High vacuum arc pump and its exhaust unit

A high vacuum and arc technology, applied in vacuum evaporation coating, pumps, mechanical equipment, etc., can solve the problems of collision between electrons and gas molecules, small ionization probability, low density of space gas molecules, and difficulty in achieving effective cooling, etc., achieving huge The effect of instantaneous pumping flow, improving the quality of vacuum products, and eliminating oil vapor pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

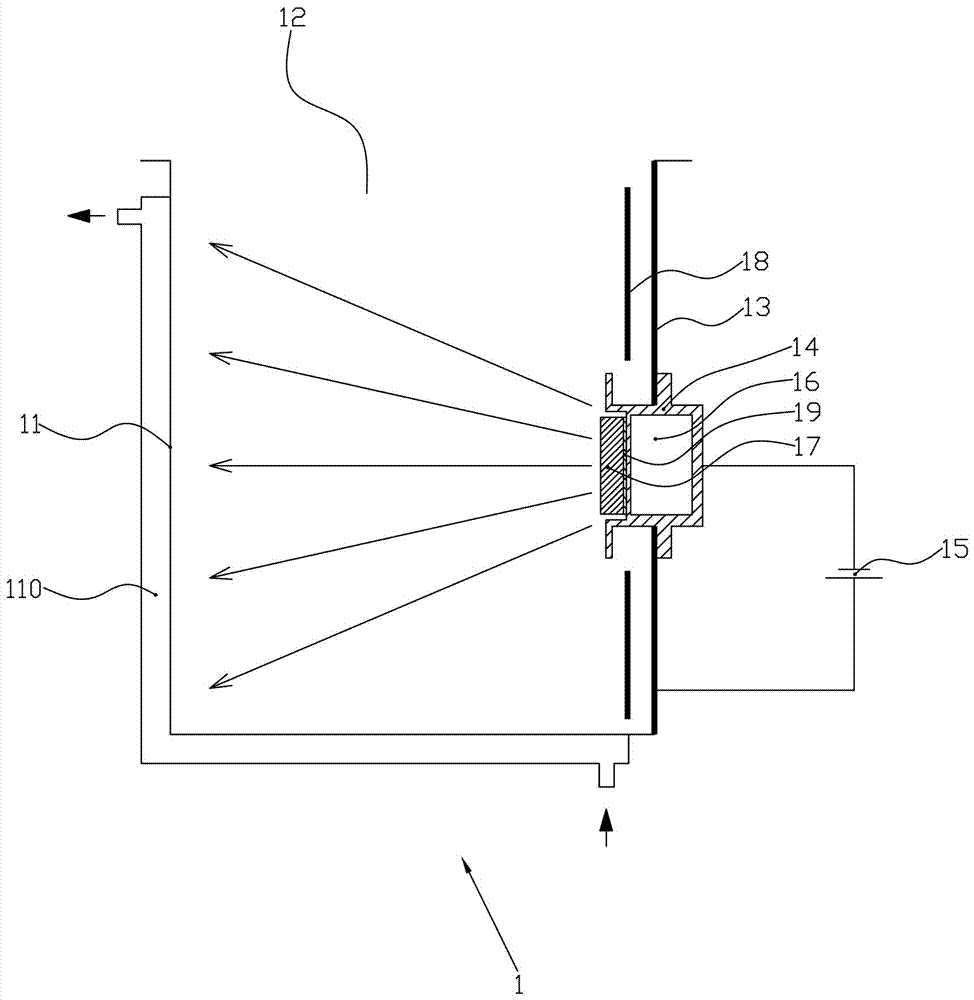

[0037] Embodiment one high vacuum arc pump

[0038] Such as figure 1 As shown, a high vacuum arc pump 1 provided by Embodiment 1 of the present invention includes a pump casing 11, a pump port 12 is opened on the upper part of the pump casing 11, and an openable panel 13 is located on the right side of the pump casing 11. On the panel 13 A base 14 is fixed, the base 14 is insulated from the panel 13, the base 14 is electrically connected to the negative pole of the power supply 15, a cooling water jacket 16 is provided on the base 14, and cooling water is passed through the cooling water jacket 16 to realize Cooling of the base 14, the inner end of the base 14 is fixedly connected to the cathode target 17, the positive pole of the power supply 15 is electrically connected to the pump casing 11, and the pump casing 11 is also provided with a metal baffle 18 between the cathode target 17 and the panel 13 , The metal baffle 18 is preferably stainless steel or aluminum, and the m...

Embodiment 2

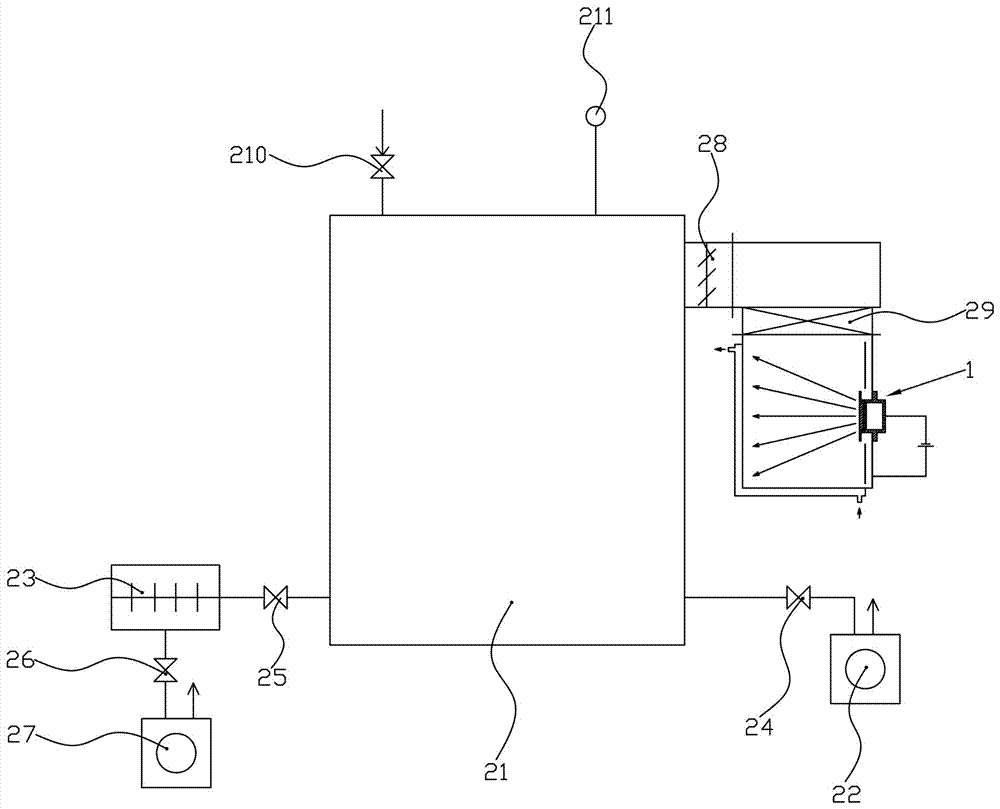

[0045] Embodiment 2 High vacuum arc pump unit

[0046] Such as figure 2 As shown, a high vacuum arc pump unit provided in Embodiment 2 of the present invention includes a vacuum chamber 21, and the vacuum chamber 21 is respectively connected with a roughing pump 22, a traction molecular pump 23, and the high vacuum arc pump as described in Embodiment 1. 1;

[0047] Specifically, the vacuum chamber 21 is connected to the rough pump 22 through the first vacuum valve 24, the vacuum chamber 21 is connected to the drag molecular pump 23 through the second vacuum valve 25, and the drag molecular pump 23 is connected to the backing pump 27 through the third vacuum valve 26. Connected, the vacuum chamber 21 is connected with the high vacuum arc pump 1 through the dust shield 28 and the fourth vacuum valve 29 in turn, the dust shield 28 is preferably an electrostatic dust shield, and the vacuum chamber 21 is also connected with an air release valve 210 and a vacuum gauge 211 respecti...

Embodiment 3

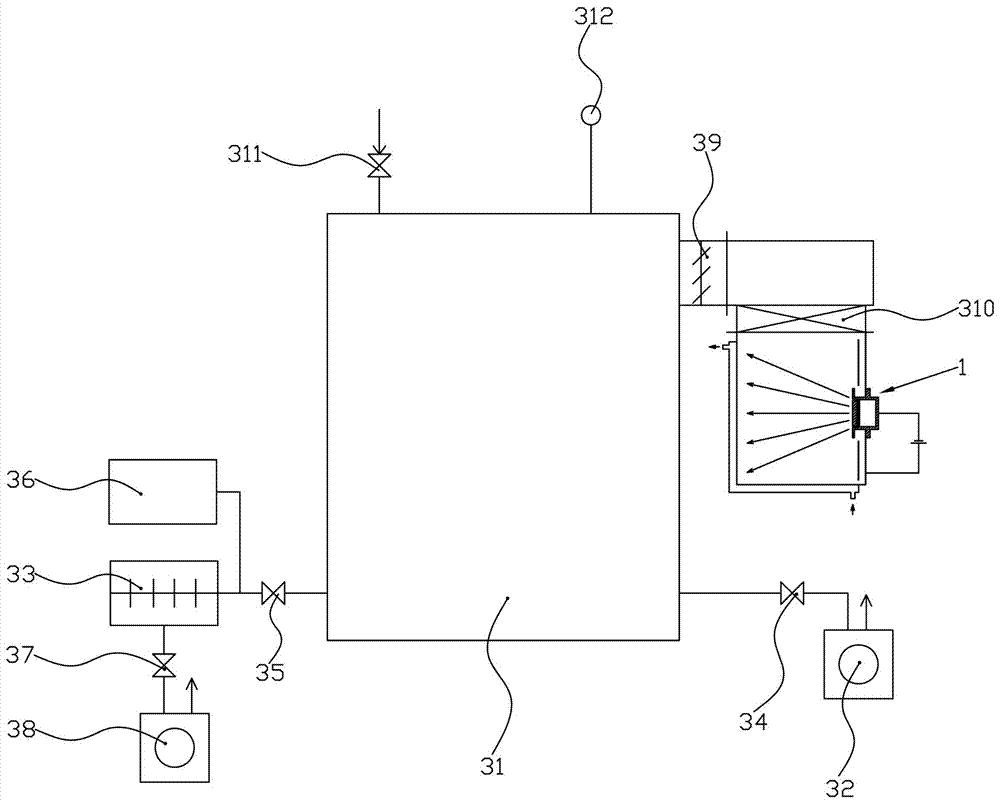

[0054] Embodiment 3 Cryogenic high vacuum arc pump unit

[0055] Such as image 3 As shown, the third embodiment provides a cryogenic high vacuum arc pump unit, including a vacuum chamber 31, the vacuum chamber 31 is respectively connected with a roughing pump 32, a traction molecular pump 33 and the high vacuum arc as described in the first embodiment. pump 1;

[0056] Specifically, the vacuum chamber 31 is connected to the roughing pump 32 through the first vacuum valve 34, and the vacuum chamber 31 is respectively connected to the cryogenic pump 36 and the dragging molecular pump 33 directly or through the second vacuum valve 35, and the dragging molecular pump 33 passes through the third The vacuum valve 37 is connected to the backing pump 38, the vacuum chamber 31 is respectively connected to the high vacuum arc pump 1 through the dust shield 39 and the fourth vacuum valve 310, and the vacuum chamber 31 is also connected to the air release valve 311 and the vacuum gauge ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com