High strength aerogel panels

a technology of aerogels and panels, applied in the direction of chemistry apparatus and processes, synthetic resin layered products, transportation and packaging, etc., can solve the problems of affecting the application of aerogels in certain sectors of the insulation market, affecting the application of aerogels, and affecting the quality of the produ

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 2

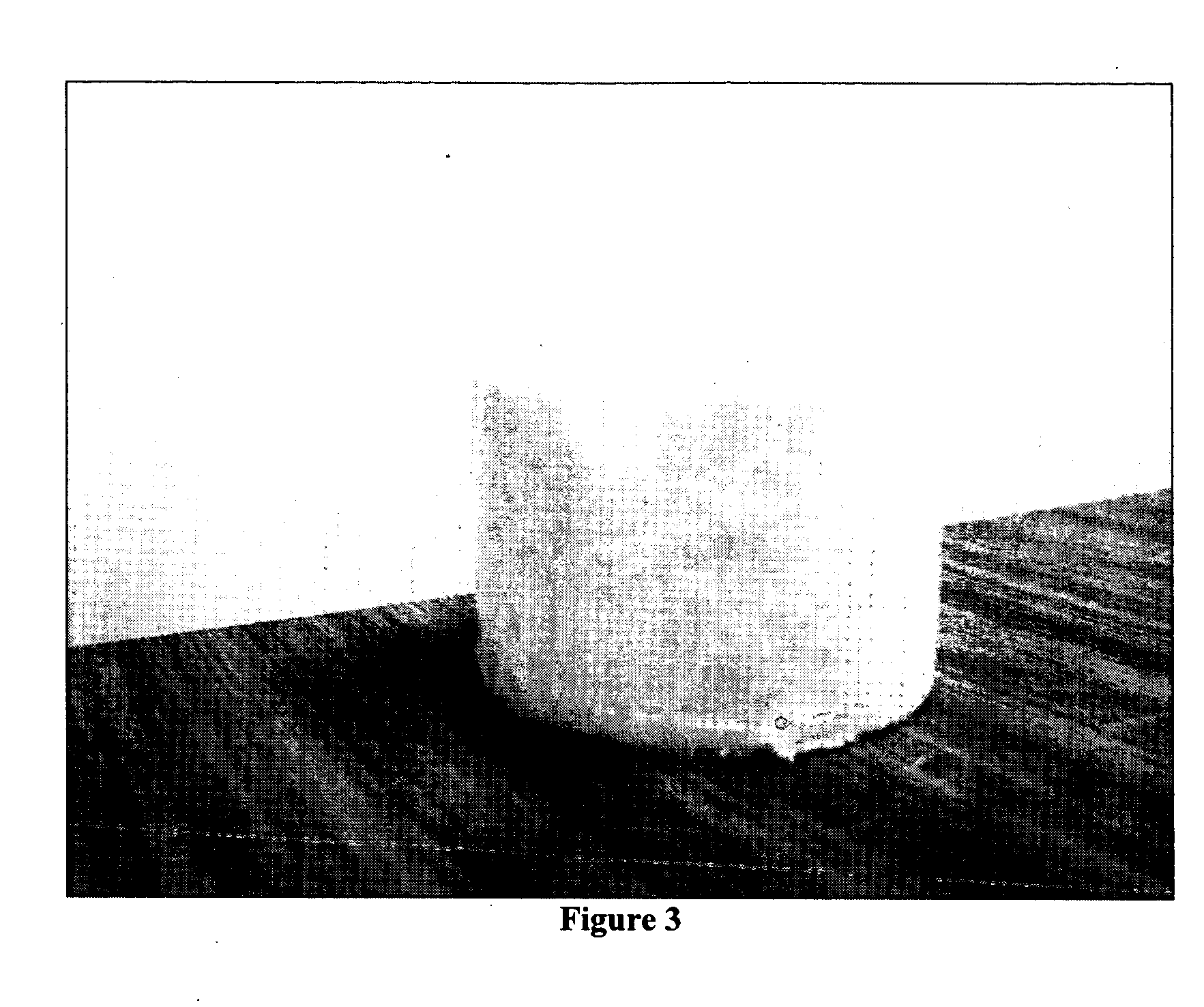

[0034] This example illustrates the formation of a rigid thermal insulation panel. The binder of example 1 was coated as a layer between three pieces of 1′×1′ foot fiber-reinforced PMA / silica hybrid aerogel blankets with a density of about 0.16 g / cm3. The three hybrid aerogel blankets were affixed to one another with a binder layer between every two blankets. The five-layer coupon was placed into an oven set at 75° C. for 2 hours. The resultant structure, which is in the form of a panel shows a density of about 0.17 g / cm3; thermal conductivity of about 13.9 mW / mK under ambient conditions and flexural strength at rupture of about 101 psi. The size of this rigid insulation panel is 1′×1′ foot and 2″ inches thick. This panel deforms lass than 10% under 17.5 psi compression. For much higher compression loading of 4000 psi, this panel recovery up to 90% of its original thickness within 2 hours after compression.

example 3

[0035] Ultra large size rigid aerogel insulation panels with over 90 square feet dimension can be prepared. For example, 30∴×3′ dimension and ⅛″ thick silica-PMA aerogel composite (two blankets and a binder layer as a glue) was prepared according to this approach. In theory, there is no limitation on the size of the composite prepared with the embodiments of the present invention. It is only currently limited by the space available for drying the composite sheet. Such high strength aerogel panels show good compression resistant properties (<10% under 17.5 psi, up to 98% recovery strain after 4000 psi loading). The resulting high strength aerogel panels also exhibit good flexural strength (resist 100 psi flexural pressure). The improvement of mechanical properties in this hybrid aerogels composite was achieved without sacrificing other inherent properties of aerogel such as low density and low thermal conductivity.

[0036] In one embodiment of the present invention, a shaped structure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Structure | aaaaa | aaaaa |

| Energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com