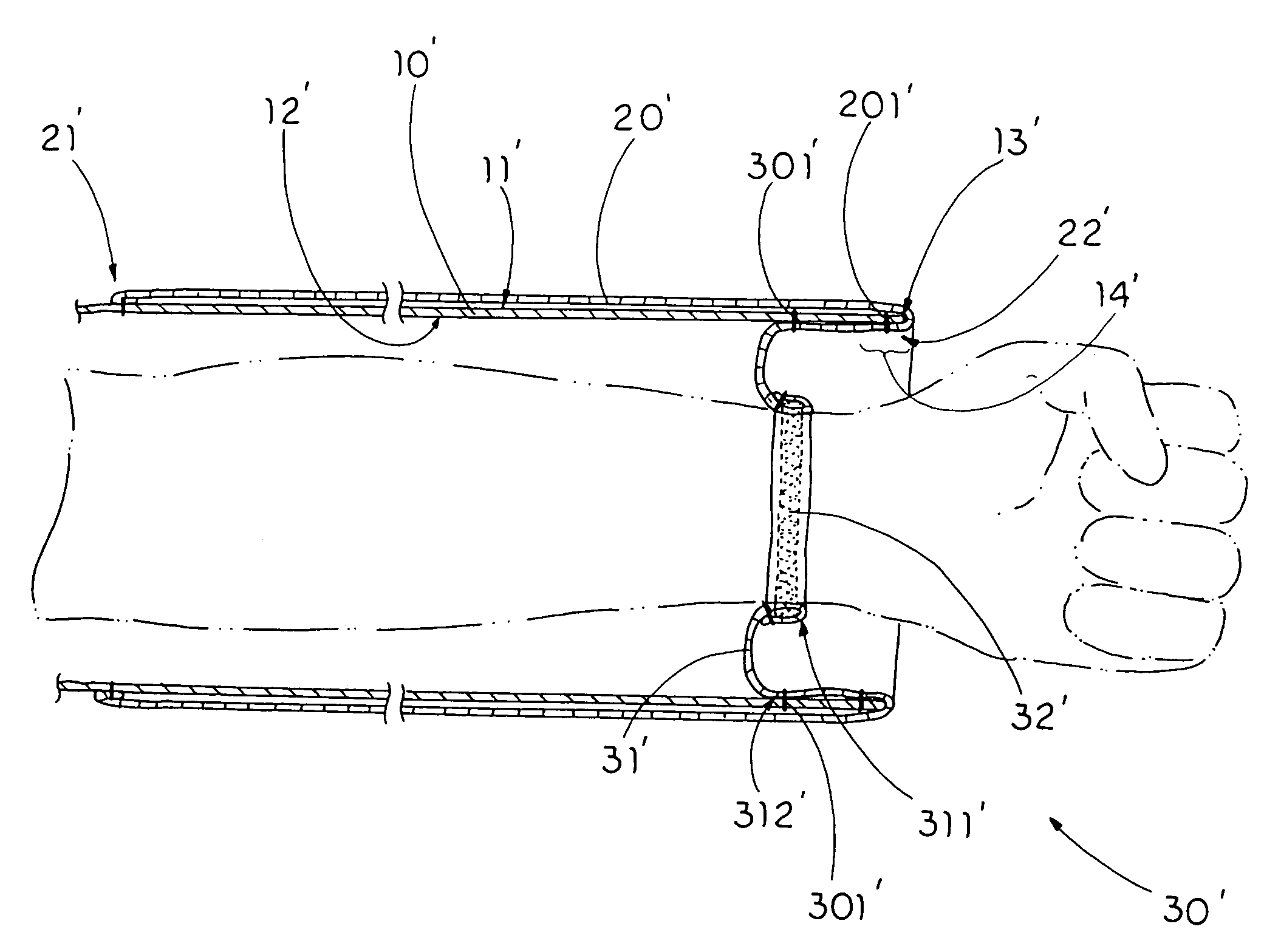

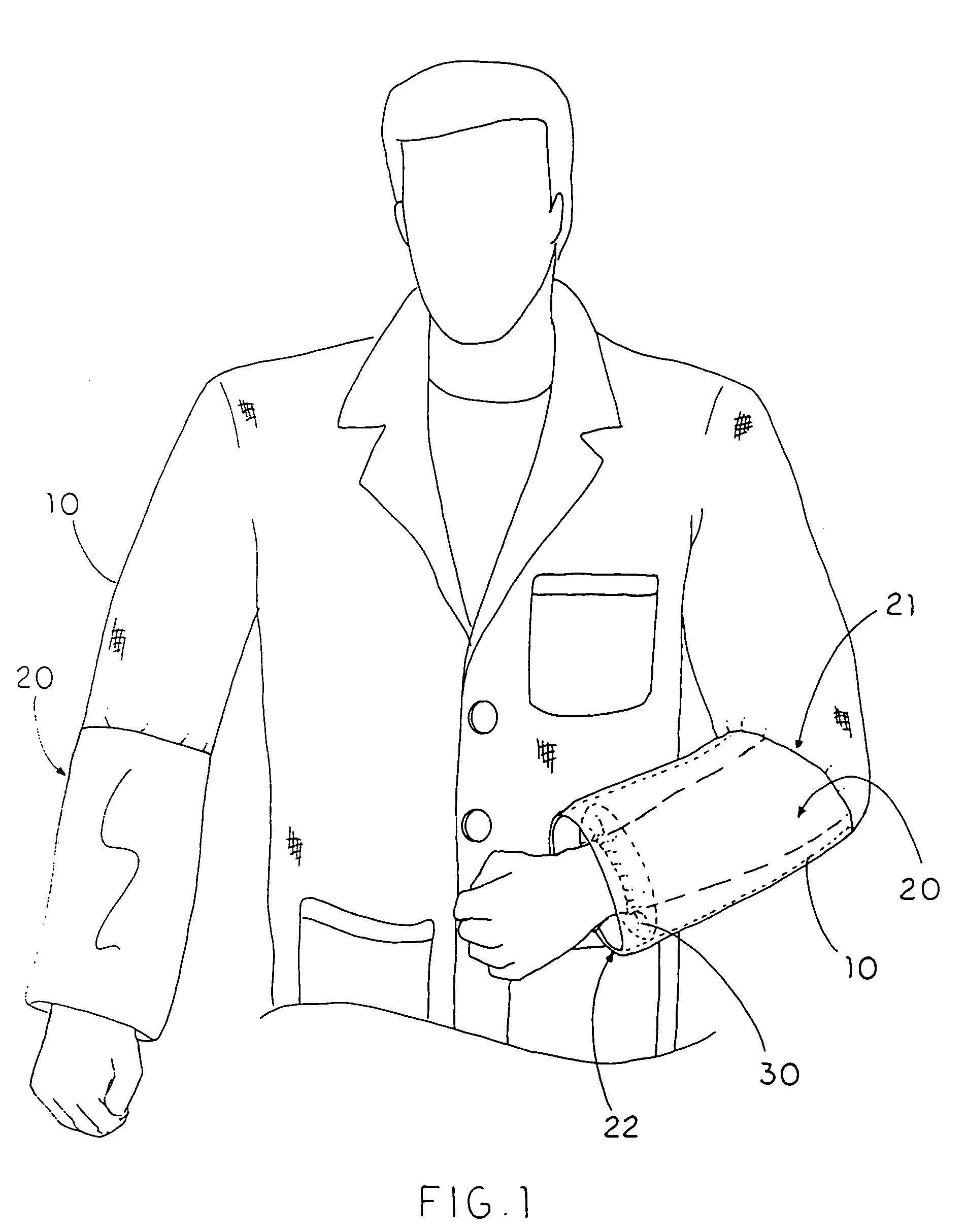

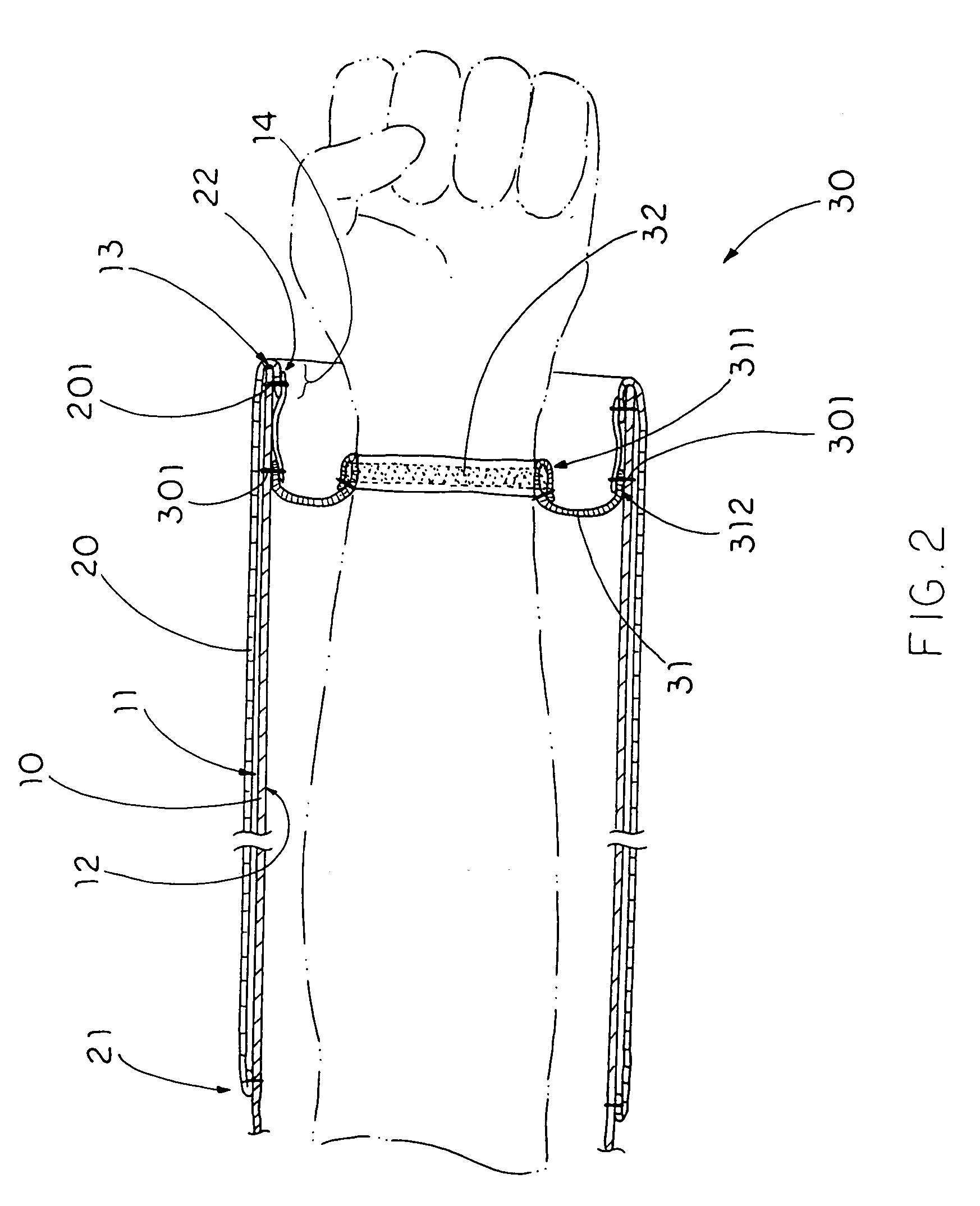

Sanitary arm sleeve structure

InactiveUS7370369B2Avoid enteringAvoid coatingDiagnosticsRestraining devicesClassical mechanicsEngineering

Owner:CHEUNG KEN

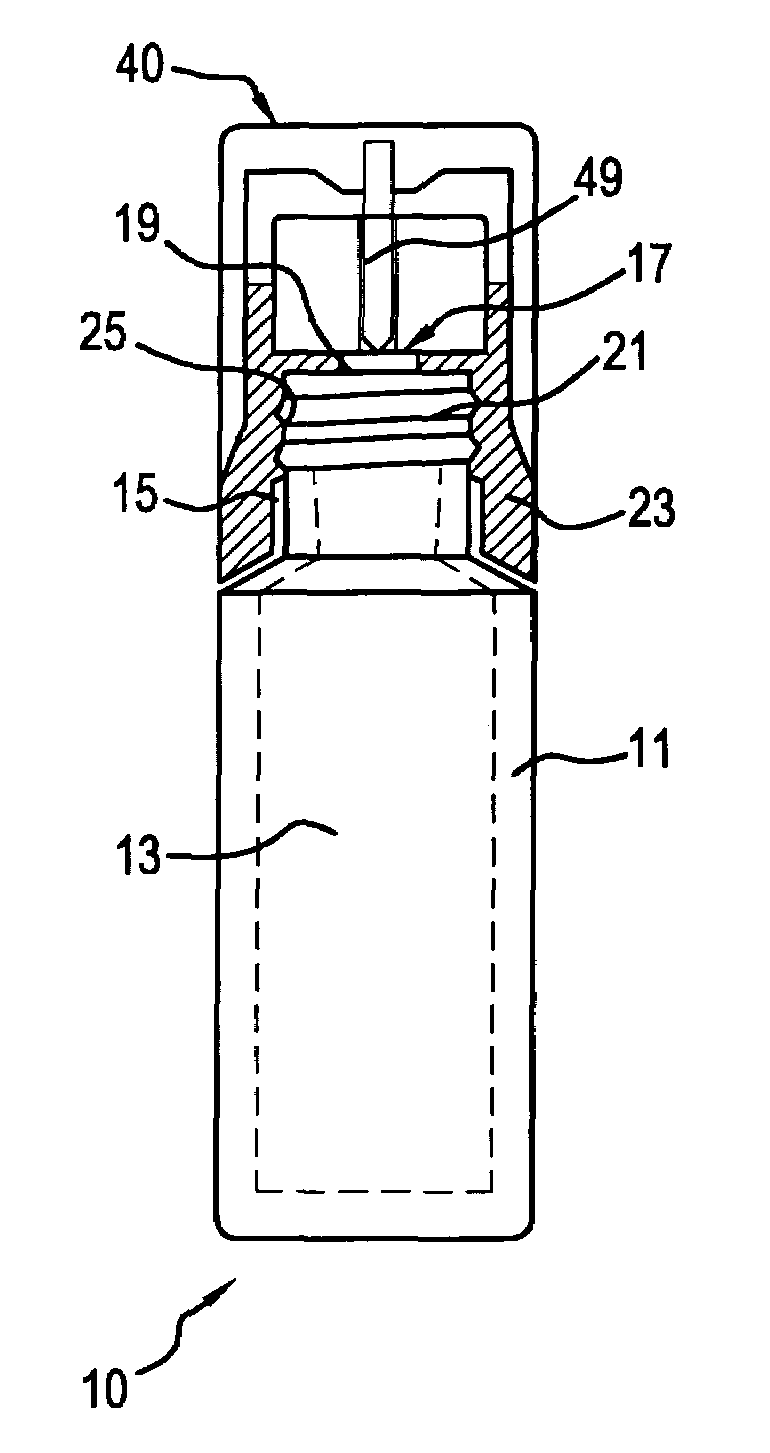

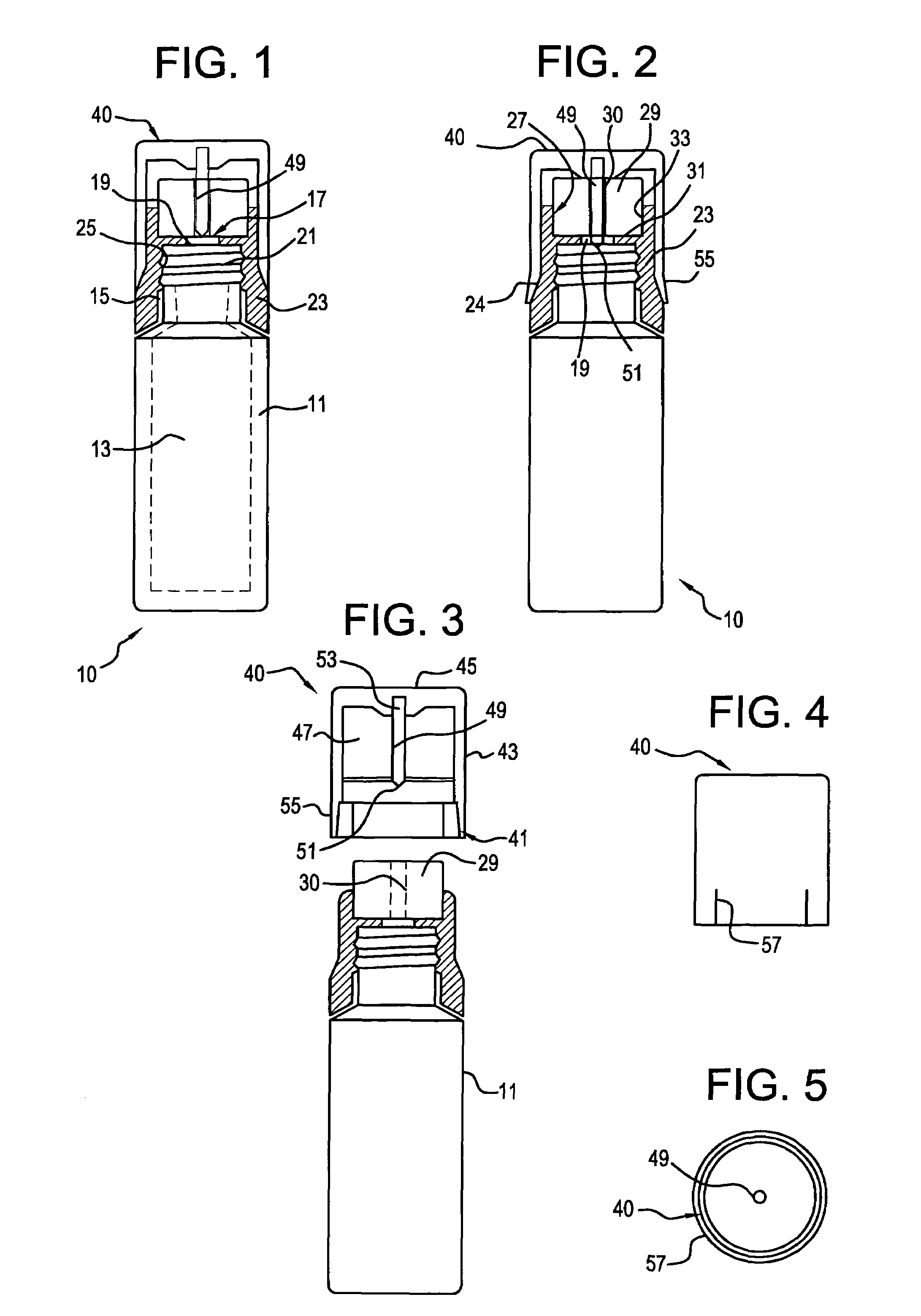

Single dose tooth whitener dispenser and applicator, and method of tooth whitening

ActiveUS7597497B2Avoid coatingAvoid unwanted applicationLiquid surface applicatorsClosuresHermetic sealEngineering

A single dose hygienic tooth whitener dispenser and applicator has a chamber. The housing is a bottle having an upper end with a neck and threads receiving a threaded sleeve. The sleeve includes a recess receiving a sponge applicator having a bottom surface overlying an upwardly facing opening of the chamber in the bottle. This opening is initially covered by a hermetic seal. An over-cap includes a bottom facing opening slidable over the sleeve and covers the applicator. Within the over-cap, a pin extends downwardly. The pin has a pointed end facing downward. When it is desired to use the inventive device to whiten the user's teeth, the over-cap is pushed down until the pointed end of the pin extends through the applicator and pierces the seal in the opening of the bottle, whereupon tooth whitener may be dispensed and applied.

Owner:GOSMILE

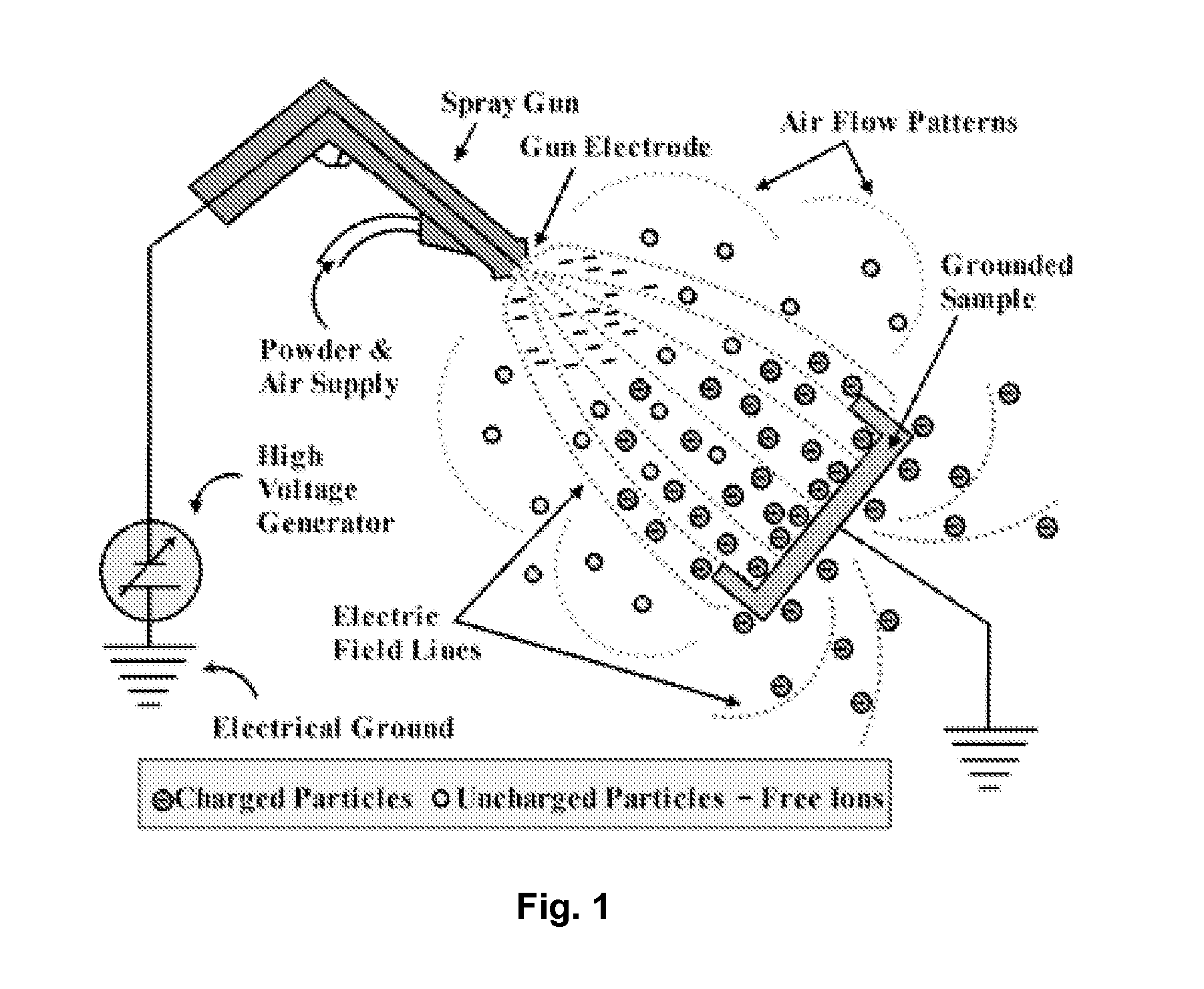

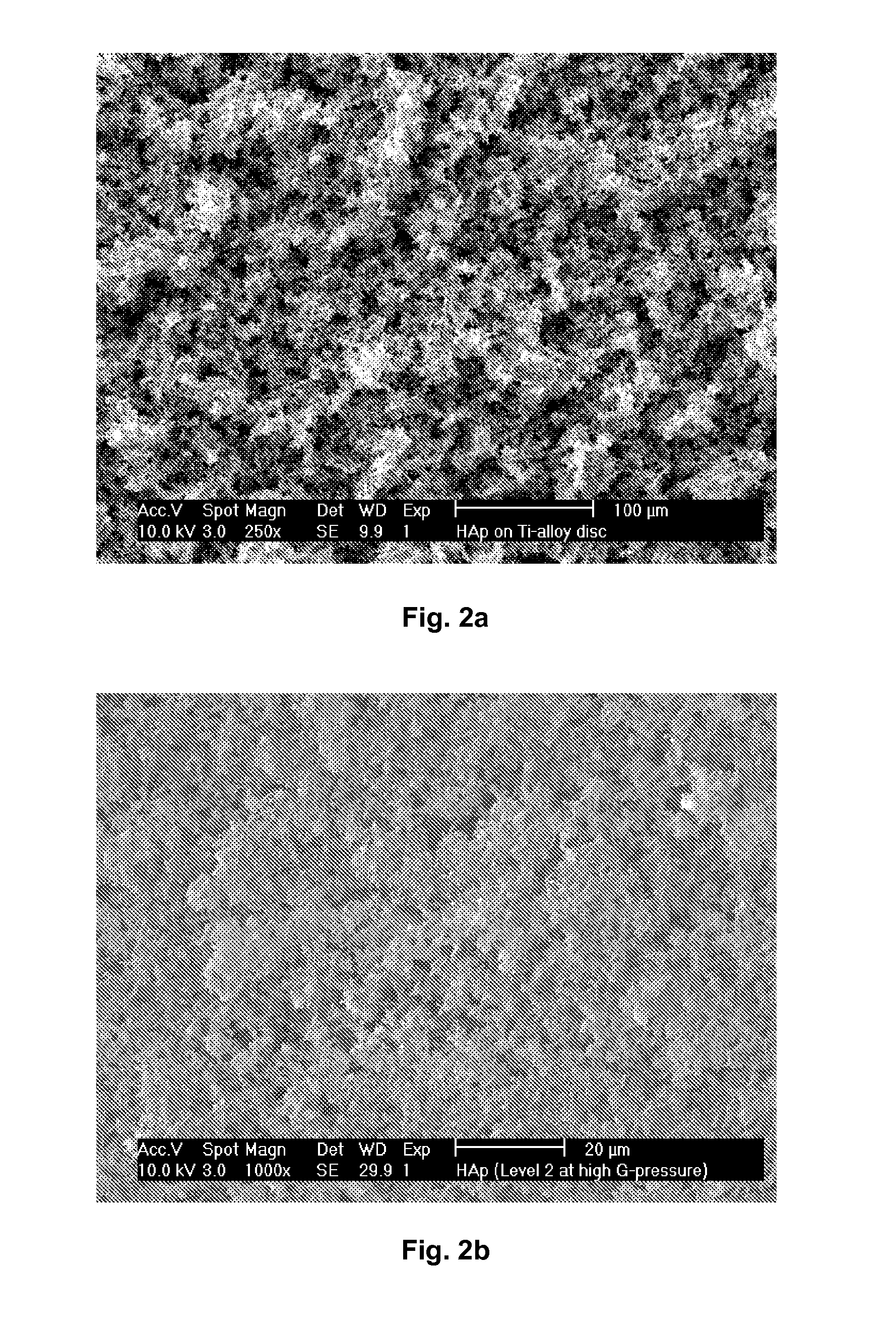

Nanostructured Hydroxyapatite Coating for Dental and Orthopedic Implants

ActiveUS20120276336A1Reduces HAp dissolutionIncrease deposition rateSpecial ornamental structuresPharmaceutical delivery mechanismOsseointegrationApatite

A high-strength coating for dental and orthopedic implants utilizing hydroxyapatite (HAp) nanoparticles provides for a high level of osseointegration through a range of surface pore sizes in the micro- to nanoscale. Zinc oxide (ZnO) nanoparticles may be incorporated with the HAp nanoparticles to form a composite coating material, with ZnO providing infection resistance due to its inherent antimicrobial properties. A textured surface, consisting of “islands” of roughly square coating structures measuring about 250 μm on a side, with spacing of 50-100 μm therebetween, may further promote the osseointegration and antimicrobial properties of the implant coating.

Owner:P&S GLOBAL HLDG LLC +1

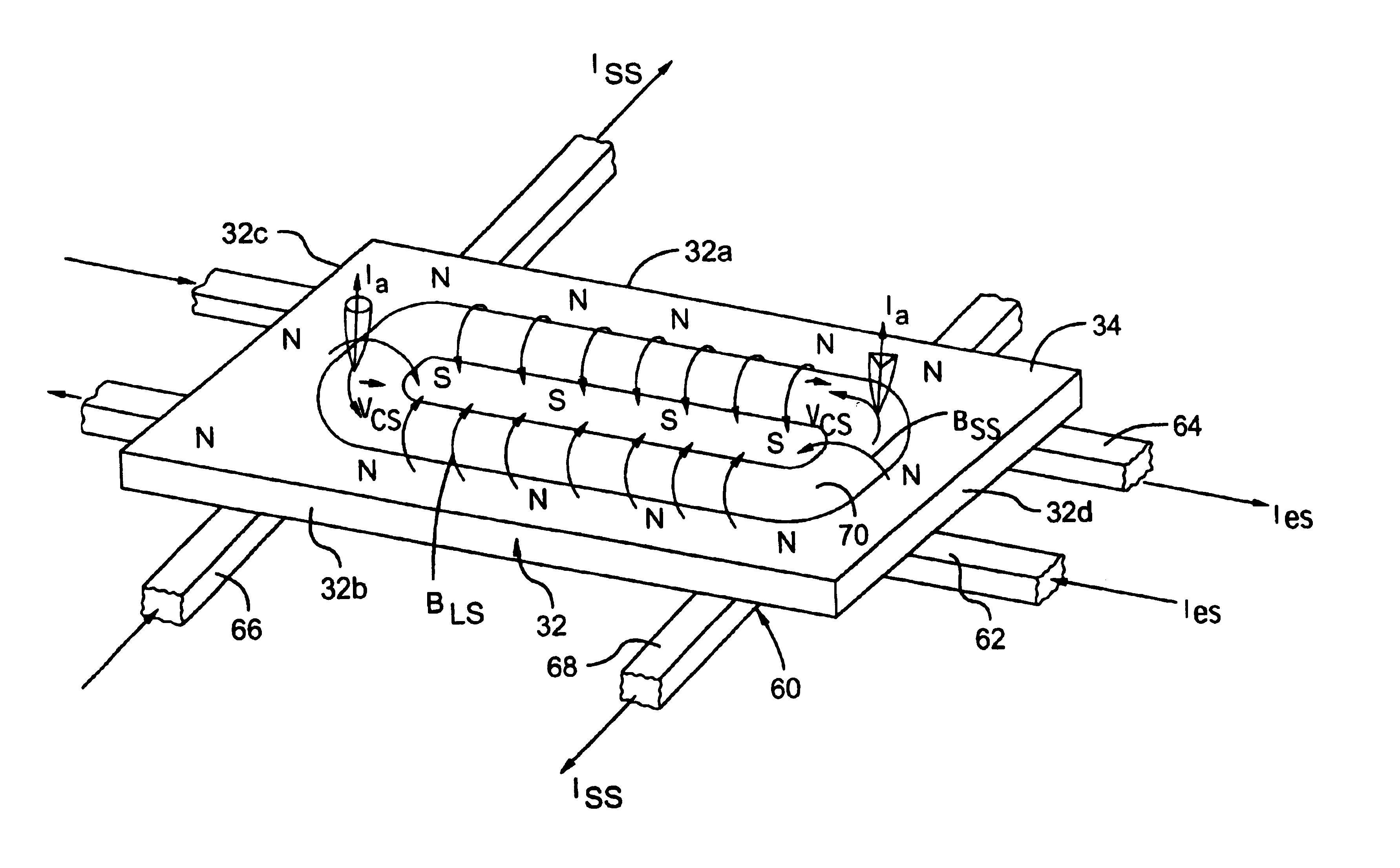

Rectangular cathodic arc source and method of steering an arc spot

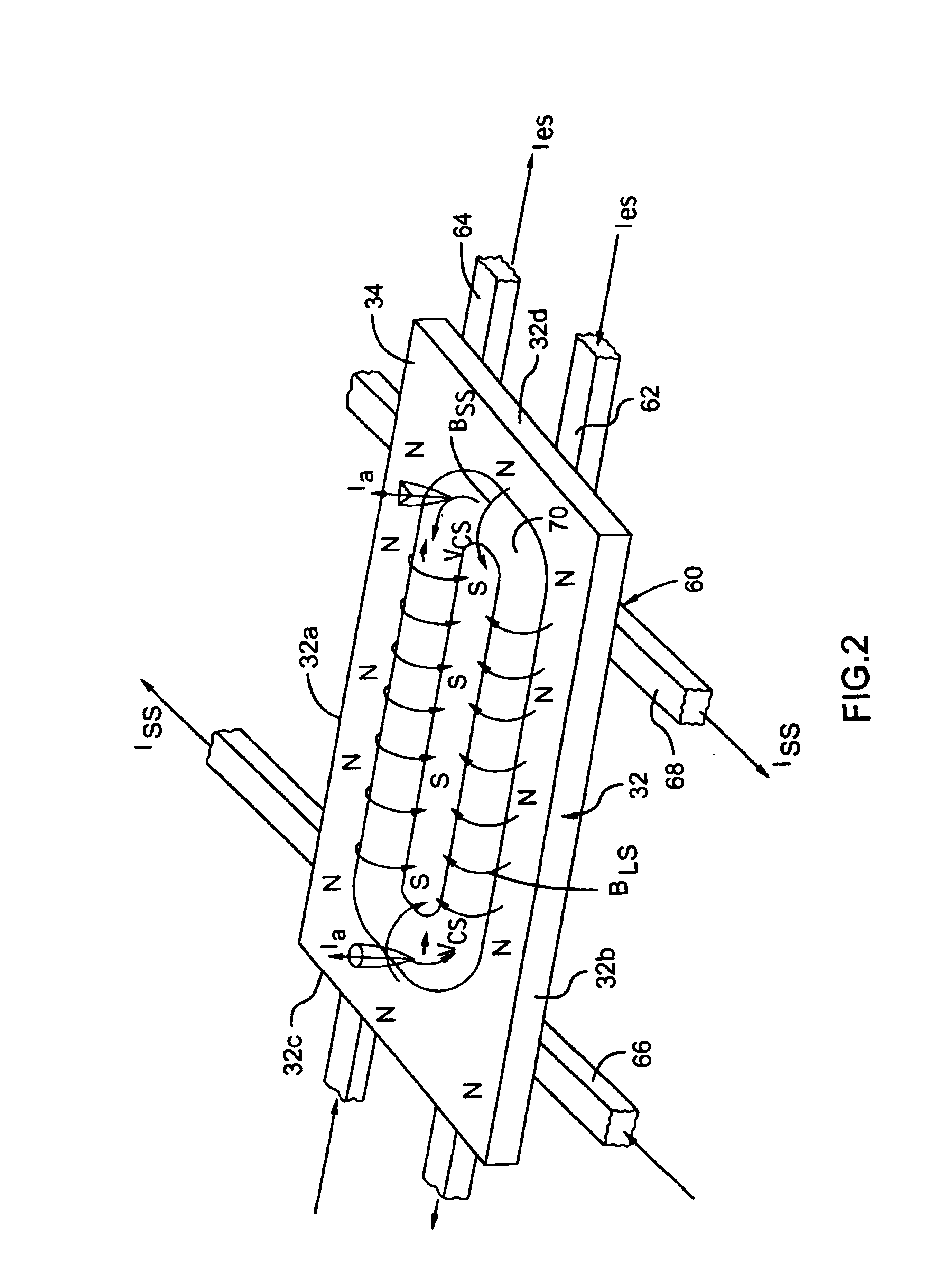

InactiveUS6929727B2Improve distributionUniform coatingCellsLiquid surface applicatorsElectrical conductorEvaporation

The invention provides an arc coating apparatus having a steering magnetic field source comprising steering conductors disposed along the short sides of a rectangular target behind the target, and a magnetic focusing system disposed along the long sides of the target in front of the target which confines the flow of plasma between magnetic fields generated on opposite long sides of the target. The plasma focusing system can be used to deflect the plasma flow off of the working axis of the cathode. Each steering conductor can be controlled independently. In a further embodiment, electrically independent steering conductors are disposed along opposite long sides of the cathode plate, and by selectively varying a current through one conductor, the path of the arc spot shifts to widen an erosion corridor. The invention also provides a plurality of internal anodes, and optionally a surrounding anode for deflecting the plasma flow and preserving a high ionization level of the plasma. The invention also provides a shield at floating potential, restricting the cathode spot from migrating into selected regions of the target evaporation surface outside of the desired erosion zone. The shield may be positioned immediately above the region of the target surface in the vicinity of the anode, protecting the anode from deposition of cathodic evaporate and providing better distribution of cathodic evaporate over the substrates to be coated. The invention further provides correcting magnets adjacent to the short sides of the target, to move the arc spot between the long sides.

Owner:G&H TECH LLC

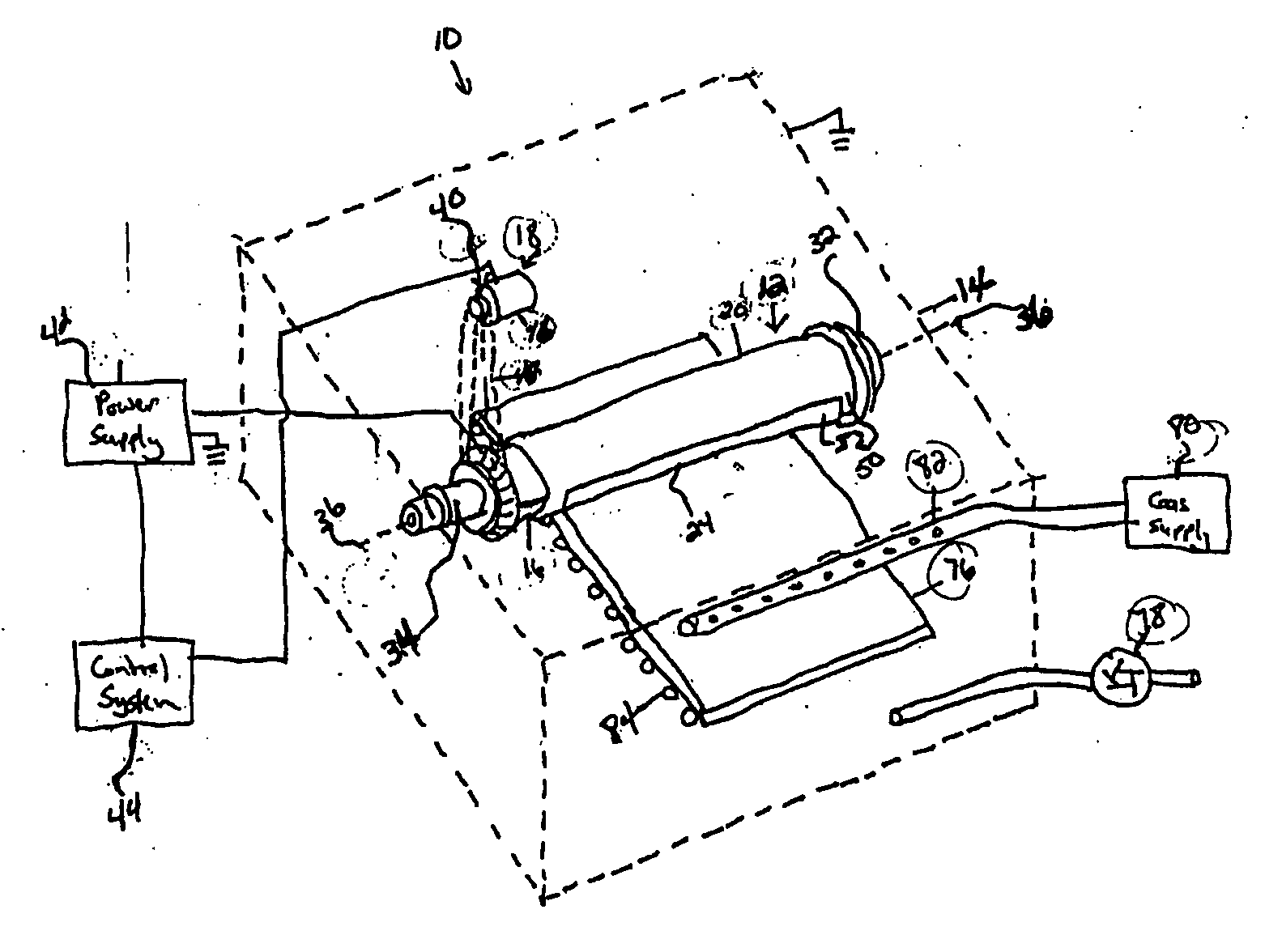

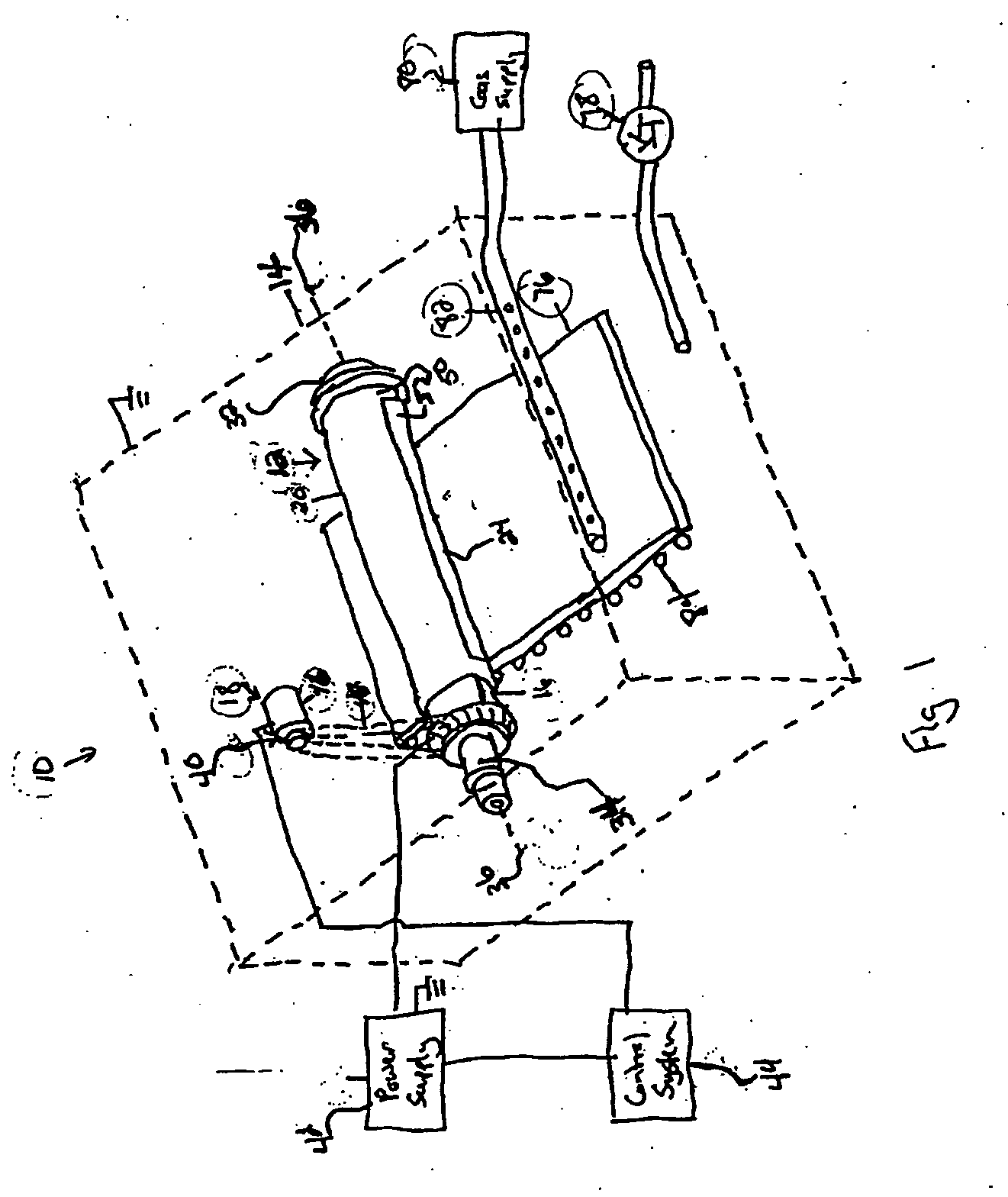

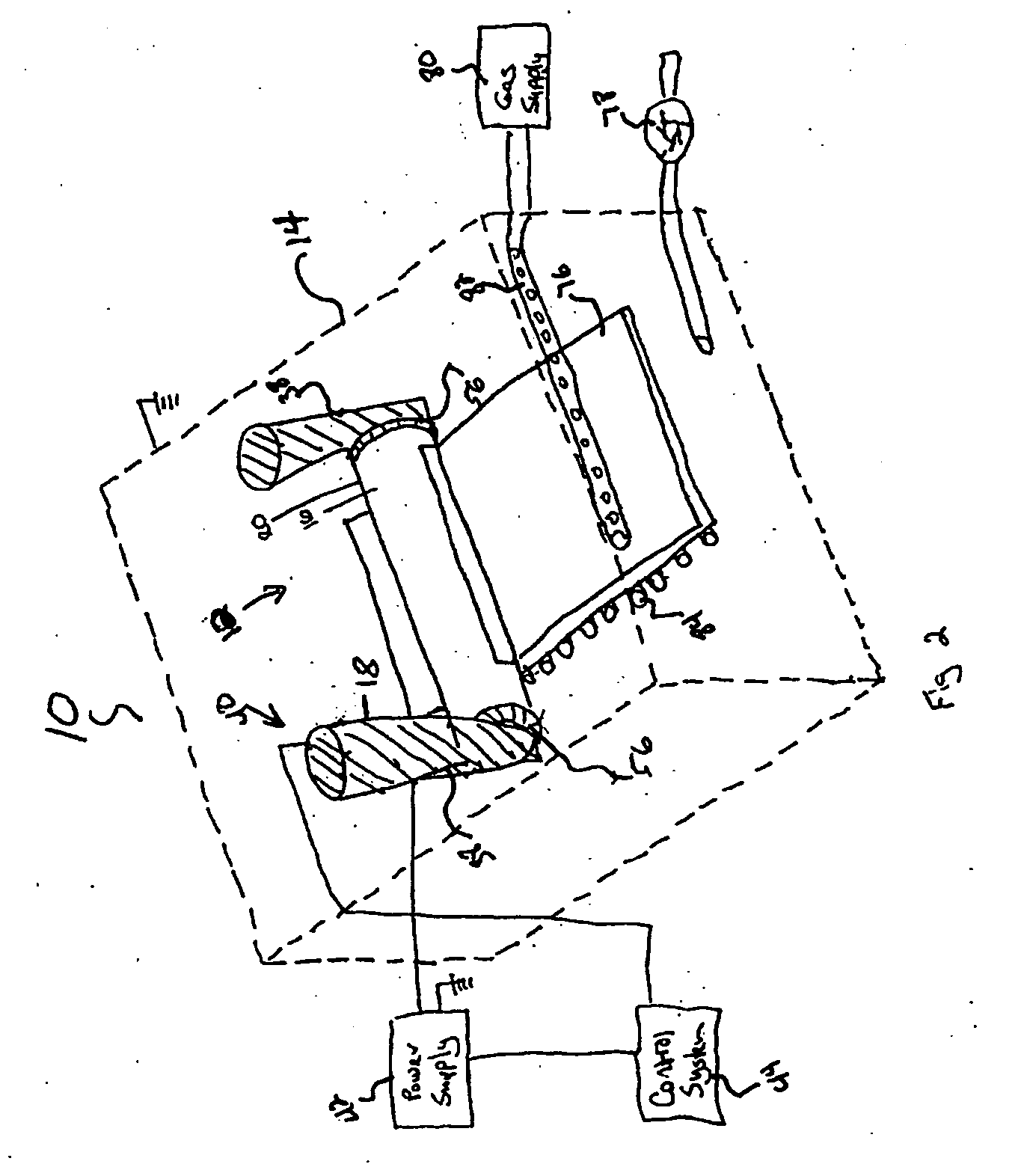

Oscillating shielded cylindrical target assemblies and their methods of use

InactiveUS20060137968A1Easy to operateShorten the timeCellsElectric discharge tubesNiobiumEngineering

The present invention relates to an oscillating shielded cylindrical target assembly comprising a cylindrical target, a motor assembly adapted to oscillate the cylindrical target, a shield, and a magnet assembly. Embodiments of the present invention also include a cylindrical target that has an outer surface containing a plurality of divided sections; the sections being disposed lengthwise around the target to form strips running lengthwise across the target. Each section includes a single sputtering material, such as silver, titanium, or niobium, that is intended to be applied as a separate coating on a substrate, such as glass.

Owner:CARDINAL CG

Protection of thermal barrier coating by impermeable barrier coating

InactiveUS20070224411A1Avoid coatingPrevents infiltration of the contaminant compositionLiquid surface applicatorsEngine manufactureMetallurgyRare earth

According to an embodiment of the invention, disclosed is a composite comprising a porous thermal barrier coating on a metallic part and an impermeable barrier coating adjacent to the outer surface of the thermal barrier coating. The impermeable barrier coating is dense and non-porous and comprises a rare earth silicate, the impermeable barrier coating thereby preventing infiltration of the contaminant composition into the thermal barrier coating.

Owner:GENERAL ELECTRIC CO

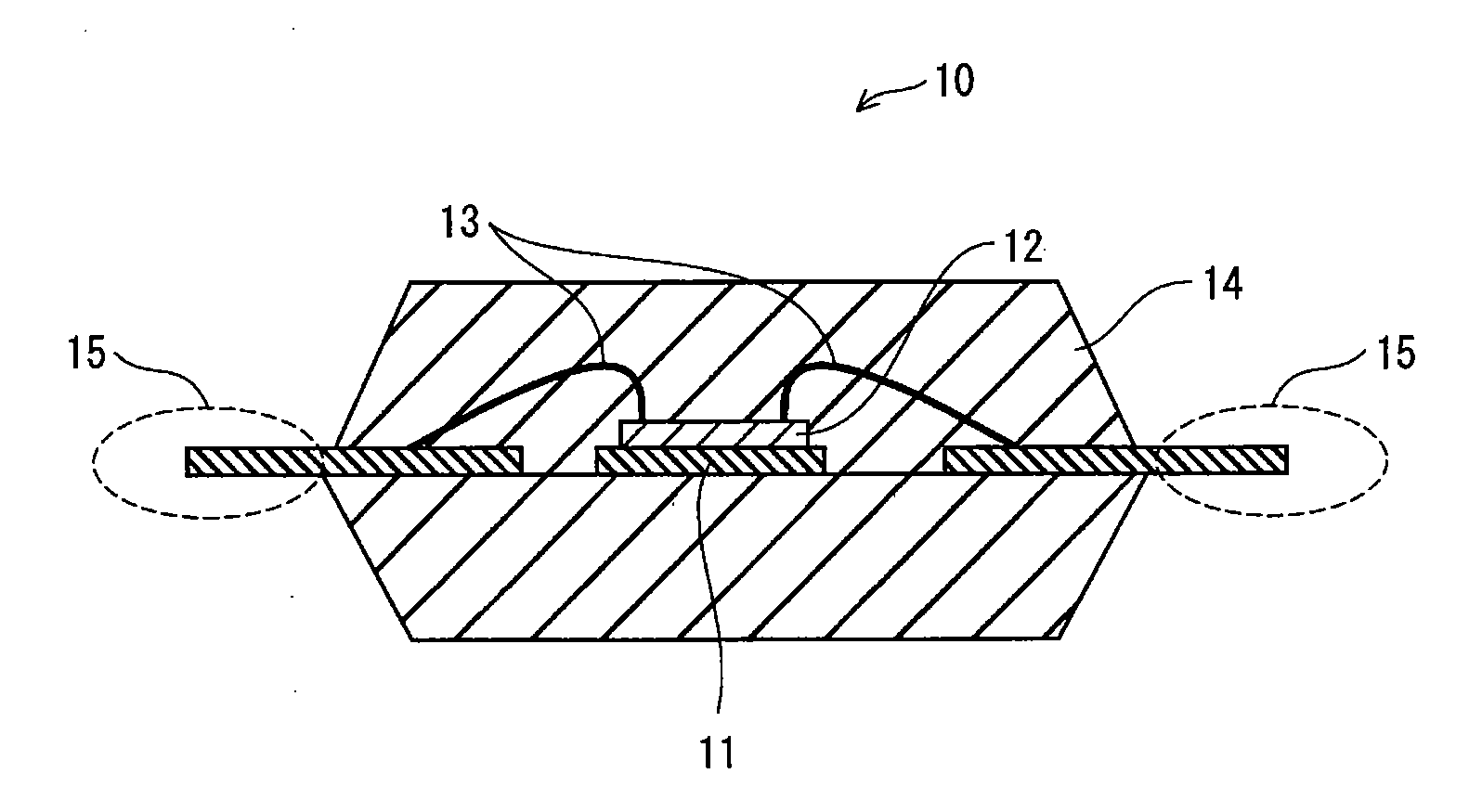

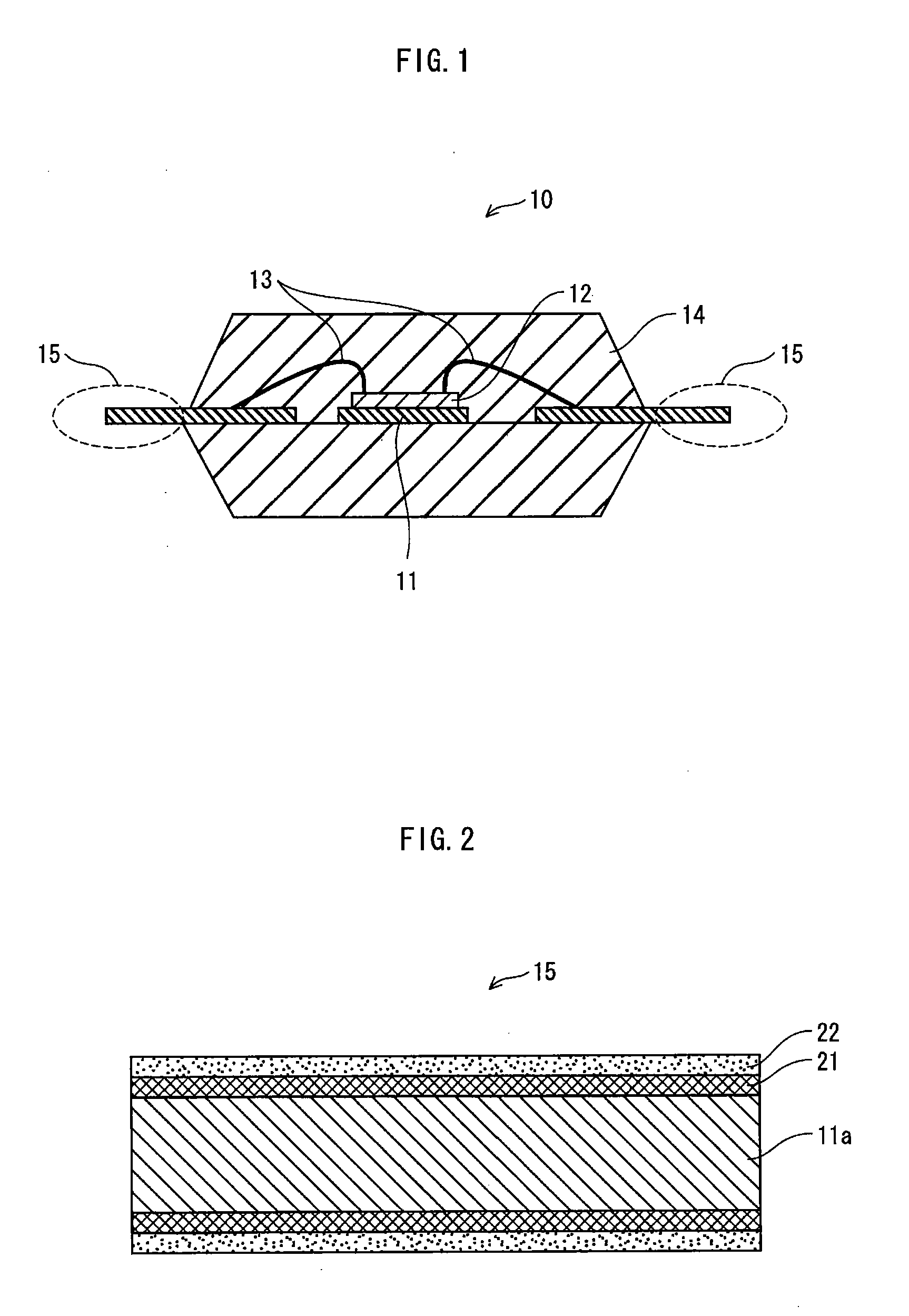

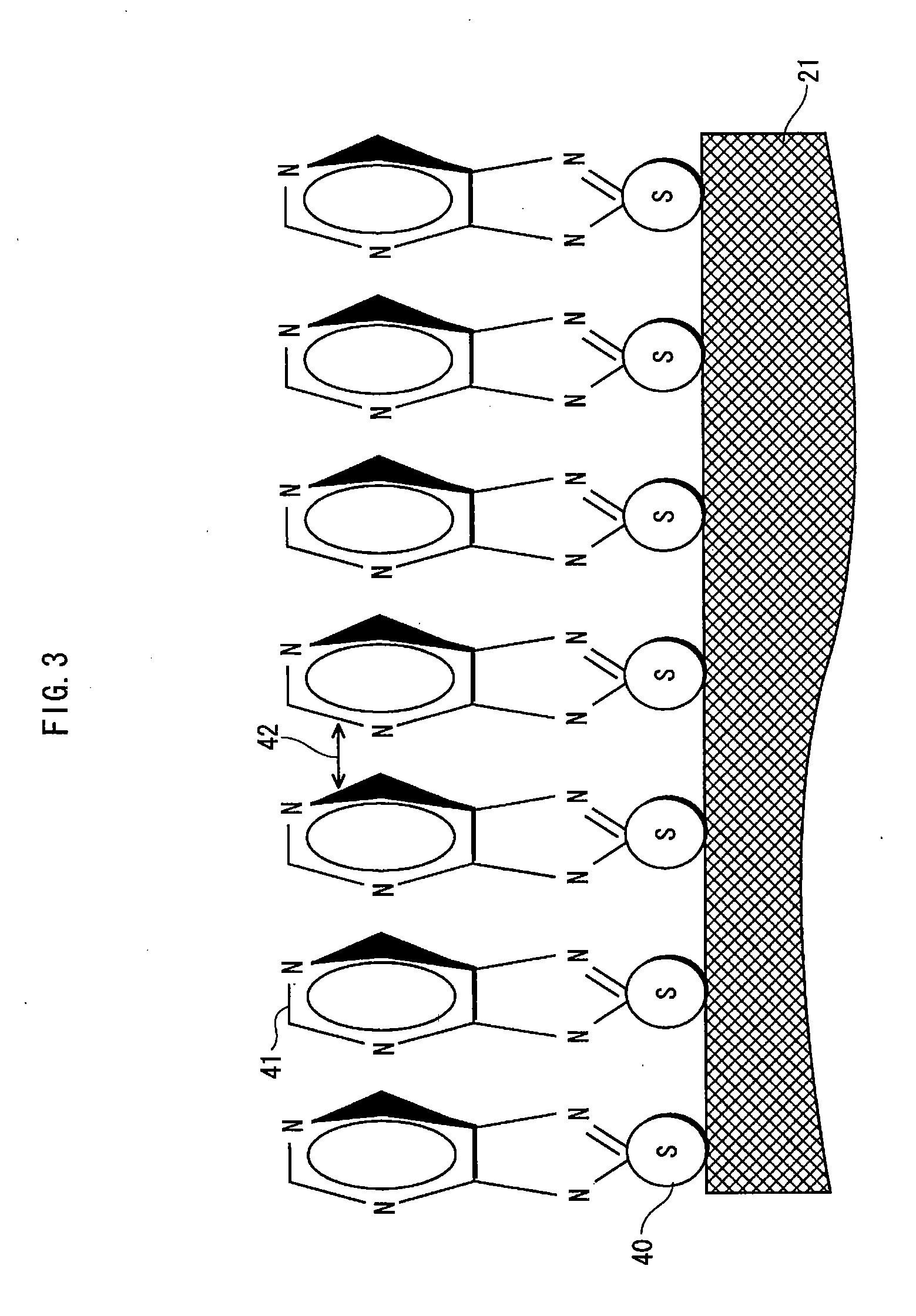

Lead, wiring member, package component, metal component with resin, resin-encapsulated semiconductor device, and methods for producing the same

ActiveUS20110163345A1Avoid coatingPrevent discolorationPlastic/resin/waxes insulatorsSemiconductor/solid-state device detailsSimple Organic CompoundsMetal coating

Owner:PANASONIC HLDG CORP

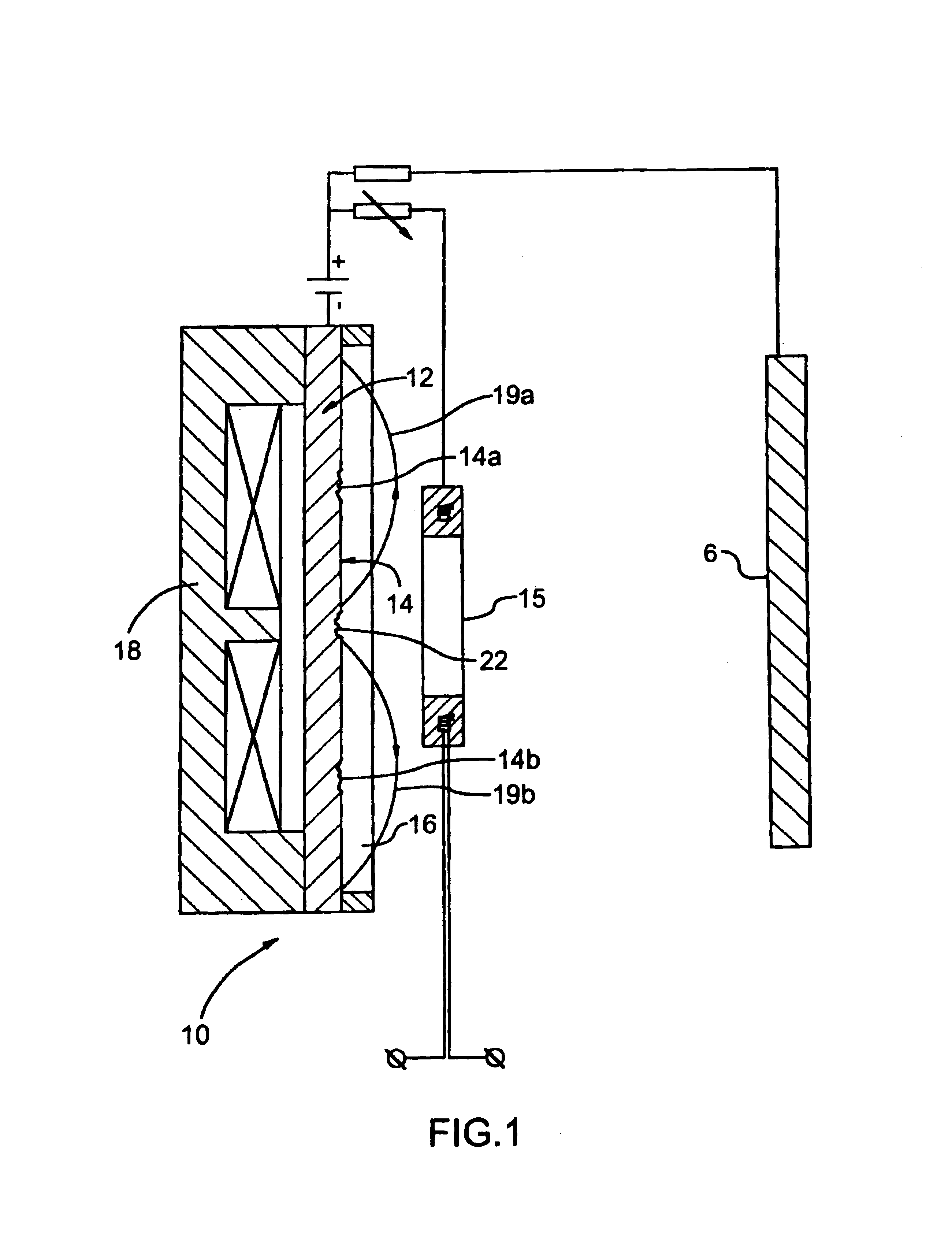

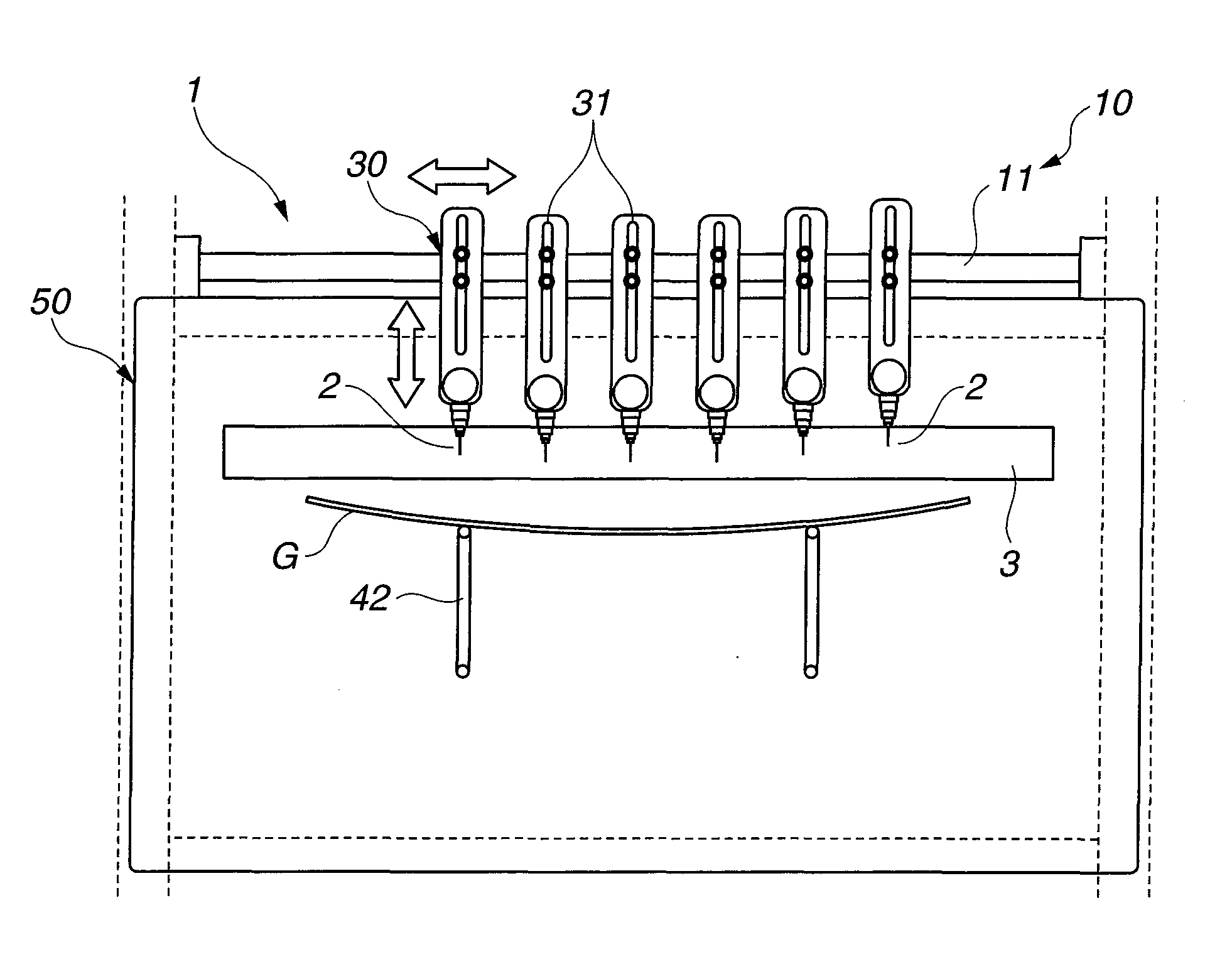

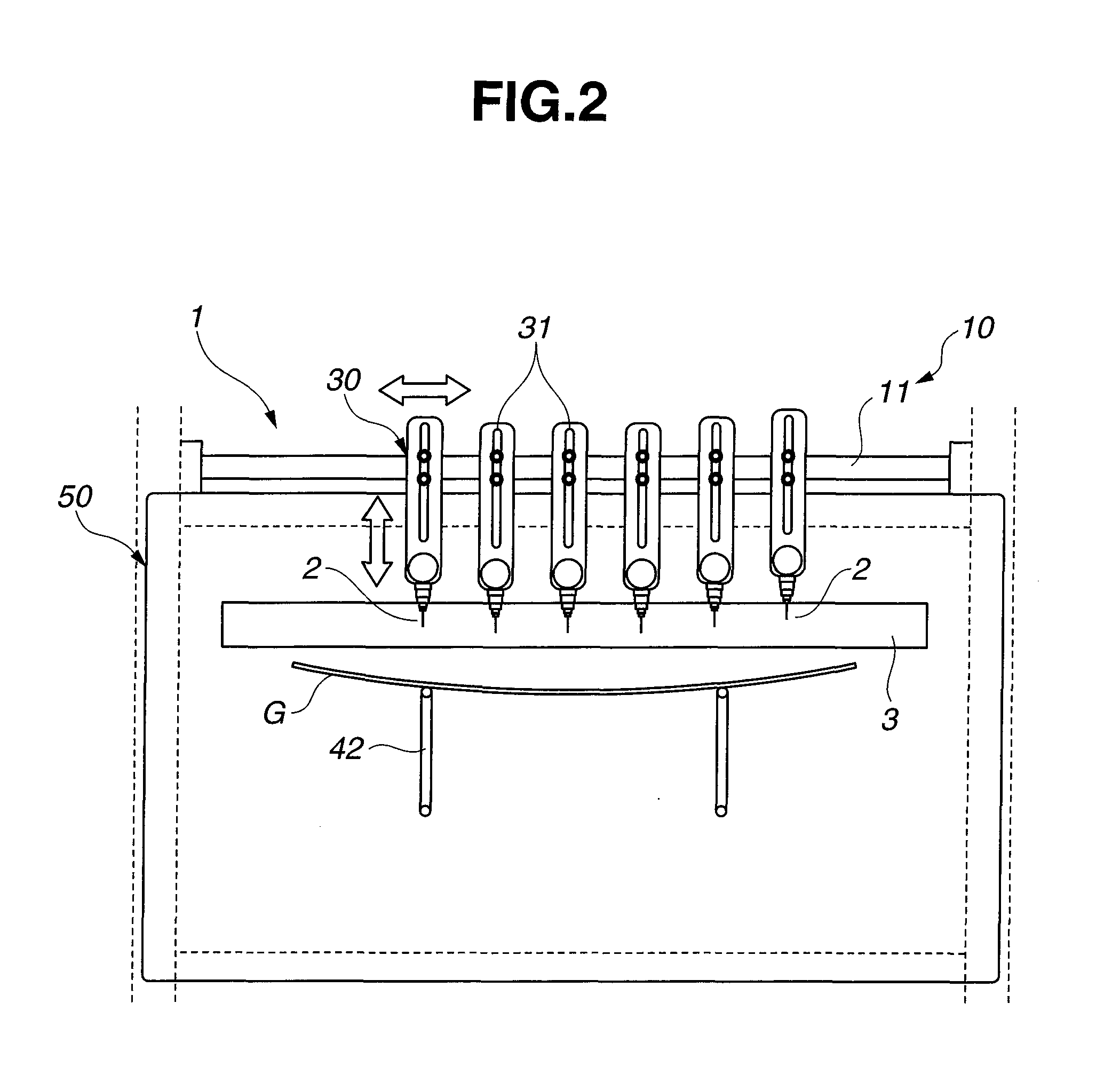

Apparatus and Method of Applying a Coating Solution

InactiveUS20100310778A1Uniform applicationReduce decreaseLiquid surface applicatorsMovable spraying apparatusLeading edgeEngineering

A method of applying a coating solution onto an upper surface of a glass plate that is transported in a substantially horizontal attitude, according to the first aspect of the present invention, the method including the steps of transporting the glass plate into a coating chamber, and opening the plurality of coating nozzles which are positioned in a row at constant intervals therebetween along a curved shape of the upper surface of the glass plate in a width direction of the glass plate perpendicular to the direction of transporting the glass plate by the nozzle position adjusting means and the nozzle height adjusting means, to thereby inject the coating solution when the coating nozzles are located in a region of the upper surface of the glass plate which extends from the leading edge of the glass plate to the rear edge of the glass plate.

Owner:CENT GLASS CO LTD

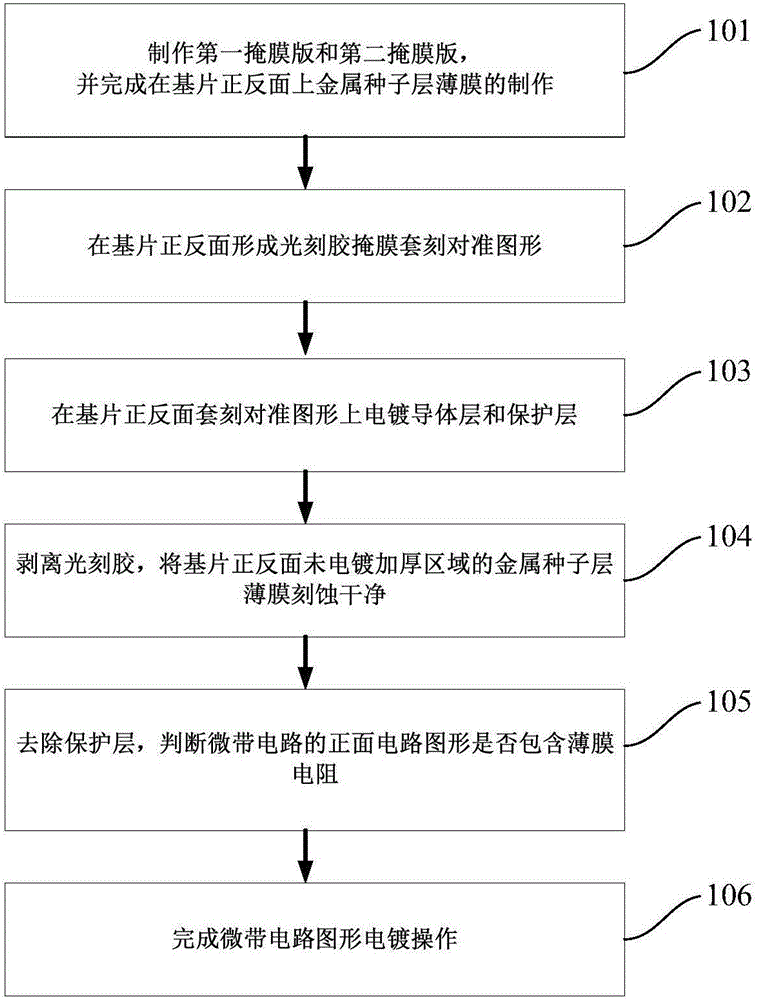

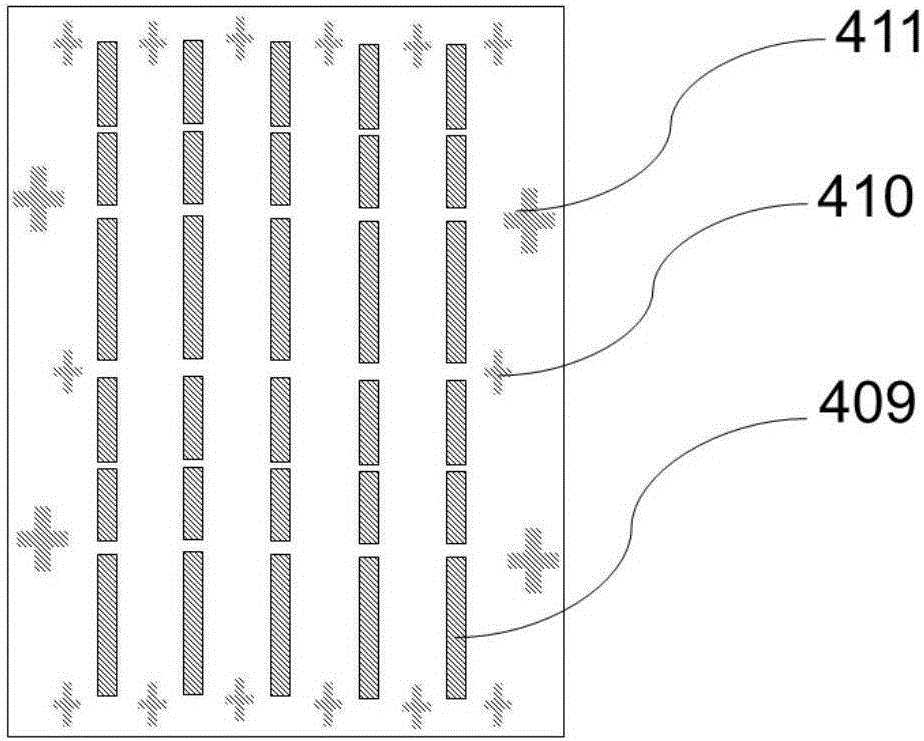

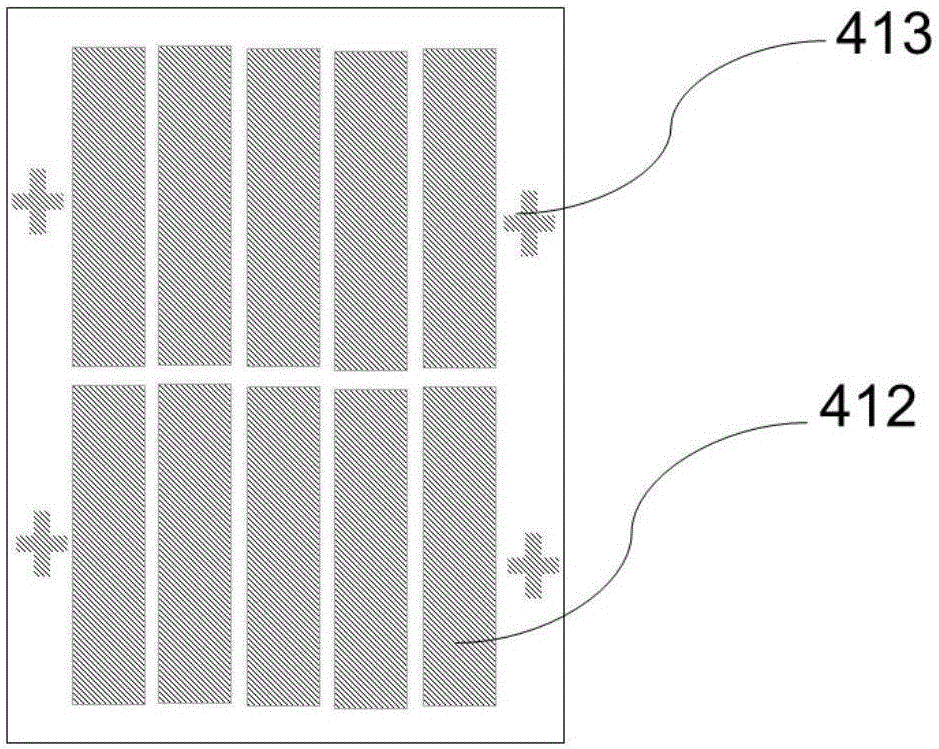

Pattern electroplating method for microstrip circuit

InactiveCN106298626AHigh precisionQuality improvementSolid-state devicesSemiconductor/solid-state device manufacturingSurface patternElectrical conductor

The invention discloses a pattern electroplating method for a microstrip circuit, wherein the pattern electroplating method belongs to the technical field of a microwave millimeter wave film mixed integrated circuit. According to the pattern electroplating method, in the microstrip circuit with relatively large number of isolated conductor patterns, an original method of combining substrate front-surface pattern electroplating and back ground-surface integral electroplating is changed to a double-surface pattern electroplating process so that a medium layer at a cutting channel position is exposed to outside, thereby effectively preventing film layer falling in cutting the microstrip circuit, improving cutting quality and yield rate of the microstrip circuit, and settling a problem of film layer warpage and falling caused by stress influence to an electroplating functional layer of the microstrip circuit in a loading process and a discharging process of the electroplating protecting layer on the cutting channel in manufacture according to an existing process. According to the pattern electroplating method, electroplating deposition of the functional layer is only performed on the conductor pattern areas on the front surface and the back surface of an array circuit, thereby preventing plating of noble metals such as gold on other areas such as cutting channels and process edges outside the array pattern, reducing electroplating area and saving cost.

Owner:THE 41ST INST OF CHINA ELECTRONICS TECH GRP

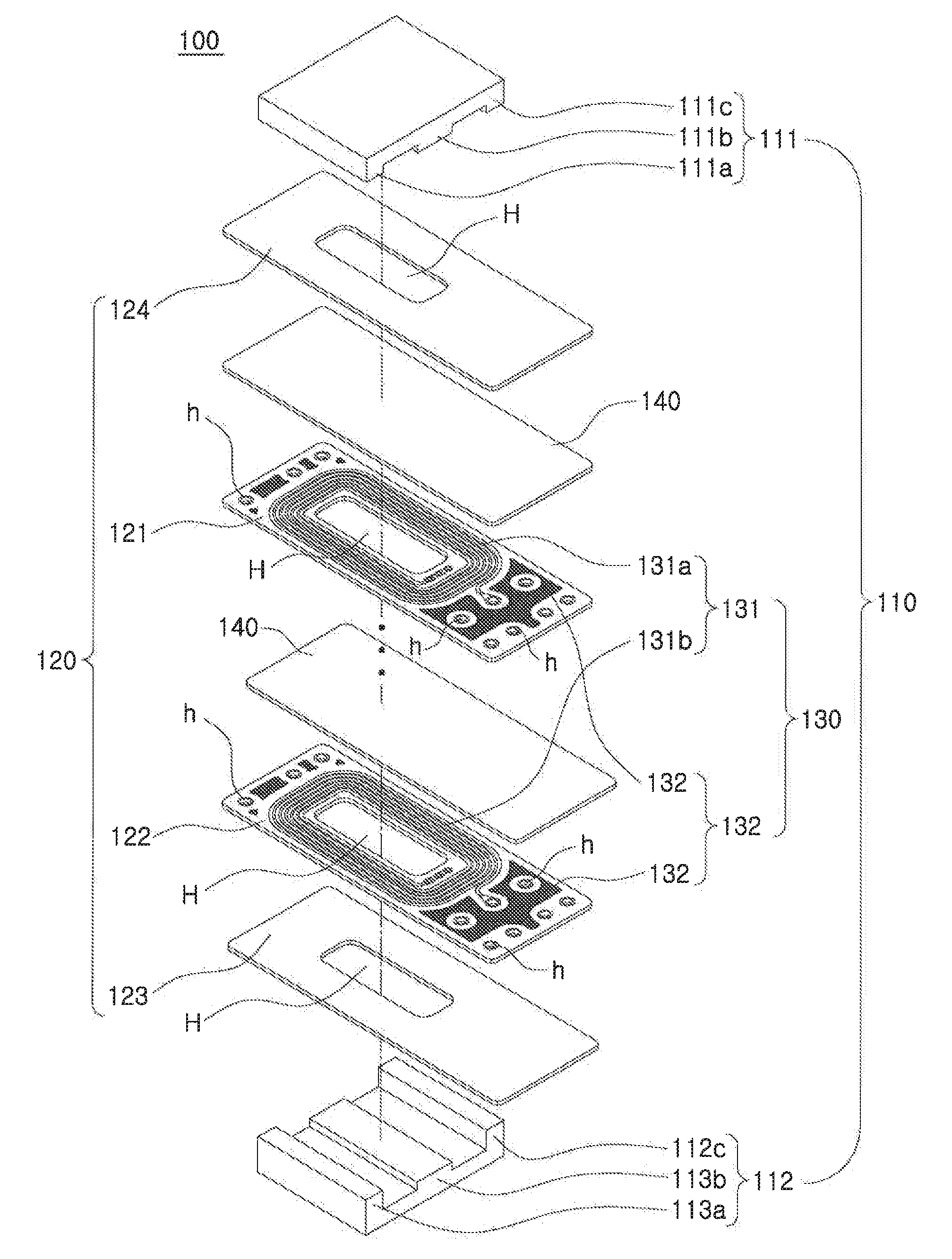

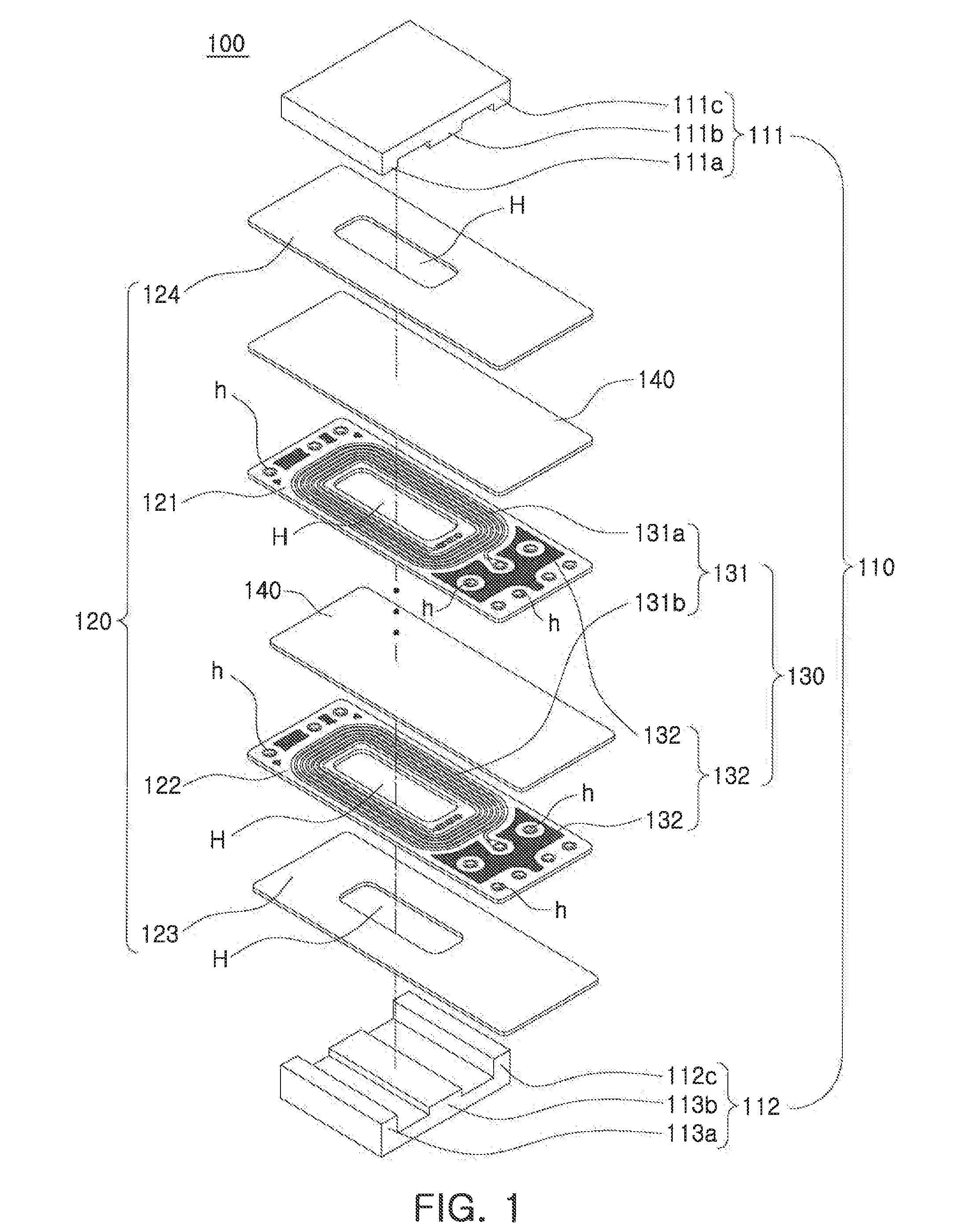

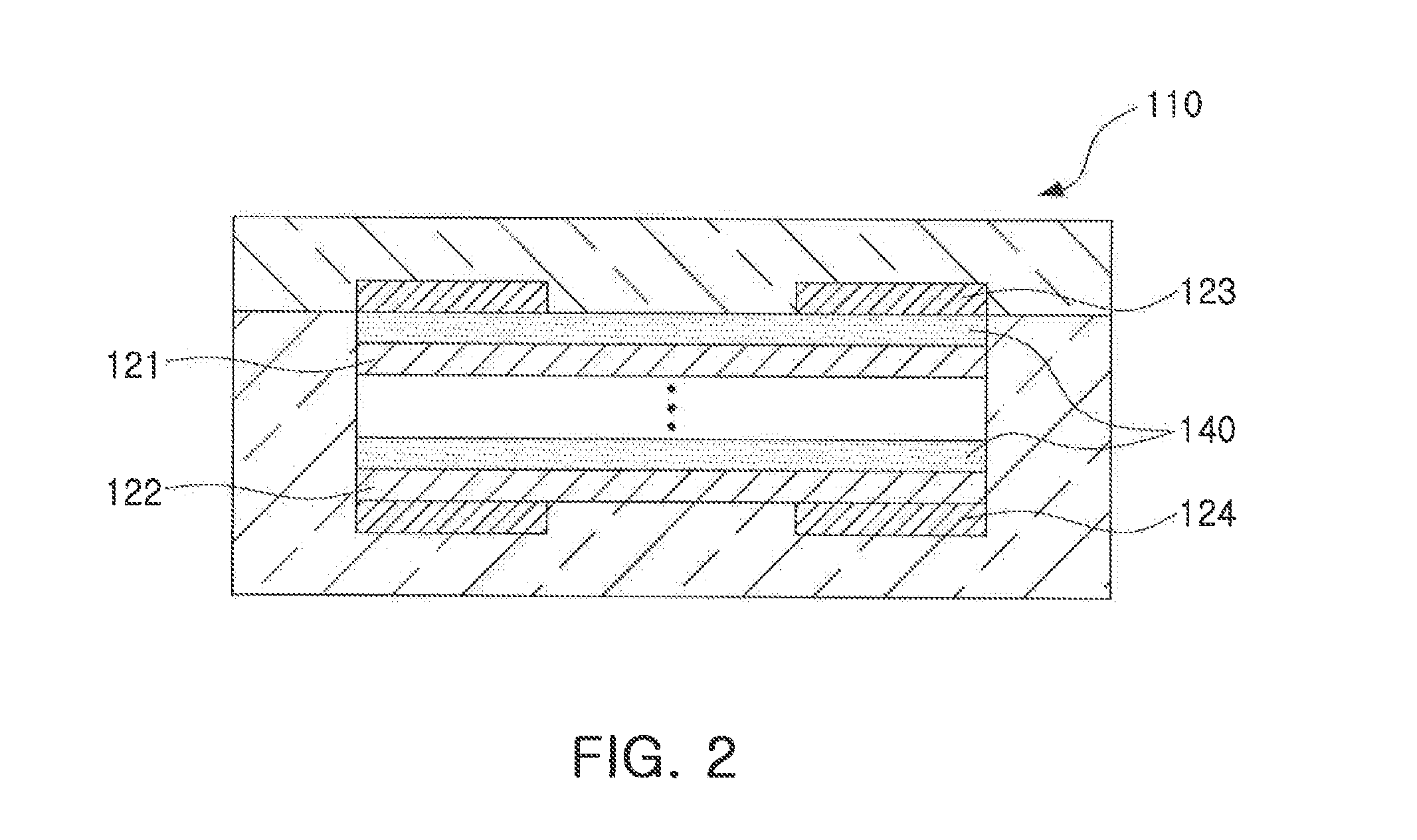

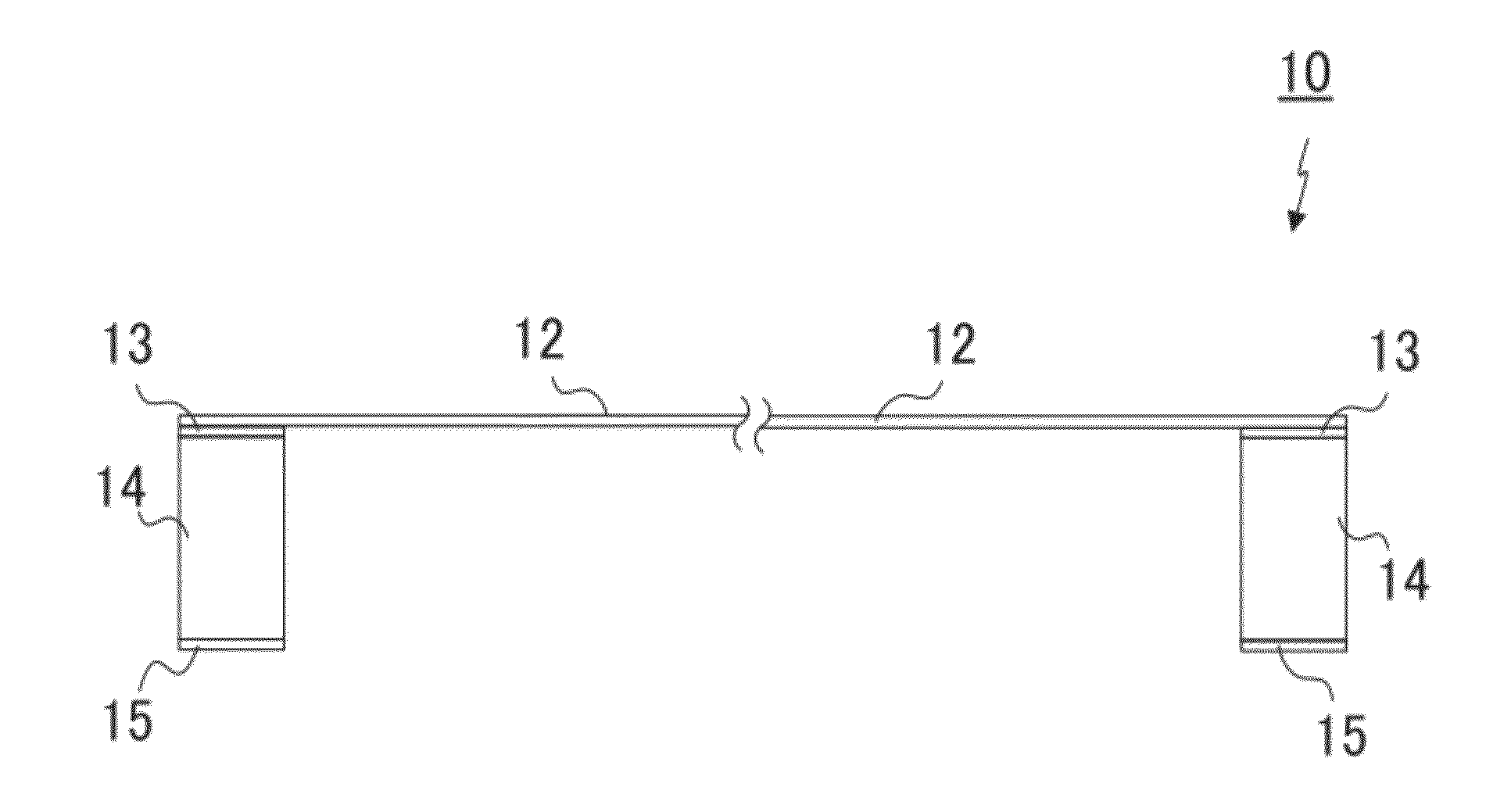

Planar transformer and method of manufacturing the same

InactiveUS20110241816A1Avoid coatingTransformers/inductances coils/windings/connectionsSolid-state devicesElectromagnetic couplingElectric power transmission

There are is a planar transformer and a method of manufacturing the same that can prevent resin being coated from being separated from a conductor during the manufacturing of a transformer by forming a dummy pattern on a board. A planar transformer according to an aspect of the invention may include: a core part having a pair of cores electromagneticaliy coupled to each other; a board part having a plurality of boards disposed between the pair of cores and stacked upon one another; a pattern part having a power transmission pattern provided on at least one board of the plurality of boards of the board part and transmitting power being input, and a dummy pattern provided on the same board having the power transmission pattern thereon and separated from the power transmission pattern by a predetermined interval; and a resin part being coated over the at least one board of the plurality of boards, the at least one board having the pattern part thereon.

Owner:SOLUM CO LTD

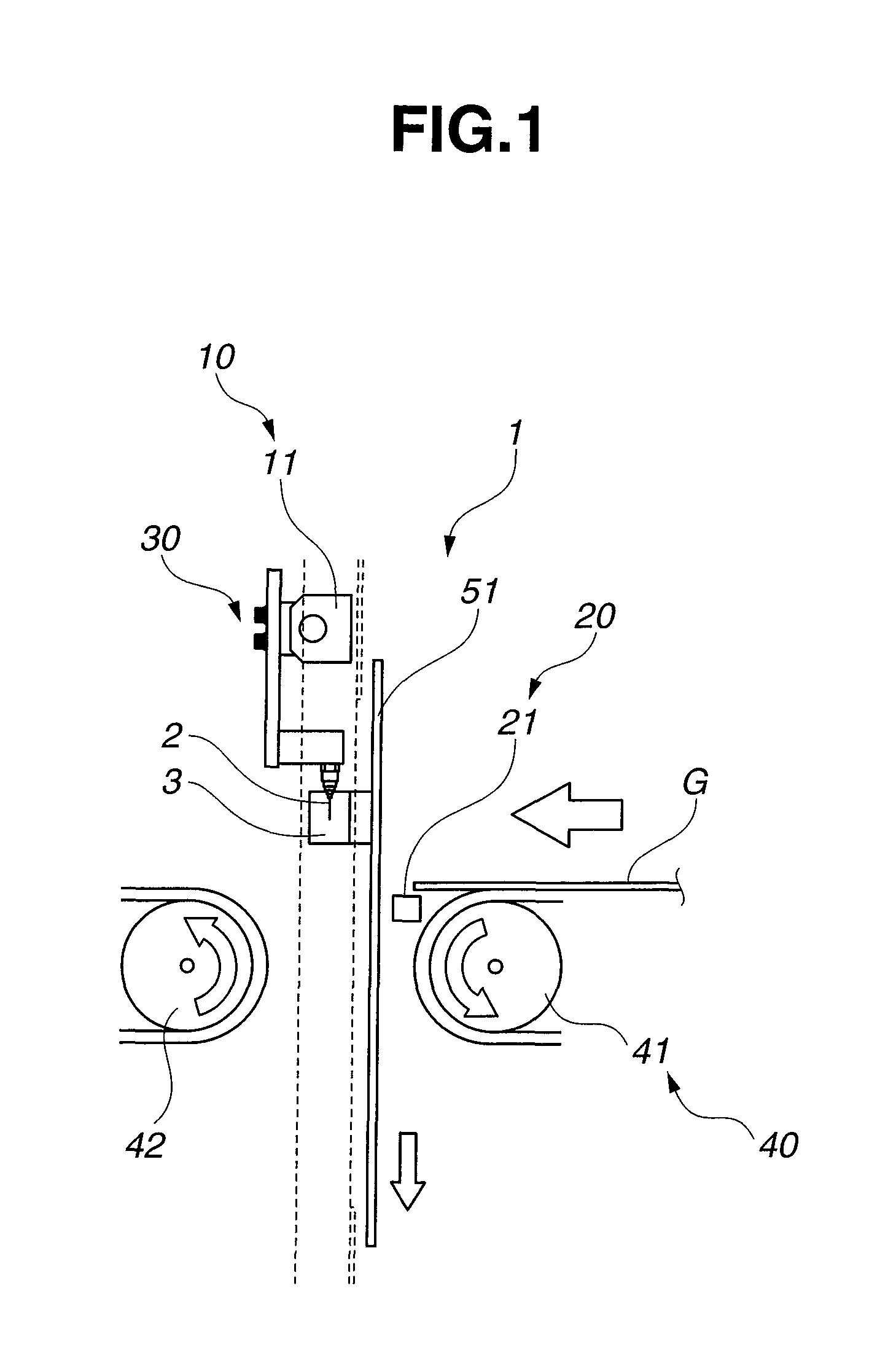

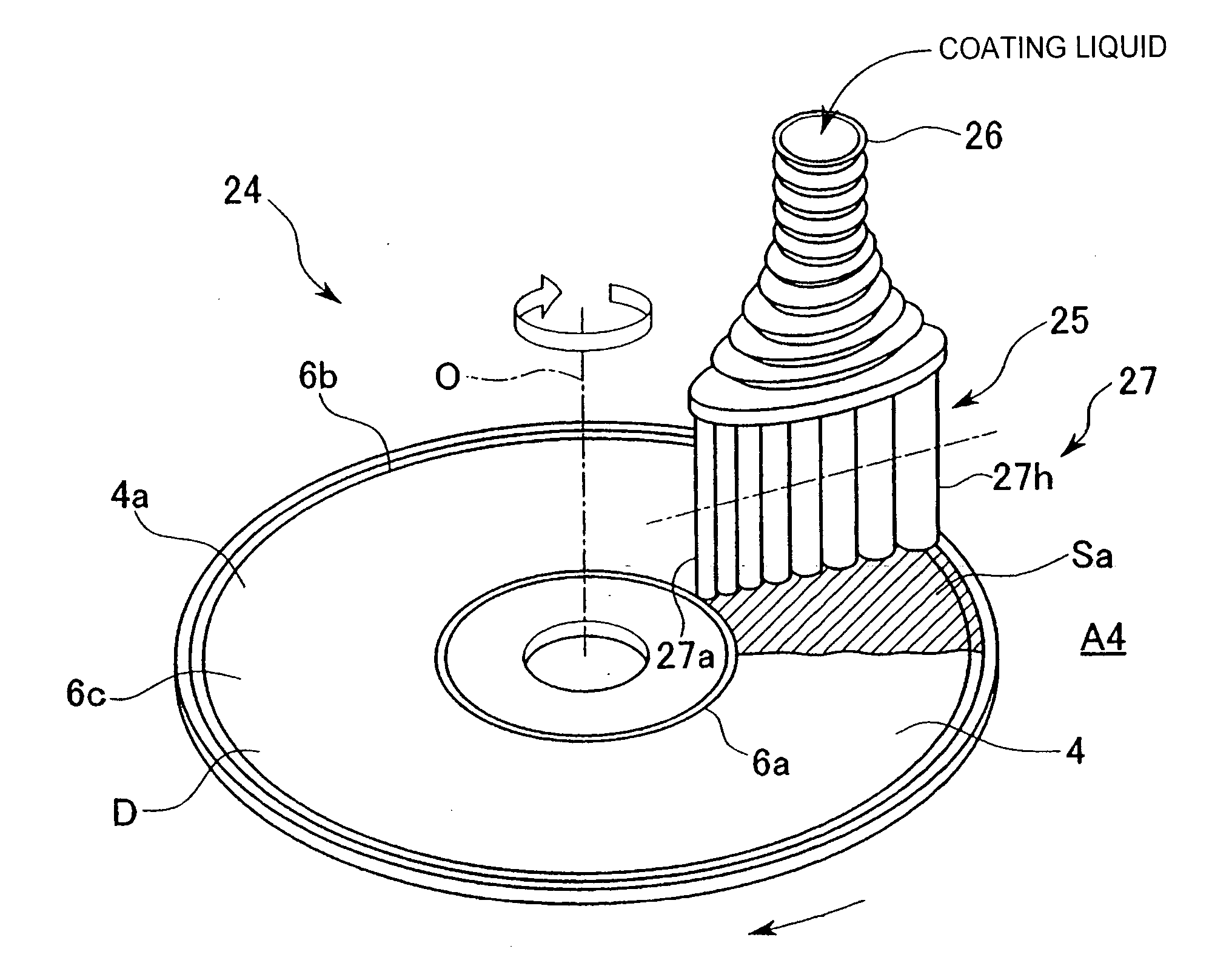

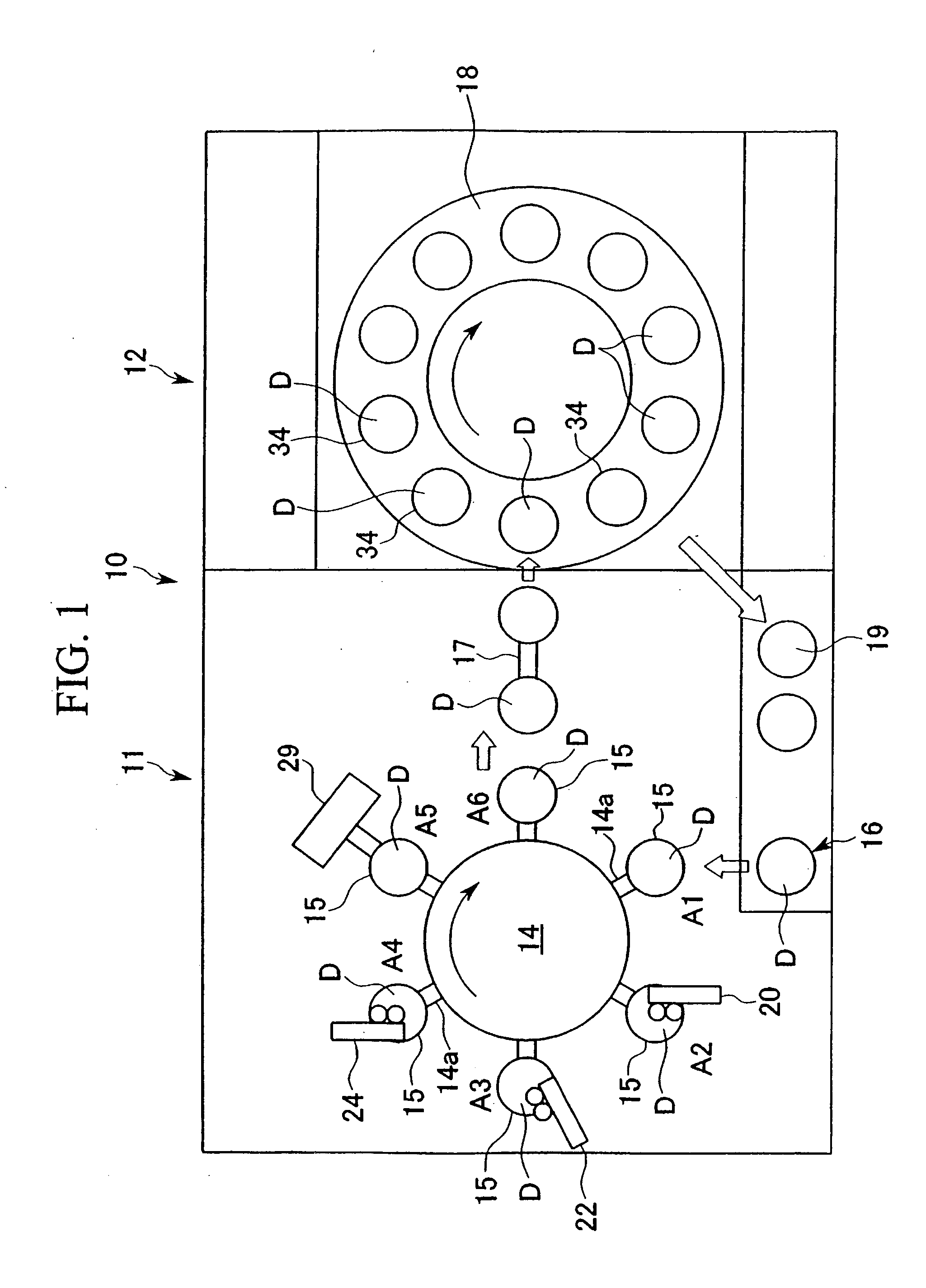

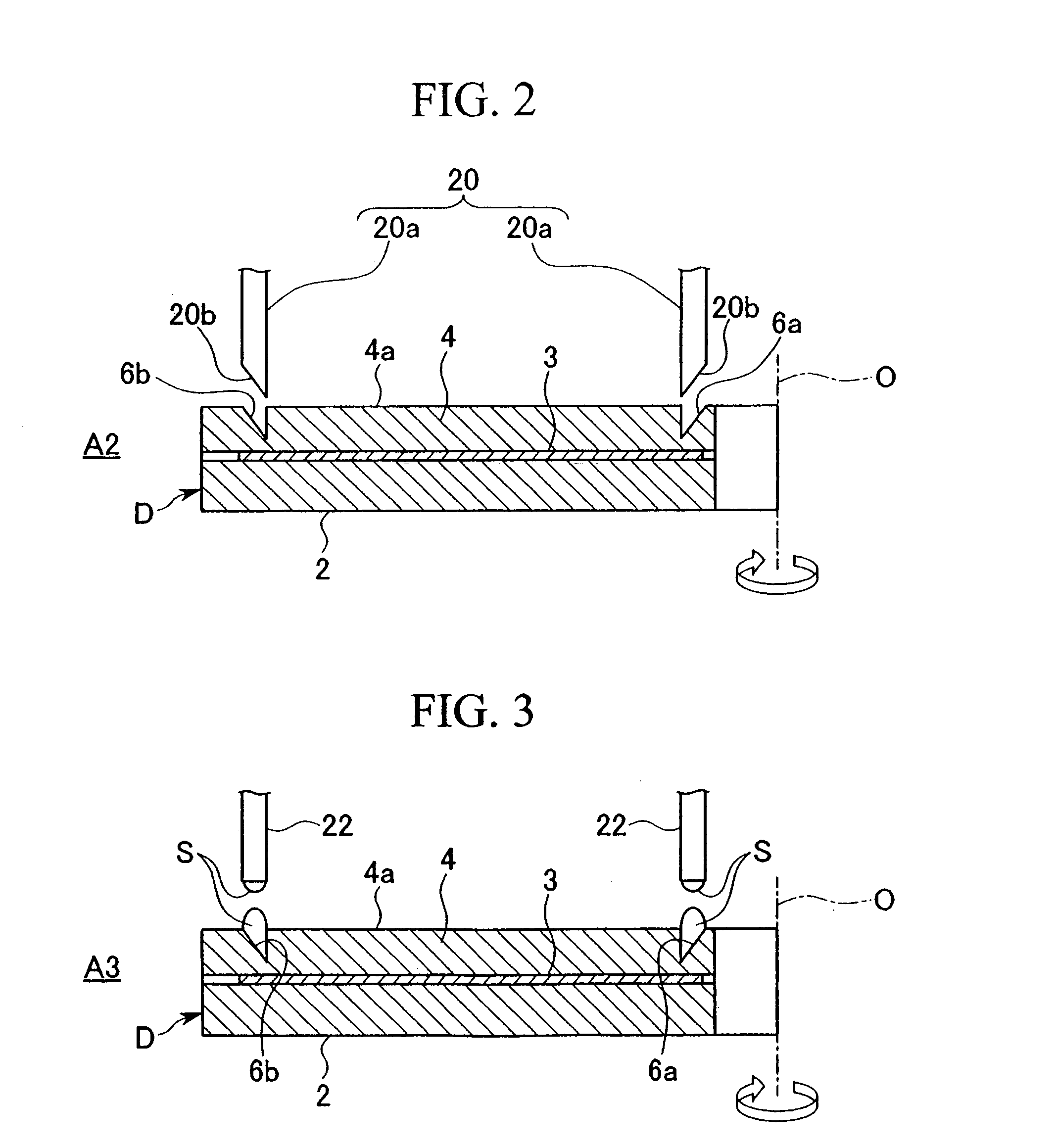

Ink jet-use receptive layer forming method and device, and disk formed with ink jet-use receptive layer

InactiveUS20060177597A1Promote resultsEasy to optimizeDuplicating/marking methodsPretreated surfacesEngineeringMechanical engineering

Concave grooves for forming a receiving layer for inkjet printing are provided at the inner peripheral and outer peripheral boundary portions of an application region on a disk substrate. The concave grooves are formed with a substantially V-shaped cross section, and with a depth d that is at least equal to the film thickness of the coating film within a central region between the concave grooves. A plurality of nozzles of a supply device is arrayed in a radial direction across the central region between the concave grooves, and a substantially constant quantity of coating liquid per unit of surface area is applied so as to form a coating film of a predetermined thickness. The applied coating liquid portions are flattened by a mutual leveling effect. During drying, the coating film inside the concave grooves does not dry first, but rather dries and contracts at substantially the same time as the coating film within the central region, meaning a receiving layer of uniform film thickness can be formed over the entire central region.

Owner:MITSUBISHI PAPER MILLS LTD +1

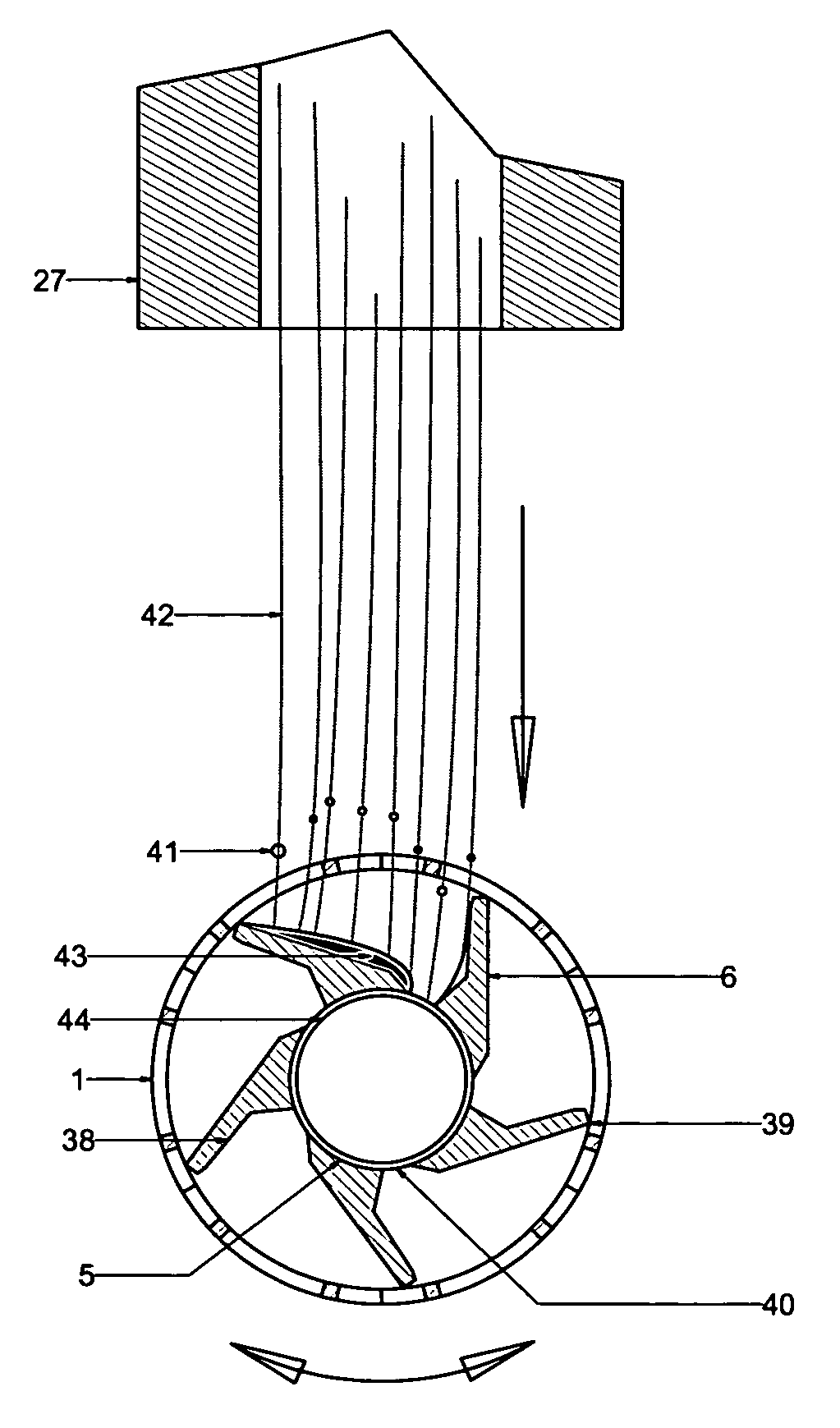

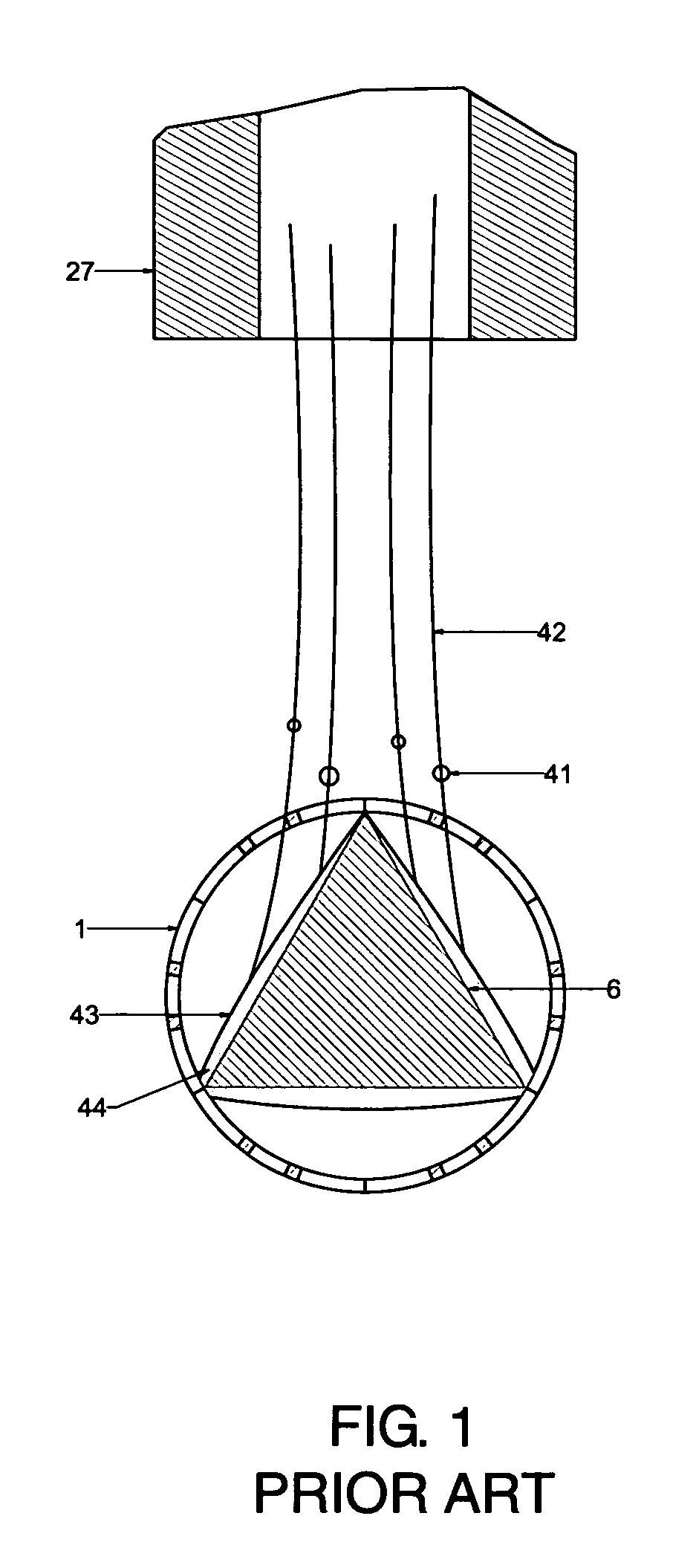

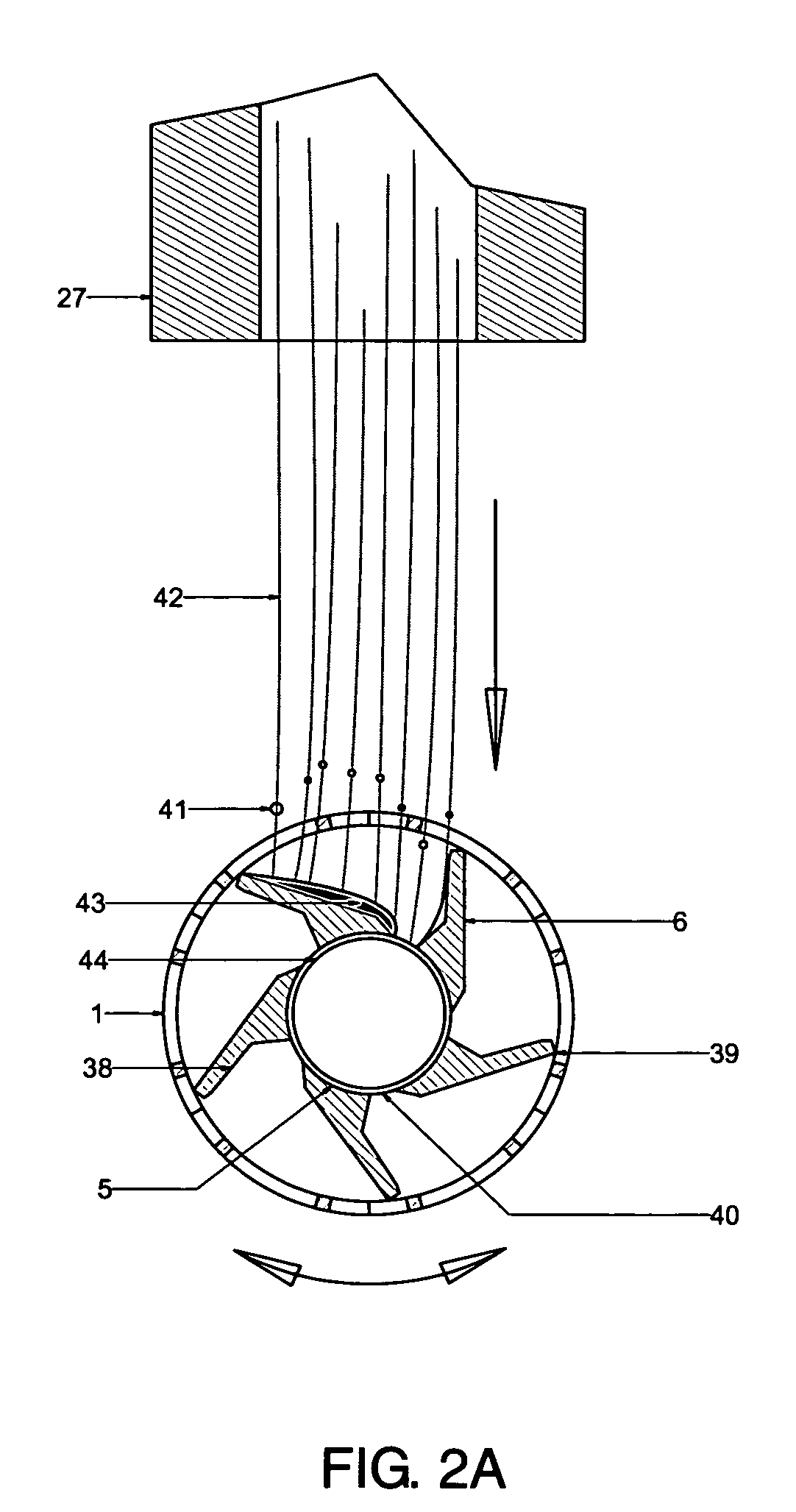

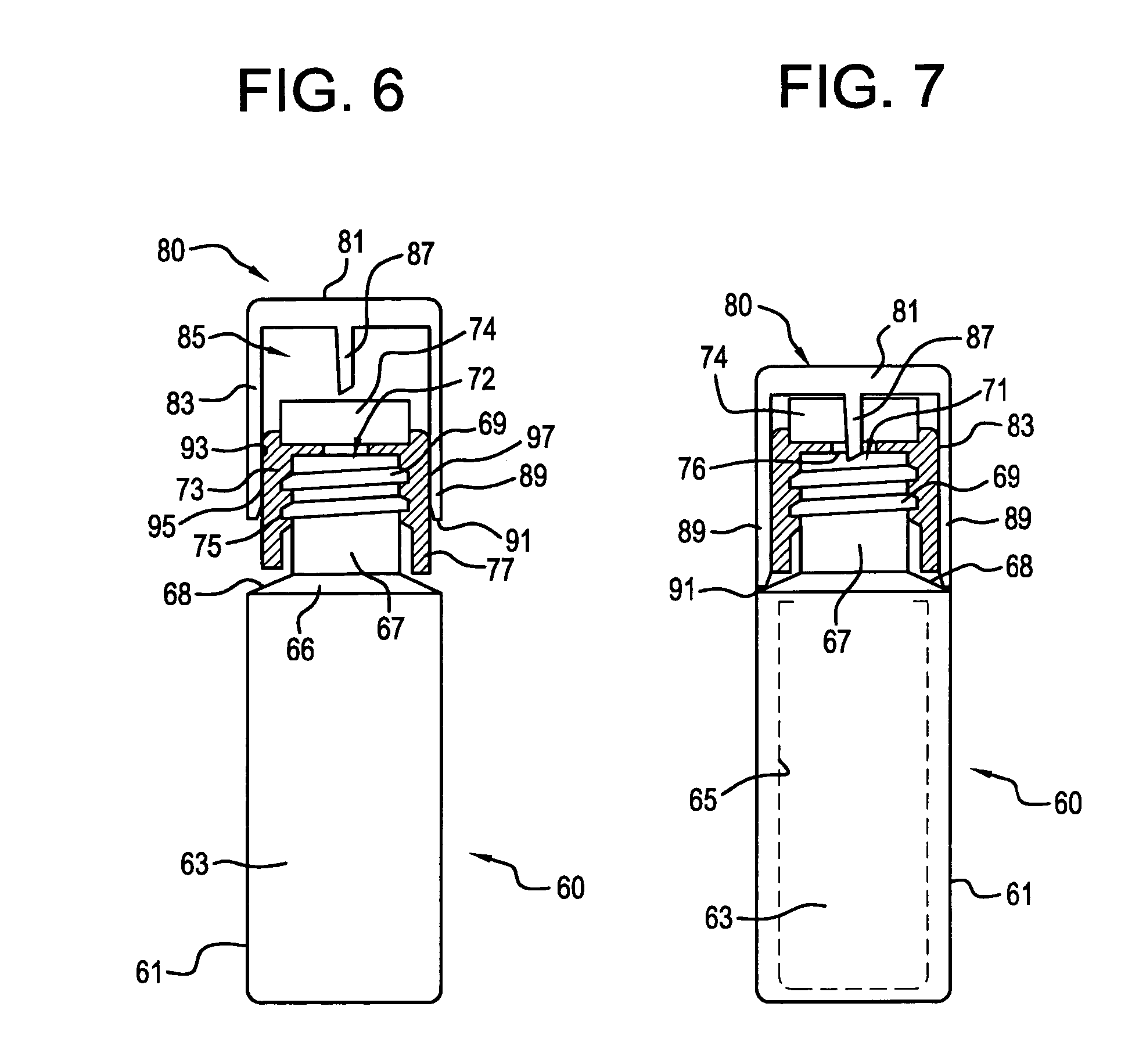

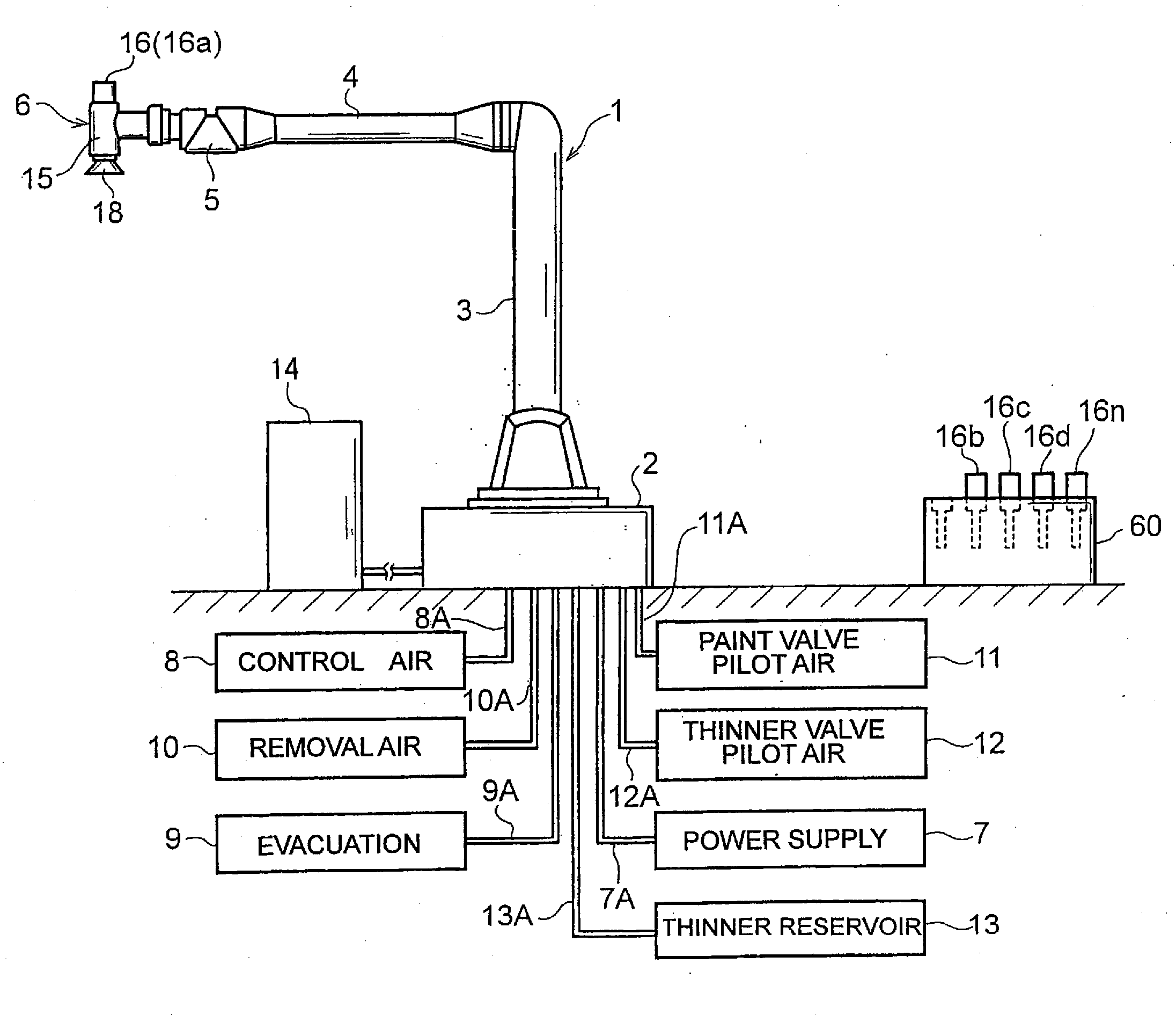

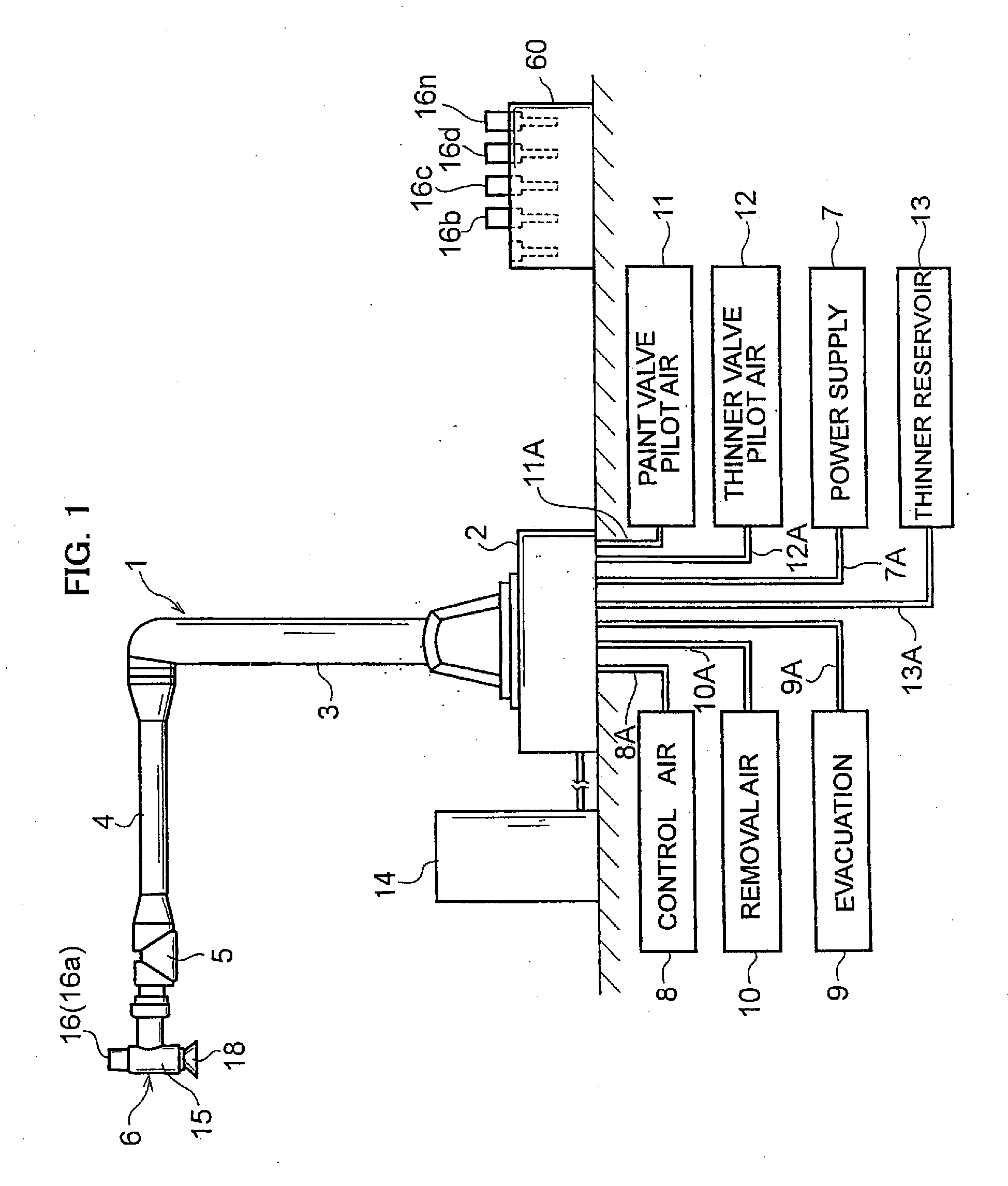

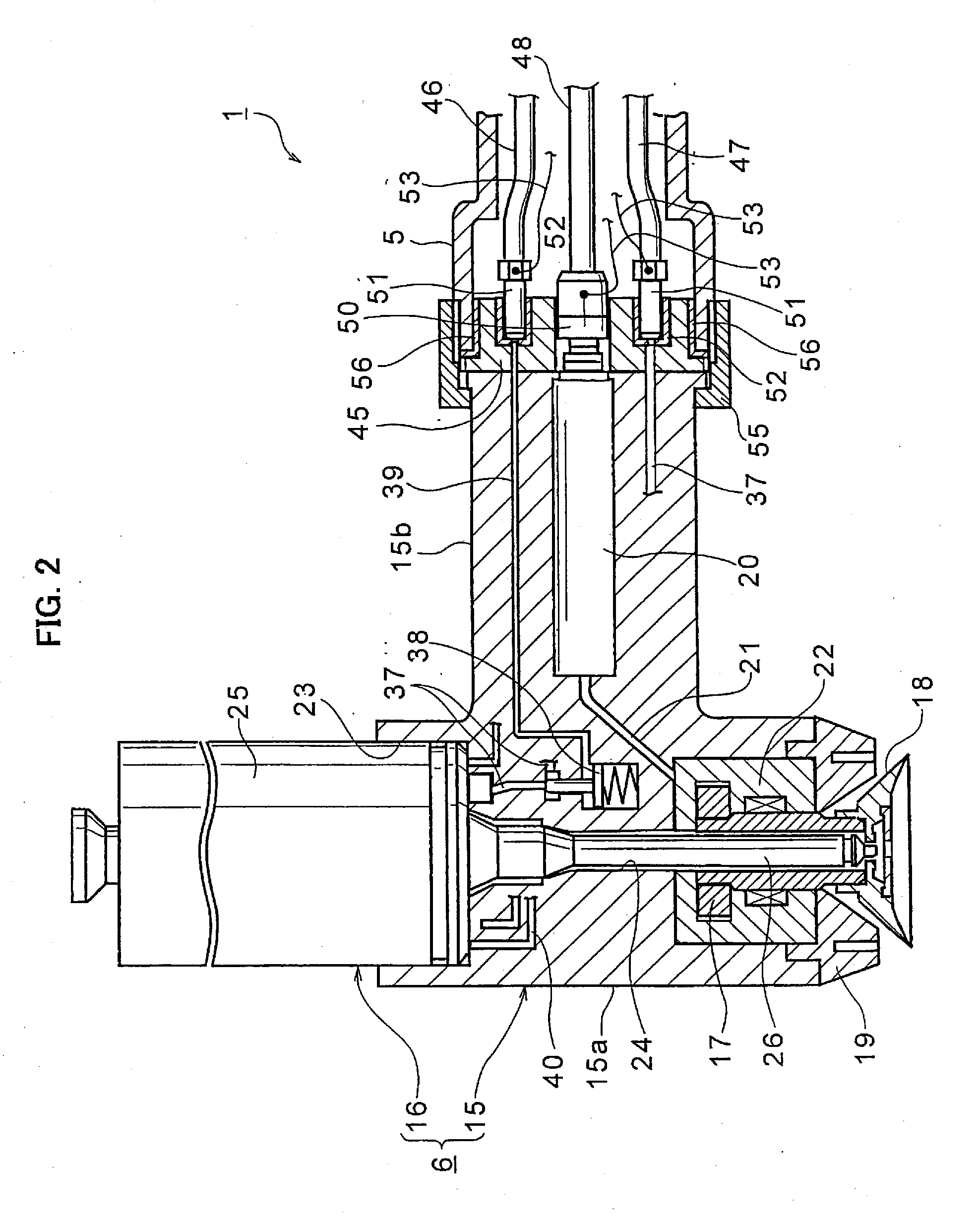

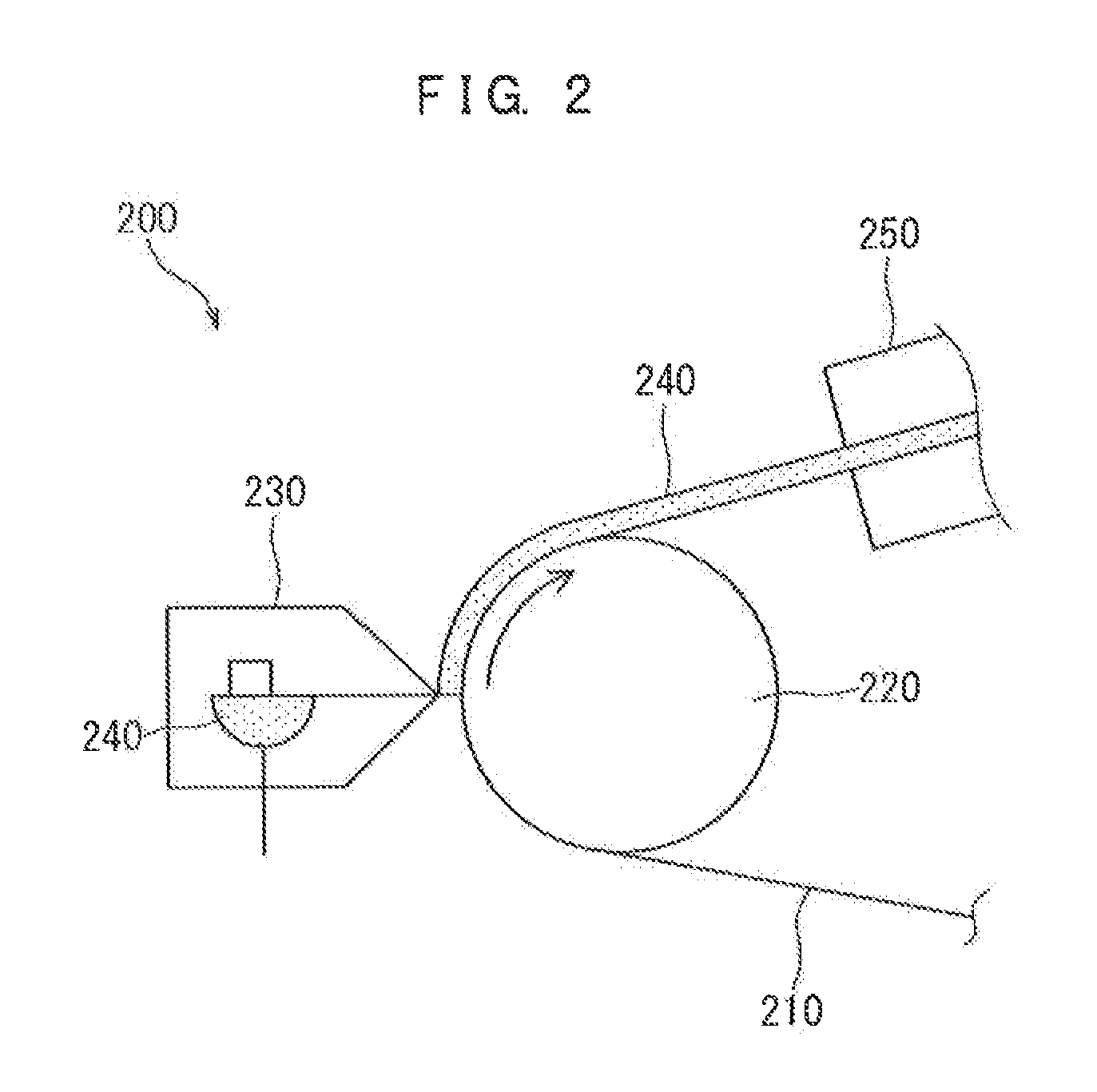

Electrostatic Coating System

ActiveUS20090108109A1Quickly cope with situationLarge economic lossBurnersSpraying power supplyNebulizerElectrostatic coating

An electrostatic coating system includes a coating robot (1) and an electrostatic atomizer (6) attached to a polyarticular wrist portion (5) of the robot (1). The atomizer (6) includes an end plate (45), metallic connector (50) fixed to the end plate (45) in electric conduction, high voltage generator (20) and bell head (18). Electric power is supplied to the high voltage generator (20) through the connector (50). Wires (53) are connected to the connector (50) to take out high voltage leak caused by contamination like a deposition of paint on outer surfaces of the atomizer (6) through the wires 53 to control the high voltage generator (20) to lower the value of the high voltage applied to the bell head (18) of high voltage leak detected through the wires (53) is larger than a predetermined threshold value.

Owner:TOYOTA JIDOSHA KK +1

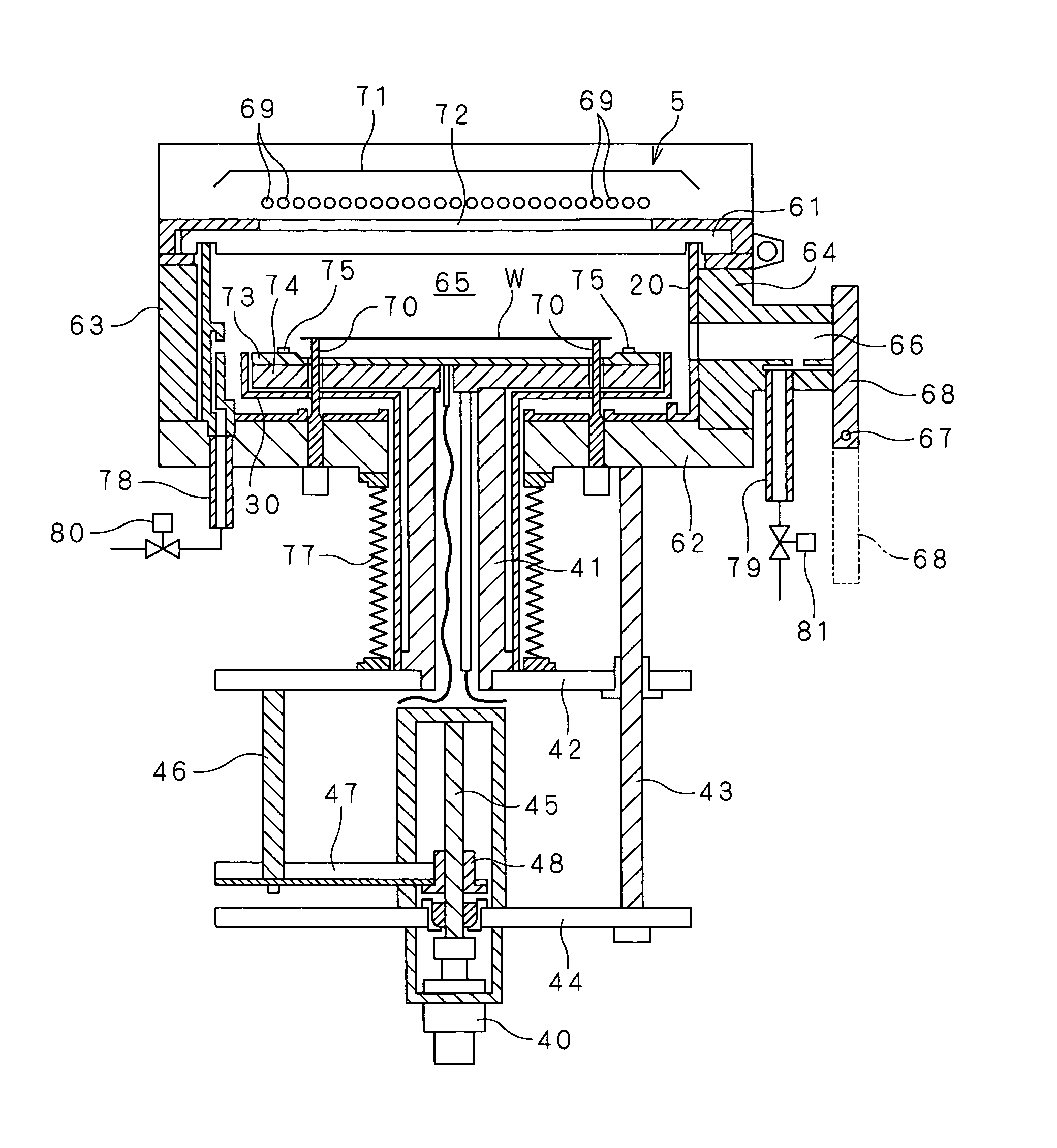

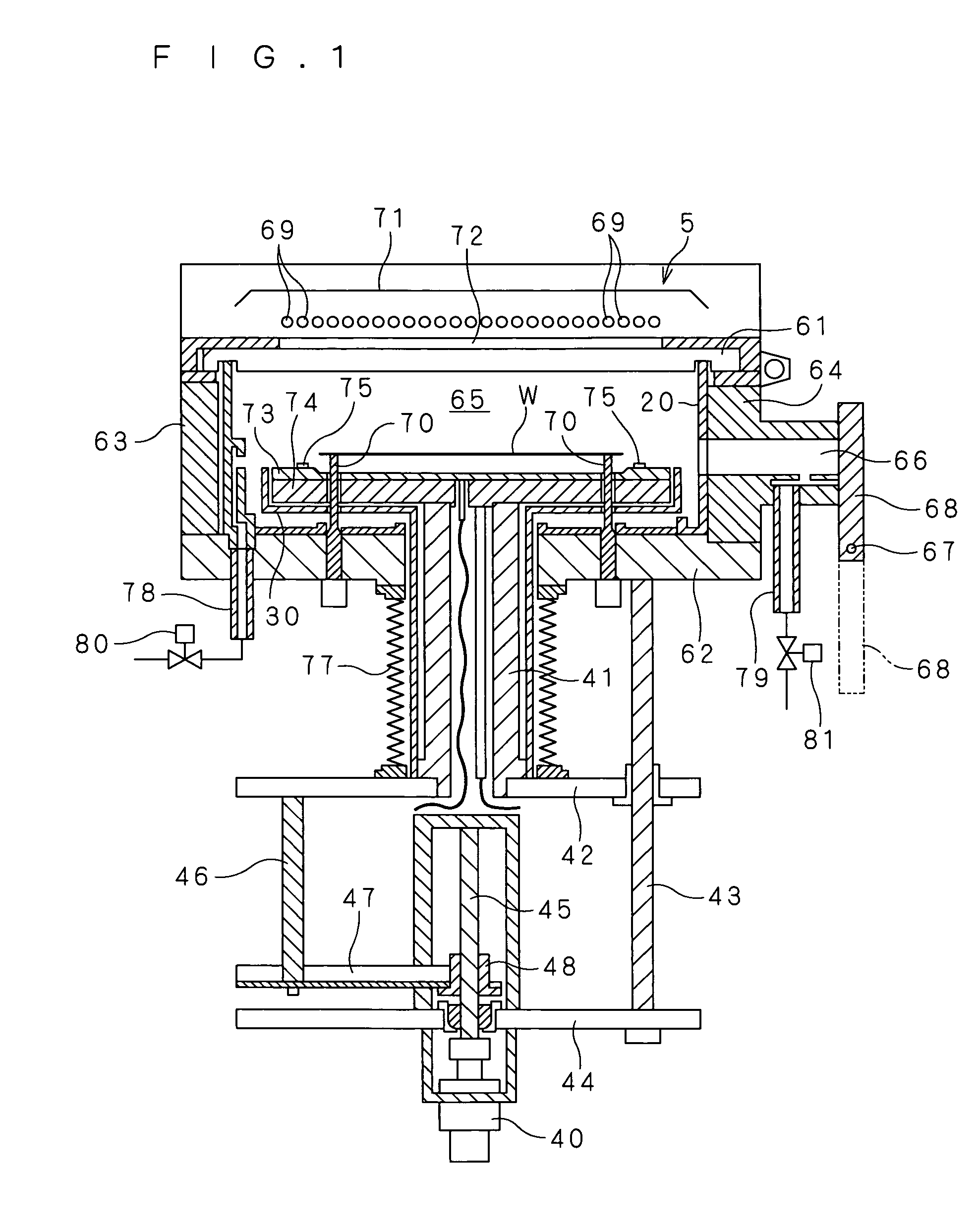

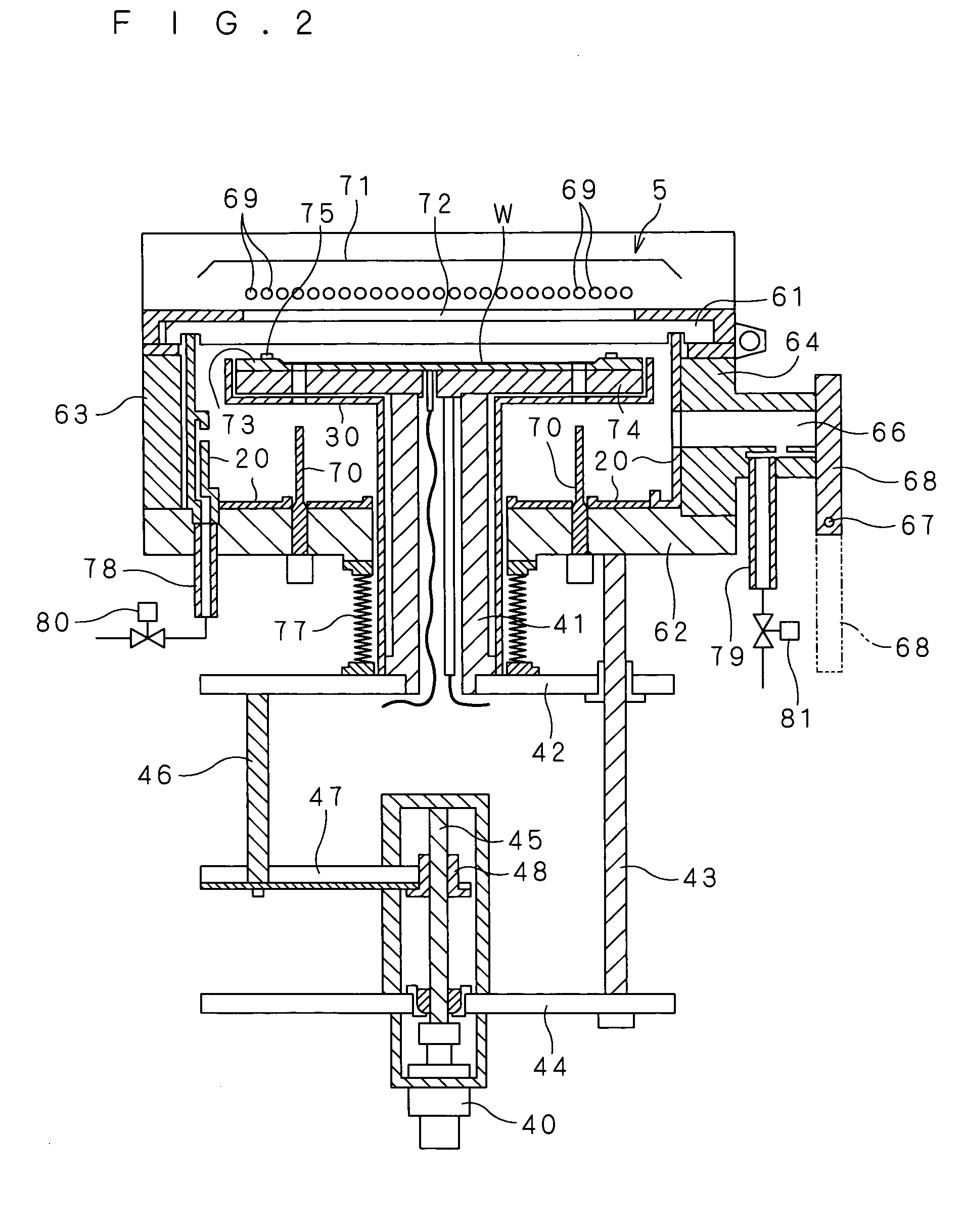

Heat treatment apparatus by means of light irradiation

ActiveUS7091453B2Easy to cleanAvoid coatingDrying solid materials with heatMuffle furnacesFlash-lampLight source

A chamber has a wall surface fitted with a liner. The liner is removably provided to the chamber with no fixed relation therebetween. By simply opening a light source to remove a heat diffusion plate, a hot plate and a tubular member from the chamber, the liner can be easily detached accordingly from the chamber. When a semiconductor wafer cracks to litter the chamber with its fragments, the chamber can be easily cleaned by simply detaching the liner. The liner has an outer surface subjected to surface roughening by honing. When a flash lamp emits flashlight of considerably high intensity, the roughened outer surface of the liner serves to block this flashlight. As a result, the metal surface inside the chamber is prevented from being exposed to the flashlight emitted from the flash lamp.

Owner:SCREEN HLDG CO LTD

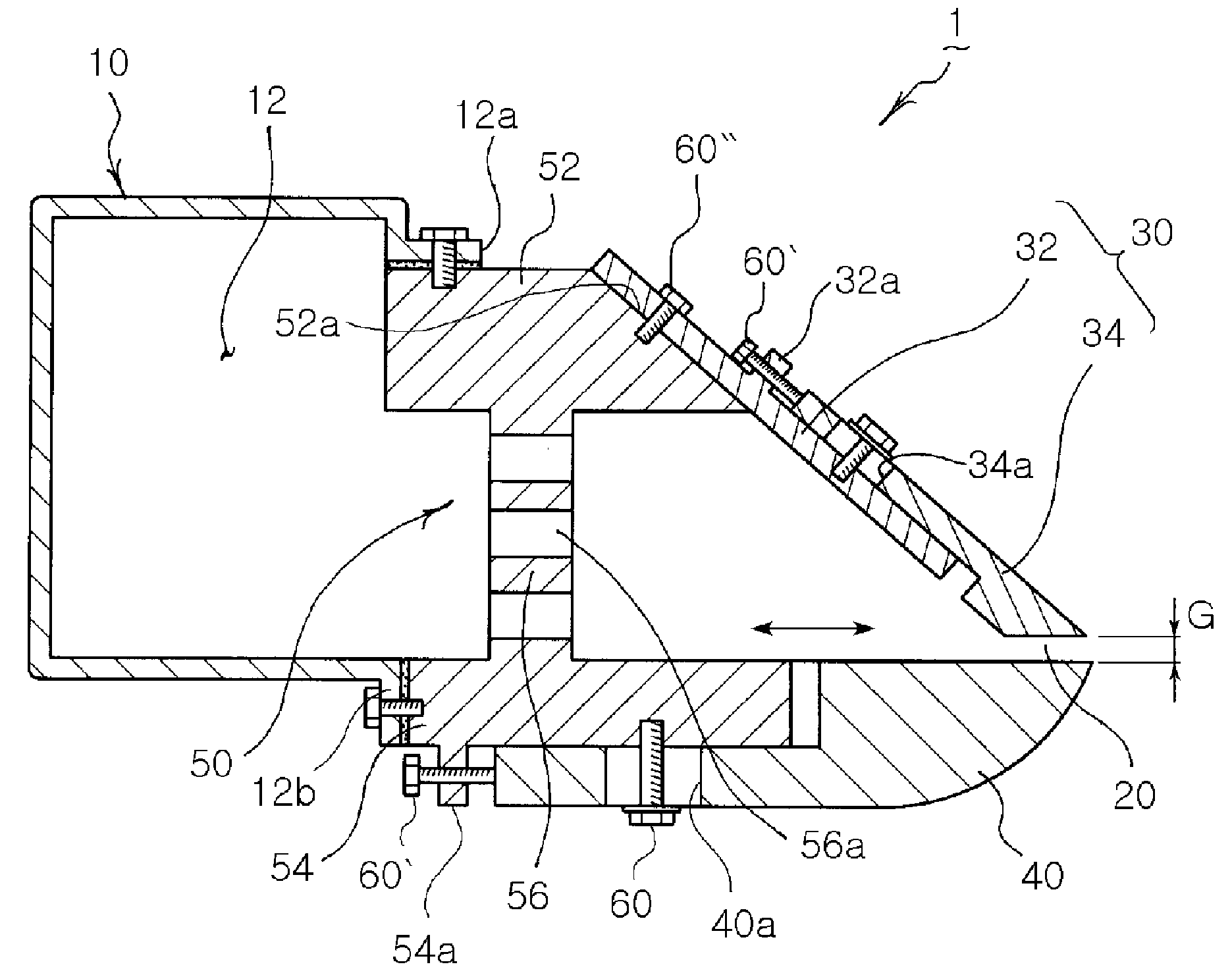

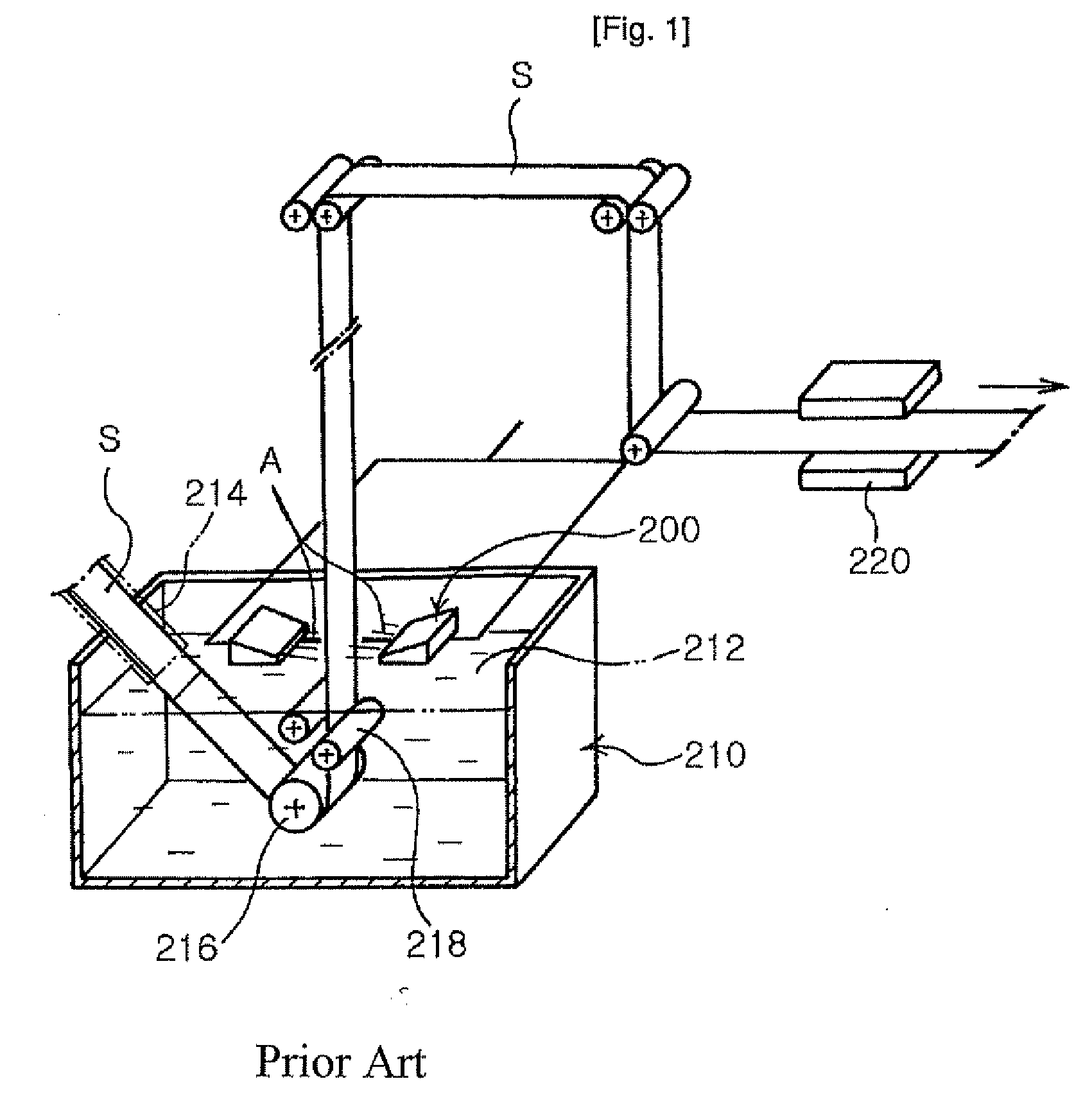

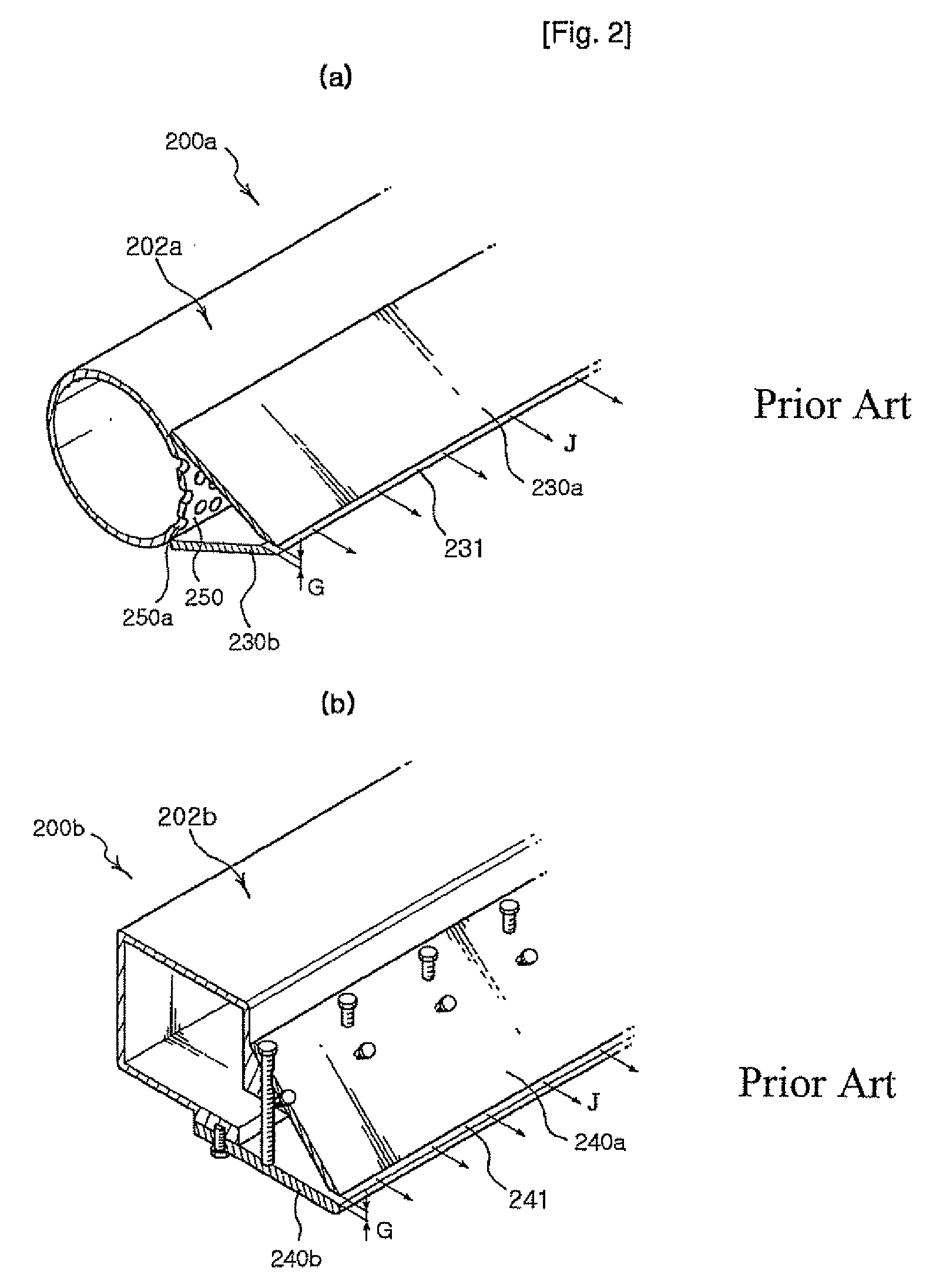

Gas wiping apparatus

ActiveUS20090114149A1Easy to installEasy to adjustHot-dipping/immersion processesLiquid surface applicatorsProduct gasUpper lip

A gas wiping apparatus for use in coating a molten metal onto a steel strip. In the apparatus, a chamber, to which a high pressure gas is supplied, defines a multistage uniform pressure space. A lip support unit is associated with a front of the chamber to allow the high pressure gas to flow therethrough, the lip support unit supporting the apparatus against load. Upper and lower lips are associated with a front of the lip support unit to cooperatively define an outlet. The upper lip adjusts a gap of a gas outlet cooperatively with the lower lip, and can be easily installed in a lip support unit while adjusting the gap of the gas outlet stably. Also, edge over coating (EOC) of the steel strip can be prevented without an additional auxiliary nozzle.

Owner:POHANG IRON & STEEL CO LTD

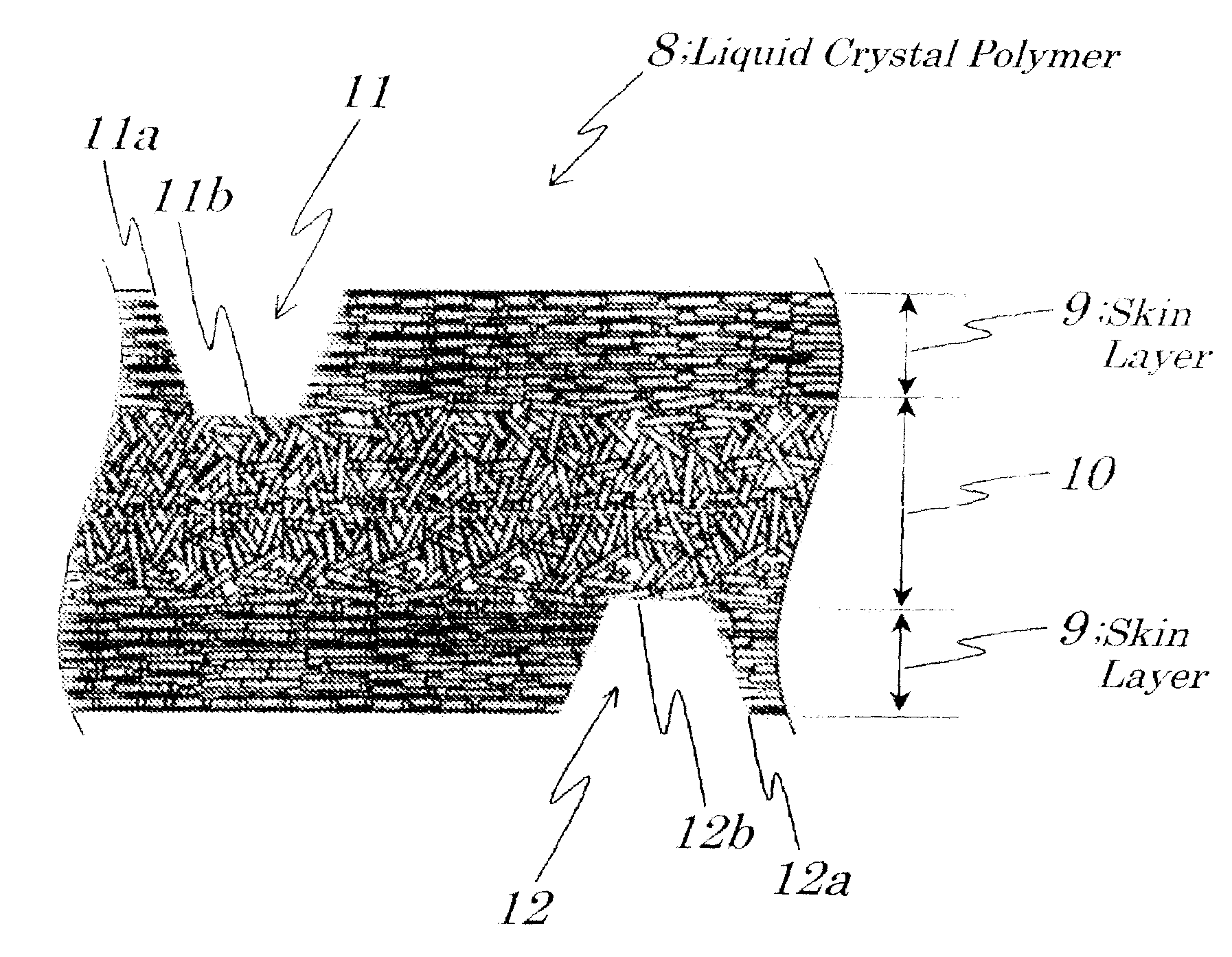

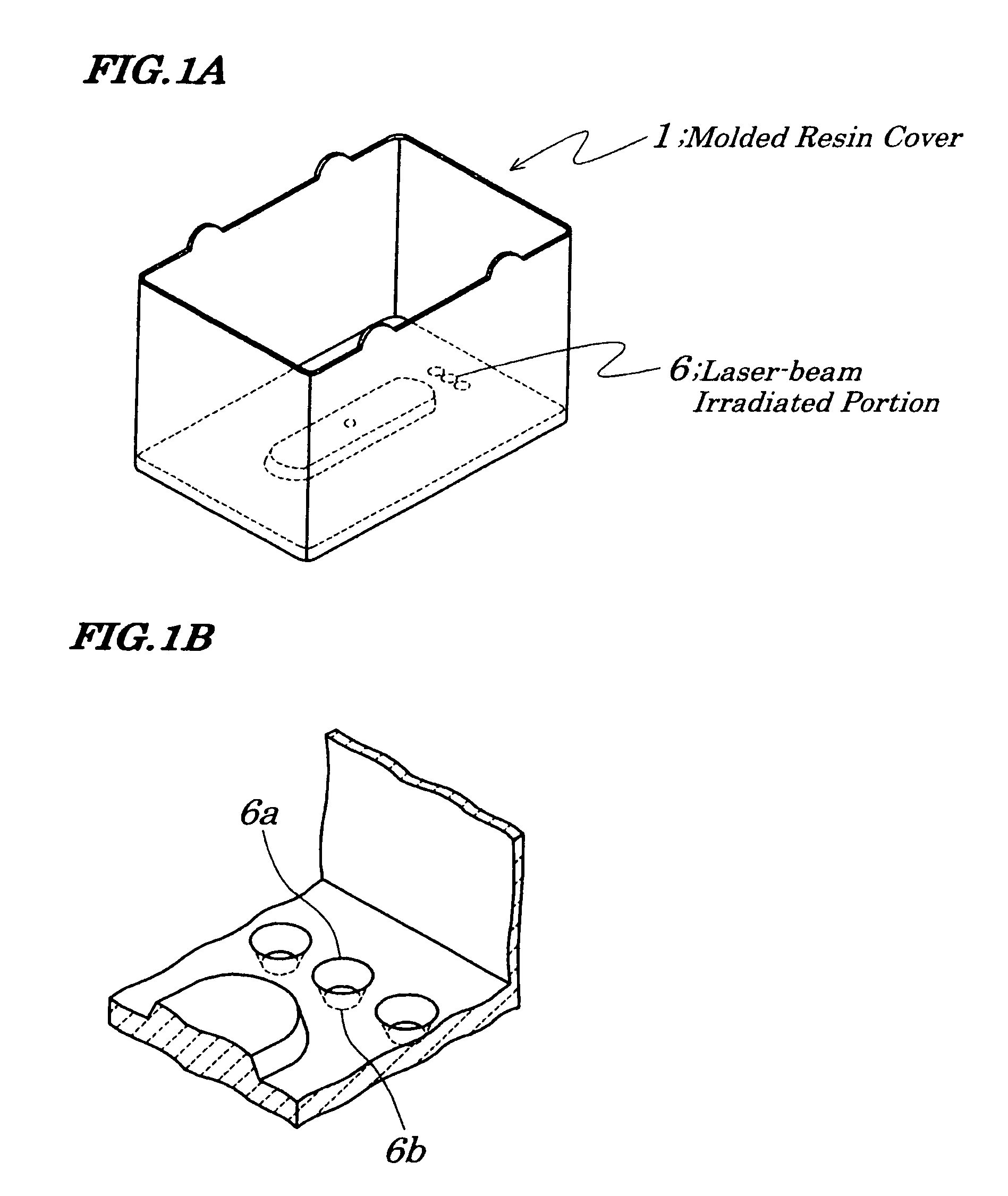

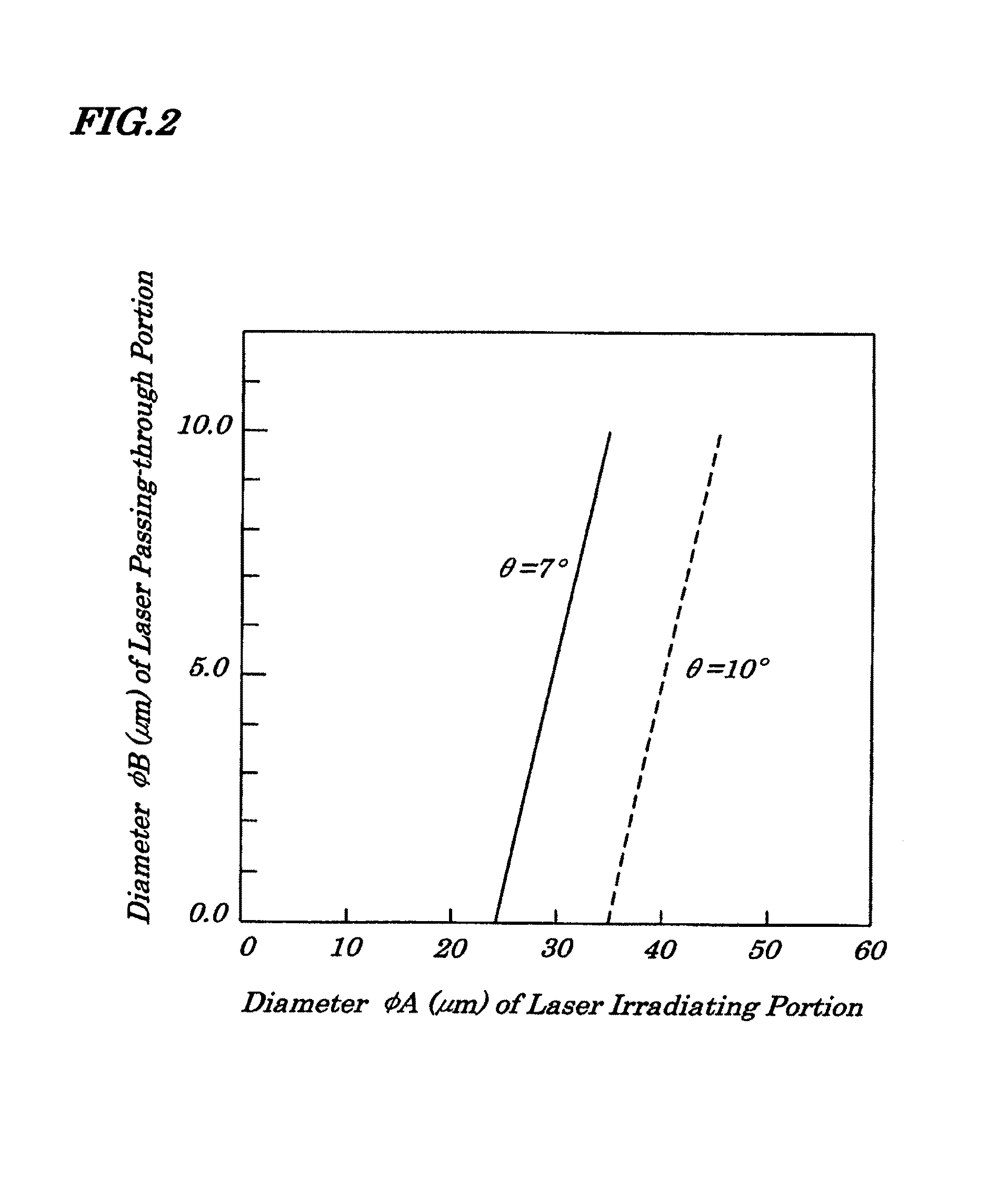

Electromagnetic relay

ActiveUS7538645B2Prevent intrusionMaintaining air permeability and resistance to waterElectric switchesElectromagnetic relay detailsLiquid-crystal displayEngineering

An electromagnetic relay is provided which enables a coating process with a coating agent even after being mounted on a printed circuit board having undergone reflow heating by preventing invasion of water while maintaining air permeability. A main body making up the electromagnetic relay includes an electrical contact portion, electromagnetic driving portion and molded resin base and is covered with the molded resin cover. One or more through holes are formed by applying laser beam from a rear side of the molded resin cover. A spot diameter of each through hole on a surface of an outside of the molded resin cover is 0.1 μm to 10 μm. Instead of the molded resin cover, through-holes each having a size of 0.1 μm to 10 μm may be formed by applying the laser beam to the molded resin base. Moreover, a liquid crystal polymer may be used as the molded resin cover or base having a filtering function, by forming holes to pass through only skin layers making up the liquid crystal polymer by applying the laser beam to the liquid crystal polymer.

Owner:EM DEVICES CORP

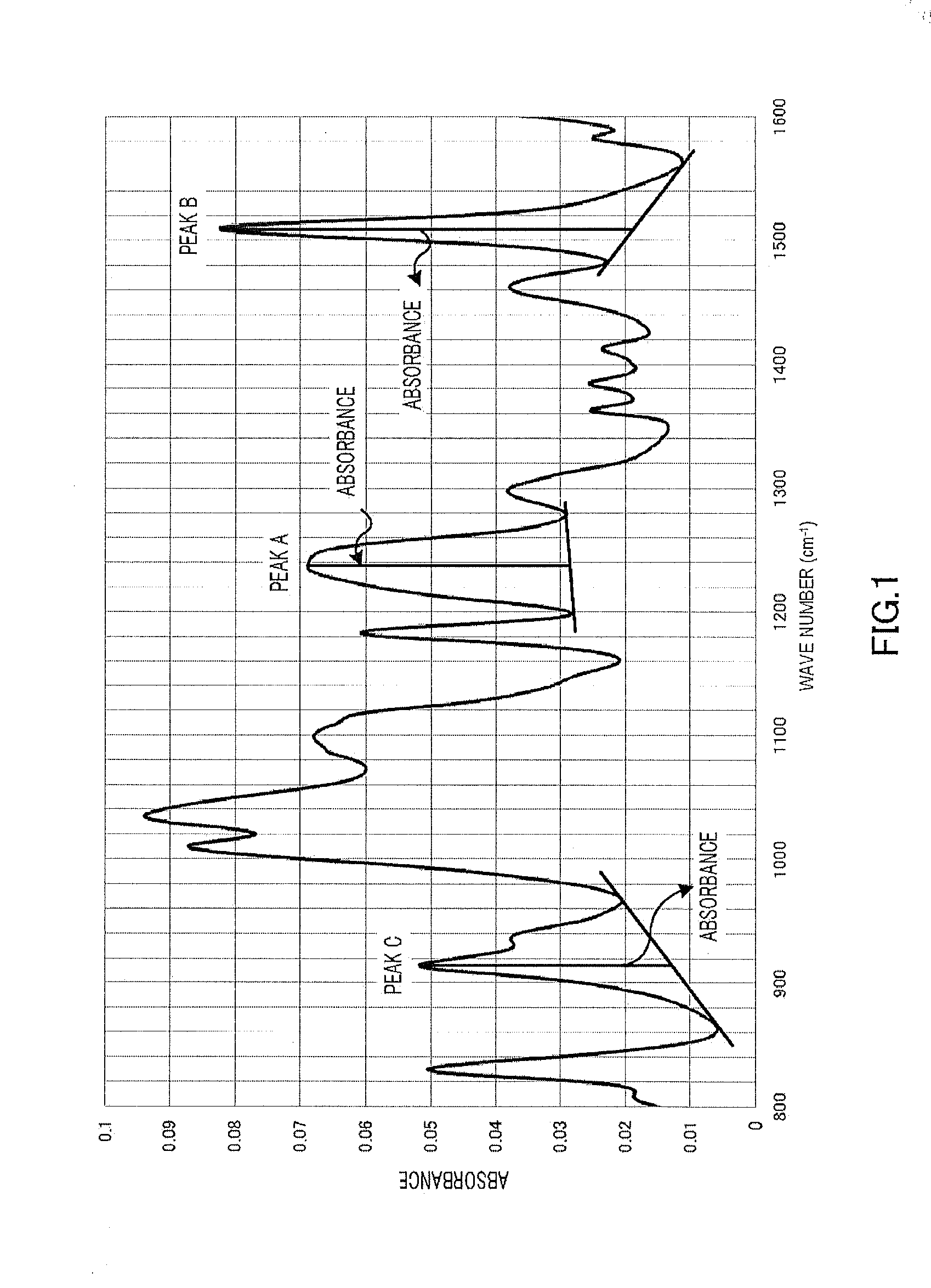

Pellicle frame and pellicle containing same

ActiveUS20120122025A1Moderate film strengthGood chemical resistanceSynthetic resin layered productsRecord information storageEpoxyHigh resistance

Provided is a pellicle that has appropriate membrane strength, high resistance to chemicals, and a low degree of sulfate ion generation and outgassing. A provided pellicle frame supports the outer rim of a pellicle membrane, and an epoxy resin coating is formed on the surface of the pellicle frame. In the infrared absorption spectrum of said epoxy resin coating, the ratio of the absorbance of a peak in the range between 1450 cm−1 and 1550 cm−1 to the absorbance of a peak in the range between 1200 cm−1 and 1275 cm−1 is at least 0.5 and at most 3; also, the ratio of the absorbance of a peak in the range between 1450 cm−1 and 1550 cm−1 to the absorbance of a peak in the range between 905 cm−1 and 930 cm−1 is at least 1 and less than 7.

Owner:MITSUI CHEM INC

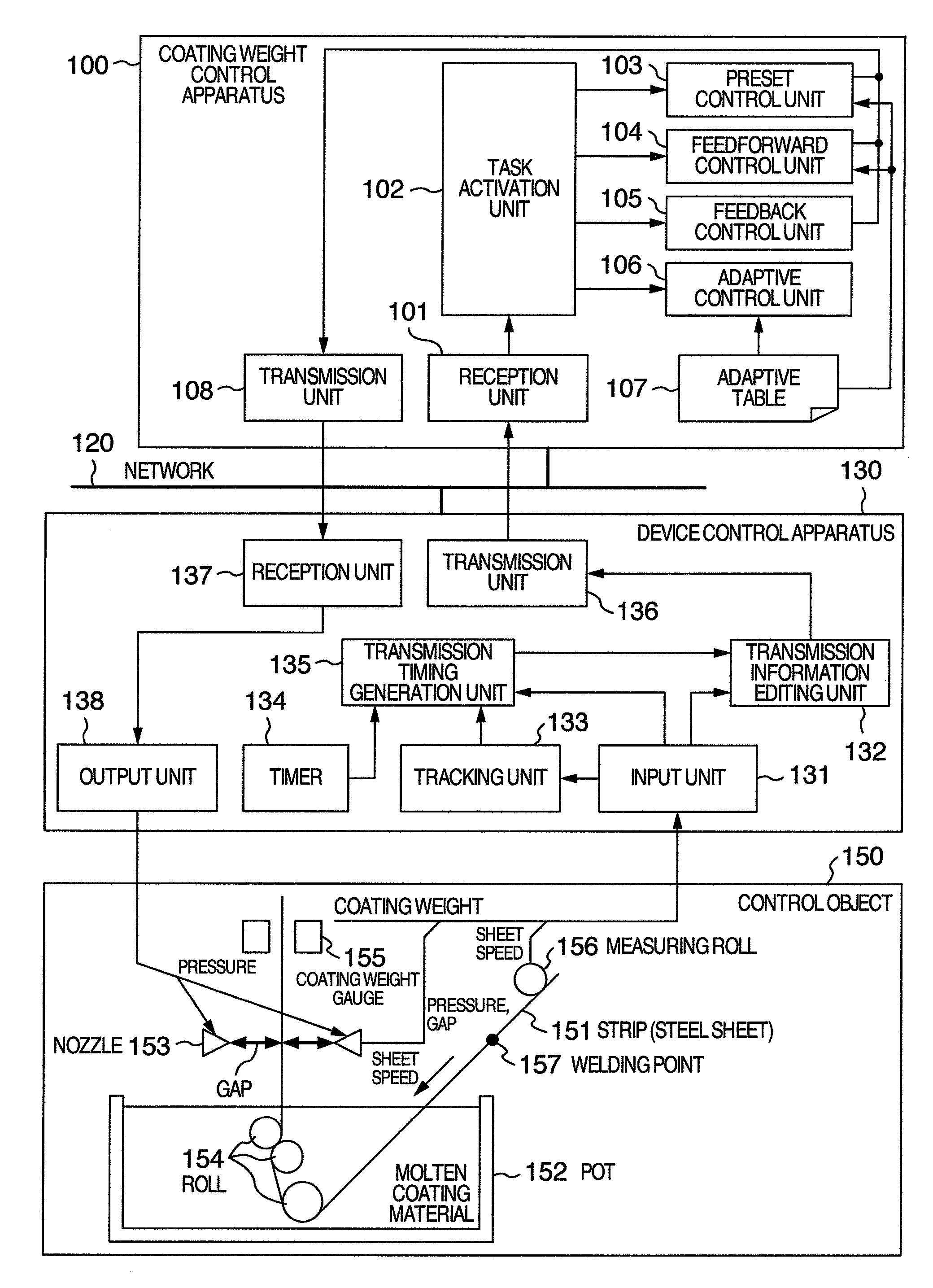

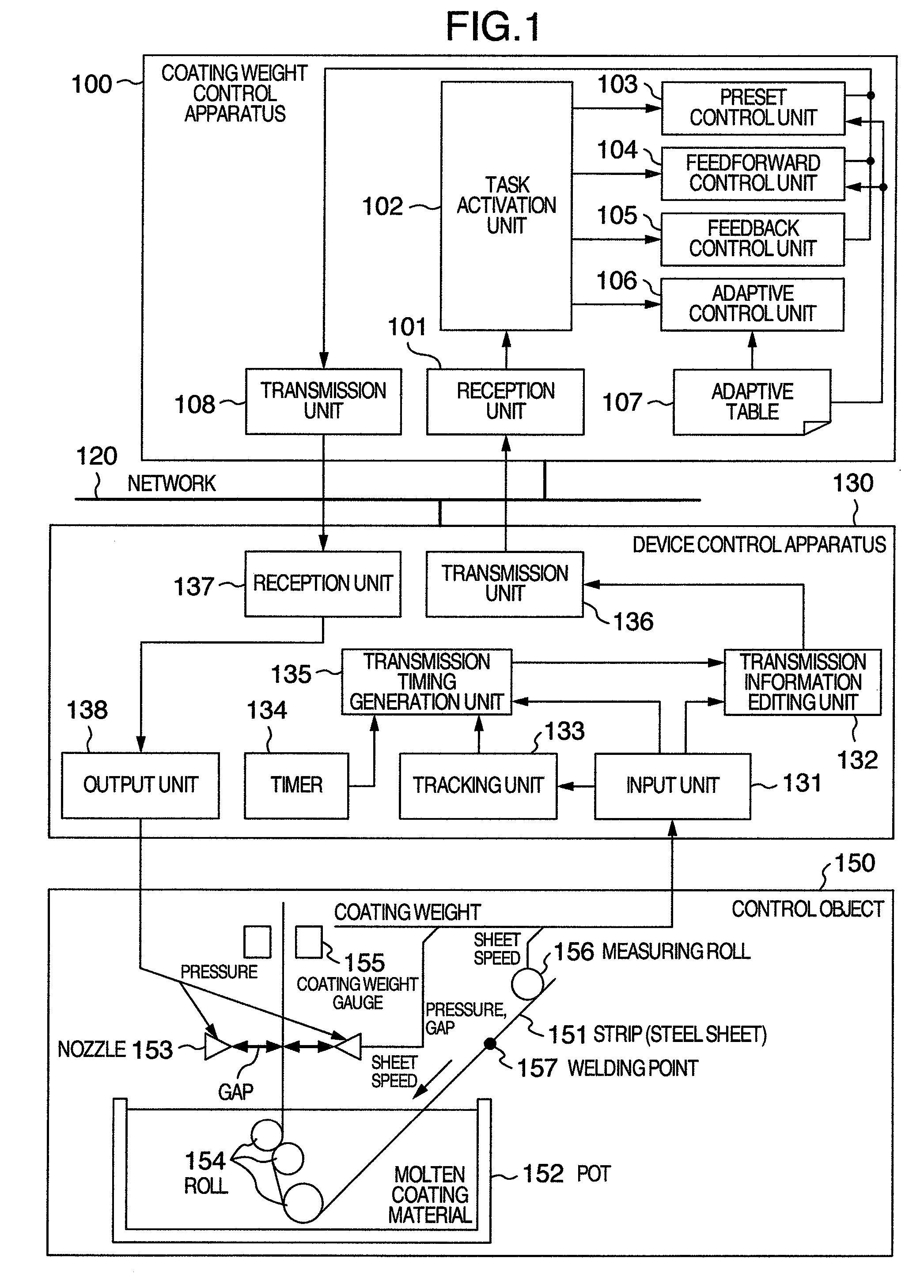

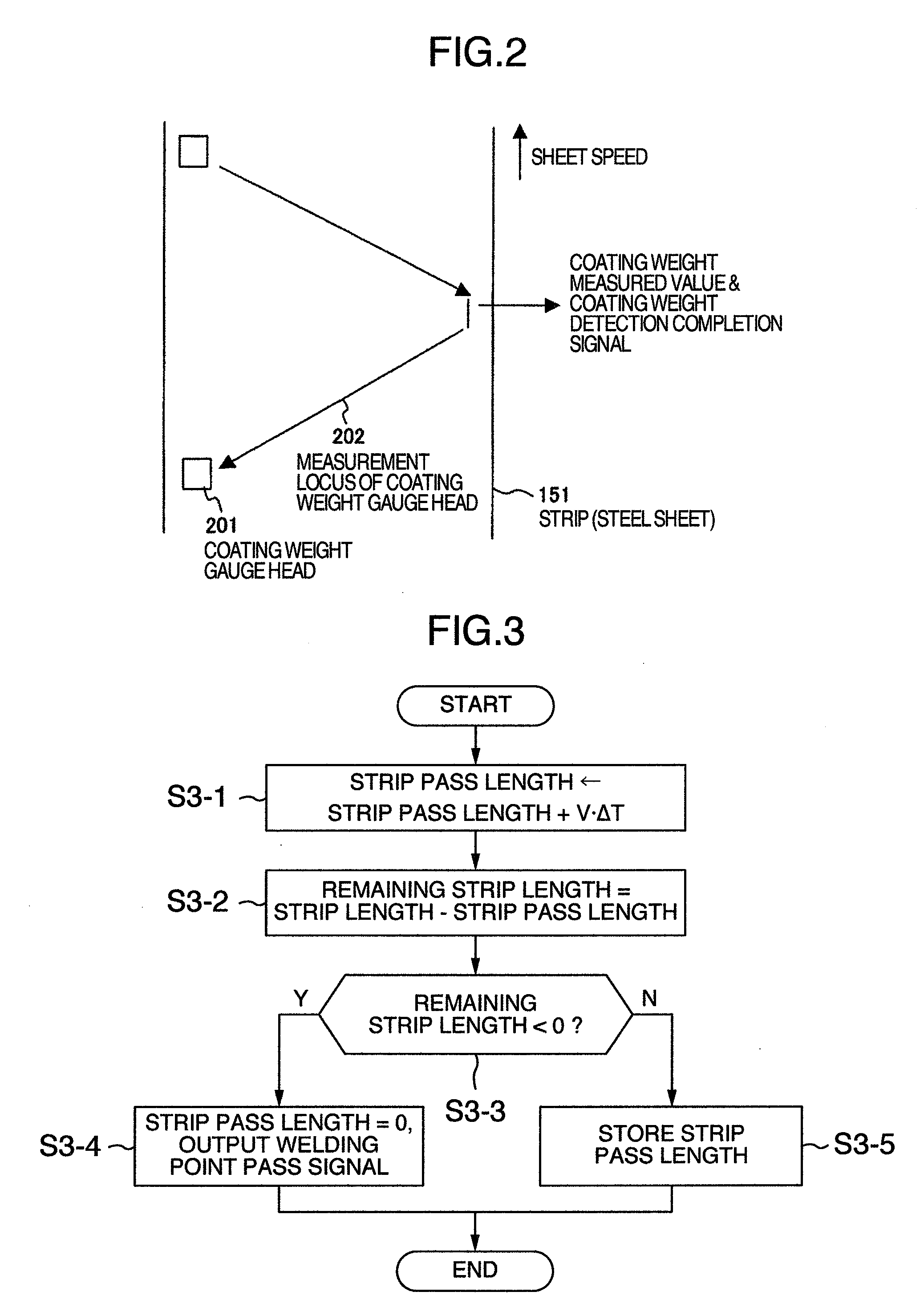

System and method for controlling plating amount

InactiveUS20080026134A1Sequencing is complicatedLong calculation timeHot-dipping/immersion processesLiquid surface applicatorsStrip steelBiological activation

An apparatus for performing a coating weight control calculation and an apparatus for generating an activation timing of each process in coating weight control are separately managed. A strip welding point pass event, a completion event of scan measurement of a steel strip in a width direction by a coating weight gauge, and a constant period event are related respectively to activation timings of preset control, feedback control and feedforward control respectively of a coating weight. In a coating weight control apparatus and method, the activation timing generation apparatus is equipped with a function of calculating a timing of changing a pressure reference avoiding insufficient coating in accordance with response characteristics of a pressure as an operation terminal, and if a target coating weight is changed from thin coating to thick coating, generating a preset control activation reference in accordance with the calculation result.

Owner:HITACHI LTD

Aluminum alloy sheet, method for producing the same, and aluminum alloy container

InactiveUS20060240270A1Excellent ERV propertyHigh degreeMetal layered productsNumber densityIntermetallic

An aluminum alloy sheet contains 0.1% to 0.4% by mass of Cu, 0.5% to 1.5% by mass of Mg, 0.5% to 1.5% by mass of Mn, 0.2% to 0.7% by mass of Fe, and 0.1% to 0.3% by mass of Si. The number density of Al—Mn—Fe—Si-based intermetallic compound having a maximum length of 8 to 15 μm per unit area is 179 grains / mm2 or less. An oxide film having an average thickness of 30 nm or less is formed on the surface of the aluminum alloy sheet. The arithmetic average roughness Ra of the surface of the aluminum alloy sheet is 0.30 to 0.45 μm.

Owner:KOBE STEEL LTD

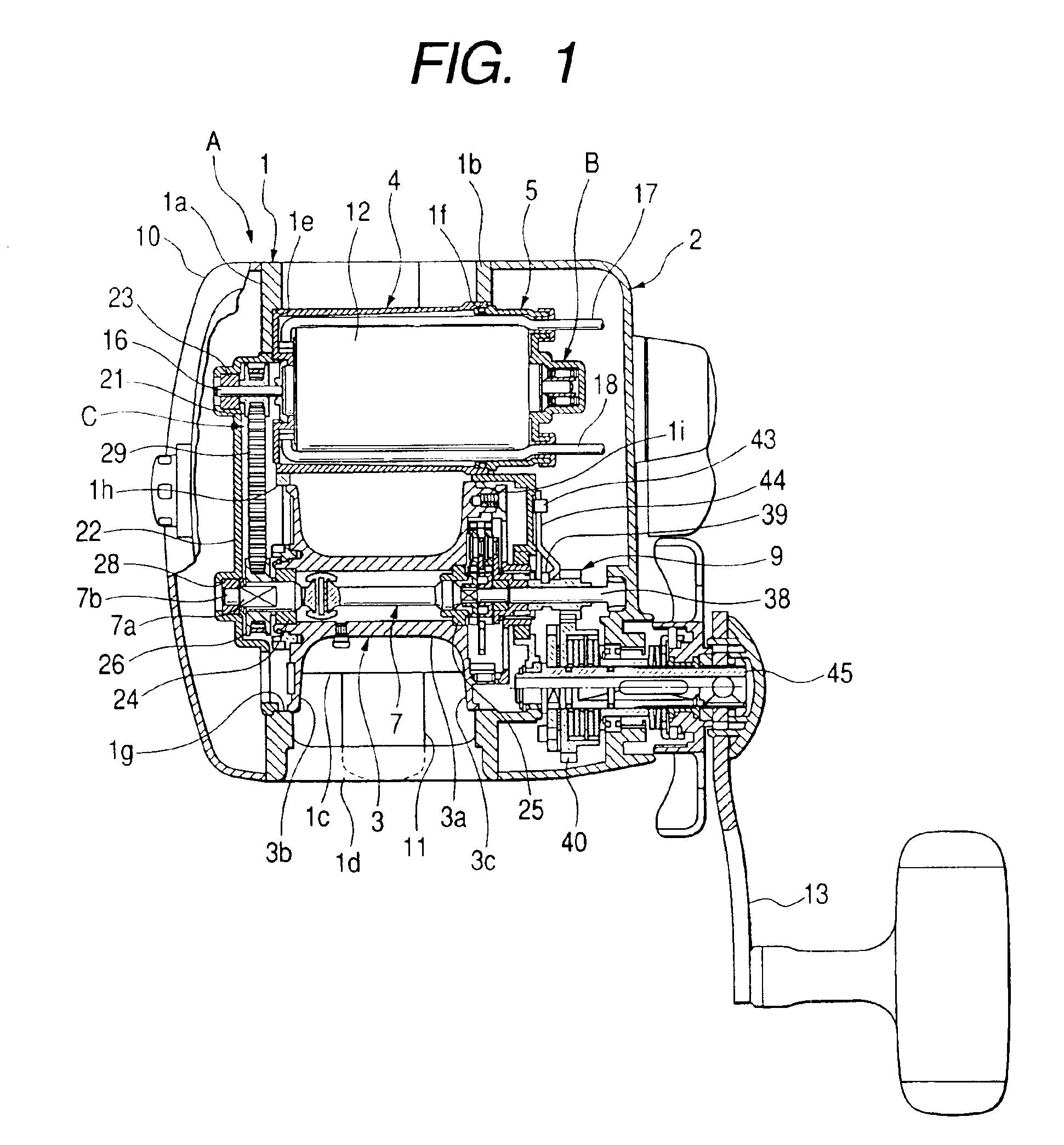

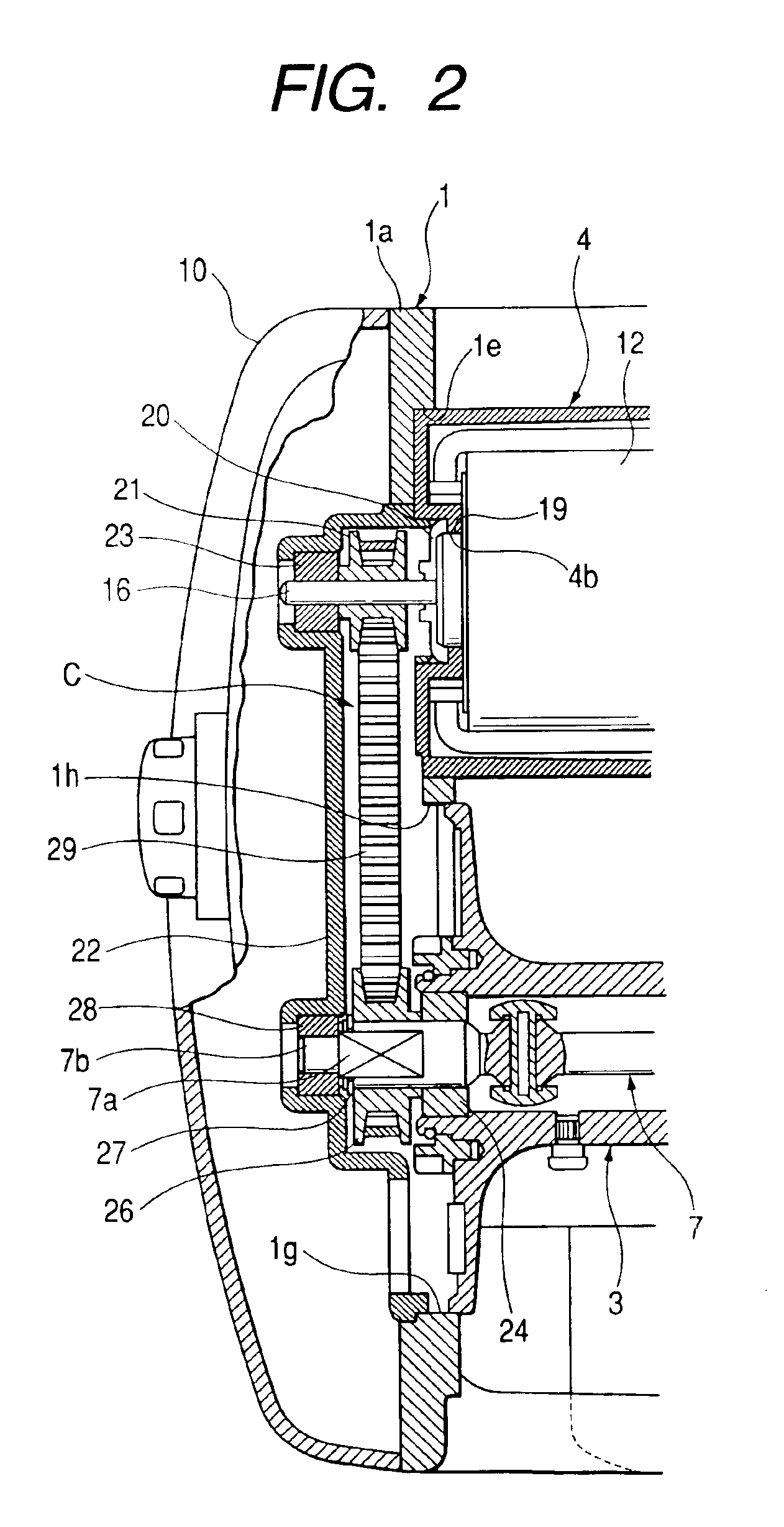

Fishing reel

A belt and pulleys are used as a power transmitting unit in a fishing reel for avoiding uncomfortable vibration or noises while fishing. A spool motor is supported in a motor receiving case provided at front and lower parts between both side frames, and a toothed pulley 21 is urged in the other side of a rotating shaft and is made detent. Another toothed pulley is fitted in a detent portion of a spool shaft by an E-ring, and a toothed belt is expanded between the toothed pulley and the other toothed pulley.

Owner:DAIWA SEIKO CORPORATION

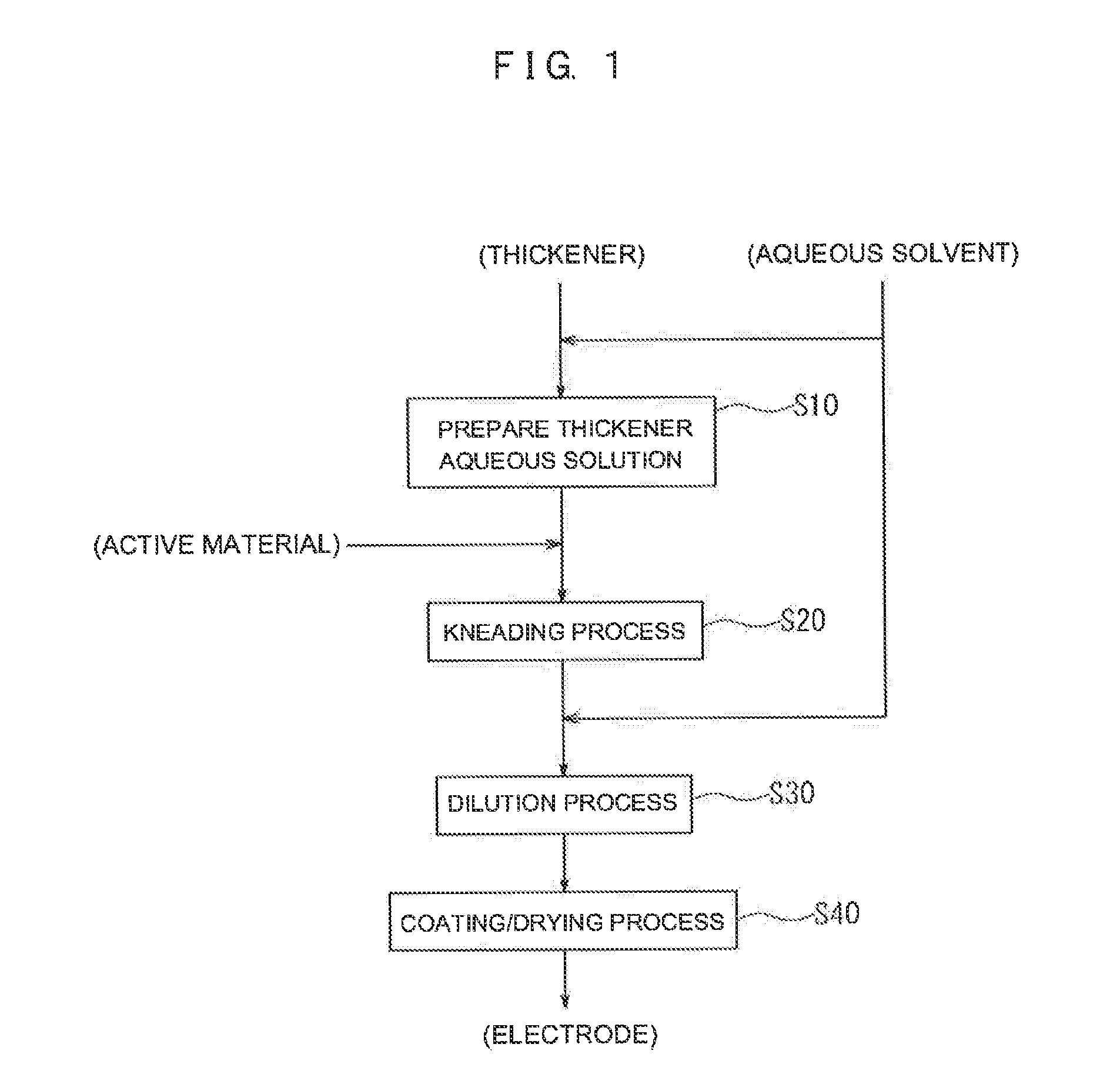

Battery manufacturing method (as amended)

ActiveUS20130202781A1Good adhesivenessImprove quality stabilityFinal product manufactureSecondary cellsSolventAqueous solution

The present invention provides a battery manufacturing method including: a step of preparing a thickener aqueous solution by dissolving a thickener in an aqueous solvent (S10); a kneading step of introducing an active material into the prepared thickener aqueous solution and kneading a result (S20); a diluting step of adding an aqueous solvent to a kneaded material resulting from the kneading step such that the kneaded material is diluted, whereby an active material layer forming paste is obtained from the kneaded material (S30); and a step of obtaining an electrode in which an active material layer is formed on a current collector by coating the current collector with the active material layer forming paste and then drying the paste (S40).

Owner:TOYOTA JIDOSHA KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com