Patents

Literature

51results about How to "High coating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

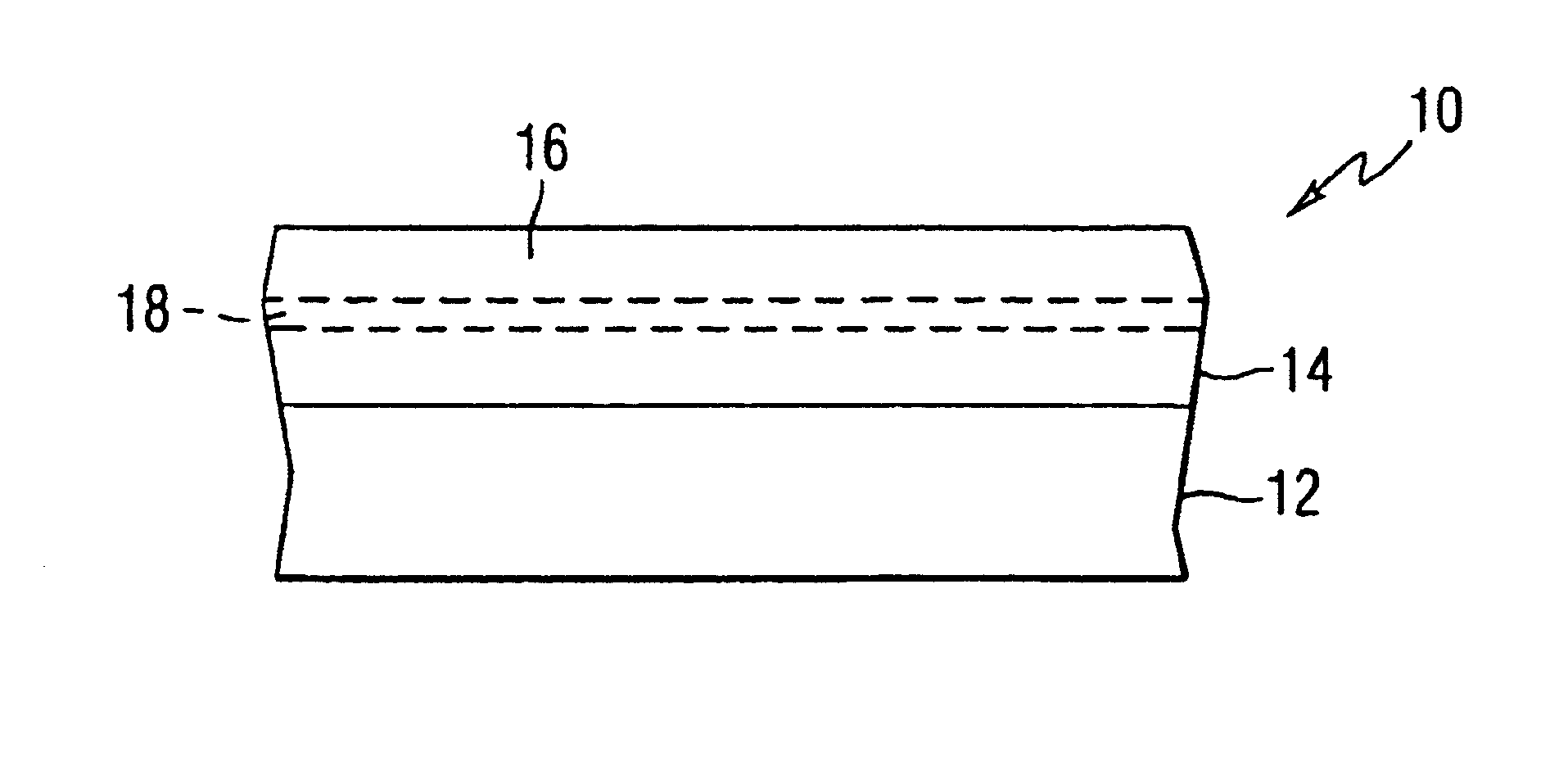

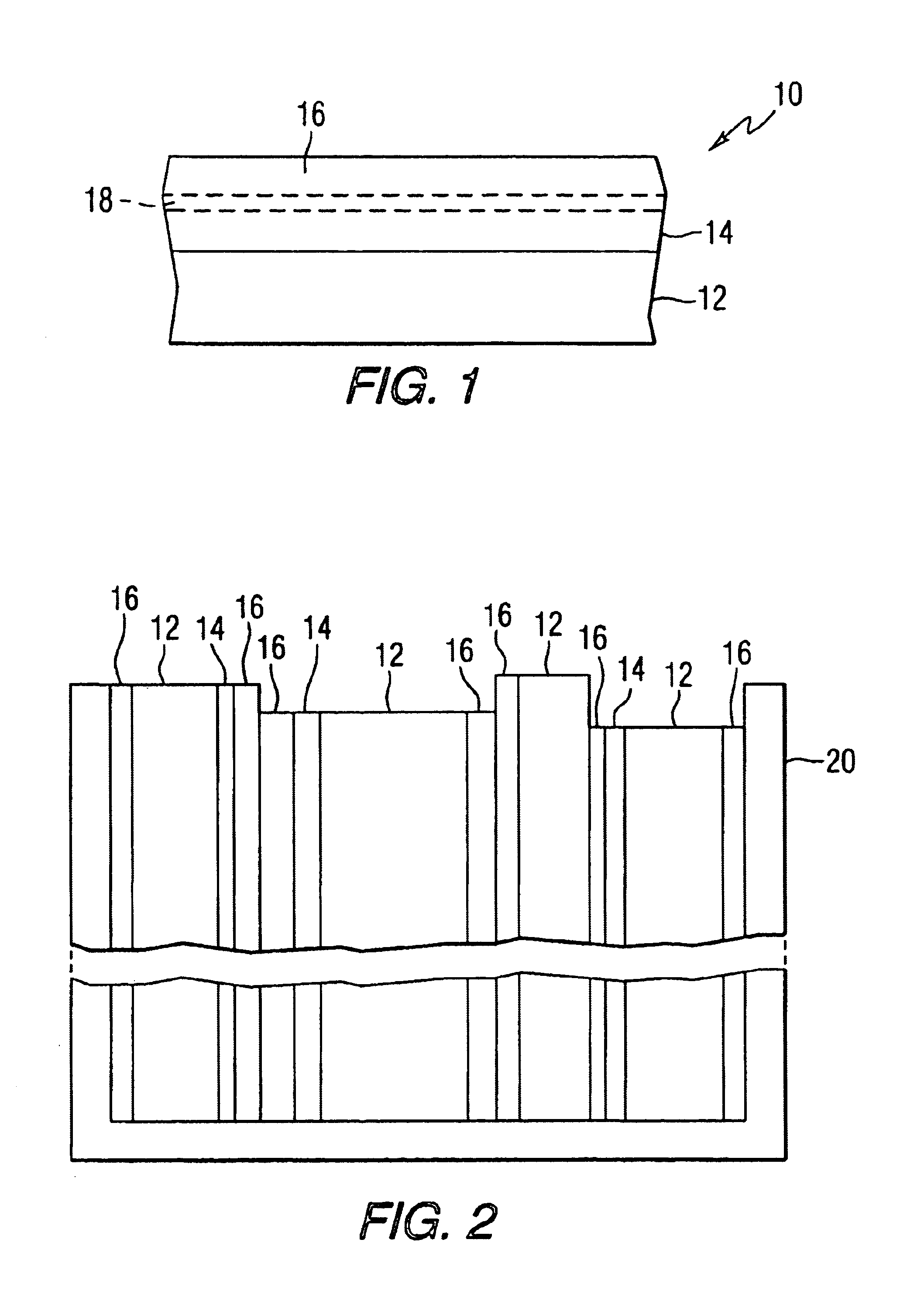

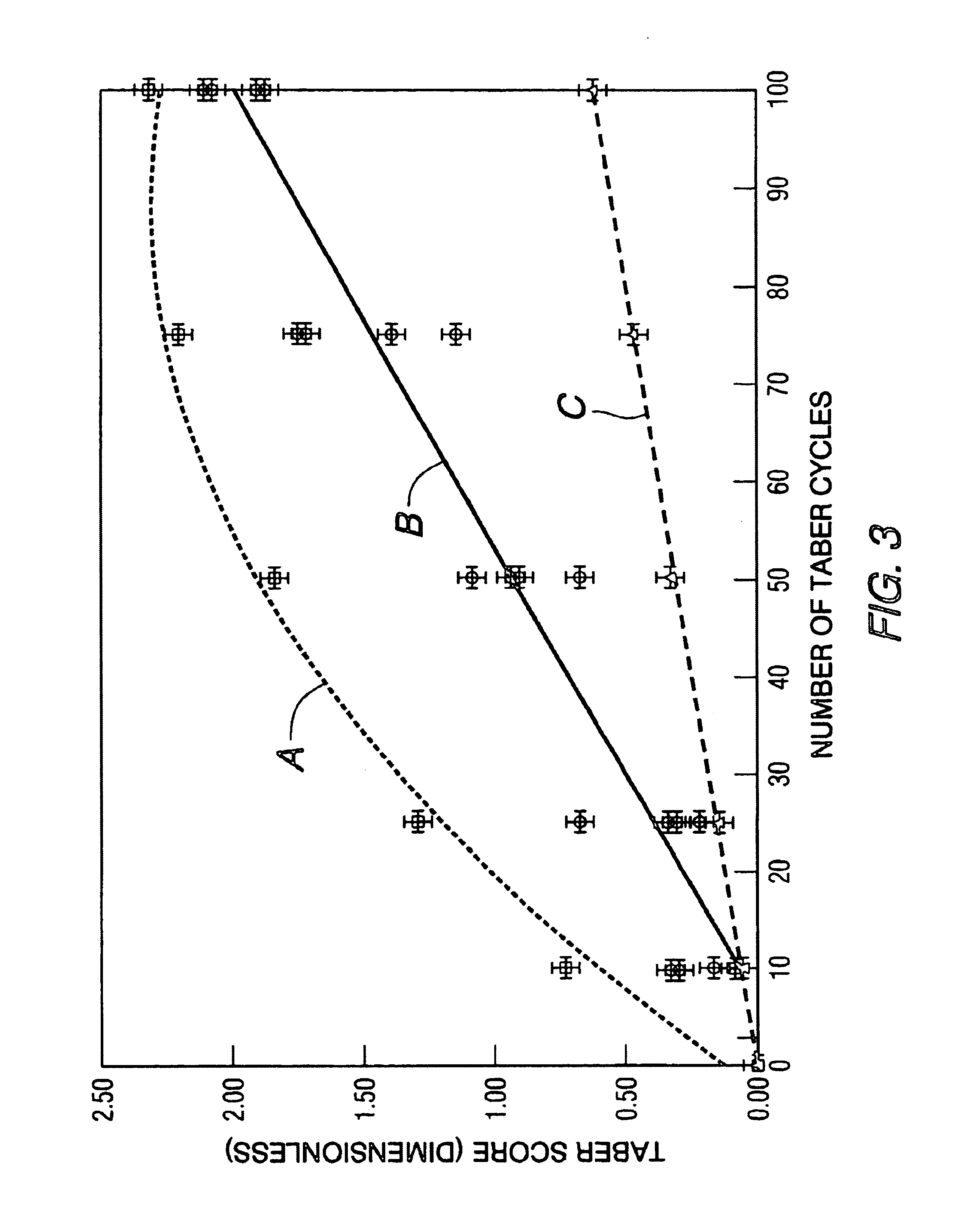

Light-transmitting and/or coated article with removable protective coating and methods of making the same

InactiveUS6849328B1Heating evenlyIncrease heat absorptionSynthetic resin layered productsPaints with biocidesCombustionPolyvinyl alcohol

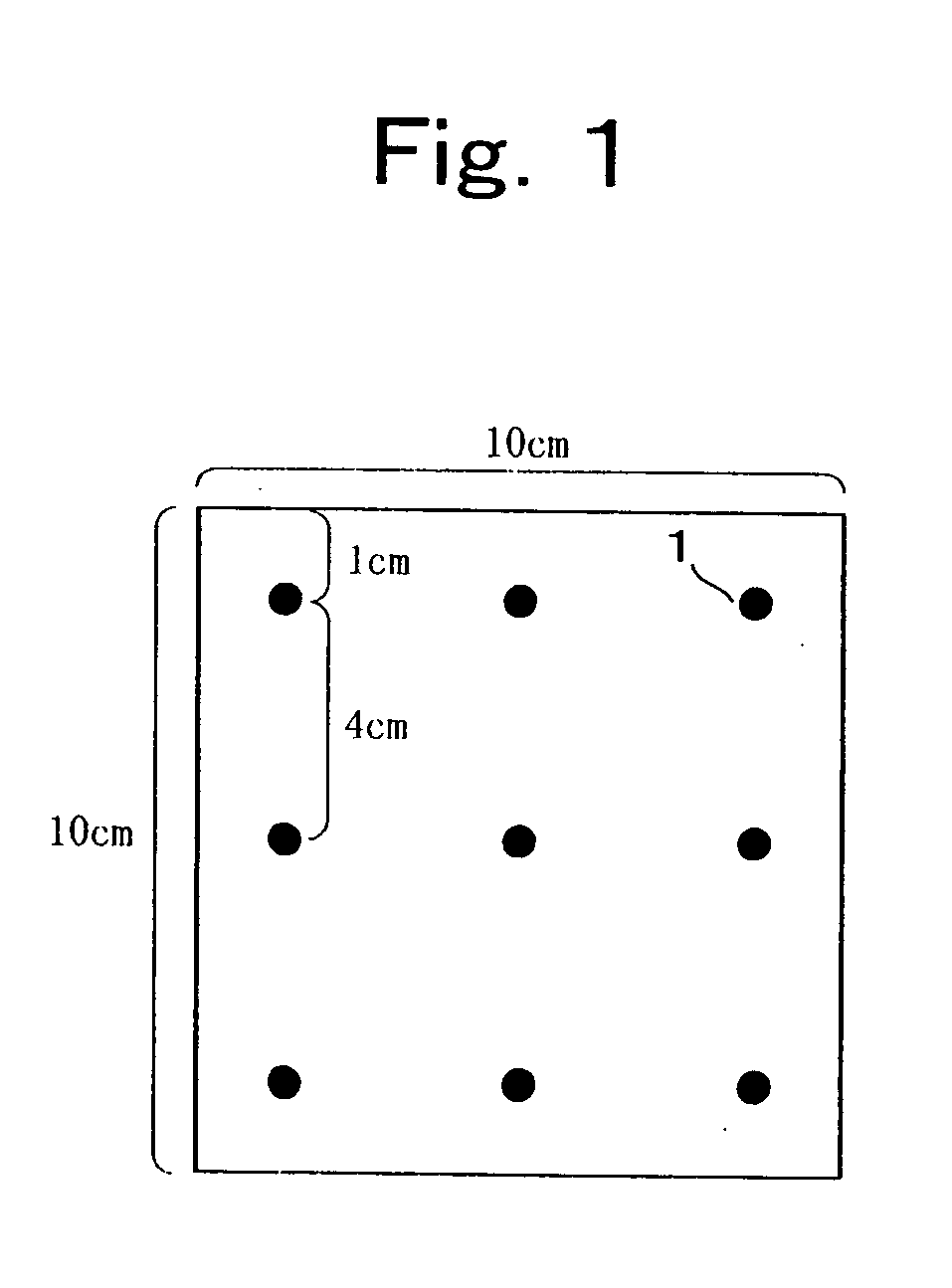

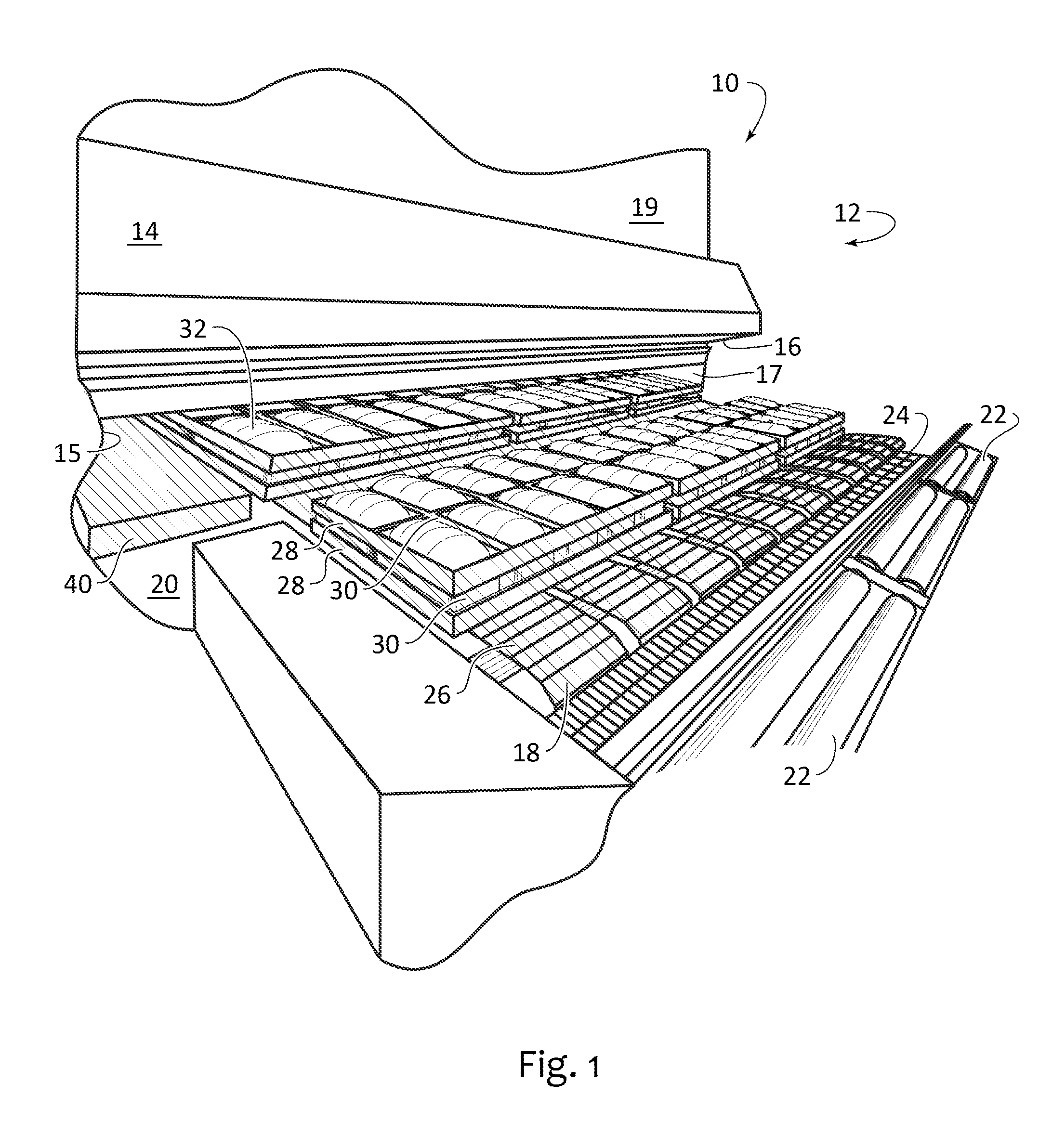

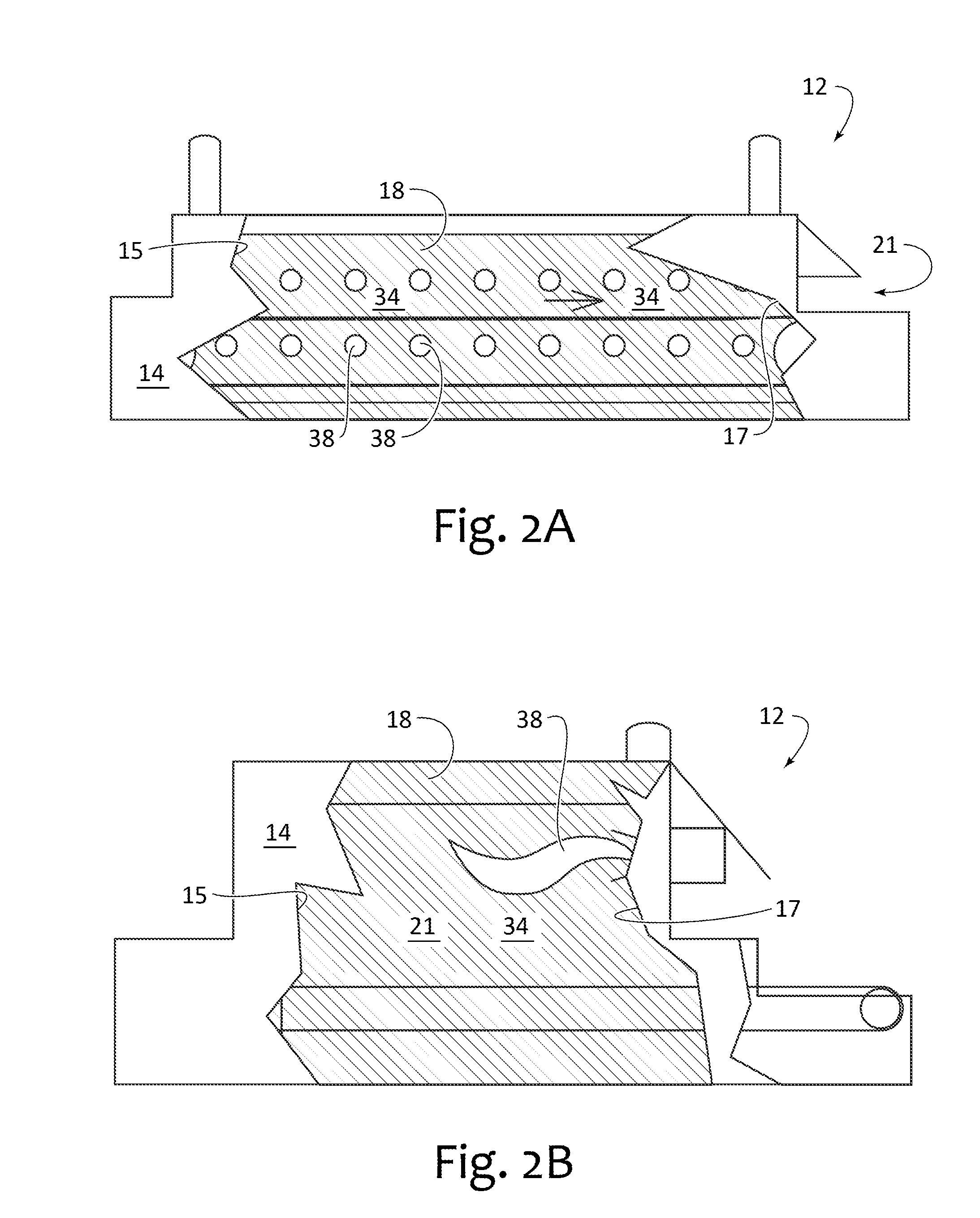

A method and coating are provided for temporarily protecting a substrate or article during shipping, handling or storage by applying a removable protective coating over at least a portion of the substrate. The substrate may be flat or curved and may have zero, one or more functional coatings. A plurality of substrates with the protective coating of the invention may be arranged in a shipping container so that the protective coating reduces the possibility of damage to the substrate or optional functional coating. In one embodiment, the protective coating is the evaporation or reaction product of an aqueous coating composition containing a polyvinyl alcohol polymer which may be subsequently removed by aqueous washing, thermal decomposition or combustion. In another embodiment, the protective coating is formed by sputtering a substantially carbon coating onto the substrate. The carbon coating is subsequently removed by combustion. The protective coating may have identification materials, such as colorants or fragrance materials, such that different types of substrates and / or functional coatings can be distinguished from each other. Additionally, the temporary protective coating can improve the heating of a functionally coated glass substrate.

Owner:VITRO FLAT GLASS LLC

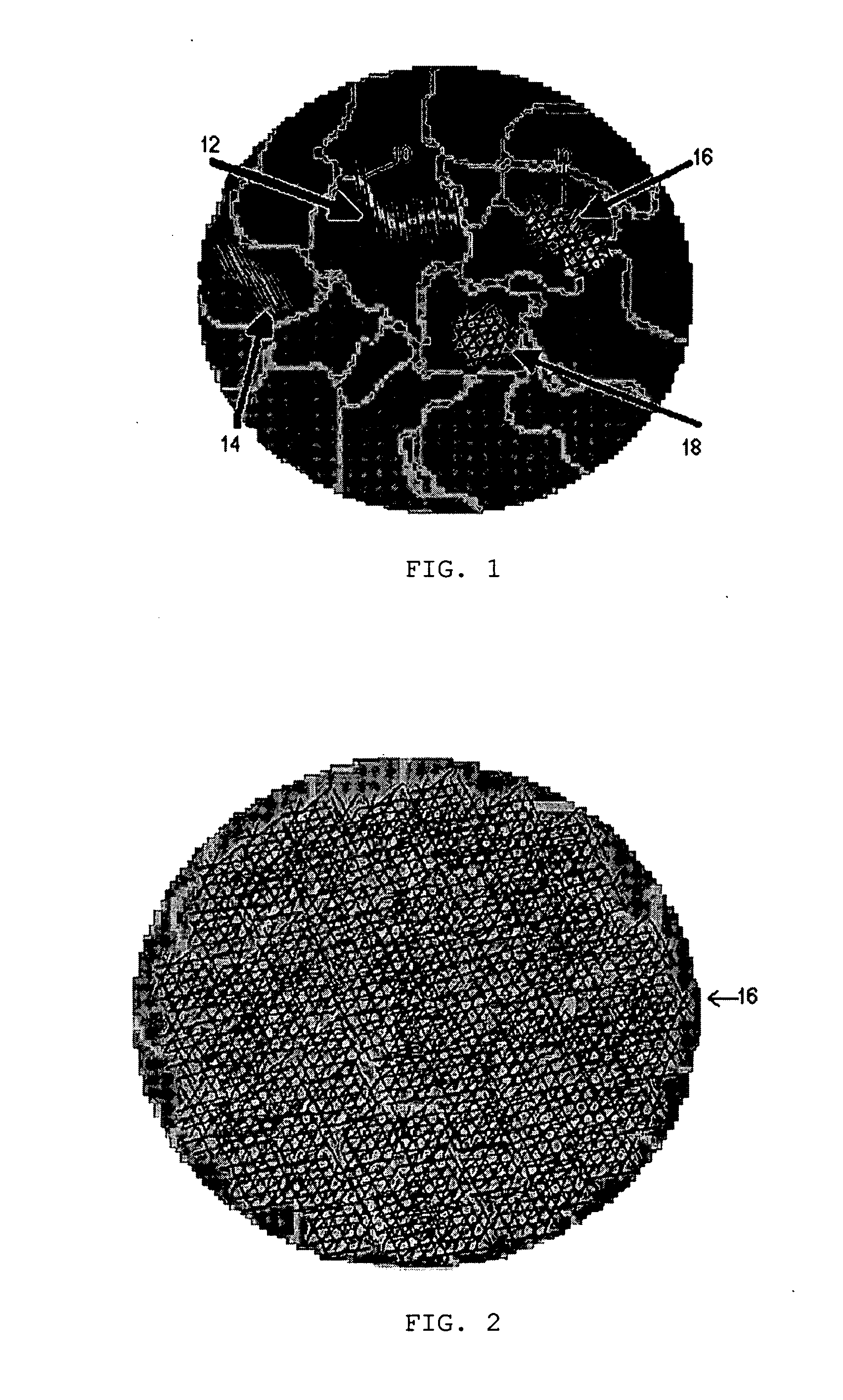

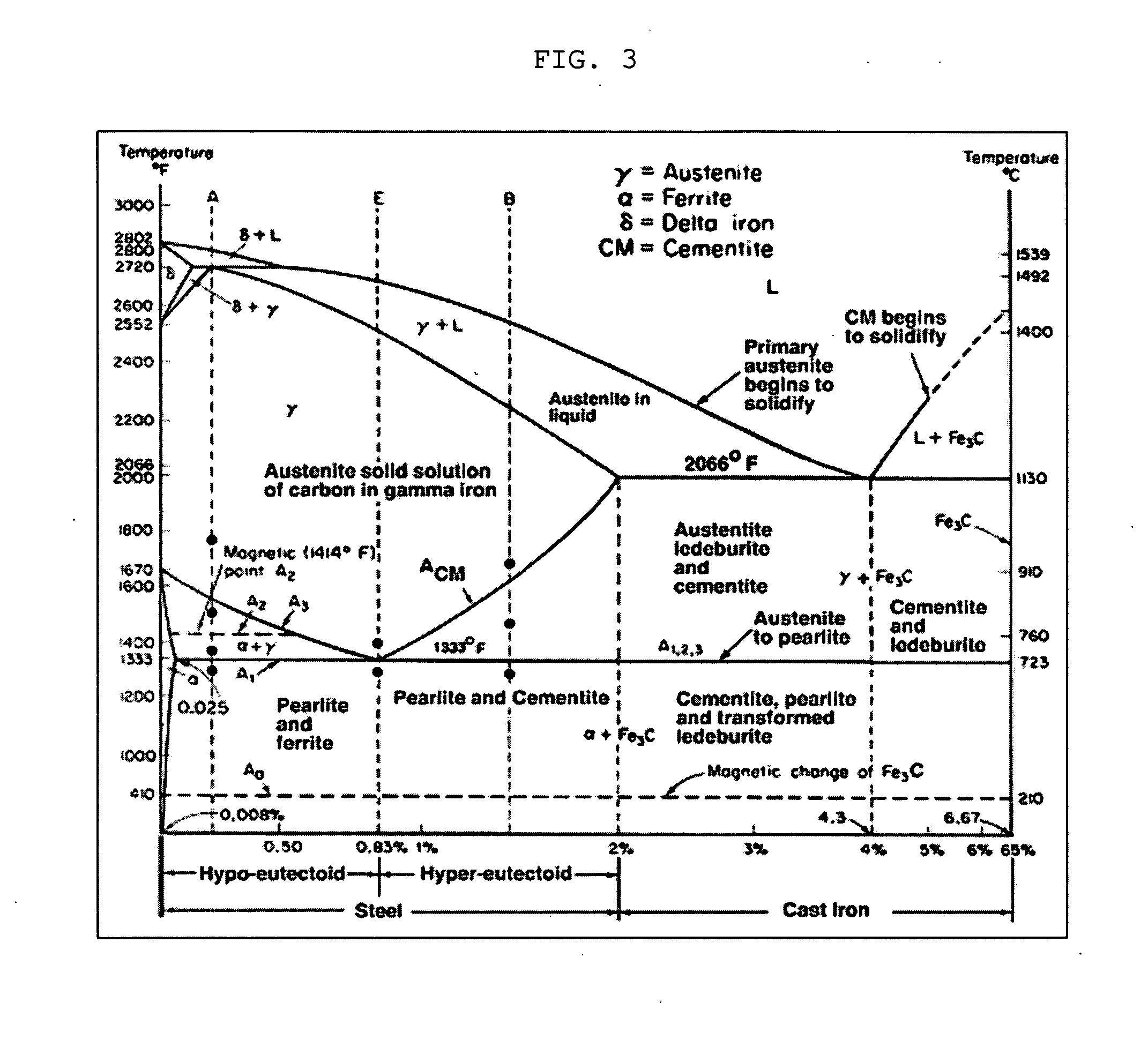

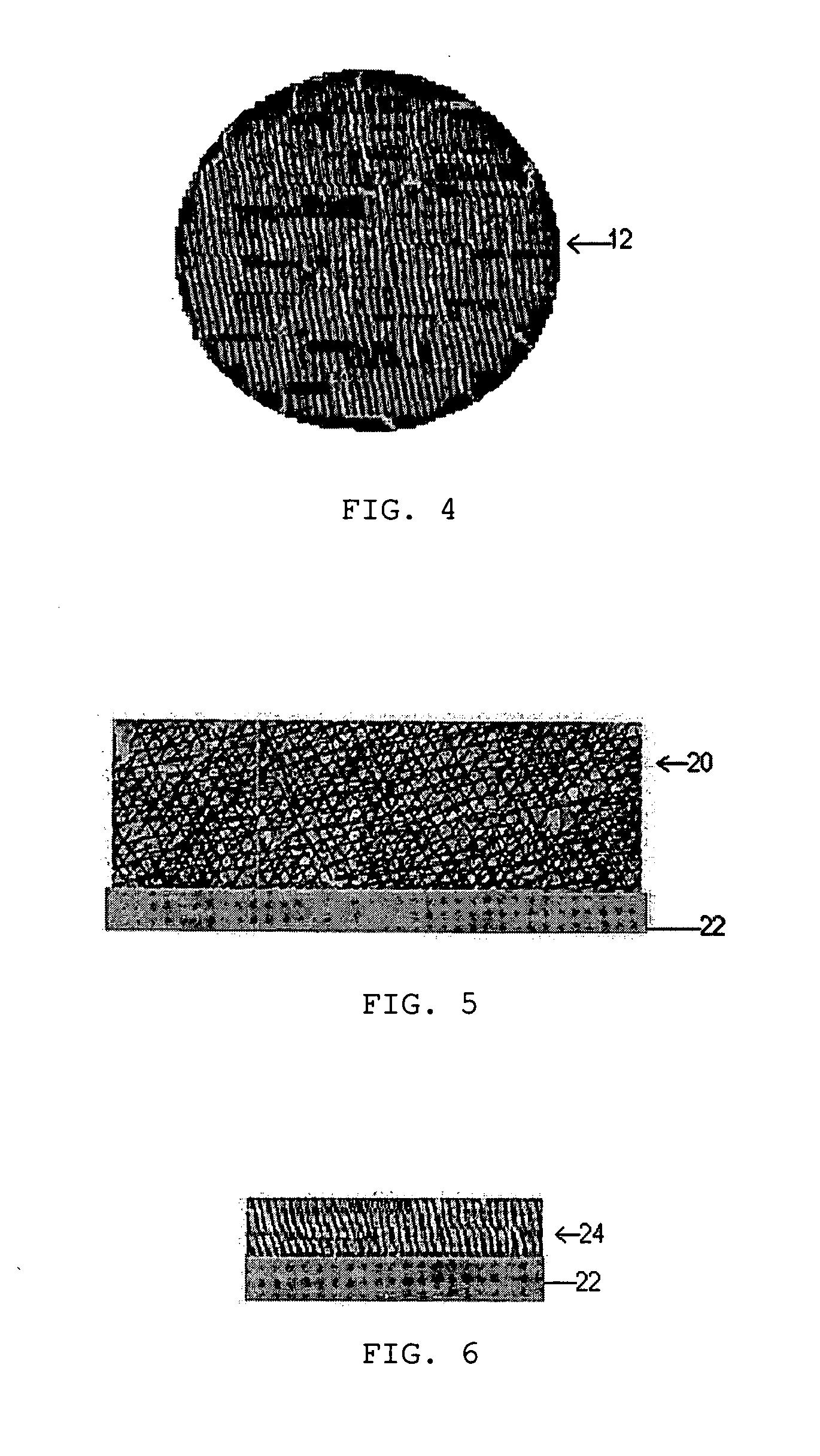

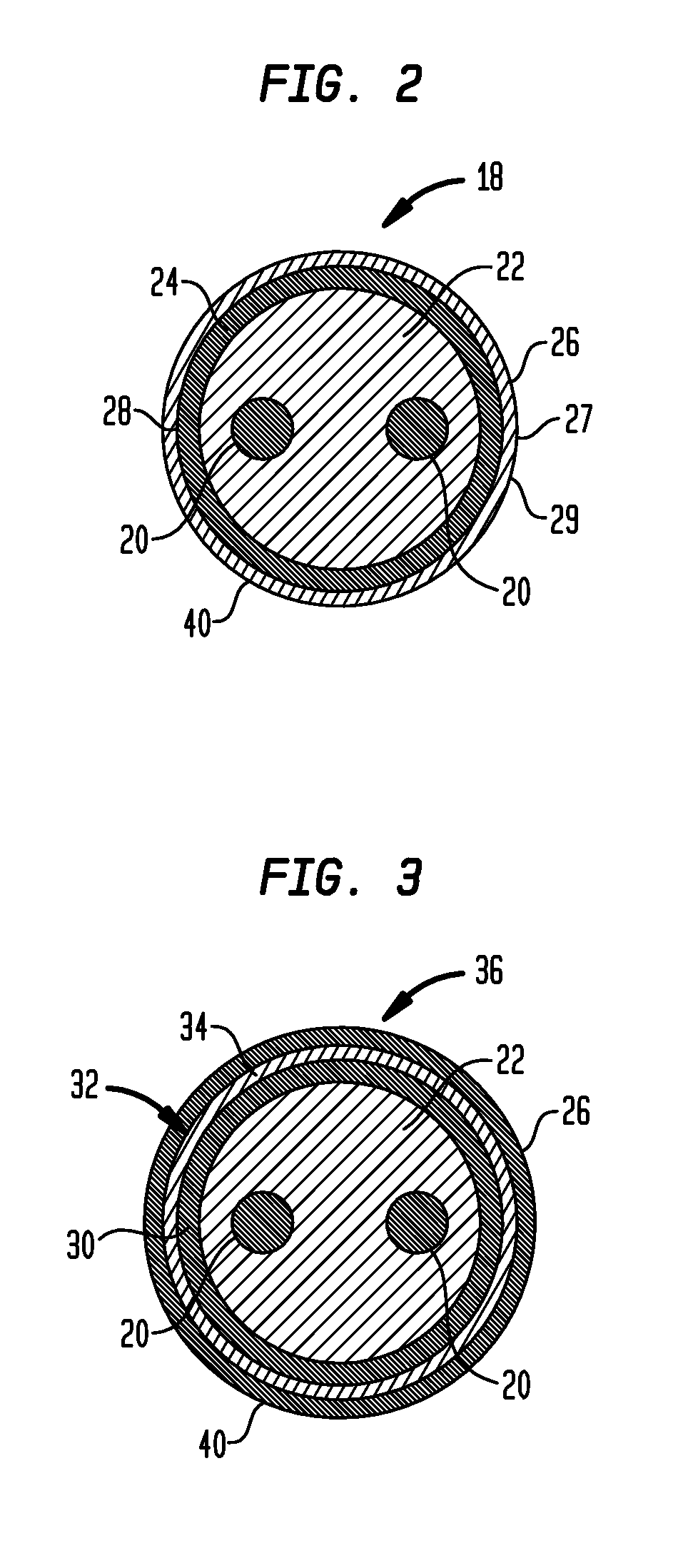

Nanostructured composite reinforced material

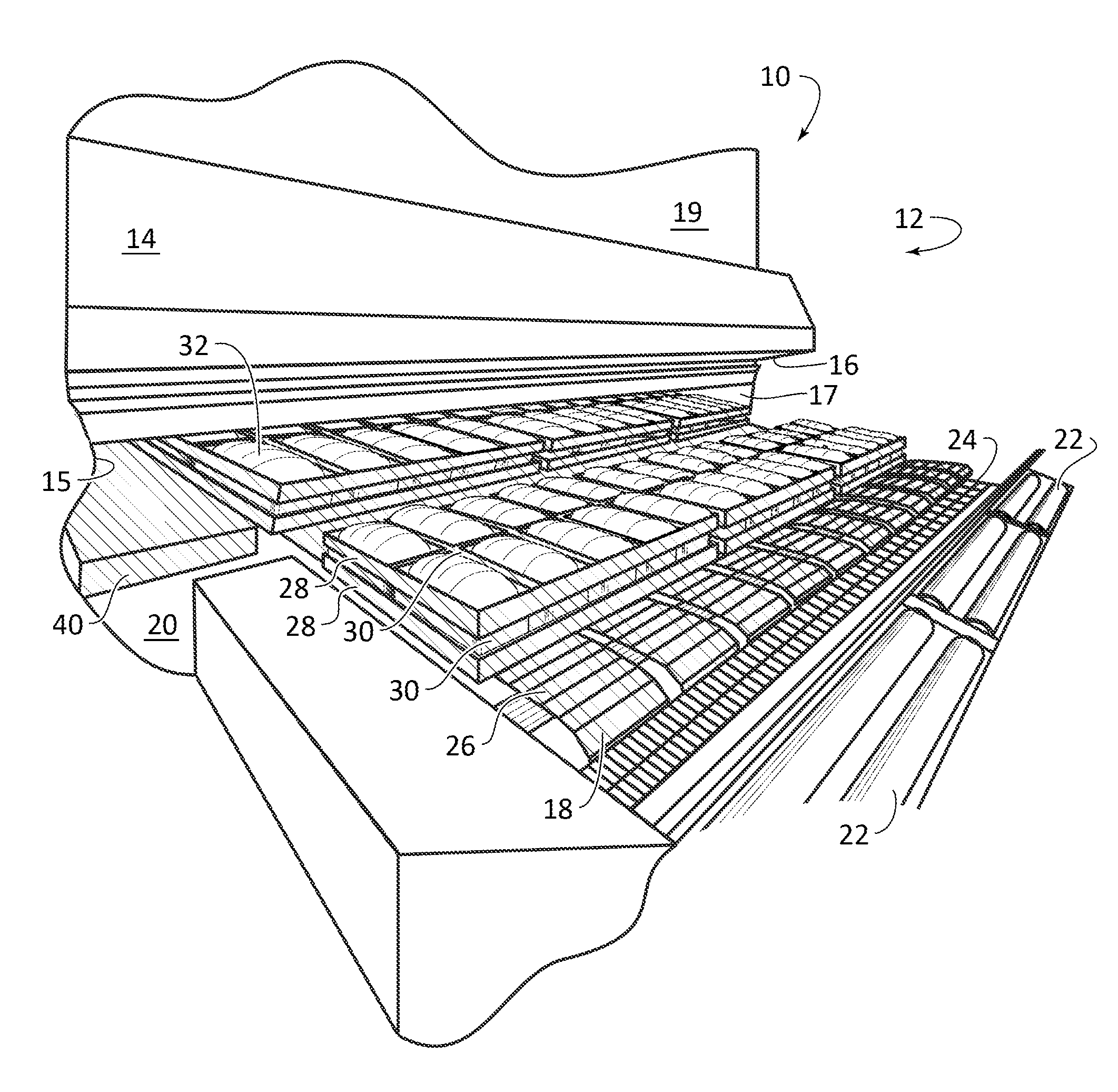

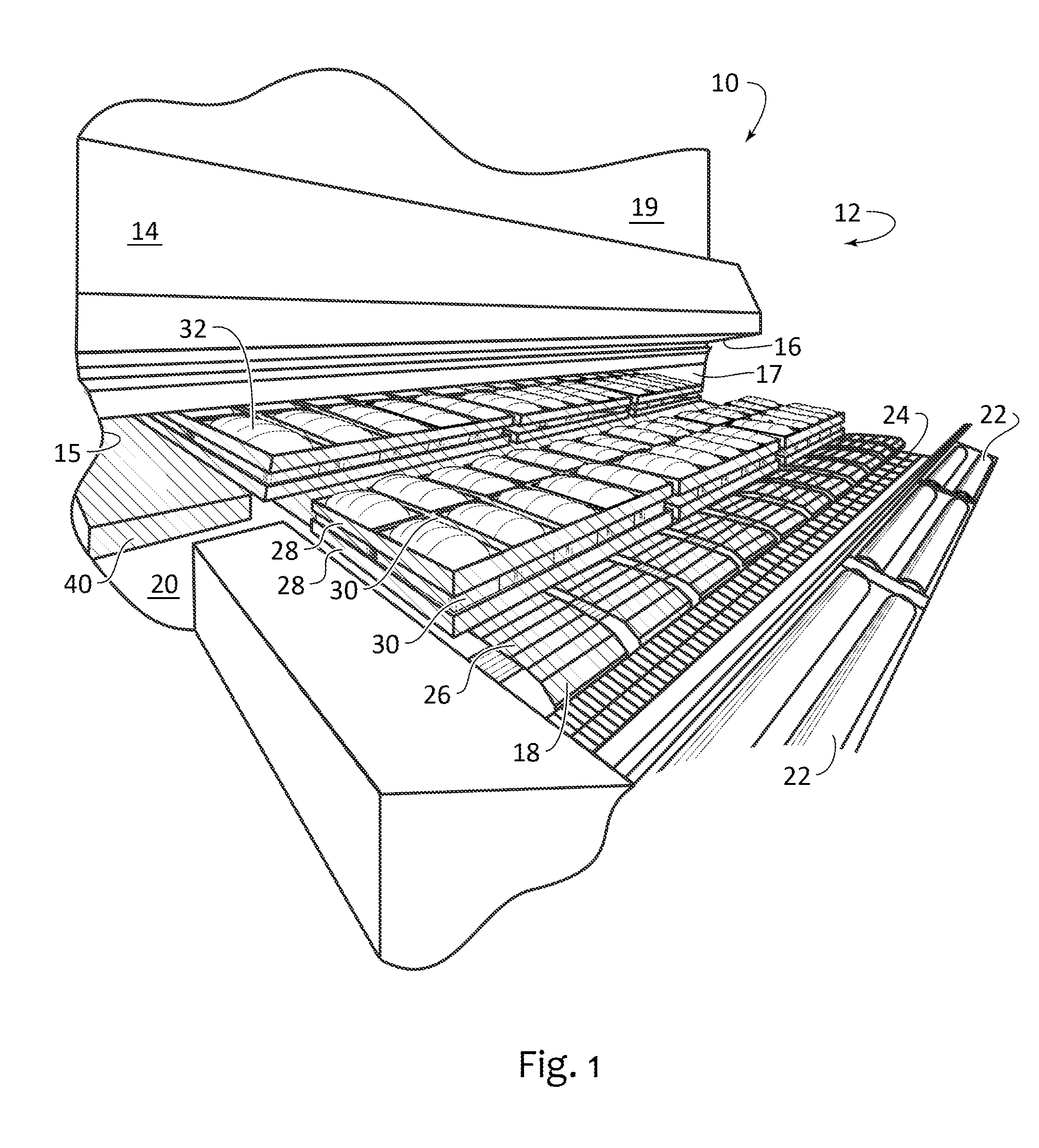

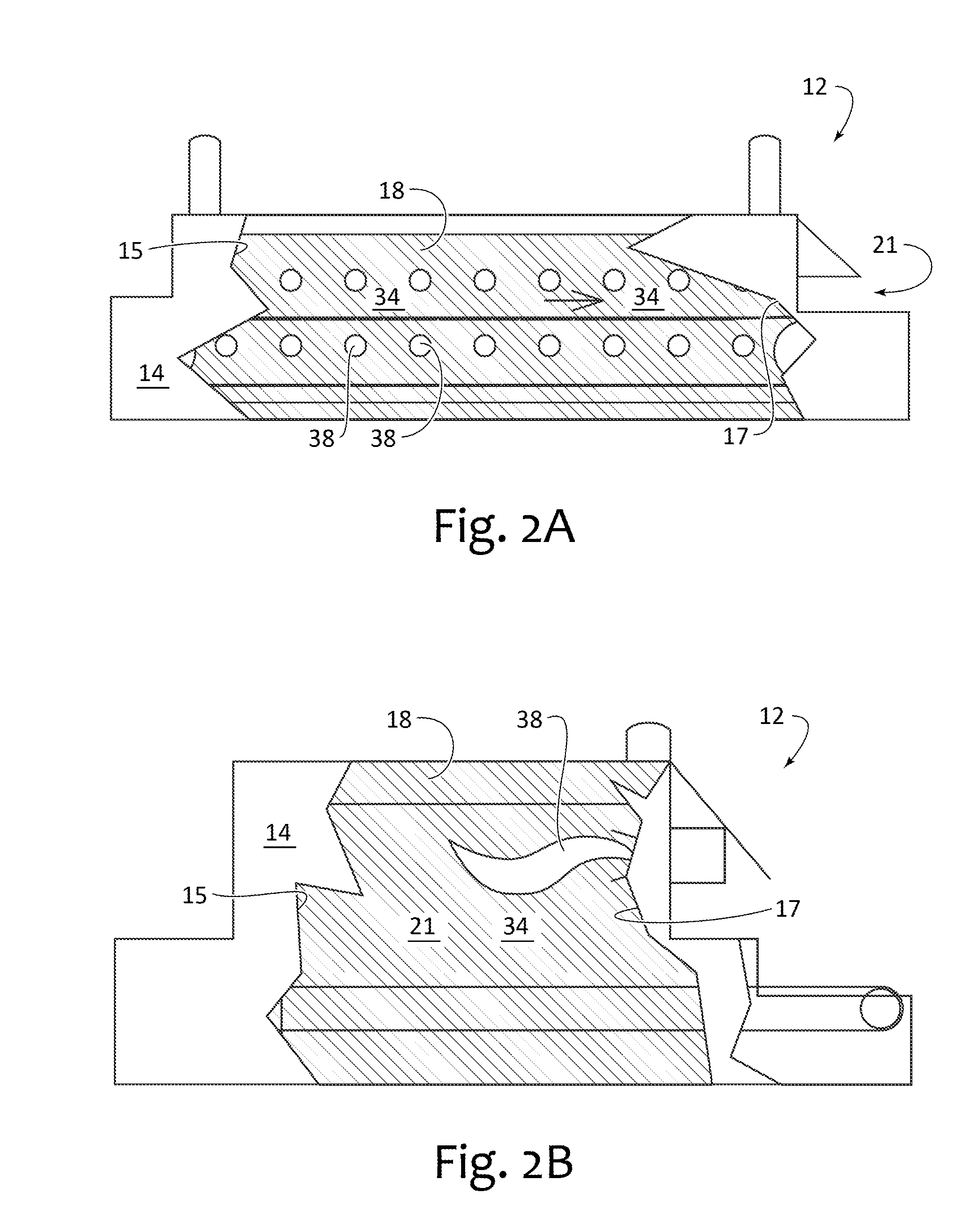

ActiveUS20120177905A1Maximum performanceImprove material performanceMaterial nanotechnologyAnimal housingDecrease weightAlloy

A family of materials wherein nanostructures and / or nanotubes are incorporated into a multi-component material arrangement, such as a metallic or ceramic alloy or composite / aggregate, producing a new material or metallic / ceramic alloy. The new material has significantly increased strength, up to several thousands of times normal and perhaps substantially more, as well as significantly decreased weight. The new materials may be manufactured into a component where the nanostructure or nanostructure reinforcement is incorporated into the bulk and / or matrix material, or as a coating where the nanostructure or nanostructure reinforcement is incorporated into the coating or surface of a “normal” substrate material. The nanostructures are incorporated into the material structure either randomly or aligned, within grains, or along or across grain boundaries.

Owner:UT BATTELLE LLC +1

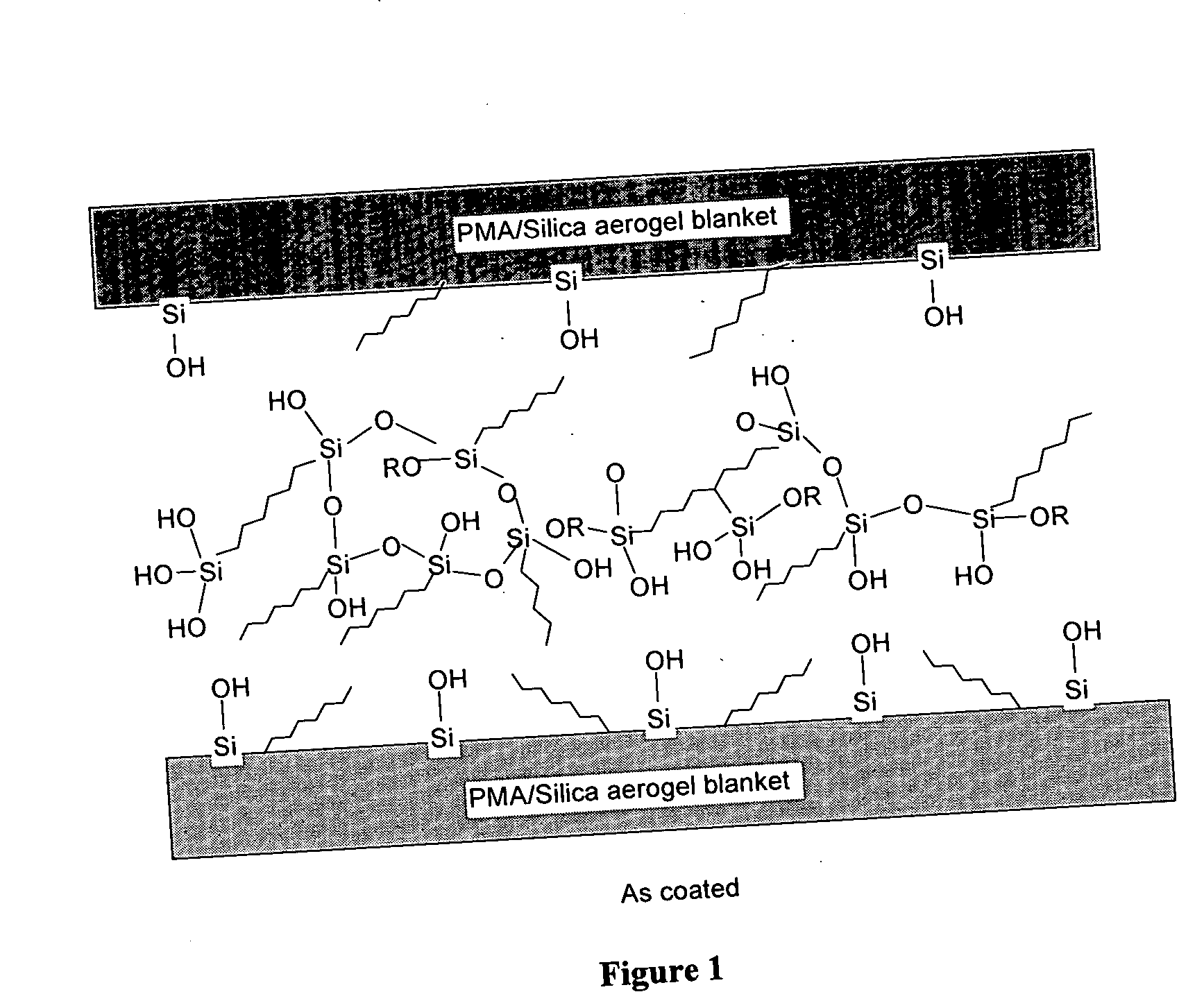

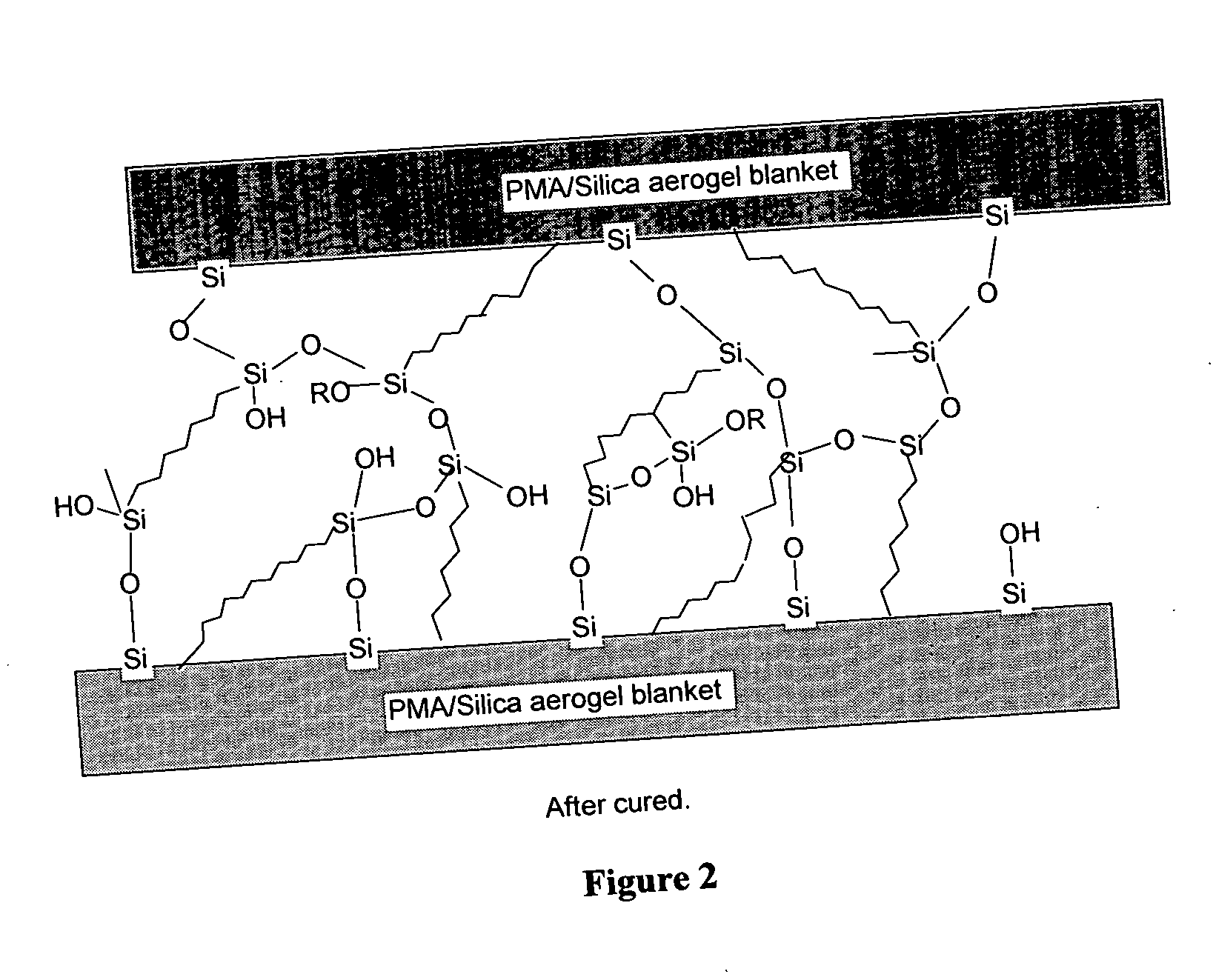

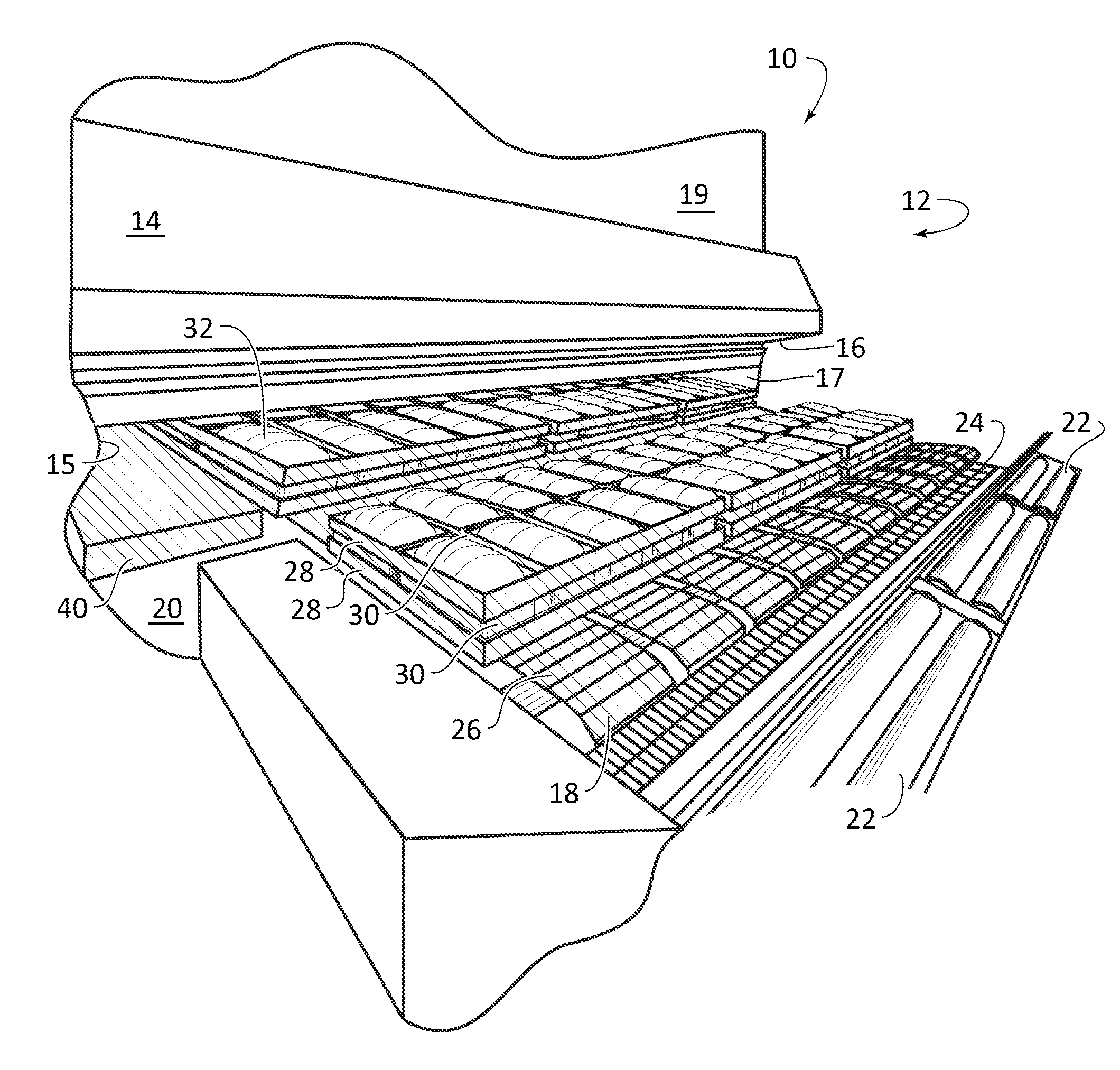

High strength aerogel panels

InactiveUS20060263587A1High coatingSynthetic resin layered productsConstructions elementsFiberUltimate tensile strength

Embodiments of the present invention describe a structure comprising at least one fiber-reinforced aerogel layer and at least one binder layer, said binder layer comprising a silicon-containing organic material and where the binder layer is bonded to at least one surface of a fiber-reinforced aerogel layer.

Owner:ASPEN AEROGELS INC

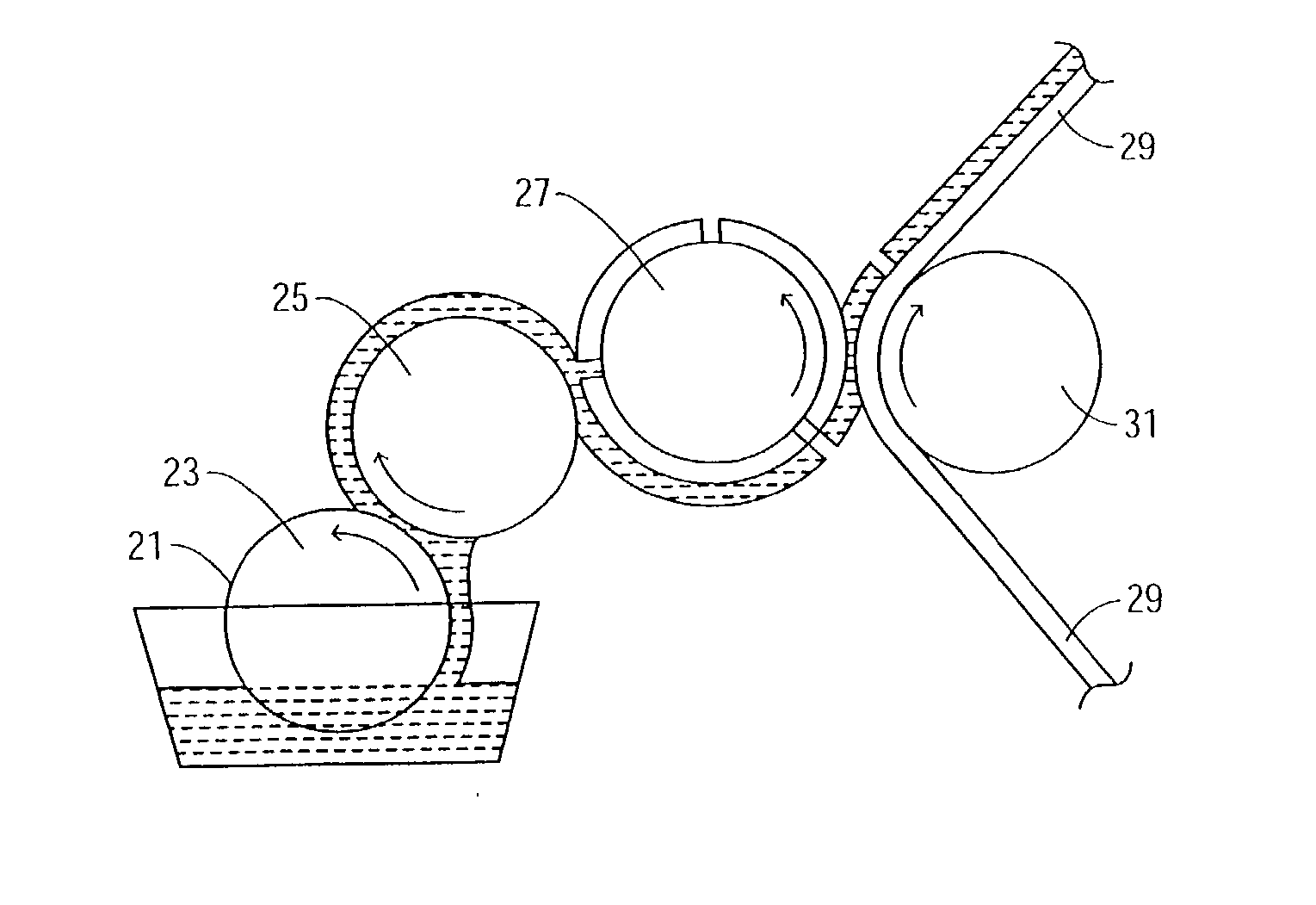

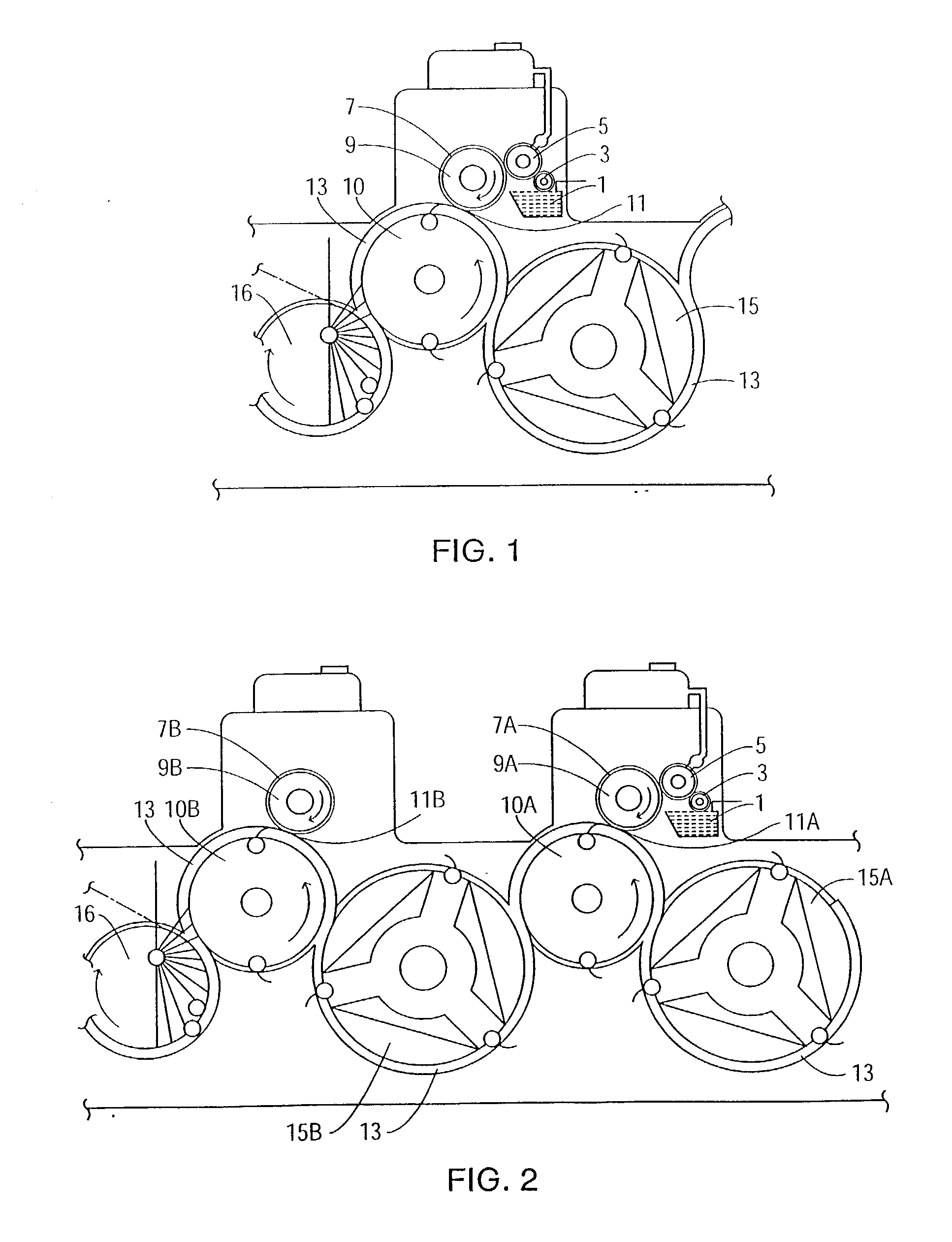

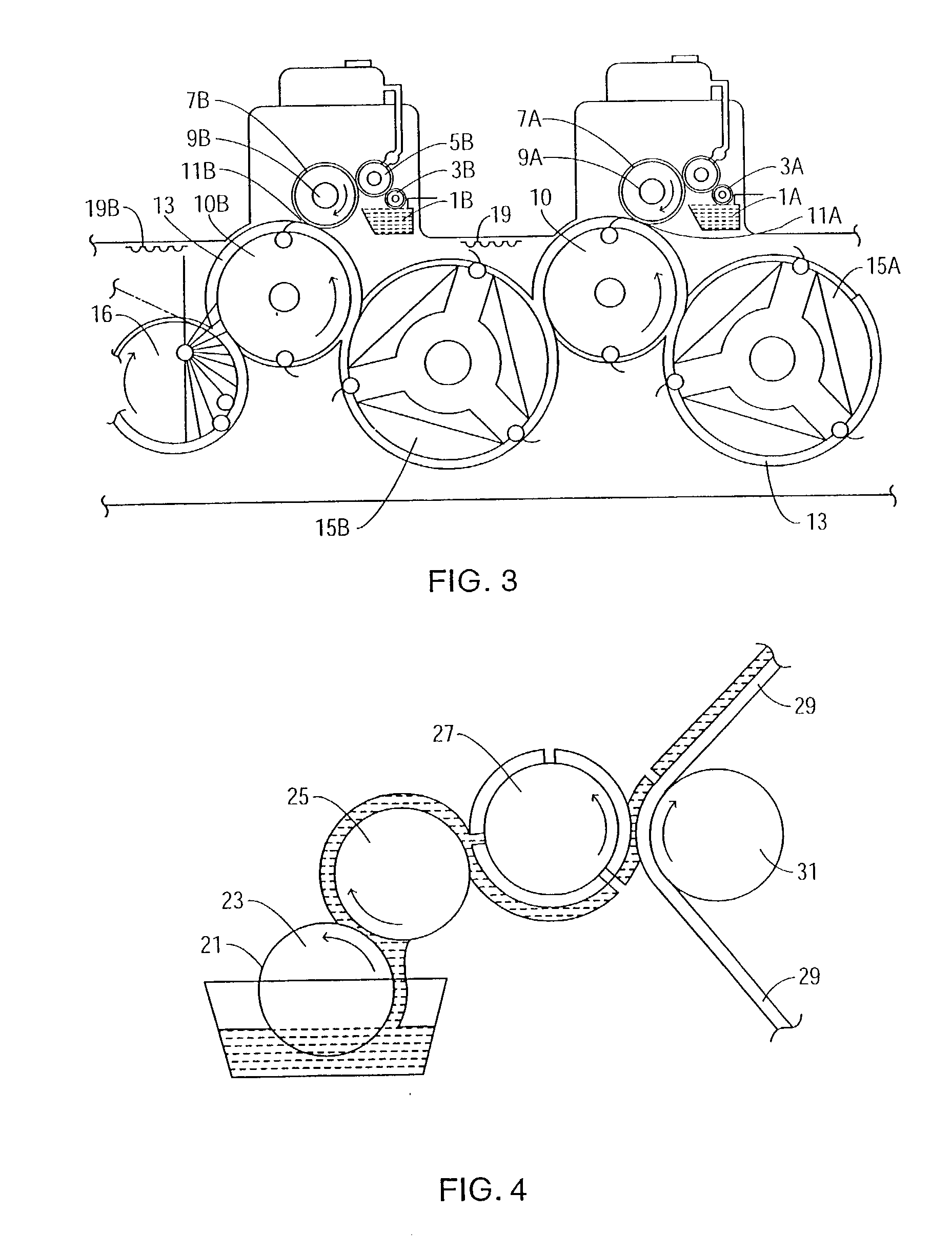

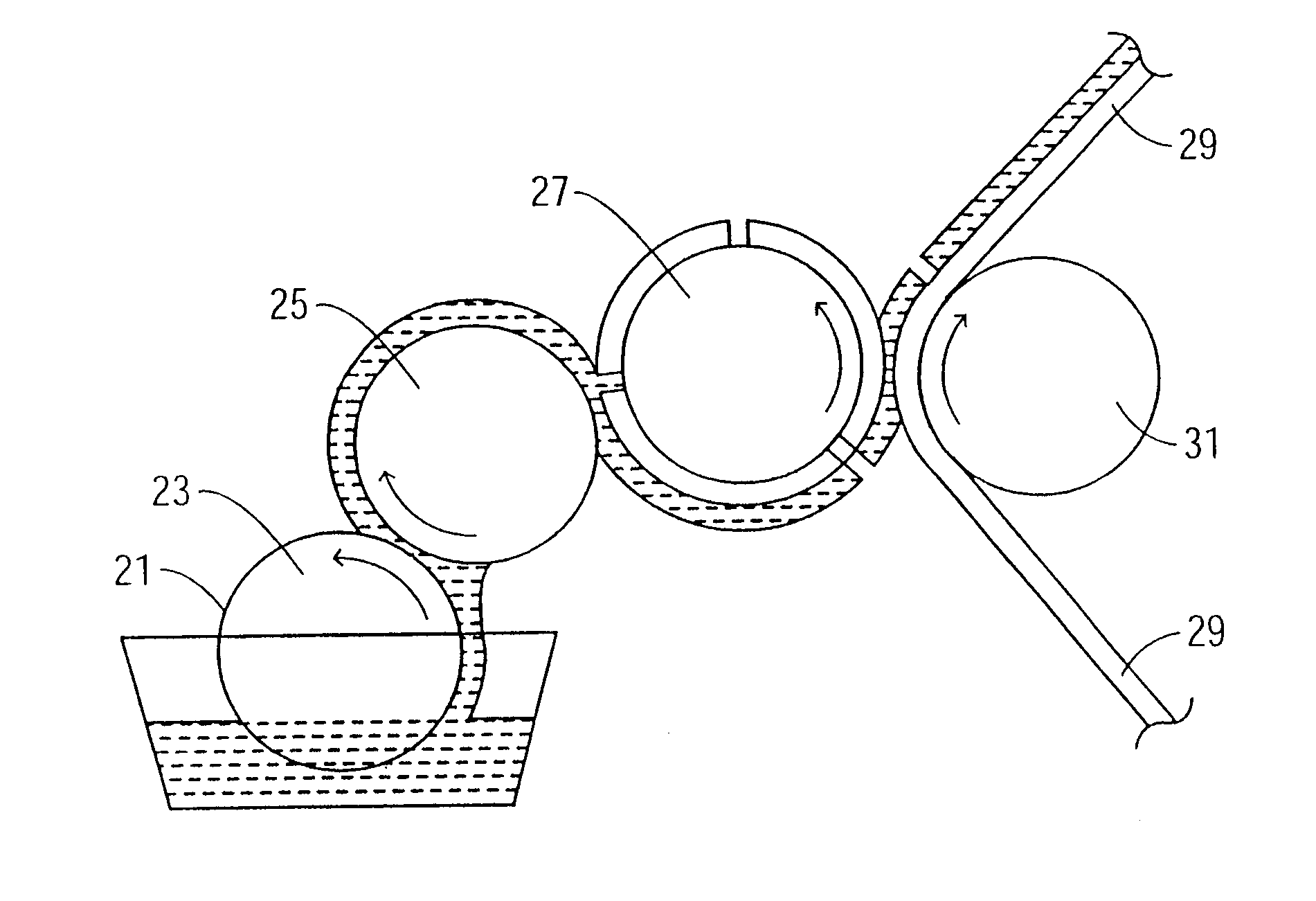

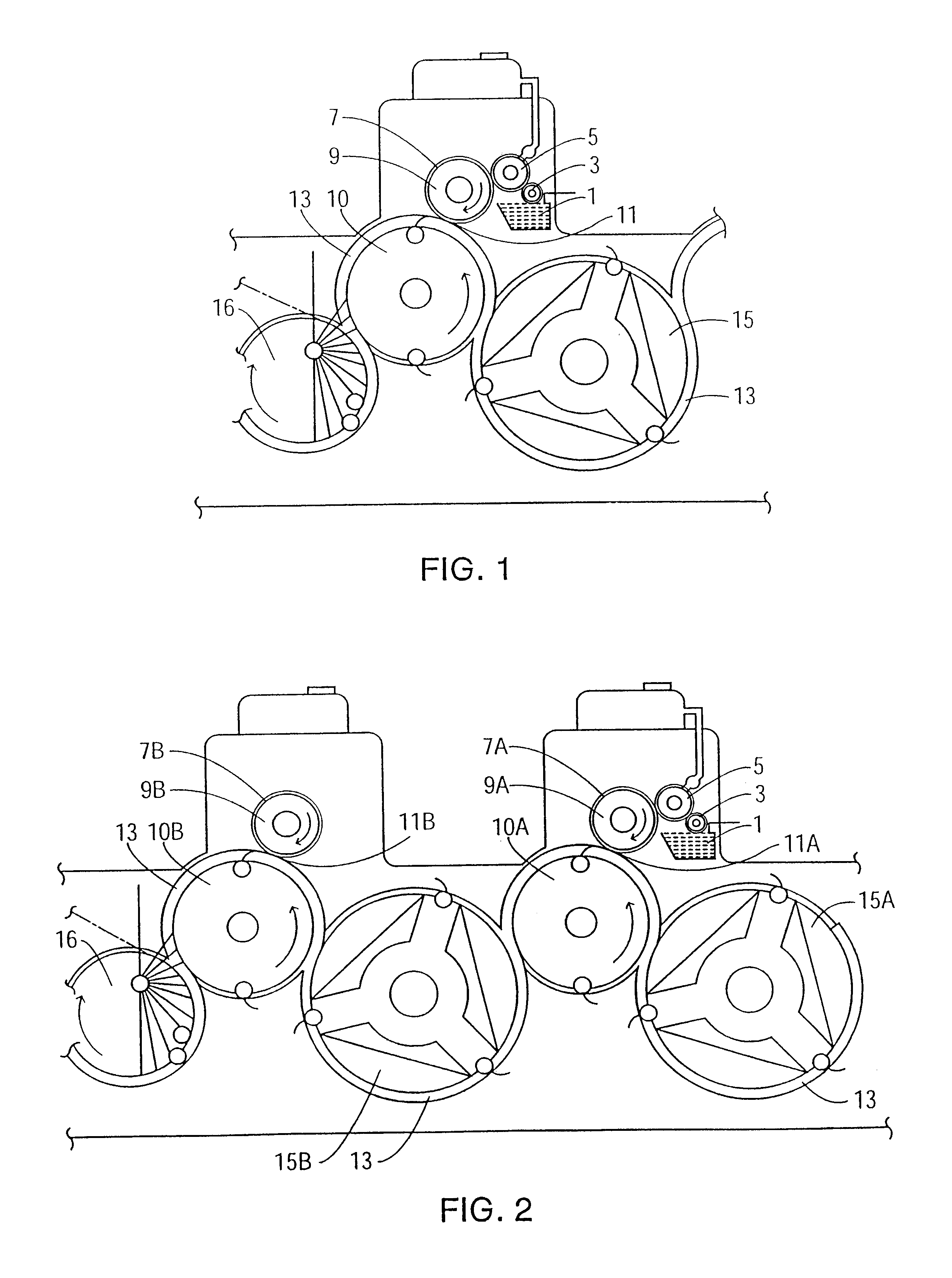

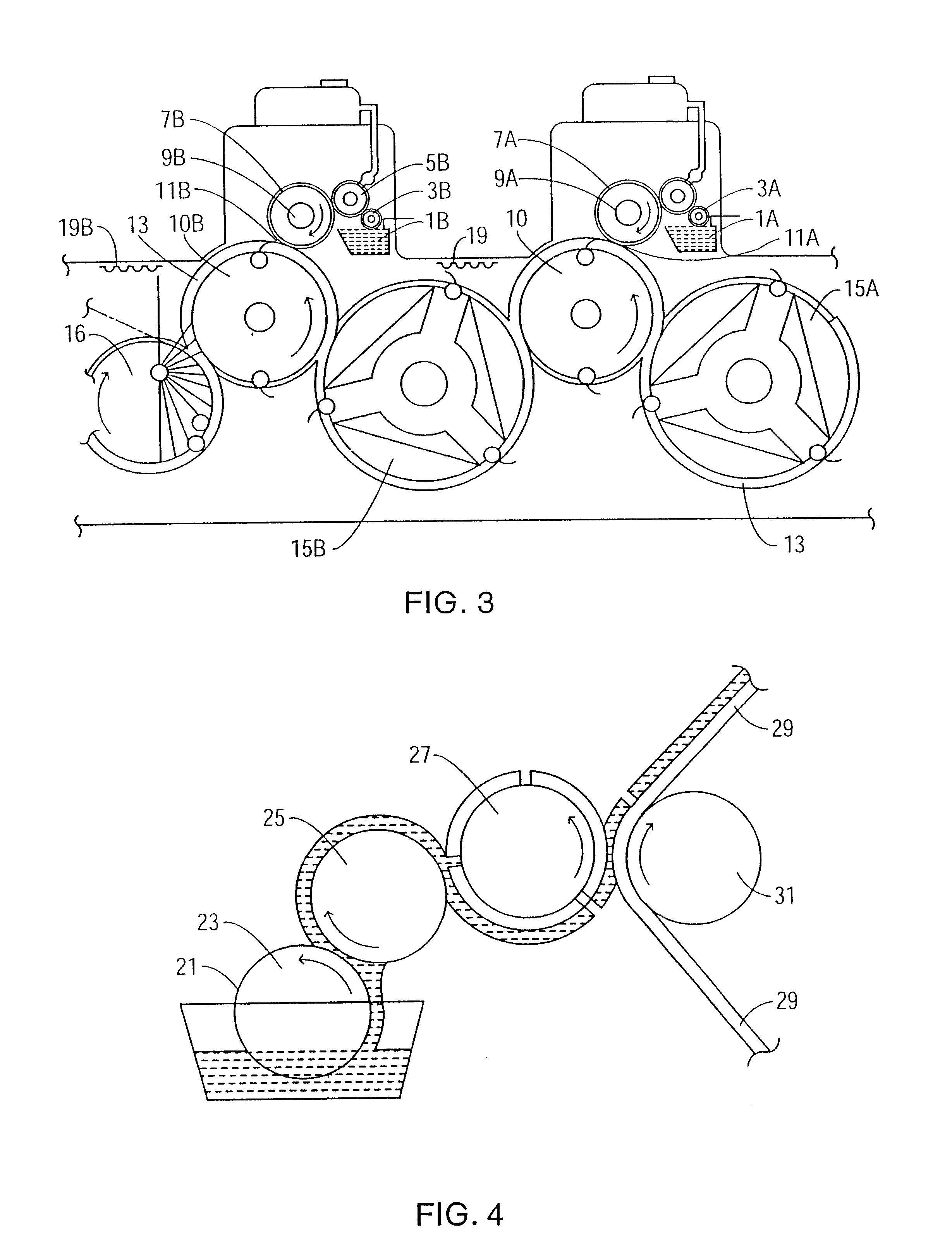

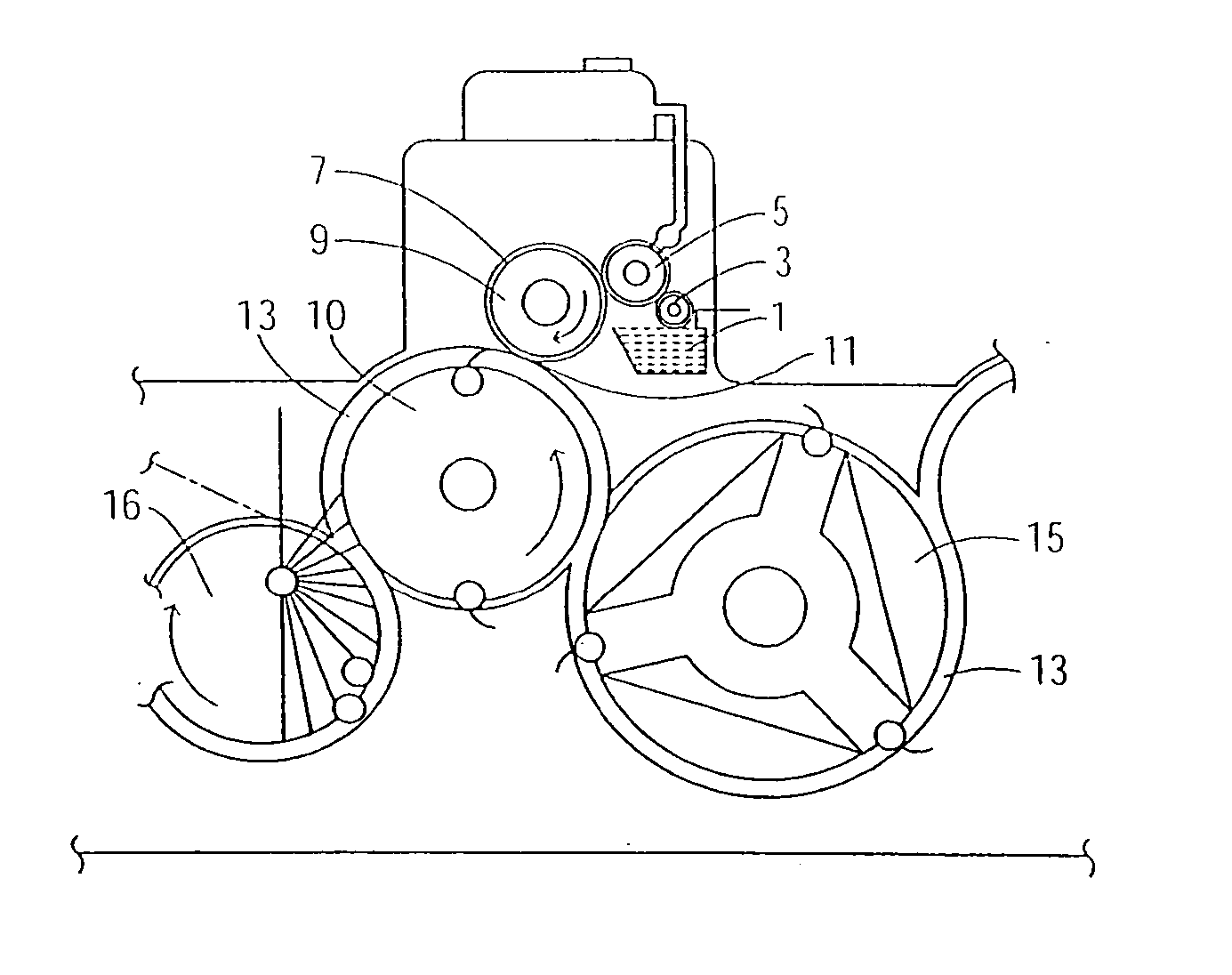

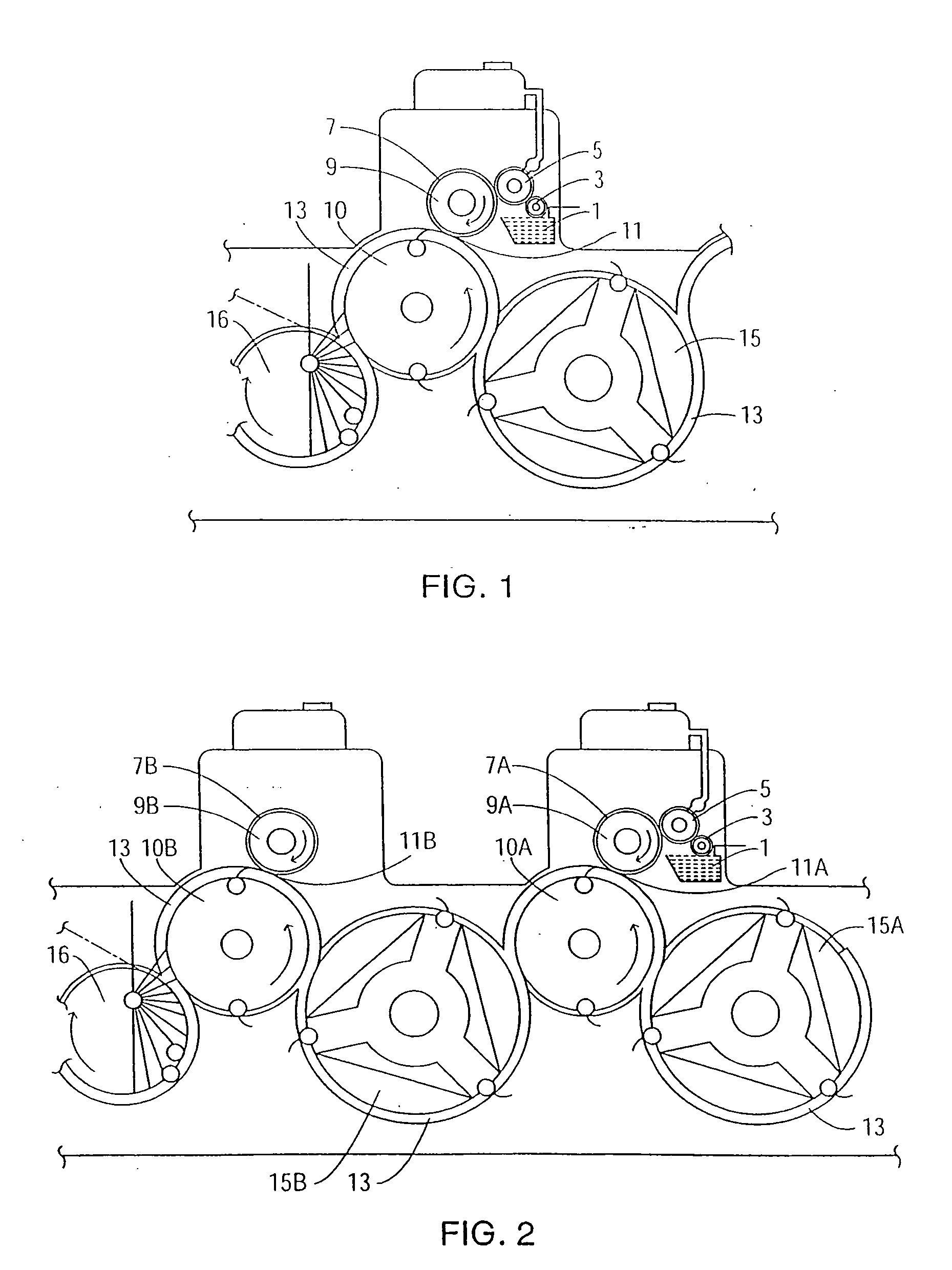

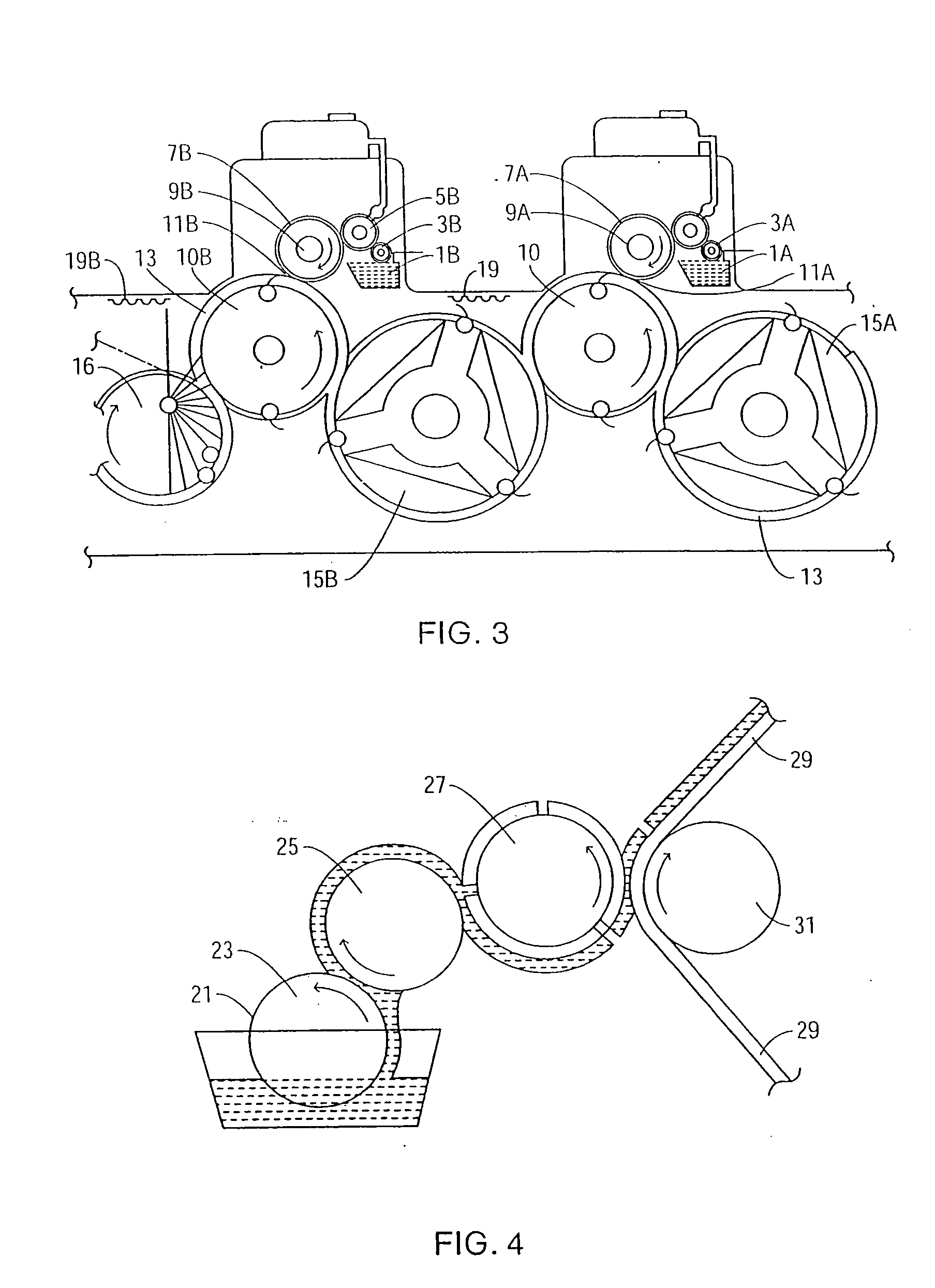

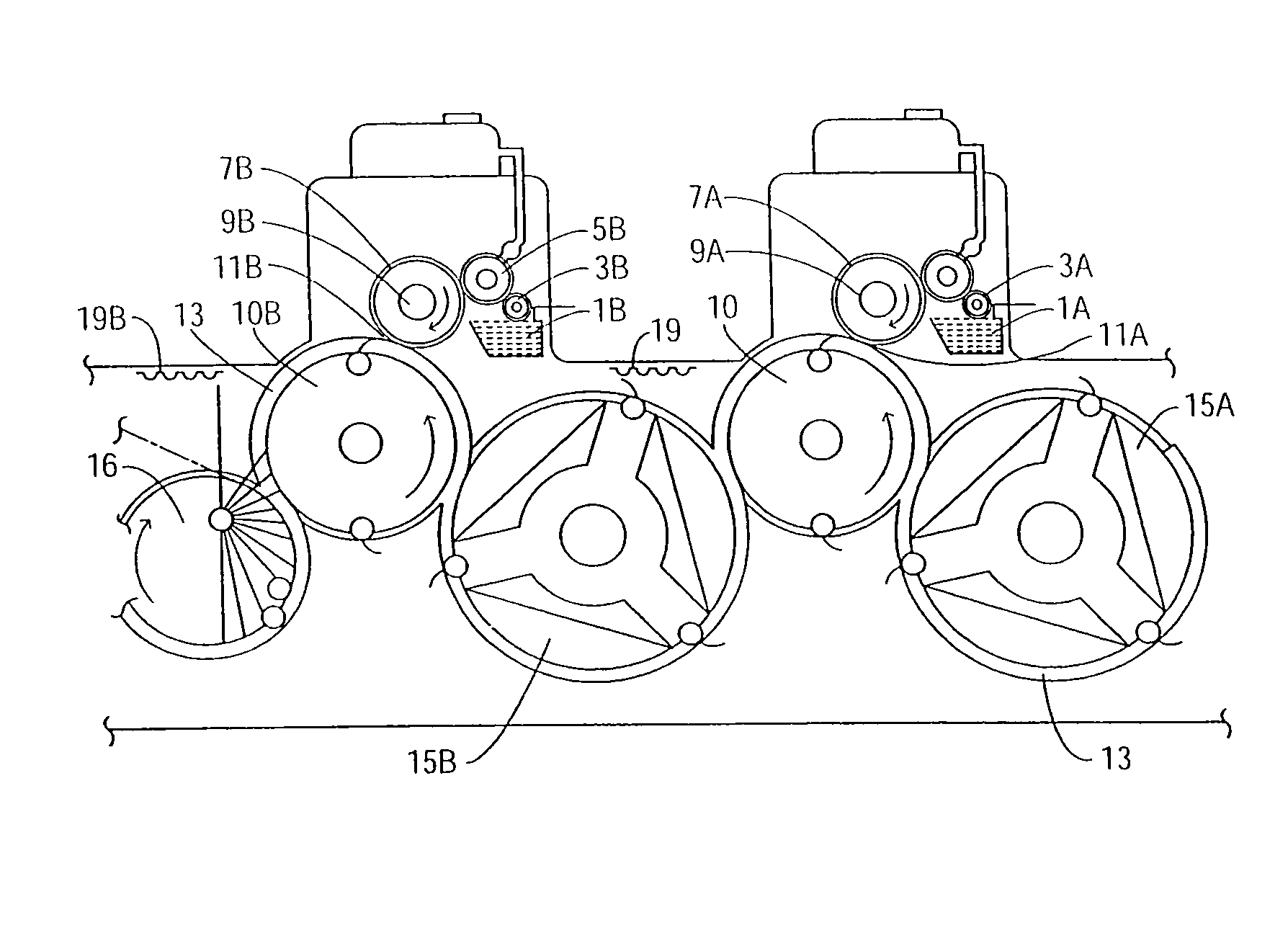

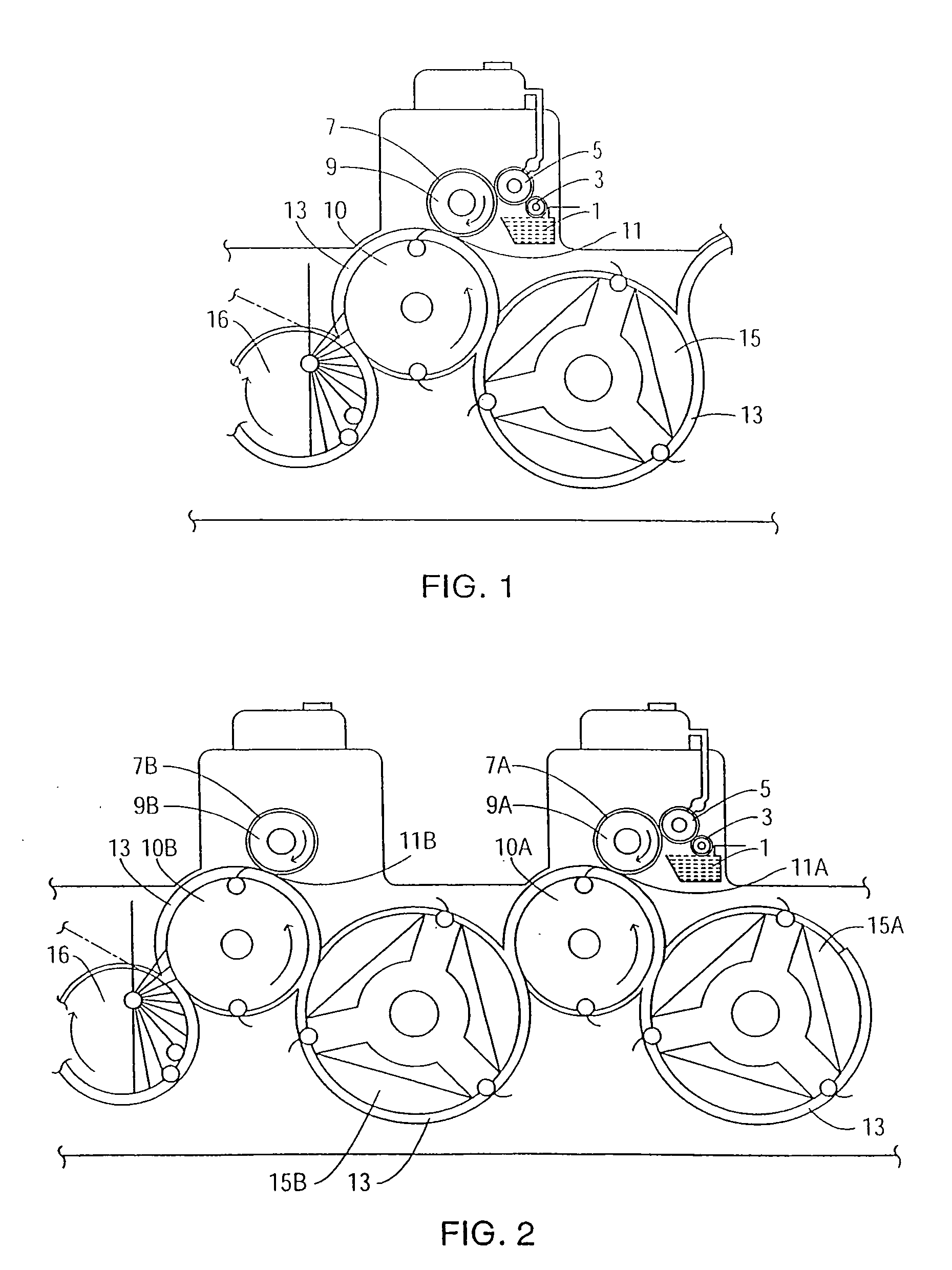

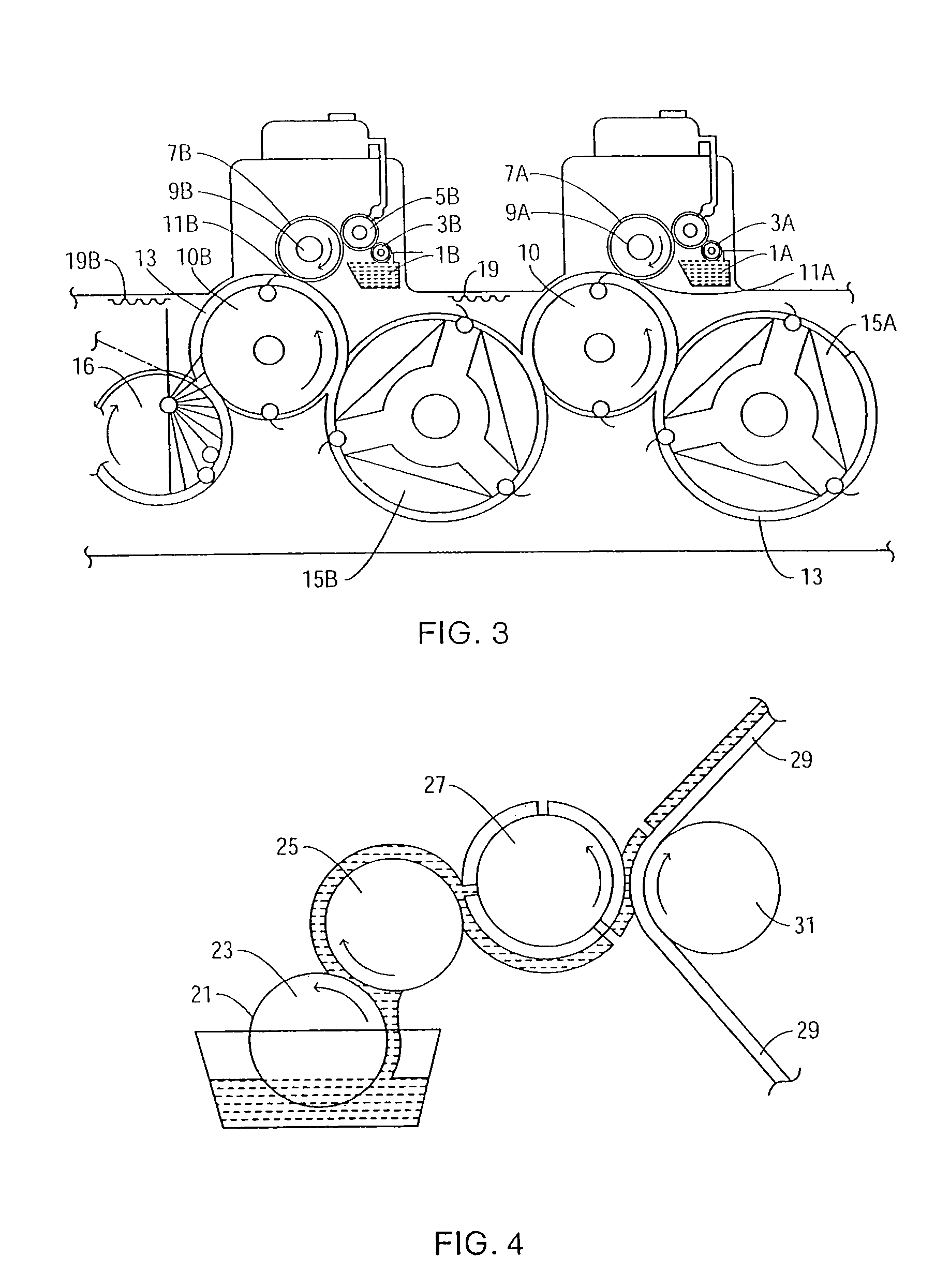

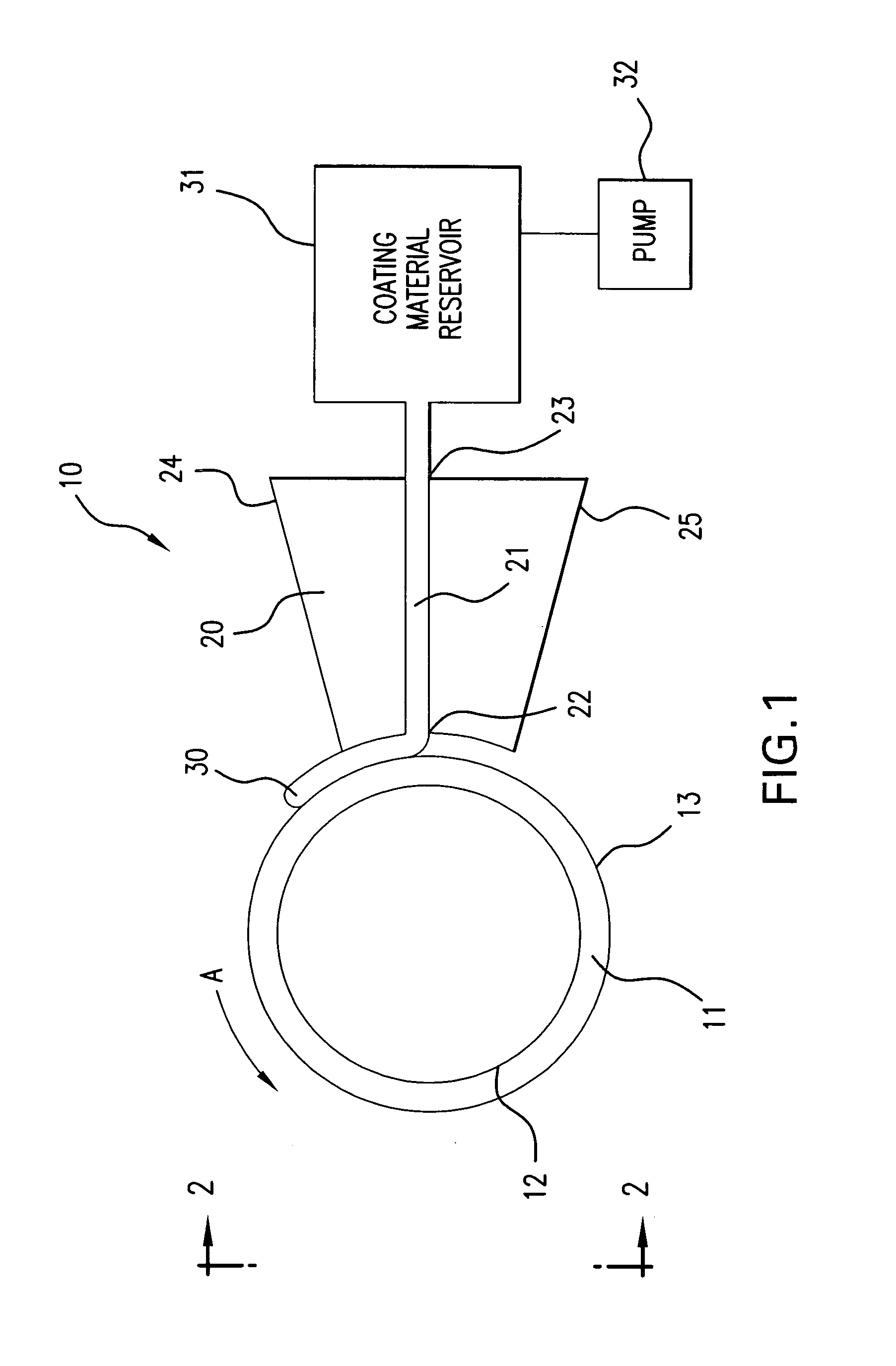

Method of producing a high gloss coating on a printed surface

InactiveUS20030113466A1High coatingLow production costCylinder pressesTransfer printingPresent methodPaper sheet

The present invention is directed to a method for producing a high gloss coating on a printed surface. In the present method, an aqueous coating composition is deposited onto a surface to be printed using a blanket roller coating face which is a low energy, non-stick, smooth surface profile. In the present method, simultaneous with the deposition of aqueous coating onto a substrate, or shortly thereafter, pressure either alone or in combination with heat may be applied to the coating in order to create a substantially tack-free surface conforming to the surface of the coating face. By using a highly polished coating face, high gloss coatings may be readily obtained using this methodology in a number of traditional printing techniques including wet trap inline sheet-fed printing, heat-set offset printing, dry trap inline flexographic printing, offset web-fed printing and gravure printing. Coatings which are produced utilizing the present invention have high gloss values heretofore unobtainable using aqueous coating compositions.

Owner:FRAZZITTA JOSEPH +1

Porous membrane for secondary battery, slurry for secondary battery porous membrane and secondary battery

ActiveUS20130330590A1Easy to slideFew powder fall-offActive material electrodesLi-accumulatorsAcrylonitrilePorous membrane

The porous membrane according to the present invention comprises non-conductive particles, a binder, and a water-soluble polymer, and is characterized in that: the three dimensions of the non-conductive particles, namely the length (L), thickness (t), and width (b), are such that the length (L) is 0.1 to 0 μm, the ratio (b / t) of the width (b) and the thickness (t) is 1.5 to 100; the binder is a copolymer containing (meth)acrylonitrile monomer units and (meth)acrylic acid ester monomer units; and the water-soluble polymer contains sulfonic acid groups, and has a weight average molecular weight of 1000 to 15000. The slurry for a porous membrane according to the present invention is characterized by being formed by dispersing the non-conductive particles, the binder, and the soluble polymer, in water. Thus, the present invention provides: a porous membrane that can be formed into a thin film, has an excellent sliding property, and generates few particles; and a slurry for porous membranes which is capable of producing porous membrane easily and quickly, and has excellent storage stability.

Owner:ZEON CORP

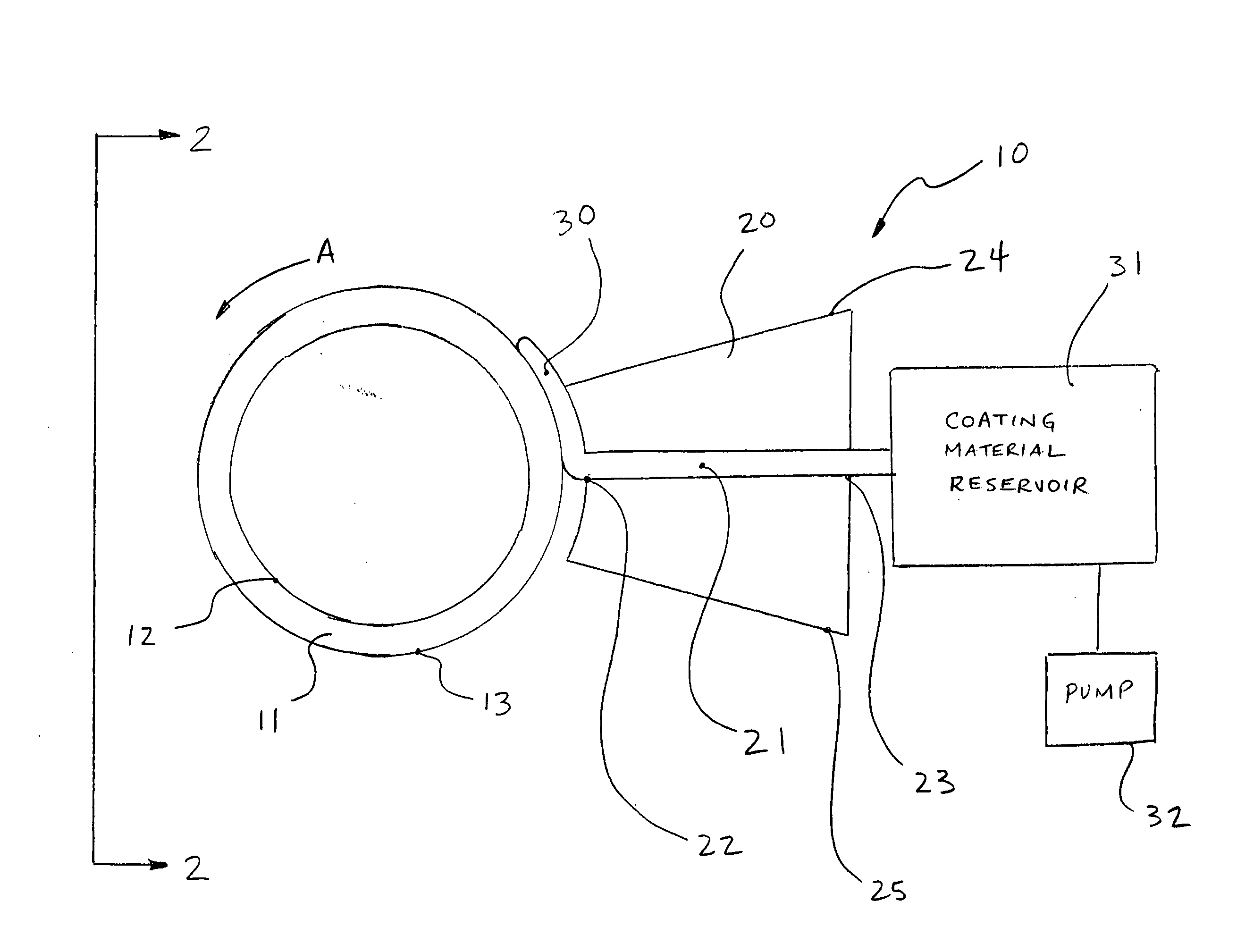

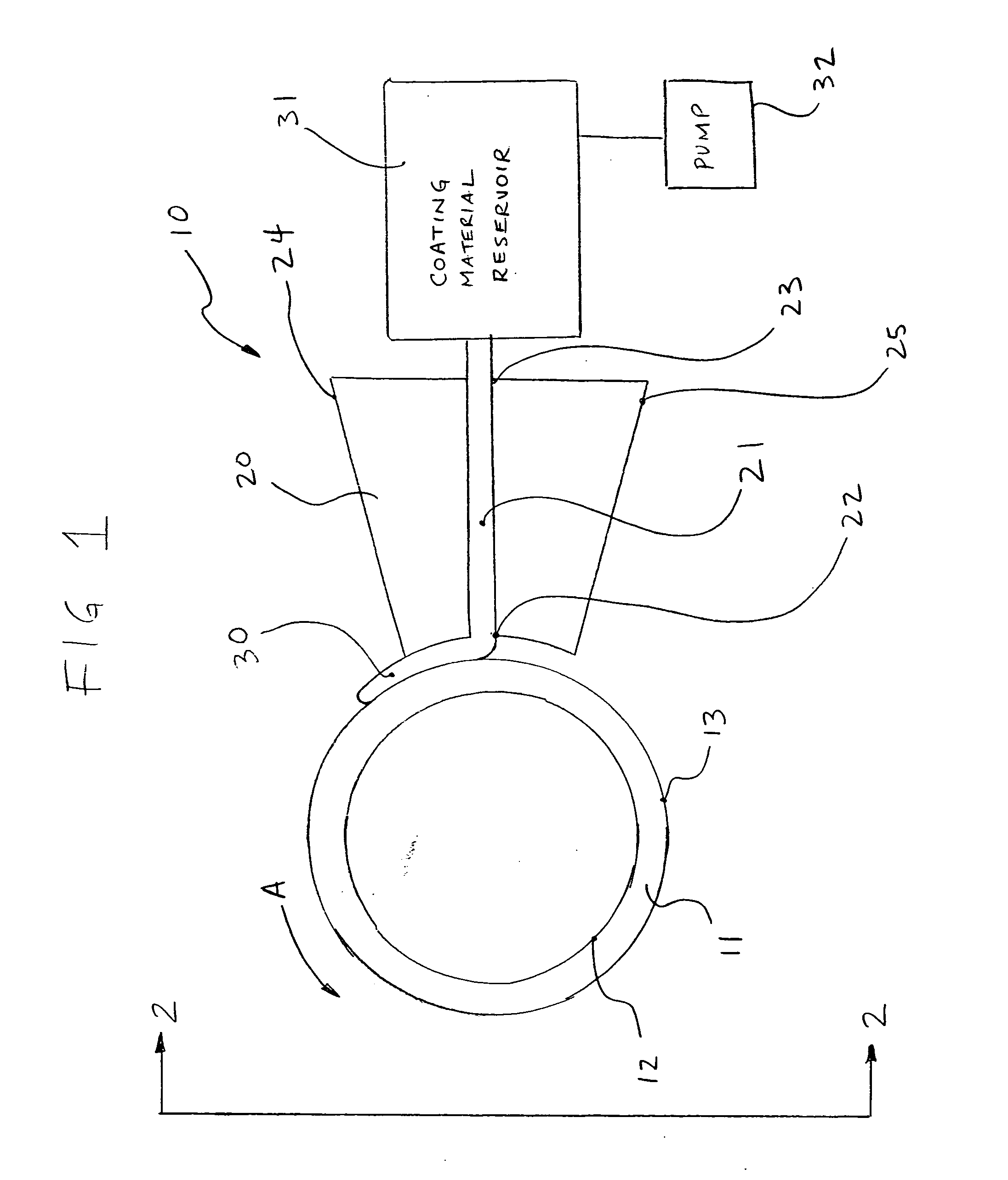

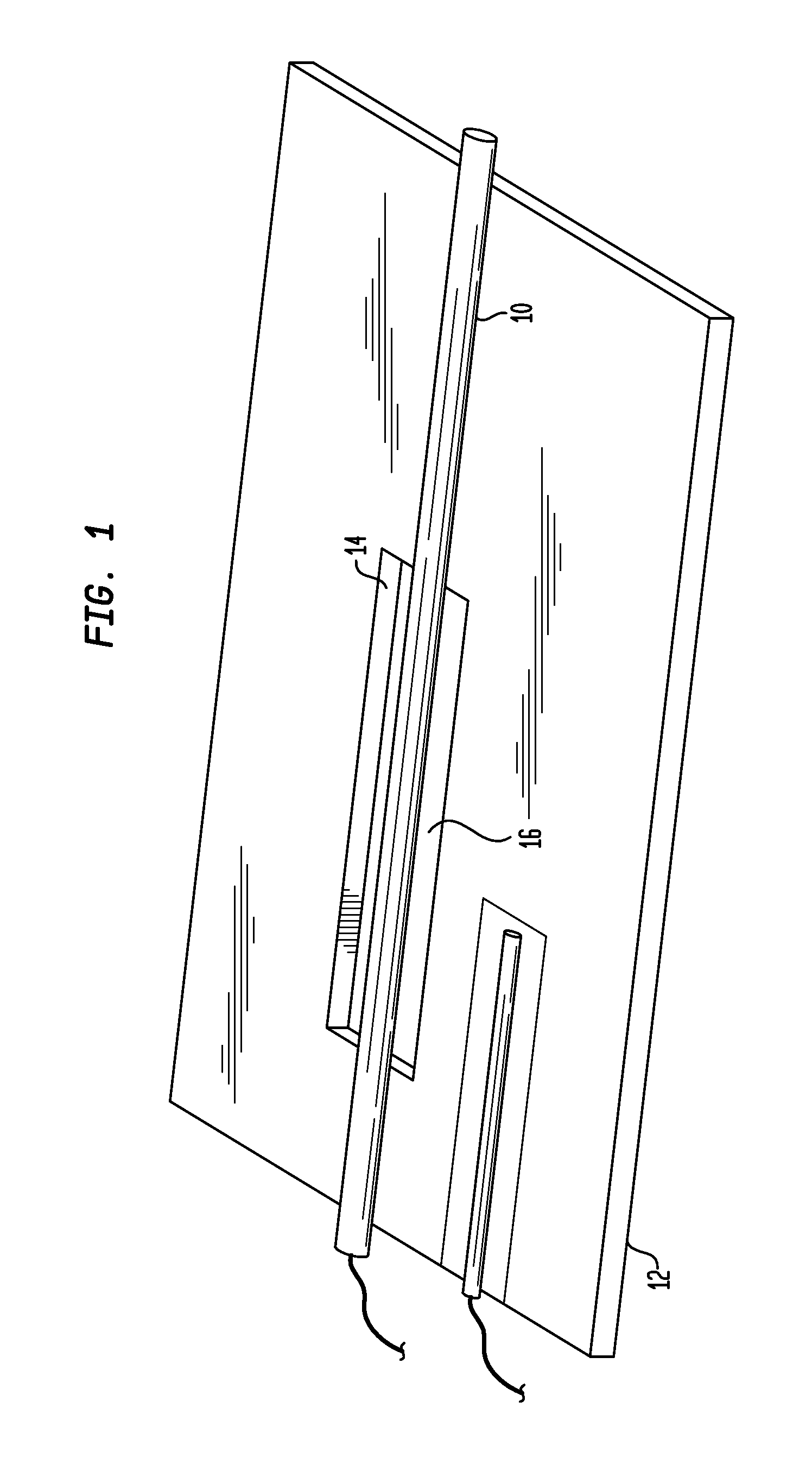

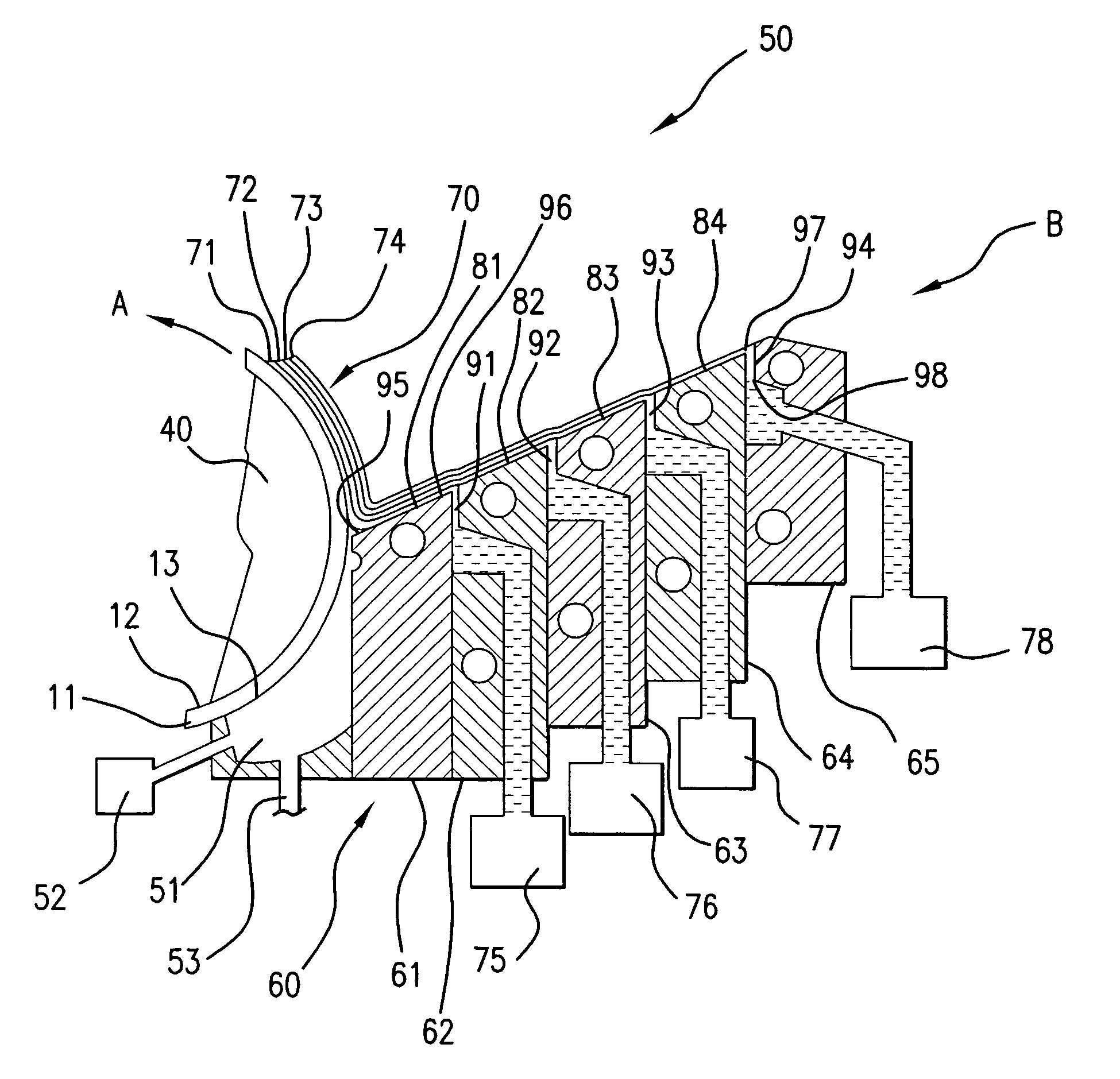

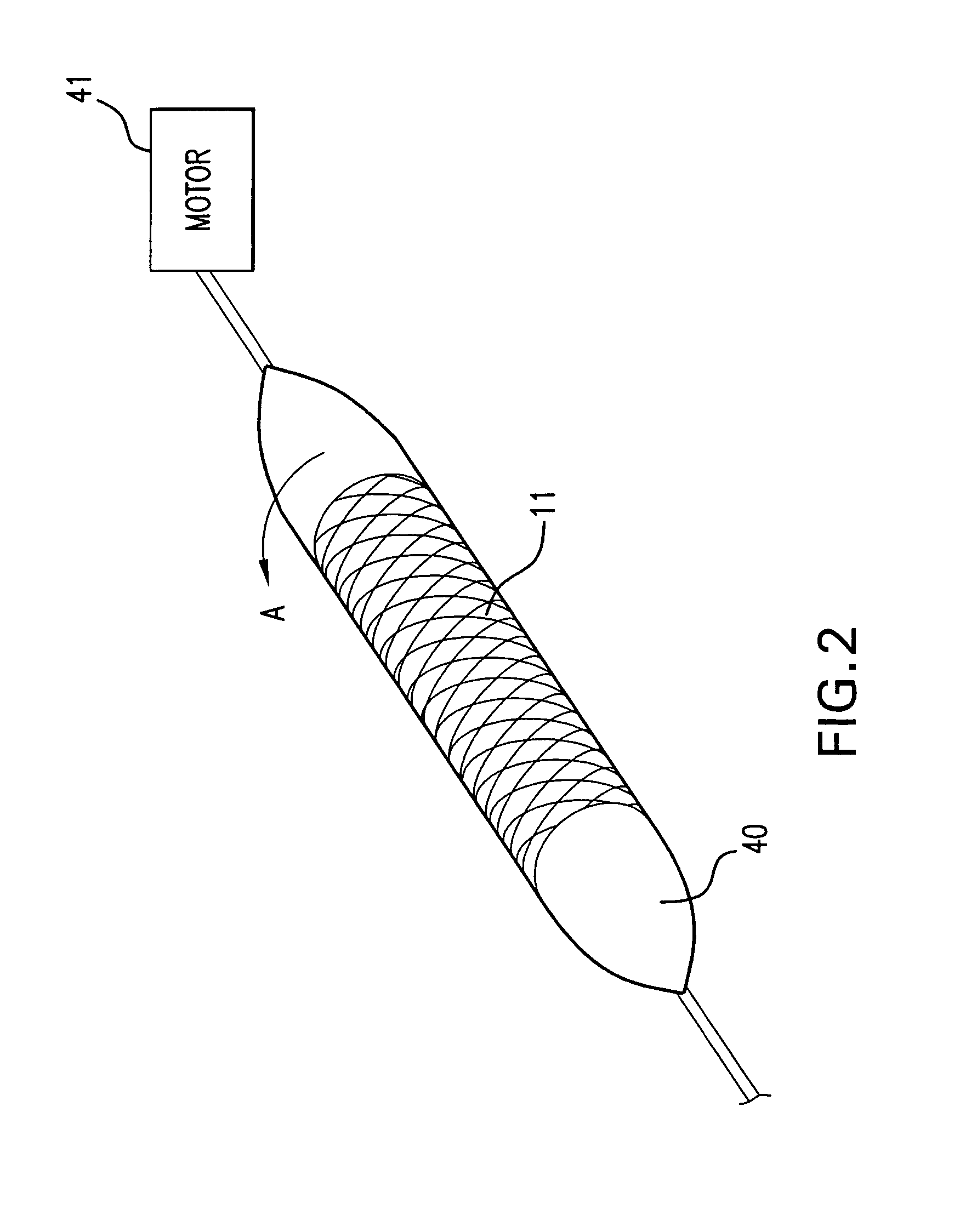

Method and apparatus for coating a medical device using a coating head

Methods and apparatuses for coating surface of medical devices using coating heads are disclosed. In one embodiment, the invention includes a coating method using a coating head, wherein the coating head comprises at least one outlet orifice from which flows a coating material, to deposit at least one layer of coating material dispelled through the outlet orifice onto the surface of the medical device. In another embodiment, a slide coating head is used to deposit multiple layers of superposed coating materials. These methods are used to apply one or more coating materials, simultaneously or in sequence. In certain embodiments of the invention, the coating materials include therapeutic agents, polymers, sugars, waxes, or fats.

Owner:BOSTON SCI SCIMED INC

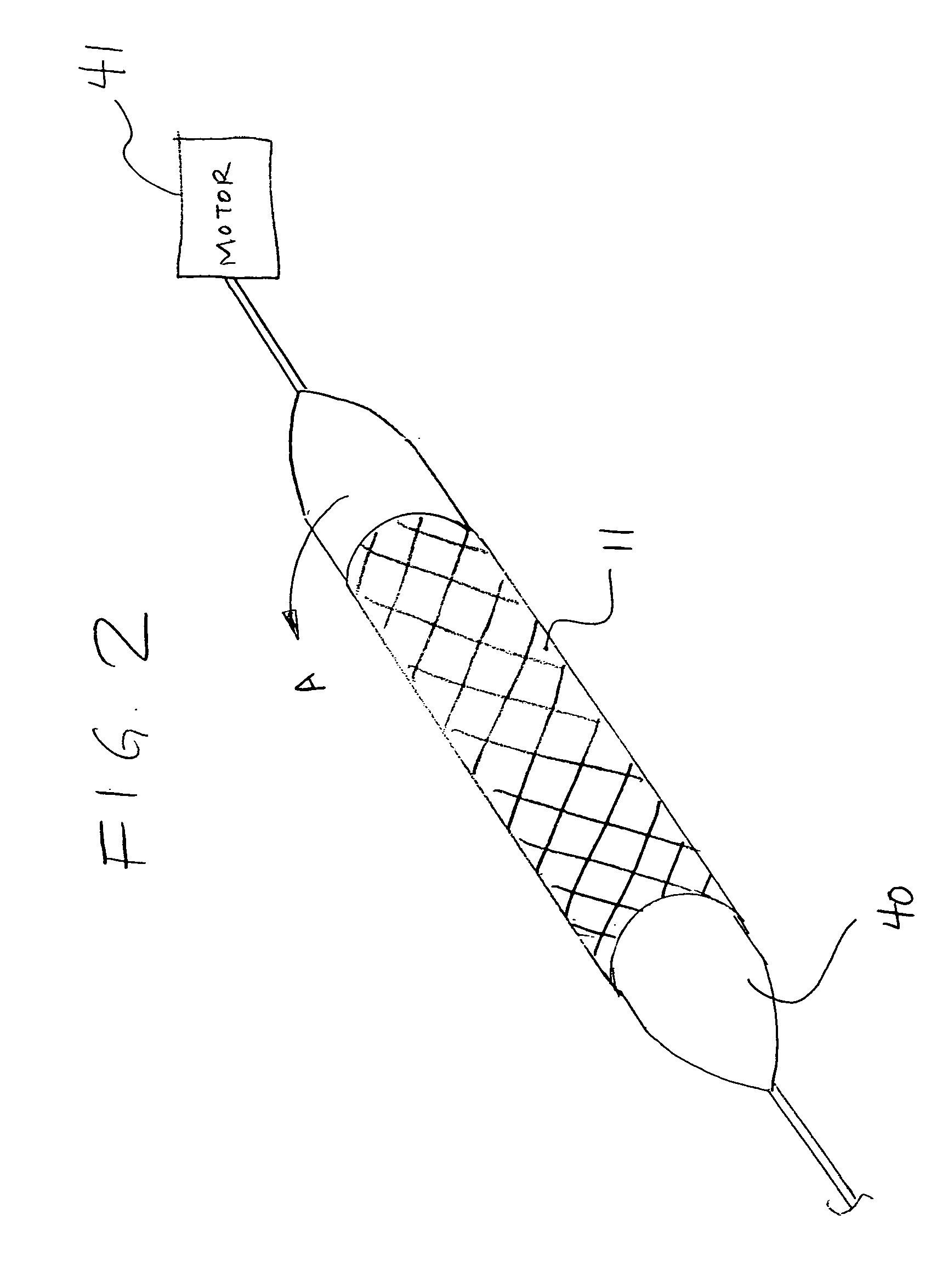

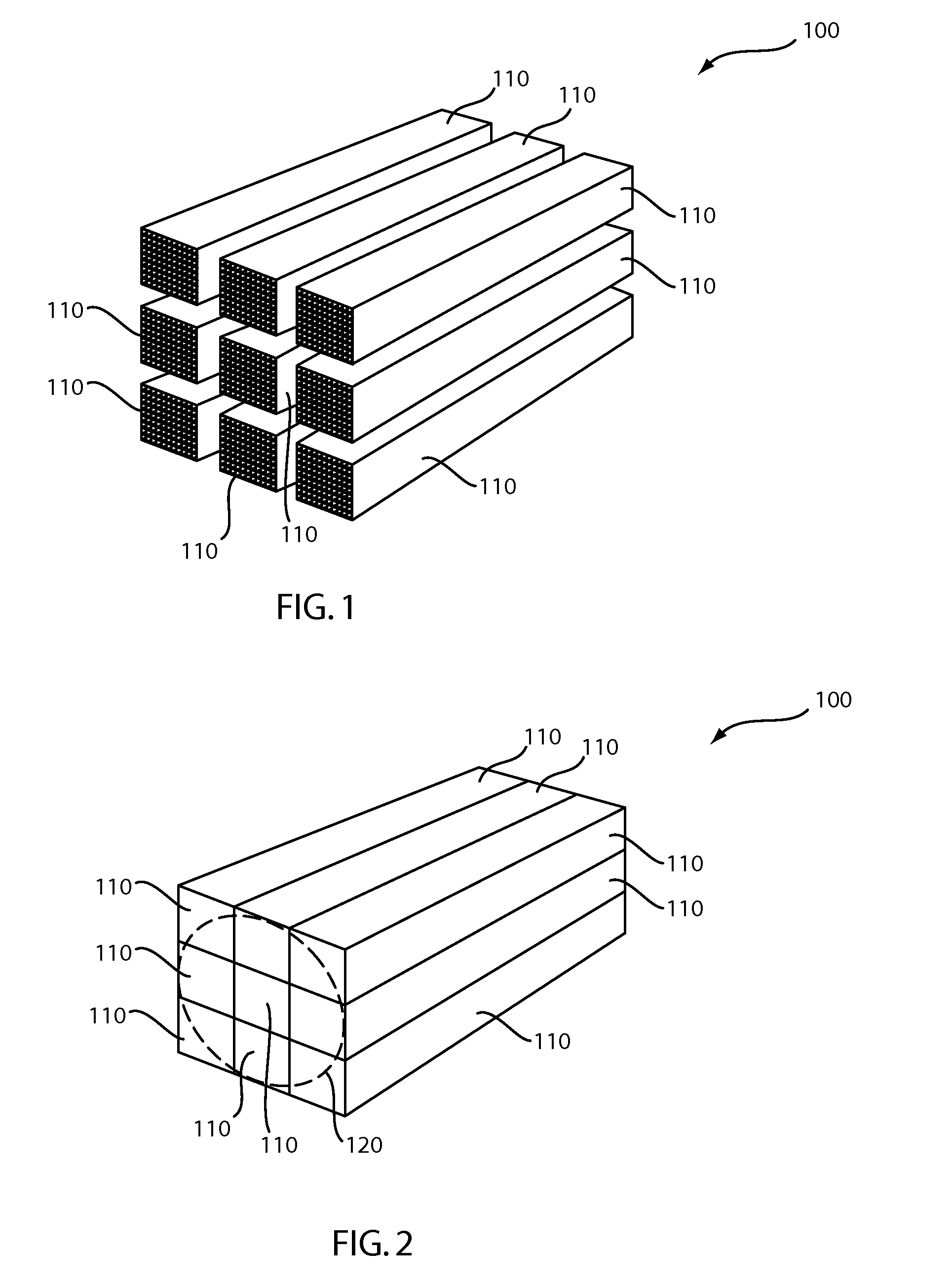

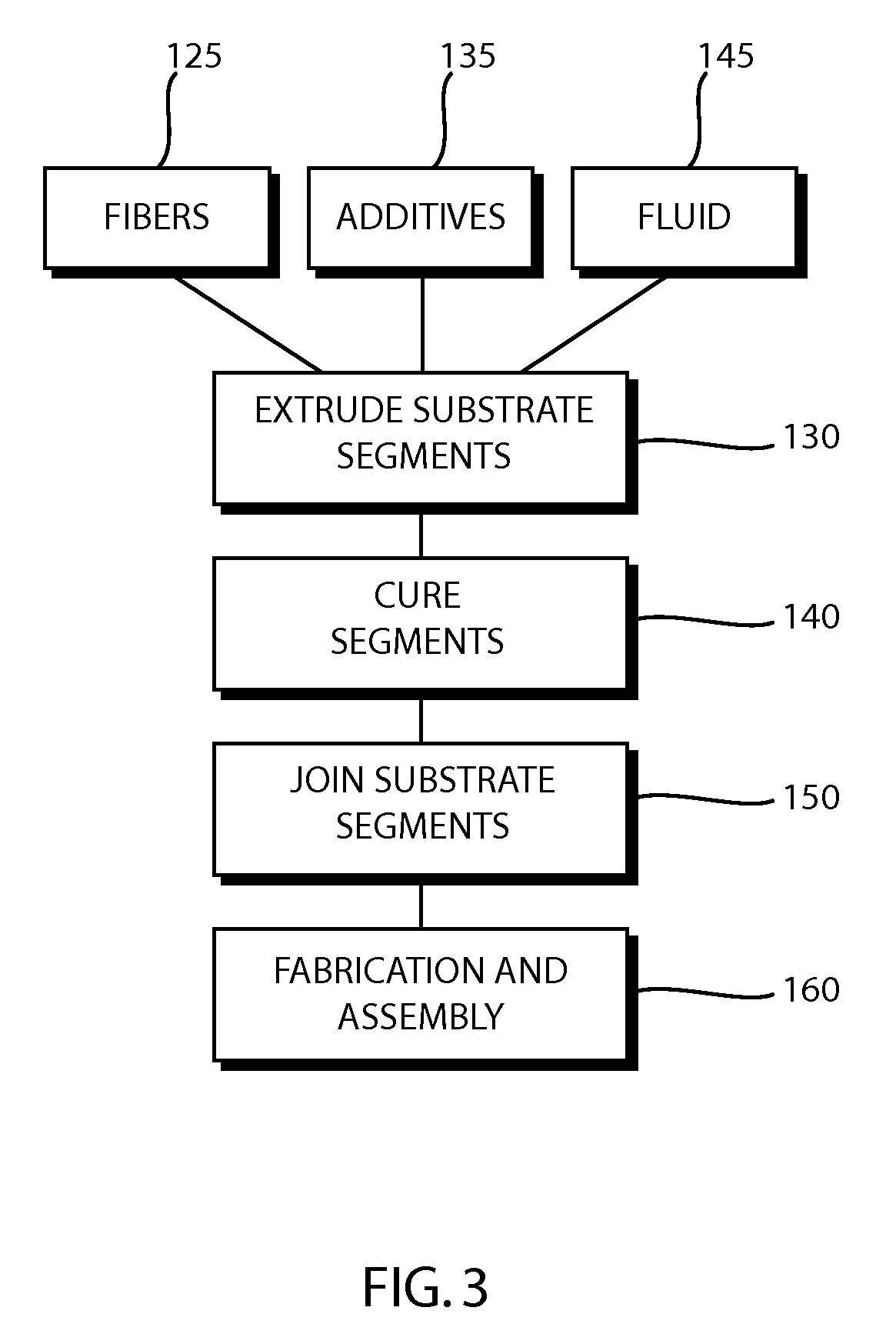

Porous Substrate and Method of Fabricating the Same

InactiveUS20080178992A1Improve production efficiencyImproved thermalPaper/cardboard articlesLayered productsPorous substrateFiber

A porous substrate produced by an extrusion process consisting essentially of bonded fibers is fabricated as a segmented substrate by joining a plurality of substrate segments with an adhesive that comprising fibers. The adhesive is bonded to fibers in the substrate segments to provide mechanical strength of the segmented substrate. The fibers in the adhesive provide a reduced elastic modulus in the adhesive layer that maintains a highly elastic structure between the segments in order to mitigate thermally induced mechanical stress when thermal gradients develop within the porous substrate during operation. The segmented porous fibrous substrate disclosed can be fabricated from a variety of materials to provide for effective filtration and as a catalytic host in various applications, including exhaust filtration of internal combustion engines.

Owner:GE02 TECH INC

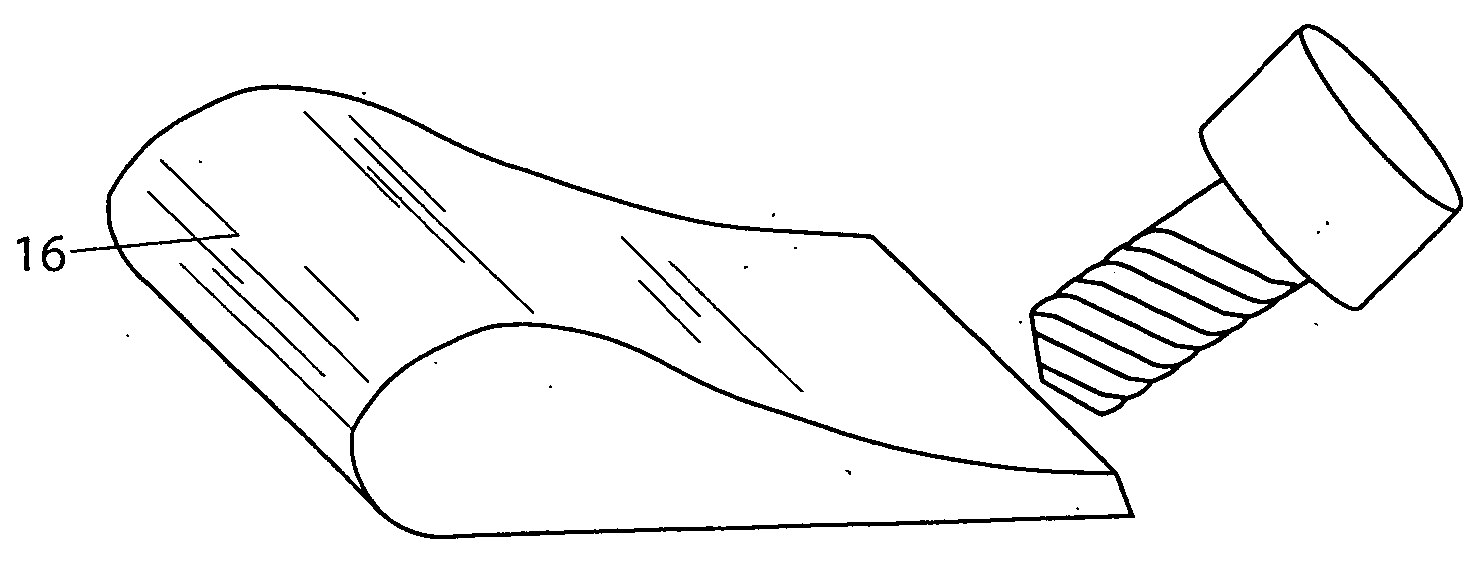

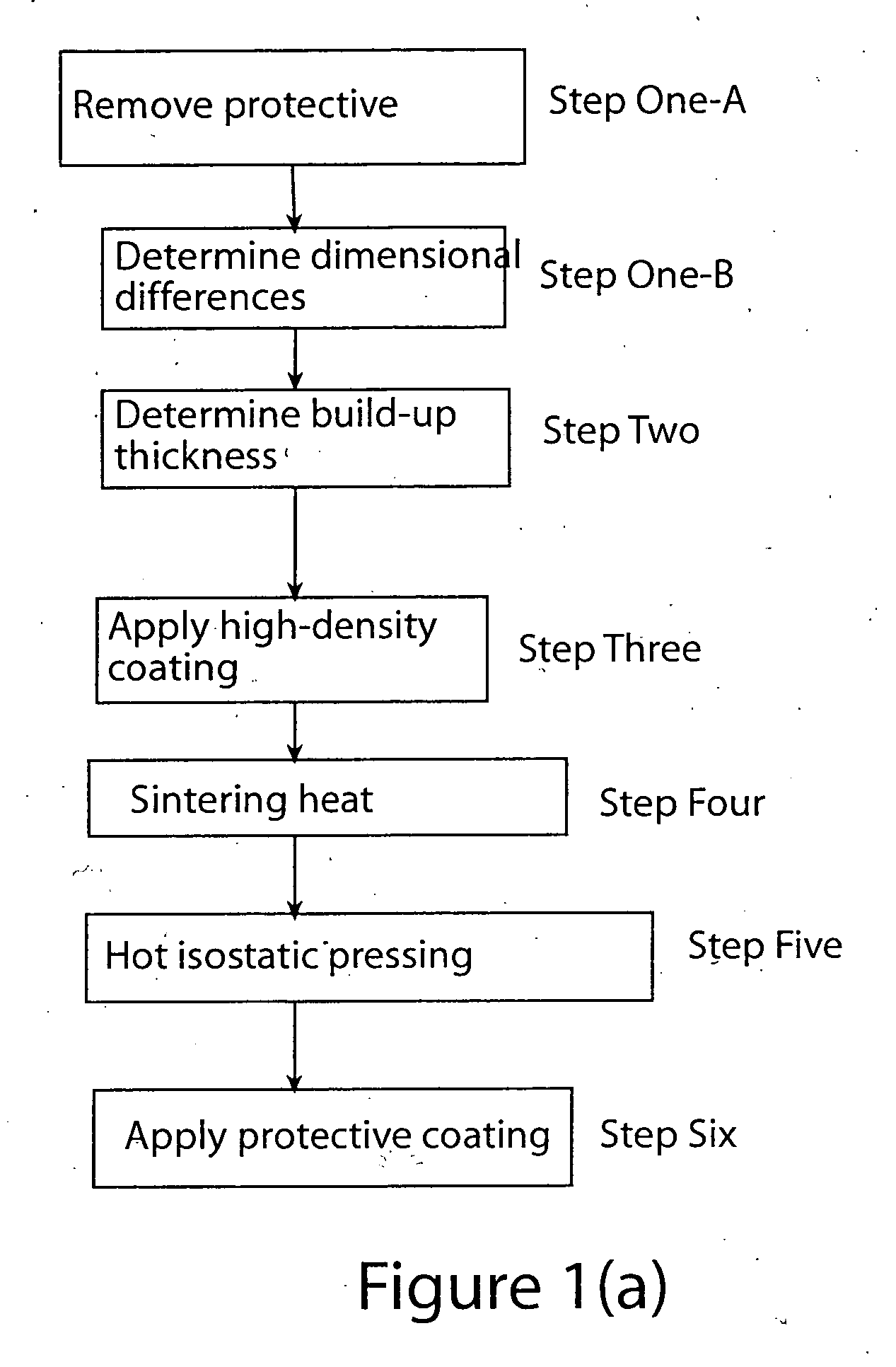

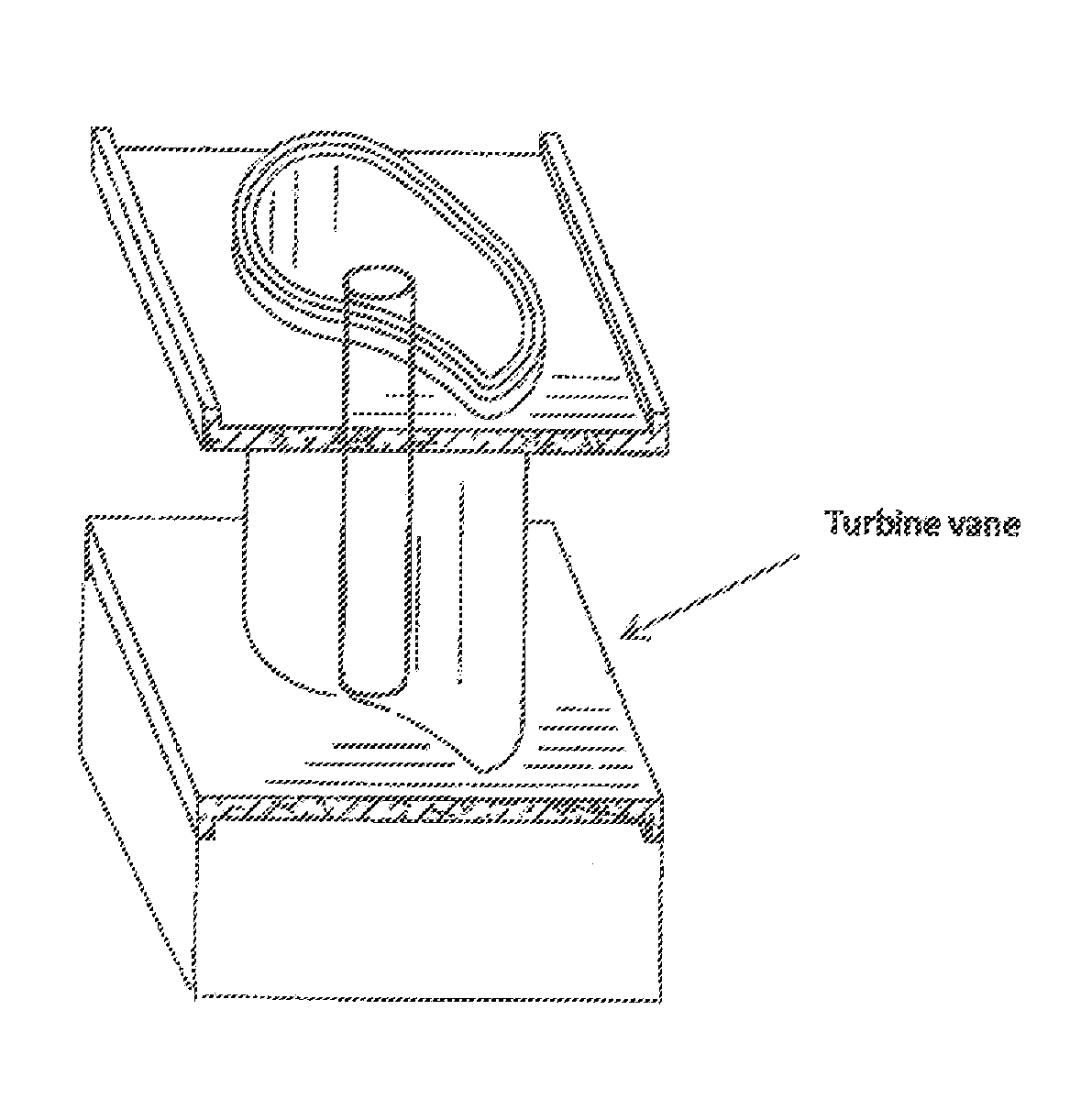

Method for repairing a gas turbine engine airfoil part using a kinetic metallization process

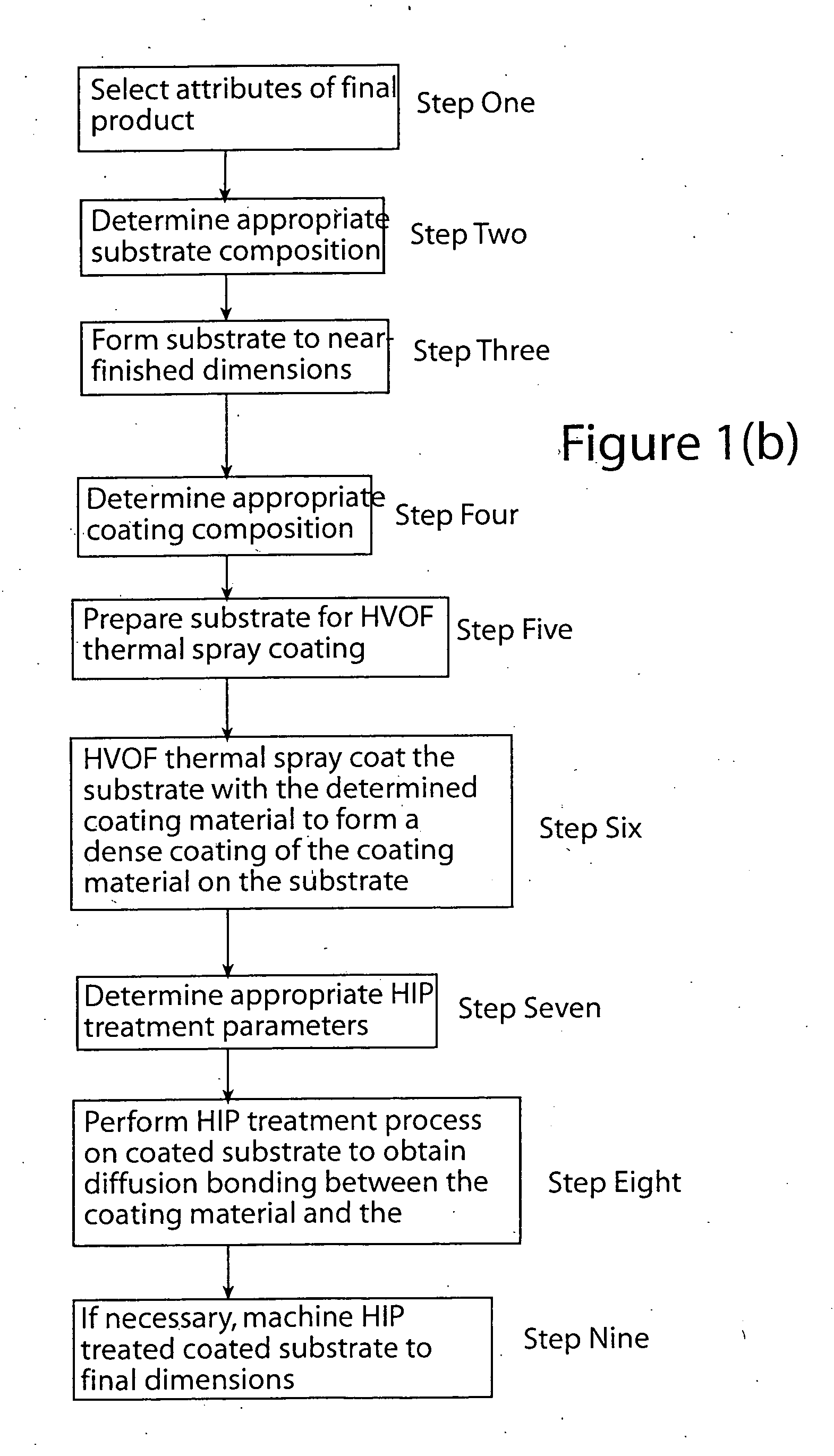

A method of repairing a turbine engine airfoil part includes the step of first determining dimensional differences between pre-repaired dimensions of a turbine engine airfoil part and desired post-repair dimensions of the turbine engine airfoil part. The turbine engine airfoil part has a metal alloy substrate. A build-up thickness is determined of coating material that is required to obtain the desired post-repair dimensions of the airfoil part. A high-density coating process is performed to coat the turbine engine airfoil part substrate with a coating material to build-up a thickness of coating material effective to obtain desired finished dimensions after performing a hot isostatic pressing treatment. The high density coating process comprises the steps of accelerating metal particles in an inert carrier gas, and directing the accelerated metal particles onto the turbine engine airfoil part so that high-speed collision of the metal particles causes deformation of the particles resulting in a large increase in the surface area of the particles producing the controlled buildup of a high density coating of the deformed metal particles. The hot isostatic pressing treatment is performed to obtain a post-repair turbine engine airfoil part having the desired post-repair dimensions and having diffusion bonding between the coating material and the turbine engine airfoil substrate.

Owner:RECAST AIRFOIL GROUP

Method of producing a high gloss coating on a printed surface

InactiveUS6472028B1High coatingLow production costPretreated surfacesCoatingsPresent methodPaper sheet

The present invention is directed to a method for producing a high gloss coating on a printed surface. In the present method, an aqueous coating composition is deposited onto a surface to be printed using a blanket roller coating face which is a low energy, non-stick, smooth surface profile. In the present method, simultaneous with the deposition of aqueous coating onto a substrate, or shortly thereafter, pressure either alone or in combination with heat may be applied to the coating in order to create a substantially tack-free surface conforming to the surface of the coating face. By using a highly polished coating face, high gloss coatings may be readily obtained using this methodology in a number of traditional printing techniques including wet trap inline sheet-fed printing, heat-set offset printing, dry trap inline flexographic printing, offset web-fed printing and gravure printing. Coatings which are produced utilizing the present invention have high gloss values heretofore unobtainable using aqueous coating compositions.

Owner:FRAZZITTA JOSEPH

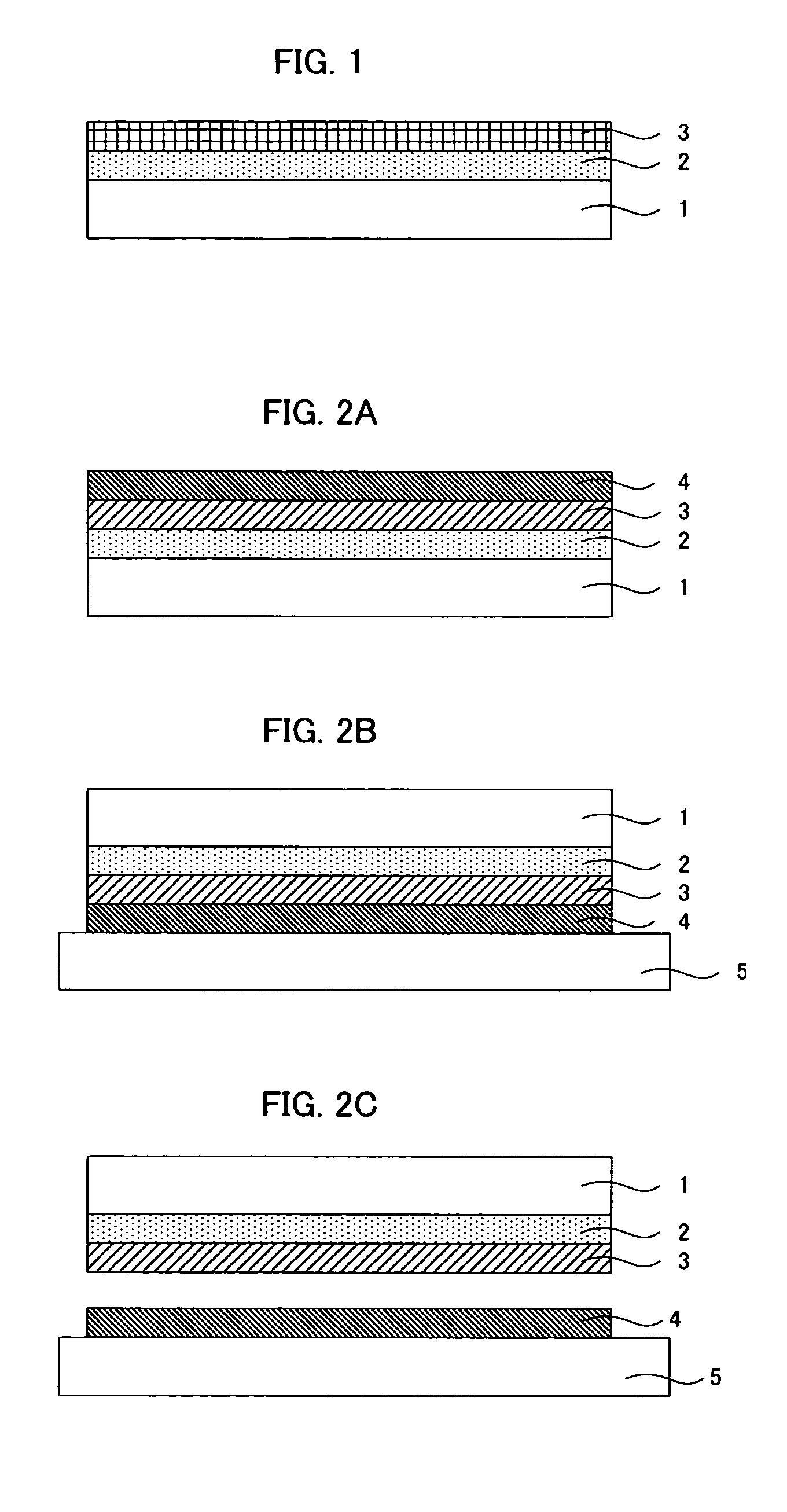

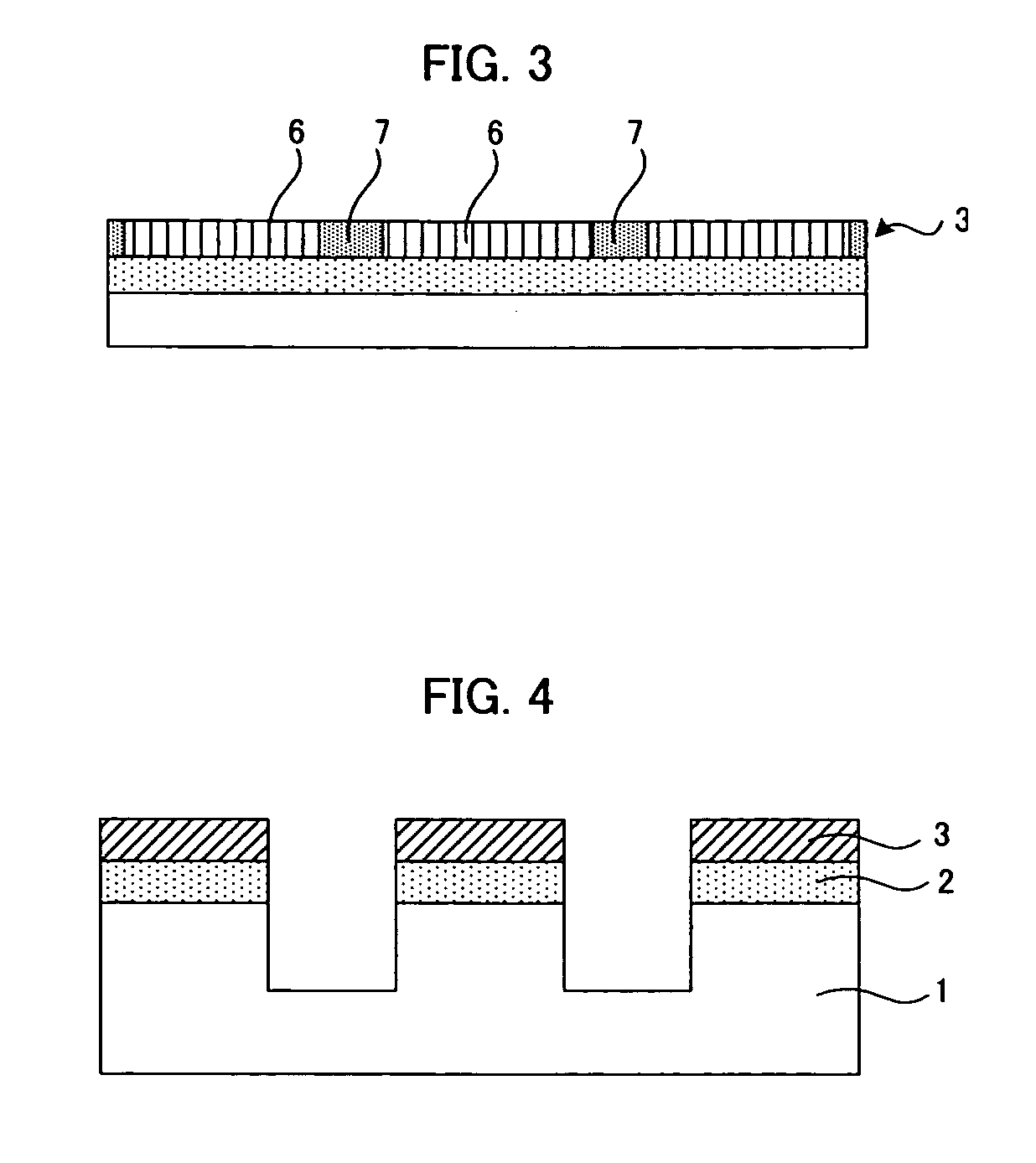

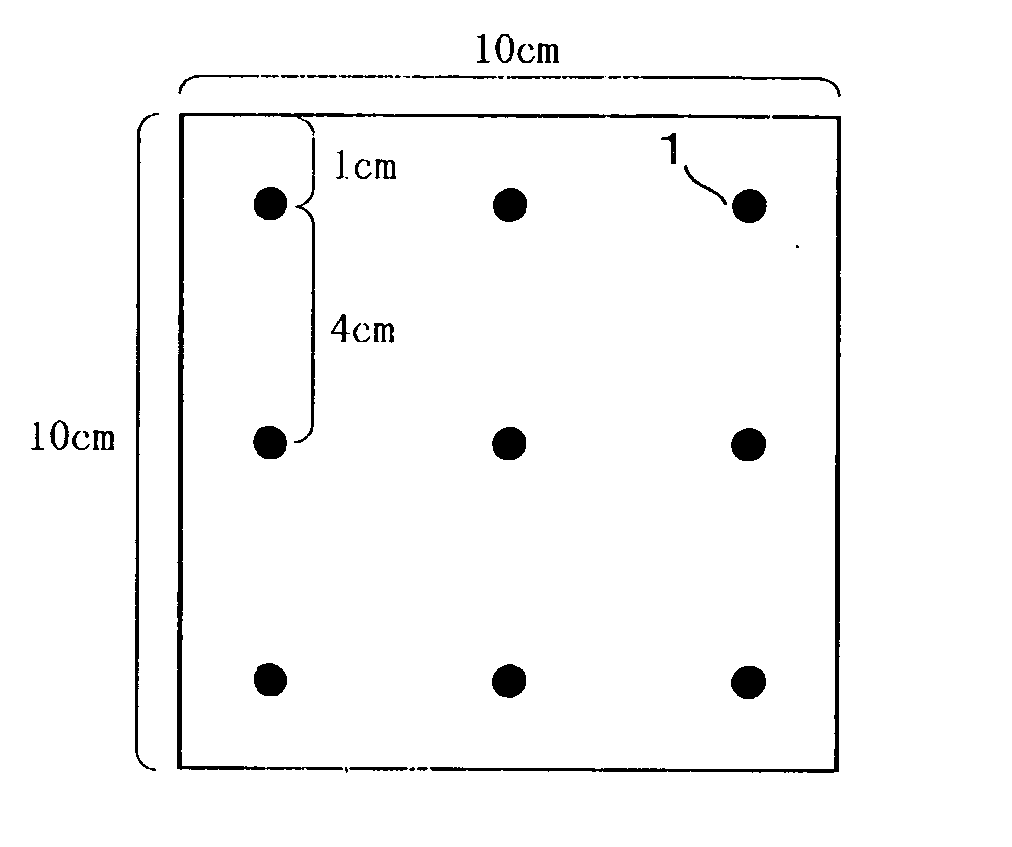

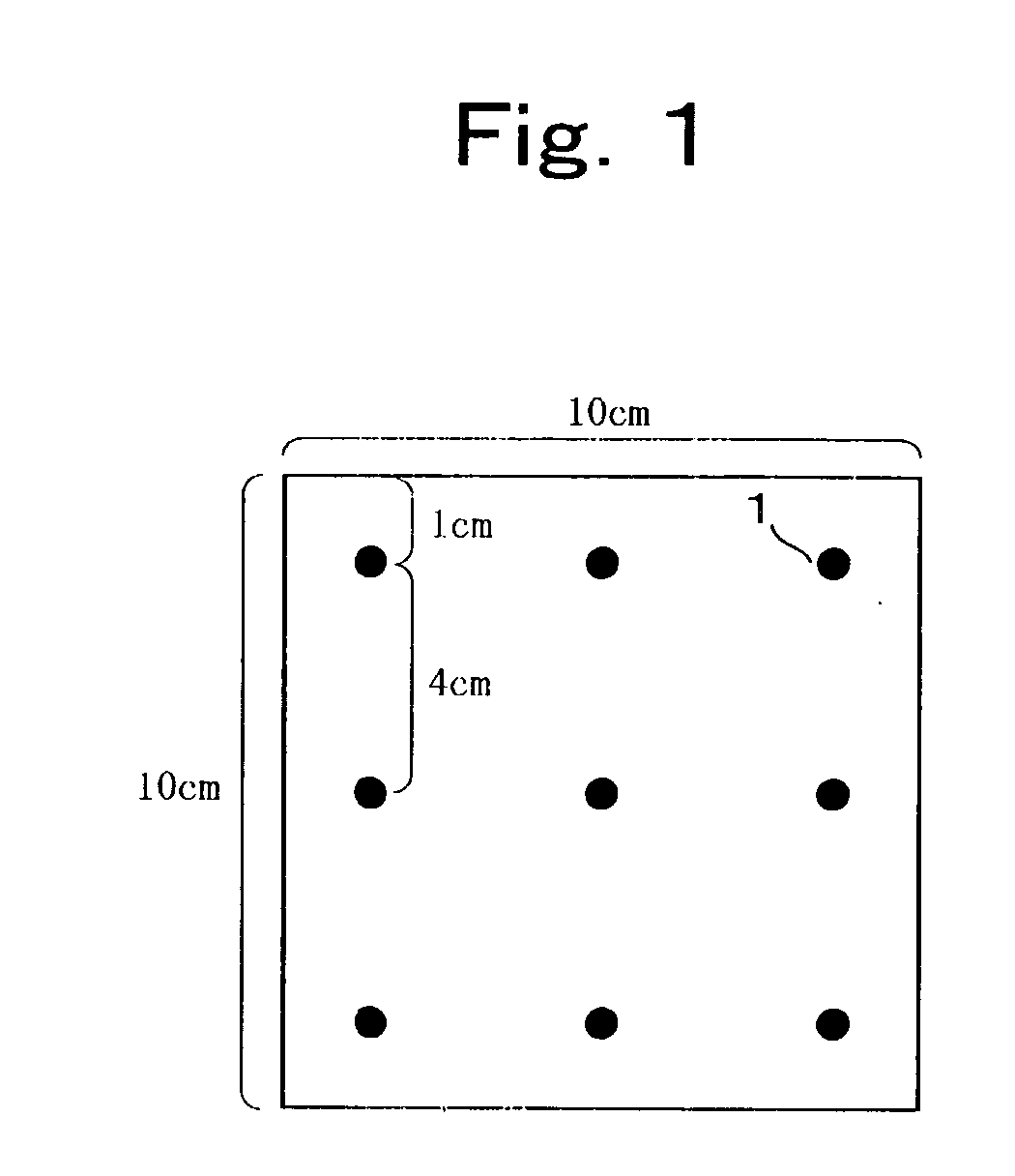

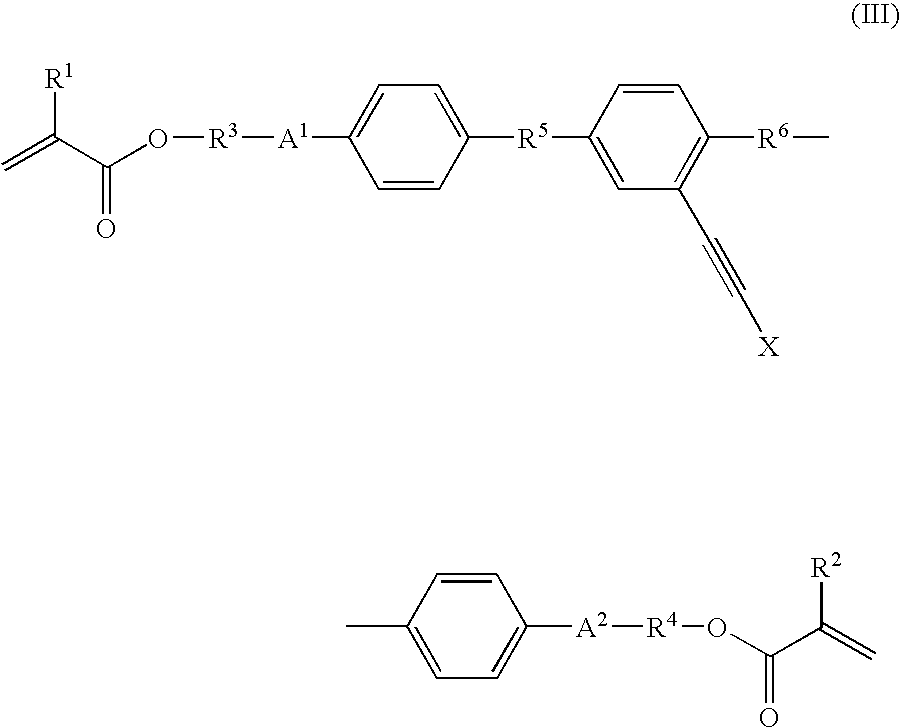

Substrate for cell transfer

ActiveUS20070015277A1Form evenlyLow wettabilityBioreactor/fermenter combinationsBiological substance pretreatmentsVessel networkLymphatic vessel

A main object of the present invention is to provide a cell transfer substrate capable of transplanting cells, maintaining a pattern as it is, on a living body tissue or the like, even when: the size of the cell sheet is extremely small; the cells are cultured sparsely; the cells are in a form of a small colony; or the cells are cultured in a pattern, for example, as a blood vessel, a vessel network such as a lymphatic vessel, or a nerve network, and to provide a substrate for cell transfer to be used for the cell transfer substrate. In order to achieve the above-mentioned object, the present invention provides a substrate for cell transfer comprising: a polymer base material; an intermediate layer formed on the polymer base material; and a cell transfer layer formed on the intermediate layer.

Owner:DAI NIPPON PRINTING CO LTD

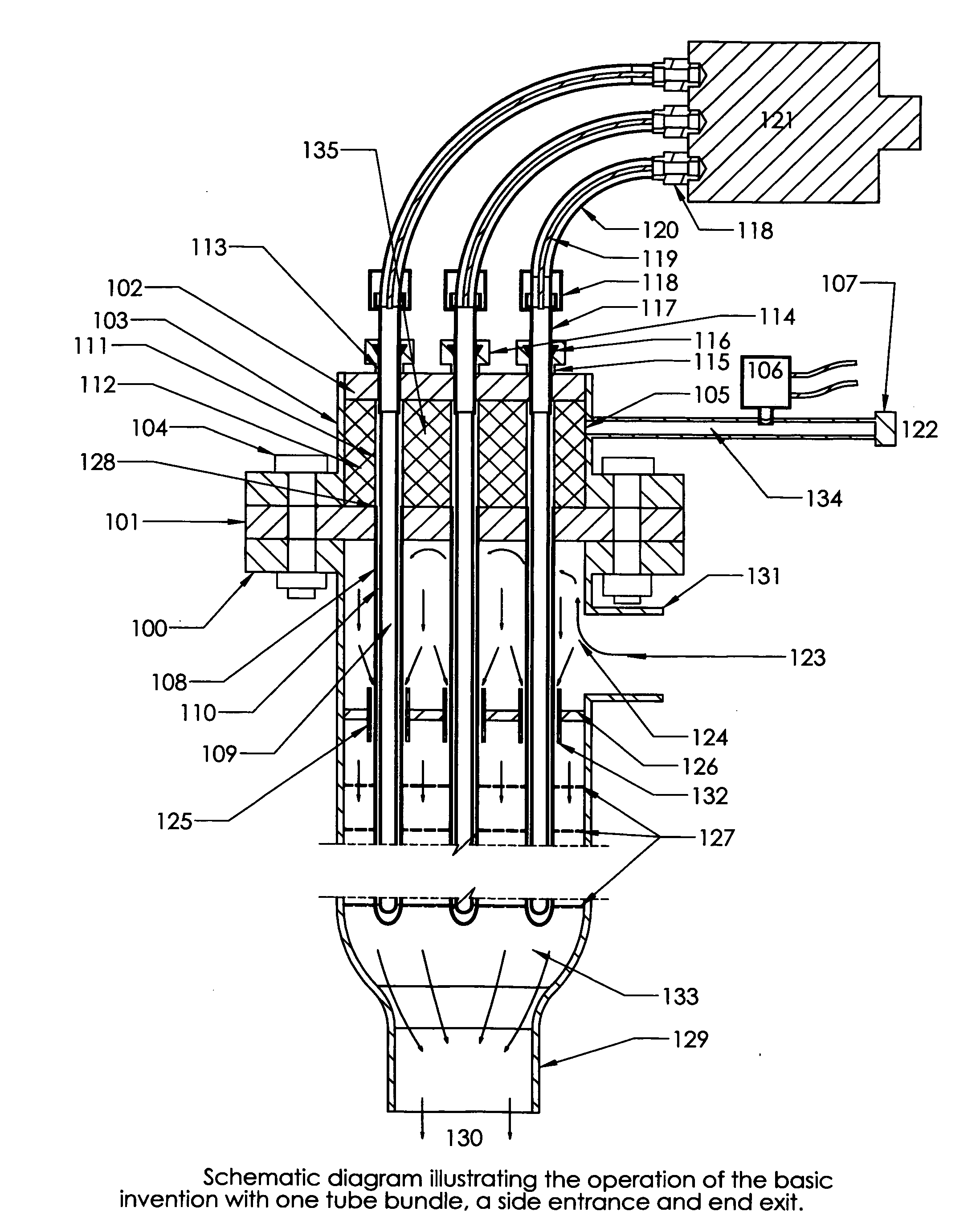

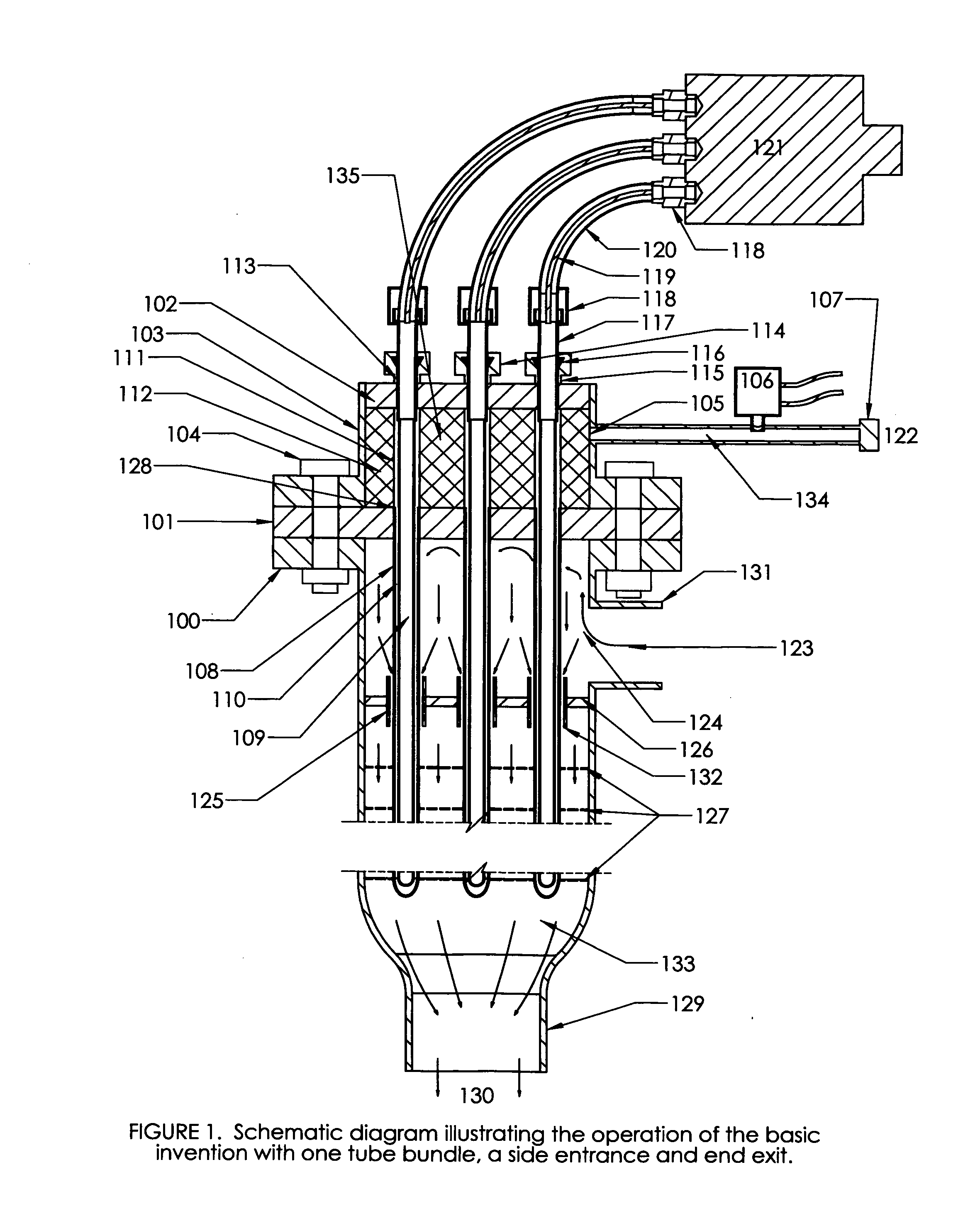

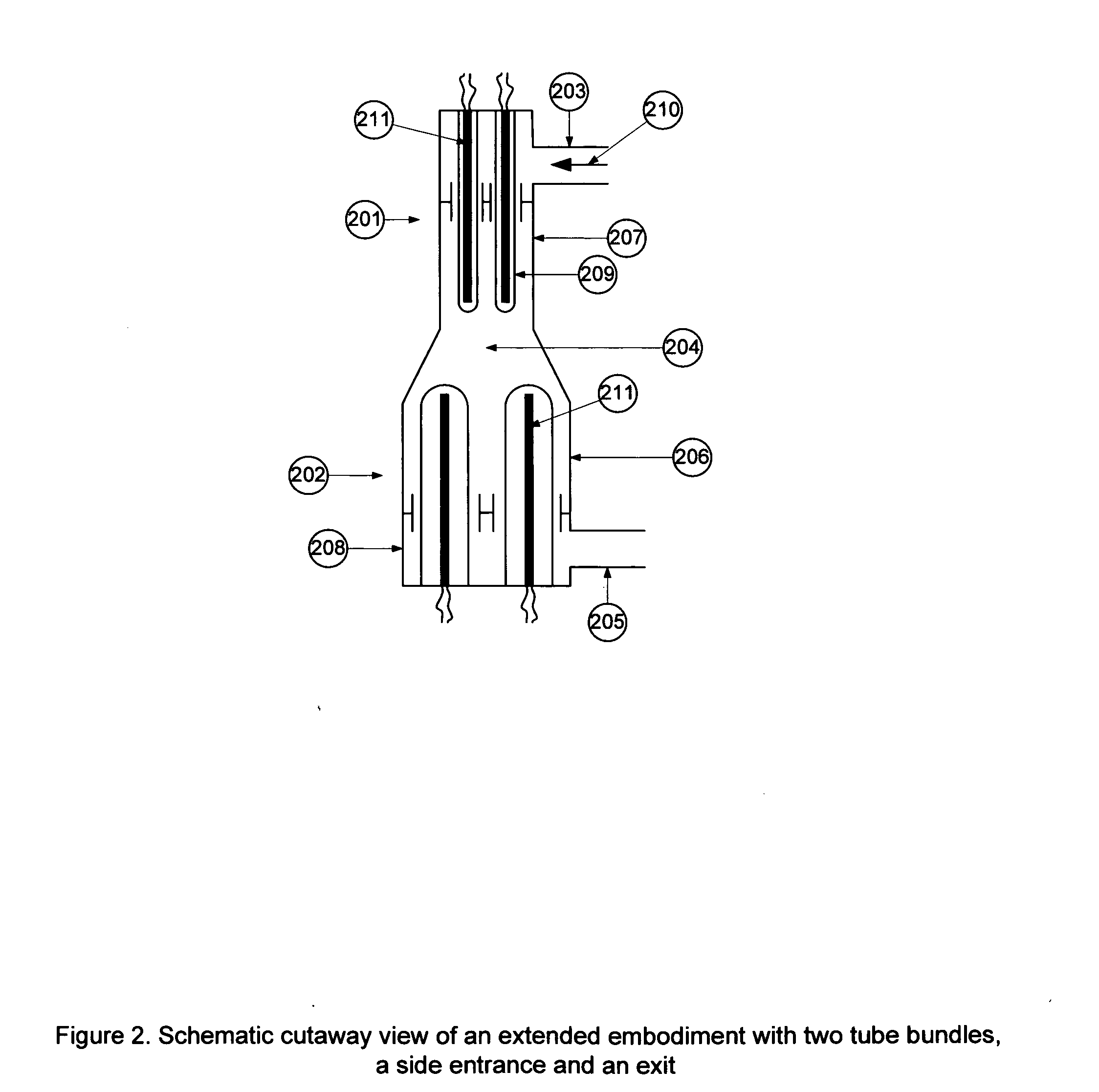

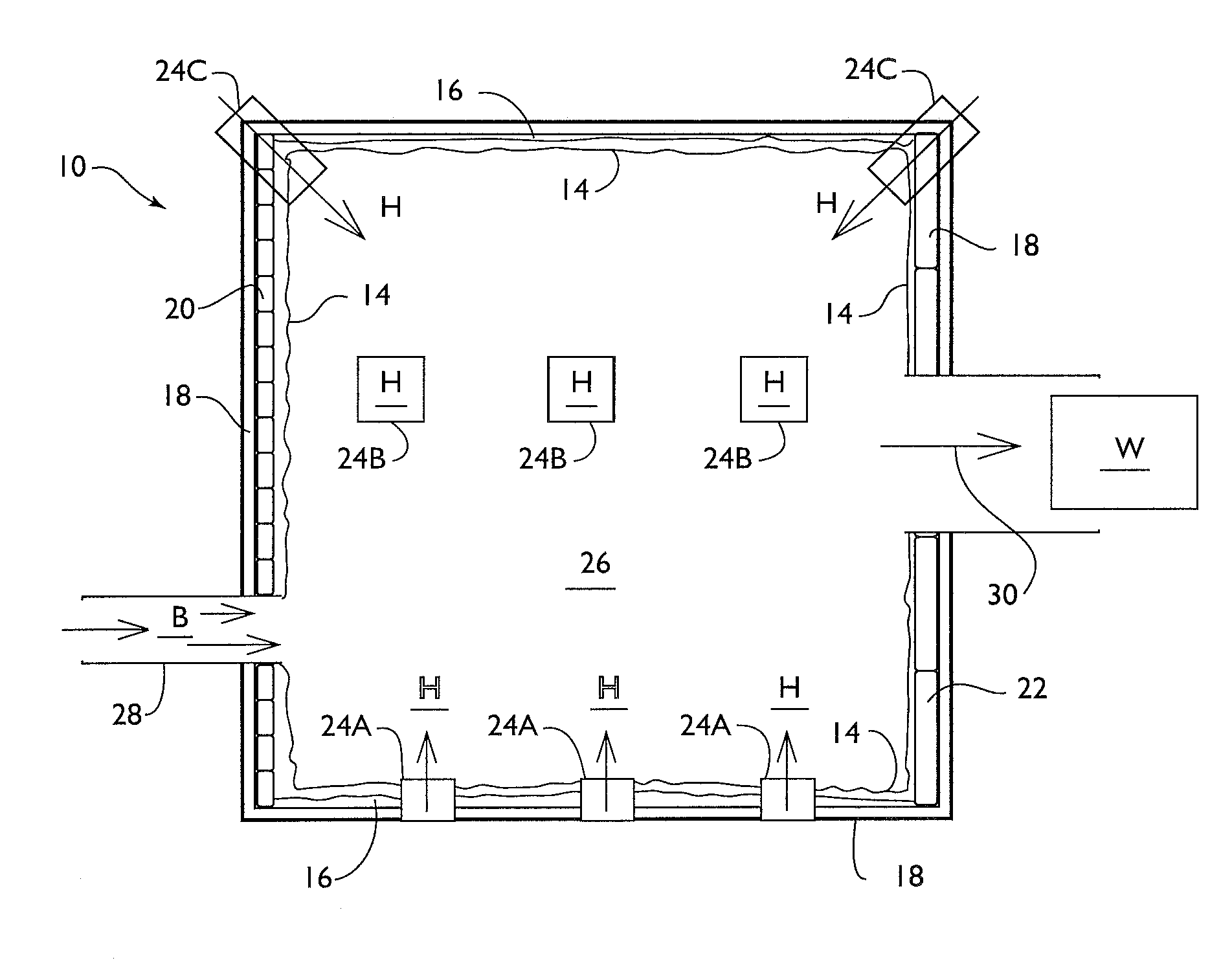

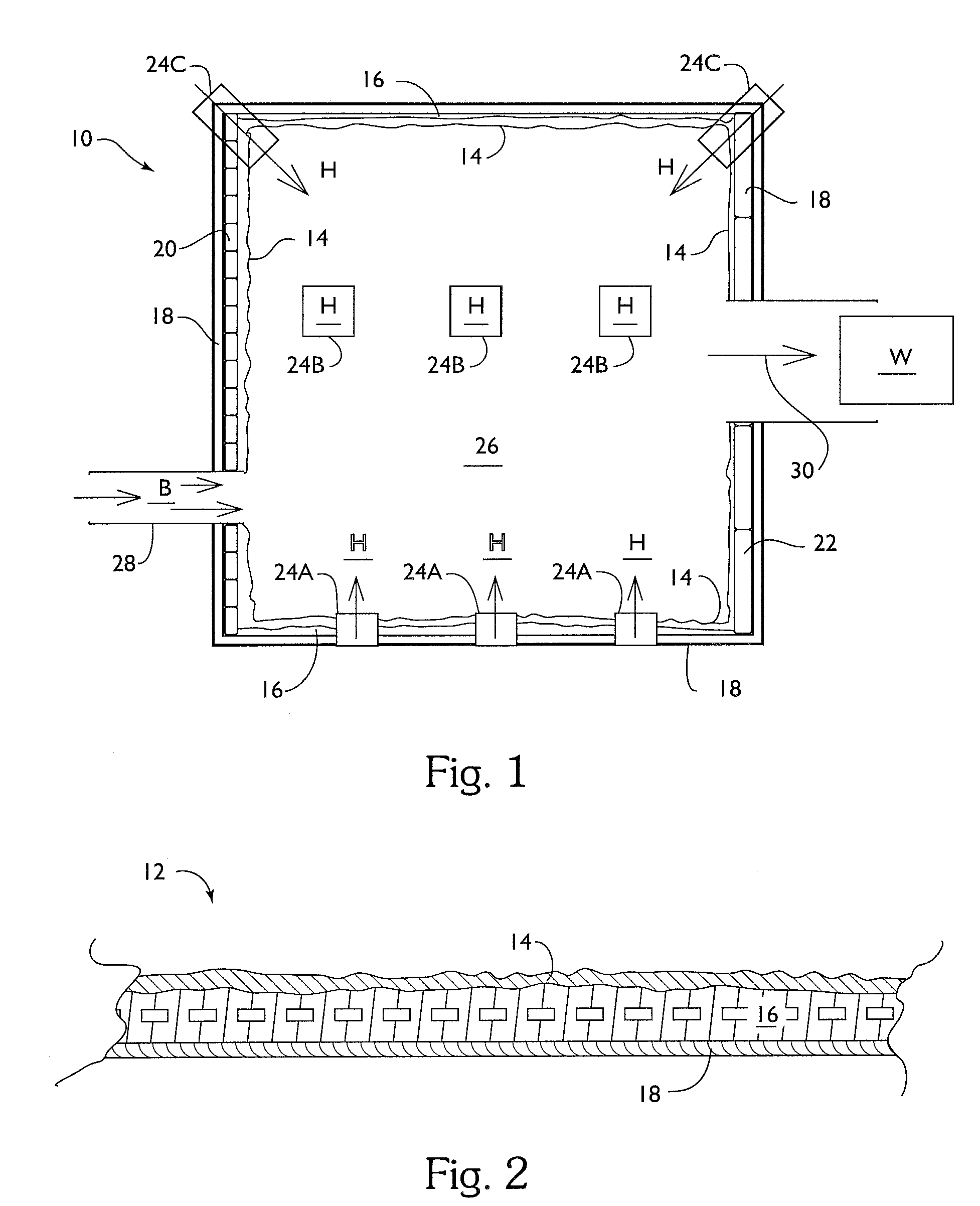

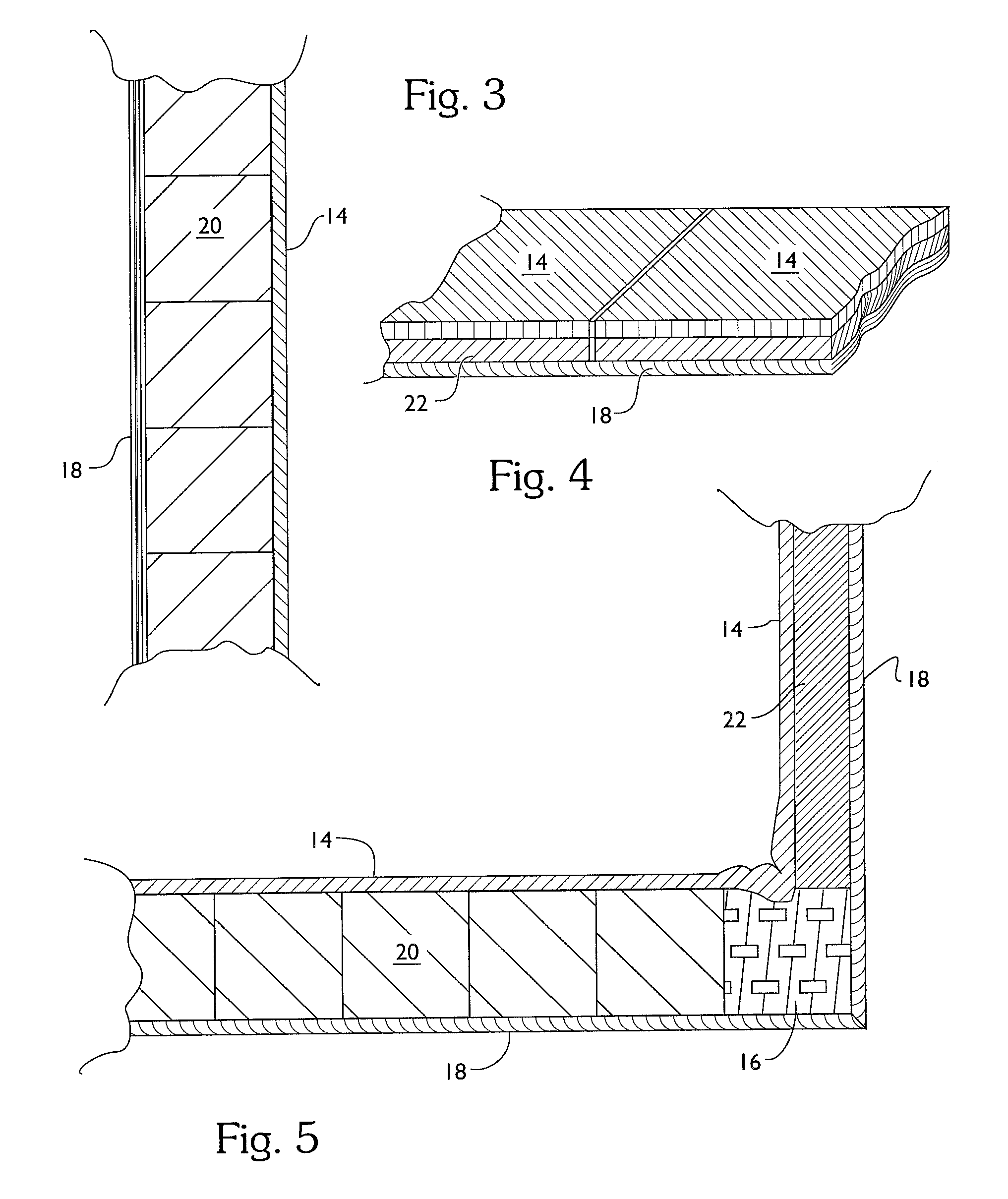

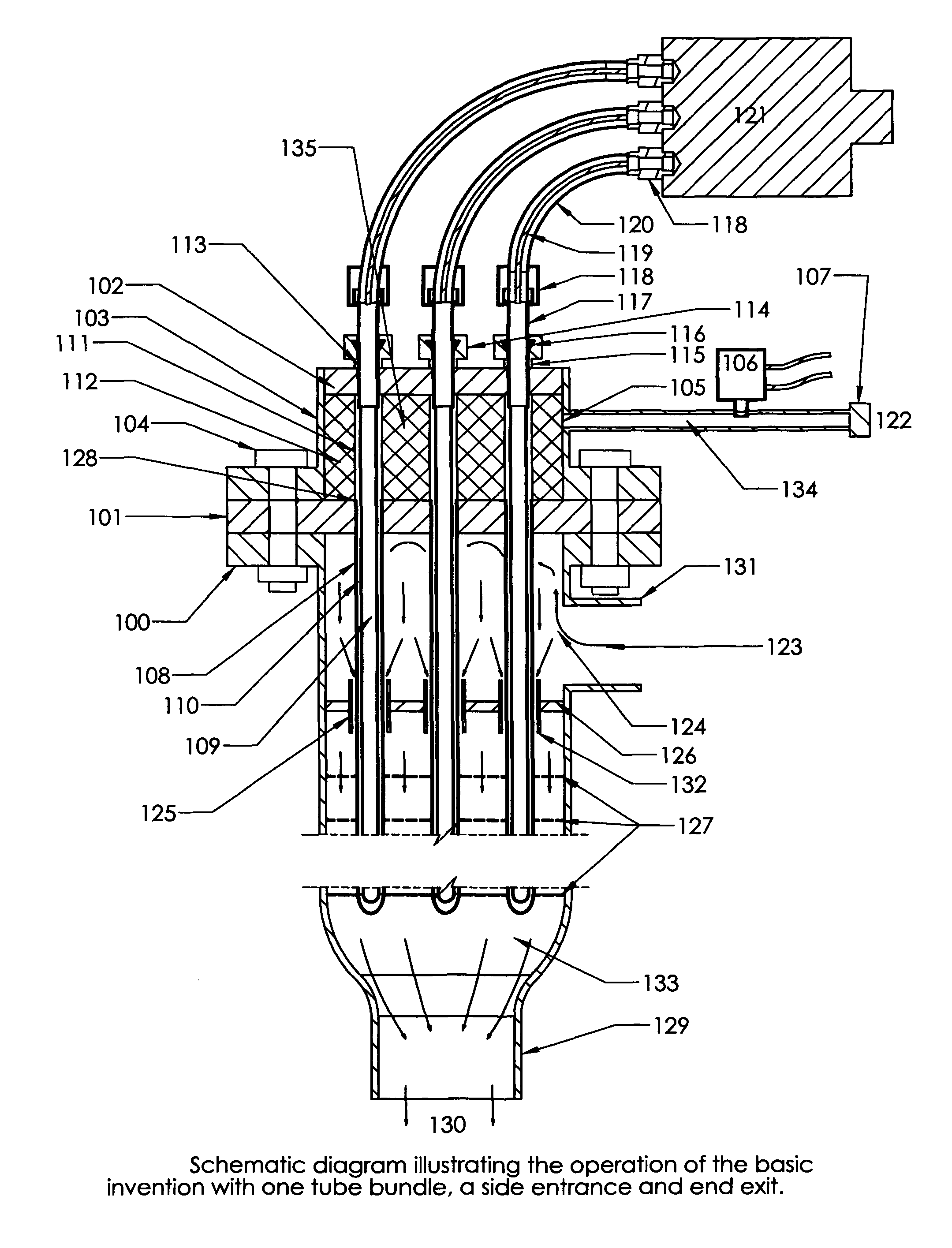

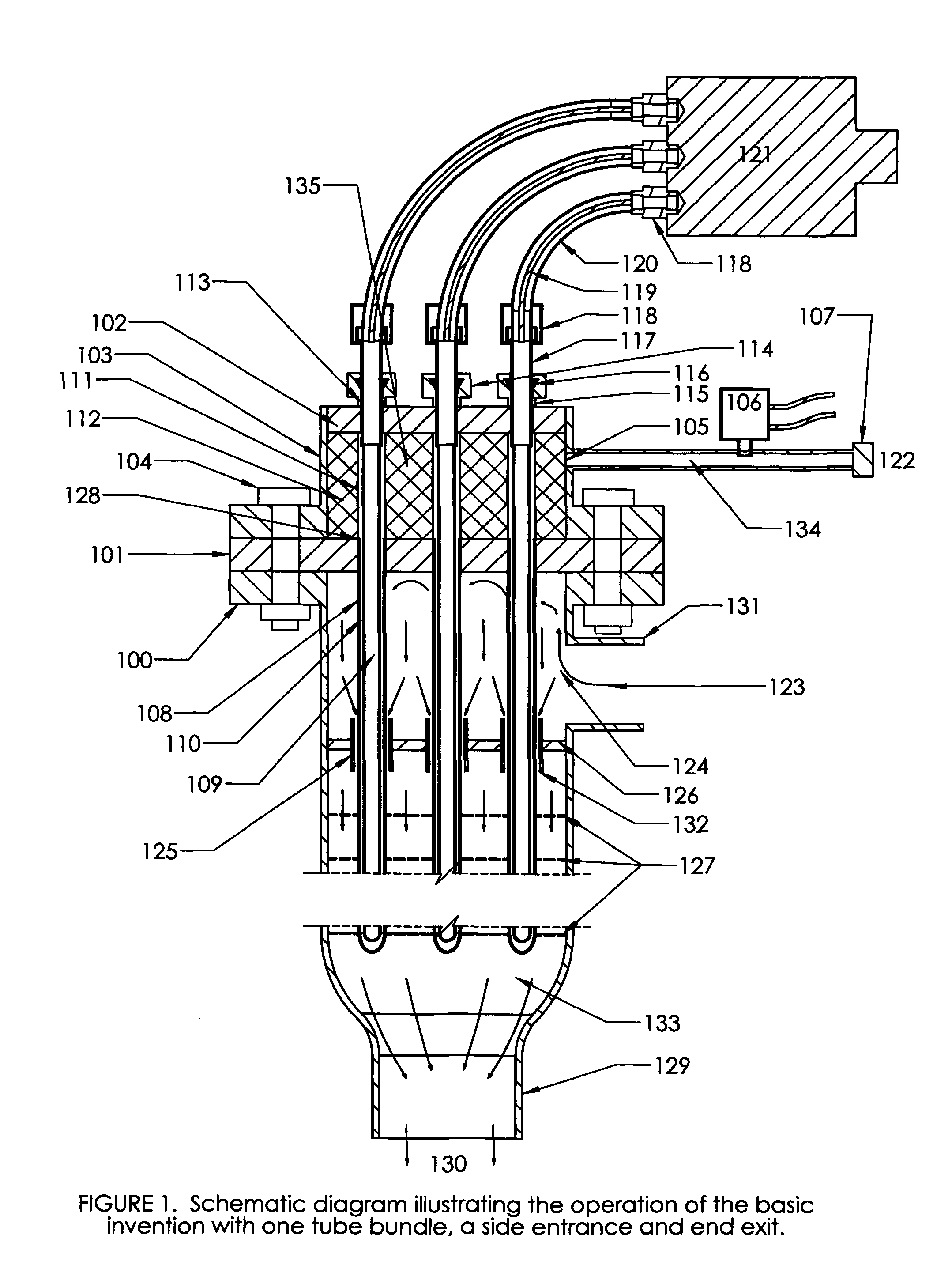

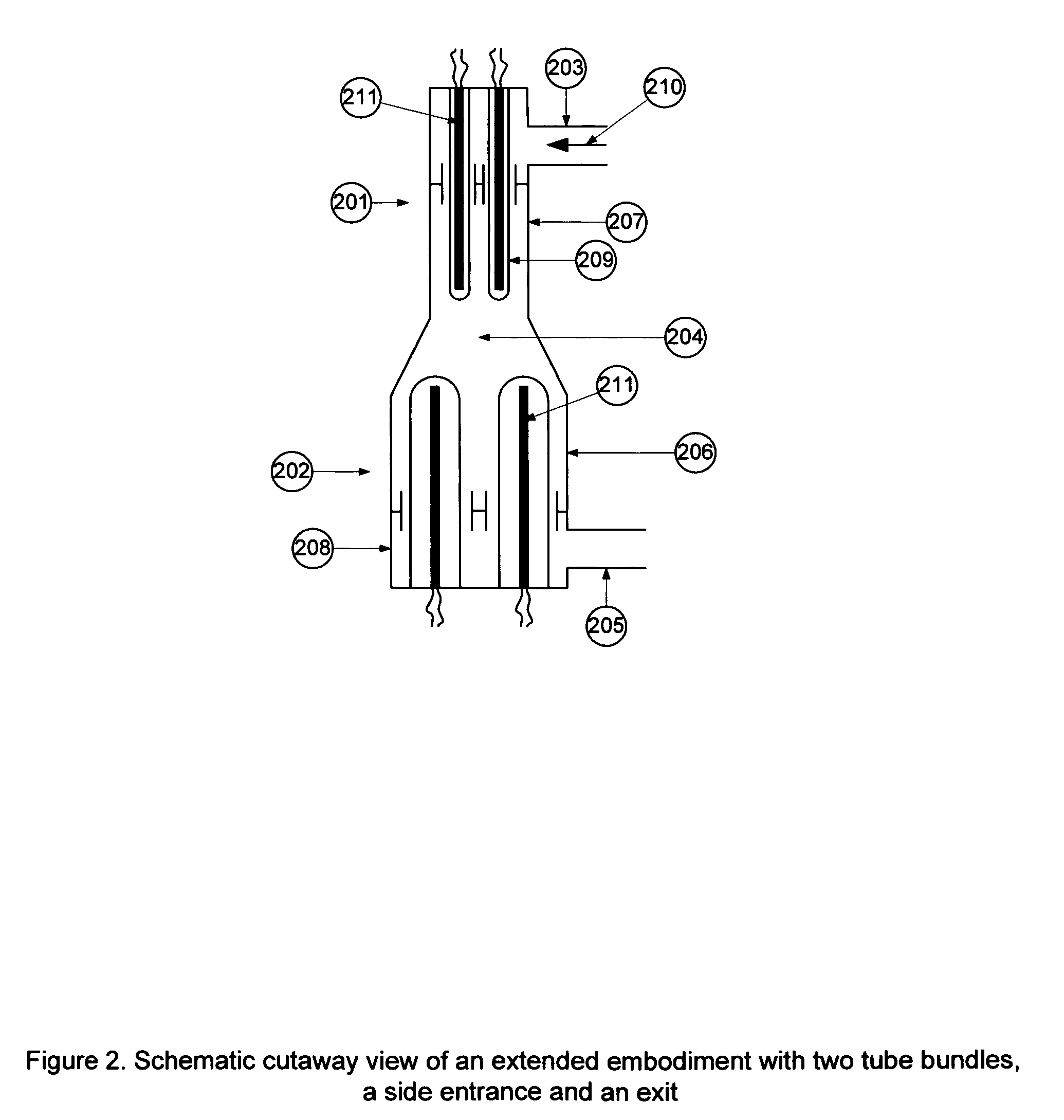

Dual wall axial flow electric heater for leak sensitive applications

A dual wall axial flow electric heater for leak sensitive applications provides an improved corrosion and leak resistant assembly and includes protective tubes over electrical heater rods, double tubesheets spaced apart by a plenum and leak detectors positioned to sensor leaks through the walls of the protective tubes. The design includes the option of two or more tube bundles with each inserted into opposite ends of a shell surrounding the tube sheets and heaters. The design provides ease of maintenance since each heater rod can be replaced independently while the unit is in service. Variable heat flux is provided from standard single flux heater rods by providing protective tubes of varying diameters. A built-in thermowell is provided to allow the rod temperatures to be monitored directly. Hot spots are avoided by the use of turning baffles and vibration is avoided by use of spider baffles to support the tubes.

Owner:LORD LTD LP

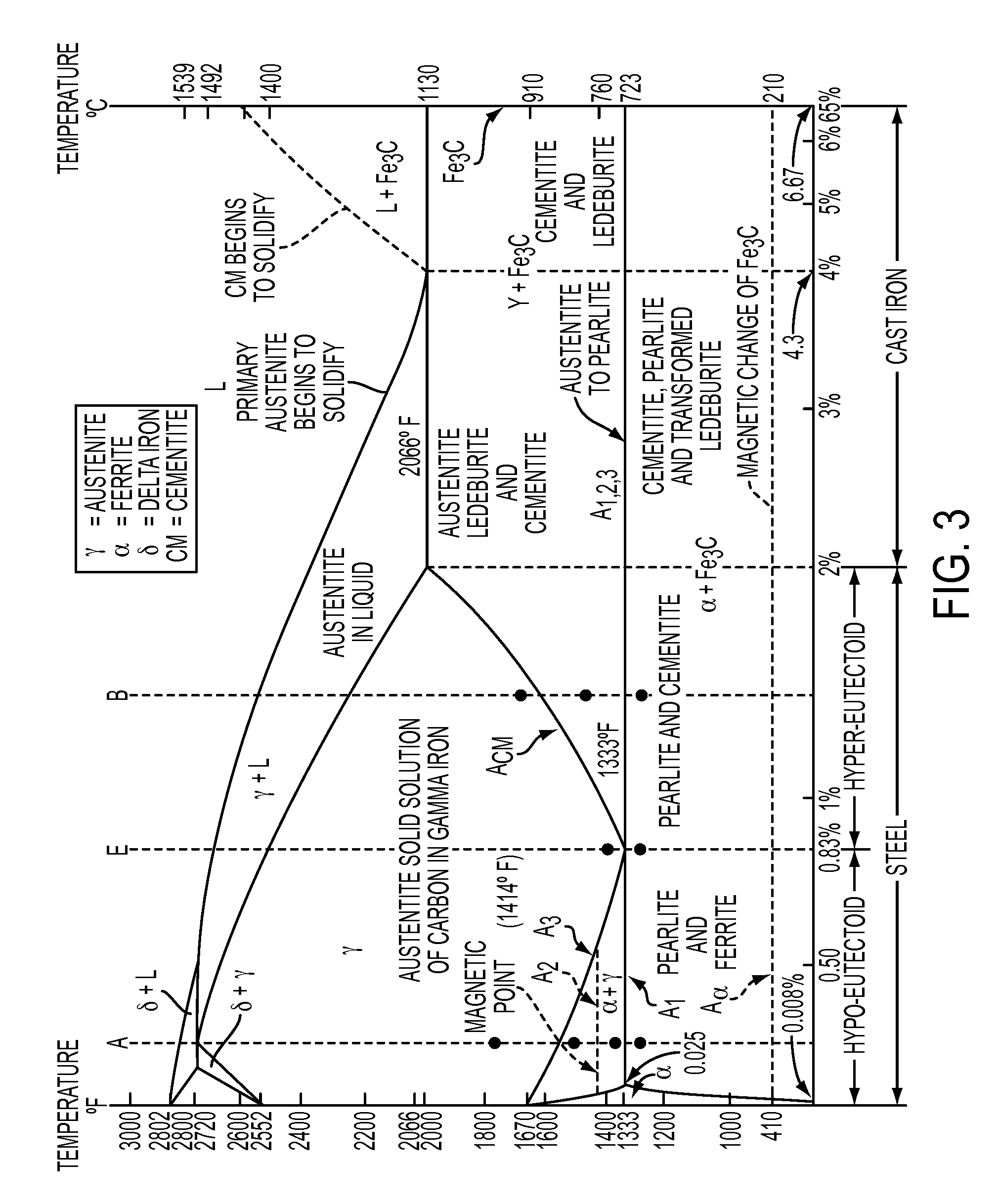

Biomass Combustion Chamber and Refractory Components

InactiveUS20090293786A1Improve combustion efficiencyImprove thermal efficiencyLiquid surface applicatorsGlass/slag layered productsColloidal silicaEmissivity

A combustion chamber has refractory walls, with an input feeding biomass into the chamber, and an ignition source to ignite the biomass. Each refractory wall component, refractory brick, panel or castable, has a surface exposed to heat generated within the chamber with a thermal protective layer consisting of a thermal enhancing high emissivity coating disposed on the exposed refractory surface. The coating contains from about 5% to about 35% of colloidal silica, colloidal alumina, or combinations thereof, from about 23% to about 79% of a filler, and from about 1% to about 20% of one or more emissivity agents.

Owner:FUJITSU LTD

Food product and method and apparatus for baking

ActiveUS20120074122A1Less timeLess energyEnvelopes/bags making machineryCharge supportsColloidal silicaCooking & baking

Provide an oven and optional cooking accessories having a high emissivity thermal protective layer on a substrate surface which comprises a metal or ceramic. The layer comprises from about 5% to 30% of an inorganic adhesive, from about 45% to 92% of at least one filler, and from about 1% to 25% of one or more emissivity agents; or from about 5% to 35% of colloidal silica, colloidal alumina, or combinations thereof, from about 23% to 79% of at least one filler, and from about 1% to 25% of one or more emissivity agents.

Owner:EMISSHIELD +1

Mineral insulated cable having reduced sheath temperature

ActiveUS20140008350A1Reduce sheath temperatureThermal conductivityHeater elementsHeating element shapesElectricityEmissivity

A mineral insulated heating cable for a heat tracing system. The heating cable includes a sheath having at least a first, and optionally a second layer, wherein the thermal conductivity of the second layer is greater than a thermal conductivity of the first layer. In addition, the first and second layers are in intimate thermal contact. The heating cable also includes a least one heating conductor for generating heat and a dielectric layer located within the sheath for electrically insulating the heating, conductor, wherein the sheath, heating conductor and dielectric layer form a heating section. In addition, the heating cable includes a conduit for receiving the heating section. Further, the heating cable includes a cold lead section and a hot-cold joint for connecting the heating and cold lead sections. In addition, a high emissivity coating may be formed on the first layer.

Owner:NVENT SERVICES GMBH

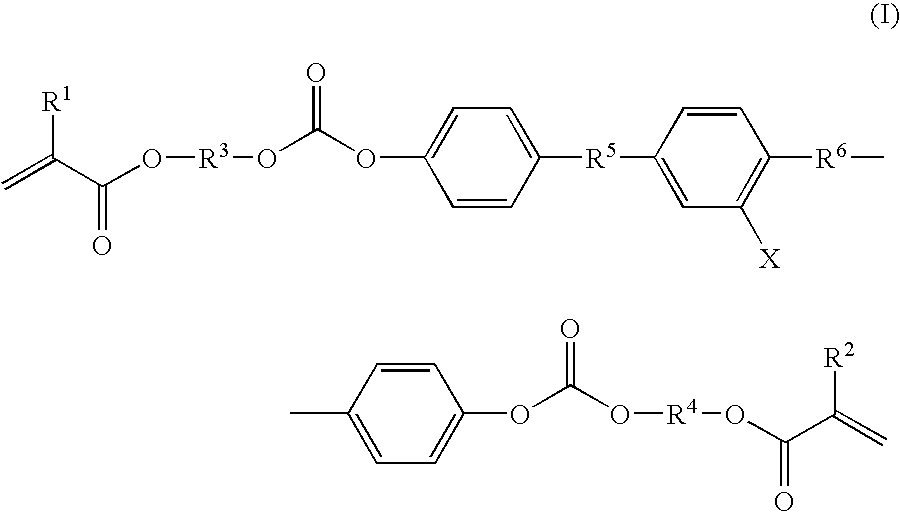

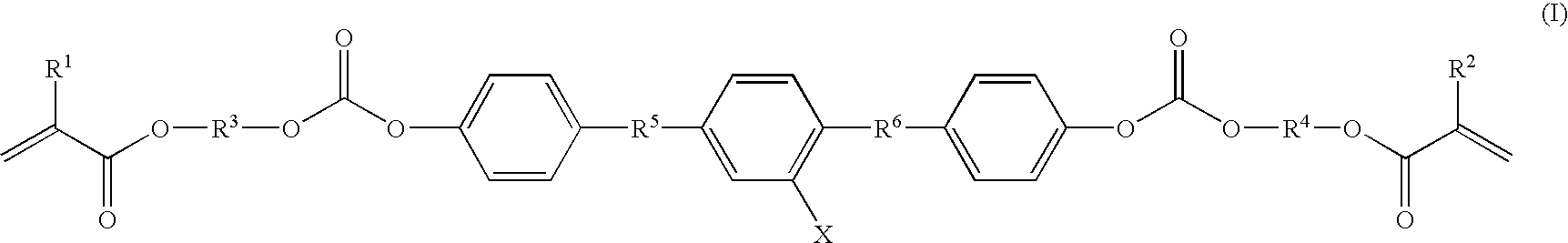

Liquid crystalline di(meth)acrylate compound, phase difference film, optical film, polarizing plate, liquid crystal panel and liquid crystal display device

InactiveUS20060040071A1High transparencyHigh coating precisionLiquid crystal compositionsPhotosensitive materialsLiquid crystallineMethacrylate

A phase difference film characterized in that said film is obtained by orienting and fixing, on a substrate, a composition containing a polymerizable liquid crystal monomer represented by the following formula (I): wherein, in the formula (I), X represents any one of Br, a halogen atom other than Br, —SMe and —SPh, R1 and R2 represent each independently a hydrogen atom or a methyl group, R3 and R4 represent each independently an alkylene group of a carbon number of 2 to 12, and R5 and R6 represent each independently —O—CO— or —CO—O—.

Owner:NITTO DENKO CORP

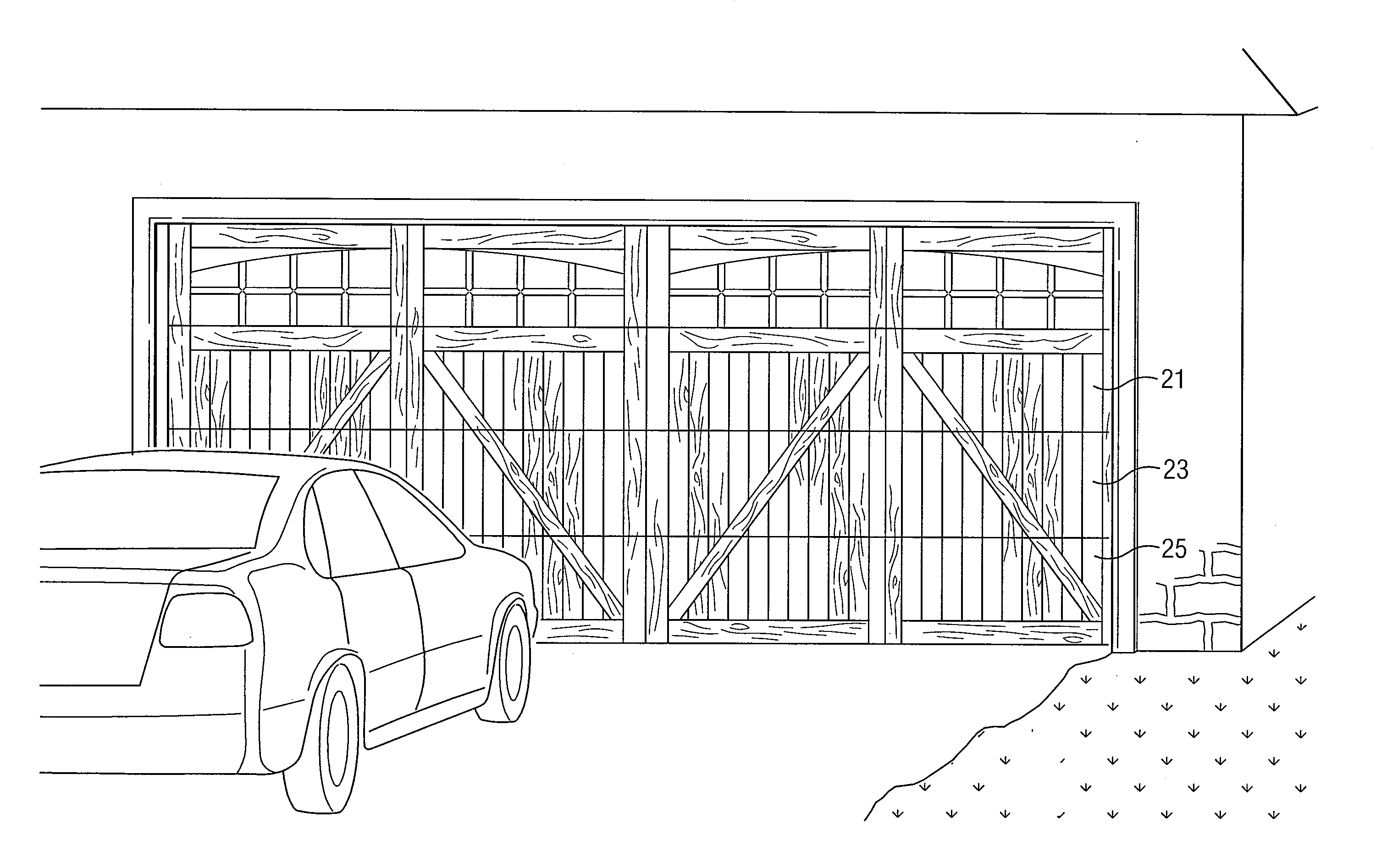

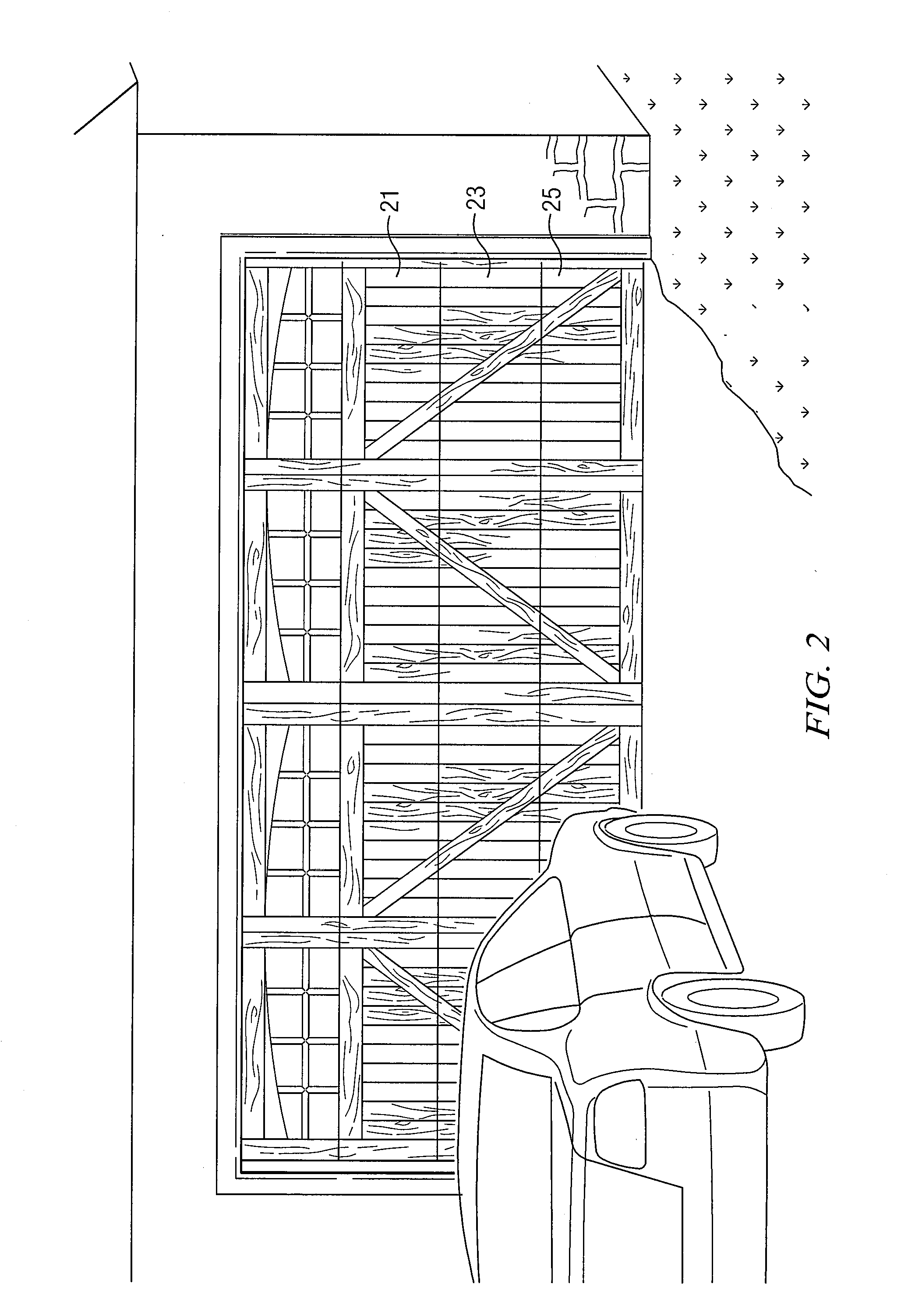

Overlay Panel System for an Overhead Garage Door and Method of Installation

InactiveUS20130097939A1High coatingDoor/window applicationsEngineeringElectrical and Electronics engineering

A method for constructing a horizontal section of an overhead garage door begins by providing a previously manufactured metal door section. A sheet of moldable material is shaped by heating and vacuum forming in order to produce a decorative overlay panel. The overlay panel has a front exposed surface which forms a front face for the door section of the garage door when overlaid on the door section. The overlay panel is mounted on the horizontal door section to provide a decorative appearance to the door section. A number of the door sections so overlaid are assembled to produce the resulting hinged overhead garage door.

Owner:NAT DOOR INDS

Method of producing a high gloss coating on a printed surface

InactiveUS20050123685A1High coatingLow production costPretreated surfacesLiquid/solution decomposition chemical coatingCoated surfacePresent method

The present invention is directed to a method for producing a high gloss coating on a printed surface. In the present method, an aqueous coating composition is deposited onto a surface to be printed using a blanket roller coating face which is a low energy, non-stick, smooth surface profile. In the present method, simultaneous with the deposition of aqueous coating onto a substrate, or shortly thereafter, pressure either alone or in combination with heat may be applied to the coating in order to create a substantially tack-free surface conforming to the surface of the coating face. By using a highly polished coating face, high gloss coatings may be readily obtained using this methodology in a number of traditional printing techniques including wet trap inline sheet-fed printing, heat-set offset printing, dry trap inline flexographic printing, offset web-fed printing and gravure printing. Coatings which are produced utilizing the present invention have high gloss values heretofore unobtainable using aqueous coating compositions.

Owner:FRAZZITTA JOSEPH

Dual wall axial flow electric heater for leak sensitive applications

ActiveUS8260126B2Reduce riskReduction and elimination of overheatingHeating fuelAir heatersHeat fluxHeater Rod

A dual wall axial flow electric heater for leak sensitive applications provides an improved corrosion and leak resistant assembly and includes protective tubes over electrical heater rods, double tubesheets spaced apart by a plenum and leak detectors positioned to sensor leaks through the walls of the protective tubes. The design includes the option of two or more tube bundles with each inserted into opposite ends of a shell surrounding the tube sheets and heaters. The design provides ease of maintenance since each heater rod can be replaced independently while the unit is in service. Variable heat flux is provided from standard single flux heater rods by providing protective tubes of varying diameters. A built-in thermowell is provided to allow the rod temperatures to be monitored directly. Hot spots are avoided by the use of turning baffles and vibration is avoided by use of spider baffles to support the tubes.

Owner:LORD LTD LP

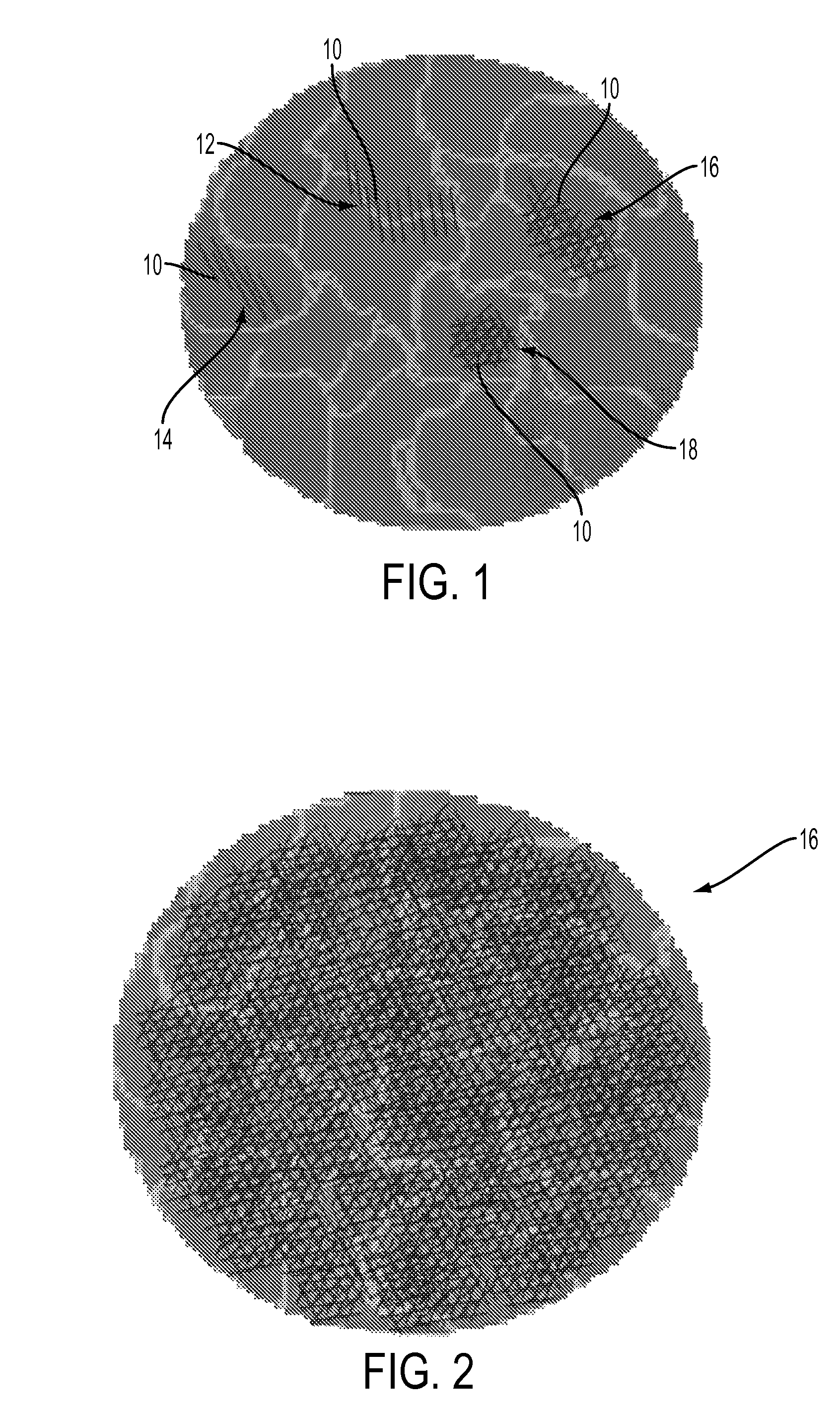

Nanostructured composite reinforced material

ActiveUS8231703B1Maximum performanceImprove material performanceAnimal housingThin material handlingDecrease weightAlloy

A family of materials wherein nanostructures and / or nanotubes are incorporated into a multi-component material arrangement, such as a metallic or ceramic alloy or composite / aggregate, producing a new material or metallic / ceramic alloy. The new material has significantly increased strength, up to several thousands of times normal and perhaps substantially more, as well as significantly decreased weight. The new materials may be manufactured into a component where the nanostructure or nanostructure reinforcement is incorporated into the bulk and / or matrix material, or as a coating where the nanostructure or nanostructure reinforcement is incorporated into the coating or surface of a “normal” substrate material. The nanostructures are incorporated into the material structure either randomly or aligned, within grains, or along or across grain boundaries.

Owner:UT BATTELLE LLC +1

Liquid crystalline di(meth) acrylate compound, phase difference film, optical film, polarizing plate, liquid crystal panel and liquid crystal display device

InactiveUS20080003382A1High transparencyHigh coating precisionLiquid crystal compositionsOrganic chemistryLiquid crystallineMethacrylate

A liquid crystalline di(meth)acrylate compound represented by the following formula (III): wherein, in the formula (III), R1 and R2 represent each independently a hydrogen atom or a methyl group, R3 and R4 represent each independently an alkylene group of a carbon number of 2 to 12, R5 and R6 represent each independently —O—CO— or —CO—O—, A1 and A2 represent each independently —O— or —O—CO—O—, and X represents an aromatic substituent.

Owner:NITTO DENKO CORP

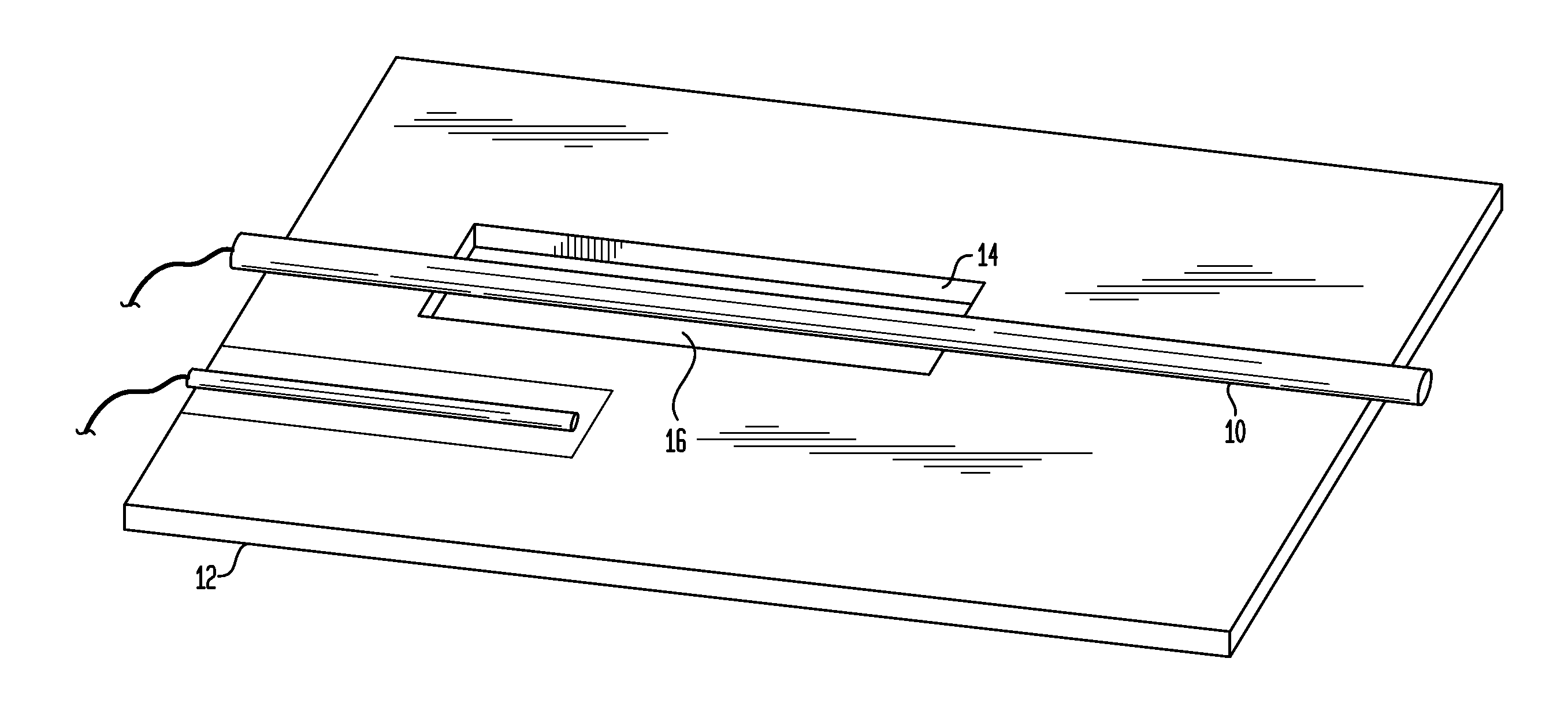

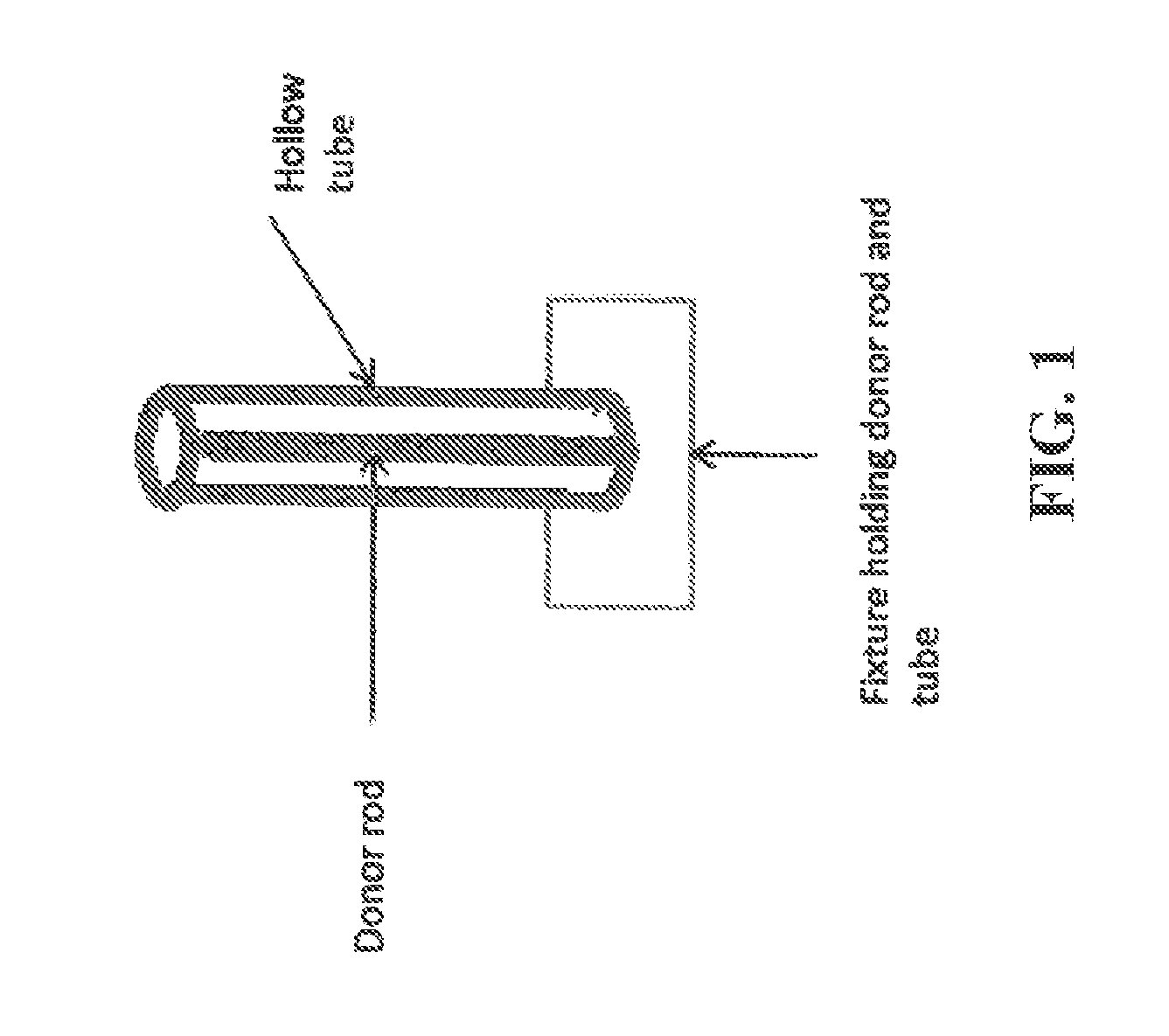

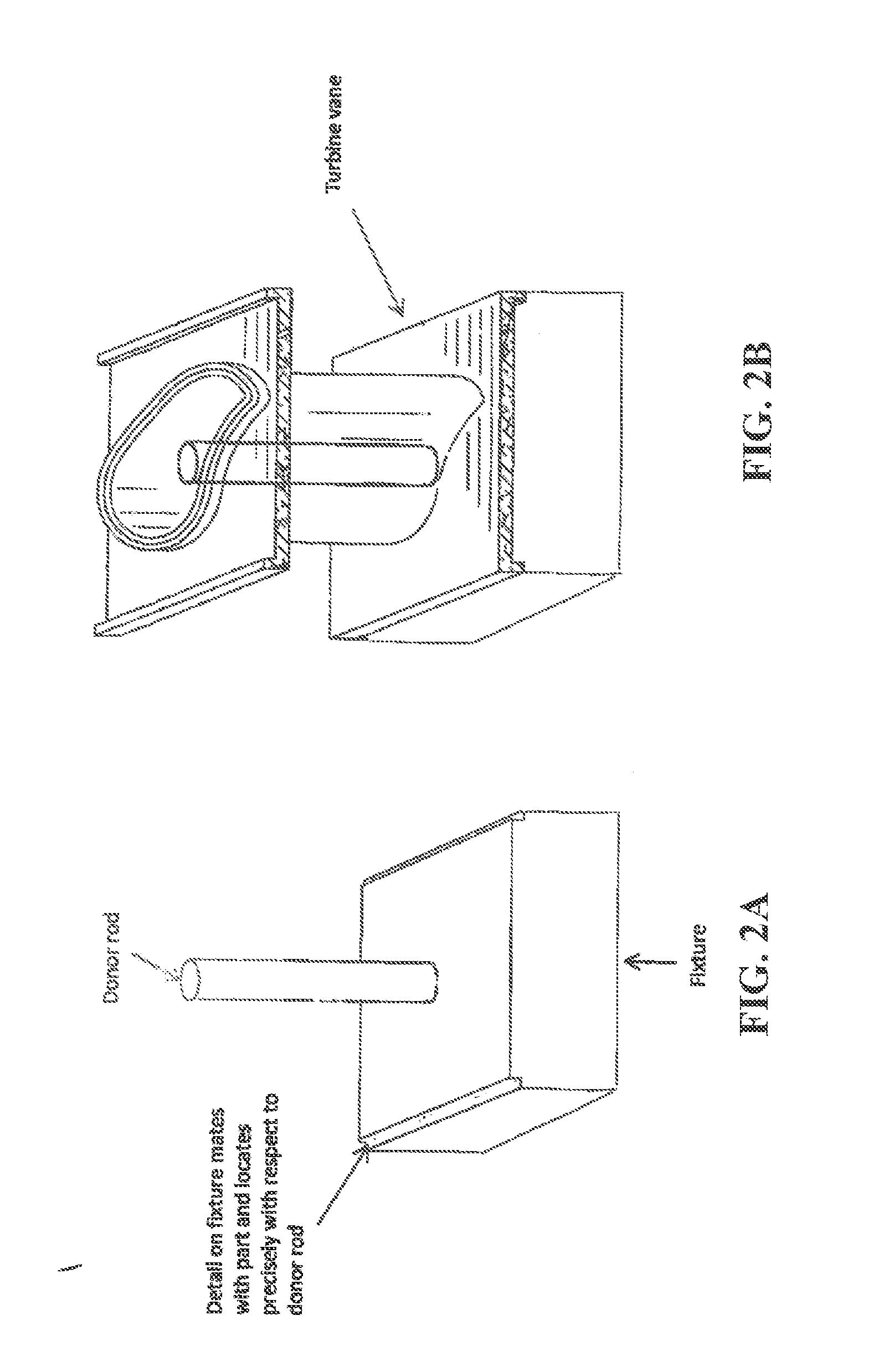

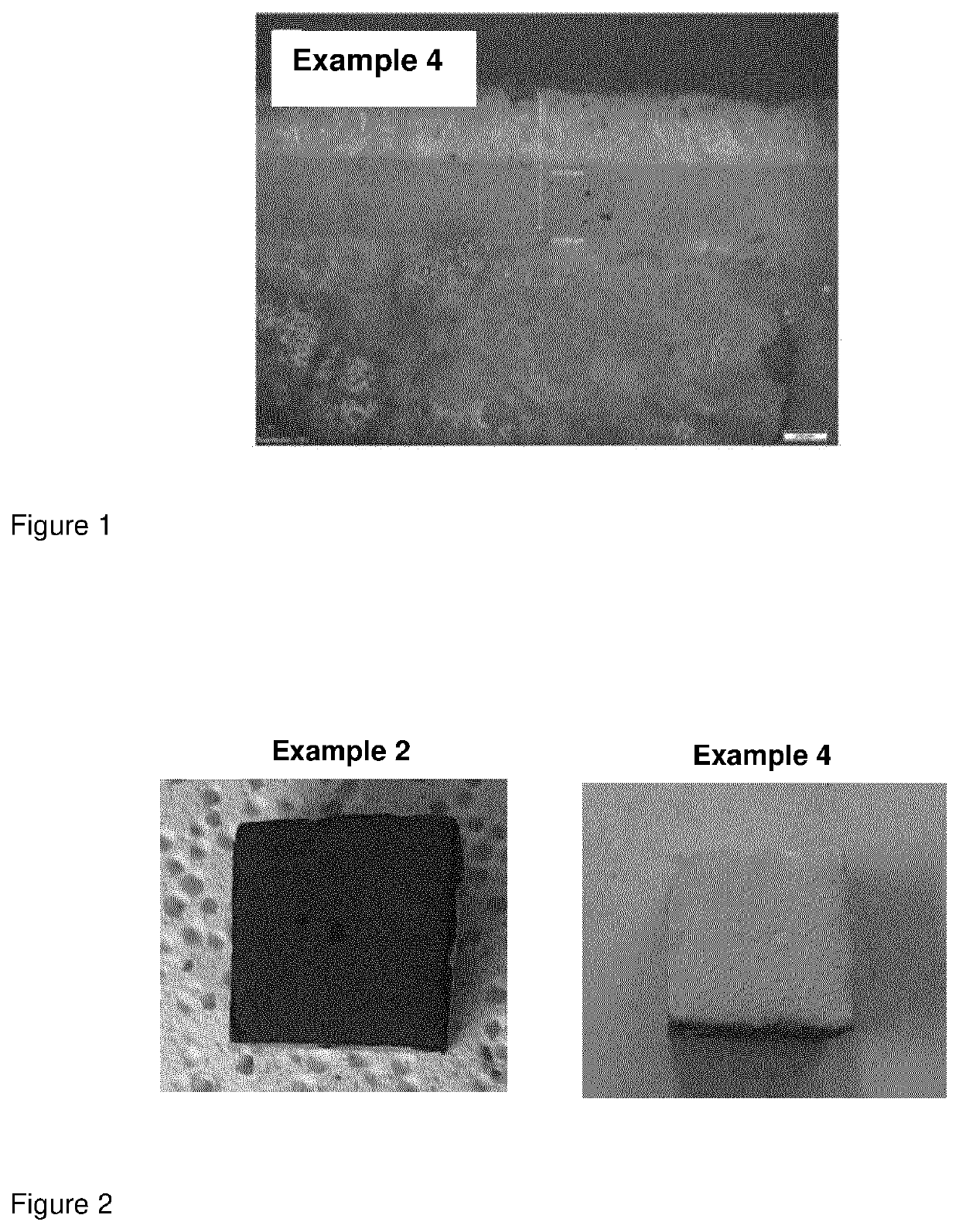

Method and apparatus for producing diffusion aluminide coatings

ActiveUS20150132485A1Reduces eliminates riskHigh coatingLiquid surface applicatorsVacuum evaporation coatingSource materialImproved method

Unique and improved methods and coating apparatuses for applying diffusion aluminide materials onto internal sections of various parts are disclosed. The source material is coated onto an elongated member, such as a wire or rod, which is subsequently inserted at a specific location into a hollow cavity of the component to be coated. Improvements in the coating process and resultant coating include the ability to coat complex geometries and coat components with uniform thicknesses that do not require post-coating steps for removal of oxides and / or residual bisque.

Owner:PRAXAIR ST TECH INC

High Emissivity Cerium Oxide Coating

PendingUS20220250995A1Increases resistance to stress and thermal stressHigh compositionCoatingsDopantPhysical chemistry

The present invention relates to a coating composition comprising: 10 to 80 wt % of cerium oxide comprising a dopant based upon the total weight of the composition, wherein said dopant is selected from iron oxide, cobalt oxide, chromium oxide, lanthanum oxide, or mixtures thereof, and the atomic ratio of dopant metal to cerium is in the range 0.01:1 to 0.5:1; and 10 to 50 wt % of binder based upon the total weight of the composition.

Owner:SCG CHEM CO LTD

Method of producing a high gloss coating on a printed surface

InactiveUS7329438B2High coatingLow production costPretreated surfacesLiquid/solution decomposition chemical coatingPresent methodPaper sheet

Owner:FRAZZITTA JOSEPH

Food product and method and apparatus for baking

ActiveUS8840942B2Less timeLess energyEnvelopes/bags making machineryDough treatmentColloidal silicaCooking & baking

Provide an oven and optional cooking accessories having a high emissivity thermal protective layer on a substrate surface which comprises a metal or ceramic. The layer comprises from about 5% to 30% of an inorganic adhesive, from about 45% to 92% of at least one filler, and from about 1% to 25% of one or more emissivity agents; or from about 5% to 35% of colloidal silica, colloidal alumina, or combinations thereof, from about 23% to 79% of at least one filler, and from about 1% to 25% of one or more emissivity agents.

Owner:EMISSHIELD +1

Solvent-based coating compositions

Coating compositions are disclosed. In some embodiments, the coating compositions are used to coat substrates such as packaging materials and the like for the storage of food and beverages. The coating compositions can be prepared by reacting an epoxidized vegetable oil and a hydroxyl functional material in the presence of an acid catalyst to form a hydroxyl functional oil polyol, mixing the hydroxyl functional oil polyol (with or without epoxidized polybutadiene) with a functional polyolefin copolymer to form a mixture,reacting the mixture with an ethylenically unsaturated monomer component in the presence of an initiator to form a graft copolymer, and crosslinking the graft copolymer with a crosslinker to form the coating composition.

Owner:AKZO NOBEL COATINGS INT BV

Method and apparatus for coating a medical device using a coating head

Methods and apparatuses for coating surface of medical devices using coating heads are disclosed. In one embodiment, the invention includes a coating method using a coating head, wherein the coating head comprises at least one outlet orifice from which flows a coating material, to deposit at least one layer of coating material dispelled through the outlet orifice onto the surface of the medical device. In another embodiment, a slide coating head is used to deposit multiple layers of superposed coating materials. These methods are used to apply one or more coating materials, simultaneously or in sequence. In certain embodiments of the invention, the coating materials include therapeutic agents, polymers, sugars, waxes, or fats.

Owner:BOSTON SCI SCIMED INC

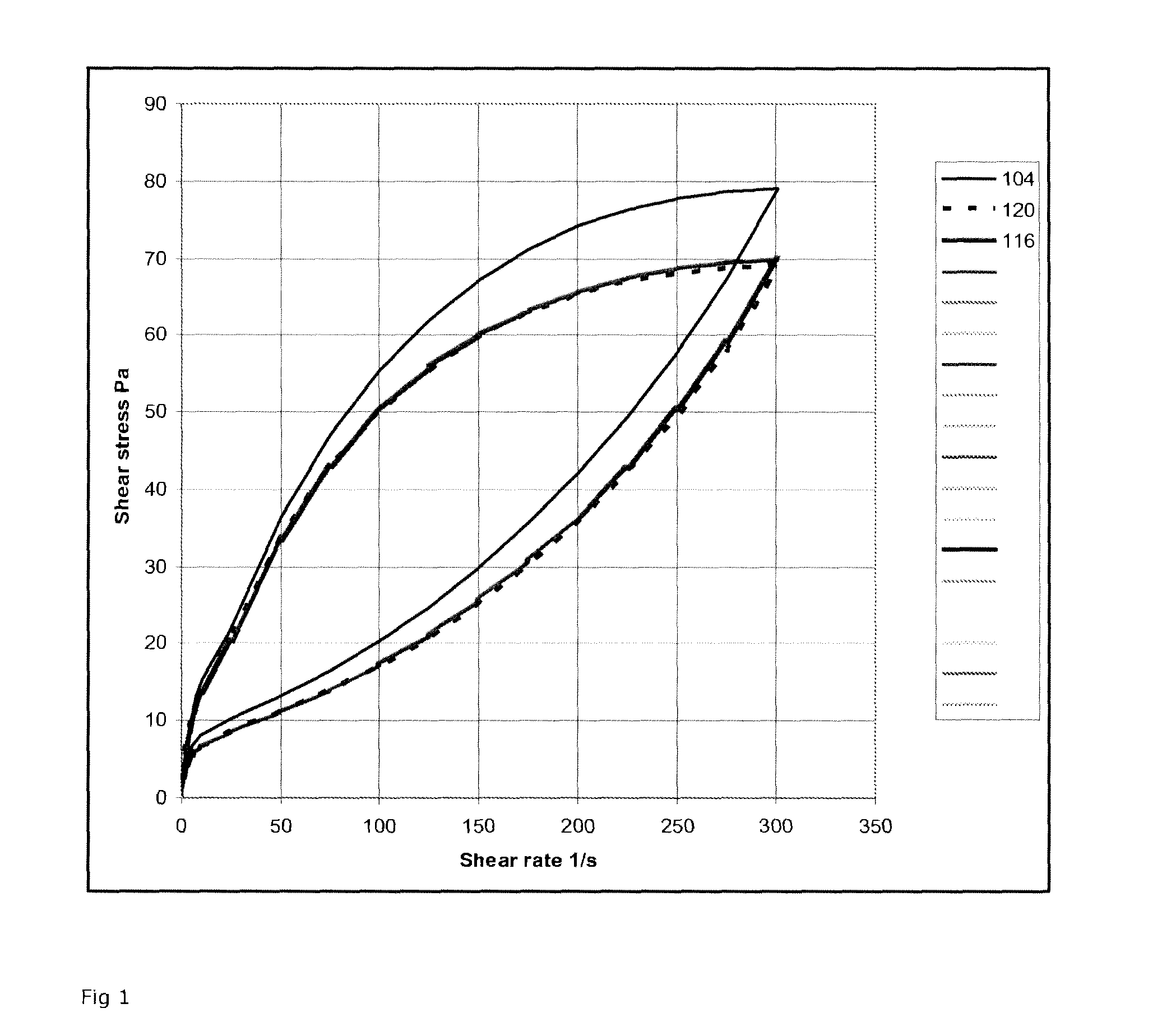

Processes for preparing coated printing paper

InactiveUS20130011553A1Gloss appearance likeGood quality likeDuplicating/marking methodsPaper coatingSpray coatingEngineering

Herein provided are processes for preparing coated printing paper having good print quality by spray coating. Specifically, a coated printing paper is prepared by a process for preparing a coated printing paper having one or more coating layers on at least one side of a base paper, comprising the steps of: preparing a spray coating solution containing a pigment and an binder including a starch, wherein (a) the starch is present at 30-100% by weight of the total amount of the binder, and (b) the Brookfield viscosity measured at 30° C., 100 rpm is 300 mPa·s or less; and applying the coating solution by spray coating to form the outermost coating layer.

Owner:NIPPON PAPER IND CO LTD

Method for producing a fermented milk product

InactiveUS20140348980A1High viscosityPleasant flavorMilk preparationBacteriaMilk productsFermented milk products

Owner:CHR HANSEN AS

Porous membrane for secondary battery, slurry for secondary battery porous membrane and secondary battery

ActiveUS9293753B2Easy to slideFew powder fall-offSecondary cell gas removalLi-accumulatorsMeth-Acrylonitrile

The porous membrane according to the present invention comprises non-conductive particles, a binder, and a water-soluble polymer, and is characterized in that: the three dimensions of the non-conductive particles, namely the length (L), thickness (t), and width (b), are such that the length (L) is 0.1 to 0 μm, the ratio (b / t) of the width (b) and the thickness (t) is 1.5 to 100; the binder is a copolymer containing (meth)acrylonitrile monomer units and (meth)acrylic acid ester monomer units; and the water-soluble polymer contains sulfonic acid groups, and has a weight average molecular weight of 1000 to 15000. The slurry for a porous membrane according to the present invention is characterized by being formed by dispersing the non-conductive particles, the binder, and the soluble polymer, in water. Thus, the present invention provides: a porous membrane that can be formed into a thin film, has an excellent sliding property, and generates few particles; and a slurry for porous membranes which is capable of producing porous membrane easily and quickly, and has excellent storage stability.

Owner:ZEON CORP

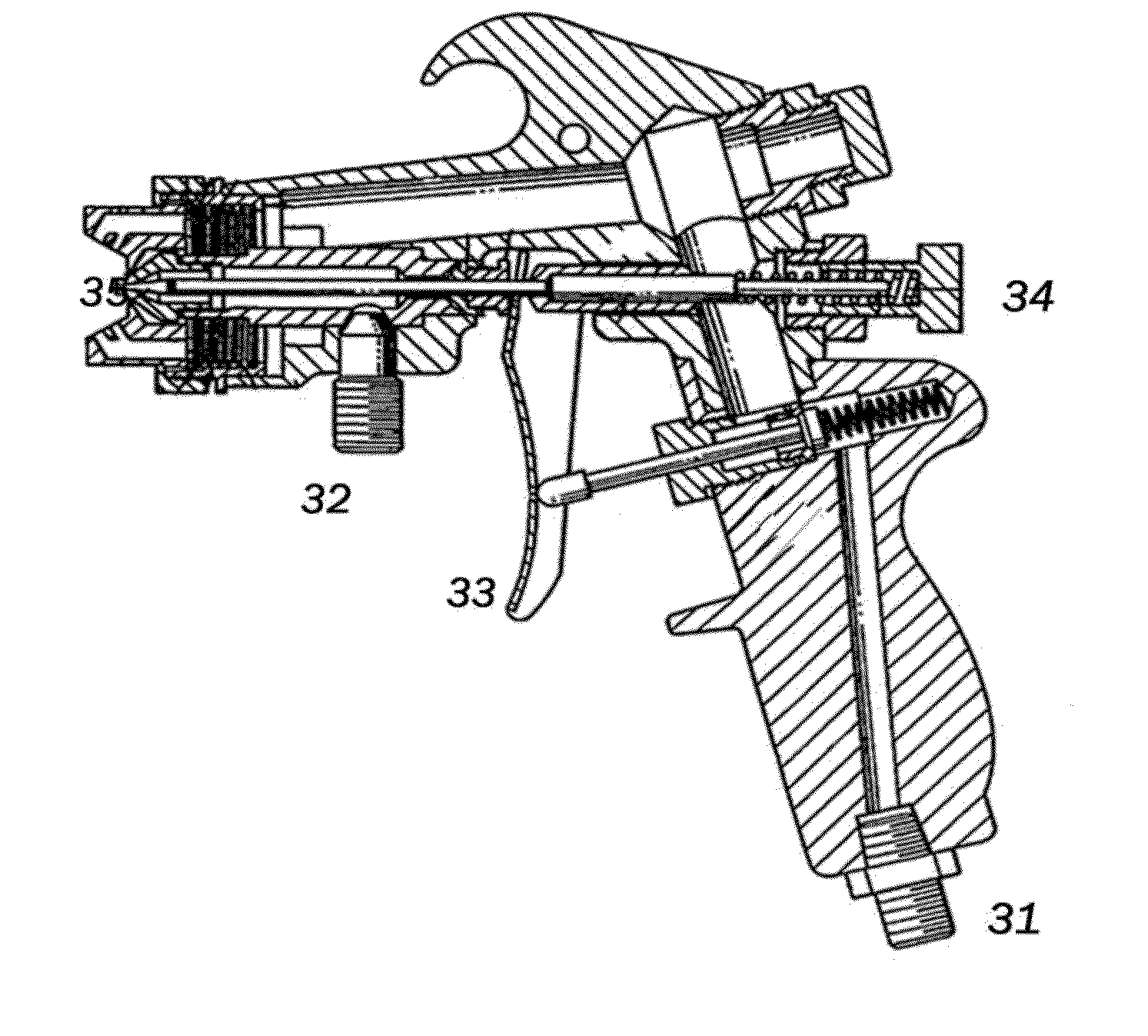

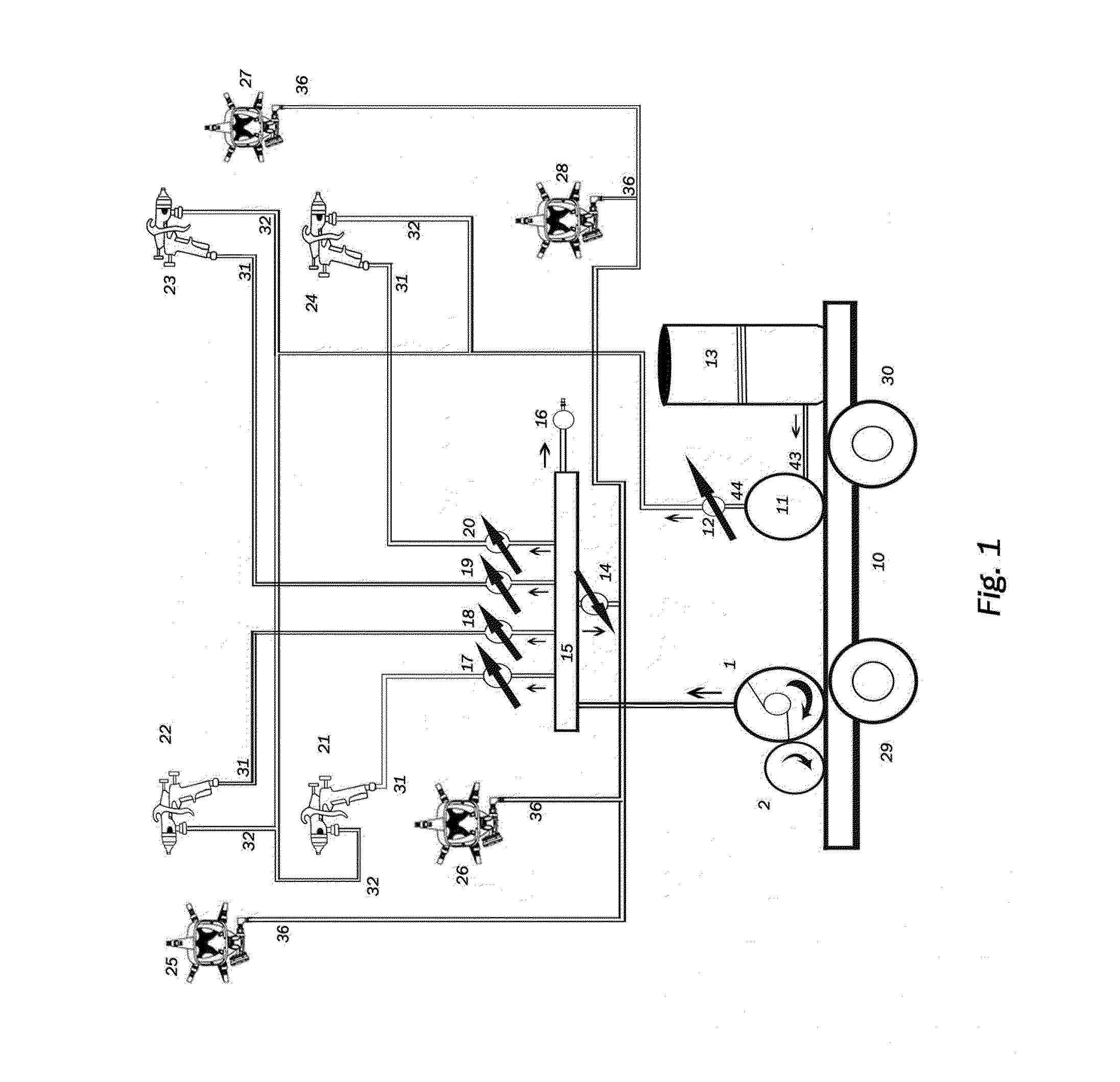

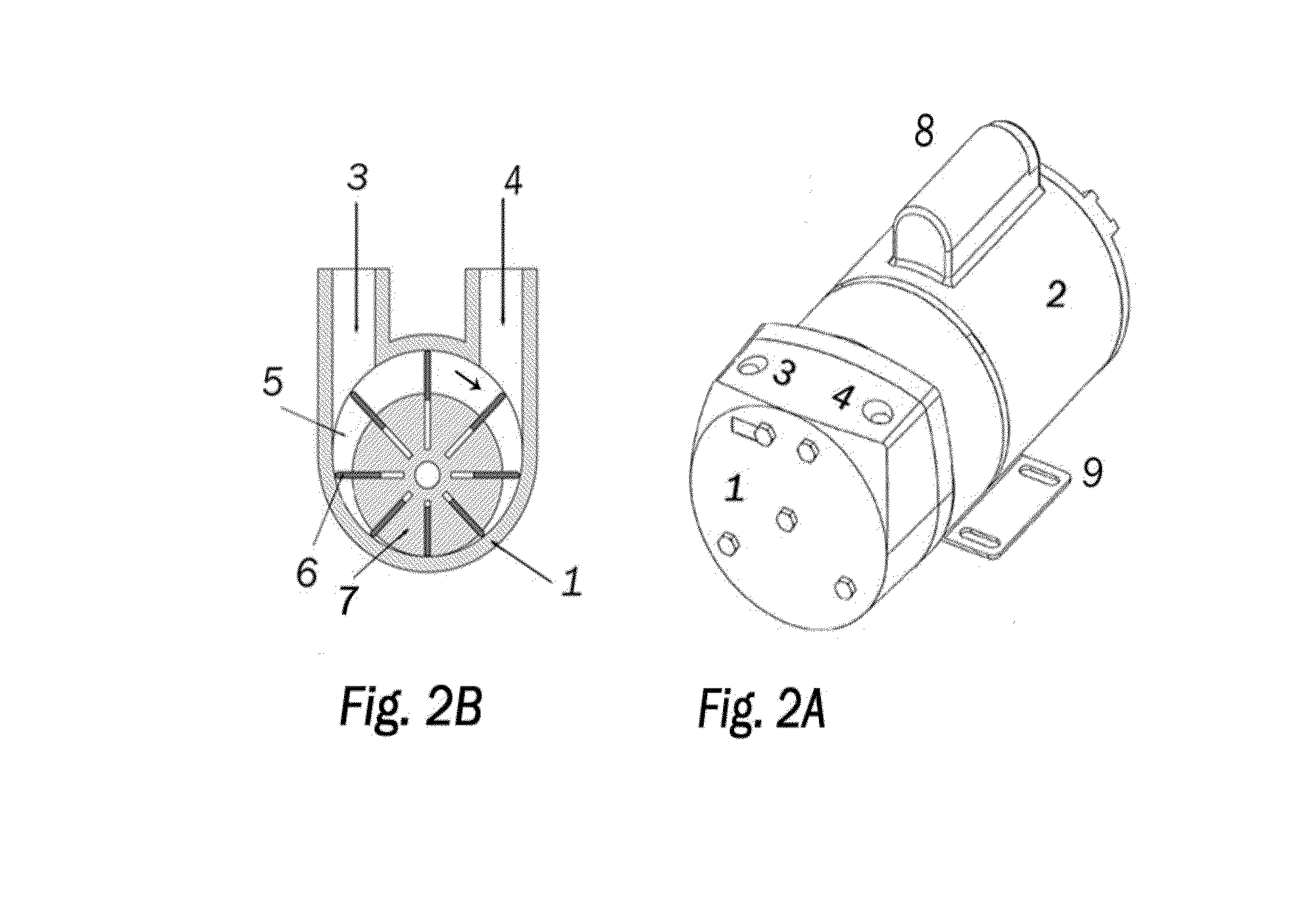

Multiple Station HVLP Spray Coating System Utilizing a Rotary Vane Pump and Manifold Design with a Control System Function

ActiveUS20150224524A1Increase the number ofReduce the amount requiredBreathing filtersBreathing masksControl systemSpray coating

A high volume low pressure (HVLP) coating application system employing a rotary vane pump and manifold assembly that provides an improved source of air for increased spray gun atomization of high solid coatings and faster applications of more even coated surfaces with continuous HVLP pressures of 10 PSI at the spray gun output and the ability to power multiple spray guns and breathing apparatus from a single manifold system.

Owner:APOLLO SPRAYERS INT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com