Patents

Literature

102 results about "Rotary vane pump" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A rotary vane pump is a positive-displacement pump that consists of vanes mounted to a rotor that rotates inside a cavity. In some cases these vanes can have variable length and/or be tensioned to maintain contact with the walls as the pump rotates. It was invented by Charles C. Barnes of Sackville, New Brunswick, who patented it on June 16, 1874. There have been various improvements, including a variable vane pump for gases (1909) They are considered less suitable than other vacuum pumps for high-viscosity and high-pressure fluids, and are complex to operate. They can endure short periods of dry operation, and are considered good for low-viscosity fluids.

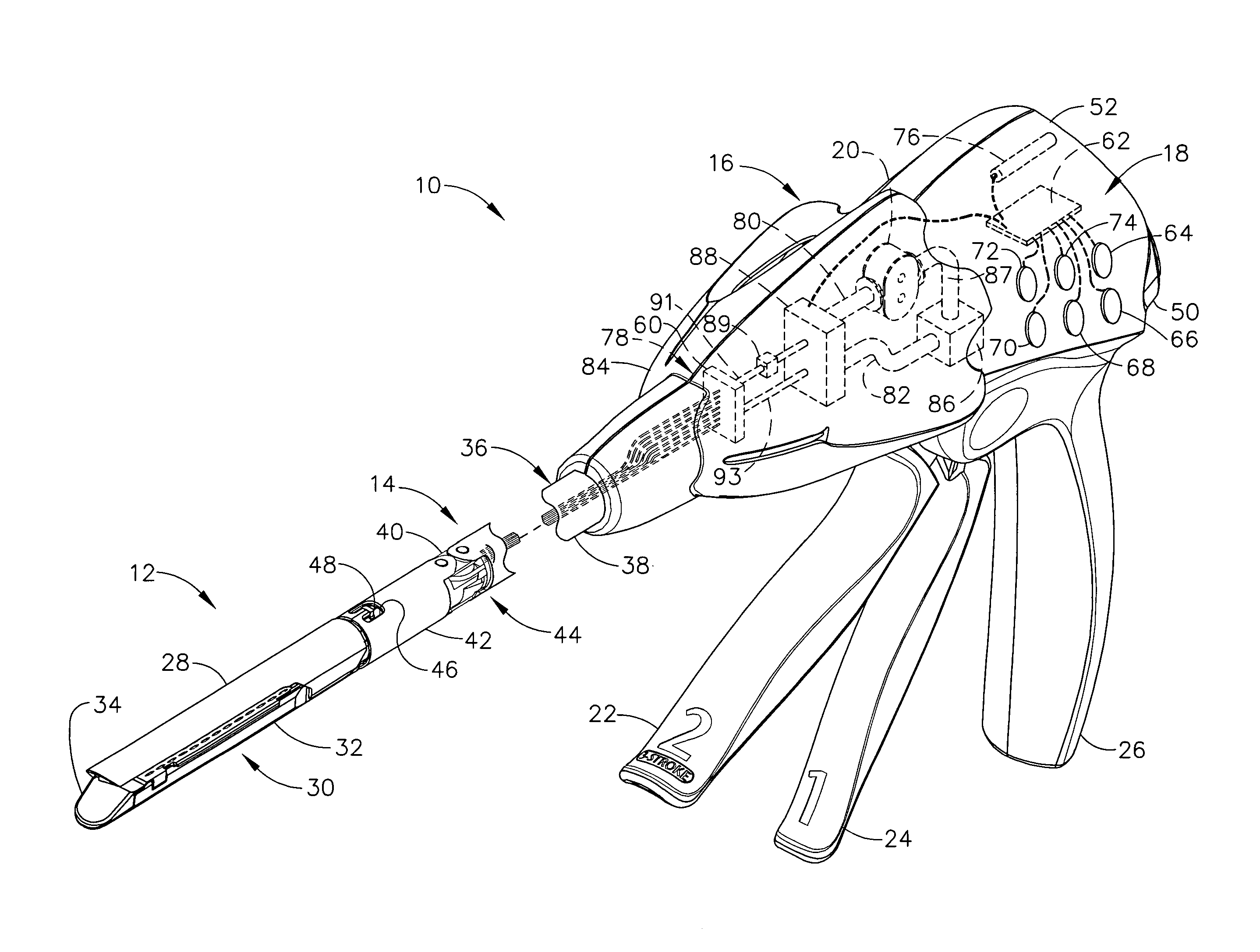

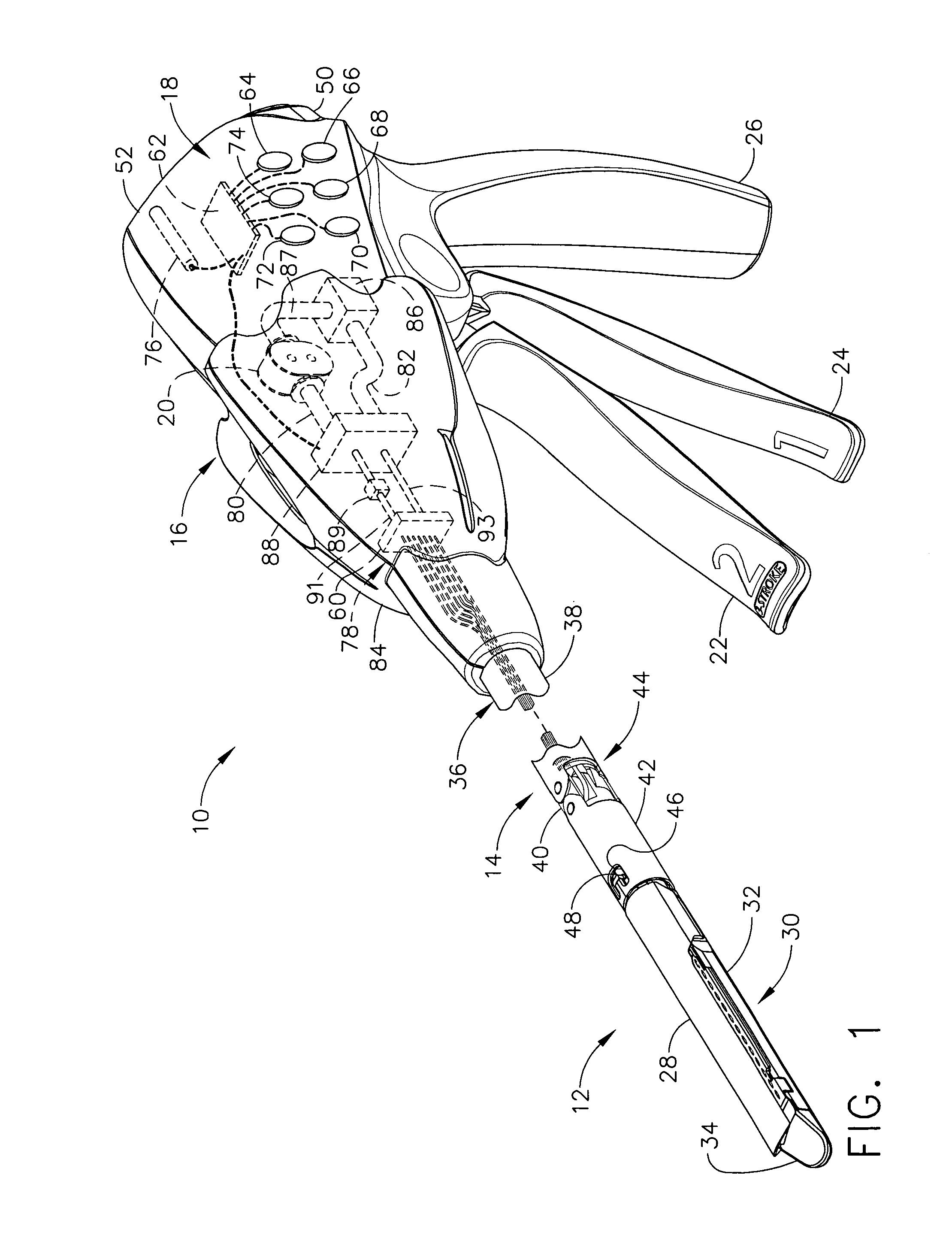

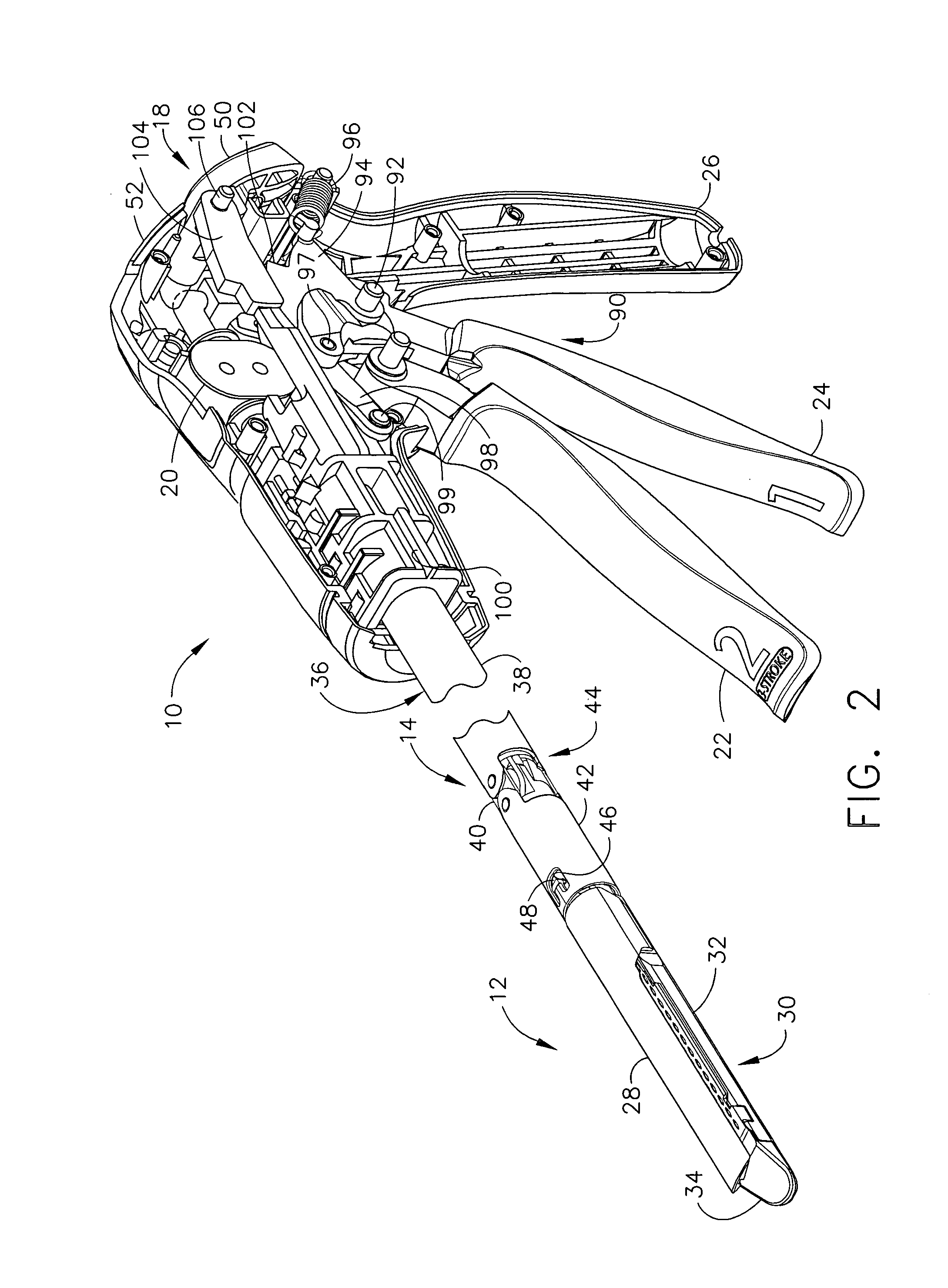

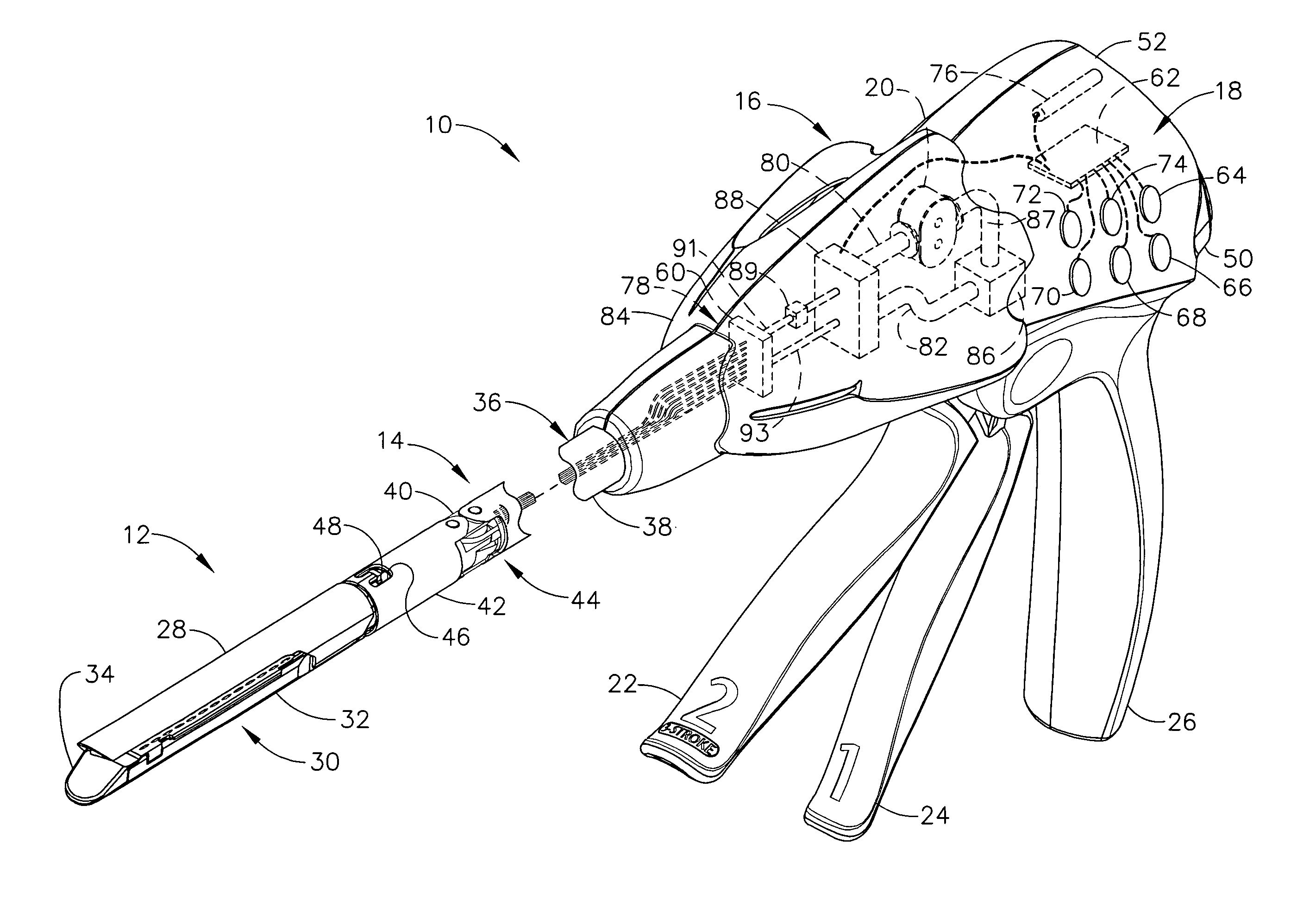

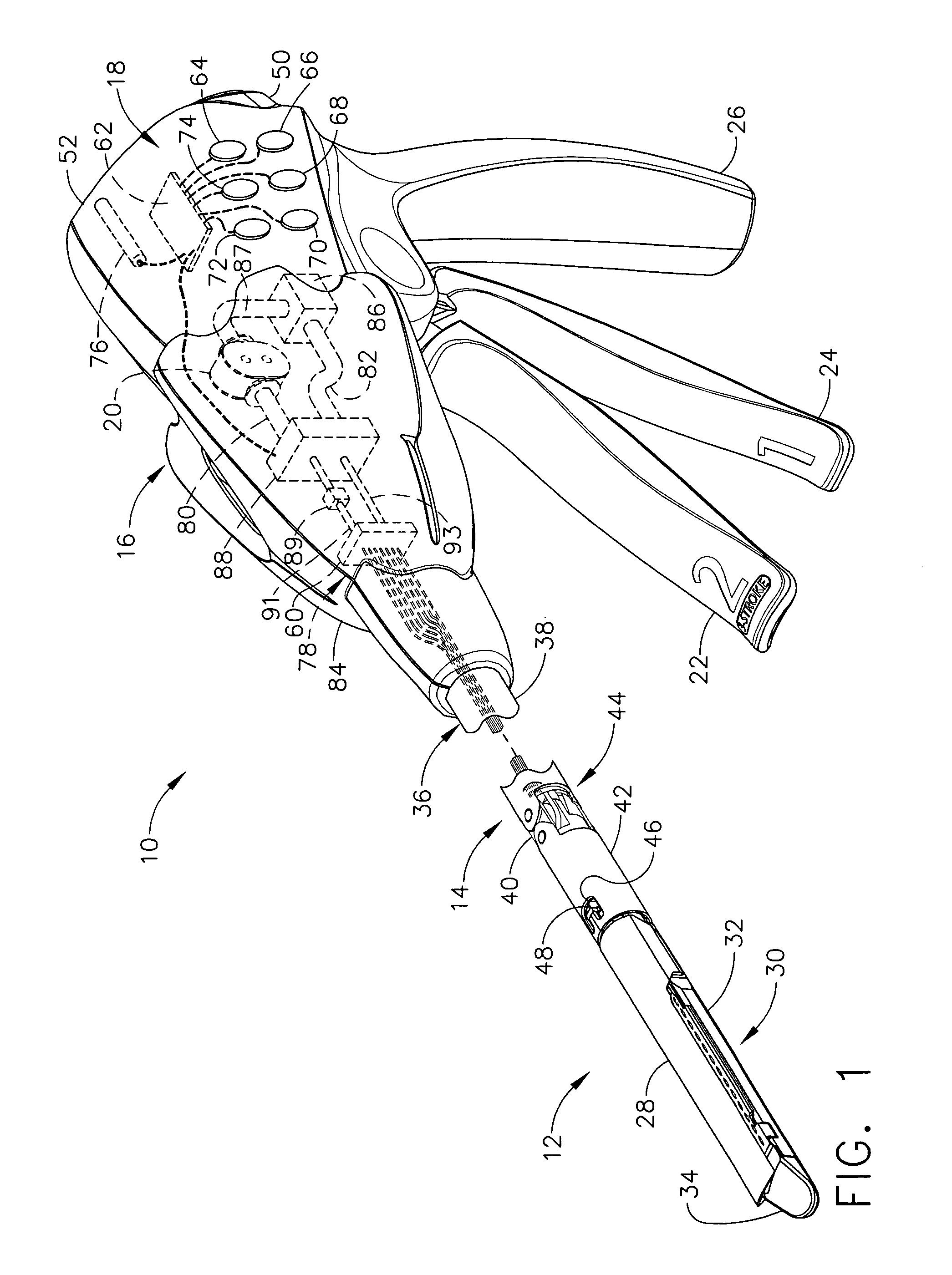

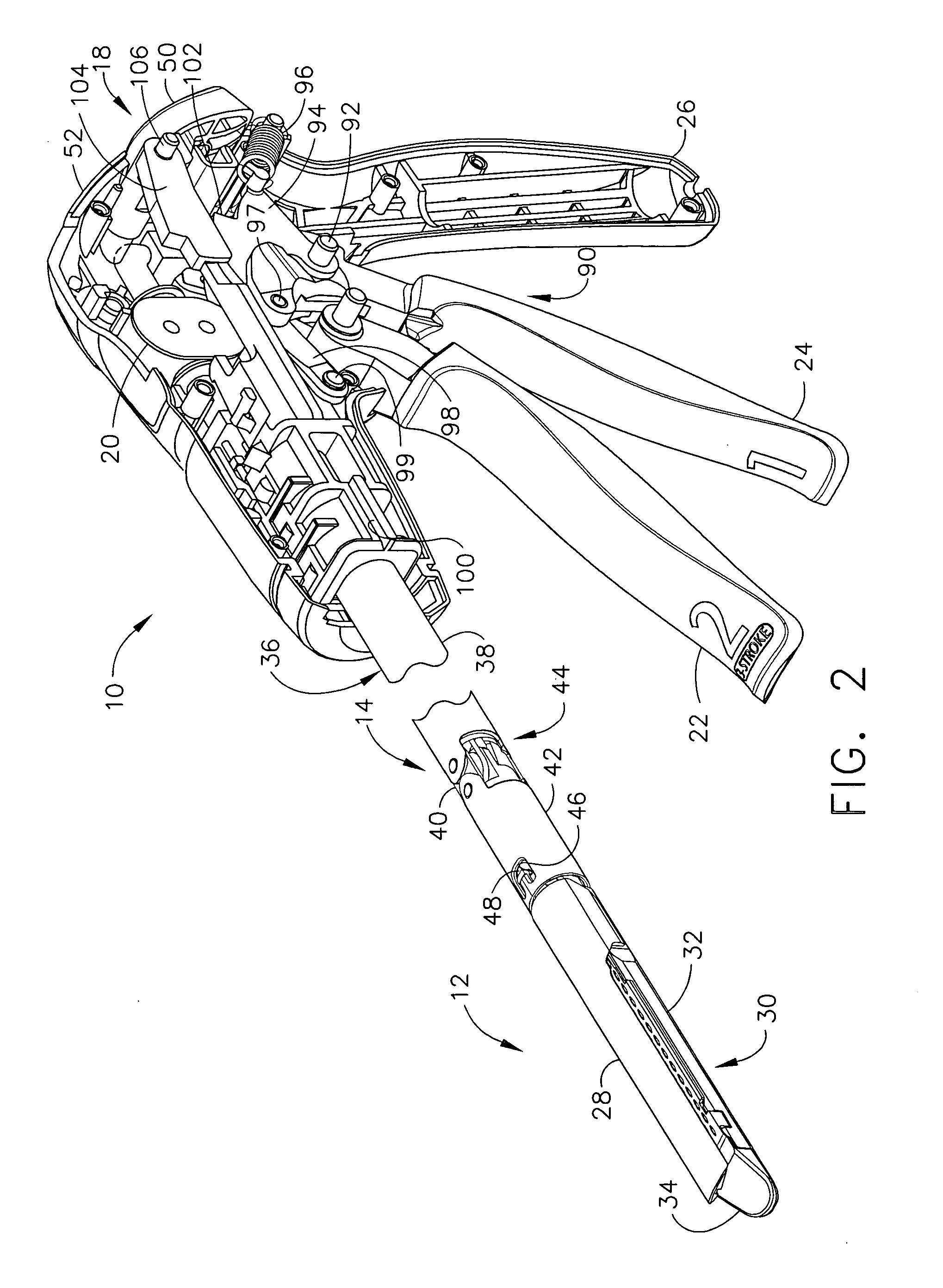

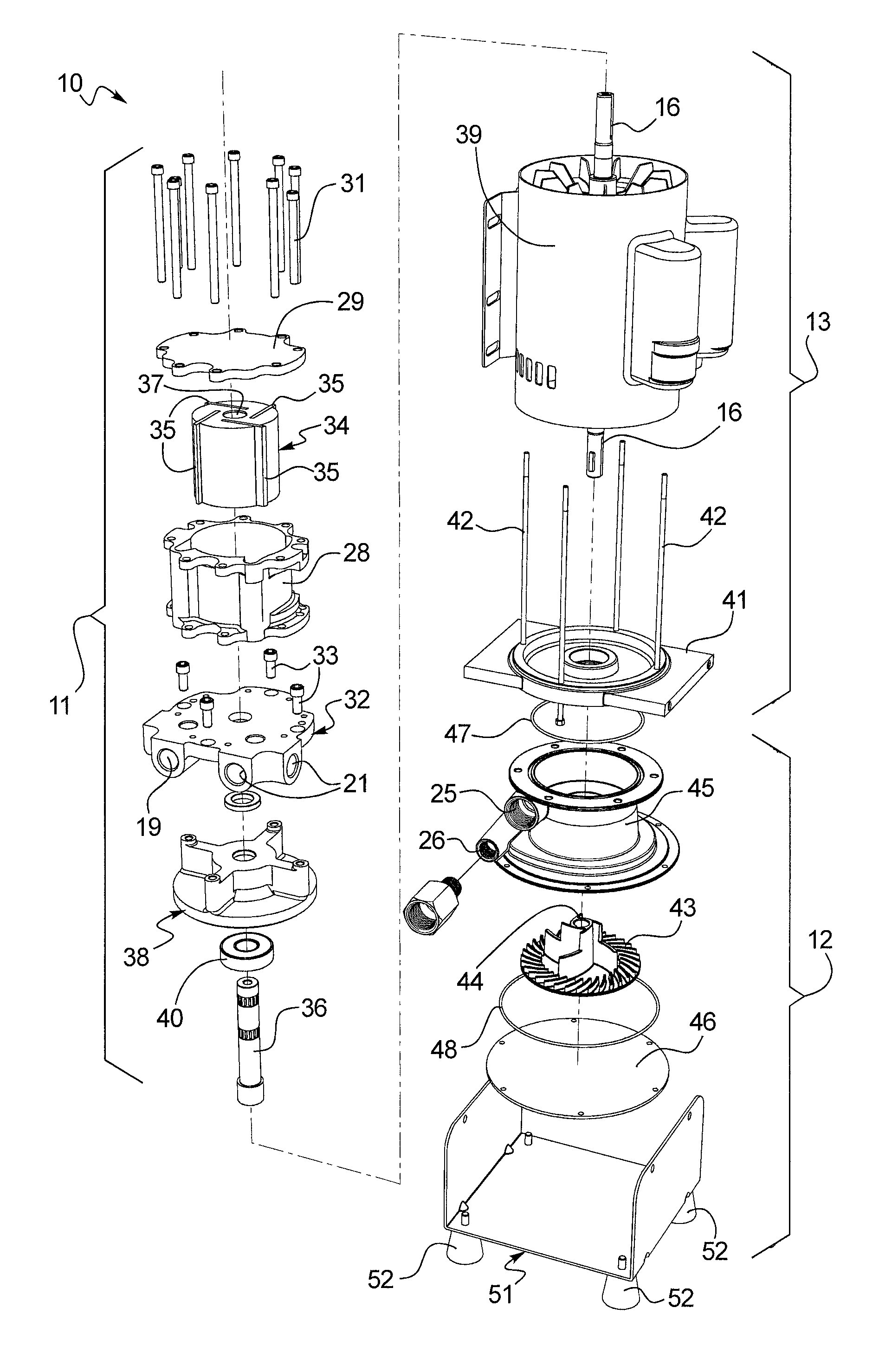

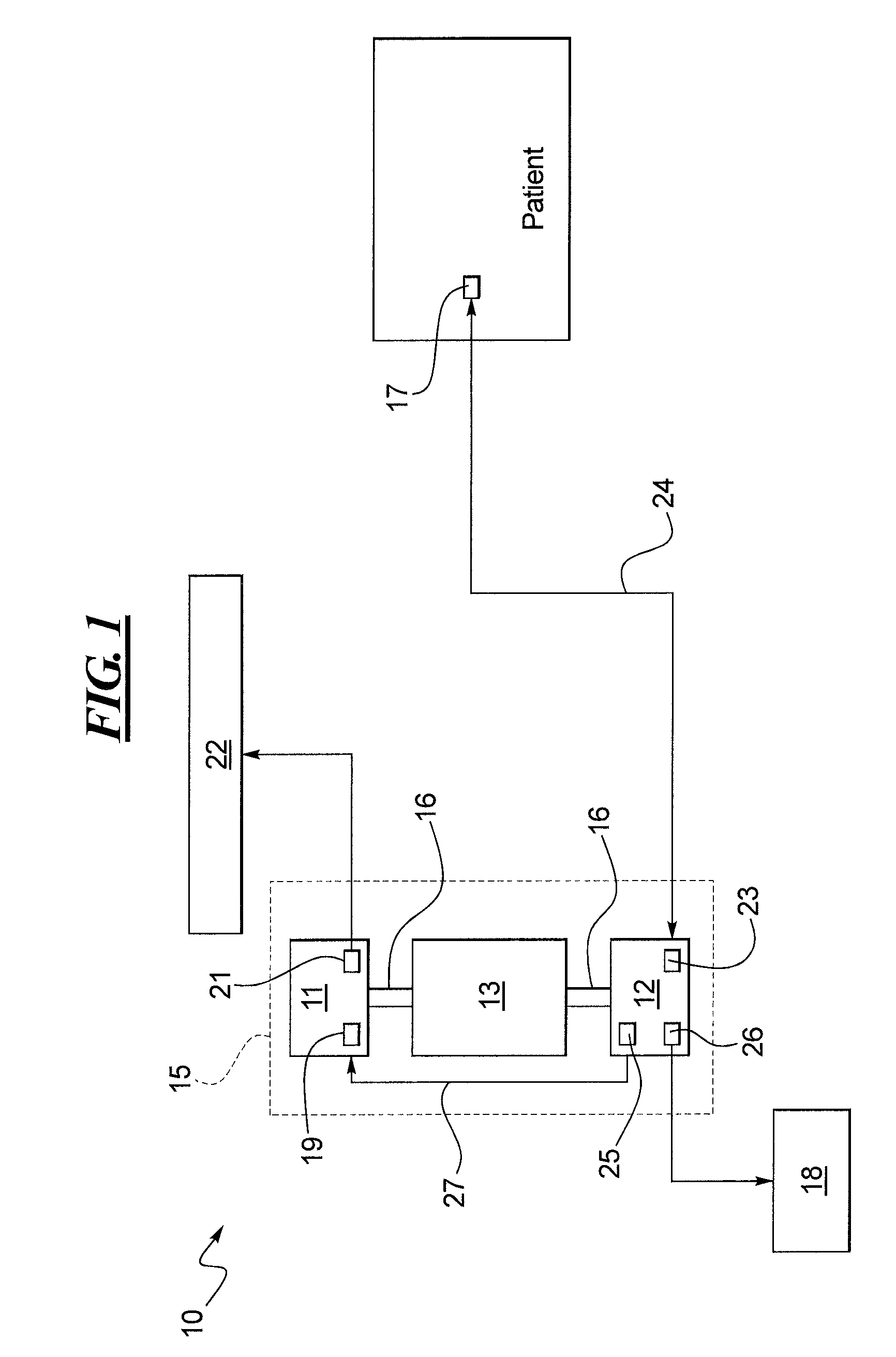

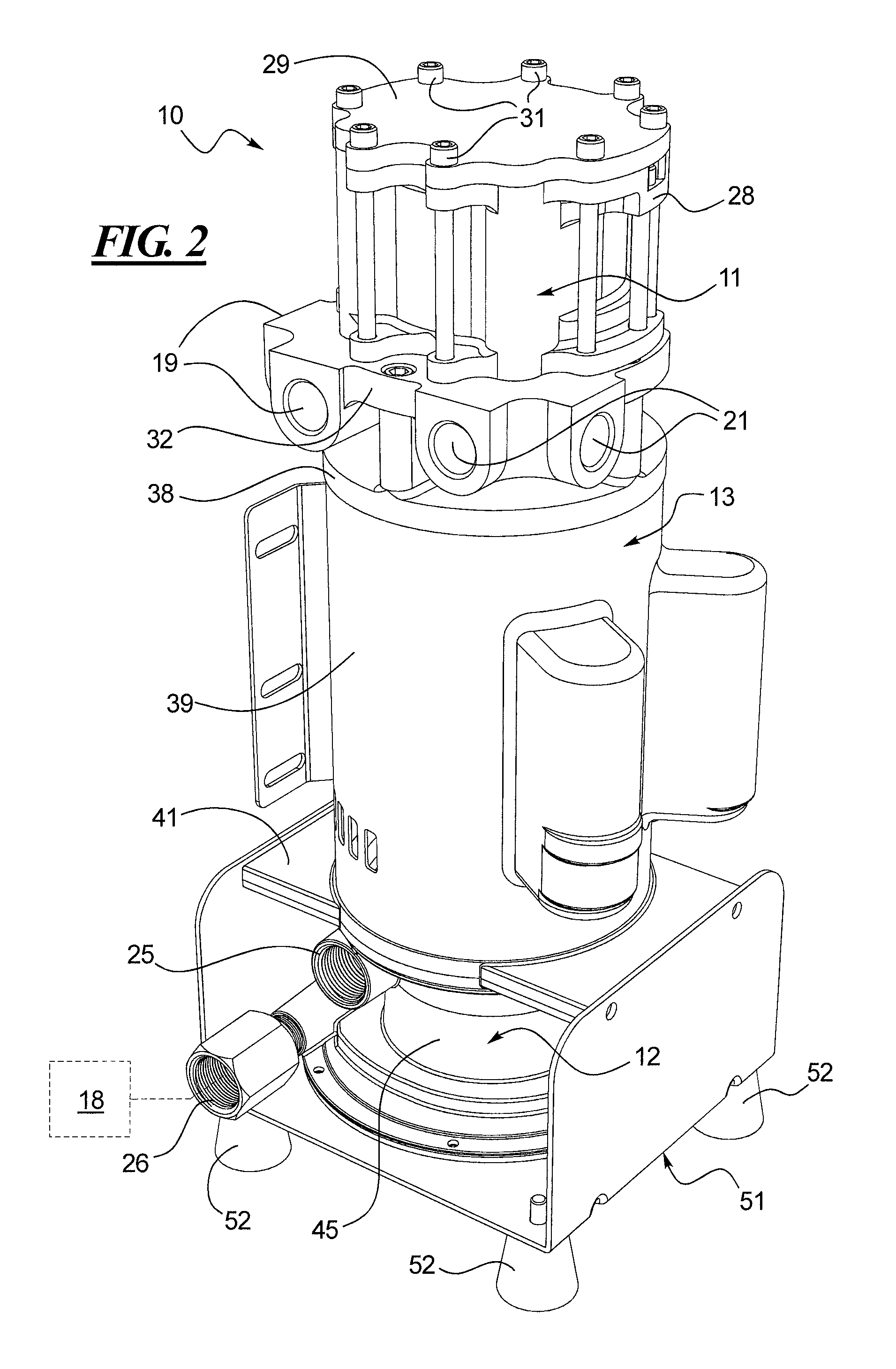

Rotary hydraulic pump actuated multi-stroke surgical instrument

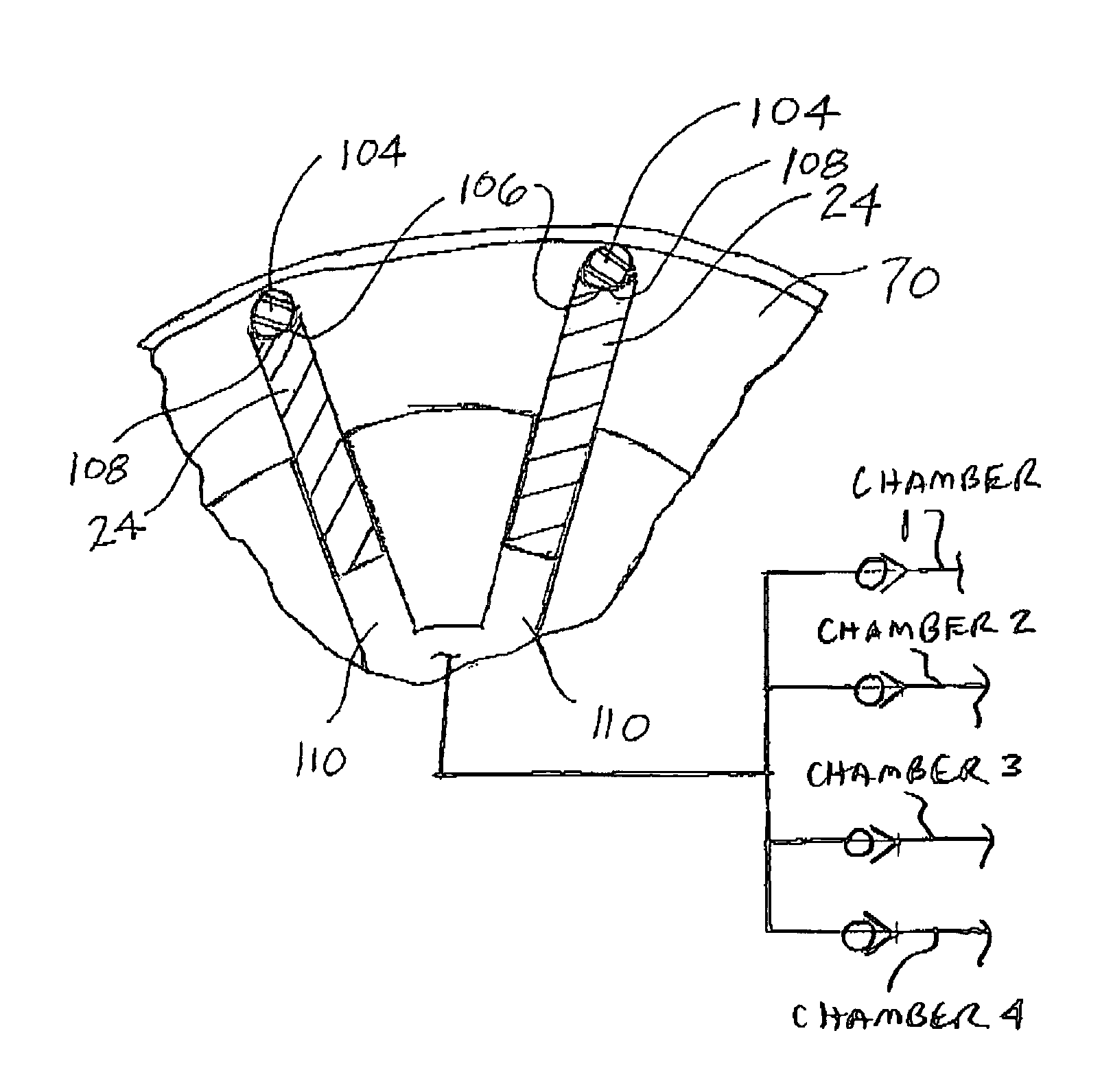

A surgical instrument (e.g., endocutter, grasper, cutter, staplers, clip applier, access device, drug / gene therapy delivery device, and energy device using ultrasound, RF, laser, etc.) may benefit from having a plurality of hydraulically actuated subsystems (e.g., severing, stapling, articulation, locking / unlocking, lockout enabling / disabling, grasping, etc.) supplied with hydraulic power from a trigger actuated rotary pump (e.g., lobe pump, rotary gear pump, internal rotating gear pump, flexible vane rotor pump, rotary vane pump). Thereby, an available amount of mechanical advantage available at a firing trigger may be optimally distributed to various end effector components, perhaps sequenced by an electroactive polymer or piezoelelectrically actuated function switch block.

Owner:ETHICON ENDO SURGERY INC

Rotary hydraulic pump actuated multi-stroke surgical instrument

A surgical instrument (e.g., endocutter, grasper, cutter, staplers, clip applier, access device, drug / gene therapy delivery device, and energy device using ultrasound, RF, laser, etc.) may benefit from having a plurality of hydraulically actuated subsystems (e.g., severing, stapling, articulation, locking / unlocking, lockout enabling / disabling, grasping, etc.) supplied with hydraulic power from a trigger actuated rotary pump (e.g., lobe pump, rotary gear pump, internal rotating gear pump, flexible vane rotor pump, rotary vane pump). Thereby, an available amount of mechanical advantage available at a firing trigger may be optimally distributed to various end effector components, perhaps sequenced by an electroactive polymer or piezoelectrically actuated function switch block.

Owner:ETHICON ENDO SURGERY INC

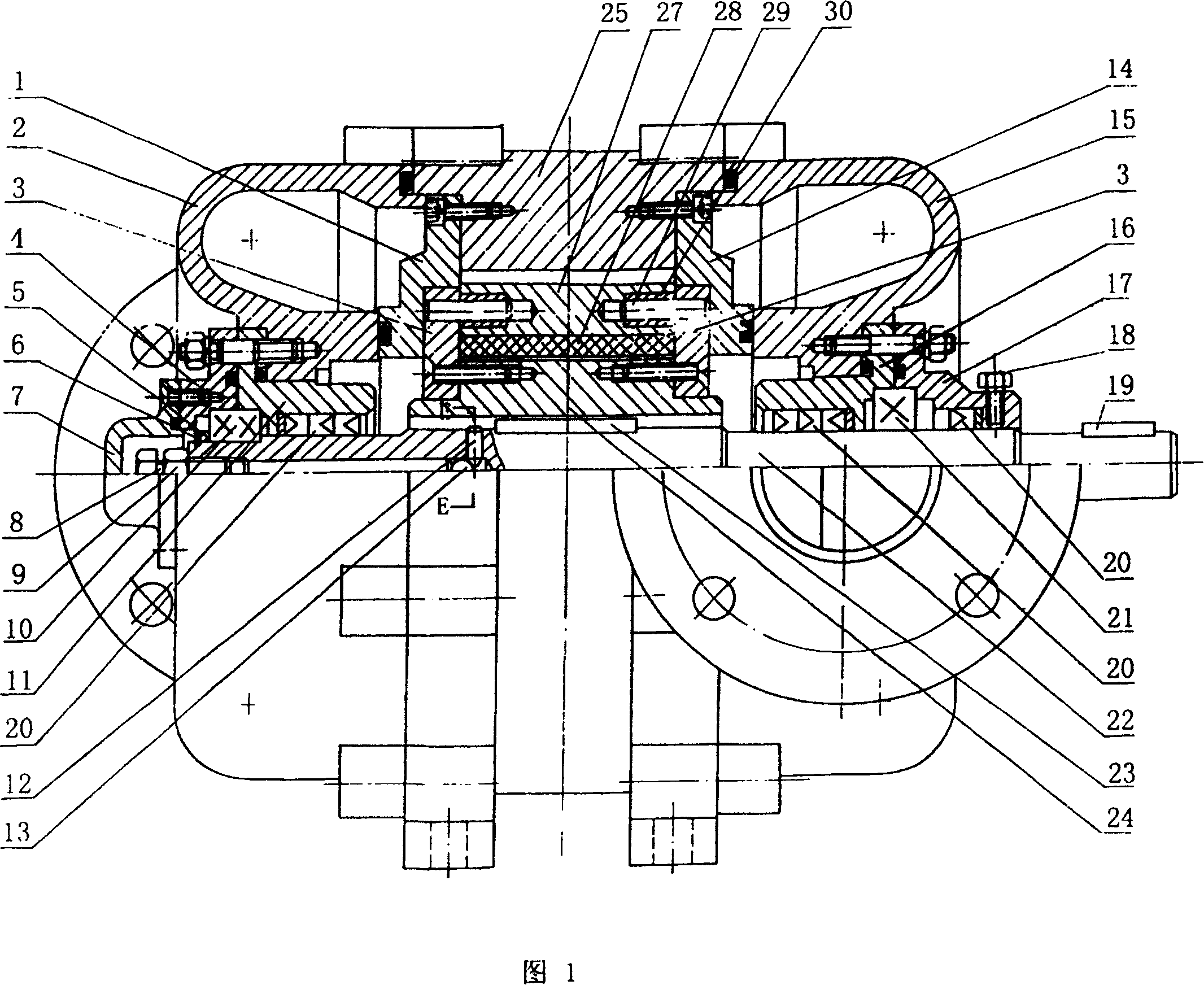

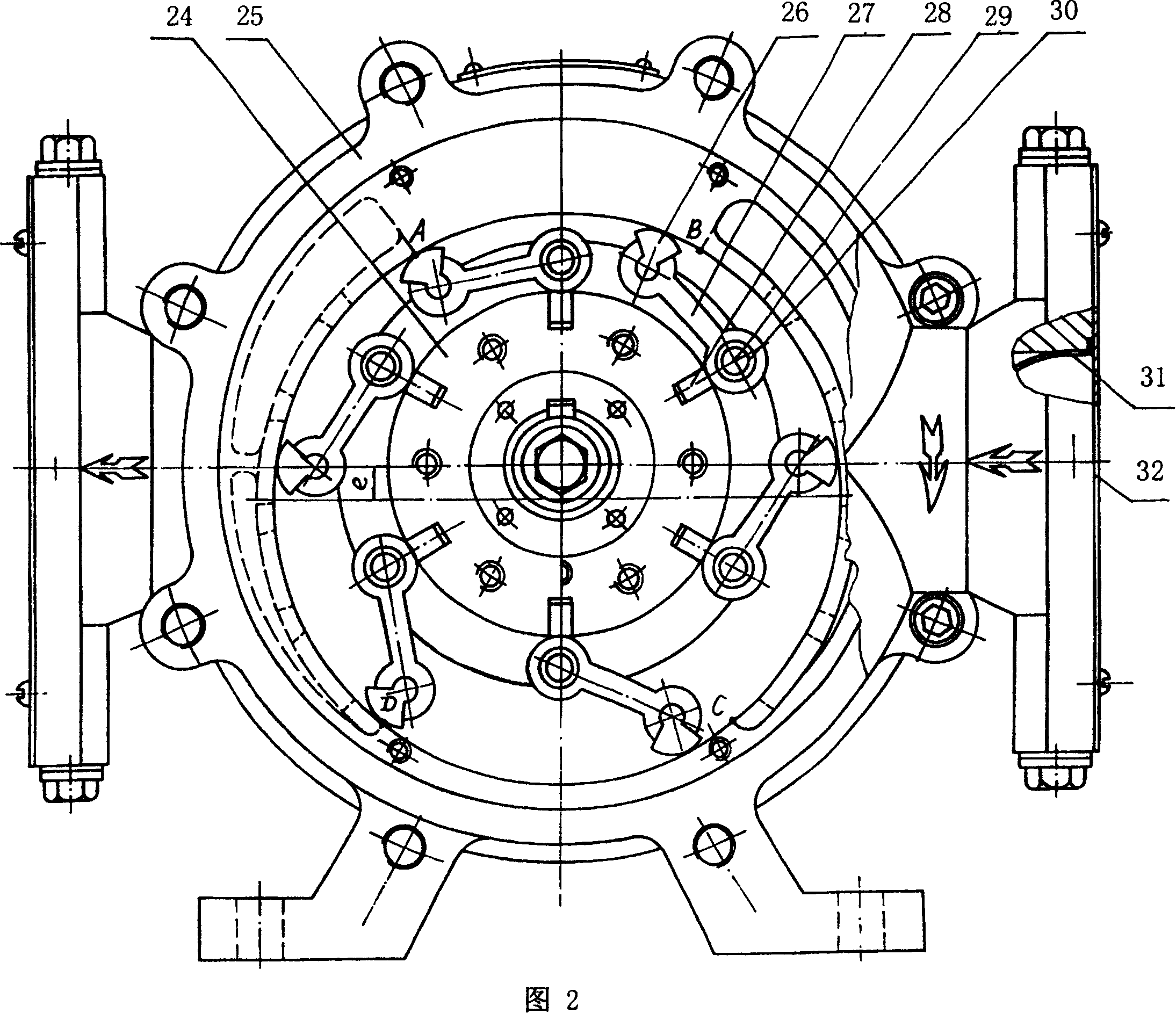

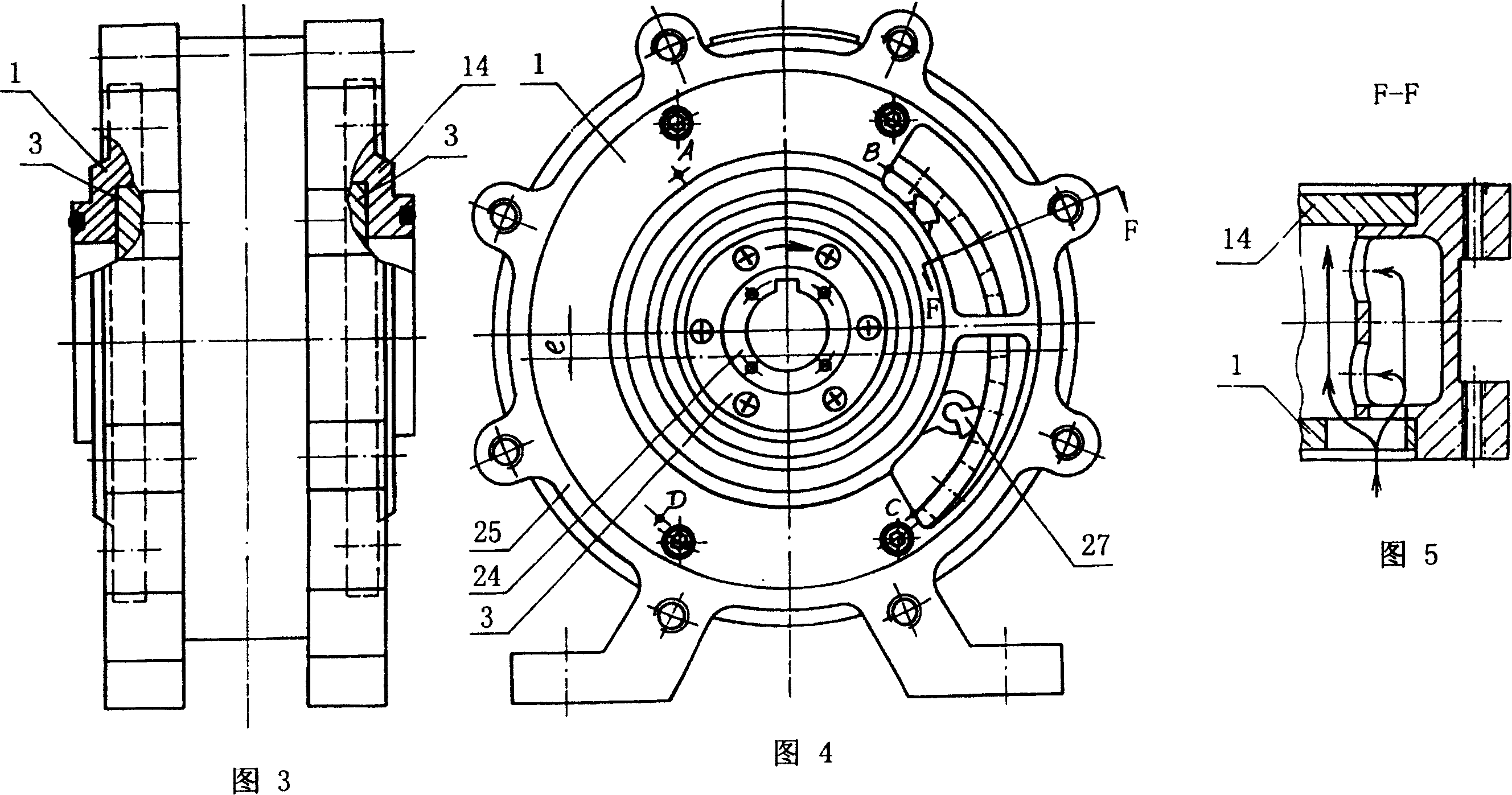

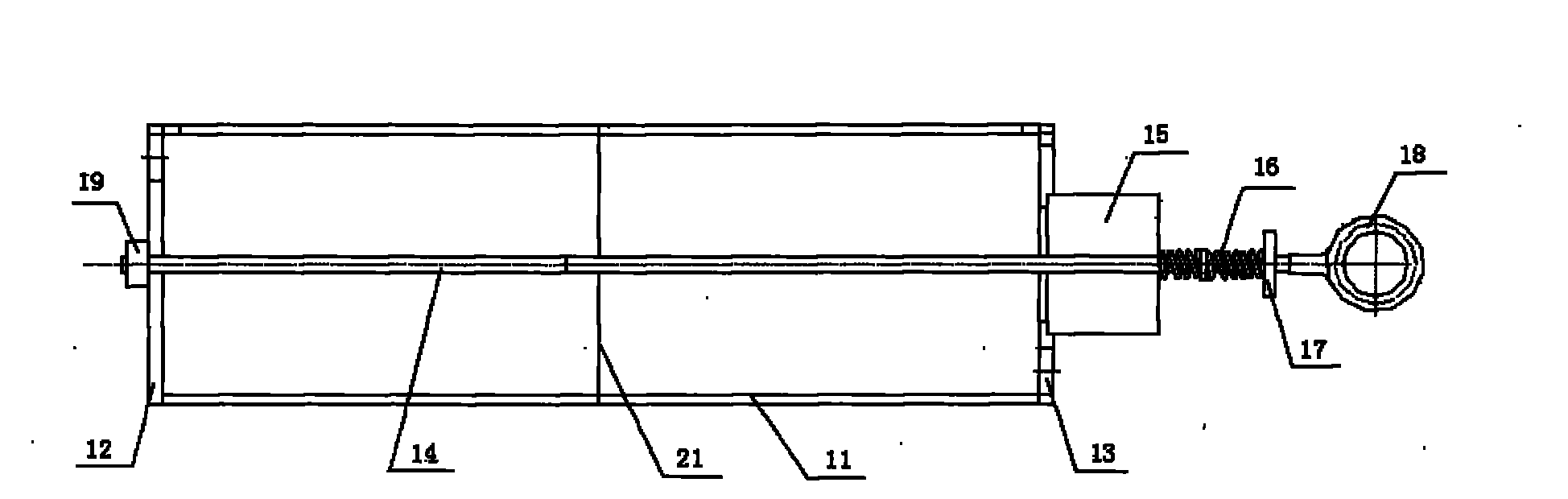

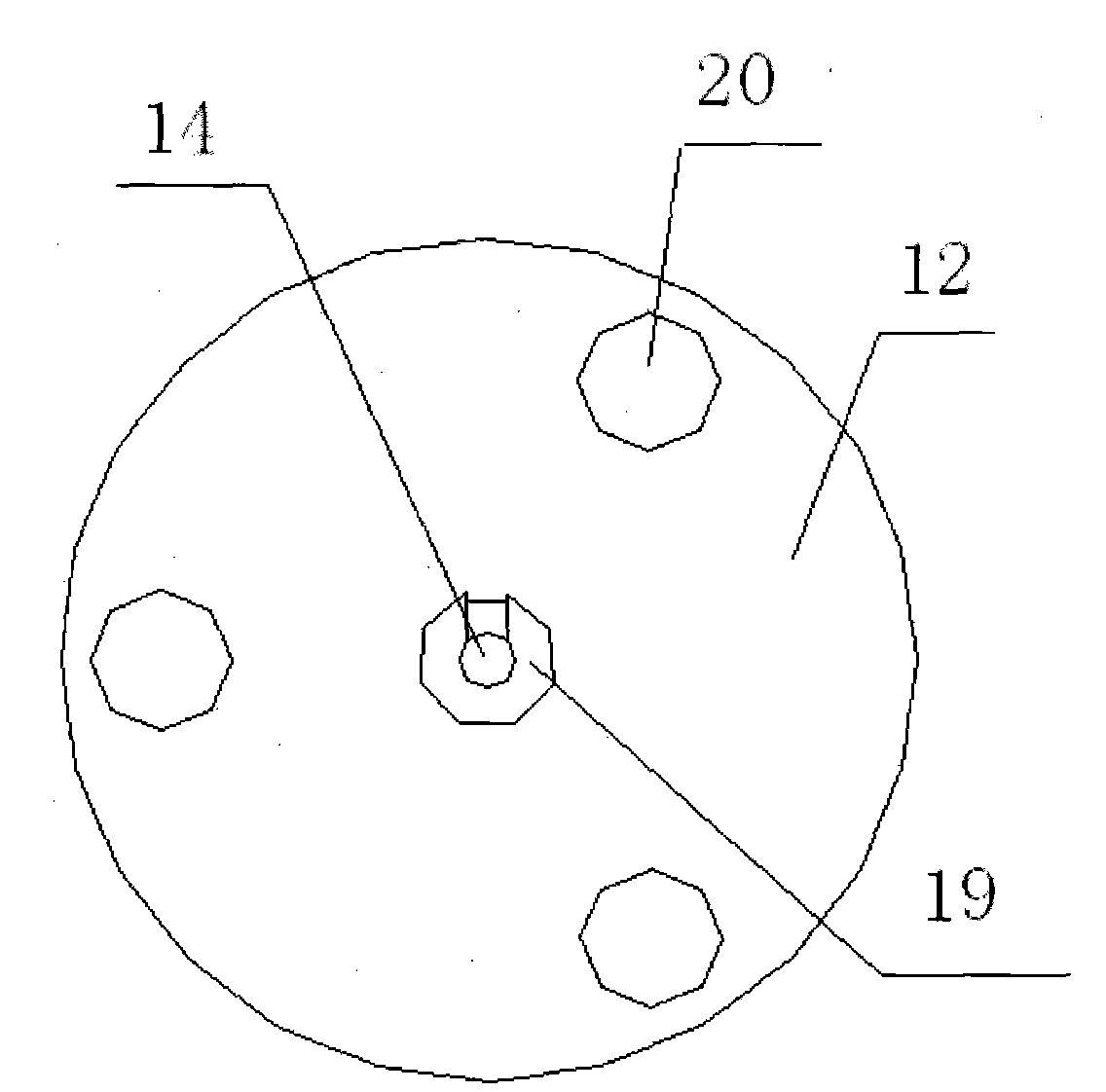

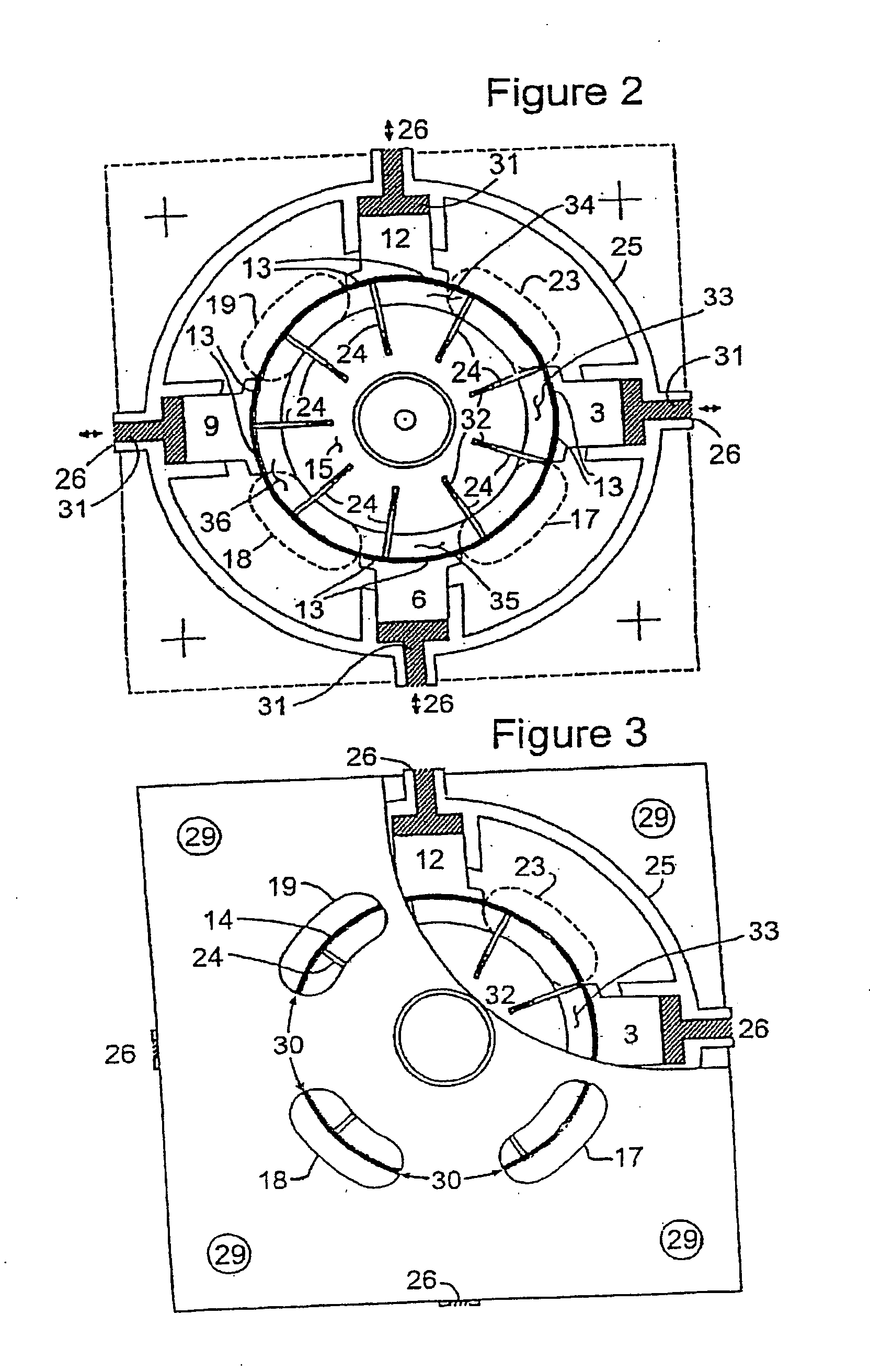

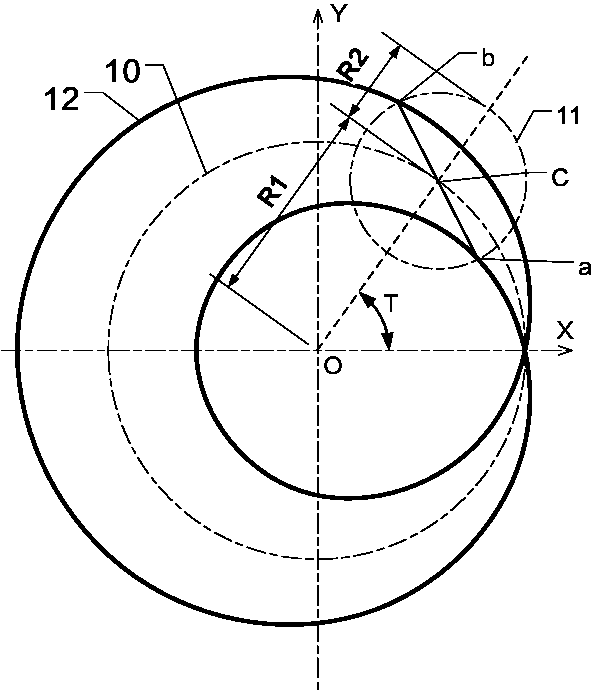

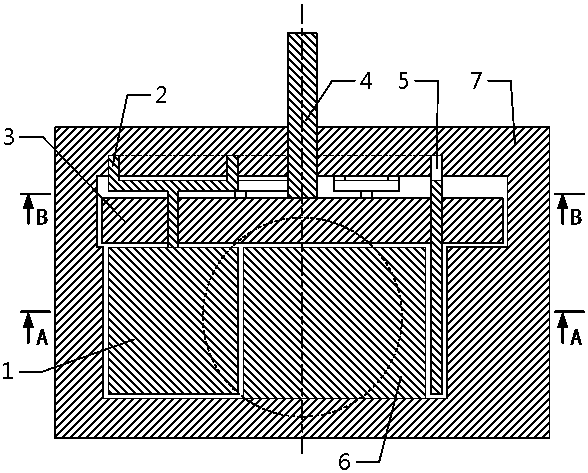

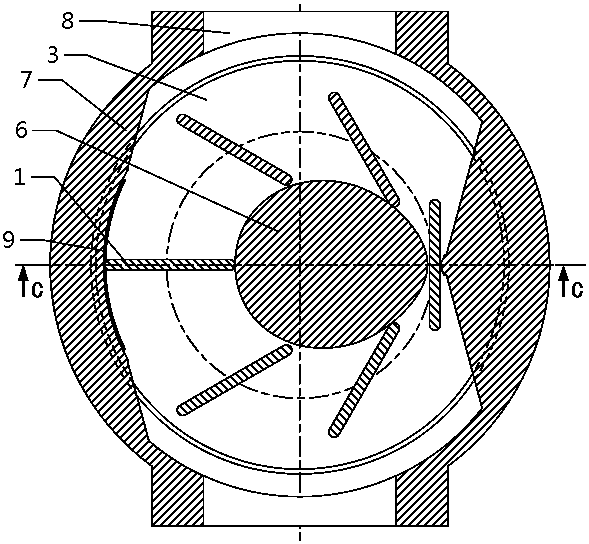

Rotary blade pump

InactiveCN100374725CReduce line speedEliminate cavitationRotary piston pumpsRotary piston liquid enginesClassical mechanicsEngineering

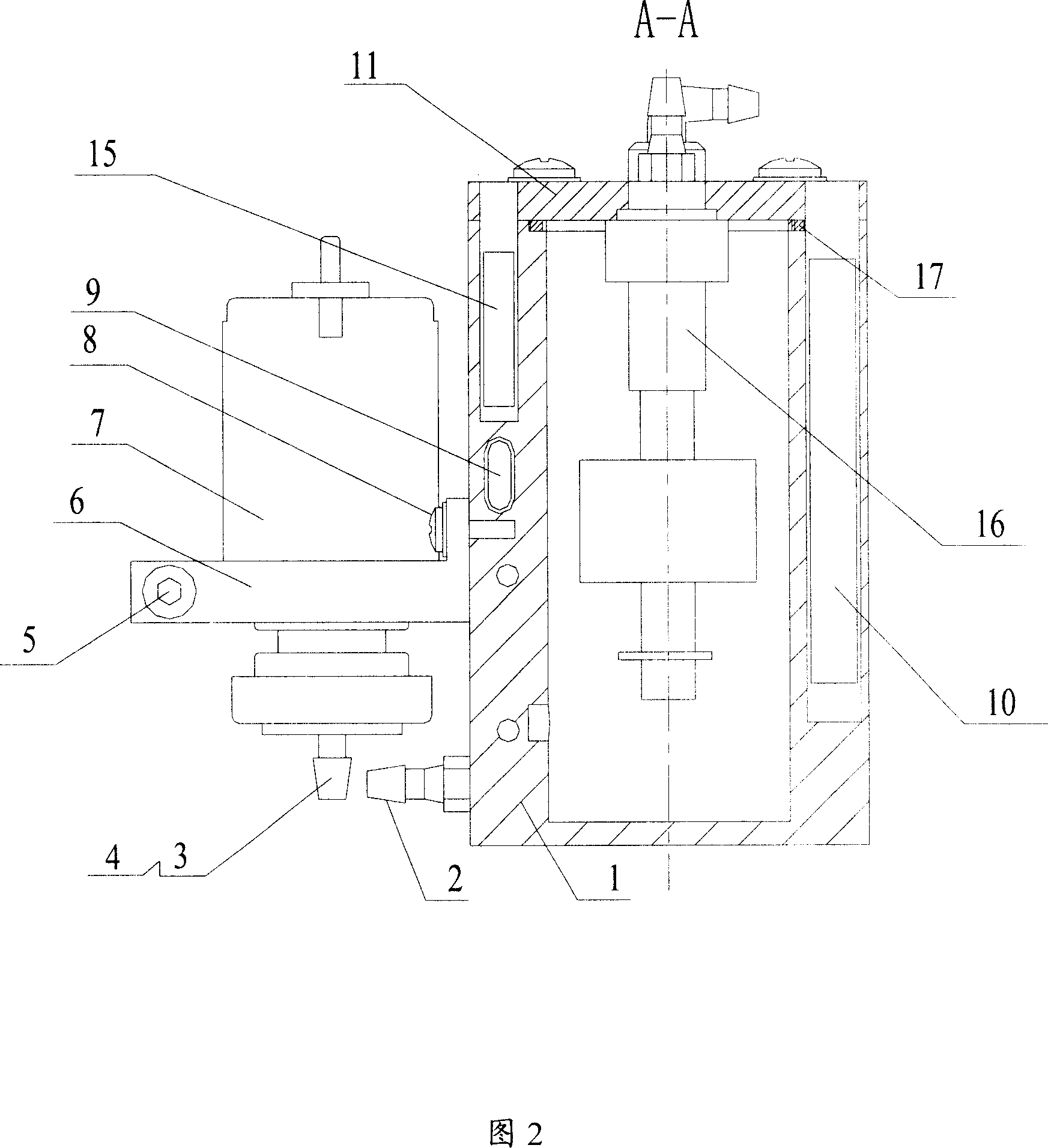

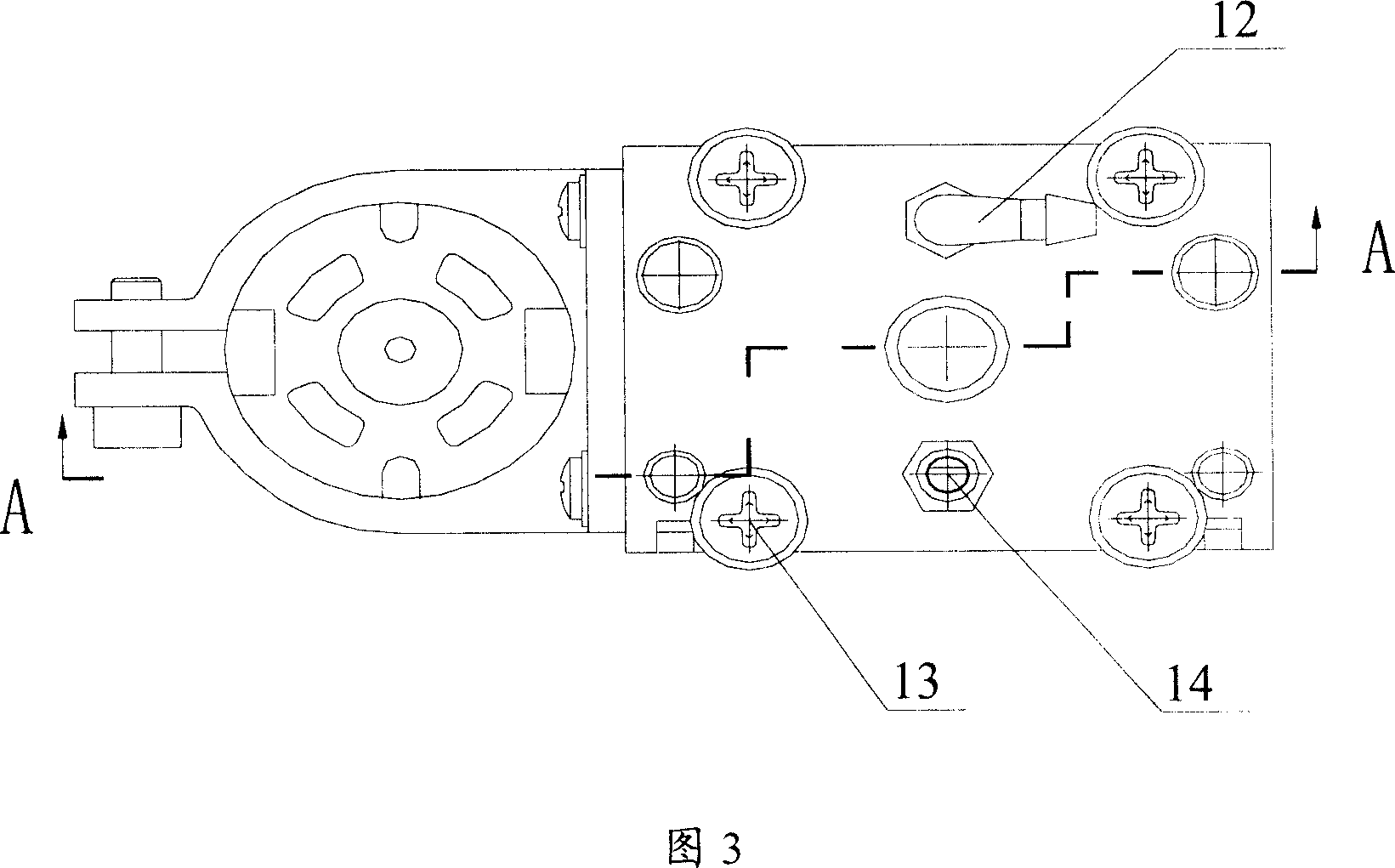

In the invention, an inlet-outlet oil flow plate is fixed at two ends of a pump case stator. A radial inlet-outlet runner is built-up on the pump case stator to realize axial and radial inlet and outlet oil at the same time. A rotor is mounted in the internal cavity of the pump case stator and there is an offsetting e between the rotor and the ID of the pump case stator. Rotary vanes are mounted on a rotating board fixed on the two end faces of the rotor. The rotor is mounted on the pump spindle via a rotor key. A rotor locking device is assembled on the front part of the pump spindle. The inlet-outlet oil pump covers are fixed at two ends of the pump stator separately. A ring inlet-outlet oil passageway is disposed in inlet-outlet oil pump. A bearing support and sealing device is assembled on the central of the inlet-outlet oil pump cover.

Owner:王振忠 +1

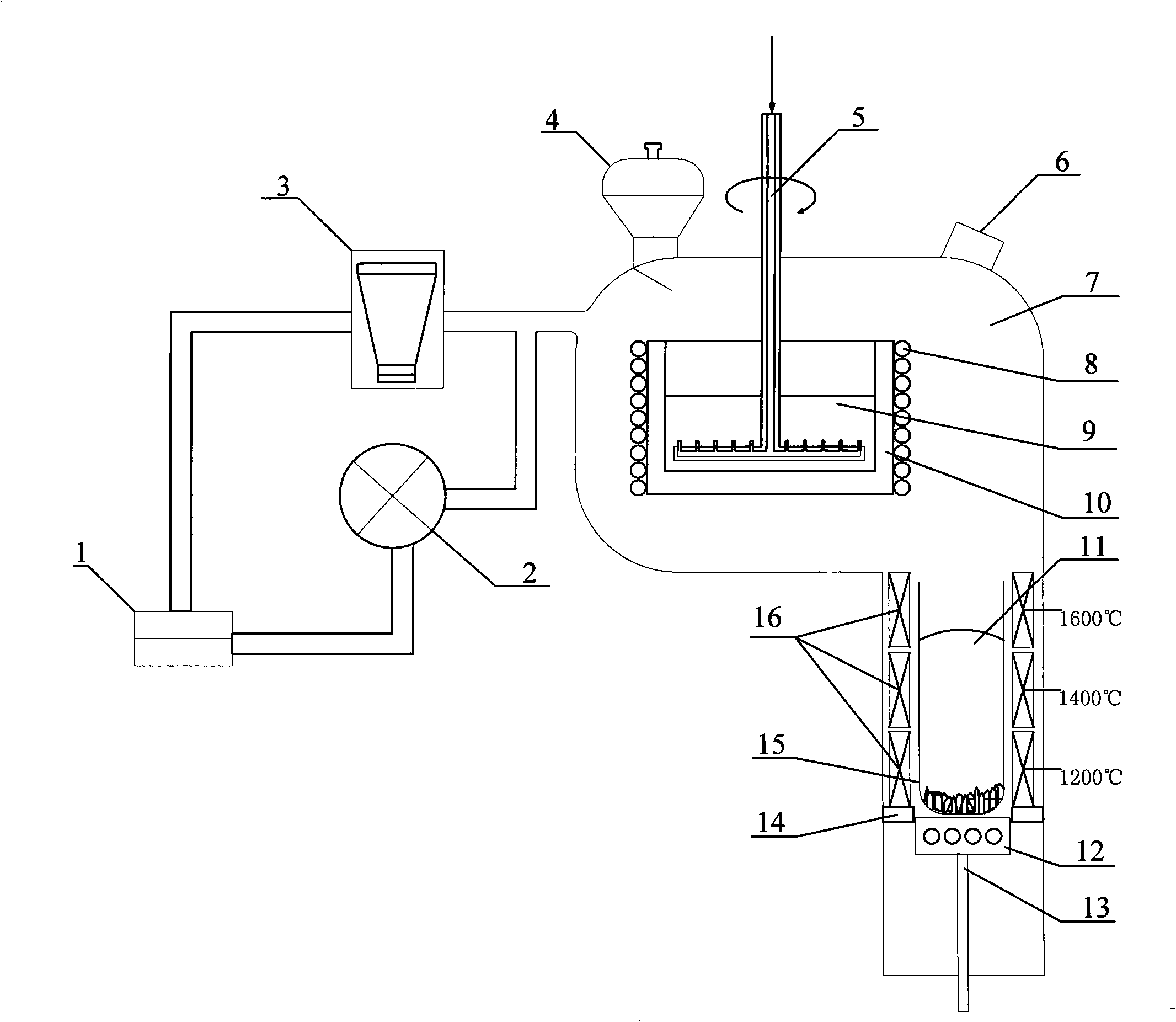

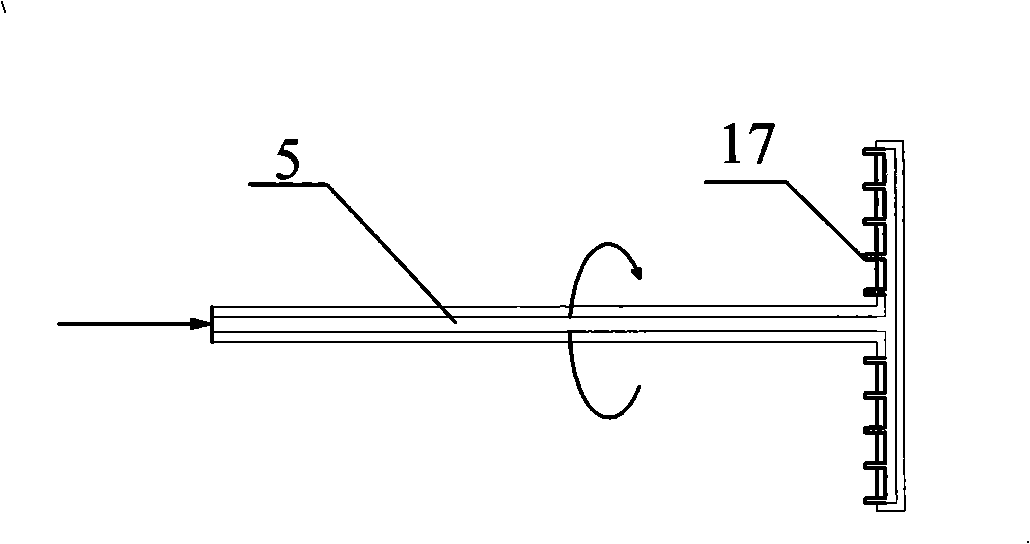

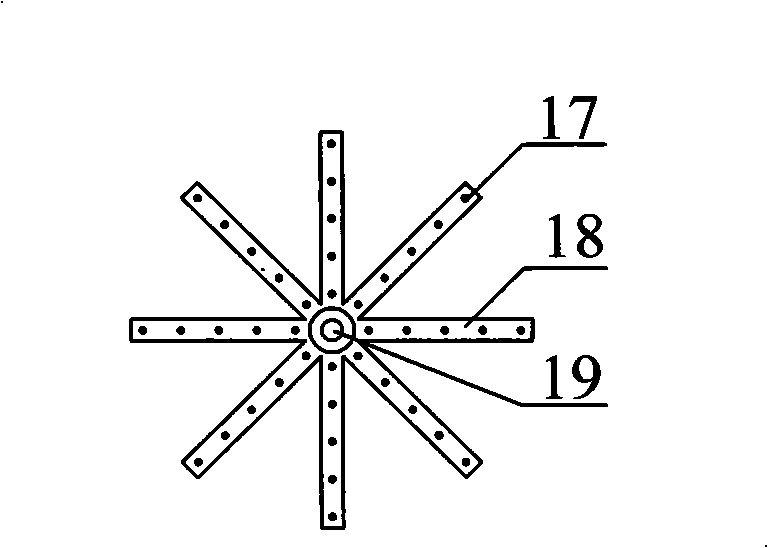

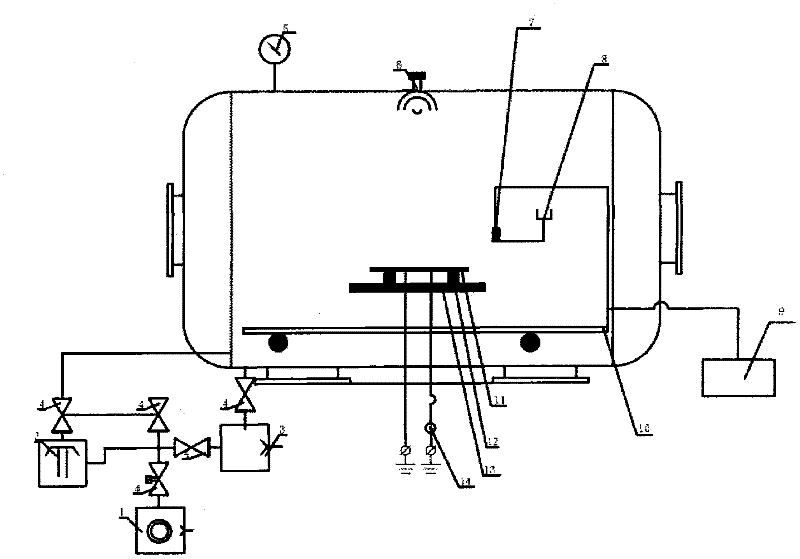

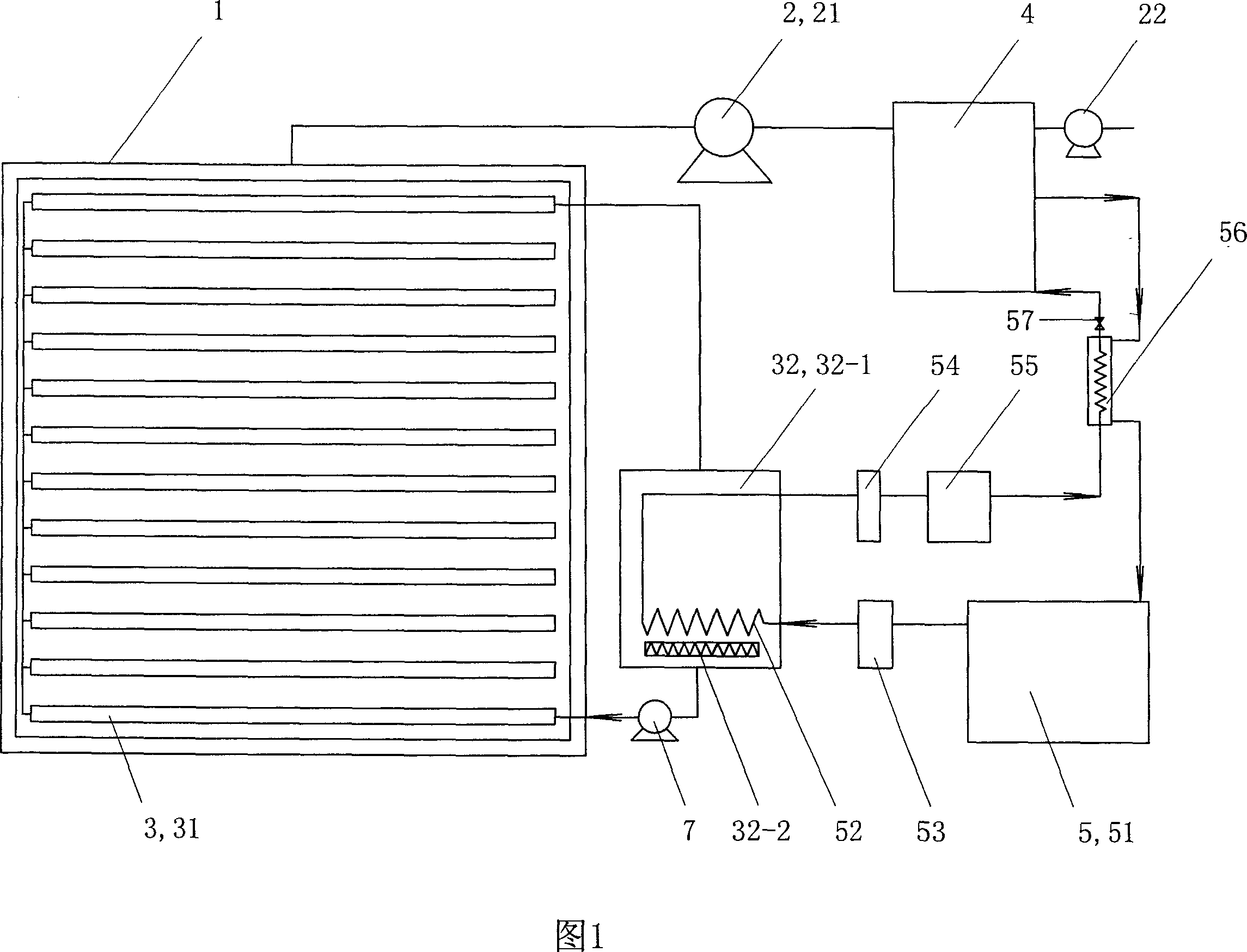

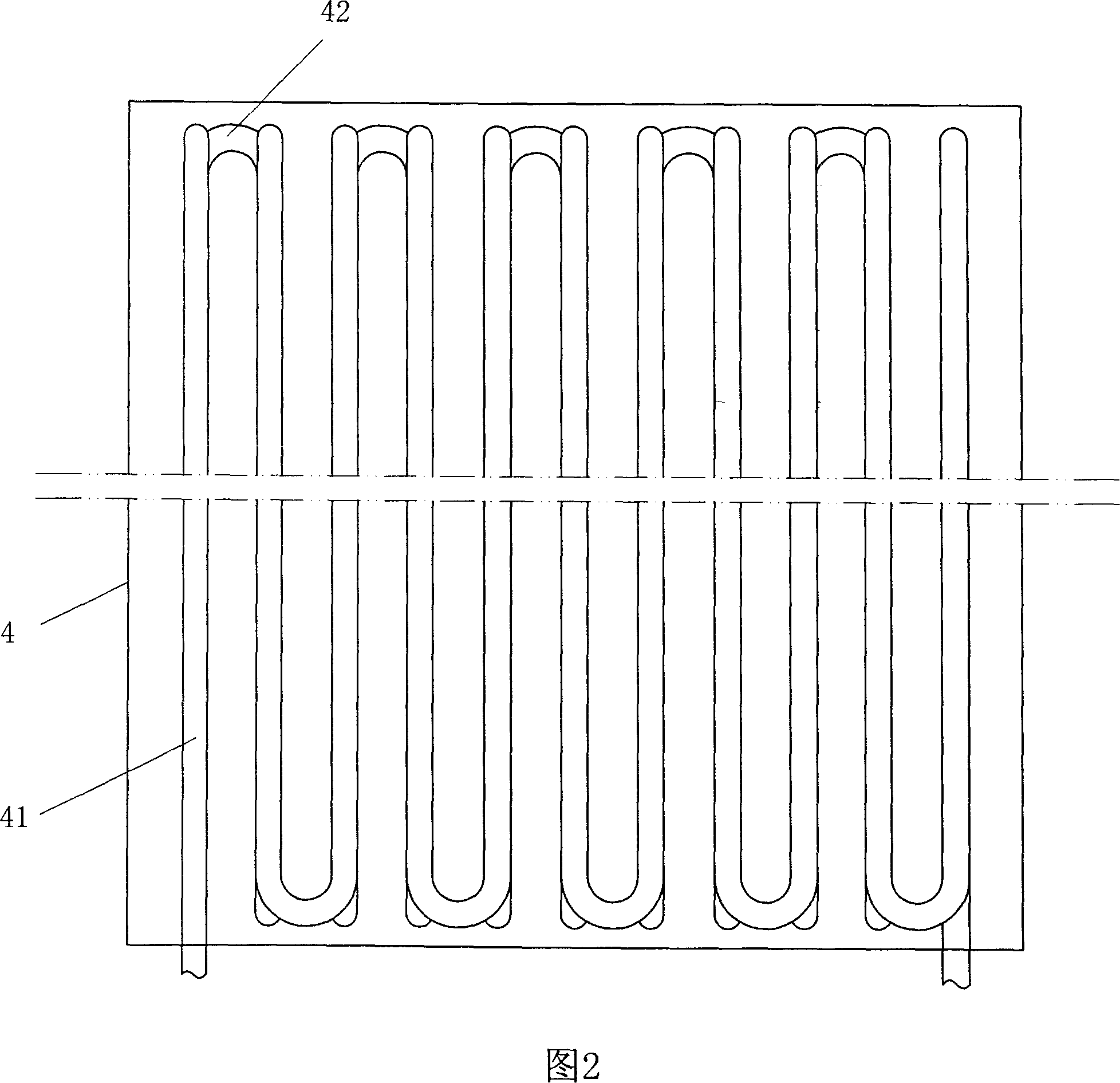

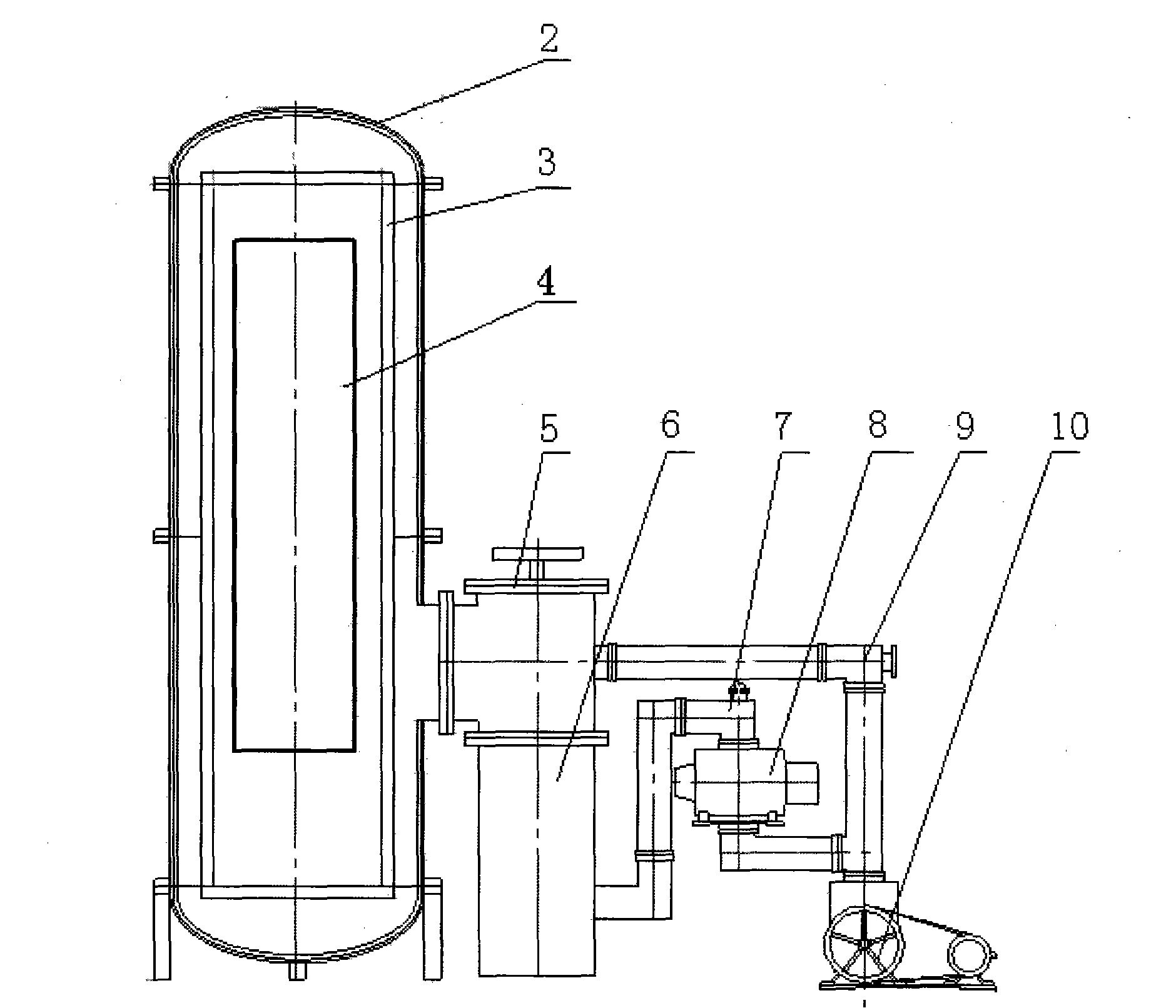

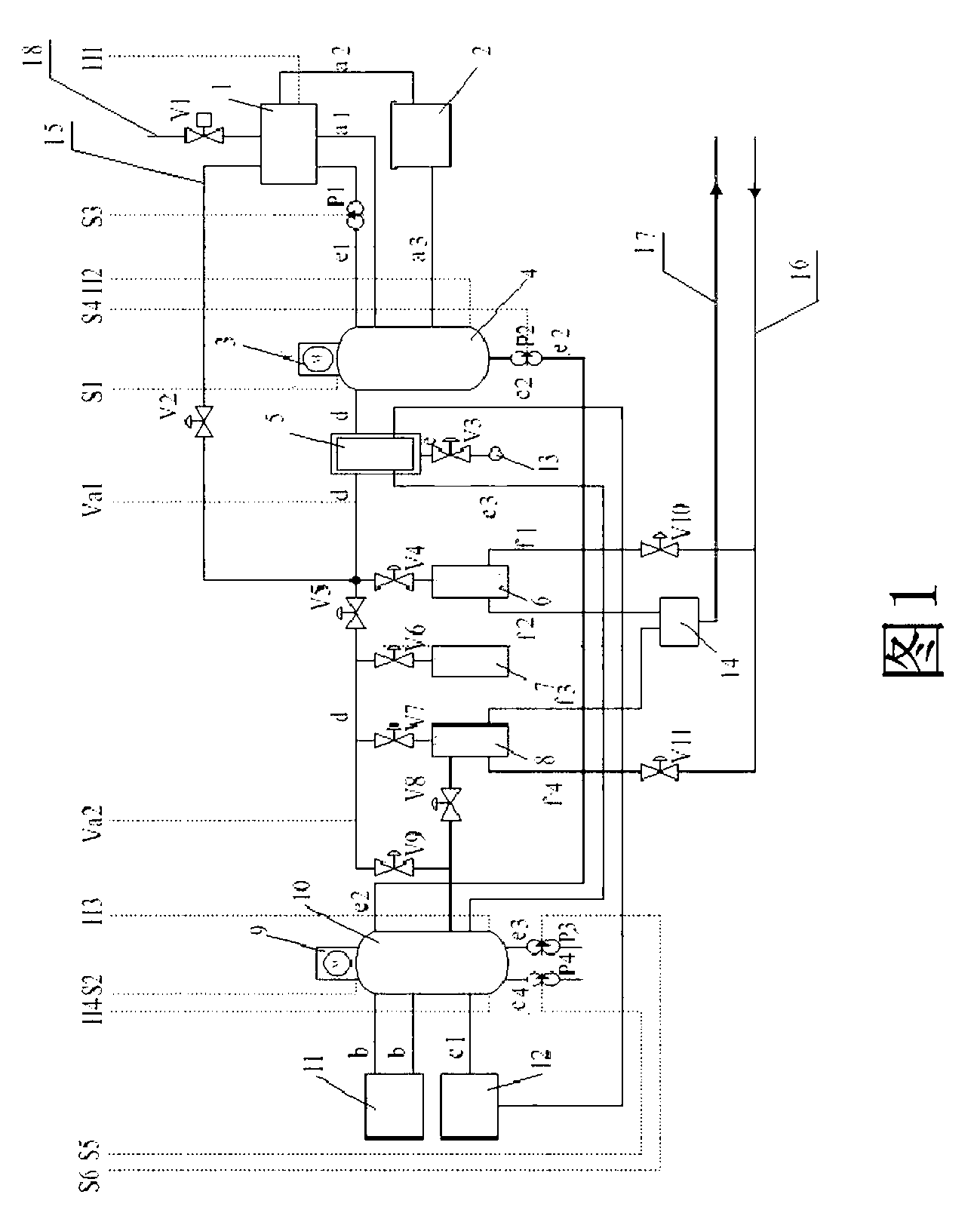

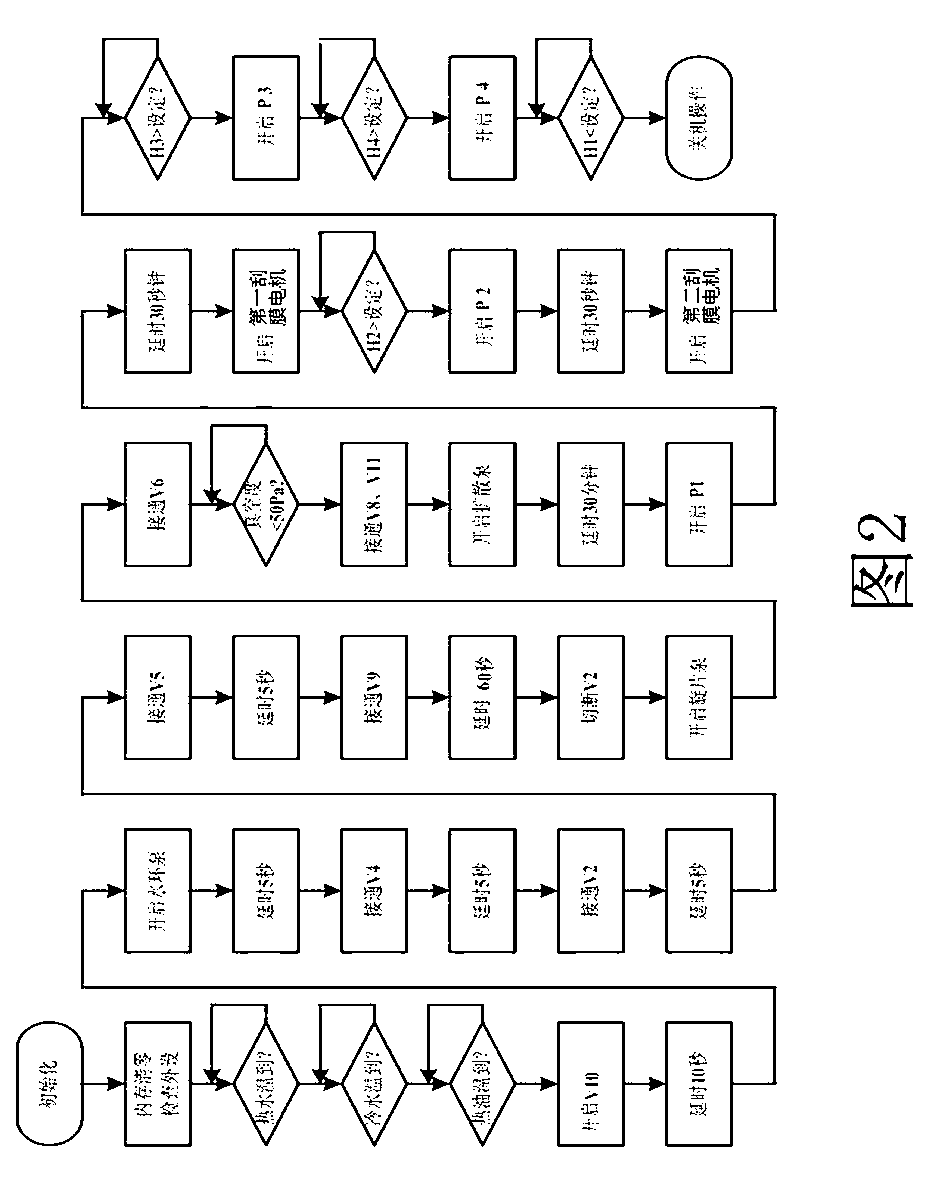

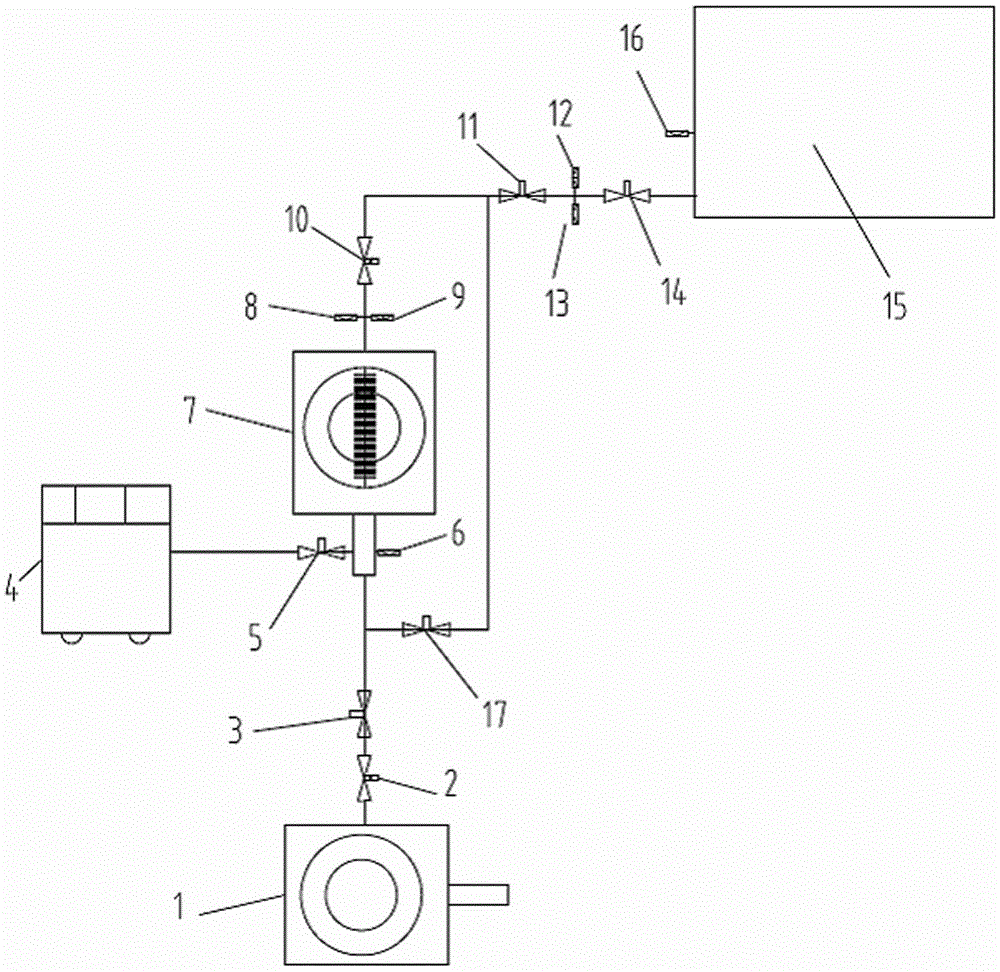

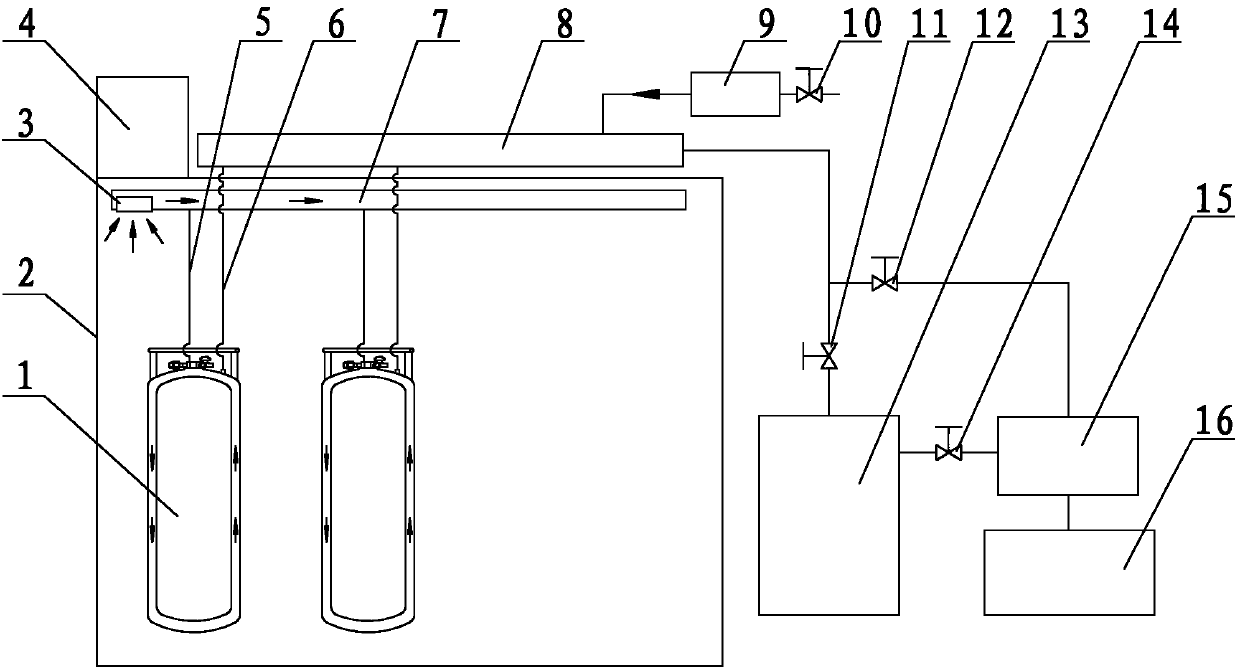

Purification apparatus and method for solar energy level polysilicon

Disclosed are a purification device as well as a purification method of solar-grade polysilicon, relating to a polysilicon, which provides a purification device and a purification method of solar-grade polysilicon characterized by low cost, high purity, simple process, easy operation and suitability for large-scale production. The purification device is equipped with a vacuum system, a melting system and a directional solidification system; wherein the vacuum system is provided with a mechanical rotary vane pump, a lobed element pump and an oil diffusion pump, and the melting system is provided with a vacuum chamber, a secondary feeder, an observation window, a rotary ventilation device which can be raised and lowered, an induction coil and a graphite crucible; and the directional solidification system is disposed at the lower part of the vacuum chamber and is equipped with an electric resistance-wire heating and holding furnace, a graphite mold, a holding furnace frame, a water-cooled copper tray and an elevating lever which can control speed. The metal silicon is treated by induction heating to be molten, the oxidizing gas is fed under conditions of low vacuum and high temperature to remove boron, and then under conditions of high temperature and high vacuum to remove phosphorus, and finally the molten silicon solution is poured into a directional mold to strictly conduct directional solidification to remove metal impurities.

Owner:XIAMEN UNIV

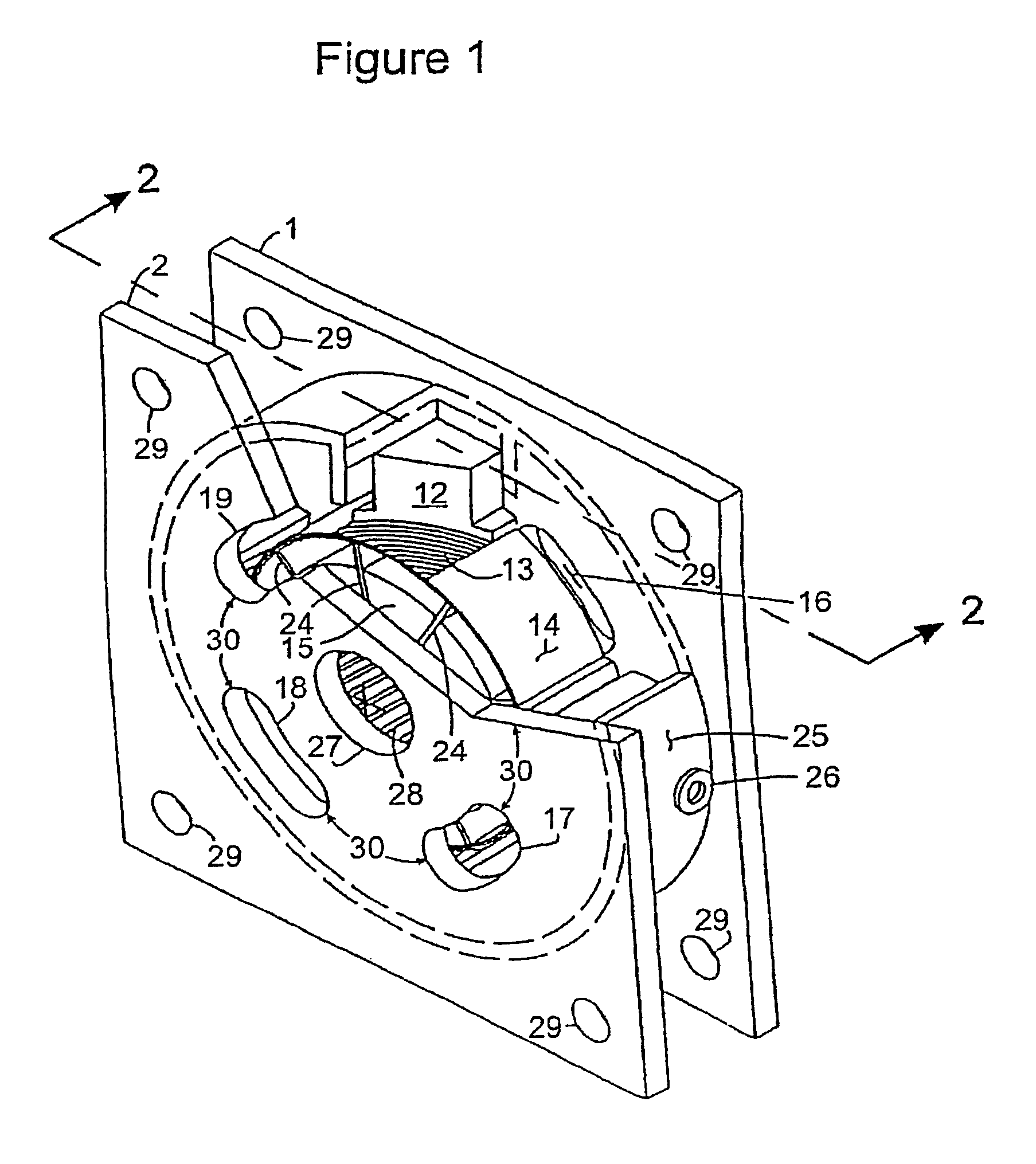

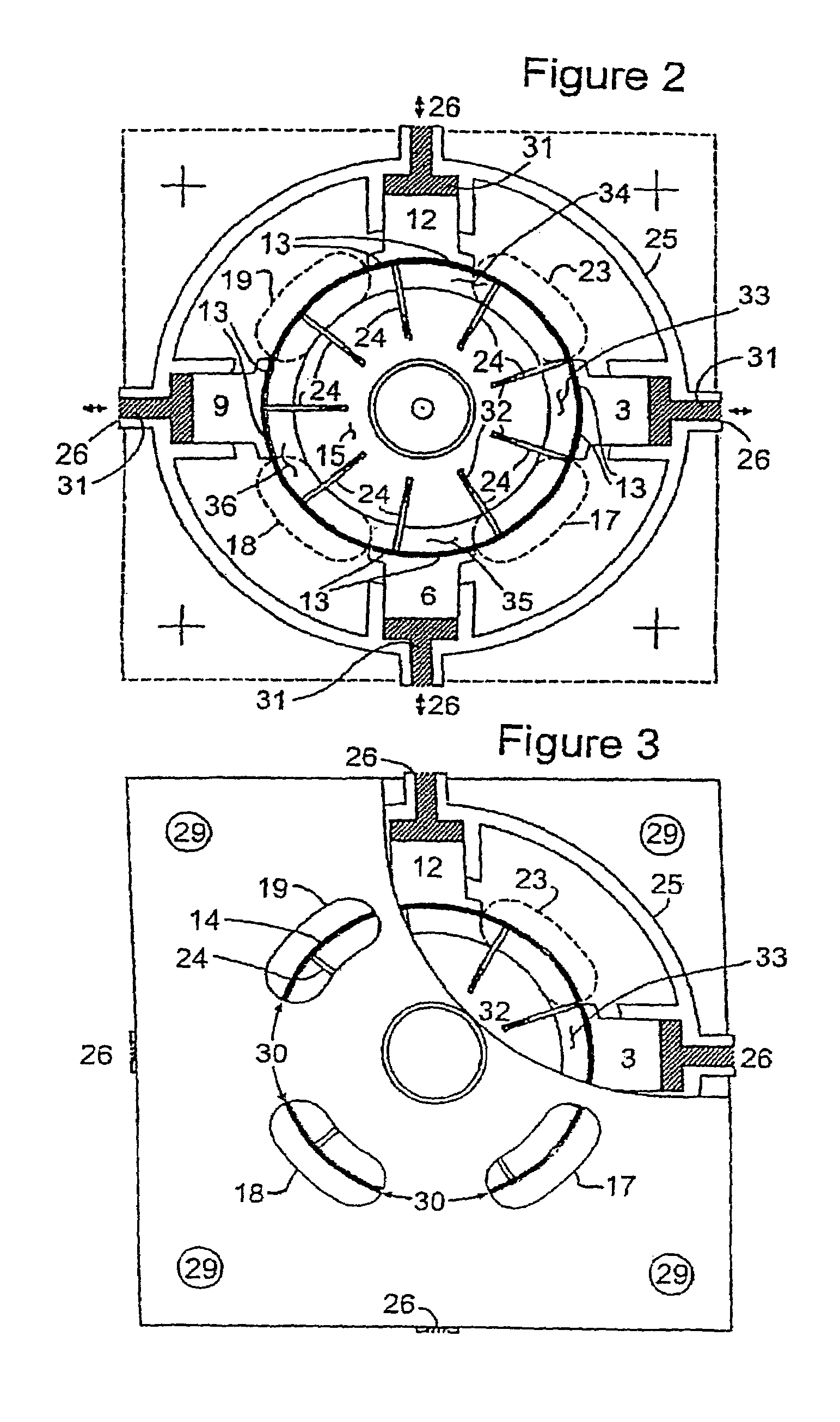

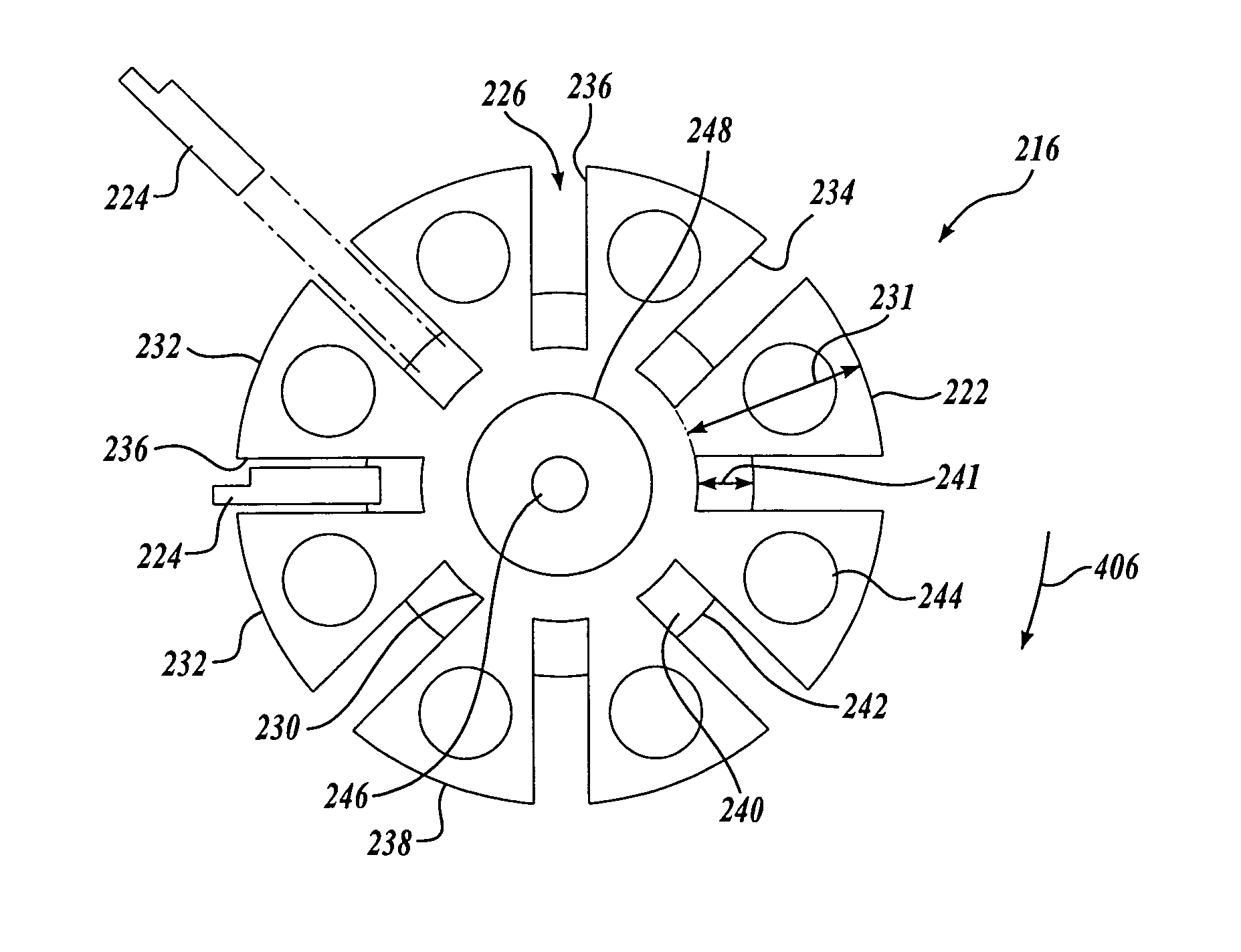

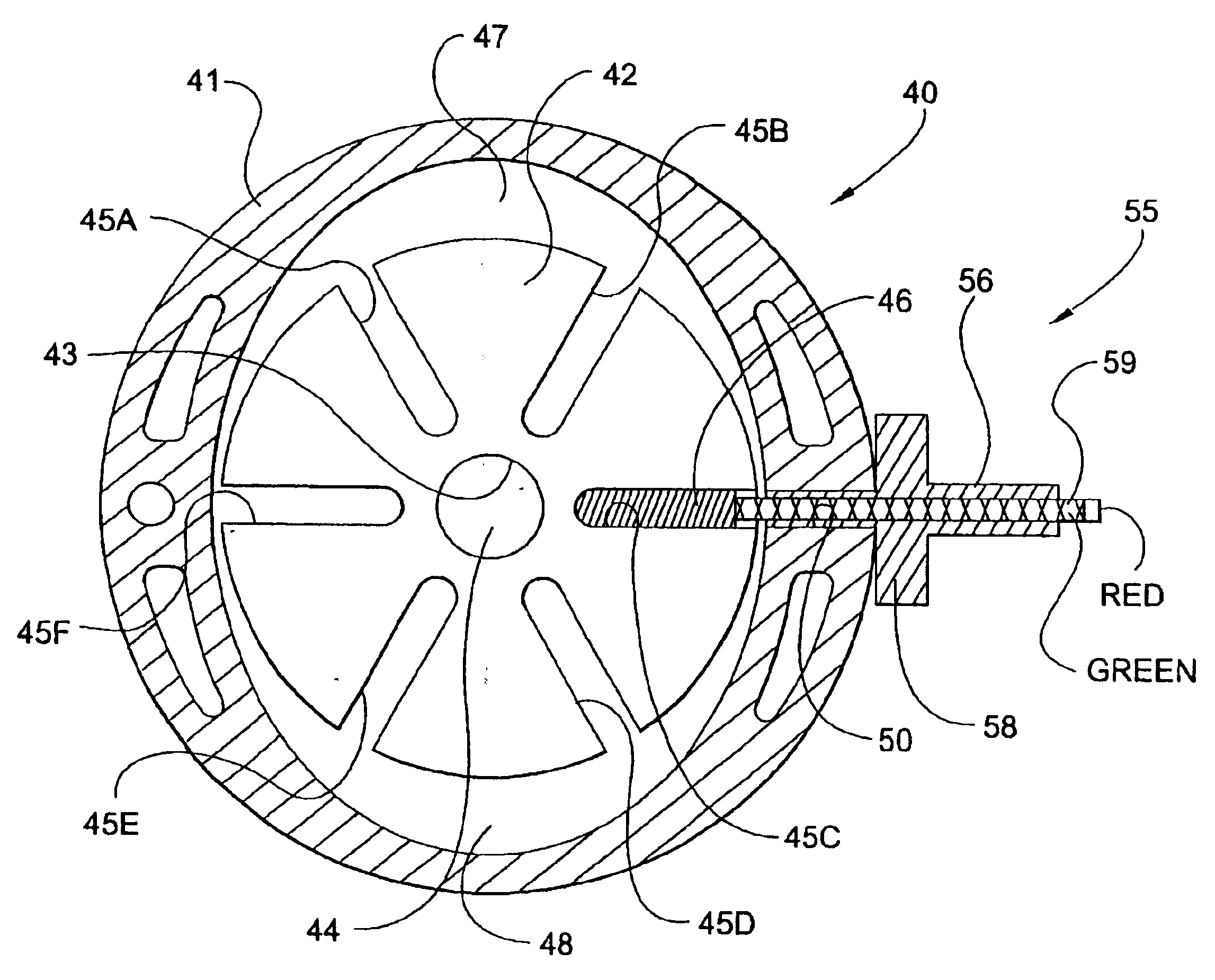

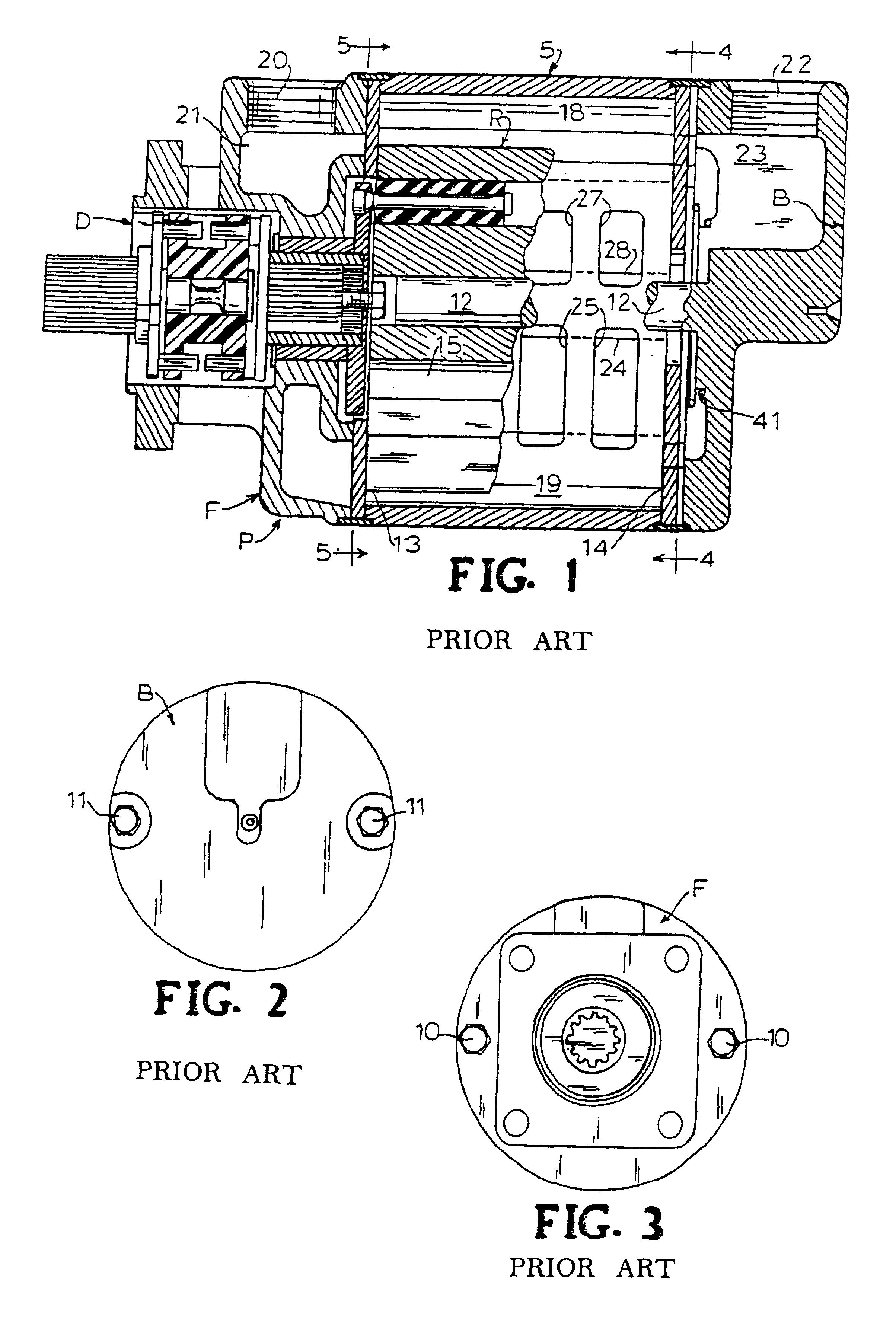

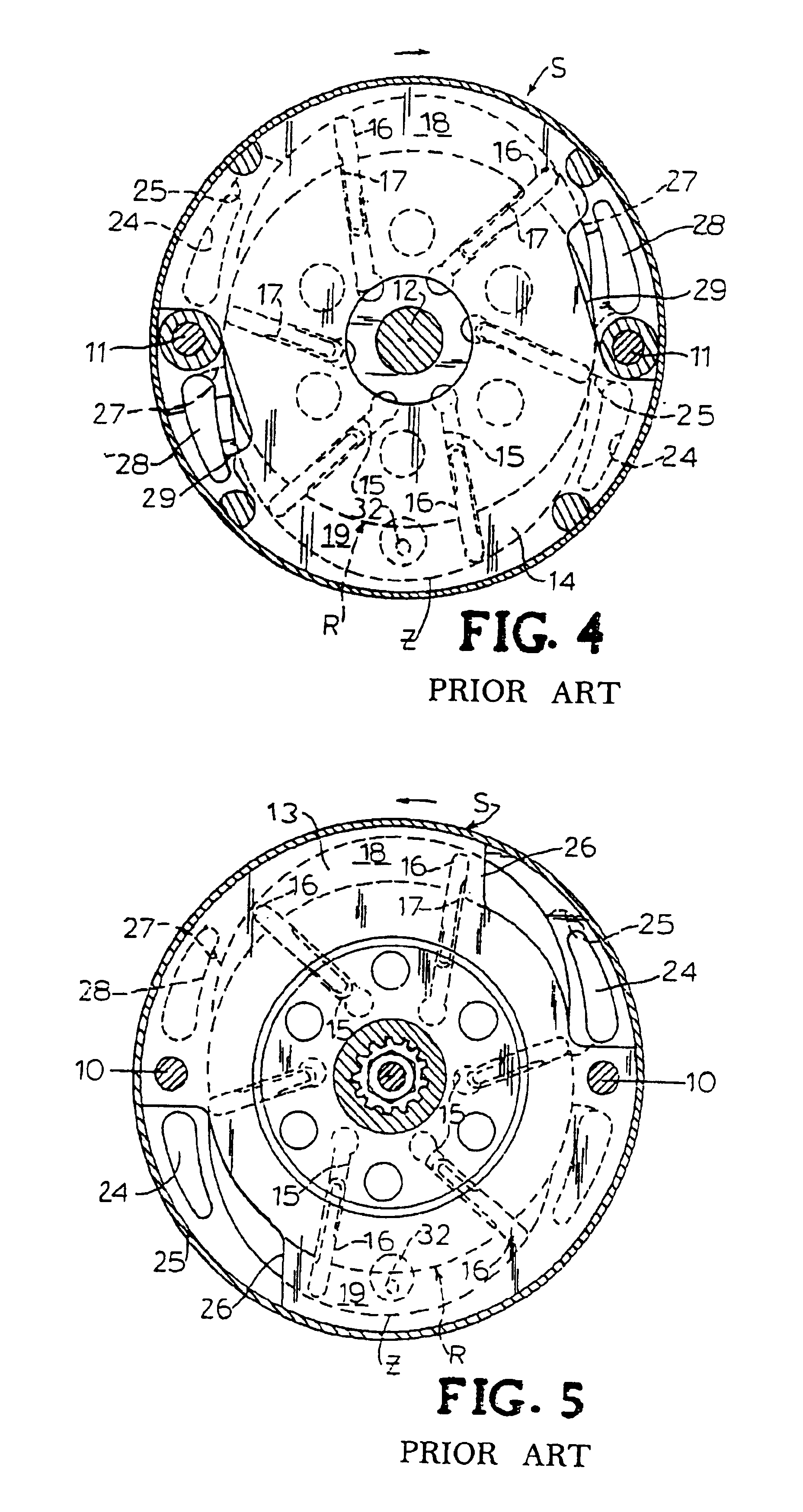

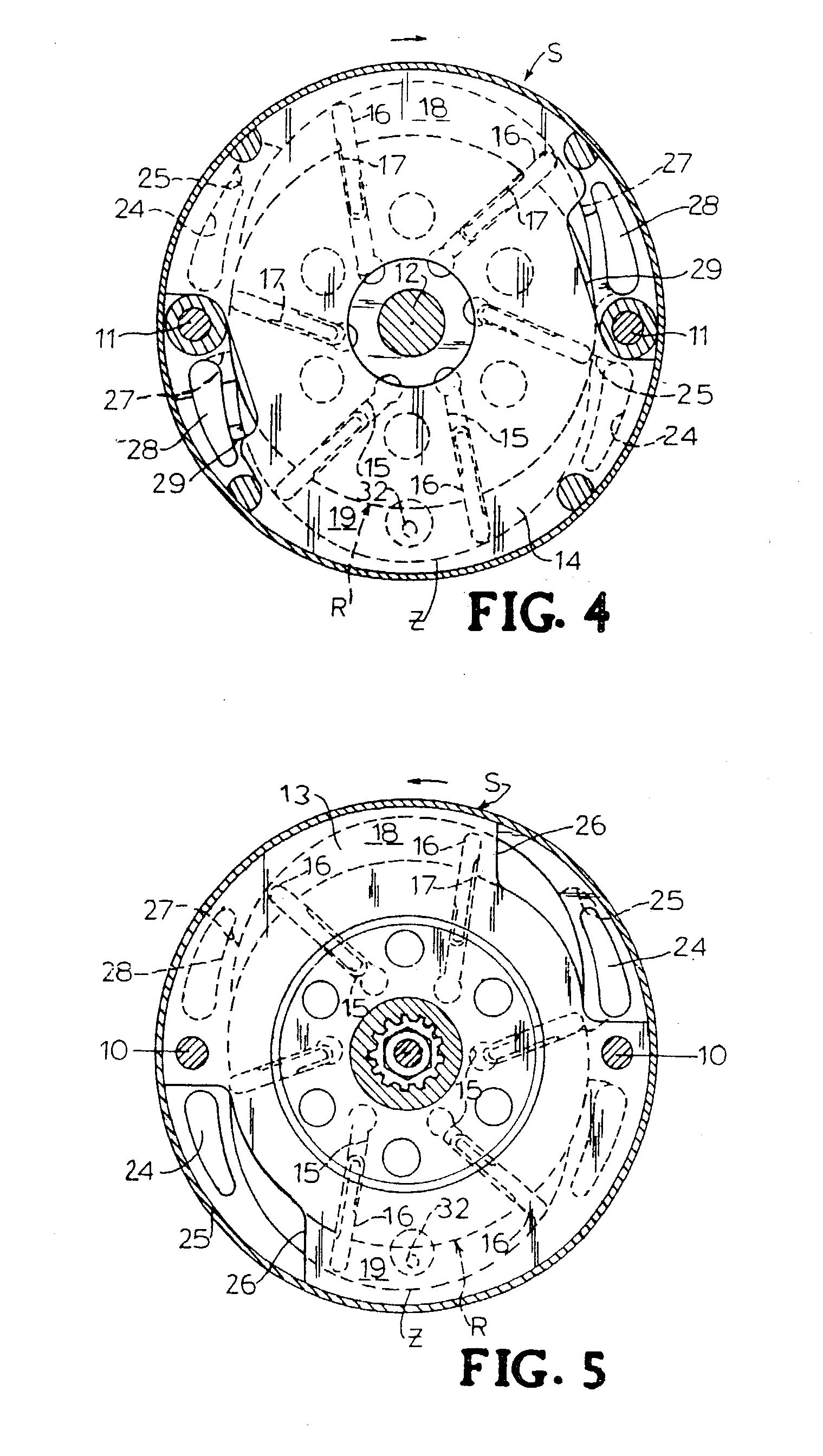

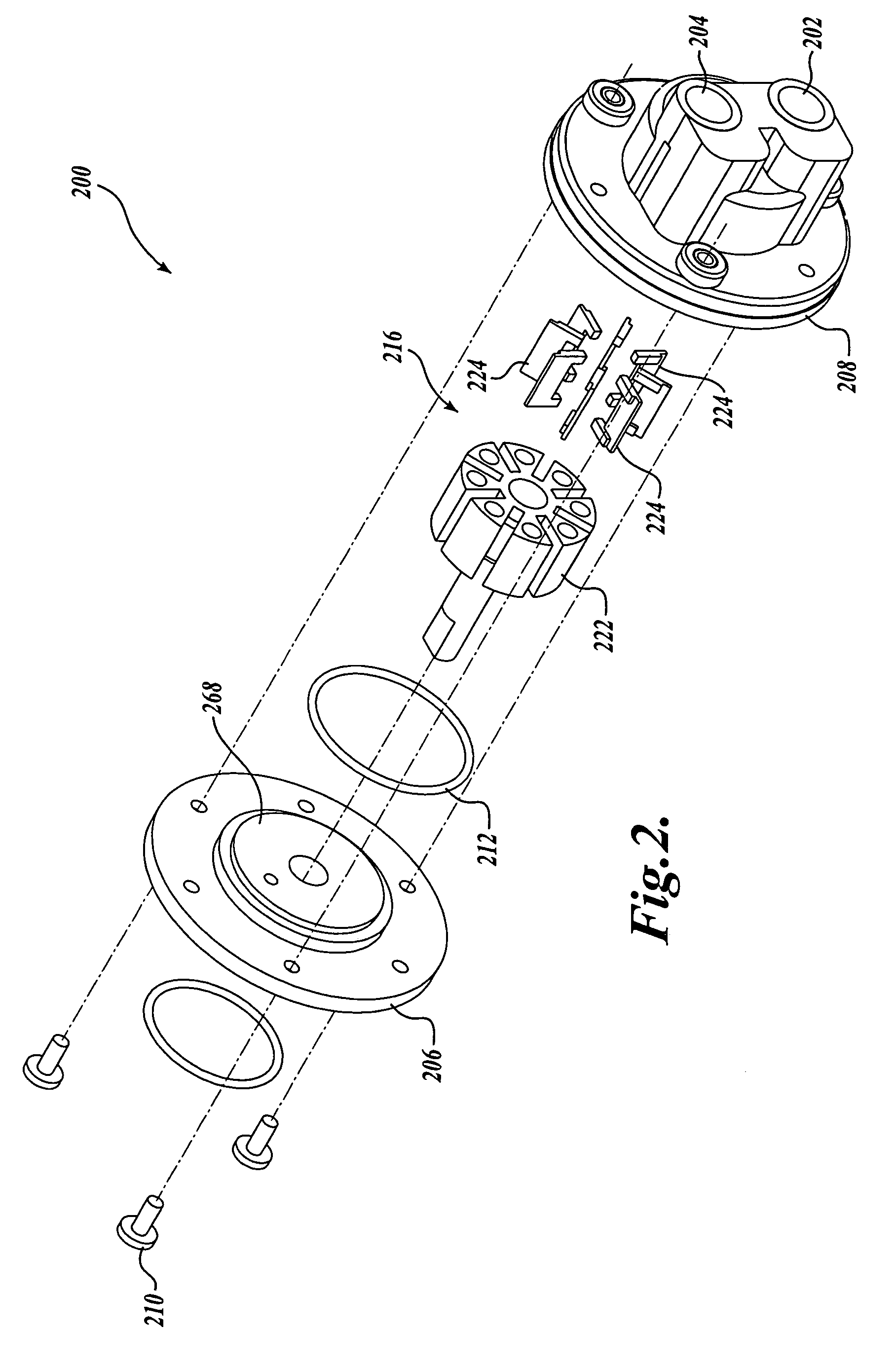

Rotary vane pump

InactiveUS20050214153A1Oscillating piston enginesSealing arrangement for pumpsEngineeringMechanical engineering

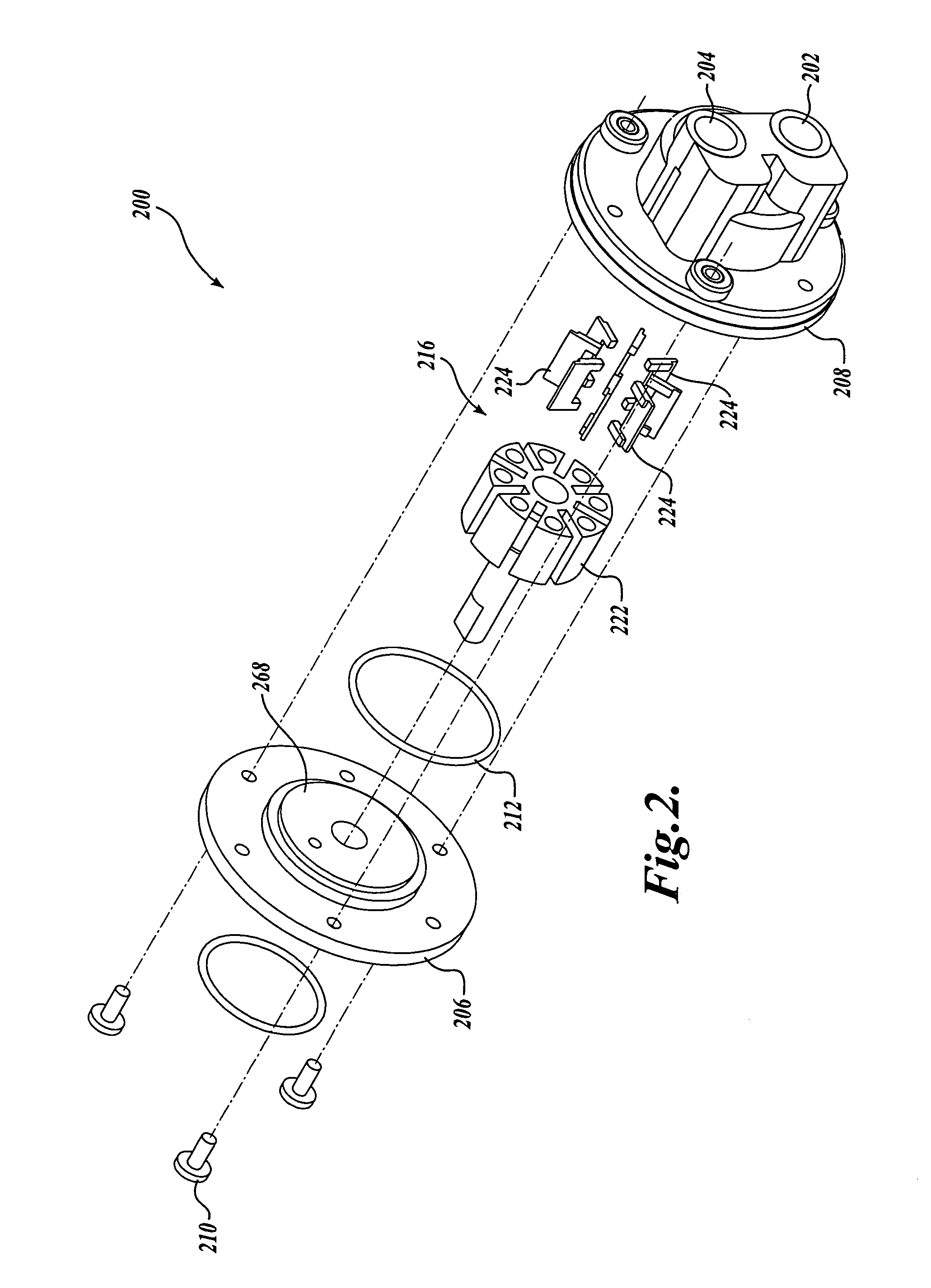

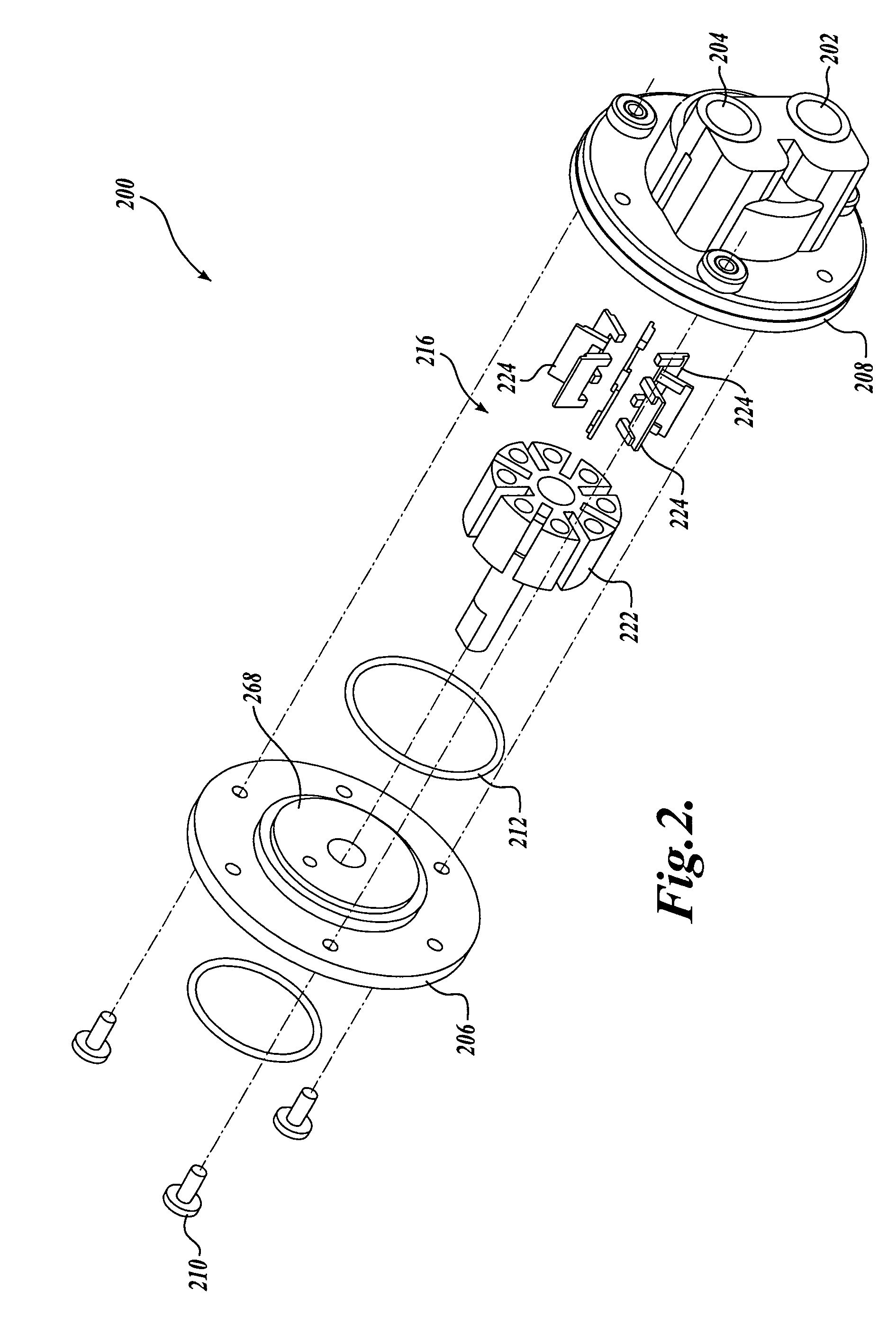

A rotary vane pump (200) for pumping a fluid. The rotary vane pump includes a pump housing (206 and 208) and a rotor having a plurality of dividing members (232) and a plurality of slots (226) disposed between adjacent dividing members. The rotary vane pump also includes a plurality of strengthening members (240), each strengthening member disposed in one of the plurality of slots and coupled to adjacent dividing members. The rotary vane pump also includes a plurality of vanes (224), each vane moveably disposed in one of the plurality of slots.

Owner:TUTHILL CORP

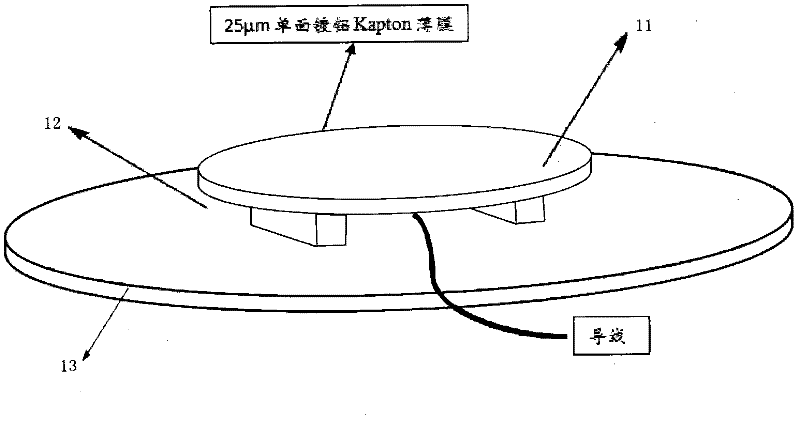

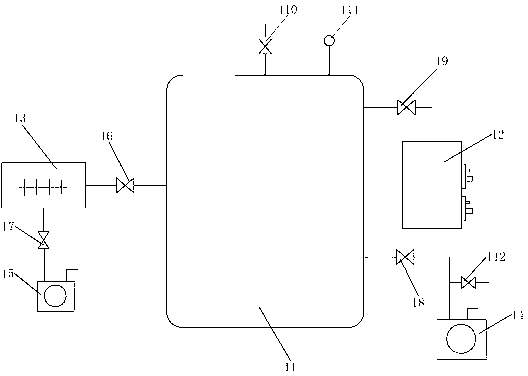

Charge-discharge test equipment for medium material

ActiveCN102162825AFacilitated releaseImprove test automationResistance/reactance/impedenceUltrasound attenuationCurrent meter

The invention discloses charge-discharge test equipment for a medium material. The charge-discharge test equipment comprises a vacuum system, a charge-discharge system and a potential test system, wherein the vacuum system comprises a vacuum tank, a mechanical pump (3), a diffusion pump (2), a multistage rotary vane pump (1), a valve, a sealing pipeline and a workbench; the charge-discharge system comprises an electronic gun (6) and a sample (11) mounting system; the potential test system comprises a potentiometer (9) and a micro current meter (14); a vacuum valve (4) and a vacuum gauge (5) are arranged in the vacuum tank; in addition, a baffle valve A (15), a baffle valve B (16) and a copper plate (13) are further provided; in conclusion, the equipment measures the attenuation relation of surface potential with time by using a surface potential probe, and the conductivity of the sample can be calculated according to the measured sample surface attenuation potentials at different moments. The conductivity test equipment provided by the invention is suitable for estimating deep charging hazard, and can supply valuable engineering data to protection of deep charging and discharging effect.

Owner:NO 510 INST THE FIFTH RES INST OFCHINA AEROSPAE SCI & TECH

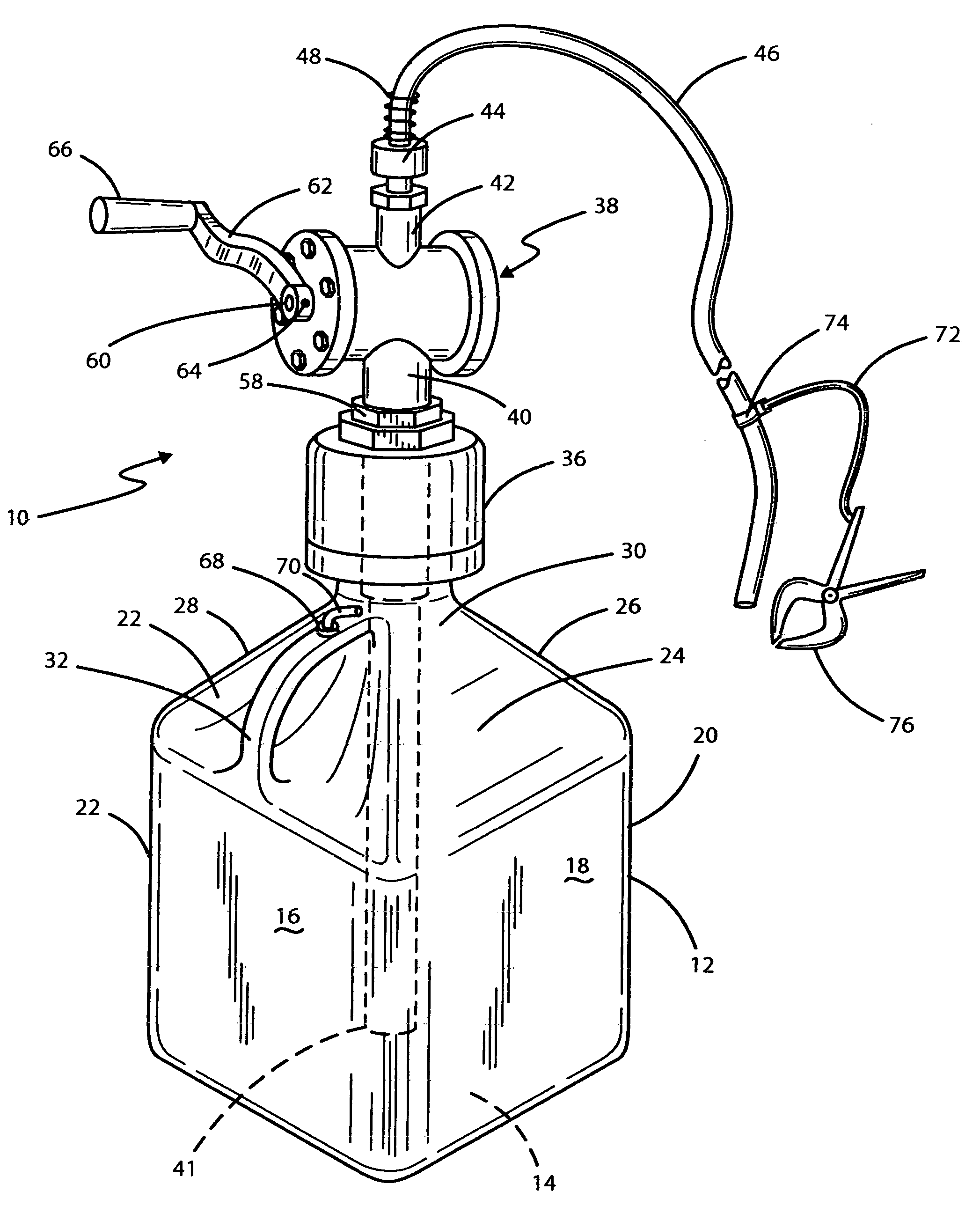

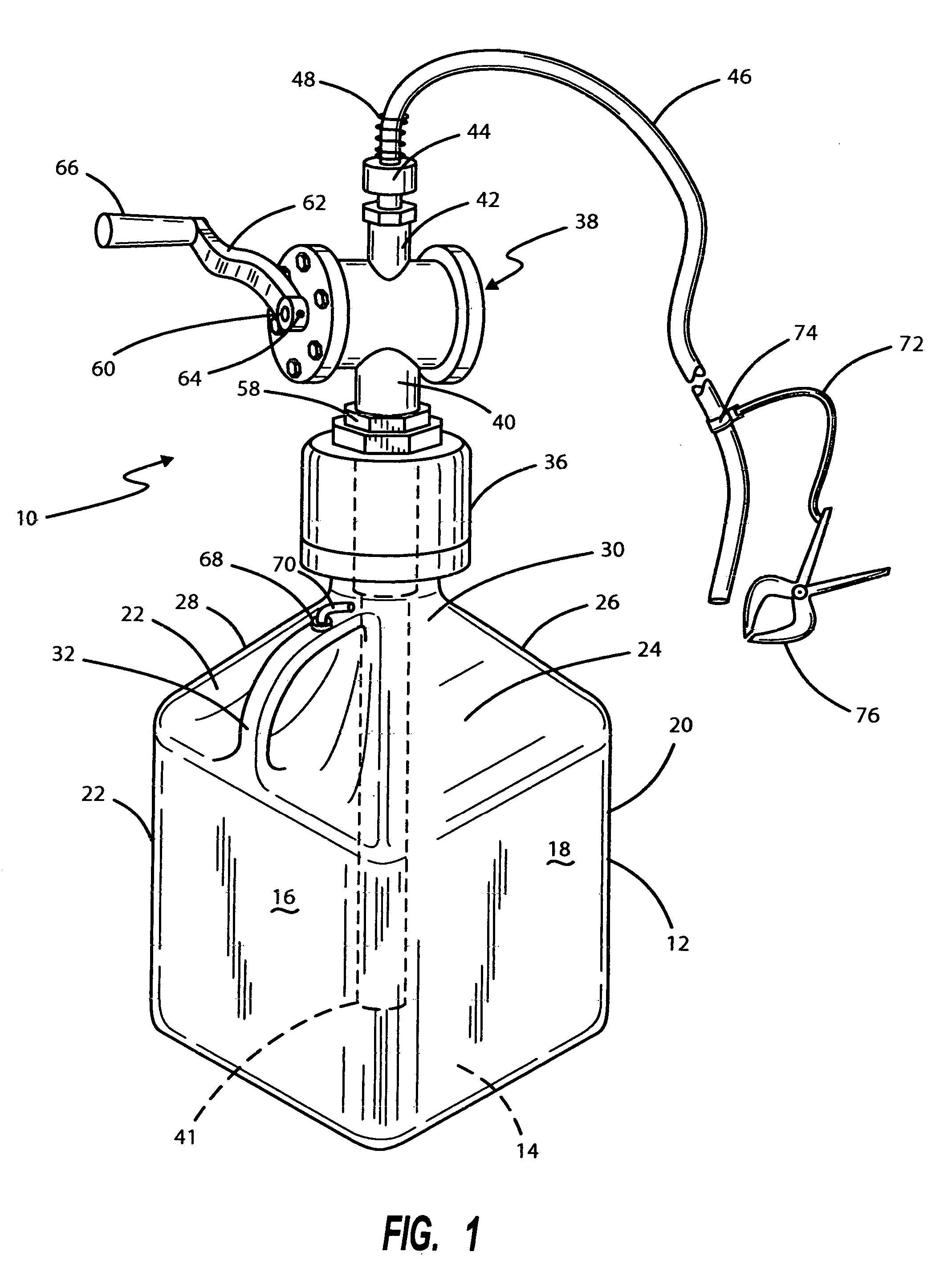

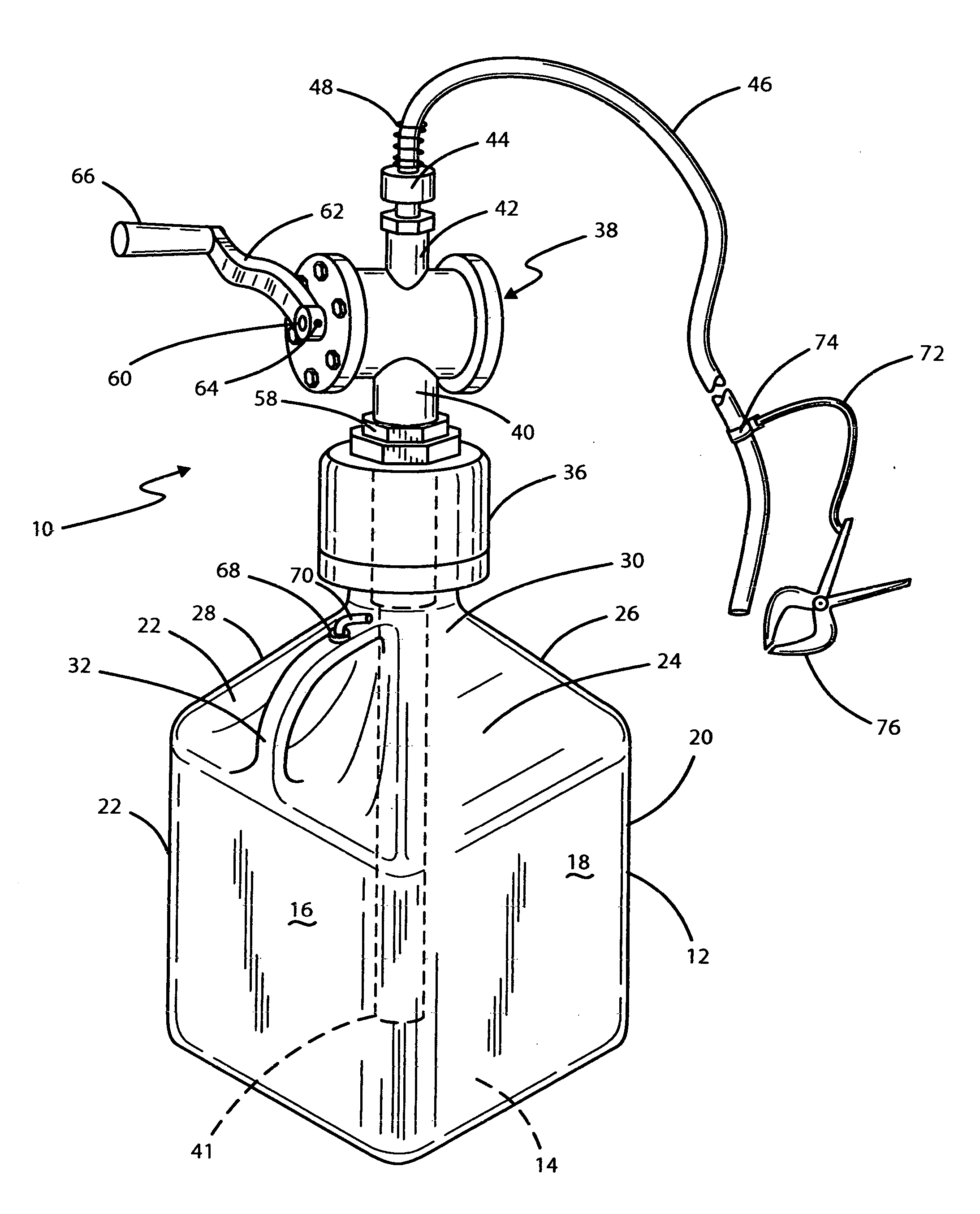

Fluid transfer system

Owner:FRANKS NORMAL ALTON

Vacuum drying apparatus

InactiveCN101025330AImprove protectionIncrease contact areaDrying using combination processesDrying machines with local agitationThermal energyOrganic solvent

The invention is about a kind of Minton dryer, composing of case vacuum pump and heating groupware. The heating groupware composes of hot plate set in the case and heater offering heat energy to the hot plate out of the case; the vacuum is made up of Roots pump and rotary vane pump, concatenating refrigerating catcher between the Roots pump and rotary vane pump. The refrigerating catcher, expansion valve and heat exchanger build up refrigeration circular system. The invention can recover organic solvent, benefit lowering production costs and environmental protection, reduce pressure quickly, keep vacuum effectiveness good, dries quickly under the low temperature and consume less energy.

Owner:李志平 +1

Rotary vane pump seal

Owner:KASMER THOMAS E

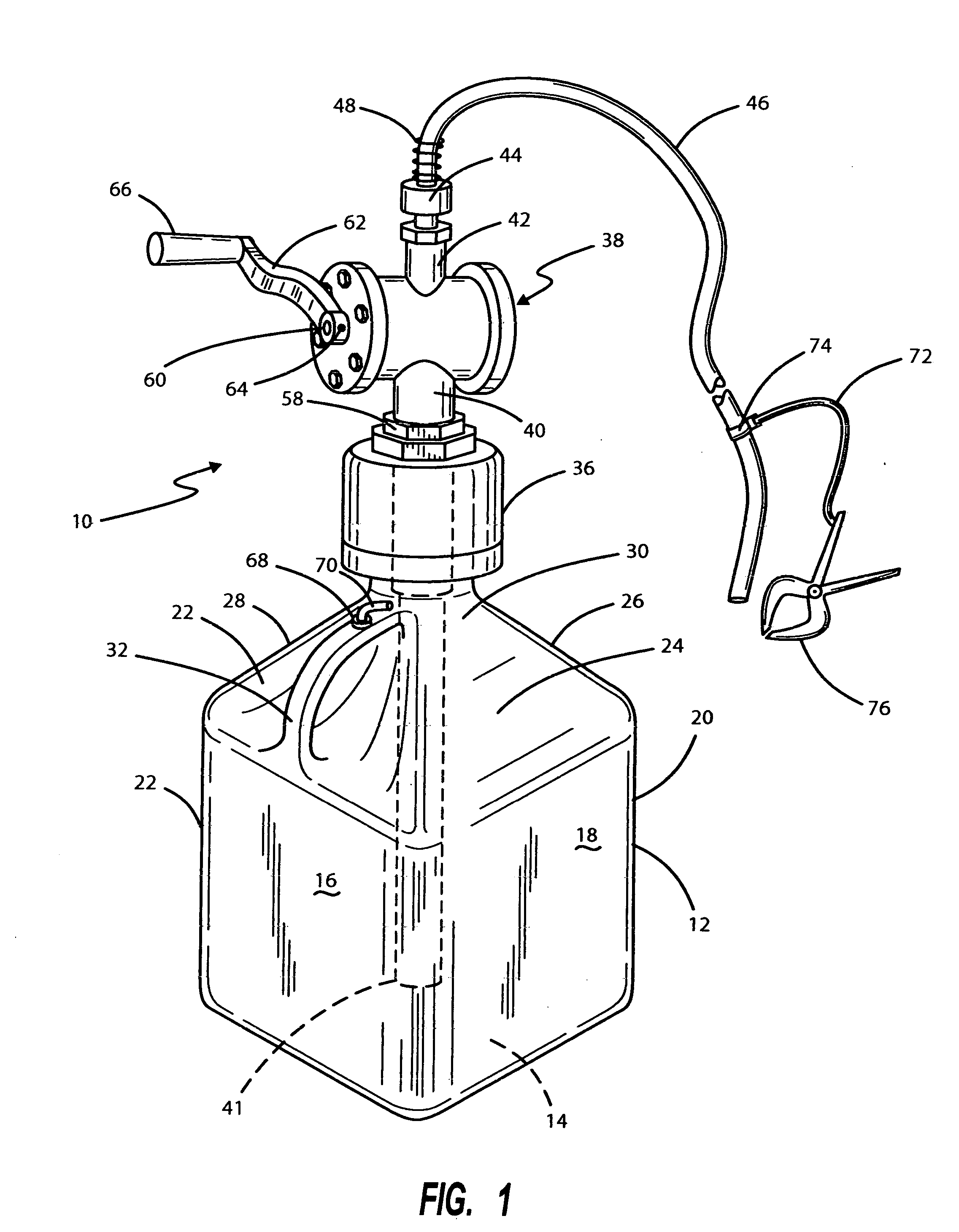

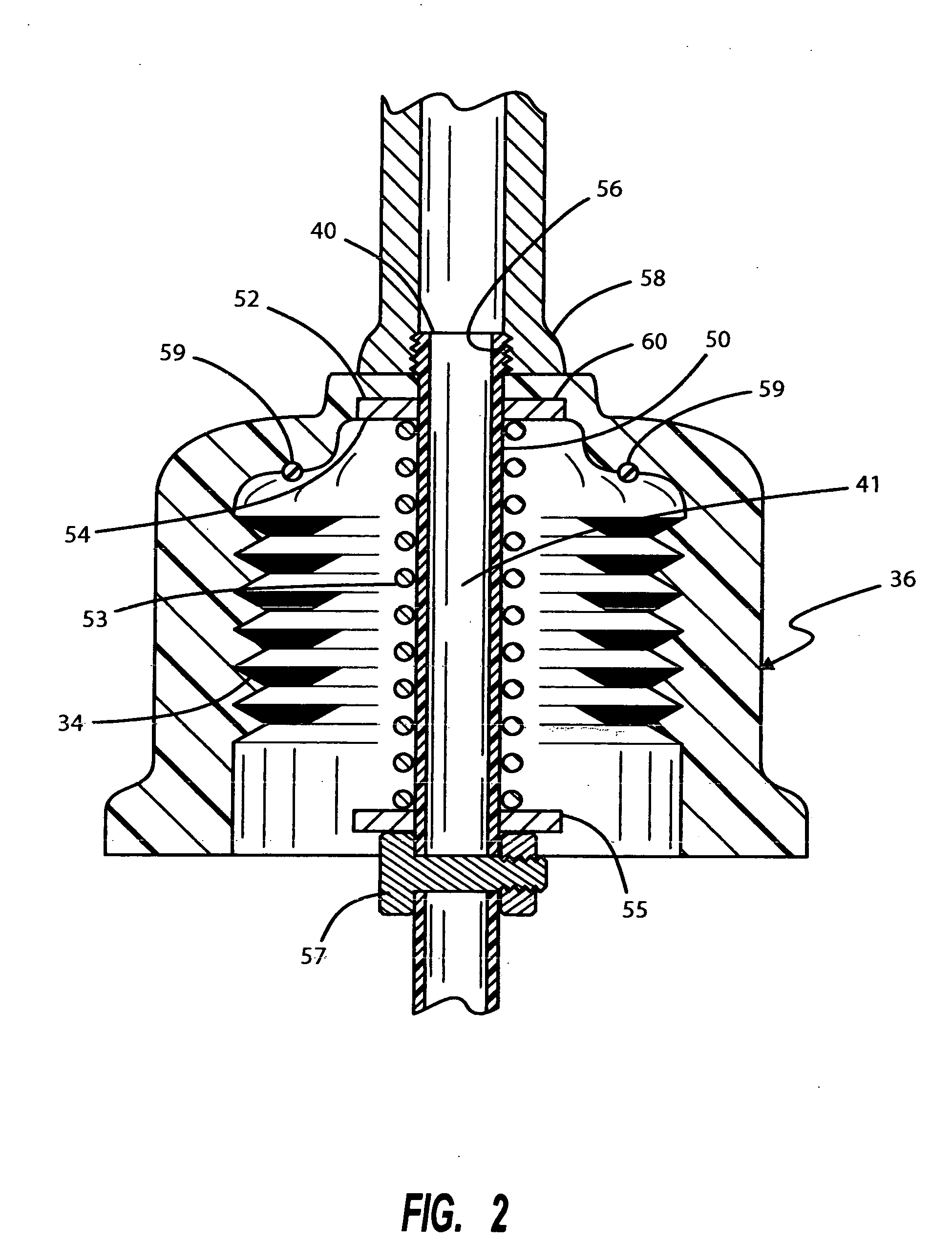

Fluid transfer system

A portable fluid transfer apparatus for handling volatile fuels or other chemicals comprises a jug-like container of a convenient volume having a removable cap that can be screwed or clamped onto the neck of the jug and mounted atop the cap is a manually operable rotary vane pump having a first inlet / outlet port disposed within the container when the cap is in place and a second inlet / outlet port external of the jug or container. An elongated, suction / discharge hose having a tether for anchoring the end of the hose in place is affixed to the second inlet / outlet. Manual actuation of the vane pump is then used to transfer a liquid from or into the portable container.

Owner:FRANKS NORMAL ALTON

Evaporation coating device and air extracting process thereof

InactiveCN103320752AReduce energy consumption of pumpingEliminate pollutionVacuum evaporation coatingSputtering coatingEvaporationTitanium

The invention relates to an evaporation coating device and an air extracting process thereof. The evaporation coating device adopts a set of an electric arc titanium pump, a traction molecular pump and a prepump with parallel air extracting to replace the seat of a conventional diffusion pump, a roots pump and a slide valve pump (or rotary vane pump) with series air extracting, wherein an active gas with high vacuum can be fast extracted by the electric arc titanium pump; an inert gas with high vacuum and a middle vacuum gas can be fast extracted by the traction molecular pump set. Because the electric arc titanium pump and the traction molecular pump are both low energy consumption pumps, the electric arc titanium pump mainly runs in a refined extracting stage and a coating stage and the running time is less than 1 / 3 of the entire air extracting time, air extracting energy consumption can be greatly reduced by the evaporation coating device. In addition, the set of the conventional diffusion pump, the roots pump and the slide valve pump does not have oil vapor pollution so that the oil vapor pollution of a conventional evaporation coating device is also eliminated by the evaporation coating device.

Owner:苏州摩星真空科技有限公司

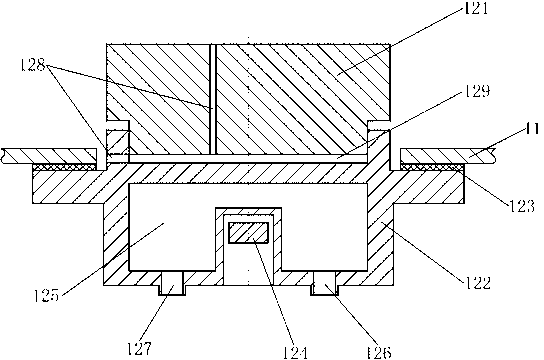

Brazing process of ceramic vacuum pipe with diameter greater than 300mm and device

ActiveCN101767236AEnsuring natural capillarityEvenly distributedSoldering apparatusTubular articlesShielding gasNitrogen gas

The invention provides a brazing process of a ceramic vacuum pipe with diameter greater than 300mm and a device, comprising the following steps: firstly, cleaning the ceramic pipe and a titanium ring, then putting them into a vacuum furnace, conducting temperature-rising weld under vacuum condition, providing shielding gas after welding, taking the ceramic pipe out from the furnace, and completing the butt-weld of two ceramic vacuum pipes. The device provided by the invention comprises a first-class mechanical rotary vane pump, a second-class Roots pump, and a third-class oil diffusion pump; the pumps are arranged in serial, meanwhile, the device is provided with a pipeline for transmitting high-purity inert gas (such as nitrogen and argon) into the furnace. The advantages of the invention are as follows: the brazing process of the ceramic vacuum pipe with diameter greater than 300mm and the device is provided, the vacuum leak rate at welded joint of the welded ceramic pipes is less than 5 * 10-12Pa. M3 / s, and no crack exists on the ceramic pipe.

Owner:上海克林技术开发有限公司

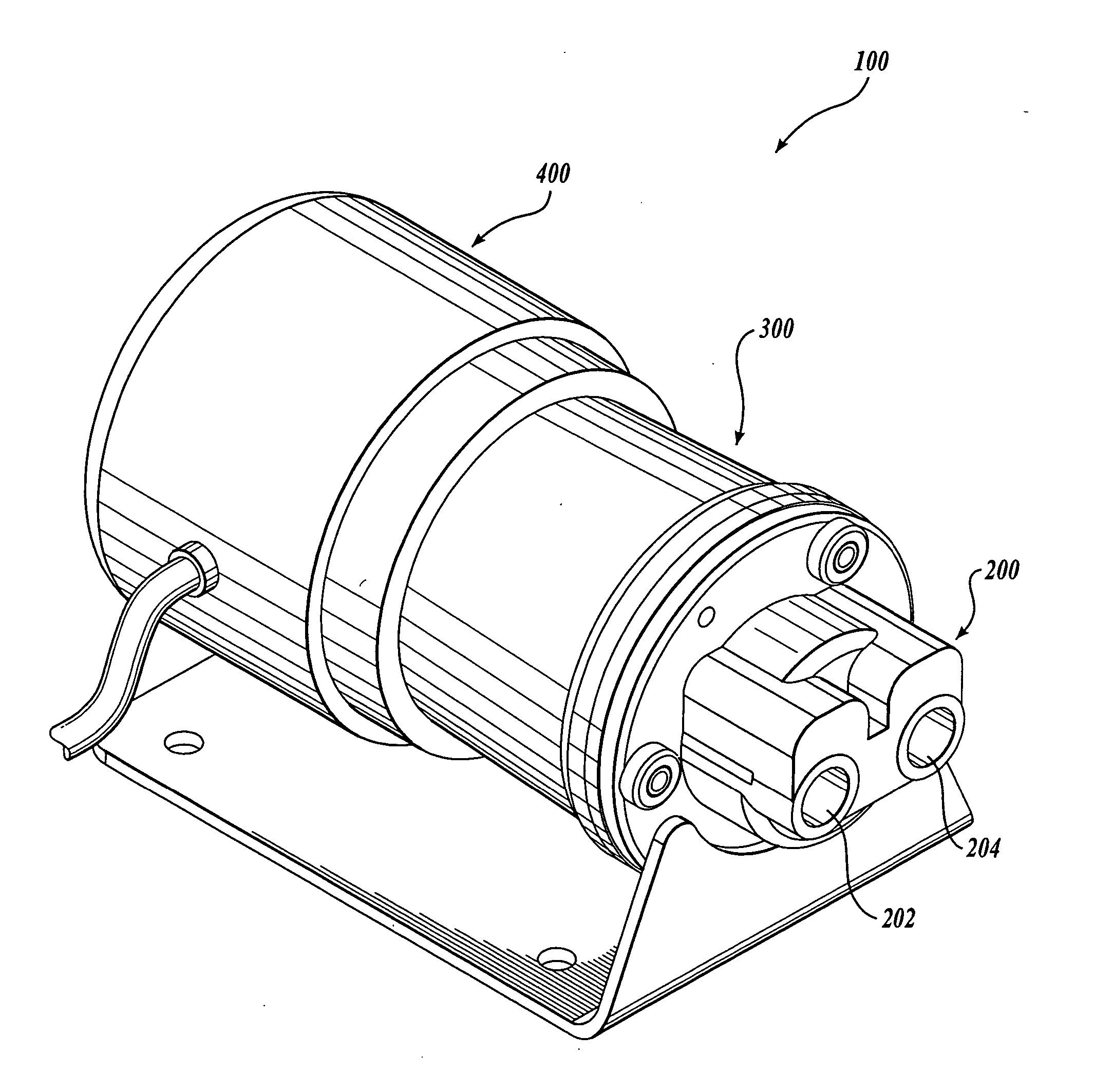

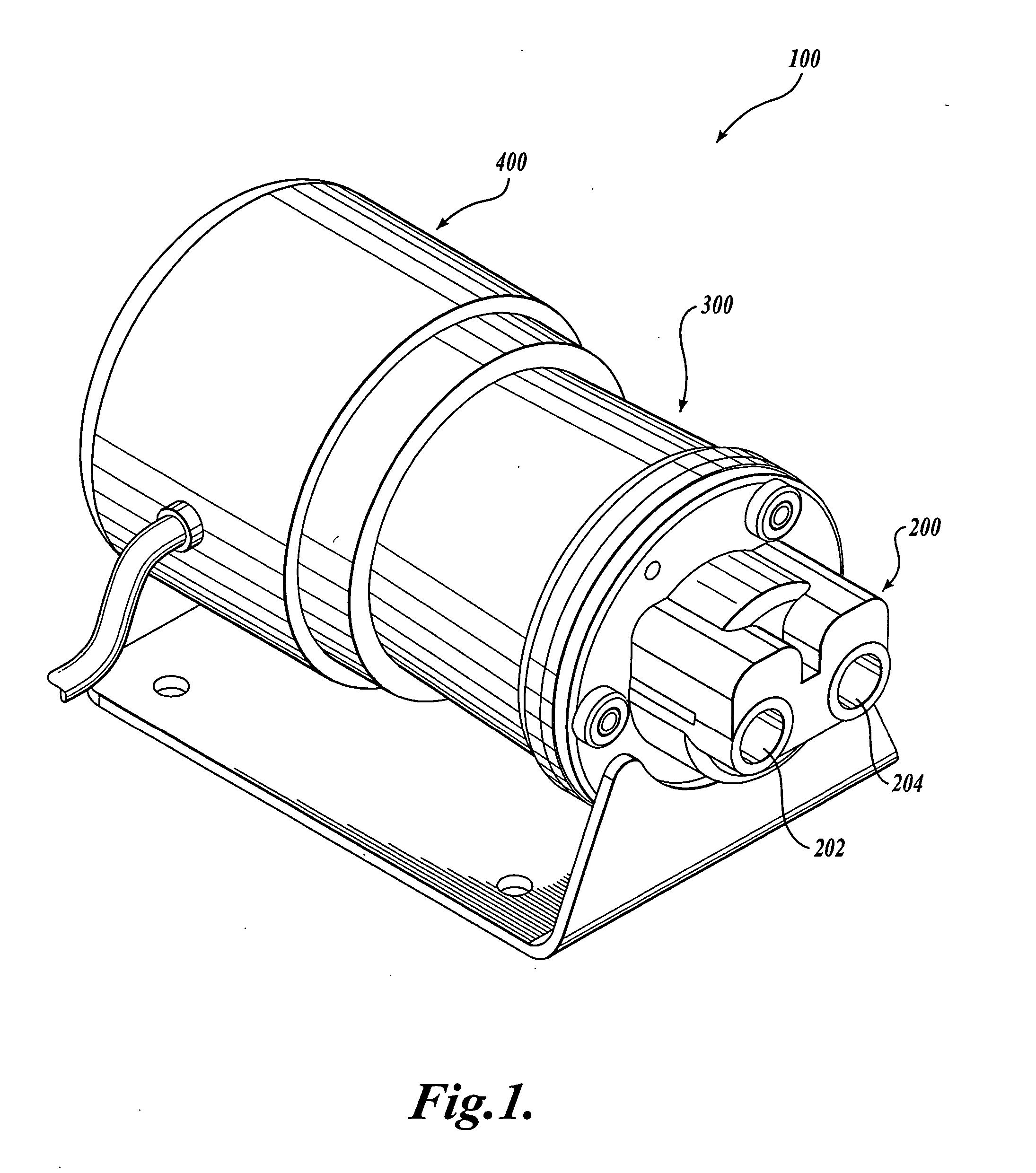

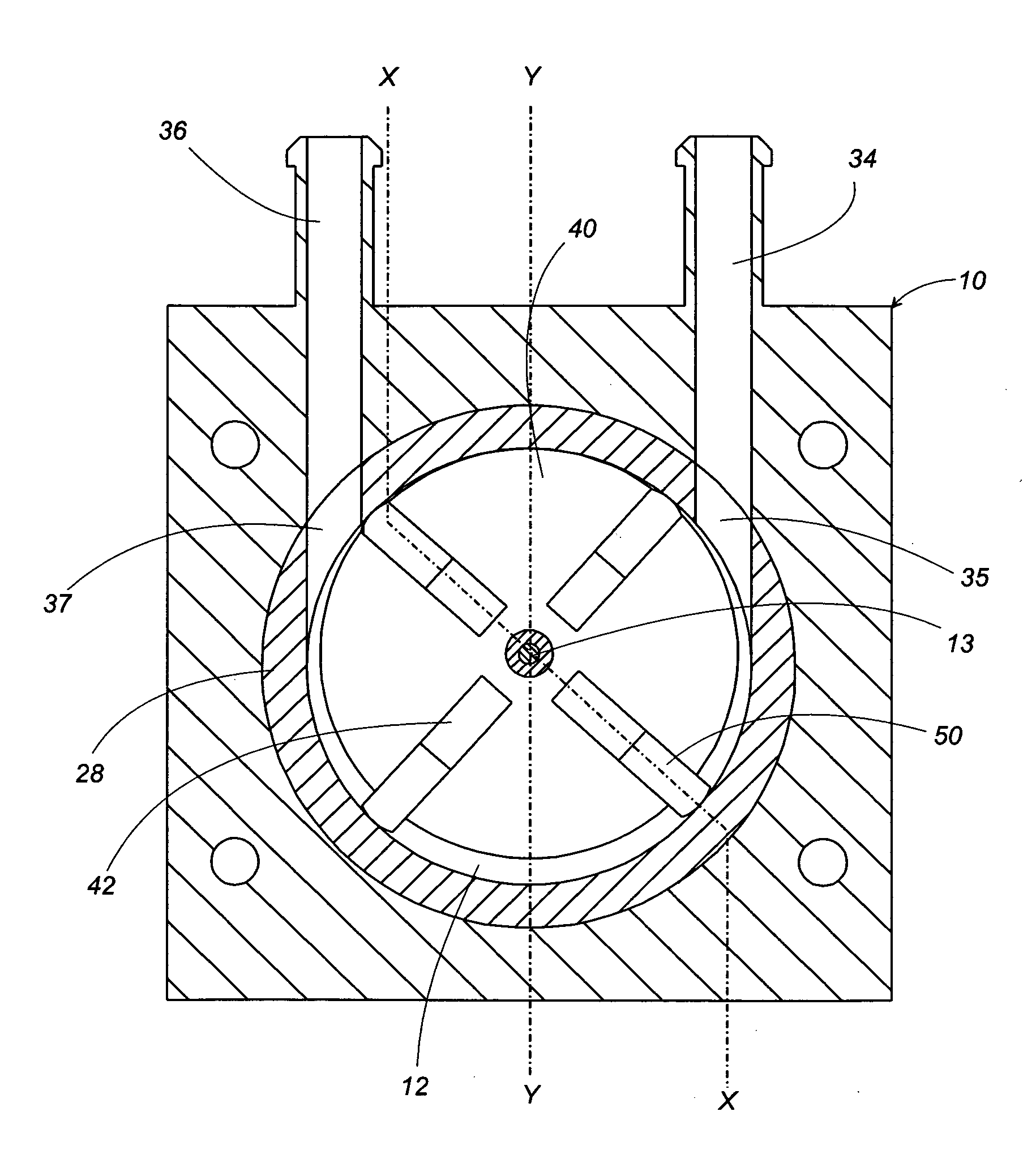

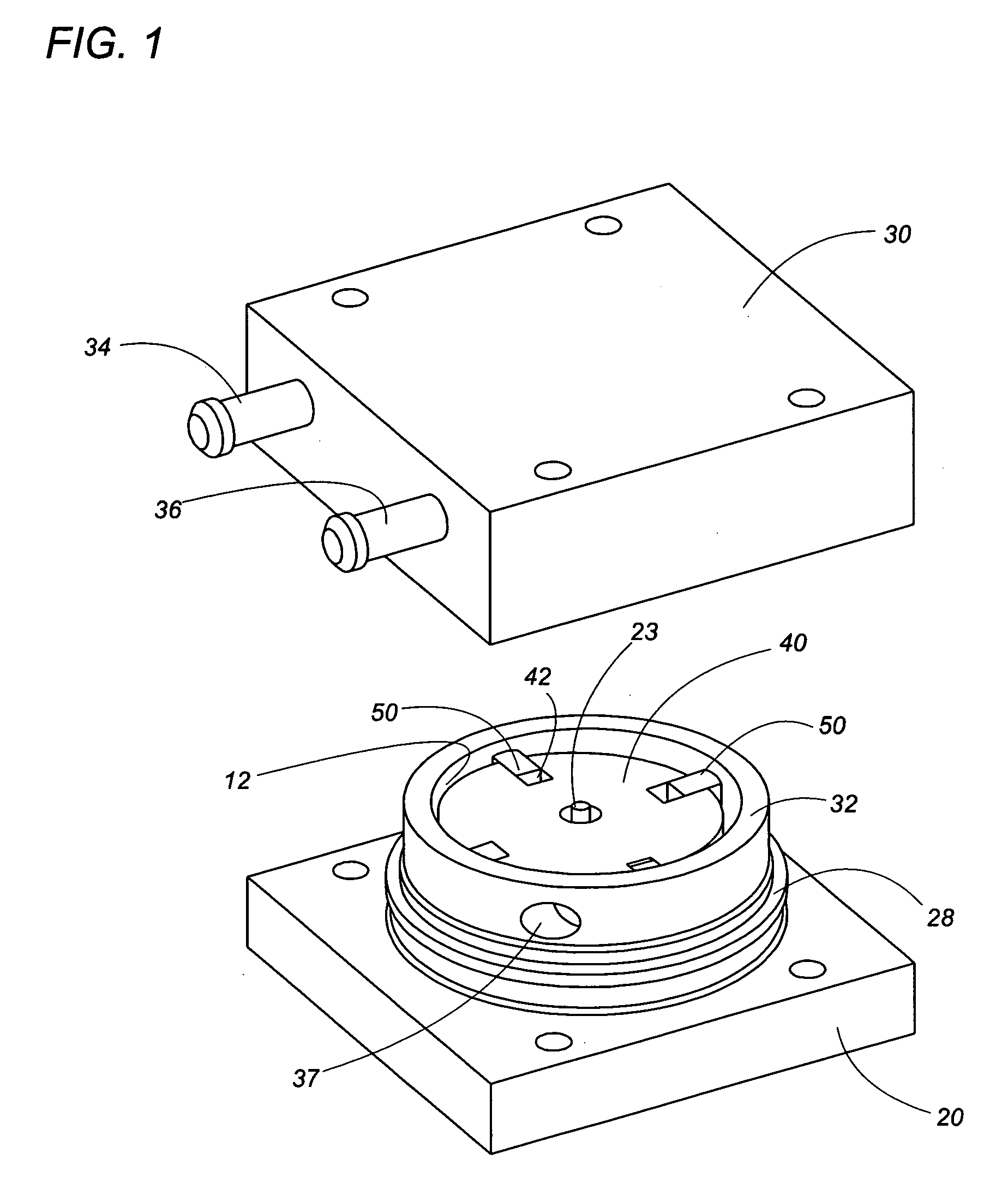

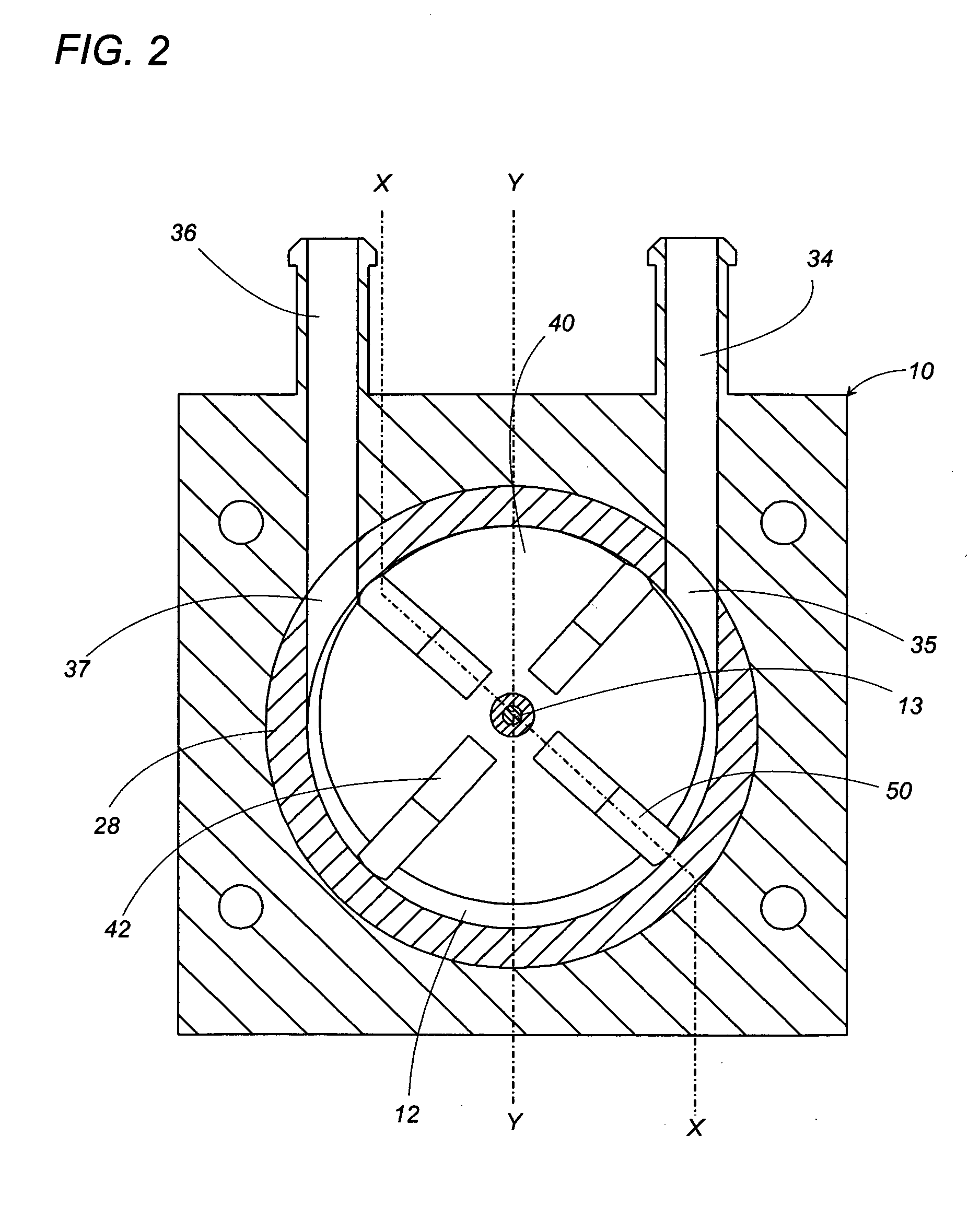

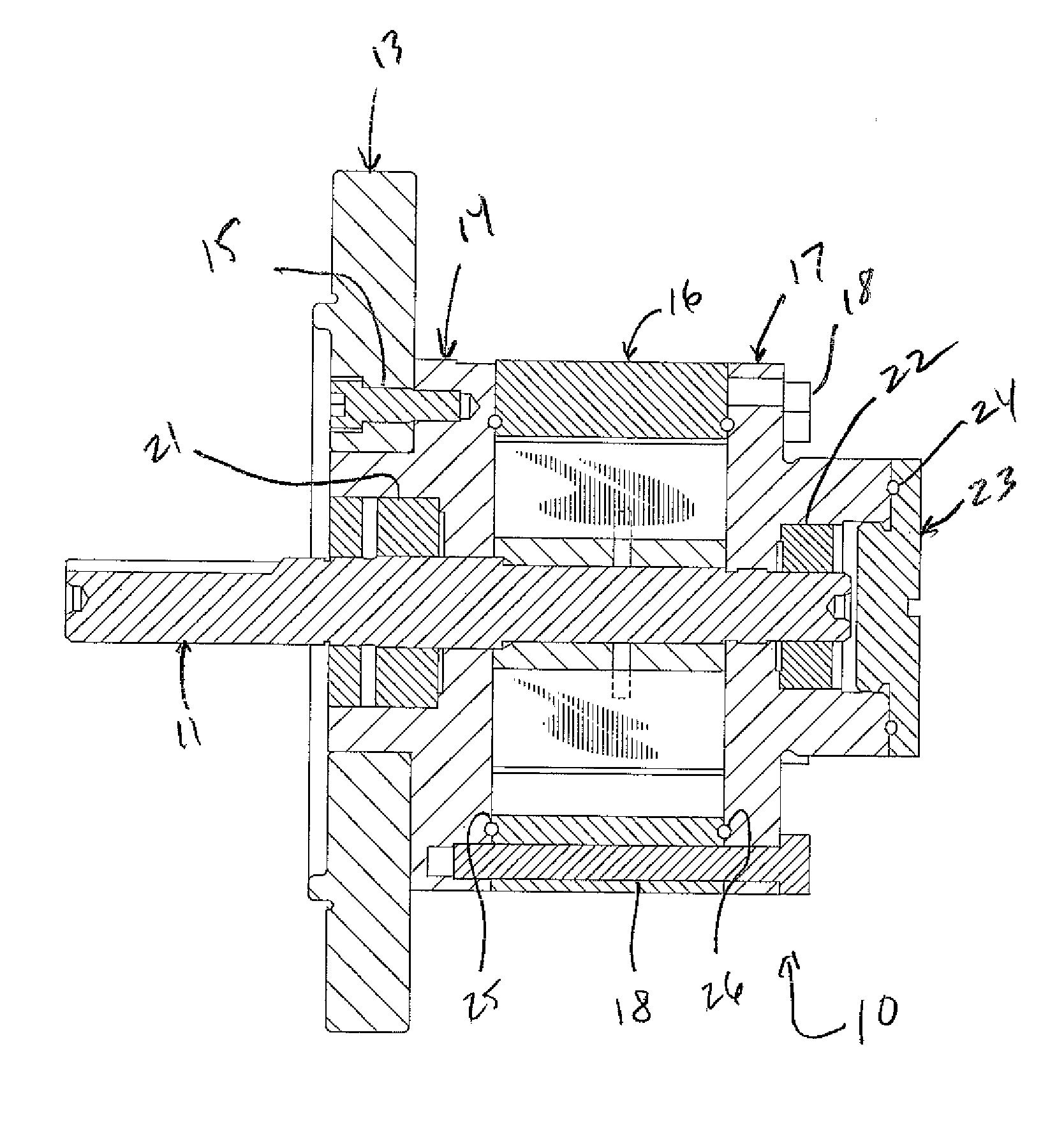

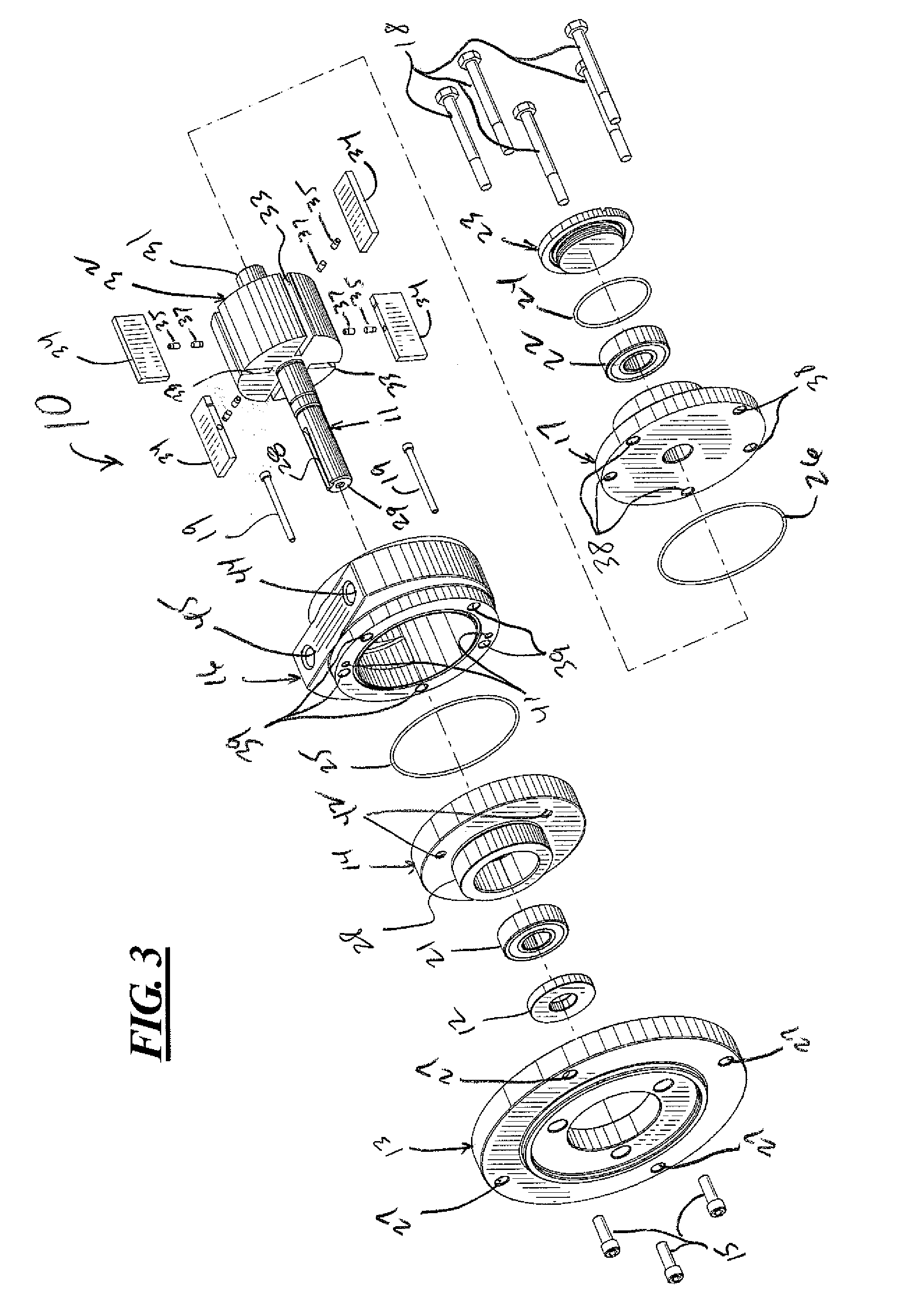

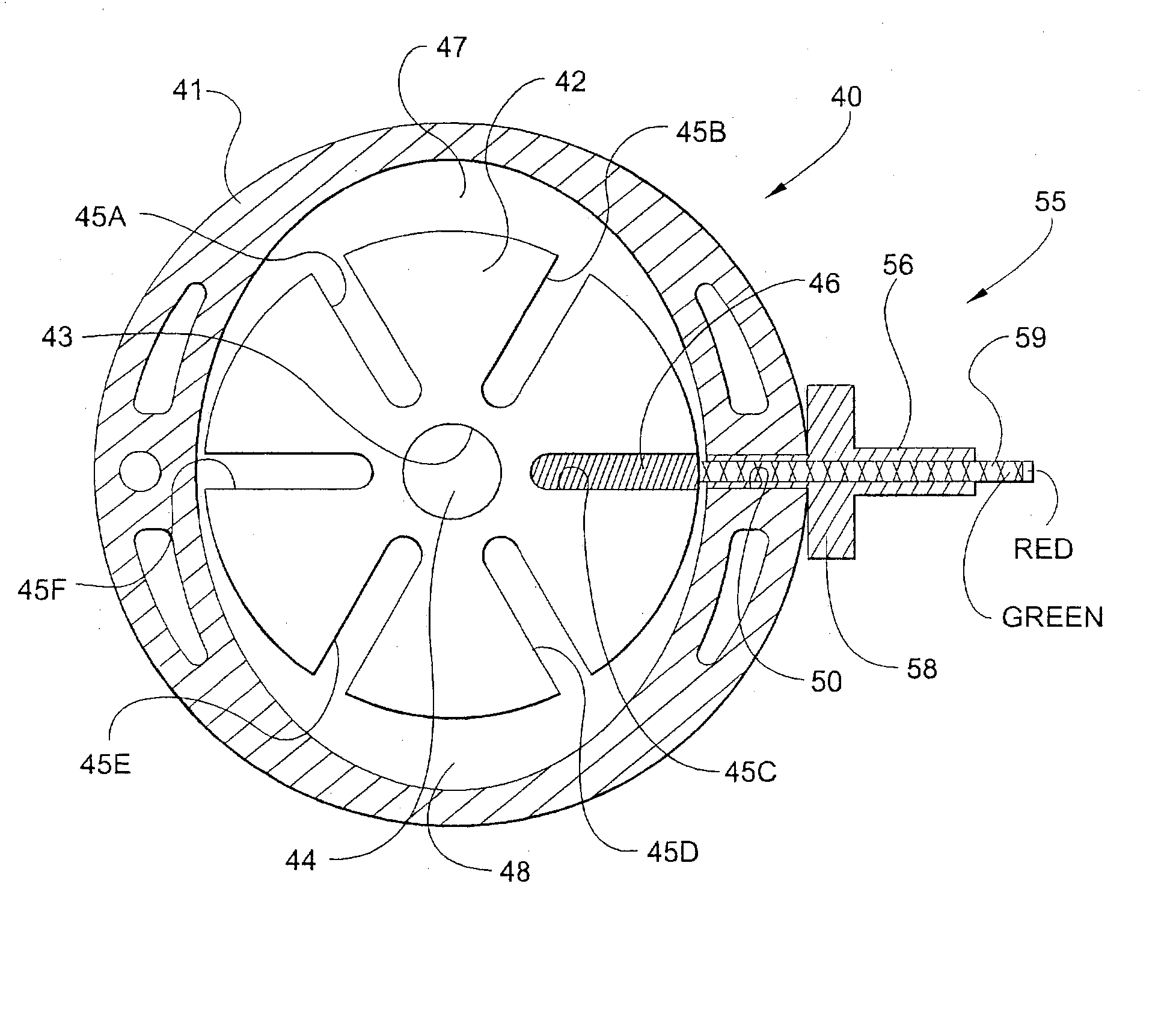

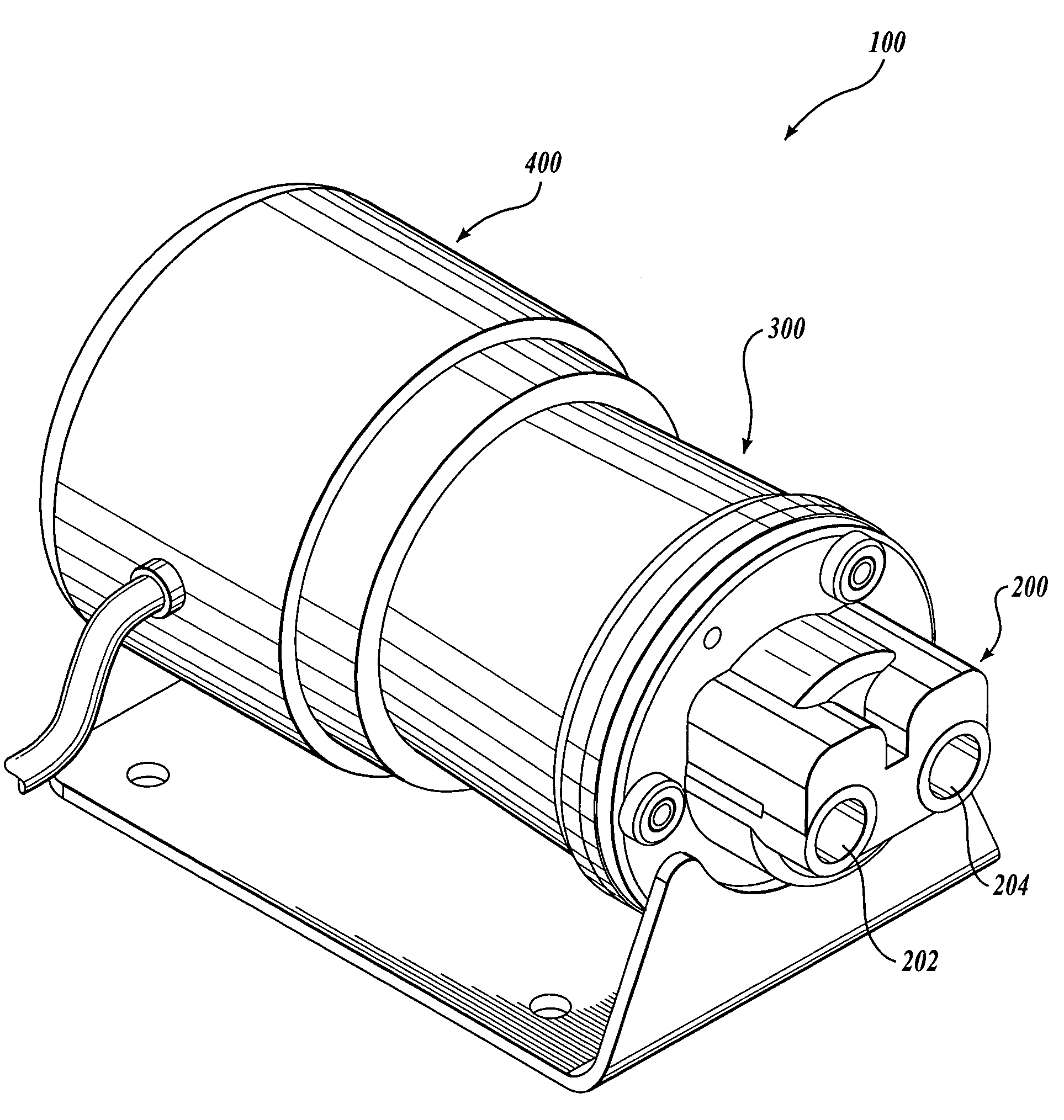

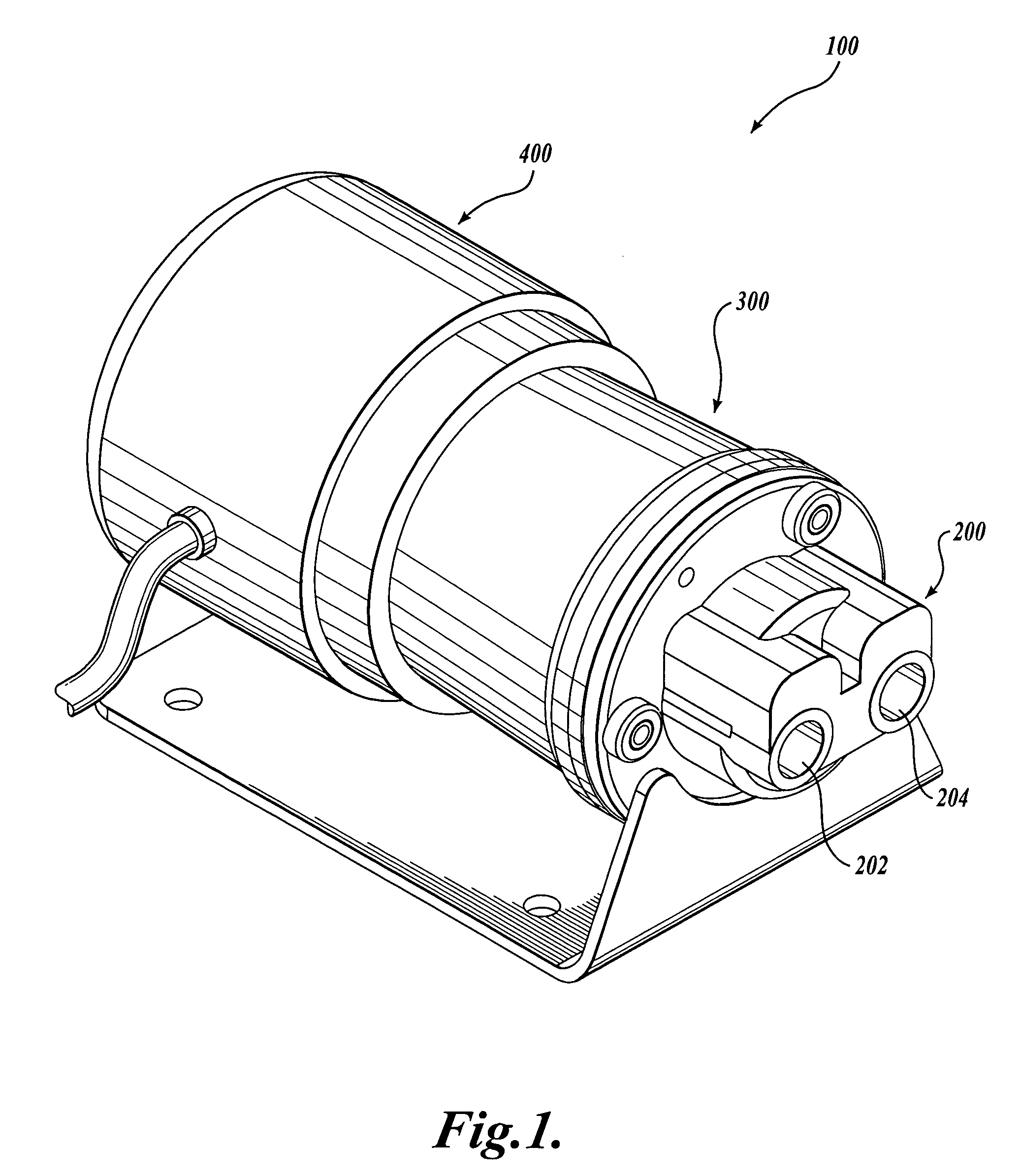

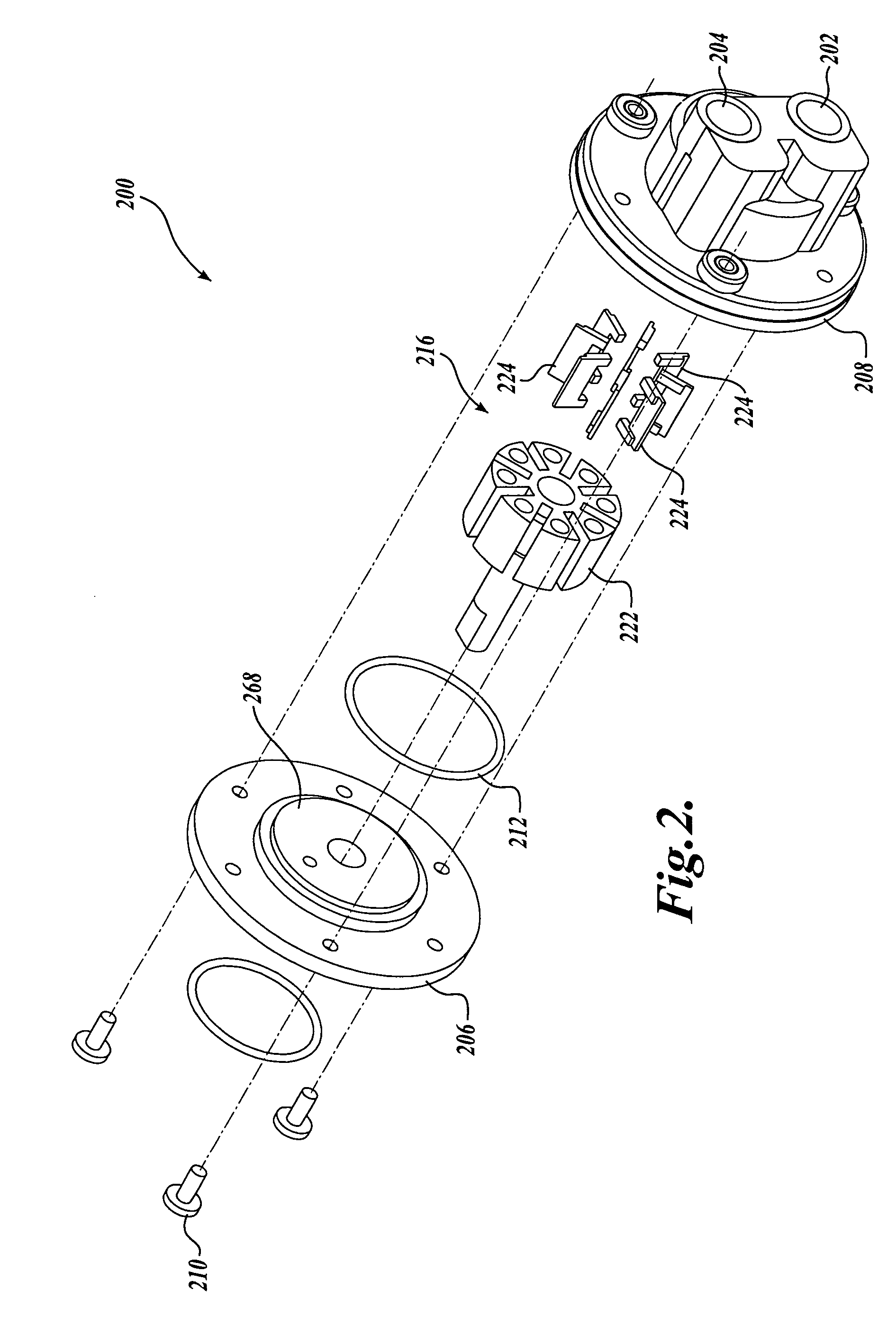

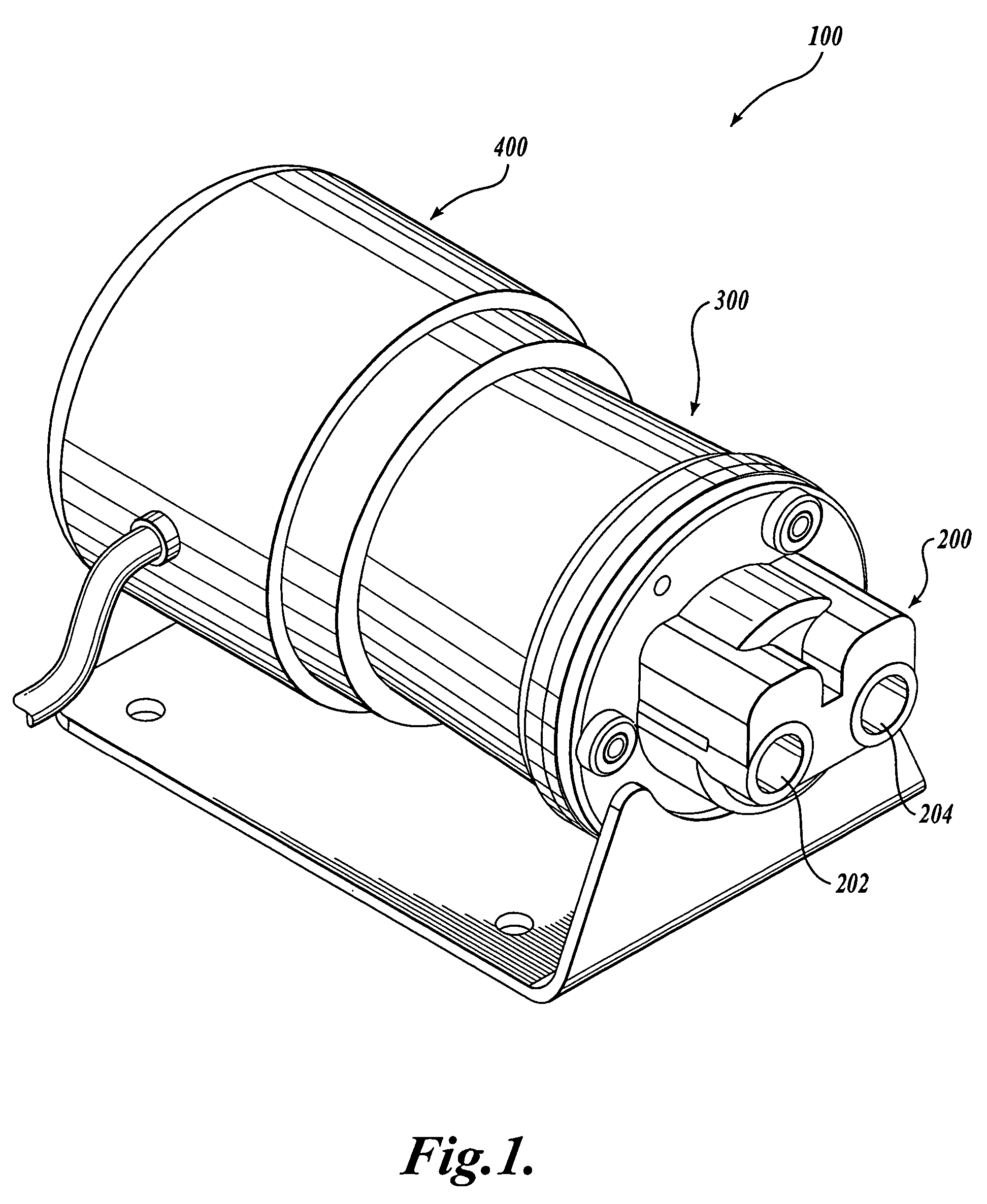

Rotary vane pump

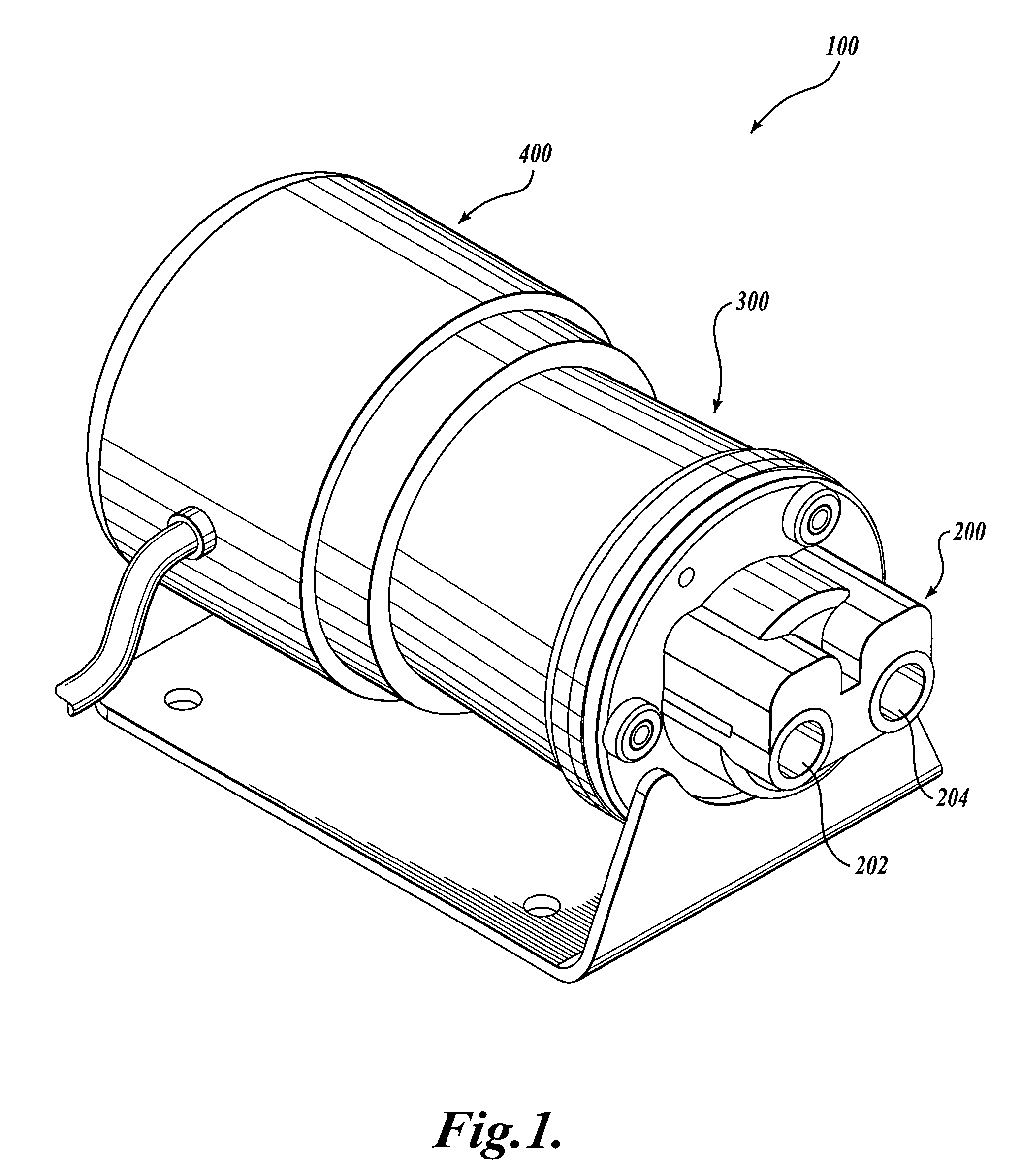

A pump assembly (100) having a pump housing (206 and 208) and a rotor (222) rotatingly disposed within the housing, the rotor having a plurality of slots (226). The pump assembly includes a plurality of vanes (224), each vane moveably disposed in one of the plurality of slots, and an input shaft (228) coupled to the rotor for applying a torque to the rotor. The pump assembly (100) also includes a prime mover (400) for generating a torque and a magnetic coupling unit (300) for magnetically transferring the torque generated by the prime mover to the input shaft. The vanes may have a leg (256) which extends radially inward from a blade (254). The rotor and input shaft may be integrally formed.

Owner:TUTHILL CORP

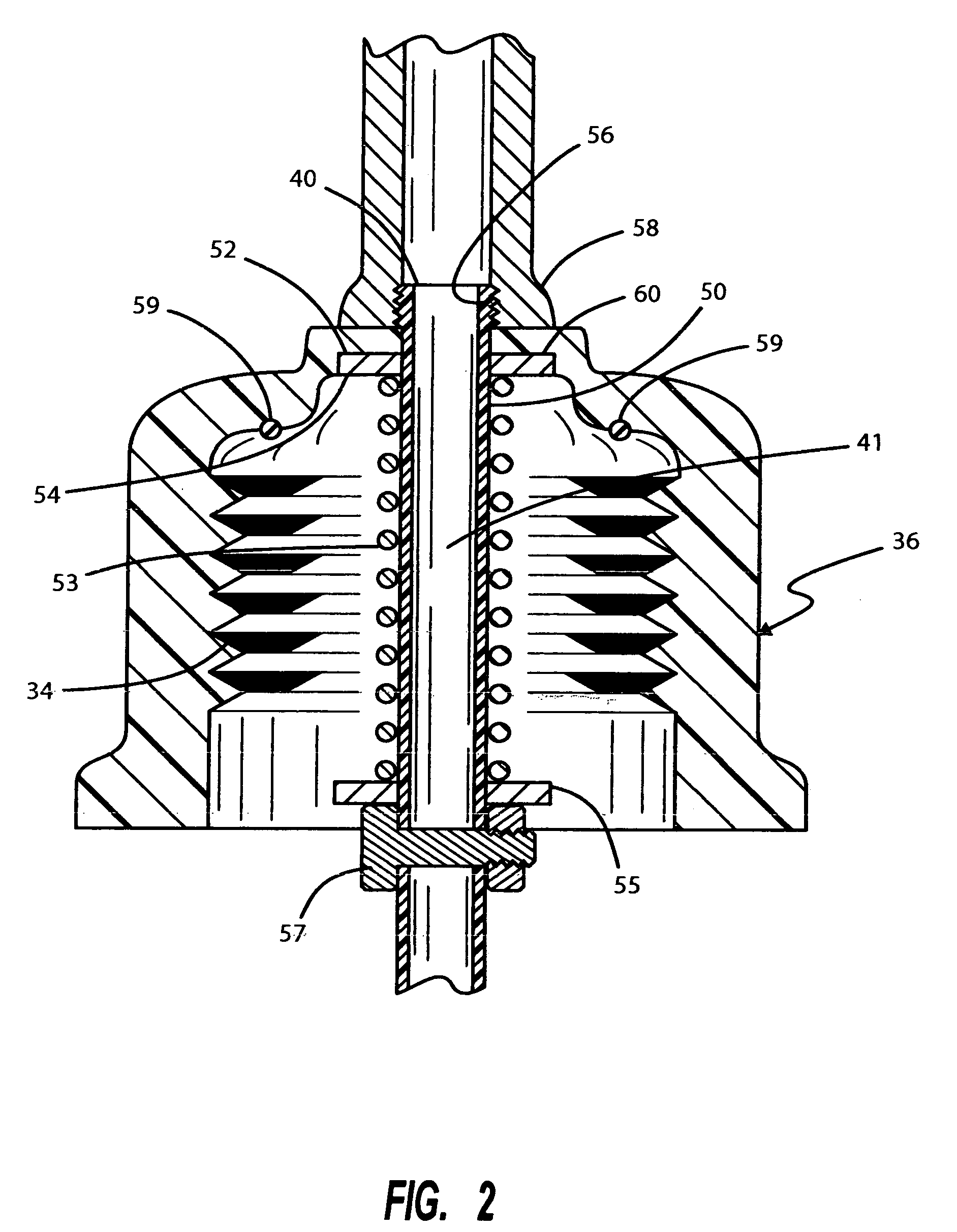

Rotary vane pump seal

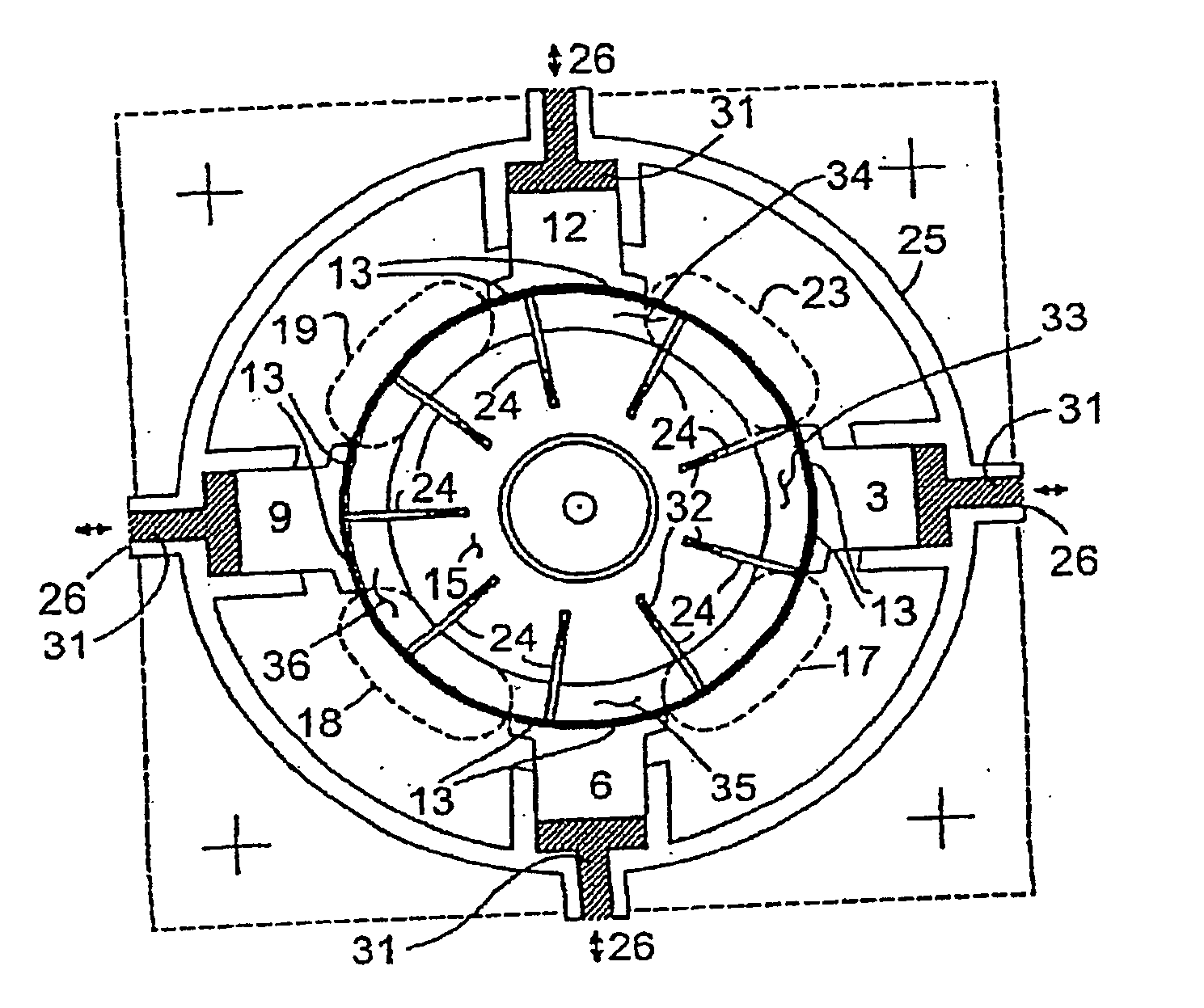

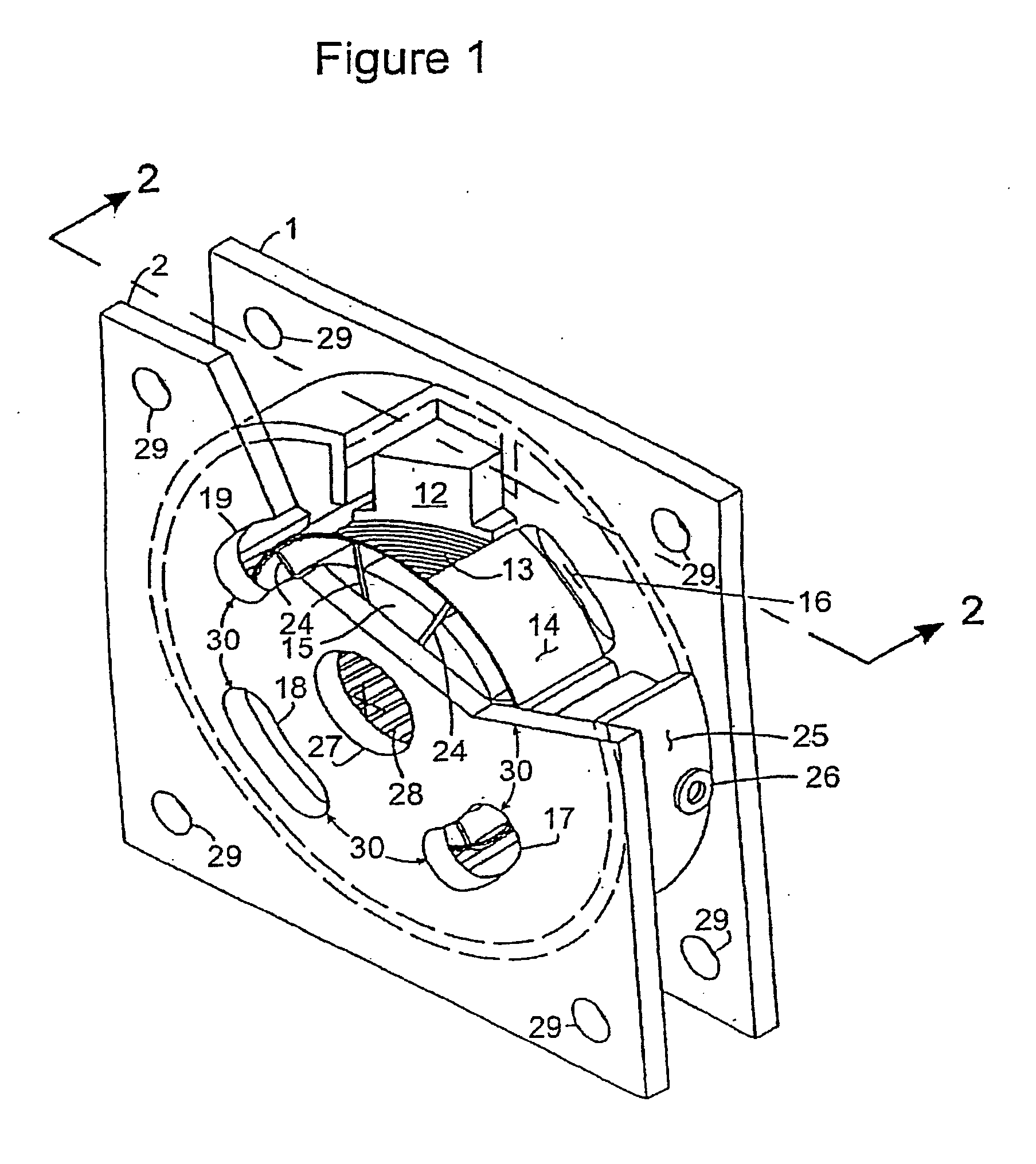

InactiveUS20050036897A1Easily lend itself to digital controlImprove efficiencyOscillating piston enginesBlade accessoriesCheck valveFluid Leak

A rotary vane pump is provided that provides an improved fluid replenishment and pressure relief system within a rotary vane pump system. A system, containing a rotary vane pump containing at least one relief cut between the housing and the rotor, functions to relieve fluid pressure normally found between the housing and the rotor. The fluid leaks from areas such as the rotational clearance required between the rotor and an inner wall of the housing. The system includes a reservoir in fluid communication with the relief cut wherein fluid leaks are then retained within the reservoir. A fluid distribution manifold employing a plurality of check valves, each corresponding to a respective chamber within the rotor, provides a controlled fluid feed from the reservoir to the rotor thereby balancing the fluidic pressure existing between the radially innermost ends of the vanes and the radially outermost ends of the vanes.

Owner:KASMER THOMAS E

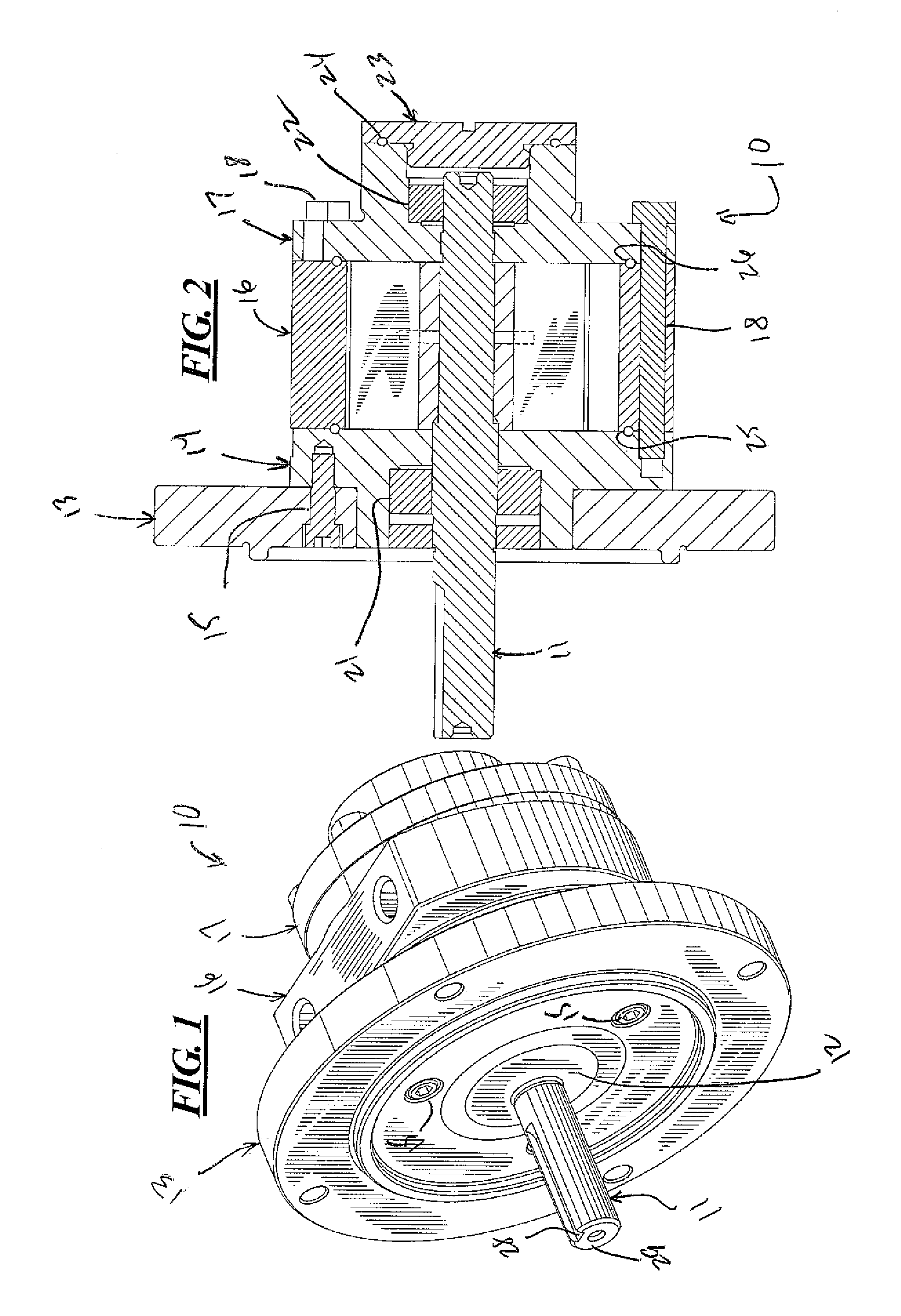

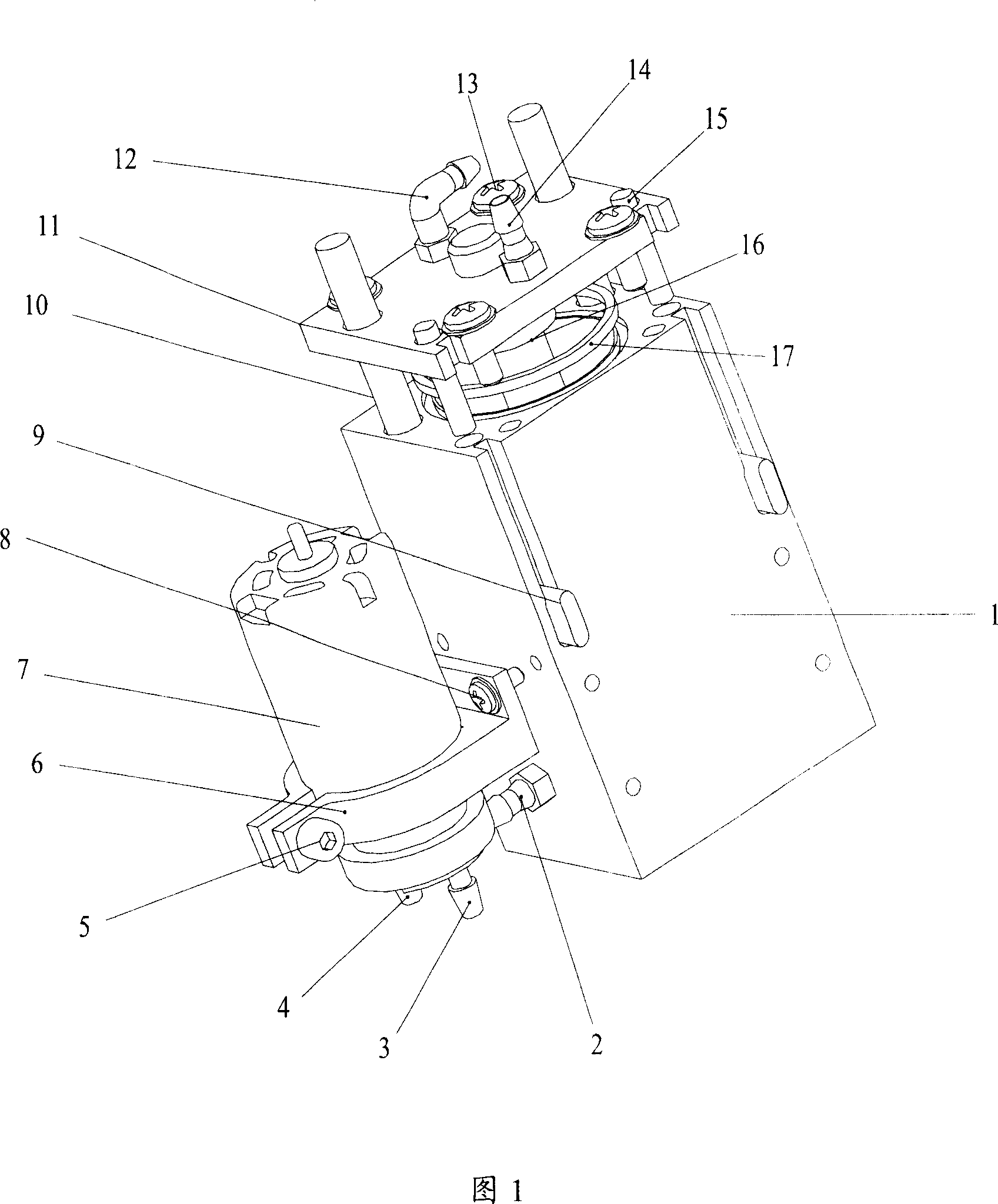

Magnetic drive vane pump

InactiveUS20080219875A1Compact structureOscillating piston enginesSealing arrangement for pumpsMagnetic tension forceRotor magnets

A magnet drive rotary vane pump has a casing with a pump cavity. A rotor carrying a plurality of vanes is disposed within the pump cavity to be rotatable about an eccentric axis with respect to the pump cavity for drawing the fluid into the pump cavity and expelling it out of the pump cavity. The rotor is configured to have a rotor magnet which is magnetically coupled to a stator magnet mounted on the casing outwardly of the pump cavity for driving the rotor. The rotor magnet is configured to have its major portion disposed in an overlapping relation with the stator magnet. Thus, the rotor magnet can be mechanically isolated from the stator magnet disposed outside of the casing to establish a sealless coupling therebetween for realizing leakage free pump.

Owner:MATSUSHITA ELECTRIC WORKS LTD

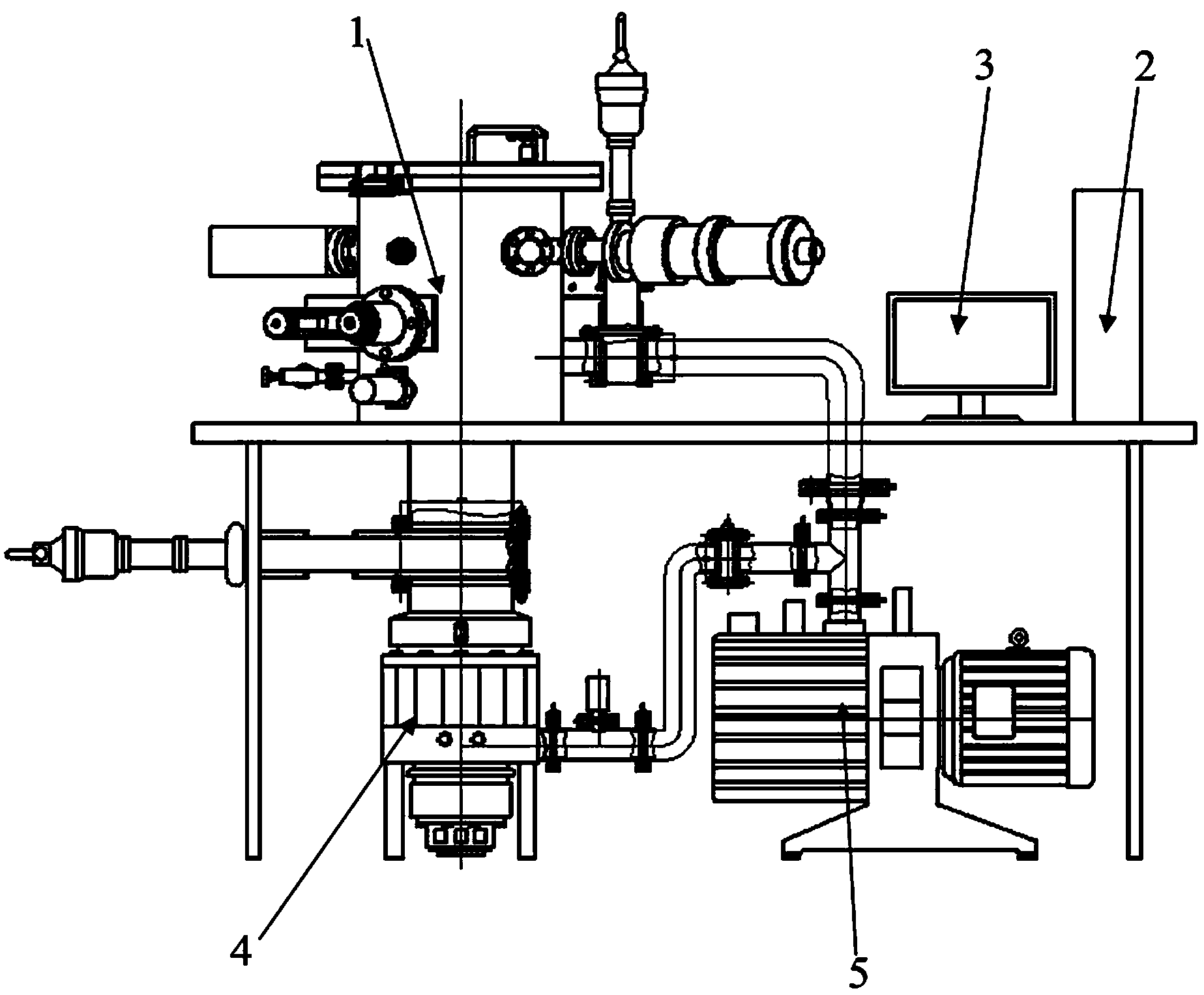

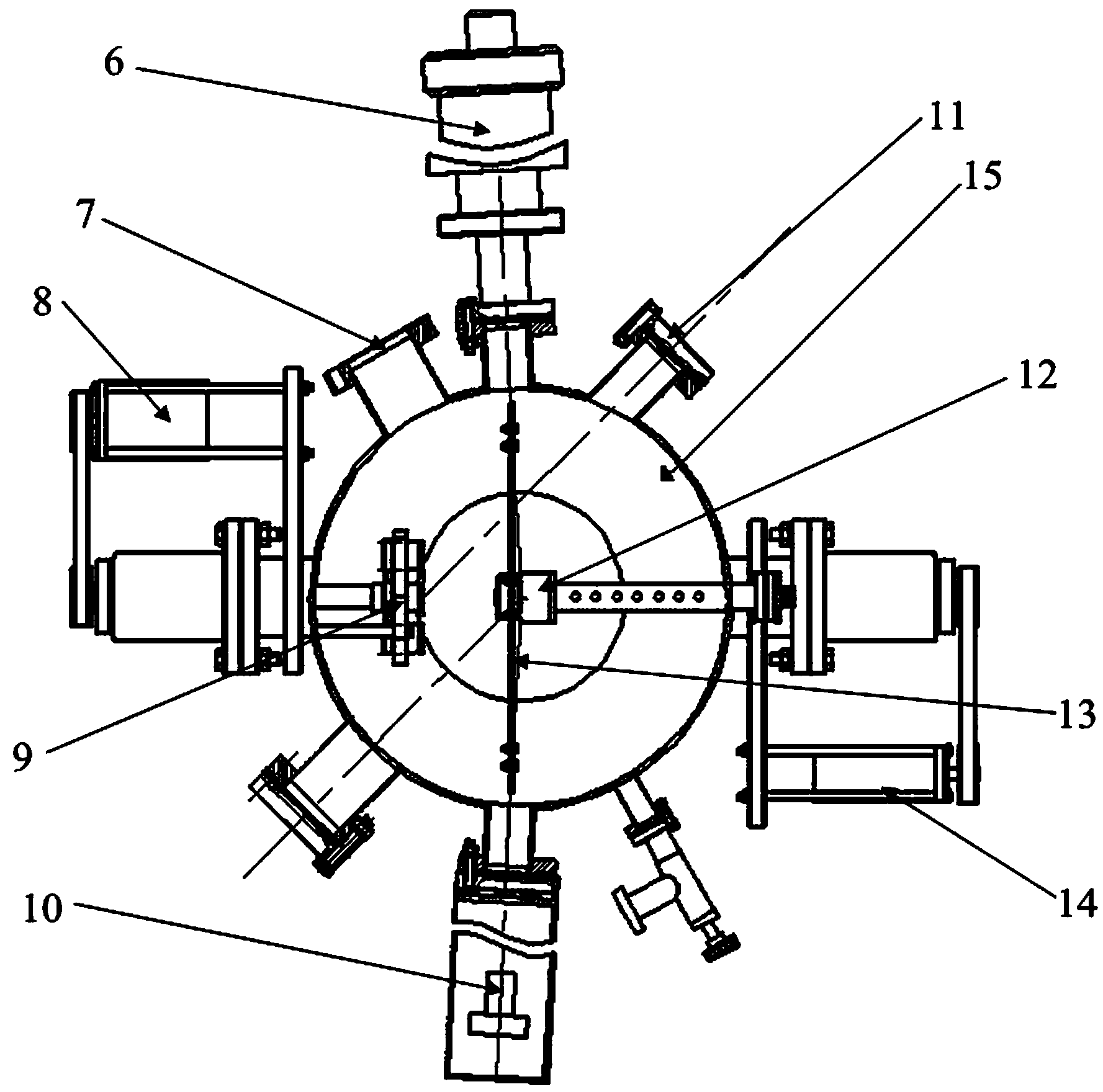

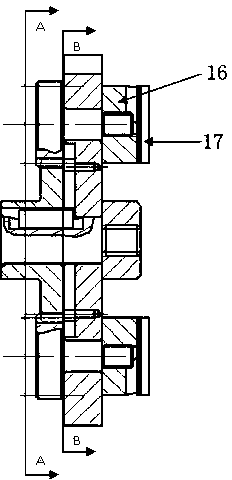

Device and method for preparing combined film material warehouse

InactiveCN104032265ASpread evenlySimple and fast operationVacuum evaporation coatingSputtering coatingLaser coatingEngineering

The invention belongs to the technical field of film material preparation and particularly relates to a device and method for preparing a combined film material warehouse. The device disclosed by the invention is composed of a combined pulse laser coating machine, a laser, a computer, a compound molecular pump and a double-stage rotary vane pump, wherein the combined pulse laser coating machine is composed of an RHEED (Reflection High-Energy Electron Diffraction) electronic gun, a pre-pumping pipeline, a stepping motor, a target selection swing mechanism, an RHEED fluorescent screen, a CCD (Charge Coupled Device) image sensor, a laser window, a substrate frame, a mask frame, a servo motor and a vacuum chamber, wherein the target selection swing mechanism is used for controlling target switching. A method provided by the invention comprises the steps of designing a mask with a corresponding structure according to a deposition film, and precisely and controllably depositing a multi-element component film warehouse through the combined pulse laser coating machine. The device disclosed by the invention is simple and convenient to operate, modularized in structure, convenient to maintain, capable of filling up the blank of the device for depositing the film material warehouse at high controllability at present and providing a novel feasible method for preparing the film material warehouse and wide in application prospect.

Owner:NORTHEASTERN UNIV

Molecular-distillation purification method of celery seed oil and purification device thereof

InactiveCN103215127ALow costHigh degree of automation controlFatty-oils/fats refiningPurification methodsDistillation

The invention discloses a molecular-distillation purification method of celery seed oil and a purification device thereof. The purification device consists of a hot oil machine, a cold water machine, a material tank, a thermostatic bath, a grade-I evaporator, a grade-II evaporator, a cold well, a water ring pump, a rotary vane pump, a diffusion pump and a controller, wherein the hot oil machine is communicated with the grade-II evaporator through a hot oil pipe; one end of the cold water machine is communicated with the grade-II evaporator through a first cooling water pipeline; the other end of the cold water machine is communicated with the cold well through a second cooling water pipeline; and the grade-I evaporator is communicated with the grade-II evaporator through a vacuum cavity pipeline and a second material conveying pipeline. The molecular-distillation purification method comprises the steps of: first, preparation work; second, the process of distillation separation; and third, shutdown. The method and the device have the beneficial effects of greatly enhancing the production efficiency, lowering the cost of purifying the celery seed oil, improving the working environment of workers, truly raising the automation control degree in purification of the celery seed oil, and being high in reliability and remarkable in practical effect.

Owner:CHANGCHUN UNIV OF TECH

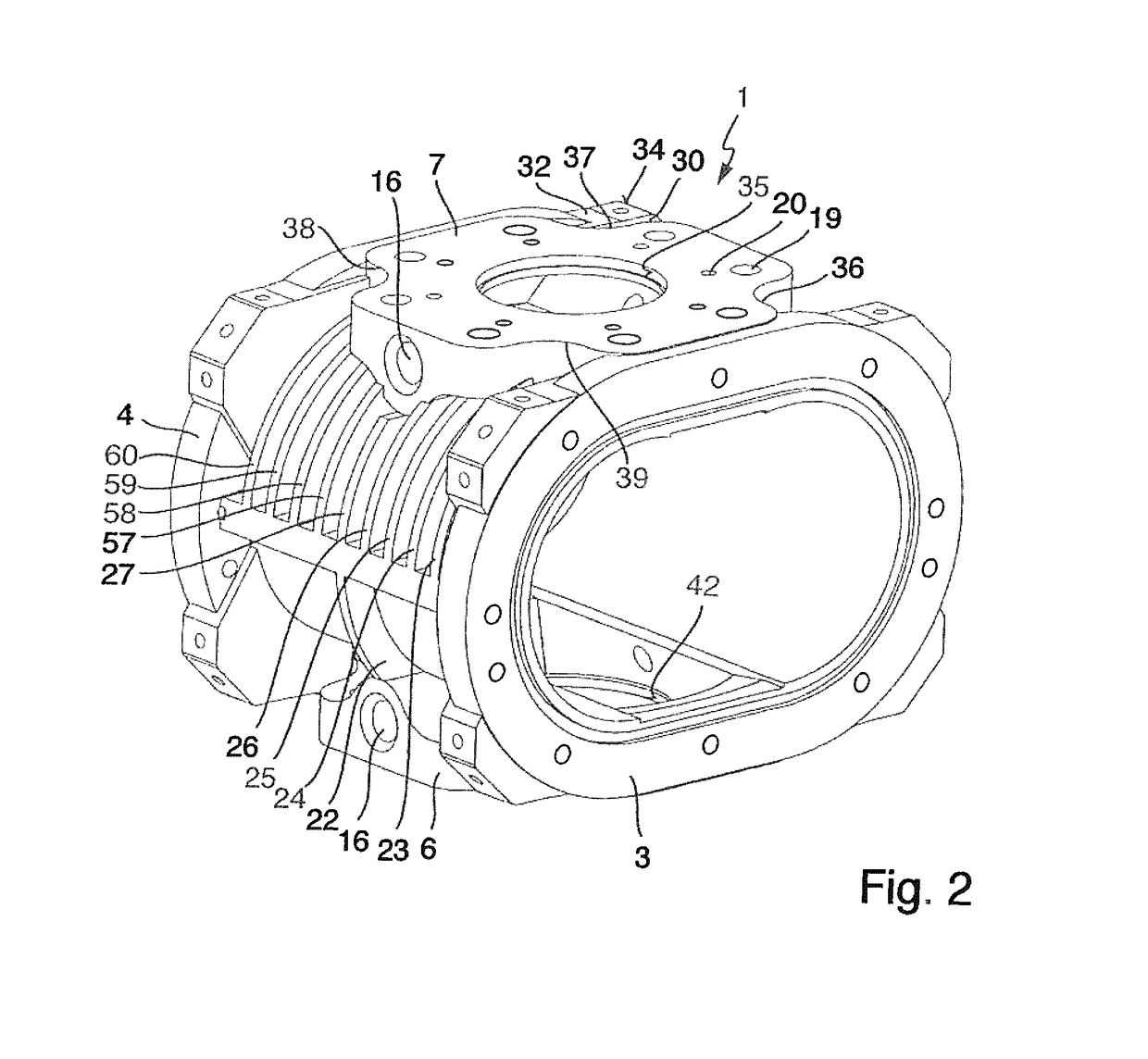

Magnetic vane ejection for a rotary vane air motor

A magnetic rotary vane pump is disclosed which includes a rotor disposed within a casing that comprises a cavity having an inlet and an outlet. The rotor includes at least one radial slot and at least one vane carried by the radial slot. The vane includes an inner edge directed towards a central axis of the rotor and an outer edge directed towards the casing. The inner edge of the vane is connected to a first magnet. The slot in the rotor includes an inner wall that abuttingly engages or faces the inner edge of the vane when the vane is fully received within the slot. The inner wall of the slot is connected to a second magnet. The two magnets are arranged so that like pole of the magnets face each other thereby biasing the vane out of the slot and against the inner wall of the casing as the rotor rotates. Accordingly, no spring or pin is required to bias the vane outward against the casing or into recesses or slots disposed in the casing wall. The resulting design may be operated faster than conventional vane pumps and with less lubrication or no lubrication than conventional vane pumps.

Owner:GAST MFG

Rotary vane pump with vane wear access port and method

InactiveUS6769886B2Extended service lifeAccurate insertionOscillating piston enginesRotary piston pumpsRotary pumpEngineering

A rotary vane pump, including a housing within which is rotatably mounted a rotor having a plurality of slots therein with a vane positioned for sliding movement within each of the slots. An access port is formed in the housing communicating with the rotor at a reference position in relation to the slots. The access port is sized to permit alignment of any one of the slots with the access port by rotating the rotor, maintaining the vane within the aligned one slot and at a datum within the slot, and permitting entry into the access port of an aligned slot of a stylus having a predetermined length in relation to the datum for determining the length of the vane. A determination of whether wear to the vane has met or exceeded a predetermined amount can be determined by reference to a portion of the stylus exterior to the access port.

Owner:TIMOTHY H HENDERSON

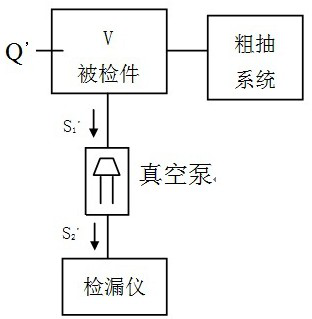

Unit forevacuum and leak detector integration system for molecular pump

InactiveCN105673461AImprove protectionExtended service lifePump testingPump installationsVacuum pumpingSolenoid valve

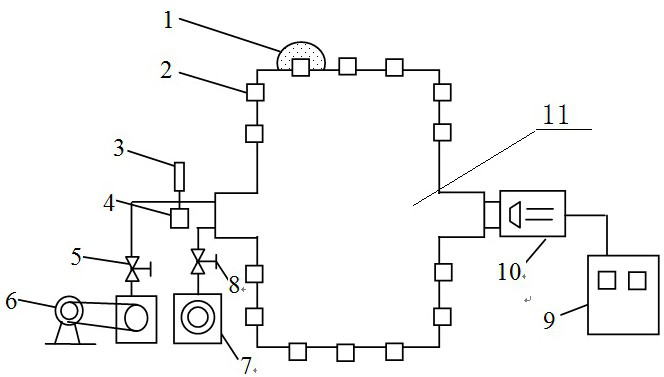

The invention discloses a molecular pump unit pre-evacuation and molecular pump leak detector integrated system, including a vacuum chamber, the vacuum chamber is connected to a product vacuum valve through a pipeline, the product vacuum valve is connected to a high vacuum baffle valve through a pipeline, and a high vacuum baffle The valve is connected to the high-vacuum solenoid through the pipeline, the high-vacuum solenoid is connected to the molecular pump through the pipeline, the molecular pump is connected to the manual flapper valve through the pipeline, the manual flapper valve is connected to the electromagnetic charging valve through the pipeline, and the electromagnetic charging valve is connected to the front rotary vane pump, molecular pump The pipeline between the manual flapper valve is connected to the leak detection valve through the pipeline, and the leak detection valve is connected to the leak detector through the pipeline; the pipeline between the molecular pump and the manual flapper valve is connected to the bypass pre-pumping flapper valve through the pipeline, The bypass pre-extraction baffle valve is connected to the pipeline between the high vacuum baffle valve and the high vacuum solenoid valve through a pipeline. The invention solves the problems of long evacuation and leak detection reaction time in the manufacturing process of the low-temperature pressure vessel and the problems of energy consumption and man-hour waste in the interlayer high-vacuum evacuation process.

Owner:HEBEI CHANGHUA AUTOMOBILE

Vacuum pumping device for interlayer of cryogenic insulation cylinder

InactiveCN103343878AEasy to replaceFast deflationContainer filling methodsPressure vesselsVacuum pumpingGas cylinder

The invention relates to a vacuum pumping device for an interlayer of a cryogenic insulation cylinder, which belongs to the technical field of cryogenic insulation vacuum. The vacuum pumping device is mainly technically characterized by comprising the cryogenic insulation cylinder, a heating oven, an internal air circulating fan, a combustion machine, a heating branch pipe, an exhaust branch pipe, an internal heating main pipe, an external exhaust main pipe, a nitrogen heating device, a nitrogen displacement valve, a pneumatic flapper valve I, a pneumatic flapper valve II, a diffusion pump, a pneumatic flapper valve III, a rotary vane pump and a Roots pump, wherein the internal air circulating fan is used for introducing heated high-temperature air into the interlayer of the cylinder. The two surfaces of an outer cylinder body and an inner liner are heated simultaneously, so that hydrogen, helium and other low molecular weight gas molecules, water molecules and the like, which are adsorbed in a heat insulation material in the interlayer, can be activated, the gas release speed of the interlayer is enhanced, and the vacuum pumping speed of the interlayer is effectively improved. The vacuum pumping device has the advantages of reasonable structure, safety and convenience in use, high vacuum pumping degree, no re-bounce of vacuum degree, long holding time and the like.

Owner:江南工业集团有限公司

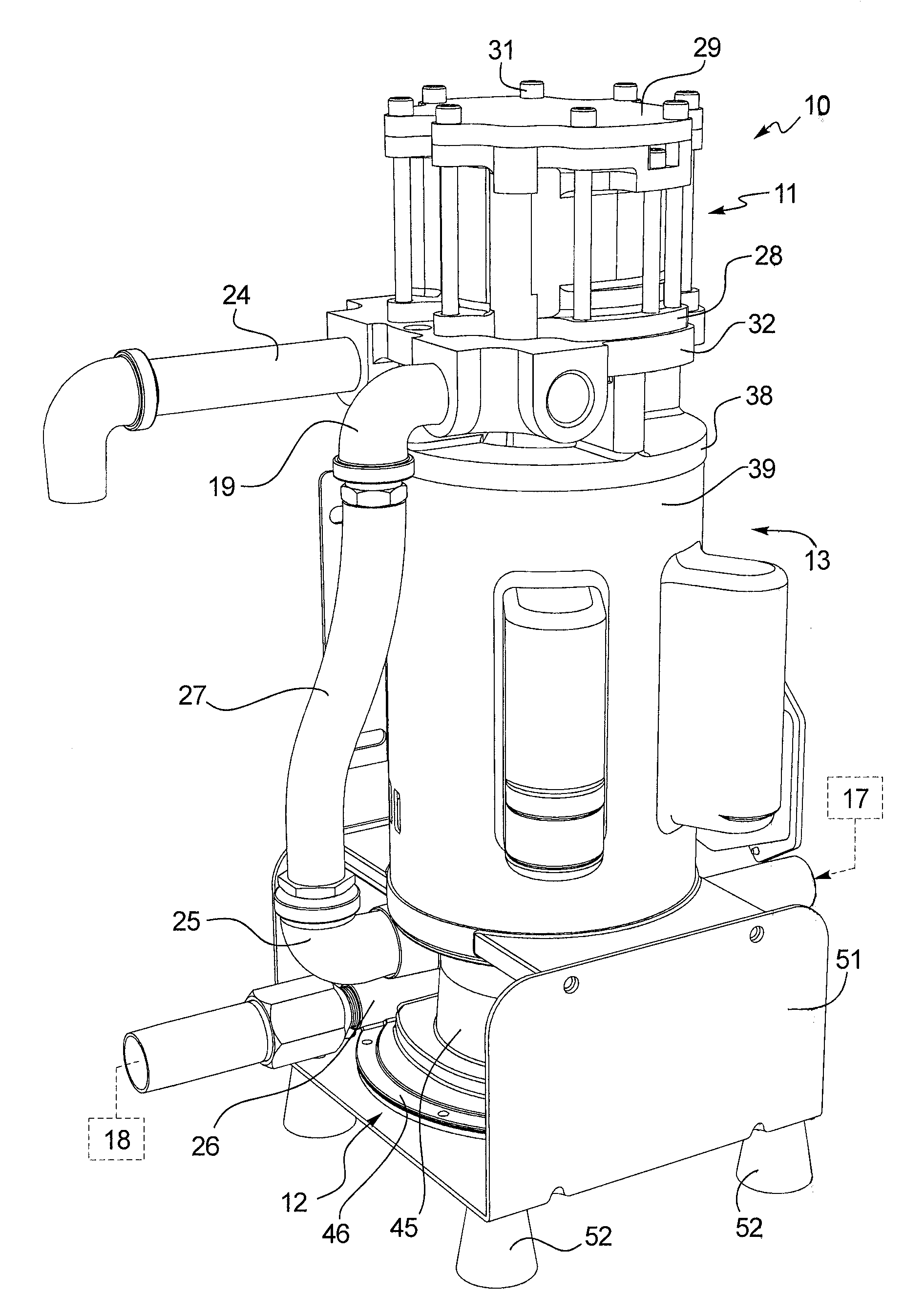

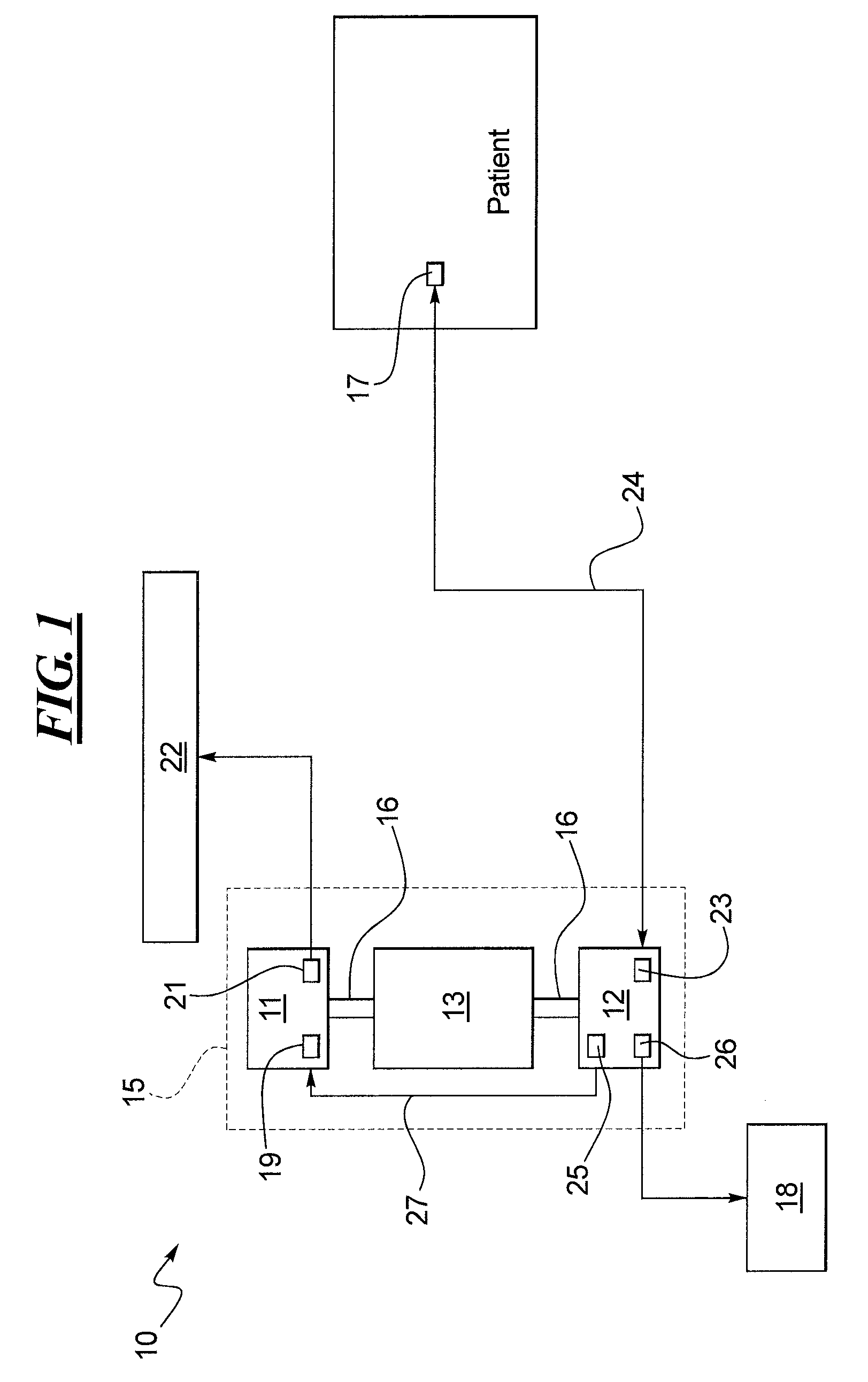

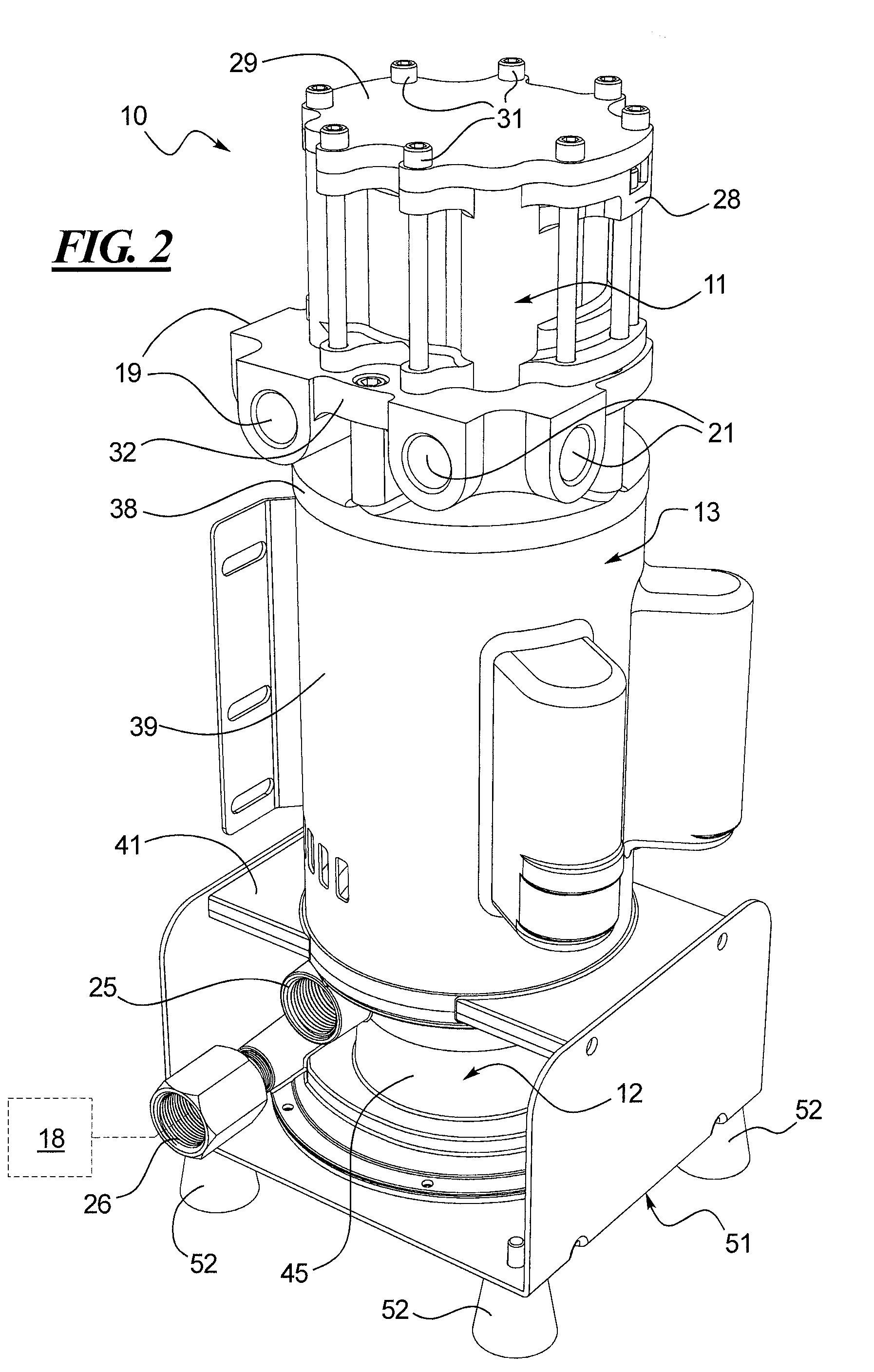

Combination vertical rotary vane suction pump and liquid separator

InactiveUS20110143311A1Combination devicesAuxillary pretreatmentVapor–liquid separatorWaste management

Owner:GAST MFG

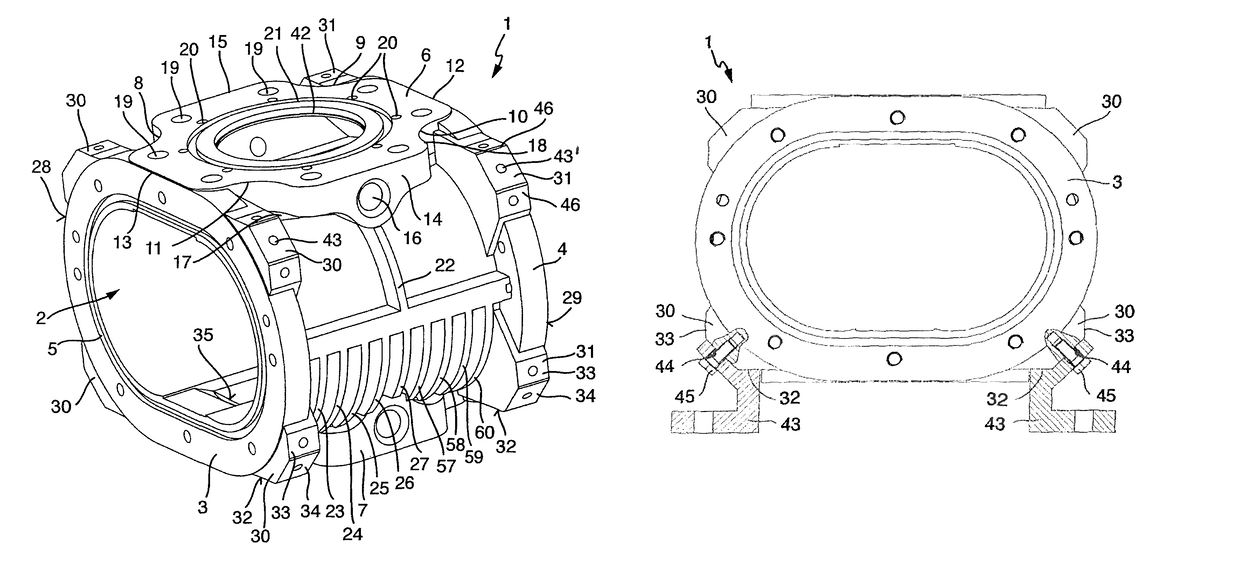

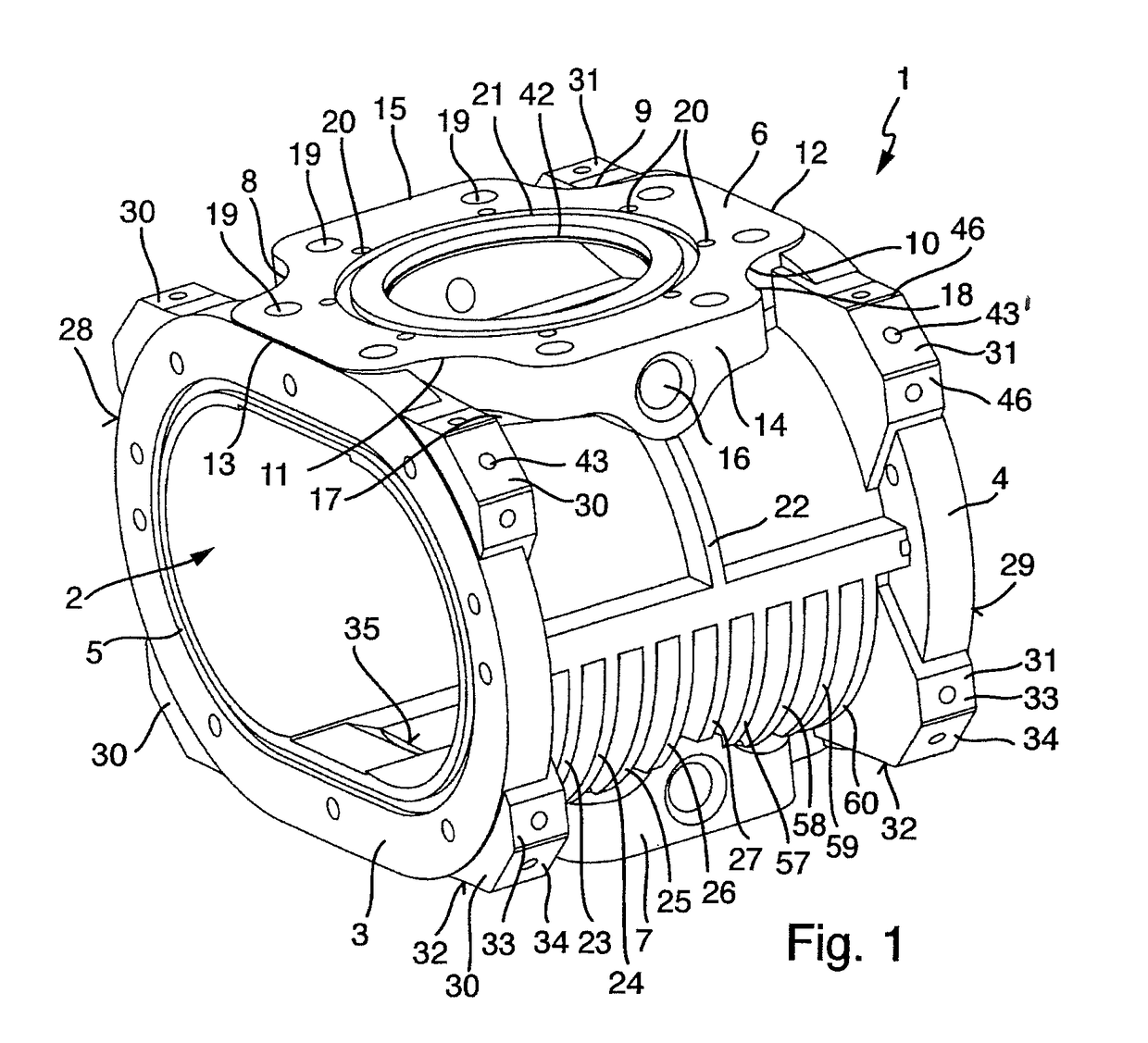

Housing for a rotary vane pump

InactiveUS9745978B2Avoid deformationAvoid tensionOscillating piston enginesRotary piston pumpsInternal pressureEngineering

Owner:PFEIFFER VACUUM GMBH

Rotary vane pump with vane wear access port and method

InactiveUS20030124010A1High strengthAvoid wear and tearOscillating piston enginesRotary piston pumpsRotary pumpEngineering

A rotary vane pump, including a housing within which is rotatably mounted a rotor having a plurality of slots therein with a vane positioned for sliding movement within each of the slots. An access port is formed in the housing communicating with the rotor at a reference position in relation to the slots. The access port is sized to permit alignment of any one of the slots with the access port by rotating the rotor, maintaining the vane within the aligned one slot and at a datum within the slot, and permitting entry into the access port of an aligned slot of a stylus having a predetermined length in relation to the datum for determining the length of the vane. A determination of whether wear to the vane has met or exceeded a predetermined amount can be determined by reference to a portion of the stylus exterior to the access port.

Owner:TIMOTHY H HENDERSON

Rotary vane pump

A pump assembly (100) having a pump housing (206 and 208) and a rotor (222) rotatingly disposed within the housing, the rotor having a plurality of slots (226). The pump assembly includes a plurality of vanes (224), each vane moveably disposed in one of the plurality of slots, and an input shaft (228) coupled to the rotor for applying a torque to the rotor. The pump assembly (100) also includes a prime mover (400) for generating a torque and a magnetic coupling unit (300) for magnetically transferring the torque generated by the prime mover to the input shaft. The vanes may have a leg (256) which extends radially inward from a blade (254). The rotor and input shaft may be integrally formed.

Owner:TUTHILL CORP

Rotary vane pump/motor

InactiveCN107178494ASimple structureWorking condition reversibleRotary piston pumpsRotary piston liquid enginesHigh energyAir pump

The invention provides a rotary vane pump / motor with simple structure, which includes vanes, synchronous claws, runners, power shafts, synchronous chute, shroud, casing and inlet and outlet ports. A plurality of self-rotating blades are installed on the runner connected to the power shaft, and the ratio of the rotation speed of the blades to the speed of the runner is 1:2. The invention is applicable to various fluids, the working conditions are reversible, the fluid flow direction is reversible, the structure is simple, and the energy efficiency is high. Through the difference design of the blade and the guide structure, it can be used as the design prototype of the water pump, the water turbine, the air pump / motor, and the hydraulic pump / motor respectively. .

Owner:吴其兵

System for heating spray head in spray-painting device

ActiveCN1958297AIncrease heating capacityTemperature does not dropTypewritersDiaphragm pumpEngineering

A heating system for the jet head of ink jet plotter is composed of a water storage unit able to heat the water in it, a water tube of jet head, a rotary vane pump for pumping the hot water into said water tube of jet head in order to heat jet head, a liquid level sensor, and a diaphragm pump for automatically filling water in said water storage unit.

Owner:SHENZHEN RUNTIANZHI DIGITAL EQUIP

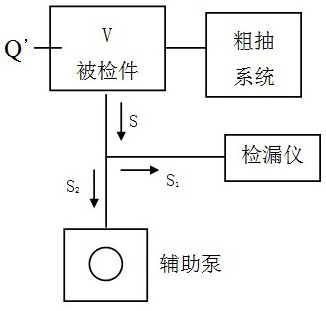

Device and detection method for detecting airtightness of large-cavity multi-sealing structure container

The invention discloses a device and method for detecting the airtightness of a large-cavity multi-sealing structure container, and the device is characterized in that a first through hole is formed in one side of the large-cavity multi-sealing structure container, and is sequentially connected with a vacuum gauge with a standard leak hole, a first valve and a roots pump through a connecting pipeline; a pipeline connected with a second through hole of the device on the side is connected with a rotary vane pump through a second valve, a third through hole is formed in the other side of the large-cavity multi-sealing structure container, and a pipeline connected with the third through hole is connected with a leak detector through a molecular pump. The detection method comprises the following steps: sequentially opening and closing the rotary vane pump and the roots pump to enable a detected piece to reach a specified vacuum degree, opening the detector and the molecular pump, opening a standard leak hole, respectively installing a helium cover on each sealing part of the detected piece, and determining the position of the leak hole. According to the invention, the leakage link can be accurately positioned, the leakage detection sensitivity is improved, the local helium cover is accurately positioned, the response time of a leakage detection system is effectively shortened, the air exhaust time of the system is shortened, and the leakage detection efficiency is improved.

Owner:63653 FORCES PLA

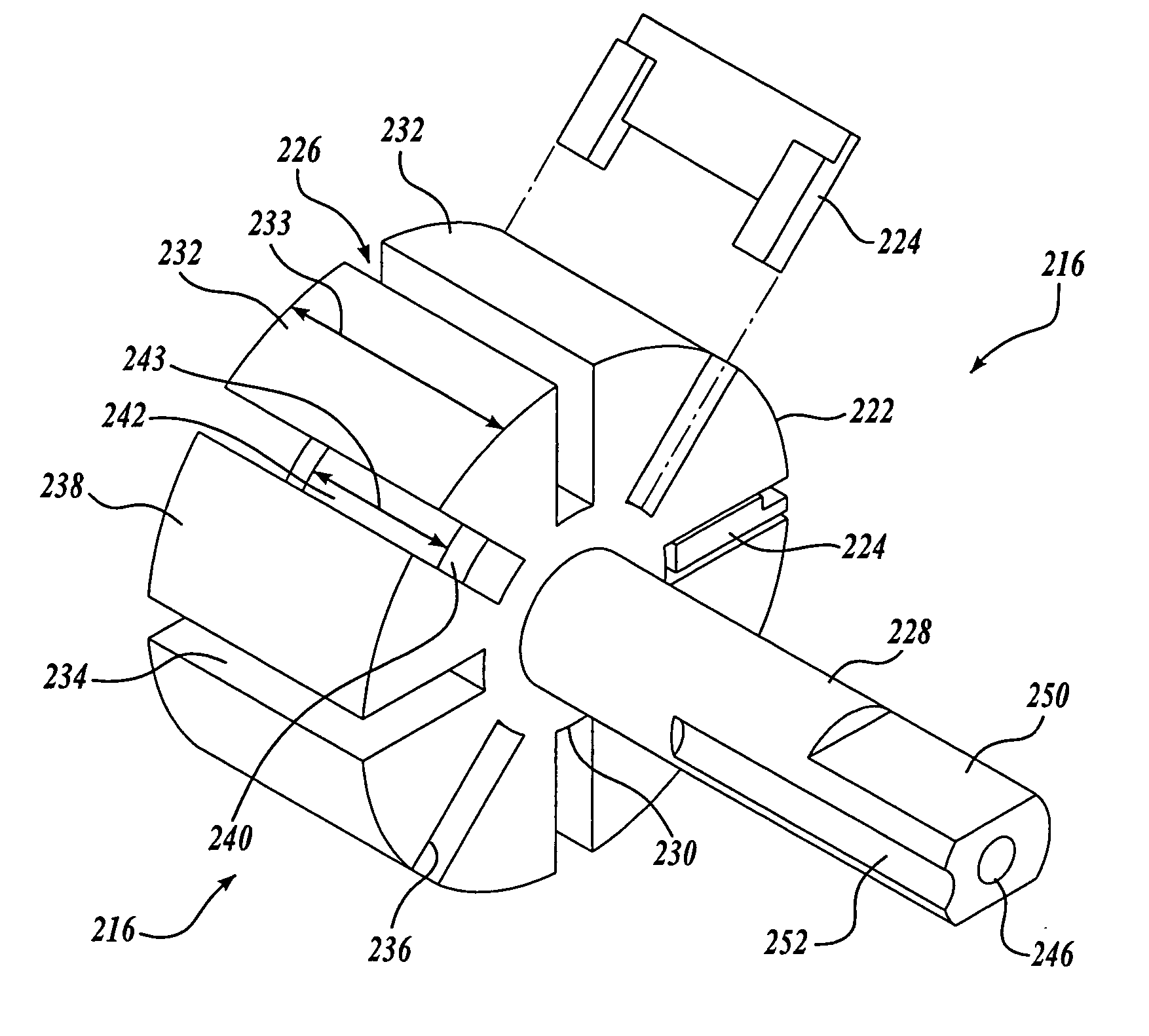

Rotary vane pump

InactiveUS7393192B2Oscillating piston enginesSealing arrangement for pumpsMechanical engineeringRotary vane pump

A rotary vane pump (200) for pumping a fluid. The rotary vane pump includes a pump housing (206 and 208) and a rotor having a plurality of dividing members (232) and a plurality of slots (226) disposed between adjacent dividing members. The rotary vane pump also includes a plurality of strengthening members (240), each strengthening member disposed in one of the plurality of slots and coupled to adjacent dividing members. The rotary vane pump also includes a plurality of vanes (224), each vane moveably disposed in one of the plurality of slots.

Owner:TUTHILL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com