Purification apparatus and method for solar energy level polysilicon

A solar-grade, purification method technology, applied in chemical instruments and methods, silicon compounds, inorganic chemistry, etc., can solve the problems of high cost, waste of environment, large amount of slag, etc., and achieve considerable market prospects, convenient operation, and low investment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

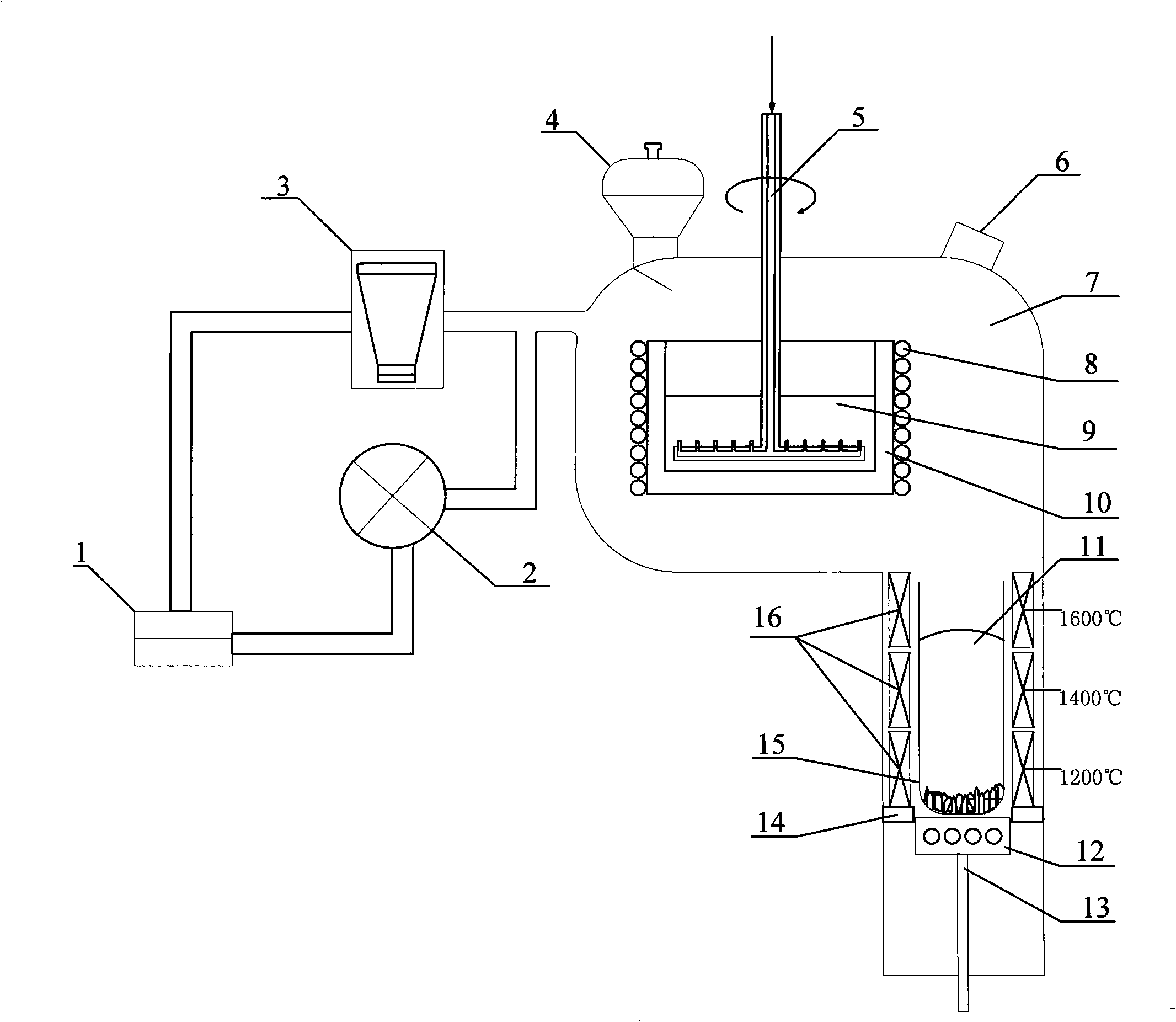

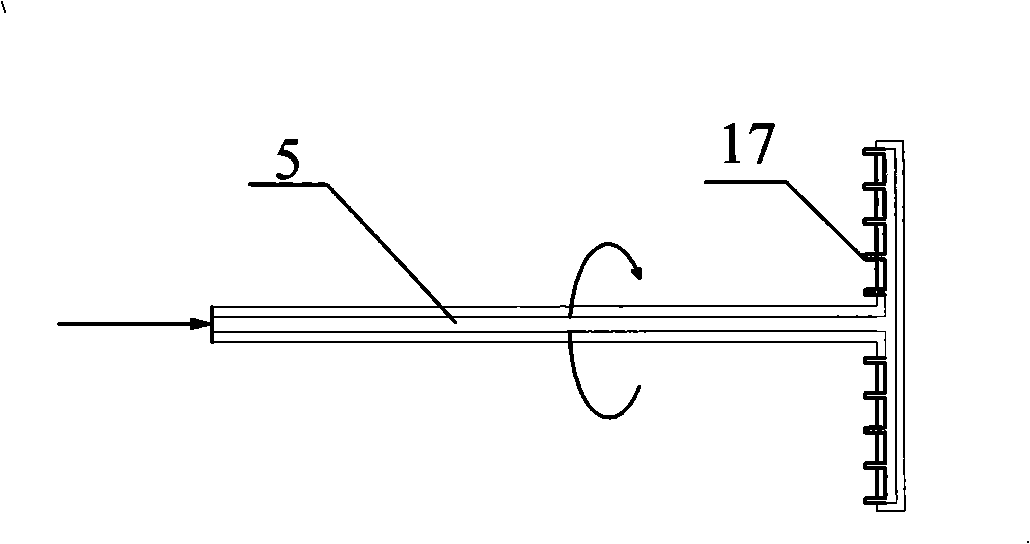

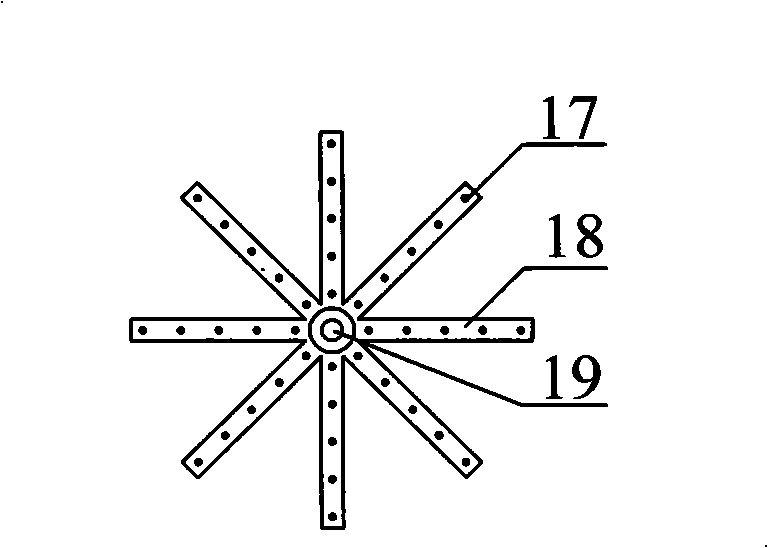

Embodiment 1

[0044] Embodiment 1: Start the heater of the resistance wire heating holding furnace, and set the temperature according to the upper, middle and lower temperature sections as 1415°C, 1200°C, and 1000°C respectively. Put 50kg of polycrystalline silicon (block) into a graphite crucible, close the vacuum chamber, and turn on the mechanical rotary vane pump. When the vacuum degree of the vacuum chamber reaches 10Pa, the induction coil is powered on with an alternating current at 50kW until the silicon is completely melted. Turn on the power of the oil diffusion pump for preheating. When the temperature of the silicon liquid reaches 1800°C, lower the rotary aeration device to the surface of the silicon liquid for preheating, and after 10 minutes, inject 99% Ar+2% O from the inlet of the aeration device. 2 , and then put the aeration device in the graphite crucible at a position 10mm from the bottom, start the rotation button, aerate while rotating and stirring, the rotation speed i...

Embodiment 2

[0045] Embodiment 2: technological process is with embodiment 1. The temperature of the upper, middle and lower temperature zones of the resistance wire heating and holding furnace is set at 1500°C, 1350°C, and 1150°C; the raw material is 100kg of bulk polysilicon, the AC power is 80kW, and the temperature of the silicon liquid reaches 1700°C for ventilation and rotation. The ventilation device was preheated for 5 minutes, 99% Ar+3% water vapor was introduced, the rotation speed was 60 rpm, the ventilation volume was 2.5 L / min, and the ventilation time was 45 minutes. Vacuum up to 3.9×10 -2 Pa, the vacuum melting time is 90min, and the stainless steel lifting rod drives the mold to move downward at a speed of 20mm / h. After the directional solidification is completed, break the vacuum to take out the silicon ingot, cut off 1 / 10 of the upper part, and measure the P content of the polysilicon by plasma inductively coupled mass spectrometer (ICP-MS) to be 0.05ppmw, the B content ...

Embodiment 3

[0047] Technological process is with embodiment 1. The temperature of the upper, middle and lower temperature zones of the resistance wire heating and holding furnace is set at 1600°C, 1350°C, and 1150°C; the raw material is 180kg of powdered polysilicon, the AC power is 100kW, and the temperature of the silicon liquid reaches 1500°C for ventilation and rotation. The ventilation device was preheated for 8 minutes, 98% Ar+1% water vapor was introduced, the rotation speed was 120 rpm, the ventilation volume was 1 L / min, and the ventilation time was 90 minutes. Vacuum up to 1.2×10 -2 pa, the vacuum melting time is 90min, and the stainless steel lifting rod drives the mold to move downward at a speed of 20mm / h. After the directional solidification is completed, break the vacuum and take out the silicon ingot, cut off 1 / 10 of the upper part, and measure the P content of the polysilicon by a plasma inductively coupled mass spectrometer (ICP-MS) to be 2.8ppmw, the B content to be 4....

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com