Patents

Literature

114results about How to "Increase pumping rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

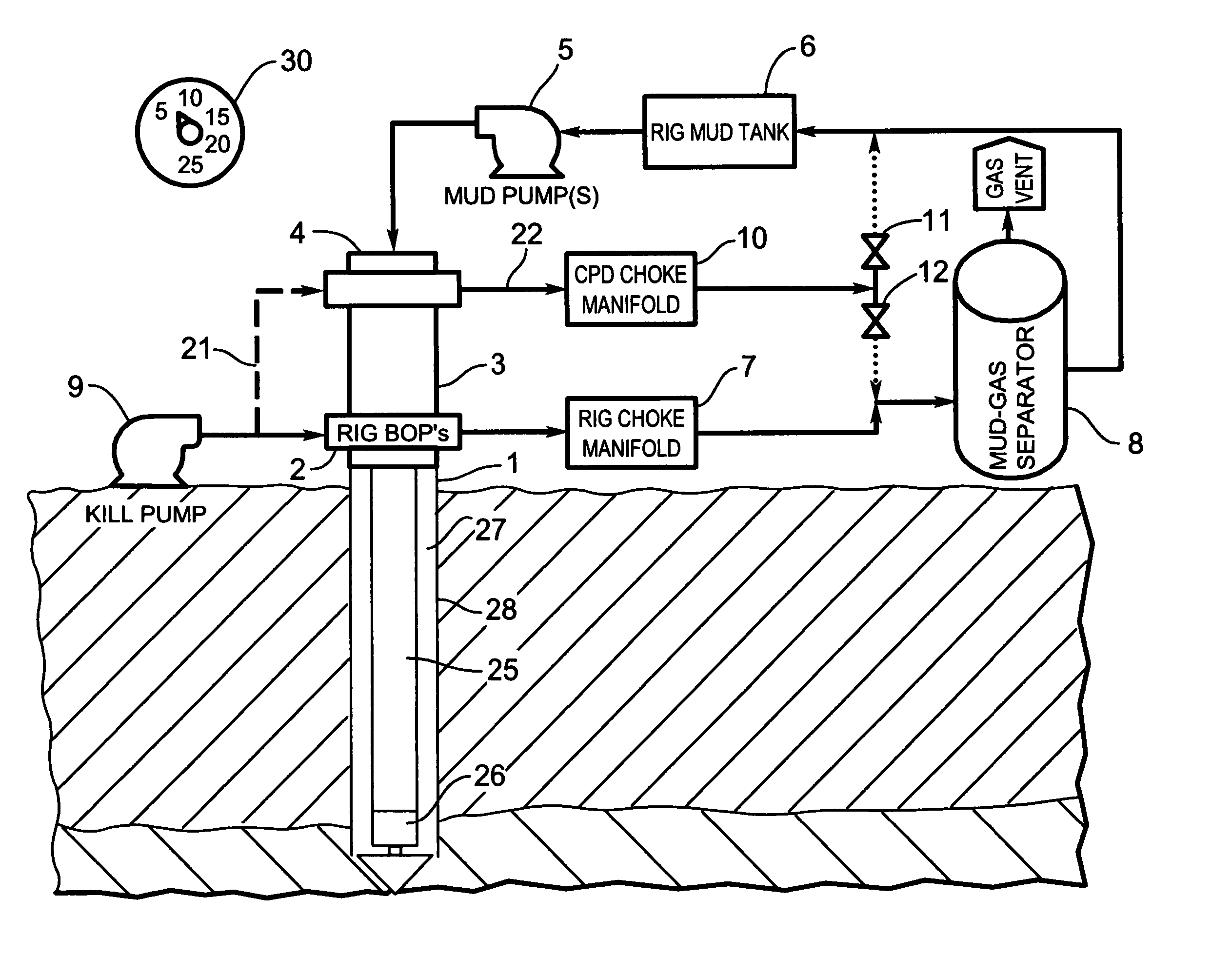

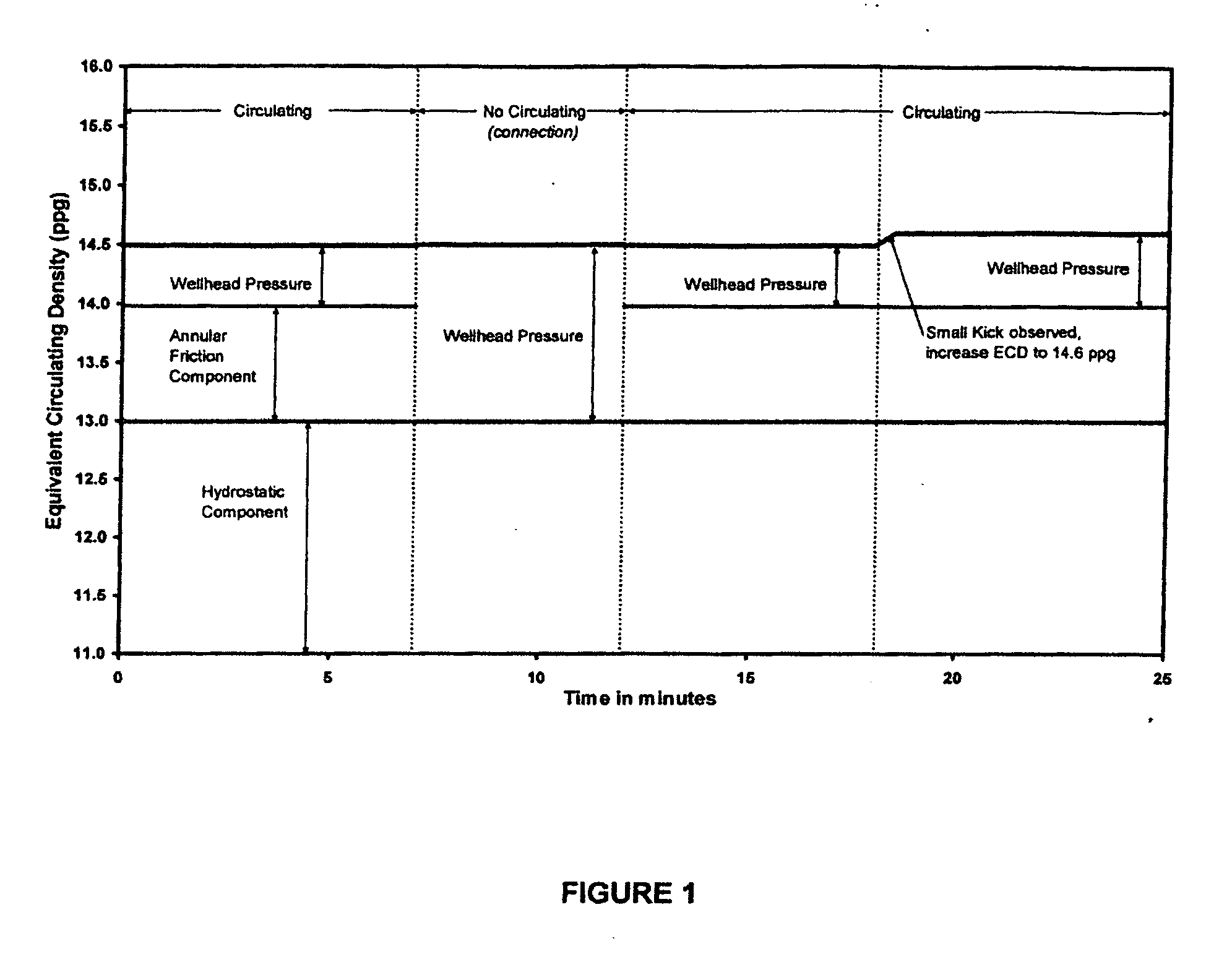

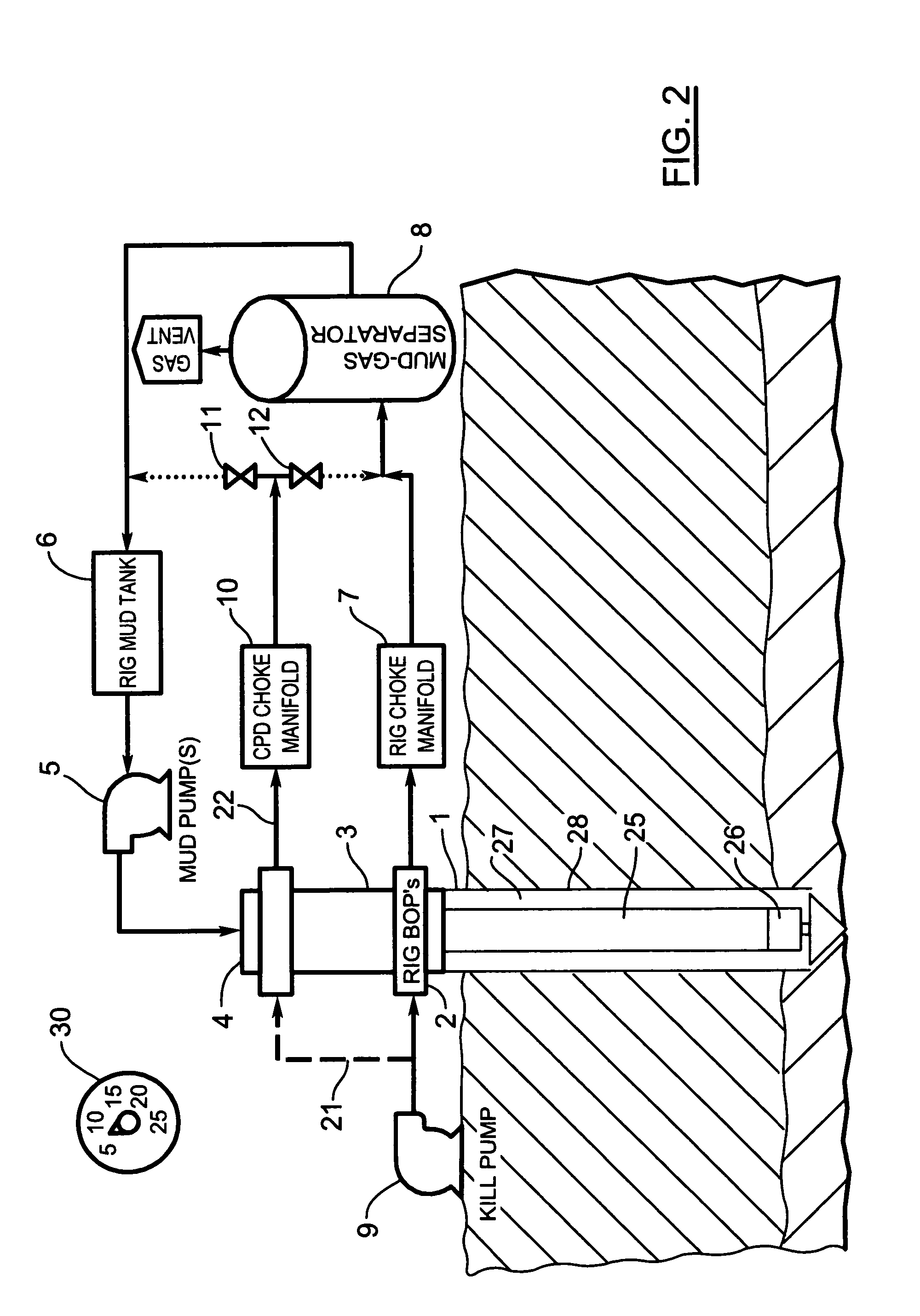

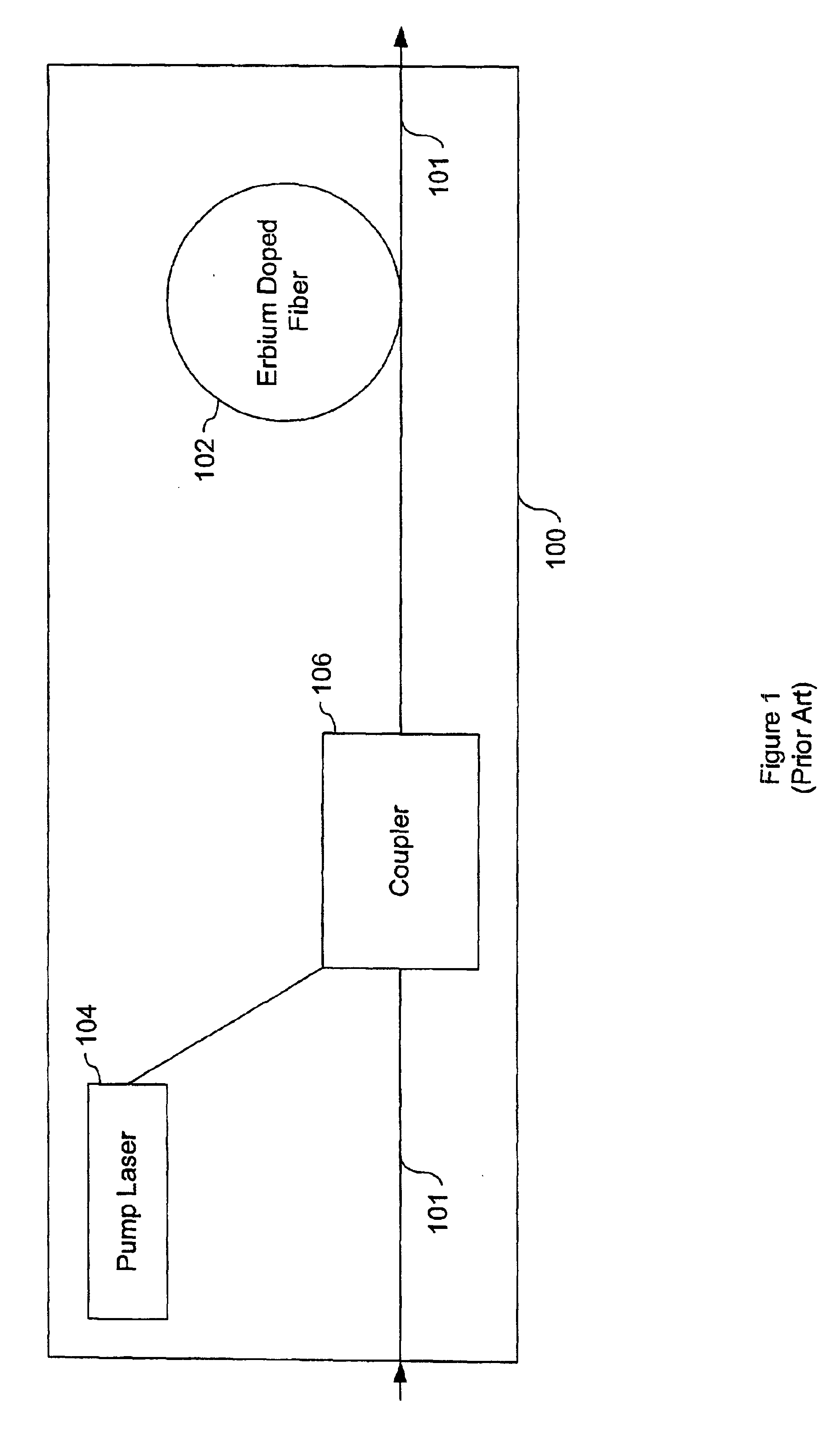

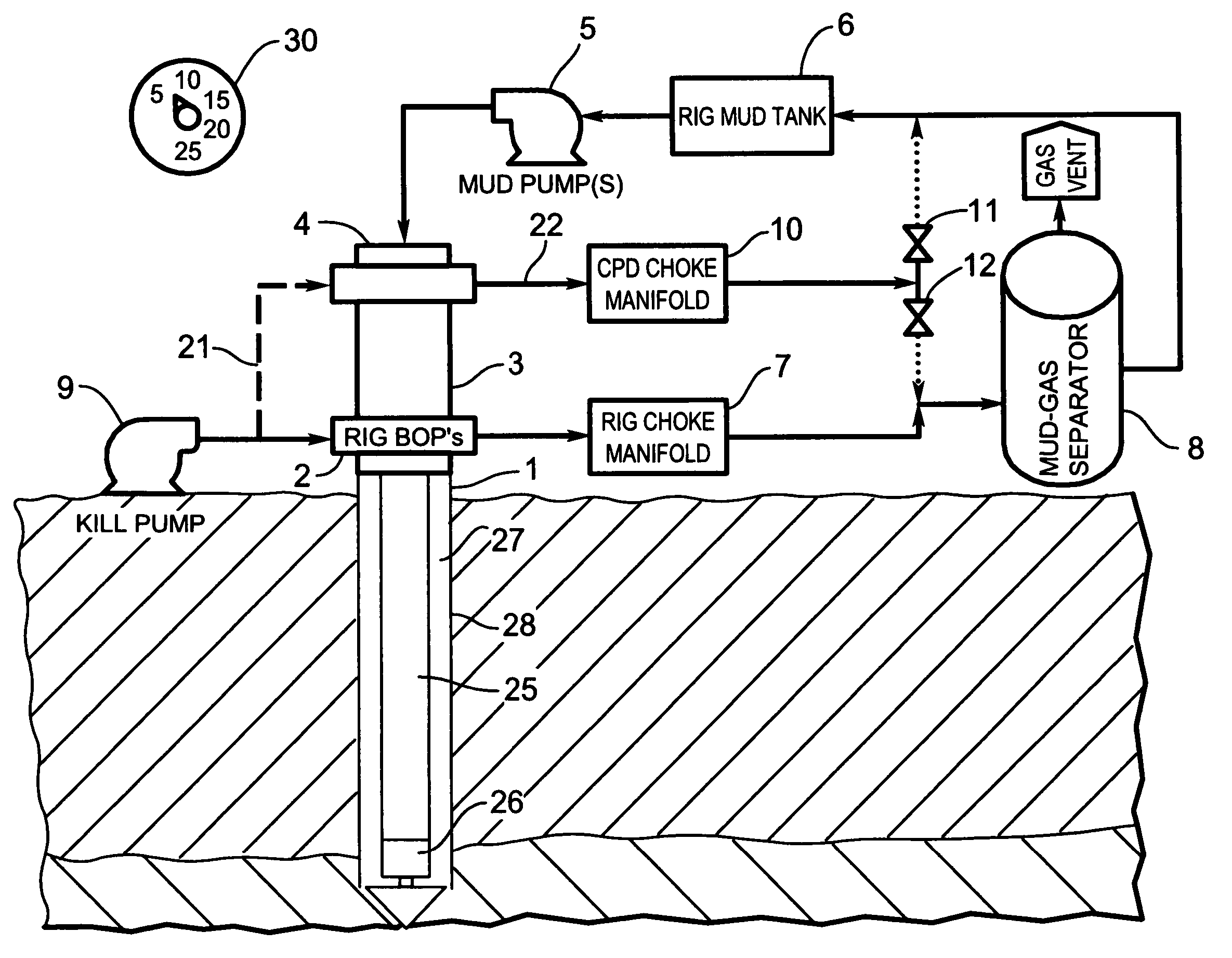

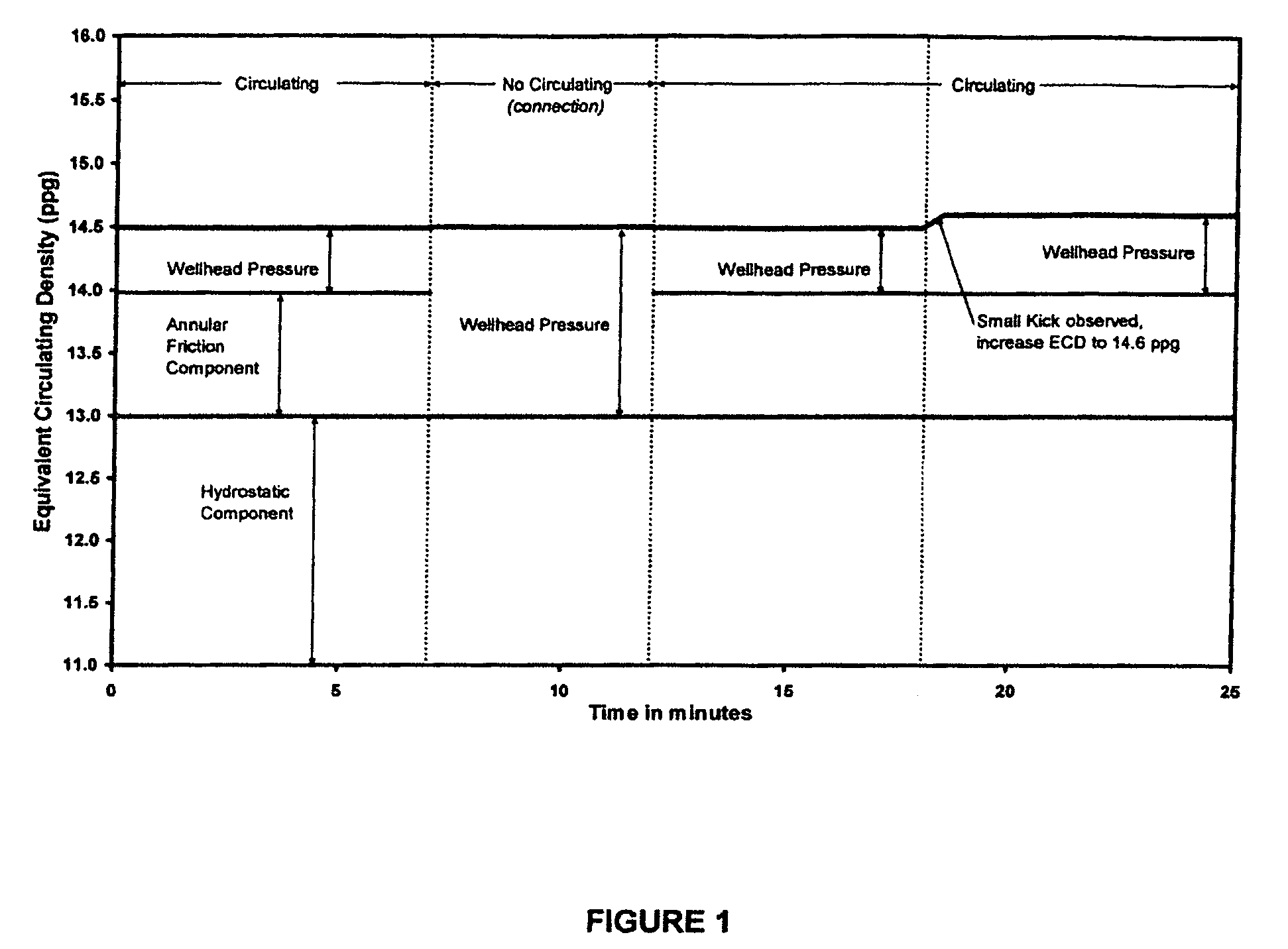

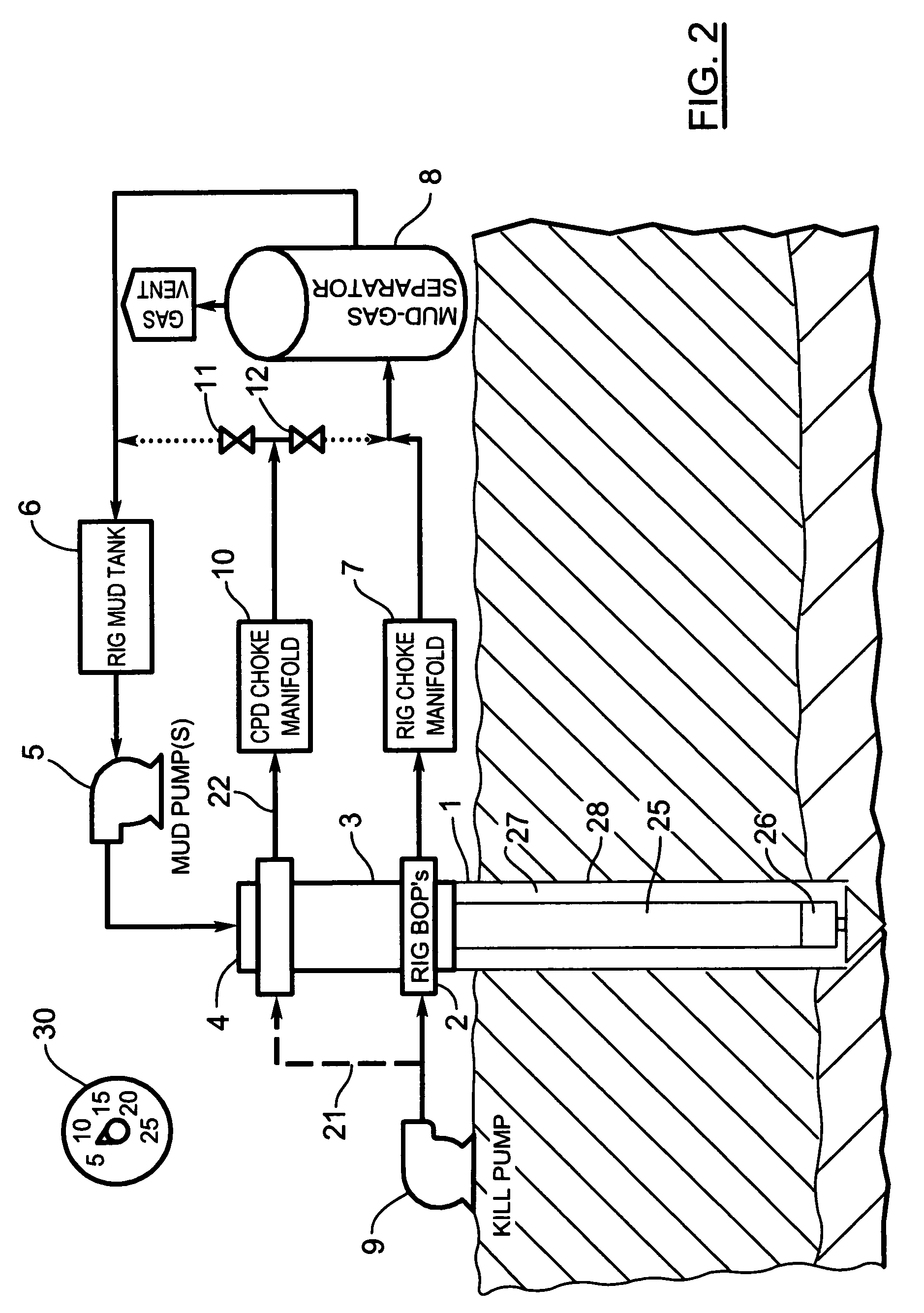

Method of dynamically controlling open hole pressure in a wellbore using wellhead pressure control

ActiveUS20060207795A1Simplified and efficient and relatively inexpensiveIncrease pumping rateFlushingDrilling compositionPressure controlled ventilationThrottle

A method of dynamically controlling open hole pressure within a wellbore having a drill string positioned therein. The method comprising the steps of pumping a fluid down the drill string, into an annulus formed by the drill string and the interior of the wellbore, and then subsequently up the annulus to the surface of the ground; selectively applying wellhead pressure to the annulus through selectively pumping an additional quantity of the fluid or a quantity of a secondary fluid across the annulus; and, controlling the application of wellhead pressure applied to the annulus by controlling one, or both, of (a) the operation of a wellhead pressure control choke, and (b) the flow rate of the additional quantity of fluid or the secondary fluid pumped across the annulus, to thereby maintain open hole pressure within a desired range.

Owner:WEATHERFORD CANADA

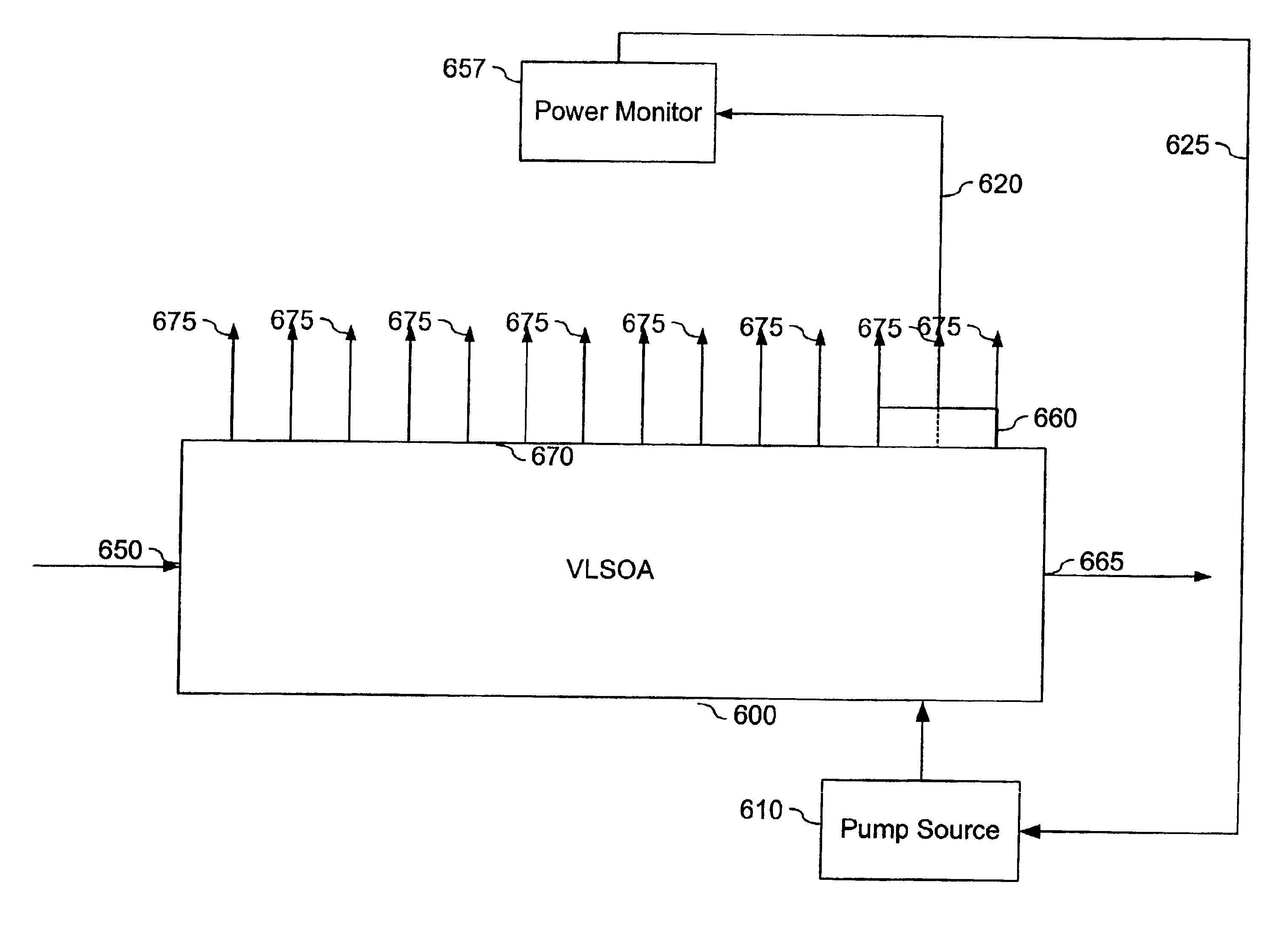

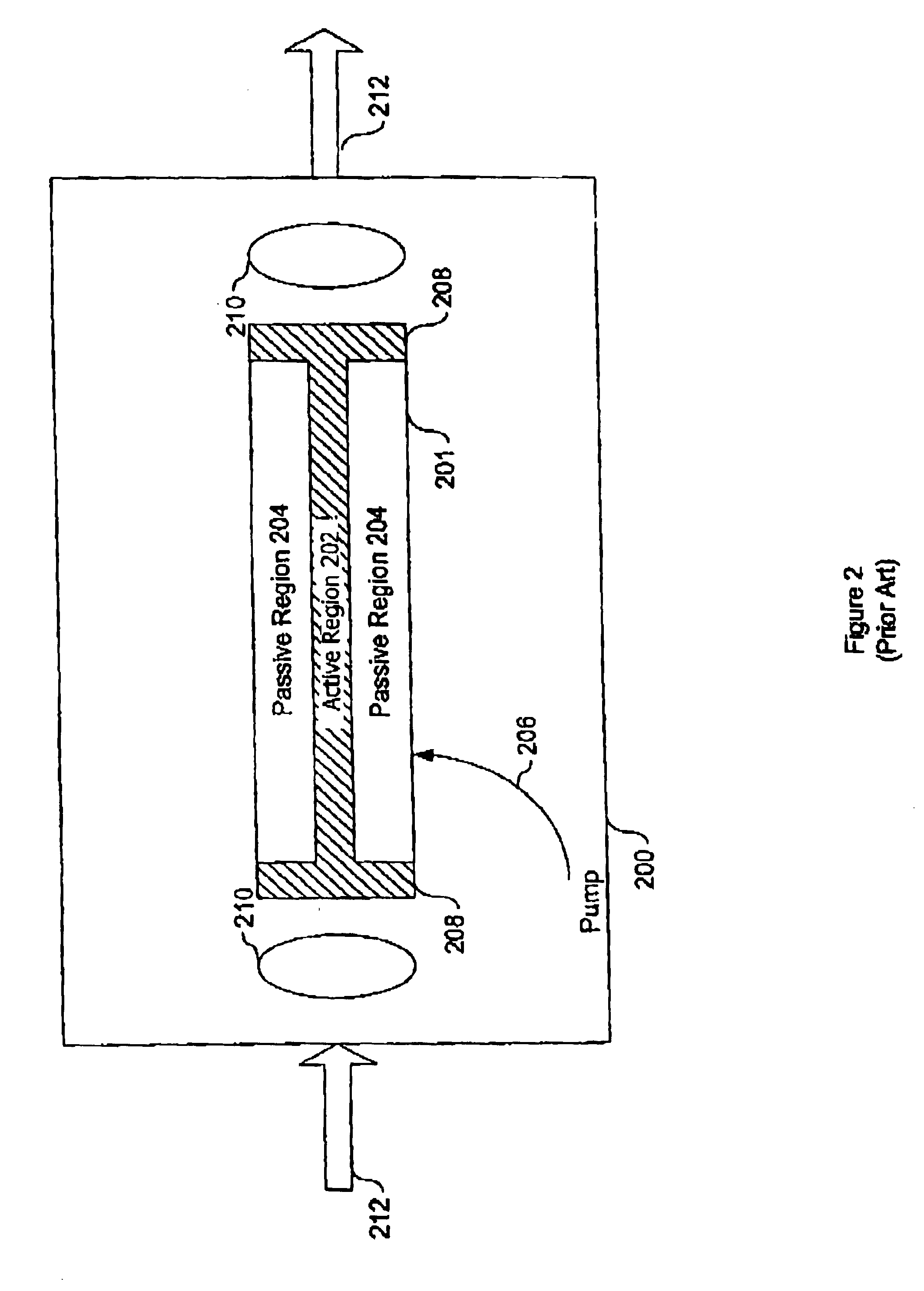

Lasing semiconductor optical amplifier with output power monitor and control

InactiveUS6801555B1Prevent gain saturationDecrease and increase in rateLaser detailsLaser optical resonator constructionElectrical ballastControl system

An optical signal power monitoring and control system is described. The system comprises at least one lasing SOA that receives, amplifies, and outputs the optical signal. During the signal amplification, a ballast laser signal is output through a substrate of the lasing SOA. This ballast laser signal is indicative of the output power of the lasing SOA. At least one detector converts the ballast laser signal to an electrical signal and transmits this electrical signal to a power monitor circuit. Using the electrical signal, the power monitor determines the output power of the lasing SOA. A pump control adjusts the rate at which the lasing SOA is pumped in order to change the saturation level of the lasing SOA and its corresponding power output ceiling. According to one embodiment, the power monitor identifies when the lasing SOA is approaching saturation or is saturated. If the lasing SOA is saturated or approaching saturation, the pump control increases its pumping rate causing the saturation level of the lasing SOA to rise. As a result, the lasing SOA is provided protection from saturation.

Owner:II VI DELAWARE INC

Method of dynamically controlling open hole pressure in a wellbore using wellhead pressure control

ActiveUS7407019B2Simplified and efficient and relatively inexpensiveIncrease pumping rateFlushingDrilling compositionEngineeringMechanics

A method of dynamically controlling open hole pressure within a wellbore having a drill string positioned therein. The method comprising the steps of pumping a fluid down the drill string, into an annulus formed by the drill string and the interior of the wellbore, and then subsequently up the annulus to the surface of the ground; selectively applying wellhead pressure to the annulus through selectively pumping an additional quantity of the fluid or a quantity of a secondary fluid across the annulus; and, controlling the application of wellhead pressure applied to the annulus by controlling one, or both, of (a) the operation of a wellhead pressure control choke, and (b) the flow rate of the additional quantity of fluid or the secondary fluid pumped across the annulus, to thereby maintain open hole pressure within a desired range.

Owner:WEATHERFORD CANADA

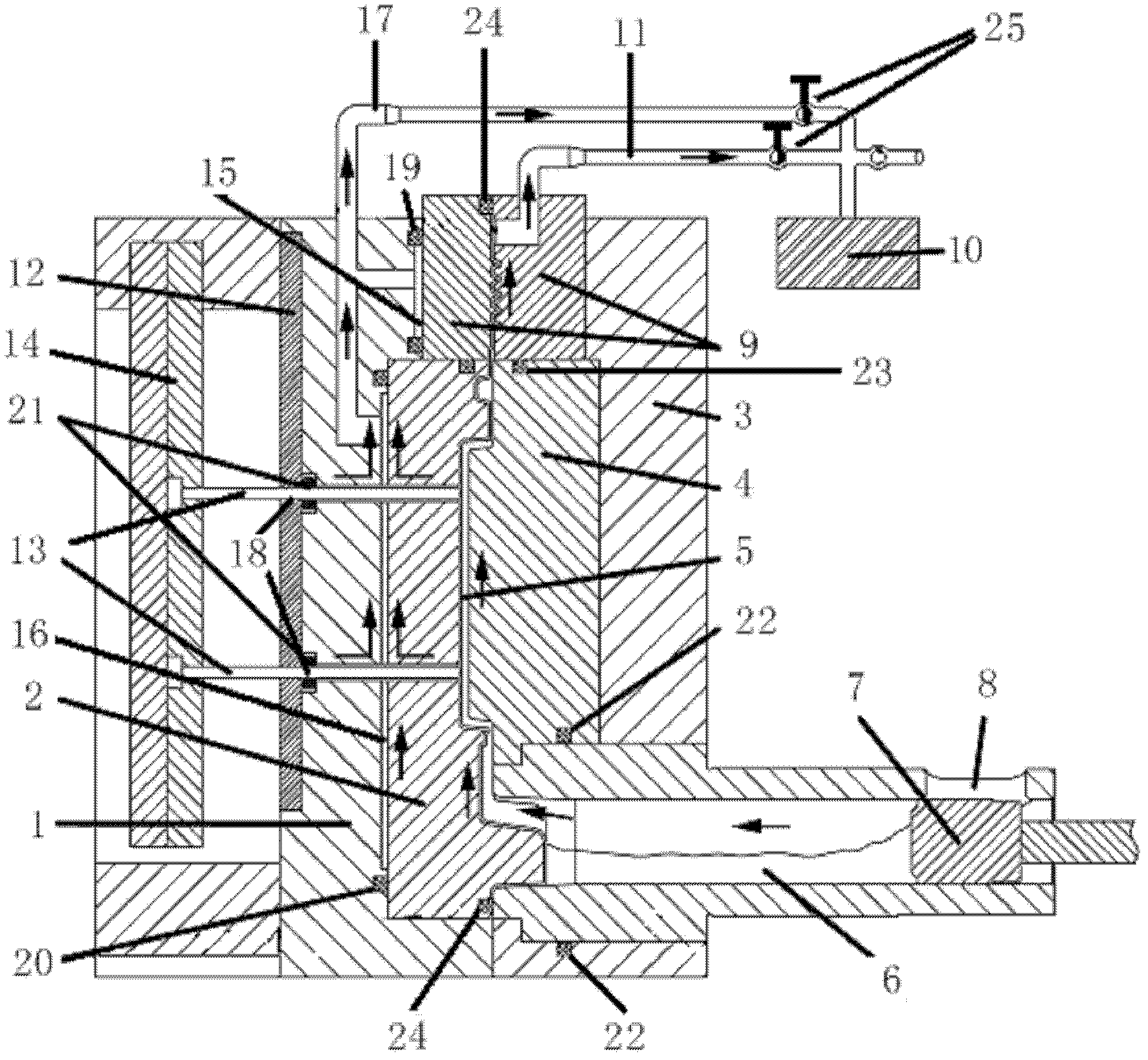

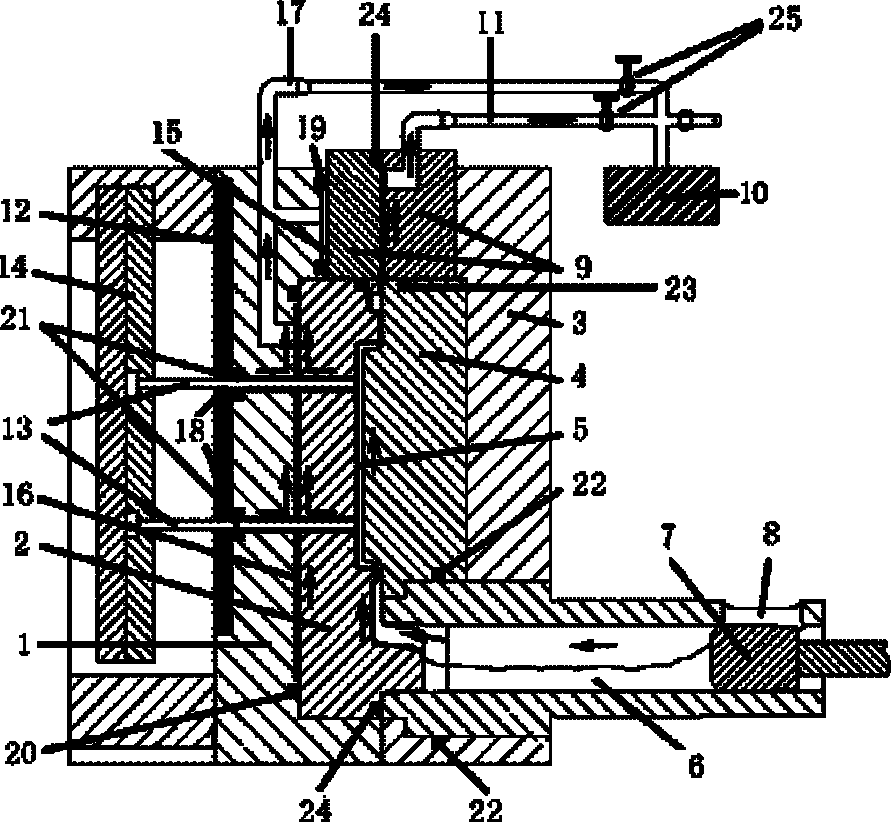

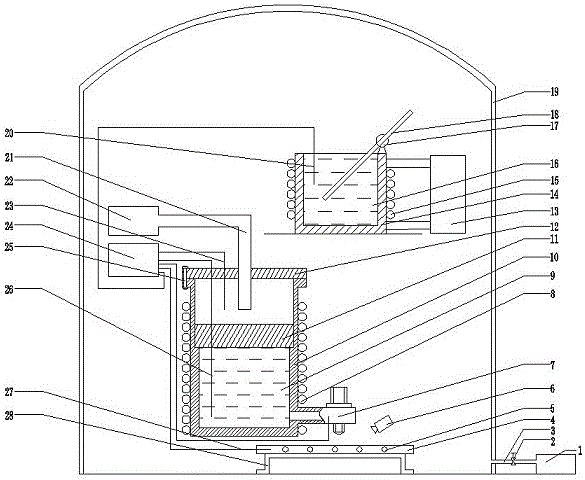

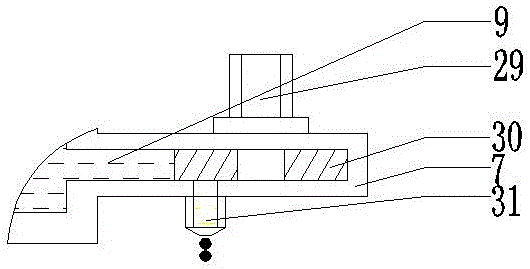

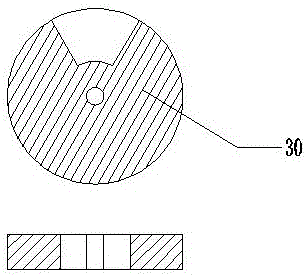

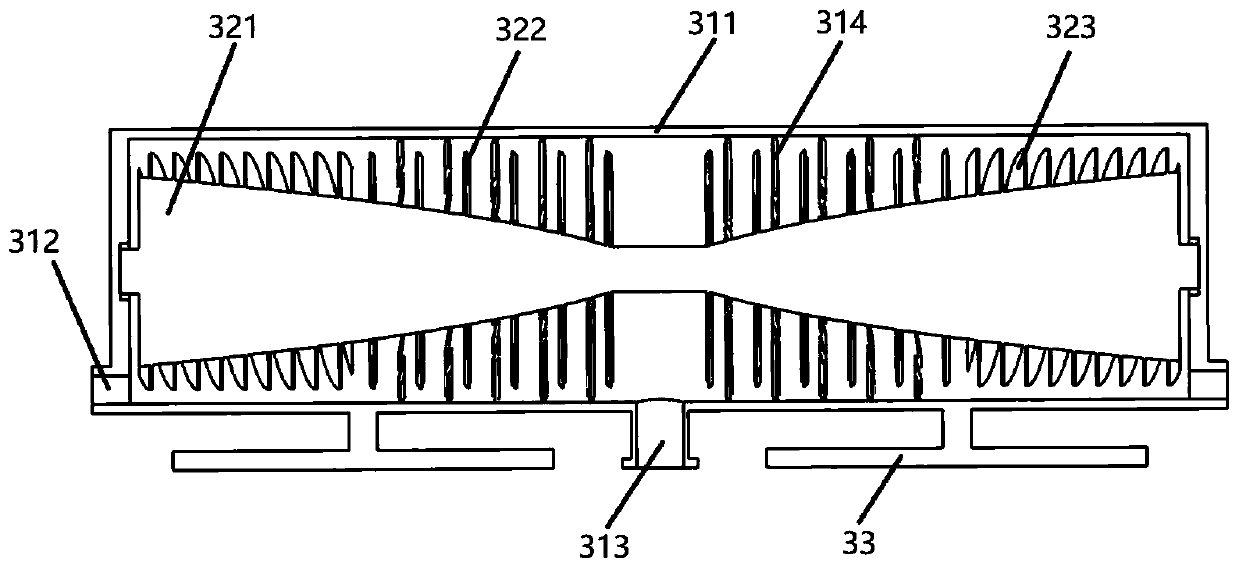

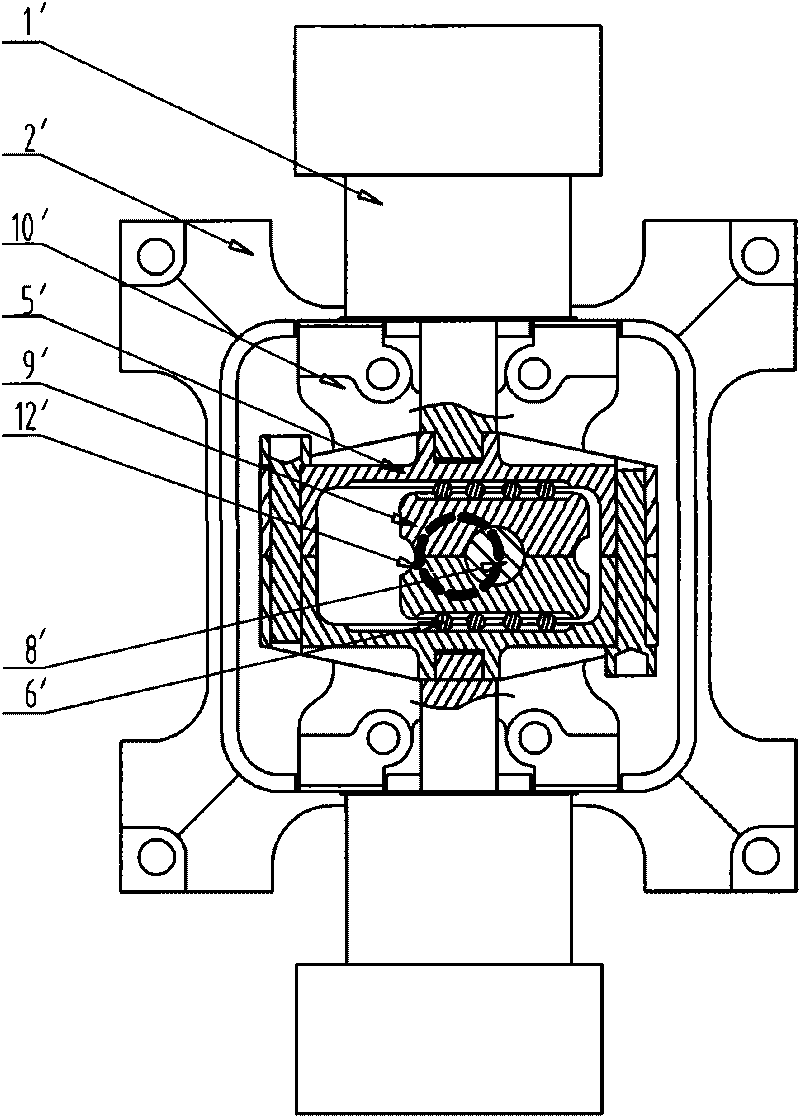

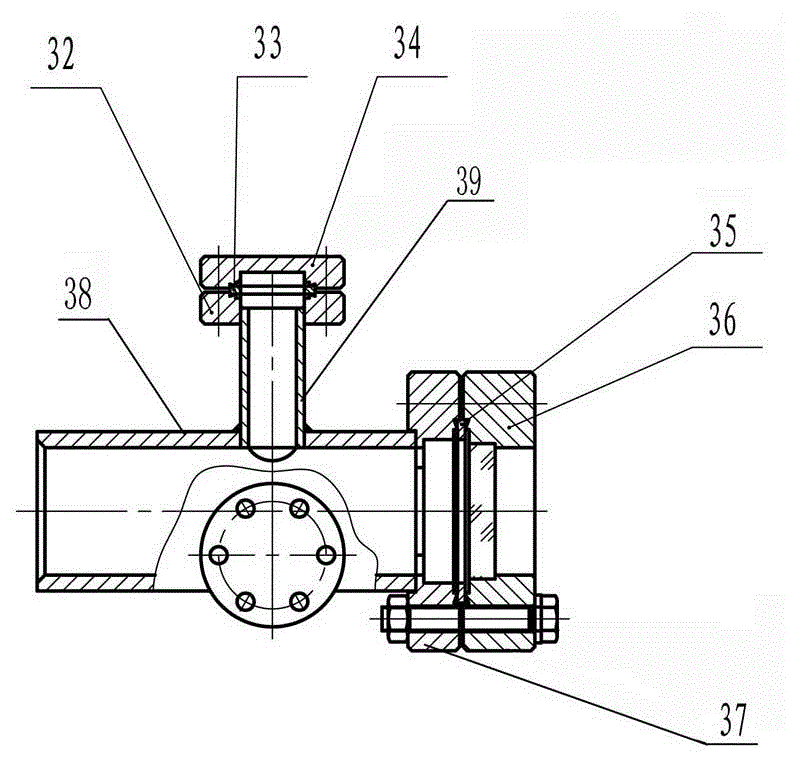

Vacuum die casting mould

The invention relates to a vacuum die casting mould, which comprises a movable mould area and a static mould area. The movable mould area comprises a movable mould frame, a movable lining mould, a press plate and a top cover with a top rod. The static mould area comprises a static mould frame, a static lining mould and a press chamber. An air discharge valve is arranged at the top of the movable lining mould and the static lining mould and communicated with an external vacuum machine through air discharge pipelines. A gap is respectively retained between the movable mould frame and the air discharge valve and between the movable mould frame and the movable lining mould, and two rows of air cavities are formed through sealing elements and are communicated with the external vacuum machine through the air discharge pipelines. A sealing element is arranged on the inner side of a top rod hole of each top rod contacted with the press plate. Sealing elements are arranged between the static lining mould and the static mould frame and the outer circle of the material outlet end of the press chamber. A sealing element is respectively arranged between the top of the movable lining area and the bottom of the air discharge valve and between the top of the static lining mould and the bottom of the air discharge valve. A sealing element is arranged at the mould assembly position of the movable mould area and the static mould area. The vacuum die casting mould is capable of being used for die casting process production in high vacuum, and vacuum pressure of a cast piece cavity can be reduced to below 5kPa to achieve high vacuum level.

Owner:TSINGHUA UNIV

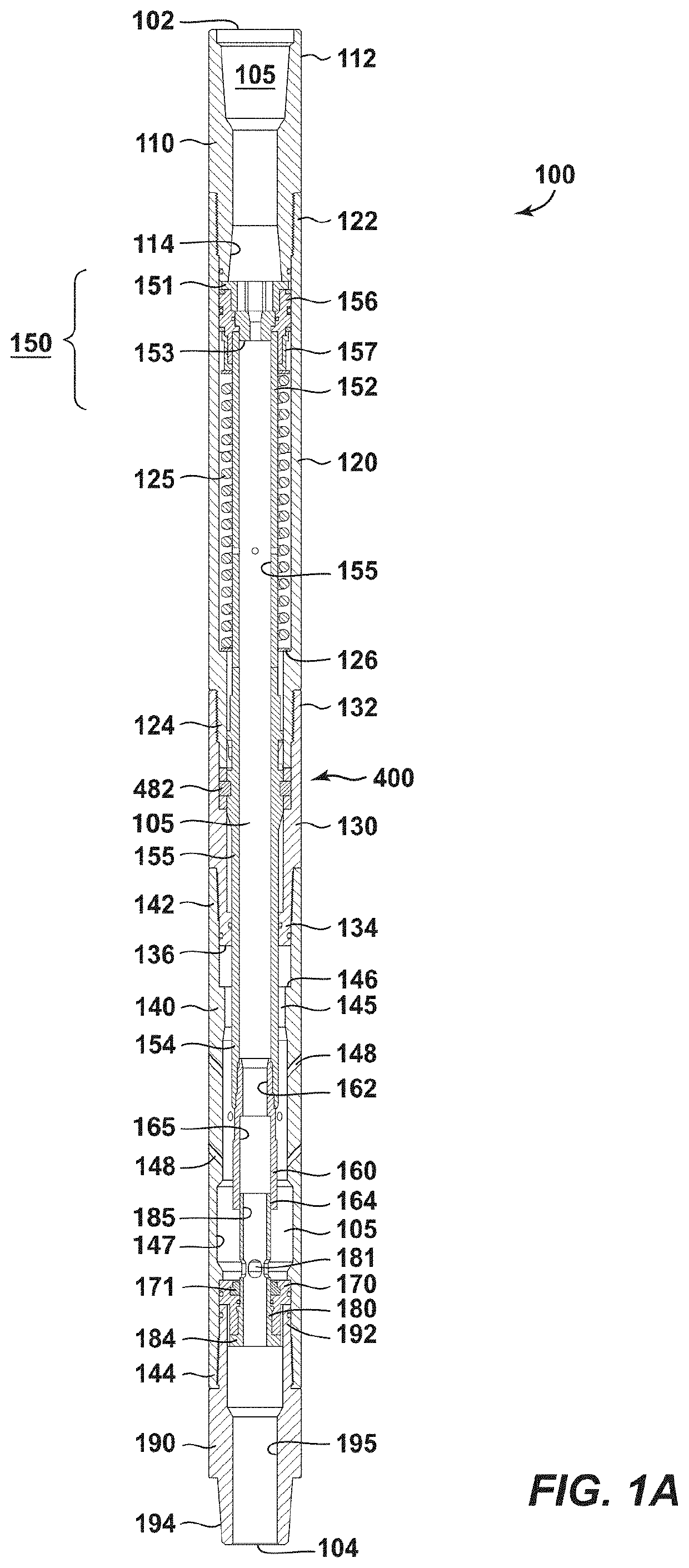

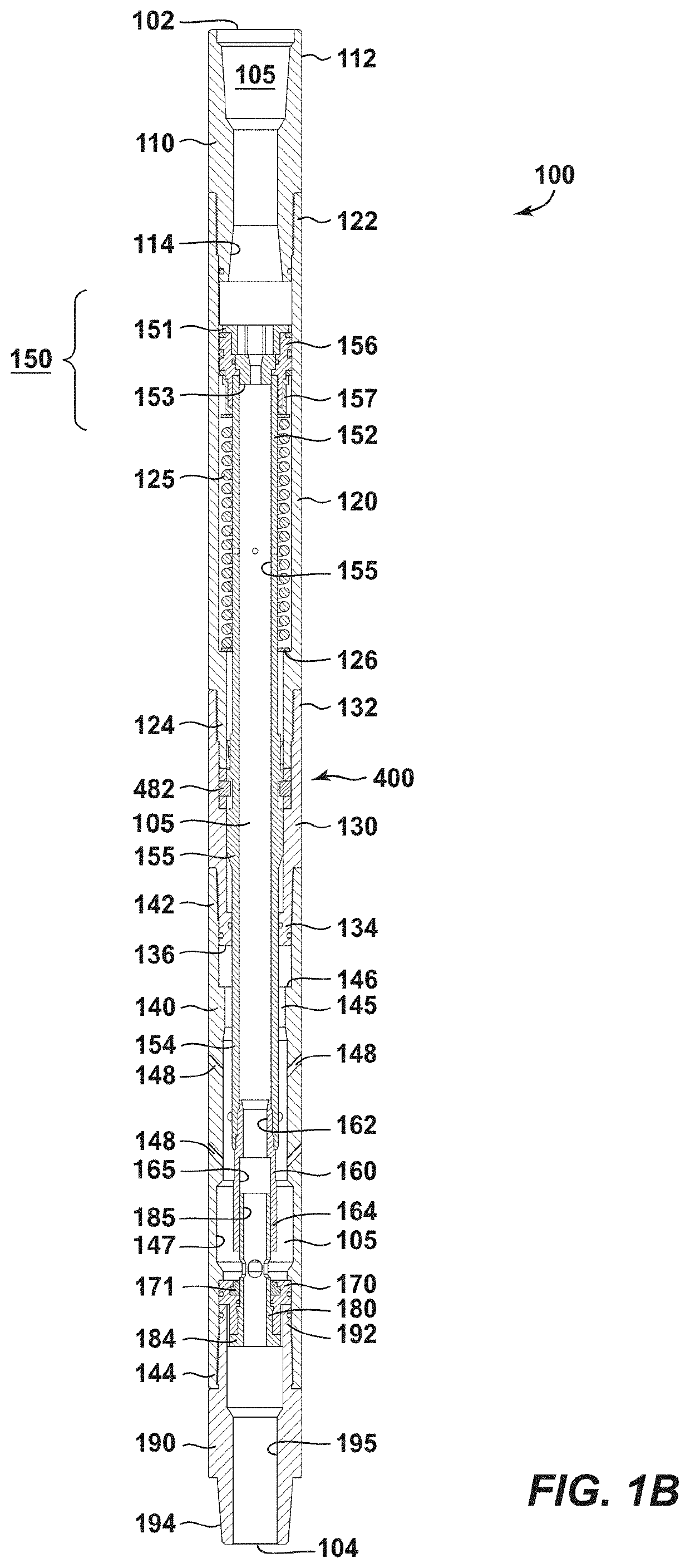

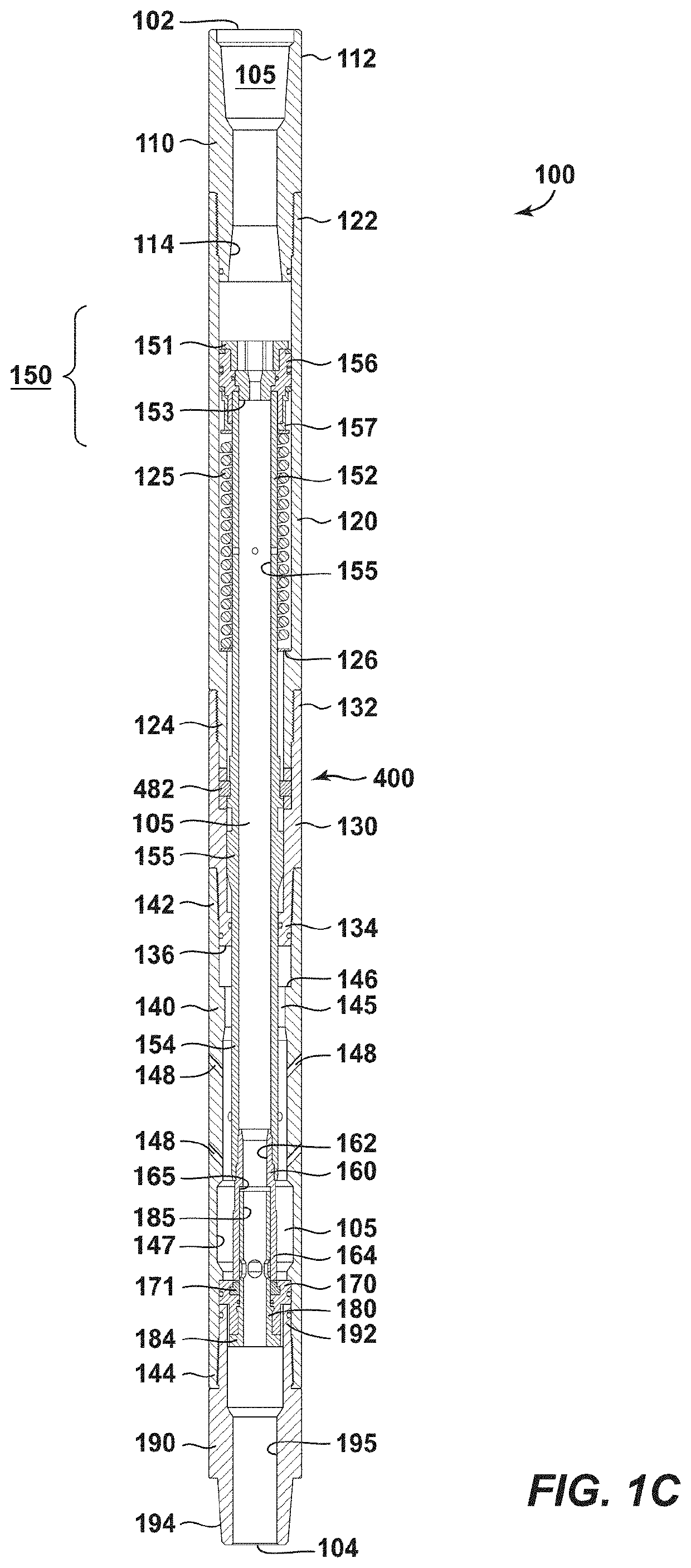

Pressure response fracture port tool for use in hydraulic fracturing applications

ActiveUS20140284058A1Increase pumping rateHydraulic fracturingConstructionsFluid removalHydraulic fracturingEngineering

A pressure response fracture port tool and method for its use reliably provides a noticeable indication at surface to an operator as to when the flow port is opened. The tool includes an outer housing and a sliding sleeve which resides within the outer housing. The outer housing has a first and second set of flow ports. The inner mandrel moves between a first position and a third position to expose the flow ports to the wellbore. The first set of flow ports, with its smaller area relative to the second set of flow ports, creates a noticeable pressure increase or spike that can be observed at surface when exposed to the wellbore. The second set of flow ports creates a noticeable pressure drop when it is exposed to the wellbore.

Owner:WATSON WELL SOLUTIONS

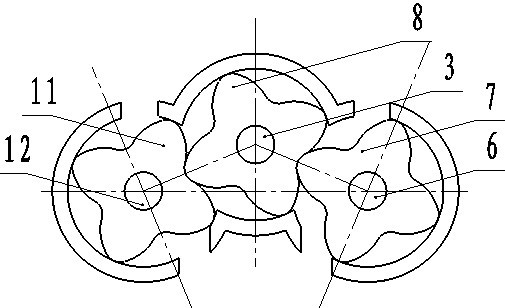

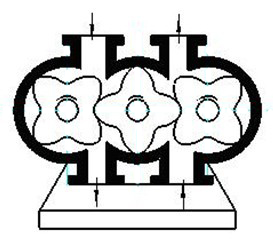

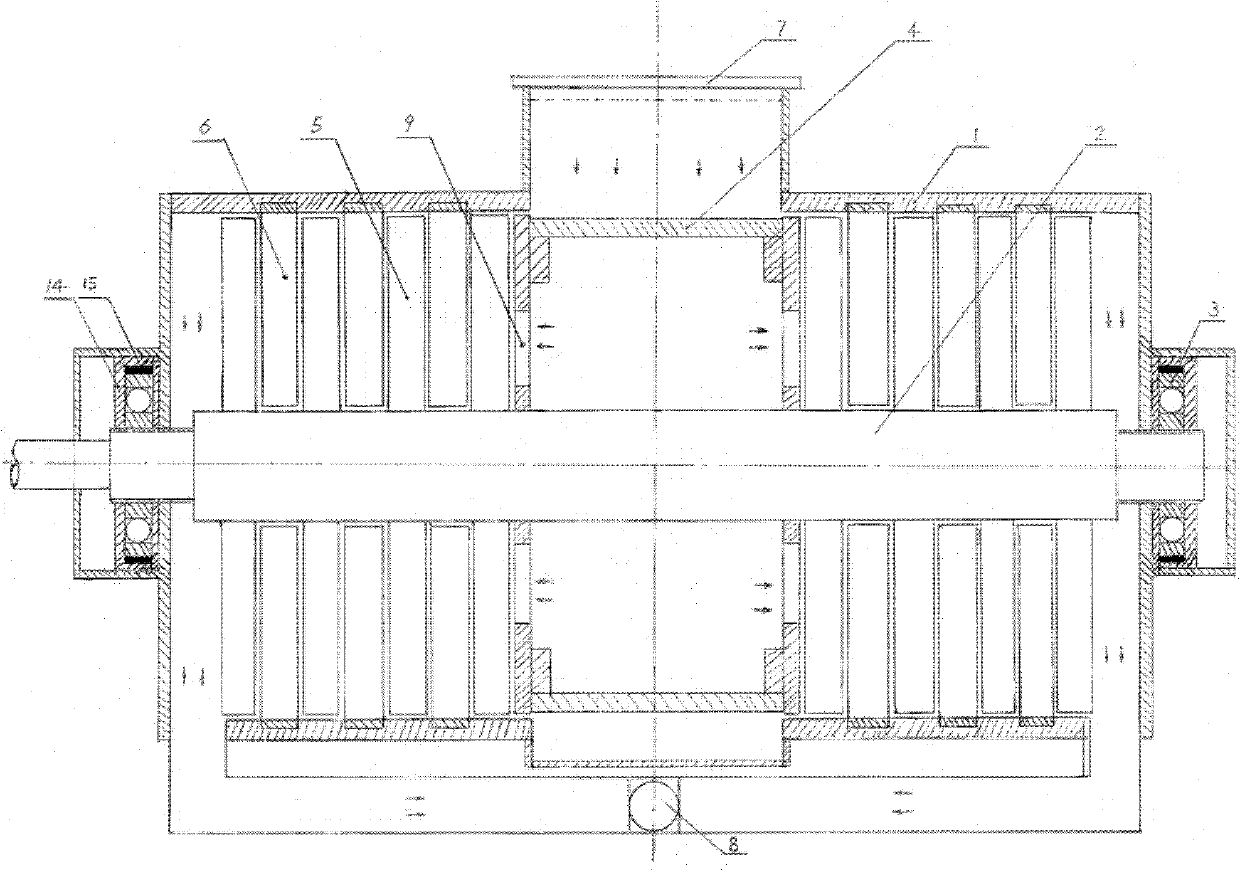

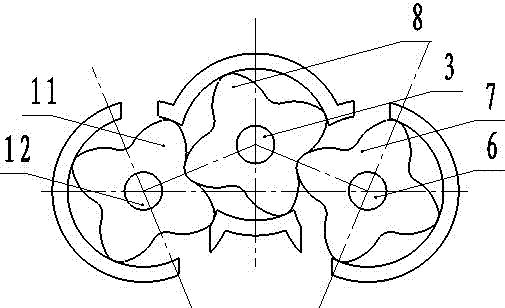

Three-axis Roots vacuum pump

ActiveCN101985935AImprove balanceCompact structureRotary piston pumpsRotary piston liquid enginesDrive shaftGear wheel

The invention relates to a vacuum pump, in particular to a three-axis Roots vacuum pump, which comprises a motor, a spindle and driven shafts, wherein the spindle is provided with a driving gear; driven gears meshed with the driving gear are arranged on the driven shafts; Roots rotors are arranged on the spindle and the driven shafts; and the two driven shafts are parallelly and symmetrically arranged on two sides of the spindle. The three-axis Roots vacuum pump has the characteristics of compact and symmetric structure, air suction under the action of the three axes and no oil in a pump cavity and realizes a high air suction speed.

Owner:NORTHEASTERN UNIV +1

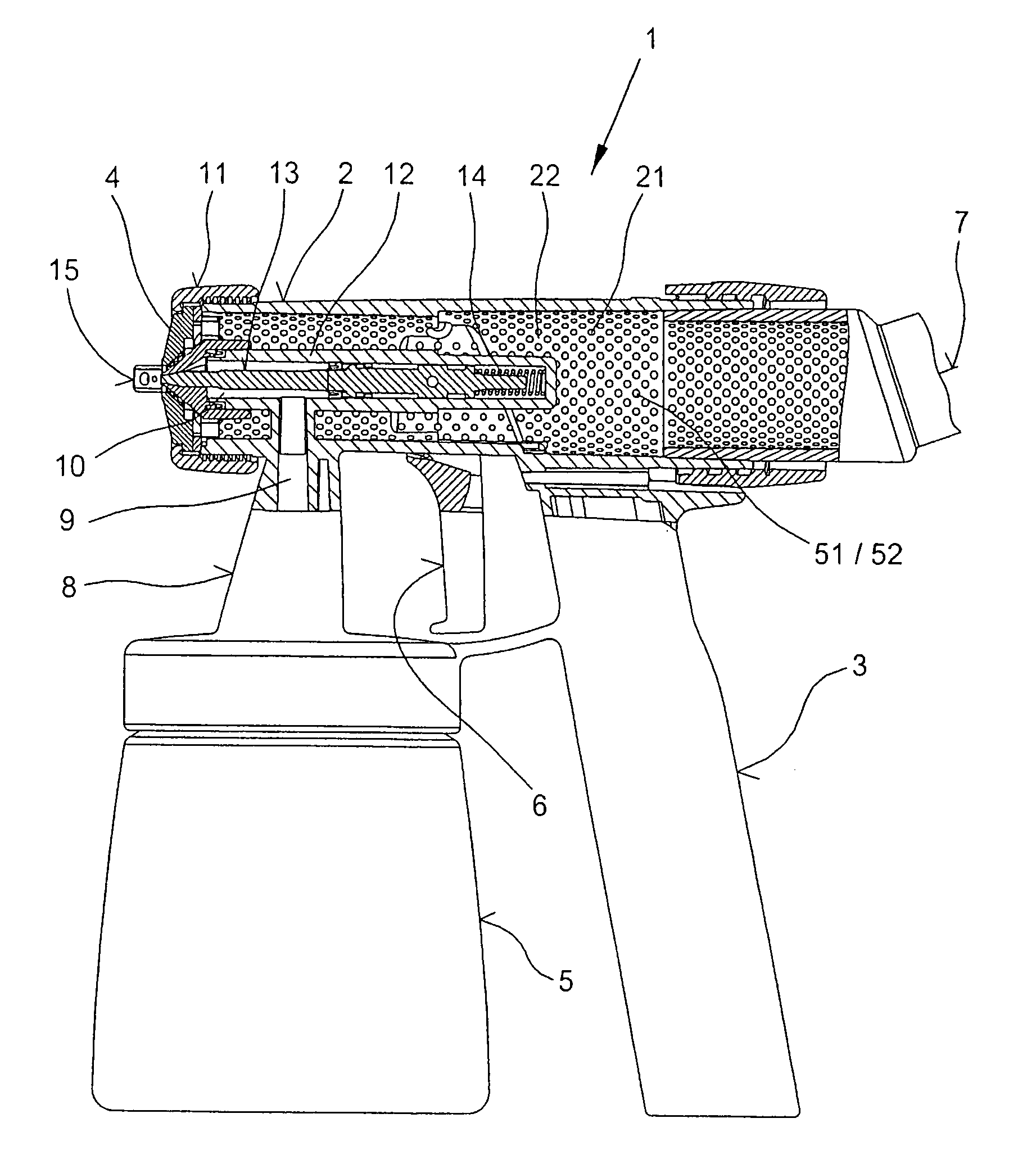

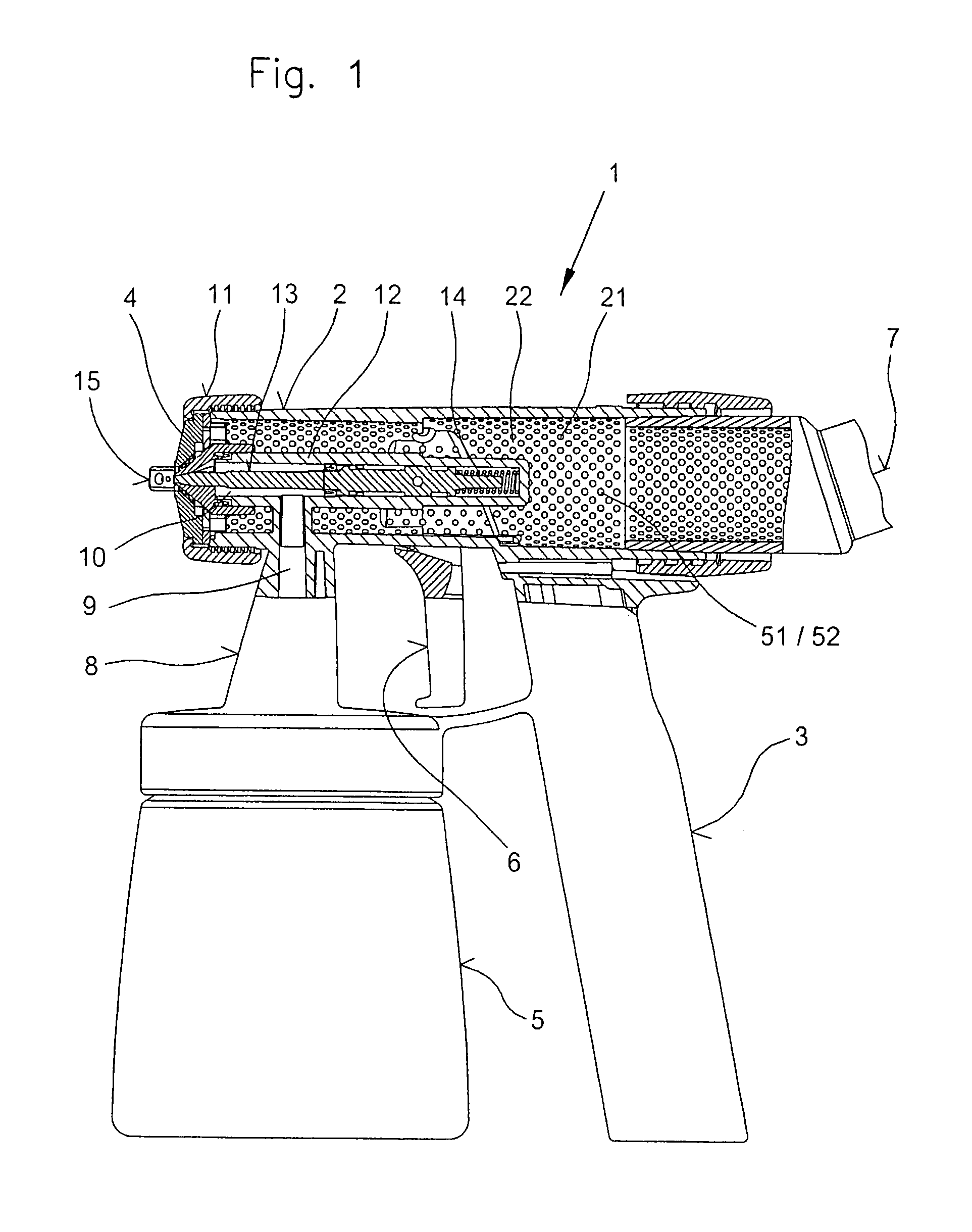

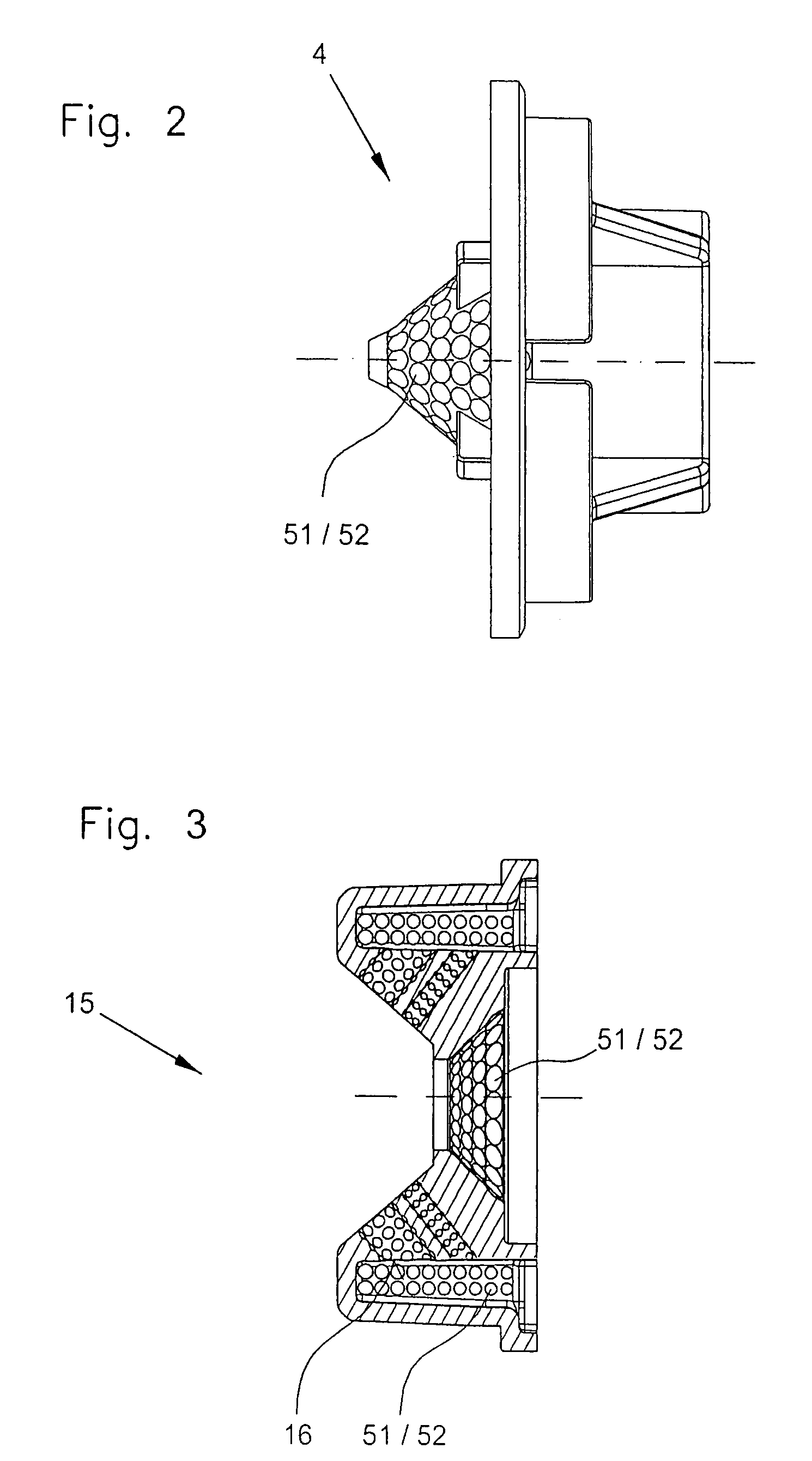

Spray gun

ActiveUS7431223B2Increased rate of transportationIncrease pump speedSpray nozzlesFluid dynamicsEngineeringViscous medium

A spray gun for spraying paints and similar viscous media that can be propelled pneumatically, comprising a gun housing for accommodating components of the spray gun that effect propulsion, mixture and / or metering, a handle projecting from the gun housing, and a reservoir tank removably attached to the gun housing for holding the medium to be processed, with the housing of the spray gun provided with an air guidance duct through which the compressed air responsible for atomization flows to an atomizer nozzle, wherein surfaces of the air guidance duct and / or atomizer nozzle, and / or an air cap, which come into contact with the stream of compressed air, or are wetted, are provided wholly or in part with a structured surface in the form of indentations and / or protrusions worked into the surfaces.

Owner:J WAGNER GMBH

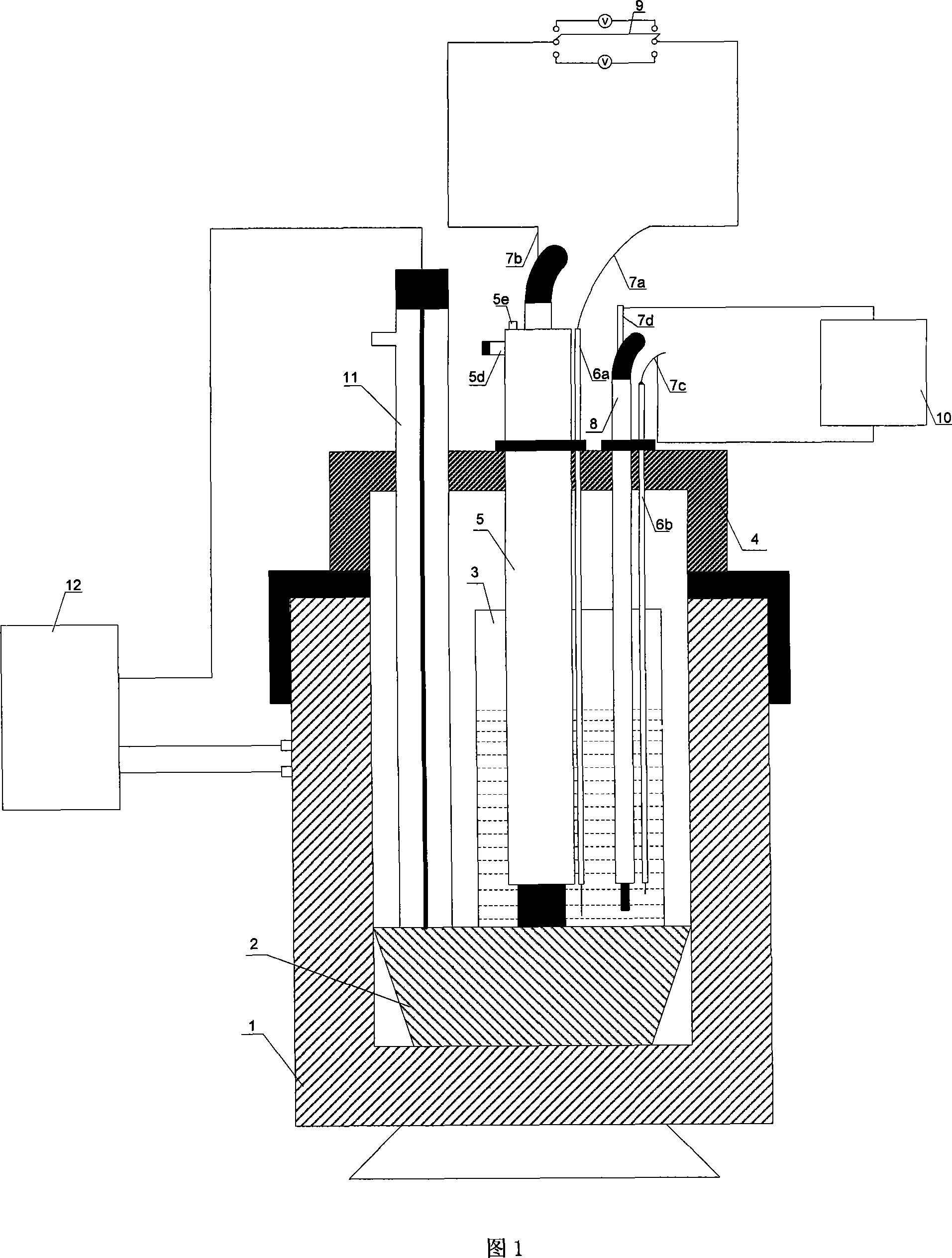

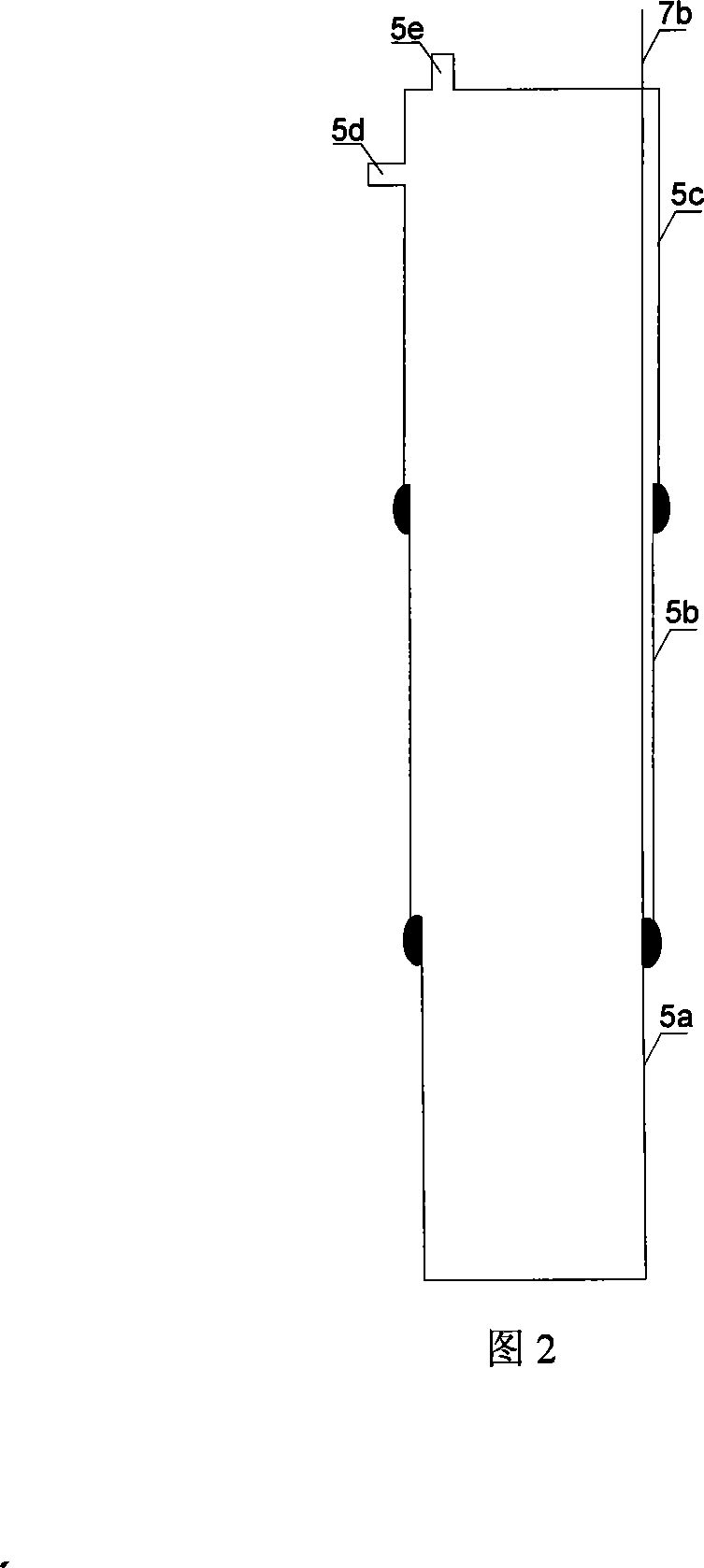

Dehydrogenation method for aluminum or aluminum alloy fused mass by using solid-state proton conductor and device thereof

The invention relates to a dehydrogenation process for aluminum or aluminum alloy flux through utilizing solid proton conductor and a device. The device comprises an aluminum-smelting channel, a heating-furnace, temperature-controlling thermocouple and a hydrogen-testing sensor. The key points lie in that a hydrogen extraction device is formed by the mutual connection of a proton conductor pipe, an alumina pipe and a metal pipe, by a contact conductor which is assembled in the hydrogen extraction device and an another contact conductor with alumina pipe protective sleeve connecting with an external power switch. The proton conductor chooses chemical formula of BaCe 1-XYXO3-a or BaCe1-XSmxO3-a, wherein X is equal to 0.05-0.25 or is made from CaZr 0.9 In 0.1O3-a material. The dehydrogenation process adopts short-circuit dehydrogenation under the stirring condition of aluminum or aluminum alloy flux temperature is 750-800 DEG C, or adopts the combination carrying or vacuum extraction hydrogenation after short-circuit hydrogenation or adopts applied voltage to hydrogenate. The hydrogenation effects of the invention are that the content of hydrogen is smaller 0.15ml / 100gAl, and the content of hydrogen is smaller 0.12ml / 100Al for high strength aluminum alloy flux. The invention has the advantages of simple technology and device, convenient operation, environment-friendly and less investment, which is easy to realize industrialization.

Owner:NORTHEASTERN UNIV

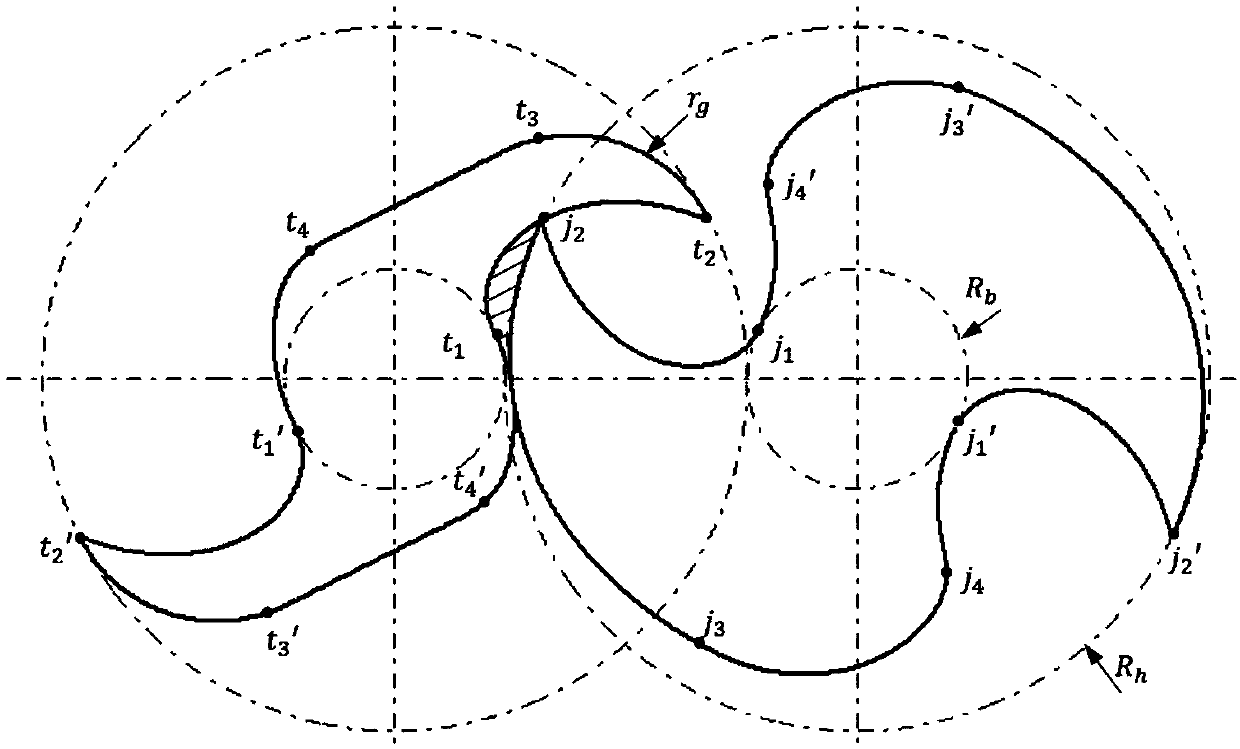

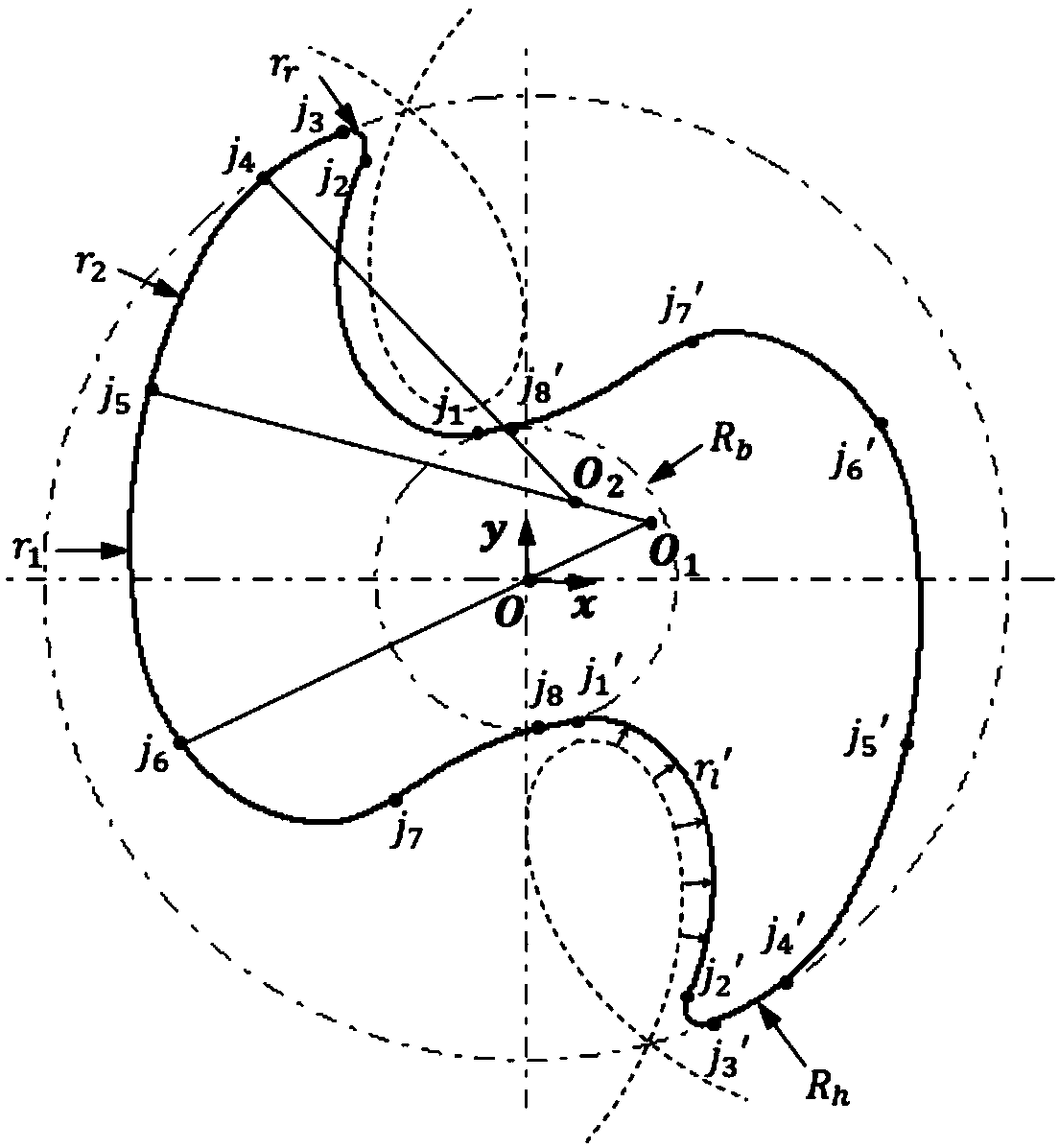

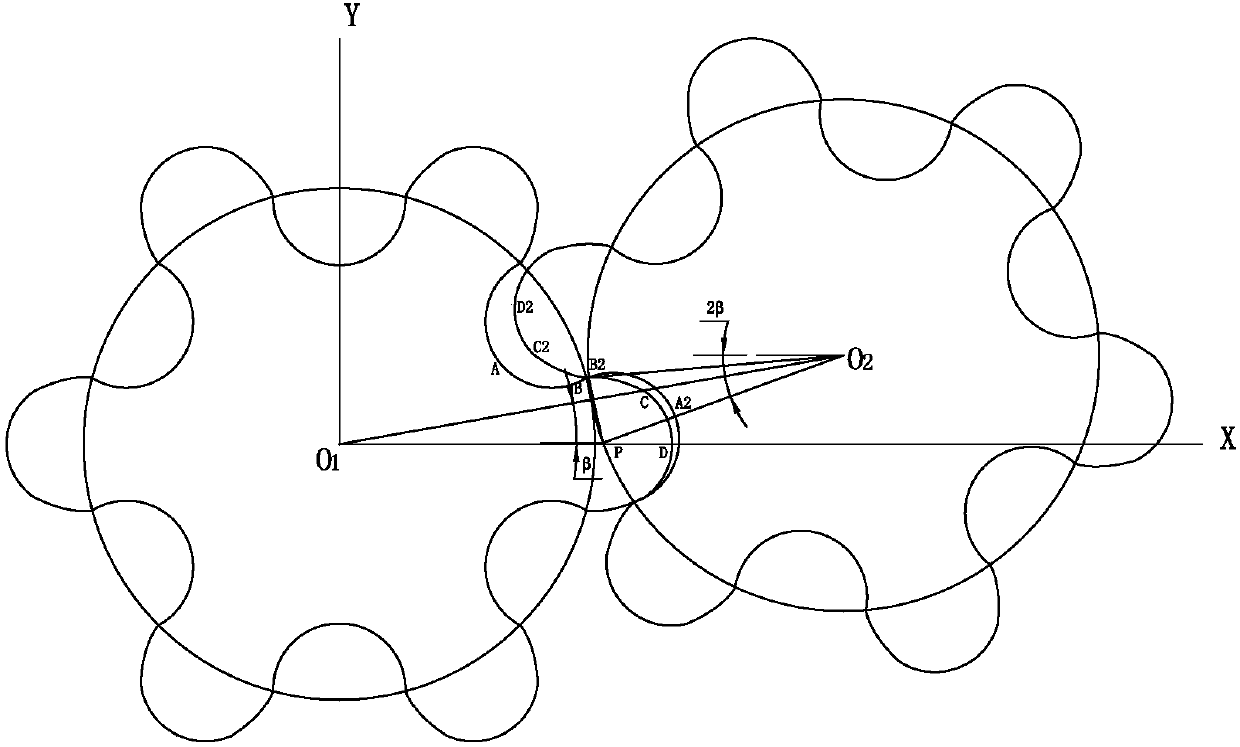

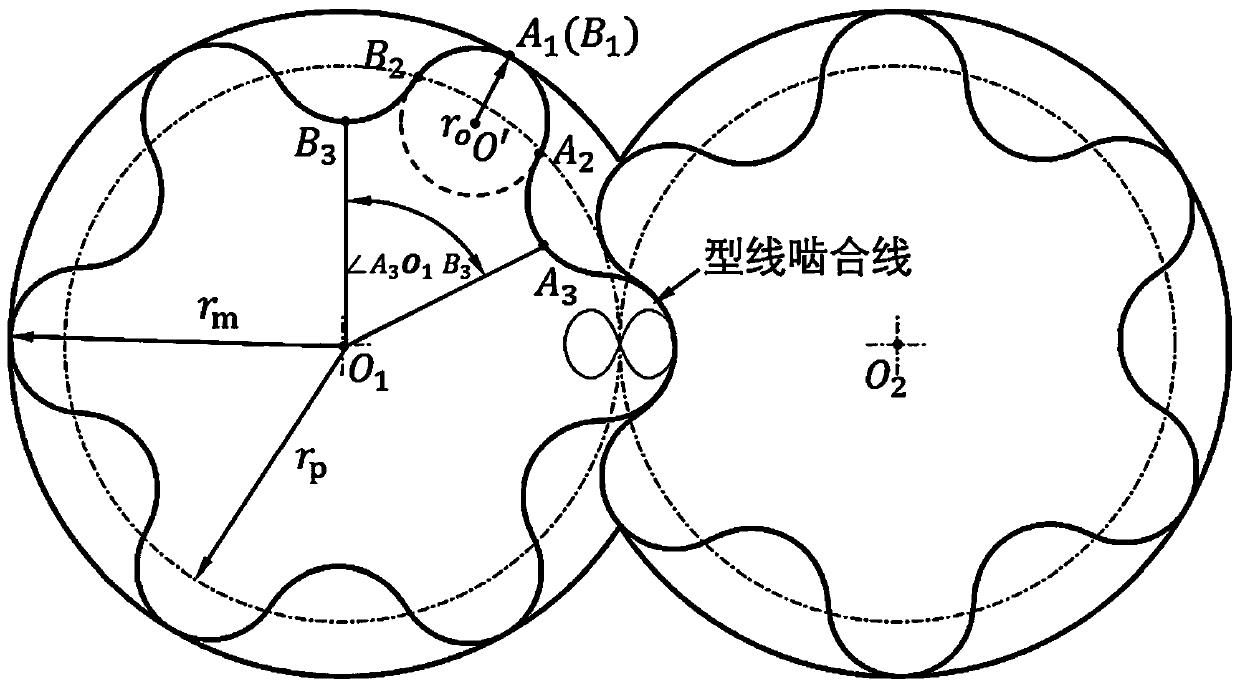

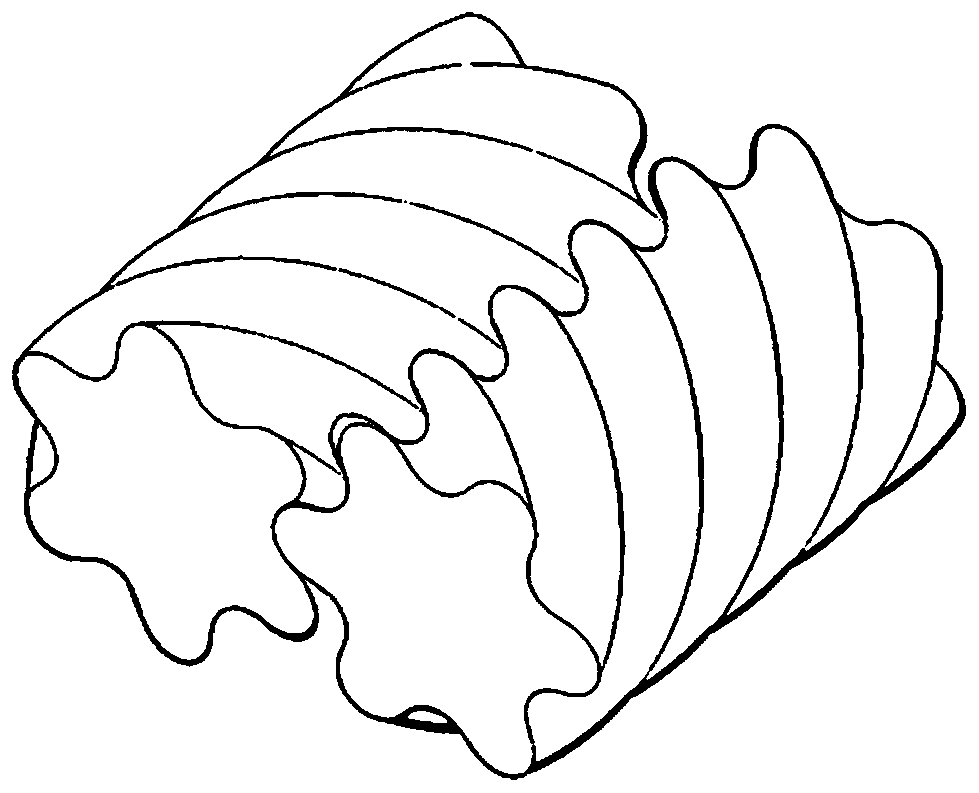

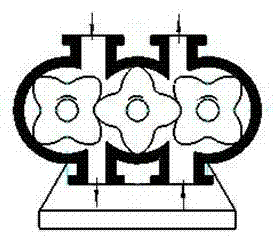

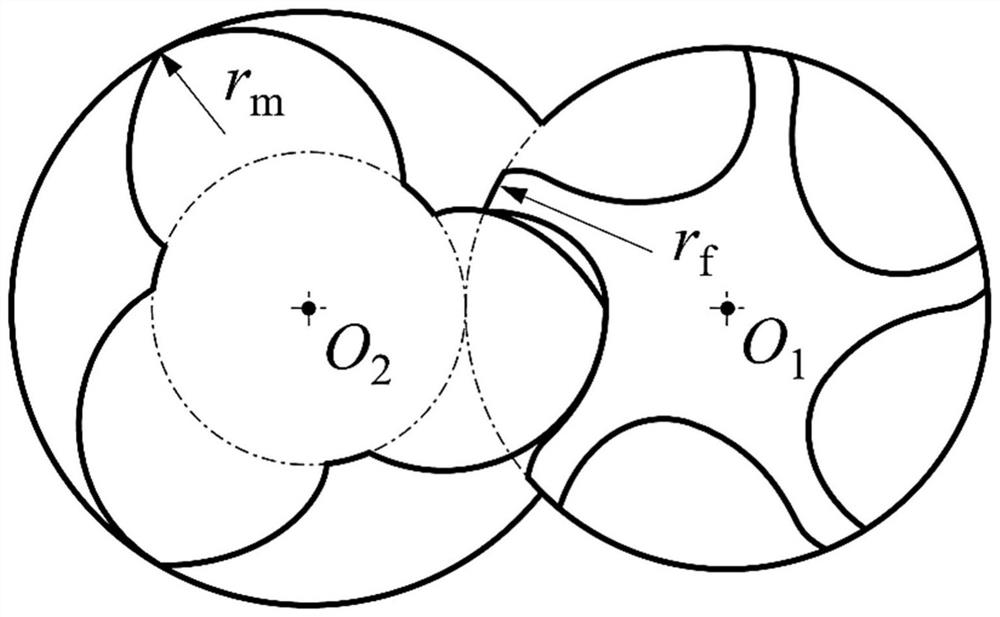

Double-head claw pump rotor and its molded line

ActiveCN108930650AAvoid severe wear and tearIncrease design parameter spaceRotary piston pumpsRotary piston liquid enginesEngineeringSharp point

The invention relates to a double-head claw pump rotor and its molded line. The molded line comprises an equidistance curve of a point meshing epicycloid, a modified arc segment, a tooth top arc segment, an intermediate connecting arc segment, an arc conjugate curve segment, and a tooth root arc segment. Two rotors adopt a central symmetrical structure. By setting the modified arc segment, the sharp points are eliminated, and severe wearing phenomenon of the rotors during operation can be avoided. The equidistance curve of the point meshing epicycloid and the modified arc segment are always spaced apart to avoid the formation of suction and exhaust closed volume, and a design parameter space of the rotor molded line is increased, the power consumption is reduced, and the pump efficiency isimproved. The molded line is designed in the double-head claw pump, compared with the other conventional pumps, the pump in the invention has the advantages of less wearing parts, compact structure,high pumping rate, no surge, and low vibration noise.

Owner:宝风压缩机科技(浙江)有限公司

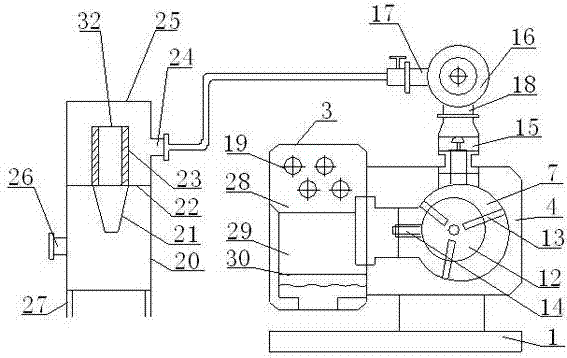

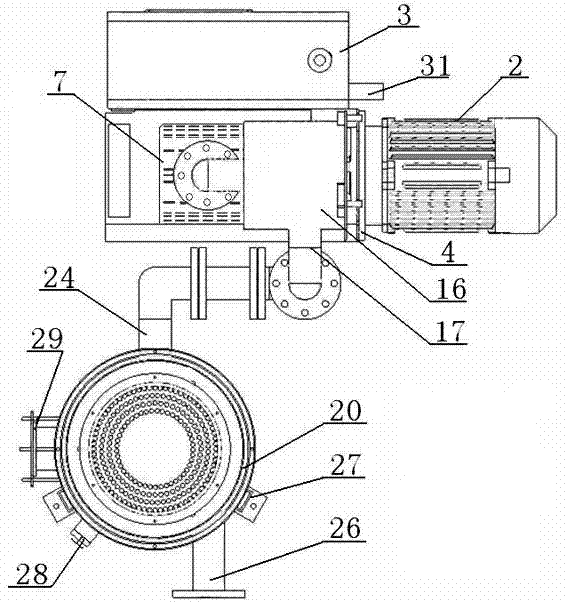

Rotary-vane efficient energy-saving environmental-friendly vacuum pump

ActiveCN102889212AGuaranteed cleanlinessEasy to useChemical industryPumpsChemical industryAir filter

The invention discloses a rotary-vane efficient energy-saving environmental-friendly vacuum pump, relates to a rotary-vane vacuum pump for a tile vacuum-extruder, belongs to the technical field of vacuum pumps and is suitable for being used as vacuuming equipment for standby use in building material industry, chemical industry, medicine industry, electronic industry, ceramics industry and the like, especially suitable for the rotary-vane vacuum pump used for the tile vacuum-extruder. The rotary-vane efficient energy-saving vacuum pump comprises a gas-water separator, an air filter, a pump body stator, a rotator, rotary vanes, a vent valve assembly, a side-placed oil tank, an air-cooled oil-pumping cooler, a venting oil mist filter, a centrifugal fan, a housing, a frame and a motor, wherein the gas-water separator comprises a cylinder body, a clapboard, a netting filter net cylinder and a cone river diversion port; the air filter is provided with a filter cylinder body which is internally provided with an exhaust duct; the filter cylinder body is internally provided with a filter core assembly; and the centrifugal fan is arranged on a coupler, the housing is arranged on the outer sides of the pump body and the air-cooled oil-pumping cooler, so as to form an air-cooled oil-pumping cooler and a pump body cooling air duct.

Owner:南通诺博特机器人制造有限公司

Pulse on-off valve type metal 3D printing device

ActiveCN106378454AReal-time monitoring of melt temperature changesAdjust heating powerAdditive manufacturing apparatusIncreasing energy efficiencyMolten metalMaterials science

The invention discloses a pulse on-off valve type metal 3D printing device capable of realizing precise spray-deposition 3D printing formation of molten metal under the control of a pulse on-off valve. More specifically, the pulse on-off valve type metal 3D printing device is characterized in that a metal liquid is purified through melting and filtering, the precise controllable continuous spray of the molten metal is realized through controlling the pulse on-off of a rotating blade-shaped valve at a printing spray head, the movement of the spray head is controlled through a three-dimensional coordinate platform, a forming platform is provided with stable temperature by a printing substrate, and low-cost additive manufacturing equipment capable of realizing rapid metal melting, multistage purification and precise controllable spray deposition is finally designed.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH

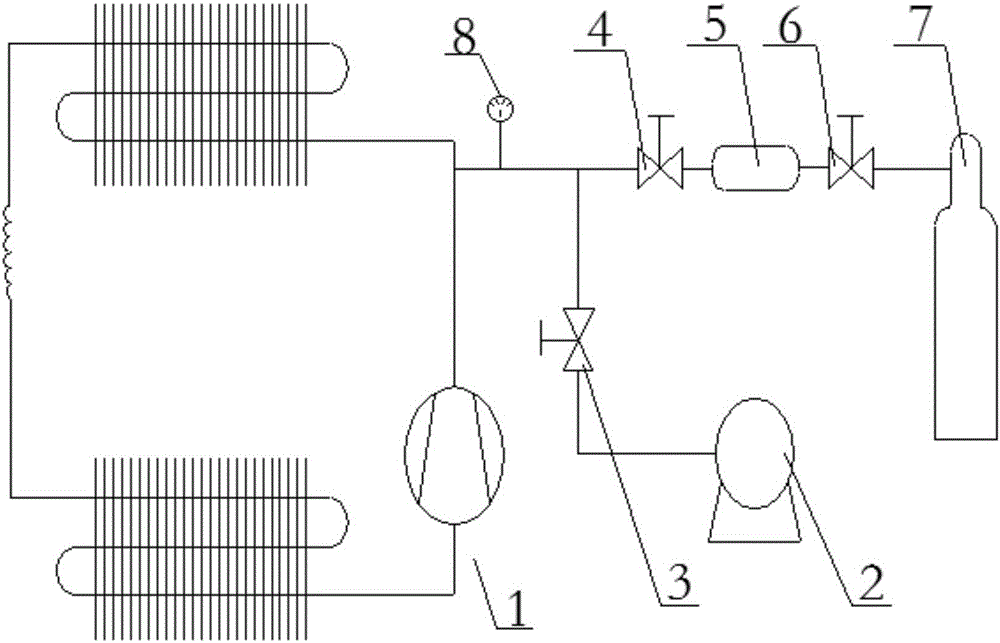

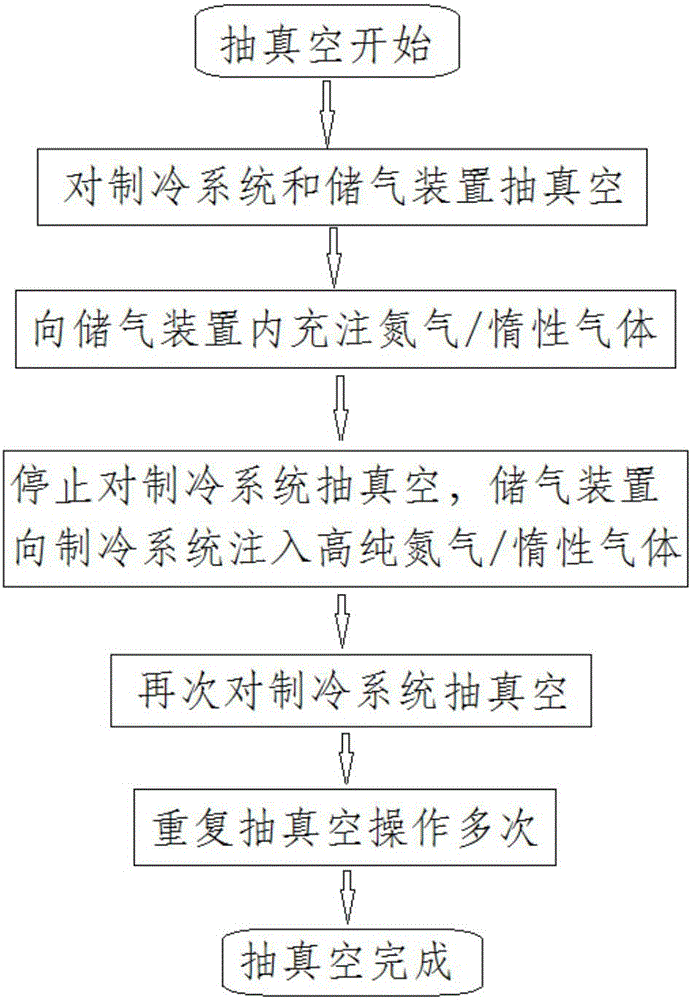

Gas displacement method air conditioner vacuum pumping device and vacuum pumping method

InactiveCN106352626AFully removedTo achieve the purpose of vacuumingRefrigeration componentsVacuum pumpingGas cylinder

The invention discloses a gas displacement method air conditioner vacuum pumping device and a vacuum pumping method, and belongs to the technical field of air conditioner vacuum pumping. The air conditioner vacuum pumping device comprises a vacuum pump, a gas storage device and a gas storage bottle, wherein the vacuum pump is connected with a refrigeration system; two branches are led out from a gas extraction pipeline of the refrigeration system; one branch is connected with the vacuum pump; a first control valve is arranged on the pipeline; a second control valve, the gas storage device, a third control valve and the gas storage bottle are sequentially connected onto the other branch; during vacuum pumping, through the mutual matching of the three control valves, impurity gas in the refrigeration system can be displaced; the circulation gas extraction on the refrigeration system can be realized, so that the gas and water in the refrigeration system can be sufficiently discharged; the vacuum pumping goal is achieved; the vacuum degree and the gas extraction efficiency of the refrigeration system are improved.

Owner:马鞍山汉德绿色建筑环境科技有限公司

Cooking utensil

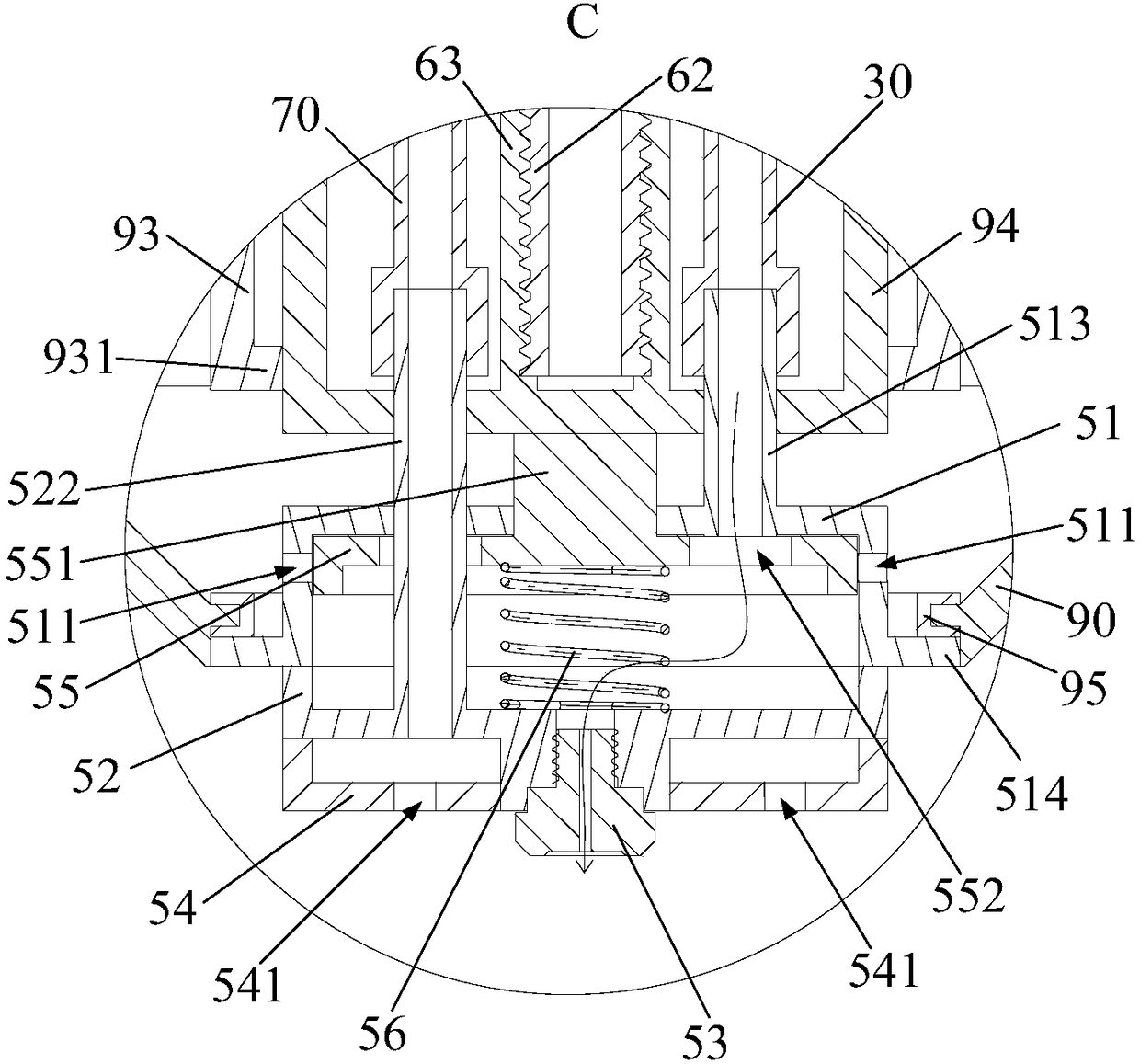

PendingCN109247840ASimple structureIncrease pumping rateCooking-vessel lids/coversSteam cooking vesselsAirflowEngineering

The invention provides a cooking utensil. The cooking utensil comprises a cover, an inner pot and an air inlet pipe, wherein the inner pot is positioned below the cover, and is used for bearing waterand materials; and the delivery end of the air inlet pipe communicates with the inner pot, and is used for conveying air flow to the inner pot, so that the materials and water generate relative movement under the effect of the air flow, and then the materials are washed. For the cooking utensil provided by the invention, the materials including rice and water are placed in the inner pot, high-pressure air flow is conveyed into the inner pot through the air inlet pipe, then the materials and water generate the movements including rolling, friction, rotation and the like under the effect of theair flow, namely, the purpose of automatic washing is realized by utilizing pneumatic stirring, thus the stirring device and relevant structures driving the stirring device to contract and stretch inthe prior art are saved, and therefore, the structure of the cooking utensil is greatly simplified.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

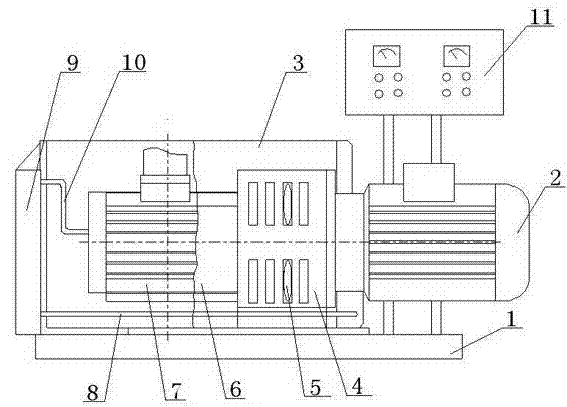

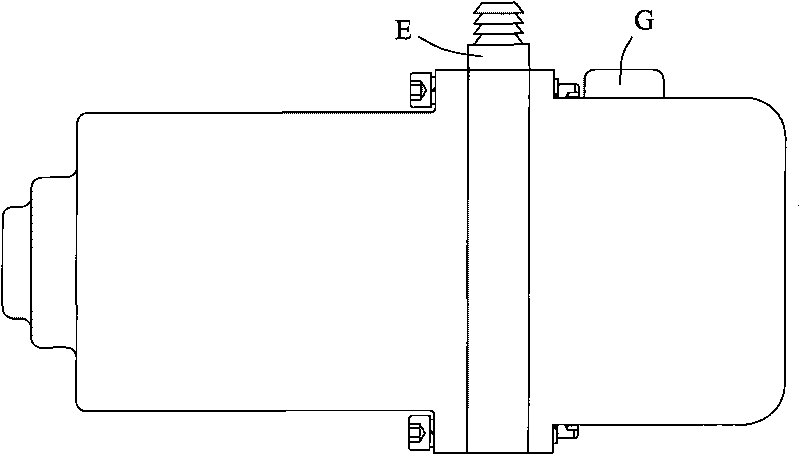

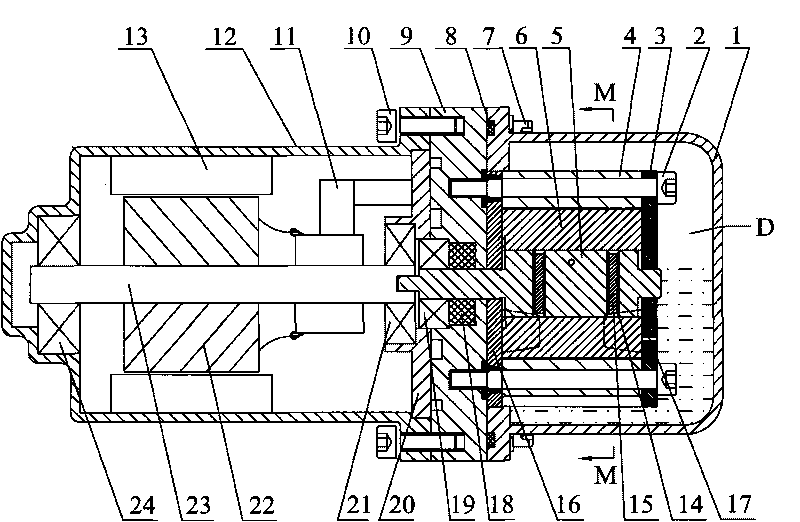

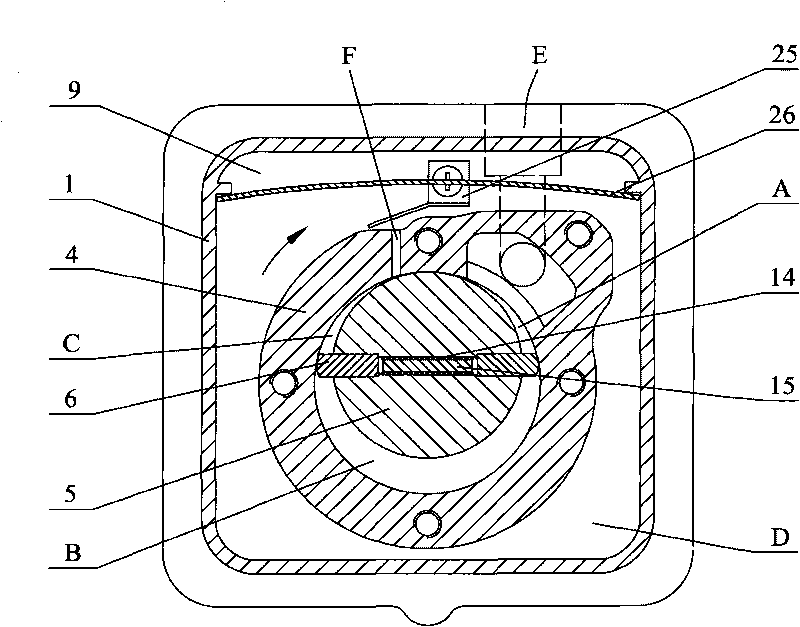

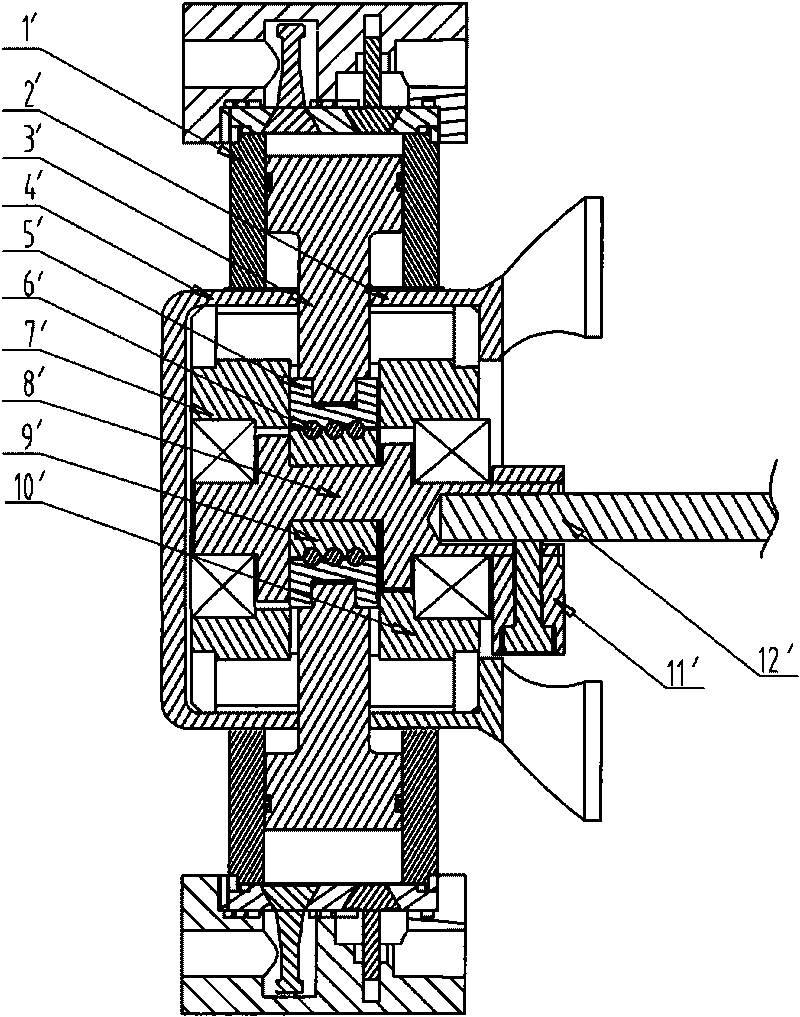

Wet-type rotary vane electric vacuum pump for automobile

ActiveCN101709700AHigh working reliabilityIncrease pumping rateRotary piston pumpsRotary piston liquid enginesCylinder blockAir cavity

The invention discloses a wet-type rotary vane electric vacuum pump for an automobile, which comprises a pump body assembly, wherein the pump body assembly comprises a rear end cover and a supporting seat which are fixedly connected; the supporting seat is fixedly connected with a cylinder body through a cover plate and a bottom plate; the inside of the cylinder body is eccentrically provided with a rotor; one end of a rotating shaft of the rotor is connected with the cover plate and the other end of the rotating shaft of the rotor runs through the bottom plate and the supporting seat sequentially for through connection; the supporting seat is provided with a pumping hole E; the top of the cylinder body is provided with an exhaust port F; the rotor is adjustably connected with two vanes; a spring device is arranged in the rotor, so that end parts of the vanes are always pressed against the inner wall of the cylinder body; an air cavity A, an air cavity B and an air cavity C are formed among the vanes, the rotor and the cylinder body; and the air cavity A corresponds to the pumping hole E, and the air cavity C corresponds to the exhaust port F. The wet-type rotary vane electric vacuum pump effectively meets the vacuum demands during the repeated braking of vehicles under the condition of idle speed, and the response speed is quick; and simultaneously, the vacuum pump is provided with a vacuum pump oil-way circulation, and vacuum pump oil is attached to the cylinder body, the rotor and vane surfaces uniformly with the vanes, so that operating noises are reduced effectively, and the operating reliability is improved.

Owner:ZHEJIANG VIE SCI & TECH

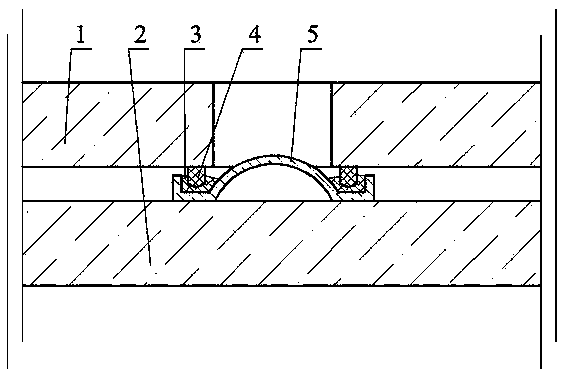

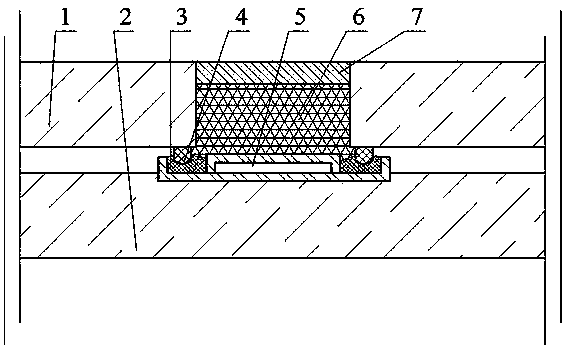

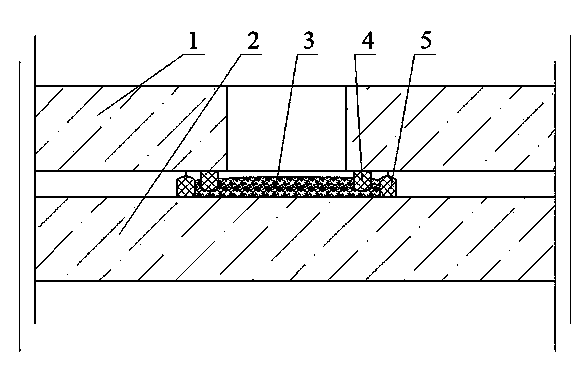

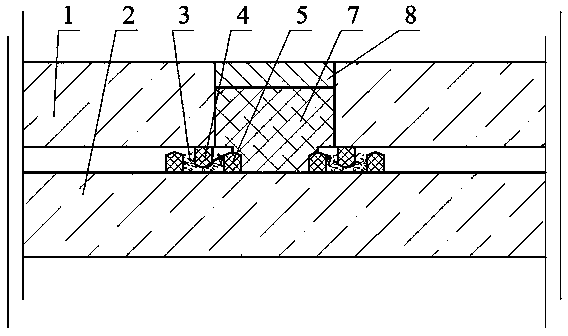

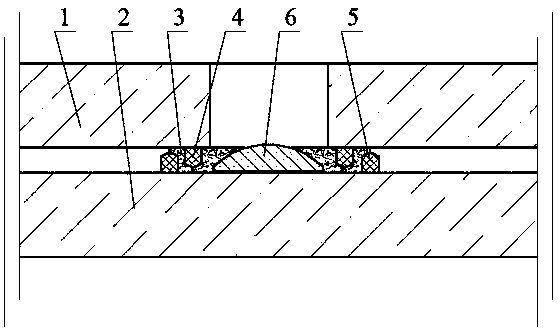

Vacuum glass air-exhaust port and manufacturing method thereof

InactiveCN104291632ASimple structureStable structureGlass reforming apparatusGlass productionEngineeringMechanical engineering

The invention relates to a vacuum glass air-exhaust port. The air-exhaust port is characterized in that the upper glass of the vacuum glass is perforated, such that the air-exhaust port is formed. A sealing ring is prepared on the lower surface of the upper glass at the periphery of the air-exhaust port. A sealing box is placed at a place on the upper surface of the lower glass and corresponding to the air-exhaust port. The sealing ring can be inserted into the sealing box. After edge-sealing of the upper and lower glass, a metal solder is placed into the air-exhaust port. The air-exhaust port is vacuumed and heated such that the metal solder is molten into liquid, and the liquid is retained in the sealing box. The sealing ring is also immersed in the liquid. The air-exhaust port is automatically sealed according to a liquid sealing principle. After cooling, the liquid is solidified, such that air-tight sealing upon the air-exhaust port is realized. The method provided by the invention can be used in mass productions. With the method, vacuum glass production efficiency and qualification rate can be greatly improved, and production cost can be reduced.

Owner:戴长虹

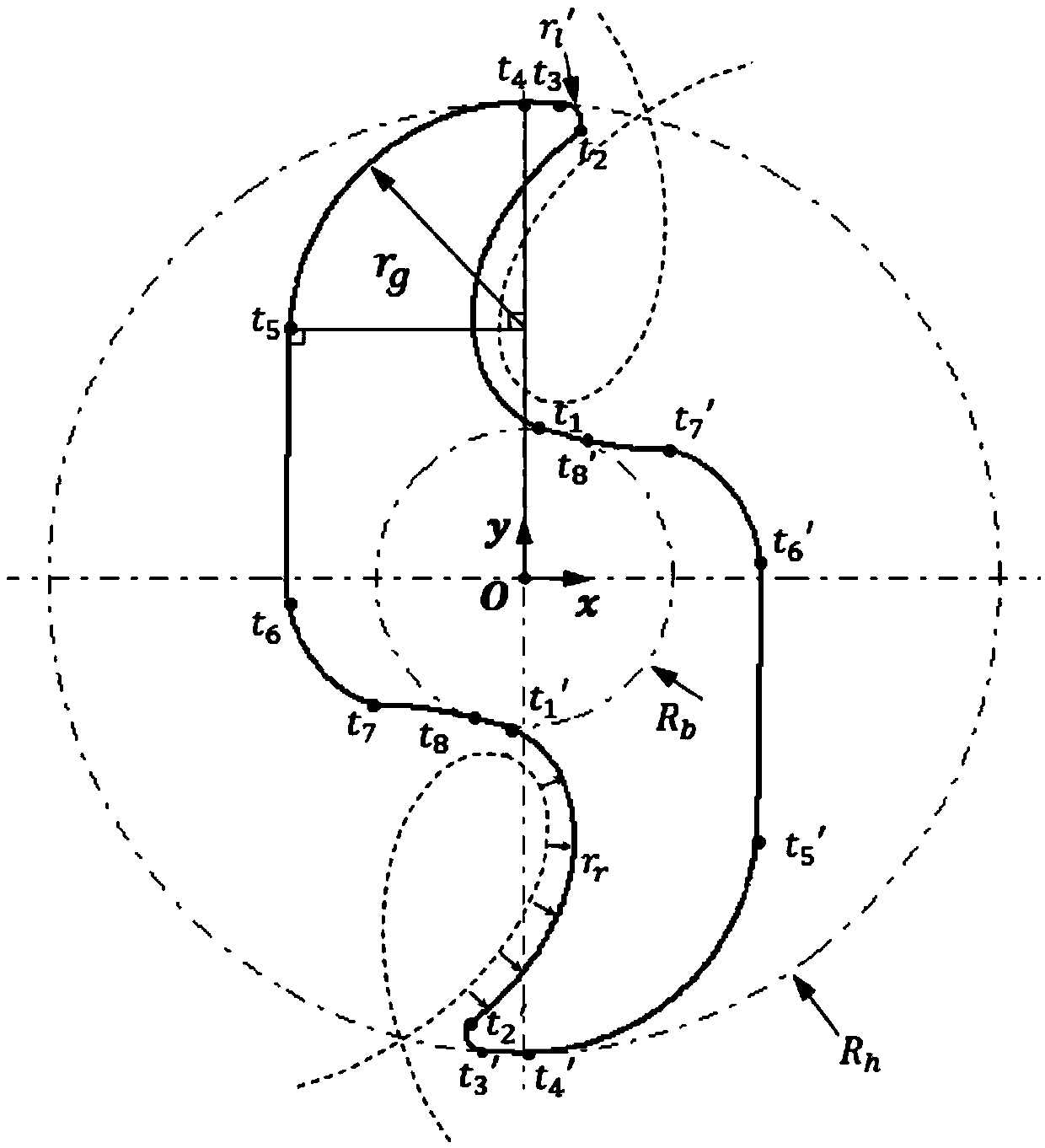

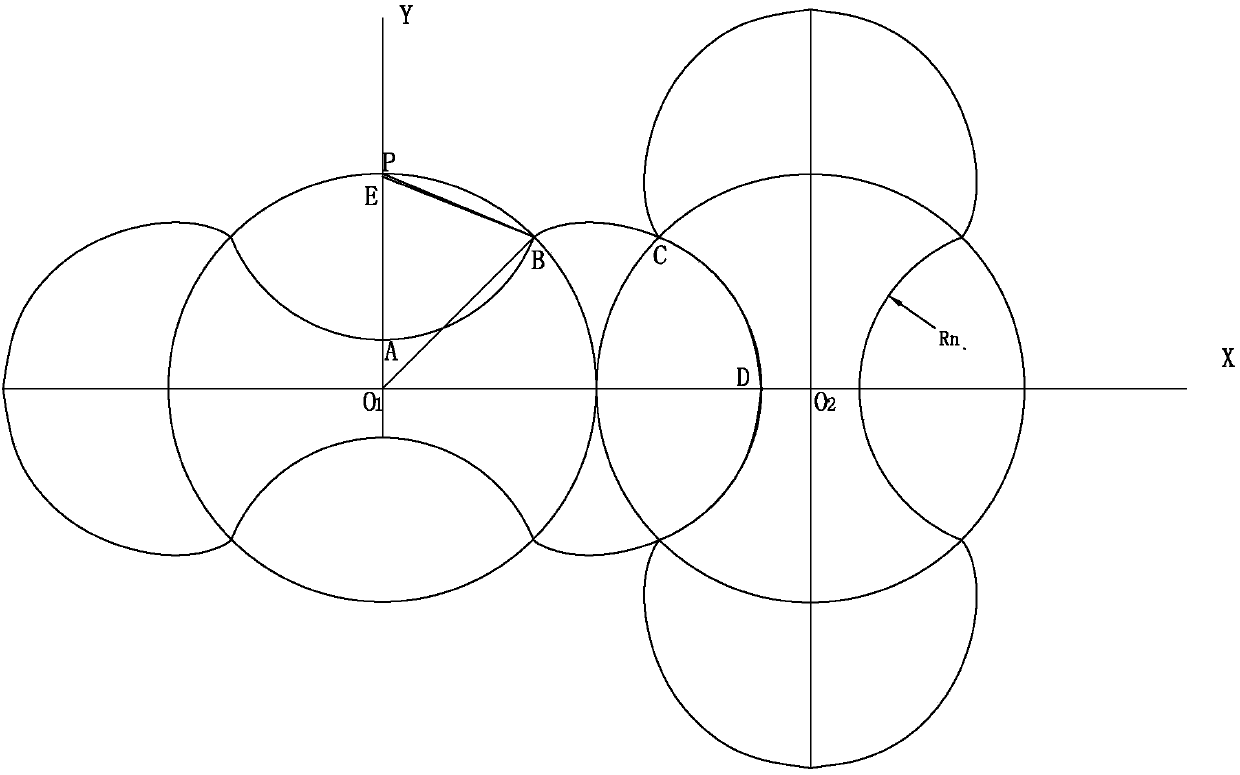

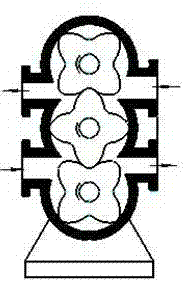

Multi-blade roots pump universal profile

InactiveCN107725364AAchieve proper engagementLarge area utilization factorRotary piston pumpsRotary piston liquid enginesGeneral purposeAir volume

The invention relates to a general profile of a multi-lobe Roots pump, in particular to a rotor profile of a multi-lobe Roots pump suitable for a Roots blower and a Roots vacuum pump. 2. n is a positive integer. The rotor body is composed of a valley shape and a peak shape connected in sequence. The profile line from the lowest point of any valley shape to the highest point of its adjacent peak shape is sequentially composed of the root arc AB section, the cycloid BC section and The conjugate curve CD segment of the root arc is composed. The radius ratio Rm / R of the top circle radius Rm to the pitch circle radius R of the general profile of the multi-lobe Roots pump of the present invention exceeds the extreme value, the area utilization coefficient of the rotor is high, and the air volume and air extraction rate are large.

Owner:SHANDONG BOZHONG VACUUM EQUIP LIMITED

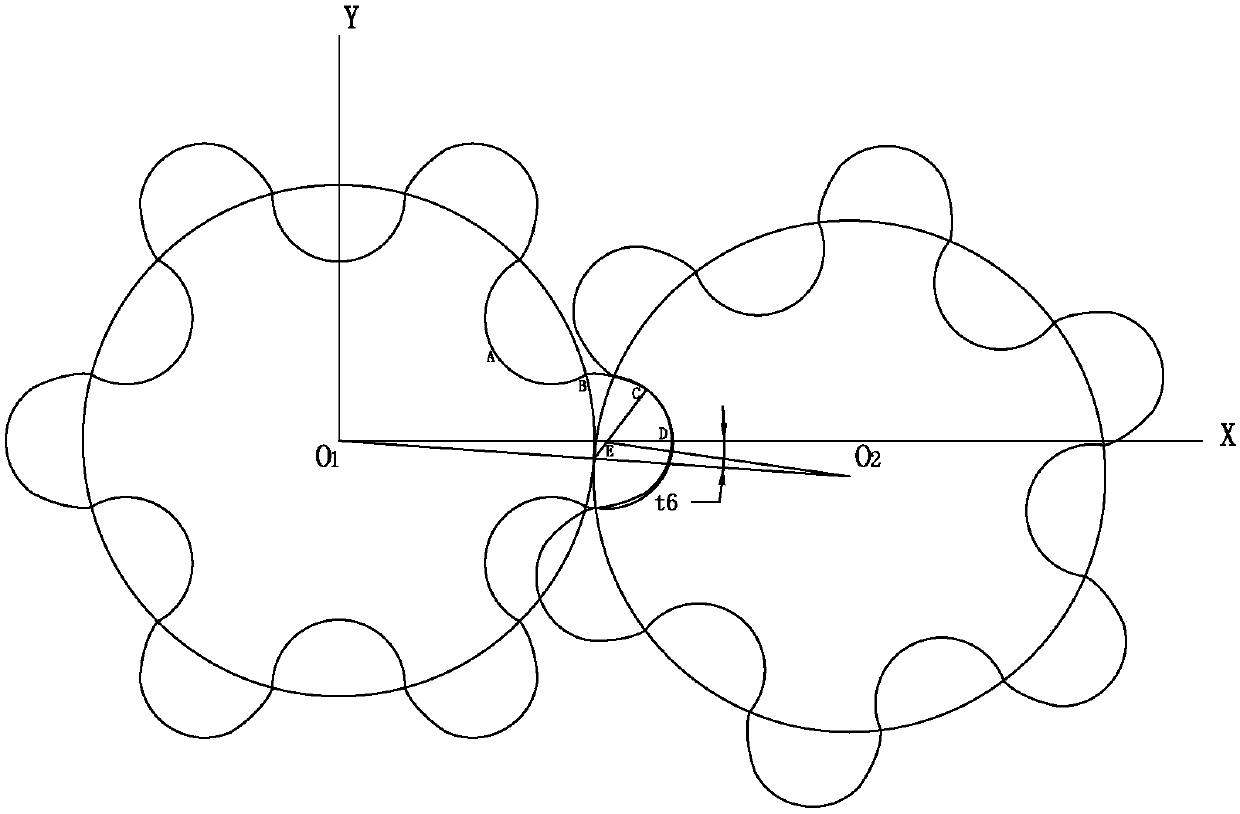

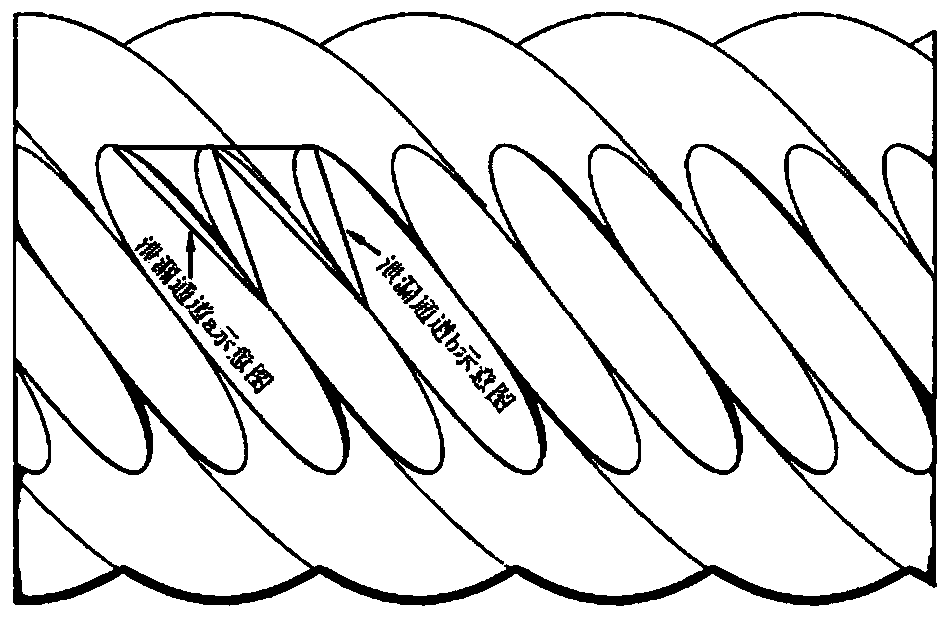

Asymmetric elliptic twisted blade roots rotor, compressor and expander

ActiveCN110762004AImprove machine performanceImprove volumetric efficiencyPump componentsEngine of intermeshing engagement typeShaft lengthSingle tooth

The invention discloses an asymmetric elliptic twisted blade roots rotor, a compressor and an expander. A single-tooth shape B3B2AlA2A3 of a rotor molded line consists of an elliptic arc section A1A2,an elliptic arc section B1B2, an elliptic envelope line section B2B3 and an elliptic envelope line section A2A3 connected end to end in sequence; two rotors can realize correct engagement in the rotary engagement process; the long and short shaft lengths of the elliptic arc section A1A2 and the long and short shaft lengths of the elliptic arc section B1B2 have different values; a complete rotor molded line is formed by repeating the following operations by n times: the single-tooth shape B3B2AlA2A3 is connected with a tooth shape B3B2A1A2A3 end to end after rotation around a rotor molded lineorigin O1; and n is the tooth number of the molded line. The asymmetric elliptic twisted blade roots rotor can effectively inhibit leakage between working cavities to improve overall performance of the twisted blade roots compressor or expander.

Owner:XI AN JIAOTONG UNIV

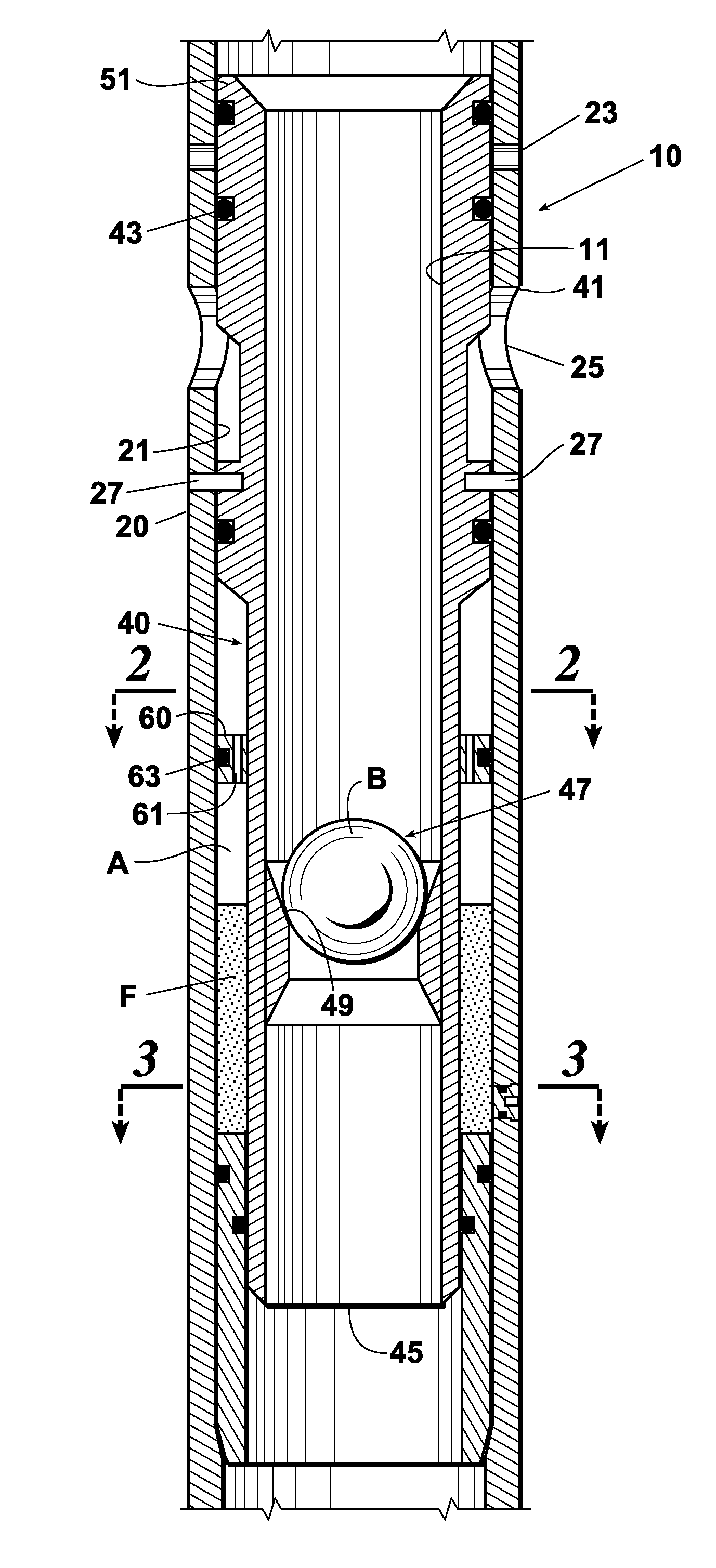

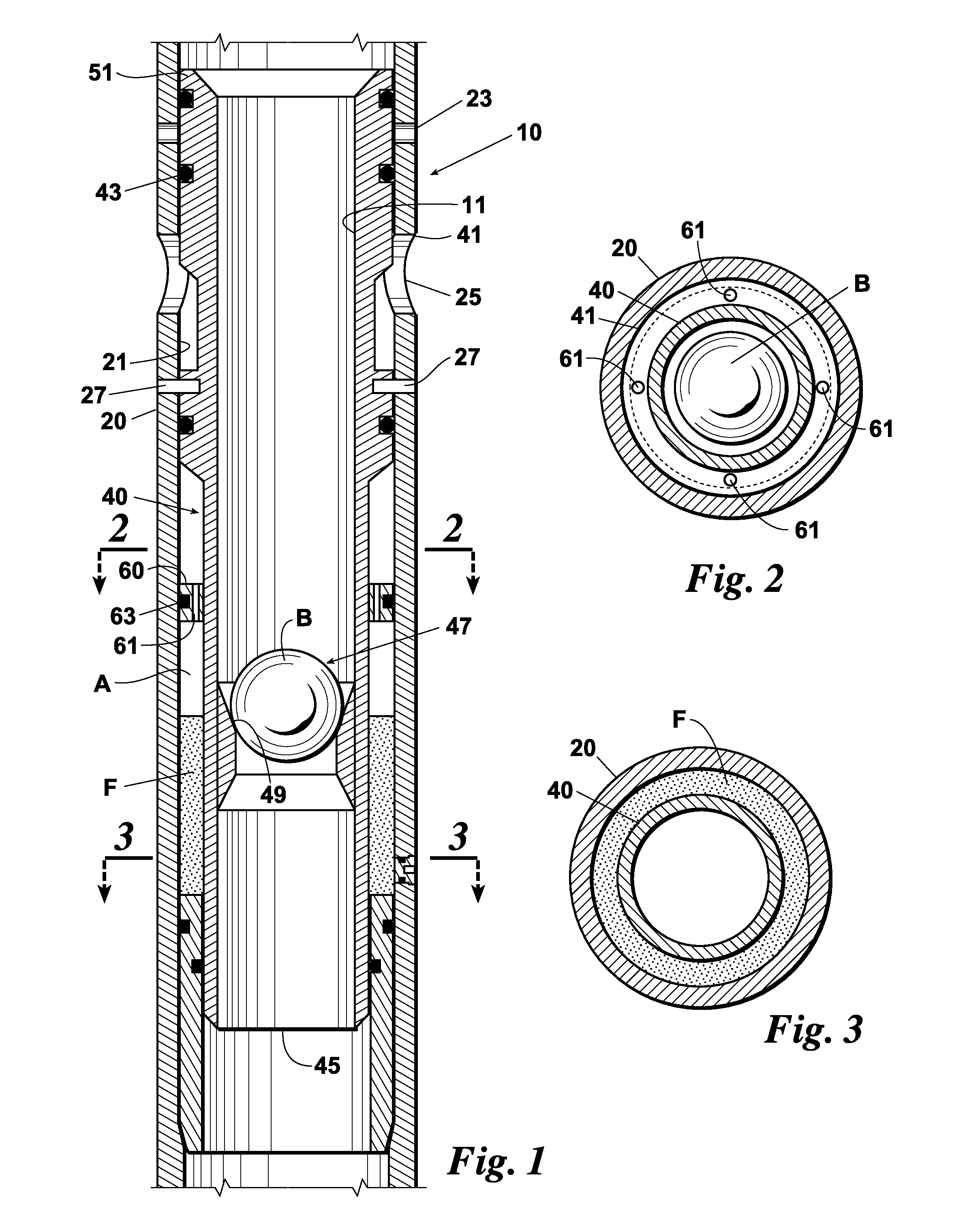

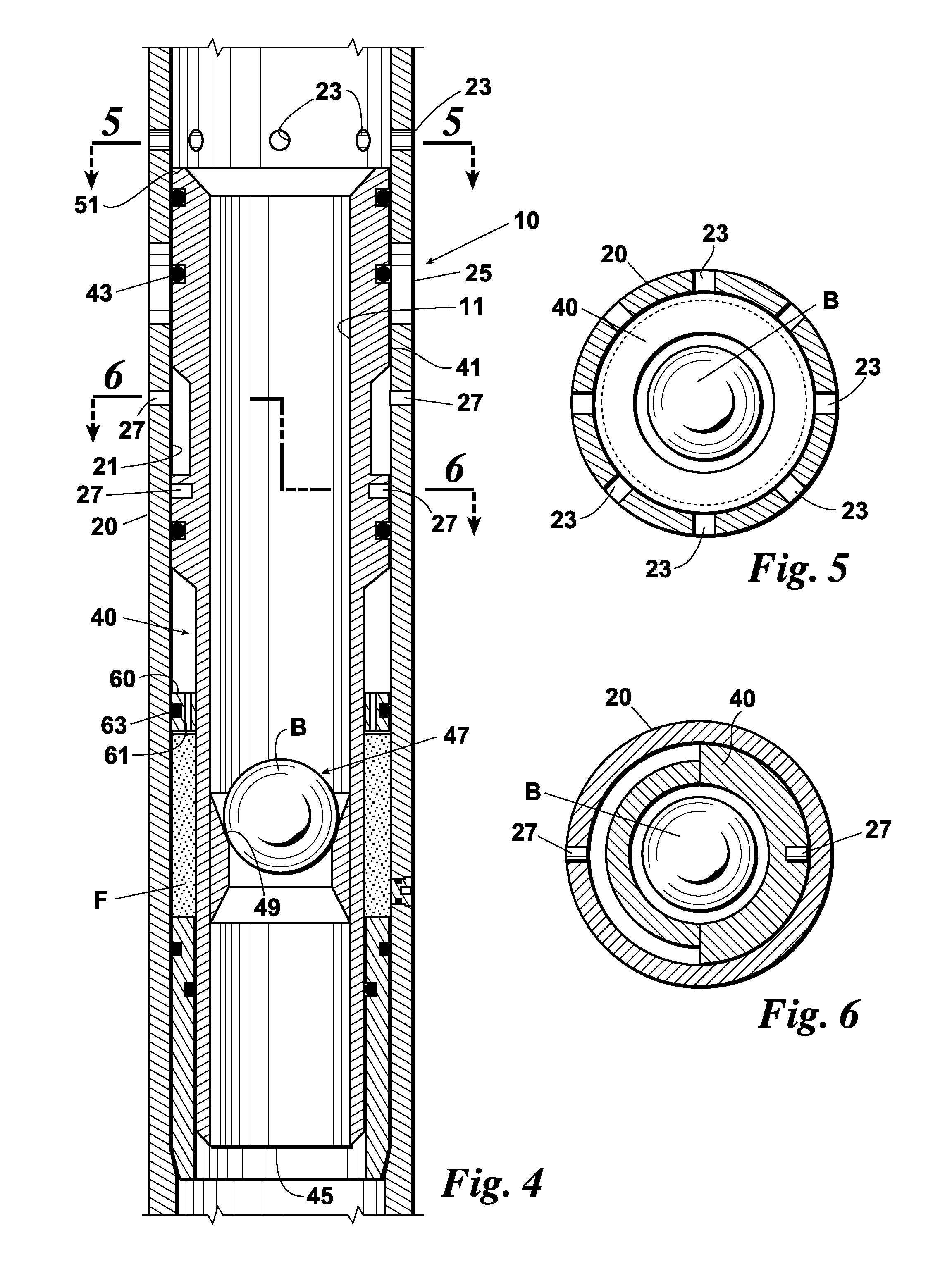

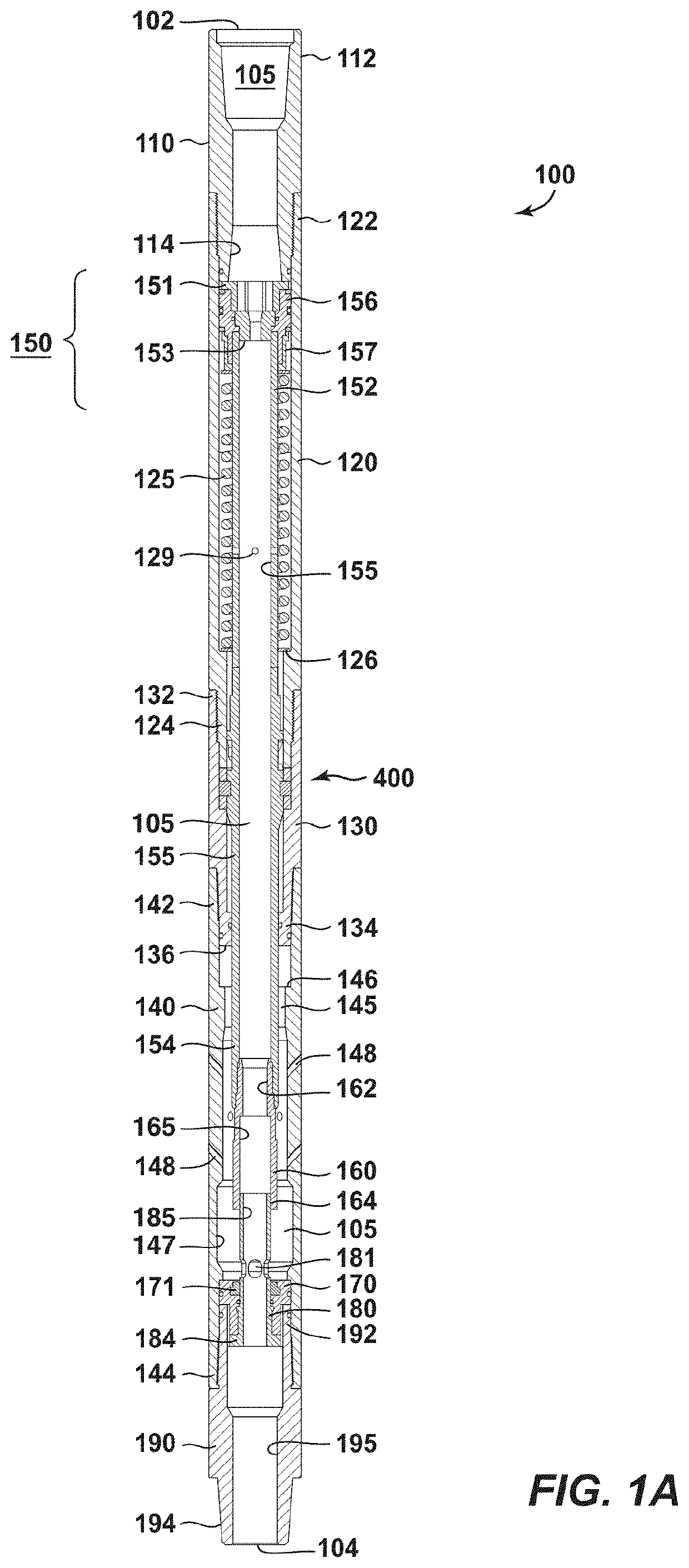

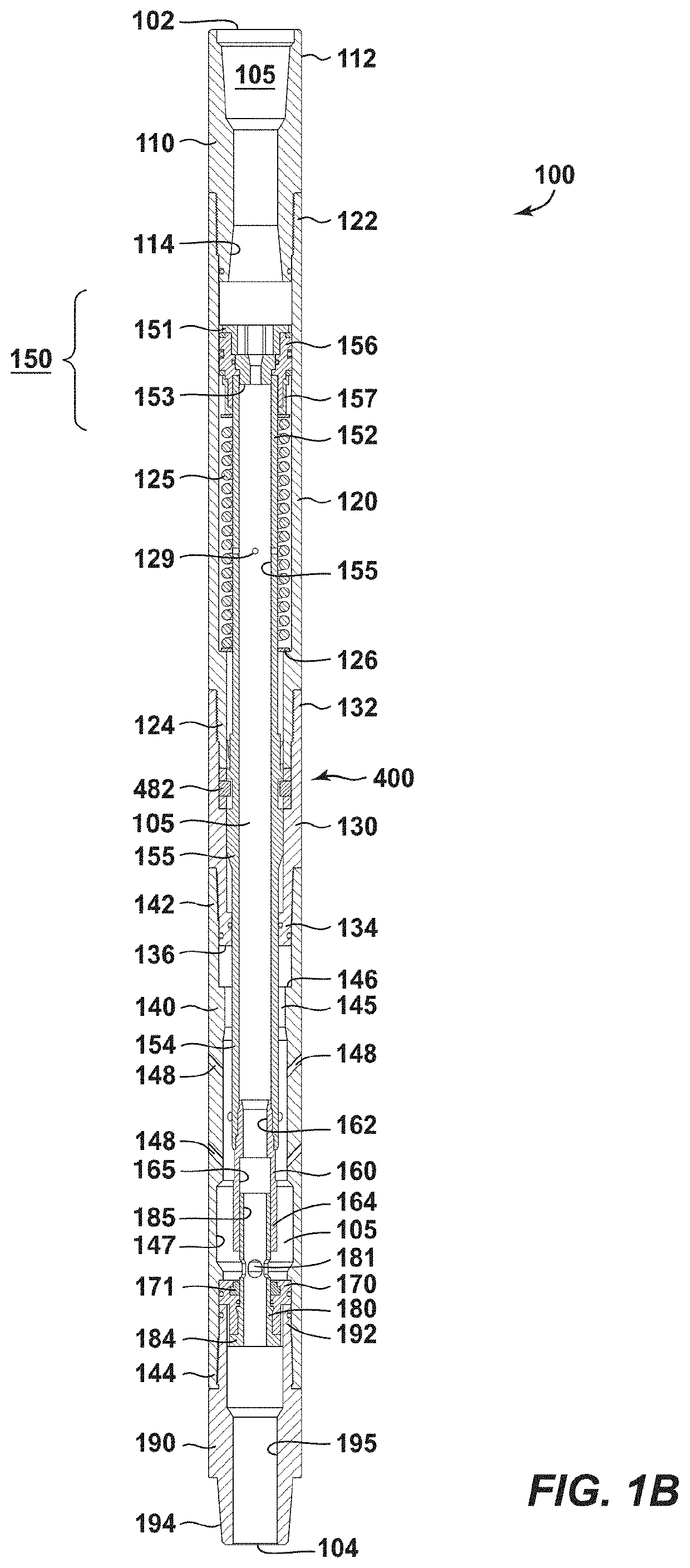

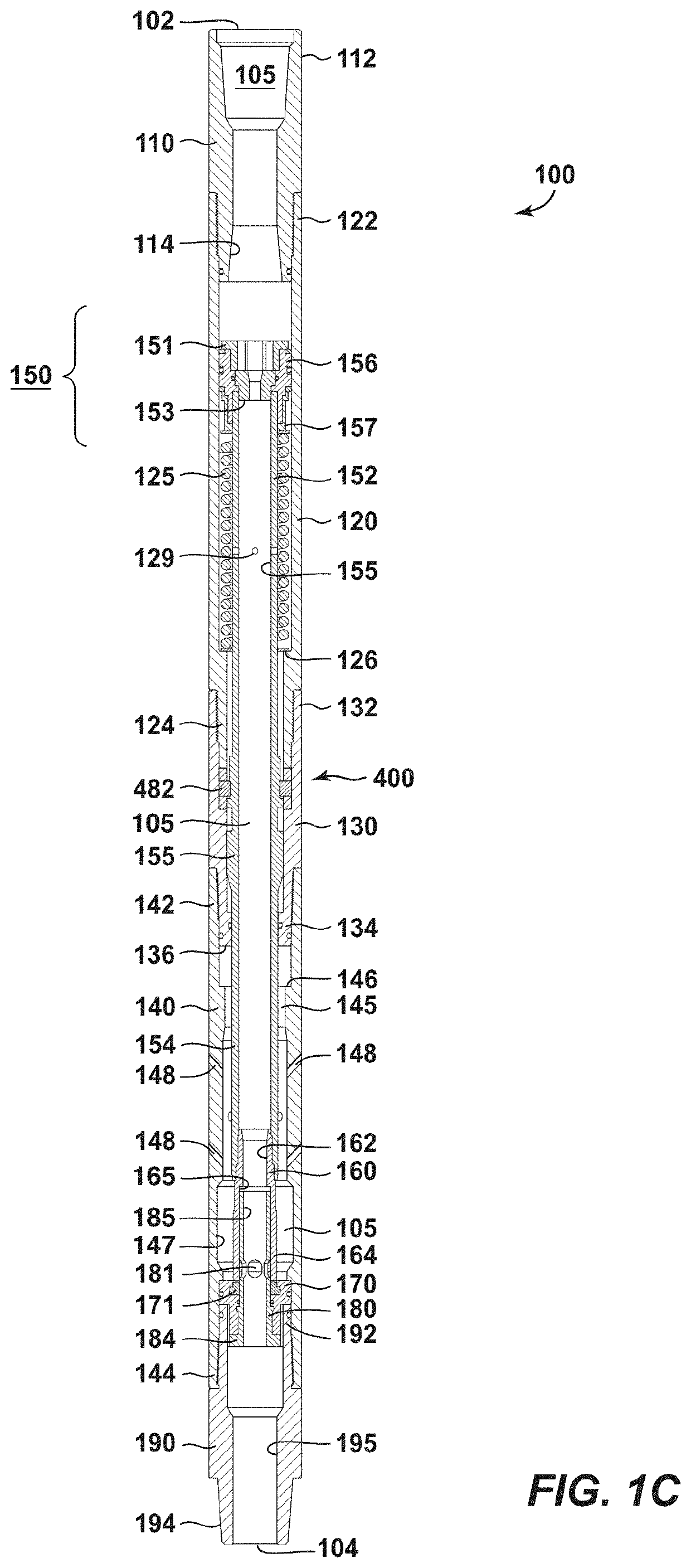

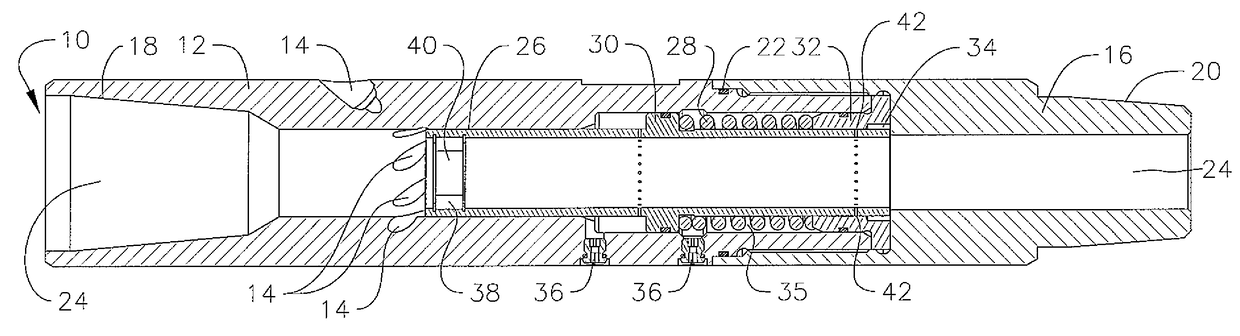

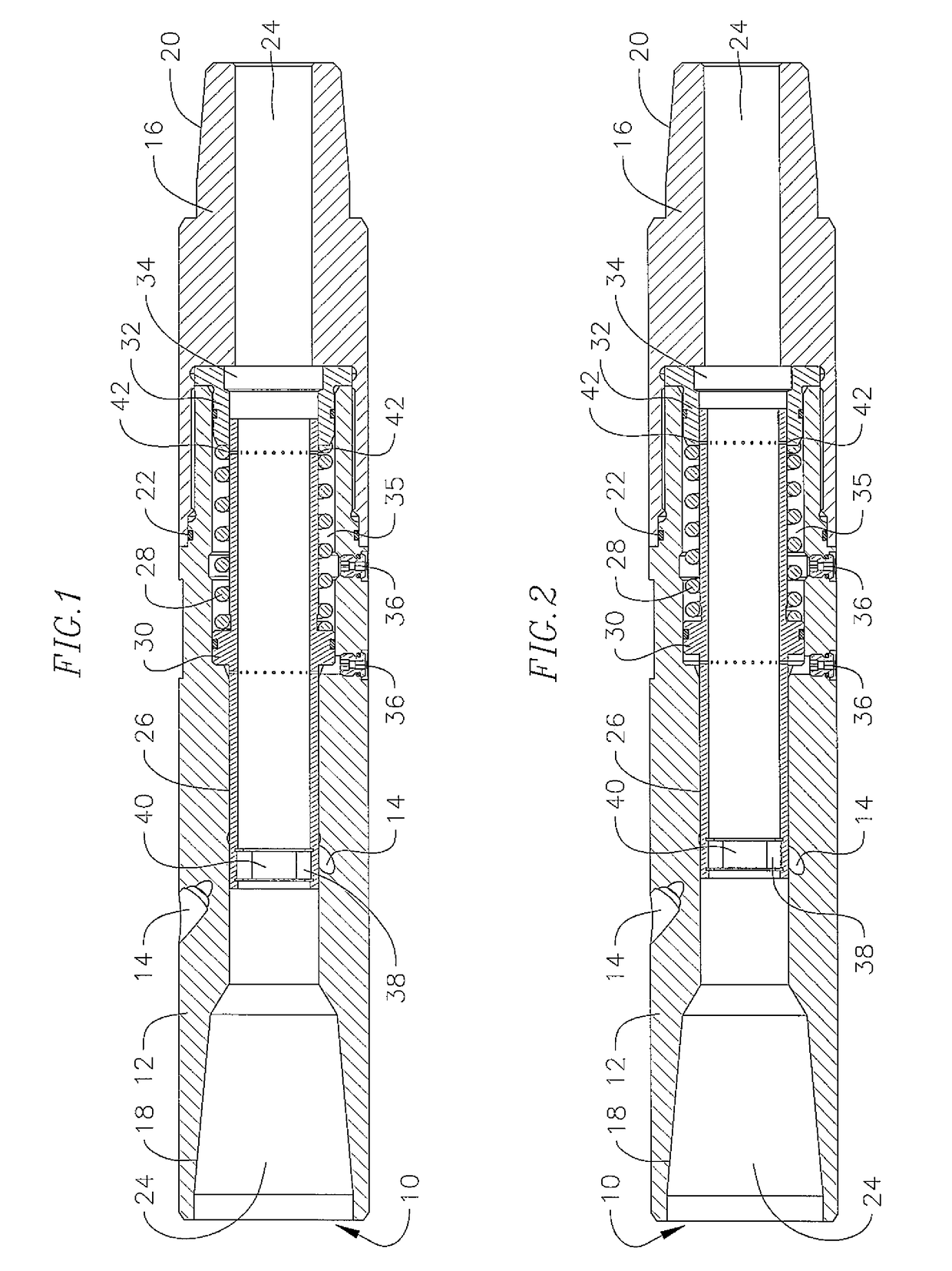

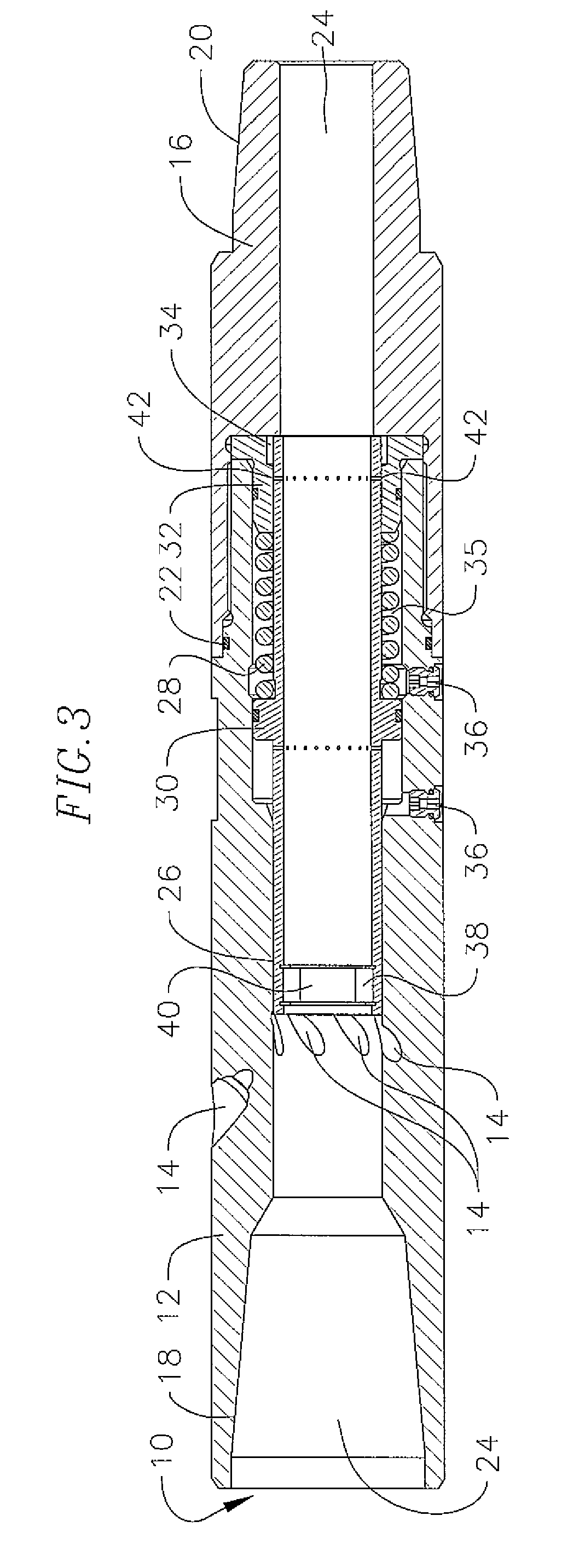

Multi-Cycle Wellbore Clean-Out Tool

ActiveUS20190360308A1Reduce distanceNot be restrictConstructionsCleaning apparatusEngineeringCoiled tubing

A clean-out tool and method of cleaning out a wellbore. The clean-out tool is placed at the end of a coiled tubing or other conveyance string. The clean-out tool comprises a tubular housing providing an elongated bore through which fluid flows. The tubular housing has back-jetting ports disposed at an upward angle therein. The clean-out tool is configured to operate in a back-jetting mode when the clean-out fluid is pumped into the tubular housing at a first flow rate. In this mode, a portion of clean-out fluid flows through the bore, up an annular region and then through the back jetting ports. The clean-out tool is further configured to operate in a fluid flow-through mode when the clean-out fluids are pumped into the bore of the tubular housing at a second flow rate. In this mode, all of the clean-out fluid flows through the clean-out tool.

Owner:STANG TECH

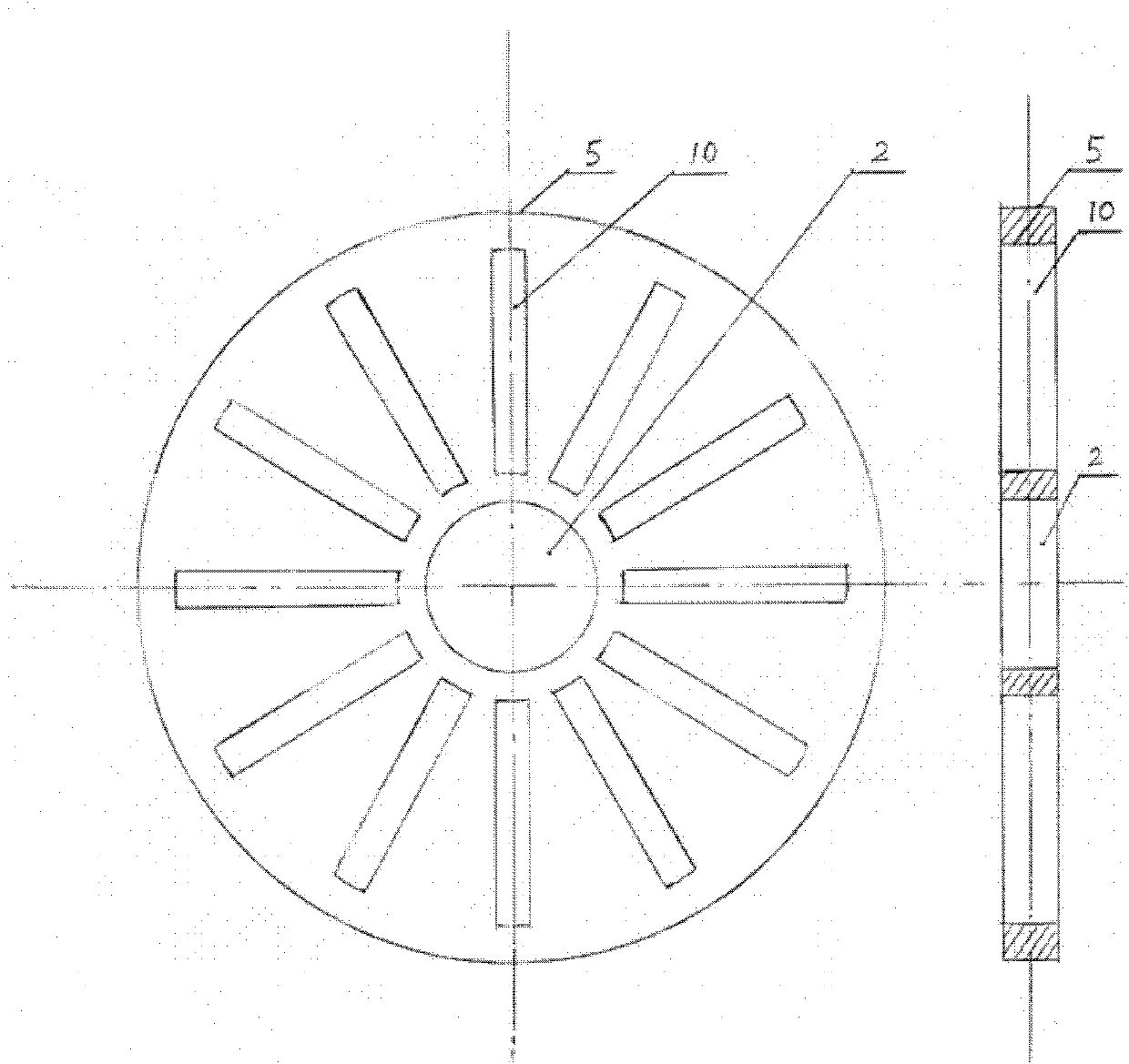

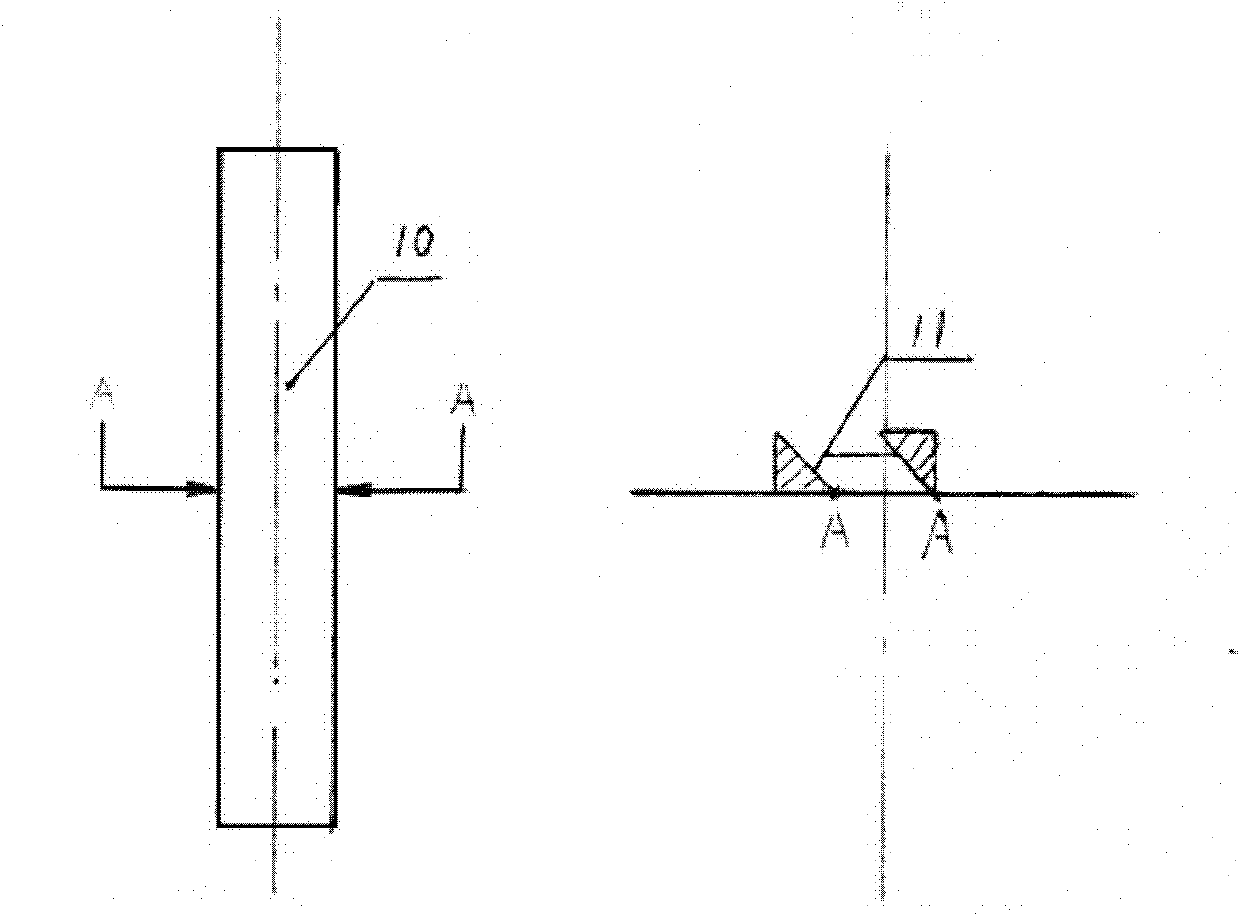

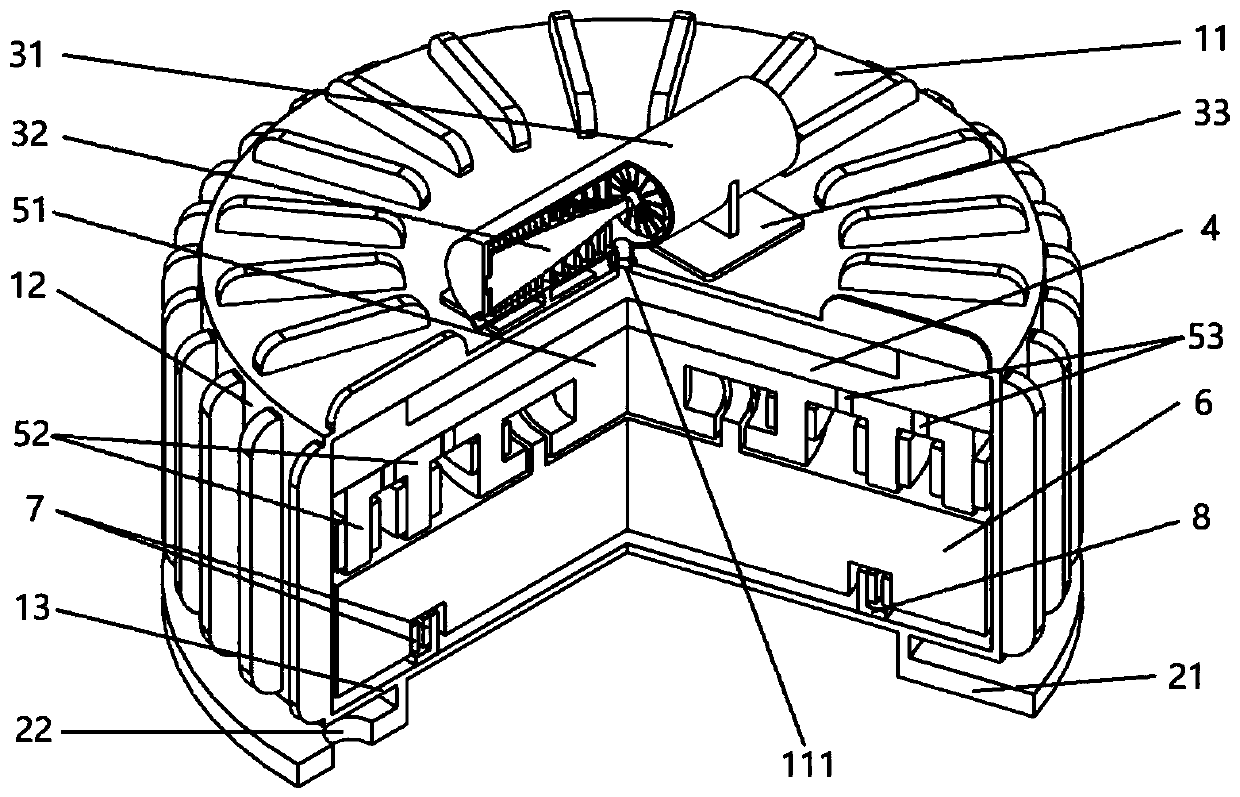

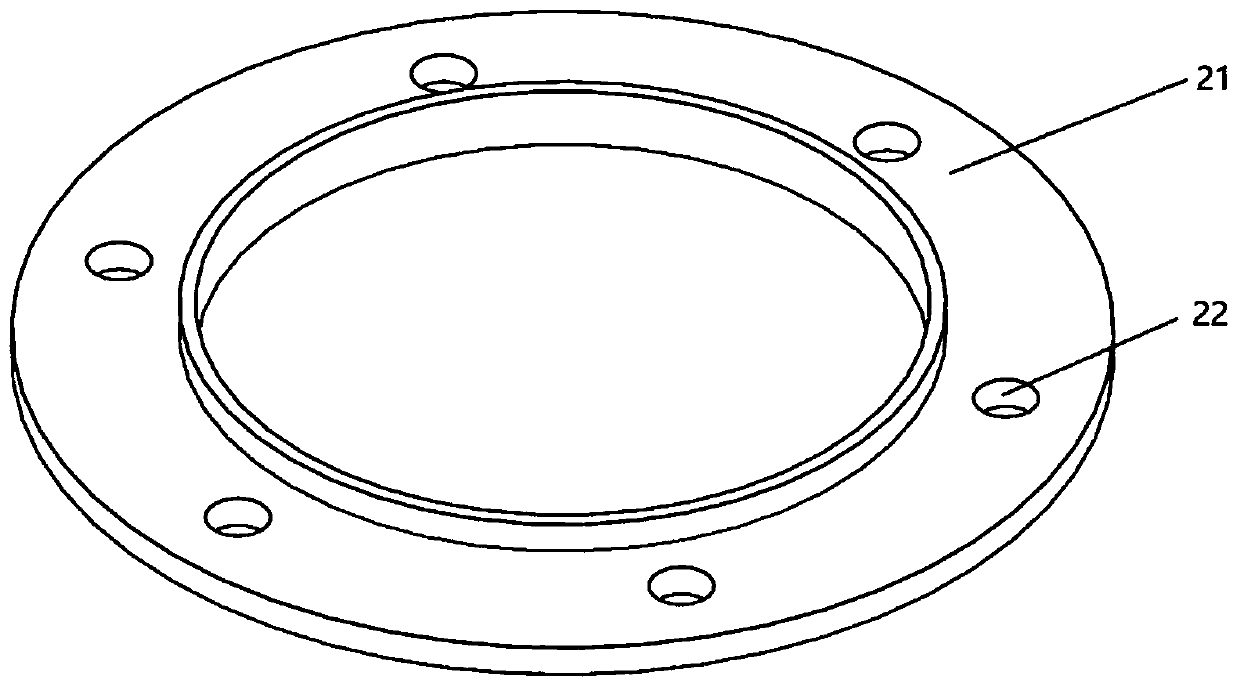

Disc type molecular pump

ActiveCN102889219AAvoiding the Cons of DamageIncrease pumping ratePump componentsAxial flow pumpsHigh resistanceSlant angle

The invention discloses a disc type molecular pump, which comprises a motive disc, a static disc and a pump body. The disc type molecular pump is characterized in that a radial rectangular or a ladder-shaped air flue is arranged on the motive disc and the static disc with certain thicknesses, so as to allow gas molecules on the discs to communicate; and slant angles between the two radial sides of the air flue and the horizontal planes of the discs can be changed from 0 to 180 degrees respectively. In the two radial sides of the air flue on the motive disc and the static disc, as one side mainly for delivering gas molecules, the inclination direction of the two is opposite, while the other side is subject to associating with the delivery of the gas molecules. An air exhaust unit comprising multi-stage motive discs and static discs drives the gas molecules to move in the fixed direction, so as to drag, deliver and compress the gas molecules, thereby performing air exhaust. The disc type molecular pump has the characteristics of simple structure, convenience in manufacturing and processing, large mechanical strength and high resistance against large flow gas impact, and can be widely applied to the medium and high vacuum fields.

Owner:李晨 +1

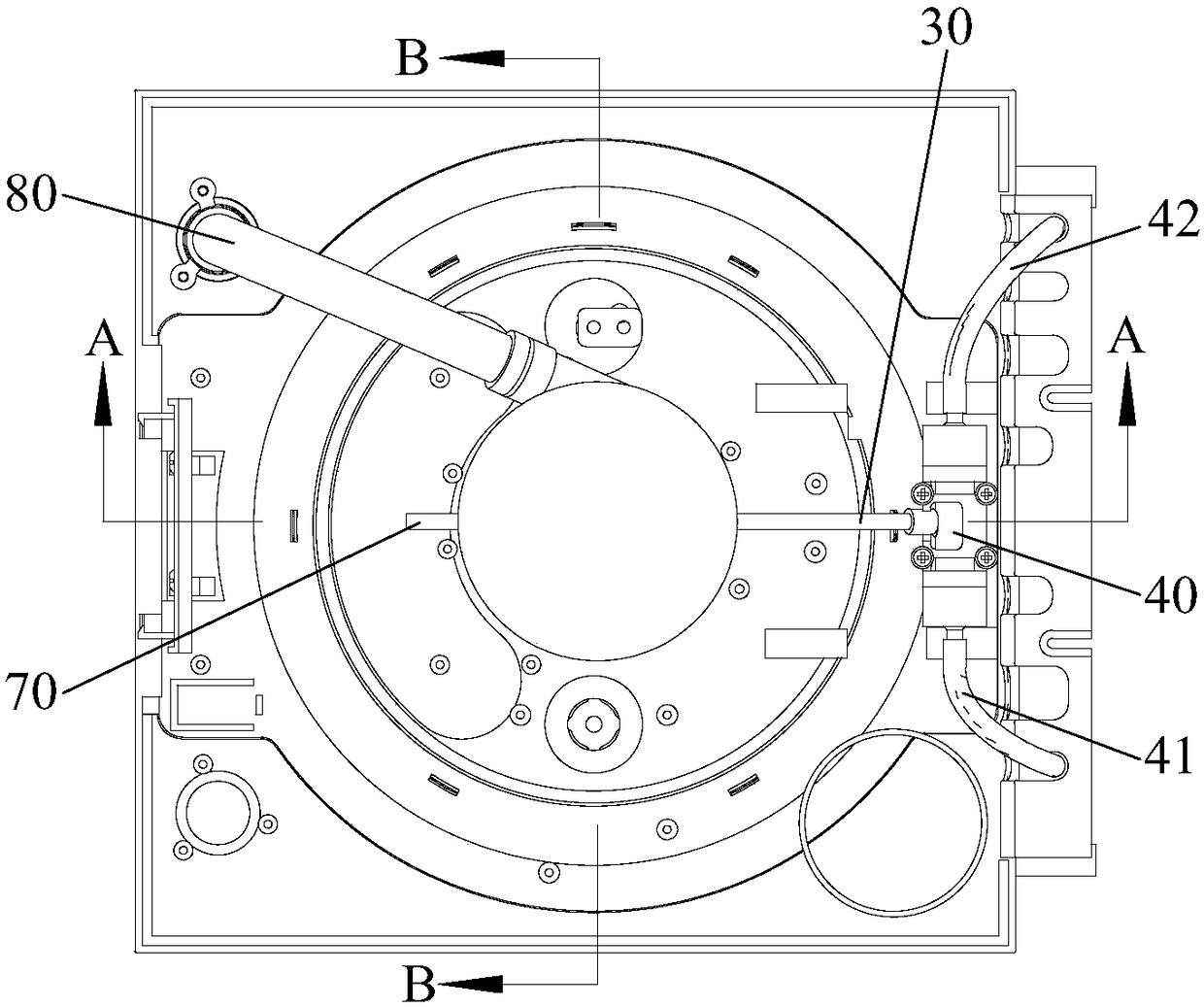

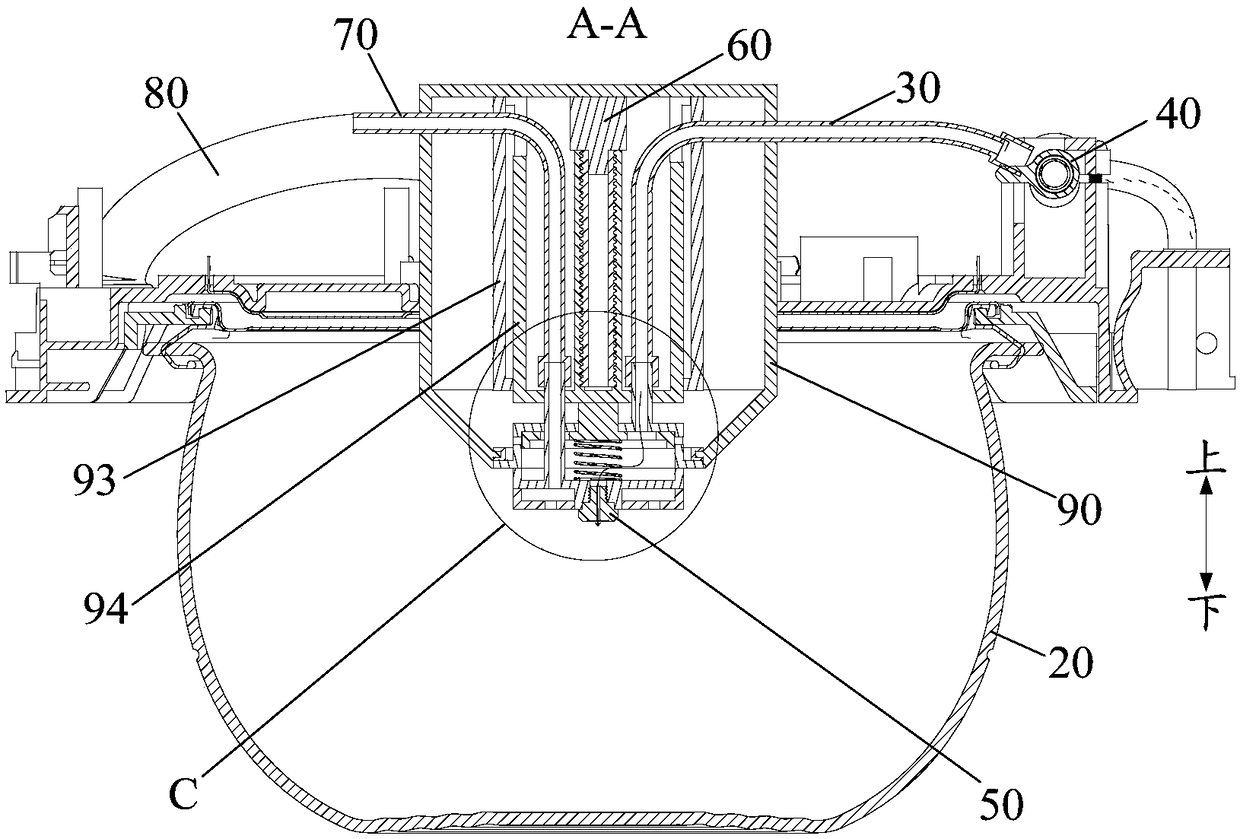

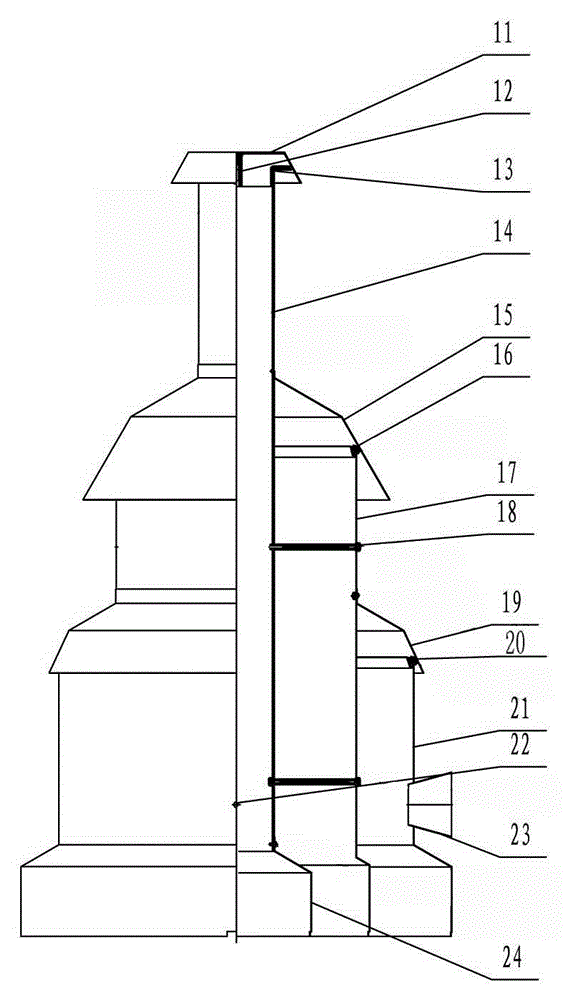

High-integration flywheel energy storage device with novel horizontal self-vacuum chamber

ActiveCN110165821ARealize integrationShorten the axial lengthMechanical energy handlingMagnetic bearingFlywheel energy storage

The invention discloses a high-integration flywheel energy storage device with a novel horizontal self-vacuum chamber. A vacuum chamber is formed through a casing, an upper end of the vacuum chamber is a three-degree-of-freedom magnetic bearing fixedly connected with the casing by a bracket, which includes a radial magnetic bearing, an axial magnetic bearing and a permanent magnet, a lower end ofthe three-degree-of-freedom magnetic bearing is a flywheel rotor, a single-winding outer rotor bearingless motor is located at a lower end of the flywheel rotor, a rotor of the motor is mounted in anannular groove at a lower surface of the flywheel rotor, and a stator is fixed to a lower end of the casing by a bracket. The device is advantaged in that five-degree-of-freedom balance of the flywheel rotor is realized by the three-degree-of-freedom magnetic bearing combined with the single-winding outer rotor bearingless motor, a control mode is simplified, the integration degree is improved, ahorizontal composite vacuum pump is arranged at an upper end of the casing, a vacuum pump is a double-rotor structure which is mirror-symmetrical to the left and right, and the vacuum degree and the pumping speed are improved.

Owner:JIANGSU UNIV

Multi-Cycle Wellbore Clean-Out Tool

ActiveUS20200087999A1Reduce the radial distanceReduce distanceCleaning apparatusFlushingCoiled tubingEngineering

A clean-out tool and method of cleaning out a wellbore. The clean-out tool is placed at the end of a coiled tubing or other conveyance string. The clean-out tool comprises a tubular housing providing an elongated bore through which fluid flows. The tubular housing has back-jetting ports disposed at an upward angle therein. The clean-out tool is configured to operate in a back-jetting mode when the clean-out fluid is pumped into the tubular housing at a first flow rate. In this mode, at least a portion of clean-out fluid flows through the bore, up an annular region and then through the back jetting ports. The clean-out tool is further configured to operate in a fluid flow-through mode when the clean-out fluids are pumped into the bore of the tubular housing at a second flow rate. In this mode, all of the clean-out fluid flows through the clean-out tool.

Owner:STANG TECH

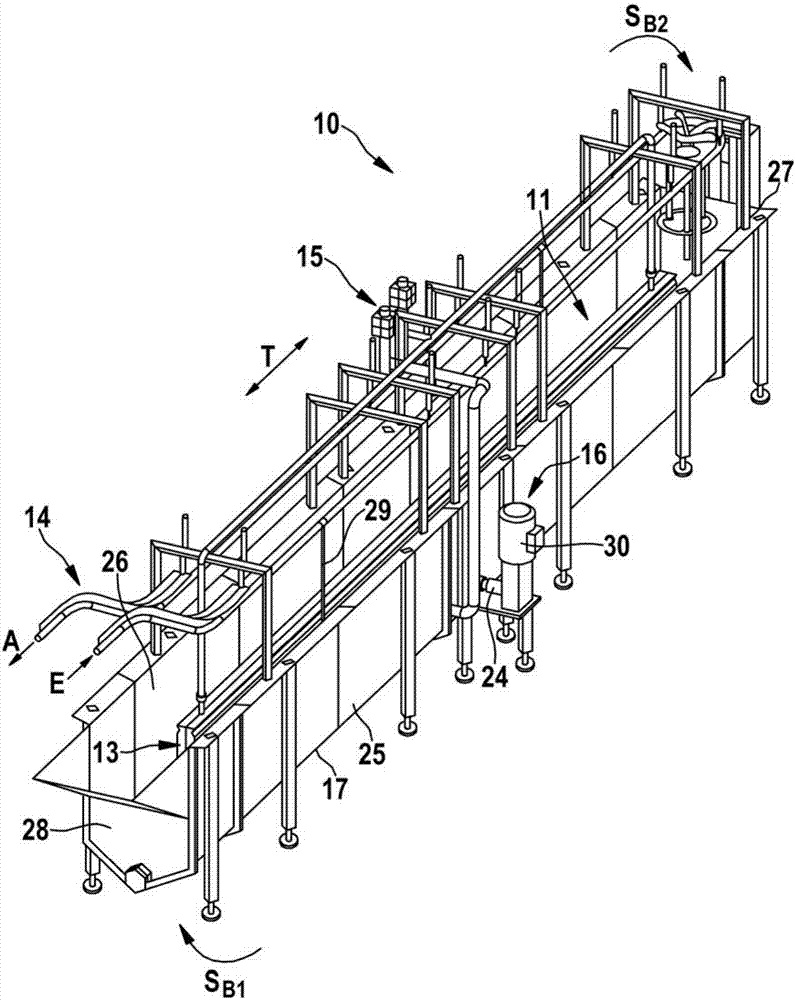

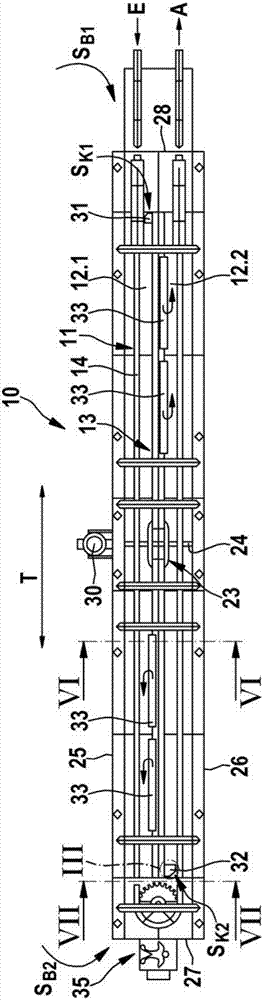

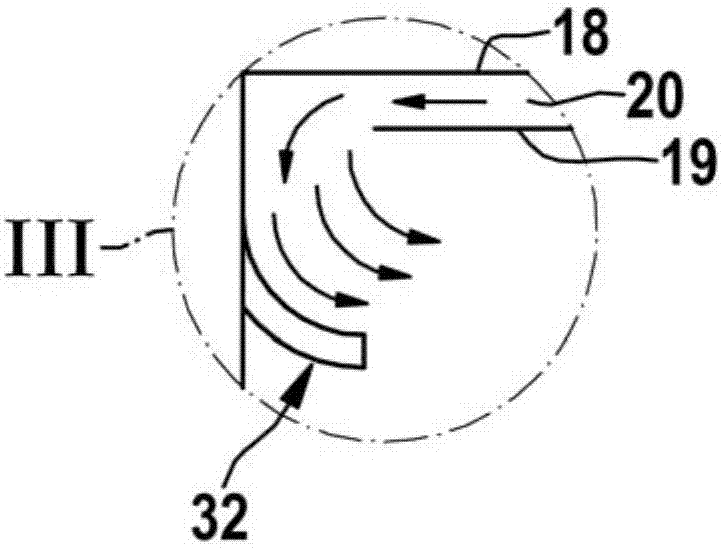

Device and method for scalding slaughtered poultry

ActiveCN107427015AEasy maintenanceRisk of impact preventionClimate change adaptationSlaughtering accessoriesEngineeringDrive shaft

Owner:丹麦巴德尔食品系统公司

Multi-cylinder oilless compressor of refrigerating agent recovery machine

InactiveCN101725497AImprove work efficiencyIncrease pumping rateMulti-stage pumpsPositive-displacement liquid enginesExhaust valveRefrigerant reclamation

The invention discloses a multi-cylinder oilless compressor of a refrigerating agent recovery machine, comprising a box body, a cylinder, a crankshaft arranged inside the box body, and a motor provided with an output main shaft connected with the crankshaft, wherein the crankshaft is provided with an eccentric shaft part which is taken as a common driving shaft of a plurality of connecting rods; the eccentric shaft part is movably connected with the plurality of connecting rods which are sequentially arranged along the axial direction of the eccentric shaft part; the box body is provided with cylinders which have the number being same as that of the connecting rods; the cylinders are evenly distributed along the circumference correspondingly to the center of the crankshaft; each cylinder is internally provided with an air inlet valve, an exhaust valve and a piston; and the pistons are connected with the corresponding connecting rods in the cylinders where the pistons are arranged. The multi-cylinder oilless compressor overcomes the limitation that the existing compressor only has a single cylinder or double cylinders, expands the structure of three cylinders, four cylinders, six cylinders or eight cylinders on the basis of the double cylinders, and has the characteristics of small volume, light weight, simple and compact structure, rapid refrigerating agent recovery and thorough recovery.

Owner:蒋友荣

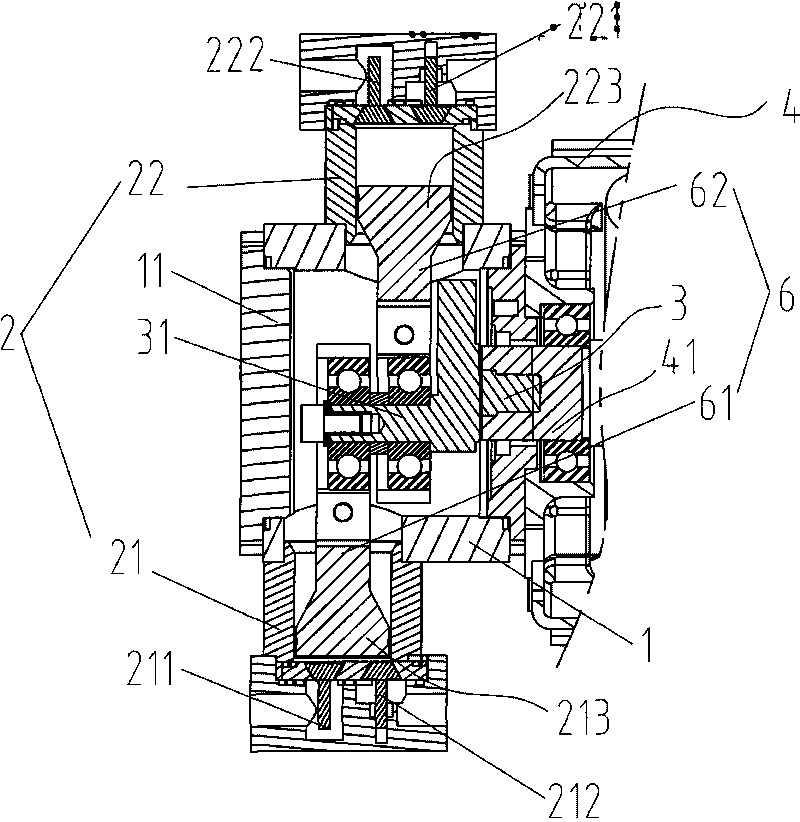

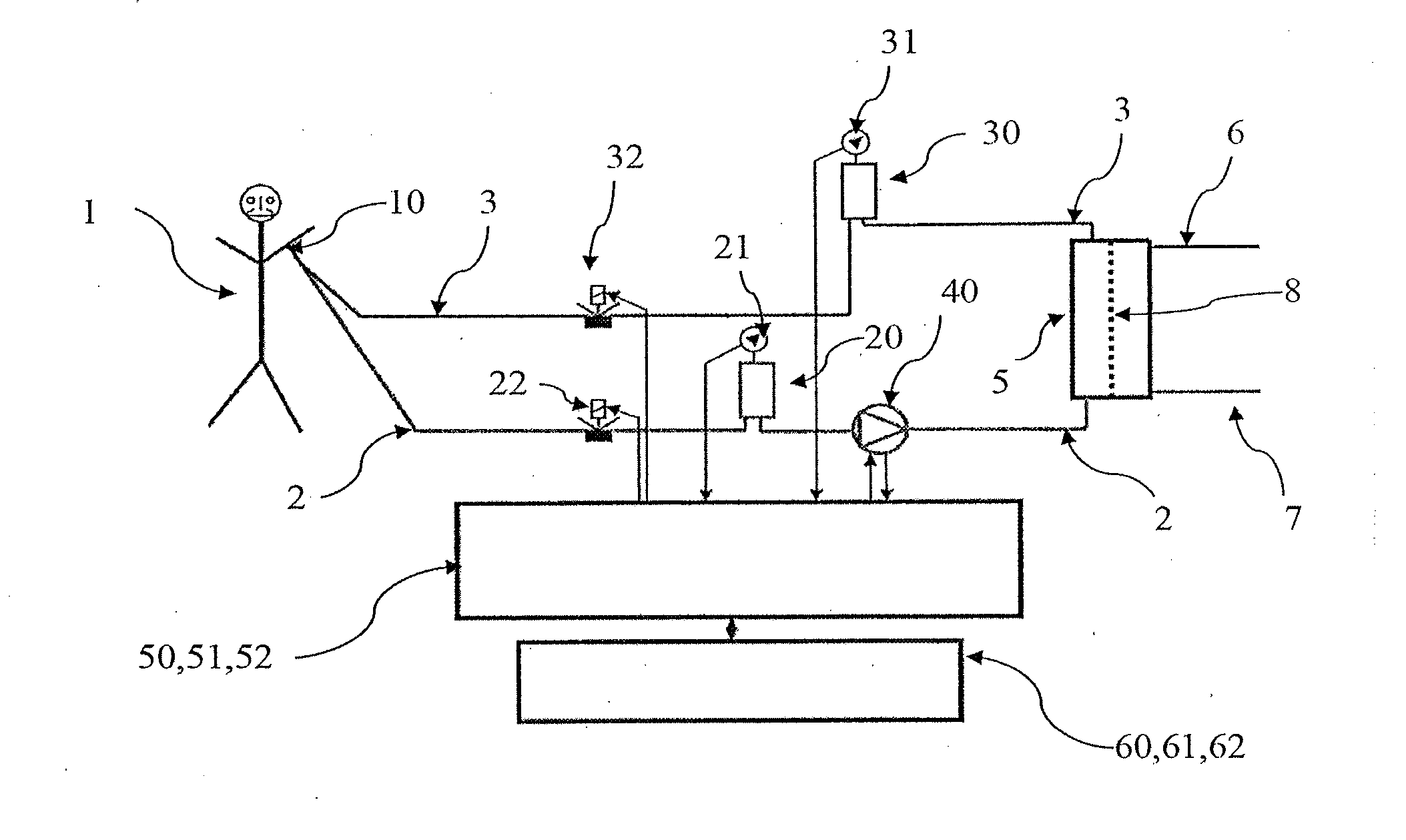

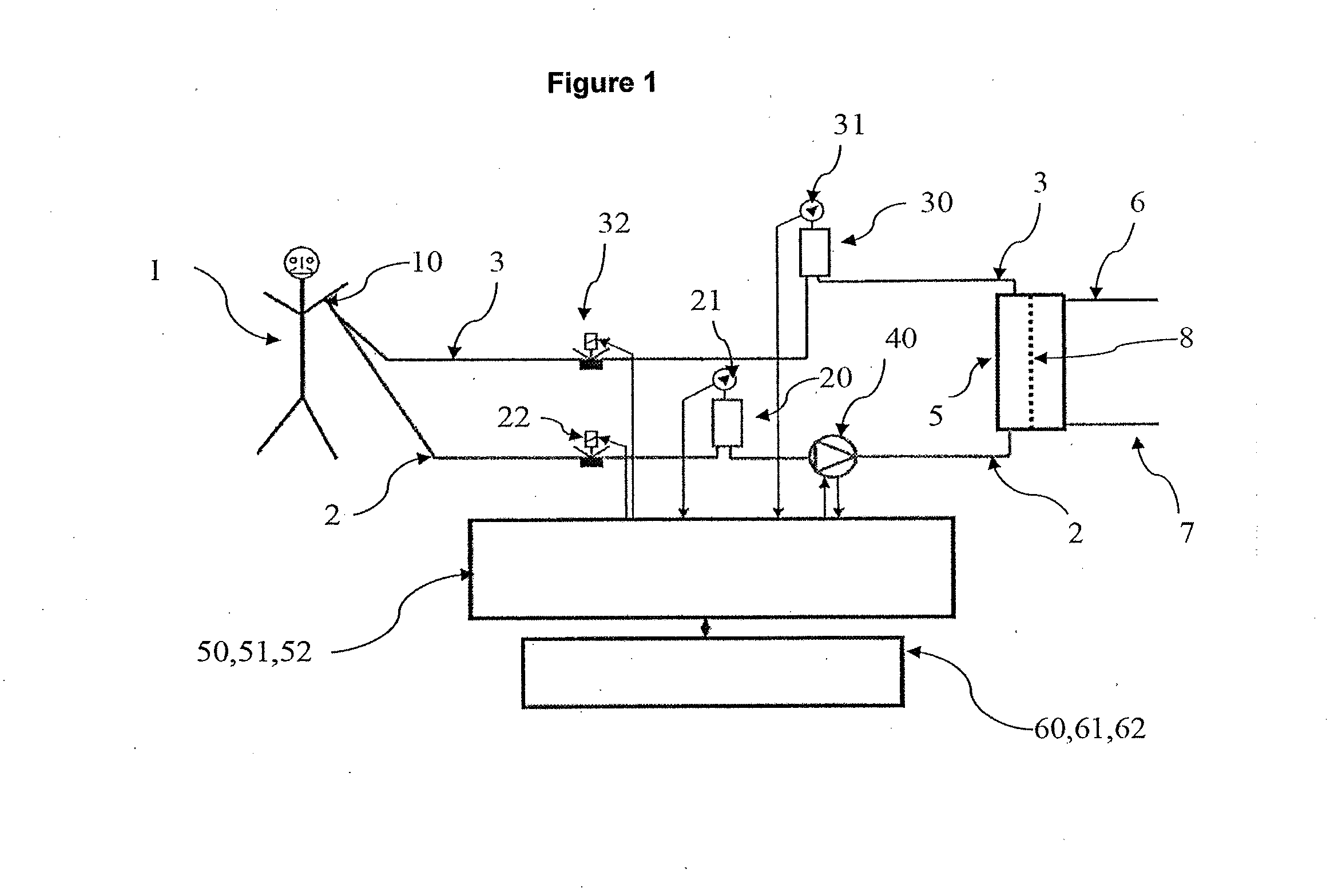

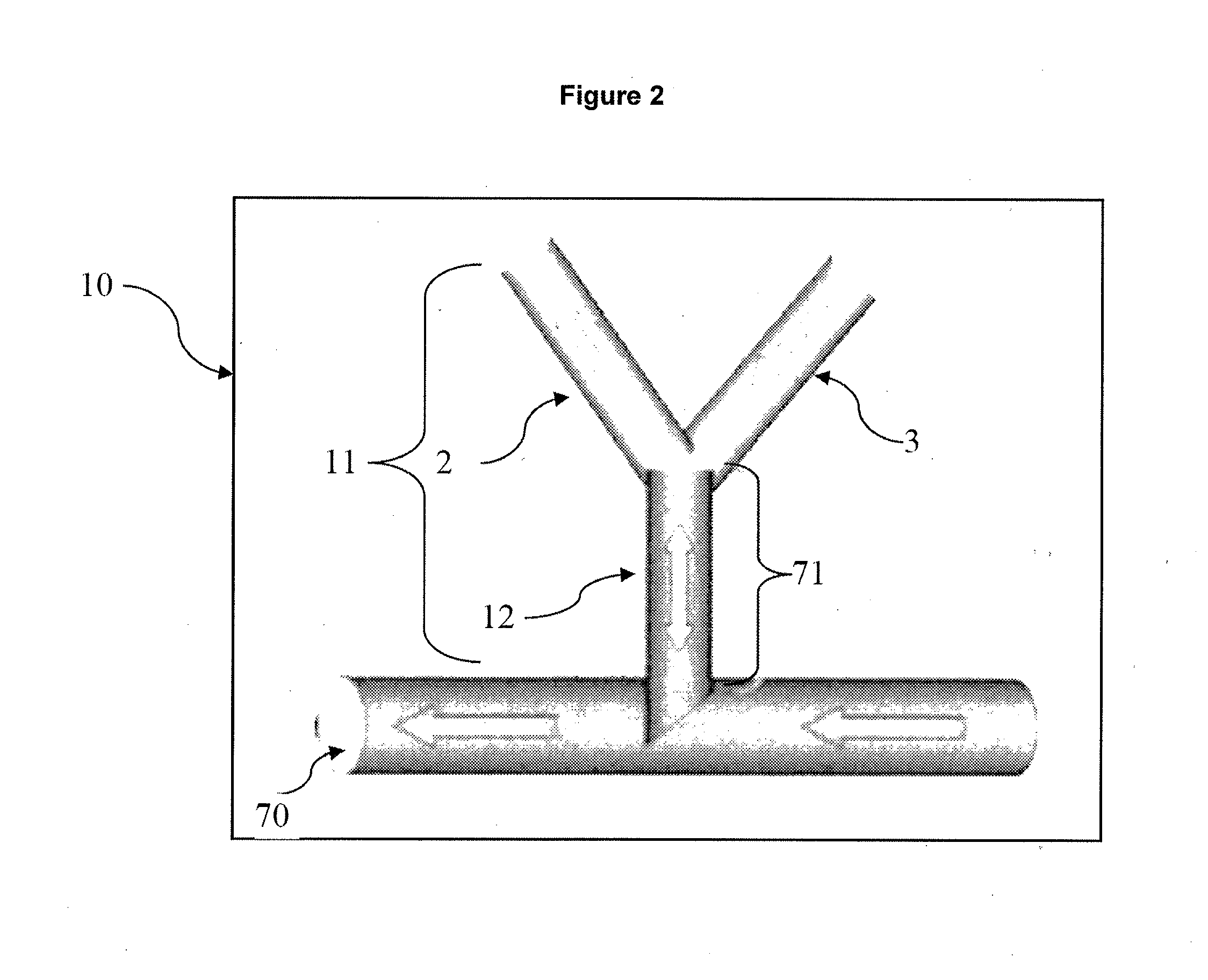

Extracorporeal blood treatment appliance

ActiveUS20130331758A1Effective performanceReduce rateMedical devicesReciprocating systemVenous lineVein

The invention relates to an extracorporeal blood treatment apparatus witha control device (50) for controlling the opening and closing of an arterial line (2) with simultaneous closing and opening of a venous line (3) in a single-lumen-arrangement (10), with which untreated blood is removed through the single-lumen-arrangement (10) and the arterial line (2), led through a blood treatment device (5) and treated blood is fed back through the venous line (3) and the single-lumen-arrangement (10),an arterial line container (20) which is arranged in the arterial line (2) in front of the blood treatment device (5),a venous line container (30) which is arranged in the venous line (3) following the blood treatment device (5),a sensor device (31) for detecting an amount of treated blood being above a limit value in the venous line container (30),a sensor device (21) for detecting an amount of untreated blood being below a limit value in the arterial line container (20),an arterial line closure device (22) for closing the arterial line (2) with simultaneous opening of the venous line (3) in response to a signal A which is transmitted by the sensor device (31) to the arterial line closure device (22),a venous line closure device (32) for closing the venous line (3) with simultaneous opening of the arterial line (2) in response to a signal B which is transmitted by the sensor device (21) to a venous line closure device (32) andat least one pump (40) and is characterized in that a control device (50) is provided, with which a phase volume Vact is adjustable automatically in dependence on the current pumping rate QBP of the at least one pump (40) during a phase to a predefined value Vnom (FIG. 1).

Owner:B BRAUN AVITUM

Three-axis Roots vacuum pump

ActiveCN101985935BImprove balanceCompact structureRotary piston pumpsRotary piston liquid enginesDrive shaftGear wheel

The invention relates to a vacuum pump, in particular to a three-axis Roots vacuum pump, which comprises a motor, a spindle and driven shafts, wherein the spindle is provided with a driving gear; driven gears meshed with the driving gear are arranged on the driven shafts; Roots rotors are arranged on the spindle and the driven shafts; and the two driven shafts are parallelly and symmetrically arranged on two sides of the spindle. The three-axis Roots vacuum pump has the characteristics of compact and symmetric structure, air suction under the action of the three axes and no oil in a pump cavity and realizes a high air suction speed.

Owner:NORTHEASTERN UNIV LIAONING +1

Vacuumizing hole of vacuum glass and manufacturing method thereof

InactiveCN104291663ASimple structureStable and reliable productionGlass reforming apparatusGlass productionAir tightnessMaterials science

A vacuumizing hole of a vacuum glass is characterized in that the a manufacturing method includes following steps: punching an upper glass of the vacuum glass to form the vacuumizing hole; manufacturing a sealing ring around the vacuumizing hole on the lower surface of the upper glass and manufacturing the sealing ring at the position corresponding to the vacuumizing hole on the upper surface of the lower glass, wherein the sealing ring on the upper glass can be inserted into the sealing ring on the lower glass to form a vacuumizing channel between the two sealing rings; vacuumizing the vacuumizing hole and performing a heating process to enable a metal solder to melt into a liquid which is remained in the sealing ring on the lower glass, wherein the sealing ring on the upper glass is also sunk in the liquid; enabling the vacuumizing hole to seal automatically through a liquid sealing principle; decreasing the temperature to solidifying the liquid to achieve air-tightness sealing of the vacuumizing hole. The method can achieve mass production, can greatly improve production efficient and qualification ratio of a vacuum glass and can reduce production cost.

Owner:戴长虹

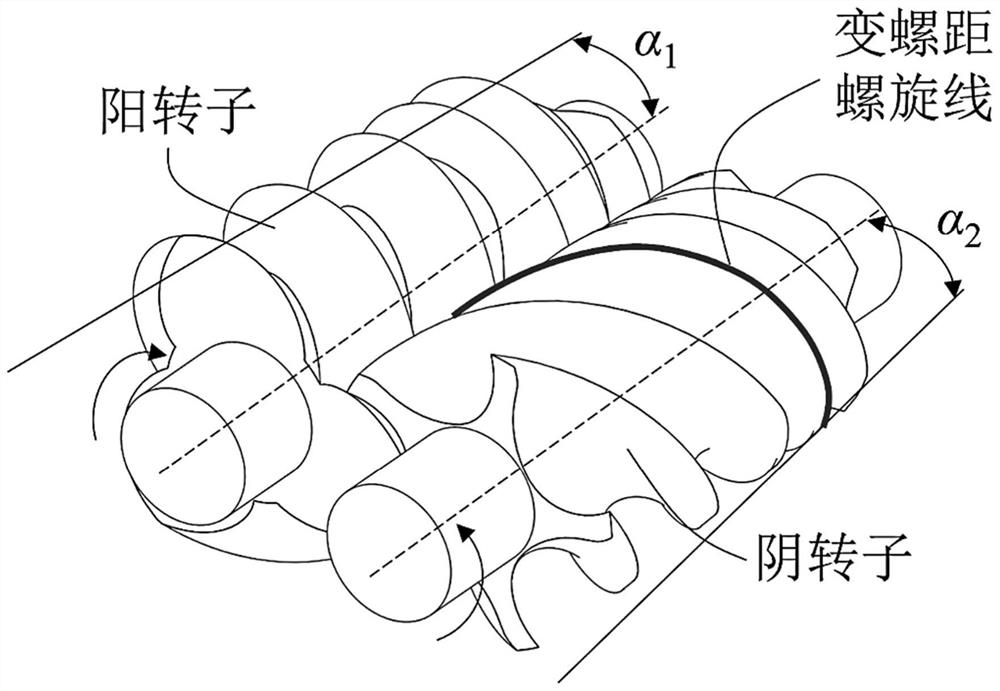

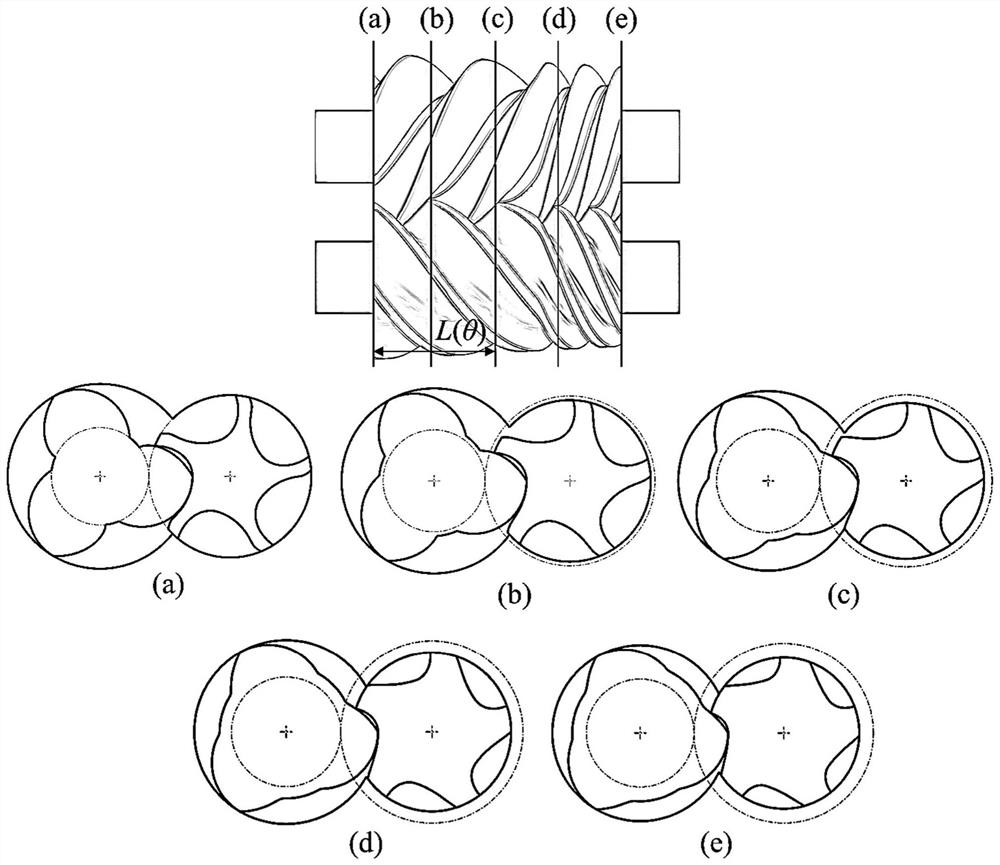

Variable-line double-screw rotor and design method thereof

ActiveCN113153742AIncrease the areaImprove efficiencyGeometric CADInternal combustion piston enginesClassical mechanicsAxial distance

The invention discloses a variable-line double-screw rotor and design method thereof. A rotor structure comprises a female screw rotor and a male screw rotor with the outer contours of conical structures, guide spiral lines of the female screw rotor and the male screw rotor both adopt a variable pitch mode, the guide spiral lines are divided into two parts, when the rotor rotation angle is smaller than a set value, a larger rotor pitch is adopted, when the rotor rotation angle is larger than the set value, and a smaller rotor screw pitch is adopted, so that axial exhaust ports of the rotors are enlarged, along with the increase of the axial distance of the rotors, the tooth crest radius of the female screw rotor and male screw rotor is linearly reduced to form taper angles of the female screw rotor and male screw rotor, and the volume of the working cavity of the double-screw rotors is reduced along with the opening corner of an exhaust orifice, so that the opening corner of the exhaust orifice is opened in advance under the same internal volume ratio, and the area of the exhaust orifice is increased. According to the variable-line double-screw rotor and design method thereof, the area of the exhaust orifice of a screw compressor is effectively enlarged, resistance loss at the exhaust position is reduced, pressure pulsation of the exhaust side is reduced, and therefore the effects of improving the efficiency of the screw rotors and reducing noise are achieved.

Owner:XI AN JIAOTONG UNIV

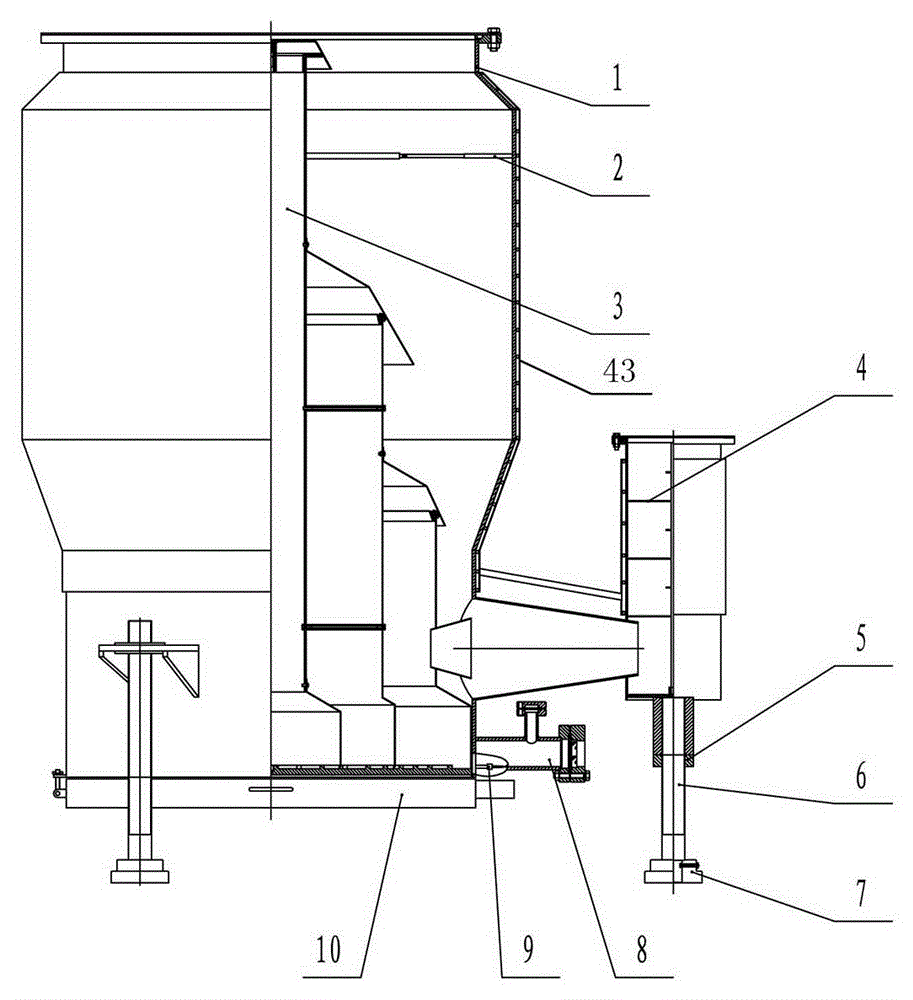

Large-caliber high vacuum oil diffusion pump

ActiveCN104989679ACompact structureShort heating timeMachines/enginesDiffusion pumpsElectricityCore component

The invention discloses a diffusion pump, and particularly relates to a large-caliber high vacuum oil diffusion pump, which is suitable for a vacuum furnace and a vacuum coating machine. The large-caliber high vacuum oil diffusion pump comprises a pump body, and a pump core component arranged in the pump body, wherein a heater is arranged at the bottom of the pump body; an oil stop device is arranged in an exhaust port of the pump body; the pump body adopts a convex cavity structure; the pump core component is vertically mounted in a center oil tank in the pump body, and is formed into an integral structure by a first-stage guide pipe, a second-stage guide pipe and a third-stage guide pipe arranged in sequence from inside to outside; umbrella cap-shaped diffusion nozzles are respectively arranged at the upper parts of all the guide pipes; a spraying nozzle is vertically welded at the bottom of the third-stage guide pipe; the first-stage guide pipe is higher than the second-stage guide pipe; and the second-stage guide pipe is higher than the third-stage guide pipe. The large-caliber high vacuum oil diffusion pump has the characteristics of large caliber, high limit vacuum degree, high pumping rate, low oil return rate and low electricity consumption.

Owner:LIAONING ZHENLONG VACUUM EQUIP MFG

Clean out sub

A clean out sub for use in a drill string having a tool body with a cavity for passage of drilling fluid and annular fluid circulation ports extending through the tool body, a valve spool is positioned within the tool body cavity having a reduced diameter orifice, a compression spring is located within the tool body cavity adjacent the valve spool, wherein a drop in fluid pressure created by the orifice imparts a downhole force on the valve spool and at a predetermined force overcomes a set resistive force of the compression spring thereby moving the valve spool to open the annular fluid circulation ports.

Owner:WWT NORTH AMERICA HLDG

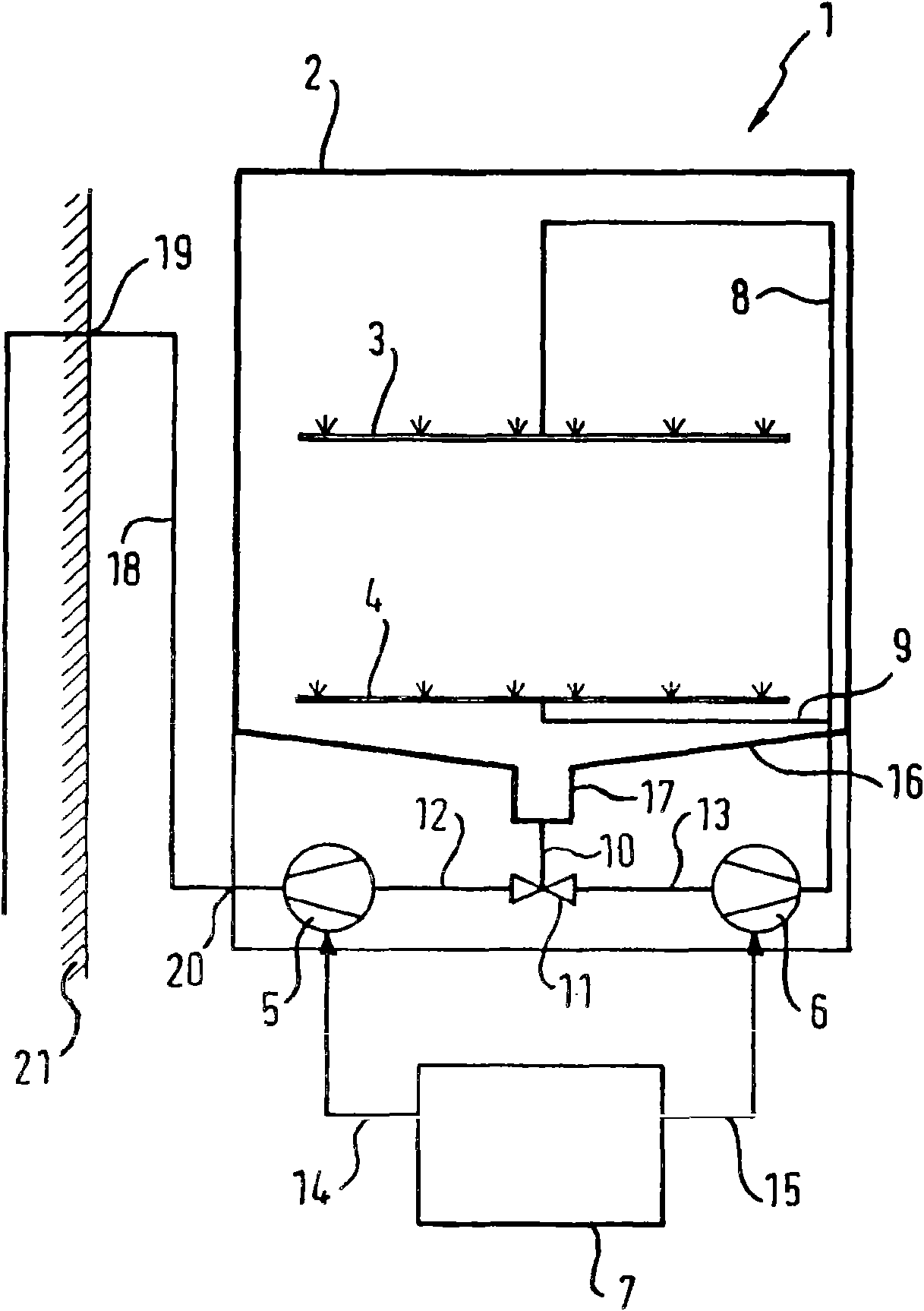

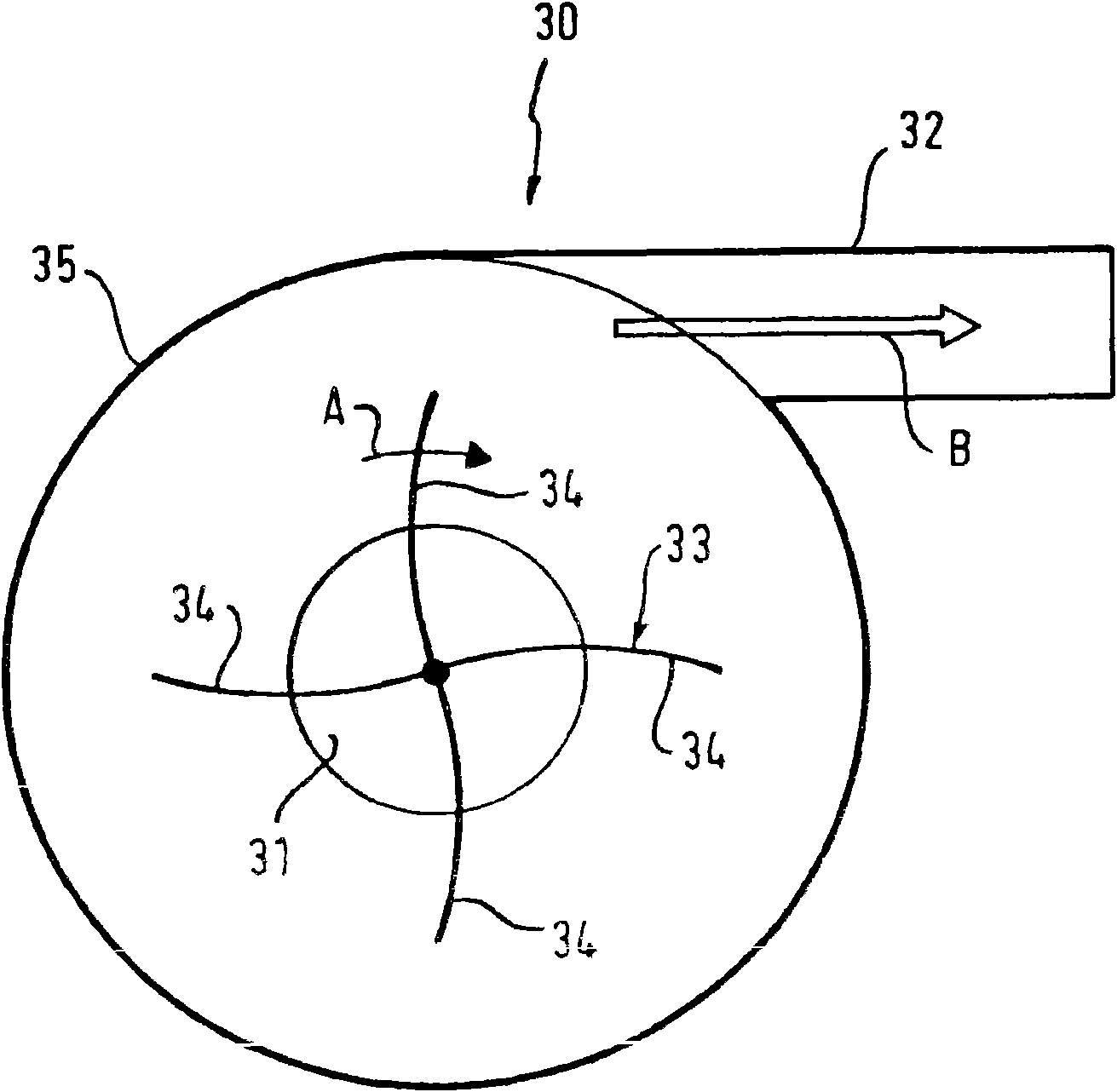

Dishwashing machine with a pump with a brushless permanent magnet motor

ActiveCN101686791AIncrease pumping rateHydraulic improvementTableware washing/rinsing machine detailsAutomatic washing/rinsing machine detectionPermanent magnet motorEngineering

The invention relates to a dishwashing machine (1) having at least one conveying unit for conveying washing detergent, wherein the conveying unit has at least one pump with a brushless permanent magnet motor. The conveying unit has a first pump (5) and a second pump (6), each with a brushless permanent magnet motor, particularly a brushless direct current motor (Brushless DC, BLDC), and a shared controller electronic device (7) is provided for the first and the second pump of the conveying unit. The invention also relates to a controller electronic device (7) and a pump (5, 6; 30).

Owner:BOSCH SIEMENS HAUSGERATE GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com