Patents

Literature

71results about "Diffusion pumps" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

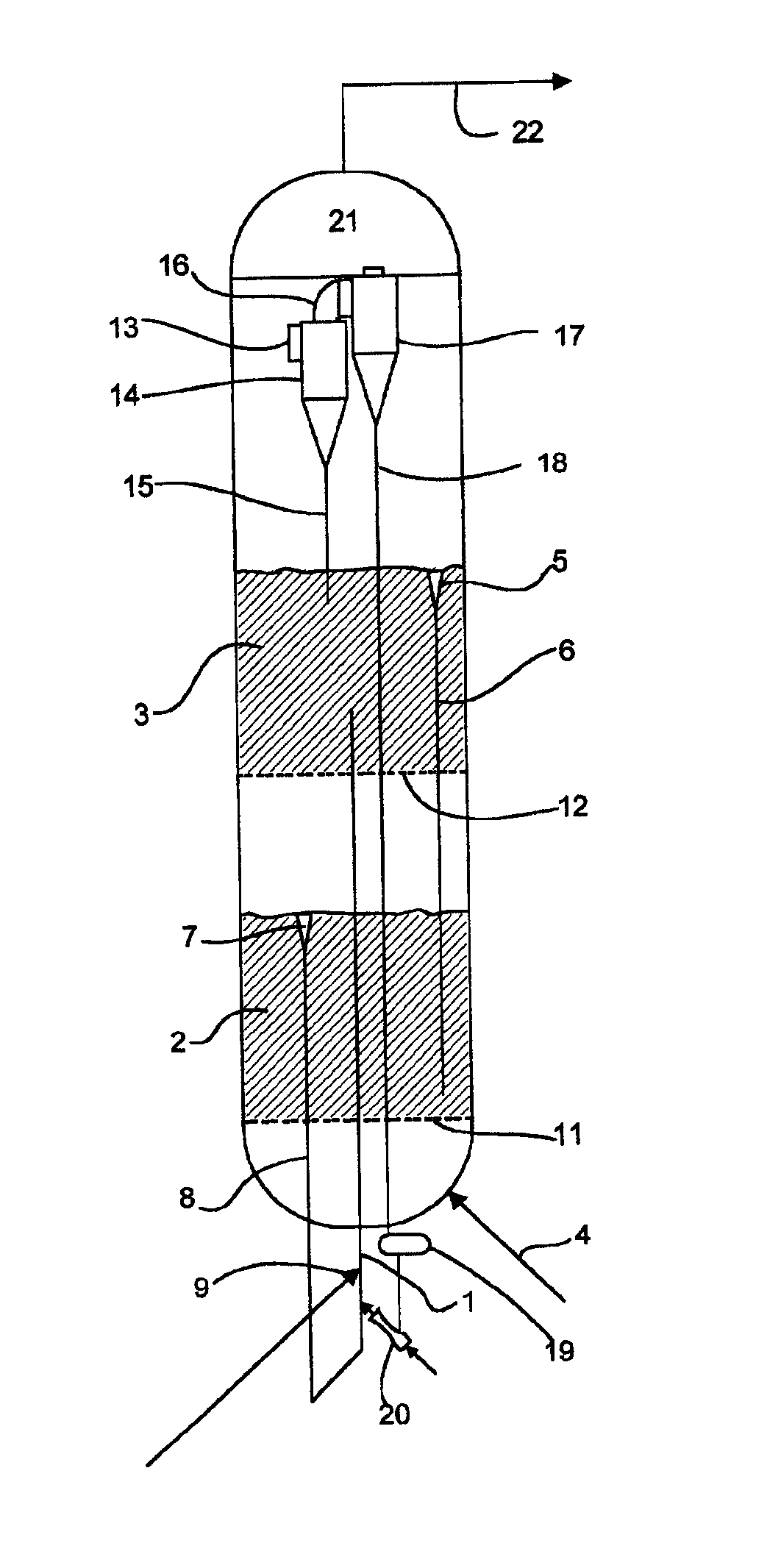

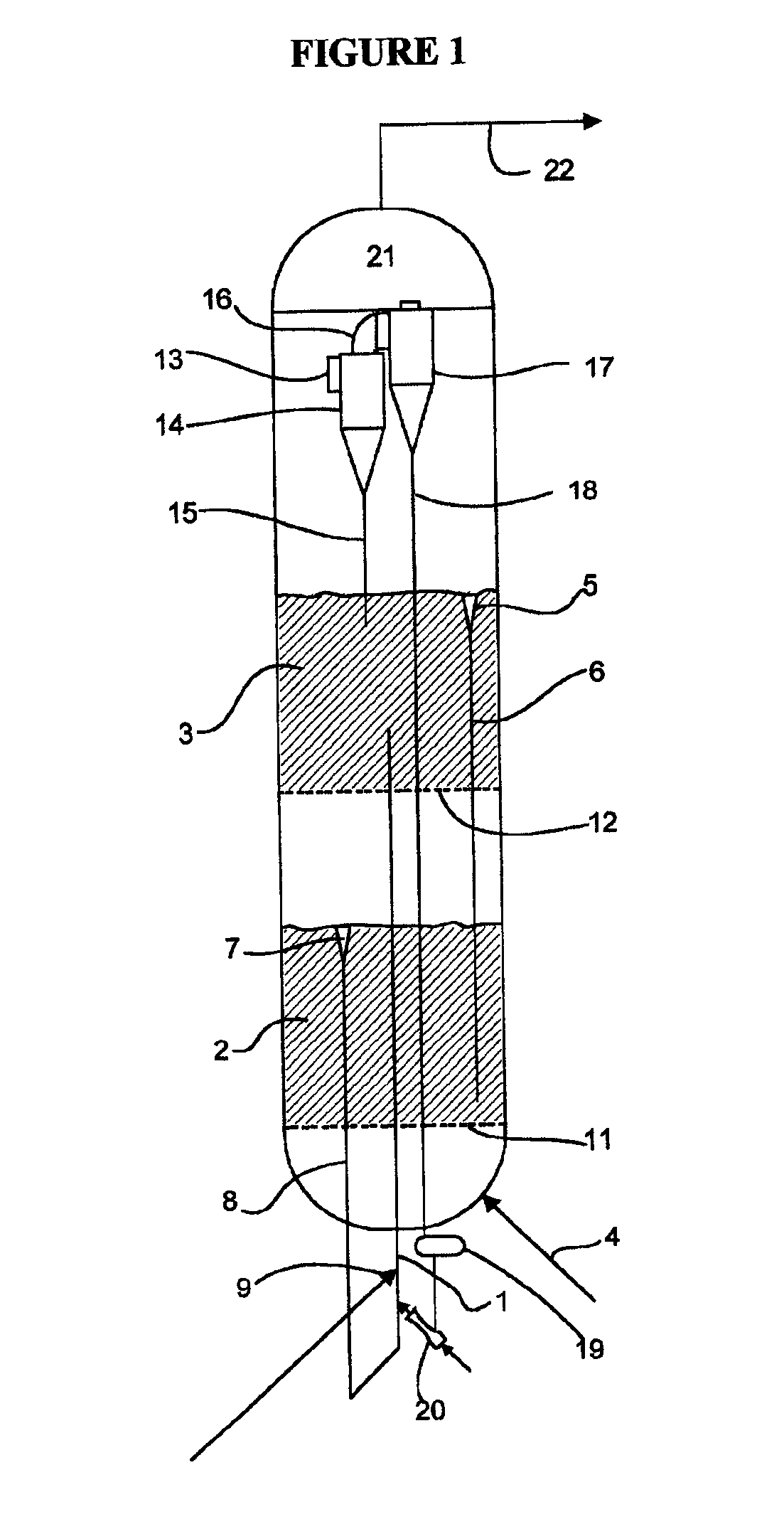

Conversion of petroleum residua to methane

InactiveUS6955695B2Eliminate needReduce usageThermal non-catalytic crackingElectrolysis componentsParticulatesGas phase

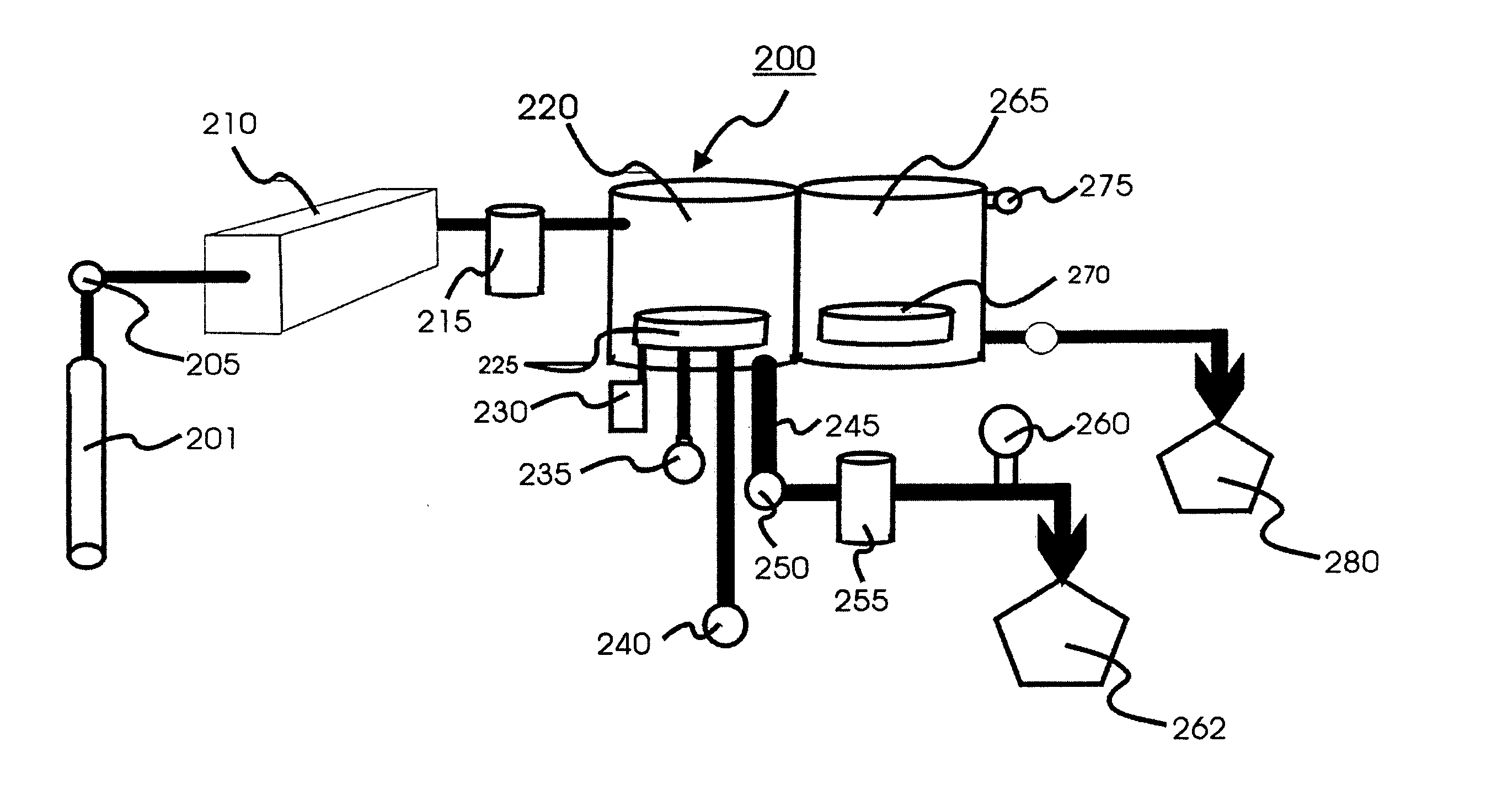

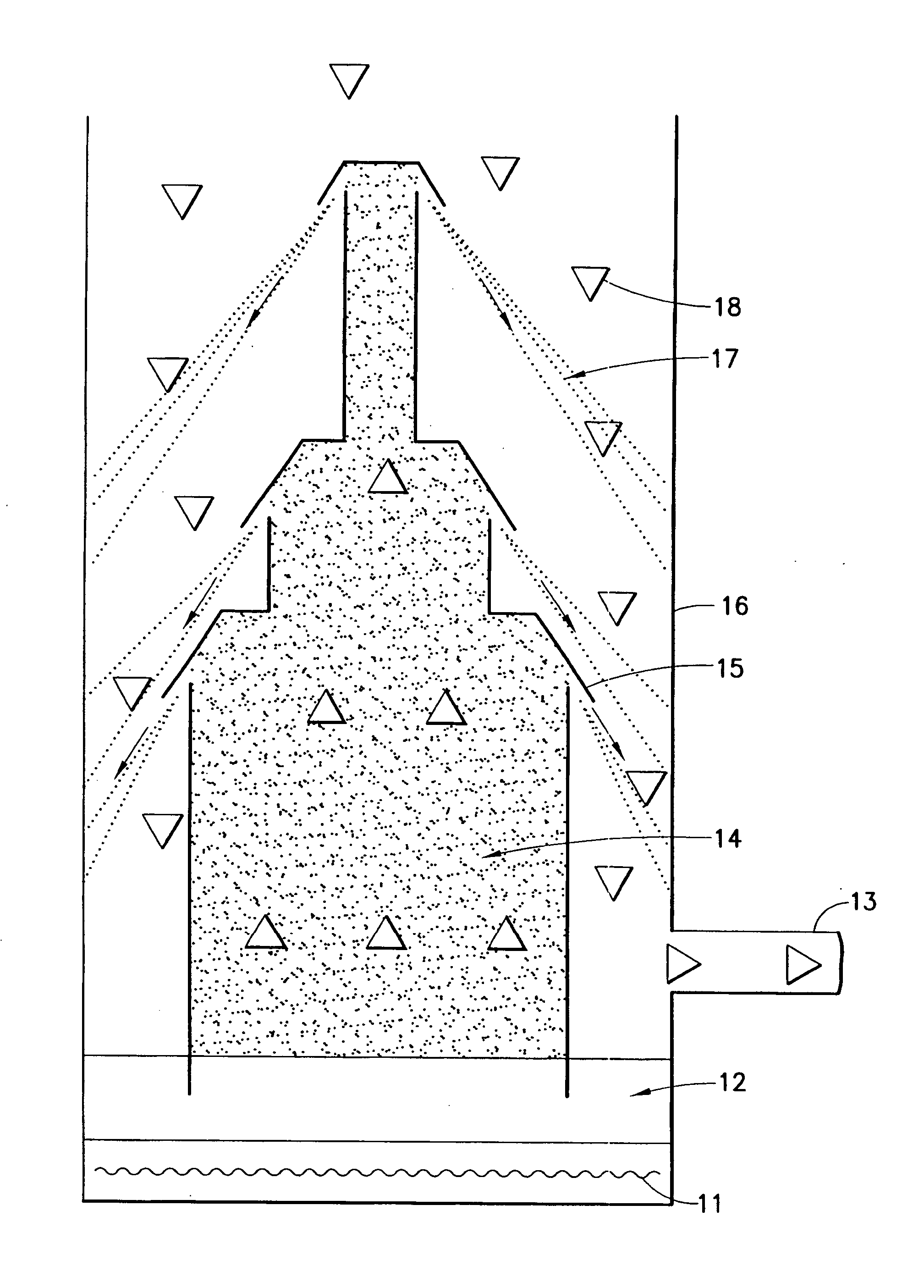

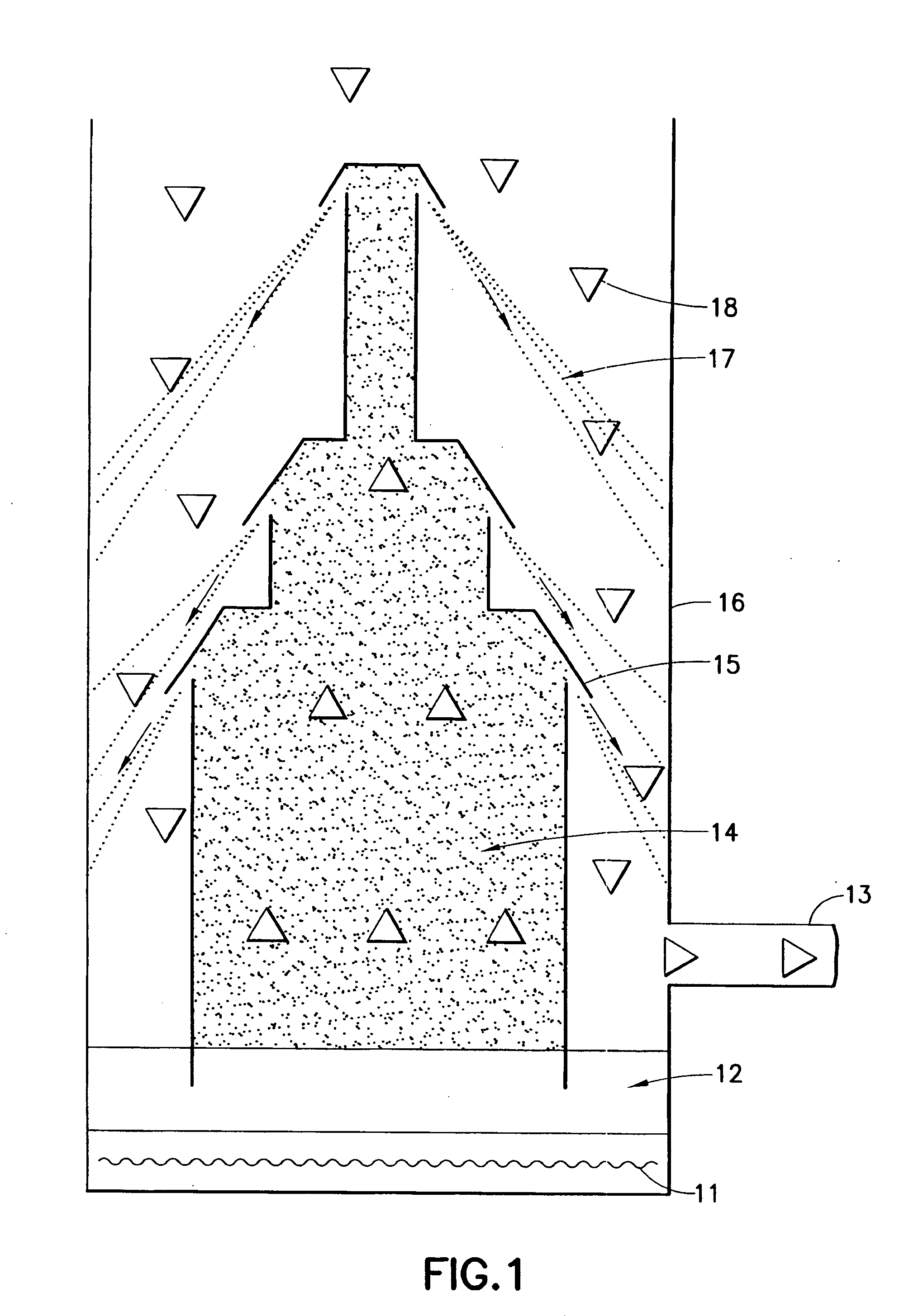

This invention discloses improvements on previous inventions for catalytic conversion of coal and steam to methane. The disclosed improvements permit conversion of petroleum residua or heavy crude petroleum to methane and carbon dioxide such that nearly all of the heating value of the converted hydrocarbons is recovered as heating value of the product methane. The liquid feed is distributed over a fluidized solid particulate catalyst containing alkali metal and carbon as petroleum coke at elevated temperature and pressure from the lower stage and transported to the upper stage of a two-stage reactor. Particulate solids containing carbon and alkali metal are circulated between the two stages. Superheated steam and recycled hydrogen and carbon monoxide are fed to the lower stage, fluidizing the particulate solids and gasifying some of the carbon. The gas phase from the lower stage passes through the upper stage, completing the reaction of the gas phase.

Owner:PETRO2020

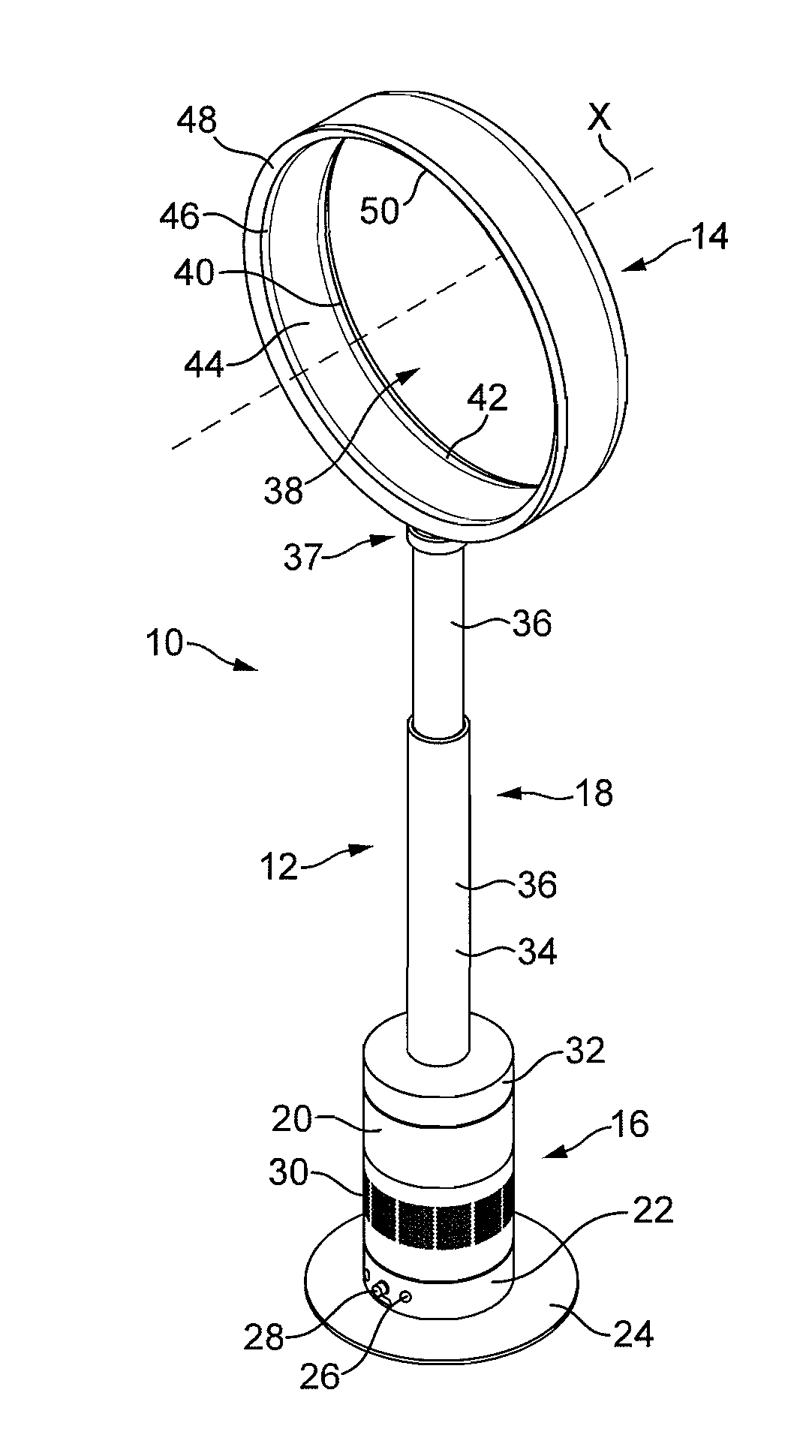

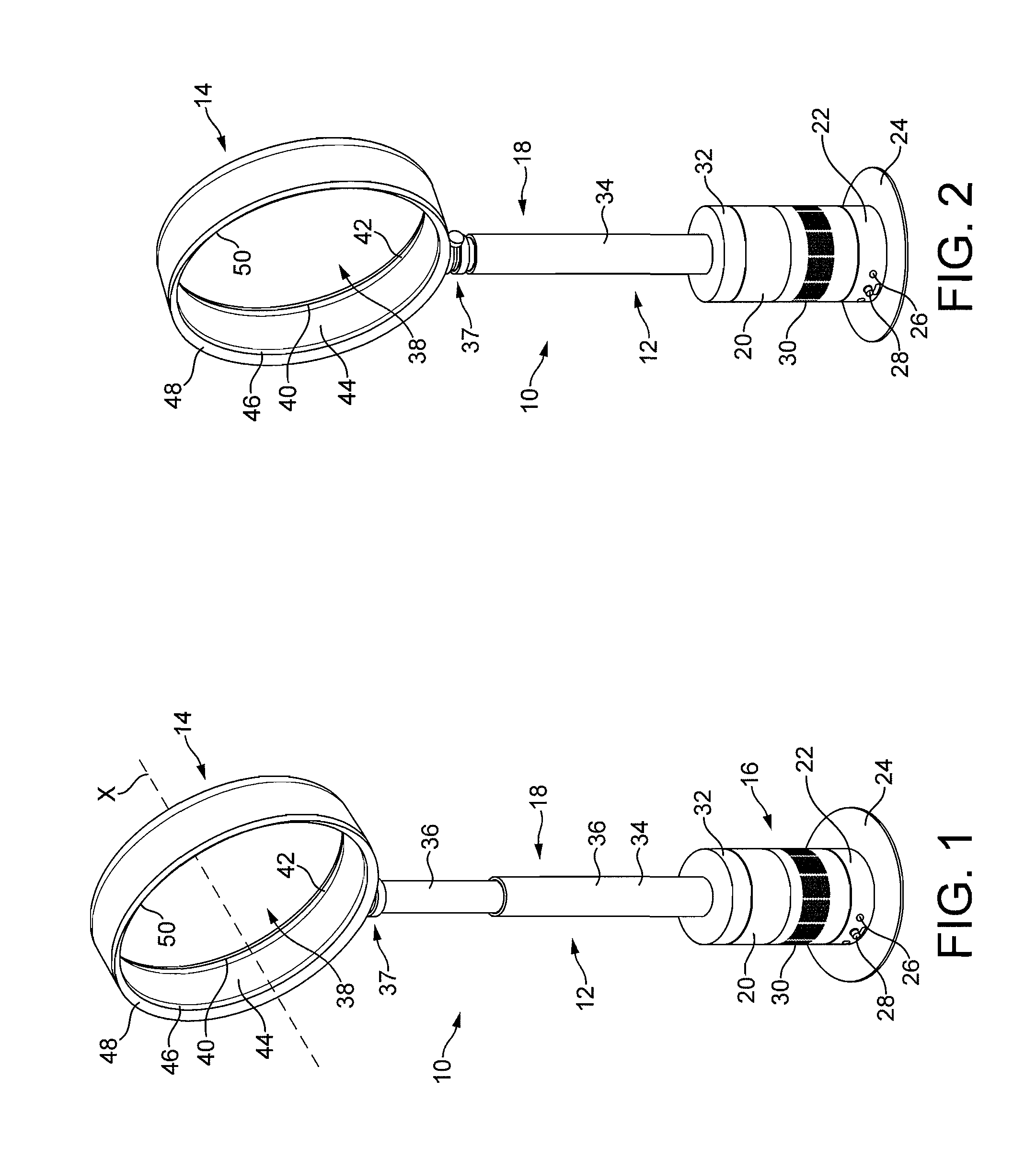

Fan

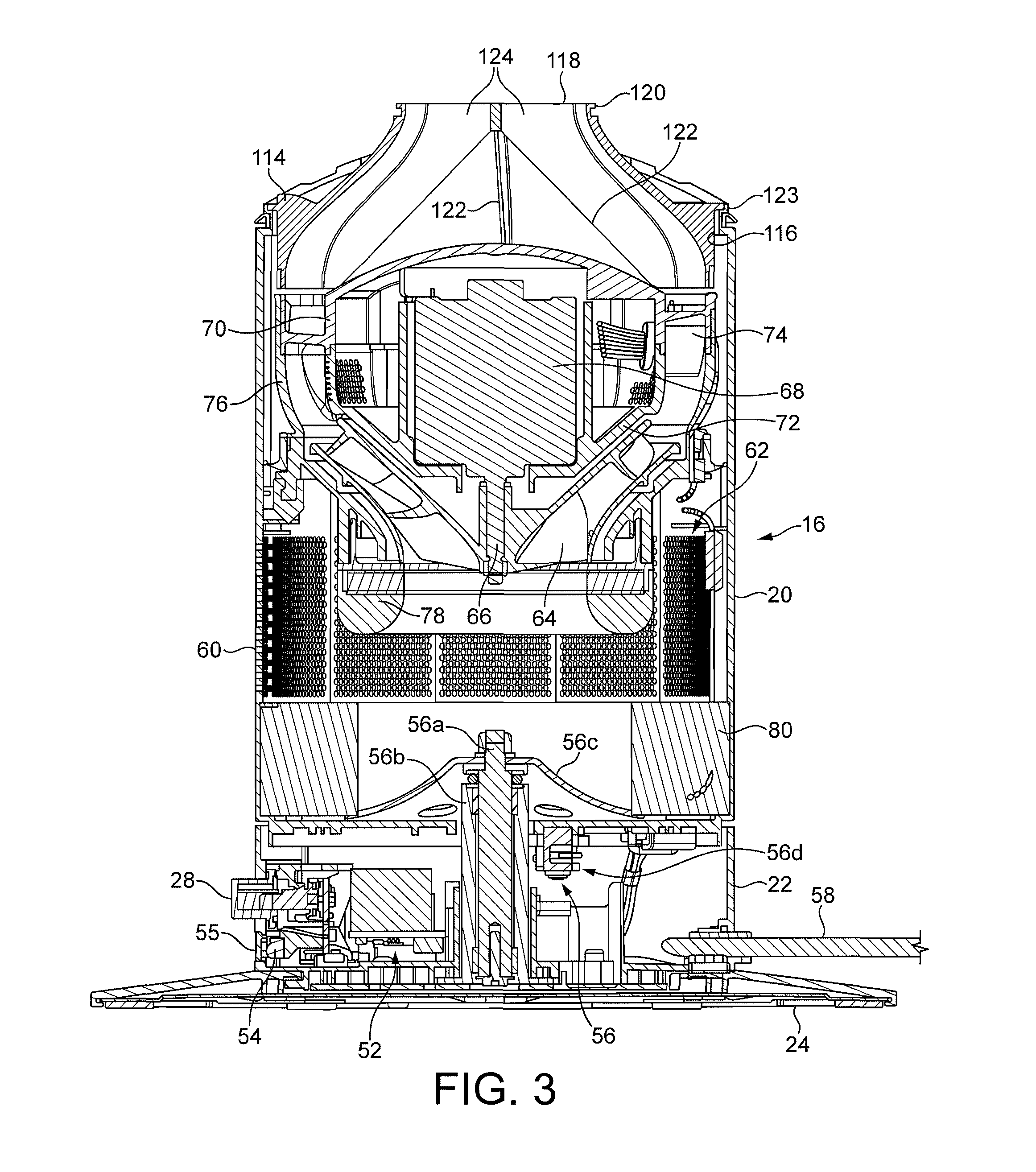

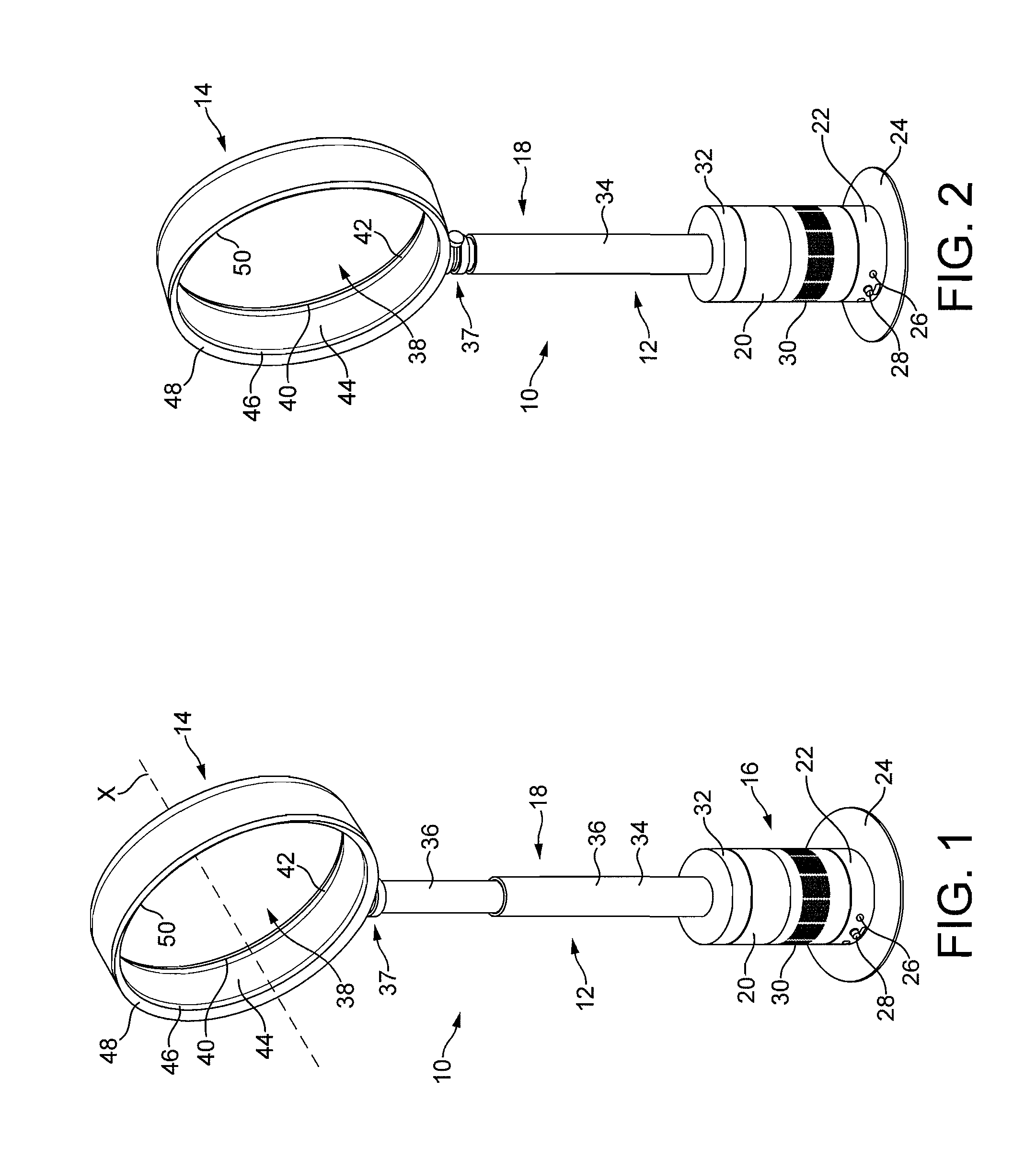

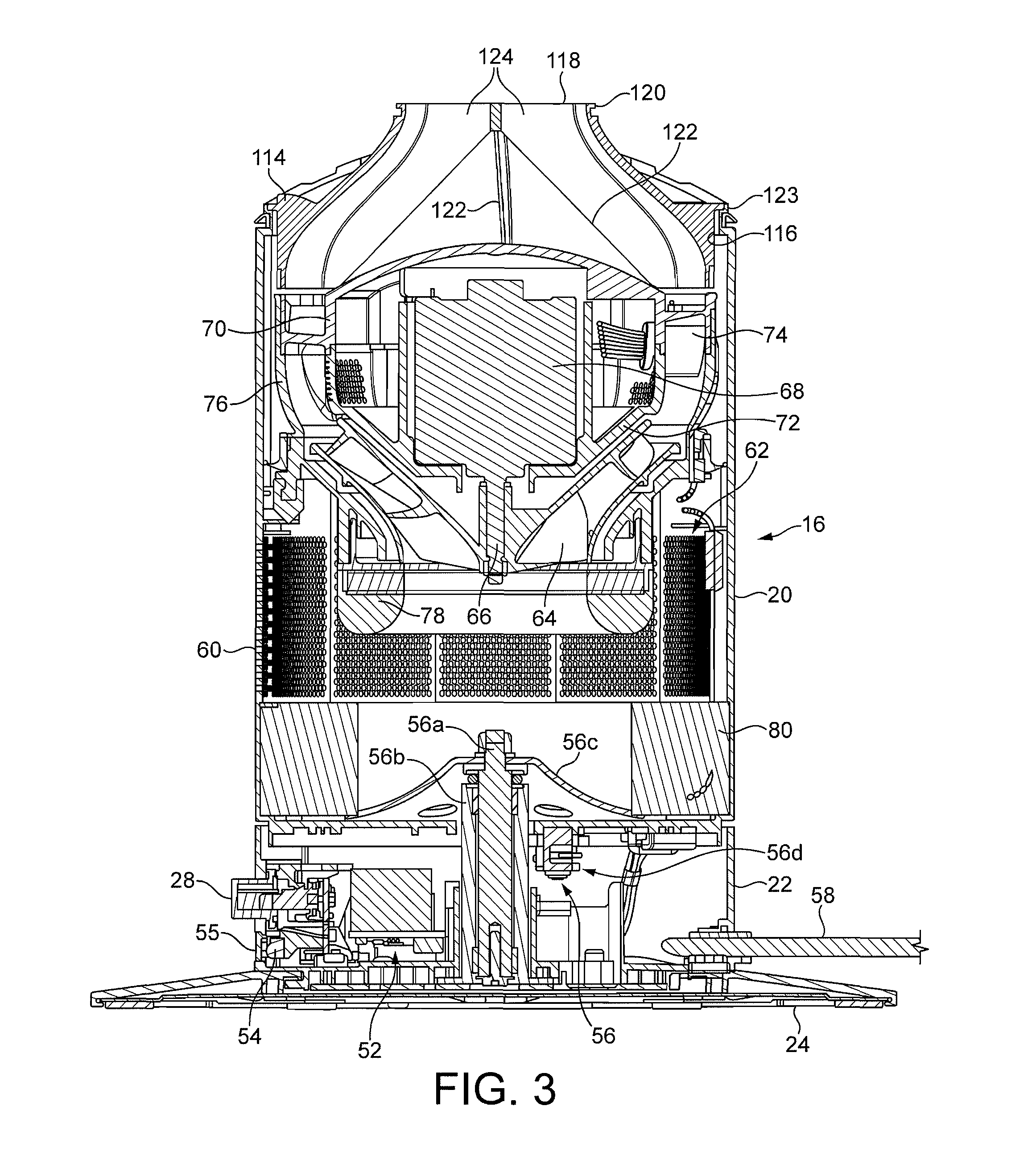

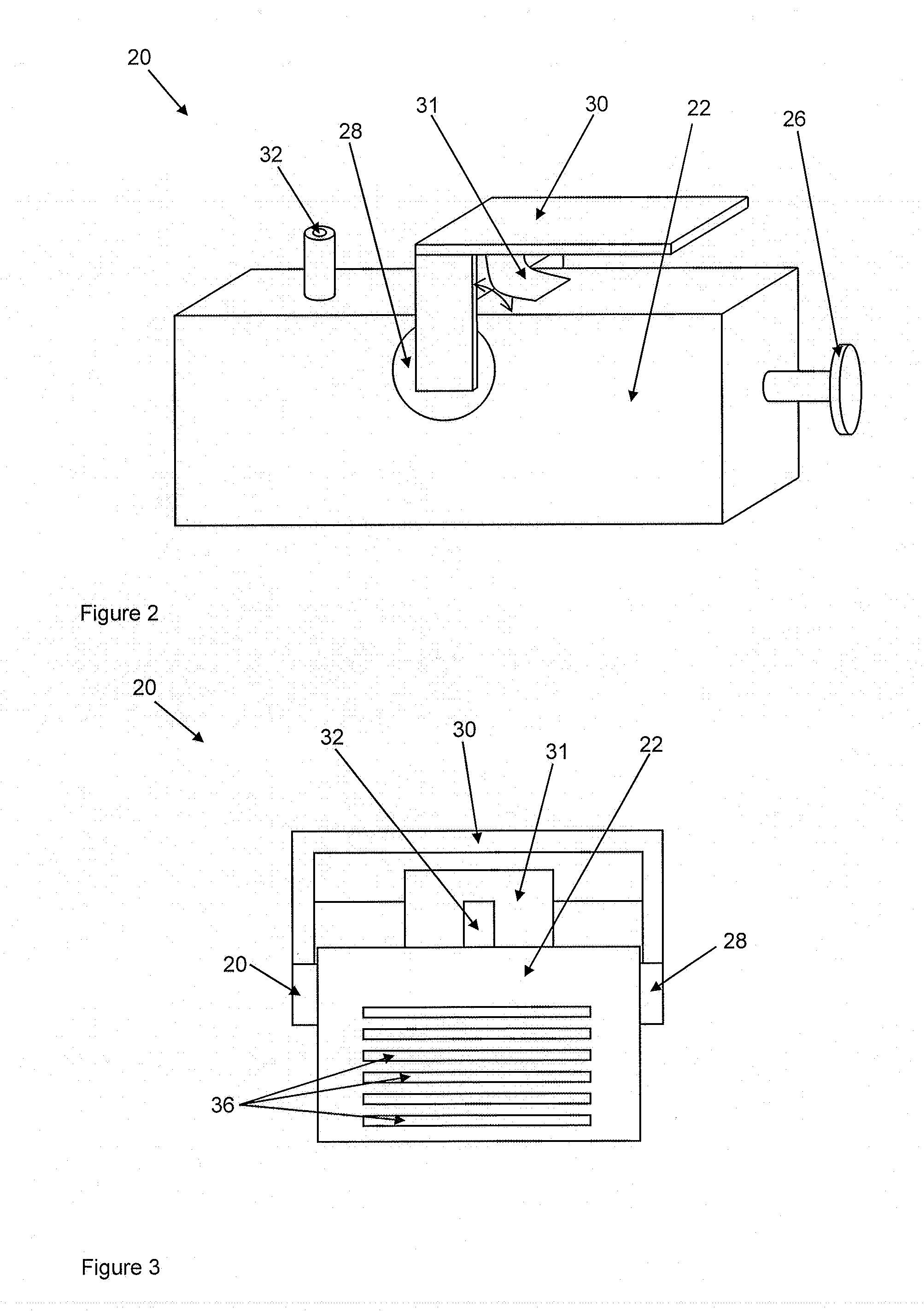

ActiveUS20110110805A1Emission reductionWide operating speed rangePositive displacement pump componentsJet pumpsImpellerRemote control

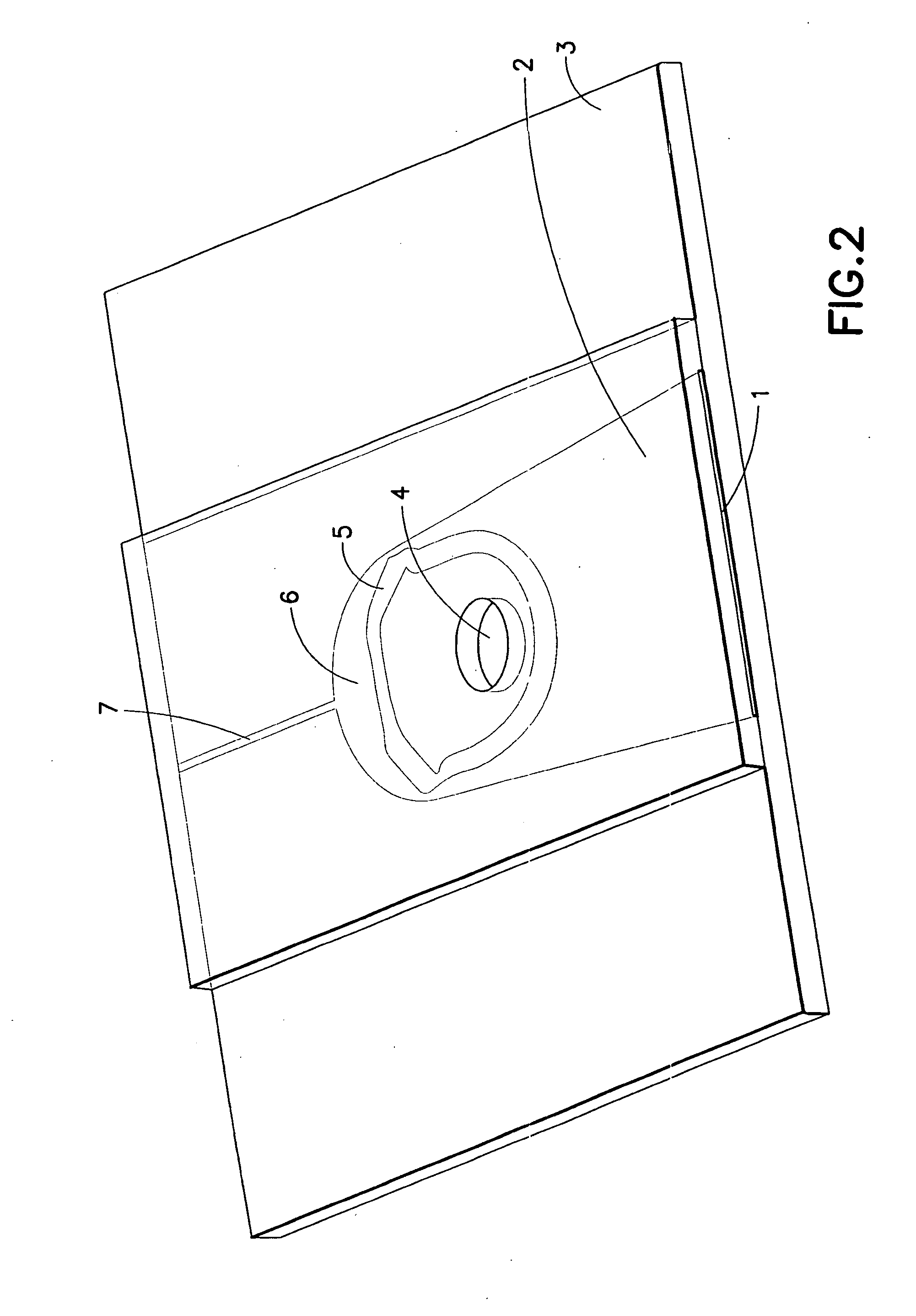

A fan assembly for creating an air current includes an air inlet, an air outlet, an impeller, a motor for rotating the impeller to create an air flow passing from the air inlet to the air outlet, the air outlet comprising an interior passage for receiving the air flow and a mouth for emitting the air flow, the air outlet defining an opening through which air from outside the fan assembly is drawn by the air flow emitted from the mouth, a control circuit for controlling the motor, a remote control for transmitting control signals to the control circuit, and at least one magnet for attaching the remote control to the air outlet.

Owner:DYSON TECH LTD

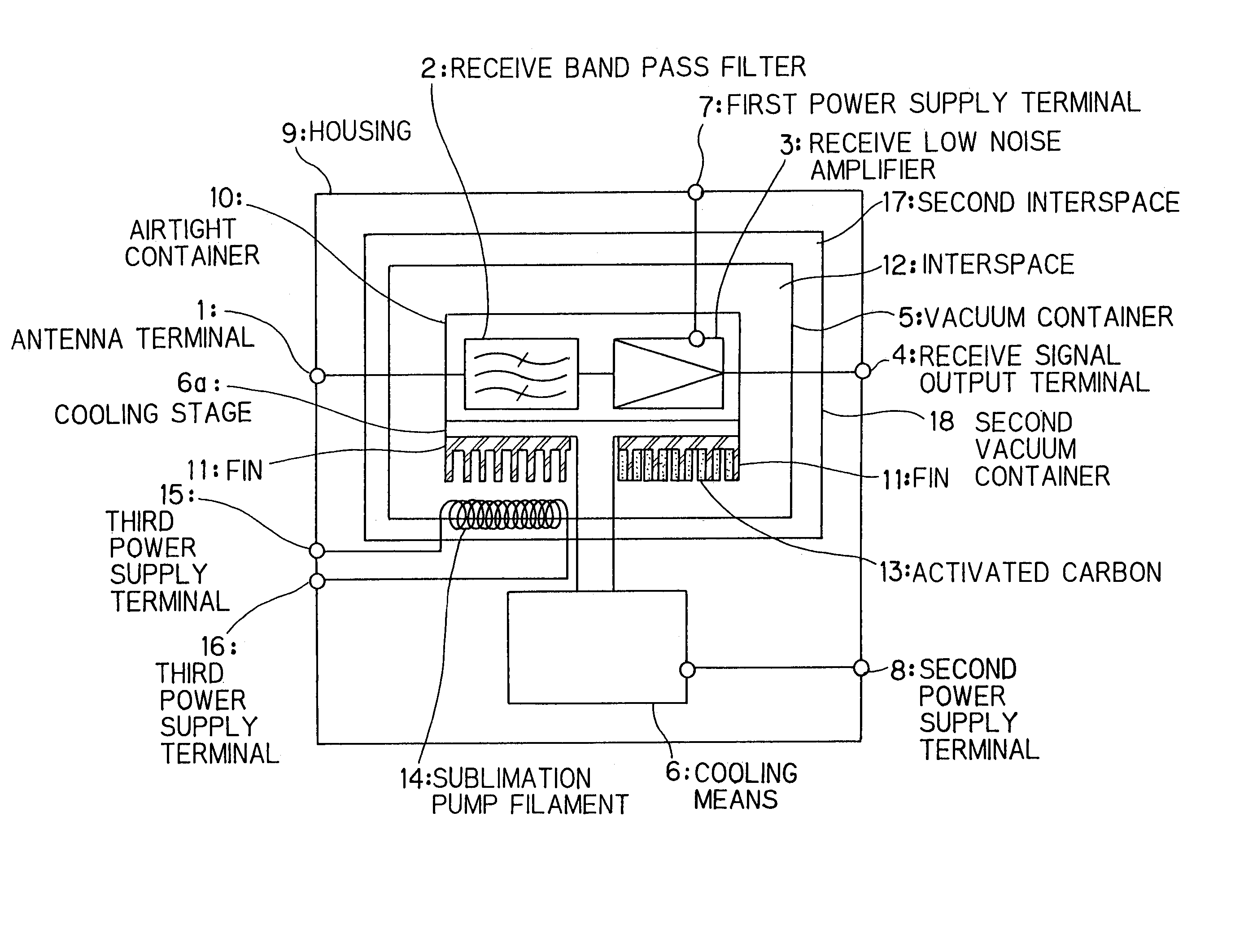

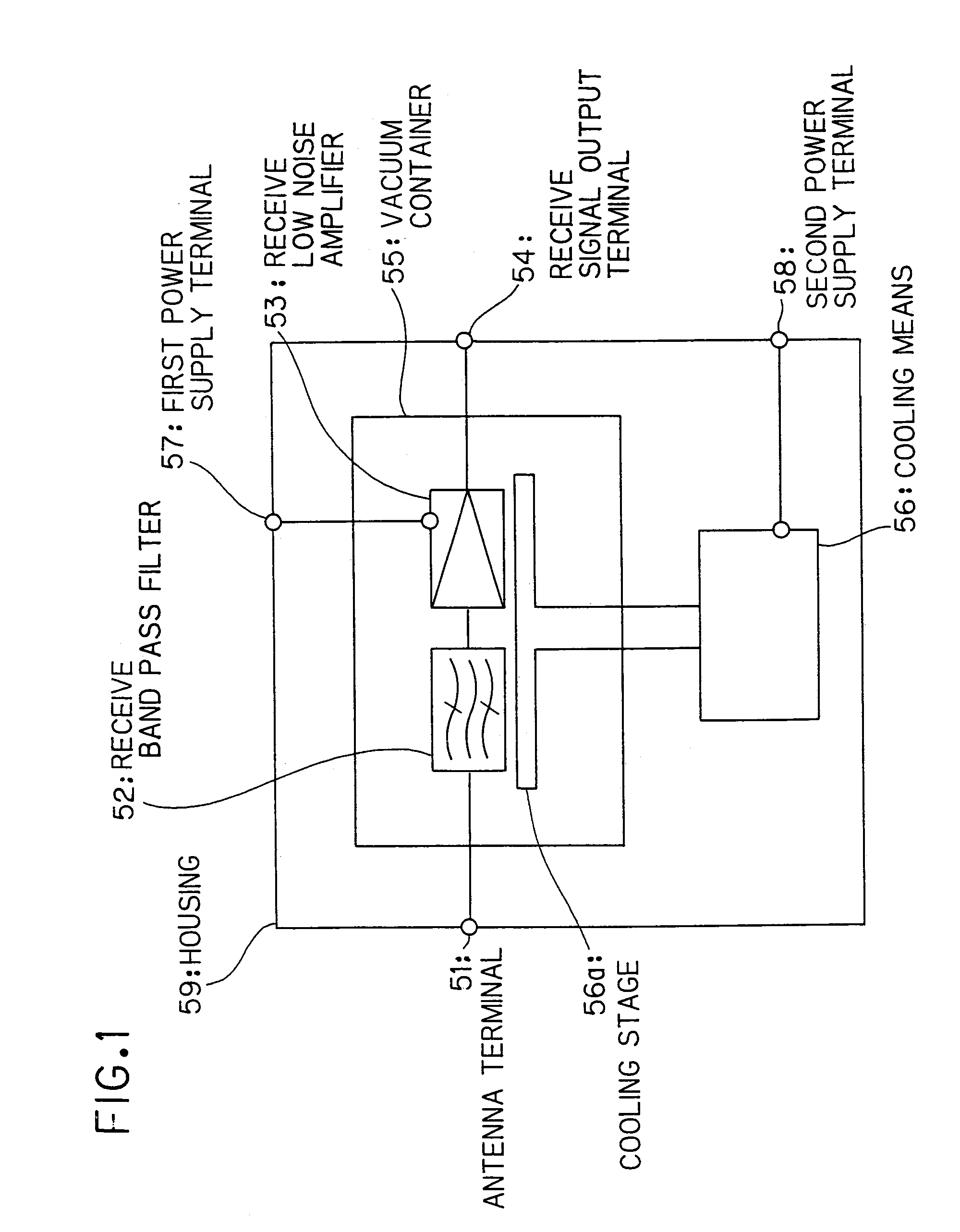

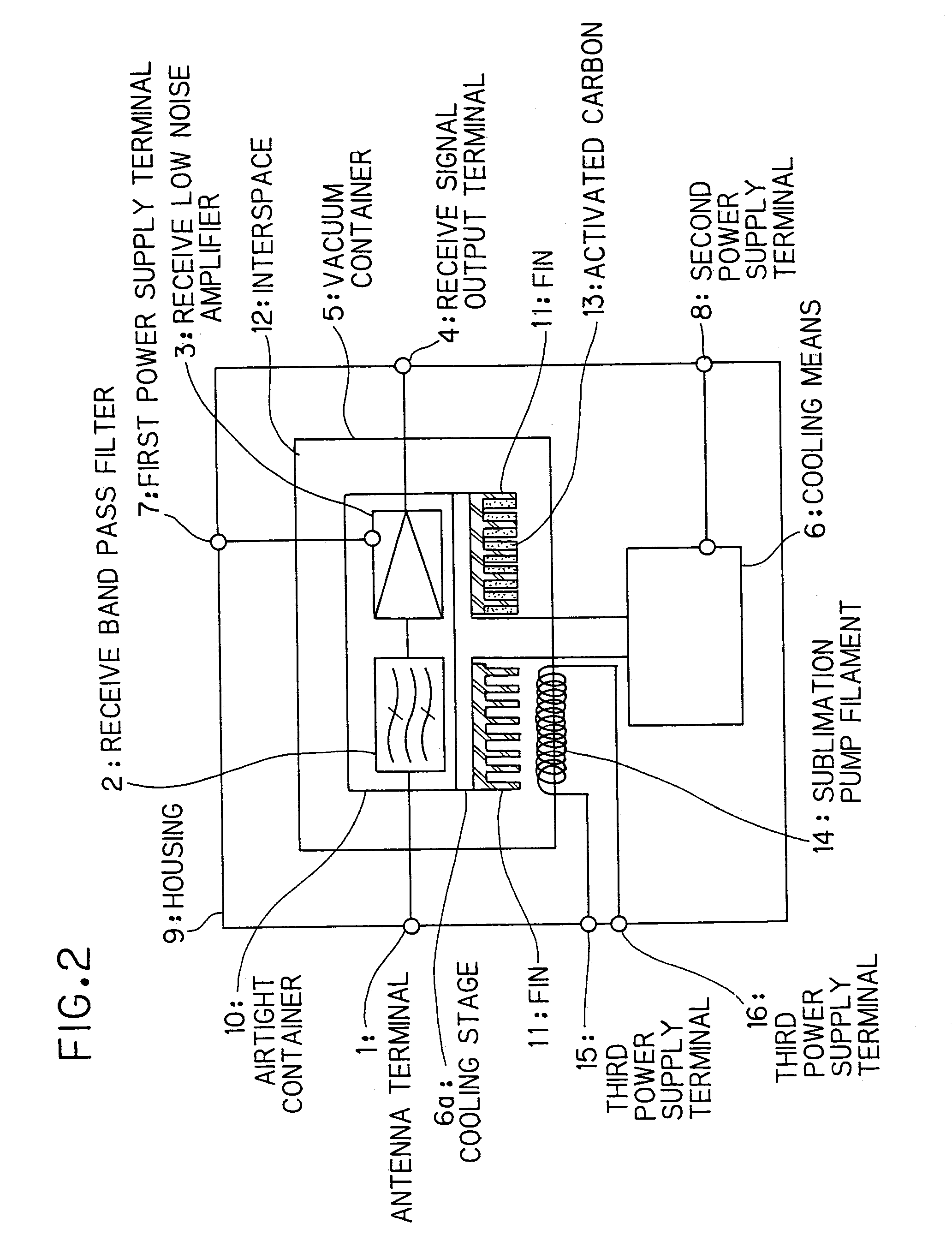

Radio receiver

InactiveUS7206605B2Reduce maintenance costsDomestic refrigeratorsSuperconductor detailsBandpass filteringRadio reception

A radio receiver disclosed is composed of a signal processing part, which includes a receive band pass filter 2 and a receive low noise amplifier 3, to process receive signal and discharge gas with time, the signal processing part being cooled by the cooling means 6, wherein the radio receiver is provided with an airtight container 10 that operates as inner sealing means to seal the receive band pass filter 2 and the receive low noise amplifier 3 to retain the gas, and a vacuum container 5 that operates as outer sealing means to seal in vacuum the airtight container 10 such that an interspace 12 between that and the airtight container 10 forms a vacuum insulating space to insulate in vacuum the airtight container 10 from outside.

Owner:NEC CORP

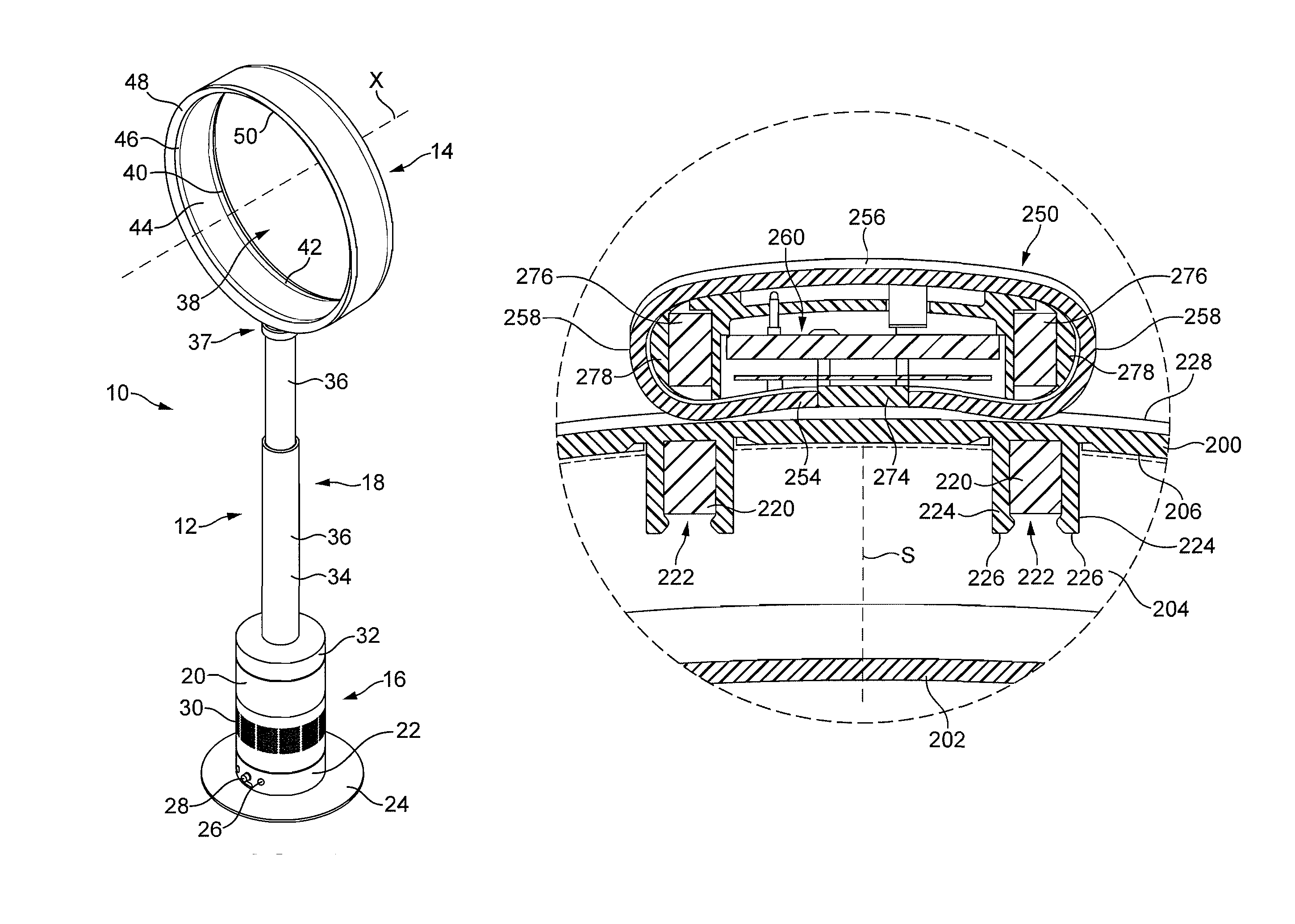

Fan having a magnetically attached remote control

ActiveUS8454322B2Improve accessibilityUniform appearancePositive displacement pump componentsJet pumpsImpellerControl signal

A fan assembly for creating an air current includes an air inlet, an air outlet, an impeller, a motor for rotating the impeller to create an air flow passing from the air inlet to the air outlet, the air outlet comprising an interior passage for receiving the air flow and a mouth for emitting the air flow, the air outlet defining an opening through which air from outside the fan assembly is drawn by the air flow emitted from the mouth, a control circuit for controlling the motor, a remote control for transmitting control signals to the control circuit, and at least one magnet for attaching the remote control to the air outlet.

Owner:DYSON TECH LTD

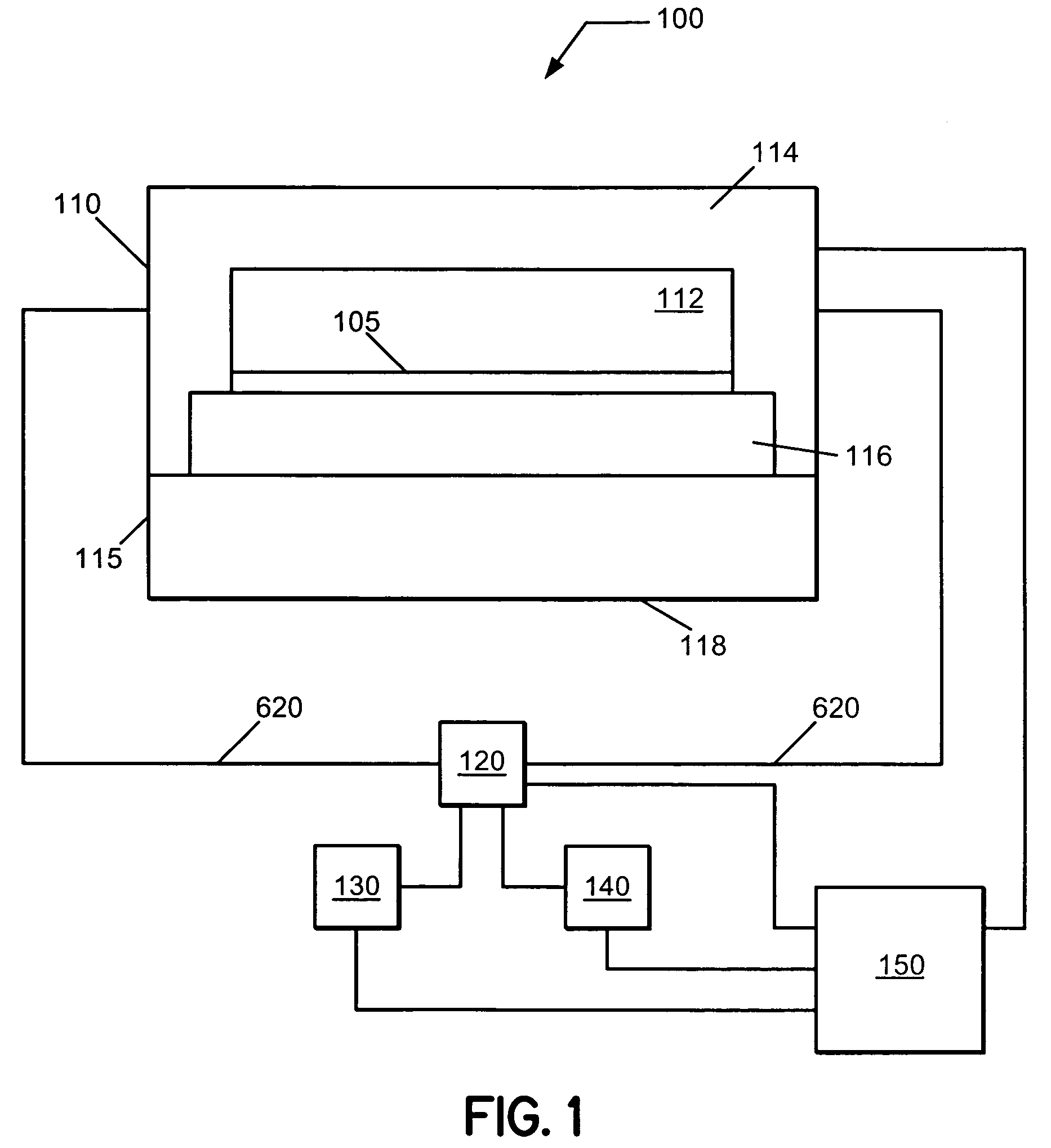

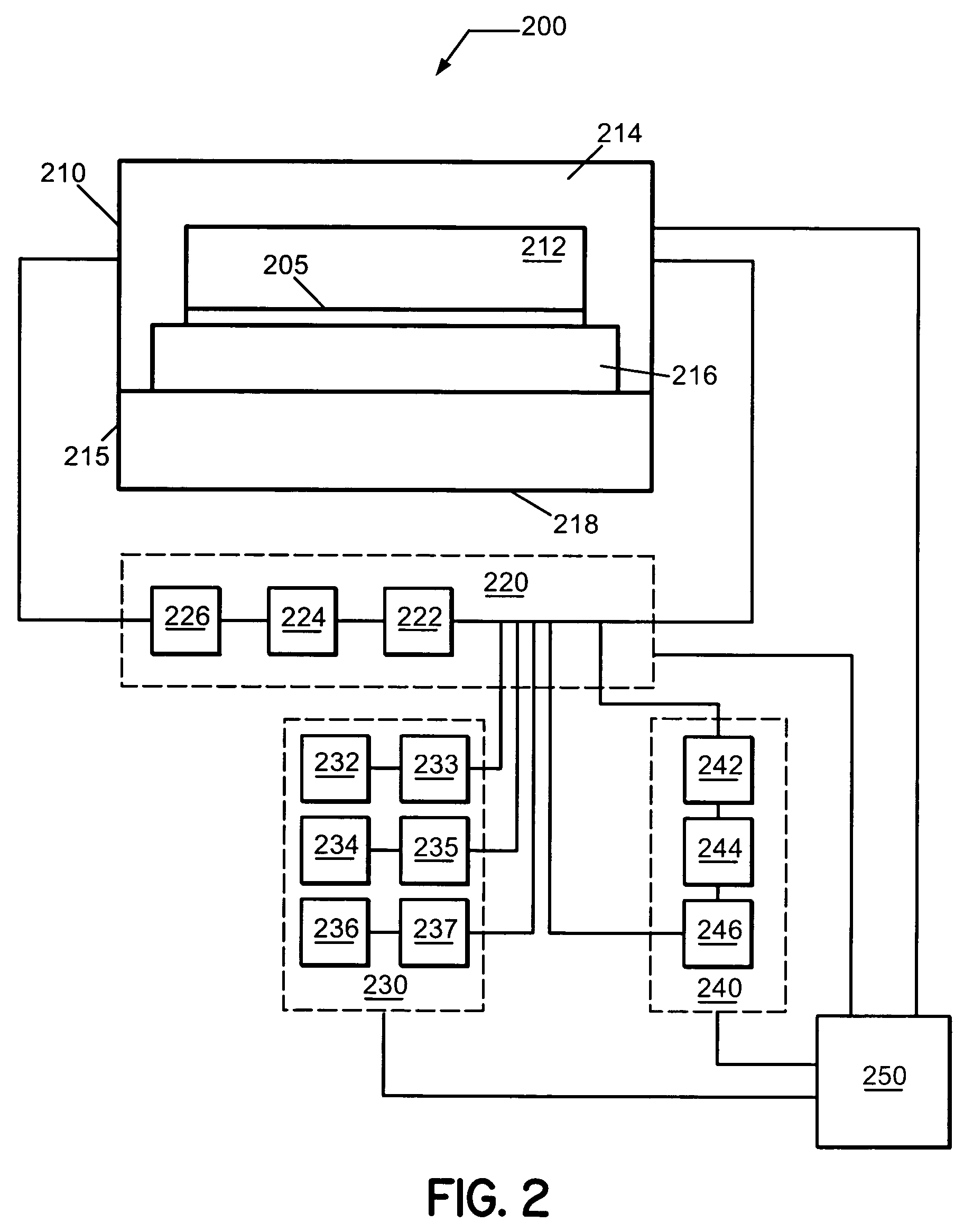

Process modules for transport polymerization of low epsilon thin films

A Process Module (“PM”) is designed to facilitate Transport Polymerization (“TP”) of precursors that are useful for preparations of low Dielectric Constant (“∈”) films. The PM consists primarily of a Material Delivery System (“MDS”) with a high temperature Vapor Phase Controller (“VFC”), a TP Reactor, a Treatment Chamber, a Deposition Chamber and a Pumping System. The PM is designed to facilitate TP for new precursors and for film deposition and stabilization processes.

Owner:DIELECTRIC SYST INT

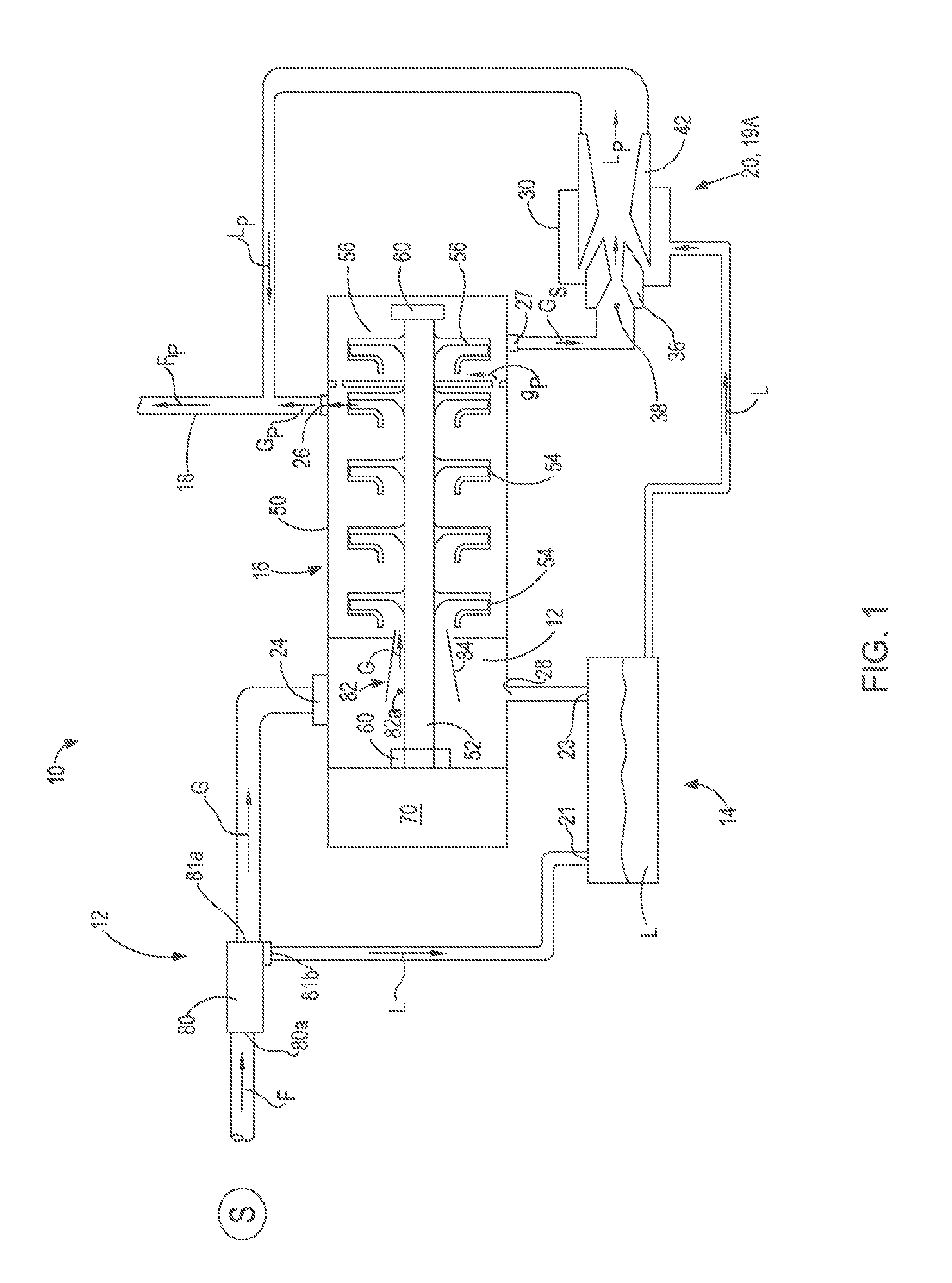

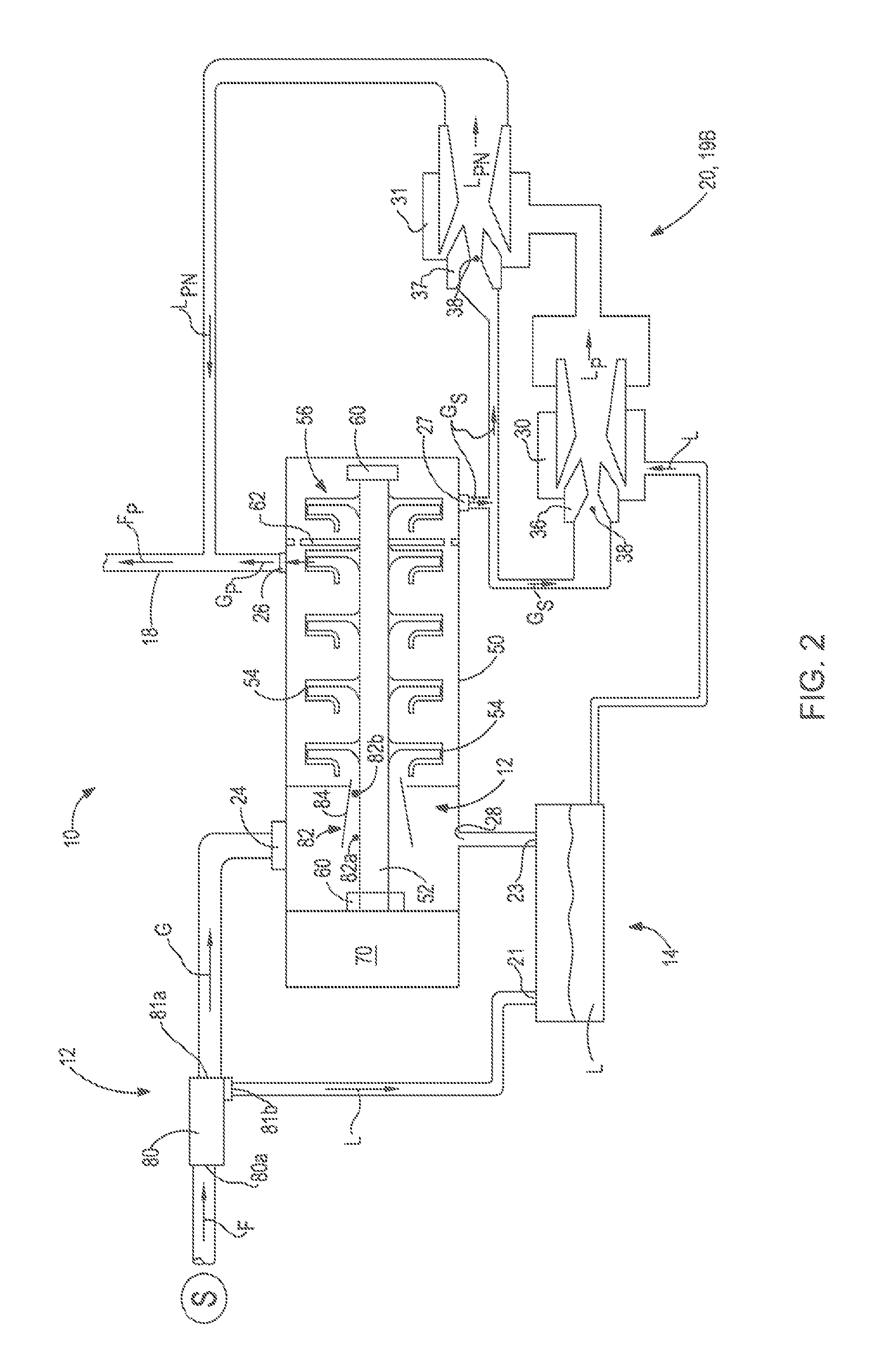

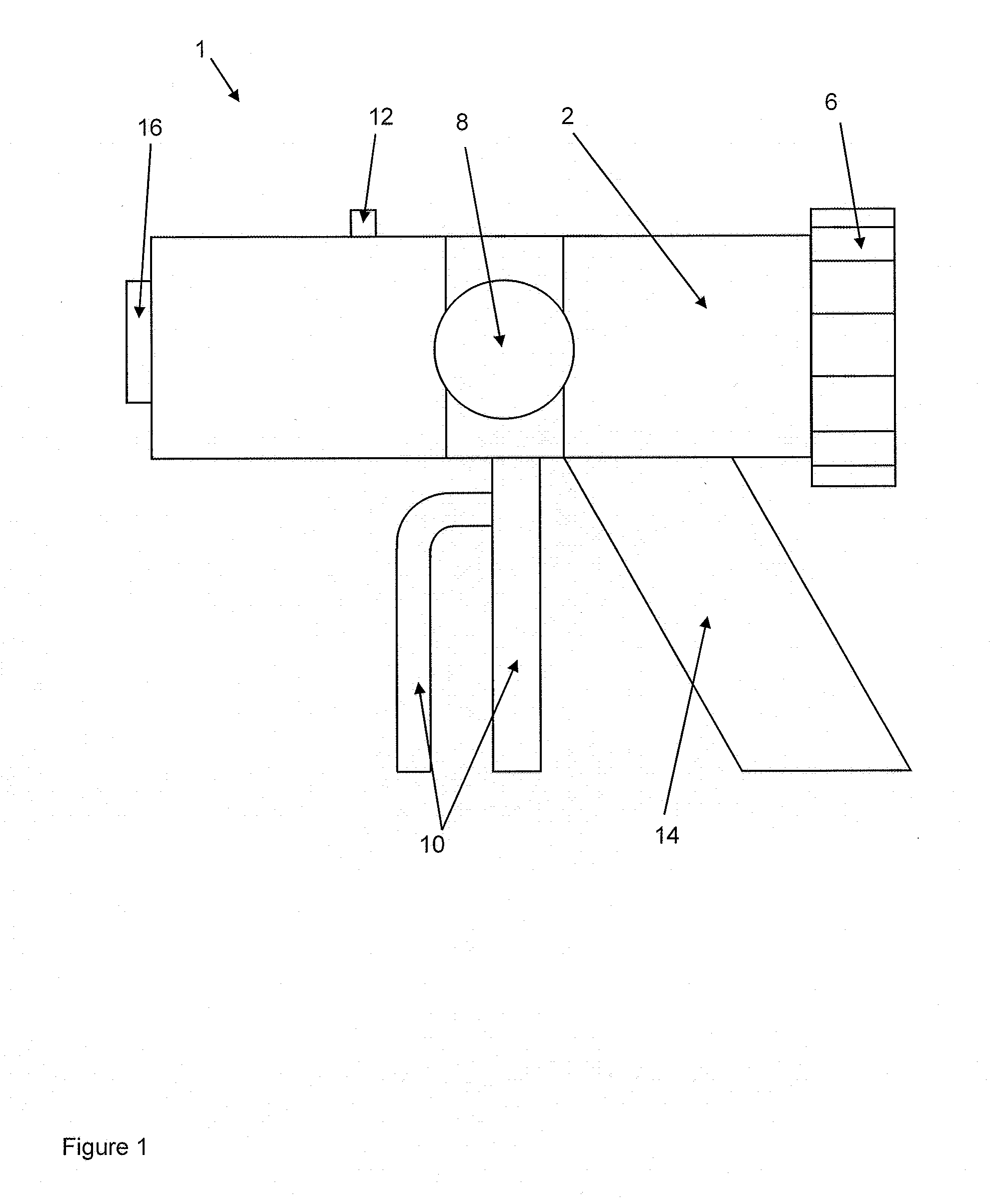

Compressor assembly including separator and ejector pump

InactiveUS20110017307A1Add dimensionPump componentsUsing liquid separation agentEngineeringInjection pump

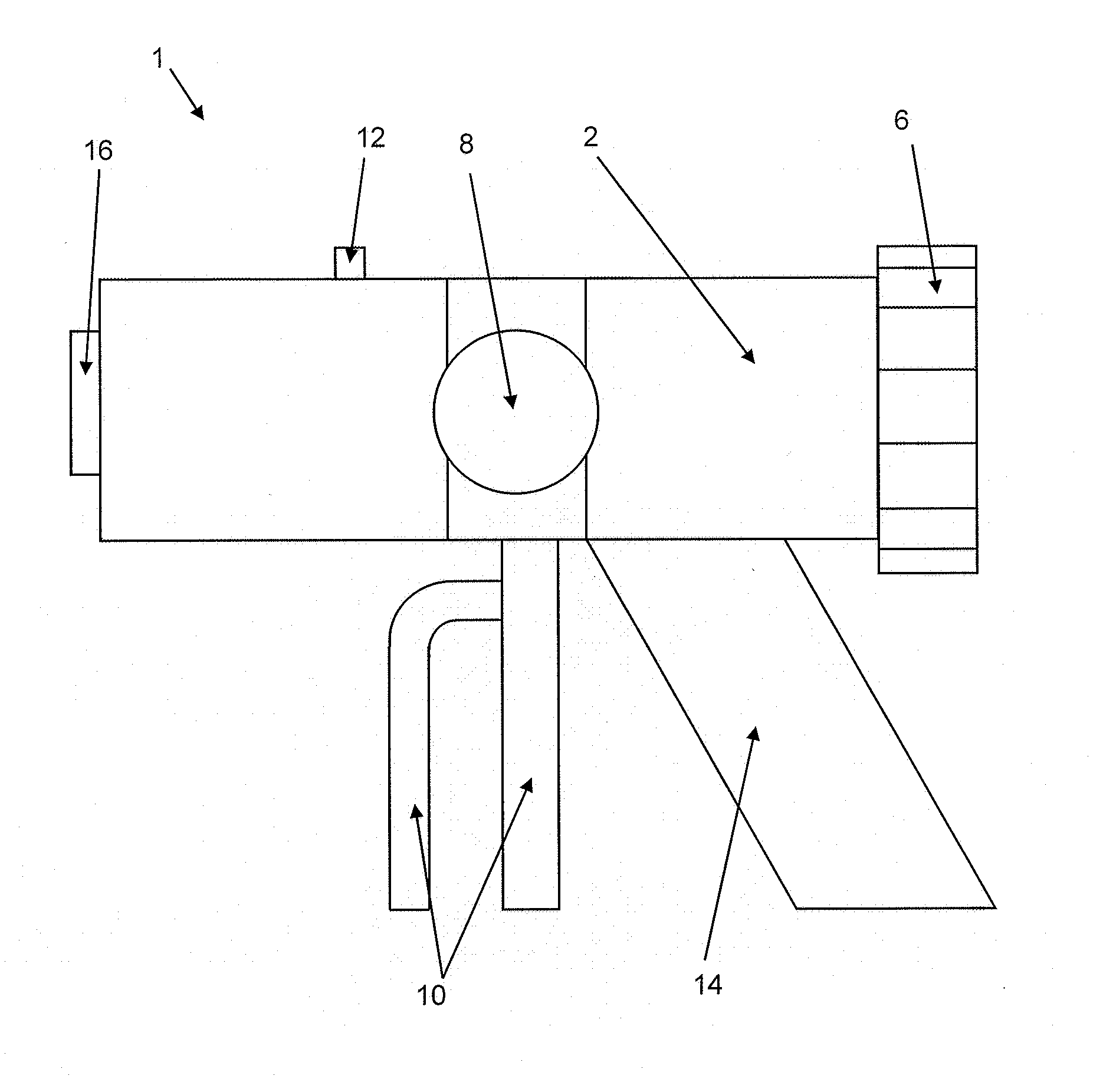

A fluid processing device for processing a multiphase fluid stream including a mixture of at least a gas and a liquid is disclosed. The fluid processing device may include at least one separator configured to separate the fluid stream into a liquid portion and a gaseous portion and deposit the liquid portion into a liquid reservoir. The gaseous portion may be directed to a compressor configured to pressurize and discharge a pressurized gas into a fluid discharge line. A portion of the pressurized gas may be further pressurized and directed to at least one ejector pump fluidly coupled to the liquid reservoir and configured to draw in liquid and discharge pressurized liquid into the fluid discharge line.

Owner:DRESSER RAND CO

Process for foaming a wet hydrocarbon composition

A composition of a wet hydrocarbon foaming agent including a siloxane can foam wet hydrocarbons. The siloxane wet hydrocarbon foaming agent advantageously foams hydrocarbons that have as little as 5 percent water present and those hydrocarbons having as much as 90 percent water present. The wet hydrocarbon foaming agent can be used in oil and gas production for gas lift and foam blocking applications. The foaming agent can also be used for clearing hydrocarbons from pipelines and other vessels used for transporting oil and gas.

Owner:BAKER HUGHES INC

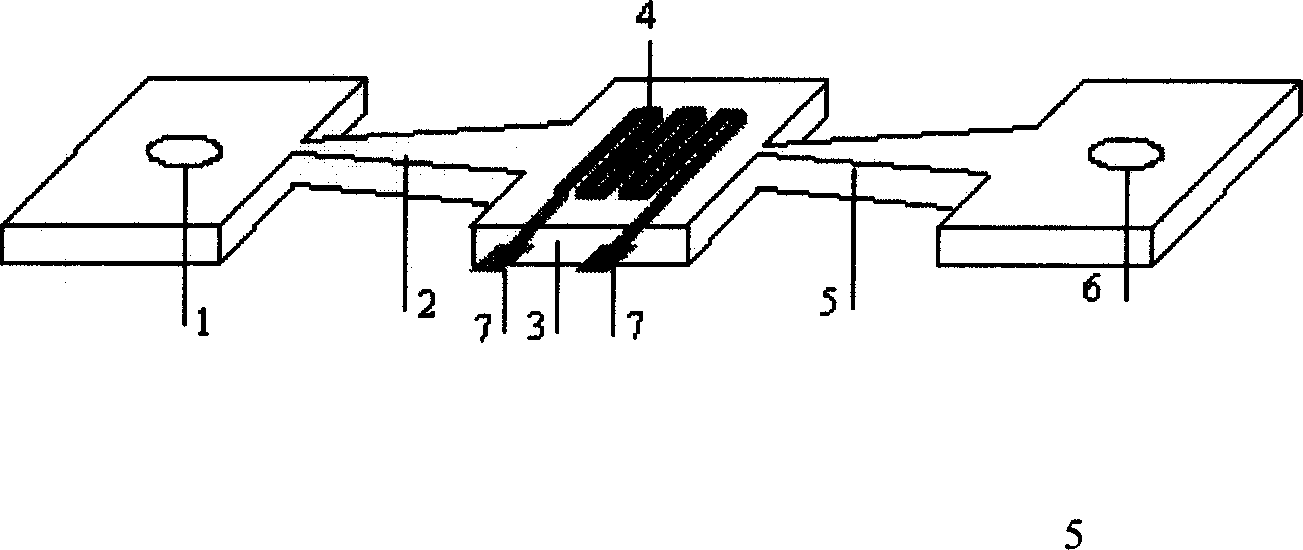

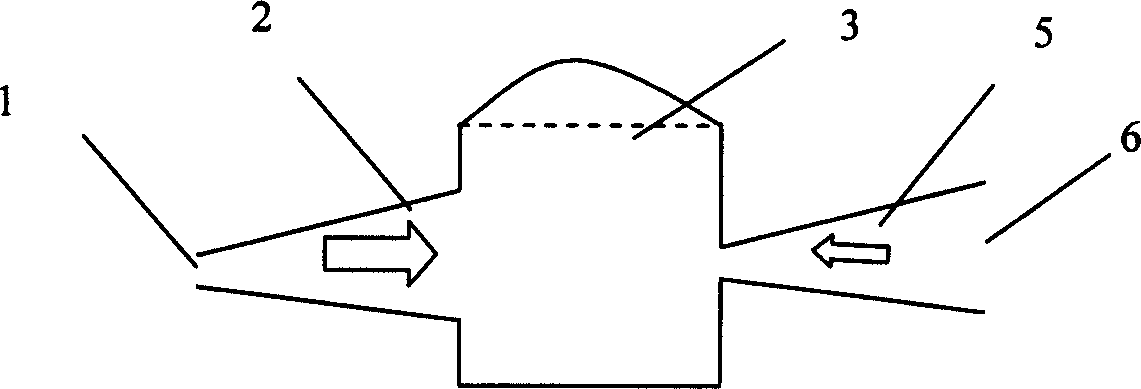

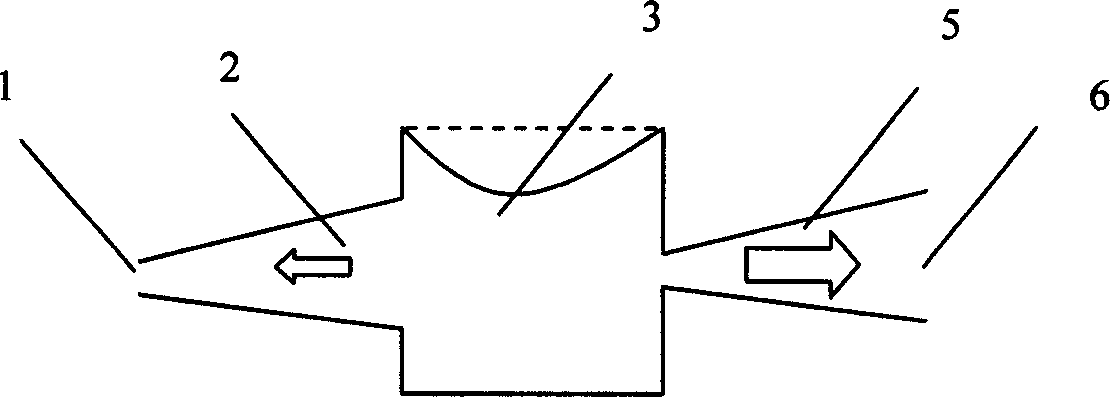

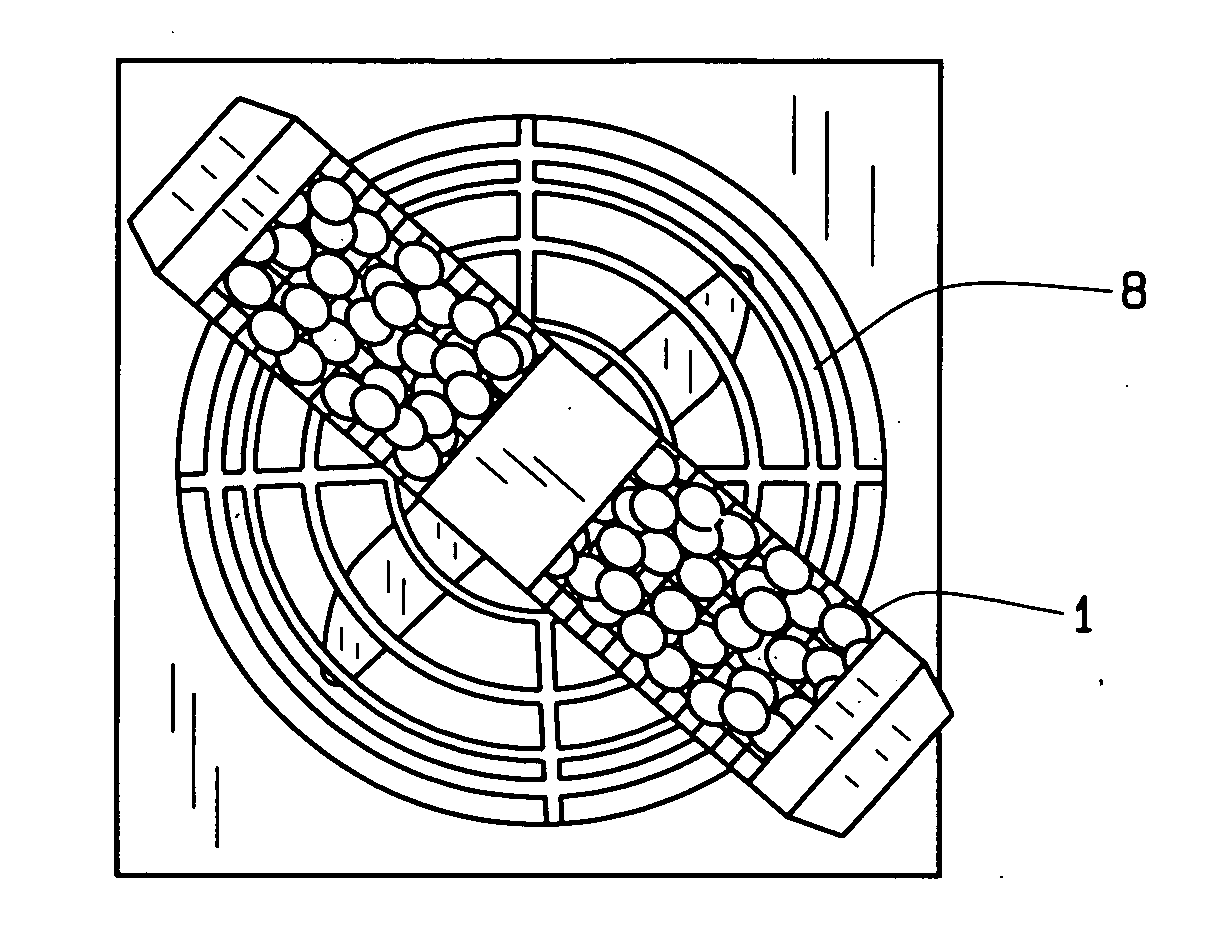

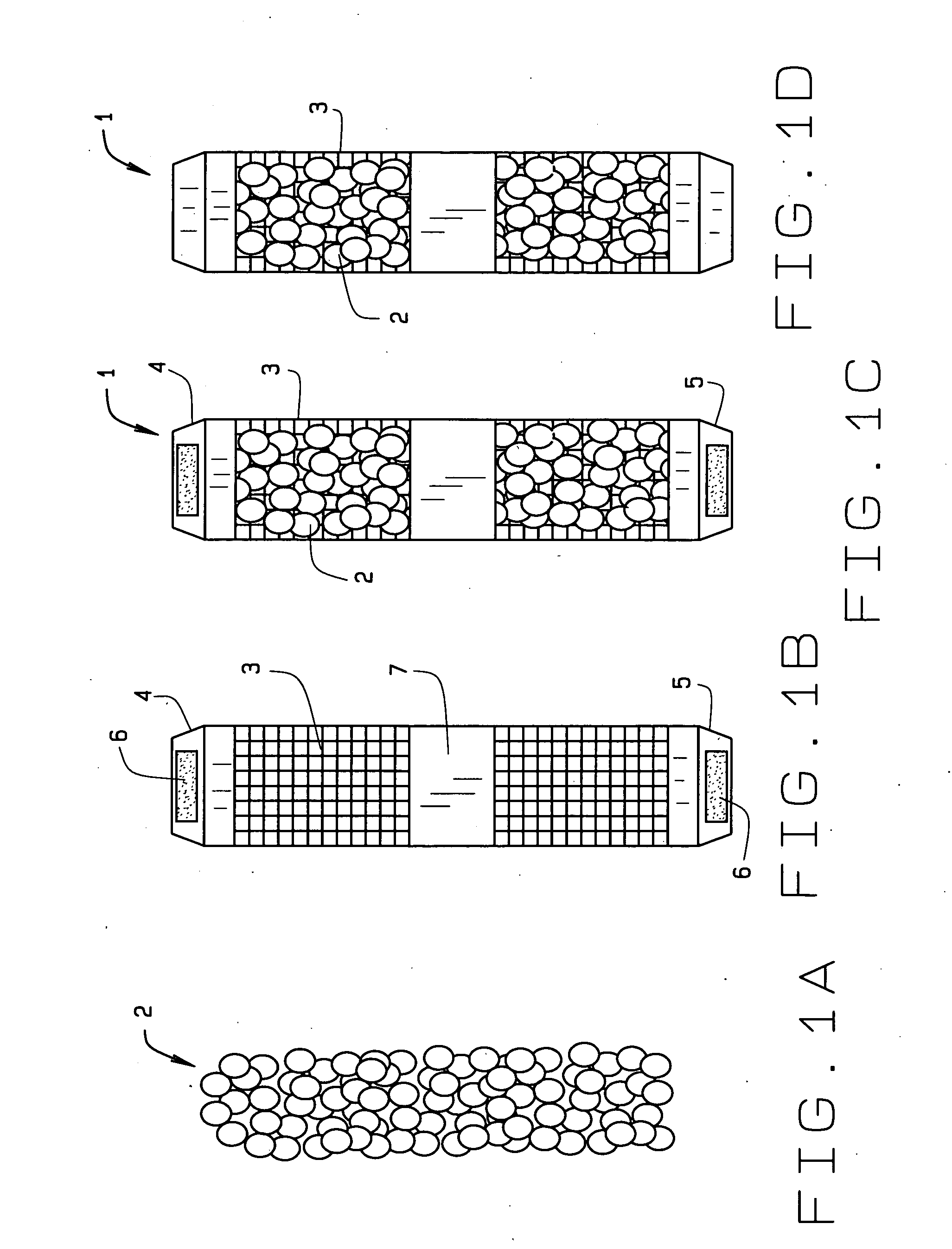

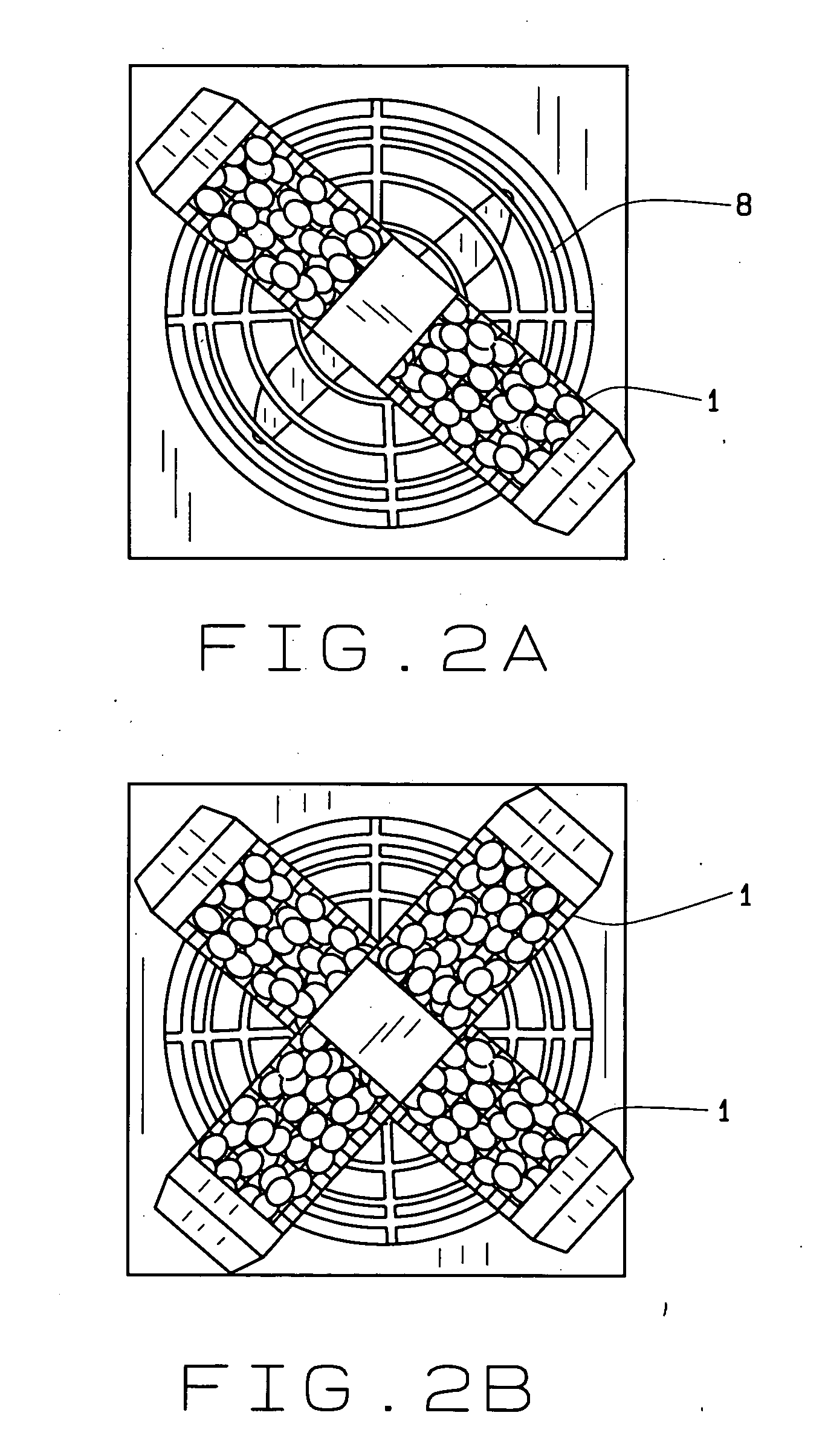

Minisize diffusion pump and preparation method thereof

InactiveCN1844681AReduce processing difficultyNo increase in processing difficultyMachines/enginesDiffusion pumpsMicrofluidicsPump chamber

The invention discloses a micro disperse pump which comprises a pump chamber, a one-way valve, a pump inlet, a pump outlet and a driving device inside the pump chamber; wherein, the one-way valve is between the pump chamber and the pump inlet, and between the pump chamber and the pump outlet; the one-way valve is a wedge disperse tube with different positive and passive fluxes; the fluid of pump chamber can be expanded and contracted to generate pressure difference, and according to the different pressures of positive and passive fluxes in the wedge disperse tube, to generate one-way continuous fluid transmission. The inventive micro disperse pump can drive fluid via adsorbing fluid or directly drive fluid. The production is based on silicon micro-mechanical processing technique and micro-mould technique, with simple process, lower cost, high reliability and the application for integrating other micro-fluid systems. It has wider application in the micro-fluid control analysis chip.

Owner:PEKING UNIV

Check valve

A check valve which is positioned in the vacuum air line of an internal combustion engine. The check valve includes a single-piece valve body having an outlet port and two or more inlet ports, with one outlet port located substantially in line with the inlet port and connected by a venturi tube. The second inlet port is separated from the main air flow line by the valve stem and a diaphragm which allows communication there between and prevents back pressure. The second inlet port communicates with the outlet port through the valve stem and a second venturi tube which provides a vacuum boost to a device, usually vehicle brakes, connected to the inlet.

Owner:NYLONCRAFT INC

Method for Recovering Oil From a Gas-Lifted Oil Well Penetrating a Subterranean Oil-Bearing Formation

InactiveUS20070246222A1Reduce surface tensionFluid removalMachines/enginesActive agentPhysical chemistry

In a method for optimizing gas lift operations in the production of crude oil, a surfactant is injected with the lift gas into the an oil well such that the surface tension between the lift gas and the formation fluid being produced is reduced and / or a lift gas-formation fluid foam is formed. The reduction in surface tension and / or foam formation increases the efficiency of the lift gas for lifting the formation fluid to the surface. The surfactant is selected to minimize corrosion. The surfactants consist essentially of sultaines, hydroxy sultaines, and their salts. It is emphasized that this abstract is provided to comply with the rules requiring an abstract which will allow a searcher or other reader to quickly ascertain the subject matter of the technical disclosure. It is submitted with the understanding that it will not be used to interpret or limit the scope or meaning of the claims. 37 CFR 1.72(b)

Owner:BAKER HUGHES INC

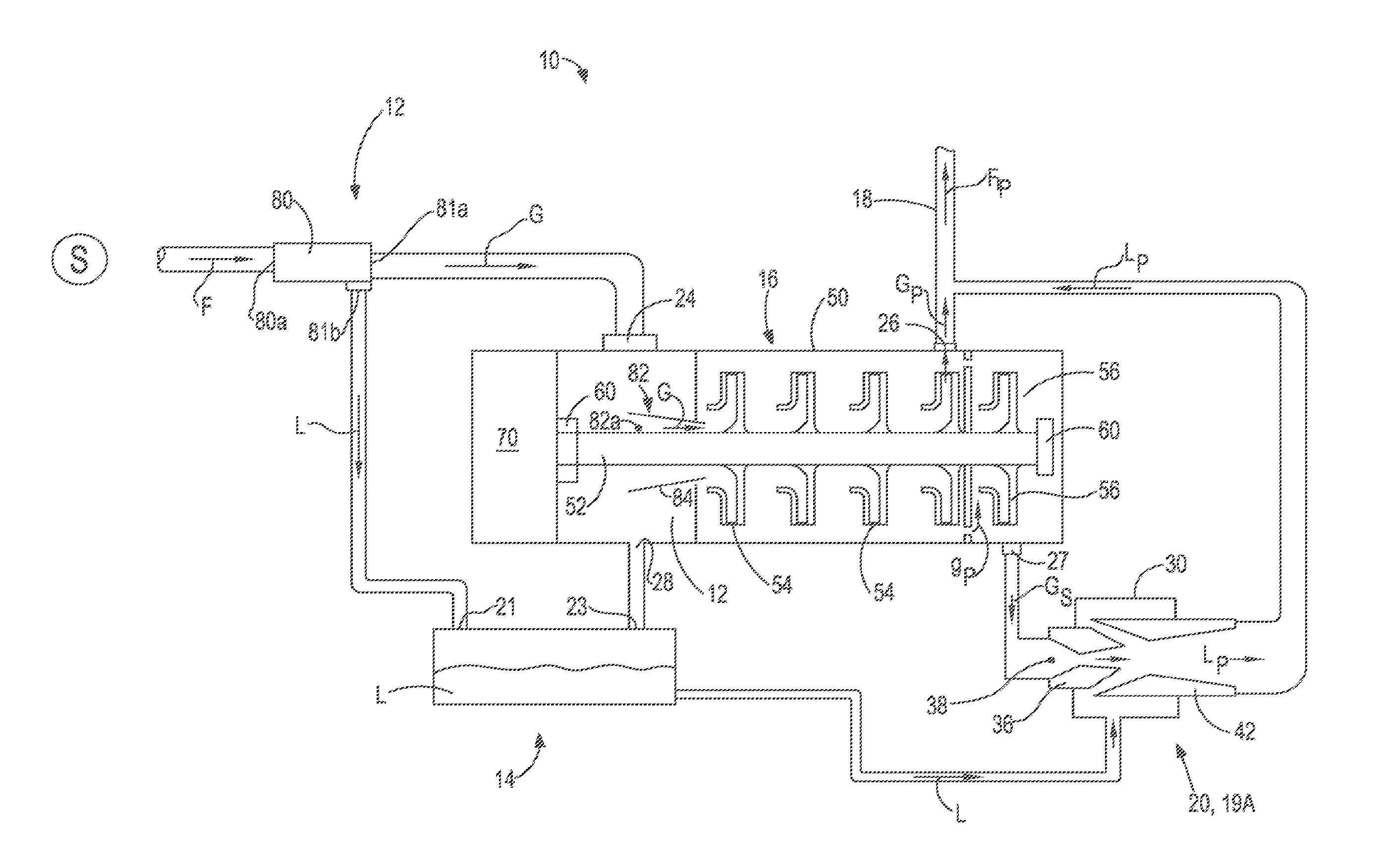

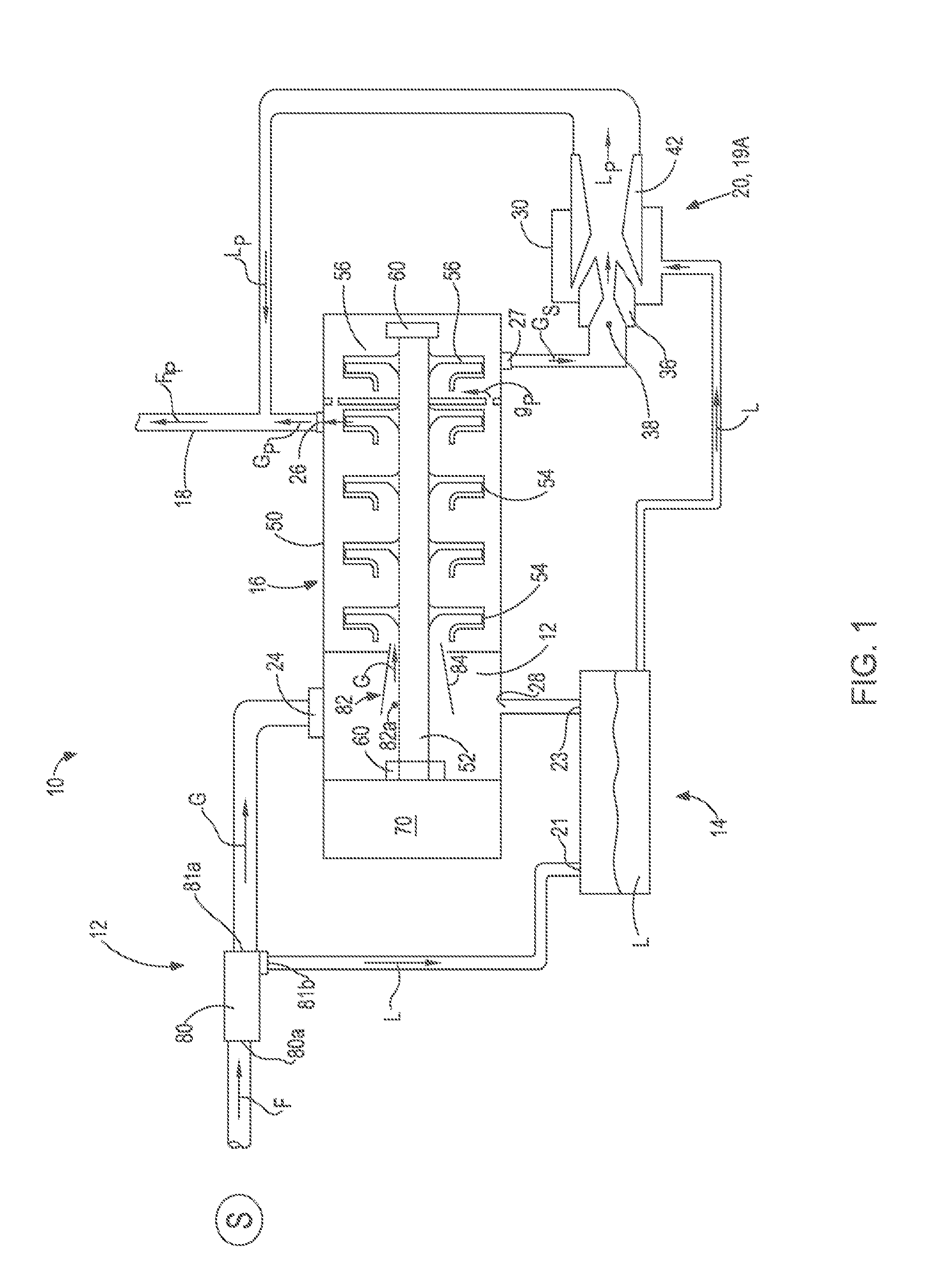

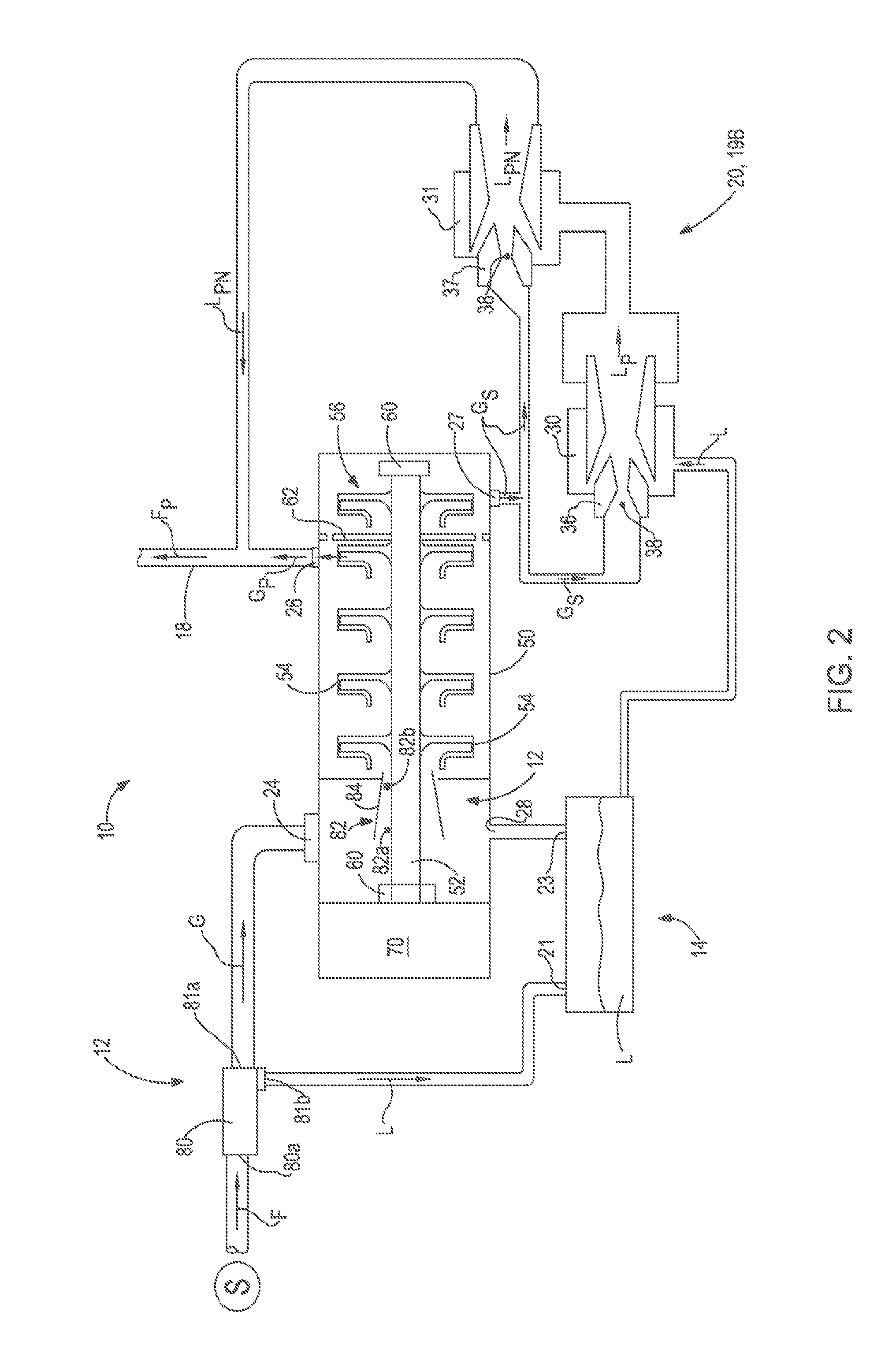

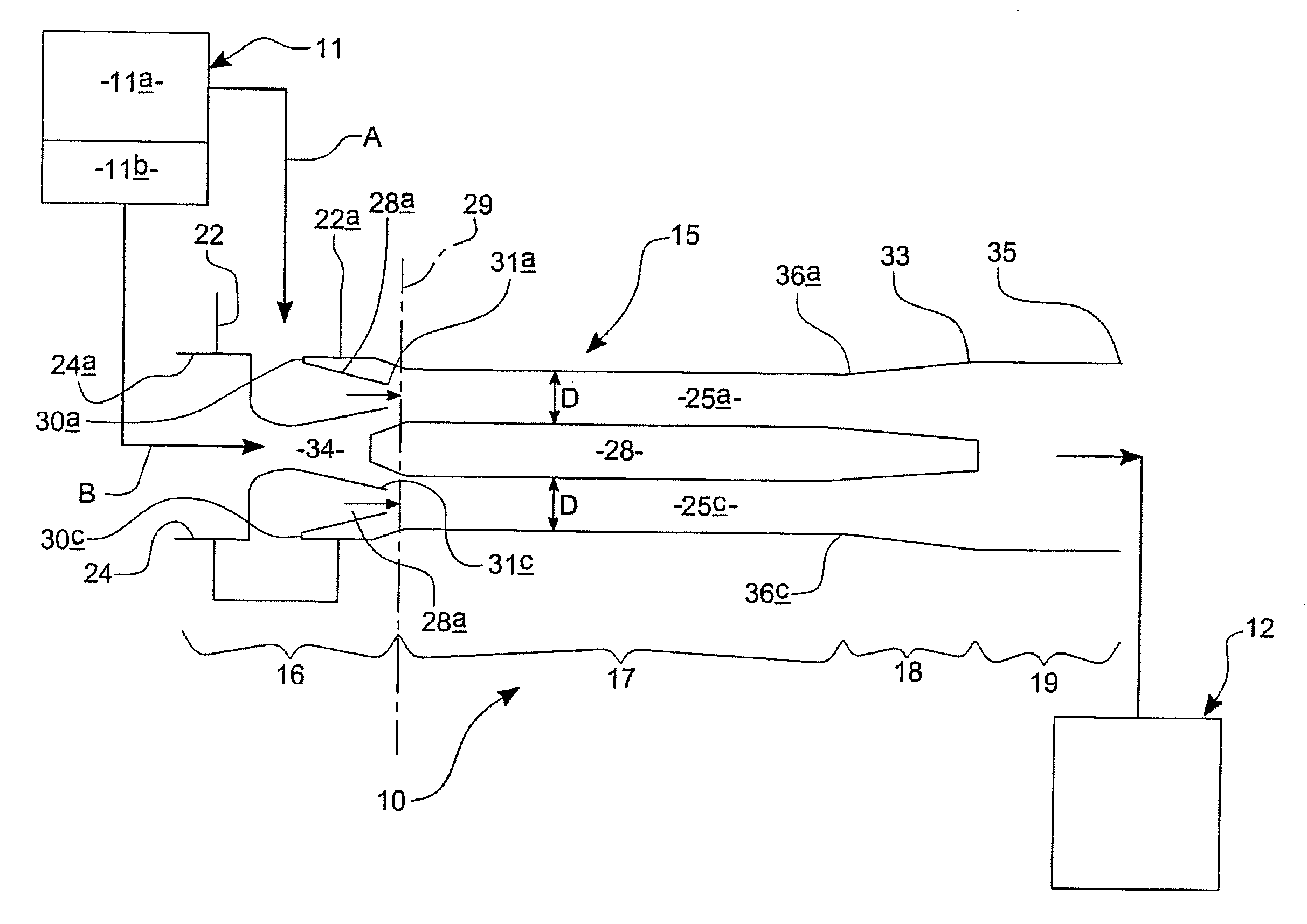

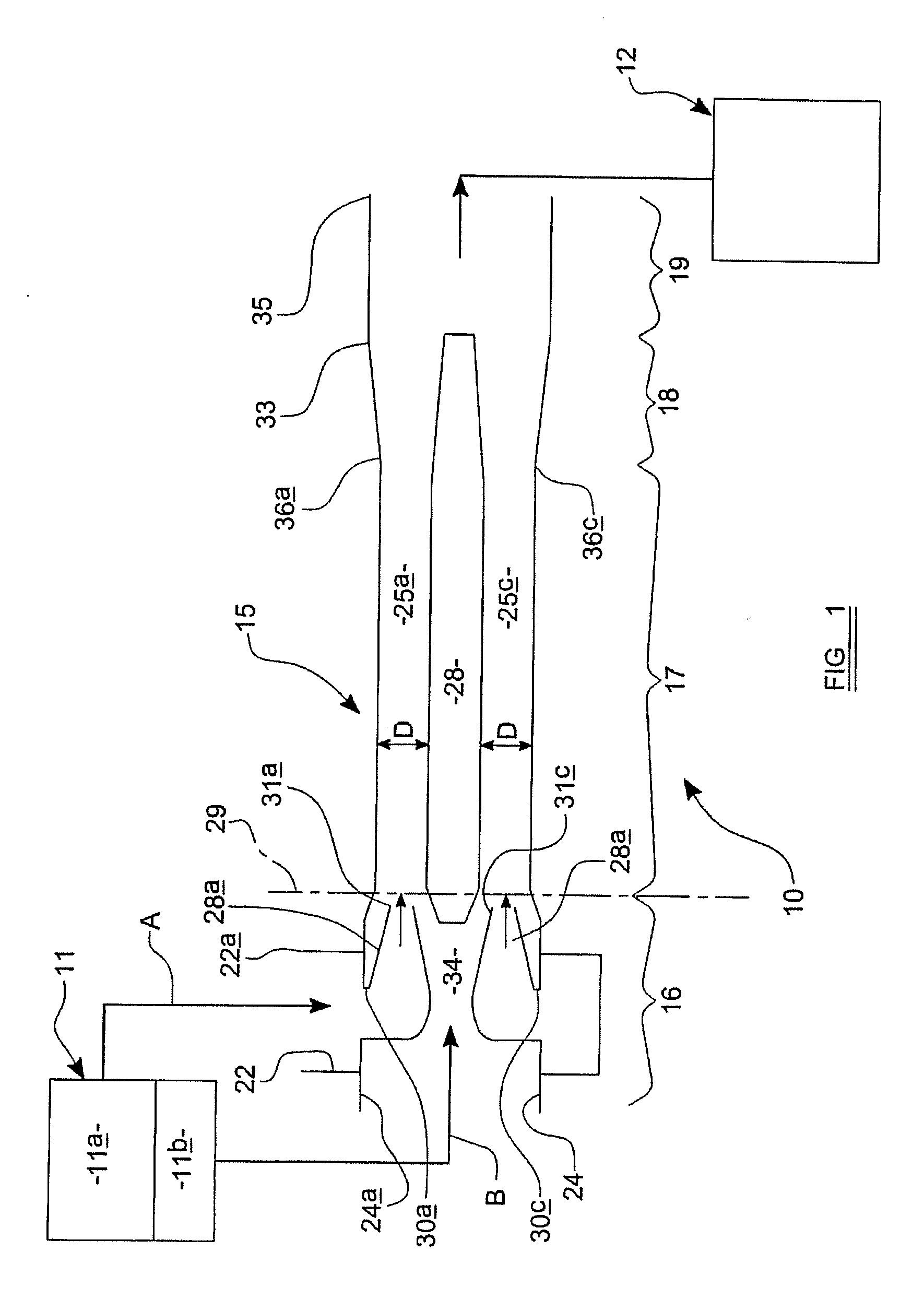

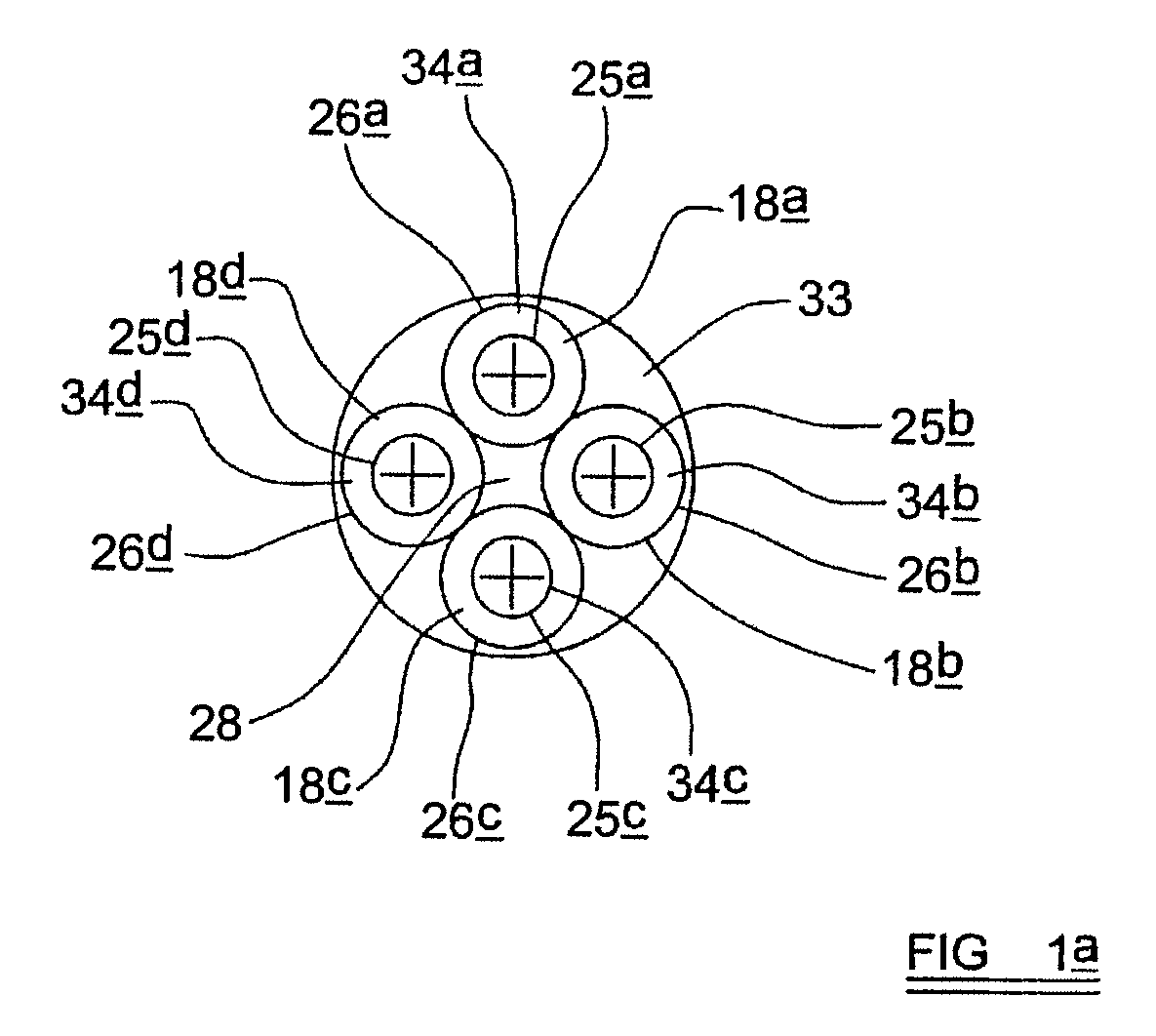

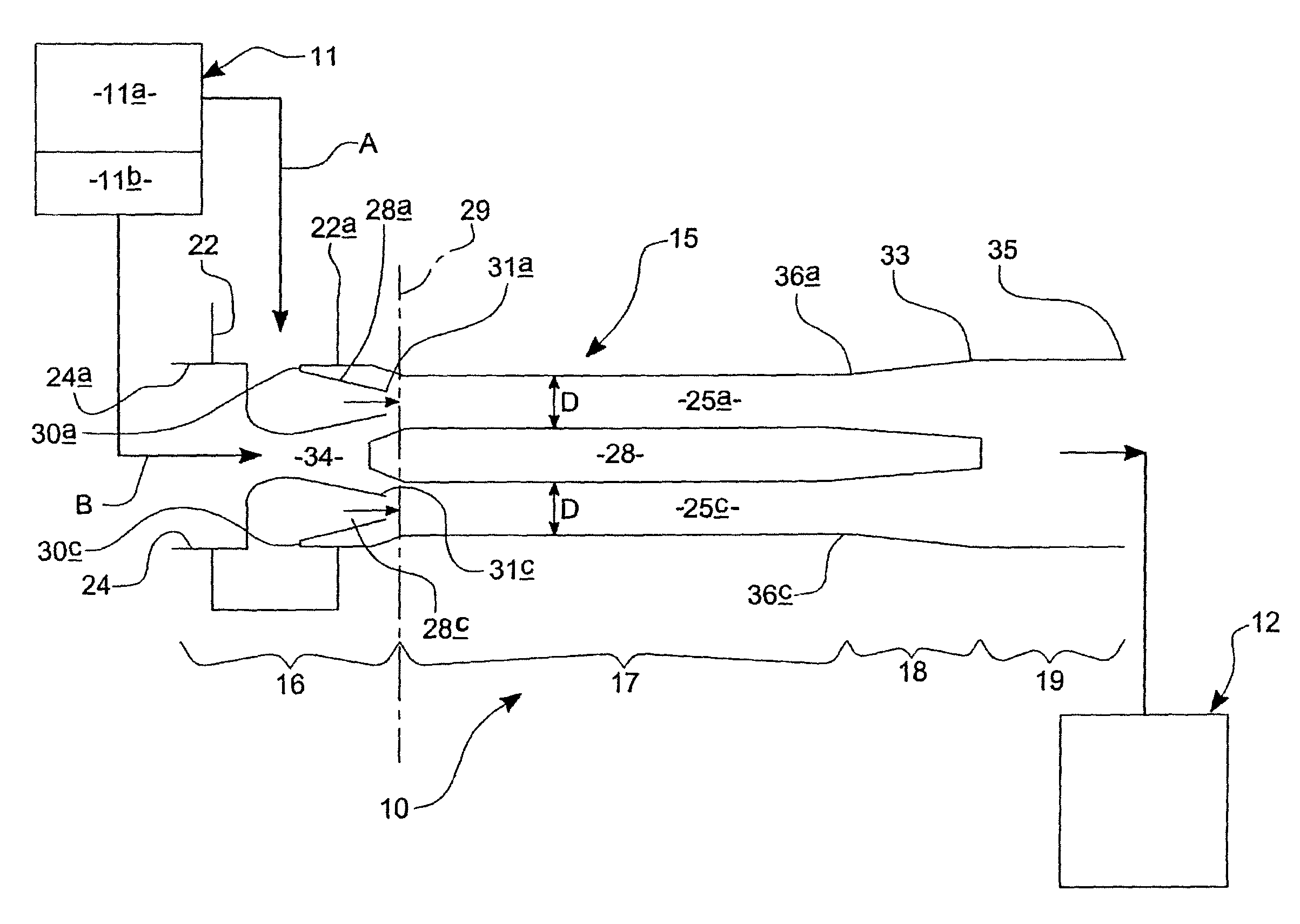

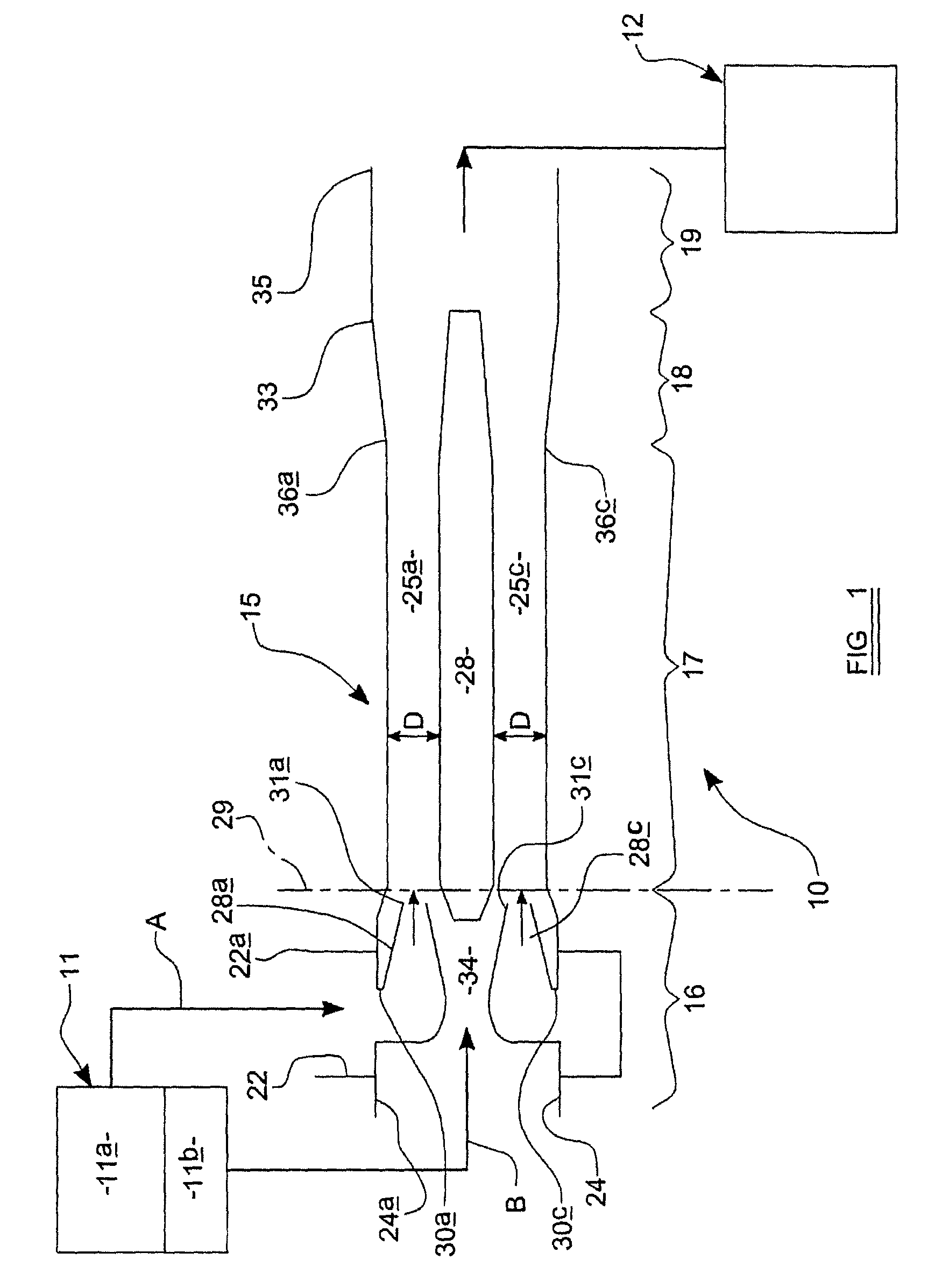

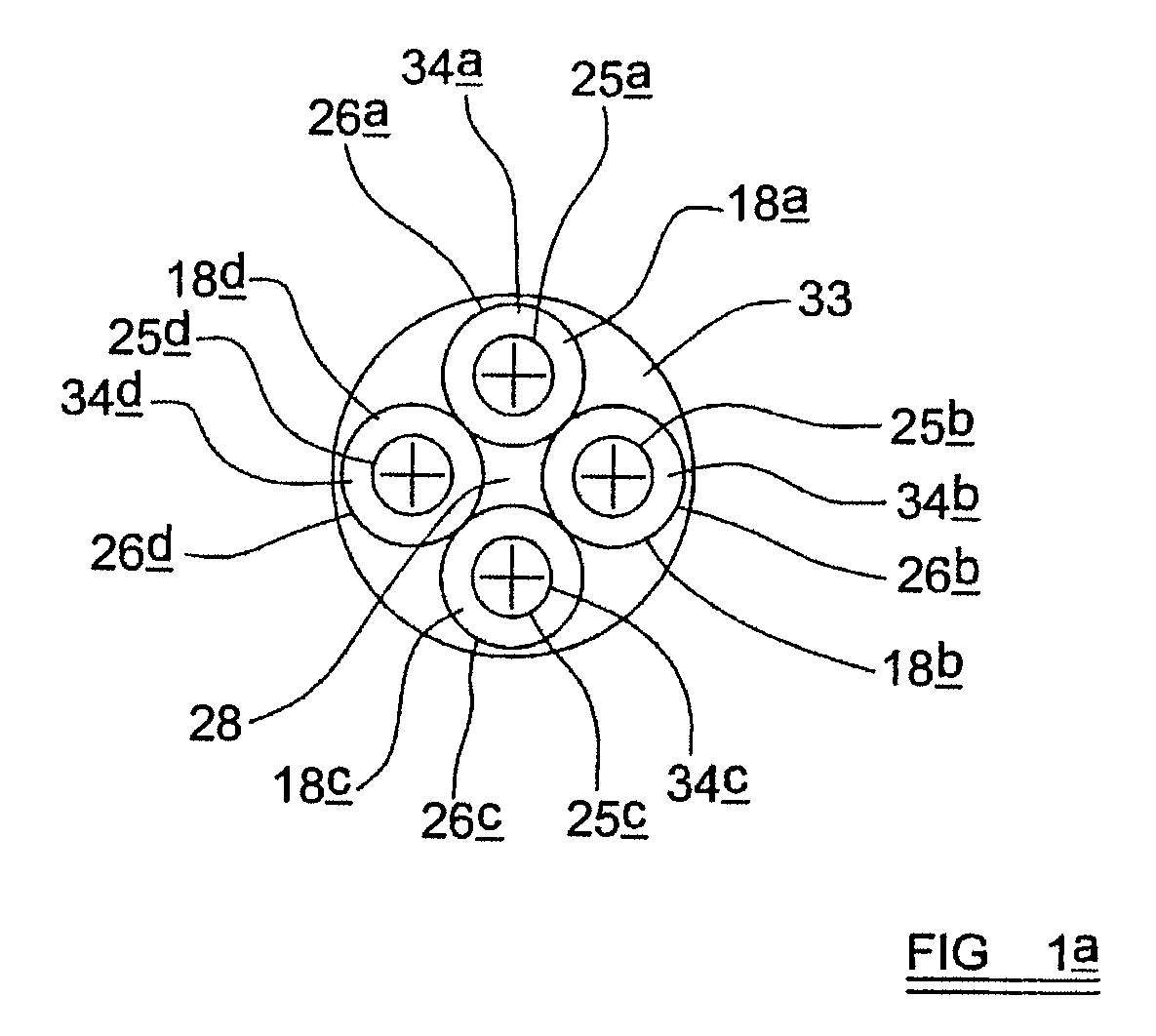

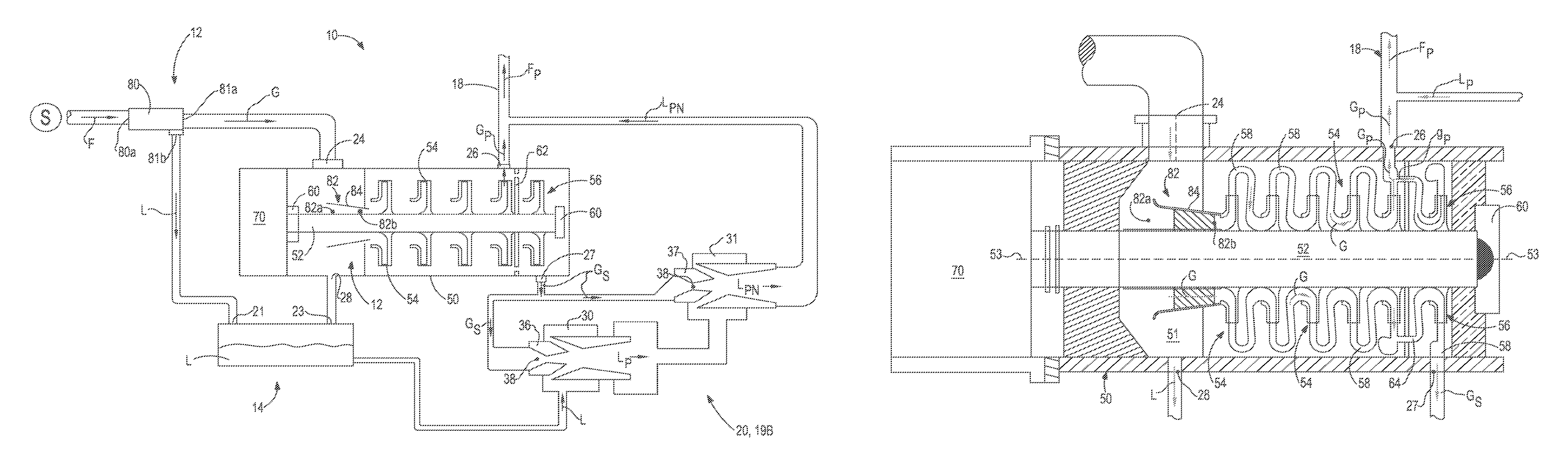

Jet pump apparatus

A jet pump apparatus for mixing a higher pressure gas from a higher pressure gas supply and a lower pressure gas from a lower pressure gas supply, includes an inlet section, an outlet section, a diffuser section and a mixing section, the inlet section including a higher pressure gas inlet and a lower pressure gas inlet, the mixing section including a plurality of separated mixing chambers, and the diffuser section including diffusers for receiving mixed gases from each of the mixing chambers, and the outlet section receiving mixed gases from the diffuser section and conveying the mixed gases to a mixed gas outlet, and the inlet section including a higher pressure gas inlet duct which receives higher pressure gas from the higher pressure gas inlet, and a lower pressure gas inlet duct which receives lower pressure gas from the lower pressure gas inlet, and for each of the plurality of mixing chambers, there being a primary nozzle for introducing primarily higher pressure gas from the higher pressure gas inlet duct to a respective mixing chamber, and there being a secondary inlet for introducing primarily lower pressure gas from the lower pressure inlet duct to each of the mixing chambers, the higher pressure gas being derived from a compressor section of a gas turbine engine.

Owner:HONEYWELL NORMALAIR GARRETT HLDG

Jet pump apparatus

A jet pump apparatus for mixing a higher pressure gas and a lower pressure gas, includes an inlet section, an outlet section, a diffuser section and a mixing section. Inlet section includes a higher pressure inlet and a lower pressure inlet. Mixing section includes a plurality of separated mixing chambers. The diffuser section includes diffusers for receiving mixed gases from the mixing chambers. The outlet section receives mixed gases from the diffuser section and conveys those gases to an outlet. The inlet section includes a higher pressure inlet which receives higher pressure gas, and a lower pressure gas inlet which receives lower pressure gas. Each of the mixing chambers has a primary nozzle for introducing primarily higher pressure gas from to a respective mixing chamber, and a secondary inlet for introducing primarily lower pressure gas to each of the mixing chambers.

Owner:HONEYWELL NORMALAIR GARRETT HLDG

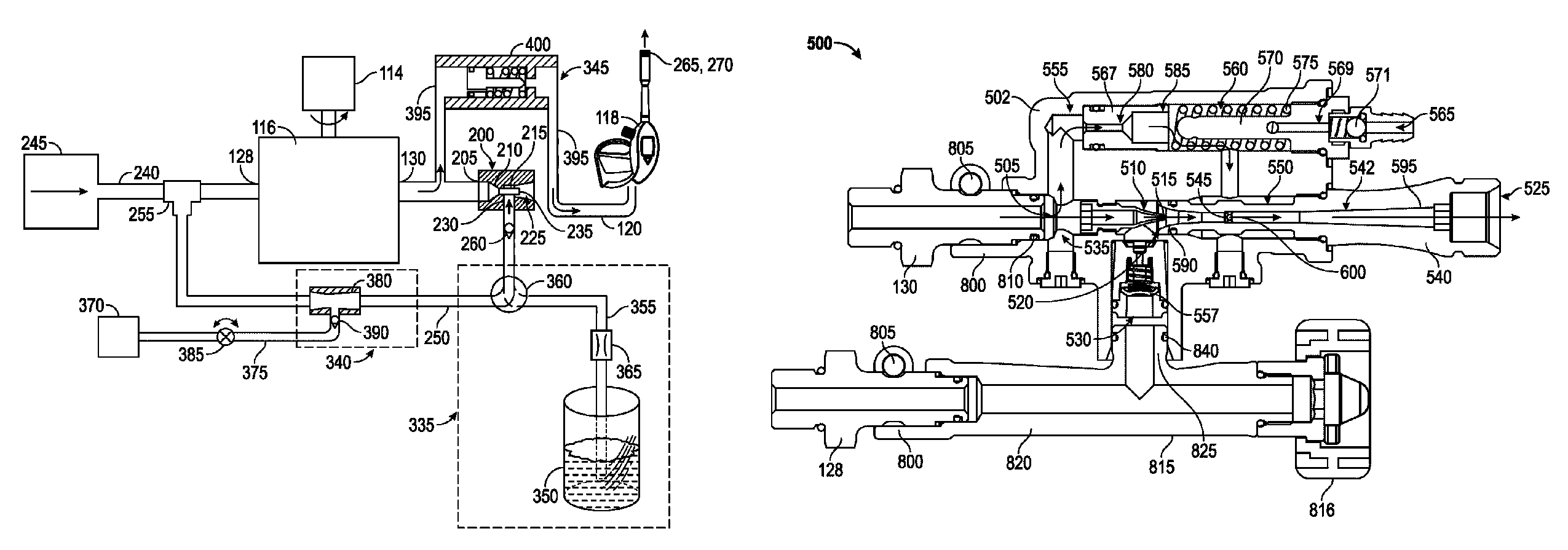

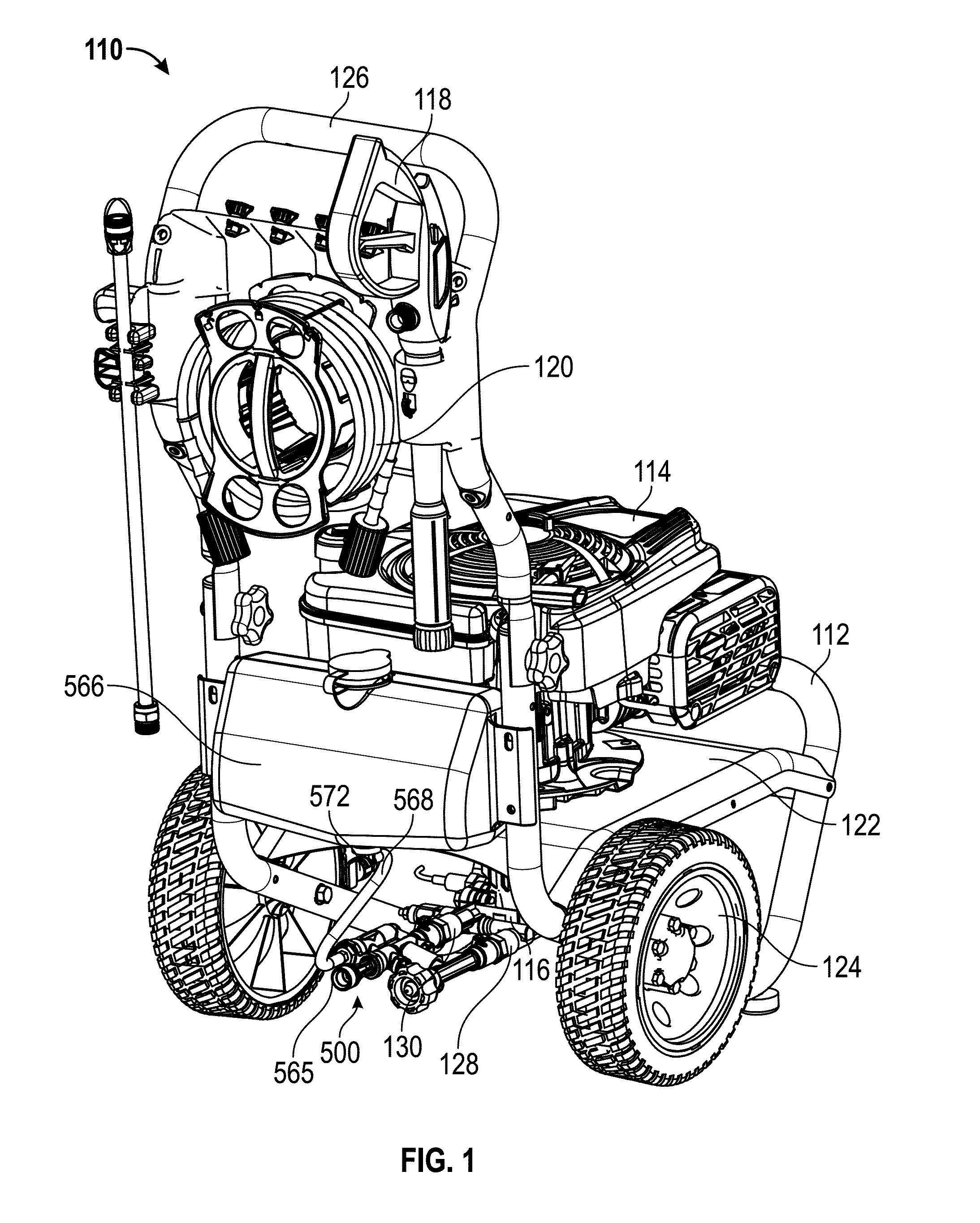

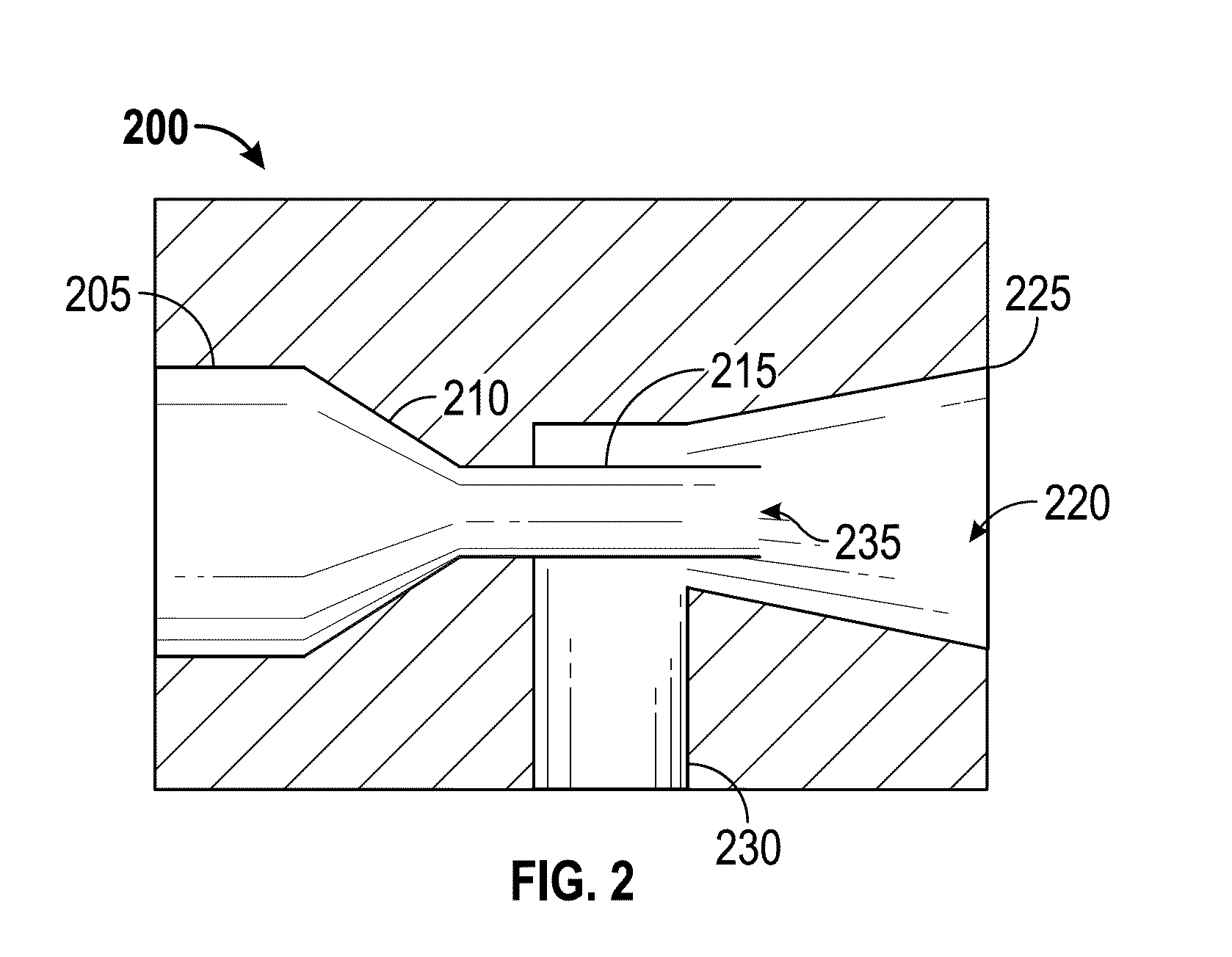

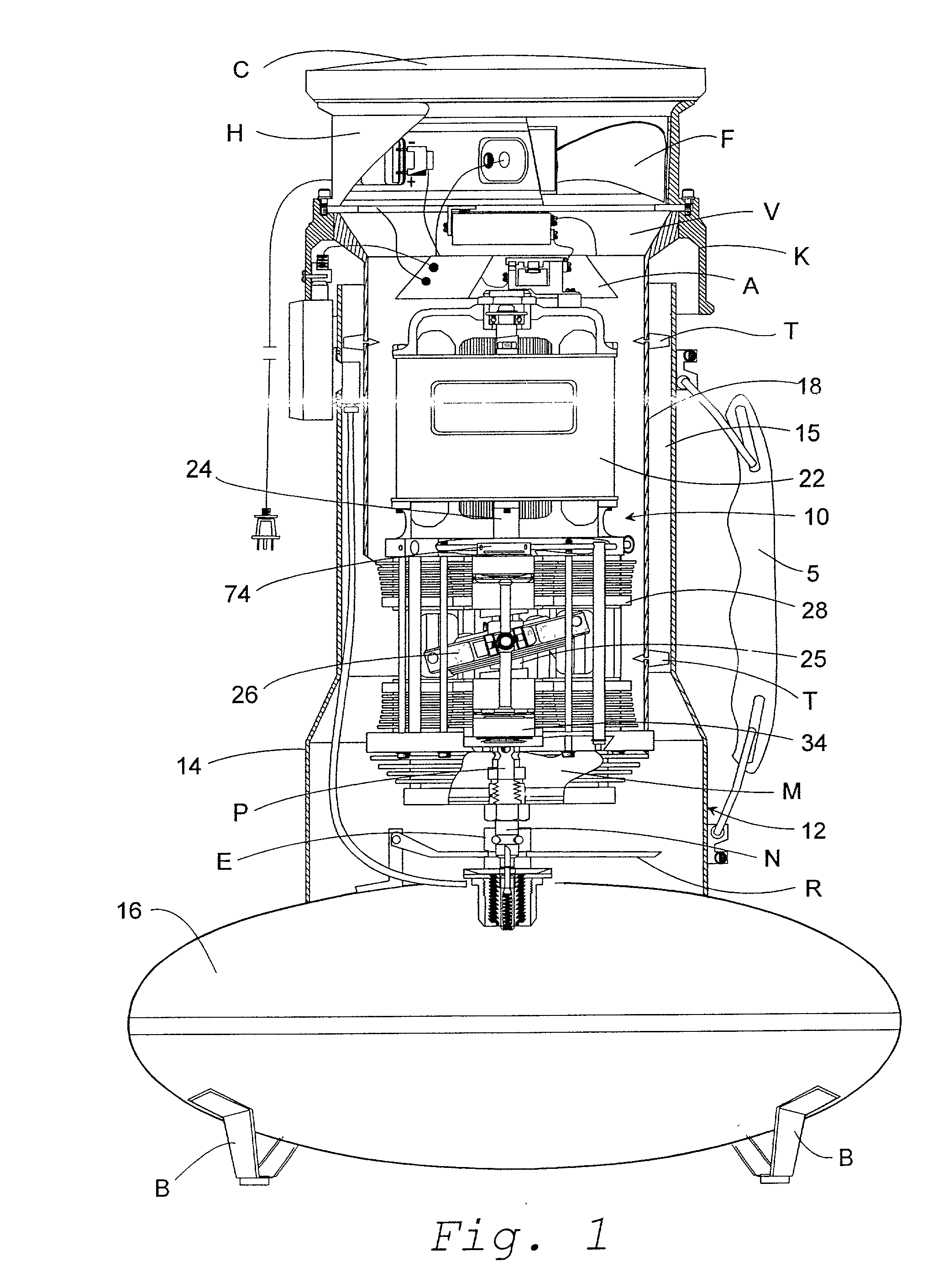

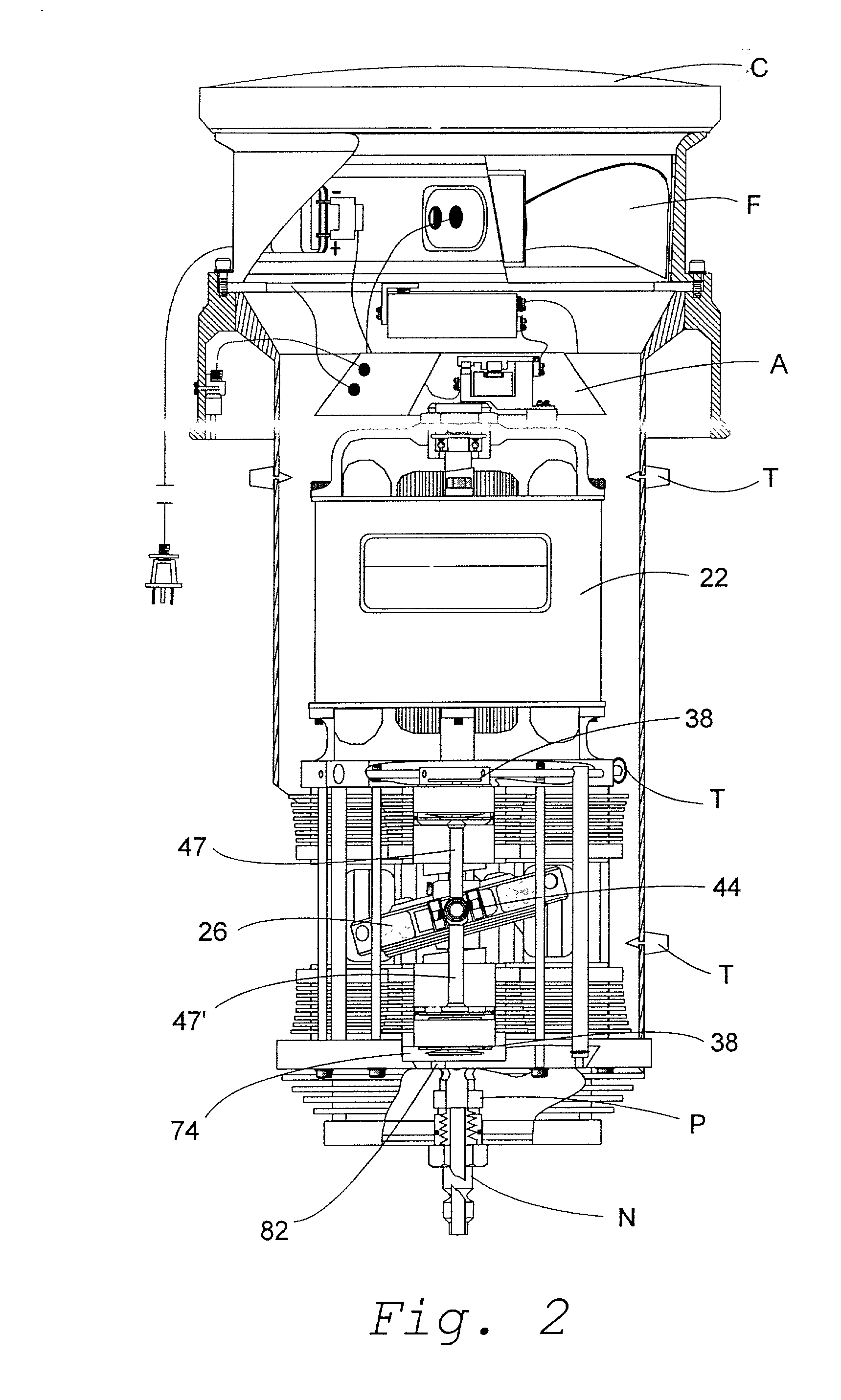

Pressure washers including jet pumps

A pressure washer includes a prime mover, a water pump, the water pump including a pump inlet for receiving fluid from a fluid source and a pump outlet for supplying a pressurized primary fluid, a jet pump including a primary fluid inlet fluidly coupled to the pump outlet, a secondary fluid inlet, and a fluid outlet, and a spray gun configured to be fluidly coupled to the fluid outlet of the jet pump, the spray gun including a spray gun outlet having a variable effective flow area. Wherein, in operation, in a high pressure operating mode, the pressurized primary fluid flows through the jet pump and exits through the fluid outlet of the jet pump, and in a high flow operating mode, the pressurized primary fluid flows through the jet pump and entrains a secondary fluid supplied through the secondary fluid inlet, resulting in a combined fluid flow.

Owner:BRIGGS & STRATTON LLC

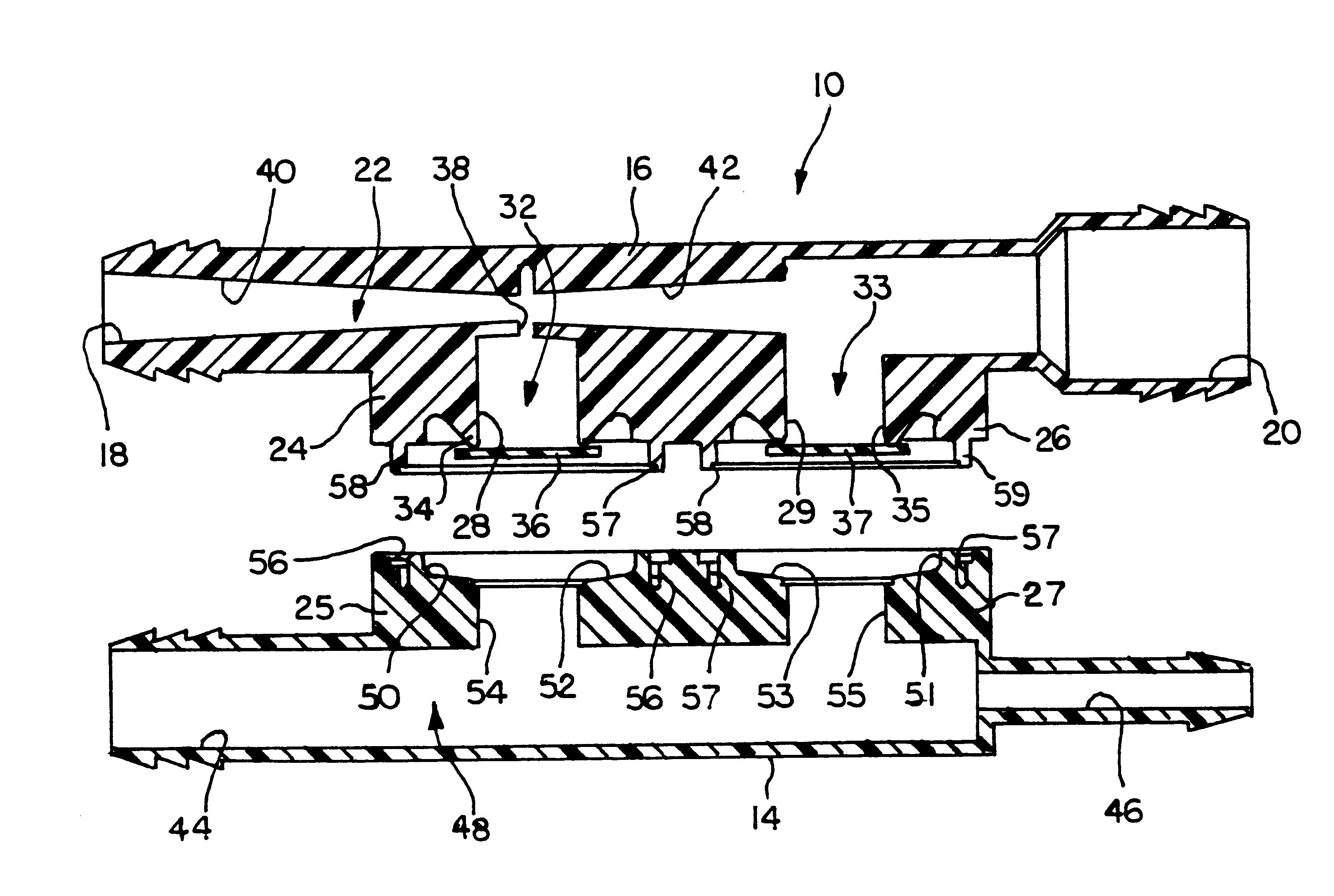

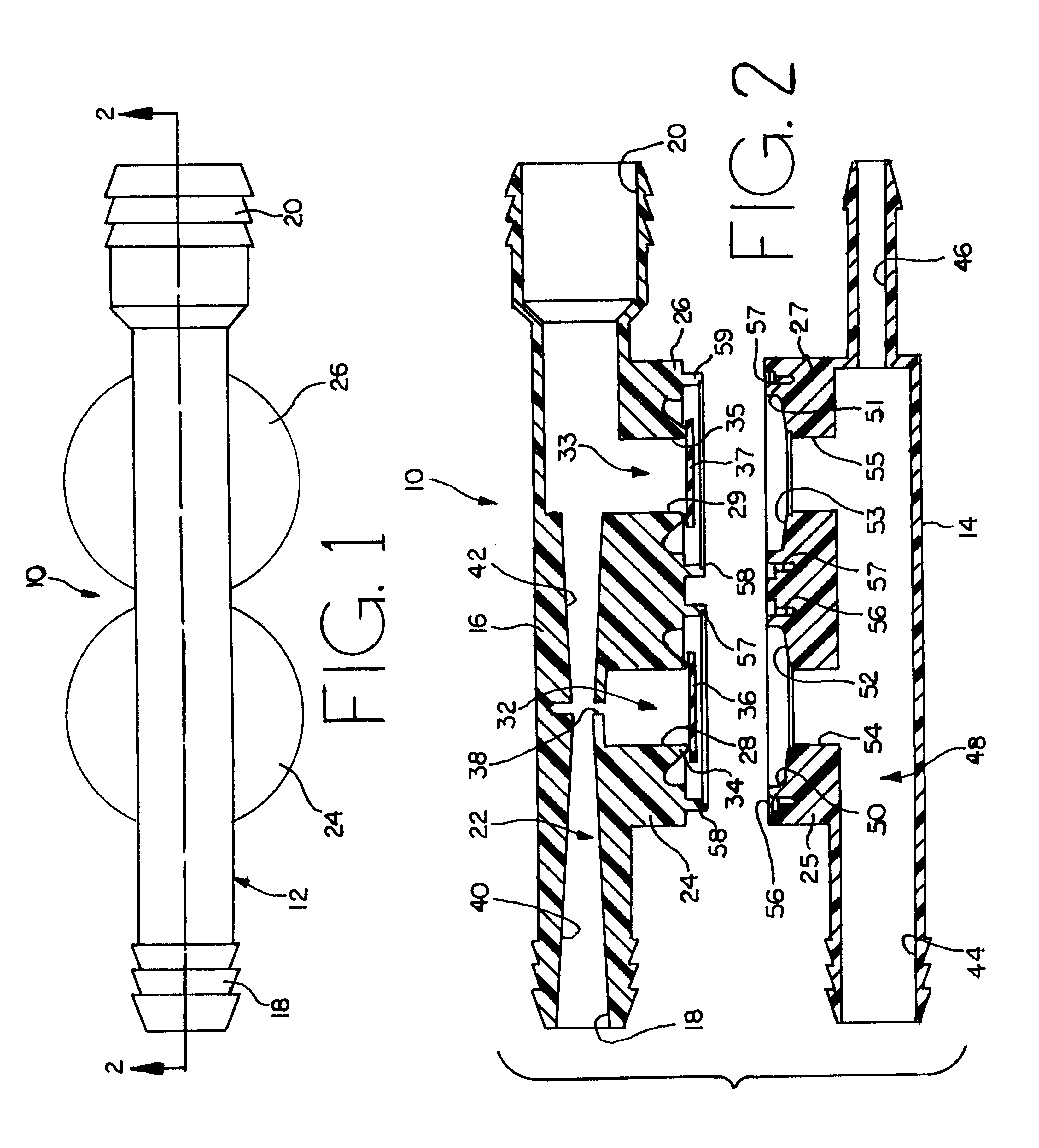

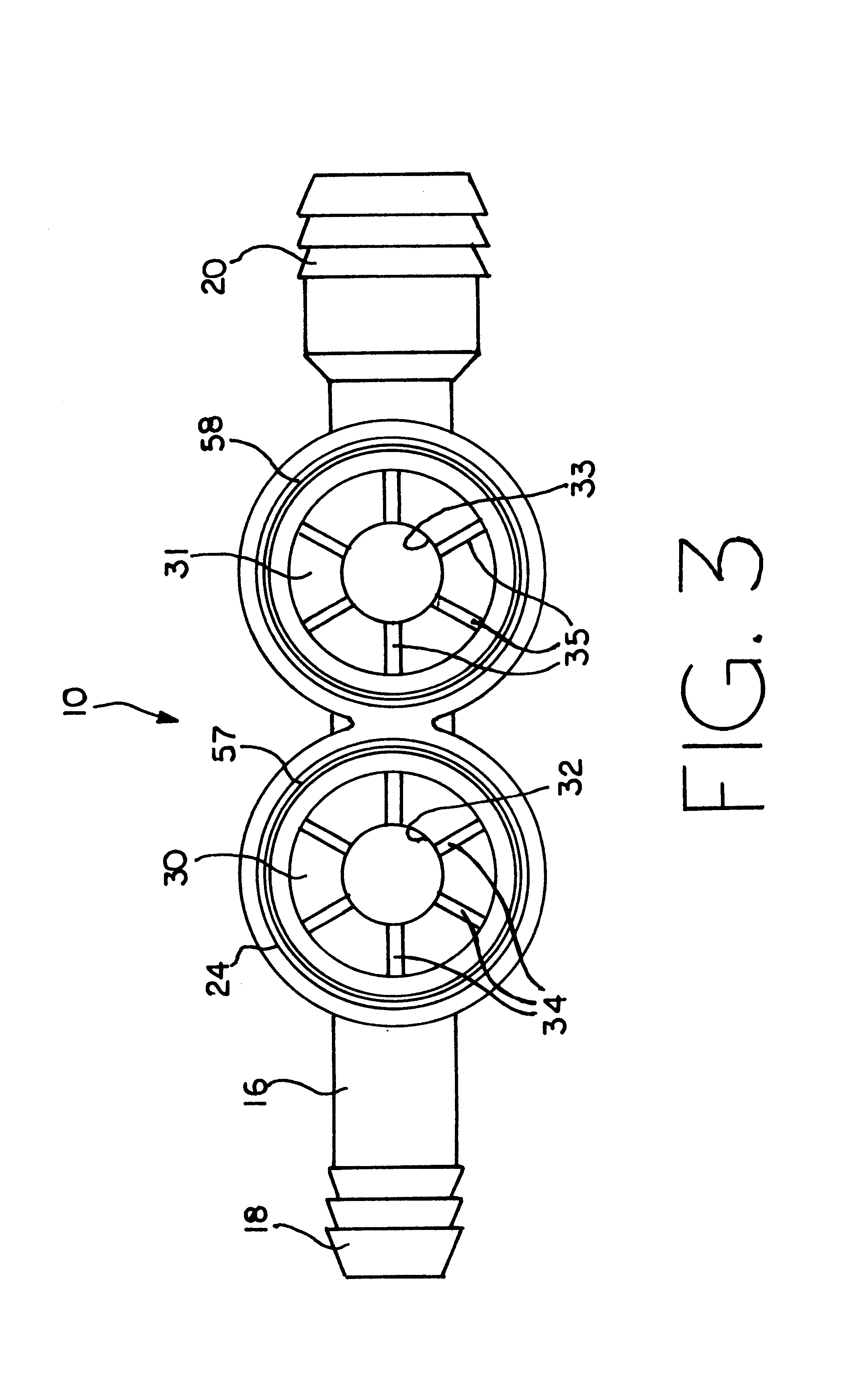

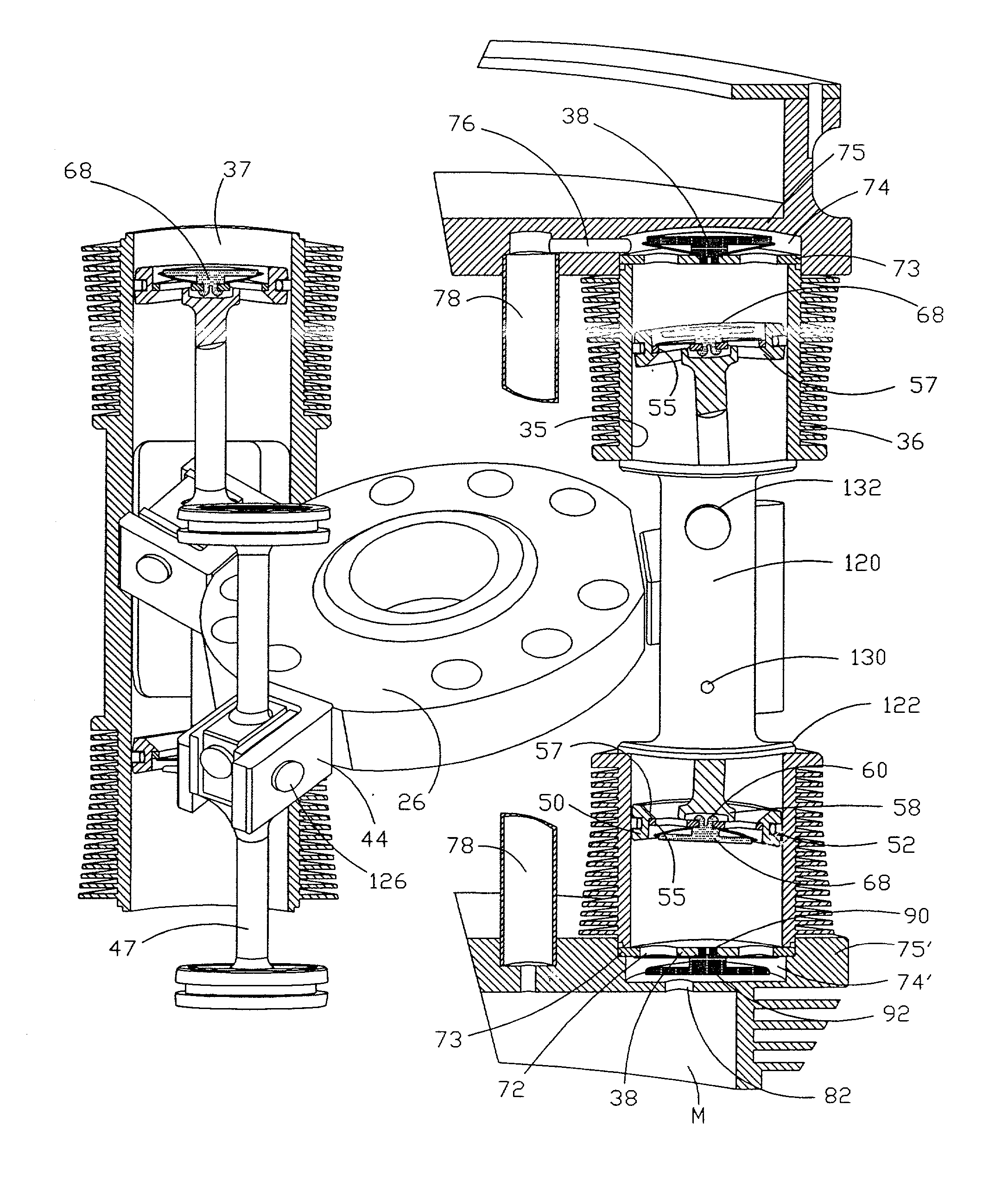

Shuttle piston assembly with dynamic valve

InactiveUS20030072654A1Increase volumeStress minimizationPositive displacement pump componentsDiffusion pumpsReciprocating motionPrecession

A portable, high capacity air compressor system for charging air tanks over wide pressure ranges with maximum volumetric efficiency is characterized by employing a shuttle piston assembly in which piston pairs are arranged with axially aligned cylinder pairs to reciprocate in response to precession of a wobble plate, and each of the pistons is further characterized by being of one-piece construction with a built-in leaflet-type intake valve in its piston head, and a universal connector between each of the piston pairs and wobble plate which is stabilized within a pair of guide rails.

Owner:GREAT WEST GRP

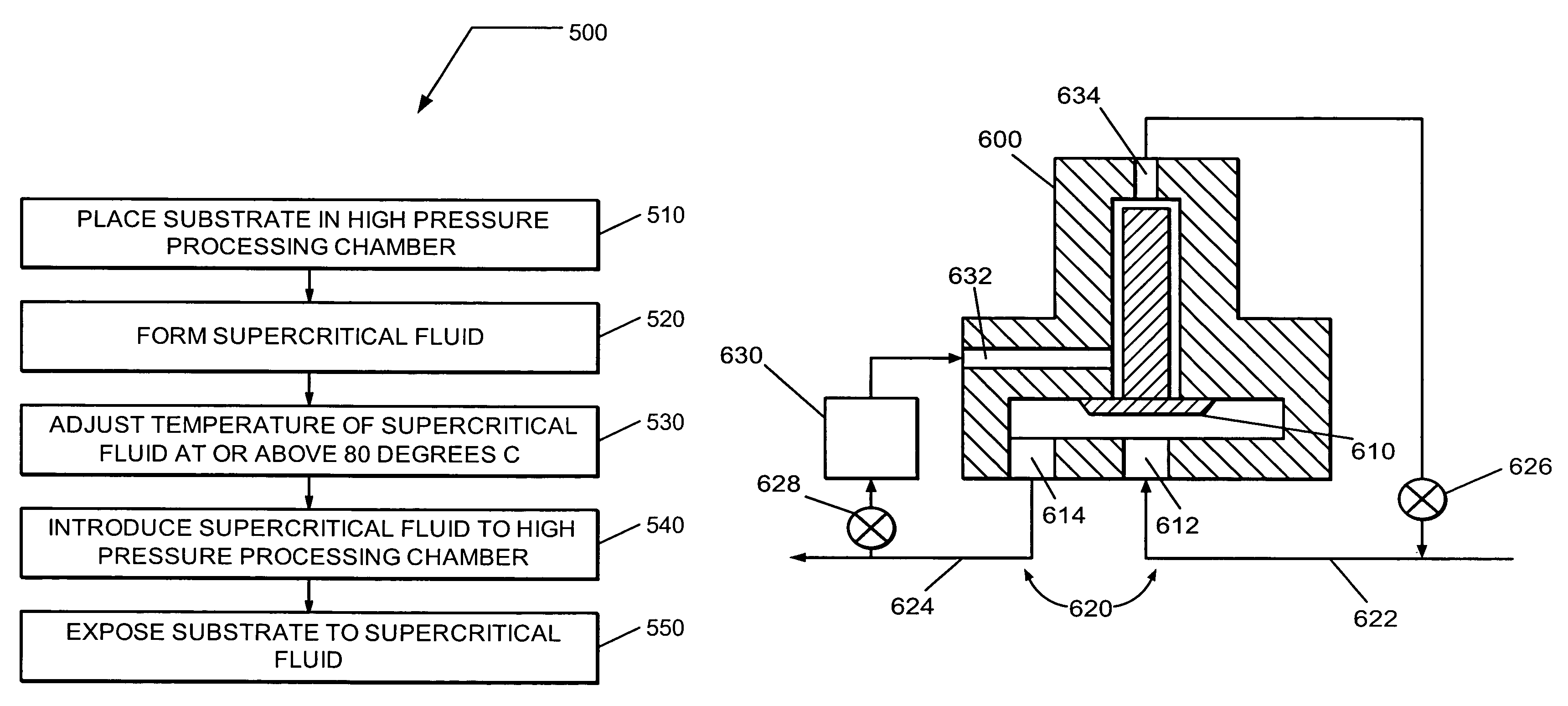

Method and system for cooling a pump

InactiveUS7491036B2Specific fluid pumpsPositive displacement pump componentsEngineeringHandling system

A processing system utilizing a supercritical fluid for treating a substrate is described as having a pump for recirculating the supercritical fluid over the substrate. For various applications in supercritical fluid processing, the fluid temperature for the treatment process can elevate above the temperature acceptable for safe operation of the pump. Therefore, in accordance with one embodiment, a fraction of supercritical fluid from the primary recirculating flow of supercritical fluid over the substrate is circulated from the pressure side of the pump, through a heat exchanger to lower the temperature of the supercritical fluid, through the pump, and it is returned to the primary flow on the suction side of the pump. In accordance with yet another embodiment, supercritical fluid is circulated through the pump from an independent source to vent.

Owner:TOKYO ELECTRON LTD

Compressor assembly including separator and ejector pump

A fluid processing device for processing a multiphase fluid stream including a mixture of at least a gas and a liquid is disclosed. The fluid processing device may include at least one separator configured to separate the fluid stream into a liquid portion and a gaseous portion and deposit the liquid portion into a liquid reservoir. The gaseous portion may be directed to a compressor configured to pressurize and discharge a pressurized gas into a fluid discharge line. A portion of the pressurized gas may be further pressurized and directed to at least one ejector pump fluidly coupled to the liquid reservoir and configured to draw in liquid and discharge pressurized liquid into the fluid discharge line.

Owner:DRESSER RAND CO

Attachment to air moving device or system for the purpose of scenting spaces

InactiveUS20100254829A1Increase aromaEasy and convenient applicationFluid removalMachines/enginesCardboardAir movement

An attachment for a fan, blower of other air moving device encompassing, and made of or designed to hold a scented material. The attachment may be constructed from any flexible, rigid or semi rigid material. A scented material base utilizing or made of paper, polymer, plastic, cardboard, ceramic, gel or other fragrance containing substrate that can be contained or placed inside said attachment. When the fan or blower is turned on a scent is emitted throughout the space. The attachment is available in standard or custom sizes, scents, shapes or colors to fit any standard fan or blower. The air movement produced creates a scent dispersion / diffusion effect.

Owner:HARRIS NEAL F

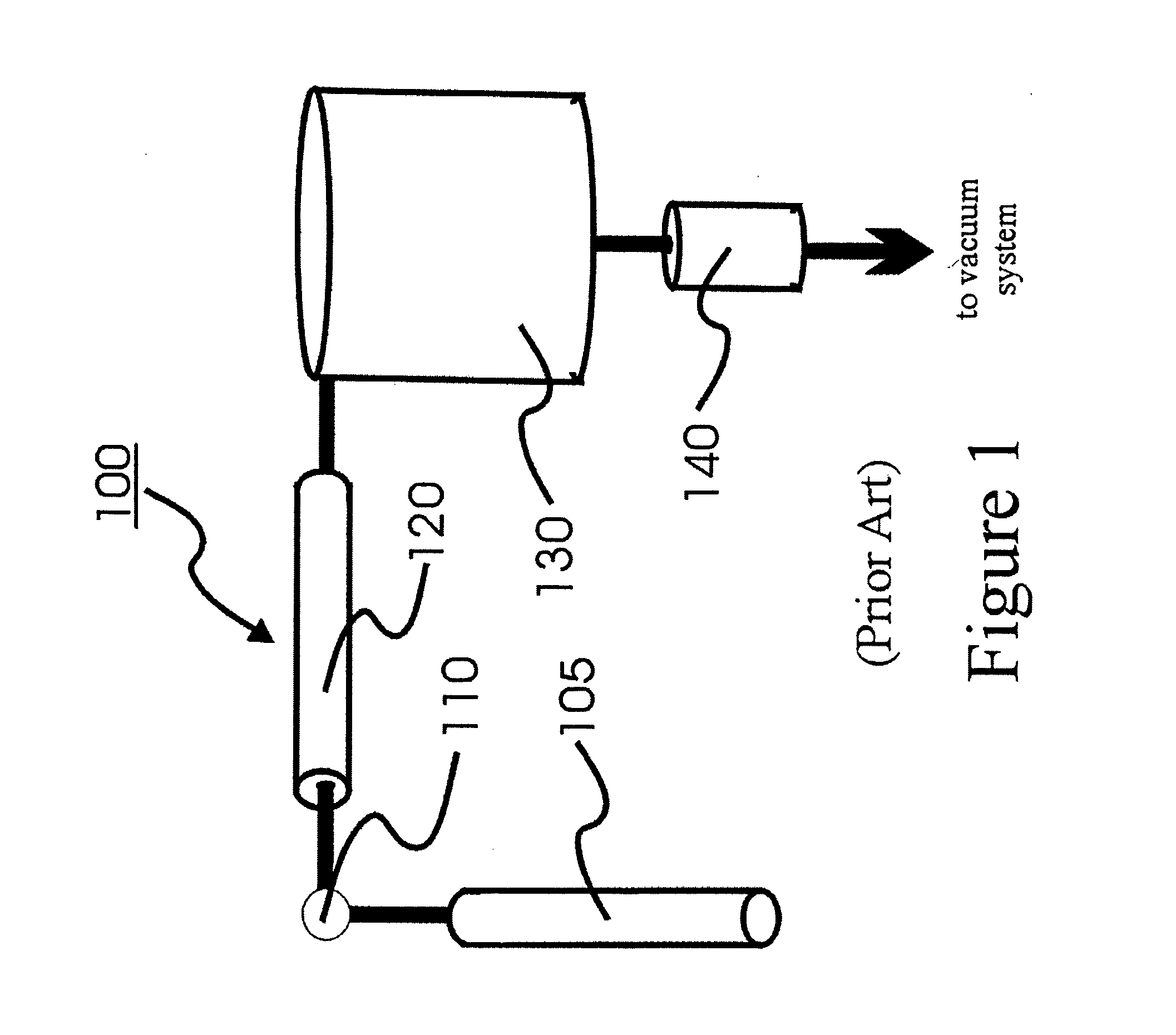

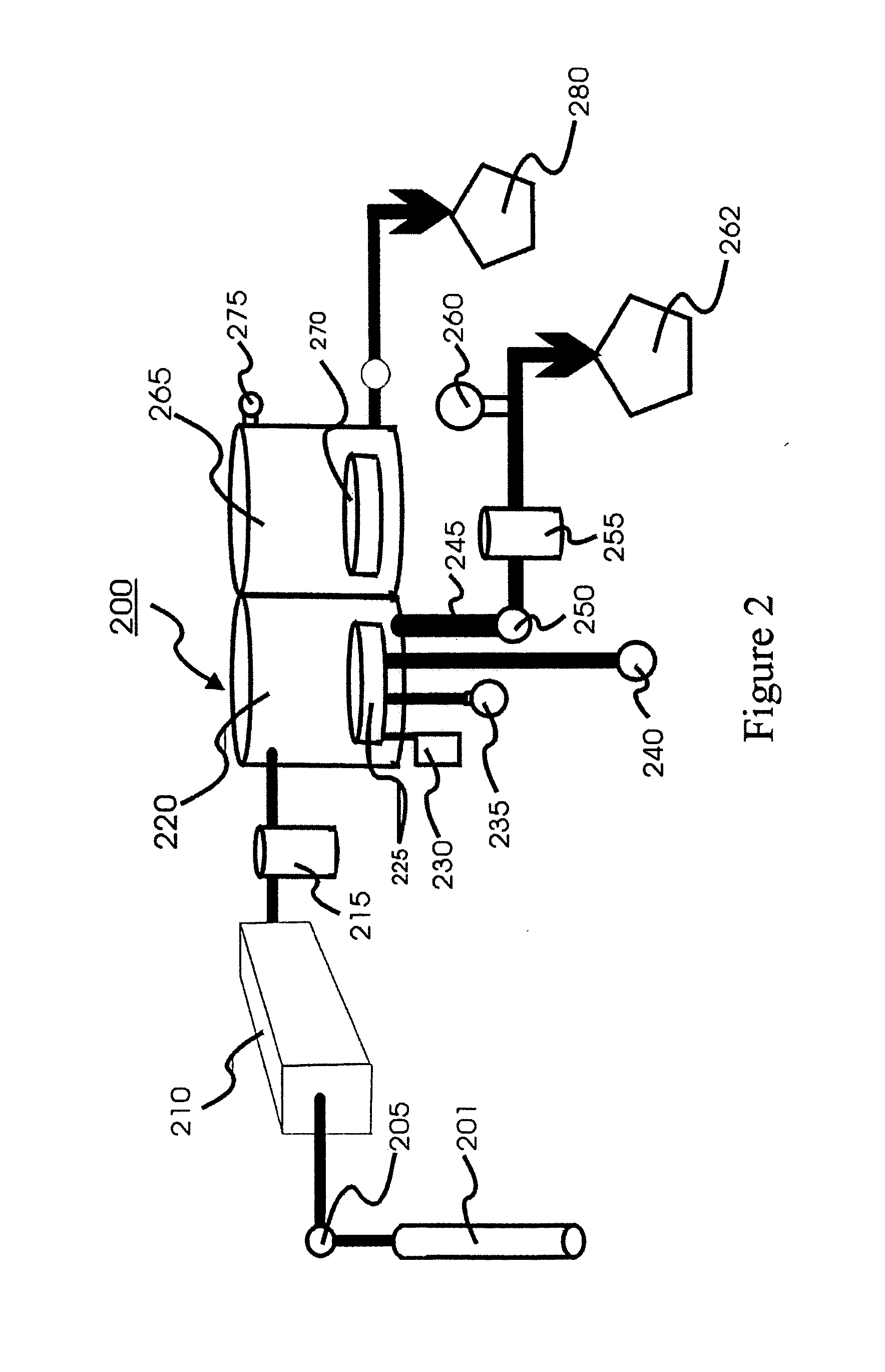

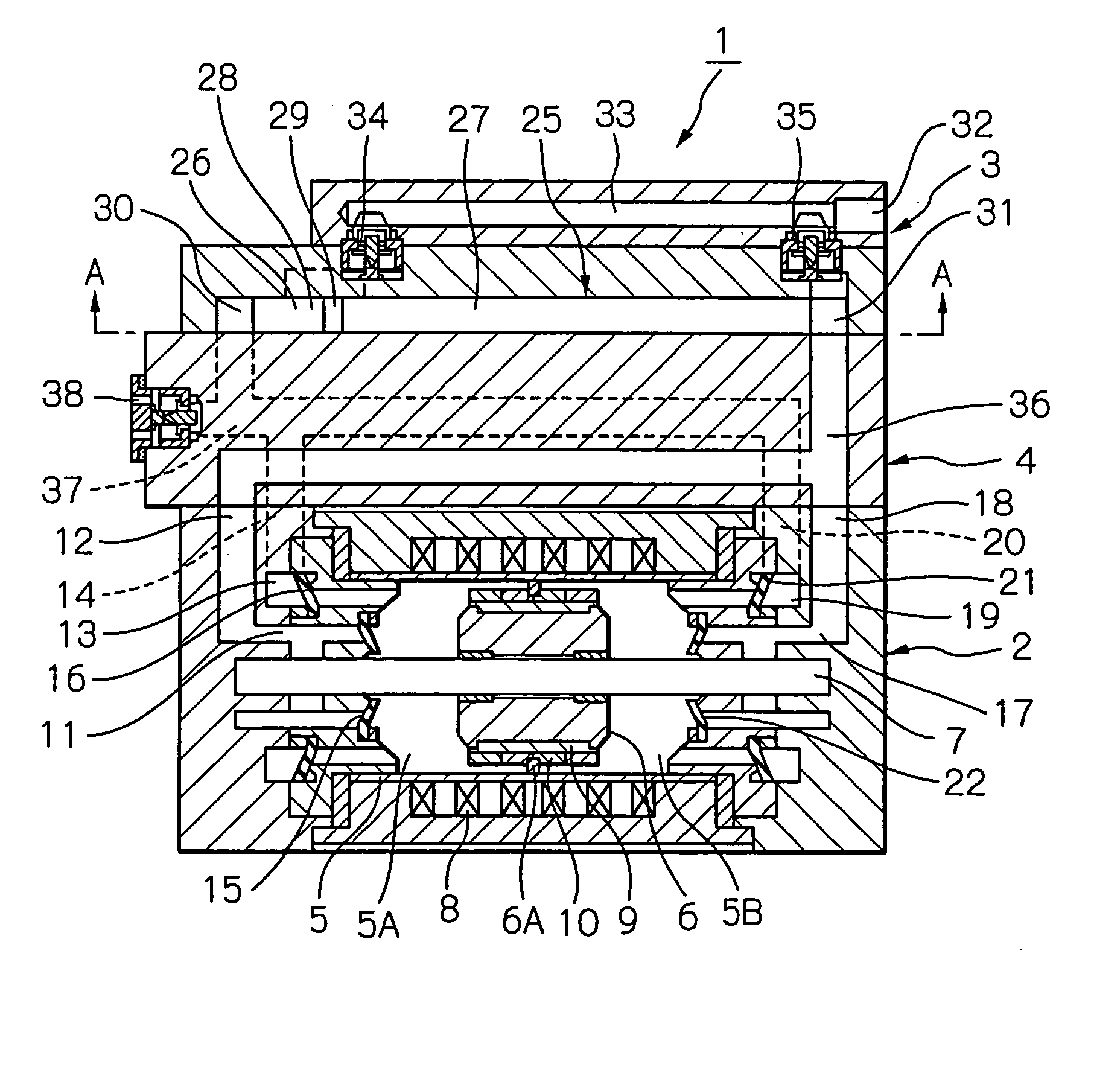

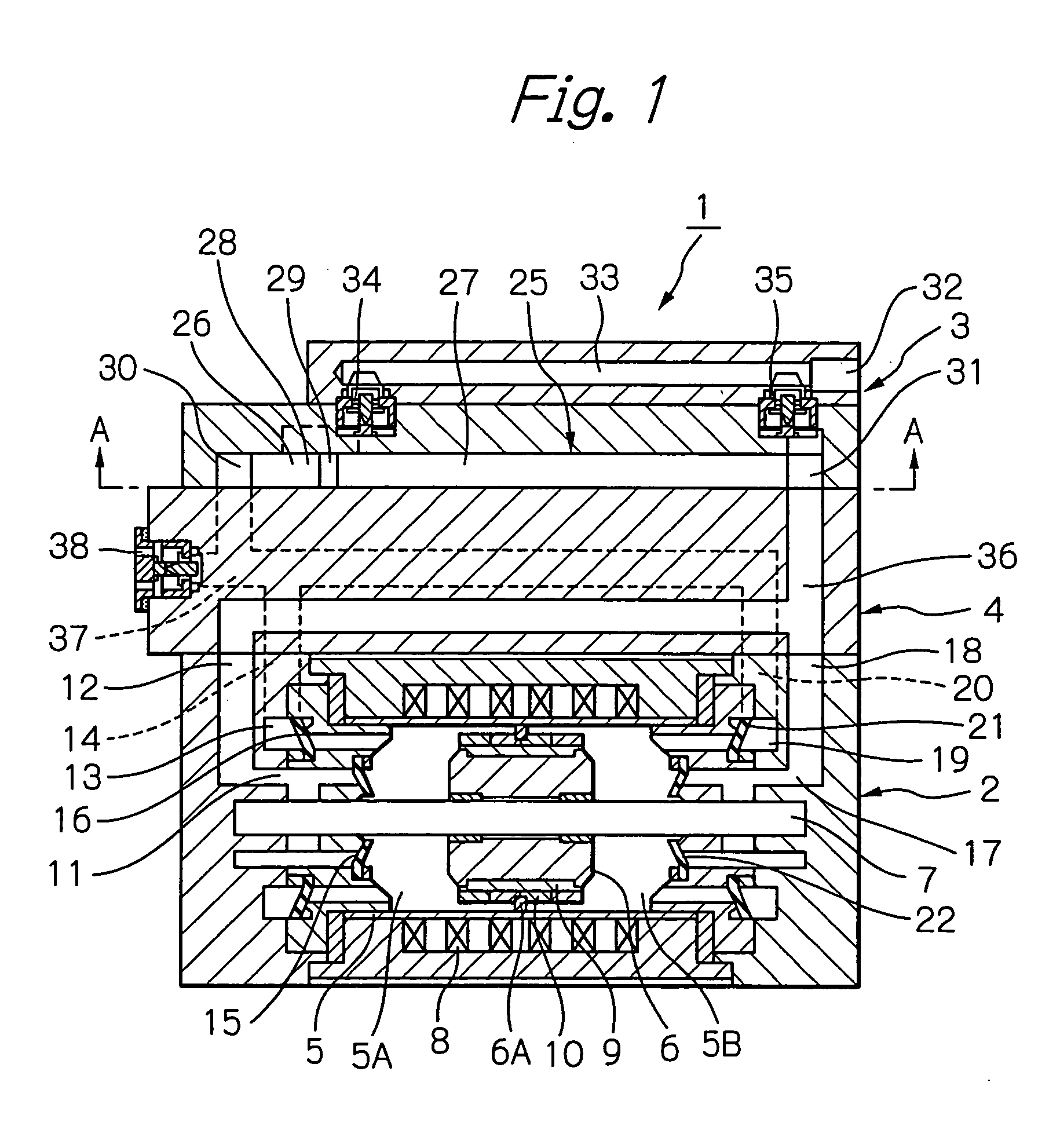

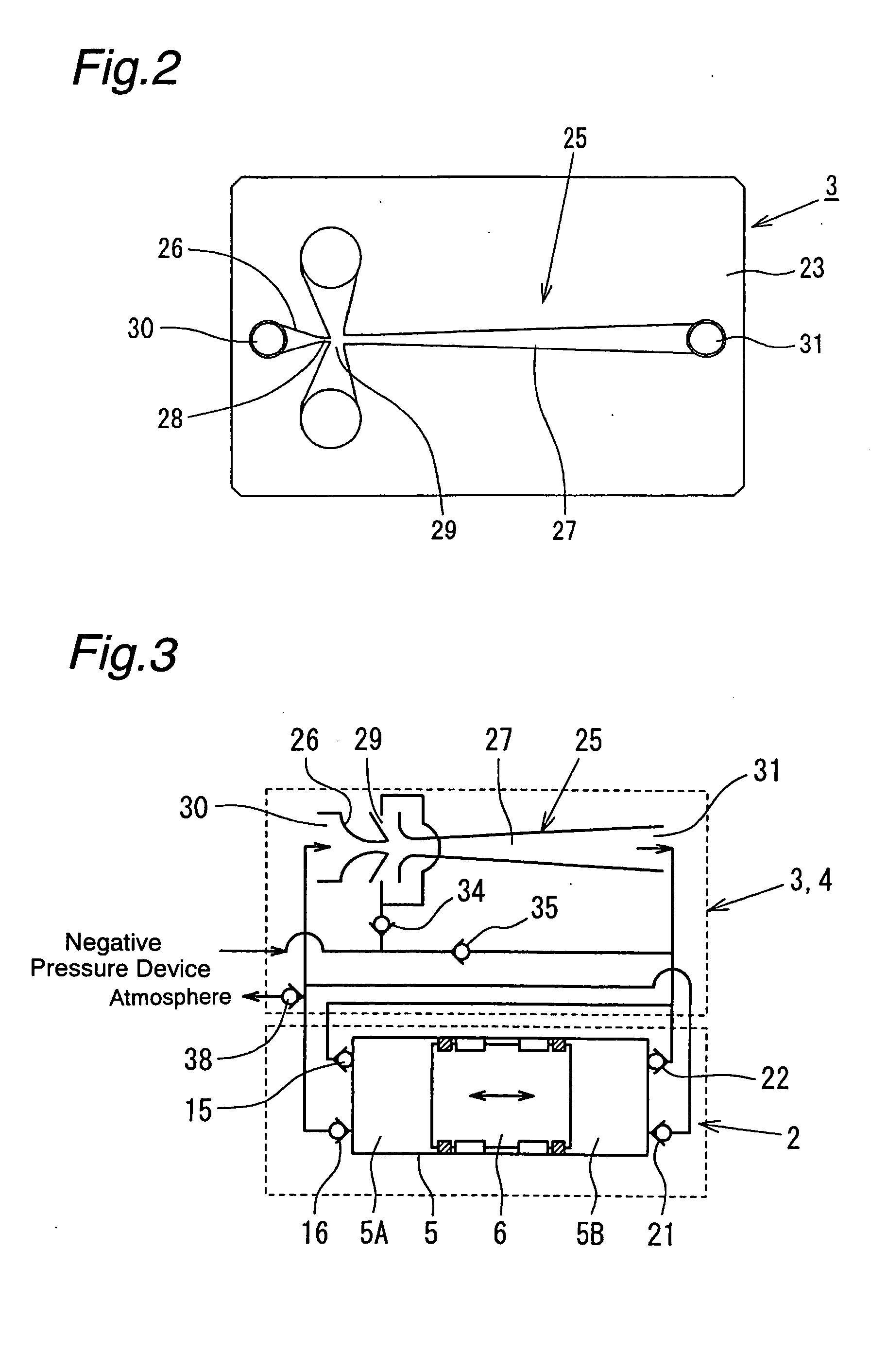

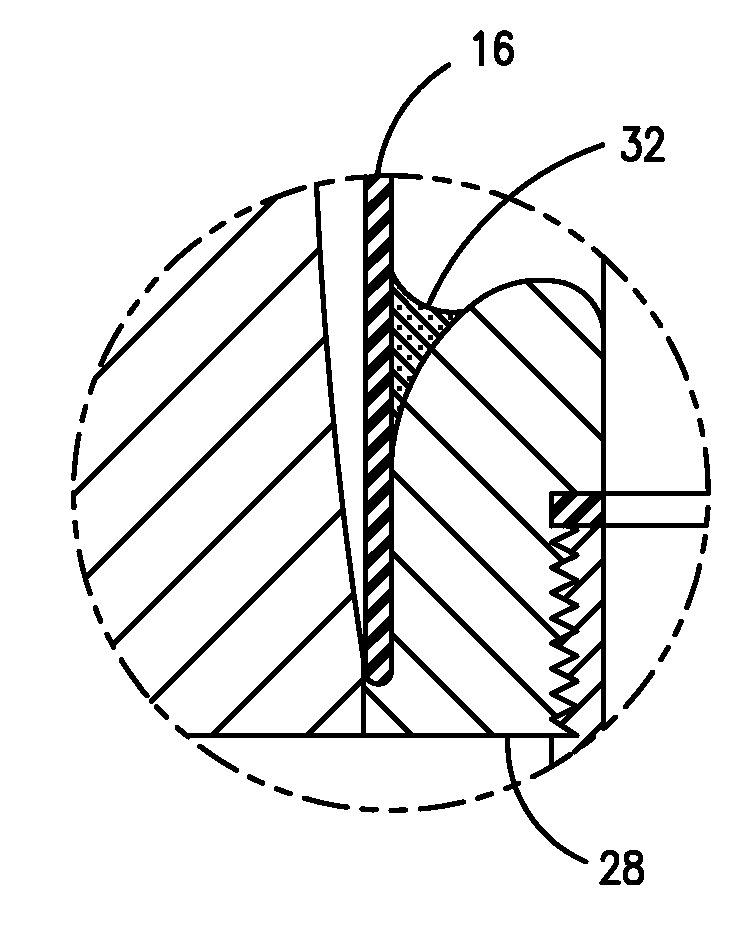

Negative pressure supply apparatus

InactiveUS20050095142A1Low production costReduce sizing costsDetection of fluid at leakage pointCircuit elementsReciprocating motionEngineering

When coils of a vacuum pump unit are excited by energization, a piston equipped with magnets reciprocates in a cylinder. Thus, air is sucked in from an outlet passage of a diffuser of an ejector, and air discharged from the vacuum pump unit is supplied to an inlet of a nozzle of the ejector. Consequently, a fast jet occurs in a throat portion of the nozzle, and a negative pressure of higher degree of vacuum than that of the suction negative pressure of the vacuum pump unit is produced at a vacuum port of the ejector. The negative pressure is supplied from a negative pressure supply port. The ejector can supply a negative pressure of high degree of vacuum while reducing the load on the vacuum pump unit.

Owner:HITACHI LTD

Process for foaming a wet hydrocarbon composition

A composition of a wet hydrocarbon foaming agent including a siloxane can foam wet hydrocarbons. The siloxane wet hydrocarbon foaming agent advantageously foams hydrocarbons that have as little as 5 percent water present and those hydrocarbons having as much as 90 percent water present. The wet hydrocarbon foaming agent can be used in oil and gas production for gas lift and foam blocking applications. The foaming agent can also be used for clearing hydrocarbons from pipelines and other vessels used for transporting oil and gas.

Owner:BAKER HUGHES INC

Method for recovering oil from a gas-lifted oil well penetrating a subterranean oil-bearing formation

In a method for optimizing gas lift operations in the production of crude oil, a surfactant is injected with the lift gas into the an oil well such that the surface tension between the lift gas and the formation fluid being produced is reduced and / or a lift gas-formation fluid foam is formed. The reduction in surface tension and / or foam formation increases the efficiency of the lift gas for lifting the formation fluid to the surface. The surfactant is selected to minimize corrosion. The surfactants consist essentially of sultaines, hydroxy sultaines, and their salts. It is emphasized that this abstract is provided to comply with the rules requiring an abstract which will allow a searcher or other reader to quickly ascertain the subject matter of the technical disclosure. It is submitted with the understanding that it will not be used to interpret or limit the scope or meaning of the claims. 37 CFR 1.72(b).

Owner:BAKER HUGHES INC

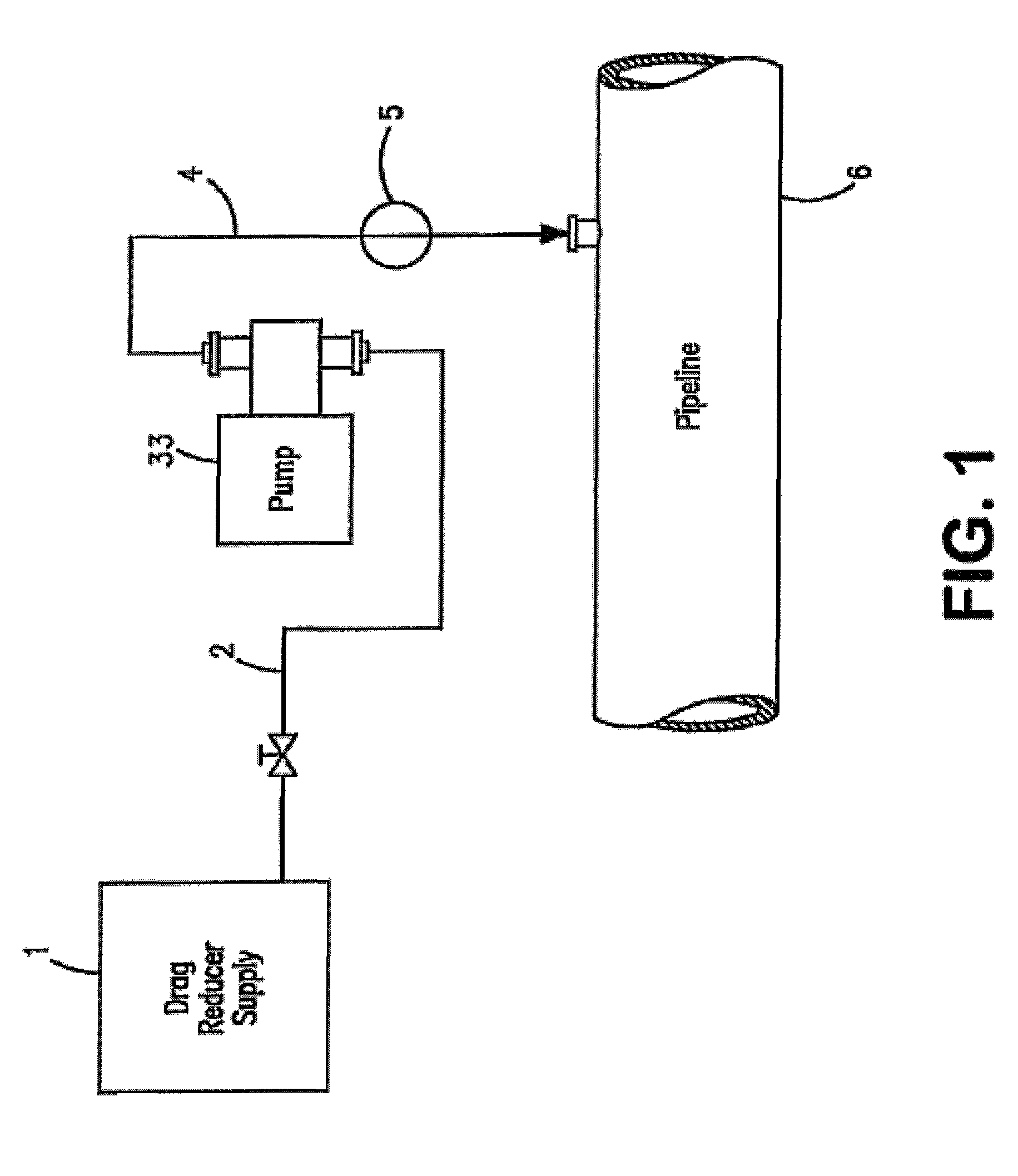

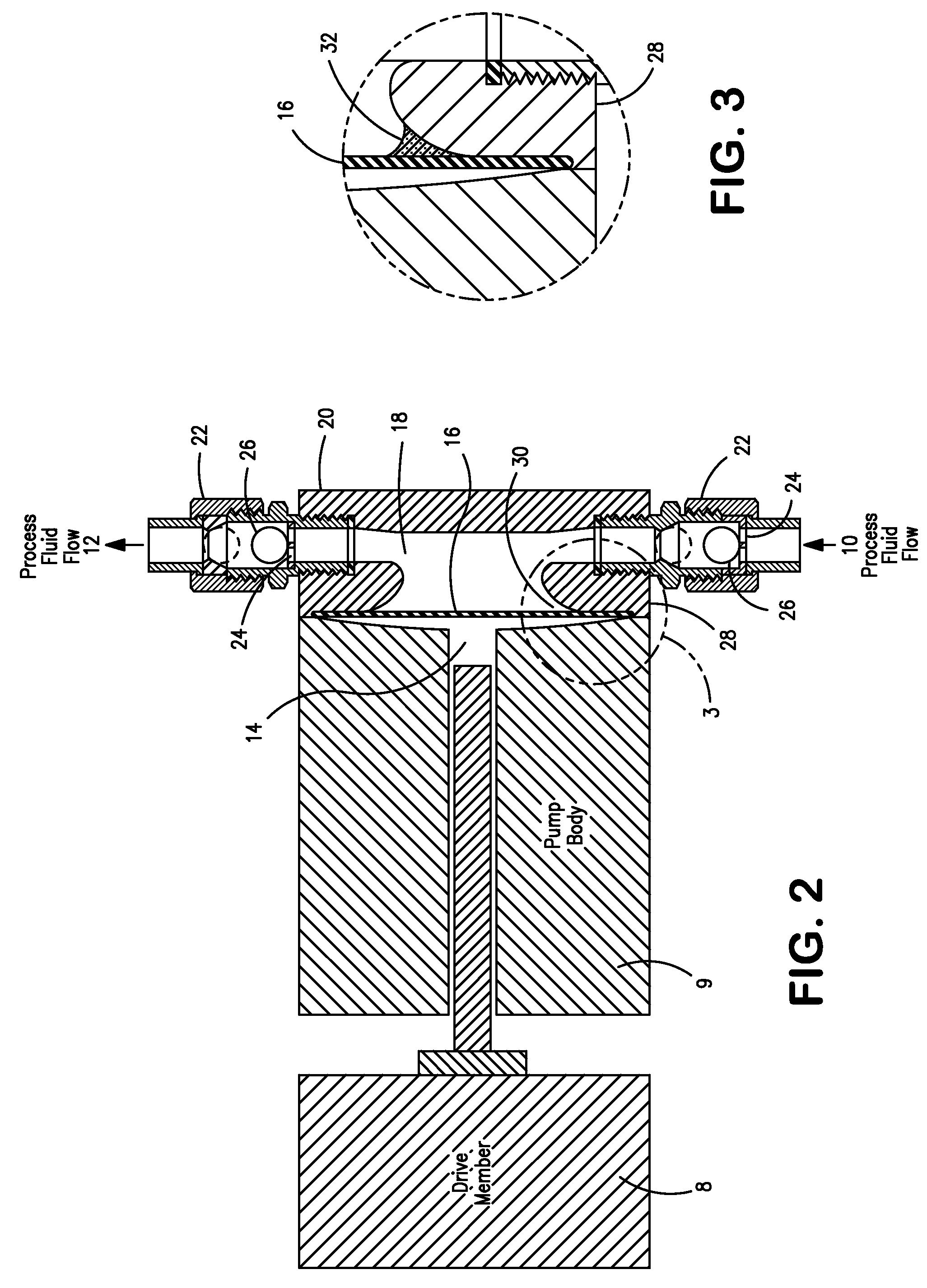

Diaphragm pumps and transporting drag reducers

ActiveUS8215930B2Lower overall pressure dropFlexible wall reciprocating enginesEngine diaphragmsDiaphragm pumpReducer

An apparatus for a diaphragm pump and a method for transporting at least a portion of a latex and / or a latex drag reducer through a diaphragm pump are disclosed. A method for reducing the pressure drop associated with flowing a hydrocarbon-containing fluid through a pipeline also is disclosed.

Owner:LIQUIDPOWER SPECIALTY PROD INC

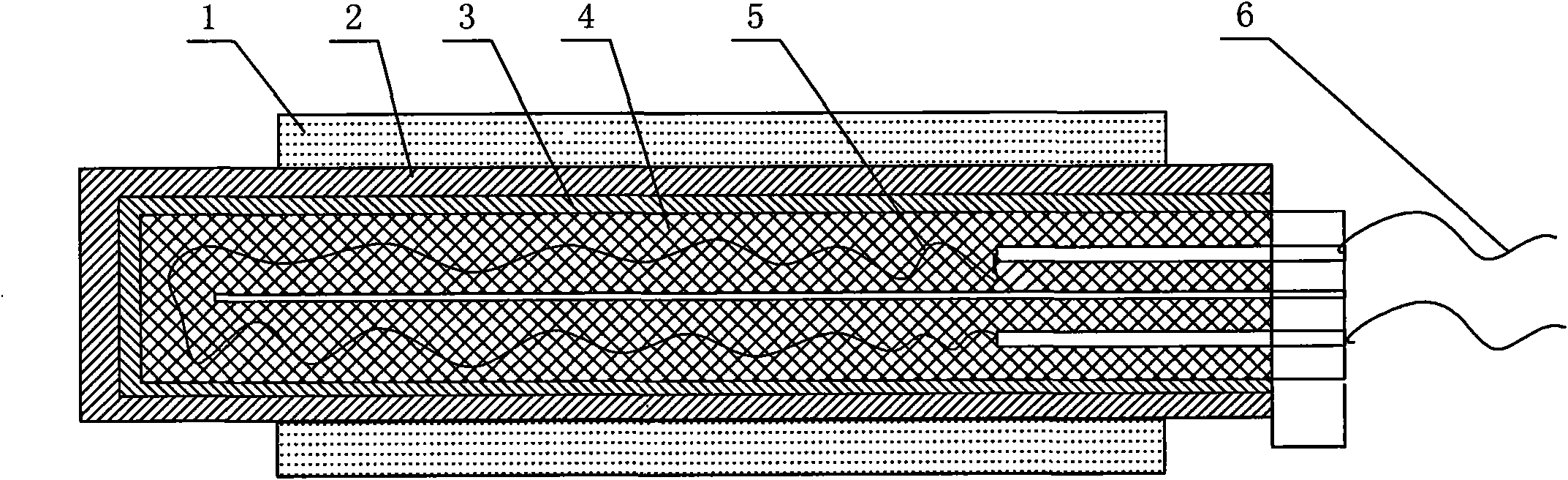

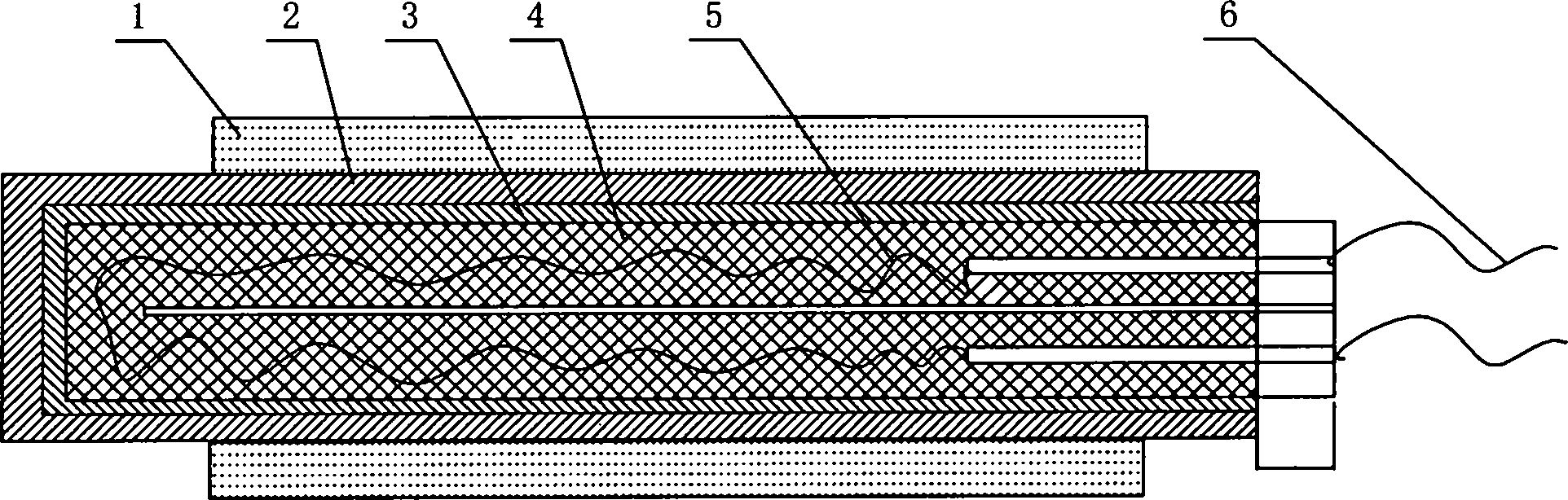

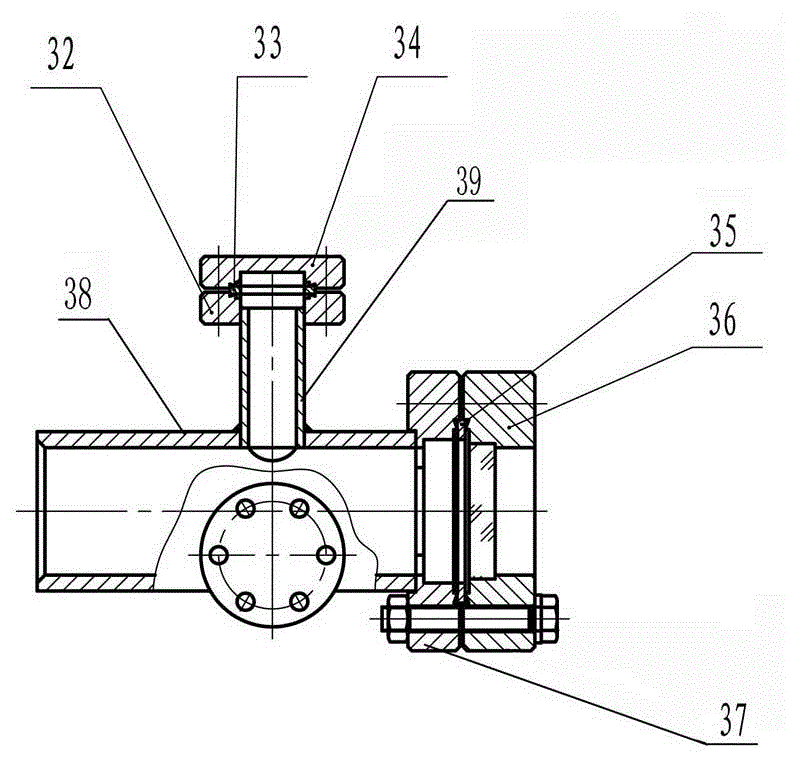

Heater of oil diffusion pump

InactiveCN102378420AExtend working lifeIncrease temperatureMachines/enginesHeating element shapesEngineeringDiffusion pump

The invention relates to a heater of an oil diffusion pump. The heater comprises a casing and an electric heating tube, wherein the electric heating tube is arranged in the casing, closely contacts the casting, extends out of the casting and is externally connected with a power cord. The invention provides an electric heating device of a high vacuum diffusion pump, which can effectively heat the diffusion pump at a high efficiency in a centralized mode and is convenient to maintain.

Owner:扬州市中日电器设备有限公司

Motivating fluid vacuum pump

InactiveUS20080075613A1Achieve speedIncrease the differential pressureFlexible member pumpsJet pumpsPump chamberParallel plate

The invention relates to a driving agent vacuum pump used in microsystems technology, comprising an evaporator chamber and a pump chamber that are separated by a jet arrangement. The design of the driving agent vacuum pump is improved by: a planar arrangement of at least one jet, which extends vertically in depth and which is situated between two, in particular, parallel plates, these plates closing the evaporator chamber and the pump chamber; an opening in the pump chamber, preferably above the jet arrangement, for drawing in a medium to be pumped, and; an opening for expelling a preferably compressed gas underneath the jet arrangement.

Owner:BAYER TECH SERVICES GMBH

Device and Method for Generating Vacuum for Vacuum Cementing Systems

ActiveUS20130115111A1Easy to handleEconomically manufacturedTransportation and packagingMixersSpray nozzleVacuum cementing

A device is provided for generating a vacuum for a vacuum cementing device, the device including a channel and a connector for a gas cartridge. The connector has an opener for opening the gas cartridge, and connects the gas cartridge to the channel in a pressure-tight manner, such that gas from the opened gas cartridge flows along the channel to the surroundings of the device. The channel includes at least one T-piece, provided as Venturi nozzle, having a vacuum connector for the vacuum cementing device, such that gas from the opened gas cartridge flowing through the channel generates a negative pressure at the vacuum connector. A method is also provided including steps of opening a gas cartridge, flowing gas from the gas cartridge through a Venturi nozzle, whereby by a negative pressure is generated, and applying the negative pressure to a vacuum cementing system.

Owner:HERAEUS MEDICAL

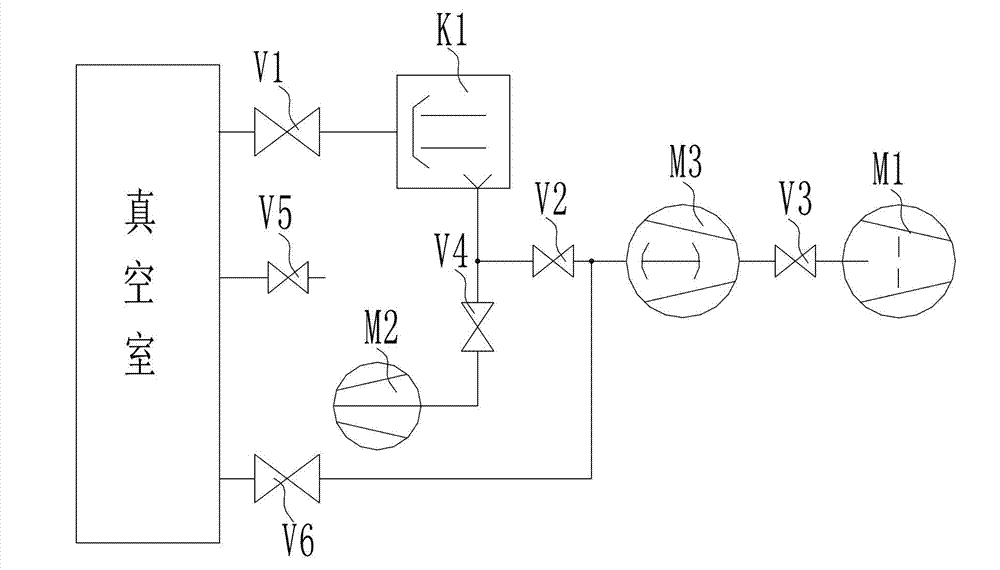

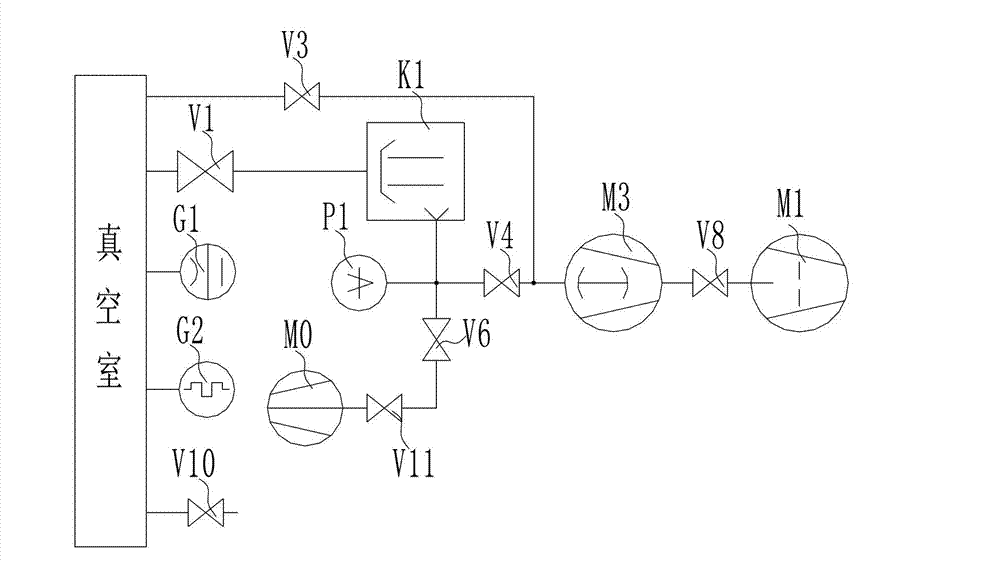

Anti-explosion oil diffusion pump vacuum system and anti-explosion control method thereof

InactiveCN102829004AAvoid explosionGuaranteed reliabilityMachines/enginesDiffusion pumpsReal-time dataControl system

The invention relates to an anti-explosion oil diffusion pump vacuum system and an anti-explosion control method of the vacuum system. The anti-explosion oil diffusion pump vacuum system comprises an oil diffusion pump system, wherein the oil diffusion pump system is provided with an oil diffusion pump, an air extraction opening of the oil diffusion pump is communicated with an air outlet of a vacuum chamber through a pipeline; the anti-explosion oil diffusion pump vacuum system further comprises a control system; the control system comprises a pressure detecting device which is arranged at a front-stage air exhaust pipeline of the oil diffusion pump, a temperature measuring device which is arranged inside the oil diffusion pump and which is used for detecting the oil temperature in real time, and a pressure measuring device for measuring the pressure inside the vacuum chamber; the control system is provided with a critical pressure Pq and an anti-explosion pressure Pfb; and the opening and closing of pump packages and valve groups in the oil diffusion pump system are controlled by the control system by acquiring real-time data measured by the pressure detecting device, the temperature measuring device and the pressure measuring device. According to the vacuum system, the oil temperature, the front stage pressure and the pressure of the vacuum chamber are monitored in real time through the control system, and are compared with the set critical pressure and the anti-explosion pressure, and corresponding measures are taken if a danger is detected, so that the oil diffusion pump is prevented against explosion.

Owner:常州大成绿色镀膜科技有限公司 +2

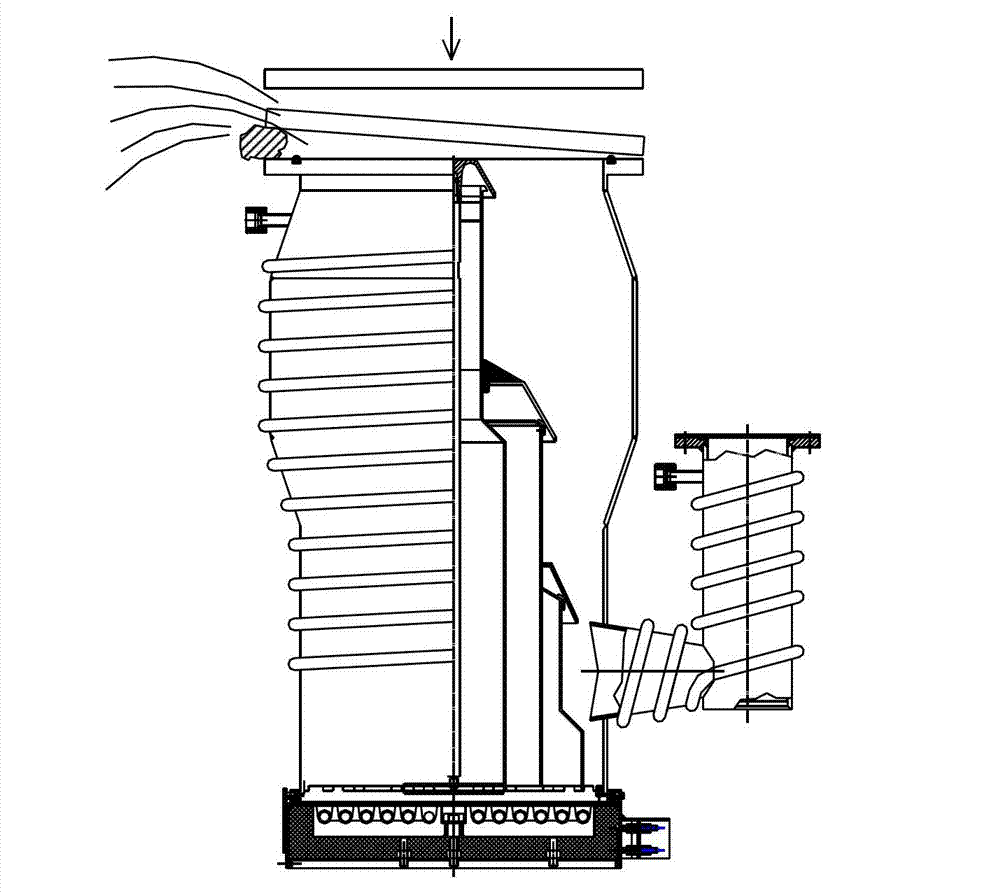

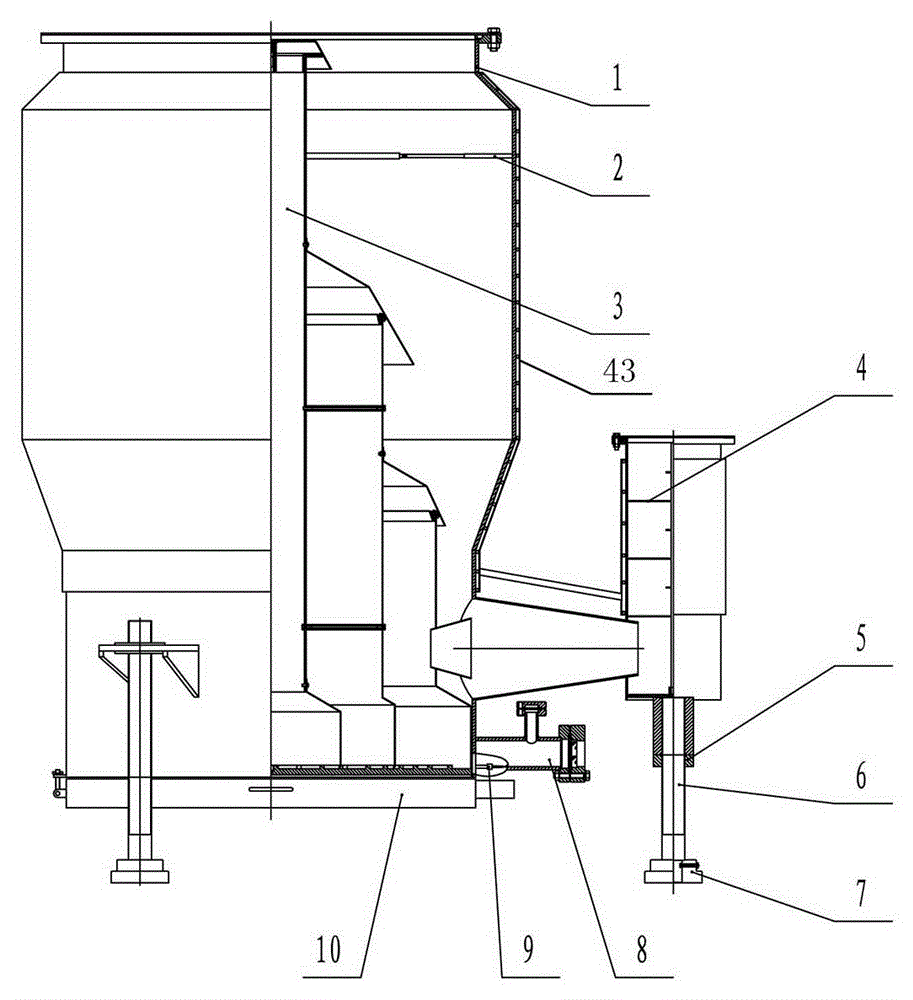

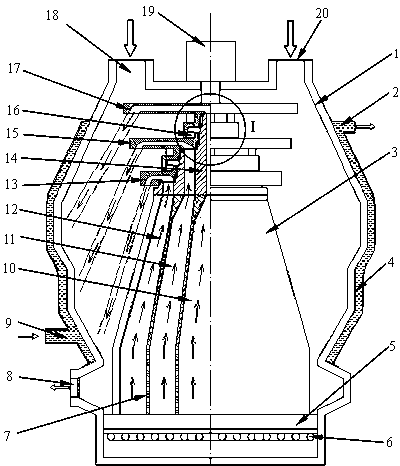

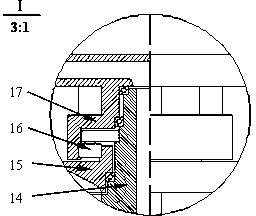

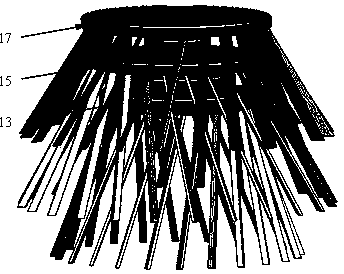

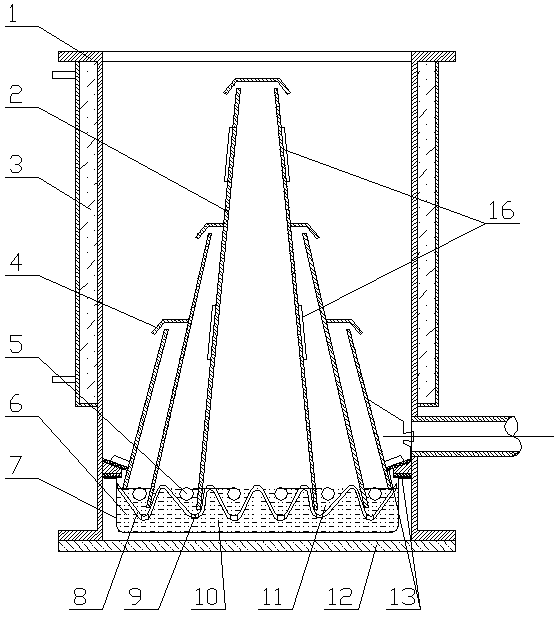

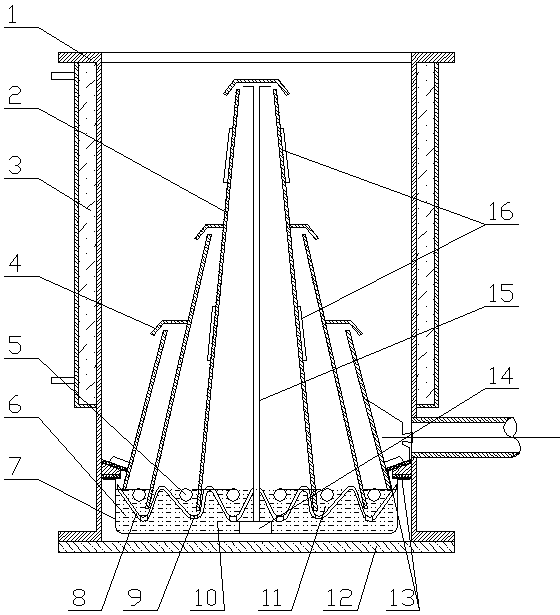

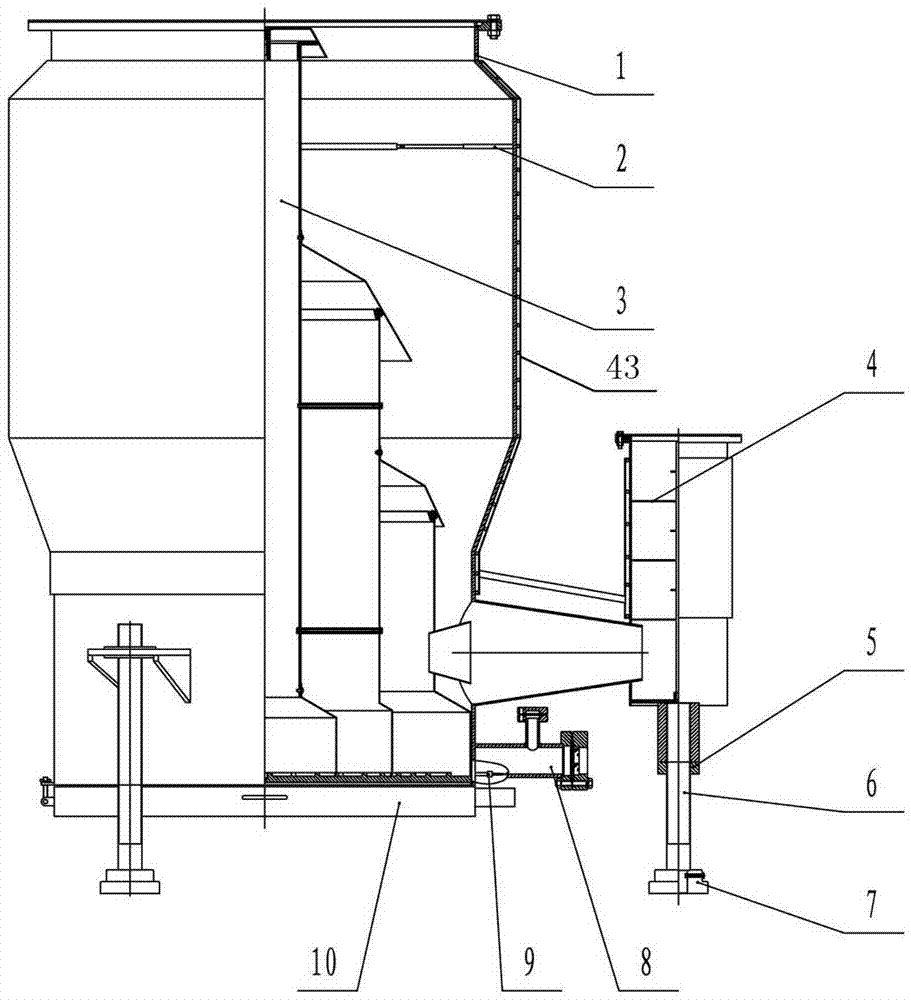

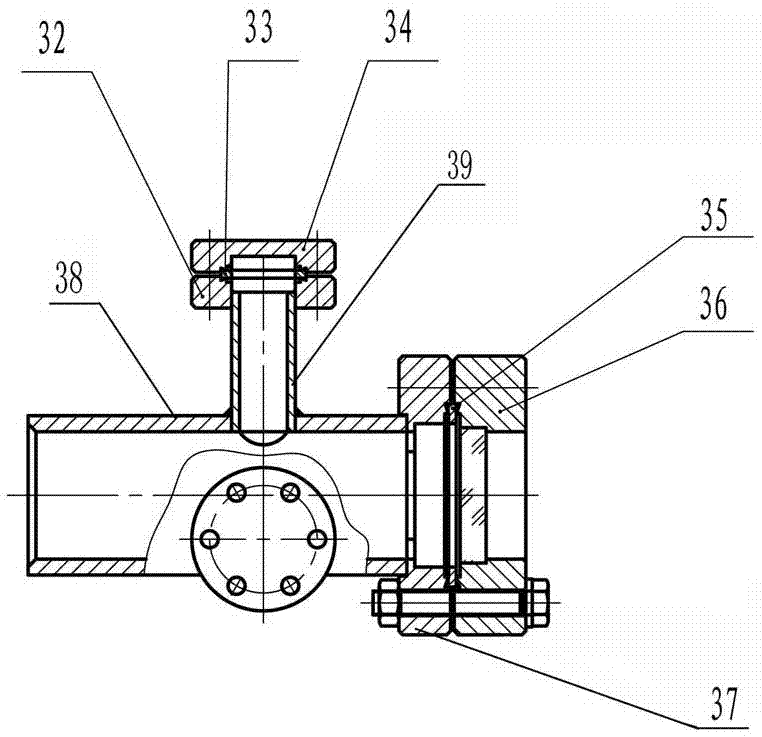

Large-caliber high vacuum oil diffusion pump

ActiveCN104989679ACompact structureShort heating timeMachines/enginesDiffusion pumpsElectricityCore component

The invention discloses a diffusion pump, and particularly relates to a large-caliber high vacuum oil diffusion pump, which is suitable for a vacuum furnace and a vacuum coating machine. The large-caliber high vacuum oil diffusion pump comprises a pump body, and a pump core component arranged in the pump body, wherein a heater is arranged at the bottom of the pump body; an oil stop device is arranged in an exhaust port of the pump body; the pump body adopts a convex cavity structure; the pump core component is vertically mounted in a center oil tank in the pump body, and is formed into an integral structure by a first-stage guide pipe, a second-stage guide pipe and a third-stage guide pipe arranged in sequence from inside to outside; umbrella cap-shaped diffusion nozzles are respectively arranged at the upper parts of all the guide pipes; a spraying nozzle is vertically welded at the bottom of the third-stage guide pipe; the first-stage guide pipe is higher than the second-stage guide pipe; and the second-stage guide pipe is higher than the third-stage guide pipe. The large-caliber high vacuum oil diffusion pump has the characteristics of large caliber, high limit vacuum degree, high pumping rate, low oil return rate and low electricity consumption.

Owner:LIAONING ZHENLONG VACUUM EQUIP MFG

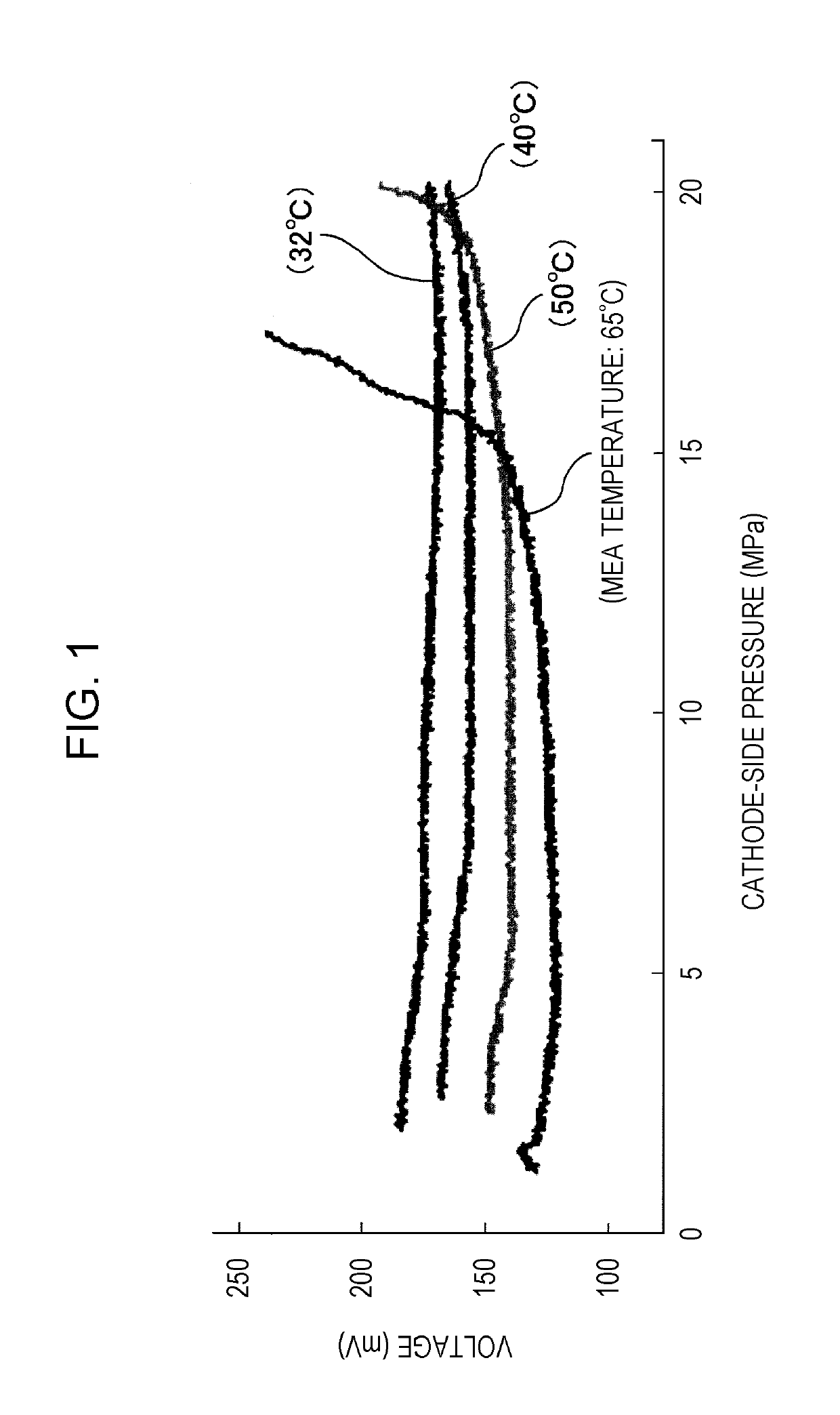

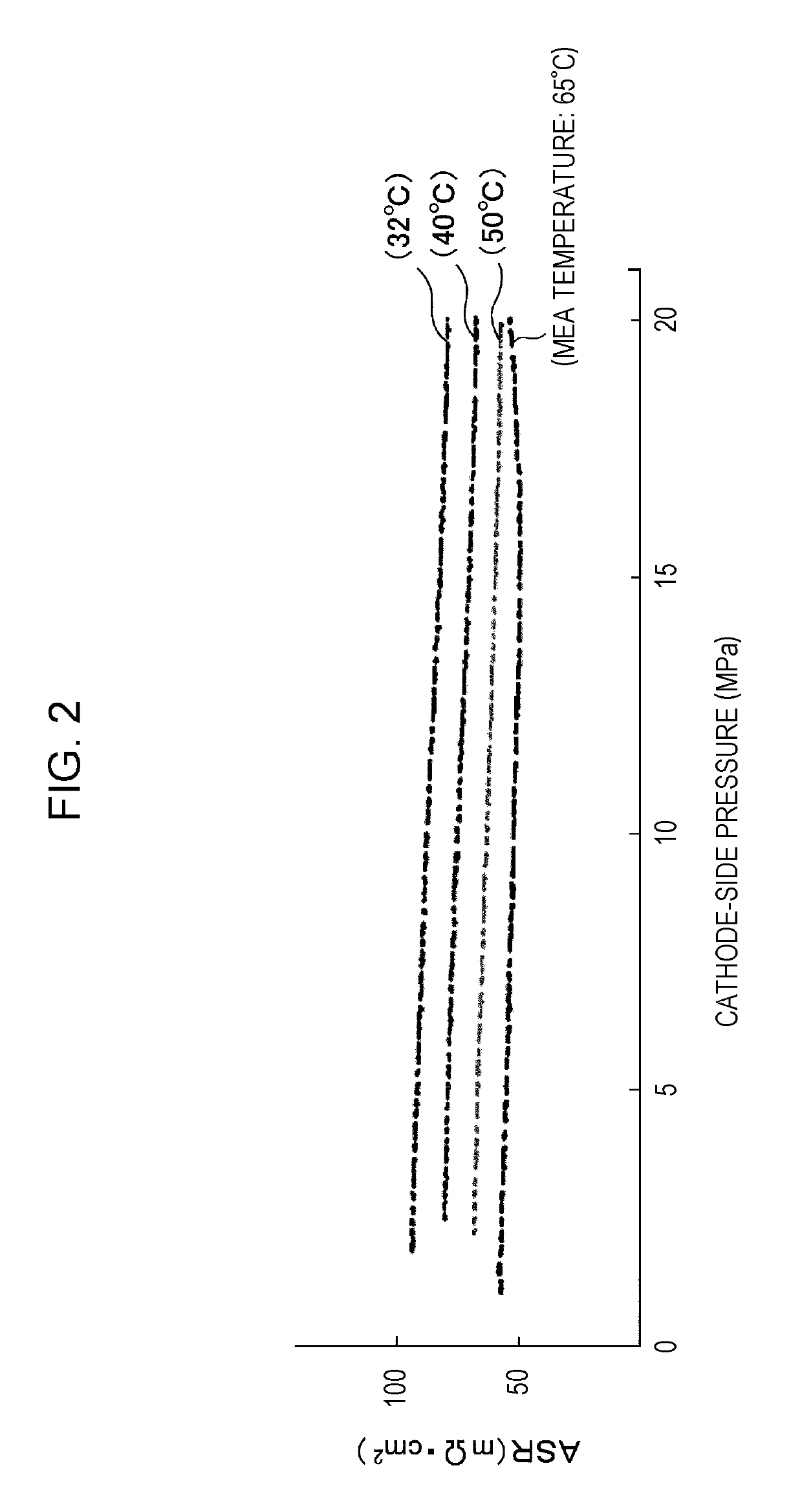

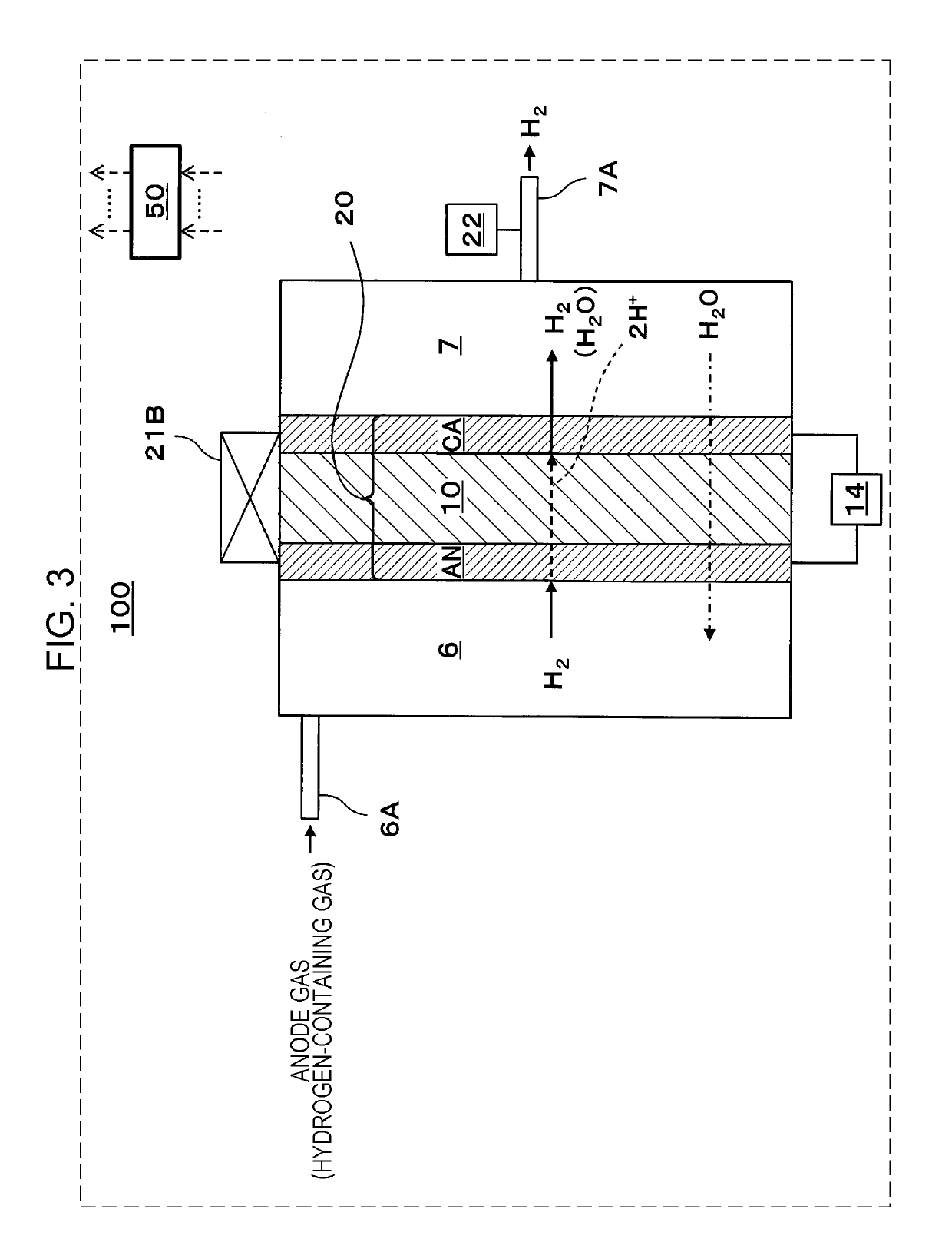

Electrochemical hydrogen pump and method for operating electrochemical hydrogen pump

ActiveUS20190316603A1Improve hydrogen efficiencyImprove efficiencyCellsDispersed particle separationHydrogenElectrical battery

An electrochemical hydrogen pump includes: a cell including a proton conductive electrolyte membrane having a first main surface and a second main surface, a cathode disposed on the first main surface of the proton conductive electrolyte membrane, and an anode disposed on the second main surface of the proton conductive electrolyte membrane; a voltage applier that applies a voltage between the anode and the cathode; a cooler that cools the cell; and a controller that controls the cooler to increase an amount of cooling per unit time of the cell when a pressure of a cathode gas flow path on the cathode increases.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

Rotation type vacuum diffusion pump

InactiveCN103742456AIncrease pumping speedIncreased air molecular weightMachines/enginesDiffusion pumpsRotation velocityEvaporation

The invention relates to the field of vacuum pumps, in particular to a rotation type vacuum diffusion pump. The diffusion pump achieves traction and compression of air with rotation type movement by adopting multiple levels of high-velocity vapor steam with each level containing multiple pieces of slice-shaped high-velocity vapor steam, and therefore the vacuum degree is obtained. In addition, an evaporation oil cavity is in a cone shape, by designing the sizes of different oil cavity branch layers, a high jetting velocity of oil vapor is obtained at a jetting opening, and meanwhile light fractions of the outer layer gains a higher flow velocity than heavy fractions of the inner layer. The rotation velocities of nozzles of different levels form a velocity gradient from top to bottom, and therefore gas is continuously extruded to the bottom layers of a pump body and discharged by a mechanical pump. Transmission between the nozzles is achieved through planetary gear mechanisms and the nozzles are driven by a motor. The rotation velocities of the nozzles form the velocity gradient from top to bottom, the fusiform pump body is adopted, the length of a jet stream is increased, and therefore the ultimate vacuum is better.

Owner:JIANGSU UNIV

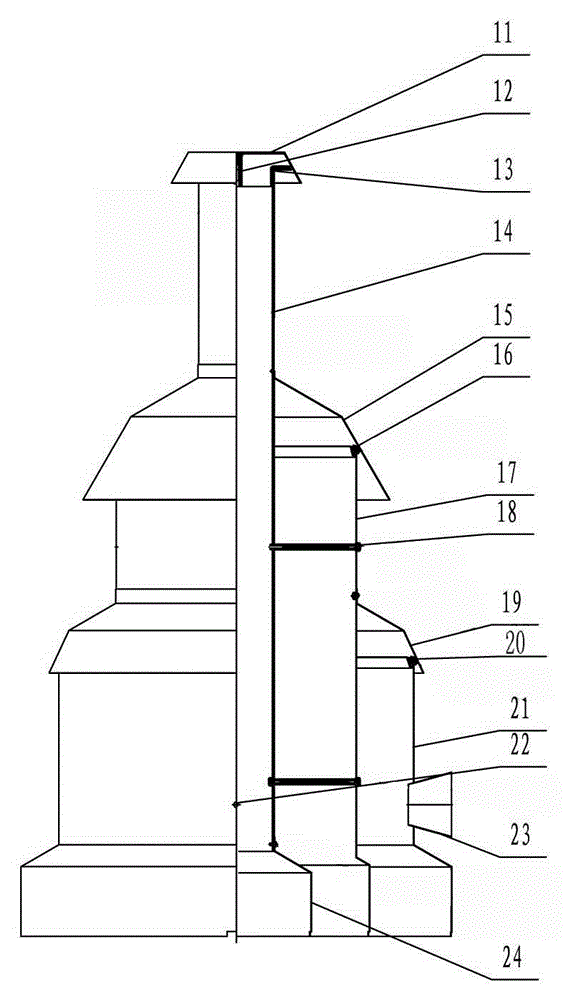

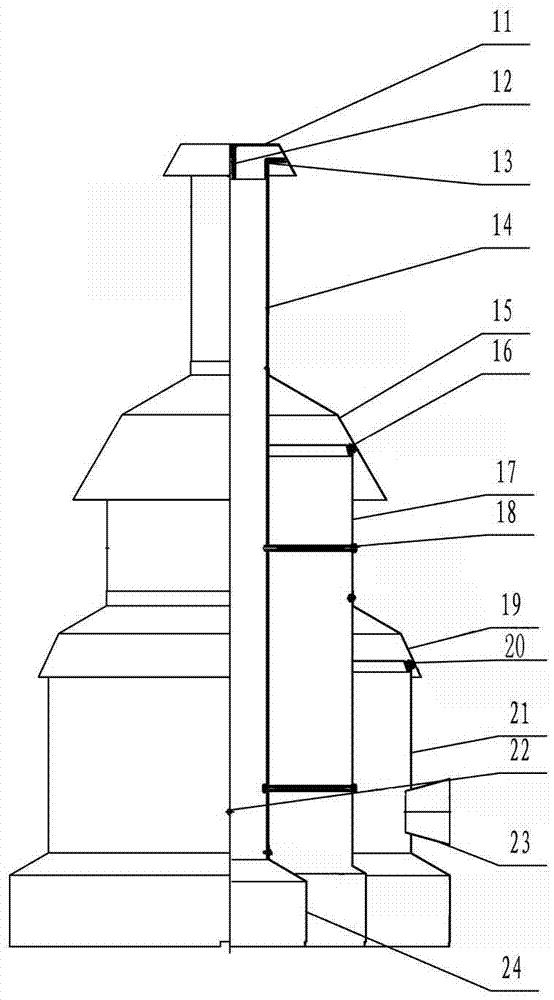

Floating heating type rapid start diffusion pump

ActiveCN108691819AReduce the temperatureTemperature low to highMachines/enginesDiffusion pumpsControl systemEvaporation

The invention provides a floating heating type rapid start diffusion pump. The floating heating type rapid start diffusion pump comprises a pump body, pump oil, a pump core, an evaporation system, a cooling system, an injection system and a control system. A floating heating manner is adopted for the evaporation system. The evaporation system comprises an evaporator, a heater and a temperature measurement and control element. The evaporator is provided with a heating area and an oil storage area, the heating area and the oil storage area are separated through a middle partition plate and communicate with each other through oil holes in the partition plate. The heater is arranged in the heating area and heats the pump oil in the heating area so that the pump oil can be evaporated instantlyto become steam. The heater is fixed to the middle partition plate, the middle partition plate can float on the pump oil, and the heating area can always keep constant and unchanged within a normal pump oil range. A heating device is arranged on or around a steam guide pipe in the injection system, the temperature of the pump core and the steam can be increased, the rate and kinetic energy of theinjected steam are increased, and rapid start of the diffusion pump can be realized.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Large diameter high vacuum oil diffusion pump

ActiveCN104989679BCompact structureShort heating timeMachines/enginesDiffusion pumpsElectricityCore component

Owner:LIAONING ZHENLONG VACUUM EQUIP MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com