Large-caliber high vacuum oil diffusion pump

An oil diffusion pump and high vacuum technology, applied in the field of diffusion pumps, can solve problems such as high power consumption, limited application fields, and low pumping speed, and achieve the effects of reducing power consumption costs, improving service life, and providing contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

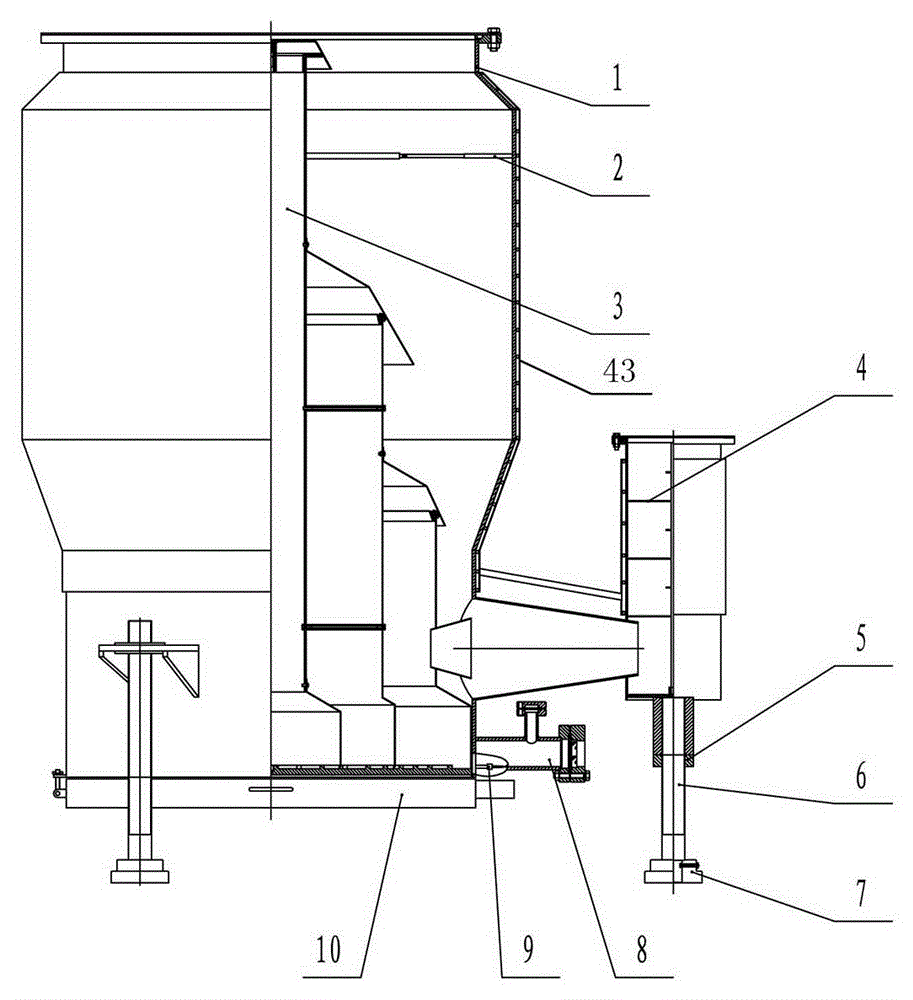

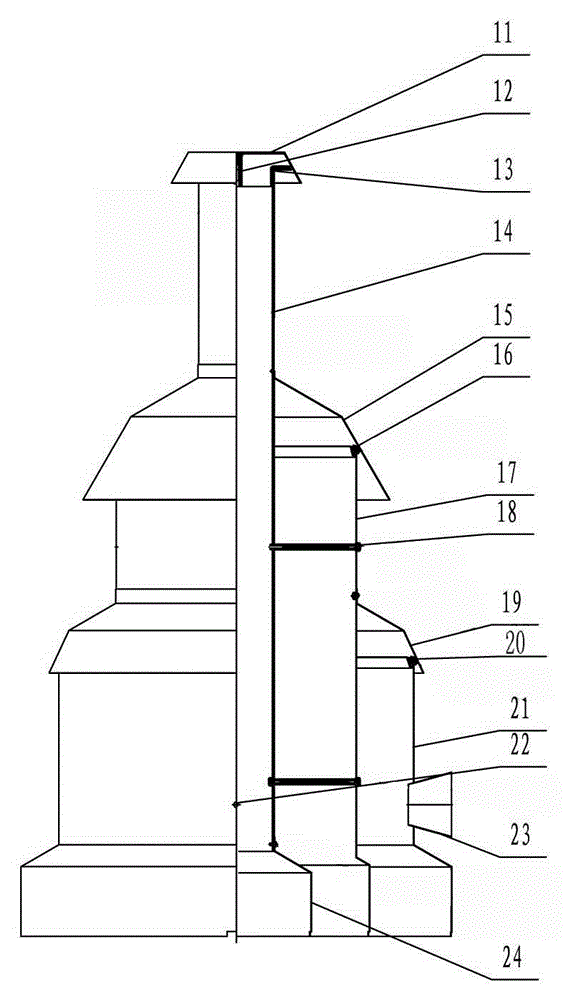

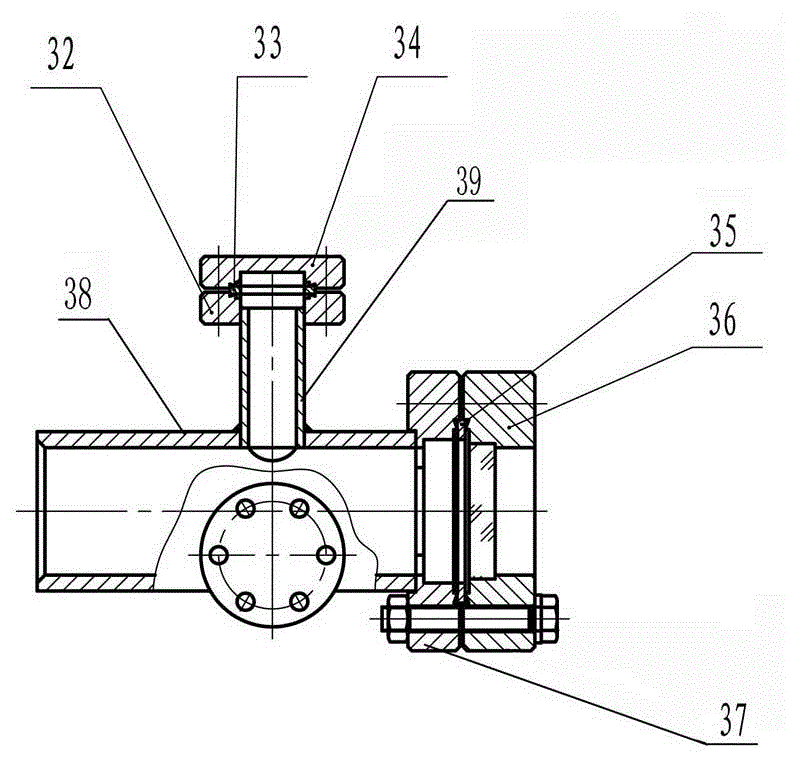

[0033] like figure 1 As shown, the large diameter high vacuum oil diffusion pump of the present invention has the following structure: it includes a pump body 1, a pump core assembly 3 arranged in the pump body 1, a heater 10 arranged at the bottom of the pump body 1, a 1 The oil retaining device 4 in the exhaust port, the upper part of the pump core assembly 3 is supported and fastened by the support frame assembly 2 and the inner wall of the pump body 1, and the pump body 1 is supported on the ground by the lock nut 5, the support rod 6, and the foot seat 7 , The lower part of the pump body 1 is provided with an observation window 8 and a temperature measuring resistance 9.

[0034] The temperature measuring resistor 9 of the pump oil temperature measuring device is installed, and the working temperature of the pump liquid is expressed by the oil temperature digital display meter, which is convenient for observing the working condition of the pump.

[0035] like figure 1 A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com