Evaporation coating device and air extracting process thereof

An evaporative coating and equipment technology, applied in the field of evaporative coating equipment and its air extraction process, can solve the problems of serious oil vapor pollution, low utilization rate of air extraction, long start-up time, etc., to ensure the quality of coating products and eliminate oil vapor pollution , the effect of saving equipment and money

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

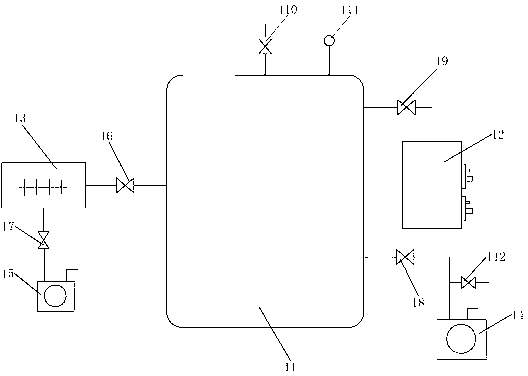

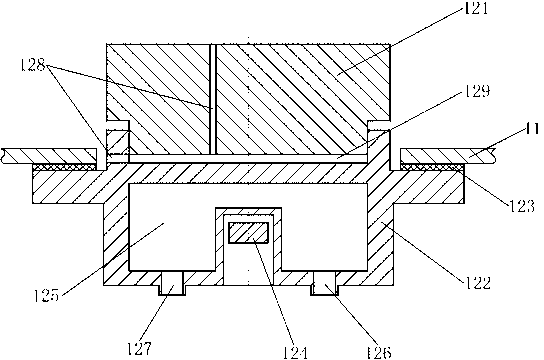

[0031] Such as figure 1 with figure 2 As shown, the evaporation coating equipment provided in the first embodiment of the present invention can be used for coating enhancement, decoration, and adding new functions to the surface of the workpiece to be coated. The evaporation coating equipment includes a vacuum coating chamber 11, the vacuum coating chamber 11 is respectively connected with an arc titanium pump 12, a traction molecular pump 13, and a rough pump 14, the traction molecular pump 13 is connected with a fore-stage pump 15, the vacuum coating chamber 11 and the traction A first vacuum valve 16 is provided between the molecular pump 13, a second vacuum valve 17 is provided between the traction molecular pump 13 and the backing pump 15, and a third vacuum valve 18 is provided between the vacuum coating chamber 11 and the rough pump 14 A fourth vacuum valve 19 is provided between the vacuum coating chamber 11 and the arc titanium pump 12; among them, the rough pump 14 i...

Embodiment 2

[0049] The second embodiment is roughly the same as the first embodiment, and the difference is that the remaining space at the connection between the titanium target and the cathode arc source base of the second embodiment is also provided with an elastic thermally conductive layer, which is preferably a metal material ( Such as copper or copper alloy, etc.), the elastic thermal conductive layer can also be made of non-metallic thermal conductive materials (such as graphite, carbon fiber, etc.). When cooling water is passed into the cooling water tank in the cathode arc source base to cool the titanium target, the elastic heat conduction layer can increase the heat transfer speed between the titanium target and the cathode arc source base, and further improve the cooling of the titanium target. effectiveness.

Embodiment 3

[0051] The third embodiment is roughly the same as the first embodiment. The difference is that the evaporative coating equipment of the third embodiment is additionally equipped with a cryogenic water vapor pump, which is connected to the vacuum coating chamber. The middle vacuum stage, fine pumping and coating stages help to extract water vapor and shorten the pumping time for evaporation and coating.

[0052] The third embodiment is particularly suitable for evaporation coating equipment with a short coating cycle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com